Page 1

HPE Edgeline EL8000 Converged Edge System

Setup and Configuration Guide

Abstract

This document is for the person who installs, administers, and troubleshoots servers and storage systems.

Hewlett Packard Enterprise assumes you are qualified in the servicing of computer equipment and trained in

recognizing hazards in products with hazardous energy levels.

Part Number: P12853-003

Published: October 2019

Edition: 1

Page 2

Notices

The information contained herein is subject to change without notice. The only warranties for Hewlett Packard Enterprise

products and services are set forth in the express warranty statements accompanying such products and services. Nothing

herein should be construed as constituting an additional warranty. Hewlett Packard Enterprise shall not be liable for technical

or editorial errors or omissions contained herein.

Confidential computer software. Valid license from Hewlett Packard Enterprise required for possession, use, or copying.

Consistent with FAR 12211 and 12212, Commercial Computer Software, Computer Software Documentation, and Technical

Data for Commercial Items are licensed to the U.S. Government under vendor's standard commercial license.

Links to third-party websites take you outside the Hewlett Packard Enterprise website. Hewlett Packard Enterprise has no

control over and is not responsible for information outside the Hewlett Packard Enterprise website.

Acknowledgments

Microsoft®, Windows®, and Windows Server® are either registered trademarks or trademarks of Microsoft Corporation in the

United States and/or other countries.

Page 3

Contents

Overview...................................................................................................................................6

Setup and configuration........................................................................................................ 7

Planning the installation........................................................................................................8

Component identification...................................................................................................... 9

Checklist...........................................................................................................................................................................................................................................7

Safety and regulatory compliance....................................................................................................................................................................................8

Site requirements....................................................................................................................................................................................................................... 8

Space and airflow requirement.........................................................................................................................................................................8

Power requirement.................................................................................................................................................................................................. 8

Temperature requirements.................................................................................................................................................................................8

System components..................................................................................................................................................................................................................9

HPE Edgeline EL8000 Converged Edge system.....................................................................................................................................................9

EL8000 chassis with 1U server blades installed....................................................................................................................................9

EL8000 chassis with 2U server blades installed.................................................................................................................................10

EL8000 Chassis with both 1U and 2U server blades installed...................................................................................................10

Power supply LEDs................................................................................................................................................................................................................ 11

Chassis manager components......................................................................................................................................................................................... 12

Rack mount option................................................................................................................14

Installing the two-post rack mount kit........................................................................................................................................................................14

Installing the four-post rack mount kit.......................................................................................................................................................................17

Associated hardware procedures...................................................................................... 21

Powering down the system............................................................................................................................................................................................... 21

Powering up the system......................................................................................................................................................................................................21

Removing the blade from the chassis......................................................................................................................................................................... 21

Installing the server blade into the chassis..............................................................................................................................................................22

Configuration.........................................................................................................................24

Prepare for configuration................................................................................................................................................................................................... 24

Connecting to Edgeline EL8000 Chassis Manager the first time...............................................................................................................24

Connecting to the web interface using Ethernet................................................................................................................................ 24

Connecting to the CLI in a serial session................................................................................................................................................. 25

Edgeline EL8000 Chassis Manager web interface.............................................................................................................................................. 25

Enabling JavaScript for Internet Explorer...............................................................................................................................................26

Logging in to the web interface.................................................................................................................................................................... 26

About the Edgeline EL8000 Chassis Manager web interface controls..................................................................................27

Complete the network configuration using Edgeline EL8000 Chassis Manager .............................................................................27

Network connection management ...............................................................................................................................................................................27

Viewing the network configuration summary.......................................................................................................................................28

3

Page 4

Network configuration summary details................................................................................................................................ 28

IPv4 Summary details........................................................................................................................................................................28

IPv6 Summary details........................................................................................................................................................................28

Configuring Host Name Settings..................................................................................................................................................................29

Host name and domain name limitations...............................................................................................................................29

Configuring IPv4 settings................................................................................................................................................................................. 30

DHCPv4 Configuration setting.................................................................................................................................................... 30

Static IPv4 Address Configuration settings..........................................................................................................................30

IPv4 DNS Configuration settings................................................................................................................................................30

Configuring IPv6 settings................................................................................................................................................................................. 31

IPv6 Configuration settings........................................................................................................................................................... 31

Viewing installed firmware information..................................................................................................................................................................... 32

Firmware types........................................................................................................................................................................................................32

Firmware details....................................................................................................................................................................................32

Updating firmware................................................................................................................................................................................................ 32

Adding components to the Edgeline EL8000 Chassis Manager Repository......................................................................33

Installing a component from the Edgeline EL8000 Chassis Manager Repository.......................................................... 33

Managing chassis power and resetting Edgeline EL8000 Chassis Manager ......................................................................................33

Prepare the system for daily use....................................................................................................................................................................................34

Registering the product.......................................................................................................................................................................................................34

Troubleshooting....................................................................................................................35

Troubleshooting preparation........................................................................................................................................................................................... 35

Prerequisites for troubleshooting................................................................................................................................................................ 35

Important safety information ........................................................................................................................................................................ 35

Symbols on equipment......................................................................................................................................................................35

Warnings and cautions......................................................................................................................................................................36

Electrostatic discharge......................................................................................................................................................................37

Collecting symptom information...................................................................................................................................................................38

Preparing the EL8000 system for diagnosis.........................................................................................................................................38

Hardware problems................................................................................................................................................................................................................38

General hardware problems............................................................................................................................................................................ 38

The CM configured with static IP address reverts to DHCP when moved to a new chassis................... 38

Power problems......................................................................................................................................................................................................39

HPE Edgeline 1500 CM module powers on without being fully inserted to the chassis...........................39

Warranty and regulatory information.............................................................................. 40

Warranty information............................................................................................................................................................................................................40

Regulatory information........................................................................................................................................................................................................40

Notices for Eurasian Economic Union......................................................................................................................................................................... 40

Turkey RoHS material content declaration..............................................................................................................................................................41

Ukraine RoHS material content declaration............................................................................................................................................................ 41

Federal Communications Commission notice for Class A equipment...................................................................................................... 41

Canada, Industry Canada (IC) Notices .......................................................................................................................................................................42

Brazil certification notice.................................................................................................................................................................................................... 43

Japanese certification notice............................................................................................................................................................................................43

Korean certification notice for class A equipment...............................................................................................................................................43

Specifications.........................................................................................................................44

Environmental specifications............................................................................................................................................................................................44

Mechanical specifications................................................................................................................................................................................................... 45

Power supply specifications..............................................................................................................................................................................................45

1500W Hot-plug Power Supply....................................................................................................................................................................46

4

Page 5

-48VDC Hot Plug Power Supply...................................................................................................................................................................46

Websites................................................................................................................................. 48

Support and other resources.............................................................................................. 49

Accessing Hewlett Packard Enterprise Support................................................................................................................................................... 49

Accessing updates..................................................................................................................................................................................................................49

Customer self repair...............................................................................................................................................................................................................50

Remote support........................................................................................................................................................................................................................50

Warranty information............................................................................................................................................................................................................50

Regulatory information........................................................................................................................................................................................................50

Documentation feedback....................................................................................................................................................................................................51

Acronyms and abbreviations..............................................................................................52

5

Page 6

Overview

The HPE Edgeline EL8000 Converged Edge System is designed to help communication service providers capitalize on dataintensive, low-latency services for media delivery, connected mobility, and smart cities. With the ability to process the

increasing amount of data in real time directly at the edge, the system boosts flexibility and reduces costs by using open

standards. By reducing the need for proprietary edge systems, the HPE EL8000 enables enhanced performance and versatility

for data-intensive real-time digital services while providing a compact, ruggedized design, modular blade and chassis options,

and even one-click provisioning and remote system management.

The HPE EL8000 Chassis Manager is a remote management tool embedded in certain HPE Edgeline systems. The software

allows system administrators to remotely configure, update, and monitor chassis health and activity. The embedded EL8000

CM management module has its own network connection and IP address to which administrators connect on their dedicated

management network. HPE Edgeline systems with the EL8000 CM can be connected to a management network using

Ethernet. The EL8000 CM oers both a web-based console (GUI) and a command line interface (CLI).

This guide includes setup and configuration information for the HPE EL8000 chassis. See http://www.hpe.com/support/

e910-UMG-en for information about HPE ProLiant e910 Server Blade setup, configuration, and operating system installation.

6 Overview

Page 7

Setup and configuration

Checklist

Complete this checklist to set up, install, and configure your new HPE Edgeline EL8000 Converged Edge System.

1. Unbox the system and identify the components.

2. Verify that the intended installation site conforms to space, airflow, temperature, and power requirements.

3. Install one or more blades in the chassis if necessary.

4. Determine the rack depth compatibility of the system, and then install it in a rack:

• Two-post rack

• Four-post rack

5. Prepare to configure the system:

a. Verify network connectivity

b. Plan for network address

6. Connect to the Edgeline EL8000 Chassis Manager and configure the system using one of the available methods:

• Connect to the Edgeline EL8000 Chassis Manager web interface.

• Connect to the Edgeline EL8000 Chassis Manager CLI using serial cable.

7. Register your system with HPE.

TIP: Did you know that HPE has QR codes on all systems? Scan one to access important information on your mobile

device:

Not interested is scanning the QR code? Click the following link to access the mobile pages for quick setup, maintenance,

and troubleshooting information:

http://www.hpe.com/qref/el8000

Setup and configuration 7

Page 8

Planning the installation

Safety and regulatory compliance

For safety, environmental, and regulatory information, see Safety and Compliance Information for Server, Storage, Power,

Networking, and Rack Products, available at the HPE website (http://www.hpe.com/support/Safety-Compliance-

EnterpriseProducts).

Site requirements

Before installing the system, verify that the following site requirements are met:

• Space and airflow requirements

• Temperature requirements

• Power requirements

Hewlett Packard Enterprise recommends that you install or position the system in a location with restricted access, where the

access is secured and controlled. The users/technicians handling the system must be informed about the restrictions applied

and precautions to be taken.

