Page 1

USER INSTRUCTIONS

MHP-TN centrifugal pump

Single-stage,axial suction, vertical discharge type

centrifugal pump

PCN=71576313 – 02/07 (E)

Installation

Operation

Maintenance

These instructions must be read prior to installing,

operating, using and maintaining this equipment.

Page 2

MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

CONTENTS

Page

1 INTRODUCTION AND SAFETY ......................... 4

Page

6 MAINTENANCE................................................ 21

1.1 General........................................................4

1.2 CE marking and approvals............................4

1.3 Disclaimer.....................................................4

1.4 Copyright......................................................4

1.5 Duty conditions.............................................4

1.6 Safety...........................................................5

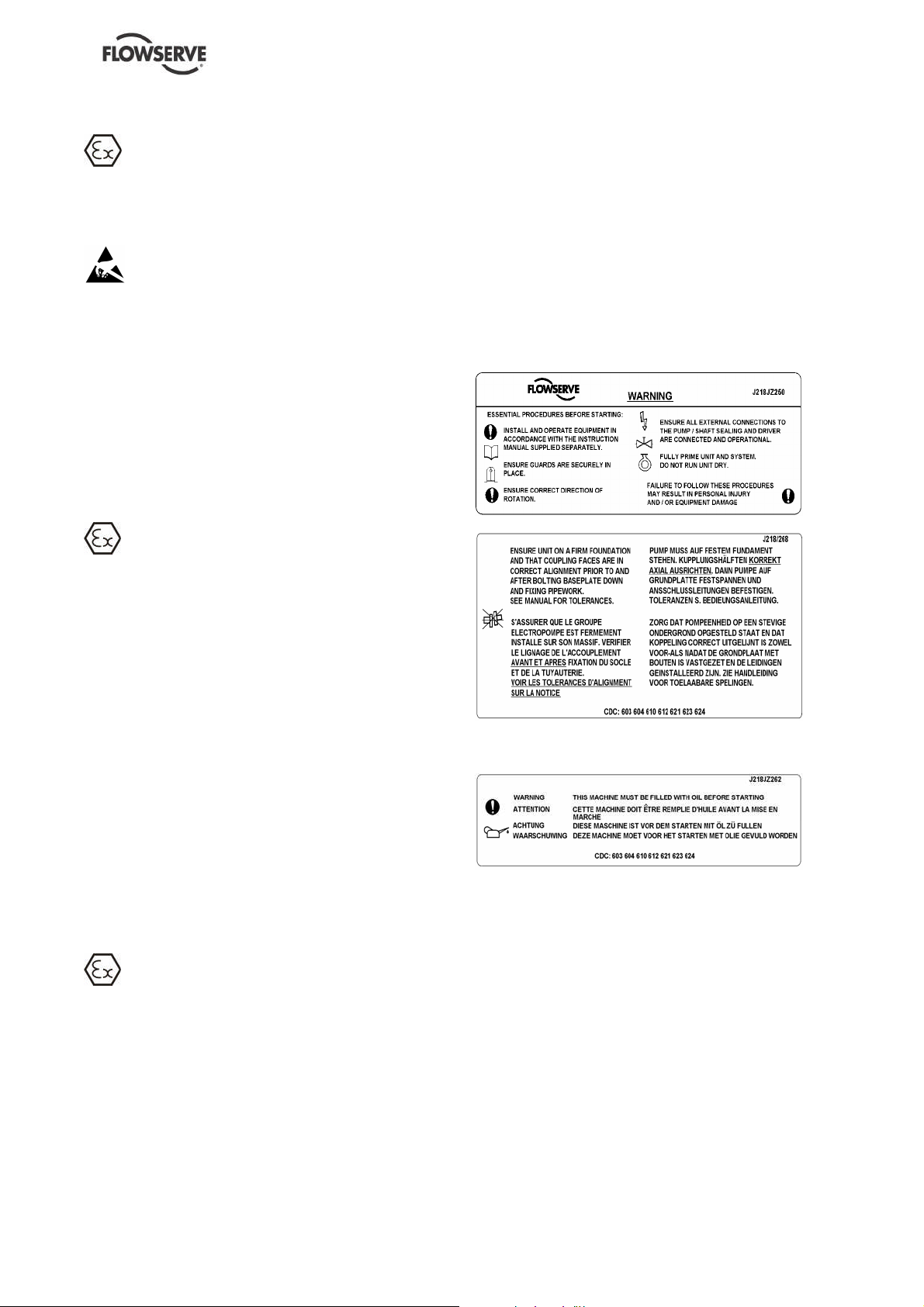

1.7 Nameplate and safety labels.........................8

1.8 Specific machine performance......................8

1.9 Noise level....................................................9

2 TRANSPORT AND STORAGE......................... 10

2.1 Consignment receipt and unpacking...........10

2.2 Handling.....................................................10

2.3 Lifting..........................................................10

2.4 Storage.......................................................11

2.5 Recycling and end of product life ................11

3 PUMP DESCRIPTION...................................... 11

3.1 Configurations............................................11

3.2 Nomenclature.............................................12

3.3 Coveragecharts.........................................12

4 INSTALLATION................................................. 13

4.1 Location......................................................13

4.2 Foundation .................................................13

4.3 Grouting.....................................................14

4.4 Initial alignment...........................................14

4.5 Piping.........................................................15

4.6 Electrical connections.................................16

4.7 Final shaft alignment check.........................17

4.8 Protection systems.....................................17

6.1 General...................................................... 21

6.2 Maintenance schedule................................ 22

6.3 Spare parts.................................................24

6.4 Recommended spares and consumable items

........................................................................ 24

6.5 Disassembly............................................... 24

7 FAULTS; CAUSES AND REMEDIES.................25

8 PARTS LIST AND DRAWINGS..........................26

8.1 Sectional drawings..................................... 26

8.2 Sectional drawings part list.........................27

8.3 General arrangement drawing.................... 27

9 CERTIFICATION............................................... 27

10 OTHER RELEVANT DOCUMENTATION AND

MANUALS ...........................................................27

10.1 Supplementary User Instructions.............. 27

10.2 Change notes........................................... 27

10.3 Additional sources of information.............. 27

5 COMMISSIONING, START-UP, OPERATION AND

SHUTDOWN ....................................................... 17

5.1 Direction of rotation.....................................17

5.2 Guarding.....................................................17

5.3 Priming and auxiliary supplies.....................17

5.4 Starting the pump........................................18

5.5 Running the pump ......................................19

5.6 Stoppingand shutdown...............................20

5.7 Hydraulic, mechanical and electrical duty....20

5.8 Pumps for Food Use or PotableWater........21

Page 2 of 28 flowserve.com

Page 3

INDEX

MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

Page

Page

Additional sources (10.3).....................................27

Alignment of shafting(see 4.2, 4.4 and 4.7)

ATEX marking (1.6.4.2).........................................7

CE marking and approvals (1.2).............................4

Certification (9)....................................................27

Change notes (10.2)............................................27

Cleaning prior to operation (5.8.1) .......................21

Commissioning, start-up, operation (5).................17

Compliance, ATEX (1.6.4.1)...................................6

Configurations (3.1).............................................11

Copyright (1.4).......................................................4

Coverage charts (3.3)..........................................12

Direction of rotation (5.1)......................................17

Disassembly (6.5)................................................24

Discharge piping(4.5.3) ......................................16

Disclaimer (1.3).....................................................4

Dismantling (see 6.5, Disassembly) .....................24

Drawings (8.1).....................................................26

Duty conditions (1.5)..............................................4

Electrical connections (4.6)..................................16

End of product life (2.5)........................................11

Faults; causes and remedies (7)..........................25

Final checks (4.5.4) ............................................16

First pump start up (5.4.2) ...................................18

Foundation (4.2)..................................................13

Forces and moments (see 4.5.1)..........................15

Generalarrangement drawing (8.3) .....................27

Gland packing (6.2.4)...........................................23

Grouting (4.3) ......................................................14

Guarding (5.2).....................................................17

Handling (2.2)......................................................10

Hydraulic, mechanical and electrical duty (5.7).....20

Inspection (6.2.2 and 6.2.3) .................................22

Installation (4)......................................................13

Internal coating(6.2.5).........................................23

Lifting (2.3) ..........................................................10

Location (4.1).......................................................13

Maintenance (6)...................................................21

Maintenance schedule (6.2).................................22

Nomenclature (3.2)..............................................11

Nameplate (1.7.1)..................................................8

Operating limits (see 3.1).....................................12

Orderingspare parts (6.3.1).................................24

Parts lists (8.2).....................................................27

Piping (4.5)..........................................................15

Protection systems (4.8)......................................17

Pump masses (2.2.2) ..........................................10

Receipt and unpacking(2.1)................................10

Recommended spares (6.4).................................24

Recycling (2.5).....................................................11

Replacement parts (see 6.3 and 6.4)...................24

Running the pump (5.5) .......................................19

Safety action (1.6.3)...............................................5

Safety labels (1.7.2)...............................................8

Safety markings (1.6.1)..........................................5

Safety, protectionsystems (see 1.6 and 4.8)

Sectional drawings (8.1)...................................... 26

Sound level (see 1.9, Noise level).......................... 9

Sources, additional information (10.3).................. 27

Spare parts (6.3)................................................. 24

Specific machine performance (1.8)...................... 8

Standard maintenance (6.2.1) ............................ 22

Starting the pump (5.4)........................................ 18

Stop/start frequency (5.5.5).................................20

Stoppingand shutdown (5.6)............................... 20

Storage, pump (2.4) ............................................ 11

Storage, spare parts (6.3.2)................................. 24

Suction piping(4.5.2) .........................................15

Supplementary manuals or information sources.. 27

Thermal expansion (4.4.1) .................................. 14

Transport and storage (2) ................................... 10

Trouble-shooting (see 7)..................................... 25

Vibration (5.5.4)................................................... 19

Page 3 of 28 flowserve.com

Page 4

MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

1 INTRODUCTION AND SAFETY

1.1 General

These instructions mustalways be kept

close to the product's operating location or

directly with the product.

