Page 1

Shertech Operating Instructions, Performance,

Specifications and Parts Manual

lease read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install,

P

perate or maintain the product described. Protect yourself and others by observing all safety information. The Safety Instructions are contained in the

o

General Operating Instructions. Failure to comply with the safety instructions accompanying this product could result in personal injury and/or property

damage! Retain instructions for future reference.

Bronze Models GCBN2V, GGCBN3V, GCBN22V and GCBN33V

Cast Iron Models GCCV2V, GCCV3V, GCCV22V and GCCV33V

Carbonator-Mount Rotary

Close-Coupled External Gear Pumps

Refer to form L-4082 for General Operating and Safety Instructions.

Description

Shertech self-priming, positive displacement, external rotary gear pumps are ideal for a wide range of intermittent and

light-duty industrial, marine, agricultural, and commercial applications, providing a nearly pulseless flow. Close-coupled

models are available directly mounted to NEMA framed, AC ODP single-phase, thermally overload-protected motors or as

pump heads only for custom installations. All models include a pressure relief valve. Motor-driven models are HP configured to

handle up to 500 SSU at 100 psi (specific gravity of 1.0).

Uses: For use with non-particulate and non-abrasive fluids compatible with pump wet-end construction component materials.

• Flows to 4.4 GPM.

• Max. RPM: 1725.

• Max. PSI: 100.

• Maximum viscosity of 500 SSU at 1725 RPM (max. input tor

• Pumps can operate bi-directionally (reversible). In reverse operation, the pressure relief valve will not function.

• Temperature ranges from -20° to 210°F.

• Maximum working pressure: 150 PSI.

que of 45 in.-lbs.).

CARBONATOR-MOUNT CAST IRON PUMPS (INTERMITTENT DUTY) – Specifically designed for use with oil-based fluids. Not

to be used with water-based fluids. Pumps include steel spur gears with steel shafts and cast iron shaft support; standard

pressure relief valves that can be ported internally or externally and a Viton mechanical carbon/ceramic-faced seal with

temperature range of 32° to 280° F. Wet-end parts are constructed from cast iron, steel, stainless steel (302, 303 and/or 18-8),

carbon, ceramic, and Viton.

CARBONATOR-MOUNT BRONZE PUMPS (INTERMITTENT DUTY) – Excellent for water-based fluids. Feature 303 stainless steel

shafts, carbon graphite bushings, and Buna-N mechanical carbon/ceramic faced seal with a temperature range of -20° to 210° F.

Standard pressure relief valves can be ported internally or externally. Wet-end parts are constructed from bronze, brass,

stainless steel (302, 303 and/or 18-8), graphite, carbon, and Buna-N.

PUMP HEADS (NO MOTOR) – Close-coupled gear pump heads are designed to direct couple to carbonator pump motors

(See NEMA Spec. MGI-18.739, Dimensions of Carbonator Motor mounting). The face of this gear pump has been machined to

match the carbonator motor face. Pump and motor held together with a stainless steel beveled “V” band clamp. Coupling of

shafts is done by mating the carbonator motor’s slot with the pump’s slot using the Oldham coupling (See Figure 2). This positive

displacement characteristic offers a wide range of applications.

NOTE: See Rotary Gear Pump Selection Guide in the Motor Manual for suggestions concerning installation, selection, options,

and accessories.

ARNING: Do not use to pump flammable or explosive fluids such as gasoline, fuel oil, ker

W

and/or explosive atmospher

purpose. For your protection, always wear proper clothing, eye protection, etc. in case of any malfunction. For proper handling techniques

and cautions, contact your chemical supplier

could result in personal injury and/or property damage.

es. When pumping hazardous or dangerous materials, use only in room or area designated for that

, insurance company and local agencies (fir

e dept., etc.). Failur

osene, etc. Do not use in flammable

e to comply with this war

ning

Form L-4083 (1/06)

Page 2

hertech Operating Instructions, Performance,

S

pecifications and Parts Manual

S

Bronze Models GCBN2V, GCBN3V, GCBN22V and GCBN33V

ast Iron Models GCCV2V, GCCV3V, GCCV22V and GCCV33V

C

Carbonator-Mount Rotary

Close-Coupled External Gear Pumps

Model Ordering Codes and Options

Example Model: GCBN33V

(1) (2) (3) (4) (5) (6)

GC B N 3 3 V

1st 2nd 3rd 4th 5th 6th

Mounting Material Sealing Gear Size: Ports AC Motor Options

GC: Gear

Carbonator

:

OTE

N

Not all or

configurations may r

Manufacturer reserves the right to change model order codes, standard models, specifications, and performance without

notification.

Maximum motor speed is 1725 RPM.

Cast iron is not for use with water-based fluids.

B: Brass

C: Cast Iron

der code combinations (configurations) ar

equir

dering standard components and/or optional parts that will need to be assembled by the customer.

e or

N: Nitrile

(Buna-N)

V: Viton

e standar

2: 1/4"

3: 1/2"

d models available fr

1: 1/4 HP

2: 1/3 HP

3: 1/2 HP

If blank, motor is

not included with

pump head.

om the manufactur

V: Pressure

Relief Valve

(Standard)

. Custom model

er

Form L-4083 (1/06)

