Page 1

HP FlexFabric 12500E Routing Switch Series

Installation Guide

Part number: 5998-4857a

Document version: 6PW101-20160331

Page 2

Legal and notice information

© Copyright 2016 Hewlett-Packard Development Company, L.P.

No part of this documentation may be reproduced or transmitted in any form or by any means without

prior written consent of Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice.

HEWLETT-PACKARD COMPANY MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS

MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE. Hewlett-Packard shall not be liable for errors contained

herein or for incidental or consequential damages in connection with the furnishing, performance, or

use of this material.

The only warranties for HP products and services are set forth in the express warranty statements

accompanying such products and services. Nothing herein should be construed as constituting an

additional warranty. HP shall not be liable for technical or editorial errors or omissions contained

herein.

Page 3

Contents

Preparing for installation ············································································································································· 1

Safety recommendations ·················································································································································· 1

General safety recommendations ··························································································································· 1

Electricity safety ························································································································································ 1

ESD prevention ························································································································································· 1

Switch moving ·························································································································································· 2

Laser safety ································································································································································ 3

Examining the installation site ········································································································································· 3

Weight support ························································································································································· 3

Temperature ······························································································································································ 3

Humidity ···································································································································································· 3

Operating altitude ···················································································································································· 4

Cleanness ·································································································································································· 4

EMI ············································································································································································· 4

Grounding ································································································································································· 5

Power supply ····························································································································································· 5

Cooling ······································································································································································ 5

Space ········································································································································································· 7

Installation tools ······························································································································································ 12

Installing the switch ···················································································································································· 14

Confirming installation preparations ···························································································································· 14

Removing the power frame mounting brackets ··········································································································· 15

Installing an expansion cable management bracket (optional) ················································································ 15

Installation preparation ········································································································································· 15

Installation procedure ··········································································································································· 16

Installing a chassis air filter (optional) ························································································································· 18

Installing an air filter on a 12508E ····················································································································· 18

Installing an air filter on a 12518E ····················································································································· 19

Installing the switch in a rack ········································································································································ 19

Installation preparation ········································································································································· 19

Installing slide rails and cage nuts to the rack ··································································································· 20

Mounting the switch in the rack ··························································································································· 23

Verifying the installation ······································································································································· 24

Installing the switch on a workbench ··························································································································· 24

Installation preparation ········································································································································· 25

Installation procedures ·········································································································································· 25

Grounding the switch ···················································································································································· 27

Installing a power supply ·············································································································································· 28

Installation preparation ········································································································································· 28

Installing an AC power supply ····························································································································· 29

Installing a DC power supply ······························································································································· 30

Installing a fan tray ························································································································································ 30

Installing a card ······························································································································································ 31

Installation preparation ········································································································································· 31

Installation procedure ··········································································································································· 32

Connecting power cords ··············································································································································· 33

Connecting an AC power cord ··························································································································· 33

Connecting a DC power cord ······························································································································ 34

i

Page 4

Verifying the installation ················································································································································ 36

Connecting the switch to the network ······················································································································· 37

Cable routing recommendations ·································································································································· 37

Logging in to the switch ················································································································································· 37

Connecting the console cable ······························································································································ 37

Setting up a configuration environment ·············································································································· 40

Powering on the switch·················································································································································· 43

Powering on the switch ········································································································································· 43

Verification after power-on ··································································································································· 45

Connecting the switch to the network ·························································································································· 45

Connecting the switch to the network through the AUX port ············································································ 46

Connecting the switch to the network through a copper Ethernet port ··························································· 46

Connecting the switch to the network through a fiber Ethernet port ································································ 46

Hardware management ············································································································································· 50

Displaying the electrical label data for your switch ··································································································· 50

Displaying the card information for your switch ········································································································· 51

Rebooting your switch ··················································································································································· 53

Managing the power supply system ···························································································································· 54

Displaying the electrical label data for the power monitor module ································································· 54

Enabling power supply management ·················································································································· 55

Configuring the number of redundant power supplies ····················································································· 55

Manually starting or stopping power supply to a card ····················································································· 56

Displaying the power supply system information about your switch ······························································· 57

Configuring temperature thresholds for a card ··········································································································· 58

Configuring temperature thresholds for a card ·································································································· 59

Displaying the temperature information on your switch ···················································································· 59

Isolating a card ······························································································································································ 60

Configuration restrictions and guidelines ··········································································································· 60

Configuration procedure ······································································································································ 60

Configuring hardware failure detection and protection ···························································································· 61

Specifying the actions to be taken for hardware failures ················································································· 61

Enabling hardware failure protection for interfaces ·························································································· 61

Enabling hardware failure protection for aggregation groups ········································································ 62

Displaying the operating state of fans ························································································································· 63

Displaying alarms present on your switch ··················································································································· 64

Verifying and diagnosing transceiver modules ·········································································································· 65

Verifying transceiver modules ······························································································································ 65

Diagnosing transceiver modules ·························································································································· 67

Replacement procedures ··········································································································································· 70

Cleaning the air filters ··················································································································································· 70

Cleaning the chassis air filters ····························································································································· 70

Cleaning a power frame air filter ························································································································ 71

Replacing a power component ···································································································································· 72

Preparing for the replacement ····························································································································· 72

Replacing a power module ·································································································································· 72

Replacing a power monitoring module ··············································································································· 73

Replacing a card ···························································································································································· 74

Preparing for the replacement ····························································································································· 74

Replacement procedure ········································································································································ 75

Replacing a fan tray ······················································································································································ 76

Preparing for the replacement ····························································································································· 76

Replacement procedure ········································································································································ 76

Replacing a CF card ······················································································································································ 77

ii

Page 5

Replacing a transceiver module ··································································································································· 79

Replacing the XFP, SFP+, SFP, and QSFP+ modules ························································································· 79

Replacing the CFP transceiver module ················································································································ 80

Replacing the SFP+ cable and QSFP+ cable ····································································································· 81

Appendix A Chassis views and technical specifications ························································································ 83

Chassis views ································································································································································· 83

12508E ·································································································································································· 83

12518E ·································································································································································· 85

Technical specifications ················································································································································· 87

Chassis ··································································································································································· 87

Cards ······································································································································································ 88

Fan trays ·········································································································································································· 94

Power supply system ······················································································································································ 94

12508E/12518E AC power supply ·················································································································· 94

12508E/12518E DC power supply ·················································································································· 95

Power component specifications·························································································································· 96

Power cords ··························································································································································· 97

Expansion cable management brackets ······················································································································ 98

Appendix B LEDs ························································································································································ 99

Power system LEDs ························································································································································· 99

Power monitoring module LEDs ··························································································································· 99

Power module LEDs ··············································································································································· 99

Fan tray LEDs ································································································································································ 100

MPU LEDs ······································································································································································ 100

CF card status LED ··············································································································································· 101

Network management port LEDs ······················································································································· 101

Switching fabric module LED ····························································································································· 102

LPU status LED ······················································································································································ 102

Fan status LED ······················································································································································ 102

Power status LED ·················································································································································· 102

MPU LEDs ····························································································································································· 103

LPU LEDs ········································································································································································ 103

Interface LEDs ······················································································································································· 103

RUN LED ······························································································································································· 104

Switching fabric module LEDs ····································································································································· 104

Appendix C Transceiver modules ·························································································································· 106

100-GE CFP transceiver modules ······························································································································· 106

40-GE QSFP+ transceiver modules ···························································································································· 107

10-GE XFP transceiver modules ·································································································································· 107

10-GE SFP+ transceiver modules ······························································································································· 108

10-GE SFP+ cables ······················································································································································ 109

FE/GE SFP transceiver modules ································································································································· 109

Appendix D Lightning protection ··························································································································· 112

Connecting the AC power supply to a power strip with lightning protection ······················································· 112

Installing a lightning protector for a network port ···································································································· 113

Appendix E Engineering labels ······························································································································ 115

Labels for cables··························································································································································· 115

Labels for signal cables ······································································································································ 115

Labels for power cords ······································································································································· 115

Generic labels······················································································································································ 116

Labels for devices ························································································································································· 117

Filling in labels ····························································································································································· 117

iii

Page 6

Affixing labels ······························································································································································· 117

Affixing a label to a signal cable ······················································································································ 117

Affixing a label to a power cord ······················································································································· 118

Affixing a generic label ······································································································································ 119

Affixing a label to a device ································································································································ 120

Guidelines ····································································································································································· 120

Examples ······································································································································································· 120

Engineering labels for network cables ·············································································································· 120

Engineering labels for optical fibers·················································································································· 122

Engineering labels for DC power cords ··········································································································· 124

Engineering labels for AC power cords ··········································································································· 125

Engineering labels for devices ··························································································································· 125

Appendix F Cable management ···························································································································· 127

Cable management guidelines ··································································································································· 127

Cable management examples ···································································································································· 129

Support and other resources ·································································································································· 131

Contacting HP ······························································································································································ 131

Subscription service ············································································································································ 131

Related information ······················································································································································ 131

Documents ···························································································································································· 131

Websites ······························································································································································· 131

Conventions ·································································································································································· 132

Index ········································································································································································ 134

iv

Page 7

Preparing for installation

Safety recommendations

To avoid any equipment damage or bodily injury caused by improper use, read the following safety

recommendations before installation. Note that the recommendations do not cover every possible

hazardous condition.

General safety recommendations

• Take adequate safety measures to avoid injury and switch damage. For example, wear an ESD

wrist strap.

• Make sure the ground is dry and flat and anti-slip measures are in place.

• Keep the chassis clean and dust-free.

• Do not place the switch on a moist area and avoid liquid surrounding the switch.

• Keep the chassis and installation tools away from walk areas.

• Move the switch and heavy components (such as the power supplies or chassis) with other people

rather than doing that alone.

Electricity safety

• Clear the work area of possible hazards, such as ungrounded power extension cables, missing

safety grounds, and wet floors.

• Locate the emergency power-off switch in the room before installation. Shut the power off at once in

case accident occurs.

• Unplug all the external cables (including power cords) before moving the chassis.

• Do not work alone when the switch has power.

• Always check that the power has been disconnected.

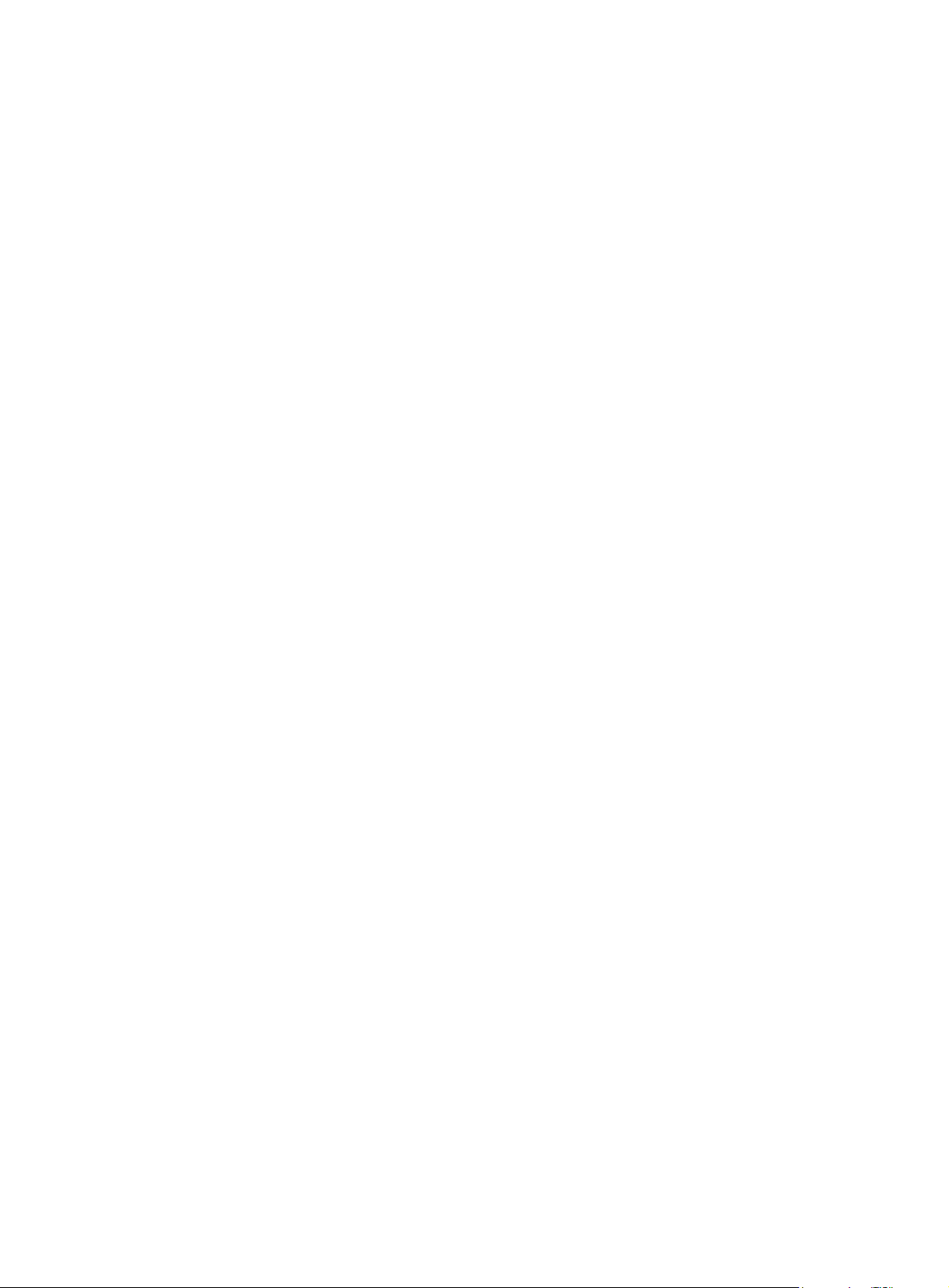

ESD prevention

To prevent the electronic components from being damaged by the electrostatic discharge (ESD), follow

these guidelines:

• Ground the switch correctly. For how to ground your switch, see "Installing the switch."

