Page 1

HP power and cooling technologies for the

data center

Technology brief, 2nd edition

Introduction ......................................................................................................................................... 2

ProLiant server efficiency....................................................................................................................... 2

High-efficiency features ..................................................................................................................... 2

Power monitoring and reporting tools ................................................................................................. 3

Power control tools ........................................................................................................................... 3

Power distribution ................................................................................................................................ 4

HP Intelligent Power Discovery ........................................................................................................... 4

HP Power Advisor ............................................................................................................................ 6

HP uninterruptible power supplies ...................................................................................................... 6

Cooling .............................................................................................................................................. 7

HP 10000 G2 Rack Air Duct ............................................................................................................. 8

HP Modular Cooling System G2 ........................................................................................................ 8

Data center power management with HP Insight Control .......................................................................... 9

Data center power topology management ........................................................................................... 9

Data gathering and archiving .......................................................................................................... 10

Power monitoring ........................................................................................................................... 11

Data center thermal profiles ............................................................................................................. 12

Available power reporting .............................................................................................................. 14

HP Performance Optimized Datacenters ............................................................................................... 15

HP POD 40c and 20c .................................................................................................................... 16

HP POD 240a ............................................................................................................................... 17

Conclusion ........................................................................................................................................ 18

For more information .......................................................................................................................... 19

Page 2

Introduction

In this technology brief, we describe a broad range of HP products and technologies that raise

energy efficiency, maximize use of the power capacity, and simplify management of your data

center’s power and cooling infrastructure. We begin in the ―IT processing‖ section by describing the

technologies and tools that help you measure, monitor, and control the power usage of HP ProLiant

servers to get the maximum performance per watt. Then we go outside the server in ―Power

Distribution‖ to describe HP products and technologies that improve data center power distribution

efficiency, monitoring, and provisioning.

High-density heat loads and unforeseen airflow anomalies in data centers can disrupt some of the

best power and cooling strategies. In ―Cooling‖ we describe HP products that improve cooling

efficiency and eliminate issues caused by air mixing and hot spots.

One undisputable fact in all data centers is that you can’t manage what you can’t measure. In "Data

center power management with HP Insight Control", we describe the features that allow you to

monitor and control the power consumption and thermal output of hundreds of systems using HP

Insight Control power management.

When your data center can’t keep pace with IT demand, the budget pressure to do more with less

precludes the option to build a new facility or expand your existing facility. Therefore, it’s time to

consider alternatives to the traditional brick-and-mortar data center. In ―HP Performance Optimized

Datacenters (PODs)‖, we describe our family of modular PODs that can help you do more with less—

less capital, power, and footprint.

We develop HP power and cooling products and technologies around three strategies to help you

manage the total costs of owning and operating a data center:

Consume less power by increasing the efficiency of IT, power distribution, and cooling equipment.

Fit more IT equipment into the available data center capacity by adjusting the power and cooling

infrastructure for the real IT load.

Work smarter by measuring every watt and degree and automating energy management decisions

wherever possible.

ProLiant server efficiency

Servers are often the largest consumers of power and IT labor in the data center. Therefore, we focus

on improving server efficiency to help reduce operating expenses and help facilities cope with the

complexities of higher compute densities. This section summaries the high-efficiency features, power

control tools, and provisioning technologies we build into ProLiant servers to address data center

challenges.

High-efficiency features

We design and develop ProLiant servers to be as energy efficient as possible so they give you the

highest possible performance per watt. We accomplish this by examining every key element,

including power supplies, processors, thermal sensors, and internal fans.

HP Common Slot Power Supplies

ProLiant rack-mount servers and the HP BladeSystem c7000 Enclosure (G6 and above) have power

supply slots that accommodate HP Common Slot Power Supplies. HP Common Slot Power Supplies

have a common form factor and are available in three AC capacities—460 W, 750 W, and 1200

W—and a 1200 W 48 V DC version. These capacities let you match the power supply wattage with

the server’s power requirements, thereby operating closer to the power supply’s peak efficiency and

2

Page 3

consuming less energy. The ability to use Common Slot Power Supplies across multiple platforms

simplifies maintenance and reduces inventory. All HP Common Slot AC Power Supplies meet 80

PLUS® Silver, Gold, or Platinum specifications. The AC power supplies work with input voltages from

100 to 240 V, making them functional worldwide. Administrators can use the HP Power Advisor

utility at http://h18004.www1.hp.com/products/solutions/power/index.html to select the right

power supply for each server’s configuration. Read the ―HP Common Slot Power Supply technology‖

white paper at http://h20195.www2.hp.com/v2/GetPDF.aspx/4AA3-2676ENW.pdf for more

information.

