Page 1

HP Designjet L65500 Printer

Maintenance and troubleshooting guide (second edition)

Page 2

Legal notices

Trademarks

© 2009 Hewlett-Packard Development

Company, L.P.

The information contained herein is subject

to change without notice.

The only warranties for HP Products and

services are set forth in the express warranty

statement accompanying such products and

services. Nothing herein should be

construed as constituting an additional

warranty. HP shall not be liable for technical

or editorial errors or omissions contained

herein.

Microsoft® and Windows® are U.S.

registered trademarks of Microsoft

Corporation.

Page 3

Table of contents

1 Safety precautions

General safety guidelines ..................................................................................................................... 1

Warnings and cautions ......................................................................................................................... 2

Warning labels ...................................................................................................................................... 2

Emergency stop buttons ....................................................................................................................... 4

2 Printer status

Check printer status ............................................................................................................................. 5

Printer alerts ......................................................................................................................................... 5

3 Printer calibration

Align the printheads .............................................................................................................................. 6

Substrate-advance compensation ........................................................................................................ 7

Color calibration ................................................................................................................................... 8

Ink restrictions .................................................................................................................................... 10

Color profiles ...................................................................................................................................... 10

4 Hardware maintenance

Maintain the ink cartridges ................................................................................................................. 11

Maintain the printheads ...................................................................................................................... 11

Maintain the substrates ...................................................................................................................... 11

Check the printheads ......................................................................................................................... 12

Clean the carriage cover .................................................................................................................... 12

Clean the carriage rails ...................................................................................................................... 13

Clean the exterior of the printer .......................................................................................................... 15

Clean the ink deposits ........................................................................................................................ 15

Clean the line sensor and aerosol inlets ............................................................................................ 16

Clean the main roller .......................................................................................................................... 17

Clean the substrate edge holders ...................................................................................................... 17

Clean the pinch wheels ...................................................................................................................... 18

Clean the platen ................................................................................................................................. 18

Clean the printheads .......................................................................................................................... 18

Clean the substrate-advance sensor .................................................................................................. 18

Clean the temperature sensors .......................................................................................................... 19

Maintain the printhead primers ........................................................................................................... 20

Replace the carriage oiler foams ........................................................................................................ 21

Replace the line sensor box ............................................................................................................... 23

ENWW iii

Page 4

Replace the printhead cleaning roll and aerosol filters ....................................................................... 24

Move the printer ................................................................................................................................. 27

Printer maintenance kits ..................................................................................................................... 28

Cleaning kit ......................................................................................................................................... 28

5 Software maintenance

Maintain the HP Internal Print Server ................................................................................................. 29

Update the firmware ........................................................................................................................... 30

6 Troubleshoot substrate issues

The substrate cannot be loaded successfully .................................................................................... 31

The substrate has jammed ................................................................................................................. 31

The substrate is not attached to the input core .................................................................................. 32

The substrate sticks to the platen ....................................................................................................... 33

The ink is still wet when the substrate emerges ................................................................................. 33

There are ink marks on the substrate ................................................................................................. 33

7 Troubleshoot print-quality issues

General advice ................................................................................................................................... 34

Banding .............................................................................................................................................. 34

Colors are misaligned ......................................................................................................................... 36

The print is grainy ............................................................................................................................... 37

The print is smudged .......................................................................................................................... 38

The substrate is not flat ...................................................................................................................... 38

Edges of objects are rough or blurred ................................................................................................ 38

Colors look washed out ...................................................................................................................... 38

Colors are inaccurate ......................................................................................................................... 39

8 Troubleshoot ink cartridge and printhead issues

Cannot insert an ink cartridge ............................................................................................................ 40

Cannot insert a printhead ................................................................................................................... 40

The front panel recommends replacing or reseating an ink cartridge ................................................ 40

The front panel recommends replacing or reseating a printhead ....................................................... 40

A printhead has overheated ............................................................................................................... 41

A printhead has damaged the substrate ............................................................................................ 41

Incorrect printhead cleaning roll errors ............................................................................................... 41

9 Troubleshoot other issues

The printer does not print ................................................................................................................... 42

The printer seems slow ...................................................................................................................... 42

The HP Internal Print Server cannot detect the printer ...................................................................... 42

Upgrade the HP Internal Print Server ................................................................................................. 43

Print job files have not been properly deleted .................................................................................... 43

Color calibration fails .......................................................................................................................... 43

iv ENWW

Page 5

10 Front-panel error messages

11 When you need help

Documentation ................................................................................................................................... 48

HP Proactive Support ......................................................................................................................... 48

HP Customer Care ............................................................................................................................. 48

Service information ............................................................................................................................. 50

Appendix A Preset creation flowchart

Index ................................................................................................................................................................... 52

ENWW v

Page 6

vi ENWW

Page 7

1 Safety precautions

General safety guidelines

WARNING! Internal circuits use hazardous voltage capable of causing death or serious personal

injury.

No operator serviceable parts inside. Refer servicing to qualified service personnel.

The disconnecting devices for servicing are two Branch Circuit Breakers located in the building's Power

Distribution Unit (PDU).

Electric shock hazard

Due to risk of electrical shock, do not attempt the following actions:

Dismantle the electrical control cabinet.

●

Safety precautions

Dismantle the drying and curing subsystems of the printer.

●

Remove or open any other closed system covers or plugs.

●

NOTE: Fuses that blow after being replaced may indicate malfunctioning electrical circuits within the

system. Have the system checked by qualified service personnel, and do not attempt to replace the fuse

again.

Mechanical hazard

The printer has moving parts that can cause injury. To avoid personal injury, take the following

precautions when working close to the printer.

Keep your clothing and all parts of your body away from the printer's moving parts.

●

Avoid wearing necklaces, bracelets and other hanging objects.

●

If your hair is long, try to secure it so that it will not fall into the printer.

●

Take care that sleeves or gloves do not get caught in the printer's moving parts.

●

Avoid standing close to the fans, which could cause injury and could also affect print quality (by

●

obstructing the air flow).

Heat hazard

The drying and curing subsystems of the printer operate at high temperatures and can cause burns if

touched. To avoid personal injury, take the following precautions.

Avoid direct contact with the drying and curing area of the printer.

●

Take special care when accessing the substrate path.

●

ENWW General safety guidelines 1

Page 8

Safety precautions

Fire hazard

Heavy substrate hazard

Ink handling

CAUTION: The drying and curing subsystems of the printer operate at high temperatures.

To avoid the risk of fire, take the following precautions when operating the printer:

Do not manipulate the heating modules.

●

Load substrates that withstand temperatures of 125°C.

●

Special care must be taken to avoid personal injury when handling heavy substrates.

Handling substrate rolls always requires at least two people. Care must be taken to avoid back

●

strain and/or injury.

Always use a forklift, pallet truck or other handling equipment to lift substrates.

●

Always wear personal protective equipment including boots and gloves.

●

Your printer does not use solvent inks and does not have the traditional problems associated with them.

However, HP recommends that you wear gloves when handling ink cartridges or printhead cleaner rolls.

Warnings and cautions

The following symbols are used in this manual to ensure the proper use of the printer and to prevent

the printer from being damaged. Follow the instructions marked with these symbols.

WARNING! Failure to follow the guidelines marked with this symbol could result in serious personal

injury or death.

CAUTION: Failure to follow the guidelines marked with this symbol could result in minor personal injury

or damage to the product.

Warning labels

Label Explanation

Current leakage may exceed 3.5 mA.

The printer can be connected to power supplies at different

voltages.

2 Chapter 1 Safety precautions ENWW

Page 9

Label Explanation

Identifies the main earth terminal

Danger of electric shock. Do not touch.

Danger of electric shock. Do not touch.

Danger of electric shock. In case of operation of the fuse, parts

of the printer that remain energized may represent a hazard

during servicing. Therefore, ensure that the printer is

completely turned off before servicing.

Safety precautions

Printer parts may sometimes become hot. Do not touch.

Use protective gloves for handling printer parts, supplies or

waste.

When substrate has been loaded, the carriage descends into

its normal position, and could crush your hand or anything else

left underneath it.

Danger that your hands may become trapped between

gearwheels

ENWW Warning labels 3

Page 10

Safety precautions

Emergency stop buttons

Label Explanation

When the printer is printing, the printhead carriage travels back

and forth across the substrate.

Beware of this moving part.

