Page 1

Installation Manual

Model D640

HP 5000

Cut Sheet

Printers

(Printer and Accessories)

Page 2

HP 5000

D640 Cut Sheet Printer

Installation Manual

(for Printer and Accessories)

Hewlett-Packard Company

HP Part No. C5620-90015

E1196

Page 3

Notice

The contents of this manual may be revised without prior notice and without obligation to

incorporate changes and improvements into units already shipped.

Every effort has been made to ensure that the information included here is complete and

accurate at the time of publication. However, Hewlett-Packard cannot be held r esponsible

for errors and omissions.

Copyright ©1996 Hewlett-Packard

Printed in USA. All rights reserved. No part of this manual may be repr oduced or trans-

lated, stored in database or retrieval system, or transmitted, in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, without the prior written

permission of Hewlett-Packard.

Trademarks

Hewlett-Packard Corporation: PCL, HP-GL/2, Bi-Tronics

Adobe Systems, Inc: PostScript

Centronics Data Comput er Cor por ati o n: Cent ron ic s

Apple Computer, Inc.: Apple Talk, Local Talk

Novel, Inc.: Netware

Other product names mentioned in this manual may also be trademarks and are used here

for identification only.

Printing History

The dates on the title page change only when a new edition is published.

Edition 1.1....................November 1996

ii

Page 4

Caution and Warning Notes

The CAUTION note denotes a hazard. It calls attention to a procedure which, if done

incorrectly or inatten tivel y, co ul d d amage o r des troy part or all of the produ ct. Do n ot pr oceed beyond a CAUTION note until the indicated conditions are fully understoo d and met.

The WARNING note denotes a hazard. It calls attention to a procedure, practice, or the

like, which, if not done correctly or adhered to, could result in injury. Do not proceed

beyond a WARNING sign until the indicated conditio ns are fully understood and met.

The following conventions are used throughout this manual:

NOTE:

CAUTION:

WARNING:

Notes contain important information set off from the text.

Caution messages indicate procedures which, if not observed, could

result in damage to equipment.

Warning messages call attention to situations that could result in

personal injury.

iii

Page 5

WARNING:

Disconnect the printer from its power source whenever performing

any maintenance or installation procedure.

WARNING:

WARNING:

WARNING:

Please address any comments or questions with respect to this document to:

Hewlett-Packard Company

HP 5000 Printers - MS 44MC

System Peripherals Operation

19111 Pruneridge Ave.

Cupertino, California 95014-9804

The printer is equipped with safety interlock switches on most of its

covers. The switches disable parts of the printer when the covers are

opened. These areas present the ri sk of electric shock, burns, and

injury from mechanical hazards.

Any unauthorized removal of safety covers, manipulation of safety

switches, and interference with the safety system is strictly

prohibited. Such actions can cause personal injury and can damage

the system. Also make sure that the operating and maintenance

areas are not obstructed in any way.

With any drive mechanism, loosely hanging items of clothing and

jewelry, such as ties, belt ends, neck lace s, br ace lets, a nd rings, and

unprotected hair can cause injury if caught in the mechanism.

iv

Page 6

Preface

The Installation Manual contains all the information needed to install and set up the

HP 5000 model D640 printer and it’s accessories.

The information within is directed toward printer users who are familiar with printer con-

figuration operations and are comfortable performing basic mechanical operations.

Other Manuals

The HP 5000 D640 User Manual, contains all the information needed to operate

Hewlett-Packard D640 printers.

The HP 5000 D640 Service Manual, C5620-90013, is a comprehensive technical refer-

ence to all mechanical and electronic components in the printer. Th e Ser vice Manu al helps

you perform fault diagnosis and isolation, then guides you through replacement of subassemblies.

The

HP 5000 D640 Technical Reference Manual,

about software conventions and hardware components not covered in the User, Service, or

Installation Manuals.

The HP 5000 D640 Paper Specifications Guide, C5620-90001, explains the var ious kind s

of papers usable in the printer, how to care for them, and how to minimize paper-related

problems with the D640.

C5620-90002, provides information

v

Page 7

Table of Contents

Chapter 1 Introduction

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Chapter 2 Installation

Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

The Installation Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Procedure 1: Identifying the Printer Installation Boxes . . . . . . . . . . . . . . . . . . 2-7

Procedure 2: Opening the Starter Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Procedure 3: Unpacking the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Procedure 4: Getting To Know Your Printer . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Procedure 5: Inside the Front Door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Procedure 6: Installing Ozone Filter and Manual Pocket . . . . . . . . . . . . . . . . 2-39

Procedure 7: Removing Paper Tray Packing Material . . . . . . . . . . . . . . . . . . 2-41

Procedure 8: Powering On the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

Procedure 9: Adding New Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

Procedure 10: Setting the Paper Trays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-60

Procedure 11: Installing Function Code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-71

Procedure 12: Setting the Date and Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-76

Procedure 13: Printing a Setup Report. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-79

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-81

Procedure 14: Securing the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-82

Procedure 15: Paper Path Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-83

vii

Page 8

Chapter 3 Host Computer Interface

Installation and Configuration

Printer Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Procedure 1: Install the Interface Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Procedure 2: Configure the Printer on Your Host System . . . . . . . . . . . . . . . .3-11

Procedure 3: Setting the Printer’s Communication Interface . . . . . . . . . . . . .3-21

Procedure 4: Confirm the Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

Interface Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

Chapter 4 Accessories

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Procedure 1: High-Capacity Input (HCI) Installation. . . . . . . . . . . . . . . . . . . . .4-4

Procedure 2: High-Capacity Output (HCO) Installation . . . . . . . . . . . . . . . . .4-16

Procedure 3: Installing Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-34

Procedure 4: Installing PostScript . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-42

Procedure 5: Custom Tray Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-46

Appendix A Packing and Shipping

Packing and Shipping the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Appendix B Warranty and Support

Where To Call For Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

viii

Page 9

Chapter 1 Introduction

Chapter 1

Introduction

Introduction

Introduction 1-1

Page 10

Introduction

Thank you for purchasing the D640 printer.

Introduction

This installation manual is written in a logical, step by step format for quick and easy

installation of the D640 printer and all available accessories. A typical installation will

take about 1 to 2 hours to complete. We strongly encourage you to follow the procedures

in the order they are presented to avoid missing any critical steps. If you run into any questions or problems during the installation, you can call Hewlett-Packard and receive immediate assistance. See Warranty and Support for support telephone numbers.

You may need the following tools to complete the installation:

• Cutter to remove packaging straps

• Pliers to remove shipping lock inserts

• #2 Phillips head screwdriver (to install HCI, HCO, and/or Memory).

• Medium flat blade screwdriver (to install HCO).

The installation manual is organized as these chapters:

Chapter 2, Installation:

This chapter is broken down into a number of procedures that covers every step of the

unpacking and installation process for the basic printer.

Chapter 3, Host Computer Interface Installation and Configuration:

This chapter covers the basic information needed to connect the printer to a h ost computer.

Chapter 4, Accessories:

This chapter covers all the details for unpacking and installing each of the available acces-

sory products used with the printer.

Introduction

Appendix A, Packing and Shipping:

This chapter shows you the required steps to repackage your printer in case it needs to be

shipped to another location.

Appendix B, Warranty and Support:

This chapter provides a list of phone number where you can call for free assistance during

the installation process, and a list of telephone nu mbe rs to call if there are problems with

the printer hardware.

Introduction 1-3

Page 11

Chapter 2 Installation

Chapter 2

Installation

Installation

Installation 2-1

Page 12

Site Preparation

Site Preparation

This chapter provides step-by-step instructions for installing your printer.

You may have purchased one of the following D640 accessories:

• PostScript

• Additional memory

• Custom tray

• High-Capacity Input (HCI)

• High-Capacity Output (HCO)

Install them only after you have completely installed and successfully te sted the printer.

Instructions for installing these accessories appear in Chapter 4, Accessories.

Before you begin, make sure the location you have selected for your printer meets the

space and environmental requirements, as shown in Table 2-1.

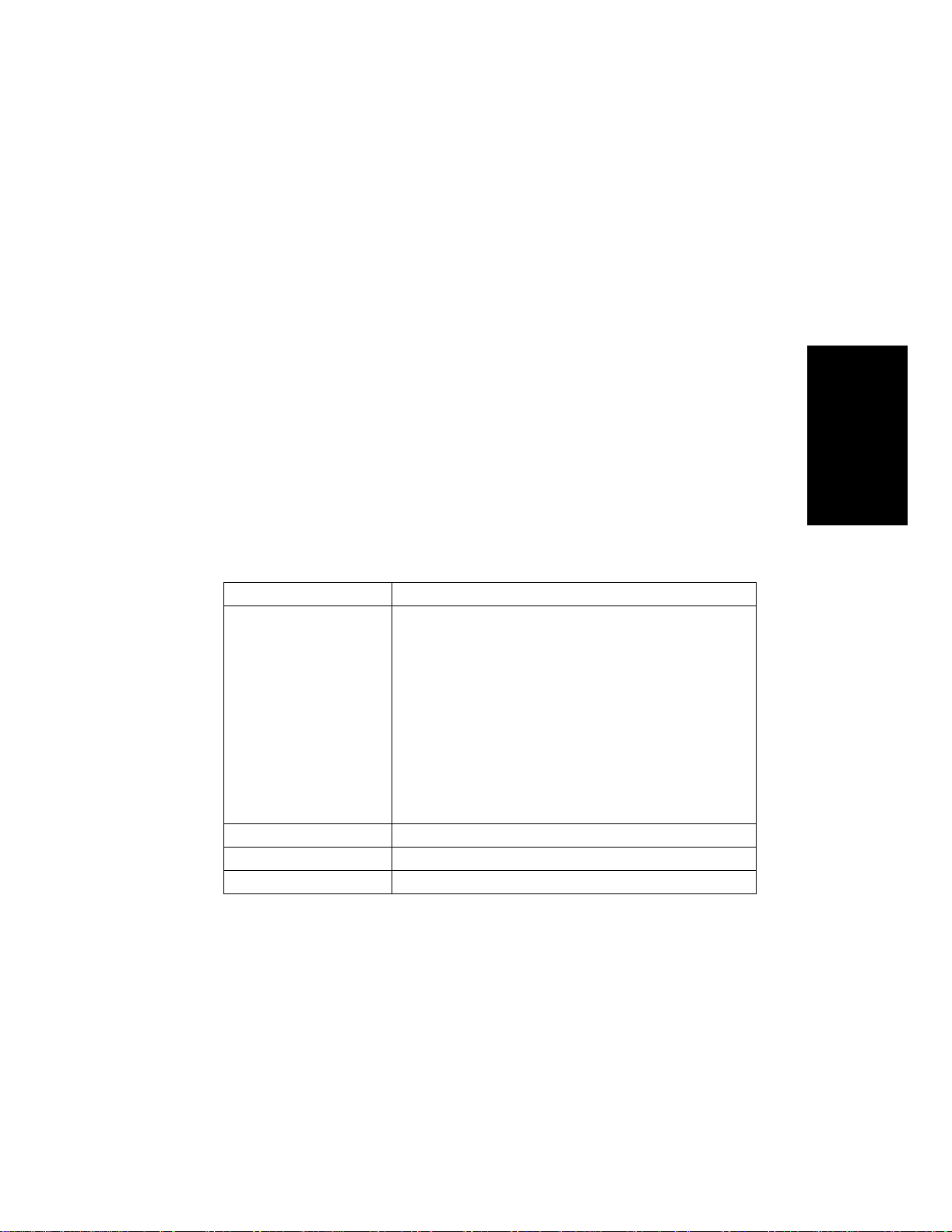

Table 2-1 Printer Environment Specifications

Power Requirements 120-127 or 200-240 Vac ±10%, 50/60Hz, 12 or 7A.

Physical Dimensions

(without HCI/HCO)

Length:

Depth:

Height:

Physical Dimensions

(with HCI/HCO)

Length:

Depth:

Height:

Weight 298lbs (135kg)

Temperature Operating: 59° F to 95°F (15° – 35°C)

Relative humidity 40%–60% (optimal)

23.0in (585mm)

25.2in (640mm)

40.6in (1,030mm)

55.7in (1414mm)

25.2in (640mm)

40.6in (1030mm)

Installation

Refer to the following illustrations for help in situating th e printer. Remember to leave

adequate space for opening the front and side covers, and for air circulation to the ventilation openings on the rear of the printer. If you have purchased the HCI or HCO, you need

to reserve space for them as well.

Installation 2-3

Page 13

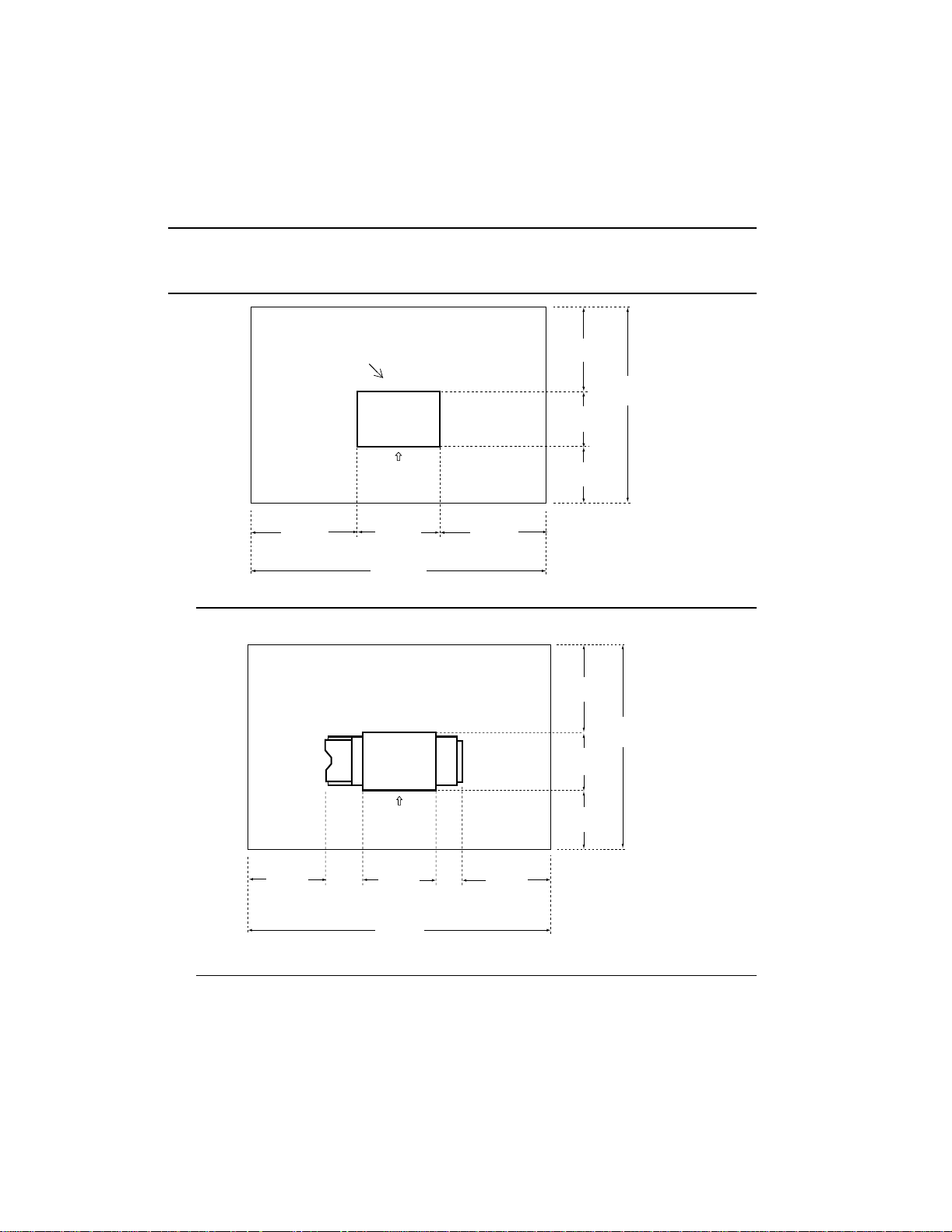

Site Preparation

CAUTION: Provide for adequate ventilation when selecting your site. To ensure

reliable operation, do not block the ventilation slots and openings on

the exterior of the printer.