Flowserve products are designed, developed and

manufactured with state-of-the-art technologies in

modern facilities. The unit is produced with great

care and commitment to continuous quality control,

utilizing sophisticated quality techniques, and safety

requirements.

Flowserve is committed to continuous quality

improvement and being at service for any further

information about the product in its installation and

operation or about its support products, repair and

diagnostic services.

These instructions are intended to facilitate

familiarization with the product and its permitted use.

Operating the product in compliance with these

instructions is important to help ensure reliability in

service and avoid risks. The instructions may not

take into account local regulations; ensure such

regulations are observed by all, including those

installingthe product. Always coordinate repair

activity with operations personnel, and follow all plant

safety requirements and applicable safety and health

laws and regulations.

These instructions must be read prior to

installing, operating, using and maintaining the

equipment in any region worldwide. The

equipment must not be put into service until all

the conditions relating to safety noted in the

instructions, have been met.

1.2 CE marking and approvals

It is a legal requirement that machinery and

equipment put into service within certain regions of

the world shall conform with the applicable CE

MarkingDirectives covering Machinery and, where

applicable, Low Voltage Equipment, Electromagnetic

Compatibility (EMC), Pressure Equipment Directive

(PED) and Equipment for Potentially Explosive

Atmospheres (ATEX).

To confirmthe Approvals applying andif the product is

CE marked,checkthe serial number plate markings

andthe Certification. (Seesection 9,Certification.)

1.3 Disclaimer

Information in these User Instructions is believed

to be reliable.In spite of all the efforts of Flowserve

Corporation to providesoundand all necessary

information the content of this manualmay appear

insufficient and is notguaranteedby Flowserveas

to itscompleteness or accuracy.

Flowserve manufacturesproducts toexacting

International Quality ManagementSystemStandards

as certifiedandaudited by externalQuality Assurance

organizations. Genuine parts and accessories have

beendesigned,testedand incorporated intothe

productsto help ensure their continuedproduct quality

and performance in use. As Flowservecannot test

parts andaccessories sourced fromothervendors the

incorrectincorporationof such parts andaccessories

may adversely affect the performance andsafety

features of theproducts. Thefailure to properly select,

installor useauthorized Flowserve parts and

accessories is considered to be misuse. Damageor

failurecausedby misuse is notcovered by the

Flowservewarranty. In addition,any modificationof

Flowserve products or removalof originalcomponents

may impairthe safety ofthese products in their use.

1.4 Copyright

All rights reserved. No part of these instructions may

be reproduced, stored in a retrievalsystem or

transmitted in any form or by any means without

prior permission of Flowserve.

1.5 Duty conditions

This product has been selected to meet the

specifications of your purchaser order. The

acknowledgement of these conditions has been sent

separately to the Purchaser.A copy should be kept

with these instructions.

The product must not be operated beyond

the parameters specified for the application. If

there is any doubt as to the suitability of the

product for the application intended, contact

Flowserve for advice, quoting the serial number.

Where applicable the Directives and anyadditional

Approvalscoverimportantsafety aspects relating to

machinery and equipmentand thesatisfactory

provisionof technical documents andsafety

instructions.Where applicable thisdocument

incorporatesinformationrelevantto these Directives

and Approvals.

Page 4 of 28 flowserve.com

If the conditions of service on your purchase order

are going to be changed (for example liquid pumped,

temperature or duty) it is requested that the user

seeks the written agreement of Flowserve before

start up.

Page 5

MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

1.6 Safety

1.6.1 Summary of safety markings

These UserInstructions containspecific safety

markings where non-observance of aninstruction

wouldcause hazards.Thespecific safety markings are:

This symbol indicates electrical safety

instructions where non-compliance will involve a high

risk to personal safety or the loss of life.

This symbol indicates safety instructions where

non-compliance wouldaffect personal safety and

could result in loss of life.

This symbol indicates “hazardous substances

and toxic fluid”safety instructions where noncompliance would affect personalsafety and could

result in loss of life.

This symbol indicates safety

instructions where non-compliance will involvesome

risk to safe operation and personalsafetyand would

damage the equipment or property.

1.6.3 Safety action

This is a summary of conditions and actions to

prevent injury to personnel and damage to the

environment and to equipment. For products

used in potentially explosive atmospheres

section 1.6.4 also applies.

NEVER DO MAINTENANCE WORK

WHEN THE UNIT IS CONNECTED TO POWER

GUARDS MUST NOT BE REMOVED WHILE

THE PUMP IS OPERATIONAL

DRAIN THE PUMP AND ISOLATE PIPEWORK

BEFORE DISMANTLING THE PUMP

The appropriate safety precautions should be taken

where the pumped liquids are hazardous.

FLUORO-ELASTOMERS (When fitted.)

When a pump has experienced temperatures over

250 ºC (482 ºF), partial decomposition of fluoro-

elastomers (example: Viton) will occur. In this

condition these are extremely dangerous and skin

contact must be avoided.

This symbol indicates explosive atmosphere

zone marking according to ATEX. It is used in safety

instructions where non-compliance in the hazardous

area would cause the risk of an explosion.

This symbol is used in safety instructions to

remind not to rub non-metallic surfaces with a dry

cloth; ensure cloth is damp. It is used where non-

compliance in the hazardous area would cause the

risk of an explosion.

Thissignis nota safety symbol butindicates

an importantinstruction in theassembly process.

1.6.2 Personnel qualification and training

All personnelinvolved in the operation, installation,

inspection and maintenance of the unit must be

qualified to carry out the work involved. If the

personnel in question do not already possess the

necessary knowledge and skill, appropriate training

and instruction must be provided. If required the

operator may commission the manufacturer/supplier

to provide applicable training.

Always coordinate repair activity with operations and

health and safety personnel, and follow all plant

safety requirements and applicable safety and health

laws and regulations.

HANDLING COMPONENTS

Many precision parts havesharp corners and the

wearing of appropriate safety gloves and equipment

is required when handling these components. To lift

heavy pieces above 25 kg (55 lb) use a crane

appropriate for the mass and in accordance with

current local regulations.

THERMALSHOCK

Rapid changes in the temperature of the liquid within

the pump can cause thermal shock, which can result

in damage or breakage of components and should

be avoided.

NEVERAPPLY HEAT TO REMOVE

IMPELLER

Trapped lubricant orvaporcould cause an explosion.

HOT (and cold) PARTS

If hot or freezing components or auxiliary heating

supplies can present a danger to operators and

persons enteringthe immediate area action must be

taken to avoid accidental contact. If complete

protection is not possible, the machine access must

be limited to maintenance staff only, with clear visual

warnings and indicators to those entering the

immediate area. Note: bearing housings must not be

insulated and drive motors and bearings may be hot.

If the temperature is greater than 68 °C (175 °F)

or below 5 °C (20 °F) in a restricted zone, or

exceeds local regulations, action as above shall

be taken.

Page 5 of 28 flowserve.com

Page 6

MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

HAZARDOUS LIQUIDS

Whenthe pump is handling hazardous liquidscare

must be takento avoid exposureto the liquid by

appropriate sittingofthe pump, limitingpersonnel

access and byoperator training. If the liquidis

flammableand/or explosive, strict safety procedures

must be applied.

Gland packingmust not be used when pumping

hazardous liquids.

PREVENTEXCESSIVE EXTERNAL

PIPE LOAD

Do not use pumpas a support for piping. Do not

mount expansion joints, unless allowed by Flowserve

in writing, so that their force, due to internal

pressure, acts on the pump flange.

1.6.4 Products used in potentially explosive

atmospheres

The following instructionsfor pumps andpump

units wheninstalled in potentiallyexplosive

atmospheresmust be followed to helpensure

explosion protection.

The terminology and procedures ensure that the

installed pump is in compliance with theEuropean

Directive 94/9/EC, known asthe ATEXDirective, which

is mandatory in Europe and mayalso be specifiedin

other countries.Where applicable, both electricaland

non-electricalequipment must meet therequirements

94/9/EC.

