Page 1

the SCSI

interface

hp ultrium drives

technical reference manual

generation 2 SCSI and FC drives

volume 3: the SCSI interface

Part Number: C7379–90900 Volume 3

Edition 4, February 2003

Page 2

Notice

The information contained in this

document is subject to change

without notice.

Hewlett-Packard makes no

warranty of any kind with regard to

this material, including, but not

limited to, the implied warranties o f

merchantability and fitness for a

particular purpose. Hewlett-Packard

shall not be liable for errors

contained herein or direct, indirect,

special, incidental or consequential

damages in connection with the

furnishing, performance, or use of

this document.

This document contains proprietary

information which is protected by

copyright. All rights reserved. No

part of this document may be

photocopied, reproduced or

translated to another language

without the prior written consent of

Hewlett-Pack ard.

© Copyright 2000–2003 by

Hewlett-Packard Limited

Revision History

Version Date Changes

Edition 1 Nov. 2000 All

Edition 2 Mar. 2001 Addition of Read and Write attribute commands and Drive Error Codes

Edition 3 May 2002 Inclusion of the Request Block Address command and the Control mode

page, together with numerous small changes

Edition 4 Feb 2003 Generation 2 SCSI and FC drive version

This document is frequently revised and updated. To find out if there is a

later version, please ask your HP OEM Representative.

2

Page 3

The Purpose of this Manual

This is one of five volumes that document HP Ultrium drives. This volume

provides background information for driver and application developers. The

following products are covered. Capacities are when the drive is using data

compression with a compression ratio of 2:1, where applicable:

■ HP Ultrium Generation 2 Full-Height SCSI Internal Drive

■ HP Ultrium Generation 2 Full Height FC Internal Drive

Note Throughout this manual frequent reference is made to SCSI

commands. For more information on SCSI commands for

HP Ultrium drives see volume 3, the SCSI Interface, of the

HP Ultrium Technical Reference Manual. Ordering details are

given below.

Related Documents

The following documents provide additional information:

Document s S p ecific to HP Ultrium Drives

■ Hardware Integratio n G u id e, volume 1 of the HP Ultrium Technical

Reference Manual

■ The SCSI Interface, volume 3 of the HP Ultrium Technical Reference

Manual

■ Specifications, volume 4 of the HP Ultrium Technical Reference Manual

■ HP Ultrium Configuration Guide, volume 5 of the HPUltrium Technical

Reference Manual

■ Background to Ultrium Drives, volume 6 of the HP Ultrium Technical

Reference Manual

Please contact your HP supplier for copies.

■ The features and benefits of HP Ultrium drives are discussed in the

HP Ultrium Technology White Paper.

■ For a general backgrounder on LTO technology and licensing, go to

http://www.lto-tec hnolog y.com .

3

Page 4

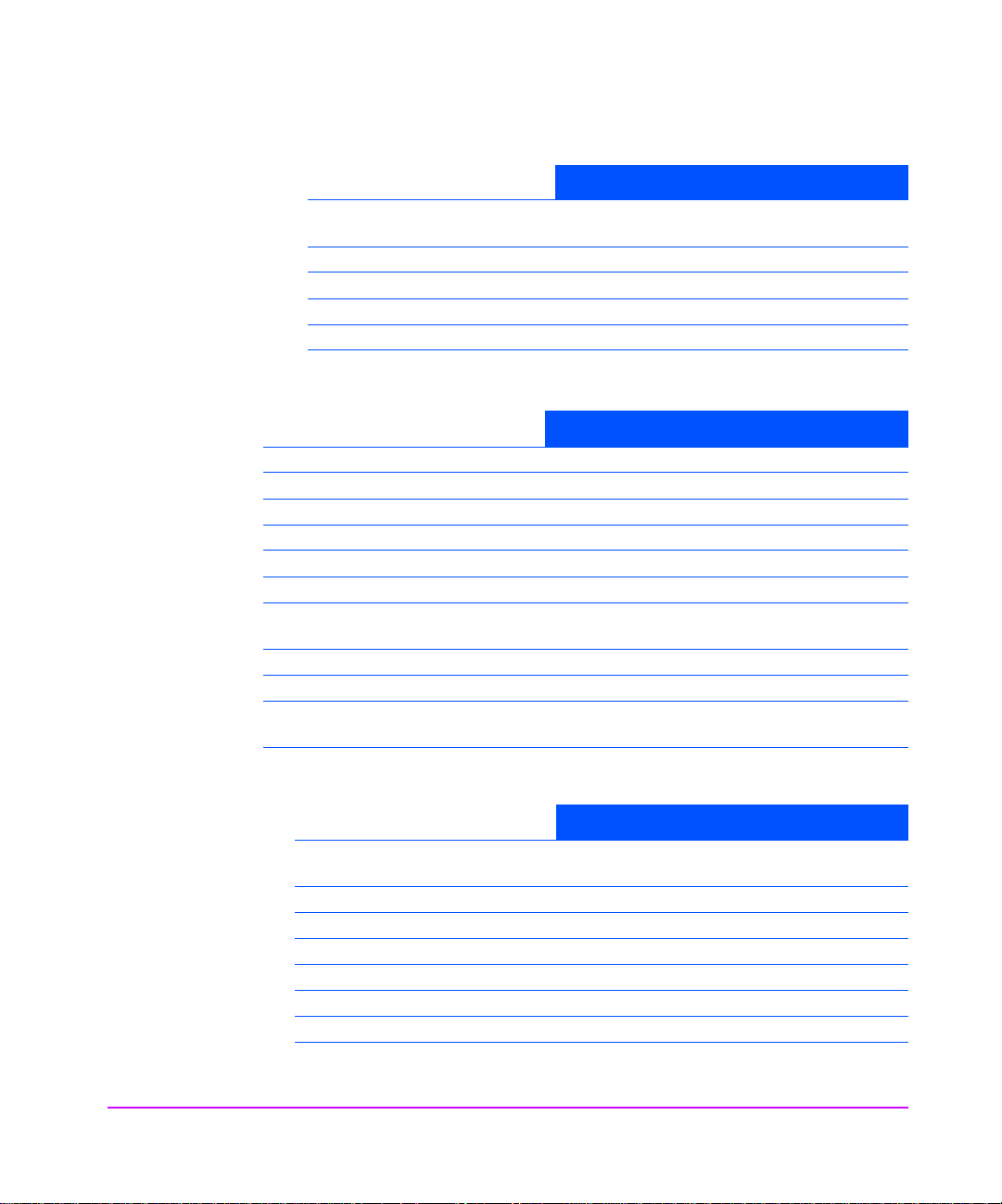

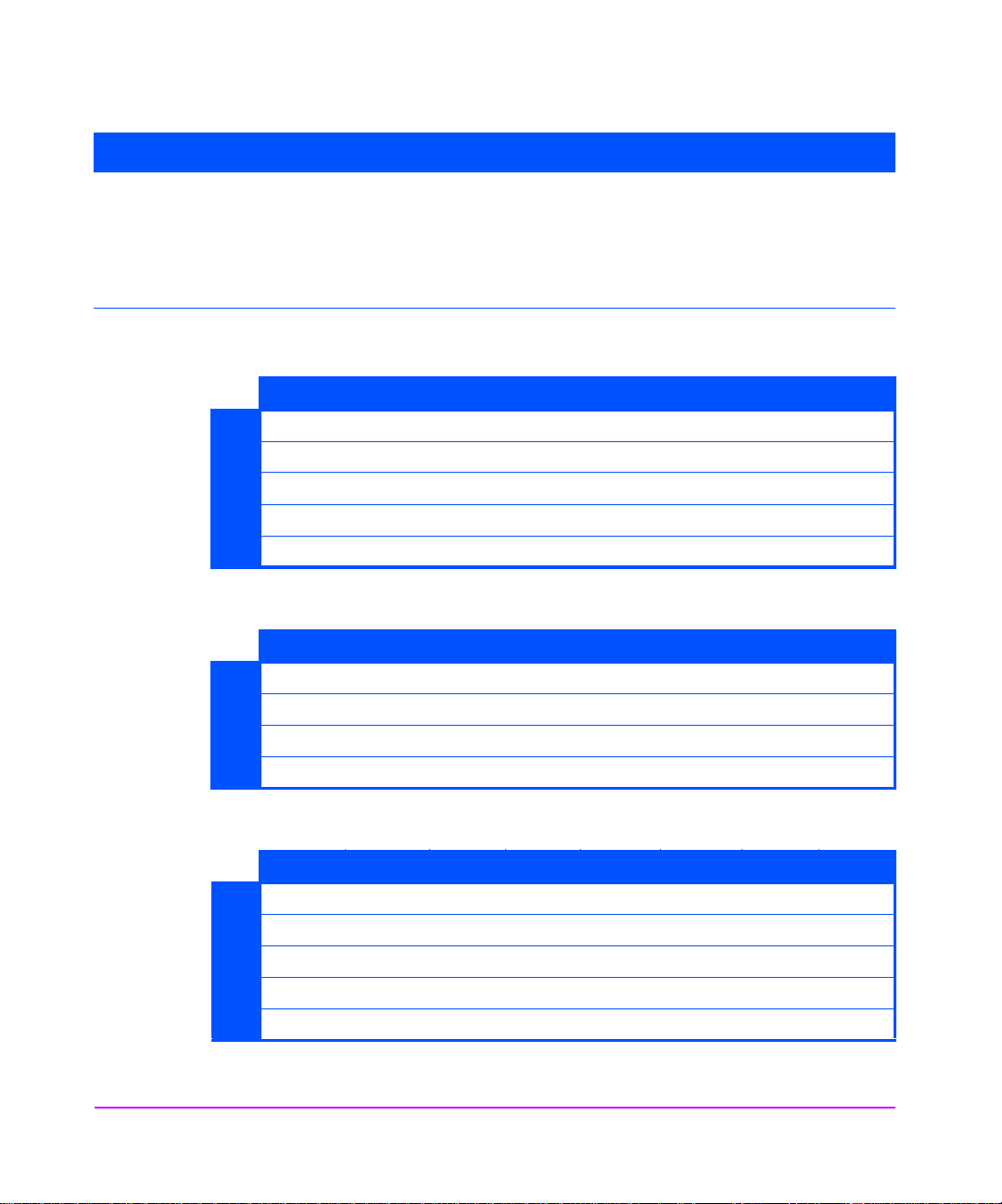

Documentation Map

The following will help you locate information in the 6-volume Technical

Reference Manual:

Drives—general

Connectors 1 HW Integration : ch. 7 1 HW Integration: ch. 4

Controller architecture

Front Panel LEDs 1 HW Integration : ch. 6 1 HW Integration: ch. 3

Mechanism and hardware 6 Background: ch. 3

Specifications

Installation and Configuration

Connectors 1 HW Integration: ch. 7 1 HW Integration: ch. 4

Determining the configuration

External drives (SCSI only) 1 HW Integration: ch. 5n/a

In Libraries 1 HW Integration: ch. 1

In Servers (SCSI only) 1 HW Integration: ch. 4n/a

In Tape Arrays (SCSI only)

