Page 1

D640 Cut Sheet Printer

Service Manual

Hewlett-Packard Company

C5620-90028

0699

Page 2

D640 Printer Service Manual

WARNING!

This document is intended for service-trained personnel who are aware of the hazards

involved. Procedures in this manual may expose the service person to electrical shock

hazards that could cause serious personal injury or death, and to mechanical hazards

from moving parts that may cause serious injury.

Notice

Hewlett-Packard makes no warranty of any kind with regard to this material, including,

but not limited to, the implied warranties of merchantability and fitness for a particular

purpose. Hewlett-Packard shall not be liable for errors contained herein or for incidental

or consequential damages in connection with the furnishing, performance, or use of this

material.

Hewlett-Packard assumes no responsibility for the use or reliability of its software on

equipment that is not furnished by Hewlett-Packard.

This document contains proprietary information which is protected by copyright. All

rights are reserved. No part of this document may be photocopied, reproduced, or

translated to another language without the prior written consent of Hewlett-Packard

Company. The information contained in this document is subject to change without

notice.

Printing History

The dates on the title page change only when a new edition is published.

Edition 2.0. . . . . . . . . . . . . . .February 1998

Edition 2.1. . . . . . . . . . . . . . .May 1998 (online only)

Edition 2.2. . . . . . . . . . . . . . .June 1998 (online only)

Edition 2.3. . . . . . . . . . . . . . .August 1998 (online only)

Edition 3.0. . . . . . . . . . . . . . .September 1998 (online only)

Edition 3.1. . . . . . . . . . . . . . .October 1998 (online only)

Edition 3.2. . . . . . . . . . . . . . .January 1999 (online only)

Edition 3.3. . . . . . . . . . . . . . .April 1999 (online only)

Edition 3.4. . . . . . . . . . . . . . .June 1999 (online only)

Copyright ©1999 Hewlett-Packard Company

All rights reserved.

June 1999

Please address any comments or questions to:

Publications Manager

Department LaserJet Division-Cupertino

MS 44MC

Hewlett-Packard Company

19111 Pruneridge Avenue

Cupertino, CA 95014

ii June 08, 1999

Page 3

Copyrights and Trademark Credits

D640 Printer Service Manual

Adobe™, PostScript™

Adobe Systems Incorporated which may be registered in certain jurisdictions.

Arial, Times New Roman,

Corporation.

Bi-Tronics

Helvetica

or other countries.

Macintosh

Microsoft

LAN Manager™ are trademarks of Microsoft Corporation.

Novell™ is a trademark of Novell, Incorporated.

TrueType

WordPerfect

ITC Zapf Dingbats is a U.S. registered trademark of International Typeface Corporation.

Albertus, Antique Olive, Arial, CG Omega, CG Times, Clarendon Condensed, Coronet,

Courier, Garamond, Letter Gothic, Marigold, Symbol, Times New Roman, Univers,

Univers Condensed, Wingdings are trademarks of Agfa Division of Miles Inc.

CG Times, a product of Agfa Corporation, is based on Times New Roman, a registered

trademark of Monotype Corporation PLC.

™, PCL5™, and REt™ are trademarks of Hewlett-Packard Company.

and

Univers

computer is a product of Apple Computer, Inc.

® is a U.S. registered trademark of Microsoft Corporation; Windows™ and

™ is a trademark of Apple Computer, Inc.

is a registered trademark of WordPerfect Corporation.

, PostScript II and the

and

Monotype

are trademarks of Linotype AG and/or its subsidiaries in the U.S.

PostScript Logo

are registered trademarks of the Monotype

™ are trademarks of

Centronics is a trademark of Centronics Data Computer Corp.

Intellifont is a trademark of Miles Inc.

Portions of the software in the PostScript upgrade are Copyright© 1990-1997 Pipeline

Associates, Inc. Certain portions protected by U.S. Patent No. 5,150,454.

Other product names mentioned in this manual may also be trademarks and are used

here for identification only.

June 08, 1999 iii

Page 4

D640 Printer Service Manual

Manual Conventions

Note A note denotes important information that sho uld be read.

CAUTION A CAUTION denotes a hazard. It calls attention to a procedure which, if done incorrectly or

inattentively , could damage or destroy par t or all of the product. Do no t proceed beyond a Caution

until the indicated conditions are fully understood and met.

WARNING! A WARNING! denotes a hazard. It calls attention to a procedure or practice, which, if not done

correctly or adhered to, could result in personal injury . Do not proceed beyond a WARNING! s ign

until the indicated conditions are fully understood and met.

For More Information

For a list of internal and external web sites, see 1-1.2 "Web Sites for More Information,"

on page 1-5.

iv June 08, 1999

Page 5

D640 Printer Service Manual

Contents

Chapter 1: Specifications

1-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1-1.1 Related Documents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1-1.2 Web Sites for More Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1-2 Printer Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1-2.1 Printer General Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1-2.2 Printer Print Speed Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1-2.3 Printer Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1-2.4 Printer Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1-2.5 Environmental Specifications For All Equipment . . . . . . . . . . . . . . . . .1-9

1-2.6 Printer Laser Equipment Compliance Label . . . . . . . . . . . . . . . . . . . . .1-9

1-3 Summary of Optional Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

1-4 Printer Custom Paper Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

1-5 PostScript Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

1-6 16 MB Memory Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

1-7 Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

1-8 Printable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

1-8.1 Printing Position Precision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

1-8.2 Simplex and Duplex Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

Chapter 2: Functional Overview

2-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

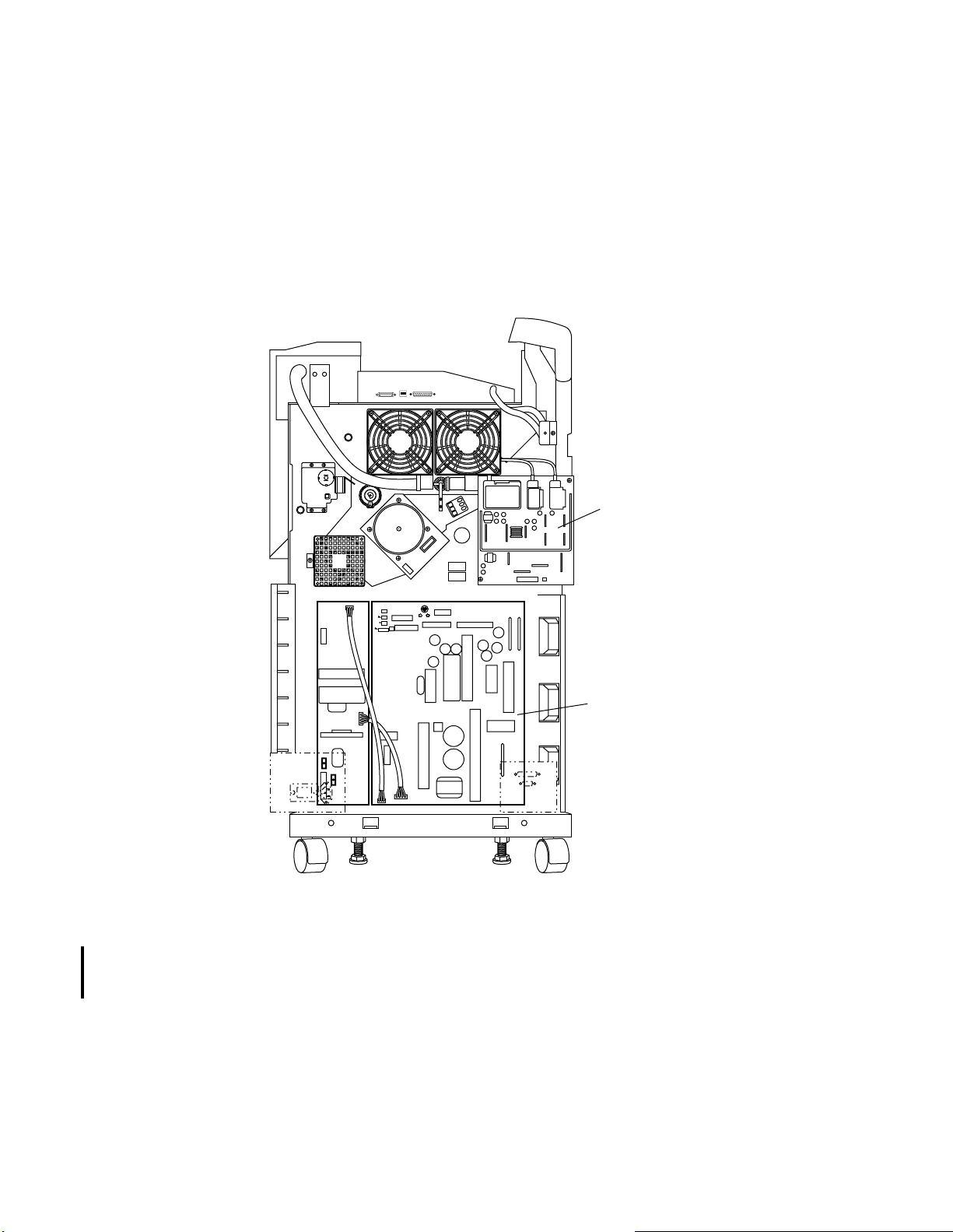

2-2 Physical Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2-2.1 Control Panel and External Front Cover . . . . . . . . . . . . . . . . . . . . . . . .2-4

2-2.2 Slots and Ports Accessible from Top Front Cover . . . . . . . . . . . . . . . .2-5

2-2.3 Parts Accessible from the Front Door . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2-2.4 Parts Accessible from the Top Cover and Ejection Cover . . . . . . . . . .2-8

2-2.5 Parts Accessible from the Upper Right Cover. . . . . . . . . . . . . . . . . . . .2-9

2-2.6 Parts Accessible from the Lower Right Cover. . . . . . . . . . . . . . . . . . .2-10

2-2.7 External Parts Accessible from the Rear and Sides . . . . . . . . . . . . . .2-11

2-2.8 Parts Accessible from the Rear Cover . . . . . . . . . . . . . . . . . . . . . . . .2-12

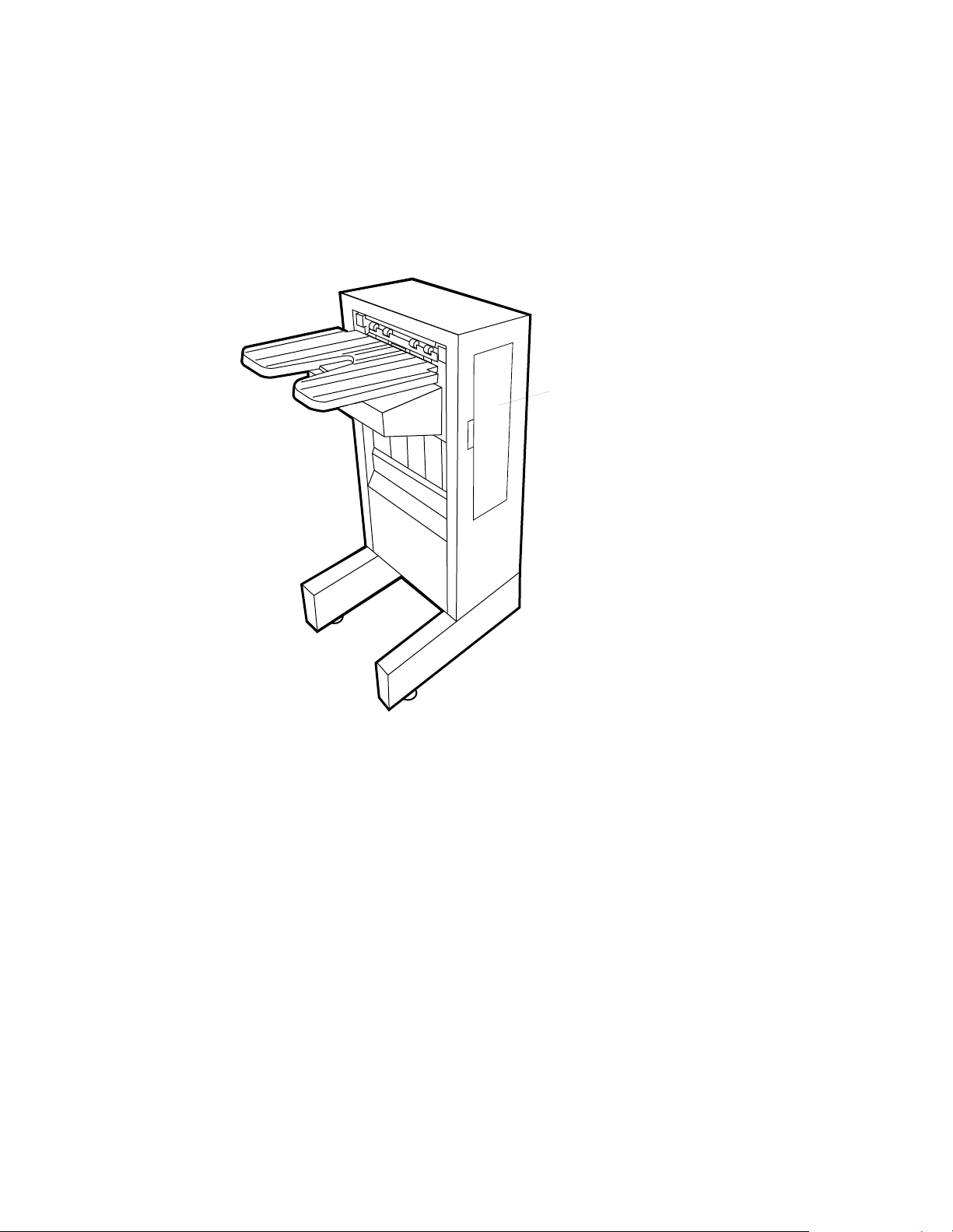

2-2.9 High Capacity Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

2-2.10 2,000-sheet High Capacity Output . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

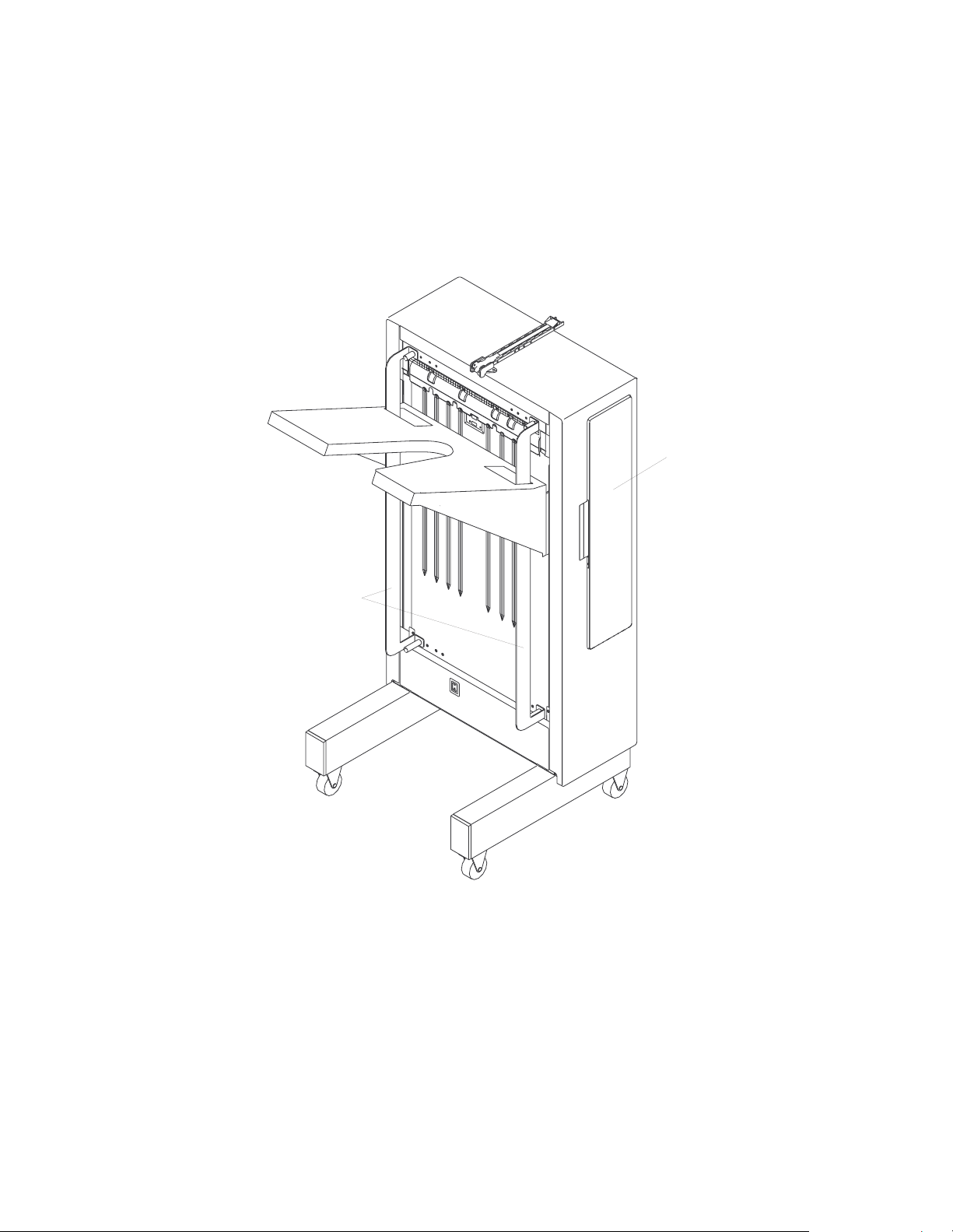

2-2.11 3,000 Sheet High Capacity Output . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

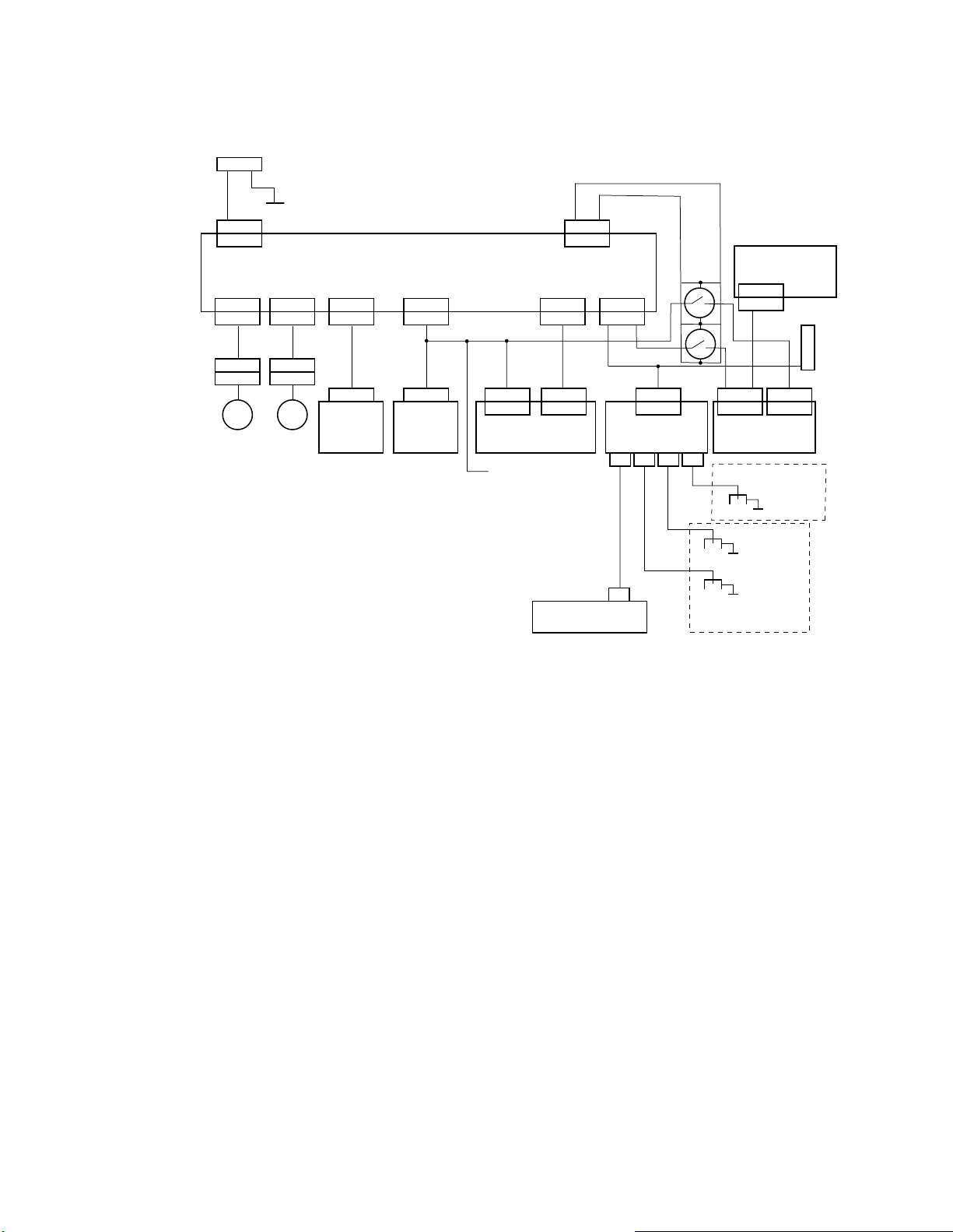

2-3 System Controllers, Control Panel, and Ports . . . . . . . . . . . . . . . . . . . . . . . . .2-16