Evenif theinstallationis in a region where ATEXis not

theapplicable regulation, the general measures

described shallbe followedtoensure safeoperation.

ENSURE CORRECT LUBRICATION

(See section 5, Commissioning, startup, operation

and shutdown.)

START THE PUMP WITH OUTLET

VALVE PART OPENED

(Unless otherwise instructed at a specific point in the

User Instructions.)

This is recommended to minimize the risk of

overloading and damaging the pump motor at full or

zero flow. Pumps may be started with the valve

further open only on installations where this situation

cannot occur. Pumpoutlet valve shall may need to

be adjusted to comply with the duty followingthe runup process. (See section 5, Commissioning start-up,

operation and shutdown.)

NEVER RUN THE PUMP DRY

INLET VALVES TO BE FULLY OPEN

WHEN PUMP IS RUNNING

Running the pumpat zero flow or belowthe

recommended minimum flow continuously willcause

damage to theseal.

DO NOT RUN THE PUMP AT

ABNORMALLY HIGH OR LOW FLOW RATES

Operating at a flow rate higher than normal or at a

flow rate with no backpressure on the pump may

overload the motor and cause cavitation.Low flow

rates may cause a reduction in pump/bearing life,

overheating of the pump, instability and

cavitation/vibration.

The measures are explained under the headings of:

Avoiding excessive surface temperature

Preventing build up of explosive mixtures

Preventing the generation of sparks

Preventing leakages

Maintaining the pump to avoid hazard

1.6.4.1 Scope of compliance

Use equipmentonlyinthe zone forwhichit is

appropriate. Alwayscheckthatthe driver, drive

coupling assembly, sealand pump equipment are

suitably ratedand/orcertified for theclassification of the

specific atmosphere inwhichtheyare to beinstalled.

WhereFlowserve hassupplied onlythe bare shaft

pump, the Ex rating appliesonly to the pump. The

partyresponsible for assembling the pump set shall

selectthe coupling, driver and any additional

equipment, with the necessary CE Declaration of

Conformity establishing it is suitablefor the area in

whichit is to beinstalled.

The output froma variable frequency drive (VFD)can

causeadditionalheatingaffectsin the motorandso, for

pumps sets witha VFD,the ATEX Certification forthe

motor must statethat it iscoversthesituation where

electricalsupply is fromthe VFD. This particular

requirementstill applies evenif the VFD isin a safe

area.

Page 6 of 28 flowserve.com

Page 7

MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

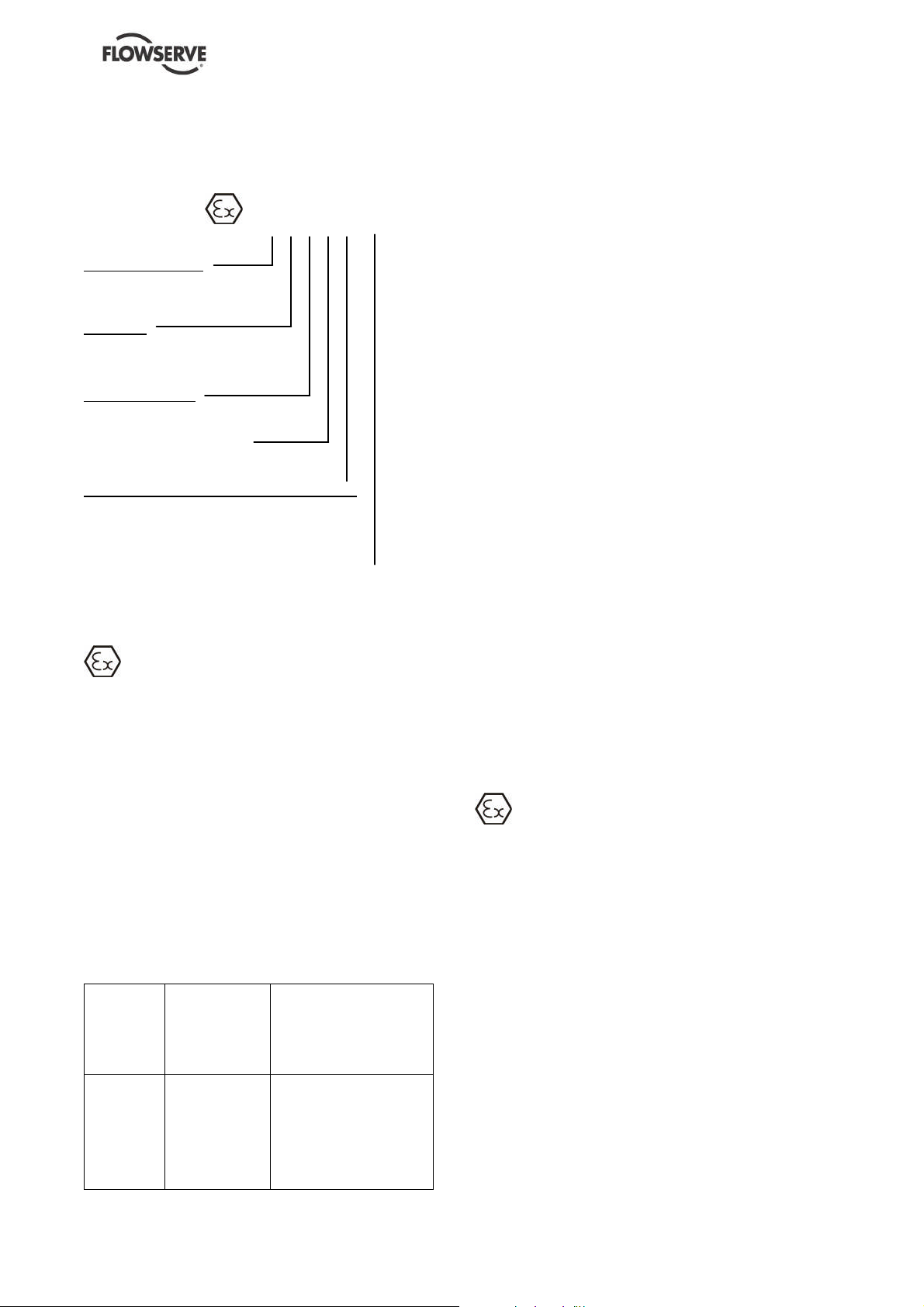

1.6.4.2 Marking

Anexample of ATEX equipment marking is shown

below. The actual classification of the pumpwill be

engraved on the nameplate.

II 2 GD c IIC 135 ºC (T4)

Equipment Group

I = Mining

II = Non-mining

Category

2 or M2 = High level protection

3 = normal levelof protection

Gas and/orDust

G = Gas; D= Dust

c = Constructionalsafety

(in accordance withEN 13463-5)

Gas Group (Equipment Category 2 only)

IIA– Propane (typical)

IIB – Ethylene(typical)

IIC– Hydrogen (typical)

Maximumsurface temperature (TemperatureClass)

(seesection 1.6.4.3)

1.6.4.3 Avoiding excessive surface temperatures

ENSURE THE EQUIPMENT TEMPERATURE

CLASS IS SUITABLE FOR THE HAZARD ZONE

Pumps have a temperature class as stated in the

ATEX Ex rating on the nameplate. These are based

on a maximumambient of 40 °C (104 °F); refer to

Flowserve for higher ambient temperatures.

The responsibility for compliance with the

specified maximum liquid temperature is with the

plant operator.

Temperature classification “Tx” is used when the

liquid temperature varies and the pumpcould be

installed in different hazardous atmospheres. In this

case the user is responsible for ensuring that the

pump surface temperature does not exceed that

permitted in the particular hazardous atmosphere.

If an explosive atmosphere exists during the

installation, do not attempt to check the directionof

rotation by starting the pump unfilled. Even a short

run time may give a high temperature resultingfrom

contact between rotating and stationary components.

Furthermore, confinement of liquid in the pump and

pipes must be avoided (valve closed). If the liquid

heats up this may cause excessive pressure and

lead to bursting of pump components.

Wherethere is any risk of the pump being run against

a closed valve generating high liquidand casing

externalsurfacetemperatures it is recommended that

users fit an externalsurfacetemperature protection

device.

Avoid mechanical, hydraulic or electrical overload by

using motor overload trips, temperature monitor or a

power monitor and make routine vibration monitoring

checks.

In dirty or dusty environments, regular checks must

be made and dirt removed from areas aroundclose

clearances, bearing housings and motors.

1.6.4.4 Preventing the build up of explosive

mixtures

The surface temperature on the pump is influenced

by the temperature of the liquid handled. The

ENSURE PUMP IS PROPERLY FILLED AND

VENTED AND DOES NOT RUN DRY.

maximum permissible liquid temperature depends on

the temperature class and must not exceed the

values in the table that follows.

