HP Designjet L25500 printer series

Maintenance and troubleshooting guide (first edition)

Legal notices

Trademarks

© 2009 Hewlett-Packard Development

Company, L.P.

The information contained herein is subject

to change without notice.

The only warranties for HP Products and

services are set forth in the express warranty

statement accompanying such products and

services. Nothing herein should be

construed as constituting an additional

warranty. HP shall not be liable for technical

or editorial errors or omissions contained

herein.

Microsoft® and Windows® are U.S.

registered trademarks of Microsoft

Corporation.

Table of contents

1 Safety precautions

General safety guidelines ..................................................................................................................... 1

Electrical shock hazard ........................................................................................................................ 1

Heat hazard .......................................................................................................................................... 2

Fire hazard ........................................................................................................................................... 2

Mechanical hazard ............................................................................................................................... 2

Heavy substrate hazard ....................................................................................................................... 3

Ink handling .......................................................................................................................................... 3

Warnings and cautions ......................................................................................................................... 3

Warning labels ...................................................................................................................................... 3

2 Printer status

Check printer status ............................................................................................................................. 5

Check the status of the ink system ....................................................................................................... 5

Check the status of the ink cartridges .................................................................................................. 5

Check the status of a printhead ............................................................................................................ 6

Check the file system ........................................................................................................................... 7

Check printer usage statistics .............................................................................................................. 7

Printer alerts ......................................................................................................................................... 7

3 Firmware update

4 Hardware maintenance

Align the printheads ............................................................................................................................ 10

Clean the electrical connections on a printhead ................................................................................. 11

Clean the exterior of the printer .......................................................................................................... 14

Clean the platen ................................................................................................................................. 14

Clean (recover) the printheads ........................................................................................................... 16

Clean the substrate-advance sensor window ..................................................................................... 16

Lubricate the printhead carriage ......................................................................................................... 17

Lubricate the platen rollers ................................................................................................................. 18

Maintain the ink cartridges ................................................................................................................. 20

Move or store the printer .................................................................................................................... 20

Service maintenance .......................................................................................................................... 20

Use the printhead status plot .............................................................................................................. 21

ENWW iii

5 Troubleshoot print-quality issues

General advice ................................................................................................................................... 23

Graininess .......................................................................................................................................... 24

Horizontal banding ............................................................................................................................. 24

Vertical banding .................................................................................................................................. 26

Misaligned colors ................................................................................................................................ 26

Lack of sharpness .............................................................................................................................. 27

Black areas look hazy ........................................................................................................................ 27

Subtle stains or uneven appearance .................................................................................................. 27

The ink smudges when touched, or looks oily .................................................................................... 27

The total length of the print is wrong or inconsistent .......................................................................... 27

6 Troubleshoot substrate issues

The substrate cannot be loaded successfully .................................................................................... 29

The substrate has jammed ................................................................................................................. 29

The substrate is deformed or wrinkled ............................................................................................... 31

The automatic cutter does not work ................................................................................................... 31

Take-up reel substrate jam ................................................................................................................. 32

Take-up reel does not wind ................................................................................................................ 32

7 Troubleshoot ink-system issues

Cannot insert an ink cartridge ............................................................................................................ 34

Cannot insert a printhead ................................................................................................................... 34

Cannot insert the printhead cleaning cartridge ................................................................................... 34

Front panel recommends reseating or replacing a printhead ............................................................. 34

Clean the printheads .......................................................................................................................... 34

Align the printheads ............................................................................................................................ 35

8 Troubleshoot other issues

The printer cannot get an IP address ................................................................................................. 38

Cannot access the Embedded Web Server ....................................................................................... 38

The printer is not printing .................................................................................................................... 39

The software program slows down or stalls while generating the print job ........................................ 39

The printer seems slow ...................................................................................................................... 39

Cannot access files on the hard disk .................................................................................................. 39

Communication failures between computer and printer ..................................................................... 40

“Out-of-memory” error message ......................................................................................................... 40

The platen rollers squeak ................................................................................................................... 40

9 Front-panel error messages

10 When you need help

Introduction ......................................................................................................................................... 46

Documentation ................................................................................................................................... 46

HP Instant Support ............................................................................................................................. 46

HP Customer Care Centers ............................................................................................................... 47

iv ENWW

Service information ............................................................................................................................. 52

Index ................................................................................................................................................................... 53

ENWW v

vi ENWW

1 Safety precautions

Before using your printer, read the following safety precautions to make sure you use the equipment

safely.

General safety guidelines

Refer to installation instructions before connecting the printer to the supply.

●

There are no operator-serviceable parts inside the printer. Refer servicing to qualified service

●

personnel.

Turn off the printer, unplug both power cords from the power outlets, and refer servicing to HP

●

qualified service personnel in any of the following cases:

The power cord or plug is damaged.

◦

Safety precautions

Liquid has entered the printer.

◦

There is smoke or an unusual smell coming from the printer.

◦

The printer has been dropped or the drying or curing module damaged.

◦

The printer's built-in Residual Current Circuit Breaker (Ground Fault Circuit Interrupter) has

◦

been repeatedly tripped.

Fuses have blown.

◦

The printer is not operating normally.

◦

Turn off the printer and unplug both power cords from the power outlets in either of the following

●

cases:

During a thunderstorm

◦

During a power failure

◦

Electrical shock hazard

WARNING! The drying and curing modules operate at hazardous voltages capable of causing death

or serious personal injury.

The printer uses two power cords. Unplug both power cords before servicing the printer. The printer

must be connected to earthed mains outlets only.

To avoid the risk of electric shock:

Do not attempt to dismantle the drying and curing modules or the electrical control cabinet.

●

Do not remove or open any other closed system covers or plugs.

●

Do not insert objects through slots in the printer.

●

ENWW General safety guidelines 1

Safety precautions

NOTE: A blown fuse may indicate malfunctioning electrical circuits within the system. Have the system

checked by qualified HP service personnel, and do not attempt to replace the fuse yourself.

Heat hazard

The drying and curing subsystems of the printer operate at high temperatures and can cause burns if

touched. To avoid personal injury, take the following precautions.

Do not touch the internal enclosures of the printer's drying and curing modules. Even after opening

●

the window latch that disconnects drying and curing power, the internal surfaces could be hot.

Take special care when accessing the substrate path.

●

Fire hazard

The drying and curing subsystems of the printer operate at high temperatures. Contact qualified HP

service personnel if the printer's built-in Residual Current Circuit Breaker (Ground Fault Circuit

Interrupter) is repeatedly tripped.

To avoid the risk of fire, take the following precautions.

Use the power supply voltage specified on the nameplate.

●

Connect the power cords to dedicated lines, each protected by a branch circuit breaker according

●

to the rating of the wall socket. Do not use a power strip (relocatable power tap) to connect both

power cords.

Use only the power cords supplied by HP with the printer. Do not use a damaged power cord. Do

●

not use the power cords with other products.

Do not insert objects through slots in the printer.

●

Take care not to spill liquid on the printer.

●

Do not use aerosol products that contain flammable gases inside or around the printer.

●

Do not block or cover the openings of the printer.

●

Do not attempt to dismantle the drying or curing module, or the electrical control cabinet.

●

Load substrates that can be used at an operating temperature of up to 125°C (257°F), and have

●

auto-ignition temperatures above 250°C (482°F).

Mechanical hazard

The printer has moving parts that could cause injury. To avoid personal injury, take the following

precautions when working close to the printer.

Keep your clothing and all parts of your body away from the printer's moving parts.

●

Avoid wearing necklaces, bracelets and other hanging objects.

●

If your hair is long, try to secure it so that it will not fall into the printer.

●

Take care that sleeves or gloves do not get caught in the printer's moving parts.

●

Avoid standing close to the fans, which could cause injury and could also affect print quality (by

●

obstructing the air flow).

Do not touch gears or moving rolls during printing.

●

2 Chapter 1 Safety precautions ENWW

Heavy substrate hazard

Special care must be taken to avoid personal injury when handling heavy substrates.

Handling heavy substrate rolls may require more than one person. Care must be taken to avoid

●

back strain and/or injury.

Consider using a forklift, pallet truck or other handling equipment.

●

When handling heavy substrate rolls, wear personal protective equipment including boots and

●

gloves.

Ink handling

Your printer does not use solvent inks and does not have the traditional problems associated with them.

However, HP recommends that you wear gloves when handling ink system components.

Warnings and cautions

The following symbols are used in this manual to ensure the proper use of the printer and to prevent

the printer from being damaged. Follow the instructions marked with these symbols.

WARNING! Failure to follow the guidelines marked with this symbol could result in serious personal

injury or death.

Safety precautions

CAUTION: Failure to follow the guidelines marked with this symbol could result in minor personal injury

or damage to the product.