2-3.1 Mechanism Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

2-3.2 Main Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

2-3.3 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-26

2-4 Power Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

2-4.1 Low Voltage Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-29

2-4.2 High Voltage Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

2-4.3 Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-34

2-5 Developer and Toner Hopper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-35

2-5.1 Toner Hopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-35

2-5.2 Developer Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-36

2-5.3 Waste Toner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-37

2-5.4 Drive D Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-37

June 08, 1999 v

Page 6

D640 Printer Service Manual

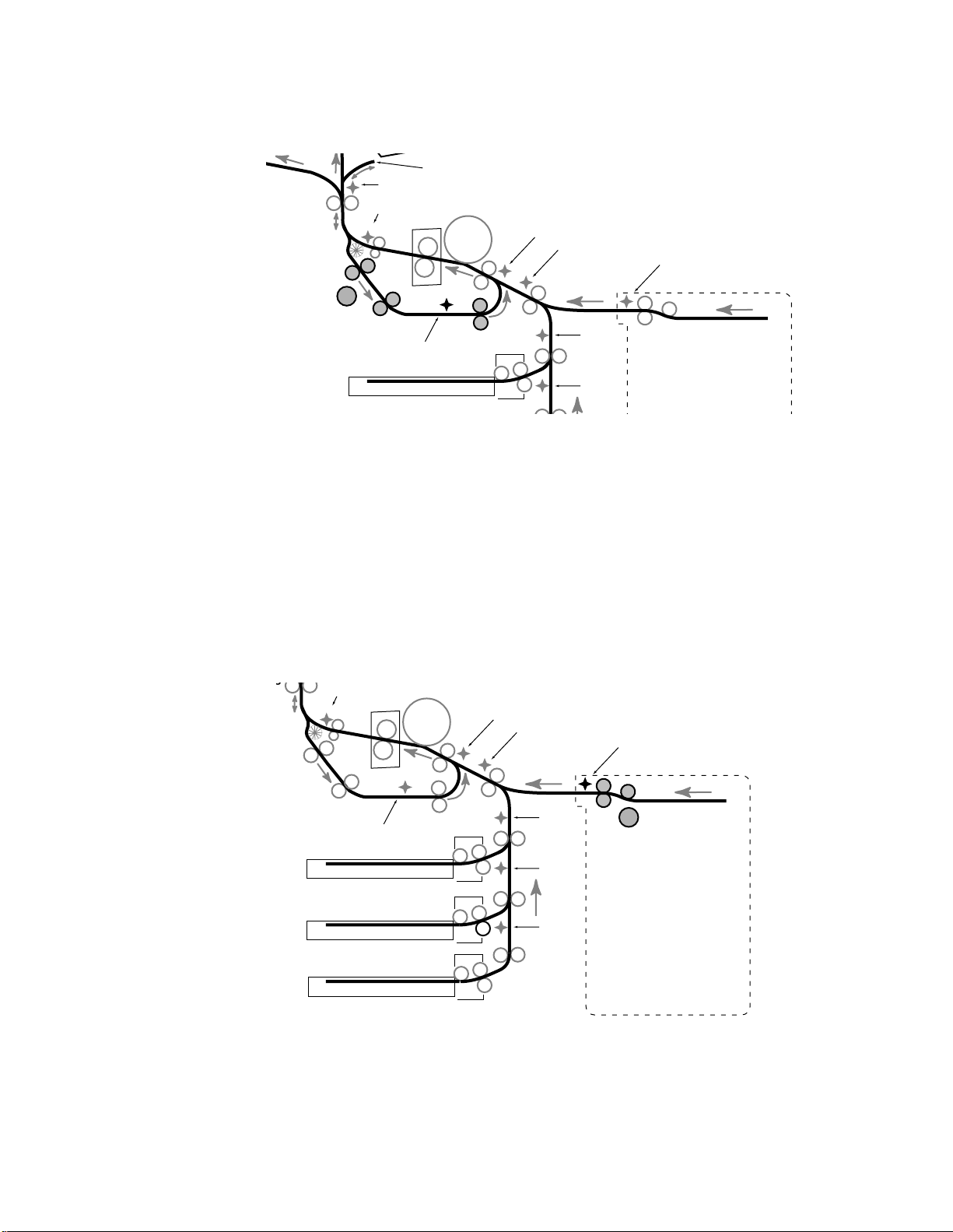

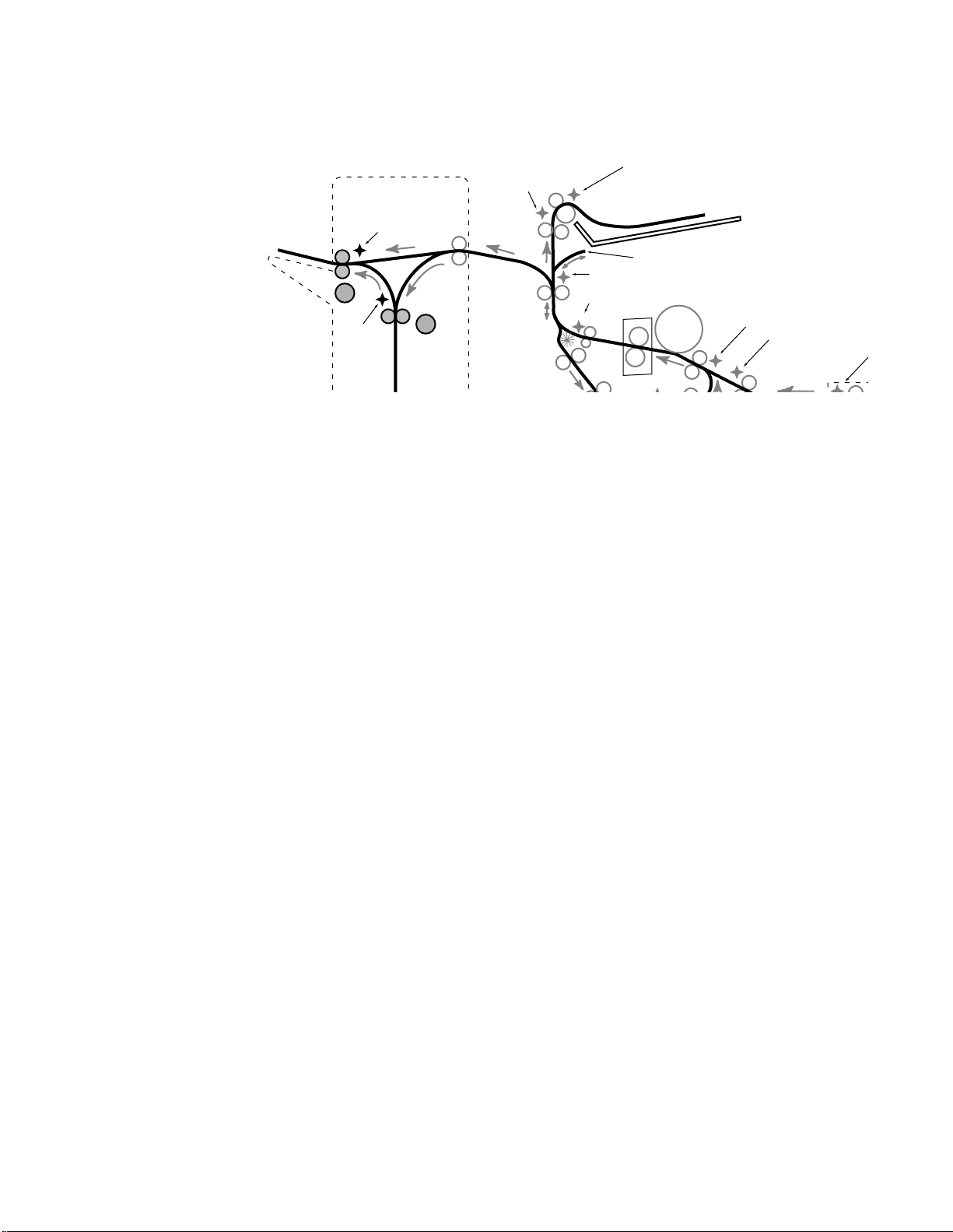

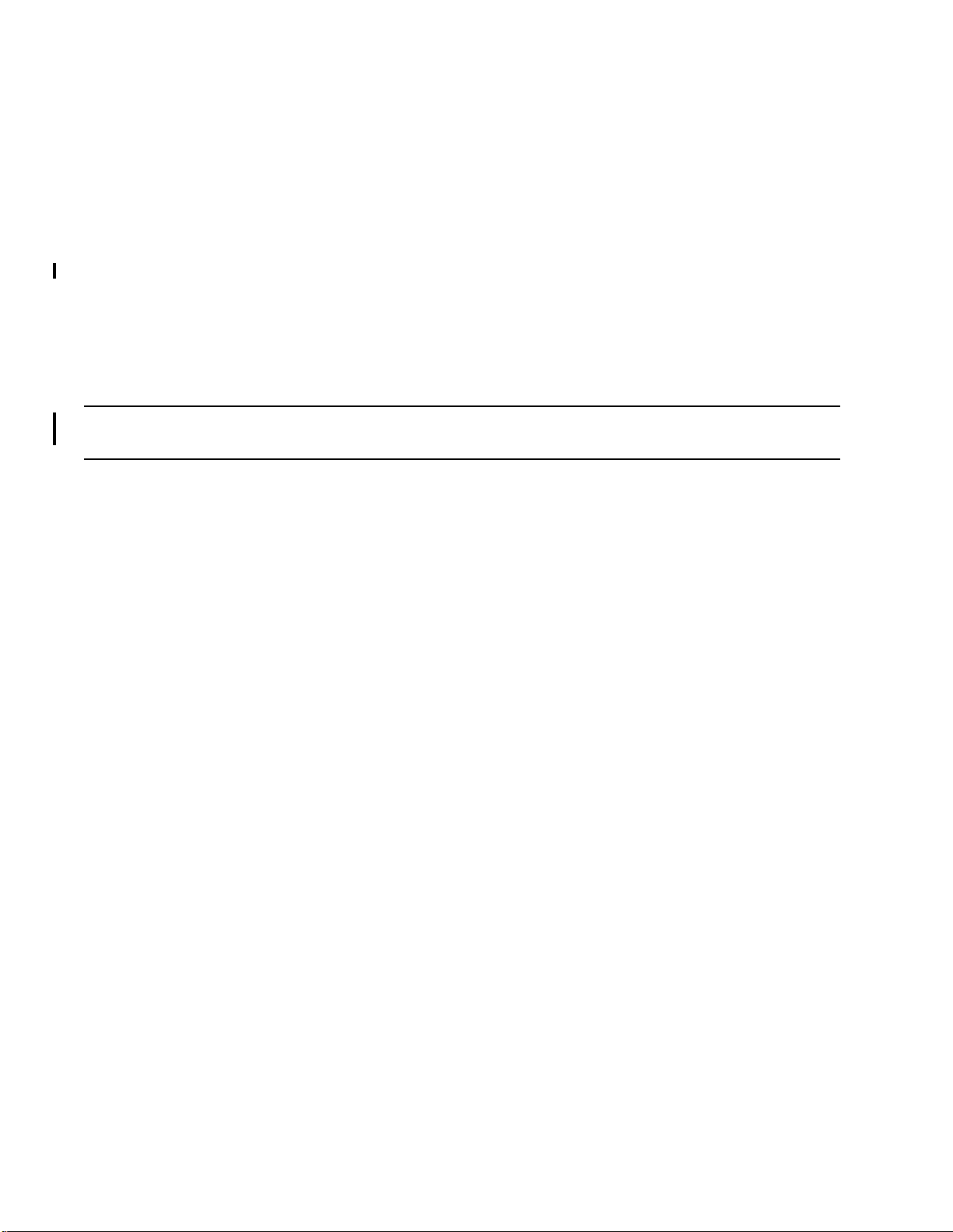

2-6 Electrophotographic Printing Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

2-7 Paper Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

2-8 Paper Feed and Transport from Trays and HCI . . . . . . . . . . . . . . . . . . . . . . . 2-52

2-9 Print Engine Feed Path and the Print Process . . . . . . . . . . . . . . . . . . . . . . . . 2-58

2-10 Ejection Path for Ejection Unit and HCO . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-68

2-5.5 Toner Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

2-5.6 D640 Density Level Settings (and Engine Limits) . . . . . . . . . . . . . . . 2-38

2-6.1 Drum Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

2-7.1 D640, HCI, and HCO Paper Feeding Motor Systems . . . . . . . . . . . . 2-45

2-7.2 Pick Motor System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

2-7.3 Transport Motor System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

2-7.4 Main Motor System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

2-7.5 Reversing Motor System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

2-7.6 Duplex Motor System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

2-7.7 KMOT Motor System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

2-7.8 HCO Feed Motor System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

2-7.9 HCO Exit and Switchback Motor System . . . . . . . . . . . . . . . . . . . . . 2-50

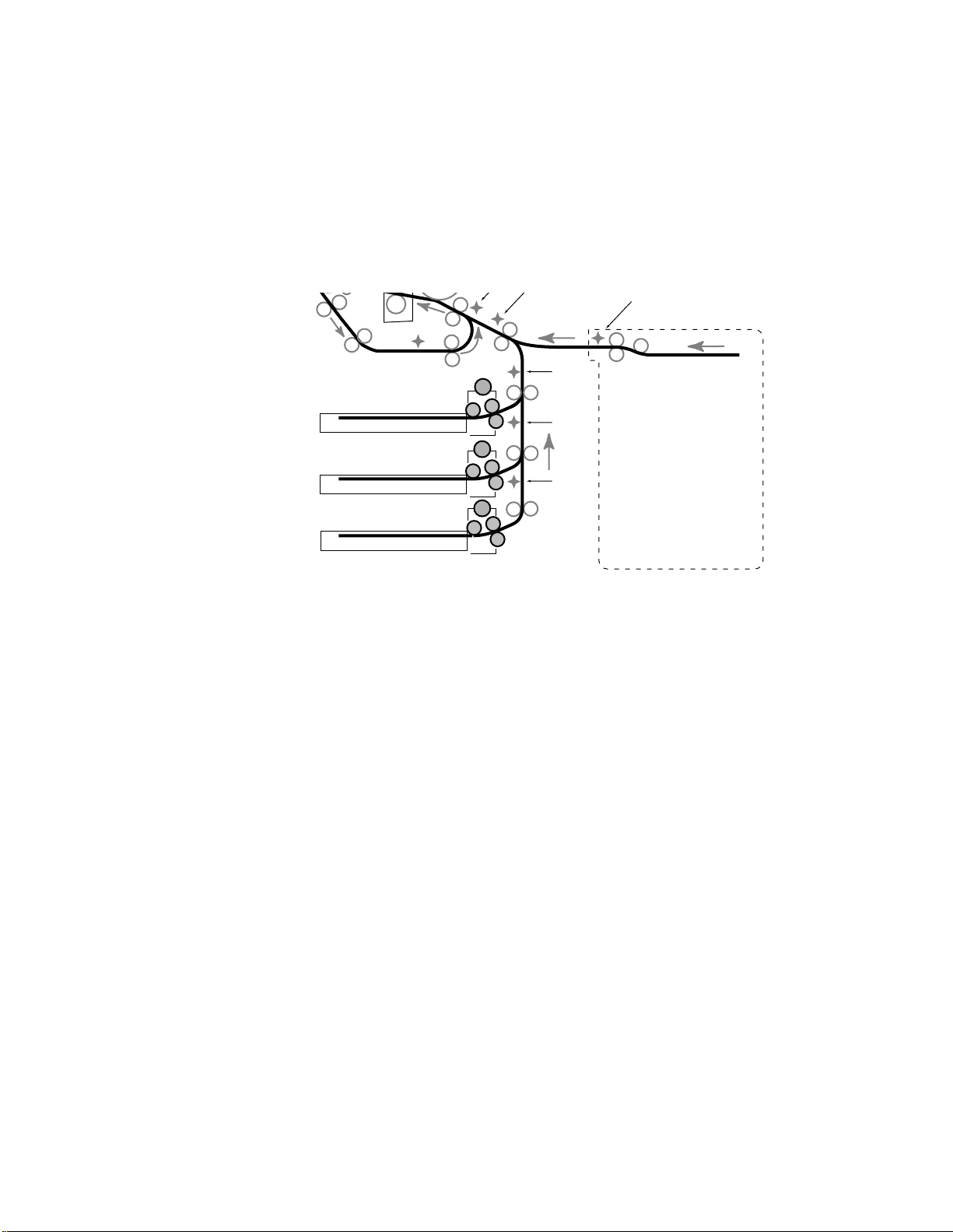

2-8.1 Paper Tray Lift Process - Paper Trays . . . . . . . . . . . . . . . . . . . . . . . 2-52

2-8.2 Paper Tray Lift Process - HCI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

2-8.3 Paper Pick Process - Paper Trays . . . . . . . . . . . . . . . . . . . . . . . . . . 2-55

2-8.4 Paper Pick Process - HCI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-56

2-8.5 Transport Feed Path - Paper Tray and HCI . . . . . . . . . . . . . . . . . . . 2-57