There are four emergency stop buttons distributed around the printer. If an emergency occurs, simply

push one of the emergency stop buttons to stop all printing processes. A system error message is

displayed on the front panel, and the fans turn at maximum speed. Ensure that all emergency stop

buttons are released before restarting the printer.

4 Chapter 1 Safety precautions ENWW

Page 11

2 Printer status

Check printer status

You can check the current status of the printer in the following ways:

The HP Internal Print Server displays the status of the printer, the loaded substrate and the ink

●

system. The latest alerts are summarized at the bottom of the main window (see

on page 5).

The front panel displays the ink levels by default; otherwise, you can see the ink levels by selecting

●

the the Ink System icon

Printer alerts

Printer status

. In addition, the most important current alert, if any, is displayed in

the front panel.

Printer alerts

The printer can communicate two types of alerts:

Errors: When the printer is unable to print.

●

Warnings: When the printer needs attention for an adjustment, such as a calibration, preventive

●

maintenance or ink cartridge replacement.

Printer alerts appear primarily at the HP Internal Print Server, but one alert at a time also appears at the

front panel.

HP Internal Print Server: A summary list of alerts appears at the bottom left of the main window.

●

To display a more complete and detailed list, select Information > Alerts.

Front-panel display: The front panel shows only one alert at a time, which is judged to be the

●

most important. It generally requires the user to press the OK key for confirmation, but in the case

of a warning, it disappears after a while. Some alerts reappear when the printer is idle and there

is nothing more important to report.

The following alerts require a service engineer:

Preventive maintenance #1 required

●

Preventive maintenance #2 required

●

Preventive maintenance #3 required

●

Preventive maintenance #4 required

●

ENWW Check printer status 5

Page 12

Printer calibration

3 Printer calibration

Align the printheads

Precise alignment between printheads is essential for color accuracy, smooth color transitions and sharp

edges in graphical elements.

To align the printheads, go to the HP Internal Print Server and select Printer > Printhead alignment.

You can select automatic or manual alignment; the HP Internal Print Server will recommend one or the

other, but you can always choose.

Automatic alignment is a fully automated procedure that ensures optimal print quality in most cases.

●

The printer prints some patterns and scans them with the built-in line sensor. This is the

recommended method for any smooth, high-quality substrates (including vinyl, banners or backlit).

If the printheads have many defective nozzles, automatic alignment may not give good results.

The procedure takes about 14 minutes and consumes 9 inches of substrate.

Manual alignment provides reasonable print quality when automatic alignment is not possible,

●

typically because a highly-textured or non-white substrate is loaded (mesh, perforated, some

fabrics, transparent, colored). The printer prints 8 series of patterns, and you must choose the best

result from each of the series (for example, number 10 in the picture below).

The procedure takes about 15 minutes and consumes 9 inches of substrate.

6 Chapter 3 Printer calibration ENWW

Page 13

Troubleshoot printhead alignment

Automatic printhead alignment may fail occasionally. In some cases, you may see the front panel error

message "Automatic Printhead Alignment is cancelled because of scanning errors". In other cases,

there is no error message but the print quality is not satisfactory. Here are some possible explanations.

There is some problem with substrate advance (see

●

on page 7). After fixing any substrate-advance issue, retry automatic printhead alignment.

You are using a highly-textured (some banners), non-white or very reflective (some satinated

●

offset) substrate. Please use manual printhead alignment in these cases.

The substrate is wrinkled. Check that the substrate is correctly loaded with uniform tension. If

●

necessary, try adjusting substrate parameters such as tension or drying and curing temperatures.

The substrate is not wide enough. Repeat the alignment process using a substrate roll at least 24

●

inches (610 mm) wide.

The printer window was open during the printhead alignment process.

●

The printheads are not clean. See

●

If the problem persists, please try using manual printhead alignment, or call your service representative

HP Customer Care Centers on page 49).

(see

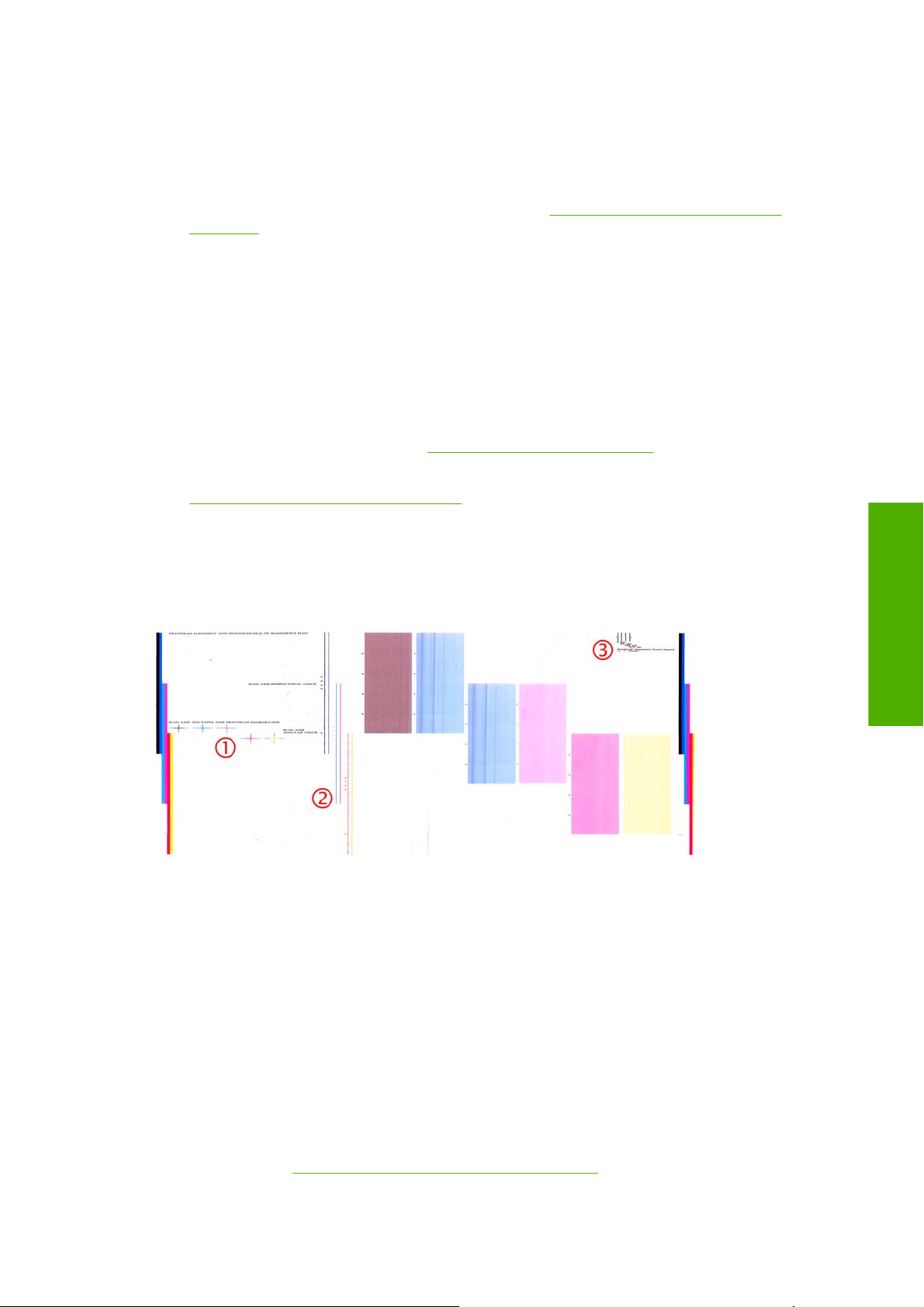

Printhead alignment diagnostic plot

The printer offers a printhead alignment diagnostic plot, to assess the quality of the current printhead

alignment. To print it, start the HP Internal Print Server and select Printer > Printhead alignment >

Diagnostics plot.

Substrate-advance compensation

Clean the printheads on page 18.

1. The colored crosses on the left side of the plot should show the lines well aligned with each other.

2. The vertical lines to left of center should be straight, without kinks.

3. Of the four vertical lines at the top right of the plot, the leftmost two should be straight, without kinks.

Substrate-advance compensation

Accurate substrate advance is important to print quality because it is part of controlling the proper

placement of dots on the substrate. If the substrate is not advanced the proper distance between

printhead passes, light or dark bands appear on the print, and there may be an increase in graininess.

