Page 1

High-Definition LCD TV Service Manual

Models: LT3200, LT3700, LT4200, LT4700

Page 2

Copyright 2007 Hewlett-Packard Development Company, L.P. The information contained herein is subject

to change without notice.

Microsoft and Windows are trademarks of Microsoft Corporation in the U.S. and other countries.

The only warranties for HP products and services are set forth in the express warranty statements

accompanying such products and services. Nothing herein should be construed as constituting an

additional warranty HP shall not be liable for technical or editorial errors or omissions contained herein.

This document contains proprietary information that is protected by copyright. No part of this document

may be photocopied, reproduced, or translated to another language without the prior written consent of

Hewlett-Packard Company.

Service Reference Guide

Business PCs

First Edition (June 2007)

Document Part Number: 454404-001

Page 3

Table of Contents

Important Service Safety Precautions.................................................................................................................1

Warnings and Cautions.................................................................................................................................... 1

Safe Handling and Servicing............................................................................................................................. 2

Repair Tips .................................................................................................................................................. 3

About Lead-Free Solder ................................................................................................................................. 3

Suggested Pb-Free Solder .............................................................................................................................. 4

Servicing of Surface-Mounted Devices (SMDs).................................................................................................. 4

Rework on Ball Grid Array (BGA) ICs.............................................................................................................. 5

Product Information and Specifications ..............................................................................................................6

Product Information .......................................................................................................................................... 6

Product Profile.............................................................................................................................................. 6

Specifications .................................................................................................................................................. 6

LCD Panel Module........................................................................................................................................ 6

General TV Specifications LT3200 and LT3700 ............................................................................................... 7

General TV Specifications LT4200 and LT4700 ............................................................................................... 9

I/O Connectors ......................................................................................................................................... 11

Factory Preset Display Modes ...................................................................................................................... 11

Controlling the Onscreen Display................................................................................................................. 12

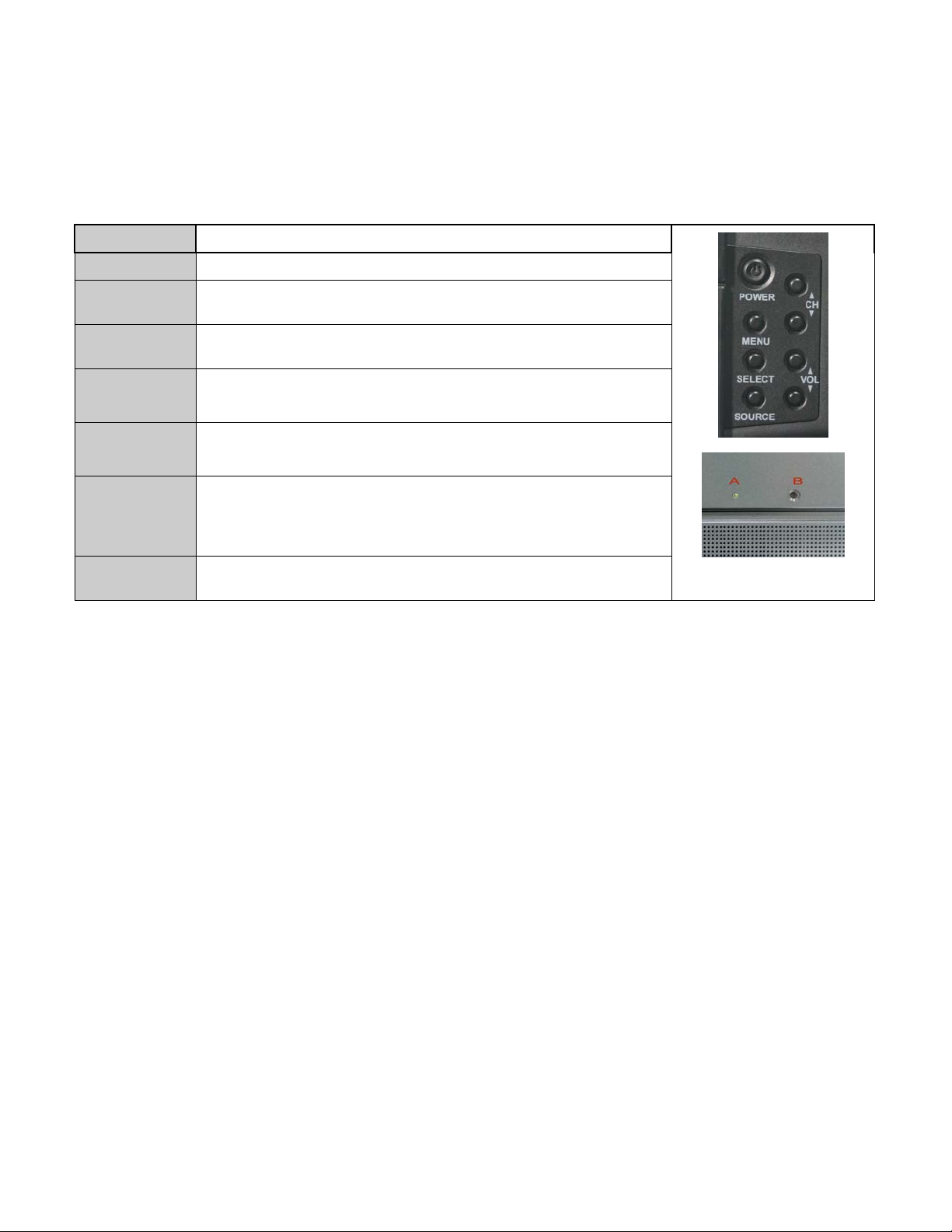

TV Indicators and Controls .......................................................................................................................... 12

Remote Control .......................................................................................................................................... 13

TV Connectors ........................................................................................................................................... 14

Connectors................................................................................................................................................ 17

Basic Operation........................................................................................................................................... 20

Basic Operation............................................................................................................................................. 20

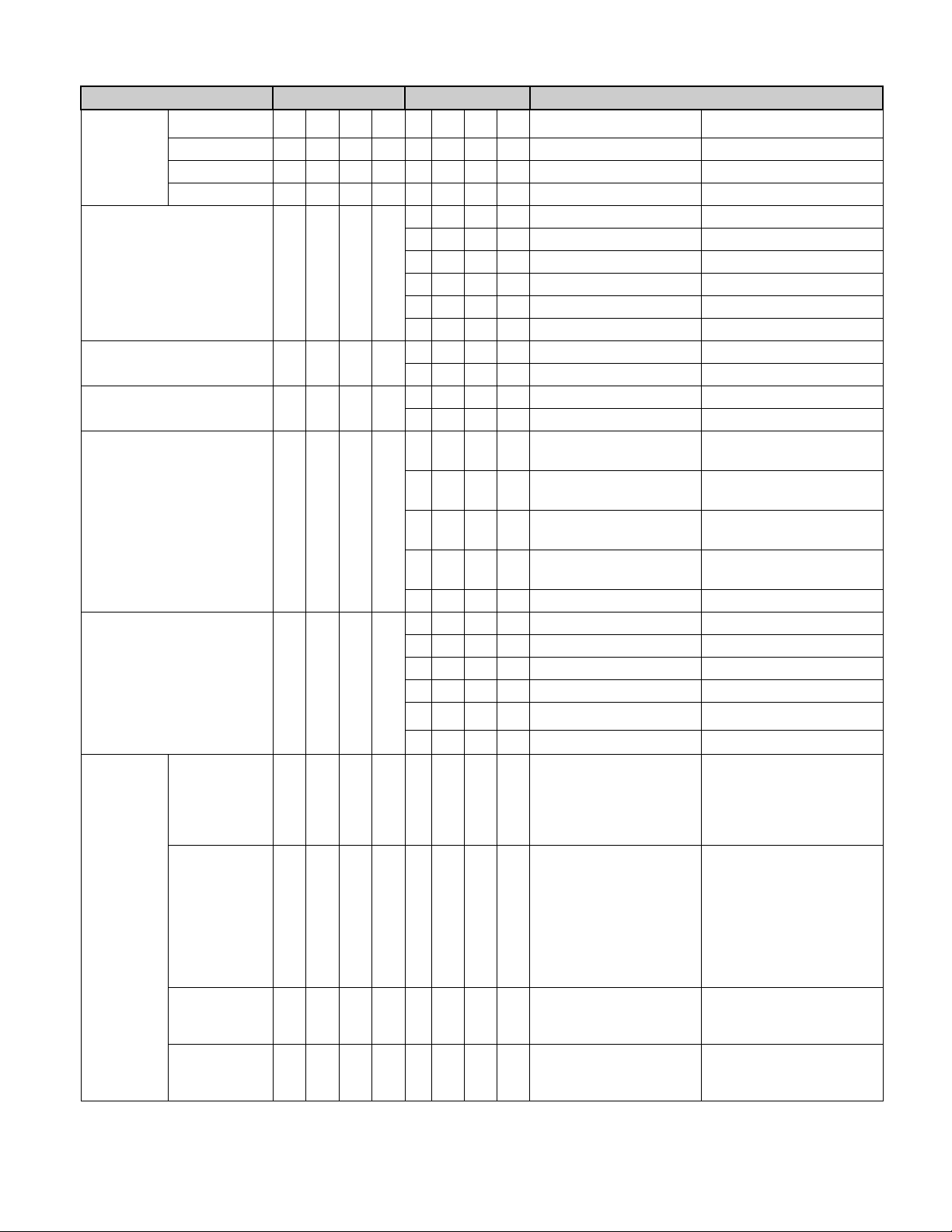

OSD (On-Screen Display) Functions – Simplemenu

OSD Functions – Fullmenu

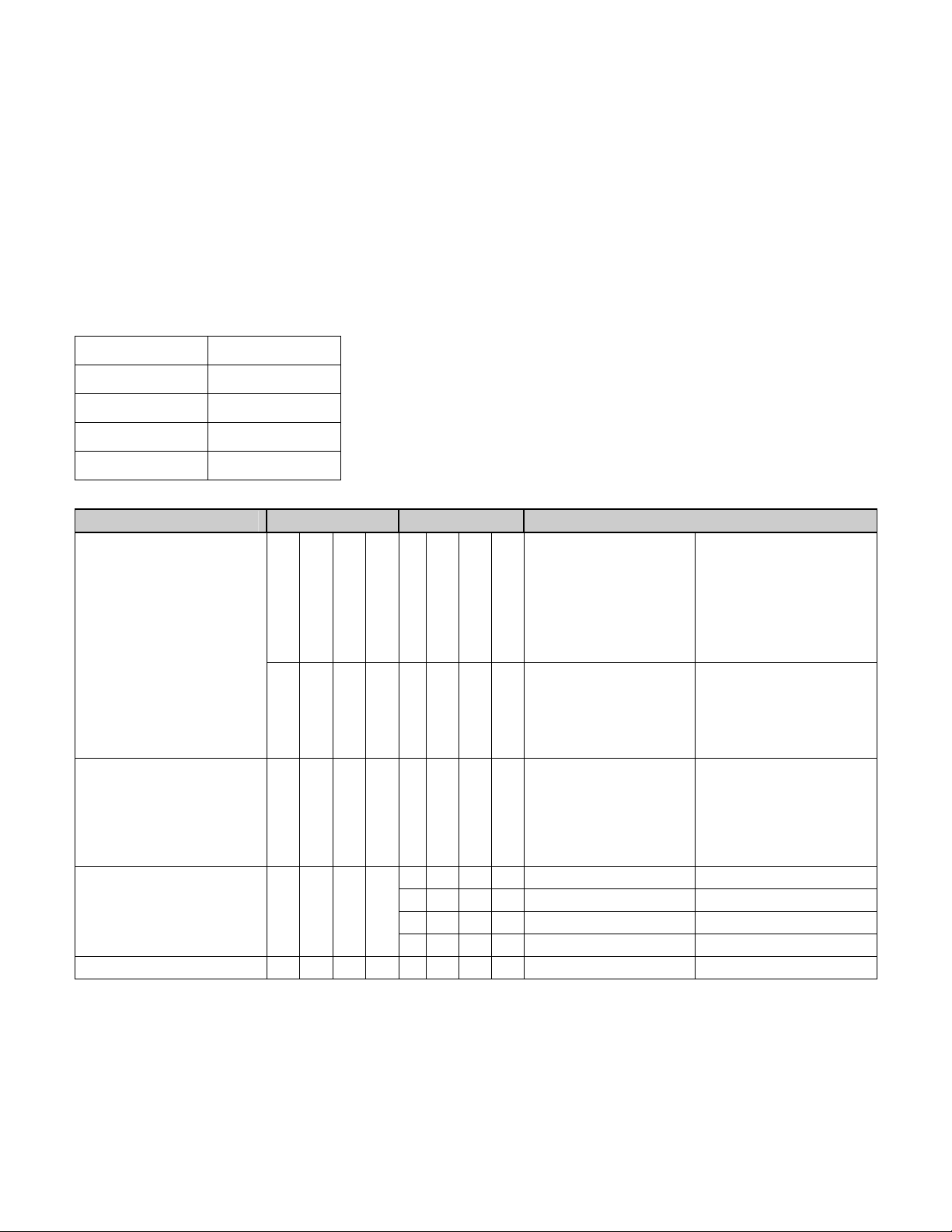

Command Table RS232 .................................................................................................................................. 25

Return messages............................................................................................................................................. 31

Special command extension......................................................................................................................... 31

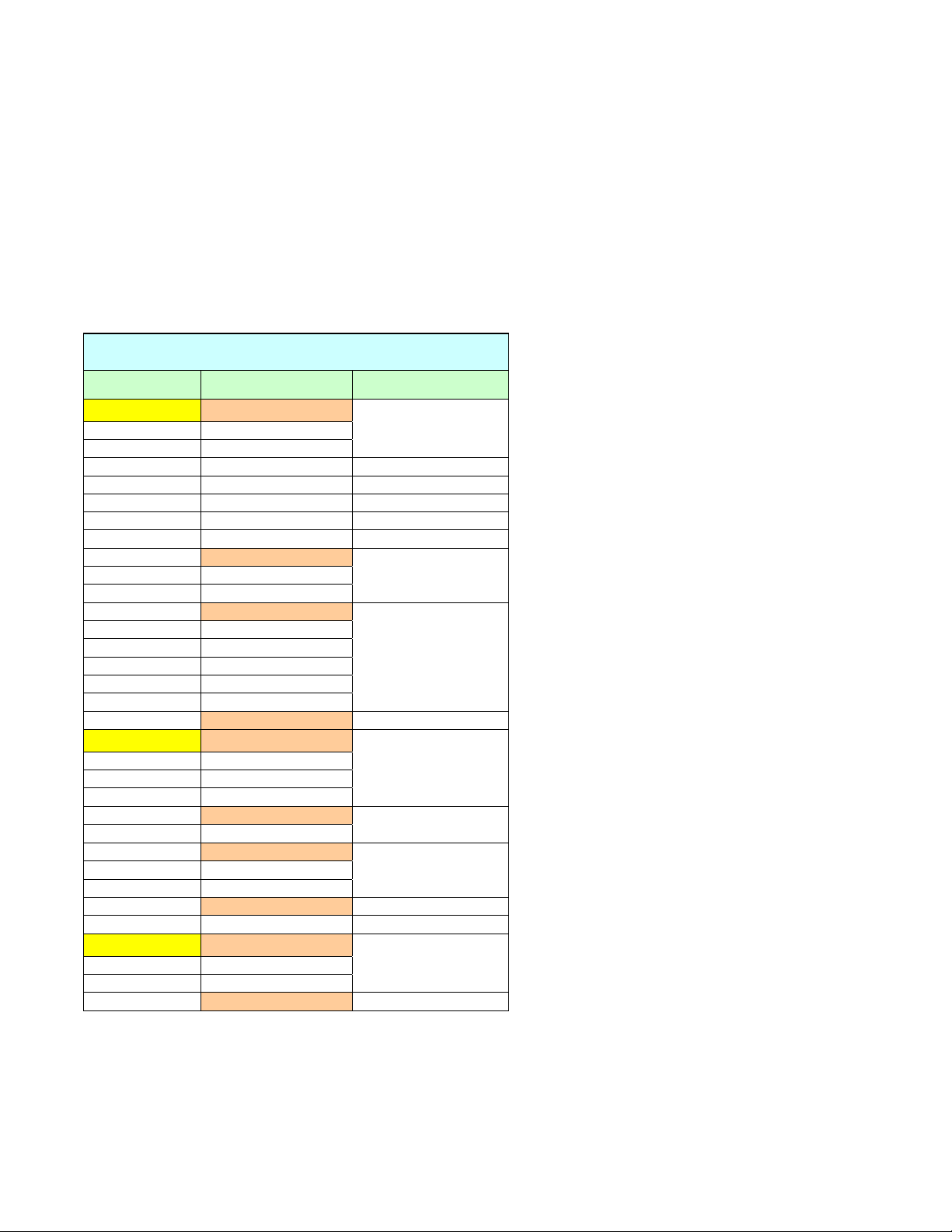

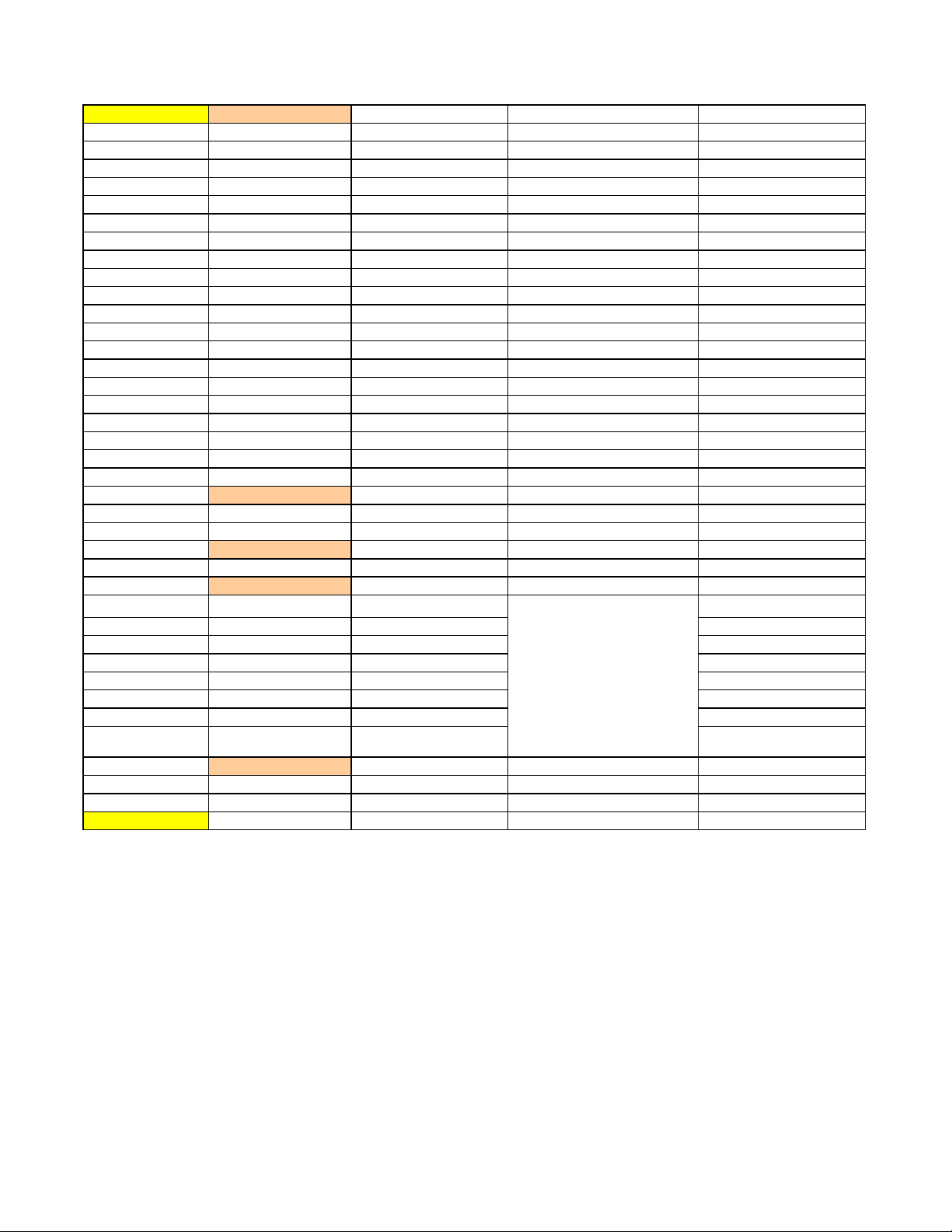

Replaceable Parts......................................................................................................................................... 32

Parts List by Model ..........................................................................................................................................32

Model LT3200 ............................................................................................................................................32

Model LT3700........................................................................................................................................... 33

Model LT4200........................................................................................................................................... 34

Model LT4700........................................................................................................................................... 35

Replacement Parts List Reference Pictures....................................................................................................... 36

Removal and Replacement.............................................................................................................................41

Equipment and Tools Needed for Removal and Replacement ............................................................................... 41

Tools......................................................................................................................................................... 41

After Service Checklist................................................................................................................................. 41

Basic Adjustment Settings ............................................................................................................................ 41

........................................................................................................................... 21

......................................................................................... 20

HP High-Definition LCD TV Service Manual iii

Page 4

Four Models – Comparison Pictures ...................................................................................................................42

LT3200 ......................................................................................................................................................42

LT3700.......................................................................................................................................................42

LT4200 ..................................................................................................................................................... 43

LT4700...................................................................................................................................................... 43

