Page 1

INSTRUCTIONS–PARTS LIST

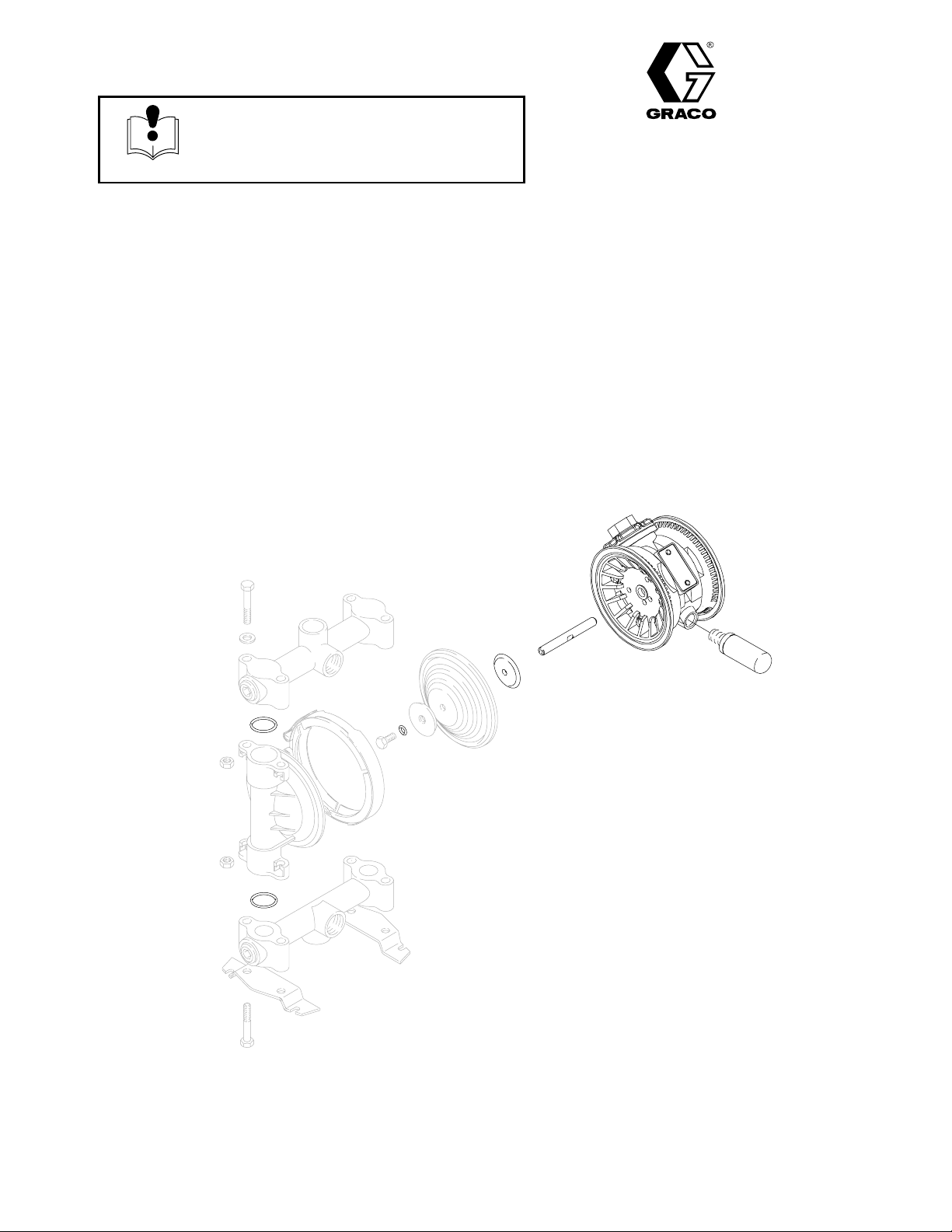

Parts

308983

See instruction manual 308981 for

important warnings and information.

READ AND KEEP FOR REFERENCE.

INSTRUCTIONS

For converting METAL Husky 715 air-operated diaphragm pumps

First choice when

quality counts.

Rev. B

Husky 716 Air Motor Retrofit Kits

Part No. 241631

with standard air motor

Part No. 241664

with remote-operated air motor

9090A

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

COPYRIGHT 1999, GRACO INC.