2

Page 3

hertech Operating Instructions, Performance,

S

pecifications and Parts Manual

S

Bronze Models GCBN2V, GCBN3V, GCBN22V and GCBN33V

Cast Iron Models GCCV2V, GCCV3V, GCCV22V and GCCV33V

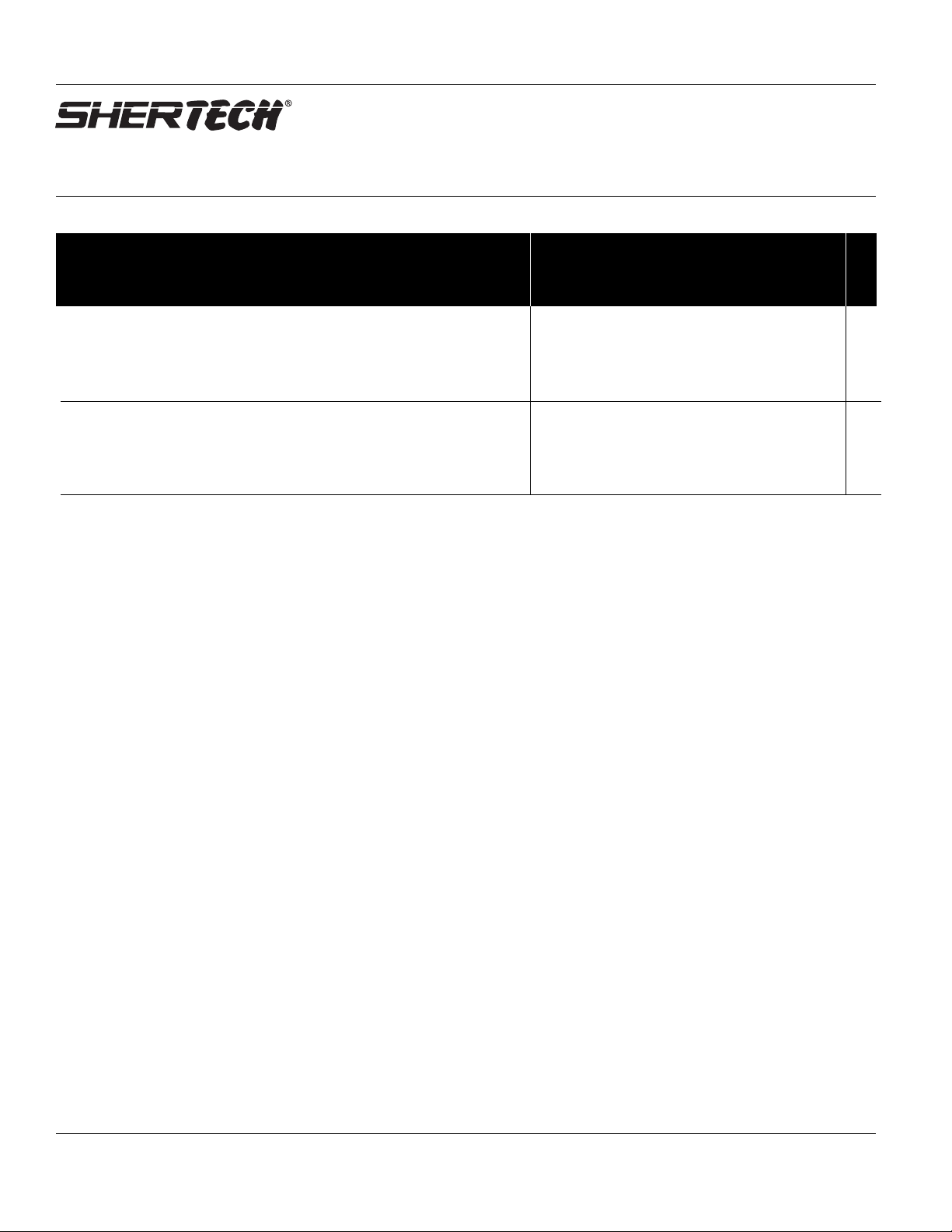

Performance

ronze Cast Iron Port Motor RPM Max. Input Suction Free Flow 20 PSI 40 PSI 60 PSI 80 PSI 100 PSI

B

odels Models Size* HP Torque in.-lbs. Lift** GPM GPM GPM GPM GPM GPM

M

odels with Motors Equipped

M

GCBN22V GCCV22V 1/4 1/3 1725 45 3.2 2.2 2.1 2.0 1.8 1.7 1.6

GCBN33V GCCV33V 3/8 1/2 1725 45 3.6 4.4 4.3 4.2 4 3.8 3.6

Models without Motors Suggested

GCBN2V GCCV2V 1/4 1/3*** 1725 45 3.2 2.2 2.1 2.0 1.8 1.7 1.6

GCBN3V GCCV3V 3/8 1/2*** 1725 45 3.6 4.4 4.3 4.2 4 3.8 3.6

est data taken on SAE 10 wt. oil at 70° F (500 SSU).

T

P

erformance in water will decrease by about 10%, and HP required will also be reduced by 10%. (Don’t use water with Cast Iron.)

Pump performance when pump is new. As pump wears, the performance will decrease.

(*) NPT inlet and outlet (in inches).

(**) Suction lift requires wetted gears and primed seal chamber.

(***) Motor not provided.

NOTES: Pumps with motors are HP rated to handle up to 500 SSU at 100 PSI and specific gravity of 1.0.

Max. PSI = 100

Max. Viscosity = 500 SSU

Max. RPM = 1725

Max. Specific Gravity = 1.1 at 100 PSI, up to 1.6 at lower PSI & viscosity.

Max. Input Torque = See chart above.

Reverse Rotation = Pumps are equipped with pressure relief valves and can be run in reverse rotation; however, pressure relief valve will not

function when pump is reversed unless pump relief valve cover is rotated 180°.

The pump relationship between volume (GPM), pressure (PSI), speed (RPM) and horsepower is shown on performance chart in Shertech Motor

Manual form L-4082. When pumping a more viscous liquid, a slower speed, a larger pipe size pump, and possibly a larger motor should be selected.

Manufacturer reserves the right to change performance without notification.

GPM Pumping 10 Wt. Oil at 70° F (500 SSU)

Form L-4083 (1/06)

3

Page 4

hertech Operating Instructions, Performance,

S

pecifications and Parts Manual

S

Bronze Models GCBN2V, GCBN3V, GCBN22V and GCBN33V

ast Iron Models GCCV2V, GCCV3V, GCCV22V and GCCV33V

C

Carbonator-Mount Rotary

Close-Coupled External Gear Pumps

Specifications

NEMA Min PUMP CONSTRUCTION (Wet End)

Motor Motor AC Thermal Port Pressure Ship

Model Required Req Voltage Amps Frame Hz Class Protection Duty Bearings RPM *** Cover Gear Shaft Bushings Valve**** Seals** (lbs.)

Models with Motors

GCBN22V 48Y 1/3 115 6.0 ODP 60 A Yes†Cont. Sleeve 1725 1/4 BZ BZ 303 SS CG BR & SS Buna Mech 19.8

GCBN33V 48Y 1/2 115/230 8.2/4.1 ODP 60 B Yes

GCCV22V 48Y 1/3 115 6.0 ODP 60 A Yes

GCCV33V 48Y 1/2 115/230 8.2/4.1 ODP 60 B Yes†Cont. Ball 1725 3/8 CI CRS CRS CI CRS & SS Viton Mech 22.3

Models without Motors

GCBN2V* 48Y - - - - - - - - - 1725 1/4 BZ BZ 303 SS CG BR & SS Buna Mech 4.3

GCBN3V* 48Y - - - - - - - - - 1725 3/8 BZ BZ 303 SS CG BR & SS Buna Mech 4.8

GCCV2V* 48Y - - - - - - - - - 1725 1/4 CI CRS CRS CI CRS & SS Viton Mech 4.0

GCCV3V* 48Y - - - - - - - - - 1725 3/8 CI CRS CRS CI CRS & SS Viton Mech 4.3

BZ = Br

(*) Motor not provided.

