Page 1

installation and

reference guide

hp surestore

fc switch 6164

www.hp.com

Page 2

Notice

© Hewlett-Packard Company, 2001. All rights reserved.

Part number: A7326-90902

Edition: E0801

Hewlett-Packard Company makes no warranty of any

kind with regard to this material, including, but not

limited to, the implied warranties of merchantability and

fitness for a particular purpose. Hewlett-Packard shall not

be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing,

performance, or use of this material.

This document contains proprietary information, which is

protected by copyright. No part of this document may be

photocopied, reproduced, or translated into another

language without the prior written consent of

Hewlett-Packard. The information contained in this

document is subject to change without notice.

All other brands, product or service names are or may be

trademarks or service marks of, and are used to identify

products of services of their respective owners.

Brocade Extended Fabrics, Brocade Fabric Manager,

Brocade Fabric OS, Brocade Fabric Watch, Brocade

QuickLoop, Brocade Remote Switch, Brocade Web Tools,

and Brocade Zoning are hereafter referred to as Extended

Fabrics, Fabric Manager, Fabric OS, Fabric Watch,

QuickLoop, Remote Switch, Web Tools, and Zoning

respectively.

Safety notices

Any servicing, adjustment, maintenance, or repair must be

performed only by authorized service-trained personnel.

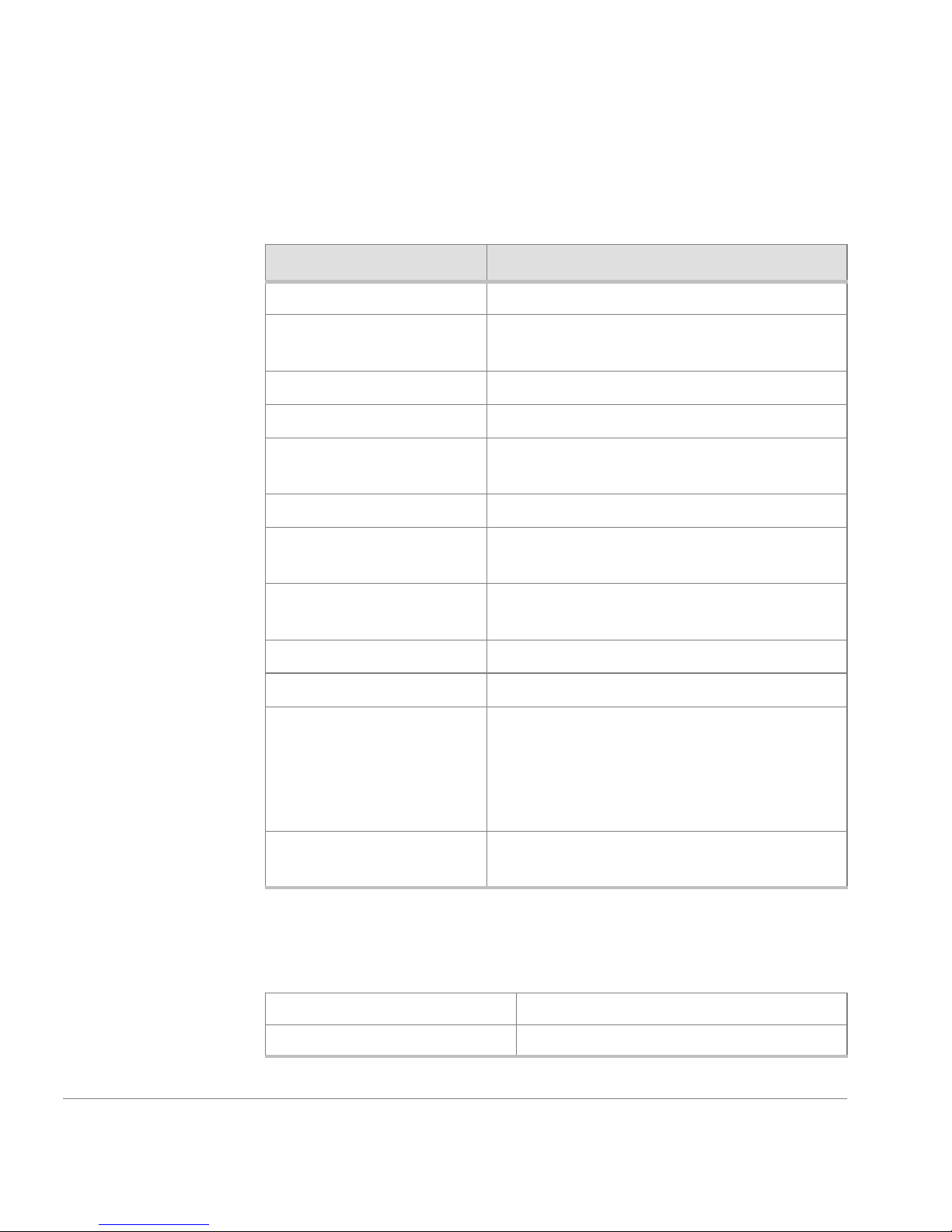

Format conventions

variable Indicates that you must supply a value.

Use, duplication, or disclosure by government is subject

to restrictions as set forth in subdivision (c) (1) (ii) of the

Rights in Technical Data and Computer Software Clause

at DFARS 252.227.7013.

Warranty

If you have any questions about the warranty for this

product, contact your dealer or local Hewlett-Packard

sales representative.

Trademarks

Brocade, SilkWorm, Brocade Extended Fabrics, Brocade

Fabric Manager, Brocade Fabric OS, Brocade Fabric

Watch, Brocade QuickLoop, Brocade Remote Switch,

Brocade Web Tools, and Brocade Zoning are trademarks

or registered trademarks of Brocade Communications

Systems, Inc. in the United States and/or in other

countries.

output Denotes text displayed on the screen.

[ ] Indicates that the enclosed element is

optional and may be left out.

{ } Indicates that you must specify one of the

listed options.

| Separates alternatives.

. . . Indicates a repetition of the preceding

parameter.

Denotes ideas for enhanced product usage.

Tip

Note Denotes significant concepts or operating

instructions.

CAUTION Denotes a hazard that can cause hardware or

software damage.

WARNING Denotes a hazard that can cause personal

injury or death.

2

Page 3

CONTENTS

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

About This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Getting Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Getting Software Updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1 Introducing the FC 6164 . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Management Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Fabric-level Management Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Switch-level Management Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2 Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . 15

Chassis-level Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Weight Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Thermal Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

GBICs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Fiber Optic Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3

Page 4

Switch-level Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

General Information About the 2250 Switch . . . . . . . . . . . . . . . . . . 19

Switch Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2250 Switch Physical Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Switch Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Environmental Specifications for each Switch . . . . . . . . . . . . . . . . . 21

LED Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3 Installing and Configuring the FC 6164 . . . . . . . . . . . . . 25

Installation Considerations and Safety Guidelines . . . . . . . . . . . . . . . . . 25

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Items Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Unpacking the FC 6164 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Installing the FC 6164 in the Rack . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Configuring the FC 6164 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4 Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . . . 57

Switch Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

ISL Cable Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

5 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Diagnostic Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6 Introducing Fabric Manager . . . . . . . . . . . . . . . . . . . . . . . 81

Views Available in Fabric Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

4 HP Surestore FC Switch 6164 Installation and Reference Guide

Page 5

7 Installing Fabric Manager . . . . . . . . . . . . . . . . . . . . . . . . 89

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Switch Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Workstation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Installing Fabric Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Installing a Web Browser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Configuring the Web Browser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Installing the Java Plug-in on the Workstation . . . . . . . . . . . . . . . . . 93

Installing Fabric Manager on the Workstation . . . . . . . . . . . . . . . . . 94

Launching Fabric Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Adding the Browser Pathname to the Properties File . . . . . . . . . . . . . . 100

Uninstalling Fabric Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

8 Using Fabric Manager . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Fabric View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Fabric Events View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Fabric Topology View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Name Server Table View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Zone Administration View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Alias Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Zone Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

QuickLoop Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Config Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Fabric Manager Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Switch View for the FC 6164 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Switch View for Individual Switches . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Switch Events View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Port Information View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

PortStats Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

GBIC Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Loop Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Fabric Watch View (Optional Software) . . . . . . . . . . . . . . . . . . . . . . . 151

Alarm Notifications Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Configure Thresholds Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Current Settings Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Contents 5

Page 6

Performance View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Administrative Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Switch Admin Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

User Admin Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Firmware Upgrade Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Reboot Switch Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

SNMP Admin Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

License Admin Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Remote Switch Tab (Optional Software) . . . . . . . . . . . . . . . . . . . . 171

QuickLoop Admin Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Config Admin Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Extended Fabric Tab (Optional Software) . . . . . . . . . . . . . . . . . . . . 177

Telnet Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

9 Telnet Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

islTopoCheck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

islTopoShow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

sgroupDelete . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

sgroupRename . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

sgroupSet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

sgroupShow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

sgroupSupportShow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

sgroupSwReplace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

switchStatusPolicySet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

switchStatusPolicyShow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

snmpMibCapSet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

A FC 6164 Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Product Regulatory Information . . . . . . . . . . . . . . . . . . 213

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

6 HP Surestore FC Switch 6164 Installation and Reference Guide

Page 7

Revision History

July 2001 First release.

7

Page 8

8 HP Surestore FC Switch 6164 Installation and Reference Guide

Page 9

About This Guide

This document provides both hardware and software information to support

the HP Surestore FC Switch 6164, and is organized as follows:

PREFACE

Chapter 1

Introducing the FC 6164

Chapter 2

Installing and

Configuring the FC 6164

Chapter 3

Mechanical

Specifications

Chapter 4

Diagnostics

Chapter 5

Maintenance Procedures

Chapter 6

Introducing Fabric

Manager

Chapter 7

Installing Fabric

Manager

Provides general information about the FC 6164

and an overview of the installation procedure.

Provides information about installing and

configuring the FC 6164.

Provides the mechanical details of the FC 6164.

Provides information about diagnostic tests and

error messages.

Provides maintenance procedures for the

FC 6164.

Provides an overview of Fabric Manager, the

management software provided with the

FC 6164.

Provides system requirements and instructions

for installing and launching Fabric Manager.

9

Page 10

Chapter 8

Using Fabric Manager

Provides information about each of the screens

available through Fabric Manager.