Space and airflow requirement

To allow for servicing and adequate airflow, leave a minimum clearance of 20 cm (79 in) around the system.

Power requirement

Installation of this equipment must comply with local and regional electrical regulations governing the installation of

information technology equipment by licensed electricians. This equipment is designed to operate in installations covered by

NFPA 70, 1999 Edition (National Electric Code) and NFPA-75, 1992 (code for Protection of Electronic Computer/Data

Processing Equipment). For electrical power ratings on options, see the product rating label or the user documentation

supplied with that option.

Single power supply workload planning

HPE recommends that you plan your system workloads carefully for systems with single power supply units. Workload

planning is particularly important when running the maximum number of 1U ProLiant e910 Server Blades in a system on a

single power supply. Avoid heavy workloads when running this configuration, or contact HPE to order a second power supply.

Temperature requirements

To ensure continued safe and reliable equipment operation, install or position the system in a well-ventilated, climatecontrolled environment.

Configuration Temperature

Chassis with blades installed Operating temperature of up to 55°C (131°F)

8 Planning the installation

Page 9

Component identification

This chapter describes the external and internal server features and components.

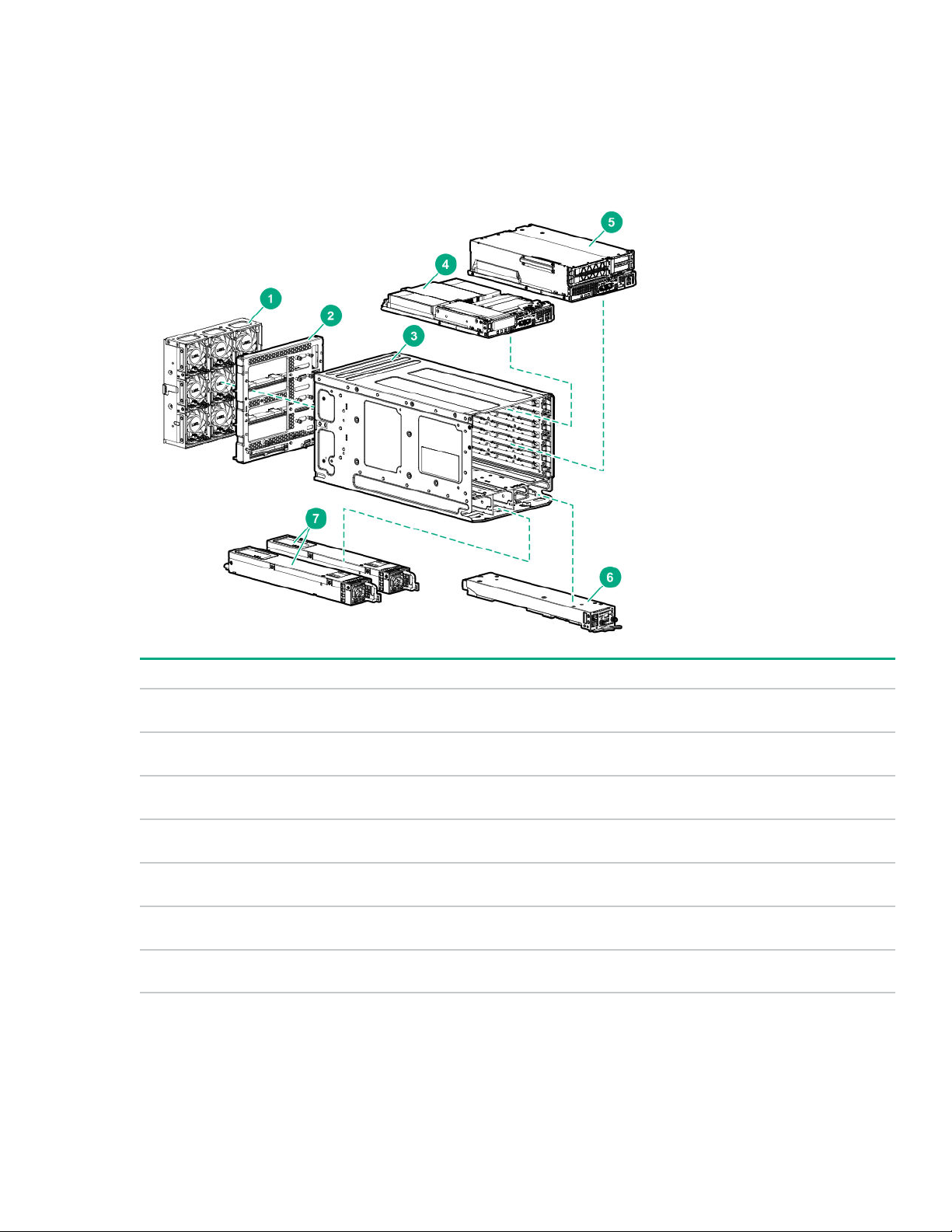

System components

Item Description

1 Fan assembly

2 Midplane assembly

3 HPE Edgeline EL8000 Converged Edge chassis

4 HPE ProLiant

5 HPE ProLiant e9102U server blade

6 Chassis Manager

7 Power supplies

HPE Edgeline EL8000 Converged Edge system

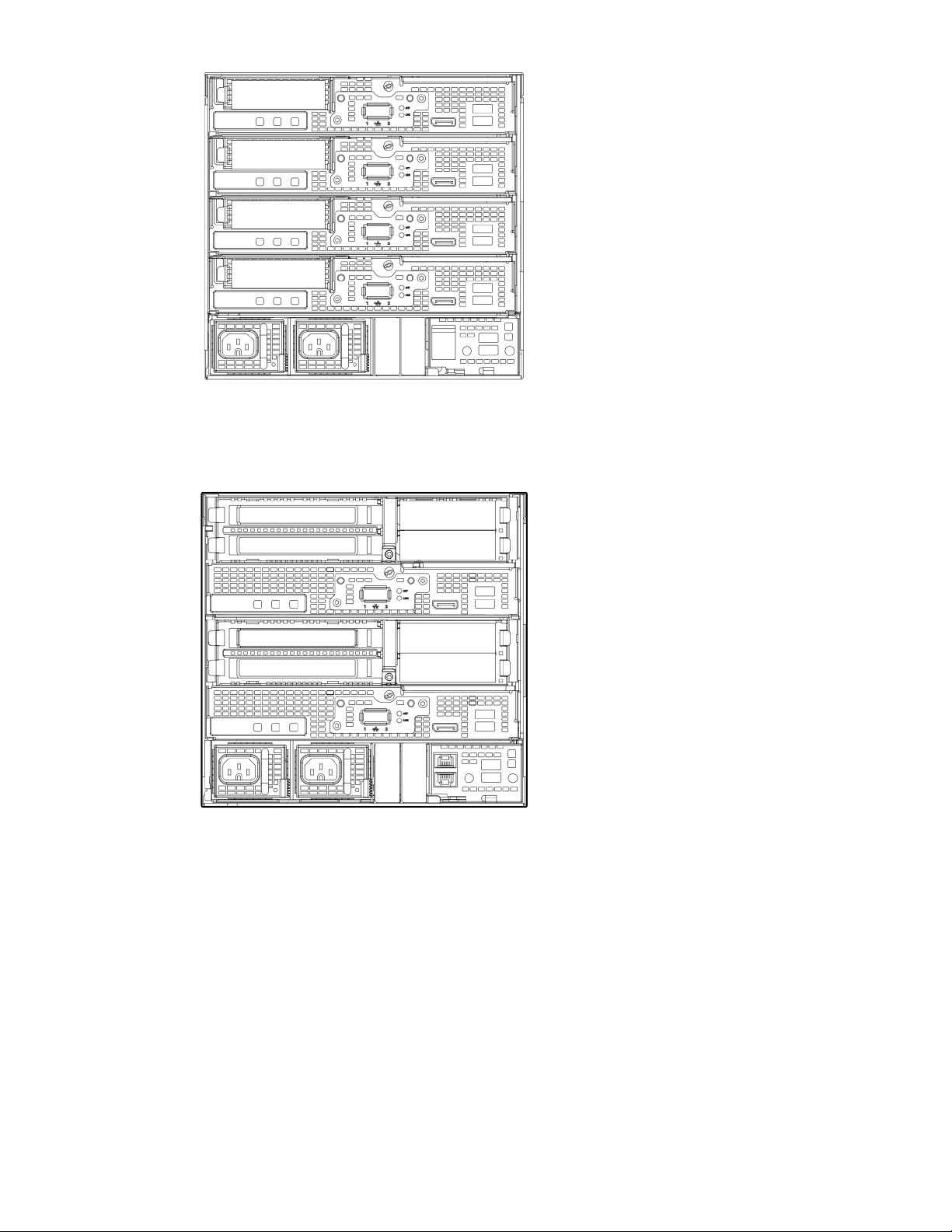

EL8000 chassis with 1U server blades installed

The EL8000 system can accommodate up to four 1U HPE ProLiant e910 server blades.

e9101U server blade

Component identification 9

Page 10

EL8000 chassis with 2U server blades installed

The EL8000 chassis can accommodate up to two 2U HPE ProLiant e910 server blades.

EL8000 Chassis with both 1U and 2U server blades installed

The EL8000 chassis with one 2U and two 1U server blades installed.