The printer has a substrate-advance sensor and is calibrated to advance correctly with all the substrates

appearing in the front panel. When you select the type of loaded substrate, the printer adjusts the rate

at which to advance the substrate while printing. However, if you are using a custom substrate or not

satisfied with the default calibration of your substrate, you may wish to change the substrate-advance

compensation. See

substrate-advance compensation will solve your issue.

Troubleshoot print-quality issues on page 34 for steps to determine whether

Printer calibration

ENWW Substrate-advance compensation 7

Page 14

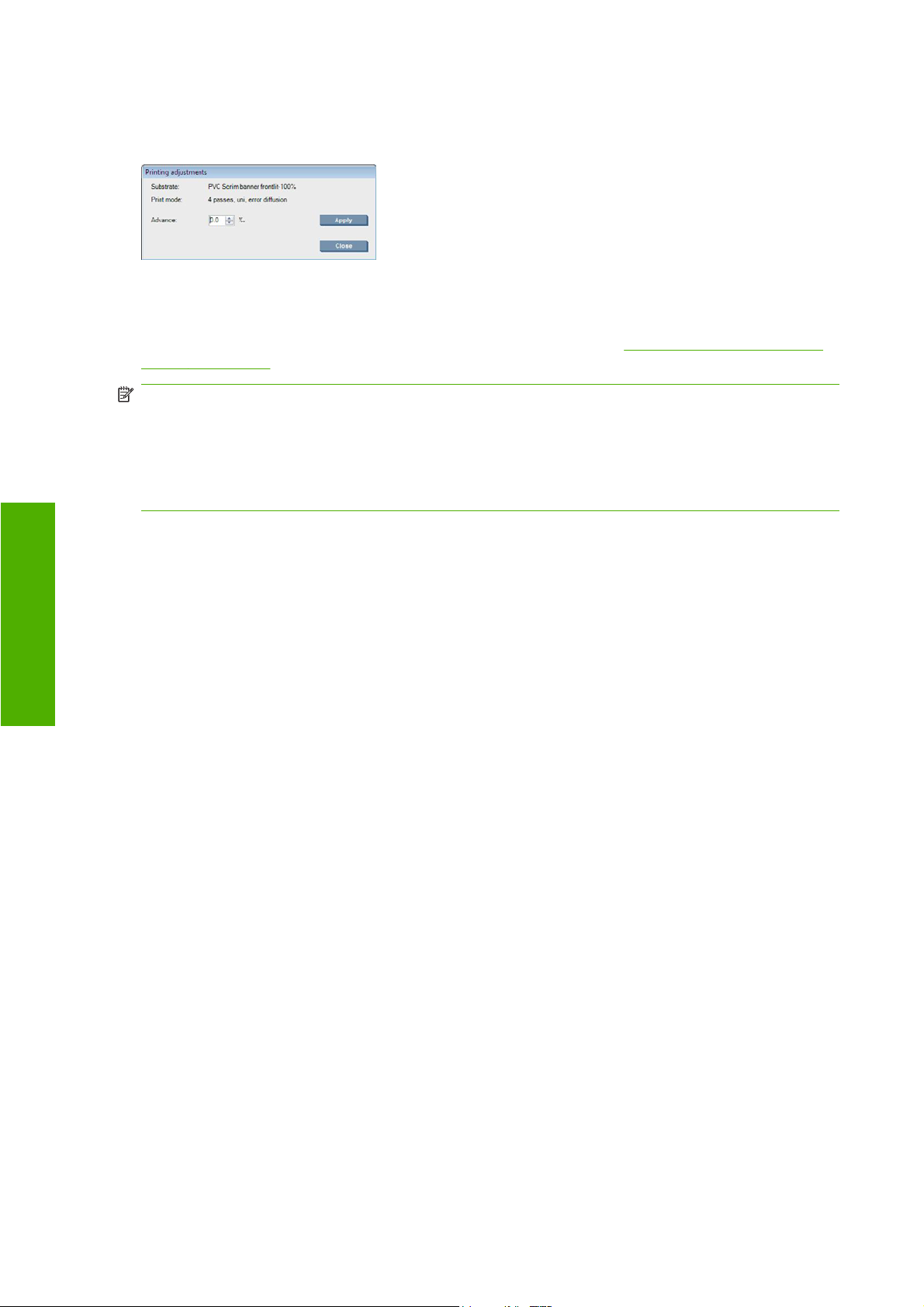

You can view and change the substrate-advance compensation of the currently loaded substrate at any

time from the HP Internal Print Server by selecting the print job and then the Printing Adj. button, or by

selecting Printer > Printing adjustments.

If you prefer the print quality after changing the figure in the Advance field, press the Apply button, and

thereafter your preferred substrate-advance compensation will always be used for that particular

substrate type.

Printer calibration

The substrate-advance sensor may not work correctly if it is dirty. See

sensor on page 18.

NOTE: Some substrates are invisible to the substrate-advance sensor; in which case, the sensor will

not work and should be turned off. You can turn it off by using the Automatic Tracking (OMAS) field in

the Loaded Substrate window of the HP Internal Print Server. An alert will advise you if necessary.

NOTE: The substrate-advance sensor scans the back side of the substrate, which it expects to be of

a single color and shade. It is not guaranteed to work correctly if the back side has been printed on; in

this case, there may be no alert from the printer, but the sensor should be turned off.

Color calibration

Color calibration enables your printer to produce consistent colors with a particular substrate type, even

if printheads, ink cartridges and environmental conditions change. After color calibration, you can expect

to get prints with the same colors from any two different printers situated in different geographical

locations.

The color calibration test chart is printed using the following print mode, depending on the ink density

used with your substrate.

Six passes for 100% ink density

●

Eight passes for 150% ink density

●

Clean the substrate-advance

Fourteen passes for 250% ink density

●

For this reason, you are strongly recommended to have fine-tuned the appropriate print mode before

starting color calibration. To fine-tune your substrate preset for a specific print mode, see the User's

guide.