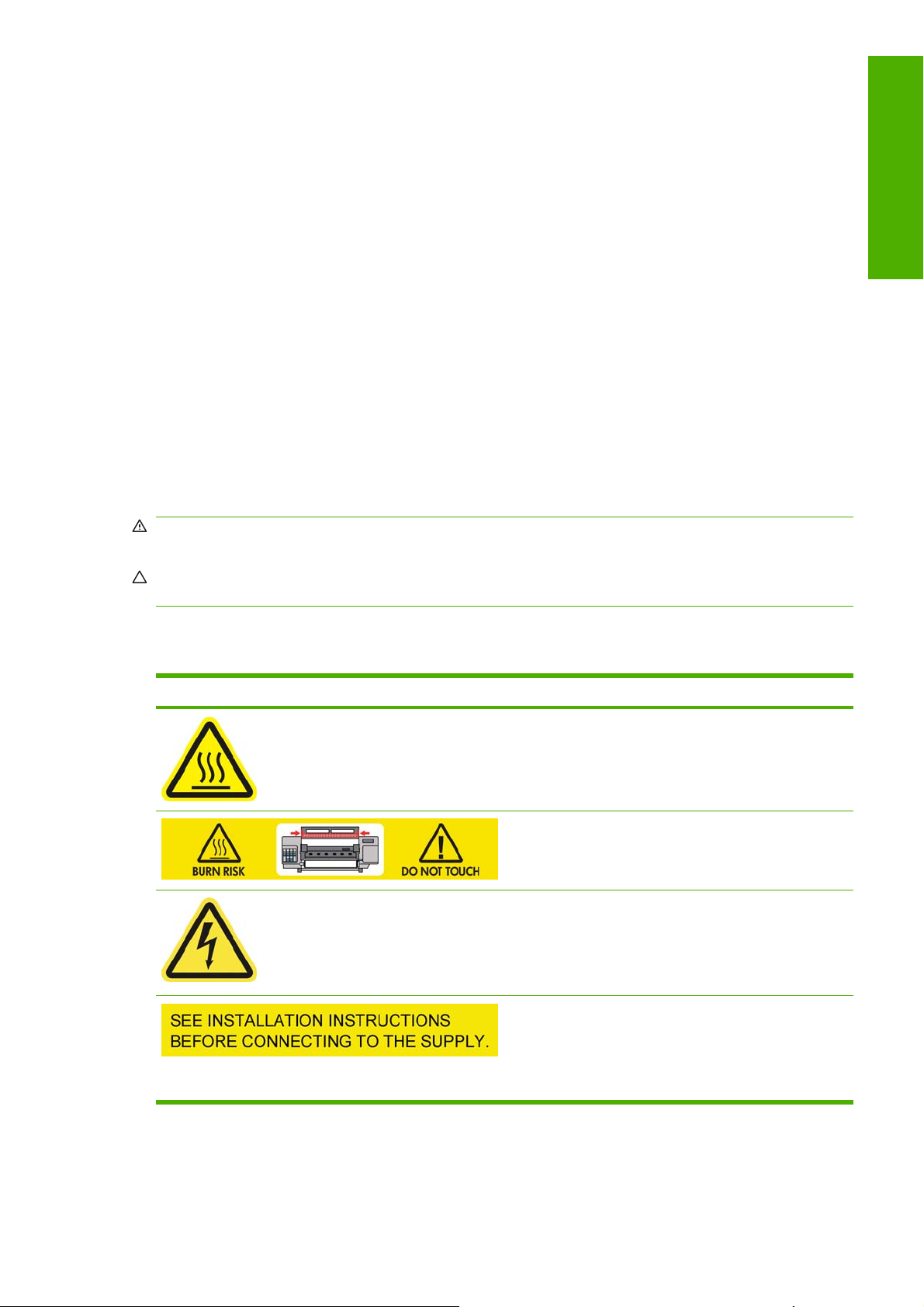

Warning labels

Label Explanation

Risk of burns. Do not touch the internal enclosures of drying

and curing modules of the printer.

Risk of burns. Do not touch the drying enclosure of the printer.

Even after opening the window latch, which disconnects the

power to the drying and curing modules, the internal surfaces

could be hot.

Electric shock hazard. The printer has two input power cords.

A voltage is still present in the drying and curing modules after

the main switch is turned off. There are no operatorserviceable parts inside the printer. Refer servicing to qualified

service personnel. Disconnect all power cords before

servicing.

See installation instructions before connecting to the supply.

Ensure that the input voltage is within the printer's rated voltage

range. The printer requires two dedicated lines, each protected

by a branch circuit breaker according to the rating of the wall

socket outlet. Use only earthed mains outlets and the power

cords supplied by HP with the printer.

ENWW Heavy substrate hazard 3

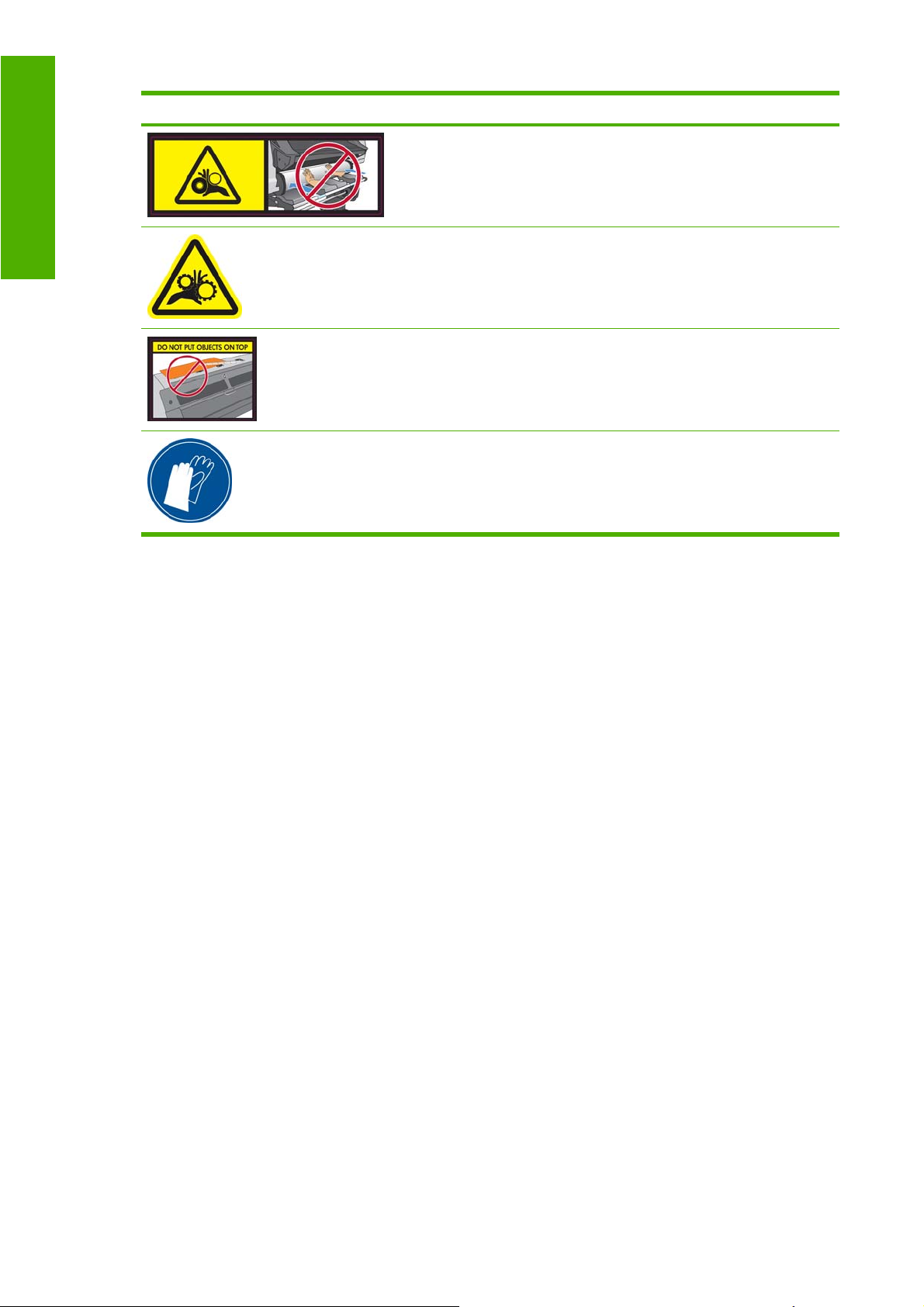

Safety precautions

Label Explanation

Risk of trapped hands. Do not push the roll while loading. Lift

the loading table to ease the spindle into the printer.

Risk of trapped fingers. Do not touch spindle gears while

moving.

Do not put objects on top of the printer. Do not cover the fans.

You are recommended to wear gloves when handling ink

cartridges, printhead cleaning cartridges and the printhead

cleaning container.

4 Chapter 1 Safety precautions ENWW

2 Printer status

Check printer status

You can check the current status of the printer in the following ways:

The Embedded Web Server displays the status of the printer, the loaded substrate and the ink

●

system.

The front panel displays the ink levels by default; otherwise, you can see the ink levels by selecting

●

the the Ink System icon

front panel.

. In addition, the most important current alert, if any, is displayed in the

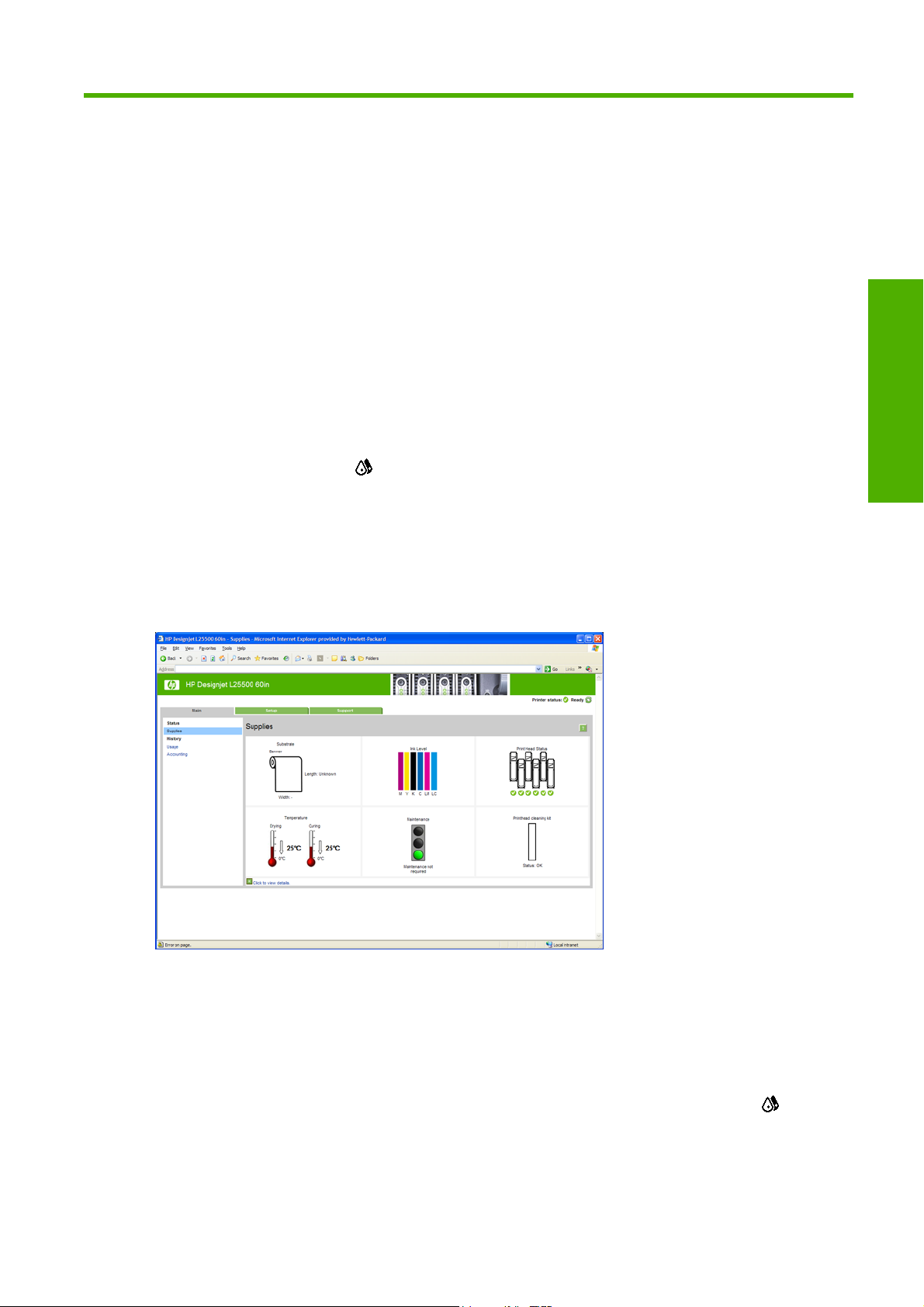

Check the status of the ink system

1. Access the Embedded Web Server (see the User's guide).

2. Go to the Supplies page on the Main tab.

Printer status

The Supplies page shows you the status of the ink cartridges (including the ink levels), the printheads,

