20 mm (0.8 inch)

Seven Segment Displays

H

Technical Data

Features

• Industry Standard Size

• Industry Standard Pinout

15.24 mm (0.6 in.) DIP Leads

on 2.54 mm (0.1 in.) Centers

• Choice of Colors

Red, AlGaAs Red, High

Efficiency Red, Yellow, Green

• Excellent Appearance

Evenly Lighted Segments

Mitered Corners on Segments

Gray Package Gives Optimum

Contrast

± 50° Viewing Angle

• Design Flexibility

Common Anode or Common

Cathode

Left and Right Hand Decimal

Points

± 1. Overflow Character

• Categorized for Luminous

Intensity

Yellow and Green Categorized

for Color

Use of Like Categories Yields a

Uniform Display

• High Light Output

• High Peak Current

• Excellent for Long Digit

String Multiplexing

Intensity and Color

Selection Option

See Intensity and Color

Selected Displays Data Sheet

• Sunlight Viewable AlGaAs

Description

The 20 mm (0.8 inch) LED seven

segment displays are designed

for viewing distances up to 10

metres (33 feet). These devices

use an industry standard size

package and pinout. All devices

are available as either common

anode or common cathode.

HDSP-340X Series

HDSP-390X Series

HDSP-420X Series

HDSP-860X Series

HDSP-N15X Series

These displays are ideal for most

applications. Pin for pin

equivalent displays are also

available in a low current design.

The low current displays are ideal

for portable applications. For

additional information see the

Low Current Seven Segment

Displays data sheet.