Graco Inc. is registered to I.S. EN ISO 9001

Page 2

Installation

Pressure Relief Procedure

WARNING

PRESSURIZED EQUIPMENT HAZARD

The equipment stays pressurized until pressure is

manually relieved. To reduce the risk of serious

injury from pressurized fluid, accidental spray, or

splashing fluid, follow this procedure whenever you

Are instructed to relieve pressure

Stop pumping

Check, clean, or service any system equipment

Install or clean fluid nozzles

1. Shut off the air to the pump.

2. Open the dispensing valve, if used.

3. Open the fluid drain valve to relieve all fluid

pressure, and have a container ready to catch the

drainage.

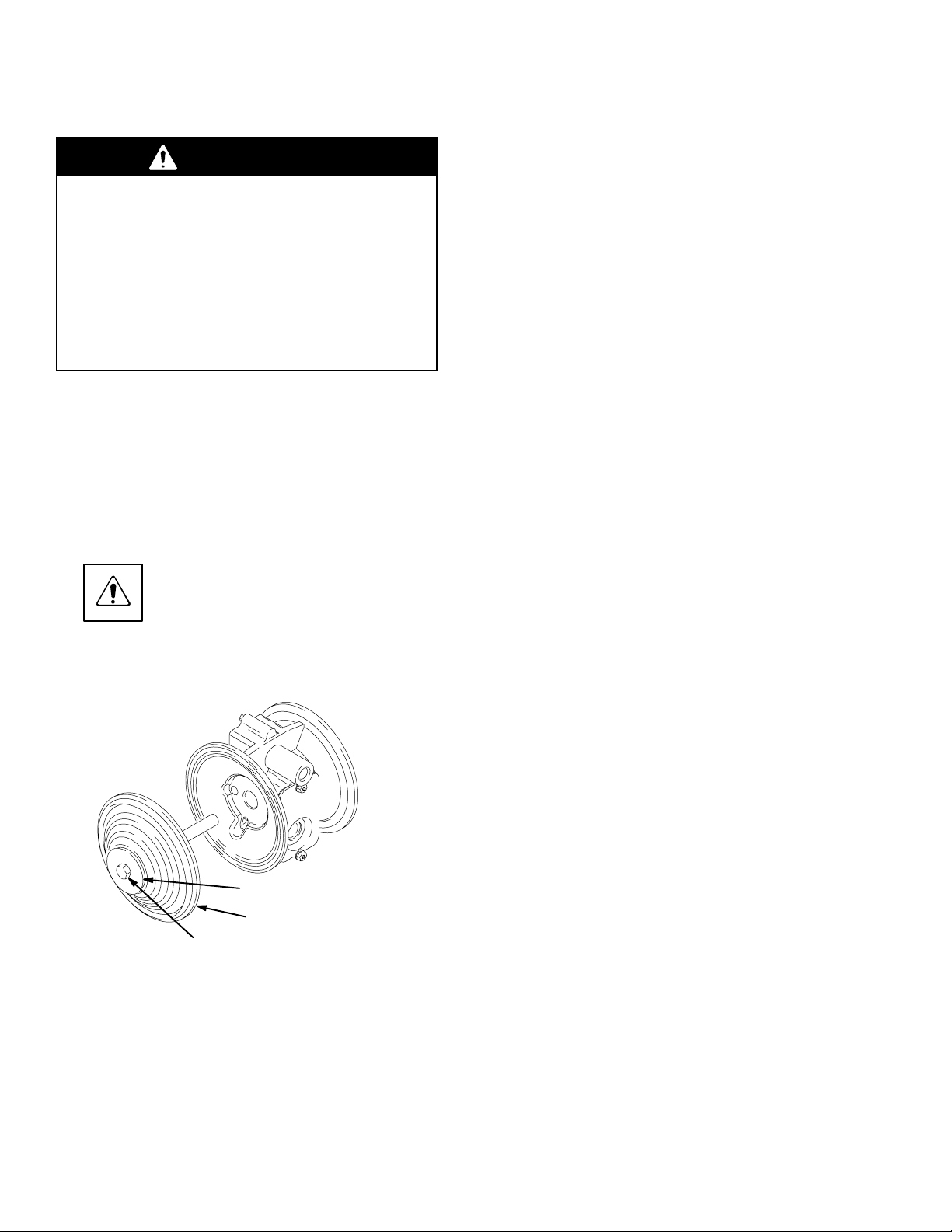

Removing the Existing Air Motor

Installing the New Air Motor

1. Apply medium-strength (blue) Loctite (9) or

equivalent to threads of diaphragm shaft screw.

Install on one end of the diaphragm shaft the

following parts (see proper order in Parts

Drawing): air-side diaphragm plate, diaphragm,

fluid-side diaphragm plate, packing o-ring (7), and

diaphragm shaft screw.