• Always wear an ESD wrist strap when installing components, especially the electronic printed circuit

boards.

• Hold a PCB by its edges. Do not touch any electronic components or printed circuit.

• Check the resistance of the ESD wrist strap for safety. The resistance reading should be in the range

of 1 to 10 megohm (Mohm) between human body and the ground.

To attach the ESD wrist strap:

1

Page 8

1. Wear the wrist strap on your wrist.

2. Lock the wrist strap tight around your wrist to keep good contact with the skin.

3. Insert the ESD wrist strap into the ESD socket on the switch chassis.

Make sure the ESD wrist strap is correctly grounded.

Figure 1 Attaching an ESD wrist strap to a 12508E

Switch moving

IMPORTANT:

For personal safety, at least four people are required to move a 12518E switch.

When you move an HP 12500E switch, follow these guidelines:

• Remove all the external cables (including the power cords) before moving the chassis.

• For personal safety, have several people to move the switch carefully.

• When moving the switch, hold the handles at both sides of the chassis. Do not hold the plastic panel

of the chassis, the handle of the fan tray, the handle of the back cover of the chassis, or the air vents

2

Page 9

of chassis. Any attempt to carry the switch with these parts might cause equipment damage or even

W

g

p

bodily injury.

Laser safety

ARNING!

Do not stare into any fiber port when the switch has power. The laser li

might hurt your eyes.

Examining the installation site

The HP 12500E Routing Switch Series can only be used indoors. To ensure that th e switch works corre ctly

and to prolong its service lifetime, the installation site must meet the following requirements:

Weight support

Make sure the floor can support the total weight of the rack, chassis, cards, power supplies, and all other

components. Additionally, the floor loading plan must also consider system expansion, such as adding

more cards.

ht emitted from the optical fiber

Temperature

CAUTION:

If condensation appears on the switch when you move it to a high-temperature environment, dry the switch

before powering it on to avoid short circuits.

To ensure the normal operation of the switch, make sure the room temperature meets the requirements

described in Table 1.

Table 1 Temperature r

Tem

erature Range

Operating temperature

Storage temperature –40°C to +70°C (–40°F to +158°F)

Humidity

equirements

• Long term:

0°C to 40°C (32°F to 104°F)

• Short term:

–10°C to +50°C (14°F to 122°F) (no more than 96 hours of

continuous operation in less than 15 days in one year)

• Lasting high relative humidity can cause poor insulation, electricity creepage, mechanical property

change of materials, and metal corrosion.

• Lasting low relative humidity can cause washer contraction and ESD and bring problems including

loose captive screws and circuit failure.

3

Page 10

Maintain appropriate humidity in your equipment room, as described in Table 2.

p

p

p

g

g

Table 2 Humidity requirements

Item S

Operating humidity (noncondensing) 5% to 95%

Storage humidity (noncondensing) 5% to 95%

Operating altitude

Table 3 Operating altitude requirements

Item S

Operating altitude

Cleanness

Dust buildup on the chassis might result in electrostatic adsorption, which causes poor contact of metal

components and contact points, especially when indoor relative humidity is low. In the worst case,

electrostatic adsorption can cause communication failure.

Table 4 Dust concentration limit in the equipment room

ecifications

ecifications

≤ 4000 m (13123.36 ft) (available altitude)

≤ 3000 m (9842.52 ft) (certificated altitude)

EMI

Substance Concentration limit (

Dust particles ≤ 3 x 104 (no visible dust on the tabletop over three days)

NOTE:

Dust particle diameter ≥ 5 μm

articles/m3)

The equipment room must also meet strict limits on salts, acids, and sulfides to eliminate corrosion and

premature aging of components, as shown in Table 5.

Table 5 Harmful gas li

Gas Avera

SO2 0.3 1.0

H2S 0.1 0.5

NO2 0.004 0.15

NH

3

Cl

2

mits in the equipment room

e (mg/m3)Max. (m

1.0 3

0.1 0.3

/m3)

All electromagnetic interference (EMI) sources, from outside or inside of the switch and application

system, adversely affect the switch in a conduction pattern of capacitance coupling, inductance coupling,

4

Page 11

electromagnetic wave radiation, or common impedance (including the grounding system) coupling. To

prevent EMI, take the following actions:

• If AC power is used, use a single-phase three-wire power receptacle with protection earth (PE) to

filter interference from the power grid.

• Keep the switch far away from radio transmitting stations, radar stations, and high-frequency

devices.

• Use electromagnetic shielding, for example, shielded interface cables, when necessary.

• Route interface cables only indoors to prevent signal ports from getting damaged by overvoltage or

overcurrent caused by lightning strikes.

Grounding

Using a good grounding system to protect your switch against lightning shocks, interferences, and ESD

is essential to the operating reliability of your switch.

Make sure the resistance between the chassis and the ground is less than 1 ohm.

Power supply

To meet the power supply requirements:

1. Calculate the system power consumption.

2. Select power modules according to the system power consumption and power supply mode.

3. Verify that the power source on the installation site meets the requirements of the power modules.

For the power consumption and power module specifications of the switch, see "Appendix A Technical

specifications."

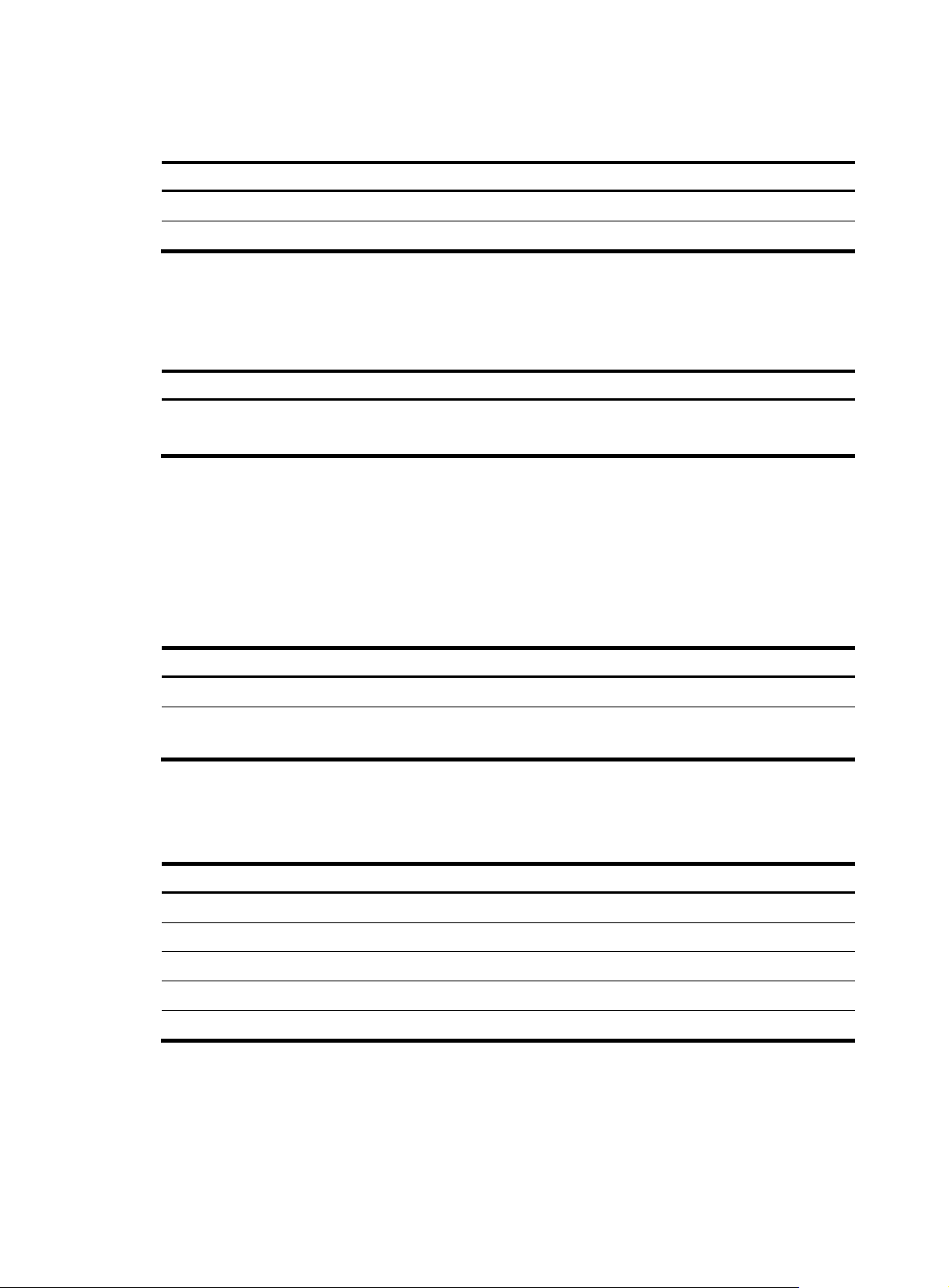

Cooling

Plan the installation site for adequate ventilation.

• Leave at least 10 cm (3.94 in) of clearance around the air intake vents and exhaust vents.

• Equip a good cooling system for the cabinet to install the switch.

• Equip a good cooling system for the installation site.

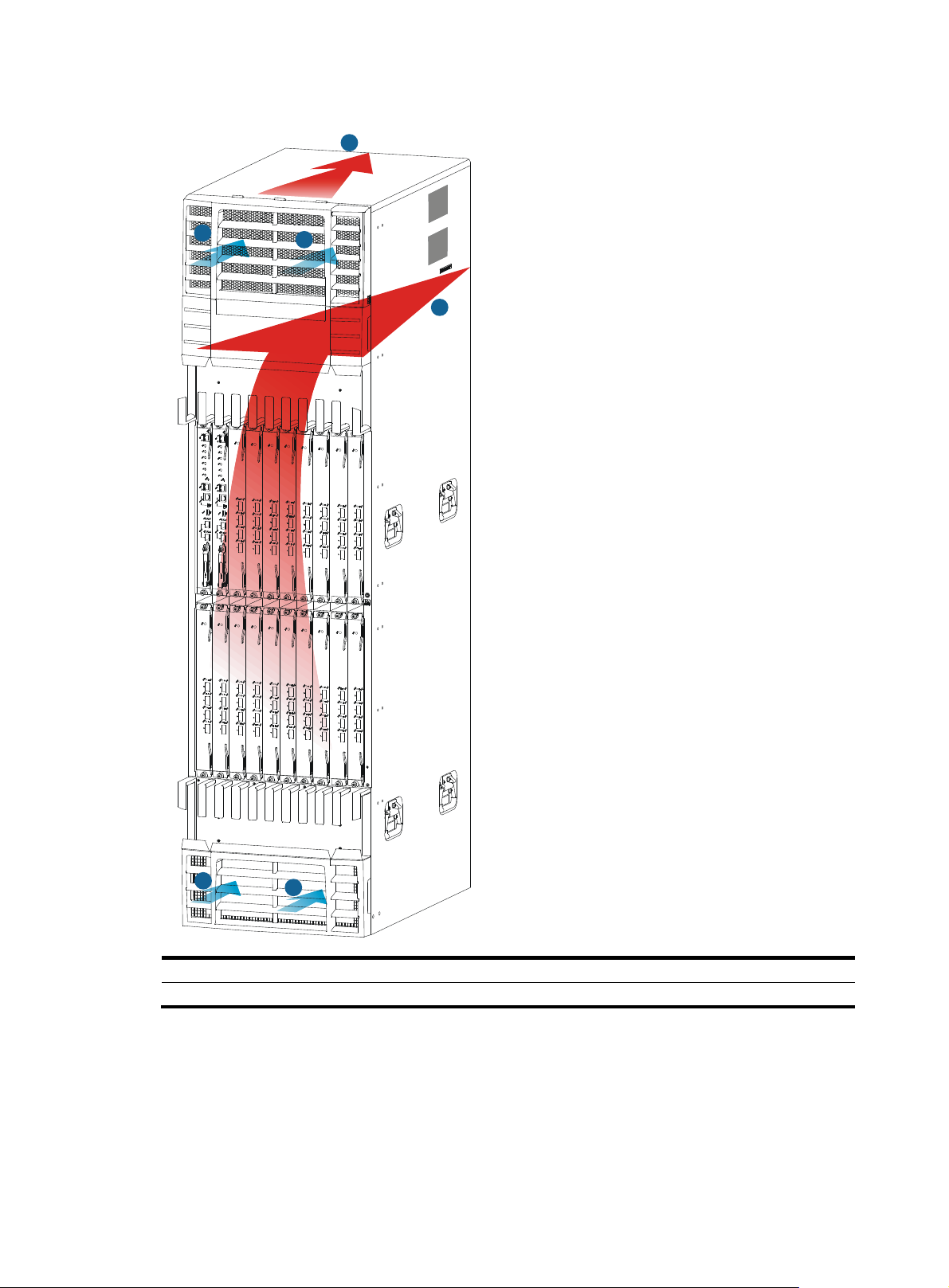

Figure 2, and Figure 3 sho

To ensure normal operation of the switch, make sure the maximum output power of the power

modules is greater than the system power consumption of the switch (reserve certain power for

redundancy). After determining the system power consumption and power supply mode (AC or

DC power supply), you can select power modules as needed.

Make sure the power source of the installation site is steady and can meet the requirements of the

power modules, including the input method and rated input voltage.

w the ventilation of the 12508E, and 12518E.

