Page 1

HPE XP P9500 Getting Started

Guide

Abstract

This guide is intended for system administrators, Hewlett Packard Enterprise representatives, and authorized service providers

involved in planning, installing, configuring, and operating XP P9500.

Part Number: AV400-96635R

Published: November 2015

Page 2

© Copyright 2014, 2015 Hewlett Packard Enterprise Development LP

The information contained herein is subject to change without notice. The only warranties for Hewlett Packard Enterprise products and services

are set forth in the express warranty statements accompanying such products and services. Nothing herein should be construed as constituting

an additional warranty. Hewlett Packard Enterprise shall not be liable for technical or editorial errors or omissions contained herein.

Confidential computer software. Valid license from Hewlett Packard Enterprise required for possession, use, or copying. Consistent with FAR

12.211 and 12.212, Commercial Computer Software, Computer Software Documentation, and Technical Data for Commercial Items are licensed

to the U.S. Government under vendor's standard commercial license.

Links to third-party websites take you outside the Hewlett Packard Enterprise website. Hewlett Packard Enterprise has no control over and is not

responsible for information outside the Hewlett Packard Enterprise website.

Acknowledgments

Microsoft® and Windows® are trademarks of the Microsoft group of companies.

Adobe® and Acrobat® are trademarks of Adobe Systems Incorporated.

Page 3

Contents

1 Introduction..........................................................................................................5

P9500 overview....................................................................................................................................5

Hardware overview...............................................................................................................................5

Controller chassis............................................................................................................................6

Drive chassis...................................................................................................................................8

Specifications........................................................................................................................................8

2 Planning the Installation....................................................................................11

Responsibilities...................................................................................................................................11

User Hewlett Packard Enterprise..................................................................................................11

Hewlett Packard Enterprise responsibilities..................................................................................11

Installation planning checklist.............................................................................................................12

System specifications and requirements............................................................................................14

General safety guidelines..............................................................................................................14

Work safety guidelines..................................................................................................................14

Warning about moving parts..........................................................................................................15

Electrical safety guidelines.......................................................................................................15

3 Installation requirements...................................................................................16

General site requirements..................................................................................................................16

Equipment clearances...................................................................................................................16

Equipment weight..........................................................................................................................17

Storage requirements....................................................................................................................17

Data center requirements...................................................................................................................17

Data communication requirements.....................................................................................................17

C-Track...............................................................................................................................................18

Insight Remote Support......................................................................................................................18

System specifications and requirements............................................................................................20

Mechanical specifications..............................................................................................................20

Electrical specifications.................................................................................................................22

Grounding.................................................................................................................................24

Power connection.....................................................................................................................24

AC Power - PDU Options.........................................................................................................24

Environmental specifications.........................................................................................................26

Heat output and air flow.................................................................................................................26

Equipment noise............................................................................................................................29

Service clearance, floor cutout, and floor load rating.........................................................................29

Single rack configuration...............................................................................................................29

Two rack configuration (one DKC)................................................................................................31

Two rack configuration (two DKC).................................................................................................33

Three rack configuration (left module)...........................................................................................35

Three rack configuration (right module)........................................................................................36

Four rack configuration (left module).............................................................................................38

Four rack configuration (right module)..........................................................................................39

Five rack configuration..................................................................................................................42

Six rack configuration....................................................................................................................43

Operational requirements...................................................................................................................45

4 Power On/Off procedures..................................................................................46

Safety and environmental information................................................................................................46

Standby mode.....................................................................................................................................46

Power On/Off procedures...................................................................................................................46

Power On procedures....................................................................................................................46

Power Off procedures....................................................................................................................47

Contents 3

Page 4

Battery backup operations..................................................................................................................47

Cache destage batteries................................................................................................................48

Battery life .....................................................................................................................................48

Long term array storage................................................................................................................49

5 Technical Specifications....................................................................................55

Mechanical specifications...................................................................................................................55

Electrical specifications.......................................................................................................................55

System heat and power specifications...............................................................................................55

System components heat and power specifications ..........................................................................56

AC power - PDU options.....................................................................................................................57

Environmental specifications..............................................................................................................58

A Technical Specifications....................................................................................55

Mechanical specifications...................................................................................................................55

Electrical specifications.......................................................................................................................55

System heat and power specifications...............................................................................................55

System components heat and power specifications ..........................................................................56

AC power - PDU options.....................................................................................................................57

Environmental specifications..............................................................................................................58

B Warranty and regulatory information.................................................................60

Warranty information...........................................................................................................................60

Regulatory information........................................................................................................................60

Belarus Kazakhstan Russia marking.............................................................................................60

Turkey RoHS material content declaration....................................................................................61

Ukraine RoHS material content declaration..................................................................................61

4 Contents

Page 5

1 Introduction

P9500 overview

The P9500 is a high capacity, high performance disk array that offers a wide range of storage

and data services, software, logical partitioning, and simplified and unified data replication across

heterogeneous disk arrays. Its large scale, enterprise class virtualization layer combined with

Smart Tiers and Thin Provisioning software, delivers virtualization of internal and external storage

into one pool.

Using this system, you can deploy applications within a new framework, leverage and add value

to current investments, and more closely align IT with business objectives. P9500 disk arrays

provide the foundation for matching application requirements to different classes of storage and

deliver critical services including:

• Business continuity services

• Content management services (search, indexing)

• Non disruptive data migration

• Thin Provisioning

• Smart Tiers

• High availability

• Security services

• I/O load balancing

• Data classification

• File management services

New technological advances improve reliability, serviceability and access to disk drives and other

components when maintenance is needed. Each component contains a set of LEDs that indicate

the operational status of the component.

The system includes new and upgraded software features, including Smart Tiers, and a

significantly improved, task oriented version of Remote Web Console that is designed for ease

of use and includes context sensitive online help. The system documentation has been changed

to a task oriented format that is designed to help you find information quickly and complete tasks

easily.

For host connectivity information, see the P9500 disk array configuration guide.

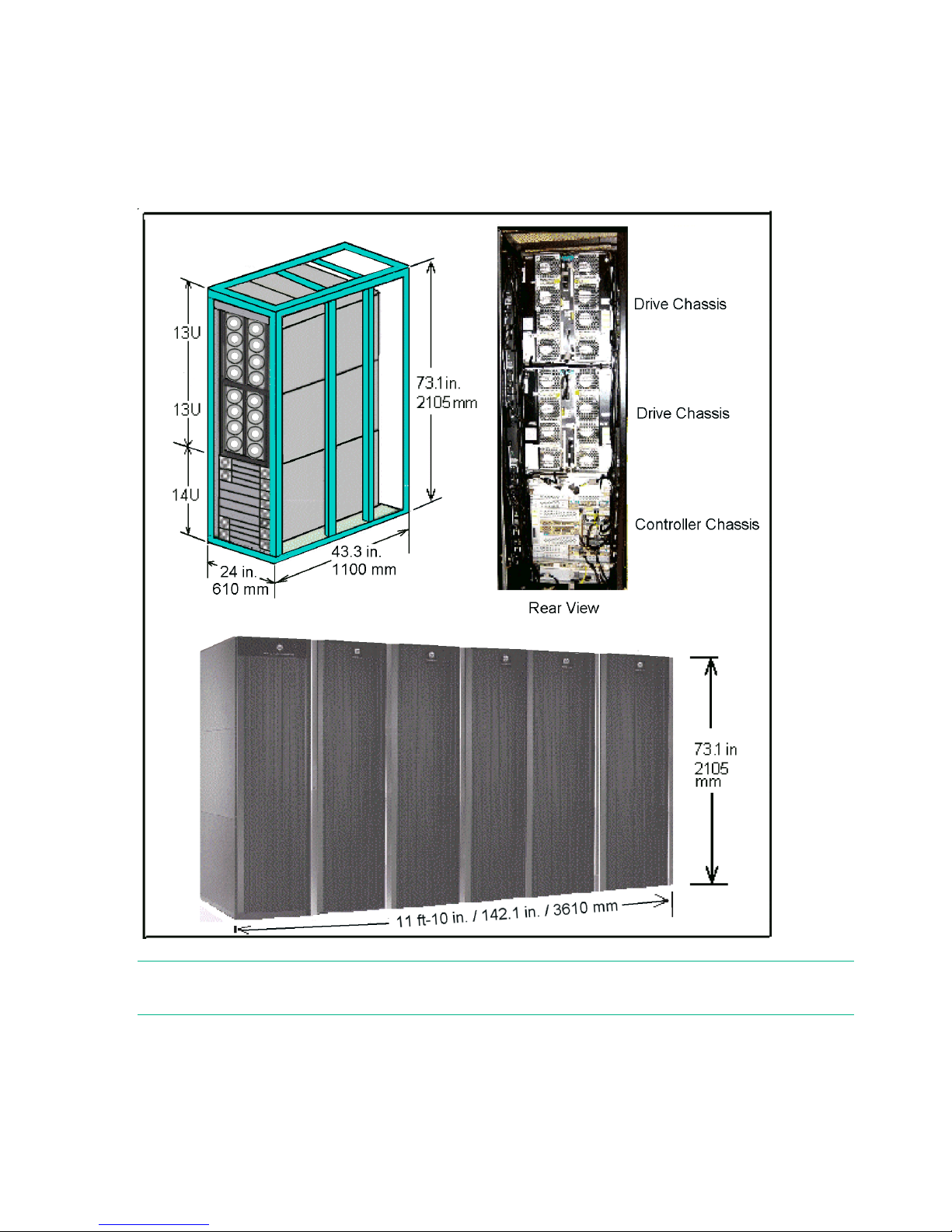

Hardware overview

The P9500 disk arrays contain significant new technology that was not available in previous disk

arrays. The system can be configured in many ways, starting with a small (one rack) to a large

(six rack) system that includes two controller chassis, up to 2048 HDD drives which include up

to 256 solid state drives, and a total of 1024 GB cache. The system provides a highly granular

upgrade path, allowing the addition of disk drives to the drive chassis, and Processors Blades

and other components to the controller chassis in an existing system as storage needs increase.

The controller chassis (or DKU) of the P9500 disk array can be combined so that what would

previously have been two separate disk arrays are now a single disk array with homogeneous

logic control, cache, and front end and back end interfaces, all mounted in custom HPE 19 inch

racks.

A basic P9500 disk array is a control rack (Rack- 00) that contains a controller chassis and two

drive chassis (factory designation DKU). The fully configured P9500 disk array consists of two

controller chassis and sixteen drive chassis for fully configured system. The controller chassis

contains the control logic, processors, memory, and interfaces to the drive chassis and the host

P9500 overview 5

Page 6

servers. A drive chassis consists of disks or SSD drives, power supplies, and the interface circuitry

connecting it to the controller chassis. The remaining racks (Rack-01, Rack-02, Rack-10 and

Rack-11) contain from one to three drive chassis.

The following sections provide descriptions and illustrations of the P9500 disk array and its

components.

Figure 1 P9500 disk array

NOTE: Each Rack is 600mm wide without side covers. Add 5mm to each end of entire assembly

for each side cover.

