Page 1

hp Integrity cx2600

Installation Guide

Regulatory Model Number: RSVLA-0303-DC

Version 3.0

Manufacturing Part Number: AB216-90001

March 2004

U.S.A.

© Copyright 2004 Hewlett-Packard Development Company, L.P..

Page 2

Legal Notices

Copyright Notices. © Copyright 2004 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products

and services are set forth in the express warranty statements accompanying such products and services.

Nothing herein should be construed as constituting an additional warranty. HP shall not be liable for

technical or editorial errors or omissions contained herein.

Adobe and Acrobat are trademarks of Adobe Systems Incorporated. HP-UX Release 10.20 and later and

HP-UX Release 11.00 and later (in both 32 and 64-bit configurations) on all HP 9000 computers are Open

Group UNIX 95 branded products. Intel and Itanium are trademarks or registered trademarks of Intel

Corporation or its subsidiaries in the United States and other countries. Linux is a registered trademark of

Linus Torvalds. UNIX is a registered trademark of The Open Group. Windows is a registered trademark of

Microsoft Corporation.

Printed in the U.S.A.

Reproduction, adaptation, or translation of this document without prior written permission is prohibited,

except as allowed under the copyright laws.

Related Documents. The HP Server Documentation CD-ROM has been provided with your server. It

contains a complete documentation set for the server, including localized versions of key documents. Included

on the CD-ROM are the Site Preparation and Operations and Maintenance guides, which contain in-depth

troubleshooting, installation, and repair information.

The CD will autorun when you insert it into a Windows® workstation, or, point your browser at the index.htm

file located under the Start directory of the CD. All users, including UNIX®/Linux, can access a complete

manual set by viewing the directory manuals. The manuals are in Adobe® Acrobat® Reader (pdf) format.

IMPORTANT The latest versions of these documents, and any updates to these documents, are posted under

the appropriate server at http://docs.hp.com.

Where to Get Help. For online access to technical support information, self-solve tools, online assistance,

community forums of IT experts, broad multivendor knowledge base, and monitoring and diagnostic tools, go

to http://www.hp.com/support.

2

Page 3

1. About This Document

What’s in This Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Typographical Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

HP Encourages Your Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Where to Get Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Information to Collect Before You Contact Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2. Server Overview and Unpacking

Server Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Unpacking the Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Unpacking the Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Removing the HP Server from the Shipping Container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installing the HP Server into a Rack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3. Installing Additional Components

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Service Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Accessing a Rack Mounted Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Installing Components When the Server is in a Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Remove the Server from a Rack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Install the Server into a Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installing Disk Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Removing Hot-Plug Disk Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Installing Hot-Plug Disk Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Hot-Swap Power Supply Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Removing and Replacing a Hot-Swap Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Front Grill and Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Removing the Front Grill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Replacing the Front Grill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Removing the Top Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Replacing the Top Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Hot-Swap Chassis Fan Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Removing and Replacing a Front Panel Hot-Swap Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Removing and Replacing a Rear Panel Hot-Swap Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

PCI Card Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Removing the PCI Card Cage Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Removing a PCI Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Installing a PCI Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Installing the PCI Card Cage Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Installing Processors and Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Removing a Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Installing a Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Installing Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Contents

4. Troubleshooting

3

Page 4

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Troubleshooting Methodology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Using the Front Panel Power Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

If the Server Will Not Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

If EFI Is Not Available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

If the Operating System Will Not Boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

If the Operating System Will Boot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

If Intermittent Server Problems Occur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

If DVD Problems Occur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

If Hard Drive Problems Occur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

If Console Problems Occur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Troubleshooting Using Beep Codes (System e-buzzer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Troubleshooting Using LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Front Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Rear Panel LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Error Messages and Event Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

EFI Error and Warning Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Event Logs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Management Processor (MP) Event Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Troubleshooting Using Offline Support Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Offline Diagnostic Environment (ODE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

E-Diag Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Other Event Logs and General Diagnostic Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Hypothetical Troubleshooting Scenario. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5. Cable Connections

Input Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Wire Selection and Terminal Lugs for Connection of DC Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Core I/O Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Management Processor (MP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Booting the Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4

Page 5

Figures

Figure 2-1. hp Integrity cx2600 Server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 2-2. hp Integrity cx2600 Server (front view). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 2-3. hp Integrity cx2600 Server (rear view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 3-1. Chassis Ground Lug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 3-2. Front View of the hp Integrity cx2600 Server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 3-3. Disk Drives in Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 3-4. Hot-Swap Power Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 3-5. Removing a Hot-Swap Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 3-6. Power Supply Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 3-7. Removing the Front Grill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 3-8. Removing the Top Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 3-9. Removing a Front Panel Hot-Swap Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 3-10. Removing a Rear Panel Hot-Swap Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 3-11. Removing the PCI Card Cage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 3-12. PCI Card Retaining Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 3-13. Installing the PCI Card Cage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 3-14. Processors in Server Chassis (Top Cover Removed) . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 3-15. Processor Airflow Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 3-16. Disconnecting the Power Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 3-17. Loosen the Turbo Fan Heatsink Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 3-18. Unlocking the Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 3-19. Installing the Turbo Fan and Processor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 3-20. Memory Airflow Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 3-21. DIMM Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 3-22. Inserting DIMM into a DIMM Socket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 4-1. Front Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 4-2. Rear Panel LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 4-3. Offline Diagnostic Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 5-1. hp Integrity cx2600 Power Supply (rear view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 5-2. hp Integrity cx2600 Server (rear view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5

Page 6

Figures

6

Page 7

1 About This Document

This document describes how to install your hp Integrity cx2600 Server, Regulatory Model Number:

RSVLA-0303-DC.

The document printing date and part number indicate the document’s current edition. The printing date will

change when a new edition is printed. Minor changes may be made at reprint without changing the printing

date. The document part number will change when extensive changes are made.

Document updates may be issued between editions to correct errors or document product changes. To ensure

that you receive the updated or new editions, you should subscribe to the appropriate product support service.

See your HP sales representative for details.

IMPORTANT The latest version of this document can be found online at http://docs.hp.com.

What’s in This Document

The hp Integrity cx2600 Server Installation Guide contains these chapters:

• Chapter 2, “Server Overview and Unpacking.” Use this chapter to learn how to unpack and setup

your hp Integrity cx2600 Server.

• Chapter 3, “Installing Additional Components.” Use this chapter to learn how to install additional

components.

• Chapter 4, “Troubleshooting.” Use this chapter to learn how to perform minimal troubleshooting of

your system.

• Chapter 5, “Cable Connections.” Use this chapter to learn about core I/O ports, SCSI ports, and

management processor LAN ports.

Typographical Conventions

This document uses the following conventions.

Title The title of a document or a CD.

KeyCap The name of a keyboard key. Note that Return and Enter both refer to the same key.

Emphasis Text that is emphasized.

Bold Text that is strongly emphasized, such as the summary text in bulleted paragraphs.

ComputerOutput Text displayed by the computer.

UserInput Commands and other text that you type.

Command A command name or qualified command phrase.

Chapter 1

7

Page 8

About This Document

Related Documents

Related Documents

The HP Server Documentation CD-ROM has been provided with your server. It contains a complete

documentation set for the server, including localized versions of key documents. Included on the CD-ROM are

the Site Preparation and Operations and Maintenance guides, which contain in-depth troubleshooting,

installation, and repair information.

The CD will autorun when you insert it into a Windows workstation, or, point your browser at the index.htm

file located under the Start directory of the CD. All users, including UNIX/Linux, can access a complete

manual set by viewing the directory manuals. The manuals are in Adobe Acrobat Reader (pdf) format.

IMPORTANT The latest version of this document can be found online at http://docs.hp.com.

HP Encourages Your Comments

HP encourages your comments concerning this document. We are truly committed to providing

documentation that meets your needs.

Please send any comments by contacting us at http://docs.hp.com/assistance/index.html.

Please include document title, manufacturing part number, and any comment, error found, or suggestion for

improvement you have concerning this document.

Where to Get Help

For online access to technical support information, self-solve tools, online assistance, community forums of IT

experts, broad multivendor knowledge base, and monitoring and diagnostic tools, go to

http://www.hp.com/support.

For the latest information on HP-UX patches, check the HP IT Resource Center at http://itrc.hp.com.

Information to Collect Before You Contact Support

Before you contact HP support, you should:

Step 1. Check information on troubleshooting and attempt to solve the problem. See Chapter 4,

“Troubleshooting.”

• Note failure symptoms and error indications (LEDs and messages) by checking the SEL and

FPL logs.

• Try to determine precisely what did or did not happen.

Step 2. Collect the following information:

• The model number of your server (for example, cx2600).

8

Chapter 1

Page 9

• The product number of your server. This can be found on the identification label, which is found

at the front of the unit (typically A6837B A6838B, and so on).

• The serial number of your server. This can be found on the identification label.

Step 3. Become familiar with your system configuration:

• Are you using the LAN, RS232, or web interface to monitor the server?

• How many processors, DIMMs, and PCI cards have been installed?

• What versions of processor, memory, and PCI cards are used and where are they installed?

• What accessories are installed?

Step 4. Determine the following:

• Which firmware versions are in use?

• When did the problem start?

• Have recent changes been made to the system?

• Which operating system and version is in use?

About This Document

Where to Get Help

Chapter 1

9

Page 10

About This Document

Where to Get Help

10

Chapter 1

Page 11

2 Server Overview and Unpacking

Server Overview

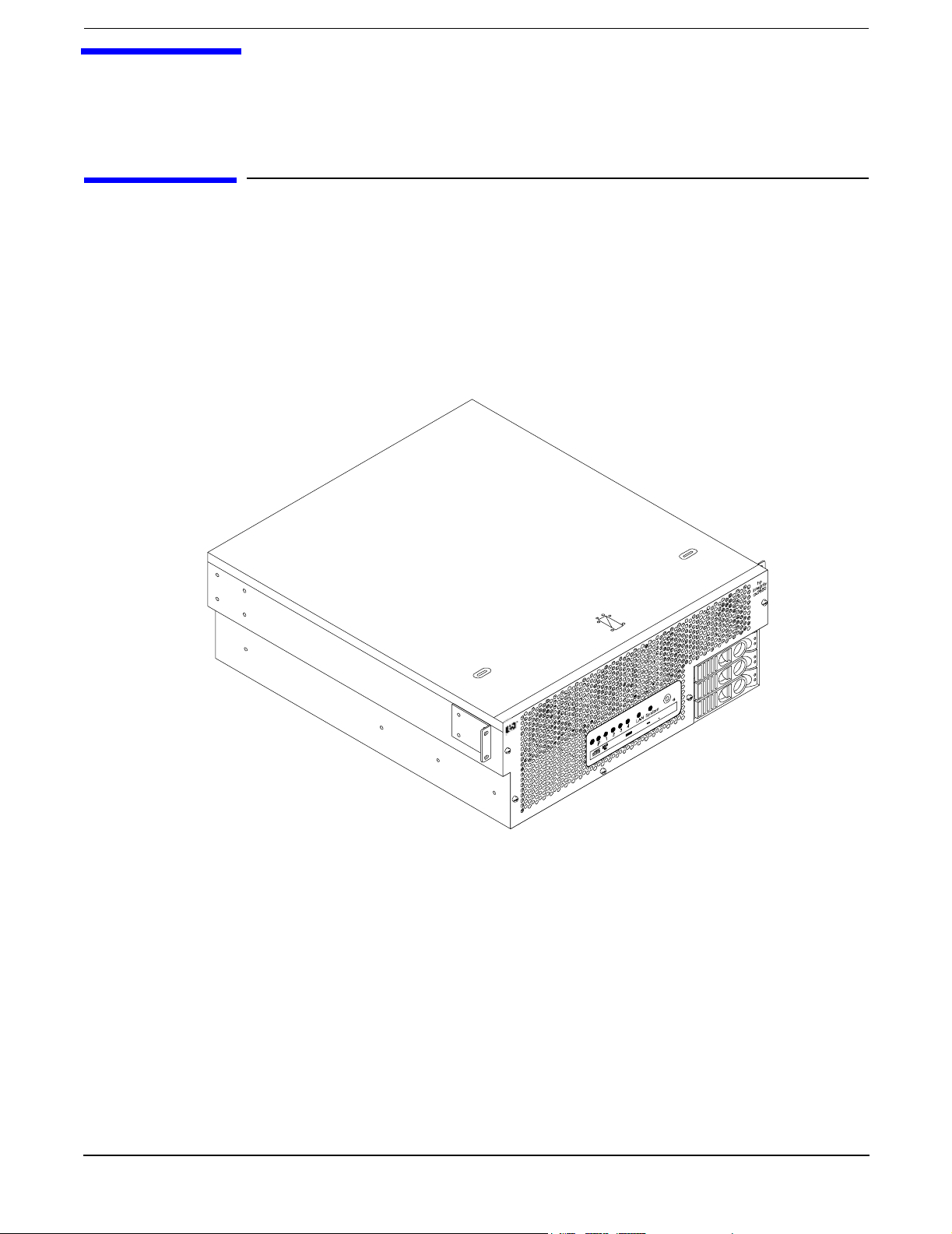

The hp Integrity cx2600 Server (Regulatory Model No. RSVLA-0303-DC) is a 1- or 2-way, IA-64, carrier grade

server based on the Itanium processor family architecture. This server is NEBS level-3 compliant and is

intended for Telco users. The hp Integrity cx2600 Server accommodates 1 or 2 processors, from 4 to 12 DIMMs

(providing 1 to 24 GB of memory), and internal peripherals including up to 3 disks and a CD/DVD-ROM. Its

high availability features include hot-swap fans and power supplies, and hot-plug disk drives. The hp

Integrity cx2600 Server uses the Debian CG 5.0+ operating system (Linux).