Chapter 9

Telnet Commands

Related Publications

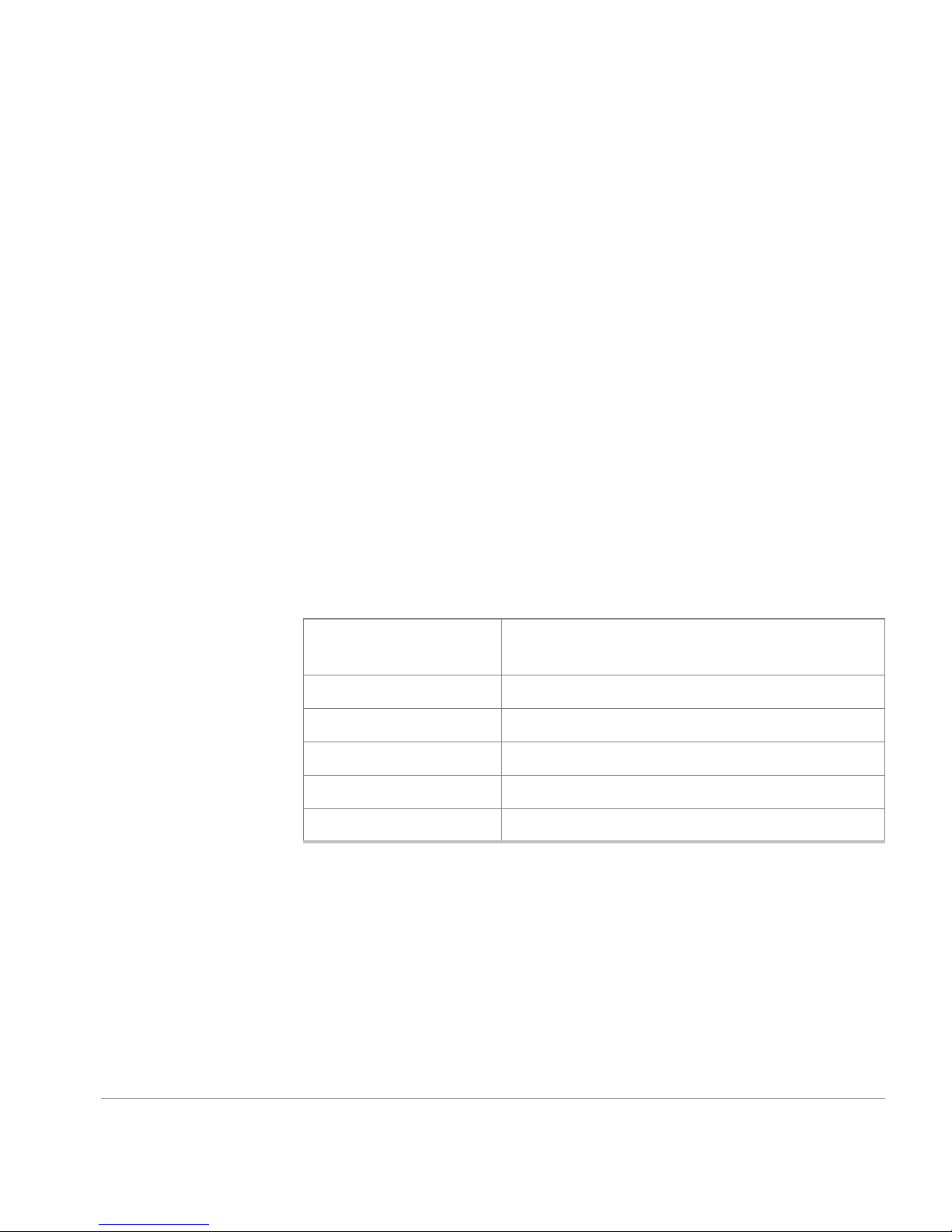

Related product information can be found in the following publications.

Those publications with part numbers are provided as printed copies with

your product. The HP Surestore FC Switch 6164 Documentation CD

contains all publications listed in the table below and is also provided with

your product.

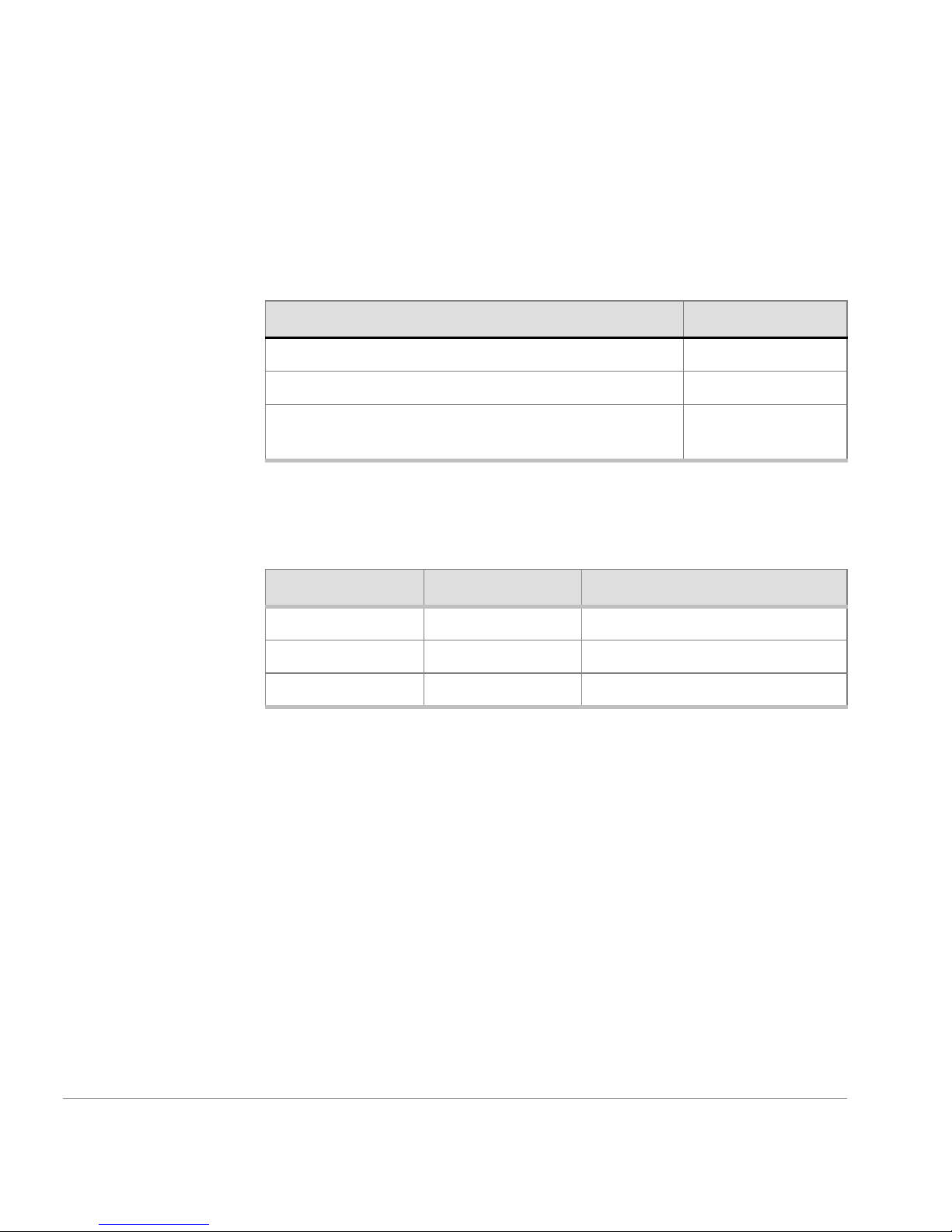

Title Part Number

HP Surestore FC Switch 6164 Documentation

CD

HP Surestore FC Switch 6164 Installation and

Reference Guide

HP Surestore FC Switch 6164 Quick Start Guide A7326-90901

Provides information about the Telnet

commands that are specific to administration of

the FC 6164.

A7326-11011

A7326-90902

Distributed Fabrics User’s Guide, version 2.2 Available only on CD

Fabric OS Reference Manual, version 2.4 Available only on CD

Fabric Watch User’s Guide, version 2.2 Available only on CD

MIB Reference Manual, version 2.3 Available only on CD

QuickLoop User’s Guide, version 2.3 Available only on CD

Web Tools User’s Guide, version 2.3 Available only on CD

Zoning User’s Guide, version 2.2 Available only on CD

For information about Fibre Channel standards, visit the Fibre Channel

Association web site, located at

http://www.fibrechannel.com.

10 HP Surestore FC Switch 6164 Installation and Reference Guide

Page 11

Getting Help

For support information, visit the HP web site located at:

http://www.hp.com

Getting Software Updates

Firmware and software updates are found on the HP web site at:

http://www.hp.com

New switch firmware can be installed from the following host operating

systems:

• UNIX

• Windows NT

• Windows 2000

• Windows 98

• Windows 95

Preface 11

Page 12

12 HP Surestore FC Switch 6164 Installation and Reference Guide

Page 13

1

INTRODUCING THE FC 6164

The HP Surestore FC Switch 6164 provides a 64-port enterprise-class fibre

channel switching solution for any-to-any connectivity requirements in a

Storage Area Network (SAN). The FC 6164 provides a cost-effective

means of meeting the large-port-count requirements of workgroups and

enterprises.

The FC 6164 is a rack-mountable solution, comprised of a chassis and six

fully integrated switch modules, with preconfigured inter-switch link (ISL)

fiber optic cables and enhanced management software. The FC 6164

includes Fabric Manager, a management application that provides a

centralized view of the integrated switch modules to simplify

administration and maintenance.

Using this preconfigured, stand-alone fabric as a building block of larger

fabrics, you can scale your storage environment as needed while leveraging

your existing server and storage infrastructure.

13

Page 14

Management Tools

You can manage the FC 6164 at the fabric level and at the switch level.

Fabric-level Management Tool

•Fabric Manager

Fabric Manager provides a centralized, high-level fabric view of the FC

6164, and all other switches if connected in a larger SAN, allowing for

easy administration of the fabric. When more detailed information is

requested, Fabric Manager interacts seamlessly with Web Tools to

provide switch-level information.

Fabric Manager is included with the FC 6164 product, and is installed

on a workstation computer, instead of on the switch, thereby using less

switch resources. The workstation computer must be on the same

network as the switches being managed.

Switch-level Management Tools

The following software is installed on each of the six switches in the

integrated fabric:

• Fabric Operating System (OS) v2.4

• Full Fabric (E_Port)

•Fabric Watch Profile

• QuickLoop – The FC 6164 is shipped with all ports defaulted to fabric

mode.

•Web License

• Zoning License

• Enterprise Bundle:

–Zoning

–Web Tools

–Fabric Watch

14 HP Surestore FC Switch 6164 Installation and Reference Guide

Page 15

2

MECHANICAL SPECIFICATIONS

The FC 6164 is a plug-and-play fabric that provides 64 user ports, and is

comprised of the following items:

• a chassis with a removable front door

• six FC Silkworm 2250 switches (Each 2250 switch has one serial port

and one Ethernet port)

• one serial cable

• six power cables

• all required ISL (inter-switch link) fiber optic cables and ISL GBICs

Chassis-level Information

The FC 6164 chassis includes cable-routing holes in the upper, lower, and

side panels for easy cable management.

A color-coded ISL cable diagram is provided on the inside bottom of the

chassis, for reference when switches or ISL cables are being replaced (see

Chapter 4, “Maintenance Procedures”, for the cable and switch replacement

procedures). Each port should be connected by the ISL cable to the other

15

Page 16

port that has the same color in the diagram. This color should also match

the label color on the associated ISL cable.

