Page 1

TM 11-6625-1514-15

DEPARTMENT OF THE ARMY TECHNICAL MANUAL

ORGANIZATIONAL, DS, GS,

AND DEPOT MAINTENANCE MANUAL

HEWLETT-PACKARD

VOLTMETER

400D, 400H, 4001

This copy is a reprint which includes current

pages from Changes 1.

VACUUM TUBE

MODELS

AND H02-400D

HEADQUARTERS, DEPARTMENT OF THE ARMY

MAY 1967

Page 2

WARNING

DANGEROUS VOLTAGES

EXIST IN THIS EQUIPMENT

Be careful when working on the power supplies and

their circuits, or on the 230 or 115-volt ac line

connections.

DO NOT TAKE CHANCES

Page 3

TM 11-5625-1514-15

C1

C

HANGE

HEADQUARTERS

DEPARTMENT OF THE ARMY

No. 1

Washington DC, 28 September 1982

Organizational, Direct Support, General Support and

Depot Maintenance Manual

HEWLETT–PACKARD VACUUM TUBE VOLTMETER MODELS

400D, 400H, 400L, and H02-400D

(NSN 6625-00-643-1670)

TM 11-6625-1514-15, 23 May 1967, is changed as follows:

1. Title of manual is changed as shown above.

2. New or changed material is indicated by a vertical bar in the margin.

3. Added or revised illustrations are indicated by a vertical bar next to the figure caption.

4. Remove old pages and insert new pages as indicated below:

Remove pages

None. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i and 1-0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i, ii and 1-0

1-0.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-0.1

10-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

5. File this change sheet in front of the publication for reference purposes.

. Warning page a/(b blank)

Insert pages

By Order of the Secretary of the Army:

Official:

ROBERT M. JOYCE

Major General, United States Army

The Adjutant General

Distribution:

To redistributed in accordance with special list.

E. C. MEYER

General, United States Army

Chief of Staff

Page 4

Page 5

TM 11-6625-1514-15

SAFETY STEPS

IS THE VICTIM

TO FOLLOW IF

OF ELECTRICAL

SOMEONE

SHOCK

DO NOT TRY TO PULL OR GRAB THE INDIVIDUAL

IF POSSIBLE , TURN OFF THE ELECTRICAL POWER

IF YOU CANNOT TURN OFF THE ELECTRICAL

POWER, PULL, PUSH, OR LIFT THE PERSON TO

SAFETY USING A WOODEN POLE OR A ROPE OR

SOME OTHER INSULATING MATERIAL

SEND FOR HELP AS SOON AS POSSIBLE

AFTER THE INJURED PERSON IS FREE OF

CONTACT WITH THE SOURCE OF ELECTRICAL

SHOCK, MOVE THE PERSON A SHORT DISTANCE

AWAY AND IMMEDIATELY START ARTIFICIAL

RESUSCITATION

Change 1 a/(b blank)

Page 6

Page 7

This manual contains copyright material reproduced by permission of the Hewlett-Packard Company.

TM 11-6625-1514-15

Technical Manual

HEADQUARTERS

DEPARTMENT OF THE ARMY

No. 11-6625-1514-15

Washington, DC, 23 May 1967

ORGANIZATIONAL, DIRECT SUPPORT, GENERAL SUPPORT AND

DEPOT MAINTENANCE MANUAL

HEWLETT-PACKARD VACUUM TUBE VOLTMETER MODELS

400D, 400H, 400L, AND H02-400D

(NSN 6625-00-643-1670)

Paragraph

Section

Section

Section

Section

Section

I.

GENERAL DESCRIPTION

Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index of Technical Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance Forms, Records, and Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reporting Errors and Recommending Improvements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reporting Equipment Improvement Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Administrative Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Destruction of Army Electronics Materiel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

II.

INSTALLATION

Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Voltage Requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Line Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

III.

OPERATING INSTRUCTIONS

Instrument Turn-On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Operating Information.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Low-Level Measurements and Ground Currents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measurement of Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measurement of Decibels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Impedance Correction Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Use of Voltmeter Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IV.

CIRCUIT DESCRIPTION

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Voltage Divider and Step Attenuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Broadband Voltmeter Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Indicating Meter Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

V.

MAINTENANCE

Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Precautions . . . . . . . . . . . . . . . . . . . . . . . .

Test Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Meter Zero Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabinet Removal . . . . . . . . . . . .

Tube Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement of Special Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing Voltmeter Performance

Calibration and Frequency Response Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-A.1

1-A.2

1-A.3

1-A.4

1-A.5

1-A.6

1-A.7

1-1

1-4

2-1

2-3

2-5

2-8

2-10

3-1

3-3

3-12

3-14

3-17

3-20

3-22

4-1

4-3

4-7

4-10

4-14

5-1

5-3

5-5

5-7

5-9

5-10

5-13

5-17

5-20

5-22

5-24

Page

1-0.1

1-0.1

1-0.1

1-0.1

1-0.1

1-0.1

1-0.1

1-1

1-1

2-1

2-1

2-1

2-1

2-1

3-1

3-1

3-2

3-2

3-3

3-3

3-4

4-1

4-1

4-1

4-1

4-2

5-1

5-1

5-1

5-1

5-2

5-2

5-2

5-3

5-3

5-5

5-8

Change 1 i

Page 8

TM 11-6625-1514-15

Section

Section

Section

Section

Section

ILLUSTRATED PARTS BREAKDOWN

VI.

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GROUP ASSEMBLY PARTS BREAKDOWN

VII.

Vacuum Tube Voltmeter 400D/H/L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Chassis Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Range Switch Assembly 400D-19A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printed Circuit Board Assembly 400D-75G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printed Circuit Board Assembly 400D-75F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printed Circuit Board Assembly 400D-65C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VIII.

NUMERICAL INDEXES

Part No. Numerical Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hewlett-Packard Stock No. Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REFERENCE DESIGNATION INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IX.

AUXILIARY EQUIPMENT

X.

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Matching Transformer Model 11004A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bridging Transformer Model 11005A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Final Performance Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paragraph

