Page 1

HP A8800 Routers

Installation Guide

Part number: 5998-1416

Document version: 6W104-20130912

Page 2

Legal and notice information

© Copyright 2011-2013 Hewlett-Packard Development Company, L.P.

No part of this documentation may be reproduced or transmitted in any form or by any means

without prior written consent of Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice.

HEWLETT-PACKARD COMPANY MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS

MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE. Hewlett-Packard shall not be liable for errors contained

herein or for incidental or consequential damages in connection with the furnishing, performance, or

use of this material.

The only warranties for HP products and services are set forth in the express warranty statements

accompanying such products and services. Nothing herein should be construed as constituting an

additional warranty. HP shall not be liable for technical or editorial errors or omissions contained

herein.

Page 3

Contents

Preparing for installation ············································································································································· 1

Overview ············································································································································································ 1

Safety recommendations ·················································································································································· 1

Installation site requirements ··································································································································· 2

Rack-mounting requirements ···································································································································· 3

Installation tools ································································································································································· 3

Accessories supplied by the router ························································································································· 3

User-supplied tools and equipment ························································································································ 3

Installing the router ······················································································································································· 5

Installation prerequisites ··················································································································································· 5

Installing the router in a rack ··········································································································································· 5

Mounting slide rails to the rack ······························································································································ 6

Installing cage nuts to the rack ······························································································································· 7

Installing the cable management brackets ············································································································· 7

Installing the mounting brackets ······························································································································ 9

Installing an impedance carrier (optional) ·········································································································· 10

Installing the router to a rack ······························································································································· 10

Verifying the installation ······································································································································· 11

Grounding the router ····················································································································································· 11

Installing the power system ··········································································································································· 12

Installing a DC power supply ······························································································································· 13

Installing an AC power supply ····························································································································· 13

Installing a card ······························································································································································ 14

Installing an SPE subcard ·············································································································································· 15

Connecting power cables ············································································································································· 16

Connecting an AC power cable ·························································································································· 17

Connecting DC power cables ······························································································································ 17

Verifying the installation ················································································································································ 19

Connecting the router to the network ······················································································································· 20

Logging in to the router ················································································································································· 20

Connecting the console cable ······························································································································ 20

Setting up a configuration environment ·············································································································· 21

Powering on the router ········································································································································· 26

Verifying router operation (recommended) ········································································································ 28

Connecting the router to the network ··························································································································· 28

Connecting through an AUX cable ····················································································································· 29

Connecting through an Ethernet twisted pair cable ·························································································· 29

Connecting through an optical fiber ··················································································································· 29

Cable routing recommendations ·································································································································· 31

Hardware management ············································································································································· 33

Displaying electrical label data ···································································································································· 33

Displaying card information ········································································································································· 33

Rebooting the router ······················································································································································ 34

Displaying the router power supply system ················································································································· 35

Configuring temperature alarm thresholds for a card································································································ 36

Displaying temperature information for a router ········································································································ 36

Configuring in-service hardware failure diagnosis ···································································································· 36

iii

Page 4

Displaying the operating state of a fan ······················································································································· 37

Displaying alarm information for a card ····················································································································· 37

Verifying and diagnosing transceiver modules ·········································································································· 38

Introduction to transceiver modules ····················································································································· 38

Verifying transceiver modules ······························································································································ 38

Diagnosing transceiver modules ·························································································································· 40

Troubleshooting ·························································································································································· 43

Configuration terminal problems ·································································································································· 43

No terminal display ·············································································································································· 43

Garbled terminal display ······································································································································ 43

Power supply system failure ·········································································································································· 43

Fan failure ······································································································································································· 44

MPU failure ····································································································································································· 45

LPU failure ······································································································································································· 46

Interface failure ······························································································································································· 46

Technical support ··························································································································································· 47

Replacement procedures ··········································································································································· 48

Replacing a power supply system ································································································································ 48

Replacing a DC power supply ····························································································································· 48

Replacing an AC power supply ··························································································································· 49

Cleaning a power supply air filter ······························································································································· 51

Replacing a card ···························································································································································· 51

Replacing a subcard ······················································································································································ 53

Replacing a fan tray ······················································································································································ 54

Replacing a fan tray for an A8805/A8812 ······································································································ 54

Replacing a fan tray for an A8808 ···················································································································· 55

Replacing a chassis air filter ········································································································································· 56

Replacing chassis air filters for an A8808 ········································································································· 56

Replacing an air filter for an A8805/A8812 ··································································································· 57

Replacing a CF card ······················································································································································ 57

Replacing a transceiver module ··································································································································· 59

Hardware specifications ············································································································································ 61

Environmental requirements ·········································································································································· 61

Technical specifications ················································································································································· 61

Chassis ··································································································································································· 61

Cooling system ······················································································································································ 68

Card specifications ··············································································································································· 71

Power supply system ············································································································································· 77

LEDs ············································································································································································· 84

Power supply LEDs ························································································································································· 84

Fan LEDs ·········································································································································································· 84

MPU LEDs ········································································································································································ 85

CF card status LED ················································································································································· 85

Network management port LEDs ························································································································· 85

LPU status LEDs ······················································································································································· 86

MPU status LEDs ···················································································································································· 86

SPC card LEDs ································································································································································ 86

LINK/ACT LED ······················································································································································· 87

Combo interface LED ············································································································································ 87

LINK and ACT LEDs ··············································································································································· 87

SPE card LED ·································································································································································· 88

Subcard LEDs ·································································································································································· 88

iv

Page 5

v

Transceiver modules ··················································································································································· 89

10-GE XFP transceiver modules ···································································································································· 89

FE/GE SFP transceiver modules ··································································································································· 90

OC-48/STM-16 SFP transceiver modules ··················································································································· 92

OC-12/STM-4 SFP transceiver modules ······················································································································ 92

OC-3/STM-1 SFP transceiver modules ························································································································ 92

Lightning protection ···················································································································································· 94

Connecting the AC power supply to a power strip with lightning protection ························································· 94

Installing a lightning protector for a network port ······································································································ 95

Engineering labels ····················································································································································· 96

Labels for cables····························································································································································· 96

Labels for signal cables ········································································································································ 96

Labels for power cables ········································································································································ 96

Generic labels························································································································································ 97

Labels for devices ··························································································································································· 98

Filling in labels ······························································································································································· 98

Affixing labels ································································································································································· 98

Affixing a label to a signal cable ························································································································ 98

Affixing a label to a power cable ······················································································································· 99

Affixing a generic label ······································································································································ 100

Affixing a label to a device ································································································································ 101

Guidelines ····································································································································································· 101

Examples ······································································································································································· 101

Engineering labels for network cables ·············································································································· 101

Engineering labels for optical fibers·················································································································· 103

Engineering labels for DC power cables ·········································································································· 105

Engineering labels for AC power cables ·········································································································· 106

Engineering labels for devices ··························································································································· 106

Cable management ················································································································································ 108

Cable management guidelines ··································································································································· 108

Cable management examples ···································································································································· 109

Support and other resources ·································································································································· 112

Contacting HP ······························································································································································ 112

Subscription service ············································································································································ 112

Related information ······················································································································································ 112

Documents ···························································································································································· 112

Websites ······························································································································································· 112

Conventions ·································································································································································· 113

Page 6

Preparing for installation

Overview

This series is a line of data center routers. You can deploy the A8800 routers at the core layer and

distribution layer of large-scale MANs, the core layer of enterprise networks, and the distribution layer

of carrier networks. Table 1 lists the chassis models in the series.

Table 1 Router chassis

Chassis Power in

p

ut Card slot orientation MPU slots LPU slots

A8805 AC/DC Horizontal 2 5

A8808 AC/DC Vertical 2 8

A8812 AC/DC Horizontal 2 12

NOTE:

•

An MPU is the supervisor engine of a router. An LPU receives and forwards traffic and provides network

services.

