Page 1

Whnt HEWLETT

%L'tLM PACKARD

HP E361XA 30W BENCH SERIES DC POWER SUPPLIES

OPERATING AND SERVICE MANUAL FOR MODELS:

HP E3610A, Serials KR20600101 and above

HP E3611A, Serials KR20600101 and above

HP E3612A, Serials KR20600l01 and above

Table of Contents

SAFETY SUMMARY

GENERAL INFORMATION

Description

Specifications and Characteristics

Options

Instrument Identification

INSTAI i ATION

Inspection

Location and Cooling

Input Power Requirements

Power Cord

OPERATION

Turn-On Checkout Procedure

Constant Voltage Operation

Constant Current Operation

Connecting Loads

Operation Beyond Rated Output

Pulse Loading

Capacitive Loads

Reverse Current Loading

SERVICE INFORMATION

1-2

1-2

1-2

1-3

1-4

1-4

1-4

1-4

1-4

1-4

1-4

1-5

1-5

1-5

1-5

1-5

1-5

1-6

1-6

1-6

A-1

Manual Part No. B9B9-6304

Microfiche Part No. 5959-5307

Printed:

February, 1992

Page 2

SAFETY SUMMARY

The following general safety precautions must be observed

during all phases of operation, service, and repair of this

instrument. Failure to comply with these precautions or with

specific warnirtgs elsewhere in this manual violates safety

standards of design, manufactures, ar>d intended use of the

instrument. Hewlett-Packard Company assumes no liability

for the customer's failure to comply with these requirements.

Before Applying Power

Verify that the product is set to match the available line

voltage.

Ground The Instrument

This product is a Safety Class I instrument (provided with

a protective earth terminal). To minimize shock hazard, the

instrument chassis and cabinet must be connected to an

electrical ground. The instrument must be connected to the

ac power supply mains through a three-corrductor power

cable,

with the third wire firmly connected to an electrical

grourrd(safety ground) at the power outlet. Any interruption

of the protective(grounding) conductor or disconnection of

the protective earth terminal will cause a potential shock

hazard that could result in personal injury. If the instrument

is to be energized via an external autotransformer for

voltage reduction, be certain that the autotransformer

common terminal is connected to the neutraKearthed pole)

of the ac power lines (supply mains).

Do Not Operate in An Explosive Atmosphere

Do not operate the instrument in the presence of flammable

gases or fumes.

Keep Away From Live Circuits.

Operating personnel must not remove instrument covers.

Component replacement and internal adjustments must be

made by qualified service personnel.

Safety Symt>ols

A

IwARNIHcj

Instrument manual symbol; the

product will be marked with this

symbol when it is necessary for

the user to refer to the instruction

manual.

Indicate earth(grour>d) terminal.

The WARNING sign denotes a

hazard.

It calls attention to a proce-

dure,

practice, or the like, which, if

not correctly performed or adhered

to,

could result in personal injury.

Do not proceed beyond a WARNING sign until the indicated

conditions are fully understocxJ and

met.

The CAUTION sign denotes a hazard.

It calls attention to an operating

procedure, or the like, which, if not

correctly performed or adhered to,

could result in damage to or destruction of part or all of the product.

Do not proceed beyond CAUTION

sign until the indicated conditions

are fully understood and met.

GENERAL INFORMATION

Description

This operating and service manual covers three dual range

HP power supplies, E3610A, E3611A, and E3612A. All

models are compact, general purpose bench supplies that

are particulariy useful for powering developmental IC

circuits, both linear and digital. Unless stated otherwise, all

information in this manual applies equally to all three

models. The desired output range is selected by the front

panel RANGE push button. The output can be continuously

adjusted for voltage and current throughout either output

range.

The front panel VOLTAGE control can be used to establish

the voltage limit when the supply is used as a constant

current source arrd the CURRENT control can be used to

establish the output current limit when the supply is used as

a constant voltage source. The CC SET push button allows

the current limit value to be conveniently set using the

CURRENT control without shorting the output.

The front panel includes a digital voltmeter/ammeter.

A 3 1/2 digit (E3611A 3 digit) voltage display and 3 digit

current display accurately show the output voltage and

current respectively. The output ratings for each model are

shown in the Specifications Table.

1-2

Page 3

Specifications

and

Supplemental Characteristics

INPUT:

115 Vac ±

10%, 47-63 Hz,

0.8 A, 70 W

100

Vac ±

10%, 47-63 Hz,

0.8 A, 70 W

230

Vac

±10%, 47-63

Hz, 0.4 A, 70 W

OUTPUT: E3610A:

0 to 8 V, 0 to 3 A or 0 to 15 V,

0to2

A

E3611 A:

0 to 20 V, 0 to 1.5 A or 0 to 35 V,

0

to

0.85

A

E3612A:

0 to 60 V, 0 to 0.5 A or 0 to 120V,

to 0.25

A

LOAD REGULATION:

Constant Voltage - Less than 0.01 % plus

2 mV for a

full load

to rto

load change

in

output current.

Constant Current - Less than 0.01 % plus

1 mA for a

zero

to

maximum change

in

output voltage.

UNE REGULATION:

Constant Voltage - Less than 0.01 % plus

2 mV for any

line voltage change within

the

input rating.

Constant Current - Less than 0.01 % plus

1 mA for any

line voltage change within

the

input rating.

RIPPLE AND NOISE:

Constant Voltage - Less than

200 uV rms and 2 mV

peak

topeak(10Hz-10MHz)

Constant Current - Less than

200 uA rms and 1 mA

peak

topeak(10Hz-10MHz)

TEMPERATURE RANGE:

0 to

40°C

for

full rated output.

Derate current 1%

per

degree C between 40°C-55°C

'TEMPERATURE COEFFICIENT:.

Constant Voltage - Less than 0.02% plus

1 mV per

degree

C.

Constant Current - Less than 0.02% plus

2 mA per

degree

C.

TRANSIENT RESPONSE TIME:

Less than

50

usee

for

output recovery

to

within

10 mV

following a change

in

output current from full load

to

half

load,

or

vice versa.

ISOLATION:

± 240 Vdc

•OUTPUT DRIFT:

Constant Voltage - Loss than 0.1 % plus

5 mV

total drift

for 8 hours after

an

initial warm-up

of 30

minutes.

Constant Current - Less than

0.1%

plus

10 mA

total drift

for 8 hours after

an

initial warm-up

of 30

minutes.

METER ACCURACY: ±0.5%

-i- 2 counts

at

25°C

± S'C

'OVERLOAD PROTECTION:

A continuously acting constant current circuit protects

the

power supply

for all

overioads including a direct short

placed across

the

terminals.

The

constant voltage circuit

limits

the

output voltage

in

constant current operation.

•OUTPUT TERMINALS:

Three output terminals

are

provided

on the

front panel.

They are isolated from the chassis and either the positive

or

negative terminal may be connected

to

the ground terminal.