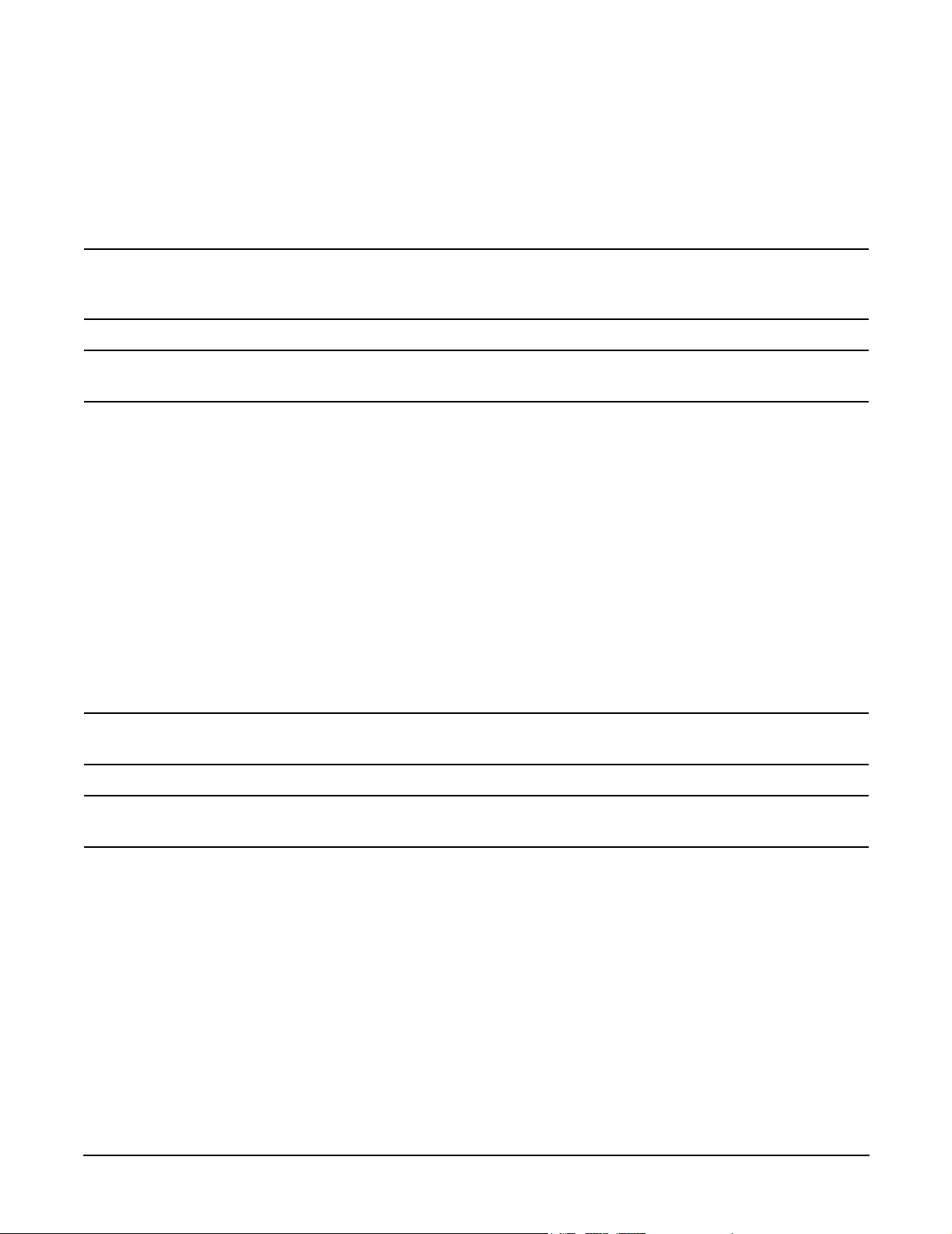

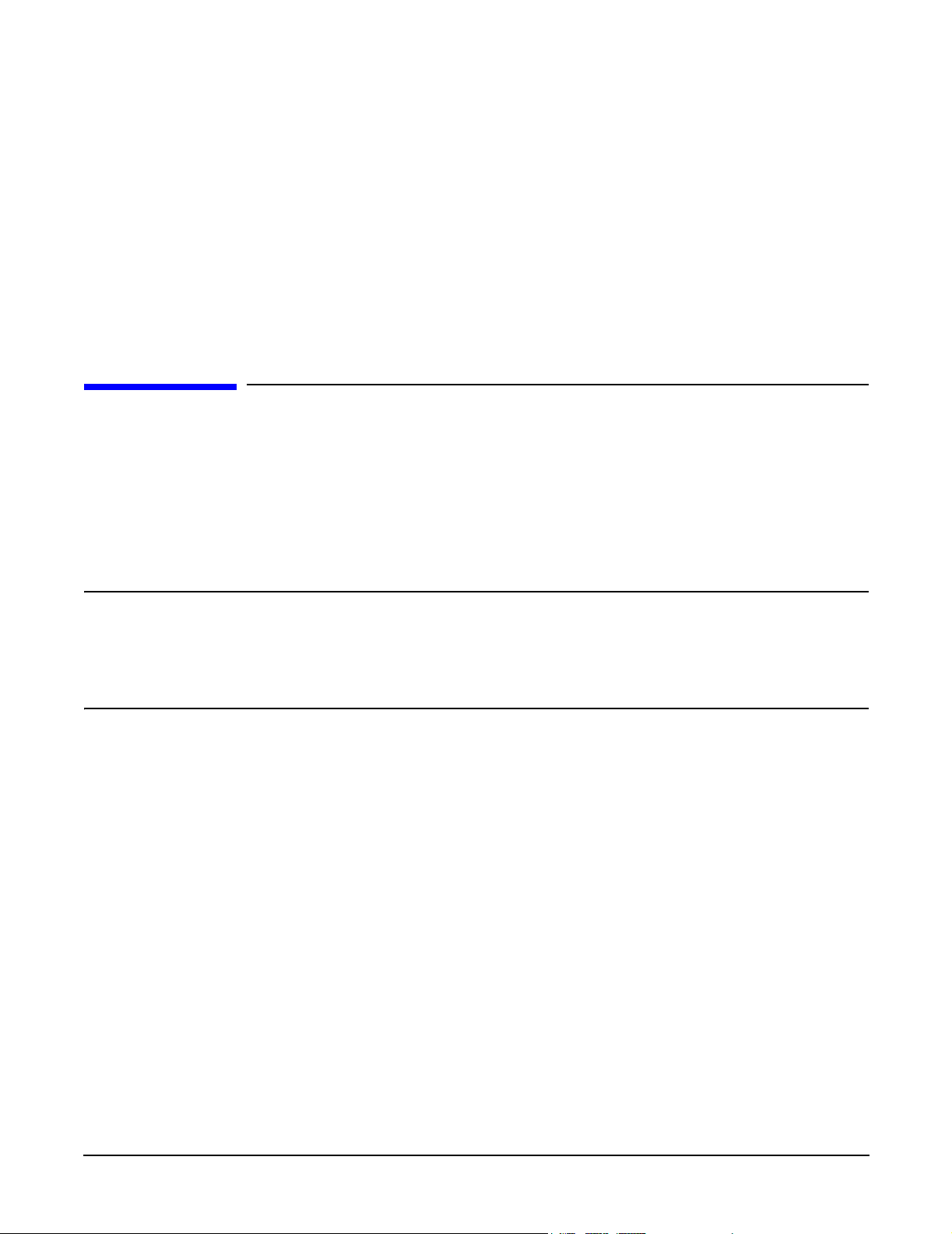

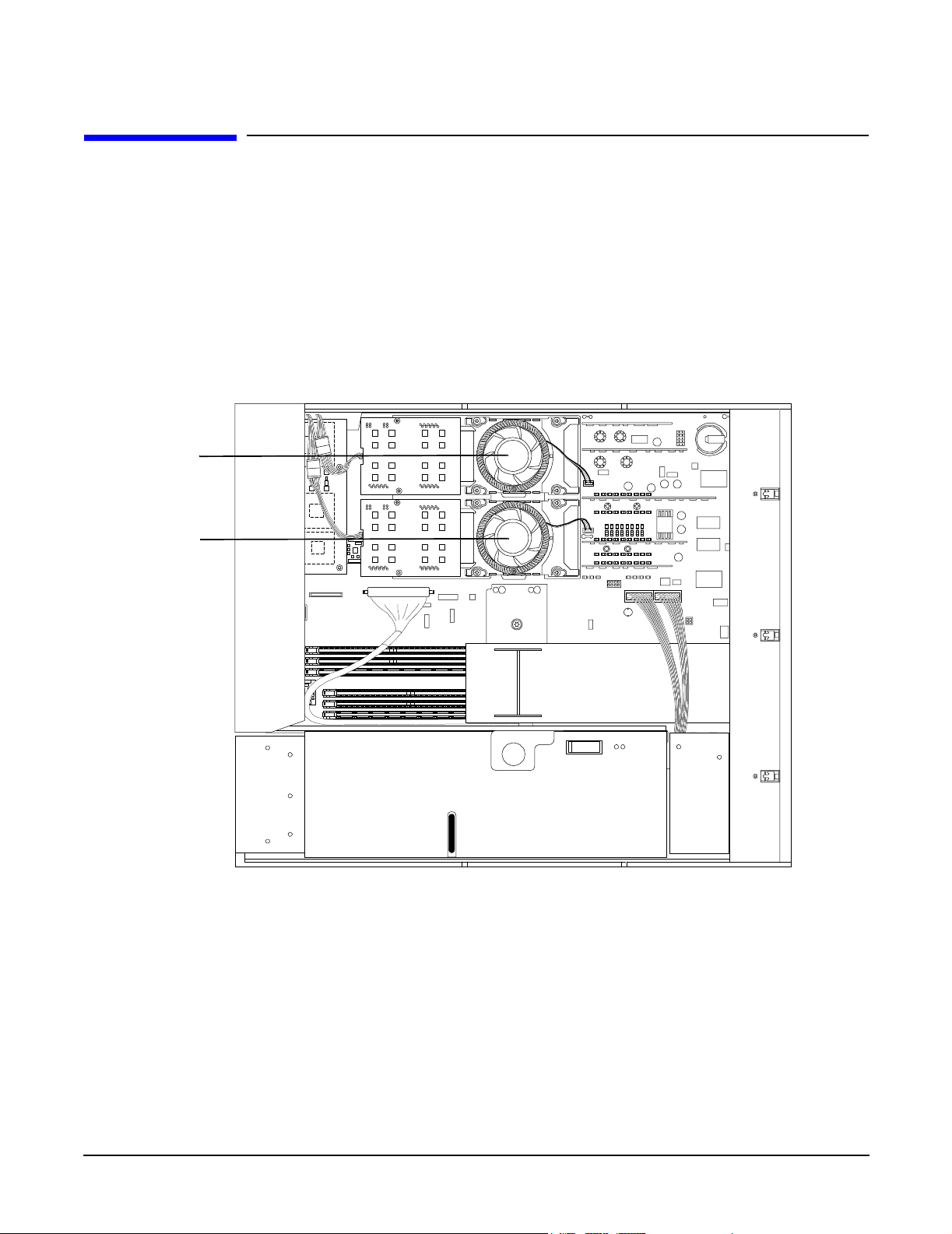

Figure 2-1 hp Integrity cx2600 Server

Chapter 2

chasoblq

11

Page 12

Server Overview and Unpacking

Server Overview

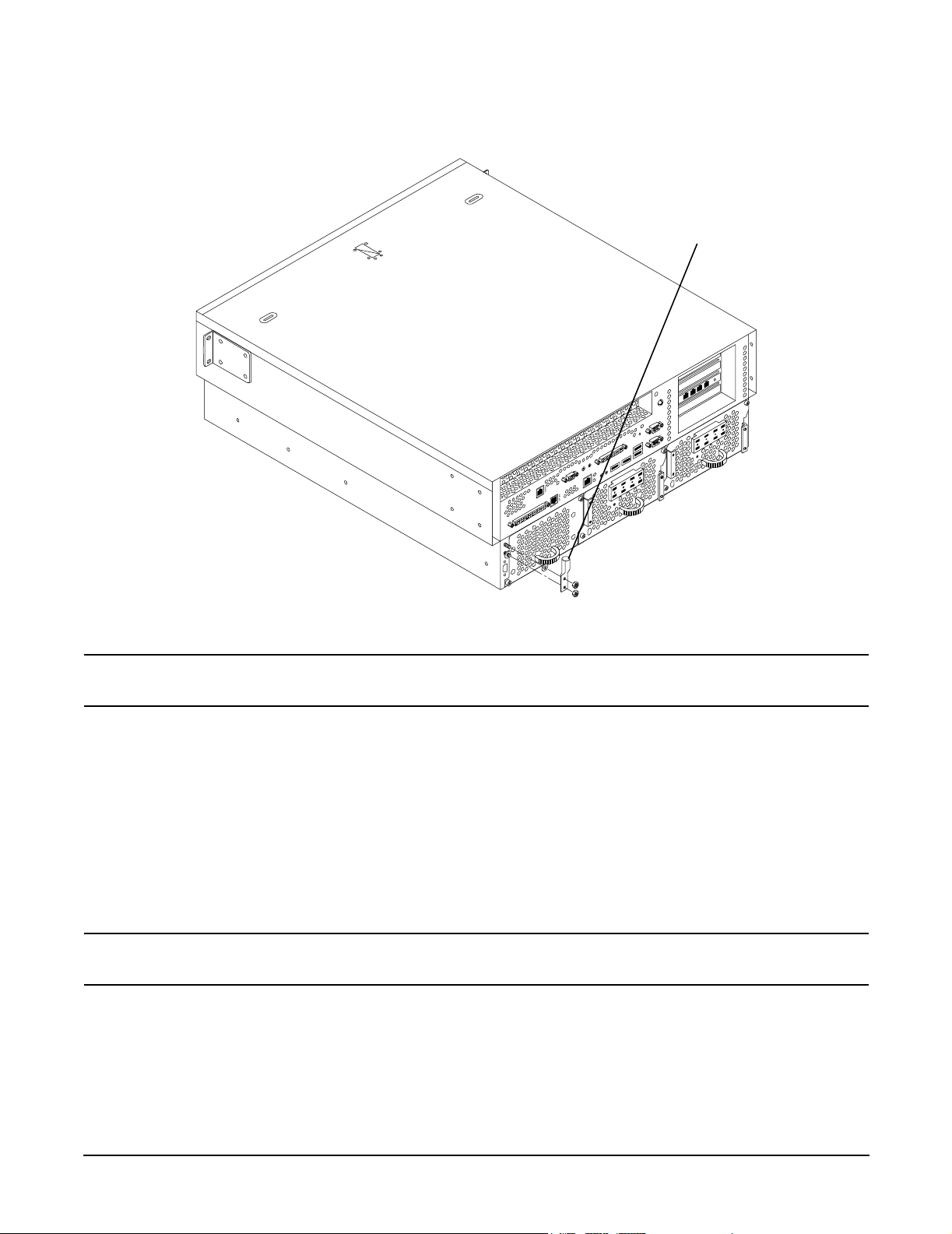

Figure 2-2 hp Integrity cx2600 Server (front view)