Ensure pump and relevant suction and discharge

pipeline system is totally filled with liquid at all times

during the pump operation, so that an explosive

The temperature rise at the seals, bearings and due

to the minimum permitted flow rate is taken into

account in the temperatures stated.

atmosphere is prevented. In addition it is essential to

make sure that seal chambers, auxiliary shaft seal

systems and any heatingand cooling systems are

properly filled.

Temperature limit of liquid

handled (* depending on

material and construction

variant - check which is

lower)

If the operation of the systemcannot avoid this

condition the fitting of an appropriate dry run

protection device is recommended (eg liquid

Temperature

classto

EN13463-1

Maximum

surface

temperature

permitted

detection or power monitor).

T6

T5

T4

T3

T2

T1

85 °C (185°F)

100°C (212°F)

135°C (275°F)

200°C (392°F)

300°C (572°F)

450°C (842°F)

Consult Flowserve

Consult Flowserve

115 °C (239 °F) *

180 °C (356 °F) *

275 °C (527 °F) *

400 °C (752 °F) *

To avoid potential hazards from fugitive emissions of

vapor or gas to atmosphere the surrounding area

must be well ventilated.

Page 7 of 28 flowserve.com

Page 8

MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

1.6.4.5 Preventing sparks

To prevent a potential hazard from mechanical

contact, the coupling guard must be non-sparking.

To avoid the potential hazardfrom random induced

current generating a spark the ground contact on the

baseplate must be used.

Avoid electrostatic charge: do not rub nonmetallic surfaces with a dry cloth, ensure cloth is

damp.

Where applicable the coupling must be selected to

comply with 94/9/EC and correct alignment must be

maintained.

Additional requirements for metallic pumps on

non-metallic baseplates

When metallic components are fitted on a nonmetallic baseplate they must be individually earthed

(grounded).

1.6.4.6 Preventing leakage

The pump must only be used to handle liquids

for which it has been approved to have the correct

corrosion resistance.

Where there is a risk fromsuch tools or materials;

maintenance must be conducted in a safe area.

It is recommended that a maintenance plan and

schedule is adopted. (Seesection 6, Maintenance.)

1.7 Nameplate and safety labels

1.7.1 Nameplate

For details of nameplate, see the Declaration of

Conformity, or separate documentation included with

these User Instructions.

1.7.2 Safety labels

Avoidentrapmentof liquidin thepump andassociated

pipingdue toclosingof suctionand dischargevalves,

which couldcause dangerousexcessive pressures to

occurif there is heatinputto the liquid. This canoccurif

the pump is stationary or running.

Burstingof liquid containing parts due to freezing

must be avoided by draining or protecting the pump

and ancillary systems.

Where there is the potential hazard of a loss of a

seal barrier fluid or external flush, the fluid must be

monitored.

If leakage of liquid to atmosphere can result in a

hazard, the installation of a liquid detection device is

recommended.

1.6.4.7 Maintenance to avoid the hazard

CORRECTMAINTENANCE IS REQUIRED

TO AVOID POTENTIAL HAZARDS WHICH GIVE A

RISK OF EXPLOSION

The responsibility for compliance with

maintenance instructions is with the plant operator.

Oil lubricated units only:

1.8 Specific machine performance

For performance parameters see section 1.5, Duty

conditions.When the contract requirement specifies

these to be incorporated into User Instructions these

are included here. Where performance data has

been supplied separately to the purchaser these

should be obtained and retained with these User

Instructions if required.

To avoid potential explosion hazards during

maintenance, the tools, cleaningand painting

materials used must not give rise to sparking or

adversely affect the ambient conditions.

Page 8 of 28 flowserve.com

Page 9

MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

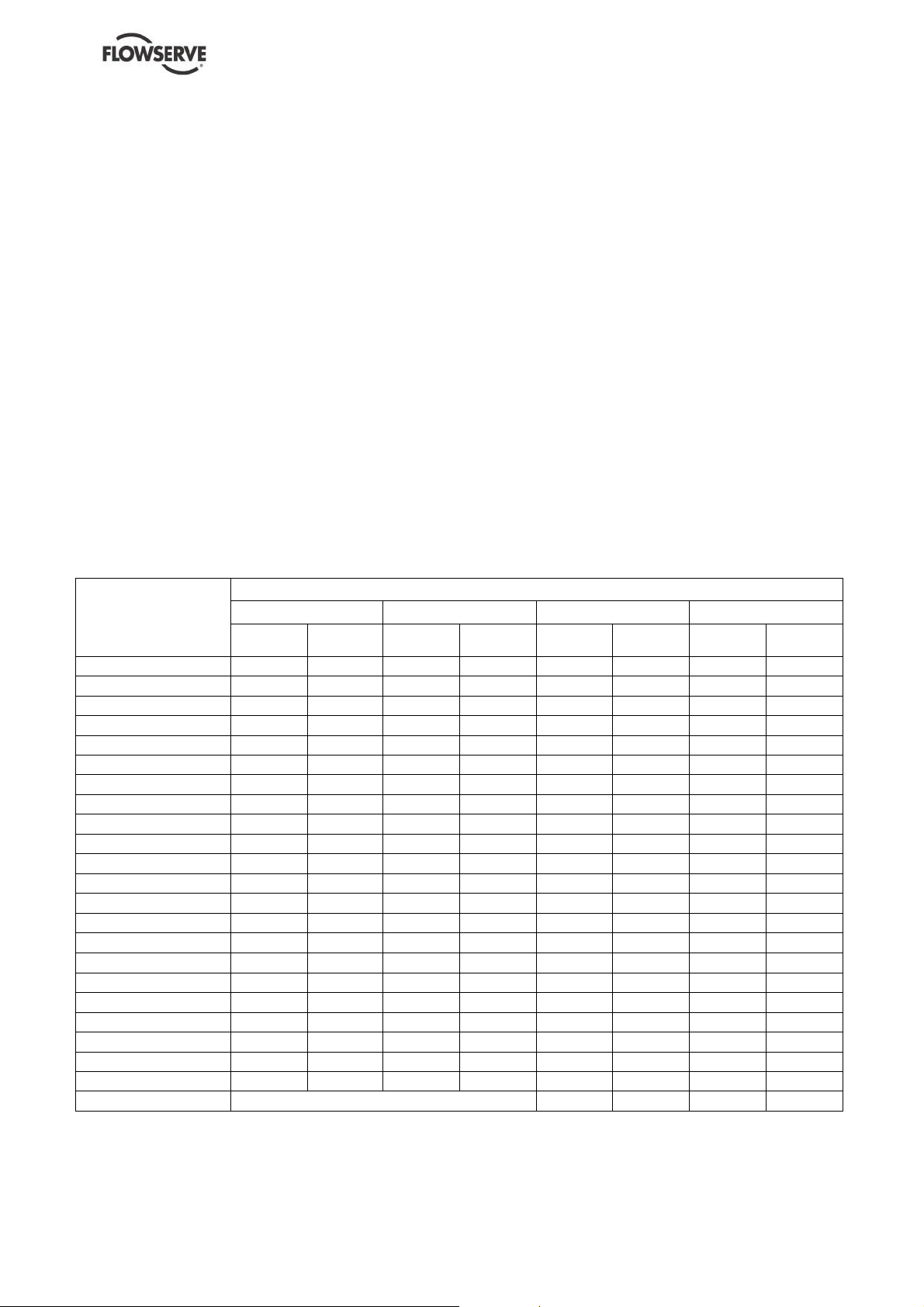

1.9 Noise level

Attention must be given to the exposure of personnel

to the noise, and local legislation will define when

guidance to personnel on noise limitation is required,

and when noise exposure reduction is mandatory.

This is typically 80 to 85 dBA.

The usual approach is to control the exposuretime

to the noise or to enclose the machine to reduce

emitted sound.

You may have already specified a limiting noise level

when the equipment was ordered, however if no

noise requirements were defined, then attention is

drawn to the followingtable to give an indication of

equipment noise level so that you can take the

appropriate action in your plant.

Pump noise level is dependent on a number of

operational factors, flow rate, pipework design and

acoustic characteristics of the building, and so the

values given are subject to a 3 dBAtolerance and

cannot be guaranteed.

Similarly the motor noise assumed in the “pump and

motor” noise is that typically expected from standard

and high efficiency motors when on load directly

driving the pump. Note that a motor driven by an

inverter may show an increased noise at some

speeds.

If a pump unit only has been purchased for fitting

with your own driver then the “pumponly” noise

levels in the table should be combined with the level

for the driver obtained from the supplier. Consult

Flowserve or a noise specialist if assistance is

required in combining the values.

It is recommended that where exposure approaches

the prescribed limit, then site noise measurements

should be made.

The values are in sound pressure level LpAat 1 m

(3.3 ft) fromthe machine, for “free field conditions

over a reflecting plane”.

For estimating sound power level LWA (re 1 pW)

then add 17 dBA to the sound pressure value.