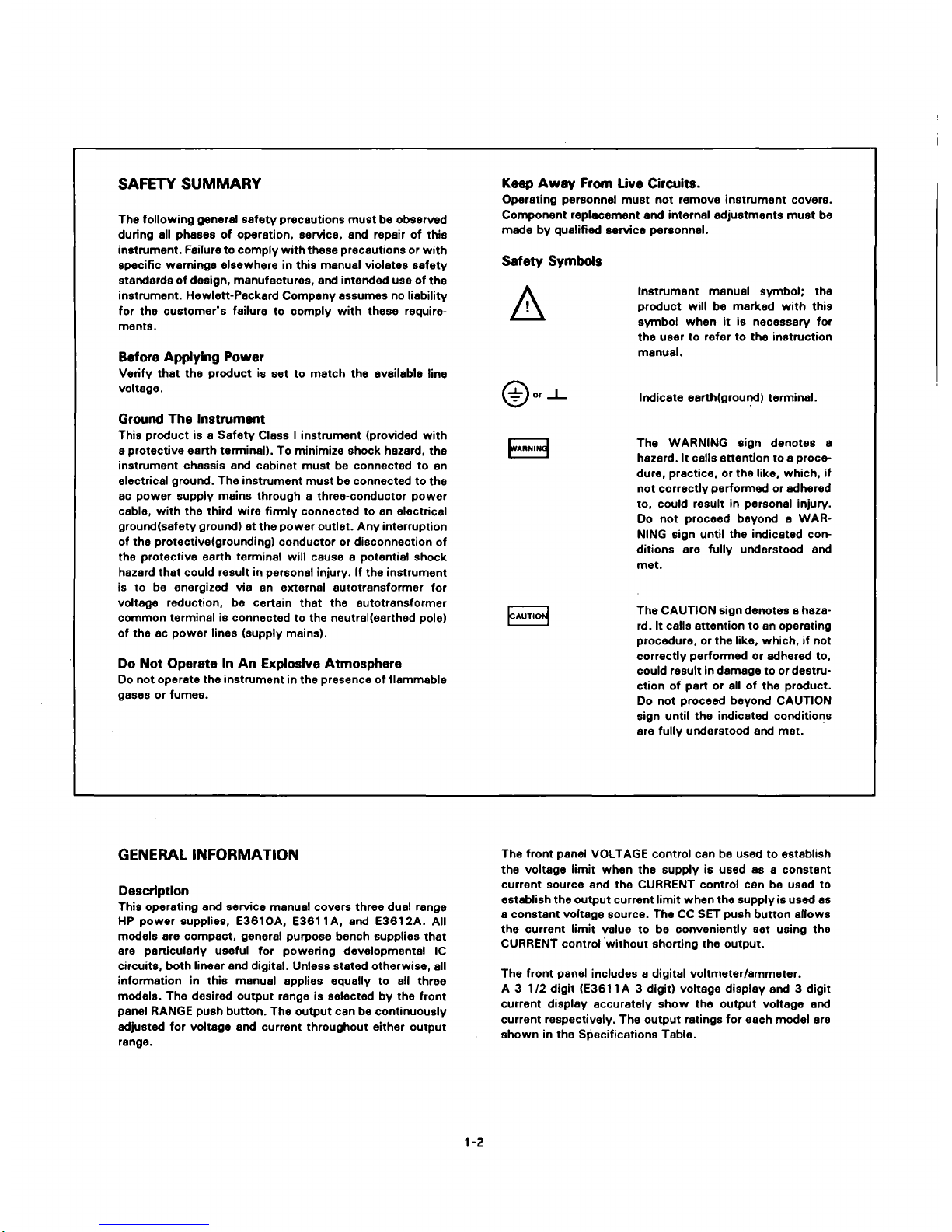

•OUTPUT CHARACTERISTICS

A

Veitt

Vo,

^2

loi

Pour

MAX

30 Watts

1^2

Cmrrcnt

NOTE:

Output voltages higher than

VQJ

are possible

at low

current when

the

high current range

is

selected.

E3610A: Vn,

=15 V V,

01

E3611A: Voi=35

V

E3612A:Voi=120V

'02-

^02

=

Vo2

'oi=2A

lo,

= 3

A

'02

= 8

V

20

V

= 60V 1(5, =0.25

A lo2

01 =0.85 A IQ2 = 1.5

A

= 0.5

A

•METER RESOLUTION

Voltage: E3610A

10 mV

E3611A

100 mV

E3612A

100 mV

Current: E3610A

10 mA

E3611A

10 mA

E3612A

1 mA

•DOWN PROGRAMMING

SPEED:

Maximum time

for

output

voltage

to

change between

100% to

0.1%

of

maximum

rated output voltage

at NO

LOAD condition.

E3610A: maximum

2.5 sec

E3611 A: maximum

1.0 sec

E3612A: maximum

1.5 sec

•RESOLUTION: Minimum output voltage

or

current change

that

can be

obtained using panel controls.

E3610A: Voltage

10 mV

Current

5 mA

E3611 A: Voltage

10 mV

Current

5 mA

E3612A: Voltage

100 mV

Current

2 mA

COOLING: Convection cooling

is

employed.

WEIGHT:

8.4

lbs/3.8

Kg net, 9.3

lbs/4.2

Kg

shipping.

(NOTE) * SUPPLEMENTAL CHARACTERISTICS

1-3

Page 4

D

88.1 mm

3.469

in

269.2 mm

10591

in

m

•I

m

212 3 mm

^ 8.354

in

1

1

1

iill iiiilll

l_J

l-o '

318 4 mm

•

12.534

in

FIGURE 1: OUTLINE DIAGRAM

Options

The following factory installed options are available with

this instrument.

Option Description

0E3 Input Power

:

230 Vac 4^/10%, 47-63 Hz, Single Phase

0E9 Input Power

:

100 Vac

-^/-10%,

47-63 Hz, Single Phase

Instrument Identification

Hewlett-Packard power supplies are identified by one serial

number. The letter "KR" designates Korea as the country of

manufacture,

the

first digit indicates

the

year

(1=91,

2 =

92,

etc), the second two digits indicate the week, and

the last five digits

of

the serial number are a different

sequential number assigned to each power supply.

If the serial number on your instrument does not agree with

those on the title page

of

this manual, a yellow change

sheet may be included

if

a design change has affected the

contents of this manual.

INSTALLATION

Inspection

When you receive your power supply, inspect

it

for any

obvious damage that may have occurred during shipment.

If there

is

damage, notify the carrier and the nearest HP

Sales Office immediately. Warranty information is printed on

the inside front cover

of

this manual. Save the shipping

carton and packing materials in case the supply has to be

returned to Hewlett-Packard in the future.

If

you return the

supply for service, attach a tag identifying the owner and

model number. Also include a brief description

of the

problem.

The "Turn-On Checkout Procedure" in this manual can be

used as an incoming inspection check

to

verify that the

supply is operational. See the appendix for tests that verify

the supply's specifications.

Location And Cooling

Figure 1 shows the outline shape and dimensions

of

the

unit.

It

is shipped ready for bench operation after connec-

tion

to an ac

power source. The supply

is air

cooled.

Sufficient space should be allotted so that a free flow

of

cooling air can reach the rear of the instrument when it is in

operation.

It

should be used in an area where the ambient

temperature does not exceed 40 degrees C. The current

derates 1% per degree C between 40°C-55°C.

Input Power Requirements

Depending on the line voltage option ordered, the supply is

ready to be operated from one of the power sources listed

in the Specification Table. The input voltage range, and the

input current ar>d power at high line voltage and full load is

listed for each option.

Power Cord

This instrument is equipped with a three conductor power

cable.

The third corKiuctor

is

the grourxl conductor and

when the cable is plugged into an appropriate receptacle,

the instrument

is

grour>ded. The offset pin on the power

cable three prong connector is the ground connection. In no

event should this instrument

be

operated without

an

adequate cabinet ground connection.

The power supply was shipped with a power cord for the

type of outlet used at your location.