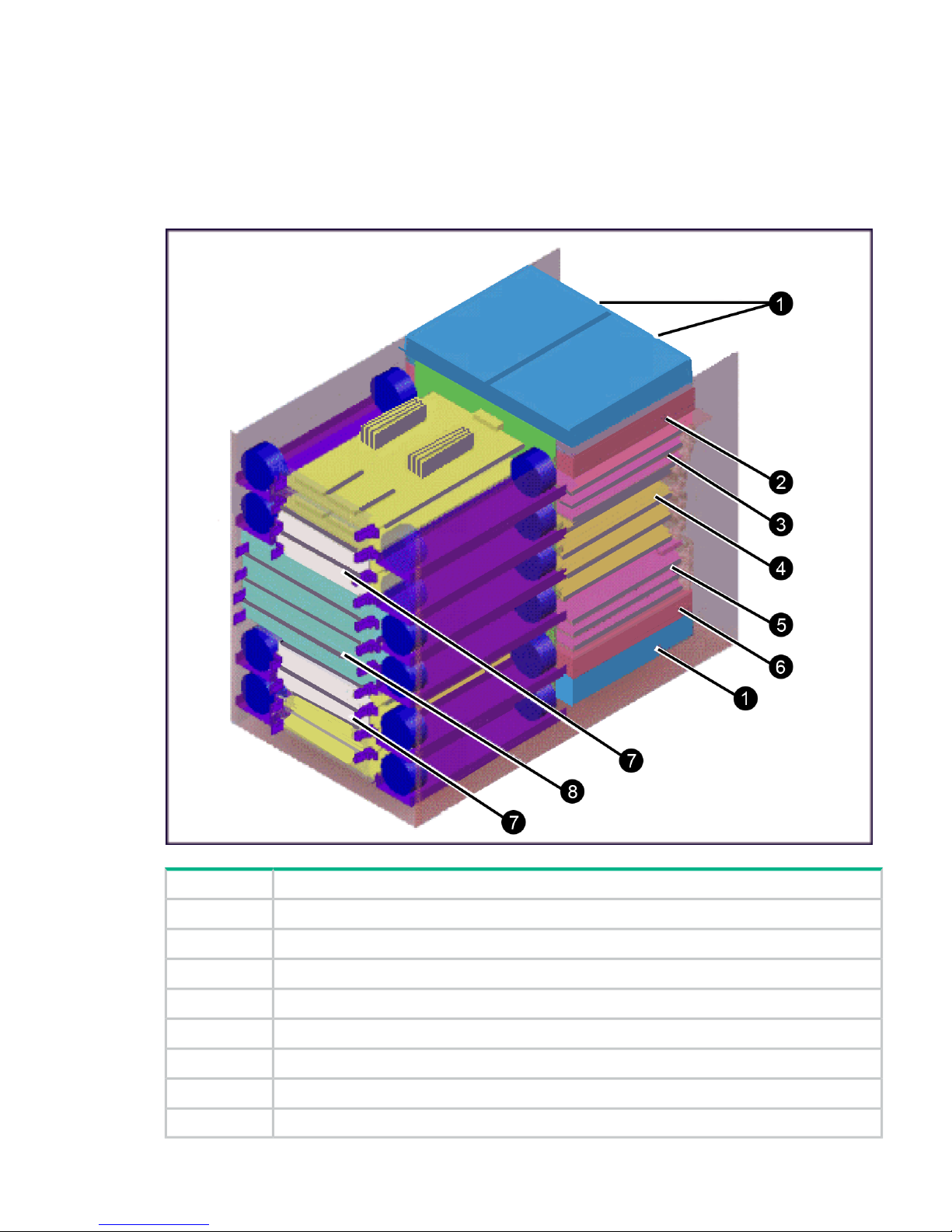

Controller chassis

The controller chassis (factory designation DKC) includes the logical components, memory, disk

drive interfaces, and host interfaces. It can be expanded with a high degree of granularity to a

system offering up to twice the number of processors, cache capacity, host interfaces and disk

storage capacity.

6 Introduction

Page 7

The controller chassis includes the following maximum number of components: two service

processors, 512 GB cache memory, four grid switches, four redundant power supplies, eight

channel adapters, four disk adapters, and ten dual fan assemblies. It is mounted at the bottom

of the rack because it is the heavier of the two units. If a system has two SVPs, both SVPs are

mounted in controller chassis #0.

The following illustration shows the locations of the components in the controller chassis.

Figure 2 Controller chassis

DescriptionItem

AC/DC: Power Supply 2 or 4 per controller1

Service Processor: One or two units in the #0 controller chassis2

CHA3

Grid switches4

CHA (up to 7) and DKA (up to 4)5

Service Processor: One or two units in the #0 controller chassis6

Cache: 2 to 8 cache boards in pairs (2, 4, 6, 8)7

P9500: 2 to 4 microprocessor boards8

Hardware overview 7

Page 8

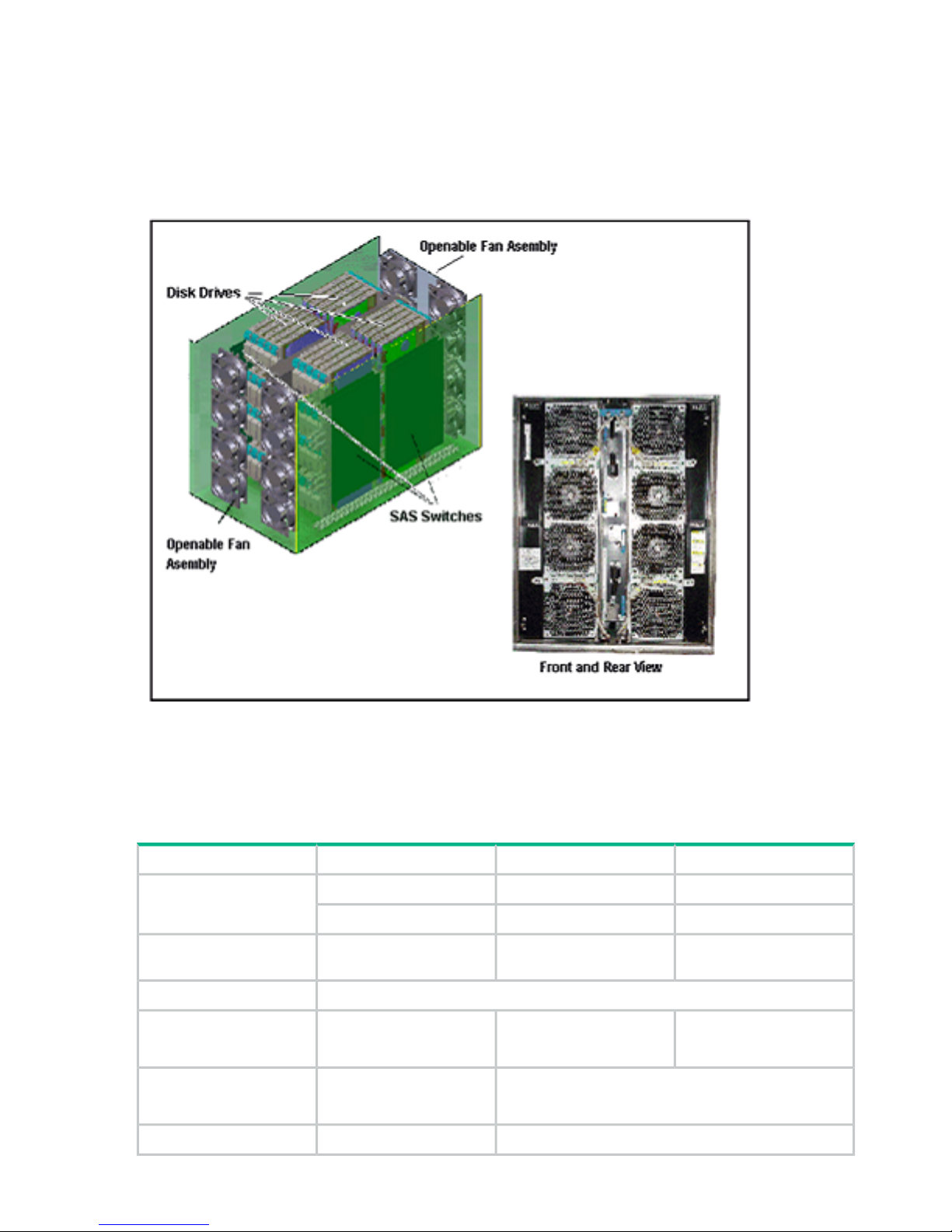

Drive chassis

The drive chassis (factory designation DKU) consists of SAS switches, slots for 2 1/2 inch HDD

or SSD drives, and four 4 fan door assemblies that can be easily opened to allow access to the

drives. Each drive chassis can hold 128 2 1/2 inch HDD or SSD drives. The maximum number

of 2 1/2 inch drives in a P9500 system is 2048.

Figure 3 Disk Unit

Specifications

The following tables provide general specifications of the P9500.

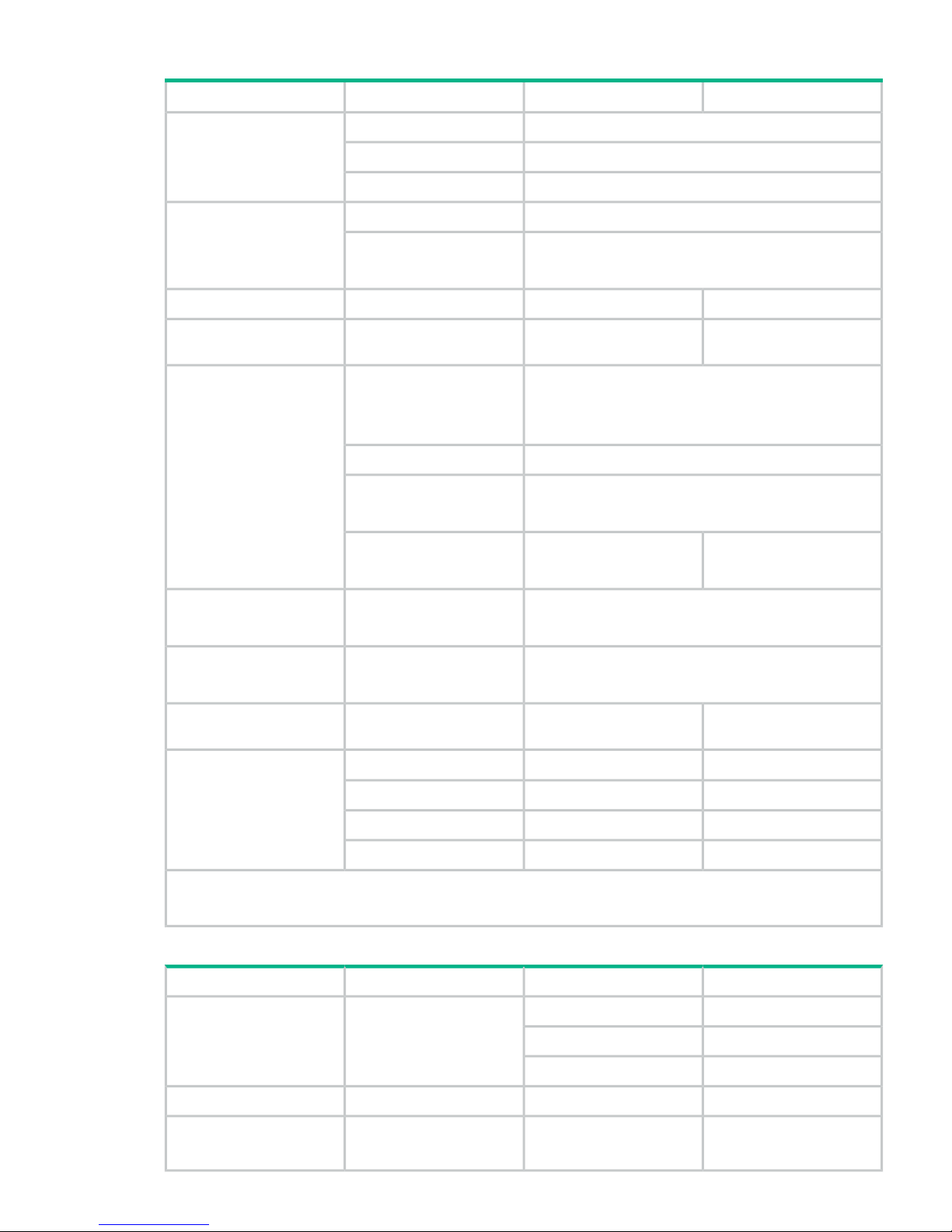

Table 1 P9500 specifications

Dual ModuleSingle ModuleSizeItem

589 TB294 TBInternalMaximum Capacity (based

on 900GB HDDs)

247 PB247 PBExternal

64k64k-Maximum number of

volumes

See Table 2 (page 9).Supported drives

Min 128 GBMin 64 GB.Cache memory capacity

Max 1024 GBMax 512 GB

Min 64 GB.Cache flash memory

capacity

Max 1028 GB

RAID1, RAID5, RAID6.RAID Level

8 Introduction

Page 9

Table 1 P9500 specifications (continued)

Dual ModuleSingle ModuleSizeItem

2D+2D, 4D+4DRAID1RAID GroupConfiguration

3D+1P, 7D+1PRAID5

6D+2PRAID6

Hierarchical Star NetArchitectureInternal Path

Cache Path = 128 GB/sMaximum Bandwidth

Control Path = 64 GB/s

64 (2WL*32)32 (2WL*6)SAS 6GBack-end Path

160/16,880 /16,8FC 2/4/8GNumber of ports per

installation unit

SAS/Dual PortController chassisDevice I/F

drive chassis

Interface

Max. 6 GBpsData transfer rate

256 (2.5 inch HDD)Maximum number

of HDD per SAS I/F

8 if drives installed4 if drives installedMaximum number of CHAs

12 if diskless6 if diskless

1/2/4 GBps Fibre Channel: 16MFS/16MFLMainframeChannel I/F

2/4/8 GBps Fibre Channel: 16MUS/16MUL

2/4/8 GBps Fibre Shortwave:Open systems

8UFC/16UFC

32 cores16 coresQuantityManagement Processor

Cores

6

1

6

1

CHAsMicro Processor Blade

configuration

2 / 80 or 2 / 42DKAs

Minimum/maximum

2 / 162 / 8Cache

4 / 82 / 4Switches /CSW

Notes:

1. All CHA configuration, no DKAs (diskless system).

Table 2 Drive specifications

Speed (RPM)Drive CapacitySizeDrive Type

15,000300 GB2 1/2 inchHDD (SAS)

10,000300, 600, and 900 GB

7,200500 GB and 1 TB

n/a200, 400, and 800 GB2 1/2 inchSSD (Flash)

Dual ModuleSingle ModuleDrive ChassisDrive Type

(6 rack system)(3 rack system)

Specifications 9

Page 10

Table 2 Drive specifications (continued)

Speed (RPM)Drive CapacitySizeDrive Type

20481024128HDD, 2 1/2 inch

256

2

128

2

128

1

SSD (Flash)

Notes.