• The LPU slots can hold SPE cards, SPC cards, and OAA modules. For card specifications, see

"Hardware specifications."

Safety recommendations

W

ARNING!

Before installation and operation, read all of the safety instructions in the

Compliance and Safety Gui

de

supplied with your device.

This section provides general recommendations. For more information, see the Compliance and

Safety Guide.

• Turn off all power and remove all power cables before opening the chassis.

• Unplug all power and external cables before moving the chassis.

• Locate the emergency power-off switch before installation and shut off power immediately if

necessary.

• Always wear an ESD-preventive wrist strap when installing the router.

• Do not stare into the open optical interface. The laser light emitted from the optical fiber may

hurt your eyes

• Use a good grounding system to protect your router against lightning shocks, interference, and

ESD. This is essential to the operating reliability of your router.

• Make sure the resistance between the chassis and the ground is less than 1 ohm.

1

Page 7

Installation site requirements

The following tables provide information about temperature and humidity, cleanness, and air quality

requirements.

CAUTION:

If condensation appears on the router when you move it to a high-temperature environment, dry the

router before powering it on to avoid short circuits.

To ensure normal operation of the router, make sure the room temperature meets the requirements

described in Table 2.

Table 2 Temperature requirements

Tem

p

erature Range

Operating temperature

Long term: 0°C to 45°C (32°F to 113°F)

Short term: –10°C to +55°C (14°F to 131°F) (no more than 96 hours of

continuous operation in less than 15 days in one year)

Storage temperature –40°C to +70°C (–40°F to +158°F)

Maintain appropriate humidity in your equipment room, as described in Table 3.

Table 3 Humidity requirements

Humidit

y

Range

Operating humidity (noncondensing) 5% to 95%

Storage humidity (noncondensing) 5% to 95%

Lasting high relative humidity tends to cause poor insulation, increased electricity consumption,

mechanical property change of materials, and corrosion of metal parts. Lasting low relative humidity

is likely to result in loose screws due to washer contraction, and even ESD, which causes the circuits to

fail.

Table 4 Dust concentration limit in the equipment room

Ph

y

sical active substance Concentration limit (particles/m3)

Dust particle ≤3 x 104 (No visible dust on desk over three days)

Note: Dust particle diameter ≥ 5μm

Table 5 Limits on harmful gases in the equipment room

Gas Ma

x

concentration (mg/m3)

SO

2

0.2

H2S 0.06

NH

3

0.05

Cl

2

0.01

2

Page 8

Rack-mounting requirements

Before rack-mounting a router, make sure the rack meets the following requirements:

• HP recommends that the router is mounted in an open rack. If you mount a router in a closed

rack, make sure there is a good heat dissipation system.

• The rack is steady enough to support the router and accessories.

• The router fits the rack size. Leave some space beside the left and right panels of the router for

chassis heat dissipation.

Installation tools

Accessories supplied by the router

Item Quantity Purpose

Console cable 1

Connecting the console port and the configuration

terminal for router login

Grounding cable 1 Grounding the router

Mounting brackets 1 pair Fastening the router to the rack

Cable management

brackets

1 pair Cable management

M4*8 screw 1 set

• Fastening the mounting brackets to the router

• Fastening the cable management brackets to the

router

M6*12 screw 1 set

Fastening the router to the rack

M6 cage nut 1 set

ST2.9*9.5 selftapping screw

1 set

Fastening the cable management brackets to the

mounting brackets (excluding the A8808)

Impedance carrier

1 (supplied with the

A8808 only)

Installed at the rear of the router to block air from

entering the chassis

ESD-preventive wrist

strap

1 ESD prevention

NOTE:

The number of screws and nuts supplied with the router may vary.

User-supplied tools and equipment

• Cross-head screwdriver P1 – 100 mm, P2 – 150 mm, and P3 – 250 mm

• Flat-blade screwdriver P4 – 75 mm

• Diagonal pliers, wire-stripping pliers, and wire clippers

• Meters and equipment such as hub and multimeter

3

Page 9

4

The rack accessories and installation tools are not described in this section. The accessories and

installation tools may vary depending on the rack model. For more information, see the installation

guide for the corresponding rack.

Page 10

Installing the router

Figure 1 shows the steps for installing the router.

Figure 1 Installation flowchart

Installation prerequisites

Before installing the router:

• Read "Preparing for installation" carefully and make sure the installation site meets all of the

requirements.

• Using the packing list supplied with your router, inspect the router to make sure you have all of

the items listed and verify that the router was not damaged during shipment. If anything is

damaged or missing, contact HP immediately.

Installing the router in a rack

Confirm the following before starting installation:

• The rack is sturdy and securely grounded.

• There is at least 0.8 m (2.62 ft) of clearance around the rack for heat dissipation and installation.

5

Page 11

• There is no debris inside or around the rack.

• The router can be installed only in a 4-post 19-inch standard rack.

Mounting slide rails to the rack

If the rack already has slide rails, skip this section. Slide rails or rack shelves are not provided with the

router. Prepare them yourself or order them from HP. Make sure the slide rails or rack shelves you use

are standard accessories.

In addition to slide rails, you can use a rack shelf to support the router. This document describes how

to install slide rails only.

The following procedure uses a 19-inch rack as an example.

Before installing the slide rails, verify that the slide rails can support the weight of the router. For the

weights of the router, see "Hardware specifications."

To install the slide rails:

1. Mark the positions of the slide rails on the rack. Make sure the space above the slide rails is

greater than the height of the router chassis. For the router dimensions, see "Hardware

specifications."

2. Install the slide rails to the lowest possible position when installing a single router on the rack.

Make sure the bottom edge of the slide rail aligns with the middle of the narrower metal area

between holes.

3. Align the screw holes on the two sides of the slide rails with the corresponding holes on the

rack, and then fasten the screws.

4. Install the other slide rail in the same way. Keep the two slide rails at the same height so that

the router can be placed evenly.

The height of the front panel of the rack is a measurement of one RU (44.45 mm, or 1.75 in). As

shown in Figure 2, each 1 RU has three holes with center-to-center spacing between the holes of

15.87 mm (0.63 in), 15.87 mm (0.63 in), and 12.70 mm (0.5 in).

Figure 2 Installing the slide rails

(1) Middle of the narrower metal area between holes (2) 1 RU

6

Page 12

NOTE:

The appearance and installation methods of slide rails depend on the slide rail types.

Installing cage nuts to the rack

Before mounting the chassis to the rack, install cage nuts to the front square-holed brackets of the rack,

as shown in Figure 3.

When preparing for installation, make sure the total height of the routers to be installed does not

exceed the height of the rack, and reserve enough clearance for cable routing.

1. Align the mounting bracket with the left rack post, making sure the bottom edge and the slide

rail are level.

2. Mark the positions of the cage nuts on the rack post according to the installation holes on the

mounting bracket.

3. Install the cage nuts to the right positions. (Each installation hole on the mounting bracket

corresponds to one cage nut.)

4. Repeat steps 1 through 3 to install cage nuts to the correct rack post.

Figure 3 Installing the cage nuts

Installing the cable management brackets

This section includes separate steps for installing the cable management brackets on the A8808 and

A8805/A8812.

Installing the cable management brackets on the A8808

The A8808 has two cable management brackets and are installed using the same procedure. The

signal cable management brackets are installed at the upper part of the router, and the power cable

management brackets are installed at the lower part of the router.

7

Page 13

To install a cable management bracket:

1. Attach the cable management bracket to the chassis, and align the screw holes on the cable

management bracket with the screw holes on the chassis, as shown in Figure 4.

2. Screw in and fasten the M4 screws with a screwdriver.

Figure 4 Installing the cable management brackets on the A8808

Installing the cable management brackets on the A8805/A8812

Install the cable management brackets to the mounting brackets (cable management brackets and

mounting brackets are required at both sides of the chassis). Figure 5 shows how to install a right

cable management bracket. The method for installing the left cable management bracket is the same

as the right.