HP Power Regulator

HP Power Regulator is an OS-independent power management feature included on all HP ProLiant

servers (200-series and above). Power Regulator directly monitors processor utilization and uses this

information to adjust the processor performance state (frequency and voltage). This gives processors

full power when they need it and reduces power when they do not. Read the ―Power Regulator for

ProLiant servers‖ technology brief at

http://h20000.www2.hp.com/bc/docs/support/SupportManual/c00300430/c00300430.pdf for

more information.

Optimized fan power

ProLiant ML, DL, and BL G6 and G7 servers include a ―sea of thermal sensors‖ located throughout the

server, including components such as DDR3 DIMMs and hard drives. The number of sensors varies by

server platform. The server uses the sensors to construct an accurate view of its internal thermal

profile. The server’s iLO management controller uses a sophisticated control algorithm to set the speed

for each internal fan based on the server’s thermal profile. This improved monitoring technology

prevents overcooling within the server, lets the fans consume less power, and produces less acoustical

noise.

HP engineers designed Active Cool fan technology for HP BladeSystem c-Class Enclosures. Active

Cool 200 fans are ducted (the fan is longer than it is wide) to generate high-volume, high-pressure

airflow with low acoustical noise levels. HP Active Cool 200 fans use minimal power; they can cool

16 server blades using as little as 150 watts of power.

Power monitoring and reporting tools

ProLiant servers include tools that measure and report their power use to HP Insight Control so that

you can react faster and smarter to unexpected changes and track long-term trends. When a server

boots, it runs its components at full power for a few seconds to measure the maximum power use for

its configuration. The server’s iLO device reports this Calibrated Max Power to Insight Control. Also,

ProLiant servers monitor and report their peak and average power use to their iLO controller. The iLO

device collects this power usage information every 5 minutes. Administrators can view the peak and

average power usage over the previous 20 minutes or 24 hours through the local iLO interface

through Insight Control.

Power control tools

Our provisioning tools—Dynamic Power Capping and HP Enclosure Dynamic Power Capping—

reduce the uncertainty normally involved in determining worst-case power requirements for servers.

This helps administrators maximize data center power utilization by fitting more IT equipment in the

available space and power and cooling capacity. These tools are summarized below. For a more

detailed description, read the ―HP Power Capping and HP Dynamic Power Capping for ProLiant

servers‖ technology brief.

3

Page 4

HP Dynamic Power Capping

We use HP Dynamic Power Capping technology in most of the enterprise-class G5 ProLiant servers

and beyond. Dynamic Power Capping uses sophisticated monitoring and control circuitry to prevent

server power from exceeding a preset level. Because Dynamic Power Capping is hardware-based, it

can quickly control sudden surges in power use from servers and prevent tripping even the fastest

circuit breakers used in HP PDUs. You can set a power cap for an individual server from the iLO user

interface. For groups of servers, you can set the power caps from the power management module

within Insight Control.

HP Enclosure Dynamic Power Capping

We designed Enclosure Dynamic Power Capping technology specifically for BladeSystem enclosures.

It lets you set a power cap for an HP BladeSystem Enclosure by using Insight Control (version 2.0 or

later) or Onboard Administrator (firmware version 2.30 or later). The Onboard Administrator

monitors and maintains the power cap for the entire enclosure by adjusting cap levels on individual

server blades. As one server blade becomes busy and another becomes idle, Onboard Administrator

adjusts the individual caps to give each server blade what it needs while maintaining the total

enclosure power below the cap.

Power distribution

Power distribution extends from the utility grid to the branch circuits that deliver power to the IT

equipment. No distribution system is 100% efficient, so some power is lost during this process.

Between 2% and 12% of the power delivered to the data center is lost during distribution from the

utility power grid to the IT devices. The biggest power losses occur each time the distribution system

converts or steps-down the voltage to reach the level required by the IT devices. These power

distribution losses are costly because they don’t perform work and they generate heat that needs to be

extracted.

Follow these two basic power distribution principles to reduce your data center power losses:

Minimize power conversions to reduce power losses and heat generation.

Distribute high voltage power as close to the load as possible. High voltage circuits have lower

transmission losses than low voltage circuits and require a less expensive wiring infrastructure.