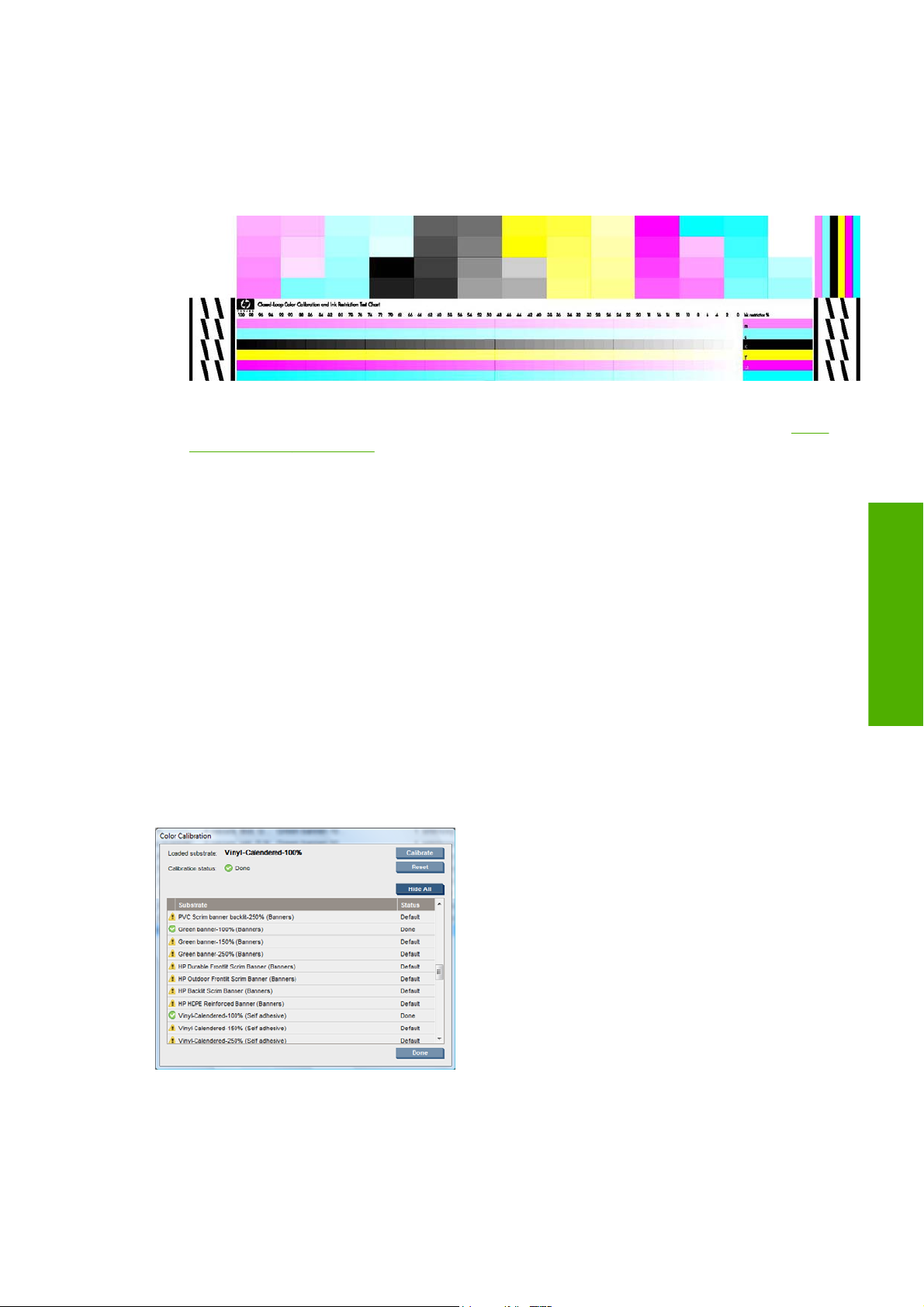

To start color calibration from the HP Internal Print Server, select Substrate > Color calibration, then

click the Calibrate button.

8 Chapter 3 Printer calibration ENWW

Page 15

The calibration process is fully automatic and can be performed unattended after you have loaded

substrate of the type you wish to calibrate. The process takes about 18 minutes and consists of the

following steps.

1. The Closed-Loop Color Calibration and Ink Restriction Test Chart is printed, which contains scales

of patches of each ink used in your printer.

2. The test chart is scanned and color-measured using the HP Embedded Spectrophotometer. If the

scan cannot be completed successfully, a message is displayed on the front panel; see

calibration fails on page 43.

3. From the measurements made by the spectrophotometer, the printer calculates the necessary

correction tables to apply to your print jobs, for consistent color printing on that substrate type.

Calibration should be done in any of the following circumstances:

Color

Whenever a printhead is replaced

●

Whenever a new substrate type is introduced that has not yet been calibrated with the current set

●

of printheads

Whenever you notice excessive color differences between prints. Such color differences can be

●

caused by aging and wear of the printheads, changes in substrate characteristics between one roll

and another, changing environmental conditions and so on.

Whenever you replace a printhead, an alert will remind you to perform color calibration, unless you have

disabled the alerts. If printhead alignment and/or substrate-advance compensation are also needed,

color calibration should always be the last operation.

You can check the color calibration status of your substrates with the HP Internal Print Server or the

front panel. In the HP Internal Print Server, select Substrate > Color calibration > Show all.

Printer calibration

Default status indicates that the substrate has never been calibrated. In this case, the factory

●

default color tables will be applied to print jobs.

Done status indicates that a color calibration has been performed successfully on this substrate.

●

Obsolete status indicates that a printhead has been changed since the substrate was last

●

calibrated, and therefore the substrate should be recalibrated.

ENWW Color calibration 9

Page 16

Printer calibration

Color calibration is based on the color measurement of printed color patches, using the HP Embedded

Spectrophotometer. Some characterisitics of substrates, such as surface roughness or transparency,

may make reflective color measurement of some substrate types very inaccurate. Color calibration of

these substrates will fail or produce unacceptable printing results.

The suitability of particular substrate types for color calibration can be found in the table of supported

substrate types in the User's guide. Only substrates wider than 36 inches (914 mm) can be calibrated.

It is possible to recover from a bad color calibration by restoring the factory default calibration. In the

HP Internal Print Server, select Substrate > Color calibration > Reset.

You should calibrate a substrate type before creating its color profile; however, you can later recalibrate

without needing to recreate the color profile.

Ink restrictions

Ink restrictions allow you to set the maximum amount of each primary ink (cyan, magenta, yellow, black,

light cyan, light magenta) that can be laid down onto a given substrate.

To adjust ink restriction percentages from the HP Internal Print Server, select Substrate > Edit >

Color.

Ink restriction percentages can be set from 50% to 100% for all inks by filling in the appropriate boxes.

In general, a figure of about 80% is recommended.

High percentage settings (approaching 100%) use more ink and may therefore increase color gamut,

at the cost of leaving less margin for the operation of the color calibration system, which may reduce

color consistency.

Lower percentages use less ink, provide a smaller color gamut and a higher range of compensation for

best color consistency.

NOTE: Ill-defined ink restrictions may lead to unpredictable results. You can restore the default ink

restriction settings by selecting Substrate > Edit > Color > Reset.

The Closed-Loop Color Calibration and Ink Restriction Test Chart contains printed ink ramps in 2%

steps, which can be useful as a visual guide for selecting the ink restriction percentages.

To print the Closed-Loop Color Calibration and Ink Restriction Test Chart, select Substrate > Edit >

Color > Print plot.

Color profiles

Color calibration provides consistent colors, but consistent colors are not necessarily accurate. For

instance, if your printer prints all colors as black, its colors may be consistent but they are not accurate.

In order to print accurate colors, it is necessary to convert the color values in your files to the color values

that will produce the correct colors from your printer, your inks and your substrate. An ICC color profile

is a description of a printer, ink and substrate combination that contains all the information needed for

these color conversions.

These color conversions are performed by your Raster Image Processor (RIP), not by the printer. For

further information on the use of ICC profiles, see the documentation for your application software and

for your RIP.

10 Chapter 3 Printer calibration ENWW

Page 17

4 Hardware maintenance

Maintain the ink cartridges

During the normal lifetime of a cartridge, no specific maintenance is required. However, in order to

maintain the best print quality, replace a cartridge when it reaches its expiration date. An alert notifies

you when any cartridge reaches its expiration date.

You can also check a cartridge's expiration date at any time: see

Maintain the printheads

During the normal lifetime of a printhead, no regular maintenance is required. However, in order to

maintain the best print quality, replace a printhead when it reaches its expiration date. An alert notifies

you when any printhead reaches its expiration date.

You can also check a printhead's expiration date at any time: see

Printheads may need to be cleaned and aligned from time to time: see

on page 18 and Align the printheads on page 6.

To check the printheads for blocked nozzles, see

TIP: If you remove an unexpired printhead from the printer, planning to reuse it later, the best way to

protect it is by replacing the protective caps that you removed before inserting it into the printer.

Maintain the substrates

Keep substrates in their sealed wrapping material while they are in storage, and store rolls vertically to

avoid the migration of plasticizers in some materials.

Move substrates from the storage area to the print production area at least 24 hours before use, so that

they can adapt to its temperature and humidity.

Check printer status on page 5.

Check printer status on page 5.

Clean the printheads

Check the printheads on page 12.

ENWW Maintain the ink cartridges 11

Hardware maintenance

Page 18

Check the printheads

If you believe that one or more of the printheads is performing poorly:

1. Go to the HP Internal Print Server and select Printer > Printhead cleaning.

2. Press the Check button to perform routine cleaning.

3. If the problem persists, press the Print button in the same window to print the following display.

Each color is printed by a single printhead and shows the performance of that printhead.

Hardware maintenance

If a significant number of printhead nozzles are blocked, you will see missing lines in this display,

as shown below.

4. In the same window, select any printheads that are showing missing lines, and press the Hard

clean button.

5. When the hard clean has finished, press the Print button again to see whether the printheads have

improved.

6. Check that the printheads' electrical contacts are clean. See

or reseating a printhead on page 40.

7. If you still see five or more missing lines in any one color, you are recommended to replace that

printhead. With fewer missing lines, the printer can maintain good quality when printing with four

or more passes.

If the above printout seems blurred or grainy, you may need to change the substrate-advance

compensation (see

Substrate-advance compensation on page 7).

The front panel recommends replacing

Clean the carriage cover

The printhead carriage cover is designed to reflect the radiation of the drying lamps in order to avoid

overheating the printheads. If the cover becomes dirty, it reflects less heat. To avoid possible damage

12 Chapter 4 Hardware maintenance ENWW

Page 19

to the printheads, the carriage cover may need to be cleaned about once every two months, depending

on your use of the printer. An alert is displayed when the cover needs to be cleaned.

1. Go to the front panel and select Clean carriage cover from the Preventive Maintenance menu

. The carriage moves into the electrical compartment.