(**) In addition to elastomer noted, mechanical seal components have carbon on ceramic faces and 18-8 SS metal components.

(***) NPT inlet and outlet (in inches).

(****) Bronze models are made of brass and/or bronze, stainless steel (302, 303 and/or 18-8). Cast Iron models are made of cast iron, cold rolled steel

and stainless steel (302, 303 and/or 18-8 SS).

(†) Thermal overload protection reset may be automatic or manual.

NOTES:48Y motor frame also r

Frame HP Motor Motor Motor Insulation Overload Motor MAX Size Body & Relief O-Rings & Wt.

†

Cont. Ball 1725 3/8 BZ BZ 303 SS CG BR & SS Buna Mech 22.8

†

Cont. Sleeve 1725 1/4 CI CRS CRS CI CRS & SS Viton Mech 19.3

onze BR = Brass CG = Carbon Graphite CI = Cast Ir

red to as carbonator motor.

Motor base may be removable, movable or fixed.

Motor may be split-phase or capacitor start.

Motor driver subject to change without notice (refer to motor nameplate).

Manufacturer reserves the right to change specifications without notification.

efer

on CRS = Cold Rolled Steel ODP = Open Drip-Pr

oof

Form L-4083 (1/06)

4

Page 5

hertech Operating Instructions, Performance,

S

pecifications and Parts Manual

S

Bronze Models GCBN2V, GCBN3V, GCBN22V and GCBN33V

Cast Iron Models GCCV2V, GCCV3V, GCCV22V and GCCV33V

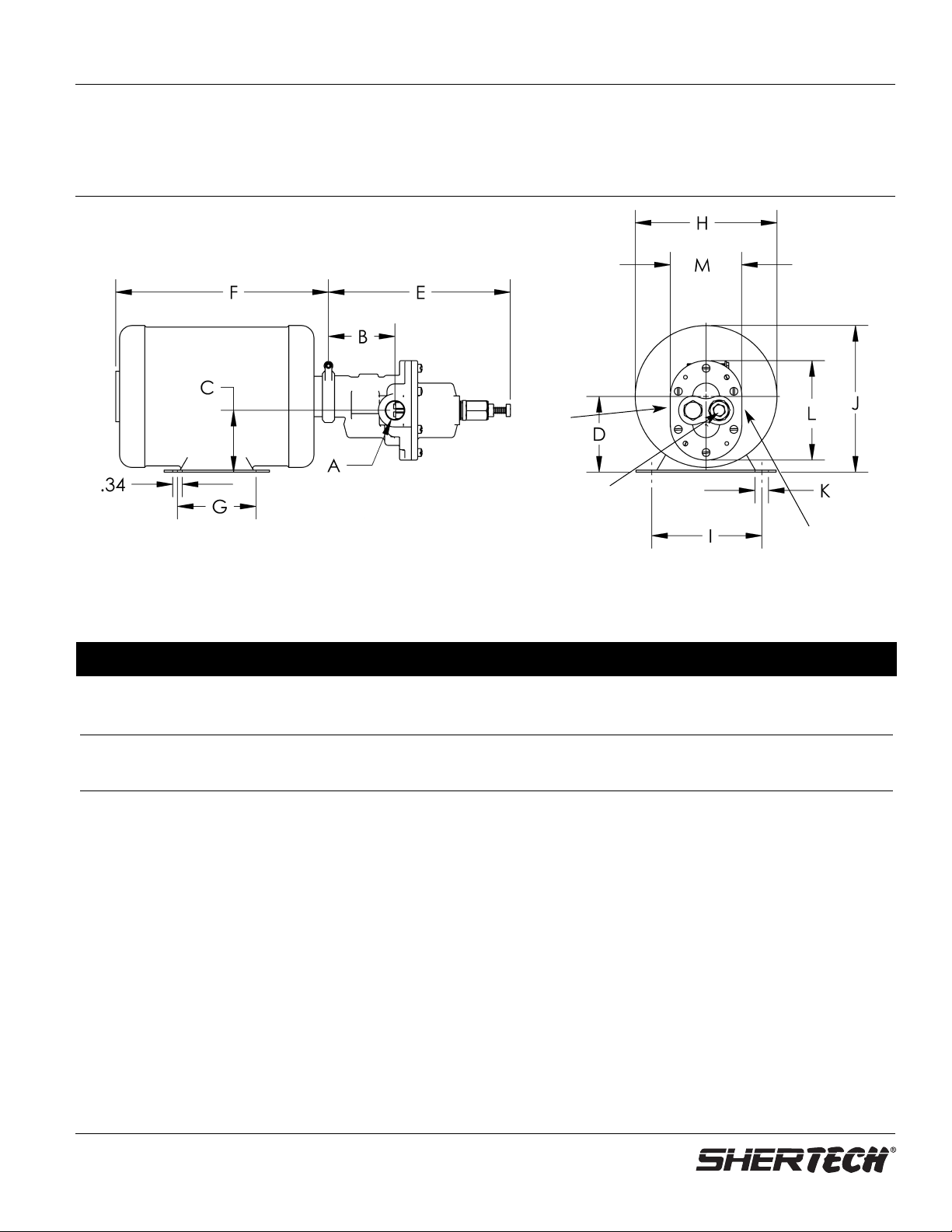

Dimensions

Port Width

Inlet

NPT Inlet

and Outlet

Figure 1 - Dimensions

Pressure

Relief Valve

(On outlet side)

Outlet

Pump Direction

Clockwise Rotation

(When standing in front

of the pump head)

Dimensions

Model A* B C D E F** G** H** I** J** K** L M

Models with Motors

GCBN22V, GCCV22V 1/4 1

GCBN33V, GCCV33V 3/8 2

29

/32 27/16 36

1

/4 27/16 378

Models without Motors

GCBN2V, GCCV2V 1/4 1

GCBN3V, GCCV3V 3/8 2

(*) NPT inlet and outlet (in inches).

