Page 1

Service Guide

3DUW1XPEHU(

$SULO

)RU:DUUDQW\LQIRUPDWLRQUHIHUWRWKHEDFNRIWKHPDQXDO

&RS\ULJKW$JLOHQW7HFKQRORJLHV,QF

$OO5LJKWV5HVHUYHG

$JLOHQW($

'&3RZHU6XSSO\

Page 2

The Agilent Technologies E3631A is a high performance 80 watt-triple output

DC power supply with GPIB and RS-232 interfaces. The combination of benchtop and system features in this power supply provides versatile solutions for

your design and test requirements.

Convenient bench-top features

• Triple output

• Easy-to-use knob control for voltage and current settings

• Highly visible vacuum-fluorescent display for voltage and current meters

• Tracking operation for ±25V outputs

• Excellent load and line regulation and low ripple and noise

• Operating states storage

• Portable, ruggedized case with non-skid feet

Flexible system features

• GPIB (IEEE-488) and RS-232 interfaces are standard

• SCPI (Standard Commands for Programmable Instruments) compatibility

• I/O setup easily done from front-panel

Agilent E3631A

Triple Output

DC Power Supply

Page 3

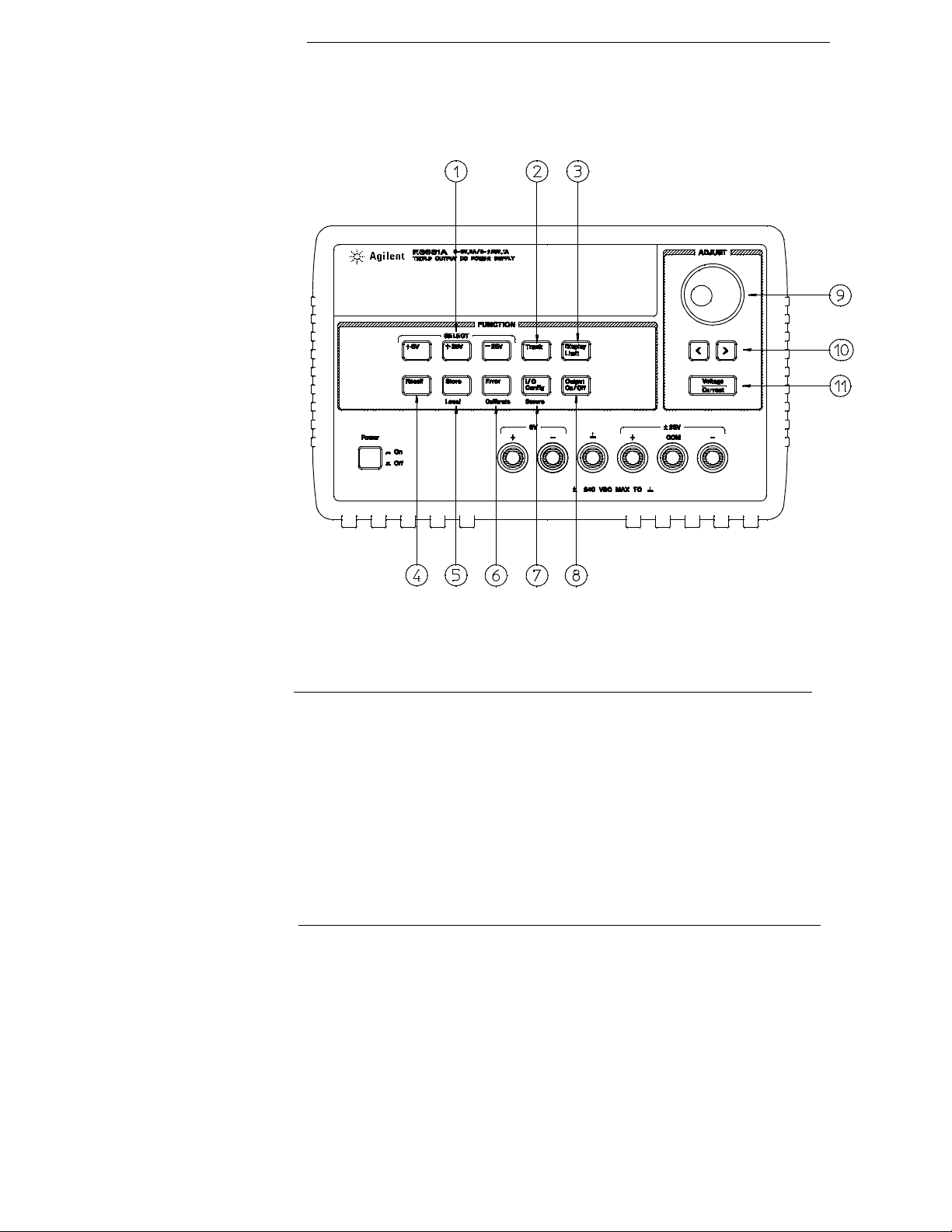

The Front Panel at a Glance

1 Meter and adjust selection keys

2 Tracking enable/disable key

3 Display limit key

4 Recall operating state key

5 Store operating state/Local key

6 Error/Calibrate key

2

7 I/O Configuration / Secure key

8 Output On/Off key

9 Control knob

10 Resolution selection keys

11 Voltage/current adjust selection key

Page 4

1 Meter and adjust selection keys Select the output voltage and current of any one

supply (+6V, +25V, or -25V output) to be monitored on the display and allow knob

adjustment of that supply.

2 Tracking enable / disable key Enables / disables the track mode of

±25V supplies.

3 Display limit key Shows the voltage and current limit values on the display and allows

knob adjustment for setting limit values.

4 Recall operating state key Re calls a prev iously stor ed ope r atin g stat e from locati on

"1", "2", or "3".

1

5 Store operating state / Local key

Stores an operating state in location "1", "2", or

"3" / or returns the power supply to local mode from remote interface mode.

2

6 Error / Calibrate key

Displays error codes generated during operations, self-test

and calibration / or enables calibration mode (the power supply must be unsecured

before performing calibration).

3

7 I/O Configuration / Secure key

Configures the power supply for remote interfaces

/ or secure and unsecure the power supply for calibration.

8 Output On/Off key Enables or disables all three power supply outputs. This key

toggles between two states.

9 Control knob Increases or decreases the value of the blinking digit by turning

clockwise or counter clockwise.

10 Resolution selection keys Move the flashing digit to the right or left.

11 Voltage/current adjust selection key Selects the knob function to voltage control

or current control.

1

The key can be used as the "Local" key when the power supply is in the remote

interface mode.

2

You can enable the "calibration mode" by holding down this key when you turn on

the power supply.

3

You can use it as the "Secure" or "Unsecure" key when the power supply is in the

calibration mode.

3

Page 5

Front-Panel Voltage and Current Settings

You can set the voltage and current from the front panel using the following

method.

Use the voltage/current adjust selection key, the resolution selection keys, and

the control knob to change the limiting or limitings value of voltage or current.

1 Press the key after turning on the power supply.

2 Set the knob to the voltage control mode or current control mode using the voltage/

current adjust selection key.

3 Move the blinking digit to the appropriate position using the resolution selection keys.

4 Change the blinking digit to the desired value using the control knob.

5 Press the key to enable the output. After about 5 seconds, the

display will go to the output monitor mode automatically to display the voltage and

current at the output.

Display Limit

Output On/Off

Note All front panel keys and controls can be disabled with remote interface commands.

The Agilent E3631A must be in "Local" mode for the front panel keys and controls to

function.