Ventilation slots

Operating

33.5 in.

(850 mm)

(585 mm)

(2285 mm)

Printer

Side

23.0 in.

90.0 in.

33.5 in.

(850 mm)

33.5 in.

(850 mm)

25.2 in.

(640 mm)

25.6 in.

(650 mm)

Figure 2-1 Operating Area Space Without HCI or HCO

33.5 in.

(850 mm)

Printer HCIHCO

25.2 in.

(640 mm)

84.3 in.

(2140 mm)

84.3 in.

(2140 mm)

Operating

Side

33.5 in.

(850 mm)

21.25 in.

(540 mm)

23.0 in.

(585 mm)

122.6 in.

(3114 mm)

11.4 in.

(289 mm)

33.5 in.

(850 mm)

Figure 2-2 Operating Area Space With HCI and HCO

2-4 Installation

25.6 in.

(650 mm)

Page 14

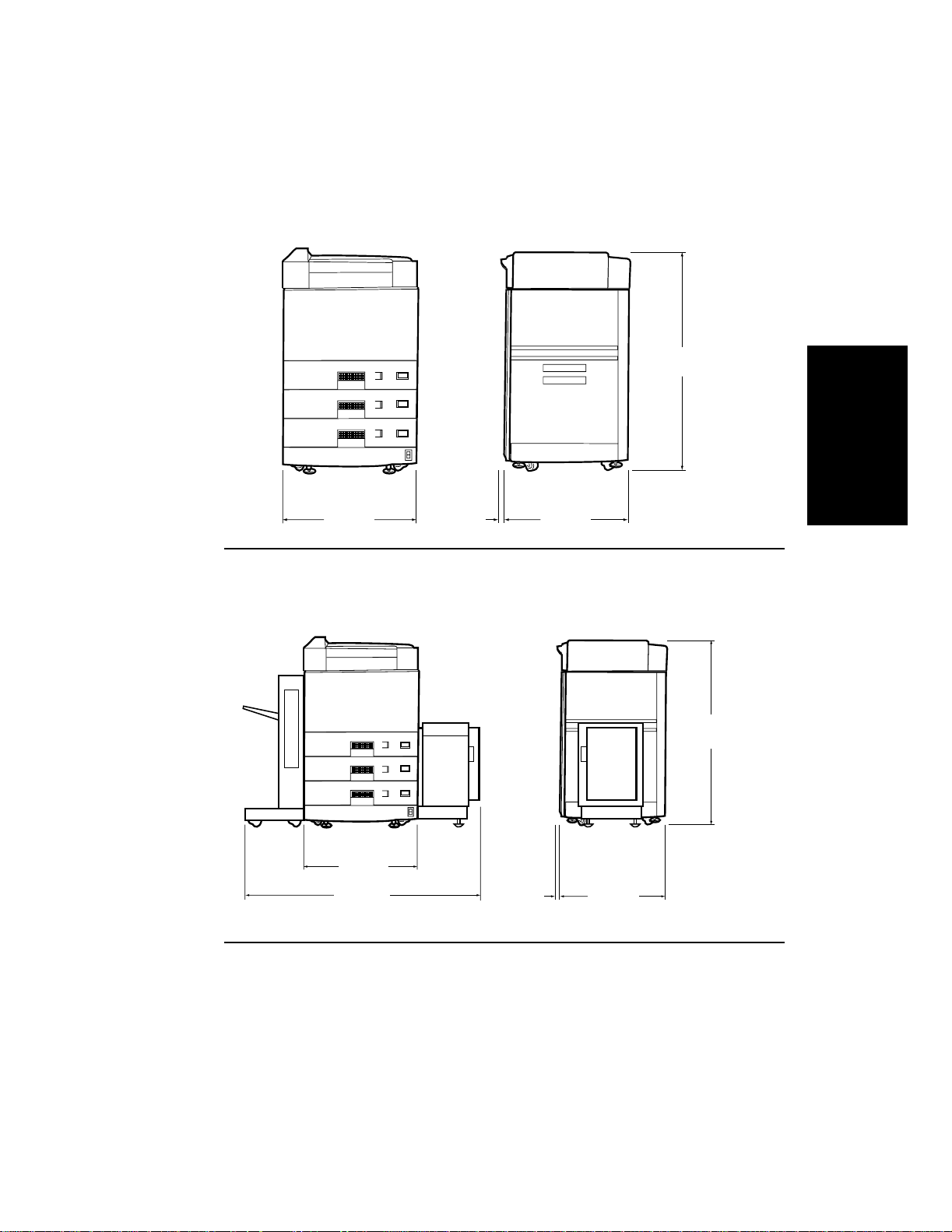

Site Preparation

40.5 in.

LTR

LTR

LTR

1030 mm

Installation

23.0 in.

585 mm

1.4 in.

35 mm

25.2 in.

640 mm

Figure 2-3 Physical Dimensions (Front and Right Side View)

Without HCI or HCO

LTR

LTR

LTR

23.0 in.

(585 mm)

55.66 in.

(1413.7 mm)

1.4 in.

(35 mm)

Figure 2-4 Physical Dimensions (Front and Right Side View)

With HCI and HCO

25.2 in.

(640 mm)

40.5 in.

(1030 mm)

Installation 2-5

Page 15

The Installat ion Process

The Installation Process

The installation process is broken down into a number of key procedures, each of which

contains several different activities concentrated in a particular physical location of the

printer. The procedures covered in this chapter include:

• Procedure 1: Identifying the Printer Installation Boxes, on page 2-7

• Procedure 2: Opening the Starter Kit, on page 2-9

• Procedure 3: Unpacking the Printer, on page 2-12

• Procedure 4: Getting To Know Your Printer, on page 2-21

• Procedure 5: Inside the Front Door, on page 2-25

• Procedure 6: Installing Ozone Filter and Manual Pocket, on page 2-39

• Procedure 7: Removing Paper Tray Packing Material, on page 2-41

• Procedure 8: Powering On the Printer, on page 2-43

• Procedure 9: Adding New Supplies, on page 2-47

• Procedure 10: Setting the Paper Trays, on page 2-60

• Procedure 11: Installing Function Code, on page 2-71

• Procedure 12: Setting the Date and Time, on page 2-76

• Procedure 13: Printing a Setup Report, on page 2-79

• Procedure 14: Securing the Pri nte r, on page 2-82

• Procedure 15: Paper Path Alignment, on page 2-83

Once you have completed these procedures, the printer will be up and running as a standalone unit.

Save packing materials for repacking later, if necessary.

Required Tools

You will need the following additi onal tools for installation:

• Pliers to remove plastic lock inserts.

• Cutter to remove plastic strapping material.

• #2 Phillips screwdriver (if you are installing Memory, HCI or HCO).

• Medium flat blade screwdriver (if you are installing an HCO).

NOTE: Move the printer close to its final loc ation before unpacking. M ake sure

you have room to lower the ramp before moving the printer off of the

pallet.

2-6 Installation

Page 16

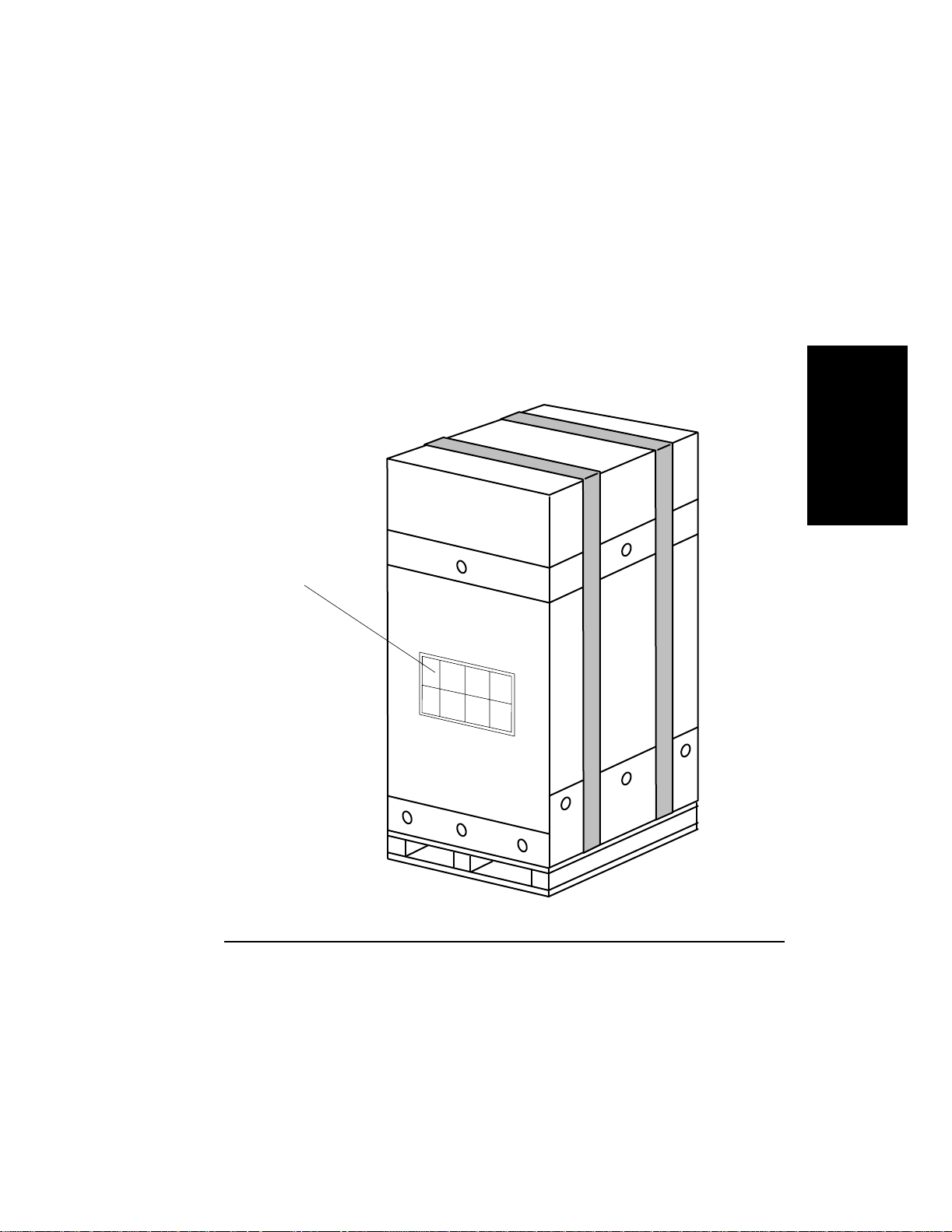

Procedure 1: Identifying the Printer Installation Boxes

Procedure 1: Identifying the Printer Installation Boxes

There are at least two boxes comprising the printer installation; two more if yo u have purchased the High Capacity Input (HCI) and High Capacity Output (HCO). The printer and

starter kit boxes are illustrated in Figure 2-5.

STARTER KIT

Unpacking

instructions

PRINTER

Installation

Figure 2-5 Printer Boxes

Installation 2-7

Page 17

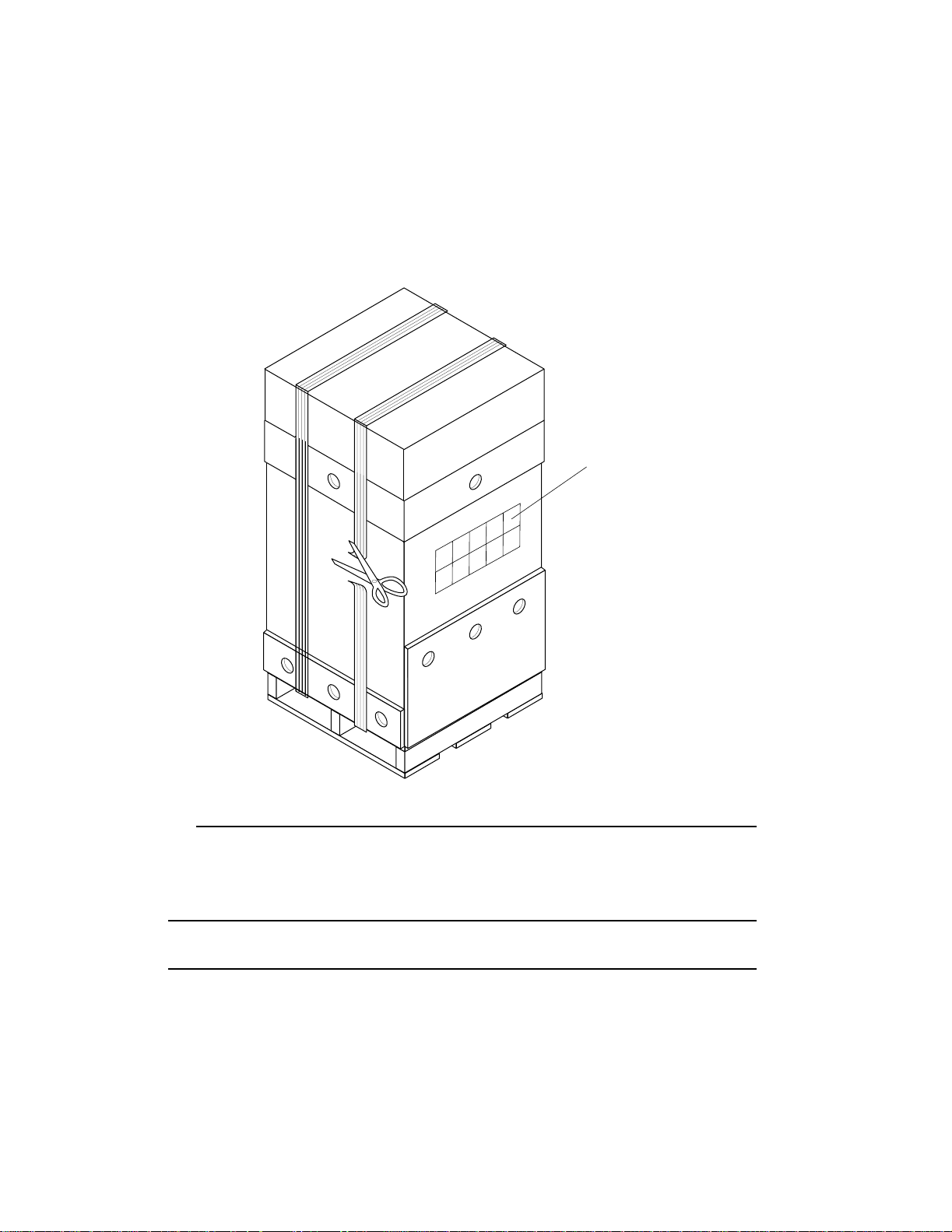

Procedure 1: Identify ing the Printer Installation Boxes

1. Cut the plastic strap as shown in Figure 2-6.

STARTER KIT

Figure 2-6 Cutting Plastic Strap

2. Remove Starter Kit box from the top of the printer.

3. Proceed to Procedure 2: Opening the Starter Kit.

Unpacking

instructions

NOTE: If you purchased any accessories, do not open them at this time, they will

be installed later.