Motor size

and speed

kW (hp)

< 0.55(< 0.75) 72 72 64 65 62 64 62 64

0.75(1) 72 72 64 66 62 64 62 64

1.1(1.5) 74 74 66 67 64 64 62 63

1.5(2) 74 74 66 71 64 64 62 63

2.2(3) 75 76 68 72 65 66 63 64

3 (4) 75 76 70 73 65 66 63 64

4 (5) 75 76 71 73 65 66 63 64

5.5 (7.5) 76 77 72 75 66 67 64 65

7.5 (10) 76 77 72 75 66 67 64 65

11 (15) 80 81 76 78 70 71 68 69

15 (20) 80 81 76 78 70 71 68 69

18.5 (25) 81 81 77 78 71 71 69 71

22 (30) 81 81 77 79 71 71 69 71

30 (40) 83 83 79 81 73 73 71 73

37 (50) 83 83 79 81 73 73 71 73

45 (60) 86 86 82 84 76 76 74 76

55 (75) 86 86 82 84 76 76 74 76

75 (100) 87 87 83 85 77 77 75 77

90 (120) 87 88 83 85 77 78 75 78

110 (150) 89 90 85 87 79 80 77 80

150 (200) 89 90 85 87 79 80 77 80

200 (270)

300 (400) 87 90 85 86

The noise level of machines in this range will most likely be of values which require noise exposure control, but typical values are

inappropriate.

Note: for 1 180 and 960 r/min reduce 1 450 r/min values by 2 dBA. For 880 and 720 r/min reduce 1 450 r/min valuesby 3 dBA.

3 550 r/min 2 900 r/min 1 750 r/min 1 450 r/min

Pump

only

Typical sound pressure levelLpAat 1 mreference20 μPa, dBA

Pump and

motor

Pump

only

Pump and

motor

Pump

only

85 87 83 85

Pump and

motor

Pump

only

Pump and

motor

Page 9 of 28 flowserve.com

Page 10

MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

In areas where the staff has to intervene, remember

that when the level of the soundpressure is:

below 70 dBA: it is not necessary to take special

precautions.

above 70 dBA: people working continuously in

the machine room must be supplied with

protective devices against noise.

below 85 dBA: no particular measures need to

be taken for casual visitors stayingin the room

during a limited period.

above 85 dBA: the room must be considered as

a dangerous area because of the noise and a

warning sign must be fixed at each entry warning

the people cominginto the room, even for a

short period, that they must wear hearing

protection.

above 105 dBA: special hearing protection

adapted to this noise level and to the spectral

noise components must be installed and a

warning sign to this effect erected at each entry.

The staff in the room must wear ear protection.

Make sure that the noise, which travels through the

walls and windows, does not generate too highnoise

levels in the machine room's surroundings.

2 TRANSPORT AND STORAGE

To lift machines or pieces with one or several

suspension rings, only use hooks and chains in

compliance with the local regulations concerning

safety.

Never put cables, chains or ropes directly on or in

the suspension rings. Cables, chains or lifting ropes

must never present excessive bending.

Never bend the lifting hooks, suspension rings,

chains, etc., which should only be made to endure

stresses within, calculated limits. Remember that the

capacity of a lifting device decreases whenthe

direction of the liftingforce direction makes an angle

with the device axis.

To increase the safety and the efficiency of the lifting

device, all the lifting elements must be as

perpendicular as possible. If necessary a lifting beam

can be placed between the winch and the load.

When heavy pieces are lifted up, never stay or work

under the load or in the area, which couldbe in the

path of the load if it were to swing or fall away. Never

leave a load hanging from a winch. The acceleration

or the slowing-down of lifting equipment must stay in

the safety limits for the staff.

2.1 Consignment receipt and unpacking

Immediately after receipt of the equipment it must be

checked against the deliveryand shipping

documents for its completeness and that there has

been no damage in transportation.

Any shortage and or damage must be reported

immediately to Flowserve and received in writing

within one month of receipt of the equipment. Later

claims cannot be accepted.

Check any crate, boxes and wrappings for any

accessories or spare parts that may be packed

separately with the equipment or attached to

sidewalls of the box or equipment.

Each product has a unique serial number. Check

that this number corresponds with that advised and

always quote this number in correspondence as well

as when ordering spare parts or further accessories.

2.2 Handling

2.2.1 General instructions concerning handling

Boxes, crates, pallets or cartons may be unloaded

using forklift vehiclesor slings dependent on their

size and construction. See 2.3.1 for positioning of

slings.

A winch must be positioned in such a way that the

load will be raised perpendicularly. Where possible

necessary precautions must be taken to avoid the

swing of the load, using for example two winches

making approximately the same angle, below 30°,

with the vertical.

2.2.2 Pumpmasses

Pump type

MHP-TN100-65-315 134 295

MHP-TN125-100-315 152 335

Pump mass

kg lb

All motors (for masses see the motor

description plate) must be handled with a winch.

For masses above 25 kg (55 lb), manual

handling is forbidden.

2.3 Lifting

2.3.1 Slinging of motor pumps units

Use handling means in accordance with motor

pump unit mass mentioned on the CE plate. For the

masses of the pumps bare end of shaftsee table §

2.2.2 and nameplate.

To lift heavy pieces above 25 kg (55 lb), use a winch

adapted to the mass and in accordance with the

current local regulations.

should be lifted as shown.

To avoid distortion, the pump unit

Page 10 of 28 flowserve.com

Page 11

MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

Motor pump unit

Bareshaft pump

This also includes the liquids and or gases in the

"seal system" or other utilities.

Make sure that hazardous substances or toxic

fluid are disposed of safely and that the correct

personal protective equipment is used. The safety

specifications must be in accordance with the current

regulations at all times.

3 PUMP DESCRIPTION

3.1 Configurations

The centrifugal motor pump is designed for the

pumping of cold water or all clear liquids which are

not solid and liquid mixtures, non-corrosive, nonabrasive when in contact with the pump motor unit

and its workingparts (Important: for other liquids

consultFlowserve for beforehand advice).

The MHP-TNpump is a centrifugal, single-stage

pump with axial inlet and outlet in the vertical axis.

The pump must be stored in a non explosive,

ventilated location, sheltered from bad weather, dust

and vibrations.

When handling always wear gloves, safety

boots and an industrial safety helmet.

For masses above 25 kg (55 lb), manual

handling is forbidden.

2.4 Storage

Store the pump in a clean, dry

location away from vibration. Leave piping

connection covers in place to keep dirt and other

foreign material out of pumpcasing. Turn pump at

intervals to prevent brinellingof the bearings and the

seal faces, if fitted, from sticking.

Do not store pumps starting on the fan guard.

The pump may be stored as above for up to 6

months. Consult Flowserve for preservative actions

when a longer storage period is needed.

2.5 Recycling and end of product life

At the end of the service life of the product or its

parts, the relevant materials and parts shouldbe

recycled or disposed of using an environmentally

acceptable method and local regulations. If the

product contains substances which are harmful to

the environment, these should be removed and

disposed of in accordance with current regulations.

The reliability of the delivered machine can only be

ensured if it is used according to the conditions given

in this manual. The maximum values specified in this

manual must never be exceeded.

Maximum working pressure at discharge

................................................. 16 bar (232 psi)

Maximumworking pressure at suction

................................................. 10 bar (145 psi)

Maximum pumped fluid temperature

- Gland packing without cooling

.............................................. 105 °C (221 °F)

Minimum pumped fluid temperature

.................................................... -10 °C (14 °F)

Maximumambient temperature.... 40 °C (104 °F)

Maximumsolid suspension

........................................50 g/m3(0.003 lbm/ft3)

Density ..................................1

Viscosity................................1 mm2/s (31 SSU)

Maximumrotation speed (frequency 50 Hz)

....................................................... 2900 min

The maximum speed is shown on the

pump nameplate.

-1

Page 11 of 28 flowserve.com

Page 12

MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

3.2 Nomenclature

Characteristics shown on the nameplate fixed on the pump are as shown below:

Each pump is supplied with the following nameplate:

Speed of rotation

Pump type

Flowrate

Head

Radial/thrust bearing

Year of construction +

Manufacture number

Mass

Maximum admissible

Pressure at 20 °C (68 °F)

Maximum / minimum

temperature

Each pump unit is supplied with the following nameplate:

Mass of the set

3.3 Coverage charts

3.3.1 2900 min-1(50 Hz): coverage charts (Q, H)

Page 12 of 28 flowserve.com

Page 13

MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

NF E 27 811

4 INSTALLATION

Equipment operated in hazardous locations

must comply with the relevant explosion protection

regulations. See section 1.6.4, Products used in

potentially explosive atmospheres.

All equipment must be grounded.

4.1 Location

The pump should be located to allow room for

access, ventilation, maintenance and inspection

with ample headroom for lifting and should be as

close as practicable to the supply of liquid to be

pumped.

4.2 Foundation

Provide sufficient space in the foundation to

accommodate the anchor bolts. If necessary,

provide concrete risers.

Usually the pump and its drive are mounted on a

common base plate. If not, individual base plates

underneath each machine foot shall be installed.

Base plates are to be fully grouted.