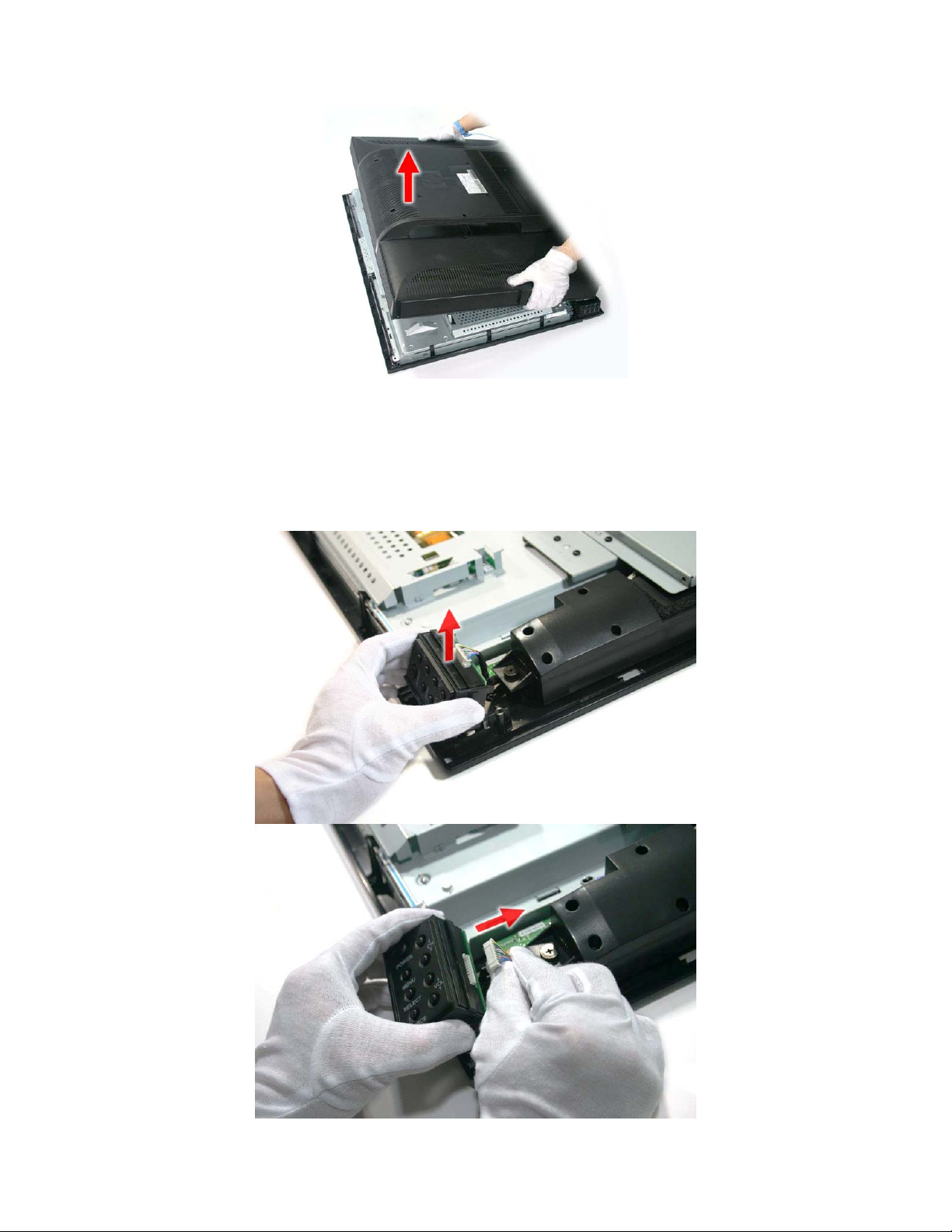

Removal Procedures........................................................................................................................................ 44

Removal Order........................................................................................................................................... 44

Screws ...................................................................................................................................................... 44

Removing the Pedestal................................................................................................................................. 45

Disassembling the Pedestal .......................................................................................................................... 46

Removing the Back Cover.............................................................................................................................47

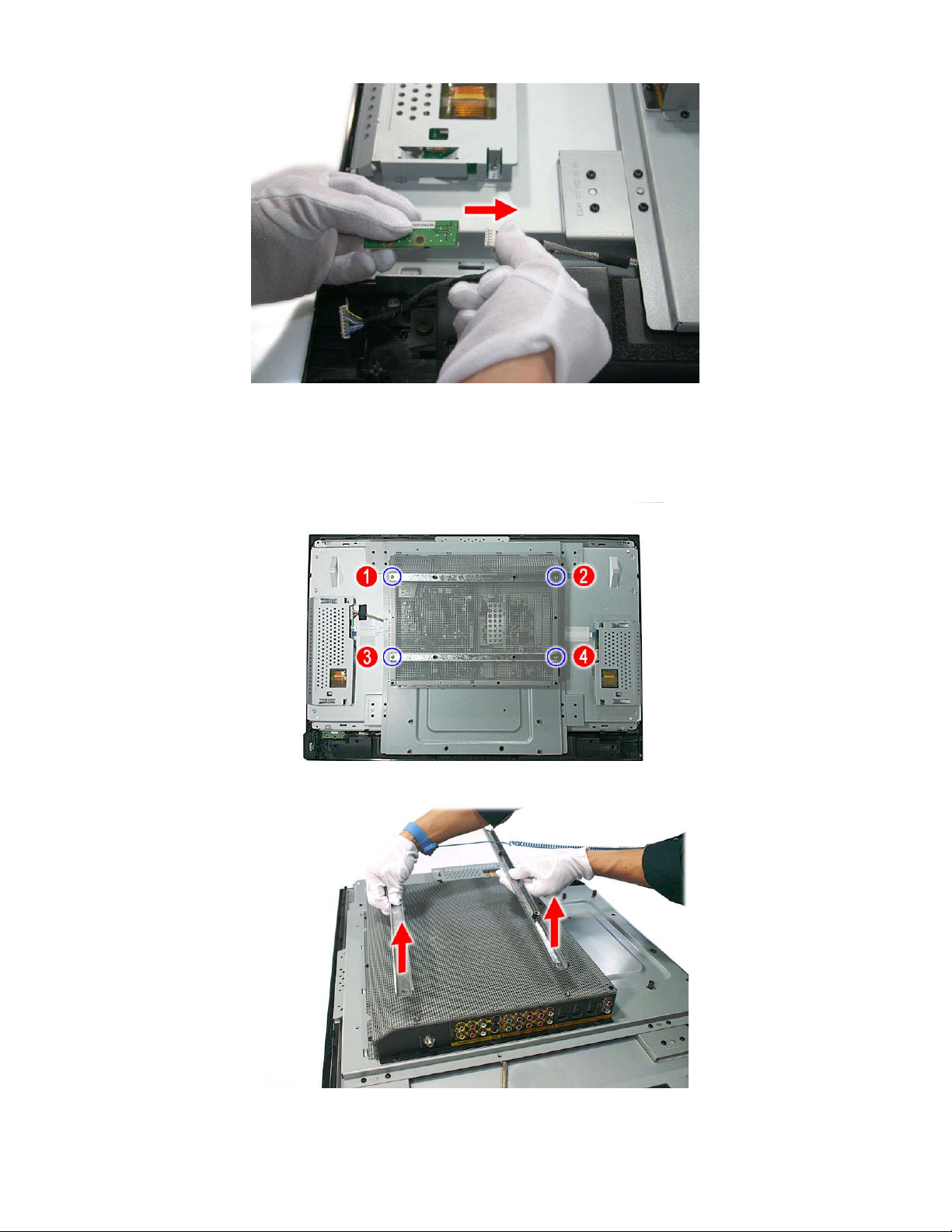

Removing the Function Keyboard .................................................................................................................. 48

Removing the Infrared Board.........................................................................................................................49

Removing the Wall Mount Brackets............................................................................................................... 50

Removing the Board Cover .......................................................................................................................... 51

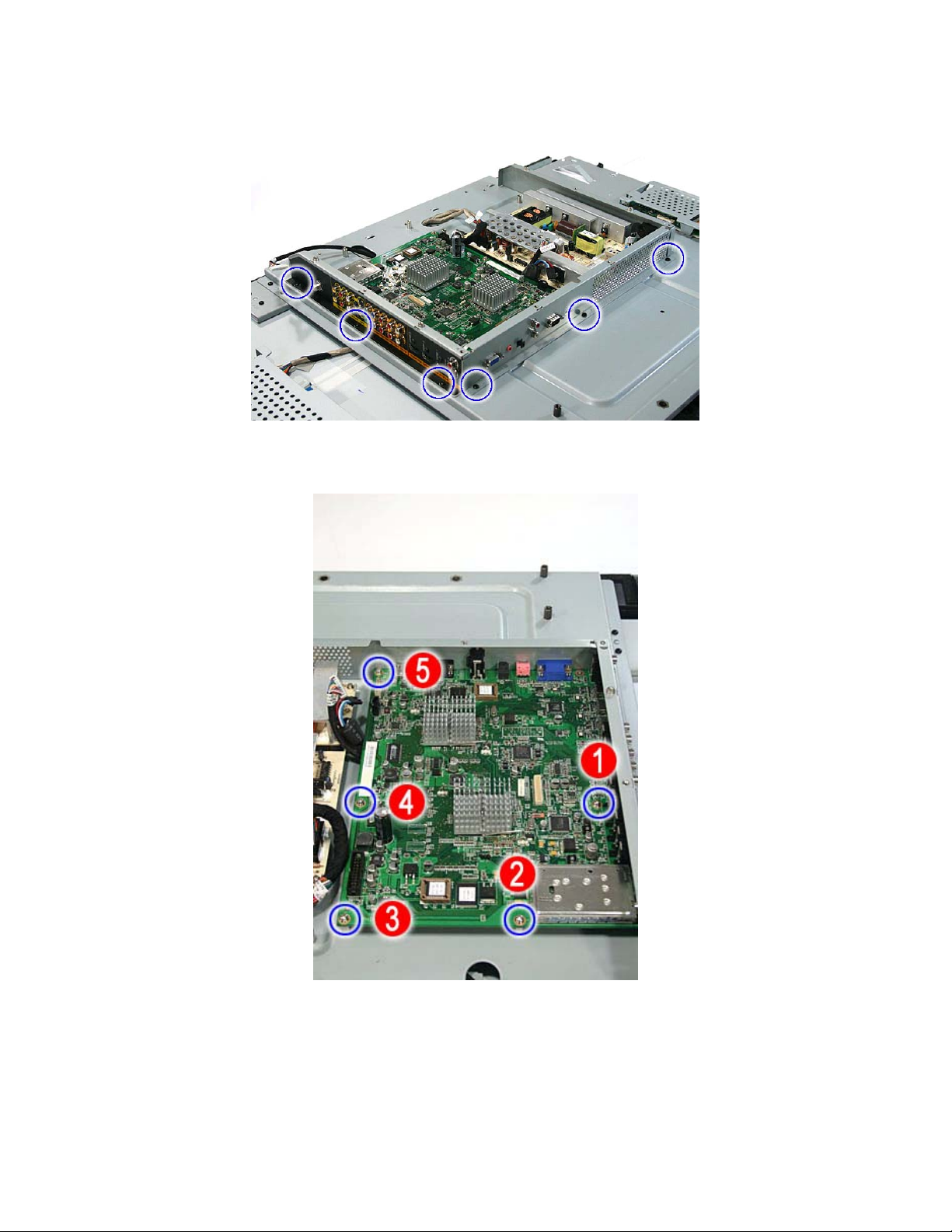

Removing the Main Board ........................................................................................................................... 51

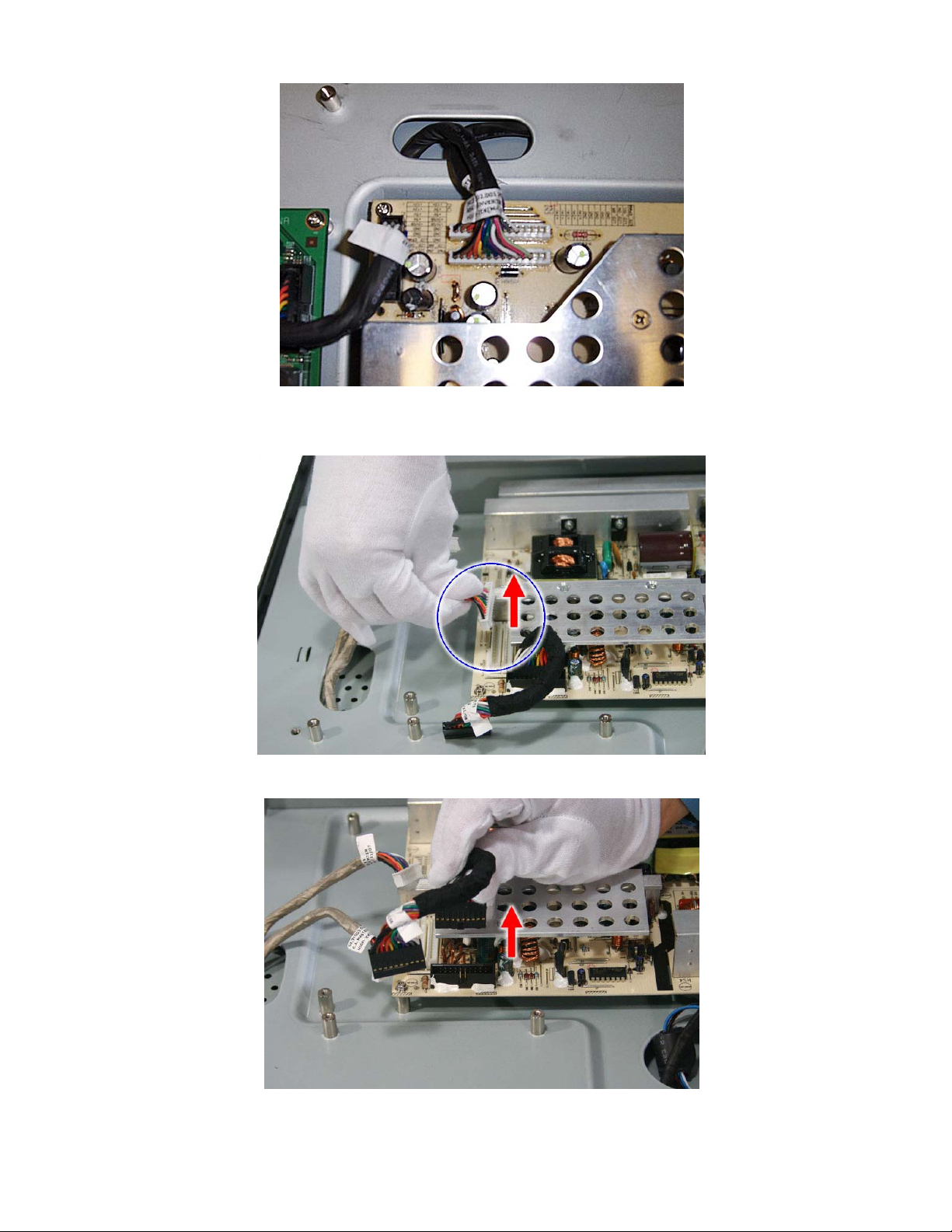

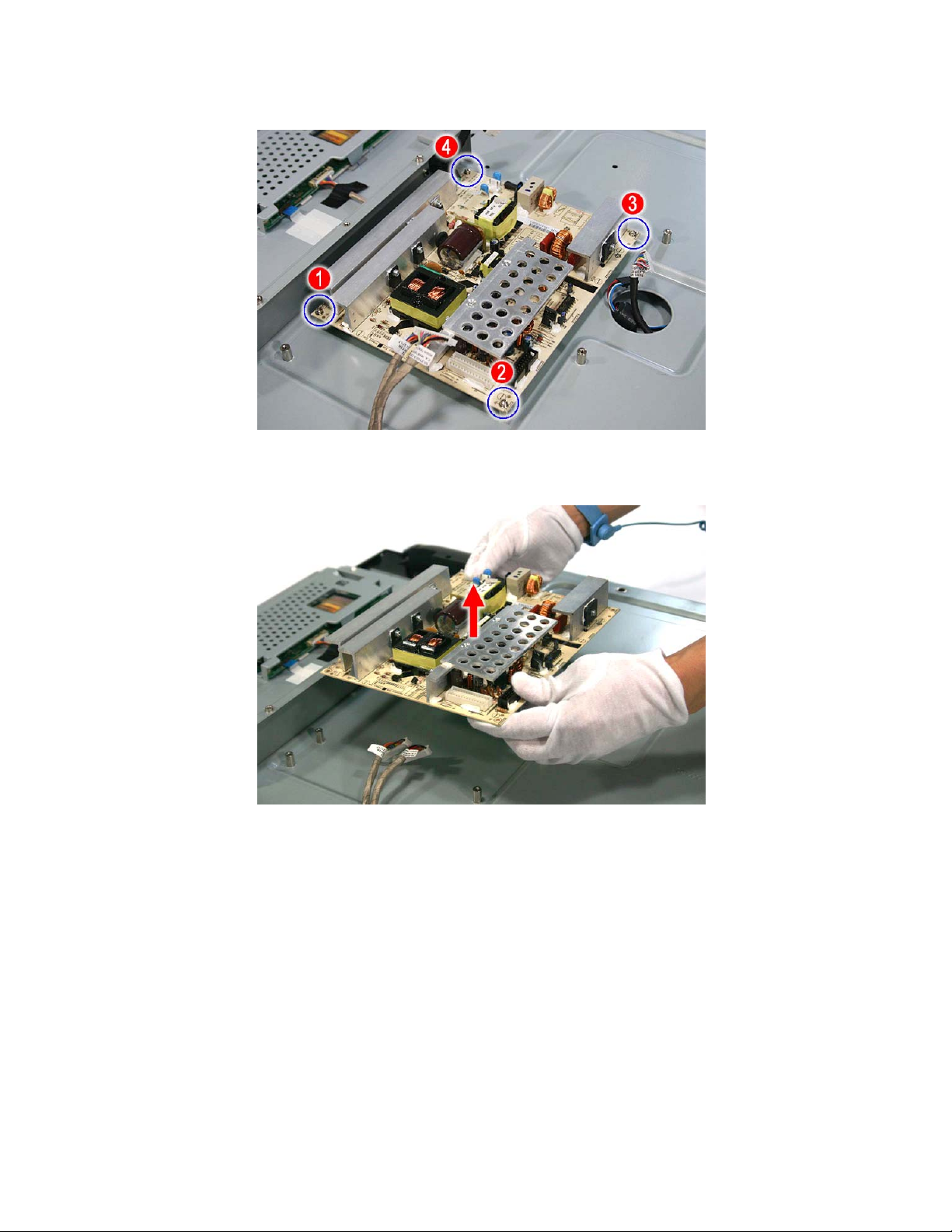

Removing the Power Supply ..........................................................................................................................55

Removing the Main Bracket...........................................................................................................................59

Removing the Inverters................................................................................................................................. 60

Removing the Speakers ............................................................................................................................... 63

Removing the Control Board ........................................................................................................................ 65

Removing the Front Bezel..............................................................................................................................69

Diagnostics ................................................................................................................................................. 70

LED Indicators.............................................................................................................................................70

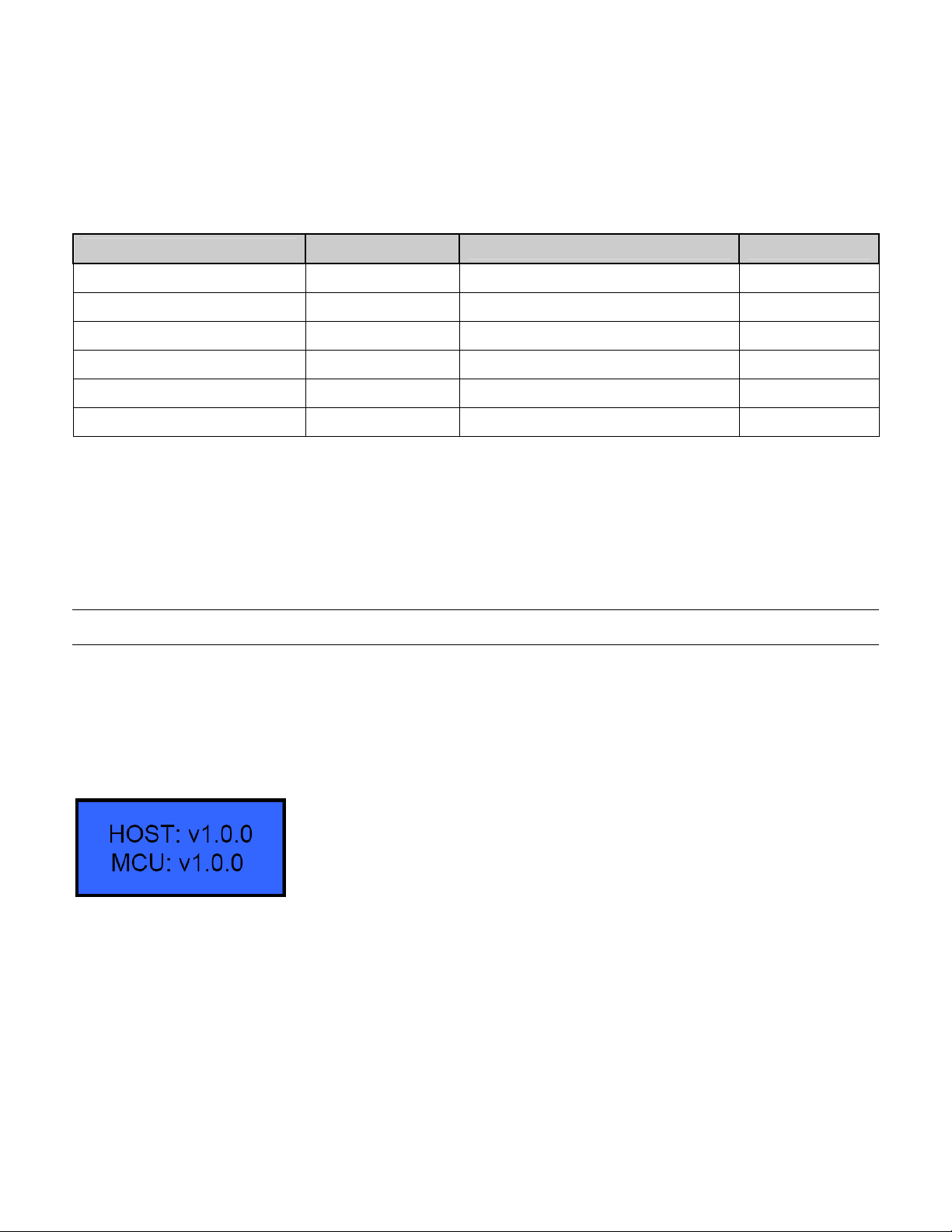

Software version information.............................................................................................................................70

How to run diagnostics ....................................................................................................................................70

How to get back to normal TV operation after running diagnostics....................................................................... 71

Installation menu ............................................................................................................................................ 71

Hotel mode ....................................................................................................................................................73

How to enable and disable ..........................................................................................................................73

Troubleshooting ........................................................................................................................................... 74

Remote Control ...............................................................................................................................................74

Function Key ...................................................................................................................................................75