LAN4321 System

chasfront

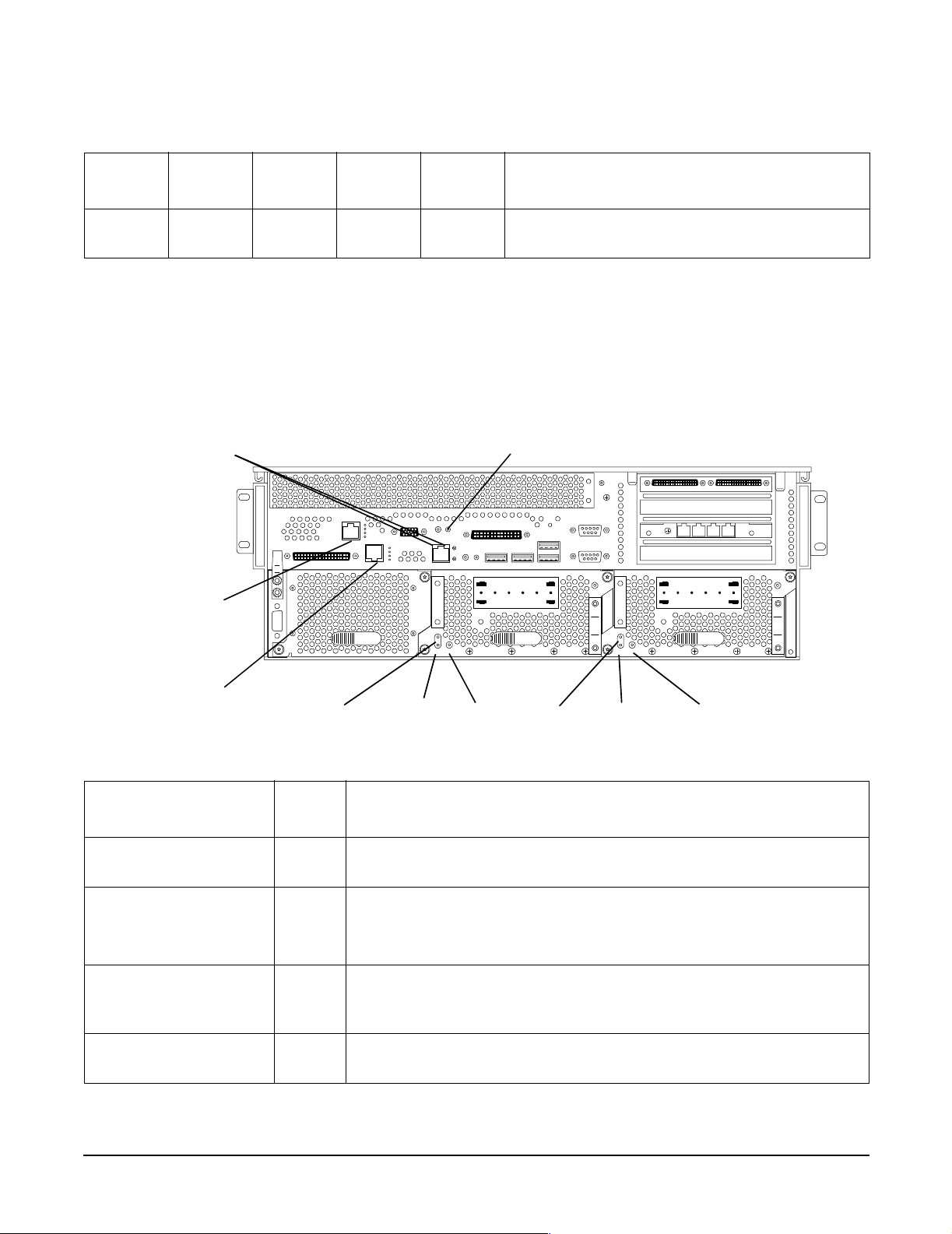

Figure 2-3 hp Integrity cx2600 Server (rear view)

hp

integrity

cx2600

rearview

Fault

DC Out DC In

Fault

DC Out DC In

12

Chapter 2

Page 13

Server Overview and Unpacking

Unpacking the Server

Unpacking the Server

Hewlett-Packard shipping containers protect their contents under normal shipping conditions. After the

equipment arrives, carefully inspect each carton for signs of shipping damage. If damage is found, document

the damage with photographs and contact the transport carrier immediately.

If the equipment has any damage, a damage claim form must be obtained from the shipping representative.

The customer should complete the form and return it to the shipping representative.

Unpacking the Server

WARNING Because a filled hp Integrity cx2600 shipping container may weigh as much as 95

pounds (43 kilograms), two people should lift the container together. Do not lift or

carry the HP Server alone. The unit should be transported on a cushioned, wheeled

cart or carrier. Failure to heed this warning could result is serious personnel injury.

Removing the HP Server from the Shipping Container

WARNING The hp Integrity cx2600 Server may weigh as much as 95 pounds (43 kilograms). Two

people are required to lift the unit and remove packing material. Failure to heed this

warning could result in serious personal injury or damage to the HP Server.

The hp Integrity cx2600 Server is shipped in a standard container, but is cushioned against shock. Open the

top of container and lift the HP Server and packing material from the box. Place the unit on a level work

surface and remove the packing material.

Installing the HP Server into a Rack

HP Rack

Any hp Integrity cx2600 Server that is to be installed into a rack is shipped with a mounting kit or equipment

slides. With every mounting kit and slides comes an installation guide. Follow the steps in this installation

guide to determine where and how to place the server into the rack.

Non-HP Rack

There is a guide for evaluating the installation of HP equipment in non-HP racks. This document should be

utilized when there is a need to evaluate and qualify whether any HP equipment can be installed,

maintained, and serviced in a non-HP rack. The guide is located on the Web at:

http://www.hp.com/racksolutions.

Once there, select “mounting information” from the menu on the left side, then select the guide titled

Mounting in Non-HP Racks.

Chapter 2

13

Page 14

Server Overview and Unpacking

Unpacking the Server

14

Chapter 2

Page 15

3 Installing Additional Components

Safety Information

This chapter describes installing additional or optional hardware to your hp Integrity cx2600 Server.

Follow the procedures listed below to ensure safe handling of components and to prevent harm to both you

and the HP Server:

• Use an antistatic wrist strap and a grounding mat, such as those included in the Electrically Conductive

Field Service Grounding Kit (HP 9300-1609).

• Handle accessory boards and components by the edges only. Do not touch any metal-edge connectors or

any electrical components on accessory boards.

• Do not wear clothing that is subject to static charge build-up, such as wool or synthetic materials.

WARNING Hazardous energy is present inside the HP Server. Always remove power from

the server before working inside the unit. Serious injury may result if this

warning is not observed.

Service Tools Required

Service of this product may require one or more of the following tools:

• Electrically Conductive Field Service Kit (P/N 9300-1609)

• 1/4 inch flat blade screwdriver

• ACX-15 torx screwdriver

• ACX-10 torx screwdriver

• IPF CPU install tool (P/N 5069-4551—supplied with processors shipped separately)

Accessing a Rack Mounted Server

The hp Integrity cx2600 Server is designed to be rack mounted. The following procedure explains how to gain

access to an hp Integrity cx2600 Server that is mounted in an approved rack.

WARNING Ensure that all anti-tip features (front and rear anti-tip feet installed; adequate

ballast properly placed, and so on) are employed prior to extending the server.

Chapter 3

15

Page 16

Installing Additional Components

Accessing a Rack Mounted Server

Installing Components When the Server is in a Rack

Power supplies, disks and fans can be installed when the server is fully inserted into a rack. Only front and

rear access is required.

Internal components can be accessed by removing the top cover. Proceed as follows:

WARNING Hazardous energy is present inside the HP Server. Always remove power from the

server before working inside the unit. Serious injury may result if this warning is

not observed.

NOTE Ensure that there is enough area (approximately 1.5 meters [5 ft.]) to fully extend the server

out the front of the rack and work on it.

Step 1. Turn off and disconnect system power. Disconnect power at the DC source end of the power cable(s),

using the disconnect device that is part of the rack or facility power system.

Step 2. Label and disconnect all cables from the unit rear panel connectors.

Step 3. Remove or loosen (as appropriate) the screws that fasten the server to the rack.

Step 4. If the server is slide-mounted, slowly pull the chassis forward (or push from the rear) to extend the

chassis from the rack. The server is fully extended when the rail clips are locked in place. If the

server is tray-mounted, it is not held in the rack and can fall from its mounting. Do not extend the

server from the rack but remove it from the rack for internal access.

Step 5. Remove the top cover. Refer to “Removing the Top Cover” on page 25.

Remove the Server from a Rack

WARNING Do not attempt to lift the server alone. The server may weigh as much as 32

kilograms (70 lbs). Serious injury may result if this warning is not observed.

NOTE Ensure that there is enough area (approximately 1.5 meters [5 ft.]) to fully extend the server

out the front of the rack and work on it.

To remove the server from the rack, perform the following steps:

Step 1. Turn off and disconnect system power. Disconnect power at the DC source end of the power cable(s),

using the disconnect device that is part of the rack or facility power system.

Step 2. Label and disconnect all cables from the unit rear panel connectors.

Step 3. Remove or loosen (as appropriate) the screws that fasten the server to the rack.

Step 4. Label and disconnect the rack/facility ground cable from the chassis rear panel. (See Figure 3-1.)

16

Chapter 3

Page 17

Figure 3-1Chassis Ground Lug

Installing Additional Components

Accessing a Rack Mounted Server

Chassis

Ground

Lug

chasgndlug

WARNING Do not attempt to lift the server alone. The server may weight as much as 32

kilograms (70 lbs). Serious injury may result if this warning is not observed.

Step 5. If the server is slide-mounted, slowly pull the chassis forward (or push from the rear) to extend the

chassis from the rack. The server is fully extended when the rail clips are locked in place. Do not

extend tray-mounted servers. Tray-mounted servers are not locked in place and can fall if extended

from rack.

Step 6. Disengage the slides or mounting hardware and take the server to a static-free work station.

Install the Server into a Rack

To insert the server into the rack, perform the following steps:

WARNING Do not attempt to lift the server alone. The server may weigh as much as 32

kilograms (70 lbs). Serious injury may result if this warning is not observed.

Step 1. Engage the server slides or mounting kit, as appropriate.

Step 2. Slide the server inward and push the server into the rack until it is in position.

Step 3. Connect server cables to rear-panel connectors.

Step 4. Connect rack/facility ground cable to chassis ground lug. (See Figure 3-1.)

Chapter 3

17

Page 18

Installing Additional Components

Installing Disk Drives

Step 5. Replace or tighten (as appropriate) the screws that fasten the server to the rack.

Installing Disk Drives

The supported configuration of an hp Integrity cx2600 Server includes 1, 2 or 3 Low-Voltage-Differential

(LVD), hot-plug disk drives. If any of the three disk drives are not installed a disk filler must be installed in

the disk location.

Hot-plug disk drives are located at the front of the server. The following sections describe removing and

reinstalling a disk drive.

CAUTION A hot-plug device may require interaction with the operating system before the device can be

safely removed from or installed into the server. Determine if the operating system supports

replacement of disk drives while the operating system is running. If the operating system does

not support this feature, shut down the operating system before performing these procedures.

Failure to observe this caution could result in system failure.

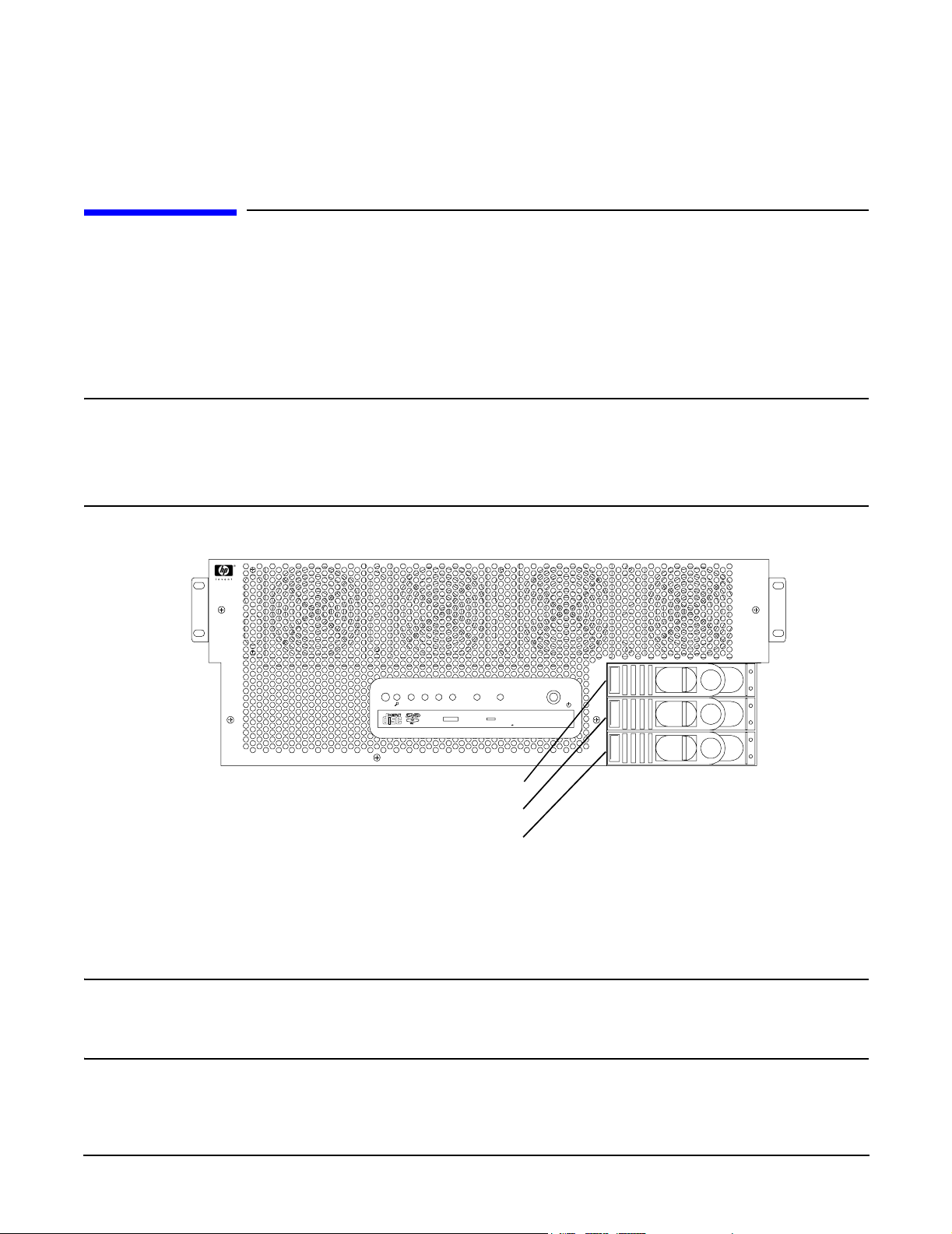

Figure 3-2 Front View of the hp Integrity cx2600 Server

hp

integrity

cx2600

LAN4321 System

chasfront

Disk Slot 2

Disk Slot 1

Disk Slot 0

Removing Hot-Plug Disk Drives

Slots are provided for up to three hot-plug disk drives in your hp Integrity cx2600 Server. When disk drives

are not installed, filler assemblies are installed to prevent air leakage and ensure adequate cooling.

