HP Designjet L25500 printer series

Site preparation guide (first edition)

Legal notices

© 2009 Hewlett-Packard Development

Company, L.P.

The information contained herein is subject

to change without notice.

The only warranties for HP Products and

services are set forth in the express warranty

statement accompanying such products and

services. Nothing herein should be

construed as constituting an additional

warranty. HP shall not be liable for technical

or editorial errors or omissions contained

herein.

Table of contents

1 Overview

Introduction ........................................................................................................................................... 1

Customer responsibility ........................................................................................................................ 1

Installation time schedule ..................................................................................................................... 1

2 Site preparation requirements

Physical space requirements ............................................................................................................... 2

Unloading route ................................................................................................................... 2

Fire fighting equipment ........................................................................................................ 3

Environmental specifications ............................................................................................... 3

Ventilation and air conditioning ............................................................................................ 3

RIP workstation characteristics ............................................................................................................ 4

Networking ........................................................................................................................................... 4

Printing supplies ................................................................................................................................... 4

Electrical configuration ......................................................................................................................... 4

Single phase power ............................................................................................................. 4

Circuit breakers .................................................................................................................... 5

Wall receptacles and power cords ....................................................................................... 5

Powerline disturbances ........................................................................................................................ 8

Grounding ............................................................................................................................................. 8

3 Site preparation checklist

ENWW iii

iv ENWW

1Overview

Introduction

This Site preparation guide should be used for HP Designjet L25500 printers, both 42 inch and 60 inch.

Specifications and requirements are stated for both printer widths wherever necessary.

Your printer is supplied ready to use after a few simple installation procedures described in detail in

the Assembly instructions. It is important to read the information provided in this guide thoroughly and

to ensure complete compliance with all installation and operation requirements, safety procedures,

warnings, cautions and local regulations. A well prepared site helps to provide a smooth and easy

installation.

Customer responsibility

Overview

You are responsible for all preparations of the physical site to install and place the printer:

Prepare the building's electrical system used to power the printer to meet the printer's requirements

●

and the Electrical Code requirements according to the local jurisdiction of the country where the

equipment is installed, and power up the printer on the day of installation. See

configuration on page 4.

NOTE: Make sure a certified electrician reviews the setup and configuration of the electrical

system used to power the printer. See

Meet temperature and humidity requirements and ensure proper ventilation for the printer. See

●

Environmental specifications on page 3.

Supply all necessary emergency equipment. See

●

Meet all RIP requirements, networking and printing supplies. See

●

characteristics on page 4, Networking on page 4 and Printing supplies on page 4.

Prepare the unloading route so the printer can be unloaded and maneuvered into place. See

●

Unloading route on page 2.

Installation time schedule

Allow a minimum of three hours for the installation. The installer may require the help of three people

to perform certain tasks during installation.

Electrical

Electrical configuration on page 4.

Fire fighting equipment on page 3.

RIP workstation

ENWW Introduction 1

2 Site preparation requirements

Requirements

Physical space requirements

Unloading route

The route between the unloading area of the printer and the installation site, including any corridors and

doorways through which the printer must be transported, is important to proper site preparation and

must be checked before the arrival of the printer. This pathway must be clear when the printer arrives.

Table 2-1 42-in printer physical specifications

Printer Packaging

Length 78 in (1.99 m) 87.79 in (2.23 m)

Width 27.5 in (0.69 m) 40.94 in (1.04 m)

Height 54 in (1.37 m) 47.64 in (1.21 m)

Weight 355 lb (161 kg) 550 lb (250 kg)

Table 2-2 60-in printer physical specifications

Printer Packaging

Length 97 in (2.47 m) 105.9 in (2.69 m)

Width 27.5 in (0.69 m) 40.94 in (0.81 m)

Height 54 in (1.37 m) 46.61 in (1.18 m)

Weight 399 lb (181 kg) 682 lb (310 kg)

Doorways: minimum width 40 in (1.01 m) x minimum height 66 in (1.67 m) required.

The space required for assembly is 10 ft (3 m) in front and 3.5 ft (1 m) at the sides and rear.

Most of the installation process requires one person, but four people are required to perform certain

tasks.

2 Chapter 2 Site preparation requirements ENWW

Fire fighting equipment

You must provide two fire extinguishers for the site. Make sure the extinguishers are placed where they

are easily accessible in case of fire.

