Page 1

HP FlexFabric 11900 Switch Series

A

g

Installation Guide

bstract

This document guides you through installation of HP products, including installing the device, connectin

network, hardware management, and troubleshooting.

to the

Part number: 5998-4089

Document version: 6W102-20131018

Page 2

Legal and notice information

© Copyright 2013 Hewlett-Packard Development Company, L.P.

No part of this documentation may be reproduced or transmitted in any form or by any means without

prior written consent of Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice.

HEWLETT-PACKARD COMPANY MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS

MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE. Hewlett-Packard shall not be liable for errors contained

herein or for incidental or consequential damages in connection with the furnishing, performance, or use

of this material.

The only warranties for HP products and services are set forth in the express warranty statements

accompanying such products and services. Nothing herein should be construed as constituting an

additional warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

Page 3

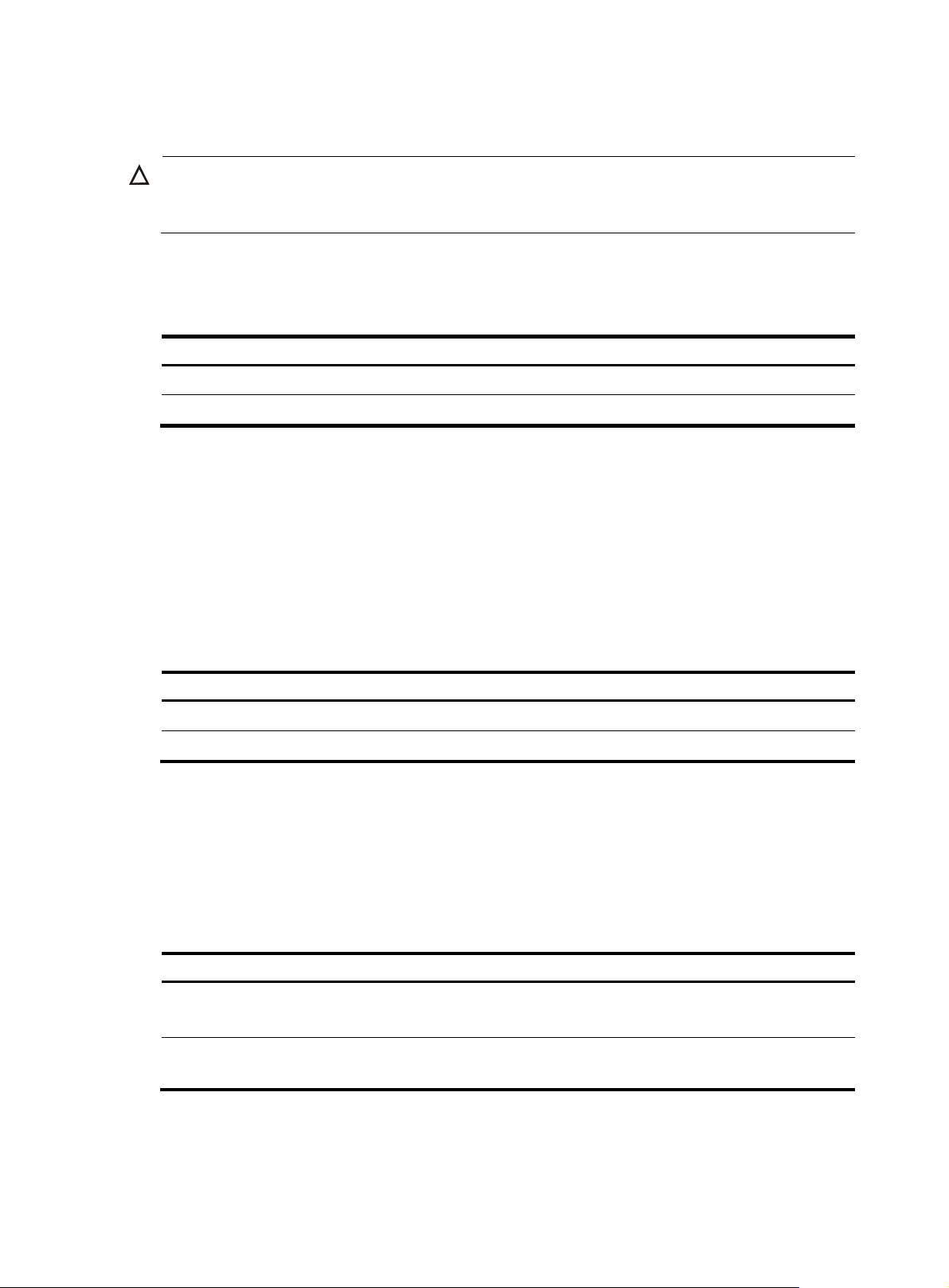

Contents

Preparing for installation ············································································································································· 1

Safety recommendations ·················································································································································· 1

General safety recommendations ··························································································································· 1

Electricity safety ························································································································································ 1

Handling safety ························································································································································ 2

ESD prevention ························································································································································· 2

Laser safety ································································································································································ 2

Examining the installation site ········································································································································· 2

Weight support ························································································································································· 2

Temperature ······························································································································································ 3

Humidity ···································································································································································· 3

Cleanness ·································································································································································· 3

EMI ············································································································································································· 4

Grounding ································································································································································· 4

Power ········································································································································································· 4

Cooling ······································································································································································ 4

Space ········································································································································································· 5

Installing the switch ······················································································································································ 6

Confirming installation preparations ······························································································································· 6

Installing the switch in a 19-inch rack ····························································································································· 6

Attaching slide rails and cage nuts to the rack ····································································································· 6

Installing mounting brackets and cable management brackets ········································································ 11

Mounting the switch to the rack ··························································································································· 13

Mounting the switch on a workbench or floor ············································································································ 14

Installation preparation ········································································································································· 14

Installation procedures ·········································································································································· 15

Grounding the switch ···················································································································································· 16

Grounding the switch with a grounding strip ····································································································· 16

Grounding the switch through the PE wire of an AC power supply ································································ 17

Grounding the switch through the RTN wire of a DC power supply ······························································· 18

Installing FRUs ···························································································································································· 20

Attaching an ESD wrist strap ········································································································································ 20

Installing a card ······························································································································································ 21

Installing an MPU/LPU ·········································································································································· 22

Installing a switching fabric module ···················································································································· 22

Installing a power supply ·············································································································································· 24

Connecting the power cable········································································································································· 26

Connecting an AC power cable ·························································································································· 26

Connecting a DC power cable ···························································································································· 27

Installing a transceiver module (optional) ···················································································································· 28

Installing an SFP+/SFP/QSFP+ module ·············································································································· 28

Connecting an SFP+/QSFP+/QSFP+ to SFP+ cable ································································································· 29

Setting up an IRF fabric ············································································································································· 30

IRF fabric setup flowchart ·············································································································································· 30

Planning IRF fabric setup ··············································································································································· 31

Planning IRF fabric size and the installation site ································································································ 31

Identifying the master switch and planning IRF member IDs ············································································ 31

i

Page 4

Planning IRF topology and connections ·············································································································· 32

Identifying physical IRF ports on the member switches ····················································································· 32

Installing IRF member switches ····································································································································· 32

Configuring basic IRF settings ······································································································································· 32

Connecting the physical IRF ports ································································································································ 33

Verifying the IRF fabric configuration ·························································································································· 34

Connecting your switch to the network ···················································································································· 35

Accessing the switch for the first time ·························································································································· 35

Setting up the configuration environment ··········································································································· 35

Setting terminal parameters ·································································································································· 36

Powering on the switch ········································································································································· 39

Configuring the switch ··················································································································································· 41

Configuring authentication on a user interface ·································································································· 41

Configuring the basic access function ················································································································ 41

Configuration example ········································································································································· 42

Verifying the network configuration ···················································································································· 43

Connecting the switch to the network ·························································································································· 43

Connecting your switch to the network through twisted pair cables ······························································· 43

Connecting your switch to the network through optical fibers ········································································· 44

Testing connectivity ························································································································································ 45

Troubleshooting ·························································································································································· 46

Troubleshooting methods··············································································································································· 46

Configuration terminal problems ·································································································································· 46

No terminal display ·············································································································································· 46

Garbled terminal display ······································································································································ 47

Troubleshooting the switch during the operation ······························································································· 47

Power supply system failure ·········································································································································· 47

Fan failure ······································································································································································· 48

MPU failure ····································································································································································· 48

LPU and switching fabric module failure ····················································································································· 48

Interface failure ······························································································································································· 49

Replacement procedures ··········································································································································· 50

Replacing a power supply ············································································································································ 50

Replacing a card ···························································································································································· 51

Replacing an MPU or LPU ···································································································································· 51

Replacing a switching fabric module ·················································································································· 52

Replacing a fan tray ······················································································································································ 54

Removing a fan tray ·············································································································································· 54

Installing a fan tray ··············································································································································· 55

Replacing a transceiver module ··································································································································· 56

Replacing an SFP+/SFP/QSFP+ module ············································································································ 56

Replacing an SFP+/QSFP+/QSFP+ to SFP+ cable ··························································································· 56

Support and other resources ····································································································································· 57

Contacting HP ································································································································································ 57

Subscription service ·············································································································································· 57

Related information ························································································································································ 57

Documents ······························································································································································ 57

Websites ································································································································································· 57

Conventions ···································································································································································· 58

Appendix A Chassis views and technical specifications ························································································ 60

Chassis views ································································································································································· 60

