Page 1

b

Maintenance & Service Guide

Compaq Evo Workstation W8000

Document Part Number: 229690-001

Spare Part Number: 229781-001

May 2001

Page 2

© 2001 Compaq Computer Corporation

Compaq and the Compaq logo Registered in U. S. Patent and Trademark Office.

Evo is a trademark of Compaq Information Technologies Group, L. P. in the United States and other

countries.

Microsoft, Windows, Windows NT are trademarks of Microsoft Corporation in the United States and other

countries.

Intel and Pentium are trademarks of Intel Corporation in the United States and other countries.

All other product names mentioned herein may be trademarks of their respective companies.

Compaq shall notbe liable for technical or editorial errors or omissions contained herein. The information in

this document is provided “as is” without warranty of any kind and is subject to change without notice. The

warranties for Compaq products are set forth in the express limited warranty statements accompanying such

products. Nothing herein should be construed as constituting an additional warranty.

Maintenance & Service Guide

First Edition (May 2001)

Document Part Number: 229690-001

Spare Part Number: 229781-001

Page 3

Contents

Preface

ABOUTTHISGUIDE................................................... vi

SymbolsandConventions............................................. vi

TechnicianNotes....................................................vii

LocatingAdditionalInformation........................................vii

1 Product Description

1.1 Product Features ...................................................1–2

1.1.1 FrontPanelControlsandLEDs..................................1–2

1.1.2 Rear Panel Connectors ........................................1–3

1.1.3 DrivePositions ..............................................1–4

1.2 SerialNumberLocation.............................................1–5

2 Spare Parts

3 Removal & Replacement Preliminaries

3.1 ElectrostaticDischargeInformation....................................3–1

3.1.1 GeneratingStatic.............................................3–2

3.1.2 PreventingElectrostaticDamagetoEquipment.....................3–2

3.1.3 PersonalGroundingMethodsandEquipment.......................3–3

3.1.4 Grounding the Work Area. . ....................................3–3

3.1.5 RecommendedMaterialsandEquipment..........................3–4

3.2 RoutineCare......................................................3–5

3.2.1 GeneralCleaningSafetyPrecautions.............................3–5

3.2.2 CleaningtheChassisExterior...................................3–5

3.2.3 Cleaning the Keyboard ........................................3–5

3.2.4 CleaningtheMonitor..........................................3–6

3.2.5 CleaningtheMouse...........................................3–6

3.3 ServiceConsiderations..............................................3–6

3.3.1 Power Supply Fan ............................................3–6

3.3.2 ToolsandSoftwareRequirements................................3–7

3.3.3 Screws.....................................................3–7

3.3.4 CablesandConnectors ........................................3–7

3.3.5 HardDrives.................................................3–7

3.3.6 LithiumCoinCellBattery......................................3–8

Maintenance & Service Guide iii

Page 4

Contents

4 Removal & Replacement Procedures

4.1 DisassemblySequenceChart.........................................4–1

4.2 PreparationforDisassembly..........................................4–2

4.3 CableLock.......................................................4–3

4.4 WorkstationFeet...................................................4–4

4.5 AccessPanel......................................................4–5

4.6 Battery...........................................................4–6

4.7 HoodSensor......................................................4–7

4.8 ShippingBracket...................................................4–8

4.9 MemoryComponents...............................................4–9

4.9.1 Overview...................................................4–9

4.9.2 RemovingtheMemoryExpansionBoard.........................4–10

4.9.3 RIMMInstallationGuidelines..................................4–11

4.9.4 RIMMSlotLocations........................................4–12

4.9.5 RIMMSocketConfigurations..................................4–12

4.9.6 InstallingaMemoryDevice...................................4–13

4.10 FrontBezel.....................................................4–14

4.11 BlankDriveBezel................................................4–15

4.12 FrontI/OBoardandPowerSwitchAssembly..........................4–16

4.13 EMI/CoolingShield..............................................4–17

4.14 MassStorageDevices.............................................4–18

4.14.1 DrivePositions ............................................4–18

4.14.2 SpareScrews..............................................4–19

4.14.3 RemovingaHardDrivefromBays5or6 .......................4–20

4.14.4 CD-ROMDrive............................................4–21

4.14.5 DisketteDrive.............................................4–22

4.15 ExpansionBoards................................................4–23

4.15.1 RemovinganExpansionBoard................................4–24

4.15.2 Installing an Expansion Board.................................4–25

4.16 AirBaffles......................................................4–26

4.16.1 MainBaffle...............................................4–26

4.16.2 Power Supply Air Baffle . . ...................................4–27

4.17 PowerSupply...................................................4–28

4.18 RemovableHardDriveCage.......................................4–29

4.18.1 RemovingtheRemovableHardDriveCage......................4–29

4.18.2 Removing a Hard Drive from the Removable

HardDriveCage(Bays1-3)..................................4–30

4.18.3 Installing a Hard Drive in the Removable

HardDriveCage(Bays1-3)..................................4–31

4.19 Heatsink and Processor 4–33

4.19.1 SeparatingtheHeatsink-ProcessorAssembly.....................4–33

HeatsinkCool-DownTime....................................4–33

HeatsinkWarm-UpTime.....................................4–33

4.19.2 RemovingtheHeatsinkandProcessor..........................4–34

4.19.3 Installing an Additional Processor..............................4–36

HardwareAbstractionLayer...................................4–36

AdditionalProcessorInstallation ...............................4–36

4.20 SystemBoard...................................................4–39

4.21 RearFan.......................................................4–40

4.22 ProcessorFan...................................................4–41

4.23 Speaker........................................................4–42

4.24 CardGuide.....................................................4–43

4.25 AirPlenumFan..................................................4–44

iv Maintenance & Service Guide

Page 5

5 Connectors and Jumpers

5.1 SystemBoard.....................................................5–1

5.1.1 ConnectorsandJumpers.......................................5–2

5.1.2 SystemBoardTroubleshootingLEDs.............................5–3

LED Based Hardware Troubleshooting Tables . . . ..................5–3

5.1.3 DisableandClearPasswordJumper..............................5–6

5.1.4 ClearingCMOS..............................................5–7

5.2 MassStorage......................................................5–8

5.2.1 HardDrives.................................................5–8

5.2.2 CD-ROMorDVD-ROMDrive..................................5–8

5.2.3 ZipDrive...................................................5–8

A SCSI Devices

SCSIGuidelines...................................................... A–1

Using the Multi-Mode SCSI Cable........................................ A–2

UsingSCSISelectwithSCSIDevices ..................................... A–3

SMART............................................................. A–3

B Specifications

SystemSpecifications.................................................. B–1

SystemInterrupts..................................................... B–1

Contents

Index

Maintenance & Service Guide v

Page 6

ABOUT THIS GUIDE

This Maintenance & Service Guide is a troubleshooting and repair guide that can be used for

reference when servicing the Compaq Evo Workstation W8000. Only authorized technicians

trained by Compaq should attempt to repair this equipment.

Compaq Computer Corporation reserves the right to make changes to the these models

without notice.

Symbols and Conventions

The following text and symbols mark special messages throughout this guide:

WARNING: Text set off in this manner indicates that failure to follow directions in the

Å

warning could result in bodily harm or loss of life.

CAUTION: Text set off in this manner indicates that failure to follow directions could result

Ä

in damage to equipment or loss of data.

Preface

Text set off in this manner presents commentary, sidelights, clarifying

✎

information, or specific instructions.

Maintenance & Service Guide vi

Page 7

Preface

Technician Notes

WARNING: Only authorized technicians trained by Compaq should attempt to repair this

Å

equipment. All troubleshooting and repair procedures are detailed to allow only

subassembly/module level repair. Because of the complexity of the individual boards and

subassemblies, no one should attempt to make repairs at the component level or to make

modifications to any printed wiring board. Improper repairs can create a safety hazard.

Any indications of component replacement or printed wiring board modifications may void

any warranty.

WARNING: To reduce the risk of electric shock or damage to the equipment:

Å

■ Do not disable the power grounding plug. The grounding plug is an important safety

feature.

■ Plug the power cord into a grounded (earthed) electrical outlet that is easily

accessible at all times.

■ Disconnect the power from the computer by unplugging the power cord either from

the electrical outlet or the computer.

CAUTION: To properly ventilate your system, you must provide at least 3 inches (7.6 cm)

Ä

of clearance at the front and back of the computer.

Locating Additional Information

The following documentation is available to support these products:

■ User Documentation

■ Technical Training Guides

■ Compaq Service Advisories and Bulletins

■ Compaq QuickFind

■ Technical Reference Guide

■ Compaq Quick Reference Guide

■ Compaq Service Reference Guide

■ Compaq Quick Troubleshooting Guide

vii Maintenance & Service Guide

Page 8

Product Description

This chapter describes the model offerings and features of the Compaq Evo

Workstation W8000.

1

Maintenance & Service Guide 1–1

Page 9

Product Description

1.1 Product Features

The W8000 ships with a mouse and keyboard. Some models are also equipped with a

CD-ROM, DVD-ROM, or CDRW drive. A Compaq color monitor or other compatible

monitor does not ship with the workstation.

