Page 1

TL881 MiniLibrary Drive Upgrade Procedure

First Edition (May 1999)

Part Number ER-TL881-DA. A01/138248-001

Compaq Computer Corporation

Page 2

Notice

The information in this publication is subject to change without notice.

COMPAQ COMPUTER CORPORATION SHALL NOT BE LIABLE FOR TECHNICAL OR

EDITORIAL ERRORS OR OMISSIONS CONTAINED HEREIN, NOR FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES RESULTING FROM THE FURNISHING, PERFORMANCE, OR

USE OF THIS MATERIAL. THIS INFORMATION IS PROVIDED “AS IS” AND COMPAQ

COMPUTER CORPORATION DISCLAIMS ANY WARRANTIES, EXPRESS, IMPLIED OR

STATUTORY AND EXPRESSLY DISCLAIMS THE IMPLIED WARRANTIES OF

MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSE, GOOD TITLE AND AGAINST

INFRINGEMENT.

This publication contains information protected by copyright. No part of this publication may be

photocopied or reproduced in any form without prior written consent from Compaq Computer

Corporation.

© 1999 Compaq Computer Corporation.

All right s re served. Printed in the U.S.A.

The software described in this guide is furnished under a license agreement or nondisclosure agreement.

The software may be used or copied only in accordance with the terms of the agreement.

Com paq, Deskpro, Fastart , C ompaq In sight Manager, Systempro, Sy stempr o/LT, ProLia nt, ROMPaq,

QVision, SmartStart, NetFlex, QuickFind, PaqFax, ProSignia, registered United States Patent and

Trademark Office.

Neoserver, Netelligent, Systempro/XL, SoftPaq, QuickBlank, QuickLock are trademarks and/or service

marks of Compaq Computer Corporation.

Microsoft, MS -DO S, Win dow s, and Windows NT are registered trade ma rks of Microsoft Corp or at ion.

Pentium is a registered trademark and Xeon is a trademark of Intel Corporation.

Other product na me s ment ioned herein may be trad emarks and/or regist ered trademarks of the ir

respective companies.

TL881 MiniLibrary Drive Upgrade Procedure

First Edition (May 1999)

Part Number ER-TL881-DA. A01/138248-001

Page 3

Contents

About This Guide

Text Conventions.................................................................................................... v

Symbols in Text..................................................................................................... vi

Symbols on Equipment..........................................................................................vi

Rack Stability.......................................................................................................vii

Getting Help.........................................................................................................vii

Compaq Technical Support............................................................................vii

Compa q Website...........................................................................................viii

Compaq Authorized Reseller...........................................................................ix

Adding a Second Tape Drive

Parts Lo cation.........................................................................................................1

Overall Procedure...................................................................................................2

Removing and Replacing the Skin Cover (Desktop Models Only).....................3

Removing and Replacing the Cover Plate.........................................................4

Removing and Replaci n g the Drive Caddy Assem bly ....................................... 5

Installing the Second Tape Drive......................................................................7

Index

Page 4

iv TL881 MiniLibrary Drive Upgrade Procedure

List of Figures

Figure 1. Parts Location.........................................................................................1

Figure 2. Removing the Skin Cover........................................................................3

Figure 3. Removing the Cover Plate.......................................................................5

Figure 4. Drive Caddy Assembly Parts...................................................................6

List of Tables

Table 1 Parts Location............................................................................................2

Page 5

This guide is designed to be used as step-by-step instructions for installation

and as a reference for operation, troubleshooting, and future upgrades.

Text Conventions

This document uses the following conventions to distinguish elements of text:

Keys Keys appear in boldface. A plus sign (+) between

About This Guide

two keys indicates that they should be pressed

simultaneously.

USER INPUT

FILENAMES File names appear in uppercase italics.

Menu Options,

Command Names,

Dialog Box Names

COMMANDS,

DIRECTORY NAMES,

and DRIVE NAMES

Type When you are instructed to typ e information, type

Enter

User input appears in a different typeface and in

uppercase.

These el ements app ea r in initial capital lette r s .

These elements appear in uppercase.

the information without pressing the Enter key.

