Page 1

hp StorageWorks

HSG80 Array Controller V8.7

Troubleshooting Reference Guide

Part Number: EK–G80TR–SA. B01

Second Edition (August 2002)

Product Version: 8.7

This guide provides troubleshooting instructions for the HSG80

array controllers running array controller software (ACS) Versions

8.7F, 8.7G, 8.7P, 8.7R, 8.7S and 8.7W. It contains information on

various utilities, software templates, and event reporting codes

Page 2

© Hewlett-Packard Company, 2002. All rights reserved.

Hewlett-Packard Company makes no warranty of any kind with regard to this material, including, but

not limited to, the implied warranties of merchantability and fitness for a particular purpose.

Hewlett-Packard shall not be liable for errors contained herein or for incidental or consequential

damages in connection with the furnishing, performance, or use of this material.

This document contains proprietary information, which is protected by copyright. No part of this

document may be photocopied, reproduced, or translated into another language without the prior

written consent of Hewlett-Packard. The information contained in this document is subject to change

without notice.

Microsoft, MS-DOS, Windows, and Windows NT are trademarks of Microsoft Corporation in the U.S.

and/or other countries.

All other product names mentioned herein may be trademarks of their respective companies.

Hewlett-Packard Company shall not be liable for technical or editorial errors or omissions contained

herein. The information is provided “as is” without warranty of any kind and is subject to change

without notice. The warranties for Hewlett-Packard Company products are set forth in the express

limited warranty statements accompanying such products. Nothing herein should be construed as

constituting an additional warranty.

Printed in the U.S.A.

HSG80 Array Controller V8.7 Troubleshooting Reference Guide

Second Edition (August 2002)

Part Number: EK–G80TR–SA. B01

Page 3

Contents

About this Guide

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Symbols in Text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Symbols on Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Rack Stability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Getting Help. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

StorageWorks Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

StorageWorks Website . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

StorageWorks Authorized Reseller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

1 Troubleshooting Information

Typical Installation Troubleshooting Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

Troubleshooting Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Significant Event Reporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–12

Reporting Events That Cause Controller Operation to Halt . . . . . . . . . . . . . . . . . 1–13

Flashing OCP Pattern Display Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–13

Solid OCP Pattern Display Reporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–15

Last Failure Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–21

Reporting Events That Allow Controller Operation to Continue . . . . . . . . . . . . . 1–21

Spontaneous Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–22

CLI Event Reporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–22

Running the Controller Diagnostic Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–23

ECB Charging Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–23

Battery Hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–23

Caching Techniques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–24

Read Caching. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–24

Read-Ahead Caching. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–25

Write-Through Caching. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–25

Write-Back Caching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–26

Fault-Tolerance for Write-Back Caching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–26

HSG80 Array Controller V8.7 Troubleshooting Reference Guide iii

Page 4

Contents

Nonvolatile Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–26

Cache Policies Resulting from Cache Module Failures . . . . . . . . . . . . . . . . . 1–27

Enabling Mirrored Write-Back Cache . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–32

2 Utilities and Exercisers

Fault Management Utility (FMU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

Displaying Failure Entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

Translating Event Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–3

Controlling the Display of Significant Events and Failures. . . . . . . . . . . . . . . . . . . 2–5

Video Terminal Display (VTDPY) Utility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–7

Restrictions with VTDPY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–7

Running VTDPY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–8

VTDPY Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–9

VTDPY Display Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–10

Default Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–11

Controller Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–11

Cache Performance Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–12

Device Performance Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–13

Host Ports Statistics Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–15

Resource Statistics Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–17

Remote Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–17

Interpreting VTDPY Screen Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–18

Screen Header . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–19

Common Data Fields. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–20

Unit Performance Data Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–21

Device Performance Data Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–23

Device Port Performance Data Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–25

Host Port Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–26

TACHYON Chip Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–28

Runtime Status of Remote Copy Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–29

Device Port Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–31

Controller/Processor Utilization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–32

Resource Performance Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–34

Disk Inline Exerciser (DILX). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–35

Checking for Unit Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–35

Finding a Unit in the Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–35

Testing the Read Capability of a Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–36

Testing the Read and Write Capabilities of a Unit . . . . . . . . . . . . . . . . . . . . . 2–37

iv HSG80 Array Controller V8.7 Troubleshooting Reference Guide

Page 5

DILX Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–40

Format and Device Code Load Utility (HSUTIL). . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–40

Configuration (CONFIG) Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–42

Code Load and Code Patch (CLCP) Utility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–42

Clone (CLONE) Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–42

Field Replacement Utility (FRUTIL). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–43

Change Volume Serial Number (CHVSN) Utility. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–43

3 Event Reporting Templates

Passthrough Device Reset Event Sense Data Response . . . . . . . . . . . . . . . . . . . . . . . . 3–1

Last Failure Event Sense Data Response (Template 01) . . . . . . . . . . . . . . . . . . . . . . . . 3–2

Multiple-Bus Failover Event Sense Data Response (Template 04). . . . . . . . . . . . . . . . 3–4

Failover Event Sense Data Response (Template 05) . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

Nonvolatile Parameter Memory Component Event Sense Data Response (Template 11) .

3–7

Backup Battery Failure Event Sense Data Response (Template 12). . . . . . . . . . . . . . . 3–9

Subsystem Built-In Self-Test Failure Event Sense Data Response (Template 13) . . . 3–10

Memory System Failure Event Sense Data Response (Template 14) . . . . . . . . . . . . . 3–11

Device Services Nontransfer Error Event Sense Data Response (Template 41) . . . . . 3–13

Disk Transfer Error Event Sense Data Response (Template 51). . . . . . . . . . . . . . . . . 3–15

Data Replication Manager Services Event Sense Response (Template 90) . . . . . . . . 3–17

Contents

4 ASC/ASCQ, Repair Action, and Component Identifier Codes

Vendor Specific SCSI ASC/ASCQ Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

Recommended Repair Action Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–4

Component ID Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–11

5 Instance Codes

Instance Code Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

Instance Codes and FMU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

Notification/Recovery Threshold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–2

Repair Action. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–2

Event Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–2

Component ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–3

6 Last Failure Codes

Last Failure Code Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

Last Failure Codes and FMU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

HSG80 Array Controller V8.7 Troubleshooting Reference Guide v

Page 6

Contents

Parameter Count. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–2

Restart Code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–2

Hardware/Software Flag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–2

Repair Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–3

Error Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–3

Component ID Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–3

Glossary

Index

Figures

2–1 VTDPY commands and shortcuts generated from the Help command. . . . . . 2–10

2–2 Sample of the VTDPY default screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–11

2–3 Sample of the VTDPY status screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–12

2–4 Sample of the VTDPY cache screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–13

2–5 Sample of regions on the VTDPY device screen . . . . . . . . . . . . . . . . . . . . . . 2–14

2–6 Sample of the VTDPY host screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–16

2–7 Sample of the VTDPY resource screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–17

2–8 Sample of the VTDPY remote status screen (ACS version 8.7P only). . . . . . 2–18

5–1 Structure of an Instance Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

6–1 Structure of a Last Failure Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

Tables

1 Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

1–1 Troubleshooting Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

1–2 Flashing OCP Pattern Displays and Repair Actions . . . . . . . . . . . . . . . . . . . . 1–13

1–3 Solid OCP Pattern Displays and Repair Actions. . . . . . . . . . . . . . . . . . . . . . . 1–16

1–4 ECB Capacity Based On Memory Size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–24

1–5 Cache Policies—Cache Module Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–27

1–6 Resulting Cache Policies—ECB Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–29

2–1 Event Code Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–4

2–2 FMU SET Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–5

2–3 VTDPY Key Sequences and Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–8

2–4 VTDPY—Common Data Fields Column Definitions: Part 1 . . . . . . . . . . . . . 2–20

2–5 VTDPY—Common Data Fields Column Definitions: Part 2 . . . . . . . . . . . . . 2–21

2–6 VTDPY—Unit Performance Data Fields Column Definitions . . . . . . . . . . . . 2–22

2–7 VTDPY—Device Performance Data Fields Column Definitions. . . . . . . . . . 2–24

vi HSG80 Array Controller V8.7 Troubleshooting Reference Guide

Page 7

Contents

2–8 VTDPY—Device Port Performance Data Fields Column Definitions. . . . . . 2–25

2–9 Fibre Channel Host Status Display—Known Host Connections . . . . . . . . . . 2–26

2–10 Fibre Channel Host Status Display—Port Status . . . . . . . . . . . . . . . . . . . . . . 2–26

2–11 Fibre Channel Host Status Display—Link Error Counters. . . . . . . . . . . . . . . 2–27

2–12 First Digit on the TACHYON Chip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–28

2–13 Second Digit on the TACHYON Chip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–29

2–14 Remote Display Column Definitions— ACS Version 8.7P Only . . . . . . . . . 2–29

2–15 Device Map Column Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–31

2–16 Controller/Processor Utilization Definitions . . . . . . . . . . . . . . . . . . . . . . . . . 2–32

2–17 VTDPY Thread Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–33

2–18 Resource Performance Statistics Definitions . . . . . . . . . . . . . . . . . . . . . . . . . 2–34

2–19 DILX Control Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–37

2–20 Data Patterns for Phase 1: Write Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–37

2–21 DILX Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–40

2–22 HSUTIL Messages and Inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–40

3–1 Passthrough Device Reset Event Sense Data Response Format. . . . . . . . . . . . 3–2

3–2 Template 01—Last Failure Event Sense Data Response Format . . . . . . . . . . . 3–3

3–3 Template 04—Multiple-Bus Failover Event Sense Data Response Format. . . 3–4

3–4 Template 05—Failover Event Sense Data Response Format. . . . . . . . . . . . . . 3–6

3–5 Template 11—Nonvolatile Parameter Memory Component Event Sense Data

Response Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–8

3–6 Template 12—Backup Battery Failure Event Sense Data Response Format . . 3–9

3–7 Template 13—Subsystem Built-In Self Test Failure Event Sense Data Response

Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–10

3–8 Template 14—Memory System Failure Event Sense Data Response Format 3–12

3–9 Template 41—Device Services Non-Transfer Error Event Sense Data Response

Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–14

3–10 Template 51—Disk Transfer Error Event Sense Data Response Format. . . . 3–16

3–11 Template 90—Data Replication Manager Services Event Sense Data Response

Format (ACS Version 8.7P Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–18

4–1 ASC and ASCQ Code Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

4–2 Recommended Repair Action Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–4

4–3 Component ID Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–11

5–1 Instance Code Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

5–2 Event Notification/Recovery (NR) Threshold Classifications . . . . . . . . . . . . . 5–2

5–3 Instance Codes and Repair Action Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–4

