Page 1

HP Scitex FB910 Printer

User Manual

0706472 Revision A

Page 2

Hewlett-Packard Company

11311 K-Tel Drive

Minnetonka, Minnesota 55343

United States of America

World Wide Web: www.colorspan.com

www.hp.com

Technical Support

World Wide Web: www.colorspan.com

E-mail: cs.support@hp.com

North America

Voice.........+1 800.925.0563 or +1 952.944.4040

Fax.............+1 952.943.3611 or +1 952.944.8509

Latin America (Español)

Voice..........................................+1 952.943.3627

Fax.............................................+1 952.944.8509

Europe, Middle East, and Africa

Voice.......................................... .+31 23.5622000

Fax..............................................+31 23.5627944

© Copyright 2008 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only

warranties for HP products and services are set forth in the express warranty

statements accompanying such products and services. Nothing herein should be

construed as constituting an additional warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

Printed in the US.

Ink Sales

North America

Voice.........+1 800.723.3002 or +1 952.944.9330

Fax.............................................+1 952.943.8622

Europe, Middle East, and Africa

Voice.......................................... .+31 23.5622000

Fax..............................................+31 23.5631240

Page 3

Regulatory Statements

DOC (Canada) This digital apparatus does not exceed the Class A limits for radio noise for digi-

FCC-A This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used in acco rdance

with the instruction manual, may cause harmful interference to rad io co mmu nica tions. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at

his or her own expense.

This equipment must be installed exactly as instructed in this manual using only

the components supplied. If a supplied component ever needs to be replaced, it

must be replaced with the same part supplied by the manufacturer. It is your

responsibility to follow these instructions in order to maintain compliance with the

FCC regulations. Changes or modifications not expressly app rov ed b y the manufacturer could void your authority to operate this equipment. In particular, this

device must be operated with shielded cables to maintain FCC compliance.

A booklet is available from the Federal Communications Commission entitled,

How to Identify and Resolve Radio-TV Interference Problems (#004-000-00345-

4). Write to the U.S. Government Printing Office, Washington, DC 20402.

tal apparatus set out in the Radio Interference Regulations of the Canadian

Department of Communications.

Normes de Sècuritè (Canada)

Le présent appariel numérique n’émet pas de bruits radioélectriques dépassant

les limites applicables aux appareils numériques de la Classe A prescrites dans le

réglements sur le brouillage radioélectrique édictés par le Ministére des Communications du Canada.

Telecommunications

Network Statement

Regulatory Statements iii

The VideoNet port on this device is not intended to be connected to a public telecommunications network. Connection of this device to a public telecommunications network in a European Community Member State will be in violation of

national law implementing Directive 91/263/EEC on the approximation of laws of

the Member States concerning telecommunication terminal equipment, including

the mutual recognition of their conformity.

Der VideoNet port ist nicht dafür vorgesehen an ein öffentliches Telefonnetz

angeschlossen zu werden. Der Anschluß dieses Gerätes an ein öffentliches

T elefonnetz in einem Mitgliedst aat der EU, verstößt gegen nationale Gesetze zur

Ausführung der Direktive 91/263/EEC, die sich mit der Annäherung von

Gesetzen von Mitgliedstaaten beschäftigt, betreffend Telekommuniktionsanlagen

und die gegenseitige Anerkennung ihrer Konformität.

Page 4

Related Documentation

• Release Notes — describes new versions of the printer’s

embedded software and other new information not included

in this user manual.

• Tips & Tricks — how to get the best results with special

applications of the printer, such as edge-to-edge and double-sided printing.

• Material Safety Data Sheets — information for safe han-

dling of the inks and printhead flush used with the pr int er.

If you are using the HP Software RIP:

• HP Software RIP User Guide — describes how to use the

RIP.

• Printing Tools User Guide — describes how to add print-

ers to your operating system, and how to use the utility software.

If you are using a third-party RIP with the printer, refer to the

documentation that accompanies it for instructions.

iv Related Documentation

Page 5

Table of Contents

Regulatory Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

FCC-A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

DOC (Canada). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Telecommunications Network Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Related Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

Getting Started

Quick Tour. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Basic Printer Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Daily Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

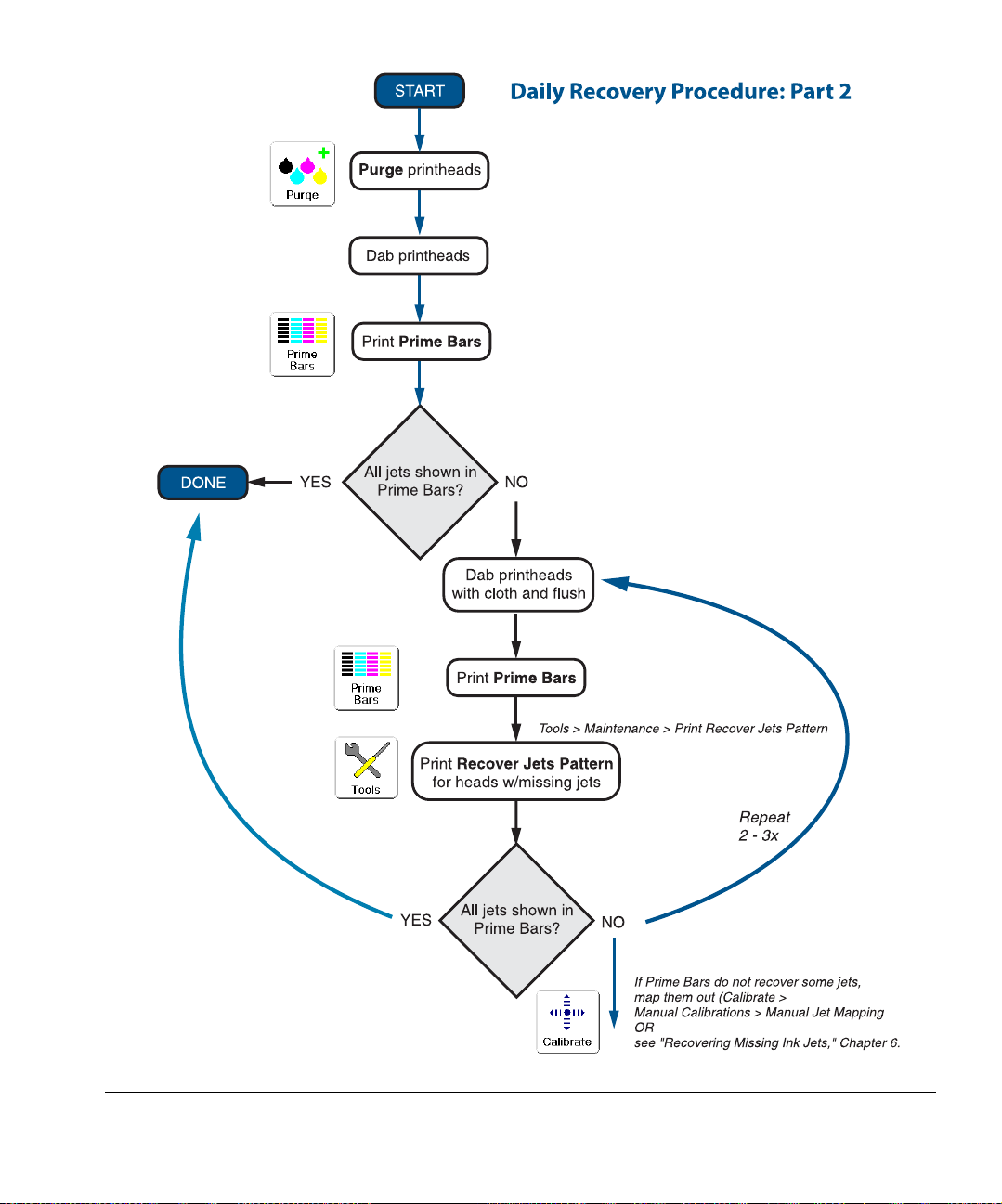

Recover Jets Part 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Recover Jets Part 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

600x300 Printing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Daily Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

Important Operating Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

Safety Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

English . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

Deutsch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-18

Español. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-18

Français . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-20

Italiano. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-21

Printing

Configure Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Configure Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Media Wizard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Load and Print on Rigid Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Quick Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Multi-Sheet N-UP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Margins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Using the Camera to Locate the Sheets . . . . . . . . . . . . . . . . . . . . . . . .2-10

“Incomplete” Rows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Stored Jobs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Load and Print on Roll-Fed Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

New Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Restore Loaded State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

Printing Tips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-21

Pause-Swapping Ink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

Checking Jet Health. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-23

Print Prime Bars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-23

Map Out Missing Jets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-23

Print Jet-Out Lines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-24

Table of Contents v

Page 6

Ink

Ink System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

UV Lamps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Loading Ink. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

When to Load Ink. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Unloading an Empty Ink Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Loading a Full Ink Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Pause-Swapping Ink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Calibrating the Printer

When to Calibrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

AutoJet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

AutoTune . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Quality Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Auto Calibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Manual Calibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Manual X Head Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Manual BiDi Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Manual Jet Mapping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Report Individual Bad Jets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Clear Individual Bad Jets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

View Current Bad Jets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Clear All Bad Jets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Jet Status Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Media Feed Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Print Jet-Out Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Default Registration Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Linearization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Using the Control Panel

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Front Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Menu Tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Calibrate Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Printer Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

User Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Warnings & Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Print Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Service Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

vi Table of Contents

Page 7

Maintaining the Printer

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Clean the Media Drive Belt and Encoder. . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Media Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Media Drive Belt Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

Clean the Media Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

Clean the Rail and Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

Carriage Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

Recover Missing Ink Jets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

Clean the Drip Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

Replace Ink Filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

UV Lamp Operation and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-17

Operating Tips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-18

Replacing UV Lamp Bulbs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-19

Balancing Lamp Hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-19

Clean the Quartz Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-20

Clean the Ionizer Bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-22

Printhead Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-24

Power Down and Restart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-25

Specifications

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Troubleshooting

Troubleshooting Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Head Strike or Carriage Motion Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Head Strike Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Media Feed Errors (Sheet-Fed Printing) . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Ink Not Curing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Shaking or Vibrations from Media Drive Servo . . . . . . . . . . . . . . . . . . . . . B-6

Banding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Shutter Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Warranty Claims . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-10

Hewlett-Packard Technical Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-11

Supplies and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-12

Index

Table of Contents vii

Page 8

viii Table of Contents

Page 9

Chapter 1

• Quick Tour (page 1-2)

• Basic Printer Operations (page 1-6)

• Important Operating Notes (page 1-14)

