Page 1

Keysight i3070 Inline PLC Software Version 1.46 Release Note

Dear Customer,

Keysight Technologies is pleased to introduce the i3070 Inline PLC software version 1.46 (PLC 1.46) for our

existing i3070 Series 5i Inline in-circuit testers. No pre-requisite is required to install this release.

What’s new in PLC 1.46 release?

1. Memory storage for 50 recipe profiles based on unique fixture ID

2. Ability to load/unload fixture in one single step.

3. Display of fixture ID at Production mode

4. Read Press positions and error codes from computer

While the PLC 1.46 release improves the stability of the PLC software, the key enhancement is in fixture

management. With the memory storage for 50 recipe profiles, you can now calibrate each individual fixture

with the i3070 Inline system. The calibration data can then be stored based on the fixture ID for fast recall

in future use, reducing setup time during product change. Fixture setup time is further reduced with the

new one touch “Change Jig” command.

In addition, the test engineer no longer needs to navigate the touch panel in search of fixture ID and Press

parameters. The fixture ID is now displayed at Production mode and all the Press parameters such as

Standby position and error codes can be read from the PC. The engineer can also log these parameters and

error codes into a log file for reference purpose.

The PLC 1.46 release will be the last software version supporting standard fixture profile namely; 75 mm,

85 mm and 100 mm. With the above enhancement, these 3 standard fixture profiles have become

redundant and will be removed from future PLC software releases (effective from version 2.00).

Other enhancements are listed in the Appendix.