4.2.1 Setting the base plate for anchoring

a) Clean the foundation surface thoroughly.

b) Put shims on the foundation surface [approx

20-25 mm (0.79-0.98 in.) thick], one on each

side of the bolt hole (as an alternative, leveling

screws can be used).

There are many methods of

installingpump units to their foundations. The

correct method depends on the size of the pump

unit, its location and noise vibration limitations.

Non-compliance with the provision of correct

foundation and installation may lead to failure of

the pump and, as such, wouldbe outside the

terms of the warranty.

The base plate should be mounted onto a firm

foundation, either an appropriate thickness of

quality concrete or sturdy steel framework.

It should NOT be distorted or pulled down onto the

surface of the foundation, but should be supported

to maintain the original alignment.

Anchor bolts must be in accordance with the foot

bolt holes. Use anchor bolts of accepted standards

and sufficient to ensure a secure fitting in the

foundation.

Particularly, this applies to individual plates where

the anchor bolts have to withstandthe driving

torque.

c) Lay the base plate and level in both directions

with extra shims. The base plate should be

level to within 0.5 mm per 1 m (0.02 in. per 3.3

ft).

d) If anchor bolts have been pre-cast in the

foundation slightly tighten the anchor bolts.

Otherwise let them hang in the foundation

holes.

Page 13 of 28 flowserve.com

Page 14

MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

4.3 Grouting

4.3.1 Base plate grouting

a) Prepare the site for grouting. Before grouting

clean the foundation surface thoroughly and

provide external barriers as shown:

b) Prepare groutingproduct (concrete, resin) in

accordance with manufacturers' instructions.

4.4.2 Alignment methods

Ensure pump and driver are isolated

electrically and the half couplings are

disconnected. Ensure that the pump pipework,

suction and discharge, is disconnected.

The alignment MUST be checked.

Althoughthe pump will have been aligned at the

factory it is most likely that this alignment will have

been disturbed during transportation or handling. If

necessary, align the motor to the pump, not the

pump to the motor.

Alignment

Parallelism and concentricity check:

Check the alignment at three or

four points, before pipingassembly.

c) Use grouting products with anti-shrinking

components.

d) To grout up to the required level. Polish

surfaces. Take necessary precautions to avoid

air bubbles.

e) Lay-downthe barrier, break external angles,

and polish the different surfaces.

f) After grout starts to cure, definitively tighten

anchor bolts.

g) Control the alignment such as described as

follows.

4.4 Initial alignment

Before connecting the couplings

verify the motor rotation direction.

4.4.1 Thermal expansion

with a rule with a comparator

Admissible marginfor a motor with roller bearings

with European couplings:

= 0.15 mm parallel checking

= 0.1 mmangular checking

For US supplied couplings values to be used are:

= 0.02 in. parallel checking

= 0.05 in. angular checking

Check the couplings manualfor further details.

Angular checking:

with a sliding rule with a caliper gauge

The alignment will be definitive only

after pipe connection (see § 4.5.4).

If necessary, improve the machine alignment:

The pump and motor will normally

have to be aligned at ambient temperature and

should be corrected to allow for thermal expansion

at operating temperature. In pump installations

involving high liquid temperatures, the unit should

be run at the actual operating temperature, shut

down and the alignment checked immediately.

Page 14 of 28 flowserve.com

Complete unit mounted on common base plate:

The machines are first aligned accurately in our

workshops. Usually, any misalignment observed

on site is due to a wrong adjustment under the

base plate (disturbed during transport or because

of forces exerted by the piping).

Page 15

MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

Valve

Non return valve

Moto

r

Continuous

It is only necessary to rectify the adjustment under

base plate. If it proves to be insufficient, modify the

motor and the piping.

Pump and motor mounted on individual base

plates:

Machines are (or must be) first mounted on their

own base plate in the workshop. Once the pump is

set, it will be regarded as the fixed piece. Any

alignment necessary shall be carried out on the

motor.

Never connect the electric motor

before the setting has been completely finished.

4.5 Piping

The user must verify that the equipment is

isolated from any external sources of vibration.

Protective covers are fitted to the

pipe connections to prevent foreign bodies

entering during transportation and installation.

Ensure that these covers are removed fromthe

pump before connectingany pipes.

Forces

Fv

maxFhmax

daN

daN

(lbf)

(lbf)

140

105

(315)

(236)27(199)

180

125

(405)

(281)47(347)

Moments

Mt max

m.daN

(lbf.ft)

Pump type

MHP-TN

100-65-315

MHP-TN

125-100-315

Suction

DNA

mm

(in.)

100

(4”)

125

(5”)

Discharge

DNR

mm

(in.)

65

(2”1/2)

100

(4”)

Forces and moments values are applied to the

whole flanges and not flange-by-flange.For their

sharing out on the pump flanges, refer to standard

NFCR 13 931.

Ensure piping and fittings are

flushed before use.

4.5.1 Suction and discharge piping

The dimensions of the pipes do not directly

depend on suction and discharge diameters of the

pump:

a) First, choose a flow speed < 2 m/s (7 ft/s) at

suction, and about 3 m/s (10 ft/s) at discharge.

b) Take into account the available NPSH, which

must be superior to the required NPSH of the

pump.

Never use pump as a support for

piping.

Do not mount expansion joints in

such a way that their force, due to internal

pressure, may act on the pump flange.

Maximumforces and moments allowed on the

pump flanges vary with the pump size and type.

These external strains may cause misalignment,

hot bearings, worn couplings, vibrationsand the

possible failure of the pumpcasing.

When designingthe pipes (§ 4.5.2.1, § 4.5.2.2, §

4.5.3.1) take necessary precautions in order not to

exceed maximumallowed strains.

Forces and moments applied to the pump flanges

must never exceed the values shown in the

followingtable:

Ensure piping for hazardous liquids is

arranged to allow pump flushing before removal of

the pump.

4.5.2 Suction piping

4.5.2.1 Design of a flooded suction line

The suction line must be as short and direct as

possible, never mount an elbow directly on the

inlet flange of the pump.

flow valve

Baseplate

CouplingCoupling guard

Flooded suction configuration

a) Avoid sharp elbows or sudden narrowing. Use

convergent 20° (total angle).

b) Arrange the pipingso that there are no air

pockets (no bulges).

Page 15 of 28 flowserve.com

Page 16

MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

I

Control manometer

c) If high points cannot be avoided in suction line,

provide themwith air relief cocks.

d) If a strainer is necessary, its net area should

be three or four times the area of the suction

pipe.

e) If an inlet valve is necessary, choose a model

with direct crossing.

Do not tighten flanges before the

final check (see § 4.5.4).

4.5.2.2 Design of a suction lift line

The inlet pipe must be as short and as direct as

possible, never place an elbow directly on the

pump inlet nozzle.

Sufficient

immersion

If necessary, a control manometer (pressure

gauge) can be connected on the piping.

Do not tighten flanges before the

final check (see § 4.5.4).

4.5.4 Final checks

a) Check the tighteningof anchor bolts. Tighten

themif necessary.

b) Check that protective coverson suction and

discharge flanges are removed.

c) Check that holes of pipingflanges are parallel

and correspond to those of the pump.

d) Tighten suction and discharge flanges.

I 3 x D

Sump suction configuration

a) Avoid sharp elbows or sudden narrowing. Use

convergent 20° (total angle) with upright

generating.

b) Arrange that the suction piping is inclined

upwards towards the pump ensuring that there

are no peaks.

c) If a foot valve is necessary, do not oversize it

because it would generate pulsations (valve

beating).

Do not tighten flanges before the

final check (see § 4.5.4).

4.5.3 Discharge piping

4.5.3.1 Design of a discharge line

a) If discharge line is provided with a divergent,

its total angle will be between 7° and 12°.

b) Install the discharge valve after the non-return

valve downstream.

4.6 Electrical connections

Electrical connections must be made

by a qualified Electrician in accordance with

relevant local national and international

regulations. This includes any grounding.

It is important to be aware of the

EUROPEAN DIRECTIVE on potentially explosive

areas where compliance with IEC60079-14 is an

additional requirement for making electrical

connections.

Avoid mechanical, hydraulic or electrical

overload by using motor overload trips or a power

monitor and make routine vibration monitoring.

Itis important tobe awareofthe EUROPEAN

DIRECTIVE on electromagnetic compatibility when

wiringupand installingequipmenton site.Attention

must be paidtoensurethatthe techniques used

during wiring/installation donot increase

electromagnetic emissions or decreasethe

electromagnetic immunity of theequipment, wiringor

anyconnected devices.If in doubt,contact

Flowservefor advice.

The non-return valve will be set in the discharge

pipe to protect the pump from any excessive

pressure surge and from reverse rotation.

Page 16 of 28 flowserve.com

The motor must be wired up in

accordance with the motor manufacturer's

instructions (normally supplied within the terminal

box) including any temperature, earth leakage,

current and other protective devices as

appropriate.

Page 17

MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

The identification nameplate shouldbe checked to

ensure the power supply is appropriate. A device

to provide emergency stopping shall be fitted.