10 Component identification

Page 11

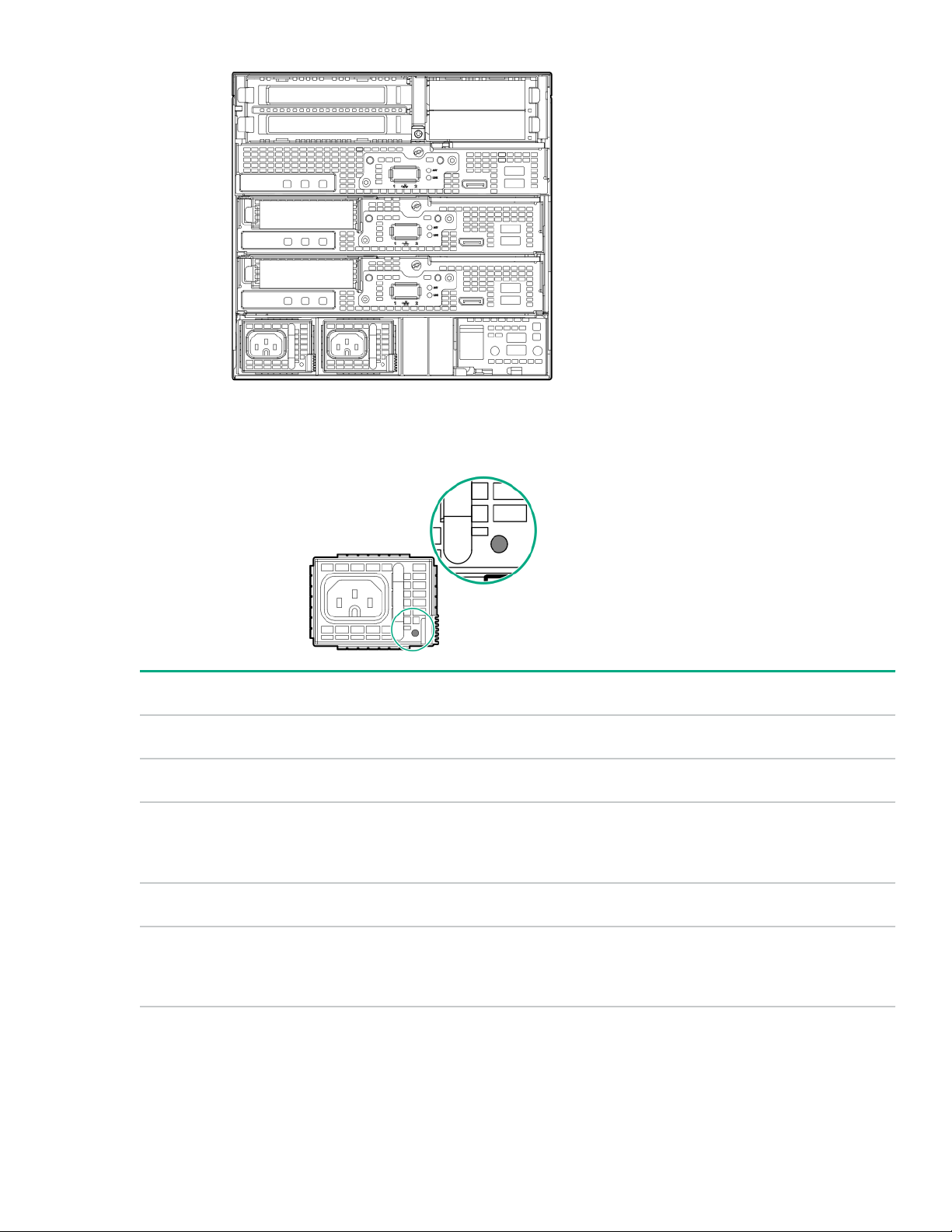

Power supply LEDs

AC power supply LED

Status Description

Solid Green System On and normal operation

Flashing Green Standby power present (power supply o)

Solid Amber Power supply failed (overvoltage/undervoltage,

overtemperature, overcurrent, short-circuit), fan failed, or

input overvoltage protection

Flashing Amber Power supply error

O No power present or standby power failed (overvoltage/

undervoltage, overtemperature, overcurrent, short-circuit, fan

lock)

Component identification 11

Page 12

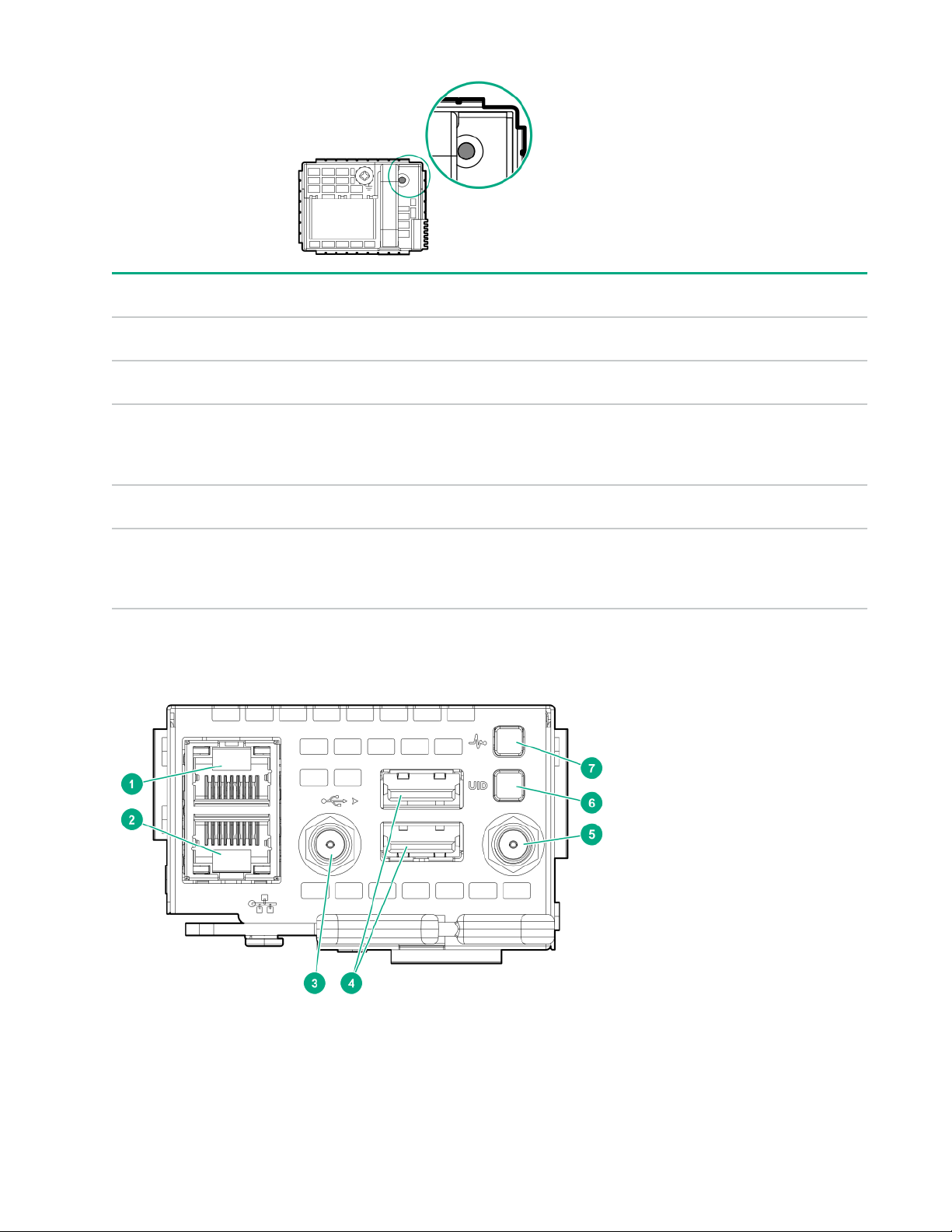

DC power supply LED

Status Description

Solid Green System On and normal operation

Flashing Green Standby power present (power supply o)

Solid Amber Power supply failed (overvoltage/undervoltage,

overtemperature, overcurrent, short-circuit), fan failed, or

input overvoltage protection

Flashing Amber Power supply error

O No power present or standby power failed (overvoltage/

Chassis manager components

undervoltage, overtemperature, overcurrent, short-circuit, fan

lock)

12 Component identification

Page 13

Item Description

1 Management Network port

2 Blade maintenance network port

3 Antenna 1

4 Chassis manager USB ports

5 Antenna 2

6 Chassis UID Button/LED

7 Chassis Health LED

Component identification 13

Page 14

Rack mount option

There are two rack options available for installing the EL8000 chassis:

• Two-post rack mount option

• Four-post rack mount option

Installing the two-post rack mount kit

The two-post rack is available in 19 in and 23 in depth.

Prerequisites

Before you perform this procedure, make sure that you have the following items available:

• T-10 Torx screwdriver

• T-25 Torx screwdriver

Procedure

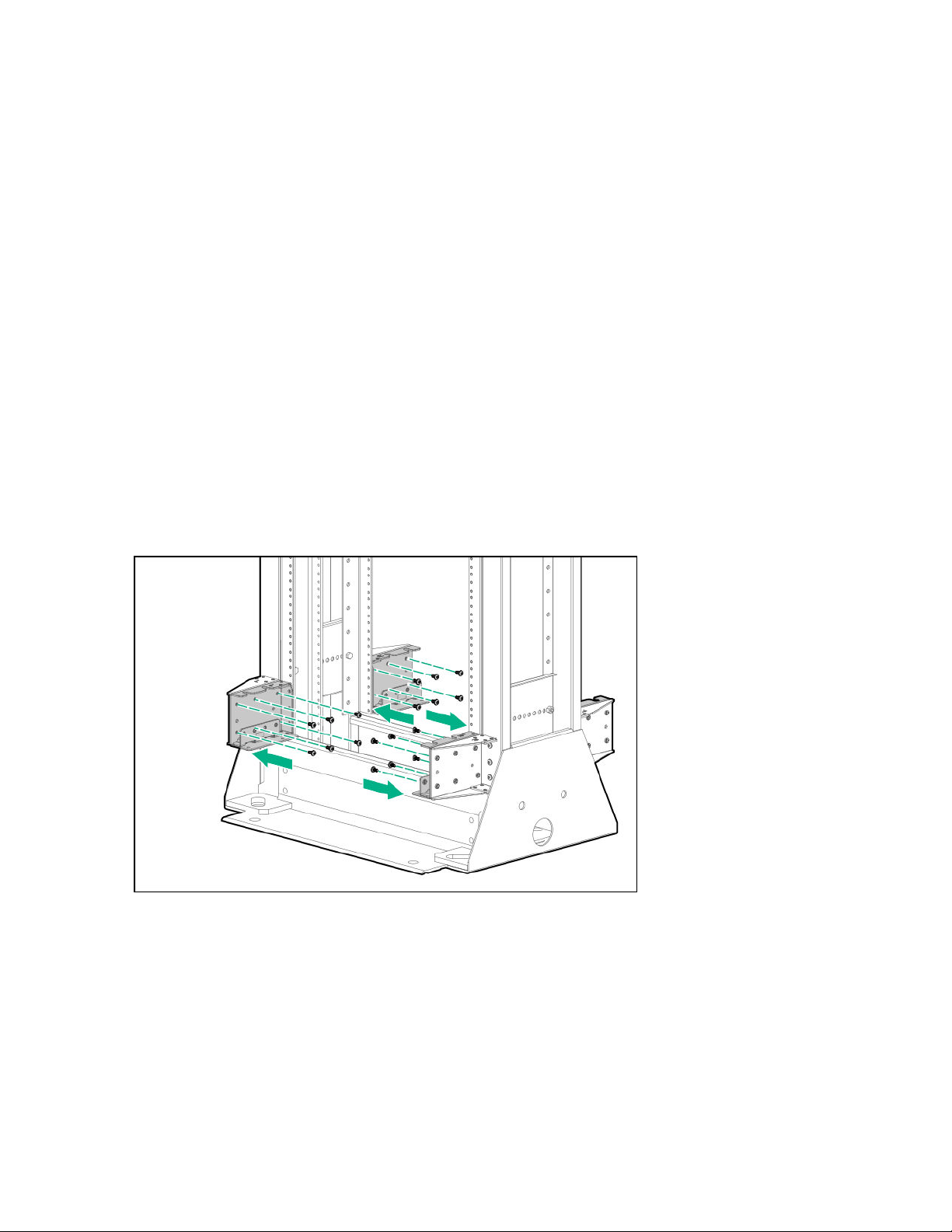

1. Install the brackets on rack columns.

When installing the rail kit on 19 in rack columns, remove the outer brackets and install only the inner brackets.

2. Loosen the screws on each bracket, to enable them to move freely.

14 Rack mount option

Page 15

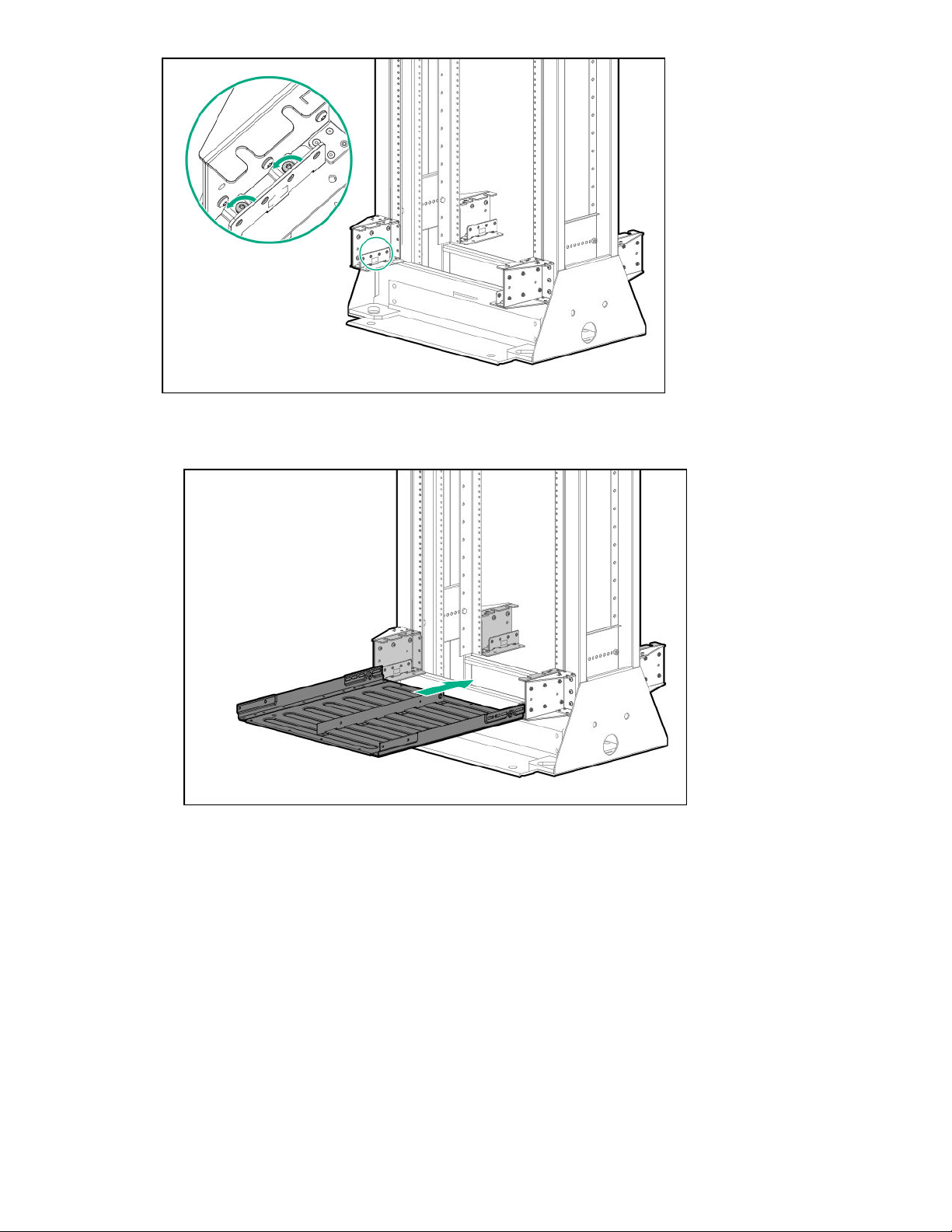

3. Install the rack tray into the brackets:

a. Install the tray into the brackets.

b. Install two screws in the front and rear brackets each, and then tighten them.

Rack mount option 15

Page 16

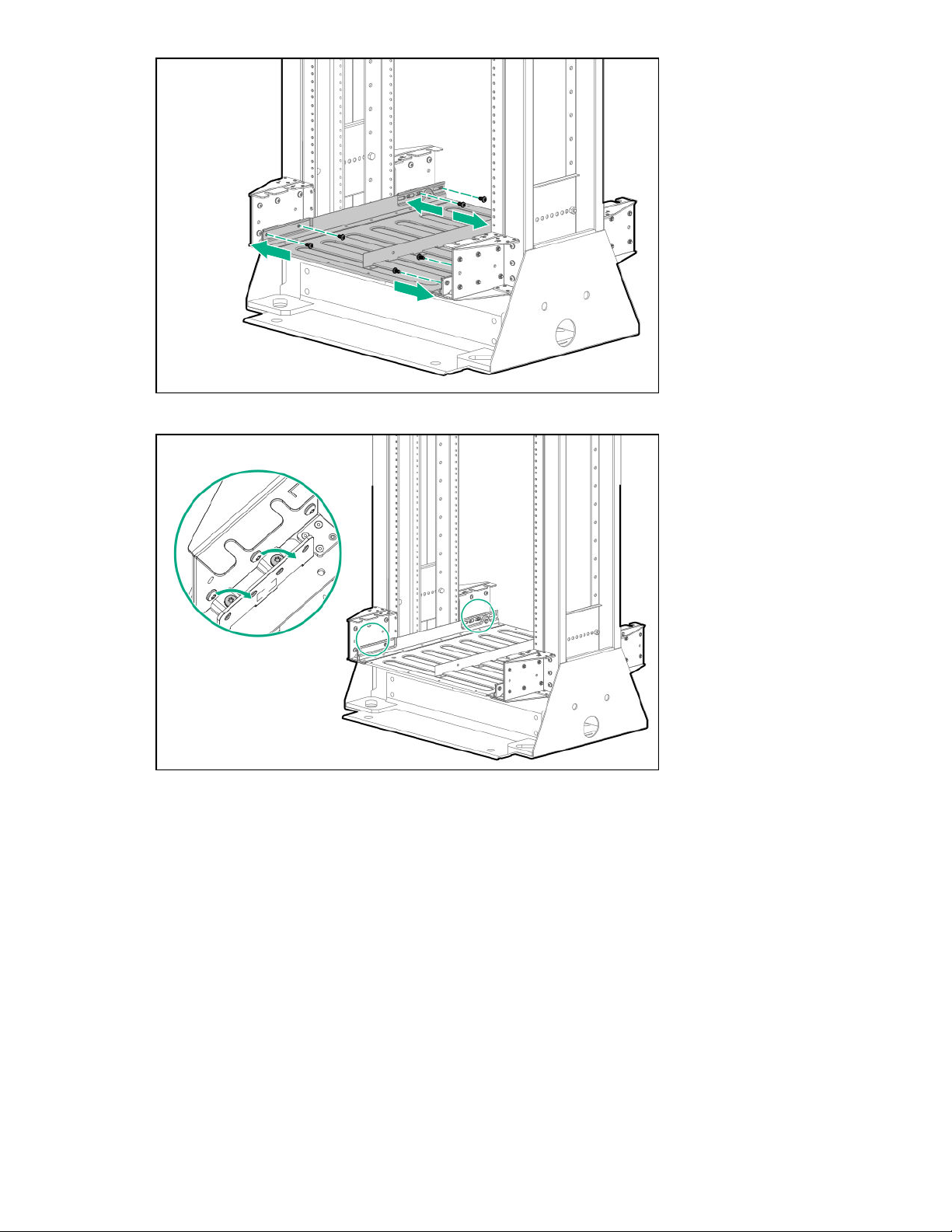

c. Tighten the eight screws that were loosened in step 2.

4. Install the chassis on the rack tray:

a. Place the chassis on the rack tray.

b. Secure the chassis with two screws on the front.

16 Rack mount option

Page 17

c. Secure the chassis with two screws on the rear.

Installing the four-post rack mount kit

Two mounting locations are available for the four-post rack mounting:

•

Forward chassis rack mount- This mounting position is preferred when the cables connected to the chassis are at the rear

of the rack.