Please visit http://www.keysight.com/find/i3070patches

Page 2

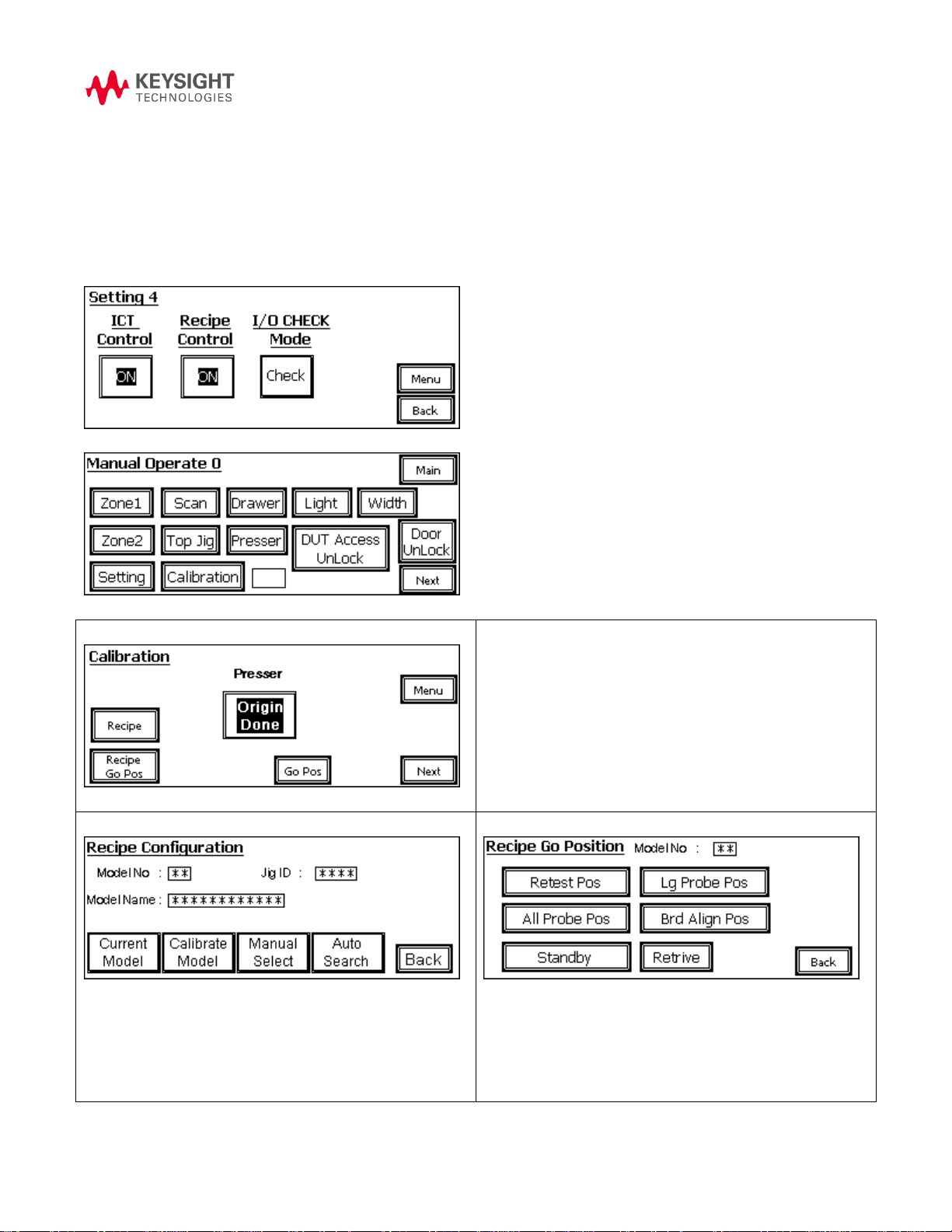

Then, initialize the Press to “Origin Done”, select “Recipe” to

enter into “Recipe Configuration”

Select “Recipe Go Pos” to enter “Recipe Go Position” to

validate Press profiles.

Current Model - view the existing Press height profiles in

detail.

Calibrate Model - Adjust Press Height profile

Manual Select - manually select Press Height profile

Auto Search – Automatically select Press Height profile based

on Top Jig ID

Validate Press positioning

Appendix:

1. 50 recipe profiles for unique fixture ID and Press height

This feature is also known as Recipe control, in short. There are a total of 50 memory profiles and each

memory profile can store a unique fixture ID along with its Press height positions. To use this, set Recipe

Control to ON at Setting 4.