Getting St arted

Getting Started 1-1

Page 10

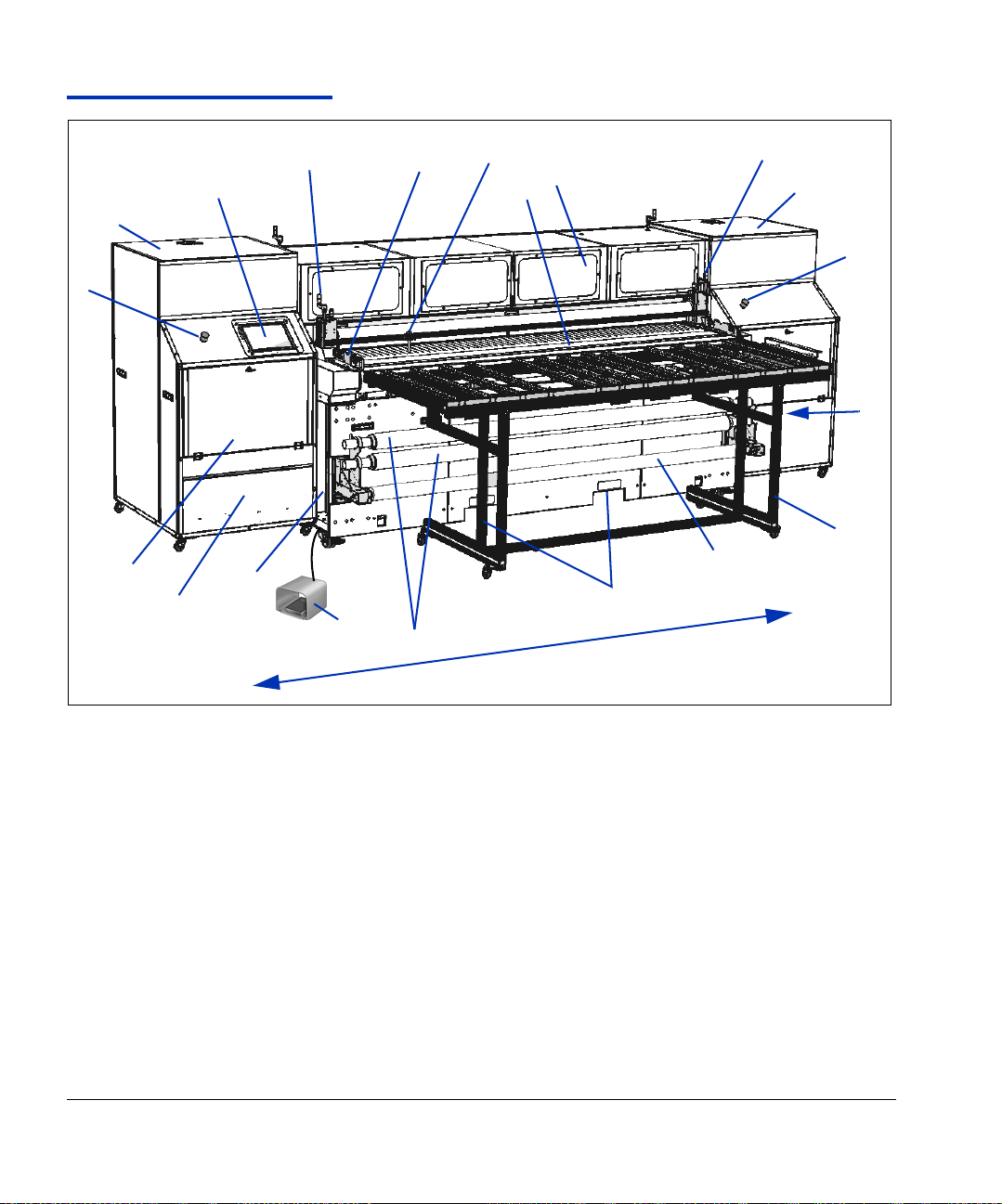

Quick Tour

1

4

2a

3

9

10

User End

11

13

5

16

6

8

7

12

1

2b

3

13

15

16

Service End

Fig. 1-1. Input Side view

1. Input media roller height adjusters

2. Endcap cabinet (2a - User End, 2b - Service End)

3. Emergency stop switch

4. Control panel

5. Media fence

6. Multiple sheet positioning pins

7. Media feed belt

8. UV-filtered observation window

1-2 Quick Tour

Page 11

9. Ink supply access door

10. Ink filter/pump access panel

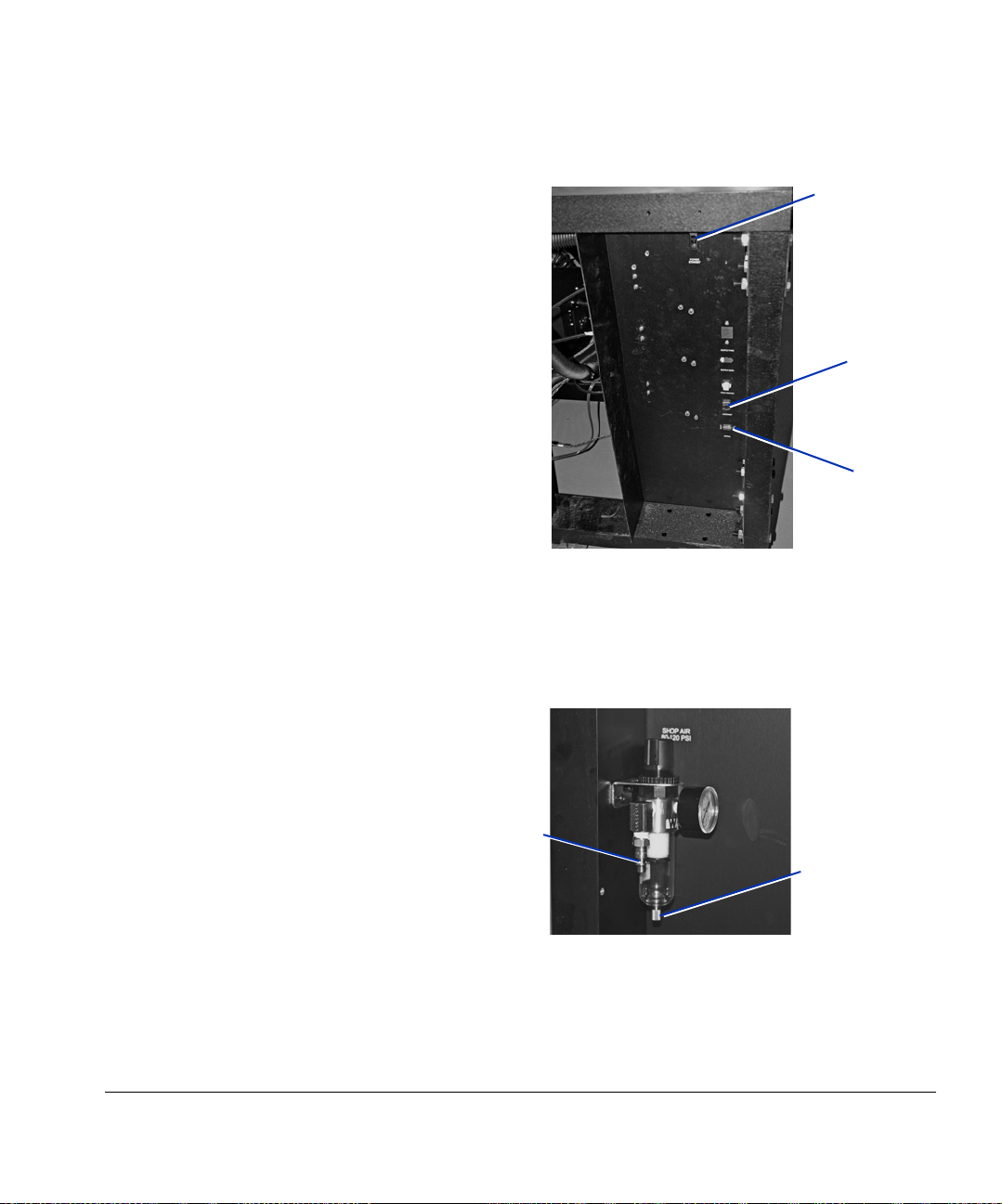

11. Standby power switch, foot switch port, VideoNet port

Standby

power switch

Foot switch

port

VideoNet

port

12. Fork lift points

13. Sheet Ready foot switch

14. Shop air input (Service End of printer), industrial quick

connect

Hose connection

Drain valve

15. Rigid media input table

16. Roll-fed media supply spool (optional)

17. Roll-fed media foam rollers storage (optional)

Quick Tour 1-3

Page 12

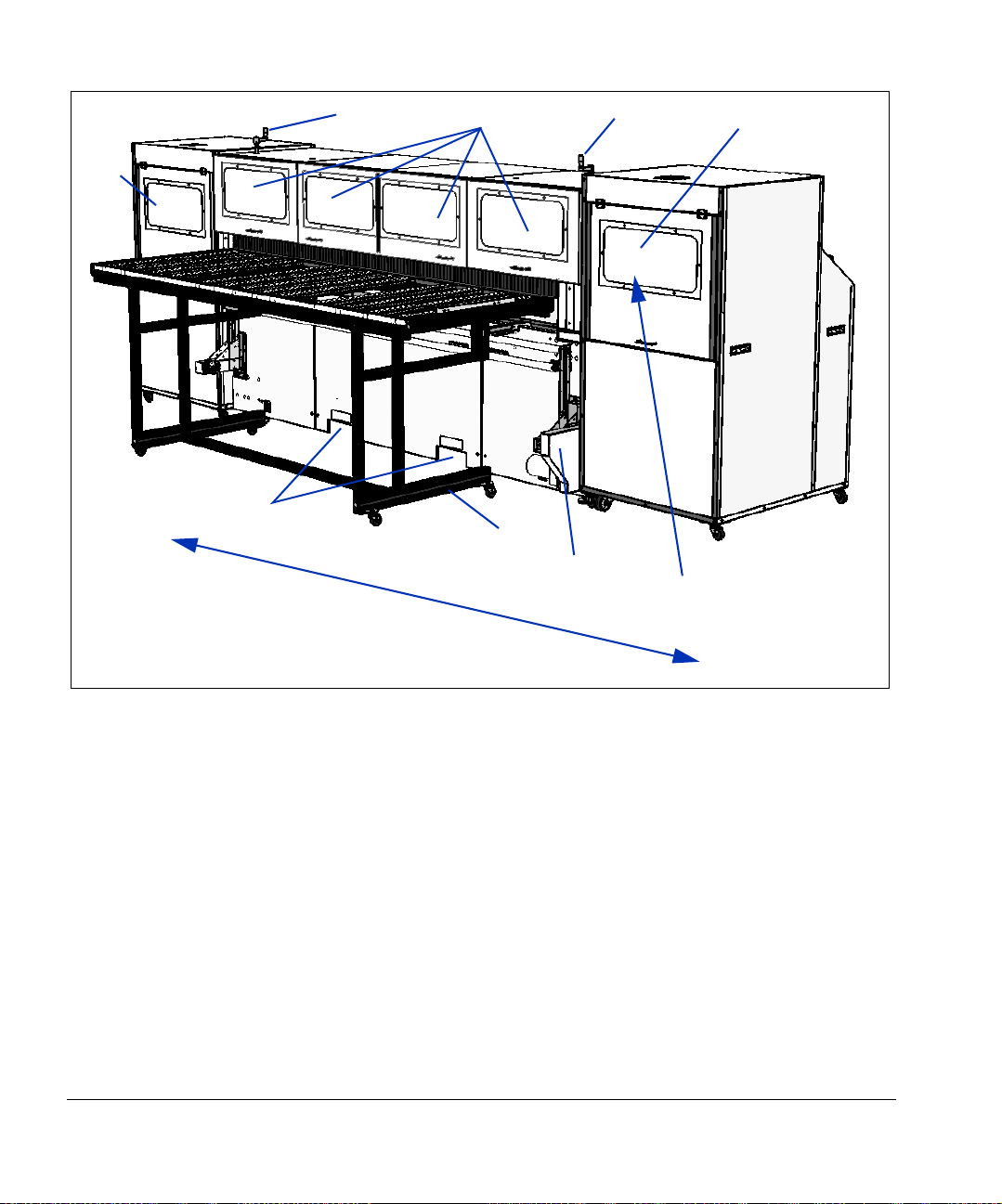

2

1

2

1

1

Service End

3

4

5

6

User End

Fig. 1-2. Output Side view

1. Access door with UV-filtered observation window (opening

any door on the output side will halt printing)

2. Output media roller height adjusters

3. Fork lift points

4. Output table

5. Roll-fed takeup system (optional)

6. Printhead wipe station

1-4 Quick Tour

Page 13

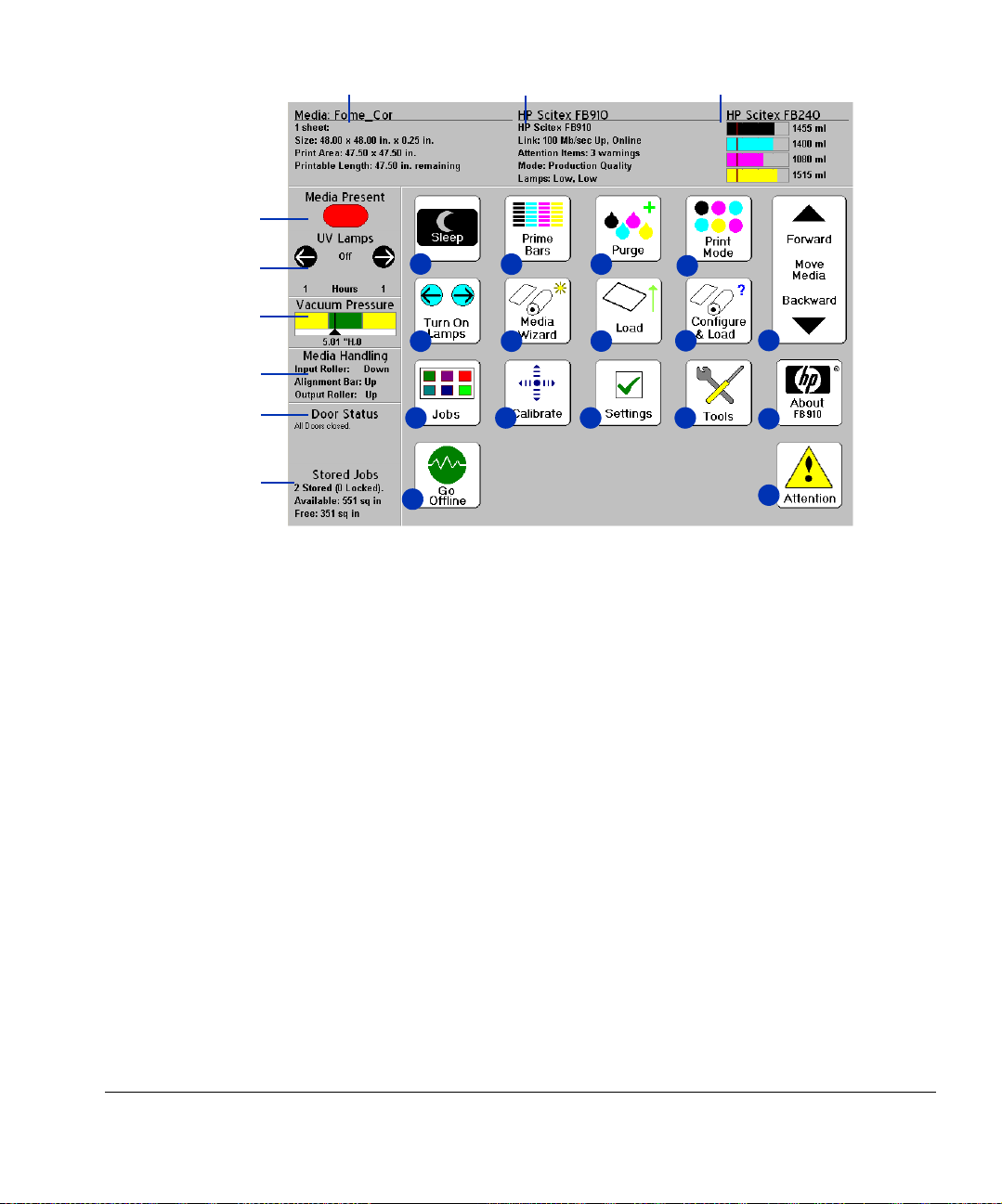

12 3

4

5

10

6

14 15

7

8

19

9

24

1. Media information

2. Printer status

3. Ink levels

4. Media detector (red=media out, green=media

detected)

5. UV lamps status

6. Vacuum Pressure gauge

7. Media Handling status

8. Printer doors status

9. Stored jobs status

11

12

16 17

20 21

Fig. 1-3. Front Page screen

14. Turn On/Turn Off Lamps