6-1

7-1

7-2

7-3

7-4

7-5

7-6

10-1

10-3

10-7

10-8

Page

6-1

7-1

7-3

7-8

7-9

7-10

7-12

8-1

8-2

9-1

10-1

10-1

10-5

10-5

ii

Change 1

Page 9

Page 10

1-0

Change 1

TM 11-6625-1514-15

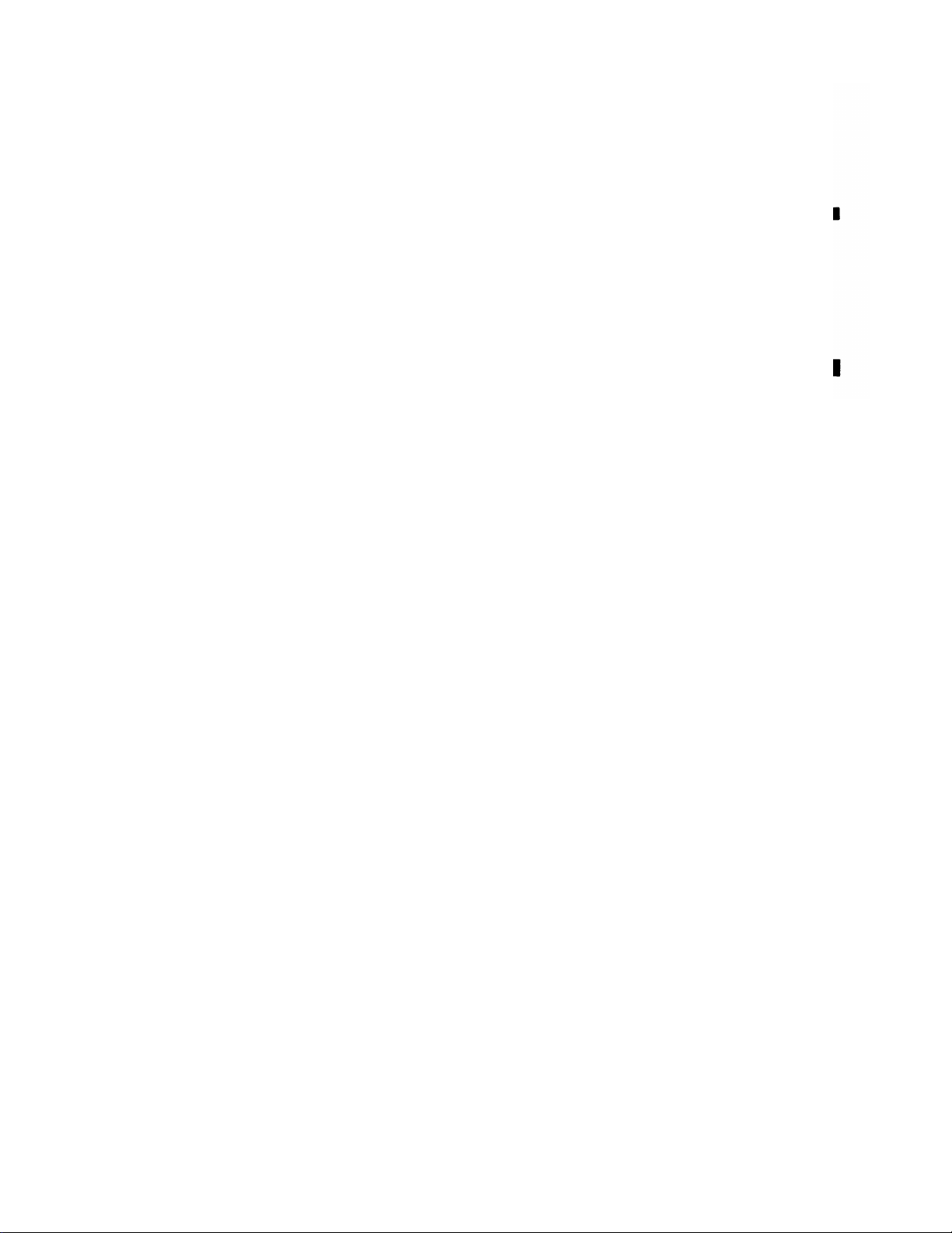

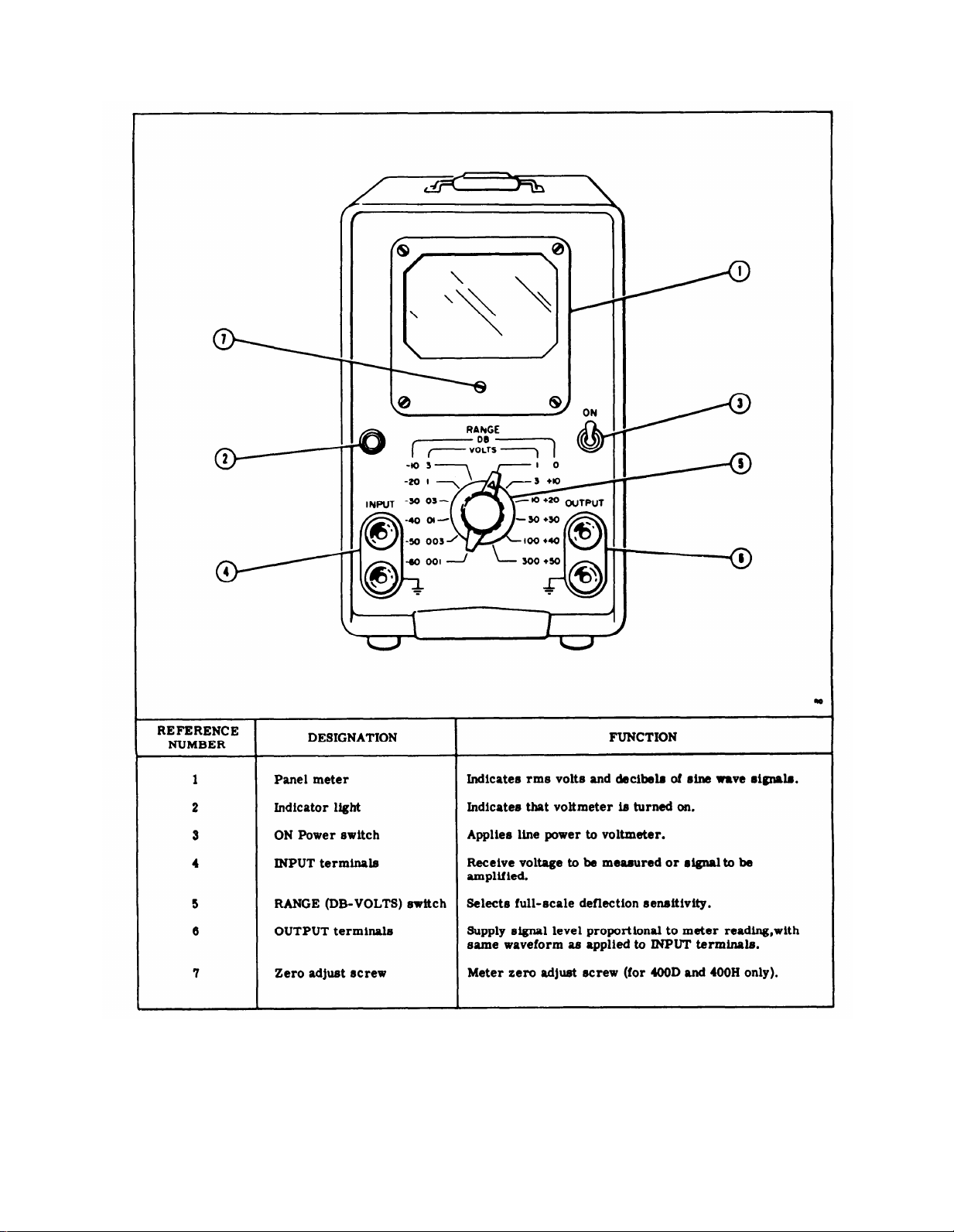

Figure 1-1.

Page 11

SECTION I

GENERAL DESCRIPTION

TM 11-6625-1514-15

1-A.1. Scope

This manual includes installation and operation instructions and covers operator’s, organizational,

direct support (DS), general support (GS), and depot

maintenance. It describes Hewlett-Packard (Federal

Supply Code 28480) Vacuum Tube Voltmeter Models

400D and H02-400D, serial numbers 310-45571 and

higher; and Models 400H and 400L, serial numbers

313-22177 and higher. A basic issue items list for this

equipment is not included in this manual.

1-A.2. Index of Technical

Publications

Refer to the latest issue of DA Pam 310-4 to determine whether there are new editions, changes or additional publications pertaining to the equipment.

1-A.3. Maintenance Forms, Records,

and Reports

a. Reports of Maintenance and Unsatisfactory

Equipment.

cedures used for equipment maintenance will be

those prescribed by TM 38-750, The Army

Maintenance Management System (Army). Air Force

personnel will use AFR 66-1 for maintenance reporting and TO-00-35D54 for unsatisfactory equipment

reporting.

b. Report of Packaging and Handling Deficien-

cies. Fill out and forward SF 364 (Report of

Discrepancy (ROD)) as prescribed in AR 735-11-2/

DLAR 4140.55/NAVMATINST 4355.73/AFR 40054/MCO 4430.3E.

c. Discrepancy in Shipment Report (DISREP)

(SF 361).

ment Report (DISREP) (SF 361) as prescribed in AR

55-38/NAVSUPINST 4610.33B/AFR 75-18/MCO

P4610.19C/DLAR 4500.15.

Department of the Army forms and pro-

Fill out and forward Discrepancy in Ship-

1-A.4. Reporting Errors and Recom-

mending Improvements

You can help improve this manual. If you find any

mistakes or if you know of a way to improve the procedures, please let us know. Mail your letter or DA

Form 2028 (Recommended Changes to Publications

and Blank Forms) direct to Commander, US Army

Communications-Electronics Command and Fort

Monmouth, ATTN: DRSEL-ME-MQ, Fort Monmouth, NJ 07703. A reply will be furnished direct to

you.

1-A.5. Report Equipment Improve-

ment Recommendations (EIR)

If your vacuum tube voltmeter needs improvement,

let us know. Send us an EIR. You, the user, are the

only one who can tell us what you don’t like about

your equipment. Let us know why you don’t like the

design. Tell us why a procedure is hard to perform.

Put it on an SF 368 (Quality Deficiency Report).

Mail it to Commander, US Army CommunicationsElectronics Command and Fort Monmouth, ATTN:

DRSEL-ME-MQ, Fort Monmouth, NJ 07703. We’ll

send you a reply.

1-A.6. Administrative Storage

Administrative storage of equipment issued to and

used by Army activities will have preventive

maintenance performed before storing. When

removing

storage, the PMCS should be performed to assure

operational readiness.

1-A.7. Destruction of Army Elec-

Destruction of Army electronics materiel to prevent

enemy use shall be in accordance with TM 750244-2.

the equipment from administrative

tronics Materiel

Change 1

1-0.1

Page 12

Page 13

TM 11-6625-1514-15

Paragraphs 1-1 to 1-5

Section I

1-1. INTRODUCTION.

1-2. This manual contains operating and servicing

instructions, and a parts breakdown, for the Models

400D, 400H, and 400L Vacuum Tube Voltmeters manufactured by the Hewlett- Packard Company. The Model

400D Voltmeter is similar to a military counterpart,

Electronic Voltmeter ME-30A/U, in appearance and

operation, but contains modified electrical circuits

to obtain improved performance. Applicable Federal

Stock Numbers for the voltmeters are as follows:

Model 400D: 6625-643-1670

Model 400H: 6625-557-8261

Model 400L: 6625-729-8360

1-3. The Models 400D, 400H, and 400L Voltmeters

are the same except for the differences listed in Figure 1-2.

a. Voltage Range: 400D/H - 0.1 millivolt to 300

volts; 400L - 0.3 millivolt to 300 volts, in 12 ranges

providing full-scale readings of the following voltages:

0.001

0.003 0.300 30.00

0.010

0.030 3.000

b. Decibel Range: -72 to +52 db, in 12 ranges.

c. Frequency Range: 10 cps to 4 mc.

d. Input Impedance: 10 megohms shunted by 15 pf

(15 µµf) on ranges 1.0 volt to 300 volts; 25 pf on ranges

0.001 volt to 0.3 volt.

e. Stability: Line voltage variations of ±10% do not

reduce the specified accuracy, and line voltage transients

are not reflected in the meter reading. Electron tube

deterioration to 75% of normal transconductance affects

accuracy less than 0.5% from 20 cps to 1 mc.

f. Amplifier: OUTPUT terminals are provided so

that the voltmeter can be used to amplify small signals

or to enable monitoring of waveforms under test with

an oscilloscope. Output voltage is approximately 0.15

volt rms on all ranges with full-scale meter deflection.

Amplifier frequency response is same as the voltmeter.

Internal impedance is approximately 50 ohms over

entire frequency range.

(See figure l-l. )

0.100

1.000

10.00

100.00

300.00

a. The front panel meters are different in each

model, as described in paragraph 1-6.

b. The accuracy specifications are different for

each model, as described in figure 1-2.

1-4. DESCRIPTION.

1-5. The Hewlett-Packard Models 400D, 400H, and

400L Vacuum Tube Voltmeters are general purpose,

portable electronic a-c voltmeters of high sensitivity

and stability. They are suited to both laboratory and.

field use. Models 400 D/H measure a-c voltages from

0.001 to 300 volts and Model 400L from .003 to 300

volts rms full scale, with a frequency bandwidth covering 10 cps to 4 megacycles. The voltmeters are compact, accurate, and rugged and have fast meter response, high input impedance, stable calibration accuracy, and freedom from the effects of normal line

—

voltage variations.

long instrument life with a minimum of servicing.

g. Accuracy: Model 400D -

± 2% of full scale, 20 cps to 1 mc;

± 3% of full scale, 20 cps to 2 mc;

± 5% of full scale, 10 cps to 4 mc.

Model 400H -

± 1% of full scale, 50 cps to 500 kc;

± 2% of full scale, 20 cps to

± 3% of full scale, 20 cps to

+ 5% of full scale, 10 cps to

Model 400L -

±2% of reading or ±1% of full scale,

whichever is more accurate,

50 cps to 500 kc.

±3% of reading or ±2% of full scale,

whichever is more accurate,

20 cps to 1 mc.

±4% of reading or ±3% of full scale,

whichever is more accurate,

20 cps to 2 mc.

±5% of reading 10 cps to 4 mc.

h. Power Requirement:

1000 cps, approximately 100 watts.

i. Size: 11-3/4 in. high, 7-1/2 in. wide, 12 in. deep.

j. Weight: 18 lbs; shipping weight approximately

23 lbs.

The voltmeters are designed for

1 mc;

2 mc;

4 mc.

115/230 volts ±10%, 50 to

00102-3

Figure 1-2. Table of Specifications

1-1

Page 14

TM 11-6625-1514-15

Section I

Paragraphs 1-6 to 1-10

1-6. Each model voltmeter has three calibrated scales

on the panel meter.

two linear VOLTS scales, 0 to 1 and 0 to 3, and one

DECIBELS scale,

the Models 400H and 400L are larger and include a

mirror to eliminate parallax in viewing and to facilitate

use of the higher scale calibration accuracy of these

models. The Model 400L VOLTS scales are logarithmic

in calibration, from 0.3 to 1 and 0.8 to 3; and the

DECIBELS scale is linear. In all models, the VOLTS

scales are calibrated to indicate the root-mean-square

(rms) value of an applied sine wave. Actual meter

deflection is proportional to the average value of the

applied signal, thereby minimizing additional meter

deflection due to noise and harmonic distortion.