To calibrate the Press height profile, goto Maintenance -> Calibration

Page 3

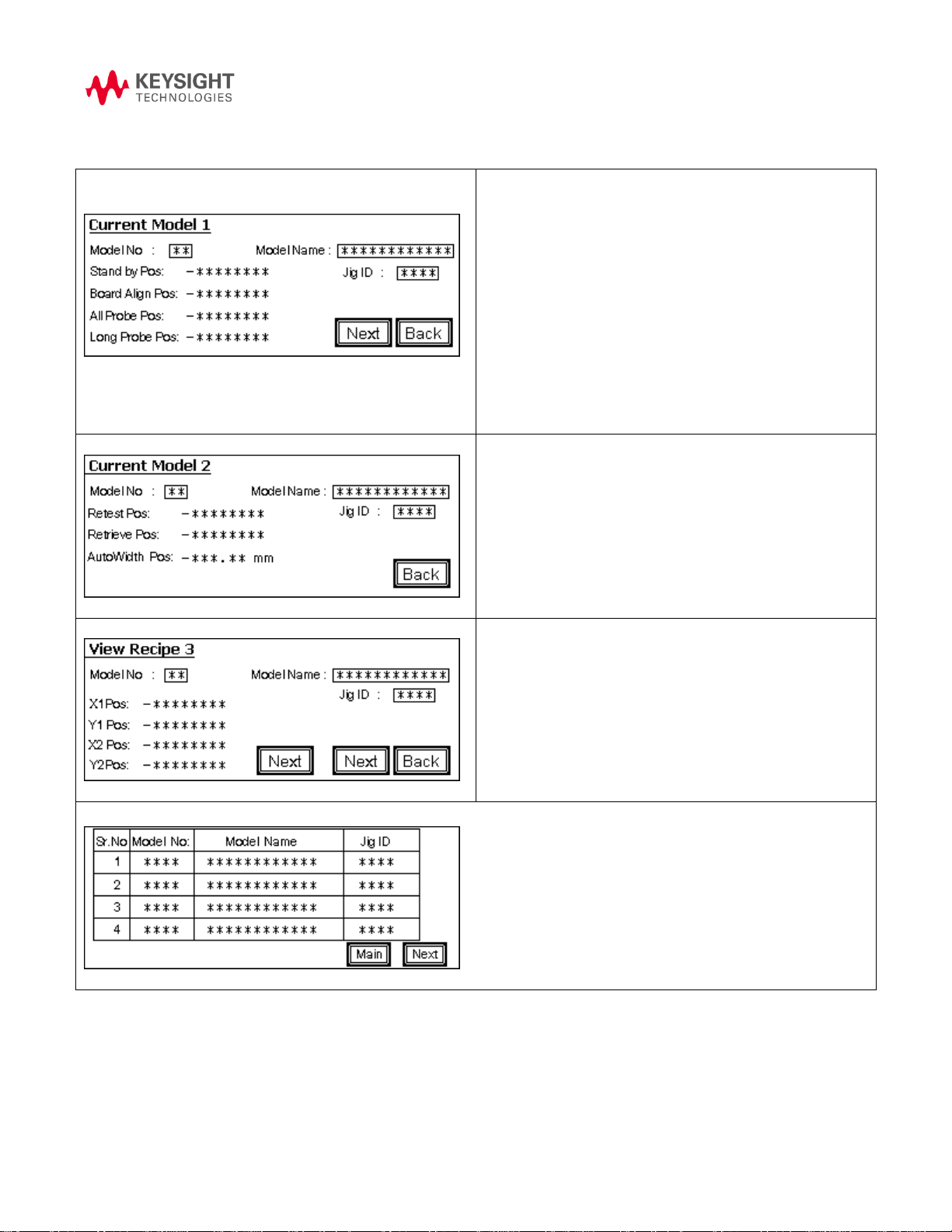

Select Current Model

Model No: Series numbering from 01 – 50

Model Name: Project or Product name

Jig ID: Top fixture ID or Autofile

Standby Pos: Position of the Press when idling, to allow board

transfer between zones

Board Align Pos: Position of the Press when verifying if the

board is seated properly on the tooling pin and support plate.

All Probe Pos: Position of the Press where board is in contact

with all probes for analog and digtal in-circuit testing.

Long Probe Pos: Position of the Press where board is in

contact with the long probes only.

Next: Go to next page

Back: Back to previous page

Retest Pos: Position of the Press where board doesn’t contact

any probes. Like Press Off.

Retrieve Pos: Position of the Press where fixture is safe to

remove for maintenance.

Autowidth Pos: Position of the conveyor width where board

can tranfers from one zone to another zone.

X1 Pos: 1st X-axis position for scanning a barcode.

Y1 Pos: 1st Y-axis position for scanning a barcode.

X2 Pos: 2nd X-axis position for scanning a barcode.

Y2 Pos: 2nd Y-axis position for scanning a barcode.

Select Calibrate Model

From the table listed above, select a location to store the Press profile. Recipe Setting 1 Page will show up.

Page 4

Select Jig ID, model Name, Standby Pos, Board Align Pos,

All Probe Pos, Long Probe Pos, Retest Pos, Retrieve Pos and

etc to store all the desired parameters.

Select YES at Save all Setting to save all parameters to

memory.

Select No at Save all Setting will discard all parameters

memory.

This page will appear when Jig ID is selected

Jig ID Current Installed: Top fixture ID detected

Top Jig ID Save to Model: Enter Autofile that matches the top

fixture ID.

This page will appear when Model Name is selected

Model Name: Enter Project or Product Name

Page with various positioning naming will appear when

selected

Standby Pos: Board Align Pos: All Probe Pos:

Long Probe Pos: Retest Pos: Retrieve Pos

Previous: Old Press Position saved in memory

New: New Press position to be saved in memory

Current: Existing Press Position being jogged

Set: Set Existing Press position as New position in memory

Select Search Origin to move the Press to the start

position.

Select and hold Up+ or Down– to manually jog the

Page 5

Press to the desired position

Use Slow to slow down the Press movement if needed.

Select Set to save the desired Press position to memory.

A table page will appear when “Manual Select” is selected.

Select “Next” to scroll to next page.