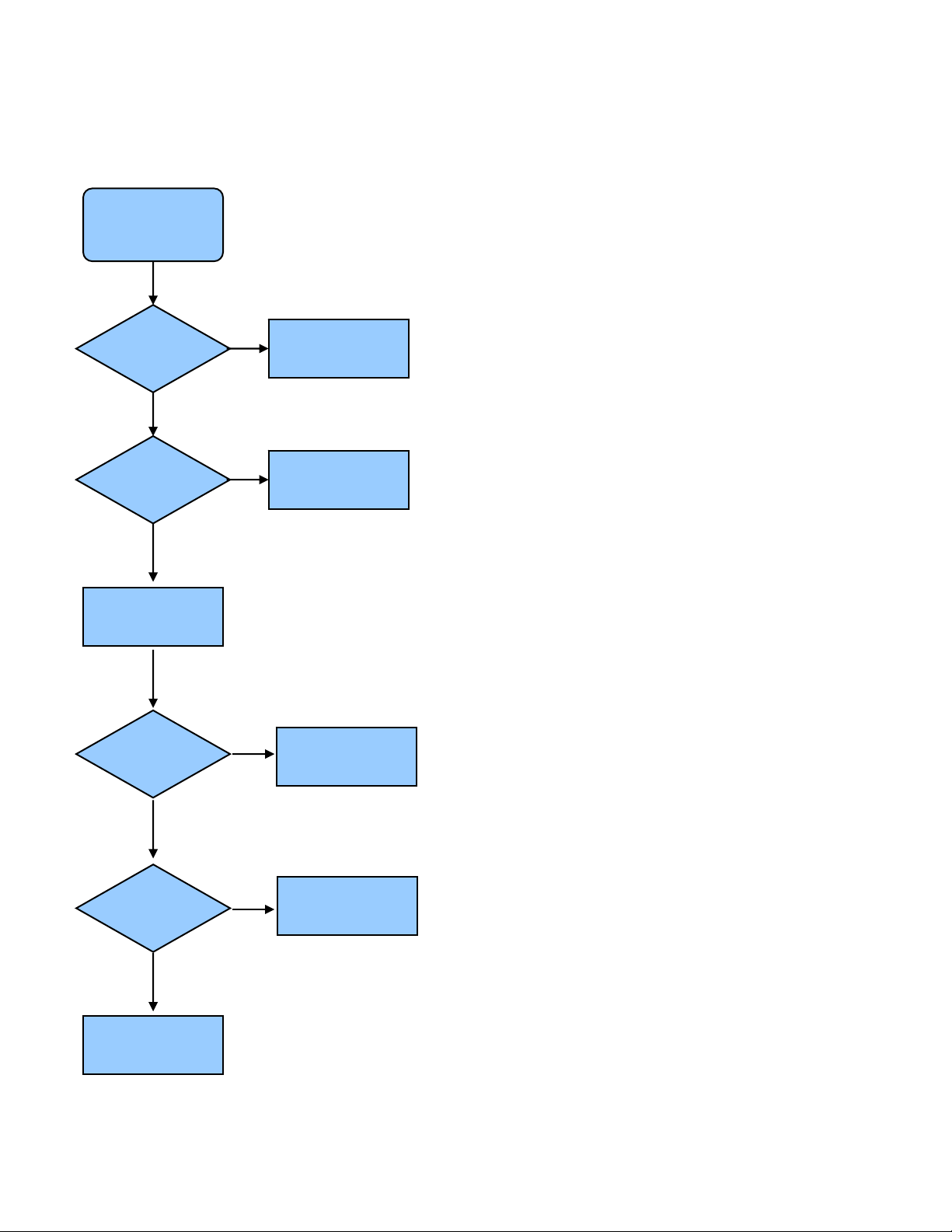

Power: TV Does Not Turn On ............................................................................................................................76

Audio ........................................................................................................................................................... 77

VGA Input ......................................................................................................................................................78

HDMI Input.....................................................................................................................................................79

DVI Input....................................................................................................................................................... 80

YPbPr Input.................................................................................................................................................... 81

TV/Video/S-video Input ...................................................................................................................................82

Troubleshooting Tips ....................................................................................................................................... 83

No Power.................................................................................................................................................. 83

No Video.................................................................................................................................................. 83

Keypad abnormal....................................................................................................................................... 83

LED Display abnormal................................................................................................................................. 83

Abnormal Display....................................................................................................................................... 83

iv HP High-Definition LCD TV Service Manual

Page 5

LED Display abnormal................................................................................................................................. 84

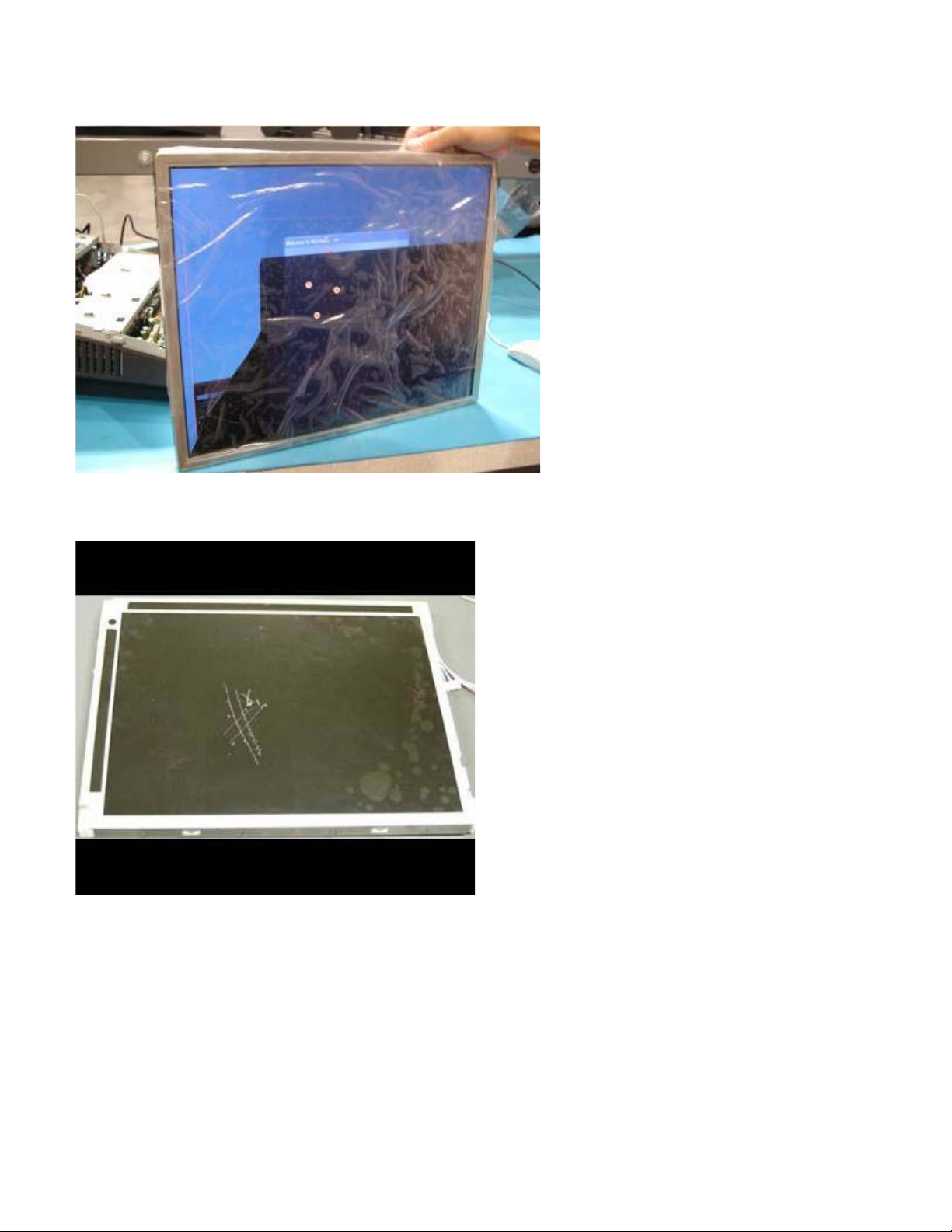

LCD Panel Troubleshooting Tips........................................................................................................................ 84

Inverter board............................................................................................................................................ 84

Control board (panel driver)......................................................................................................................... 84

LVDS cable ................................................................................................................................................ 84

Screen ...................................................................................................................................................... 84

Example of defective LCDs........................................................................................................................... 85

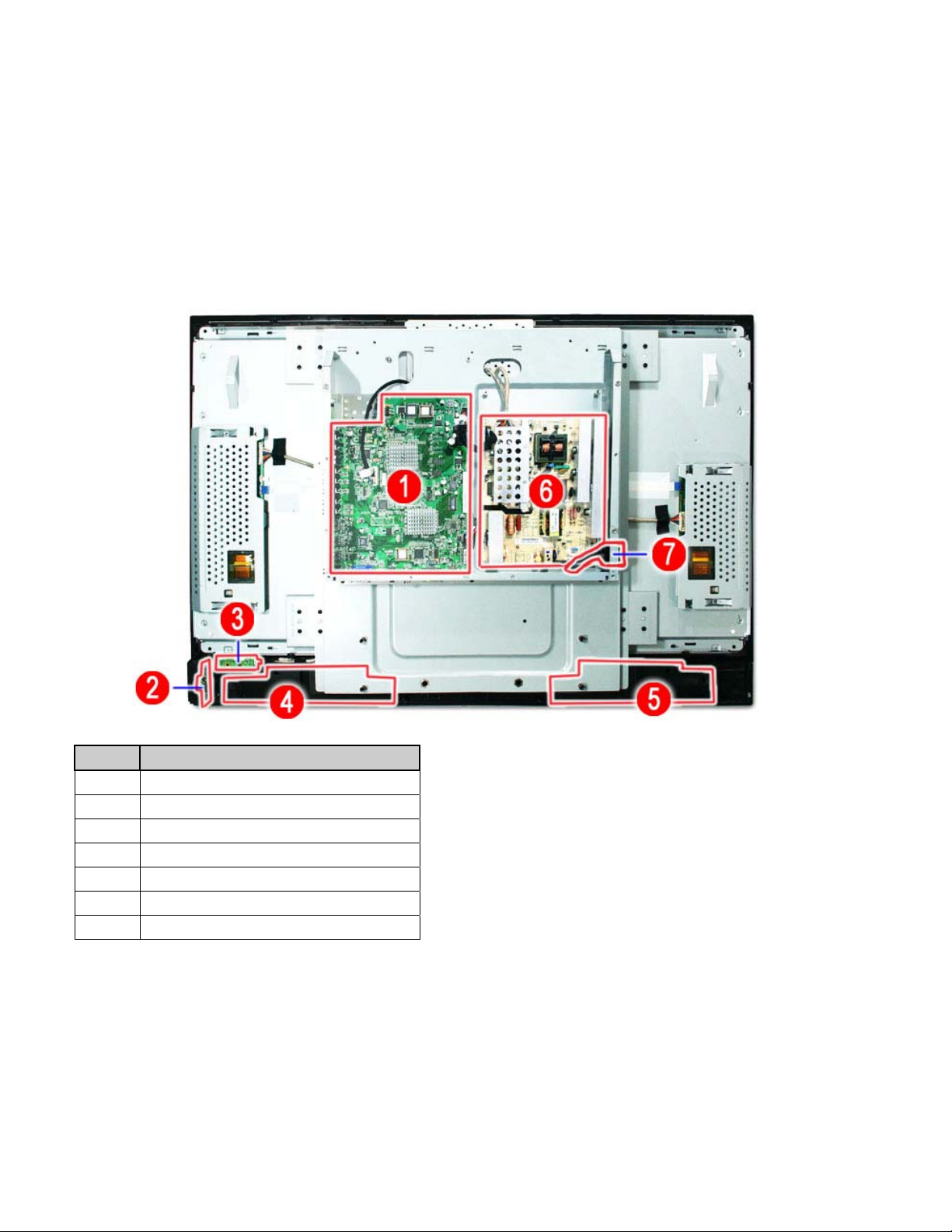

Chassis Layout and Overall Wiring Diagrams .................................................................................................. 88

Boards Layout (Typical of all models except 32-inch*) ........................................................................................ 88

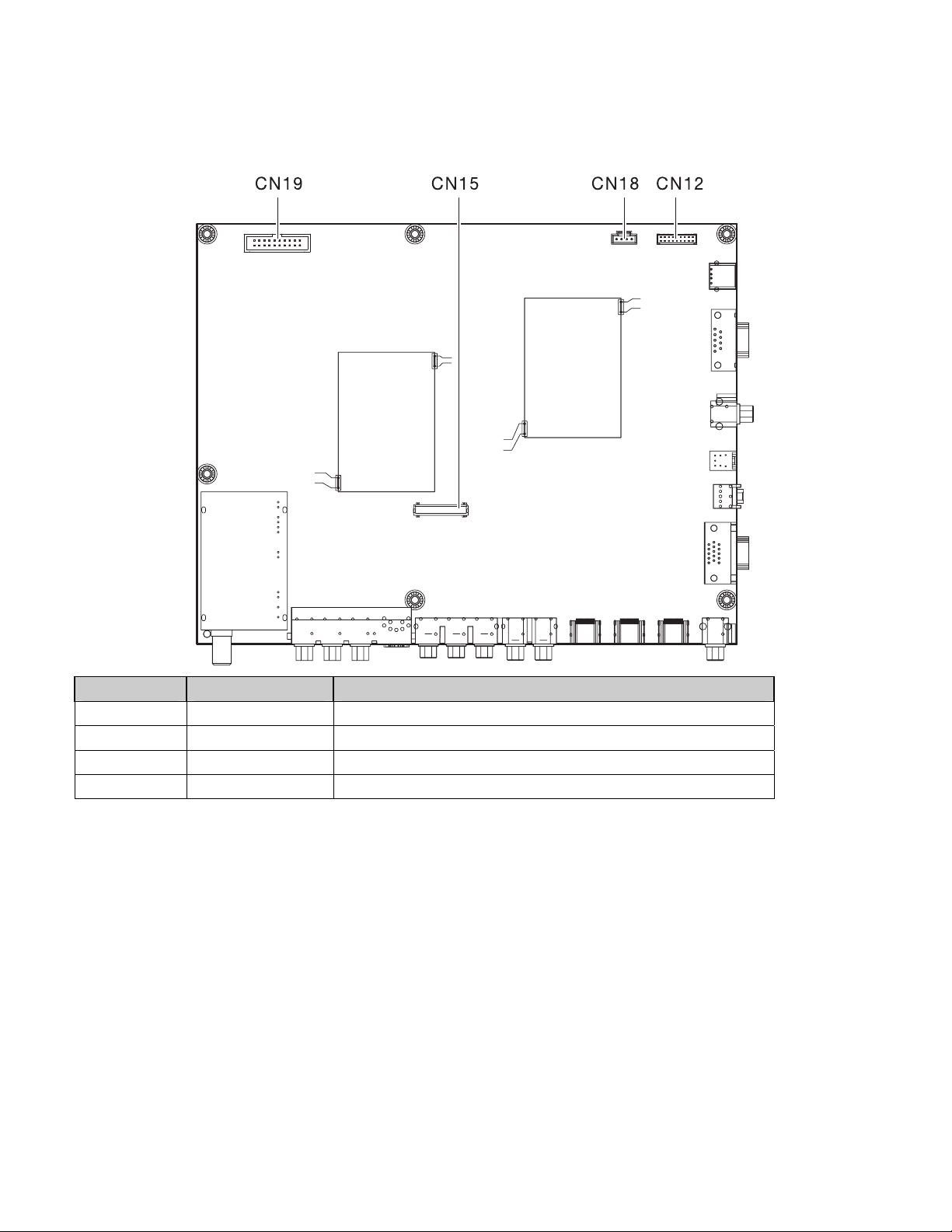

Connectors.................................................................................................................................................... 89

Main Board............................................................................................................................................... 89

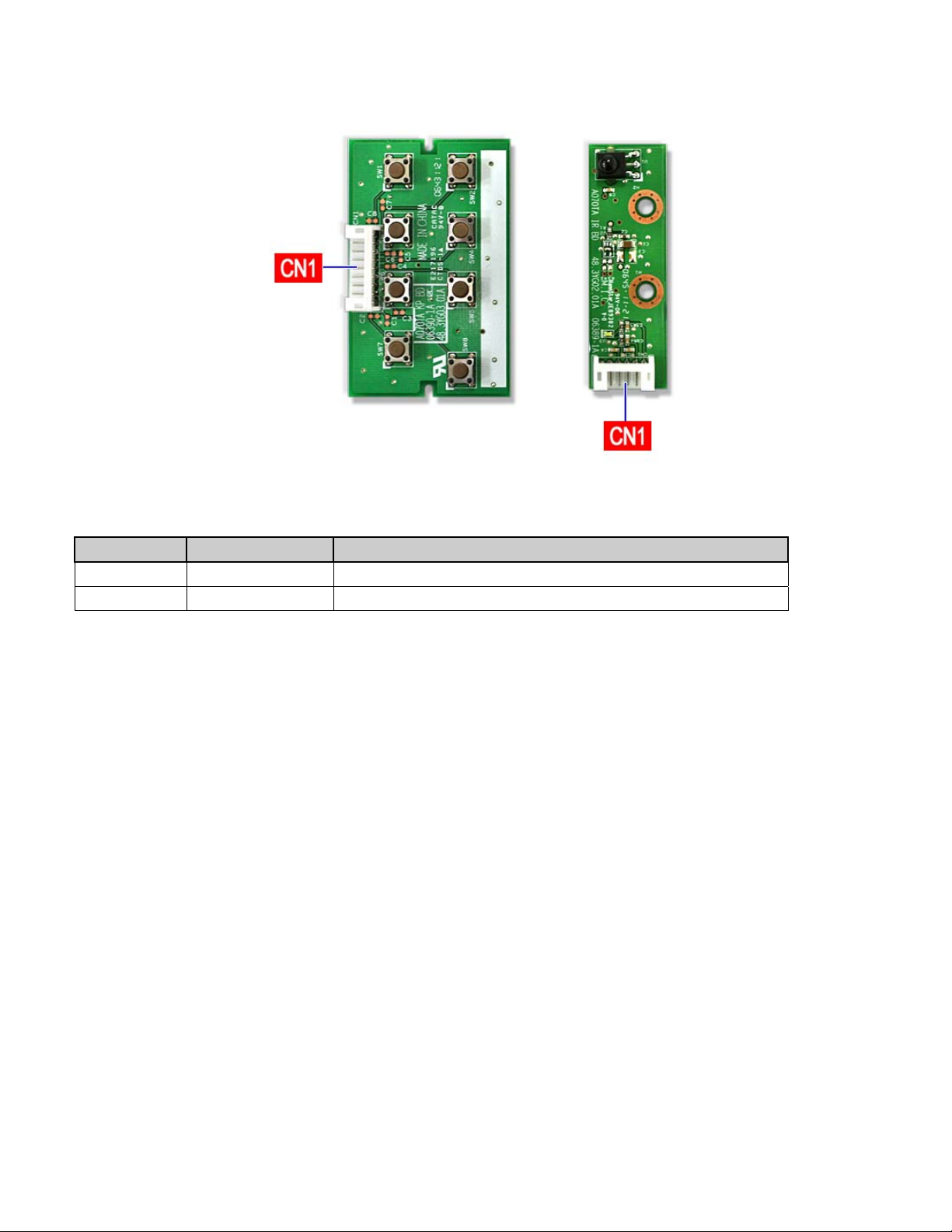

Keypad and IR Boards................................................................................................................................ 90

Wires and Cables Wiring............................................................................................................................... 91

Main Board............................................................................................................................................... 91

Wiring Diagram............................................................................................................................................. 92

Firmware Update Procedure........................................................................................................................... 93

Overview .......................................................................................................................................................93

Safe Software Update Procedure.......................................................................................................................93

Introduction.................................................................................................................................................93

Software Feature Requirement .......................................................................................................................94

Software Update Procedure ..............................................................................................................................94

Limitation of this Implementation....................................................................................................................94

Appendix A – LCD Panel Specifications ........................................................................................................... 95

Chi Mei Optoelectronics Corporation:................................................................................................................95

AU Optronics Corporation LCD Panel Product Specifications .................................................................................95

L.G. Philips LCD Panel Product Specifications ......................................................................................................95

HP High-Definition LCD TV Service Manual v

Page 6

Important Service Safety Precautions

BEFORE SERVICING THE LCD MODULE, READ THE

SAFETY PRECAUTIONS IN THIS MANUAL.

WHEN REPLACEMENT PARTS ARE REQUIRED, BE

SURE TO USE REPLACEMENT PARTS SPECIFIED BY

THE MANUFACTURER.

Proper service and repair is important to the safe,

reliable operation of all HP equipment. The service

procedures recommended by HP and described in this

service manual are effective methods of performing

service operations. Some of these service operations

require the use of tools specifically designed for their

purpose, and should be used as recommended.

It is important to note that this manual contains various

Cautions and Notices that should be carefully read in

order to minimize the risk of personal injury to service

personnel. Improper service methods may damage the

equipment. It is also important to understand that these

Cautions and Notices are not exhaustive. HP could not

possibly know, evaluate, and advise the service trade

of all conceivable ways in which service might be

done or of the possible hazardous consequences of

each way. Consequently, HP has not undertaken any

such broad evaluation. Service technicians who use

service procedures or tools that are not recommended

by HP must exercise caution and be sure that neither

their safety nor the safe operation of the equipment will

be jeopardized by the service method selected.

Warnings and Cautions

WARNING: Critical components having special

safety characteristics are identified with a

the reference number in the parts list.

WARNING: Use of substitute replacement parts,

which do not have the same specified safety

characteristics, may create shock, fire, or other

hazards. Under no circumstances should the

original design be modified or altered without

written permission from HP. HP assumes no

liability, express or implied, arising out of any

unauthorized modification of design. The service

technician assumes all liability.

by

CAUTION: To ensure the continued reliability of

this product, use only the original manufacturer’s

replacement parts, which are listed with their part

numbers in the “Replaceable Parts List” section of

this service manual.

WARNING: All ICs and many other

semiconductors are susceptible to electrostatic

discharges (ESDs). Careless handling during repair

can be life-threatening. When repairing, make sure

that you are connected with the same potential as

the mass of the set by a wristband with resistance.

Keep components and tools also at this same

potential.

WARNING:

1 Never replace modules or other components

while the unit is turned on.

2 When making settings, use plastic rather than

metal tools. This will prevent any short circuits

and the danger of a circuit becoming unstable.

WARNING: To prevent electrical shock, do not use

the polarized AC plug with an extension cord,

receptacle, or the outlet unless the blades can be

fully inserted to prevent blade exposure. To prevent

electrical shock, match the wide blade or plug to a

wide slot and fully insert.

WARNING: When replacement parts are

required, be sure to use replacement parts

specified by the manufacturer or have the same

characteristics as the original part. Unauthorized

substitutions may result in fire, electric shock, or

other hazards.

HP High-Definition LCD TV Service Manual 1

Page 7

WARNINGS:

Safety regulations require that after a repair the set

must be returned in its original condition. In particular

attention should be paid to the following points:

NOTE: The wiring should be routed correctly and fixed

with the mounted cable clamps. The insulation of the

main leads should be checked for external damage.

• Do not touch the signal and the power connector

while this product is operating. Do not touch the EMI

ground part and the heat sink of the film filter.

• Do not supply a voltage higher than that specified to

this product. This may damage the product and may

cause a fire.

• Do not use this product in locations where the

humidity is extremely high, where it may be

splashed with water, or where flammable materials

surround it. Do not install or use the product in a

location that does not satisfy the specified

environmental conditions. This may damage the

product and may cause a fire.

• If a foreign substance (such as water, metal, or

liquid) gets inside the panel module, immediately

turn off the power. Continuing to use the product,

may cause fire or electric shock.

• If the product emits smoke or an abnormal smell, or

it makes an abnormal sound, immediately turn off

the power. Continuing to use the product, may

cause fire or electric shock.