4

Page 6

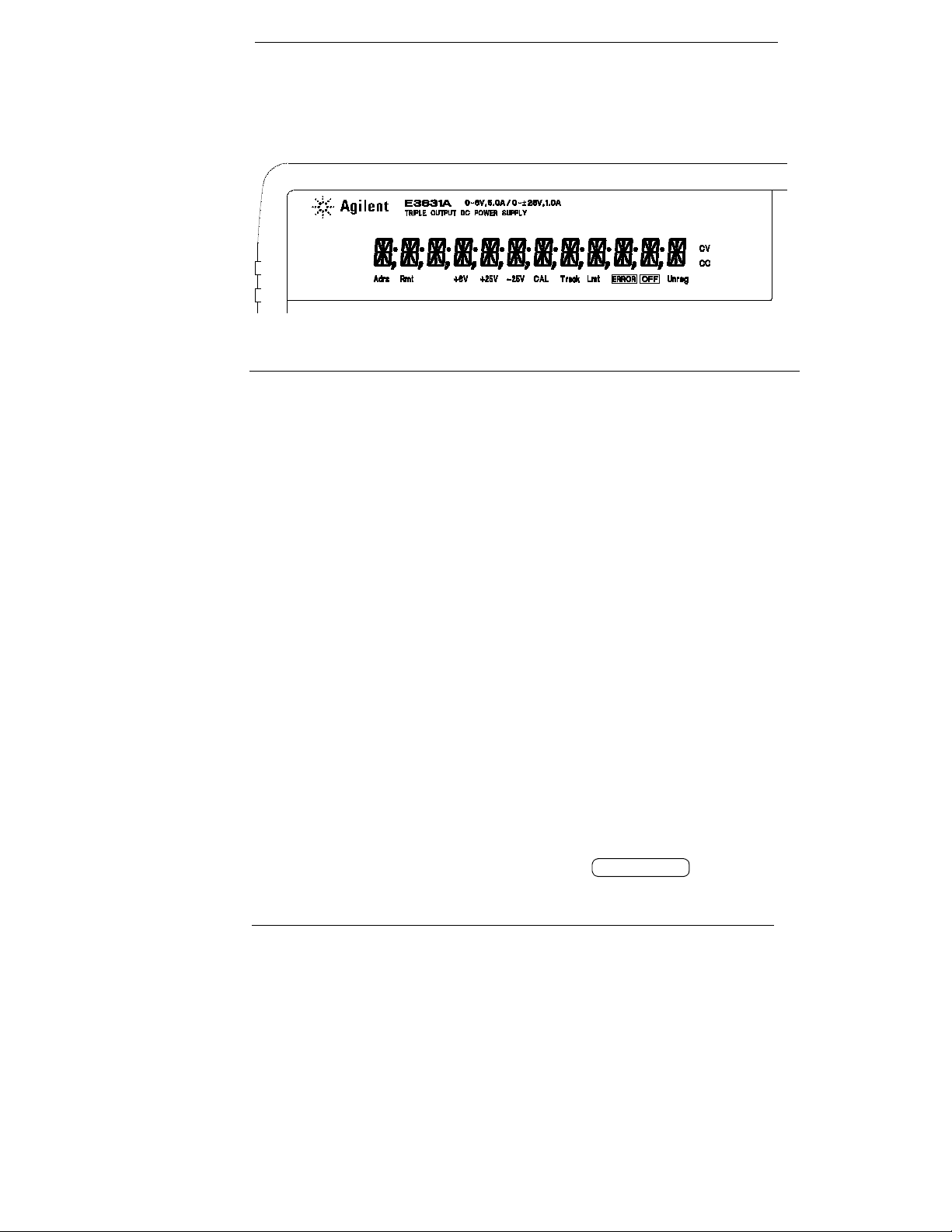

Display Annunciators

Adrs Power supply is addressed to listen or talk over a remote interface.

Rmt Power supply is in remote interface mode.

+6V Displays the output voltage and current for +6V supply. Knob is active for

+6V supply.

+25V Displays the output voltage and current for +25V supply. Knob is active for

-25V Displays the output voltage and current for -25V supply. Knob is active for

CAL power supply is in calibration mode.

Track The outputs of +25V and -25V supplies are in track mode.

Limit The display shows the voltage and current limit value of a selected supply.

ERROR Hardware or remote interface command errors are detected and also the

OFF The three ouputs of the power supply are disabled.

Unreg The displayed output is unregulated (output is neither CV nor CC).

CV The displayed output is in constant-voltage mode.

CC The displayed output is in constant-current mode.

+25V supply.

-25V supply.

error bit has not been.

To review the display annunciators, hold down key as you

Display Limit

turn on the power supply.

5

Page 7

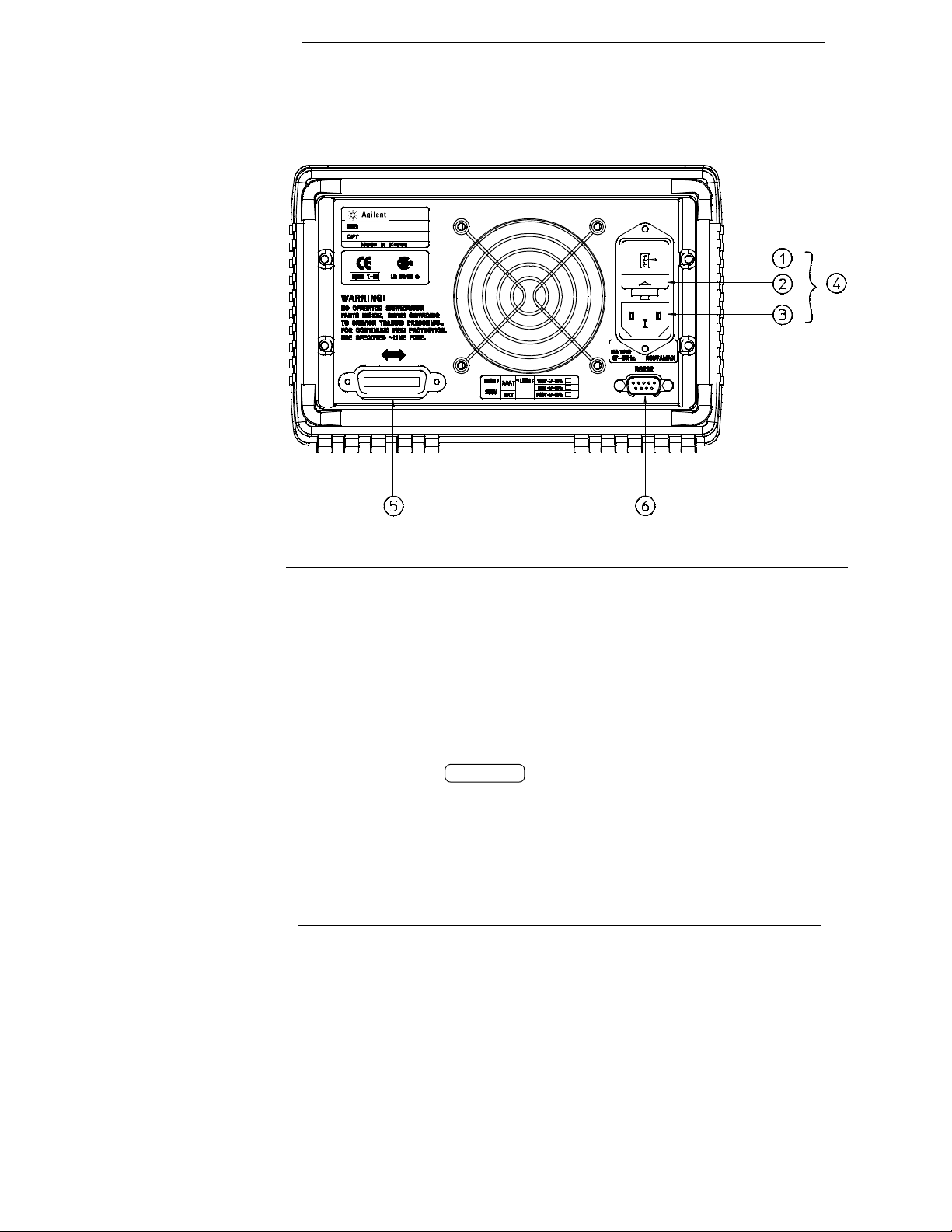

The Rear Panel at a Glance

1 Power-line voltage setting

2 Power-line fuse-holder assembly

3 AC inlet

Use the front-panel key to:

• Select the GPIB or RS-232 interface (see chapter 3).

• Set the GPIB bus address (see chapter 3).

• Set the RS-232 baud rate and parity (see chapter 3).

I/O Config

4 Power-line module

5 GPIB (IEEE-488) interface connector

6 RS-232 interface connector

6

Page 8

In This Book

Specifications Chapter 1 lists the power supply’s specifications and

describes how to interpret these specifications.

Quick Start

familiar with the front-panel features.

Calibration Procedures Chapter 3 provides performance verification and

calibration procedures.

Theory of Operation Chapter 4 describes block and circuit level theory

related to the operation of the power supply.

Service Chapter 5 provides guidelines for returning your power supply to

Agilent Technologies for servicing, or for servicing it yourself.

Replaceable Parts Chapter 6 contains a detailed parts list of the power

supply.

Backdating Chapter 7 describes the difference between this manual and

older issues of this manual.

Chapter 2 prepares the power supply for use and helps you get

Schematics Chapter 8 contains the power supply's schematics, disassembly

drawings, and component locator drawings.

If you have questions relating to the operation of the power supply, call

1-800-452-4844 in the United States, or contact your nearest Agilent

Technologies Sales Office.