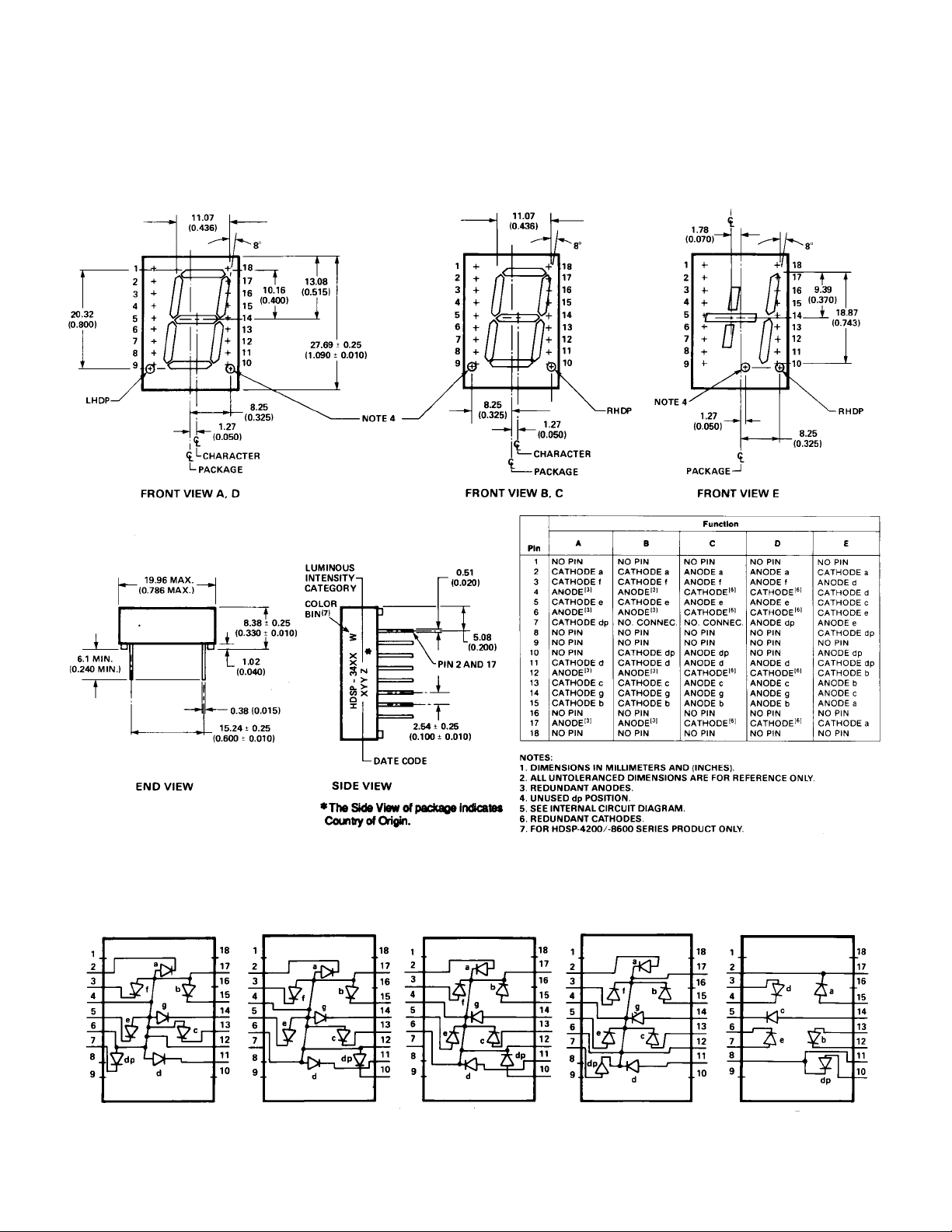

Devices

Red AlGaAs

HDSP- HDSP- HDSP- HDSP- HDSP- Description Drawing

3400 N150 3900 4200 8600 Common Anode Left Hand Decimal A

3401 N151 3901 4201 8601 Common Anode Right Hand Decimal B

3403 N153 3903 4203 8603 Common Cathode Right Hand Decimal C

3405 N155 3905 4205 8605 Common Cathode Left Hand Decimal D

3406 N156 3906 4206 8606 Universal ± 1. Overflow

Notes:

1. These displays are recommended for high ambient light operation. Please refer to the HDSP-N10X AlGaAs data sheet for low current

operation.

2. Universal pinout brings the anode and cathode of each segment's LED out to separate pins. See internal diagram E.

3-92

[1]

HER Yellow Green Package

[2]