Weights and dimensions ··············································································································································· 61

ii

Page 5

Module power consumption and system power consumption ·················································································· 62

Card power consumption ····································································································································· 62

Fan tray power consumption ································································································································ 63

System power consumption ·································································································································· 63

Heat dissipation ····························································································································································· 63

Environmental specifications ········································································································································· 64

Noise ··············································································································································································· 64

Appendix B FRUs and compatibility matrixes ·········································································································· 65

MPUs ··············································································································································································· 65

LPUs ················································································································································································· 65

Switching fabric modules ·············································································································································· 67

Power supplies ································································································································································ 67

Fan trays ·········································································································································································· 68

Mounting accessories ···················································································································································· 68

Transceiver modules ······················································································································································ 68

DC power cable ····························································································································································· 71

Appendix C LEDs ······················································································································································· 73

MPU LEDs ········································································································································································ 73

LPU LEDs ·········································································································································································· 75

Switching fabric module LEDs ······································································································································· 76

Fan tray status LEDs ······················································································································································· 76

Power supply LEDs ························································································································································· 76

Appendix D Cables ··················································································································································· 78

Console cable ································································································································································· 78

Ethernet twisted pair cable ············································································································································ 78

RJ-45 connector ······························································································································································ 79

Cable pinouts ························································································································································· 79

Cable type ······························································································································································ 79

Pin assignments ····················································································································································· 81

Making an Ethernet twisted pair cable ··············································································································· 81

Optical fiber ··································································································································································· 82

Precautions ····························································································································································· 83

SFP+ cable ······································································································································································ 84

QSFP+ cable ··································································································································································· 84

QSFP+ to SFP+ cable ···················································································································································· 84

Appendix E Cabling recommendations ··················································································································· 86

General cabling requirements ······································································································································ 86

Cable management requirements ································································································································ 86

Appendix F Repackaging the switch ························································································································ 90

Removing cables from the switch ································································································································· 90

Removing the power cable ··································································································································· 90

Removing the console cable ································································································································· 90

Removing the grounding cable ···························································································································· 90

Removing the twisted pair and optical fiber ······································································································ 91

Repackaging the switch accessories ···························································································································· 91

Repackaging the power supply ··························································································································· 91

Repackaging the card ··········································································································································· 92

Repackaging the switch chassis ··································································································································· 92

Removing the chassis from the rack ···················································································································· 92

Removing cable management brackets and mounting brackets ······································································ 93

Repackaging the switch chassis ··························································································································· 95

iii

Page 6

Index ··········································································································································································· 97

iv

Page 7

p

Preparing for installation

The HP FlexFabric 11900 Switch Series includes only the 11908-V model.

Table 1 HP FlexFabric 11900 Switch Series models

Product code HP descri

JG608A HP FlexFabric 11908-V Switch Chassis BJNGA-AC0003

IMPORTANT:

For regulatory identification purposes, HP FlexFabric 11900 switches are assigned regulatory model

numbers (RMN). These regulatory numbers should not be confused with the marketing name, for example

HP FlexFabric 11908-V Switch Chassis, or product code, for example JG608A.

tion

Safety recommendations

To avoid possible bodily injury and equipment damage, read all safety recommendations carefully

before installation. Note that the recommendations do not cover every possible hazardous condition.

General safety recommendations

• Keep the chassis clean and dust-free.

• Do not place the switch on a moist area, and avoid liquid flowing into the switch.

• Make sure the ground is dry and flat and anti-slip measures are in place.

• Keep the chassis and installation tools away from walk areas.

RMN

• Do not wear loose clothing, jewelry (for example, necklace) or any other things that could get

caught in the chassis when you install and maintain the switch.

Electricity safety

• Clear the work area of possible electricity hazards, such as ungrounded power extension cables,

missing safety grounds, and wet floors.

• Locate the emergency power-off switch in the room before installation so you can quickly shut power

off when an electrical accident occurs.

• Unplug all external cables, including power cords, before moving the chassis.

• Do not work alone when the switch has power.

• Never assume that power has been disconnected from a circuit. Always check.

1

Page 8

g

y

W

g

Handling safety

CAUTION:

Do not hold the handle of the fan tray, power supply, or back cover of the chassis, or the air vents of

chassis. Any attempt to move the switch with these parts mi

injury.

When you move the switch, follow these guidelines:

• Remove all external cables, including the power cords, before moving the chassis.

• Moving the chassis requires at least two persons, and you can use a mechanical lift as needed.

• Lift and put down the chassis slowly and never move suddenly.

• Hold the handles on the chassis.

ESD prevention

To prevent the electric component from being damaged by ESD, follow these guidelines:

• Ground the switch correctly. For how to ground your switch, see "Installing the switch."

ht cause equipment damage and even bodil

lways wear an ESD wrist strap and make sure it is well grounded when installing FRUs. For how

• A

to use an ESD wrist strap, see "Installing FRUs."

• Hold a P

• Put cards away in ESD bags for future use.

CB by its edges. Do not touch any electronic components or printed circuit.

Laser safety

ARNING!

Do not stare into any fiber port when the switch has power. The laser li

might hurt your eyes.

Examining the installation site

The HP FlexFabric 11900 switches must be used indoors. To ensure normal operation and long service life

of your switch, the installation site must meet the requirements in this section.

Weight support

Make sure the floor can support the total weight of the rack, chassis, cards, power supplies, and all other

components. Additionally, the floor loading plan must also consider system expansion, such as adding

more cards. For more information, see "Appendix A Chassis views and technical specifications."

ht emitted from the optical fiber

2

Page 9

p

y

p

Temperature

CAUTION:

To avoid short circuits, if condensation appears on the chassis when you move it to a high-temperature

environment, dry the chassis before powering it on.

To ensure normal operation of the switch, make sure the room temperature meets the requirements

in Table 2.

Table 2 Temperature r

Tem

Operating temperature 0°C to 45°C (32°F to 113°F)

Storage temperature –40°C to +70°C (–40°F to +158°F)

Humidity

Maintain appropriate humidity in your equipment room, as described in Table 3.

• Lasting high relative humidity tends to cause poor insulation, electricity creepage, mechanical

property change of materials, and corrosion of metal parts.

• Lasting low relative humidity is likely to result in loose screws due to washer contraction, and even

ESD, which causes the circuits to fail.

Table 3 Humidity requirements

Humidit

Operating humidity 10% to 95%, noncondensing

Storage humidity 5% to 95%, noncondensing

equirements

erature Range

Range

Cleanness

Dust buildup on the chassis may result in electrostatic adsorption, which causes poor contact of metal

components and contact points. In the worst case, electrostatic adsorption can cause communication

failure.

Table 4 Dust concentration limit in the equipment room

Substance Concentration limit (

Dust particles

NOTE:

Dust particle diameter ≥ 5 μm

≤ 3 x 104

(No visible dust on desk in three days)

The equipment room must also meet strict limits on salts, acids, and sulfides to eliminate corrosion and

premature aging of components, as shown in Table 5.

3

articles/m3)

Page 10

g

Table 5 Harmful gas limits in an equipment room

EMI

Gas Max. (m

SO2 0.2

H2S 0.006

NH

3

Cl

2

All EMI sources, from outside or inside of the switch and application system, adversely affect the switch

in a conduction pattern of capacitance coupling, inductance coupling, electromagnetic wave radiation,

or common impedance (including the grounding system) coupling. To prevent EMI, take the following

actions:

• Take measures against interference from the power grid.

• Use a grounding system and lighting protection system for the switch separate from those for other

electric equipment, and keep them far away as possible.

• Keep the switch far away from radio transmitting stations, radar stations, and high-frequency

devices.

• Use electromagnetic shielding, for example, shielded interface cables, when necessary.

0.05

0.01

/m3)

Grounding

Using a good grounding system to protect your switch against lightning shocks, interferences, and ESD

is essential to the operating reliability of your switch.

Make sure the resistance between the chassis and the ground is less than 1 ohm.

Power

Perform the following tasks to meet the power requirements:

1. Calculate the system power consumption.

The system power consumption varies by card type and density. For more information about

system power consumption calculation, see "Appendix A Chassis views and tec

specifications."

2. Select power supplies and identity the number of power supplies.

The total maximum output power of all power supplies must be higher than the system power

consumption. For more information about available power supplies, see "Appendix B FRUs and

compatibility matrixes."