If

the appropriate cord

was not included, contact your nearest HP Sales Office to

obtain the correct

cord.

1-4

Page 5

HEWLETT E36WA 0-ew.M/o-nr.aA

PACKARD DC KMCtt SUrPLT

]:

. ON

OFF

± 2«1 VDC MAX TO 1

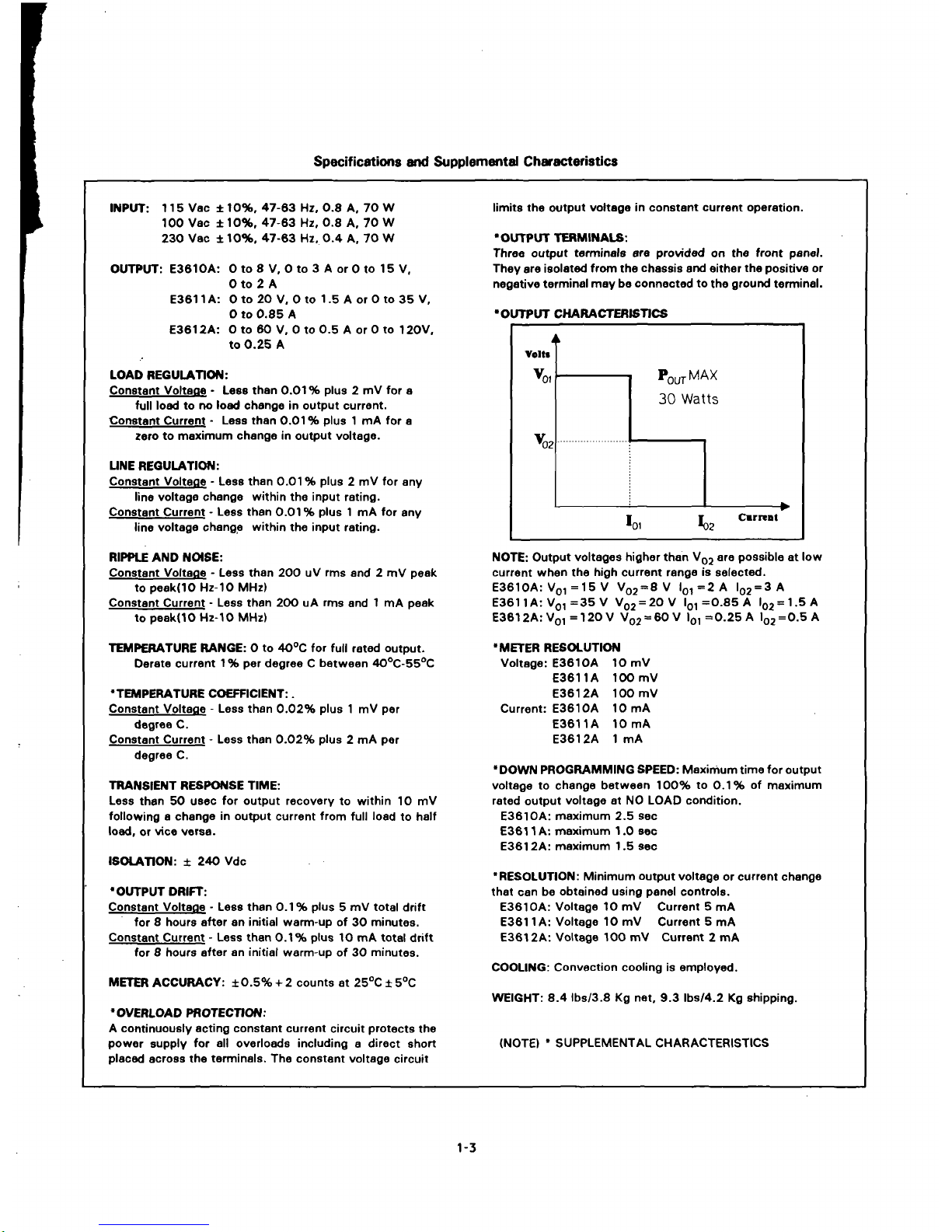

FIGURE 2: FRONT PANEL CONTROLS AND INDICATORS

OPERATION

Turn-On Checkout Procedure

The following checkout procedure describes the use of the

front panel controls and indicators illustrated in Figure 2 arxJ

ensures that the supply is operational:

a. Push LINE button to ON.

b. Set RANGE push button to desired range.

c. Turn VOLTAGE control fully counter clockwise to

ensure that output decreases to 0 Vdc then fully

clockwise to ensure that output voltage increases to

the maximum output voltage.

d.

While depressing CC SET push button, turn the

CURRENT control fully counter clockwise and then

fully clockwise to ensure that the current limit value

can be set from zero to maximum rated value.

e. Connect load to output terminals.

WARNING

Constant Current Operation

To set up a power supply for a constant current operation,

proceed as follows:

a. Turn CURRENT control fully counter clockwise to

ensure that output decreases to 0 A, and then turn on

power supply.

b. Adjust VOLTAGE controKno load connected) for

maximum output voltage allowable(voltage limit), as

determined by load cor>ditions. During actual operation,

if a load change causes the voltage limit to be

exceeded,

the power supply will automatically crossover to constant voltage operation at the preset

voltage limit and output current will drop proportionately.

c. Adjust CURRENT control for desired output current

while depressing CC SET button(CC LED will not light

until the supply is loaded)

Connecting Loads

The output of the supply is isolated from earth ground.

Either output terminal may be grounded or the output can

be floated up to 240 volts off grour>d.

Shock Hazard

Disconnect ac power before making

output terminal connections.

Constant Voltage Operation

To set up a power supply for a constant voltage operation,

proceed as follows:

a. Turn on power supply and adjust 10-turn VOLTAGE

control for desired output voltage(output terminals

open). CV LED should light.

b. While depressing CC SET push button, adjust 10-turn

CURRENT control for maximum output current allowable (current limit). During actual operation, if a load

change causes the current limit to be exceeded, the

power supply will automatically crossover to constant

current mode artd output voltage will drop proportionately.

Each load should be connected to the power supply output

terminals using separate pairs of connecting wires. This will

minimize mutual coupling effects between loads and will

retain full advantage of the low output impedance of the

power supply. Each pair of connecting wires should be as

short as possible and twisted or shielded to reduce noise

pickupdf a shield is used, connect one end to the power

supply ground terminal and leave the other erxl unconnected.).

Operation Beyond Rated Output

The output controls can adjust the voltage or current to

values above(up to 5%) the rated output as indicated on the

front panel display. Although the supply can be operated in

the 5% overrange region without being damaged, it can not

be guaranteed to meet all of its performance specifications

in this region.

1-5

Page 6

Pulse Loading Consklerations

The power supply will automatically cross over from

constant-voltage to constant-current operation in response

to an increase(over the preset limit) in the output current.

Although the preset limit may be set higher than the

average output current, Ngh peak currents(a8 occur in pulse

loading) may exceed the preset current limit and cause

crossover to occur. If this crossover limiting is not desired,

set the preset limit for the peak requirement and not the

average.

Capacitive Loads

An internal capacitor, across the output terminals of the

power supply, helps to supply high-current pulses of short

duration during constant voltage operation. Any capacitance

added externally will improve the pulse current capability.

but will decrease the safety provided by the current limiting

circuit. A high-current pulse may damage load components

t>efore the average output current is large enough to cause

the current limiting circuit to operate.