Modes of Usage (SCSI only) 1 HW Integration: ch. 8n/a

Optimizing performance (SCSI only) 1 HW Integration: ch. 8n/a

UNIX configuration 5 UNIX Confi g

SCSI Drives FC Drives

6 Background: ch. 4

4 Specs

SCSI Drives FC Drives

2 SW Integration: ch. 2 2 SW Integration: ch. 2

1 HW Integration: ch. 3n/a

2 SW Integration: ch. 4

Operation

SCSI Drives FC Drives

External drives (SCSI only) 1 HW Integration: ch. 5n/a

In Libraries 1 HW Integration: ch. 1

In Servers (SCSI only) 1 HW Integration: ch. 4n/a

In Tape Arrays (SCSI only)

4

1 HW Integration: ch. 3n/a

Page 5

Cartridges

SCSI Drives FC Drives

Cartridge Memory (LTO-CM) 2 SW Integration: ch. 5

6 HW Integration: ch. 5

Cartridges 1 HW Integration: ch. 9 1 HW Integrati on: ch. 5

Features

Managing the use of cartridges 2 SW Integration: ch. 1

Use of cartridges 2 SW Integration: ch. 3

6 HW Integration: ch. 5

Interface

SCSI Drives FC Drives

SCSI Guide 3 SCSI

Commands

Error codes 1 HW Integration: ch. 10 1 HW Integ r ation: ch. 6

Implementation 3 SCSI: ch. 1

Interpreting sense data

Messages 3 SCSI: ch. 2

Mode pages

—see the MODE SENSE comma nd

Pre-execution checks

Responding to Sense Keys and ASC/Q 2 SW Integration: ch. 6

Sense Keys and ASC/Q

—see REQUEST SENSE command

3 SCSI: ch. 4

2 SW Integration: ch. 3

3 SCSI: ch. 4

3 SCSI: ch. 3

3 SCSI: ch. 4

Maintenance and Troubleshooting

SCSI Drives FC Drives

Cleaning 2 SW Integration: ch. 5

2 SW Integration: ch. 7

External drives (SCSI only) 1 HW Integration: ch. 5n/a

In Libraries 1 HW Integration: ch. 1

In Servers (SCSI only)

In Tape Arrays (SCSI only) 1 HW Integration: ch. 3n/a

Monitoring drive and tape condition 2 SW Inte gration: ch. 7

Software troubleshooting techniques

1 HW Integration: ch. 4n/a

2 SW Integration: ch. 1

5

Page 6

Dealing with Errors

SCSI Drives FC Drives

Error Codes 1 HW Integration: ch. 10 1 HW Integ r ation: ch. 6

Handling errors 2 SW Integration: ch. 5

How error correction works 6 Background: ch. 4

Logs—see the LOG SENSE command

Recovering from write and read errors 2 SW Integration: ch. 7

Software response to error correction 2 SW Integration: ch. 3

Software response to logs

TapeAle rt l og 2 SW Integration: ch. 7

3 SCSI: ch. 4

2 SW Integration: ch. 3

Ultrium Features

SCSI Drives FC Drives

Adaptive Tape Speed (ATS) 6 Background: ch. 1

Autoload 1 HW Integration: ch. 2

Automation Control Interface (ACI) 1 HW Integration: ch. 2

6 Background: ch. 1

Cartridge Memo ry (L TO -CM)s 1 HW Integration: ch. 2

2 SW Integration: ch. 5

6 HW Integration: ch. 5

Data Compression, how it works

Data Compression, managing 2 SW Integration: ch. 5

Design principles 6 Background: ch. 1

OBDR and CD-ROM emulation

Performance optimization 1 HW Integration: ch. 8n/a

Performance, factors affecting 2 SW Integration: ch. 4

Software design 2 SW Integration: ch. 1

Supporting Ultrium features

Ultrium Format 6 Background: ch. 2

6 Background: ch. 5

6 Background: ch. 1

2 SW Integration: ch. 7

2 SW Integration: ch. 1

2 SW Integration: ch. 5

6

Page 7

General Documents and Standardization

■ Small Computer System Interface (SCSI-1), ANS I X3 .131-1986. This is the

ANSI authorized standard for SCSI implementation, available through

ANSI

■ Enhanced Small Computer System Interface (SCSI-2), ANSI X3T9.2-1993

Rev. 10L, available through ANSI

Copies of General Documents can be obtained from:

ANSI

11 West 42nd Street

New York, NY 10036-8002

USA

ISO

CP 56

CH-1211 Geneva 20

Switzerland

ECMA

Global Engineering Documents

114 Rue du Rhône

CH-1204 Geneva

Switzerland

2805 McGaw

Irvine, CA 92714

USA

Tel: +41 22 849 6000

Web URL:

http://www.ecma.c h

Tel: 800 854 7179 or 714 261 1455

7

Page 8

8

Page 9

The Purpose of this Manual 3

Related Documents 3

Documents Specific to HP Ultrium Drives 3

Documentation Map 4

General Documents and Standardization 7

1 Interface Implementation 13

The SCSI Interface 13

Supported Messages 14

Supported Commands 14

SCSI Features 15

Design Approach 15

Power-On 15

Reset Strategy 15

Abort Handling 16

Bus Parity Errors (Parallel SCSI only) 18

Disconnect Strategy (Parallel SCSI only) 19

Multi-Initiator Support 19

Fibre Channel Operation 20

Fibre Channel Addressing 20

Names 20

Addresses 21

HP’s Implementation of Names and Addresses 21

Implications for Libraries 22

Field Replaceable Units 23

Descriptions of Signals (Parallel SCSI only) 23

contents

Contents

Contents 9

Page 10

2 Messages 25

Message Out Support (Parallel SCSI only) 25

Message In Support (Parallel SCSI only) 26

Extended Message Support 27

Status 29

3 Commands—Introduction 31

Summary 31

Command Details 32

Pre-Execution Checks 32

Bad LUN Check 32

Deferred Error Check 33

Diagnostic Status Check 33

Fixed Bit Check 34

Flag Link Check 34

Illegal Command Check 34

Illegal Field/Request Check 34

Media Access Check 35

Media Information Check 36

Media Write Check 37

Parameter List Check 37

Reservation Check 37

Unit Attention Check 38

Command Descriptor Block 38

10 Contents

4 Commands 41

ERASE 19h 42

INQUIRY 12h 44

INQUIRY Data Pages 45

Vital Product Data Pages 49

Supported Vital Product Data Pages Page 49

Unit Serial Number Page 50

Device Identification Page 51

Defined Identifiers 52

Drive Component Revision Levels Pages 53

LOAD/UNLOAD 1Bh 55

Page 11

LOCATE 2Bh 58

LOG SELECT 4Ch 60

LOG SENSE 4Dh 62

Log Page Format 63

Supported Log Pages Page 64

Write Error Counters Log Page 65

Read Error Counters Log Page 66

Sequential Access Device Log Page 66

TapeAlert Log Page 67

Tape Usage Log Page 69

Tape Capacity Log Page 69

Data Compression Log Page 70

Performance Data Log Page 70

MODE SELECT 15h/55h 72

Mode Parameter Pages 74

Mode Page Representation 74

Mode Data Format 74

Mode Block Descriptor 77

Read-Write Error Recovery Mode Page 78

Disconnect-Reconnect Page 79

SCSI Drives 79

FC Drives 80

Control Mode Page 81

Data Compression Characteristics Page 82

Device Configuration Page 83

Medium Partitions Mode Page 85

Fibre Channel Logical Unit Control Mode Page 86

Fibre Channel Port Control Mode Page 87

Information Exceptions Mode Page 89

MODE SENSE 1Ah/5Ah 91

PREVENT/ALLOW MEDIUM REMOVAL 1Eh 94

READ 08h 95

READ ATTRIBUTE 8Ch 99

MAM Attribute Data 103

Attribute ID Values 104

Device Common Attributes 104

Medium Common Attributes 106

Contents

Contents 11

Page 12

Host Common Attributes 107

READ BLOCK LIMITS 05h 110

READ BUFFER 3C h 111

READ POSITION 34h 115

RECEIVE DIAGNOSTICS RESULTS 1Ch 119

RELEASE UNIT 17h/57h 121

REPORT DENSITY SUPPORT 44h 123

REPORT LUNS A0h 126

REQUEST SENSE 03h 128

Request Sense Data 129

Sense Data Management 131

Current Sense 132

UNIT ATTENTION Sense 132

DEFERRED ERROR Sense 133

Sense Keys 135

Additional Sense Codes 136

Error Codes 140

RESERVE UNIT 16h/56h 141

REWIND 01h 144

SEND DIAGNOSTIC 1Dh 145

Standard Self-Test 147

SPACE 11h 148

TEST UNIT READY 00h 151

VERIFY 13h 152

WRITE 0Ah 154

WRITE ATTRIBUTE 8Dh 157

WRITE BUFFER 3Bh 160

WRITE FILEMARKS 10h 164

12 Contents

Glossary 165

Index 169

Page 13

Interface Implementation

HP Ultrium drives use SCSI-3 as the interface to connect to the host system.

This chapter gives an overview of how the interface operates.

Full details of the messages are given in Chapter 2 and of commands in

Chapter 3 and Chapter 4.

The SCSI Interface

The Small Computer Sy stem Interf ace (SCS I) is an industry standard , a ppr o v ed

by the American National Standards Institute (ANSI). You are recommended

to read the ANSI standard document in conjunction with this manual. The

ANSI specification defines the interface in general while this document

describes the HP Ultrium implementation.

The SCSI implementation provides a drive with a standard set of features and

functions. These include the following:

■ Synchronous data transfers

1

■ Asynchronous data transfers

■ Implementation of all mandatory and most optional commands of the

Sequential Access command set

■ LVD (Low-Voltage differential) SCSI connection

■ Ultra3 wide SCSI

■ Conformance to the following SCSI standards:

— SAM-2 T10/1157-D rev.23

— SPI-3 ANSI NCITS.336:2000

— SPC-2 ANSI NCITS.351:2001

— SSC ANSI NCITS.335:2000

Interface Implem en ta tion 13

Page 14

Supported Messages

The following messages are supported by the drives:

■ ABORT

■ BUS DEVICE RESET

■ COMMAND COMPLETE

■ DISCONNECT

■ IDENTIFY

■ IGNORE WIDE RESIDUE

■ INITIATOR DETECTED ERROR

■ MESSAGE PARITY ERROR

■ MESSAGE REJECT

■ NO-OP

■ RESTORE POINTERS

■ SAVE DATA POINTER

■ Extended Message: PARALLEL PRO TOCOL REQUEST

■

■

For implementation details on these messages, see Chapter 2, “Messages”

(no operation)

Extended Message: S YNCHRONOUS DATA TRANSFER REQUEST

Extended Message: WIDE DATA TRANSFER REQUEST

Supported Commands

The following commands are supported by the drives. They include all

Mandatory and Extended commands and most Optional commands.