• Rear chassis rack mount- This mounting position is preferred when the cables connected to the chassis are at the front of

the rack. For this mounting option, the chassis is recessed in the rack.

Prerequisites

Before you perform this procedure, make sure that you have the following items available:

Rack mount option 17

Page 18

• T-10 Torx screwdriver

• T-25 Torx screwdriver

Procedure

1. Identify the mounting location, install the tray bracket, and stop the screw in correct location.

• Forward chassis rack mount

• Rear chassis rack mount

2. Install the rails into the rack.

18 Rack mount option

Page 19

3. Install the rack tray on the rails, and then secure it.

Make sure that the tray slides under the bracket.

4. Place the chassis on the tray, and then secure it.

Rack mount option 19

Page 20

20 Rack mount option

Page 21

Associated hardware procedures

This chapter describes the hardware operations carried out before and after installing or removing a hardware option, or

performing system maintenance or troubleshooting.

Powering down the system

Before powering down the system for any upgrade or maintenance procedures, back up critical system data and programs.

Before performing chassis maintenance, shut down all blades installed in the chassis.

To power down, use one of the following methods:

• Press and hold the Power on button on the server blade.

This method initiates a controlled shutdown of applications and the OS before the server enters standby mode.

• Press and hold the Power On/Standby button of the blades installed in the chassis for more than 4 seconds to force the

system to power down.

This method forces the system to power down without properly exiting applications and the OS. If an application stops

responding, you can use this method to force a shutdown.

• Use the virtual power button in the Edgeline EL8000 Chassis Manager web interface.

• Use the virtual power button in the iLO web interface hosted on the blade.

• Enter the set power off b<slot#> at the chassis manager CLI. See the HPE Edgeline EL8000 Converged Edge

System Chassis Manager CLI User Guide on the HPE website for details on CLI commands.

Before proceeding, verify that the server blade is in standby mode by observing that the system power LED is amber. See

Power supply LEDs.

Powering up the system

If the HPE Edgeline EL8000 Converged Edge chassis is connected to a power source, it powers up automatically by default.

Generally, it has to be powered up only after a manual shutdown.

Use one of the following methods to power on blades:

•

Press and release the power button on the server blade.

• Use the virtual power button in theEdgeline EL8000 Chassis Manager web interface.

• Use the virtual power button in the iLO web interface hosted on the blade.

• Enter the set power on b<slot#> at the chassis manager CLI. See the HPE Edgeline EL8000 Converged Edge

System Chassis Manager CLI User Guide on the

Before proceeding, verify that the server blade is powered on by observing that the system power LED is green. See Power

supply LEDs.

HPE website for details on CLI commands.

Removing the blade from the chassis

Prerequisites

Before performing this procedure, make sure that you have the T-15 Torx key available.

Associated hardware procedures 21

Page 22

Procedure

1. Power down the system.

2. If locked, unlock the server blade.

3. Press and open the blade latch.

4. Remove the server blade.

Installing the server blade into the chassis

The HPE Edgeline EL8000 Converged Edge chassis supports HPE ProLiant e910 Server Blade. Permissible server blades

configurations:

•

Up to four 1U server blades

• Up to two 2U server blades

• Up to one 2U and two 1U server blades

22 Associated hardware procedures

Page 23

IMPORTANT: The 2U server blades must be installed in bay 1 and bay 5.

Prerequisites

Before performing this procedure, make sure that you have the T-15 Torx key available.

Procedure

1. Align the blade and install it in the chassis:

a. Insert the blade in the chassis.

b. Close the latch on the server blade and secure it.

2. Optional: Lock the server blade.

Associated hardware procedures 23

Page 24

Configuration

Prepare for configuration

Prepare to configure your new system by completing the tasks below.

1. Verify network connectivity

Ensure that the network connection is active.

2. Plan for the network address

If you do not have DHCP enabled on the network, you must have networking details ready: An IP address to assign, subnet

mask, gateway address, and DNS name. For initial setup, it is faster to allow automatic assignment of these details by

connecting your system to a DHCP enabled network.

Connecting to Edgeline EL8000 Chassis Manager the first time

Once the system is unboxed, connected to your management network, and powered up, there are a few options for accessing

Edgeline EL8000 Chassis Manager the first time. You can initially configure Edgeline EL8000 Chassis Manager by connecting

to:

• The Edgeline EL8000 Chassis Manager web interface through the management network.

• The Edgeline EL8000 Chassis Manager CLI using a DB9 null modem serial cable and retrieving the DHCP assigned IP

address or hostname. Note that since there is no serial port available on the Edgeline EL8000 Chassis Manager, you may

need to also use a USB-to-RS232 adapter.

Connecting to the web interface using Ethernet

You can acquire the IP address or hostname through your management network.

Prerequisites

• System hardware unboxed, installed, and powered up

• Username and password noted from the chassis tag

• Ethernet cable

• DHCP enabled network

Procedure

1. Connect an Ethernet cable between the MGMT port on the system chassis and your management network.

2. Wait for the hostname of your new system to propagate onto your network through DDNS and have an IP address

assigned through DHCP.

3. On a separate computer connected to your network, enter the address https://<Chassis Manager hostname

or IP address> in a browser window. HTTPS (HTTP exchanged over an SSL encrypted session) is required for

accessing the Edgeline EL8000 Chassis Manager web interface.

To use the hostname, enter the fully qualified domain name (if your computer is outside the domain) or just the hostname

(if your computer is inside the domain).

4. Log in with the default credentials listed on the system chassis tag.

24 Configuration

Page 25

Connecting to the CLI in a serial session

If ICMP ping or other tools are disabled on your management network, retrieve the IP address in a serial session.

Prerequisites

• System hardware unboxed, installed, and powered up

• Username and password noted from the chassis tag

• Null modem serial cable with connectors or adapters suitable for your environment

NOTE: The null modem serial cable must be connected to a USB port on the chassis.

• DHCP enabled management network

Procedure

1. Connect a USB-to-RS232 (serial) adapter to the USB port of the system.

2. Connect a null modem serial cable to the serial port of the adapter. Connect the other end to the system you are using to

configure. Note that you may need a second USB-to-RS232 adapter if the system you are using to configure has no serial

port.

3. Use a standard tool like PuTTY to start a serial terminal session on the system you are using to configure. Use the following

settings:

Specification Value

Serial Line Appropriate for the system you are using to connect

Baud rate 115200

Data bits 8

Parity None

Stop bit 1

Flow control XON/XOFF

4. Log in by entering the default credentials shown on the chassis tag at the prompt.

5. To see the network details, enter the show network command.

Edgeline EL8000 Chassis Manager web interface

Use the Edgeline EL8000 Chassis Manager web interface to manage your Edgeline EL8000. You can also use the Edgeline

EL8000 Chassis Manager CLI.

Browser requirements

The Edgeline EL8000 Chassis Manager web interface requires a browser that meets the following requirements:

• JavaScript—The Edgeline EL8000 Chassis Manager web interface uses client-side JavaScript extensively.

This setting is not enabled by default in all versions of Internet Explorer. To check or change this setting, see Enabling

JavaScript for Internet Explorer on page 26.

• Cookies—Cookies must be enabled for certain features to function correctly.

Configuration 25

Page 26

• Pop-up windows—Pop-up windows must be enabled for certain features to function correctly. Verify that pop-up blockers

are disabled.

• TLS—To access the Edgeline EL8000 Chassis Manager web interface, you must enable TLS 10 or later in your browser.

Supported browsers

Edgeline EL8000 Chassis Manager supports the latest versions of the following browsers:

• Microsoft Edge

• Mozilla Firefox

• Google Chrome mobile and desktop

• Microsoft Internet Explorer 11

Enabling JavaScript for Internet Explorer

Some versions of Internet Explorer have JavaScript disabled by default. Use the following procedure to enable JavaScript.

Procedure

1. Start Internet Explorer.

2. Select Tools > Internet options.

3. Click Security.

4. Click Custom level.

5. In the Scripting section, set Active scripting to Enable.

6. Click OK.

7. Refresh your browser window.

Logging in to the web interface

Procedure

1. Enter https://<EL8000CM host name or IP address>

When you access the Edgeline EL8000 Chassis Manager web interface, you must use HTTPS (HTTP exchanged over an

SSL encrypted session).

The Edgeline EL8000 Chassis Manager login page opens. If a login security banner is configured, the banner text is

displayed above the login section.

2. Enter a local account Username and Password, and then click Log In.

TIP: When logging in to the Edgeline EL8000 Chassis Manager web interface for the first time:

26 Configuration

•

The default username is Administrator. The username is case sensitive.

• The default password is printed on the label attached to the chassis.

Page 27

About the Edgeline EL8000 Chassis Manager web interface controls

The left pane of the Edgeline EL8000 Chassis Manager web interface can be hidden from view at any time. Hiding the left

pane gives more space for the main pages to be displayed, but hides the navigation tree.

• To hide the left pane, click X or click .

To show the left pane, click

•

Logout, lock, and help

There are three icons shown at the bottom of the left pane when the pane is open:

•

• —This icon locks Edgeline EL8000 Chassis Manager and prevents configuration changes in the web interface and

• —This icon displays the online help for the Edgeline EL8000 Chassis Manager web interface.

Confirmation, status, and error messages

Some pages of the Edgeline EL8000 Chassis Manager web interface require you to scroll down to see all the options available,

or to reach an Apply button. Confirmation, status and error messages display at the top of the page, so remember to scroll

back up to the top of the page after clicking Apply.

—This icon shows the currently logged-in username and a Logout option. Clicking Logout closes your web interface

session and returns to the login screen.

CLI. Clicking the icon opens a confirmation dialog. Click Lock System or No, Go Back. You are asked to verify your choice a

second time.

.

Complete the network configuration using Edgeline EL8000 Chassis Manager

Complete the configuration by performing the following tasks.

The details for these tasks can be found in the HPE Edgeline EL8000 Converged Edge System Chassis Manager User Guide at

http://www.hpe.com/support/EL8000-CM-UserGuide-en.