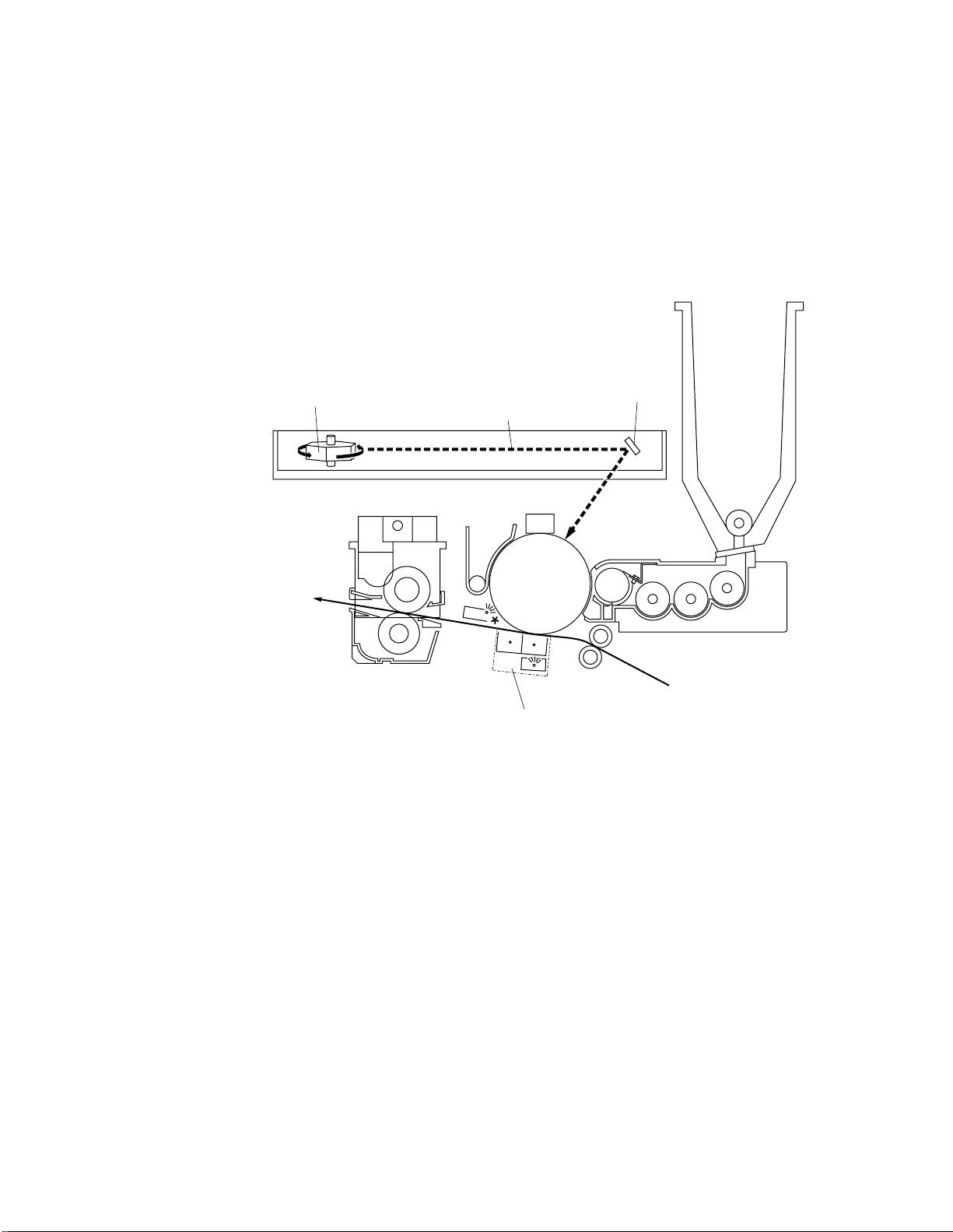

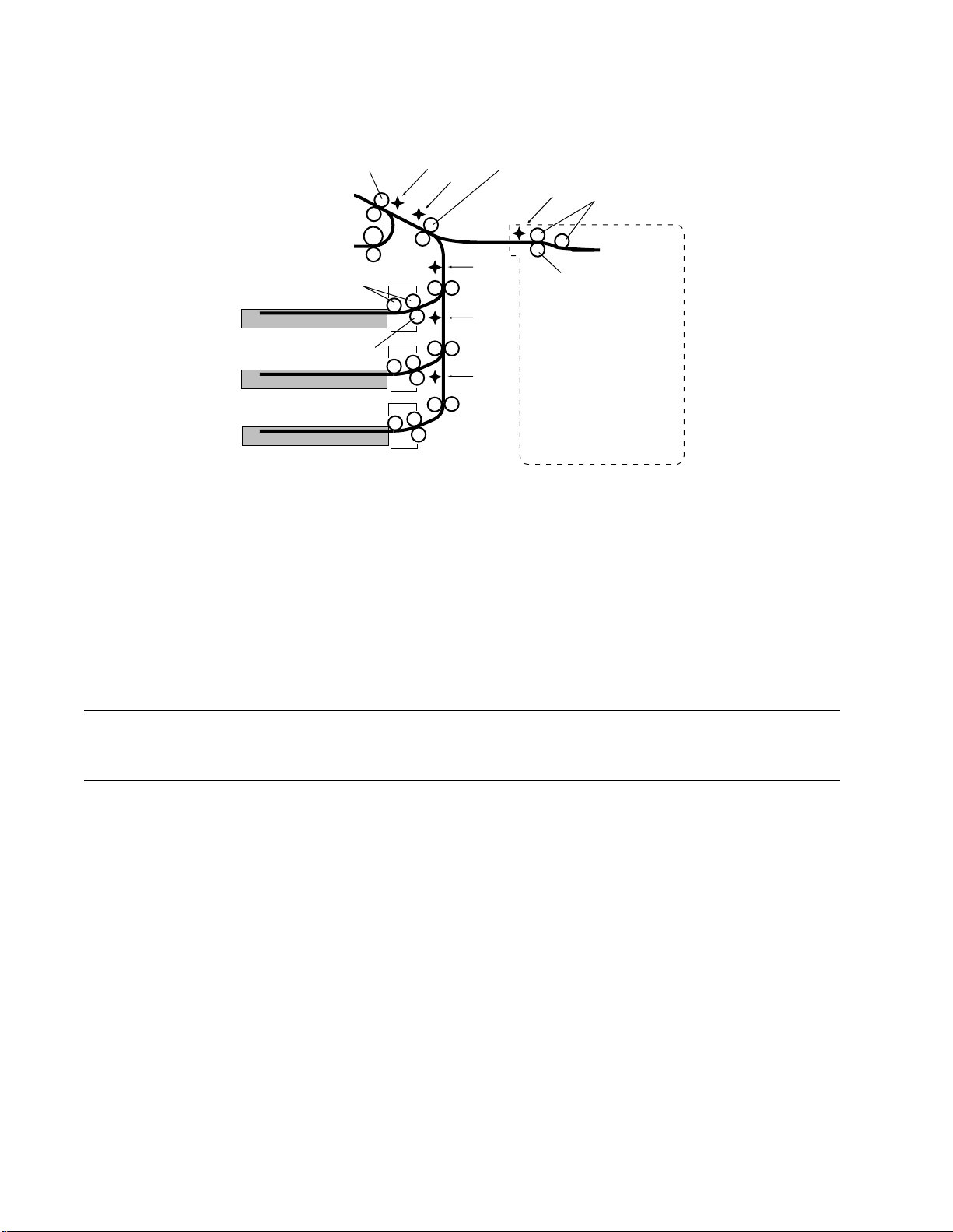

2-9.1 Engine Feed Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

2-9.2 Paper De-Skewing Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-59

2-9.3 Paper Input Shift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-61

2-9.4 Image Transfer and Drum/Paper Separation . . . . . . . . . . . . . . . . . . 2-62

2-9.5 Fuser Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-63

2-9.6 Decurler Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-64

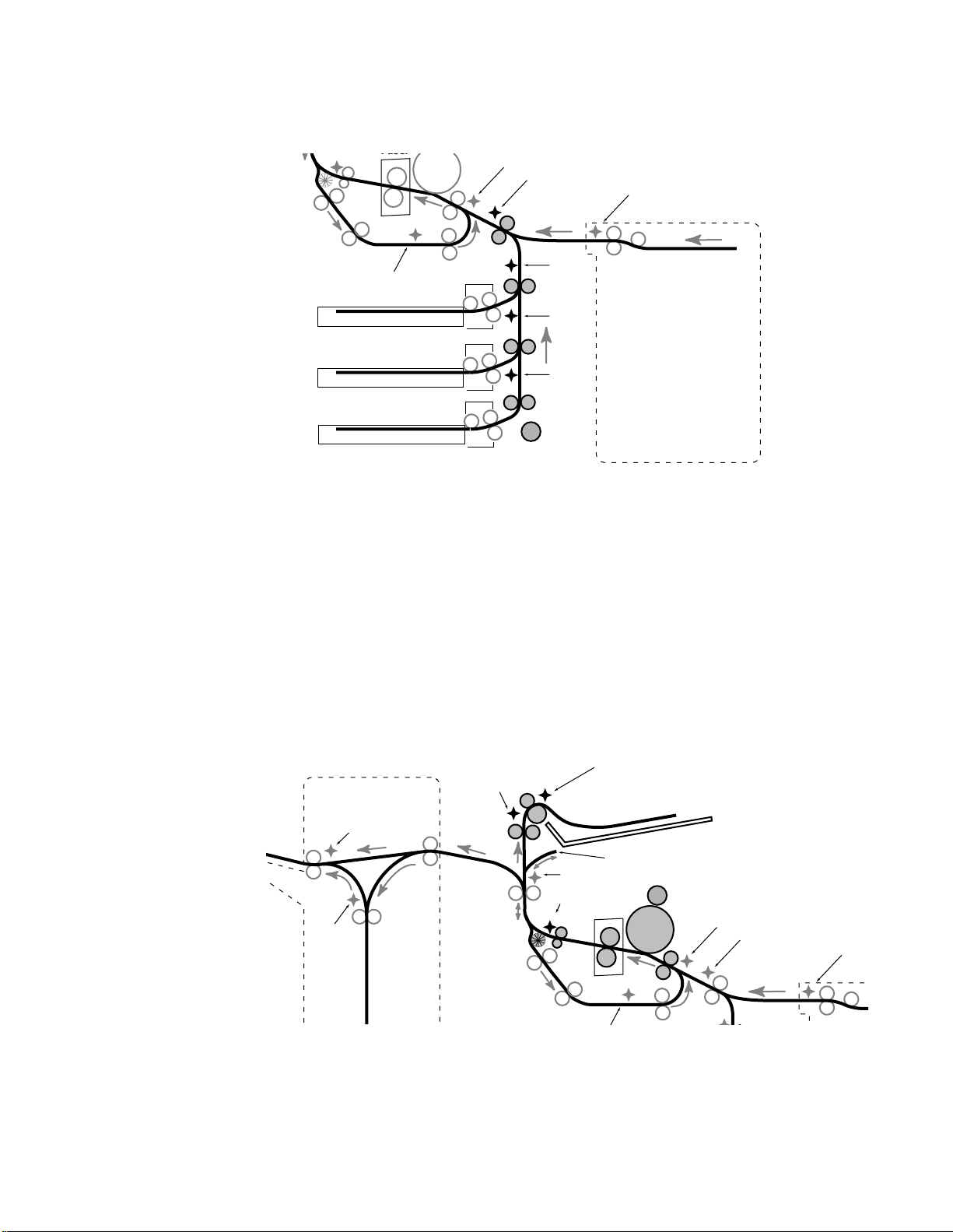

2-9.7 Reversing Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-65

2-9.8 Duplex Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-66

2-10.1 Ejection Unit and Top Bin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-68

2-10.2 2000-Sheet High Capacity Output. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-69

2-10.3 3,000-Sheet High Capacity Output . . . . . . . . . . . . . . . . . . . . . . . . . . 2-70

Chapter 3: Diagnostics

3-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-1.1 Printer Diagnostic Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-1.2 Navigating the Printer Diagnostic Program Menus . . . . . . . . . . . . . . . 3-3

3-1.3 Loading or Upgrading the Printer Diagnostic Program . . . . . . . . . . . . 3-4

3-2 Accessing the Printer Diagnostic Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3-2.1 Accessing the Program from the Control Panel . . . . . . . . . . . . . . . . . 3-5

3-2.2 Accessing the Program Using the DIP Switches. . . . . . . . . . . . . . . . . 3-6

3-2.3 Accessing the Program Using Key 5. . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3-3 Display Test and Key Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3-4 The Test Selection Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3-4.1 Accessing the Test Selection Menu . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3-4.2 Description of Test Selection Menu Tests. . . . . . . . . . . . . . . . . . . . . . 3-9

3-5 Quit Printer Diagnostic Program and Reboot (*Exit*) . . . . . . . . . . . . . . . . . . . 3-11

3-6 Hard Disk Test Menu (TestHDD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3-7 Floppy Disk Test Menu (TestFDD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3-8 Loop DRAM Test (LoopDRAM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3-9 Set Date Menu (SetDate) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

vi June 08, 1999

Page 7

D640 Printer Service Manual

3-10 Set Time Menu (SetTime) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

3-11 Set Serial Number Menu (SetSerNo). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

3-12 Clear Memory Function Menu (ClrMEM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

3-13 Engine Test/Maintenance Menu (EngMaint) . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

3-13.1 Monitoring Print Module Sensors Screens (EngMaint.Sensors). . . . .3-21

3-13.2 Doors Sensors Screen (EngMaint.Sensors.DOORS). . . . . . . . . . . . .3-22

3-13.3 Trays Sensors Screen (EngMaint.Sensors.TRAYS). . . . . . . . . . . . . .3-23

3-13.4 Paper Feed /Print /Eject Sensors Screen

(EngMaint.Sensors.PAPER FEED /PRINT /EJECT) . . . . . . . . . . . . .3-24

3-13.5 Consumer Sensors Screen (EngMaint.Sensors.CONSUMER) . . . . .3-25

3-13.6 Fan Sensors Screen (EngMaint.Sensors.FAN) . . . . . . . . . . . . . . . . .3-26

3-13.7 Switch Sensors Screen (EngMaint.Sensors.SWITCH). . . . . . . . . . . .3-27

3-13.8 HCI Sensors Screen (EngMaint.Sensors.HCI) . . . . . . . . . . . . . . . . . .3-28

3-13.9 Save & Restore Menu (EngMaint.SaveRstr). . . . . . . . . . . . . . . . . . . .3-30

3-13.10 Control Info Save Menu (EngMaint.SaveRst.CtrSave) . . . . . . . . . . . .3-31

3-13.11 Control Info Restore Menu (EngMaint.SaveRstr.CtrRstr). . . . . . . . . .3-32

3-13.12 Power Save Menu (EngMaint.PwrSave). . . . . . . . . . . . . . . . . . . . . . .3-33

3-13.13 Developer Error Reset Menu (EngMaint.DevErRst) . . . . . . . . . . . . . .3-34

3-13.14 Engine Regs Peek/Poke Menu (EngMaint.EngRegs). . . . . . . . . . . . .3-35

3-13.15 Counters Menu (EngMaint.Counters) . . . . . . . . . . . . . . . . . . . . . . . . .3-37

3-13.16 Print Unit Test Menu (EngMaint.UnitTest) . . . . . . . . . . . . . . . . . . . . .3-38

3-13.17 Paper Input Menu (EngMaint.UnitTest.Input) . . . . . . . . . . . . . . . . . . .3-40

3-13.18 Print Section Menu (EngMaint.UnitTest.Print) . . . . . . . . . . . . . . . . . .3-41

3-13.19 Fuser Lamp Menu (EngMaint.UnitTest.Print.Fuser) . . . . . . . . . . . . . .3-42

3-13.20 Erase LED Menu (EngMaint.UnitTest.Print.ErLED) . . . . . . . . . . . . . .3-43

3-13.21 Main Motor Test Menu (EngMaint.UnitTest.Print.Main) . . . . . . . . . . .3-44

3-13.22 Drive.D Unit Test Menu (EngMaint.UnitTest.Print.Drv.D) . . . . . . . . . .3-46

3-13.23 Toner Motor Menu (EngMaint.UnitTest.Print.Toner). . . . . . . . . . . . . .3-48

3-13.24 Charge Menu (EngMaint.UnitTest.Print.Charge) . . . . . . . . . . . . . . . .3-50

3-13.25 HCO Change Solenoid Menu (EngMaint.UnitTest.Print.HCO.chg) . .3-51

3-13.26 HCO Select Solenoid Menu (EngMaint.UnitTest.Print.HCO.sel) . . . .3-52

3-13.27 Clutch Test with Main Motor Menu

(EngMaint.UnitTest.Print.Clutch). . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-53

3-13.28 Print Unit Test Menu (EngMaint.UnitTest.Output). . . . . . . . . . . . . . . .3-55

3-13.29 Control Info Menu (EngMaint.Control) . . . . . . . . . . . . . . . . . . . . . . . .3-56

3-13.30 Printing Test Menu (EngMaint.PrTest) . . . . . . . . . . . . . . . . . . . . . . . .3-58

3-13.31 Error Mask Menu (EngMaint.ErrMask) . . . . . . . . . . . . . . . . . . . . . . . .3-60

3-13.32 NVRAM Menu (EngMaint.NVRAM). . . . . . . . . . . . . . . . . . . . . . . . . . .3-68

Chapter 4: Troubleshooting

4-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4-1.1 Servicing Approach. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4-2 Troubleshooting Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

4-3 Setup Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

4-3.1 Printing a Setup Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

4-3.2 Setup Report Title . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

4-3.3 Maintenance Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

4-3.4 Printer Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

4-4 Maintenance Report. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

4-4.1 Analyzing the Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

4-5 Verifying Proper Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

4-6 Performing Weekly User Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

June 08, 1999 vii

Page 8

D640 Printer Service Manual

4-7 Data Capture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4-8 Loading New Function Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4-9 SVC xx Error Messages

4-10 JAMxx Error Messages

4-8.1 Getting the Latest Function Code and Newsletters. . . . . . . . . . . . . . 4-14

4-9.1 SVC 08 Pick Motor Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

SVC 09 Pick Motor Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

SVC 0A Pick Motor Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

4-9.2 SVC 0B Reversing Motor Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

4-9.3 SVC 0D Feed Motor Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

4-9.4 SVC 0E Stacker Select Solenoid Alarm . . . . . . . . . . . . . . . . . . . . . . 4-22

4-9.5 SVC 0F Duplex Motor Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

4-9.6 SVC 27 Fuser Time-out Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

4-9.7 SVC 28 Fuser High-Temperature Alarm . . . . . . . . . . . . . . . . . . . . . . 4-28

4-9.8 SVC 29 Fuser Low-Temperature Alarm . . . . . . . . . . . . . . . . . . . . . . 4-30

4-9.9 SVC 50 Toner Motor Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

4-9.10 SVC 51 Toner Discharge Screw Alarm . . . . . . . . . . . . . . . . . . . . . . . 4-34

4-9.11 SVC 52 Developer Discharge Alarm . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

4-9.12 SVC 54 Developer Discharge Shutter Alarm. . . . . . . . . . . . . . . . . . . 4-38

4-9.13 SVC 56 Automatic Adjustment Alarm . . . . . . . . . . . . . . . . . . . . . . . . 4-40

4-9.14 SVC 57 Toner High-density Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

4-9.15 SVC 58 Toner Low-Density Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

4-9.16 SVC 59 Reference Voltage Too-High Alarm . . . . . . . . . . . . . . . . . . . 4-46

SVC 5A Reference Voltage Too-Low Alarm . . . . . . . . . . . . . . . . . . . 4-46

4-9.17 SVC 5B Toner Hopper Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

4-9.18 SVC 69 Main Motor Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-50

4-9.19 SVC 6F High Voltage Power Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . 4-52

4-9.20 SVC 79 Spindle Motor Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-56

4-9.21 SVC 7A BD1 (Beam Detection) Alarm . . . . . . . . . . . . . . . . . . . . . . . 4-58

SVC 7B BD2 (Beam Detection) Alarm . . . . . . . . . . . . . . . . . . . . . . . 4-58

SVC 7C Beam Detection High-speed Alarm . . . . . . . . . . . . . . . . . . . 4-58

SVC 7D Beam Detection Low-speed Alarm . . . . . . . . . . . . . . . . . . . 4-58

SVC 7E Laser Diode (LD) Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-58

4-9.22 SVC A0 In-Frame Fan Alarm 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-60

4-9.23 SVC A1 Fan Alarm 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-62

SVC A2 Fan Alarm 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-62

SVC A5 Fan Alarm 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-62

SVC A6 Fan Alarm 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-62

4-9.24 SVC B0 Watchdog Timer Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-64

SVC B1 Watchdog Timer Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-64

SVC B3 Mechanism Controller Communication Alarm . . . . . . . . . . . 4-64

4-9.25 SVC B4 EEPROM Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-66

4-9.26 SVC B5 Video Synchronous (VS) Alarm . . . . . . . . . . . . . . . . . . . . . 4-68

4-9.27 SVC B6 Pre-pick Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-70

4-9.28 SVC B7 Video Request (VR) Alarm . . . . . . . . . . . . . . . . . . . . . . . . . 4-72

4-9.29 SVC C4 HCI Elevator Descent Alarm . . . . . . . . . . . . . . . . . . . . . . . . 4-74

SVC C5 HCI Paper Level Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-74

4-9.30 SVC D8 HCO Stacker Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-74

4-10.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-76

4-10.2 Paper Jam Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-76

4-10.3 Paper Jam Analysis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-77

4-10.4 Paper Jam at Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-77

viii June 08, 1999

Page 9

D640 Printer Service Manual

4-10.5 Intermittent Paper Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-77

4-10.6 List of Jam Codes and Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . .4-79

4-10.7 Paper Path Status Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-80

4-10.8 JAM01 Tray 1 Pick Error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-82

JAM02 Tray 2 Pick Error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-82

JAM03 Tray 3 Pick Error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-82

4-10.9 JAM11 Feed Path Jam 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-86

JAM12 Feed Path Jam 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-86

JAM13 Feed Path Jam 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-86

4-10.10 JAM18 Feed Jam 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-90

4-10.11 JAM25 Fuser Unit Jam 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-92

JAM26 Fuser Unit Jam 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-92

4-10.12 JAM29 Ejection Unit Jam 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-96

4-10.13 JAM2B Ejection Unit Jam 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-98

4-10.14 JAM31 Duplex Printing Path Jam 1 . . . . . . . . . . . . . . . . . . . . . . . . .4-100

JAM32 Duplex Printing Path Jam 2 . . . . . . . . . . . . . . . . . . . . . . . . .4-100

4-10.15 JAM41 HCO JAM1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-104

4-10.16 JAM51 HCI Pick Error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-104

JAM52 HCI Feed Jam1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-104

4-10.17 JAM53 HCI Feed Jam 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-104

4-11 Print Quality Problems

4-11.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-106

4-11.2 Initial Print Quality Troubleshooting Procedures. . . . . . . . . . . . . . . .4-106

4-11.3 Good Quality Print. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-108

4-11.4 Background Print. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-110

4-11.5 Black or Dark Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-112

4-11.6 Blank Print. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-114

4-11.7 Blank Vertical Bands Print. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-116

4-11.8 Blurred Images or Blurred Characters Print . . . . . . . . . . . . . . . . . . .4-118

4-11.9 Dark-Specks, Dark-Lines, or Dark-Areas Print . . . . . . . . . . . . . . . . .4-120

4-11.10 Dark Vertical Lines Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-122

4-11.11 Fusing Problems Print. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-124

4-11.12 Light Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-126

4-11.13 Light Print with Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-128

4-11.14 Light Horizontal Bands Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-130

4-11.15 Light Vertical Streaks Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-132

4-11.16 Misregistration Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-134

4-11.17 Residual Images Print. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-136

4-11.18 Skewed Print. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-138

4-11.19 Varying Print Density Print. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-140

4-11.20 Voids or White Spots Print (Print Dropouts) . . . . . . . . . . . . . . . . . . .4-142

4-11.21 Washed-out Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-144

4-12 Power Related Problems

4-12.1 Blank Control Panel/Cannot Power Printer On . . . . . . . . . . . . . . . . .4-148

4-12.2 Control Panel Powers On But Printer Cannot Power On . . . . . . . . .4-162

4-12.3 Cannot Power Off Printer With Stand-by Switch. . . . . . . . . . . . . . . .4-164

4-13 Miscellaneous Problems

4-13.1 Cover Open / Interlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-168

4-13.2 Paper Tray Not Ready . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-170

4-13.3 Out of Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-174

4-13.4 Output Tray Cannot Be Cleared . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-176

4-13.5 Output Tray Cannot Be Detected . . . . . . . . . . . . . . . . . . . . . . . . . . .4-178