E

5964-6426E

Package Dimensions

Internal Circuit Diagram

A

CB

D

E

3-93

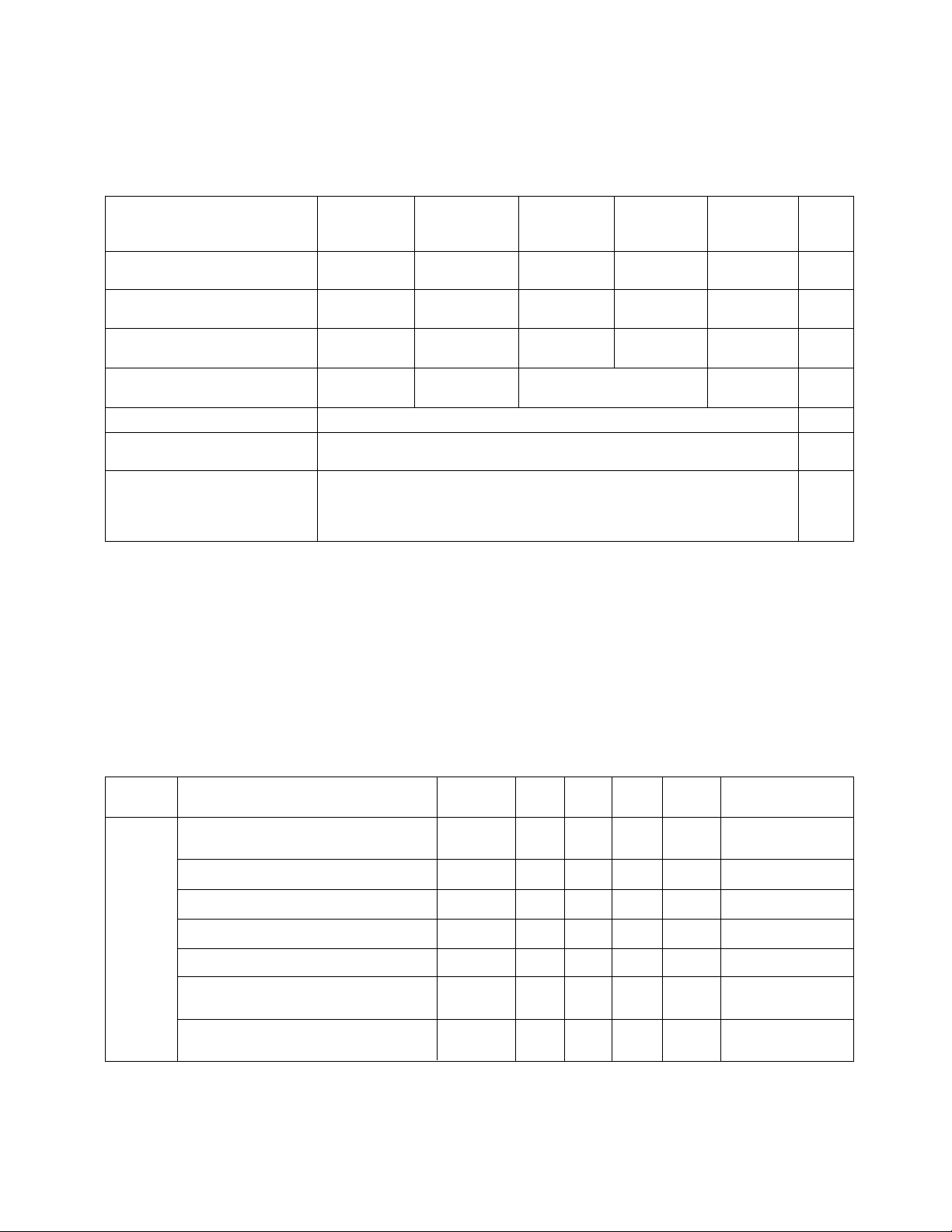

Absolute Maximum Ratings

Red AlGaAs Red HER Yellow Green

Description Series Series Series Series Series Units

Average Power per Segment 115 96 105 105 105 mW

or DP

Peak Forward Current per 200

Segment or DP

DC Forward Current per 50

Segment or DP

Operating Temperature -40 to +100 -20 to +100

Range

Storage Temperature Range -55 to +100 °C

Reverse Voltage per 3.0 V

Segment or DP

Lead Solder Temperature

for 3 Seconds (1.60 mm 260 °C

[0.063 in.] below seating

plane)

Notes:

1. See Figure 1 to establish pulsed conditions.

2. Derate above 45°C at 0.83 mA/°C.

3. See Figure 2 to establish pulsed conditions.

4. Derate above 55°C at 0.8 mA/°C.

5. See Figure 7 to establish pulsed conditions.

HDSP-3400 HDSP-N150 HDSP-3900 HDSP-4200 HDSP-8600

[1]

[2]

160

40

[4]

[3]

[5]

135

[6]

40

[9]

-40 to +100 -40 to +100 °C

6. Derate above 50°C at 0.73 mA/°C.

7. See Figure 8 to establish pulsed conditions.

8. Derate above 50°C at 0.54 mA/°C.

9. For operation below -20°C, contact your local HP

components sales office or an authorized distributor.

135

40

[6]

[5]

90

30

[7]

[8]

mA

mA

Electrical/Optical Characteristics at T

= 25°C

A

Red

Device

Series Parameter Symbol Min. Typ. Max. Units Test Conditions

[3]

[1,2]

[4]

I

V

F

PEAK

λ

d

V

R

J-PIN

500 1200 µcd IF = 20 mA

1.6 2.0 V IF = 20 mA

655 nm

640 nm

3.0 20 V IR = 100 µA

375 °C/W

Luminous Intensity/Segment

(Digit Average)

Forward Voltage/Segment or DP V

HDSP- Peak Wavelength λ

340X

Dominant Wavelength

Reverse Voltage/Segment or DP

Temperature Coefficient of ∆VF/°C -2 mV/°C

/Segment or DP

V

F

Thermal Resistance LED Junction- Rθ

to-Pin

3-94

AlGaAs Red

Device

Series Parameter Symbol Min. Typ. Max. Units Test Conditions

Luminous Intensity/Segment

(Digit Average)

[1,2,5]

I

V

6.0 14.0 mcd IF = 20 mA

1.8 V IF = 20 mA

Forward Voltage/Segment or DP V

F

2.0 3.0 V IF = 100 mA

HDSP-

N15X Peak Wavelength λ

Dominant Wavelength

Reverse Voltage/Segment or DP

[3]

[4]

PEAK

λ

d

V

R

3.0 15 V IR = 100 µA

645 nm

637 nm

Temperature Coefficient of ∆VF/°C -2 mV/°C

/Segment or DP

V

F

Thermal Resistance LED Junction- Rθ

J-PIN

430 °C/W/

to-Pin Seg

High Efficiency Red

Device

Series Parameter Symbol Min. Typ. Max. Units Test Conditions

Luminous Intensity/Segment

(Digit Average)

[1,2]

Forward Voltage/Segment or DP V

HDSP-

390X Peak Wavelength λ

Dominant Wavelength

Reverse Voltage/Segment or DP

[3]

[4]

Temperature Coefficient of ∆V

V

/Segment or DP

F

Thermal Resistance LED Junction- Rθ

to-Pin Seg

3350 7000 µcd I

I

V

4800 µcd I

F

PEAK

λ

d

V

R

/°C -2 mV/°C

F

J-PIN

3.0 25 V IR = 100 µA

2.6 3.5 V IF = 100 mA

635 nm

626 nm

375 °C/W/

= 100 mA Peak:

F

1 of 5 df

= 20 mA

F

3-95

Yellow

Device

Series Parameter Symbol Min. Typ. Max. Units Test Conditions

Luminous Intensity/Segment

(Digit Average)

[1,2]

Forward Voltage/Segment or DP V

2200 7000 µcd I

I

V

3400 µcd I

F

2.6 3.5 V IF = 100 mA

= 100 mA Peak:

F

1 of 5 df

= 20 mA

F

HDSP-

420X Peak Wavelength λ

Dominant Wavelength

Reverse Voltage/Segment or DP

[3,6]

[4]

PEAK

λ

d

V

R

581.5 586 592.5 nm

3.0 25.0 V IR = 100 µA

583 nm

Temperature Coefficient of ∆VF/°C -2 mV/°C

/Segment or DP

V

F

Thermal Resistance LED Junction- Rθ

J-PIN

375 °C/W/

to-Pin Seg

Green

Device

Series Parameter Symbol Min. Typ. Max. Units Test Conditions

Luminous Intensity/Segment

(Digit Average)` 1960 µcd IF = 50 mA Peak:

[1,2]

I

V

680 1500 µcd I

= 10 mA

F

1 of 5 df

Forward Voltage/Segment or DP V

HDSP- Peak Wavelength λ

F

PEAK

2.1 2.5 V IF = 10 mA

566 nm

860X

Dominant Wavelength

Reverse Voltage/Segment or DP

Temperature Coefficient of ∆V

/Segment or DP

V

F

Thermal Resistance LED Junction- Rθ

[3,6]

[4]

λ

d

V

R

/°C -2 mV/°C

F

J-PIN

3.0 50.0 V IR = 100 µA

571 577 nm

375 °C/W/

to-Pin Seg

Notes:

1. Case temperature of the device immediately prior to the intensity measurement is 25°C.

2. The digits are categorized for luminous intensity. The intensity category is designated by a letter on the side of the package.

3. The dominant wavelength, λd, is derived from the CIE chromaticity diagram and is that single wavelength which defines the color of

the device.

4. Typical specification for reference only. Do not exceed absolute maximum ratings.

5. For low current operation, the AlGaAs Red HDSP-N100 series displays are recommended. They are tested at 1 mA dc/segment and

are pin for pin compatible with the HDSP-N150 series.

6. The Yellow (HDSP-4200) and Green (HDSP-8600) displays are categorized for dominant wavelength. The category is designated by

a number adjacent to the luminous intensity category letter.

3-96

Red, AlGaAs Red

100

OPERATION IN

THIS REGION

REQUIRES

100 HZ

TEMPERATURE

DERATING

OF I MAX.

10

RATIO OF MAXIMUM OPERATING PEAK

CURRENT TO TEMPERATURE DERATED

MAXIMUM DC CURRENT

1

PEAK

I

DC

1 10 100

I MAX

10 kHZ

t – PULSE DURATION – µs

P

3 kHZ

1 kHZ

300 HZ

1000 10,000

Figure 1. Maximum Allowable Peak Current vs. Pulse

Duration – Red.

50

45

40

35

AlGaAs RED

30

25

20

SEGMENT – mA

DC

I MAX – MAXIMUM DC CURRENT PER

R = 525°C/W

θ

15

10

5

0

J-A

20 40 70 80 9060503010

T – AMBIENT TEMPERATURE – °C

A

RED

100 110

DC

DC OPERATION

100

OPERATION IN

THIS REGION

REQUIRES

100 HZ

10,0001000

TEMPERATURE

DERATING

OF I MAX.

10

RATIO OF MAXIMUM OPERATING PEAK

CURRENT TO TEMPERATURE DERATED

MAXIMUM DC CURRENT

1

PEAK

I

0.1 1 10 100

DC

I MAX

t – PULSE DURATION – µs

P

10 kHZ

3 kHZ

1 kHZ

300 HZ

Figure 2. Maximum Allowed Peak Current vs. Pulse

Duration – AlGaAs Red.

200

180

RED

160

140

120

100

80

SEGMENT – mA

60

F

40

I – FORWARD CURRENT PER

20

0

0.5 1.5 3.0 3.5 4.02.52.01.00

V – FORWARD CURRENT – V

F

AlGaAs RED

4.5 5.0

DC

DC OPERATION

Figure 3. Maximum Allowable DC Current vs.