1-7. A voltmeter output signal is provided at the front

panel OUTPUT terminals.

to the meter reading and has a waveshape similar to the

applied signal.

rms for a full-scale meter reading, regardless of the

input signal level. The internal impedance at the

OUTPUT terminal is 50 ohms over the full frequency

range.

adversely affect the accuracy of the voltmeter. This

output is valuable for increasing the sensitivity of

bridges, etc., where distortion added to the waveform

is not a factor.

1-8. The voltmeter chassis is constructed of aluminum

alloy throughout. The panel is finished in non-reflecting,

light-grey baked enamel; the cabinet is finished in

dark-blue, baked wrinkle paint. The cabinet is equipped

with rubber feet and a leather carrying handle. Control

markings on the front panel are engraved and black

filled. INPUT and OUTPUT terminals are special

binding posts which accept either bare wire or banana

plugs; the 3/4-inch spacing between binding posts accepts

standard dual-banana plugs. The “ground” side of the

INPUT and OUTPUT terminals is connected to the

instrument chassis which is in turn connected to the

power line ground through the third (round) prong of

the plug on the power cable.

High-impedance loads (above 100K) will not

The Models 400D and 400H have

-12 to +2 db. The meters used in

This output is proportional

This signal level is about 0.15 volts

1-9. The voltmeter is equipped with a non-detachable

power cord. Test leads, which may be plain wire leads

or coaxial cable, and test probes must be supplied by

the user.

1-10. Instruments designated Models 400DR, 400HR,

and 400LR are rack mount configurations of the 400D,

400H, and 400L, respectively. They are identical to

their cabinet model counterparts in every other re-

spect. They are designed to be mounted in a standard 19 inch wide x 7 inch high relay rack space. Refer to Appendix C for Replacement Parts information.

1-2

Page 15

2-1. UNPACKING AND INSPECTION.

TM 11-6625-1514-15

Section II

Paragraphs 2-1 to 2-11

SECTION II

INSTALLATION

2-2. There are no special precautions for unpacking

the voltmeter. Save the shipping carton and packing

materials for possible storage or reshipment. When

unpacking, inspect instrument and packing materials

for signs of damage in shipment. Make an operation

check as directed in paragraph 2-10 to determine if

performance is satisfactory. If there is any indication

of damage or deficiency, refer to

paragraph 1-A.3.

2-3. LINE VOLTAGE REQUIREMENT.

2-4. The voltmeter is wired at the factory for use on

115-volt a-c power. This voltage may vary ±10% without

adverse effect upon voltmeter performance. The voltmeter can be wired for use on 230-volt a-c power by

reconnecting the dual primary windings on the power

transformer as shown in the schematic diagram in

Section V. When using 230-volt power, change from

a 1-amp to a 1/2-amp slow-blow fuse. If necessary,

provide an adapter for attaching the standard 115-volt

plug on the voltmeter to the 230-volt outlet.

2-5. POWER LINE CONNECTION.

2-6. The three-conductor power cable on the voltmeter

is terminated in a polarized three-prong male connector.

The third contact is an offset round pin added to a standard two-blade connector, which grounds the instrument

chassis when used with the appropriate receptacle.

To connect this plug in a standard two-contact receptacle,

use an adapter. The chassis ground connection is

brought out of the adapter in a green pigtail lead for

connection to a suitable ground.

The lower INPUT and OUTPUT signal terminals

on the panel of the voltmeter are connected

directly to the chassis of the voltmeter. Any

voltage applied to the lower terminal will be

shorted directly to ground. If the ground connection in the power cord is disconnected by

use of an adapter, the entire voltmeter cabinet

will carry whatever potential is applied to the

lower terminal and may be a hazard to the

operator.

2-8. INSTALLATION.

2-9. The voltmeter is a portable instrument requiring

no permanent installation. The voltmeter is for benchtop operation, standing on its rubber feet with its front

panel near the vertical plane. A bail is provided for

raising the front of the cabinet to obtain a better viewing

angle.

2-10. OPERATION CHECK.

2-11. The voltmeter is ready for use as received from

the factory. The simple check described below can be

made by incoming inspectors to determine if electrical

damage was incurred in shipment. If more complete

proof of instrument performance is required, the over-all

performance check described in paragraph 5-22 must be

used. Make a simple performance check as follows:

a. Connect voltmeter to the power line through a

variable transformer. Set transformer for 115 volts,

turn on and allow a five-minute warmup.

2-7. The power plug normally supplied with the volt-

meter is made of molded rubber and is an integral

part of the power cable. On certain military contracts,

a modification of the Model 400D, termed the H02-400D,

is equipped with a removable plug having the same pin

configuration but constructed of corrosion-resistant

material. In all other respects the H02-400D is the

same as the Model 400D and carries the same Federal

Stock Number.

00102-2

b. Measure any sine wave voltage, excepting the power

line,

from 0.01 to 300 volts whose exact voltage is known.

Note that the lower INPUT terminal is connected to the

power line ground.

c. While making the above measurement, adjust the

line voltage from 103 to 127 volts. The reading on the

meter must not change by more than the width of the

pointer.

2-1

Page 16

TM 11-6625-1514-15

Section III

3-0

Figure 3-1. Voltmeter Front Panel, Showing Controls and Connectors

00102-2

Page 17

SECTION III

OPERATING INSTRUCTIONS

TM 11-6625-1514-15

Section III

Paragraphs 3-1 to 3-9

3-1. INSTRUMENT TURN-ON.

3-2. The voltmeter is ready for use as received from

the factory and will give specified performance after a

few minutes warmup. See Section II for information

regarding connection to the power source and to the

voltage to be measured. Controls are shown in figure 3-1.

3-3. GENERAL OPERATING INFORMATION.

3-4. METER ZERO CHARACTERISTIC. When the

Model 400D and 400H Voltmeters are turned off, the

meter pointer should rest exactly on the zero calibration

mark on the meter scale. If it does not, zero-set the

meter as instructed in paragraph 5-7. The meter

supplied in the Model 400L Voltmeter is not provided

with a mechanical meter zero adjustment. When the

voltmeter is turned on with the INPUT terminals

shorted, the meter pointer may deflect upscale slightly;

this deflection does not affect the accuracy of a reading.

NOTE

When the voltmeter RANGE switch is set to the

lowest ranges and the INPUT terminals are not

terminated or shielded, noise pickup can be

enough to produce up to full-scale meter deflection. This condition is normal and is caused

by stray voltages in the vicinity of the instrument. For maximum accuracy on the .001-volt

range, the voltage under measurement should

be applied to the voltmeter through a shielded

test lead.

3-5. METER SCALES. The two voltage scales on each

of the voltmeter models are related to each other by

a factor of 1 10 (10 db). In conjunction with the calib-

rated RANGE switch steps, this provides an intermediate

range step spaced 10 db between “power of ten” ranges,

which are 20 db apart. The relationship of the DECIBELS

scale to the 0 to 1 VOLT scale is determined by making

0 db on the DECIBELS scale equal to the voltage required

to produce 1 milliwatt in 600 ohms (0.775 volts). Thus,

the DECIBELS scale reads directly in dbm (decibels

referred to one milliwatt) across a 600-ohm circuit,

and can be used to measure absolute level of sine wave

signals. It can also be used to measure relative levels

of any group of signals which have the same waveform,

across any constant circuit impedance. The RANGE

switch changes voltmeter sensitivity in 10-db steps

accurate to within ± 1/8 db. The RANGE switch position

indicates the value of a full-scale meter reading.

3-6. CONNECTIONS. Voltmeter test leads must be

provided by the user. The type of leads and probes

used will depend upon the application, as listed below:

a For connection to low-impedance signal sources,

plain wire leads often are sufficient.

00102-2

b. For high-impedance sources, or where noise pickup

is a problem, low-capacity shielded wire must be used

with a shielded, dual banana plug for connection to the

voltmeter terminals.

c. If a probe is used, it should also be shielded to

prevent pickup from the hand.

d. For signals above a few hundred kilocycles, the

capacity of the test leads must be kept to a minimum

by using very short leads, preferably unshielded. An

alligator clip should be used at the test end so that

connection can be made without adding the capacity of

the user’s hands.

3-7. MAXIMUM INPUT VOLTAGE. Do not apply more

than 600 volts de to the INPUT terminals. To do so exceeds the voltage rating of the input capacitor.

3-8. If an applied voltage momentarily exceeds the

selected full-scale voltmeter sensitivity, a few seconds

may be required for circuit recovery, but no damage

will result.

3-9. INPUT VOLTAGE WAVEFORM. The voltmeter

is calibrated to indicate the root-mean-square value

of a sine wave; however, meter pointer deflection is

proportional to the average value of whatever waveform

is applied to the input.

is not a sine wave, the reading will be in error by an

amount dependent upon the amount and phase of the

harmonics present, as shown in figure 3-2 below.

When harmonic distortion is less than about 10%, the

error which results is negligible.

INPUT VOLTAGE

CHARACTERISTICS

Fundamental = 100

Fundamental +10%

2nd harmonic

Fundamental +20%

2nd harmonic

Fundamental +50%

2nd harmonic

Fundamental +10%

3rd harmonic

Fundamental +20%

3rd harmonic

Fundamental +50%

3rd harmonic

Note: This chart is universal in application since

these errors are inherent in all average-responding type voltage-measuring instruments.