A fire extinguisher certified for electrical fires must be in the print production area.

●

A fire extinguisher must be placed in the substrate storage area, due to the large amount of solid

●

combustibles (substrates).

Emergency exits and first aid stations should also be considered.

Environmental specifications

These environmental conditions must be kept within the specified ranges to ensure the correct operation

of the printer. Failure to do so may cause print-quality problems or damage sensitive electronic

components.

Table 2-3 Printer environmental specifications

Relative humidity range for best print quality 20–80%, depending on substrate type

Temperature range for best print quality 18 to 25°C (64 to 77°F), depending on substrate type

Temperature range for printing 15 to 30°C (59 to 86°F)

Temperature range when not in operation -25 to +55°C (-13 to +131°F)

Temperature gradient no more than 10°C/h (18°F/h)

Maximum altitude when printing 3000 m (10000 ft)

NOTE: The printer must be kept indoors.

NOTE: If the printer or ink cartridges are moved from a cold location to a warm and humid location,

water from the atmosphere can condensate on the printer parts and cartridges and can result in ink

leaks and printer errors. In this case, HP recommends that you wait at least 3 hours before turning on

the printer or installing the ink cartridges, to allow the condensate to evaporate.

In addition to controlling the temperature, humidity, and temperature gradient, there are other

environmental conditions that must be met during site preparation.

Do not install the printer where it will be exposed to direct sunlight or a strong light source.

●

Do not install the printer in a dusty environment. Remove any accumulated dust before moving the

●

printer into the area.

Requirements

Ventilation and air conditioning

The printer produces a significant amount of heat. Adequate ventilation and air conditioning is important

in the print production area.

Power dissipation (42-in printer: 3.5 Kw, 12.3 KBTU/h; 60-in printer: 4.8 Kw, 16.4 KBTU/h) and water

vapor from drying ink may require your site to have air conditioning. Adequate conditions can be

established by air renewal if the external temperature is cold enough.

It is recommended that positive airflow be maintained in the print production room. This will help prevent

dust from entering the room.

NOTE: The ventilation and air conditioning units should not blow air directly onto the printer.

ENWW Physical space requirements 3

Requirements

RIP workstation characteristics

The RIP computer and RIP software must be provided by the customer. Each RIP has specific

requirements. Check with your RIP vendor to find out the requirements for the PC that you'll be using

for the RIP station. Make sure that the RIP station is fully functional and ready for installation.

Networking

You are responsible for all networking requirements, and you must complete the following tasks:

NOTE: In order to perform remote support, the printer must have access to the Internet using the LAN

connection.

Have a Gigabit Ethernet network ready for the day of installation.

●

Provide a CAT-6 LAN cable to connect the printer to your LAN and RIP workstation.

●

Provide a Gigabit Ethernet switch.

●

Printing supplies

The following supplies should be purchased in addition to the printer and should be available on the day

of installation:

Six HP 789 ink cartridges, one for each color: black, cyan, magenta, yellow, light cyan and light

●

magenta.

At least one roll of substrate to perform calibrations and printhead alignment during printer setup.

●

Electrical configuration

NOTE: An electrician is required for the setup and configuration of the building electrical system used

to power the printer and also for printer installation. Make sure that your electrician is appropriately

certified according to local regulations and supplied with all the information regarding the electrical

configuration.

Your printer requires the following electrical components to be supplied and installed by the customer,

according to the Electrical Code requirements of the local jurisdiction of the country where the equipment

is installed.

Single phase power

Table 2-4 Single phase line specifications

60-in printer 42-in printer

Number of power cords 2 2

Input voltage 220-240 V~ (-10%+6%) 200-240 V~ (-10%+6%)

Input frequency 50 / 60 Hz 50 / 60 Hz

Power consumption 4.8 kW (overall consumption for both

power cords)

3.5 kW (overall consumption for both

power cords)

Maximum load current (per power cord) 15 A 13 A

4 Chapter 2 Site preparation requirements ENWW

WARNING! Ensure that the printer's built-in Residual Current Circuit Breaker (also known as Ground

Fault Circuit Interrupter) operates in the case of a leakage current fault to the product chassis, even

when an isolation device (such as an isolating transformer) is used to supply power to the printer.