2-8 Installation

Page 18

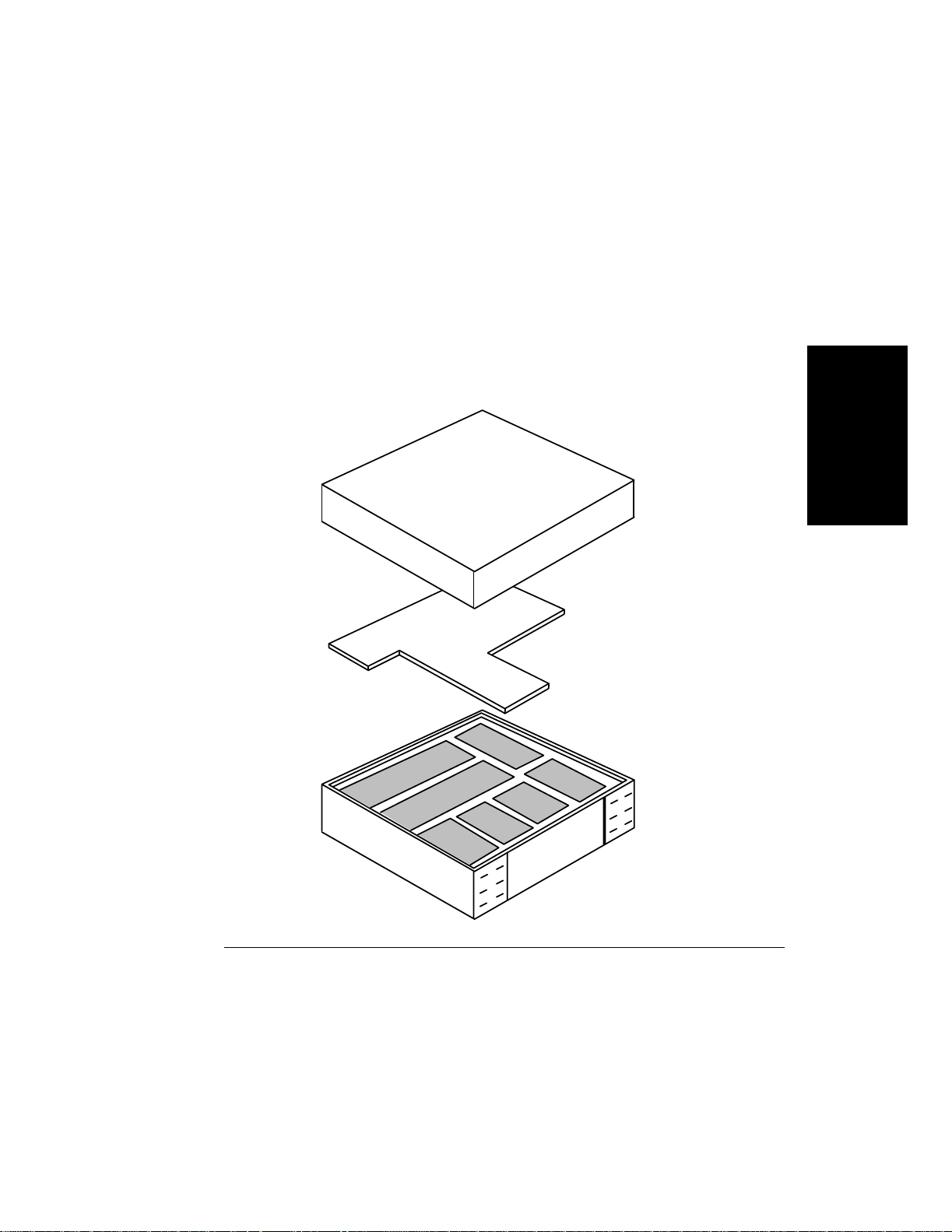

Procedure 2: Opening the Starter Kit

Procedure 2: Opening the Starter Kit

Open the package identified as Starter Kit shown in Figure 2-5, Printer Boxes, on page

2-7, and examine the cont ents, shown i n Figure 2-8 , on page 2-10. The Start er Kit cont ains

the supplies necessary to set up the printer for immediate use (see Figure 2-8). Check the

contents of the starter kit box to make sure you have all of the comp onents listed in

Table 2-2.

Installation

Figure 2-7 Starter Kit Box

Installation 2-9

Page 19

Procedure 2: Opening the Starter Kit

NOTE: Do NOT open the individual component boxes or bags at this time.

Fuser

Drum

Cleaning Cloths

Manuals

Power Cord

Paper Size Labels

Function Code Floppy

Manual Pocket Holder

Toner Developer Cleaning Brush

Ozone Filter

Figure 2-8 Starter Kit Box Contents (Packed)

Transfer assembly

2-10 Installation

Page 20

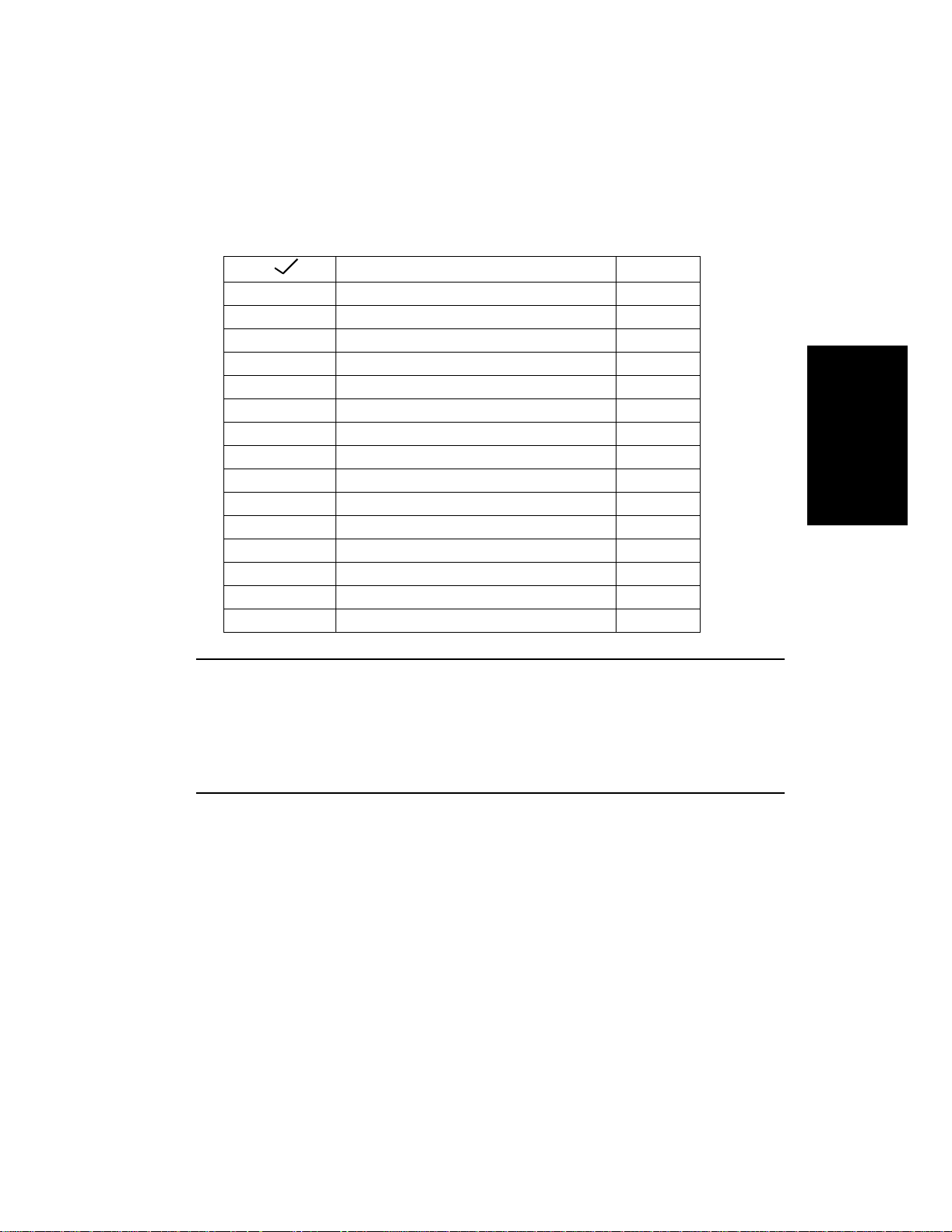

Procedure 2: Opening the Starter Kit

Table 2-2 Components Checklist

Component Quantity

Fuser 1

Drum 1

Transfer assembly 1

Toner bottle 1

Developer bottle 1

Cleaning brush 1

Installation manua l 1

User manual 1

Technical Reference manual 1

Paper Specification manual 1

Paper size car ds 3 sheets

Power cord 1

Ozone filter 1

Cleaning cloths 1 pkg

Function Code floppy 1 pkg

Installation

NOTE: Check the label on the fuser box and make sure you have the correct

voltage for your installation. The fuser comes in two versions,

120-127VAC or 200-240VAC. 120 -127VAC is more commonly used in

North America; 200 -240 VAC is more commonly used in Europe.

If you received the wrong version, call your supplier for a replacement

fuser.

Go to Procedure 3: Unpacking the Printer.

Installation 2-11

Page 21

Procedure 3: Unpacking the Printer

Procedure 3: Unpacking the Printer

NOTE: Save the printer shipping materials in case they are needed to transport

the printer to a new location. Instructions for packing your printer for

shipment are included in Packing and Shipping.

WARNING:The printer weighs 298 pounds (135 kg). Moving the printer requires

two people.

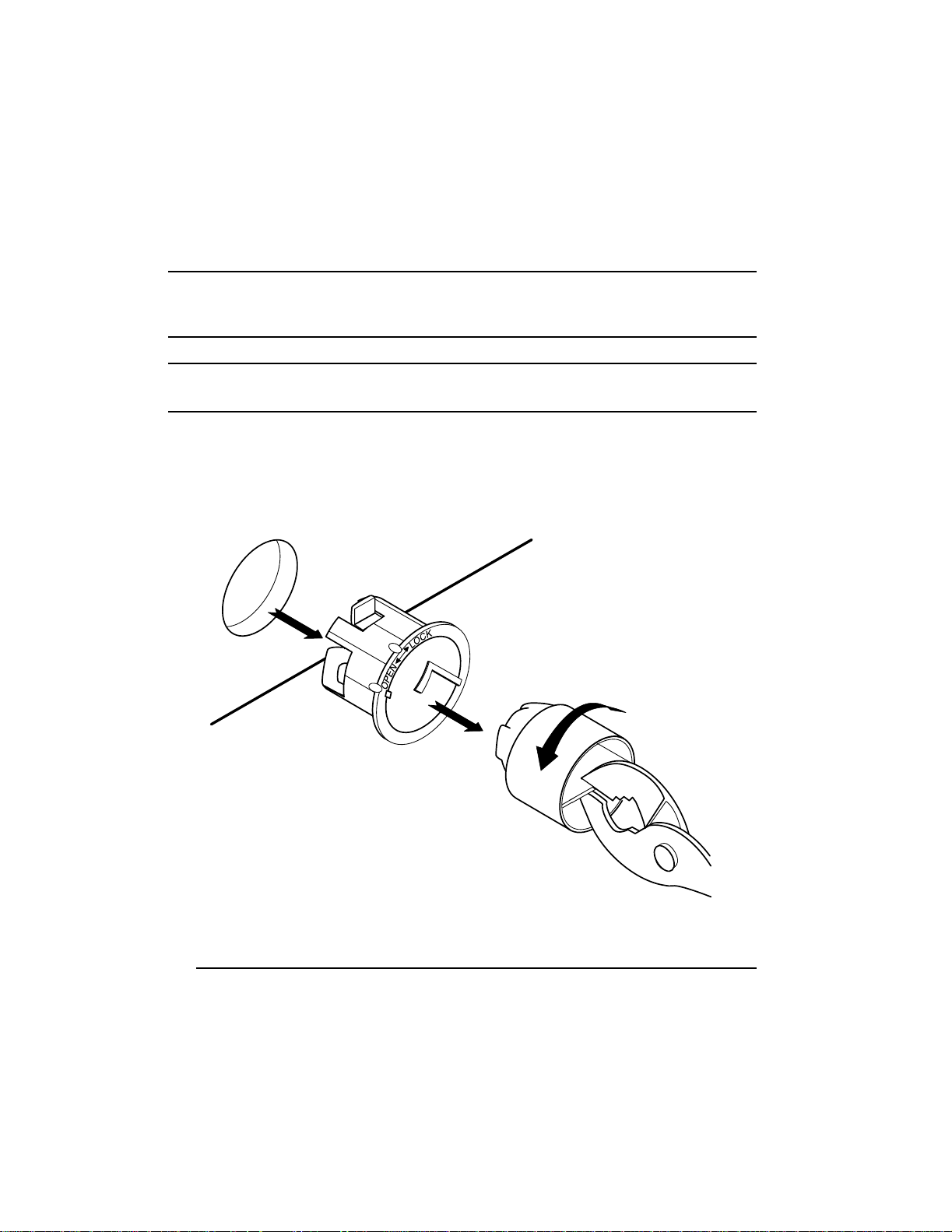

1. Use fingers or pliers to turn the plastic lock inserts counterclockwise and pull out, as

shown in Figure 2-9, Removing Plastic Lock Inserts.