6–1 Last Failure Code Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–2

6–2 Controller Restart Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–2

HSG80 Array Controller V8.7 Troubleshooting Reference Guide vii

Page 8

Contents

6–3 Last Failure Codes and Repair Action Codes . . . . . . . . . . . . . . . . . . . . . . . . . . 6–4

viii HSG80 Array Controller V8.7 Troubleshooting Reference Guide

Page 9

Document Conventions

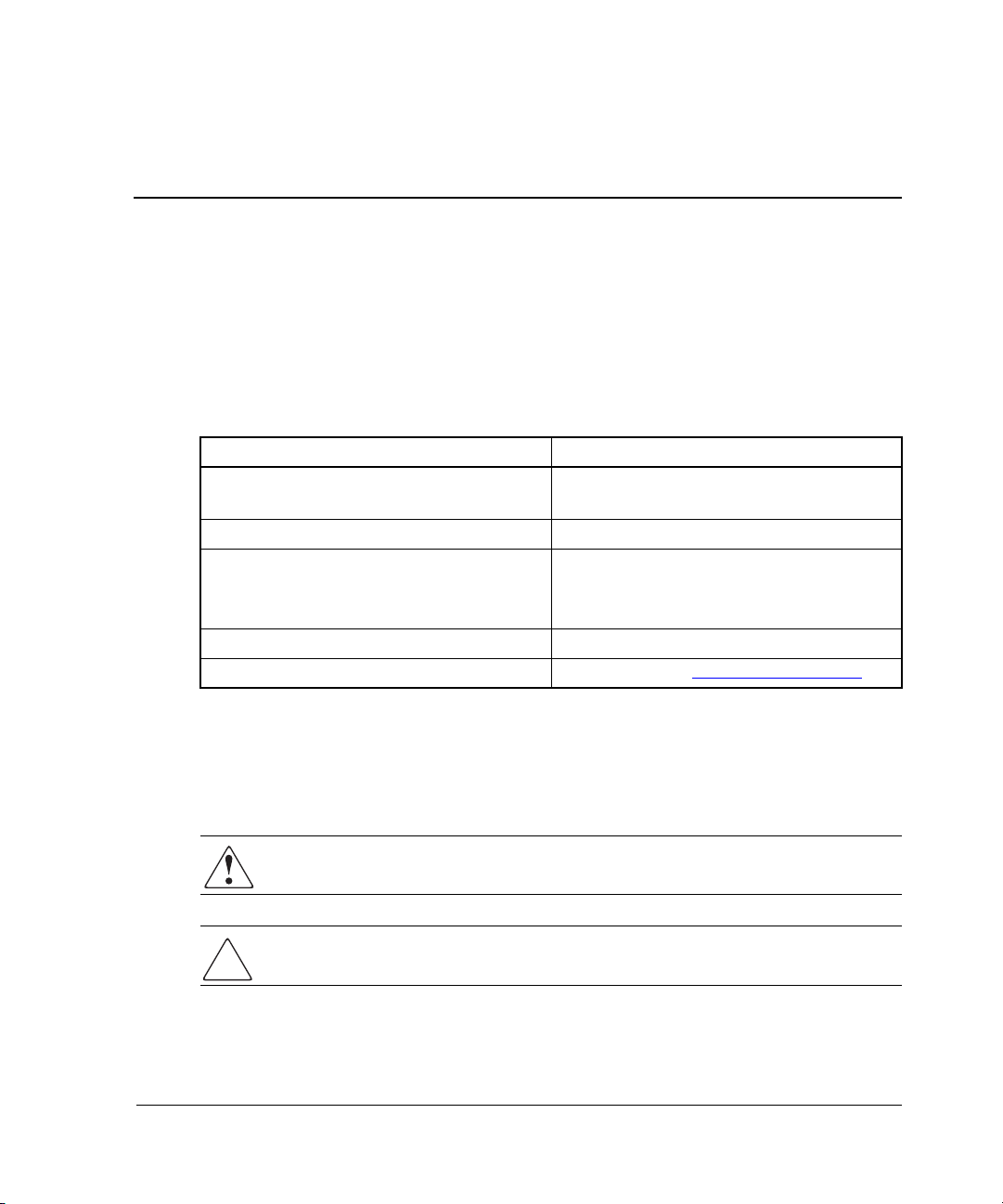

The conventions included in Table 1 apply in most cases.

Table 1: Document Conventions

Element Convention

Key names, menu items, buttons,

and dialog box titles

File names and application names Italics

User input, command names, system

responses (output and messages)

Variables Monospace, italic font

Website addresses Sans serif font (http://www.compaq.com

Symbols in Text

About this Guide

Bold

Monospace font

COMMAND NAMES are uppercase

unless they are case sensitive

)

These symbols may be found in the text of this guide. They have the following

meanings.

WARNING: Text set off in this manner indicates that failure to follow directions

in the warning could result in bodily harm or loss of life.

CAUTION: Text set off in this manner indicates that failure to follow directions could

result in damage to equipment or data.

IMPORTANT: Text set off in this manner presents clarifying information or specific instructions.

HSG80 Array Controller V8.7 Troubleshooting Reference Guide ix

Page 10

About this Guide

NOTE: Text set off in this manner presents commentary, sidelights, or interesting points of

information.

Symbols on Equipment

Any enclosed surface or area of the equipment marked with these

symbols indicates the presence of electrical shock hazards. Enclosed

area contains no operator serviceable parts.

WARNING: To reduce the risk of injury from electrical shock hazards, do

not open this enclosure.

Any RJ-45 receptacle marked with these symbols indicates a network

interface connection.

WARNING: To reduce the risk of electrical shock, fire, or damage to the

equipment, do not plug telephone or telecommunications connectors into

this receptacle.

Any surface or area of the equipment marked with these symbols

indicates the presence of a hot surface or hot component. Contact with

this surface could result in injury.

WARNING: To reduce the risk of injury from a hot component, allow the

surface to cool before touching.

Power supplies or systems marked with these symbols indicate the

presence of multiple sources of power.

WARNING: To reduce the risk of injury from electrical shock,

remove all power cords to completely disconnect power from the

power supplies and systems.

x HSG80 Array Controller V8.7 Troubleshooting Reference Guide

Page 11

Rack Stability

WARNING: To reduce the risk of personal injury or damage to the equipment, be

sure that:

• The leveling jacks are extended to the floor.

• The full weight of the rack rests on the leveling jacks.

• In single rack installations, the stabilizing feet are attached to the rack.

• In multiple rack installations, the racks are coupled.

• Only one rack component is extended at any time. A rack may become

unstable if more than one rack component is extended for any reason.

About this Guide

Any product or assembly marked with these symbols indicates that the

component exceeds the recommended weight for one individual to

handle safely.

WARNING: To reduce the risk of personal injury or damage to the

equipment, observe local occupational health and safety requirements

and guidelines for manually handling material.

Getting Help

If you still have a question after reading this guide, contact service representatives or

visit our website.

StorageWorks Technical Support

In North America, call StorageWorks technical support at 1-800-OK-COMPAQ,

available 24 hours a day, 7 days a week.

NOTE: For continuous quality improvement, calls may be recorded or monitored.

Outside North America, call StorageWorks technical support at the nearest location.

Telephone numbers for worldwide technical support are listed on the StorageWorks

website: http://www.compaq.com

Be sure to have the following information available before calling:

• Technical support registration number (if applicable)

• Product serial numbers

HSG80 Array Controller V8.7 Troubleshooting Reference Guide xi

.

Page 12

About this Guide

• Product model names and numbers

• Applicable error messages

• Operating system type and revision level

• Detailed, specific questions.

StorageWorks Website

The StorageWorks website has the latest information on this product, as well as the

latest drivers. Access the StorageWorks website at: http://www.compaq.com/storage

From this website, select the appropriate product or solution.

StorageWorks Authorized Reseller

For the name of your nearest StorageWorks Authorized Reseller:

• In the United States, call 1-800-345-1518.

• In Canada, call 1-800-263-5868.

• Elsewhere, see the StorageWorks website for locations and telephone numbers.

.

xii HSG80 Array Controller V8.7 Troubleshooting Reference Guide

Page 13

Troubleshooting Information

This chapter provides guidelines for troubleshooting the controller, cache module, and

external cache battery (ECB). See enclosure documentation for information on

troubleshooting enclosure hardware, such as the power supplies, cooling fans, and

environmental monitoring unit (EMU).

Typical Installation Troubleshooting Checklist

The following checklist identifies many of the problems that occur in a typical

installation. After identifying a problem, use Table 1–1 to confirm the diagnosis and

fix the problem.

If an initial diagnosis points to several possible causes, use the tools described in this

chapter and then those in Chapter 2 to further refine the diagnosis. If a problem cannot

be diagnosed using the checklist and tools, contact a StorageWorks authorized service

provider for additional support.

To troubleshoot the controller and supporting modules, complete the following:

1

1. Check the power to the enclosure and enclosure components.

• Are power cords connected properly?

• Is power within specifications?

2. Check the component cables.

• Are bus cables to the controllers connected properly?

• For BA370 enclosures, are ECB cables connected properly?

3. Check each program card to make sure the card is fully seated.

4. Check the operator control panel (OCP) and devices for LED codes.

See “Flashing OCP Pattern Display Reporting” on page 1–13 and “Solid OCP

Pattern Display Reporting” on page 1–15, to interpret the LED codes.

HSG80 Array Controller V8.7 Troubleshooting Reference Guide 1–1

Page 14

Troubleshooting Information

5. Connect a local terminal to the controller and check the controller configuration

with the following command:

SHOW THIS_CONTROLLER FULL

Make sure that the ACS version loaded is correct and that pertinent patches are

installed. Also, check the status of the cache module and the supporting ECB.

In a dual redundant configuration, check the “other controller” with the following

command:

SHOW OTHER_CONTROLLER FULL

6. Use the fault management utility (FMU) to check for Last Failure or “memory

system failure” entries.

Show these codes and translate the Last Failure Codes they contain. See

Chapter 2, “Displaying Failure Entries” and “Translating Event Codes” sections.

If the controller failed to the extent that the controller cannot support a local

terminal for FMU, check the host error log for the Instance or Last Failure Codes.

See Chapter 5 and Chapter 6 to interpret the event codes.

7. Check device status with the following command:

SHOW DEVICES FULL

Look for errors such as “misconfigured device” or “No device at this PTL.” If a

device reports misconfigured or missing, check the device status with the

following command:

SHOW device-name

8. Check storageset status with the following command:

SHOW STORAGESETS FULL

Make sure that all storagesets are normal (or normalizing if the storageset is a

RAIDset or mirrorset). Check again for misconfigured or missing devices using

step 7.

9. Check unit status with the following command:

SHOW UNITS FULL

Make sure that all units are available or online. If the controller reports a unit as

unavailable or offline, recheck the storageset the unit belongs to with the

following command:

SHOW storageset-name

1–2 HSG80 Array Controller V8.7 Troubleshooting Reference Guide

Page 15

Troubleshooting Information

If the controller reports that a unit has lost data or is unwriteable, recheck the

status of the devices that make up the storageset. If the devices are operating

normally, recheck the status of the cache module. If the unit reports a media

format error, recheck the status of the storageset and storageset devices.

Troubleshooting Table

After diagnosing a problem, use Table 1–1 to resolve the problem.