CAUTION: Ensure that the input voltage is within the printer's rated voltage range. The 60-in printer

requires a step-up transformer for tri-phase 208 V or 200 V power systems (voltage line to line).

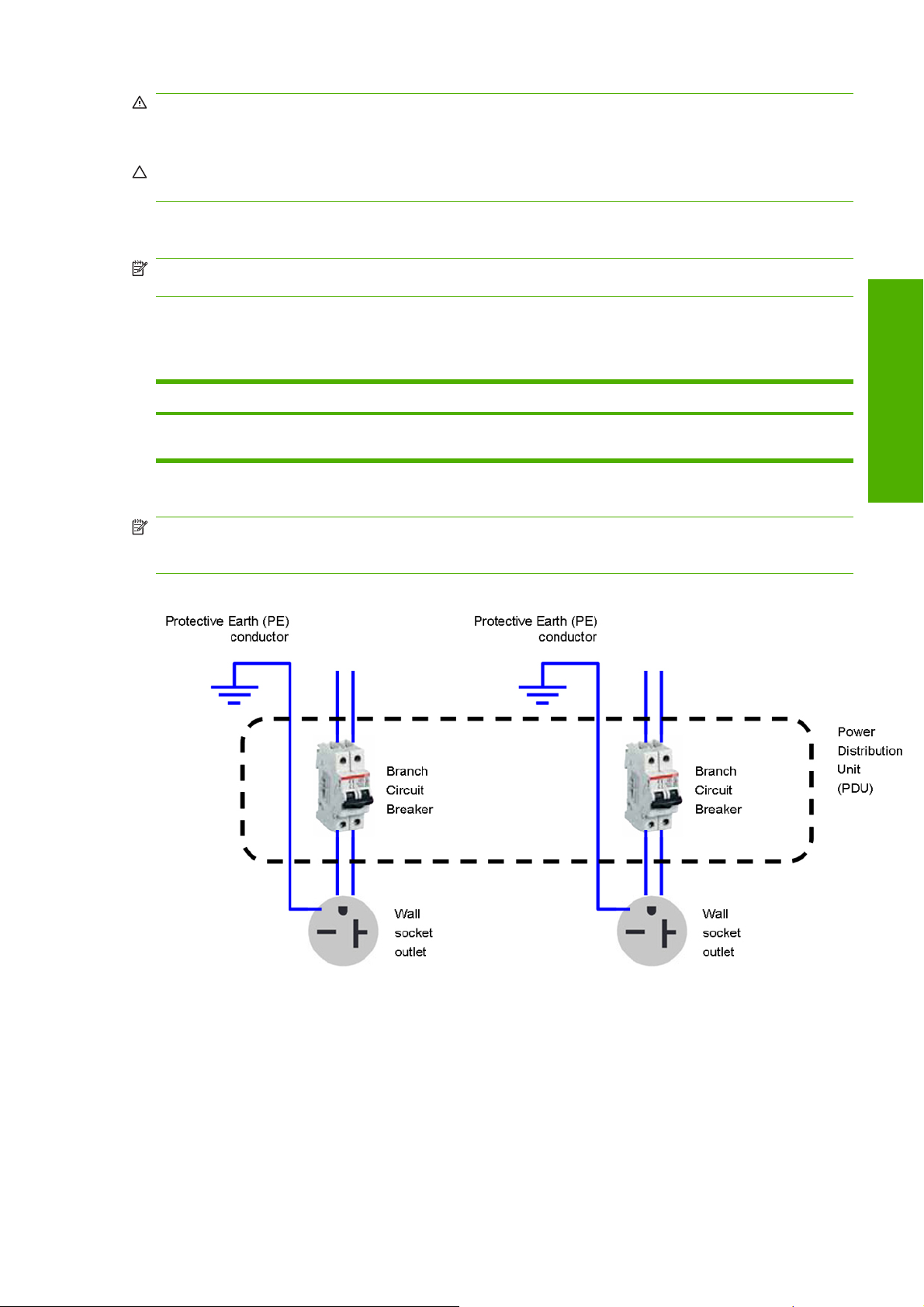

Circuit breakers

NOTE: The circuit breakers must meet the requirements of the printer and shall be in accordance with

the Electrical Code requirements of the local jurisdiction of the country where the equipment is installed.

The printer requires two dedicated lines, each protected by a branch circuit breaker according to the

rating of the wall socket outlet.