Tools and products that improve data center power distribution efficiency, monitoring, and

provisioning include:

HP Intelligent Power Discovery

HP Power Advisor tool

HP uninterruptible power supplies

HP Intelligent Power Discovery

It’s not easy to tell when a circuit is underutilized or potentially overloaded. The former can deprive

your data center of extra revenue, and the latter can lead to unscheduled downtime. It’s also difficult

to detect potential wiring errors that can cause mission-critical server failures. Intelligent Power

Discovery (IPD) removes the guesswork in determining your data center’s power and IT equipment

connectivity (topology). IPD also monitors real-time power use and detects some common wiring

errors.

4

Page 5

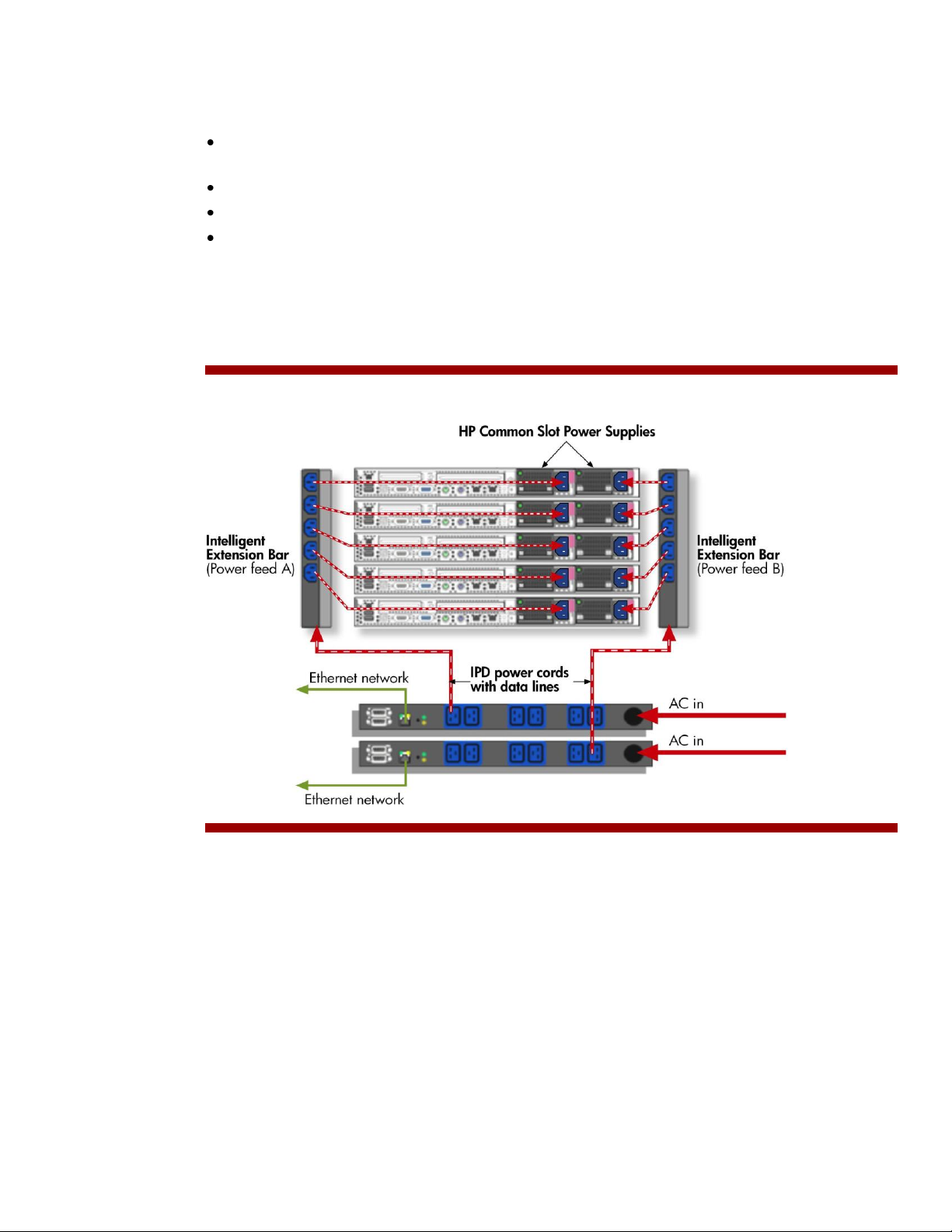

Discover the power distribution topology

Our IPD solution works with ProLiant servers with iLO 2 (firmware v2.0 or newer) or iLO 3 (firmware

v1.05 or newer). IPD components include:

An Intelligent Power Distribution Unit (iPDU) with an embedded management module and six

monitored C-19 outlets

One or more Intelligent Extension Bars, each with five monitored C-13 outlets

IPD power cords with embedded RS-232 data lines

HP Common Slot Power Supplies with IPD connectors

When you connect the IPD components as shown in Figure 1, the iPDU automatically detects and

communicates with each server’s iLO device before the server is powered on. The iPDU management

module and the iLO devices exchange identity data—hostname, IP address and serial number—

through the IPD power cords. This allows the iPDU to track the servers plugged into each of its outlets.

Figure 1: Components of the HP Intelligent Power Discovery solution

Monitor real-time power use

The iPDU collects power use data for each individual outlet twice per second. It’s 99% accurate at

1 amp and above, making it one of the most accurate monitored PDUs on the market. The iPDU’s

network connection lets you access this data locally through the HP Intelligent PDU Management GUI

or remotely through Insight Control power management software.

Eliminate human error

IPD is the only solution in the server industry today that automatically correlates server identity to

power outlets. This capability helps prevent personnel from connecting redundant power supplies to

the same circuit, which is a common cause of server failure.

Also, when you need to reset a server by cycling power to it, you must cycle the correct outlet(s) or

you will shut down the wrong server. If the server uses redundant power supplies, you have to cycle

all power supplies simultaneously to prevent boot errors and power supply errors. The iPDU

5

Page 6

management GUI and Insight Control include a Power Cycle Control switch that lets you cycle power

simultaneously to the redundant outlets for each server. The switch works similarly for a manually

entered device, such as a third-party device, for which the device’s universally unique identifier (UUID)

is properly matched to its outlets.

For more information about Intelligent Power Discovery, read the ―HP intelligent power infrastructure

solutions‖ technology brief at

http://h20000.www2.hp.com/bc/docs/support/SupportManual/c02505050/c02505050.pdf.

HP Power Advisor

Overly conservative power provisioning practices over-allocate power to IT devices and underutilize

your data center’s power capacity. Some facilities planners provision power capacity among branch

circuits based on a percentage of the total power supply (faceplate) ratings of the servers on each

circuit. This conservative method usually has a significant error margin that can unnecessarily use up

the data center’s power budget. HP Power Advisor can help you reclaim this trapped capacity and

more efficiently provision power in your data center.

The HP Power Advisor utility helps you calculate the expected power use of ProLiant and Integrity

servers to determine power distribution, power redundancy, and battery backup requirements. It lets

you calculate the power requirements for a single server, a rack of servers, or multiple racks of

servers. These calculations are based on data collected through extensive testing of various HP

ProLiant and Integrity server configurations, running a particular synthetic workload. You can adjust

the calculations to determine server power requirements at different server utilization levels that more

closely match your expected workload.

HP Power Advisor lets you build a virtual infrastructure, component-by-component and rack-by-rack. It

generates a Power Report that you can use to calculate the cost of ownership for a single server or a

rack of servers based on the cost of electricity.

The HP Power Advisor is the first step toward the goal of completely predictable and manageable

power use. Read the ―HP Power Advisor utility‖ technology brief for more information at

http://h20000.www2.hp.com/bc/docs/support/SupportManual/c01861599/c01861599.pdf.

HP uninterruptible power supplies

Conventional AC power distribution systems use an online double conversion uninterruptible power

supply (UPS) as shown in Figure 2. The online double conversion UPS converts the utility AC power to

DC, charges a battery bank, and converts it back to AC. A conventional power distribution unit (PDU)

uses a transformer to step down the AC voltage and distributes AC through branch circuits at the input

voltage of the IT devices. Inside servers, power supplies convert the AC power to DC and step down

the voltage to the levels required by the various components. From the UPS to the power supplies, this

distribution chain often delivers less than 75% of the utility power to the IT load.

6

Page 7

Figure 2: Conventional AC power distribution using an online double conversion UPS

Newer data centers may have more efficient power distribution systems, but there is still room for

improvement. We based the design of the HP eco-mode UPS and HP Rack-mountable UPS on the

basic principles we cited earlier to reduce power losses. They enable a power distribution chain that

is 84% to 86% efficient, an improvement of about 10 percentage points over conventional distribution

infrastructures.