NOTE The filler assemblies are removed and installed in the same manner as described for hard

drives. Simply pull the dummy release lever to pull the filler from the server.

When inserting a filler, simply push the filler into position.

To remove a hot-plug disk drive, perform the following steps:

18

Chapter 3

Page 19

Installing Additional Components

Installing Disk Drives

CAUTION The disk drives in the hp Integrity cx2600 Server are not hot-swappable. They are merely

hot-pluggable. A manual software procedure may be required in order to safely remove or

insert disk drives while the system is running. To avoid damage to the hard drives:

Refer to the documentation provided with the disk drive for additional information about

removing and inserting a drive.

Refer to the operating system documentation for additional information about removing and

inserting hot-plug assemblies.

Step 1. If required (OS does not support hot-plugging devices), stop the operating system.

Step 2. Squeeze inward on the colored release clip and pull the release lever to pull the drive from the

server chassis.

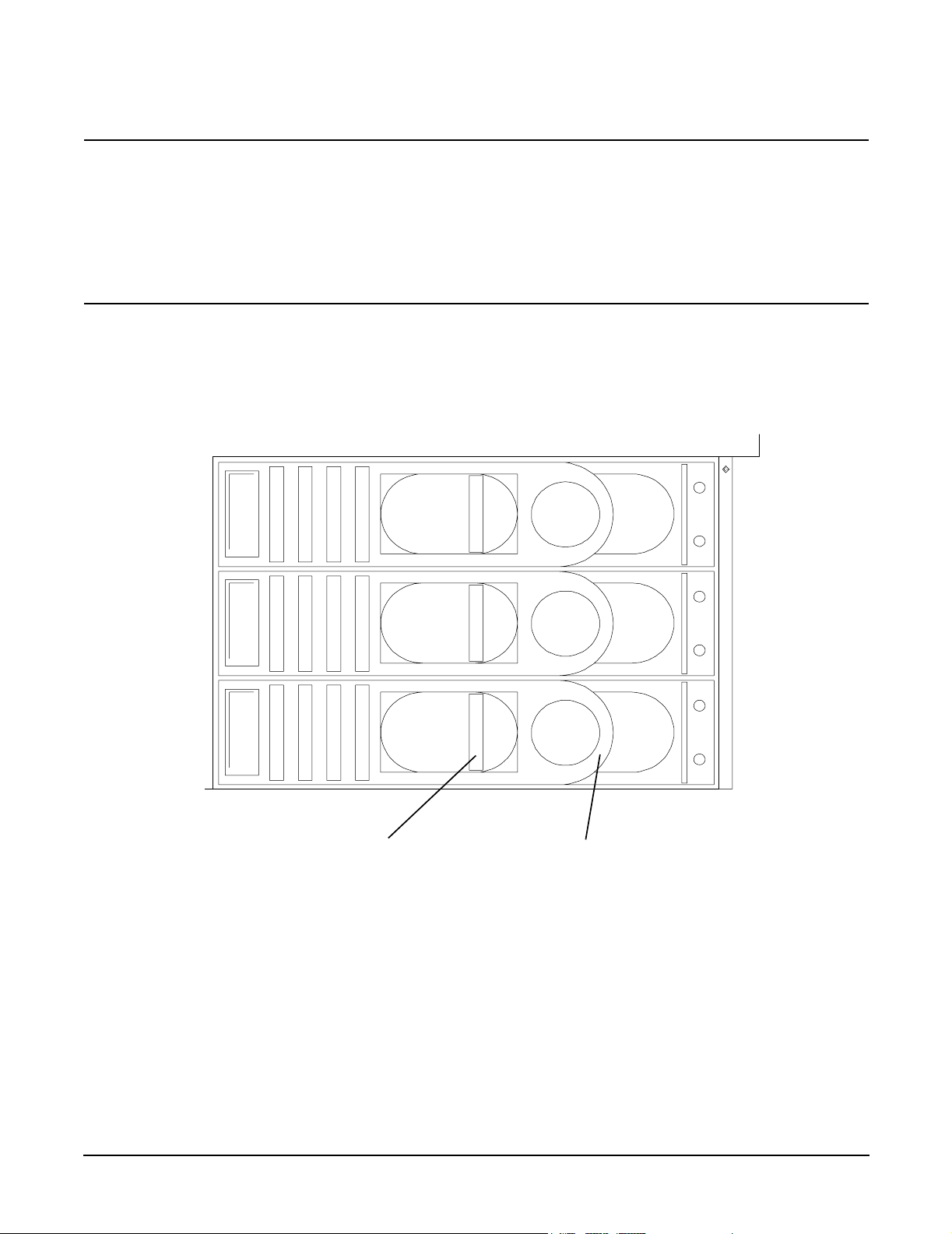

Figure 3-3Disk Drives in Server

2

1

0

S

C

S

I

dskdrvfrnt1

Release Clip

Release Lever

Installing Hot-Plug Disk Drives

Up to three hot-plug disk drives may be installed in your hp Integrity cx2600 Server. Always use low profile

disk drives (1.0" height) in your server.

To install a hot-plug disk drive, perform the following steps:

Step 1. If required (OS does not support hot-plugging devices), stop the operating system.

Step 2. If a disk filler is installed, remove it by pulling the release lever.

Step 3. With the release lever pulled out, slide a hot-plug hard disk into the disk slot until it is seated.

Chapter 3

19

Page 20

Installing Additional Components

Hot-Swap Power Supply Units

Step 4. Press the release lever until it is flush with the front of the server. You will hear it click as it locks

into position.

Step 5. If the operating system was stopped in step 1, reset the system to the EFI Boot Maintenance Menu,

to rescan the hard drives.

Step 6. If the operating system was stopped in step 1, use the EFI shell map command to verify that the

newly inserted drive has been correctly installed. Refer to Chapter 5 of this guide (Cable

Connections) and to the hp Integrity cx2600 Operation and Maintenance Guide for information

about connecting a console and using the EFI shell. (The hp Integrity cx2600 Operation and

Maintenance Guide is included on the CD provided with your system).

Hot-Swap Power Supply Units

The supported configuration of an hp Integrity cx2600 Server requires that two power supplies be installed.

During normal operations, the two power supplies share the load. Each provides power via a separate power

rail. A single power supply can provide all power needed for normal operations, but a second power supply is

installed to provide backup capability.

Hot-swap power supplies 1 and 2 are located at the rear of the chassis. The power supplies are identical and

interchangeable.

NOTE A hot-swap device does not require interaction with the operating system before the device is

removed from or installed into the server. If the second power supply is functioning correctly, a

power supply can be powered down and removed with no effect on server operations.

The power to the server (other power supply) does not have to be off to remove or replace a

hot-swap power supply.

20

Chapter 3

Page 21

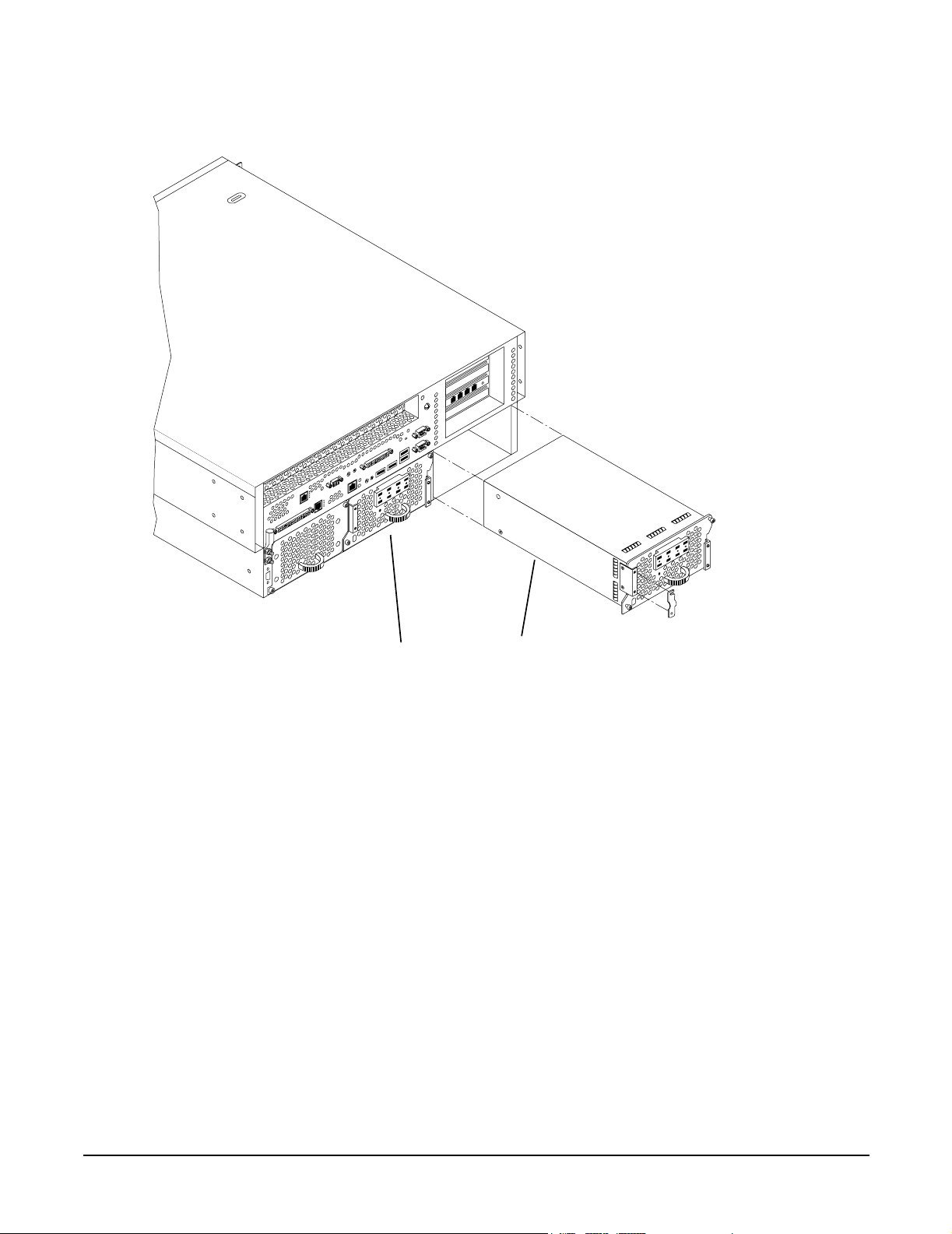

Figure 3-4 Hot-Swap Power Supplies

Installing Additional Components

Hot-Swap Power Supply Units

chaspsxtnd

Power

Supply 1

Power

Supply 2

Removing and Replacing a Hot-Swap Power Supply

A power supply can be replaced while the server is installed in a rack, with the server operating normally.

Removal and installation of a power supply will have no effect on operations if the other power supply is

functioning correctly. To remove and replace a hot-swap power supply, perform the following steps:

Chapter 3

21

Page 22

Installing Additional Components

Hot-Swap Power Supply Units

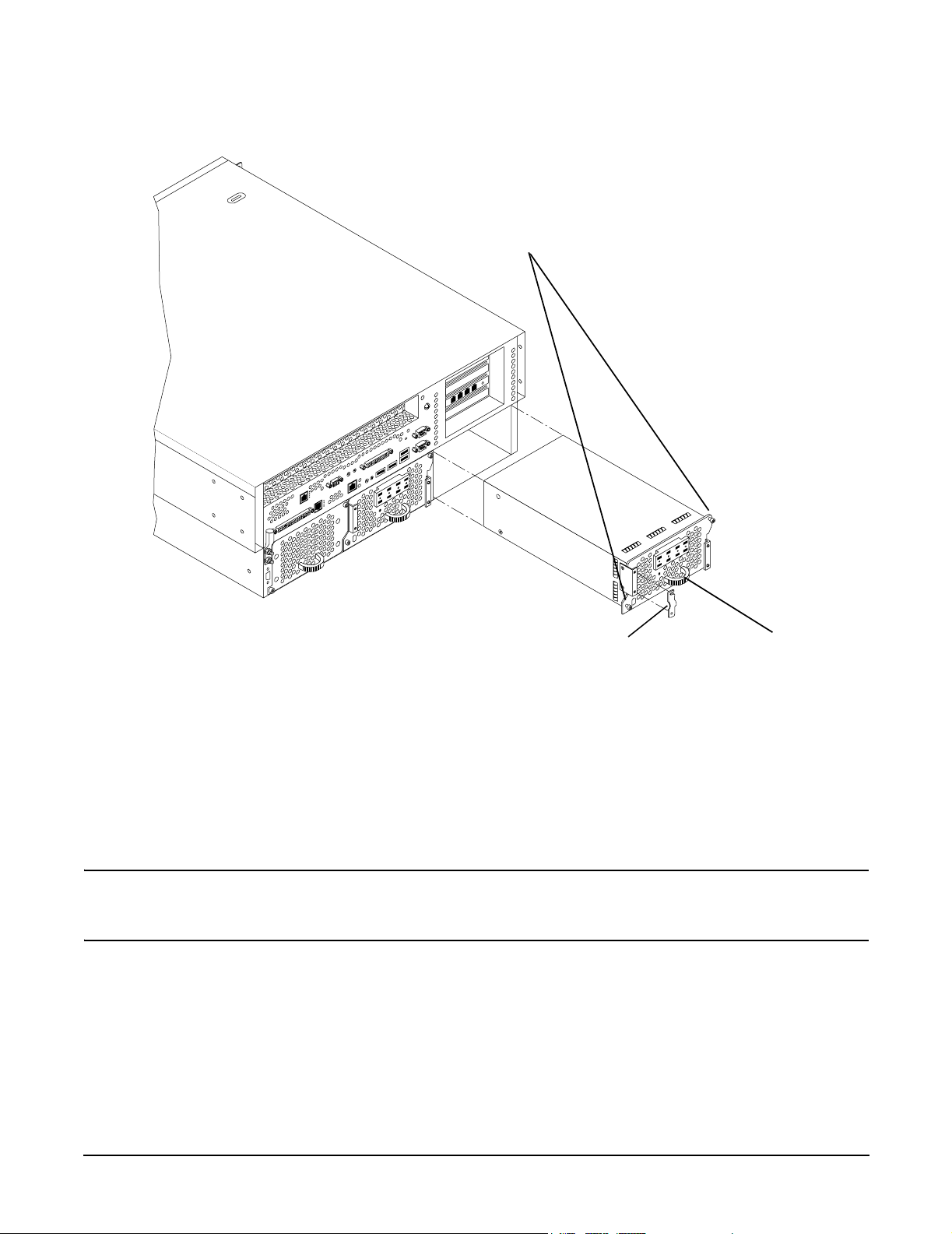

Figure 3-5 Removing a Hot-Swap Power Supply

Mounting

Screws

chaspsxtnd

Cable

Clamp

Handle

Step 1. If rack-mounted, it may be necessary to extend a slide-mounted server out from the rack for better

access. If needed, slide the server out to the fully extended position.