2. Open the printhead access door.

3. Press the OK key on the front panel.

4. Clean the carriage cover with a lint-free cloth.

5. If you find dried ink that you cannot remove with the dry cloth, try dampening the cloth with isopropyl

alcohol. After cleaning, wait for the cover to dry.

6. Close the door and press the OK key on the front panel.

Clean the carriage rails

The rails along which the carriage moves may need to be cleaned about once every two years,

depending on your use of the printer. An alert is displayed when they need to be cleaned.

1. Go to the front panel and select Clean carriage rails from the Preventive Maintenance menu

. Press OK to continue.

2. The carriage beam is automatically raised, as when loading substrate.

3. When the carriage beam has stopped rising, turn off the printer.

Hardware maintenance

ENWW Clean the carriage rails 13

Page 20

4. Standing at the front of the printer, clean the front rail using a lint-free cloth dampened with isopropyl

alcohol. You can access the rail from above.

NOTE: If you are in California, instead of isopropyl alcohol please use a VOC-certified cleaner

such as a properly diluted 'Simple Green ® All-Purpose Cleaner'.

5. Standing at the rear of the printer, clean the rear rail in the same way. You can access the rail from

below, through the gap between the platen and the pinches.

Hardware maintenance

6. Wait until the rails are dry.

7. Move the carriage manually into the electrical compartment.

8. Turn the printer back on.

14 Chapter 4 Hardware maintenance ENWW

Page 21

9. Select Carriage beam position > Move to printing (normal) from the front panel's Substrate

menu

takes about two minutes to complete.

to lower the carriage beam into its normal position, close to the substrate. This process

10. Replace the carriage oiler foams (see

replacing the foams, also replace both of the oil wicks.

Replace the carriage oiler foams on page 21). While

Clean the exterior of the printer

Clean the outside of the printer and all other parts of the printer that you regularly touch as part of normal

operation with a damp sponge or a soft cloth and a mild household cleaner such as non-abrasive liquid

soap.

WARNING! To avoid an electric shock, make sure that the printer is turned off and unplugged before

you clean it. Do not let water get inside the printer.

CAUTION: Do not use abrasive cleaners on the printer.

Clean the ink deposits

There are three ink deposits, one for each printhead. They may need to be cleaned every three or four

months, depending on your use of the printer. An alert is displayed when the ink deposits are 85% full,

and again when they are full and need to be cleaned.

1. Go to the front panel and select Clean ink deposits from the Preventive Maintenance menu

.

2. Wait until the printhead carriage has stopped moving, then open the printhead access door in the

side of the printer.

Hardware maintenance

ENWW Clean the exterior of the printer 15

Page 22

3. Clean the interior of each ink deposit with a cotton swab or cloth dampened with distilled water. If

you cannot remove the dried ink this way, try using isopropyl alcohol instead of distilled water.

4. Also clean the area around the ink deposits; but do not try to clean the printhead area.

5. Close the printhead access door.

Clean the line sensor and aerosol inlets

In the course of normal use, the line sensor becomes gradually blinded by light deposits of dried ink.

An alert is displayed when the line sensor needs to be cleaned, which may be about every two months,

depending on your use of the printer. When you see the alert, follow this procedure to clean the sensor.

Hardware maintenance

1. Go to the front panel and select Clean line sens. & inlets from the Preventive Maintenance menu

.

2. The printer raises the carriage beam so that you can access the sensor.

3. Wait for the front panel to announce that the sensor is ready for cleaning.

4. Dampen a cotton swab with isopropyl alcohol. Swabs are provided in the Cleaning Kit.

16 Chapter 4 Hardware maintenance ENWW

Page 23

5. Reach underneath the line sensor and clean it with the cotton swab as shown.

6. Use a brush to clean accumulated dust from the aerosol inlets. Do not use the brush on any other

parts.

7. Look for condensation under the carriage, and remove it with a clean lint-free cloth if necessary.

8. Press the OK button on the front panel. The printer lowers the carriage beam to its normal position.

WARNING! Do not insert your hands or anything else into the printer while the carriage is

descending.

Clean the main roller

The main roller should be cleaned whenever it is visibly dirty, or when you notice that substrate advance

is no longer smooth and regular.

Clean the main roller with a clean cloth dampened with water, and make sure that the roller is dry before

printing. Do not use petroleum-based cleaning liquids.

Clean the substrate edge holders

If you sometimes print with very small side margins, ink may accumulate on the substrate edge holders,

which can cause smears on your prints and blocked nozzles in the printheads.

Check the substrate edge holders monthly for dried ink. If necessary, clean them with a lint-free cloth

dampened with isopropyl alcohol.

TIP: It is not normally necessary to remove the edge holders from the printer, and doing so may

damage them. When not required, they can simply be pushed to the side, away from the substrate.

Hardware maintenance

ENWW Clean the main roller 17

Page 24

Clean the pinch wheels

If the pinch wheels are dirty, they can be cleaned by advancing the substrate (less than a meter).

Cleaning the wheels manually could damage them, and is not recommended.

Clean the platen

The platen should be cleaned whenever it is visibly dirty, or when you notice marks on the back of the

substrate.

Before cleaning the platen, locate the substrate-advance sensor and be careful to avoid scratching it

Clean the substrate-advance sensor on page 18).

(see

Clean the platen with a clean cloth dampened with water, and make sure that the platen is dry before

printing.

Clean the printheads

Periodic printhead cleaning is performed automatically, as long as the printer is turned on. However,

you should clean the printheads if you are experiencing poor image quality and cannot resolve the issue

by other methods. This ensures that there is fresh ink in the nozzles and helps to prevents clogged

nozzles.

If you have printed the printhead status plot, you know which colors are failing. Clean the printheads

that are not performing adequately. If you are not sure which printheads to clean, clean all of the

printheads.

Hardware maintenance

To clean the printheads, go to the HP Internal Print Server and select Printer > Printhead cleaning.

HP recommends the Check and Clean option.

If you decide on a hard clean, you can select which printheads to clean.

Clean the substrate-advance sensor

No alert is displayed to remind you to clean the substrate-advance sensor. You should clean it

periodically (every one to three months, depending on the printer usage and substrate type—see note

below), whenever you clean the platen, and whenever you have printed by accident directly onto the

platen. See

Clean the platen on page 18.

NOTE: Porous substrates or liners can allow small amounts of ink to pass through to the platen and

sensor window, to the extent that a clean sensor can become dirty before finishing a single roll. For this

reason, it is best to disable the sensor when loading a porous substrate, and to clean the platen and

sensor before loading another substrate.

18 Chapter 4 Hardware maintenance ENWW

Page 25

The sensor is located between the second and third group of three pinches, in the middle of the platen.

TIP: You may need a ladder to reach the sensor.

TIP: Cleaning is easily done by reaching over the carriage beam in its low position. If you try to do it

by putting your arms below the beam in its high position, you will find it more difficult to access the sensor

and to check that it is clean.

1. Unload the substrate.

2. Wipe the sensor with one of the cotton swabs provided in the Cleaning Kit, slightly dampened with

isopropyl alcohol, to remove dried ink. If the sensor window is heavily coated with dried ink, you

may need to apply some pressure while wiping, helping the cotton to absorb the ink. Continue

cleaning with fresh swabs until the cotton stays clean and the sensor window looks clean.

When reflecting ambient light, a clean sensor shows a blue-colored reflection that should extend

uniformly across its whole surface. You can see this reflection by moving closer and slightly

changing your angle of view.

3. Wait 3 or 4 minutes before reloading the substrate, so that the alcohol can evaporate completely.

Clean the temperature sensors

An alert is displayed when the temperature sensors need to be cleaned, which may be about every two

months, depending on your use of the printer. When you see the alert, follow this procedure to clean

the sensors.

1. Go to the front panel and select Clean temperature sensors from the Preventive Maintenance

menu

2. Unload the substrate.

3. When the substrate has finished unloading, press an emergency stop button to turn off the

mechanical and drying components of the printer. This is advisable for your own safety.

4. Wait until the dryers cool down.

CAUTION: In the following procedure you will be working close to surfaces that are hot during

normal printer operation. Check that they are cool before proceeding.

. Press OK to continue.

Hardware maintenance

5. Dampen a cotton swab with distilled water. Swabs are provided in the Cleaning Kit.

ENWW Clean the temperature sensors 19

Page 26

6. Use the swab to clean the lenses of both temperature sensors (drying and curing).

7. Check that the lenses are clean by looking directly at them from underneath the printer.

Alternatively, continue cleaning until the cotton swab remains clean after cleaning.