(**) This dimension may vary due to motor manufacturer’s specifications.

NOTE: Dimensions have a tolerance of (+ or -) 1/8".

Manufacturer reserves the right to change dimensions without notification.

29

/32 -36

1

/4 -37- -----3

Dimensions (in inches)

9

/16 82

9

/16 ------3

9

/16 23/4 55/8 41/4 53/4 11/16 35/8 21/2

3

/4 55/8 41/4 53/4 11/16 35/8 21/2

5

/8 21/2

5

/8 21/2

Form L-4083 (1/06)

5

Page 6

hertech Operating Instructions, Performance,

IN

ROTATION

Pressure relief valve

(on discharge side)

OUT

S

pecifications and Parts Manual

S

Bronze Models GCBN2V, GCBN3V, GCBN22V and GCBN33V

ast Iron Models GCCV2V, GCCV3V, GCCV22V and GCCV33V

C

Carbonator-Mount Rotary

Close-Coupled External Gear Pumps

Check motor.

It may be equipped

with an automatic resetting thermal

protector and may restart unexpectedly

(see specifications chart). Protector tripping

is an indication of motor overloading as a

result of operating the pump at too high a

pressure (over 100 PSI), too high of viscosity,

too high of specific gravity, excessively high

or low voltage, inadequate wiring, incorrect

motor connections, too small a motor

(sized incorrectly, not enough HP), or a

defective motor or pump.

Do not handle pump with wet hands

or when standing in water. Failure to

follow the General Safety Information

and all warnings could result in fatal

electrical shock!

Assembly

(If pump and motor are

pre-assembled, skip assembly.)

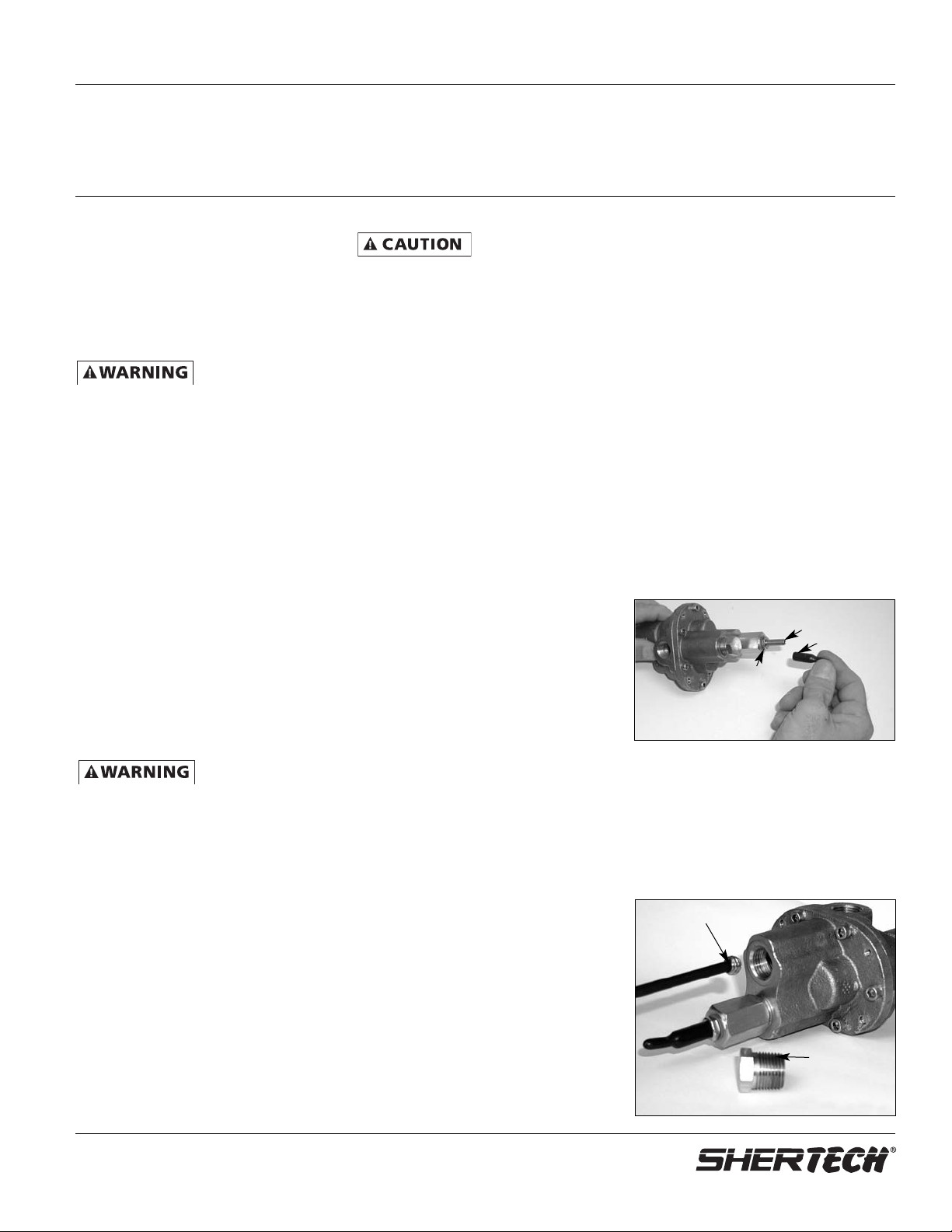

1. Refer to Figures 2 and 3.

2. Remove the hex head machine

screw from the ”V“ band clamp.

3. Slide the ”V“ band clamp away

from the mating face (do not

remove from the pump).

4. Match the pump mating face and

motor mounting hub, while mating

shafts and Oldham coupling (Ref.

No. 24, Figure 7).

end of coupling goes into pump.

Rotation: When looking at the motor

shaft end, pr

oper motor pump rotation

is clockwise (CW). Flow is left to right

(See Figure 3). Reverse the flow by

otating the pump 180˚. Standard mod-

r

els are equipped with pr

valves. It is important that the relief

valve be on the dischar

NOTE: Pump can be rotated 360

pump.

Slip the ”V“ band clamp over the

5.

pump and motor halves (See Figure

2) and tighten the hex head clamp

ew to hold the assembly together.

scr

Retighten the ”V“band clamp scr

6.

as necessary. Use thread sealant if

ew keeps coming loose.

scr

NOTE: The small

elief

e r

essur

ge side of the

Int. Ret. Ring

“V”Band Clamp

Seal Seat Assy.