Table 2-5 Circuit breaker specifications

Branch circuit breaker Quantity

Single phase line 2 poles, 16 A * (20A for NEMA 6-20R wall

1

* Rating according to wall socket outlet

socket)

1

2, one for each dedicated line

NOTE: The Power Distribution Unit (PDU) must be rated to meet the power requirements of the printer,

and shall be in accordance with the Electrical Code requirements of the local jurisdiction of the country

where the equipment is installed.

Figure 2-1 Electrical configuration diagram

Requirements

Wall receptacles and power cords

Two power cords are provided with your printer, according to the printer's electrical specifications. If

those cords do not reach your PDU and/or UPS, a certified electrician must install suitable extension

cables on the day of installation.

ENWW Electrical configuration 5

To make sure you have the right wall socket outlets (wall receptacles) ready for installation, check the

following:

Requirements

1. The wall socket outlets must be suitable for printer input ratings. See

Single phase power

on page 4.

2. The wall socket outlets must be suitable for the power cord plug type used in the country of

installation.

Table 2-6 60 inch printer power cord specifications on page 6 and Table 2-7 42 inch

printer power cord specifications on page 6 list several examples of the power cords and the

plugs provided with the printer according to the country. To make sure you have the right wall

receptacle, find your country in the appropriate table and check the plug type.

WARNING! Use only use the power cord supplied by HP with the printer. Do not use a power

strip (relocatable power tap) to connect both power cords. Do not damage, cut or repair the power

cord. With a damaged power cord, there is risk of fire and electric shock. Always replace a damaged

power cord with an HP-approved power cord.

Table 2-6 60 inch printer power cord specifications

Country HP Part Number * Length Plug type Plug

USA, Canada, Mexico,

Japan, Philippines,

Thailand

International 8120-6897 14.8 ft (4.5 m) IEC 60309, 240 V, 16

8120-6893 14.8 ft (4.5 m) NEMA 6-20P, 240 V,

20A, non-locking

A, 2L+PE

International – other 8120-6895 14.8 ft (4.5 m) Stripped end

termination, 240 V, 1.5

mm² cross sectional

area

WARNING! A

qualified electrician

must attach a suitable

plug according to local

laws where the printer

is installed, and to the

printer's electrical

requirements.

* Alternative part numbers are valid with the same specifications and markings.

Table 2-7 42 inch printer power cord specifications

Country HP Part Number * Length Plug type Plug

Argentina 8121-0925 8.2 feet (2.5 m) IRAM 2073

Brazil 8121-1101 8.2 feet (2.5 m) NBR 14136

Chile, Uruguay 8121-0923 8.2 feet (2.5 m) CEI 23-50

6 Chapter 2 Site preparation requirements ENWW

Table 2-7 42 inch printer power cord specifications (continued)

Country HP Part Number * Length Plug type Plug

USA, Canada, Mexico,

Philippines, Thailand,

Japan

Australia, New Zealand 8121-0871 14.8 feet (4.5 m) 3112-3, 15 A

China 8120-8934 8.2 feet (2.5 m) GB 1002

Continental Europe,

Korea, Indonesia,

Russia

India 8121-1074 8.2 feet (2.5 m) IS 1293

8120-6360 8.2 feet (2.5 m) NEMA 6-20P, 240 V,

20 A, non-locking

8120-6352 8.2 feet (2.5 m) CEE 7-VII

Requirements

Taiwan 8121-1033 14.8 feet (4.5 m) CNS 690

UK, Hong Kong,

Singapore

Denmark 8121-1077 8.2 feet (2.5 m) DK 2-5A

Israel 8121-1010 8.2 feet (2.5 m) SI 32

South Africa 8121-0915 8.2 feet (2.5 m) SABS 164

8121-0907 8.2 feet (2.5 m) BS 1363/A

Switzerland,

Liechtenstein

8120-6897 14.8 feet (4.5 m) IEC 60309, 240 V, 16

A, 2L+PE

ENWW Electrical configuration 7

* Alternative part numbers are valid with same specs and markings.

Table 2-8 Appliance coupler (printer connection)

Country Appliance coupler (power cable) Appliance coupler inlet (printer)

Requirements

All Detachable terminal as per IEC60320-1

NOTE: Place the wall receptacle close enough to the printer so the plug can be plugged and unplugged

easily.