Carry out the ground connections according to the

current local regulations.

To avoid any risk of jamming, the

direction of rotation will be checked after priming of

the pump (§ 5.3.1, 5.3.2) and before the first start

(§ 5.4.2).

4.7 Final shaft alignment check

a) Check the alignment pump-motor according to

the procedure § 4.4.2. Rectify if necessary by

adjusting the motor only.

b) Check by hand that the pump turns freely.

A binding indicates a distortion of the pump,

which is due to excessive pipe strain. If

necessary the pipe design must be reexamined.

c) If it provided, connect auxiliary pipe systems

(hydraulic, pneumatic, sealing system).

d) Control tightness and functionality of auxiliary

piping.

4.8 Protection systems

The following protection systems are

recommended particularly if the pump is installed

in a potentially explosive area or is handling a

hazardous liquid. If in doubt consult Flowserve.

If there is any possibility of the system allowingthe

pump to run against a closed valve or below

minimumcontinuous safe flow a protection device

should be installed to ensure the temperature of

the liquid does not rise to an unsafe level.

Except when explicitly required by the customer in

the specifications, when a possibility of reverse

rotation exists the customer must install a reverse

rotation protection device.

The customer must install all equipment required

to avoid water hammer.

5 COMMISSIONING, START-UP, OPERATION AND SHUTDOWN

These operations must be carried out by

fully qualified personnel.

5.1 Direction of rotation

Starting or operating pumps with

the wrong direction of rotation can be harmful to

the pumps. Ensure that the pump rotation is the

same as the arrow on the pump casing. It is

preferable to check the direction of rotation before

installingthe coupling. If not, the pump must be

filled in with the liquid before start-up.

If maintenance work has been

carried out to the site's electricity supply, the

direction of rotation should be re-checked as

above in case the supply phasing has been

altered.

5.2 Guarding

Guarding is supplied fitted to the pump set.

If this has been removed or disturbed ensure that

all the protective guards aroundthe pump coupling

and exposed parts of the shaft are securely fixed.

5.3 Priming and auxiliary supplies

If there are any circumstances in which the system

can allow the pumpto run dry, or start up empty, a

power monitor should be fitted to stop the pumpor

prevent it from being started. This is particularly

relevant if the pump is handlinga flammable liquid.

If leakage of product from the pump or its

associated sealing system can cause a hazard it is

recommended that an appropriate leakage

detection system is installed.

To prevent excessive surface temperatures at

bearings it is recommended that temperature or

vibration monitoring are carried out. See sections

5.5.3 and 5.5.4.

If a defect of cooling can lead to temperature

higher than those acceptable a system of cooling

surveillance must be installed.

Page 17 of 28 flowserve.com

Where there is any risk of the pump being

run against a closed valve generating high liquid

and casing external surface temperatures it is

recommended that users fit an external surface

temperature protection device.

Ensure all electrical, hydraulic,

pneumatic, sealant and lubrication systems (as

applicable) are connected and operational.

Ensure the inlet pipe and pump

casing are completely full of liquid before starting

continuous duty operation.

These operations must be carried out by personnel

with approved qualifications.

Page 18

MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

External source

5.3.1 Priming of a flooded pump

a) As discharge valve is closed, fill the pump by

openingthe valve at suction. Let air escape by

removing the plugs located on the pump.

b) The discharge pipe is headed and there is a

by-pass valve on the check valve, open

slightly the discharge valve and the by-pass of

the check valve.

c) When the pumpis totally free of air bubbles,

replace the plugs.

Air escape

Priming of a flooded pump

5.3.2 Priming of a sump suction pump

* With foot valve:

a) Fill suction pipe and casing with liquid from an

independent source (pressure1 to 2 bars or

15 to 30 psi).

b) Let air escape by removing the plugs located

on the pump.

c) When the pumpis totally free of air bubbles,

replace the plugs.

Air escape

*Without foot valve:

Priming may be accomplished by means of venting

system.

Foot valves are not recommended when

the pumped liquid has suspendedsolid particles.

They may lodge between foot valve seat and

shutter.

5.4 Starting the pump

5.4.1 Bring controls and preparation before the

first starting and after each service call

Necessarily:

a) Check the tighteningof the different plugs.

b) Check that the gland lightly tightens the

packing rings.

c) Risk of seal ring overheating.

d) Check the direction of rotation of the motor.

Refer to the rotation arrow of the pump.

e) Install all protection systems and more

particularly the coupling guard and the shield

grid (reference [9331]) of the bearing.

f) Open all suction valves (if existing).

g) Close the outlet valve and the bypass valve.

h) Ensure inlet pipe and pump casingare

completely full of liquid.

5.4.2 First pump start-up

Suction valves must be fully open

when pump is running. Never run the pump dry, it

will cause damage.

a) Start motor and check outlet pressure.

b) If pressure is satisfactory,slowly OPEN outlet

valve.

c) Do not run the pumpwith the outlet valve

closed for a period longer than 30 seconds.

d) If NO pressure, or LOW pressure, STOP the

pump. Refer to faultfindingchart for fault

diagnosis.

Priming of sump suction pump with foot valve

Page 18 of 28 flowserve.com

The pump should run smoothly and without

vibration.

The pump must never run at a capacity of less

than 40 % of that at the best efficiency.

Never remove a plug when the pump is

running.

Page 19

MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

5.5 Running the pump

5.5.1 Venting the pump

Vent the pump to enable all trappedair to

escape taking due care with hot or hazardous

liquids.

Under normal operating conditions, after the pump

has been fully primed and vented, it should be

unnecessary to re-vent the pump.

5.5.2 Pump fitted with a stuffing box

If the pump has a packed gland there must be

some leakage from the gland. Gland nuts should

initially be finger tight only. Leakage should take

place soon after the stuffing box is pressurized. If

no leakage takes place the packing will beginto

overheat. If overheating takes place the pump

should be stopped and allowed to cool before

being restarted. When the pump is restarted it

should be checked to ensure leakage is taking

place at the packedgland.

When adjusting an operating stuffing box

(shield grids removed for this operation), the

operator must be very careful. Safety gloves are

compulsory and loose clothes are not allowed

(above all to the arms) to avoid being caught by

the pump shaft.

The pump should be run for ten minutes with

steady leakage and the gland nuts tightened by 10

degrees at a time until leakage is reduced to an

acceptable level.

The temperature of the gland should be checked

after each round of tightening. If the temperature

starts to climb rapidly then back off the gland nuts

until the temperature drops down. Wait for the

temperature to stabilize before tightening again.

The leakage must not be reduced below a rate of

20 drops per minute. Beddingin of the packing

may take several hours.

Shield grids being removed during

installation of the gland packing, it must be

ensured that they are replaced as soon as this

operation is completed.

SAFETY INSTRUCTIONS WHEN THE PUMP IS

RUNNING:

If hot or freezing components of the machine

can present a danger to operators, they must be

shielded to avoid accidental contact. If a 100 %

protection is not possible, the machine access

must be confined to the maintenance staff only.

If the temperature is greater than 80 °C (176

°F), a warning plate must be clearly placedon the

pump.

It is strictly forbidden to open switch

cupboards, switch boxes, or all other live electric

equipment. If it is necessary to open them in order

to take readings, to carry out tests or adjustments

for example, only a skilledtechnician may do them

with adapted tools. Make sure that physical

protection against electrical risks are used.

5.5.3 Bearings

If the pumps are working in a potentially

explosive atmosphere, temperature or vibration

monitoring at the bearings is recommended.

If bearing temperatures are to be monitored it is

essential that a benchmark temperature is

recorded at the commissioning stage and after the

bearing temperature has stabilized.

Record the bearing temperature (t) and the

ambient temperature (ta)

Estimate the likely maximumambient

temperature (tb)

Set the alarm at (t+tb-ta+5) C [(t+tb-ta+10) F]

and the trip at 100 C (212 F) for oil

lubrication and 105 C (220 F) for grease

lubrication

It is important, particularly with grease lubrication,

to keep a check on bearing temperatures. After

start upthe temperature rise should be gradual,

reaching a maximumafter approximately 1.5 to 2

hours. This temperature rise should then remain

constant or marginally reduce with time.

5.5.4 Normal vibration levels, alarm and trip

For guidance, pumps generally fall under a

classification for rigid support machines within the

International rotating machinery standards and the

recommended maximum levels below are based

on those standards.

Alarm and trip values for installed

pumps should be based on the actual

measurements (N) taken on site on the bearing

housings of the pump in the fully commissioned as

new condition.

Page 19 of 28 flowserve.com

Page 20

MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

The example (N) value is given for the preferred

operating flow region (typically this may extend to

70 to 120 % of the pump best efficiency point);

outside the preferred flow region the actual

vibration experienced may be multiplied by up to 2.

These standard values can vary with the rotational

speed and the power absorbed by the pump. For

any special case, do not hesitate to consult us.

Measuring vibration at regular intervals will then

show any deterioration in pump or system

operating conditions.

