Page 1

HP CL2100 G3 807S Server

Abstract

Part Number: 824662-001

June, 2015

Edition: 1

This guide describes identification and maintenance procedures, diagnostic tools, specifications, and requirements for hardware components and

software. This guide is for an experienced service technician. HP assumes you are qualified in the servicing of computer equipment, trained in

recognizing hazards in products, and are familiar with weight and stability precautions.

User and Maintenance Guide

Page 2

© Copyright 2015 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth in the express

warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP

shall not be liable for technical or editorial errors or omissions contained herein.

Page 3

Contents

Component identification ............................................................................................................... 7

Front panel components ................................................................................................................................ 8

Rear panel components ................................................................................................................................ 8

Front l panel LEDs and buttons ....................................................................................................................... 9

Power supply LEDs ....................................................................................................................................... 9

Storage drive LEDs ..................................................................................................................................... 10

Board LEDs ................................................................................................................................................ 10

System board components .......................................................................................................................... 13

HDD carrier LED definitions ......................................................................................................................... 14

System components .................................................................................................................................... 15

Operations................................................................................................................................. 16

Powering up the server ............................................................................................................................... 16

Powering down the server ........................................................................................................................... 16

Shutting down the server ................................................................................................................... 16

Verifying the power status ................................................................................................................. 17

Installation ................................................................................................................................. 18

Safety measures ......................................................................................................................................... 18

Identifying the contents of the server shipping carton ...................................................................................... 18

Hard disk drives ......................................................................................................................................... 19

Removing the hot-swappable HDD assembly ....................................................................................... 19

Installing the hot-swappable hard disk drive assembly .......................................................................... 19

Removing the hard disk drive module ................................................................................................. 19

Installing the HDD module ................................................................................................................. 20

Power supply unit (PSU) .............................................................................................................................. 20

Removing the PSU ............................................................................................................................ 20

Installing the PSU ............................................................................................................................. 21

Expander board ......................................................................................................................................... 22

Removing the expander board .......................................................................................................... 22

Installing the expander board ............................................................................................................ 23

Hard disk drive backplane .......................................................................................................................... 23

Removing the hard disk drive backplane ............................................................................................ 23

Installing the HDD backplane ............................................................................................................ 25

System fans ............................................................................................................................................... 26

Cable routing .................................................................................................................................. 26

Removing the system fan assembly ..................................................................................................... 26

Installing the system fan assembly ...................................................................................................... 27

Heat sinks ................................................................................................................................................. 29

Removing the heat sink ..................................................................................................................... 29

Installing the heat sink ....................................................................................................................... 30

Processor................................................................................................................................................... 31

Removing the processor .................................................................................................................... 31

Installing the processor ..................................................................................................................... 32

DIMM modules .......................................................................................................................................... 34

DIMM: Max x16pcs DIMM ............................................................................................................... 34

Removing the DIMM module ............................................................................................................. 34

Contents 3

Page 4

Installing the DIMM module ............................................................................................................... 35

System board module ................................................................................................................................. 35

Removing the system module ............................................................................................................. 35

Installing the system board module ..................................................................................................... 36

Access panel ............................................................................................................................................. 37

Removing the access panel ............................................................................................................... 37

Installing the access panel ................................................................................................................. 38

Front control board ..................................................................................................................................... 38

Removing the front control board ....................................................................................................... 38

Installing the front control board ........................................................................................................ 39

Riser card .................................................................................................................................................. 39

Removing the riser card .................................................................................................................... 39

Installing the riser card ...................................................................................................................... 40

Powering on and selecting boot options ....................................................................................................... 41

Installing the operating system ..................................................................................................................... 41

Cabling ..................................................................................................................................... 43

Internal system cable routing ....................................................................................................................... 43

Configuration ............................................................................................................................. 46

BMC ......................................................................................................................................................... 46

Web GUI introduction ...................................................................................................................... 46

IP address ....................................................................................................................................... 46

User name and password ................................................................................................................. 46

Web browsers ................................................................................................................................. 46

Logging in ....................................................................................................................................... 46

Updating the firmware ...................................................................................................................... 47

BIOS settings ............................................................................................................................................. 51

BIOS setup menus ............................................................................................................................ 52

POST error message ......................................................................................................................... 52

Entering the pop-up boot menu .......................................................................................................... 53

Entering PXE boot ............................................................................................................................. 53

Entering the BIOS setup menu ............................................................................................................ 53

BIOS beep codes ............................................................................................................................. 54

BIOS maintenance ........................................................................................................................... 54

Checking the FW version ............................................................................................................................ 58

Checking the BIOS version using Linux ............................................................................................... 58

Checking the BIOS version using the BIOS setup utility ......................................................................... 58

Checking the BMC version using Linux ............................................................................................... 59

Checking the BMC version using the web GUI .................................................................................... 59

Checking the event log ............................................................................................................................... 60

Checking the system event log using Linux remote desktop ................................................................... 60

Checking the system event log using the web GUI ............................................................................... 60

Checking the event log using the BIOS setup utility .............................................................................. 61

Diagrams ................................................................................................................................... 65

System board diagram ............................................................................................................................... 65

Spare parts catalog .................................................................................................................... 66

Customer self repair ................................................................................................................................... 66

Parts only warranty service .......................................................................................................................... 66

Replaceable components ............................................................................................................................ 67

Troubleshooting .......................................................................................................................... 69

Troubleshooting preparation ........................................................................................................................ 69

Contents 4

Page 5

Pre-diagnostic .................................................................................................................................. 69

Symptom collection .......................................................................................................................... 69

Prepare the server for diagnosis ......................................................................................................... 70

Performing processor procedures in the troubleshooting process ........................................................... 70

Breaking the server down to the minimum hardware configuration ........................................................ 71

Diagnostic flowcharts .................................................................................................................. 72

Troubleshooting flowcharts .......................................................................................................................... 72

Start diagnosis flowchart ................................................................................................................... 72

Remote diagnosis flowchart ............................................................................................................... 73

General diagnosis flowchart .............................................................................................................. 74

Power-on problems flowchart ............................................................................................................. 75

POST problems flowchart .................................................................................................................. 76

Operating system boot problems flowchart ......................................................................................... 77

Troubleshooting general problems ............................................................................................................... 78

Resolving common problems ............................................................................................................. 78

Hardware problem troubleshooting .............................................................................................................. 81

Power problems ............................................................................................................................... 81

General hardware problems ............................................................................................................. 81

Internal system problems ................................................................................................................... 82

External device problems .................................................................................................................. 86

Software problem troubleshooting ................................................................................................................ 87

Operating system problems and resolutions ........................................................................................ 87

Application software problems .......................................................................................................... 88

ROM problems ................................................................................................................................ 89

Battery replacement .................................................................................................................... 91

Firmware update tools ................................................................................................................. 92

Firmware and drivers support ....................................................................................................... 93

Firmware list .............................................................................................................................................. 93

System board programming data ....................................................................................................... 93

HDD backplane ............................................................................................................................... 93

HBA/RAID card ............................................................................................................................... 93

Device drivers ............................................................................................................................................ 93

Regulatory information ................................................................................................................ 94

Safety and regulatory compliance ................................................................................................................ 94

USA FCC verification notice ........................................................................................................................ 94

Class A ..................................................................................................................................................... 94

Notices for Canada (Avis Canadien) ........................................................................................................... 94

Japanese Voluntary Control Council for Interference (VCCI) statement .............................................................. 95

Australia and New Zealand Class A statement .............................................................................................. 95

CCC Class A notice ................................................................................................................................... 95

European Union regulatory notice ................................................................................................................ 95

Taiwanese Class A warning statement .......................................................................................................... 96

Notice for Korea ........................................................................................................................................ 96

Belarus Kazakhstan Russia marking .............................................................................................................. 96

Safety ....................................................................................................................................................... 97

Warnings & Safety/ Warnungen & Sicherheit/ Предупреждения и безопасность .......................... 98

Important safety and compliance information ................................................................................................ 98

Wichtige Sicherheits- und Übereinstimmungsinformationen ............................................................................. 98

Важная информация по соответствию требованиям техники безопасности ............................................. 98

Safety precautions ............................................................................................................................ 98

Contents 5

Page 6

Sicherheitsvorkehrungen ................................................................................................................... 99

Меры предосторожности ............................................................................................................... 99

Symbols .................................................................................................................................................... 99

Symbole .................................................................................................................................................. 100

Предупреждающие символы ................................................................................................................. 102

Safety statements ...................................................................................................................................... 103

Sicherheitshinweise .................................................................................................................................. 105

Информация о безопасности ................................................................................................................. 107

Warnings and cautions............................................................................................................................. 108

Warnungen und Vorsichtsmaßnahmen ....................................................................................................... 109

Предупреждения и меры предосторожности .......................................................................................... 110

Electrostatic discharge .............................................................................................................................. 111

Elektrostatische Entladungen ...................................................................................................................... 112

Электростатический разряд ................................................................................................................... 113

Specifications ........................................................................................................................... 115

Environmental specifications ...................................................................................................................... 115

Mechanical specifications ......................................................................................................................... 115

Support information .................................................................................................................. 116

Before you contact HP .............................................................................................................................. 116

Contents 6

Page 7

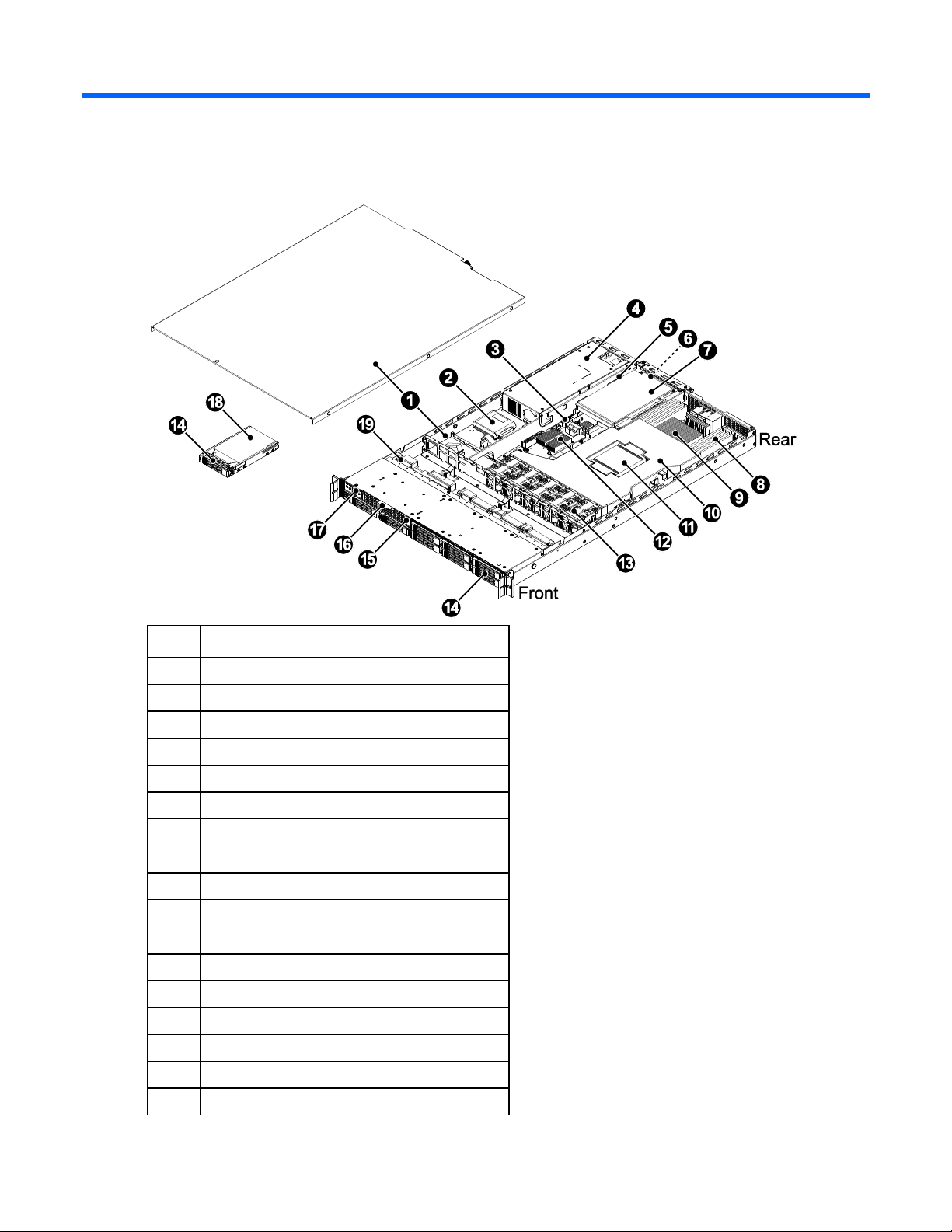

Component identification

Item

Description

1

1U chassis & access panel

2

Super cap and BBU for HBA card

3

System board

4

Fixed power supply

5

Add on card (FHHL)

6

OCP mezzanine card (10G SFP+ port) (2)

7

Riser card (1U slot)

8

DDR4 DIMM (16)

9

CPU (2)

10

Air baffle

11

Heat sink (2)

12

SASmezzanine card

13

System fan (40x40x56mm) (5)

14

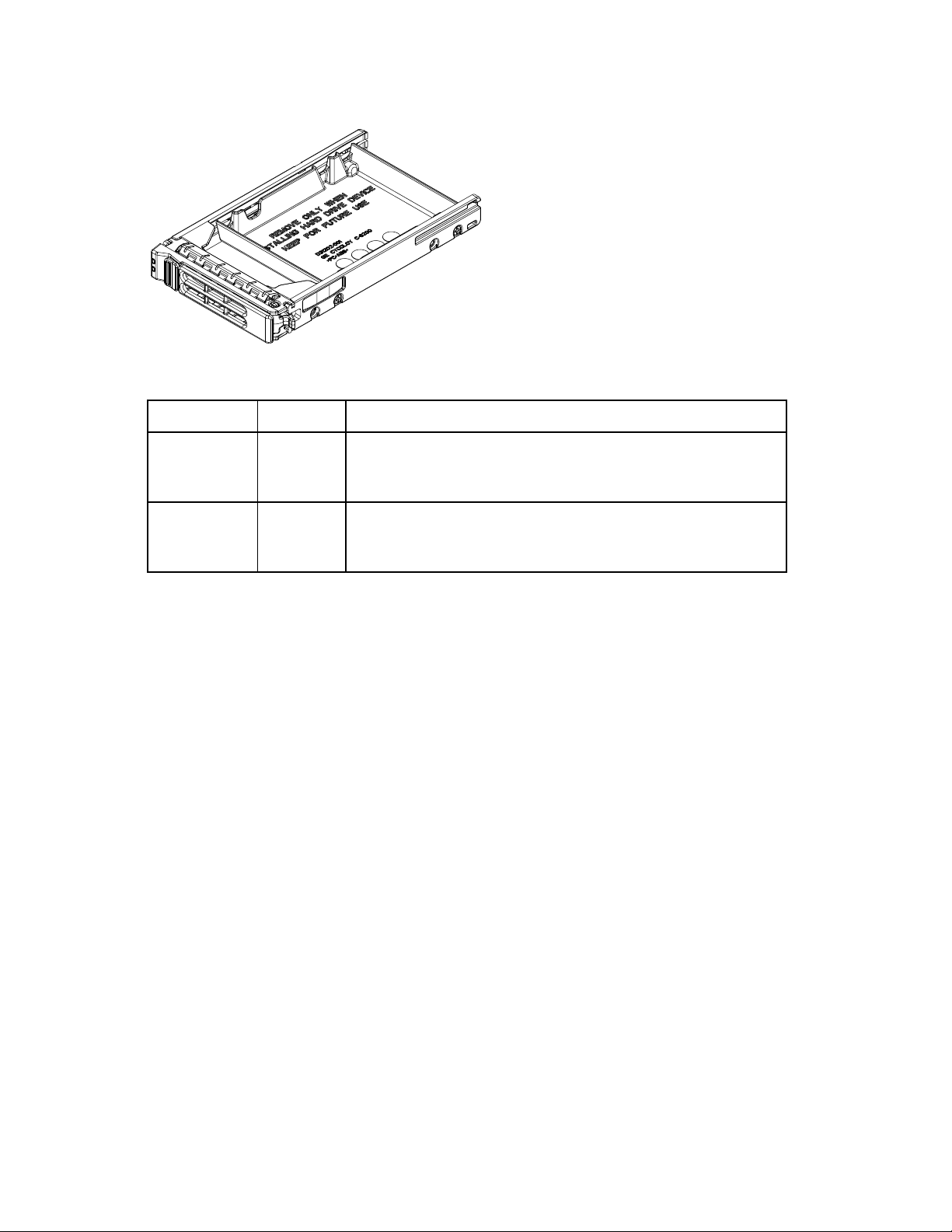

2.5” HDD carrier (8)