HP eco-mode UPS

The HP R36000/3 parallel three phase UPS is a pre-racked uninterruptible power system that

provides 36 kilowatts (kW) of power or 24 kW with N+1 redundancy. Housed in a single HP 10000

Series G2 42U rack, it can be expanded to 60 kW with N+1 simply by installing up to three

additional RP12000/3 UPS Modules. Digital signal processing, wireless-paralleling, and new on-line

on demand hybrid technology provides density, redundancy, efficiency, and flexibility.

On-line on demand combines the up to 97% efficiency of a line interactive UPS with the stability of a

double conversion on-line UPS when power fluctuates beyond acceptable limits. Hot swappable

batteries, electronics modules, and an automatic bypass reduce downtime in the event service is

needed. It uses advanced line-interactive technology, which monitors the power from the grid and

passes it directly to the IT load as long as it meets specifications. This eliminates the two conversions

and consumes significantly less power.

HP Rack-mountable UPS

For dense data center environments, we designed modular HP Rack-mountable UPS products that

allow administrators to add UPS capacity incrementally. Our Rack-mountable UPS solutions provide

powerful performance while occupying minimal rack space, leaving space to fit more IT devices.

Products sizes vary from 1U at 1500 VA to 6U at 12000 VA, providing industry leading power

density in terms of watts per-U-space. They also deliver up to 97% efficiency.

Administrators can manage Rack-mountable UPSs locally and remotely using HP Power Manager. HP

Power Manager is a web-based application that lets you configure power failure settings and define

UPS load segments for maximum uptime of critical servers. If power fails, HP Power Manager can shut

down a load segment that is connected to less critical equipment and thus extend the runtime for more

critical equipment. This type of automated energy management decision helps you work smarter.

For more information, visit http://h18004.www1.hp.com/products/servers/proliantstorage/power-

protection/rackups/index.html.

Cooling

Cooling the data center involves pumping in cold air while removing hot exhaust air. Facilities

administrators try to do both as efficiently as possible by following certain principles. These principles

include creating efficient airflow and preventing the mixing of hot and cold air. Traditional practices

such as using raised floor plenums and having separate hot and cool aisles help accomplish this for

7

Page 8

racks below about 10 kW. Today’s high-density IT racks can generate significantly more heat,

creating hot spots that need supplemental cooling or specific air channeling. Letting the entire facility

run colder to compensate for hot spots is not a cost-effective option.

The increasing heat loads require carefully planned cooling strategies such as hot-air containment and

closed-loop cooling. We designed the HP 10000 G2 Rack Air Duct and the HP Modular Cooling

System G2 around these strategies to improve cooling efficiency and eliminate hot spots.

HP 10000 G2 Rack Air Duct

The HP 10000 G2 Rack Air Duct increases cooling efficiency by containing hot air at the rear of the

rack. The Rack Air Duct channels hot exhaust air directly into the air return system, eliminating hot air

recirculation and mixing with the cold air (Figure 3). The Rack Air Duct increases the temperature of

the air returned to the computer room air handler (CRAH), allowing more efficient heat transfer.

Strategically, less mixing of hot and cold allows you to better and more predictably cool your IT

systems. For example, you can increase cooling efficiency by raising the CRAH output temperature or

the chiller water temperature with fewer unexpected side effects. You can also add new loads or

move old ones with fewer problems.

The HP 10000 G2 Rack Air Duct also has some other distinct advantages:

It has no moving parts.

It can be retrofitted into existing data centers that use HP racks.

It can increase efficiency enough to support cooling 10-15 kW rack configurations.

Figure 3: HP 10000 G2 Rack Air Duct

HP Modular Cooling System G2

The HP Modular Cooling System (MCS) G2 is a ―closed loop‖ system that can cool two 17.5 kW

racks or one rack up to 35 kW. The MCS G2 lets you add computing power without adding to the

data center heat load. It extends the life of your facility when floor space is limited, when you need to

isolate existing high-density racks, or when you’re retrofitting an open-aisle data center. The totally

enclosed airflow within the MCS G2 does not affect other racks and vice versa.

The MCS G2 is highly efficient with a partial power usage effectiveness (PUE) of 1.05 to 1.07 at full

load, depending on the input voltage (200 – 240v). It uses an enclosed air-to-water heat exchanger

connected to the chilled water system to deliver cold air to the front of the racks. Fan modules at the

rear of the rack re-direct warm air back to the internal heat exchanger where it is cooled and re-

8

Page 9

circulated (Figure 4). For more information, see the HP Modular Cooling System G2 Rack Overview

at http://h10010.www1.hp.com/wwpc/us/en/sm/WF05a/3447589-3447589-3446285-

3446371-3461917-3657806.html.