5

Page 12

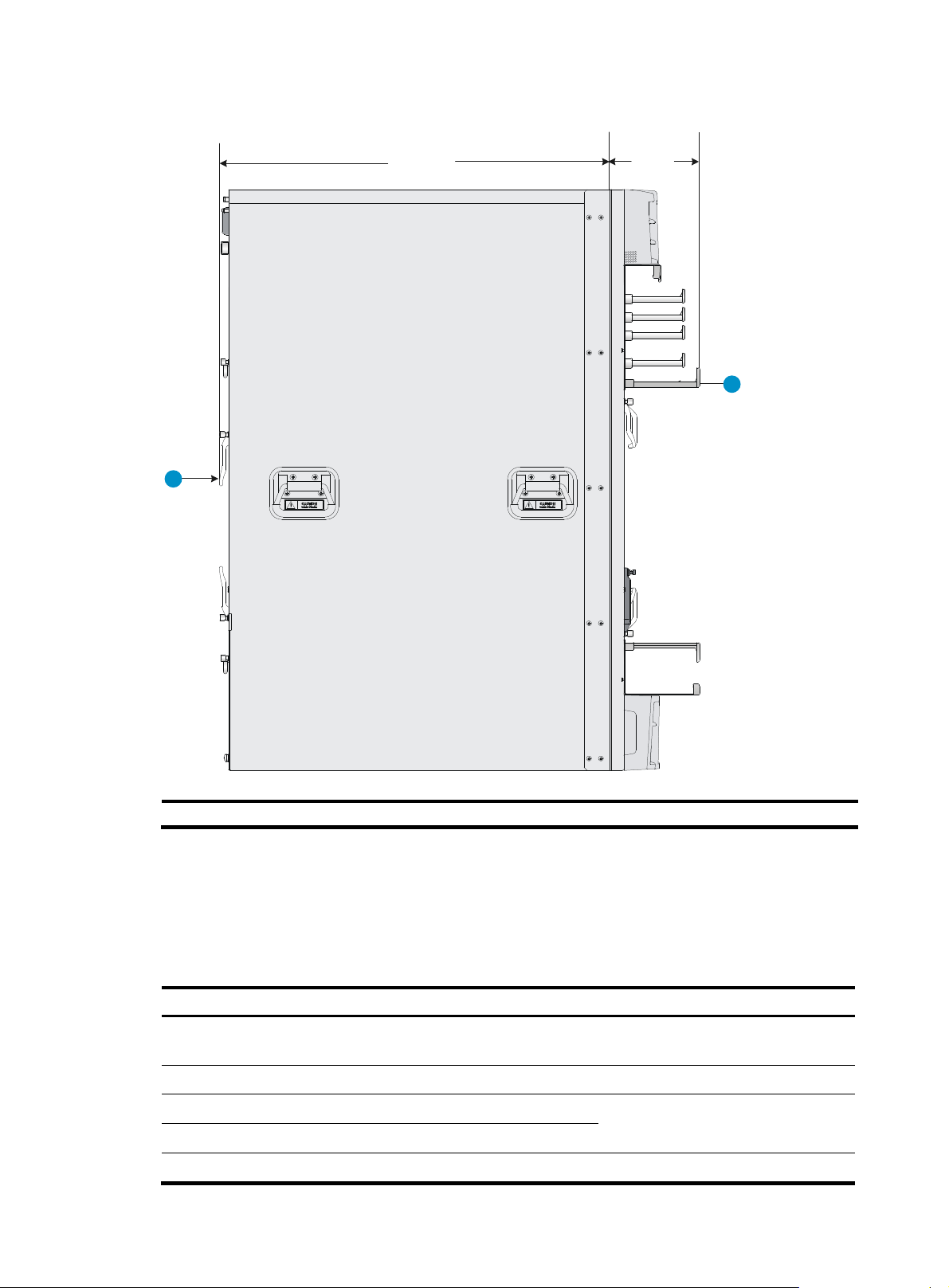

Figure 2 Airflow through a 12508E chassis

(1) Air intake direction of the chassis (2) Air exhaust direction of the chassis

(3) Air intake direction of the power supplies (4) Air exhaust direction of the power supplies

6

Page 13

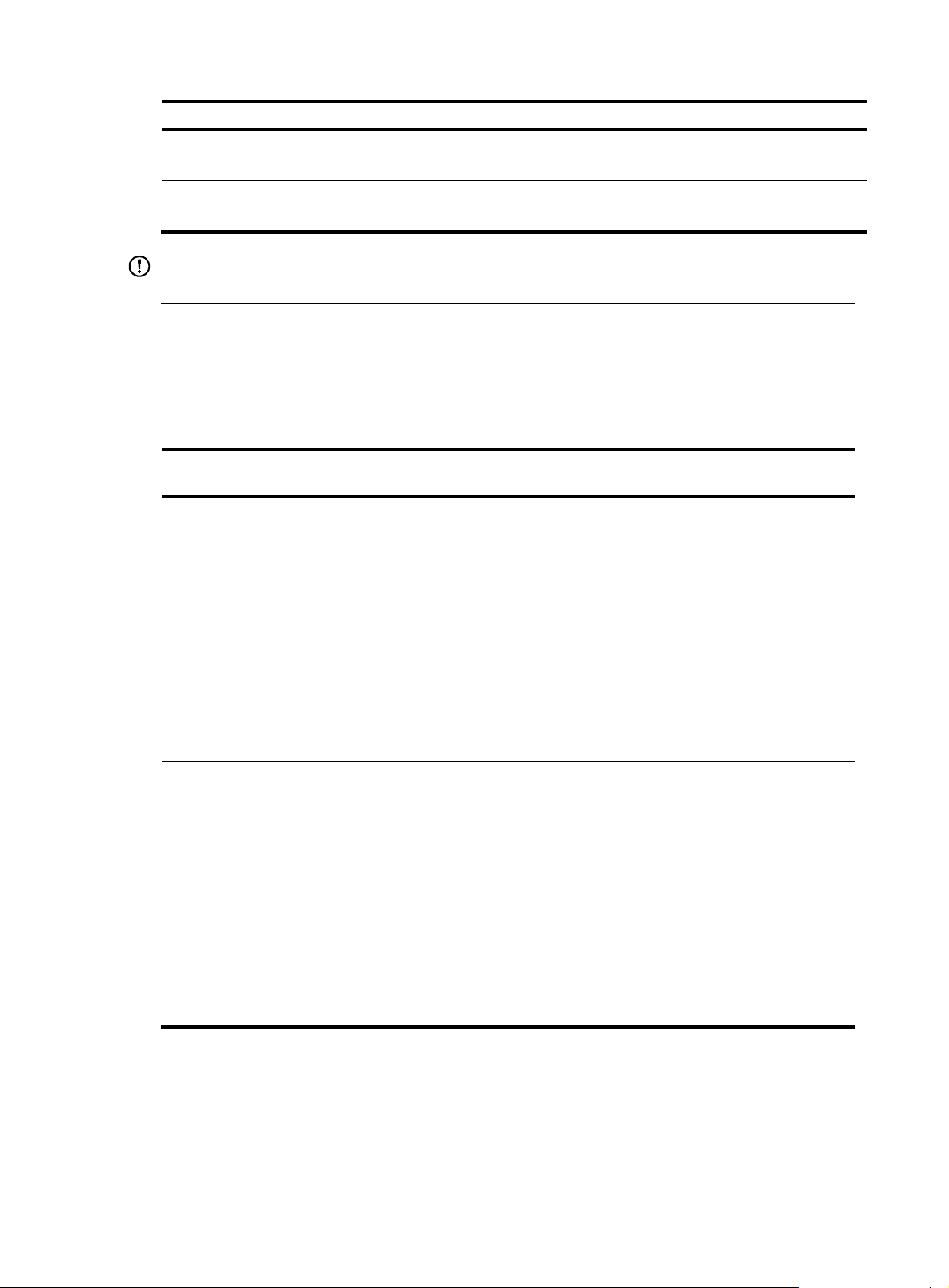

Figure 3 Airflow through a 12518E chassis

4

3

3

2

Space

For easy maintenance, follow these guidelines:

1

1

(1) Air intake direction of the chassis (2) Air exhaust direction of the chassis

(3) Air intake direction of the power supplies (4) Air exhaust direction of the power supplies

7

Page 14

Installation method Space requirements

q

Workbench-mounting

Rack-mounting

IMPORTANT:

• Width of the aisle: ≥ 0.8 m (2.62 ft)

• Clearance between the rack and walls or other devices: ≥ 0.8 m (2.62 ft)

• Clearance between the rack and walls or other devices: ≥ 1.0 m (3.28 ft)

• Equipment room height: ≥ 3 m (9.84 ft)

Follow the rack clearance requirements to make sure the switch does not block the rack doors.

HP recommends that you use a rack with a depth of 1.2 m (3.94 ft) for rack-mounting the switch. For the

chassis space requirements and rack clearance requirements, see Table 6, Figure 5, Figure 6, and Figure

7. F

or more information about switch dimensions, see "Appendix A Chassis views and technical

specifications."

Table 6 Rack mounting space requirements

Model Chassis space requirements

• Height:

{ 12508E: 975 mm (38.39 in)/22 RU

{ 12518E: 1686 mm (66.38 in)/38 RU

• Width: 442 mm (17.40 in)

• Depth:

12508E/12518E AC

{ 859 mm (33.82 in) on switches

installed with cable management

brackets

{ 913 mm (35.94 in) on switches

installed with expansion cable

management brackets

• Height:

{ 12508E: 975 mm (38.39 in)/22 RU

{ 12518E: 1686 mm (66.38 in)/38 RU

• Width: 442 mm (17.40 in)

• Depth:

12508E/12518E DC

{ 759 mm (29.88 in) on switches

installed with cable management

brackets

{ 813 mm (32.01 in) on switches

installed with expansion cable

management brackets

Minimum rack clearance

re

uirements

• Distance between the front rack

post and the inner side of the front

door:

{ 100 mm (3.94 in) on switches

installed with cable

management brackets

{ 154 mm (6.06 in) on switches

installed with expansion cable

management brackets

• Distance between the front rack

post and inner side of the rear door:

769 mm (30.28 in) (Including the

space for cabling power cords.)

• Distance between the front rack

post and the inner side of the front

door:

{ 100 mm (3.94 in) on switches

installed with cable

management brackets

{ 154 mm (6.06 in) on switches

installed with expansion cable

management brackets

• Distance between the front rack

post and inner side of the rear door:

709 mm (27.91 in) (Including the

space for cabling power cords.)

8

Page 15

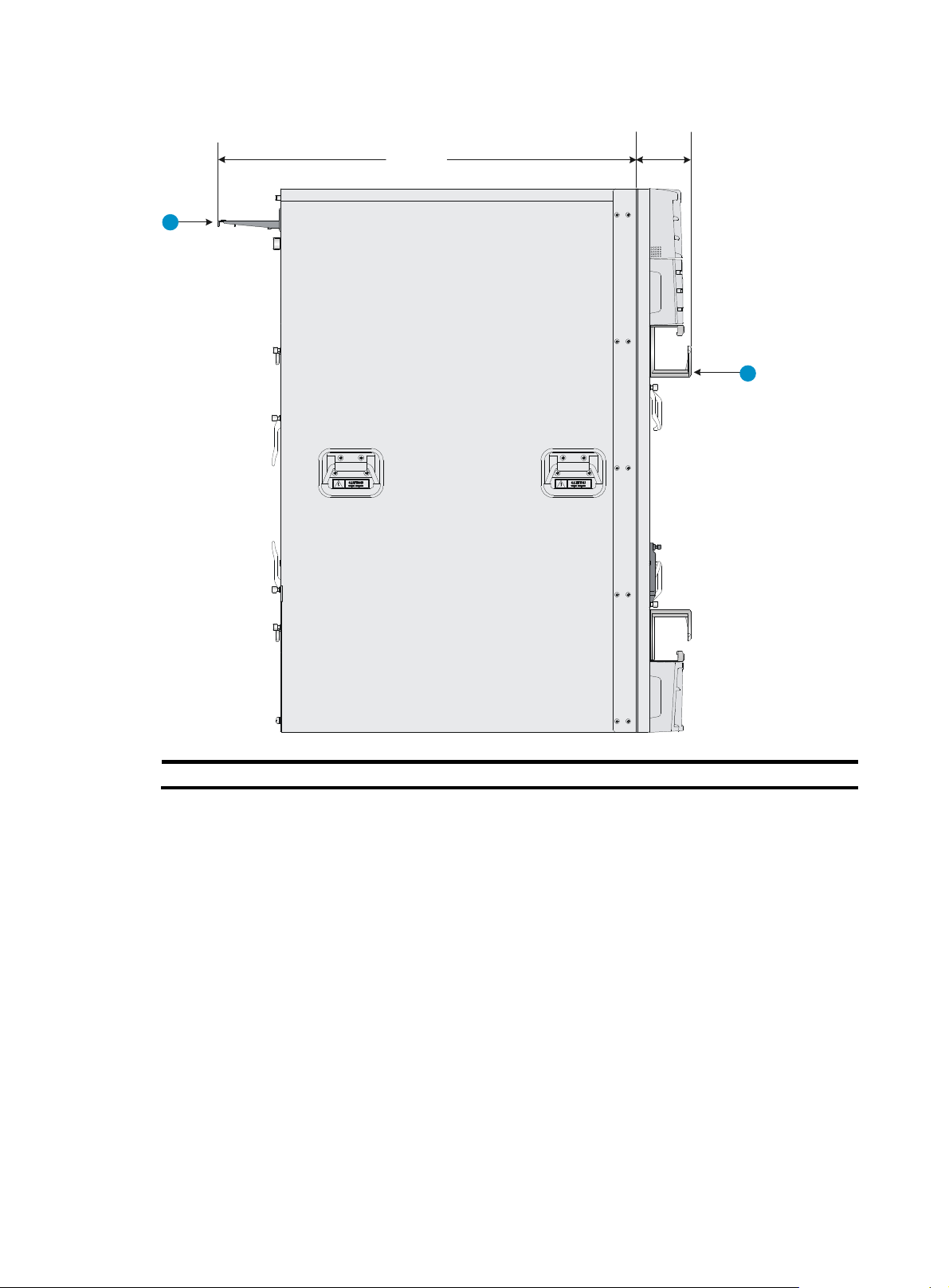

Figure 4 Depth for the 12508E/12518E AC chassis with cable management brackets

759 mm

(29.88 in)

100 mm

(3.94 in)