15

2.5” fixed SSD

16

Asset tag and HDD sequence label

17

Front control panel

Component identification 7

Page 8

Item

Description

18

2.5” HDD (8)

19

HDD backplane

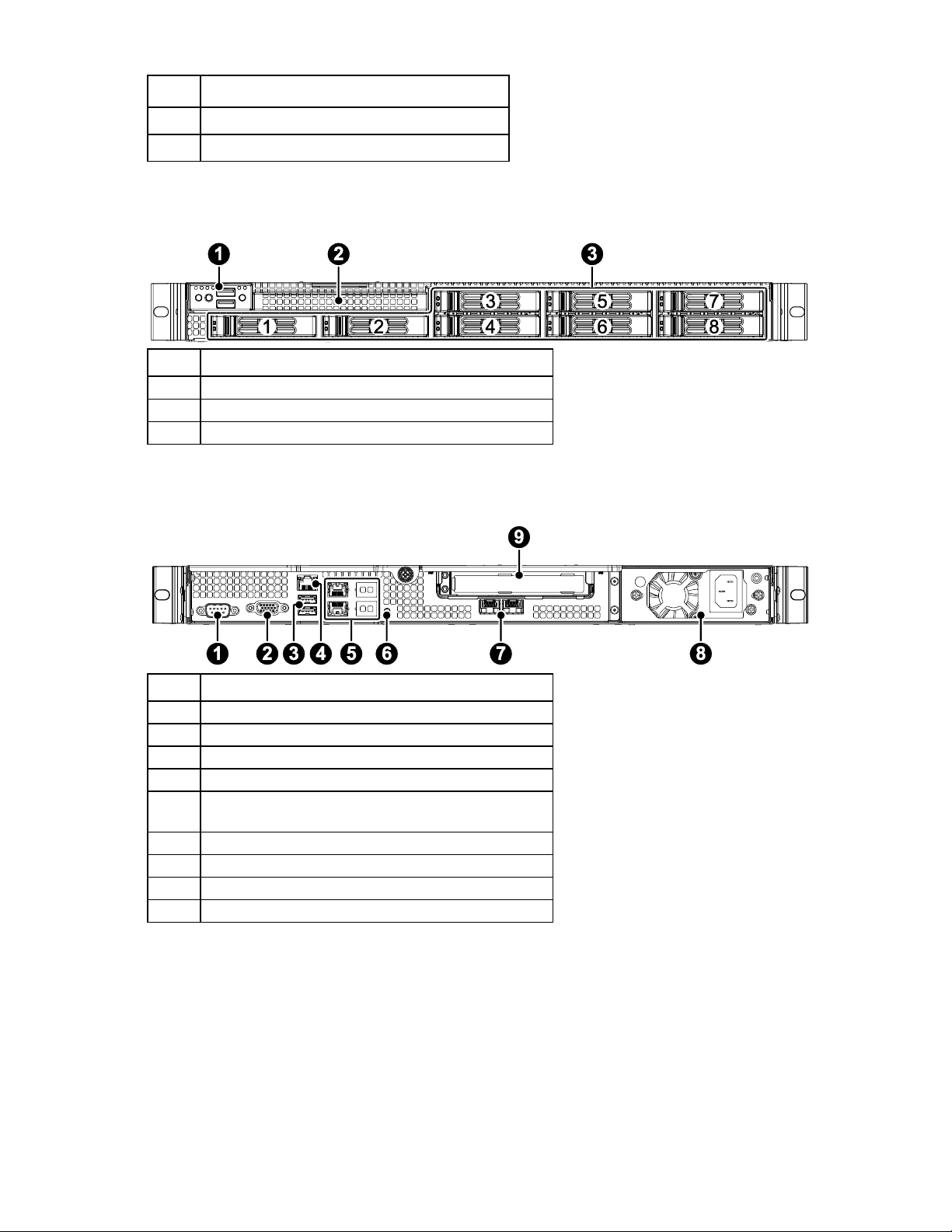

Item

Description

1

Front panel

2

SSD module

3

2.5” SAS/SATA HDD carriers (8)

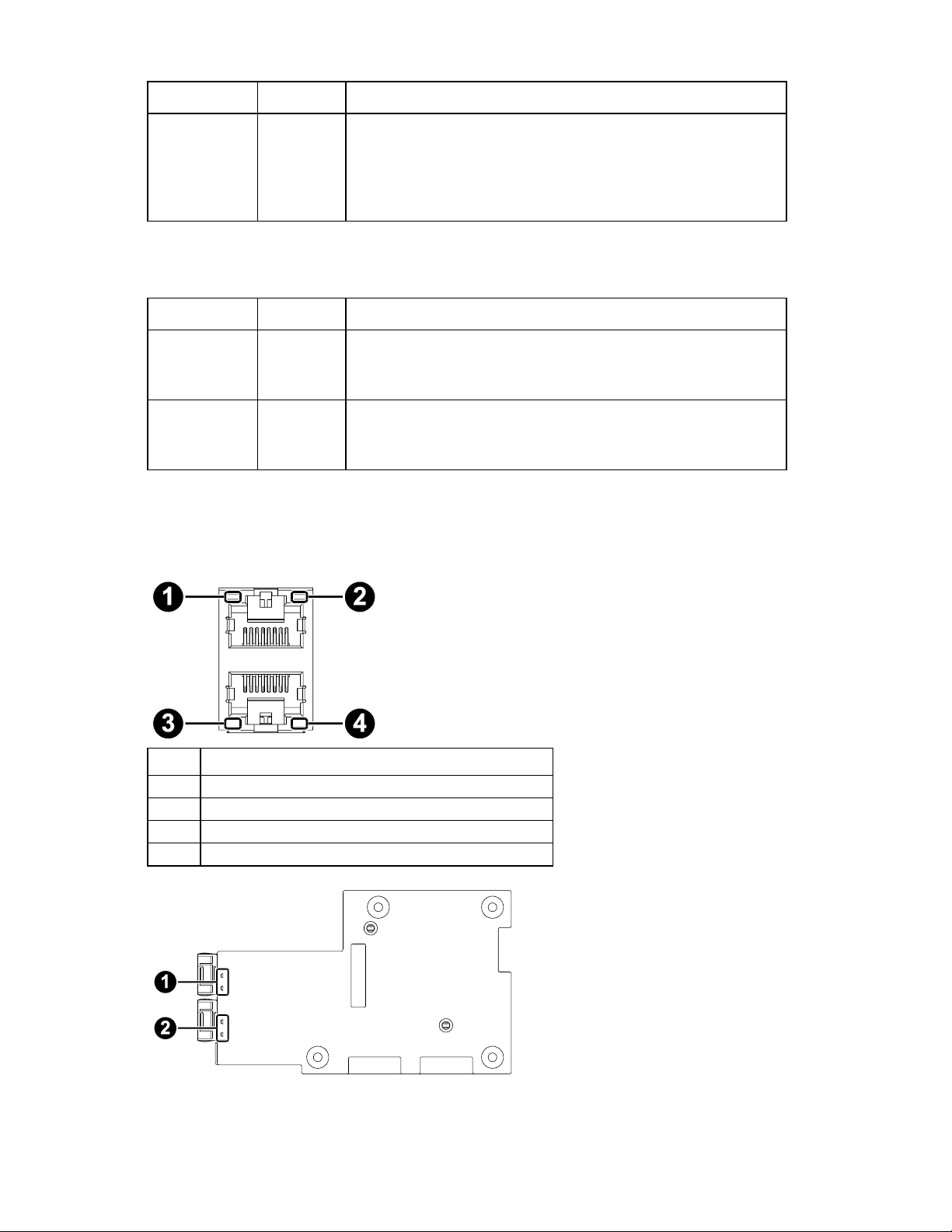

Item

Description

1

COM

2

VGA

3

USB 2.0 (2)

4

RJ45 (10M/100M)

5

RJ45 x 4 (SKUA: 0, SKUB: 4, SKUC&D: 2)

(10M/100M/1000M)

6

UID button

7

10Gb SFP+ (optional)

8

Power supply unit

9

PCIe card

Front panel components

Rear panel components

Component identification 8

Page 9

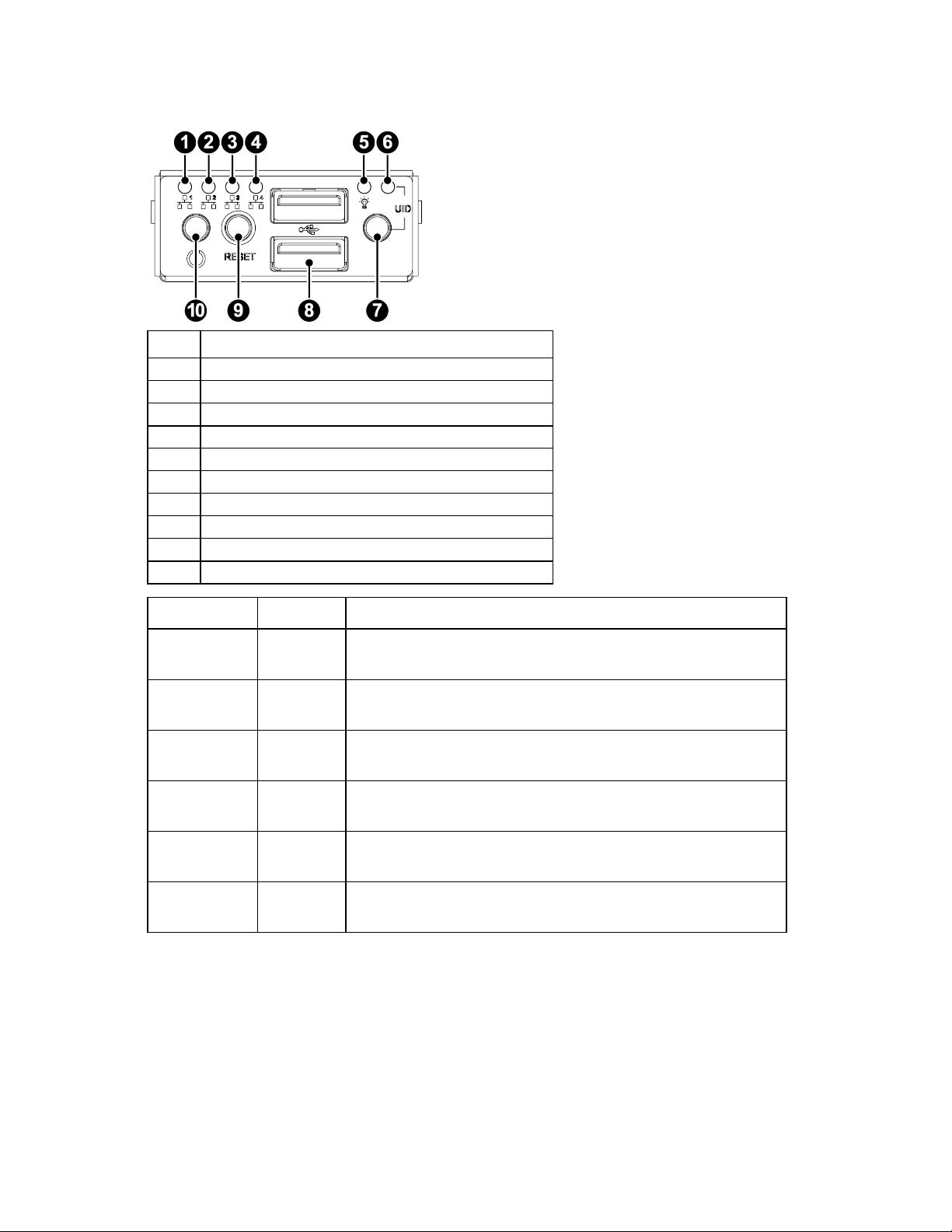

Front l panel LEDs and buttons

Item

Description

1

LAN 1 LED

2

LAN2 LED

3

LAN 3LED

4

LAN 4 LED

5

Power LED

6

UID LED

7

UID button

USB 2.0 ports

9

Reset button

10

Power button

LED Indicator

LED Color

Description

UID LED

Blue

On: System identified

Off: System not identified

LAN 1 Activity

LED

Green

Flashing: LAN1 data transfer

Off: LAN 1 no data transfer

LAN 2 Activity

LED

Green

Flashing: LAN 2 data transfer

Off: LAN 2 no data transfer

LAN 3 Activity

LED

Green

Flashing: LAN 3 data transfer

Off: LAN 3 no data transfer

LAN 4 Activity

LED

Green

Flashing: LAN 4 data transfer

Off: LAN 4 no data transfer

Power LED

Green

On: System powered up

Off: System powered down or in standby mode

Power supply LEDs

The 650W power supply comes with one LED and the LED is visible from the rear of the power supply.

Component identification 9

Page 10

LED Indicator

LED Color

Description

AC Power

Green

Off: No AC power to power supply

6.7Hz flashing: Power supply critical event causing a shutdown:

failure, OCP, OVP, fan fail

1Hz flashing: AC present/only 5VSB on (PS off)

On: Output ON and OK

LED Indicator

LED Color

Description

Activity LED

Blue

On: HDD Present without data transfer

Flashing: HDD data transfer

Off: HDD no power or not present

Fault LED

Red

On: HDD broken or Raid broken

Flashing: HDD Raid rebuilding

Off: HDD working well

Item

Description

1

LAN 2&4 Link Speed LED

2

LAN 2&4 Link/Activity LED

3

LAN 1&3 Link Speed LED

4

LAN 1&3 Link/Activity LED

Storage drive LEDs

Board LEDs

See the following illustration to locate the LED indicator for RJ45, SFP+ and PHY (Management network).