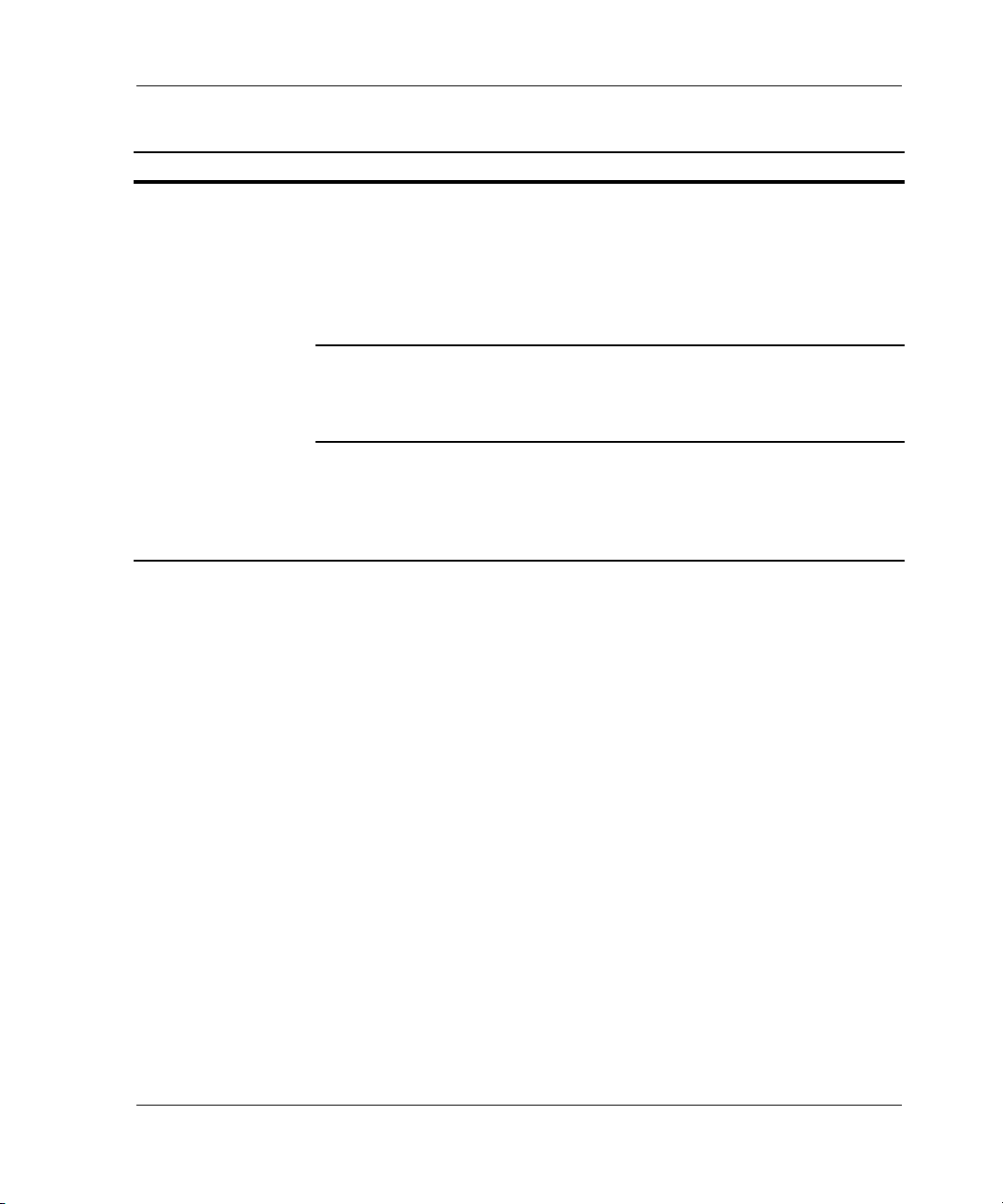

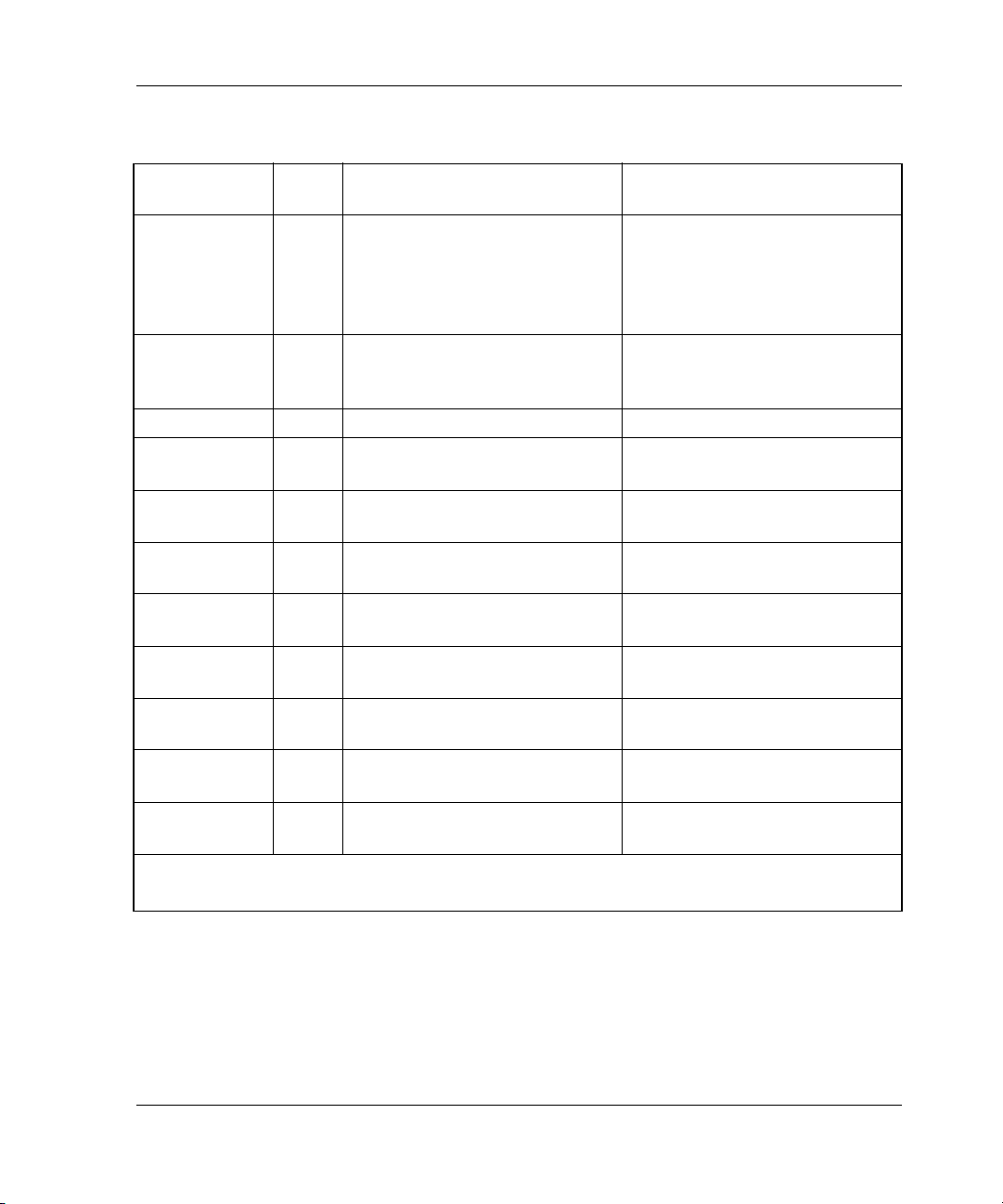

Table 1–1: Troubleshooting Guidelines (Sheet 1 of 10)

Symptom Possible Cause Investigation Remedy

Reset button not lit. No power to

subsystem.

Failed controller. If the previous

Reset button lit

steadily; other

LEDs also lit.

Various. See OCP LED Codes. Follow repair action

Check power to

subsystem and power

supplies on controller

enclosure.

BA370 enclosure

only: Make sure that

all cooling fans are

installed. If one or

more fans are missing

or all are inoperative

for more than 8

minutes, the EMU

shuts down the

subsystem.

BA370 enclosure

only: Determine if the

standby power switch

on the PVA was

pressed for more than

5 seconds.

remedies fail to

resolve the problem,

check OCP LED

codes.

Replace cord or

(BA370 enclosure

only) AC input box.

Turn off power switch

on AC input box.

Replace cooling fan.

Restore power to

subsystem.

Press the alarm

control switch on the

EMU.

Replace controller.

using Table 1–2.

HSG80 Array Controller V8.7 Troubleshooting Reference Guide 1–3

Page 16

Troubleshooting Information

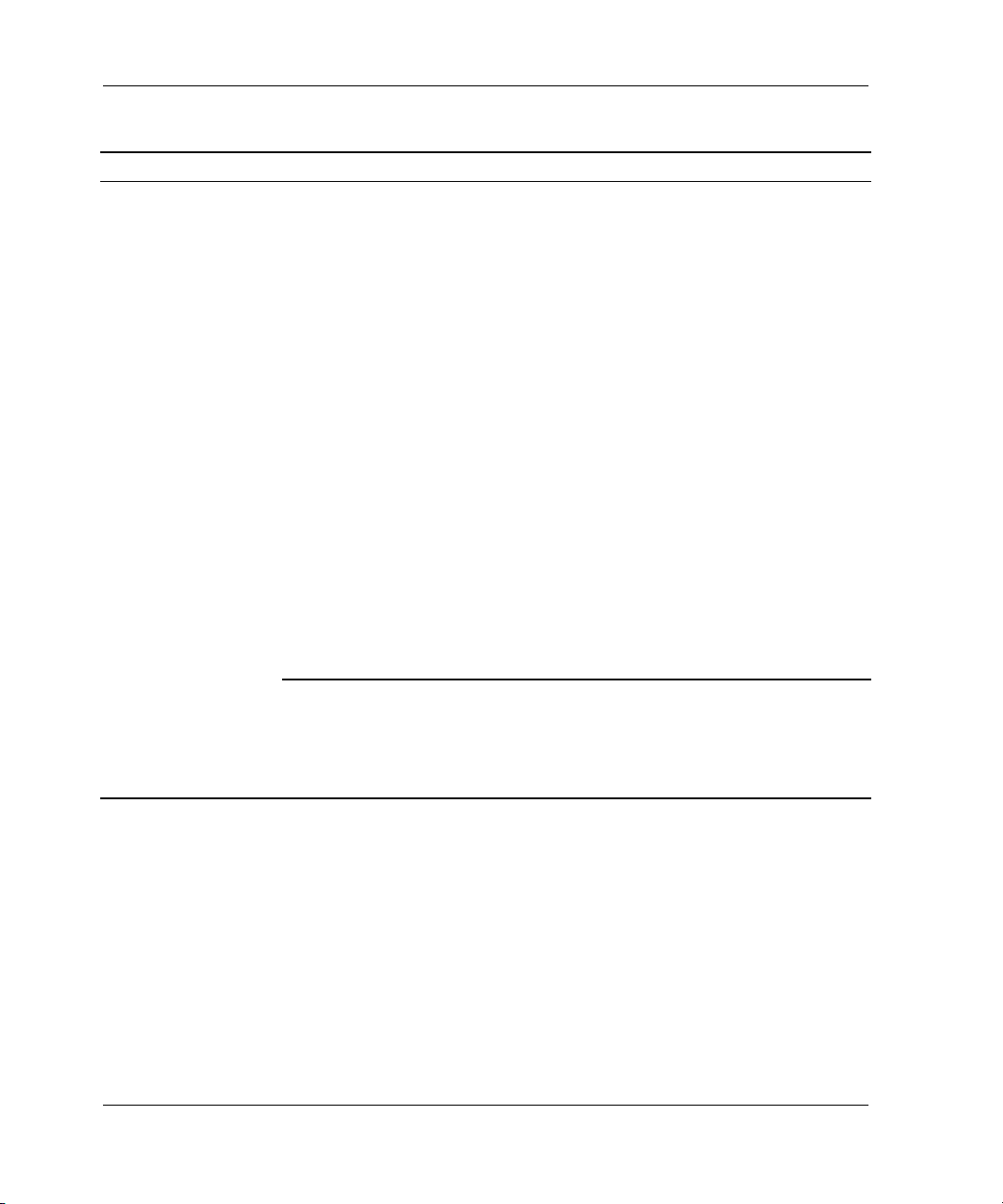

Table 1–1: Troubleshooting Guidelines (Sheet 2 of 10)

Symptom Possible Cause Investigation Remedy

Reset button

FLASHING; other

LEDs also lit.