Figure 3-2. Effect of Harmonics on Voltage

Measurements

If the input signal waveform

TRUE

RMS

VALUE

100

100.5

102

112

100.5

102

112

METER

INDICATION

100

100

100-102

100-110

96-104

94-108

90-116

3-1

Page 18

TM 11-6625-1514-15

Section III

Paragraphs 3-10 to 3-16

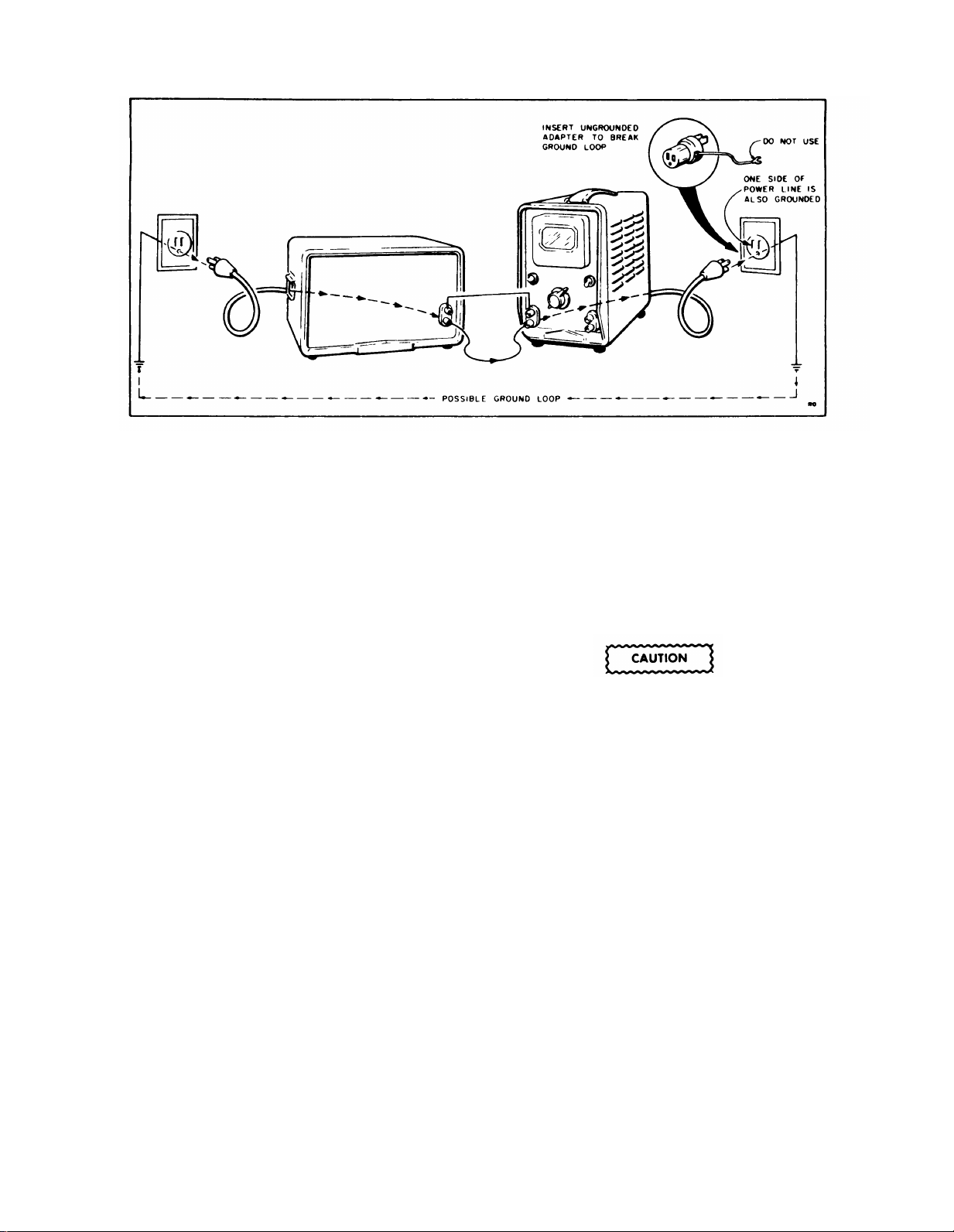

Figure 3-3. Test Setup for Avoiding Ground Loop

3-10. Since the voltmeter meter deflection is propor-

tional to the average value of the input waveform, it

is not adversely affected by moderate levels of random

noise. The effect that noise has on the accuracy of the

meter reading depends upon the waveform of the noise

and upon the signal-to-noise ratio. A square wave has

the greatest effect, a sine wave intermediate effect, and

“White” noise has the least effect on the meter reading.

3-11. If the noise signal is a 50% duty cycle square wave

and the signal-to-noise ratio is 10:1 (between peak

voltages), the error will be about 1% of the meter

reading. If the noise signal is “white” noise and the

signal-to-noise ratio 10:1, the error is negligible.

3-12. LOW-LEVEL MEASUREMENTS AND GROUND

CURRENTS.

3-13. When the voltmeter is used to measure signal

levels below a few millivolts, ground currents in the

meter test leads can cause an error in meter reading.

Such currents are created when two or more ground

connections are made between the instruments of a

test setup and/or between the instruments and the power

line ground. Two ground connections complete an

electrical circuit (ground loop) for the voltages which

are generated across all instrument chassis by stray

fields, particularly the fields of transformers. These

ground currents can be minimized by disconnecting

the ground lead in the power cord from either the

voltmeter or the signal source being measured, at the

power outlet as shown in figure 3-3, and by making

sure that in the test setup no other ground loop is

formed that can cause a ground current to flow in the

voltmeter test leads. Although the resultant voltage

developed across a test lead is in the order of microvolt, it is enough to cause noticeable errors in

measurements of a few millivolts. The presence of

ground currents can sometimes be determined by

simply changing the grounds for the instruments in the

3-2

setup and watching for a change in meter reading. If

changing the ground system causes a change in meter

reading, ground currents are present.

3-14. MEASUREMENT OF VOLTAGE.

3-15. The meter has two VOLTS scales, 0 to 1 and

0 to 3. When the RANGE switch is set to .001, .01,

.1, 1, 10, or 100 VOLTS, read the 0 to 1 scale. When

the RANGE switch is set to .003, .03, .3, 3, 30, or 300

VOLTS, read the 0 to 3 scale.

The lower (black) signal INPUT and OUTPUT terminals and the instrument case are

connected to the power system ground when

the instrument is used with a standard threeterminal (grounding) receptacle. Connect

only ground-potential circuits to the black

INPUT and OUTPUT terminals.

3-16. Operate the instrument as follows:

a. Connect the voltmeter to the a-c power source.

b. Turn the Power switch ON and allow a warmup

period of approximately five minutes.

c. Disconnect any external equipment from the OUT-

PUT terminals.

d. Set the RANGE switch to the VOLTS range which

will read the voltage to be measured at mid-scale or

above. If in doubt, select a higher VOLTS range.

e. Connect the voltage to be measured to the INPUT

terminals.

00102-2

Page 19

AVOID A SHORT CIRCUIT ACROSS THE POWER LINE! To measure power line voltage, first

connect only the upper (red) INPUT terminal to

each side of the power line, in turn, leaving it

connected to the side that causes meter indication. Then connect the lower (black) INPUT

terminal (grounded internally) to the other side

of the line. If this procedure is not followed,

the power line may be short-circuited through

the grounded INPUT terminal of the voltmeter.

TM 11-6625-1514-15

Section III

Paragraphs 3-17 to 3-21

f. Note the meter indication on the DECIBELS scale

(-12 to +2 db). The signal level is the algebraic sum of

the meter indication and the db value indicated by the

RANGE selector. Study the following examples:

Example 1

If the indication on the DECIBELS scale is +2 and the

RANGE switch is in the +20 DB position, the level is

+22 dbm.

Example 2

If the indication on the DECIBELS scale is +1.5 and the

RANGE switch is in the -40 DB position, the level is

-38.5 dbm.

f. Read the meter indication on the appropriate VOLTS

scale, in accordance with the full-scale value indicated

on the RANGE switch. Evaluate the reading in terms

of the full-scale value indicated on the RANGE switch.

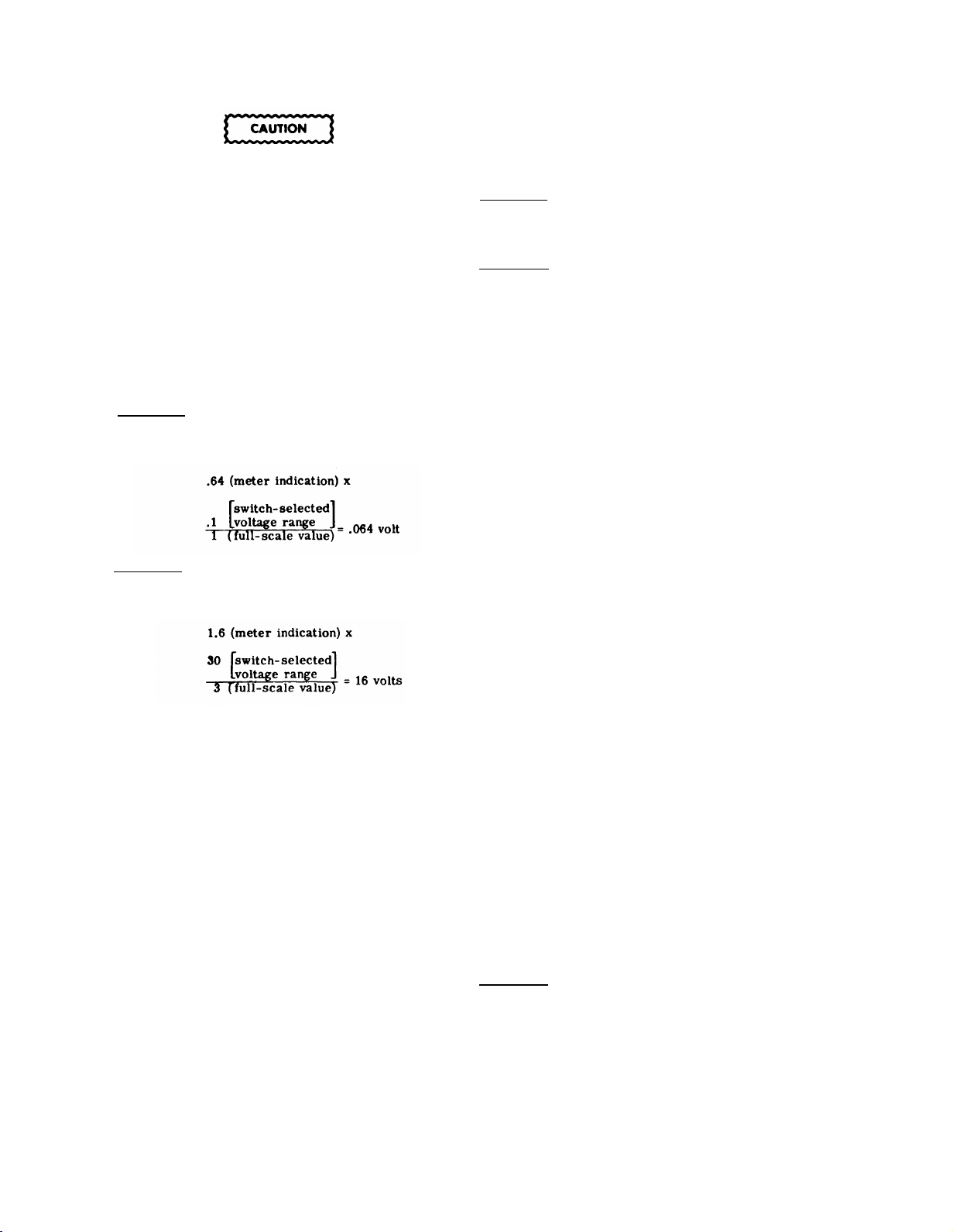

Study the following examples:

Example 1

When the RANGE switch is in the .1 VOLTS range, read

the 0 to 1 VOLTS scaIe. If the meter indicates .64 on

that scale, the voltage being measured is:

Example 2

When the WGE switch is in the 30 VOLTS range, read

the 0 to 3 VOLTS scale. If the meter indicates 1.6 on

that scale, the voltage being measured is:

3-17. MEASUREMENT OF DECIBELS.