2. Remove all 16 plastic lock inserts.

Figure 2-9 Removing Plastic Lock Inserts

2-12 Installation

Page 22

Procedure 3: Unpacking the Printer

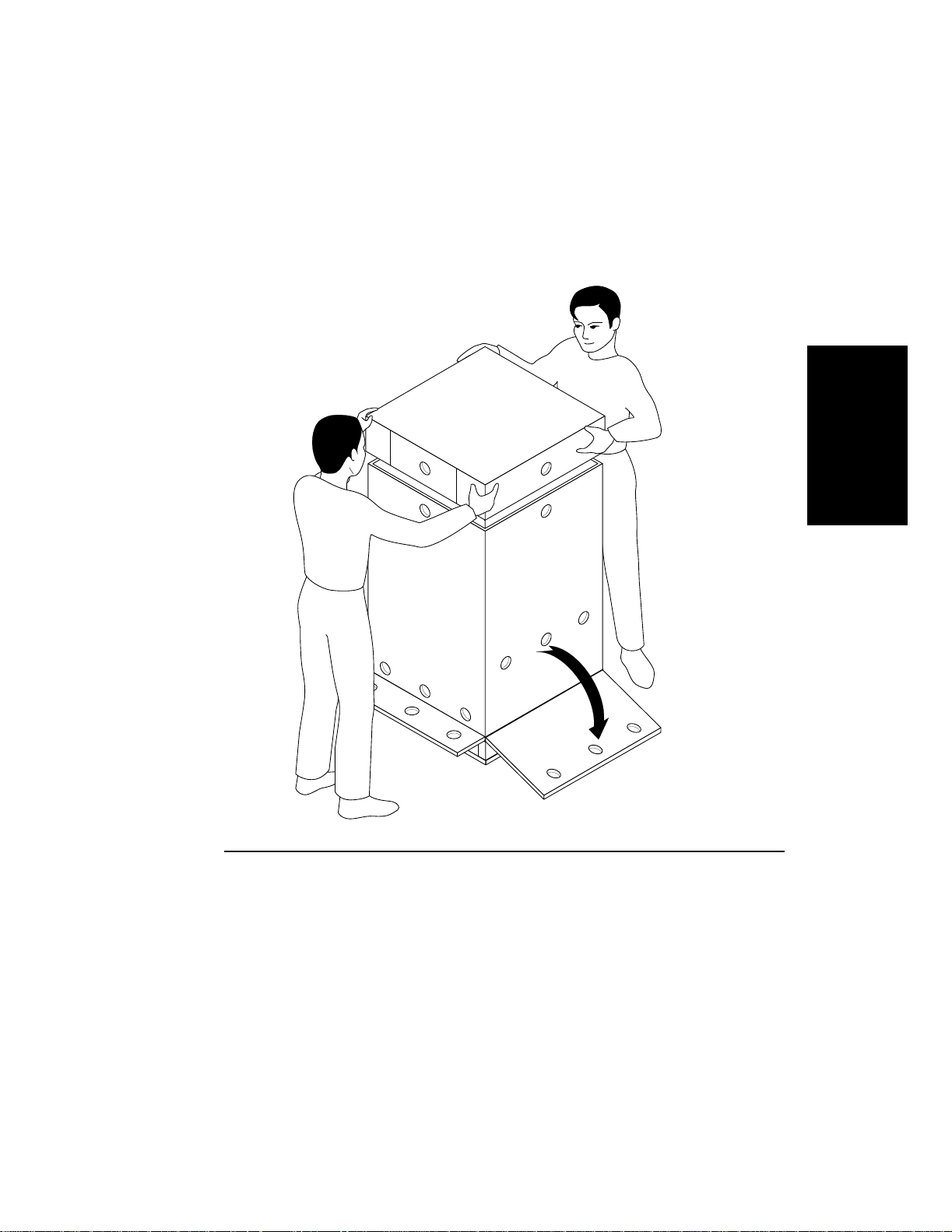

3. Lower the ramp and then remove the lid as shown in Figure 2-10.

Installation

Figure 2-10 Removi ng Lid

Installation 2-13

Page 23

Procedure 3: Unpacking the Printer

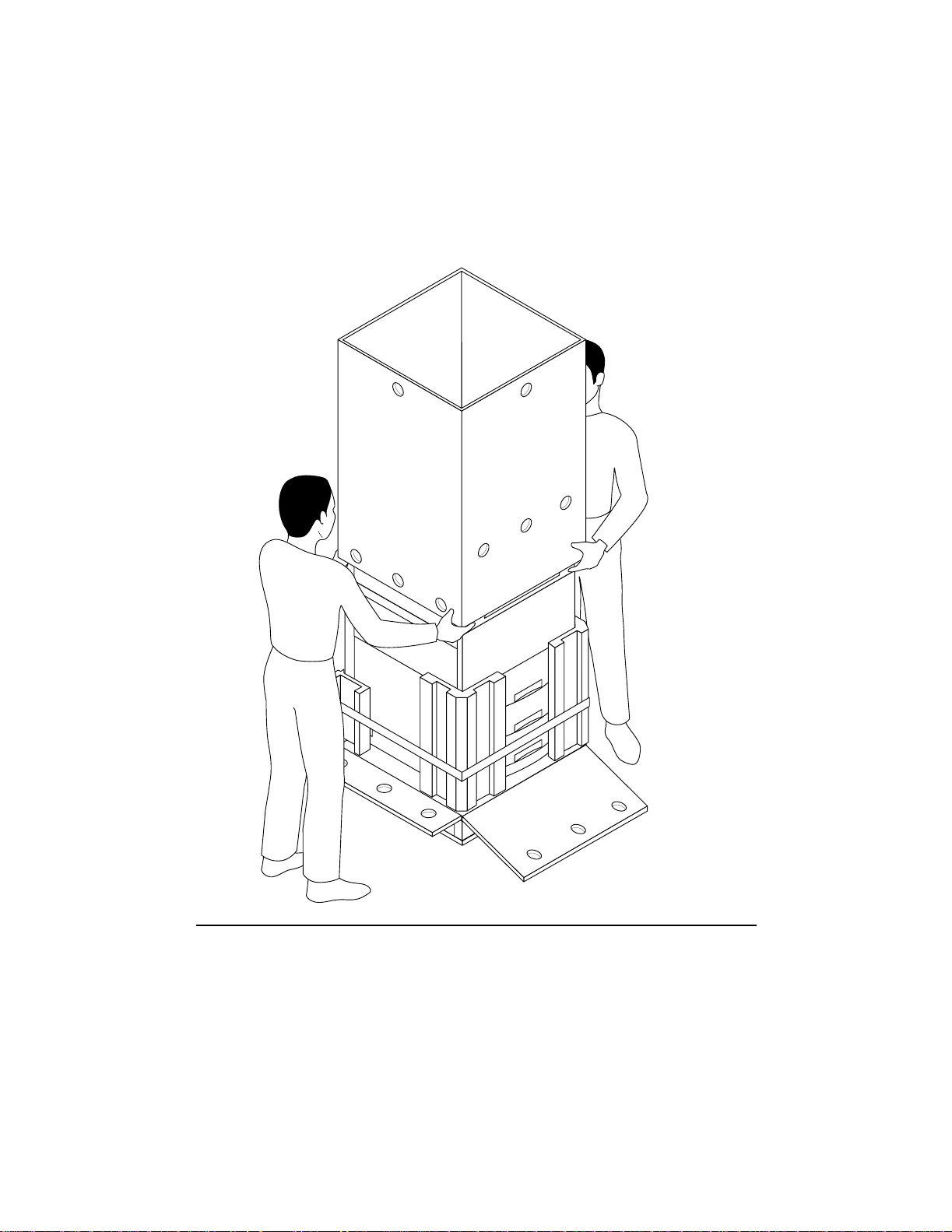

4. Remove the cardboard sleeve as shown in Figure 2-11.

Figure 2-11 Removing Sleeve

2-14 Installation

Page 24

Procedure 3: Unpacking the Printer

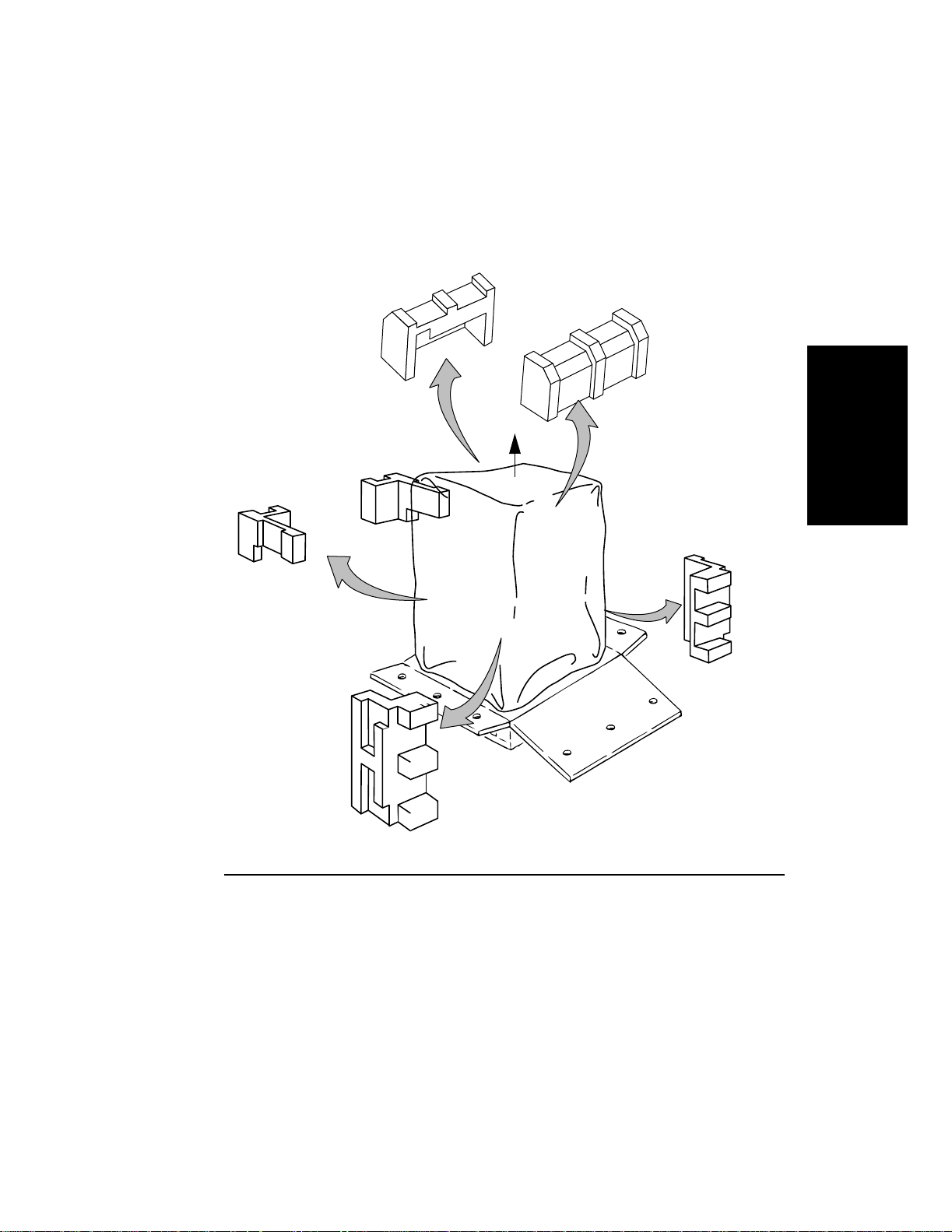

5. Cut the tape holding the lower shipping retainers and remove them as shown in

Figure 2-12.