15. Media Wizard

16. Load Media

17. Configure & Load media

18. Move Media Forward/Backward

19. Stored Jobs

20. Calibrate

21. Option Settings

22. Tools (maintenance, diagnostics, service

functions)

22

13

18

23

25‘

10. Sleep/Wake mode

11. Print prime bars

12. Purge printheads

23. About (embedded software version)

24. Online/offline switch

25. Attention messages

13. Print mode

Quick Tour 1-5

Page 14

Basic Printer Operations

Daily Startup To ensure the functioning or substitution of all inkjets, and opti-

mal output quality, follow this procedure daily:

1. Wake the printer from Sleep mode.

2. Press the Purge key on the control panel to purge the print-

heads. Follow the instructions on the control panel screen.

The printer will detect when you open and close the endcap

access door, and remove and reinstall the drip tray, to determine when you have completed certain steps in the procedure.

Note When closing the access door on the user endcap

cabinet, the pneumatic supports will pull the door

closed when the door is lowered past the horizontal

position. Hold on to the door until it is closed to stop

it from slamming closed.

3. Clean the media drive belt. See “Clean the Media Drive Belt

and Encoder” on page 6-4.

Note Failure to clean the media drive belt daily will allow

any ink on the belt to continue to cure, making later

cleaning more difficult.

4. Press the Prime Bars key on the control panel to print the

Prime Bars.

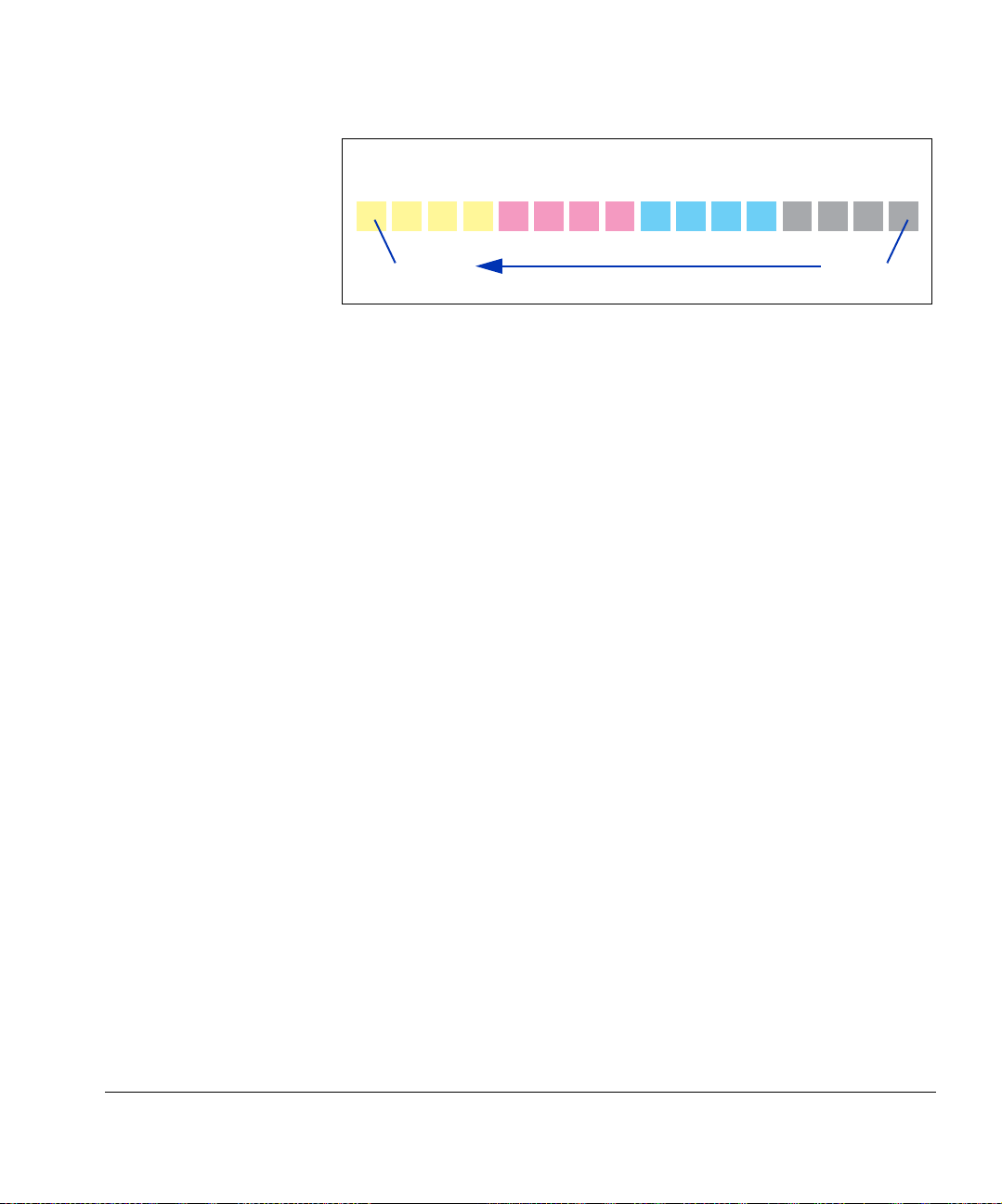

Each prime bar is a set of horizontal lines printed by the jets

in one printhead, starting with the black head 1 toward th e

service end of the carriage, and ending with yellow head 16

toward the user end. Every horizontal line in each prime bar

is printed by a single inkjet nozzle.