1. Configure all Edgeline EL8000 Chassis Manager network connection settings that you intend to use on the Network

pages:

• Configure the Domain Name on the General page.

• Choose and configure LAN addressing on the IPv4 or IPv6 pages.

Click here for detailed instructions about configuring network settings.

2. Update firmware or add files to the repository on the Firmware pages. Download firmware updates from the HPE Support

Center at http://www.hpe.com/support/hpesc.

Click here for detailed instructions about updating the firmware.

3. Register the product.

Network connection management

Edgeline EL8000 Chassis Manager provides multiple options for network connection.

Configuration 27

Page 28

To access the network settings, view or edit the network settings on the following pages:

• Summary

• General

• IPv4

• IPv6

Viewing the network configuration summary

Procedure

Click Network in the navigation tree.

The Summary tab is displayed.

Network configuration summary details

• Name—The name of the active Edgeline EL8000 Chassis Manager network interface.

• Host Name—The name assigned to the Edgeline EL8000 Chassis Manager subsystem. By default, the host name is

EL8000CM, followed by the system serial number. This value is used for the network name and must be unique.

NOTE: You can configure the Edgeline EL8000 Chassis Manager host name on the General tab.

• MAC Address—The MAC address of the Edgeline EL8000 Chassis Manager network interface.

• Permanent MAC Address—The unchangeable MAC address of the Edgeline EL8000 Chassis Manager network interface.

• FQDN—The fully qualified domain name of the system.

• IPv6 Default Gateway—When IPv6 is enabled, the gateway is the default IP address Edgeline EL8000 Chassis Manager

uses to access the network. When not enabled, this entry is blank.

• Speed (Mbps)—The speed of the wired network, measured in megabits per second.

IPv4 Summary details

• Address—The IP

• Address Origin—Indicates whether the address was supplied automatically by DHCP or is static.

• Gateway—The gateway address in use for the IPv4 protocol. If the value is 0.0.0.0, the gateway is not configured.

• Subnet Mask—The subnet mask of the IPv4 address currently in use. If the value is 0.0.0.0, no address is configured.

IPv6 Summary details

v4 address currently in use. If the value is 0.0.0.0, the IPv4 address is not configured.

• Address—The IP

• Address State—Indicates whether the address was supplied automatically or is static.

• Gateway—The gateway address in use for the IPv6 protocol. If the value is blank, the gateway is not configured.

• Prefix Length—The subnet mask of the IPv6 address currently in use.

28 Configuration

v6 address currently in use. If the value is blank, the IPv6 address is not configured.

Page 29

• Link Local Address—The IPv6 address for the network segment.

• Link Local Gateway—The IPv6 address of the local network segment gateway. If the value is blank, the gateway is not

configured.

• Prefix Length—The subnet mask of the IPv6 link-local address.

IPv6 Address Policy table

This table shows whether IPv6 or IPv4 addresses are preferred.

Configuring Host Name Settings

Use the General page to configure the Host Name and Domain Name. The host name and the domain name together

constitute the fully qualified domain name.

Prerequisites

Edgeline EL8000 Chassis Manager Admin privilege

Procedure

1. Click Network in the navigation tree, and then click the General tab.

2. Enter the Subsystem Name (Host name).

The host name is the DNS name of the Edgeline EL8000 Chassis Manager subsystem. This name can be used only if DHCP

and DNS are configured to connect to the Edgeline EL8000 Chassis Manager subsystem name instead of the IP address.

3. Enter the Domain Name if DHCP is not configured.

4. Click Apply.

Host name and domain name limitations

The Subsystem Name (Host name) is initially set at the factory, and is listed on the chassis tag. This default host name is a

combination of EL8000CM followed by the system serial number.

When reconfiguring the Host Name Settings, note the following:

• Name service limitations—The subsystem name is used as part of the DNS name.

◦ DNS allows alphanumeric characters and hyphens.

◦ Always start the hostname with a letter, and not with a number or a hyphen. Any combination of letters, numbers, and

the hyphen can be used after the first letter.

◦ Name service limitations also apply to the Domain Name.

• Namespace issues—To avoid these issues:

◦ Do not use the underscore character.

◦ Limit subsystem names to 15 characters.

◦ Verify that you can ping the Edgeline EL8000 Chassis Manager processor by IP address and by DNS name.

◦ Verify that NSLOOKUP resolves the Edgeline EL8000 Chassis Manager network address correctly and that no

namespace conflicts exist.

◦ Flush the DNS name if you make any namespace changes.

Configuration 29

Page 30

Configuring IPv4 settings

Prerequisites

Edgeline EL8000 Chassis Manager Admin privilege

Procedure

1. Click Network in the navigation tree, and then click the IPV4 tab.

2. Configure the DHCPv4 Configuration setting.

3. Configure the IPv4 Address Configuration settings.

4. Configure the DNS Configuration settings.

5. To save the changes you made on the IPv4 Settings page, click Apply.

6. When you are finished configuring the Edgeline EL8000 Chassis Manager network settings on the Network tabs, restart

the Edgeline EL8000 Chassis Manager system.

It might take several minutes before you can re-establish a connection.

DHCPv4 Configuration setting

The DHCPv4 setting is enabled by default.

Enable DHCPv4

Enables Edgeline EL8000 Chassis Manager to obtain an IP address (and other network specific address settings) from a

DHCP server.

NOTE: When DHCPv4 is enabled, the IPv4 Address Configuration section and DNS Configuration section are

automatically assigned. When the system is rebooted, these automatic assignments might change.

Static IPv4 Address Configuration settings

IPv4 Address

The Edgeline EL8000 Chassis Manager IP address. The IP address is supplied automatically when DHCP is enabled. When

DHCP is not enabled, enter a static IP address.

IPv4 Subnet Mask

The subnet mask of the IP network. The subnet mask is supplied automatically when DHCP is enabled. When DHCP is not

enabled, enter a subnet mask for the network.

IPv4 Gateway

The Edgeline EL8000 Chassis Manager gateway IP address. The Edgeline EL8000 Chassis Manager gateway IP address is

supplied automatically when DHCP is enabled. When DHCP is not enabled, enter an IP address for the gateway.

IPv4 DNS Configuration settings

Primary DNS Server

This value is supplied automatically when DHCP is enabled. If you are using a static IP address, no name servers are used.

Secondary DNS Server

This value is supplied automatically when DHCP is enabled. If you are using a static IP address, no name servers are used.

30 Configuration

Page 31

Tertiary DNS Server

This value is supplied automatically when DHCP is enabled. If you are using a static IP address, no name servers are used.

Configuring IPv6 settings

Prerequisites

Edgeline EL8000 Chassis Manager Admin privilege

Procedure

1. Click Network in the navigation tree.

2. Click the IPv6 tab.

3. Configure the Global IPv6 Configuration setting.

4. Configure the IPv6 Configuration settings.

5. Configure the DNS Configuration settings.

6. To save the changes you made on the IPv6 Settings page, click Apply.

7. If you are finished configuring the Edgeline EL8000 Chassis Manager network settings, restart Edgeline EL8000 Chassis

Manager.

It might take several minutes before you can re-establish a connection.

IPv6 Configuration settings

Global IPv6 Configuration

Client Applications use IPv6 first

This option specifies which protocol Edgeline EL8000 Chassis Manager is tried first when accessing a client application. It

is useful when both IP

applications. This setting also applies to lists of addresses received from the name resolver when using FQDNs to

configure NTP.

• Enable this option if you want Edgeline EL8000 Chassis Manager to use IPv6 first.

• Disable this option if you want Edgeline EL8000 Chassis Manager to use IPv4 first.

If communication fails when attempting to use the first protocol, Edgeline EL8000 Chassis Manager automatically tries the

second protocol.

This option is enabled by default.

IPv6 Configuration

Enable IPv6 in Auto Mode

Enable this option to configure Edgeline EL8000 Chassis Manager to use an IP

server is available, IPv6 automatically falls back to using SLAAC. This option is enabled by default.

Edgeline EL8000 Chassis Manager creates its own link-local address even when this option is not enabled.

v4 and IPv6 service addresses are configured for Edgeline EL8000 Chassis Manager client

v6 DHCP server (if found). If no IPv6 DHCP

IPv6 Static Address

When assigning static IPv6 addresses, enter the main IP address here.

Configuration 31

Page 32

IPv6 Static Address Prefix Length

When assigning static IPv6 addresses, enter the prefix length here.

IPv6 Default Gateway

When assigning static IPv6 addresses, enter the default IPv6 gateway here.

DNS Configuration

When assigning static IPv6 addresses, enter the Primary, Secondary, and Tertiary DNS Server addresses.

Viewing installed firmware information

Procedure

Click Firmware in the navigation tree.

The Firmware page displays firmware information for various components.

Firmware types

The firmware types listed on the Firmware page vary based on the system configuration.

For most configurations, the CPLD, Edgeline EL8000 Chassis Manager firmware, and base image are listed.

Firmware details

The Firmware page displays the following information for each listed firmware type:

• Firmware name—The category name of the firmware.

• Firmware version—The currently installed version number of the firmware.

Updating firmware

While firmware can be updated using components uploaded to the Edgeline EL8000 Chassis Manager Repository, you can also

update firmware directly.

Prerequisites

Edgeline EL8000 Chassis Manager Admin privilege

Procedure

1. Click Firmware in the navigation tree, and then click Update Firmware in the right pane.

2. Select the Local file or Remote file option.

3. Depending on the option you selected, do one of the following:

a. In the File box, click Browse (Internet Explorer, Edge, or Firefox) or Choose File (Chrome), and then specify the location

of the firmware component.

b. In the URL box, enter the URL for a firmware component on an accessible web server.

4. Click Flash.

The firmware update status will be visible in the event log.

32 Configuration

Page 33

Adding components to the Edgeline EL8000 Chassis Manager Repository

Prerequisites

Edgeline EL8000 Chassis Manager Admin privilege

Procedure

1. Click Firmware in the navigation tree, and then click Upload to Repository in the right pane.

2. Select the Local file or Remote file option.

3. Depending on the option you selected, do one of the following:

a. In the File box, click Browse (Internet Explorer, Edge, or Firefox) or Choose File (Chrome), and then specify the location

of the firmware component.

b. In the URL box, enter the URL for a firmware component on an accessible web server.