Reverse Current Loading

Active loads connected to the power supply may actually

deliver a reverse current to the power supply during a

portion of its operating cycle. An external source can not be

allowed to pump current into the supply without loss of

regulation and possible darnage to the output capacitor. To

avoid these effects, it is necessary to preload the supply

with a dummy load resistor so that the power supply

delivers current through the entire operating cycle of the

load devices.

1-6

Page 7

APPENDIX

SERVICE INFORMATION

AC

NPUT

XFMR

DISPUY

POWER SUPPLY

••+5V

•GND

CVrtX h»cv

INDICATOR

ORCUIT U-CC

REFERENCE ANO

BIASSIPPLY

+12

V

+5V

— CREF

-12

V

RECTinEfl

FILTER

SERIES

REGULATOR

Ofl

GATE

+«V —

GND -

CURRENT

OISPWY

CIRCUIT

VOLTAGE

DISPLAY

CIRCUIT

CONSTANT

CURRBtT

ERROR AMP

.^VS^

CREFO-

CCSET

ORCUIT

u

CONSTANT

VOLTAGE

ERROR AMP

DRIVER

METER

INPUT

ORCurr

DC

OUTPUT

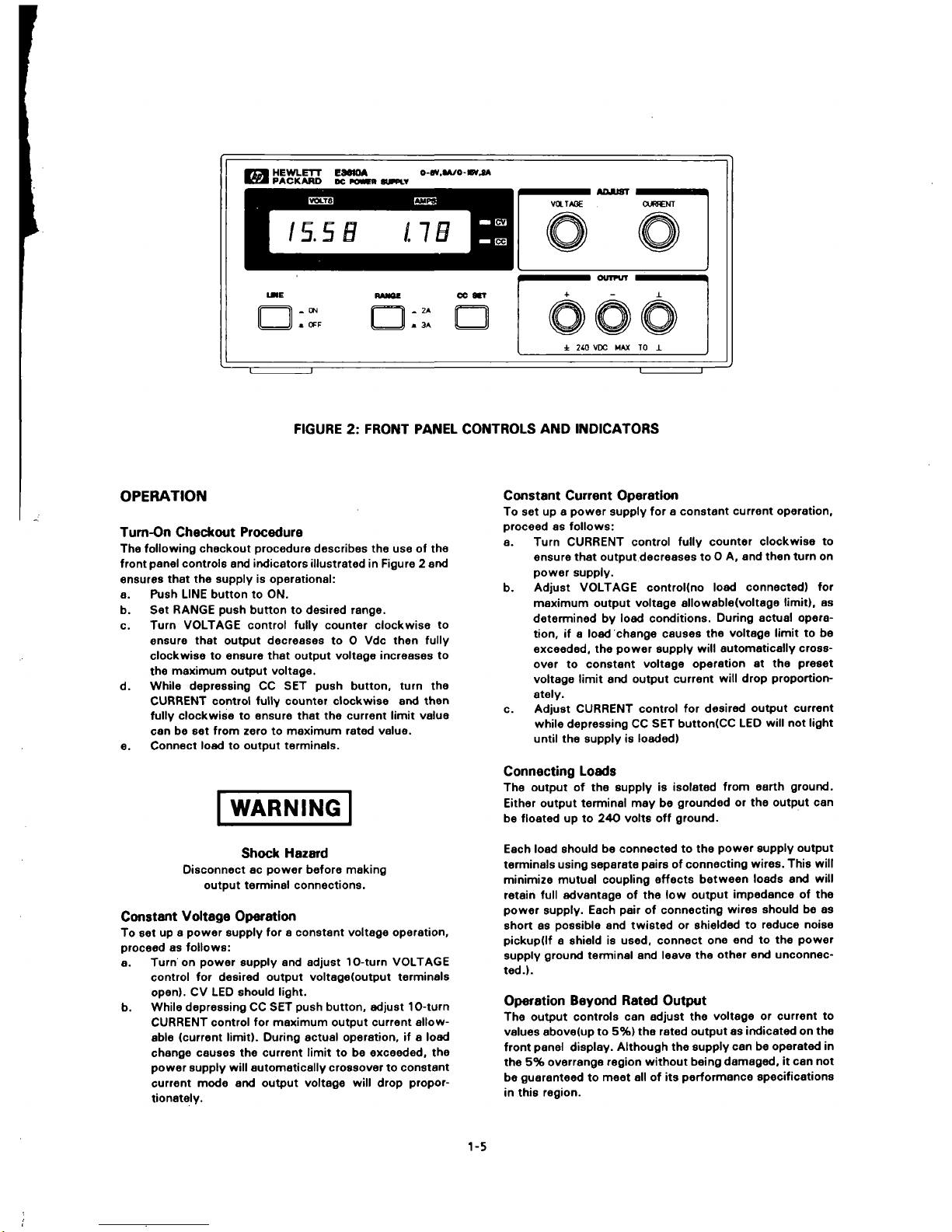

Figure

A-1.

Block Diagram

PRINCIPLES OF OPERATION

Throughout this discussion, refer to both the block diagram of Figure

A-1 and the schematic diagram at the rear of the manual. The input

AC line voltage is stepped down by the power transformer and

applied to the rectifier and filter. The rectifier-filter converts the AC

input to raw DC which is fed to the positive output terminal via

parallel series regulator(Q1 and Q3) and current sampling resistor(R2). The regulator, part of the feedback loop, is made to alter its

conduction to maintain a constant output voltage or current. The

voltage developed across the current sampling resistor is the input to

the constant current error amplifier. The constant voltage error

amplifier obtains its input by sampling the output voltage of the

supply.

Any changes in output voltage or current are detected, amplified by

the error amplifier and driver and applied to the series regulator in the

correct phase and amplitude to counteract the change in output

voltage or current.

Two error amplifiers are included in a CV/CC supply, one for

controlling output voltage, the other for controlling output current.

Since the constant voltage amplifier tends to achieve zero output

impedance and alters the output current whenever the load resistance changes, while the constant current amplifier causes the

output impedance to be infinite and changes the output voltage in

response to any load resistance change, it is obvious that the two

amplifiers can not operate simultaneously. For any given value of

load resistance, the power supply must act either as a constant

voltage source or as a constant current source - it can not be

both;

transfer between these two modes Is accomplished at a value of load

resistance equal to the ratio of the output voltage control setting to

the output current control setting.

The reference and bias circuit provides stable reference voltages

which are used by the constant voltage/current error amplifier circuits

for comparison purpose. The digital meter circuit provides an

indication of output voltage and current for constant voltage or

constant current operating modes.

The display power circuit provides voltage which is used by A/D

converter and LED drive.

Diode CR3 is connected across the output terminals in reverse

polarity. It protects the output electrolytic capacitor and the series

regulator transistor from the effects of a reverse voltage applied

across the output terminals.

PERFORMANCE TEST

The following provides the test procedure in high currant range for

verifying the unit's compliance with the specifications and characteristics of Table in page 1-3. The same test procedure may be applied

to low current range.

Test Equipment Required

The following Table lists the equipment required to perform the tests

and adjustments. You can separately identify the equipment for

performance tests, or calibration in the USE column of the Table.

A-1

Page 8

Table

A-1.