3. Verify that the power system at the installation site meets the requirements of the power supplies,

including the input method and rated input voltage.

hnical

Cooling

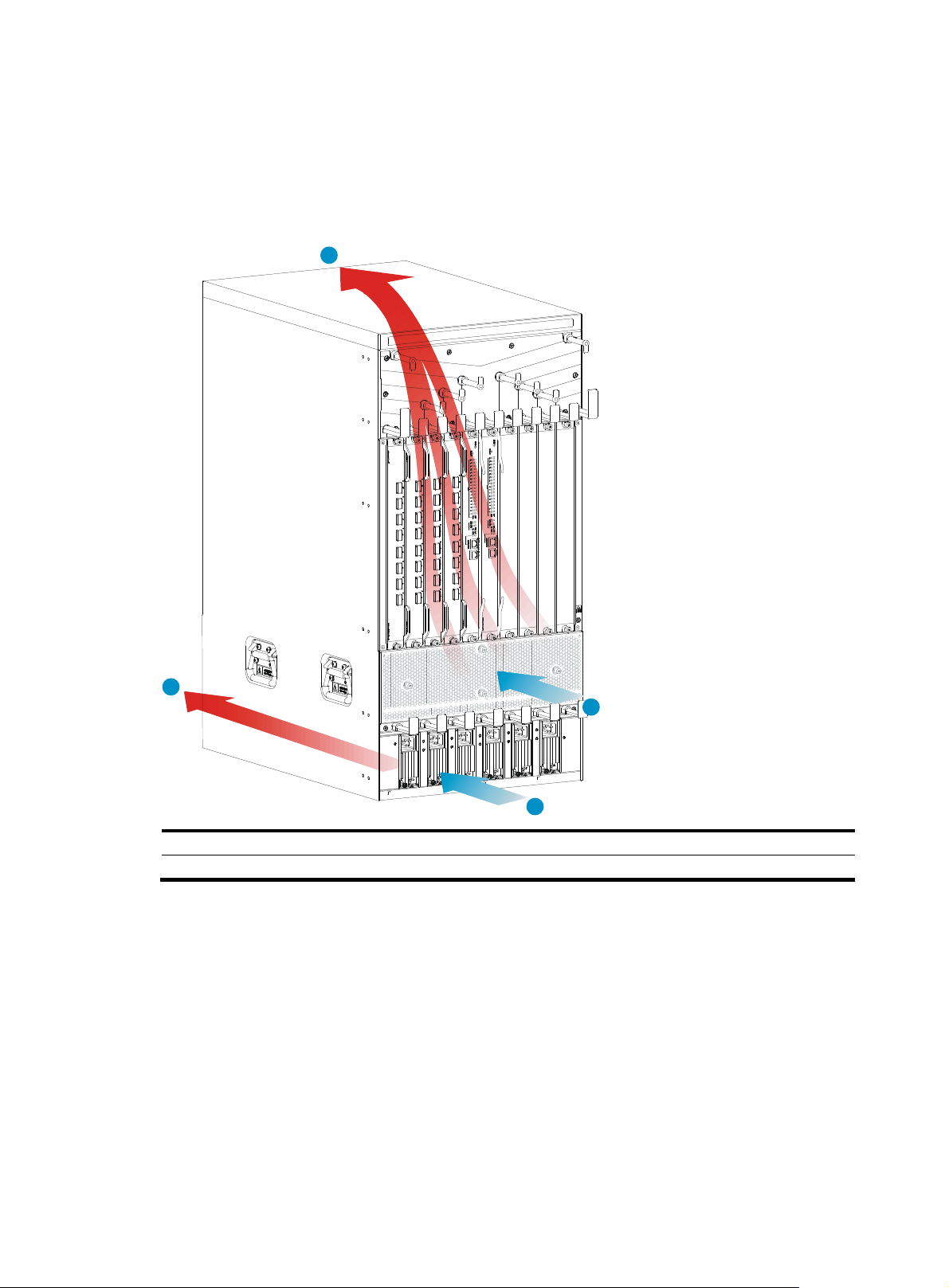

Plan the installation site for adequate ventilation.

4

Page 11

• Leave at least 10 cm (3.94 in) of clearance at the inlet and outlet air vents.

• The rack for the switch has a good cooling system.

• The installation site has a good cooling system.

• Verify that the airflow design of the chassis meets the airflow design of the installation site.

Figure 1 Airflow through the 11908-V Chassis

4

Space

For easy maintenance, follow these guidelines:

• Reserve at least 1 m (3.28 ft) of clearance between the rack and walls or other devices.

• The equipment room is at least 3 m (9.84 ft) high.

• Rack dimensions are sufficient for the chassis. For more information about chassis specifications,

2

3

1

(1) Power supply air intake vents (2) Power supply air exhaust vents

(3) Chassis air intake vents (4) Chassis air exhaust vents

see "Appendix A Chassis views and technical specifications."

5

Page 12

Installing the switch

IMPORTANT:

Keep the packages of the switch and the components for future use.

Confirming installation preparations

Before you install the switch, verify that:

• You have re ad "Preparing for installation" car

requirements.

• If you are rack-mounting the switch, verify that the following conditions are met:

{ A 19-inch rack is ready for use. For how to install a rack, see the rack installation guide.

{ The rack is sturdy and securely grounded.

{ No debris exists inside or around the rack.

{ Choose a correct rack mounting position for the switch. Make sure the heaviest device is placed

at the bottom of the rack.

{ The total height of the switches to be installed is no higher than the available installation height

of the rack, and enough clearance is reserved for cable routing.

• If you are mounting the switch on a workbench, make sure the workbench is sturdy and securely

grounded.

• The switch is ready for installation and has been carried to a place near the installation site and

convenient for moving.

efully and the installation site meets all the

Installing the switch in a 19-inch rack

Attaching slide rails and cage nuts to the rack

Installing slide rails

If the rack has slide rails, skip this section.

Before you attach slide rails to the rack, verify that the following conditions are met:

• The slide rails can support the weight of the switch. For the weights of the HP FlexFabric 1190 0

switches, see "Appendix A Chassis views and technical specifications."

HP recommen

(JC665A). For more information about the kit, see "Appendix B FRUs and compatibility matrixes."

• If y

ou install the switch in an enclosed cabinet, make sure the distance between the front rack posts

and the front door is at least 100 mm (3.94 in) for installing cable management brackets, and the

distance between the front rack posts and the rear door is at least 660 mm (25.98 in) for the chassis

with cards installed.

ds that you order the HP X421 A-Series Chassis Universal 4-Post Rack Mounting Kit

6

Page 13

g

• To ensure rack stability, install the slide rails to the lowest possible position when installing a single

switch on the rack. To install multiple switches on the rack, mount the heaviest switch at the bottom

of the rack.

• Identify the chassis and slide rail positions for the switch. For the height and other specifications, see

"Appendix A Chassis views and technical specifications."

Slide rail installation varies with rack type. This section uses the slide rails in the HP rack mounting kit

(JC665A) as an example.

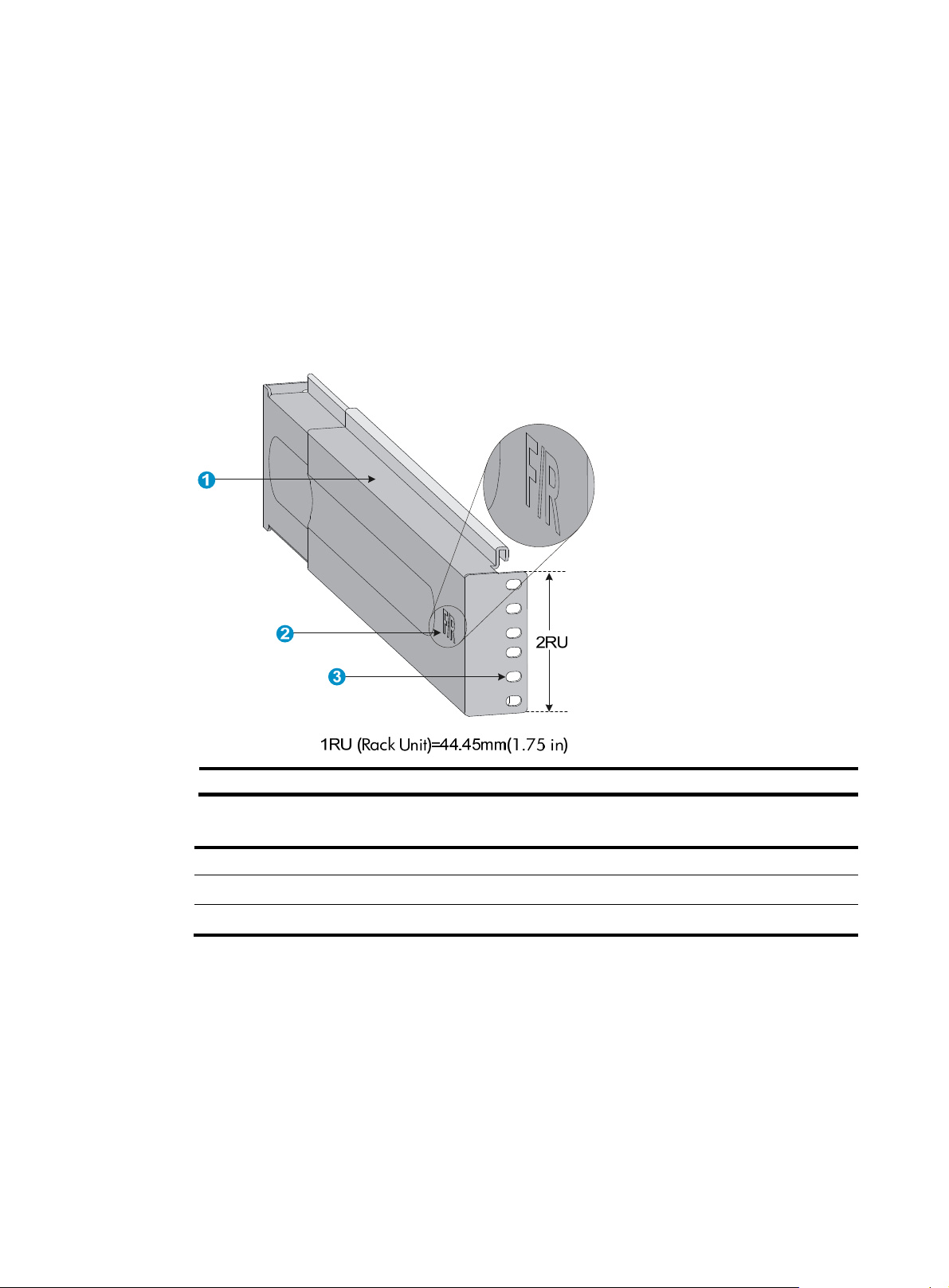

To install a slide rail:

1. Read the signs on the slide rail (see Table 6) to avoid

Figure 2 Right slide rail

making a mistake.