• Do not disconnect or connect the connector while

power to the product is on. It takes some time for the

voltage to drop to a sufficiently low level after the

power has been turned off. Confirm that the voltage

has dropped to a safe level before disconnecting or

connecting the connector.

• Do not pull out or insert the power cable from or to

an outlet with wet hands. It may cause electric

shock.

• Do not damage or modify the power cable. It may

cause fire or electric shock.

• If the power cable is damaged, or if the connector is

loose, do not use the product; this can lead to fire or

electric shock.

• If the power connector or the connector of the

power cable becomes dirty or dusty, wipe it with a

dry cloth. Continuing to use the product may cause

fire or electric shock.

• The LCD module uses a high-voltage (maximum

450V DC). Be cautious of electric shock and do not

touch the device circuitry when handling the LCD

unit. Because the capacitor of the device circuitry

may remain charged at the moment of power off,

standing by for 1 minute is strongly recommended

before touching the device circuitry.

• Use only with the cart, stand, tripod, bracket, or

table specified by the manufacturer, or sold with the

apparatus. When a cart is used, use caution when

moving the cart/apparatus combination to avoid

injury from tip-over.

Safe Handling and Servicing

The work procedures shown with the

Warning symbol are important for ensuring

the safety of the product and the servicing

work. Be sure to follow these instructions.

• Before starting the work, secure a sufficient

workspace.

• At all times, other than when adjusting and checking

the product, be sure to turn off the Power button and

disconnect the power cable from the power source

of the TV during servicing.

• To prevent electric shock and breakage of PC

board, start the servicing work at least 30 seconds

after the main power has been turned off. Especially

when installing and removing the power supply

board and the SUS board, which involve high

voltages, start servicing at least 2 minutes after the

main power has been turned off.

• While the main power is on, do not touch any parts

or circuits other than the ones specified. The highvoltage power supply block within the LCD module

has a floating ground. If any connection other than

the one specified is made between the measuring

equipment and the high voltage power supply

block, it can result in electric shock or activation of

the leakage-detection circuit breaker.

• When installing the LCD module into and removing

it from the packing carton, be sure to have at least

two people perform the work while being careful to

ensure that the flexible printed-circuit cable of the

LCD module does not get caught by the packing

carton.

• When the surface of the panel comes into contact

with the cushioning materials, be sure that there is

no foreign matter on top of the cushioning materials.

Foreign matter may scratch the surface of the panel.

• Be sure to remove static electricity from your body

before handling the circuit board.

2 HP High-Definition LCD TV Service Manual

Page 8

• Be sure to handle the circuit board by holding the

large parts such as the heat sink or transformer.

Failure to observe this precaution may result in the

occurrence of an abnormality in the soldered areas.

• Do not stack the circuit boards. Failure to observe

this precaution may result in problems resulting from

scratches on the parts, the deformation of parts, and

short-circuits due to residual electric charge.

• Routing the wires and fixing them in position must

be done in accordance with the original routing and

fixing configuration when servicing is completed. All

the wires are routed far away from the areas that

become hot (such as the heat sink). These wires are

fixed in position with the wire clamps so that the

wires do not move, thereby ensuring that they are

not damaged and their materials do not deteriorate

over long periods of time. Therefore, route the

cables and fix the cables to the original position

and states using the wire clamps.

• Perform a safety check when servicing is completed.

Verify that the peripherals of the serviced points

have not undergone any deterioration during

servicing. Also verify that the screws, parts, and

cables removed for servicing purposes have all

been returned to their proper locations in

accordance with the original setup.

• A glass plate protects the LCD display. This glass

plate can be cleaned with a slightly moist cloth. If

dirt appears between the glass plate and the LCD

display panel have only a qualified service

employee clean it.

Repair Tips

WARNING: All ICs and many other

semiconductors are susceptible to electrostatic

discharges (ESDs). Careless handling during repair

can be life-threatening. When repairing, make sure

that you are connected with the same potential as

the mass of the unit via a wrist wrap with

resistance. Keep components and tools also at the

same potential.

About Lead-Free Solder

NOTE: LEAD IS LISTED AS (PB) IN THE PERIODIC

TABLE OF THE ELEMENTS. IN THE INFORMATION

THAT FOLLOWS, PB WILL REFER TO LEAD SOLDER,

AND PBF WILL REFER TO LEAD-FREE SOLDER. THE

LEAD-FREE SOLDER USED IN OUR MANUFACTURING

PROCESS AND DISCUSSED HERE IS (SN+AG+CU).

THAT IS TIN (SN), SILVER (AG), AND COPPER (CU),

ALTHOUGH OTHER TYPES ARE AVAILABLE.

This model is manufactured using Pb-free solder for the

sake of environmental conservation. For service and

repair work, we suggest using Pb-free solder as well,

although Pb solder may be used.

PCBs manufactured using Pb-free solder have the sign

stamped on the PCB.

CAUTIONS:

• Pb-free solder has a higher melting point than Pb

solder. Typically the melting point is 50–70ºF

(30–40°C) higher. Use a high temperature soldering

iron. Adjust your solder tool so that a temperature

around 360–380ºC is reached and stabilized at the

solder joint. Heating time of the solder joint should

not exceed 4 seconds. Avoid temperatures above

400ºC; wear-out of tips will rise drastically and fluxfluid will be destroyed.

• Pb-free solder will tend to splash when heated too

high (about 1,100ºF or 600ºC).

• Mix of Pb-free solder Tin (SN)/parts with leaded

soldering Tin (SN) in/parts is possible but not

recommended. If you have to use Pb solder,

completely remove all of the Pb-free solder on the

pins or solder area before applying Pb solder. If this

is not practical, be sure to heat the Pb-free solder

until it melts, before applying Pb solder.

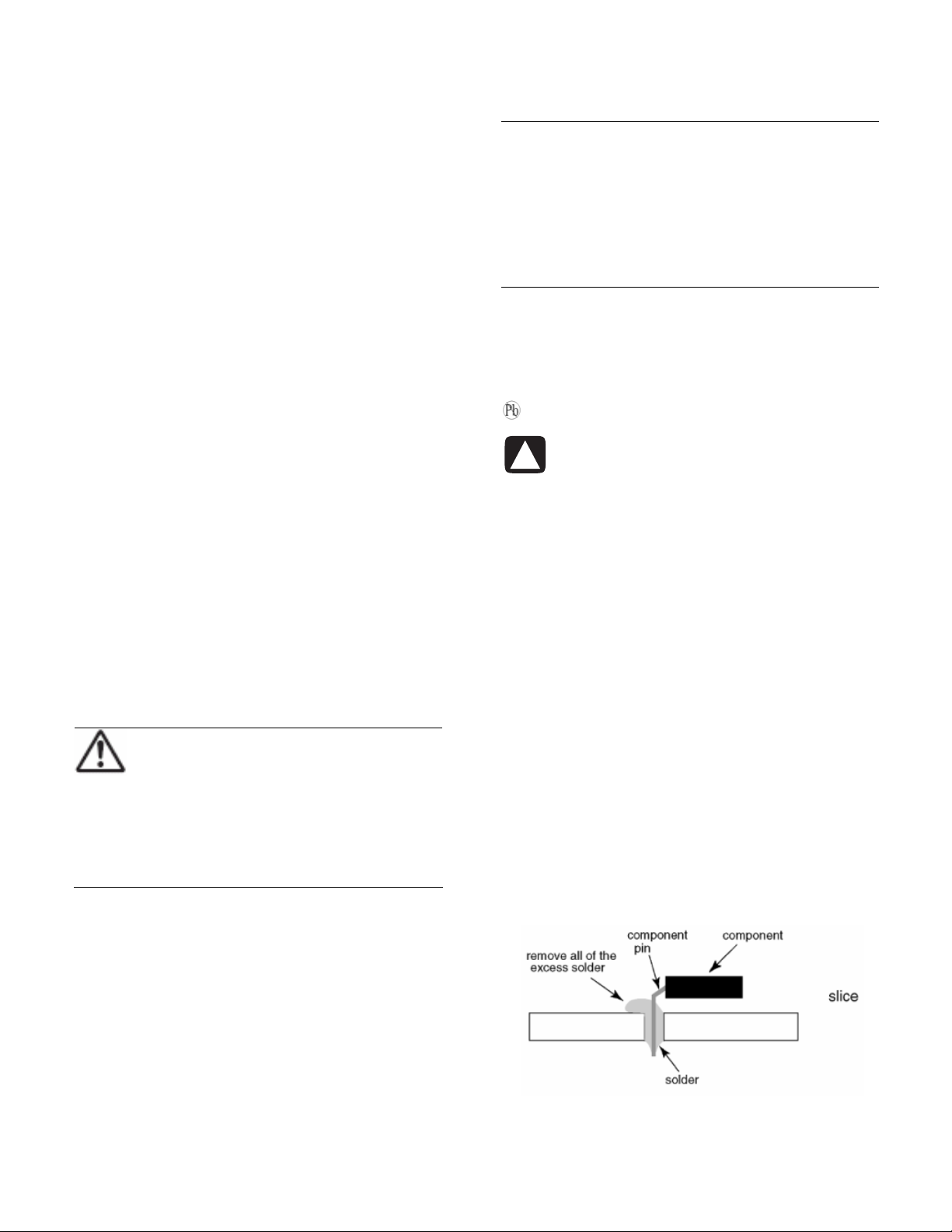

• After applying Pb-free solder to double-layered

boards, check the component side for excess solder

that may flow onto the opposite side (see the

following illustration).

HP High-Definition LCD TV Service Manual 3

Page 9

• Special information for Pb-free BGA-ICs: These ICs

will be delivered in so-called dry-packaging to

protect the IC against moisture and with the Pb-free

logo on it. This packaging may only be opened

shortly before it is used (soldered). Otherwise the

body of the IC gets wet inside, and during the

heating time the structure of the IC will be destroyed

from steam pressure. If the packaging was opened

before usage the IC has to be heated up for about

90 hours to dry. Make sure you use ESD protection!

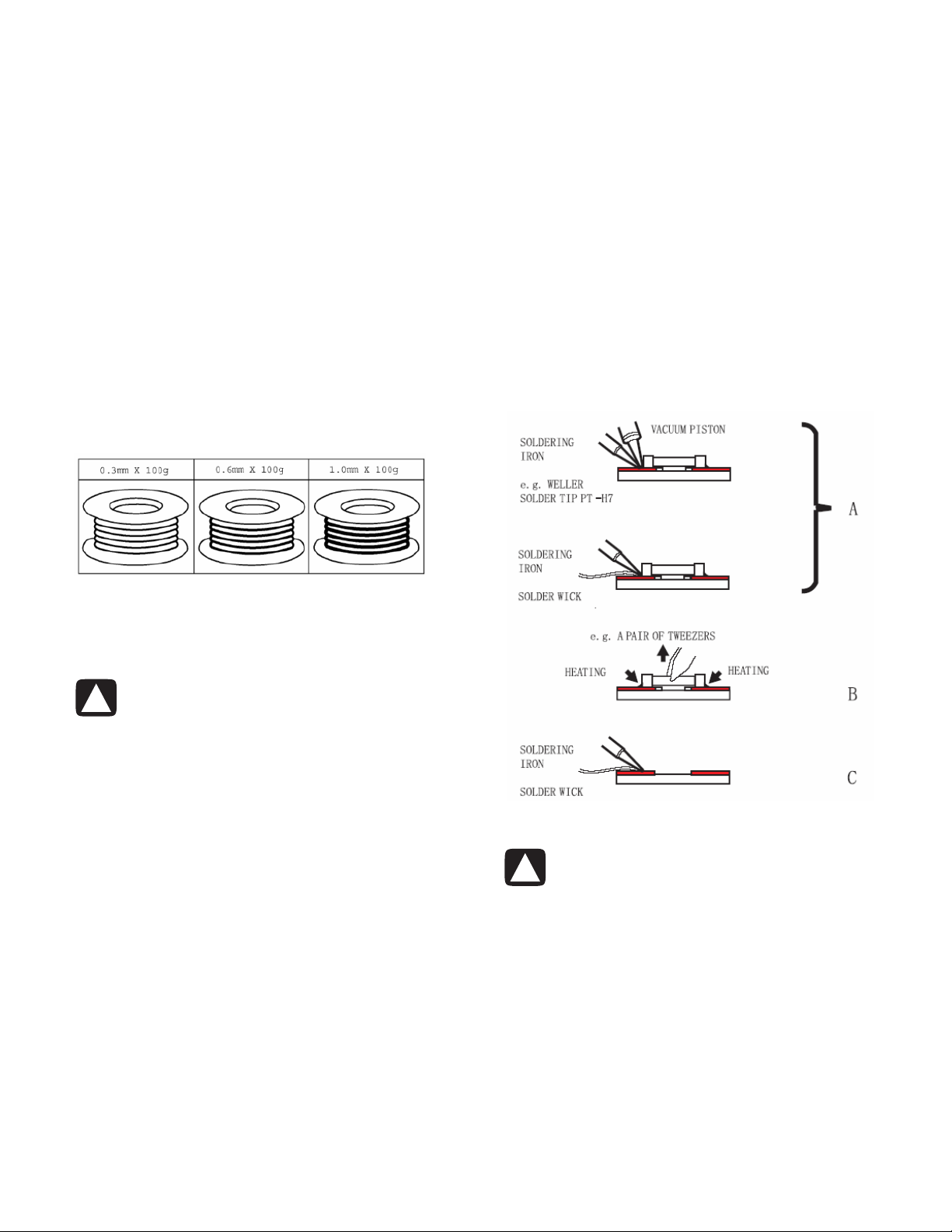

Suggested Pb-Free Solder

Several kinds of Pb-free solder (some shown in the

following illustration) are available for purchase. This

product uses Sn+Ag+Cu (tin (SN), silver (AG), copper

(CU)) solder. However, Sn+Cu (tin (SN), copper (Cu)),

Sn+Zn+Bi (tin (SN), zinc (Zn), bismuth (Bi)) solder can

also be used.

• Never rub or scrape chip components as this may

cause the value of the component to change.

Similarly, do not slide the circuit board across any

surface.

Removal of SMDs

1 Heat the solder (for 2 to 3 seconds) at each terminal

of the chip. By means of soldier wick and a slight

horizontal force, small components can be removed

with the soldering iron. They can also be removed

with a solder sucker (A).

2 While holding the SMD with a pair of tweezers, take

it off gently using the soldering iron’s heat applied to

each terminal (B).

3 Remove the excess solder on the solder lands by

means of soldier wick or a solder sucker (C).

Servicing of Surface-Mounted Devices

(SMDs)

CAUTIONS:

General cautions on handling and storage:

• Oxidation on the terminals of SMDs results in poor

soldering. Do not handle SMDs with bare hands.

• Avoid using storage places that are sensitive to

oxidation, such as places with sulphur or chlorine

gas, direct sunlight, high temperatures, or a high

degree of humidity. The capacitance or resistance

value of the SMDs may be affected by these

conditions.

• Rough handling of circuit boards containing SMDs

may cause damage to the components as well as

the circuit boards. Circuit boards containing SMDs

should never be bent or flexed. Different circuit

board materials expand and contract at different

rates when heated or cooled and the components

and/or solder connections may be damaged due to

the stress.

CAUTIONS:

• When handling the soldering iron, use suitable

pressure and be careful.

• When removing the chip, do not use undue force

with the pair of tweezers.

• The soldering iron to be used (approx. 30 W) should

preferably be equipped with a thermal control

(soldering temperature: 360º to 380º C).

• Once removed, the chip cannot be reused.

4 HP High-Definition LCD TV Service Manual

Page 10

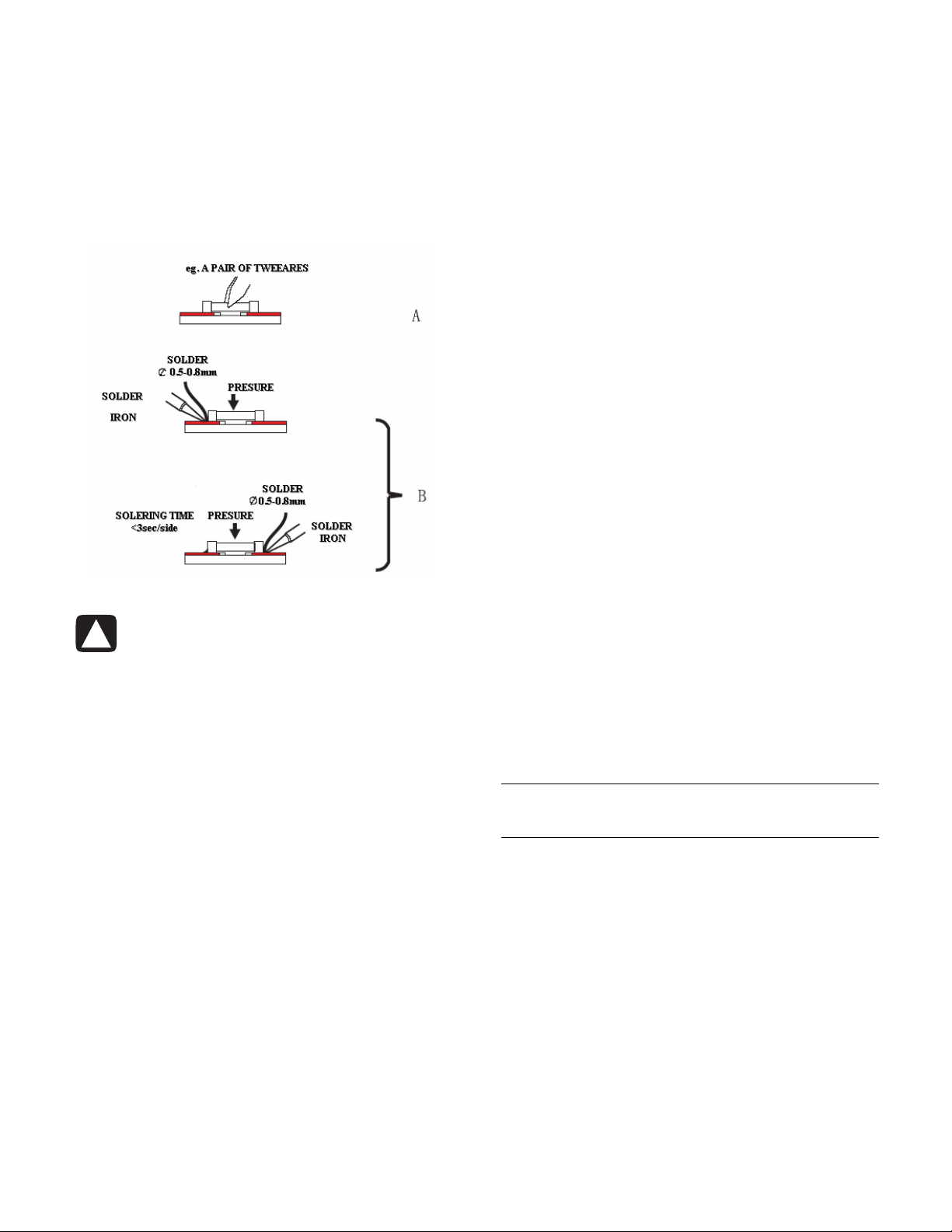

Attachment of SMDs

1 Locate the SMD on the solder lands by means of

tweezers and solder the component on one side.

Ensure that the component is positioned correctly on

the solder lands (A).

2 Complete the soldering of the terminals of the

component (B).

Rework on Ball Grid Array (BGA) ICs

General information

Although (LF) BGA assembly yields are very high, there

may still be a requirement for component rework. By

rework

, we mean the process of removing the

component from the PWB and replacing it with a new

component. If an (LF) BGA is removed from a PWB, the

solder balls of the component are deformed drastically

so the removed (LF) BGA has to be discarded.

Device removal

As is the case with any component that, it is essential

when removing an (LF) BGA, the board, tracks, solder

lands, or surrounding components are not damaged.

To remove an (LF) BGA, the board must be uniformly

heated to a temperature close to the reflow soldering

temperature. A uniform temperature reduces the

chance of warping the PWB. To do this, we

recommend that the board is heated until it is certain

that all the joints are molten. Then carefully pull the

component off the board with a vacuum nozzle. For

the appropriate temperature profiles, see the IC data

sheet.

CAUTIONS:

• When soldering the SMD terminals, do not touch

them directly with the soldering iron. The soldering

should be done as quickly as possible; care must be

taken to avoid damage to the terminals of the SMDs

themselves.

• Keep the SMD’s body in contact with the printed

board when soldering.

• The soldering iron to be used (approximately 30 W)

should preferably be equipped with a thermal

control (soldering temperature: 360º to 380º C).

• Soldering should not be done outside the

solder land.

• Soldering flux (of rosin) may be used but should not

be acidic.

• After soldering, let the SMD cool down gradually at

room temperature.

• The quantity of solder must be proportional to the

size of the solder land. If the quantity is too great,

the SMD might crack or the solder lands might be

torn loose from the printed board.

Area Preparation

When the component has been removed, the vacant IC

area must be cleaned before replacing the (LF) BGA.

Removing an IC often leaves varying amounts of solder

on the mounting lands. This excessive solder can be

removed with either a solder sucker or solder wick. The

remaining flux can be removed with a brush and

cleaning agent. After the board is properly cleaned

and inspected, apply flux on the solder lands and on

the connection balls of the (LF) BGA.

NOTE: Do not apply solder paste, as this has shown to

result in problems during resoldering.

Device replacement

The last step in the repair process is to solder the new

component on the board. Ideally, the (LF) BGA should

be aligned under a microscope or magnifying glass. If

this is not possible, try to align the (LF) BGA with any

board markers. To reflow the solder, apply a

temperature profile according to the IC data sheet. To

avoid damaging neighboring components, it may be

necessary to reduce some temperatures and times.

HP High-Definition LCD TV Service Manual 5

Page 11

Product Information and Specifications

Product Information

This specification table describes the key areas of all hardware service requirements of large entertainment High-

Definition LCD Television models LT3200, LT3700, LT4200, and LT4700. This document is for HP service personnel

(bench and in-home technicians) and ASP technicians in the repair and refurbishment of HP flat-panel televisions.

Product Profile

HP High-Definition Digital TV models LT3200, LT3700, LT4200, and LT4700 can display ATSC, NTSC and ClearQAM TV signals. All models also support High Definition Multimedia Interface (HDMI) and YPbPr (HD) display

technology. All models can be used as monitors for your PC with a VGA connector.