1.1.1 Front Panel Controls and LEDs

Ref. Component/Function Ref. Component/Functions

CD-ROM headphone connector

1

2

CD-ROM volume

3

Diskette drive activity light

4

Powe r button

5

Hard drive activity light

6

Powe r-on ligh t

7

Headphone connector

8

Two Universal Serial Bus (USB)

connectors

9

CD-ROM eject button

-

CD-ROM emergency eject opening

q

CD-ROM activity light

w

Diskette drive eject button

e

Network link/activity light

r

Microphone connector

1–2 Maintenance & Service Guide

Page 10

1.1.2 Rear Panel Connectors

Product Description

Ref. Component/Function Ref. Component/Functions

Power cord connector

1

Mouse connector

2

Keyboard connector

3

Ultra160 SCSI connector

4

Two Universal Serial Bus (USB)

5

connectors

Line-out audio connector

6

Line-in audio connector

7

Serial connector B

8

Parallel connector

9

Serial connector A

:

Network Link/Activity LED

q

Ethernet connector

w

Network Connection Speed LED

e

Video (monitor) connector

r

Maintenance & Service Guide 1–3

Page 11

Product Description

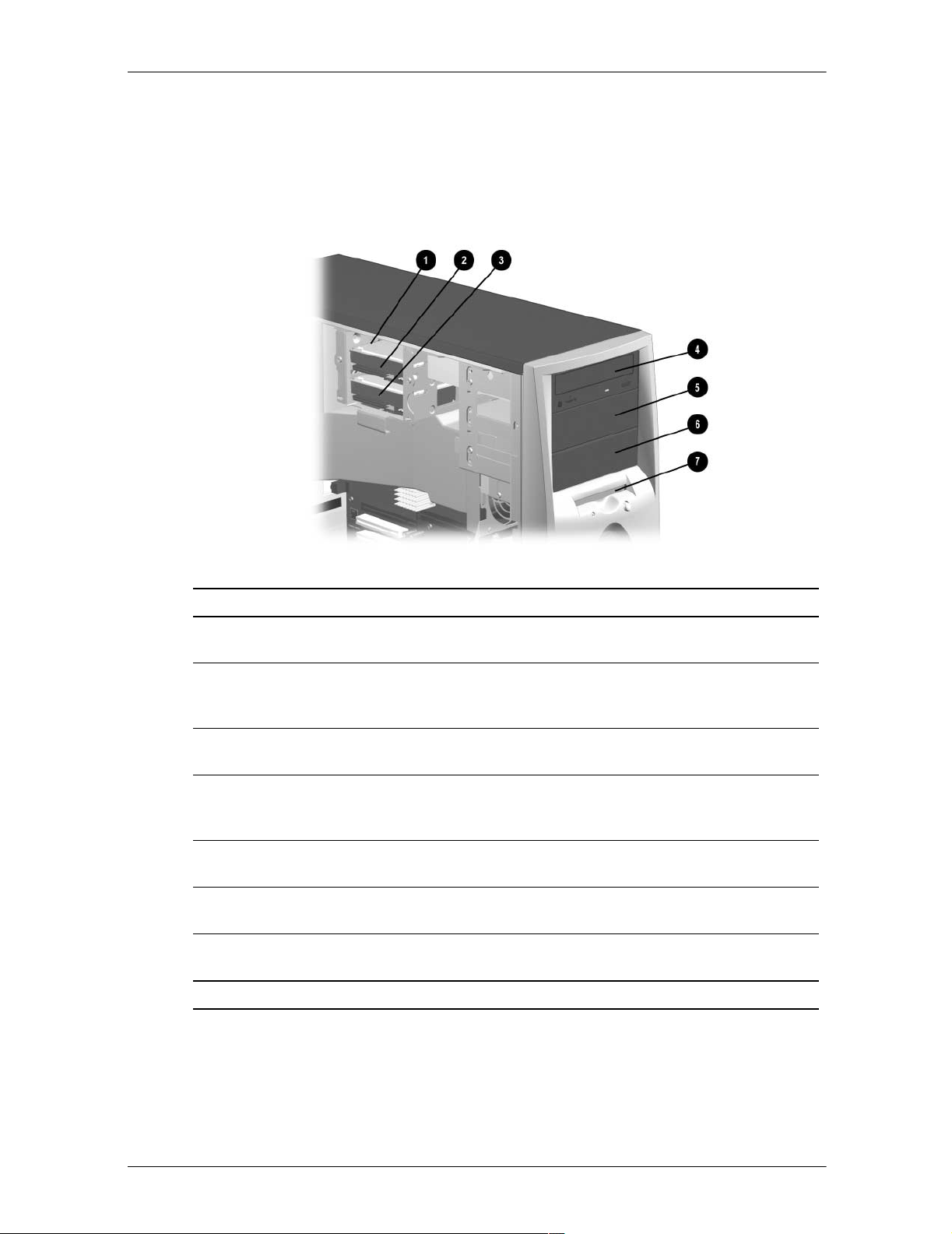

1.1.3 Drive Positions

The workstation provides seven drive bays. Bays 1 through 3 are located in the 3.5-inch

removable hard drive cage, which is located behind the side access panel of the workstation.

Drive bays 4 through 7 are located on the front of the workstation. The drives support

various drive configurations.

Item Component Description

1

2

3

4

5

6

7

*An optional Zip drive can be installed in bay 5 or 6.

Bay 1 Part of the removable hard drive cage. A 3.5-inch, third-height

bay that supports a 1.0-inch hard drive or a 1.6-inch hard drive.

Bay 2 Part of the removable hard drive cage. A 3.5-inch, third-height

bay that supports a 1.0-inch hard drive. Bay 2 is not available

when a 1.6-inch hard drive is installed in either bay 1 or bay 3.

Bay 3 Part of the removable hard drive cage. A 3.5-inch, third-height

bay that supports a 1.0-inch hard drive or a 1.6-inch hard drive.

Bay 4 5.25-inch, half-height bay that supports 1.0-inch or 1.6-inch

storage devices. Either a CD-ROM drive or DVD-ROM drive is

shipped in bay 4.

Bay 5* 5.25-inch, half-height bay that supports 1.0-inch or 1.6-inch

storage devices.

Bay 6* 5.25-inch, half-height bay that supports 1.0-inch or 1.6-inch

storage devices.

Bay 7 3.5-inch, third-height bay that supports a 1.0-inch device. A

standard 3.5-inch diskette drive is shipped in bay 7.

1–4 Maintenance & Service Guide

Page 12

1.2 Serial Number Location

Provide the workstation serial number to Compaq whenever you request information or

order spare parts. There are two serial number locations on the unit. One is located on the top

front corner of the access panel. The other is on the rear of the unit below the power supply.

For asset control, the serial number is also embedded in the Electrically Erasable

Programmable Read Only Memory (EEPROM) on the system board. If the system board is

replaced with a spare part from Compaq, an invalid serial number condition will be reported

during the Power-On Self-Tests (POST). To clear the condition, re-enter the original serial

number through Computer Setup.

Product Description

Maintenance & Service Guide 1–5

Page 13

Spare Parts

Spare parts are listed and illustrated on the Illustrated Parts Map, spare part number

229782-001.

2

Maintenance & Service Guide 2–1

Page 14

Removal & Replacement Preliminaries

This chapter provides general service information for the workstation. Adherence to the

procedures and precautions described in this chapter is essential for proper service.

CAUTION: When the workstation is plugged into an AC power source there is always

Ä

voltage applied to the system board. You must disconnect the power cord from the power

source before opening the workstation to prevent system board or component damage.

3.1 Electrostatic Discharge Information

A sudden discharge of static electricity from your finger or other conductor can destroy

static-sensitive devices or microcircuitry. Often the spark is neither felt nor heard, but

damage occurs. An electronic device exposed to electrostatic discharge (ESD) may not

appear to be affected at all and can work perfectly throughout a normal cycle. The device

may function normally for a while, but it has been degraded in the internal layers, reducing

its life expectancy.

Circuitry built into many integrated circuits provide some protection, but in many cases, the

discharge contains enough power to alter device parameters or melt silicon junctions.

3

Maintenance & Service Guide 3–1

Page 15

Removal & Replacement Preliminaries

3.1.1 Generating Static

The following table shows that:

■ Different activities generate different amounts of static electricity.

■ Static electricity increases as humidity decreases.

Event 55% 40% 10%

Walking across carpet 7,500 V 15,000 V 35,000 V

Walking across vinyl floor 3,000 V 5,000 V 12,000 V

Motions of bench worker 400 V 800 V 6,000 V

Removing DIPs* from plastic tube 400 V 700 V 2,000 V

Removing DIPs* from vinyl tray 2,000 V 4,000 V 11,500 V

Removing DIPs* from Styrofoam 3,500 V 5,000V 14,500 V

Removing bubble pack from PCB 7,000 V 20,000 V 26,500 V

Packing PCBs in foam-lined box 5,000 V 11,000 V 21,000 V

Relative Humidity

*These are then multi-packaged inside plastic tubes, trays, or Styrofoam.

700 volts can degrade a product.

✎

3.1.2 Preventing Electrostatic Damage to Equipment

Many electronic components are sensitive to ESD. Circuitry design and structure determine

the degree of sensitivity. The following proper packaging and grounding precautions are

necessary to prevent damage to electric components and accessories.

■ To avoid hand contact, transport products in static-safe containers such as tubes, bags,

or boxes.

■ Protect all electrostatic parts and assemblies with conductive or approved containers or

packaging.

■ Keep electrostatic sensitive parts in their containers until they arrive at static-free

stations.

■ Place items on a grounded surface before removing them from their container.

■ Always be properly grounded when touching a sensitive component or assembly.

■ Avoid contact with pins, leads, or circuitry.

■ Place reusable electrostatic-sensitive parts from assemblies in protective packaging or

conductive foam.

3–2 Maintenance & Service Guide

Page 16

Removal & Replacement Preliminaries

3.1.3 Personal Grounding Methods and Equipment

Use the following equipment to prevent static electricity damage to equipment:

■ Wrist straps are flexible straps with a maximum of one-megohm +/- 10% resistance in

the ground cords. Toprovide proper ground, a strap must be worn snug against bare skin.

The ground cord must be connected and fit snugly into the banana plug connector on the

grounding mat or workstation.

■ Heel straps/Toe straps/Boot straps can be used at standing workstations and are

compatible with most types of shoes or boots. On conductive floors or dissipative floor

mats, use them on both feet with a maximum of one-megohm +/- 10% resistance

between the operator and ground.