Vibration Velocity- unfiltered

Normal N 5.6 (0.22)

Alarm N x 1.25 7.1 (0.28)

Shutdown Trip N x2.0 11.2 (0.44)

Horizontal

Configuration

mm/s (in./s) r.m.s.

5.5.5 Stop/start frequency

Pumpsets are normally suitable for the number of

equally spaced stop/starts per hour shown in the

table below. Check actual capability of the driver

and control/startingsystem before commissioning.

Motor rating kW (hp)

Up to 15 (20) 15

Between 15 (20) and 90 (120) 10

90 (120) to 150 (200) 6

Above 150 (200) Refer

Maximum stop/starts

per hour

Where duty and standby pumps are installed it is

recommended that they are run alternately every

week.

5.6.3 Shutdown > 1month

a) Isolate motor.

b) Avoid reverse rotation of the pump.

c) Make sure that the discharge line pressure

does not reach the foot valve.

d) Close the outlet valve. Eventually close the

inlet valve.

e) Switch off external power supply,

flushing/quench, cooling liquid.

f) Keep the pumpfully filledwith water. In case

of pumped liquid other than water, drain the

pump entirely.

g) Turn once per week the pump shaft of one or

two turns.

h) Never restart the pump without carrying out

the verifications recommended before starting

(see § 5.4.1).

When ambient temperatures are

likely to drop below freezing point, the pump and

any coolingand flushing arrangements must be

drained or otherwise protected.

5.6.4 Restarting in continuous running

a) Ensure that the pump is completely full of

liquid.

b) Ensure a continuous supply with a sufficient

available NPSH.

c) Ensure a backpressure so that the motor

power is not in excess.

d) Respect the starting frequency

imposed by the motor manufacturer.

e) Protect the pump against water hammer

when stopping or starting.

5.6 Stopping and shutdown

According to hydraulic conditions of

the installation and its automation degree, stop

and restart procedures can have different forms.

Nevertheless all of them must respect imperatively

the followingrules:

5.6.1 Stopping < 1 hour

a) Isolate motor.

b) Avoid reverse rotation of the pump.

c) Make sure that the discharge line pressure

does not reach the foot valve.

5.6.2 Stopping < 1 month

a) Isolate motor.

b) Avoid reverse rotation of the pump.

c) Make sure that the discharge line pressure

does not reach the foot valve.

d) Close the outlet valve. Eventually close the

inlet valve.

e) Switch off external power supply,

flushing/quench, cooling liquid.

5.7 Hydraulic, mechanical and electrical duty

This product has been supplied to meet the

performance specifications of your purchase order,

however it is understood that during the life of the

product these may change. The following notes

may help the user decide how to evaluate the

implications of any change. If in doubt contact your

nearest Flowserve office.

5.7.1 Specific gravity (SG)

Pump capacity and total head in meters (feet) do

not change with SG, however pressure displayed

on a pressure gauge is directly proportional to SG.

Power absorbed is also directly proportional to SG.

It is therefore important to check that any change

in SG will not overload the pump driver or over-

pressurize the pump.

5.7.2 Viscosity

For a given flow rate the total head reduces with

increased viscosity and increases with reduced

viscosity.

Page 20 of 28 flowserve.com

Page 21

MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

Also for a given flow rate the power absorbed

increases with increased viscosity, and reduces

with reduced viscosity. It is important that checks

are made with your nearest Flowserve office if

changes in viscosity are planned.

5.7.3 Pump speed

Changing pump speed effects flow, total head,

power absorbed, NPSHR, noise and vibration.

Flow varies in direct proportion to pump speed,

head varies as speed ratio squared and power

varies as speed ratio cubed. The new duty,

however, will also be dependent on the system

curve.

If increasingthe speed, it is important therefore to

ensure the maximum pumpworking pressure is

not exceeded, the driver is not overloaded, NPSH

> NPSHR, and that noise and vibration are within

local requirements and regulations.

5.7.4 Net positive suction head (NPSHA)

NPSH available (NPSHA) is the head available at

the impeller inlet, above the vapor pressure of the

pumped liquid.

NPSHrequired(NPSHR)is the minimumhead

required at the impeller inlet,above thevapor

pressure of the pumped liquid, toavoidexcessive

cavitationandextreme performance degradation.

Itis importantthat NPSHA> NPSHR. Themargin

between NPSHA> NPSHRshould be as large as

possible.

If any change in NPSHAis proposed, ensure these

margins are not significantly eroded. Refer to the

pump performance curve to determine exact

requirements particularly if flow has changed.

If in doubt please consult your nearest Flowserve

office for advice and details of the minimum

allowable margin for your application.

5.7.5 Pumped flow

Flow must not fall outside the minimumand

maximum continuous safe flow shown on the

pump performance curve and or data sheet.

5.8 Pumps for Food Use or Potable Water

If the pump has not been specifically ordered for a

food or drinking water application it must not be

used for these types of applications. If it has been

ordered for this type of application the following

recommendations are to be followed.

5.8.1 Cleaning prior to operation

Pumps that are to be used for a food or drinking

water application should be cleaned before being

put into initial operation and after the installation of

spare parts that are in contact with the liquid.

Cleaning once the pumphas been commissioned

will depend on the application and operating

conditions. The user must ensure that the cleaning

procedures are suitable for the applicationand

operating conditions, and local regulations.

6 MAINTENANCE

6.1 General

A

If a belt drive is used, the assembly and

tension of the belts must be verified during regular

maintenance procedure.

In dirty or dusty environments, regular checks

must be made and dirt removed from areas around

close clearances, bearing housings and motors.

It is the plant operator's responsibility to

ensure that all maintenance, inspection and

assembly work is carried out by authorizedand

qualified personnel who have adequately

familiarized themselves with the subject matter by

studying this manual in detail (see also section

1.6.2).

Any work on the machine must be performed when

it is at a standstill. It is imperative that the

procedure for shutting down the machine is

followed, as described in section 5.6.

On completion of work all guards and safety

devices must be re-installed and made operative

again. Before restartingthe machine, the relevant

instructions listed in section 5, Commissioning,

start up, operation and shut down must be

observed.

Oil and grease leaks may make the ground

slippery. Machine maintenance must always

begin and finish by cleaning the ground and

the exterior of the machine.

If platforms, stairs and guardrails are required for

maintenance, they must be placed for easy access

to areas where maintenance and inspection are to

be carried out. The positioning of these

accessories must not limit access or hinder the

lifting of the part to be serviced.

Page 21 of 28 flowserve.com

Page 22

MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

When air or compressed inert gas is used in the

maintenance process, the operator and anyone in

the vicinity must be careful and have the

appropriate protection.

Do not spray air or compressed inert gas on skin.

Do not direct an air or gas jet towards other

people.

Never use air or compressed inert gas to clean

clothes.

Before workingon the pump, take measures to

prevent an uncontrolled start. Put a warning board

on the starting device with the words:

"Machine under repair: do not start".

With electric drive equipment, lock the main switch

open and withdraw any fuses. Put a warning board

on the fuse box or main switch with the words:

"Machine under repair: do not connect".

Never clean equipment with inflammable solvents

or carbon tetrachloride.

k) Check dirt and dust is removed fromareas

around close clearances, bearing housings

and motors.

l) Check couplingalignment and re-align if

necessary.

m) Verify the correct operation of thesystem.

The equipment used for maintenance and

disassembly in an ATEX zone must be in

conformity with the requirements zone.

Our specialist service personnel can helpwith

preventative maintenance records and provide

condition monitoring for temperature and vibration

to identify the onset of potential problems.

If any problems are found the followingsequence

of actions shouldtake place:

a) Refer to section 7, Faults; causes and

remedies, for fault diagnosis.

b) Ensure equipment complies with the

recommendations in this manual.

c) Contact Flowserve if the problem persists.

6.2.1 Standard maintenance

Protect yourself against toxic fumes when using

cleaning agents.

6.2 Maintenance schedule

It is recommended that a maintenance plan

and schedule is adopted, in line with these User

Instructions. It shouldinclude the following:

a) The pump must be completely vented and

drained and rendered inert before any

disassembly operation.

b) Any auxiliary systems installed must be

monitored, if necessary, to ensure they

function correctly.

c) During cleaning of the pump ensure the

compatibility between the cleaning products

and the gaskets.

d) Verify the condition of the gaskets.

e) Gland packings must be adjusted correctly to

give visible leakage and concentric alignment

of the gland follower to prevent excessive

temperature of the packing or follower.

Mechanical seals shouldpresent no leakage.

f) Check for any leaks from gaskets and seals.

The correct functioning of the shaft seal must

be checked regularly.

g) Check bearing lubricant level, and if the hours

run show a lubricant change is required.

h) Check that the duty condition is in the safe

operating range for the pump.

i) Check vibration, noise level and surface

temperature at the bearings to confirm

satisfactory operation.

j) Check the tightness of the connections.

Roller bearing

The bearing housings are provided with sealed for

life ball bearings. No maintenance is required.

6.2.2 Routine inspection (daily/weekly)

The following checks should be