When you are instructed to enter information, type

the information and then press the Enter key.

Page 6

vi TL881 MiniLibrary Drive Upgrade Procedure

Symbols in Text

These symbols may be found in the text of this guide. They have the following

meanings.

WARNING:

in the warning could result in bodily harm or loss of life.

CAUTION:

could res ult in dam a g e to eq ui pme nt or los s of inf or m at io n.

IMPORTANT:

instructions.

NOTE:

Text set off in this manner presents commentary, sidelights, or in teresting points

of informa tion.

Text set off in this manner indicates that failure to follow directions

Text set off in this manner presents clarifying information or s pec ific

Symbols on Equipment

These icons may be located on equipment in areas where hazardous conditions

may exist.

Any surface or area of the equipment marked with these symbols

indicates the presence of electrical shock hazards. Enclosed area

contains no operator serviceable parts.

WARNING:

do not open this enclosur e.

Text set off in this manner indicates that failure to follow directions

To reduce the risk of injury fr om electrical shock hazards,

Any RJ-45 receptacle marked with these symbols indicates a Network

Interface Connection.

WARNING:

the equi pme nt , do no t pl u g tele ph on e or t elecommu nic a ti ons

connectors into this receptacle.

Any surface or area of the equipment marked with these symbols

indicates the presence of a hot surface or hot component. If this

surface is contacted, the potential for injury exists.

WARNING:

the surfac e to cool befor e touchin g.

To reduce the risk of electrical shock, fire , or damage to

To reduce the risk of injury fr om a hot component, allow

Page 7

Rack Stability

About This Guide vii

Power Supplies or Systems marked with these symbols

indicate the equipment is supplied by multiple sources of

power.

WARNING: To reduce the risk of injury from electrical shock,

remove all power cords to completely disconnect power from

the system.

WARNING: To reduce the risk of personal injury or dama ge to the equipment,

be sur e that:

■ The leveling jacks are extended t o the floor.

■

The full weight of the rack rests on the leveling jacks.

■

The stabilizing feet are attache d to the rack if it is a sing le rack

installations.

■

The racks are coupled together in multiple rack installations.

■

A rack may become unstable if more than one component is extended for

any reason. Extend only one component at a time.

Getting Help

If you have a problem and have exhausted the information in this guide, you

can get further information and other help in the following locations.

Compaq Technical Support

You are entitled to free hardware technical telephone support for your product

for as long you own the product. A technical support specialist will help you

diagnose the problem or guide you to the next step in the warranty process.

In North America, call the Compaq Technical Phone Support Center at

1-800-OK-COMPAQ

Outside North America, call the nearest Compaq Technical Support Phone

Center. Telephone numbers for world wide Technical Support Centers are

1

For continuous quality improvement, calls may be recorded or monitored.

1

. This service is available 24 hours a day, 7 days a week.

Page 8

viii TL881 MiniLibrary Drive Upgrade Procedure

listed on the Compaq website. Access the Compaq website by logging on to

the Internet at http://www.compaq.com.

Be sure to have the following information available before you call Compaq:

■

Technical support registration number (if applicable)

■

Product serial number (s)

■

Product model name(s) and numbers(s)

■

Applicable error messages

■

Add-on boards or hardware

■

Third-p arty hardwa re or so ftware

■

Operating system type and revision level

■

Detailed, specific questions

Compaq Website

The Compaq website has information on this product as well as the latest

drivers and Flash ROM images. You can access the Compaq website by

logging on to the Internet at http://www.compaq.com.

Page 9

Compaq Authorized Reseller

For the name of your nearest Compaq Authorized Reseller:

■

In the United States, call 1-800-345-1518.

■

In Canada, call 1-800-263-5868.

■

Elsewhere, see the Compaq website for locations and telephone

numbers.

About This Guide ix

Page 10

Adding a Second Tape Drive

IMPORTANT:

must

step, you might cause premature failure of the mechanism.

Parts Location

Figure 1 shows the location of most of the field replaceable parts. Table 1

describes the parts.