8. Press OK at the front panel to tell the printer that the sensors have been cleaned.

9. Ensure that the emergency stop buttons are released, then restart the printer.

Maintain the printhead primers

Hardware maintenance

A problem with the printhead primers is indicated by one of the following error codes.

The code 46.1:01 indicates a problem with the yellow/magenta primer.

●

The code 46.2:01 indicates a problem with the light cyan/light magenta primer.

●

The code 46.3:01 indicates a problem with the cyan/black primer.

●

To correct the problem:

1. Go to the front panel and start the process to replace the printhead in question (see the User's

guide).

2. After lifting the printhead cover, you will see two 'O' rings that seal the joints between the printhead

cover and the printhead. Apply a little oil, grease or water to the 'O' rings to improve their

performance.

3. Close the printhead cover, the carriage cover and the printhead access door.

4. Request a hard clean of the printhead (see

5. If the error persists, call your service representative (see

on page 49).

20 Chapter 4 Hardware maintenance ENWW

Check the printheads on page 12).

HP Customer Care Centers

Page 27

Replace the carriage oiler foams

The printhead carriage contains two chunks of foam impregnated with oil that continuously lubricate the

carriage rails. They may need to be replaced about every two or three months, depending on your use

of the printer. Replacement foams are available in the Cleaning Kit.

1. Go to the front panel and select Replace oiler foam from the Preventive Maintenance menu

. The carriage moves into the electrical compartment.

2. Open the printhead access door.

3. Slide off the cover of the left oiler foam.

4. Remove the old foam, insert the new foam, and replace the cover.

ENWW Replace the carriage oiler foams 21

Hardware maintenance

Page 28

5. Open the carriage cover to access the right oiler foam.

6. Slide off the cover of the right oiler foam.

Hardware maintenance

7. Remove the old foam.

22 Chapter 4 Hardware maintenance ENWW

Page 29

8. Remove the screws and the oiler foam container, replace the foam, and reattach the container with

the screws.

9. Close the carriage cover and the printhead access door.

10. Press the OK key when finished.

Replace the line sensor box

An alert is displayed when the line sensor box needs to be replaced. The printer moves the carriage to

the right so that the box is easily accessible, and turns off power to the carriage. When you see the alert,

follow this procedure to replace the box.

1. Go to the front panel and select Replace sensor box from the Preventive Maintenance menu

.

2. The carriage moves out from the right cover.

3. Unscrew the three screws of the line sensor box and disconnect the connecting cable.

Hardware maintenance

ENWW Replace the line sensor box 23

Page 30

4. Remove the line sensor box.

5. Connect the cable to the new line sensor box.

6. Place the new box into the printer and fix it in place with the screws. No tool is needed.

7. Press OK at the front panel.

8. The printer turns on power to the carriage and checks the sensor.

Replace the printhead cleaning roll and aerosol filters

Hardware maintenance

The printhead cleaning roll is used to clean the printheads between printing passes. It must be replaced

periodically in order to maintain print quality. The frequency of replacement depends on your use of the

printer: approximately monthly with average use.

An alert is displayed when 75% of the roll has been used, and again when 95% of it has been used.

You can choose to replace the roll at any time.

If there is not enough of the roll to start a new job, the printer cancels the job.

Whenever you replace the printhead cleaning roll, you should also replace the aerosol filters. The roll

and the aerosol filters are supplied together in the same package.

TIP: You are recommended to wear gloves during these operations.

Replace the printhead cleaning roll

1.

Go to the front panel and select Replace cleaner roll from the Ink System menu

portion of the roll is wound on to the takeup roll at this time. You will be warned if the unused portion

is more than 5% of the whole roll.

TIP: If you forget to select Replace cleaner roll at the start of this procedure, do not attempt to

select it later. Instead, wait until you have replaced the aerosol filters and the cleaning roll, and

then select Check cleaner roll from the Ink System menu.

2. In order to replace the printhead cleaning roll, open the door on the front right of the printer.

. Any unused

24 Chapter 4 Hardware maintenance ENWW

Page 31

3. Grip the handle and pull the whole printhead cleaning roll assembly out through the door.

4. Slide both rolls off their axles and dispose of the roll with the used cleaning material according to

the instructions provided with the new roll. Keep the empty core to use as a takeup core.

5. Slide the new roll onto the upper axle. It clicks into place.

6. Pull the black knob on the upper left and move the pinch system aside.

7. Pass the leading edge of the roll over the upper rollers, and thread the cleaning material through

the rollers on the left.

8. There is a strip of polyester film on the leading edge of the cleaning material. Insert it into the hole

in the takeup core, which takes hold of it.

Hardware maintenance

ENWW Replace the printhead cleaning roll and aerosol filters 25

Page 32

9. Slide the takeup core onto the lower axle. It clicks into place.

NOTE: If the cleaner roll has not been properly installed, you may see a message about clearing

a printhead cleaning roll jam. Pull the whole assembly out, wind a little of the roll forward, then slide

it back in again. The printer will check the roll again

10. Restore the pinch system by moving the black knob back into place. If you feel resistance because

the cleaning roll is too tight, turn the roll slightly counter-clockwise.

11. Grip the handle and push the whole printhead cleaning roll assembly back into the printer.

12. Close the door.

Do not empty the drain container: this is done by a service engineer during preventive maintenance.

Hardware maintenance

Replace the aerosol filters

1. Open the printhead access door in the side of the printer, and lift the carriage cover.

2. The aerosol filter containers are on the near and the far sides of the printheads.

26 Chapter 4 Hardware maintenance ENWW

Page 33

3. Lift up the right-hand side of the filter container; it pivots on the left.

4. Pull the old filter out of the bottom of its container and dispose of it according to the instructions

provided with the new filter.

5. Unpack the new filters and ensure that the blue tabs at each end of each filter are at right angles

to the filter.

6. Insert the new filter into the container.

7. Ensure that the blue tabs on the filters are correctly engaged with the hooks on the containers,

otherwise the containers may not close completely.

8. Lower the container into position.

9. Lower the carriage cover and close the door. Press the OK key on the front panel.

10. If you forgot to select Replace cleaner roll before replacing the printhead cleaning roll, you should

now go to the front panel and select Check cleaner roll from the Ink System menu

Move the printer

If you wish to move the printer a short distance on the same site, across a horizontal floor with no steps

and no slopes of more than 5% inclination, see the following instructions. For more difficult movement

operations, please call your service representative (see

CAUTION: Slopes steeper than 5% may cause serious damage to the printer.

1. Turn off the printer.

.

Hardware maintenance

HP Customer Care Centers on page 49).

2. Disconnect all power and network cables from the printer.

3. Disconnect all ink cartridges and remove them from the printer. Hold the cartridge connectors in

position with adhesive tape.

ENWW Move the printer 27

Page 34

4. Raise the feet so that the wheels (A) touch the ground. To raise a foot:

a. Use a 30 mm wrench to unlock the nut at the top of the foot.

b. Rotate the nut manually down the bolt. Leave about 2 cm (0.8 in) clearance at the bottom

between nut and foot.

c. Use a 15 mm wrench to rotate the foot upwards. Use the flat faces at the bottom of the bolt

to fit the wrench.

d. Raise the foot as far as the bolt allows.

e. Use the 30 mm wrench to relock the nut.

CAUTION: Take care to raise the feet as high as you can. They may break if they touch the

ground while the printer is in motion.

Hardware maintenance

5. Push the printer from the outside corners of the top covers.

After moving the printer, you may in some cases need an electrician to reconnect the power cables.

You may also need to reconfigure the network: from the front panel, from the HP Internal Print Server

computer, and from the RIP computer. See the Installation guide for more details.

Printer maintenance kits

Maintenance kits contain printer components that may need to be replaced after long use. When one

of them is needed, an alert (such as “Preventive maintenance #2”) is displayed by the HP Internal Print

Server.

When you see the message, you should call your service representative (see

Centers on page 49) and request the maintenance kit. The kits are installed by service engineers only.

You can see how close you are to needing preventive maintenance by selecting Information >

Maintenance in the HP Internal Print Server.

Cleaning kit

A cleaning kit is provided with the printer; it is intended to provide cleaning materials for about one year

of normal use. It contains oil for the carriage rails, replacement oiling foams, gloves, sponges and cotton

swabs.

HP Customer Care

28 Chapter 4 Hardware maintenance ENWW

Page 35

5 Software maintenance

Maintain the HP Internal Print Server

The HP Internal Print Server runs under Microsoft Windows on the computer supplied with the printer.