1

2

(1) Power cabling rack (2) Cable management bracket

9

Page 16

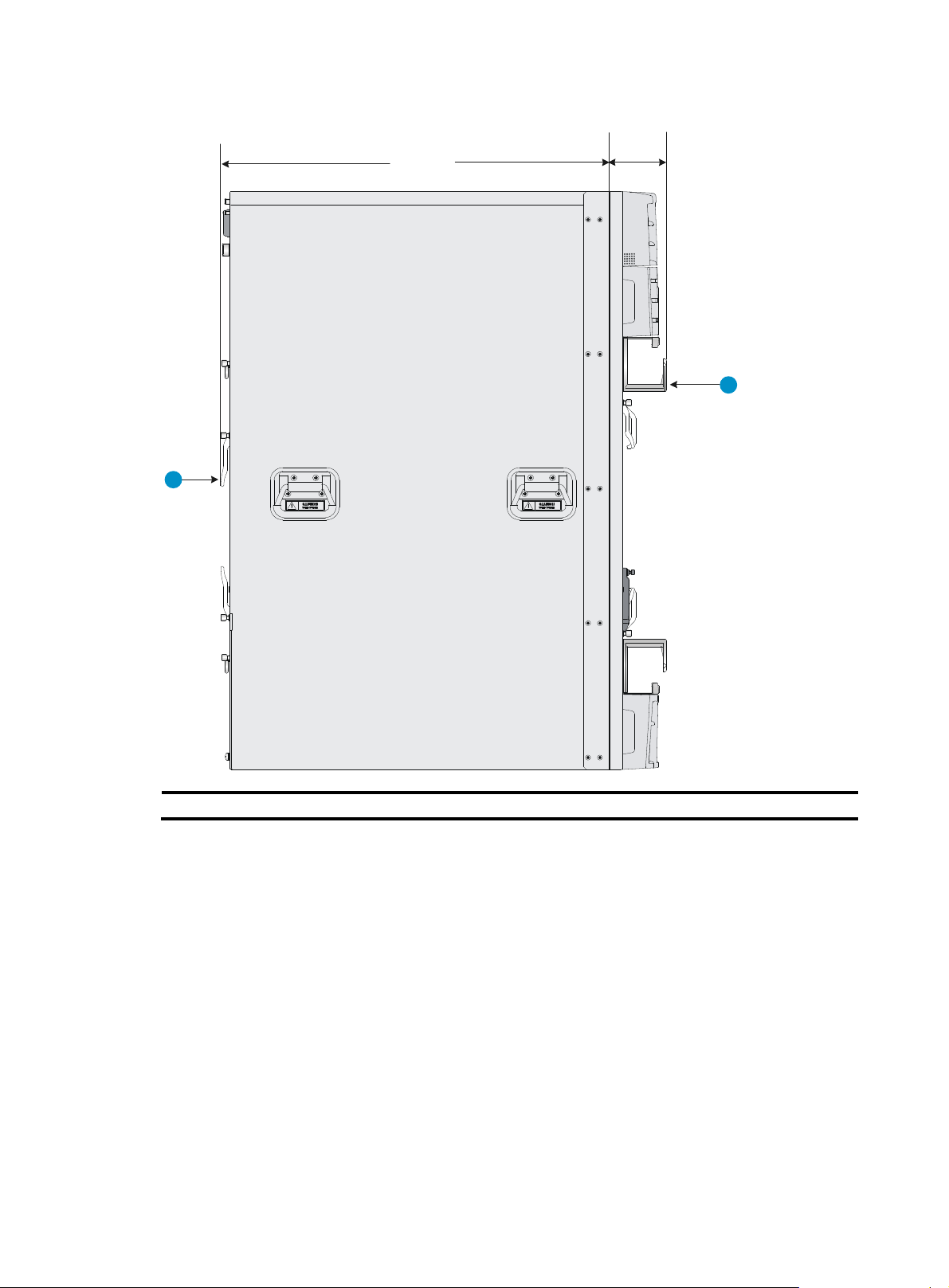

Figure 5 Depth for the 12508E/12518E DC chassis with cable management brackets

659 mm

(25.94 in)

1

100 mm

(3.94 in)

2

(1) Ejector lever on the switching fabric module (2) Cable management bracket

10

Page 17

Figure 6 Depth for the 12508E/12518E AC chassis with expansion cable management brackets

759 mm

(29.88 in)

1

154 mm

(6.06 in)

2

(1) Power cabling rack (2) Expansion cable management bracket

11

Page 18

Figure 7 Depth for the 12508E/12518E DC chassis with expansion cable management brackets

y

659 mm

(25.94 in)

1

154 mm

(6.06 in)

2

(1) Ejector lever on the switching fabric module (2) Expansion cable management bracket

Installation tools

You can use the following tools for installation.

Accessories supplied by the switch

Item Quantit

Console cable 1

Grounding cable 1 Grounds the switch.

M6*12 screw 1 set

M6 cage nut 1 set

ESD wrist strap 2 ESD prevention.

Purpose

Connects the console port and the

configuration terminal for switch login.

Secures the switch to the rack.

12

Page 19

Item Quantit

y

g

Purpose

AC/DC power cord

Cable tie Several

NOTE:

The number of screws, nuts, and cable ties supplied with the switch depends on those shipped from the

factory.

User-supplied tools and equipment

• Mechanical lift

• Phillips screwdriver P1 – 100 mm, P2 – 150 mm, and P3 – 250 mm

• Flat screwdriver P4 – 75 mm

• Marker

• Tape

• Diagonal pliers, wire-stripping pliers, and wire clippers

• Socket wrench

Same as the number of power

modules

Transmits the power

Organizes and secures AC power

cords.

Supplied with the 12508E and

12518E switches.

• Cables such as network cables and fiber cables

• Meters and equipment, such as hub and multimeter

• Configuration terminal, such as PC

NOTE:

The rack accessories and installation tools are not included in this section. They mi

the rack model. For more information, see the installation guide of the corresponding rack.

ht vary depending on

13

Page 20

W

g

Installing the switch

ARNING!

To avoid bodily injury, do not touch any wire, terminal, or part marked with a high-volta

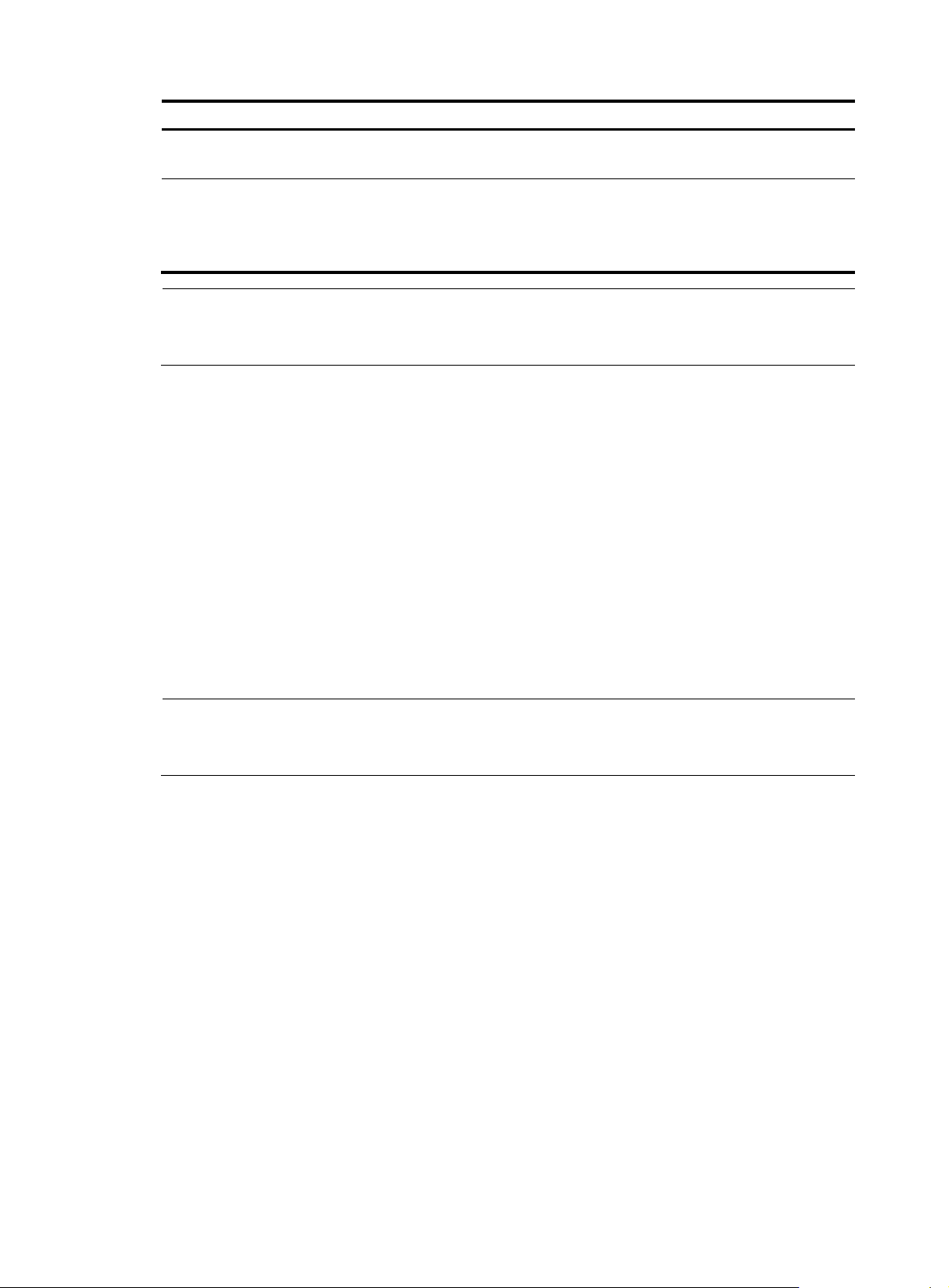

Figure 8 Switch installation procedure

Start

Remove the power frame mounting brackets

e hazard sign.

Install an expansion cable

management bracket (optional)

Determine the

installation method

Install the switch to a rack

Ground the switch

Install a power module

Install a fan tray

Connect the power cord

Install a chassis air filter

(optional)

Mount the switch on a

workbench

Install a card

Verify the installation

End

Confirming installation preparations

Before installing an HP 12500E switch, verify that:

• You have read "Preparing for installation" carefully and the installation site meets all the

requirements.

14

Page 21

• You have all the items listed in the packing list, and the switch was not damaged during shipment.

If anything is damaged or missing, contact the sales agent or customer representative immediately.

For regulatory compliance and safety information, see "Regulatory compliance and safety information."

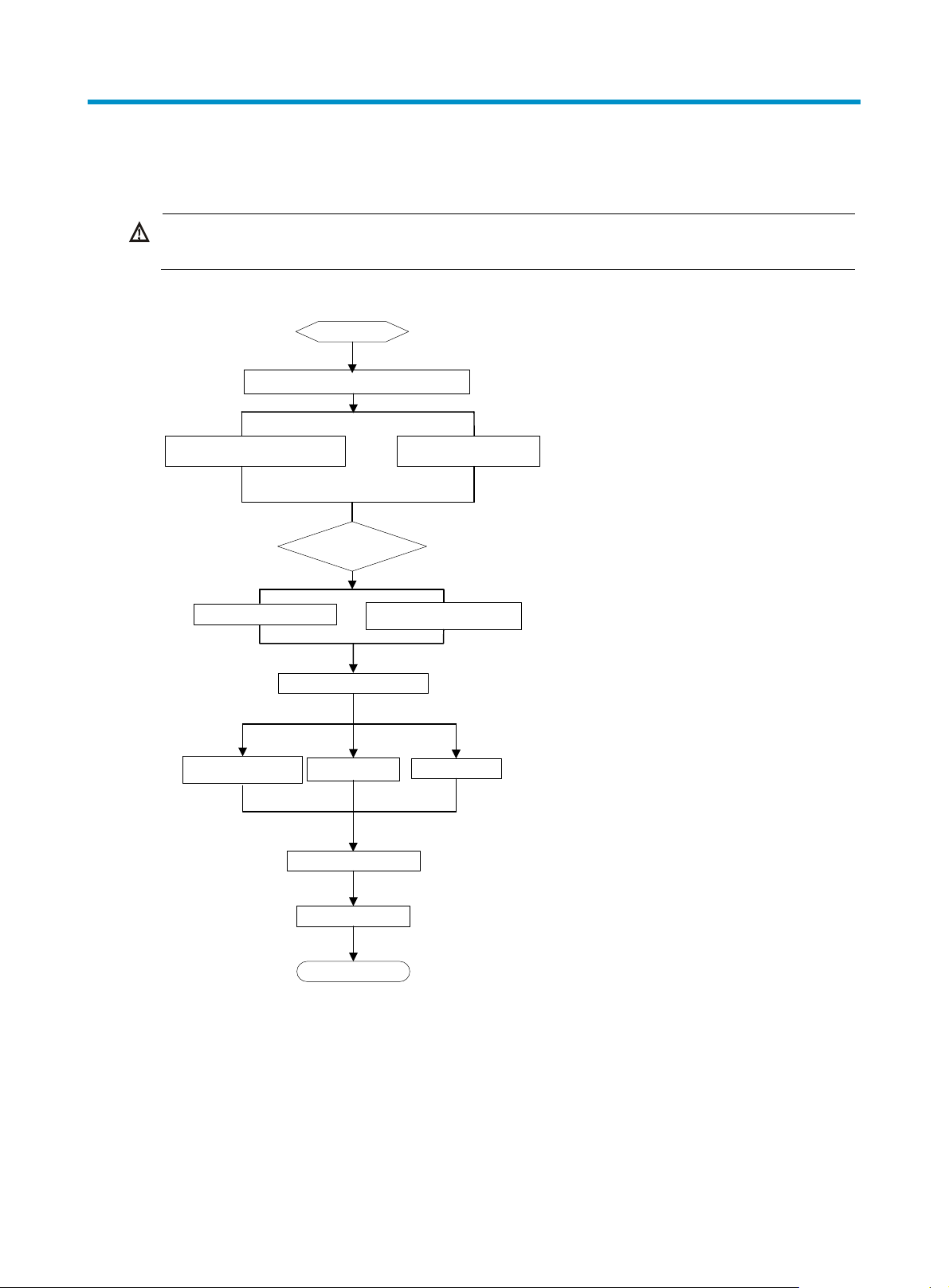

Removing the power frame mounting brackets

The mounting brackets are used to fix the power frame and to protect the frame during transportation. To

ensure smooth installation, remove the mounting brackets from the power frame with a Phillips

screwdriver before you install the switch in the rack. A switch cannot be installed in a rack if the mounting

brackets are not removed.