1. SSD drives can be mounted all in one drive chassis or spread out among all of the chassis in the storage system.

2. Recommended maximum number.

10 Introduction

Page 11

2 Planning the Installation

NOTE: The GUI illustrations in this guide were created using a Windows computer with the

Internet Explorer browser. Actual windows may differ depending on the operating system and

browser used. GUI contents also vary with licensed program products, storage system models,

and firmware versions.

Responsibilities

The responsibilities for installation planning are shared by the customer and Hewlett Packard

Enterprise support. The required installation planning tasks must be scheduled and completed

to ensure successful and efficient installation of the P9500 disk array.

NOTE: The P9500 disk array must be installed by trained Hewlett Packard Enterprise personnel

or trained Hewlett Packard Enterprise Technical Support. The P9500 disk array is not a customer

installable product.

User Hewlett Packard Enterprise

You are responsible for performing the following tasks to prepare for installation of the P9500

disk array.

• Understand the applicable safety requirements associated with installing a P9500 disk array.

• Understand the installation requirements for the P9500 disk array. You can use the information

in this manual to determine the specific requirements for your installation. As needed, review

the P9500 user and reference guide to familiarize yourself with the components, features,

and functions of the P9500 disk array.

• Verify that the installation site meets all installation requirements. A checklist is included in

this section to help you with this task.

• Provide electrical hardware, including cables, connectors and receptacles that are required

to connect the P9500 disk array to site power.

• As needed, work with Hewlett Packard Enterprise support to create an installation plan.

Allow enough time to complete any changes to the plan, so your site is ready when the

equipment arrives.

Hewlett Packard Enterprise responsibilities

Hewlett Packard Enterprise support is responsible for completing the following tasks:

• Assist you as needed during the installation planning process for your specific site and

operational configuration

• Coordinate Hewlett Packard Enterprise resources to ensure a successful installation and

configuration of the P9500 disk array.

Responsibilities 11

Page 12

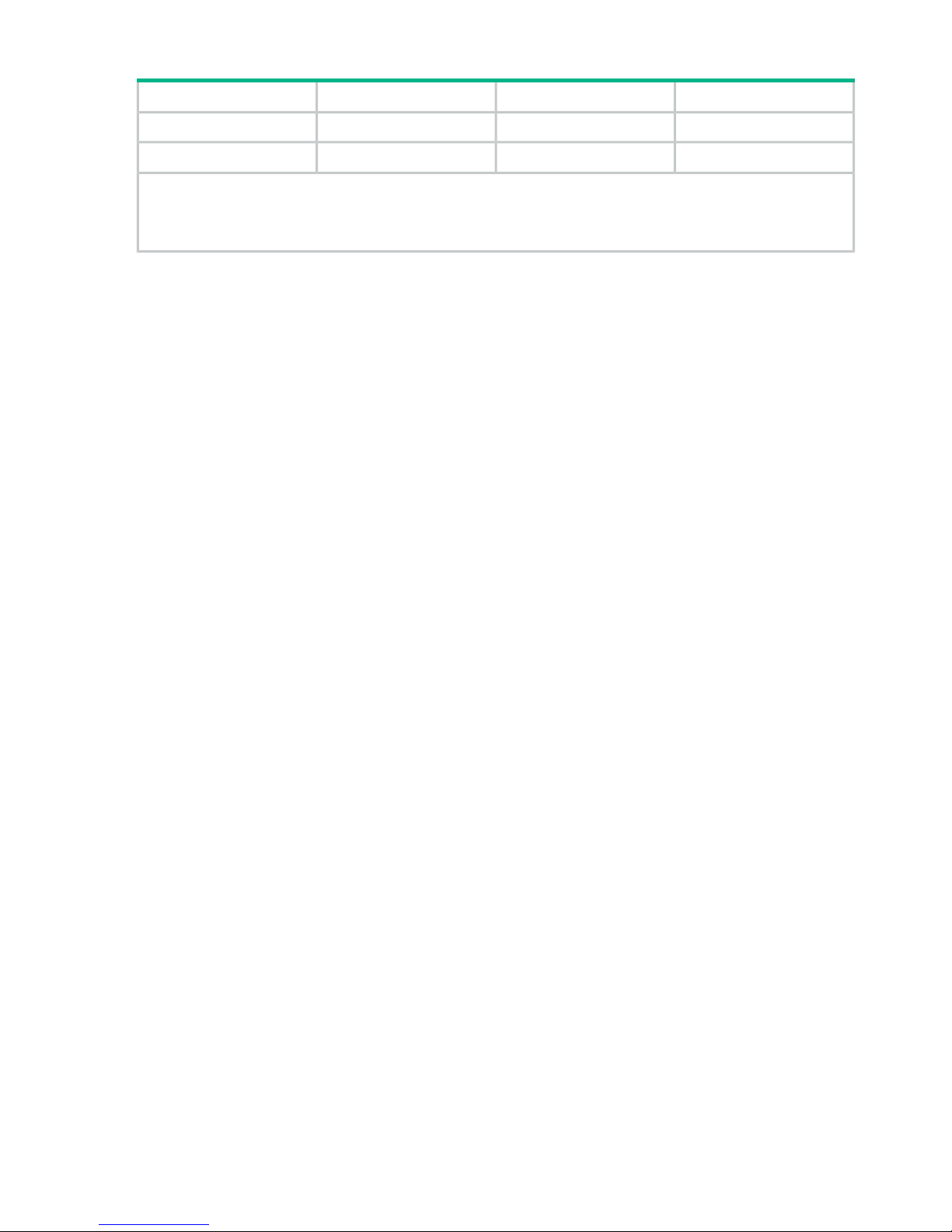

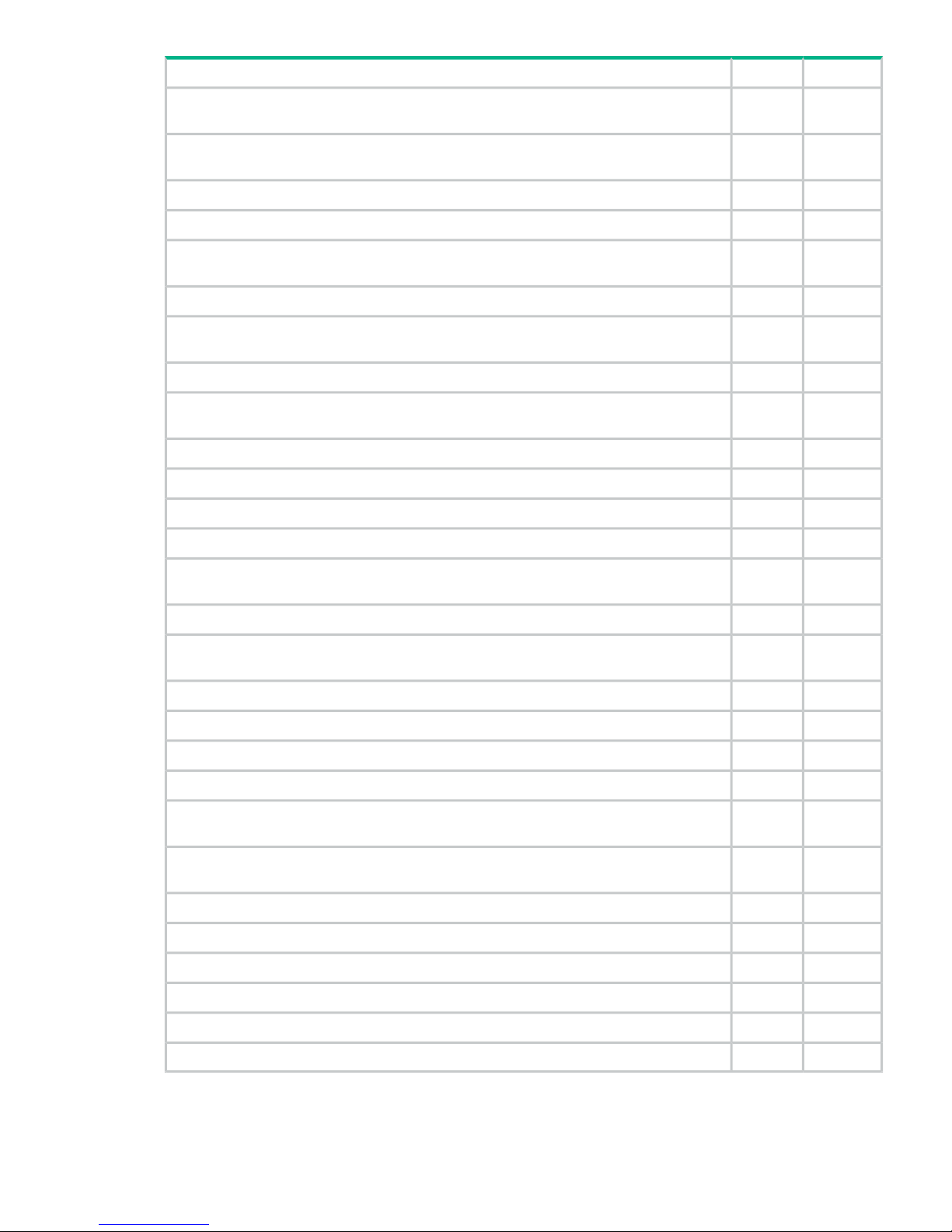

Installation planning checklist

The following checklist can help you ensure that your site meets all requirements needed to

install the P9500 disk array. You can make copies of this checklist for each installation you

perform and check each step after it has been performed. Keep the blank checklist in this

document for future use to verify that all installation requirements for the P9500 disk array are

met. Completing this checklist can help ensure smooth and efficient installation of the P9500

disk array.

Definition of terms

Equipment: The hardware delivered to the customer site that includes the P9500 disk array

components and rack(s).

Location: The specific location in the data center (area or “footprint” on the floor) where the

P9500 disk array will be installed.