8

Page 14

Figure 5 Installing the cable management bracket on the A8805/A8812

Installing the mounting brackets

Before installing the router to the rack, install the mounting brackets to the chassis. Figure 6 shows

how to install the mounting brackets to an A8805 router.

Figure 6 Installing the mounting brackets

9

Page 15

Installing an impedance carrier (optional)

An impedance carrier is shipped with the A8808 only. You can install the impedance carrier at the

rear of the chassis (where an air filter is located) to block the airflow from entering the rear of the

chassis.

Install an impedance carrier for routers that have front-to-rear airflow, as shown in Figure 7.

To install an impedance carrier:

1. Loosen the captive screws on the air filter to remove the air filter.

2. Install the impedance carrier, and fasten the captive screws on the impedance carrier.

Figure 7 Installing an impedance carrier

Installing the router to a rack

CAUTION:

• Make sure you have installed a rack shelf or slide rails on the rack for supporting the router, and the

rack shelf or the slide rails are sturdy enough to support the weight of the router chassis and all

accessories. Do not install the router to the rack using only mounting brackets.

• To install multiple routers on the rack, mount the heaviest router at the bottom of the rack.

To mount the router in the rack:

1. Use several people to place the router on the rack shelf or slide rails, and then slide the router

into the rack until the mounting brackets on the router touch the front rack posts.

2. Fasten the mounting brackets to the rack posts with mounting screws, as shown in Figure 8. If

the screw holes on the mounting brackets cannot align with the cage nuts on the rack, verify

10

Page 16

that the bottom edge of the slide rail aligns with the middle of the narrowest metal area

between holes, and that the cage nuts are installed in the correct holes.

Figure 8 Installing the router in a standard 19-inch rack

Verifying the installation

Use the following checklist to make sure the router has been installed correctly.

Table 6 Installation checklist

Item

Result

Remarks

Yes No

Mounting brackets are firmly attached to the router.

The router is installed in the correct position.

Mounting brackets on the router are firmly attached to the rack.

There is enough space for heat dissipation around the router.

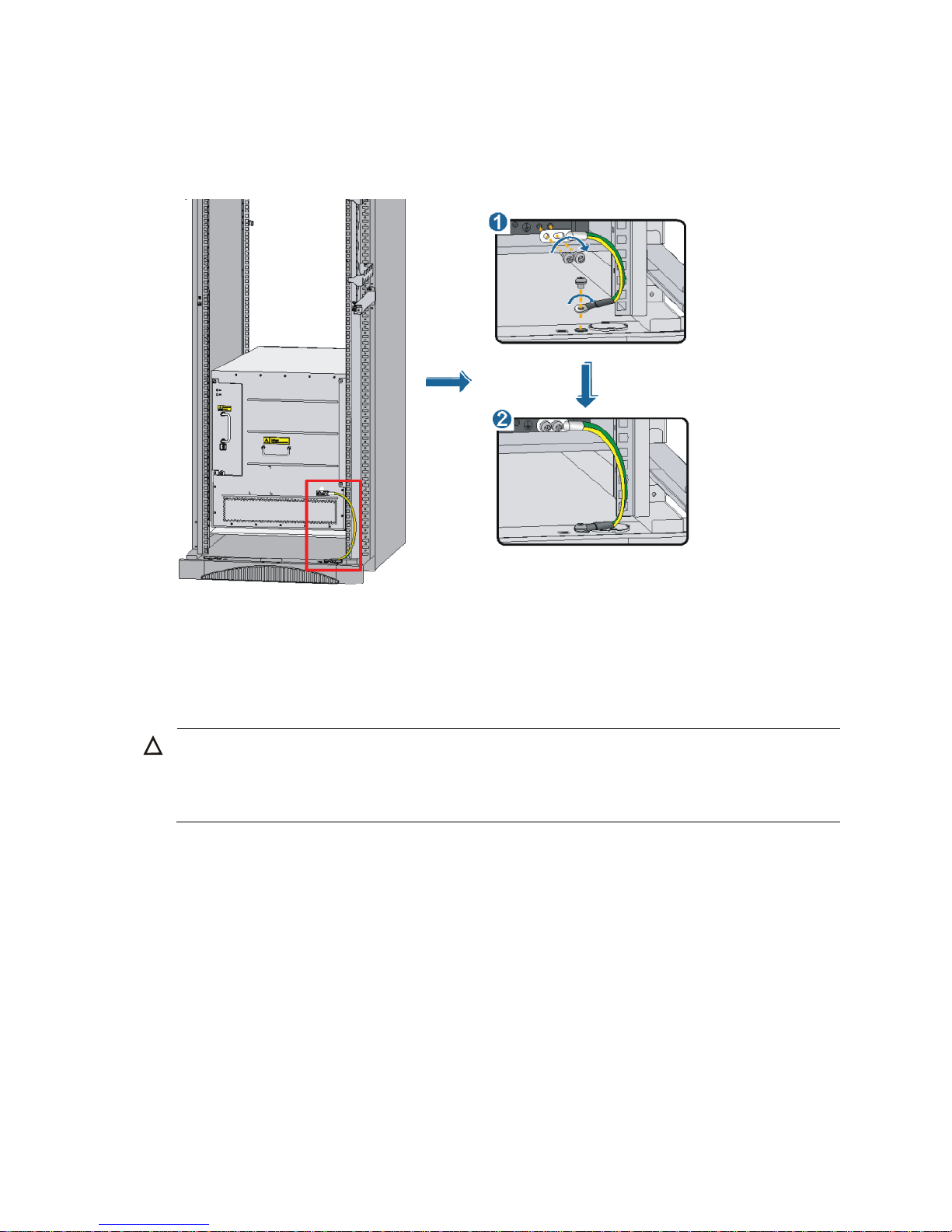

Grounding the router

W

ARNING!

For the safety of operators and equipment, ground the router securely. Make sure the resistance

reading between the router chassis and the ground is less than 1 ohm. Most racks are equipped with a

grounding strip. You can connect the yellow-green grounding cable of the router to the

g

rounding strip.

Connect the grounding cable to the earthing system in the equipment room. Do not connect it to a fire

main or lightning rod.

The positions of the grounding terminals on the A8805, A8808, and A8812 are similar. The

following procedure uses the A8805 as an example.

To connect the grounding cable:

1. Remove the grounding screw from the router chassis, as shown in Figure 9.

2. Put the supplied OT terminal of the grounding cable on the grounding screw. Use the supplied

grounding cable (CAT 6 cable with dual-hole OT terminals).

11

Page 17

3. Insert the grounding screw into the grounding hole and tighten the screw.

4. Connect the other end of the grounding cable to the grounding strip of the rack in the same

way.

Figure 9 Connecting the grounding cable

If there is no grounding point on the rack, you can attach the grounding cable to a grounding strip.

The installation procedures are similar.

Installing the power system

CAUTION:

Hold a power supply by the bottom when moving it. Never attempt to lift a power supply by its handle

because the handle is not desi

g

ned to support weight. Doing so might result in bodily injury or damage

to the power supply.

The router supports both AC and DC power supply modes. You can select either AC or DC power

supply mode as needed. 1+1 redundancy is recommended.

• DC power supply—Includes NEPS2000-D and NEPS3500-D models.

• AC power supply—One or two AC power supplies are installed in the AC power frame

NEPS3500-A.

To prepare for installation:

1. Put on an ESD-preventive wrist strap and make sure it is properly grounded.

2. Make sure the power switch of the power supply is in the OFF position.

3. Remove the blank panel (if any) from the slot to be used.

12

Page 18

Installing a DC power supply

1. Remove the air filter frame of the power supply and gently pull the DC power supply handle out.

2. Holding the handle of the power supply with one hand and supporting the bottom of the power

supply with the other hand, push the power supply slowly along the slide rails until it makes

close contact with the backplane, as shown in Figure 10.