19h

12h

1Bh

2Bh

4Ch

4Dh

15h/55h

1Ah/5Ah

1Eh

08h

05h

14 Interface Implementation

ERASE

INQUIRY

LOAD/UNLOAD

LOCATE

LOG SELECT

LOG SENSE

MODE SELECT

MODE SENSE

PREVENT/ALLOW MEDIUM REMOVAL

READ

READ BLOCK LIMITS

57h/17h

03h

44h

A0h

56h/16h

01h

1Dh

11h

00h

13h

0Ah

RELEASE UNIT

REQUEST SENS E

REPORT DENSITY SUPPORT

REPORT LUNS

RESERVE UNIT

REWIND

SEND DIAGNOSTIC

SPACE

TEST UNIT READY

VERIFY

WRITE

Page 15

3Ch

34h

1Ch

READ BUFFER

READ POSITION

RECEIVE DIAGNOSTIC RESULTS

SCSI Features

Design Approach

Power-On

WRITE BUFFER

3Bh

WRITE FILEMARKS

10h

For implementation details on these commands, see Chapter 3, “Commands—

Introduction” and Chapter 4, “Commands”.

The features supported by the drive are based on standards, both official and

de facto. The dr iv e is fully compliant w ith the SC SI-3 specif ication and supports

all features required by that standard. However, since most tape drive support

software has been written using the SCSI-2 standard, this document is based

on SCSI- 2 and uses SCSI-2 terminology. Since SCSI-2 is virtually a compliant

subset of SCSI-3, this is not inconsistent. However, where SCSI-3 makes an

option in SCSI-2 a requirement, the SCSI-3 requirement is always used. Also,

all required SCSI-3 extensions are supported by the drive.

Interface Implementation

Reset Strategy

Soft Resets On receiv ing a r e set through the Host Interf ace (S CS I or FC), the Host Interfac e

The drive will respond to TEST UNIT READY, INQUIRY, REPORT LUNS and

REQUEST SENSE commands within 5 seconds of power on. The first command

other than Inquiry or Request Sense from any initiator will get a

CONDITION

this, any medium access command will be reported with a sense key of

READY

Medium access commands will be reported with additional sense of 0401h

(drive in process of becoming ready).

is returned to a known base state. If the reset command is received over the

Automation Controller Interface serial port, the SCSI and ACI interfaces are

returned to known bas e states . The baud r at e fo r the port will be r eturned to its

status with UNIT ATTENTION sense data for the power on. After

and additional sense of 3E00h (LUN has not self-configured yet).

Interface Implem en ta tion 15

CHECK

NOT

Page 16

default setting. The know n base s tate is def ined in the S CS I-3 specifi cation and

includes the following:

■ The current I/O process is aborted.

■ Any queued I/O processes from other initiators are removed.

■ All reservations are cleared.

■ All mode values are reset to their defaults.

■ Synchronous/Wide negotiations are cleared (SCSI drives only).

■ A UNIT ATTENTION condition is set.

■ Any buffered writes are flushed to tape.

■ The logical position is undefined.

Hard Resets The Reset button on the front panel and the ACI_RESET_L line on the

Abort Handling

The drive will be able to respond to

SENSE

and REPORT LUNS within 250 ms of the reset line being released. The

first command other than these from any initiator will get a

CONDITION

status with UNIT ATTENTION sense data for the reset. However,

TEST UNIT RE ADY, INQUIRY, REQUEST

CHECK

other commands may not be processed until the internal state of the drive has

been reset. Any commands which cannot be processed will be accepted and

queued until the drive is ready to process them.

Automation Controller Interface are both connected to the Power-Up Reset

interrupt on the processor. The effect is equivalent to power-cycling the drive.

The contents of the tape and cartridge memory may not be consistent after the

action and any data in the drive buffer will be lost.

If an abort condition is detected before a command phase completes, the bus

is set to bus free and the command is not executed.

If an abort condition is detected between the end of the command phase and

the start of the status phase, then the bus is set to bus free and the processing

below is carried out.

If an abort condition is detected during status phase, the bus is set to bus free.

If a command, other than

TEST UNIT READY, INQUIRY and REQUEST SENSE, is

received after the abort but before the drive is ready to process the command,

the drive will disconnect and wait until the abort processing has completed

before executing the command. A

TEST UNIT READY command will report with

16 Interface Implementation

Page 17

GOOD status immediately. A REQUEST SENSE command will give NO SENSE.

An

INQUIRY command will return the required data and give GOOD status.

Command Abort Processing

ERASE

INQUIRY

LOAD/UNLOAD

LOCATE

LOG SEL ECT

LOG SENSE

MODE SELECT

MODE SENSE

PREVENT/ALLOW

MEDIUM REMOVAL

READ

Long erase is aborted as quickly as possible without corrupting tape format.

Short erase completes.

None

Load completes and logically positions tape at BOT. Unload is aborted

leaving logical position at BOT unless operation is past the “point of no

return” in which case the tape is ejected.

The logical position is set back to that at the start of the operation unless the

operation is past its “point of no return”, in which case the operation

completes.

If data transfer is complete, command is completed, otherwise, no action is

taken

None

If data transfer is complete, command is completed, otherwise, no action is

taken.

None

The command completes.

The current position is set to the first record boundary at or after the start of

the current data burst.

Interface Implementation

READ BLOCK LIMITS

READ BUFFER

READ POSITION

RECEIVE DIAGNOSTICS

RESULTS

RELEASE UNIT

REQUEST SENSE

None

None

None

None

The command completes.

None

Interface Implem en ta tion 17

Page 18

Command Abort Processing

RESERVE UNIT

REWIND

SEND DIAGNOST IC

SPACE

The command completes.

The command completes.

Vendor Unique

The logical position is set back to that at the start of the operation unless the

operation has passed its “point of no return”, in which case the operation

completes.

TEST UNIT READY

WRITE

None

The data up to first record boundary in the current burst is written to tape.

Any subsequent data is discarded. If there is no record boundary in the

current burst, the record is truncated to the amount of data transferred and

written to tape.

WRITE BUFFER

If data transfer is complete, command is completed, otherwise, no action is

taken.

WRITE FILEMARKS

VERIFY

The command completes.

The logical position is set to the next record boundary after the point where

the verify was aborted.

Bus Pari ty Errors (Parallel SCSI only)

On detecting a bus parity error during a Command or Data Out phase or

receiv ing an Initiator det ected er r or mess age during a Dat a In or S tatus phase ,

the drive attempts t o r e try the bus phase. A Restor e Poin t er s me ssage is sen t t o

the initiator and the transfer is repeated. Only one retry is attempted. If the

retry fails or the restore pointers message is rejected, then the drive goes to

status phase and attempts to report

an initiator detected error message, t he dri ve goes t o bus fr ee . Th e sense ke y is

set to

error) or 4B00h (data phase error).

If an Initiator Detected Error or Message Parity Error message is received

during Message In phase, the initiator has detected an error in the message.

The dri v e will go to Messag e In and r esen d the mess age tha t was in err o r . If the

subsequent message is rejected with an Initiator Detected Error, then the drive

goes to Status phase and sends

18 Interface Implementation

CHECK CONDI T ION st atu s. If this f ails with

ABORTE D C O MMA ND w ith additional sense of 4A00h (command phase

CHECK CONDITION status. The sense k ey is set

Page 19

to ABORTED COMMAND with additional sense of 4800h (Initiator Detected

Error).

If the subsequent message is rejected with an Message Parity Error, then the

driv e goes to Status phase and sends

is set to

ABORTED COMMAND with additional sense of 4300h (message

error).

On detecting a bus parity error during a Message Out phase, the drive will

handshake in all message bytes until ATN is deasserted. It will then stay in

Message Out phase to indicate to the initiator that the whole Message Out

phase should be resent.

Disconnect Strategy (Parallel SCSI only)

The disconnect strategy used by the drive is based on the assumption of

maximizing bus utiliz atio n for large sequen tial data transf ers fr om a large data

buffer. The drive will disconnect whenever it believes that it will provide better

bus utilization. This may be between command and data phases, between

bursts of data or before sending status. However, the drive will guarantee that

it will send the configured maximum burst size or the remaining data in the

transfer in any single data phase burst if the max imum burst size has been set

to a value other than zero.

Multi-Ini t iator Support

CHECK CONDITION status. The sense key

Interface Implementation

All drives will support at least two initiators on the same bus. If more initiators

are supported, all features are supported for the supported number of

initiators.

The drive supports untagged queueing when operating with multiple initiators.

If a command from one initiator is being processed when a command, other

than

TEST UNIT READY, INQUIRY, REPORT LUNS and REQUEST SENSE, is

received from a second initiator, then the drive will disconnect and the new

command is queued. Commands other than

these from different initiators are

always executed in strict order of receipt. If the queue is full or disconnect

privilege is not granted in the new command, the drive will report

T

EST UNIT READY, INQUIRY, REPORT L UNS an d RE Q UE S T SENSE co mmand s ar e

BUSY status.

always processed immediately, irrespective of whether a command from

another initiator is being processed.

The drive will maintain sense data for the supported number of initiato r s. If an

additional initiator connects to the drive, the drive will erase all sense data for

Interface Implem en ta tion 19

Page 20

the initiator that least recently connected before processing the command for

the new initiator. See “Sense Data Management” on page 131 for more

details.

Fibre Channel Operation

Note This applies only to Fibre Channel drives.

The following sections have information specific to Fibre Channel operation:

■ “Fibre Channel Logical Unit Control Mode Page” on page 86

■ “Fibre Channel Port Control Mode Page” on page 87

■ “Vital Product Data Pages” on page 49

Fibre Channel Addressing

Before describing HP’s implementation of Fibre Channel addressing, the

concepts of Names and Addresses need to be clarified.