Component identification 10

Page 11

Item

Description

1

10G SFP+ Up LED

2

10G SFP+ Down LED

Item

Description

1

PHY Left LED

2

PHY Right LED

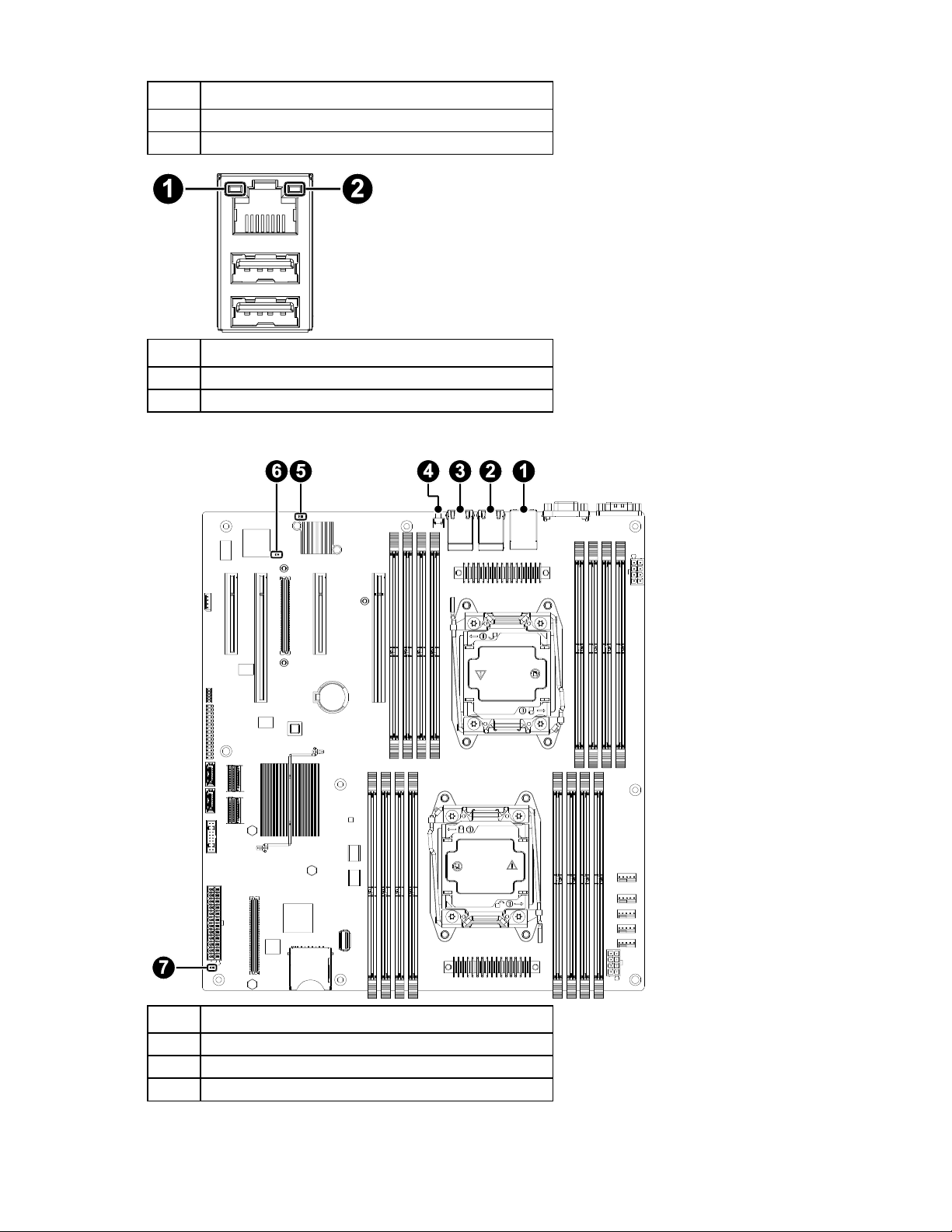

Item

Description

1

PHY LED

2

LAN LED

3

LAN LED

See the following illustration to locate the system board LED indicator:

Component identification 11

Page 12

Item

Description

4

UID LED

5

System Status LED

6

BMC_HEARTBEAT_LED

7

Standby LED

LED Name

Voltage

Sources

LED Color State

Description

STBY_LED

P5V_STBY

Green

On

AC On

Off

AC Off

UID LED

P5V_STBY

Blue

On

Unit selected for identification

Off

Unit not selected

SYS LED

P3V3_AUX

Green

On

System health OK

Yellow

On

Error occurred

BMC Heartbeat

LED

P3V3_AUX

Green

Flashing

BMC is ready

Off

BMC is not ready

LAN_0-1,

LAN_2-3

P3V3_AUX

Green (Right)

On

LAN link up but no activity

Green (Right)

Flashing

LAN link up and activity

(Right)

Off

LAN link down

Green (Left)

On

Green, link speed is 1000Mbps

Orange (Left)

On

Amber, link speed is 100Mbps

(Left)

Off

Off, link speed is 10Mbps

MGNT LAN LED

P3V3_AUX

Orange (Left)

On

Amber, link speed is 100/10Mbps

Green (Right)

Flashing

LAN link up and activity

Green (Right) and

Orange (Left)

Off and On

LAN link up but no activity

Green (Right) and

Orange (Left)

Off and Off

Disconnected

Component identification 12

Page 13

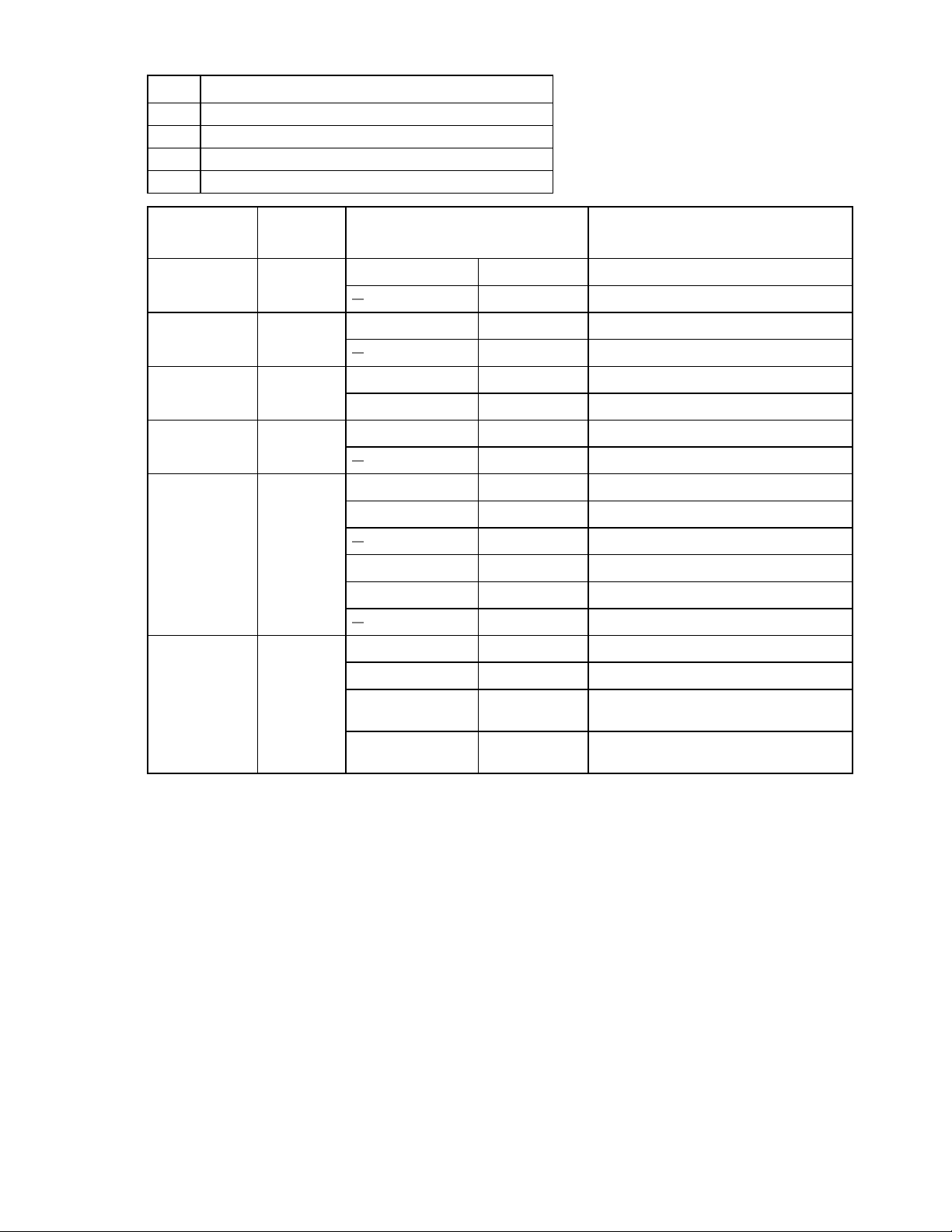

System board components

Item

Description

1

8pin Processor1 power

2

DIMM slot (16)

3

Processor1

4

Processor0

5

Fan header (5)

6

8pin Processor0 power

7

MiniSAS connector (2)

8

SAS mezzanine connector

9

24pin main power

10

Front USB connector

11

SATA3.0 (SATA DOM)

12

SATA3.0

13

Front control connector

14

OCP mezzanine card slot

15

PCIe slot (3), PCIe slot (1) (optional with OCP mezzanine)

16

UID switch

17

RJ45 x 4 (SKUA: 0, SKUB: 4, SKUC&D: 2)

18

RJ45 and USB 2.0 x 2

19

VGA

20

COM

Component identification 13

Page 14

HDD carrier LED definitions

LED Indicator

LED Color

Description

Activity LED

Blue

On: HDD Present without data transfer

Flashing: HDD data transfer

Off: HDD no power or not present

Fault LED

Red

On: HDD broken or Raid broken

Flashing: HDD Raid rebuilding

Off: HDD working well

Each drive tray supports two light pipes to direct light from the drive status LEDs on the backplane to the

face of the tray, allowing it to be viewable from the front of the system.

Important: The fault LED function is only supported when a HBA/RAID card is installed.

Component identification 14

Page 15

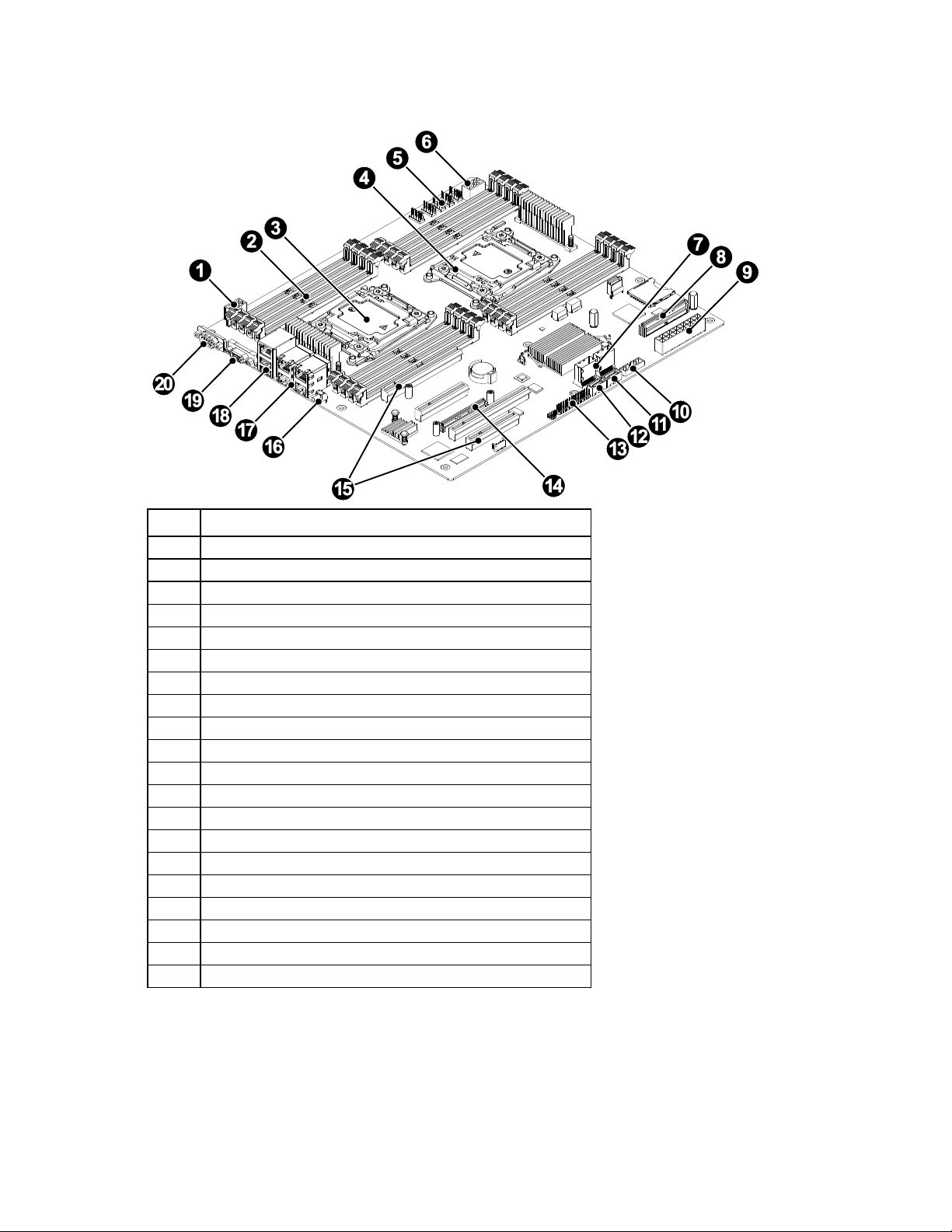

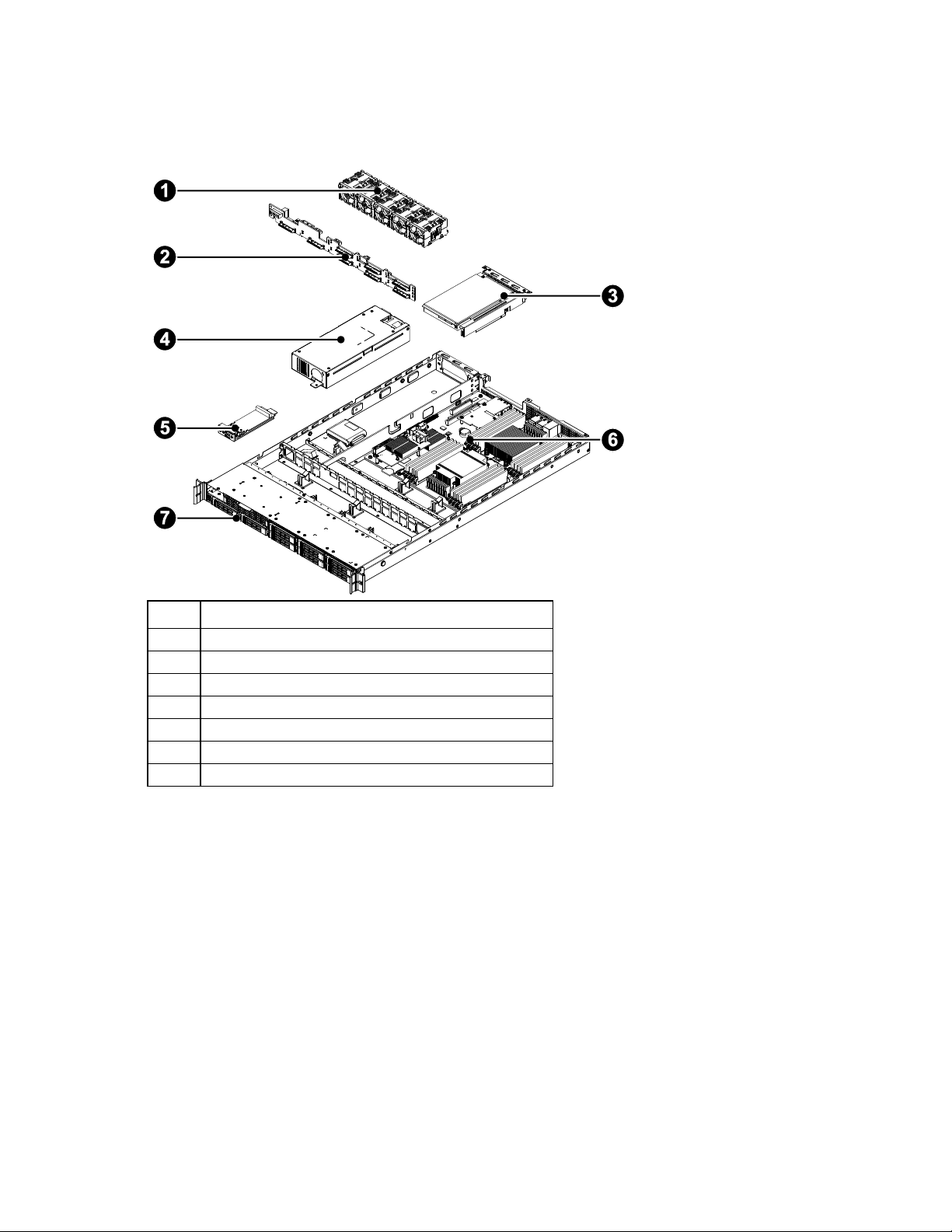

System components

Item

Description

1

System fan (40x40x56mm) (5)

2

HDD backplane

3

Riser rard (1U slot)

4

Fixed power supply

5

Front control panel

6

System board

7

2.5” HDD (8)

The following figure shows specific components of the server system. See the following figure and table to

become familiar with the server components.