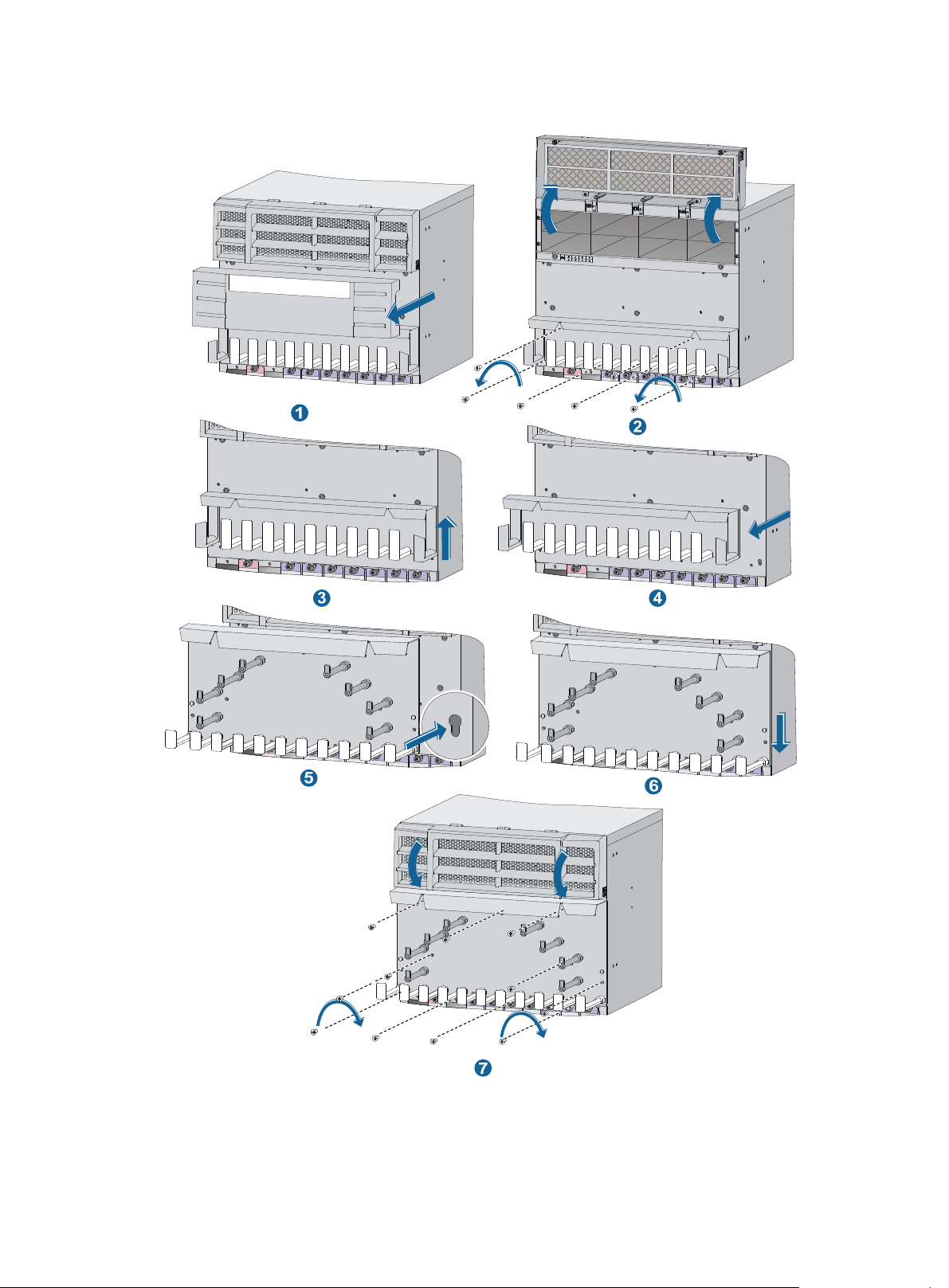

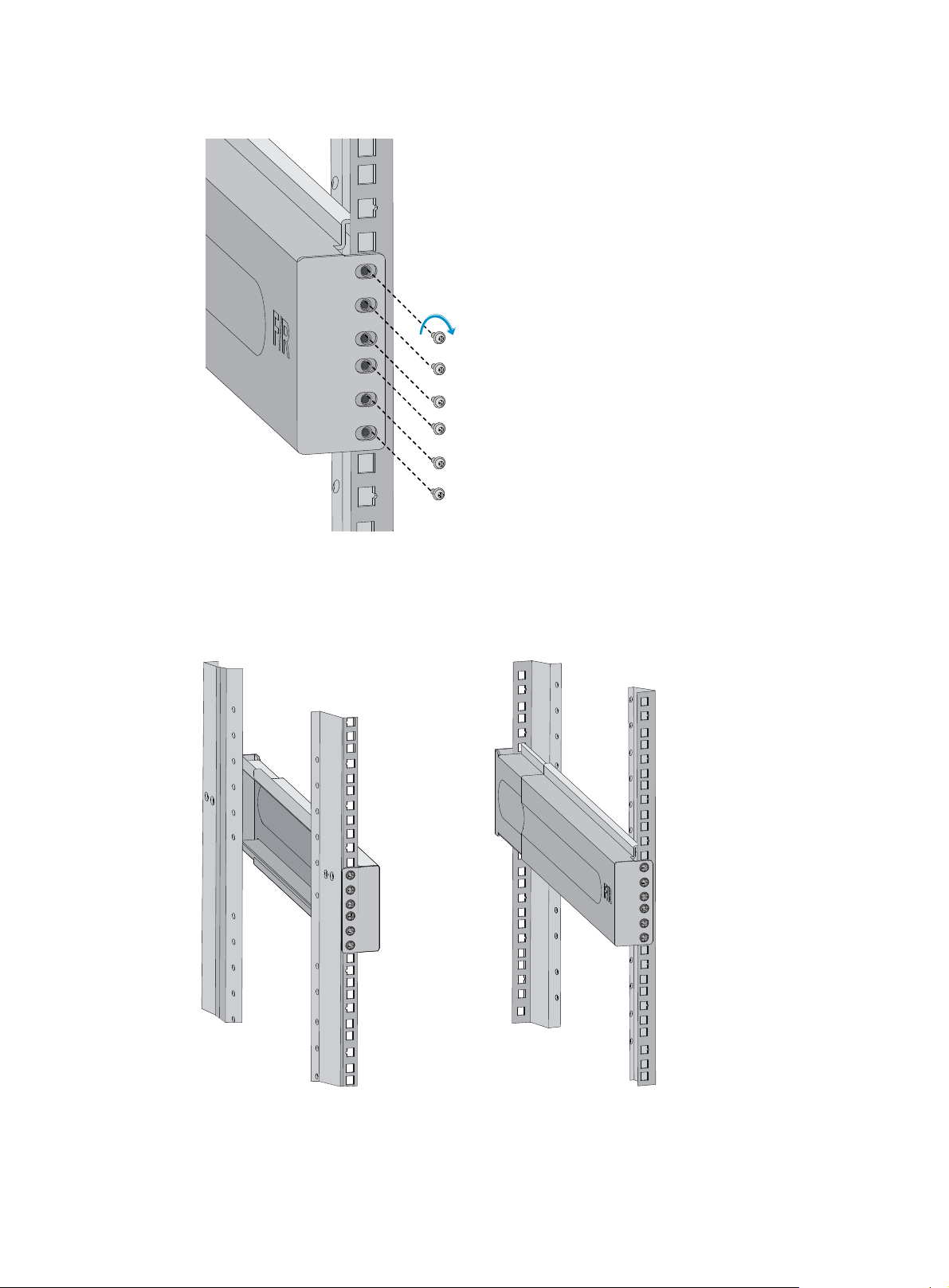

Figure 9 Removing the power frame mounting brackets

Installing an expansion cable management bracket (optional)

Each 12508E and 12518E switch provides two types of chassis cable management brackets. You can

select either type as needed.

• Cable management brackets—Shipped with the switch. For more information, see " Chassis views

and technical specifications."

• Expansion cable management brackets—Upper cable management bracket with a mark, and

lower cable management bracket with no mark. They are installed in the same positions as the

cable management brackets shipped with the switch except that they can route more cables.

To install expansion cable management brackets, remove the cable management brackets shipped with

the switch first.

Installation preparation

1. Wear an ESD wrist strap and make sure the wrist strap is well grounded.

2. Unpack the expansion cable management brackets.

15

Page 22

IMPORTANT:

• Make sure no filler panel or card is installed on the front panel of the switch before you remove or

install a lower cable management bracket.

• Keep the removed chassis panel and cable management brackets for future use.

Installation procedure

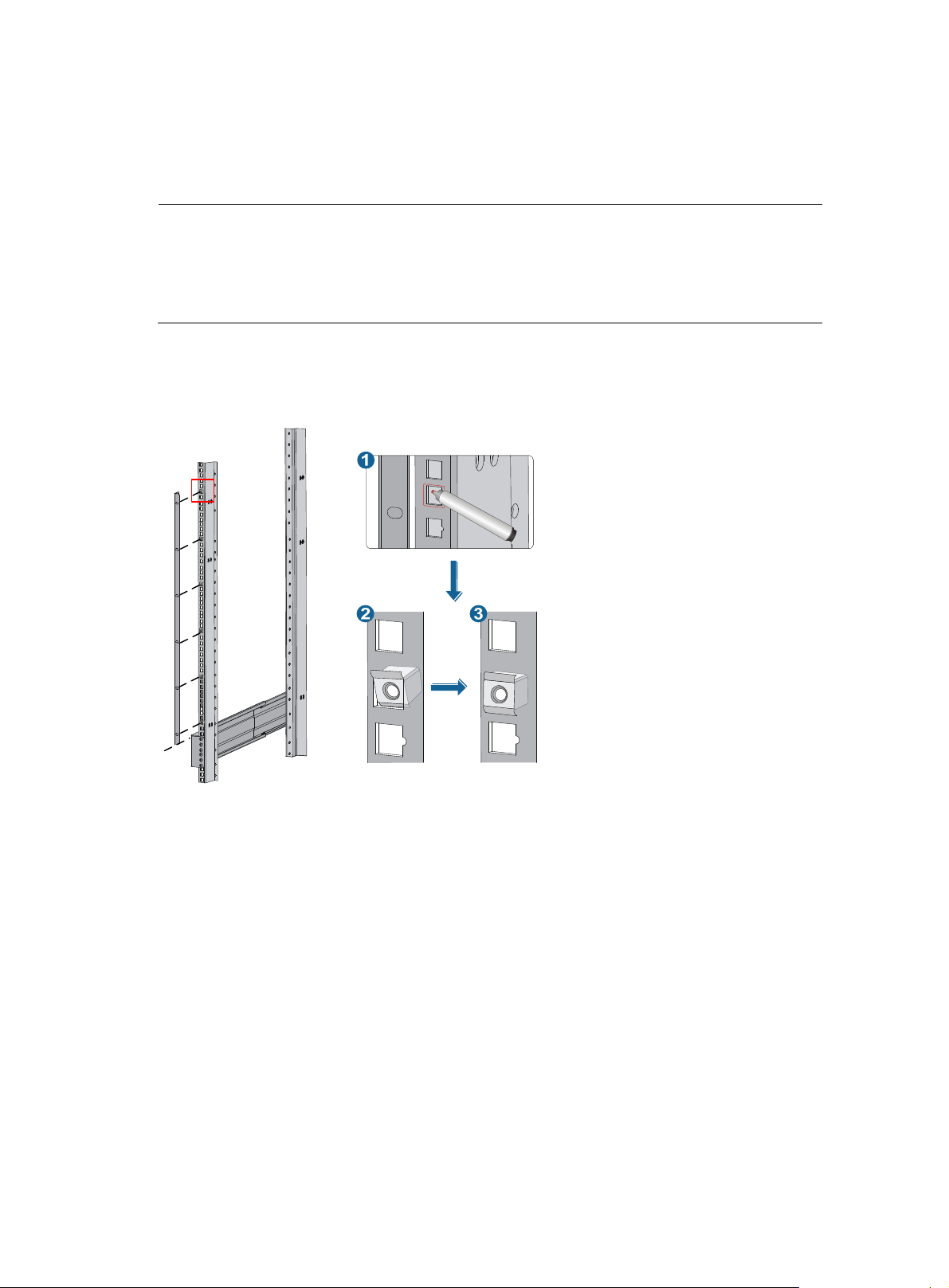

Each 12500E switch has keyhole standoffs on its cable management bracket and keyholes on the chassis

for securing the cable management bracket to the chassis. See Figure 10.

Figure 10 K

(1) Keyhole standoff (2) Keyhole

eyhole standoff and keyhole

Installing an upper expansion cable management bracket

1. Holding the notches on both sides of the chassis panel above the upper cable management

bracket, gently remove the panel.

2. Pressing the two sides of the front panel, pivot the power frame front panel upward.

3. Loosen the fastening screws on the upper cable management bracket with a Phillips screwdriver.

4. Align the keyhole standoffs on the rear of the cable management bracket with the keyholes on the

chassis and remove the cable management bracket.

5. Align the keyhole standoffs on the upper expansion cable management bracket (with a mark) with

the keyholes on the chassis.

6. Push the expansion cable management bracket forward until it makes close contact with the chassis.

Then pull the expansion cable management bracket downwards a little until the keyhole standoff fits

into the keyhole on the chassis.