the printhead cleaning cartridge, and the loaded substrate.

The traffic light shows whether maintenance is required. For further information, click View details.

Check the status of the ink cartridges

To view the ink levels in your ink cartridges, go to the printer's front panel and select the icon.

Click the + sign for more details, or use the ink menu.

You can also view the status of the ink cartridges in the Embedded Web Server.

ENWW Check printer status 5

Ink menu procedure

Printer status

1. On the front panel, select the icon, then select Ink cartridge information.

2. Select the cartridge about which you want information.

3. The front panel shows the following information:

Color

●

Product name

●

Product number

●

Serial number

●

Status

●

Ink level, if known

●

Total ink capacity in milliliters

●

Expiration date

●

Warranty status

●

Manufacturer

●

Check the status of a printhead

The printer automatically checks and services the printheads after each print. Follow these steps to get

more information on your printheads.

1. On the front panel, select the

2. Select the printhead for which you want to see information.

3. The front panel shows the following information:

Colors

●

Product name

●

Product number

●

Serial number

●

Status (See

●

Volume of ink it has used

●

Warranty status

●

You can also use the Embedded Web Server to check the printhead status and the warranty status.

NOTE: If the warranty status is See warranty note, this indicates that non-HP ink is being used. Printer

service or repairs required as a result of using "non-HP" ink are not covered under warranty. See the

Legal Information document for detailed warranty implications.

Front-panel error messages on page 41.)

icon, then select Printhead information.

6 Chapter 2 Printer status ENWW

Check the file system

It is possible to check the integrity of the file system on the printer's hard disk, and automatically correct

any errors. You are recommended to do this about once every six months, or if you notice any trouble

in accessing files on the hard disk.

To execute the file system check, go to the front panel and select the

check.

If the printer is aware of damage to the file system, for instance after a severe software problem, it may

start a file system check automatically. This can take about half an hour.

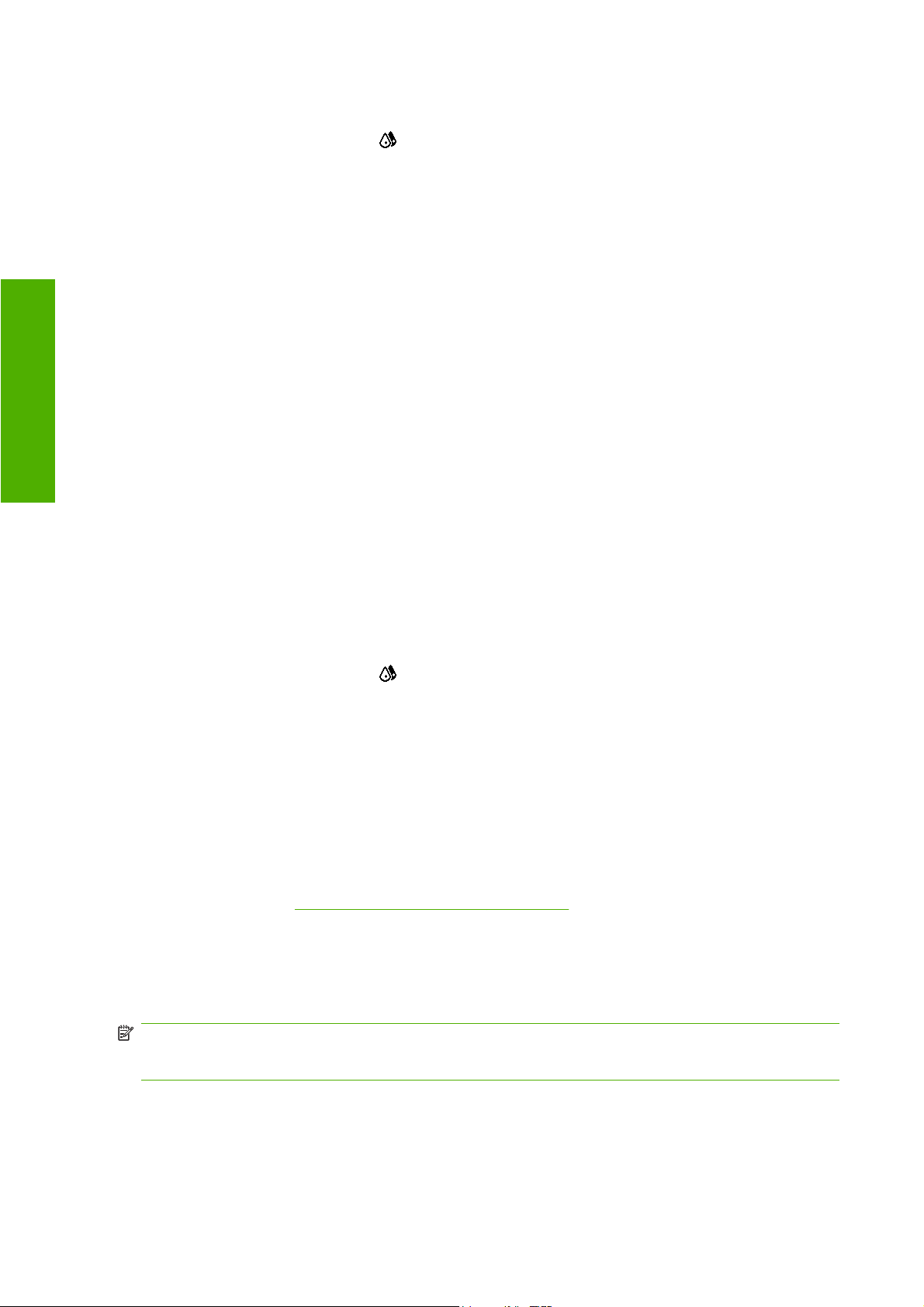

Check printer usage statistics

To check your printer-usage, statistics are available.

NOTE: The accuracy of the usage statistics is not guaranteed.

Printer statistics with the Embedded Web Server

1. Access the Embedded Web Server (see the User's guide).

2. Go to the Usage page on the Main tab.

icon, then select File system

Printer status

Printer alerts

The printer can communicate two types of alerts:

Errors: When the printer is unable to print.

●

Warnings: When the printer needs attention for an adjustment, such as a calibration, preventive

●

maintenance or ink cartridge replacement.

ENWW Check the file system 7

Printer alerts appear in the front panel and in the Embedded Web Server.

Front-panel display: The front panel shows only one alert at a time, which is judged to be the

●

most important. It generally requires the user to press the OK key for confirmation, but in the case

of a warning, it disappears after a while. Some alerts reappear when the printer is idle and there

is nothing more important to report.

Embedded Web Server: The alert displayed in the front panel also appears in the top right corner

●

of the Embedded Web Server window.

Printer status

An alert may require you to perform a maintenance operation; see

on page 10.

The following alerts require a service engineer:

Service Maintenance Kit 1

●

Service Maintenance Kit 2

●

Service Maintenance Kit 3

●

Hardware maintenance

8 Chapter 2 Printer status ENWW

3 Firmware update

The printer's various functions are controlled by software that resides in the printer, also known as

firmware.

From time to time, firmware updates from Hewlett-Packard become available. These updates increase

the printer's functionality and enhance its features.

Firmware updates can be downloaded from HP's Web site (

installed in your printer using the printer's Embedded Web Server.