Names

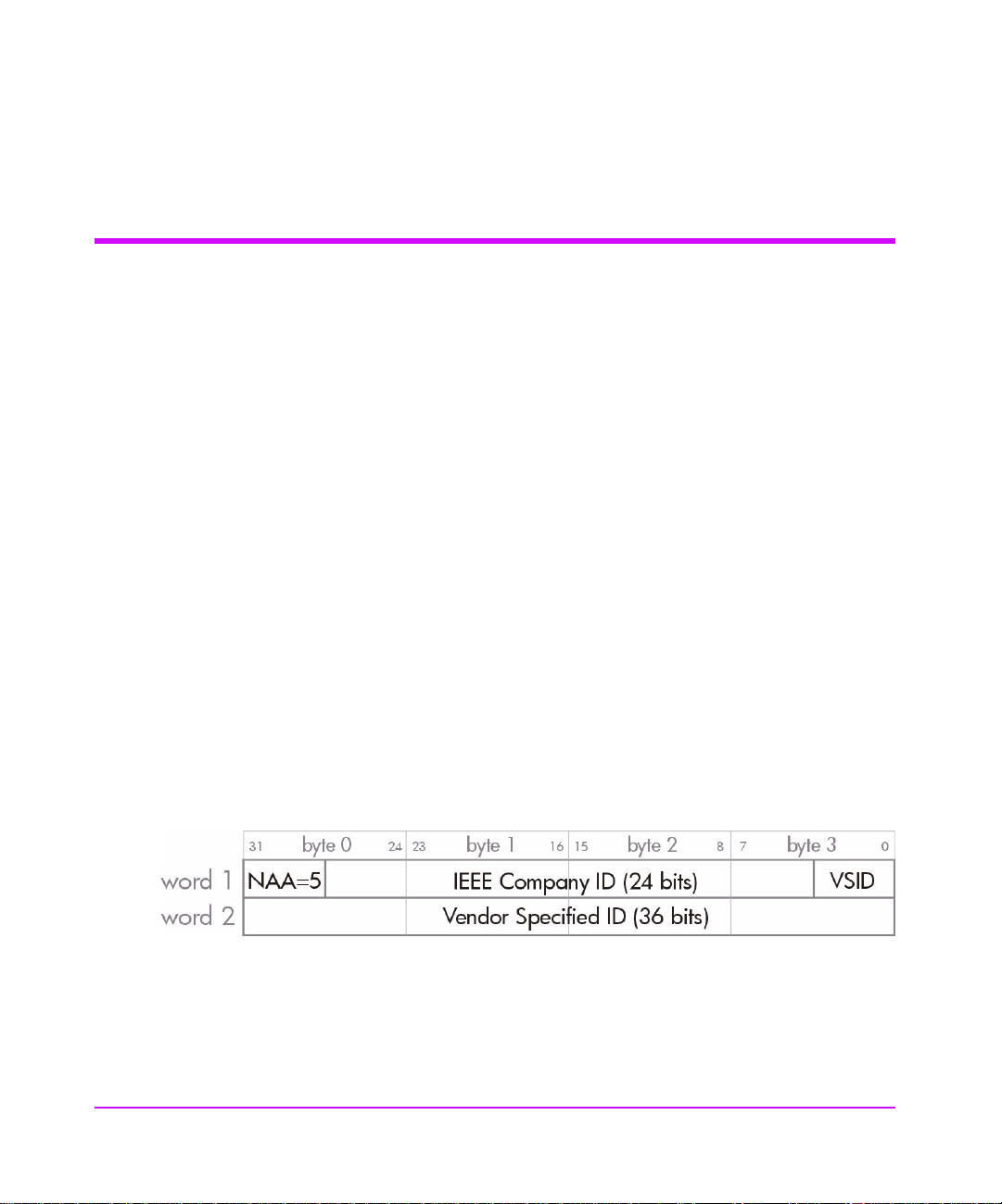

Names are 64-bit identifiers assigned permanently to the tape drive during

manufacture. They are commonly referred to as World Wide Names since they

must be guaranteed unique. The names are typically used for identifying the

device to operating systems, since addresses are assigned dynamically. There

at least eight different name formats distinguished by the Network Address

Authority (NAA). Only one is used on HP Ultrium drives. This is the IEEE

Registered Name (NNA=5) and has the following format:

This name is made up of three fields:

■ NAA Identifier (4 bits). “5” indicates a IEEE Registered Name.

■ IEEE Company ID (24 bits). Assigned by IEEE to the company.

■ Vendor Specified ID (36 bits). Assigned by the company.

20 Interface Implementation

Page 21

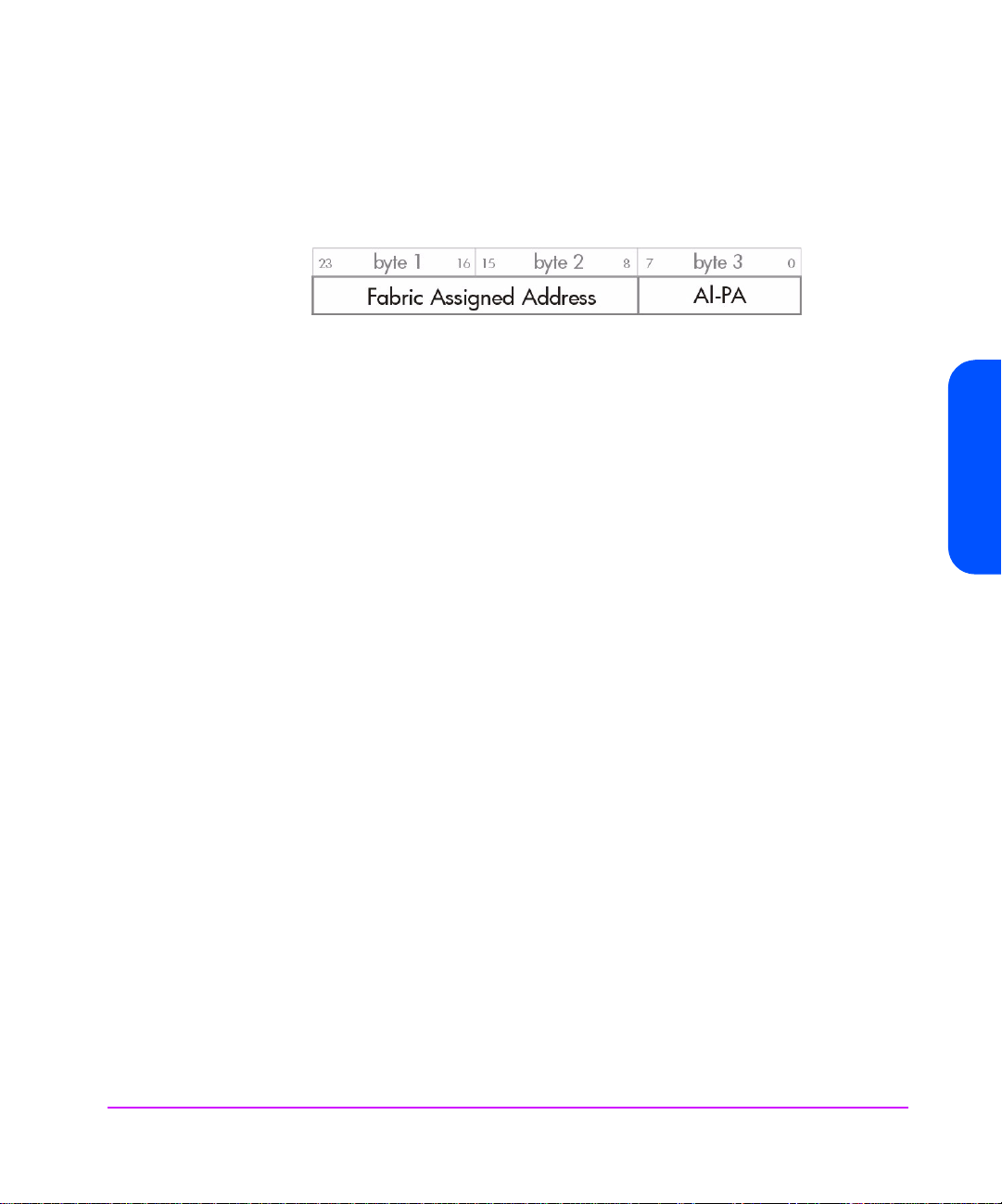

Addresses

Each Fibre Channel port also has a Port Address which is assigned during

loop initialization and/or Fabric Login. This is a 24-bit value in the following

format:

The AL_PA is the Arbitrated Loop Physical Address. This is normally assigned

dynamically during loop initialization.

If the loop is not attached to a fabric (in other words, when it is private,) the top

two bytes will be zero. If the loop is attached to a fabric, the tape drive is

assigned the top two bytes when it logs into the fabric.

Together, the three bytes pr o vi de a unique addres s on the F ibr e Channel f abr ic

that is used for frame addressing. It forms the equivalent of the Target ID or

Initiator ID in SCSI.

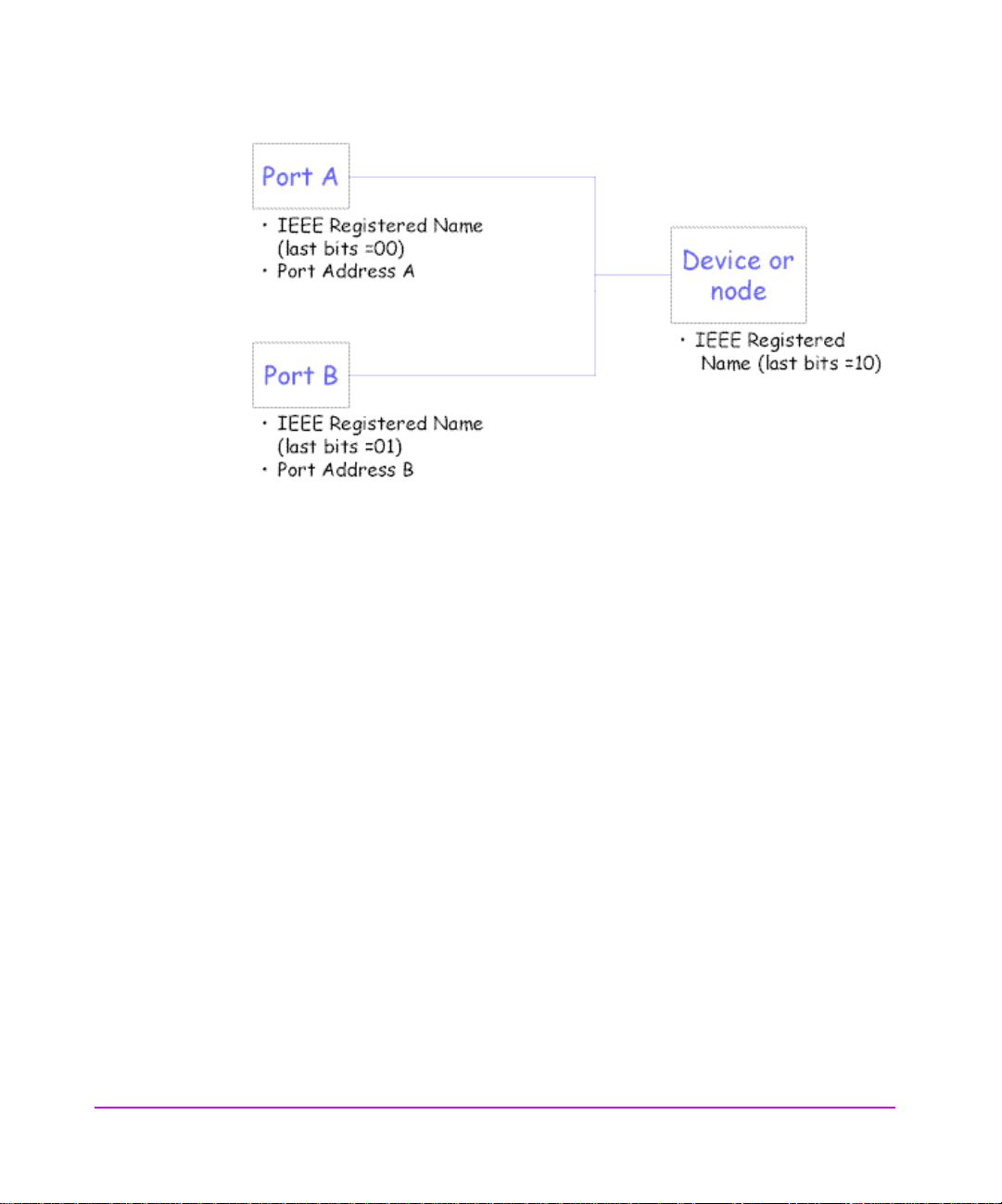

HP’s Implementation of Names and Addresses

The HP implementation uses three adjacent IEEE Registered Names:

■ The first (last bits = 00) is used as the Port A World Wide Name.