Component identification 15

Page 16

Operations

CAUTION: All applications and files will be closed without saving changes, file system

corruption might occur.

Powering up the server

The following procedure assumes that at least one power cord is connected to the server to supply power

to the server and that the server has been previously powered on.

1. Verify the power cord, power supply LED indicator, and power LED indicator on front control panel.

Turn the power supply LED on immediately to indicate the power is being supplied to the power

supply and the system in the standby power state. Power LED off to indicate the server is not powered

on or has been powered off in standby mode.

2. Power up the server

o Local server power-on: Press and release the power button on the front control panel of the server

to power on the server.

o BMC web interface power-on: Log in to the BMC web interface and select power on from the

power control action list box.

o Log in to the BMC CLI and execute the IPMI command to power on system.

Powering down the server

The following procedures show how to shut down the server and verify the power status.

Shutting down the server

Graceful shutdown

To perform a graceful shutdown: Save all open files, network service, and close all applications prior

to shut down.

Stop or terminate all necessary system processes to bring down the operating system and power off

the compute node.

Press and release the power button on the front panel of ACPI-enabled (Advanced Configuration and

Power Interface) operating systems to perform an orderly shutdown of the operating system. Servers

not running ACPI-enabled operating systems will shut down immediately.

Emergency shutdown

To perform an emergency shutdown, press and hold down the power button on the front panel for at least

five seconds to shut down and enter standby power mode.

BMC CLI shutdown

Log in to the BMC and execute the IPMI command to shut down the server.

Operations 16

Page 17

Verifying the power status

Verify all power LED indicators of the server and make sure the power LED light is off before replacing and

removing the server components from the rack.

Operations 17

Page 18

Installation

Safety measures

Static electricity discharges can damage computer components and electronic circuit boards. Working on

computers that are still connected to a power supply can be extremely dangerous. Follow these guidelines

to avoid self-injury and damage to the computer:

Always disconnect the server from the power outlet when working inside of the computer case.

If possible, wear a grounded wrist strap when working inside the computer case. Alternatively,

discharge any static electricity by touching the bare metal chassis of the computer case, or the bare

metal body of any other grounded appliance.

Hold electronic circuit boards only by the edges. Do not touch the components on the board unless it

is necessary to do so. Do not flex or stress the circuit board.

Leave all components inside the static-proof packaging until ready to use the component for the

installation.

Identifying the contents of the server shipping carton

Unpack the server shipping carton and locate the materials for installing the server.

The contents of the server shipping carton include:

Server

Power cord (optional)

Rack-mounting hardware (optional)

In addition to the supplied items, you might need:

Operating system or application software

Hardware options

Installation 18

Page 19

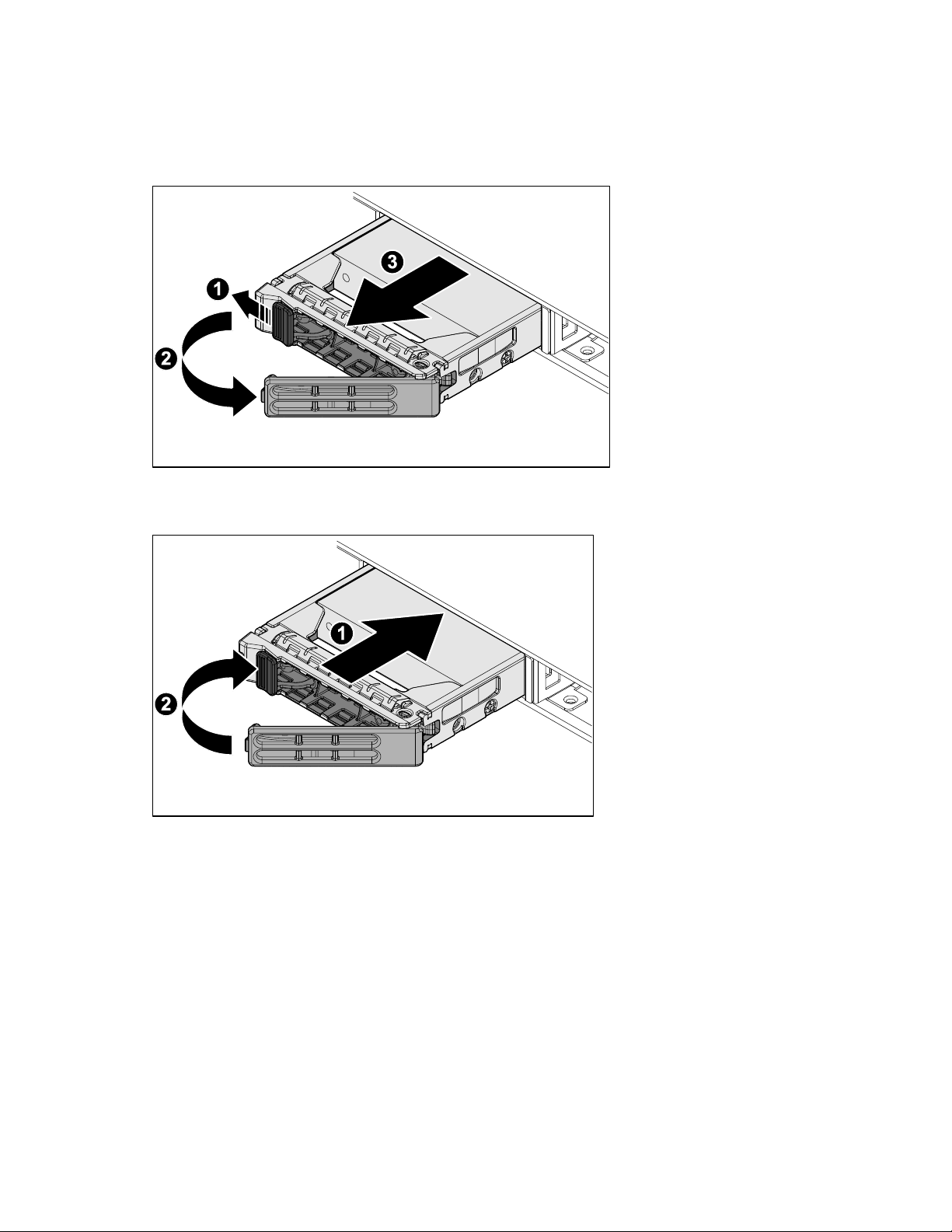

Hard disk drives

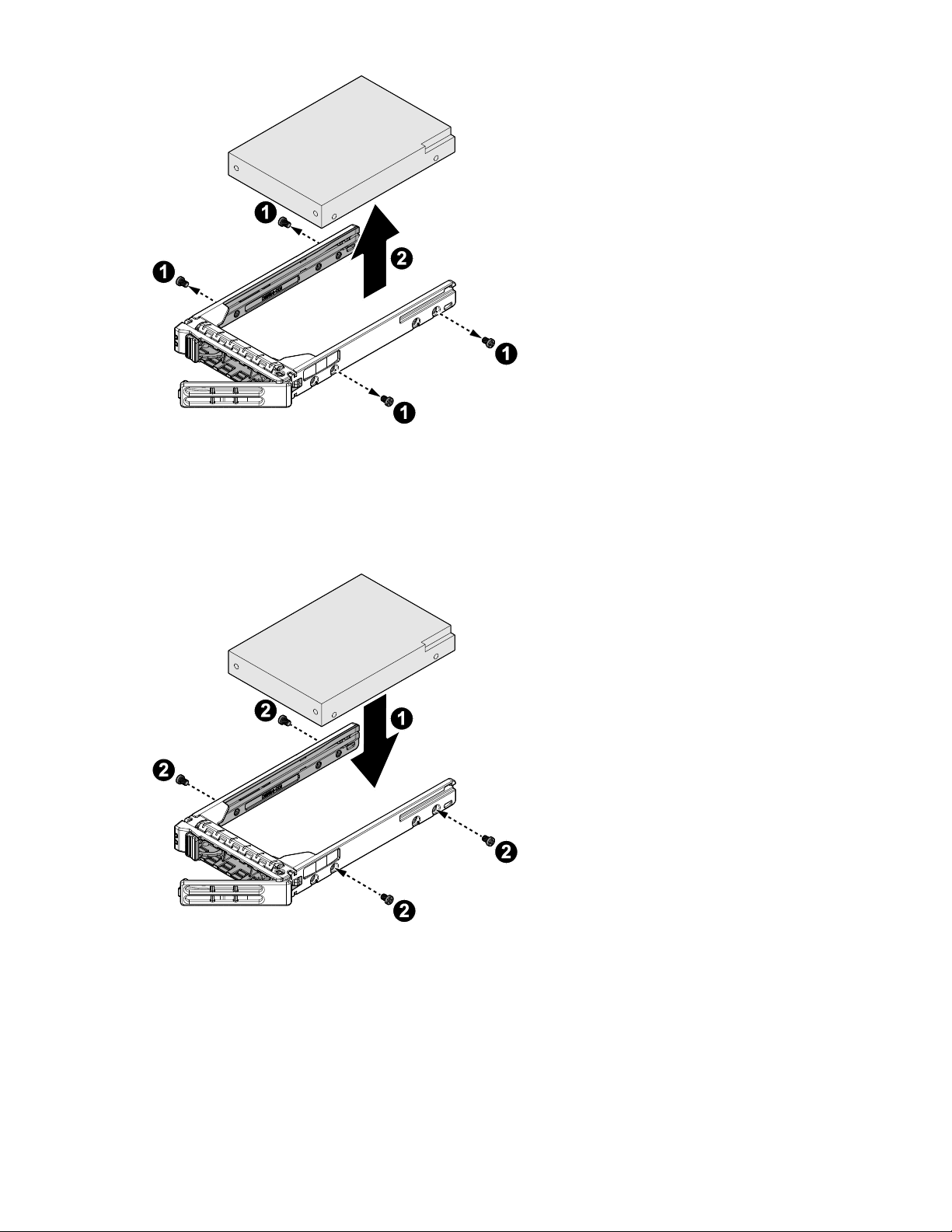

Removing the hot-swappable HDD assembly

Installing the hot-swappable hard disk drive assembly

Removing the hard disk drive module

To remove the HDD module:

1. Remove the hot-swap HDDs assembly (on page 19).

2. Remove the screws securing the HDD from the HDD carrier.

3. Remove the HDD from the HDD carrier.

Installation 19

Page 20

Installing the HDD module

To install the HDD module:

1. Align the HDD in the HDD carrier, connectors facing the opening of the carrier.

2. Secure the HDD and the HDD carrier with the screws.

3. Install the hot-swap HDDs assembly (on page 19).

Power supply unit (PSU)

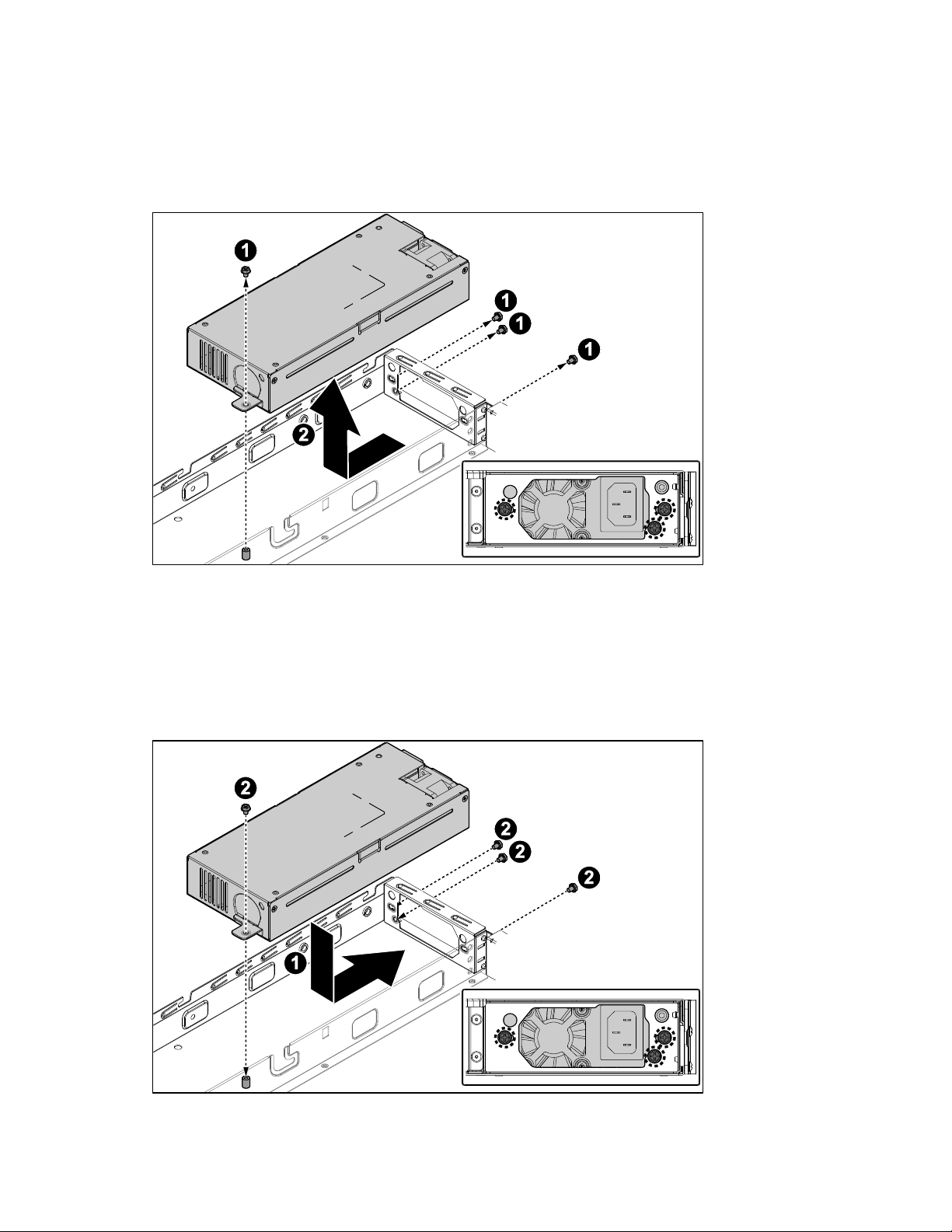

Removing the PSU

To remove the power supply unit:

Installation 20

Page 21

1. Power down the server, and then detach all power cords from the power supplies.

2. Remove the access panel (on page 37).

3. Locate the PSU and remove the cabling attached to the system board and components.

4. Remove the screws to release the PSU from the chassis.

5. Slide the PSU out to remove it.

Installing the PSU

To install the power supply unit:

1. Align the PSU on the chassis and install in place.

2. Secure the PSU with the screws.

3. Connect the cabling to the system board and the PSU.

Installation 21

Page 22

4. Install the access panel (on page 38).

Expander board

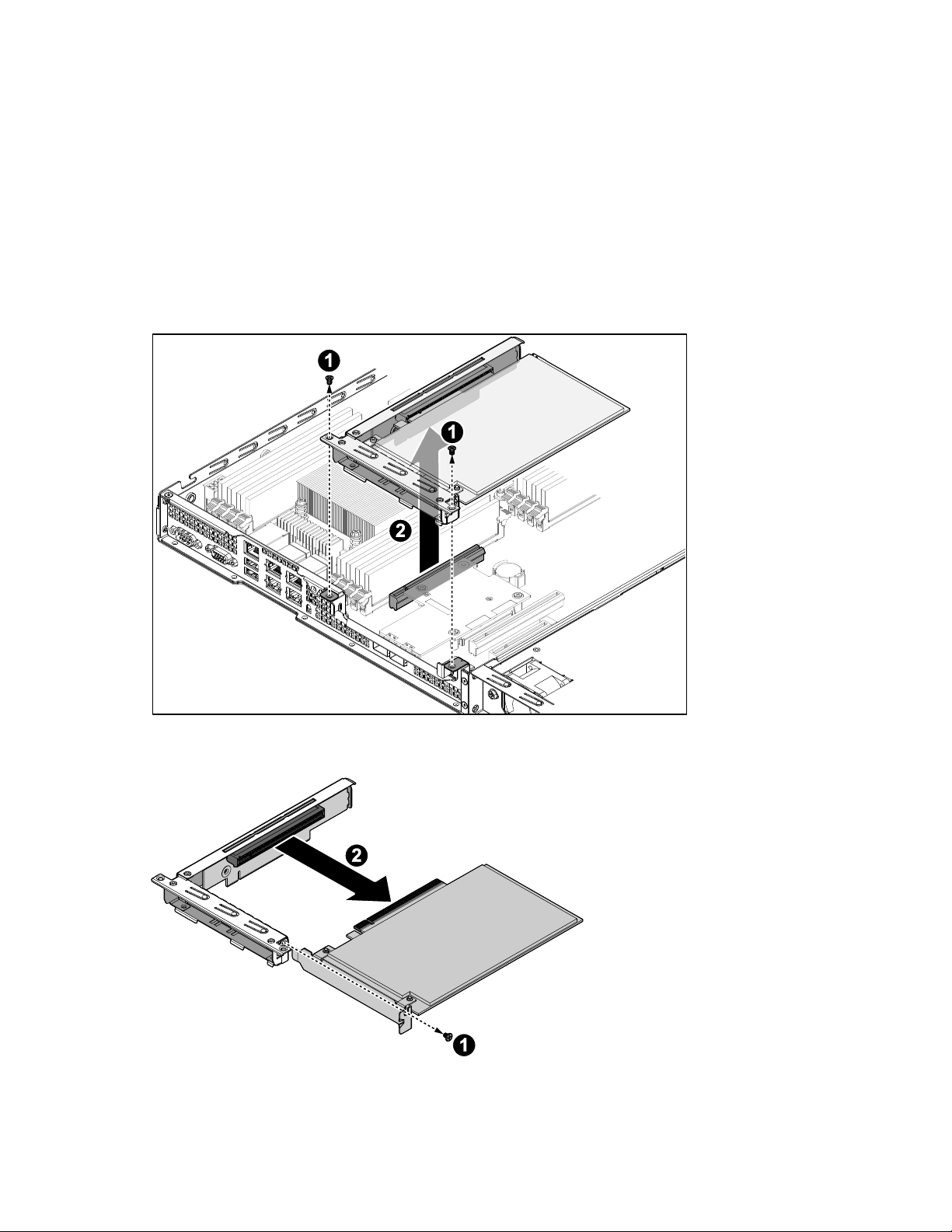

Removing the expander board

To remove the expander board:

1. Power down the server and detach all power cords from the power supplies.

2. Remove the access panel (on page 37).

3. Remove the PCIe assembly from the chassis.

4. Disconnect the PCIe card from the riser card.

5. Remove the PCIe card.

Installation 22

Page 23

Installing the expander board

To install the hard expander board:

1. Orient the PCIe card with the riser guide slot and push in the direction of the arrow until the PCIe card

is secured in the PCIe card connector.

2. Install the PCIe assembly. Press down gently to seat it in place.

3. Install the access panel (on page 38).

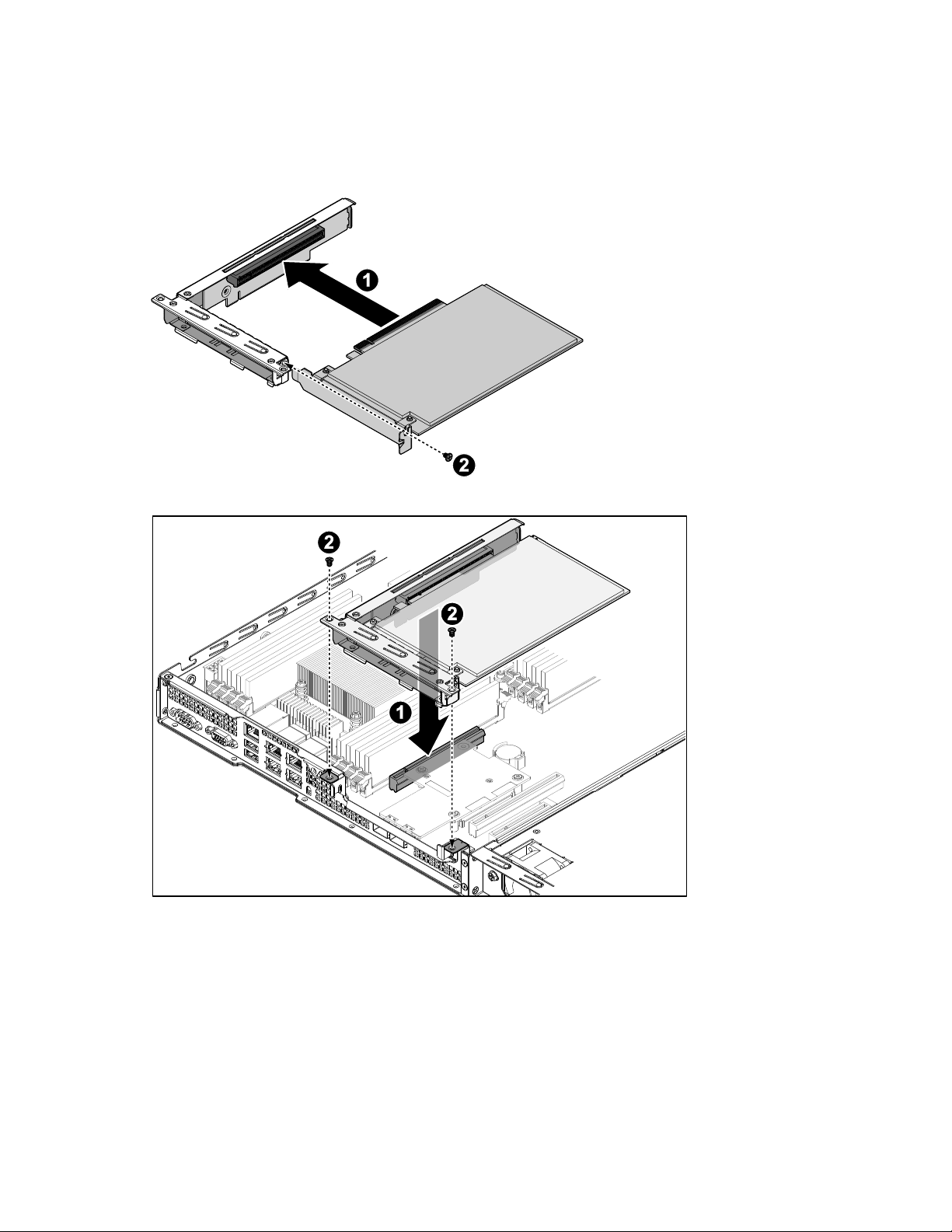

Hard disk drive backplane

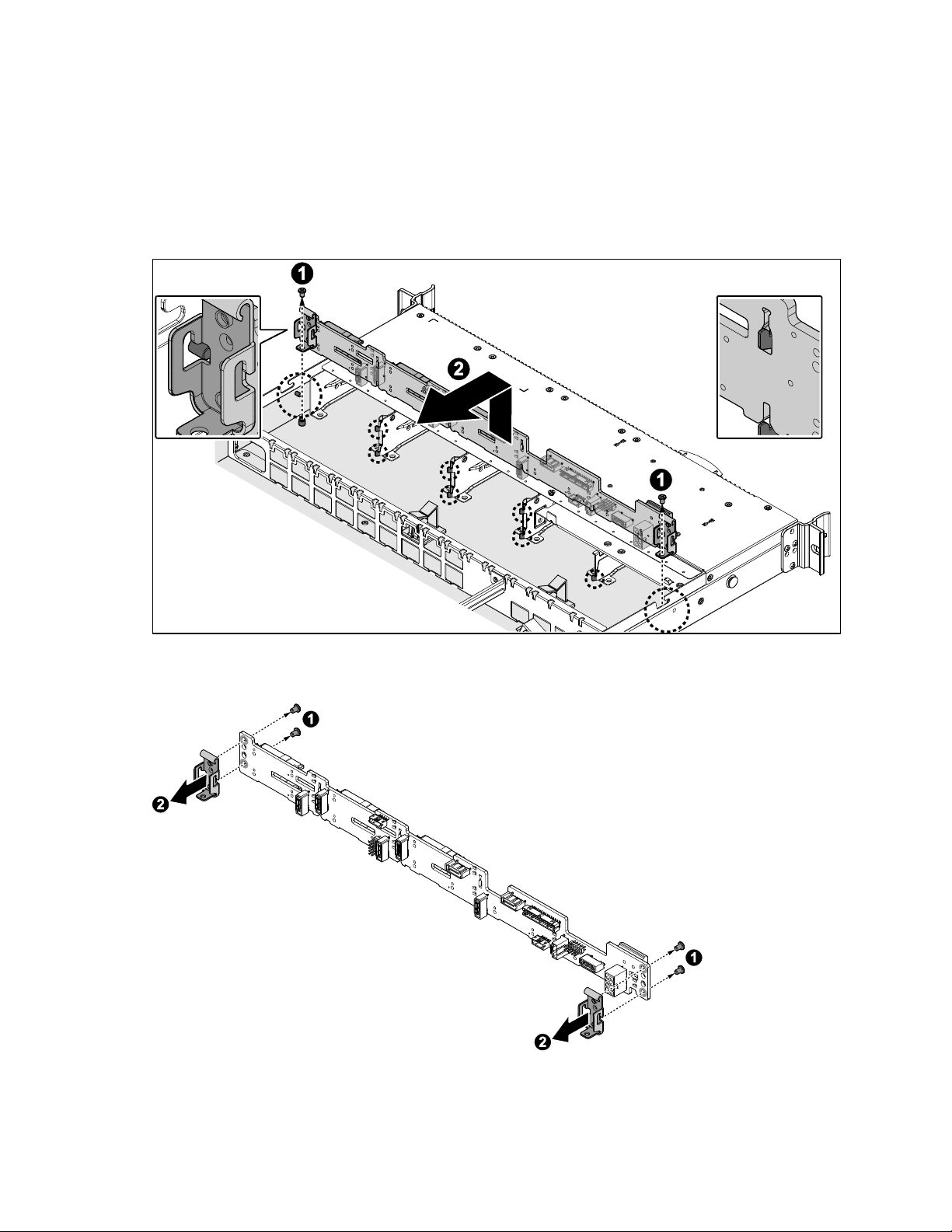

Removing the hard disk drive backplane

To remove the HDD backplane:

1. Power down the server and detach all of the power cords from the power supplies.

Installation 23

Page 24

2. Remove the access panel (on page 37).

3. Remove all the hot-swappable HDDs assemblies (on page 19).

4. Remove the front control board (on page 38).

5. Disconnect all the cables from the HDD backplane.

6. Remove the screws securing the HDD backplane assembly to the chassis.

7. Release the HDD backplane assembly from the guide tabs on the chassis, and then remove the HDD

backplane.

8. Remove the screws securing the HDD backplane to the HDD assembly bracket (1).

9. Remove the HDD backplane (2).

Installation 24

Page 25

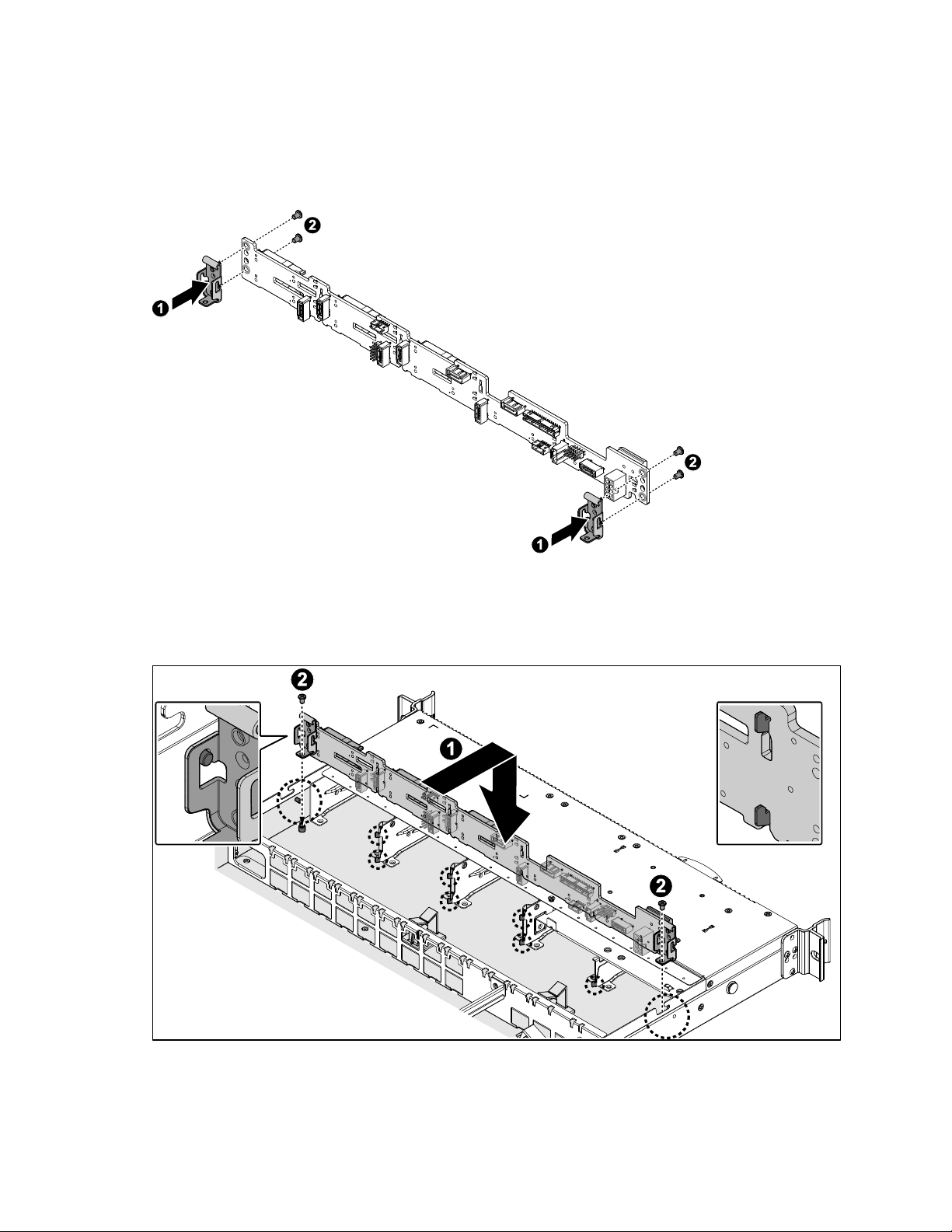

Installing the HDD backplane

To install the HDD backplane:

1. Align the screw holes on the HDD backplane with the screw holes on HDD assembly bracket. (1)

2. Secure the HDD backplane and HDD assembly bracket with the screws. (2)

3. Align the screw holes on the HDD backplane assembly with the screw holes on the chassis, the HDD

SAS connectors must face inward.