7. Unpack the screws come with the expansion cable management bracket and fasten them with a

Phillips screwdriver to secure the expansion cable management bracket to the chassis.

8. Close the power frame front panel.

16

Page 23

Figure 11 Installing an upper expansion cable management bracket

Installing a lower expansion cable management bracket

1. Remove the filler panel or card on the front panel. For how to remove them, see "Replacement

procedures."

17

Page 24

2. Loosen the fastening screws on the lower cable management bracket with a Phillips screwdriver.

3. Align the keyhole standoffs on the rear of the lower cable management bracket with the keyholes

on the chassis and remove the cable management bracket.

4. Align the keyhole standoffs on the lower expansion cable management bracket (with no mark)

with the keyholes on the chassis.

5. Push the expansion cable management bracket forward until it makes close contact with the chassis.

Then pull the expansion cable management bracket downwards until the keyhole standoff fits into

the keyhole on the chassis.

6. Unpack the screws come with the expansion cable management bracket and fasten them with a

Phillips screwdriver to secure the expansion cable management bracket to the chassis.

7. Install the removed filler panel or card. For more information, see "Installing a card."

For illustration of the installation procedure for a lower cable management bracket, see callouts 2 to 7

in Figure 11.

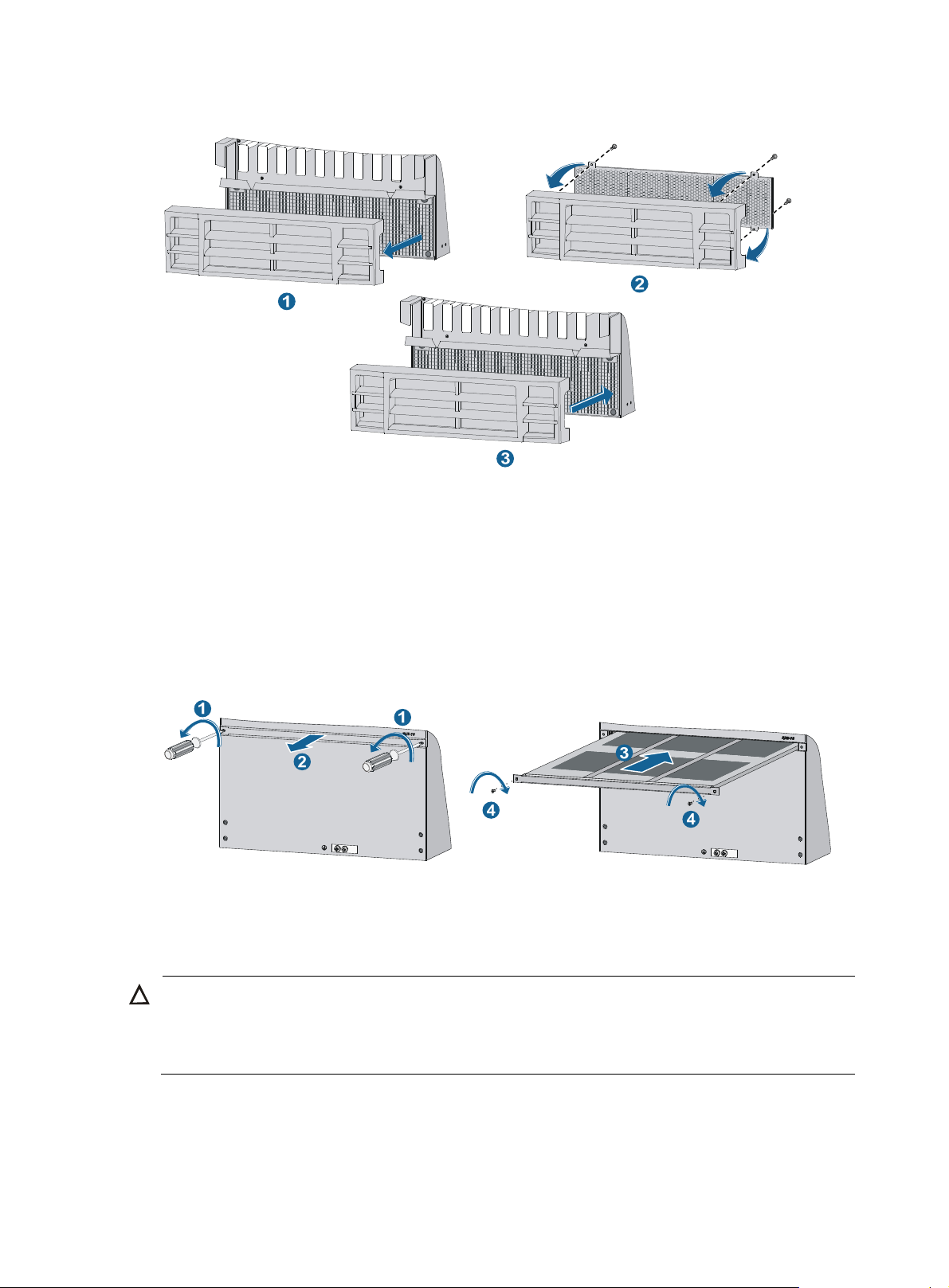

Installing a chassis air filter (optional)

Chassis air filters are installed at the air intake vents to prevent dust from entering the chassis. Chassis air

filters of the 12500E switches are optional. You can order them as needed.

If you have ordered chassis air filters, HP recommends you to install the air filters before mounting the

switch to the rack.

• 12 50 8 E —The air filter is located at the front of the chassis. For the installation procedures, see

"Installing an air filter on a 12508E."

• 12

Installing an air filter on a 12508E

1. Hold the notches of the front plastic panel at the bottom part of the chassis, and gently pull the

518 E —The air filter is located at the rear of the chassis. For the installation procedures, see

"Installing an air filter on a 12518E."

plastic panel out.

2. Unpack the air filter, attach it to rear of the plastic panel, align installation holes on the air filter

with the screw holes on the plastic panel, and secure the air filter to the plastic panel with screws.

3. Mount the plastic panel back to the chassis.

18

Page 25

W

A

Figure 12 Installing an air filter

Installing an air filter on a 12518E

1. Use a Phillips screwdriver to loosen the screws at both sides of the plastic panel and remove the

panel.

2. Insert the air filter into the rear of the chassis along the slide rails, and then fasten the screws at both

sides of the air filter.

Figure 13 Installing an air filter

Installing the switch in a rack

CAUTION:

hen moving the switch, hold the handles at both sides of the chassis. Do not hold the plastic panel of the

chassis, the handle of the fan tray, the handle of the back cover of the chassis, or the air vents of chassis.

ny attempt to carry the switch with these parts might cause equipment damage or even bodily injury.

Installation preparation

Confirm the following preparations before starting installation:

19

Page 26

A

• The rack is sturdy and securely grounded.

• There is sufficient clearance of 0.8 m (2.62 ft) around the rack for heat dissipation and installation.

• There is no debris inside or around the rack.

• The total height of the switches to be installed is no higher than the height of the rack and enough

clearance is reserved for cable routing.

• Make sure the clearance above the slide rail is sufficient for the switch and the slide rails can

support the weight of the switch. For the dimensions and weight of the 12500E switch, and the

weight of the hardware components, see "Appendix A Technical specifications."

Installing slide rails and cage nuts to the rack

Before installing the switch in the rack, secure slide rails to the rack. Besides slide rails, you can use a rack

shelf to support the switch. This document describes how to install slide rails only.

To ensure correct installation, use industry-standard slide rails or rack shelves. Slide rails or rack shelves

are not provided with the switch. HP recommends that you order HP slide rail LSTM2KSGD0. The slide

rail can be used in racks where the distance between the front and rear rack posts is in the range of 500

mm to 800 mm (19.69 in to 31.50 in).

Installing slide rails

If the rack has slide rails, skip this section.

The appearance and installation methods of slide rails depend on the slide rail types.

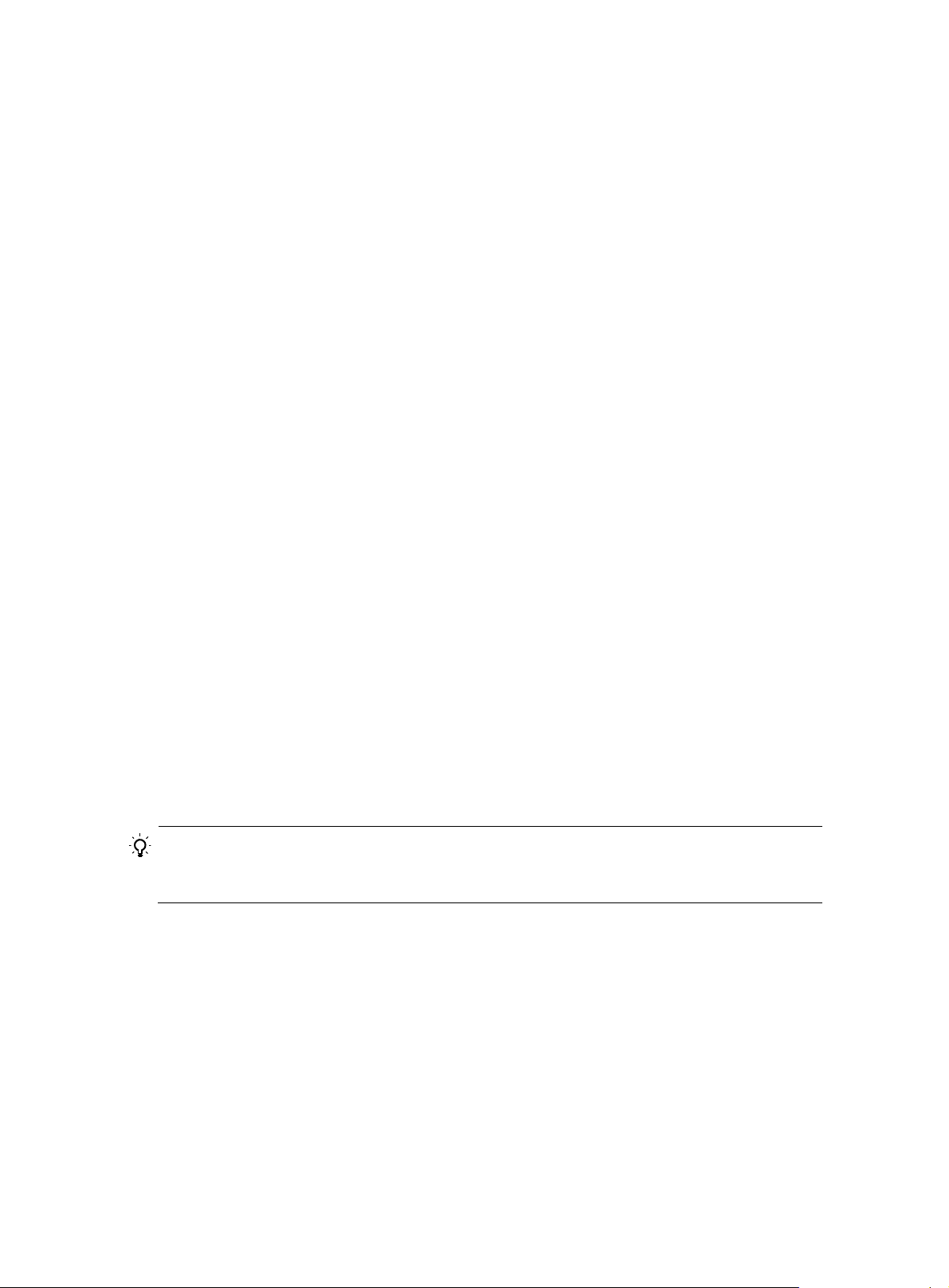

This section uses a 19-inch rack as an example to describe the installation procedures. The rack unit (RU)

(44.45 mm, or 1.75 in) measures the height of rack posts. As shown in Figure 14, eac

h 1 RU has three

mounting holes with center-to-center separations of 15.88 mm (0.63 in), 15.88 mm (0.63 in), and 12.70

mm (0.5 in). When installing the slide rails, make sure the bottom edge of the slide rails aligns with the

middle of the narrowest separation between mounting holes.

To install the slide rails:

1. Mark the position of the slide rail on the rack posts. Make sure the bottom edge of the slide rails

or rack shelf aligns with the middle of the narrower metal area between holes as shown in Figure

14.

TIP:

total of six screws are required within the 2 RU of installation space for each side of the slide rail.

You can mark the position for the top cage nut only.

20

Page 27

Figure 14 Locating the installation position of the slide rails

(1) Middle of the narrower metal area between holes

2. Install the cage nuts on the rack posts.

a. Insert the upper ear (callout 1 in Figure 15) of a cage

nut into the corresponding installation

hole.

b. Push the cage nut to lead its lower ear (callout 2 in Figure 15) into th

e same hole.

c. Repeat steps a and b to complete installation of 24 cage nuts on the rack post. (Six cage nuts

for each rack post.

Figure 15 Installing the cage nuts

3. Align the screw holes on the two sides of the right slide rail (marked with F/R) with the marked

holes on the right rack posts, and then fasten the screws.

21

Page 28

Figure 16 Fastening the screws

4. Use the same method described in step 3 to install the left slide rail to the left rack posts.

Keep the two slide rails at the same height so that the switch can be placed evenly.