3-18. The DECIBELS meter scale is provided for

measuring dbm directly across 600 ohms and for

measuring db ratio for comparison purposes when

each measurement is made across the same circuit

impedance. To measure signal level directly in dbm

(0 dbm equals 1 milliwatt into 600 ohms) proceed as

follows:

a. Connect the voltmeter to the a-c power source.

b. Turn the Power switch ON and allow a warmup

period of approximately five minutes.

c. Disconnect any external equipment from the OUT-

PUT terminals.

d. Set the RANGE switch to the DB range which will

give an upscale reading of the signal to be measured.

If in doubt, select a higher-level scale.

e. Connect the voltage to be measured to the INPUT

terminals.

00102-2

3-19. To measure db across impedances other than

600 ohms, follow the above procedure and evaluate the

results as follows:

NOTE

Since the measurement is made across other

than 600 ohms, the level obtained in step f is in

db, but not in dbm.

a. To obtain the difference in db between measurements made across equal impedances, algebraically

subtract the levels being compared.

b. To obtain the reading of a single measurement

in dbm, note the impedance across which the measurement is made and refer to the Impedance Correction

Graph, described in paragraph 3-20.

c. To obtain the difference in dbm between measure-

ments made across different impedances, convert each

measurement to dbm using the Impedance Correction

Graph described in paragraph 3-20. Then algebraically

subtract the dbm levels being compared.

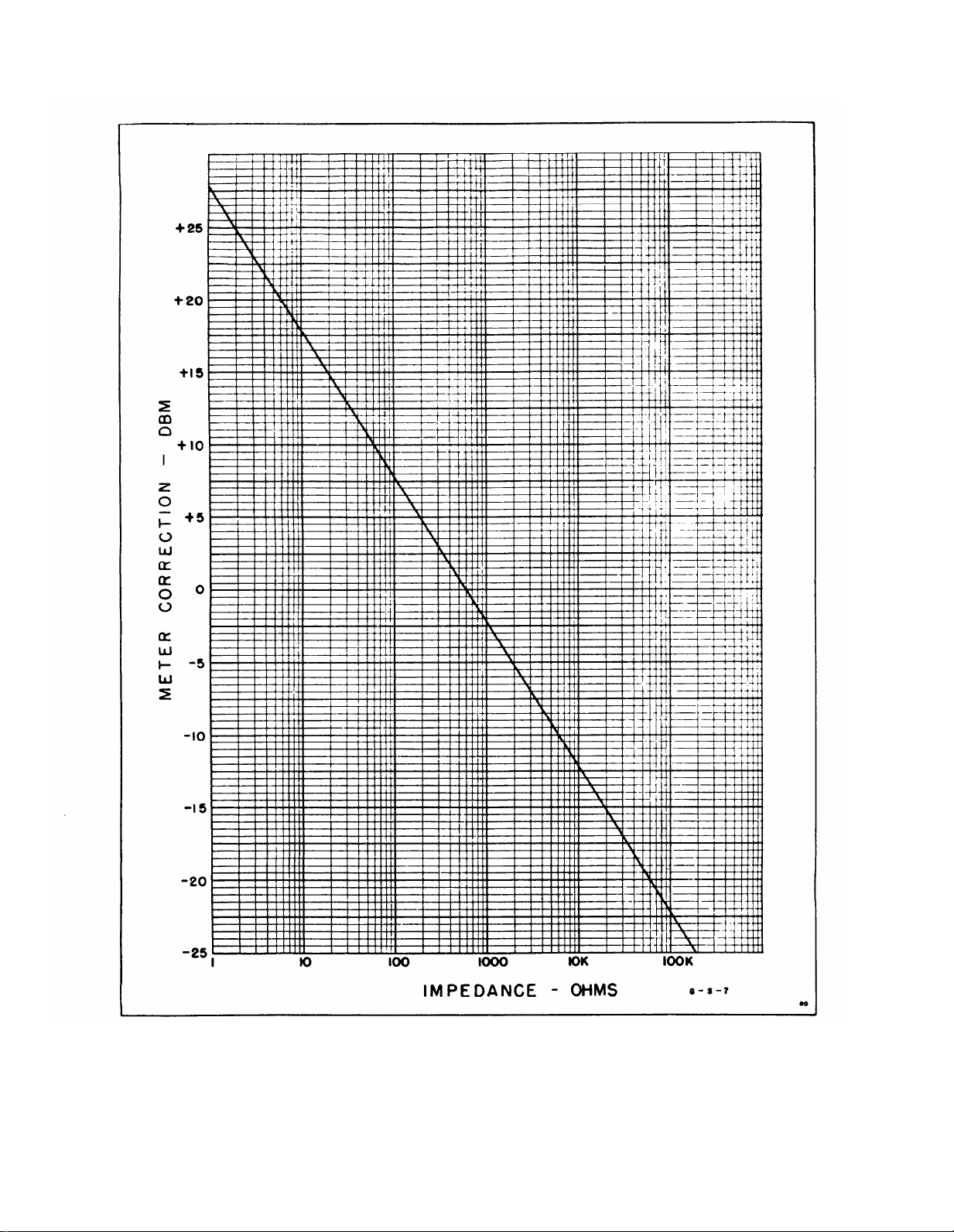

3-20. IMPEDANCE CORRECTION GRAPH.

3-21. As the voltmeter DECIBELS scale is calibrated

to indicate dbm for measurements made across 600-ohm

circuits, a correction factor must be used when measurements are made across circuit impedances other

than 600. ohms, if absolute dbm levels are desired. The

correction factor is not necessary in measuring relative

db levels (not dbm) across the same impedance, but it is

required for comparison of db levels measured across

different impedances.

in figure 3-4 gives the correction factor for conversion

of the meter reading to dbm when the impedance of

the circuit under test is known. To use the graph, read

the conversion factor corresponding to the test circuit

impedance and add it to the meter reading determined

by the method of paragraph 3-17. Observe the algebraic

sign of the correction factor in making the algebraic

addition. Use the following examples:

Example 1

If the measurement is made across 90 ohms, the

indication on the DECIBELS scale is +2, and the RANGE

switch is at the +30 DB position, the level in dbm is

obtained as follows:

The Impedance Correction Graph

3-3

Page 20

TM 11-6625-1514-15

Section III

Paragraphs 3-22 to 3-25

+ 2 (meter indication)

+30

(RANGE switch position)

+32 (sum)

+8

(correction factor from the Impedance

+40 dbm

Example 2

For the same conditions as given above, except that

the measurement is made across an impedance of 60,000

ohms, the level in dbm is obtained as follows:

+ 2 (meter indication)

+30

(RANGE switch position)

+32 (sum)

-20

(Correction factor from the Impedance

+12 dbm

3-22. USE OF VOLTMETER AMPLlFIER.

3-23. The amplifier in the voltmeter may be used for

amplifying weak signals. With full-scale meter deflection, the open-circuit output of the amplifier is approxi-

mately 0.15 volt rms regardless of the RANGE switch

position. The impedance looking into the OUTPUT

terminals is approximately 50 ohms. The frequency

Correction Graph)

Correction Graph)

response and calibration of the voltmeter may be

affected by the impedance of a load applied to the

OUTPUT terminals. To check the effect of the applied

load: observe the meter reading obtained with no load

connected to the OUTPUT terminals and then note any

shift of reading when the external circuit is connected

to the OUTPUT terminals. If the shift is negligible,

the measurement is not being affected appreciably by

the load. Whenever the input signal is changed, i.e., a

different frequency or band of frequencies is applied,

repeat the quick check described above.

3-24. Maximum gain from the amplifier is obtainable

only on the lowest (.001 volts) range, since output level

is the same for all bands. This is due to the 10-db

amplification loss per step inserted by the RANGE

switch as it is turned clockwise. Amplification may

also be obtained on the .003, .01, .03, and 1 volt ranges.

3-25. When the voltmeter is used as an amplifier,

select a range which gives a meter deflection near

full scale. Off-scale signals more than twice the value

of the position of the RANGE switch will cause severe

distortion.

3-4

00102-2

Page 21

TM 11-6625-1514-15

Section III

Figure 3-4. Impedance Correction Graph

3-5

Page 22

4-0

Section IV

TM 11-6625-1514-15

00102-2

Figure 4-1.