4. Install the HDD backplane assembly to the guide tabs on the chassis.

5. Secure the HDD backplane assembly and the chassis with the screws.

6. Connect all the cables to the HDD backplane assembly.

7. Install the front control board (on page 39).

Installation 25

Page 26

8. Install all the hot-swappable HDDs assemblies (obpage 19).

9. Install the access panel (on page 38).

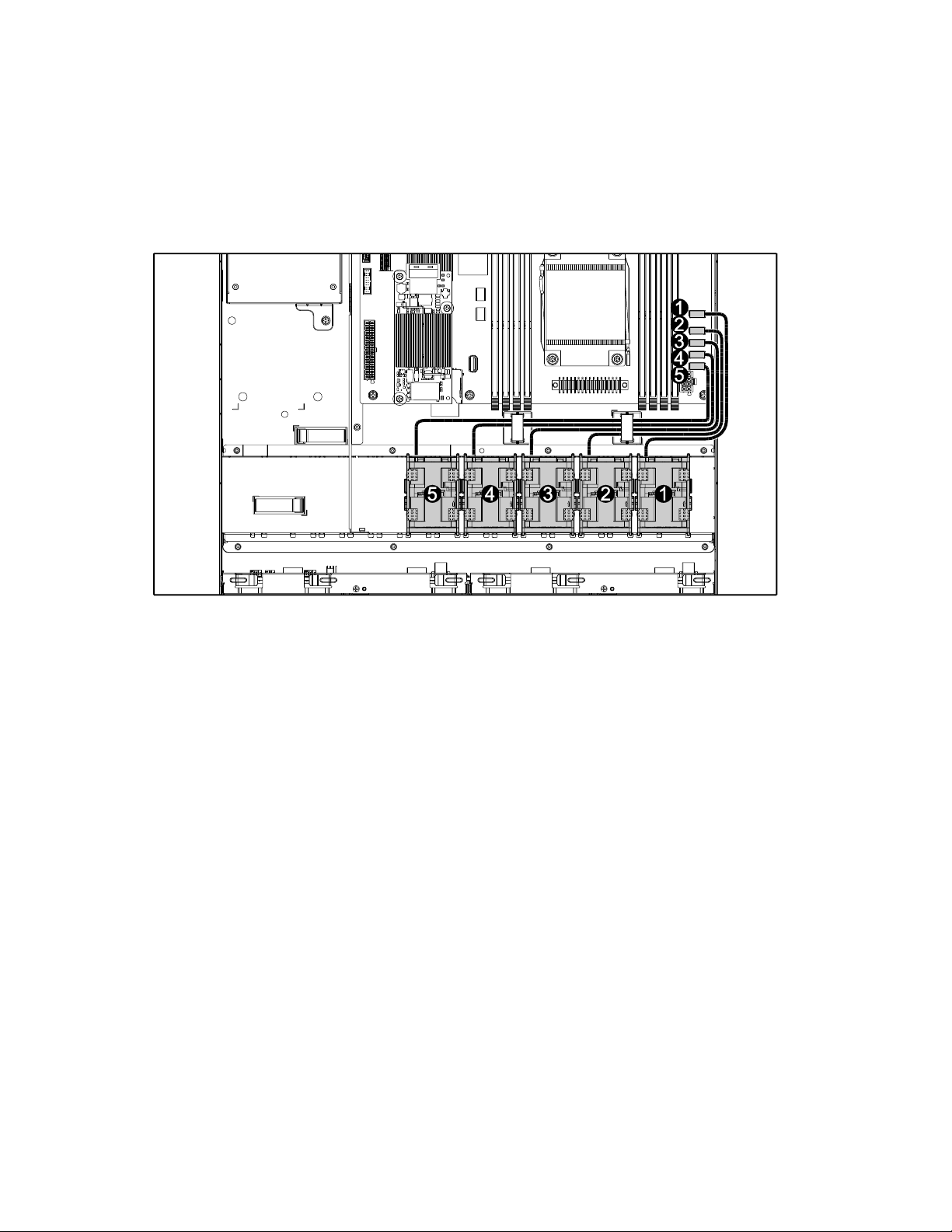

System fans

Cable routing

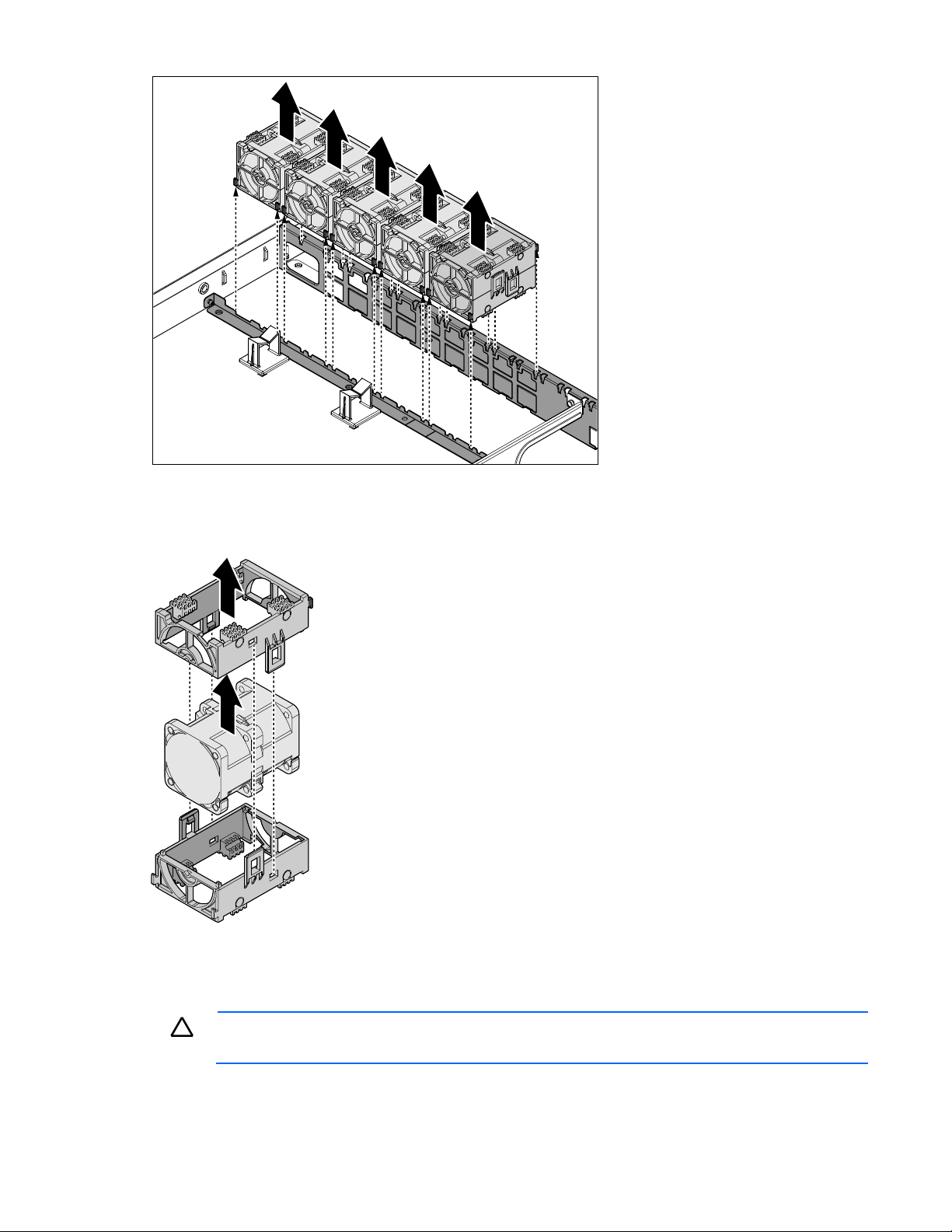

Removing the system fan assembly

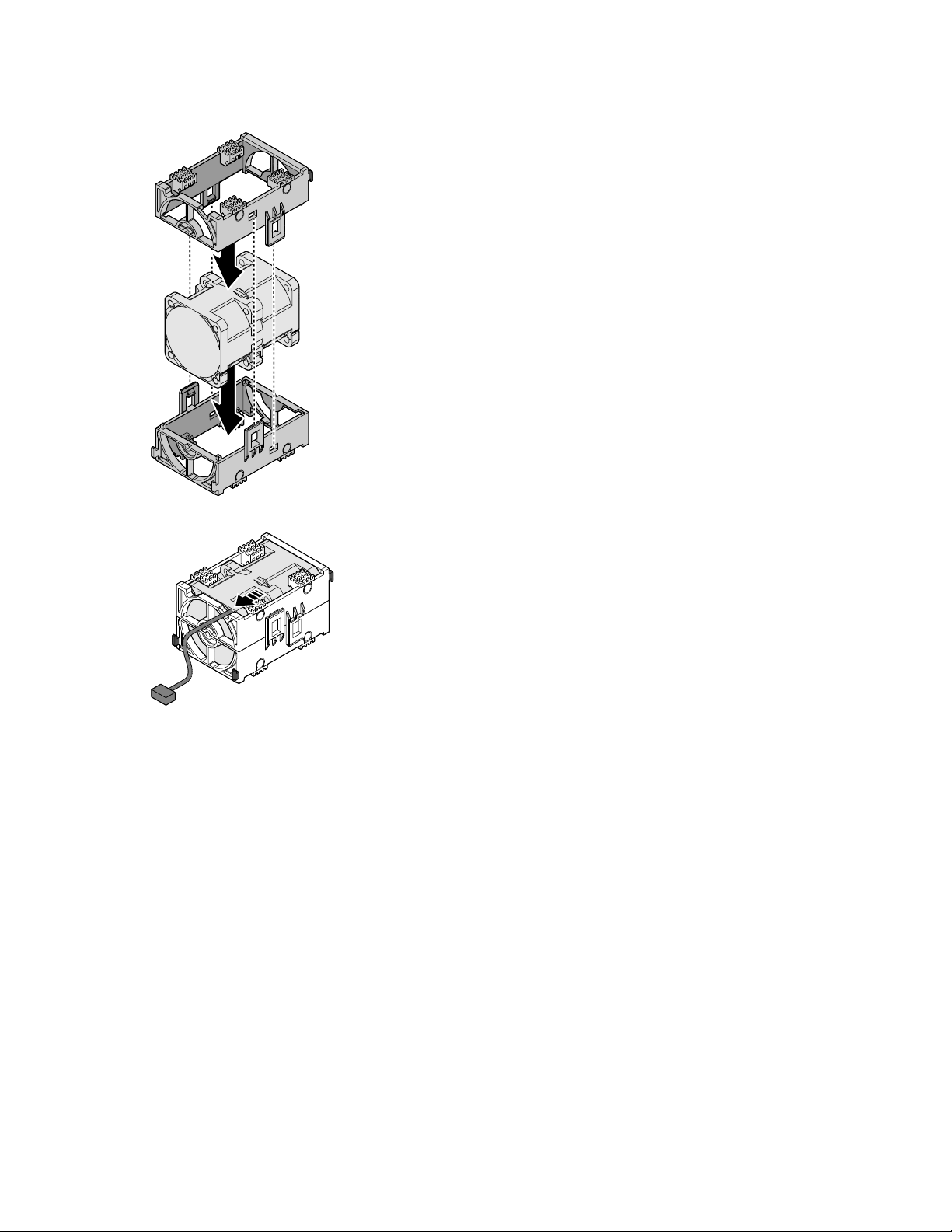

To remove a system fan assembly:

1. Power down the server and detach all of the power cords from the power supplies.

2. Remove the access panel (on page 37).

3. Disconnect the five (5) fan cables from the system board. See page 13 for location.

4. Remove the fan module.

Installation 26

Page 27

5. Unlock the fan assembly bracket.

CAUTION: Make sure the airflow arrows on the system fan are pointing towards the rear of

the system to prevent system overheating.

6. Remove the upper fan assembly bracket.

7. Remove the fan.

8. Repeat the procedure for the remaining fans.

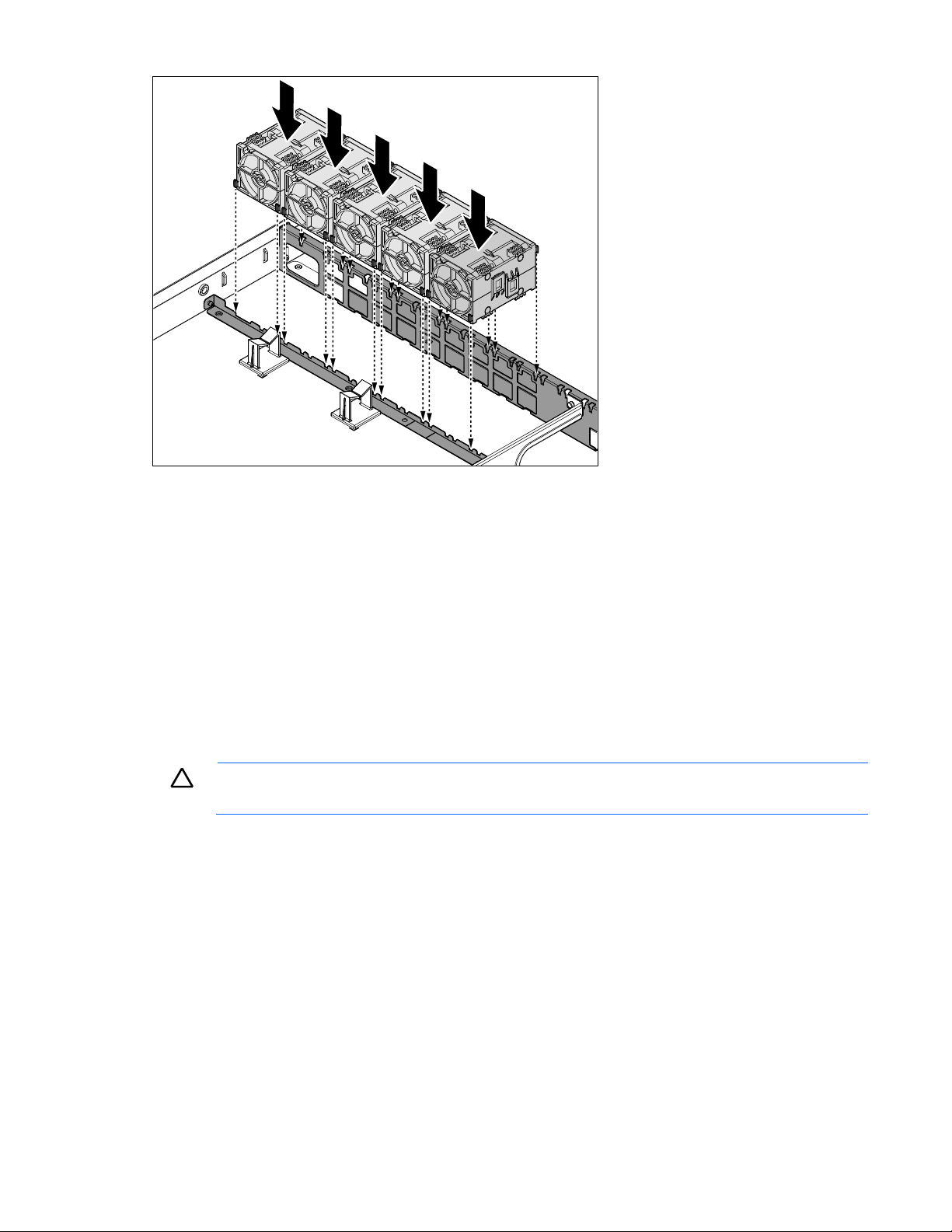

Installing the system fan assembly

To install the system fan assembly:

Installation 27

Page 28

1. Install the fan into the lower fan assembly bracket.

2. Install the upper fan assembly bracket and lock it.

3. Guide the fan cable through the gap in the upper bracket.

4. Align the fan assembly with the chassis and fan cable facing the rear of the chassis.

5. Install the fan assembly into the chassis.

Installation 28

Page 29

6. Repeat the procedure for the remaining fans.

CAUTION: If only one processor is installed, only one heat sink needs to be installed.

A CPU0 heat sink is different than a CPU1 heat sink.

7. Connect the five (5) fan cables to the system board. See page 13 for location.

8. Install the access panel (on page 38).

Heat sinks

Passive heat sinks cool processors. To achieve optimal cooling performance, the underside of the heat sink

must be properly attached to the processor with TIM. The mechanical performance of the heat sink is

designed to meet the requirements of Intel processors. The heat sink is necessary to maintain chipset

temperature at or below temperature limits.