Test Equipment Required

TYPE

Oscilloscope

RMS Voltmeter

Multimeter

Electronic Load

Load Re8istor(For high current

range)

Current Sampling Resistor

Variable Voltage Auto Transformer

REQUIRED CHARACTERISTICS

Sensitivity : 2 mV

Bandwidth : 10 MHz/100 MHz

Input : Differentia), 50 ohm, 100 ohm

True rms, 10 MHz bandwidth

Sensitivity : 1 mV

Accuracy : 5%

Resolution : 100 nV

Accuracy : 0.0035%

Voltage Range : 240 Vdc

Current Range : 10 Adc

Open and short switches

Transient on/off

2.6 ohm 50 W, 13.3 ohm 50 W, 120 ohm

50W

0.1 ohm

0.1%

low, 1 ohm 1% 10 W

Range : 85-130 and 200-260 Volts

USE

P

P

P.A

P,A

P

P.A

P

RECOMMENDED MODEL

HP54600A

HP3400A

HP3456A

HP6063A

P = Performance testing

A =

Calibration adjustments.

Constant Voltage(CV) Test

The measuring device must

be

connected

as

close

to the

output

terminals

as

possible when measuring

the

output impedance,

transient response, regulation,

or

ripple

of the

power supply

in

order

to achieve valid measurements. A measurement made across

the

load includes

the

impedance

of the

leads

to the

load

and

such lead

lengths

can

have

an

impedance several orders

of

magnitude greater

than

the

supply output impedance, thus Invalidating

the

measure-

ment.

For all CV

tests

set the

output current

at

full rated output

to

assure

CV

operation.

Load Effect(Load Regulation)

Definition:

CV

Load Effect

is the

change

in dc

output voltage when

load resistance changes from open circuit

to

full load

or

from full load

to open circuit.

Test Parameters:

Measured Variable: Output Voltage

Expected Results: Less than 0.01 % plus

2 mV

Test Procedure:

a. Connect

the

test equipment

as

shown

in

Figure A-2. Operate

the electronic load

in

constant current mode

and set its

current

to the

full rated value

of the

power supply (E3610A:

3.0

A,

E3611

A: 1.5 A,

E3612A:

0.5 A).

b. Turn

the

unit's power

on and

turn CURRENT control fully

clockwise.

c. Turn

up

output voltage

to the

full rated value (E3610A:

8.0

V.

E3611

A: 20 V,

E3612A:

60 V) as

read

on the

digital

voltmeter.

d.

Record

the

output voltage

at the

digital voltmeter.

e. Operate

the

electronic load

in

Opendnput

Off)

mode.

f.

When

the

reading settles, record

the

output voltage again.

Check that

the two

recorded readings differ

no

more than

0.01

% of

output voltage plus

2 mV .

POWER SUPPLY

UNDER TEST

+

-

2^^

\

DIGITAL

VOLTMt.

ILR

TO

DVM

6

ELECTRONIC

LOAD

Rs= 0.1 ohm

0.1%

10 W

Figure A-2. Basic Test Setup

Source EffectlLine Regulation)

Definition:

Source effect

is the

change

in dc

output voltage when

the

ac input voltage changes from a minimum

to

maximum value!

± 10%

of nominal voltage).

Test Parameter:

Measured Variable: Output Voltage

Expected Results: Less than 0.01% plus

2 mV

Test Procedure:

a. Connect

the

test equipment

es

shown

in

Figure A-2. Operate

the electronic load

in

constant current mode

and set its

A-2

Page 9

current to the full rated value of power supply.

b. Connect the unit to the ac power line through a variable

autotransformer which is set for low line voltage(104 Vac for

115 Vac).

c. Turn the unit's power on and turn CURRENT control fully

clockwise.

d.

Turn up output voltage to the full rated value as read on the

digital voltmeter.

e. Record the output voltage at the digital voltmeter.

f. Adjust autotransformer to high line voltage) 127 Vac for

115 Vac).

g.

When the reading settles, record the output voltage again.

Check that the two recorded readings differ no more than

0.01%

of output voltage plus 2 mV.

Load Transient Recovery Time

d.

Set the electronic load to transient operation mode between

one half of unit's full rated value and unit's full rated value at

a 1 KHz rate with 50% duty cycle.

e. Set the oscilloscope for ac coupling, internal sync and lock on

either the positive or negative load transient.

f. Adjust the oscilloscope to display transients as in Figure A-3.

g.

Check that the pulse width of the transients at 10 mV from

the base line is no more than 50 usee as shown.

PARD(Ripple and Noise)

Definition:

Periodic ar>d random deviation(PARD) in the unit's output

ripple and noise combine to produce a residual ac voltage superimposed on the dc output voltage. Constant voltage PARD is specified

as the root-mean-square(rms) or peak-to-peak(pp) output voltage in

a frequency range of 10 Hz to 10 MHz.

Definition : This is the time for the output voltage to return to within

a specified band around its voltage following a step change in

load.

Test Paramater:

Measured Variable: Output Voltage Transients

Expected Results: Less than 50 usee (at 10 mV from base line)

Test Procedure:

a. Connect the test equipment as shown in Figure A-2, but

replace the DVM with the oscilloscope. Operate the electronic

load in constant current mode.

b. Turn the unit's power on and turn CURRENT control fully

clockwise.

c. Turn up output voltage to the full rated value.

PARD(RMS) Measurement

Test Parameter:

Measured Variable: Output Voltage(rms)

Expected Results: Less than 200 uV rms

Test Procedure:

a. Connect the test equipment as shown in Figure A-4.

b. Turn the unit's power on and turn CURRENT control fully

clockwise.

c. Turn up output voltage to the full rated value. Check that the

unit's CV indicator remains lighted. Reduce VOLTAGE control

if not lighted.

d.

Check that the rms noise voltage at the true rms voltmeter is

no more than 200 uV.

hp

Stopped

—

....

'

-••

1

—1 - •••

\ j

1 •/-

1 / •

•\-j

rvW-^

1

1-—

1

^ -1

1

-H

1

!-:•

.

•

4

•

f.

.

•

-'<••

\i

\

1

\

•—+—

-'•>•••

...

, ,

i

i

....

—

"

...

.1:^^

—

1

10.0

nV/div

offseli-600

uV

1.000:1

ac

-100.000

us

VBiarker2( 1 ) 7.813

VaarkerK 1 ) -2. 188

delta V( 1 ) 10.001

0.00000 s

20.0 us/div

mV stop marker

mV start marker

mV

delta t

1/de1ta

t

100,000 us

12.4000US

-13.2000US

25.6000US

39.0625kHi

1 "^ 30.00 nV

Figure A-3. Load Transient Recovery Waveform

A-3

Page 10

POWER SUPPLY

UNDER TEST

-1-

-

^

RL

L^VWV—

1

\

E3610A

E3611A

E3612A

-O - TRUE

_(-,,

VOLB

RL

2.6 ohm

13.3 ohm

120 ohm

-RMS

/lETER

Figure A-4. RMS Measurement Test Setup

PARD(Peak-to-Peak) Measurement

Test Parameter:

Measured Variable: Output voltage(peak-to-peak)

Expected Results: Less than 2 mV p-p

Test Procedure:

a. Connect the test equipment as shown in Figure A-5.

b. Turn the unit's power on and turn CURRENT control fully

clockwise.

c. Turn up output voltage to the full rated value. Check that the

unit's CV Indicator remains lighted. Reduce VOLTAGE control

if not lighted.

d.

Set the oscilloscope to AC mode and bandwidth to 10 MHz.

e. Check that the peek-to-peak noise is no more than 2 mV.

the load current is fed to the extremes of the wire leading to the

resistor while the sampling terminals are located as close as possible

to the resistance portion itself. Generally, any current sampling

resistor should be of the low noise, low temperature coefficient type

arxl should be used at no more than 5% of its rated power so that its

temperature rise will be minimized.