Device in error or

failedset on

corresponding

SHOW device FULL. Follow repair action

using Table 1–3.

device port with

other LEDs lit.

Cannot set failover

to create

dual-redundant

configuration.

Incorrect command

syntax.

Different software

versions on

controllers.

See the controller CLI

reference guide for

the SET FAILOVER

command.

Check software

versions on both

controllers.

Use the correct

command syntax.

Update one or both

controllers so that

both are using the

same software

version.

Incompatible

hardware.

Check hardware

versions.

Upgrade controllers

so that they are

using compatible

hardware.

Controller

previously set for

failover.

Make sure that

neither controller is

configured for failover.

Use the SET

NOFAILOVER

command on both

controllers, then

reset “this controller”

for failover.

Failed controller. If the previous

remedies fail to

resolve the problem,

Follow repair action

using Table 1–2 or

Table 1–3.

check for OCP LED

codes.

1–4 HSG80 Array Controller V8.7 Troubleshooting Reference Guide

Page 17

Troubleshooting Information

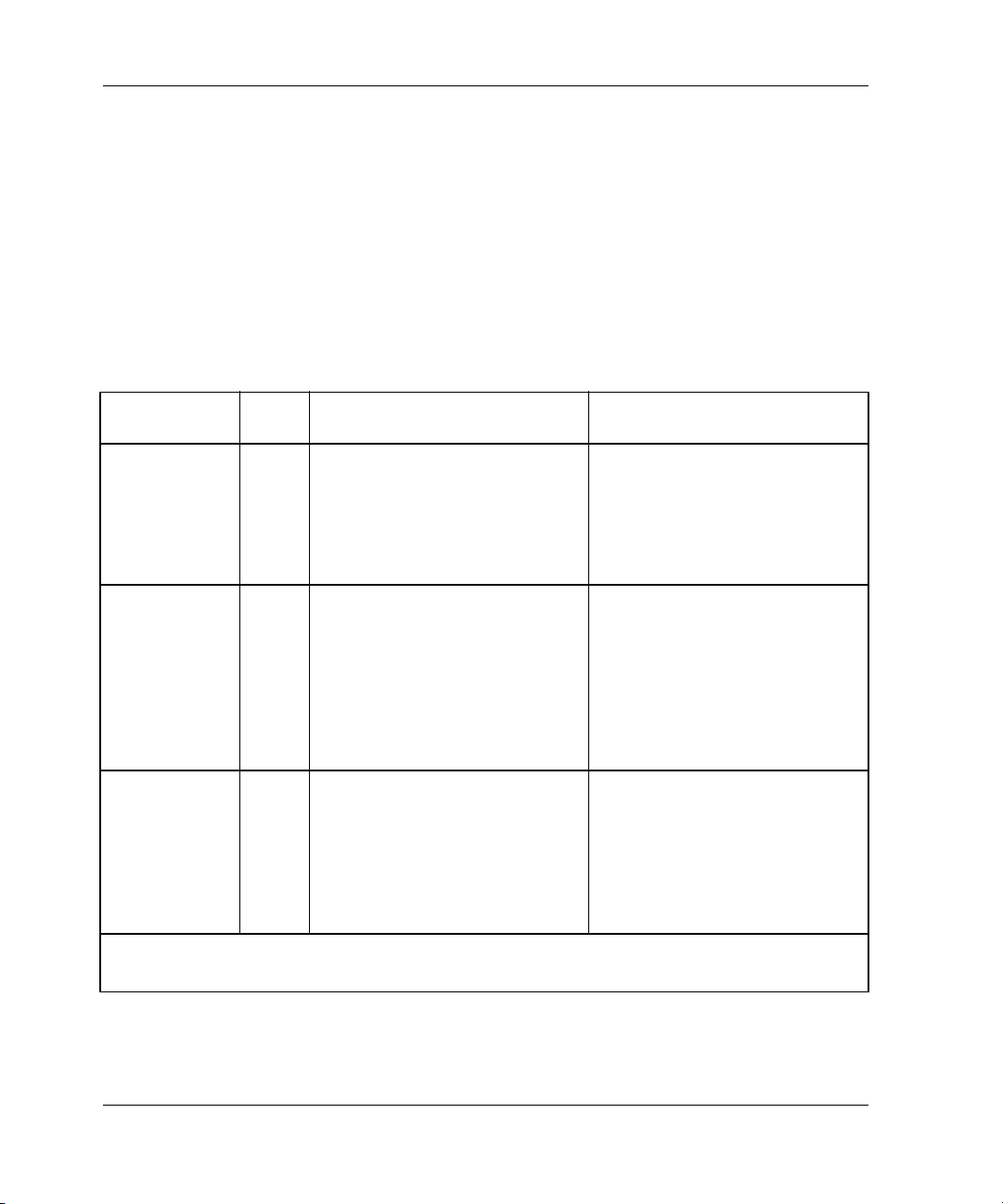

Table 1–1: Troubleshooting Guidelines (Sheet 3 of 10)

Symptom Possible Cause Investigation Remedy

Node ID is all zeros. SHOW_THIS to see if

node ID is all zeros.

Set node ID using

the node ID (bar

code) that is located

on the frame in

which the controller

sits. See SET

THIS_CONTROLLE

R NODE_ID in the

controller CLI

reference guide.

Also, be sure to copy

in the right direction.

If cabled to the new

controller, use SET

FAILOVER COPY=

OTHER_CONTROL

LER. If cabled to the

old controller, use

SET FAILOVER

COPY=THIS_CONT

ROLLER.

Nonmirrored

cache: controller

reports failed

DIMM in Cache A

or B.

Improperly installed

DIMM.

Remove cache

module and make

sure that the DIMM is

fully seated in the slot.

Failed DIMM. If the previous remedy

Reseat DIMM.

Replace DIMM.

fails to resolve the

problem, check for

OCP LED codes.

Mirrored cache:

“this controller”

reports DIMM 1 or

2 failed in Cache A

or B.

Improperly installed

DIMM in “this

controller” cache

module.

Failed DIMM in “this

controller” cache

module.

Remove cache

module and make

sure that DIMMs are

installed properly.

If the previous remedy

fails to resolve the

problem, check for

Reseat DIMM.

Replace DIMM in

“this controller”

cache module.

OCP LED codes.

HSG80 Array Controller V8.7 Troubleshooting Reference Guide 1–5

Page 18

Troubleshooting Information

Table 1–1: Troubleshooting Guidelines (Sheet 4 of 10)

Symptom Possible Cause Investigation Remedy

Mirrored cache:

“this controller”

reports DIMM 3 or

4 failed in Cache A

or B.

Improperly installed

DIMM in “other

controller” cache

module.

Failed DIMM in

“other controller”

cache module.

Remove cache

module and make

sure that the DIMMs

are installed properly.

If the previous remedy

fails to resolve the

problem, check for

Reseat DIMM.

Replace DIMM in

“other controller”

cache module.

OCP LED codes.

Mirrored cache:

controller reports

battery not

present.

Memory module

was installed before

the cache module

was connected to

an ECB.

BA370 enclosure:

ECB cable not

connected to cache

module.

Model 2200

enclosure: ECB not

installed or seated

BA370 enclosure:

Connect ECB cable

to cache module,

then restart both

controllers by

pushing their reset

buttons

simultaneously.

properly in backplane.

Model 2200

enclosure: install or

reseat ECB.

Mirrored cache:

controller reports

cache or mirrored

cache has failed.

Primary data and

the mirrored copy

data are not

identical.

SHOW

THIS_CONTROLLER

indicates that the

cache or mirrored

cache has failed.

Spontaneous FMU

message displays:

“Primary cache

declared failed - data

inconsistent with

mirror,” or “Mirrored

cache declared failed

- data inconsistent

Enter the

SHUTDOWN

command on

controllers that

report the problem.

(This command

flushes the cache

contents to

synchronize the

primary and mirrored

data.) Restart the

controllers that were

shut down.

with primary.”

1–6 HSG80 Array Controller V8.7 Troubleshooting Reference Guide

Page 19

Troubleshooting Information

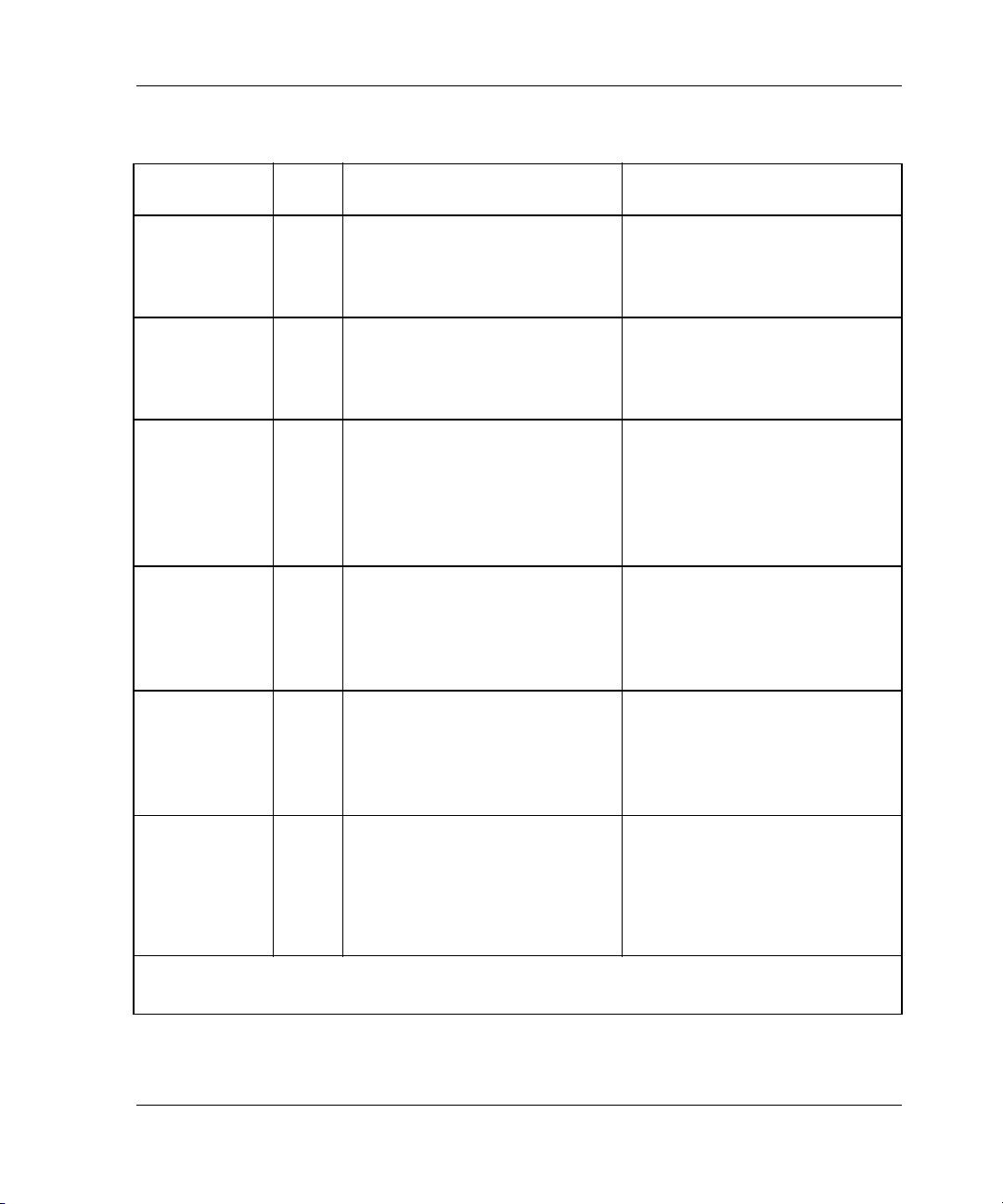

Table 1–1: Troubleshooting Guidelines (Sheet 5 of 10)

Symptom Possible Cause Investigation Remedy

Invalid cache. Mirrored-cache

mode discrepancy.