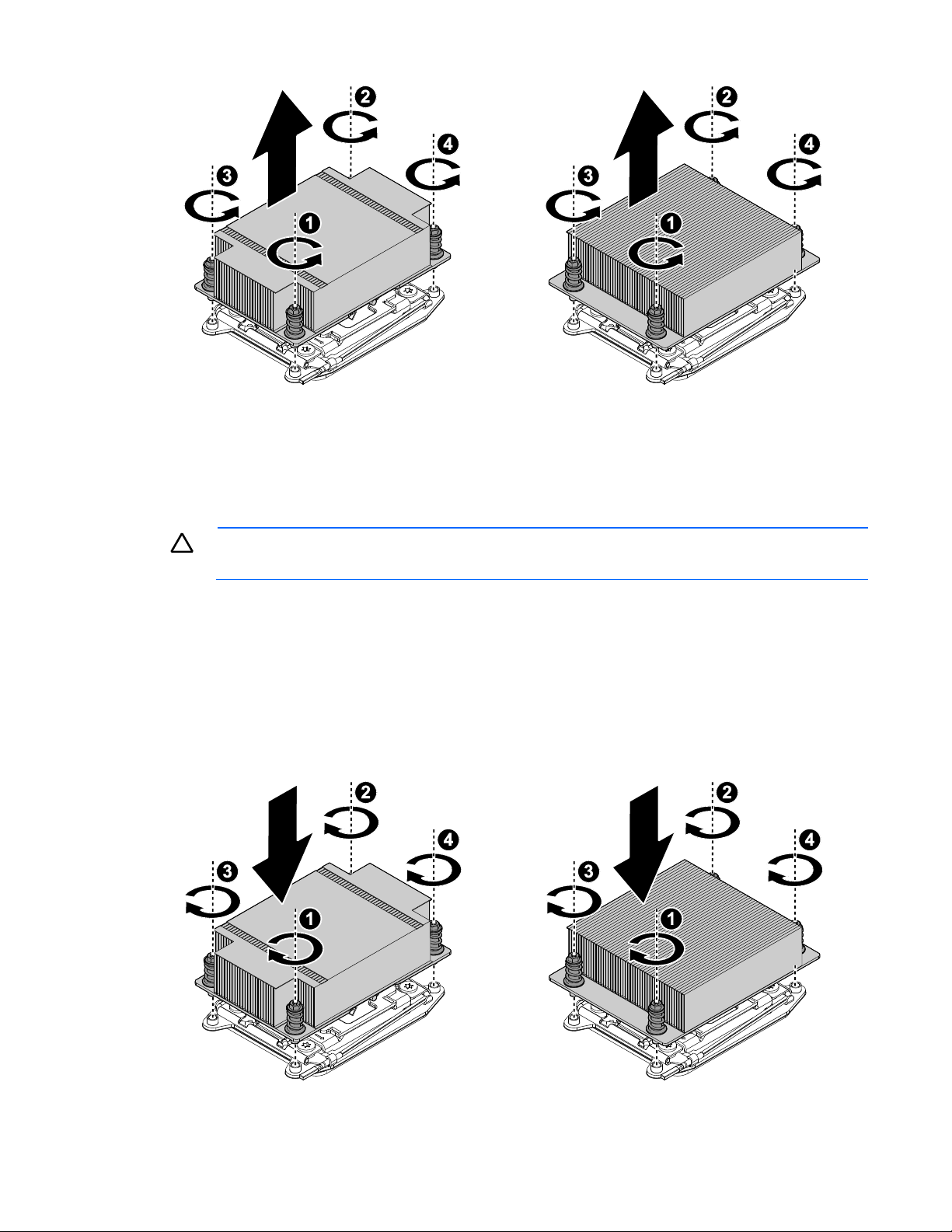

Removing the heat sink

To remove the heat sink:

1. Power down the server and then detach all power cords from the power supplies.

2. Remove the access panel (on page 37).

3. Loosen the four screws in the order shown.

Installation 29

Page 30

Processor0

Processor1

4. Remove the heat sink.

CAUTION: Do not apply an excessive amount of thermal compound to prevent damage to the

system board.

Processor0

Processor1

5. Repeat the procedure for the additional heat sink.

Installing the heat sink

To install the heat sink

1. Make sure the top of the processor is clean.

2. Apply a small drop of thermal compound in the middle of the processor.

3. Remove the protective cover from the underside of the heat sink.

4. Align the heat sink so the sticker label faces the DIMM module.

5. Place the heat sink on top of the processor until it is seated firmly in place.

6. To secure the heat sink, tighten the four retaining screws clockwise, in the order shown.

Installation 30

Page 31

7. Repeat the procedure for the additional heat sink.

CAUTION: In a single processor configuration, the single processor must be installed in the

Processor0 socket (see page 13 for location).

ESD protection must be worn during the procedure to avoid damaging the components.

8. Install the access panel (on page 38).

Processor

Removing the processor

To remove the processor:

1. Power down the server and detach all of the power cords from the power supplies.

2. Remove the access panel (on page 37).

3. Remove the heat sink (on page 29).

4. Press downward and inward on the right processor locking lever to release it.

5. Press downward and inward on the left processor locking lever, pulling it fully open.

6. Lift the processor load plate to the fully open position.

Installation 31

Page 32

7. Lift the processor out of the socket.

CAUTION: ESD protection must be worn during the procedure to avoid damaging the

components.

8. Repeat the procedure for the additional processor.

Installing the processor

To install the processor:

1. Align the gold triangle identifying pin 1 of the processor with the triangular cutout of the socket and

the key-indent on the socket.

2. Insert the processor into the socket, and make sure that the four keys on the socket fit into the

corresponding keys on the processor.

Installation 32

Page 33

3. Lower the processor load plate over the processor.

4. Push the left processor locking lever down (1), and then latch it into the locked position (2). The

protective plastic cover pops out as the latch is engaged.

5. Push the right processor locking lever down and latch it into the locked position (3).

6. Repeat the procedure for the additional processor.

7. Install the heat sink (on page 30).

8. Install the access panel (on page 38).

Installation 33

Page 34

DIMM modules

DIMM: Max x16pcs DIMM

Removing the DIMM module

The system board includes 16 (four DIMM channels per processor) DIMM slots for the installation of DDR4

1600/1866/2133 MHz DIMMs.

To remove the DIMM module:

1. Power down the server, and then detach all power cords from the power supplies.

2. Remove the access panel (on page 37).

3. Push the locking latches of the DIMM slot downward and outward to eject the DIMM module.

4. Remove the DIMM module.

Installation 34

Page 35

Installing the DIMM module

CAUTION: When removing any component, wear a properly grounded static strap to prevent

static discharge.

The system board includes 16 (four DIMM channels per processor) DIMM slots for the installation of DDR4

1600/1866/2133 MHz DIMMs.

To install the DIMM module:

1. Pull the locking latches of the DIMM slot outward.

2. Place the DIMM module into the socket so the notch and obstruction are aligned.

3. Press the edge connector of the DIMM module into the slot. Press down firmly so that the locking

latches of the DIMM slot are levered upwards to secure the DIMM module.

4. Install the access panel (on page 38).

System board module

Removing the system module

To remove the system board module:

1. Power down the server and detach all power cords from the power supplies.

2. Remove the access panel (on page 37).

3. Remove the DIMM modules (on page 34).

4. Remove the heat sinks (on page 29).

5. Remove the processors (on page 31).

6. Disconnect all of the cables from the system board.

7. Remove the screws from the system board module.

8. Lift the front of the system board and pull it away from the rear of the system. Make sure the I/O ports

clear the chassis before lifting the system board.

9. Remove the system board module.

Installation 35

Page 36

CAUTION: When removing any component, wear a properly grounded static strap to prevent

static discharge.

Installing the system board module

To install the system board module:

1. Align the I/O ports on the system board with the slots on the chassis.

2. Slide the system board into position. Make sure the I/O ports are seated correctly.

3. Lower the system board onto the chassis. Make sure the screw holes on the system board and chassis

are aligned.

4. Secure the system board module to the chassis with the screws.

Installation 36

Page 37

CAUTION: Be sure that the server is powered down and the AC power cords are

disconnected from the server power supplies to avoid personal injury or server damage.

5. Connect the cables.

6. Install the processors (on page 32).

7. Install the heat sinks (on page 30).

8. Install the DIMM modules (on page 35).

9. Install the access panel (on page 38).

Access panel

Removing the access panel

Installation 37

Page 38

Installing the access panel

Front control board

Removing the front control board

To remove the front control board:

1. Power down the server and detach all of the power cords from the power supplies.

2. Remove the screw from the top of the chassis.

3. Slide the front control board out of the chassis.

Installation 38

Page 39

Installing the front control board

To install the front control board:

1. Slide the front control board into the chassis.

2. Secure the front control board to the chassis with the screw.

Riser card

Removing the riser card

To remove the riser card:

Installation 39

Page 40

1. Power down the server and detach all of the power cords from the power supplies.

2. Remove the access panel (on page 37).

3. Disconnect the riser assembly from the system board.

4. Remove the screw securing the riser card to the riser bracket.

5. Remove the riser card from the riser bracket.

Installing the riser card

To install the riser card:

1. Align the screw holes on the riser card with the screw holes on the riser bracket.

2. Secure the riser card to the riser bracket with the screw.

Installation 40

Page 41

3. Align the connector on riser assembly with the connector on the system board.

4. Attach the riser assembly. Press down gently to seat in place.

5. Install the access panel (on page 38).

Powering on and selecting boot options

1. Connect the Ethernet cable.

2. Press Power On/Standby.

3. During the initial boot:

o To modify the BIOS default settings, press F2 or DEL when prompted from the start-up sequence to

enter the BIOS setup utility. By default, the BIOS setup utility runs in the English language.

o It is not necessary to modify the server configuration, press F7 during system boot to select the

boot device for system software installation.

o To enter PXE boot, press F12 during boot time when prompted from the start sequence.

Installing the operating system

To operate properly, the server must have a supported OS.

Installation 41

Page 42

To install an OS on the server, use one of the following methods:

Local installation (USB key or USB optical disc)

Remote deployment installation (PXE, virtual KVM)

Follow up install OS step and reboot system

Installation 42

Page 43

Cabling

Item

Description

Quantity

1

24 pin main power

1

from PSU

2&3

2x16 pin to 8 pin CPU1 &

8 pin CPU0 Power Y cable

1

from PSU

4

2x4 pin HDD BP power

cable from PSU

1

from PSU

Internal system cable routing

The server internal cable routing is listed in the following figure and table:

Cabling 43

Page 44

System Interconnection Signal (by PCH)

Item

Description

Quantity

1

System board (2x10 pin )

to F-USB board (2x5 pin)

Cable

1

from system board

to front USB board

2

System board (2x15 pin) to

FP (2x15 pin) cable

1

from system board

3

From onboard PCH to HDD

backplane cable

2

from onboard

MiniSAS

4

From system fan to system

board (1x5 pin) cable

5

from fan

5

From PSU to system board

PMBUS (1x5 pin) cable

1

from PSU

6

From system board SATA

to SSD cable

1

from system board

SATA

Cabling 44

Page 45

System Interconnection Signal (by 3rd RAID Card)

Item

Description

Quantity

1

System board (2x10 pin) to

F-USB board (2x5 pin)

cable

1

from system board

to front USB board

2

System board (2x15 pin) to

FP (2x15 pin) cable

1

from system board

3

From RAID card to HDD

backplane

2

from RAID card

MiniSAS

4

From system fan to system

board (1x5 pin) cable

5

from fan

5

From PSU to system board

PMBUS (1x5 pin) cable

1

from PSU

6

From system board SATA

to SSD cable

1

from system board

SATA

Cabling 45

Page 46

Configuration

BMC

Web GUI introduction

The web GUI is a friendly interface for the end users. A user can access the iBMC FW via a web browser,

and then go through the server status and do many configurations to the IBMC FW.

The default user privilege is set to administrator. The web function access rights are determined by different

privileges. For example, the administrator privilege can access all functions, but the user privilege cannot.

The web GUI provides many useful functions, such as:

firmware update

system power control

system event log (SEL)

current sensor reading

configuration for: BMC network, user accounts, serial, PEF, alerts, SOL, information about BMC, and

the system

IP address

Static and DHCP are the two common IP sources of iBMC FW. The default setting is DHCP. The detailed IP

address information is available from the BIOS setup menu.

User name and password

A user name and password are required to establish a web GUI session. The user should also have

accessibility to the LAN channel. Use the system management software to set the user name, password,

and grant access. The default setting is shown below:

ID 2: User Name = admin Password = Password1

Web browsers

iBMC FW supports either Microsoft Internet Explorer (Windows platform) or Firefox (Linux platform).

The embedded web serve provides full access. The web GUI is accessible via the HTTP protocol or via the

encrypted HTTPS protocol.

Logging in

To log in to the web GUI, enter the iBMC FW IP address into a web browser. An example of using the

HTTP protocol is http://10.141.104.176. An example of using the encrypted HTTPS protocol is

https://10.141.104.176

Configuration 46

Page 47

Updating the firmware

Many common problems can be resolved by updating the firmware. The BMC FW can be updated

through a host-based utility or through the web GUI.

Restoring the default configuration

The BMC FW supports an OEM command to restore all of the configuration values to their defaults. Using

the OEM command restores all IPMI configuration parameters and all Linux user configuration files

(password, group, and so on).. The OEM command is not available to the end user, but the web GUI

provides a friendly interface to do this. This command does not restore the SEL records.

BMC FW version

The “Get Device ID” command (NetFn Application, Command 1) reports the firmware revision. The

“Get Device ID” command also reports the auxiliary firmware revision.

The firmware build ID can map from the firmware revision. Naming convention of build ID is J2BTxxy. “xx”

is minor revision (BCD encoded), and “y” is auxiliary firmware revision. “y” is “a” if auxiliary firmware

revision is 0, and “y” is “b” if auxiliary firmware revision is 1, and so on. For example, if the firmware

revision is 0.12.0, the build ID is J2BT12A; if the firmware revision is 0.12.1, the build ID is J2BT12B.

End-users can confirm whether restore default configuration when updating firmware through the utilities or

through the web GUI.

The default configuration should be restored when when SDR is changed.

Updating BMC using Linux

To update BMC using Linux:

1. Log into Linux.

2. Open the terminal.

3. Create new directory “/work”, command:

mkdir /work

4. Copy the BMC FW package to the /work directory using the command:

cp file_name.zip /work

5. Change the directory using the /work, command:

cd /work

6. Uncompress the BMC FW package using the command:

upzip file_name.zip

7. Enter directory of uncompressed before, command:

cd file_name/Linux/linux64bit/

8. Add execute permission for all of the files in the file_name folder.

9. Execute /FullUpdate.sh or ./Reserve.sh to update BMC.

Configuration 47

Page 48

10. The following screen shot shows that BMC successfully updated.

Updating BMC via a web GUI

To update BMC using the web GUI:.

1. Log into the web GUI using a web browser.

2. Select Update from the left tree view, and then click Browse.

Configuration 48

Page 49

3. Select the BMC FW image file.

4. Click Upload. If the file is a valid file, all other sessions are terminated, and then the image upload

begins. If the upload fails, a message displays with a notification to upload another file.

Configuration 49

Page 50

5. For a successful upload, the current firmware version and the version of the new file are displayed, as

well as the Preserve Configuration checkbox, Update button and Cancel button.

* Preserve Configuration: Clear to default FW settings or not.

6. Click Update to begin the firmware update process and to view the status of the update.

Configuration 50

Page 51

7. When the update is completed, the embedded software automatically reboots.

Clicking Cancel terminates the process, and then the embedded software reboots.

BIOS settings

There are eight menus in the BIOS setup utility, which appear in the following order: Main, Advanced,

IntelRCSetup, Server Mgmt, GPNV Logs, Security, Boot, and Save & Exit. Use the arrow keys to navigate

the menus or options that are listed on the menu. Configurable menu options or fields appear in color. For

further instructions about how to navigate and change settings in the BIOS setup utility, see the on-screen

instructions that are provided on the menu.