Installation

Figure 2-12 Removing the Shipping Retainers

6. Remove the nylon cover.

Installation 2-15

Page 25

Procedure 3: Unpacking the Printer

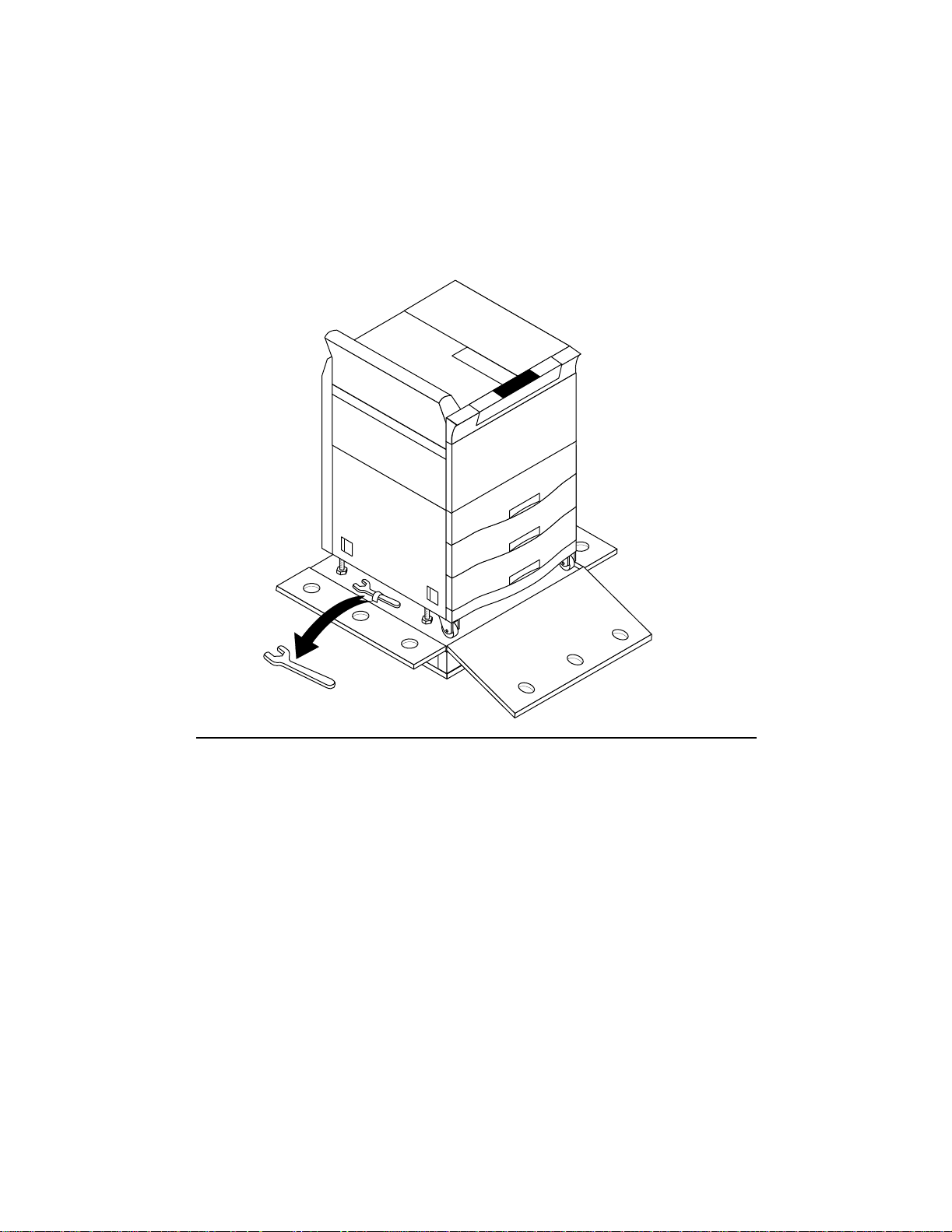

7. Remove the wrench taped to the pallet, as shown in Figure 2-13.

Figure 2-13 Removi ng the Wrench

2-16 Installation

Page 26

Procedure 3: Unpacking the Printer

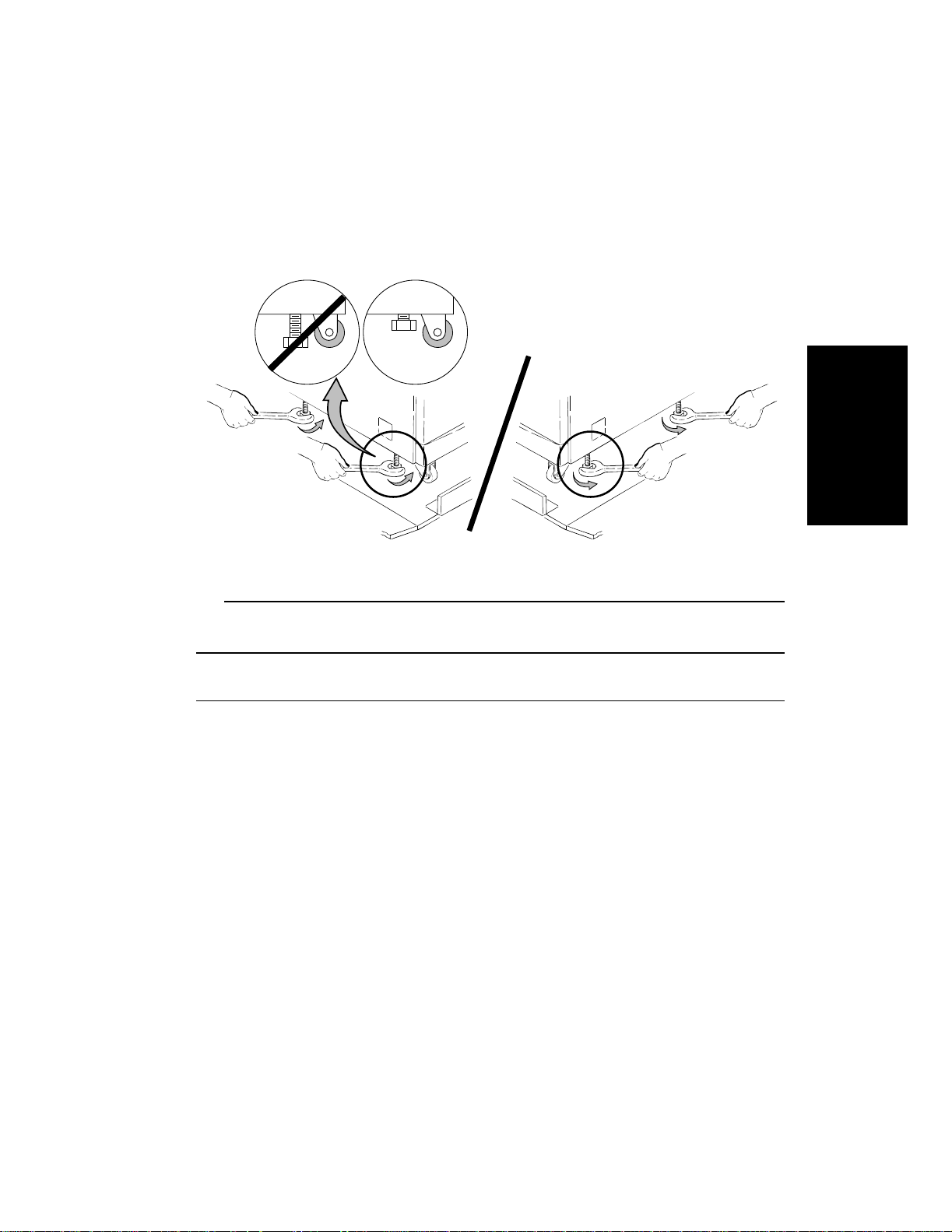

8. Use the wrench to raise all four leveling bolts by turning the leveling bolts counter-

clockwise as far as they will go. See Figure 2-14.

Figure 2-14 Raising the Leveling Bolts

Installation

CAUTION: Make sure all four leveli ng bolts are fully raised before moving the

printer or damage may occur.

Installation 2-17

Page 27

Procedure 3: Unpacking the Printer

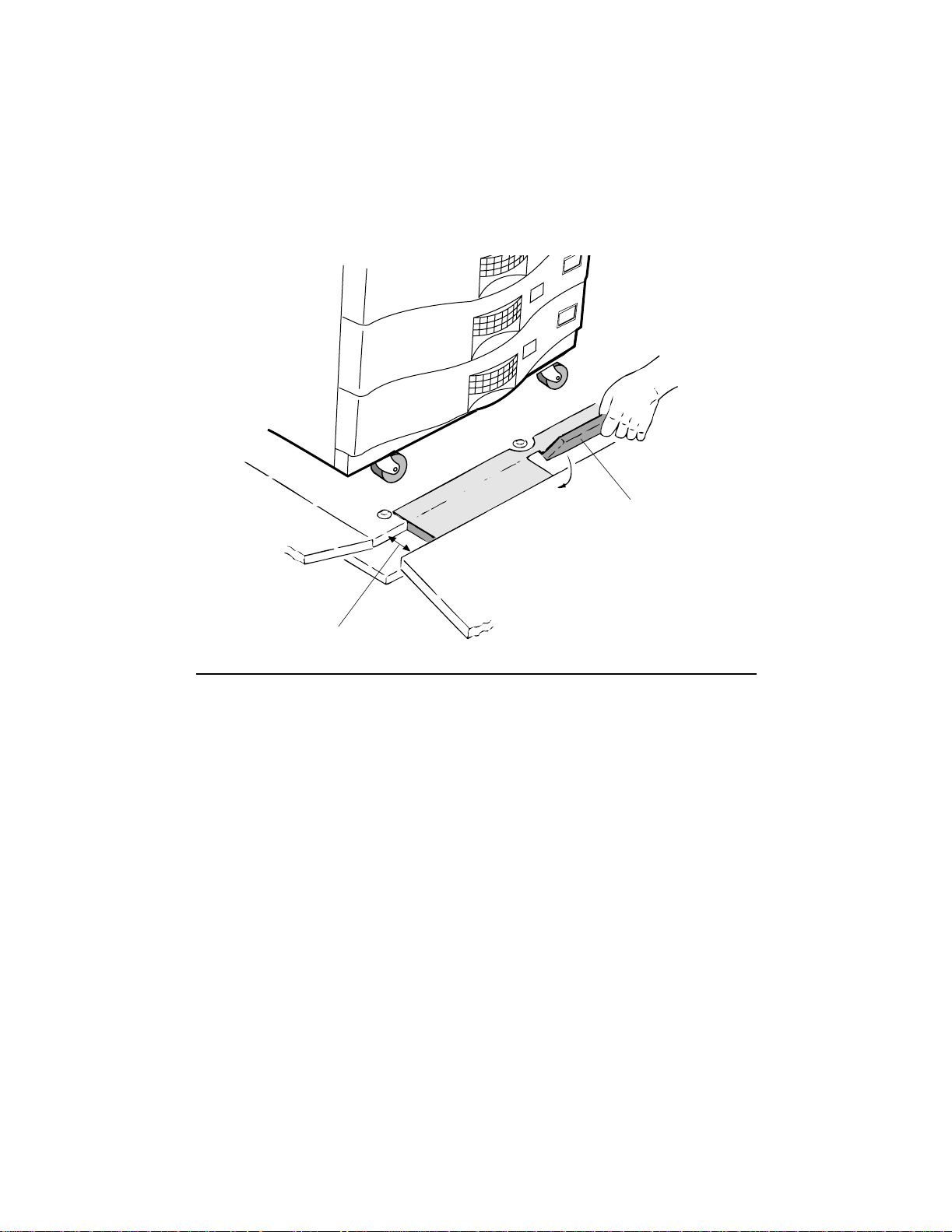

9. Flip the two small wood spacers into the groove on the slope edge of pallet ramp, as

shown in Figure 2-15.

Wooden spacer

Groove on slope edge

Figure 2-15 Securing Wood Spacers

2-18 Installation

Page 28

Procedure 3: Unpacking the Printer

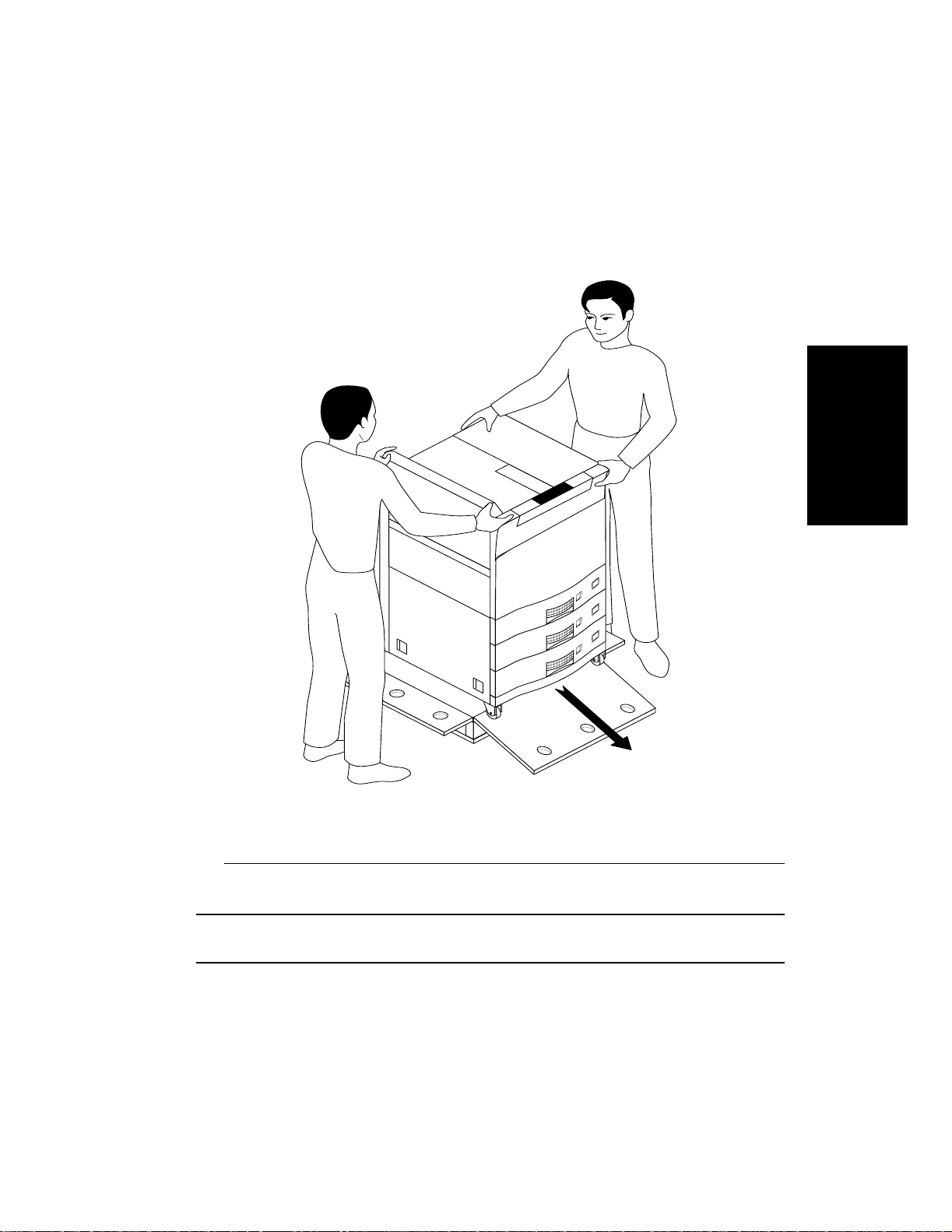

10. Move the printer off the pallet by carefully sliding it down the slope edge of the pallet

ramp, as shown in Figure 2-16. Then move the printer to the installation location.

Installation

Figure 2-16 Unloading the Printer from the Pallet

CAUTION: While moving the printer, use two people. Be careful not to subject it

to strong vibration.

Installation 2-19

Page 29

Procedure 3: Unpacking the Printer

NOTE: If the printer is not close to its final location, please move the printer to

its final location before proceeding.

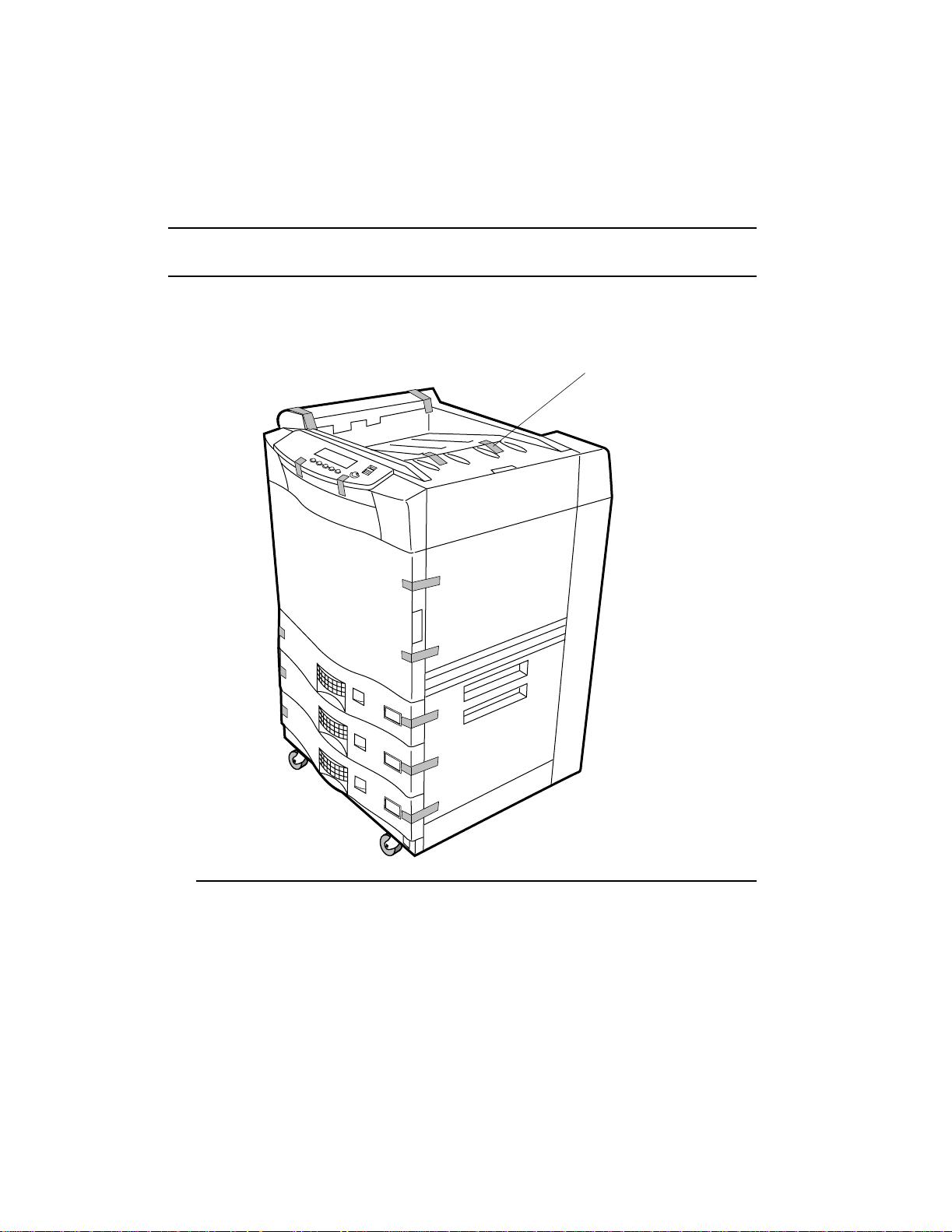

11. Remove all shipping tape attached to the exterior of the printer, as shown in

Figure 2-17.