Weight Specifications

Table 1. Weight Specifications

Hardware Weight

Chassis (empty) ~ 65 Pounds

Individual 2250 switch ~ 20 Pounds

Chassis with all six switches installed

(fully loaded with GBICs and fiber optic cables)

Dimensions

The FC 6164 chassis has the following dimensions:

Dimension Size Smallest Rack Space

Height 25 inches 14 Units

Width 19 inches 19 inches

Depth 24 inches 30 inches

The FC 6164 chassis has a 14 unit (25 inch) rack height, 19 inch rack

width, and is 24 inch deep, fitting in a 30 inch deep rack.

Thermal Characteristics

Each of the six 2250 switches has built-in axial fans to cool the units. The

direction of air flow is from the air inlet side to the service side (the front,

where the ports and ISL cables are) of the units. The entire FC 6164 is

optimized to provide proper cooling for a maximum power rating of

70 Watts per 2250 switch. Total system power is 420 Watts.

~ 200 Pounds

The FC 6164 has an operating range in 10 to 40°C at 3 km (9,800 feet).

16 HP Surestore FC Switch 6164 Installation and Reference Guide

Page 17

GBICs

Fiber Optic Cables

The FC 6164 is compatible with the following types of GBICs:

• short wave GBICs

• long wave GBICs

• short wave serial ID GBICs

• long wave serial ID GBICs

• smart GBICS (available from Finisar)

The FC 6164 product includes SWL (short wave length) GBICs for the

ISL (inter-switch link) ports. GBICs for the user ports are not included.

The FC 6164 product includes gray fiber optic cables for the ISL ports.

Fiber optic cables for the user ports are not included.

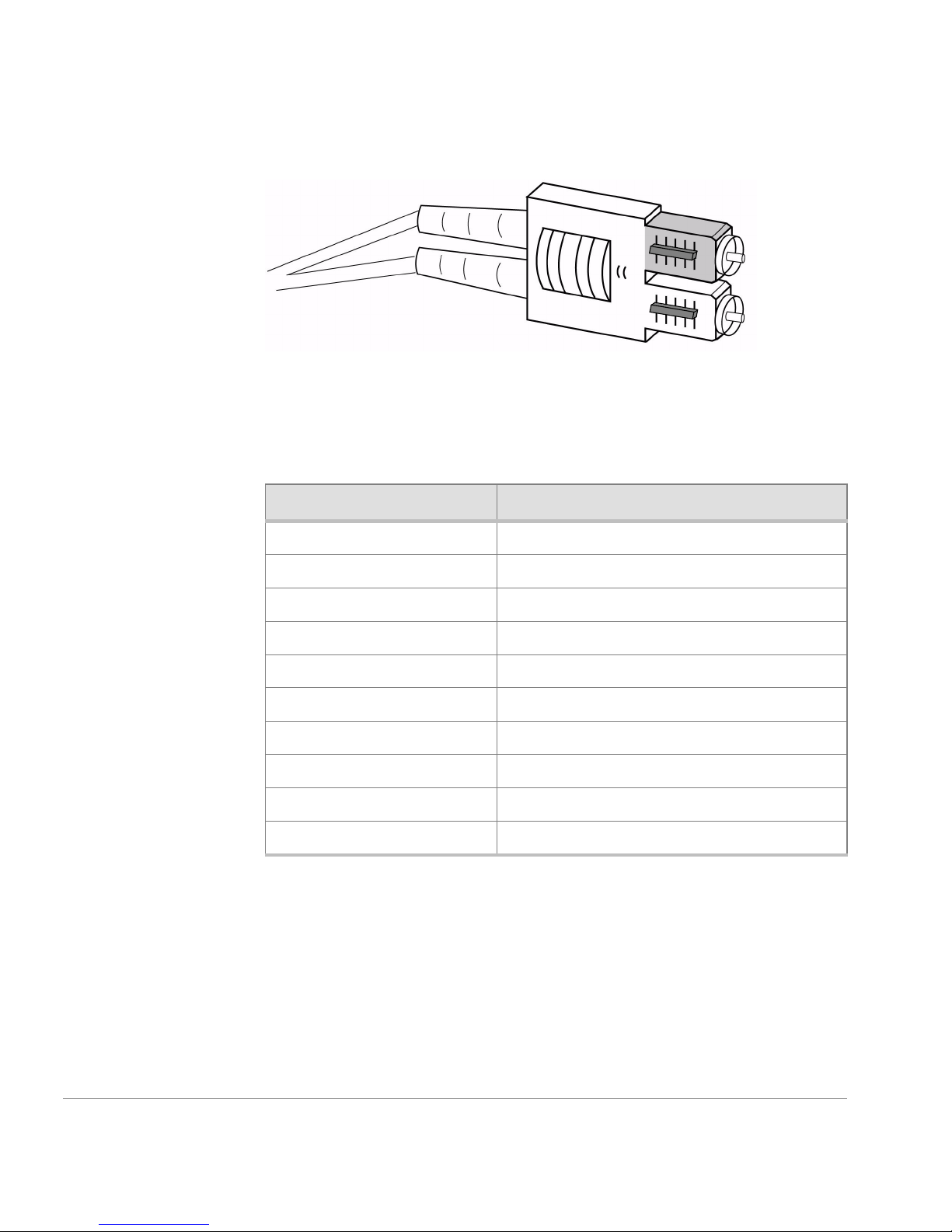

Standard fiber optic cables can be used for the user ports, and connections

can be made to the GBICs inserted in the user ports using standard dual SC

plug connectors, as shown in Figure 1. The fiber optic connectors are keyed

and must be inserted into the GBIC module connector in proper alignment.

CAUTION

The fiber optic cables are fragile and should not be bent to a

radius of less than 0.5 inches.

Do not force the fiber optic plug into the GBIC module because this can

damage the connector, the GBIC module, or both. Verify that the fiber optic

connector is clean, free of dust or debris, and correctly aligned before

inserting the connector into the GBIC module.

Mechanical Specifications 17

Page 18

Figure 1. Dual SC Fiber Optic Plug Keyed Connector

The acceptable environmental ranges for the FC 6164 are shown in Tabl e 2.

These environmental ranges also apply to each switch.

Table 2. FC 6164 Environmental Specifications

Specification Value

Temperature (operating) 10 to 40°C

Temperature (nonoperating) -35 to 65°C

Operating humidity 5 to 85% noncondensing at 40°C

Nonoperating humidity 95% RH nonconducting at 40°C

Operating altitude 0 to 3 km above sea level

Nonoperating altitude 0 to 12 km above sea level

Operating shock 4 G, 11-MS duration, half sine

Nonoperating shock 20 G, 11-MS duration, sq.wave

Operating vibration 5 G, 0 to 3 kHz

Nonoperating vibration 10 G, 0 to 5 kHz

18 HP Surestore FC Switch 6164 Installation and Reference Guide

Page 19

Switch-level Information

General Information About the 2250 Switch

The 2250 switch has full fabric capability, which allows the 2250 switch to

be linked to multiple other fibre channel switches to build a scalable SAN

fabric, capable of supporting large numbers of attached storage devices.

The FC 6164 supports F_Port, FL_Port, and E_Port connections and a

Distributed Name Server (DNS). There is no On/Off switch; the switch is

powered on or off when the power cable is connected or disconnected.

AC module

Figure 2.

Mechanical Specifications 19

2250 Switch

DB-9 port

GBIC port

10/100BaseT port

Page 20

Switch Specifications

Tabl e 3 lists general switch specifications for the 2250 switch.

Table 3. Switch Specifications

Specification Description

Fabric initialization Complies with FC-SW 3.2

IP over Fibre Channel

Complies with FC-IP 2.3 of the FCA profile

(FC-IP)

System architecture Nonblocking shared-memory switch

System processor Superscalar 33-Mhz Intel i960RP

Number of Fibre Channel

16 GBIC ports

ports

Fibre Channel port speed 1.0625-Gbps full duplex

Modes of operation Fibre Channel Class 2 service and Fibre

Channel Class 3 connectionless service

Aggregate switch I/O

16 Gbps, full duplex

bandwidth

Frame buffers 16 buffers per port at 2112 bytes per frame

Port to port latency Less than 2 microseconds with no contention

Data transmission range Up to 500 m (1,625 ft.) for short wave length

optical link

Chassis type Back-to-front airflow (AC power connection

2250 Switch Physical Dimensions

Table 4. 2250 Switch Physical Specifications

Rack Mount Dimensions: 1.5U, 19-in. rack mount (EIA compliant)

Weight: 20.0 lbs.

20 HP Surestore FC Switch 6164 Installation and Reference Guide

Up to 10 km (32,820 ft.) for long wave

length optical link

out front)

Page 21

Switch Memory

Power Supply

The available memory for the FC 6164 is as follows:

• Main memory: 16 MB per switch

• Flash memory: 4 MB per bank, with 2 banks in the 2250 switch

(mirrored for redundancy)

The 2250 switch is powered on when the power cable is connected to the

switch and to a power source. The switch automatically performs a power

on self test (POST), which is a diagnostic test that takes approximately 2

minutes.

The 2250 switch has a universal power supply capable of functioning

worldwide without voltage jumpers or switches. The power supply module

is autoranging in terms of accommodating input voltages and line

frequencies.

Table 5. Power Supply Requirements

Total P/S power 70 to 120 W (70-W convection, without fan;

120-W with 30 CFM forced air, with fan)

Max. switch power 60 to 70W

Input voltage 85 to 264 VAC

Input line frequency 47 to 63 Hz

Harmonic distortion Power factor correction per IEC61000-3-2

BTU rating 110 W x 3.412 BTU/hr/W = 375 BTU/hr

Environmental Specifications for each Switch

The acceptable environmental ranges for the 2250 switch are the same as

for the entire FC 6164, and are listed under “Thermal Characteristics” on

page 16.