(1) Guide rail (2) Sign (3) Installation hole

Table 6 Description of signs on the slide rails

Si

n Meaning Remarks

F/L Front end of the left slide rail Mount this end to the front left rack post.

F/R Front end of the right slide rail Mount this end to the front right rack post.

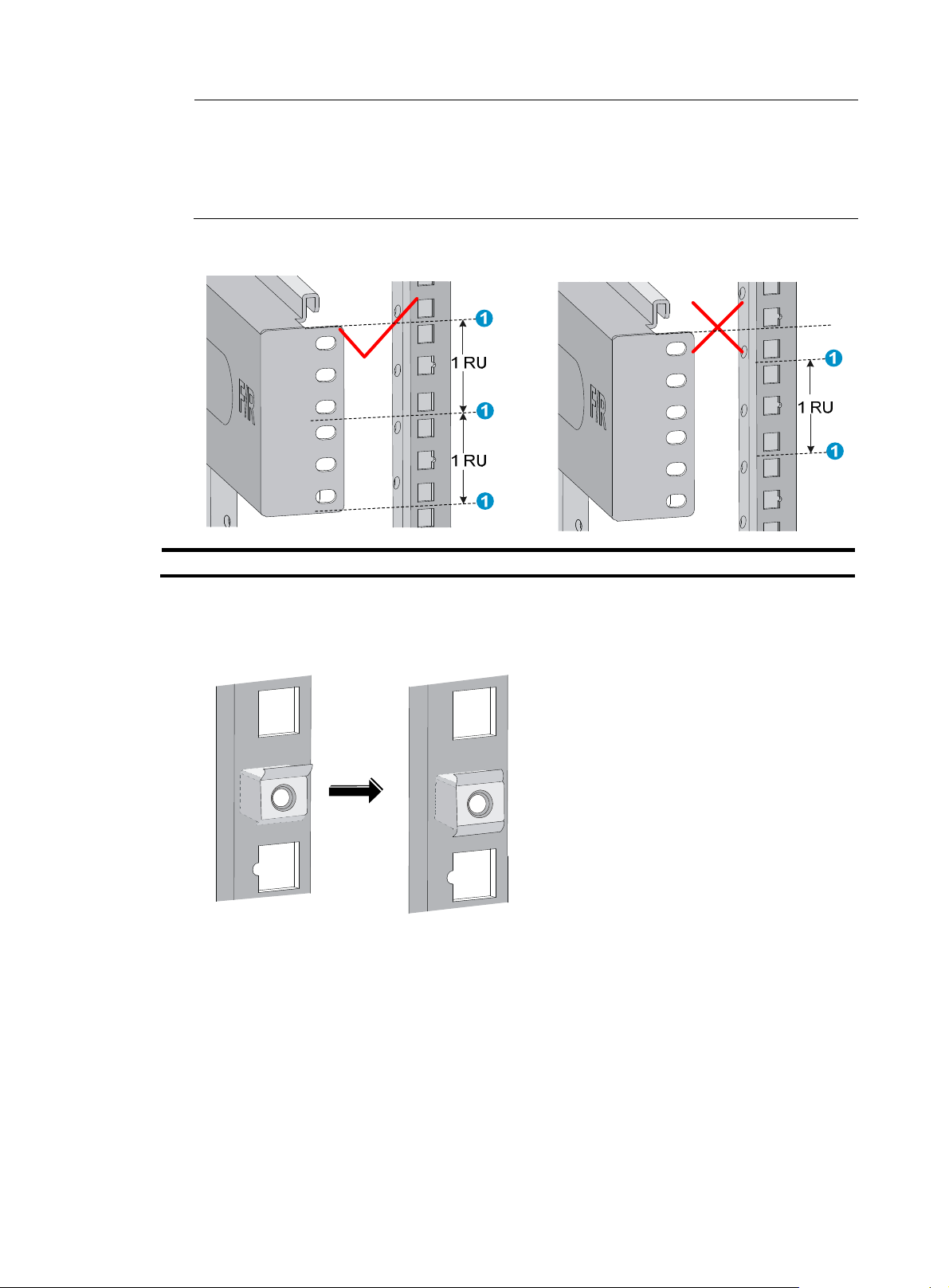

2. Mark the position on the rack for installing the slide rail:

a. Make sure the bottom edge of the slide rail aligns with the middle of the narrower metal area

between holes, as shown in Figure 3.

ach rack post r e quires six screws to at tach the slide rail. Mark the uppermost square hole and

b. E

lowermost square hole for installation.

c. Mark the square holes at the same height on the other three rack posts.

7

Page 14

NOTE:

One rack unit has three holes, the middle of which is an auxiliary installation hole, and the other two

are standard installation holes. You can distinguish them by the space between each two holes. The

space between a standard installation hole and an auxiliary installation hole is wider than that

between two adjacent standard installation holes.

Figure 3 Locating the rack position for installing slide rails

(1) Middle of the narrower metal area between holes

3. Install six cage nuts in the square holes in each rack post, as shown in Figure 4.

Figure 4 Installing a cage nut

4. Align the installation holes on the front end of the slide rail with the cage nuts on the front rack post,

and attach them with screws, as shown in Figure 5.

8

Page 15

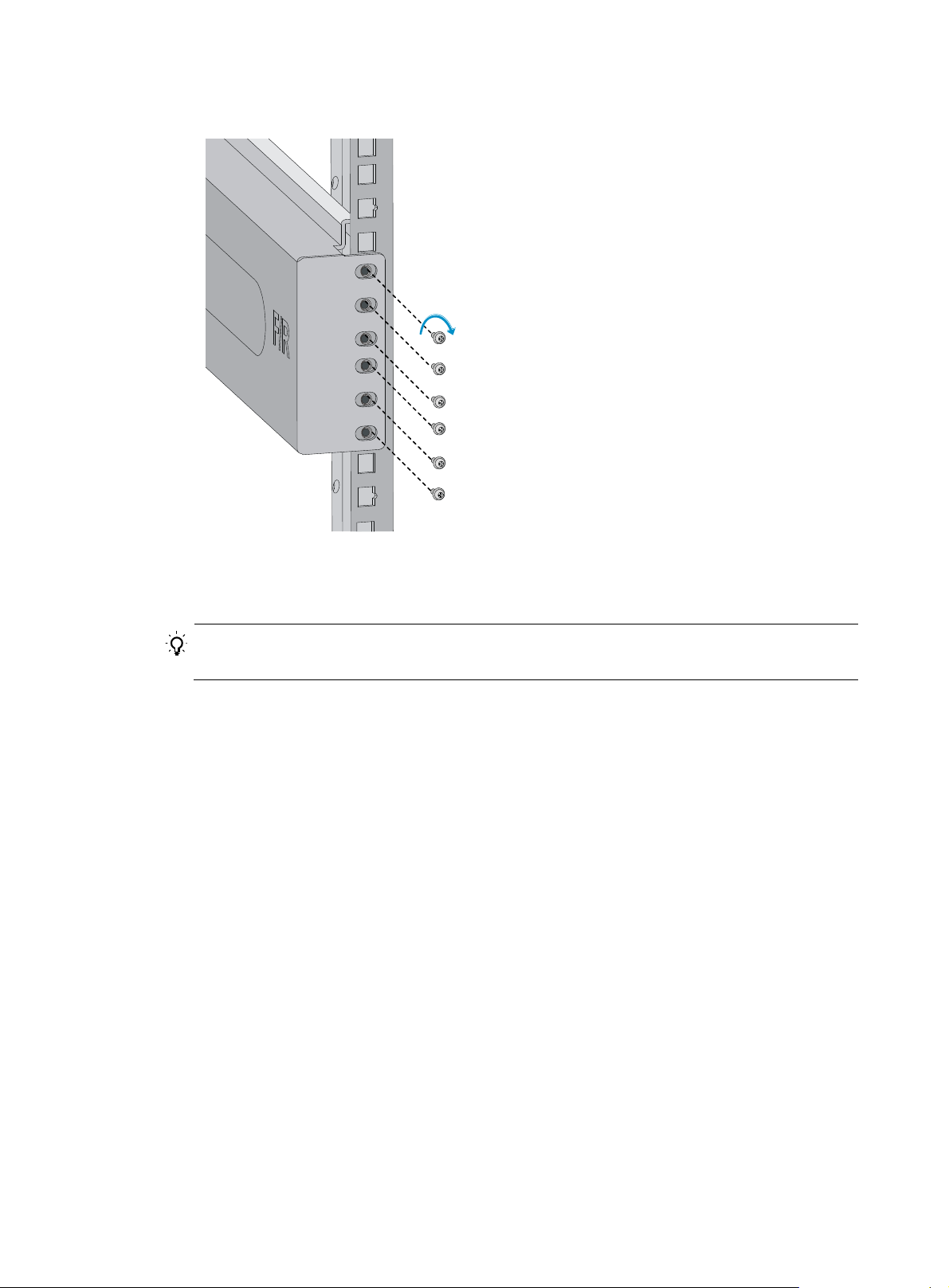

Figure 5 Attaching the slide rail to the cage nuts with screws

5. Keep the slide rail horizontally and adjust its length until the installation holes on the rear end of the

slide rail touch the cage nuts on the rear rack post. Then screw in screws and fasten.