Step 2. Remove power from the power supply being replaced. Disconnect power at the DC source end of the

power cable, using the disconnect device that is part of the rack or facility power system.

Step 3. Loosen the two knurled knobs on the power supply cable clamp to release the power feed leads.

Step 4. Press up on the two lower tabs of the terminal barrier strip cover to snap off the cover.

WARNING Always check that the power cable is not connected to a power source

before attempting to disconnect the power cable from power supply

terminals. Failure to heed this warning could result in injury.

Step 5. Loosen or remove (as appropriate) the screws that secure power cable leads to the terminal strip

and disconnect the power cable leads from the power supply.

Step 6. Reinstall the terminal strip hardware and the barrier strip cover (removed in steps 4 and 5) to

prevent loss. Hang the cover on the upper tabs and snap the cover into place.

Step 7. Using an ACX-15 torx screwdriver, loosen the two captive mounting screws that secure the power

supply to the server chassis.

22

Chapter 3

Page 23

Installing Additional Components

Front Grill and Top Cover

Step 8. Pull the power supply from the server chassis by pulling the curved handle.

Step 9. Orient the replacement power supply such that the securing screws are aligned with the

corresponding holes in the server chassis. Gently push the power supply into position.

Step 10. When the power supply is fully inserted into the server chassis, tighten the two mounting screws to

secure the power supply in place.

Step 11. Press up on the two lower tabs on the terminal barrier strip cover to snap off the cover.

WARNING Always check that the power cable is not connected to a power source

before attempting to connect the power cable to power supply terminals.

Failure to heed this warning could result in injury.

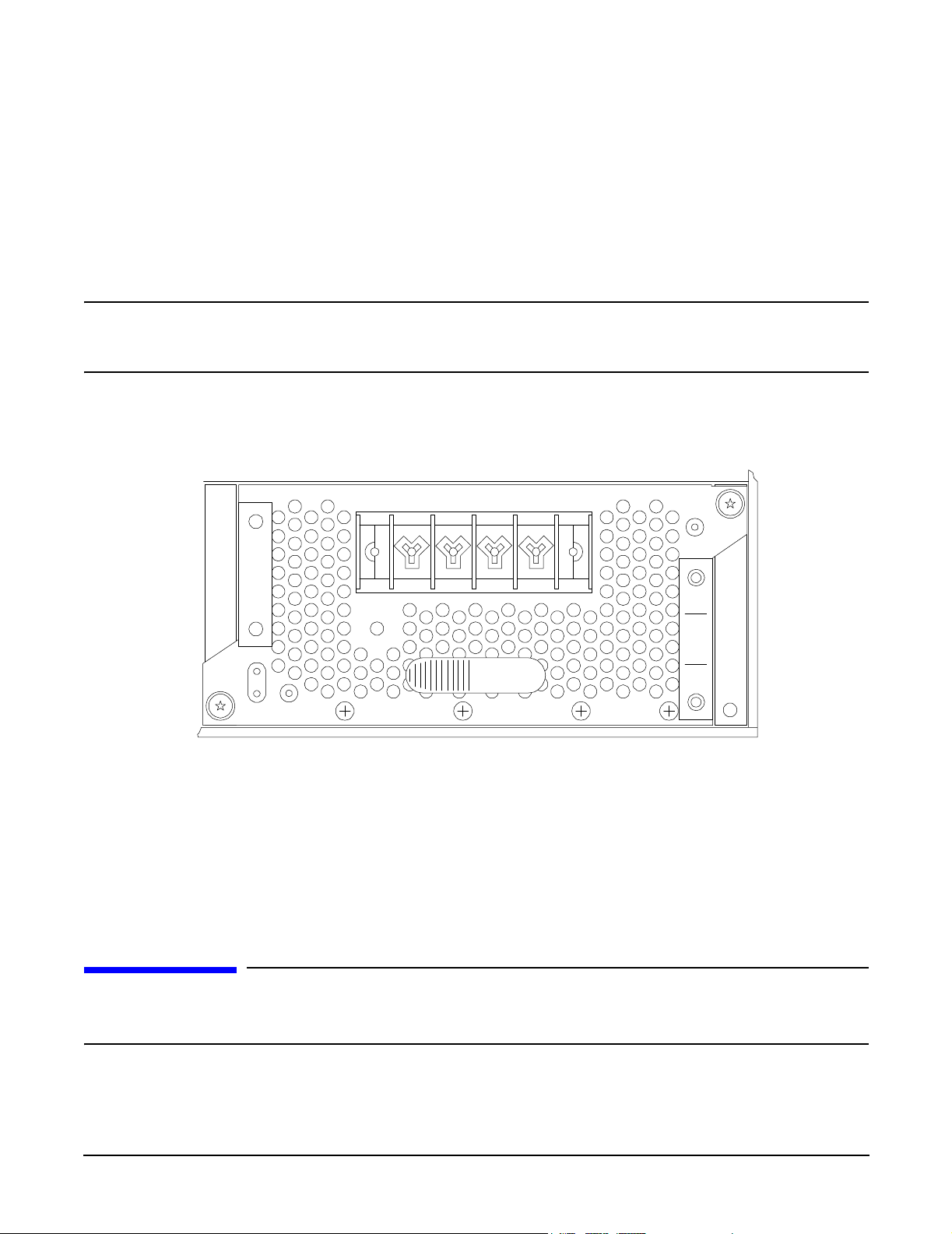

Step 12. Connect the power cable leads to the power supply terminals. (Connect the leads as shown in

Figure 3-6.)

Figure 3-6Power Supply Terminals

++––

Fault

DC Out DC In

psrearpnl2

Step 13. Reinstall the terminal barrier strip cover (removed in step 11). Hang the cover on the upper tabs

and snap the cover into place.

Step 14. Route the power cable through the power supply cable clamp and tighten the two knurled knobs to

secure the cable in place.

Step 15. Connect the power cable to the DC power source.

Front Grill and Top Cover

CAUTION Operation of the HP Server without the front grill and top cover in place will make the server

susceptible to EMI and overheating problems, which can result in system failure. Keep the

front grill and top cover in place during normal operation.

Chapter 3

23

Page 24

Installing Additional Components

Front Grill and Top Cover

Observe all ESD safety precautions while performing this procedure. Failure to follow ESD

safety precautions could result in damage to the server.

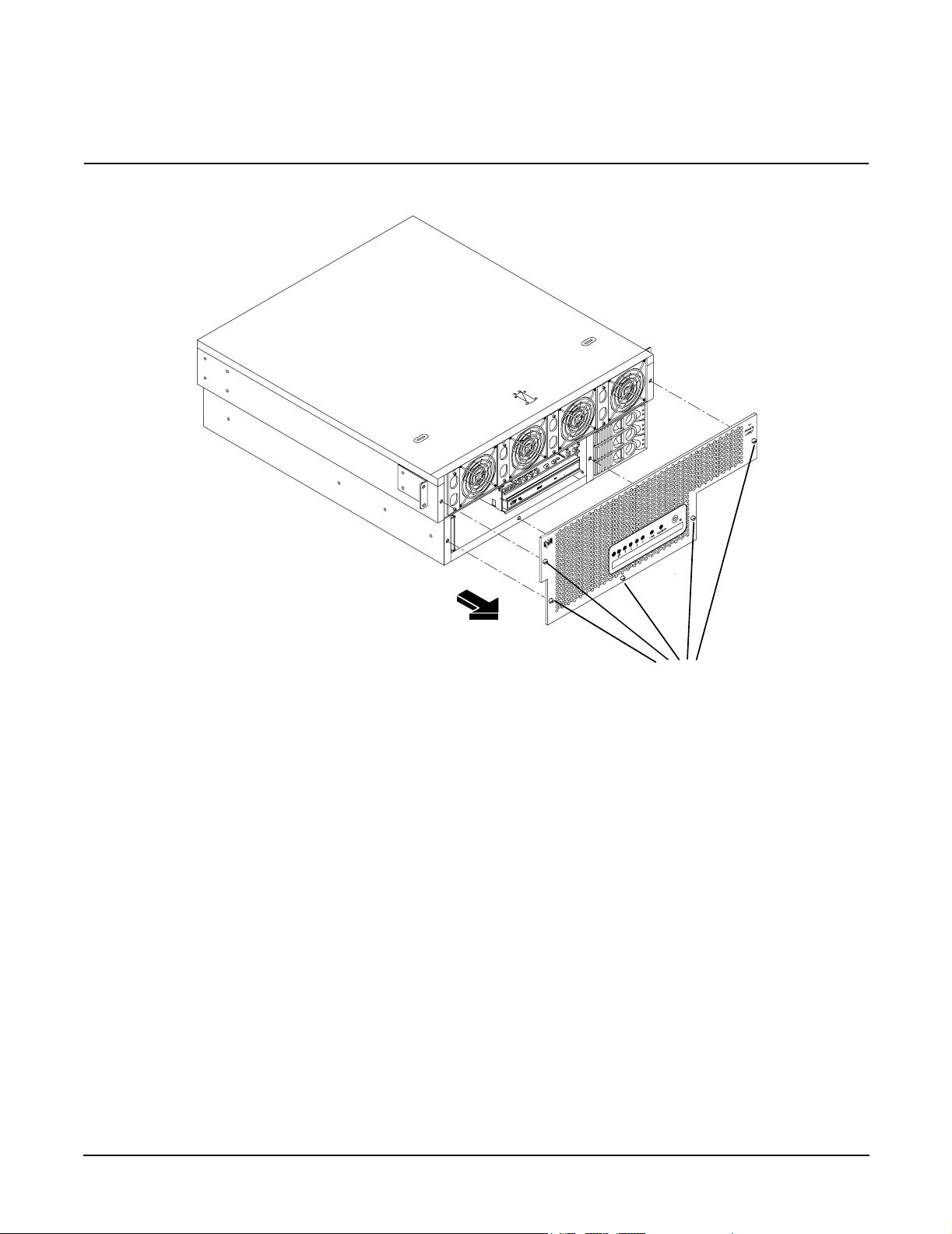

Figure 3-7 Removing the Front Grill

chasfrntoff

Captive Screws

Removing the Front Grill

You must remove the front grill for access to the front mounted fans or the optical drive. To remove the front

grill, perform the following steps:

Step 1. Using an ACX-15 torx screwdriver, loosen the five captive screws that secure the grill to the

chassis.

Step 2. Pull the grill from the front of the server chassis.

Replacing the Front Grill

To replace the front grill, perform the following steps:

Step 1. Hold the grill against the front of the server chassis, in mounting position.

Step 2. Tighten the five captive screws to secure the grill to the server chassis.

24

Chapter 3

Page 25

Removing the Top Cover

Figure 3-8 Removing the Top Cover

Holding

Installing Additional Components

Front Grill and Top Cover

Cover

Screw

Slots for Tabs

in Cover

(2 each side)

ESD Ground

Jack (Connect

wrist strap here)

topupwguide

Cover Tabs

Slots for Tabs

To remove the top cover, perform the following steps:

Chapter 3

25

Page 26

Installing Additional Components

Front Grill and Top Cover

WARNING Hazardous energy is present within the server when power is applied. Do not

remove the server top cover without first turning off and disconnecting power.

Always replace the top cover before turning the system on.

Step 1. Turn off and disconnect system power. Disconnect power at the DC source end of the power cable(s),

using the disconnect device that is part of the rack or facility power system.

Step 2. Slide the server out from the rack until it stops. Refer to “Accessing a Rack Mounted Server” on

page 15.

Step 3. If desired, remove the server from the rack at this time. Refer to “Remove the Server from a Rack”

on page 16.

Step 4. Using an ACX-15 torx screwdriver, loosen the captive screw that holds the top cover in place.

Step 5. Slide the cover toward the rear of the server chassis and lift it straight up.

Replacing the Top Cover

To replace the top cover, perform the following steps:

Step 1. Align each pair of tabs on the left and right sides of the cover with the corresponding slots in the

chassis. Set the cover in place on the chassis.

Step 2. Align the three tabs on the front of the cover with the corresponding apertures at the top front of

the chassis and insert the tabs into the slots.

Step 3. Push the cover forward until it seats on the chassis.

Step 4. Tighten the captive screw to secure the cover in place.

26

Chapter 3

Page 27

Installing Additional Components

Hot-Swap Chassis Fan Units

Hot-Swap Chassis Fan Units

There are five hot-swap chassis fan units in the HP Server. Fan units 1, 2, 3 and 4 are accessible from the

front of the chassis. Fan unit 5 is accessible from the rear of the chassis. Fan units 1, 2, 3 and 4 are identical

and interchangeable.

If a fan failure is total (both rotors), or if the fan has been removed from the chassis for more than 30 seconds,

a system will log the event as a critical error. A critical error will cause the System LED to flash red and will

require a reboot to reset the error status. A total fan failure (including removal) for more than 2 minutes will

result in system shutdown. If you are hot-swapping a fan assembly in response to an error message, and the

system is operating normally, hot-swapping the fan in less than 30 seconds will eliminate the requirement for

a system reboot. Hot-swapping a fan in less than 2 minutes will allow continued operation and prevent

automatic shutdown.

CAUTION Operating the server with the front grill removed will risk EMI. Operate the server with the

front grill removed only when hot-swapping a fan. Always replace the front grill immediately

after replacing the fan.

Observe all ESD safety precautions while performing this procedure. Failure to follow ESD

safety precautions could result in damage to the server.

NOTE A hot-swap device does not require interaction with the operating system before the device is

removed from or installed into the server.

The power to the server does not have to be off to remove or replace a hot-swap chassis fan unit.

Chapter 3

27

Page 28

Installing Additional Components

Hot-Swap Chassis Fan Units

Removing and Replacing a Front Panel Hot-Swap Fan

Figure 3-9 Removing a Front Panel Hot-Swap Fan

Fan 1

chasfan1xtnd

Fan 2

Captive

Screws

Fan 3

Fan 4

The server does not need to be removed or extended from the rack to allow fan replacement. To remove and

replace a hot-swap fan from the front of the server chassis, perform the following steps:

Step 1. Remove the front grill. Refer to “Removing the Front Grill” on page 24.

Step 2. Using an ACX-15 torx screwdriver, loosen the two captive screws on the plastic fan extractor

handle (left side of fan).

CAUTION Hot-swapping a fan can interrupt system operation. If you are hot-swapping a fan

assembly in response to an error message, and the system is operating normally,

hot-swapping the fan in less than 30 seconds will eliminate the requirement for a

system reboot. Hot-swapping the fan in less than 2 minutes will allow continued

operation and prevent automatic shutdown.