3. Fasten the mounting screws on the power supply panel with a Phillips screwdriver.

4. Cover the power supply with the removed air filter frame.

Figure 10 Installing a DC power supply

Installing an AC power supply

Installing a NEPS3500-A AC power frame

For a router that requires power supply redundancy, install the same number of power supplies in the

two power frames.

1. Push the power frame slowly along the slide rails until it makes close contact with the backplane.

2. Fasten the mounting screws on the power frame panel with a Phillips screwdriver.

Figure 11 Installing a NEPS3500-A power frame

13

Page 19

Installing an NEPS1800-A AC power supply

1. Pull the handle of the power supply downward to the unlock position.

2. Gently push the power supply into the AC power frame (NEPS3500-A) until the rear side of the

power supply makes close contact with the power frame backplane.

3. Push the handle upward so that it locks the power supply in place.

Figure 12 Installing an AC power supply

Installing a card

All cards (excluding subcards) for the routers are hot-swappable.

You install MPUs and LPUs in the same way.

To prepare for installation:

1. Put on an ESD-preventive wrist strap and make sure it is properly grounded.

2. Remove the blank panel (if any) from the slot to be used. Keep the blank panel and protection

cover for future use

3. Prepare the card to be installed.

To install a card:

1. Remove the protection cover before installing the card:

a. Put on an ESD-preventive wrist strap, and then use a Phillips screwdriver to loosen the

captive screws that fasten the card to the protection cover.

b. Gently pull the card out of the protection cover, as shown in Figure 13.

14

Page 20

Figure 13 Removing the protection cover

2. Move the ejector levers of the card outward. Supporting the bottom of the card with both hands,

slowly push the card into the slot along the slide rails.

3. Push the ejector levers inward to ensure close contact between the card and the backplane.

4. Position the screws in the holes and fasten them with a screwdriver to attach the card.

Figure 14 Installing a card

Installing an SPE subcard

CAUTION:

Do not install a subcard to the SPE card when the router is powered on.

This section describes how to install a subcard to an SPE card. The installation of an SPE card is the

same as a common card. For more information, see "Installing a card"

The subcards are not hot-swappable. You can install a subcard using one of the following methods:

• Power off the router and install the subcard to the SPE card on the router.

• When the router is powered on, install the subcard to the SPE card that has not been installed,

and then install them to the router.

To prepare for installation:

1. Put on an ESD-preventive wrist strap and make sure it is properly grounded.

2. Make sure the router is powered off and installed with the SPE card.

15

Page 21

3. Remove the blank panel (if any) from the slot to be used on the SPE card.

4. Unpack the subcard.

To install a subcard:

1. Turn the ejector levers of the subcard outward simultaneously with both hands, and then slide

the subcard (with the right side up) straight into the SPE card along the slide rails until the

ejector levers touch the panel of the SPE card, as shown in Figure 15.

2. Push against the front panel of the subcard. When the front panel is close enough to the SPE

card, pivot the ejector levers of the subcard inward with both hands so that the front panel is

flush with the panel of the SPE card.

3. Use a Phillips screwdriver to fasten the mounting screws on the subcard.

Figure 15 Installing a subcard

Connecting power cables

Check the following items before connecting power cables:

• For lightning protection, the AC power should be routed through an external lightning device

into the router. For more information, see "Lightning protection."

• The power switch on the power supply is in the OFF position.

16

Page 22

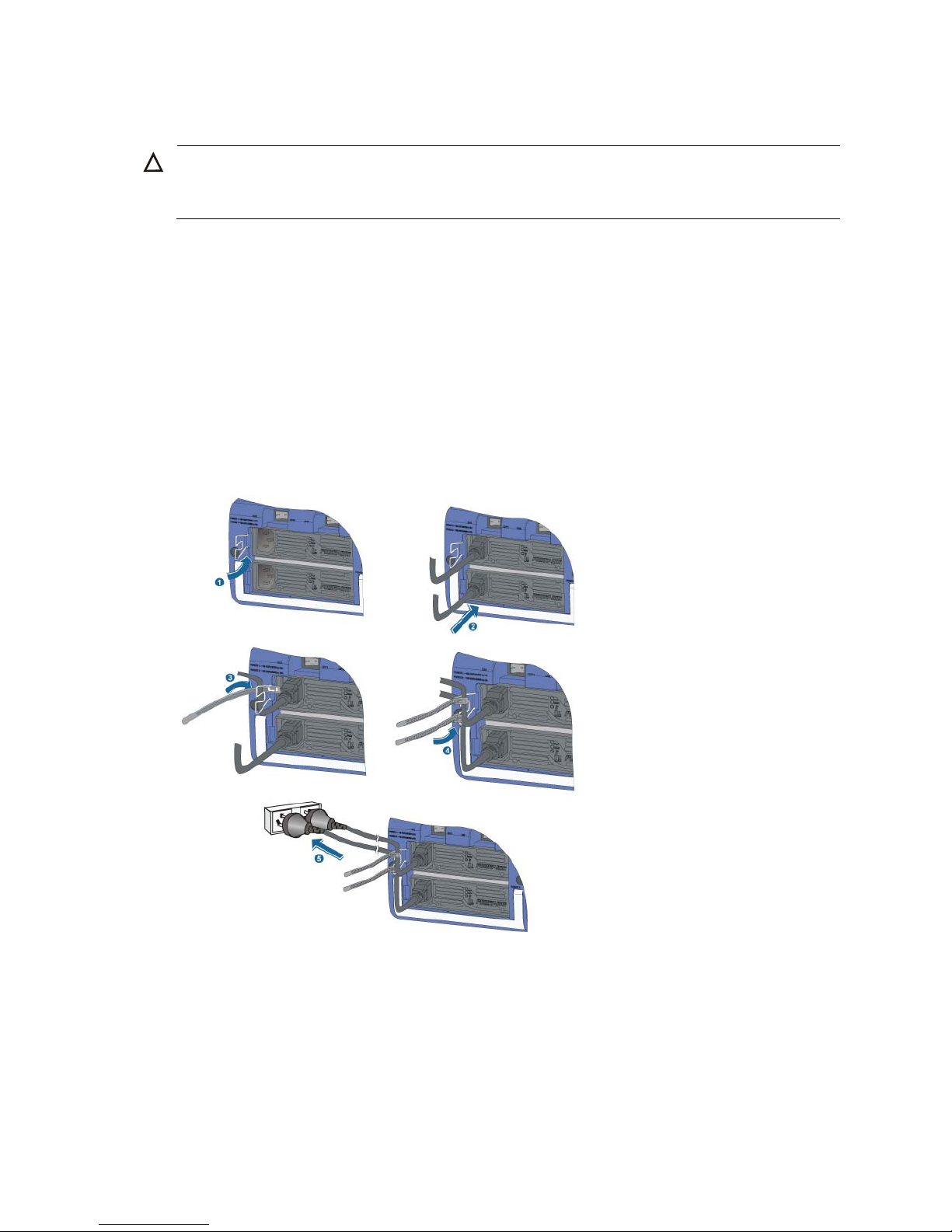

Connecting an AC power cable

CAUTION:

NEPS3500-A requires a 16 A power cable (AC), so you must use a 16 A busbar and make sure the

A

C power source can provide enough power.

The following procedure uses the AC power supply that comprises one 3500 W AC power frame and

two 1800 W power supplies to show how to install AC power cables.

To connecting an AC power cable:

1. Insert the ends of the bail latch into the holes on the left side of the upper power supply.

2. Connect one end of the AC power cable to the AC receptacle on the module.

3. Use a wiring tie through a notch of the bail latch, and bend the power cable so that the wiring

tie can bind the power cable with the bail latch.

4. Repeat steps 2 and 3 to bind another power cable with a wiring tie through the other notch.

5. Connect the other end of the AC power cable to the external power supply system.

Figure 16 Connecting a NEPS3500-A AC power cable

Connecting DC power cables

The DC power cables for the NEPS2000-D and NEPS3500-D are connected in the same way. The

procedure in this section uses the NEPS2000-D.