Static Shielding Protection Levels

Method Voltage

Antistatic plastic 1,500

Carbon-loaded plastic 7,500

Metallized laminate 15,000

3.1.4 Grounding the Work Area

To prevent static damage to the work area, use the following precautions:

■ Cover the work surface with approved static-dissipative material. Provide a wrist strap

connected to the work surface and properly grounded tools and equipment.

■ Use static-dissipative mats, foot straps, or air ionizers to give added protection.

■ Handle electrostatic sensitive components, parts, and assemblies by the case or PCB

laminate. Handle them only at static-free work areas.

■ Turn off power and input signals before inserting and removing connectors or test

equipment.

■ Use fixtures made of static-safe materials when fixtures must directly contact dissipative

surfaces.

■ Keep work area free of nonconductive materials such as ordinary plastic assembly aids

and Styrofoam.

■ Use field service tools, such as cutters, screwdrivers, and vacuums, that are conductive.

Maintenance & Service Guide 3–3

Page 17

Removal & Replacement Preliminaries

3.1.5 Recommended Materials and Equipment

Materials and equipment that are recommended for use in preventing static electricity

include:

■ Antistatic tape

■ Antistatic smocks, aprons, or sleeve protectors

■ Conductive bins and other assembly or soldering aids

■ Conductive foam

■ Conductive tabletop workstations with ground cord of one-megohm +/- 10% resistance

■ Static-dissipative table or floor mats with hard tie to ground

■ Field service kits

■ Static awareness labels

■ Wrist straps and footwear straps providing one-megohm +/- 10% resistance

■ Material handling packages

■ Conductive plastic bags, opaque shielding bags, transparent metallized shielding bags

■ Conductive plastic tubes

■ Conductive tote boxes

■ Transparent shielding tubes

3–4 Maintenance & Service Guide

Page 18

3.2 Routine Care

3.2.1 General Cleaning Safety Precautions

1. Never use solvents or flammable solutions to clean the workstation.

2. Never immerse any parts in water or cleaning solutions; apply any liquids to a clean

cloth and then use the cloth on the component.

3. Always unplug the workstation when cleaning with liquids or damp cloths.

4. Always unplug the workstation before cleaning the keyboard, mouse, or air vents.

5. Disconnect the keyboard before cleaning it.

6. Wear safety glasses equipped with side shields when cleaning the keyboard.

3.2.2 Cleaning the Chassis Exterior

Follow all safety precautions in Section 3.2.1 before cleaning the workstation.

■ To clean the workstation case, follow the procedures described below:

■ To remove light stains or dirt, use plain water with a clean, lint-free cloth or swab.

Removal & Replacement Preliminaries

■ For stronger stains, use a mild dishwashing liquid diluted with water. Rinse well by

wiping it with a cloth or swab dampened with clear water.

■ For stubborn stains, use isopropyl (rubbing) alcohol. No rinsing is needed as the alcohol

will evaporate quickly and not leave a residue.

■ After cleaning, always wipe the unit with a clean, lint-free cloth.

■ Occasionally clean the air vents on the workstation. Lint and other foreign matter can

block the vents and limit the airflow.

3.2.3 Cleaning the Keyboard

Follow all safety precautions in Section 3.2.1 before cleaning the keyboard.

To clean the tops of the keys or the keyboard body, follow the procedures described in

Section 3.2.2.

When cleaning debris from under the keys, review all rules in Section 3.2.1 before following

these procedures:

CAUTION: Use safety glasses equipped with side shields before attempting to clean

Ä

debris from under the keys.

■ Visible debris underneath or between the keys may be removed by vacuuming or

shaking.

■ Canned, pressurized air may be used to clean debris from under the keys. Caution should

be used as too much air pressure can dislodge lubricants applied under the wide keys.

■ If you remove a key, use a specially designed key puller to prevent damage to the keys.

This tool is available through many electronic supply outlets.

Maintenance & Service Guide 3–5

Page 19

Removal & Replacement Preliminaries

CAUTION: Never remove a wide leveled key (like the space bar) from the keyboard. If

Ä

these keys are improperly removed or installed, the keyboard may not function properly.

■ Cleaning under a key may be done with a swab moistened with isopropyl alcohol and

squeezed out. Be careful not to wipe away lubricants necessary for proper key functions.

Use tweezers to remove any fibers or dirt in confined areas. Allow the parts to air dry

before reassembly.

3.2.4 Cleaning the Monitor

■ Wipe the monitor screen with a clean cloth moistened with water or with a towelette

designed for cleaning monitors. Do not use sprays or aerosols directly on the screen, the

liquid may seep into the housing and damage a component. Never use solvents or

flammable liquids on the monitor.

■ To clean the monitor body follow the procedures in Section 3.2.2.

3.2.5 Cleaning the Mouse

Before cleaning the mouse, ensure that the power to the workstation is turned off.

■ Clean the mouse ball by first removing the retaining plate and the ball from the housing.

Pull out any debris from the ball socket and wipe the ball with a clean dry cloth before

reassembly.

■ To clean the mouse body, follow the procedures in Section 3.2.2.

3.3 Service Considerations

Listed below are some of the considerations that you should keep in mind during the

disassembly and assembly of the workstation.

3.3.1 Power Supply Fan

The power supply fan is a variable-speed fan based on the temperature in the power supply.

CAUTION: The cooling fan is off only when the workstation is turned off or the power

Ä

cable has been disconnected.

The cooling fan is always on in all other instances (when the workstation is either in the

“On,” “Standby,” or “Suspend” mode).

You must disconnect the power cord from the power source before opening the

workstation to prevent system board or component damage.

3–6 Maintenance & Service Guide

Page 20

3.3.2 Tools and Software Requirements

To service the workstation, you need the following:

■ Torx T-15 screwdriver (Compaq screwdriver with bits, PN 161946-001)

■ Phillips screwdriver (may sometimes be used in place of the Torx screwdriver)

■ Diagnostics software

■ Compaq tamper-resistant T-15 wrench (Smart Cover FailSafe Key, PN 166527-001) or

Compaq tamper-resistant bits (Smart Cover FailSafe Key, PN 166527-002)

3.3.3 Screws

The screws used in the workstation are not interchangeable. They may have standard or

metric threads and may be of different lengths. If an incorrect screw is used during the

reassembly process, it can damage the unit. Compaq strongly recommends that all screws

removed during disassembly be kept with the part that was removed, then returned to their

proper locations.

As each subassembly is removed from the workstation, it should be placed away

✎

from the work area to prevent damage.

Removal & Replacement Preliminaries

3.3.4 Cables and Connectors

Most cables used throughout the unit are flat, flexible cables. These cables must be handled

with care to avoid damage. Apply only the tension required to seat or unseat the cables

during insertion or removal from the connector. Handle cables by the connector whenever

possible. In all cases, avoid bending or twisting the cables, and ensure that the cables are

routed in such a way that they cannot be caught or snagged by parts being removed or

replaced.

CAUTION: When servicing this workstation, ensure that cables are placed in their proper

Ä

location during the reassembly process. Improper cable placement can damage the

workstation.

3.3.5 Hard Drives

Handle hard drives as delicate precision components, avoiding all physical shock and

vibration. This applies to failed drives as well as replacement spares.

■ If a drive must be mailed, place the drive in a bubble-pack mailer or other suitable

protective packaging and label the package “Fragile: Handle With Care.”

■ Do not remove hard drives from the shipping package for storage. Keep hard drives in

their protective packaging until they are actually mounted in the CPU.

■ Avoid dropping drives from any height onto any surface.

■ If you are inserting or removing a hard drive, turn off the workstation. Do not remove a

hard drive while the workstation is on or in standby mode.

Maintenance & Service Guide 3–7

Page 21

Removal & Replacement Preliminaries

■ Before handling a drive, ensure that you are discharged of static electricity. While

handling a drive, avoid touching the connector. For more information about preventing

electrostatic damage, refer to Section 3.1, “Electrostatic Discharge.”

■ Do not use excessive force when inserting a drive.

■ Avoid exposing a hard drive to liquids, temperature extremes, or products that have

magnetic fields such as monitors or speakers.

3.3.6 Lithium Coin Cell Battery

The battery that comes with the workstation provides power to the real-time clock and has a

minimum lifetime of about three years.

See Chapter 4, “Removal and Replacement Procedures,” for instructions on the replacement

procedures.

WARNING: This workstation contains a lithium battery. There is a risk of fire and

Å

chemical burn if the battery is handled improperly. Do not disassemble, crush, puncture,

short external contacts, dispose in water or fire, or expose it to temperatures higher than

140°F (60°C).

CAUTION: Batteries, battery packs, and accumulators should not be disposed of

Ä

together with the general household waste.

3–8 Maintenance & Service Guide

Page 22

Removal & Replacement Procedures

This chapter provides general service information for the workstation. Adherence to the

procedures and precautions described in this chapter is essential for proper service.

After completing all necessary removal and replacement procedures, run the Diagnostics

utility to verify that all components operate properly.