Mechanical Specifications 21

Page 22

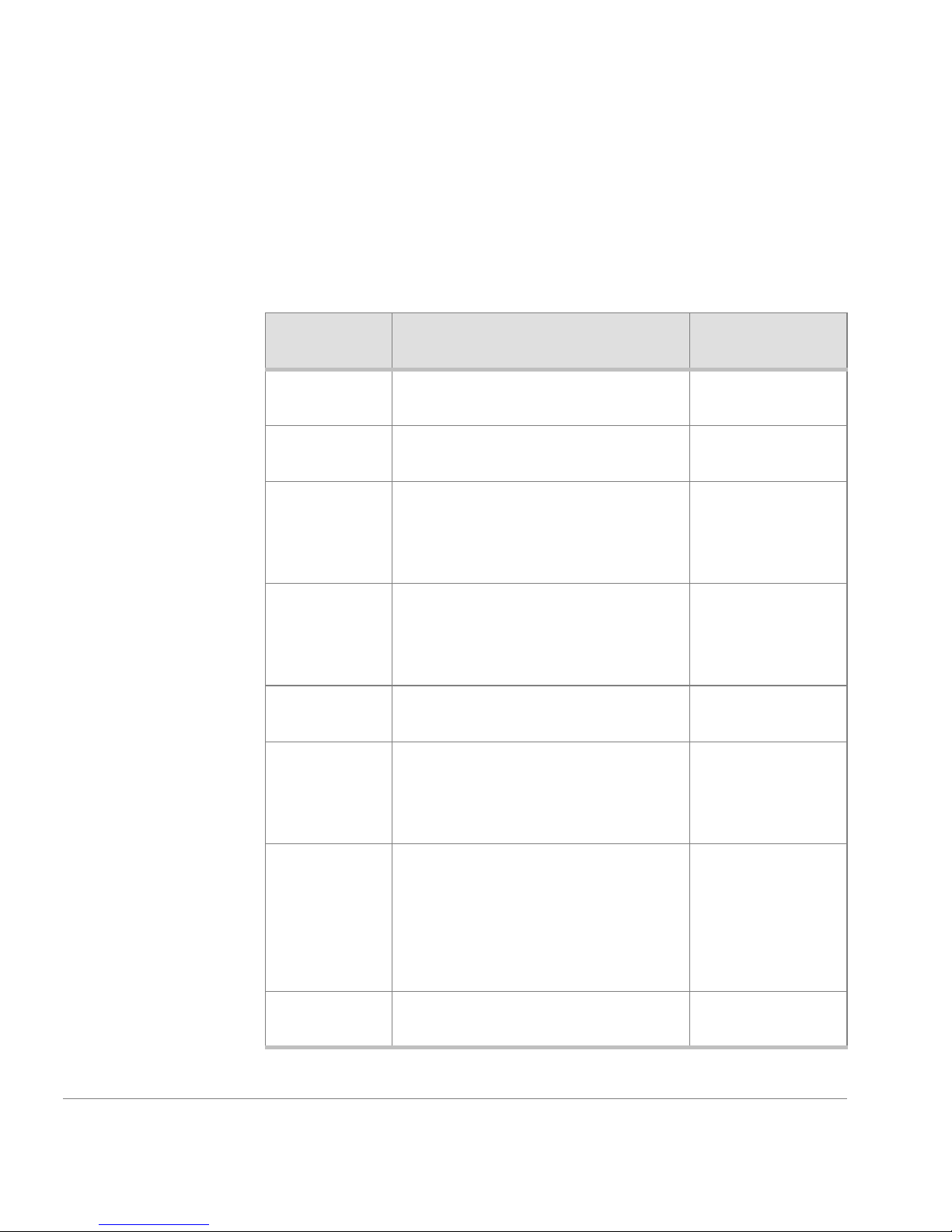

LED Status Indicators

Each port, and the AC power connection, has an LED that indicates the

status for that port or power connection. Table 6 provides a description of

port and AC power status indicators and possible corrective actions in case

of faulty status.

Table 6. LED Status Indicators

LED/Time

Interval

No light

showing

Status/Description Action

No light or signal carrier (no module,

no cable) for media interface LEDs.

Steady yellow Receiving light or signal carrier, but

not yet online.

Slow yellow

(on for one

Port is disabled (result of diagnostics

or port disable command).

second; off for

one second)

Fast yellow

Error, fault with port. Reset switch.

(on for 1/4

second; off for

1/4 second)

Steady green Port is online but no traffic

(connected with device over cable).

Slow green

(on for one

second; off for

Port is online but segmented

(loopback cable or incompatible

switch).

one second)

Check media

connection.

No action

required.

Reset at

management

station.

No action

required.

Check media

connection at both

ends.

Fast green

(on for 1/4

second;

(off for 1/4

second)

Flickering

green

22 HP Surestore FC Switch 6164 Installation and Reference Guide

Internal loopback (diagnostic). No action

required.

Port is online with traffic flowing

through port.

No action

required.

Page 23

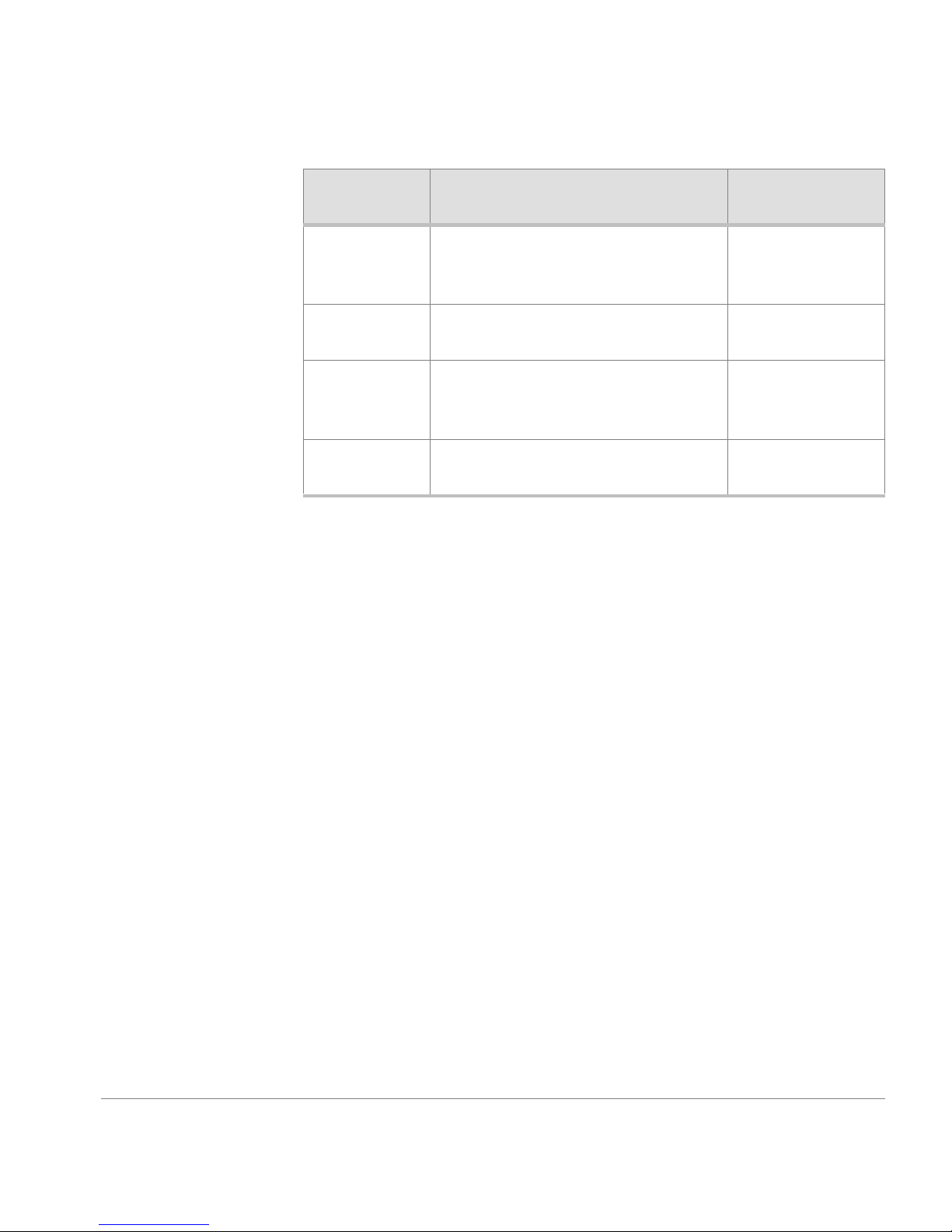

Table 6. LED Status Indicators (continued)

LED/Time

Interval

Interleaving

Status/Description Action

Port is bypassed. Reset at

green and

yellow

AC Power

Status/Description Action

LED

No light

showing

No power is being supplied to the

switch.

Steady green Receiving power and switch is

online.

management

station.

Check power cord

connection to the

switch.

No action

required.

Mechanical Specifications 23

Page 24

24 HP Surestore FC Switch 6164 Installation and Reference Guide

Page 25

3

INSTALLING AND CONFIGURING

THE FC 6164

This chapter provides instructions for installing and configuring the

FC 6164.

Note

referenced in this chapter, enter

at the Telnet prompt. For example, to display information about the

fabricShow

For detailed information about any of the Fabric OS commands

help

command, enter the following:

followed by the

help fabricShow

[command name]

Installation Considerations and Safety Guidelines

WAR NING

handling and lifting equipment, such as a hydraulic lift, to reduce the

possibility of injury or product damage.

The FC 6164 weighs approximately 200 pounds. Use proper

25

Page 26

The FC 6164 is a high-port count integrated fabric comprised of six switch

modules in a rack mountable chassis.

• If installing the FC 6164 in a closed or multi-rack assembly, ensure the

air temperature measured inside the FC 6164 chassis door does not

exceed 40°C during operation.

• Ensure the airflow available to the switch fabric is at least 300 cfm

(cubic feet per minute).

• Verify that the fully-loaded chassis does not unbalance the rack or

exceed the rack’s mechanical limits, with all six FC 6164 switches

secured in the chassis and with one switch partially extended out of the

chassis.

• Verify the supply circuit, line fusing, and wire size are adequate

according to the electrical rating on the switch nameplate.

• Verify that all equipment installed in the rack has a reliable branch

circuit ground connection.

• It is strongly recommended that the EIA Rack be mechanically secured

to prevent tipping over in an earthquake.

Procedures

Use the procedures in this section to upack, install, and configure a the

FC 6164. The overall procedure of installing and configuring the FC 6164

involves the following secondary procedures, described on the indicated

pages:

1. “Unpacking the FC 6164” on page 28

2. “Installing the FC 6164 in the Rack” on page 28

3. “Configuring the FC 6164” on page 51

26 HP Surestore FC Switch 6164 Installation and Reference Guide

Page 27

Items Required

The following items must be available before you begin the installation

procedures:

• FC 6164

• 30” deep rack space, 14 rack units high and 19” wide

• Six Ethernet cables, one for each switch

• Six power outlets, one for each switch

• FC 6164 worksheet, provided in Appendix A, “FC 6164 Worksheet”

• Serial cable connected to the workstation, long enough to connect to

each of the switches in the chassis

• Workstation that has a terminal emulator application (such as

HyperTerminal)

• Six unused IP addresses

• Ethernet connection between the workstation and the FC 6164 (such as

through a hub)

• #2 Phillips screwdriver

• T20 Torx screwdriver

• Genie lift (to transport the switch) For information on the lift, see:

http://www.genielift.com/ml-series/ml-1-2.html

or

http://slick2.atl.hp.com/ceworld/siteservices/tools/genie/genielift_ordering.htm

Installing and Configuring the FC 6164 27

Page 28

Unpacking the FC 6164

To unpack the FC 6164:

1. Open the shipping carton.

2. Remove all of the packaging materials.

3. Remove the screws holding the FC 6164 to the pallet.

Installing the FC 6164 in the Rack

This section provides the step-by-step procedure for installing the

FC Switch 6164 in either an HP rack or a Compaq/Rittal 19-inch rack.

Note

Most of the steps in this procedure are unnecessary if the FC 6164

was installed at an HP integration center prior to shipment. However, Steps

18 and 19 (assembling and installing the plenum) and Step 21 (installing

the switch door) must be performed for factory-integrated switches (see

pages 47 and 50).