Figure 4: Airflow in the HP Modular Cooling System G2

Data center power management with HP Insight Control

HP Insight Control is a suite of licensed management software components that build on and

complement HP SIM, which is included on all ProLiant servers. HP introduced data center power

management capabilities in Insight Control 6.0 through the HP Insight Control power management

plug-in.

Insight Control power management software has the following capabilities:

It provides centralized monitoring and control of server power consumption and thermal output.

It allows you to set power regulation policies for groups of servers.

It lets you visualize the layout of devices in racks, including summaries of temperature and power

consumption.

Insight Control power management software enables you to reduce errors and make better-informed

decisions. Some of the features of Insight Control power management include:

Data center power topology management

Data gathering and archiving

Power monitoring

Data center thermal profiles

Available power reporting

Data center power topology management

HP Insight Control power management software lets you visualize, monitor, and control the power

topology of a complete rack system from a central console, either locally or remotely (Figure 5).

9

Page 10

Insight Control can discover and communicate with iPDUs to retrieve the power topology (see

―Discover the power distribution topology‖ above) and retrieve power measurement data. With HP

iPDU technology, Insight Control knows which servers are connected to each iPDU. So when you drag

and drop the iPDU to the rack on the Power/Layout, all the attached servers follow. You can repeat

this procedure to create a model of each rack in the data center.

Insight Control also detects and identifies common errors such as a critical IT load that connects to

only one power feed but should be configured for power redundancy. Insight Control provides

specific recommendations for resolving this situation and other common errors found within the data

center, helping you work smarter.

Figure 5: Intelligent power discovery with Insight Control power management

Data gathering and archiving

HP Insight Control power management software provides a higher level of power monitoring and

reporting functionality than the iLO controller alone. Insight Control collects data from iLO and iPDUs

about your systems’ power consumption, inlet air temperature, and processor utilization. Insight

Control can archive this information for up to three years. This replaces guesswork with real data and

lets you monitor power and thermal trends in your data center (Figure 6).

10

Page 11

Figure 6: Power consumption graph in Insight Control showing the and average and peak observed power

consumption and the power cap for a rack of servers.

Power monitoring

As we mentioned earlier, potentially overloaded circuits can lead to unscheduled downtime. The

power monitoring capabilities of Insight Control let you accurately measure power use so you can

manage it better. Insight Control provides a detailed power summary at several distribution levels,

including the data center, rack, PDU, and server. Figure 7 displays a Power Summary meter for a

server showing the following information:

Peak Observed Power is the peak power consumption concurrently observed for all attached

devices during a recorded history of up to three years.

Calibrated Max Power is a prediction of the server’s maximum power use based on a benchmark

test that occurs when the server boots.

Minimum Power is the least amount of power required to power-on the server

Capacity is the available or maximum power limit of the power delivery device, such as a circuit

breaker or PDU.

Power cap (yellow dot) is the capped power consumption of the server.

You can safely use the Calibrated Max Power to reserve enough capacity for the server, based on its

present configuration, without relying on inaccurate estimates made from faceplate ratings or other

11

Page 12

generalized practices. The difference between the Calibrated Max Power and Peak Observed Power

represents the potential power capacity that you can reclaim by applying the power cap value. The

green range between the circuit Capacity and the Power Cap represents available circuit capacity.

Figure 7: Power meter summary for a server

Insight Control lets you identify potential electrical overloads at the PDU, rack, and data center level. It

also allows users to identify potential thermal overloads at the rack level. In Figure 8, the red range

between the Calibrated Max Power and the circuit Capacity represents the potential overload of the

circuit. This means that an overload would occur if all of the servers running the application were to

consume as much power as they consumed during the benchmark measurement at the last boot. In

this case, setting a cap at the PDU capacity would not impact the performance of the servers. But it

would protect the circuits from an overload by an unexpected increase in application workload.

Figure 8: Power meter summary for a rack of servers

Data center thermal profiles

Although the overall cooling in your data center may be sufficient, there may be areas with poor

airflow, excessive heat output, or airflow mixing at the ends of aisles. Insight Control lets you identify

such areas by displaying your data center’s temperature profile. The profile is based on data from

thermal sensors in each ProLiant server.