Ambient Temperature.

2.50

2.25

2.00

1.75

1.50

1.25

AlGaAs RED

1.00

0.75

0.50

(NORMALIZED TO 1 AT 20 mA)

RELATIVE LUMINOUS INTENSITY

0.25

0

515 3035402520100

I – FORWARD CURRENT PER SEGMENT – mA

F

RED

45 50

Figure 5. Relative Luminous Intensity vs. DC

Forward Current.

Figure 4. Forward Current vs. Forward Voltage.

1.2

1.1

1.0

0.9

0.8

PEAK

(NORMALIZED TO 1 AT 20 mA)

ú

0.7

µ – RELATIVE EFFICIENCY

0.6

AlGaAs RED

2 30 40 200

I – PEAK FORWARD CURRENT

PEAK

PER SEGMENT

RED

100502054310

Figure 6. Relative Efficiency (Luminous Intensity

per Unit Current) vs. Peak Current.

3-97

HER, Yellow, Green

100

10

RATIO OF MAXIMUM OPERATING PEAK

CURRENT TO TEMPERATURE DERATED

MAXIMUM DC CURRENT

1

PEAK

I

DC

1 10 100

I MAX

10 kHZ

t – PULSE DURATION – µS

P

1 kHZ

100 HZ

1000 10,000

Figure 7. Maximum Allowed Peak Current vs. Pulse

Duration – HER, Yellow.

50

45

40

35

30

25

20

SEGMENT – mA

15

10

5

DC

I MAX – MAXIMUM DC CURRENT PER

0

GREEN

R = 525° C/W

J-A

θ

20 40 70 80 9060503010

T – AMBIENT TEMPERATURE – °C

A

HER / YELLOW

100 110

OPERATION IN

THIS REGION

REQUIRES

TEMPERATURE

DERATING

OF I MAX.

DC

DC OPERATION

100

10

RATIO OF MAXIMUM OPERATING PEAK

CURRENT TO TEMPERATURE DERATED

MAXIMUM DC CURRENT

1

PEAK

I

0.1 1 10 100

DC

I MAX

10 kHZ

t – PULSE DURATION – µS

P

3 kHZ

1 kHZ

300 HZ

100 HZ

10,0001000

Figure 8. Maximum Allowed Peak Current vs. Pulse

Duration – Green.

140

120

100

80

60

40

20

F

0

I – FORWARD CURRENT PER SEGMENT – mA

0.5 1.5 3.0 3.52.52.01.00

V – FORWARD VOLTAGE – V

F

HER

YELLOW

GREEN

OPERATION IN

THIS REGION

REQUIRES

TEMPERATURE

DERATING

OF I MAX.

DC

DC OPERATION

Figure 9. Maximum Allowable DC Current vs.

Ambient Temperature.

4.0

3.5

3.0

2.5

2.0

1.5

1.0

RELATIVE LUMINOUS INTENSITY

YELLOW; AT 10 mA FOR GREEN)

0.5

(NORMALIZED TO 1 AT 20 mA FOR HER AND

GREEN

HER AND

YELLOW

0

515 30354025

100

20

I – FORWARD CURRENT PER SEGMENT – mA

F

Figure 11. Relative Luminous Intensity vs. DC

Forward Current.

3-98

Figure 10. Forward Current vs. Forward Voltage.

1.5

1.4

1.3

1.2

1.1

1.0

0.9

0.8

0.7

0.6

PEAK

ú

0.5

µpeak – RELATIVE EFFICIENCY

AND YELLOW; AT 10 mA FOR GREEN)

0.4

(NORMALIZED TO 1 AT 100 mA FOR HER

0.3

GREEN

HER

YELLOW

20 40 70 80 9060503010

I – PEAK FORWARD CURRENT

PEAK

PER SEGMENT – mA

100 110

120 130

Figure 12. Relative Efficiency (Luminous Intensity per

Unit Current) vs. Peak Current.

Contrast Enhancement

For information on contrast

enhancement please see

Application Note 1015.

Soldering/Cleaning

Cleaning agents from the ketone

family (acetone, methyl ethyl

ketone, etc.) and from the

chlorinated hydrocarbon family

(methylene chloride, trichloroethylene, carbon tetrachloride,

etc.) are not recommended for

cleaning LED parts. All of these

various solvents attack or

dissolve the encapsulating

epoxies used to form the package

of plastic LED parts.

For information on soldering

LEDs please refer to Application

Note 1027.

3-99

Loading...

Loading...