Pump

Shaft

Ext.

Ret.

R

ing

H

ex. Head

Clamp Screw

Figure 2 - “V” Band Clamp Assembly

Figure 3 - Rotation

Installation

IMPORTANT: In any installations where

property damage and/or personal

injury can occur when the pump is

not operating due to power outages,

discharge line freezing, or any other

reason, a back-up system(s) and/or

war

ning system(s) should be used.

In order to safely use this product, familiarize yourself with this pump and also with

the liquid (chemical, etc.) that is going to

be pumped through the unit. This pump is

not suitable for many liquids.

.

°

1. Locate the pump as close to the

liquid source as possible, making

the suction line as short and direct

as possible.

ew

motor should not exceed 104˚F (40˚C).

Ambient

temperature around

Oldham

C

oupling

Motor

Shaft

2. Open drip-proof motors are

designed to be used in clean, dry

locations with access to an adequate

supply of cooling air.

3. For outdoor installations, the motor

must be protected by a cover that

does not block air flow to and

around the motor.

4. The motor should be securely

fastened to a rigid surface,

preferably metallic. For rigidity,

use largest bolts that will fit

ough the base holes.

thr

Do not use to

pump flammable or

explosive fluids such as gasoline, fuel oil,

kerosene, etc. Do not use in flammable

and/or explosive atmospheres. When

pumping hazardous or dangerous materials,

use only in room or area designated for

that purpose.

For your protection, always wear proper

clothing, eye protection, etc. in case of any

malfunction. For proper handling techniques

and cautions, contact your chemical supplier,

insurance company and local agencies (fire

dept., etc.). Failure to comply with this

warning could result in personal injury

and/or property damage.

PIPING

SUCTION

1. Avoid excessive lengths or number of

fittings and bends in the suction line.

2. Attach suction line to suction inlet.

3. It is recommended that same size

pipe as pump ports be used or, in

cases requiring lengthy piping, the

next larger size pipe be used.

4. If suction lift is greater than what is

indicated in the performance chart,

attach a foot valve below liquid

level at end of suction line to ensure

positive priming. Also note: If fluid

specific gravity is greater than 1.4 or

viscosity greater than 500 SSU, a

foot valve is also recommended.

If solid contaminates ar

5.

e suspected

in a liquid, place a filter in the

suction line.

Form L-4083 (1/06)

6

Page 7

hertech Operating Instructions, Performance,

S

pecifications and Parts Manual

S

Bronze Models GCBN2V, GCBN3V, GCBN22V and GCBN33V

Cast Iron Models GCCV2V, GCCV3V, GCCV22V and GCCV33V

6. Be certain all suction piping connecions are airtight.

t

OTE: Assure airtight pipe connections

N

with the use of a pipe joint sealant.

DISCHARGE

1. Attach discharge piping to the

discharge outlet.

Support pump and

piping during assembly and after installation. Failure to do so may

cause piping to break, pump to fail, motor

bearing failures, etc. All of which can result

in property damage and/or personal injury.

NOTE: Should the pump need to be

self-draining, the pump head should be

mounted in the vertical position with

the suction port facing down. When

pumping high viscosity fluids, the

vertical position can be used with the

suction port facing up and the pump

mounted under the source. Increasing

the suction pipe size and eliminating

bends and elbows also assists in pumping high viscosity fluids. Max. viscosity is

500 SSU at 1725 RPM.

2. If a shut-off valve or handgun is

required in discharge line, provide

a pressure relief valve for pump

pr

otection.

Shutting off

discharge without

providing pressure relief can cause extreme

over-pressure which can result in pump

and/or motor failur

pump or system pressure.

e. Do not exceed 100 PSI

3. Operation under shut-off discharge

conditions will overheat and

damage pump.

NOTE: Globe valve or other restrictive

valves should not be used as shut-off

mechanism as they are restrictive in

nature and will seriously affect pump

performance.

4. After all piping and controls (not

supplied with unit) have been

installed, unit is ready for operation.

Operation

Do not run pump dry,

as permanent damage

to the pump gears, seal, and bearings will

result. Suction pressure should never be

greater than the discharge pressure.

1. All pumps must be primed before

start-up. Never operate a pump

unless it is secured to a solid

foundation.

2. Gear pumps are built to very close

tolerances and this tolerance must

not be altered. The liquids must,

therefore, be free of all abrasives.

Sand, silt, wettable powders, etc.

must be avoided.

NOTE: Cast iron pumps are for oil-based

fluids only.

3. When pumping a more viscous

(beyond 500 SSU) liquid, a slower

speed, a larger pipe size pump,

and possibly a larger motor should

be selected.

NOTE: See performance chart for Max.

Torque.

4. Recheck motor rotation. Proper

motor/pump rotation is clockwise

(CW) looking at the motor shaft

(See Figure 3).

On all models, the pressure relief

5.

valve is always on discharge side

(See Figure 3).

PRESSURE RELIEF VALVE

6. Standard model rotary gear pumps

are supplied with a built-in pressure

relief valve. The valve may be adjusted and used to set system operating

e, or used as a system relief

essur

pr

valve to prevent pump and motor

damage that can occur when discharge line is closed off. This relief

valve is not factor

operation (over one minute) under

shut-off conditions could cause pump

to overheat, leak, and damage itself.

7. To increase the relief valve pressure

setting, remove protective cap,

y set. Extended

loosen lock nut, then turn the set

screw (Figure 4 & 7, Ref. No. 18) in

clockwise). Turning the set screw

(

out (counterclockwise) will reduce

the pressure setting. When desired

pressure is achieved, tighten lock

nut and reinstall protective cap.

8. The pressure relief valve can be

converted to an external relief. This

will allow the relief to dump back

to tank and allow longer periods of

relief without pump damage.

However, this is not a full-line relief

valve, and in cases where frequent

extended relief valve operation is

anticipated, a full-line size relief

valve should be piped in the discharge line and connected either

back to the tank or well downstream of the pump suction inlet.