17

Page 23

W

ARNING!

To protect operators from being shocked, install the protection cover over the DC terminal block

immediately after you connect the power cables.

To connect the DC power cables:

1. Remove the protection cover of the DC terminal block from the DC power supply.

2. Loosen the fastening screws on the top two terminals with a Phillips screwdriver.

3. Connect one end of the blue –48 VDC power cable to the negative terminal (–) on the power

supply and fasten the screw. Connect the other end of the cable to the negative –48 V terminal

(–) on the power source.

The –48 VDC cable is marked with a minus sign (–).

4. Connect one end of the black DC power cable to the RTN (+) terminal on the power supply and

fasten the screw. Connect the other end of the cable to the RTN (+) terminal on the power

source.

The black DC power cable is marked with a plus (+) sign.

5. Put the protection cover over the DC terminal block.

Figure 17 Connecting DC power cables

18

Page 24

Verifying the installation

W

ARNING!

Before verifying the installation, make sure you have turned off the power to avoid bodily injury and

router damage.

Use the following checklist to make sure the router has been installed correctly.

Table 7 Installation checklist

Item

Result Remarks

Yes No

The grounding cable is grounded correctly.

Power supplies are installed correctly and firmly seated.

Power cables are connected correctly.

MPUs are installed correctly and have close contact with the

backplane.

LPUs and subcards are installed correctly and have close contact

with the backplane.

19

Page 25

Connecting the router to the network

Logging in to the router

The most common way to log in to a router is through the console port. It is also the prerequisite to

configuring other login methods.

Connecting the console cable

A console cable is an 8-core shielded cable, with a crimped RJ-45 connector at one end for

connecting to the console port of the router, and a DB-9 female connector at the other end for

connecting to the serial port on the console terminal, as shown in Figure 18.

Figure 18 Console cable

Table 8 Console cable pinouts

RJ-45 pin Signal DB-9 pin Signal

1 RTS 8 CTS

2 DTR 6 DSR

3 TXD 2 RXD

4 CD 5 SG

5 GND 5 SG

6 RXD 3 TXD

7 DSR 4 DTR

8 CTS 7 RTS

20

Page 26

Figure 19 Connecting the router and the PC through the console port

To connect the console cable:

1. Connect the DB-9 connector of the console cable to the serial port of a PC or terminal.

2. Connect the RJ-45 connector of the console cable to the console port of the MPU of the router.

3. When you remove the console cable, first unplug the RJ-45 end, and then unplug the DB-9 end.

Setting up a configuration environment

1. Launch a terminal emulation utility (such as HyperTerminal in Windows XP/Windows 2000).

Select Start > All Programs > Accessories > Communications > HyperTerminal to access the

HyperTerminal window.

The Connection Description dialog box appears.

21

Page 27

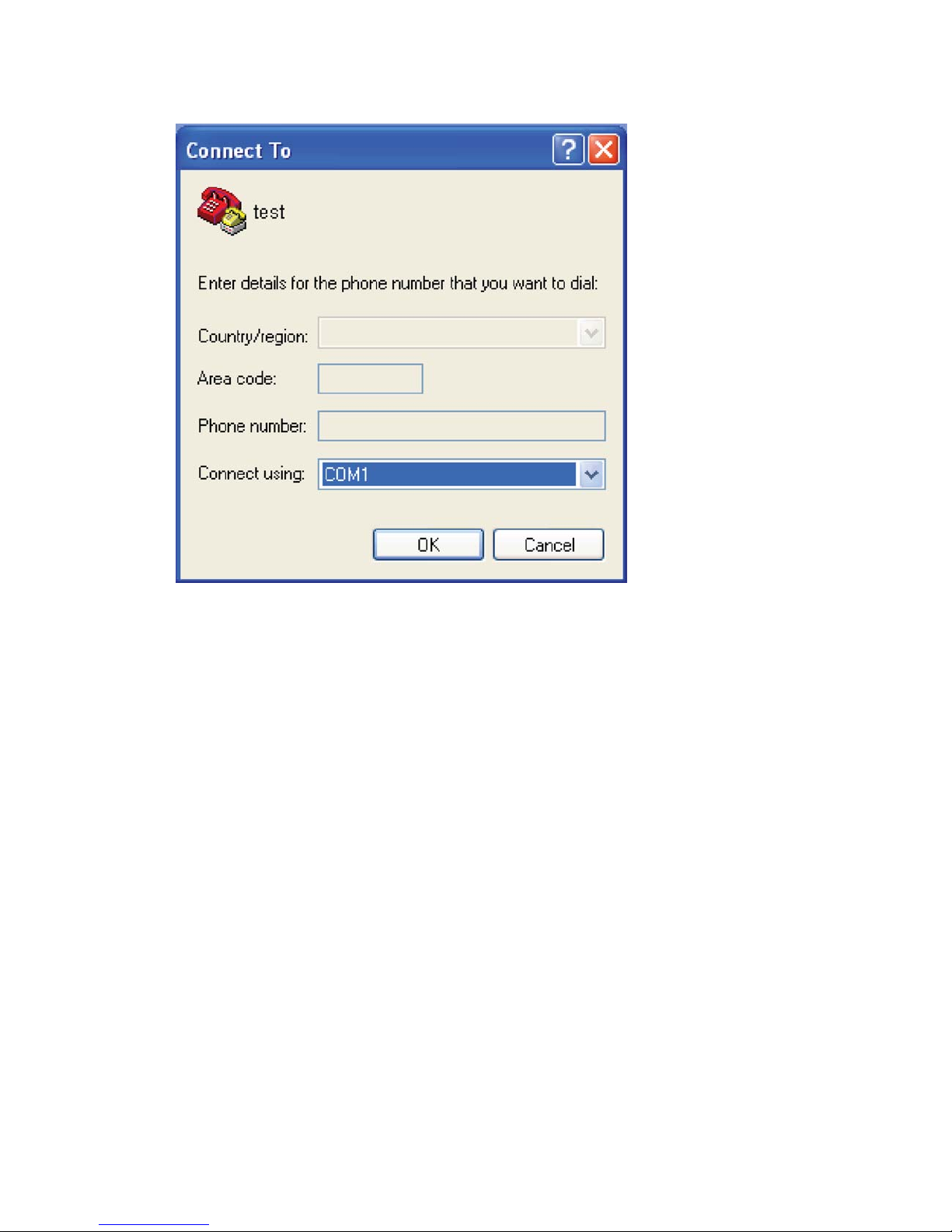

Figure 20 Connection Description dialog box for HyperTerminal

2. Enter the name of the new connection in the Name box, and then click OK.

The system displays the interface, as shown in Figure 21.