7

Page 9

8

Page 10

Contents

Chapter 1 Specifications

Performance Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Supplemental Characteristics - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Chapter 2 Quick Start

To prepare the power supply for use - - - - - - - - - - - - - - - - - - - - - - 23

To check the rated voltages of the power supply - - - - - - - - - - - - 25

To check the rated currents of the power supply - - - - - - - - - - - - 27

To use the power supply in constant voltage mode - - - - - - - - - - 29

To use the power supply in constant current mode - - - - - - - - - - 31

To use the power supply in track mode- - - - - - - - - - - - - - - - - - - - 33

To store and recall the instrument state - - - - - - - - - - - - - - - - - - - 34

To rack mount the power supply - - - - - - - - - - - - - - - - - - - - - - - - - 36

Chapter 3 Calibration Procedures

Agilent Technologies Calibration Services - - - - - - - - - - - - - - - - - 41

Calibration Interval- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 41

Automating Calibration Procedures - - - - - - - - - - - - - - - - - - - - - - 42

Recommended Test Equipment - - - - - - - - - - - - - - - - - - - - - - - - - - 42

Test Considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 43

Performance Verification Tests - - - - - - - - - - - - - - - - - - - - - - - - - - 44

Self-Test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 44

Performance Verification Tests- - - - - - - - - - - - - - - - - - - - - - - - - 44

Measurement Techniques- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 45

Setup for Most Tests - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 45

Electronic Load - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 46

Current-Monitoring Resistor - - - - - - - - - - - - - - - - - - - - - - - - - - - 46

Programming - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 46

Voltage and Current Values - - - - - - - - - - - - - - - - - - - - - - - - - - - - 46

Constant Voltage (CV) Verifications - - - - - - - - - - - - - - - - - - - - - - 47

Constant Voltage Test Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - 47

Voltage Programming and Readback Accuracy - - - - - - - - - - - - 47

CV Load Regulation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 49

CV Line Regulation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 50

Normal Mode Voltage Noise (CV Ripple and Noise) - - - - - - - - 51

Common Mode Current Noise- - - - - - - - - - - - - - - - - - - - - - - - - - 52

Load Transient Response Time - - - - - - - - - - - - - - - - - - - - - - - - - 53

Contents

9

Page 11

Contents

Chapter 3 Calibration Procedures (continued)

Constant Current (CC) Verifications - - - - - - - - - - - - - - - - - - - - - - 54

Constant Current Test Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - 54

Current Programming and Readback Accuracy - - - - - - - - - - - - 54

CC Load Regulation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 56

CC Line Regulation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 57

Normal Mode Current Noise (CC Ripple and Noise) - - - - - - - - 58

Performance Test Record for Agilent E3631A - - - - - - - - - - - - - - - 59

CV Performance Test Record- - - - - - - - - - - - - - - - - - - - - - - - - - - 59

CC Performance Test Record- - - - - - - - - - - - - - - - - - - - - - - - - - - 60

Calibration Security Code - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 61

To Unsecure the Power Supply for Calibration - - - - - - - - - - - - 62

To Unsecure the Power Supply Without the Security Code - - - 64

Calibration Count - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 65

Calibration Message - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 65

General Calibration/Adjustment Procedure - - - - - - - - - - - - - - - - - 66

Aborting a Calibration in Progress - - - - - - - - - - - - - - - - - - - - - - - - 71

Calibration Record for Agilent E3631A - - - - - - - - - - - - - - - - - - - - 72

Error Messages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 73

Calibration Program - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 75

Chapter 4 Theory of Operation

Block Diagram Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 81

AC Input and Bias Supplies - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 83

Floating Logic - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 84

D-to-A Converter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 86

A-to-D Converter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 87

Power Mesh and Control- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 88

Earth-Referenced Logic - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 90

Front Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 90

Chapter 5 Service

Operating Checklist - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 93

Is the Power Supply Inoperative? - - - - - - - - - - - - - - - - - - - - - - - 93

Does the Power Supply Fail Self-Test? - - - - - - - - - - - - - - - - - - - 93

Types of Service Available - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 94

Standard Repair Service (worldwide) - - - - - - - - - - - - - - - - - - - - 94

Express Exchange (U.S.A. only) - - - - - - - - - - - - - - - - - - - - - - - - 94

10

Page 12

Contents

Chapter 5 Service (continued)

Repacking for Shipment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 95

Electrostatic Discharge (ESD) Precautions - - - - - - - - - - - - - - - - 96

Surface Mount Repair - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 96

To Replace the Power-Line Fuse - - - - - - - - - - - - - - - - - - - - - - - - - 96

Troubleshooting Hints - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 97

Unit is Inoperative - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 97

Unit Reports Errors 740 to 748 - - - - - - - - - - - - - - - - - - - - - - - - - 97

Unit Fails Self-Test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 97

Bias Supplies Problems - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 98

Self-Test Procedures- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 99

Power-On Self-Test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 99

Complete Self-Test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 99

Chapter 6 Replaceable Parts

Replaceable Parts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 104

To Order Replaceable Parts- - - - - - - - - - - - - - - - - - - - - - - - - - - 104

Backdating and Parts Changes - - - - - - - - - - - - - - - - - - - - - - - - 104

E3631-60002 Top PCB Assembly - - - - - - - - - - - - - - - - - - - - - - - 105

E3631-60003 VFD Assembly- - - - - - - - - - - - - - - - - - - - - - - - - - - 111

E3631-60002 Bottom PCB Assembly - - - - - - - - - - - - - - - - - - - - 112

E3631-60002 Front Frame Assembly - - - - - - - - - - - - - - - - - - - - 116

E3631A Power Supply Assembly - - - - - - - - - - - - - - - - - - - - - - - 116

Manufacturer’s List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 117

Chapter 7 Backdating - - - - - - - - - - - - - - - - - - - - - - - - - 119

Chapter 8 Schematics

Mechanical Disassembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 123

E3631-60002 Component Locator - - - - - - - - - - - - - - - - - - - - - - - 124

E3631-60003 Component Locator - - - - - - - - - - - - - - - - - - - - - - - 125

E3631-60004 Component Locator - - - - - - - - - - - - - - - - - - - - - - - 126

AC Input and Bias Supplies Schematic - - - - - - - - - - - - - - - - - - - 127

Floating Logic Schematic - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 128

ADC and DAC Schematic - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 129

25V Power Circuit Schematic- - - - - - - - - - - - - - - - - - - - - - - - - - - 130

+6V Power Circuit and Isolation Schematic - - - - - - - - - - - - - - - 131

Earth-Referenced Logic Schematic - - - - - - - - - - - - - - - - - - - - - - 132

Display and Keyboard Schematic - - - - - - - - - - - - - - - - - - - - - - - 133

Contents

11

Page 13

Contents

12

Page 14

1

1

Specifications

Page 15

Specifications

The

performance

are warranted in the temperature range of 0 to 40°C with a resistive load.

Supplemental

performance determined either by design or testing. Chapter 3 "Calibration

Procedures" contains procedures for verifying the performance specifications.

All specifications apply to the three outputs unless otherwise specified.

specifications are listed in the following pages. Specifications

characteristics, which are not warranted but are descriptions of

14

Page 16

Chapter 1 Specifications

Performance Specifications

Performance Specifications

Output Ratings (@ 0°C - 40°C)

+6V Output 0 to +6 V ; 0 to 5 A

+25V Output 0 to +25 V ; 0 to 1 A

-25V Output 0 to -25 V ; 0 to 1 A

[1]

Programming Accuracy

+6V Output

Voltage 0.1% + 5 mV 0.05% + 20 mV 0.05% + 20 mV

Current 0.2% + 10 mA 0.15% + 4 mA 0.15% + 4 mA

12 months (@ 25°C ± 5°C), ±(% of output + offset)

+25V Output -25V Output

1

Readback Accuracy

to actual output @ 25°C ± 5°C), ±(% of output + offset)

Voltage 0.1% + 5 mV 0.05% + 10 mV 0.05% + 10 mV

Current 0.2% + 10 mA 0.15% + 4 mA 0.15% + 4 mA

Ripple and Noise (with outputs ungrounded, or with either output terminal grounded,

20 Hz to 20 MHz)

Voltage <0.35 mV rms <0.35 mV rms <0.35 mV rms

Current <2 mA rms <500 mA rms <500 mA rms

Common mode current <1.5 mA rms

Load Regulation,

Change in output voltage or current for any load change within ratings

Voltage <0.01% + 2 mV

Current <0.01% + 250 mA

Line Regulation,

Change in output voltage and current for any line change within ratings

Voltage <0.01% + 2 mV

Current <0.01% + 250 mA

[1]

12 months (over GPIB and RS-232 or front panel with respect

+6V Output

+6V Output

<2 mV p-p <2 mV p-p <2 mV p-p

+25V Output -25V Output

+25V Output -25V Output

±(% of output + offset)

±(% of output + offset)

[1]

Accuracy specifications are after an 1-hour warm-up and calibration at 25°C

15

Page 17

Chapter 1 Specifications

Performance Specifications

Programming Resolution

+6V Output

Voltage 0.5 mV 1.5 mV 1.5 mV

Current 0.5 mA 0.1 mA 0.1 mA

Readback Resolution

+6V Output

Voltage 0.5 mV 1.5 mV 1.5 mV

Current 0.5 mA 0.1 mA 0.1 mA

Meter Resolution

+6V Output

Voltage 1 mV 10 mV 10 mV

Current 1 mA 1 mA 1 mA

Transient Response Time

Less than 50 msec for output recover to within 15 mV following a change in output

current from full load to half load or vice versa

+25V Output -25V Output

+25V Output -25V Output

+25V Output -25V Output

Command Processing Time

Programming Commands : Maximum time for output to change after receipt of APPLy

and SOURce commands : <50 msec

Readback Command : Maximum time to readback output by MEASure? command :

<100 msec

The Other Commands : < 50 msec

Tracking Accuracy

±25V outputs track each other within ± (0.2% of output + 20 mV).