• If all jets (indicated by a printed line) are working, the

printer is ready to print.

1-6 Basic Printer Operations

Page 15

• If there are any missing jets, print the Prime Bars again

three or four times until all jets are working.

BlackCyanMagentaYellow

Head 1Head 16

Fig. 1-4. Prime Bars

5. If any missing jets are present after printing the Prime Bars,

proceed to the next step, “Recover Jets Part 1” on page 1-8.

Basic Printer Operations 1-7

Page 16

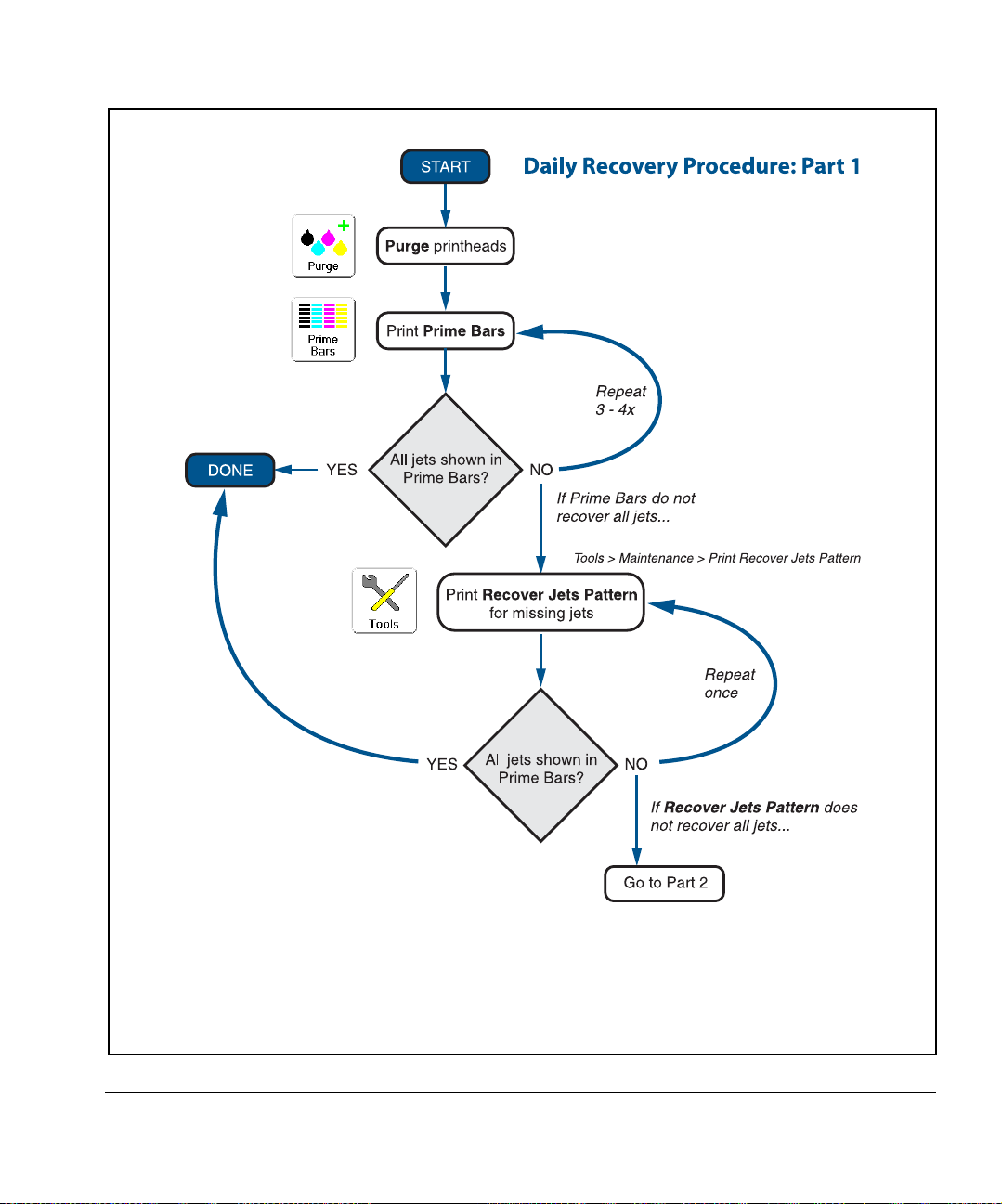

Recover Jets Part 1 6. Press the Purge key on the control panel to purge the print-

heads. Follow the instructions on the control panel screen.

The printer will detect when you open and close the endcap

access door, and remove and reinstall the drip tray, to determine when you have completed certain steps in the procedure.

7. Press the Prime Bars key on the control panel to print the

Prime Bars.

• If all jets (indicated by a printed line) are working, the

printer is ready to print.

• If there are any missing jets, print the Prime Bars again

three or four times until all jets are working.

8. If any missing jets are present after printing the Prime Bars,

print a Recover Jets Pattern (Tools > Maintenance > Print

Recover Jets Pattern).

This is a special pattern designed to recover missing i nkjet s.

After printing this pattern, the prime bars are printed again.

• If all jets (indicated by a printed line) are working, the

printer is ready to print.

• If there are any missing jets (induca te d by no pr int ed

line), print the Recover Jets Pattern again. If this shows

any missing jets, proceed to the next step, “Recover Jets

Part 2” on page 1-10.

1-8 Basic Printer Operations

Page 17

Basic Printer Operations 1-9

Page 18

Recover Jets Part 2 If any missing jets are observed after printing the Recover Jets

Pattern a second time, Purge the printheads.

9. Press the Purge key on the control panel to purge the printheads. Follow the instructions on the control panel screen.

The printer will detect when you open and close the endcap

access door, and remove and reinstall the drip tray, to determine when you have completed certain steps in the procedure.

10. Press the Prime Bars key and examine the printed bars.

• If all jets (indicated by a printed line) are working, the

printer is ready to print.

• If the Prime Bars show any missing jets, dab only the

printheads that have missing jets. Dab or blot the printheads with a lint-free cloth moistened with HP Scitex

MF50 Flushing Solution.

11. Print the Prime Bars again.

12. Print the Recover Jets Pattern for those printheads with

missing jets.

After printing this pattern, the prime bars are printed again.

• If all jets (indicated by a printed line) are working, the

printer is ready to print.

• If there are any missing jets, repea t ste ps 9 throug h 12

two or three times until all jets are working.

13. If the Prime Bars show any missing jets, map them out using

the Manual Jet Mapping function (Calibrate > Manual Cali-

brations > Manual Jet Mapping). See “Manual Jet Mapping” on page 4-16 for instructions. Select “Report individual

hard bad jets” to map out these jets permanently.

Alternatively, you can run AutoJet to automatically map out

jets. See “AutoJet” on page 4-3 for instructions.

Y ou can a ttempt to recover the remaining missing jet s again.

See “Recover Missing Ink Jets” on page 6-11 for instructions.

1-10 Basic Printer Operations

Page 19

Basic Printer Operations 1-11

Page 20

Printing When the printer is connected to a HP RIP, here is how a typical

print job progresses from the client workstation to the printer. If

you are using a non-HP RIP, refer to the documentation that

accompanies it for details.

1. The operator sends a file to be printed from a client

workstation (for example, by copying the file to a Hot

Folder).

2. The print job is received by the RIP.

Once it reaches the print server, the print job may be reprior-

itized, combined with other jobs, re-routed, or otherwise

manipulated. Refer to the online help or manual for instructions.

The raster image processing (RIP) process translates the

PostScript language data that comprises the print job into

the data required by the printer.

3. The RIP sends the image to the printer for printing, or,

depending on its route, to an output queue for printing later.

Tip To avoid the UV lamps warm-up period (approxi-

mately 1-3 minutes), you can turn on the lamps

manually before sending the first print job from the

RIP or printing a calibration pattern. See the menu

at Tools > Turn UV Lamps On. The lamps will turn

off automatically after the period of no pr inting

defined in the menu at Settings > UV Lamps Idle

Time.

600x300 Printing

The default printing resolution is 600x600 dpi. To print a document at 600x300 dpi, configure the RIP to rasterize print jobs at

this resolution (in the HP Software RIP, under the RIP tab of the

Port Properties screen). For best results, sele ct a color profile on

the RIP that matches the resolution setting of the RIP, and color

calibrate at the resolution at which you will be printing. Refer to

the Software RIP User Guide (part number 0706399) for instructions.

1-12 Basic Printer Operations

Page 21

Daily Shutdown DO NOT POWER DOWN THE PRINTER.

The printer will automatically enter a Sleep mode when it has

been idle for a user-defined period of time (see page 5-4 and

page 5-12 for details).

If the printer must be shipped or power remove d for an extended

period, contact Technical Services for instructions.

Basic Printer Operations 1-13

Page 22

Important Operating Notes

• UV CURE INK IS PERISHABLE. Unlike

other inks used in wide format printing, UV

cure ink has a limited shelf life. Plan to rotate

your ink stock and use it promptly by the date

printed on the ink box.