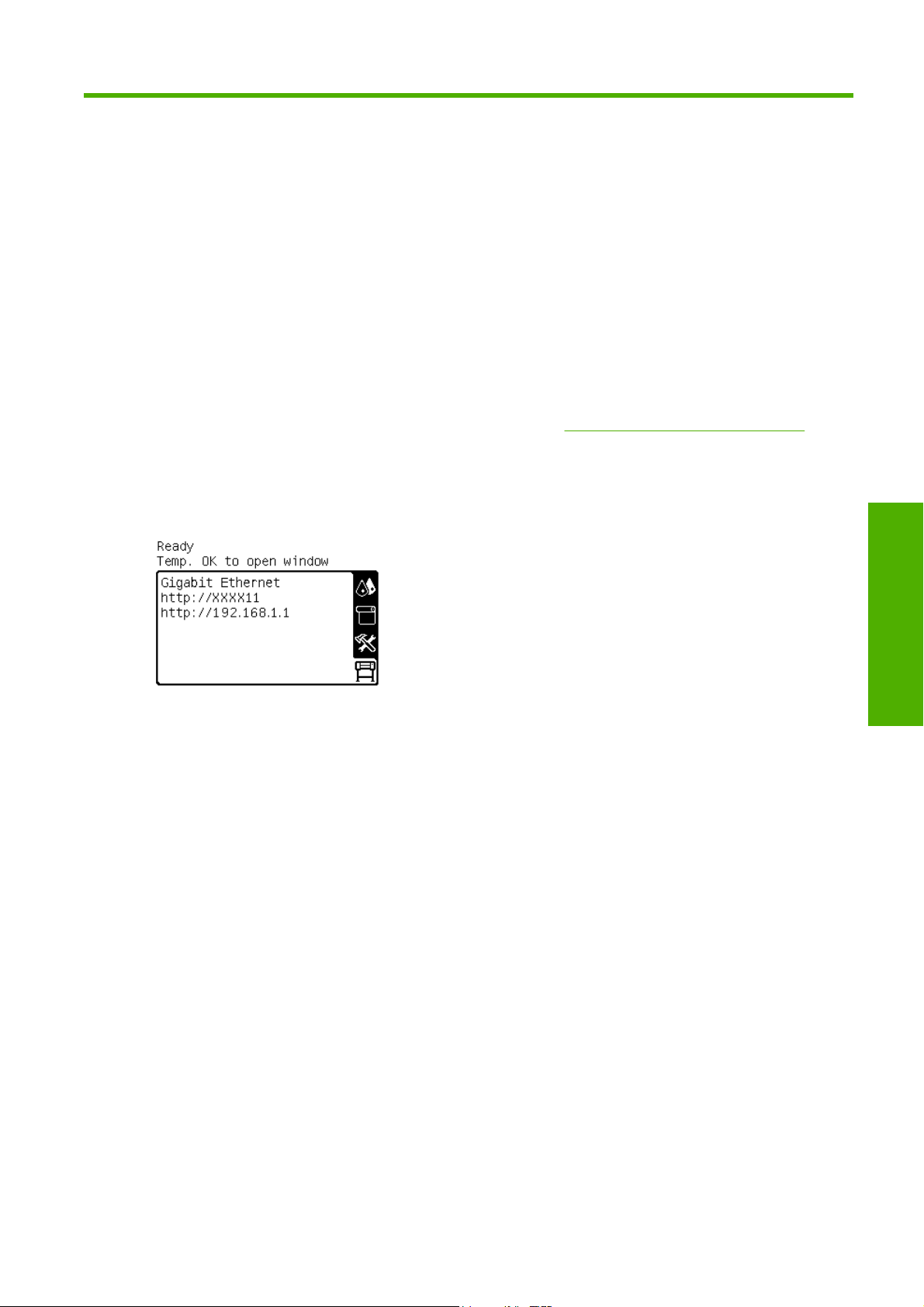

To use the Embedded Web Server on any computer, open your Web browser and type the printer's

URL. The printer's URL appears on the status screen on the printer's front panel (http://192.168.1.1 in

this example):

In the Embedded Web Server, select the Setup tab and then Firmware update.

Follow the on-screen instructions to download the firmware file and store it on your hard disk. Then

select the downloaded file and click Update.

If you experience very slow progress while uploading the firmware file to the printer, the reason could

be that you are using a proxy server. In that case, try bypassing the proxy server and accessing the

Embedded Web Server directly.

In Internet Explorer 6 for Windows, go to Tools > Internet Options > Connections > LAN

●

Settings, and select the Bypass proxy server for local addresses check box. Alternatively, for

more precise control, click the Advanced button and add the printer's IP address to the list of

exceptions, for which the proxy server is not used.

http://www.hp.com/go/graphic-arts/) and

Firmware update

In Firefox 3.0 for Windows, go to Tools > Options > Network > Connection > Settings, and select

●

the Direct connection to the Internet check box. Alternatively, when the Manual proxy

configuration check box is selected, add the printer's IP address to the list of exceptions, for which

the proxy server is not used.

In Firefox 2.0 for Linux, go to Edit > Preferences > Network > Connection > Settings, and select

●

the Direct connection to the Internet check box. Alternatively, when the Manual proxy

configuration check box is selected, add the printer's IP address to the list of exceptions, for which

the proxy server is not used.

ENWW 9

4 Hardware maintenance

For the tasks in this chapter, you may need the User Maintenance Kit that was provided with your printer.

Align the printheads

The printer performs printhead alignment whenever printheads are replaced. If no substrate is loaded

when a printhead is replaced, the printer will perform the alignment the next time you load substrate.

You may also be recommended to align the printheads to solve a print-quality problem.

Automatic alignment

First make sure that you have a roll of opaque, white substrate loaded in the printer. Colored substrates,

glossy canvas, and transparent materials such as translucent bond, clear film, tracing substrate, and

vellum are not suitable for automatic printhead alignment; for these substrates, you should align the

printheads manually (see

Manual alignment on page 10).

To request printhead alignment from the front panel (if the alignment is not performed automatically),

select the

alignment.

To request printhead alignment from the Embedded Web Server, select the Setup tab, then select Align

printheads > Automatic PH alignment > Print.

Hardware maintenance

The process takes about 10 minutes and starts immediately, unless an image is currently being printed.

If a print job is in process, the alignment will be done as soon as the current print job is finished.

Manual alignment

To request a manual printhead alignment from the front panel, select the icon, then select Image

quality maintenance > Align printheads > Manual PH alignment > Print alignment pattern.

To request manual printhead alignment from the Embedded Web Server, select the Setup tab, then

select Align printheads > Manual PH alignment > Print.

The printer prints 17 rows labelled from A to Q. Inspect the print and write down the number of the

straightest line in each row (for example, A:9).

icon, then select Image quality maintenance > Align printheads > Auto PH

10 Chapter 4 Hardware maintenance ENWW

When you have done this, enter the correction values into the front panel or the Embedded Web Server.

To enter the correction values in the front panel, select the

maintenance > Align printheads > Manual PH alignment > Enter correction values. Enter each

value into the window labelled with the same letter as the corresponding pattern.

To enter the correction values in the Embedded Web Server, select the Setup tab, then select Align

printheads > Manual PH alignment, and enter each value into the window labelled with the same letter

as the corresponding pattern.

icon, then select Image quality

Clean the electrical connections on a printhead

It is possible that the printer will not recognize a printhead after it has been installed. This can happen

when ink builds up on the electrical connections between the printhead and the printhead carriage.

Under these circumstances, HP recommends that you clean the electrical connections on the printhead.

However, routine cleaning of the connections when no problems are apparent is not recommended.

A carriage interconnect wiper is included with your printer in the User Maintenance Kit.

Use this to clean the electrical interconnects on both the printhead carriage and the printhead if the

Reseat or Replace message persists next to the printhead on the front-panel display.

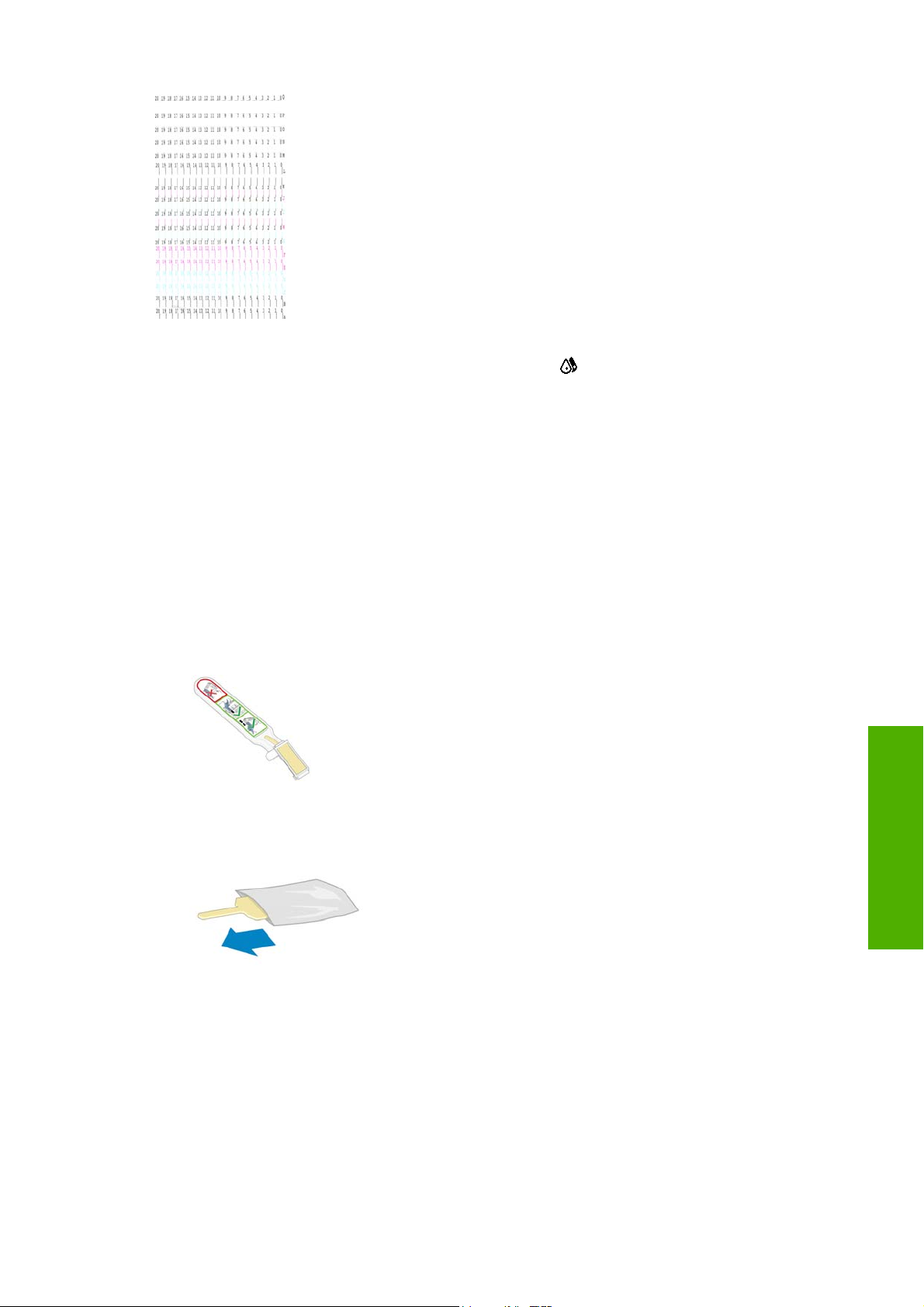

1. Remove a new pre-moistened replacement sponge from its pouch.

A supply of sponges is included in the box with the wiper. If all sponges have been used, more can

be obtained by calling your service representative.