Select “Main” to scroll back to Recipe Configuration page.

Select a row that is associated with JIG ID to manually load

and use the profile.

Model selection screen pop-out. Review and select

Yes: Accept and use Jig ID

No: Reject and Exit

Select “Chg. Jig” button to enter to “Change Fixture” screen

Lock: Secure the Top and Bottom fixture clamp

Unlock: Press auto jog to Retrieve position, Unlock Top and

bottom fixture clamp.

Auto Search: Automatically select Press Height profile based

on Top Jig ID

Main: Back to Main Page

2. Ability to load/unload fixture in one single step

3. Display of Fixture ID at Production Mode

Page 6

I/O Check: Check sensors, board stoppers reed switch,

SMEMA and etc

Press NonByPass/Press ByPass: Bypassing Press to allow

board transfer without testing. Example: link conveyor

Reset: Raise the Press to Retrieve position and eject the board

if present in zone 2.

Press Position

Address Byte

Read Byte

Standby Position

D5402+D5401

4

Board Align Position

D5404+D5403

4

All Probe Position

D5406+D5405

4

Long Probe Position

D5408+D5407

4

Retest Position

D5410+D5409

4

Retrieve Position

D5412+D5411

4

AutoWidth Position

D5414+D5413

4

Model No

D5400

2

Model Name

D5435+D5434+D5433+D5432+D5431+D5430

12

Jig ID

D5438

2

4. Read Press Positions and Error Codes from Computer

Here is the listing of PLC addresses used to read the Press positions.

An example of the subroutine to verify the position is also shown below.

!##############################################################

sub Check_Press_Height

global Using_BtBasic

! This routine is to check the Press height

print using "@"

print "Reading Press Height from PLC"

Read_Address1$ = "5401" !Standby LSB

Read_Address2$ = "5402" !Standby MSB

Read_Address3$ = "5403" !Board Align LSB

Read_Address4$ = "5404" !Board Align MSB

call Read_PLC (Read_Address1$, Read_Data1$)

call Read_PLC (Read_Address2$, Read_Data2$)

Page 7

Address

ERROR ID

Message

D7500

#1

Unable to Turn ON Zone1 Stopper.

D7500

#2

Unable to Turn OFF Zone1 Stopper.

D7500

#4

## Not in Use ##

D7500

#8

Unable to Turn Off Zone2 Stopper

D7500

#10

Unable to Turn ON Zone2 Stopper

D7500

#20

## Not in Use ##

D7500

#40

Board Jam at Zone1 Conveyor

D7500

#80

Board Jam at Zone2 Conveyor

D7500

#100

Board Zone1 to Zone2 Transfer Error

D7500

#200

Double Board Error ,Zone1 to Zone2 Transfer Error

D7500

#400

## Not in Use ##

D7500

#800

Unable to Move Press, Zone2 Entry or Exit Sensor triggered

D7500

#1000

Drawer Up Error

D7500

#2000

Drawer Down Error

D7500

#4000

Top Jig Lock Error

D7500

#8000

Top Jig UnLock Error

D7501

#1

Bottom Jig Lock Error

D7501

#2

Bottom Jig UnLock Error

D7501

#4

Press Home Move Error

D7501

#8

Lower Limit Trigger while Press Move

D7501

#10

Upper Limit Trigger while Press Move

D7501

#20

Board Orientation Error

D7501

#40

## Not in Use ##

D7501

#80

## Not in Use ##

D7501

#100

## Not in Use ##

D7501

#200

## Not in Use ##

call Read_PLC (Read_Address1$, Read_Data3$)

call Read_PLC (Read_Address2$, Read_Data4$)

Standby_Pos$= Read_Data2$&Read_Data1$

Board_Align_Pos$= Read_Data4$&Read_Data3$

print "Standby Position is: "; hti(Standby_Pos$)

print "Standby Position is: "; hti(Board_Align_Pos$)

subend

!##############################################################

User also can read the Error flag with following address and data byte.