TIP:

Install a screw in each mounting hole of the slide rail to ensure its weight bearing capacity.

6. Repeat steps 4 and 5 to install the other slide rail. Make sure the two slide rails are at the same

height so the device can be placed on them horizontally.

9

Page 16

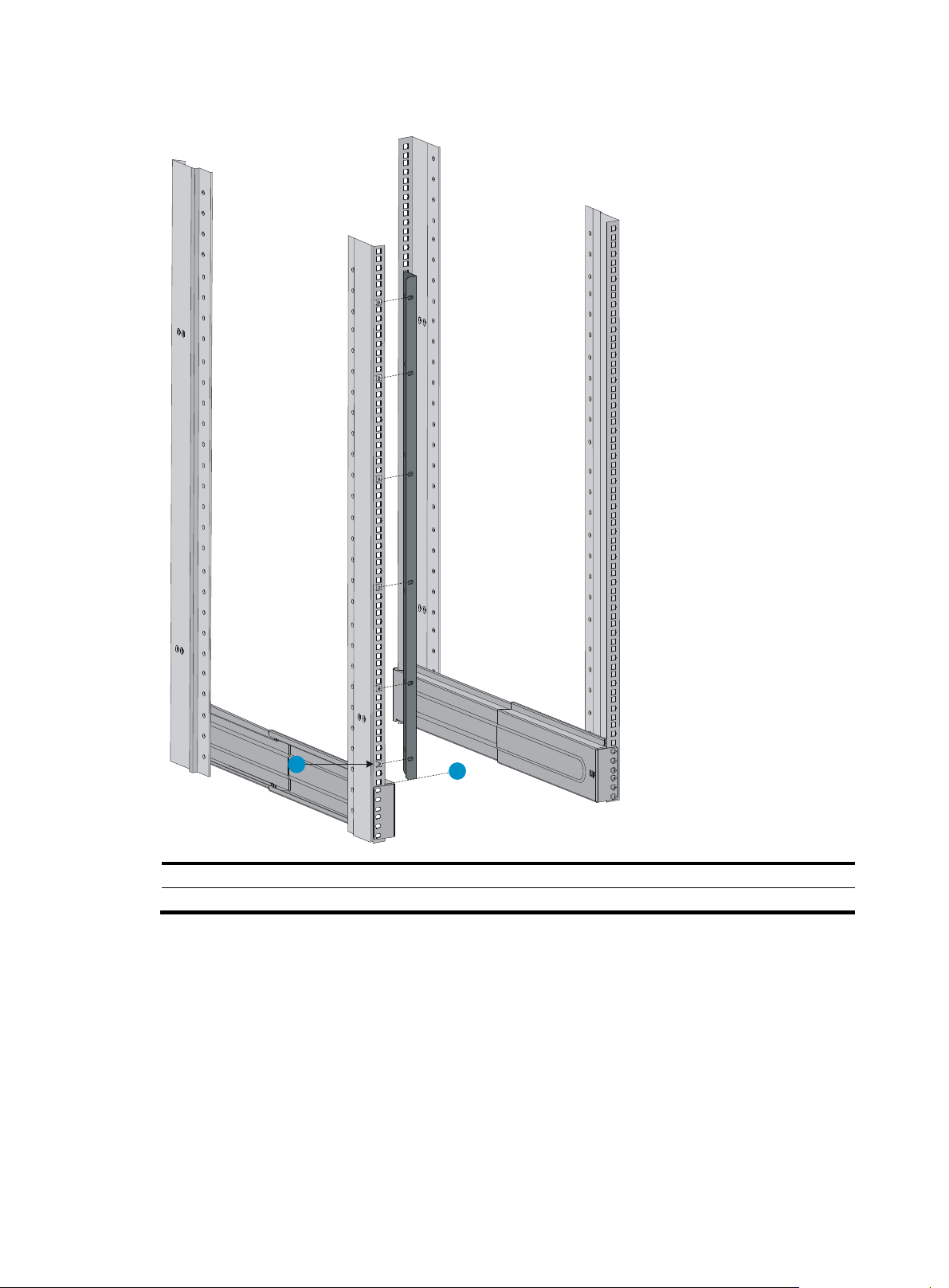

Figure 6 Installed slide rails

Installing cage nuts

To install cage nuts to the front square-holed brackets of the rack:

1. Determine the placement of the cage nuts, depending on holes in the mounting brackets and the

mounting position of the slide rails, as shown in Figure 7.

2. Install c

age nuts on the square holes on each rack post, as shown in Figure 4.

10

Page 17

Figure 7 Installing cage nuts

2

1

(1) Place the bottom edge of the mounting bracket and the slide rail at the same level

(2) Locate the installation positions of cage nuts

Installing mounting brackets and cable management brackets

Before installing the switch to the rack, install the cable management brackets and mounting brackets

shipped with the switch. Cable management brackets (signal cable and power cable management

brackets) are used for cabling the switch, and mounting brackets are used for attaching the chassis to the

rack.

11

Page 18

Installing cable management brackets

The 11908-V has two cable management brackets: the cable management brackets are installed at the

upper part of the switch, and the power cable management brackets are installed at the lower part of the

switch. They are installed in the same way. For more information, see Figure 8.

T

o install a cable management bracket:

1. Unpack the cable management brackets.

2. Attach the cable management bracket to the chassis, and align the screws with the mounting holes

on the chassis, as shown in Figure 8.

3. Fasten the s

crews.

Figure 8 Attaching cable management brackets to a 11908-V

(1) Attach the cable management bracket to the chassis.

(2) Mounting holes for installing the cable management bracket.

(3) Screws for attaching the cable management bracket to the chassis.

(4) Cable management bracket (installed at the upper part of the chassis).

(5) Power cable management bracket (installed at the lower part of the chassis).

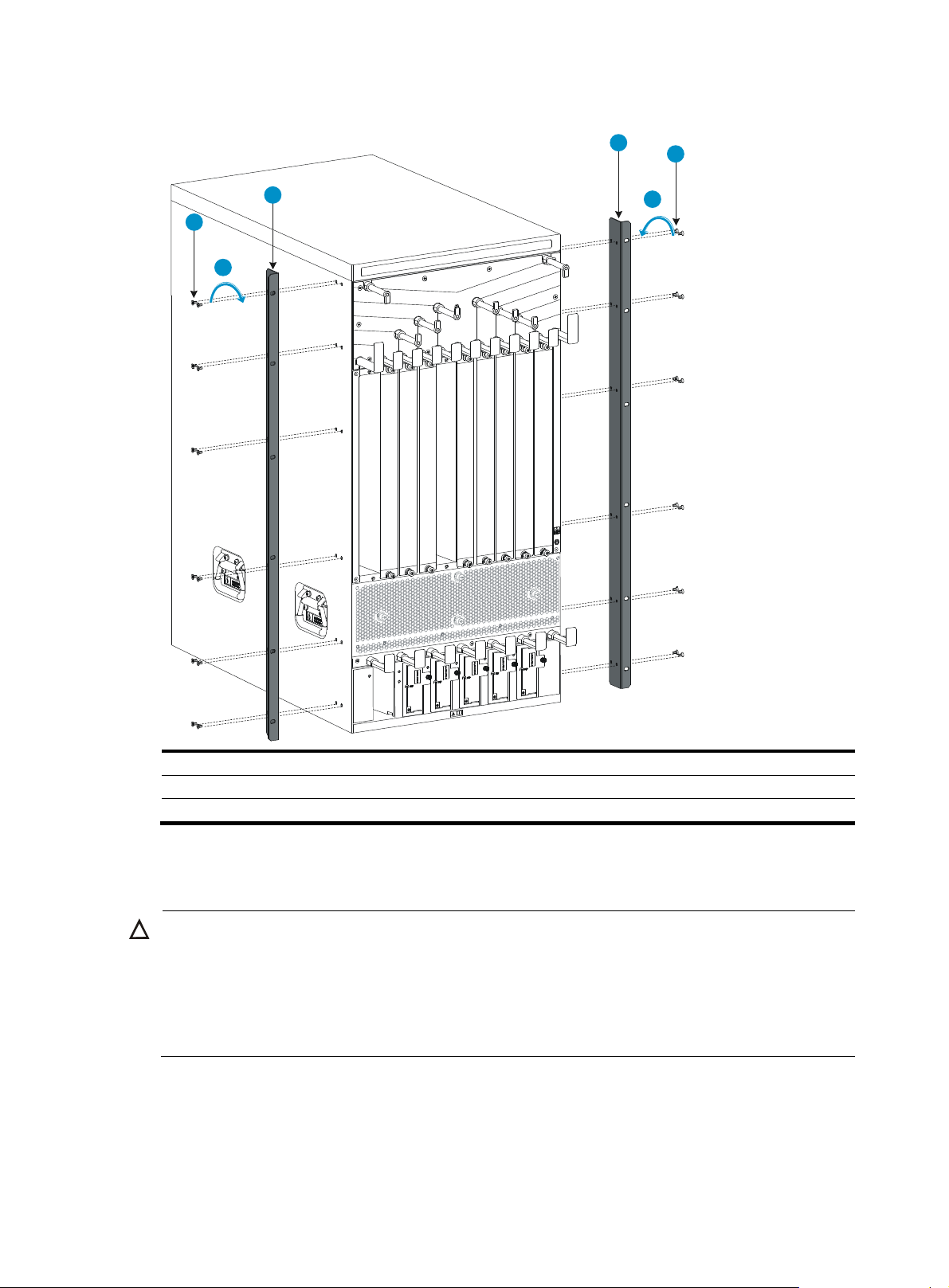

Attaching mounting brackets to the chassis

1. Identify the left mounting bracket (marked L) and the right mounting bracket (marked R) on the

inner surface of the mounting brackets.