Page 23

SECTION IV

CIRCUIT DESCRIPTION

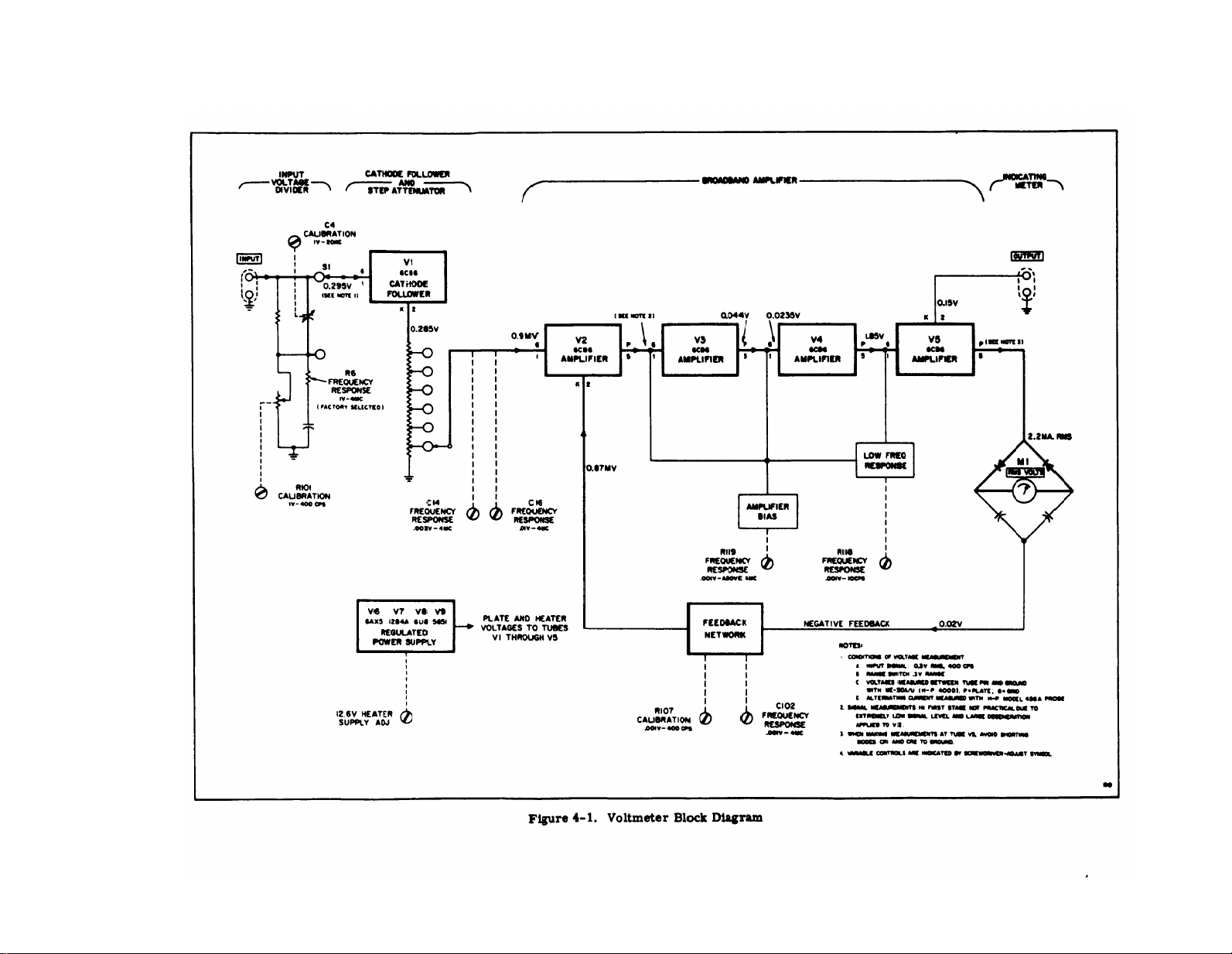

4-1. BLOCK DIAGRAM.

4-2. The electrical circuits of the voltmeter are shown

in the block diagram in figure 4-1; they consist of an input

voltage divider controlled by the RANGE switch, a cathode

follower input tube, a precision step attenuator controlled

by the RANGE switch, a broadband amplifier, an indicating meter, and a regulated power supply. The voltage

applied to the INPUT terminals for measurement is

divided by 1000 before application to the input cathode

follower when the RANGE switch is set to the 1-volt

range and higher; the input voltage is applied directly

to the cathode follower on the lower ranges. The voltage

from the cathode follower is divided in the precision

attenuator to be less than 1 millivolt for application to

the voltmeter amplifier.

is rectified in a full-wave bridge rectifier with a d-c

milliammeter across its midpoints. The resultant

direct current through the meter is directly proportional

to the input voltage.

4-3. INPUT VOLTAGE DIVIDER AND STEP

ATTENUATOR.

4-4. The input voltage divider limits the signal level

applied to the input cathode follower to less than 0.3

volt rms when voltages above this level are measured

with the RANGE switch set at the 1-volt range or above.

The divider consists of a resistive branch with one

element made adjustable to obtain exact 1000:1 division

at middle frequencies and a parallel capacitive branch

with one element made adjustable to maintain exact

1000:1 division to beyond 4 megacycles. The input

impedance of the voltmeter is established by this divider

and is the same for all positions of the RANGE switch.

On the six low-voltage positions of the RANGE switch,

the input divider provides no attenuation of the input

voltage. (See figure 5-10 for the complete schematic.)

4-5. The step attenuator in the cathode circuit of the

input cathode follower reduces the voltage to be measured

to 1 millivolt or less for application to the voltmeter

amplifier. Each step of the attenuator lowers the signal

level by exactly 10 db (1: 10). The attenuator consists

of six precision wirewound resistors which are selected

to very high accuracy and carefully mounted on a 12-

position rotary switch. The RANGE switch rotor has two

contractors (see figures 5-9 and 5-10); the first contacts

each resistor in turn while the input divider is in the

non-attenuating position; the second rotor finger repeats

these contacts while the input attenuator is in the attenuating position.

(C15) is automatically connected to provide flat frequency

response beyond 4 megacycles. In the .003- and the .01volt ranges, separate adjustable capacitors (C14, C16)

are automatically connected to the attenuator to permit

setting the frequency response at 4 megacycles. C14 and

C16 are also connected to the attenuator on the 3- and

10-volt ranges.

connected) flattens frequency response on the .03- and

30-volt ranges.

00102-2

On the .001-volt range a fixed capacitor

Fixed capacitor C106 (permanently

The output of the amplifier

TM 11-6625-1514-15

Paragraphs 4-1 to 4-11

4-6. Cathode follower V1 provides a constant, high input

impedance to the input voltage divider and INPUT terminals of the voltmeter and provides a relatively low

impedance in its cathode circuit to drive the step attenuator.

4-7. BROADBAND VOLTMETER AMPLIFlER.

4-8. Amplification of the signal voltage is provided

by a four-stage stabilized amplifier consisting of tubes

V2 through V5 and associated circuits. The amplifier

provides between 55- and 60-db gain with about 55 db

of negative feedback at mid-frequencies. The feedback

signal is taken from the plate of the output amplifier (V5)

through the meter rectifiers and gain-adjusting circuit

to the cathode of the input amplifier (V2). Variable

resistor R107 in the feedback network adjusts the negative

feedback level to set the basic gain of the amplifier at

mid-frequencies, while adjustable capacitor C102 permits

setting amplifier gain at 4 megacycles. Variable resistor

R118 in the coupling circuit between V4 and V5 permits

adjusting the gain of the amplifier at 10 cycles per

second by controlling the phase shift of low-frequency

signals between these two stages (increasing phase

shift decreases degeneration and increases gain).

4-9. Variable resistor R119 in the grid return path for

V3, V4, and V5 adjusts the total transconductance of

these tubes in order to restrict the maximum gainbandwidth product of the amplifier. The gain-bandwidth

product must be restricted to give a smooth frequency

response rolloff above 4 megacycles and to prevent

possible unstable operation at frequencies far above

4 megacycles when tubes having unusually high trans-

conductance are used (tube transconductance tolerances

during manufacture permit wide variations in new tubes;

the adjustment permits the use of such tubes). The

plate voltage from V5 is rectified by the meter rectifiers and drives the feedback network. The cathode

voltage of V5 is fed to the meter OUTPUT terminals

for monitoring purposes.

thus the signal voltage at the cathode, is affected by

the loading of the meter rectifiers. For signal levels

causing third- scale or more meter deflection, this dis-

tortion consists of a very small irregularity near 0 volts

on the waveform as each diode begins conduction.

4-10. INDICATING METER CIRCUIT.

4-11. The meter rectifier circuit consists of two silicon

diodes and two capacitors connected as a bridge with the

indicating meter across the mid-points as shown in

figure 4-2. The diodes provide full-wave rectification

of the signal current for operating the meter. Electron

flow through the meter is supplied in the following manner

(see figure 4-2). During the positive-going half cycle

of plate voltage on V5, rectifier CR1 conducts electrons

from both C32 and C33 back to the B+ buss. The portion

of electrons from C33 flows through the meter on the way

to B+. At this point in the cycle, both C32 and C33 are

charged to the potential of B+ less some small drop in

R51 and R52.

The voltage gain factor across V1 is 0.95.

The current through V5, and

Section IV

4-1

Page 24

TM 11-6625-1514-15

Section IV

Paragraphs 4-12 to 4-16

4-12. During the negative-going half cycle of the plate

voltage of V5, rectifier CR2 conducts electrons back to

both C32 and C33 from the plate of V5. That portion

of electrons going back to C32 flows through the meter

on the way (in the same direction that the electrons

flowed in the first, positive, half cycle). At this point

in the cycle, both C32 and C33 are discharged. The

pulsating current through the meter is smoothed by

C34 to prevent meter pointer vibration when measuring

low-frequency signals.

the arithmetic average value of the waveform amplitude of the signal.

based on the mathematical ratio between the average and

rms values of true sine wave current.

4-13. In addition, the bridge serves as a segment of a

voltage divider (in series with L11 and R108) connected

across the output of the amplifier. The negative feedback

voltage fed to the input of the amplifier is obtained across

L11 and R108. The alternating charge and discharge of

C32 and C33 produce at their junction with L11 an alternating current of the same phase and waveform as

that at the plate of V5. This phase is negative with

respect to the input signal applied to the first stage of

the amplifier (V2), and drives the negative feedback

network.

4-14. POWER SUPPLY.

4-15. The power supply consists of tubes V6 through V8

and the associated circuits, as shown in the complete

The current is proportional to

Meter calibration in rms volts is

schematic diagram, figure 5-10. The power supply

furnishes regulated +250V d-c voltage for the grid and

plate bias circuits of tubes V1 through V5, unregulated

12.6V d-c voltage for the heater supply of tubes V1

through V4, and 6.3V a-c voltage for the heater supply

of tubes V5 through V8. The power supply is designed

to operate from either a 115-volt (±10%) or a 230-volt

(±10%) a-c power source of 50 to 1000 cps. The primary

winding of power transformer T1 is arranged in two

sections, which can be strapped either in parallel or in

series, to permit operation on 115V or 230V, respectively.

4-16. The output of rectifier V6 is applied to the voltage

regulator circuit consisting of V7 through V9 which

supplies a constant, +250 volts dc to the stabilized amplifier circuit of the voltmeter. Tube V7 is the series

regulator tube, and V9 provides a fixed reference voltage

drop, with which the output voltage is compared in ampli-

fier V8B. V8A is a cathode follower which couples the

reference voltage from V9 to V8B without loading V9.

The regulated output voltage is applied to the control

grid of V8B, while the reference voltage is applied to

its cathode. The difference between the control grid

and cathode voltages controls the operating point of

V8B and thus its plate voltage, which in turn supplies the

grid voltage for regulator V7. Any change in the regulated output of V7 produces a correcting change in the

grid bias of V7 through the action of V8B, thus maintaining

an essentially constant output voltage despite changes in

line voltage or load on the supply. The gain of V8B is

high enough to keep the output at the V7 cathode regulated

4-2

Figure 4-2. Simplified Schematic of Meter Bridge Circuit

00102-2

Page 25

TM 11-6625-1514-15

Section IV

Paragraph 4-17

to within ±1 volt dc as the V7 plate voltage is varied ±10%,

with about 60 ma of load current. The response of the

regulating circuits is fast enough to reduce ripple in

the output voltage to less than 1 millivolt, supplementing

the filtering action of C30. C36 couples the ripple component in the regulated output directly to V8B to avoid

attenuation in R62. R57 shunts a small portion of the

load current around V7 to prevent excessive V7 plate

dissipation at high line voltages. R63 and C35 constitute

a low-pass filter which prevents noise generated in V9

from reaching V8B.