Step 3. Using the extractor handle, pull the fan from the server chassis.

Step 4. Orient the replacement fan such that the extractor handle is at the left. Insert the fan into the

chassis opening and press firmly into place.

Step 5. Tighten the two captive screws that secure the fan in place.

28

Chapter 3

Page 29

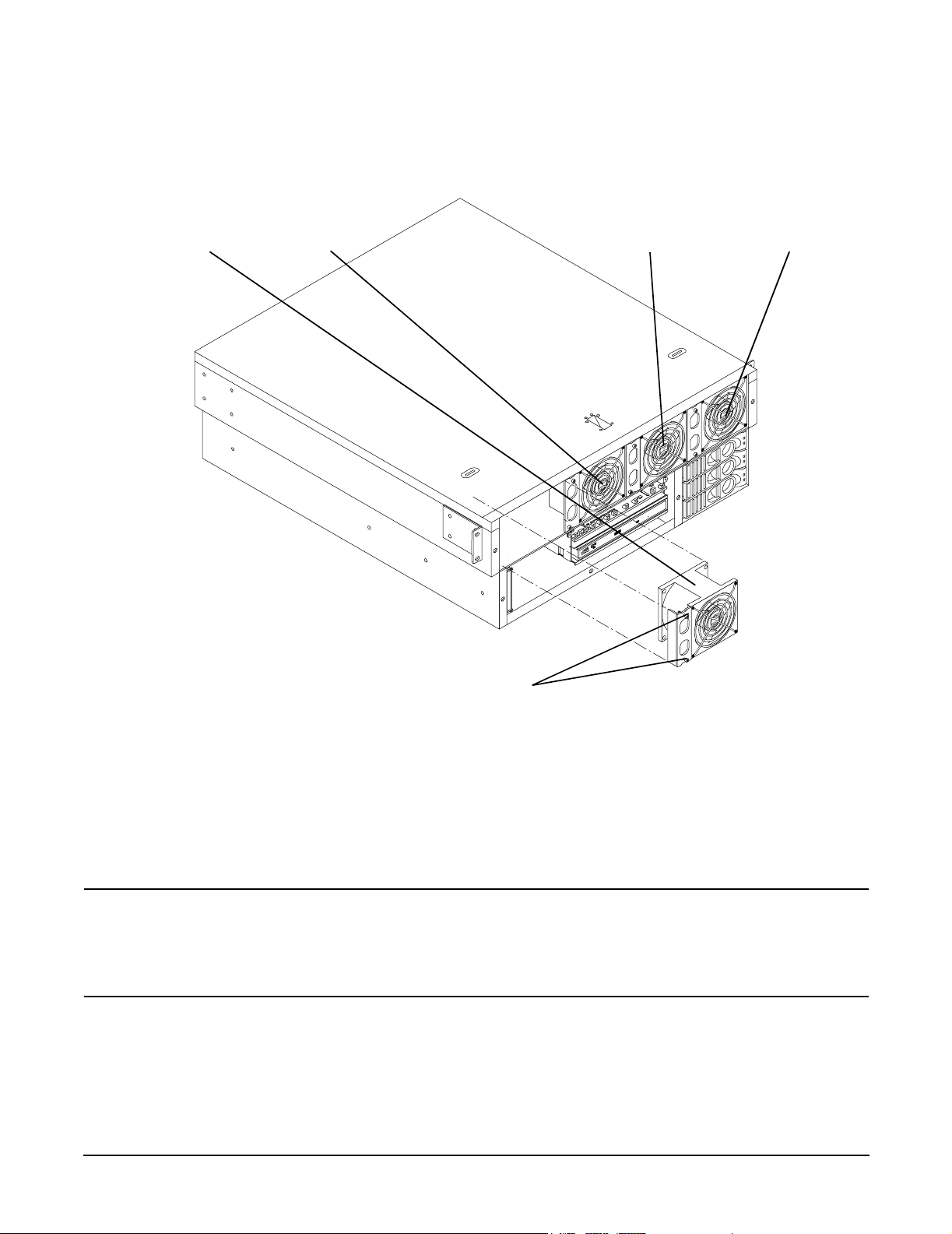

Removing and Replacing a Rear Panel Hot-Swap Fan

Figure 3-10 Removing a Rear Panel Hot-Swap Fan

Installing Additional Components

Hot-Swap Chassis Fan Units

Fan 5

Mounting

Screws

chasfan5xtnd

To remove and replace the hot-swap fan from the rear of the server chassis, perform the following steps:

NOTE The server does not need to be removed from the rack to allow fan replacement.

Step 1. If rack-mounted, it may be necessary to extend a slide-mounted server out from the rack for better

access. If needed, slide the server out to the fully extended position.

Chapter 3

29

Page 30

Installing Additional Components

Hot-Swap Chassis Fan Units

Step 2. Using an ACX-15 torx screwdriver, loosen the two captive screws that secure the fan unit to the

server chassis.

CAUTION Hot-swapping a fan can interrupt system operation. If you are hot-swapping a fan

assembly and the system is operating normally, hot-swapping the fan in less than 30

seconds will eliminate the requirement for a system reboot. Hot-swapping the fan in

less than 2 minutes will allow continued operation and prevent automatic shutdown.

Step 3. Pull the fan assembly from the server chassis by pulling the curved handle.

Step 4. Orient the replacement fan assembly such that the curved handle is at the bottom. Gently push the

fan unit into position.

Step 5. Tighten the two captive screws that secure the fan unit to the server chassis.

30

Chapter 3

Page 31

Installing Additional Components

PCI Card Installation

PCI Card Installation

The hp Integrity cx2600 Server has four 64-bit, 133 MHz PCI-X accessory card sockets located in a removable

card cage. The PCI card cage must be removed before PCI cards can be removed or installed. The following

sections remove and open the card cage, remove and install PCI cards, and reinstall the card cage.

Removing the PCI Card Cage Assembly

To remove the PCI card cage assembly, perform the following steps:

Step 1. If rack mounted, extend a slide-mounted server out from the rack until it stops. Refer to “Accessing

a Rack Mounted Server” on page 15.

Step 2. Turn off the system. Disconnect all external cables.

Step 3. If desired, remove the server from the rack and place it on an ESD-protected work surface. Refer to

“Remove the Server from a Rack” on page 16.

WARNING Ensure that the system is powered down and all power sources have been

disconnected from the server prior to removing or replacing the PCI card

cage assembly.

Voltages and hazardous energy can be present at various locations within

the server whenever a power source is connected. This hazard is present

even when the power switch is in the off position.

Failure to observe this warning could result in personal injury or damage

to equipment.

Step 4. Remove the top cover from the chassis. Refer to “Removing the Top Cover” on page 25.

CAUTION Observe all ESD safety precautions while performing this procedure. Failure to

follow ESD safety precautions could result in damage to the server.

Step 5. Pull up on the PCI card cage release lever (colored lever) and the back edge of the card cage, then

lift the card cage out of the server chassis.

Chapter 3

31

Page 32

Installing Additional Components

PCI Card Installation

Figure 3-11Removing the PCI Card Cage

PCI Card

Cage

Release

Lever

chaspciccdwn

Step 6. Place the card cage on an ESD-protected work surface.

Step 7. Orient the card cage such that PCI card connectors (within the card cage) are at the bottom, when

viewed through the open side of the card cage, and cards can be removed by lifting them from the

sockets.

Step 8. Remove the cover that is now on top of the card cage by sliding the cover toward the rear of the card

cage and lifting the cover. Remove the cover from the card cage.

NOTE The four connectors within the card cage are identical and have the same capabilities. A

compatible PCI card can be installed in any slot.

Removing a PCI Card

NOTE The PCI card cage must be removed from the server chassis to allow access to the PCI cards.

To remove a PCI card, perform the following steps:

Step 1. Remove the PCI card cage from the server chassis. Refer to “Removing the PCI Card Cage

Assembly” on page 31.

Step 2. Remove the cover from the PCI card cage.

32

Chapter 3

Page 33

Installing Additional Components

PCI Card Installation

CAUTION Observe all ESD safety precautions while performing this procedure. Failure to

follow ESD safety precautions could result in damage to the server.

Step 3. If a cable will block card removal, or if it is connected to the card to be removed, disconnect the

cable(s) from card connector(s) at this time.

Step 4. Using an ACX-15 torx screwdriver, remove the retaining screw that secures the card in place. See

Figure 3-12.

Figure 3-12PCI Card Retaining Screws

Card

Retaining

Screws

pciccscrw2

Step 5. Grasp the card by the two opposing edgers and lift the card from the socket.

Step 6. If no card will be installed in the empty socket, install a blank panel in the bulkhead opening at the

end of the card cage. The blank panel is necessary to ensure correct air flow and EMI protection

when the card cage is installed in a working server.

Installing a PCI Card

NOTE The PCI card cage must be removed from the server chassis to allow installation of PCI cards.

The four connectors in the PCI card cage are identical and have the same capabilities. A compatible PCI card

may be installed in any slot. To install a PCI card, perform the following steps:

Step 1. Remove the PCI card cage from the server chassis. Refer to “Removing the PCI Card Cage

Assembly” on page 31.

Chapter 3

33

Page 34

Installing Additional Components

PCI Card Installation

Step 2. Remove the cover from the PCI card cage.

CAUTION Observe all ESD safety precautions while performing this procedure. Failure to

follow ESD safety precautions could result in damage to the server.

Step 3. If a blank panel is installed at the end of the card cage (for the card position/socket which will be

used), remove the blank panel.

Step 4. Grasp the card to be installed by opposing edges and orient the card such that its connector is

aligned with the card cage socket and the PCI interface connector can be extended through the

opening at the end of the card cage. Insert the card into the desired socket.

Step 5. Secure the card in the card cage using the retaining screw provided.

Step 6. Connect any cables (if appropriate) to card sockets at this time.

Installing the PCI Card Cage Assembly

To install the PCI card cage assembly, perform the following steps:

WARNING Ensure that the system is powered down and all power sources have been

disconnected from the server prior to removing or replacing the PCI card cage

assembly.

Voltages and hazardous energy can be present at various locations within the server

whenever a power source is connected. This hazard is present even when the power

switch is in the off position.

Failure to observe this warning could result in personal injury or damage to

equipment.

CAUTION Observe all ESD safety precautions while performing this procedure. Failure to follow ESD

safety precautions could result in damage to the server.

Step 1. If the card cage cover has been removed, insert the cover tabs (fan end of cover) into the

corresponding slots on the card cage and press the cover into position on the card cage. Slide the

cover toward the front of the card cage to secure the cover in place.

Step 2. Orient the PCI card cage as shown in Figure 3-13. Lift the release lever and hold it in the open

position. Lower the card cage into position and press gently to seat card cage connectors.

34

Chapter 3

Page 35

Figure 3-13Installing the PCI Card Cage

PCI Card

Cage

Installing Additional Components

PCI Card Installation

Release

Lever

chaspciccup

Step 3. Press the release lever down (into position) to lock the card cage in place in the chassis.

Step 4. Reinstall the chassis top cover. Refer to “Replacing the Top Cover” on page 26.

Step 5. Reconnect rear panel cables, and turn on the system.

Step 6. Run info io at the EFI shell to verify that the PCI card(s) has been correctly installed.

Chapter 3

35

Page 36

Installing Additional Components

Installing Processors and Memory

Installing Processors and Memory

This section provides information about removing and installing processors and memory. The processors and

memory are located on the system board and are accessible after removing the top cover and air guides.

Processor 0 (CPU 0) is located closer to the chassis side panel and processor 1 (CPU 1) is located closer to the

DIMM sockets. (See Figure 3-14.)

Your hp Integrity cx2600 Server may be delivered with one or two processors installed. You may wish to

install the second processor, or replace the processors with newer, compatible processors. Additional or larger

DIMMs may be available for installation. The following sections provide detailed procedures for removal and

installation of processors and memory.

Figure 3-14 Processors in Server Chassis (Top Cover Removed)

CPU 0

CPU 1

chastop2cpus

Removing a Processor

To remove a processor, proceed as follows:

F

R

O

N

T

Step 1. If rack-mounted, extend the server out from the rack on slides until it stops. Refer to “Accessing a

Rack Mounted Server” on page 15.

36

Chapter 3

Page 37

Installing Additional Components

Installing Processors and Memory

WARNING Voltages and hazardous energy can be present at various locations within

the server whenever a power source is connected. This hazard is present

even when the power switch is in the off position.

Ensure that the system is powered down and all power sources have been

disconnected from the server prior to performing the following procedures.

Failure to observe this warning could result in personal injury or damage

to equipment.

Step 2. Turn off the system. Disconnect all external cables.

Step 3. If desired, remove the server from the rack and place it on an ESD-protected work surface. Refer to

“Remove the Server from a Rack” on page 16.

Step 4. Remove the chassis top cover. Refer to “Removing the Top Cover” on page 25.

CAUTION Observe all ESD safety precautions while performing processor removal. Failure to

follow ESD safety precautions could result in damage to the server.

Step 5. Remove the processor airflow guide. (See Figure 3-15).