User Information

Company

Address

Contact

Phone

Mobile

Email

Contact

Phone

Mobile

Email

Information

Contact

Phone

Mobile

Email

Contact

Phone

Mobile

Email

Notes

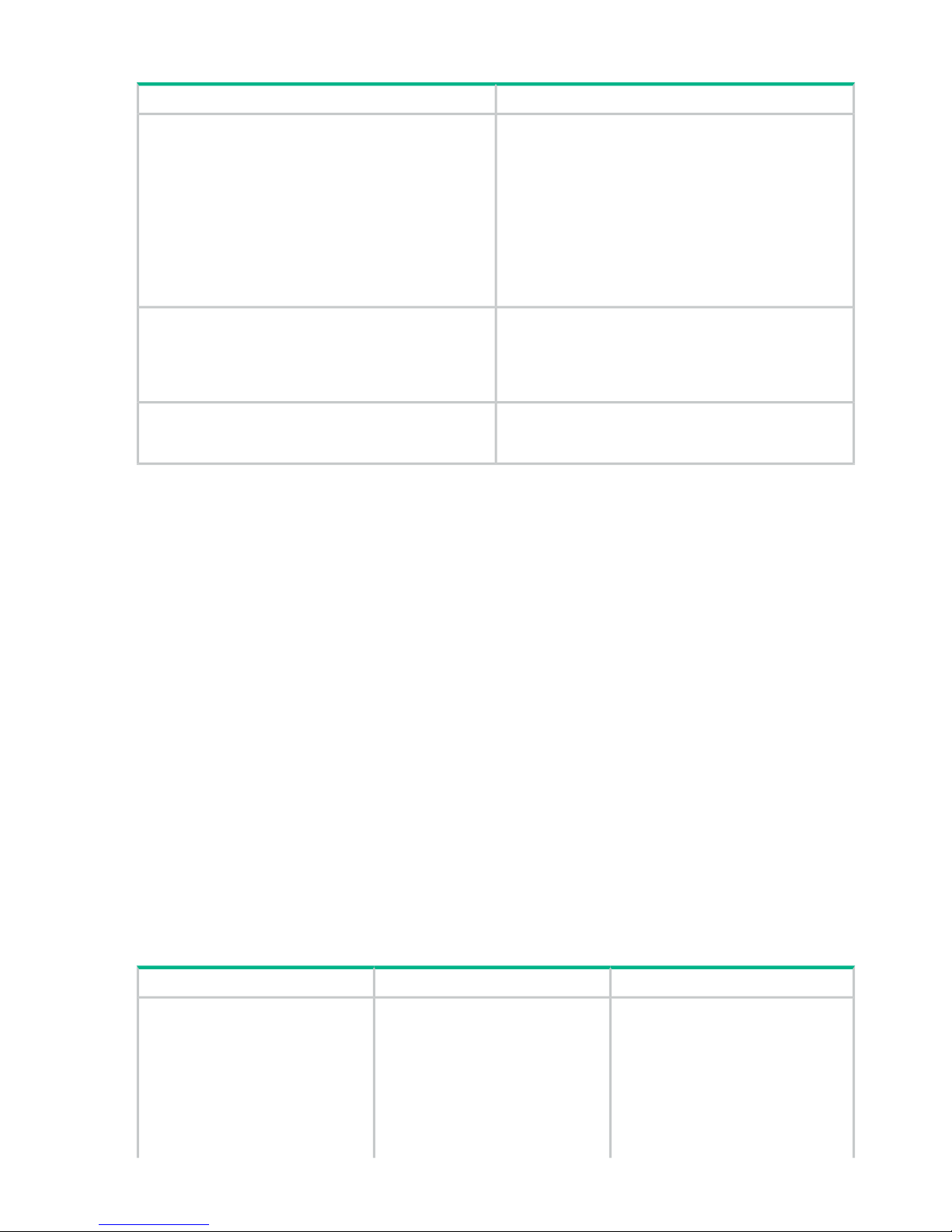

NoYesInstallation Planning Checklist

Safety Requirements

Is the data center equipped to protect the equipment from fire?

Is the data center free of hazards (for example, cables that obstruct access)?

Delivery Requirements

12 Planning the Installation

Page 13

NoYesInstallation Planning Checklist

Is the receiving area adequate for equipment delivery and unloading? (Can the area handle

crated equipment at least 90 in./2.29 m high?)

Are all doors, hallways, elevators, and ramps wide enough and high enough to allow the

equipment to be moved from the receiving area to the installation area?

Can the floors, elevators, and ramps support the weight of the equipment?

Storage Requirements

If the equipment will be stored after delivery and prior to installation, does the storage

location meet the environmental requirements for storing a P9500 disk array?

Facilities Requirements

Does the data center provide appropriate fire protection for computer equipment such as

P9500 disk arrays?

Does the data center have a raised floor?

Does the location meet the requirements for service clearance and cable routing (for example,

floor cutouts)?

Does the location meet the floor load rating requirements?

Power Requirements

Does the data center meet the AC input power requirements?

Does the data center meet the circuit breaker and plug requirements?

Is the customer supplied hardware such as connectors, receptacles, and cables ready for

the installation?

Environmental Requirements

Does the data center meet the operational temperature requirements for a P9500 disk

array?

Does the data center meet the operational humidity requirements for a P9500 disk array?

Does the data center meet the operational altitude requirements for a P9500 disk array?

Does the data center meet the air flow requirements for a P9500 disk array?

Does the data center provide adequate protection from ESD?

Does the data center provide adequate protection from electrical/radio frequency

interference?

Does the data center provide adequate protection from dust, pollution, and particulate

contamination?

Does the data center provide adequate acoustic insulation to operate the P9500 disk array?

Operational Requirements

Does the data center provide a LAN for Remote Web Console?

..hb-Is the infrastructure available for the default Internet based remote support solution?

Does the location meet the cable length requirements for the CHAs?

Does the location meet the requirements for attaching external storage?

Installation planning checklist 13

Page 14

System specifications and requirements

General safety guidelines

Observe the following general site guidelines:

• General Requirements: The data center must comply with all applicable safety regulations,

standards, and requirements for installing and operating industrial computer equipment

similar to a P9500 disk array.

• Fire protection: The data center must have an operational fire protection system appropriate

for use with computer and electrical equipment.

• Hazards: The data center must be free of hazards (for example, cables on the floor that

block access or that can cause people to trip).

• Equipment modifications: Do not make mechanical or electrical modifications to the

equipment. Hewlett Packard Enterprise is not responsible for regulatory compliance of a

modified Hewlett Packard Enterprise product.

• Earthquake Safety: To minimize personal injury in the event of an earthquake, securely

fasten the control and drive chassis to a rigid structure extending from the floor to the ceiling

or from the walls of the room in which the system is located.

• Cabling: Do not block walkways when routing cables. Do not place heavy materials on

cables. Do not place cables near any possible source of heat.

• Warning and safety labels: Safety warnings, cautions, and instructions in various languages

are attached to the P9500 disk array components. The safety warnings provide guidelines

to follow when working with any equipment. Hewlett Packard Enterprise recommends that

you read all warning labels on the hardware. If warning labels become dirty, damaged,

unreadable, or peel off, contact the Hewlett Packard Enterprise support center.

• Authorized personnel: Allow only qualified and authorized personnel (for example, a

certified electrician) to perform hazardous tasks.

Work safety guidelines

Observe the following site guidelines:

• Do not wear loose clothing that could get caught in the equipment or mounting hardware.

Fasten your tie or scarf and roll up your sleeves.

• Wear safety glasses when working under conditions that are hazardous to your eyes.

• Do not perform any action that creates a potential hazard to people or makes the equipment

or rack unsafe.

• Keep walkways clear of tools, power cables, and parts to prevent them from being stepped

on or causing people to trip and fall over them.

• Do not work on the equipment or disconnect cables during a thunderstorm, when wearing

a wool sweater or other heavy wool clothing, or when power is applied.

• Keep floors dry to prevent slips and falls.

• Do not use ungrounded power cables.

• Keep the area clear and dust free during and after installation.

• Do not block or cover equipment openings. Ensure that all equipment has adequate airflow.

Failure to follow these guidelines can cause overheating and affect the system reliability.

• The rack is equipped with casters so that you can move it short distances to position it for

final installation. Use enough personnel when moving a rack, especially on sloping loading

docks and ramps to a raised computer room floor. Move the cabinet slowly and deliberately,

14 Planning the Installation

Page 15

and make sure that the floor is free from foreign objects and cables that the cabinet could

roll over.

WARNING! To avoid injury, wear protective footwear when moving equipment.

Warning about moving parts

Even though customers do not install or maintain equipment, these guidelines are provided to

prevent possible injury when working with authorized service personnel. Observe the following

warning related to moving parts:

• Tuck in any loose clothing so that it cannot be caught by a moving or rotating part such as

a fan.

• Tie up long hair.

• Unless otherwise specifically instructed, do not supply power to any device that contains

rotating or moving parts that are not properly covered.

Electrical safety guidelines

Even though customers do not install or maintain equipment, these guidelines are provided to

prevent possible injury when working with authorized service personnel in the area where

equipment is installed. Observe the following electrical safety guidelines:

• Disconnect all power before installation, deinstallation, or moving equipment.

• Ensure that the voltage and frequency of your power source match the voltage and frequency

required by the system.

• All equipment should be properly grounded for proper operation and safety. To reduce the

risk of electric shock or damage to equipment, follow proper grounding procedures.

System specifications and requirements 15

Page 16

3 Installation requirements

General site requirements

The customer site must accommodate the delivery and movement of the equipment from the

receiving dock to the installation location in the data center.

Equipment clearances

Receiving area: The receiving dock, storage area, and receiving area must be large enough to

allow movement of and access to crated or packed equipment. The dimensions of a shipping

crate for a single rack are shown in the following table.

Table 3 P9500 shipping crate dimensions

DepthWidthHeightItem

53 in./1346 mm39 in./991 mm87 in./2210 mmShipping crate, single rack

NOTE: P9500 disk array racks are shipped in one of three standard packaging configurations:

• Environmental pack - This packaging configuration consists of stretch wrap over corner

protectors. Environmental pack is used for most shipments within the USA that are shipped

directly from the factory to the customer. Hewlett Packard Enterprise uses authorized carriers

with a dedicated fleet of trucks and specially trained personnel for Environmental pack

deliveries.

WARNING! P9500 rack shipments delivered in Environmental packs must not be forwarded

by carriers that are not authorized by Hewlett Packard Enterprise. Only Hewlett Packard

Enterprise authorized carriers can transport the P9500 racks in Environmental pack. Contact

Hewlett Packard Enterprise to arrange for Full Factory packaging when the P9500 rack will

be transported after initial delivery by Hewlett Packard Enterprise.

• Full Factory packaging - This packaging configuration consists of a pallet, wooden loading

ramp, inner packaging, and outer corrugated carton assembly. Full Factory packaging is

used for EMEA and for indirect ground shipments in USA and Canada.

WARNING! Full Factory packaging must be used any time a P9500 rack is transported

after initial delivery from the factory. Contact Hewlett Packard Enterprise to arrange for Full

Factory packaging.

• Full Factory packaging with wooden crate - This packaging configuration consists of full

packaging and encased in a wooden crate. Full Factory packaging with wooden crate is

used for air freight shipments from USA.

Other areas: The hallways, doorways, ramps, and elevators must be large enough to allow a

single unpacked rack to be moved to the installation location. Unless the distance between the

receiving dock and the data center is very long, P9500 disk arrays are typically unpacked in the

receiving area and the individual racks with pre-installed equipment are rolled on their casters

to the data center. The following table provides the dimensions of the P9500 disk array.

Table 4 P9500 single rack dimensions

DepthWidthHeightItem

45 in. (1145 mm) (includes

doors)

23.6 in. (600 mm) (add 0.4

in/10mm for side panels)

79 in. (2006 mm)Single rack

16 Installation requirements

Page 17

Equipment weight

The floors, elevators, and ramps must be able to support the weight of the delivered equipment

as it is moved to the installation location. Spreader plates may be required to distribute the load

and protect the floor as the equipment is moved from the receiving area to the installation location.

Consult the system bill of materials to establish the anticipated summary weights.

The weight of the equipment depends on the disk array configuration. The weight for a fully

configured disk array with 6 racks can reach 8560 pounds/3883 kilograms. The following table

provides weights of typical system configurations.

Table 5 Weight of typical P9500 system configurations

Dual ModuleSingle ModuleSingle RackDimension

(6 racks)(3 racks)

7500/34023750/17011120/508 (Diskless)Min (lbs/kg)System

Weight

8560/38834319/19591558/707Max (lbs/kg)

Storage requirements

If the equipment must be stored after delivery and prior to installation, the storage location must

meet the storage environmental requirements for the P9500 disk array. See Table 13 (page 26)

in this chapter for environmental storage requirements.

Data center requirements

The data center must meet the following facilities requirements:

Table 6 Data center requirements

DescriptionItem

The data center must provide appropriate power, air conditioning, cabling, and fire

protection.

General

The data center must provide adequate protection from electrostatic discharge (ESD).ESD

The data center must provide adequate protection from electrical/radio frequency

interference.

Electrical interference

The data center must provide adequate protection from dust, pollution, and particulate

contamination.

Contamination

The data center must provide adequate acoustic insulation for operating the system.Acoustics

This includes cables, connectors, and receptacles that must be available and ready

when the system is installed.

User-supplied hardware

Data communication requirements

Route data communication cables away from areas of high static electric fields created by power

transformers and heavy foot traffic. Use shielded data communication cables that meet approved

industrial standards to reduce the effects of external fields.

The P9500 frames support top access and bottom access for host cables. Routing the host cables

in a P9500 requires Hewlett Packard Enterprise support personnel to install. The data

communication infrastructure needed for the P9500 disk array is described in “Data communication

requirements” (page 18).

Data center requirements 17

Page 18

Table 7 Data communication requirements

Column HeadColumn Head

For the C-Track Internet connectivity, Hewlett Packard

Enterprise representatives will help you obtain and set

Internet connectivity infrastructure for C-Track

Internetbased remote support option.

up/order the necessary infrastructure, including your

choice of router configurations, a supported CMS

management server, and access to SMTP server

(optional) and DNS servers, in order to support reliable

file transfer and serve the overall objectives of the remote

support solution. An Hewlett Packard Enterprise

representative will configure C-Track , see “C-Track”

(page 18) or contact your Hewlett Packard Enterprise

representative.