June 08, 1999 ix

Page 10

D640 Printer Service Manual

Chapter 5: Maintenance

5-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

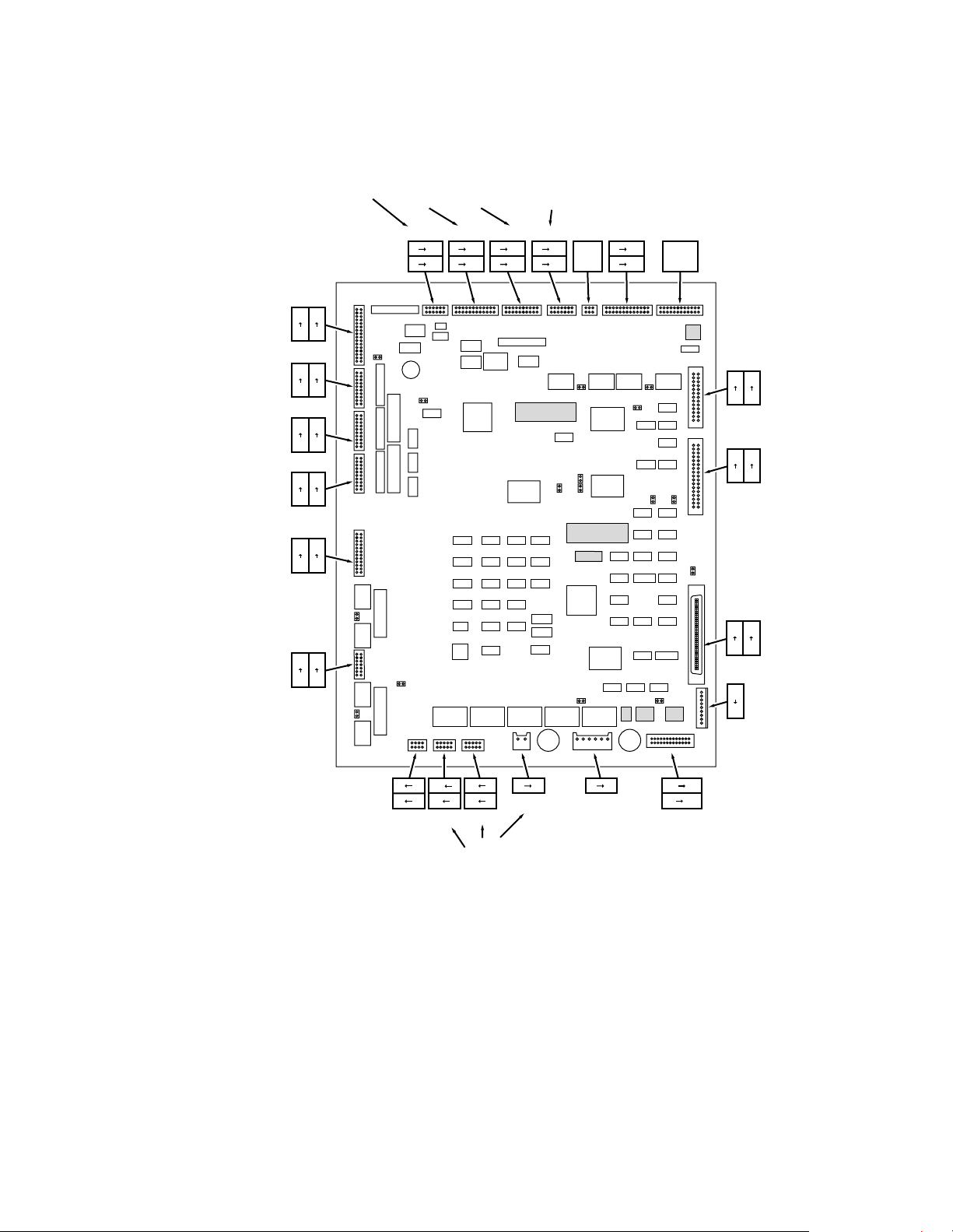

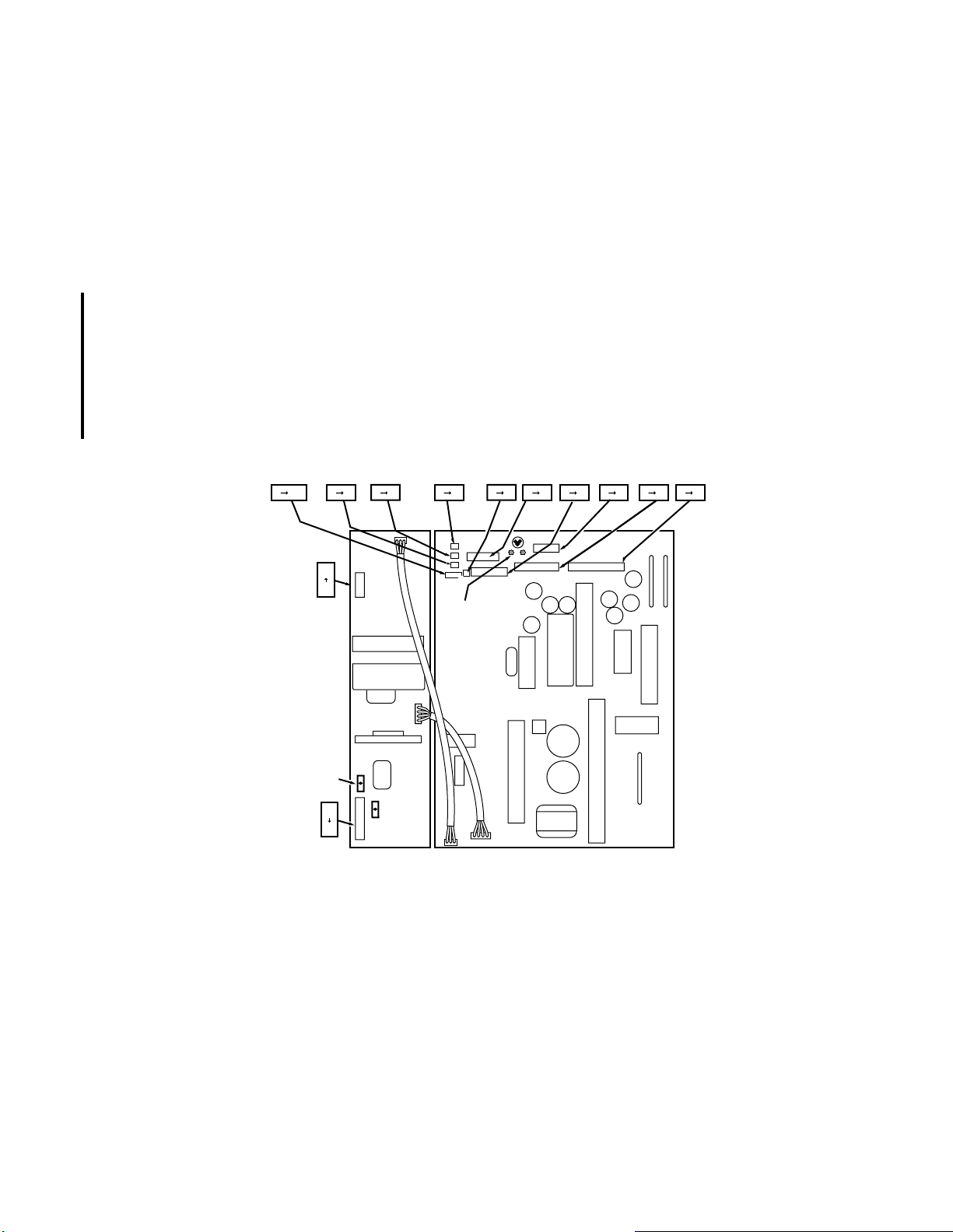

5-2 Printer Board Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5-3 Printer Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5-4 Printer Microswitch Location Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5-5 FRUs Accessed from the Front of Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

5-6 FRUs Accessed from the Top of Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-44

5-7 FRUs Accessed from the Rear of Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-50

4-13.6 HCI Sensing Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-180

4-13.7 HCO Stacker Full Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-180

4-13.8 HCO Door Open Related Problems . . . . . . . . . . . . . . . . . . . . . . . . 4-180

4-13.9 HCO Stacker Tray Up/Down Movement Problem . . . . . . . . . . . . . . 4-180

4-13.10 HCO Not Sensed By Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-180

5-1.1 HCO Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5-1.2 HCI Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5-1.3 Standard Tools and Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5-1.4 Hints and Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5-2.1 Main Controller Board DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5-2.2 Mechanism Controller Board Switches . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5-3.1 2,000 Sheet HCO Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5-3.2 Low Voltage Power Supply (LVPS) +5V Adjustment . . . . . . . . . . . . . 5-8

5-3.3 Laser Start Position Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5-3.4 Paper Feed System Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5-4.1 Developer Mixture Collector Bottle Detection Microswitch . . . . . . . . 5-15

5-4.2 Developer Unit Shutter Detection Microswitch . . . . . . . . . . . . . . . . 5-16

5-4.3 Drum Unit Interlock Microswitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

5-4.4 Ejection Unit Cover Interlock Microswitch . . . . . . . . . . . . . . . . . . . . . 5-18

5-4.5 Front Door Interlock Microswitch. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

5-4.6 Paper Tray Detection Microswitch. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

5-4.7 Lower-right Cover Interlock Microswitch . . . . . . . . . . . . . . . . . . . . . . 5-21

5-4.8 Upper-right Cover Interlock Microswitch . . . . . . . . . . . . . . . . . . . . . . 5-22

5-5.1 Duplex Unit Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . 5-24

5-5.2 PS5 - Duplex Unit Paper Path Sensor Replacement Procedure. . . . 5-26

5-5.3 LED Erase Unit Replacement Procedure . . . . . . . . . . . . . . . . . . . . . 5-28

5-5.4 Transfer Assembly Guide Replacement Procedure . . . . . . . . . . . . . 5-30

5-5.5 Decurler Unit Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . 5-34

5-5.6 Paper Tray Lift Motor Replacement Procedure. . . . . . . . . . . . . . . . . 5-36

5-5.7 Printer Pick Roller Kit - Tray Pick Rollers Replacement Procedure . 5-38

5-6.1 Control Panel Board Replacement Procedure . . . . . . . . . . . . . . . . . 5-44

5-6.2 Main Controller Board Replacement Procedure . . . . . . . . . . . . . . . . 5-45

Hard Disk Drive (HDD) Replacement Procedure . . . . . . . . . . . . . . . 5-45

Floppy Disk Drive (FDD) Replacement Procedure . . . . . . . . . . . . . . 5-45

5-6.3 Optical Unit Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . 5-48

5-7.1 Drive D Unit Motor Assembly Replacement Procedure. . . . . . . . . . . 5-50

5-7.2 Registration Roller Clutch Replacement Procedure . . . . . . . . . . . . . 5-51

5-7.3 Mechanism Controller Board Replacement Procedure . . . . . . . . . . . 5-52

5-7.4 Low Voltage Power Supply (LVPS) Replacement Procedure . . . . . . 5-56

5-7.5 Low Voltage Power Supply Fan 5 Replacement Procedure . . . . . . . 5-58

5-7.6 High Voltage Power Supply Replacement Procedure. . . . . . . . . . . . 5-59

5-7.7 Power Sequencing Relay Replacement Procedure . . . . . . . . . . . . . 5-60

5-7.8 Drive M Unit Lower Fan (Fan7) Replacement Procedure . . . . . . . . . 5-62

x June 08, 1999

Page 11

D640 Printer Service Manual

5-7.9 Drive M Unit Upper Fans (Fan2 and Fan4) Replacement Procedure.5-63

5-7.10 Drive M Unit Replacement Procedure. . . . . . . . . . . . . . . . . . . . . . . . .5-64

5-7.11 Drive M Unit Fuser Unit Interlock Switch (TINTSW)

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-68

5-7.12 Waste Toner Unit Replacement Procedure . . . . . . . . . . . . . . . . . . . .5-70

5-7.13 Waste Toner Screw Sensor Replacement Procedure . . . . . . . . . . . .5-74

5-7.14 Drive E Unit Gear Assembly Replacement Procedure . . . . . . . . . . . .5-76

Drive E Unit to Ejection Unit Belt Replacement Procedure. . . . . . . . .5-76

5-8 FRUs Accessed from the Left Side of Printer. . . . . . . . . . . . . . . . . . . . . . . . . .5-78

5-8.1 Reversing Unit Replacement Procedure. . . . . . . . . . . . . . . . . . . . . . .5-78

5-8.2 PS6 - Reversing Unit Paper Path Sensor Replacement Procedure . .5-80

5-8.3 Ejection Unit Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . .5-82

5-8.4 PS7 - Ejection Unit Paper Path Sensor Replacement Procedure. . . .5-84

Ejection Tray - Paper Path Stacker Full Sensor

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-84

5-9 FRUs Accessed from the Right Side of Printer . . . . . . . . . . . . . . . . . . . . . . . .5-86

5-9.1 Developer Unit Replacement Procedure. . . . . . . . . . . . . . . . . . . . . . .5-86

5-9.2 Developer Retaining Plate Replacement Procedure. . . . . . . . . . . . . .5-89

5-9.3 Toner Hopper Assembly Replacement Procedure . . . . . . . . . . . . . . .5-90

5-9.4 Main Power Switch Replacement Procedure . . . . . . . . . . . . . . . . . . .5-92

5-9.5 Paper Feed Unit Replacement Procedure . . . . . . . . . . . . . . . . . . . . .5-94

5-9.6 Paper Feed Unit Transport Feed Motor Replacement Procedure . . .5-98

5-9.7 PS1 - Tray Empty Sensors (PS1-1/2/3) Replacement Procedure . .5-100

5-9.8 PS2 - Paper Path Timing Sensor Replacement Procedure . . . . . . .5-102

5-9.9 PS3 - Paper Path Registration Sensor Replacement Procedure . . .5-103

5-9.10 PS4 - Paper Path Decurling Sensor Replacement Procedure . . . . .5-104

5-9.11 HCI Input (Mylar) Guide Replacement Procedure . . . . . . . . . . . . . .5-105

5-9.12 Upper and Lower Transport Rollers Replacement Procedure . . . . .5-106

5-9.13 Upper Registration Roller Replacement Procedure . . . . . . . . . . . . .5-108

5-9.14 Lower Registration Roller Replacement Procedure . . . . . . . . . . . . .5-110

Chapter 6: Replaceable Parts

6-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6-2 Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6-3 HCI Replaceable Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6-4 HCO Replaceable Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6-5 Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

6-6 Printer Parts and Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

6-6.1 Miscellaneous Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

6-6.2 Cover Assemblies - Front View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

6-6.3 Cover Assemblies - Back View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

6-6.4 Duplex Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

6-6.5 Transfer Assembly Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

6-6.6 Paper Tray, Paper Lift Motor, and Tray Installed Sensor . . . . . . . . . .6-16

6-6.7 Main Controller and Optical Units . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-18

6-6.8 Ejection Unit and Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-20

6-6.9 Reversing Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-22

6-6.10 Paper Path Transport Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-24

6-6.11 Paper Feed Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-26

6-6.12 Toner Hopper and Developer Units . . . . . . . . . . . . . . . . . . . . . . . . . .6-28

6-6.13 Main Frame Assembly, Decurler, and Registration Rollers . . . . . . . .6-30

6-6.14 Drive M Unit and Waste Toner Unit . . . . . . . . . . . . . . . . . . . . . . . . . .6-34

June 08, 1999 xi

Page 12

D640 Printer Service Manual

Part Number Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-47

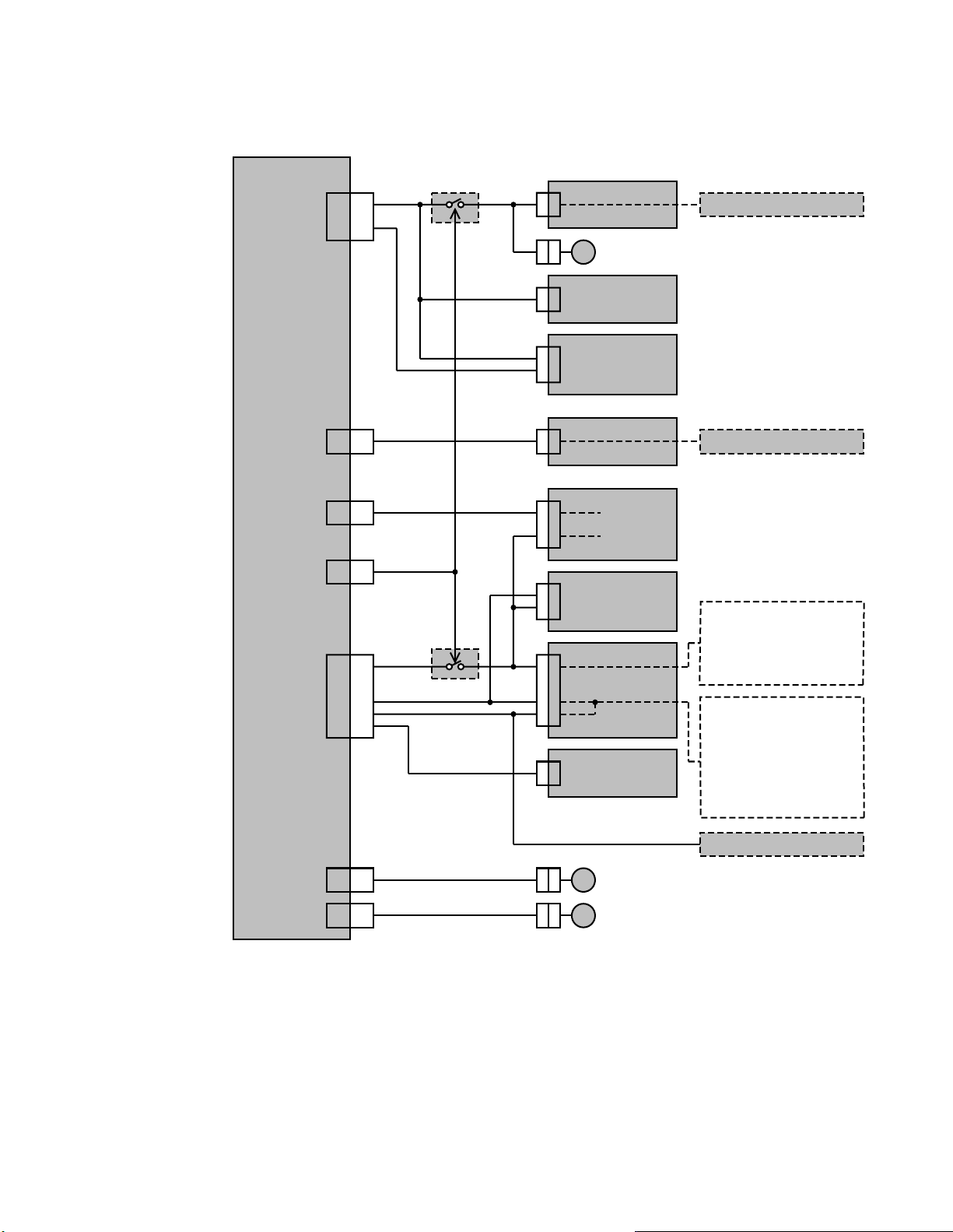

Appendix A: Reference Diagrams

A-1 Printer Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

A-2 Printer Component Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-20

A-3 Printer Power Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-24

A-4 Power-on Sequence Timing Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-28

Appendix B: 3,000-Sheet H igh-Capacity Output

B-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

B-2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

B-3 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

B-4 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-12

B-5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-37

6-6.15 Mechanism Controller, Power Supplies, and Fans . . . . . . . . . . . . . . 6-36

6-6.16 Drive D Unit Motor, Drive E Unit, Drive E Unit Belt . . . . . . . . . . . . . . 6-38

6-6.17 Mechanism Controller Wire Harnesses. . . . . . . . . . . . . . . . . . . . . . . 6-40

6-6.18 Main Controller Wire Harnesses . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-42

6-6.19 High Voltage PS and Low Voltage PS Wire Harnesses . . . . . . . . . . 6-44

B-1.1 Related Documents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

B-2.1 Paper Handing Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

B-2.2 Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

B-2.3 Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

B-2.4 Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

B-3.1 Running a Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

B-3.2 Normal Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

B-3.3 Sensor and Switch Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

B-3.4 Motors and Solenoid Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-10

B-3.5 Feeding Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-11

B-4.1 General Troubleshooting Information . . . . . . . . . . . . . . . . . . . . . . . . B-12

B-4.2 SVC D8 HCO Stacker Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-14

B-4.3 HCO Stacker Jams - HCO JAM 1/JAM41 . . . . . . . . . . . . . . . . . . . . . B-18

B-4.4 HCO Stacker Full Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-20

B-4.5 HCO Cover (Door) Open Problems. . . . . . . . . . . . . . . . . . . . . . . . . . B-24

B-4.6 HCO Tray Continuous Up-Down Problems. . . . . . . . . . . . . . . . . . . . B-28

B-4.7 HCO Tray Stays Down Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . B-30

B-4.8 HCO Not Recognized By Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-34

B-4.9 HCO Not Installed But Recognized By Printer . . . . . . . . . . . . . . . . . B-36