Shipping tape

....

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Figure 2-17 Exterior Shipping Tape

12. Proceed to Procedure 4: Getting To Know Your Printer.

2-20 Installation

Page 30

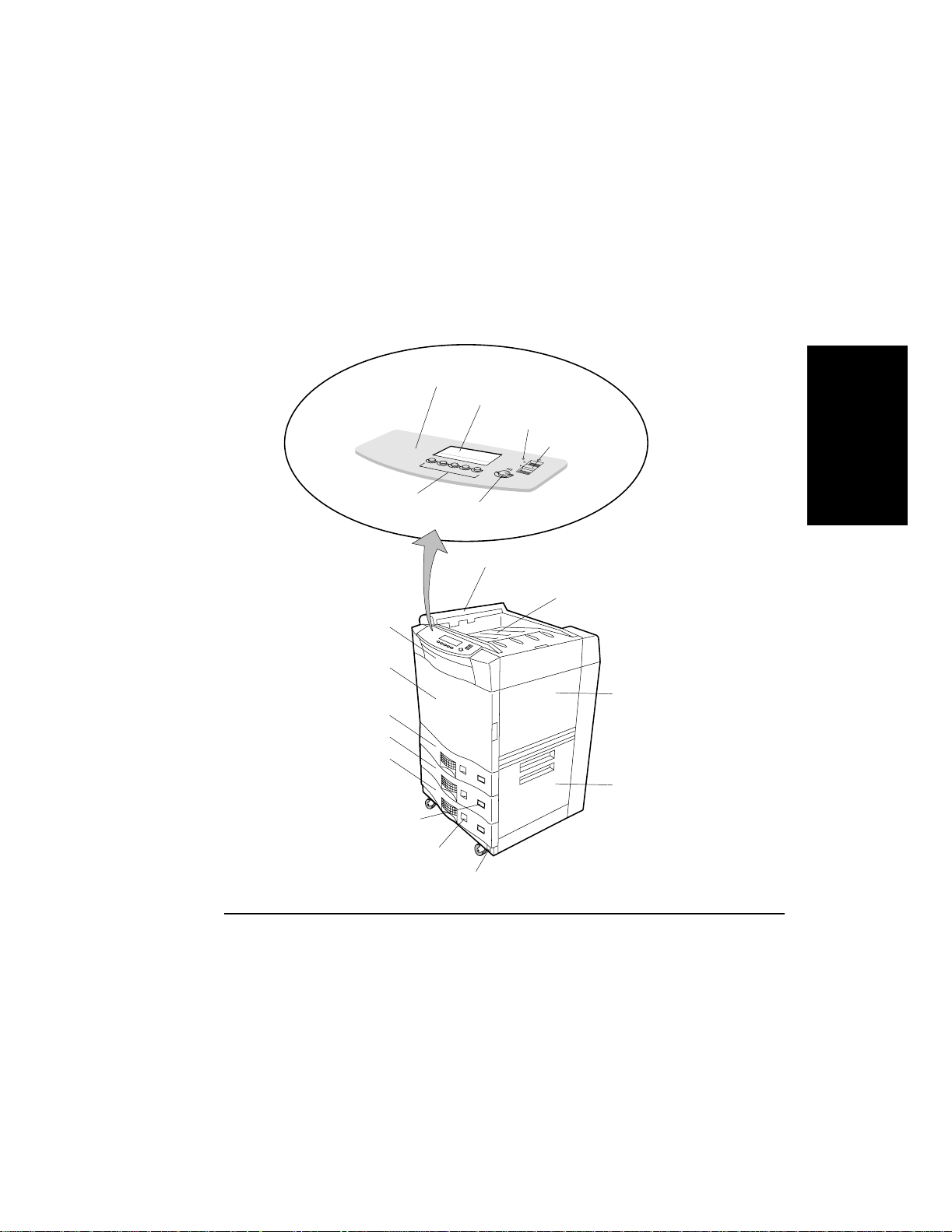

Procedure 4: Getting To Know Your Printer

Procedure 4: Getting To Know Your Printer

Now that your printer is unpacked, familiarize yourself with the printer features and components. Figure 2-18, identifies the front and side view features of the printer.

Control panel

LCD Panel (64 x 240 dots)

Power save indicator

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Standby switch

ON

Function

buttons

Display

Contrast control

Ejection unit

Paper output tray

Front cover

....

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Front door

Tray1

Tray2

Tray3

Paper size indicators

Paper level indicators

Main power switch

Figure 2-18 Printer Features, Front and Side View

Installation

Upper right cover

Lower right cover

Installation 2-21

Page 31

Procedure 4: Getting To Know Your Printer

Figure 2-19, identifies the rear view features of the printer.

Mounting holes

for manual pocket

Parallel

interface

connector

RS 232C/422A

interface connector

Ozone filter holder

HCO connector

HCI connector AC inlet

Figure 2-19 Printer Features, Rear View

2-22 Installation

Lower connector not used

( for future functionality)

Page 32

Procedure 4: Getting To Know Your Printer

Figure 2-20, identifies features inside the front door.

Brush holder

Location for fuser

Location for Drum

(Foam Shipping Retainer)

Transfer assembly guide

Sponge Shipping Retainer

....

.

.

.

.

.

.

.

.

.

.

.

.

.

.

PULL OUT

Installation

Figure 2-20 Printer With Front Door Open

Installation 2-23

Page 33

Procedure 4: Getting To Know Your Printer

Figure 2-21, identifies features inside the upper right cover.

Toner filler flap

Developer filler flap

....

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Toner collector bottle

Space for

developer purge bottle

Figure 2-21 Printer With Upper Right Cover Open

Proceed to Procedure 5: Inside the Front Door.

2-24 Installation

Page 34

Procedure 5: Inside the Front Door

Procedure 5: Inside the Front Door

This procedure describes how to install and prepare the components within the printer’s

front door. In this procedure you will:

• Remove packing material from inside front door

• Identify Starter Kit contents

• Install the Fuser

• Install the Drum

• Install the Transfer Assembly

• Install Cleaning Brush

Removing Packing Material From Inside the Front Door

1. Open the front door.

2. While holding the transfer assembly guide, remove sponge retainer, then lower the

guide. See Figure 2-22.

Transfer assembly guide

Sponge retainer

PULL OUT

Installation

Figure 2-22 Removing Sponge Retainer

Installation 2-25

Page 35

Procedure 5: Inside the Front Door

3. Turn Lever b1 to the right to the OPEN position. See Figure 2-23.

4. Pull out foam retainer.

Foam retainer

PULL OUT

Lever b1

Figure 2-23 Removing Foam Retainer

2-26 Installation

Page 36

Procedure 5: Inside the Front Door

5. Remove magnetic roller protector, as shown in Figure 2-24.

Magnetic roller

protector

Installation

Figure 2-24 Removing Magnetic Roller Protector

Installation 2-27

Page 37

Procedure 5: Inside the Front Door

6. Figure 2-25, shows where the components are installed in this procedure.

Space for drum

Space for fuser

Space for transfer assembly

Figure 2-25 Inside the Front Door

2-28 Installation

Page 38

Procedure 5: Inside the Front Door

Starter Kit Contents (Unpacked)

Now that you are ready to install the components, familiarize yourself with the printer

components you will be using. Figure 2-26, shows the components shipped in the Starter

Kit box after they have been unpacked.

LGR LTR LGL

A3 A4 A5

EXEC B4 B5

Toner

Cleaning cloths

Developer

Transfer assembly

Drum

Manual pocket

Power Cord

Cleaning brush

Parallel cable

Paper size cards

Fuser

Ozone Filter

Manuals

Installation

Function Code

Floppy

Figure 2-26 Starter Kit Box Contents (Unpacked)

Installing the Fuser

1. Locate the fuser in the Starter Kit. See Figure 2-8.

2. Remove the fuser from its packaging.

Installation 2-29

Page 39

Procedure 5: Inside the Front Door

NOTE: Check the voltage indication on the fuser. It is marked 120V-127V or

200V-240V. If you did not receive the correct f user for your installation,

contact your supplier for a replacement.

3. Push the fuser all the way into the printer until it stops. See Figure 2-27, below. Make

sure the fuser is properly seated.

Fuser

Figure 2-27 Installing the Fuser

2-30 Installation

Page 40

Procedure 5: Inside the Front Door

4. Maintain pressure on the fuser and finger-tighten the Fuser Locking Knob clockwise

to engage the frame and secure the fuser in position. See Figure 2-28.

NOTE: If the fuser does not seat properly, do not force it. Instead, refer to Figure

2-29, on page 2-32, while following the next two steps.

Fuser locking knob

Decurler roller knob

Installation

Figure 2-28 Tighten Fuser Locking Knob

1. Hold the fuser up against the printer using light pressure.

2. Carefully rotate the Decurler Roller Kno b clockwise until the fuser seats flush against

the printer.

Installation 2-31

Page 41

Procedure 5: Inside the Front Door

Decurler roller knob

Fuser locking knob

Figure 2-29 Securing the Fuser

2-32 Installation

Page 42

Procedure 5: Inside the Front Door

Unpacking the Drum

1. Locate the drum packaged in the Starter Kit. See Table 2-8, “Starter Kit Box Contents

(Packed),” on page 2-10.

2. Open the vacuum sealed bag containing the drum and remove the contents, as shown

in Figure 2-30.

3. Hold the drum by the handle o n top, set it on a solid surf ace, and caref ully remov e the

protective cover from the drum.

NOTE: Do not touch the surface of the drum. Finger prints and scratches on the

surface of the drum may adversely affect print quality.

Drum

Installation

Figure 2-30 Unpacking the Drum and Removing the Protective Cover

Installation 2-33

Page 43

Procedure 5: Inside the Front Door

Installing the Drum

1. Make sure Lever b1 is in the OPEN position.

2. Use the drum handles on the top and front to insert the drum along the guide rails until

it stops, as shown in Figure 2-31. Push the drum in as far as the it will go to ensure

correct positioning.

NOTE: Make sure the alignment pins on the printer line up with the alignment-

pin holes on the drum.

Alignment

pin holes

Top handle

Guide rails

Drum alignment

pins

Lever b1

Front handle

Figure 2-31 Inserting the Drum

2-34 Installation

Page 44

Procedure 5: Inside the Front Door

3. Gently push the drum unit onto the positioning pins, maintain pressure on the drum,

and finger-tighten the Drum Locking Knob clockwise to engage the frame and secure

the drum, as shown in Figure 2-32.

Drum locking knob

Drum locking pins

Installation

Figure 2-32 Securing the Drum

LTR

Installation 2-35

Page 45

Procedure 5: Inside the Front Door

Installing the Transfer Assembly

1. Open the box in the Starter Kit that contains the transfer assembly. See Figure 2-8, on

page 2-10.

2. Remove the transfer assembly from its packaging.

3. Using the alignment pin located on the end of the transfer assembly, insert the alignment pin of the transfer assembly into the left rail of the transfer assembly guid e at a

slight angle and push in until it clicks into place. See Figure 2-33.

CAUTION: As you handle the transfer assembly, avoid contact or damage to the

transfer wire contained in the assembly.

Transfer assembly guide

Transfer assembly

Transfer assembly guide

Pin

Transfer assembly

Wire

Figure 2-33 Inserting the Transfer Assembly

2-36 Installation

LTR

Page 46

Procedure 5: Inside the Front Door

4. Lift the transfer assembly guide until it locks in place, as shown in Figure 2-34.

5. Turn Lever b1 counterclockwise to the SET position.

NOTE: The front door will not close unless Lever b1 is in the SET position.

Transfer assembly

guide

Figure 2-34 Securing Transfer Assembly

Lever b1

Installation

Installation 2-37

Page 47

Procedure 5: Inside the Front Door

Installing the Cleaning Brush

1. Locate the cleaning brush (packed in Starter Kit). See Figure 2-8, on page 2-10.

2. Remove from plastic bag and place the cleaning brush in the front door, as shown in

Figure 2-35.

Front door

....

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Cleaning brush holder

Figure 2-35 Clea ning Brush Holder

3. Close the printer’s front door.

4. Proceed to Procedure 6: Installing Ozone Filter and Manual Pocket.

2-38 Installation

Page 48

Procedure 6: Installing Ozone Filter and Manual Pocket

Procedure 6: Installing Ozone Filter and Manual Pocket

In this procedure you will:

• Install the ozone filter

• Install manual pocket

Installing the Ozone Filter

1. Locate the ozone filter packaged in the Starter Kit. See Figure 2-8, on page 2-10.

2. Remove and insert the new ozone filter in its holder located on the rear cover.

See Figure 2-36.

Installation

Handle

Figure 2-36 Inserting the Ozone Filter

Ozone filter holder

Installation 2-39

Page 49

Procedure 6: Installing Ozone Filter and Manual Pocket

Installing the Manual Pocket

1. Locate the manual pocket packaged in the Starter Kit. See Figure 2-8, on page 2-10.

2. Remove from box and mount the manual pocket on the rear of the printer. See

Figure 2-37.

Manual pocket

Mounting holes

Figure 2-37 Installing the Manual Pocket

3. Proceed to Procedure 7: Removing Paper Tray Packing Material.

2-40 Installation

Page 50

Procedure 7: Removing Paper Tray Packing Material

Procedure 7: Removing Paper Tray Packing Material

NOTE: Paper will be added in a later procedure.