Figure 17 Slide rails installed correctly

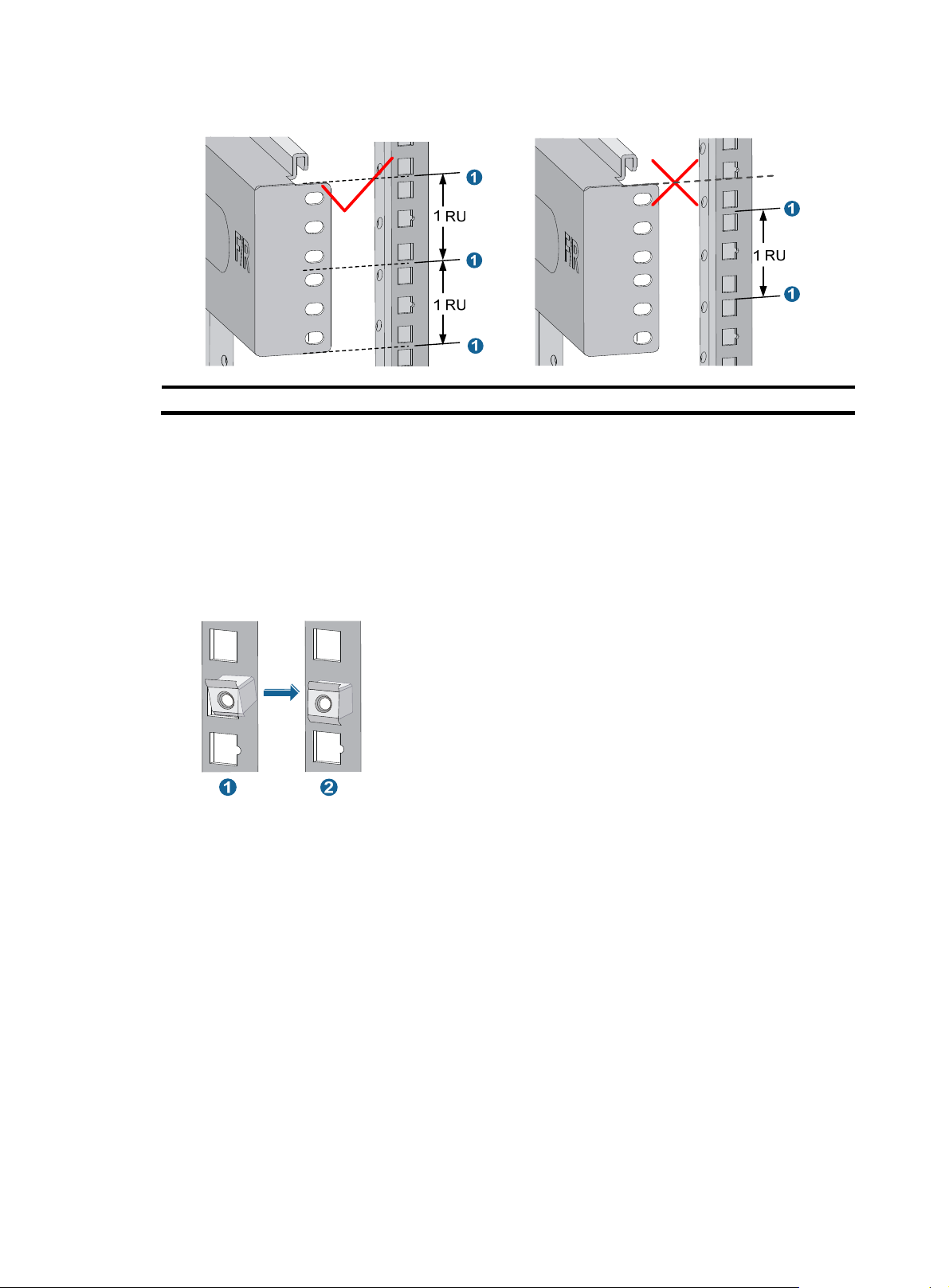

Installing cage nuts

Before mounting the chassis to the rack, install cage nuts to the front square-holed brackets of the rack.

22

Page 29

g

To install cage nuts to the rack:

1. Align the mounting bracket with the left rack post, making sure its bottom edge and the slide rail

are level. Mark the positions of the cage nuts on the rack post according to the mounting holes on

the mounting bracket. (Each mounting hole on the mounting bracket corresponds to one cage nut.)

NOTE:

The mounting brackets are fixed on the chassis of the 12508E and 12518E before delivery from the

factory. To determine the installation holes for cage nuts, you can remove a mountin

bracket from

the chassis and mark the nut holes, or use a pattern tool to record the installation holes of the

mounting brackets and mark the nut holes accordingly.

2. Install cage nuts to the rack posts using the method described in relevant steps in "Installing slide

rails."

Figure 18 Installing the

cage nuts

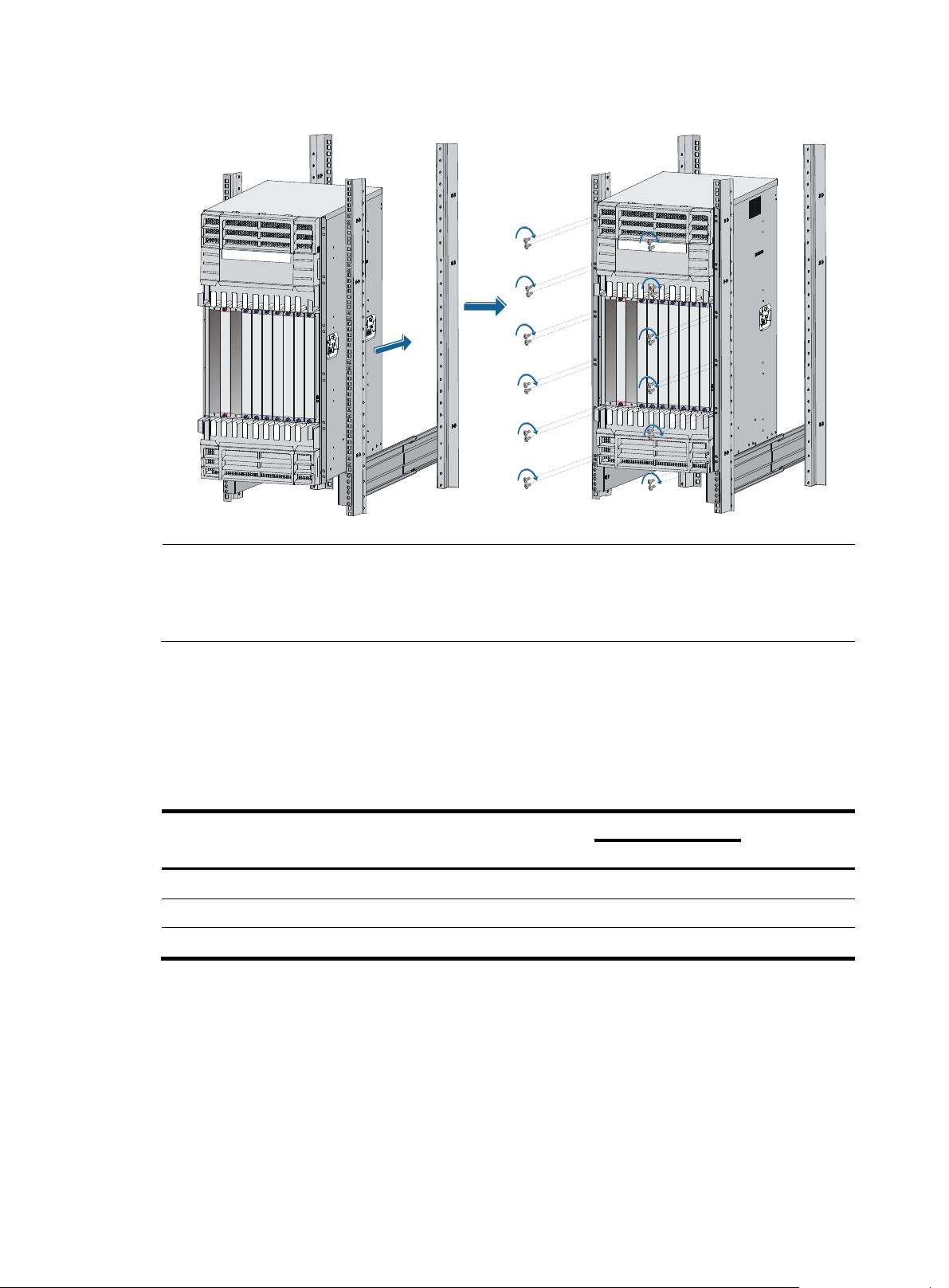

Mounting the switch in the rack

Before yo u mount the swi tch in the rack, make sure yo u have ins talled s lide rai ls o r a rack sh elf on the rack

for supporting the switch.

To maximize the stability of the rack, mount the heaviest switch at the bottom of the rack when you install

multiple switches on the rack.

To mount the switch in the rack:

1. Cooperate with several people to place the switch on the slide rails or rack shelf and slide the

switch into the rack until the mounting brackets on the switch touch the front rack posts.

2. Attach the mounting brackets to the rack posts with mounting screws. See Figure 19.

23

Page 30

Figure 19 Installing the switch in a standard 19-inch rack (for the 12508E)

NOTE:

If the screw holes on the mounting brackets cannot align with the cage nuts on the rack, verify that the

bottom edge of the slide rail aligns with the middle of the narrowest metal area between mounting holes

and that the cage nuts are installed in the correct holes.

Verifying the installation

After the installation is completed, check the installation against the following checklist. Make sure all

check results are positive.

Table 7 Installation checklist

Result

Item

Yes No

The mounting brackets are firmly attached to the switch.

The switch is sturdy and installed in the right position.

The mounting brackets on the switch are firmly attached to the rack.

Installing the switch on a workbench

Remarks

You can install the switch on a clean, sturdy workbench or on the floor if no rack is available for switch

installation at the site.

24

Page 31

A

A

Installation preparation

Before placing the switch on a workbench or on the floor, confirm the following preparations:

• The workbench or floor is sturdy enough to support the weight of the chassis and its accessories.

• The workbench or floor is correctly grounded.

• The wall anchors are installed.

a. Position the installation holes and drill holes.

Make sure each hole is exact in diameter and depth for the anchor.

b. Assemble each wall anchor by inserting the spade-shaped wedges on the plug into the

grooves on the shank.

c. Put the assembled wall anchors into installation holes and hammer them into the ground.

Figure 20 Installing the wall anchor

(1) Shank (2) Groove

(3) Plug (4) Spade-shaped wedge

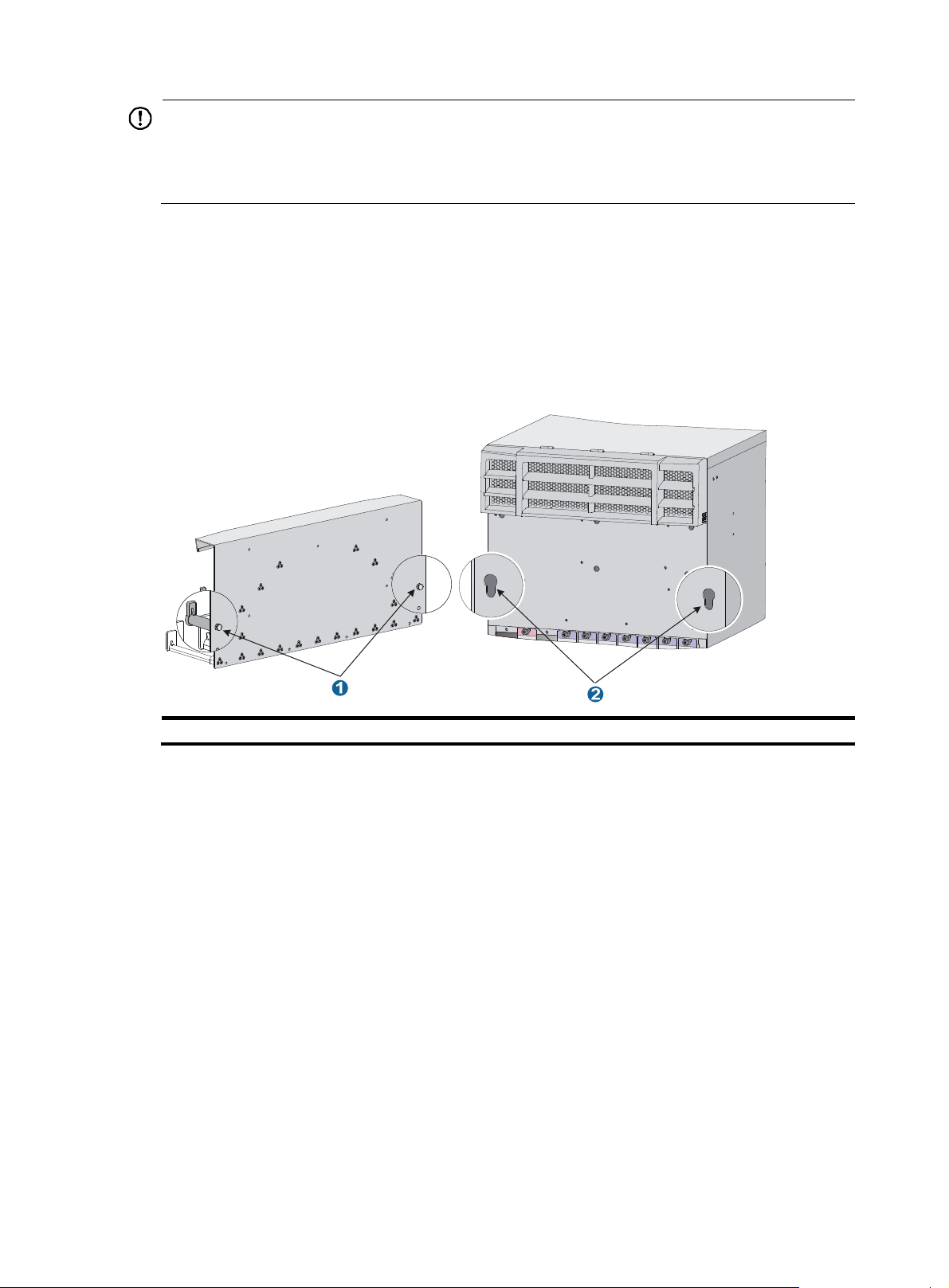

Installation procedures

IMPORTANT:

llow 0.8 m (2.62 ft) of clearance around the switch for heat dissipation.

To install the switch:

1. Hold the two sides of the switch and steadily move the switch to the workbench.

2. Lift the switch a little higher than the workbench and put it on the workbench.

3. (Optional.) Install the cable management brackets on both sides of the switch and fasten the

screws, as shown in Figure 21.

NOTE:

The circled areas in Figure 21 are the cable management bracket installation holes.