Load Effect(Load Regulation)

Definition : CC Load Effect is the change in dc output current when

load resistance changes from short circuit to full load or from full load

to short circuit.

Test Parameter:

Measured Variable: Output Current

Expected Results: Less than 0.01% plus 1 mA

Test Procedure:

a. Connect the DVM across R, in Rgure A-2. Operate the

electronic load in constant voltage mode and set its

voltage to the full rated value of power supply.

b. Turn the unit's power on and turn VOLTAGE control fully

clockwise.

c. Turn up output current to the full rated value. Check that the

AMPS display reads full rated values and CC indicator remains

lighted.

Reduce CURRENT control if not lighted.

d.

Record the voltage across Rs and convert it to current

through dividing by R,.

e. Operate the electronic load in short(input short mode).

f. When the reading settles, record voltage across R, again.

Check that the two' recorded readings differ no more than

0.01%

of output current plus 1 mA.

Source Effect(Line Regulation)

Definition:

Source Effect is the change in dc output current when the

ac input voltage changes from the minimum to maximum value( ± 10% of nominal voltage).

POWER SUPPLY

UNDER TEST

RL

LAAAAr-l

-^1—Q-

0.01 uF

0.01

uF V_

-O-i"O-

DIFFERENTIAL

-0+ OSCILLOSCOPE

-O-

RL

E3610A

E3611A

E 3612 A

2.6 ohm

• 13.3 ohm

• 120 ohm

Figure A-5. Peak-to-Peak Measurement Test Setup

Test Parameter:

Measured Variable: Output Current

Expected Results: Less than 0.01% plus 1 mA

Test Procedure:

a. Connect the DVM across R, in Figure A-2. Operate the

electronic load in constant voltage mode and set its voltage to

the full rated value of power supply.

b. Connect the unit to the ac power line through a variable

autotransformer that set for low line voltage(104 Vac for

115 Vac).

c. Turn the unit's power on and turn VOLTAGE control fully

clockwise.

d.

Turn up output current to the full rated value. Check that the

AMPS display reads full rated values and CC IrKlicator remains

lighted.

Reduce CURRENT control if not lighted.

e. Record output voltage across Rs and convert it to current

through dividing by R, .

f. Adjust autotransformer to the high line voItage(127 Vac for

115 Vac).

g.

When the reading settles, record the voltage across R, again.

Check that the two recorded readings differ no more than

0.01%

of output current plus 1 mA.

Constant Current(CC) Tests

For output current measurements the current sampling resistor must

be treated as a four terminal device. In the manner of a meter shunt.

PARD(Ripple and Noise)

Definitioii:

Periodic and rarxJom deviation(PARD) in the unit's output

ripple and noise combine to produce a residual ac current as well as

A-4

Page 11

an ac voltage superimposed on the dc output. Constant Current

PARD is specified as the root-mean-square(rms) output current in a

frequency range of 10 Hz to 10 MHz with the unit in CC operation.

PARD{RMS) Measurement

Test Parameter:

Measured Variable: Output Current(rms)

Expected Results: Less than 200 uA rms

Test Procedure:

a. Connect the test equipment as shown in Figure A-6.

b. Turn the unit's power on and turn the VOLTAGE control fully

clockwise.

c. Turn up output current to the full rated value. Check that the

CC indicator remains lighted. Reduce CURRENT control if not

lighted.

d.

Record rms voltage across R^ ar>d convert it to current through

dividing by R,.

e. Check that the rms noise current is no more than 200 uA.

PARD(Peak-to-Peak) Measurement

Test Parameter:

Measured Variable: Output Current(peak-to-peak)

Expected Results: Less than 1 mA p-p

Test Procedure:

a. Connect the test equipment as shown in Figure A-6, but

replace the RMS voltmeter with oscilloscope.

b. Set the oscilloscope to AC mode and bandwidth to 10 MHz.

c. Turn the unit's power on and turn the VOLTAGE control fully

clockwise.

d.

Turn up output current to the full rated value. Check that the

CC indicator remains lighted. Reduce CURRENT control if not

lighted.

e. Record peak-to-paak voltage across R^ and convert it to

current through dividing by R^. Check that the peak-to-peak

noise current is no more than 1 mA.

POWER SUPPLY

-t-

o o

<

<

<

>"^

R5 =

1

ohm. 1

TRUE-RMS

VOLTMETER

9 9

,i.

10 W

CALIBRATION PROCEDURE

To calibrate ammeter and full scale current, connect test equipments

as shown in Rgure A-7.

POWER SUPPLY

O

-IO

DIGITAL

VOLTMETER

-E

Q 0

Rs= 0.1 ohm.

0.1%.

10 W

Figure A-6. RMS Measurement Test setup

Figure A-7. Calibration Test Setup

Calibration in High Current Range

a. Turn VOLTAGE and CURRENT control fully clockwise.

b. Set RANGE push button to high current range.

c. Turn on power supply and adjust R31 so that DVM indicates

exactly as follows (5% over rated current):

E3610A: 0.315 V E3611

A:

0.158 V E3612A:

0.053

V

d.

Adjust R3 on the display board so that the displayed value on

the front panel is equal to DVM value divided by R,.

e. While depressing CC SET push button, adjust R20 so that the

displayed value on the front panel is equal to DVM value

divided by R,.

Calibration in Low Current Range

a. Set RANGE push button to low current range.

b. Adjust R32 so that DVM indicates exactly as follows (5% over

rated current).

E3610A:0.21V E3611 A: 0.089 V E3612A: 0.026 V

Calibration of VOLTS Meter

a. Disconnect the current shunt(Rj) and connect DVM across

output of supply.

b. Set RANGE push button to low current range at no

load.

c. Adjust VOLTAGE control till DVM indicates exactly as

follows (full rated voltage):

E3610A:15V E3611A:35V E3612A:120V

d.

Adjust RIO on the display board so that the value of the front

panel display is the same as the value of DVM.

A-5

Page 12

E361XA REPLACEABLE PARTS LIST

Reference

Designation

E361XASTD/0E9

E361XA0E3

E3610AQ1.3

E3611AQ1,3

E3612AQ1,3

82

S3

SI

E3610ASTDT1

E3610A0E9T1

E3610A 063X1

E3611ASTDT1

E3611A0E9T1

E3611A0E3T1

E3612ASTDT1

E3612A0E9T1

E3612A0E3T1

E3aiXASTD/0E9F4

E361XA0E3F4

Cl

E3610AC2

E3611AC2

E3612AC2

E3610AC3

E3611AC3

E3612AC3

C4,5

E3810A,11AC6

E3612A C6

C7

E3aiOA.11AC10

E3612AC10

Cll.16

C8,14,18

C9,15.19

E3610AC12

E3611AC12

E3612AC12

C13

HP Part

Number

ESaiXA

0403-0424

5041-8602

6041-8603

5041-8604

0371-3806

0371-3807

5959-5304

8120-1378

8120-1689

9220-4867

9220-4868

ESe

1X60001

0340-0140

0340-0168

0515-0926

0515-1162

0515-1711

0535-0007

1400-0307

1854-0611

1854-1257

1855-0536

2190-0585

2190-0586

2190-0587

3050-0894

3101-3070

3101-2985

3101-3115

9100-4959

9100-4958

9100-4957

9100-4956

9100-4955

9100-4954

9100-4996

9100-4995

9100-4994

0890-1788

5062-3403

04700357

08901788

5062-3401

0360-0268

0515-0910

1252-4214

21100702

2110-0599

5021-8105

E361X-60002

0160-7077

0180-4352

01804361

0180-4351

0180-4355

0180-3595

01803937

01600269

01607548

0160-4787

01804085

01607547

01603585

0160-6225

01607449

01803970

0160-7456

01607080

01607082

0180-4355

Qty

.