Needed to connect the HPE system to an available

Ethernet port on the customer's LAN. To ensure network

A twisted pair (Cat 5) cable.

security, consult with an Hewlett Packard Enterprise

representative and your network administrator before

selecting the appropriate location of your LAN drop.

Needed to allow your staff and Hewlett Packard Enterprise

representatives to communicate inside and outside your

site.

A public voice phone line near the disk array.

C-Track

The C-Track remote support solution detects and reports events to the Hewlett Packard Enterprise

Support Service. C-Track transmits heartbeats, SIMs, and configuration information for remote

data collection and monitoring purposes. C-Track also enables the Support Service to remotely

diagnose issues and perform maintenance (if the customer allows the remote maintenance). The

C-Track solution offers Internet connectivity only. If you choose the Internet-based remote support

solution, additional infrastructure and site preparation are required. Additional preparation may

include server and router requirements, which you and Hewlett Packard Enterprise may be

responsible for implementing.

Insight Remote Support

Hewlett Packard Enterprise strongly recommends that you install HPE Insight Remote Support

software to complete the installation or upgrade of your product and to enable enhanced delivery

of your Hewlett Packard Enterprise Warranty, Care Pack Service or Hewlett Packard Enterprise

contractual support agreement. Insight Remote Support supplements your monitoring, 24x7 to

ensure maximum system availability by providing intelligent event diagnosis, and automatic,

secure submission of hardware event notifications to Hewlett Packard Enterprise, which will

initiate a fast and accurate resolution, based on your product’s service level. Notifications may

be sent to your authorized Hewlett Packard Enterprise Channel Partner for on-site service, if

configured and available in your country. The Insite Remote Support products available for the

P9500 disk arrays are described in Table 8 (page 18).

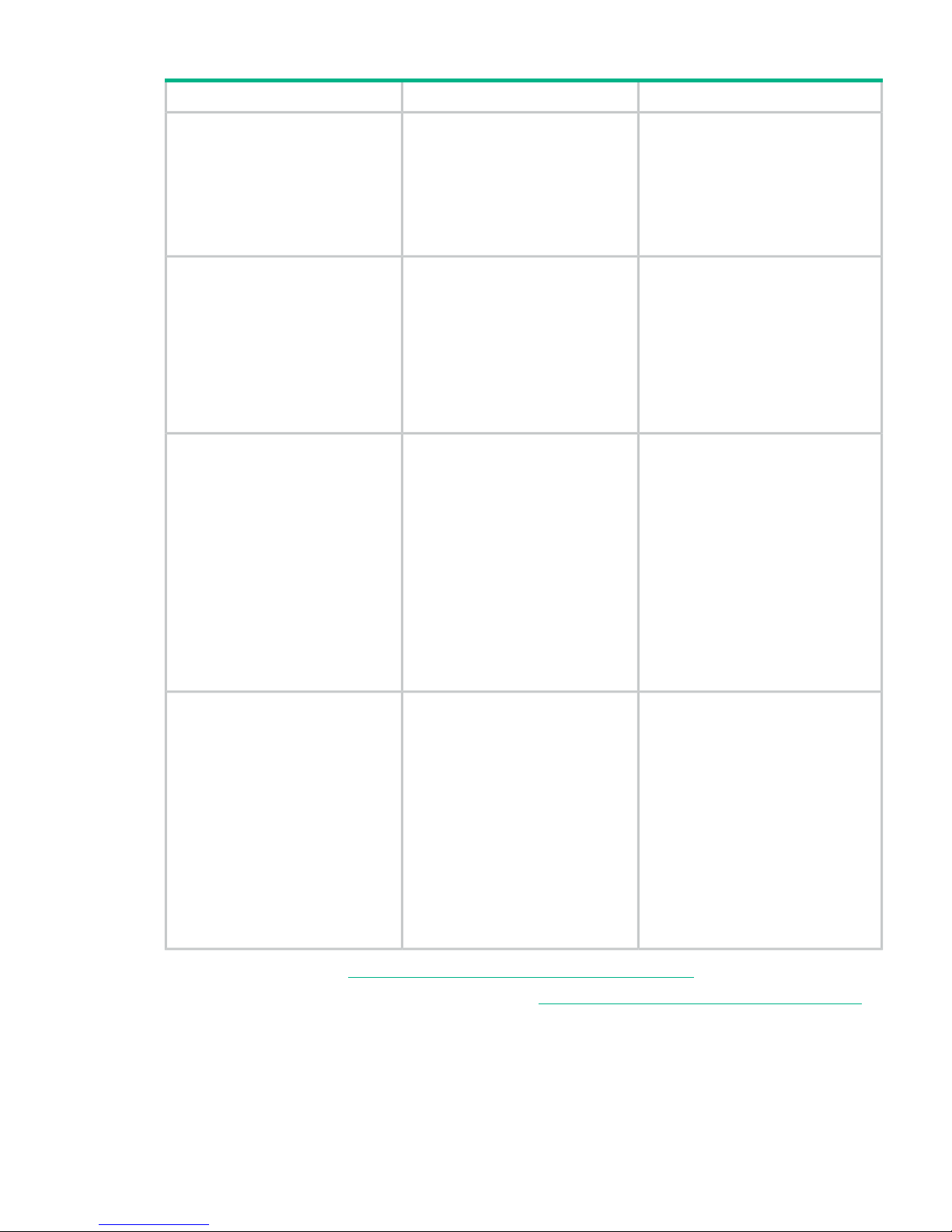

Table 8 XP9500 disk array remote support products

ApplicationDescriptionProduct

For customers that fully commit to use

Hewlett Packard Enterprise Remote

XP/XP9500 Remote Device Access

Support

AE241A

Support. It uses Insight Remote

Support for XP7 Remote Device

Monitoring utilizing LAN/Internet

connectivity and Remote Device

Access Support. This configuration is

required to meet the objectives of XP

disk array’s Internet connectivity with

18 Installation requirements

Page 19

Table 8 XP9500 disk array remote support products (continued)

ApplicationDescriptionProduct

Remote Device Access initiative and

prerequisites for Critical Support

contracts. Hewlett Packard Enterprise

recommends that the AE241A product

with Internet connectivity should be

utilized for all new XP7 installations, to

ensure the optimal support model and

highest TCE.

For customers that commit to utilize

Internet and Insight Remote Support

XP/XP9500 Remote Device Access

Support

AE242A

connectivity for XP9500 Remote

Device Monitoring but will not allow for

Remote Device Access to the XP9500

array from Hewlett Packard Enterprise

for proactive and critical support

processes. Without Remote Device

Access, Critical Support contract

prerequisites cannot be met.

For a customer with strict security

protocols specifically prohibits

HPE/XP9500 Mission Critical No LAN

Support

AE244A

inbound/outbound traffic to/from the

data center and thus will not allow

Remote Support connection by either

modem or LAN/internet connectivity;

but does have Mission Critical Services

with Customer Engineer onsite

included in the terms of the support

contract. Factory Authorization will be

required to order this product. Proof of

valid Customer Engineer on-site

Mission Critical support contract must

be provided for Factory Authorization

approval.

For a customer with strict security

protocols specifically prohibits

HPE/XP9500 No Mission Critical No

LAN Support

AE245A

inbound/outbound traffic to/from the

data center and thus will not allow

Remote Support connection by either

modem or LAN and does not have a

Mission Critical Services on-site

contract. The added costs of this

configuration only covers the additional

warranty support cost to Hewlett

Packard Enterprise during warranty

period. Other additional costs can also

be incurred for support contracts for

customers who do not have remote

support configured.

Details are available at: http://www.hpe.com/info/insightremotesupport

To download the software, go to Software Depot: http://www.hpe.com/support/softwaredepot

Select Insight Remote Support from the menu on the right.

Insight Remote Support 19

Page 20

System specifications and requirements

This section describes the physical characteristics of a P9500 disk array, including

• “Mechanical specifications” (page 20)

• “Electrical specifications” (page 22)

• “Environmental specifications” (page 26)

Mechanical specifications

The following table lists the mechanical specifications of the P9500 disk array.

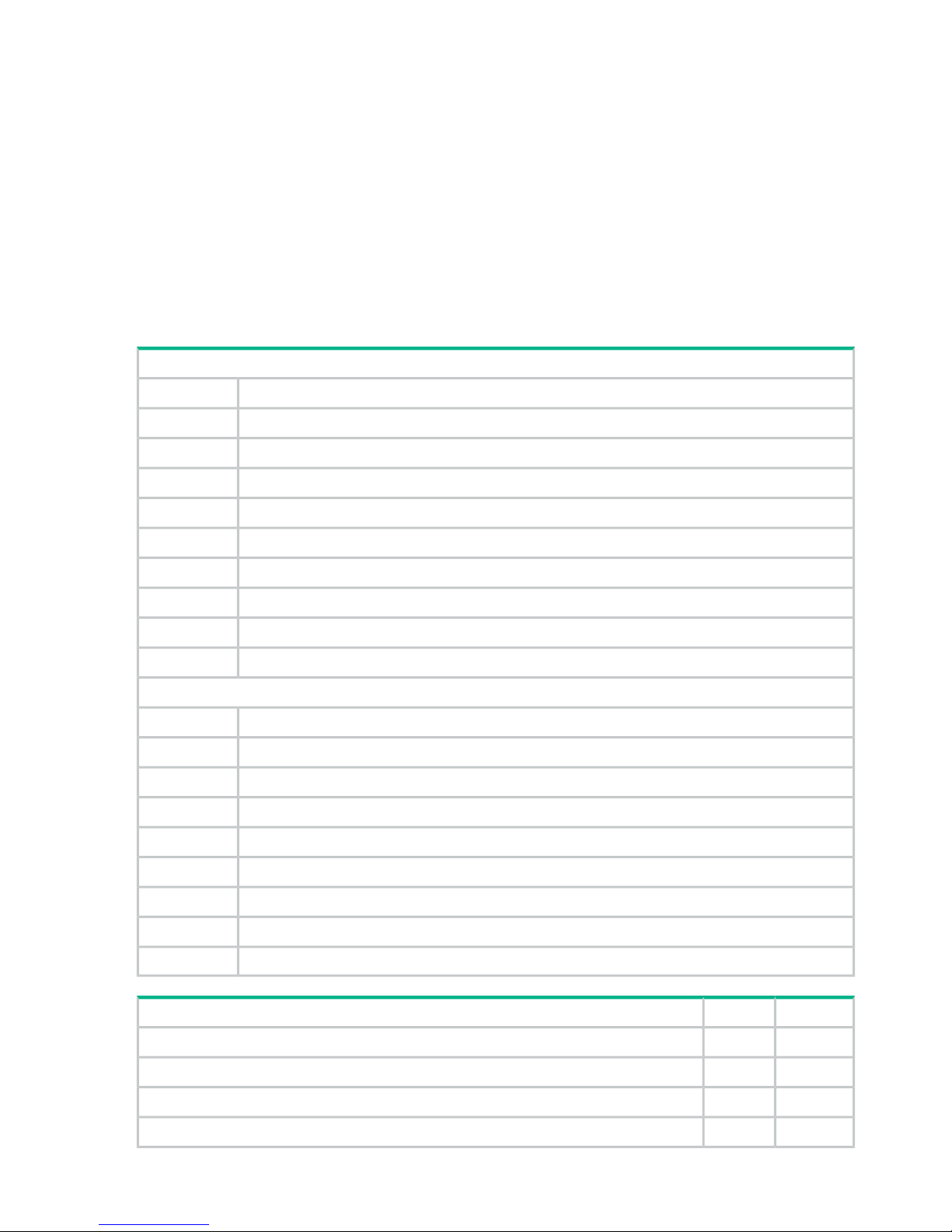

Table 9 P9500 mechanical specifications

Six RacksFive RacksFour RacksThree RacksTwo RacksOne RackDimension

142 inches118.5 inches95 inches71.3 inches47.6 inches24.0 inchesWidth

(3610 mm)(3010 mm)(2410 mm)(1810 mm)(1210 mm)(610 mm)(includes 1 set of

side panels)

45 inches45 inches45 inches45 inches45 inches45 inchesDepth

(1145 mm)(1145 mm)(1145 mm)(1145 mm)(1145 mm)(1145 mm)(including doors)

79 inches79 inches79 inches79 inches79 inches79 inchesHeight

(2006 mm)(2006 mm)(2006 mm)(2006 mm)(2006 mm)(2006 mm)(including casters)

The following illustration shows an overview of a P9500 disk array.

20 Installation requirements

Page 21

Figure 4 P9500 disk array

NOTE: Each Rack is 600mm wide without side covers. Add 5mm to each end of entire assembly

for each side cover.