ENWW Clean the electrical connections on a printhead 11

Hardware maintenance

2. Open the carriage interconnect wiper.

3. Load the sponge by positioning the sponge on the face of the carriage interconnect wiper with the

shorter tab in the locating slot.

4. Close the carriage interconnect wiper, trapping the sponge in place.

Hardware maintenance

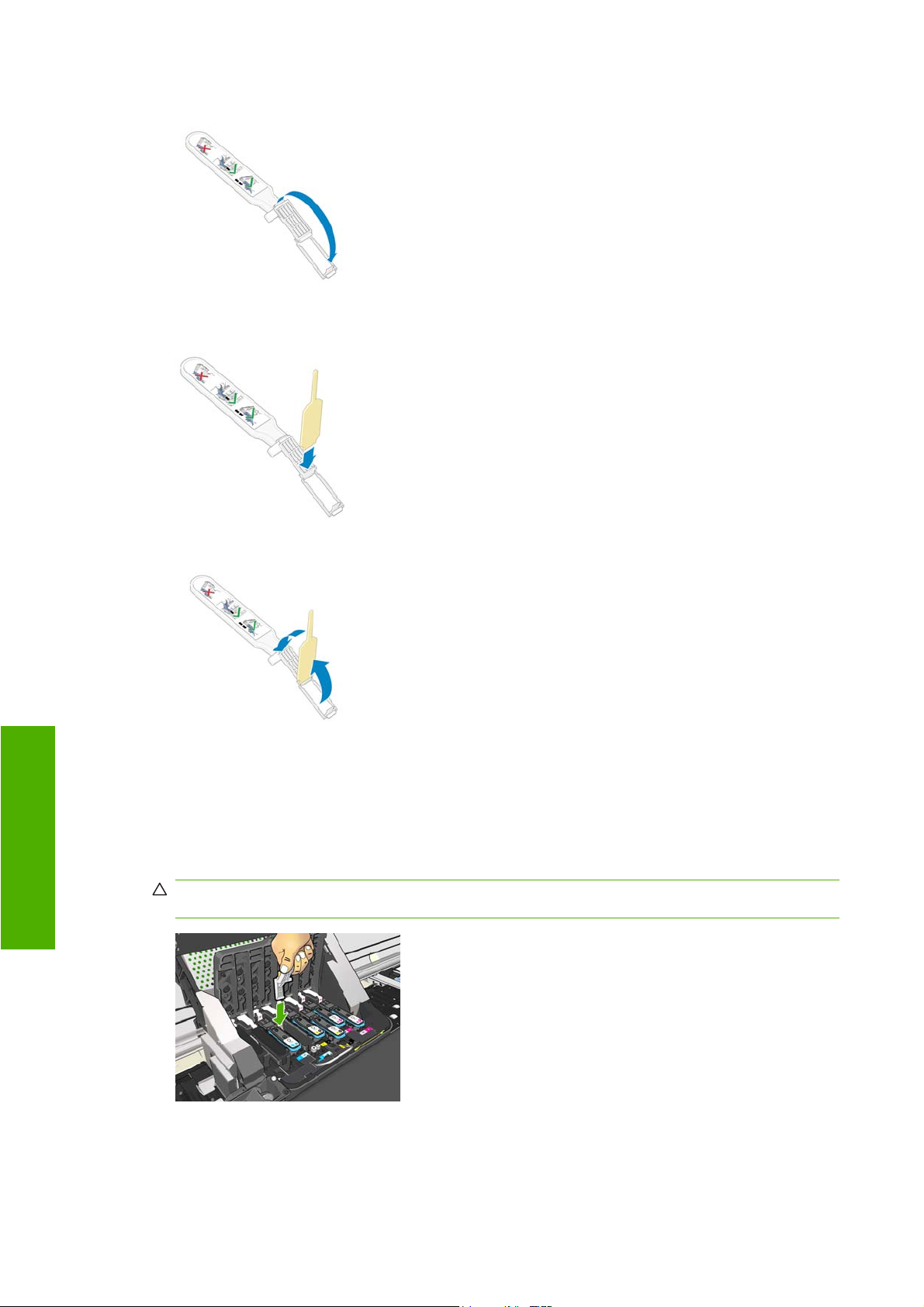

5. Open the printhead carriage latch and extract the printhead that is causing the problem, as

indicated on the front panel. See the User's guide.

6. Insert the carriage interconnect wiper into the printhead slot at the back. Wipe the electrical contacts

by inserting the tool between the electrical connections at the back of the slot and the steel spring,

with the sponge facing away from you and towards the electrical contacts. Try to avoid picking up

any ink deposit that may have accumulated on the bottom surface of the slot.

CAUTION: If the carriage remains in the central part of the printer for more than 7 minutes, it

attempts to return to its home position to the right.

12 Chapter 4 Hardware maintenance ENWW

7. Rub the sponge against the contacts with a light force along the entire depth of the flex connector,

inserting the wiper as far as allowed by the mechanical stop on the tool.

8. Take special care to clean all contacts thoroughly, including the ones at the lowest point of the

connector.

9. Using the same sponge, clean the lower strip of electrical contacts on the printhead (unless the

printhead is new). Avoid touching the upper set of electrical contacts.

CAUTION: Do not touch the surface of the printhead that contains the nozzles, because the

nozzles are easily damaged.

10. After waiting a few moments to allow both connectors to dry, replace the printhead into the printhead

carriage. See the User's guide.

11. After completing the cleaning process, open the carriage interconnect wiper by pulling on the

sponge tab.

Hardware maintenance

ENWW Clean the electrical connections on a printhead 13

12. Remove the soiled sponge from the carriage interconnect wiper.

13. Dispose of the soiled sponge in a safe place to prevent the transfer of ink onto hands and clothing.

If the front panel continues to show the Reseat or Replace message, replace the printhead or call your

service representative.

Clean the exterior of the printer

Use a damp sponge or a soft cloth and a mild household cleaner such as non-abrasive liquid soap to

clean the outside of the printer and all other parts of the printer that you regularly touch as part of normal

operation (for example, ink cartridge drawer handles).

There may be some dampness from condensation under the fans of the curing module, which should

be wiped with a dry cloth.

Hardware maintenance

WARNING! To avoid an electric shock, make sure that the printer is turned OFF and unplugged before

you clean it. Do not let water get inside the printer.

CAUTION: Do not use abrasive cleaners on the printer.

Clean the platen

You should clean your printer's platen every few months, or when necessary.

NOTE: If you print on wide substrate after having printed on narrower substrate, you might find that

the left side of the platen has become dirty. If this contaminated section of the platen is not cleaned, it

might leave marks on the back of the substrate.

WARNING! Be careful not to damage the substrate-advance sensor when cleaning the platen. The

sensor is the very small rectangular window (less than 1 square centimeter) found close to the third

pinchwheel from the right. See

Clean the substrate-advance sensor windowon page 16.

Follow these instructions to clean the platen.

1. Unload all substrate from the printer. See the User's guide.

14 Chapter 4 Hardware maintenance ENWW

2. Turn off the printer and wait until it has cooled down, then unlock and open the printer window.

3. With a dry brush, remove ink deposits from the cutter groove. A brush is available in the User

Maintenance Kit.

4. With the same dry brush, remove ink deposits from the platen surface.

5. Use a clean, absorbent lint-free cloth that has been slightly dampened with isopropyl alcohol to

wipe loosened ink deposits from the platen.

NOTE: Isopropyl alcohol is not provided in the User Maintenance Kit.

Hardware maintenance

CAUTION: Do not use commercial cleaners or abrasive cleaners. Do not wet the platen directly,

because you will leave too much moisture behind.

ENWW Clean the platen 15

6. Use the damp cloth to clean the cutter ramp.

7. Use a dry cloth to clean the exposed part of the wheels. Ideally, you should clean the entire

circumference of these wheels.

8. Remove the isopropyl alcohol and the cloth from the vicinity of the printer.

9. Wait three or four minutes to let the alcohol evaporate, before turning on the printer and reloading

the substrate.

Clean (recover) the printheads

To clean the printheads (which often enables them to recover from problems), go to the printer's front

Hardware maintenance

panel and select the

which printheads you would like to clean. You can clean all of the printheads or only some of them.

Select from these options:

Print test plot

●

Clean all

●

Clean LC-C

●

Clean Y-MK

●

Clean LM-M

●

Cleaning all printheads takes about 5 minutes. Cleaning any two printheads takes about 3 minutes.

NOTE: Cleaning all printheads uses more ink than cleaning a single pair.

icon, then select Image quality maintenance > Clean printheads. Specify

Clean the substrate-advance sensor window

The substrate-advance sensor is the very small rectangular window (less than 1 square centimeter in

size) close to the third pinchwheel from the right.

16 Chapter 4 Hardware maintenance ENWW

HP recommends that you clean the substrate-advance sensor window whenever you clean the print

platen and if you are experiencing print quality issues.

1. Unload the substrate by using the front panel procedure. See the User's guide.

2. Turn off the printer and wait until it has cooled down.

3. Wipe the sensor with one of the cotton swabs provided in the User Maintenance Kit, slightly

dampened with isopropyl alcohol, to remove dried ink.

If the sensor window is heavily coated with dried ink, you may need to apply some pressure while

wiping, helping the cotton to absorb the ink. Continue cleaning with fresh swabs until the cotton

stays clean and the sensor window looks clean. When reflecting ambient light, a clean sensor

shows a blue-colored reflection that should extend uniformly across its whole surface. You can see

this reflection by moving closer and slightly changing your angle of view.

4. Remove the isopropyl alcohol and the cotton swabs from the vicinity of the printer.

5. Wait three or four minutes to let the alcohol evaporate, before turning on the printer and reloading

the substrate.

Lubricate the printhead carriage

The printhead carriage occasionally (about twice a year) needs lubrication so that it continues to slide

easily along the slider rod. This is recommended by the front panel when the time comes.

1. To gain access to the carriage, go to the front panel and select the

roller lubrication. The carriage slides to the middle section of the printer.

CAUTION: If the carriage remains in the central part of the printer for more than 7 minutes, it

attempts to return to its home position on the right.

2. Take the bottle of oil from the User Maintenance Kit that is supplied with your printer. A replacement

kit can be ordered if necessary.