B-5.1 Top Cover Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-37

B-5.2 Right Cover (between HCO and printer) Removal . . . . . . . . . . . . . . B-37

B-5.3 Rear Cover Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-38

B-5.4 Front Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-38

B-5.5 Left Cover Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-38

B-5.6 Power Supply Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-39

B-5.7 Main Controller Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . B-39

B-5.8 Tray Sensors Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-39

(Paper Height Sensor, Tray Home Position Sensor). . . . . . . . . . . . . B-39

B-5.9 Tray Belt and Tray Belt Pulley Replacement. . . . . . . . . . . . . . . . . . . B-40

B-5.10 Connecting (Docking) Sensor Replacement . . . . . . . . . . . . . . . . . . . B-41

B-5.11 Door Switch Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-42

xii June 08, 1999

Page 13

D640 Printer Service Manual

B-5.12 Tray Full Sensor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-42

B-5.13 HCO Cutoff Switch Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . B-42

B-5.14 Feed Roller Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-43

B-5.15 Feed Motor Kit Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-43

B-5.16 Paper Path Solenoid Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . B-44

B-5.17 Paper Feed Unit Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-45

B-5.18 Paper Offset Solenoid and Harness Replacement . . . . . . . . . . . . . . B-46

B-5.19 Exit Motor Kit Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-46

B-5.20 Exit Kit Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-47

B-5.21 Reverse Roller Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-48

B-5.22 Power Switch Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-49

B-5.23 Tray Motor Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-49

B-5.24 Timing Belt Kit and Tray Pulley Kit Replacement . . . . . . . . . . . . . . . B-50

B-5.25 Upper Guide Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . . B-51

B-5.26 Lever Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-52

B-5.27 Reverse Guide Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . B-53

B-6 Parts and Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-54

B-6.1 Top Assembly Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-54

B-6.2 Paper Feed Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-58

B-6.3 General Maintenance Kit (Kit 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-61

B-6.4 Feed Roller Kit (Kit 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-62

B-6.5 Lever Kit (Kit 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-63

B-6.6 Exit Kit (Kit 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-64

B-6.7 Feed Motor Kit (Kit 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-66

B-6.8 Exit Motor Kit (Kit 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-67

B-6.9 Tray Pulley Kit (Kit 7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-68

B-6.10 Timing Belt Kit (Kit 8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-69

B-6.11 Tray Belt Kit (Kit 9) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-70

B-6.12 Tray Sensors Kit (Kit 10). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-71

B-6.13 Offset Solenoid Kit (Kit 12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-72

B-6.14 Mounting Hardware Kit (Kit 13). . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-73

B-6.15 Stacking Upgrade Kit (Kit 14) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-74

B-7 Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-75

B-7.1 Power Supply Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-77

B-7.2 Printer to HCO Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-77

B-7.3 Door Switch and Connecting Switch Interface . . . . . . . . . . . . . . . . . B-78

B-7.4 Paper Height Sensor and Tray Home Position Sensor Interface . . . B-79

B-7.5 Paper Sensors Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-79

B-7.6 Tray Motor Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-80

B-7.7 Feed Motor Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-80

B-7.8 Exit Motor Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-81

B-7.9 Path Solenoid and Offset Solenoid Interface . . . . . . . . . . . . . . . . . . B-81

Appendix C: 2,000-Sheet High-Capacity Output

C-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

C-1.1 Related Documents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

C-2 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

C-2.1 Paper Handling Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

C-2.2 Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

C-2.3 Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

C-2.4 Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

C-3 Diagnostics - Normal Operation (Connected to Printer). . . . . . . . . . . . . . . . . . C-7

June 08, 1999 xiii

Page 14

D640 Printer Service Manual

C-4 Diagnostics - Stand-Alone Operation (Disconnected from Printer). . . . . . . . . C-16

C-5 Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-18

C-6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-19

C-7 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-48

C-8 Parts and Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-53

C-3.1 Normal Operation HCO Diagnostic . . . . . . . . . . . . . . . . . . . . . . . . . . . C-7

C-3.2 LED Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-9

C-3.3 Photo-Sensor Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-10

C-3.4 Microswitch Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-12

C-3.5 Motor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-14

C-4.1 Stand-Alone Preliminary Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-16

C-6.1 SVC D8 HCO Stacker Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-19

C-6.2 JAM41 HCO JAM1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-28

C-6.3 HCO Stacker Full Related Problems. . . . . . . . . . . . . . . . . . . . . . . . . C-36

C-6.4 HCO Door Open Related Problems . . . . . . . . . . . . . . . . . . . . . . . . . C-40

C-6.5 HCO Stacker Tray Up/Down Movement Problem . . . . . . . . . . . . . . . C-44

C-6.6 HCO Not Sensed By Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-46

C-7.1 Top Cover Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-48

C-7.2 Rear Cover Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-48

C-7.3 Front Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-48

C-7.4 Right Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-49

C-7.5 Left Cover Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-49

C-7.6 Power Supply Replacement Procedure. . . . . . . . . . . . . . . . . . . . . . . C-49

C-7.7 HCO Controller Replacement Procedure . . . . . . . . . . . . . . . . . . . . . C-50

C-7.8 Paper Feed Unit Replacement Procedure. . . . . . . . . . . . . . . . . . . . . C-51

C-7.9 HCO Exit Roller and Exit Pulley Replacement Procedure. . . . . . . . . C-52

C-8.1 HCO Attachments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-53

C-8.2 Stacker Frame Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-56

C-8.3 Controls and Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-58

C-8.4 Input-Paper Transport Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . C-60

C-8.5 Output-Paper Transport Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . C-62

Appendix D: High-Capacity Input

D-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

D-1.1 Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

D-2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

D-2.1 Paper Handling Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

D-2.2 Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

D-2.3 HCI Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-5

D-2.4 Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-5

D-3 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-6

D-4 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-8

D-4.1 SVC C4 HCI Elevator Descent Alarm . . . . . . . . . . . . . . . . . . . . . . . . . D-8

SVC C5 HCI Paper Level Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-8

D-4.2 JAM51 HCI Pick Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-12

JAM52 HCI Feed Jam1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-12

D-4.3 JAM53 HCI Feed Jam 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-16

D-4.4 HCI Sensing Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-18

D-5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-20

D-5.1 Sensor Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-20

D-5.2 HCI Pick Rollers Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-21

D-6 Parts and Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-28

xiv June 08, 1999

Page 15

D640 Printer Service Manual

D-6.1 HCI Base. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-28

D-6.2 HCI Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-30

D-6.3 HCI Paper Feed Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-32

D-6.4 HCI Paper Transport Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-34

Index

June 08, 1999 xv

Page 16

D640 Printer Service Manual

xvi June 08, 1999

Page 17

1

D640 Printer Service Manual

Specifications

Chapter 1 contents:

1-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1-1.1 Related Documents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1-1.2 Web Sites for More Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1-2 Printer Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1-2.1 Printer General Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1-2.2 Printer Print Speed Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1-2.3 Printer Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1-2.4 Printer Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1-2.5 Environmental Specifications For All Equipment . . . . . . . . . . . . . . . . .1-9

1-2.6 Printer Laser Equipment Compliance Label . . . . . . . . . . . . . . . . . . . . .1-9

1-3 Summary of Optional Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

1-4 Printer Custom Paper Tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1-5 PostScript Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1-6 16 MB Memory Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1-7 Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

1-8 Printable Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

1-8.1 Printing Position Precision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

1-8.2 Simplex and Duplex Printing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

June 08, 1999 Specifications 1-1

Page 18

D640 Printer Service Manual

1-2 Specifications June 08, 1999

Page 19

1-1 Introduction

This chapter provides specifications for the D640 cut sheet printer and its optional High

Capacity Input (HCI) and High Capacity Output (HCO) paper handlers. This information

includes:

specifications

l

safety compliance

l

options

l

available supplies

l

supported printing area

l

notes on duplex printing on pre-punched forms

l

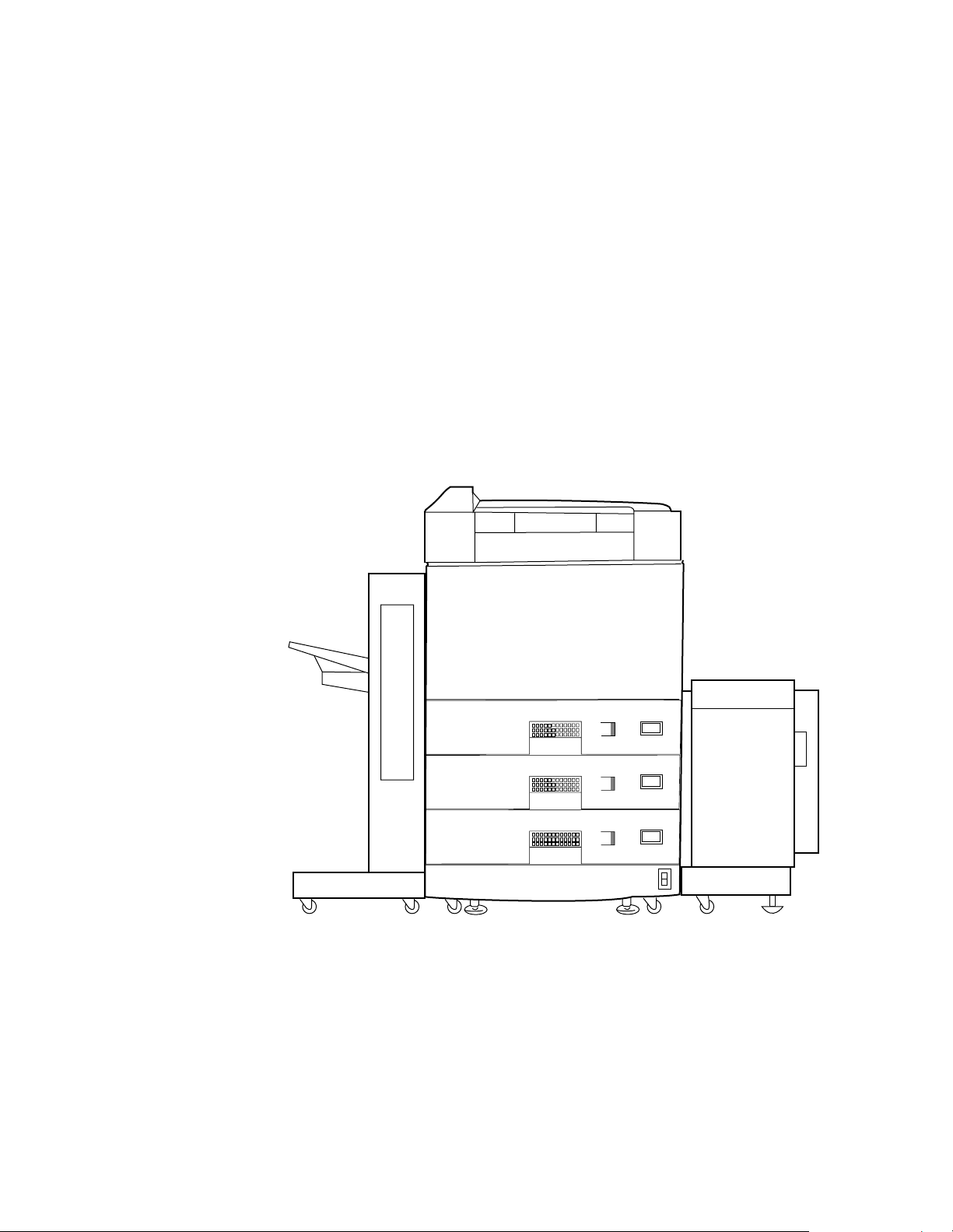

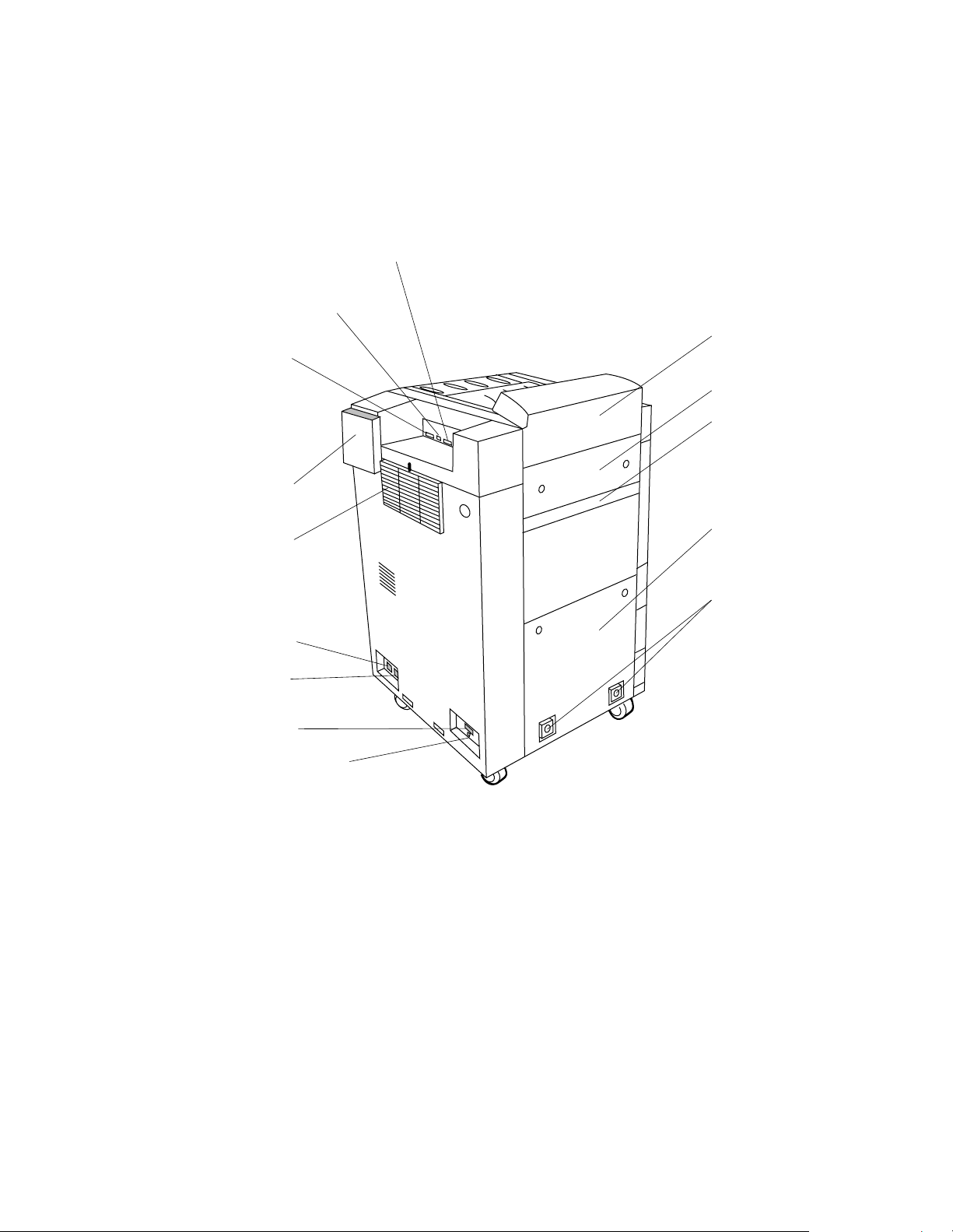

The D640 combines semiconductor laser optical technology and two-component dry

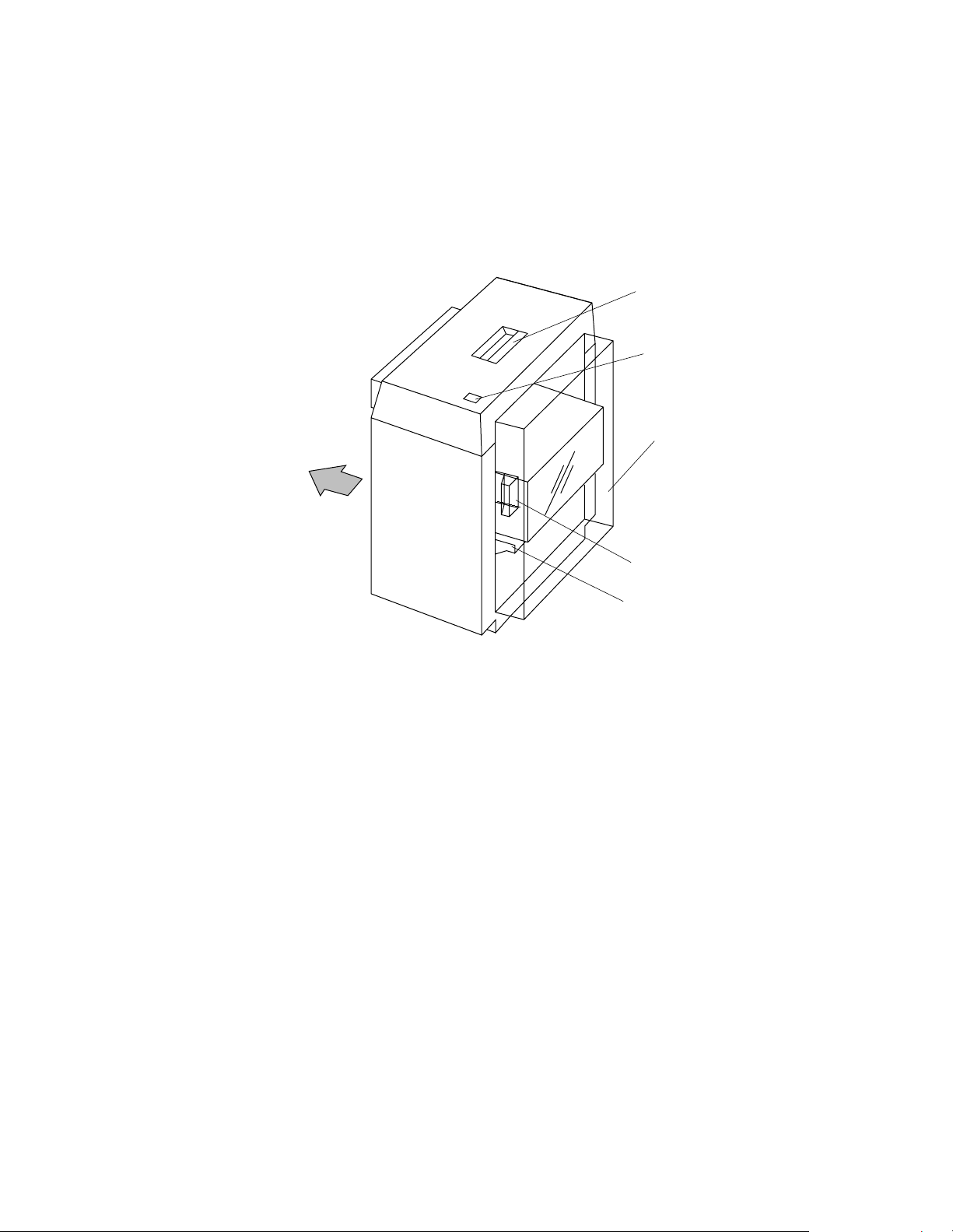

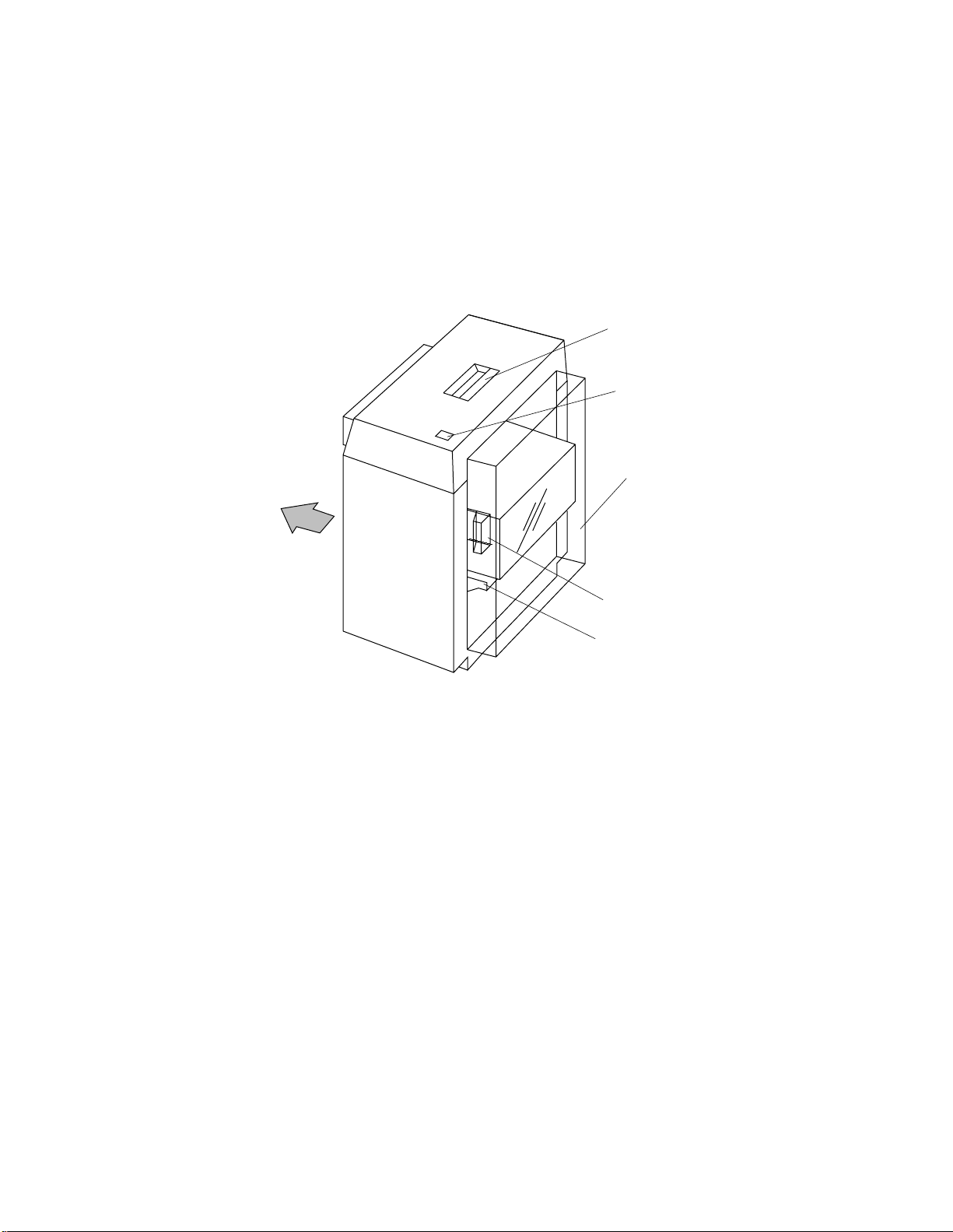

development process technology to print on cut-sheet plain paper. Figure 1-1 illustrates