In this procedure you will:

• Remove packing material from paper trays

Removing Packing Material From Paper Trays

1. Pull out the paper trays one at a time. See Figure 2-38.

....

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Installation

Figure 2-38 Pulling out Paper Tray

Installation 2-41

Page 51

Procedure 7: Removing Paper Tray Packing Material

2. Remove the foam packing material from each tray. See Figure 2-39.

Packing

material

Figure 2-39 Removing Foam Packing Material

3. Close each tray.

4. Proceed to Procedure 8: Powering On the Printer.

2-42 Installation

Page 52

Procedure 8: Powering On the Printer

Procedure 8: Powering On the Printer

In this procedure you will:

• Connect the power cord

• Power on the printer

Connecting Power Cord

Connect the power cord as follows:

1. Locate the power cord included in the Starter Kit. See Figure 2-8, on page 2-10.

NOTE: Use only the power cord supplied with the printer. This power cord is

keyed for your printer and should be used with the printer at all times.

WARNING: The printer relies upon grounding for protection against electric

shock and to assure compliance with Electromagnetic Compatibility

Regulations. Always connect printer to a proper grounded outlet.

Installation

Installation 2-43

Page 53

Procedure 8: Powering On the Printer

2. Insert the power cord plug, female side in the printer and male side in the AC power

(grounded) outlet, as shown in Figure 2-40.

Grounded outlet

Figure 2-40 Connecting the Power Cord

Power On the Printer

3. Locate the main power switch and standby switch as shown in Figure 2-41.

2-44 Installation

Page 54

Procedure 8: Powering On the Printer

ON

....

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Standby switch

ON

Installation

OFF

Main power switch

Figure 2-41 Standby Switch and Main Power Switch

4. Turn on the main power switch.

5. Turn on the standby switch, as shown in Figure 2-42, by holding the switch in the up

position momentarily.

Standby switch

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

MODEL D640

5000

ON

Figure 2-42 Turning On the Standby Switch

Installation 2-45

Page 55

Procedure 8: Powering On the Printer

6. If you do not see anything on the display, turn the contrast control knob to the

2:00 o’clock (1400) position, as shown in Figure 2-43.

MODEL D640

5000

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Contrast control

ON

Figure 2-43 Contrast Control Knob

Control Panel Display at Power On

Figure 2-44, shows the control panel display screen at power on for initial installation.

Developer Injection

Open right door and rear flap

then Fill new developer

then Press Done

LTR

LTR

LTR

Done Exit

Figure 2-44 Control Panel Screen at Installation Power-On

You are now ready to load the toner and developer. The next procedure, Procedure 9:

Adding New Supplies, describes these steps.

2-46 Installation

Page 56

Procedure 9: Adding New Supplies

Procedure 9: Adding New Supplies

Before addi ng the developer as described in Figure 2-4 4, you need to remove a shipping

protector and add toner.

In this procedure you will:

• Remove plastic shipping protector

• Install Toner

• Install Developer

• Install Developer Purge bottle

Removing Plastic Shipping Protector

1. Open front door.

2. Turn Lever b1 to the right to the OPEN position (see Figure 2-45).

NOTE: Lever b1 should be in the OPEN position when removing the shipping

protector.

Lever b1

Installation

Front door

Figure 2-45 Lever b1

....

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Installation 2-47

Page 57

Procedure 9: Adding New Supplies

3. Open upper right cover.

4. Slowly and firmly lift up then pull down and out at an angle to remove plastic protective cover. See Figure 2-46.

NOTE: A small amount of toner may spill when this protector is removed.

Remove slowly to avoid any spillage. If toner does spill, use the supplied

cleaning cloths to clean it up.

....

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Clear plastic protector

Figure 2-46 Removing Plastic Protective Cover

5. Turn Lever b1 counterclockwise to the SET position.

6. Close the front door.

You are now ready to add the toner.

2-48 Installation

Upper right cover

Page 58

Procedure 9: Adding New Supplies

Adding Toner

1. Locate and remove the toner bottle from the Starter Kit. See Figure 2-8, on page 2-10.

2. Remove the toner bottle from its packaging.

3. Open the toner fill flap (front flap), as shown in Figure 2-47.

Toner fill flap

Installation

Figure 2-47 Opening the Toner Fill Flap

CAUTION: Check the toner bottle cap and make sure it is closed before shaking

the bottle.

4. Shake the contents of the toner bottle to loosen any toner that has settled and packed

during shipment. See Figure 2-48 .

Figure 2-48 Shake Toner Bottle

Installation 2-49

Page 59

Procedure 9: Adding New Supplies

5. Line up the guide pins on the bottle with the guide pin openings on the toner fill.

Insert and turn the toner bottle clockwise 180° to start filling. See Figure 2-49.

Toner bottle

Guide pin

Figure 2-49 Filling the Toner

NOTE: It takes about 30 seconds for the bottle to empty into the toner hopper.

2-50 Installation

Page 60

Procedure 9: Adding New Supplies

6. When empty, turn the toner bottle counterclockwise 180° and remove, as shown in

Figure 2-50.

Empty toner bottle

Installation

Figure 2-50 Removi ng the Toner Bottle

Installation 2-51

Page 61

Procedure 9: Adding New Supplies

7. Close the toner fill flap, as shown in Figure 2-51.

Toner fill flap

Figure 2-51 Closing the Toner Fill Flap

8. Discard the toner bottle.

NOTE: The toner bottle is made of recyclable materials. Dispose of in

accordance with local regulations.

2-52 Installation

Page 62

Procedure 9: Adding New Supplies

Installing the Developer

1. Locate and remove the Developer from the Starter Kit.

2. Remove the developer bottle from its packaging.

3. Open the developer fill flap, as shown in Figure 2-52.

Developer fill flap

Installation

Figure 2-52 Opening the Developer Fill Flap

Installation 2-53

Page 63

Procedure 9: Adding New Supplies

4. Line up the guide pins on the bottle with the guide pin openings on the developer fill.

Insert and turn the developer bottle clockwise 180° to start filling, as shown in

Figure 2-53.

Developer bottle

Figure 2-53 Filling the Developer

2-54 Installation

Guide pin

Page 64

Procedure 9: Adding New Supplies

5. When almost empty, gently tap the developer bottle to dislodge any remaining devel-

oper as shown in Figure 2-54.

Developer bottle

Installation

Figure 2-54 Tapping the Developer Bottle

Installation 2-55

Page 65

Procedure 9: Adding New Supplies

6. Turn the developer bottle counterclockwise 180° and remove, as shown in

Figure 2-55.

Empty developer bottle

Figure 2-55 Removing the Developer Bottle

NOTE: Do not discard the empty bottle, it is used in a later step.

2-56 Installation

Page 66

Procedure 9: Adding New Supplies

7. Close the developer fill flap, as shown in Figure 2-56.

Figure 2-56 Closing the Developer Fill Flap

Installation

8. Press the

Figure 2-57, since you are installing the developer for the first time, you do not have

to worry about the old bottle.

Developer Injection Complete

Remove and Cap Old Bottle

Install Empty New Bottle

Close Cover and Press Done

Figure 2-57 Developer Complete

9. Before you close the cover, proceed to the next section “Installing Developer Purge

Bottle.”

Done button on the Control Panel. You will see the screen sh own in

Done

Installation 2-57

Page 67

Procedure 9: Adding New Supplies

o

Installing Developer Purge Bottle

1. Remove small cap on the side of the developer bottle.

2. Turn cap around and place in the storage location, as shown in Figure 2-58.

Empty bottle

Cap in storage locati

Figure 2-58 Installing Developer Purge Bottle

3. Insert developer purge bottle into storage position.

NOTE: The bottle will not fit into the storage position if the cap is not moved.

2-58 Installation

Page 68

Procedure 9: Adding New Supplies

4. Close the upper right cover and press Done on the Control Panel. You will see the

screen shown in Figure 2-59.

TRAY1 out of paper

Load paper

PCL 12.145

Offline

Online

Offline Custom

Figure 2-59 Tray 1 Not Ready

You are now ready to set the trays, and load the paper. The next procedure,

Procedure 10: Setting the Paper Trays, describes these steps.

Menu Test PapSize

600dpi

LTR

LTR

LTR

Installation

Installation 2-59

Page 69

Procedure 10: Setting the Paper Trays

Procedure 10: Setting the Paper Trays

Before you can print you must first set the paper trays.

In this procedure, you will:

• Set the paper tray size

• Load paper

• Configure the printer

Setting the Paper Trays

1. Pull the upper paper tray out until it stops. See Figure 2-60.

Tray

Figure 2-60 Pulling out the Tray

To change the tray paper size, perform the following steps, otherwise proceed to the next

section “Loading Paper”.

NOTE: The printer is preset for letter (LTR) size paper.

2-60 Installation

Page 70

Procedure 10: Setting the Paper Trays

1. Each paper guide has a blue locking device, as shown in Figure 2-61.

Guides

(3) Locking devices

Figure 2-61 Paper Guides

2. Turn the blue locking device, for each paper guide, counterclockwise to the OPEN

position. See Figure 2-62.

Installation

S

E

O

L

O

C

LTR

LGR

P

E

N

Paper size

Figure 2-62 Locking Device

3. Lift paper guides and place in new paper size location. The paper size can be seen in

the round circle on the paper guide. See Figure 2-62.

Installation 2-61

Page 71

Procedure 10: Setting the Paper Trays

4. Adjust each paper guide for the same paper size. See Figure 2-63.

LTR

LTR

Figure 2-63 Paper Size Locations

LGR

B4

LGL

S

E

O

L

O

C

P

E

N

B5

A5

5. Turn the blue locking device, for the paper guide, clock wise to the CLOSE position to

secure. See Figure 2-64.

C

L

O

LTR

LTR

LGR

S

E

O

P

E

N

Figure 2-64 Securing the Paper Guide

6. Close the paper tray.

To change the paper size for tray2 and tray3, perform steps 1 through 6 for each tray.

2-62 Installation

Page 72

Procedure 10: Setting the Paper Trays

Paper-Size Indicator

Perform the following steps to indicate paper sizes.

1. Open the plastic bag in the Starter Kit containing the paper-size cards.

2. Break off the label that indicates the correct paper size for each tray. See Figure 2-65.

LGR LTR LGL

A3 A4 A5

EXEC B4 B5

LGR

LTR

A3

EXEC

A4

B4

L

G

L

A5

B5

Installation

Figure 2-65 Paper-Size Labels

Installation 2-63

Page 73

Procedure 10: Setting the Paper Trays

3. Pull out each tray and push out the paper-size holder, as shown in Figure 2-66.

Paper-size holder

L

G

L

LGL

Figure 2-66 Paper-Size Holder

4. Place the paper-size label in the paper-size holder of each tray.

NOTE: You can store the remaining paper-size labels in each paper-size holder.

5. Replace the paper-size holders.

6. Close trays.

You are now ready to load the paper as described in the next section, “Loading Paper”.

2-64 Installation

Page 74

Procedure 10: Setting the Paper Trays

Loading Paper

To load the paper in the paper trays do the following:

1. Remove the paper from the package with the seam side up as shown in Figure 2-67.

Read the manufacturer’s label and note which side of the paper should be printed

first. Most manufacturers note this with a “Print This Side First” arrow.

PRINT THIS SIDE FIRST

Installation

Figure 2-67 Removing the Paper From the Package

2. Inspect the paper for inden ted or interlocked edg es, bent corners, wrinkled sheets, and

excess glue from the wrapper. Discard any damaged sheets.

3. Open tray1.

Installation 2-65

Page 75

Procedure 10: Setting the Paper Trays

4. Load the paper in the tray print side down. Do not stack the paper above the paper-full

mark. See to Figure 2-68).

Paper

LTR

Paper-full mark

Figure 2-68 Loading the Paper in the Tray

• If the paper is not placed with the correct side down, the paper may jam or have

excessive curl.

• Never mix the types of paper loaded in a tray. Mixing paper can result in multiple

sheet feeds and other paper handling problems.

5. Close the tray.

6. Repeat the above steps (1 through 5) when loading paper in the two remainin g trays.

NOTE: Never load paper above the full mark or you may get paper jams and

skewed print.

2-66 Installation

Page 76

Procedure 10: Setting the Paper Trays

Paper Level Indicator

The blue paper level indicator shows t he appr oximat e l evel of the p aper i n the tray. When

the indicator is in the upper position, the paper tray is full. As th e paper level lowers, so

does the indicator. See Figure 2-69, Paper Level Indicator.

Installation

Figure 2-69 Paper Level Indicator

Installation 2-67

Page 77

Procedure 10: Setting the Paper Trays

Control Panel Display

The right hand side of the Control Panel display shows a diagram of the printer. The display includes installed paper trays and associated paper sizes as shown in Figure 2-70.

Printer diagram

Ready - - free

JUN 18 05:32.23

PCL

Offline

Online

Offline

Figure 2-70 Control Panel Display, Main Screen

Custom Menu Test PapSize

600dpi

LTR

LTR

LTR

• LTR indicates letter size paper and that the paper tray has paper.

• LTR indicates letter size paper and that the paper tray is empty.

The display also shows the selected paper path, from the selected tray, ou t to the selected

paper output.

Configuring the Printer

1. Press the PapSize button on the Main Screen (see Figure 2-70) to display the PapSize menu shown in Figure 2-71.

PapSize

tray1size =LETTER

tray2size =LETTER

tray3size =LETTER

Online

Online

Figure 2-71 PapSize Menu

The PapSize submenu provides access to paper size selections for each tray.

2-68 Installation

Page 78

Procedure 10: Setting the Paper Trays

Using the Menus

The function buttons shown in Figure 2-72 are used to maneuver in and make selections

within the submenus. Table 2-3 describes each submenu button.

PapSize

tray1size =LETTER

tray2size =LETTER

tray3size =LETTER

HCIsize =LETTER

Online

Online

Up Down Right Left

Figure 2-72 Submenu Buttons

Table 2-3 Submenu Buttons Description

The

up arrow button moves the selection back to the prev ious item

on the submenu list.

down arrow button moves the selection to the next item on the

The

submenu list.

right arrow button selects the next level of the subm enu struc-

The

ture.

left arrow button goes back to one submenu level above the cur-

The

rent one.

Installation

Refer to Chapter 2 in the User Manual for more detailed information.

Installation 2-69

Page 79

Procedure 10: Setting the Paper Trays

1. Press the

Ready - - free

JUN 18 05:32.23

PCL

Figure 2-73 Main Screen

2. Proceed to Procedure 11: Installing Function Code.

left arrow button to return to the Main Screen shown in Figure 2-73.

Offline

Online

Offline

Custom Menu Test PapSize

600dpi

LTR

LTR

LTR

2-70 Installation

Page 80

Procedure 11: Installing Function Code

Procedure 11: Installing Function Code

The D640 comes with its operating function code (software) and fonts preinstalled in the

printer. When the printer is shipped to you, the latest version of the code is shipped on diskette and may be more current than the version preinstalled in the printer.

Follow the steps in this procedure to install the latest version in your printer.