The

16

Page 18

Chapter 1

Specifications

Supplemental Characteristics

Supplemental Characteristics

Output Programming Range (maximum programmable values)

+6V Output +25V Output -25V Output

Voltage 0 to 6.18 V 0 to 25.75 V 0 to -25.75 V

Current 0 to 5.15 A 0 to 1.03 A 0 to 1.03 A

Temperature Coefficient, ±(% of output + offset)

Maximum change in output/readback per °C after a 30-minute warm-up

+6V Output +25V Output -25V Output

Voltage 0.01% + 2 mV 0.01% + 3 mV 0.01% + 3 mV

Current 0.02% + 3 mA 0.02% + 0.5 mA 0.02% + 0.5 mA

Stability, ±(% of output + offset)

Following a 30-minute warm-up, change in output over 8 hours under constant load,

line, and ambient temperature

+6V Output +25V Output -25V Output

Voltage 0.03% + 1 mV 0.02% + 2 mV 0.02% + 2 mV

Current 0.1% + 3 mA 0.05% + 1 mA 0.05% + 1 mA

1

Voltage Programming Speed

Maximum time required for output voltage to settle within 1% of its total excursion (for

resistive load). Excludes command processing time.

+6V Output +25V Output -25V Output

Full load Up 11 msec 50 msec 50 msec

Full load Down 13 msec 45 msec 45 msec

No load Up 10 msec 20 msec 20 msec

No load Down 200 msec 400 msec 400 msec

Isolation

The 0-6V supply is isolated from the ±25V supply up to ±240 Vdc. Maximum isolation

voltage from any terminal to chassis ground ±240 Vdc.

AC Input Ratings (selectable via rear panel selector)

std 115 Vac ± 10%, 47 to 63 Hz

opt 0E3 230 Vac ± 10%, 47 to 63 Hz

opt 0E9 100 Vac ± 10%, 47 to 63 Hz

Maximum Input Power

350 VA with full load

17

Page 19

Chapter 1 Specifications

Supplemental Characteristics

Cooling

Fan cooled

Operating Temperature

0 to 40°C for full rated output. At higher temperatures, the output current is derated

linearly to 50% at 55°C maximum temperature.

Output Voltage Overshoot

During turn-on or turn-off of ac power, output plus overshoot will not exceed 1 V if the

output control is set to less than 1 V. If the output control is set to 1 V or higher, there

is no overshoot.

Programming Language

SCPI (Standard Commands for Programmable Instruments)

State Storage Memory

Three (3) user-configurable stored states

Recommended Calibration Interval

1 year

Dimensions

212.6 mmW x 132.6 mmH x 348.2 mmD (8.4 x 5.2 x 13.7 in)

*See the next page for detailed information.

Weight

Net 8.2 kg (18 lb)

Shipping 11 kg (24 lb)

*

18

Page 20

Chapter 1 Specifications

Supplemental Characteristics

1

Figure 1-1. Dimensions of Agilent E3631A Power Supply

19

Page 21

Chapter 1 Specifications

Supplemental Characteristics

20

Page 22

2

2

Quick Start

Page 23

Quick Start

One of the first things you will want to do with your power supply is to become

acquainted with its front panel. Written procedures in this chapter prepare the

power supply for use and familiarize you with most front-panel operations.

• The power supply is shipped from the factory configured in the front-panel

operation mode. At power-on, the power supply is automatically set to

operate in the front-panel operation mode. When in this mode, the frontpanel keys can be used. When the power supply is in remote operation mode,

you can return to front-panel operation mode at any time by pressing the

Local

key if you did not previously send the front-panel lockout command.

A change between front-panel and remote operation modes will not result

in a change in the output parameters.

• When you press the key (the Lmt annunciator blinks), the

display of the power supply goes to the limit mode and the present limit

values of the selected supply will be displayed. In this mode, you can also

observe the change of the limit values when adjusting the knob. If you press

Display Limit

the key again or let the display time-out after several

seconds, the power supply will return the display to the meter mode (the

Lmt annunciator turns off). In this mode, the actual output voltage and

current will be displayed.

• All outputs of the power supply can be enabled or disabled from the front

panel using the key. When the output of the power supply

is off, the OFF annunciator turns on and the three outputs are disabled.

• The display provides the present operating status of the power supply with

annunciators and also informs the user of error codes. For example, the +6V

supply is operating in CV mode and controlled from the front panel, then

the CV and +6V annunciators will turn on. If, however, the power supply is

remotely controlled, the Rmt annunciator will also turn on, and when the

power supply is being addressed over GPIB interface, the Adrs annunciator

will turn on. see

Display Limit

Output On/Off

"Display Annunciators"

on page 5 for more information.

Throughout this chapter the key to be pressed is shown in the left margin.

22

Page 24

Power

Output On/Off

Chapter 2 Quick Start

To prepare the power supply for use

To prepare the power supply for use

The following steps help you verify that the power supply is ready for use.

1 Check the list of supplied items.

Verify that you have received the following items with your power supply. If

anything is missing, contact your nearest Agilent Technologies Sales Office.

One appropriate power cord for your location.

One User's Guide.

This Service Guide.

Certificate of Calibration.

2 Verify that the correct power-line voltage setting is selected and that

the correct power-line fuse is installed.

The line voltage is set to 100, 115 or 230 Vac from the factory according to the

input power option selected when you ordered the power supply. Change the

voltage setting if it is not correct for your location (see the next page for

detailed information). For 100 or 115 Vac operation, the correct fuse is 2.5 AT

(Agilent part number 2110-0913) and for 230 Vac operation, the correct fuse is

2 AT (Agilent part number 2110-0587).

3 Connect the power cord and turn on the power supply.

A power-on self-test occurs automatically when you turn on the power supply.

The front-panel display will light up while the power supply performs its

power-on self- test. After performing the self-test, the power supply will go into

the power-on / reset state; a ll outp u ts are d i sabled (the OFF annunciator turns

on); the display is selected for the +6V supply (the +6V annunciator turns on);

the knob is selected for voltage control.

4 Enable the outputs

Press the key to enable the outputs. The OFF annunciator

turns off and the +6V and CV annunciators are lit. The blinking digit can be

adjusted by turning the knob. Notice that the display is in the meter mode.

"Meter mode" means that the display shows the actual output voltage and

current.

Output On/Off

2

23

Page 25

Chapter 2 Quick Start

To prepare the power supply for use

1 Remove the power cord.

Remove the fuse-holder assembly

with a flat-blade screwdriver from

the rear panel.

3 Rotate the power-line voltage

selector until the correct voltage

appears.

2 Install the corect line fuse.

Remove the power-line voltage

selector from the power-line

100 or 115 Vac, 2.5 AT fuse

230 Vac, 2 AT fuse

4 Replace the power-line voltage

selector and the fuse-holder

assembly in the rear panel.

100, 115 or 230 Vac

Install the correct fuse and verify that the correct line voltage appears in the

window.

24

Page 26

Power

Output On/Off

Chapter 2 Quick Start

To check the rated voltages of the power supply

To check the rated voltages of the power supply

The following procedures check to ensure that the power supply develops its

rated voltage outputs with no load and properly responds to operation from

the front panel.

For each step, use the keys shown on the left margins.

1 Turn on the power supply.

The power supply will go into the power-on / reset state; all outputs are disabled

(the OFF annunciator turns on); the display is selected for the +6V supply (the

+6V annunciator turns on); and the knob is selected for voltage control.

2 Enable the outputs.

The OFF annunciator turns off and the +6V and CV annunciators are lit. The

blinking digit can be adjusted by turning the knob. Notice that the display is

in the meter mode. "Meter mode" means that the display shows the actual

output voltage and current.

3 Check that the front-panel voltmeter properly responds to knob

control for +6V supply.

Turn the knob clockwise or counter clockwise to check that the voltmeter

responds to knob control and the ammeter indicates nearly zero.

4 Ensure that the voltage can be adjusted from zero to the maximum

rated value.

Adjust the knob until the voltmeter indicates 0 volts and then adjust the knob

until the voltmeter indicates 6.0 volts.

1

2

1

You can use the resolution selection keys to move the blinking digit to the right or

left when setting the voltage.

25

Page 27

Chapter 2 Quick Start

To check the rated voltages of the power supply

+25V

-25V

5 Check the voltage function for the +25V supply.

Select the meter and adjust selection key for the +25V supply. The CV

annunciator is still lit and the +25V annunciator will turn on. Repeat steps (3)

and (4) to check the voltage function for the +25V supply.

6 Check the voltage function for the -25V supply.

Select the meter and adjust selection key for the -25V supply. The CV

annunciator is still lit and the -25V annunciator will turn on. Repeat steps (3)

and (4) to check the voltage function for the -25V supply.

26

Page 28

Power

Output On/Off

Display Limit

Vol/Cur

Chapter 2 Quick Start

To check the rated currents of the power supply

To check the rated currents of the power supply

The following procedures check to ensure that the power supply develops its

rated current outputs with a short and properly responds to operation from

the front panel.

For each step, use the keys shown on the left margin.

1 Turn on the power supply.

The power supply will go into the power-on / reset state; all outputs are disabled

(the OFF annunciator turns on); the display is selected for the +6V supply (the

+6V annunciator turns on); and the knob is selected for voltage control.

2 Connect a short across (+) and (-) output terminals of +6V supply with

an insulated test lead.