Configuration 51

Page 52

BIOS setup menus

BIOS Menu

Description

Main

General product information including BIOS/memory information, system language, and

time/date

Advanced

Configuration information for legacy option ROM support, PCI subsystem, WHEA, trust

computing, CPU, SATA, USB, serial port redirection, and network stack

IntelRCSetup

Server chipset configuration for the north/south bridge and ME subsystem

Server Mgmt

BMC self-test status, timer settings, event log settings, and BMC network settings

GPNV Logs

View the system and SMBIOS event logs system

Security

Set or change the user and supervisor passwords

Boot

Configure the boot device priority

Save & Exit

Save changes and exit, discard changes and exit, discard changes, or load defaults

SMBIOS Event Log

Description

0x07

POST memory resize

0x08

POST errors

0x10

System limit exceeded

0x16

Log area reset

0x17

System boot

0xFF

End of log

0x80

IDE device failed

0x81

Flash device update operation failed

0x82

No more PCI resources available

0x83

No space for any more legacy OPROM

0x84

Invalid password entered three times

0x85

Clear CMOS

The following table provides descriptions for the top-level BIOS setup menus.

POST error message

There are three methods to treat the event/errors detected during POST:

Log to SMBIOS

Log to SEL

Shown on-screen during POST

SMBIOS event log

Configuration 52

Page 53

System event log (POST)

Sensor

Name

Sensor

Type

Sensor

Number

E/R

Type

Event

Data1

Event

Data2

Event

Data3

Description

BIOS POST

Sensor

0x0F

0x09

0x6F

0xC0

0x01

0xFF

System firmware error. No system

memory is physically installed in

the system.

0x0F

0x6F

0xC0

0x02

0xFF

System firmware error. No usable

system memory, all installed

memory has experienced an

unrecoverable failure.

0x0F

0x6F

0xC0

0x0A

0xFF

System firmware error. No video

device detected.

0x07

0x6F

0x02

0xFF

0xFF

FRBI/BIST failure.

0x10

0x6F

0x04

0xFF

0xFF

SEL full.

Entering the pop-up boot menu

To enter the pop-up boot menu, press F7 during system boot when the Press <F7> to enter Popup Boot

Menu message displays.

The pop-up boot menu screen displays as shown in the following figure.

Entering PXE boot

To access PXE boot:

1. Set Network as the first boot device in BIOS setup menu.

2. Select Network device from the pop-up boot menu.

Entering the BIOS setup menu

The BIOS setup menu is accessible using the following methods:

Connect a USB keyboard, mouse, and VGA monitor directly to the server.

Use a console (or terminal emulator connected to a computer) through the serial port on the rear of

the server.

To access the BIOS setup utility menus:

Configuration 53

Page 54

1. Press the power button on the front control panel to power up the server.

Beep Numbers

Description

1

Memory was not installed

1

Memory was installed twice (Install PEI memory routine in PEI core was called twice)

2

BIOS recovery started

3

DXE IPL was not found. Cannot locate DXE IPL PPI

DXE core firmware volume was not found. Cannot load DXE core file into memory

4

BIOS recovery failed

5

No memory detected

7

PEI reset is not available

Beep Numbers

Description

1

Invalid password

4

Some of the architectural protocols are not available

6

Flash update failed

7

DXE reset is not available

8

Platform PCI resource requirements cannot be met

2. Press F2 or DEL during system boot when the Press <DEL> or <F2> to enter setup displays.

3. Use the left and right arrow keys to navigate the different menu options. When a menu option is

selected, the top-level screen for that option appears.

4. Use the up and down arrow keys to scroll up and down to select an item on a top-level screen. When

the up and down arrow keys are pressed, the only options that are highlighted are the options that

can be modified.

o If an item can be modified, user instructions for modifying the option appear in the right column of

the screen.

o If an item is a link to a sub-screen, a prompt to press Enter to access the sub-screen appears in

the right column.

5. Modify the setup item and press F4 to save the changes and exit the screen.

6. Follow the instructions on the Save & Exit menu screen to save or discard your changes and exit the

BIOS setup utility.

BIOS beep codes

This section provides the BIOS beep codes including the PEI to report errors during memory initialization

and DXE to report errors during hardware initialization.

PEI beep codes

DXE beep codes

BIOS maintenance

This section provides information about upgrading the BIOS, clearing the BIOS password, clearing

CMOS, BIOS recovery, and a BIOS jumper description.

Configuration 54

Page 55

Upgrading the BIOS using DOS

The flash memory update utility loads a fresh copy of the BIOS into flash ROM. This utility only updates the

BIOS region.

BIOS update utility: AFUDOS.EXE

Boot the system to DOS environment and execute the following command to update BIOS:

AFUDOS <BIOS ROM File Name>[Option 1][Option 2]

or

AFUDOS<Output BIOS ROM File Name><Commands>

Commands

Use the mandatory field to select an operation mode.

o /O Save current ROM image to file

o /U Get and display ROM ID from BIOS ROM file

o /S Refer to Option: /S

o /D Verification test of given ROM File without flashing BIOS.

Options

Use the optional field to supply more information for flashing the BIOS ROM. The following lists the

supported optional parameters and format:

o /P Program main bios image

o /B Program Boot Block

o /N Program NVRAM

o /E Program Embedded Controller block if present

o /K Program all non-critical blocks

o /Kn Program n'th non-critical block only (0>= n <=7)

o /Q Quiet mode enable

o /REBOOT Reboot after update BIOS done

o /X Do not check ROM ID

o /S Display current system's BIOS ROM ID

o /R Preserve all SMBIOS structures during NVRAM programming.

o /Rn Preserve SMBIOS type N during Boot Block programming.

o /ECUF Update EC BIOS when newer version is detected.

o /Shutdown Shutdown after programming.

Rules

o Any parameter enclosed by <> is a mandatory field.

o Any parameter enclosed by [ ] is an optional field.

o <Commands> cannot co-exist with any [Options].

o The main BIOS image is the default flashing area if no options are present.

o [/REBOOT], [/X], and [/S] automatically enables the [/P] function automatically.

o If [/B] is present alone, only the boot block area needs to be updated.

o If [/N] is present alone, only the NVRAM area needs to be updated.

Configuration 55

Page 56

o If [/E] is present alone, only the embedded controller block needs to be updated.

Flash Command

Description

afudos XXXX.ROM /P

Program main BIOS image

afudos XXXX.ROM /P /B

Program main BIOS and BB (Boot Block)

afudos XXXX.ROM /P /B /N

Program main BIOS, BB and NVRAM

afudos XXXX.ROM /P /B /R

Program BB and main BIOS without SMBIOS

Clearing the BIOS password

If the user and/or administrator password is lost or forgotten, clear both passwords by moving the

password clear jumper into the clear position.

The BIOS determines if the password clear jumper is in the clear position during BIOS POST and clears

any passwords if necessary. The password clear jumper must be restored to its original position for the

new password to remain set.

Clearing the CMOS

The CMOS clear jumper uses RTCRST# to:

Clear CMOS values

Set the RTC power well configuration bits to default.

To compatible legacy BIOS for user who is used to use legacy BIOS, BIOS provide the function to restore

the default settings of BIOS Setup when CMOS is cleared, even though UEFI BIOS store BIOS settings to

NVRAM.

There are two methods to clear the CMOS:

Clear the CMOS jumper.

Remove the CMOS battery when the system is in AC OFF status.

Important: After clearing the CMOS, the BIOS setup default is restored, but the password that was set by

the user is still reserved.

Recovering the BIOS

If the BIOS image is corrupt, a system BIOS update fails, or the system fails to complete POST, the BIOS

must enter recovery mode. In recovery mode, an entire BIOS image can be refreshed to BIOS flash part.

To recover the BIOS:

1. Turn off the system power.

2. Open the chassis.

3. Move the BIOS recovery jumper from the normal positions 1-2 to the recovery positions 2-3.

4. Close the chassis.

5. Copy the latest BIOS image file (DC1F1XXX.ROM) to a USB drive, XXX is the revision number. A

bootable USB is not required.

6. Insert the USB drive into the system.

7. Power up the system.

8. The system display setup <Recovery> screen displays automatically and flash update automatically

runs.

Configuration 56

Page 57

9. Select Proceed with flash update. Flash update automatically runs.

Jumper

Description

Jumper Adjustment

J12

PASSWORD CLEAR

1-2 (Default): Normal operation

2-3: Password clear

J11

CMOS CLEAR

1-2 (Default): Normal RTC reset

2-3: Clear RTC registers

J19

MEFIRMWARE

RECOVER

1-2 (Default): Normal operation

2-3: Force ME to enter recovery default

J17

BIOS RECOVERY

MODE

1-2 (Default): Normal operation

2-3: Force BIOS to enter recovery mode

J21

ME

MANUFACTURING

MODE

1-2: ME Flash Override (used for ME entire update)

2-3 (Default):Normal

10. Wait until <Program new data> completes, and then press Enter to shut down the system.

If the signature of FV_MAIN area is invalid, the BIOS automatically enters recovery mode; if this occurs,

only perform steps 5 through 10.

After recovery completes, if the recovery jumper forces the BIOS recovery turn off the system, and then

restore the jumper to its normal position.

BIOS jumpers

This section provides information about the BIOS. See the following table to locate the BIOS maintenance

jumpers.

Configuration 57

Page 58

Item

Description

1

Clear password J12

2

Clear CMOS J11

3

BIOS recovery J17

4

ME firmware recover J19

5

ME manufacturing mode J21

Checking the FW version

Checking the BIOS version using Linux

1. Log into Linux.

2. Open the terminal. Execute the dmidecode t 0 command to display the BIOS version, as shown in

the following figure.

Checking the BIOS version using the BIOS setup utility

1. Log into the BIOS setup utility.

2. Use the arrow keys to select the Main, menu to display the BIOS version as shown in the following

figure.

Configuration 58

Page 59

Checking the BMC version using Linux

1. Log into Linux.

2. Open the terminal. Execute the ipmitool –I open mc info command to display the BMC version

as shown in the following figure.

Checking the BMC version using the web GUI

1. Log into the web GUI.

2. Click Properties to display the BMC version, as shown in the following figure.

Configuration 59

Page 60

Checking the event log

Checking the system event log using Linux remote desktop

1. To check the system event log using Linux Log into Linux.

2. Open the terminal.

3. Execute the ipmitool -I lanplus –H BMCIP –A admin –P password sel list command

to check the system event log.

The system event log is shown in the following figure.

Checking the system event log using the web GUI

To check the system event log using the web user interface:

1. Log into the web GUI.

2. Click System Event Log to display the system event log, as shown in the following figure.

Configuration 60

Page 61

Checking the event log using the BIOS setup utility

To check the event log using the BIOS setup utility:

1. Enter the BIOS setup utility, and then select the Event Logs menu.

Configuration 61

Page 62

2. Use the arrow keys to select to the View SMBIOS Event Log option, and then press Enter key.

The SMBIOS Event Log displays. The possible error messages that the event log might display are

shown in the following table.

3. Take one log for example, move cursor to the second log, then detailed event information will be

shown on top right corner as below.

4. Use the arrow keys to select the View System Event Log option, and then press the Enter. The list

of system events appears in the System Event Log, as showing in the following figure. The BMC web

user interface can also report system event logs.

Configuration 62

Page 63

5. Use the arrow keys to select one of the event logs. The detailed information for the event log displays

under Event Description: in the right pane.

Configuration 63

Page 64

Configuration 64

Page 65

Diagrams

System board diagram

Diagrams 65

Page 66

Spare parts catalog

Customer self repair

HP products are designed with many Customer Self Repair (CSR) parts to minimize repair time and allow

for greater flexibility in performing defective parts replacement. If during the diagnosis period HP (or HP

service providers or service partners) identifies that the repair can be accomplished by the use of a CSR

part, HP will ship that part directly to you for replacement. There are two categories of CSR parts:

Mandatory Parts for which customer self-repair is mandatory. If you request HP to replace these

parts, you will be charged for the travel and labor costs of this service.

Optional Parts for which customer self-repair is optional. These parts are also designed for

customer self-repair. If, however, you require that HP replace them for you, there may or may not be

additional charges, depending on the type of warranty service designated for your product.

Important: Some HP parts are not designed for customer self-repair. In order to satisfy the customer

warranty, HP requires that an authorized service provider replace the part. These parts are identified as

“No” in the Illustrated Parts Catalog.

Based on availability and where geography permits, CSR parts will be shipped for next business day

delivery. Same day or four-hour delivery may be offered at an additional charge where geography

permits. If assistance is required, you can call the HP Technical Support Center and a technician will help

you over the telephone. HP will specify if a defective part must be returned to HP. In cases where it is

required to return the defective part to HP, you must ship the defective part back to HP within a defined

period of time, normally five (5) business days. The defective part must be returned with the associated

documentation in the provided shipping material. Failure to return the defective part may result in HP

billing you for the replacement. With a customer self-repair, HP will pay all shipping and part return costs

and determine the courier/carrier to be used.

For more information about HP's Customer Self Repair program, contact your local service provider. For

the North American program, refer to the HP website.

Parts only warranty service

Your HP Limited Warranty may include a parts only warranty service. Under the terms of parts only

warranty service, HP will provide replacement parts free of charge.

For parts only warranty service, CSR part replacement is mandatory. If you request HP to replace these

parts, you will be charged for the travel and labor costs of this service.

Spare parts catalog 66

Page 67

Item

Description

Spare Part Number

Customer Self Repair

1

Front USB board

35102SS00-245-G

Mandatory

2

Front panel control board

10010SS00-600-G

Mandatory

3

HDD backplane

1A219PC00-600-G

Mandatory

4

1U-1slot PCIe riser

1A32QG600-600-G

Mandatory

5

OCP mezz card, 10G 82599, Intel, dual port

1A32LVP00-600-G

Mandatory

6

MB-Hercules-SKU_A (OCP+2x16+1x8)

1A32UTH00-600-G

Mandatory

MB-Hercules-SKU_B (4GbE+2x16+1x8)

1A32UTJ00-600-G

Mandatory

MB-Hercules-SKU_C (2GbE+2x16+2x8)

1A32UTL00-600-G

Mandatory

MB-Hercules-SKU_D

(OCP+2 x 1G LAN+2x16+1x8)

1A32UYV00-600-G

Mandatory

7

2-AIRDUCT_HERCULES.PRT

1B511A600-600-G

Mandatory

8

Power to HDD BP switch cable

35072F700-245-G

Mandatory

9

CPU power Y cable

35072F900-245-G

Mandatory

10

Front USB cable

35102SS00-245-G

Mandatory

11

Front control board cable

35102ST00-245-G

Mandatory

12

CPU1 heatsink,

106mm(L) x 70mm(W) x 26.5mm(H)

460404T00-548-G

Mandatory

13

CPU2 heatsink,

106mm(L) x 80mm(W) x 25.5mm(H)

48011FA00-548-G

Mandatory

14

System 4056 FAN

490204P00-065-G

Mandatory

15

650W platinum PSU(PMBus Rev 1.2)

(with HVDC and common cable design)

860204A00-515-G

Mandatory

16

LSI 9271-8i Card

10040JH00-432-G

Mandatory

17

LSI 9271-8i with Cache Vault LSICVM01 Card

1A32YEK00-600-G

Mandatory

18

LSI-2308 SAS HBA MEZZ Card

1A32ULQ00-600-G

Mandatory

19

HP CL2100 807S LSI Crd SAS Cable Kit

1A21AWB00-600-G

20

Onboard PCH Mini SAS to BP cable Assembly

1A32YGL00-600-G

21

Tool-less Friction Rail Kit

1A32W7700-600-G

Mandatory

22

Intel E5-2680v3

11010S800-187-G

Mandatory

Intel E5-2660v3

11010S900-187-G

Mandatory

Intel E5-2630v3

11010SA00-187-G

Mandatory

Intel E5-2620v3

11010S100-187-G

Mandatory

Intel E5-2603v3

11010S200-187-G

Mandatory

23

DIMM,8GB PC4-2133P-R,1Gx4

800305S00-216-G

Mandatory

DIMM,8GB PC4-2133P-R,1Gx4

800305T00-026-G

Mandatory

DIMM,16GB PC4-2133P-R,1Gx4

800305D00-216-G

Mandatory

DIMM,16GB PC4-2133P-R,1Gx4

800305U00-220-G

Mandatory

Replaceable components

Spare parts catalog 67

Page 68

Item

Description

Spare Part Number

Customer Self Repair

24

1TB SATA 7.2k HDD SFF

81050AL00-509-G

Mandatory