This discrepancy

might occur after

installing a new

controller. The

existing cache

module is set for

mirrored caching,

but the new

controller is set for

unmirrored caching.

This discrepancy

might also occur if

the new controller is

set for mirrored

SHOW

THIS_CONTROLLER

indicates “invalid

cache.”

Spontaneous FMU

message displays:

“Cache modules

inconsistent with

mirror mode.”

Connect a terminal

to the maintenance

port on the controller

reporting the error

and clear the error

with the following

command—all on

one line:

CLEAR_ERRORS

THIS_CONTROLLE

R INVALID_CACHE

NODESTROY_UNF

LUSHED_ DATA.

See the controller

CLI reference guide

for more information.

caching, but the

existing cache

module is not.

HSG80 Array Controller V8.7 Troubleshooting Reference Guide 1–7

Page 20

Troubleshooting Information

Table 1–1: Troubleshooting Guidelines (Sheet 6 of 10)

Symptom Possible Cause Investigation Remedy

Cache module

might erroneously

contain unflushed

write-back data.

This might occur

after installing a

new controller. The

existing cache

module might

indicate that the

cache module

contains unflushed

write-back data, but

the new controller

expects to find no

data in the existing

SHOW

THIS_CONTROLLER

indicates “invalid

cache.”

No spontaneous FMU

message.

Connect a terminal

to the maintenance

port on the controller

reporting the error,

and clear the error

with the following

command—all on

one line:

CLEAR_ERRORS

THIS_CONTROLLE

R INVALID_CACHE

DESTROY_UNFLUS

HED_ DATA. See the

controller CLI

reference guide for

more information.

cache module.

This error might

also occur if

installing a new

cache module for a

controller that

expects write-back

data in the cache.

1–8 HSG80 Array Controller V8.7 Troubleshooting Reference Guide

Page 21

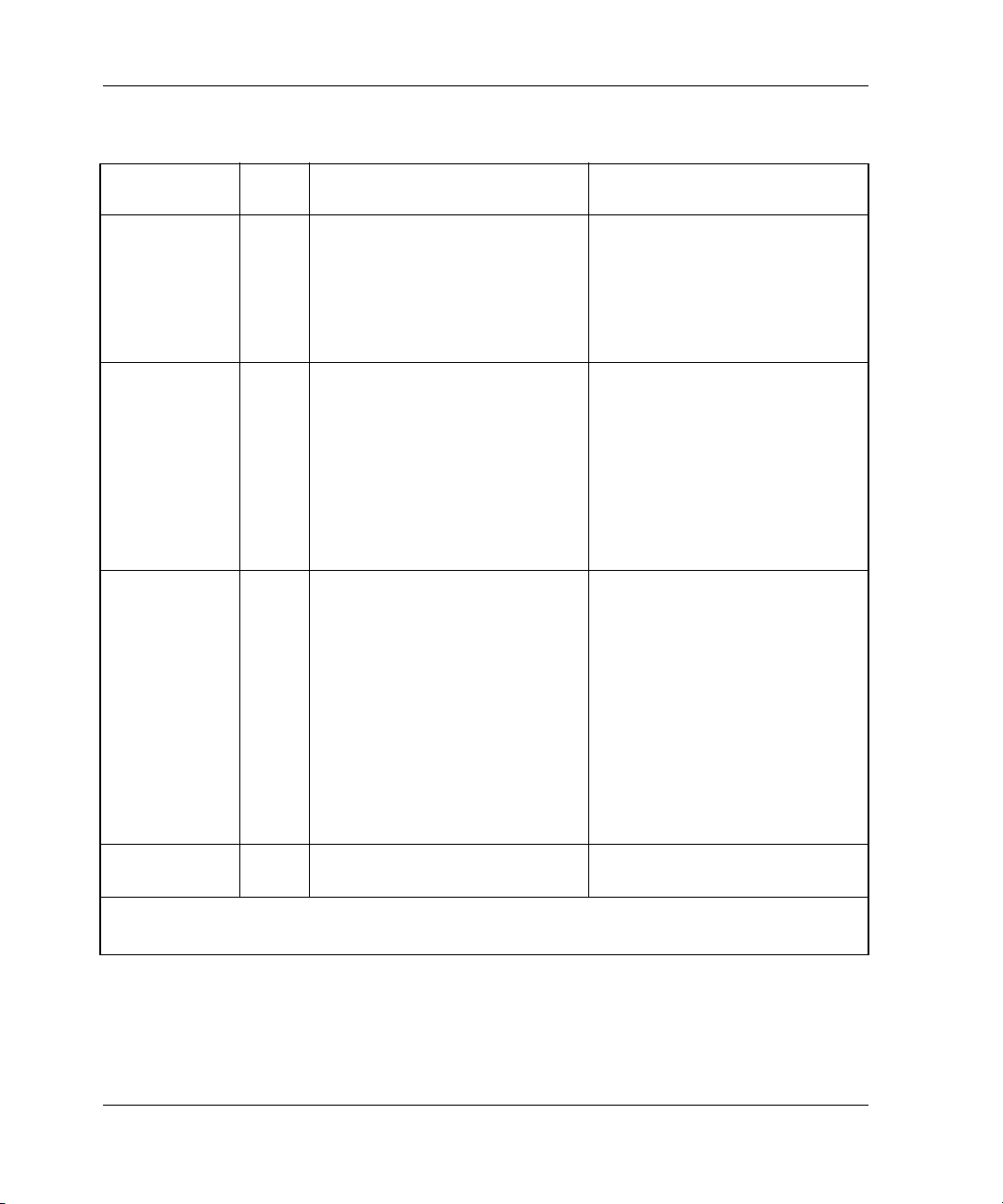

Troubleshooting Information

Table 1–1: Troubleshooting Guidelines (Sheet 7 of 10)

Symptom Possible Cause Investigation Remedy

Cannot add device. Illegal device. See product-specific

Replace device.

release notes that

accompanied the

software release for

the most recent list of

supported devices.

Device not properly

installed in

Check that the device

is fully seated.

Firmly press the

device into the bay.

enclosure.

Failed device. Check for presence of

device LEDs.

Follow repair action

in the documentation

provided with the

enclosure or device.

Failed power

supplies.

Check for presence of

power supply LEDs.

Follow repair action

in the documentation

provided with the

enclosure or power

supply.

Failed bus to

device.

If the previous

remedies fail to

Replace enclosure.

resolve the problem,

check for OCP LED

codes.

HSG80 Array Controller V8.7 Troubleshooting Reference Guide 1–9

Page 22

Troubleshooting Information

Table 1–1: Troubleshooting Guidelines (Sheet 8 of 10)

Symptom Possible Cause Investigation Remedy

Cannot configure

storagesets.

Incorrect command

syntax.

Exceeded

maximum number

of storagesets.

See the controller CLI

reference guide for

the ADD storageset

command.

Use the SHOW

command to count the

number of

Reconfigure

storageset with

correct command

syntax.

Delete unused

storagesets.

storagesets

configured on the

controller.

Failed battery on

ECB. An ECB or

uninterruptible

power supply (UPS)

Use the SHOW

command to check

the ECB battery

status.

Replace the ECB if

required.

is required for

RAIDsets and

mirrorsets.

Cannot assign unit

number to

storageset.

Unit is available but

not online.

Incorrect command

syntax.

This is normal.

Units are “available”

See the controller CLI

reference guide for

correct syntax.

Reassign the unit

number with the

correct syntax.

None None

until the host

accesses them, at

which point their

status is changed to

“online.”

Host cannot see

device.

Broken cables. Check for broken

cables.

Replace broken

cables.

1–10 HSG80 Array Controller V8.7 Troubleshooting Reference Guide

Page 23

Troubleshooting Information

Table 1–1: Troubleshooting Guidelines (Sheet 9 of 10)

Symptom Possible Cause Investigation Remedy

Host cannot

access unit.

Host files or device

drivers not properly

installed or

configured.

Check for the required

device special files.

Configure device

special files as

described in the

installation and

configuration guide

that accompanied

the software release.

Invalid Cache See the description

for the invalid cache

symptom on page

See the description

for the invalid cache

symptom.

1–7.

Units have lost data. Issue the SHOW

UNITS FULL

command.

Clear these units

with:

CLEAR_ERRORS

unit-number

LOST_DATA.

HSG80 Array Controller V8.7 Troubleshooting Reference Guide 1–11

Page 24

Troubleshooting Information

Table 1–1: Troubleshooting Guidelines (Sheet 10 of 10)

Symptom Possible Cause Investigation Remedy

Host log file or

maintenance

terminal indicates

that a forced error

occurred when the

controller was

reconstructing a

RAIDset or

mirrorset.

Unrecoverable read

errors might have

occurred when the

controller was

reconstructing the

storageset. Errors

occur if another

member fails while

the controller is

reconstructing the

storageset.

Host requested data

from a normalizing

storageset that did

not contain the

data.

Conduct a read scan

of the storageset

using the appropriate

utility from the host

operating system,

such as the “dd” utility

for a TRU64 UNIX

host.

Use the SHOW

storageset-name

command to see if all

storageset members

are “normal.”

Rebuild the

storageset, then

restore storageset

data from a backup

source. While the

controller is

reconstructing the

storageset, monitor

the host error log

activity or

spontaneous event

reports on the

maintenance

terminal for any

unrecoverable

errors. If

unrecoverable errors

persist, note the

device on which they

occurred, and

replace the device

before proceeding.

Wait for normalizing

members to become

normal, then resume

I/O to them.

Significant Event Reporting

Controller fault management software reports information about significant events

that occur. These events are reported by:

• Maintenance terminal displays

• Host error logs

• OCP LEDs

1–12 HSG80 Array Controller V8.7 Troubleshooting Reference Guide

Page 25

Troubleshooting Information

Some events cause controller operation to halt; others allow the controller to remain

operable. Both types of events are detailed in the following sections.

Reporting Events That Cause Controller Operation to Halt

Events that cause the controller to halt operations are reported in three possible ways:

•a

FLASHING OCP pattern display

•a

SOLID OCP pattern display

• Last Failure reporting

Use Table 1–2 to interpret

FLASHING OCP patterns and Table 1–3 to interpret SOLID (ON)

OCP patterns. In the Error column of the solid OCP patterns, there are two separate

descriptions. The first denotes the actual error message that appears on the terminal,

and the second provides a more detailed explanation of the designated error.

Use the following legend to interpret both tables as indicated:

= reset button F

n

o

= reset button O

l

= LED FLASHING (in Table 1–2) or ON (in TABLE 1–3)

m

= LED O

NOTE: If the reset button is FLASHING and an LED is ON, either the devices on the bus that

corresponds to the LED do not match the controller configuration, or an error occurred in one of

the devices on that bus.

Also, a single LED that is turned O

FF

LASHING (in Table 1–2) or ON (in TABLE 1–3)

FF

N indicates a failure of the drive on that bus.