3. Unlock and open the printer window, and apply a few drops of the oil to the pads on either side of

the carriage.

icon, then select Carriage

Hardware maintenance

ENWW Lubricate the printhead carriage 17

4. Apply a few drops of oil directly to the slider rod on either side of the carriage.

Press OK when this has been done.

5. Clean the substrate jam reflector using a lint-free cloth dampened with distilled water. If you find

dried ink that you cannot remove, try using a lint-free cloth dampened with isopropyl alcohol.

Press OK when this has been done.

6. If the front panel prompts you to oil the rollers, see

Press OK when this has been done.

7. Close and lock the printer window.

Lubricate the platen rollers

Hardware maintenance

If you notice that the platen rollers are squeaking, it is time to lubricate them. Locate the oil bottle in the

User Maintenance Kit that came with your printer.

1. Unlock and open the printer window.

Lubricate the platen rollers on page 18.

18 Chapter 4 Hardware maintenance ENWW

2. Locate the small holes in the platen near some of the rollers.

3. Put three drops of oil into each hole in the platen.

NOTE: Be careful not to spill oil onto the platen.

4. If oil spills onto the platen, wipe the platen clean by using the cloth that was supplied with the User

Maintenance Kit.

5. Close and lock the printer window.

Hardware maintenance

ENWW Lubricate the platen rollers 19

Maintain the ink cartridges

During the normal lifetime of a cartridge, no specific maintenance is required. You should replace a

cartridge when it has reached its expiration date. See the ink cartridge information on the front panel for

the expiration date.

Move or store the printer

If you need to move your printer or store it for an extended period of time, prepare it correctly to avoid

possible damage.

1. Do not remove the ink cartridges, printheads or printhead cleaning cartridge.

2. Make sure that no substrate is loaded.

3. Make sure that the printhead carriage is located in the service station (at the right end of the printer).

4. Make sure that the Ready message appears on the front panel.

5. Turn off the power by using the Power button on the front panel.

6. Also switch off the two power switches at the rear of the printer.

7. Disconnect the two power cables and any cables that connect the printer to a network, a computer,

or a scanner.

8. If you have a take-up reel installed, remove the take-up reel sensor and cable-housing unit from

the foot of the printer stand. For your convenience, you can place the sensor and cable-housing

unit on the printer-stand crossbar and use the blue, plastic screw to affix the housing unit to the

leg of the stand, while you move the printer (see the following graphic). When reinstalling the

housing unit, make sure that the wheel on the foot of the printer stand is pointing forward.

Hardware maintenance

NOTE: If the printer or ink cartridges are moved from a cold location to a warm and humid location,

water from the atmosphere can condensate on the printer parts and cartridges and can result in

ink leaks and printer errors. In this case, HP recommends that you wait at least 3 hours before

turning on the printer or installing the ink cartridges, to allow the condensate to evaporate.

9. To avoid ink leakage, keep the printer upright at all times and do not turn it upside down or on its

side. Cover the top of the ink funnel with tape, and clean the tube from the printhead cleaning

container.

10. For correct environmental storage conditions, see the specifications in the User's guide.

Service maintenance

During the life of your printer, components that are used constantly can wear out.

To avoid having these components degrade to the point that the printer breaks down, the printer keeps

track of the number of cycles that the printer carriage makes across the axis of the printer, and also

monitors the total quantity of ink used.

20 Chapter 4 Hardware maintenance ENWW

The printer uses these numbers to track the need for service maintenance, and displays one of the

following messages on the front panel:

Service Maintenance Kit 1

●

Service Maintenance Kit 2

●

Service Maintenance Kit 3

●

These messages mean that some components are nearing the end of their lives. You can continue

printing for quite some time, depending on your use of the printer. However, HP strongly recommends

that you call your service representative and arrange for a service maintenance visit. The service

engineer can then replace the worn parts on-site, which will prolong the life of the printer.

The benefits of arranging a service engineer's visit when these messages appear on the front panel are

two-fold:

The printer components can be replaced at a time that is convenient for you, and so will not disturb

●

your daily workflow.

During a service maintenance visit, the service engineer replaces several parts at once. This

●

eliminates the need for repeat visits.

Use the printhead status plot

The printhead status plot consists of patterns that are designed to highlight printhead-reliability

problems. It helps you to check the performance of the printheads that are currently installed in your

printer, and to determine whether any printhead is experiencing clogging or other problems.

Print the printhead status plot

To print the printhead status plot:

1. Use the same substrate type that you were using when you detected a problem.

2. Check that the selected substrate type is the same as the substrate type that is loaded into the

printer.

3. On the printer's front panel, select the

test plots.

It takes about 2 minutes to print the printhead status plot.

Interpret the printhead status plot

The print consists of small dashes, one for each nozzle on each printhead.

For each individual colored pattern, make sure that most of the dashes are present.

icon, then select Image quality maintenance > Print all

Hardware maintenance

ENWW Use the printhead status plot 21

Corrective action

1. Clean any faulty printheads. See Clean the printheads on page 34. Then reprint the printhead

status plot to see whether the problem has been solved.

2. If the problem persists, clean the printheads again, and reprint the printhead status plot to see

whether the problem has been solved.

3. If the problem continues to persist, replace any persistently faulty printheads. See the User's

guide.

What to do if problems persist

If you still experience print-quality problems after applying the advice in this chapter, here are some

additional tips to consider:

Try selecting a higher print-quality option in your RIP software.

●

Check that your printer firmware is up to date. See

●

Check that you have the correct settings in your software program.

●

Call your service representative. See

●

Hardware maintenance

Firmware update on page 9.

When you need help on page 46.

22 Chapter 4 Hardware maintenance ENWW

5 Troubleshoot print-quality issues

General advice

Use the following approach when you have any print-quality problem:

To achieve the best performance from your printer, use only genuine HP supplies and accessories,

●

whose reliability and performance have been thoroughly tested to give trouble-free performance

and best-quality prints. For details of recommended substrates, see the User's guide.

Make sure that the substrate type that you select on the front panel, and in your RIP software, is

●

the same as the substrate type that is loaded in the printer. Make sure that the substrate type has

been calibrated.

CAUTION: If you have the wrong substrate type selected, you could experience poor print quality

and incorrect colors, and perhaps even damage to the printheads.

Make sure that you are using appropriate print-quality settings in your RIP software.

●

Make sure that you are using the correct ICC profile for your substrate and print-quality settings.

●

Make sure that your environmental conditions (temperature, humidity) are in the recommended

●

range. See the User's guide.

Make sure that your ink cartridges and printheads have not passed their expiration dates. See

●

Maintain the ink cartridges on page 20.

Avoid touching the substrate while printing is in progress.

●

ENWW General advice 23

Troubleshoot images

Graininess

The printheads may be misaligned. This is likely if you have not aligned the printheads for a long

●

time, or if there has been a substrate jam. Align the printheads if necessary (see

printheads on page 10). You can check whether it is necessary by using the printhead status plot

(see

If you are printing with eight or more passes, the substrate advance may need adjustment. See

●

Adjust the substrate advance on page 25.

If graininess is more visible in dark or saturated colors, there may be a problem of ink coalescence.

●

Try the following suggestions.

◦

◦

Align the

Use the printhead status plot on page 21).

Use a higher number of passes: you will probably see less grain with ten or more passes.

Lower the ink quantity.

If the problem persists, call your service representative. See

Horizontal banding

Try the following remedies if your printed image suffers from added horizontal lines as shown (the color

may vary).

If bands affect mostly dark or saturated colors, or only area fills near the edges of the substrate,

●

the cause could be insufficient drying of the ink. Try the following suggestions.

◦

Troubleshoot images

◦

If bands affect all colors across the width of the printed image, and you are using no more than six

●

passes, the cause is probably a substrate advance problem. Use the front panel to adjust the

substrate advance on the fly. If you have dark bands, increase the substrate advance; if you have

light bands, decrease it. When you find the right adjustment, store the value in the RIP for future

prints on the same substrate.

When you need help on page 46.

Reduce the ink quantity.

Increase the number of passes.

Another cause could be a fiber attached to one of the printheads. Remove the printheads one at

a time and remove any fibers that you see attached to them.

24 Chapter 5 Troubleshoot print-quality issues ENWW

If bands affect only some colors, the cause could be a defective printhead.

●

Print the printhead status plot (see

◦

clean the printheads (see

clean them again.

If the problem persists, try aligning the printheads (see

◦

necessary, try aligning them manually.

If the problem persists, print the printhead status plot again. Identify the printhead with the

◦

greatest number of blocked nozzles, and replace it.

If bands affect most of the colors, the printheads could be misaligned. This is likely if you have not

●

aligned the printheads for a long time, or if there has been a substrate jam. Align the printheads if

necessary (see

the printhead status plot (see

If banding occurs mostly in black areas, create a new color profile using pure black and not a mixture

●

of other colors. See your RIP documentation.

If the problem persists, call your service representative (see the User's guide).

Align the printheads on page 10). You can check whether it is necessary by using

Adjust the substrate advance

The substrate advance sensor measures the advance of the substrate and compensates for

irregularities at every pass of the printheads. However, to fine-tune the quality of your print, you may

need to calibrate the rate at which the substrate advances. The substrate advance determines the

placement of dots on the substrate. If the substrate is not advanced correctly, light or dark bands appear

in the printed image and the grain in the print may increase.

Use the printhead status plot on page 21). If necessary,

Clean (recover) the printheads on page 16). If the problem persists,

Align the printheads on page 10). If

Use the printhead status plot on page 21).

You can modify the substrate advance with the Substrate Advance parameter in the RIP's substrate

preset.

1. On the front panel, select the

advance calibration > Print adjustment plot. The printer prints a substrate-advance adjustment

image.

2. The calibration image consists of several columns with a number at the bottom of each one. Locate

the lightest of the columns and enter its number into the RIP's Substrate Advance parameter for

the current substrate preset. The value chosen in this example should be “–6”.

icon, then select Image quality maintenance > Substrate

Substrate advance adjustment on the fly

If you are using no more than six passes, you can fine-tune the substrate advance while printing: select

icon, then select Image quality maintenance > Substrate advance calibration > Adjust

the

substrate advance. Select a value of change from –10 mm/m to +10 mm/m (or mils/inch). To correct

light banding, decrease the value. To correct dark banding, increase the value.