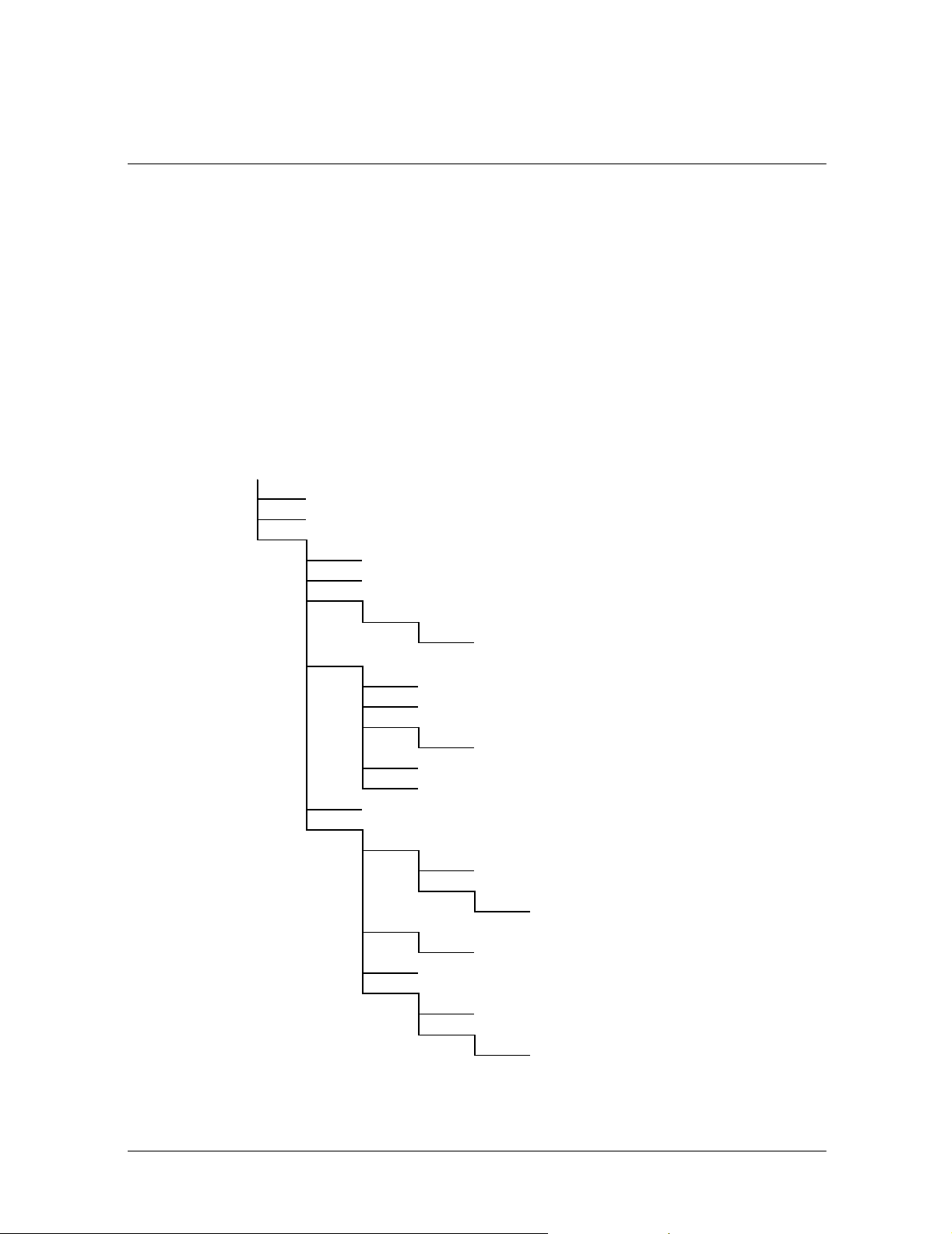

4.1 Disassembly Sequence Chart

Use the chart below to determine the disassembly sequence for removing components from

the workstation.

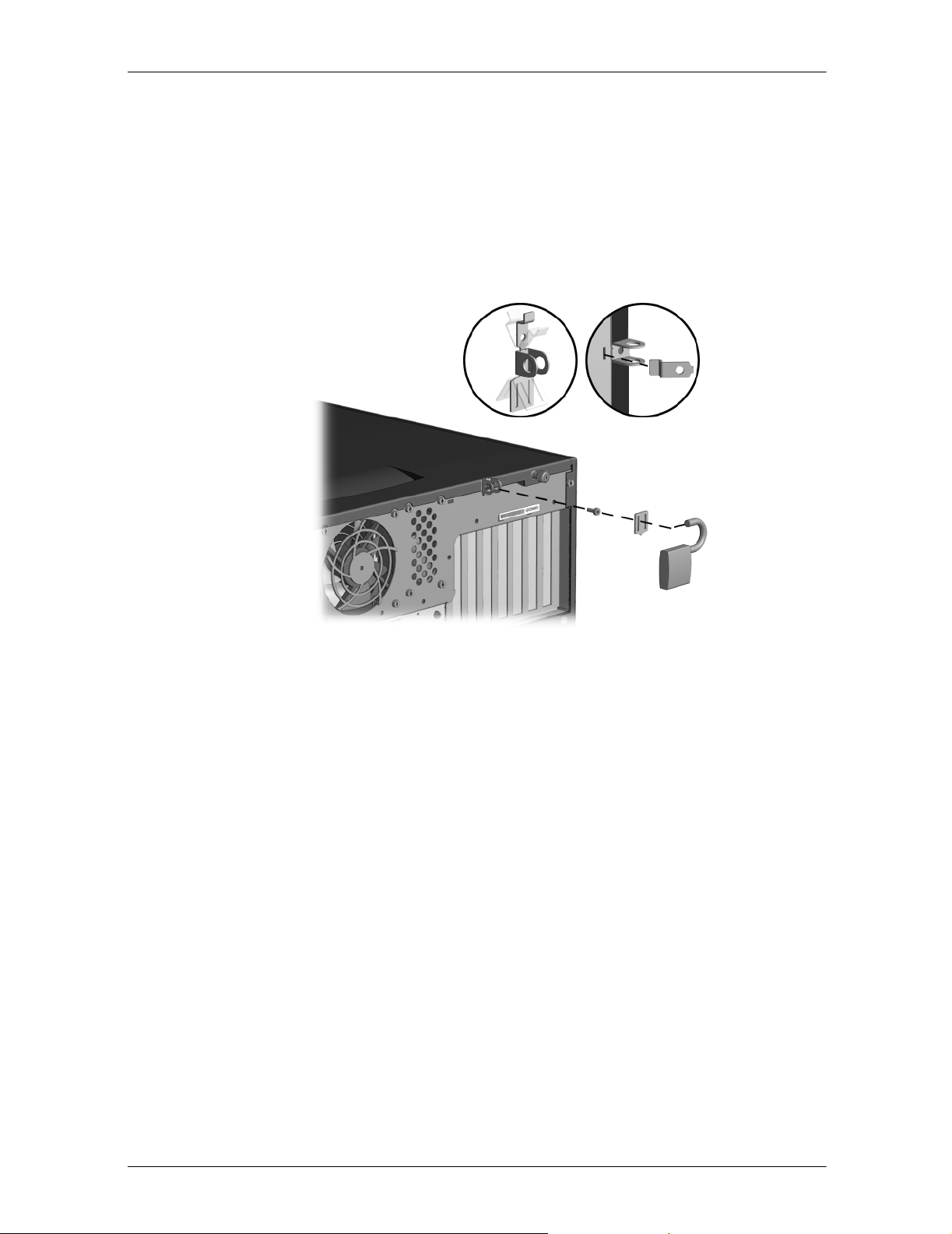

4.3 Cable Lock

4.4 Workstation Feet

4.5 Access Panel

4.6 Battery

4.7 Hood Sensor

4.8 Shipping Bracket

4.9.2

4.9.6 RIMM Installation

4.10 Front Bezel

4.11 Blank Drive Bezel

4.12 Front I/O Board and Power Switch Assembly

4.13 EMI/Cooling Shield

4.14.3 Hard Drive from Bays 5 or 6

4.14.4 CD-ROM Drive

4.14.5 Diskette Drive

4.15.1

4.16.1 Main Air Baffle

4.16.2 Power Supply Air Baffle

4.17 Power Supply

4.18.1 Removable Hard Drive Cage

4.18.2 Hard Drive from Removable Hard Drive Cage

4.19.2 Heatsink and Processor

4.20 System Board*

4.21 Rear Fan

4.22 Processor Fan

4.23 Speaker

4.24

4.25 Air Plenum Fan

Expansion Boards*

Memory Expansion Board*

Card Guide*

4

*These steps are interdependent.

Maintenance & Service Guide 4–1

Page 23

Removal & Replacement Procedures

4.2 Preparation for Disassembly

See Chapter 3, “Removal and Replacement Preliminaries,” for initial procedures.

1. Close any open software applications.

2. Exit the operating system.

3. Remove any diskette or compact disc from the workstation.

4. Turn off the workstation and any peripheral devices that are connected to it.

CAUTION: Turn off the workstation before disconnecting any cables.

Ä

5. Disconnect the power cord from the grounded AC outlet and then from the workstation.

CAUTION: The power supply in the W8000 has an auxiliary power section. This section

Ä

is always active as long as the unit is plugged into a live AC outlet. Be sure to turn off the

switch and unplug the power cord before performing any service work.

CAUTION: Electrostatic discharge can damage electronic components of the

Ä

workstation. Before beginning these procedures, be sure you are properly grounded. See

Chapter 3, “Removal and Replacement Preliminaries” for more information.

6. Disconnect all peripheral device cables from the workstation.

During disassembly, label each cable as you remove it, noting its position and

✎

routing. Keep all screws with the units removed.

In some of the removal procedures in this chapter, you will be asked to place the

✎

workstation on its side when servicing certain internal components.

CAUTION: The screws used in the workstation are of different thread sizes and lengths;

Ä

using the wrong screw in an application may damage the unit.

4–2 Maintenance & Service Guide

Page 24

4.3 Cable Lock

The workstation comes standard with a cable lock provision for attaching a padlock and/or

cable lock. If installed, the locks must be removed before accessing internal components.

1. Unlock and remove the cable lock or the padlock.

Removal & Replacement Procedures

2. Remove the security bracket (plate) seated over the cable lock bracke

3. Unfasten the retaining screw to release the cable lock bracket.

t.