2. Facing the chassis front, mount the left and right mounting brackets to the two sides of the chassis,

as shown in Figure 9.

12

Page 19

g

y

Figure 9 Installing the mounting brackets to a 11908-V

2

2

1

3

1

3

(1) Screws for attaching the mounting brackets to the chassis

(2) Mounting brackets

(3) Fasten the screws

Mounting the switch to the rack

CAUTION:

• Do not hold the handle of the fan tray, power supply, or the back cover of the chassis, or the air vents of

chassis. Any attempt to carry the switch with these parts may cause equipment dama

injury.

• After placing the switch on the slide rails, do not let go right away because this may tip the switch,

damage the switch, or cause bodily injury.

To mount the switch to the rack:

1. Move the chassis to face the rear of the chassis towards the front of the rack.

2. Use at least two people to lift the switch by using the handles or supporting the bottom of the

chassis until the bottom of the switch is a little higher than the slide rails on the rack.

e or even bodil

13

Page 20

HP recommends using a mechanical lift for moving your switch.

3. Place the switch on the slide rails and slide the switch along the slide rails until the mounting

brackets on the switch touch the front rack posts, as shown in callout 1 on Figure 10.

4. Attach the ch

Figure 10 Installing the chassis to the rack

(1) Slide the chassis into the rack

(2) Mounting brackets

(3) Screws for attaching the mounting brackets to the rack

assis to the rack with mounting screws.

NOTE:

If the mounting holes in the mounting brackets cannot align with the cage nuts on the rack, verify that the

bottom edge of the slide rail aligns with the middle of the narrower metal area between holes and that the

cage nuts are installed in the correct holes.

Mounting the switch on a workbench or floor

You can install the switch on a clean, sturdy workbench or on the floor.

Installation preparation

Before you mount the switch on a workbench or on the floor:

• Position the installation holes and drill holes. Make sure the holes are exact in diameter and depth

for the anchors to work correctly.

• Remove the shank and plug from a wall anchor, insert the spade-shaped wedges into the grooves

on the shank, put them into an installation hole, and hammer the shank into the ground. See Figure

11.

14

Page 21

g

g

w

IMPORTANT:

Before you hammer the shank to the workbench or floor, insert the spade-shaped wed

es into the grooves

on the shank. Otherwise, the wall anchor cannot be installed correctly.

Figure 11 Installing the shank to the plug

1

2

3

4

(1) Shank (2) Groove

Installation procedures

CAUTION:

Do not use the fan tray handles, power supply handles, chassis air vents, or handle of chassis back cover

for moving the chassis. These parts are not designed for weight support. Any attempt to carry the chassis

ith these parts might cause equipment damage or even bodily injury.

This task requires at least two people. HP recommends that you use a mechanical lift to move the chassis.

1. Hold the handles on the chassis or support the chassis bottom and steadily move the chassis to the

workbench or floor.

2. Gently put the chassis on the workbench or floor.

3. Attach the L-shaped brackets to the workbench or floor with wall anchors.

(3) Plu

(4) Spade-shaped wedge

15

Page 22

g

Figure 12 Attaching L-shaped brackets with wall anchors

(1) Fastening screw

(2) L-shaped bracket

(3) Wall anchor

Grounding the switch

CAUTION:

Before using the switch, connect the grounding cable changely to guarantee lightning protection and

anti-interference of the switch.

Grounding the switch with a grounding strip

CAUTION:

• Use the supplied grounding cable (yellow-green grounding cable).

• Connect the

main or lightning rod.

If a grounding strip is available at the installation site, connect the grounding cable through the

grounding strip.

rounding cable to the earthing system in the equipment room. Do not connect it to a fire

To connect the grounding cable:

1. Unpack the grounding cable.

The grounding cable provided with the switch is compliant with the NEBS standards.

16

Page 23

g

2. Remove the grounding screws from the grounding holes at the rear of the chassis, as shown in

callout 1 on Figure 13.

3. Fasten the gr

ounding screws, which are attached with the dual-hole terminals of the grounding

cable, into the grounding holes of the chassis.

4. Connect the ring terminal of the grounding cable to the grounding post of the grounding strip, and

fasten the grounding cable to the grounding strip with the hex nut.

Figure 13 Connecting the grounding cable to a grounding strip

(1) Grounding sign

(3) Grounding strip

(6) Hex nut

(2) Attach the grounding screws with dual-hole terminals to the grounding holes

(4) Grounding post

(5) Rin

terminal

Grounding the switch through the PE wire of an AC power supply

CAUTION:

Make sure the AC power supply uses a three-wire cable with a protection wire, and the PE wire of the AC

power supply is well grounded at the power distribution room or AC power supply transformer side. In

addition, make sure the PE connector on the switch is well connected to the PE wire of the AC power

supply.

If the switch is AC powered and no grounding strip is available at the installation site, you can ground

the switch through the PE wire of the AC power supply, as shown in Figure 14.

17

Page 24

Figure 14 Grounding the switch through the PE wire of the AC power supply

Grounding the switch through the RTN wire of a DC power supply

CAUTION:

Make sure the RTN wire is well grounded from the DC egress of the DC power cabinet.

If the switch is powered by a –48 VDC power supply and no grounding strip is available at the

installation site, you can ground the switch through the return (RTN) wire of the DC power supply, as

shown in Figure 15.

18

Page 25

Figure 15 Grounding the switch through the RTN wire of the DC power supply

DC power box

-48V strip

RTN strip

PGND strip

Ground

19

Page 26

Installing FRUs

There is no required order for installing FRUs. HP recommends that you connect power cords after

installing all required FRUs.

TIP:

Keep the chassis and component packages for future use.

Attaching an ESD wrist strap

The switch provides an ESD wrist strap. To minimize ESD damage to electronic components, wear the

ESD wrist strap and make sure it is well grounded when installing modules.

To use an ESD wrist strap:

1. Make sure the switch is well grounded. For how to ground your switch, see "Installing the switch."

2. Put on the wrist strap.

3. Tighten the wrist strap to keep good skin contact. Make sure the resistance reading between your

body and the ground is between 1 and 10 megohms.

4. As shown in Figure 16, insert the ESD wrist strap into th

it to the grounding screw of the chassis with an alligator clip.

e ESD port on the switch chassis, or attach

20

Page 27

Figure 16 Attaching an ESD-prevent wrist strap (on a 11908-V)

(1) ESD wrist strap port (having an ESD sign)

Installing a card

Unless otherwise stated, MPUs, LPUs, and switching fabric modules are collectively referred to as "cards"

in this document.

All cards of the HP FlexFabric 11900 switches are hot swappable.

After all cards are installed, you can verify the running status of a card by referring to the card status LED

(SLOT) on the MPU of the switch. If the RUN LED blinks, the card in the slot operates correctly. For more

information about card status LED (SLOT), see "Appendix C LEDs."

IMPORTANT:

• Before installing a card to the chassis, make sure the connectors on the card are not broken or blocked

to avoid damaging the backplane.

• To ensure good ventilation, install a blank filler panel over an empty MPU, LPU, or switching fabric

module slot. MPU slots use the same type of blank filler panels as LPU slots.

21

Page 28

Installing an MPU/LPU

The pink edged MPU slots and purple edged LPU slots of a 11908-V switch are located at the front panel.

The MPUs and LPUs are vertically oriented. When installing an MPU or LPU, make sure its PCB faces left.

To install an MPU or LPU:

1. Wear an ESD wrist strap, and make sure it makes good skin contact and is well grounded. For

more information, see "Attaching an ESD wrist strap."

2. As shown in

panel for future use.

Some card slots do not have a blank filler panel. The figures in this section are for illustration only.

3. As shown in callout 2 on Figure 17, hold the c

the card bottom with the other. Slide the card steadily into the slot along the guide rails.

4. When most part of the card is inserted in the slot, press the ejector levers on the card outward.

5. Push the card until the positioning pin on card touches the hole on the chassis.

6. As shown in callout 3 on Figure 17, pres

panel tightly and the card seats into the backplane

7. As shown in callout 4 on Figure 17, fasten the c

Figure 17 Installing a card

callout 1 on Figure 17, rem

ove the blank filler panel from the slot. Keep the blank filler

ard by the front panel with one hand and support

s the ejector levers inward until the ejector levers touch the

aptive screws on the card.

(1) Loosen the captive screws (2) Insert the card into the slot

(3) Press the ejector levers inward (4) Fasten the captive screws

Installing a switching fabric module

The gray edged switching fabric module slots of a 11908-V switch are located at the rear panel. The

switching fabric modules are horizontally oriented. When installing a switching fabric module, make sure

its PCB faces up.

To install a switching fabric module:

1. Wear an ESD wrist strap, and make sure it makes good skin contact and is well grounded. For

more information, see "Attaching an ESD wrist strap."

22

Page 29

2. Remove the filler panel (if any) from the target slot. Keep the filler panel for future use. See callout

1 on Figure 17.

3. Loo

sen the captive screws on the protection box on the switching fabric module for the 11908-V

switch, hold the ejector levers on the switching fabric module, pressing the buttons on the levers,

pull the ejector levers outward, and pull out the module. See Figure 18.

Keep the prot

ection box for future use.