22

Page 28

Figure 21 Selecting a port for the HyperTerminal connection

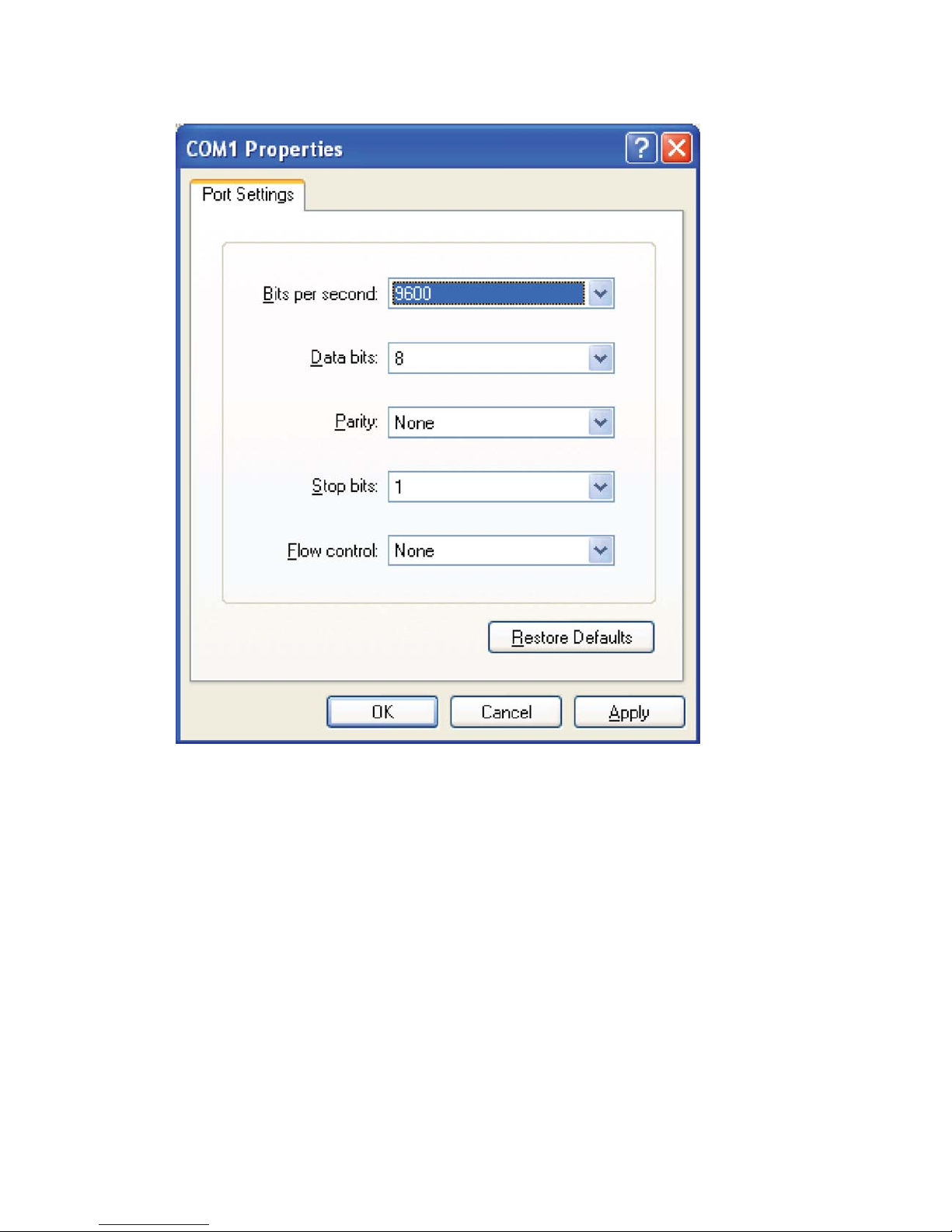

3. Select a port from the Connect using list, and then click OK.

4. Set the Bits per second to 9600, Data bits to 8, Parity to None, Stop bits to 1, and Flow control

to None, and click OK.

23

Page 29

Figure 22 Setting the serial port parameters

24

Page 30

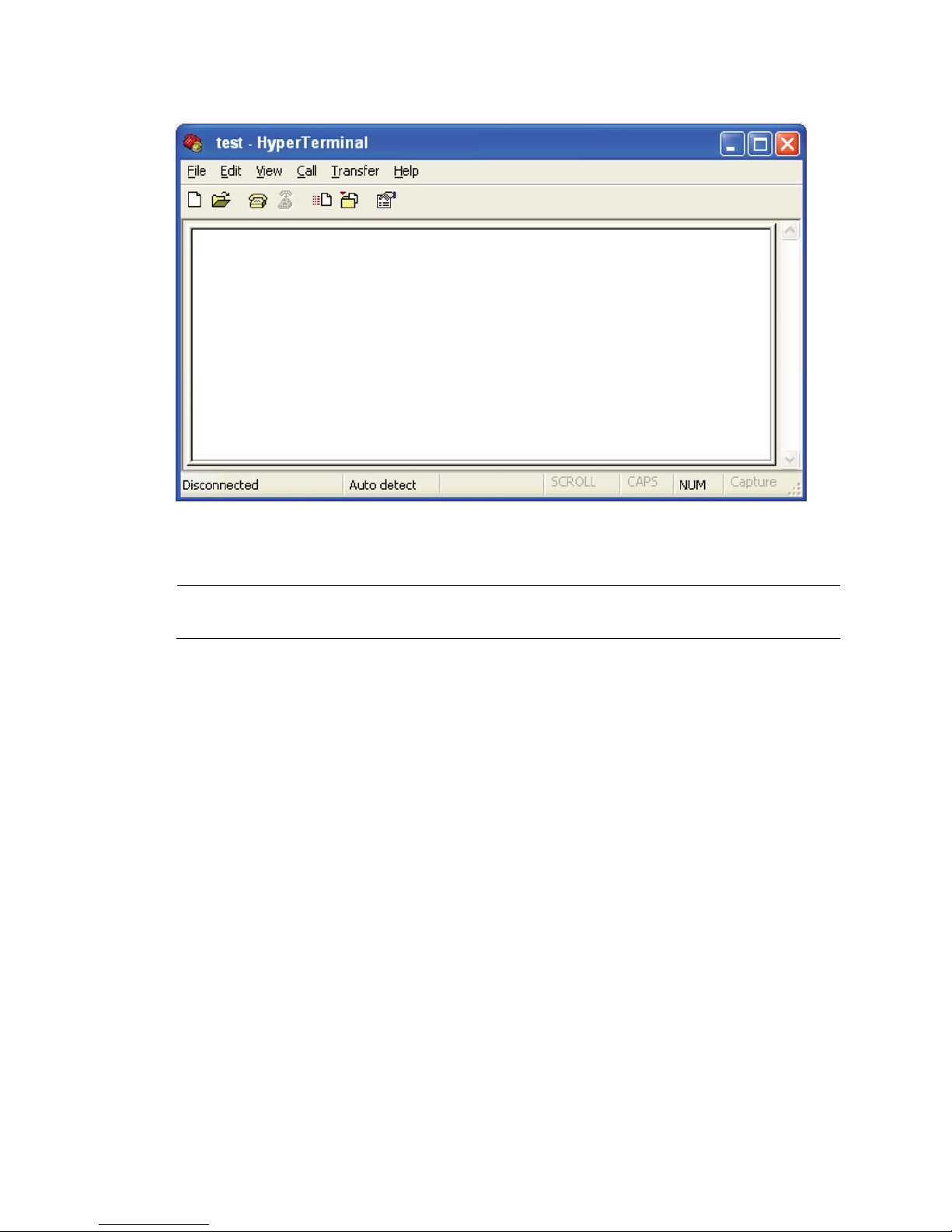

Figure 23 HyperTerminal window

5. Select File > Properties in the HyperTerminal window.

6. On the Settings tab, select VT100 for terminal emulation, and click OK.

NOTE:

HP recommends that you select the Windows keys option.

25

Page 31

Figure 24 Setting the terminal emulation parameters

Powering on the router

CAUTION:

Before powering on the router, locate the power switch in the equipment room so that you can

disconnect the power supply promptly in case of an emergency.

Before powering on the router, confirm the following:

• The interface cables, power cables, and grounding cable are connected correctly.

• The power outlet voltage is the same as indicated on the router label.

• The console cable is correctly connected, the console terminal or PC is powered on, and the

terminal parameters are configured properly.

To power on the router:

1. Turn on the power switch of the power source providing power to the router.

26

Page 32

2. Turn on the power switch on the router.

Before the router is powered on, the following information is displayed:

DDR2 SDRAM test successful.

System is starting...

Booting Normal Extend BootWare

The Extend BootWare is self-decompressing..........................

Done!

****************************************************************************

* *

* HP A8800 BootWare, Version 1.10 *

* *

****************************************************************************

Copyright (c) 2010-2011 Hewlett-Packard Development Company, L.P.