■ The second (last bits = 01) is used as the Port B World Wide Name.

Interface Implementation

■ The third name (last bits = 10) is used for the Device World Wide Name.

(These are assigned during manufacture from HP’s pool of names, although

only the first will actually be stored in the drive NV-RAM).

The port addresses will be assigned using the ‘standard’ AL_PA initialization

mechanisms. The ‘Fibre Channel Port Control mode page’ controls this. The

drive has the ability to support hard addresses as part of this scheme.

Interface Implem en ta tion 21

Page 22

The values of the names can be obtained using the Device Identification Vital

Product Information Page (part of the

INQUIRY command).

Implications for Libraries

■ Normally a standalone drive will operate using its own ‘hard’ names.

■ The drive kno ws it is in a library or other ‘managed’ environment since one

of the signal lines on the ACI (Automation Control Interface) will be tied

down.

In this case, the dr iv e wi ll not go on the FC loop until it is t old to . The libr ary

can optionally download a new, soft base name (Port A/Device Name)

into the drive at this point. The drive will then use this as the origin of its

names. The library manufacturer would be responsible for obtaining this

IEEE Registered Name. It would be a property of the library, not the drive.

■ If the library wants to ‘warm swap’ drives, it can. It just ‘turns off’ the drive

with the soft name using the ACI and then turns on the spare drive,

downloading the same name to it.

■ If a drive is r emo ved f rom th e library, it will not have the ACI signal tied low

and so will re v ert to its or iginal h ard name . It should f or get the s oft name in

this case.

■ If the library controller breaks, the drive will time out the ACI interface in

~10 seconds. The drive still knows it is in a library since the ACI signal is

22 Interface Implementation

Page 23

still tied low, so in this case it will use the soft name last downloaded. This

will allow drive access without confusing the host.

Field Replaceable Units

An FRU code identifies which part of the hardware is considered to have

failed. These codes turn up in sense data byte 14 and as the sense code

qualifier for sense codes 4400h (internal target failure) and 40XX (diagnostic

failure).

Althoug h the r e are no actual Field Replaceable Units on HP Ultrium dri ves, the

following sub-assemblies can be replaced at Repair Centres:

■ Drive PCA ■ Head Assembly

■ Mechanism ■ Front Panel

Descriptions of Signals (Parallel SCSI only)

The SCSI interface consists of 2 7 signals—9 contr ol lines, 16 data lines and 2

parity lines. A description of these signals is given in the following table.

Interface Implementation

Signal Name Driven by Description

-BSY

-SEL

-C/D

-I/O

Busy — OR-tied signal used to indicate that the SCSI bus is in use.

Select Initiator

Target

Control/Data Target Indicates whether control or data information is on the data

Input/Output Target Controls the direction of data movement on the bus with

Used to select a target during the Selection phase.

Used to select an initiator during the Reselection phase.

bus.

True (low) Control information

False (high) Data information

respect to the Initiator. This signal is also used to distinguish

between Selection and Reselection phases.

Interface Implementation 23

Page 24

Signal Name Driven by Description

True (low) Input to the initiator

False (high) Output from the initiator

-MSG

Message Target Indicates a Message phase on the bus.

True (low) Message phase

False (high) Command, Data or Status phases

-REQ

-ACK

Request Target Indicates a request for a REQ/ACK data transfer handshake.

Acknowledge Initiator Indicates an acknowledgment for a REQ/ACK data transfer

handshake.

-ATN

Attention Initiator Indicates that the initiator has a message to send to the

target.

-RST

Reset — OR-tied signal that is used to indicate a Reset condition.

DB(15-0) Data Bus — 16 data-bit signals that, with the parity-bit signal, form the

data bus. DB15 is the most significant bit , and has the highest

priority during the Arbitration phase.

DB(P1-P0) Data Bus — Data parity bits that ar e s et t o odd, but are jumper-selectable

options. There are two discrete parity bits, one for the lower 8

data bits, the other for the upper 8 bits. Parity is not valid

during the Arbitration phase.

24 Interface Implementation

Page 25

Messages

2

This chapter includes all SCSI messages, both supported and unsupported.

Parts of this chapter come from Section 5, Logical Characteristics, of the SCSI

standards (see page 13).

The message system provides an initiator and a target on the SCSI bus with a

means of managing communication. The available messages are listed in this

chapter.

Message Out Support (Parallel SCSI only)

Name Code Support

Abort 06h An abort condition is generated (see “Abort Handling” on page 16).

Bus Device Reset 0Ch A reset condition is generated (see “Reset Strategy” on page 15).

Extended Message 01h See “Extended Message Support” below.

Identify 80h+ The Identify Out message is sent by the initiator to identify the Logical Unit

to be accessed and to set Disconnect Privilege.

Initiator Detected

Error

05h The initiator has detected an error in the data being sent in a Command,

Data or Status phase. The drive will send a restore data pointers message

to retry the data transfer. (See “Message In Support (Parallel SCSI only)”

below for details).

If the message is received immediately after an Identify message or after

the Command Complete message has been sent, the drive will go Bus

Free.

Messages 25

Page 26

Name Code Support

Message Parity

Error

Message Reject 07h This message is sent when the initiator does not support a message sent b y

No Operation 08h This message has no effect and is ignored.

09h The initiator has detected a parity error in a message. The drive will retry

the message. (See ““Message In Support (Parallel SCSI only)” below for

details).

If the message is received immediately after an Identify message or after

the Command Complete message has been sent, the drive will go Bus

Free.

the drive or that the message is inappropriate. If the message being

rejected is Disconnect, Synchronous Data Transfer Request or Wide Data

Transfer Request, the operation continues without those features. For all

other messages, the message is treated as an Abort message.

If the message is received during a Command, Data or Status phase,

immediately after an Identify message or after the Command Complete

message has been sent, the drive will go Bus Free.

Message In Support (Parallel SCSI only)

Name Code Support

Command Complete 00h This message is sent by the drive at the end of the status phase to

indicate that a command is complete. Once the message is sent, the

drive releases the bus and goes to Bus Free.

Disconnect 04h This message is sent by the driv e to indicate that it is about to disconnect

from the bus and go to Bus Free. During a Data phase, it is always preceded by a Save Data P o inter s message. If a Message Rej ect message is

received in response to this message, then the disconnect is prevented.

Extended Message 01h See “Extended Message Support” below.

Identify 8Xh The Identify In message is sent to the initiator during reconnect to

indicate which Logical Unit is reconnecting.

26 Messages

Page 27

Name Code Support

Ignore Wide

Residue

23h This message is sent by the drive to the host to indicate that a byte on a

wide bus is not valid.

This is supported whenever a wide transfer is acti ve. It should be sent at

the end of the data phase. The standard action of the drive is to send

this message between the data phase and the status phase with no

disconnect.

Message Reject 07h This message is sent to the initiator when the message received by the

drive is unsupported or inappropriate.

Restore Pointers 03h This message causes the initiator to reset its data transfer pointers to the

values they held when the last save data pointers message was sent. It

will be sent when a parity error is detected on the bus or when an

Initiator Detected Error message is received in order to retry the data

phase.

Save Data Pointers 02h This message instructs the initiator to save its current data transfer

pointers for use with a subsequent Restore pointers message. This

message will always be sent before a Disconnect message during data

phases.

Extended Message Support

Name Code Support

Messages

Synchronous Data

Transfer Request

01h The drive will never initiate a Synchronous data transfer negotiation, but

will expect the initiator to do so.

If the message is received after selection and befor e the command phase,

it will then go to message-in phase and respond with a valid r esponse to

complete the negotiation.

Wide Data Transfer 03h The drive will never initiate a Wide data transfer negotiation but will

expect the initiator to do so.

If the message is received after selection and befor e the command phase,

it will then go to message-in phase and respond with a valid r esponse to

complete the negotiation.

Note that SDTR negotiated parameter s will become asynchr onou s after a

WDTR.

Messages 27

Page 28

Name Code Support

Parallel Protocol

Request

04h The drive will never initiate a Parallel Protocol Request transfer

negotiation but will expect the initiator to do so.

If the message is received after selection and befor e the command phase,

it will then go to message-in phase and respond with a valid r esponse to

complete the negotiation.

Synchronous Data Transfer Request

7 6 5 4 3 2 1 0

0

1

2

3

4

Extended Message (01h)

Extended Message Length (03h)

SDTR (01h)

Transfer Period Factor

Req/Ack Offset

Wide Data Transfer Request

7 6 5 4 3 2 1 0

0

1

2

3

Extended Message (01h)

Extended Message Length (02h)

WDTR (01h)

Transfer Width Exponent

28 Messages

Parallel Protocol Request

7 6 5 4 3 2 1 0

0

1

2

3

4

Extended Message (01h)

Extended Message Length (06h)

Parallel Protocol Request (04h)

Transfer Period Factor

Reserved (0)

Page 29

7 6 5 4 3 2 1 0

5

6

7

Reserved (0) QAS_Req DT_Req IU_Req

Req/Ack Offset

Transfer Width Exponent

Fields:

Transfer Period

Factor

09h Transfer period of 12.5s (FAST-80). Only valid when DT transfers have been

requested

0Ch Transfer period of 50s (FAST-20) — LVD/SE drives only

19h Transfer period of 100s (FAST-10)

32h Transfer period of 200s (FAST-5)

Req/Ack Offset This has a maximum value of 255.

Transfer Width

Exponent

For ST transfers, this can be either 0 (Narrow) or 1 (Wide).

For DT transfers, it must be set to 1.

QAS_Req 0 This bit will be ignored and the drive will always return zero.

DT_Req This bit determines whether DT mode has been requested, in other words, packetized

data transfers.