4. Click Upload.

The file is uploaded to the repository and displayed in the repository contents list.

IMPORTANT: Do not exceed the repository storage capacity. Exceeding the storage capacity will force all open

sessions to the Edgeline EL8000 Chassis Manager to log out. If this happens, log in again and delete stored files until

the repository storage is below the maximum capacity.

Installing a component from the Edgeline EL8000 Chassis Manager Repository

You can install new firmware from the Edgeline EL8000 Chassis Manager Repository page.

Prerequisites

Edgeline EL8000 Chassis Manager Admin privilege

Procedure

1. Click Firmware in the navigation tree, and then click Repository.

2. Click the install component icon next to the component you want to install.

3. Click Yes, install now.

The update begins immediately.

Managing chassis power and resetting Edgeline EL8000 Chassis Manager

Prerequisites

Edgeline EL8000 Chassis Manager Admin privilege

Procedure

1. Click Power and Thermal in the navigation tree, and then click the Management Power tab.

2. To reset the chassis manager power supply, click Auxiliary Reset, and then click Yes, Reset Now.

Configuration 33

Page 34

Resetting the chassis manager power supply resets all chassis manager components, including the Ethernet switch

connection to the blade iLO processors. An auxiliary reset causes a short disruption to the internal management and

production networks, but does not aect blade power.

3. To reset the Edgeline EL8000 Chassis Manager, click Reset EL8000CM, and then click Yes, Reset Now.

Using the Reset option does not make any configuration changes, but ends all active connections to the firmware. If a

firmware file upload is in progress, it is terminated. If a firmware flash is in progress, you cannot reset until the process is

finished. Wait a few minutes before attempting to log in to a new session.

Prepare the system for daily use

Prepare your new system for service by completing the following tasks.

The details for these tasks can be found in the HPE Edgeline EL8000 Converged Edge System Chassis Manager User Guide at

http://www.hpe.com/support/EL8000-CM-UserGuide-en.

• Access Edgeline EL8000 Chassis Manager from practically anywhere, or use a link on the Blades page to access the host

operating system using iLO Remote Console (after acquiring an iLO Advanced license).

• Add authorized user accounts in Edgeline EL8000 Chassis Manager on the User Administration page.

NOTE: The default Administrator account cannot be deleted.

• Add SSH keys for each user on the Security page.

• Replace the default self-signed certificate and create a trusted SSL certificate for Edgeline EL8000 Chassis Manager on the

SSL Certificate page.

• Control the system and chassis power, and view temperatures, from the Power and Thermal pages.

• Back up the Edgeline EL8000 Chassis Manager configuration on the Backup & Restore page.

• Troubleshoot system issues by viewing the Health and Event logs on the Logs page.

Registering the product

To experience quicker service and more eicient support, register the product at the Hewlett Packard Enterprise Product

Registration website.

34 Configuration

Page 35

Troubleshooting

Troubleshooting preparation

Prerequisites for troubleshooting

Complete the following steps before preparing the system for diagnosis.

Prerequisites

WARNING: To avoid potential issues, ALWAYS read the warnings and cautionary information in the product

documentation before removing, replacing, reseating, or modifying system components.

Procedure

1. Review the important safety information.

2. Gather symptom information.

3. If it is necessary to contact Hewlett Packard Enterprise, submit a support case through Active Health System Viewer.

For more information, see the Active Health System Viewer user guide on the Hewlett Packard Enterprise website (http://

www.hpe.com/support/ahsv-docs).

Important safety information

Familiarize yourself with the safety information in the following sections before troubleshooting the system.

Important safety information

Before servicing this product, read Safety and Compliance Information for Server, Storage, Power, Networking, and Rack

Products on the Hewlett Packard Enterprise website.

Symbols on equipment

The following symbols might be found on the equipment to indicate the presence of potentially hazardous conditions.

This symbol indicates the presence of hazardous energy circuits or electric shock hazards. Refer all

servicing to qualified personnel.

WARNING: To reduce the risk of injury from electric shock hazards, do not open this enclosure. Refer

all maintenance, upgrades, and servicing to qualified personnel.

This symbol indicates the presence of electric shock hazards. The area contains no user or field

serviceable parts. Do not open for any reason.

WARNING: To reduce the risk of injury from electric shock hazards, do not open this enclosure.

Troubleshooting 35

Page 36

This symbol on an RJ-45 receptacle indicates a network interface connection.

WARNING: To reduce the risk of electric shock, fire, or damage to the equipment, do not plug telephone

or telecommunications connectors into this receptacle.

This symbol indicates the presence of a hot surface or hot component. If this surface is contacted, the

potential for injury exists.

WARNING: To reduce the risk of injury from a hot component, allow the surface to cool before touching.

This symbol indicates that the component exceeds the recommended weight for one individual to

handle safely.

WARNING: To reduce the risk of personal injury or damage to the equipment, observe local

occupational health and safety requirements and guidelines for manual material handling.

These symbols, on power supplies or systems, indicate that the equipment is supplied by multiple

sources of power.

WARNING: To reduce the risk of injury from electric shock, remove all power cords to disconnect power

from the system completely.

Warnings and cautions

WARNING: Only authorized technicians trained by Hewlett Packard Enterprise should attempt to repair this equipment.

All troubleshooting and repair procedures are detailed to allow only subassembly/module-level repair. Because of the

complexity of the individual boards and subassemblies, no one should attempt to make repairs at the component level

or to make modifications to any printed wiring board. Improper repairs can create a safety hazard.

WARNING: To reduce the risk of personal injury or damage to the equipment, consult the safety information and user

documentation provided with the server before attempting the installation.

Some servers contain high energy circuits, high current circuits, moving parts (such as fan blades), or any combination of

these hazards, that may be exposed if covers and access panels are removed while the product is connected to a power

source. These products are intended to be serviced only by qualified personnel who have been trained to deal with

these hazards. Do not remove enclosures or attempt to bypass any interlocks designed to guard against these

hazardous conditions.

WARNING: To reduce the risk of personal injury or damage to the equipment, be sure that:

• The leveling feet are extended to the floor.

• The full weight of the rack rests on the leveling feet.

• The stabilizing feet are attached to the rack if it is a single-rack installation.

• The racks are coupled together in multiple-rack installations.

• Only one component is extended at a time. A rack may become unstable if more than one component is extended for

any reason.

36 Troubleshooting

Page 37

WARNING: To reduce the risk of electric shock or damage to the equipment:

• Do not disable the power cord grounding plug. The grounding plug is an important safety feature.

• Plug the power cord into a grounded (earthed) electrical outlet that is easily accessible at all times.

• Unplug the power cord from the power supply to disconnect power to the equipment.

• Do not route the power cord where it can be walked on or pinched by items placed against it. Pay particular

attention to the plug, electrical outlet, and the point where the cord extends from the system.

WARNING: To reduce the risk of personal injury or damage to the equipment:

• Observe local occupation health and safety requirements and guidelines for manual

handling.

• Obtain adequate assistance to lift and stabilize the chassis during installation or

removal.

• The server is unstable when not fastened to the rails.

• When mounting the server in a rack, remove the power supplies and any other

removable module to reduce the overall weight of the product

CAUTION: To properly ventilate the system, you must provide at least 76 cm (30 in) of clearance at the front and back

of the server.

CAUTION: The server is designed to be electrically grounded (earthed). To ensure proper operation, plug the AC power

cord into a properly grounded AC outlet only.

Electrostatic discharge

Preventing electrostatic discharge

To prevent damaging the system, be aware of the precautions you must follow when setting up the system or handling parts.

A discharge of static electricity from a finger or other conductor may damage system boards or other static-sensitive devices.

This type of damage may reduce the life expectancy of the device.

Procedure

•

Avoid hand contact by transporting and storing products in static-safe containers.

• Keep electrostatic-sensitive parts in their containers until they arrive at static-free workstations.

• Place parts on a grounded surface before removing them from their containers.

• Avoid touching pins, leads, or circuitry.

• Always be properly grounded when touching a static-sensitive component or assembly.

Grounding methods to prevent electrostatic discharge

Several methods are used for grounding. Use one or more of the following methods when handling or installing electrostaticsensitive parts:

Troubleshooting 37

Page 38

• Use a wrist strap connected by a ground cord to a grounded workstation or computer chassis. Wrist straps are flexible

straps with a minimum of 1 megohm ±10 percent resistance in the ground cords. To provide proper ground, wear the strap

snug against the skin.

• Use heel straps, toe straps, or boot straps at standing workstations. Wear the straps on both feet when standing on

conductive floors or dissipating floor mats.

• Use conductive field service tools.

• Use a portable field service kit with a folding static-dissipating work mat.

If you do not have any of the suggested equipment for proper grounding, have an authorized reseller install the part.

For more information on static electricity or assistance with product installation, contact an authorized reseller.

Collecting symptom information

Before troubleshooting a system issue, collect the symptom information. Download the Active Health System Log using the

Active Health System Viewer, if possible.

For more information, see the Active Health System Viewer user guide on the Hewlett Packard Enterprise website (http://

www.hpe.com/support/ahsv-docs).

Preparing the EL8000 system for diagnosis

Procedure

1. Verify that the system is in the proper operating environment with adequate power, air conditioning, and humidity control.

2. Record any error messages displayed by the system.

3. Collect all tools and utilities necessary to troubleshoot the issue, such as a Torx screwdriver, loopback adapters, an ESD

wrist strap, and software utilities.

For product-specific information, Hewlett Packard Enterprise recommends that you have access to the product

information.

4. Review the iLO Integrated Management Log (IML).

5. Record the data displayed in the iLO logs.

Hardware problems

General hardware problems

The CM configured with static IP address reverts to DHCP when moved to a new chassis

Symptom

The CM configured with static IP address reverts to DHCP when moved to a new chassis.