• DO NOT POWER DOWN THE PRINTER. Constant vacuum

at the printheads is required to prevent ink from flowing from

the printheads when not printing. If the printer must be powered down for shipping, contact Technical Services for

instructions.

Caution Do not switch off the UV lamp power supply

unless the lamps have fully completed their controlled cool-down cycle (with fans and heat extrac-

tion). Removing power from hot lamps can result in

overheating and permanent damage. If sudden

removal of power occurs, contact technical support

before starting the printer again.

Caution Do not connect any equipment to the line condi-

tioner for the UV power supply, except as specified

in this manual.

• To dab the printheads, use only genuine HP Scitex MF50

Flushing Solution. (See “Recover Missing Ink Jets” on page

6-11 for instructions.) DO NOT USE ISOPROYPL ALCOHOL.

• The maximum diameter allowed on the takeup spool is 7.0

inches (178 mm) on a 3-inch core. When the takeup spool

has a diameter of 6.5 inches (165.0 mm) or more, the control panel displays a warning about possible print quality

issues. The supply-takeup system can support rolls of up to

approximately 125 pounds (56.7 kg).

• The media supply may be wound either printed-side-out or

printed-side-in, but the takeup, if used, must be loaded

printed-side-in.

• The default head height set to 0.085 inches (2.2 mm) above

the media. (The space below the carriage will be 0.070

inches due to the printhead protection frame around the outside of the carriage.)

1-14 Important Operating Notes

Page 23

• The Media Wizard stores a set of operational parameters for

predefined and user-defined media types. When you load a

new media type, select an existing Media Wizard set, or create a custom set. Media Wizard parameter sets can be

selected at any time from the control panel.

• Enable AutoTune during long periods of unattended print-

ing. AutoTune runs AutoJet at user-defined intervals to

ensure that all jets are either working or substituted with

working jets. (See “AutoTune” on page 4-4 for instructions.)

• Wear cotton gloves when loading media to prevent finger-

prints that could show after printing.

• DO NOT rest or store a media roll on end, or you could

cause edge creases that could strike the printheads during

printing.

• DO NOT clean the printhead surfaces with a dry cloth or

paper towel of any kind. Use only a lint-free (Class 100

cleanroom) cloth, such as those supplied with the printer and

available from Supplies Sales, moistened with HP Scitex

MF50 Flushing Solution.

• DO NOT reprint over any output that has not completely

cured. If ink does get onto the media rollers, clean them with

a minimal amount of isopropyl alcohol and dry them thoroughly before printing again.

• DO NOT set heavy objects on the power cord or printer

cable; do not bend the cables or force them into contorted

positions.

• DO NOT place heavy objects anywhere on the printer.

• DO NOT print on the media drive belt. If printing on the belt

does occur, clean as soon as possible to avoid buildup. The

ink will continue to cure after initial curing by the lamps, making later removal more difficult. See “Clean the Media Drive

Belt and Encoder” on page 6-4 for instructions.

• DO NOT attempt to lift the printer by its rail or the media

drive motor. Lift with a fork lift at marked lifting points only.

• DO NOT operate the printer without the endcap cabinets

installed. The endcap cabinets are an integral component of

the printer's ESD grounding system. During operation of the

printer, they must be attached to the body of the printer with

the screws provided in order to avoid an ESD event which

could damage printer electronics. The endcap cabinets are

Important Operating Notes 1-15

Page 24

also required by UL compliance as protection from UV light

and moving parts hazards.

• DO NOT rest or store the roll-feed foam rollers (“lift roller”

and “press roller”) on a horizontal surface, or a per sistent flat

spot on the roller will be created. When not in use, store the

foam rollers in the storage rack provided; see item 16 in Fig.

1-1.

1-16 Important Operating Notes

Page 25

Safety Warnings English

• UV light — the ultraviolet (UV) curing lamps emit high po wer

UV light. The printer must be operated with all safety shielding installed to protect the operator from eye and skin damage. When operated according to manufacturer’s

instructions, safety glasses or other protective cloth in g ar e

not necessary.

• Mechanical hazards — Keep fingers away from carriage

and media path. Use a fork lift truck to lift the printer. Do not

exceed the maximum weight load of the input or output

tables, as printed on the label.

• Ink — read and practice safety guidelines as outlined in the

Material Safety Data Sheet (MSDS) for the ink, and post the

document in the work area as required by prevailing law.

Avoid any contact with skin and eyes. Provide adequate

general and local exhaust ventilation. Avoid breathing

vapors. Respirator protection may be required under exceptional circumstances when excessive air contamination

exists. None of the component substances have established

exposure standards per OSHA, NIOSH or ACGIH.

• Electrical — WITH THE POWER SWITCH IN THE OFF

POSITION, POWER MAY STILL BE SUPPLIED TO THE

PRINTER COMPONENTS. To completely cut po we r fro m

the printer, you must unplug the power cord from the power

outlet.

• Ozone — the high power UV light emitted by the curing

lamps reacts with oxygen and produces ozone. This formation tends to be greatest during lamp start-up. The printer

should be operated in a well-ventilated area to avoid minor

effects such as headaches, fatigue, and dryness of the

upper respiratory tract. Normal air movement will mix the

ozone with fresh air, causing it to revert back to oxygen.

• Hazardous waste — THE PRINTER ELECTRONICS

ASSEMBLY CONTAINS A LITHIUM BATTERY DEVICE.

THERE IS A DANGER OF EXPLOSION IF THE BATTERY

IS INCORRECTL Y REPLACED. The battery must be

replaced only by authorized service provide rs , an d mu st be

replaced only with the same or equivalent type. Dispose of

this lithium battery device in accordance with local, state (or

province), and Federal (or country) solid waste requirements.

Important Operating Notes 1-17

Page 26

Deutsch

• UV-Licht – die ultravioletthärtenden Lampen strahlen

Hochleistungs-UV-Licht ab. Der Drucker muss mit allen

installierten Sicherheitsabschirmungen betrieben werden, um

den Bediener vor Augen- und Hautschäden zu schützen.

Sicherheitsbrillen oder andere Schutzkleidung ist nicht

erforderlich, wenn gemäß den Herstelleranweisungen gearbeitet wird.

• Mechanische Risiken – Halten Sie die Finger fern vom

Laufwagen und von der Medienzuführung. Überschreiten Sie

nicht die maximale Gewichtsauslastung der Eingabe- oder

Ausgabetische, die auf dem Etikett aufdruckt sind.

• Tinte – lesen und beachten Sie die Sicherheitsrichtlinien, wie

sie im Material-Sicherheitsdatenblatt (MSDS) für die Tinte

dargestellt sind und bringen Sie das Dokument, wie von der

aktuellen Rechtsprechung gefordert, im Arbeitsbere ich an.

Vermeiden Sie jeden Kontakt mit Haut und Augen. Stellen

Sie ausreichende generelle und lokale Absaugvorrichtungen

bereit. Vermeiden Sie das Einatmen von Dämpfen. Eine

Atemschutzmaske könnte unter außergewöhnlichen

Umständen, wenn erhöhte Luftverschmutzung besteht,

erfoderlich sein. Keine der Bestandteile hab en Gefahrenstandards nach OSHA, NIOSH oder ACGIH etabliert.

• Ozon – das Hochleistungs-UV-Licht, das von den Aushärtungslampen abgegeben wird, reagiert mit Sauerstoff und

produziert Ozon. Diese Entwicklung ist am größten, während

die Lampe hochgefahren wird. Der Drucker sollte in einem

gut gelüftetem Umfeld betrieben werden, um geringfügige

Auswirkungen, wie Kopfschmerzen, Müdigkeit und Austrocknen der oberen Atemwege zu vermeiden. Die normale Luftbewegung vermischt das Ozon mit Frischluft, wodurch es

wieder zu Sauerstoff umgewandelt wird.

Español

• Luz UV — Las lámparas de curado ultravioleta (UV) emiten

luz UV de alta intensidad. La impresora debe ser manejada

con filtros de seguridad instalados para prot eger al operador

de posibles daños en ojos y piel. Si la operativa del equipo se

ajusta a las instrucciones del fabricante no será necesario el

uso de gafas de seguridad ni vestimenta de protección.

1-18 Important Operating Notes

Page 27

• Riesgos mecánicos — Mantener los dedos fuera del camino tanto del cabezal como del soporte. No debe excederse

el peso máximo de carga de las mesas de entrada y salida,

según lo especificado en la etiqueta.

• Tinta - Lea y ponga en práctica las recomendaciones de seguridad recogidas, en la Hoja de Datos de Seguridad del

Material (Material Safety Data Sheet - MSDS), para la tinta y

exponga dicho documento en el área de trabajo, tal y como

requiere la legislación vigente. Evite todo contacto con piel y

ojos. Asegúrese de disponer de una adecuada ventilación y

extracción tanto general como local. Evite la inhalación de

vapores. Un respirador de protección puede llegar a ser necesario, bajo circunstancias excepcionales, cuando exista una

excesiva contaminación del aire. Ninguna de las sustancia s

componentes tienen estándares de exposición establecidos

por OSHA, NIOSH o ACGIH.

• Eléctrico — CON EL INTERRUPTOR DE POTENCIA EN

POSICIÓN "OFF", LA POTENCIA PUEDE SEGUIR SIENDO

SUMINISTRADA A LOS COMPONENETES DELA IMPRESORA. Para cortar totalmente el suministro de corriente a la

impresora, deberá desenchufar los cables de potencia de las

tomas.

• Ozono — La luz UV de alta intensidad emitida por las lámparas de curado reacciona con el oxígeno y produce ozono.

Esta reacción tiende a ser de mayor relevancia durante el

proceso de arranque de lámparas. La impresora deberá ser

operada en un área bien ventilada para evitar pequeños

efectos secundarios como dolor de cabeza, fatiga y

sequedad de las vías respiratorias superiores. El movimiento

normal del aire mezclará el ozono con aire fresco, haciendo

que reaccione de forma inversa, a oxígeno.

• Residuos Peligrosos — EL GRUPO ELECTRÓNICO DE

LA IMPRESORA CONTIENE UNA BATERÍA DE LITIO.

EXISTE RIESGO DE EXPLOSIÓN SI LA BATERÍA ES

REEMPLAZADA DE FORMA INCORRECTA. La batería

debe ser reemplazada únicamente por personal técnico

autorizado y sólo por otra igual o equiva lente. De shágase de

esta batería de litio según los requisitos de tratamiento de

residuos sólidos establecidos por su localidad, provincia y

país.