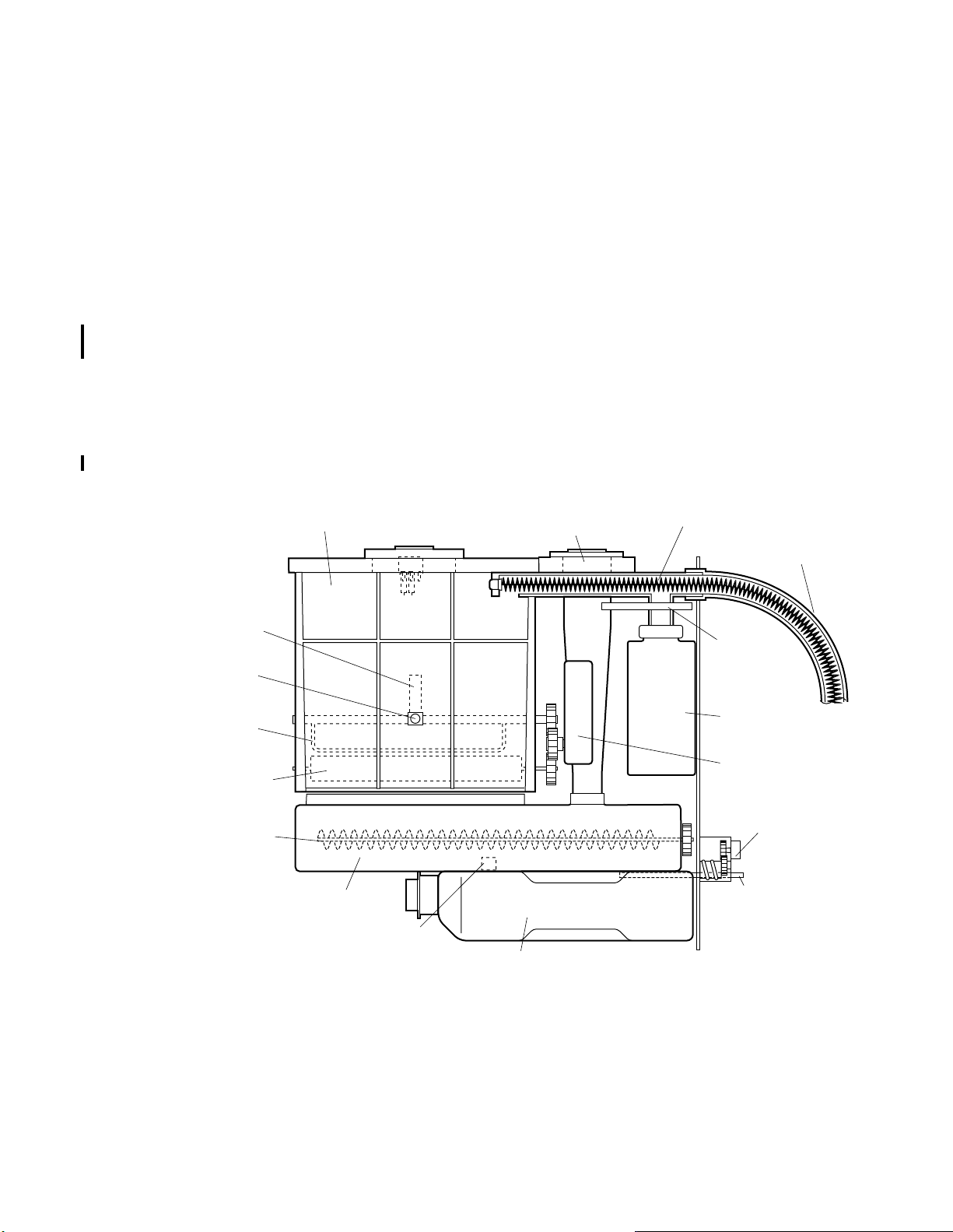

an installed printer and the external high-capacity paper handling options.

D640 Printer Service Manual

LTR

LTR

LTR

HCO D640 HCI

Figure 1-1 D640 Printer With Optional High Capacity Input (HCI) and Output

(HCO) Paper Handlers

June 08, 1999 Specifications 1-3

Page 20

D640 Printer Service Manual

1-1.1 Related Documents

The following manuals are shipped with each printer and provide additional information

on the printer. The information in these manuals is not repeated in this manual.

D640 Printer Installation Manual

l

l

D640 Printer User Manual

l

D640 Technical Reference Manual

l

D640 Enhanced Features Manual

For more information about the D640 printer, see the following documents. Most of

these documents are available on the DLD-Cupertino web site (see 1-1.2 "Web Sites for

More Information," on page 1-5):

D640 Printer Installation Manual

l

Guides you through unpacking, setup, testing, and configuration of your printer.

D640 Printer User Manual

l

Contains the information needed by the customer to operate the D640 printer.

D640 Technical Reference Manual

l

Guide to using fonts and the PCL and PJL emulations on the D640. It also

documents additional aspects of printer usage in detail.

D640 Paper Specifications Guide

l

Guide outlines specifications for selecting print media appropriate for use in the

D640 printers.

3,000-Sheet HCO Installation and User Manual

l

D640 PostScript Emulation Manual

l

D640 Training Kit (Part # C5620-60010) contains:

l

• Maintenance Video Training Tape - NTSC (Part # C5620-90010)

• Maintenance Video Training Tape - PAL (Part # C5620-90011)

D640 Workbook

•

• Function Code Kit (Part # C5620-60021)

(Part # C5620-90012)

(Part # C5620-90015)

(Part # C5620-90024)

(Part # C5620-90002)

(Part # C5620-90001)

(Part # C5638-90001)

(Part # C5630-90002)

• D640 Printer Installation Manual

• D640 Printer User Manual

•

D640 Service Manual

Solutions Guide

l

Technical Data Sheet

l

D640 Demo CD-ROM

l

(Part #5966-7174)

(Part # 5965-7408)

(Part # 5966-4253)

1-4 Specifications June 08, 1999

Page 21

1-1.2 Web Sites for More Information

Web sites are available with updated information, such as updated manuals, alert

bulletins, software revisions, and technical support information. Many of the sites are

available to only internal HP employees.

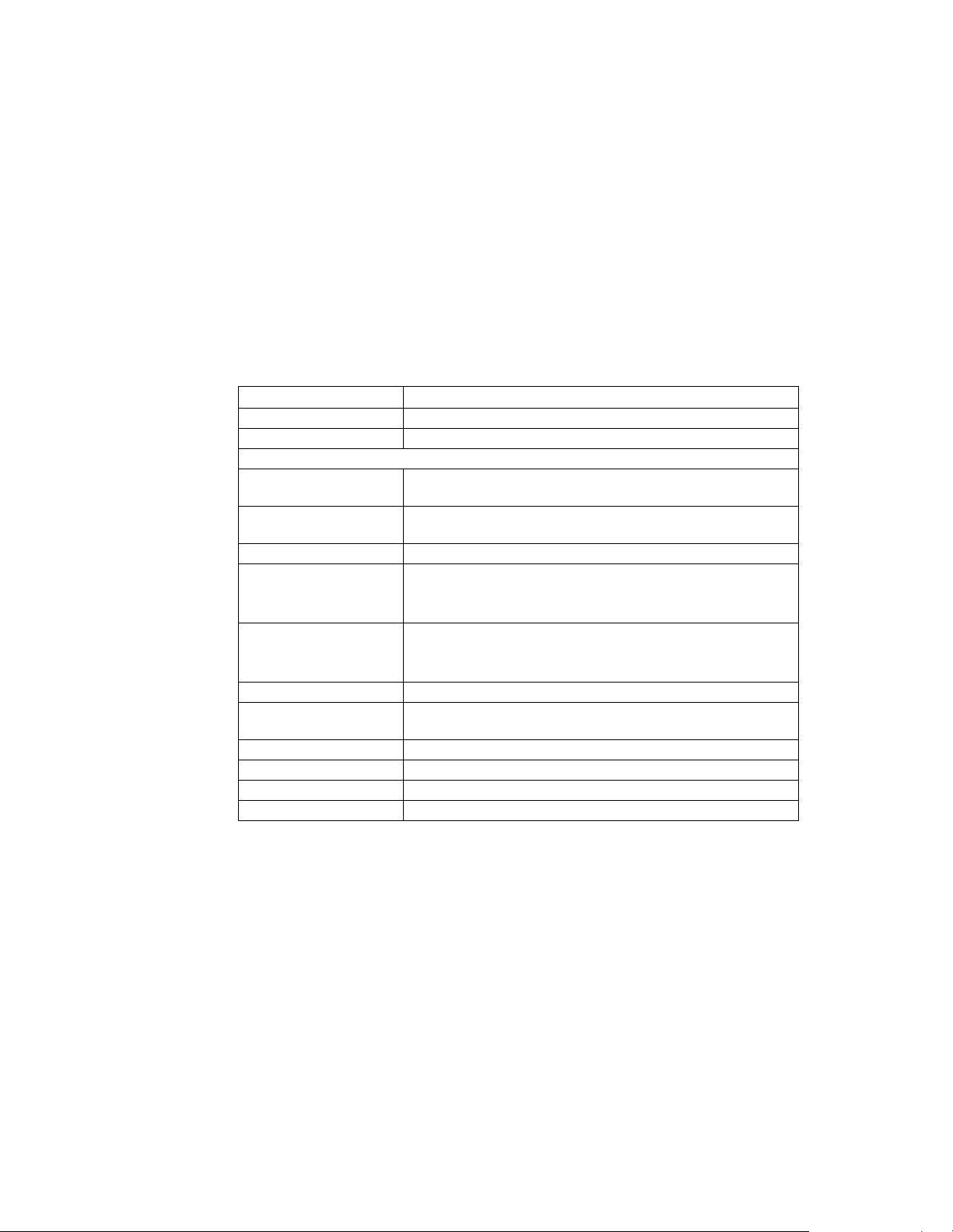

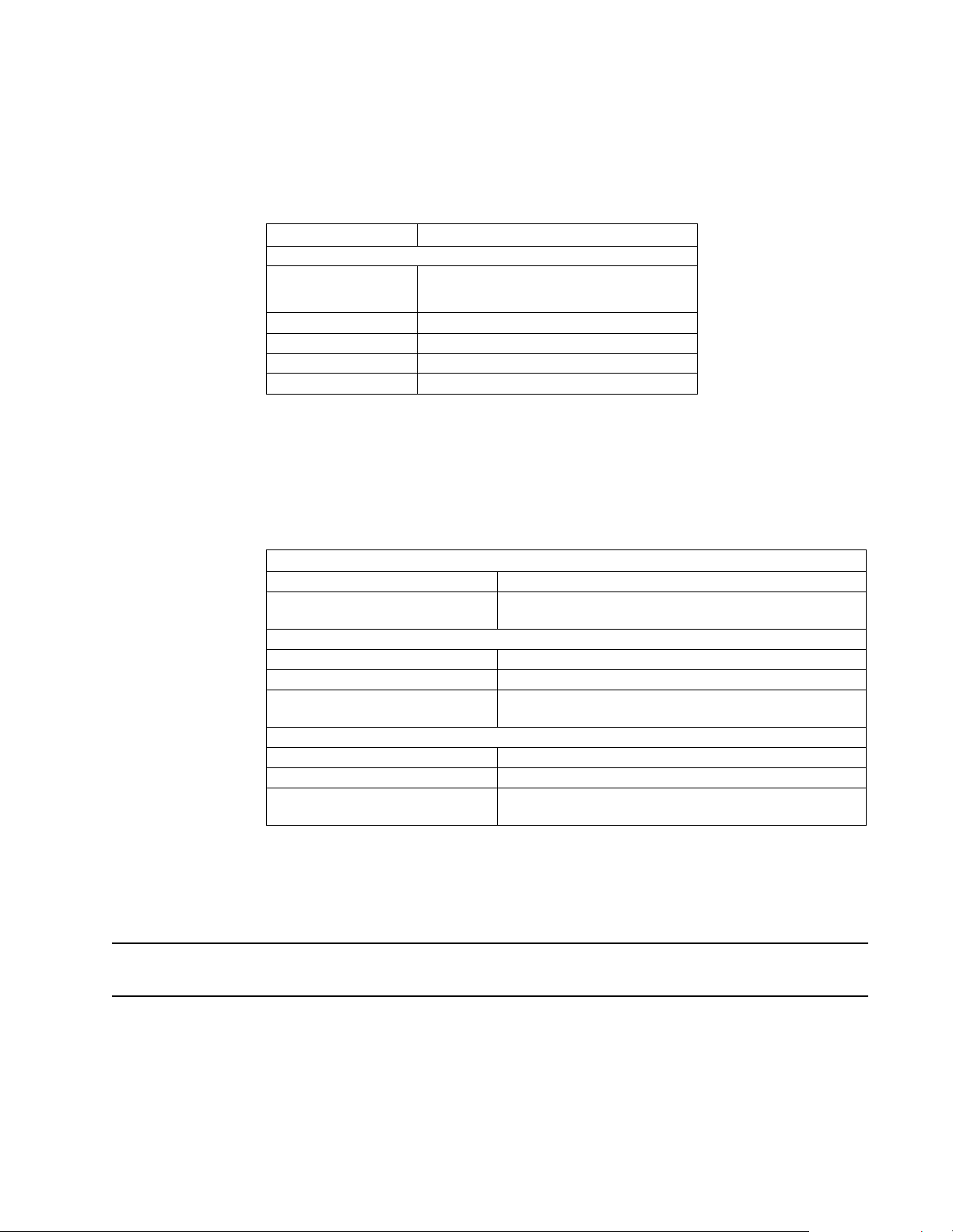

Table 1-1. D640 Web Sites

D640 Printer Service Manual

Name

DLD-Cupertino Web

Site

DLD-Cupertino

Customer Web Site

German Response

Center

Global Support

Logistics - The Parts

Page

HP Internal/

External

HP internal http://itweb1.cup.hp.com/dld-cuprtino/

For updated version of this service manual:

1.Click DLD-Cupertino Document Database

2.Click Service Documents

3.Click HP D640

External http://partners1.americas.hp.com/spo/spodocpu.nsf/

WelcomeNavigator?OpenNavigator

HP internal http://grcad149.grc.hp.com/sys_prn

(The information is in German and English).

HP internal http://smomvts.rose.hp.com/

Access

June 08, 1999 Specifications 1-5

Page 22

D640 Printer Service Manual

1-2 Printer Specifications

This section provides general specifications for the printer, as well as detailed

specifications for print speed and the printer’s physical, electrical, and environmental

requirements. In addition, this chapter includes safety standards applicable to all

equipment and an illustration of the printer laser equipment warning label.

1-2.1 Printer General Specifications

Table 1-2 lists general specifications for the D640 printer.

Table 1-2. D640 Printer General Specifications

Item Specification

Printing technology Laser diode, Electro-photography

Printing speed 40 ppm (Letter/A4 landscape)

Paper

Resolution 600 x 600 dpi (selectable 100, 300, or 600 dpi)

Paper capacity

Stacker capacity

Emulation PCL, HEX, optional PostScript (PS)

Interface Parallel: IEEE1284C Bitronics/Centronics

Warm-up time Less than 150 seconds

First print time Less than 18 seconds

Resident RAM 16 MB standard/ 64 MB maximum

Resident font Bitmap font: 1, Outline fonts: 45

Size A3, A4, A5, Letter, Legal, Ledger, Exec utive, B4 (JIS), B5

(JIS), custom sizes

Type Plain paper, label paper, recycle paper, transparency paper,

bond paper, pre-punched paper

• 3 trays: 500 sheets (64 g/m2) standard

• High Capacity Input (optional): 3,000 sheets

(A4,Letter size only)

• Face down tray: 500 sheets each (75 g/m2)

• High Capacity Output (optional): 2,000 sheets or

3,000 sheets

Serial: RS232C/422A

1-6 Specifications June 08, 1999

Page 23

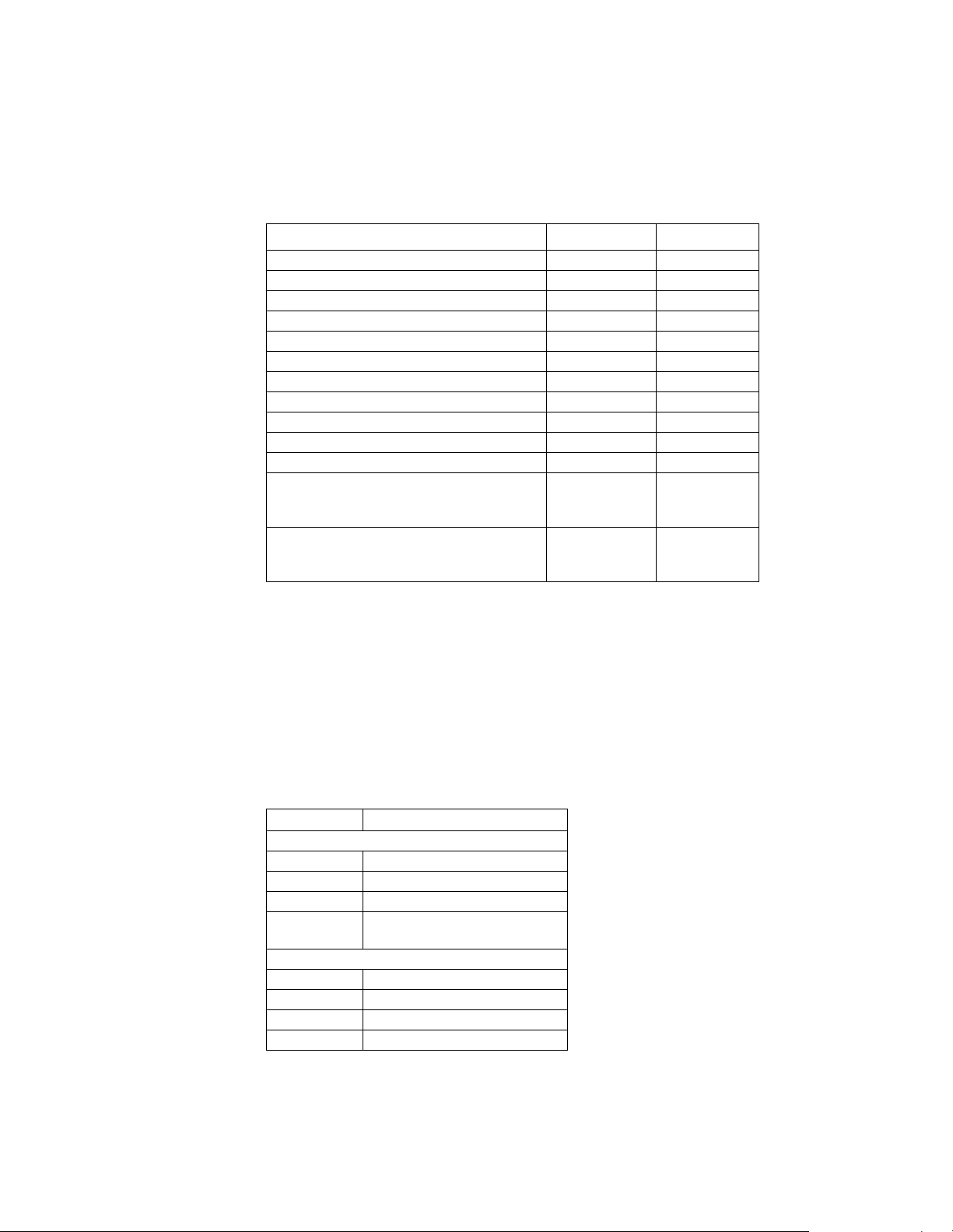

1-2.2 Printer Print Speed Specifications

The print speed specification for the D640 printer is 40 ppm (letter/A4 landscape).