If you are using eight passes or more, a wrong advance adjustment will not produce banding but

graininess, which is harder to assess visually. Therefore, in this case you are recommended to use only

the adjustment plot.

ENWW Horizontal banding 25

Troubleshoot images

When you have chosen a value and pressed OK, the rest of your job will be printed with that value, but

it will be reset to zero at the end of the job. Add the value found to the Substrate Advance value in the

RIP preset to print all future jobs with the new setting.

A simpler and faster way to adjust the substrate advance while the printer is printing is by pressing

the Move Substrate button on the front panel, which then displays the following instructions.

As you modify the setting, the new setting is applied immediately to the current job by the printer. When

you press OK to save the value, it is saved in the printer to be used throughout the current job.

Vertical banding

If vertical bands of different colors (and sometimes of different graininess) appear in the first 200 mm of

the print, this is probably caused by the curing process of the previous print, which may have distorted

the substrate. In this case:

1. Set the extra bottom margin to 100 mm.

2. If the problem persists, set the extra bottom margin to 200 mm. This margin will apply only to jobs

that start printing when the printer is idle, and when the cutter is disabled.

3. If the problem persists, decrease the warm-up drying temperature in steps of 5°C.

If vertical banding affects the whole of the print, the drying temperature may be too high.

1. Reduce the drying temperature in steps of 5°C, down to a minimum of 40°C.

2. If the problem disappears but then there is bleeding, coalescence or not enough durability, try using

more passes or less ink.

3. If the problem persists, restore the drying temperature to its original value and select unidirectional

printing in the RIP.

Misaligned colors

Troubleshoot images

If the colors are misaligned in any direction, the printheads may be misaligned. This is likely if you have

not aligned the printheads for a long time, or if there has been a substrate jam. Align the printheads if

necessary (see

printhead status plot (see

26 Chapter 5 Troubleshoot print-quality issues ENWW

Align the printheads on page 10). You can check whether it is necessary by using the

Use the printhead status plot on page 21).

Lack of sharpness

If text, lines or solid areas are rough or blurred, the printheads may be misaligned. This is likely if you

have not aligned the printheads for a long time, or if there has been a substrate jam. Align the printheads

if necessary (see

printhead status plot (see

Align the printheads on page 10). You can check whether it is necessary by using the

Use the printhead status plot on page 21).

Black areas look hazy

If black areas look hazy or not sufficiently black, try these suggestions.

Increase the number of passes.

●

Laminate the print.

●

Subtle stains or uneven appearance

Subtle color differences may be seen on some substrates if they are stored partially covered after

printing. In the period immediately after printing, such substrates should be stored either totally covered

or totally uncovered. It may be advisable to avoid the prolonged contact of two printed faces. This

problem tends to disappear if the substrate is left uncovered for some time.

Alternatively, some individual rolls of substrate may have a defective coating. The solution in this case

is to use another roll.

The ink smudges when touched, or looks oily

These symptoms suggest that the curing temperature was too low.

If you see the problem only in the first 200 mm of the print, increase the warm-up curing temperature in

steps of 5°C until the problem disappears. If you cannot solve the problem this way, increase the number

of passes.

If the problem affects the whole print, increase the curing temperature in steps of 5°C until the problem

disappears. If you cannot solve the problem this way, increase the number of passes.

If the oily finish appears minutes or hours after printing, do not store the prints with printed faces touching

each other. Consider using the take-up reel.

The total length of the print is wrong or inconsistent

As the substrate is heated during the drying and curing processes, some substrates will shrink after the

image has been printed. This may be inconvenient if the print has to be framed or if several prints are

to be to be tiled one next to the other.

As a general rule, you can expect the following percentages of shrinkage:

Photorealistic: less than 0.4%

●

Paper-Solvent, Paper-Aqueous: less than 0.5%

●

Self-adhesive: less than 1.2%

●

Banner: less than 3% shrinkage (if you disable the substrate-advance sensor, less than 7%)

●

The framing problem may be solved by printing a sample and adjusting the length of the image in the

RIP. You may reuse this value for all your future prints with the same substrate, although special care

ENWW Lack of sharpness 27

Troubleshoot images

must be taken when using banners, as the shrinkage may vary up to 1% depending on the amount of

ink used in the print.

You can expect the following variations from one print to another:

Photorealistic, Paper-Solvent, Paper-Aqueous: less than 0.4%

●

Self-adhesive: less than 0.7%

●

Banner: less than 1%

●

To solve the tiling problem and improve the repeatability of the printed length, you are recommended

to ensure that the substrate-advance sensor is enabled in the RIP's substrate preset, as this will improve

the stability of the prints over time. You are also recommended to tile together areas with similar amounts

of ink. If this is not possible, print the areas with different amounts of ink as different jobs and modify the

length of the job with less ink in the RIP to match its length with the job with high ink content.

Troubleshoot images

28 Chapter 5 Troubleshoot print-quality issues ENWW

6 Troubleshoot substrate issues

The substrate cannot be loaded successfully

Here are a few things to check if you cannot successfully load the substrate.

The substrate might be loaded at an angle (skewed or mislocated). Make sure that the right edge

●

of the substrate is aligned with the roll on the input spindle.

The substrate might be crumpled or warped, or have irregular edges.

●

If the substrate jams in the substrate path to the platen, the leading edge of the substrate might

●

not be straight or clean. Remove the initial 2 cm (1 in) of substrate from the roll and try again. This

might be necessary even with a new roll of substrate.

Make sure that the spindle is correctly inserted.

●

Troubleshoot substrate

Make sure that the substrate is correctly loaded on the spindle, and that it loads over the roll towards

●

you.

Make sure that the substrate is wound tightly.

●

The substrate has jammed

When a jam occurs, the Possible substrate jam message usually appears in the front panel, with one

of several error codes (see

If you are trying to load a very thin or very thick substrate, remember to follow the special procedure

described in the User's guide for loading such substrates.

Check the substrate path

This problem can occur when a roll has finished and the end of the roll is stuck to the cardboard

●

core. If this has happened, cut the end of the roll away from the core. Then feed the substrate

through the printer, and load a new roll.

Front-panel error messages on page 41).

Otherwise, follow the procedure described under

●

ENWW The substrate cannot be loaded successfully 29

Check the printhead path on page 30

Troubleshoot substrate

Check the printhead path

1. Turn off the printer at the front panel, then also switch off the power switch at the rear.

2. Wait for the printer to cool down, then unlock and open the printer window.

3. Try to move the printhead carriage out of the way.

4. Lift the substrate-adjustment lever as far up as it will go.

30 Chapter 6 Troubleshoot substrate issues ENWW

5. Carefully remove any of the jammed substrate that you can lift up and out from the top of the printer.

Cut the substrate if necessary.

6. Carefully pull the remainder of the roll down and out of the printer.

7. Lower the substrate-adjustment lever, check that there is no substrate left in the printer (especially

not in the curing module), then close and lock the window.

8. Turn on the printer.

9. Reload the roll.

10. If some substrate continues to cause an obstruction within the printer, it can often be cleared by

loading a rigid substrate type into the printer.

Troubleshoot substrate

11. If you find that you have print-quality problems after a jam, try realigning the printheads. See

the printheads on page 10.

Avoiding substrate jams

Substrate jams may be caused by loading the substrate with too much skew: do not ignore the warning

message that appears during the loading process in this case.

They may also be caused by not enough vacuum suction in the printing zone. If you decide to increase

the suction, do not exceed the following limits: 20 mmH

O for other substrate families.

mmH

2

O for banners, 35 mmH2O for vinyl, and 50

2

The substrate is deformed or wrinkled

If your substrate is deformed or wrinkled by the drying and curing process, change the temperature

settings before printing the next job, and advance the substrate, using the Move Substrate key on the

front panel, so that the next job will be printed on undamaged substrate.

If the problem appears only at the beginning of the print, try the following suggestions.

Disable the automatic cutter.

●

Go to the front panel and select the

●

margin. Set the margin 100 mm. If that is not enough, try 200 mm. This extra margin will apply

only to jobs that start printing when the printer is idle and when the cutter is disabled.

icon, then Substrate handling options > Extra bottom

Align

Decrease the warm-up drying temperature in steps of 5°C, without reducing it below the drying

●

temperature.

The automatic cutter does not work

The automatic cutter is disabled when the take-up reel is in use. To use the cutter, disable the take-up

reel on the front panel by selecting the

ENWW The substrate is deformed or wrinkled 31

icon, then selecting Take-up reel > Disable take-up reel.

Troubleshoot substrate

Also check that the cutter is enabled: select the icon, then Substrate handling options

.

NOTE: The cutter is automatically disabled for some of the heaviest substrate types, which it cannot

cut.

Take-up reel substrate jam

If the substrate is severely damaged on the take-up reel spindle, do not use the printer's cutter to cut

and remove the substrate. Instead, cut the substrate manually as close as possible to the printer window,

then remove the roll.

If the problem remains after removing the substrate jam, unload the take-up reel from the front panel

and load it again.

Take-up reel does not wind

Predictably, if the take-up reel is not winding as anticipated, the printed output is likely to end up on the

floor. If the printer recognizes a problem with the take-up reel, it interrupts the print job until the issue is

corrected. If the printer does not recognize a problem, the job continues to print. The following table

highlights possible issues and solutions.

Take-up reel LED

status

Blinking quickly Take-up reel is not

Blinking slowly Take-up reel is not

Solid red Take-up reel is not

Issue Print job interrupted? Possible cause Possible solution

winding

winding

winding

Yes The sensor beam was

blocked for more than 3

seconds.

No The sensor cables are

loose or unplugged.

No There is too much

resistance on the takeup reel motor.

Make sure that the

take-up reel sensors

are not blocked by a

strip of substrate or any

objects. See the

following graphic.

Make sure that the

collection bin is placed

behind the foot brace.

Also ensure that the

take-up reel power

switch is in the On

position.

Ensure that the sensor

cables are correctly

secured.

Ensure that the

substrate is not winding

too tightly. A loopshaping core should be

inserted and hanging

as shown in the User's

guide.

32 Chapter 6 Troubleshoot substrate issues ENWW

Take-up reel LED

status

Issue Print job interrupted? Possible cause Possible solution

Solid green Take-up reel is not

winding

Solid green Take-up reel is winding

in the wrong direction

No The take-up reel power

switch is in the Off

position

No The take-up reel wind-

direction switch is in the

wrong winding position.