Important Operating Notes 1-19

Page 28

Français

• Lumière UV — Les lampes à séchage ultraviolet (UV) diffusent une puissance de lumière UV importante. L'imprimante doit être utilisée en tenant compte de toutes les

mesures de sécurité mises en place pour protéger l'opéra teur de blessures aux yeux et sur la peau. Quand vous utilisez l'imprimante, les lunettes de protection et vêtements de

protection ne sont pas nécessaire.

• Risques mécaniques — Garder les mains éloignées du

chariot et du chemin papier. Ne pas dépasser le poids maximum pour des tableaux en entrée et en sortie, comme

indiqué sur la fiche.

• Encre — Concernant les encres, lire et respecter toutes les

mesures de sécurité comme indiqué dans le Material Safety

Data Sheet (MSDS) et placer ce document dans l'espace de

travail comme requis par la loi. Eviter tout contact avec les

yeux et la peau. Mettre en place une ventilation générale et

locale adéquate. Eviter de respirer les vapeurs. Des protections respiratoires peuvent être nécessaires dans des circonstances exceptionnelles lorsque qu'une contamination

excessive de l'air existe. Aucun des composant standard n'a

été établi comme une menace our OSHA, NIOSH ou ACGIH.

• Electricité — Lorsque la touche ON/OFF est sur la position

OFF , l'électricité est quand même fourni e aux composants de

l'imprimante. Pour éteindre totalement l'imprimante, il faut

débrancher le câble électrique de la prise.

• Ozone — L'émission importante de lumière UV émise pour le

séchage par les lampes réagit à l'oxygène et produit de

l'ozone. Cette réaction tend à être plus importante au

moment du démarrage des lampes. L'imprimante doit être

utilisée dans un espace ventilé pour éviter des réactions

mineures de type maux de tête, fatigue, sécheresse de la

partie supérieure de l'appareil respiratoire. Un mouvement

normal de l'air mixe l'ozone avec de l'air frais pour revenir à

de l'oxygène.

• Déchets hasardeux — Le système électronique de l'imprimante contient une batterie en lithium. Il y a un danger

d'explosion si la batterie n'est pas correctement remplacée.

La batterie doit être remplacée par du personnel autorisé p ar

le fournisseur et doit être remplacée par un type de batterie

1-20 Important Operating Notes

Page 29

identique ou équivalent. Se débarrasser de cette batterie en

lithium en accord avec la réglementation de gestion des

déchets locale, régionale ou gouvernementale.

Italiano

• Luce Ultravioletta (UV) — Le lampade UV, emettono raggi

ultravioletti ad alta intensita'. Bisogna operare il plotter con

tutti i filtri di protezione installati, per proteggere l'operatore

da eventuali esposizioni dannosi agli occhi e alla pelle. Se ci

si attiene alle disposizioni e istruzioni d'uso del fabbricante,

non sono necessary occhiali o ulteriori materiali aggiuntivi di

protezione.

• Rischi parti meccaniche in movimento — Tenere le dita e

le mani lontano dal movimento del supporto delle testine di

stampa. Non eccedere il peso massimo consentito sui tavoli

di supporto, come specificato sulle etichette.

• Inchiostri — Leggere attentamente le istruzioni e le raccomandazioni degli inchiostri contenute nella documentazione

(Material Safety Data Sheet-MSDS) e metterlo in chiara

esposizione all'interno dell' area di lavoro come prevede la

normativa di legge. Evitare qualsiasi contatto con gli occhi e

la pelle. Assicurarsi che l'ambiente di lavoro sia sufficentemente ventilato. Evitare di respirare le emissioni di vapori.

L'uso di una maschera di protezione potrebbe essere necessaria in una situazione eccezionale con un eccessiva contaminazione dell'aria. Nessuna delle sostanze contenute

negli inchiostri tiene emissioni standard come descritte da

OSHA, NIOSH o ACGIH.

• Sistema elettrico — Anche se l'interruttore di accensione si

trova nella posizione spenta (OFF) potrebbe comunque

fornire tensione a componenti del plotter. Per staccare totalmente la tensione elettrica, scollegare completamente I cavi

di alimentazione dalle relative prese.

• Ozono — La elevate intensita' ultravioletta delle lamp ade UV,

reagisce con l'ossigeno e produce ozono. Questo processo

tende ad essere piu' elevato nella fase di riscaldamento d elle

lampade. Il plotter deve operare in un area ben ventilata, per

evitare leggeri disturbi, tipo mal di testa, affaticamento e irritazione delle vie respiratorie superiori.Con l'emissione di aria

fresca, l'ozono reagisce e si ritrasforma in ossigeno.

Important Operating Notes 1-21

Page 30

• Residui pericolosi — All' interno del gruppo elettrico del

plotter, si trova una b atteria al litio il qua le se non sostituit a in

maniera corretta puo' rischiare di esplodere. Per t ale motivo,

solamente personale tecnico specializzato deve eseguire

tale operazione. Per lo smaltimento della batteria usata o

danneggiata, verificare le modalit a' locali, provinciali o nazionali in materia.

1-22 Important Operating Notes

Page 31

Chapter 2

Printing

This chapter shows you how to set print mode and media options, load

media, and print:

• Configure Printing (page 2-2)

• Configure Media (page 2-6)

• Load and Print on Rigid Media (page 2-8)

• Load and Print on Roll-Fed Media (page 2-15)

• Printing Tips (page 2-21)

• Checking Jet Health (page 2-23)

Printing 2-1

Page 32

Configure Printing The printer can print in several different modes for the combina-

tion of quality, resolution, and speed that you require.

Mode

Billboard Quality

with 600x300 dpi jobs 811 sq. ft/hr (74.3 sq. m/hr) No

with 600x600 dpi jobs 438 sq. ft/hr (40.7 sq. m/hr) No

Production Quality

with 600x300 dpi jobs 438 sq. ft/hr (40.7 sq. m/hr) Yes

with 600x600 dpi jobs 225 sq. ft/hr (20.9 sq. m/hr) Yes

High Quality

with 600x300 dpi jobs 225 sq. ft/hr (20.9 sq. m/hr) Yes

with 600x600 dpi jobs 112 sq. ft/hr (10.4 sq. m/hr) Yes

Maximum Speed

(bidirectional printing)

Jet

Replacement

Jet replacement refers to the printer’s ability to locate and

replace inkjets that are clogged or misfiring. High Quality mode

has the best jet replacement, Billboard Quality mode has the

highest speed, but without jet replacement.

The current print mode is shown in the top center of the control

panel. To change the print mode, follow these instructions.

1. On the control panel, press the Print Mode key.

The print mode menu appears, with these options

:

• Billboard Quality

• Production Quality

• High Quality

2. Press a print mode to select it.

A menu appears with these options:

• Bidirectional

• Unidirectional - Print From User to Service Side

• Unidirectional - Print From Service to User Side

The printer can print in both directions (bidirectional) or in

one direction only (unidirectional). Unidirectional printing can

2-2 Configure Printing

Page 33

occur in either direction. Printing occurs at about half the

speed of the corresponding bidirectional pr int mod e. Unidirectional printing eliminates the bidirectional misalignment

that occurs when printing on media that is not perfectly flat.

Tip The service hours for each lamp is shown on the

printing direction screen. If you are selecting a unidirectional mode, and the user-side lamp has a much

larger number of service hours than the service-side

lamp, rebalance these hours by selecting Unidirec-

tional - Print From User to Service Side. This will

turn off the user-side (trailing) lamp and cure with

the service-side (leading) lamp only.

If the service-side lamp has more hours than the

user-side lamp, select Unidirectional - Print From

Service to User Side.

Service-side lamp

Service end

User end

Fig. 2-1. Printhead carriage

User-side lamp

3. Press a direction option to select it.

In Production and High Quality modes, a menu appe ars with

these options:

• Normal — prints at full speed.

• Sharp Edge — improves the appearance at the edges of

larger text, colored borders, graphics, and images by

directing the inkjet overspray into the printed area. This

mode requires an additional print pass than Normal

mode. (Not available with unidirectional printing or in Billboard mode.)

Configure Printing 2-3

Page 34

• Fine Text — prints at half the normal head speed to

improve the output quality of fine text and line art by eliminating overspray.

Caution Printing in Fine Text mode, which prints at 50% of

the speed of the "normal" Production and High

Quality modes, may expose the media to excessive

heat from the UV lamps, which could result in bowing of the center of the media, and possible contact

with the printheads. Thinner rigid media such as

fluted polypropylene (Coroplast) are susceptible. To

avoid warping, set a media delay in Printer Set-

tings > Printing Delay, or in a custom Media Wizard parameter set for Fine Text printing.

This could also be an issue with Sharp Edge printing, although this mode prints at 80% speed, so it is

less susceptible to excessive heat buildup.

4. Press an option to select it.

The UV lamps settings appear.

Fig. 2-2. Select Lamp Mode screen

2-4 Configure Printing

Page 35

5. Configure the UV lamps operation by touching the “High,”

“Low,” or “Shuttered” options for the leading and trailing

lamps. Buttons will appear or disappear to present only valid

combinations (for example, you cannot set both lamps to

Shuttered).

• For standard media listed in the Media Wizard, leave the

lamp settings at their default values, then adjust as

needed.

• Faster print modes require higher lamp settings to ensure

sufficient curing.

• If the ink is not curing, increase the setting. The lamps

will gradually lose curing effectiveness, so increasing the

setting eventually may become necessary. (For infomation about UV lamp life, see “Replacing UV Lamp Bulbs”

on page 6-19.)

• If the media is wrinkling or warping from the heat of the

lamps, lower the setting.

6. Press Proceed to save the settings and return to the Front

Page, or Cancel to restore the previous print mode settings.

Configure Printing 2-5

Page 36

Configure Media Before the printer will accept a print job, it must be configured for

a specific media type. The currently-configured media type, if

any, is displayed in the upper left corner of the control panel.

1. If the control panel displays the media type you intend to

print, press the Load key and go to “Load and Print on Rigid

Media” on page 2-8. Otherwise, go to step 2.

2. From the Front Page screen, press the Configure & Load

key.

The Select Media to Load menu appe ars. T he list o f media

ends with the option Create Media Type.

Tip Start by using one of the standard media types. If

you are not using a standard media type, select the

standard media type that most closely matches the

media you are using. Then only if necessary, create

a new media type using the standard type you

selected as a starting point, and adjust it as needed.