4-17. The heater supply for the voltmeter tubes is

divided into two sections. One section supplies d-c

voltage for the tubes in the input cathode follower and

the amplifier. The other section supplies a-c voltage

for the tubes in the power supply. The voltage required

for the heaters of tubes V1 through V4 is obtained from

6.3V and 7.3V secondary windings of transformer T1,

which are series connected. The voltage developed

across the two series-connected windings is rectified

by full-wave rectifier CR3, reduced to 12.6 volts by

R66 and R68 in parallel, and applied to the seriesparallel-connected heaters of V1 through V4, as shown

in figure 5-10.

four heaters establishes a voltage of 6.3V for each.

The heater of V5 receives 6.3V ac from one of the wind-

ings which drives CR3.

V8 receive 6.3V ac from a separate 6.3V secondary

winding on T1.

The series-parallel connection of the

The heaters of V6, V7, and

00102-2

4-3

Page 26

Page 27

SECTION V

MAINTENANCE

TM 11-6625-1514-15

Section V

Paragraphs 5-1 to 5-8

5-1. SCOPE.

5-2. This section contains complete instructions for

repairing and calibrating the voltmeter. This material

is covered in the following groups of paragraphs: b. Do not remove tubes when the voltmeter is turned

Lead

Paragraph

5-3.

5-5.

5-7.

5-9.

5-10.

5-13.

5-17. Trouble Shooting

5-20. Testing the Power Supply

5-22.

5-24.

5-3. PRECAUTIONS.

5-4. Observe the following precautions:

a. Make no adjustments and replace no parts in the

voltmeter except as described in one of the following

INSTRUMENT TYPE

Electronic

Multimeter

Precautions

Test Equipment Required

Meter Zero Adjustment

Cabinet Removal

Tube Replacement

Replacement of Special Parts

Testing Voltmeter Performance

Calibration and Frequency Response

Adjustments

Topic

REQUIRED CHARACTERISTICS

0 to 300 a-c and d-c volts;

accuracy of ±3% or better;

input impedance 100 megohms.

procedures. If an adjustment or replacement of parts

is made without following instructions or understanding

the effects, further trouble shooting may be complicated.

on. Before replacing tubes refer to paragraph 5-10.

5-5. TEST EQUIPMENT REQUIRED.

5-6. The test equipment required for complete testing

of the voltmeter is listed in figure 5-1. Equivalent

instruments may be substituted for those listed.

5-7. METER ZERO ADJUSTMENT.

5-8. The meter is properly zero-set when its pointer

rests over the zero calibration mark on the meter scale

when the instrument is 1) at normal operating tempera-

ture, 2) in its normal operating position, and 3) turned

off. Adjust the zero-set if necessary, as follows:

a. Allow the voltmeter to operate for 20 minutes so

that the meter movement will reach normal operating

temperature.

b. Turn the voltmeter off and allow one minute for all

capacitors to discharge.

USE

Voltage and resistance ME -26 B/U or

measurement.

DESIGNATION

H-P 410B

Oscillator 10 cps to 300 kc; 3 volts

Voltmeter Calibrator

(Precision Voltage 0.001 to 300 volts at mid-frequencies.

Source)

Frequency 300-kc to 4-mc range;

Response 3 volts output into 50-ohm load; frequency response.

Test Set 10-db steps, 0 to 70 db.

Oscilloscope or

AC Voltmeter

Variable Adjust line voltage between 103

Transformer and 127V ac with 1-amp load.

D-C Current

Test Set

(Milliammeter)

00102-3

output into 50-ohm load. testing and calibration

400-cps output voltage;

in 10-db steps ±0.2%; 0.1 to

1.0 volt in 0.1 volt steps ±0.2%.

10-cps to 4-mc range.

Clip-on type measurement;

current range up to 100 ma. power supply.

Figure 5-1. Test Equipment Required

Signal source for

Calibrating voltmeter

Calibrating voltmeter

Trouble shooting by

signal tracing.

Checking voltmeter

operation with

varying line

voltage.

Checking load on

H-P 200S

H-P 738BR

H-P 739A

H-P 160B or

H-P 400D

CN-16/U or

Ohmite VT2

H-P 428B

5-1

Page 28

TM 11-6625-1514-15

Section V

Paragraphs 5-9 to 5-16

c. Rotate mechanical zero-adjustment screw clock-

wise until meter pointer is to the left of zero and mov-

ing upscale toward zero.

d. Continue to rotate adjustment screw clockwise;

stop

when pointer is exactly on zero. If pointer over-

shoots zero, repeat steps c

e. When pointer is exactly on zero, rotate adjust-

ment screw approximately 15 degrees counterclockwise.

screw from the meter suspension. If pointer moves

turned too far counterclockwise, repeat the procedure

This is enough to free the zero adjustment

during this step, because the adjustment screw is

of steps c

5-9. CABINET REMOVAL.

a. Remove the two cabinet retaining screws at the

rear of the instrument.

b. Push the instrument chassis forward out of the

cabinet. The bezel ring remains attached to the front

panel.

c. When replacing cabinet, pull power cable through

opening at rear of cabinet. Be sure power cable is

not caught between chassis and cabinet. Replace re-

taining screws.

5-10. TUBE REPLACEMENT.

5-11. In many cases instrument malfunction can be

corrected by replacing a weak or defective tube. Check

tubes by substitution while following the voltmeter

through d.

Do not remove tubes from the voltmeter when

power is applied.

voltmeter.

and d.

To do so may damage the

performance check procedure in paragraph 5-22. Results obtained through the use of a “tube checker” can

be misleading.

instrument, mark the original tubes so they can be

returned to the same socket if they are not defective.

Replace only those tubes proven to be defective.

5-12. Figure 5-2 lists each tube in the voltmeter with

its function and the check or adjustment required if

the tube is replaced.

5-13. REPLACEMENT OF SPECIAL PARTS.

5-14. PRECISION RESISTORS AND INDUCTORS. Sev-

eral parts used in the voltmeter have closer tolerances

than those used in most test equipment. Resistors

R104, R105, R108, and R111 through R116 are pre-

cision components. If these resistors require replace-

ment, use the same value and type as the original, as

shown in the parts breakdown.

are used or component positions are moved, the calibration of the voltmeter may be inaccurate or the fre-

quency response may be altered. The inductance of

L10 and L11 affects the frequency response of the

voltmeter. Do not alter the shape or position of these

coils. Install replacement components in the same

positions the original components occupied, as nearly

as possible.

5-15. DIODE RECTIFIERS. Special high-performance

silicon diodes selected by the Hewlett-Packard Co.

are used for CR1 and CR2. When replacing the sili-

con diodes, be careful in soldering; heat can damage

them.

on each diode lead close to the diode body to conduct

the heat away.

voltmeter calibration and frequency response must

be checked as described in paragraph 5-22.

5-16. RANGE SWITCH. Because of the critical con-

struction and wiring of switch S1, it is not practical

to attempt a major repair on the switch. When mech-

anical failure occurs in switch S1, replace the complete

Place a heat sink (such as a long-nose pliers)

Before removing the tubes from the

If different values

If CR1 and CR2 are replaced, the

CIRCUIT

REF.

V1

V2

V3

V4

V5

V6

V7

V8

V9

* Note that V1 must be replaced by a 6CB6, aged and selected for low noise and microphonics

Part No. 5080-0621).

5-2

TYPE

6CB6*

6CB6

6CB6

6CB6

6CB6

6AX5

12B4A

6U8

5651

Figure 5-2. Adjustments Required When Tubes Are Replaced

FUNCTION

Cathode Follower

1st Amplifier

2nd Amplifier

3rd Amplifier

4th Amplifier

High Voltage Rectifier

Series Regulator

Control Tube

Reference Tube

Calibration and frequency response (para. 5-22)

Test of the power supply (para. 5-20)

CHECK OR

ADJUSTMENT

00102-3

Page 29

switch assembly. Use the following procedure. (Locate

parts by referring to figures 5-3 and 5-4; RANGE switch

connections are shown in figure 5-9.)

a. Remove voltmeter cabinet. (See paragraph 5-9.)

b. Loosen setscrews in RANGE switch knob and

remove knob.

c. Disconnect capacitor C104 from switch S1.

d. Disconnect white leads from capacitors C14 and

C16. Label each lead with a tag.

e. Remove the two screws and one nut which retain

the switch shield plate.

f. Disconnect white leads from switch contacts. Tag

each lead to permit easy connection to the new switch.

g. Disconnect the heavy dark-green switch lead, the

heavy light-green switch lead, and the heavy black switch

lead at terminal strips. Tag each lead.

NOTE

The input shield must be removed for access

to the terminal board connection of the darkgreen lead.

h. Remove the nut which holds the switch bushing to

the front panel.

i. Remove RANGE switch assembly.

j. The sequence for installing the replacement RANGE

switch assembly is the reverse of the removal procedure.

k. After replacement of switch S1, check the calibra-

tion and frequency response of the voltmeter and make

necessary adjustments.

5-17. TROUBLE SHOOTING.

5-18. The first step in trouble shooting is to learn

the nature of the symptoms of the malfunction with as

much detail as possible. Inspect the test setup being

used when symptoms of malfunction were observed, to

be sure that the source of trouble is not external to the

voltmeter. Then remove the voltmeter cabinet as

directed in paragraph 5-9 and inspect the circuits of

the voltmeter, looking for signs of overheating, deterioration, and physical damage or tampering. Check the

fuse. If the fuse is blown, try another fuse to see if it

blows; if it does, measure the d-c resistance of filter

capacitors C1, C17, C30, C39, rectifier CR3, and the

windings of transformer T1 to locate the short circuit

without applying power to the voltmeter.

5-19. If the voltmeter can be turned on safely (without

the fuse blowing), measure the line voltage applied to T1

and the voltmeter power supply output voltages (see

paragraph 5-20). Check the tubes of the power supply

if the regulated voltage is not the proper value or is

unstable. Use the procedures of figure 5-5 and the

tests described in paragraph 5-22 to learn the full

nature of the trouble symptom. Watch for marginal

TM 11-6625-1514-15

paragraphs 5-17 to 5-21

operation by operating the voltmeter at 103 and 127

line volts while making tests. Check the tubes in the

voltmeter amplifier. Measure the tube element voltages

at the tube sockets and compare readings with the values

shown in the voltage and resistance diagram in figure

5-8. Apply a test signal to the input and measure the

voltage of the test signal while tracing it through each

coupling network and each stage of amplification.

Compare readings with those shown in the block diagram,

figure 4-1. In figure 4-1, an a-c current probe, H-P

Model 456A, is recommended for the measurement of

a-c current in the meter circuit without breaking any

leads. If this current probe is not available, avoid

measurement of the a-c current. Check meter indications as directed in paragraph 5-22 instead. An

oscilloscope may be used for observing test signal

waveshape and measuring amplitude, if desired.