IU-Req 0 This bit will be ignored and the drive will always return zero.

Status

A Status byte is sent from the drive to the host during the Status phase at the

end of each command as specified in the SCSI specification, unless the

command has been cleared by an

message, or by a hard reset.

ABORT message, by a BUS DEVICE RESET

Messages

The Status bytes that the drive returns are as follows:

00h GOOD: This status indicates that the drive has successfully completed the command.

02h CHECK CONDITION: Any er r o r, exception, or abnor mal condition that causes sense data

to be set returns

CHECK CONDITION. The REQUEST SENSE command should be sent

following this status to determine the nature of the error.

04h CONDITION MET: This status will never be returned by an HP Ultrium tape drive.

Messages 29

Page 30

08h BUSY: The drive is unable to execute the command at this time. Try again later. The drive

tries to avoid using this status code during normal operation. It can sometimes be used

after commands have been aborted, during power-on and if there are multiple selecting

initiators.

10h INTERMEDIATE: This status will never be returned by an HP Ultrium tape drive.

14h INTERMEDIATE CND: This status will never be returned by an HP Ultrium tape drive.

18h RESERVATION CONFLICT: Returned if the drive is reserved by another party. See the

Reservation check.

22h COMAND TERMINATED: This status will never be returned by an HP Ultrium tape drive.

28h QUEUE FULL: This status can be returned by an HP Ultrium FC drive but will never be

returned by a SCSI tape drive.

30 Messages

Page 31

Commands—Introduction

This chapter contains general notes relating to the SCSI commands listed in

Chapter 4.

Summary

The following table is a summary of the SCSI commands for sequential access

devices, showing the operation code:

3

Opcode

(hex)

00

01

03

05

08

0A

10

11

12

13

15

16

17

19

1A

1B

1C

1D

Command Name

TEST UNIT READY

REWIND

REQUEST SENSE

READ BLOCK LIMITS

READ

WRITE

WRITE FILEMARKS

SPACE

INQUIRY

VERIFY

MODE SELECT

RESERVE UNIT

RELEASE UNIT

ERASE

MODE SENSE

LOAD/UNLOAD

RECEIVE DIAG RESULTS

SEND DIAGNOSTIC

Opcode

(hex)

1E

2B

34

3B

3C

44

4C

4D

55

56

57

5A

8C

8D

A0

Command Name

PREVENT MEDIUM REMOVAL

LOCATE

READ POSITION

WRITE BUFFER

READ BUFFER

REPORT DENSITY SUPPORT

LOG SELECT

LOG SENSE

MODE SELECT (10)

RESERVE UNIT (10)

RELEASE UNIT (10)

MODE SENSE (10)

READ ATTRIBUTE

WRITE ATTRIBUTE

REPORT LUNS

Commands—Introduction 31

Page 32

Command Details

The command descriptions in this section are listed in alphabetical order of

command name. Each command is described briefly. This is followed by a list

of pre-execution checks which are described below. The Command Descriptor

Block (CDB) is then given, with details of the various parameter bits and fields.

Pre-Execution Checks

Note In compliance with the SCSI specification, the drive terminates a

command with a

key to

is received which is not zero.

Before executing a command, the drive makes a number of checks. They fall

into three categories:

■ Checks on the command sent by the host. T hese ensure that no rese rved or

fixed fields have been set to illegal values. They check the syntax of

commands, in other words the cross dependency of fields. F or ex ample, the

Flag bit must not be set if the Link bit is not set.

■ Checks to ensure that there are no outstanding UNIT ATTENTION or

DEFERRED ERROR events posted for the host that has sent the command.

CHECK CONDITION status and sets the sense

ILLEGAL REQUEST when a reserved bit, byte, field or code

■ Checks on media access abilities. These are performed for commands

The checks are described below in alphabetical order. The usual order of

execution is Illegal Field, Fixed Bit, Flag Link, Bad LUN, Reservation, Deferred

Error, Unit Attention, Media Access, Media W r ite , Diagnosti c Statu s, Humidity ,

Parameter List.

Bad LUN Check

For all commands except INQUIRY 12h, this checks that the LUN specified by

the host is zero. The LUN is taken from the lowest 5 bits of the host’s

message.

32 Commands—Introduction

requiring access to the cartridge. A command is rejected if it attempts to

access the cartridge when no cartridge is present or the cartridge is

unloaded.

IDENTIFY

Page 33

■ If no IDENTIFY message is supplied, the LUN is taken from the host’s

■ If an IDENTIFY message is supplied, the LUN in the host’s Command

■ If the LUN is unsupported, and the host command is not REQUEST SENSE,

■ If the LUN is unsupported, and the host command is REQUEST SENSE, the

Deferred Error Check

A deferred error is generated when a command with immediate report fails

after the report has been returned. The check looks to see if a deferred error

exists f or the host whic h sent the command, in othe r words , a deferr ed err or fo r

which

exists, then the drive reports

command is set to

previous command failed).

Note that if a

both exist for an initiator, the

This is because the operation leading to the deferred error must have been

older than that leading to the unit attention. The drive reports the conditions in

the order in which they arose.

Command Descriptor Block.

Descriptor Block is ignored

CHECK CONDITION is reported to the host with a sense key of ILLEGAL

REQUEST

original sense data is replaced with a sense key of

, and additional sense of 2500h (logical unit not supported).

ILLEGAL REQ UEST, and

additional sense of 2500h (logical unit not supported). This new sense

data is returned to the host. Once the command has completed

successfully, the sense data is cleared.

CHECK CONDITION status has not yet b een reported. If such an error

CHECK CONDITION. The sense data for the

DEFERRED ERROR (which was generated when some

UNIT ATTENTION condition and a DEFERRED ERROR condition

DEFERRED ERROR condition will be reported first.

Diagnostic Status Check

This ensures that the drive is in a fit state to access the media. It does this by

checking that there is no

If the drive has failed diagnostics,

key of

on component X).

Commands—Introduction

DIAGNOSTI C FAIL status within the drive.

CHECK CONDI TION i s r e port ed w ith a se nse

HARDWARE ERROR and additional sense of 400Xh (diagnostic failure

Commands—Introduction 33

Page 34

Fixed Bit Check

For the READ, VERIFY and WRITE commands, a Fixed bit set to 1 indicates that

the length parameter of the command is for fixed block mode. If fixed block

mode is selected then the block size in the Mode Select block descriptor must

not be zero. Otherwise

set as described for the

Flag Link Check

This check ensur es tha t the host ha s not se t the F lag b it in the contr ol b yte o f the

command without setting the Link bit as well. If the test fails then

CONDITION

sense of 2400h (invalid field in CDB). The Flag field is identified as the bad

field.

Illegal Command Check

If the drive does not recognize the opcode of the command that it has been

sent, it will do one of the following:

■ Report CHECK CONDITION status. The sense key will be set to ILLEGAL

REQUEST

command opcode).

■ Report an invali d f i eld in the command descriptor block. The sense key will

be set to

(invalid field in CDB) and the field pointer in the sense data will be zero.

CHECK CONDITION is reported and the sense data is

ILLEGAL FIELD check.

CHECK

is reported with a sense key of ILLEGAL REQUEST and additional

and the additional sense code will be set to 2000h (invalid

ILLEGAL REQUEST, the additional sense code will be set to 2400h

Illegal Field/Request Check

Checks are performed to ensure the host has not set any of the following in the

command descriptor block:

■ a fixed field

■ a reserved field

■ the control field

■ two or more fields to logically conflicting values

If a field has been set to an illegal value:

■ CHECK CONDITION status is reported to the host with a sense key of

ILLEGAL REQUEST and additional sense of 2400h “invalid field in CDB”.

34 Commands—Introduction

Page 35

■ The sense key specific bit is set and the sense key specific bytes will be a

■ The command/data bit is set, indicating that the illegal parameter was in

Note Command descriptor blocks ar e scanned from left (bit 7) to right

Media Access Check

This checks if the drive is able to perform media access commands. If the

media is inaccessible then

key of

associated with the

field pointer.

the command.

(bit 0), and down (from byte 0 to byte n). The field pointer will

be set to point to the first bit of the first illegal field encountered

using this scanning route. In some cases, where multiple fixed

fields are conti guous, th e fi eld pointer mi ght be set to poin t to the

first bit o f the first fixed fi el d in the group of fixed fie lds , w he reas

the actual illegality may lie in a later bit.

CHECK CONDITION status is reported with a sense

NOT READY. The additional sense will be set to one of the codes

NOT READY key.

Commands—Introduction 35

Commands—Introduction

Page 36

Media Information Check

Durin g po w er-on and fol lo w in g a S CS I r e set , kno w ledg e o f the w he r eabo ut s of

the cartridge is unavailable. It is not possible to execute commands which

assume that this knowledge is available until the drive has recovered from the

power-on or reset.

The test checks whether the drive knows if a cartridge is physically present in

the drive.

If information about the tape cartridge is not available, the test fails with

CHECK CO NDIT ION, a sens e ke y o f NOT READ Y, and additional sense of 3E00

(logical unit has not self-configured yet).

36 Commands—Introduction

Page 37

Media Write Check

This checks whether the media is write-pr otected . If it is, CHE CK CONDI TION is

reported with a sense key of

(write-protected).

Parameter List Check

For LOG SELECT, MODE SELECT and some diagnostic commands, the

associated data sent to the drive is in the form of parameter lists. These are

described under the command names in the next chapter. Checks are

performed to test the following:

■ Fixed and reserved fields have not been modified. Fixed fields are

■ A field has been set to an invalid value.

■ The syntax of the page of parameters has been violated—for example,

DATA PROTECT and additional sense of 2700h

indicated by a number in round brackets following the field name.

wher e a p art ic ul ar v alu e in on e f i el d i mpo s es li mit ati ons o n t he v a li d range

for another field.

Reser vation Check

If a field has been set to an illegal value,

host with a sense key of

(invalid field in parameter list).

The drive scans the data in the Command Description Block from “left” (bit 7)

to “right”, and “down” (from byte 0 to byte n). It sets the field pointers to the

first bit of the first bad field encountered. If the bad field is contained in a

contiguous group of fixed fields, the pointers indicate the first bit of the first

field in the group, even though the error may be in a later field in the group.

Note With

parameter list before acting on an y par amete r s, so all the mode

parameters need to be correct before any of them are

implemented.

This chec ks t o see if t he dr i ve h as been reserved for u se b y a h ost , an d if it h as,

whether the host is the same host that sent the command being executed.

If the drive has been reserved for some other host then

status is reported.

See the

RESERVE UNIT (page 141) and RELEASE UNIT (page 121) commands.

ILLEGAL REQUEST and additional sense of 2600h

Mode Select, the drive checks the integrity of the whole

CHECK CONDITION is reported to the

RESERVAT IO N C ONFLIC T

Commands—Introduction

Commands—Introduction 37

Page 38

Unit Attention Check

This checks if a UNIT ATTENTION condition exists for the host which sent the

command. If it does, the drive reports

key of

UNIT ATTENTION. The remaining sense data will be set according to the

unit attention condition which exists. See Unit Attention Sense in the

description of the

REQUEST SENSE command on page 132.