In that operating environment, there are various things you can check in order to maintain optimum

performance. You can make these checks after restarting the computer and before starting the HP

Internal Print Server.

The user account should be a Standard account and not an Administrator account.

●

No software should be installed on the computer except the software initially provided by HP.

●

If an antivirus program is installed, it should not be allowed to check the file system constantly.

●

In the Performance tab of the Task Manager, CPU usage should be below 5% (preferably below

●

3%).

Memory usage should be below 1 GB (preferably below 800 MB).

●

Free space on the hard disk should be at least 10 GB.

●

In the Control Panel, Hardware and Sound > Power Options, the high-performance power plan

●

should be selected and sleep mode disabled.

A blank screen saver should be used.

●

Press the start button and right-click Computer. Select Manage > Device Manager > Disk

●

drives. Right-click the hard disk, and select Properties > Policies. Ensure that Optimize for

performance, Enable write caching on the disk and Enable advanced performance are all

enabled.

Ensure that scheduled defragmentation is enabled. Press the start button and right-click

●

Computer. Select Manage > Disk Management. Right-click the hard disk, and select

Properties > Tools > Defragment Now, and ensure that Run on a schedule is enabled.

In the Control Panel, select System > Advanced system settings > Advanced > Performance

●

> Visual Effects > Custom. Ensure that all effects are disabled except Enable Desktop

composition, Enable transparent glass, Smooth edges of screen fonts and Use visual styles

on windows and buttons.

Open Internet Explorer and select Tools > Internet options >

●

proxy server is used, ensure that Bypass proxy server for local addresses is enabled.

Ensure that the computer is connected to the Internet and use Windows Update to ensure that all

●

available updates (including Windows Service Packs) have been installed successfully.

Connections > LAN settings. If a

Start the HP Internal Print Server, and use File > Delete job to delete any jobs for which there is

●

no further use.

ENWW Maintain the HP Internal Print Server 29

Software maintenance

Page 36

Update the firmware

The printer's various functions are controlled by software that resides in the printer, otherwise known

as firmware.

From time to time firmware updates will be available from Hewlett-Packard. These updates increase the

printer's functionality and enhance its features.

Firmware updates can be downloaded from the Internet and installed in your printer using the HP Internal

Print Server: select Firmware update from the Main tab.

Follow the instructions on your screen to download the firmware file and store it on your hard disk. Then

select the downloaded file and click Update.

Software maintenance

The firmware includes a set of the most commonly used substrate presets. Extra substrate presets can

be downloaded separately; see the User's guide.

30 Chapter 5 Software maintenance ENWW

Page 37

6 Troubleshoot substrate issues

The substrate cannot be loaded successfully

A substrate cannot be loaded unless all printer subsystems (e.g. the ink system) are ready.

●

If the printer is unaware of the carriage beam position (after a printer recovery or shutdown), go to

●

the front panel and select the Substrate Management icon

> Carriage system recovery.

Check that the spindle is correctly inflated.

●

Try using the front panel to advance the substrate at least 10 ft (3 m), then move it back and try to

●

load it again. If it will not load, perhaps the substrate is not attached to the input core: try a different

roll.

, then Carriage beam position

Substrate issues

The substrate has jammed

If the printer reports a substrate jam, follow these steps.

1. If the carriage is still moving or trying to move, press an emergency stop button as quickly as

possible to minimize damage to the printheads.

If the printer shuts itself down automatically before you reach an emergency stop button, turn off

circuit breaker ACB-1.

2. Wait about ten minutes for the printer to cool down.

ENWW The substrate cannot be loaded successfully 31

Page 38

Substrate issues

3. If feasible, manually move the carriage slowly and carefully to the side, away from the substrate.

If this is not feasible because of the severity of the jam, try raising the carriage beam to its maximum

height.

4. Remove all substrate and pieces of substrate from the printing zone and from any other parts of

the printer into which they may have fallen. Check the curing zone in particular. If you are unable

to remove them all, please call your service representative (see

on page 49).

5. Before restarting the printer and reloading the substrate, check that all circuit breakers are on and

all emergency stop buttons released.

HP Customer Care Centers

The substrate is not attached to the input core

If the roll is not firmly attached to the input core, you may see banding on your prints, or the printer may

report the end of the roll. To correct the problem, proceed as follows.

1. Unload the roll from the input spindle and load it onto the output spindle. Take care to avoid

telescoping.

2. Raise the pinches and, in the front panel's Substrate Management menu, raise the carriage beam

to its maximum height.

3. Unload substrate from the roll and pass it backwards through the printer towards the input spindle.

Attach it to the empty core on the input spindle, securing it with adhesive tape. Wrap a couple of

turns of substrate around the input core. Take care to align the substrate with the output roll.

4. Lower the pinches.

5. At the front panel, exit the Substrate Management menu, replying “Yes” when asked about

checking the substrate.

NOTE: If the substrate check fails, return the roll to the input side and attach it to an empty core

on the output side. Raise the pinches and use the front panel's Substrate Management menu to

move all the substrate onto the output core.

6. Select the correct substrate in the HP Internal Print Server.

7. Press the Form Feed key on the front panel, then the Back key, and wait until all the roll has been

wound onto the input spindle.

8. You may decide to cancel rewinding when the substrate is detached from the output roll. Then

attach it to the output core to print immediately, or rewind it completely onto the input core if you

want to remove the roll.

32 Chapter 6 Troubleshoot substrate issues ENWW

Page 39

The substrate sticks to the platen

When the substrate sticks to the platen, the most likely causes are excessive heat and excessive

vacuum. Therefore, try decreasing the drying temperature or the vacuum.

For information on how to adjust printer settings, see the User's guide.

The ink is still wet when the substrate emerges

1. Reduce the ink limits.

2. Increase temperature settings for drying and curing.

For information on how to adjust printer settings, see the User's guide.

There are ink marks on the substrate

This problem can be caused by the carriage touching the substrate and smearing the ink.

1. If the ink marks occur at the sides of the substrate and not in the center, check that the substrate

edge holders are correctly placed.

2. Check that the vacuum and tension levels are correct.

3. If you see large drops of ink, clean the printheads to remove any loose fibers.

For information on how to adjust printer settings, see the User's guide.

Substrate issues

ENWW The substrate sticks to the platen 33

Page 40

7 Troubleshoot print-quality issues

Print-quality issues

General advice

When you have any print-quality problem:

To achieve the best performance from your printer, use only genuine HP supplies and accessories,

●

whose reliability and performance have been thoroughly tested to give trouble-free performance

and best-quality prints. For details of recommended substrates, see the User's guide.

Check that the substrate type selected in the HP Internal Print Server is the same as the substrate

●

type loaded into the printer.

CAUTION: If you have the wrong substrate type selected, you could experience poor print quality

and incorrect colors, and perhaps even damage to the printheads.

Check that your substrate has been color-calibrated.

●

●

●

●

●

●

●

Banding

Banding means that your printed image suffers from added horizontal lines as shown (the color of the

lines may vary).

Check that you are using the correct ICC profile for your substrate and print mode.

Check that you are using the most appropriate print-quality settings for your purposes (see the

User's guide).

Check that the environmental conditions (temperature, humidity) are in the recommended range

(see the User's guide).

Check that the printheads have been aligned.

Check whether there are any outstanding printer alerts.

Avoid touching the substrate while printing is in progress.

34 Chapter 7 Troubleshoot print-quality issues ENWW

Page 41

If there are thin white lines across the width of the substrate:

1. From the HP Internal Print Server, clean and check the printheads, and check for blocked nozzles.

If there are blocked nozzles, increase the number of passes.

●

If there is a substrate-advance problem, decrease the substrate-advance setting.

●

2. If the problem persists, increase the number of passes.

If there are thin dark lines across the width of the substrate:

1. Increase the substrate-advance setting in the HP Internal Print Server.

2. If the lines are visible only in dark or saturated colors, try the following remedies in this order:

a. Increase the number of passes.

b. Lower the ink limit for the selected print mode.

c. Increase the drying temperature.

If you have adjusted the substrate-advance setting but there are still white and dark lines distributed

randomly across the same print:

1. Check the substrate-advance status in the HP Internal Print Server. If there is a warning message:

a. Unload the substrate and clean the substrate-advance sensor.

b. Reload the substrate and check it as usual.

c. If the warning message persists, probably the substrate type is invisible to the substrate-

advance sensor, so you should turn off the sensor (in the Loaded Substrate window in the HP

Internal Print Server) and adjust the substrate advance manually.