12508E or 12518E switch has one column of installation holes.

25

Page 32

Figure 21 Installing cable management brackets on both sides of the switch

1

2

(1) Installation holes (2) Cable management brackets

4. Secure the L-shaped bracket to the switch.

5. Move the switch to make sure holes in the L-shaped bracket align with wall anchor holes in the

ground.

6. Insert the anchor bolts in the holes, and use a wrench to fasten the bolts.

26

Page 33

W

g

g

g

Figure 22 Installing L-shaped brackets

(1) Anchor bolt (2) L-shaped bracket

Grounding the switch

ARNING!

For the safety of operators and equipment, securely

between the switch chassis and the ground is less than 1 ohm.

Most racks are equipped with a grounding strip. You can connect the yellow-green grounding cable of

the switch to the grounding strip.

CAUTION:

Connect the grounding cable to the earthin

or lightning rod.

Use the supplied grounding cable (CAT 6 cable with dual-hole ring terminals).

To connect the grounding cable:

1. Remove the two grounding screws from the switch chassis.

2. Use the grounding screws to attach one end of the grounding cable to the chassis.

round the switch. Make sure the resistance readin

system in the equipment room. Do not connect it to a fire main

3. Connect the other end of the grounding cable to the grounding strip of the rack in the same way.

27

Page 34

g

Figure 23 Connecting the grounding cable for the 12508E

If there is no grounding point on the rack, you can attach the grounding cable to a grounding strip. The

installation procedures are similar.

Installing a power supply

The 12500E switches supports both AC and DC power supply. You can select either AC or DC power

supplies as needed. For how to connect power cords, see "Connecting power cords."

Installation preparation

CAUTION:

• Hold power module by the bottom when moving it. Never attempt to lift a power module with its handle

because the handle is not desi

to the module.

• When inserting or removing a power module, verify that the switch is sturdy. To prevent bodily injury,

avoid tipping the switch chassis.

• When hot-plugging power modules, make sure the insertion interval is no less than 30 seconds.

ned to support weight. Doing so might result in bodily injury or damage

To prepare for installation:

1. Wear an ESD wrist strap and make sure it is correctly grounded.

2. Remove the blank panel (if any) from the slot to be used.

28

Page 35

Installing an AC power supply

Installing an AC power module

IMPORTANT:

• Make sure the number of power modules is sufficient for the switch to operate correctly.

• Each receptacle on the rear of the power frame corresponds to a power module slot. To enable an AC

power module to operate correctly, provide power supply to the relevant receptacle.

• Distribute power modules in the upper and lower frames evenly on the 12508E.

1. Rotate the power frame panel out with both hands to open the panel.

2. Pull the clip at the bottom left corner of the power module to the left to open the power module

cover.

3. Insert the power module slowly into the slot until it fits in completely.

4. Close the power module cover and press the clip at the bottom left corner of the power module.

5. Push in the power module cover to ensure secure installation of the power module.

Figure 24 Installing a power module for the 12508E

6. Repeat steps 1 to 5 to install other power modules and then close the power frame panel.

29

Page 36

Figure 25 Closing the power frame panel for the 12508E

Installing a DC power supply

The procedure for installing a DC power module is similar to installing an AC power module. For more

information, see "Installing an AC power module."

Installing a fan tray

CAUTION:

• The fan trays are heavy. Do not try to move a fan tray by yourself.

• Hold a fan tray by the bottom when moving it. Never attempt to lift a fan tray with its handle because the

handle is not designed to support weight. Doing so might result in bodily injury or damage to the

module.

Each of the 12508E and the 12518E has two fan trays. They are installed in the same way.

To install a fan tray:

1. Wear an ESD wrist strap and make sure it is correctly grounded.

2. Unpack the fan tray.

3. Remove the blank panel from the slot to be used.

Figure 26 Removing the blank panel from the fan tray slot of the 12508E

30

Page 37

4. Lift the fan tray and push it into the slot until it is firmly seated in the slot.

5. Fasten the captive screws on the front panel of the fan tray.

Figure 27 Installing a fan tray

Installing a card

On a 12508E or 12518E, install at least one MPU, one LPU, and seven switching fabric modules.

The 12500E does not support intermixing of the MPU, LPU, and switching fabric modules.

Use one of the following positions to install the card:

• Install MPUs, Ethernet interface cards, and OAA cards at the front of the switch chassis. Slot 0 and

Slot 1 are for MPUs and other slots (slots 2 to 9 for the 12508E, and slots 2 to 19 for the 12508E)

are for Ethernet interface cards and OAA cards.

• Install switching fabric modules in the switching fabric module slots (slots 10 to 18 for the 12518E,

and slots 20 to 28 for the 12518E) at the rear of the chassis.

You can install MPUs, LPUs, and switching fabric modules in a similar way. This section describes how to

install an MPU as an example.

Installation preparation

1. Wear an ESD wrist strap and make sure it is correctly grounded.

2. Remove the blank panel (if any) from the slot to be used.

3. Unpack the card to be installed.

31

Page 38

NOTE:

• Keep the removed the blank panel and protection cover for future use.

• All the cards for the 12500E are hot-swappable.

Installation procedure

IMPORTANT:

• Fasten the screws of each card right after you insert it.

• To avoid damage to a card, do not use excessive force when installing and removing the card.

• You can remove a protective cover of any model by using the same way illustrated in this document.

To install a card:

1. Remove the protection cover before installing an MPU or an LPU. Skip this step if the card does not

have a protection cover:

a. Wear an ESD wrist strap and then loosen the captive screws that attach the MPU or the LPU to

the protection cover with a Philips screwdriver.

b. Pull the MPU or the LPU out of the protection cover gently.

Figure 28 Removing the protection cover

2. Move the ejector levers on the front panel of the MPU outwards, hold up the MPU by one hand

without touching any electronic components on the MPU, and hold the front panel by the other

hand to push the MPU into the slot along the slide rails slowly.

32

Page 39

3. Push the ejector levers inward to ensure close contact between the MPU and the backplane.

4. Position the screws into the holes and fasten them with a screwdriver to attach the MPU.

Figure 29 Installing an MPU

1

3

2

4

Connecting power cords

Follow these guidelines before connecting power cords:

• For lightning protection, the AC power should be led through an external lightning device into a

12500E switch. For more information, see "Appendix D Lightning protection."

• Make sure the power switch on the power frame is in the OFF position.

• For personal and switch safety, do not connect the power cords with the power. Power off the

grounding strip, connect the power cords, power on the grounding strip, and then power on the

switch.

Connecting an AC power cord

Each Power receptacle corresponds to a power module slot. For example, if slot 1 is installed with a

power module, the number 1 Power receptacle must be connected to a power source with an AC power

cord to make the power module operate correctly.

The AC power system for the 12500E requires 16A AC power cords. You need to prepare 16A power

strips, and make sure the AC power supply system can provide enough power. For AC power cords used

in different countries or regions, see "Appendix A Technical specifications."

The 12508E-AC and 12518E-AC models adopt the PSE20KA1 AC power system.

33

Page 40

A

To connect the PSE20KA1 AC power cords:

1. Secure the power cabling rack to the power frame using screws with spring washers and flat

washers.

Figure 30 Installing the power cabling rack

2. Insert the connector of an AC power cord into the power receptacle.

3. Secure the AC power cord to the cabling rack with cable ties.

4. Repeat steps 2 and 3 to organize and secure other AC power cords.

5. Connect the other end of the AC power cords to the power source.

Figure 31 Connecting AC power cords

16A

4

5

3

2

1

Connecting a DC power cord

CAUTION:

plastic protection cover is installed in front of the terminal block to protect operators from being shocked.

Remove the protection cover before connecting power cords and then install the protection cover

promptly.

34

Page 41

Eight pairs of wiring terminals (marked PSU1 through PSU8) are available on the DC terminal block of

the 12508E/12518E. The wiring terminals correspond to the power modules. The power source provides

power to the switch through the wiring terminals. If slot 1 is installed with a power module, the wiring

terminals marked PSR1 or PSU1 must be connected to the power source with a DC power cord to make

the power module operate correctly.

The 12508E-DC and 12518E-DC models adopt the PSE20KD1 DC power system.

To connect the PSE20KD1 DC power cords:

1. Remove the screws from the power frame.

2. Secure the blue DC power cord to the NEG (–) terminal on the terminal block with screws using a

Phillips screwdriver.

3. Secure the ring terminal of the black power cord to the RTN (+) terminal on the terminal block with

screws using a Phillips screwdriver.

Figure 32 Connecting the DC power cords to terminals on the power supply

4. Connect the other end of the DC power cord to the power source:

{ Connect the other end of the black DC power cord to the RTN (+) terminal that provides power

to the switch.

{ Connect the other end of the blue DC power cord to the –48V terminal that provides a power

supply to the switch.

5. Install the protection cover:

a. Remove the screws on the DC power frame.

b. Install the protection cover on the wiring terminals.

c. Fasten the screws using a Phillips screwdriver.

35

Page 42

W

A

Figure 33 Installing the protection cover

2

1

1

Verifying the installation

ARNING!

12508E has one power switch, and a 12518E has two power switches. Make sure you have turned off

the power before checking the installation to avoid bodily injury and switch damage.

After the installation is completed, verify the installation against the following list. Be sure that all check

results are positive.

Table 8 Installation checklist

Item

3

2

4

4

Result

Remarks

Yes No

The grounding cable is correctly grounded.

Fan trays are correctly installed and make close contact

with the backplane.

Power modules are correctly installed and have close

contact with the frames.

The power switch is off (the power switch is at the OFF

position).

Power cords are correctly connected.

MPUs are correctly installed and have close contact with

the backplane.

LPUs are correctly installed and have close contact with

the backplane.

Switching fabric modules are correctly installed and have

close contact with the backplane.

36

Page 43

Connecting the switch to the network

Cable routing recommendations

Interface cables and power cords should be separately routed. Reasonable cable routing can improve

efficiency by facilitating installation and removal of fan trays and some other components. Follow these

guidelines when you route the cables:

• Interface cables of a 12508E and 12518E are routed through the upper and lower cable

management brackets on the chassis and bound at cabling racks on chassis sides, depending on

the available equipment room condition.

• Put all the data signal cable adapters neatly under the chassis (instead of any places outside the

chassis in case of unexpected damages).

• The power cords run along the left-rear of the chassis and out of the chassis either from the chassis

top or the raised floor depending on the equipment room conditions (power distribution rack,

lightning protection box, and connector strip, etc.) of the exchange office.

• Attach cables as near the switch as possible. The cables between the fixing point and switch

interfaces must be bound loosely.

• Long cables can be bound with cable ties. Do not bind cables at the air exhaust vent to prevent the

cables from aging too fast. For more information, see "Appendix E Cable management."

• To identify cables, you can stick labels on them. For more information, see "Appendix F

Engineering labels for cables."

Logging in to the switch

Co nsole port log in or USB console port l ogin, which is most co mmonly used, i s the only method for initial

login to the switch. It is the prerequisite to configuring other login methods.

Connecting the console cable

Before login through the console port or USB console port, connect the PC (or terminal) and the switch

using the following methods accordingly:

• Console port—Use the console cable to connect the serial port on the PC (or terminal) to the console

port on the switch.

• USB console port—Use the console cable to connect the USB port on the PC (or terminal) to the USB

console port on the switch.

Introduction to console cables

• Console cables connecting the console port on a switch and serial port on a PC or terminal

The console cable is an 8-core shielded cable, with a crimped RJ-45 connector for connecting to

the console port of the switch, and a DB-9 female connector for connecting to the serial port on the

console terminal.

Figure 34 shows the console c

able and Table 9 shows its pinouts.

37

Page 44

p

p

Figure 34 Console cable connecting the serial port and the console port

Table 9 Pinouts for the console cable connecting the serial port and the console port

RJ-45

1 RTS 8 CTS

2 DTR 6 DSR

3 TXD 2 RXD

4 CD 5 SG

5 GND 5 SG

6 RXD 3 TXD

7 DSR 4 DTR

8 CTS 7 RTS

in Signal DB-9

in Signal

• Console cables connecting the USB console port on a switch and the USB port on a PC or terminal

The console cable consists of one mini-USB A/B connector for connecting to the USB console port

on the switch and one USB A connector for connecting to the USB port on the PC or terminal.

Figure 35 shows the console c

able and Table 10 shows its pinouts.

Figure 35 Console cable connecting the USB port and the USB console port

Table 10 Pinouts for the console cable connecting the USB port and the USB console port

USB A pin

1 VBUS 1 VBUS

2 D- 2 D-

3 D+ 3 D+

4 ID(NC)

4 GND 5 GND

Signal mini-USB A/B pin Signal

38

Page 45

Connection procedure

Figure 36 Connecting through the console port and the serial port

To connect the console cable through the console port:

1. Connect the DB-9 connector of the console cable to the serial port on a PC or terminal.

2. Connect the RJ-45 connector of the console cable to the console port on the MPU of the switch.

To connect the console cable through the USB console port:

3. Connect the USB-A connector of the console cable to the USB port on a PC or terminal.

4. Connect the mini-USB A/B connector of the console cable to the USB console port on the MPU of

the switch.

NOTE:

• If two MPUs are installed on the switch, log in through the console port or USB console port on the active

MPU (typically with a smaller slot number) for the first login.

• When you remove the console cable, first disconnect the switch end, and then disconnect the PC end.

39

Page 46

Setting up a configuration environment

If you use the Windows 2003 Server operating system on your PC, add a HyperTerminal, and then log

in to and manage the switch as described in this document. If you use Windows 2008 Server, Windows

7, Windows Vista, or any other operating system on your PC, use the third party terminal software. For

how to use the third party terminal software, see the user guide or online help of that software.

Windows 2000 and Windows XP operating systems have the HyperTerminal. This section takes

Windows XP as an example.

To set up a configuration environment:

1. Select Start > All Programs > Accessories > Communications > HyperTerminal.

The Connection Description dialog box appears.

2. Enter the name of the new connection in the Name field and click OK.

Figure 37 Connection description