3 Enable the outputs.

The OFF annunciator turns off and the +6V annunciator turns on. The CV or

CC ann un ci at or is li t d ep en din g o n t he re si st an ce of th e t es t l ea d. Th e blinking

digit can be adjusted by turning the knob. Notice that the display is in the meter

mode. "Meter mode" means that the display shows the actual output voltage

and current.

4 Adjust the voltage limit value to 1.0 volt.

Set the display to the limit mode (the Lmt annunciator will be blinking).

Adjust the voltage limit to 1.0 volt to assure CC operation. The CC annunciator

will light.

5 Check that the front-panel ammeter properly responds to knob control

for the +6V supply.

Set the knob to the current control, and turn the knob clockwise or counter

clockwise when the display is in the meter mode (the Lmt annunciator is off).

Check that the ammeter responds to knob control and the voltmeter indicates

nearly zero (actually, the voltmeter will show the voltage drop caused by the

test lead).

2

27

Page 29

Chapter 2 Quick Start

To check the rated currents of the power supply

+25V

-25V

Note

6 Ensure that the current can be adjusted from zero to the maximum

rated value.

1

Adjust the knob until the ammeter indicates 0 amps and then until the ammeter

indicates 5.0 amps.

7 Check the current function for the +25V supply.

Disable the outputs by pressing the key and connect a short

Output On/Off

across (+) and (COM) output terminals of the ±25V supply with an insulated

test lead. Repeat steps (3) through (6) after selecting the meter and adjust

selection key for the +25V supply.

8 Check the current function for the -25V supply.

Disable the outputs by pressing the key and connect a short

Output On/Off

across (-) and (COM) output terminals of the ±25V supply with an insulated

test lead. Repeat steps (3) through (6) after selecting the meter and adjust

selection key for the -25V supply.

If an error has been detected during the output checkout procedures, the

ERROR annunciator will turn on. See "Error Messages" for more

information, starting on page 113 in chapter 5 of the User's Guide.

1

You can use the resolution selection keys to move the blinking digit to the

right or left when setting the current.

28

Page 30

Power

Output On/Off

Display Limit

Chapter 2 Quick Start

To use the power supply in constant voltage mode

To use the power supply in constant voltage mode

To set up the power supply for constant voltage (CV) operation, proceed as

follows.

For each step, use the keys shown on the left margin.

1 Connect a load to the desired output terminals.

With power-off, connect a load to the desired output terminals.

2 Turn on the power supply.

The power supply will go into the power-on / reset state; all outputs are disabled

(the OFF annunciator turns on); the display is selected for the +6V supply (the

+6V annunciator turns on); and the knob is selected for voltage control.

3 Enable the outputs.

The OFF annunciator turns off and the +6V and CV annunciators are lit. The

blinking digit can be adjusted by turning the knob. Notice that the display is

in the meter mode. "Meter mode" means that the display shows the actual

output voltage and current.

To set up the power supply for +25V supply or -25V supply operation, you

should press the or key to select the display and adjust for +25V

supply or -25V supply before proceeding to the next step.

4 Set the display for the limit mode.

Notice that the Lmt annunciator blinks, indicating that the display is in the

limit mode. When the disp lay is in the limit mode, you can see the voltage and

current limit values of the selected supply.

+25V -25V

2

In constant voltage mode, the voltage values between meter mode and

limit mode are the same, but the current values are not. Further if the

display is in the meter mode, you cannot see the change of current limit

value when adjusting the knob. We recommend that you should set the

display to "limit" mode to see the change of current limit value in

constant voltage mode whenever adjusting the knob.

29

Page 31

Chapter 2 Quick Start

To use the power supply in constant voltage mode

Vol/Cur

Vol/Cur

Display Limit

Note

5 Adjust the knob for the desired current limit.

1

Check that the Lmt annunciator still blinks. Set the knob for current control.

The second digit of ammeter will be blinking. Adjust the knob to the desired

current limit.

6 Adjust the knob for the desired output voltage.

1

Set the knob for voltage control. The second digit of the voltmeter will be

blinking. Adjust the knob to the desired output voltage.

7 Return to the meter mode.

Display Limit

key or let the display time-out after several seconds to return

to the meter mode. Notice that the Lmt annunciator turns off and the display

returns to the meter mode. In the meter mode, the display shows the actual

output voltage and current of the selected supply.

8 Verify that the power supply is in the constant voltage mode.

If you operate the +6V supply in the constant voltage (CV) mode, verify that

CV and +6V annunciators are lit. If you operate the power supply for +25V

supply or -25V supply, the +25V or -25V annunciator will turn on. If the CC

annunciator is lit, choose a higher current limit.

During actual CV operation, if a load change causes the current limit to be

exceeded, the power supply will automatically crossover to constant current

mode at the preset current limit and the output voltage will drop

proportionately.

1

You can use the resolution selection keys to move the blinking digit to the right or

left when setting the voltage and current.

30

Page 32

Power

Output On/Off

Display Limit

Chapter 2 Quick Start

To use the power supply in constant current mode

To use the power supply in constant current mode

To set up the power supply for constant current (CC) operation, proceed as

follows.

For each step, use the keys shown on the left margin.

1 Connect a load to the output terminals of the desired supply.

With power-off, connect a load to the desired output terminals.

2 Turn on the power supply.

The power supply will go into the power-on / reset state; all outputs are disabled

(the OFF annunciator turns on); the display is selected for the +6V supply (the

+6V annunciator turns on); and the knob is selected for voltage control.

3 Enable the outputs

The OFF annunciator turns off and the +6V and CV annunciators are lit. The

blinking digit can be adjusted by turning the knob. Notice that the display is

in the meter mode. "Meter mode" means that the display shows the actual

output voltage and current.

To set up the power supply for +25V supply or -25V supply operation, you

should press the or key to select the display and adjust for +25V

supply or -25V supply before proceeding to the next step.

4 Set the display for the limit mode.

Notice that the Lmt annunciator blinks, indicating that the display is in the

limit mode. When the disp lay is in the limit mode, you can see the voltage and

current limit values of the selected supply.

+25V -25V

2

In constant current mode, the current values between meter mode and

limit mode are the same, but the voltage values are not. Further if the

display is in the meter mode, you cannot see the change of voltage limit

value when adjusting the knob. We recommend that you should set the

display to "limit" mode to see the change of voltage limit value in

constant current mode whenever adjusting the knob.

31

Page 33

Chapter 2 Quick Start

To use the power supply in constant current mode

Vol/Cur

Display Limit

Note

5 Adjust the knob for the desired voltage limit.

1

Check that the knob is still selected for voltage control and the Lmt

annunciator blinks. Adjust the knob for the desired voltage limit.

6 Adjust the knob for the desired output current.

1

Set the knob for current control. The second digit of the ammeter will be

blinking. Adjust the knob to the desired current output.

7 Return to the meter mode.

Press the key or let the display time-out after several seconds

Display Limit

to return the meter mode. Notice that the Lmt annunciator turns off and the

display returns to the meter mode. In the meter mode, the display shows the

actual output voltage and current of the selected supply.

8 Verify that the power supply is in the constant current mode.

If you operate the +6V supply in the constant current (CC) mode, verify that

CC and +6V annunciators are lit. If you operate the power supply for +25V

supply or -25V supply, the +25V or -25V annunciator will turn on. If the CV

annunciator is lit, choose a higher voltage limit.

During actual CC operation, if a load change causes the voltage limit to be

exceeded, the power supply will automatically crossover to constant voltage

mode at the preset voltage limit and the output current will drop

proportionately.

1

You can use the resolution selection keys to move the blinking digit to the right or

left when setting the voltage and current.

32

Page 34

Track

Chapter 2 Quick Start

To use the power supply in track mode

To use the power supply in track mode

The ±25V supplies provide 0 to ±25 V tracking outputs. In the track mode, two

voltages of the ±25V supplies track each other to within ±(0.2% of output + 20

mV) for convenience in varying the symmetrical voltages needed by

operational amplifiers and other circuits using balanced positive and negative

inputs.

To operate the power supply in the track mode, proceed as follows:

1 Set the +25V supply to the desired voltage as described in previous

section "To use the power supply in constant voltage mode" (see page

29 for detailed information).

2 Enable the track mode.

Track

The key must be depressed for at least 1 second to enable the track

mode. When the track mode is first enabled, the -25V supply will be set to the

same voltage level as the +25V supply. Once enabled, any change of the voltage

level in either the +25V supply or the -25V supply will be reflected in other

supply. The current limit is independently set for each of the +25V or the -25V

supply and is not affected by the track mode.

3 Verify that ±25V supplies track each other properly.

You can verify that the voltage of the -25V supply tracks that of the +25V supply

within ±(0.2% of output + 20 mV) from the front-panel display by comparing

the voltage values of the +25V supply and the -25V supply.

2

In the track mode, if the CC annunciator is lit when the display is

selected for the +25V supply, choose a higher current limit for the +25V

supply. If the CC annunciator is lit when the display is selected for the

-25V supply, choose a higher current limit for the -25V supply.

33

Page 35

Store

Chapter 2 Quick Start

To store and recall the instrument state

To store and recall the instrument state

You can store up to three different operating states in non-volatile memory.