Specifications

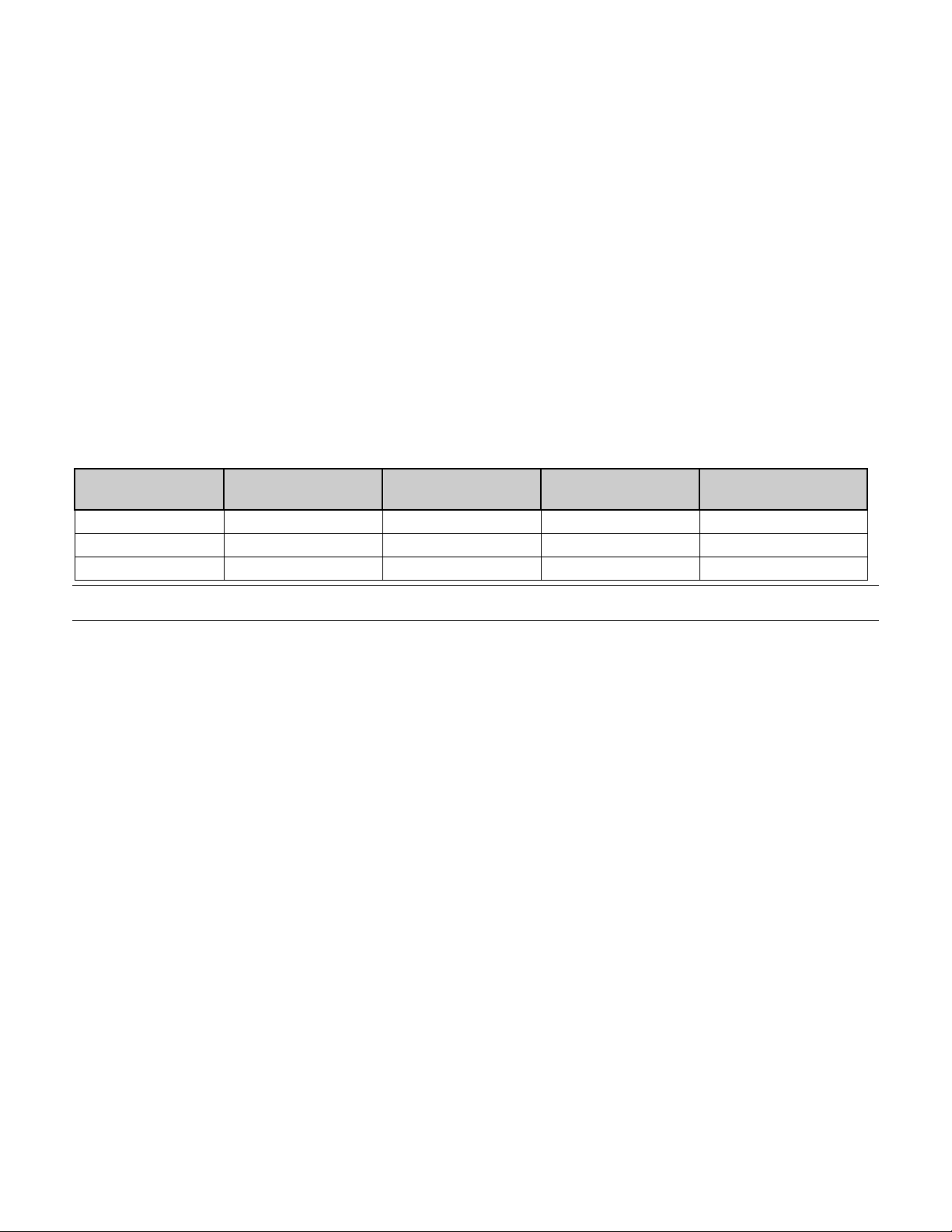

LCD Panel Module

Model name LT3200

(32” Model)

Number of pixels 1366 (H) x 768 (V) 1366 (H) x 768 (V) 1920 (H) x 1080 (V) 1920 (H) x 1080 (V)

Panel Manufacturer CMO LPL CMO CMO

Expected lifetime 60,000 hours 60,000 hours 60,000 hours 60,000 hours

NOTE: For more detailed specifications, refer to the panel specification documentation in the Appendix.

LT3700

(37” Model)

LT4200

(42” Model)

LT4700

(47” Model)

6 HP High-Definition LCD TV Service Manual

Page 12

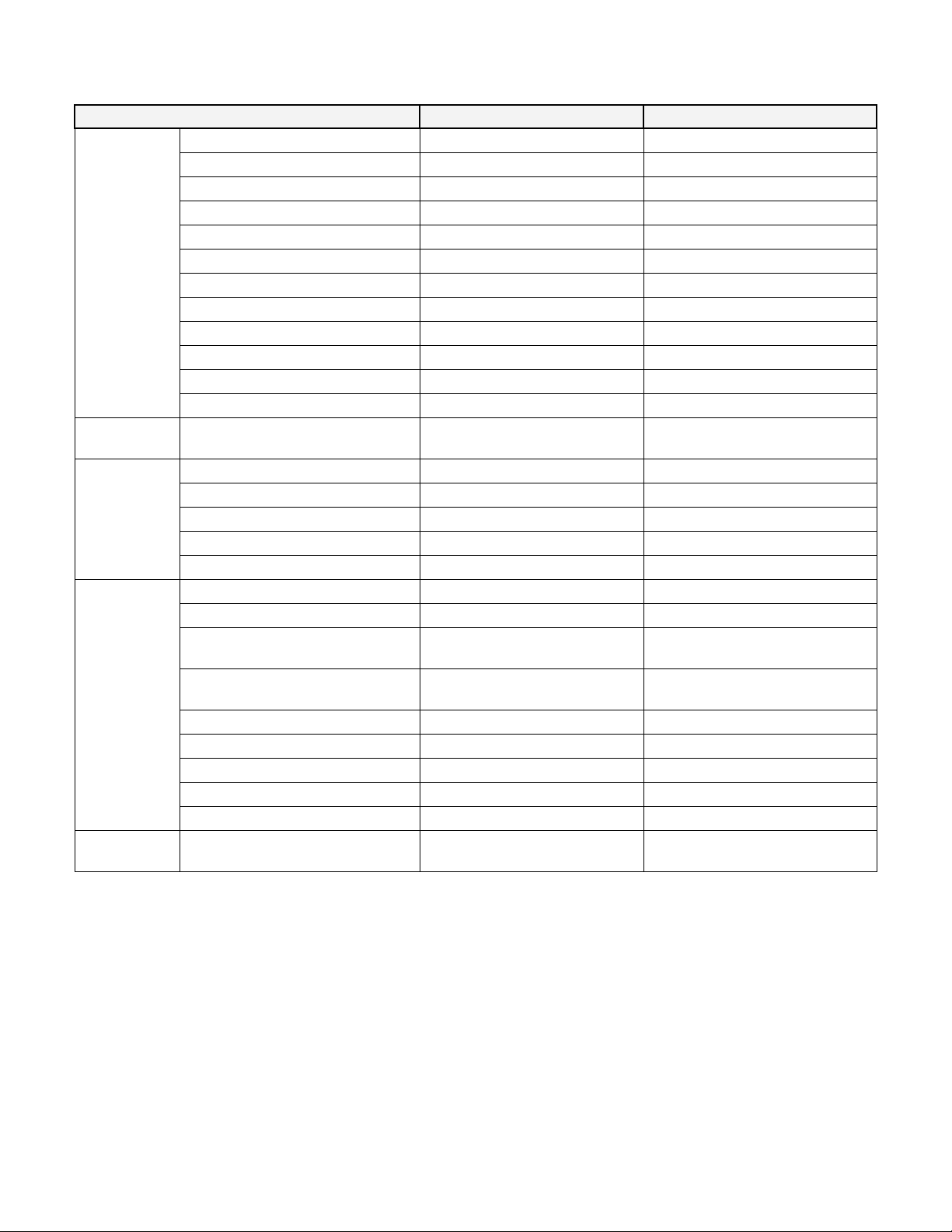

General TV Specifications LT3200 and LT3700

Model number LT3200 LT3700

Description 32” HDTV 37” HDTV

Availability June 2007 June 2007

Video

Tuning

Video

enhancers

Audio

Connectivity

Brightness

Resolution

Contrast Ratio

Viewing Angle

Response Time

Scalar

Supported Input

ATSC/NTSC/Clear -QAM 1 1

Unidirectional Cable

Card

3D Digital Comb Filter

Video Noise Reduction

3:2 Pull Down

HP Visual Fidelity Engine

Photorealistic Sharpness

Enhancement

3D Color Enrichment

Motion-Adaptive

Deinterlacer

Speakers 2 x 10W, 1 way 2 x 10W, 1 way

Dolby Digital Out Yes Yes

Virtual Surround Sound Theater, Music Hall Theater, Music Hall

SAP/MTS Yes Yes

AV In 2 2

Component In (YPbPr) 2 2

HDMI 3 3

S-Video In 2 2

Antenna In (RF) 1 1

PC VGA In 1 1

Analog Audio In (L/R) 5 5

PC Audio In 1 1

RS-232c 1 1

USB Port (service only) 1 1

Audio Out 1 1

SPDIF Out 1 1

Composite 0 0

500 cd/m2

1366 x 768

1200:1

176 degrees

8 ms

Trident PX66

480i, 480p, 720p, 1080i, 1080p

(HDMI only)

No No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

500 cd/m2

1366 x 768

1000:1

178 degrees

6 ms

Trident PX66

480i, 480p, 720p, 1080i, 1080p

(HDMI only)

Yes

Yes

Yes

Yes

Yes

Yes

Yes

HP High-Definition LCD TV Service Manual 7

Page 13

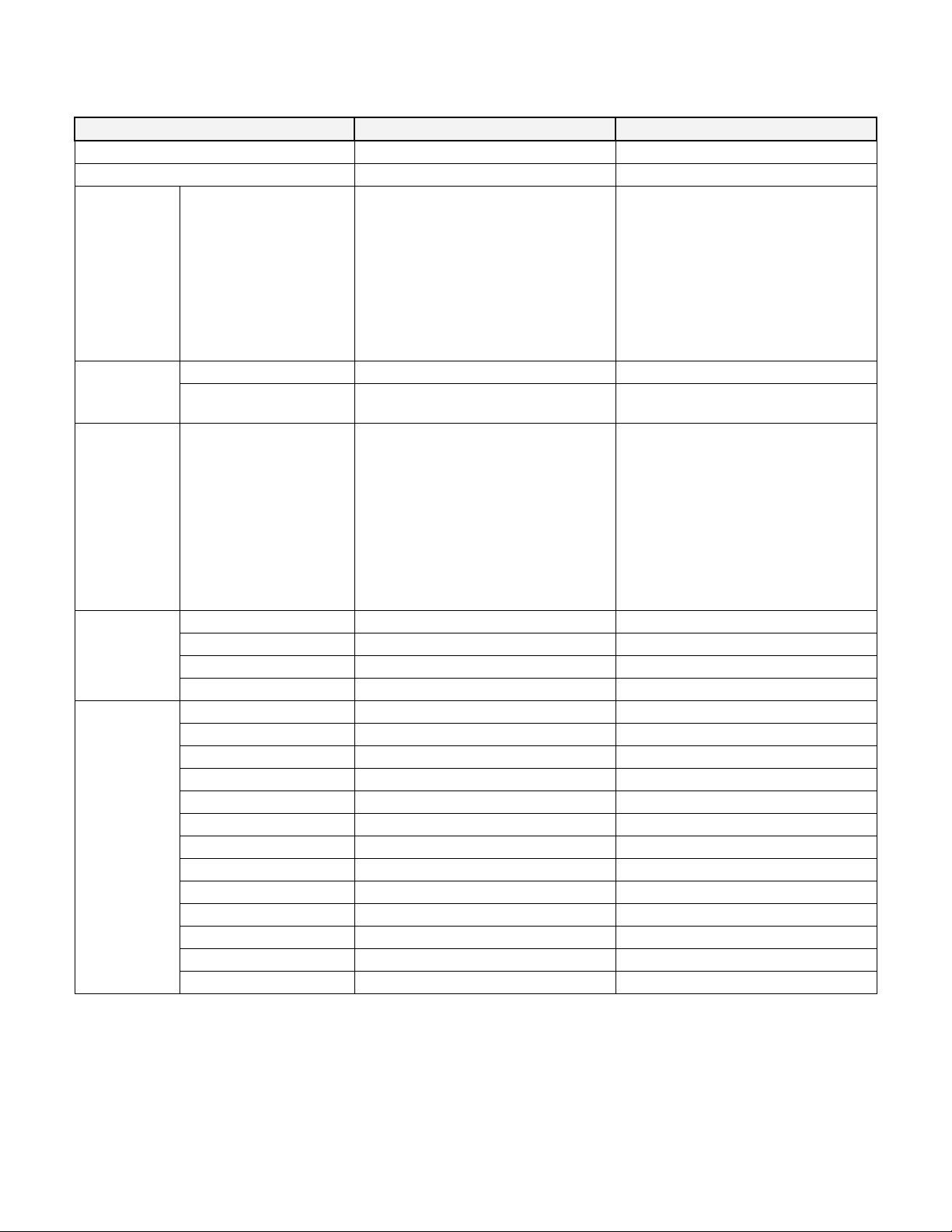

General TV Specification Continued

Model number LT3200 LT3700

OSD Languages English/French/Spanish English/French/Spanish

Custom Input Presets Yes Yes

Custom Input Labeling Yes Yes

V-Chip Yes Yes

Closed Captioning Yes Yes

Convenience

Finish and

Color

Accessories

General

Regulatory

compliance

Sleep Timer Yes Yes

Favori te Channels Yes Yes

PIP/POP No No

Split Screen No No

Clock No No

Auto On No No

EPG TV Guide Support No TV Guide No TV Guide

Bezel and Stand

Stand Detachable (included) Detachable (included)

Speakers Integrated Integrated

Remote Standard, Philips, 35-button Standard, Philips, 35-button

Wall mounts Optional/recommended Optional/recommended

Media Center/DEC Optional/recommended Optional/recommended

Power supply 120V AC 60Hz 120V AC 60Hz

Power consumption (W) 180W 220W

Dimensions with stand

(H/W/D) (inches/centimeter)

Dimensions without stand

(H/W/D) (inches/centimeter)

Weight (with stand) 40.7 lb/18 kg 49.5 lb/22 kg

Weight (without stand) 33 lb/15 kg 40.7 lb/18 kg

VESA wall mount standard VESA 200mm VESA 200mm

Energy Star Yes Yes

Front Bezel Trademarks

Safety

40%-60% Gloss Midnight Black,

Bezel and Stand

24.0 (60.7) x 30.9 (78.5) x 9.4

(23.9)

21.6 (54.8) x 30.9 (78.5) x 5.0

(12.7)

Dolby Digital Dolby Digital

FCC Class B, C-UL and UI FCC Class B, C-UL and UI

40%-60% Gloss Midnight Black,

Bezel and Stand

26.7 (67.8) x 35.7 (90.7) x 11.0

(27.9)

24.3 (61.7) x 35.7 (90.7) x 5.2

(13.2)

8 HP High-Definition LCD TV Service Manual

Page 14

General TV Specifications LT4200 and LT4700

Model number LT4200 LT4700

Description 42” HDTV 47” HDTV

Availability (On Ad) June 2007 June 2007

500 cd/m2

1920 x 1080

1200:1

176 degrees

6.5 ms

Trident LX66

480i, 480p, 720p, 1080i, 1080p

(HDMI only)

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Video

Tuning

Video

enhancers

Audio

Connectivity

Brightness

Resolution

Contrast Ratio

Viewing Angle

Response Time

Scalar

Supported Input

ATSC/NTSC/Clear -QAM 1 1

Unidirectional Cable

Card No No

3D Digital Comb Filter

Video Noise Reduction

3:2 Pull down

HP Visual Fidelity Engine

Photorealistic Sharpness

Enhancement

3D Color Enrichment

Motion-adaptive

Deinterlacer

Speakers 2 x 10W, 1 way 2 x 10W, 1 way

Dolby Digital Out Yes Yes

Virtual Surround Sound Theater, Music Hall Theater, Music Hall

SAP/MTS Yes Yes

AV 2 2

Component In (YPbPr) 2 2

HDMI 3 3

S-Video In 2 2

Antenna In (RF) 1 1

PC VGA In 1 1

Analog Audio In (L/R) 5 5

PC Audio In 1 1

RS-232c 1 1

USB Port (service only) 1 1

Audio Out 1 1

SPDIF Out 1 1

Composite 0 0

500 cd/m2

1920 x 1080

1200:1

176 degrees

8 ms

Trident LX66

480i, 480p, 720p, 1080i, 1080p

(HDMI only)

Yes

Yes

Yes

Yes

Yes

Yes

Yes

HP High-Definition LCD TV Service Manual 9

Page 15

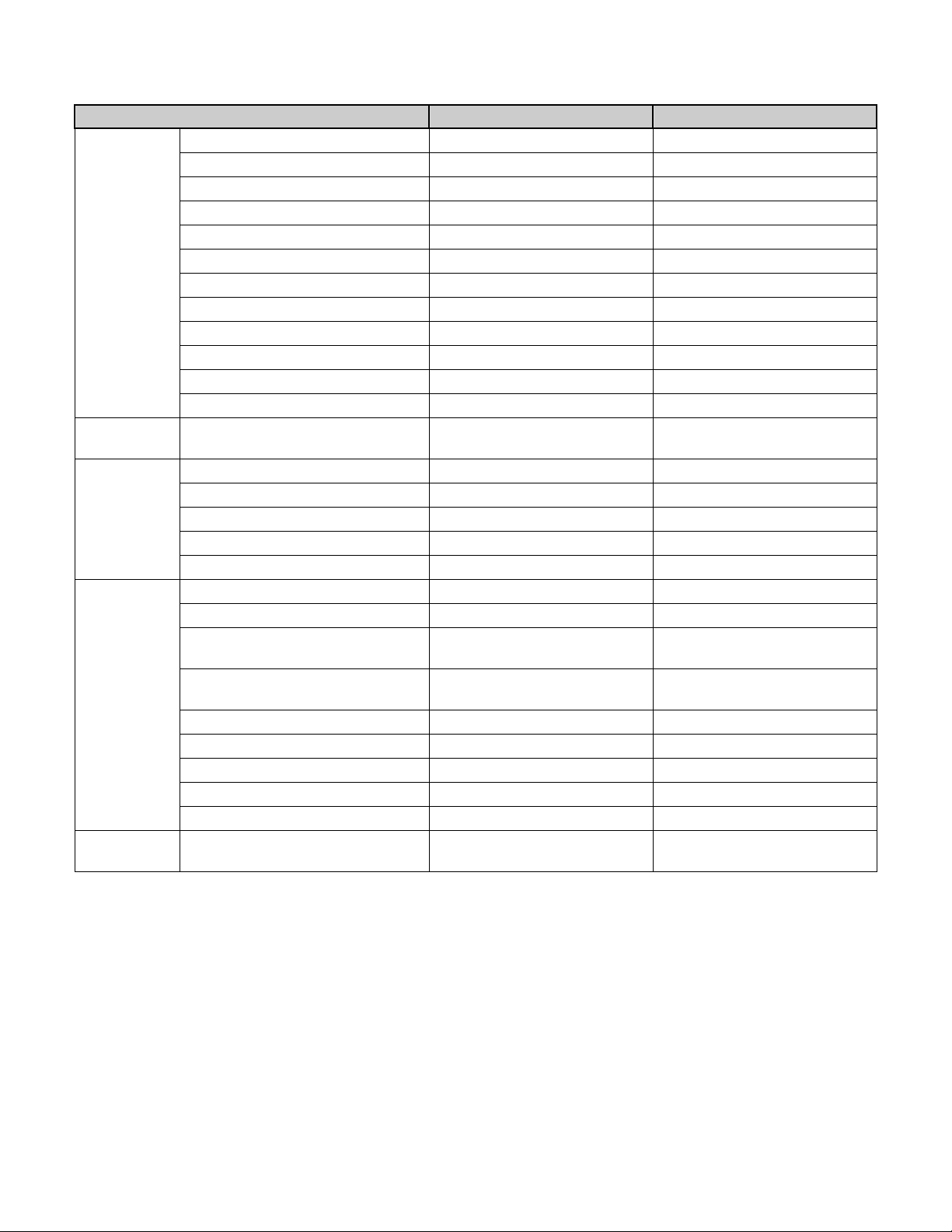

General TV Specification Continued

Model number LT4200 LT4700

OSD Languages English/French/Spanish English/French/Spanish

Custom Input Presets Yes Yes

Custom Input Labeling Yes Yes

V-Chip Yes Yes

Closed Captioning Yes Yes

Convenience

Finish and

Color

Accessories

General

Regulatory

compliance

Sleep Timer Yes Ye s

Favori te Channels Yes Yes

PIP/POP No No

Split Screen No No

Clock No No

Auto On No No

EPG TV Guide Support No TV Guide No TV Guide

Bezel and Stand

Stand Detachable (included) Detachable (included)

Speakers Integrated Integrated

Remote Standard, Philips, 35-button Standard, Philips, 35-button

Wall mounts Optional/recommended Optional/recommended

Media Center/DEC Optional/recommended Optional/recommended

Power supply 120V AC 60Hz 120V AC 60Hz

Power consumption (W) 300W 330W

Dimensions with stand

(H/W/D) (inches/centimeter)

Dimensions without stand

(H/W/D) (inches/centimeter)

Weight (with stand) 61.6 lb/28 kg 75.9 lb/24 kg

Weight (without stand) 52.8 lb/24 kg 66.0 lb/30 kg

VESA wall mount standard VESA 200mm VESA 200mm

Energy Star Yes Yes

Front Bezel Trademarks

Safety

40%-60% Gloss Midnight Black,

Bezel and Stand

28.5 (72.4) x 40.0 (101.6) x

11.0 (27.9)

26.6 (67.6) x 40.0 (101.6) x 5.3

(13.5)

Dolby Digital, e-Star (on top) Dolby Digital, e-Star (on top)

FCC Class B, C-UL and UI FCC Class B, C-UL and UI

40%-60% Gloss Midnight Black,

Bezel and Stand

31.7 (80.5) x 44.4(112.8) x

11.0 (27.9)

29.3 (74.4) x 44.4 (112.8) x 5.4

(13.7)