2

1

14

13

All screws that do not use lock washers, captive washers or lock nuts

have Loctite 222 applied when parts are reassembled in the field. If you ignore this

12

5

4

3

8

9

1011

6

7

SHR-1201

Figure 1. Parts Location

Page 11

2 TL881 MiniLibrary Drive Upgrade Procedure

(1) Magazine door

(2) Door opener/Magazine lock

(3) Shuttle cable

(4) Shuttle

(5) Shuttle motor

(6) Drive caddy assembly

(7) Fan

(8) Powe r supply

(9) Controller PWB

(10) AC power switch

Table 1

Parts Location

Number Part

(11) Control panel

(12) Unlock/open switch

(13) Magazine security lock

(14) Leadscrew

Overall Procedure

NOTE:

If the base module is part of an expanded TL881 MiniLibrary subsystem, refer to

the

TL881 Mini Library Service Manual

from the subsystem.

To add a second drive to the ba se modul e you must do t he foll owing ste ps.

1. Remove the skin cover, i f present , using t he proc e dure i n t his

document.

2. Remove the cover plate using the procedure in this document.

3. Remove the drive c addy a ssembl y using the proc edure i n thi s

document.

for information on removing the base module

Page 12

4. Install the new drive using the procedure described in this document.

5. Replace the drive caddy assembly.

6. Replace the cover plate.

7. Replace the skin cover.

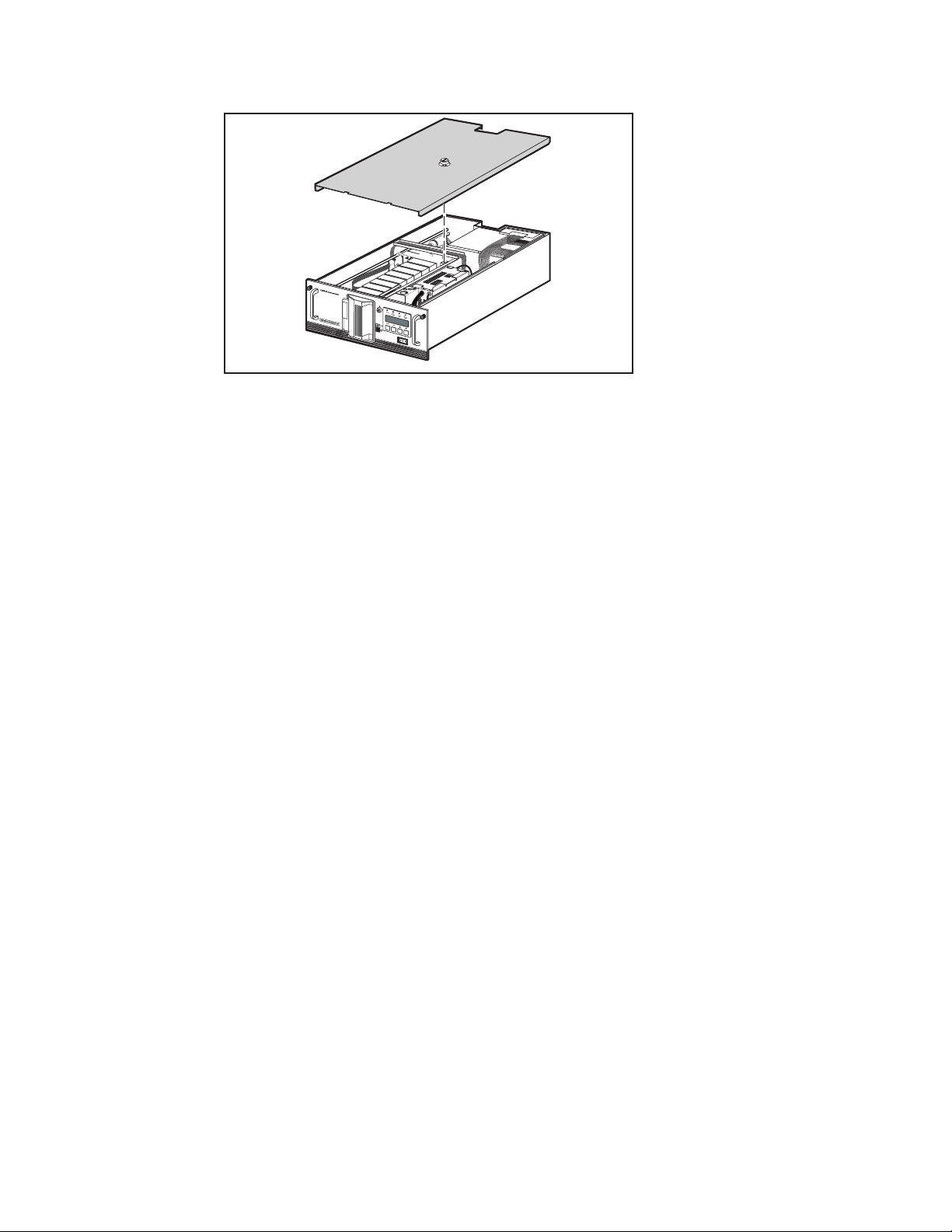

Removing and Replacing the Skin Cover (Desktop

Models Only)

The skin cover is held in place by two screws on each side of the base

module (Figure 2).

Adding a Second Tape Drive 3

Figure 2. Removing the Skin Cover

Removing

Do these steps to remove the skin cove r from the ba se modul e .

1. Remove the two screws on each side of the base module.

2. Grasp the cover by the sides at the bottom edge and pull outwards

slightly while lifting the cover straight up and off the chassis.

Replacing

Do these steps to replace the skin cover on the base module.

SHR-1433

Page 13

4 TL881 MiniLibrary Drive Upgrade Procedure

1. Position the skin cover over the base module with the two angled

surfaces facing toward the front.

2. Slide the skin cover over the module until it touches the front panel.

3. Insert the two screws on each side through the skin cover into the base

module; insert and start all four screws before you tighten any of them.