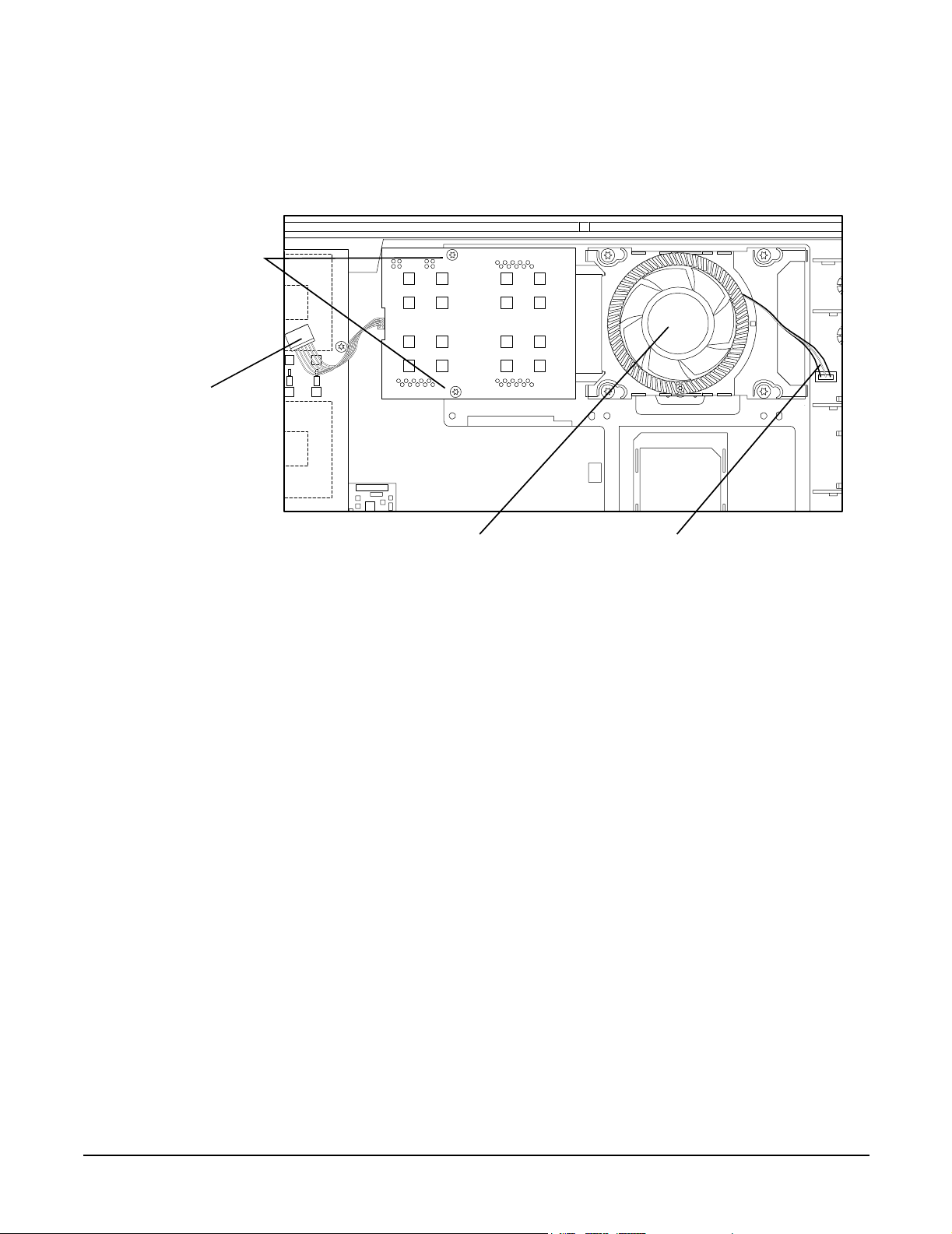

Figure 3-15Processor Airflow Guide

Processor

Airflow

Guide

chascvroff

Step 6. Unplug the CPU power module cable.

Chapter 3

37

Page 38

Installing Additional Components

Installing Processors and Memory

Step 7. Loosen the power module mounting screws and disconnect the module from its processor by sliding

it toward the back of the chassis.

Figure 3-16Disconnecting the Power Module

Power Module

Mounting

Screws

Power

Module

Cable

cpu1wpm1

Processor

Fan

Turbo Fan

Power

Cable

Step 8. Remove the CPU power module from the server chassis.

Step 9. Disconnect the turbo fan power cable.

Step 10. Loosen the four heatsink captive screws using the special processor tool that was shipped with your

processor.

Step 11. Slide the sequencing retainer plate toward the back of the chassis to open the hole in the edge of the

turbo fan heatsink for insertion of the special processor tool into the processor locking mechanism.

38

Chapter 3

Page 39

Figure 3-17Loosen the Turbo Fan Heatsink Screws

Sequencing

Retainer

Plate

Insert Processor

To o l H e re

Installing Additional Components

Installing Processors and Memory

cputopvue

Step 12. Insert the processor tool into the hole that runs down through the edge of the turbo fan heatsink.

Figure 3-18Unlocking the Processor

Insert Processor

To o l H ere

Unlocked

cpusoclock

Locked

Step 13. Unlock the processor locking mechanism by rotating the tool counterclockwise 180 degrees. (See

Figure 3-18).

Step 14. Remove the turbo fan heatsink and processor from the chassis.

Chapter 3

39

Page 40

Installing Additional Components

Installing Processors and Memory

Installing a Processor

The following procedure is applicable to installation of processor 0 or processor 1. Processor 0 must be

installed before installing processor 1. Proceed as follows:

NOTE Installation instructions are provided with replacement processors. Read those instructions

carefully. Changes in processor design (and installation) may have occurred since this

procedure was written. Always follow the instructions provided with a replacement processor.

Step 1. If rack mounted, extend a slide-mounted server out from the rack until it stops. Refer to “Accessing

a Rack Mounted Server” on page 15.

WARNING Voltages and hazardous energy can be present at various locations within

the server whenever a power source is connected. This hazard is present

even when the power switch is in the off position.

Ensure that the system is powered down and all power sources have been

disconnected from the server prior to performing the following procedures.

Failure to observe this warning could result in personal injury or damage

to equipment.

Step 2. Turn off the system. Disconnect all external cables.

Step 3. If desired, remove the server from the rack and place it on an ESD-protected work surface. Refer to

“Remove the Server from a Rack” on page 16.

Step 4. Remove the chassis top cover. Refer to “Removing the Top Cover” on page 25.

CAUTION Observe all ESD safety precautions while performing processor installation. Failure

to follow ESD safety precautions could result in damage to the server.

Step 5. Remove the processor airflow guide. (See Figure 3-15)

Step 6. Ensure that the processor locking mechanism is rotated to the unlocked position. (See Figure 3-18.)

Step 7. Inspect the pins of the processor to be installed. Verify that processor pin(s) are not bent.

Step 8. Use the four locator posts on the heatsink and the turbo fan power cable to properly align the fan

and processor assembly on the system board. The four locator posts will fit in locator holes on the

processor mount of the system board. The turbo fan power cable must be positioned so that it is

located on the side of the heatsink that faces the front of the chassis.

40

Chapter 3

Page 41

Figure 3-19Installing the Turbo Fan and Processor Assembly

Screw 1 (not shown)

(Tighten first)

Screw 4

(Tighten

last)

Locator

Post

Insert Processor

Tool H e r e

Installing Additional Components

Installing Processors and Memory

Screw 3

(Tighten third)

Screw 2

(Tighten

second

Locator

Hole

Locator

Post

Locator

Hole

cpu1noppm3

Step 9. Use the special processor tool shipped with processor assemblies to lock the processor in place on

the system board. To do this, insert the special processor tool into the hole that runs down the side

of the heatsink and rotate it clockwise 180 degrees.

Step 10. Slide the sequencing retainer plate toward the front of the system.

Step 11. Tighten the four captive screws of the heatsink in the order shown in Figure 3-19. Tighten each

screw 1/2 turn, and then tighten the next screw. Continue this sequence until the heatsink is

secured to the system board.

Step 12. Connect the power cable for the processor turbo fan to its connector on the system board.

Step 13. Slide the CPU power module on the system board metal mounting bracket so that the power

module connector aligns with the connector on the processor. Align the two mounting screw holes

on the power module with their screw holes on the system board’s metal mounting bracket. Screw

in the power module mounting screws.

Step 14. Connect the CPU power module power cable.

Step 15. Place the processor airflow guide in position.

Step 16. Install the chassis top cover. Refer to “Replacing the Top Cover” on page 26.

Chapter 3

41

Page 42

Installing Additional Components

Installing Processors and Memory

Step 17. If necessary, reinstall the chassis in the rack. Refer to “Install the Server into a Rack” on page 17.

Step 18. Reconnect power and system cables to rear panel connectors.

Step 19. Turn on the system.

Step 20. Run info cpu at the EFI shell prompt to verify that the processor has been installed correctly. Refer

to Chapter 5 of this guide (Cable Connections) and to the hp Integrity cx2600 Operation and

Maintenance Guide for information about connecting a console and using the EFI shell. (The hp

Integrity cx2600 Operation and Maintenance Guide is included on the CD provided with your

system).

Installing Memory

Your hp Integrity cx2600 Server comes with 4, 8, or 12 DIMMs installed. The system is minimally configured

with 1 GB of memory (four 256 MB DIMMs loaded in quad 0 (slots 0A, 0B, 1A, and 1B). The system is

maximally configured with 24 GB of memory (four 2 GB DIMMs loaded in each of quads 0, 1, and 2 (quad 0

slots 0A, 0B, 1A, and 1B, quad 1 slots 2A, 2B, 3A, and 3B, and quad 2 slots 4A, 4B, 5A, and 5B.

You may replace these DIMMs, or insert DIMMs into unused quads if desired. When adding DIMMs, you

must use a minimum of four like-sized DIMMs in the next available quad.

Supported DIMM Sizes

Supported DIMM sizes are 256 MB, 512 MB, 1 GB, 2 GB. Dissimilar DIMM sizes may be used in the system,

but all four DIMMs in each quad must be identical.

Removing DIMMs

To remove a DIMM, perform the following steps:

WARNING Voltages and hazardous energy can be present at various locations within the server

whenever a power source is connected. This hazard is present even when the power

switch is in the off position.

Ensure that the system is powered down and all power sources have been

disconnected from the server prior to performing the following procedures.

Failure to observe this warning could result in personal injury or damage to

equipment.

Step 1. If rack mounted, extend a slide-mounted server out from the rack until it stops. Refer to “Accessing

a Rack Mounted Server” on page 15.

Step 2. Turn off the system. Disconnect all external cables.

Step 3. If desired, remove the server from the rack and place it on an ESD-protected work surface. Refer to

“Remove the Server from a Rack” on page 16.

Step 4. Remove the top cover from the chassis. Refer to “Front Grill and Top Cover” on page 23.

CAUTION Observe all ESD safety precautions while performing DIMM removal. Failure to

follow ESD safety precautions could result in damage to the server.

Step 5. Remove the memory airflow guide. (See Figure 3-20).

42

Chapter 3

Page 43

Figure 3-20Memory Airflow Guide

Memory

Airflow

Guide

Installing Additional Components

Installing Processors and Memory

chascvroff

Step 6. Locate the DIMM(s) to be removed. (See Figure 3-21).