10 HP High-Definition LCD TV Service Manual

Page 16

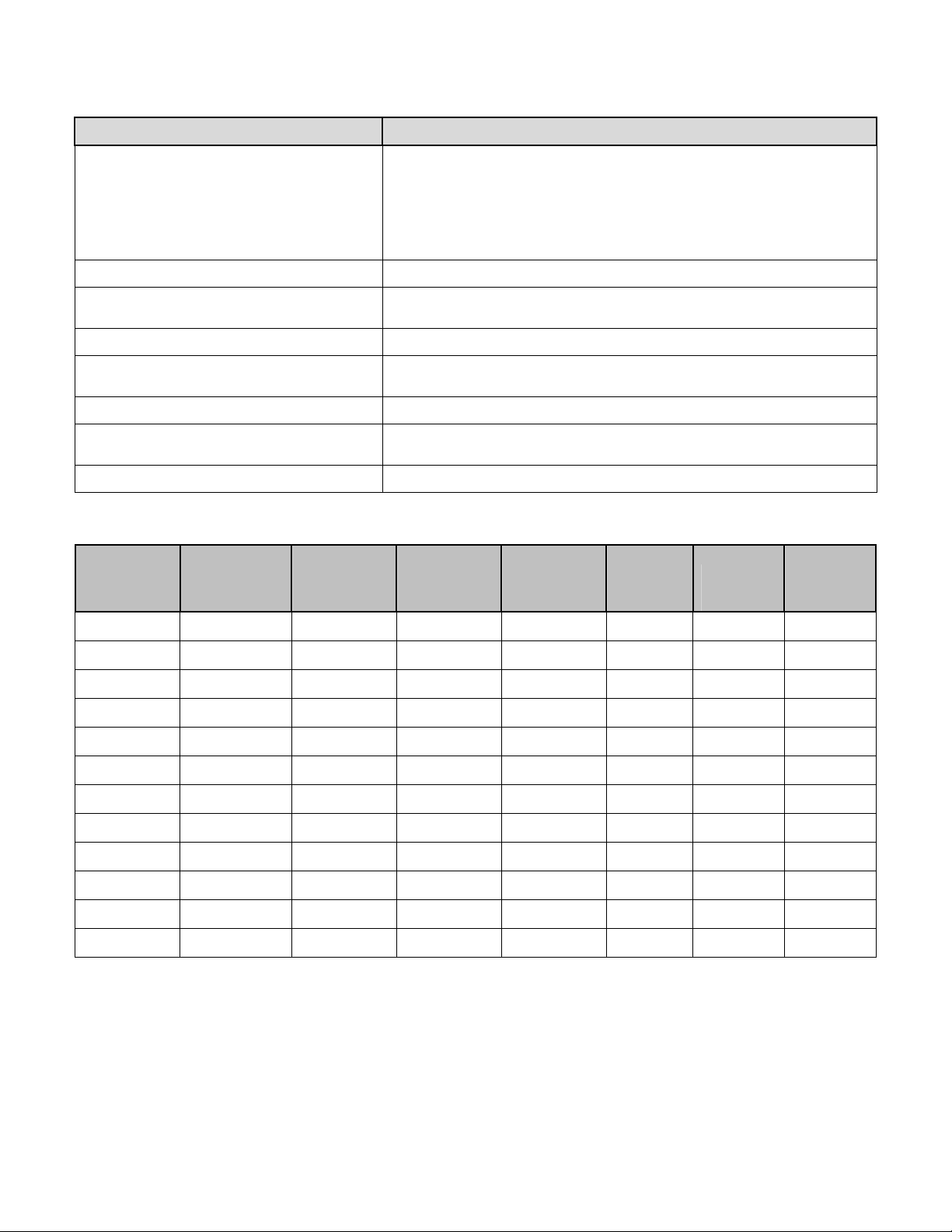

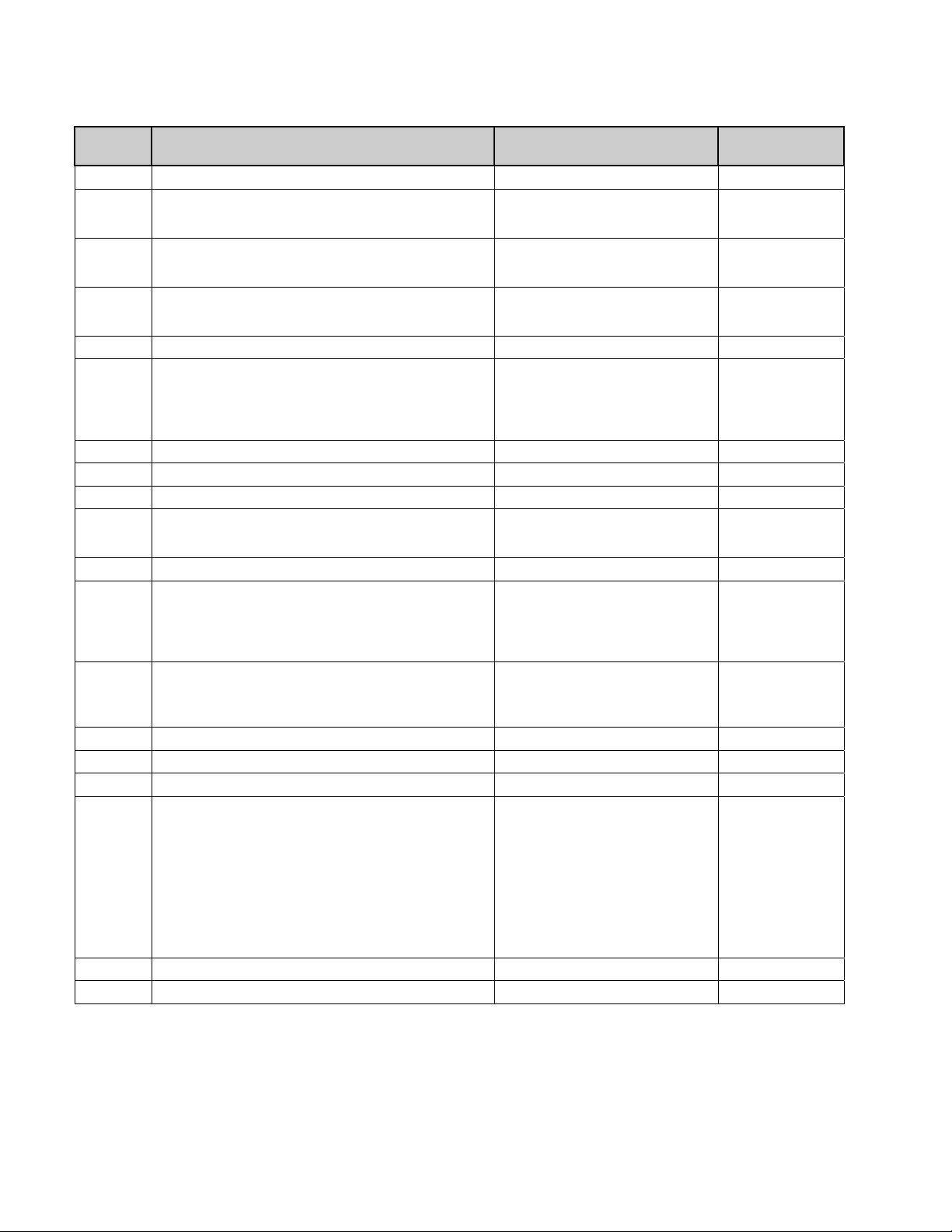

I/O Connectors

Name Description

HDMI Digital High Definition Input Video Input Connector with HDCP — Type A

• HDMI 1 (with HDMI audio in L and R)

• HDMI 2

• HDMI 3

Audio L and R must be set to PCM at the source across HDMI.

VGA VGA monitor input with audio L/R (line in)

Audio Output

• Digital (Optical) in Dolby Digital or PCM format) (S/PDIF)

• Audio Output L and R stereo analog (RCA)

ANT/Cable in (RF input) 75-ohm unbalanced, F-type for VHF/UHF/CATV in

Component High Definition Input

• 1: Y, Pb, and Pr, and audio L and R

• 2: Y, Pb, and Pr, and audio L and R

Serial RS-232 Serial input (Commercial use only)

Standard Definition Input

• AV Input 1: S-Vid, Video, and Audio L and R

• AV Input 2: S-Vid, Video, and Audio L and R

Service Port USB (For firmware upgrade use)

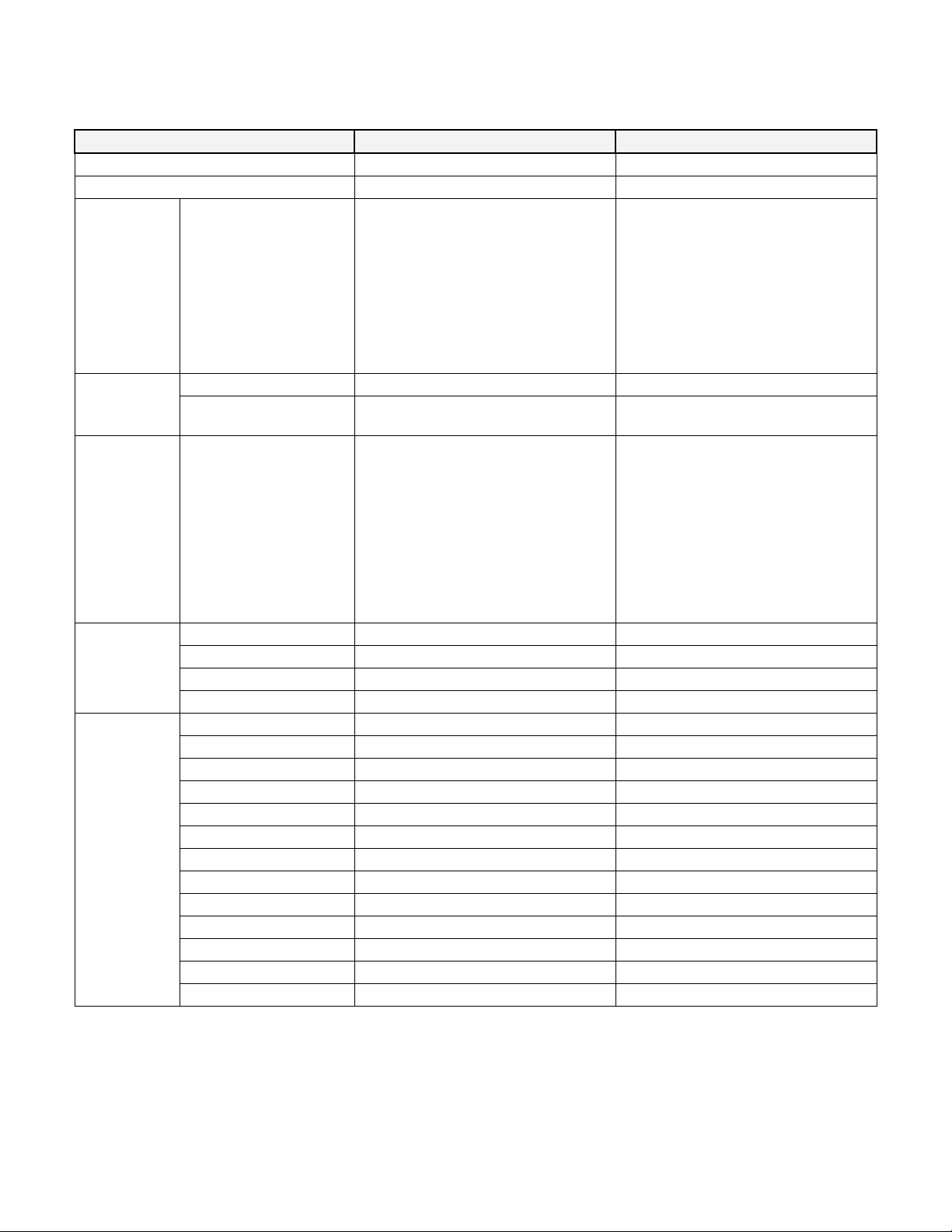

Factory Preset Display Modes

Preset Pixel format

Horizontal

frequency

(kHz)

Horizontal

polarity

Vertical

frequency

(Hz)

Vertical

polarity

Pixel Clk

(MHz) Source

1 640 x 480 31.469 – 59.940 – 25.175 VGA

2 640 x 480 37.500 – 75.000 – 31.500 VESA

3 720 x 400 31.469 – 70.087 + 28.322 VGA

4 800 x 600 37.879 + 60.317 + 40.000 VESA

5 800 x 600 46.875 + 75.000 + 49.500 VESA

6 1024 x 768 48.363 – 60.004 – 65.000 VESA

7 1024 x 768 56.476 – 70.069 – 75.000 VESA

8 1024 x 768 60.023 – 75.029 – 78.750 VESA

9 1280 x 768 47.396 + 59.995 – 68.250 VESA

10 1280 x 1024 63.981 + 60.020 + 108.000 VESA

11 1366 x 768 47.712 + 60.015 + 85.500 VESA

12 1920 x 1080 65.000 + 30.000 + 74.250 EIA

HP High-Definition LCD TV Service Manual 11

Page 17

Controlling the Onscreen Display

The onscreen display (OSD) is controlled by using the remote control or the bezel buttons on the left side of the TV.

The TV indicators (A and B) are located on the front of the TV.

TV Indicators and Controls

POWER Power button turns on the TV or places it in standby mode.

MENU Menu displays the onscreen display (OSD) or closes the OSD menu.

SELECT SELECT starts the Auto Sync function for a connected PC signal. In an OSD

menu, selects the highlighted item in the OSD.

SOURCE Source (SRC) selects the input Menu. In an OSD menu, this functions as a

back button or moves you up one item or menu level.

+CH

–CH

+VOL

–VOL

A - LED Indicator Amber: TV is powering on (light turns off after about 30 seconds).

B - Remote

Control Sensor

Channel (CH) selects the next or previous channel. In an OSD menu, press

these buttons to move up or down in the menu.

Volume (VOL) raises or lowers the sound level. In an OSD menu, press these

buttons to move right or left in the menu or to adjust an item.

HP Aqua Blue: TV is off but plugged into the power source.

No light: TV is on or AC power cord is disconnected.

Receives the signal from the remote control.

12 HP High-Definition LCD TV Service Manual

Page 18

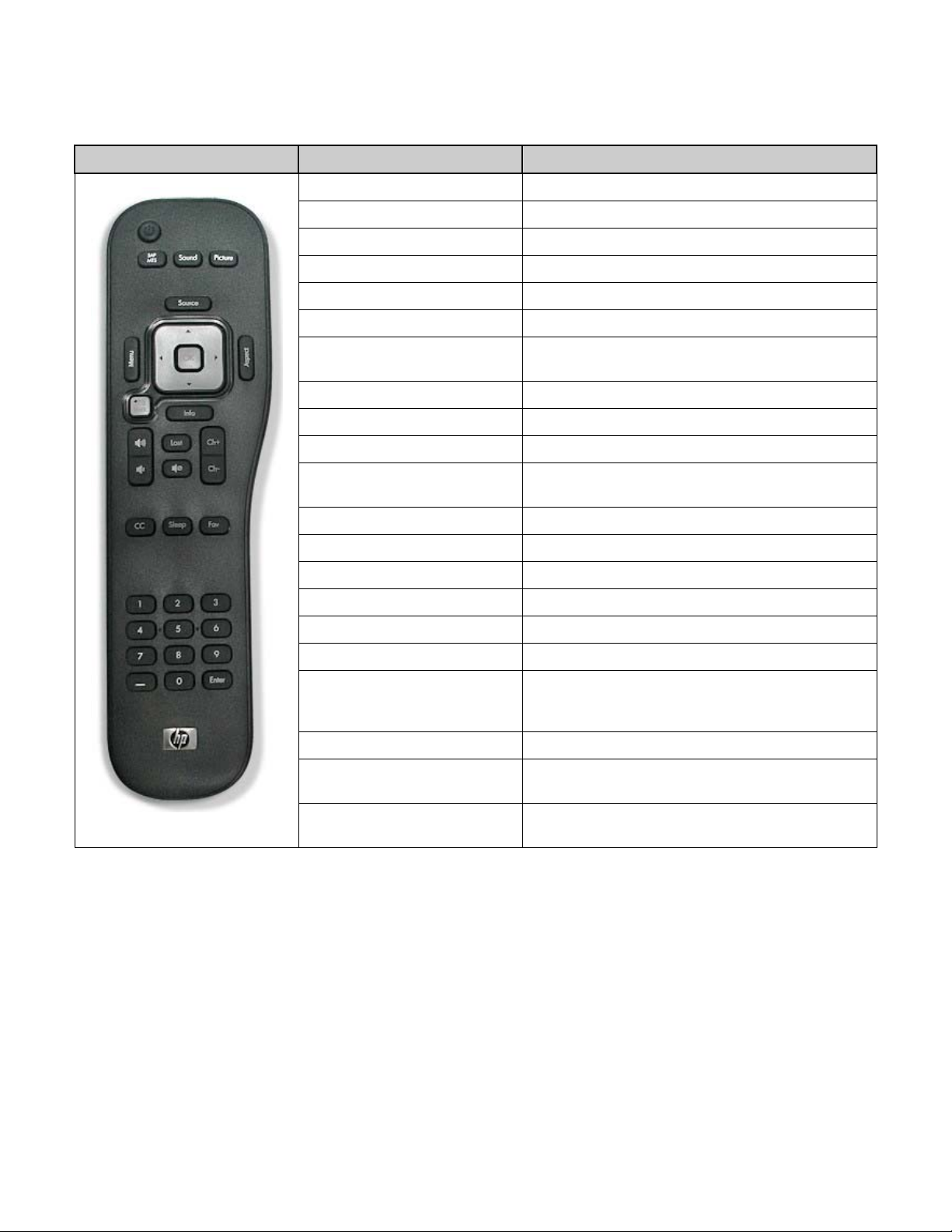

Remote Control

(IR protocol: RC6)

Remote control Remote control button label Remote control function

Power Use to turn power on or place TV into standby mode.

SAP/MTS Turn secondary audio program on and off.

Sound Select audio mode: Voice, Music, Standard, User.

Picture Select video mode: Vivid, Standard, Movie, or User.

Source Display list of input source.

Menu Open and exit OSD menu.

Arrows Move cursor left/right/up/down in the OSD menu or

adjust a selected item

OK Choose the current menu option.

Aspect Change the image aspect ratio.

Back Go up one menu level when the OSD is displayed.

Info Display channel information about your current TV

program.

Volume Turn volume up and down.

Last Go back to the previous channel.

Mute Turn the sound on and off.

Ch+/Ch- Move the channels up and down.

CC Display the closed caption content.

Sleep Display the sleep timer (15, 30, 60, 90,120 minutes).

Fav Shows Favorite channel list and allows adding current

channel to the list and allows replacing one from the list

with current channel.

Numeric keypad Enter channel number.

_ (Dash) Enter a dash for a subchannel number of a digital

channel.

Enter Select desired channel after entering the channel

number with the numeric keypad.

HP High-Definition LCD TV Service Manual 13

Page 19

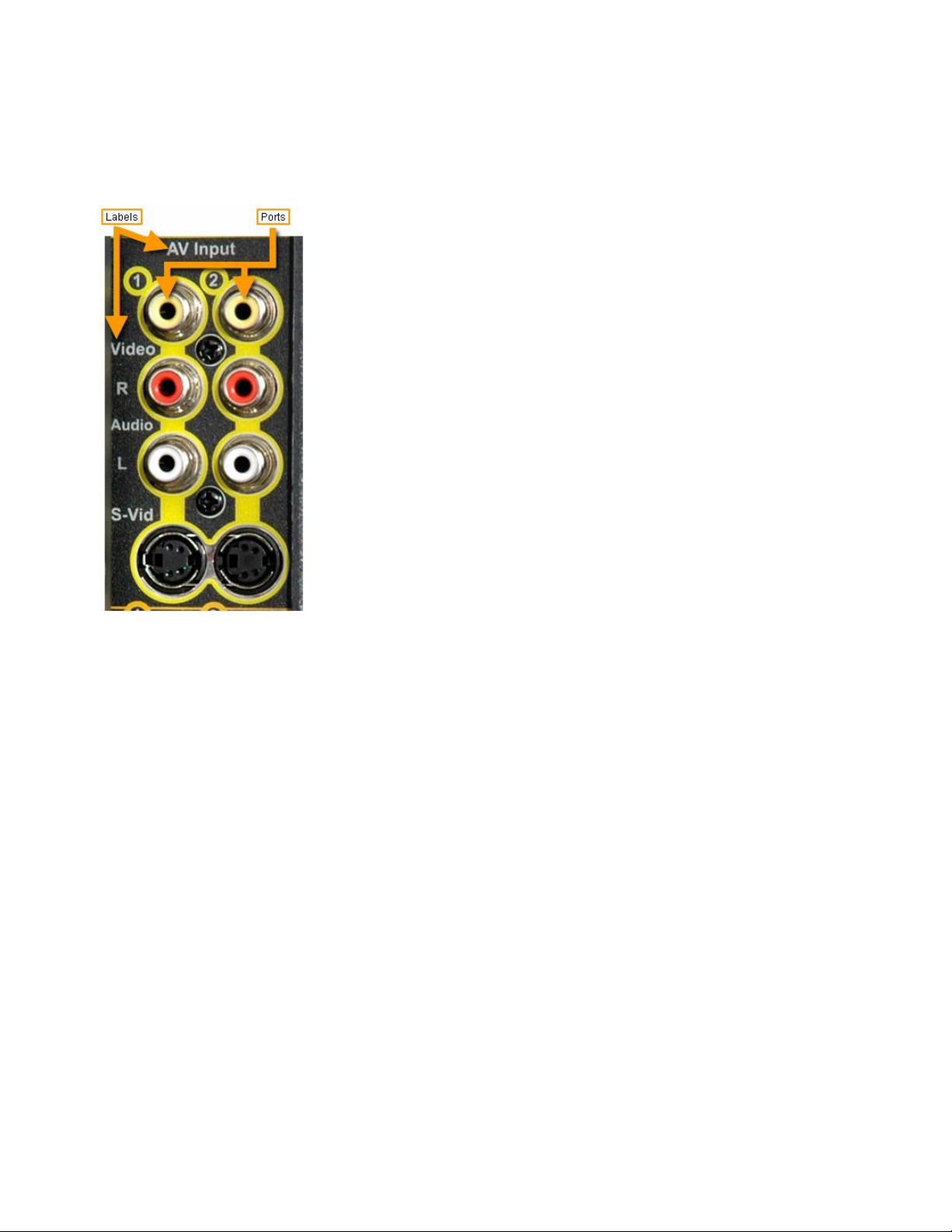

TV Connectors

The connectors listed in the table following the images are located on the right and left sides and back of the TV.

While only one model is shown below, all four models (LT3200, LT3700, LT4200, LT4700) use the same connector

configurations.

14 HP High-Definition LCD TV Service Manual

Page 20

HP High-Definition LCD TV Service Manual 15

Page 21

16 HP High-Definition LCD TV Service Manual

Page 22

Connectors

AV Input

You can connect two sources of AV (audio/video) input simultaneously. The left column of ports is for Source 1 and the

right column of ports is for Source 2. Each set consists of four ports:

• The yellow ports labeled Video connect single-channel composite video, which provides a sharper image than a

coaxial RF connection.

• The adjacent red and white input ports labeled Audio connect the stereo audio soundtrack corresponding to

composite or S-Video connections. The white port is for the left channel and the red port is for the right channel.

• The black ports labeled S-Vid connect S-Video, which transmits video in separate color and black-and-white image

signals and delivers a sharper image than a composite video connection.