Powerline disturbances

Reliable operation of your printer depends on the availability of relatively noise-free AC power.

In order to ensure optimum performance and reliability, your printer should be protected from

●

variations in line voltage. Lightning, line faults or the switching of lighting or machinery can generate

line transients that far exceed the peak value of the applied voltage. If not reduced, these

microsecond pulses can disrupt system operation and damage the printer.

It is recommended to include overvoltage (OVP) and transient protection in the power supply to

●

the printer.

C19 (squared type)

Detachable intlet as per IEC60320-1 C20

(squared type)

All electrical noise-generating equipment, such as fans, fluorescent lighting and air-conditioning

●

systems, should be kept separate from the power source used for your printer.

Grounding

The printer must be connected to a good-quality ground line in order to avoid electrical risk. Please note

your obligation to comply with the Electrical Code requirements of the local jurisdiction of the country

where the equipment is installed.

The following grounding tasks must be fulfilled to meet the site preparation requirements:

Grounding wires must be insulated and at least equal in size to the phase conductors.

●

Ground impedance must be less than 0.5 Ω.

●

8 Chapter 2 Site preparation requirements ENWW

3 Site preparation checklist

Safety requirements Yes No Comments

Is there an emergency exit in the print production area, with easy access and

free from any obstruction?

Have the two fire extinguishers been fitted in the prescribed locations in the

print production and storage areas? Is the print production fire extinguisher

rated for electrical fire?

Electrical installation requirements Yes No Comments

Is the electrician aware of all requirements and specifications highlighted in

this guide?

Is the single-phase line voltage inside the specified voltage range?

42-in printer: 200–240 V~ (–10%, +6%)

●

60-in printer: 220–240 V~ (–10%, +6%)

●

For the 60-in printer, the tri-phase 208 V or 200 V power systems (voltage

line-to-line) require a step-up transformer.

Are there two dedicated lines to connect the printer's two power cords?

NOTE: Do not use a power strip (relocatable power tap) to connect both

power cords.

Have branch circuit breakers (2 poles, 16 A general or 20 A for NEMA 6-20R

only) been correctly installed for each dedicated line?

(Required)

(Required)

Specify nominal mains voltage:

(Required)

(Required)

Checklist

Has the single-phase branch circuit breaker (2 poles, 20 A) been correctly

installed?

Is the Power Distribution Unit (PDU) correctly installed? (Required)

Are the grounding conductors properly installed for each wall receptacle (wall

socket)?

Are the wall receptacles (wall sockets) suitable for the power cord plug type

provided by HP?

Are the wall receptacles (wall sockets) and electrical installation suitable for

the printer's rated current ?

NOTE: The printer's rated current is 15 A for 60-in printers, and 13 A for

42-in printers.

(Required)

(Required)

(Required)

(Required)

ENWW 9

Electrical installation requirements Yes No Comments

Are the wall receptacles (wall sockets) placed close enough to the printer

that the plugs can be plugged and unplugged easily?

NOTE: The power cord length is 14.8 ft (4.5 m) for 60-in printers, and 8.2

ft (2.5 m) for 42-in printers.

Would the printer's built-in Residual Current Circuit Breaker (also known as

Ground Fault Circuit Interrupter) operate in the case of a current leakage fault

to the product chassis (even if an isolation device is installed)?

Electrical configuration requirements Yes No Comments

(Required)

(Required)

Checklist

Do you need an Uninterrupted Power Supply (UPS) or step-up transformer?

If so, is it correctly installed?

Networking and computer requirements Yes No Comments

Is the RIP computer and software ready for installation?

Have network connections been supplied?

Do you have a color sensor that is compatible with your RIP?

Do you have a LAN cable long enough to connect the printer to the network?

Environmental requirements Yes No Comments

Have the temperature and humidity requirements been satisfactorily met in

the print production area, and is there adequate ventilation or air

conditioning?

Have the temperature and humidity requirements been satisfactorily met in

the storage area?

Is the print production area free from dirt and dust?

Does the print production area have sufficient lighting?

Other requirements Yes No Comments

Have you arranged for supplies such as substrate and ink cartridges to be

available on the day of installation?

Have you met the requirements specified in this guide? (Required)

10 Chapter 3 Site preparation checklist ENWW

Loading...

Loading...