1

2

8

2

2

4

4

6

2

2

2

4

2

2

2

.240

3

3

3

2

3

3

1

1

1

1

IDescription

E361XA POWEX SUPPLY

BUMPER FOOT-AEJH MTG

f^VRCAP

TOP COVER

BOTTOM COVER

KEYCAP-WH

KEY CAP-GRANITE

OPERATION AND SERVICE MANUAL

POW^I CORD OPT903

POWER COM) OPT902

PAD-PACtCAGING.FRONT

PAD-PACKAGING.FSAR

MAIN BODY ASSY

INSULATOR-XSTR MICA

INSULATOR BUSHING

SCR-MACH IM4X0.7

SCR-MACH M5X08

SCR-MACH M3.5X06

NUT-HEX DBL-CHAM M3.5X0.6

CABLE TIE

XSTR

NPN

2N6055 SI DARL TO-3

XSTR NPN BU323A SI DARL TO-3

XSTR MOSFET IW^40

N-CHAN

TO-3

VreHR-LK M3.5 ID

Vt/SHR-LK M4.0 ID

Vy^HR-LK M5.0 ID

WreHR-FL MTLC 5.0

SW-PBDPOT6A250V

SW-PBDPST4A250V

SW-PB .5A 250VAC

TRANSFORMER, E3610A 115V

TRANSFORMER, E3610A lOOV

TRANSFORMEa E3810A 230V

TRANSFORMER, E3611A 115V

TRANSFORMER. E3611A 100V

TRANSFORMER

E361

IA 230V

TRANSFORMER.

E361

2A 115V

TRANSFORMER, E3612A 100V

TRANSFORMER, E3612A 230V

SLEEVING FLEXIBLE

WIRE HARNESS ASSY-DISPLAY

SIUCONE RUB8ER-RTV

SLEEVING FLEXIBLE

HFAT SINK ASSY

TEre*SOLDER LUG

SCR-MACH M4X0.7

CONNECTOR-AC POW/ER

FUSE 2A 250V NTD

FUSE 250V IA

HEAT SINK-DIECASTING

MAIN BOARD ASSY

CAP0.1UF 630V 10% POLYE-MET

CAP 10000UF SOV 20% AL-ELEC

CAP4700UF 100V 20% AL-EUC

CAP 1000UF 250V 20% AL-EUC

CAP 470UF 50V 20% AL-ELEC

CAP 220UF 100V 20% AL-ELEC

CAP 100UF 250V 20% AL-ELEC

CAP0.1UF500V20%CER

CAP 2200PF 50V 10% CER

CAP22PF100V5%CER

CAP 330UF 35V 20% AL-ELEC

CAP 1000PF 500V 5% CER

CAP 1UF 250V 20% AL-ELEC

CAP .33UF 250V 10% POLYE-MET

CAP.33UF50V10%PE

CAP 1UF 50V 20% AL-EIEC

CAP180PF50V5%CER

CAP 220PF 50V 5% CER

CAP 120PF 50V 5% CER

CAP 470UF SOV 20% AL-ELEC

Mfr

Code

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

04713

04713

04713

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

Mfr Part

Number

2N605S

BU323A

ire:44o

A-6

Page 13

E361XA REPLACEABLE PARTS LIST

Reference

[>esignation

C17

C20

E3612AC22,23

E3610AR1

E3611AR1

E361

2A Rl

£361 OA R2

E3611AR2

E3612AR2

R3

R4,25

R5

E3610A,11AR6

E3612AR6

E3610A,11AR8

E3612AR8

E3610A,11AR10

E3612AR10,38,39

E3611A.12ARn,12

E3610AR12

E3eiOA.nAR13

E3612AR13

R14

E3610AR15

E3611AR15

E3612AR15

R16,26

R17

E3610AR18

E3611A,12AR18

R20

E3610A.11AR22,23

E3612AR22,23

R24

E3610AR27

E3611AR27

E3612AR27

E3610A.11AR28

E3612AR28

R29,30

R31.32

E3610AR33

E3611AR33

E3612AR33

E3610AR34

E3611AR34

E3610AR35,36

E3611AR35,36

E3612AR35,36

R40

R41

E3612AR43

E3612AR44,45

F1,2

F3

Ul

U2

U3

U4

U5

U6

U7

02

E3612AQ4,5

CR2

CR3

CR4,5

CR6,7,10,11

CR8

CR9,13

HP

Part

Number

018O3990

01606071

01604832

0811-1806

0811-2188

0699-3105

0811-3478

0811-3839

0811-3861

0699-2882

0698-4254

0698-4002

0699-3266

81504920

0698-4254

0698-4002

0698-4254

0757-0398

0757-0442

81504920

0813-0001

0811-2188

0698-4254

0698.4307

0757 0290

0811-3873

0698-4278

0699-1063

0698-8020

0757-0288

2100-4306

0698-6250

0757-0440

0698-4009

0698-8812

0699-3200

81504920

0757-0439

0757-0290

0761-0021

21004305

0698-4440

0698-0063

0698-4471

0698-8957

0698-8825

0811-3864

0811-3874

0811-3886

0698-4531

0698-3155

0698-8020

0698-3160

21100665

0699-2715

1826-0961

1826-0147

1826-1297

1826-1075

1826-0412

1826-0221

1826-0144

1853-0041

1854-0477

1906-0255

1901-0848

1901-0461

1901-0033

1901-0327

1906-0284

03602359

0515-0911

0515-0918

Qty

2

2

3

2

2

2

2

2

2

2

2

2

1

1

1

2

2

1

1

1

1

1

1

1

1

1

2

1

1

2

4

1

2

10

1

3

Description

CAP

4700UF

25V 20%

AL-ELEC

CAP18PF

100V 5% CER

CAPO1UF50V20%CER

RES 2K 5% 3W PWI

RES 5K 5% 3W

PWrt

RES 45K 5% 2W MO

RES.1

1%5WPWN

RES .2

1%5W/PWN

RES 1.78

1%5WPWN

RES 1.2K 1%

.5WTF

RES IK 5%

.125W/TF

RES5K

1%

.125WTF

RES1.5M5%

.125WTF

JUMPER WIRE 22AWG

1X2

RES IK 5%

.125WTF

RES5K

1%.125WTF

RES IK 5%

.125WTF

RES 75 1%

.125WTF

RES 10K 1%

.125WTF

JUMPER

WIRE,

22AWG

1X22

RES IK 5%

3WPVVI

RES 5K 5% 3W PWI

RES IK 5%

.1.25WTF

RES 14.3K 1%

.125WTF

^i

RES6.19K

1%

.125WTF

.'

RES3.65K

1%

3WPWN

RES 10K5%

.125WTF

RES900K

1%

.125WTF

RES 100K 1%

.125WTF

RES9.09K

1%

.125WTF

RES-TMMR

50K 10% 25T

RES2.5K

1%

.125WTF

RES7.5K

1%

.125WTF

RES50K

1%

.125WTF

RES 1 1%

.125WTF

RES 6.8 1%

.125WTF

JUMPER WARE 22AWG

1X22

RES 6.8 IK 1% .125WTF-- '

RES6.19K

1%

.125WTF

RES IK 5% 1WM0

RES-TMMR

10K 10% 25T

RES

3.40K

1%

..125WTF

<.