12

Page 13

Before Insight Control can generate the temperature profile, you need to describe the physical

positions of your systems and racks. You can do this by importing a database (UCMDB or Microsoft®

Excel worksheet), using enclosure information from HP BladeSystem Onboard Administrator, or by

manually defining rack groups. Then you can view the peak observed temperature in each area of

your data center over 24 hours through the Power/Thermal Analysis views page (Figure 9). If you

configured thermal limits for any racks, you can immediately see potential violations of these limits.

Figure 9: Data center temperature profile on the Power/Thermal tab

13

Page 14

At the rack level, the Power/Layout tab displays a specific rack configuration with power distribution

devices, enclosures, and servers. The view in Figure 10 shows the rack height and the power

distribution connections on Side A and Side B. The color of the enclosures and systems in a rack

represents the thermal status of the particular enclosure or system as referenced by the temperature

legend at the bottom of the screen. The monitored temperature range is from 59°F (15°C) to 86°F

(30°C). You can click on an enclosure or system in the rack to view its power consumption and

thermal information.

Figure 10: Rack thermal view

Available power reporting

Insight Control software collects the electrical inventory and the power required for each HP device.

This gives you a precise view of both the total power required and the amount of power available for

14

Page 15

new devices. Insight Control also polls the iPDUs daily and updates the rack configuration if a server

is moved or a new server is plugged into an iPDU. If you need a place to deploy a new server, Insight

Control can identify the rack(s) with available power where you can put it (Figure 11). You simply

click on the Available Power tab to determine where you have enough power for the server or device

you need to deploy.

Dynamic Power Capping, controlled on multiple servers through Insight Control, completes the

solution. It allows you to control power use, ensuring that power used by the servers conforms to the

available power capacity.

Figure 11: Available Power tab in Insight Control power management software

HP Performance Optimized Datacenters

HP Performance Optimized Datacenters (PODs) are modular, self-contained data centers that help

enterprises expand capacity rapidly and efficiently. The HP POD family includes three data center

designs that you can deploy in weeks. The HP POD 40c and 20c are chilled-water data centers and

the HP POD 240a uses free-air cooling and air conditioning. Free-air cooling takes advantage of

regional climate conditions for more efficient operation.

15

Page 16

HP POD 40c and 20c

The POD 40c is 40 feet (12 m) long with 1100U of rack capacity and twenty-two 50U 19-inch

(482 mm) deep racks (Figure 12). It offers capacity equivalent to a 5,000 ft2 (464 m2) traditional

data center. It provides up to 600 kW of non-redundant capacity or 380 kW of fully redundant

capacity. Facilities personnel can connect it directly into 480 V utility power and the chilled water

system.

The POD 20c is 20 feet (6 m) long with 500U of rack capacity in ten 50U 19-inch (482 mm) deep

racks. It offers capacity equivalent to a 2,000 ft2 (186 m2) traditional data center. It provides up to

290 kW of non-redundant power capacity or 145 kW of fully redundant capacity. Facilities

personnel can connect it directly into 480 V utility power and the chilled water system.

Figure 12: The design of the HP POD 40c

We engineered the HP POD 40c and 20c for the highest efficiency of a water-cooled data center

with standard air-cooled IT. The PODs minimize power losses by decreasing the number of power

conversions. High-voltage 3-phase AC (400-480v AC depending upon location) is used as the input

to the POD and then delivered directly to the racks as separate single-phase feeds for distribution to

the servers. Highly efficient airflow and separate hot and cold aisles minimizes mixing and

recirculation, and it maximizes cooling efficiency with a cold aisle that can be run up to 90°F (32°C).

16

Page 17

As a result, the HP POD 40c and 20c can have a PUE ratio as low as 1.25 depending on the

configuration of the IT equipment and the water-cooling facility to which they connect.

We can ship the HP POD 40c or 20c in as little as 6 weeks. For more information, visit

http://h18000.www1.hp.com/products/servers/solutions/datacentersolutions/pod/index.html.

HP POD 240a

The HP POD 240a (nicknamed EcoPOD) is engineered for the ultra-high efficiency that is possible

only with free-air cooling. The EcoPOD contains 2200U of rack space, suitable for 44 50U 19-inch

racks. This IT capacity is equivalent to a 10,000 ft2 (3,048 m2) traditional data center, but at onetenth the space. The EcoPOD consists of two 40-ft IT modules with a common 8-ft wide (2,438 mm)

hot aisle (Figure 13) that allows you to easily remove and service IT equipment up to a rack at a time.