Adjust pressure

relief valve screw

Protective

cap

Loosen

lock nut

Figure 4 - Pressure

Relief Valve Adjustment

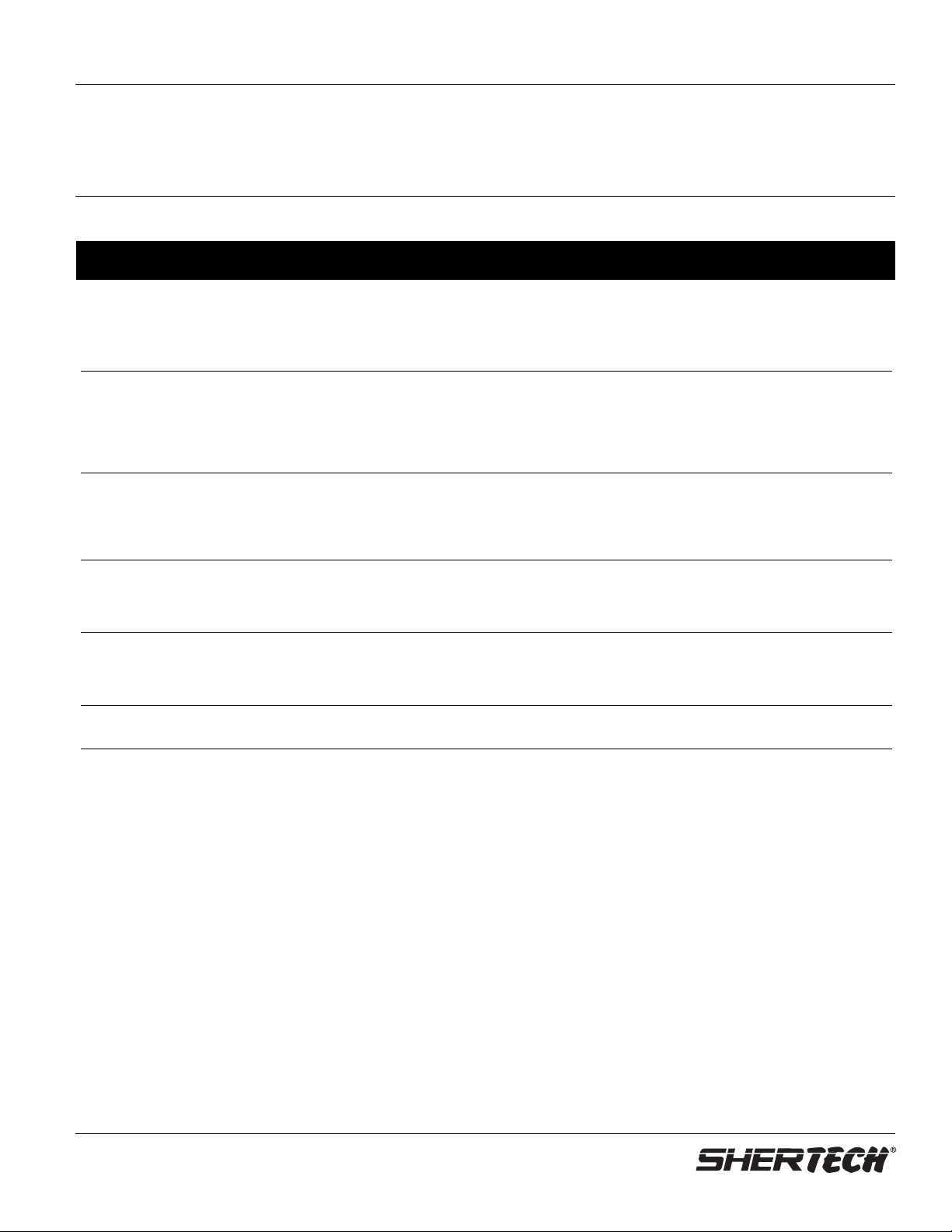

9. To convert the relief valve to external relief, remove the 1/4 NPT pipe

plug from the pump cover (Figure 5

&

7, Ref. No. 13) and discard. This

plug is next to the relief valve. In

the bottom of the 1/4 NPT hole,

ther

e is a second drilled and tapped

Optional

external

bypass plug

Remove and

discard plug

Figure 5 - External Bypass Installation

Form L-4083 (1/06)

7

Page 8

hertech Operating Instructions, Performance,

S

pecifications and Parts Manual

S

Bronze Models GCBN2V, GCBN3V, GCBN22V and GCBN33V

ast Iron Models GCCV2V, GCCV3V, GCCV22V and GCCV33V

C

Carbonator-Mount Rotary

Close-Coupled External Gear Pumps

Operation (Continued)

ole of 1/4 size. An optional exter-

h

nal bypass plug (Figure 5 & 7, Ref.

No. 14 included) should be inserted

n this hole and bottomed out. The

i

open 1/4 NPT port must now be

piped back to the tank or well

downstream of the pump suction.

10. For operation of the pump with

pressure relief valve in reverse rotation, the motor may be reversed,

allowing for reverse rotation.

Standard models are equipped with

pressure relief valves and the pump

can be run in reverse, however, the

pressure relief valve will not function. For continuous reverse rotation, the cover plate must be r

ed 180˚. This is accomplished by

removing the six cover plate screws,

rotating the cover plate, and reattaching the screws. The relief valve

should now be on the opposite side.

This will allow operation of the

pump with a functioning pressure

relief valve in reverse rotation.

otat-

Maintenance

Make certain that the

power source is disconnected before attempting to service or disassemble any components! If the power disconnect is out of sight, lock it in the open position

and tag to prevent application of power.

GENERAL

Check the pump for pr

daily, weekly, monthly, etc. If anything

has changed (pump noise, motor noise,

leaks, etc.) since the pump was new, the

pump should be removed, examined and

repaired if necessary. This is a difficult

motor/pump to repair, therefore, only

qualified electricians or service technicians should attempt to repair this unit.

Improper repair and/or assembly can

cause problems with the electric motor

used with this unit. See General Safety

Information.

Retighten the ”V“ band clamp screw as

necessary. Use Loctite or similar thread

sealant if screw keeps coming loose.

Rotary gear pumps must be drained

completely if subject to freezing

temperature and should not be

operated until temperature permits.

oper operation

To store the pump, place a small quantity

f light oil or some other storage preser-

o

vative compatible with your application

in the pump and rotate the shaft very

lowly to work the oil throughout the

s

gears and the body.

DISASSEMBLY AND ASSEMBLY

Refer to Figure 7 for parts identification

during disassembly and assembly.

[Assumes pump is separated fr

motor and that Oldham coupling

(Ref. No. 24) is removed.]