Rackmount Safety Guidelines

In a rackmount installation, follow these safety guidelines:

• When installing a switch in a closed or multi-rack assembly, make

certain the air temperature, measured at the front panel, does not exceed

40° C during operation.

• Ensure that the airflow available to the switch is at least 300 cfpm.

• Verify the supply circuit, line fusing, and wire size are adequate. Refer

to the switch’s nameplate for its power requirements.

• Verify that all equipment installed in the rack has a reliable ground

connection. Do not rely on connection to a branch circuit, such as power

strips.

• Route and support the power cord to ensure that it does not become

crimped or damaged and to prevent it from interfering with other

equipment and cabling installed in the rack.

• The FC 6164 weighs approximately 200 pounds. A lift is required to

move and position the switch safely, and at least two people are required

28 HP Surestore FC Switch 6164 Installation and Reference Guide

Page 29

to lift and position the switch onto the lift. Two or more people are also

required to move the switch from the lift into the rack and when

positioning the switch in the rack. Move the switch chassis slowly and

carefully at all times, and continue supporting it until it is correctly

positioned on the rail tray and fastened to the rack. Use extreme caution

when handling or transporting the switch to prevent injury to personnel,

damage to the switch, and/or damage to the rack and other equipment

mounted in it.

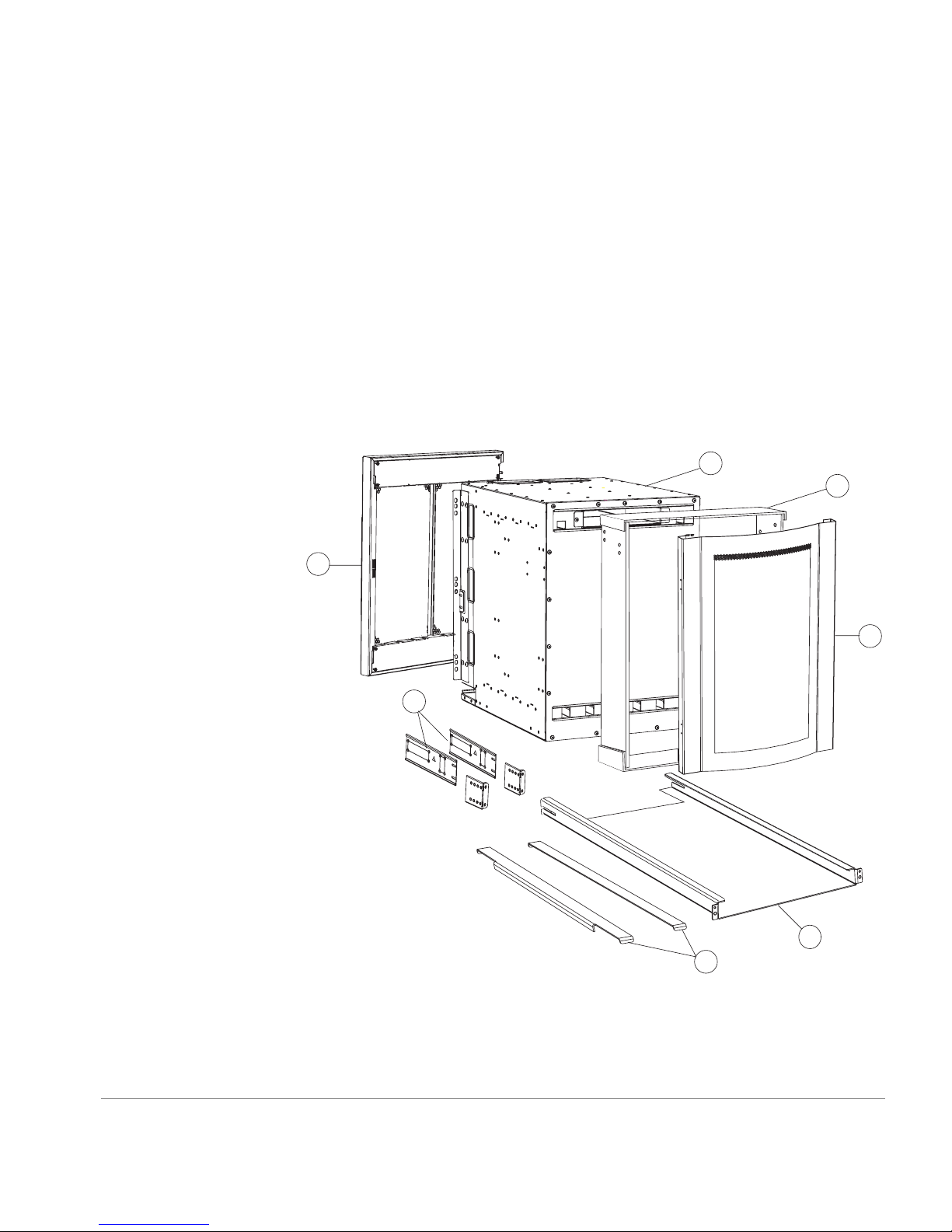

Package Contents

Figure 3 shows the major items contained in the FC 6164 shipping

carton(s). Table 7 lists the contents of the shipping carton.

A

G

B

F

F

Figure 3. Major Items Contained in the Shipping Carton(s)

C

D

E

Installing and Configuring the FC 6164 29

Page 30

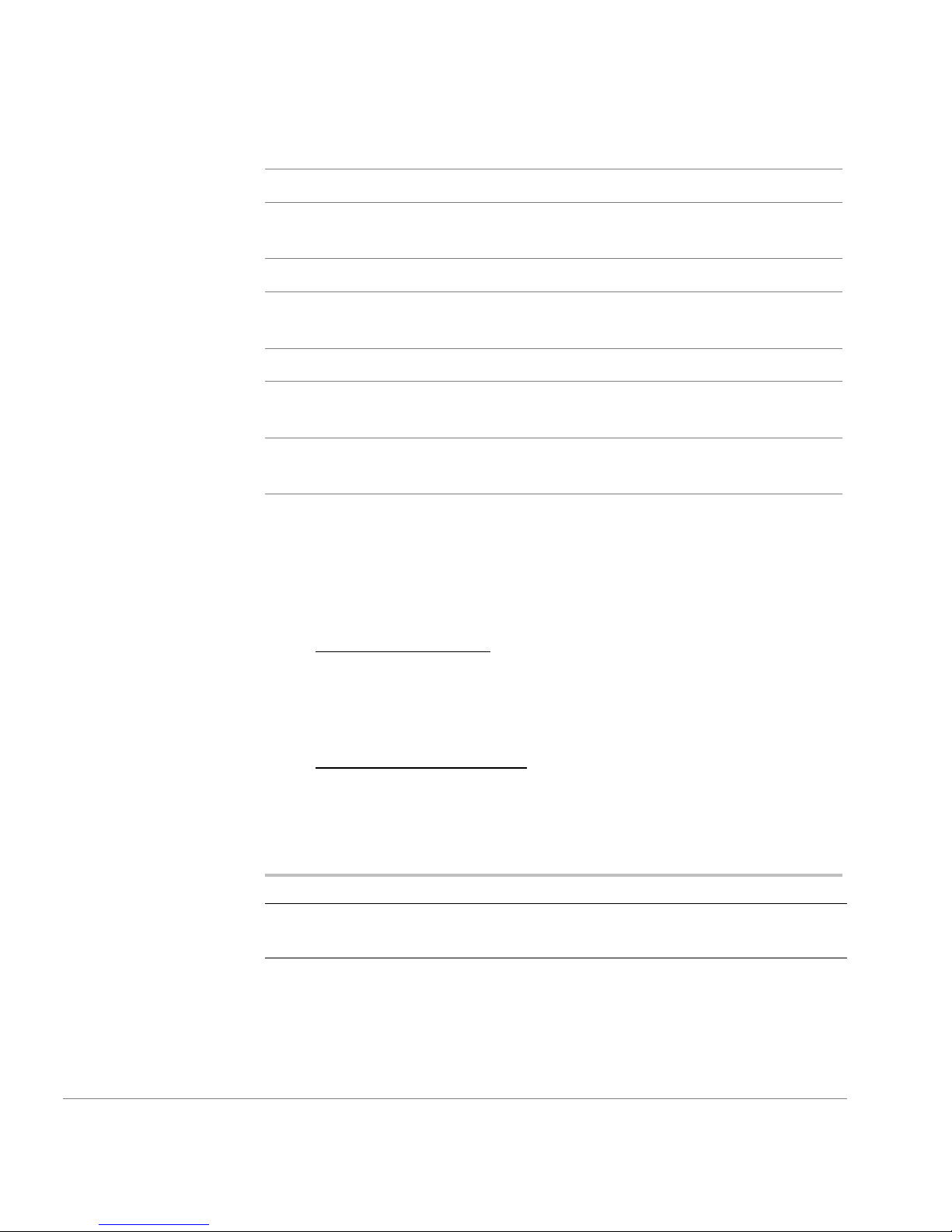

Table 7. Contents of the Shipping Carton(s)

ASwitch

B Plenum kit (4 rectangular sheets of Lexan with 6 adhesive strips

pre-attached) (HP P/N A7326-87903)

C Front bezel (HP P/N A7326-40001)

D Rail Tray kit (Rail tray, 2 brackets, 2 M5 Tinnerman nuts, 4 M5 Torx

screws) (HP P/N A6534-60016)

E Shim plates (2 ea. HP P/N A7326-87904)

F Rack Mount Bracket set (2 Rack-Mount brackets)

(HP P/N A7326-87901)

G Switch door (part of Accessory kit [HP P/N A7326-70001], which

also includes: Software CD, Documentation CD, and Serial cable)

H Miscellaneous hardware: (not shown) (HP P/N A7326-87905)

Note: The hardware in the Standard hardware package (unmarked plastic bag)

is required to install the switch in an HP rack. Some of the hardware in the

Standard hardware package and the hardware in the Compaq/Rittal hardware

package is required to install the switch in a Compaq/Rittal rack.

Standard hardware package

8 #8-32 x .375-inch (.3125) flat-head screws w/patchlock.

8 M5 Torx screws with lock washers

6 M5 Tinnerman nuts

4 1/4-20 x 1/2-inch Phillips pan-head screws with lock washers

Compaq/Rittal hardware package

6 #10-32 Tinnerman nuts

6 #10-32 x 5/8-inch Phillips pan-head screws with captive lock washers

6 Spacers

4 1/4-inch flat washers

4 M5 flat washers

Note

A package containing two mounting rails may be included with the

switch. These rails are not used and can be discarded.

30 HP Surestore FC Switch 6164 Installation and Reference Guide

Page 31

Hardware Identification

Figure 4 contains drawings and descriptions of the hardware used when

installing the FC 6164 in an HP rack or a Compaq/Rittal rack. Use this key

to help identify the hardware specified in the installation procedure in this

chapter.