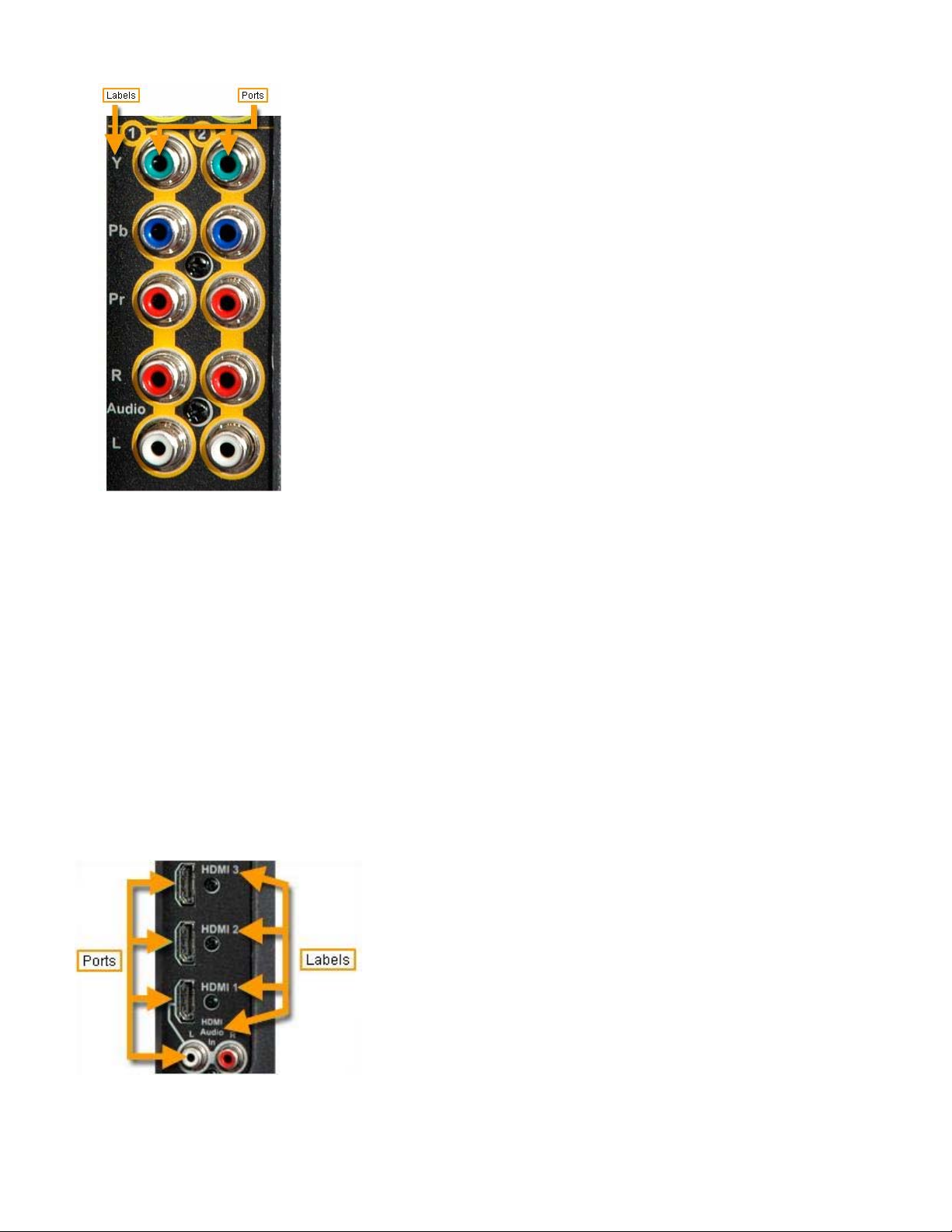

Component Video Ports

Component video provides the highest video quality currently available. Component video is used by HDTV receivers,

as well as some DVD players and other audio/video devices equipped with component video output. You can connect

two component video sources simultaneously by using the left column of ports for Source 1 and the right column of

ports for Source 2.

HP High-Definition LCD TV Service Manual 17

Page 23

Component video cables transmit video in three channels—Y, Pb, and Pr. Some cables are five-headed with three

channels of video and two of audio, whereas others are three-headed and require a separate stereo audio cable. The

cables are connected as follows:

• The green port labeled Y connects to the cable carrying the Y signal.

• The blue port labeled Pb connects to the cable carrying the Pb signal.

• The red port labeled Pr connects to the cable carrying the Pr signal.

• The red port labeled R connects to the right audio channel.

• The white port labeled L connects to the left audio channel.

These connectors support 480i, 480p, 720p, and 1080i analog standard and high-definition format inputs. The TV

automatically determines what format is being used by the currently connected device.

HDMI Connectors

High Definition Multimedia Interface (HDMI) is an all digital audio/video interface. This series of TVs uses HDMI

version 1.2 and supports 480i, 480p, 720p, and 1080i digital-format inputs. The TV automatically determines what

format is being used by the currently connected device.

18 HP High-Definition LCD TV Service Manual

Page 24

HDMI devices are usually HDTV receivers or DVD players. They connect using a single cable with a multipin

connector. These TVs have three HDMI ports, so up to three HDMI devices can be connected at the same time.

The HDMI 1 port additionally supports separate HDMI audio. This configuration requires a DVI-to-HDMI converter that

connects a DVI cable from optional DVI equipment and connects to the HDMI audio in ports using a pair of stereo

audio connectors. The white port is for the left channel and the red port is for the right channel.

RS-232 Port

The RS-232 connector works like a serial port on a PC and is also sometimes called a serial port. It is used to receive

digital instructions from control applications running on a computer.

HP High-Definition LCD TV Service Manual 19

Page 25

Basic Operation

Basic Operation

For more information about using your HP LCD TV, refer to the

There are two menus available – a customer-based menu (Simplemenu) and an advanced menu (Fullmenu). Simplemenu is

the default setting.

Default selections are shown in bold.

HP HD LCD TV User’s Guide

included with your TV.

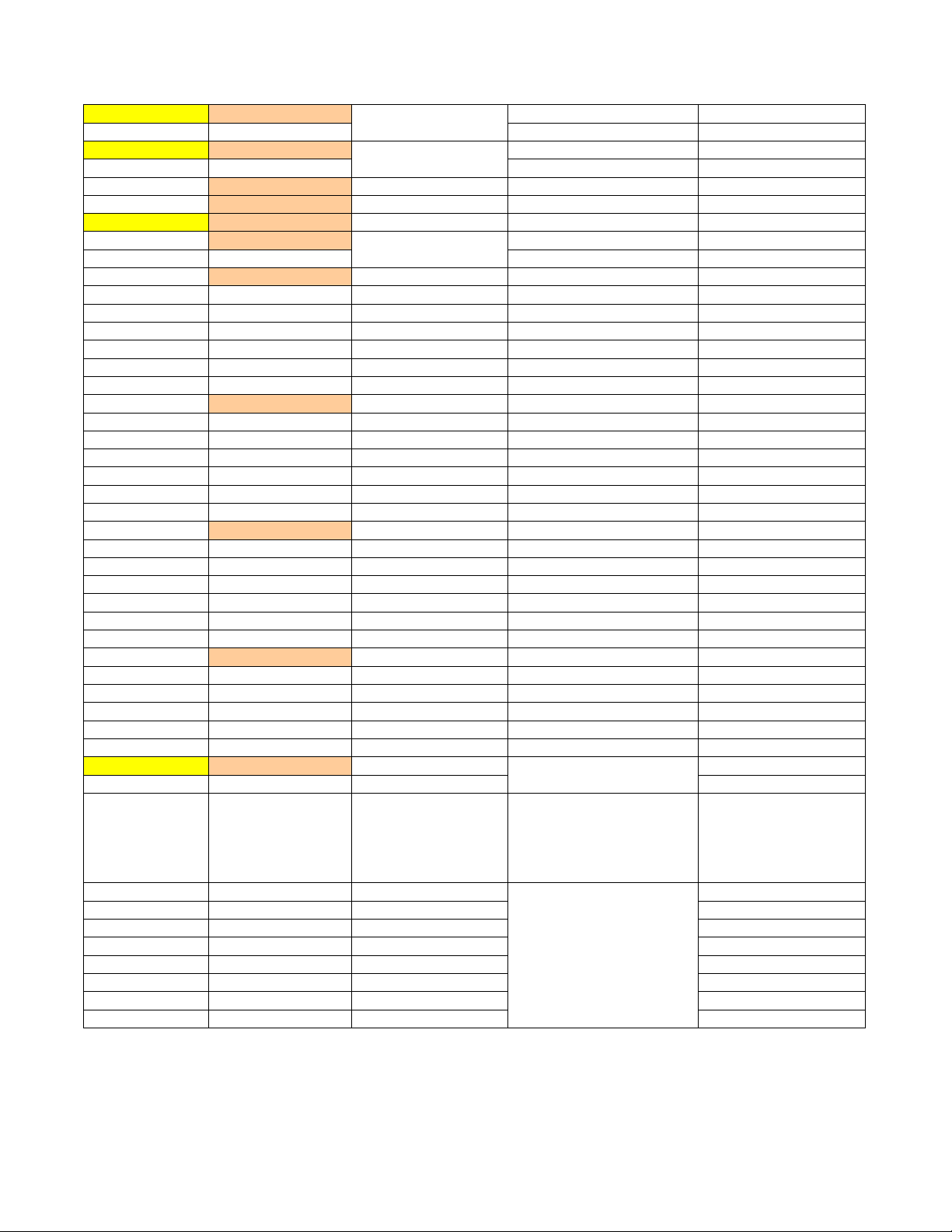

OSD (On-Screen Display) Functions – Simplemenu

TV OSD Menu Structure - Simplemenu

Main

Picture

Sub1

Mode

Color Temp

Aspect Ratio

PC

Audio

Mode

Auto Volume

Virtual Surround

Setup

Speaker

Caption

Default Settings

Sub2/Options

Vibrant

Standard

Studio User

Brightness

Contrast

Saturation

Hue

Sharpness

Cool

Standard

Warm

Auto

16:9 Mode

4:3 Mode

Zoom1

Zoom2

Panorama

Auto Sync

Voice

Standard

Music

User

On

Off

Off

Theater

Music

On

On

Off

On Mute

Reset

Hall

20 HP High-Definition LCD TV Service Manual

Page 26

OSD Functions – Fullmenu

U

l

y

To access Fullmenu, select SETUP > Caption. Note that Caption Menu is only valid when current input selection is

either TV, AV1/S-Video, or Component. Otherwise, caption menu will be disabled. Press the following remote keys:

MTS > 7 > 0 > 4. To return to Simplemenu, select Simplemenu from Fullmenu.

TV OSD Menu Structure - Fullmenu

Main

Picture

Sub1

Mode

Color Temp

Aspect Ratio

PC

Audio

Mode

Balance

Auto Volume

SAP/MTS

Digital

Audio

Virtual Surround

Sub2/Options

Vibrant

Standard

Studio User

Brightness

Contrast

Saturation

Hue

Sharpness

Cool

Standard

Warm

Auto

16:9 Mode

4:3 Mode

Zoom1

Zoom2

Panorama

H-Position

V-Position

H-Size

V-Size

Phase Adjust

Clock Adjust

Auto Sync

Default

Voice

Standard

Music

User

Treble

Bass User mode only

Sub3/Options

Options

ser mode on

On

Off

Mono

Stereo

SAP

English

Spanish

French

Dolby Digital

PCM

Off

Theater

Music Hall

HP High-Definition LCD TV Service Manual 21

Page 27

A

A

g

A

Audio

Speaker

Channel

Channel Scan

Parental

Channel List

Signal Strength

Change Password

Lock Enable

MP

US TV Ratin

Canadian English E

Canadian French E

Setup

Time

On

Off

Air

Cable

On

Off

G

PG

PG-13

R

NC-17

X

Not Rated

FV, V, S, L, D

TV-Y

TV-Y7

TV-G

TV-PG

TV-14

TV-M

C

C8+

G

PG

14+

18+

G

8 ans+

13 ans+

16 ans+

18 ans+

Clock Mode

Clock Set

Time Zone

Auto

Manual

Month,

Day,

YR, Hr.

Min,

AM/PM

NST

AST

EST

CST

MST

PST

AKST

HST

Show/Hide channel

Active

for "Auto".

22 HP High-Definition LCD TV Service Manual

Page 28

v

Setup

(cont)

Time

Caption

(cont)

Daylight Saving

Sleep Timer

Mode

Service Analog

Service Digital

Style

On

Off

Off

15 min

30 min

60 min

120 min

150 min

On

Off

On Mute

CC1

CC2

CC3

CC4

Text1

Text2

Text3

Text4

Ser

Service2

Service3

Service4

Service5

Service6

Font Size

Font Style

Foreground Color

Background Color

ice1

Active

Default

Small

Standard

Large

Default

Style0

Style1

Style2

Style3

Style4

Style5

Style6

Style7

Default

White

Black

Red

Green

Blue

Yellow

Magenta

Cyan

Default

White

Black

Red

Green

for "Auto".

HP High-Definition LCD TV Service Manual 23

Page 29

)

)

y

g

y

g

[

]

[

]

Setup

(cont)

Caption

OSD Language

Setup

Input Labels

Default Settings

(cont)

Wizard

Style(cont

English

Spanish

French

Start

AV1

AV2

Component 1

Component 2

HDMI 1

HDMI 2

HDMI 3

VGA

Reset

Background Color(cont

Foreground Opacit

Background Opacit

Edge Style

Default

AVR

DVD

PVR

CABLE

DEC

AUX

SAT

VCR

Blue

Yellow

Magenta

Cyan

Default

Solid

Translucent

Transparent

Flashin

Default

Solid

Translucent

Transparent

Flashin

Default

Edge Style0

Edge Style1

Edge Style2

Edge Style3

Edge Style4

Edge Style5

SimpleMenu™

24 HP High-Definition LCD TV Service Manual

Page 30

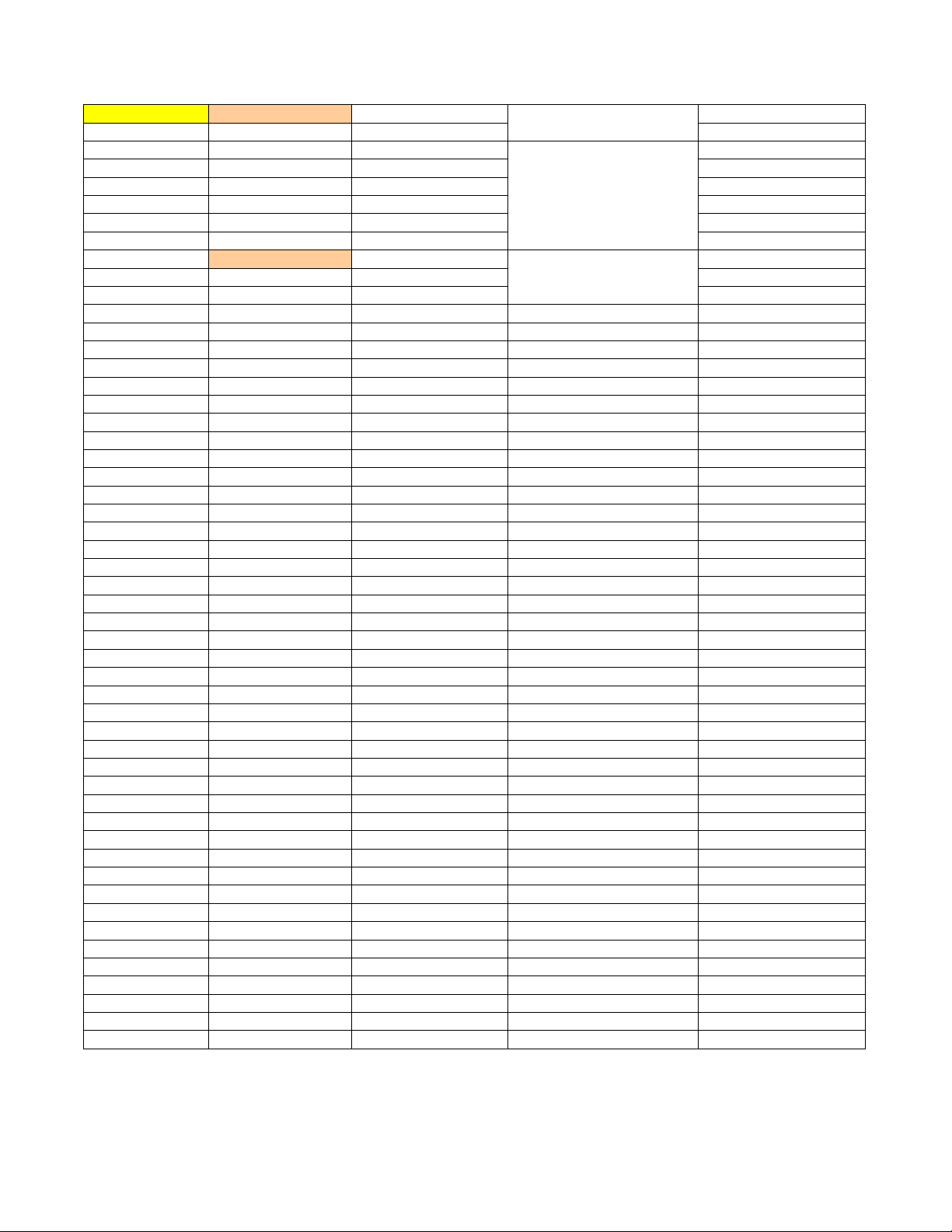

Command Table RS232

COMMAND: 3 bytes

PARAMETER: 4 byte

CR (Carriage Return) at the end of string

“OK” + CR: success

“ERR” + CR: fail

20 Remote Commands Over RS232c Port

Set the RS-232c communications settings on the PC to match the TV’s communication conditions. The TV’s

communications settings are as follows:

Baud rate 9600 bps

Data length 8 bits

Parity bit None

Stop bit 1 bit

Flow control CTS/RTS

Control Item Command Param eter Control Contents

Power setting

Input Select I N P S x _ _ _ Input terminal number

AV mode selection A V M D

Volume V O L M * * * _ Volume (0–100)

P O W R 0 _ _ _ Off Shifts TV to standby if it is

in power-on mode.

In Slow boot mode, when

TV is in the middle of

booting sequence, this

command is processed by

MCU.

P O W R 1 On Shifts TV to power-on mode

if it is in standby mode.

In Slow boot mode, this

command is processed by

external MCU.

It input-switches to INPUT0

(0–8)

0 _ _ _ Movie

1 _ _ _ Vivid

2 _ _ _ Standard

3 _ _ _ USER

~ INPUT8 (the sequence is

Air/Cable, CBVBS1,

S-Video1, CVBS2, SVideo2, YPbPr1, YPbPr2,

VGA, HDMI)

HP High-Definition LCD TV Service Manual 25

Page 31

Control Item Command Param eter Control Contents

osition

Aspect A S P T

Audio Selection A C H A

Sleep Timer O F T M

H-Position H P O S * * * _ PC mode (0–100)

V-Position V P O S * * * _ PC mode (0–100)

Clock C L C K * * * _ ONLY PC mode (0–100)

Phase P H S E * * * _ ONLY PC mode (0–100)

0 _ _ _ Auto mode

1 _ _ _ 16:9 mode

2 _ _ _ 4:3 mode

3 _ _ _ Zoom1 mode

4 _ _ _ Zoom2 mode

5 _ _ _ Panorama mode Only TV mode

0 _ _ _ Mute On Mute M U T E

1 _ _ _ Mute Off

0 _ _ _ PCM Dolby Virtual A C D V

1 _ _ _ Dolby

0 _ _ _ Analog- Mono/Digital-

audio1

1 _ _ _ Analog- Sap/Digital-

audio2

2 _ _ _ Analog- Stereo/Digital-

audio3

3 _ _ _ Analog-Sap+Stereo

/Digital-audio 4

* * _ _ Digital-audio X

0 _ _ _ Off

1 _ _ _ Off Timer – 15 Min.

2 _ _ _ Off Timer – 30 Min.

3 _ _ _ Off Timer – 60 Min.

4 _ _ _ Off Timer – 90 Min.

hannel

Direct

Channel

(Analog)

Direct

Channel

(Digital)

CH Up C H U P 0 _ _ _ The channel number of TV

CH Down C H D W 0 _ _ _ The channel number of TV

D C H A * * * _ The channel number of TV

D C H D * * * * (1.0–135.99) Digital channel number. The

26 HP High-Definition LCD TV Service Manual

5 _ _ _ Off Timer – 120 Min.

(1–125)

+1

–1

An input change is included

if it is not TV display. In air,

channel 2 to channel 69 are

effective. In cable, channel 1

to channel 125 are effective.

first two bytes are major

number and following two

bytes are minor number.

Major number is in hex

mode. If major number is less

than 0xf, the first byte should

be 0.

If it is not TV, it will inputswitch to TV. (same function

as CH)

If it is not TV, it will inputswitch to TV. (same function

as CH)

Page 32

Control Item Command Param eter Control Contents

CC operation C L C P

Brightness B R T N * * * _ Brightness (0–100)

Contrast C T R T * * * _ Contrast (0–100)

Color C L O R * * * _ Color (0–100)

Hue H U E E * * * _ Hue (0–100)

Sharpness S H R P * * * _ Sharpness (0–100)

Color temperature C T E P

Auto sync A U S Y 0 Auto sync, only in PC

Audio mode A U M D

0 _ _ _ CC off

1 _ _ _ CC on

2 _ _ _ CC Mute Toggle CC on while audio

0 _ _ _ Warm

1 _ _ _ Normal

2 _ _ _ Cold

0 _ _ _ Off Blue screen B L S C

1 _ _ _ On

mode

0 _ _ _ Voice mode

1 _ _ _ Music mode

2 _ _ _ Standard mode

3 _ _ _ User mode

muted

Air/cable selection for Auto

Search

Start auto search A T S H 0 _ _ _ Start auto search if

Manual search M A S H * * * _ Manually search a

Skip analog

channel

Skip digital

channel

Reset to default R T D F 0 _ _ _ Reset all settings to

A C S L

C H K A * * * _ Skip a certain valid

C H K D * * * * Skip a certain valid

0 _ _ _ Air for Auto Scan Move this command to

1 _ _ _ Cable for Auto Scan This command does not

current source is TV.

Need input type

(air/cable) selection

before starting auto

search

certain channel if current

source is TV. If fails ,go

back to the previous

status

analog channel

digital channel

default

Auto Search.

change RF input or

channel map tables

between air and cable.

This command has NO

correlation with Ant button

on remote.

Digital air channel: 2~69

Cable channel: 2~135

Channel skip

HP High-Definition LCD TV Service Manual 27

Page 33

Control Item Command Param eter Control Contents

0 _ _ _ Auto Set time mode S T M D

1 _ _ _ Manual

Set time

Time Zone T M Z N

Set time year S T T Y * * * * Year, if time mode is

manual

(1990~2037)

Set time

month

Set time day S T T D * * _ _ Day, if time mode is

Set time hour S T T H * * _ _ Hour, if time mode is

Set time

minute

S T T M * * _ _ Month, if time mode is

manual

(01~12)

manual

(01~31)

manual

(00~23)

S T T I * * _ _ Minute, if time mode is

manual

(00~59)

0 _ _ _ AST

1 _ _ _ EST

2 _ _ _ CST

3 _ _ _ MST

4 _ _ _ PST

5 _ _ _ AKST

6 _ _ _ HST

7 _ _ _ NST

Set auto on mode S A O M

Set auto on time S A O N * * * * Auto on time

Set auto off mode S A F M

Set auto off time S A O F * * * * Auto off time

Select analog CC service S A C S

0 _ _ _ Off

1 _ _ _ On ,but once

2 _ _ _ On, daily

hour (00~23)

minute (00~59)

0 _ _ _ Off

1 _ _ _ On, but once

2 _ _ _ On, daily

Hour (00~23)

Minute (00~59)

0 _ _ _ CC1

1 _ _ _ CC2

2 _ _ _ CC3

3 _ _ _ CC4

4 _ _ _ T1

5 _ _ _ T2

6 _ _ _ T3

7 _ _ _ T4

If hour is less then 10, the

first byte should be 0.