Maintenance & Service Guide 4–3

Page 25

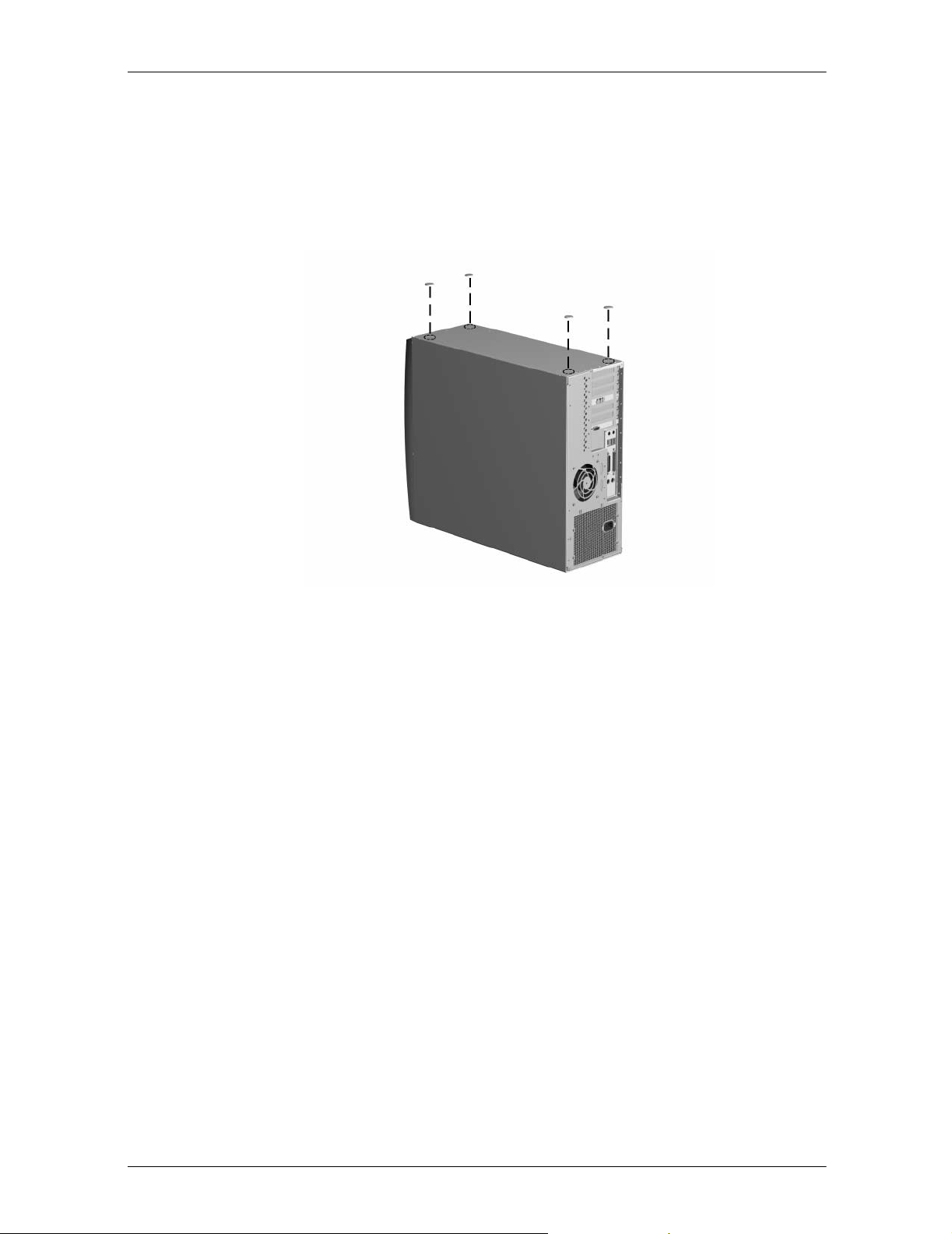

Removal & Replacement Procedures

4.4 Workstation Feet

Four (4) rubber feet are mounted to the chassis, as shown below. No parts have to be

removed to access the feet. The replacement feet have an adhesive surface and are shipped

with a protective backing in place. Remove the backing from the feet before installation.

If necessary, remove the old feet and remove any adhesive residue from the chassis.

To replace the feet, reverse the above procedure.

4–4 Maintenance & Service Guide

Page 26

4.5 Access Panel

CAUTION: Do not operate the workstation with the access panel removed. The panel is

Ä

an integral part of the cooling system; removing it while the system is running may

adversely affect data integrity and the life of your system.

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

CAUTION: Before removing the access panel, ensure that the workstation is turned off,

Ä

and all cables are disconnected from the back of the workstation.

2. Loosen the four rear panel thumbscrews 1 and slide off the access panel 2.

Removal & Replacement Procedures

WARNING: To reduce the risk of personal injury from hot surfaces, allow the internal

Å

system components to cool before touching them.

WARNING: When replacing the access panel, be sure to tighten all four thumbscrews.

Å

To replace the access panel, reverse the above procedure.

Maintenance & Service Guide 4–5

Page 27

Removal & Replacement Procedures

4.6 Battery

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

WARNING: Power is continuous to the system board and power supply even when the

Å

power switch is turned off. To prevent damage to the unit, disconnect the power cord from

the power source or the unit before beginning disassembly procedures.

2. Remove the access panel (Section 4.5).

3. Locate the battery on the system board. If there are expansion boards installed, you may

need to remove them to gain access to the battery.

4. Lift the battery out of the holder.

5. Slide the replacement battery into position with the positive side up. The battery holder

automatically secures the battery in the proper position.

6. If you removed expansion boards, reinstall them now.

7. Replace the access panel.

8. Reassemble the workstation.

9. Reconnect the AC power cord and turn on the workstation.

10. Reset the date and time, your passwords, and any special system setups, using

Compaq Computer Setup.

WARNING: This workstation contains a lithium-ion battery pack. There is a risk of fire

Å

and chemical burn if the battery pack is handled improperly. Do not disassemble, crush,

puncture, short external contacts, dispose in water or fire, or expose it to temperatures

higher than 60°C (140°F).

In North America, dispose of nickel metal hydride or lithium-ion batteries by taking advantage of

N

the Compaq battery recycling program. You will be provided with a postage-paid battery pack

mailer preaddressed to a reclamation facility where the metals are recycled. Call the telephone

number listed for your location in the Contacting Customer Support guide for more information.

In Europe, do not dispose of batteries with general household waste. Dispose of or recycle them

by using the public collection system or returning them to Compaq, your authorized Compaq

partners, or their agents.

4–6 Maintenance & Service Guide

Page 28

4.7 Hood Sensor

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

CAUTION: Before removing the access panel, ensure that the workstation is turned off,

Ä

and all cables are disconnected from the back of the workstation.

2. Remove the access panel (Section 4.5).

3. Unplug the cable from the system board 1.

4. Slide the sensor toward the front side of the workstation 2.

5. Remove the sensor from the chassis 3.

Removal & Replacement Procedures

To replace the hood sensor, reverse the above procedure.

Maintenance & Service Guide 4–7

Page 29

Removal & Replacement Procedures

4.8 Shipping Bracket

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

CAUTION: Before removing the access panel, ensure that the workstation is turned off,

Ä

and all cables are disconnected from the back of the workstation.

2. Remove the access panel (Section 4.5).

3. Remove the four screws that connect shipping bracket to the front of the chassis.

4. Remove the shipping bracket from the chassis.

To replace the shipping bracket, reverse the above procedure.

4–8 Maintenance & Service Guide

Page 30

4.9 Memory Components

The W8000 includes a memory expansion board that must be removed from the system

board to remove and replace memory modules.

4.9.1 Overview

The W8000 has two Direct Rambus memory channels and uses Error Checking and

Correcting (ECC) Direct Rambus Inline Memory Modules (RIMMS). Continuity RIMMs

(CRIMMs) are also available to populate empty RIMM slots.

Dual Direct Rambus memory channels operate on the following three principles:

1. Dual channels maximize performance by doubling the speed at which data in transferred

to and from memory, compared to single channel systems. Memory hubs divide each

main channel into two sub-channels. For example, channel A is divided into channel

A-top and channel A-bottom, and channel B is divided into channel B-top and channel

B-bottom. Each sub-channel consists of two RIMM sockets.

2. Dual channels operate in unison, not independently, thus identical RIMMs must be

installed in pairs across channels. For example, if you install a RIMM in RIMM socket 3

(channel B-top), you must also install an identical RIMM in RIMM socket 4 (channel

A-top).

Removal & Replacement Procedures

3. Dual channels must have electrical continuity for your system to boot. For example, if

you install identical RIMMs in RIMM sockets 3 and 4, but fail to install CRIMMs in

RIMM sockets 1 and 2, the continuity will be broken and your system will not boot.

4. For optimal performance, RIMMs should be placed in the sockets closest to the memory

repeater hubs. For example, having RIMMs in sockets 3 & 4 and CRIMMs in sockets

1 & 2 will result in better performance than having RIMMs in sockets 1 & 2 and

CRIMMs in sockets 3 & 4.

Maintenance & Service Guide 4–9

Page 31

Removal & Replacement Procedures

4.9.2 Removing the Memory Expansion Board

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

2. Remove the access panel (Section 4.5).

3. Locate the memory expansion board that is connected to the system board.

4. Remove the torx screw on the back of the metal slot cover that secures the memory

board to the expansion board slot.

5. To release the memory expansion board, press downward on the plastic release latch 1

that holds the memory expansion board in the card guide.

6. Carefully remove the memory board from the memory expansion board socket 2.

To install the memory expansion board, reverse the above procedure.

4–10 Maintenance & Service Guide

Page 32

4.9.3 RIMM Installation Guidelines

WARNING: To reduce the risk of personal injury when replacing or removing RIMMs,

Å

allow the module being removed from the RIMM slot sufficient time to cool. RIMM

temperatures can reach 100°C (212°F).

CAUTION: When handling a RIMM, be careful not to touch any of the contacts. Doing so

Ä

may damage the module.

CAUTION: Static electricity can damage the electronic components of the workstation or

Ä

optional boards. Before beginning these memory upgrade procedures, ensure that you

are discharged of static electricity by briefly touching a grounded metal object.