Compiled Date : Apr 22 2011

CPU Type : MPC8548E

CPU L1 Cache : 32KB

CPU L2 Cache : 512KB

CPU Clock Speed : 1000MHz

Memory Type : DDR2 SDRAM

Memory Size : 1024MB

Memory Speed : 400MHz

BootWare Size : 4MB

Flash Size : 128MB

cfa0 Size : 247MB

NVRAM Size : 1024KB

BASIC CPLD Version : 001F

EXTEND CPLD Version : 001F

PCB Version : Ver.B

The router initiates the POST and the results are displayed at the console terminal.

Board self testing...........................

Board steady testing... [ PASS ]

Board SlotNo... [ 0 ]

Subcard exist testing... [ PASS ]

DX246 testing... [ PASS ]

PHY88E1111 testing... [ PASS ]

CPLD1 testing... [ PASS ]

CPLD2 testing... [ PASS ]

NS16550 register testing... [ PASS ]

The device's Mac address... [00:23:89:D4:00:00]

CF Card testing... [ PASS ]

BootWare Validating...

Press Ctrl+B to enter extended boot menu...

When the POST is complete, the router boots the applications. The following information appears on

the terminal screen (only a portion is shown in this example):

Starting to get the main application file--cfa0:/A8800.BIN!..

The main application file is self-decompressing.............................

System application is starting...

27

Page 33

kbd->bi_immr_base = 0xff700000.

Starting kernel at 0x10000 ...

Now beginning to initialize system

User interface con0 is available.

After the router completes booting the applications, the following information appears on the terminal

screen:

Press ENTER to get started.

3. Press Enter to begin configuring the router at the prompt:

<HP>

NOTE:

• The router displays a CLI. For more information about the CLI, see

HP A8800 Routers Fundamentals

Configuration Guide

.

• The output depends on your router model.

Verifying router operation (recommended)

HP recommends that you verify the following after the router is powered on:

• The cooling system is working. You should be able to hear fan rotation noise and feel air being

blown out.

• All LEDs are functioning correctly.

Table 9 ED status when the router is operating correctly

Part LED Name Status

MPU

MPU status LED

SFC Steady green

ACT

Active MPU: Steady green

Standby MPU: Off

RUN Flashing green

LPU status LED RUN Flashing green

Power

supply

Power supply input/output LED

IN Steady green

OUT Steady green

Fan tray Fan tray status LED

RUN Steady green

ALM Off

For the card LED description, see "LEDs."

Connecting the router to the network

You can connect the router to the network using the following cable types:

• AUX cable

• Ethernet twisted pair

• Optical fiber

28

Page 34

Connecting through an AUX cable

You need an AUX cable when configuring a router using a remote dial-up modem.

An AUX cable is an 8-core shielded cable. At one end of the cable is an RJ-45 connector. At the

other end is a DB-9 (male) connector. An AUX cable is the same as a console cable. For more

information, see Figure 18 and Table 8.

To connect the AUX port:

1. Plug the RJ-45 connector of the AUX cable into the AUX port of the router.

2. Plug the DB-9 (male) connector at the other end into the serial port of the modem.

Connecting through an Ethernet twisted pair cable

The 10/100/1000Base-T copper ports of the router support MDI/MDI-X autosensing. They are

connected to the network through Category 5 (or higher) twisted pairs equipped with RJ-45

connectors.

No Ethernet twisted pair cables are shipped with the router. Prepare them yourself.

To con nec t a 10 / 100/ 1000 Bas e -T por t:

1. Plug one end of an Ethernet twisted pair cable into the copper Ethernet port (RJ-45 port) to be

connected on the router.

2. Plug the other end of the cable into the RJ-45 port of the peer device.

Connecting through an optical fiber

Use an optical fiber to connect an optical fiber port (for example, XFP fiber port or SFP fiber port) on

the router to the network. You must install a transceiver module to the router, and then insert the fiber

connector into the module.

This section describes only the LC connector.

Figure 25 LC connector

Follow these precautionary steps:

1. When selecting a fiber network facility, make sure the type of the connector and the fiber match

the adopted optical port.

2. Install the dust cover if the optical port is not connected to a fiber connector.

3. Never stare at the optical port directly. Invisible rays may be emitted from the optical port if the

optical port is not connected to a fiber connector or the dust cover is removed.

4. Never bend or curve a fiber when connecting it.

29

Page 35

Installing a transceiver module

CAUTION:

During installation, do not touch the golden finger of the SFP module.

The installation procedures for an XFP module and SFP module are similar. The following procedure

uses an SFP module as an example.

To install an SFP module:

1. Put on an ESD-preventive wrist strap, and make sure it makes good skin contact, and is well

grounded.

2. Unpack the SFP module. Close the clasp by pushing it up over the SFP module, and then gently

insert the SFP module into the interface slot until it clicks into place, as shown in Figure 26.

Figure 26 Installing an SFP module

IMPORTANT:

• Do not remove the dust plug of the SFP module port before installing an optical fiber.

• For an SFP module installed with an optical fiber, remove the fiber before you install the SFP module

into the slot.

Connecting an optical fiber

1. Put on an ESD-preventive wrist strap, and make sure it is well grounded.

2. Remove the protective cap from the fiber connector, and use dust free paper and absolute

alcohol to clean the end face of the fiber connector.

3. Connect one end of the fiber to the SFP module of the router.

4. Connect the other end of the fiber to the peer device.

30

Page 36

Figure 27 Connecting an optical fiber to an SFP module

Installing an FMT (optional)

The FMT is installed in a cabinet for winding redundant fibers between the router and other devices.

Confirm the following prerequisites:

• The cabinet is attached.

• The router is installed.

The installation involves the following materials:

• FMT

• M5×10 self-tapping screws (two screws for one FMT)

To install the FMT:

1. Align the FMT and the installation holes on the column of the cabinet.

2. Use a Phillips screwdriver to attach each FMT with two M5×10 self-tapping screws.

Figure 28 Installing the FMT

Cable routing recommendations

31

Page 37

CAUTION:

Do not bind cables at the air exhaust vent to prevent the cables from aging too fast. For more

information, see "Cable management."

Interface cables and power cables should be routed separately. Proper cable routing can improve

efficiency by facilitating installation and removal of fan trays, the PEM, and other components.

Follow these recommendations when you route cables:

• Interface cables are routed through the cable management brackets on the left and right sides of

the chassis and bound at cabling racks on chassis sides, depending on the available equipment

room condition.

• Put all data signal cable adapters neatly under the chassis (instead of any places outside the

chassis in case of unexpected damages).

• The power cables run along the left-rear of the chassis and out of the chassis either from the

chassis top or the raised floor depending on the equipment room conditions (power distribution

cabinet, lightning protection box, and connector strip, etc.) of the exchange office.

• Attach cables as close to the router as possible. The cables between the attachment point and

router interfaces must be bound loosely.

• Long cables can be bound with cable ties. Do not bind cables at the air exhaust vent to prevent

the cables from aging too fast. For more information, see "Appendix E Cable management."

• To identify cables, you can stick labels on them. For more information, see "Appendix F

Engineering labels for cables."

32

Page 38

Hardware management

This chapter describes the hardware management functions of the router.

Displaying electrical label data

Electrical label data is also called permanent configuration data or archive information, which is

written to the storage component of a card during device debugging or testing. The information

includes name of the card, card serial number, and vendor name.

Use the display device manuinfo command to display the electronic label data for your router,

including the card name, serial number, MAC address, manufacturing date, and vendor name.

# Display the electrical label data for the card in slot 3 on your router.

<Sysname> display device manuinfo slot 3

Slot 3:

DEVICE_NAME : SPC-1010-II

DEVICE_SERIAL_NUMBER : 210231A0E50103000002

MAC_ADDRESS : 000f-e200-5600

MANUFACTURING_DATE : 2011-02-28

VENDOR_NAME : HP

Slot 3 Subslot 1:

DEVICE_NAME : PIC-TCP8L

DEVICE_SERIAL_NUMBER : 210231A85JH105000015

MAC_ADDRESS : NONE

MANUFACTURING_DATE : 2010-05-24

VENDOR_NAME : HP

NOTE:

The output depends on your router model.