After 3 seconds, the

printer recognizes the

problem and interrupts

the print job. See the

first error listed in this

table.

The following graphic shows the take-up reel sensors and cable.

Ensure that the take-up

reel power switch is in

the On position.

Flip the take-up reel

wind-direction switch to

the correct position.

Troubleshoot substrate

1. Take-up reel sensor

2. Take-up reel sensor and cable housing unit

ENWW Take-up reel does not wind 33

7 Troubleshoot ink-system issues

Troubleshoot ink

Cannot insert an ink cartridge

1. Check that you have the correct type of cartridge (model number).

2. Check that the colored label on the cartridge is the same color as the label on the slot.

3. Check that the cartridge is correctly oriented, the arrow on the front of the ink cartridge should face

CAUTION: Never clean inside the ink cartridge slots.

Cannot insert a printhead

1. Check that you have the correct type of printhead (model number).

upwards.

2. Check that you have removed the orange protective caps from the printhead.

3. Check that the colored label on the printhead is the same color as the label on the slot.

4. Check that the printhead is correctly oriented (compare with the others).

5. Check that you have closed and latched the printhead cover.

Cannot insert the printhead cleaning cartridge

Check that the printhead cleaning cartridge has the correct model number and is correctly oriented.

Front panel recommends reseating or replacing a printhead

1. Remove the printhead and check that it is free from physical damage and from ink stains on the

electrical connections.

2. If necessary, clean the electrical connections between the printhead and the carriage. See

the electrical connections on a printhead on page 11.

3. Reinsert the printhead into the carriage and check the front panel message.

4. If the problem persists, insert a new printhead.

Clean

Clean the printheads

Periodic printhead cleaning is performed automatically, as long as the printer is kept turned on. However,

you should clean the printheads if you are experiencing poor image quality and cannot resolve the issues

by other methods. This ensures that there is fresh ink in the nozzles and helps to prevents nozzle clogs.

34 Chapter 7 Troubleshoot ink-system issues ENWW

If you have printed the printhead status plot, you know which colors are failing. Clean the pair of

printheads that are not performing adequately. If you are not sure which printheads to clean, clean all

of the printheads.

To clean the printheads, go to the printer's front panel and select the

maintenance > Clean printheads, then select which printheads you want to clean. You can clean all

of the printheads or only some of them. Your choices are:

Print test plot

●

Clean all

●

Clean LC-C

●

Clean Y-MK

●

Clean LM-M

●

Cleaning all printheads takes about 5 minutes. Cleaning any two printheads takes about 3 minutes.

NOTE: Cleaning all printheads uses more ink than cleaning a single pair.

Align the printheads

Precise alignment between printheads is essential for color accuracy, smooth color transitions, and

sharp edges in graphical elements. Your printer has an automatic printhead alignment process which

runs whenever a printhead has been reseated or replaced.

In the case of a substrate jam, if you have used a custom substrate, or if you are experiencing problems

with color accuracy; you might need to align the printheads. See

icon, select Image quality

Troubleshoot ink

Align the printheads on page 10.

NOTE: If you experience a substrate jam, HP recommends that you reseat and align the printheads.

TIP: Use the same substrate you intend to print on to align the printheads.

WARNING! Colored substrates, glossy canvas, and transparent materials such as translucent bond,

clear film, tracing paper, and vellum are not suitable for aligning the printheads. However, if you must

perform printhead alignment with a material that is not supported, make sure you use a material with

the same thickness as the material you are going to use for printing.

Reinsert printheads procedure

1. If the printhead alignment process is running and the wrong substrate is loaded, press the

Cancel button on the front panel.

CAUTION: Do not print if the printhead alignment process has been canceled.

2. Load the substrate you want to use. Photo paper is recommended for the best results.

WARNING! Colored substrates, glossy canvas, and transparent materials such as translucent

bond, clear film, tracing paper, and vellum are not suitable for aligning the printheads. However, if

you must perform printhead alignment with a material that is not supported, make sure you use a

material with the same thickness as the material you are going to use for printing.

ENWW Align the printheads 35

3. Remove and reinsert all of the printheads. See the User's guide. This starts the printhead alignment

Troubleshoot ink

4. The process takes about 6 minutes. Wait until the front panel shows that the process is complete

Image Quality Maintenance menu procedure

1. Load the substrate you want to use. Photo paper is recommended for the best results. Plain; bond;

process.

NOTE: Make sure the printer window is closed during printhead alignment.

before using the printer.

NOTE: A calibration image is printed during the printhead alignment process. The front panel

shows if there were any errors in the process.

and thin, coated substrates are acceptable, but provide marginal results.

WARNING! Colored substrates, glossy canvas, and transparent materials such as translucent

bond, clear film, tracing paper, and vellum are not suitable for aligning the printheads. However, if

you must perform printhead alignment with a material that is not supported, make sure you use a

material with the same thickness as the material you are going to use for printing.

2. Go to the front panel and select the icon, then select Image quality maintenance > Align

printheads > Auto PH alignment. The printer verifies that a sufficient amount of substrate exists

to perform printhead alignment.

3. If the substrate type that is loaded is acceptable for printhead alignment, the printer performs the

alignment and prints an alignment pattern.

NOTE: Make sure the printer window is closed during printhead alignment.

4. The process takes about 5 minutes. Wait until the front panel shows that the process is complete

before using the printer.

Scan errors during alignment

If the alignment process fails, a Scanning problems message appears on the front panel. This indicates

that the alignment was not completed successfully. Therefore, the printheads are not aligned and the

36 Chapter 7 Troubleshoot ink-system issues ENWW

alignment should be repeated before printing. The problem might be because of one of the following

scenarios:

The type of substrate used in the printhead alignment process was not acceptable. Repeat the

●

alignment process using one of the recommended substrate types.

The printheads are not clean. Clean the printheads. See

●

The printer window was open during the printhead alignment process. Repeat the alignment

●

process with the printer window closed.

If the problem persists after following the recommended remedies, try replacing all of the printheads. If

the problem persists after replacing the printheads, a failure in the scanning system may exist.

Clean the printheads on page 34.

Troubleshoot ink

ENWW Align the printheads 37

8 Troubleshoot other issues

The printer cannot get an IP address

If your network has no DHCP server, the printer cannot automatically retrieve an IP address. In this

case, you must set the printer's IP address manually, in the following way.

1. Select the

IP > IPV4 settings > Config method > Manual.

2. From the IPV4 Settings menu, select Manual settings > IP address.

3. Enter the IP address that you wish to use, and press the OK key when finished.

Troubleshoot other

Cannot access the Embedded Web Server

If you have not done so already, please read the instructions in the User's guide.

1. Go to the front panel and select the

2. Select Connectivity > Advanced > Embedded Web Server > Allow EWS > On.

3. Go to the front panel and select the

information.

4. The information should read: IP enabled: Yes. If it does not, you might need to use a different

connection.

If you still cannot access the Embedded Web Server, turn the printer off with the Power button on the

front panel and then turn it on again.

If you experience very slow progress while trying to access the Embedded Web Server, the problem

could be that you are using a proxy server. Try bypassing the proxy server and accessing the Embedded

Web Server directly.

icon, then select Connectivity > Gigabit Ethernet > Modify information > TCP/

icon.

icon, then select Connectivity > Gigabit Ethernet > View

In Internet Explorer 6 for Windows, go to Tools > Internet Options > Connections > LAN

●

Settings, and select the Bypass proxy server for local addresses check box. Alternatively, for

more precise control, click the Advanced button and add the printer's IP address to the list of

exceptions, for which the proxy server is not used.

In Firefox 3.0 for Windows, go to Tools > Options > Network > Connection > Settings, and select

●

the Direct connection to the Internet check box. Alternatively, when the Manual proxy

configuration check box is selected, add the printer's IP address to the list of exceptions, for which

the proxy server is not used.

In Firefox 2.0 for Linux, go to Edit > Preferences > Network > Connection > Settings, and select

●

the Direct connection to the Internet check box. Alternatively, when the Manual proxy

configuration check box is selected, add the printer's IP address to the list of exceptions, for which

the proxy server is not used.

38 Chapter 8 Troubleshoot other issues ENWW

The printer is not printing

Possible reasons why a file you have sent from your computer is not printing when expected, include

the following:

There may be a problem with the electrical power. If the printer is not performing and the front panel

●

does not respond, check that the power switch at the rear is on, the residual current circuit breakers

are up, the power cable is correctly connected, and the electrical socket is providing power.

Unusual electromagnetic phenomena may exist, such as strong electromagnetic fields or severe

●

electrical disturbances. Such occurrences can cause the printer to behave strangely, or even stop

working. Turn off the printer by using the Power button on the front panel, wait until the

electromagnetic environment has returned to normal, then turn the printer on again. If the problems

persist, call your service representative.

One of the following substrate scenarios may exist:

●

The substrate name that appears on the front panel does not reflect the substrate that is

◦

loaded in the printer.

There is not a sufficient amount of substrate on the loaded roll to print the entire job.

◦

Under these conditions, one print job might be printed, while another print job is held in the print

queue. To resolve this issue, unload the roll from the printer and load a new roll, using the front

panel to guide you through the process.

The software program slows down or stalls while generating the print job

Large quantities of data might be necessary to generate a high-quality large-format print job. This can

cause your software program to slow down significantly or stall. Lowering the print resolution may help

to avoid this scenario, however, lowering the print resolution reduces image quality.

The printer seems slow

Here are some possible explanations.

If you request the highest possible print quality in the RIP, printing will be relatively slow compared

●

with draft-quality printing.

Check that the substrate loaded in the printer belongs to the substrate family that appears on the

●

front panel.

Is your printer connected to a network? Check that all components used in the network (network

●

interface cards, hubs, routers, switches, and cables) are capable of high-speed operation. Is there

a lot of traffic from other devices on the network?

Are the printheads in good condition? Printing time tends to increase when a printhead needs

●

cleaning. Check the printhead status on the front panel or through the Embedded Web Server.

Clean or replace printheads if necessary.

Troubleshoot other

Does your image contain high-density black fills? That may increase printing time.

●

See also the information about printer states in the User's guide.

Cannot access files on the hard disk