#8-32 x .375-inch flat-head Phillips screw

M5 Torx screw with captive lock washer

M5 Tinnerman nut

1/4-20 x 1/2 inch Phillips screw and washer

#10-32 Tinnerman nut

#10-32 X 5/8-inch pan-head Phillips screw

Spacers for Compaq/Rittal racks

1/4-inch flat washer

M5 flat washer

Figure 4. Hardware Key

Installing and Configuring the FC 6164 31

Page 32

Installing the FC 6164 in the Rack

WAR NING

Mount the switch as low as possible in the rack to ensure that

the weight of the switch does not make the rack unstable. 15 Rack Units

(RUs) are required (see Figure 5).

Back

of

switch

15 RU

Figure 5. Switch Mounted Back-to-Front and Low in the Rack

CAUTION

of the rack. When the switch is mounted this way, the air flows through the

switch in the same direction as it does through the other equipment in the

rack (see Figure 5).

32 HP Surestore FC Switch 6164 Installation and Reference Guide

Front of rack

The switch must be installed with the front end facing the back

Page 33

Note

In these instructions, the 15 RUs used to mount the switch are called

RU-1 through RU-15 (see Figure 5); RU-1 is the lowest of the 15 RUs.

1. Check the contents of the shipping carton and the kits within the carton

to verify that all of the required parts and hardware are available (see

Figure 3, Tab le 7, and Figure 5).

2. Choose a mounting location in the rack for the switch (see the WARNING

at the beginning of this section and Figure 5).

3. Install the rail tray in the rack:

a. Locate the lowest RU of the 15 you chose for mounting the switch

(this is RU-1).

b. Attach the rear rail-tray brackets to the rear rack uprights at RU-1:

For an HP rack, use 1 M5 torx screw for each bracket (see Figure 6).

For a Compaq/Rittal rack, insert spacers in the upper and lower holes

where the brackets are to be mounted, position the brackets on the

spacers, and use 1 M5 torx screw with captive lock washer and two

M5 flat washers to attach each bracket (see Figure 6).

Installing and Configuring the FC 6164 33

Page 34

HP rack

M5 Screw

with attached

lock washer

Compaq/Rittal

rack

M5 Screw

with attached

lock washer

Figure 6. Installing the Rear Rail-Tray Brackets

M5

flat

washer

Spacer

M5

flat

washer

Rear Tray

bracket

Rear Tray

bracket

Note

mounting instructions on the label attached to the rail tray (some rail

trays do not have this label).

34 HP Surestore FC Switch 6164 Installation and Reference Guide

When installing the rail tray in a Compaq/Rittal rack, ignore the

Page 35

c. Install Tinnerman nuts for the top holes of RU-1 in both of the rack’s

front uprights (see Figure 7).

Note

The Tinnerman nuts used for the two types of racks (HP and

Compaq/Rittal) are of different styles and different sizes. Refer to

Figure 5 and Figure 7 to identify the correct Tinnerman nut to use with

the rack you are installing the switch in.

Tinnerman

nut

Spacer

Inner surface of

Outer surface of

HP rack

Compaq/Rittal

rack

Figure 7. Installing Tinnerman Nuts and Spacers on the Front Uprights

d. For a Compaq/Rittal rack, insert spacers in the holes immediately

below the Tinnerman nuts you inserted in Step 3c (see Figure 7).

Installing and Configuring the FC 6164 35

Page 36

e. Orient the rail tray as shown in Figure 8, and insert it into the rack

from the front. The slots in the sides of the rail tray must slide over

the posts on the rear rail-tray brackets, and the posts on the rail tray’s

front mounting flanges must be inserted in the center holes of RU1.

Figure 8. Inserting the Rail Tray in the Rack

f. Insert M5 torx screws through the top holes in both of the rail tray

mounting flanges. The screws pass through the holes in the rack

uprights and thread into the Tinnerman nuts you installed on the

uprights in Step 3c. Tighten the screws.

36 HP Surestore FC Switch 6164 Installation and Reference Guide

Page 37

4. Place a shim plate on each side of the rail tray (see Figure 9).

Figure 9. Placing the Shim Plates on the Rail Tray

CAUTION

The shim plates must be placed on top of both sides of the

rail tray to prevent misalignment between the mounting holes in the

switch flanges and the holes in the rack uprights.

Installing and Configuring the FC 6164 37

Page 38

5. Insert Tinnerman nuts onto the center holes of RU-5 and the top holes of

RU-12 in both of the rack’s rear uprights (see Figure 10).

12

11

M5 Tinnerman nuts

5

4

#10-32Tinnerman nuts

Rack uprights

1

HP Rack Rittal Rack

Figure 10. Installing Tinnerman Nuts in RU-5 and RU-12

12

11

5

4

1

6. Install the rack-mount brackets on the switch:

a. The rack-mount brackets consist of a stationary plate and an adjustable

plate that are attached to each other with two screws. Remove the

screws that attach the adjustable plates to the stationary plates. Set the

screws and the adjustable plates aside for later use (see Figure 11).

Figure 11. Separating the Rack-Mount Bracket Plates

38 HP Surestore FC Switch 6164 Installation and Reference Guide

Page 39

a. Use four #8-32 x 5/16-inch Phillips flat-head screws to mount one of

the stationary plates onto each side of the switch. The plates must be

oriented so that the end of the plate that has the slotted holes protrudes

past the back of the switch, and if the plate has arrows stamped into

it, the arrows must point up (see Figure 12). Do not tighten the screws

fully at this time.

Note

Some stationary plates have arrows stamped into them, and some

do not. The arrow determines which side of the switch the plate must be

mounted on. If the stationary plates provided with the switch do not

have arrows, they can be mounted on either side.

Installing and Configuring the FC 6164 39

Figure 12. Mounting the Rack-Mount Bracket Stationary Plates to the Switch

Note

If you have adequate access to the back of the rack to insert the

switch from the back, skip Steps 7, 8, and 9. If you do not have adequate

access to the back of the rack, proceed with Step 7.

Page 40

Note

If you cannot insert the switch into the rack from the back, you

must remove several pieces of hardware from the sides of the switch at

the front end as described in Steps 7, 8, and 9. If you have adequate

access to insert the switch into the rack from the back, you can skip

these steps.

7. Remove the four #6-32 x ¼-inch flat-head screws that attach each of the

two hinge plates to the left side of the switch at the front end (see

Figure 13). Set the screws and the hinge plates aside for later use.

x 8

Figure 13. Removing the Hinge Plates from the Switch

40 HP Surestore FC Switch 6164 Installation and Reference Guide

Page 41

8. Remove the two screws that attach the latch plate to the right side of the

switch at the front, and remove the latch plate (see Figure 14). Set the

latch plate and the screws aside for later use.

Note

The latch plate fits through a cutout in the rack-mounting flange

on the right side of the switch.

Rack-mounting

flange

Latch plate

9. Remove the eight #10-32 Phillips screws that attach each of the

Installing and Configuring the FC 6164 41

Figure 14. Removing the Latch Plate and the Mounting Flanges

rack-mounting flanges to the sides of the switch at the front, and remove

the rack-mounting flanges (see Figure 14). Set the rack-mounting flanges

and the screws aside for later use.

Page 42

WAR NING

If the rack you are mounting the switch in is on wheels,

make sure the leveling feet are down or the wheels are locked to prevent

the rack from moving while you are installing the switch. Failure to

prevent the rack from moving could result in injury to personnel and/or

damage to the switch, the rack, or other equipment.

10.Insert the switch in the rack:

WAR NING

The FC 6164 weighs approximately 200 pounds. A lift is

required to move and position the switch safely, and at least two people

are required to lift and position the switch onto the lift. Two or more

people are also required to move the switch from the lift into the rack

and when positioning the switch in the rack. Move the switch chassis

slowly and carefully at all times, and continue supporting it until it is

correctly positioned on the rail tray and fastened to the rack. Use

extreme caution when handling or transporting the switch to prevent

injury to personnel, damage to the switch, and/or damage to the rack and

other equipment mounted in it.

a. Place the switch on a lift. If you are installing the switch from the front

of the rack, orient the switch so its front end FACES THE FRONT OF

THE RACK is at the edge of the lift. If you are installing the switch

from the back of the rack, orient the switch so that its back end is at

the edge of the lift. (The switch must be installed so the front of the

switch faces the back of the rack.)

b. Position the lift close to the rack, and raise it until the bottom of the

switch is even with or very slightly above the top surfaces of the shim

plates that you positioned on top of the rail tray in Step 4.

c. Carefully slide the switch from the lift onto the shim plates on the rail

tray.

d. Position the switch so that its front end protrudes out the back of the

rack approximately six inches.

42 HP Surestore FC Switch 6164 Installation and Reference Guide

Page 43

11.If you inserted the switch into the rack from the back, skip this step.

Reinstall the removed hardware:

a. Use the 16 #10-32 Phillips screws you removed in Step 9 to re-attach

the rack-mounting flanges to the switch (see Figure 14).

b. Use the two screws you removed in Step 8 to re-attach the latch plate

(see Figure 14). Make sure that there is a gap of approximately

3/16-inch between the edges of the latch plate and the edges of the

cutout in the rack-mounting flange.

c. Orient the hinge plates so that the sides that have the loops face each

other (see Figure 15). Use the eight #6-32 x ¼-inch flat-head screws

you removed in Step 7 to re-attach the hinge plates to the left side of

the switch at the front end (see Figure 13).

Loops

Figure 15. Orienting the Hinge Plates Prior to Reinstallation

Installing and Configuring the FC 6164 43

Page 44

12.Re-attach the rack-mount bracket adjustable plates:

a. From the front of the rack, slide the switch forward a small distance.

b. Insert one of the adjustable plates into one the stationary plates (see

Figure 16).

Figure 16. Re-attaching the Rack-Mount Bracket Adjustable Plates

c. Insert the screws you removed in Step 6a through the slotted holes in

the stationary plate and into the second set of threaded holes in the

adjustable plate from the rack-mounting flange (see Figure 16). Do

not tighten the screws at this time.

d. Repeat Steps b and c for the rack-mount bracket on the opposite side

of the switch.

e. Move the switch forward in the rack as far as it can go. The amount

of movement is limited by the rack-mount bracket adjustable plates

contacting the rack uprights.

44 HP Surestore FC Switch 6164 Installation and Reference Guide

Page 45

WAR NING

The FC 6164 weighs approximately 200 pounds.Two or

more people are required when positioning the switch in the rack. Move

the switch chassis slowly and carefully at all times, and continue

supporting it until it is correctly positioned on the rail tray and fastened

to the rack. Use extreme caution when handling or transporting the

switch to prevent injury to personnel, damage to the switch, and/or

damage to the rack and other equipment mounted in it.

f. Put flat washers on four ¼-20 screws with captive lock washers, and

insert the screws through the holes in the rack uprights and into the

threaded holes in the flanges of the rack-mount bracket adjustable

plates (see Figure 16). Do not tighten the screws at this time.