System specifications and requirements 21

Page 22

Figure 5 Example P9500 disk array configurations

Electrical specifications

“System heat and power specifications” (page 22) and “System components heat and power

specifications ” (page 22) list the heat and power specifications for the P9500 disk array and

components.

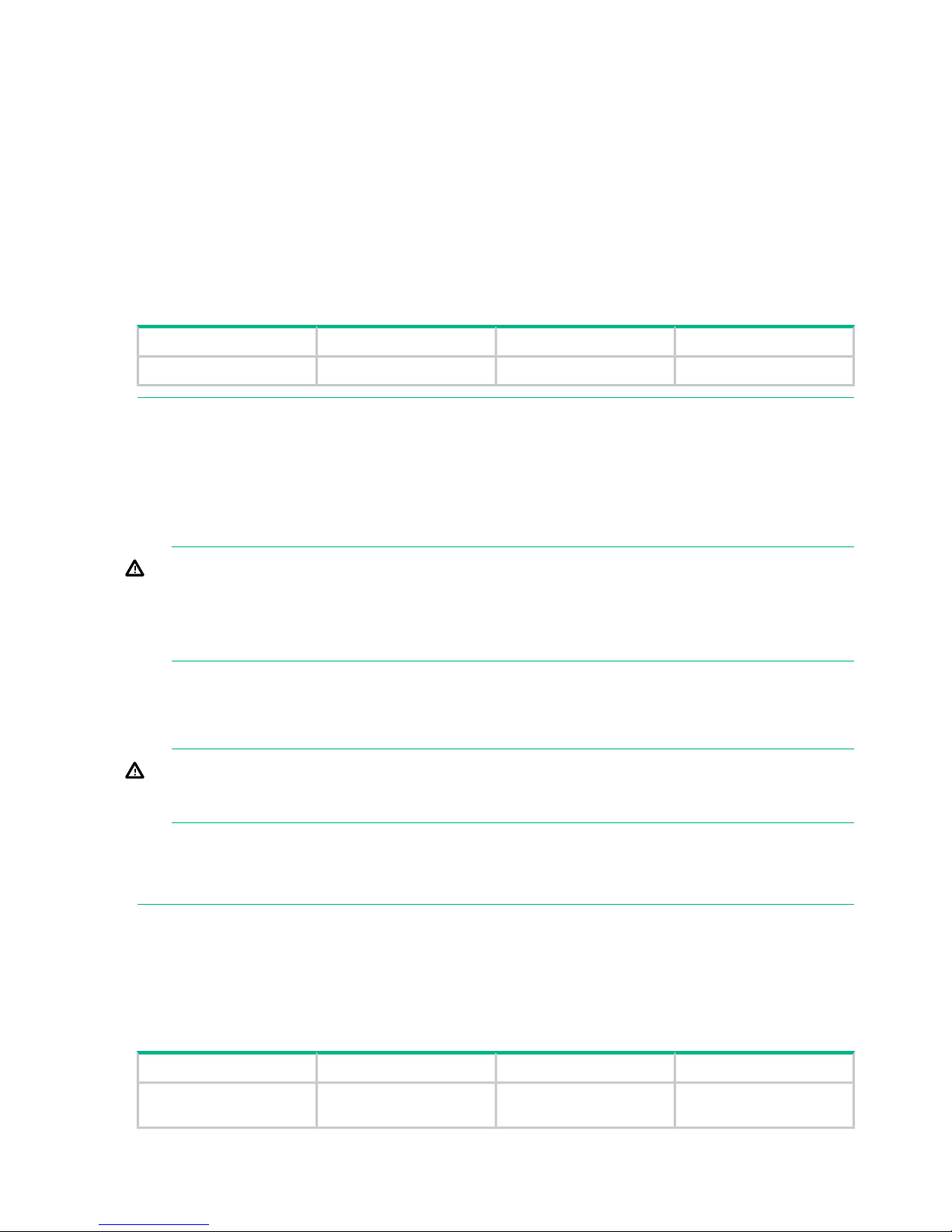

Table 10 System heat and power specifications

Full Array

(DKC-0 plus

DKU RackDKC Module-1DKC Module-0

Parameter

1, 2

DKC-1 plus DKU

x4)

33.15.455.425.87Max Power

consumption

(kVA)

Heat Dissipation

and Power

Consumption

Specifications

31.45.175.155.57Max Heat

dissipation (kW)

(Maximum

configuration)

107155176431757119012Max BTUs per

hour

27002444644284791Max Kcal per hour

1

Heat (KW, BTU, Kcal) and Power (kVA) values are for determining load for site planning. Actual heat generation

and power demand may be less.

2

Calculated values with drives at a typical I/O condition. (Random Read and Write, 50 IOPSs for HDD, 2500 IOPSs

for SSD, Data Length: 8Kbytes). These values may increase for future compatible drives.

Table 11 System components heat and power specifications

Power

Consumption

(kVA)

1

Heat Output

(kW)

1

P9500 Disk Array Component

Component Product

Number

0.640

4

0.600

4

Flash Module ChassisAV375A

0.018

3

0.017

3

Flash ModuleAV392A, AV393A

1.971.88Disk Array DKC Module-0 RackAV400A

1.931.83DKC Module-1 RackAV401A, AV401B

1.541.47DKU Disk Unit RackAV402A,AV402B

see note 5see note 5Base 2.5in Drive ChassisAV411B

22 Installation requirements

Page 23

Table 11 System components heat and power specifications (continued)

Power

Consumption

(kVA)

1

Heat Output

(kW)

1

P9500 Disk Array Component

Component Product

Number

0.6000.57Complete 2.5in Drive ChassisAV412B

0.1030.120Drive Chassis SAS Switch KitAV413A

0.0760.0728-port 2-8 Gbps FC CHAAV423A, AV423B

0.0760.07216-port 2-8 Gbps FC CHAAV424A, AV424B

0.1240.11816p 1-4 Gbps SW FICON CHAAV425A

0.1240.11816p 1-4 Gbps LW FICON CHAAV426A

0.0760.07216p 2-8 Gbps SW FICON CHAAV427A, AV427B

0.0760.07216p 2-8 Gbps LW FICON CHAAV428A

0.0760.072P9500 8-port 10 Gbps FCoE CHAAV429A

0.2000.19Processor BladeAV440A, AV440B

0.0100.010DKC Hub KitAV442A

0.0550.0522nd SVP High Reliability KitAV443A

0.0720.068Cache Memory AdapterAV444A

0.0200.01916GB Cache Memory ModuleAV447A, AV447B

0.0200.01932GB Cache Memory ModuleAV448A, AV448B

0.005

2

0.005

2

64GB Cache Backup Memory ModuleAV451A

0.005

2

0.005

2

128GB Cache Backup Memory ModuleAV452A

0.0840.08SAS DKA Drive AdapterAV455A

0.0740.07Express Switch AdapterAV458A

0.0074

3

0.0070

3

500GB 6G SAS 7.2K 2.5in DP HDDAV467A

0.0087

3

0.0082

3

1TB SAS 7.2K 2.5in DP HDDAV468A

0.0083

3

0.0079

3

300GB SAS 10K 2.5in DP HDDAV474A

0.0085

3

0.0080

3

600GB SAS 10K 2.5in DP HDDAV475A

0.0095

3

0.0090

3

900GB SAS 10K 2.5in DP HDDAV476A

0.0087

3

0.0083

3

1.2 TB SAS 10K 2.5in DP HDDAV477A

0.0084

3

0.0080

3

146GB SAS 15K 2.5in DP HDDAV482A

0.0090

3

0.0086

3

300GB SAS 15K 2.5in DP HDDAV483A

0.0134

3

0.0127

3

200GB SAS 2.5in DP SLC SSDAV490A

0.0024

3

0.0023

3

400GB SAS 2.5in DP SLC SSDAV491A

0.0028

3

0.0026

3

200GB SAS 2.5in DP MLC SSDAV492A

0.0028

3

0.0026

3

400GB SAS 2.5in DP MLC SSDAV493A

0.0071

3

0.0067

3

800GB SAS 2.5in DP MLC SSDAV494A

1

Heat (KW, BTU, Kcal) and Power (kVA) values are for determining rated load for site planning. Actual heat generation

and power demand may be less.

System specifications and requirements 23

Page 24

Table 11 System components heat and power specifications (continued)

Power

Consumption

(kVA)

1

Heat Output

(kW)

1

P9500 Disk Array Component

Component Product

Number

2

Power is consumed during the battery back-up time only.

3

Actual values at a typical I/O condition. (Random Read and Write, 50 IOPSs for HDD, 2500 IOPSs for SSD, Data

Length: 8 KB). These values may increase for future compatible drives.

4

Maximum values with all fans rotate at maximum.

5

AV411B Base 2.5 inch Drive Chassis does not include power supplies consequently demands zero (0) kVA and

generates no (0) kW heat.

NOTE: Site power can be connected to the PDUs at either the top or bottom of the racks.

Grounding

The site and equipment must meet all of the following three conditions of installation for grounding.

• An insulated grounding conductor that is identical in size and insulation material and thickness

to the grounded and ungrounded branch-circuit supply conductors. It must be green, with

or without yellow stripes, and must be installed as a part of the branch circuit that supplies

the unit or system.

• The grounding conductor mentioned above should be grounded to earth at the service

equipment or other acceptable building earth ground such as the building frame in the case

of a high rise steel-frame structure.

• The attachment-plug receptacles in the vicinity of the unit or system must include a ground

. The grounding conductors serving these receptacles must be connected to earth ground

at the service equipment or other acceptable building earth ground such as the building

frame in the case of a high-rise steel-frame structure.

Power connection

The AC power input for the P9500 disk array has a duplex PDU structure. This duplex structure

enables the entire rack to remain powered on if power is removed from one of the two power

distribution panels.

CAUTION: When installing a system, connect the AC cables between the PDUs and PDPs

correctly. Otherwise, a system failure can occur when one of the AC inputs is interrupted.

AC Power - PDU Options

The P9500 is configured for input power using separate rackmount PDU products. PDUs are

available for three phase or single phase power for NEMA and IEC compliance applications.

NOTE: When ordering systems, Hewlett Packard Enterprise does not allow mixtures of different

phase PDUs in a system (even though there are no technical issues). Only upgrade orders can

ship with difference phase PDUs in a system.

Table 12 P9500 AC PDU Options

Notes

Facility

receptacle

neededPlug Type

Branch circuit

requirements

per PDU

Number of

PDU per

Rack

1

Local Power

Product

Number

For customers

with, 200 - 220

NEMA

L15-30R

NEMA

L15-30P

200-220V, 3Ø,

4-wire, 30A

23 phase (4

wire)

AV404A

AV404AU

VAC, 3-Phase,

4-Wire Power

24 Installation requirements

Page 25

Table 12 P9500 AC PDU Options (continued)

Notes

Facility

receptacle

neededPlug Type

Branch circuit

requirements

per PDU

Number of

PDU per

Rack

1

Local Power

Product

Number

Distribution

System

For customers

with 380 - 415

IEC60309 4

pole, 5-wire,

IEC60309 4

pole, 5-wire

380-415V, 3Ø,

5-wire, 16A

23 phase (5

wire)

AV405A

AV405AU

VAC,380-415 VAC,

16A

380-415VAC,

16A Three-Phase,

5-Wire Wye

Power

Distribution

System

For customers

with single

NEMA L6-30RNEMA L6-30P200-240V, 1Ø,

3-wire, 30A

4single phase

NEMA

AV406A

AV406AU

phase power

and need

NEMA L6-30P

plug

For customers

with single

IEC60309 2

pole, 3-wire,

240VAC, 32A

IEC60309 2

pole, 3-wire,

240VAC, 32A

200-240V, 1Ø,

3-wire, 32A

4single phase

IEC

AV407A

AV407AU

phase power

and need

IEC60309 32A

plug

Notes

1. Each PDU has one fixed power cord with attached plug. Power cord is not removable.

NOTE: PDU models can be changed in the field by ordering the upgrade PDU model required.

Figure 6 P9500 AC Power Configuration Diagram

*1 (left): When connected correctly, one of the two PDUs can supply power to the DKC-DKU

rack.

System specifications and requirements 25

Page 26

*1 (right): When connected correctly, one of the four PDUs can supply power to the DKC-DKU

rack.

Environmental specifications

Table 13 (page 26) provides the environmental specifications and requirements for the P9500

disk array.