When installing RIMMs, you must follow the guidelines listed below or the workstation will

not function:

1. A RIMM can be installed only one way. Be sure to match the two key slots on the RIMM

with the tabs on the RIMM socket. Push the RIMM down into the RIMM socket,

ensuring that it is fully inserted and properly seated, and that the retaining arms are

locked in place.

Removal & Replacement Procedures

2. CRIMMs must be installed i n all empty RIMM sockets on channels that are used. The

CRIMMs are removed when you populate the sockets with RIMMs. For examples of the

correct configuration sequence (Section 4.9.5).

3. Install RIMMs in pairs across both memory channels. Each RIMM socket populated

with a RIMM or CRIMM on Channel A must be populated with an identical RIMM or

CRIMM on Channel B.

4. Do not exceed 32 Direct RDRAM devices on each Direct Rambus memory channel. A

label on the RIMM will indicate the number and speed of Direct RDRAM devices on the

RIMM.

The number of Direct RDRAM devices on a RIMM cannot be changed.

✎

5. Use only 800-MHz RIMMs.

6. Use only RIMMs that have been tested and approved by Compaq. Not all RIMMs meet

the Compaq standard for quality and reliability.

Only 800-MHz RIMMs can be used in this workstation. The workstation will

✎

not function if RIMMs of different speeds are inserted.

Maintenance & Service Guide 4–11

Page 33

Removal & Replacement Procedures

4.9.4 RIMM Slot Locations

The W8000 ships with an eight-RIMM socket memory expansion board (two RIMM sockets

per memory channel).

Identifier RIMM Socket Memory Channel

1

2

3

4

5

6

7

8

RIMM Socket 1 Channel B-Top

RIMM Socket 2 Channel A-Top

RIMM Socket 3 Channel B-Top

RIMM Socket 4 Channel A-Top

RIMM Socket 5 Channel B-Bottom

RIMM Socket 6 Channel A-Bottom

RIMM Socket 7 Channel B-Bottom

RIMM Socket 8 Channel A-Bottom

4.9.5 RIMM Socket Configurations

When installing RIMMs on the eight-RIMM slot memory board, you must follow one of the

following four configurations.

CRIMMs must be installed in all unpopulated RIMM sockets on channels

✎

being used.

Config 1

Location

1 Pair

RIMMs

Config 2

2 Pair

RIMMs

Config 3

3 pairs

RIMMs

Config 4

4 pairs

RIMMS

RIMM Sockets 1 and 2 CRIMM CRIMM RIMM RIMM

RIMM Sockets 3 and 4 RIMM RIMM RIMM RIMM

RIMM Sockets 5 and 6 Empty RIMM RIMM RIMM

RIMM Sockets 7 and 8 Empty CRIMM CRIMM RIMM

4–12 Maintenance & Service Guide

Page 34

4.9.6 Installing a Memory Device

WARNING: To reduce the risk of personal injury when replacing or removing RIMMs,

Å

allow the module being removed from the RIMM slot sufficient time to cool. RIMM

temperatures can reach 100°C (212°F).

CAUTION: When handling a RIMM, be careful not to touch any of the contacts. Doing so

Ä

may damage the module.

CAUTION: Static electricity can damage the electronic components of the workstation or

Ä

optional boards. Before beginning these memory upgrade procedures, ensure that you

are discharged of static electricity by briefly touching a grounded metal object.

Before installing additional RIMMs, read “RIMM Installation Guidelines” in this chapter.

CRIMMs must be installed in all unpopulated RIMM sockets on channels

✎

being used.

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

Removal & Replacement Procedures

2. Remove the access panel (Section 4.5).

3. Remove the memory expansion board (Section 4.9.2).

4. Press outward on the two RIMM slot retainer latches 1.

5. Place the RIMM in the appropriate RIMM socket 2 ensuring that it is fully inserted and

properly seated.

CAUTION: Be sure to follow the correct configuration guidelines or your system will not

Ä

function.

6. Press inward on the two retainer latches 3 to secure the RIMM in the socket.

To remove a memory module from a RIMM slot, reverse the above procedure.

Maintenance & Service Guide 4–13

Page 35

Removal & Replacement Procedures

4.10 Front Bezel

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

CAUTION: Before removing the access panel, ensure that the workstation is turned off,

Ä

and all cables are disconnected from the back of the workstation.

2. Remove the access panel (Section 4.5).

3. Press the two front bezel release latches 1 and remove the front bezel 2.

To replace the front bezel, reverse the above procedure.

4–14 Maintenance & Service Guide

Page 36

4.11 Blank Drive Bezel

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

CAUTION: Before removing the access panel, ensure that the workstation is turned off,

Ä

and all cables are disconnected from the back of the workstation.

2. Remove the access panel (Section 4.5).

3. Remove the front bezel (Section 4.10).

4. Pinch together the retainer snaps on the back of the front bezel 1. This allows the bezel

blank to move pass the retainer snaps.

5. Rotate the bezel blank outward, detaching it from the front bezel 2.

Removal & Replacement Procedures

To replace the blank drive bezel, reverse the above procedure.

Maintenance & Service Guide 4–15

Page 37

Removal & Replacement Procedures

4.12 Front I/O Board and Power Switch Assembly

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

2. Remove the access panel (Section 4.5).

3. Remove the front bezel (Section 4.10).

4. Disconnect the cable from the system board 1.

5. Remove the four screws connecting the cage to the chassis 2, then remove the cage from

the chassis 3.

6. Disconnect the cable from the I/O board mounted in the cage 4.

7. Thread the cable though the hole in the front of the chassis 5 and through the hole in the

side of the air plenum.

8. Remove the four screws connecting the I/O board to the cage 6.

9. Remove the I/O board from the cage 7.

To replace the assembly, reverse the above procedure.

4–16 Maintenance & Service Guide

Page 38

4.13 EMI/Cooling Shield

An EMI/cooling shield covers bays 5 and 6 to provide proper cooling and EMI protection.

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

CAUTION: Before removing the access panel, ensure that the workstation is turned off,

Ä

and all cables are disconnected from the back of the workstation.

2. Remove the access panel (Section 4.5).

3. Remove the front bezel (Section 4.10).

4. Remove the two screws that connect the EMI/cooling shield to the front of the chassis.

5. Remove the EMI/cooling shield from the drive slot.

Removal & Replacement Procedures

Important: Replace the shield after a hard drive is installed in the bay.

To replace an EMI/cooling shield, reverse the above procedure.

Maintenance & Service Guide 4–17

Page 39

Removal & Replacement Procedures

4.14 Mass Storage Devices

4.14.1 Drive Positions

The W8000 can house up to seven mass storage devices. The following illustration identifies

the physical drive locations. Refer to the corresponding table for a list of the recommended

drive configurations.

Item Component Description

1

2

3

4

5

6

Bay 1 Part of the removable hard drive cage. A 3.5-inch, third-height

bay that supports a 1.0-inch hard drive or a 1.6-inch hard drive.

Bay 2 Part of the removable hard drive cable. A 3.5-inch, third-height

bay that supports a 1.0-inch hard drive. Bay 2 is not available

when a 1.6-inch hard drive is installed ion either bay 1 or bay 3.

Bay 3 Part of the removable hard drive cage. A 3.5-inch, third-height

bay that supports a 1.0-inch hard drive or a 1.6-inch hard drive.

Bay 4 5.25-inch, half-height bay that supports 1.0-inch or 1.6-inch

storage devices. Either a CD-ROM drive or DVD-ROM drive is

shipped in bay 4.

Bay 5* 5.25-inch, half-height bay supporting 1.0-inch or 1.6-inch storage

devices.

Bay 6*

5.25-inch, half-height bay supporting 1.0-inch or 1.6-inch

storage devices.

7

*An optional Zip drive can be installed in bay 5 or 6.

CAUTION: If a drive is not installed in bays 5 or 6 or if the bays are empty, be sure an

Ä

EMI/cooling shield is installed to ensure proper airflow and cooling.

Bay 7 3.5-inch, third-height bay that supports a 1.0-inch device. A

standard 3.5-inch diskette drive is shipped in bay 7.

4–18 Maintenance & Service Guide

Page 40

4.14.2 Spare Screws

A total of 17 extra spare screws are provided on the side of the air plenum. The top group of

eight screws are standard 6-32 x 3/16-inch long screws and are for installing hard drives in

the removable hard drive cage. The bottom group of nine screws are metric M-3 x 5 mm long

and are for installing removable media storage devices in the front drive bays.

Removal & Replacement Procedures

Maintenance & Service Guide 4–19

Page 41

Removal & Replacement Procedures

4.14.3 Removing a Hard Drive from Bays 5 or 6

Drive bays 5 and 6 can be configured with either a 1.0-inch or 1.6-inch hard drive. To

remove a hard drive:

Before removing a SCSI device, please read the “SCSI Devices” appendix.

✎

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

2. Remove the access panel (Section 4.5).

3. Remove the front bezel (Section 4.10).

4. Remove the EMI/Cooling shield (Section 4.13).

5. Remove the cables from the back of the hard drive.

6. Remove the screws from the side of the drive and remove the drive from the drive bay.

To replace the hard drive, reverse the previous procedure.

4–20 Maintenance & Service Guide

Page 42

4.14.4 CD-ROM Drive

This procedure also applies to removing other similar devices.

✎

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

2. Remove the access panel (Section 4.5).

3. Remove the front bezel (Section 4.10).

4. Remove the two screws securing the right side of the drive.

5. Slide the drive slightly out of the drive cage.

6. Disconnect all cables from the rear of the drive.

7. Pull the drive straight out of the chassis.

Removal & Replacement Procedures

To replace the drive, reverse the above procedure.

CAUTION: Use only 3/16-inch or 5-mm long screws as guide screws. Longer screws can

Ä

damage the internal components of the drive. Be sure to transfer the guide screw from

the old drive to the new one. The screw is installed on the right front side of the drive.

Note that extra guide screws are provided on the side of the air plenum.