2. If the problem persists, increase the number of passes.

3. If the problem persists, recreate the substrate preset.

If there are one or more thick lines across the width of the substrate, where one color seems to be

missing:

1. Request a hard clean of the printhead that seems to be failing. See

on page 18.

2. Open the door on the front right of the printer and pull out the printhead cleaning roll assembly.

Clean the printheads

Print-quality issues

3. You should see ink on the upper, horizontal part of the roll and also on the vertical part of the roll.

If you see no ink on the vertical part of the roll, there may be a fault in the primer pump. In this case,

please call your service representative (see

ENWW Banding 35

HP Customer Care Centers on page 49).

Page 42

If the back side of the substrate varies in color or shade (for instance, if something has been printed on

it), you may see banding in parts of your print because the substrate-advance sensor has become

confused. In this case, turn off the sensor (in the Loaded Substrate window in the HP Internal Print

Server) and adjust the substrate advance manually.

If you see banding while printing on self-adhesive substrate with four or five passes, press the

Change button in the Job Properties window, and try changing the halftoning method to G.N.

Print-quality issues

For information on how to adjust printer settings, see the User's guide.

Colors are misaligned

This problem can have various slightly different visible symptoms.

Colors are misaligned vertically

If magenta prints higher on the substrate than the other colors, increase the substrate-advance

●

setting in the HP Internal Print Server.

If magenta prints lower on the substrate than the other colors, decrease the substrate-advance

●

setting in the HP Internal Print Server.

If the misalignment appears to be random, try the solutions recommended for banding (see

●

Banding on page 34).

36 Chapter 7 Troubleshoot print-quality issues ENWW

Page 43

Colors are misaligned horizontally

1. Ensure that the substrate is not skewed. If there is any skew, reload the substrate to correct it.

2. Check the carriage beam position. If it is high and the substrate type doesn't require a high position,

lower it.

3. If the problem persists, realign the printheads.

4. If the problem persists despite automatic printhead alignment, try manual printhead alignment.

5. If the misalignment appears at the sides of the substrate but not in the center, you have a problem

of substrate expansion.

Print-quality issues

If you are using a plastic substrate, recreate the substrate preset, decreasing the curing and

●

drying temperatures as much as possible.

If you are using a porous, paper-based substrate, recreate the substrate preset, increasing

●

the drying temperature as much as possible.

Some substrate types (especially paper-based substrates) may expand because of the

●

ambient temperature and humidity. Try using a higher-quality substrate that is less sensitive

to temperature and humidity.

If you see the problem in printed black text, check in your application or in the RIP that the

●

text color is pure black and does not contain other colors.

The print is grainy

1. Check that you are printing on the correct side of the substrate.

2. Make a diagnostic print and adjust the substrate-advance setting.

3. If the problem persists, align the printheads.

4. If the graininess is more visible in dark or saturated colors (coalescence):

ENWW The print is grainy 37

Page 44

a. Increase the number of passes.

b. Increase the drying temperature.

c. Decrease the ink limit.

For information on how to adjust printer settings, see the User's guide.

The print is smudged

Print-quality issues

This indicates that the ink is not dry. The characteristics of the substrate may have changed. Recreate

the substrate preset.

The substrate is not flat

If the substrate does not lie flat when it comes out of the printer, but has shallow waves in it, you are

likely to see defects in the printed image, such as vertical stripes. This can happen when you use thin

substrate that becomes saturated with ink.

1. Check that the substrate type you have loaded corresponds to the substrate type selected in the

front panel and in your software.

2. Try changing to a thicker substrate type.

Edges of objects are rough or blurred

1. Check that the carriage beam position is not high. If it is high, the printheads have to be aligned

manually.

2. Align the printheads.

3. Recreate the substrate preset.

For information on how to adjust printer settings, see the User's guide.

Colors look washed out

1. If you are using fewer than four passes, increase the number of passes.

2. Increase the ink density.

3. Check that you are using the correct ICC profile for your substrate and print mode.

For information on how to adjust printer settings, see the User's guide.

38 Chapter 7 Troubleshoot print-quality issues ENWW

Page 45

Colors are inaccurate

1. Check that the substrate has been correctly loaded.

2. Check that the loaded substrate is the same as the substrate selected in the HP Internal Print

Server.

3. Check that the ICC profile used by the RIP is correct for the loaded substrate.

Print-quality issues

ENWW Colors are inaccurate 39

Page 46

8 Troubleshoot ink cartridge and

printhead issues

Cannot insert an ink cartridge

1. Use the correct procedure to change ink cartridges, through the front panel. See the User's

guide.

2. Check that there is no obstruction in the ink cartridge connector.

3. Check that the ink cartridge is of the correct color. A connector will refuse to connect to a cartridge

of the wrong color.

Ink system issues

4. Check that the ink cartridge is correctly oriented (compare with the others).

Cannot insert a printhead

1. Use the correct procedure to change printheads, through the front panel. See the User's guide.

2. Check that there is no obstruction in the printhead slot.

3. Check that the printhead is correctly oriented (compare with the others).

4. Check that you have closed and latched the printhead cover.

The front panel recommends replacing or reseating an ink cartridge

1. Disconnect the ink cartridge.

2. Reconnect the ink cartridge and check the front panel message.

3. If the problem persists, insert a new ink cartridge.

4. If the problem still persists, call your service representative (see

on page 49).

HP Customer Care Centers

The front panel recommends replacing or reseating a printhead

1. Remove the printhead.

2. Reinsert the printhead into the carriage and check the front panel message.

3. If the problem persists, remove the printhead again. Illuminate the printhead slot in the carriage

and check the electrical connections to the printhead for dirt. If they look dirty, clean them as

follows.

40 Chapter 8 Troubleshoot ink cartridge and printhead issues ENWW

Page 47

a. Turn off the printer.

b. Place a piece of paper underneath the carriage to collect any dirt that falls through.

c. Use the brush from the Cleaning Kit to clean the electrical connections gently but thoroughly.

d. Use the pneumatic air gun (provided for inflating the spindles) to dislodge any remaining dirt.

You can use paper or cloth to prevent the spread of dirt.

e. Remove any paper or cloth you have used to prevent the spread of dirt.

f. Again illuminate the electrical connections and check that they are clean and undamaged.

4. Reinsert the printhead into the carriage and check the front panel message.

5. If the problem persists, insert a new printhead.

6. If the problem still persists, call your service representative (see

on page 49).

A printhead has overheated

A printhead may overheat for several reasons.

The room temperature may be too high.

●

The printhead may be suffering from blocked nozzles. You may be able to cure this problem by

●

cleaning the printheads (see

The printhead may be suffering from an internal failure, in which case it must be replaced.

●

Clean the printheads on page 18).

A printhead has damaged the substrate

When a printhead touches and damages the substrate, the most likely cause is excessive heat.

Therefore, try decreasing the drying temperature.

For information on how to adjust printer settings, see the User's guide.

HP Customer Care Centers

Ink system issues

Incorrect printhead cleaning roll errors

You should not touch the printhead cleaner roll except when you need to replace it. Any interference

with the roll may prevent the printer from keeping track of roll usage, in which case you may see spurious

error messages, and a printing job may be cancelled unnecessarily.

ENWW A printhead has overheated 41

Page 48

9 Troubleshoot other issues

The printer does not print

If all is in order (substrate loaded, all ink components installed and no file errors), there are still reasons

why a file you have sent from your computer may not start printing when expected:

You may have an electrical power problem. If there is no activity at all from the printer, and the front

●

panel does not respond, check that the power cables are connected correctly and that there is

power available at the source.

You may be experiencing unusual electromagnetic phenomena, such as strong electromagnetic

●

fields or severe electrical disturbances, which can cause the printer to behave strangely or even

stop working. In this case, turn off the printer, wait until the electromagnetic environment has

returned to normal, then turn it on again. If you still experience problems, please call your service

representative (see

HP Customer Care Centers on page 49).

General printer issues

The printer seems slow

In some circumstances, the printer will deliberately print more slowly than usual to prevent the printheads

from overheating. There are several possible reasons why a printhead may start to overheat.

The room temperature is too high.

●

The printhead is suffering from blocked nozzles (see

●

The printhead is faulty and should be replaced.

●

Clean the printheads on page 18).

The HP Internal Print Server cannot detect the printer