Chapter 3

43

Page 44

Installing Additional Components

Installing Processors and Memory

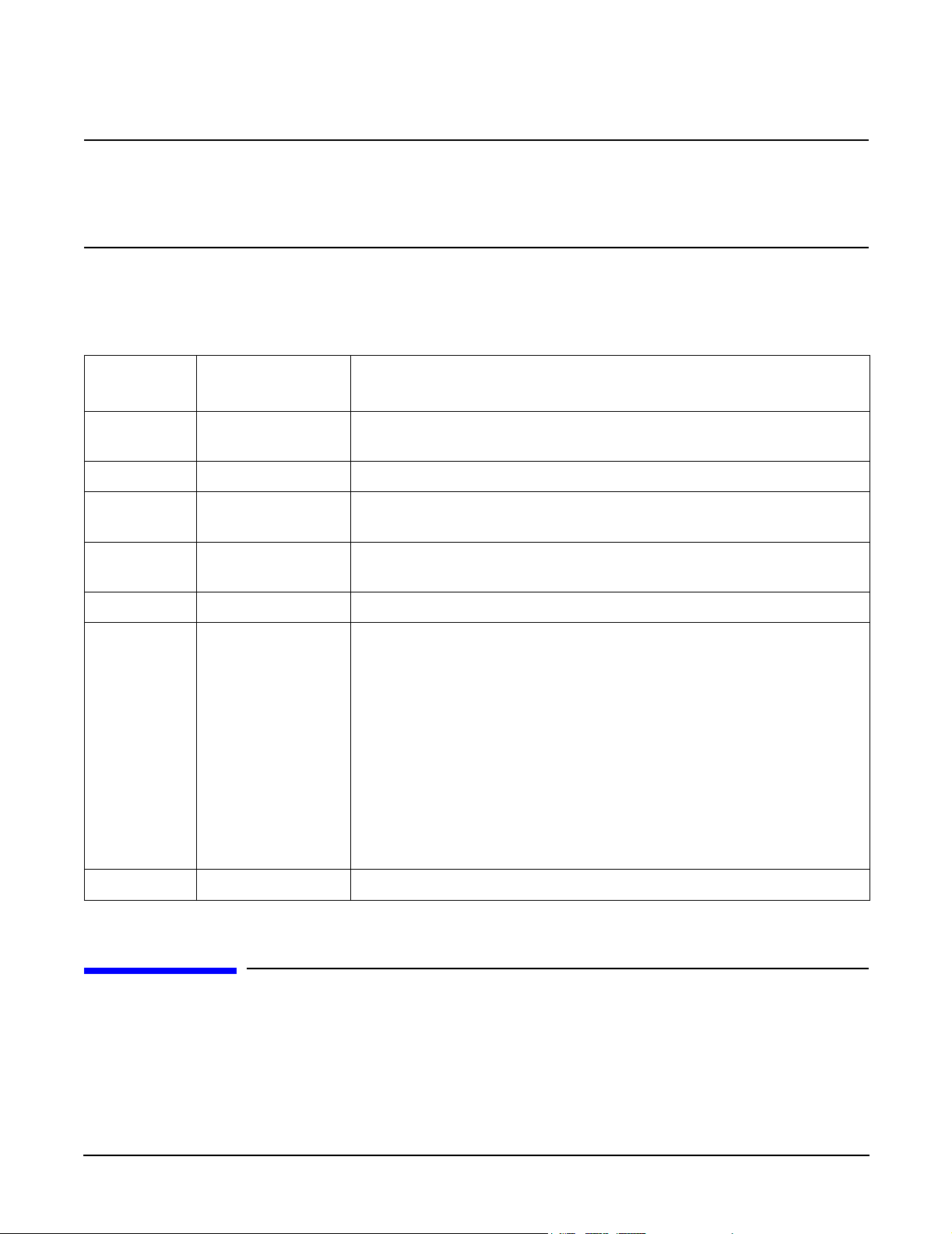

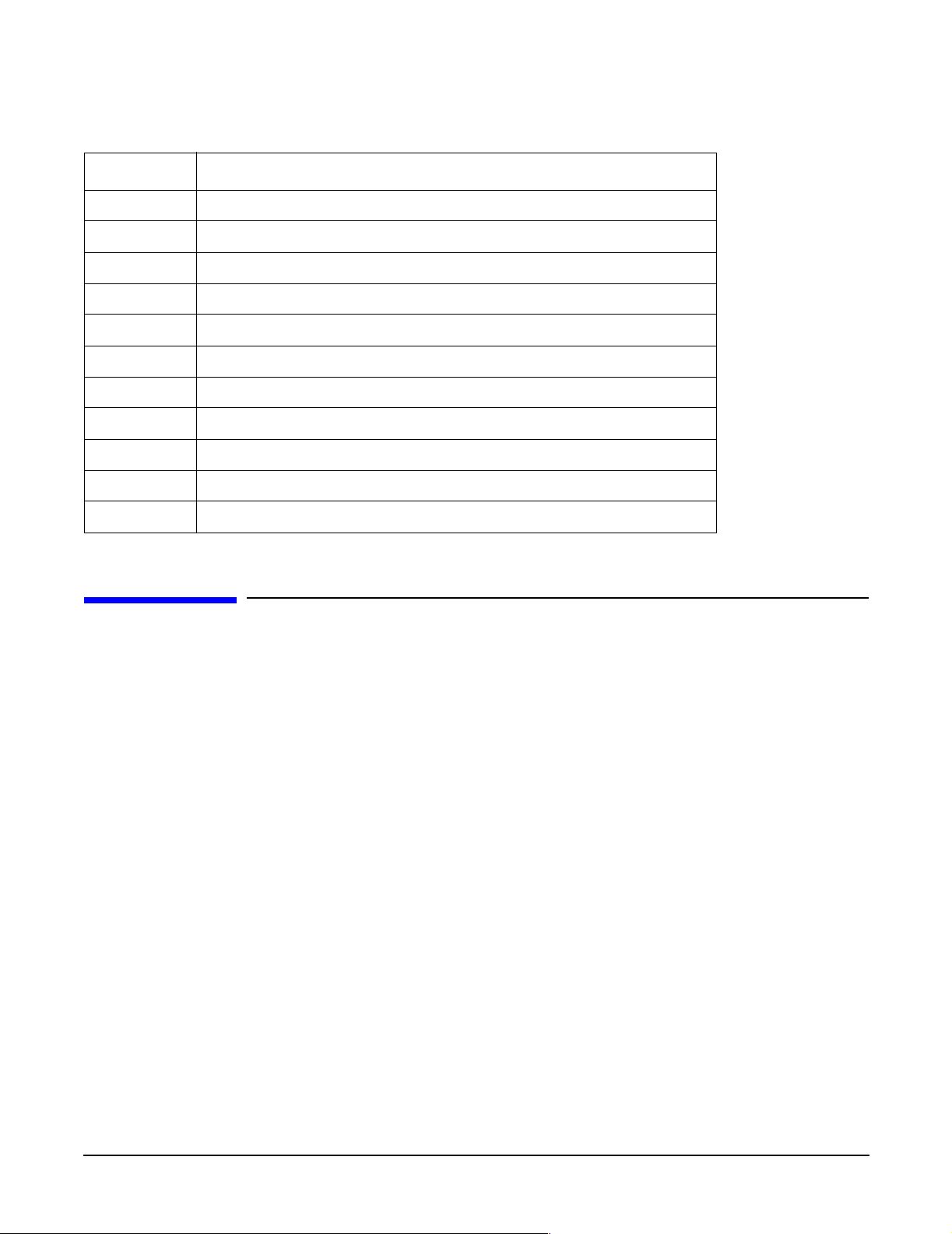

Figure 3-21DIMM Slots

0B

4B

2B

0A

4A

2A

sysbrd1cpu

1B

5B

3B

1A

5A

3A

Step 7. Press down on the DIMM retainer clips on either end of the DIMM connector, and lift the DIMM

from the system board socket.

Step 8. If the removed DIMM is functional, store it for future use. (Store the DIMM in a static-free

container.)

Step 9. Repeat steps 6 through 8 for each DIMM to be removed.

Step 10. If DIMMs will not immediately be installed, set the memory airflow guide in position and reinstall

the top cover. Refer to “Replacing the Top Cover” on page 26.

Installing DIMMs

DIMMs must be installed in groups of 4 (quads), and in specific locations. DIMM sockets are shown in

Figure 3-21. The first quad (4 DIMMs) must be installed in sockets 0A, 0B, 1A, and 1B. The second quad must

be installed in sockets 2A, 2B, 3A, and 3B. The third (and final) quad must be installed in sockets 4A, 4B, 5A,

and 5B. If DIMMs of different sizes are to be installed, the smallest DIMMs (least memory) must be installed

in the first quad. DIMMs in the second quad can be equal to or larger (more memory) than the DIMMs in the

first quad. If DIMMs are to be installed in the third quad, they must be equal to or larger than the DIMMs in

the second quad.

To install DIMMs, perform the following steps:

WARNING Voltages and hazardous energy can be present at various locations within the server

whenever a power source is connected. This hazard is present even when the power

switch is in the off position.

Ensure that the system is powered down and all power sources have been

disconnected from the server prior to performing the following procedures.

44

Chapter 3

Page 45

Installing Additional Components

Installing Processors and Memory

Failure to observe this warning could result in personal injury or damage to

equipment.

NOTE DIMMs must be installed in matched groups of four. DIMM sizes can vary between quads, but

all DIMMs within a quad must be identical.

Step 1. If rack mounted, extend a slide-mounted server out from the rack until it stops. Refer to “Accessing

a Rack Mounted Server” on page 15.

Step 2. Turn off the system. Disconnect all external cables.

Step 3. If desired, remove the server from the rack and place it on an ESD-protected work surface. Refer to

“Remove the Server from a Rack” on page 16.

Step 4. Remove the top cover from the chassis. Refer to “Front Grill and Top Cover” on page 23.

CAUTION Observe all ESD safety precautions while performing DIMM installation. Failure to

follow ESD safety precautions could result in damage to the server.

Step 5. Remove the memory airflow guide. (See Figure 3-20).

Step 6. Locate the DIMM sockets in which DIMMs will be installed. See Figure 3-21.

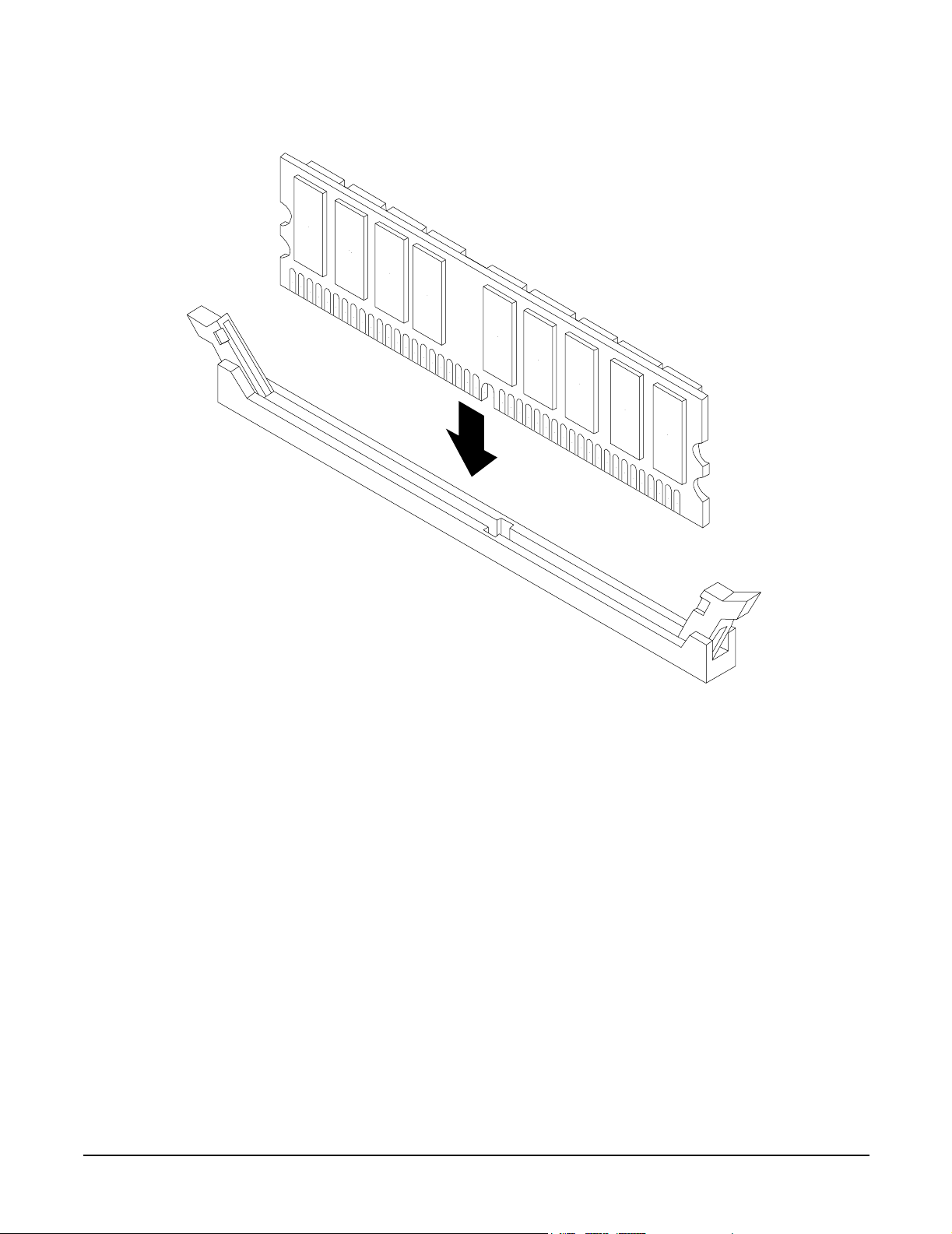

Step 7. Holding the DIMM by its edges, orient the DIMM such that the component side is facing the

processors, then insert the DIMM into the appropriate socket.

NOTE DIMM connectors are keyed so that they can be installed in only the correct

orientation.

Step 8. Gently and evenly push on each side of the DIMM until it seats in the socket. Observe that the

socket retainer clips return to the upright position when the DIMM is fully inserted.

Chapter 3

45

Page 46

Installing Additional Components

Installing Processors and Memory

Figure 3-22Inserting DIMM into a DIMM Socket

dimm_sokt

Step 9. Snap the socket retainer clips into place, ensuring that the DIMM is locked in the socket.

Step 10. Repeat steps 6 through 9 for each DIMM to be installed.

Step 11. Set the memory airflow guide in position and reinstall the top cover.

46

Chapter 3

Page 47

4 Troubleshooting

Introduction

This chapter presents troubleshooting information. Basic tips for start-up problems are presented, audio cues

and LED indicators are described and interpreted, and error messages (and how to retrieve them) are

described. In addition, problems that are associated with I/O functions and paths are discussed here.

Troubleshooting Methodology

WARNING Always disconnect the power cords and unplug telephone cables before removing

the server cover. Disconnect telephone cables to avoid exposure to shock hazard

from telephone ringing voltages. Disconnect the power cords to avoid exposure to

high energy levels that may cause burns when parts are short-circuited by metal

objects such as tools or jewelry.

CAUTION Do not operate the server for more than 2 minutes with any cover (including power supplies

and disk drives) removed. The covers also provide EMI containment and direct airflow within

the chassis. Depending on which cover or assembly is missing, the server may shutdown,

interrupting operations. In addition, damage to system components may result due to

overheating.

You can safely remove the front grill while the HP Server is running to remove and replace

hot-swap fans. The hot-swap power supplies and one hot-swap fan (accessible from the rear of

the chassis) can be replaced at any time. For any other service activity requiring access to

internal components, power down the server and observe all safety precautions.

The server was tested prior to shipping and should be in perfect working order. Failures encountered during

installation may be due to damage that occurred in transit. Reseating connectors may clear problems that

result from rough handling. If you are installing components or assemblies, compatibility problems or

incorrect installations may be the cause of problems. If you are installing components or assemblies, check

that items are correctly installed and that all connectors are fully engaged. If the unit will not power on,

check the power source before proceeding.

If a problem is encountered during initial operation, remove any add-in or optional components and retest the

server before continuing. Verify basic server operation before installing additional cards and configuring

software and hardware for your system requirements.

Troubleshooting is based on observation of server status indications and error messages, and by checking

system event logs. The system e-buzzer will provide an immediate indication of any start-up problems. LED

indicators can be observed on the front and rear of the server. Error messages are displayed on local and

remote consoles. System history (console, event, and history logs) are available through the management

processor, and can be accessed through the console. Additional information about troubleshooting can be

found in the hp Integrity cx2600 Operation and Maintenance Guide.

Chapter 4

47

Page 48

Troubleshooting

Troubleshooting Methodology

Offline troubleshooting programs are available on the resource CD that is shipped with your HP Server. To

troubleshoot your system you should be familiar with the Offline Diagnostics Environment (ODE) which runs

in the Extensible Firmware Interface (EFI). Descriptions and user information about offline troubleshooting

tools are available at http://docs.hp.com. The offline tools are available for downloading at

http://software.hp.com.

Using the Front Panel Power Button

The server power button on the front panel operates differently, depending on how long the button is held in

and on what the system is doing when the button is pressed. You must be aware of its uses to properly

troubleshoot the system.

If the server is off, and power is not connected to server power supplies, pressing the power button has no

effect.

If the server is off, and power is connected to server power supplies, the front panel power LED will blink at a

1-Hz rate. In this state, standby power is available to server circuits, but main power is off. Pressing and

holding the power button will accomplish the following:

• 1 – 3 seconds. System power turns on. The e-buzzer will beep if an error is encountered. (Refer to

“Troubleshooting Using Beep Codes (System e-buzzer)” on page 50 for a description of the e-buzzer.)

• 3 – 5 seconds. The e-buzzer will repeat the last stored error message (beep code).

If the server is on and the system is at the EFI, pressing and holding the power button will accomplish the

following:

• 1 – 3 seconds. System power turns off immediately (hard power down).

• 3 – 5 seconds. The e-buzzer will repeat the last stored error message (beep code).

• 5 seconds or longer. System power turns off immediately (hard power down).

If the server is on and the operating system is running, pressing and holding the power button will

accomplish the following:

• 1 – 3 seconds. System power turns off (software controlled power down).

• 3 – 5 seconds. The e-buzzer will repeat the last stored error message (beep code).

• 5 seconds or longer. System power turns off immediately (hard power down).

If the Server Will Not Power Up

Power problems during installation are usually related to the install process. If your server will not power up,

check the LED indicators on the power supply rear panels. Refer to “Rear Panel LEDs” on page 57 and

perform the following:

• If the DC In indicators are lit, it can be assumed that power is available to the server.

• If a fault indicator is lit, reseat the power supply. If the problem persists, remove and reseat boards within

the server. If the problem still persists, replace the power supply and/or the power supply interface board.

• If the DC Out indicators are lit, it can be assumed that power is supplied to the server circuits. If the

console shows that the server is powered up, but server LEDs indicate that power is off, remove and

reseat connectors on the LED status board. (If the problem still persists, replace the LED status board.) If

the console shows that the server is not powered up (server is off), remove and reseat connectors on the

system board. (If the problem still persists, replace the power supply interface board, the MP board, or the

system board.)

48

Chapter 4

Page 49

Troubleshooting

Troubleshooting Methodology

If EFI Is Not Available

If it is not possible to reach the EFI (from either the main disk partition or CD), then you must use the

following tools to help solve your problem:

• Front panel LEDs (page 52)

• Management processor (MP) (page 62)

— Console messages

— System event logs (SEL)

If the Operating System Will Not Boot