4. Hold the switching fabric module by the front panel with one hand and support its bottom with the

other. Slide the switching fabric module steadily into the slot along the guide rails.

Do not touch the components on the PCB.

5. As shown in callout 1 in Figure 19, push t

he switching fabric module until the brakes on the ejector

levers touch the slot edges tightly.

6. As shown in callout 2 in Figure 19, press t

he ejector levers inward until the ejector levers touch the

panel tightly and the switching fabric module seats into the backplane.

7. As shown in callout 3 in Figure 19, fasten

the captive screws on the switching fabric module.

Figure 18 Removing the protection box

(1) Loosen the captive screws (2) Press down the buttons

(3) Pull the ejector levers outward (4) Pull out the switching fabric module

23

Page 30

Figure 19 Installing the switching fabric module

(1) Insert the card into the slot until the brakes touch the slot edges tightly

(2) Press the ejector levers inward

(3) Fasten the captive screws on the switching fabric module

Installing a power supply

CAUTION:

• Provide a circuit breaker for each power supply and make sure the circuit breaker is off before

installation.

• Do not install power supplies of different models on the same switch.

• To avoid power supply damage or bodily injury, support the bottom of a power supply instead of

holding its handle for power supply movement.

The switch uses N + 1 or N + N power redundancy and supports AC or DC power input.

The power supply slots are vertical on a 11908-V switch.

Strictly follow the order shown in Figure 20 to a

Figure 20 Power supply installation flow

void security hazards.

24

Page 31

AC and DC power supplies are installed in the same way. This section uses an AC power supply as an

example. For information about AC and DC power supplies, see HP FlexFabric 1190 0 250 0W AC Po we r

Supply User Guide and HP FlexFabric 11900 2400W DC Power Supply User Guide.

Some power supply slots do not have blank panels. The figures in this section are for illustration only.

To install the power supply:

1. Wear an ESD wrist strap and make sure it makes good skin contact and is well grounded. For

more information, see "Attaching an ESD wrist strap."

2. Use a Phillip

s screwdriver to loosen the captive screws on the blank filler panel (if any) to remove

the blank filler panel.

3. Unpack the power supply.

4. Follow the installation graph printed on the blank filler panel of the power supply to install the

power supply in a correct direction:

a. Grasp the handle of the module with one hand and support the module bottom with the other.

b. Push the power supply along the guide rails into the slot until it has firm contact with the slot,

as shown in callout 1 on Figure 21.

5. Press the han

6. As shown in callout 2 on Figure 21, us

dle inward until the handle seats into the slot.

e a Phillips screwdriver to fasten the captive screw on the

handle to attach the power supply.

25

Page 32

W

Figure 21 Installing an AC power supply

1

2

(1) Install the power supply to the chassis. (2) Fasten the captive screw.

Connecting the power cable

Connecting an AC power cable

ARNING!

Before connecting the power cable, make sure the circuit breaker on the power cable is switched off.

To connect an AC power cable:

1. Plug the power cable into the power receptacle of the power supply.

2. Use a cable tie to secure the power cable to the cable management bracket.

{ Figure 22 shows how to connect the power cable for a 119 0 8- V.

26

Page 33

W

3. Plug the other end of the power cable to the AC power receptacle of the power source and switch

on the circuit breaker.

4. Verify the power supply input status LED.

If the LED is on, the power cable is correctly connected. For description of power supply status LEDs,

see "Appendix C LEDs."

Figure 22 Securing the

power cable

Connecting a DC power cable

ARNING!

• Make sure each power cable has a separate circuit breaker.

• Before you connect the power cable, make sure the circuit breaker on the power cable is switched off.

• Make sure the circuit breaker at the power input end is off when you connect the DC power cable to the

terminals on the power source.

To connect a DC power cable:

1. Plug the power cable into the power receptacle of the power supply.

2. Fasten the screw to secure the power cable.

27

Page 34

Figure 23 Connecting the power cable

(1) Insert the power cable plug into the power supply. (2) Fasten the screw.

3. (Optional.) Use a cable tie to secure the power cable to the cable management bracket. For more

information, see Figure 22.

4. Connec

t one end of the blue DC power cable marked with –48V to the negative terminal (–48V)

on the power source and the RTN end of the black DC power cable to the positive terminal (RTN).

Installing a transceiver module (optional)

CAUTION:

• To avoid component damage, read this section carefully before installing a transceiver module.

• Do not remove the protection cover from a transceiver module before connecting an optical fiber.

• Remove the optical fiber, if any, from a transceiver module before installing it.

The transceiver modules available for the switch include SFP, SFP+, and QSFP+.

Installing an SFP+/SFP/QSFP+ module

1. Wear an ESD wrist strap and make sure it makes good skin contact and is well grounded. For

more information, see "Attaching an ESD wrist strap."

2. Unpack the m

3. Pivot the clasp of the module up. Holding the module, gently push the module into the slot until it

has firm contact with the slot (when the top and bottom spring tabs catch in the slot), as shown

in Figure 24.

odule. Do not touch the golden finger of the module.

{ For a QSFP+ module that uses a plastic pull latch, skip this step. QSFP+ modules use either a

metal or plastic pull latch. They are installed in the same way except that you must pivot the

clasp up for the module that uses a metal pull latch.

{ For an SFP+ module, press the module down against the upward force of the bottom spring tab

so you can push the module straight into the port.

{ If you cannot hold the module by its two sides because of high module density, press the module

on its head end to push it in.

28

Page 35

4. Connect the fiber to the module. For the installation procedure, "Connecting your switch to the

network."

Figure 24 Installing an SFP+/SFP/QSF

P+ module

Connecting an SFP+/QSFP+/QSFP+ to SFP+ cable

Use SFP+ cables to connect SFP+ ports, QSFP+ cables to connect QSFP+ ports, and QSFP+ to SFP+

cables to connect QSFP+ and SFP+ ports. All these cables are hot swappable.

To connect an SFP+, QSFP+, or QSFP+ to SFP+ cable:

1. Wear an ESD wrist strap and make sure it makes good skin contact and is well grounded. For

more information, see "Attaching an ESD wrist strap."

2. Unpac

3. Plug the cable connector into the port. Make sure the cable connector is the right side up.

k the cable.

The bend radius of the cable must be at least eight times the cable diameter.

29

Page 36

Setting up an IRF fabric

You can use HP IRF technology to connect and virtualize the switches into a large virtual switch called an

"IRF fabric" for flattened network topology, high availability, scalability, and manageability. For more

information about IRF, see HP FlexFabric 11900 Switch Series IRF Configuration Guide.

IRF fabric setup flowchart

The setup flow is shown in Figure 25. For the actual procedure, see HP FlexFabric 11900 Switch Series IRF

Configuration Guide for the software release you are using.

Figure 25 IRF fabric setup flowchart

To set up an IRF fabric:

30

Page 37

Step Description

Plan the installation site and IRF fabric setup parameters:

• Planning IRF fabric size and the installation site

1. Plan IRF fabric setup.

• Identifying the master switch and planning IRF member IDs

• Planning IRF topology and connections

• Identifying physical IRF ports on the member switches

2. Install IRF member switches.

3. Power on the switches.

4. Configure basic IRF settings on

each switch in standalone

mode.

5. Connect the physical IRF ports.

6. Enable IRF mode.

7. Verify the IRF settings.

8. Configure other settings in IRF

mode.

See "Installing the switch."

N/A

See HP FlexFabric 11900 Switch Series IRF Configuration Guide.

Connect physical IRF ports on switches.

See HP FlexFabric 11900 Switch Series IRF Configuration Guide.

Log in to the IRF fabric at any member switch and verify that you can

configure all member switches as if they were one node.

See HP FlexFabric 11900 Switch Series IRF Configuration Guide.

Planning IRF fabric setup

This section describes issues that an IRF fabric setup plan must cover.

Planning IRF fabric size and the installation site

Plan IRF fabric size and the installation site, using the following procedure:

1. Use HP FlexFabric 11900 Switch Series IRF Configuration Guide as a reference to identify the

number of member switches that your system software version supports for an IRF fabric.

All member switches must use the same system software version.

2. Select LPUs that can provide 10-GE/40-GE ports.

The switches require 10-GE/40-GE ports for IRF connection. For more information about LPUs, see

"Appendix B FRUs and compatibility matrixes."

3. Select SFP+/QSFP+ transceiver modules and fibers for long-haul IRF connection, or select

SFP+/QSFP+/QSFP+ to SFP+ cables for short-haul IRF connection. Select 10Gbase-T twisted-pair

cables for short-haul IRF connection.

For more information about transceiver modules and cables, see "Appendix B FRUs and

compatibility matrixes."

4. Plan the installation site.

Identifying the master switch and planning IRF member IDs

Determine which switch you want to use as the master for managing all member switches in the IRF

fabric.

31

Page 38

An IRF fabric has only one master switch. You configure and manage all member switches in the IRF

fabric at the CLI of the master. IRF member switches will automatically elect a master. You can affect the

election result by assigning a high member priority to the intended master switch. For more information

about master election, see HP FlexFabric 11900 Switch Series IRF Configuration Guide.

Prepare an IRF member ID assignment scheme. An IRF fabric uses member IDs to uniquely identify and

manage its members, and you must assign each IRF member switch a unique member ID.

Planning IRF topology and connections

Connect the IRF member switches through IRF ports, the logical interfaces for the connections between

IRF member switches. Each IRF member switch has two IRF ports: IRF-port 1 and IRF-port 2. To use an IRF

port, you must bind at least one physical port to it.