1. Remove screws (Ref. No. 3) and

cover (Ref. No. 2). Refer to

INSPECTION procedures below.

2. Lift out idler shaft (Ref. No. 8).

3. Remove internal retaining ring (Ref.

No. 12) from drive end of the pump

body (Ref. No. 1) using TruArc-type

internal snap-ring pliers.

4. Carefully pry out ceramic seat (Ref.

No. 11) and then seal (parts of

seal seat assembly using a suitable

hooked tool).

om

Form L-4083 (1/06)

8

Page 9

hertech Operating Instructions, Performance,

S

pecifications and Parts Manual

S

Bronze Models GCBN2V, GCBN3V, GCBN22V and GCBN33V

Cast Iron Models GCCV2V, GCCV3V, GCCV22V and GCCV33V

NOTE: If seal rubber has become bond-

ed to the shaft, use a pliers to remove

the seal (Ref. No 10) and replace with a

new seal assembly. Refer to INSPECTION

procedures below.

5. Remove the seal assembly spring

and metal seat.

6. Remove external retaining ring (Ref.

No. 9) from the shaft (Ref. No. 5)

using external snap-ring pliers

1

⁄2” legs).

(2

7. Remove the gear assembly and drive

shaft (Ref. No. 4 & 5).

Pump Inspection

Inspect components for signs of

excessive wear.

Excessive wear of the pump will usually

show up as degradation of performance.

This can be seen by the flow dropping

off under pressure, excessive noise

and/or excessive wear inside the pump.

Gear pump components are precision

fit. When the gears are worn, so is the

body, shafts, bushings or shaft pockets

and housing. At that point, the pump

head should be replaced.

8. Assemble the pump in reverse order

of disassembly. Tighten cover screws

(Ref. No. 3) in opposing sequence.

As the cover (Ref. No. 2) is incr

mentally tightened, the shaft

(Ref. No. 5) should be periodically

ned. This ensures cover-to-body

tur

alignment and pr

of shaft.

events binding

e-

9. Assemble pump to motor. (See

Assembly 3 through 5.)

10. All pumps must be primed before

start-up and the seal chamber needs

to be filled.

Do not run pump

dry, as permanent

damage to the pump gears, seal, and

bearings will result. Suction pressure should

never be greater than the discharge pressure.

Figure 6 - Mechanical Seal Replacement

Mechanical Seal Replacement (Refer to

Figures 6 & 7 for parts identification.)

1. Remove pump from motor, if not

already done.

2. Remove snap ring (

out seal seat (

mechanical seal (

(See Assembly 3 through 5.)

3. Reinstall new mechanical seal (

No. 10

) on drive shaft using water as

a lubricant. Do not push on carbon

face of new mechanical seal. Push

with a hallowed out wood dowel or

piece of cardboard.

Ref. No. 12

Ref. No. 11

Ref. No. 10

). Pry

). Pull

) off shaft.

Ref.

4. Install seal seat (

water as a lubricant, on the O-ring

with shiny white ceramic face facing

the carbon seal

touching either of the seal faces.

Scratching the seal faces will cause

the seal to leak. Using anything

other than water as a lubricant,

when installing seal and seat, may

cause seal to leak.

NOTE: The carbon and ceramic seal

faces spin against each other providing

for the functional seal. The seal ceramic

seat o-ring is not the functional seal,

but its purpose is to hold the seal

ceramic seat in place.

5. Reinstall the snap ring (

Relief Valve Disassembly and Assembly

(Refer to Figure 7 for parts

identification.)

1. Standard models are equipped with

a pressure relief valve. Remove the

relief valve cap (

O-ring

(

Ref. No. 19)

2. Remove the spring (Ref. No. 22)

and piston (Ref. No. 23). A worn

or broken relief valve is a sign of

excessive pump wear. The pump

head should be replaced.

3. Assemble the relief valve in reverse

der.

or

Ref. No. 11), with

(

Ref. No. 10

Ref. No. 15)and

.

) without

Ref. No. 12

).

Form L-4083 (1/06)

9

Page 10

hertech Operating Instructions, Performance,

S

pecifications and Parts Manual

S

Bronze Models GCBN2V, GCBN3V, GCBN22V and GCBN33V

ast Iron Models GCCV2V, GCCV3V, GCCV22V and GCCV33V

C

Contact a Shertech Distributor

Distributors can be found at www.shertech.com or www.hyproindustrial.com

(The factory only sells pumps and parts to distributors.)

Please provide following information:

-Model number

-Serial number (if any)

-Part description and number

as shown in parts list

Figure 7 - Repair Parts Illustration

NOTE: Seals and the coupling components can be replaced. If the performance or

function of the pump is impaired due to wear or other causes, it is strongly advised

that the pump head be replaced. Note that seals and o-rings used in each material

type are interchangeable. The Viton components from the cast iron models can be used

in the bronze, and the Buna in the bronze models can be used in the cast iron models.

Form L-4083 (1/06)

10

Page 11

hertech Operating Instructions, Performance,

S

pecifications and Parts Manual

S

Bronze Models GCBN2V, GCBN3V, GCBN22V and GCBN33V

Cast Iron Models GCCV2V, GCCV3V, GCCV22V and GCCV33V

Repair Parts List

ef. Part No. For Model:

R

No. Description GCBN2V GCBN3V GCCV2V GCCV3V GCBN22V GCBN33V GCCV22V GCCV33V Qty.

1 Body NA NA NA NA NA NA NA NA 1

2

pt. Plain Cover (non-relief)

O

3 Soc. Head Screw NA NA NA NA NA NA NA NA 6

4 Gear NA NA NA NA NA NA NA NA 2

5 Drive Shaft NA NA NA NA NA NA NA NA 1

6 Bushing NA NA NA NA NA NA NA NA 4

7 O-ring (standard) 18927 18927 19276 19276 18927 18927 19276 19276 1

Opt. O-ring Buna-N NA NA 18927 18927 NA NA 18927 18927 Opt. O-Ring Viton 19276 19276 NA NA 19276 19276 NA NA -

8 Idler Shaft NA NA NA NA NA NA NA NA 1

9 Ext. Ret. Ring NA NA NA NA NA NA NA NA 1

10 & 11

Opt.

Opt.