Command Descriptor Block

A SCSI command descriptor block (CDB) is a sequence of 6, 10, 12 or 16

bytes sent by a host to a SCSI target with the bus in command phase. The CDB

tells the drive what action should be perfor med . The f inal byt e is know n as the

Control byte.

7 6 5 4 3 2 1 0

0 Group Code Operation Code

1 Reserved (0)

CHECK CONDITION status with a sense

2 (MSB)

n

-1 (LSB)

n Vendor Unique (0)

There are a number of fields in a CDB which are common to all commands.

These are shown in the following table.

Group Code

Operation Code

and

The operation code uniquely identifies the command. The top three bits of the

operation code are known as the group code and these define the length of the

command descriptor block:

Group 0

Group 1

Group 2

Group 3

Group 4

Group 5

Group 6

Group 7

38 Commands—Introduction

Six-byte commands

Ten-byte commands

Ten-byte commands

Six-byte commands

Sixteen-byte commands

Twelve-byte commands

not supported

not supported

Multi-Byte Parameter

Reserved (0)

NACA(0) Flag (0) Link (0)

Page 39

Reserved A reserved field should always be set to zero. The drive checks reserved fields, and if one is

Multi-Byte

Parameter

non-zero then it will reject the command with

A multi-byte parameter field in a co mm and is “big-endian”, that is, bit 7 of the first byte of this

field is the most significant.

CHECK CONDITION.

Control The control field i s mainly c oncerne d with the u se of link ed comm ands. Thes e are not support ed

by the LTO SCSI Command Set, so a CHECK CONDITION will be generated if this field is set to

anything other than zero.

Vendor-Unique This field is ignored by the firmware

NACA 0 The Normal ACA flag is 0, indicating that it is not supported.

Flag 0

Link 0 Linked commands are not supported.

Commands—Introduction 39

Commands—Introduction

Page 40

40 Commands—Introduction

Page 41

Commands

4

This chapter describes all SCSI commands. Parts of the chapter are based on

sections of the SCSI specification (see page 13).

For general notes on the command descriptions, see Chapter 3.

Commands 41

Page 42

ERASE 19h

The ERASE command is used to erase data on tape from the current logical

position. The Long bit is used to decide whether the ‘old’ data is physically

overwritten or not.

Pre-Execution Checks:

Illegal Field Reservation Deferred Error Unit Attention

Media Access Media Write Diagnostic Status

Command Descriptor Block:

7 6 5 4 3 2 1 0

0

1

2

3

4

5

Operation Code (19h)

Reserved (0) Immed Long

Reserved (0)

Reserved (0)

Reserved (0)

Control

CDB Fields:

Immed 0 The drive reports st atus after the command h as completed.

1 The drive reports status when it starts the command (after any pre-

execution checks and prerequisite unloads have completed).

Long The Long bit controls the distance to be erased.

0 The current position becomes the end of logical data.

1 End of Data is written, followed b y Data Set Separators to the end of the

tape.

Note The only use for short erase is to truncate data at current logical

position. It cannot be used to create a “hole” in the tape into

which data can subsequently be written “in place”. This will

merely cause the drive to streamfail. The logical tape position is

unaffected by this command. A

CHECK CONDITION for Early

42 Commands

Page 43

Warning EOM (drive error code 2C98h) will only be given if the

tape was logically positioned past EOT immediately prior to this

command.

Erase Specific Status:

Event Status Key Additional Sense

The erase fail s CHECK CONDITION HARDWARE ERROR 5100h (era se failure)

Commands

Commands 43

Page 44

INQUIRY 12h

INQUIRY tells the drive to return information about the basic operating

parameters to the host . These par ameters cannot be changed. T he driv e re turns

Inquiry data to the host in a data-in phase.

Note This command is immune from most of the pre-execution checks

that other commands must pass (for ex am ple , it can be execut ed

while the unit is reserved for another host). U

deferred error conditions are preserved and reported on

subsequent commands.

Pre-Execution Checks:

Only the Illegal Field Check is performed before the command is executed.

nit attention and

If the EVP D bit is clear, the page code must b e zero, otherwis e

reported.

If the EVPD b i t i s s e t, the page code must be on e o f t h e su p po r te d p a ge cod e s

for Inquiry data. Otherwise

Command Descriptor Block:

7 6 5 4 3 2 1 0

0

1

2

3

4

5

LUN Reserved (0) EVPD

CDB Fields:

LUN This field is ignored.

EVPD Enable Vital Product Data

01Normal inquiry data is returned.

A page of vital product data is returned.

illegal request is

illegal request is reported.

Operation Code (12h)

Page Code

Reserved (0)

Allocation Length

Control

44 Commands

Page 45

Page Code If the EVPD bit is zero the Page Code field must be zero.

If the EVPD bit is set to 1, the drive returns the Inquiry page in this Page Code field:

00h

Supported Vital Product Pages page

80h

Unit Serial Number page

83h

Device Identification page

C0h

Firmware Revision Levels page

C1h

Hardware Revision Levels page

C2h

PCA Revision Level s page

C3h

Mechanism Revision Levels page

C4h

Head Assembly Revision Levels page

C5h

ACI page

C6h

ARM Firmware Revision Levels page

C7h

HI Glue Logic Levels page—Fibre Channel only

Allocation

Length

The maximum amount of data (in bytes) that should be returned. If more than this is available,

the amount returned is truncated to allocation length. No error is reported.

INQUIRY Data Pages

Returned Data:

INQUIRY returns its standard data if the EVPD bit is zero, or returns a page of

data as specified by the Page Code field when EVPD is one.

Commands

Standard Inquiry Data Format (LUN0)

This is the data returned by the drive in response to an Inquiry command with

its EVPD bit set to zero . The data also depends on the value of the LUN field in

the Inquiry CDB, the LUN value in the identify message and the configuration

of the drive.

Note that the data below is for the standard distribution firmware.

7 6 5 4 3 2 1 0

0

Peripheral Qualifier (000b) Peripheral Device Type (01h)

1

RMB (1) Reserved (0)

2

3

AERC (0) Obsolete NACA(0) HiSup(0) Response Data Format (2)

4

Version Number (3)

Additional L e n gt h (5Bh)

Commands 45

Page 46

7 6 5 4 3 2 1 0

5

6

BQue(0) EncSvr(0) VS(0) MultiP MChngr Obsolete Obsolete Adr16

7

RelAdr(0) Obsolete WBus16 Sync Linked(0) TranDis(0) CmdQue(0) VS(0)

8

(MSB)

15

16

(MSB)

31

32

(MSB)

35

36

(MSB)

55

56

57

58

59

72

73

74

95

(MSB)

(MSB)

(MSB)

Reserved (0) Clocking QAS (0) IUS (0)

Reserved (0)

Vendor Identification

(“HP “)

Product Identification

Product Revision Level

Reserved (0)

Reserved (0)

Version Descriptor 1

- - - - - - - -

Version Descriptor 8

Reserved (0)

(LSB)

(LSB)

(LSB)

(LSB)

(LSB)

(LSB)

(LSB)

46 Commands

The Standard Inquiry Data is based on the SCSI 3 standard for Standard

Inquiry Data.

For the LUN to which the drive is attached, the Peripheral Qualifier field is set

to 000b, the P er ipher al Dev i ce Type field is set to 01h, the Remova ble Medium

(RMB) flag is set to 1 and the Device-type modifier is set to 0.

Page 47

Inquiry Data Fields

Peripheral Qua lifier 000b

There is a device on the logical unit selected, so the LUN field in the identify

message was 0.

011b

The LUN field in the identify message has specified an unsupported logical unit.

This means any LUN other than 0.

Peripheral Dev i ce

Type

01h

Sequential Access Device

08h

Medium Changer Device

1Fh

No Device (the Peripheral Qual ifier will be 011b in this case)

RMB 1 The Removable Medium bit is one, indicating that the tape can be removed.

Device-Type Modifier 0 This is a six-bit user defined code, set to zero.

Version Number 3 The Version Number is always set to 3, indicating that the drive complies to

ANSI X3.301:1997

AERC 0 This field is zero, indicating that Asynchronous Event Reporting Capability is not

supported.

NACA 0 The Normal ACA flag is 0, indicating that it is not supported.

HiSup 0 The Hierarchical Support flag is 0, indicating that the hierarchical addressing

model is not supported.

Response Data

Format

2 This field has the value 2, indica ting that the Inq uiry Data format compl ies with the

ANSI version of SCSI-2.

Additional Length The length in bytes of the length of the rest of the Inquiry data.

5Bh There are 91 (5Bh) more bytes of Inquiry data.

BQue Basic Queuing flag

0 The flag is zero for SCSI drives. Together with the CmdQue flag being zero this

indicates that the device does not support tagged tasks for this logical unit.

1 The flag is 1 for Fibre Channel drive, indicating the basic queuing is supported.

Commands

EncSvr The Enclosure Services flag is zero to indicate that the tape drive does not support

Enclosure Services command.

MultiP 0 The drive has a single port and does not implement multi-port requirements.

1 The drives has multiple ports.

MChngr The Medium Changer bit:

01The drive is not embedded within or attached to a medium transport element.

The drive is embedded wit h in or att ac hed to a medium transport elem en t .

Adr16 The 16-Bit Address flag is set according to whether the hardware supports this bus

feature. The flag is only valid for parallel SCSI and is clear for all other low level

interfaces.

RelAdr 0 Relative Addressing is not supported.

Commands 47

Page 48

WBus16 The Wide Bus 16 flag is set according to whether the hardware supports this bus feature.

The flag is only valid for parallel SCSI and is clear for all oth e r low level interfaces.

Sync 0 Synchronous data transfer is not supported. The flag should be zero for all low-

level interfaces apart from parallel SCSI.

1 Synchronous data transfer is supported. The flag is only valid for parallel SCSI.

Linked 0 The device does not support linked commands.

CmdQue 0 The CmdQue flag is always zero. If the Basic Queuing (BQue) flag is also zero, this

indicates that the device does not support tagged tasks for this logical unit.

Vendor

Identification

Product Iden tification A left-justified, vendor-specific, 16-byte string field of ASCII characters with space

Product Revision Level A vendor-specific string of four ASCII characters: “CYMV”:

Clocking 0For FC drives.

A vendor-specific, 8-byte string of ASCII characters, left justified and padded with space

characters “HP”.

character padding on the right. The string consists of two parts:

■ First half (bytes 16–23): “Ultrium”

■ Second half (bytes 24–31): “<generation>-<interface type>”

■ The following strings have been defined:

■ Generation 2 FC drive: “Ultrium 2-SCSI” (“SCSI” is not a typo!)