This also enables you to recall the entire instrument state with just a few key

presses from the front panel.

The memory locations are supplied from the factory for front panel operation

with the following states: display and knob selection for +6V output; *RST

values of voltage and current limits for three outputs; output disabled; and

track off state. *RST values for +6V supply are 0 V and 5 A and 0 V and 1 A

for the ±25V supplies.

The following steps show you how to store and recall an operating state.

1 Set up the power supply for the desired operating state.

The storage feature "remembers" the display and knob selection state, the limit

values of voltage and current for three outputs, output on/off state, and track

mode state.

2 Turn on the storage mode.

Three memory locations (numbered 1, 2, and 3) are available to store the

operating states. The operating states are stored in non-volatile memory and

are remembered when being recalled.

Store 1

This message appears on the display for approximately 3 seconds.

3 Store the operating state in memory location "3".

Turn the knob to the right to specify the memory location 3.

Store 3

To cancel the store operation, let the display time-out after 3 seconds or press

any other function key except the key. The power supply returns to

the normal operating mode and to the function pressed.

34

Store

Page 36

Chapter 2 Quick Start

To store and recall the instrument state

Store

Recall

Recall

4 Save the operating state.

The operating state is now stored. To recall the stored state, go to the following

steps.

done

This message appears on the display for approximately 1 second.

5 Turn on the recall mode.

Memory location "1" will be displayed in the recall mode.

recall 1

This message appears on the display for approximately 3 seconds.

6 Recall the stored operating state.

Turn the knob to the right to change the displayed storage location to "3".

recall 3

If this setting is not followed within 3 seconds with a key stroke, the

power supply returns to normal operating mode and will not recall the

instrument state 3 from memory.

7 Restore the operating state.

The power supply should now be configured in the same state as when you

stored the state on the previous steps.

Recall

2

done

This message appears on the display for approximately 1 second.

35

Page 37

Chapter 2

Quick Start

To rack mount the power supply

To rack mount the power supply

The power supply can be mounted in a standard 19-inch rack cabinet using one

of three optional kits available. A rack-mounting kit for a single instrument is

available as Option 1CM (P/N 5062-3957). Installation instructions and

hardware are included with each rack-mounting kit. Any Agilent Technologies

System II instrument of the same size can be rack-mounted beside the Agilent

E3631A power supply. To rack mount the power supply, follow these

procedures.

Remove the front and rear bumpers before rack-mounting the power supply.

Front

To remove the rubber bumper, stretch a corner and then slide it off.

To rack mount a single instrument, order adapter kit 5063-9243.

36

Rear (bottom view)

Page 38

Chapter 2

Quick Start

To rack mount the power supply

To rack mount two instruments of the same depth side-by-side, order lock-link

kit 5061-9694 and flange kit 5063-9214.

2

To install two instruments in a sliding support shelf, order suport shelf 50639256, and slide kit 1494-0015.

37

Page 39

Chapter 2 Quick Start

To rack mount the power supply

38

Page 40

3

Calibration Procedures

Page 41

Calibration Procedures

This chapter contains procedures for verification of the power supply's

performance and calibration (adjustment). The chapter is divided into the

following sections:

• Agilent Technologies Calibration Services, page 41

• Calibration Interval, page 41

• Automating Calibration Procedures, page 42

• Recommended Test Equipment, page 42

• Test Considerations, page 43

• Performance Verification Tests, page 44

• Measurement Techniques, page 45

• Constant Voltage (CV) Verifications, page 47

• Constant Current (CC) Verifications, page 54

• Performance Test Record for Agilent E3631A, page 59

• Calibration Security Code, page 61

• Calibration Count, page 65

• Calibration Message, page 65

• General Calibration/Adjustment Procedure, page 66

• Aborting a Calibration in Progress, page 71

• Calibration Record for Agilent E3631A, page 72

• Error Messages, page 73

• Calibration Program, page 75

The performance verification tests for constant voltage (CV) and constant

current (CC) operations use the power supply's specifications listed in chapter

1, Specifications, starting on page 13.

40

Page 42

Chapter 3 Calibration Procedures

Agilent Technologies Calibration Services

Closed-Case Electronic Calibration The power supply features closedcase electronic calibration since no internal mechanical adjustments are

required for normal calibration. The power supply calculates correction

factors based upon the input reference value you enter. The new correction

factors are stored in non-volatile memory until the next calibration adjustment

is performed. (Non-volatile memory does not change when power has been off

or after a remote interface reset.)

Agilent Technologies Calibration Services

When your power supply is due for calibration, contact your local Agilent

Technologies Service Center for a low-cost calibration. The Agilent E3631A

power supply is supported on calibration processes which allow Agilent

Technologies to provide this service at competitive prices.

Calibration Interval

The power supply should be calibrated on a regular interval determined by the

accuracy requirements of your application. A 1-year interval is adequate for

most applications. Agilent Technologies does not recommend extending

calibration intervals beyond 1 year for any application. Agilent Technologies

recommends that complete re-adjustment should always be performed at the

calibration interval. This will increase your confidence that the Agilent E3631A

will remain within specification for the next calibration interval. This criteria

for re-adjustment provides the best long-term stability.

3

41

Page 43

Chapter 3

Calibration Procedures

Automating Calibration Procedures

Automating Calibration Procedures

You can automate the complete verification procedures outlined in this chapter

if you have access to programmable test equipment. You can program the

instrument configurations specified for each test over the remote interface.

You can then enter readback verification data into a test program and compare

the results to the appropriate test limit values.

You can also enter calibration constants from the remote interface. Remote

operation is similar to the local front-panel procedure. You can use a computer

to perform the adjustment by first selecting the required setup. The calibration

value is sent to the power supply and then the calibration is initiated over the

remote interface. The power supply must be unsecured prior to initiating the

calibration procedure. An Agilent BASIC program for calibration over the GPIB

interface is listed at the end of this chapter.

For further details on programming the power supply, see chapters 3 and 4 in

the Agilent E3631A User's Guide.

Recommended Test Equipment

The test equipment recommended for the performance verification and

adjustment procedures is listed below. If the exact instrument is not available,

use the accuracy requirements shown to select substitute calibration

standards.

Table 3-1 Recommended Test Equipment

Instrument Requirements

GPIB Controller Full GPIB capabilities

Oscilloscope 100 MHz Agilent 54602A

RMS Voltmeter 20 MHz Measure rms ripple & noise

Digital Voltmeter

Electronic Load

Resistive Loads (RL)

Current monitoring

Resistor (Shunt)

Resolution: 0.1 mV

Accuracy: 0.01%

Voltage Range: 50 Vdc

Current Range: 10 Adc

Open and Short Switches

Transient On/Off

1.2Ω, 100 W

25Ω, 100 W

0.1Ω, 0.01% Constant current test setup

Recommended

Model

Agilent 82341C

interface card

Agilent 34401A Measure dc voltages

Agilent 6063A

Programming and

readback accuracy

Display transient response

and ripple & noise

waveform

Measure load and line

regulations and transient

response time.

Measure ripple and noise

Use

42

Page 44

Chapter 3 Calibration Procedures

Test Considerations

Test Considerations

To ensure proper instrument operation, verify that you have selected the

correct power-line voltage prior to attempting any test procedure in this

chapter. See page 24 in chapter 2 for more information.

• Assure that the calibration ambient temperature is stable and between 20°C

and 30°C.

• Assure ambient relative humidity is less than 80%.

• Allow a 1-hour warm-up period before verification or calibration.

• Keep cables as short as possible, consistent with the impedance

requirements.

Caution The tests should be performed by qualified personnel. During performance

verification tests, hazardous voltages may be present at the outputs of the power

supply.

3

43

Page 45

Chapter 3 Calibration Procedures

Performance Verification Tests

Performance Verification Tests

The performance verification tests use the power supply's specifications listed

in chapter 1, "Specifications", starting on page 13.

You can perform two different levels of performance verification tests:

• Self-Test A series of internal verification tests that provide high

confidence that the power supply is operational.

• Performance Verification Tests These tests can be used to verify the

power supply's specifications following repairs to specific circuits. The

performance test procedures must be performed on each output.

Self-Test

A powe r-on self-test occurs automatically when you turn on the power supply.

This limited test assures you that the power supply is operational.

The complete self-test is enabled by pressing the key (actually any

front panel keys except the key) and the power-line switch

simultaneously and then continuing to press the key for 5 seconds.

The complete self-test will be finished in 2 more seconds.

You can also perform a self-test from the remote interface (see chapter 3 in

the Agilent E3631A User's Guide).

• If the self-test is successful, "PASS" is displayed on the front panel.

• If the self-test fails, "FAIL" is displayed and the ERROR annunciator turns

on. If repair is required, see chapter 5, "Service", starting on page 91, for

further details.

• If self-test passes, you have a high confidence that the power supply is

operational.

Error

Recall

Recall

Performance Verification Tests

These tests can be used to verify the power supply's specifications following

repairs to specific circuits. The following sections explain all verification

procedures in detail. All of the performance test specifications are shown in

each test.

44

Page 46

Chapter 3

Calibration Procedures

Measurement Techniques

Measurement Techniques

Setup for Most Tests

Most tests are performed at the front terminals as shown in the following figure.