Flashing OCP Pattern Display Reporting

Certain events can cause a FLASHING display of the OCP LEDs. Each event and the

resulting pattern are described in Table 1–2.

IMPORTANT: Remember that a solid black pattern represents a FLASHING display. A white

pattern indicates OFF.

All LEDs F

Table 1–2: FLASHING OCP Pattern Displays and Repair Actions (Sheet 1 of 3)

LASH at the same time and at the same rate.

OCP

Pattern

Code Error Repair Action

nmmmmml 1 Program card EDC error. Replace program card.

Legend:

■ = reset button F

HSG80 Array Controller V8.7 Troubleshooting Reference Guide 1–13

LASHING ❏ = reset button OFF ● = LED FLASHING ❍ = LED OFF

Page 26

Troubleshooting Information

Table 1–2: F

LASHING OCP Pattern Displays and Repair Actions (Sheet 2 of 3)

OCP

Pattern

nmmmlmm 4 Timer zero on the processor is

Code Error Repair Action

Replace controller.

bad.

nmmmlml 5 Timer one on the processor is

Replace controller.

bad.

nmmmllm 6 Processor Guarded Memory

Replace controller.

Unit (GMU) is bad.

nmmlmll B Nonvolatile Journal Memory

(JSRAM) structure is bad

because of a memory error or

an incorrect upgrade

procedure.

nmmllml D One or more bits in the

diagnostic registers did not

match the expected reset

value.

Verify the correct upgrade (see

the controller release notes

and cover letters, if available). If

error continues, replace

controller.

Press the reset button to

restart the controller. If this

does not correct the error,

replace the controller.

nmmlllm E Memory error in the JSRAM. Replace controller.

nmmllll F Wrong image found on

program card.

nmlmmmm 10 Controller Module memory is

Replace program card or

replace controller if needed.

Replace controller.

bad.

nmlmmlm 12 Controller Module memory

Replace controller.

addressing is malfunctioning.

nmlmmll 13 Controller Module memory

Replace controller.

parity is not working.

nmlmlmm 14 Controller Module memory

Replace controller.

controller timer has failed.

nmllmml 15 The Controller Module memory

Replace controller.

controller interrupt handler has

failed.

Legend:

■ = reset button F

LASHING ❏ = reset button OFF ● = LED FLASHING ❍ = LED OFF

1–14 HSG80 Array Controller V8.7 Troubleshooting Reference Guide

Page 27

Troubleshooting Information

Table 1–2: F

LASHING OCP Pattern Displays and Repair Actions (Sheet 3 of 3)

OCP

Pattern

nmllllm 1E During the diagnostic memory

Code Error Repair Action

Replace controller.

test, the Controller Module

memory controller caused an

unexpected Non-Maskable

Interrupt (NMI).

nlmmlmm 24 The card code image changed

Replace controller.

when the contents were copied

to memory.

nllmmmm 30 The JSRAM battery is bad. Replace controller.

nllmmlm 32 First-half diagnostics of the

Replace controller.

Time of Year Clock failed.

nllmmll 33 Second-half diagnostics of the

Replace controller.

Time of Year Clock failed.

nllmlml 35 The processor bus-to-device

Replace controller.

bus bridge chip is bad.

nlllmll 3B An unnecessary interrupt

Replace controller.

pending.

nllllmm 3C An unexpected fault during

Replace controller.

initialization.

nllllml 3D An unexpected maskable

Replace controller.

interrupt during initialization.

nlllllm 3E An unexpected NMI during

Replace controller.

initialization.

nllllll 3F An invalid process ran during

Replace controller.

initialization.

Legend:

■ = reset button F

LASHING ❏ = reset button OFF ● = LED FLASHING ❍ = LED OFF

Solid OCP Pattern Display Reporting

Certain events cause the OCP LEDs to display ON or SOLID. Each event and the resulting

pattern are described in Table 1–3.

HSG80 Array Controller V8.7 Troubleshooting Reference Guide 1–15

Page 28

Troubleshooting Information

Information related to the solid OCP patterns is automatically displayed on the

maintenance terminal (unless disabled with the FMU) using %FLL formatting, as

detailed in the following examples:

%FLL--HSG> --13-MAY-2001 04:39:45 (time not set)-- OCP

Code: 38

Controller operation terminated.

%FLL--HSG> --13-MAY-2001 04:32:26 (time not set)-- OCP

Code: 26

Memory module is missing.

Table 1–3: Solid OCP Pattern Displays and Repair Actions (Sheet 1 of 6)

OCP

Pattern

ommmmmm 0 Catastrophic controller or

nmmmmmm 0 No program card detected or

nlmmlml 25 Recursive Bugcheck detected.

Legend:

■ = reset button O

Code Error Repair Action

Check power. If good, reset

power failure.

controller. If problem persists,

reseat controller module and

reset controller. If problem is

still evident, replace controller

module.

Make sure that the program

kill asserted by other controller.

Controller unable to read

program card.

card is properly seated while

resetting the controller. If the

error persists, try the card with

another controller; or replace

the card. Otherwise, replace

the controller that reported the

error.

Reset the controller. If this fault

The same bugcheck has

occurred three times within 10

minutes, and controller

operation has halted.

pattern is displayed repeatedly,

follow the repair actions

associated with the Last Failure

code that is repeatedly

terminating controller

execution.

N ❏ = reset button OFF ● = LED ON ❍ = LED OFF

1–16 HSG80 Array Controller V8.7 Troubleshooting Reference Guide

Page 29

Troubleshooting Information

Table 1–3: Solid OCP Pattern Displays and Repair Actions (Sheet 2 of 6)

OCP

Pattern

nlmmllm 26 Indicated memory module is

Code Error Repair Action

Insert memory module (cache

missing.

board).

Controller is unable to detect a

particular memory module.

nlmmlll 27 Memory module has

insufficient usable memory.

Replace indicated DIMMs.

This indication is only provided

when Fault LED logging is

enabled.

nlmlmmm 28 An unexpected Machine

Reset the controller.

Fault/NMI occurred during Last

Failure processing.

A machine fault was detected

while a Non-Maskable Interrupt

was processing.

nlmlmml 29 EMU protocol version

incompatible.

The microcode in the EMU and

the software in the controller

are not compatible.

nlmlmlm 2A All enclosure I/O modules are

not of the same type.

Enclosure I/O modules are a

combination of single-ended

Upgrade either the EMU

microcode or the software

(refer to the release notes that

accompanied the controller

software).

Make sure that the I/O modules

in an extended subsystem are

either all single-ended or all

differential, but not both.

and differential.

nlmlmll 2B Jumpers, not terminators,

found on backplane.

One or more SCSI bus

terminators are either missing

from the backplane or broken.

Make sure that enclosure SCSI

bus terminators are installed

and that no jumpers are

installed. Replace the failed

terminator if the problem

continues.

Legend:

■ = reset button O

N ❏ = reset button OFF ● = LED ON ❍ = LED OFF

HSG80 Array Controller V8.7 Troubleshooting Reference Guide 1–17

Page 30

Troubleshooting Information

Table 1–3: Solid OCP Pattern Displays and Repair Actions (Sheet 3 of 6)

OCP

Pattern

nlmllmm 2C Enclosure I/O termination

Code Error Repair Action

Make sure that all of the

power out of range.

Faulty or missing I/O module

causes enclosure I/O

termination power to be out of

enclosure device SCSI buses

have an I/O module. If problem

persists, replace the failed I/O

module.

range.

nlmllml 2D Master enclosure SCSI buses

are not all set to ID 0.

Set the PVA ID to 0 for the

enclosure with the controllers.

If the problem persists, try the

following repair actions:

1. Replace the PVA module.

2. Replace the EMU.

3. Remove all devices.

4. Replace the enclosure.

nlmlllm 2E Multiple enclosures have the

same SCSI ID.

More than one enclosure has

the same SCSI ID.

Reconfigure the PVA ID to

uniquely identify each

enclosure in the subsystem.

The enclosure with the

controllers must be set to PVA

ID 0; additional enclosures

must use PVA IDs 2 and 3. If

the error continues after PVA

settings are unique, replace

each PVA module one at a

time. Check the enclosure if the

problem remains.

nlmllll 2F Memory module has illegal

DIMM configuration.

Verify that DIMMs are installed

correctly.

Legend:

■ = reset button O

N ❏ = reset button OFF ● = LED ON ❍ = LED OFF

1–18 HSG80 Array Controller V8.7 Troubleshooting Reference Guide

Page 31

Troubleshooting Information

Table 1–3: Solid OCP Pattern Displays and Repair Actions (Sheet 4 of 6)

OCP

Pattern

nllmmmm 30 An unexpected bugcheck

Code Error Repair Action

Reinsert controller. If that does

occurred before subsystem

initialization completed.

An unexpected Last Failure

occurred during initialization.

not correct the problem, reset

the controller. If the error

persists, try resetting the

controller again, and replace

the controller if no change

occurs.

nllmmml 31 ILF$INIT unable to allocate

Replace controller.

memory.

Attempt to allocate memory by

ILF$INIT failed.

nllmmlm 32 Code load program card write

Replace program card.

failure.

Attempt to update program

card failed.

nllmmll 33 Nonvolatile program memory

(NVPM) structure revision too

low.

NVPM structure revision

Verify that the program card

contains the latest software

version. If the error persists,

replace controller.

number is lower than can be

handled by the software

version attempting to be

executed.

nllmlml 35 An unexpected bugcheck

Reset controller.

occurred during Last Failure

processing.

Last Failure Processing

interrupted by another Last

Failure event.

nllmllm 36 Hardware-induced controller

Replace controller.

reset expected and failed.

Legend:

■ = reset button O

N ❏ = reset button OFF ● = LED ON ❍ = LED OFF

HSG80 Array Controller V8.7 Troubleshooting Reference Guide 1–19

Page 32

Troubleshooting Information

Table 1–3: Solid OCP Pattern Displays and Repair Actions (Sheet 5 of 6)

OCP

Pattern

nllmlll 37 Software-induced controller

Code Error Repair Action

Replace controller.

reset expected and failed.

nlllmmm 38 Controller operation halted.

Reset controller.

Last Failure event required

termination of controller

operation, for example:

SHUTDOWN via the command

line interface (CLI).

nlllmml 39 NVPM configuration

Replace controller.

inconsistent.

Device configuration within the

NVPM is inconsistent.

nlllmlm 3A An unexpected NMI occurred

Replace controller.

during Last Failure processing.

Last Failure processing

interrupted by a Non-Maskable

Interrupt (NMI).

nlllmll 3B NVPM read loop hang.

Replace controller.

Attempt to read data from

NVPM failed.

nllllmm 3C NVPM write loop hang.

Replace controller.

Attempt to write data to NVPM

failed.

nllllml 3D NVPM structure revision higher

than image.

NVPM structure revision

Replace program card with one

that contains the latest

software version.

number is higher than the one

that can be handled by the

software version attempting to

execute.

Legend:

■ = reset button O

N ❏ = reset button OFF ● = LED ON ❍ = LED OFF

1–20 HSG80 Array Controller V8.7 Troubleshooting Reference Guide

Page 33

Troubleshooting Information

Table 1–3: Solid OCP Pattern Displays and Repair Actions (Sheet 6 of 6)

OCP

Pattern

nllllll 3F DAEMON diagnostic failed

Legend:

■ = reset button O

Code Error Repair Action

Verify that cache module is

hard in non-fault tolerant mode.

DAEMON diagnostic detected

critical hardware component

failure; controller can no longer

operate.