When connecting two neighboring IRF member switches, you must connect the physical ports of IRF-port

1 on one switch to the physical ports of IRF-port 2 on the other switch.

A two-member IRF fabric must use the daisy chain topology.

If the system software version you are using supports more than two IRF members, you can create an IRF

fabric that comprises more than two members in daisy chain topology or more reliable ring topology. In

ring topology, the failure of one IRF link does not cause the IRF fabric to split as in daisy chain topology.

Instead, the IRF fabric changes to a daisy chain topology without interrupting network services.

Identifying physical IRF ports on the member switches

Identify the physical IRF ports on the member switches according to your topology and connection

scheme.

On the switch, only 10-GE/40-GE ports can be used for IRF connection.

The switch supports multi-card link aggregation for IRF ports. You can bind up to eight physical ports to

one IRF port.

Installing IRF member switches

Step Reference

1. Prepare the installation site.

2. Rack mount the IRF member switches.

3. Install modules on IRF member switches.

Preparing for installation

Installing the switch

Installing FRUs

Configuring basic IRF settings

After you install the IRF member switches, power on the switches, and log in to each IRF member switch

(see "Connecting your switch to the network") t

port bindings.

Follow these guidelines when you configure the switches:

o configure their member IDs, member priorities, and IRF

32

Page 39

• First configure the member IDs, member priorities, and IRF port bindings for the IRF member

switches, save the configuration, connect the member switches, and change the operating mode of

the switches to IRF mode.

• Assign the master switch higher member priority than any other switch.

• Bind physical ports to IRF-port 1 on one switch and to IRF-port 2 on the other switch.

• Execute the display irf configuration command to verify the basic IRF settings.

For more information about configuring basic IRF settings, see HP FlexFabric 11900 Switch Series IRF

Configuration Guide.

Connecting the physical IRF ports

Follow these guidelines when selecting transceiver modules and cables:

• Use SFP+ transceiver modules and fibers for long-distance connection, or use SFP+ cables to

connect SFP+ ports for short-distance connection.

• When connecting SFP+ ports, connect the transmit port of an SFP+ transceiver module at one end

to the receive port of an SFP+ transceiver module at the other end.

• Use QSFP+ transceiver modules and fibers for long-distance connection, or use QSFP+ cables to

connect QSFP+ ports for short-distance connection.

• Use twisted-pair cables to connect 10Gbase-T ports.

• The transceiver modules at the two ends of an IRF link must be the same type.

For more information about installing transceiver modules, see "Installing FRUs." F

about connecting fibers, see "Connecting your switch to the network."

Figure 26 Connecting two IRF member switches

or more information

33

Page 40

g

P

Verifying the IRF fabric configuration

After you finish configuring basic IRF settings and connecting IRF ports, verify the basic functionality of

the IRF fabric, as follows:

1. Log in to the IRF fabric through the console port of any member switch.

2. Create a Layer 3 interface, assign it an IP address, and make sure the IRF fabric and the remote

network management station can reach each other.

3. Use Telnet or SNMP to access the IRF fabric from the network management station. (See HP

FlexFabric 11900 Switch Series Fundamentals Configuration Guide.)

4. Verify that you can manage all member switches as if they were one node.

5. Display the running status of the IRF fabric by using the commands in Table 7.

Table 7 Displaying and maintaining IRF configuration and runni

Task Command

Display information about the IRF fabric. display irf

Display topology information about the IRF fabric. display irf topology

NOTE:

To avoid IP address collision and network problems, confi

presence of multiple identical IRF fabrics and handle collisions. For more information about MAD, see

FlexFabric 11900 Switch Series IRF Configuration Guide.

ng status

ure at least one MAD mechanism to detect the

H

34

Page 41

Connecting your switch to the network

This chapter describes how to connect your switch to a network.

The first time you access the switch you must log in through the console port. On the switch, you can

configure Telnet or SSH for remote access through Ethernet ports. You manage console login users at

AUX user lines, and manage Telnet and SSH users at VTY user lines. For more information about login

methods and user lines, see HP FlexFabric 11900 Switch Series Fundamentals Configuration Guide.

NOTE:

• The switch with one MPU supports one AUX user and the switch with two MPUs supports up to two

concurrent AUX users. The total number of AUX users that an IRF fabric supports equals the number of

MPUs in the IRF fabric.

• An HP FlexFabric 11900 switch supports up to 16 concurrent VTY users.

Accessing the switch for the first time

The first time you access the switch you must use a console cable to connect a console terminal, for

example, a PC, to the console port on the switch.

Setting up the configuration environment

To connect a terminal (for example, a PC) to the switch:

1. Plug the DB-9 female connector of the console cable to the serial port of the PC.

2. Plug the RJ-45 connector of the console cable to the console port of the switch.

3. Power on the PC.

NOTE:

• Identify the mark on the console port and make sure you are connecting to the correct port.

• The serial ports on PCs do not support hot swapping. If the switch has been powered on, connect the

console cable to the PC before connecting to the switch, and when you disconnect the cable, first

disconnect from the switch.

35

Page 42

Figure 27 Connecting a console port to a terminal

Setting terminal parameters

To configure and manage the switch, you must run a terminal emulator program on the console terminal.

If your PC runs Windows 2003 Server, add the HyperTerminal component before performing the

following steps to log in to and manage the switch. If your PC runs Windows 2008 server, Windows 7,

Windows Vista, or any other operating system, prepare third-party terminal control software, and follow

the software user guide or help to configure the terminal.

The following are the required terminal settings:

• Bits per second—9,600

• Data bits—8

• Parity—None

• Stop bits—1

• Flow control—None

• Emulation—VT100

To set terminal parameters, for example, on a Windows XP HyperTerminal:

1. Select Start > All Programs > Accessories > Communications > HyperTerminal.

The Connection Description dialog box appears.

2. Enter the name of the new connection in the Name field and click OK.

36

Page 43

Figure 28 Connection description

3. Select the serial port to be used from the Connect using list, and click OK.

Figure 29 Setting the serial port used by the HyperTerminal connection

4. Set Bits per second to 9600, Data bits to 8, Parity to None, Stop bits to 1, and Flow control to None,

and click OK.

37

Page 44

Figure 30 Setting the serial port parameters

5. Select File > Properties in the HyperTerminal window.

Figure 31 HyperTerminal window

6. On the Settings tab, set the emulation to VT100 and click OK.

38

Page 45

Figure 32 Setting terminal emulation in Switch Properties dialog box

Powering on the switch

Before powering on the switch, confirm the following:

• You know where the emergency power-off switch for the equipment room is located.

• The switch has been securely mounted.

• All the cards have been correctly installed.

• The unused slots have been installed with blank filler panels.

• All the network cables, fibers, power cables, and grounding cables have been correctly connected.

• The input power voltage meets the requirement of the switch.

• The console cable is correctly connected, the terminal or PC used for configuration has started, and

the configuration parameters have been set.

To power on the switch:

Turn on the power source of the switch to power on the switch.

The following is sample output you can see on the terminal:

System is starting...

Press Ctrl+D to access BASIC-BOOTWARE MENU...

Press Ctrl+T to start memory test

Press Ctrl+V to start heavy memory test

Booting Normal Extended BootWare....

39

Page 46

The Extended BootWare is self-decompressing......Done.

****************************************************************************

* *

* BootWare, Version 1.08 *

* *

****************************************************************************

Compiled Date : Jan 7 2013

CPU Type : XLP316

CPU Clock Speed : 1200MHz

Memory Type : DDR3 SDRAM

Memory Size : 8192MB

Memory Speed : 667MHz

BootWare Size : 1536KB

Flash Size : 500MB

BASIC CPLD Version : 1.0

EXTENDED CPLD Version: 1.0

PCB Version : Ver.A

BootWare Validating...

Press Ctrl+B to access EXTENDED-BOOTWARE MENU...

normal boot app

Loading the main image files...

Loading file flash:/11900-CMW710-SYSTEM-A2102.bin.......................

............................................................................

............................................................................

............................................................................

............................................................................

............................................................................

...................................................Done.

Loading file flash:/11900-CMW710-BOOT-A2102.bin.........................

............................................................................

............................................Done.

Image file flash:/11900-CMW710-BOOT-A2102.bin is self-decompressing.....

............................................................................

...............Done.

System image is starting...

User interface aux4/0 is available.

Press ENTER to get started.

Press Enter at the prompt. When the prompt <Sysname> appears, you can configure the switch.

After powering on the switch, verify the following items:

• The cooling system is operating, and you can hear fan rotating noise and feel air being blown out.

40

Page 47

g

• The system status LEDs on the MPUs show that the system is operating correctly. For more

information about LED behaviors, see "Appendix C LEDs."

Configuring the switch

By default, the switch does not authenticate the console login user at an AUX interface. To increase

system security and enable remote management:

• Configure remote access services, for example, Telnet or SSH.

• Configure authentication on each user interface, including the AUX interfaces.

Configuring authentication on a user interface

You can configure authentication on a user interface to control access to the switch.

Table 8 de

scribes the Telnet login authentication methods available for a VTY user line.

Table 8 Telnet login authentication methods

Authentication

method

None

Password

Username and

password

Feature Application scenarios

Easy to configure, allows any user to Telnet to

your switch, and lowest in security

Easy to configure, secure, and flat user

management

Complex to configure, secure, and

hierarchical user management

For more information about login methods, see HP FlexFabric 11900 Switch Series Fundamentals

Configuration Guide.

Configuring the basic access function

The switch without any configuration can perform basic data forwarding immediately after it is plugged