Measure the dc voltage directly at the (+) and (-) terminals on the front panel.

3

Figure 3-1. Performance Verification Test Setup

Electronic Load

Many of the test procedures require the use of a variable load resistor capable

of dissipating the required power. Using a variable load resistor requires that

switches be used to connect, disconnect, and short the load resistor. An

electronic load, if available, can be used in place of a variable load resistor and

switches. The electronic load is considerably easier to use than load resistors.

It eliminates the need for connecting resistors or rheostats in parallel to handle

power, it is much more stable than carbon-pile load, and it makes easy work

of switching between load conditions as is required for the load regulation and

load transient response tests. Substitution of the electronic load requires minor

changes to the test procedures in this chapter.

General Measurement Techniques

To achieve best results when measuring load regulation, peak to peak voltage,

and transient response time of the power supply, measuring devices must be

connected through the hole in the neck of the binding post at (A) while the

45

Page 47

Chapter 3

Calibration Procedures

Measurement Techniques

load resistor is plugged into the front of the output terminals at (B). A

measurement made across the load includes the impedance of the leads to the

load. The impedance of the load leads can easily be several orders of the

magnitude greater than the power supply impedance and thus invalidate the

measurement. To avoid mutual coupling effects, each measuring device must

be connected directly to the output terminals by separate pairs of leads.

Front Panel Terminal Connections (Side View)

Current-Monitoring Resistor

To eliminate output current measurement error caused by the voltage drops

in the leads and connections, connect the current monitoring resistor between

the (-) output terminal and the load as a four-terminal device. Connect the

current-monitoring leads inside the load-lead connections directly at the

monitoring points on the resistor element (see RM in Figure 3-1).

Programming

Most performance tests can be performed only from the front panel. However,

a GPIB or RS-232 controller is required to perform the voltage and current

programming accuracy and readback accuracy tests.

The test procedures are written assuming that you know how to program the

power supply either from the front panel or from an GPIB or RS-232 controller.

Complete instructions on front panel and remote programming are given in the

Agilent E3631A User's Guide.

Voltage and Current Values

The full-scale and maximum values of each supply are listed below. You can

use this table when you test CV and CC performance verification tests.

Table 3-2 Power Supply Voltage and Current Values

Output

+6V Output +6 V +6.18 V 5 A 5.15 A

+25V Output +25 V +25.75 1 A 1.03 A

-25V Output -25 V -25.75 1 A 1.03 A

Full-Scale

Voltage

46

Max. Prog.

Voltage

Full-Scale

Current

Max. Prog.

Current

Page 48

Chapter 3 Calibration Procedures

Constant Voltage (CV) Verifications

Constant Voltage (CV) Verifications

Constant Voltage Test Setup

If more than one meter or a meter and an oscilloscope are used, connect each

to the (+) and (- ) terminals b y a sepa rate pai r of leads to a void mutua l coupling

effects. Use coaxial cable or shielded 2-wire cable to avoid noise pick-up on

the test leads.

Voltage Programming and Readback Accuracy

This test verifies that the voltage programming and GPIB or RS-232 readback

functions are within specifications. Note that the readback values over the

remote interface should be identical to those displayed on the front panel.

You should program the power supply over the remote interface for this test

to avoid round off errors.

Turn off the power supply and connect a digital voltmeter between the (+) and

1

(-) terminals of the output to be tested as shown in Figure 3-1.

Turn on the power supply. Enable the outputs and select the desired output to

2

be tested by sending the commands:

OUTP ON

INST {P6V|P25V|N25V}

Program the selected output to zero volts and maximum programmable

3

current (see Table 3-2) by sending the commands:

VOLT 0

CURR 5.15

CURR 1.03

Record the output voltage reading on the digital voltmeter (DVM). The readings

4

should be within the limits specified below for each output tested. Also, note

that the CV, Adrs, Lmt, and Rmt annunciators are on.

Output Programming Accuracy

+6V 0 ± 5 mV

+25V 0

-25V 0

± 20 mV

± 20 mV

for the +6V supply or

for the ±25V supply

3

47

Page 49

Chapter 3 Calibration Procedures

Constant Voltage (CV) Verifications

Readback the output voltage of the selected output over the remote interface

5

by sending the command:

MEAS:VOLT? {P6V|P25V|N25V}

Record the value displayed on the controller. This value should be within the

6

limits specified below for each output tested.

Output Programming Accuracy

+6V DVM ± 5 mV

+25V DVM

-25V -(DVM

Program the selected output's voltage to full scale value by sending the

7

± 10 mV

± 10 mV)

commands.

VOLT 6.0

VOLT 25.0

Record the output voltage reading on the digital voltmeter (DVM). The readings

8

for the +6V supply or

for the ± 25V supply

should be within the limits specified below for each output tested.

Output Programming Accuracy

+6V 6 V ± 11 mV

+25V 25 V

-25V -(25 V

Readback the output voltage of the selected output over the remote interface

9

± 32.5 mV

± 32.5 mV)

by sending the command:

MEAS:VOLT? {P6V|P25V|N25V}

Record the value displayed on the controller. This value should be within the

10

limits specified below for the output to be tested.

Output Programming Accuracy

+6V DVM ± 11 mV

+25V DVM

-25V -(DVM

Repeat steps (1) through (10) for the remaining outputs.

11

± 22.5 mV

± 22.5 mV)

48

Page 50

Chapter 3 Calibration Procedures

Constant Voltage (CV) Verifications

CV Load Regulation

This test measures the change in the output voltage resulting from a change in

the output current from full to no load.

Turn off the power supply and connect a digital voltmeter between the (+) and

1

(-) terminals of the output to be tested as shown in Figure 3-1.

Turn on the power supply and select the desired output to be tested using the

2

meter and adjust selection key on the front panel. Enable the outputs and set

the display to the limit mode. When the display is in the limit mode, program

the current of the selected output to the maximum programmable value and

the voltage to the full-scale value (see Table 3-2).

Operate the electronic load in constant current mode and set its current to the

3

full scale value of the output to be tested (see Table 3-2). Check that the front

panel CV annunciator remains lit. If not lit, adjust the load so that the output

current drops slightly until the CV annunciator lights. Record the output

voltage reading on the digital voltmeter.

Operate the electronic load in open mode (input off). Record the output voltage

4

reading on the digital voltmeter again. The difference between the digital

voltmeter readings in steps (3) and (4) is the CV load regulation. The difference

of the readings should be within the limit specified below for each output

tested.

3

Output Programming Accuracy

+6V 2.6 mV

+25V 4.5 mV

-25V 4.5 mV

Repeat steps (1) through (4) for the remaining outputs.

5

49

Page 51

Chapter 3 Calibration Procedures

Constant Voltage (CV) Verifications

CV Line Regulation

This test measures the change in output voltage that results from a change in

ac line voltage from the minimum value (10% below the nominal input voltage)

to maximum value (10% above the nominal input voltage).

Turn off the power supply and connect a digital voltmeter between the (+) and

1

(-) terminals of the output to be tested as shown in Figure 3-1.

Connect the ac power line through a variable voltage transformer.

2

Turn on the power supply and select the desired output to be tested using the

3

meter and adjust selection key on the front panel. Enable the outputs and set

the display to the limit mode. When the display is in the limit mode, program

the current of the selected output to the maximum programmable value and

the voltage to full-scale value (see Table 3-2).

Operate the electronic load in constant current mode and set its current to the

4

full scale value (see Table 3-2) of the output to be tested. Check that the front

panel CV annunciator remains lit. If not lit, adjust the load so that the output

current drops slightly until the CV annunciator lights.

Adjust the transformer to low line voltage limit (104 Vac for nominal 115 Vac,

5

90 Va c f or no mi nal 10 0 V ac , o r 20 7 V ac fo r n omin al 23 0 Vac ). Re co rd th e o ut pu t

reading on the digital voltmeter.

Adjust the autotranformer to high line voltage (127 Vac for nominal 115 Vac,

6

110 Vac for nominal 100 Vac, or 253 Vac for nominal 230 Vac). Record the

voltage reading on the digital voltmeter. The difference between the digital

voltmeter readings in steps (5) and (6) is the CV line regulation. The difference

of the readings should be within the limit specified below for each output

tested.

Output Difference

+6V 2.6 mV

+25V 4.5 mV

-25V 4.5 mV

Repeat steps (1) through (6) for the remaining outputs.

7

50

Page 52

Chapter 3 Calibration Procedures

Constant Voltage (CV) Verifications

Normal Mode Voltage Noise (CV Ripple and Noise)

The normal mode voltage noise is in the form of ripple related to the line

frequency plus some random noise. The normal mode voltage noise is specified

as the rms or peak-to-peak output voltage in a frequency range from 20 Hz to

20 MHz.

Turn off the power supply and connect the output to be tested as shown in Figure

1

3-1 to an oscilloscope (ac coupled) between (+) and (-) terminals. Set the

oscilloscope to AC mode and bandwidth limit to 20 MHz. Connect a resistive

load (1.2 for +6V supply and 25 for ±25V supplies) as shown in Figure 3-1 (see

Table 3-2).