N ❏ = reset button OFF ● = LED ON ❍ = LED OFF

present. If the error persists,

replace controller.

Last Failure Reporting

Last failures are automatically displayed on the maintenance terminal (unless disabled

via the FMU) using %LFL formatting. The example below shows a Last Failure

report:

%LFL--HSG> --13-MAY-2001 04:39:45 (time not set)-- Last Failure Code:

20090010

Power On Time: 0. Years, 14. Days, 19. Hours, 58. Minutes, 42. Seconds

Controller Model: HSG80

Serial Number: AA12345678 Hardware Version: 0000(00)

Software Version: V087P(FF)

Informational Report

Instance Code: 0102030A

Last Failure Code: 20090010 (No Last Failure Parameters)

Additional information is available in Last Failure Entry: 1.

In addition, Last Failures are reported to the host error log using Template 01,

following a restart of the controller. See Chapter 4 for a more detailed explanation of

this template.

Reporting Events That Allow Controller Operation to Continue

Events that do not cause controller operation to halt are displayed in one of two ways:

• Spontaneous event log

• CLI event reporting

HSG80 Array Controller V8.7 Troubleshooting Reference Guide 1–21

Page 34

Troubleshooting Information

Spontaneous Event Log

Spontaneous event logs are automatically displayed on the maintenance terminal

(unless disabled with the FMU) using %EVL formatting, as illustrated in the

following examples:

%EVL--HSG> --13-OCT-2000 04:32:47 (time not set)-- Instance Code: 0102030A (not yet

reported to host)

Template: 1.(01)

Power On Time: 0. Years, 14. Days, 19. Hours, 58. Minutes, 43. Seconds

Controller Model: HSG80

Serial Number: AA12345678 Hardware Version: 0000(00)

Software Version: V087P(FF)

Informational Report

Instance Code: 0102030A

Last Failure Code: 011C0011

Last Failure Parameter[0.] 0000003F

%EVL--HSG> --13-OCT-2000 04:32:47 (time not set)-- Instance Code: 82042002 (not yet

reported to host)

Template: 13.(13)

Power On Time: 0. Years, 14. Days, 19. Hours, 58. Minutes, 43. Seconds

Controller Model: HSG80

Serial Number: AA12345678 Hardware Version: 0000(00)

Software Version: V087P(FF)

Header type: 00 Header flags: 00

Test entity number: 0F Test number Demand/Failure: F8 Command: 01

Error Code: 0008 Return Code: 0005 Address of Error: A0000000

Expected Error Data: 44FCFCFC Actual Error Data: FFFF01BB

Extra Status(1): 00000000 Extra Status(2): 00000000 Extra Status(3): 00000000

Instance Code: 82042002

HSG>

Spontaneous event logs are reported to the host error log using SCSI Sense Data

Templates 01, 04, 05, 11, 12, 13, 14, 41, 51, and 90. See Chapter 3 for a more detailed

explanation of templates.

CLI Event Reporting

CLI event reports are automatically displayed on the maintenance terminal (unless

disabled with the FMU) using %CER formatting, as shown in the following example:

%CER--HSG> --13-OCT-2000 04:32:20 (time not set)-- Previous controlleroperation stopped with display of solid fault code, OCP Code: 3F

HSG>

1–22 HSG80 Array Controller V8.7 Troubleshooting Reference Guide

Page 35

Running the Controller Diagnostic Test

During startup, the controller automatically tests the device ports, host ports, cache

module, and value-added functions. If intermittent problems occur with one of these

components, run the controller diagnostic test in a continuous loop rather than

restarting the controller repeatedly.

Use the following steps to run the controller diagnostic test:

1. Connect a terminal to the controller maintenance port.

2. Start the self-test with one of the following commands:

SELFTEST THIS_CONTROLLER

SELFTEST OTHER_CONTROLLER

NOTE: The self-test runs until an error is detected or until the controller reset button is pressed.

If the self-test detects an error, the self-test saves information about the error and

produces an OCP LED code for a “daemon hard error.” Restart the controller to write

the error information to the host error log, then check the host error log for a “built-in

self-test failure” event report. This report will contain an instance code, located at

offset 32 through 35, that can be used to determine the cause of the error. See

Chapter 2, “Translating Event Codes” for help translating instance codes.

Troubleshooting Information

ECB Charging Diagnostics

Whenever restarting the controller, the diagnostic routines automatically check the

charge of each ECB battery. If the battery is fully charged, the controller reports the

battery as good and rechecks the battery every 24 hours. If the battery is charging, the

controller rechecks the battery every 4 minutes. A battery is reported as being either

above or below 50 percent capacity. A battery below 50 percent capacity is referred to

as low.

The 4-minute polling continues for the maximum allowable time to recharge the

battery—up to 10 hours for a BA370 enclosure, or 3.5 hours for a Model 2200

enclosure. If the battery does not charge sufficiently after the allotted time, the

controller declares the battery as failed.

Battery Hysteresis

When charging an ECB battery, write-back caching is allowed as long as a previous

downtime did not drain more than 50 percent battery capacity. When an ECB battery

is operating below 50 percent capacity, the battery is considered to be low and

write-back caching is disabled.

HSG80 Array Controller V8.7 Troubleshooting Reference Guide 1–23

Page 36

Troubleshooting Information

ECB battery capacity depends on the size of the cache module memory configuration

as shown in Table 1–4. For example, when the batteries are fully charged, an ECB can

preserve 512 MB of cache memory for 24 hours (1 day).

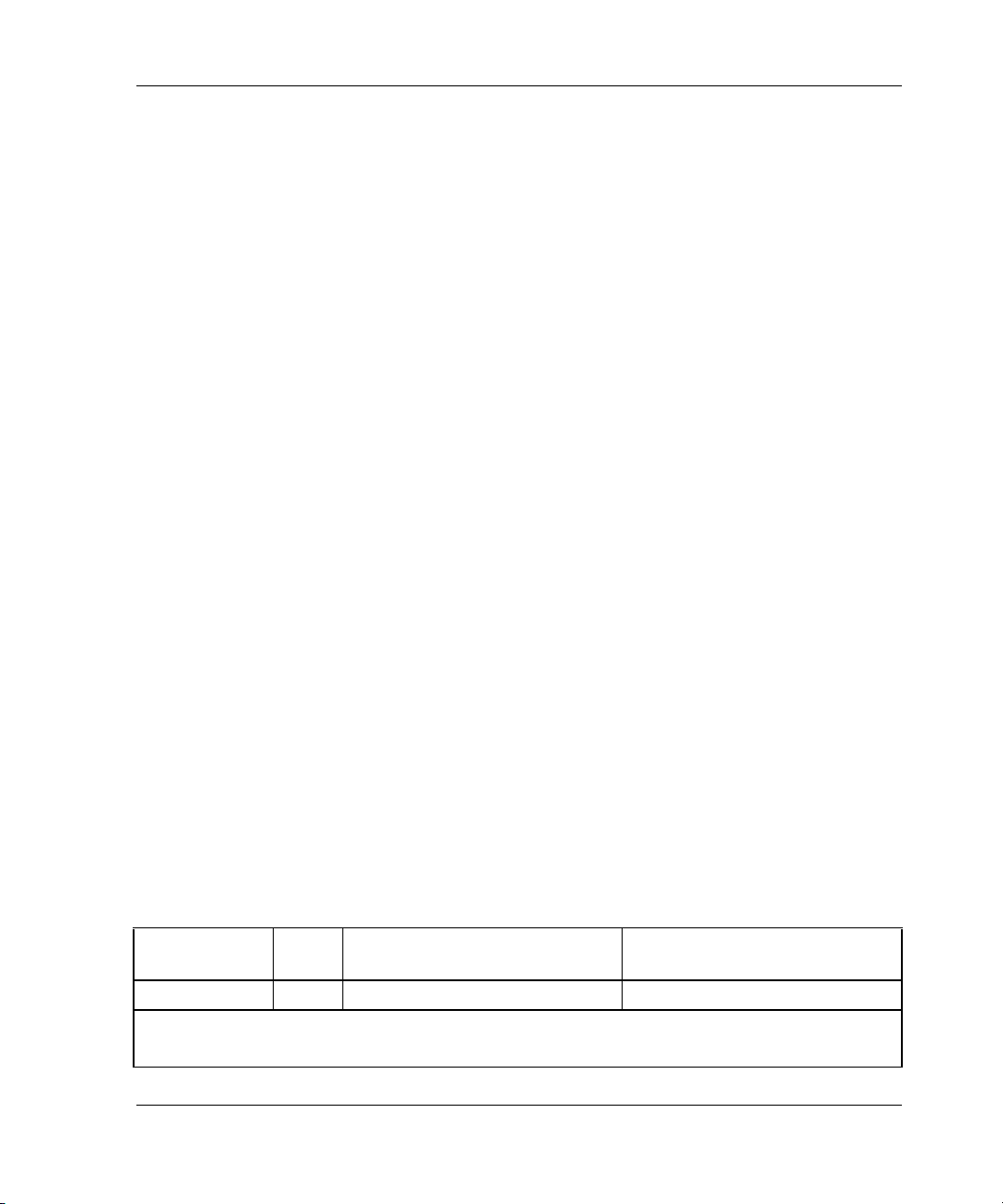

Table 1–4: ECB Capacity Based On Memory Size

Size

128 MB Four, 32 MB each 96 (4)

128 MB One, 128 MB each 96 (4)

256 MB Two, 128 MB each 48 (2)

512 MB Four, 128 MB each 24 (1)

CAUTION: StorageWorks recommends replacing the ECB every 2 years to prevent

battery failure.

NOTE: If a UPS is used for backup power and set to DATACENTER_WIDE, the controller does

not check the battery. See the controller configuration planning guide, controller installation and

configuration guide and controller CLI reference guide for information about the UPS switches.

DIMM

Combinations

Capacity in Hours

(Days)

Caching Techniques

The cache module supports the following caching techniques to increase subsystem

read and write performance:

• Read caching

• Read-ahead caching

• Write-through caching

• Write-back caching

Read Caching

When the controller receives a read request from the host, the controller reads the data

from the disk drives, delivers the data to the host, and stores the data in the supporting

cache module. Subsequent reads for the same data will take this data from the

supporting cache module rather than access the data from the disk drives. This process

is called read caching.

1–24 HSG80 Array Controller V8.7 Troubleshooting Reference Guide

Page 37

Read caching can decrease the subsystem response time to many host read requests. If

the host requests some or all of the cached data, the controller satisfies the request

from the supporting cache module rather than from the disk drives. Read caching is

enabled by default for all storage units.

For more details, refer to the following CLI commands in the controller CLI reference

guide:

SET unit-number MAXIMUM_CACHED_TRANSFER=nn

SET unit-number MAX_READ_CACHED_TRANSFER_SIZE=nn

SET unit-number READ_CACHE

Read-Ahead Caching

Read-ahead caching begins when the controller has already processed a read request

and the controller receives a subsequent read request from the host. If the controller

does not find the data in the cache memory, the controller reads the data from the disk

drives and sends this data to the cache memory.

During read-ahead caching, the controller anticipates subsequent read requests and

begins to prefetch the next blocks of data from the disk drives as the controller sends

the requested read data to the host. These are parallel actions. The controller notifies

the host of the read completion, and subsequent sequential read requests are satisfied

from the cache memory. Read-ahead caching is enabled by default for all disk units.