Cause

The network stack compares the MAC address which is used when the configuration was saved against the current MAC

address. If the current MAC address does not match, the configuration reverts to default. The MAC address of the CM is saved

in the chassis midplane. Moving the CM between chassis results in a mismatch between the address saved in the configuration

and the current address. Hence, the CM reverts to DHCP.

38 Troubleshooting

Page 39

Action

Reconfigure the chassis manager on the new chassis.

Power problems

HPE Edgeline 1500 CM module powers on without being fully inserted to the chassis

Symptom

The HPE Moonshot 1500 CM module powers on without being fully inserted to the chassis. If the CM is not fully inserted, it

may cause the fan to make load noise and the CM fails to communicate with the cartridges.

Action

Make sure that the CM is fully inserted. Open the latch fully then press the CM in fully, then close the latch.

Troubleshooting 39

Page 40

Warranty and regulatory information

Warranty information

To view the warranty information for your product, see the links provided below:

HPE ProLiant and IA-32 Servers and Options

www.hpe.com/support/ProLiantServers-Warranties

HPE Enterprise and Cloudline Servers

www.hpe.com/support/EnterpriseServers-Warranties

HPE Storage Products

www.hpe.com/support/Storage-Warranties

HPE Networking Products

www.hpe.com/support/Networking-Warranties

Regulatory information

To view the regulatory information for your product, view the Safety and Compliance Information for Server, Storage, Power,

Networking, and Rack Products, available at the Hewlett Packard Enterprise Support Center:

www.hpe.com/support/Safety-Compliance-EnterpriseProducts

Additional regulatory information

Hewlett Packard Enterprise is committed to providing our customers with information about the chemical substances in our

products as needed to comply with legal requirements such as REACH (Regulation EC No 1907/2006 of the European

Parliament and the Council). A chemical information report for this product can be found at:

www.hpe.com/info/reach

For Hewlett Packard Enterprise product environmental and safety information and compliance data, including RoHS and

REACH, see:

www.hpe.com/info/ecodata

For Hewlett Packard Enterprise environmental information, including company programs, product recycling, and energy

eiciency,

www.hpe.com/info/environment

see:

Notices for Eurasian Economic Union

Manufacturer and Local Representative Information

Manufacturer information:

Hewlett Packard Enterprise, 6280 America Center Drive, San Jose, CA 95002 U.S.

Local representative information Russian:

• Russia

ООО "Хью

шоссе, 16А, стр.3, Телефон: +7 499 403 4248 Факс: +7 499 403 4677

• Kazakhstan

40 Warranty and regulatory information

летт Паккард Энтерпрайз", Российская Федерация, 125171, г. Москва, Ленинградское

Page 41

TOO «Хьюлетт-Паккард (К)», Республика Казахстан, 050040, г. Алматы, Бостандыкский район,

проспект Аль-Фараби, 77/7, Телефон/факс: + 7 727 355 35 50

Local representative information Kazakh:

• Russia

ЖШС "Хьюлетт Паккард Энтерпрайз", Ресей Федерациясы, 125171, Мәскеу, Ленинград тас жолы,

16A блок 3, Телефон: +7 499 403 4248 Факс: +7 499 403 4677

• Kazakhstan

ЖШС «Хьюлетт-Паккард (К)», Қазақстан Республикасы, 050040, Алматы к., Бостандык ауданы, ӘлФараби даңғ ылы, 77/7, Телефон/факс: +7 727 355 35 50

Manufacturing date:

The manufacturing date is defined by the serial number.

If you need help identifying the manufacturing date, contact tre@hpe.com.

Turkey RoHS material content declaration

Türkiye Cumhuriyeti: AEEE Yönetmeliğine Uygundur

Ukraine RoHS material content declaration

Federal Communications Commission notice for Class A equipment

This device complies with part 15 of the FCC Rules. Operation is subject to the following conditions:

This device may not cause harmful interference.

•

• This device must accept any interference received, including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required

to correct the interference at their own expense.

Warranty and regulatory information 41

Page 42

WARNING:

1. This equipment complies with radio frequency (RF) exposure limits adopted by the Federal Communications

Commission for an uncontrolled environment. This equipment should be installed and operated with a minimum

distance of 20 cm between the radiator and your body.

2. Changes or modifications not expressly approved by the party responsible for compliance could void the authority of

the user to operate the equipment.

Canada, Industry Canada (IC) Notices

This device complies with Industry Canada license-exempt RSS standards. Operation is subject to the following conditions:

1. This device may not cause interference.

2. This device must accept any interference, including interference that may cause undesired operation of the device.

Under Industry Canada regulations, the radio transmitters in this device may only operate using an antenna of a type and

maximum (or lesser) gain approved for the transmitter by Industry Canada. To reduce potential radio interference to other

users, the antenna type and its gain should be so chosen that the equivalent isotropically radiated power (e.i.r.p.) is not more

than what is necessary for successful communication.

WARNING: The device for operation in the band 5150 MHz to 5250 MHz is only for indoor use to reduce the potential

for harmful interference to cochannel mobile satellite systems.

Radio Frequency (RF) Exposure Information

This equipment complies with radio frequency (RF) exposure limits adopted by the Federal Communications Commission for

an uncontrolled environment. This equipment should be installed and operated with a minimum distance of 20 cm between the

radiator and your body.

This radio transmitter (IC:24448-EL8000530S) has been approved by Industry Canada to operate with the antenna types

listed below with the maximum permissible gain indicated. Antenna types not included in this list, having a gain greater than

the maximum gain indicated for that type, are strictly prohibited for use with this device. For maximum antenna gain, refer to

the table:

Frequency (MHz) Gain (dBi) Antenna Type Antenna Connector

2400-2500 238

5150-5250 325

5250-5350 325

5470-5725 378

5725-5850 394

Canada, avis d'Industry Canada (IC)

Cet appareil est conforme aux normes d'exemption de licence RSS d'Industry Canada.

Son fonctionnement est soumis aux deux conditions suivantes:

Dipole R-SMA

1. Cet appareil ne doit pas causer d'interférence.

2. Cet appareil doit accepter toute interférence, notamment les interférences qui peuvent aecter son fonctionnement.

Conformément aux réglementations d'Industry Canada, les émetteurs radio de cet appareil ne peuvent fonctionner qu'à l'aide

d'une antenne dont le type et le gain maximal (ou minimal) pour ces émetteurs - transmetteurs sont approuvés par Industry

42 Warranty and regulatory information

Page 43

Canada. Pour réduire le risque d'interférence éventuelle pour les autres utilisateurs, le type et le gain de l'antenne doivent être

choisis de manière à ce que la puissance isotrope rayonnée é quivalente (p.i.r.e.) minimale nécessaire à une bonne

communication soit fournie.

WARNING: Les dispositifs fonctionnant dans la bande 5150 MHz - 5250 MHz sont réservés uniquement pour une

utilisation à l'intérieur afin de réduire les risques de brouillage préjudiciable aux systèmes de satellites mobiles utilisant

les mêmes canaux.

Informations sur l'exposition à la fréquence radio (FR)

Cet équipement est conforme aux limites d'exposition aux rayonnements IC établies pour un environnement non contrôlé. Cet

équipement doit être installé et utilisé avec un minimum de 20 cm de distance entre la source de rayonnement et votre corps.

Cet émetteur radio (IC: 24448-EL8000530S) a été approuvé par Industrie Canada pour fonctionner avec les types d'antennes

énumérés ci-dessous avec le gain maximal autorisé indiqué. Les types d'antenne non inclus dans cette liste, ayant un gain

supérieur au gain maximal indiqué pour ce type, sont strictement interdits d'utilisation avec cet appareil. Le gain d'antenne

maximal (voir le tableau ci-dessous

La fréquence (MHz)

2400-2500 238

5150-5250 325

5250-5350 325

5470-5725 378

5725-5850 394

Gain (dBi) Type d'antenne Connecteur d'antenne

Dipôle R-SMA

Brazil certification notice

WARNING: Este equipamento não tem direito à proteção contra interferência prejudicial e não pode causar interferência

em sistemas devidamente autorizados

Japanese certification notice

IMPORTANT: 52GHz 帯及び 53GHz 帯の利用は、 総務省に登録済の 52GHz 帯高出力基地局等と通信する

場合を除き、屋内に限定されています.

Korean certification notice for class A equipment

CAUTION: 이 기기는 업무용 환경에서 사용할 목적으로 적합성평가를 받은 기기로서 가정용 환경에서 사용

하는 경우 전파간섭의 우려가 있습니다.

WARNING: 해당 무선설비가 전파혼신 가능성이 있으므로 인명안전과 관련된 서비스는 할 수 없음”.

Warranty and regulatory information 43

Page 44

Specifications

Environmental specifications

Table 1: Standard specifications

Specification Value

Temperature range

1

Operating 0°C to 55°C (32°F to 131°F)

—

2

Nonoperating -30°C to 60°C (-22°F to 140°F)

Relative humidity (noncondensing)

—

Operating 8% to 90% at 28°C (824°F) maximum wet bulb temperature

Non-Operating 5% to 95% at 387°C (1017°F) maximum wet bulb

temperature

1

All temperature ratings shown are for sea level. An altitude derating of 10°C per 3048 m (18°F per 1000 ft) to 3048 m (10000 ft) is

applicable. No direct sunlight allowed. Maximum rate of change is 20°C per hour (36°F per hour). No restrictions on product configurations.

Not rated for operation over 3048 m (10000 ft).

2

Fan failure might reduce performance.

Table 2: ASHRAE Class A4 specifications

Specification Value

Temperature range

1

—

Operating 0°C to 45°C (32°F to 113°F)

Nonoperating -10°C to 60°C (-22°F to 140°F)

Relative humidity (noncondensing)

Operating 8% to 90% at 28°C (824°F) maximum wet bulb temperature

Non-Operating 5% to 95% at 387°C (1017°F) maximum wet bulb

1

All temperature ratings shown are for sea level. An altitude derating of 10°C per 125 m (18°F per 410 ft) to 900 m (2953 ft) is applicable.