3. Press a media name, or Create Media Type.

• If you pressed a media name, a list of settings appears.

• If you pressed Create Media Type, the control panel dis-

plays a list of settings for you to configure.

For each media type, the Media Wizard stores the following

settings (as indicated, some settings apply to either roll-fed

or cut sheet media only):

• Media Name — for user-defined media, use the alpha-

betic keyboard displayed on the control panel to enter the

media name. (S tandard media names cannot be

changed.)

• Feed Method — Cut Sheet or Rollfed (with optional

media handler installed) or Roll-Fed.

• Rollers — sets whether the Input and Output media roll-

ers are used (yes) or not used (no).

• Weight — sets the media belt drive motor and media

advance amount to handle Light (up to 50 pounds/22 kg)

or Heavy (50-250 pounds/22-113 kg) media.

2-6 Configure Media

Page 37

Caution The input and output tables ar e rated at a maximu m

load of 80 pounds (36 kg). Do not exceed this maximum load.

Note The printer senses the weight of the media before

printing begins. If a heavy board (over 50 pounds/23

kg) is detected while the printer is set to Light, the

printer automatically switches to the Heavy setting.

This cannot be changed during printing. Printing in

Heavy mode is slower than in Light mode due to the

shorter media advances, but reduces the chance of

damage to the media belt drive motor.

• Visible to Printer — if Yes, the media sensor and image

sensor will be used. If No, the media sensor and image

sensor will not be used (with clear films, for example).

• Print Mode — quality and direction settings (see “Config-

ure Printing” on page 2-2).

• UV Lamps — see “Configure Printing” on page 2-2 for

the possible UV lamp settings.

• Vacuum — this option turns on the vacuum fans, and

displays , and ) keys on the control panel. Press ,

and ) to raise or lower the fan speed for each zone

(input zone, between the pinch rollers, and print zone).

Observe the media as the fan speed changes. If the

media is lifting off the belt, increase the fan spe ed. If the

media advance seems impeded by the vacuu m ,

decrease the fan speed.

• Printing Delay — press the , and ) keys on the con-

trol panel to increase or decrease the delay (seconds per

print swath). To increase throughput, decrease the delay.

4. Press Proceed to load the media, or press Cancel to discard your changes.

Media Wizard To view or delete settings for an existing media type, press the

Media Wizard key. The Media Wizard also lets you create a

media type without configuring it as the currently-loaded media.

Configure Media 2-7

Page 38

Load and Print on Rigid Media

1. At the end of the Configure Media process (see “Configure

Media” on page 2-6), press the Proceed key on the control

panel:

OR

from the Front Page screen, press the Load Media key.

Before you can load media, you must configure the media

as explained in “Configure Media” on page 2-6.

2. On the control panel menu, press one of the following media

rollers options:

• Flat Media — media rollers optional, which may not be

needed for unwarped media (the media drive belt and

vacuum are sufficient for unwarped media)

• Warped Media, Hold Down — media rollers used to pre-

vent warped media from striking the printhead carriage

and keep the media feeding properly. When the media

rollers are used, the printable length is reduced by several inches at the leading and trailing edges, to allow the

rollers to hold down the media during printing.

Note The media rollers are not lowered onto the media

with any force or pressure, other than their own

weight. They are designed to hold down lighter

weight media with a moderate amount of warping.

They may have no effect on heavier, badly warped

media. For best results, use flat media.

3. On the menu, press the media thickness that is closest to

the thickness of the media you are loading.

4. Load the sheet of media onto the input table, sliding it forward against the media alignment bar (under the rail), then

left along the media alignment bar until the media touches

the media fence.

5. Press the Sheet Ready foot pedal or button on the control

panel, or Cancel to cancel the media load process.

At this point you can also adjust the vacuum fans in each

zone, and the printhead height clearance from the media. If

2-8 Load and Print on Rigid Media

Page 39

the sheet warped or not being held down, you may want to

increase the vacuum or raise the head height. A lower head

height reduces overspray, but increases the chance of the

carriage or printheads striking the media.

6. Verify the height of the media rollers shown on the control

panel, and adjust if necessary.

Check and adjust the right and left sides of both media rollers (input and output). The rollers should just touch the

media or remove any warping.

Note Do not lower the rollers too far. On narrow media

(less than 98 inches/2.5 m), it is possible to lower

the input roller below the height of the media on one

side, causing the media to skew.

7. Press the Proceed key.

8. Enter the media length.

9. Enter the number of sheets:

• Single sheet

• N-UP

10. Measure media width.

The margin and imageable area are displayed, and you can

adjust them.

11. Press the Proceed key.

12. Press the Go Online key.

13. Send a print job from the RIP.

For multiple copy jobs, the printer control panel will prompt

for the next sheet a short time before the previous sheet is

done printing. Load the subsequent sheet as before, and

press the Sheet Ready foot pedal or control panel button.

The printer prints on the next sheet and will use the same

option settings on all of the copies in the print job.

Load and Print on Rigid Media 2-9

Page 40

Quick Load After printing a job, if the next job will be printed on the same

type of media with the same settings and dimensions, you can

skip these settings with Quick Load.

1. Press the Load Media key on the Front Page screen.

The control panel displays a menu with a Normal Load and

Quick Load option. If the media type or dimensions are different from the previous job, you must select Normal Load.

2. Press the Quick Load key.

3. Load the media against the media alignment bar.

4. Press the Sheet Ready foot pedal or Ready button on the

control panel.

The printer is ready to receive the next job from the RIP.

Multi-Sheet N-UP Multi-sheet N-UP allows you to print a multiple-copy job on multi-

ple sheets across the belt, and multiple rows of sheets, until the

job is complete.

To print multi-sheet N-UP, load multiple sheets on the printer,

then send a print job from the RIP with a quantity greater than or

equal to the number of sheets you loaded. The printer will

prompt you to load more sheets until the number of copies you

specified has been printed. You can also print Stored Jobs as

multi-sheet N-UP (see “Stored Jobs” on page 2-11 for details).

This type of printing works best with an image that has wide margins on all four edges, but edge-to-edge printing is also possible

with the appropriate printer settings, and by carefully matching

the dimensions of the image to the dimension s of the media

sheets.

Margins

When printing a multi-sheet N-UP job, the image positioned horizontally (left-right) as defined under the menu option: Printer

Settings > Margin Settings > Margins.

Using the Camera to Locate the Sheets

The camera is used to locate the position of each sheet as part

of the load process. You can set the printer camera to either

"measure all sheets" or "measure the first sheet only:"

2-10 Load and Print on Rigid Media

Page 41

• Measure all sheets — each sheet in every row of sheets will

be measured, and reported to the server. This aids in accurate placement of edge-to-edge images. In this mode, use of

the alignment pins is unnecessary.

• Measure first sheet only — only the first row is measured,

and those measurements are used for all subsequent rows.

Use the alignment pins to locate the sheets in subsequent

rows. This speeds throughput by eliminating the measurement step for each row.

“Incomplete” Rows

You can print any number of copies in a multi-sheet N-UP job,

even if the total number does not divide evenly into the number

of sheets per row . Typically, only the last row would have a different number of sheets.

For example: in a twenty-sheet job, you might be able to fit th ree

sheets in each row, so you might print six rows of three sheets,

plus one row of two sheets (6x3=18, 1x2=2, 18+2=20). If the last

row is a partial row , load the sheet s from the user end toward th e

service end.

Stored Jobs Whenever the printer receives a print job from the RIP, the jo b is

automatically stored in the printer’s memory, on a rotating firstin-first-out (FIFO) basis. You can “lock” a job to prevent it from

being rotated out, but this reduces the amount of memory available for subsequent jobs to be saved.

The printer can store up to ten jobs, with a total area of approximately 98 x 98 inches (2.49 x 2.49 m). Jobs RIPed at 600x300

dpi will take less memory to store than jobs RIPed at 600x600

dpi. If power is removed or the printer is restarted, these job s are

lost from the printer memory.

If a job is too large to be saved, it is simply discarded from memory after printing. If a complete print job has been received from

the RIP and you pause or cancel the print, it will still appear in

the Stored Jobs listing.

Stored Jobs can be viewed and managed from the contr ol panel.

The Front Page screen shows the following summary of the

stored jobs on the printer:

• Number of jobs stored and locked

Load and Print on Rigid Media 2-11

Page 42

• Available area for storage — the a rea (size ) of ne w pri nt jobs

that can be saved in the printer’s memory. Previously-stored,

unlocked jobs will be deleted to make room for new jobs.

Locking a stored job reduces the Available space.

• Free area for storage — the Avai lable area mi nus the area of

jobs that are currently stored in the printer memory. This is

the largest job that can be stored without deleting previously

stored jobs.

To print or manage Stored Jobs:

1. Press the Stored Jobs key on the Front Page screen.

The Stored Jobs screen appears.

Fig. 2-3. Stored Jobs screen

• To view the properties of a Stored Job, or to print a

Stored Job, press the key above its file name.

• To set up a two-sided print job using Stored Jobs,

press the Print Two Sides key. The printer will prompt

you to select a Stored Job for the front and back of the

sheet. After printing, side one of the sheet will be ejected

to the input side of the printer, and you will be prompted

to flip over and reload the sheet for printing side two.

2-12 Load and Print on Rigid Media

Page 43

After printing, the sheet will be ejected to the output side

of the printer.

• To view a log of the activity in the Stored Jo bs ar ea of

the printer’s memory, press the Job Status key.

2. When you press the key to display a Stored Job property

page, a screen similar to the following appears (exact det ails

will vary by print job):

Fig. 2-4. Stored Jobs properties screen

• To print the job, press the Print Job key. The printer will

prompt you for the number of copies to print. If you have

multiple sheets loaded, each copy will print on a separate sheet, and the printer will prompt for additional

sheets until the number of copies requested have been

printed.

• To lock or unlock the job, press the appropriate key.

Locking a job prevents it from being deleted, but subtracts from the available memory for Stored Jobs.

• To delete the job, press the Delete Job key.

Load and Print on Rigid Media 2-13

Page 44

Note If you want to print on a media type that is different

from the media specified in a Stored Job, or if you

must re-linearize the printer, do not reprint the

Stored Job. For the best color, re-send the job from

the RIP instead.

When printing a job, the printer checks that the currently loaded media matches the media type that

was loaded when the job was stored. If different, a

warning is raised. You can choose to not print the

job, or ignore the warning and print anywa y. Printing

on a media type that is different from the original

media may result in a noticeable color shift. Performing a linearization and then reprinting a Stored

Job may also result in a color shift.