CAUTION: When servicing the workstation, be sure cables are placed in their proper

Ä

locations during the reassembly process. Improper cable placement can damage the

workstation.

Maintenance & Service Guide 4–21

Page 43

Removal & Replacement Procedures

4.14.5 Diskette Drive

Important: Before beginning the removal procedure, be sure there is no diskette in

the drive.

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

CAUTION: Before removing the access panel, ensure that the workstation is turned off,

Ä

and all cables are disconnected from the back of the workstation.

2. Remove the access panel (Section 4.5).

3. Remove the front bezel (Section 4.10).

4. Disconnect the cables from the back of the diskette drive.

5. Remove the two screws that secure the diskette drive.

6. Pull the diskette drive straight out of the drive cage.

To replace the diskette drive, reverse the above procedure.

CAUTION: Use only 3/16-inch or 5-mm long screws. Longer screws can damage the

Ä

internal components of the drive. If you are replacing the drive with a new one, transfer

the guide screw from the old drive to the new one. Be sure the guide screw is placed in

the first hole on the right side of the drive. Note that extra guide screws are provided on

the side of the air plenum.

CAUTION: When servicing the workstation, be sure cables are placed in their proper

Ä

locations during the reassembly process. Improper cable placement can damage the

workstation.

4–22 Maintenance & Service Guide

Page 44

4.15 Expansion Boards

The W8000 supports 1.5V (typically 4X) AGP and AGP Pro cards only. Older

✎

type AGP cards (3.3V) are not supported and will NOT fit in the AGP socket.

This workstation contains one AGP and six PCI sockets. The following illustration identifies

the physical location of these sockets.

Removal & Replacement Procedures

Item Component

1 One 1.5V, AGP Pro Socket

2 Four 32-bit, 33-MHz PCI Sockets; primary bus

3 Two 64-bit, 66-MHz PCI Sockets; secondary bus

Maintenance & Service Guide 4–23

Page 45

Removal & Replacement Procedures

4.15.1 Removing an Expansion Board

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

CAUTION: Before removing the access panel, ensure that the workstation is turned off,

Ä

and all cables are disconnected from the back of the workstation.

2. Remove the access panel (Section 4.5).

3. Disconnect any cables attached to the expansion board.

4. Remove the expansion board retaining screw.

5. Hold the board at each end and carefully rock it back and forth until the connectors pull

free from the slot. Do not scrape the board against other components.

6. Store the board in antistatic packaging.

7. Install an expansion slot cover to close the open slot.

8. Replace the access panel.

9. Reassemble the workstation.

10. Reconfigure the workstation, if necessary.

4–24 Maintenance & Service Guide

Page 46

4.15.2 Installing an Expansion Board

1. Prepare the workstation for disassembly (Section 4.2).

2. Remove the access panel (Section 4.5) and locate the correct vacant PCI slot.

3. Remove the screw securing the expansion slot cover, then remove the slot cover

4. Slide the expansion board into the expansion slot and press the board firmly into place.

Removal & Replacement Procedures

Important: When installing an expansion board, press firmly on the board so that the whole

connector seats properly in the expansion board slot.

If you are installing a full-length PCI board, make sure the card is engaged with

✎

the card guide.

An AGP expansion board (with additional components or PCI expansion boards

attached) may occupy up to two adjacent PCI sockets on the workstation system

board.

5. Replace the screw at the side of the expansion slot.

6. Replace the access panel.

7. Connect external cables to the installed board, if necessary.

8. Reassemble the workstation.

9. Reconfigure the workstation, if necessary.

Maintenance & Service Guide 4–25

Page 47

Removal & Replacement Procedures

4.16 Air Baffles

4.16.1 Main Baffle

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

CAUTION: Before removing the access panel, ensure that the workstation is turned off,

Ä

and all cables are disconnected from the back of the workstation.

2. Remove the access panel (Section 4.5).

Depending on workstation options, you may have to unplug SCSI and/or IDE

✎

cables from the system board. Remove the memory expansion board to gain

access to these cables.

3. Grasp the end of the air baffle seated at the rear of the chassis.

4. Rotate the end of the baffle in an upward direction 1.

5. Pull the baffle tab out of the front fan bracket 2.

6. Lift the baffle out of the chassis.

To replace the air baffle, reverse the above procedure.

4–26 Maintenance & Service Guide

Page 48

4.16.2 Power Supply Air Baffle

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

CAUTION: before removing the access panel, ensure that the workstation is turned off,

Ä

and all cables are disconnected from the back of the workstation.

2. Remove the access panel (Section 4.5).

3. Remove the clear, main baffle from the chassis (Section 4.16.1).

4. Remove the power supply air baffle from the hook and loop adhesive tabs.

Removal & Replacement Procedures

To replace the power supply air baffle, reverse the above procedure.

Route the drive power cables between the baffle and the power supply.

✎

Maintenance & Service Guide 4–27

Page 49

Removal & Replacement Procedures

4.17 Power Supply

WARNING: Only qualified personnel should perform this procedure. Do not reconnect

Å

power to the workstation until the workstation cover is replaced. Connecting the power

before replacing the workstation cover can result in personal injury or equipment damage.

WARNING: To reduce the risk of electric shock or damage to the equipment:

Å

■ Do not disable the power cord grounding plug. The ground plug is an important

safety feature.

■ Plug the power cord into a grounded (to earth) electrical outlet that is easily

accessible at all times.

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

CAUTION: Before removing the access panel, ensure that the workstation is turned off,

Ä

and all cables are disconnected from the back of the workstation.

2. Remove the access panel (Section 4.5).

3. Remove the main air baffle (Section 4.16.1).

4. Remove the power supply air baffle (Section 4.16.2).

5. Unplug all power cables from the system board.

6. Remove the five screws that secure the power supply to the back of the chassis.

7. Slide the power supply toward the front of the chassis, then pull up to remove it.

To replace the power supply, reverse the above procedure.

4–28 Maintenance & Service Guide

Page 50

Removal & Replacement Procedures

4.18 Removable Hard Drive Cage

4.18.1 Removing the Removable Hard Drive Cage

Drive bays 1 through 3 are located in the removable hard drive cage.

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

2. Remove the access panel (Section 4.5).

3. Loosen the power supply air baffle, as necessary (Section 4.16.2).

4. Remove/loosen the screws 1 on top of the cage.

The removable hard drive cage may be retained by either torx screws or

✎

thumbscrews.

5. Hold the tab 2 and pull the cage up and out of the chassis.

To install the removable hard drive cage, reverse the above procedures.

CAUTION: The power supply air baffle must be properly replaced to sufficiently cool the

Ä

hard drive(s).

Maintenance & Service Guide 4–29

Page 51

Removal & Replacement Procedures

4.18.2 Removing a Hard Drive from the Removable

Hard Drive Cage (Bays 1-3)

The removable hard drive cage supports up to three 1.0-inch hard drives or two

✎

1.6-inch hard drives. Other than using different screw holes, the removal and

replacement for both drives is the same.

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

2. Remove the access panel (Section 4.5).

3. Disconnect the cables from the back of the hard drive.

4. Remove the removable hard drive cage from the chassis (Section 4.18.1).

5. Remove the four hard drive screws that secure the hard drive in the removable hard drive

cage, then pull the hard drive straight out of the hard drive cage.

CAUTION: When servicing the workstation, make sure cables are placed in their proper

Ä

locations during the reassembly process. Improper cable placement can damage the

workstation.

4–30 Maintenance & Service Guide

Page 52

Removal & Replacement Procedures

4.18.3 Installing a Hard Drive in the Removable

Hard Drive Cage (Bays 1-3)

The removable hard drive cage can be configured with up to three 1.0-inch hard drives or

two 1.6-inch hard drives. Other than using different screw holes, the installation for both

typesofdrivesisthesame.

Before installing a SCSI device, please read the “SCSI Devices” appendix.

✎

If only one SCSI hard drive is used, install it in bay 2.

✎

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

2. Remove the access panel (Section 4.5).

3. Remove the removable hard drive cage from the chassis (Section 4.18.1).

4. Remove four hard drive screws (top group of screws) from the side of the air plenum

located at the front of the workstation.

Maintenance & Service Guide 4–31

Page 53

Removal & Replacement Procedures

5. Install the drive into the drive cage using four screws. See the following illustration for

screw locations.

Item Location

1 1.0-inch drive

2 1.6-inch drive

3 1.0-inch drive

4

1.0-inch or 1.6-inch drive

6. Reinstall the removable hard drive cage.

7. Connect the SCSI signal cables and power cables to the back of the drive(s).

8. Reassemble the workstation.

4–32 Maintenance & Service Guide

Page 54

Removal & Replacement Procedures

4.19 Heatsink and Processor

4.19.1 Separating the Heatsink-Processor Assembly

The following sequential events must take place in order to remove the existing heatsink and

processor assembly:

1. Heat the heatsink-processor assembly to an optimum temperature to break the compound

bonding them together. See the following sections:

❏ “Heatsink Cool-Down Time”

❏ “Heatsink Warm-Up Time”

2. Separate the heatsink from the processor.

3. Release the processor from the processor socket.

Heatsink Cool-Down Time

The heat generated from the processor core transfers to the heatsink making the assembly too

hot to handle. From power-on to power-off, it takes up to 13 minutes to cool the heatsink

sufficiently so that it can be handled comfortably and the compound holding it to the

processor remains pliable.

Heatsink Warm-Up Time

Minimal warm-up time is required to generate enough heat to soften the compound holding

the heatsink to the processor.

CAUTION: Lifting the heatsink straight up while it is in a cold state can result in damage

Ä

to the processor, because it may pull the processor out of the processor socket. If this

should occur, you will need to open the processor socket, by lifting up on the processor

retention lever, before attempting to install the new processor.

From power-off to power-on, see the following steps to warm (but not overheat) the heatsink

so that the heatsink can be handled comfortably, and the compound holding it to the

processor will be pliable.