Troubleshooting Information

Write-Through Caching

When the controller receives a write request from the host, the controller places the

data in the supporting cache module, writes the data to the disk drives, then notifies

the host when the write operation is complete. This process is called write-through

caching because the data actually passes through—and is stored in—the cache

memory along the way to the disk drives.

If read-caching is enabled for a storage unit, write-through caching is automatically

enabled.

HSG80 Array Controller V8.7 Troubleshooting Reference Guide 1–25

Page 38

Troubleshooting Information

Write-Back Caching

Write-back caching improves the subsystem response time to write requests by

allowing the controller to declare the write operation “complete” as soon as the data

reaches the supporting cache memory. The controller performs the slower operation of

writing the data to the disk drives at a later time. For more details, refer to the

following CLI commands in the controller CLI reference guide:

SET unit-number MAXIMUM_CACHED_TRANSFER=nn

SET unit-number MAX_WRITE_CACHED_TRANSFER_SIZE=nn

SET unit-number WRITEBACK_CACHE

Write-back caching is enabled by default for all units. The controller will only provide

write-back caching to a unit if the cache memory is nonvolatile, as described in the

next section.

By default, the controller expects to use an ECB as the backup power source for the

cache module. However, if the subsystem is protected by a UPS, use one of the

following CLI commands to instruct the controller to use the UPS:

SET controller UPS=NODE_ONLY

or

SET controller UPS=DATACENTER_WIDE

Fault-Tolerance for Write-Back Caching

The cache module supports nonvolatile memory and dynamic cache policies to protect

the availability of cache module unwritten (write-back) data.

Nonvolatile Memory

The controller provides write-back caching for storage units as long as the controller

cache memory is connected to a nonvolatile backup power source, such as an ECB.

The cache module must be nonvolatile to preserve unwritten cache data during a

power failure. If the cache memory is not connected to a backup power supply, this

unwritten data will be lost during a power failure.

NOTE: Disaster-tolerant mirrorsets are not subject to this requirement.

By default, the controller expects to use an ECB as the backup power source for the

supporting cache module. However, if the subsystem is backed up using a UPS, two

options are available that tell the controller to use the UPS:

• For BA370 enclosures only: use both the ECB and the UPS together with the

following command:

SET controller UPS=NODE_ONLY

1–26 HSG80 Array Controller V8.7 Troubleshooting Reference Guide

Page 39

• Use only the UPS as the backup power source with the following command:

SET controller UPS=DATACENTER_WIDE

NOTE: See the controller CLI reference guide for detailed descriptions of these commands.

Cache Policies Resulting from Cache Module Failures

If the controller detects a full or partial failure of the supporting cache module or ECB,

the controller automatically reacts to preserve the unwritten data in the supporting

cache module. Depending upon the severity of the failure, the controller chooses an

interim caching technique—also called the cache policy—until the cache module or

ECB is repaired or replaced.

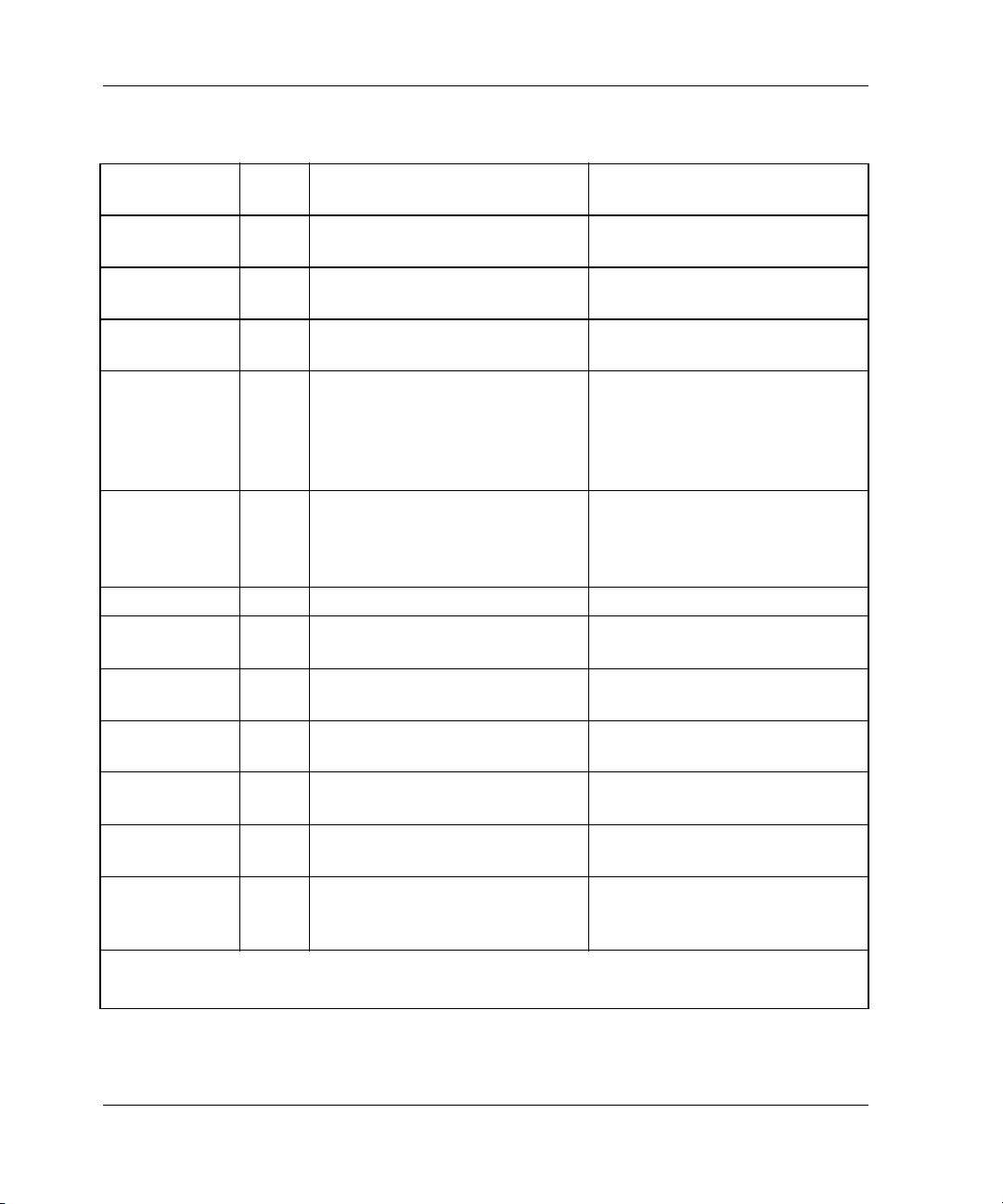

Table 1–5 shows the cache policies resulting from a full or partial failure of cache

module A (Cache A) in a dual-redundant controller configuration. The consequences

shown in Table 1–5 are the same for Cache B failures.

Table 1–6 on page 1–29 shows the cache policies resulting from a full or partial failure

of the ECB connected to Cache A in a dual-redundant controller configuration. The

consequences shown in Table 1–6 are the opposite for an ECB failure connected to

Cache B.

• If the ECB is at least 50% charged, the ECB is still good and is charging.

Troubleshooting Information

• If the ECB is less than 50% charged, the ECB is low but still charging.

Table 1–5: Cache Policies—Cache Module Status (Sheet 1 of 3)

Cache Module

Status Cache Policy

Cache A Cache B Unmirrored Cache Mirrored Cache

Good. Good. Data loss: None

Cache policy: Both controllers

support write-back caching.

Failover: None

Multibit

cache

memory

failure.

HSG80 Array Controller V8.7 Troubleshooting Reference Guide 1–27

Good. Data loss: Forced error and

loss of write-back data for

which the multibit error

occurred. Controller A detects

and reports the lost blocks.

Cache policy: Both controllers

support write-back caching.

Failover: None

Data loss: None

Cache policy: Both controllers

support write-back caching.

Failover: None

Data loss: None. Controller A

recovers lost write-back data

from the mirrored copy on Cache

B.

Cache policy: Both controllers

support write-back caching.

Failover: None

Page 40

Troubleshooting Information

Table 1–5: Cache Policies—Cache Module Status (Sheet 2 of 3)

Cache Module

Status Cache Policy

Cache A Cache B Unmirrored Cache Mirrored Cache

DIMM or

cache

memory

controller

chip

failure.

Good. Data loss: Write-back data that

was not written to media when

failure occurred was not

recovered.

Cache policy: Controller A

supports write-through caching

only; Controller B supports

write-back caching.

Failover: In transparent failover,

all units fail over to Controller B.

In multiple-bus failover with

host-assist, only those units

that use write-back caching,

such as RAIDsets and

mirrorsets, fail over to Controller

Data loss: Controller A recovers

all of write-back data from the

mirrored copy on Cache B.

Cache policy: Controller A

supports write-through caching

only; Controller B supports

write-back caching.

Failover: In transparent failover,

all units fail over to Controller B

and operate normally. In

multiple-bus failover with

host-assist, only those units that

use write-back caching, such as

RAIDsets and mirrorsets, fail

over to Controller B.

B. All units with lost data

become inoperative until they

are cleared using the CLEAR

unit-number LOST_DATA

command. Units that did not

lose data operate normally on

Controller B.

In single-controller

configurations, RAIDsets,

mirrorsets, and all units with

lost data become inoperative.

Although lost data errors can

be cleared on some units,

RAIDsets and mirrorsets

remain inoperative until the

memory on Cache A is repaired

or replaced.

1–28 HSG80 Array Controller V8.7 Troubleshooting Reference Guide

Page 41

Troubleshooting Information

Table 1–5: Cache Policies—Cache Module Status (Sheet 3 of 3)

Cache Module

Status Cache Policy

Cache A Cache B Unmirrored Cache Mirrored Cache

Cache

Board

Failure.

Good. Same as for DIMM failure. Data loss: Controller A recovers

all of write-back data from the

mirrored copy on Cache B.

Cache policy: Both controllers

support write-through caching

only. Controller B cannot execute

mirrored writes because Cache

A cannot mirror Controller B

unwritten data.

Failover: None

Table 1–6: Resulting Cache Policies—ECB Status (Sheet 1 of 4)

Cache Module

Status Cache Policy

Cache A Cache B Unmirrored Cache Mirrored Cache

At least

50%

charged.

At least

50%

charged.

Data loss: None

Cache policy: Both controllers

continue to support write-back

caching.

Failover: None

Data loss: None

Cache policy: Both controllers

continue to support write-back

caching.

Failover: None

HSG80 Array Controller V8.7 Troubleshooting Reference Guide 1–29

Page 42

Troubleshooting Information

Table 1–6: Resulting Cache Policies—ECB Status (Sheet 2 of 4)

Cache Module

Status Cache Policy

Cache A Cache B Unmirrored Cache Mirrored Cache

Less

than

50%

charged.

At least

50%

charged.

Data loss: None

Cache policy: Controller A

supports write-through caching

only; Controller B supports

write-back caching.

Data loss: None

Cache policy: Both controllers

continue to support write-back

caching.

Failover: None

Failover: In transparent failover,

all units fail over to Controller B.

In multiple-bus failover with

host-assist, only those units

that use write-back caching,

such as RAIDsets and

mirrorsets, fail over to Controller

B.

In single-controller

configurations, the controller

only provides write-through

caching to the units.

1–30 HSG80 Array Controller V8.7 Troubleshooting Reference Guide

Page 43

Troubleshooting Information

Table 1–6: Resulting Cache Policies—ECB Status (Sheet 3 of 4)

Cache Module

Status Cache Policy