Removing and Replacing the Cover Plate

Removing

Do these steps to remove the cover plate from the base module.

1. If the base module is a desktop model, remove the skin cover as

described in Removing and Re pl aci ng t he Sk i n Cove r (Desktop Mode ls

Only).

2. Disconnect the power and interface cables at the rear of the module.

3. Unscrew the captive screw in the center of the cover plate (Figure 3).

4. Slide the cover plate one-half inch toward the rear of the module.

5. Lift the cover plate off the base module.

Replacing

Do these steps to replace the cover plate on the base module.

1. Place the cover plate on the base module so that it overhangs one-half

inch at the rear of t he modul e (Figure 3).

2. Slide the cover plate toward the front of the base module until the

cover plate touches the front panel.

3. Tighten the captive screw in the center of the cover plate.

4. Connect the power and interface cables at the rear of the module.

5. If the base module is a desktop model, replace the skin cover as

described in Removing and Re pl aci ng t he Sk i n Cove r (Desktop Mode ls

Only).

Page 14

Figure 3. Removing the Cover Plate

Removing and Replacing the Drive Caddy Assembly

The drive caddy assembly i s an e ncl osure t hat hol ds one or two DLT dri ve s

and the interconnecting cables. The assembly includes the SCSI interface

connectors and cables for the ba se modul e , the power c abl e s for the dri ve s,

and communication cables from the drives to the controller PWB.

Adding a Second Tape Drive 5

SHR-1203

66

Removing

Do these steps to remove the drive c addy a ssembl y from t he base m odul e.

1. Remove the cover plate as described in Removing and Replacing the

Cover Plate.

2. Disconnect the SCSI cable connectors (1) ( Figure 4) from the

controller SCSI extension cable.

Page 15

6 TL881 MiniLibrary Drive Upgrade Procedure

5

7

4

7

2

1

5

3

6

4

SHR-1204

Figure 4. Drive Caddy Assembly Parts

3. Disconnect the drive power “Y” cable (2) from the power supply

connector.

4. Disconnect the drive 1 RS-422 cable (3) at the controller PWB end.

5. Remove two M4 x 8mm flat-he ad scre ws (4) along t he uppe r e dge of

the drive caddy assembly.

6. Remove two M4 extension screws (5) at the top of t he drive c addy

assembly.