1. Turn on the workstation and allow the operating system to boot.

2. Shut down the operating system properly, then turn off the workstation and any external

devices.

3. Disconnect the power cord from the grounded AC outlet.

Maintenance & Service Guide 4–33

Page 55

Removal & Replacement Procedures

4.19.2 Removing the Heatsink and Processor

WARNING: To reduce the risk of personal injury from hot surfaces, allow the internal

Å

system components to cool before touching them.

CAUTION: Lifting the heatsink straight up while it is in a cold state can result in damage

Ä

to the processor, because it may pull the processor out of the processor socket. If this

should occur, you will need to open the processor socket, by lifting up on the processor

retention lever, before attempting to install the new processor.If the heatsink is cold to the

touch, see “Guidelines for Separating the Heatsink/Processor Assembly” in this chapter.

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

2. Remove the access panel (Section 4.5).

3. Remove the memory expansion board (Section 4.9.2).

4. Disconnect the drive cables from the system board and move them away from the

processor area.

5. Remove the main air baffle (Section 4.16.1).

6. Ensure the heatsink is warm to the touch (Section 4.19.1).

7. Release the two metal clips that hold the heatsink to the processor retention module.

8. Twist the heatsink slightly 1 to break the compound that holds it to the processor.

9. Lift the heatsink off the processor 2.

4–34 Maintenance & Service Guide

Page 56

Removal & Replacement Procedures

10. Open the processor socket by pulling up on the processor retention lever 1.

11. Lift the processor out of the processor socket 2.

To replace the processor, reverse the above procedure.

If installing a new heatsink, be sure to remove the tear-away tab covering the

✎

thermal material on the heatsink.

Maintenance & Service Guide 4–35

Page 57

Removal & Replacement Procedures

4.19.3 Installing an Additional Processor

A manual Hardware Abstraction Layer (HAL) upgrade is necessary when

✎

installing a second processor after the system has gone through the software

bundling process. If a second processor is installed prior to unbundling, a

manual upgrade is not necessary.

Hardware Abstraction Layer

To update Windows NT 4.0 or Windows 2000 to recognize a second processor using the

Hardware Abstraction Layer (HAL), complete the following steps:

1. Start Windows.

2. Insert the upgrade diskette. Then select Start > Run.

3. Type A:\setup.exe and select OK.

4. Select Uniprocessor HAL and Kernel.

5. Select Upgrade and insert the media used to upgrade the operating system to a new

Service Pack if requested; then click Retry.

6. If prompted, insert the operating system CD and click OK.

7. After the installation is complete, close the setup program and restart the workstation.

Additional Processor Installation

You can upgrade the workstation to a multiprocessor system. When you install a second

processor, it must be the same speed, cache size, and type as the existing processor.

CAUTION: Static electricity can damage the electronic components of the workstation.

Ä

Before beginning these procedures, be sure that you are discharged of static electricity by

briefly touching a grounded metal object.

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

2. Remove the access panel (Section 4.5).

3. Remove the memory expansion board (Section 4.9.2).

4. Disconnect the cables from the hard drive and move them away from the processor area.

5. Remove the main air baffle (Section 4.16.1).

4–36 Maintenance & Service Guide

Page 58

Removal & Replacement Procedures

6. Install the second processor:

❏ Open the processor socket by pulling up on the processor retention lever 1.

CAUTION: Processor pins are delicate and bend easily. Use extreme care when placing

Ä

the processor in the socket.

❏ Insert the new processor 2 and close the retention lever. Ensure that the processor is

locked into place and is not loose in the socket.

❏ Ensure the thermal pad is on the bottom of the heatsink 3 before setting the heatsink

on top of the processor.

❏ Install the two metal clips 4 that hold the heatsink to the processor retention

module.

Ensure the metal clips are firmly attached to the retaining clips.

✎

CAUTION: A processor must always be installed in processor socket A or the workstation

Ä

will not function.

Maintenance & Service Guide 4–37

Page 59

Removal & Replacement Procedures

7. Install the Voltage Regulator Module (VRM):

❏ Make sure the VRM is fully inserted and properly seated.

CAUTION: You must install a Compaq approved VRM when installing a second

Ä

processor. Using a VRM that is incompatible with the primary VRM may severely,

permanently damage the system board.

❏ Install the VRM clip, making sure the clip snaps into place.

8. Reinstall the main air baffle.

CAUTION: The air baffle is essential to proper cooling of the processors. Without it, the

Ä

processors will slow down to avoid overheating.

Air flows across the processors from front to back. The front fan moves air over

✎

the processors while the back fan pulls the air out of the chassis.

9. Reattach the hard drive cables, memory expansion board, and reassemble the

workstation.

CAUTION: If only one processor is installed and you are replacing that processor, be

Ä

sure to install the processor in the primary processor socket or your workstation will not

function.

4–38 Maintenance & Service Guide

Page 60

4.20 System Board

The system board has nine LEDs to help troubleshoot component-related problems. See

Section 5.1.2 for more information.

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

CAUTION: Before removing the access panel, ensure that the workstation is turned off,

Ä

and all cables are disconnected from the back of the workstation.

2. Remove the access panel (Section 4.5).

3. Remove the memory expansion board (Section 4.9.2).

4. Remove any expansion boards (Section 4.15.1).

5. Remove the main air baffle (Section 4.16.1).

6. Disconnect and remove all cables plugged into the system board.

7. Remove the processor heatsink(s) (Section 4.19.2).

8. Remove the nine screws securing the system board to the chassis 1.

9. Remove the four screws (one under each heatsink bracket) that connect the system board

to the chassis 2.

Removal & Replacement Procedures

10. Carefully remove the system board from the chassis 3.

To install a new system board, reverse the above procedure.

Plug the CD analog audio cable back in before reinstalling the system board.

✎

Maintenance & Service Guide 4–39

Page 61

Removal & Replacement Procedures

4.21 Rear Fan

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

2. Remove the access panel (Section 4.5).

3. Remove the main air baffle (Section 4.16.1).

4. Disconnect the fan’s power cable from the system board.

5. Remove the four screws securing the fan to the back of the chassis 1.

6. Remove the fan from the chassis 2.

To replace the system fan, reverse the above procedure.

4–40 Maintenance & Service Guide

Page 62

4.22 Processor Fan

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

2. Remove the access panel (Section 4.5)

3. Remove the main air baffle (Section 4.16.1)

4. Disconnect the fan power cable from the system board.

5. Remove the screw securing the fan assembly to the air plenum.

6. Lift the fan assembly out of the chassis.

Removal & Replacement Procedures

7. Remove the four screws that connect the fan to the bracket.

8. Remove the fan from the bracket.

To replace the processor fan, reverse the above procedure.

Maintenance & Service Guide 4–41

Page 63

Removal & Replacement Procedures

4.23 Speaker

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

CAUTION: Before removing the access panel, ensure that the workstation is turned off,

Ä

all cables are disconnected from the back of the workstation, and the power cord is

disconnected from the grounded AC outlet.

2. Remove the access panel (Section 4.5).

3. Remove the main air baffle (Section 4.16.1).

4. Remove the front fan (Section 4.22).

5. Unplug the speaker connector from the system board and remove the cable from the clip.

6. Remove the four screws securing the front of the speaker to the chassis.

7. Remove the speaker from the workstation by sliding it back, then lifting it up and out of

the chassis.

To replace the speaker, reverse the above procedure.

4–42 Maintenance & Service Guide

Page 64

4.24 Card Guide

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

2. Remove the access panel (Section 4.5).

3. Remove the memory expansion board (Section 4.9.2).

4. Remove any expansion cards from the card guide (Section 4.15.1).

5. Remove the main air baffle (Section 4.16.1).

6. Remove the front fan (Section 4.22).

7. Remove the remaining screw attaching the card guide bracket to the air plenum.

Removal & Replacement Procedures

8. Remove the four screws securing the card guide to the card guide bracket.

9. Remove the card guide from the bracket.

To replace the card guide, reverse the above procedure.

Maintenance & Service Guide 4–43

Page 65

Removal & Replacement Procedures

4.25 Air Plenum Fan

1. Prepare the workstation for disassembly (Section 4.2), then place it on its side.

2. Remove the access panel (Section 4.5).

3. Remove the main air baffle (Section 4.16.1).

4. Remove the processor fan (Section 4.22).

5. Remove the card guide (Section 4.24).

6. Disconnect the fan cable from the system board and remove the cable from the clip.

7. Remove the four screws securing the fan to the fan bracket 1.

8. Remove the fan from the fan bracket 2.

To replace the system fan, reverse the above procedure.

4–44 Maintenance & Service Guide

Page 66

5.1 System Board

5

Connectors and Jumpers

Maintenance & Service Guide 5–1

Page 67

Connectors and Jumpers

5.1.1 Connectors and Jumpers

Ref Description Ref Description

E1 Bus parking disable header P10 Diskette drive connector

J2 VRM socket B P11 Auxiliary audio-in connector

J14 Front I/O board connector P12 AOL connector

J19 VRM socket A P20 Primary Ultra ATA connector

J20-23 32-bit, 33-MHz PCI sockets P21 Secondary Ultra ATA connector

J24-25 64-bit, 66-MHz PCI sockets P29 SCSI LED connector

J30 Memory expansion board socket P34 Boot block protection disable

header

J37 Ultra160 SCSI connector (Channel A) P49 Power-on password enable

jumper

J38 Ultra160 SCSI connector (Channel B) P70 Processor fan connector

J40 1.5V AGP Pro socket P89 Serial port connector

LEDs Troubleshooting LEDs* P120 Front fan connector

P1 24-position power connector SW50 Clear CMOS Button

P2 22-position power connector XBT1 Battery

P6 Front speaker connector XU1 Primary Processor socket

P7 CD-ROM audio connector XU2 Secondary Processor socket

P8 Rear fan connector

5–2 Maintenance & Service Guide

Page 68

5.1.2 System Board Troubleshooting LEDs