13.From the back of the rack, insert four #10-32 x 5/8-inch Phillips pan-head

screws with captive lock washers through the holes in the rack-mount

flanges attached to the front end of the switch and into the Tinnerman nuts

you placed in the rack in Step 5 (see Figure 10 and Figure 17). Tighten

the screws fully.

Note

For an HP rack, you may have to adjust the positions of the

Tinnerman nuts to get them to align properly with the holes in the rack

uprights. If necessary, use a screwdriver blade inserted through the holes

in the rack uprights to reposition the Tinnerman nuts.

Installing and Configuring the FC 6164 45

Page 46

Figure 17. Attaching the Rack-Mount Flanges to the Rack

14.Fully tighten the screws that attach the rack-mount bracket adjustable

plates to rack uprights, then fully tighten the screws that attach the

adjustable plates to the stationary plates and the screws that attach the

stationary plates to the switch chassis (see Figure 16).

46 HP Surestore FC Switch 6164 Installation and Reference Guide

Page 47

15.Assemble the plenum:

a. Position the bottom panel of the plenum on a flat surface with the two

folded ends facing up (see Figure 18).

Adhesive

strips

Adhesive

strips

Bottom of

plenum

Adhesive

strips

Figure 18. Assembling the Plenum

b. Remove the paper backing from one of the adhesive strips on one of

the plenum side panels, and carefully position the side panel against

the inner surface of one of the folded ends of the bottom panel (see

Figure 18). Press the side panel firmly against the upright end of the

bottom panel to ensure that the adhesive strip on the side panel makes

full contact with the end of the bottom panel. You can use a screwdriver

handle to increase the pressure you apply when joining the parts.

c. Repeat Step 15b for the other side panel.

d. Remove the paper backing from the adhesive strips on the upper ends

of both plenum side panels.

Installing and Configuring the FC 6164 47

Page 48

e. Carefully position the plenum top panel over the side panels so that

the folded ends of the top panel face down and are outside of the side

panels.

f. With the top panel aligned with the side panels, press one of the side

panels firmly against the inner surface of the folded end of the top

panel to ensure that the adhesive strip on the side panel makes full

contact with the folded end of the top panel. Repeat this step for the

other side panel.

16.Install the plenum in the rack:

a. Remove the paper backing from the two adhesive strips on the bottom

surface of the plenum.

b. Position the plenum against the back of the switch and slide it down

until the adhesive strips on the underside of the plenum contact the

shim plates that are on top of the rail tray (see Figure 19).

Back

of

switch

Figure 19. Inserting the Plenum

c. Press down firmly on the bottom panel of the plenum above the

adhesive strips to ensure that the adhesive strips make full contact with

the shim plates on top of the rail tray.

48 HP Surestore FC Switch 6164 Installation and Reference Guide

Page 49

17.Install the front bezel:

a. Orient the front bezel so that its outer surface is facing you.

a. Align the bottom end of the front bezel with the bottom edge of the

rail tray (see Figure 20). There are two alignment posts and two spring

clips on each side of the bezel that grip the rack uprights and hold the

bezel in position. Each of the lower alignment posts fits into the second

unused hole above the front mounting flange on each side of the rail

tray.

Installing and Configuring the FC 6164 49

Figure 20. Installing the Front Bezel

b. Press the sides of the bezel against the rack uprights until the bezel

snaps into place. Snap the bottom end in first and then the top end.

c. Inspect the bezel to ensure that it is installed so that its top edge is

aligned with the top surface of the switch.

Page 50

18.Install the switch door:

a. Rotate the knobs on the switch door so that they are in the down

position and the springs are compressed.

b. Position the door so that the hinge pins are between the loops on the

hinge plates mounted on the switch (see Figure 15 and Figure 21).

Note

When you rotate the door to the closed position, the

spring-loaded hinge pins will snap into the loops on the hinge plates.

Figure 21. Installing the Switch Door

Note

be installed, and it must be kept closed during normal operation.

50 HP Surestore FC Switch 6164 Installation and Reference Guide

To ensure that the switch does not emit RFI, the switch door must

Page 51

19.Connect each of the six power cables to a power source, and verify that

each power cable is firmly seated in the power connector of the

corresponding switch.

Note

power on self test (POST), which takes approximately two minutes and

is complete when LED activity stops. This test can be disabled by

entering the following at the Telnet prompt:

If a malfunction occurs during POST, error messages are written to the

system error log, which is accessible by Telnet. If the malfunction

prevents the switch from completing the boot process, the switch

prompt does not display when the serial port is connected.

Configuring the FC 6164

1. Obtain a copy of the FC 6164 worksheet provided in Appendix A, “FC

6164 Worksheet”, and enter the IP address and related information for

each switch, as provided by the LAN (local area network) administrator.

2. Replace the factory IP address and related information for each of the six

switches with the information provided by the LAN administrator.

a. Disable any serial communication programs running on the

Each time the switch is powered on, it automatically performs a

diagDisablePost

workstation, such as synchronization programs for a PDA.

b. Remove the shipping plug from the serial port on switch 1 (the switch

on the far left) and insert the serial cable provided with the FC 6164.

c. Insert one end of a serial cable into the serial port.

d. Connect the other end of the serial cable to an RS-232 serial port on

the workstation. If necessary, you can remove the adapter to allow for

RJ45 serial connection to the workstation.

Installing and Configuring the FC 6164 51

Page 52

e. Open and configure a terminal emulator application (such as

HyperTerminal on Windows 95 or NT, or TERM in a UNIX

environment) as follows:

Parameter Value

Bits per second: 9600

Databits: 8

Parity: None

Stop bits: 1

Flow control: None

Function arrows and Ctrl keys act as: Terminal keys

Emulation: Autodetect

f. From the terminal emulator application, log on to the first switch

through the serial connection.

g. Specify the new IP address by entering the following:

ipAddrSet

h. Enter the following information at the corresponding prompts:

Ethernet IP Address [current]:

–

Enter new Ethernet IP

address (the default is 10.77.77.77).

Ethernet Subnetmask [current]:

–

Enter new Ethernet

subnetmask (the default is 0.0.0.0).

Fibre Channel IP Address [current]:

–

Enter new fibre

channel IP address if desired.

Fibre Channel Subnet Mask [current]:

–

Enter new fibre

channel subnet mask if desired.

Gateway Address [current]:

–

Enter new gateway address

(the default is 172.17.1.1).

Set IP address now? [y = set now, n = next

–

reboot]:

Enter “y” to set now by rebooting the switch.

i. You can verify the address was set correctly by entering the following:

IPaddressShow

52 HP Surestore FC Switch 6164 Installation and Reference Guide

Page 53

j. Remove the serial cable and replace the shipping plug.

k. Repeat steps a through j for the remaining five switches in the FC 6164.

Note

The serial port is intended for initial setting of the IP address and

for service purposes. Using the serial port during normal switch

operation or for regular maintenance is not recommended.

3. Connect all six switches by Ethernet to the LAN on which the workstation

resides.

a. Remove the shipping plug from the Ethernet port on each switch.

b. Insert one end of an Ethernet cable in each Ethernet port.

c. Connect the other end to an existing Ethernet 10/100 Base-T LAN.

Note

When the Ethernet connection is made, remote Telnet and Web

access is available. If the FC 6164 becomes connected to a larger

network by this step, ensure that the system is not being modified from

more than one connection during the following steps.

4. Modify the domain IDs if desired.

Note

The default domain IDs on the six original switches shipped with

the FC 6164, starting with switch 1, are 231, 232, 233, 234, 235, and

236. If a domain ID is already in use when the FC 6164 is connected to

the fabric, the domain ID for the new switch is automatically reset to a

unique value. The current domain IDs in use can be determined by

issuing the Telnet command

fabricShow

on a switch connected to the

larger SAN fabric.

Installing and Configuring the FC 6164 53

a. Log on with administrative privileges to the first switch, using a Telnet

connection.

b. Disable the switch by entering the following:

switchDisable

c. Enter the following:

configure

Page 54

d. Enter “Y” after the “

Fabric parameters (yes, y, no, n): [no] y

Fabric parameters

” prompt.

e. Enter a unique domain ID (such as the domain ID used by the previous

switch, if still available).

Domain: (1..239) [1] 3

f. Complete the remaining prompts (or press CTRL+D to accept the

remaining settings

without completing all the prompts).

g. Re-enable the switch by entering the following:

switchEnable

h. Repeat Steps a through g for the remaining switches.

5. Specify the desired status policies for your fabric.

a. Log on to the first switch by Telnet.

b. Enter the following at the prompt:

switchStatusPolicySet

c. Specify the desired status policies. To completely deactivate the alarm

for a particular condition, enter “0” at the prompt for that condition.

d. Repeat Steps a through c for the remaining five switches in FC 6164.

6. Check the FC 6164 for port or ISL issues.

a. Log on with administrative privileges by Telnet to one of the switches

in the integrated fabric.

b. Enter the following at the Telnet prompt:

islTopoShow

This command provides general information about all the switches in

the FC 6164. Any problems are indicated by an error condition in the

Status column.

54 HP Surestore FC Switch 6164 Installation and Reference Guide

Page 55

7. Check each switch for port or ISL issues.

a. Log on with administrative privileges by Telnet to one of the switches

in the group.

b. Enter the following at the Telnet prompt:

islTopoCheck

This command provides detailed information about the local switch

(the switch currently accessed by Telnet). If there are any problems,

the Status column indicates an error condition.

c. Repeat Steps a through b for the remaining switches in the group.

8. Add GBICs and cables as needed to the user ports.

a. Remove the shipping plug from the user ports to be used.

b. Position the GBIC so that the key (the ridge on one side) on the GBIC

is aligned with the slot in the user port.

c. Insert each GBIC into the port until it is firmly seated and the latching

mechanism locks. The GBIC module is keyed so that it can be inserted

in only one way. If the module does not slide in easily, try reversing it.

d. Connect fiber optic cables to the user GBICs as appropriate to the

fabric topology.

9. Back up the configuration for each of the six switches in the FC 6164,

after any zoning configurations and other changes are completed. This

ensures a complete configuration is available for uploading to a

replacement switch, if required.

a. From the workstation, establish a Telnet connection to the switch you

want to back up, and log on with administrative privileges.

b. Enter the following command to download the configuration to the

server.

configupload

Note

A routine backup of the configuration for each switch in the FC

6164 is recommended at regular intervals, to ensure a fairly current

configuration is available for uploading to a replacement switch, if

required.

Installing and Configuring the FC 6164 55

Page 56

56 HP Surestore FC Switch 6164 Installation and Reference Guide

Page 57

MAINTENANCE PROCEDURES

Switch Replacement Procedure

Use this procedure to remove and replace any of the six switches in the FC

6164.

4

Note

referenced in this chapter, enter

Telnet prompt. For example, to display information about the

command, enter the following:

The overall procedure of replacing a switch involves the following

secondary procedures, described on the indicated pages:

1. “Preparing to Remove the Switch From the FC 6164” on page 59

2. “Physically Uninstalling the Switch” on page 61

3. “Installing the New Switch in the Chassis” on page 63

4. “Configuring the New Switch” on page 64

5. “Adding the New Switch to the Integrated Fabric” on page 69

For detailed information about any of the Fabric OS commands

help

help fabricShow

plus the

[command name]at

fabricShow

the

57

Page 58

Note

The steps are numbered consecutively throughout all the secondary

procedures.