Turn on the power supply and select the output to be tested using the meter

2

and adjust selection key on the front panel. Enable the outputs and set the

display to the limit mode. When the display is in the limit mode, program the

current of the selected output to the maximum programmable value and the

voltage to the full-scale value (see Table 3-2).

Check that the front panel CV annunciator remains lit. If not lit, adjust the load

3

down slightly.

3

Note that the waveform on the oscilloscope does not exceed the peak-to-peak

4

limit of 2 mV for each of the three outputs.

Disconnect the oscilloscope and connect an AC rms voltmeter in its place. The

5

rms voltage reading does not exceed the rms limit of 0.35 mV for each of the

three outputs.

Repeat steps (1) through (5) for the remaining outputs.

6

51

Page 53

Chapter 3 Calibration Procedures

Constant Voltage (CV) Verifications

Common Mode Current Noise

The common mode current is that ac current component which exists between

any or all outputs or output lines and chassis ground. Common mode noise can

be a problem for very sensitive circuitry that is referenced to earth ground.

When a circuit is re ference d to earth grou nd, a low level lin e-relate d ac curr ent

will flow from the output terminals to earth ground. Any impedance to earth

ground will create a voltage drop equal to the output current flow multiplied

by the impedance.

Turn off the power supply and connect a 100 k resistor (R

1

) and a 2200 pF

S

capacitor in parallel between the (-) terminal and chassis ground for +6V output

or between the (COM) terminal and chassis ground for ±25V outputs.

Connect a digital voltmeter across R

2

Turn on the power supply and select the output to be tested using the meter

3

.

S

and adjust selection key on the front panel. Enable the outputs and set the

display to the limit mode. When the display is in the limit mode, program the

current of the selected output to the maximum programmable value and the

voltage to the full-scale value (see Table 3-2).

Record the voltage across R

4

and convert it to current by dividing by the

S

resistance (DVM reading/100 k). Note that the current is less than 1.5 A for

each of the three outputs.

Repeat steps (1) through (4) for the remaining outputs.

5

52

Page 54

Chapter 3 Calibration Procedures

Constant Voltage (CV) Verifications

Load Transient Response Time

This test measures the time for the output voltage to recover to within 15 mV

of nominal output voltage following a load change from full load to half load,

or half load to full load.

Turn off the power supply and connect the output to be tested as shown in Figure

1

3-1 with an oscilloscope. Operate the electronic load in constant current mode.

Turn on the power supply and select the output to be tested using the meter

2

and adjust selection key on the front panel. Enable the outputs and set the

display to the limit mode. When the display is in the limit mode, program the

current to the maximum programmable value and the voltage to the full-scale

value (see Table 3-2).

Set the electronic load to transient operation mode between one half of the

3

output's full scale value and the output's full scale value at a 1 kHz rate with

50% duty cycle.

Set the the oscilloscope for ac coupling, internal sync, and lock on either the

4

positive or negative load transient.

3

Adjust the the oscilloscope to display transients as shown in Figure 3-2. Note

5

that the pulse width (t

more than 50 msec for each of the three outputs.

Repeat steps (1) through (5) for the remaining outputs.

6

) of the transients at 15 mV from the base line is no

2-t1

Figure 3-2. Transient Response Time

53

Page 55

Chapter 3 Calibration Procedures

Constant Current (CC) Verifications

Constant Current (CC) Verifications

Constant Current Test Setup

Follow the general setup instructions in the "Measurement Techniques" section

starting on page 45 and the specific instructions will be given in the following

paragraphs.

Current Programming and Readback Accuracy

This test verifies that the current programming and GPIB or RS-232 readback

functions are within specifications. Note that the readback values over the

remote interface should be identical to those displayed on the front panel. The

accuracy of the current monitoring resistor must be 0.1% or better.

You should program the power supply over the remote interface for this test

to avoid round off errors.

Turn off the power supply and connect a 0.1

1

9 current monitoring resistor (R

across the output to be tested and a digital voltmeter across the current

monitoring resistor (R

Turn on the power supply. Enable the outputs and select the desired output to

2

).

M

be tested by sending the commands:

OUTP ON

INST {P6V|P25V|N25V}

Program the selected output voltage to 5.0 volts and the current to 0 amps by

3

sending the commands:

VOLT 5

CURR 0

Divide the voltage drop (DVM reading) across the current monitoring resistor

4

) by its resistance to convert to amps and record this value (IO). This value

(R

M

should be within the limits specified below for each output tested. Also, note

that the CC, Adrs, Lmt, and Rmt annunciators are on.

Output Programming Accuracy

+6V 0 A ± 10 mA

+25V 0 A

-25V 0 A

± 4 mA

± 4 mA

)

M

54

Page 56

Chapter 3 Calibration Procedures

Constant Current (CC) Verifications

Readback the output current from the selected output over the remote

5

interface by sending the command:

MEAS:CURR? {P6V|P25V|N25V}

Record the value displayed on the controller. This value should be within the

6

limits specified below for each output tested.

Output Readback Accuracy

+6V I

+25V I

-25V I

Program the selected output current to the full scale value (see Table 3-2) by

7

± 10 mA

O

± 4 mA

O

± 4 mA

O

sending the commands:

3

CURR 5.0

CURR 1.0

Divide the voltage drop (DVM reading) across the current monitoring resistor

8

(R

) by its resistance to convert to amps and record this value (IO). This value

M

for the +6V supply or

for the ±25V supply

should be within the limits specified below for each output tested.

Output Programming Accuracy

+6V 5 A ± 20 mA

+25V 1 A

-25V 1 A

Readback the output current from the selected output over the remote

9

± 5.5 mA

± 5.5 mA

interface by sending the command:

MEAS:CURR? {P6V|P25V|N25V}

Record the value displayed on the controller. This value should be within the

10

limits specified below for each output tested.

Output Readback Accuracy

+6V I

+25V I

-25V I

Repeat steps (1) through (10) for the remaining outputs.

11

± 20 mA

O

± 5.5 mA

O

± 5.5 mA

O

55

Page 57

Chapter 3 Calibration Procedures

Constant Current (CC) Verifications

CC Load Regulation

Th is test m e asures th e change in ou tpu t curren t re sul tin g from a cha nge in th e

load from full-scale output voltage to short circuit.

Turn off the power supply and connect the output to tested as shown in Figure

1

3-1 with the digital voltmeter connected across the 0.1

resistor (R

Turn on the power supply and select the desired output to be tested using the

2

).

M

meter and adjust selection key on the front panel. Enable the outputs and set

the display to the limit mode. When the display is in the limit mode, program

the voltage to the maximum programmable value and the current to the fullscale value (see Table 3-2).

Opera te the el ectronic load in constant voltag e mode and set its voltage to the

3

full scale value of the output to be tested (see Table 3-2). Check that the CC

annunciator is on. If it is not, adjust the load so that the output voltage drops

slightly. Record the current reading by dividing the voltage reading on the

digital voltmeter by the resistance of the current monitoring resistor.

9 current monitoring

Operate the electronic load in short (input short) mode. Record the current

4

reading again by dividing the voltage reading on the digital voltmeter by the

resistance of the current monitoring resistor. The difference between the

current readings in step (3) and (4) is the load regulation current. The

difference of the readings should be within the limit specified below for each

output tested.

Output Difference

+6V 0.75 mA

+25V 0.35 mA

-25V 0.35 mA

Repeat steps (1) through (4) for the remaining outputs.

5

56

Page 58

Chapter 3 Calibration Procedures

Constant Current (CC) Verifications

CC Line Regulation

This test measures the change in output current that results from a change in

ac line voltage from the minimum value (10% below the nominal input voltage)

to the maximum value (10% above nominal voltage).

Turn off the power supply and connect the output to be tested as shown in Figure

1

3-1 with the digital voltmeter connected across the current monitoring resistor

).

(R

M

Connect the ac power line through a variable voltage transformer.

2

Turn on the power supply and select the desired output to be tested using the

3

meter selection key on the front panel. Enable the outputs and set the display

to the limit mode. When the display is in the limit mode, program the voltage

to the maximum programmable value and the current to the full-scale value

(see Table 3-2).

Opera te the el ectronic load in constant voltag e mode and set its voltage to the

4

full scale value of the output to be tested (see Table 3-2). Check that the CC

annunciator remains lit. If not lit, adjust the load so that the output voltage

drops slightly until the CC annunciator lights.

3

Adjust the transformer to low line voltage limit (104 Vac for nominal 115 Vac,

5

90 Va c f or no mi nal 10 0 V ac , o r 20 7 V ac fo r n omin al 23 0 Vac ). Re co rd th e o ut pu t

current reading by dividing the voltage reading on the digital voltmeter by the

resistance of the current monitoring resistor.

Adjust the transformer to 10% above the nominal line voltage (110 Vac for a

6

100 Vac nominal input, 127 Vac for a 115 Vac nominal input or 253 Vac for a

230 Vac nominal input). Record the current reading again by dividing the

voltage reading on the digital voltmeter by the resistance of the current

monitoring resistor. The difference between the current readings in step (5)

and (6) is the load regulation current. The difference of the readings should be