Table 13 P9500 environmental specifications

In StorageNot OperatingOperatingItem

-45 - 140ºF-18 - 109.4 ºF / (-10 to 43 ºC)60.8 - 80.9 ºFTemperature

(-25 to 60 ºC)-18 - 95 ºF / (-10 to 35 ºC)

8

(16 to 32 ºC)

5 to 95 %

2

8 to 90 %

2

20 to 80 %

2

Relative Humidity

84.2 ºF (29 ºC)80.6 ºF (27 ºC)78.8 ºF (26ºC)Max. Wet Bulb

68 ºF (20 ºC)50 ºF (10 ºC)50 ºF (10 ºC)Temperature

(Deviation per hour)

Sine Vibration:5 to 10 Hz: 2.5 mm10 to 300 HzVibration

4.9 m/s1, 5 min.10 to 70 Hz: 4.9 m/s

1

0.49 m/s

1

to 10Hz: 0.25 mm

At the resonant frequency with

the highest displacement found

between 3 to 100 Hz

3

70 to 99 Hz: 0.05 mm

99 to 300 Hz: 9.8 m/s

1

Random Vibration:

0.147 m2/s3

30 min, 5 to 100 Hz

4

--Up to 2.5

7

Earthquake resistance

(m/s2)

Horizontal:78.4 m/s1, 15 ms-Shock

Incline Impact 1.22 m/s

5

Vertical:

Rotational Edge 0.15 m

6

--60 to 3,000mAltitude

Notes:

1. Recommended temperature range is 21 to 24°C.

2. On shipping/storage condition, the product should be packed with factory packing.

3. The above specifications of vibration are applied to all three axes.

4. See ASTM D999-01 The Methods for Vibration Testing of Shipping Containers.

5. See ASTM D5277-92 Test Method for Performing Programmed Horizontal Impacts Using an Inclined Impact

Tester.

6. See ASTM D6055-96 Test Methods for Mechanical Handling of Unitized Loads and Large Shipping Cases and

Crates.

7. Time is 5 seconds or less in case of the testing with device resonance point (6 to 7Hz).

8. When flash modules are installed in the system.

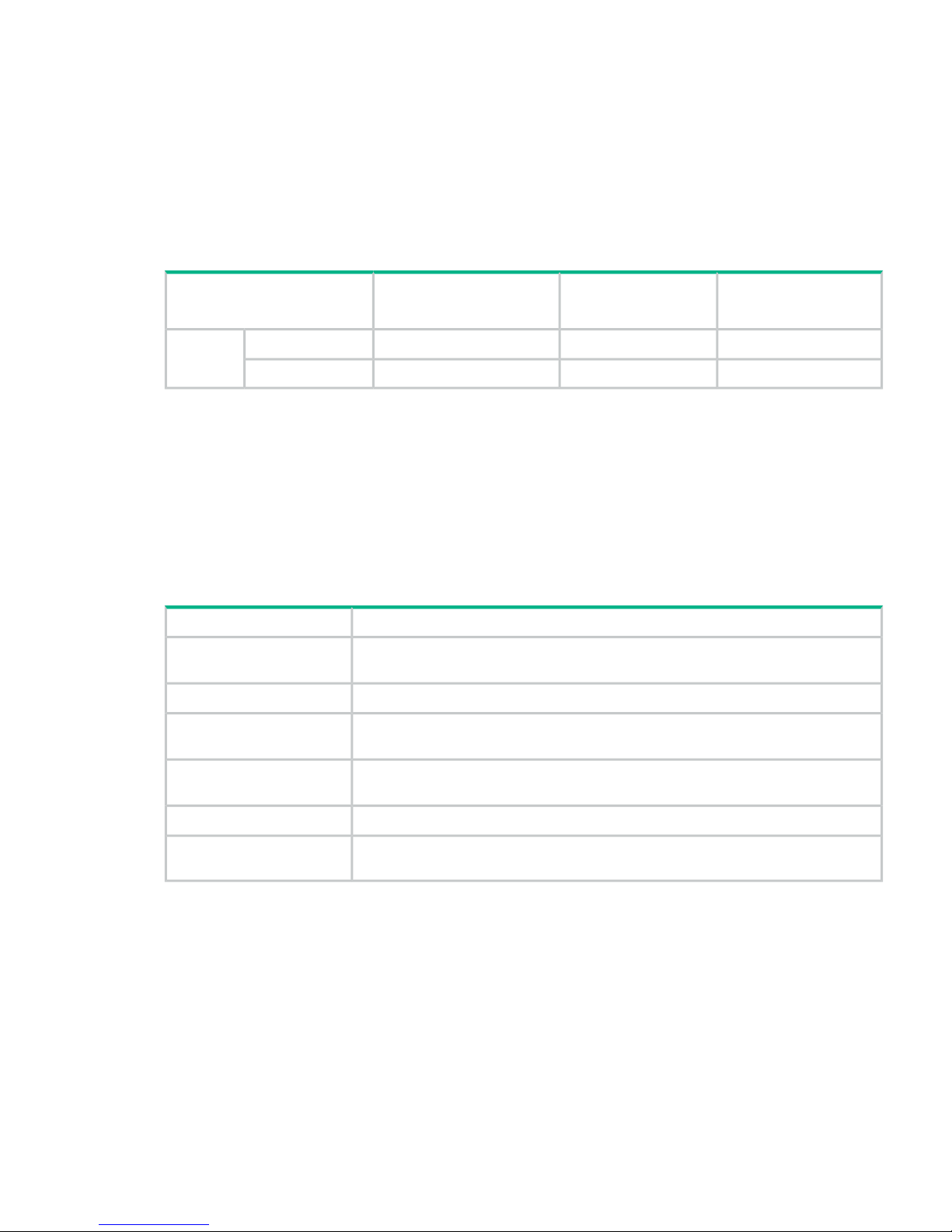

Heat output and air flow

The following table lists the heat output and air flow requirements for the P9500 disk array.

Both the control chassis and the disk chassis contain front and rear fans to circulate air through

the chassis from front to back. Air flows in through the front bezel to the rear of the component

26 Installation requirements

Page 27

and exits through the perforations in the rear door. Either the front fans or the rear fans can cool

the chassis by themselves. The racks do not contain fans. Airflow is from front to back.

Table 14 Heat, power, and airflow

Air Flow (M3/min)Power Consumption (kVA)Heat Output (kW)Model Number

-0.640

6

0.600

6

AV375A P9500 Flash

Module Chassis

-0.018

3

0.017

3

AV392A P9500 1.6TB Flash

Module

-0.018

3

0.017

3

AV393A P9500 3.2TB Flash

Module

251.97

1

1.88

1

AV400A - P9500 Disk Array

DKC Module-0 Rack

-0.900.86AV400B - P9500 Disk Array

DKC Module-0 Rack

251.93

1

1.83

1

AV401A - P9500 DKC

Module-1 Rack

-0.500.48AV401B - P9500 DKC

Module-1 Rack

271.54

1

1.47

1

AV402A - P9500 DKU Disk

Unit Rack

-0.00.0AV402B - P9500 DKU Disk

Unit Rack

-see note 5see note 5AV411B P9500 Base 2.5in

Drive Chassis

-0.60.57AV412B P9500 Complete

2.5in Drive Chassis

6

-0.0760.120AV413A - P9500 Drive

Chassis SAS Switch Kit

-0.0760.072AV423A, AV423B - P9500

8-port 2-8 Gbps FC CHA

-0.0760.072AV424A, AV424B - P9500

16-port 2-8 Gbps FC CHA

-0.1240.118AV425A - P9500 16p 1-4

Gbps SW FICON CHA

-0.0760.118AV426A - P9500 16p 1-4

Gbps LW FICON CHA

-0.0760.072AV427A, AV427B - P9500

16p 2-8 Gbps SW FICON

CHA

-0.0760.072AV428A - P9500 16p 2-8

Gbps LW FICON CHA

-0.0760.072AV429A - P9500 8-port 10

Gbps FCoE CHA

-0.2000.19AV440A, AV440B - P9500

ProcessorBlade

-0.0100.010AV442A - P9500 DKC Hub

Kit

System specifications and requirements 27

Page 28

Table 14 Heat, power, and airflow (continued)

Air Flow (M3/min)Power Consumption (kVA)Heat Output (kW)Model Number

-0.0550.052AV443A - P9500 2nd SVP

High Reliability Kit

-0.0720.068AV444A - P9500 Cache

Memory Adapter

-0.0200.019AV447A, AV447B - P9500

16GB Cache Memory

Module

-0.0200.019AV448A, AV448B - P9500

32GB Cache Memory

Module

-0.005

2

0.005

2

AV451A - P9500 64GB

Cache Backup Memory

Module

-0.005

2

0.005

2

AV452A - P9500 128GB

Cache Backup Memory

Module

-0.0840.080AV455A - P9500 SAS DKA

Drive Adapter

-0.0740.070AV458A - P9500 Express

Switch Adapter

-0.0074

3

0.0070

3

AV467A - P9500 500GB 6G

SAS 7.2K 2.5in DP HDD

-0.0087

3

0.0082

3

AV468A - P9500 1TB SAS

7.2K 2.5in DP HDD

-0.0067

3

0.0063

3

AV474A - P9500 300GB

SAS 10K 2.5in DP HDD

-0.0085

3

0.0080

3

AV475A - P9500 600GB

SAS 10K 2.5in DP HDD

-0.0087

3

0.0083

3

AV477A - P9500 1.2TB 6G

SAS 10K 2.5in DP HDD

-0.0084

3

0.0080

3

AV482A - P9500 146GB

SAS 15K 2.5in DP HDD

-0.0090

3

0.0086

3

AV483A - P9500 300GB

SAS 15K 2.5in DP HDD

-0.0134

3

0.0127

3

AV490A - P9500 200GB

SAS 2.5in DP SLC SSD

-0.0024

3

0.0023

3

AV491A - P9500 400GB

SAS 2.5in DP SLC SSD

-0.0028

3

0.0026

3

AV492A - P9500 200GB

SAS 2.5in DP MLC SSD

-0.0028

3

0.0026

3

AV493A - P9500 400GB

SAS 2.5in DP MLC SSD

-0.0071

3

0.0067

3

AV494A - P9500 800GB

SAS 2.5in DP MLC SSD

Notes:

1

Maximum values in case the all fans rotate at maximum.

28 Installation requirements

Page 29

Table 14 Heat, power, and airflow (continued)

Air Flow (M3/min)Power Consumption (kVA)Heat Output (kW)Model Number

2

Power is consumed during the battery back-up time only.

3

Actual values at a typical I/O condition. (Random Read and Write, 50 IOPSs for HDD, 2500 IOPSs for SSD, Data

Length: 8Kbytes). These values may increase for future compatible drives.

5

AV411B Base 2.5in Drive Chassis does not include power supplies consequently demands zero (0) kVA and

generates no (0) kW heat. When AV459A/AU DKU Pow supplies are installed in an AV411B/BU, then the chassis

fans will demand same power and heat as AV412B/BU.

6

Maximum values with all fans rotate at maximum.

Equipment noise

The acoustic emission values [loudness in dB (A)] for the P9500 disk array disk array are:

• Front/rear = 65 dB (A)

• Both sides = 65 dB (A)

Service clearance, floor cutout, and floor load rating

This section describes the service clearance requirements for the P9500 disk array, based on

the floor load rating and the clearance and required floor cutouts for cabling. The figures and

tables that provide this information are listed in the following table.

Table 15 Service clearance and floor load ratings

Service Clearance and Floor Load Rating

SectionNumber of racks

“Single rack configuration” (page 29)1

“Two rack configuration (one DKC)” (page 31)2

“Two rack configuration (two DKC)” (page 33)2 (two DKC)

“Three rack configuration (left module)” (page 35)3 (left module)

“Three rack configuration (right module)” (page 36)3 (right module)

“Four rack configuration (left module)” (page 38)4 (left module)

“Four rack configuration (right module)” (page 39)4 (right module)

“Five rack configuration” (page 42)5

“Six rack configuration” (page 43)6

NOTE: For safe and efficient maintenance operations, clearance (c) should be made as large

as possible. Actual clearances for installation should be determined after consulting with the

site/facilities manager, as the clearances can vary, depending on building conditions. Although

all disk chassis come pre-installed, up to 1420 mm of clearance may be required at both front

and back for a disk chassis replacement.

The figures in this section are not drawn to scale.

Single rack configuration

The following figure and table show the service clearances and floor load rating for a single rack

configuration.

Service clearance, floor cutout, and floor load rating 29

Page 30

Figure 7 Service clearances for a single rack system

*1 Clearance (a+b) is based on the floor load rating and the clearance (c). Floor load rating and

required clearances are shown in Table 16 (page 30).

*2 Clearance (d) is required over 300mm to open the front door. In the case that the clearance

(d) is less tan the clearance (a), give priority to clearance (a).

*3 Clearance (e) is required over 200mm to open the rear door. If clearance (e) is less than

clearance (b), give priority to clearance (b).