CAUTION: If you’re not careful, you might break the door levers when you lift

the drive caddy assembly out of the base module in the next step. To prevent

this, steady the caddy so it cannot rock forward as it clears the platform when

you’re lifting it up, and do not allow the door levers to touch the strut across

the top of the base module.

Page 16

Adding a Second Tape Drive 7

7. Grasp the handle on top and li ft t he drive c addy a ssembl y out of t he

base module carefull y; be c a reful t he door l e vers don’t bum p a gai nst

the chassis crossbrace.

8. Set the drive caddy assembly on the work surface and install the

second tape drive as describe d i n Instal li ng t he Se c ond Tape Drive.

Replacing

Do these steps to replace the drive caddy assembly in the base module.

CAUTION:

the drive caddy assembly down in the base module. To prevent this, steady the

assem bly as you lower it by the handle so it cannot rock forward as it

approaches the platform, and do not allow the door levers to touch the strut

across the top of the chassis.

If you’re not careful, you might break the door levers when you set

1. Grasp the drive caddy assembly by t he ha ndl e a nd l ower it i nto

position in the base module; orient it as shown in Figure 4, and be

careful the door levers don’t bump against the chassis crossbrace.

2. Replace the two M4 extension screws (5) at the top of the assembly

3. Coat the threads of the two M4 x 8mm flat-head Phillips screws (4)

with Loctite 222, and replace them on the upper edge of the drive

caddy assembly.

4. Connect the drive 1 and drive 2 RS-422 cables (3) to the controller

PWB.

5. Connect the drive power cable (2) to the power supply connector.

6. Connect the SCSI cable connectors (1) to the controller SCSI extension

cable.

7. Replace the cover plate as described in Removing and Replacing the

Cover Plate.

Page 17

8 TL881 MiniLibrary Drive Upgrade Procedure

Installing the Second Tape Drive

Do the following steps to install the second tape drive.

1. Remove the four 6-32 sems pan-head Phillips screws (7) that hold the

blank panel in place in the drive caddy assembly; there are two on the

top of the assembly (Figure 4) and two on the bot tom of t he a ssembl y.

2. Slide the blank pane l out of t he dri ve ca ddy a ssembly.

3. Disconnect the RS-422 cable toward the front on the top of the drive,

and lift the cable clear of the cable clamps; set it aside.

4. Install the door lever on the flatted shaft at the bottom of the drive.

5. Slide the drive (6) into the drive caddy assembly; position the drive so

the threaded holes in the top and bottom of the drive are aligned with

the screws holes.

6. Install the four 6-32 sems pan-head Phillips screws that were removed

in Step 1.

7. Connect the unused connector on the power Y-cable to the drive just

installed.

8. Connect the unused connector on the SCSI cable to the drive just

installed.

9. Install the RS-422 cable supplied with the kit, sliding it under the

clamps so that the connector is adjacent to the connector on top of the

new drive.

10. Install the RS-422 cable removed in Step 3 over the top of the new RS-

422 cable so that the connector is adjacent to the connector on top of

the original drive.

11. Connect the RS-422 cables to the connectors on the top of the drives,

through the holes in the top of t he drive c addy a ssembl y.

12. Replace the drive caddy assembly as described in Removing and

Replacing the Drive Caddy Assembly.

Page 18

B

base module 2

C

Index

Compaq website viii

Compq authorized resellers,

telephone numbers viii

technical support telephone

numbers vii

http://www.compaq.com viii

CAUTION

door levers 6

Compaq authorized reseller viii

cover plate 2, 4

D

drive 1 RS-422 cable 6

drive caddy assembly 2, 5

drive power "Y" cable 6

F

Field replaceable parts 1

G

getting help vii

H

help

additional sources vii

I

icons

symbols on equipment vi

L

Loctite 222 1

O

Overall Procedure 2

P

power and interface cables 4

R

RJ-45 receptacle vi

Page 19

2 TL881 MiniLibrary Drive Upgrade Procedure

S

SCSI cable connectors 5

second tape drive 7

skin cover 2

symbols in text vi

symbols on equipment vi

T

Table 1 Parts Location 2

technical support viii

telephone numbers viii

text conventions v

W

warnings

electrical shock vii

rack stability vii

www.compaq.com. viii

Loading...

Loading...