Above the IT modules, you can use up to 24 direct-expansion (DX) air conditioning units when outside

air is too hot, or otherwise not suitable.

Figure 13: HP Performance Optimized Datacenter 240a

Power capacity

The EcoPOD uses an industrial-quality programmable logic controller (PLC) to gather IT power

consumption data from up to two HP Monitored PDUs per rack. The HP Monitored PDU accepts 3phase 415 V power and outputs 240 V to the rack. It has an input current monitor that measures the

aggregate current draw on each power circuit. Administrators can view IT load data locally or

remotely with an optional management module.

Policy-based Adaptive Cooling

The PLC checks environmental conditions inside and outside the EcoPOD. The PLC monitors

temperature sensors in the hot and cold-aisles and humidity sensors included with the optional

humidifier. Users can define policy set points for Adaptive Cooling mode based on industry

parameters–ASHRAE recommended, ASHRAE allowable, or HP allowable temperatures.

Based on the IT load, environmental conditions, and user-defined policies, the EcoPOD uses an

algorithm to adjust the control surfaces, fan speeds, and the following Adaptive Cooling modes to use

the least amount of energy:

Free air mode. Ambient air within a specified temperature/humidity range provides cooling.

DX (recirculation) mode. The DX units provide all of the cooling.

17

Page 18

We can ship the HP POD 240a in as little as 12 weeks. For more information on the EcoPOD, visit

http://h17007.www1.hp.com/us/en/whatsnew/june/060611-3.aspx.

Conclusion

This paper has described the products and technologies we have developed around our three data

center strategies: consume less power, fit more IT equipment, and work smarter.

We continue to focus on improving the energy efficiency and management of ProLiant servers to help

your data center get the maximum performance per watt, maximize the use of the capital

infrastructure, and deal with the complexity of higher IT equipment densities.

Our power distribution technologies help you to ‖right size‖ your IT and power infrastructures,

measure every watt and degree, and decrease costly energy losses.

We offer products that improve the cooling efficiency of your data center through hot air containment

and closed-loop cooling. These products help you control cooling resources better and fit more highdensity IT equipment to extend the life of your data center.

HP Insight Control power management software can help you define, monitor, and control your data

center’s IT, power, and cooling infrastructures. It also helps you reclaim unused power capacity and

maximize data center utilization.

If your data center needs to scale out rapidly, our modular, energy-efficient PODs offer a complete

expansion alternative to traditional brick-and-mortar facilities. With HP PODs, you can expand IT

capacity in weeks instead of months or years with traditional facilities.

18

Page 19

© Copyright 2011 Hewlett-Packard Development Company, L.P. The

information contained herein is subject to change without notice. The

only warranties for HP products and services are set forth in the

express warranty statements accompanying such products and

services. Nothing herein should be construed as constituting an

additional warranty. HP shall not be liable for technical or editorial

errors or omissions contained herein.

Microsoft and Windows are registered trademarks of Microsoft

Corporation.

TC0000759, October 2011

Resource description

Web address

HP rack and power infrastructure

products

http://h18004.www1.hp.com/products/servers/platforms/racka

ndpower.html

Optimizing facility operation in high

density data center environments

http://h20000.www2.hp.com/bc/docs/support/SupportManual

/c00064724/c00064724.pdf

HP Rack Air Duct

http://h18004.www1.hp.com/products/servers/proliantstorage

/rack-options/rack-air-duct/index.html

HP Modular Cooling System

Generation 2 water cooling

technology

http://h20000.www2.hp.com/bc/docs/support/SupportManual

/c01490034/c01490034.pdf

HP Power Capping and Dynamic

Power Capping for ProLiant Servers

http://h20000.www2.hp.com/bc/docs/support/SupportManual

/c01549455/c01549455.pdf

Power Regulator for ProLiant servers

http://h20000.www2.hp.com/bc/docs/support/SupportManual

/c00300430/c00300430.pdf

HP Power Advisor

http://www.hp.com/go/hppoweradvisor

HP intelligent power infrastructure

solutions

http://h20000.www2.hp.com/bc/docs/support/SupportManual

/c02505050/c02505050.pdf

For more information

For additional information, refer to the resources listed below.

Send comments about this paper to TechCom@HP.com

Follow us on Twitter: http://twitter.com/ISSGeekatHP

Loading...

Loading...