Time Required

Approximately 45 minutes.

Items Required

• Silkworm 2250 switch

• Fabric OS a2.4.1

• FC 6164 Fabric Watch profile. (Configuration profile)

• Computer workstation with access to the switches in the FC 6164.

• FC 6164 worksheet, provided in Appendix A, “FC 6164 Worksheet”.

• Number 2 Phillips screwdriver.

• If more than one switch is being replaced at the same time, labels are

needed for identifying the different Ethernet and serial cables when they

are disconnected.

Procedure

Note

If multiple switches are being replaced, the simplest approach is to

replace one switch at a time.

58 HP Surestore FC Switch 6164 Installation and Reference Guide

Page 59

Figure 22. FC 6164 with All Switches Installed (Fiber Optic Cables and Other Cables Not Shown)

Preparing to Remove the Switch From the FC 6164

1. Identify the worldwide name (WWN) and the domain ID of the faulty

Maintenance Procedures 59

switch. If this information is already recorded on the FC 6164 worksheet

(provided in Appendix A, “FC 6164 Worksheet”), continue with step 2.

If the information is not already recorded, perform Steps, a through c.

a. From a computer workstation, establish a Telnet connection to one of

the functioning switches in the FC 6164, and log on with

administrative privileges.

Page 60

b. Enter

sgroupShow

at the Telnet prompt to display group information.

This command lists the WWNs for each switch in the FC 6164,

beginning with switch 1 (the switch on the far left).

Example

reg101:admin> sgroupShow

Group Type Group Name Member WWN

==============================================

S64_6_1 East Lab 10:00:00:60:60:10:60:11

10:00:00:60:60:10:60:22

10:00:00:60:60:10:60:33

10:00:00:60:60:10:60:44

10:00:00:60:60:10:60:55

10:00:00:60:60:10:60:66

Note

switches in the larger SAN fabric. For details about the

fabricShow

The

command provides information about all the

fabricShow

command, refer to the Fabric OS v2.2 manual.

c. Record the WWNs, domain IDs, IP addresses, and other relevant

information for all switches in the group on the FC 6164 worksheet

(provided in Appendix A, “FC 6164 Worksheet”).

Note

Keep the completed worksheet readily available for future work

on the FC 6164. However, do not tape the worksheet to the front door or

rear panel, to prevent disruption of airflow through the chassis.

2. If the faulty switch is partly or fully operational, back up the current

configuration.

60 HP Surestore FC Switch 6164 Installation and Reference Guide

Page 61

Note

Creating a backup copy of the switch configuration is

recommended for each switch in the FC 6164. This preserves zoning

and other switch-specific information.

a. From a workstation, establish a Telnet connection to the switch that is

being replaced, and log on as administrator.

b. Enter the following command to disable the switch:

switchDisable

c. Enter the

configupload

command to upload the configuration to the

server.

Physically Uninstalling the Switch

3. Physically disconnect the faulty switch.

Note

These switches do not have an On/Off button; they are powered

on or off by connecting or disconnecting the power cord. It is not

necessary to power off the switches that are connected to the faulty

switch.

a. Disconnect the power cable, leaving the cable in the channel below

the switch.

b. Disconnect the Ethernet cable and the serial cable. If disconnecting

more than one switch at a time, label each of the Ethernet and serial

cables (if used) with the switch number before disconnecting.

CAUTION

The fiber optic cables are fragile and should not be bent to a

radius of less than 0.5 inches.

Maintenance Procedures 61

c. Ensure that each of the fiber optic cables are still labeled with the port

and switch number.

Note

The exact cabling configuration shown in the diagram must be

implemented in order for the FC 6164 to operate correctly.

Page 62

d. Disconnect each of the fiber optic cables from the faulty switch by

firmly grasping the connector housing (black) on the cable, and pulling

the cable from the GBIC.

4. Remove the switch from the chassis.

a. Unscrew the two 1/4-20 Phillips self-retaining screws that fasten the

switch brackets to the chassis (see Figure 23). Use a number 2 Phillips

screwdriver.

b. Carefully move the cable harness out of the way so that the switch you

can slide forward without bending the cables.

c. Slide the switch forward and remove from the chassis.

5. Remove the two mounting brackets from the switch by unscrewing the

four 8-32 x 5/16 long Phillips panhead screws from each bracket. Set the

brackets and screws aside for the new switch.

Figure 23. FC 6164 with the Switch Mounting Brackets (Shown in Exploded

View)

62 HP Surestore FC Switch 6164 Installation and Reference Guide

Page 63

6. Remove all the GBICs from the faulty switch.

Note

Refer to the GBIC manufacturer’s documentation for specific

instructions about inserting and removing GBICs.

Installing the New Switch in the Chassis

7. Insert the GBICs into the new switch, inserting each GBIC into the port

until it is firmly seated and the latching mechanism becomes locked.

The GBIC module is keyed so that it can be inserted in one way only. If

the module does not slide in easily, try reversing it. The GBIC

D-connector must line up with the D-connector inside the GBIC port.

8. Install the mounting brackets on the new switch.

a. Position one of the brackets flat against the side of the switch, so that

the end with the bent lip is at the front of the switch (see Figure 23),

and align the holes in the bracket with the holes in the side of the

switch.

b. To ensure correct bracket alignment, assemble screws in the following

pattern:

Position and finger tighten the first 8/32 x .312 panhead Phillip

screw in the smallest hole in the bracket.

Position and finger tighten the second 8/32 x .312 panhead Phillip

screw in the oblong (slotted) hole.

Position and finger tighten the remaining two 8/32 x .312 panhead

Phillip screws in the remaining two holes.

Tighten all four screws to a torque of 8 inch-pounds.

c. Repeat Steps a through b with the second bracket on the other side of

the switch.

9. Install the new switch in the chassis.

a. Orient the switch so that the power connector is at the bottom of the

chassis (see Figure 23), and slide the switch into the available space.

b. Tighten the two self-retaining screws that fasten the switch brackets

to the chassis, using a number 2 Phillips screwdriver to tighten to 40

inch-pounds.

Maintenance Procedures 63

Page 64

10.Connect the following:

– power cable to the power connector

– serial cable to the serial port (if used)

– Ethernet cable to the Ethernet port

Note

Do not connect the ISL (interswitch link) or user fiber optic

cables until after the switch is configured.

Configuring the New Switch

Note

The switch can be accessed simultaneously from multiple

connections; ensure that the system is not modified from more than one

connection during the following procedure.

11.Replace the factory IP address and related information with the address

information used by the previous switch.

a. Connect the new switch to a workstation by serial cable.

b. Open and configure a terminal emulator application (such as

HyperTerminal) as follows:

Parameter Value

Bits per second: 9600

Databits: 8

Parity: None

Stop bits: 1

Flow control: None

Function arrows and Ctrl keys act as: Terminal keys

Emulation: Autodetect

c. From the terminal emulator application, log on to the new switch

through the serial connection.

64 HP Surestore FC Switch 6164 Installation and Reference Guide

Page 65

d. Specify the new IP address by entering the following:

ipAddrSet

e. Enter the following information at the corresponding prompts:

Ethernet IP Address [current]:

–

Enter new Ethernet IP

address (the default is 10.77.77.77).

Ethernet Subnetmask [current]:

–

Enter new Ethernet

subnetmask (the default is 0.0.0.0).

Fibre Channel IP Address [current]:

–

Enter new fibre

channel IP address if desired.

Fibre Channel Subnet Mask [current]:

–

Enter new fibre

channel subnet mask if desired.

Gateway Address [current]:

–

Enter new gateway address

(the default is 172.17.1.1).

Set IP address now? [y = set now, n = next

–

reboot]:

Enter “y” to set the IP address now by rebooting the

switch.

f. You can verify the address was correctly set by entering the following:

ipAddrShow

12.Log on with administrative privileges to the new switch, using a Telnet

connection.

13.From a computer workstation, disable the diagnostic tests that run after

each reboot by entering the following at the Telnet prompt:

diagDisablePost

14.Set the domain ID to the value used by the previous switch, if still

available.

The default domain IDs on the six original switches shipped with the FC

6164 are (starting with switch 1) 231, 232, 233, 234, 235, and 236.

Maintenance Procedures 65

Page 66

Note

If the domain ID (whether the default or a selected ID) is already

in use when the switch is connected to the fabric, it is automatically

reset to a unique value. You can determine which domain IDs are in use

by issuing the Telnet command

fabricShow

on one of the switches in

the integrated fabric.

a. Disable the switch by entering the following:

switchDisable

b. Enter the following:

configure

c. Enter “Y” after the “

Fabric parameters (yes, y, no, n): [no] y

Fabric parameters

” prompt.

d. Enter a unique domain ID (such as the domain ID used by the previous

switch, if still available).

Domain: (1..239) [1] 3

e. Complete the remaining prompts (or press Ctrl+D to accept the

defaults without completing the prompts).

f. Re-enable the switch by entering the following:

switchEnable

15.Download the switch configuration, if one was uploaded from the

previous switch (see Step 2).

a. Disable the switch by entering the following:

switchDisable

b. Enter the following at the Telnet prompt to download the configuration

from the server to the switch:

configDownload

Several prompts display to gather information about the file being

downloaded.

66 HP Surestore FC Switch 6164 Installation and Reference Guide

Page 67

c. Enter the requested information at the prompts, pressing Enter after

each entry:

Server Name or IP Address [host]:

–

Name or IP address

of computer on which configuration file is located.

User Name [user]:

–

File Name [/usr/switch/firmware]:

–

Login name required to access computer.

Filename or

absolute path of configuration file.

Protocol (RSHD or FTP) [rshd]:

–

Press Enter to use

RSHD, or enter FTP to use FTP protocol.

Password:

–

Enter the FTP password (only displays if FTP

protocol was selected).

d. Reboot the switch by entering the following at the prompt and pressing

Enter:

reboot

e. Re-enable the switch by entering the following:

switchEnable

16.If no previous switch configuration was downloaded, or the switch

configuration from the previous switch contained a modified Fabric

Watch profile and you want to revert to the default settings, download the

FC 6164 Fabric Watch profile to the new switch.

a. Ensure that the profile is available on the workstation or network.

b. Disable the switch by entering the following:

switchDisable

c. Enter the following at the Telnet prompt to download the profile from

the server to the switch:

configDownload

Several prompts display to gather information about the file being

downloaded

Maintenance Procedures 67

Page 68

d. Enter the requested information at the prompts, pressing Enter after

each entry:

Server Name or IP Address [host]:

–

of computer on which profile is located.

User Name [user]:

–

File Name [/usr/switch/firmware]:

–

Login name required to access computer.

absolute path of Fabric Watch profile.

Protocol (RSHD or FTP) [rshd]:

–