Table 1-3. D640 Printer Print Speed Specifications

Paper Size (direction)

Letter (landscape) 40 40

Legal (portrait) 25 25

Ledger (portrait) 21 15

Executive (portrait) 40 40

A3 (portrait) 21 15

A4 (landscape) 40 40

A5 (portrait) 40 40

B4 (ISO) (portrait) 21 15

B5 (ISO) (portrait) 40 40

B4 (JIS) (portrait) 24 24

B5 (JIS) (portrait) 34 34

Custom

paper width = 120 mm to 297 mm,

paper length = 182 mm to 215.9 mm

Custom

paper width = 120 mm to 297 mm

paper length = 215.9 mm to 431.8 mm

a. Unit of measure: Images Per Minute (IPM). All the speeds have a ±5% tolerance

when printing 6000 characters-per-page using outline font of Courier 12 point

size. Print speed is measured beginning with the second page in continuous

printing mode.

Simplex

40 40

21 15

D640 Printer Service Manual

a

Duplex

a

1-2.3 Printer Physical Specifications

Table 1-4 lists the physical specifications of the printer. Figure 1-2 illustrates the physical

specifications and dimensions of the printer and Figure 1-3 illustrates the required

service area.

Table 1-4. D640 Printer Physical Specifications

Item Specification

Dimensions

Width 585 mm (23.0 in)

Depth 640 mm (25.2 in)

Height 1,03 0 mm (40.6 in)

Weight Approximately 135 kg

(297 lbs)

Service Area

Front 650 mm (25.6 in)

Back 850 mm (33.5 in)

Left 850 mm (35.5 in)

Right 850 mm (35.5 in)

June 08, 1999 Specifications 1-7

Page 24

D640 Printer Service Manual

40.5 in.

LTR

LTR

LTR

(1030 mm)

23.0 in.

(585 mm)

1.38 in

(35 mm)

Figure 1-2 Printer Physical Dimensions

Printer

Front

Side

33.5 in.

(850 mm)

23.0 in.

(585 mm)

25.2 in.

(640 mm)

33.5 in.

(850 mm)

84.3 in.

(2140 mm)

25.2 in.

(640 mm)

25.6 in.

(650 mm)

33.5 in.

(850 mm)

90.0 in.

(2285 mm)

Figure 1-3 Required Service Area

1-8 Specifications June 08, 1999

Page 25

D640 Printer Service Manual

1-2.4 Printer Electrical Specifications

Table 1-5 lists the electrical specifications of the printer.

Table 1-5. D640 Printer Electrical Specifications

Item Specifications

Input Power

Voltage

Phase Single-phase

Frequency 50/60Hz ±5%

Power Consumption 1,300 VA or less during operating

Heat capacity 894 kcal per hour

120 to 127 Vac

200 to 240 Vac

±10%, 12 A

±10%, 7 A

1-2.5 Environmental Specifications For All Equipment

Table 1-6 lists environmental specifications applicable to the printer, High-Capacity Input

(HCI), and High-Capacity Output (HCO) units.

Table 1-6. D640 Printer, HCI Option, and HCO Option Environmental

Specifications

Item Specification

Acoustic noise 56 dB(A) or less (printer only)

Ozone emission 0.08 PPM or less: Measured under conditions of typical

printer operation and room ventilation

Operating Environment

Temperature 15° to 35° C

Humidity 20% to 80% RH (no condensation)

Temperature and humidity

gradients

Non-operating Environment

Temperature 0° to 35° C

Humidity 20% to 80% RH (no condensation)

Temperature and humidity

gradients

15° C per hour or less and 30% RH per day or less (no

condensation)

15° C per hour or less and 30% RH per day or less (no

condensation)

1-2.6 Printer Laser Equipment Compliance Label

This product is a Class 1 laser product.

CAUTION Use of controls or adjustment or performance of procedures other than those specified

herein may result in hazardous radiation exposure

Figure 1-4 illustrates the warning label located on the top of the optical unit.

June 08, 1999 Specifications 1-9

Page 26

D640 Printer Service Manual

DANGER

ATTENTION

VORSICHT

FARA

INVISIBLE LASER RADIATION WHEN OPEN AND INTERLOCK F AILED

OR DEFEATED.

AVOID DIRECT EXPOSURE TO BEAM

EXPOSITION AU LASER

INVISIBLE SI OUVERT OU SI LE

VERROUILLADE EST DEFECTUEUX EVITER

L’EXPOSITION DIRECTE AU RAYON DE

LASER.

UNSICHTBARE LASERSTRAHLUNG. WENN

ABDECKUNG GEOFFNET UND

SICHERHEITSVERRIEGELUNG UBERBRuCKT

NICHT DEM STRAHL AUSSETZEN.

Risk för stråining av osynilgt laserljus

om såkerhetsorytare är ur funktion då

tuckan öppnas.

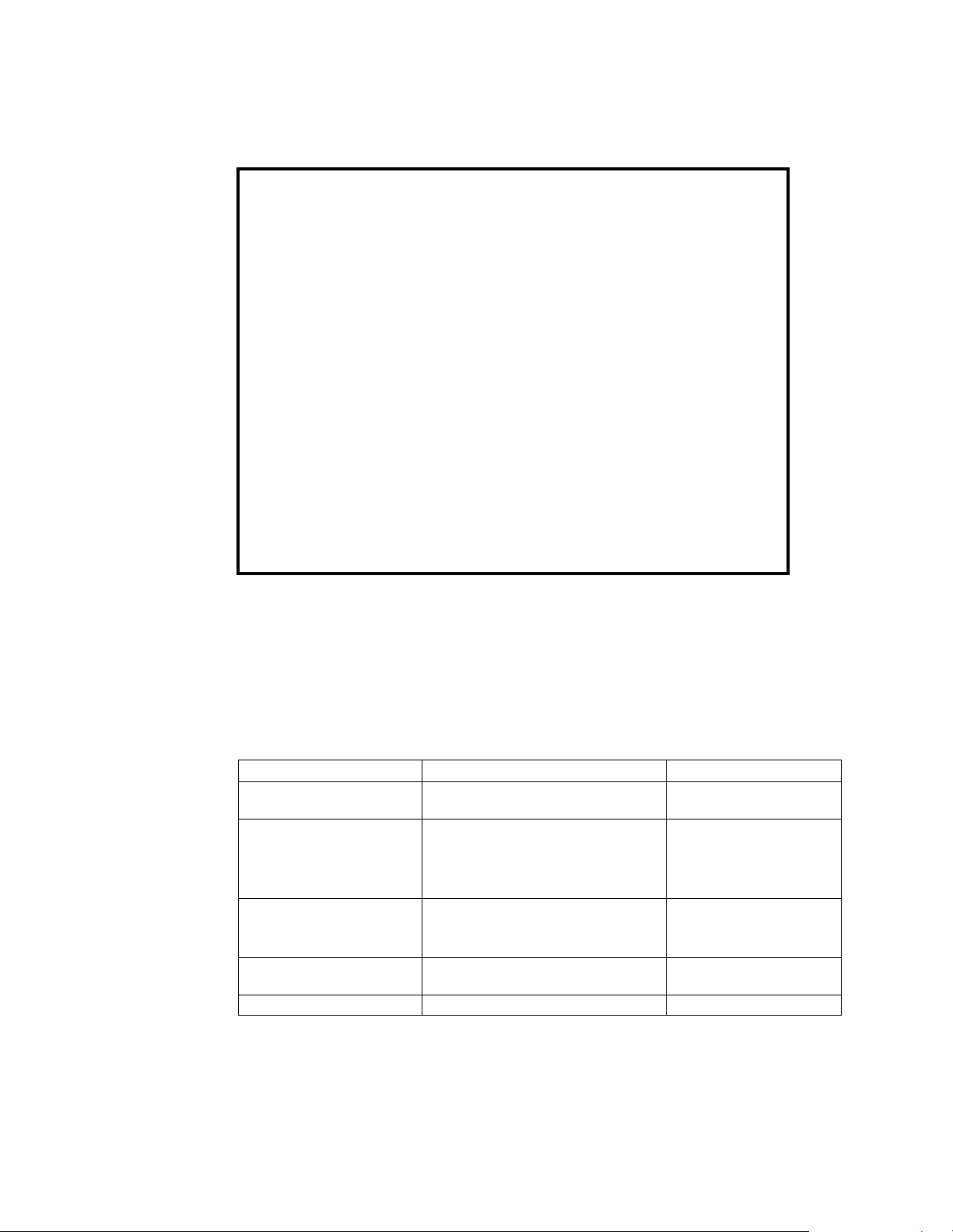

Figure 1-4 Optical Unit Warning Label

1-3 Summary of Optional Features

Table 1-7 lists the options available with the D640 printer along with their associated HP

product numbers.

Table 1-7. D640 Printer Available Options

Item Specification Model Number

High-Capacity Input (HCI)

High-Capacity Output

3,000 sheets (at 75 g/m

2,000 sheets (at 75 g/m

(HCO)

3,000 sheets (at 75 g/m

Custom paper tray

500 sheets (at 75g/m

(100 x 182 to 297 x 431. 8 mm pape r

can be used)

PostScript upgrade PostScript Level 2 + 16MB Memory

SIMM

16 MB Memory Kit 16 MB SIMM (maximum 3 SIMMs) C5635A

2

)

2

)

2

)

2

)

C5621A (Letter)

C5622A (A4)

C5623A (120 VAC)

C5624A (240 VAC)

C5638A (100-240 VAC)

C5634A

C5630A

1-10 Specifications June 08, 1999

Page 27

1-4 Printer Custom Paper Tray

The C5634A custom paper tray is an optional, user-installable custom paper tray. The

custom paper tray can hold up to 500 sheets of paper (75g/m

custom paper trays are interchangable. If more than one custom tray is installed, all

custom sizes must be identical. Paper sizes for the custom tray are selectable within the

specifications listed in Table 1-8.

Table 1-8. Custom Paper Sizes

Dimension Minimum Maximum

Width 120 mm (4.75 in) 182 mm (11.7 in)

Length 297 mm (7.2 in) 431.8 mm (17 in)

The custom tray also supports all of the standard media sizes.

The print speeds from the custom tray are listed in Table 1-3.

1-5 PostScript Upgrade

D640 Printer Service Manual

2

). The standard and

The C5630A PostScript upgrade is an optional, user-installable, software upgrade that

adds PostScript Level 2 emulation capability to the D640 printer. This option is supplied

on a 3.5-inch floppy disk with an additional 16 MB memory SIMM, C5635A. Minimum

memory size to run the Postscript option is 32 MB.

1-6 16 MB Memory Kit

The optional C5635A 16 MB Memory Kit contains one 16 MB single-inline memory

module (SIMM) for the main controller of the D640 printer. A maximum of three

additional SIMMs can be installed. This option is user installable.

June 08, 1999 Specifications 1-11

Page 28

D640 Printer Service Manual

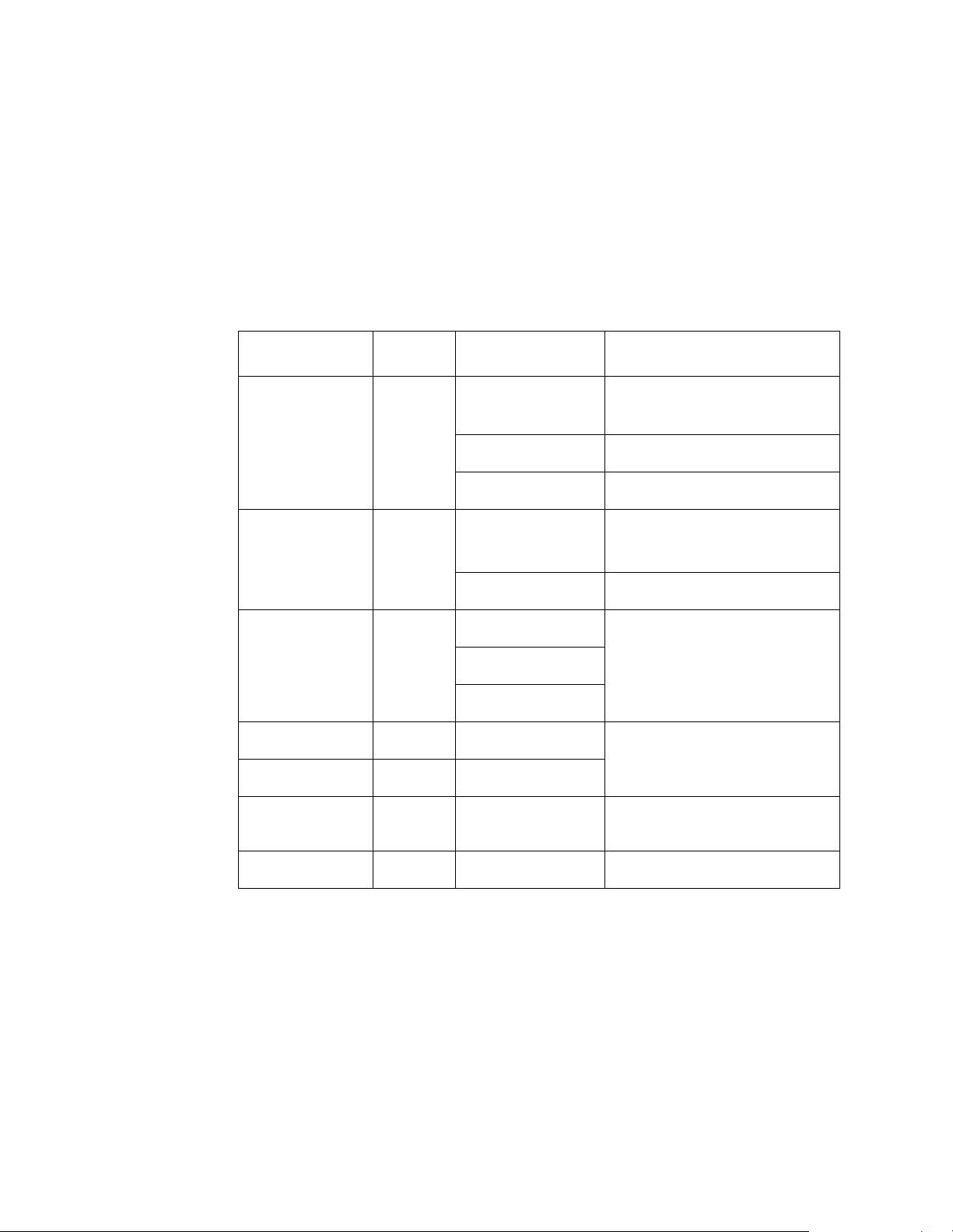

1-7 Consumables

Table 1-9 lists the specifications of the consumables used in the D640 printer and

optional High Capacity Input. For maximum print quality, ensure that the consumables

are replaced at the recommended intervals by monitoring the usage levels printed on

the first page of the Maintenance Report.

.

Table 1-9. Consumables and Replacement Cycle

Carton

Toner Kit 8-Pack C5626A Toner

Developer Kit C5632B Developer

Drum Kit C5629A Drum

Fuser

120-127Vac

Fuser

200-240Vac

Printer Pick Roller

Kit

HCI Pick Roller Kit C56 36B Pick Roller for HCI

a. Values for the replacement cycle shown in Table 1-9 are theoretical and based upon printing on l etter/

A4 size paper. Variations may occur due to improper handling, maintenance, media type, operating

environments and other factors related to printer usage.

b. The average for printed images is calculated by combining intermittent printing mode and continuous

printing mode. The result is 70% of continuous printing.

c. The drum counter increments every 150 seconds (this equals 100 images of letter/A4 paper during

continuous printing). This counter increments during warm-up and intermittent printing sequences.

d. The page length counter increments after 1 00 simplex letter/A4 images are stacked. During duplex

printing, the page length counter is incremented by two after 100 duplex images are stacked. For the

Printer Pick Roller Kit and the HCI Pick Roller Kit, this counter always increments as simplex printing.

When another size paper is used, the counter increments according to the values listed in Table 1- 10.

Product

Number Contents

8 bottles/carton

Cleaning Roller

4 /ctn.

Collector Bottle

8 bottles/carton

2 bottles/carton

Ozone Filter

1 unit/carton

1 unit/carton

Transfer Un it

1 unit/carton

Cleaning paper

10 sheets/carton

C5627A Fuser

1 unit/carton

C5628A Fuser

1 unit/carton

C5633A Pick Roller

1 set/carton

1 set/carton

Replacement Cycle

a

20K images for continuous printing

with 4% coverage for each bottle

(average 14.4K images)

b

Every other toner bottle

Every bottle of toner

1,600 drum counts for each bottle

(250K images for continuous

printing, average 114K images)

b

Every other bottle of developer

2,500 drum counts

c

(195K images for continuous

printing, average 178.5K images)

300K page length counts

d

500K page length counts each

Three kits required for ea ch printer;

one for each tray.