Follow these steps to update your printer software:

1. Open the front cover and locate the floppy drive, as shown in Figure 2-74.

Installation

Floppy disk drive

Front cover

Figure 2-74 Floppy Disk Drive

....

.

.

.

.

.

.

.

.

.

.

.

.

.

.

LTR

LTR

Installation 2-71

Page 81

Procedure 11: Installing Function Code

2. Locate the Function Code diskette(s) shipped in the Starter Kit. See Figure 2-8, on

page 2-10.

3. Insert the diskette into the drive as shown in Figure 2- 75.

Floppy disk drive

....

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Figure 2-75 Installing Function Code

2-72 Installation

LTR

LTR

LTR

Page 82

Procedure 11: Installing Function Code

4. Press the Test button on the Main Screen shown in Figure 2-76.

Ready - - free

JUN 18 05:32.23

PCL

Offline

Online

Offline

Figure 2-76 Main Screen

5. Use the

Figure 2-77, and press the

down arrow button to scroll down and highlight filesA, as shown in

Custom Menu Test PapSize

Select button.

Test

filesA

filesC

Online

Online Select

600dpi

LTR

LTR

LTR

Installation

Figure 2-77 Test Submenu

NOTE: After pressing select, there will be a few seconds delay as the printer

reads the directory from the diskette.

6. From the filesA submenu, highlight the

to start the update process.

UPDATE.LAY file. Press Select and Online

Installation 2-73

Page 83

Procedure 11: Installing Function Code

7. After a few seconds, the printer displays this message:

Installing backup to hard disk

8. Then the printer displays this message:

Loading new Function Code

9. After about 45 seconds, the printer displays this message:

EW OK

10. After a few seconds the Control Panel display goes blank (the new function code is

resetting the main controller).

11. When the new function code has fini s hed res et tin g t h e con tr ol le r, you wi ll see the display shown in Figure 2-78.

Printer initializing

Please Wait

PCL

Offline

Online

Offline

Custom Menu Test PapSize

Figure 2-78 Printer Initializing

2-74 Installation

600dpi

LTR

LTR

LTR

Page 84

Procedure 11: Installing Function Code

12. When the printer has finished initializing, you will see the Ready message, as shown

in Figure 2-79

Ready - - free

JUN 18 05:32.23

PCL

Offline

Online

Offline

Figure 2-79 Ready (Main Screen)

13. Remove the Upgrade Function Code diskette and close the front cover.

NOTE: After you remove the Upgrade Function Code diskette, store it in a safe

place.

14. Proceed to Procedure 12: Setting the Date and Time.

Custom Menu Test PapSize

600dpi

LTR

LTR

LTR

Installation

Installation 2-75

Page 85

Procedure 12: Setting the Date and Time

Procedure 12: Setting the Date and Time

The D640 prints the current date and time on test patterns and reports (such as the Ripple

Test Pattern and the Maintenance Report). When you unpack the printer, the date and time

still has the factory settings. Set the date and time to the current va lues, following these

steps:

1. At the

Figure 2-80 Menu

2. Use the

Main Screen (shown in Figure 2-73), press Menu. You will see the screen in

Figure 2-80

Online

.

down arrow to highlight Maintenance, as shown in Figure 2-81.

Online

Online

Menu

Menu

Printing

Configuration

PCL

Comms

Maintenance

Printing

Configuration

PCL

Comms

Maintenance

Figure 2-81 Maintenance Selected

3. Press the

2-76 Installation

right arrow to highlight the Maintenance screen, shown in Figure 2-82.

Page 86

Procedure 12: Setting the Date and Time

Maintenance

Online

Online

Figure 2-82 Maintenance Settings

4. Press the

Figure 2-83 date-time

down arrow to highlight the date-time setting, as shown in Figure 2-83.

Maintenance

Online

replace

alignment

density = 10

testpages = 30

monitor = OFF

date-time

replace

alignment

density

monitor

testpages

date-time

Installation

5. Press the

Figure 2-84 Maintenance.date-time Settings

6. Press the

7. Press the

right arrow to highlight the date-time settings, as shown in Figure 2-84.

Maintenance.date-time

Online

up or down arrow to highlight the date-time setting to change.

right arrow to highlight that setting.

minute

hour =16

date =16

month =16

year =16

=20

Installation 2-77

Page 87

Procedure 12: Setting the Date and Time

8. Press the

2-85. In this example of the

more selections before

of

Maintenance.date-time.date

up and down arrow to change the value of the setting, as shown in Figure

date setting, the carat (^) symbols indicate that there are

18 and after 23. The equals (=) sign indicates the current value

date, which is 20.

18

19

=

20

21

22

23

Online

Select

Figure 2-85 Maintenance.date-time.date

9. When you have mov ed to the co rrect v alue, p ress

tenance.date-time

screen shown in Figure 2-84. At this poin t, you can re peat the pr o-

Select. You will return to the Main-

cedure from step 6 to change additional values, or if you are finished, press

return to th e

Main Screen and verify the correct date and time.

Date and time

Ready - - free

600dpi

JUN 18 05:32.23

PCL

LTR

LTR

Offline

Online

Offline

Custom Menu Test PapSize

LTR

Online to

Figure 2-86 Date and Time on Control Panel

Proceed to Procedure 13: Printing a Setup Report.

2-78 Installation

Page 88

Procedure 13: Printing a Setup Report

Procedure 13: Printing a Setup Report

You are now ready to print a setup report. A successful printout indicates that all printer

components are installed and are operating correctly. Keep in mind, however, that the

printer to computer connection is not yet in place.

1. Press the

Ready - - free

JUN 18 05:32.23

PCL

Figure 2-87 Main Screen

2. Select

Select button.

Test button on the Main Screen, shown below in Figure 2-87.

Offline

Online

Offline

SETUPS from the Test submenu, as shown in Figure 2-88, and press the

Custom Menu Test PapSize

Test

SETUPS

MAINT

FONTS

TABLE

TYPES

MENUS

600dpi

LTR

LTR

LTR

Installation

Online Select

Figure 2-88 Test Submenu

Figure 2-89, Sample Setup Report, Page 1, on page 2-80, shows the information reported

when you print the

3. Check the printer setup report print. It should look similar to the sample setup report

in Figure 2-89. If it does, proceed to Procedure 14: Securing the Printer.

SETUPS submenu.

Installation 2-79

Page 89

Procedure 13: Printing a Setup Report

Figure 2-89 Sample Setup Report, Page 1

If the test was unsuccessful, refer to Troubleshooting, which follows.

If the test was successful, perform installation of any accessories according to the proce-

dures in Chapter 4, Accessories. If you have no accessories to install, proceed to Procedure 14: Securing the Printer.

2-80 Installation

Page 90

Troubleshooting

Troubleshooting

In the unlikely event that the printer does not generate a printer setup report, follow these

steps:

1. If the printer does not power on (no lights or sounds), verify that it is connected to a

live power circuit, that the Main power switch is in the ON position, and the standby

switch has been moved to the ON posi tion momentarily.

2. Write down the error code if one appears on the LCD display.

3. Refer to “Printer Error Codes” in the User Manual to determine the meaning of the

error code.

4. Use the error code to check the area specified and correct the problem. In addition,

check for:

a) Styrofoam or cover did not get removed

b) Jammed paper

c) Improper installation

5. Print a test pattern, described in Procedure 13: Printing a Setup Report, on page 2-79.

6. If you are still unsuccessful, see “Where To C all For Help ” on pag e B-3. B e p repar ed

to give the service representative the error code, and any messages appearing on the

Control Panel, to assist in troubleshootin g.

Installation

Installation 2-81

Page 91

Procedure 14: Securing the Printer

Procedure 14: Securing the Printer

Place the printer on a sturdy, smooth, level surface in a well-ventilated room. Check the

printer location to make sure it meets all necessary operational requirements.

Secure the printer to the current location only if the printer is not going to be moved or you

are not installing the HCI and HCO.

1. Manually lower all four leveling bolts until they touch the floor.

2. Use the wrench to lower the leveling bolts until the wheels are just off the ground, as

shown in Figure 2-90.

LTR

LTR

LTR

(4) Leveling feet

Figure 2-90 Securing the Leveling Feet

When you have secured the printer, perform the paper tray alignment procedure in Procedure 15: Paper Path Alignment.

2-82 Installation

Page 92

Procedure 15: Paper Path Alignment

Procedure 15: Paper Path Alignment

During transportation, the paper path alignment may change slightly from the factory set

position. The following paper path alignment procedure will set the printing alignment for

each tray to ensure correct print position. This procedure looks complicated, but it is actually quite easy. After you have performed it a once or twice, it should only take a few minutes to complete.

Note: Please read through the entire procedure before performing any of

the steps.

Step 1 - Printing Alignment Sheets

When you run the alignment p rog ram from the printer’s hard drive, the printer produ ces a

set of alignment pages.

Step 2 - Measuring Alignment

By measuring the current alignment for each tray against a ref erence standard, you simply

add two numbers to determine new alignment values.

Installation

Step 3 - Setting Alignment Values

Once you have determined new values, enter them in the Control Panel and recheck the

alignment.

Installation 2-83

Page 93

Procedure 15: Paper Path Alignment

Step 1 - Printing Alignment Sheets

1. Verify that all three paper trays and the HCI (if installed) have Letter (or A4) size

paper.

2. Press the

Test button on the Main Screen, shown in Figure 2-91.

Ready - - free

JUN 18 05:32.23

PCL

Online

Offline

Offline

Figure 2-91 Main Screen

3. Use the

Figure 2-92, and press

Figure 2-92 Test Submenu

down arrow to scroll down and highlight filesC, as shown in

Online

Online Select

Custom Menu Test PapSize

Select .

Test

filesA

filesC

600dpi

LTR

LTR

LTR

LTR

2-84 Installation

Page 94

Procedure 15: Paper Path Alignment

4. From the filesC submenu shown in Figure 2-93, use the down arrow to highlight

USER_ADJ , then press Select.

C:\

Online

Online Select

Figure 2-93 FilesC Submenu

5. Use the

See Figure 2-94.

Figure 2-94 ALIGNSET.12

down arrow to highlight ALIGNSET.*

C:\USER_ADJ\

Online

Online Select

dir

USER_ADJ\

PCLS\

PS\

MAINT\

FONTS\

dir

ALIGNSET.12

1

, then press Select once.

Installation

1. The last two numbers refer to the program version number, which may be different

from the version number shown in these illustrations.

Installation 2-85

Page 95

Procedure 15: Paper Path Alignment

6. The number

Figure 2-95.

Online

Online Select

Figure 2-95 1 ALIGNSET.*

7. Press

NOTE: After pressing Online, there will be a few seconds delay as the printer

loads the program.

The printer then produces a set of alignment sheets, one from each tray (and the HCI, if it

is installed), a Simplex feed alignment ruler sheet (see Figure 2-96), which provides:

1 appears in front of the ALIGNSET.* message, as shown in

C:\USER_ADJ\

Online once.

dir

1

ALIGNSET.12

• instructions for the alignment procedure

• a reference scale to measure the alignment sheets

• a workspace to calculate alignment values and adjustments

Duplex unit alignment ruler

and a

iest alignment values (duplexv means "duplex vertical").

sheet, which measures the duplex sideways and length-

When the printer has finished printing these pages, you are ready to begin measuring the

alignment pages (Step 2).

2-86 Installation

Page 96

Procedure 15: Paper Path Alignment

Step 2 - Measuring Alignment

You will now read the adjustment values.

1. Carefully and accurately, fold the top part of the Simplex feed alignment ruler sheet,

shown below, at the Fold here line.

Adjustment scale

Simplex feed alignment ruler

Fold line

Use this ruler to align individual feeds. Do not use ruler printed on another machine to ensure main scan direction compatibility.

For each sheet from individual feeds measure the required relative adjustment and modify accordingly using the printer operator

panel.

Fold here

0+5+10

+15

+20

+25

-5

-10

-15

-20

Align with left edge of printed sheet

-25

Line on printed sheet indicates the required relative adjustment.

Direction of paper motion

Installation

Figure 2-96 Simplex Feed Alignment Ruler Sheet

Installation 2-87

Page 97

Procedure 15: Paper Path Alignment

2. On the alignment sheet for tray 1, shown in Figure 2-97, locate the Feed 1 alignment

indicator line.

3. Place the simplex feed alignment ruler sheet adjustment scale between the ends of

the arrows (at "measure between these two arrows", shown in the illustration below).

On the next page, Figure 2-98 shows how the two sheets should look when properly

positioned, with the line labeled "Align with left edge of printed sheet" positioned

against the left edge of the alignment sheet for tray 1.

Feed alignment indicator line

Feed 1: Upper tray

Direction of paper motion

Measure between these two arrows

Figure 2-97 Sample Alignment Sheet For Tray 1

2-88 Installation

Page 98

Procedure 15: Paper Path Alignment

Feed alignment indicator line

Read measurement here

Place edge here

Align with left edge of printed sheet

Measure between these two arrows

0+5+10

+15

+20

+25-5-10

-15

-20

-25

Line on printed sheet indicates the required relative adjustment.

Feed 1: Upper tray

Direction of paper motion

Direction of paper motion

Figure 2-98 Measuring Alignment With Alignment Scale

4. The arrow printed on the alignment sheet for tray 1 will intersect the simplex feed

alignment ruler sheet scale at some value, as shown in the illustration above.

Installation

Installation 2-89

Page 99

Procedure 15: Paper Path Alignment

5. Record this value in the adjustment value area for tray 1 on the simplex feed alignment ruler sheet. See Figure 2-99.

Example

Original alignment value

currently in printer

+2

Figure 2-99 Original Alignment Value and Adjustment Value

Write in adjustment

value from line

measurement

14

+2

6. Repeat steps 2 through 4 with the alignment sheets for trays 2, 3, and the HCI (if

installed).

Note: The printer still prints a sheet for the HCI even if no HCI is present.

Simply ignore this page if you don’t have an HCI connected and

paper installed in it.

7. Now read the values for duplex pages as directed in the next section.

2-90 Installation

Page 100

Procedure 15: Paper Path Alignment

Duplex (Double-Sided) Printing Alignment

Figure 2-100 illustrates the Duplex unit alignment ruler sheet, which provides a way to

measure the alignment between the printed image on the front and back sides of a doublesided page.

Installation

Figure 2-100 Duplex Unit Alignment Ruler Sheet

1. On the duplex unit alignment ruler sheet, review each side of the paper. View

through the paper. Hold the paper up to a bright light, the side with the alignment

scale towards you.

2. The sideways indicator line runs up and down the back of the page on the left. Look

for the indicator line and note where it crosses the scale on the left. Record this value

on sheet 1 at Duplex unit sideways alignment adjustment value.

3. The

lengthwise indicator line runs across the back of the page. Look for the indicator

line and note where it crosses the scale in the middle of the page. Record this value

on sheet 1 at

Duplex unit lengthwise alignment adjustment value.

Installation 2-91

Loading...

Loading...