Page 8

D7501

#400

## Not in Use ##

D7501

#800

## Not in Use ##

D7501

#1000

## Not in Use ##

D7501

#2000

## Not in Use ##

D7501

#4000

## Not in Use ##

D7501

#8000

## Not in Use ##

D7502

#1

NC Card Error

D7502

#2

Servo Driver Error

D7502

#4

Servo Motor Brake Error

D7502

#8

## Not in Use ##

D7502

#10

Right Side Drawer Not Down while trying to move.

D7502

#20

Front Safety Hook Not Release while trying to move Press

D7502

#40

Board Manually Removed during Auto Mode. Restart

D7502

#80

Left Side Drawer not down while trying to move

D7502

#100

Rear Safety Hook Not Release while Trying to move Press

D7502

#200

Board Without status present at Zone2

D7502

#400

Scanner Timeout - No feedback signal

D7502

#800

ICT Timeout - No feedback signal

D7502

#1000

Jig Height Error

D7502

#2000

Bottom Jig Not Lock While Moving Press

D7502

#4000

Top Jig Not Lock While Moving Press

D7502

#8000

Maintenance Key is ON While Auto Mode

D7503

#1

Top JIG Not Fully IN Error While Press Move

D7503

#2

Bottom Jig Not In While Press Move

D7503

#4

Engine Not Detect

D7503

#8

## Not in Use ##

D7503

#10

Demo Mode Conveyor Reverse Error.Z2 to Z1 Error

D7503

#20

Safety Hook Not Unlock While Auto Mode

D7503

#40

Press Retest position Error

D7503

#80

## Not in Use ##

D7503

#100

## Not in Use ##

D7503

#200

## Not in Use ##

D7503

#400

## Not in Use ##

D7503

#800

## Not in Use ##

D7503

#1000

## Not in Use ##

D7503

#2000

## Not in Use ##

D7503

#4000

## Not in Use ##

D7503

#8000

Board Present at Zone2 Exit

D7504

#1

## Not in Use ##

D7504

#2

## Not in Use ##

D7504

#4

## Not in Use ##

Page 9

D7504

#8

## Not in Use ##

D7504

#10

## Not in Use ##

D7504

#20

Zone2 DC Motor Driver Error

D7504

#40

## Not in Use ##

D7504

#80

## Not in Use ##

D7504

#100

## Not in Use ##

D7504

#200

Board Not Clear on Conveyor While Auto Mode

D7504

#400

Board Not Clear on Conveyor While AutoWidth

D7504

#800

DUT Access not Lock While Auto

D7504

#1000

Board Alignment Check Error

D7504

#2000

## Not in Use ##

D7504

#4000

## Not in Use ##

D7504

#8000

## Not in Use ##

D7505

#1

Missing Model Number While Auto Mode

D7505

#2

Missing Model Name While Auto Mode

D7505

#4

Actual Jig ID Not Matching Jig ID selected While Auto Mode

D7505

#8

Standby Position No Value While Auto Mode

D7505

#10

Board Align Position No value While Auto Mode

D7505

#20

All Probe Position No value While Auto Mode

D7505

#40

Long Probe Position No Value While Auto Mode

D7505

#80

Retest Position No Value While Auto Mode

D7505

#100

Retrieve Position No Value While Auto Mode

D7505

#200

Auto Width No Value While Auto Mode

D7505

#400

## Not in Use ##

D7505

#800

## Not in Use ##

D7505

#1000

## Not in Use ##

D7505

#2000

## Not in Use ##

D7505

#4000

## Not in Use ##

D7505

#8000

Double Board Error.

5. Other Enhancements:

1. Press movement is slower now using Go position validation at Debug and Calibration

2. MCB3 no longer tripped if initializing Autowidth

3. Enhance Auto mode error message with details steps

4. Buzzer is computer controllable with autocode of Address#3004 and Data#0004.

5. Downstream timeout is optional

6. System re-starting Auto mode will check board present in zone 1 and zone 2.

7. All settings are relocated to Setting pages from 1-4.

8. Fixed Autowidth Reset to 60 mm in Maintenance mode.

Page 10

© Keysight Technologies, Inc. 2014

Printed in Malaysia 07/2014

Loading...

Loading...