RES

5.23K

1%

.125WTF

-

RES7.15K

1%

.125WTF

RES500K

1%

.125WTF

RES681K

1%

.125WTF

RES.6

5%5WPWN

RES 1.2 5%

5WPW/N

RES 10 1 % 3W PWN

RES267K

1%

.125WTF

RES4.64K

1%

.125WTF

RES 100K 1%

.125WTF

RES31.6K

1%

.125WTF

FUSE

IA 125V

FUSIBLE

RES 1 OHM 5% .5W

ICLF411CN-0PAMP

IC V

RGLTR FXD11.5/1

2.5

TO-220

IC

LM336BZ5.0V RGLTR TO-92

IC

LF442CN-0P

AMP

DUAL 8 DIP-P

IC 393

8-DIP-P

PKG

IC

MC791 2CT-V RGLTR TO-220

IC MC

7805CT-V RGLTR TO-220

XSTR

PNP SI

XSTR

NPN

2N2222ASIT0-18

DIOOE-FW BRDG 600V

6A

DIODE-PWR RECT 400V

3A

DIOOE-GEN

PRP 10V .2A

DIODE-GEN

PRP 180V .2A

DIOOE-PWR RECT 200V

1A

DIODE-FW BRDG

100V 1A

TERMINAL-TEST POINT

SCREW-MACH M3X0.5

SCREW-MACH M3.5X0.6

Mfr

Code

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

27014

04713

27014

27014

27014

04713

04713

04713

04713

28480

04713

27014

27014

28480

28480

28480

28480

28480

Mfr

Part

Number

LF411CN

MC7812CT

LM336BZ

LF442CN

LM393N

MC7912CT

MC7805CT

2N2222A

KBPC606

MR854

1N4148

1N645

A-7

Page 14

E361XA REPLACEABLE PARTS LIST

Reference

Designation

HP Part

Number

Qty

Description

Mfr

Code

Mfr Part

Number

E3610A.11A

Jl

E3610A.11A

Ll

E3612A JP1

E3610A.11A JP2

R19

E3610A.11AR37

E3612AR37

E3610A

E3611A

£3612A

E3610A

£361

IA

£3612A

1205-0595

1251-7406

2190-0584

2190-0585

5002-0202

91700894

81504920

8150^920

E361X-60003

2100^503

2100^308

210O.4307

5002-0203

5021-8104

5041-8601

E361080001

E361.1-80O01

£3612-80001

8151-0013

15100135

15100136

03703222

29500144

£3610-60005

£3611-60005

E3612-60005

.025

2

1

2

3

1

1

1

HEAT SINK SGL PLSTC

CONNECTOR-POST TYPE 10P

WSHR-LK IM3.0 ID

WSHR-LX M3.5 ID

HEAT SINK- BRIDGE DIODE

CORE-SHLO BEAD

JUMPER WIRE 22AWG 1X22

JUMPER WARE 22AWG 1X22

FRONT PANQ. ASSY

RES-VAR 10K 5% 10TURN CEPNET

RES-VAR 50K 5% 10TURN WW

RES-VAR 10OK 5% 10TURN WW

LUG-GROUND

PLATE WflNDOW

FRONT FRAME

LABEL FRONT PANEL

LABEL FRONT PANEL

LABEL FRONT PANEL

COPPER WIRE 22 AWG 1X22

BINDING POST.RED

BINDING POST.BLACK

KNOB

NUT-HEX-DBL-CHAM

DISPLAY BOARD ASSY, E3610 lOP

MSFLAY BOARD ASSY, E3611 lOP

DISPLAY BOARD ASSY, EMU lOP

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

A-8

Page 15

Component

C2

03

C6

CIO

C12

022.23

Rl

R2

R6

R8

RIO

RII

R12

R13

R15

RIB

R22,23

R27

R28

R33

R34

R35,36

R37

R38.39

R43

R44.45

Q4,5

JP1

JP2

Model 1

E3610A

lOOOOuF 50V 20% AL-ELEO

470uF 50V 20% AL-ELEO

2200pF 50V 10% CER

lOOOpF 500V 5% OER

180pF50V5%0ER

2K 5% 3W PWI

0.1

1 %

5W PWN

1.5M5%0.125WTF

1KB%0.125WTF

1K5%0.125WTF

JUMPER WIRE

IK 5% 3WPWI

14.3K 1%0.125WTF

100K 1%0.125WT7

2.5K 1%0.125WTF

1 1 % 0.125W TF

6.81K 1%0.125WTF

3.40K 1%0.125WTF

SOOK 1 % 0.1 25W TF

0.6 5% SW PWN

50K5%

10-TURN WW

JUMPER WIRE

E3611A

4700uF 100V 20% AL-ELEC

220uF 100V 20% AL-ELEC

2200pF SOV 10% CER

lOOOpF 500V S% CER

220pF SOV S% OER

5K S% 3W PWI

0.2 1% SWPWN

1.SM5%0.12SWTF

1K5%0.12SWTF

1K5%012SWTF

10K 1%0.12SWTF

lOK 1%0.12SWTF

IK 5% 3WPWI

6.19K 1%0.12SWTF

9.09K1%0.12SWTF

2.SK 1%0.12SWTF

6.8 1%0.125WTF

6.81K1%0.125WTF

5.23K 1%0.125WTF

681K 1%0.12SWTF

1.2 5% SWPWN

S0K5%

10-TURN WW

JUMPER WIRE

E3612A

lOOOuF 250V 20% AL-ELEO

lOOuF 2S0V 20% AL-ELEC

22pF 100V 5% CER

1uF260V 20% AL-ELEC

120pF SOV 5% CER

O.luF SOV 20% OER

4SK S% 2W MO

1.78 1% SWPWN

JUMPER WIRE

6K 1%0.125WTF

75 1%0.12SWTF

10K 1%0.125WTF

10K 1%0.125WTF

6K 5% 3W PWI

3.6SK 1 % 3W PWN

9.09K 1%0.125WTF

7.SK 1%0.12SWTF

JUMPER WIRE

6.19K 1%0.12SWTF

7.15K 1%0.12SWTF

10 1% SWPWN

100K5% 10-TURN WW

75 1%0.12SWTF

100K 1%0.12SWTF

31.6K 1%0.12BWTF

XSTR NPN 2N2222A SI TO-18

JUMPER WIRE

• COMPONENT VALUE TABLE

NOTES:

1.

The values of all component * marked are shown in the at>ove comporwnt value table.

2.

All resistors are 0.125W. 6%. and ohms, unless otherwise specified.

3. All capacitors are mk;rofarads. unless otherwise specified.

4.

SIA CO SET switch shown is OFF position.

5. S2B RANGE selector switch shown is high current range.

6. Voltages between TP2 and TP4 in tow current rangs are:

Model

E3610A

E3611A

E3612A

Voltage

2SV±10%

47V±10%

152V±10%

A-9

Page 16

ncc

nc

fe^

Tl I F3

CV/CC Indicator Ci rcu11

r

> Jl (S) CC INDICRTCR

I • Jl O)

DOicnroR comoN

* Jl (7) CV DOICHTO)

« Sin CC SET

^^.O > Jl (5) I*

Jl (G) I-

Meter Input

C i rcu11

> Jl (3> v+

> Jl {^) V-

Flgure A-8. Schmatic Diagram

Loading...

Loading...