500K page length counts each

c

1-12 Specifications June 08, 1999

Page 29

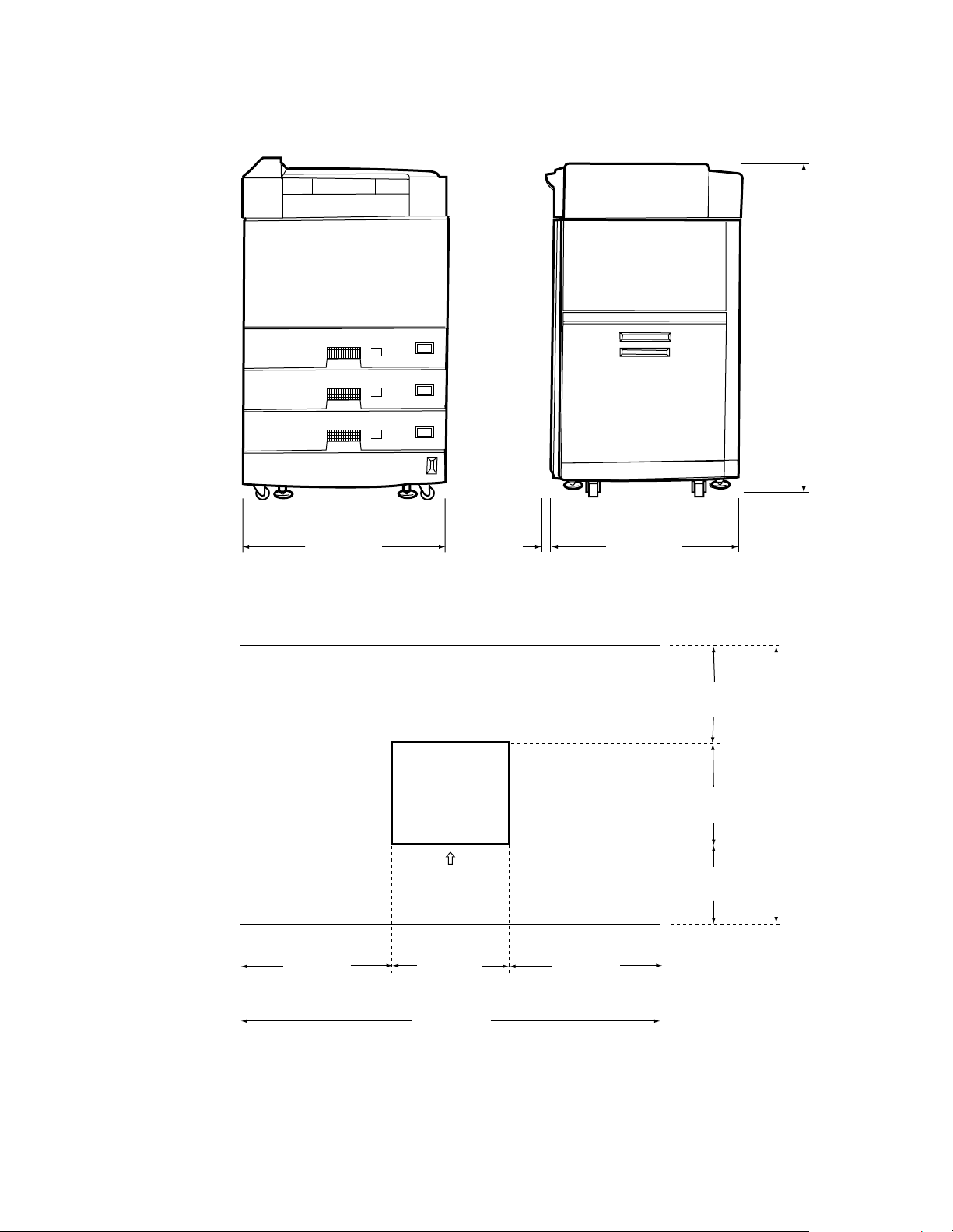

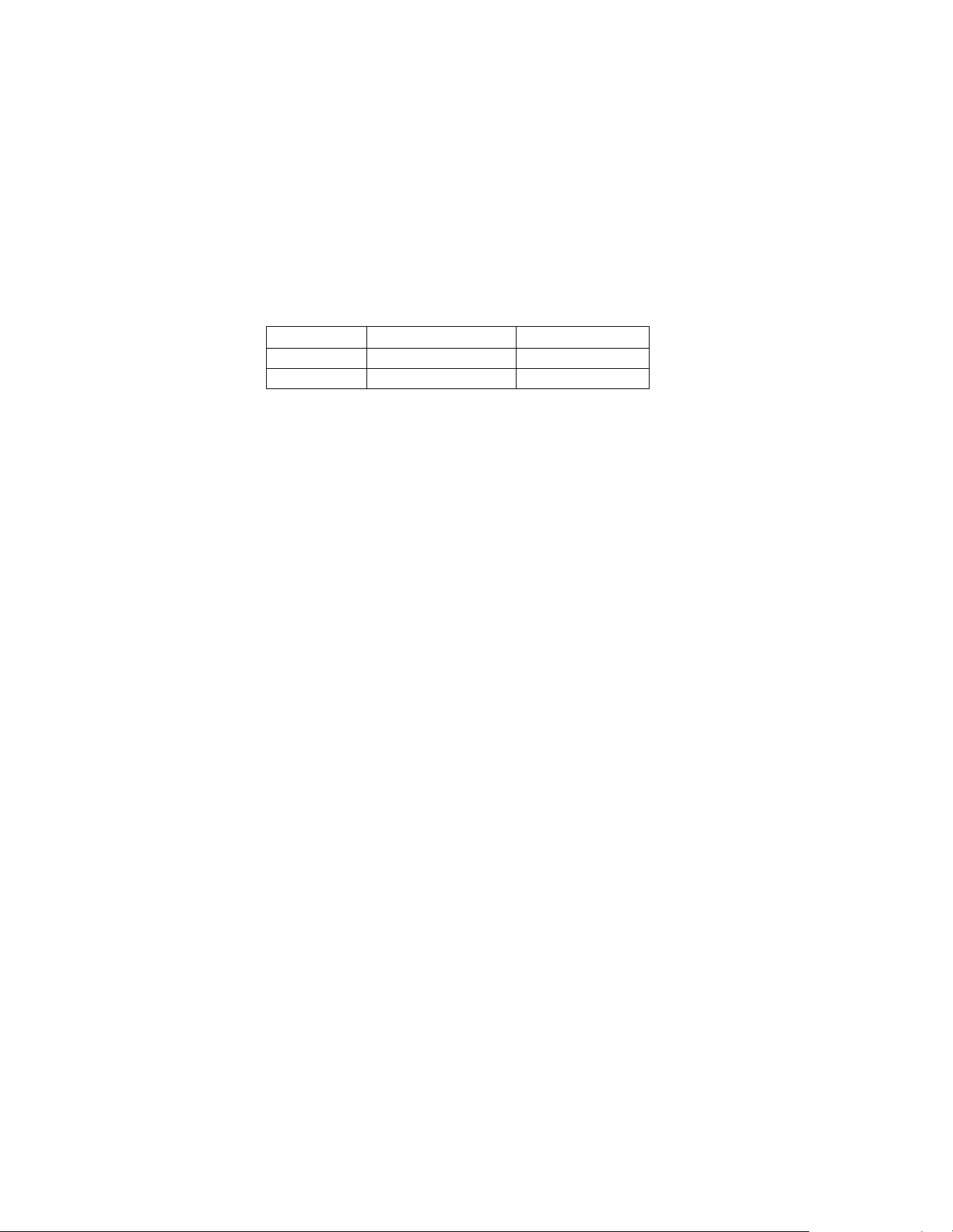

Table 1-10. Page Length Count

Paper size Increment by 100 sheets

Simplex Duplex

A5

A4

A3

Letter

Legal

Ledger

Executive

B4 (JIS)

B5 (JIS)

1.5 3

1-8 Printable Area

You can print to the paper edge, but print quality is not guaranteed within 5 mm

(1/6 inch) of the paper edge. There is a file that can be printed from the printer’s hard

disk that show the guaranteed print image area for that media. Due to various media

factors (such as curl and grain) the guaranteed print image may vary slightly from the

specification.

D640 Printer Service Manual

12

12

24

12

24

24

12

24

To print a sample of the printable area for a type of media:

Step 1

Step 2

Step 3

Step 4

Place the media in the selected tray

Go to the Utilities menu (Test.filesC.MAINT.UTIL).

Select ALL_EDGE.22.

Select Online.

Attempting to print outside the printable area can cause the following problems:

Unacceptable print quality at paper edges

l

Paper feed skew (up to ±2mm) that may cause missing characters

l

Paper transport problems that may cause a paper jam

l

June 08, 1999 Specifications 1-13

Page 30

D640 Printer Service Manual

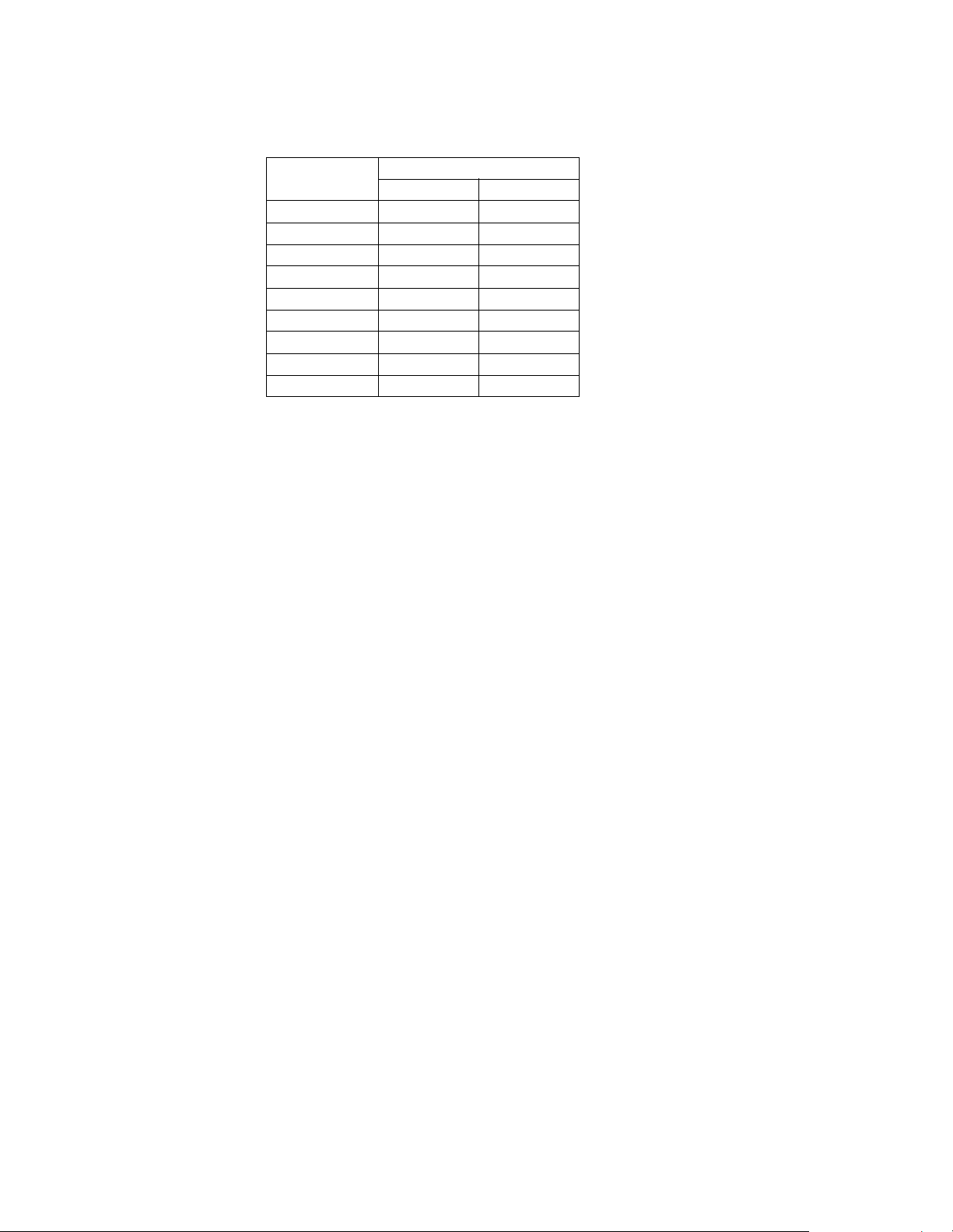

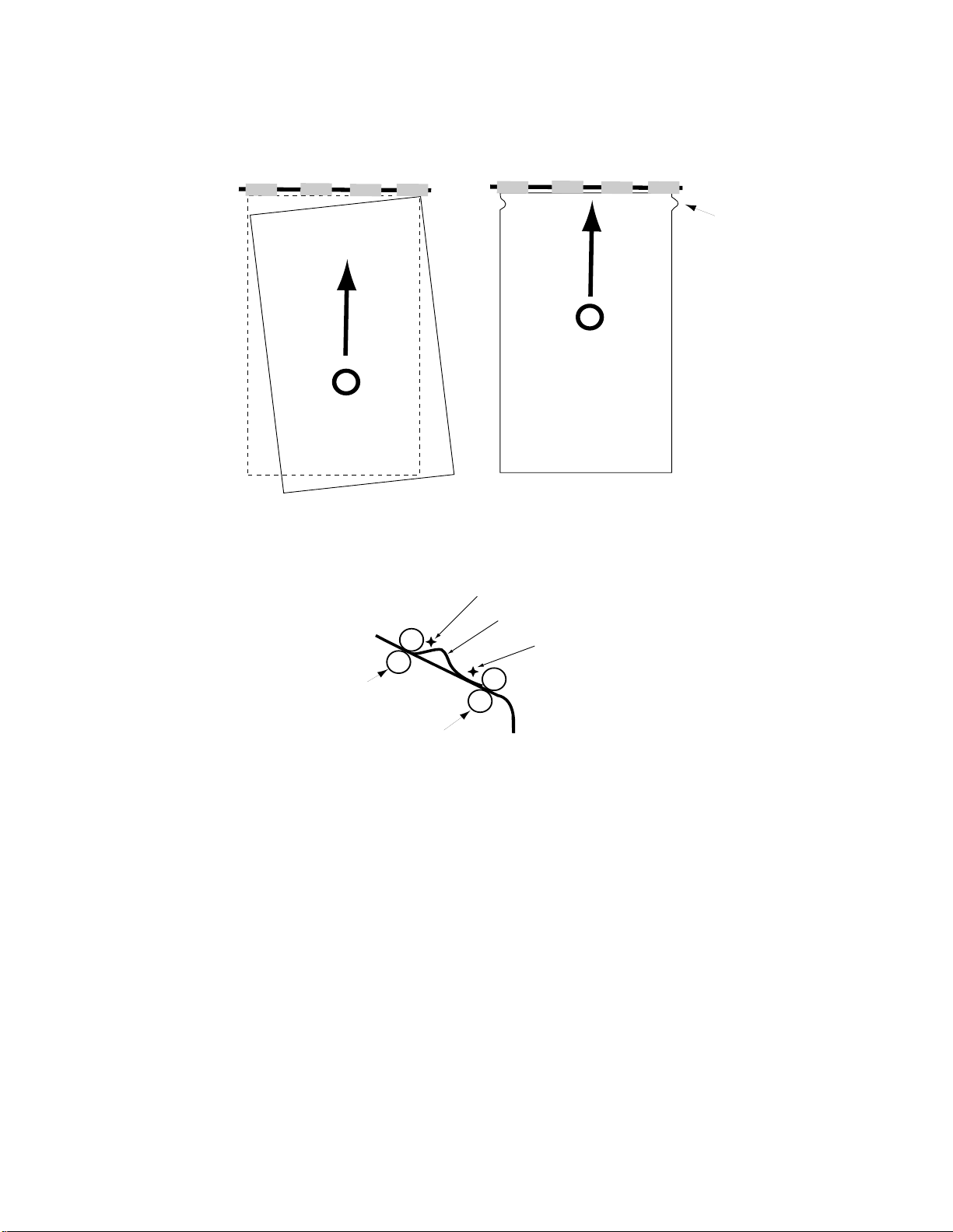

1-8.1 Printing Position Precision

Magnification

Skew

Ideal print area

H

I

A

Print area

Paper

| H-I | 2.5 mm

| J-K | 1.5 mm

J

K

Feed direction

Print section

Paper

| A-B | 2 mm over a length

of 432 mm

B

Feed direction

D

Front/Back

Image

Registration

E

F

G

Figure 1-5 Print Positions (page 1)

Back side image

Front side image

Paper

| D-E | 1.5 mm

| F-G | 1.5 mm

1-14 Specifications June 08, 1999

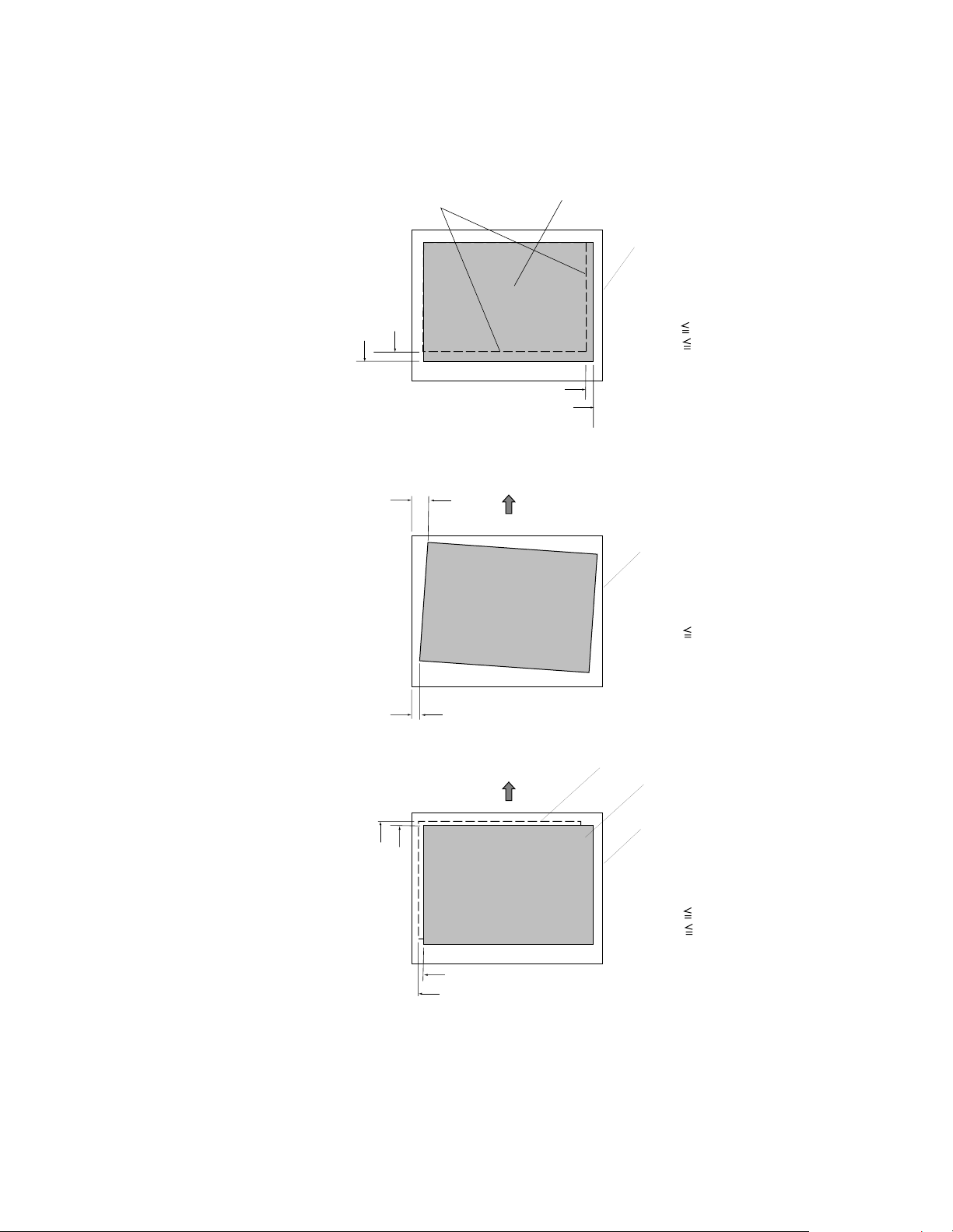

Page 31

D640 Printer Service Manual

Feed direction

A

Print section

B

Print area

Page Registration/

Margin Position

Figure 1-6 Print Positions (page 2)

1-8.2 Simplex and Duplex Printing

The following are important notes on simplex and duplex printing:

l

During

During

simplex

duplex

becomes the back side; the top side of the paper in the paper tray becomes the front

side.

The above is reversed when feeding from the High Capacity Input (HCI).

If punched paper is used for both simplex and duplex printing from the same paper

l

source, the holes and binding margin positions will not match.

If preprinted forms are used for both simplex and duplex printing from the same

l

paper source, the front and back of the preprinted forms and the printed data is

opposite for simplex or duplex paper.

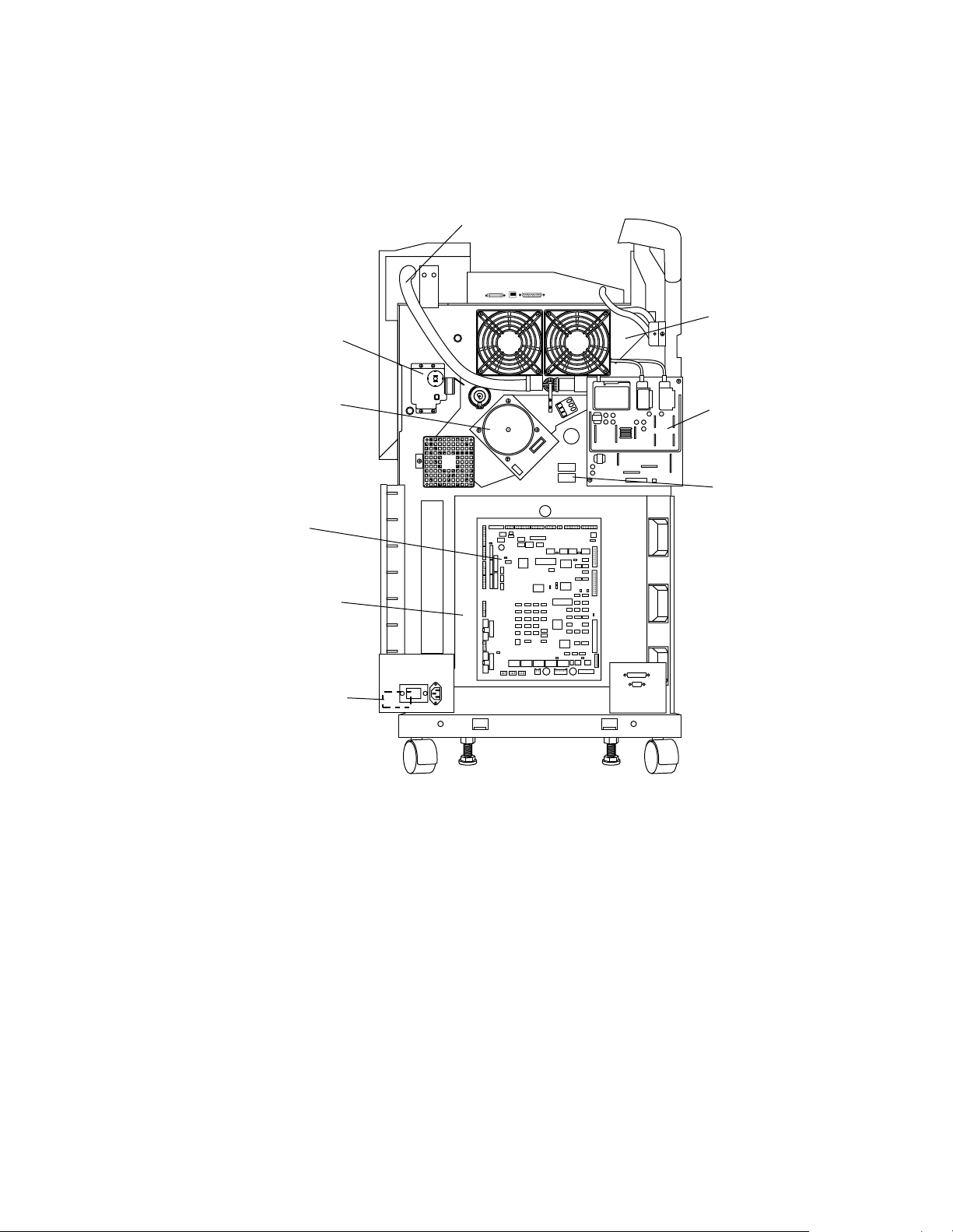

When using punched paper or preprinted forms (directional paper) for simplex and