■ Generation 2 SCSI drive: “Ultrium 2-SCSI”

■ C is the codename (F for a full-height drive)

■ Y is the year code . “0” is 2000, “1” is 2001, up to “9” for 2009. Alpha character s are

then used if needed.

■ M is the month code. “1” is January up to “B” for December.

■ V is an ASCII character representing the OEM variant of the code. “D” is the standard

distribution variant.

3 For SCSI drives, indicating that the drive supports both ST and DT transfers.

48 Commands

Page 49

Version Descriptor These fields can be used to identif y up to eight stand ards t o whi ch the d riv e con form s. The

values supported are listed below.

For SCSI drives, it is recommended that the first version descriptor is used for the SCSI

architecture standard, followed by the physical standard, if any, followed by the SCSI

protocol, followed by the appropriate SPC versio n , fo ll owe d by the device type command

set, followed by the secondary command set, if any.

The following are the SCSI version descriptors:

Value Standard

1

0054h

2

0B1Ch

3

0227h

4

021Ch

5–8

The following are the FC version descriptors:

0000h

Value Standard

1

0054h

2

0917h

3

0D7Ch

4

0DA0h

5

131Bh

6

1320h

7

0277h

8

021Ch

SAM-2 T10/1157-D rev 23

SPI-3 ANSI NCITS.336:2000

SPC-2 ANSI NCITS.351:2001

SSC ANSI NCITS.335:2000

not used

SAM-2 T10/1157-D rev 23

FCP-2 ANSI NCITS.332:1999

FC-AL-2 ANSI NCITS.350:200x

FC-FS (no version claimed)

FC-Tape T11/1315 revision 1.17

FC-FLA (no version claimed)

SPC-2 ANSI NCITS.351:2001

SSC ANSI NCITS.335:2000

Commands

Vendor Specific data may be sent after the Product Revision Level.

Vital Product Data Pages

The following tables describe the vital product data pages. These pages are

returned by the

appropriate Page Code is set in the Command Descriptor Block. They contain

vendor-specific produ ct information.

Supported Vital Product Data Pages Page

This is the data returned by the drive in response to an Inquiry command with

its EVPD bit set to one and its Page Code field set to 0.

INQUIRY command when the EVPD bit is set and the

Commands 49

Page 50

This page contains a list of all the VPD page-codes supported by the drive.

7 6 5 4 3 2 1 0

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Peripheral Qualifier (0) Peripheral Device Type (1)

Unit Serial Number Page

The Unit Serial Number Page contains a single value which is a 10-byte ASCII

string. The string, with the Vendor Identification and Product Identification

fields in the standard Inquiry data, uniquely identifies the drive.

Page Code (00h)

Reserved (0)

Page Length (0Ah for SCSI drives, 0Bh for FC drives)

Supported Pages Code (00h)

Unit Serial Number Page (80h)

Device Identification Page(83h)

Firmware Revision Levels Page (C0h)

Hardware Revision Leve ls Page (C1h)

PCA Revision Levels Page (C2h)

Mechanism Revision Levels Page (C 3h)

Head Assembly Revision Levels Page (C4h)

Auto-Changer Interface Revision Levels Page (C5h)

ARM Firmware Revision Levels page (C6h)

HI Glue Logic Levels page (C7h)—Fibre Channel only

50 Commands

13

7 6 5 4 3 2 1 0

0

1

2

3

4

Peripheral Qualifier (0) Peripheral Device Type (1)

Page Code (80h)

Reserved (0)

Page Length (0Ah)

(MSB)

Serial Number

(LSB)

Page 51

Device Identification Page

The Device Identification page contains information that identifies the tape

drive uniq uely. For SCSI, a combinati on of the Vendor ID and Serial Number is

Commands

returned. For Fibre Channel, the Port and Device Names are returned as well.

7 6 5 4 3 2 1 0

0

1

2

3

4

n

Peripheral Qualifier (0) Peripheral Device Type (1)

Page Code (83h)

Reserved (0)

Page Length (n

(MSB)

Identification Descriptors

-3)

(LSB)

Identification Descriptors are constructed as follows:

7 6 5 4 3 2 1 0

0

1

2

3

4

(MSB)

n

Reserved (0) Code Set

Reserved (0) Identifier Type

Reserved (0)

Identifier Length (n-3)

Identifier

(LSB)

Code Set 1 The Identification Descriptor is a binary field.

2 The Identification Descriptor contains only ASCII data.

Identifier Type 1 Vendor ID followed by th e produc t identification field f rom the s tandard in quiry data an d the

serial number field from the Serial Number Inquiry Page.

3 All devices with a Fibre Channel interface support an Identifier type of 3. In this case the

Identification Descriptor is the Fibre Channel 64-bit Name Identifier.

Defined Ide nti fiers

The following identifi ers will be returned in the given or der. What Port Name is

returned depends on which port the Inquiry is sent to.

Commands 51

Page 52

Device Serial Number (FC and SCSI)

7 6 5 4 3 2 1 0

11

12

27

28

37

11

0

1

2

3

4

(MSB)

(MSB)

(MSB)

Reserved (0) Code Set ( 2 )

Reserved (0) Identifier Type (1)

Reserved (0)

Identifier Length (34)

Vendor ID

(LSB)

Product Identification

(LSB)

Serial Number

(LSB)

Port Name (FC only)

7 6 5 4 3 2 1 0

0

1

2

3

4

(MSB)

Reserved (0) Code Set (1)

Reserved (0) Iden ti fier Type (3)

Reserved (0)

Identifier Length (8)

Port Name

(IEEE Registered Name)

(LSB)

52 Commands

11

Device Name (FC only)

7 6 5 4 3 2 1 0

0

1

2

3

4

(MSB)

Reserved (0) Code Set (1)

Reserved (0) Iden ti fier Type (3)

Reserved (0)

Identifier Length (8)

Device Nam e

(IEEE Registered Name)

(LSB)

Page 53

Port Identifier (FC only)

0

1

2

3

4

7

0

1

2

3

4

11

7 6 5 4 3 2 1 0

Reserved (0) Code Set (1)

Reserved (0) Identi fier Type (4)

Reserved (0)

Identifier Length (4)

(MSB)

Port Identifier

(LSB)

The Po rt Identifier will be set to 1 if the addressed port is port A, and set to 2 if

the addressed port is Port B.

SCSI Type 3 Identifier (SCSI only)

7 6 5 4 3 2 1 0

Reserved (0) Code Set (1)

Reserved (0) Iden ti fier Type (3)

Reserved (0)

Identifier Length (8)

(MSB)

SCSI Identifier

(IEEE Registered Name)

(LSB)

Commands

Driv e Component Revi sion Levels Pages

7 6 5 4 3 2 1 0

0

1

2

3

4

29

Peripheral Qualifier (0) Peripheral Device Type (1)

Page Length (5Ch)

(MSB)

Component (“CCCCCCCCCCCC”)

Page Code

Reserved (0)

(LSB)

Commands 53

Page 54

30

48

49

72

73

95

7 6 5 4 3 2 1 0

(MSB)

Version (“RRR.VVV”)

(LSB)

(MSB)

Date (“YYYY/MM/DD hh:mm”)

(LSB)

(MSB)

Variant (“XXXXXXXXXXXX”)

(LSB)

The Drive Component Revision Levels pages contain details of the revisions of

each of the major sub assemblies of the drive. For any given product, if these

pages are the same then the drive has been built with the same components

and with the same manufacturing process.

Each entry is a null-terminated ASCII string.

Page Code Page Code Component Name

C0h - Firmware

C1h - Hardware

C2h - PCA

C3h - Mechanism

C4h - Head Assembly

C5h - ACI

C6h - ARM

C7h - HI Glue Logic

Component A 12-character entry to identify the component that the revision is for.

Version A 7-character version code with a three- dig i t major revision number, a

period and a three-digit minor version num ber .

Date The date of the version.

Variant An identifier indicating what version of the product this is.

8000 0100h

8002 0100h

“HI Glue Logic” (FC only)

Generation 2 full-height SCSI

Generation 2 full-height FC

“Firmware”

“Hardware”

“PCA”

“Mechanism”

“Head Assy”

“ACI”

“IO Firmware”

54 Commands

Page 55

LOAD/UNLOAD 1Bh

The LOAD/UNLOAD command allows the host to specify that a tape cartridge

present in the drive is either made ready for data transfer (“loaded”) or

disabled for data transfer (if Prevent Media Removal is set). It can also cause

the cartridge to be ejected from the drive (“unloaded”).

Pre-Execution Checks:

Illegal Field Reservation Deferred Error

Unit Attention Diagnostic Status Media Information

If an unload is to be performed, the drive checks if the tape is currently being

loaded. If it is,

and additional sense of 0401h (becoming ready).

If a load is to be performed, the drive c hecks to ensur e that a ta pe cartri dge is

present. If not, it reports

and additional sense of 3A00h (medium not present). If the media is currently

being unloaded or ejected, it reports

NOT READY and additional sense of 0400h (cause not reportable).

Command Descriptor Block:

CHECK CONDIT ION is reported with a sense key of NOT READY

CHECK CONDITION with a sense key of NO T READY

CHECK CONDITION with sense key of

Commands

7 6 5 4 3 2 1 0

0

1

2

3

4

5

Reserved (0 ) Hold EOT (0) ReTen Load

Operation Code (1Bh)

Reserved (0) Immed

Reserved (0)

Reserved (0)

Control

CDB Fields:

Immed 0 The drive reports status afte r the command has completed.

1 The drive reports status when it starts the command (after any pre-execution checks

and prerequisite unloads have completed).

Commands 55

Page 56

Hold 0 A normal load/unload will be perfor med.

1 A load will cause the cartridge to be pull ed in and se ated in the d rive, but the t ape will

not be threaded.

An unload will cause the tape to be unthreaded, but the cartridge will not be ejected.

In Hold position, the Cartridge Memory is accessible.

ReTen This field is ignored.

Load 0 The drive perform s an unload operati o n.

1 The drive performs a load operation.

Load/Unload Specific Status:

Following a successful LOAD command, CHECK CO NDITION is posted to all

initiators other than the initiator of the

UNIT ATTENTION, with additional sense of 2800h (not ready to ready

transition). There is an exception to this: if a load occurs when the tape is

already loaded, no

UNIT A TTENTION is clear ed , unsoli cit ed positional sens e is set . The sen se

Once

key will be

NO SENSE with additional sense of 0004h (BOT detected).

If an unformatted tape is inserted, the drive loads it and it behaves as if it is a

blank tape.

If a cartridge with no Cartridge Memory or a failed Cartridge Memory is

loaded,

CHECK CONDITION is returned with a sense key of MEDIUM ERROR,

with additional sense of 5200h (cartridge fault).

UNIT ATTENTION sense is generated.

LOAD command. The sense key is set to

56 Commands

Loading a Cartridge

The drive loads a tape automatically when it is inserted, without any host