*4 Dimensions in parentheses show allowable range of the front cutout dimensions. Basically,

position the floor cutout in the center of the rack. However, the position may be off center as long

as the cutout allows smooth entrance of an external cable (check the relation between the

positions of the cutout and the opening on the bottom plate of the rack) and is within the allowable

range.

Table 16 Floor load rating and required clearances for single rack configuration

Required Clearance (a+b) mFloor Load

Rating

Clearance (c) m

(kg/m2)

C=0.6C=0.6C=0.4C=0.2C=0

00010.500

000.10.10.2450

0.10.10.20.30.3400

30 Installation requirements

Page 31

Table 16 Floor load rating and required clearances for single rack configuration (continued)

Required Clearance (a+b) mFloor Load

Rating

(kg/m2)

Clearance (c) m

C=0.6C=0.6C=0.4C=0.2C=0

0.20.30.40.40.5350

0.40.60.70.80.9300

Notes:

1. Actual clearances for installation should be determined after consulting with construction specialist responsible

for installation building, as they could vary depending on the size/layout of the system and building conditions.

2. When various configurations of disk arrays are arranged in a row, clearance values based on the largest disk

array configuration should be used.

3. From the viewpoint of maintenance operations, it is suggested that Clearance (c) be made as large as possible.

Two rack configuration (one DKC)

The following figure and table shows the service clearances and floor load rating for a two-rack

configuration.

Service clearance, floor cutout, and floor load rating 31

Page 32

Figure 8 Service clearances for a two rack system (single DKC)

*1 Clearance (a+b) is based on the floor load rating and the clearance (c). Floor load rating and

required clearances are shown in Table 17 (page 32).

*2 Clearance (d) is required over 300mm to open the front door. In the case that the clearance

(d) is less tan the clearance (a), give priority to clearance (a).

Table 17 Floor load rating and required clearances for two rack configuration

Required Clearance (a+b) mFloor Load

Rating

Clearance (c) m

(kg/m2)

C=0.6C=0.6C=0.4C=0.2C=0

00000.1500

000.10.20.3450

32 Installation requirements

Page 33

Table 17 Floor load rating and required clearances for two rack configuration (continued)

Required Clearance (a+b) mFloor Load

Rating

(kg/m2)

Clearance (c) m

C=0.6C=0.6C=0.4C=0.2C=0

00.20.30.40.5400

0.30.50.60.80.9350

0.81.01.21.31.5300

Notes:

1. Actual clearances for installation should be determined after consulting with construction specialist responsible

for installation building, as they could vary depending on the size/layout of the system and building conditions.

2. When various configurations of disk arrays are arranged in a row, clearance values based on the largest disk

array configuration should be used.

3. From the viewpoint of maintenance operations, it is suggested that Clearance (c) be made as large as possible.

Two rack configuration (two DKC)

The following figure and table shows the service clearances and floor load rating for a two-rack

configuration with two DKCs installed.

Service clearance, floor cutout, and floor load rating 33

Page 34

Figure 9 Service clearances for a two rack system (two DKC)

*1 Clearance (a+b) is based on the floor load rating and the clearance (c). Floor load rating and

required clearances are shown in Table 18 (page 34).

*2 Clearance (d) is required over 300mm to open the front door. In the case that the clearance

(d) is less tan the clearance (a), give priority to clearance (a).

*3 Clearance (e) is required over 200mm to open the rear door. If clearance (e) is less than

clearance (b), give priority to clearance (b).

Table 18 Floor load rating and required clearances for a two rack configuration (two DKC)

Required Clearance (a+b) mFloor Load

Rating

Clearance (c) m

(kg/m2)

C=0.6C=0.6C=0.4C=0.2C=0

00000.1500

000.10.20.3450

00.20.30.40.5400

34 Installation requirements

Page 35

Table 18 Floor load rating and required clearances for a two rack configuration (two DKC)

(continued)

Required Clearance (a+b) mFloor Load

Rating

(kg/m2)

Clearance (c) m

C=0.6C=0.6C=0.4C=0.2C=0

0.30.50.60.80.9350

0.81.01.21.31.5300

Notes:

1. Actual clearances for installation should be determined after consulting with construction specialist responsible

for installation building, as they could vary depending on the size/layout of the system and building conditions.

2. When various configurations of disk arrays are arranged in a row, clearance values based on the largest disk

array configuration should be used.

3. From the viewpoint of maintenance operations, it is suggested that Clearance (c) be made as large as possible.

Three rack configuration (left module)

The following figure and table shows the service clearances and floor load rating for a three-rack

configuration.

Figure 10 Service clearances for a three rack system (left module)

Service clearance, floor cutout, and floor load rating 35

Page 36

*1 Clearance (a+b) is based on the floor load rating and the clearance (c). Floor load rating and

required clearances are shown in Table 19 (page 36).

*2 Clearance (d) is required over 300mm to open the front door. In the case that the clearance

(d) is less tan the clearance (a), give priority to clearance (a).

Table 19 Floor load rating and required clearances for a three rack configuration (left

module)

Required Clearance (a+b) mFloor Load

Rating

Clearance (c) m

(kg/m2)

C=0.6C=0.6C=0.4C=0.2C=0

00000.1500

000.10.20.4450

00.30.40.60.8400

0.40.70.91.11.3350

1.11.51.71.92.3300

Notes:

1. Actual clearances for installation should be determined after consulting with construction specialist responsible

for installation building, as they could vary depending on the size/layout of the system and building conditions.

2. When various configurations of disk arrays are arranged in a row, clearance values based on the largest disk

array configuration should be used.

3. From the viewpoint of maintenance operations, it is suggested that Clearance (c) be made as large as possible.

Three rack configuration (right module)

The following figure and table shows the service clearances and floor load rating for a three-rack

configuration (Setting Up DKC-RACK in the Right Configuration).

36 Installation requirements

Page 37

Figure 11 Service clearances for a three rack system (right module)

*1 Clearance (a+b) is based on the floor load rating and the clearance (c). Floor load rating and

required clearances are shown in Table 20 (page 37).

*2 Clearance (d) is required over 300mm to open the front door. In the case that the clearance

(d) is less tan the clearance (a), give priority to clearance (a).

*3 Clearance (e) is required over 200mm to open the rear door. If clearance (e) is less than

clearance (b), give priority to clearance (b).

Table 20 Floor load rating and required clearances for a three rack configuration (right

module)

Required Clearance (a+b) mFloor Load

Rating

Clearance (c) m

(kg/m2)

C=0.6C=0.6C=0.4C=0.2C=0

00000.1500

000.10.30.4450

0 .10.30.50.60.8400

0.50.81.01.21.4350

Service clearance, floor cutout, and floor load rating 37

Page 38

Table 20 Floor load rating and required clearances for a three rack configuration (right

module) (continued)

Required Clearance (a+b) mFloor Load

Rating

(kg/m2)

Clearance (c) m

C=0.6C=0.6C=0.4C=0.2C=0

1.21.51.82.02.3300

Notes:

1. Actual clearances for installation should be determined after consulting with construction specialist responsible

for installation building, as they could vary depending on the size/layout of the system and building conditions.

2. When various configurations of disk arrays are arranged in a row, clearance values based on the largest disk

array configuration should be used.

3. From the viewpoint of maintenance operations, it is suggested that Clearance (c) be made as large as possible.

Four rack configuration (left module)

The following figure and table shows the service clearances and floor load rating for a four-rack

configuration (Setting up DKC rack in the left configuration).

Figure 12 Service clearances for a four rack system (left module)

38 Installation requirements

Page 39

*1 Clearance (a+b) is based on the floor load rating and the clearance (c). Floor load rating and

required clearances are shown in Table 21 (page 39).

*2 Clearance (d) is required over 300mm to open the front door. In the case that the clearance

(d) is less tan the clearance (a), give priority to clearance (a).

Table 21 Floor load rating and required clearances for a four rack configuration (left

module)

Required Clearance (a+b) mFloor Load

Rating

Clearance (c) m

(kg/m2)

C=0.6C=0.6C=0.4C=0.2C=0

00000.1500

000.10.30.5450

0 .10.40.60.81.1400

0.61.01.21.51.8350

1.52.02.32.63.0300

Notes:

1. Actual clearances for installation should be determined after consulting with construction specialist responsible

for installation building, as they could vary depending on the size/layout of the system and building conditions.

2. When various configurations of disk arrays are arranged in a row, clearance values based on the largest disk

array configuration should be used.

3. From the viewpoint of maintenance operations, it is suggested that Clearance (c) be made as large as possible.

Four rack configuration (right module)

The following figure and table shows the service clearances and floor load rating for a four-rack

configuration (Setting Up DKC-RACK in the right Configuration).

Service clearance, floor cutout, and floor load rating 39

Page 40

Figure 13 Service clearances for a four rack system (right module)

*1 Clearance (a+b) is based on the floor load rating and the clearance (c). Floor load rating and

required clearances are shown in Table 22 (page 40).

*2 Clearance (d) is required over 300mm to open the front door. In the case that the clearance

(d) is less tan the clearance (a), give priority to clearance (a).

*3 Clearance (e) is required over 200mm to open the rear door. If clearance (e) is less than

clearance (b), give priority to clearance (b).

Table 22 Floor load rating and required clearances for a four rack configuration (right

module)

Required Clearance (a+b) mFloor Load

Rating

Clearance (c) m

(kg/m2)

C=0.6C=0.6C=0.4C=0.2C=0

00000.1500

000.10.30.5450

0 .10.40.60.81.1400

0.61.01.21.51.8350

40 Installation requirements

Page 41

Table 22 Floor load rating and required clearances for a four rack configuration (right

module) (continued)

Required Clearance (a+b) mFloor Load

Rating

(kg/m2)

Clearance (c) m

C=0.6C=0.6C=0.4C=0.2C=0

1.52.02.32.63.0300

Notes:

1. Actual clearances for installation should be determined after consulting with construction specialist responsible

for installation building, as they could vary depending on the size/layout of the system and building conditions.

2. When various configurations of disk arrays are arranged in a row, clearance values based on the largest disk

array configuration should be used.

3. From the viewpoint of maintenance operations, it is suggested that Clearance (c) be made as large as possible.

Service clearance, floor cutout, and floor load rating 41

Page 42

Five rack configuration

This following figure and table shows the service clearances and floor load rating for a five-rack

configuration.

Figure 14 Service clearances for a five rack system

*1 Clearance (a+b) is based on the floor load rating and the clearance (c). Floor load rating and

required clearances are shown in Table 23 (page 43).

*2 Clearance (d) is required over 300mm to open the front door. In the case that the clearance

(d) is less tan the clearance (a), give priority to clearance (a).

42 Installation requirements

Page 43

Table 23 Floor load rating and required clearances for a five rack configuration

Required Clearance (a+b) mFloor Load

Rating

Clearance (c) m

(kg/m2)

C=0.6C=0.6C=0.4C=0.2C=0

00000.1500

000.10.30.6450

0 .10.40.71.01.3400

0.71.21.51.82.2350

1.82.42.83.23.7300

Notes:

1. Actual clearances for installation should be determined after consulting with construction specialist responsible

for installation building, as they could vary depending on the size/layout of the system and building conditions.

2. When various configurations of disk arrays are arranged in a row, clearance values based on the largest disk

array configuration should be used.

3. From the viewpoint of maintenance operations, it is suggested that Clearance (c) be made as large as possible.

Six rack configuration

This following figure and table shows the service clearances and floor load rating for a six-rack

configuration.

Service clearance, floor cutout, and floor load rating 43

Page 44

Figure 15 Service clearances for a six rack system

*1 Clearance (a+b) is based on the floor load rating and the clearance (c). Floor load rating and

required clearances are shown in Table 24 (page 44).

*2 Clearance (d) is required over 300mm to open the front door. In the case that the clearance

(d) is less tan the clearance (a), give priority to clearance (a).

Table 24 Floor load rating and required clearances for a six rack configuration

Required Clearance (a+b) mFloor Load

Rating

Clearance (c) m

(kg/m2)

C=0.6C=0.6C=0.4C=0.2C=0

00000.1500

000.10.40.7450

44 Installation requirements

Page 45

Table 24 Floor load rating and required clearances for a six rack configuration (continued)

Required Clearance (a+b) mFloor Load

Rating

(kg/m2)

Clearance (c) m

C=0.6C=0.6C=0.4C=0.2C=0

0 .10.50.81.11.5400

0.91.41.82.22.6350

2.12.93.33.84.4300

Notes:

1. Actual clearances for installation should be determined after consulting with construction specialist responsible

for installation building, as they could vary depending on the size/layout of the system and building conditions.