2-14 Load and Print on Rigid Media

Page 45

Load and Print on

Roll-Fed Media

If the optional roll-fed media supply and takeup system is

installed on the printer, you can print on roll-fed media.

q

p

r

o

s

u

Fig. 2-5. Media route in the takeup system

1. If installed, detach the rigid media input and output tables

from the printer, and set them aside.

2. If you will be using the takeup system, install the takeup

spool (see

3. Load the media centered onto the supply spool

Note To prevent fingerprints from showing on printed out-

4. Load the supply spool onto the supply system bracket.

You can print on either side of the media by loading the

spool so the media spools off the bottom of the roll or the top

of the roll.

u in Fig. 2-5).

put, wear gloves while handling the media.

t

n

n.

5. Configure the media as explained in “Configure Media” on

page 2-6. At the end of the Configure Media process, press

the Proceed (!) key on the control panel.

Load and Print on Roll-Fed Media 2-15

Page 46

OR

If the media is already configured, from the Front Page

screen of the control panel, press the Load key.

The printer displays a menu with the following options:

• New Load — loads a new media, discards previous

settings (see page 2-16).

• Restore Loaded State — loads media using the previ-

ously-used settings when rollfed media is already loaded

in the printer but the printer is not in a loaded state. This

can happen if the printer goes to sleep or is rebooted, or

if you press the Unload key on the front panel, but not

physically remove the media from the printer (see page

2-19).

Follow the procedure on the next sections that corresponds

to the load option you choose.

New Load 6. On the Select Thickness Units screen, press the option that

corresponds to the units you will use.

7. On the Enter Media Thickness screen, enter the media

thickness, or press the Esc key to use the default thickness.

8. As prompted by the control panel, remove the foam press

roller, then press the Proceed (!) key.

9. Pull the media from the roll, pull it over the foam lift roller

(the foam press roller

lay it on the belt up to the input media roller

10. On the control panel, press the upper (forward) Advance

Media arrow key to advance the media, with the vacuum

fans on.

You may need to hold the media down on the belt until the

vacuum grabs it.

• If using the takeup system, advance the media until it

hangs on exit side down to the takeup roller. Do not tape

the media to the core at this time.

• If not using the takeup system, advance the media at

least past the output media roller

2-16 Load and Print on Roll-Fed Media

p should not be in position yet) and

q.

r. During printing,

o

Page 47

make sure that the media does not fall behind takeup

rollers

st and u.

11. On the control panel, press the Turn Off Fans key.

Fig. 2-6. Load roll-fed media

12. Hold the upper (forward) Advance Media key down for

about five seconds.

This will help smooth out wrinkles and equalize the tension

of the media across the belt.

Since the fans are off, the media should not advance. If the

media moves, hold on to the media with your right hand

while pressing the Advance Media key with your left hand.

13. On the control panel, press the Turn On Fans key.

14. Lower the input

est positions.

Use the adjustment cranks on both the user and service

ends to lower the rollers at both ends. This will help keep

wrinkles out of the media.

Load and Print on Roll-Fed Media 2-17

q and output media rollers r to their low-

Page 48

15. Check for wrinkles in the media across the full length and

width of the belt.

If you see any wrinkles, turn off the fans and smooth them

out with your hand. Repeat steps 11 through 15 until no

wrinkles are visible.

16. Place the foam press roller

17. If you are not using the takeup system, go to step 23.

18. Align the cardboard takeup core to the media and tighten the

collets to lock the core in place.

19. Lift the first dancer bar

upper position.

20. Pull the media under the first dancer bar, over second

dancer bar

roller

Looking down the length of the takeup roller from the user

end, the roller rotates clockwise. Ensure that the media is

wrapped as shown in Figure 2-5 on page 2-15.

21. Tape the end of the media to printer side of takeup roller,

starting in the middle and working out to both ends.

Be sure to maintain even tension across the width of the

media.

22. Release the dancer bar locking lever.

t, and down to the printer side of takeup

u.

p into operating position.

s (with the gears), and lock in the

23. Press the Proceed key.

24. Enter the media length or press the Esc key for an unde-

fined length.

The printer measures the media width.

25. On the Front Page screen, press the Proceed key.

The Front Page screen appears on the control panel.

2-18 Load and Print on Roll-Fed Media

Page 49

26. Press the Go Online key.

The printer is now ready to receive a print job from the RIP.

Restore Loaded State 27. As prompted by the control panel, remove the foam press

roller, then press the Proceed (!) key.

28. Press the upper (forward) Advance Media key to advance

the media to the takeup spool and/or past any printed area

of the media.

29. On the control panel, press the Turn Off Fans key.

30. Hold the upper (forward) Advance Media key down for

about five seconds.

31. On the control panel, press the Turn On Fans key.

32. Press the Proceed key.

33. Check for wrinkles in the media across the full length and

width of the belt.

If you see any wrinkles, turn off the fans and smooth them

out with your hand. Repeat steps 29 through 33 until no

wrinkles are visible.

34. Place the foam press roller

35. If you are not using the takeup system, or if the media is

already loaded in the takeup, go to step 41.

36. Align the cardboard takeup core to the me dia and tighten the

collets to lock the core in place.

37. Llift the first dancer bar

upper position.

38. Pull the media under the first dancer bar, over second

dancer bar

roller

Looking down the length of the takeup roller from the use r

end, the roller rotates clockwise. Ensure that the media is

wrapped as shown in Figure 2-5 on page 2-15.

Load and Print on Roll-Fed Media 2-19

t, and down to the printer side of takeup

u.

p into operating position.

s (with the gears), and lock in the

Page 50

39. Tape the end of the media to printer side of takeup roller,

starting in the middle and working out to both ends.

Be sure to maintain even tension across the width of the

media.

40. Release the dancer bar locking lever.

41. Press the Proceed key.

42. Enter the media length or press the Esc key for an unde-

fined length.

The printer measures the media width.

43. Press the Proceed key.

The Front Page screen appears on the control panel.

44. On the Front Page screen, press the Go Online key.

The printer is now ready to receive a print job from the RIP.

2-20 Load and Print on Roll-Fed Media

Page 51

Printing Tips • Rigid cut-sheet media — use only flat, unwarped, undam-

aged sheets, with parallel opposite edges and 90

• Curing continues for 24-48 hours — the UV ink will con-

tinue to cure for a day or two after printing. Maximum durability and adhesion is achieved after the ink is fully cured.

° corners.

• Pausing printing — to pause printing, press the

key. While printing is paused, you can:

• Perform a Standard Purge of one or more colors, to

restore missing inkjets.

• Change media settings (vacuum, print delay).

• Pause-swap inks (see “Pause Swapping Ink,” below).

Caution Synthetic media commonly used for inkjet printing

can build up a static charge, especially in environments with low relative humidity. This charge can

pose an electrostatic discharge (ESD) hazard to

persons, the printer, and other equipment. It can be

safely discharged by draping a grounded chain or

tinsel over the top of the stack of media.

• Printing roll-fed media without the takeup — cured out-

put is dry to the touch immediately, so roll-fed output can be

allowed to collect on the floor (for example, during unattended printing) without using the takeup system, with no

damage to the output.

• Lighter, smaller media rolls — for lighter, smaller rolls of

media, you can use the rigid media tables and media rollers

to feed the media like rigid media.

(Pause)

Printing Tips 2-21

Page 52

Pause-Swapping Ink You can replace one or more ink boxes during a print by pausing

the printer:

1. On the printer control panel, press the

2. Remove the old profiler.

This signals to the printer that the ink box is being replaced.

3. Disconnect and remove the old ink box.

4. Install and connect the new ink box.

5. Install the profiler that was included with the new ink box.

6. Repeat steps 2 through 5 for any other ink boxes you want

to replace.

7. On the printer control panel, press the

(Pause) key.

(Resume) key.

2-22 Printing Tips

Page 53

Checking Jet Health When AutoJet detects a missing jet, it attempts to replace it with

a working jet on the same or another printhead (in Production

and High Quality modes). In this way, printing occurs with all jets

for maximum quality.

When you notice a decrease in print quality, one or more inkjets

may be clogged. To recover clogged jets:

1. Print a Prime Bars pattern to determine whether there are

any missing jets (see below).

2. Run AutoJet (page 4-3) or Manual Jet Mapping (page

4-16).

3. If there are any missing jets, Print Jet-Out Lines (see

below).

Repeat this process until all jets are working or substituted fo r

another jet.

Print Prime Bars 1. From the control panel Front Page screen, press the Prime

Bars key.

The control panel displays a prompt asking you to enter the

total width of the prime bar pattern you wish to print.

2. Enter a width for the prime bar pattern by pressing the )

and , keys.

3. Press the ! (Proceed) key to continue.

The printer prints the prime bar pattern. The prime bars will

show correctly working jets with a solid line, and missing jets

with no line.

Map Out Missing Jets If the Prime Bars (above) reveal a blank lines, the corre sponding

jets should be mapped out. When all missing jets have been

substituted, printed output will appear as if all jets are working.

You can map jets out temporarily (“soft bad jet s”) or perman ently

(“hard bad jets). For instructions, see “AutoJet” on page 4-3 or

“Manual Jet Mapping” on page 4-16.

Checking Jet Health 2-23

Page 54

Print Jet-Out Lines 1. From the control panel Front Page screen, press the Cali-

brate key.

The Calibrate menu appears.

2. Press Manual Calibrations.

The Manual Calibrations menu appears.

3. Press Print Jet-Out Lines.

The Jet-Out Lines pattern prints. Substituted jet s are marked

with a black square.

2-24 Checking Jet Health

Page 55

Chapter 3

This chapter describes how to use the ink.

• Ink System Overview (page 3-2)

• Loading Ink (page 3-5)

Ink

Ink 3-1

Page 56

Ink System Overview The printer’s ink system consists of the following components:

• Ink boxes — bag-in-box supply of UV cure ink, suitable for

both flexible and rigid media applications.

Note Unlike other inks used in wide format printing, UV

cure ink has a limited shelf life. Plan to rotate your

ink stock and use it promptly by the date printed on

the ink box.

• Flushing solution — used to moisten a lint-free cloth for

cleaning the printheads, also in automated flushing of the

printheads. It has no properties that work against the ink to

soften or reliquify cured ink, or any other similar cleaning

properties. It does not react with the ink, making it suitable

for use as a lubricating agent for cleaning.

Caution Use only genuine HP inks and Flushing Solution in