5-20. TESTING THE POWER SUPPLY.

5-21. The regulated power supply produces a constant

+250 vdc to operate all the tubes in the amplifier section.

The stability of the voltmeter depends directly upon the

stability of the +250 volts from the supply. When the

supply is operating satisfactorily, the +250 volt output

remains constant and the ripple level on it remains less

than about 1 millivolt for line voltages between 103 and

127 volts. Weak tubes (V6, V7, and V8) are the usual

causes of instability. An unstable regulator tube is

indicated by excessive line frequency ripple and varying

output voltage as the line voltage is changed. Marginal

operation is indicated if a trouble symptom appears

only when a low or high line voltage is applied. To test

the complete power supply proceed as follows:

a. Connect the voltmeter to an adjustable line transformer so the applied line voltage can be varied between

103 and 127 volts. Set line voltage to 115 volts, turn on

the voltmeter, and allow a five-minute warmup period.

b. Measure the d-c voltage between V6 (pin 8) and

ground. Normal value is 410 ± 10 volts with exactly

115 volt power line input. Lower line voltage 10% to

103 volts for 2 minutes.

drops below 360 volts, replace V6.

c. Measure the d-c voltage between V7 (pin 1) and

ground with line voltage adjusted to 115 volts. Correct value is 250 ± 5 volts.

d. Vary line voltage from 103 to 127 volts. The d-c

voltage observed in step c must not change more than

± 1 volt. For wrong voltage and/or poor regulation,

replace V7, V8 or V9.

e. Measure the a-c voltage between V7 (pin 1) and

ground. Ripple voltage must be less than 3 mv for any

line voltage (103 to 127 volts). High ripple voltage is

caused by defective V8, V7, V6 or V9. Replace in

this order.

f. Measure the direct current in the lead from

V7 (pin 1) which must be less than 60 milliamperes.

If the current is much too high, the regulator circuit

will not function properly. Excessive current indicates

If the d-c voltage slowly

Section V

00102-2

5-3

Page 30

TM 11-6625-1514-15

Section V

5-4

Figure 5-3. Left Side View of Voltmeter Chassis

00102-3

Page 31

TM 11-6625-1514-15

Paragraphs 5-22 to 5-23

Section V

Figure 5-4. Right Side View of Voltmeter Chassis

a short circuit or partial short in the circuits of the

voltmeter amplifier section. A clip-on type milliammeter should be used for this measurement.

g. If the output voltage is stable but is incorrect,

measure the resistance of R62 and R64. The ratio

of these two resistors determines what the output voltage

will be. If the value of one of these resistors is in-

correct and produces the wrong output voltage, replace

it with a resistor which provides the correct output

voltage.

h. Measure the d-c voltage across C39A which must

be 12.6 volts with a line voltage of 115 volts. If necessary, adjust R66 to obtain 12.6 volts. If the voltage

cannot be set to 12.6 volts, check the a-c voltage from

the associated transformer windings; also check CR3

and C39.

5-22. TESTING VOLTMETER PERFORMANCE.

5-23. The following test procedure checks the accuracy

and stability of the voltmeter at low and high frequencies

00102-3

and with low and high line voltages. It can be used for

comprehensive incoming inspection, for proof of performance, and for trouble shooting. If the readings are

within specifications during these tests, the voltmeter is

operating properly. This test is made without removing

the cabinet. Instruments used to test the accuracy of

the voltmeter (see paragraph 5-5) must be known to have

sufficient

as follows:

a. Connect the voltmeter as shown in figure 5-6.

(This setup measures calibration accuracy at midfrequencies.)

b. Set the line voltage to 115 volts, turn the voltmeter

on and allow a 30-minute warmup period.

c. Check the instrument meter zero setting as in-

structed in paragraph 5-7.

set voltmeter RANGE switch to. 001, and set voltmeter

calibrator VOLTAGE SELECTOR switch to provide 0

volts output.

accuracy to make valid measurements. Proceed

d Connect the voltmeter to the voltmeter calibrator;

5-5

Page 32

TM 11-6625-1514-15

Section V

TROUBLE

1. Power indicator lamp does not light.

a. Fuse F1 burned out.

b. Power indicator lamp DS1 defective.

c. Defective a-c power cable.

d. Power switch S2 defective.

e. Transformer T1 primary winding

terminals incorrectly connected. winding; rewire if necessary.

2. Fuse F1 blows immediately when Power switch S2 is operated to ON.

a. Tube V6 shorted. a. Replace rectifier tube V6.

b. Rectifier CR3 defective. b. Replace heater rectifier CR3.

c. Short circuit in transformer T1 or in

circuit wiring. windings. Replace transformer T1 if

3. Fuse F1 blows after Power switch S2 has been operated to ON and tube heaters have warmed up.

Short in power supply circuit. Check for short circuit at cathodes V6 and V7.

4. Power indicator lamp lights; voltmeter does not indicate on all ranges.

a. Power supply or voltage regulator a. Check tubes V6, V9, V7, and V8 in turn.

circuits defective. Check high-voltage winding of transformer

b. Rectifier CR3 or circuit component

defective.

c. Diode CR1 or CR2 defective.

5. Meter indication normal on low ranges (.001 to .3 volts). Meter sensitivity distorted on

high-voltage ranges (1 to 300 volts).

Compensated 1000:1 divider defective.

PROBABLE CAUSE

REMEDY

a. Replace fuse F1. If replaced fuse blows,

check items 2 and 3 below.

b. Replace power indicator lamp DS1.

c. Repair or replace power cable.

d. Replace Power switch S2.

e. Check connections of transformer T1 primary

c. Remove all tubes, and check transformer

defective. Check for short circuit.

Replace defective component.

T1. Replace defective component.

b. Check for 12.6 volts dc across output of

rectifier CR3, Check resistors R66 and R68.

If tubes V1 and V2 are not lighted, check

capacitor C39. Replace defective component.

c. Replace diode (paragraph 5-15).

Check C4 and R4. Replace defective component.

6. Meter indicates low on all ranges.

a. Low amplifier gain.

b. Diode CR1 or CR2 defective.

7. Meter indication unstable or erratic.

a. Power supply, circuit defective.

b. Amplifier tube V1, V2, V3, V4, and

V5 defective.

8. Meter indication normal on .001 and 1 volt range.

ranges (.003, .01, .03, .1, .3, 3, 10, 30, 100, and 300 volts).

Faulty RANGE switch S1.

Figure 5-5. Trouble-Shooting Procedure

5-6

a. Check B+ voltage (paragraph 5-20). Check

tubes V2 through V5 for low emission. If

any tube is replaced, check and recalibrate

the voltmeter (paragraph 5-22).

b. Replace diode (paragraph 5-15).

a. Check heaters and B+ voltage. Replace

defective component.

b. Check V1 through V5 for microphonics or

noise. If tube is replaced, check and

recalibrate the voltmeter (paragraph 5-22).

Meter sensitivity distorted on all other

Check switch contacts of S1. Replace RANGE

switch S1 if defective (paragraph 5-16).

00102-2

Page 33

TM 11-6625-1514-15

Section V

Figure 5-6. Test Setup for Calibration Check and Adjustments

The residual reading on voltmeter must be no higher

than the residual reading obtained with voltmeter INPUT

terminated with a 10-megohm resistor and shielded to

prevent stray pickup. If the residual reading is higher

when connected to the calibrator, refer to paragraph 3-12.

e. Set the voltmeter RANGE switch to .001. Set the

voltmeter calibrator to provide. 001 volt rms (400 cps)

output. Record deviation of voltmeter reading from 1

on the voltmeter scale.

f. Set the voltmeter RANGE switch to 1. Set the

voltmeter calibrator to provide 1 volt rms output. Record deviation of voltmeter reading from 1 on the voltmeter scale.

g. Still using the voltmeter l-volt range, reduce the

voltmeter calibrator output in 0.1 volt steps. Record

deviation of voltmeter readings from each 0.1 volt calibration mark.

h. Compare recorded deviations with the permissible

errors listed in the performance specifications in

figure 1-2.

i. Connect the voltmeter as shown in figure 5-7

and set line voltage to 115. (This setup measures

calibration accuracy at low and high frequencies.)

meter reading; it must not be higher than the residual

reading noted in step d.

k. Turn the frequency response test set RANGE

SELECTOR to EXTERNAL. Set the external oscillator

frequency to 400 cps; adjust the oscillator output level

to obtain a reading of .9 on the 0 to 1 VOLTS scale of

the voltmeter. Then adjust the METER SET control on

the frequency response test set to obtain a standard

meter indication at the SET LEVEL mark on the test

set meter.

l. Tune the external oscillator to 10 cps and adjust

its output level to keep the frequency response test set

meter reading at SET LEVEL. Do not adjust the METER

SET control as this would alter the fixed monitoring

point of the meter. Record the voltmeter deviation

from .9 on the scale. This reading must be between

0.85 and 0.95 to be within specifications.

m. Set the RANGE SELECTOR on the test set to 3-10

mc, set the FREQ. TUNING dial to 4, and adjust the

AMPLITUDE control to keep the frequency response

test set meter reading at SET LEVEL. Record the

voltmeter deviation from .9 on the scale. This reading

must be between 0.85 and 0.95 to be within specifications.

The gain and frequency response of the basic voltmeter

amplifier is now tested.

n. Repeat step m

Record voltmeter deviation from .9 on the scale.

using line voltages of 103 and 127.

j. Set voltmeter RANGE switch to .001. Set frequency

response test set OUTPUT ATTENUATOR to .001 to

measure the lowest voltmeter range; initially set

AMPLITUDE control for 0 volts output. Then note volt-

00102-3

o. Set voltmeter RANGE switch to .003 and also set

the frequency response test set OUTPUT ATTENUATOR

to .003 to check this voltmeter range. Repeat steps k

and m. Record voltmeter deviation from .9 on the scale.

5-7

Page 34

TM 11-6625-1514-15

Section V

Paragraphs 5-24 to 5-26

Figure 5-7. Test Setup for Frequency Response Check and Adjustment

p. Set voltmeter RANGE switch to .01 and also set the

frequency response test set OUTPUT ATTENUATOR to

.01 to check this voltmeter range: Repeat steps k

Record voltmeter deviation from .9 on the scale.

q. Set voltmeter RANGE switch to 1 and also set the

frequency response test set OUTPUT ATTENUATOR

to 1. Repeat step k.

r. Turn the frequency response test set RANGE

SELECTOR to EXTERNAL. Set external oscillator

frequency to 20 kc and adjust output level to keep the

frequency response test set meter reading at SET

LEVEL. Record voltmeter deviation from .9 on the

scale.

s. Repeat step m

from .9 on the scale.