NOTE: The words “AIR SIDE” on the diaphragm

and the flat side of the air-side diaphragm plate

must face toward the diaphragm shaft.

2. Put grease (8) on the diaphragm shaft, and

carefully (do not damage the shaft u-cups) run the

diaphragm shaft through the center housing bore.

3. Repeat step 1 for the other end of the diaphragm

shaft, and torque the diaphragm shaft screws to 80

to 90 in-lb (9 to 10 N-m) at 100 rpm maximum.

4. Install the muffler.

When installing vee clamps in step 6, orient center

housing so air inlet is approximately 45 above

horizontal and the muffler is approximately horizontal.

1.

2. Remove the outlet and inlet manifolds, grounding

strip, and vee clamps. Remove the center housing

(shown below) from your Husky 715 pump.

3. From the center housing that you took off of the

pump, remove the diaphragm shaft screws,

fluid-side diaphragm plates, and diaphragms. You

will re-use these. Do not re-use the diaphragm

shaft or the air-side diaphragm plates with the new

air motor.

Follow the Pressure Relief

Procedure above.

fluid-side diaphragm plate

diaphragm

diaphragm shaft screw

9091A

5. Apply thin, even film of grease on inside of vee

clamp.

6. Position fluid covers, install vee clamps around

fluid and air covers, install grounding strip on vee

clamps, and torque vee clamp nuts from 80 to 90

in-lb (9 to 10 N-m).

7. Make sure all check valve parts are in place.

8. Install manifold o-rings (6) and manifolds, and

torque manifold bolts from 80 to 90 in-lb (9 to

10 N-m).

Operating the Retrofitted Pump

See instruction manual 308981 for Operating and

Service instructions and Parts information.

2 308983

Page 3

Parts

Husky 716 Air Motor Retrofit Kit

Part No. 241631, with standard air motor

Part No. 241664, with remote-operated air motor

Ref.

No. Part No. Description Qty

1 240224 MOTOR, air, standard

Included in Kit 241631

See manual 308981 for parts.

1

Grounding Strip

1 241255 MOTOR, air, remote-operated

Included in Kit 241664

See manual 308981 for parts.

2 194246 COVER, air 2

3 114882 SCREW, torx 12

4 290045 PLATE, designation 1

5 111183 RIVET, for designation plate (4) 2

6 110636 O-RING 8

7 110004 P ACKING, o-ring 2

7 104893 PACKING, o-ring 2

8 111920 LUBRICANT, grease (not shown) 1

9 113500 ADHESIVE, anaerobic (not shown) 1

10 108808 PACKING, u-cup (not shown)

For diaphragm shaft

2

manifold bolt

outlet manifold

1

vee clamp nut

2

NOTE: Parts shown with solid lines

in the drawing below are included in

the Air Motor Retrofit Kit.

2

1

4

10

2

2

1

6

6

2

manifold bolt

7

inlet

manifold

vee

clamp

4

fluidĆside

diaphragm plate

6

diaphragm shaft

screw

fluid cover

5

diaphragm

9090A

3

diaphragm shaft

air-side diaphragm plate

For older models using 186265 fluid-side

1

diaphragem plates, use 104893 o-ring. For newer

models using 191837 fluid-side diaphragm plates,

use 110004 o-ring.

2

Torque to 80 to 9 0 in-lb (9 to 10 N-m).

Apply grease (8).

3

The words “AIR SIDE” on diaphragm must face

4

toward diaphragm shaft.

Flat side of air-side diaphragm plate must face

5

toward diaphragm shaft.

Apply medium-strength (blue) Loctite (9) or

6

equivalent to threads, and torque to 80 to 90 in-lb

(9 to 10 N-m) at 100 rpm maximum.

muffler

3308983

Page 4

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale by an authorized Graco distributor to the original purchaser for use. With the exception of any special, extended, or limited

warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment

determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property , o r a ny

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty , and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Phone Number

TO PLACE AN ORDER, contact your Graco distributor, or call this number to identify the distributor closest to you:

1–800–367–4023 Toll Free

Loctite is a registered trademark of the Loctite Corporation.

All written and visual data contained in this document reflect the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

4 308983

Foreign Offices: Belgium, Korea, Hong Kong, Japan

Sales Offices: Minneapolis, Detroit

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440 –1441

www.graco.com

PRINTED IN USA 308983 May 1999. Revised February 2000

Loading...

Loading...