If hour is less then 10, the

first byte should be 0.

28 HP High-Definition LCD TV Service Manual

Page 34

Control Item Command Parameter Control Contents

Select digital CC service S D C S 1 _ _ _ Select a certain service 1

2 _ _ _ Service 2

3 _ _ _ Service 3

4 _ _ _ Service 4

5 _ _ _ Service 5

6 _ _ _ Service 6

Select OSD language S O L G

PWR MANAGE P M G * _ _ _ SELECT 0-7, selects number of

CAPTION LOCK C A L * _ _ _ RETAIN SETTINGS 1 = Retain caption setting

STR_AUX_SOURCE S A S

SOURCE AT P-ON S O N * _ _ _ INPUT SOURCE TV input source at PWR

KEY LOCK K L K * _ _ _ KEYBOARD LOCK 1 = TV front keyboard

VIDEO MUTE ENABLE V M E * _ _ _ ENABLE 1 = Blank video (mute).

0 _ _ _ English

1 _ _ _ French

2 _ _ _ Spanish

0 _ _ _ Off All screen white mode S R W M

1 _ _ _ On Helps to erase remnants of

long time still image on

LCD screen.

0 _ _ _ Slow Boot mode Standby mode S B M D

1 _ _ _ Fast Boot mode

hours of no activity before

auto SHUT_OFF is

activated.

0=PWR Manage is OFF

(Default), 1=1 hr, 2=2 hrs,

etc.

(current setting) at power

off (Default).

0 = Captions is always

OFF at turn on.

1 _ _ _ SET (ON) 1 = Set starting with

auxiliary source/input

which is selected by

‘SOURCE AT-P-ON’

command (SON) on Power

ON.

0 _ _ _ RESET (OFF) 0 = TV starting with

“Previous” input on Power

On (Default).

on.

0: TV (Cable or AIR)

(Default). 1:AV1, 2:AV2,

3:YPbPr1, 4:YPbPr2,

5:HDMI1

except power is locked, IR

control key works.

0 = TV front keyboard is

unlocked (Default).

0 = Normal video (Default)

HP High-Definition LCD TV Service Manual 29

Page 35

Control Item Command Parameter Control Contents

REMOTE CON MODE R C M * _ _ _ REMOTE ACTIVE 0 = PC.

1 = Remote control.

2 = Enable both PC and

remote (Default).

START CHANNEL

CHANNEL LOCK C H L * _ _ _ ENABLE 1 = Enables channel lock

START VOLUME S T V * * * _ SELECT 0-100 = Select volume

MIN VOLUME M N V * * * _ SELECT 0-100 = Select MIN

MAX VOLUME M X V * * * _ SELECT 0-100 = Select MAX

MUTE DISABLE M D I * _ _ _ SELECT 1 = Disable audio mute.

S T C * * * _ SELECT (Analog

Channel)

S T A * * * _ SELECT (Digital, MAJOR

Channel)

S T I * * * _ SELECT (Digital, MINOR

Channel)

Channel a Power ON.

1-125=channel 1-125.

126=map to Ch3.

127=map to Ch4.

255=tune to last channel

before turn power OFF.

1-999 (Major channel

number)

1-999 (Minor channel

number)

so cannot change channel

from current channel from

IR remote, usually the

START channel.

0 = Default (channel lock is

disabled).

level on TV turn on.

255 = Retain last volume

setting (Default).

allowance volume setting,

0 = Default.

allowance volume setting,

100 = Default.

0 = Sound mute can be

activated (Default).

30 HP High-Definition LCD TV Service Manual

Page 36

Return messages

)

)

)

(

)

For every command, TV should return reply. Controller waits before sending another command because some

commands take time before TV is ready to accept next command. For example,

minutes.

the

“channel scan” command takes

For Normal Response

O K

CR

CR : Carriage Return (0Dh)

For Error condition:

E R R CR

CR : Carriage Return (0Dh)

Special command extension

CONTROL

ITEM

GET

STATUS

(Return

current TV

status

value)

Get Status RETURN message format for “GST”(Get Statue) command:

?

Command

G S T

O

K

PARAMETER

0 _ _ _ Power

1 _ _ _ Mute

2

3

4

5

6

Parameter

Volume

CH (major) 0 ~ 9999 (e.g.) Ch 99 : 0099, Ch 9 : 0009 in

CH (minor) 0 ~ 9999 (e.g.) Ch 99 : 0099, Ch 9 : 0009 in

Caption

Input source 0 ~ 8 : (TV Air/Cable, AV1, AV2, YPbPr1,

7

8

9

A

B

C

W

X

Aspect

Brightness 0 ~ 100 (e.g. 7 -> 0007, 77 -> 0077) in ASCII

Contrast 0 ~ 100 (e.g. 7 -> 0007, 77 -> 0077) in ASCII

Sharpness 0 ~ 100 (e.g. 7 -> 0007, 77 -> 0077) in ASCII

Color

Hue

Y

Return Data

0: Off (return from MCU), 1: On

0: Off, 1: On, 2: On Mute

Current Volume level: 0 ~ 100 (ASCII format)

ASCII

ASCII

0: Off, 1: On

YPbPr2, VGA, HDMI1, HDMI2, HDMI3

0: Auto, 1: (16:9), 2: (4:3), 3: (Zoom1), 4:

Zoom2), 5:(Panorama

0 ~ 100 (e.g. 7 -> 0007, 77 -> 0077) in ASCII

0 ~ 100 (e.g. 7 -> 0007, 77 -> 0077) in ASCII

Z

CR

0

0

0

0

Format of WXYZ (always 4 bytes):

For all return values: (add prefix with 0s, right justify).

If volume is 89, return value will be 0089 (add ‘00’).

If channel is 7, return value will be 0007 (add ‘000’).

If

Mute is 1, return value will be 0001 (add ‘000’).

HP High-Definition LCD TV Service Manual 31

Page 37

Replaceable Parts

This chapter contains the service parts lists of each model.

Parts List by Model

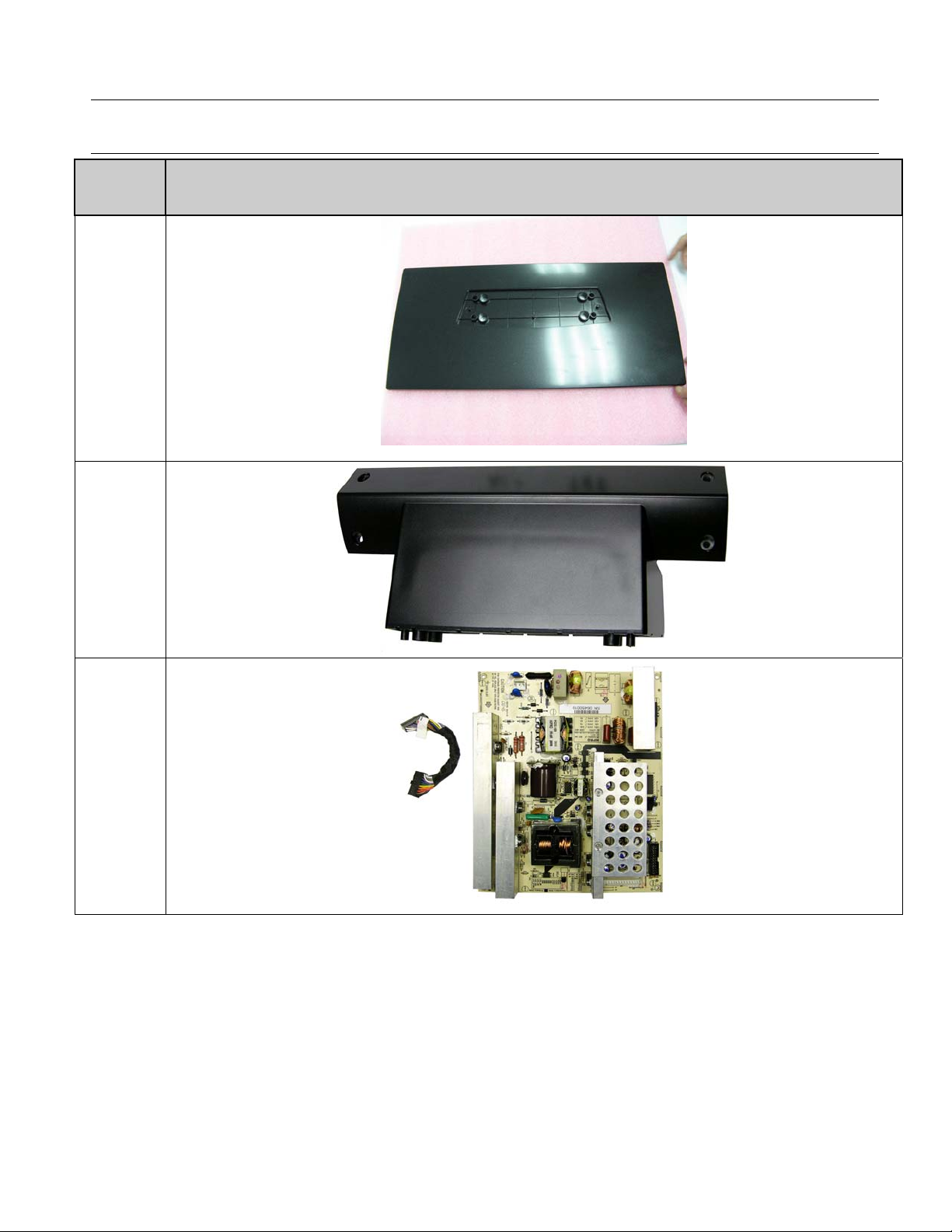

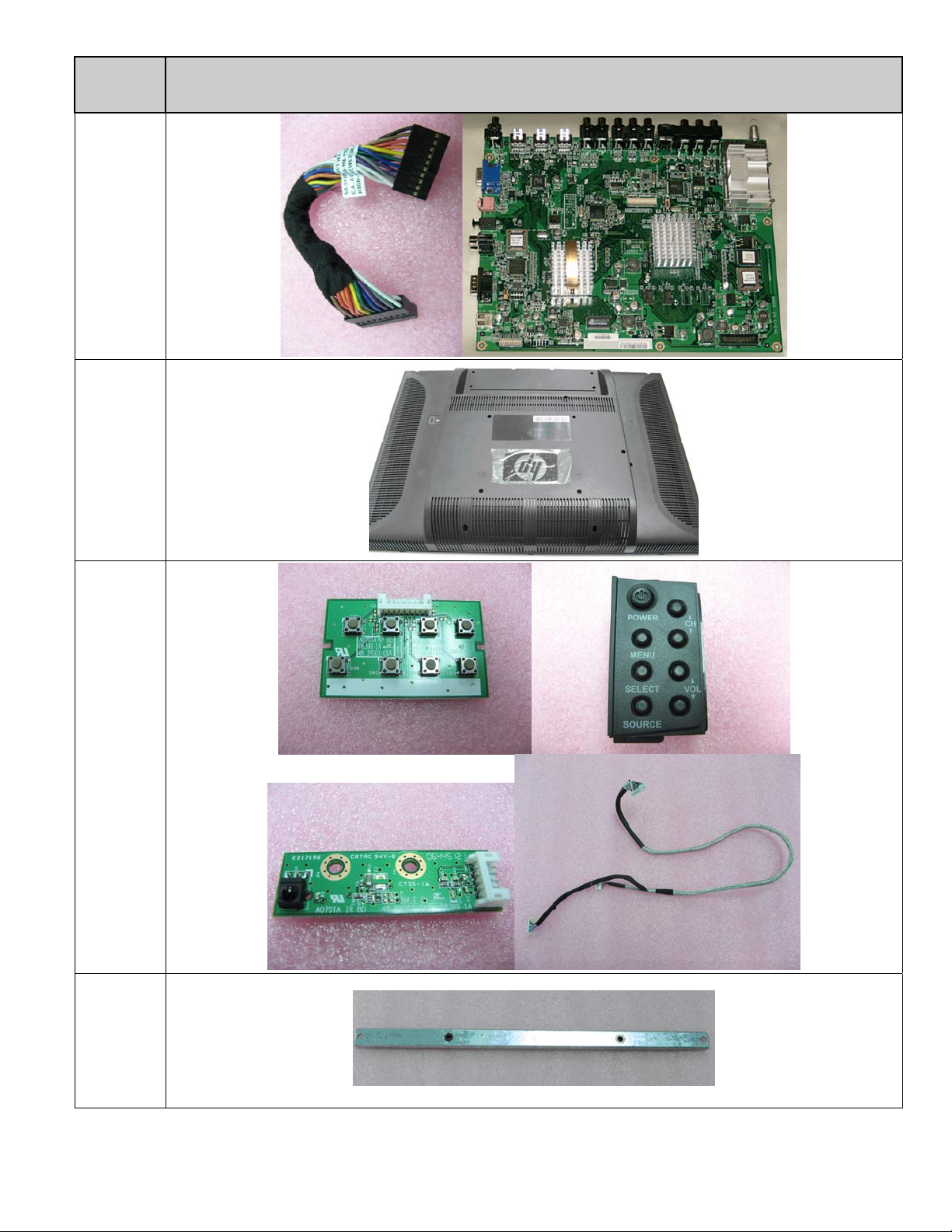

To see the pictures of the replaceable parts, go to the “Replacement Parts List Reference Picture” section.

Model LT3200

Picture

Number

1

2

3

4

5

6

7

8

9

10

11

12

13

--

--

--

--

--

--

Stand base 60.3YI02.001 452084-001

Stand neck assy

Stand neck

Repair screw kit

Power supply assy - For 3x models -230W

Power supply - 3x model

System board to power supply cable

Main Board assy

Main board

System board to power supply cable

Back cover - bucket 60.3YI07.001 452092-001

Keypad - Infrared assy

Keypad buttons

Keypad PCA board

Infrared board

System board to keypad/IR cable

Internal support wall mount 33.3YI06.001 452097-001

Mesh bracket board cover 34.3YI01.001 452098-001

Speakers (L and R and wire connectors) 23.40276.001 452108-001

Front bezel including speaker cover 60.3YI01.001 452114-001

I/O bracket with AC inlet 90.3YI28.007G 452126-001

Inverter board

Inverter board - Master

Inverter cable

Control board

Control board

LVDS cable

Power cord 8121-0740 -Remote control 5188-6301 / 90.3YI26.001 452113-00 1

Cable clamp 38.05031.001 452127-001

Repair screw kit 34.37P06.001 (2)

VGA cord -- 453143-001

Whole unit – head only -- 451704-001

Part Description OEM Part Numbers HP Part Number

42.3YI02.001

6K.3YISC.003

56.04230.Q01

50.3YJ02.001

91.3YW10.001G

50.3YJ02.001

60.3YJ03.001

91.3YK10.003G

91.3YK10.002G

50.3YJ03.001

27-D010279

50.3YI02.001

35-D013932

50.3YI01.001

86.00G29.668 (4)

86.1A334.6R0 (4)

86.1A336.6R0 (10)

86.1H524.8R0 (4)

86.RA324.100 (2)

86.VA314.6R0 (4)

86.VA326.100 (4)

86.9A338.150 (8)

86.TA526.100 (4)

455587-001

455591-001

455593-001

455604-001

455596-001

455600-001

452128-001

32 HP High-Definition LCD TV Service Manual

Page 38

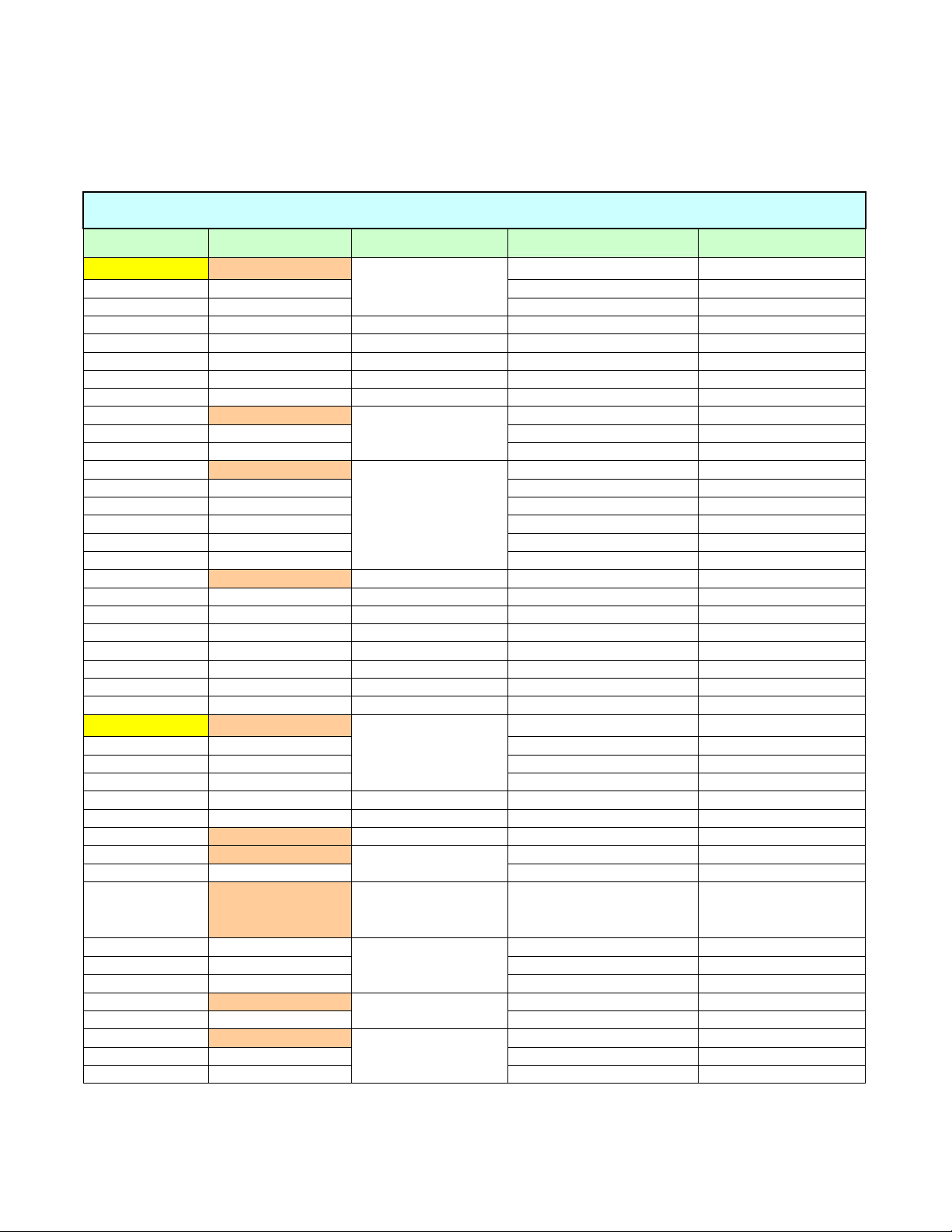

Model LT3700

To see the pictures of the replaceable parts, go to the “Replacement Parts List Reference Picture” section.

Picture

Number

1

2

3

4

5

6

7

8

9

10

11

12

13

--

--

--

--

--

--

Stand base 60.3YG11.001 452085-001

Stand neck assy

Stand neck

Repair screw kit

Power supply assy - For 3x models -230W

Power supply - 3x model

Main board to power supply cable

Main board assy

Main board

Main board to power supply cable

Back cover - bucket 60.3YI07.001 452093-001

Keypad - Infrared assy

Keypad buttons

Keypad PCA board

Infrared board

System board to keypad/IR cable

Internal support wall mount 33.3YI06.001 452097-001

Mesh bracket board cover 34.3YI01.001 452098-001

Speakers (L and R and wire connectors) 23.40276.001 452108-001

Front bezel including speaker cover 60.3YH06.001 (speaker cover)

I/O bracket assy with AC inlet 90.3YI28.007G 452126-001

Inverter board assy

Inverter boards (master and slave) (master

pictured)

Inverter cable - master or 1

Inverter cable - slave or 2

Control board assy

Control board

LVDS cable

Ribbon cables

Power cord 8121-0740 -Remote control 5188-6301 / 90.3YI26.001 452113-00 1

Cable clamp 38.05031.001 452127-001

Repair screw kit 34.37P06.001 (2)

VGA Cord -- 453143-001

Whole unit - head only -- 451705-001

Part Description OEM Part Number HP Part Number

42.3YH02.001

6K.3YISC.003

56.04230.Q01

50.3YJ02.001

91.3YW10.002G

50.3YJ02.001

60.3YJ03.001

91.3YK10.003G

91.3YK10.002G

50.3YJ03.001

adhered to 60.3YH08.001 (front

bezel)

6632L-0314A – master

6632L-0315A – slave

50.3YG03.001

50.3YG04.001

6871L-1083A

50.3YG02.001

6851L-0071E

86.00G29.668 (4)

86.1A334.6R0 (4)

86.1A336.6R0 (10)

86.1H524.8R0 (4)

86.RA324.100 (2)

86.VA314.6R0 (4)

86.VA326.100 (4)

86.9A338.150 (8)

86.TA526.100 (4)

455588-001

455591-001

455594-001

455604-001

452115-001

455597-001

455601-001

452128-001

HP High-Definition LCD TV Service Manual 33

Page 39

Model LT4200

To see the pictures of the replaceable parts, go to the “Replacement Parts List Reference Picture” section.

Picture

Number

1

2

3

4

5

6

7

8

9

10

11

12

13

--

--

--

--

--

--

Stand base 60.3YJ17.001 452086-001

Stand neck assy

Stand neck

Repair screw kit

Power supply assy - For 4x models -338W

Power Supply - 4x model

System board to power supply cable

Main board assy

Main board

System board to power supply cable

Back cover - bucket 60.3YJ05.001 452094-001

Keypad - Infrared assy

Keypad buttons

Keypad PCA board

Infrared board

System board to keypad/IR cable

Internal support wall mount 33.3YI06.001 452097-001

Mesh bracket board cover 34.3YI01.001 452098-001

Speakers (L and R speaker and wire connectors) 23.40276.001 452108-001

Front bezel including speaker cover 60.3YJ16.001 (speaker cover)

I/O bracket assy with AC inlet 90.3YI28.007G 452126-001

Inverter board assy

Inverter boards (master and slave) (master