12 Int. Ret. Ring NA NA NA NA NA NA NA NA 1

13 Pipe Plug** NA NA NA NA NA NA NA NA 1

14 External Bypass Relief Plug* NA NA NA NA NA NA NA NA 1

15 Relief Valve Cap NA NA NA NA NA NA NA NA 1

16 Washer NA NA NA NA NA NA NA NA 1

17 Hex Nut NA NA NA NA NA NA NA NA 1

18 Set Screw - 18-8 SS NA NA NA NA NA NA NA NA 1

19 O-ring NA NA NA NA NA NA NA NA 1

20 O-ring Retainer NA NA NA NA NA NA NA NA 1

21 O-ring NA NA NA NA NA NA NA NA 1

22 Spring - 302 SS NA NA NA NA NA NA NA NA 1

23 Piston - 303 SS NA NA NA NA NA NA NA NA 1

24 Oldham Coupling 19564 19564 19564 19564 19564 19564 19564 19564 1

25 V-Band Clamp 14050 14050 14050 14050 14050 14050 14050 14050 1

26 Dowel Pin NA NA NA NA NA NA NA NA 2

27 Carbonator Motor

Opt. Replacement Pump Head GCBN2V GCBN3V GCCV2V GCCV3V GCBN2V GCBN3V GCCV2V GCCV3V 1

Mech. seal and seat sold as set only (Ref. Nos. 10 & 11) – carbon ceramic faces with18-8 SS components.

When converting to a different seal/seat material, remember to order the o-ring (Ref. No. 7) of the same material.

(*) For external relief only (not installed fr

(**) For internal relief only (standard, installed from manufacturer)

(***) Optional cover without pressure relief valve porting. Bronze covers (models with “S” suffix) come with bushings installed. Cast iron covers do not require bushings.

(†) See Specifications chart for motor specifications.

(NA) Not A

Cover (relief valve standard) NA NA NA NA NA NA NA NA 1

*** 2

Mech. Seal & Seat Assy. (std.)

Buna Mech Seal & Seat Assy.

Viton Mech Seal & Seat Assy.

†

om manufactur

vailable

3570S 23570S 23574 23574 23570S 23570S 23574 23574 1

24604 24604 24608 24608 24604 24604 24608 24608 1

NA NA 24604 24604 NA NA 24604 24604 24608 24608 NA NA 24608 24608 NA NA -

NA NA NA NA 24649S 24650S 24649S 24650S 1

er, loose in packaging)

Form L-4083 (1/06)

11

Page 12

hertech Operating Instructions, Performance,

S

pecifications and Parts Manual

S

Bronze Models GCBN2V, GCBN3V, GCBN22V and GCBN33V

ast Iron Models GCCV2V, GGCCV3V, GCCV22V and GCCV33V

C

Limited Warranty on Carbonator-Mount

Rotary Close-Coupled External Gear Pumps

Hypro warrants to the original purchaser of its products (the “Purchaser”) that such products will be free from defects in

material and workmanship under normal use for the period of six (6) months, and accessories will be free from defects in

aterial and workmanship under normal use for the period of ninety (90) days. Parts carry no warranty.

m

“Normal use” does not include use in excess of recommended maximum speeds, pressures, vacuums and temperatures, or

use requiring handling of fluids not compatible with component materials. This warranty does not cover freight damage,

reezing damage, pump or motor damage from incorrect wiring (if equipped with motor), normal wear and tear, or damage

f

aused by misapplication, fault, negligence, alterations, dry running pump, or repair that affects the performance or

c

reliability of the product.

THIS WARRANTY IS EXCLUSIVE. HYPRO MAKES NO OTHER WARRANTY, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Hypro’s obligation under this warranty is, at Hypro’s option, to either repair or replace the product upon return of the entire

product to the Hypro factory in accordance with the return procedures set forth below.

ANY BREACH OF WARRANTY.

IN NO EVENT SHALL HYPRO BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY KIND, WHETHER FOR

BREACH OF ANY WARRANTY, FOR NEGLIGENCE, ON THE BASIS OF STRICT LIABILITY, OR OTHERWISE.

Only authorized distributors can return products for Warranty. Contact your distributor or visit www.shertech.com to find a

distributor for product support.

Distributors can obtain an RMA # and contact person’s name by contacting Hypro’s customer service at 800-471-0460.

Return Procedures for Distributors

All pumps or products must be flushed of any chemical (ref. OSHA Section 0910.1200 (d)(e)(f)(g)(h) and hazardous chemicals

must be labeled before being shipped* to Hypro for service or warranty consideration. Hypro reserves the right to request a

Material Safety Data sheet from the Purchaser for any pump or product Hypro deems necessary. Hypro reserves the right to

“disposition as scrap” pumps or products returned without authorization and/or which contain unknown substances, or to

charge for any and all costs incurred for chemical testing and proper disposal of components containing unknown substances.

Hypro requests this in order to protect the environment and personnel from the hazards of handling unknown substances.

Be prepared to give Hypro full details of the problem, including the following information:

1. Model number, sale record/invoice, purchase date and from whom you purchased your pump.

2. A brief description of the pump problem, including the following:

• Liquid pumped. State the pH and any non-soluble • Drive type (gas engine/electric motor; direct/belt drive;

materials, and give the generic or trade name. tractor PTO) and rpm of pump.

• Temperature of the liquid and ambient environment. • Viscosity of fluid if other than water.

• Suction lift or vacuum (measured at the pump). • Specific gravity of fluid if other than water.

• Discharge pressure. • Elevation from the pump to the discharge point.

• Size, type, and mesh of the suction strainer

• Abrasiveness or particulate size in fluids.

Hypro may request additional information and may require a sketch to illustrate the problem. Distributors should contact the

factory to receive a return material authorization before sending the product. All pumps returned for warranty work should

be sent shipping charges prepaid to:

.

• Size and material of suction and discharge line.

[RMA# and Contact Person]

HYPRO

375 Fifth Avenue NW

New Brighton, Minnesota 55112

THIS IS THE EXCLUSIVE REMEDY FOR

ves the right to “disposition as scrap” pumps or pr

NOTE:

Hypro r

riers, including U.S.P.S., airlines, UPS, gr

*Car

Failure to do so may result in a substantial fine and/or prison term. Check with your shipping company for specific instructions.

Form L-4083 (1/06)

Printed in USA

eser

eight, etc., require specific identification of any hazardous materials being shipped.

ound fr

oducts r

eturned without authorization.

Loading...

Loading...