Displaying card information

Use the display device command to display your router's card information, including the slot number,

card type, card status, and software version.

# Display summary information for all cards on your router.

<Sysname> display device

Slot No. Brd Type Brd Status Software Version

0 SR02SRP2F3 Master A8800-CMW520-R3342

1 NONE Absent NONE

2 NONE Absent NONE

3 SPE-1010-II Normal A8800-CMW520-R3342

Sub1 PIC-TCP8L Normal

4 NONE Absent NONE

5 NONE Absent NONE

33

Page 39

6 NONE Absent NONE

Table 10 Command output

Field Descri

p

tion

Slot No. Slot number of a card.

Brd Type

Hardware type of a card:

Specific card model, such as SPE-1010-II, which is the same as the mark on the card.

• NONE—No card is in the slot.

• UNKNOWN—The card is not supported by the software version and cannot start

normally.

Brd Status

Card status:

• Absent—No card is in the slot.

• Master—The card is an AMB.

• Slave—The card is a SMB.

• Normal—The card is an interface card and operates properly.

• Fault—The card in the slot has not started or fails.

• Off—The card is not powered on.

Software

Version

Software version of the current card:

• Specific software version—The software version of the router.

• NONE—No card is in the slot.

• Mismatched—The software version does not support the card and thus cannot be

uploaded.

Rebooting the router

CAUTION:

• Router reboot can interrupt network services.

• To avoid data loss, use the save command to save the current configurations before a reboot.

• Use the display startup and display boot-loader commands to check that you have correctly set the

startup configuration file and the main system software image file.

You can reboot the router in one of the following ways to recover from an error condition:

• Reboot the device immediately at the CLI.

• At the CLI, schedule a reboot to occur at a specific time and date or after a delay.

• Power off and then re-power on the device. This method might cause data loss, and is the least

preferred method.

Reboot at the CLI is also called hot start. It is mainly used to reboot a router in remote maintenance,

without performing hardware reboot of the router.

For data security, if you reboot the router while the router is performing file operations, the router does

not reboot.

The precision of the rebooting timer is 1 minute. One minute before the rebooting time, the router

prompts "REBOOT IN ONE MINUTE" and reboots in one minute.

To reboot a router:

34

Page 40

Step Command Remarks

1. Reboot a card, or the

whole system immediately.

reboot [ slot slot-number ]

Optional.

Available in user view.

The precision of the rebooting timer is 1

minute. One minute before the

rebooting time, the router prompts

"REBOOT IN ONE MINUTE" and

reboots in one minute.

If you do not specify the slot keyword,

or reboot the AMB, the reboot

command reboots the router.

If you are performing file operations

when the router is to be rebooted, the

system does not execute the reboot

command for security purposes.

2. Enable the scheduled

reboot function and

specify a specific reboot

time and date.

schedule reboot at hh:mm

[ date ]

Optional.

The scheduled reboot function is

disabled by default.

Available in user view

3. Enable the scheduled

reboot function and

specify a reboot waiting

time.

schedule reboot delay { hh:mm

| mm }

Optional.

The scheduled reboot function is

disabled by default.

Available in user view

Displaying the router power supply system

Use the display power-supply command to display the power supply system of your router.

<Sysname> display power-supply verbose

Power 1 state: Normal

Power 2 state: Absent

Slot No. Board Power Status

0 POWER ON

3 POWER ON

Table 11 Command output

Field Descri

p

tion

Power x state:

State of power supply x:

• normal—The power supply is normal.

• absent—The power supply is not in position.

Slot No Slot number of the card.

Board Power

Status

Power supply status of the card:

• power on—The card is properly supplied with power.

• power off—The card is powered off due to user operation or over-temperature

protection.

35

Page 41

Configuring temperature alarm thresholds for a

card

Use the following command to set temperature alarm thresholds for a card. When the temperature of

a card exceeds a threshold, the router generates alarm signals.

To configure temperature alarm thresholds for a card:

Step Command Remarks

1. Enter system view.

system-view N/A

2. Configure temperature alarm

thresholds for a card.

temperature-limit slot slot-number hotspot sensor-num

LowerLimit WarningLimit [ AlarmLimit ]

Optional.

Displaying temperature information for a router

Use the display environment command to display the temperature information of the sensors on the

cards, including the current temperature and temperature thresholds.

# Display the temperature information of the cards on the router.

<Sysname> display environment

System temperature information (degree centigrade):

-------------------------------------------------------------------------------

Slot Sensor Temperature LowerLimit WarningLimit AlarmLimit ShutdownLimit

0 hotspot 1 39 0 70 85 N/A

0 hotspot 2 40 20 80 95 N/A

3 hotspot 1 55 -10 60 80 N/A

3 hotspot 2 42 -5 65 85 N/A

Table 12 Command output

Field Descri

p

tion

Slot Slot number of a card.

Sensor Temperature sensor, where "hotspot" indicates the hotspot temperature sensor.

Temperature Current temperature.

Lower limit Lower limit of temperature.

WarningLimit Upper limit of temperature for warning.

AlarmLimit Upper limit of temperature for alarming.

ShutdownLimit Upper limit of temperature for shutting down the router (currently not supported).

Configuring in-service hardware failure diagnosis

A hardware failure may cause traffic forwarding failures and service interruption. To improve the

automatic failure detection and handling capabilities of the router, you can configure in-service

hardware failure diagnosis.

36

Page 42

The in-service hardware failure diagnosis includes the detection for chips, cards, and the forwarding

service, and automatic fix actions taken for the detected failures.

To configure in-service hardware failure diagnosis:

Step Command Remarks

1. Enter system view.

system-view N/A

2. Enable in-service

hardware failure detection

and configure fix actions

taken in case of hardware

failures.

hardware-failure-detection

{ chip | board | forwarding }

{ off | warning | reset |

isolate }

Required.

The fix actions taken in case of hardware

failures include:

• Off—Takes no action.

• Warning—Sends warning messages.

• Reset—Resets the failed card.

• Isolate—Shuts down the failed port,

isolates the failed card, prohibits the

failed card from loaded, or powers off

the failed card to reduce the impact of

the failure to the system.

Currently, the router supports only off and

warning operations. By default, the fix

action taken for all hardware failures is

warning.

After configuring in-service diagnosis, you can use the display hardware-failure-detection command

to check the running information of the feature.

Displaying the operating state of a fan

Use the display fan command to display the operating state of all fans on your router.

<Sysname> display fan

Fan 1 State: Normal

Fan 2 State: Normal

The output above shows that all fans of the router operate normally.

Displaying alarm information for a card

Use the display alarm command to display alarm information for a card.

<Sysname> display alarm

Slot Level Info

0 ERROR Power 2 is absent.

0 ERROR Slot 6 board state is faulty

Table 13 Command output

Field Descri

p

tion

Level

Alarm severity.

In descending order, the alarm severity levels include ERROR, WARNING,

NOTICE, and INFO.

37

Page 43

Field Description

Info Detailed alarm information.

Slot n board state is

faulty.

Card n is faulty. The reason may be the card is booting or the card fails.

Verifying and diagnosing transceiver modules

Introduction to transceiver modules

There are two types of commonly used transceiver modules, as shown in Table 14. They can be

further divided into optical transceiver modules and electrical transceiver modules based on

transmission medium.

Table 14 Commonly used transceiver modules

Transceiver

type

Application scenarios

Optical

transceiver

module?

Electrical

transceiver

module?

SFP

Generally used for 100M/1000M Ethernet

interfaces, ATM, or POS 155M/622M/2.5G

interfaces

Yes Yes

XFP

Generally used for 10G Ethernet interfaces and

10 RPR interfaces

Yes No

Verifying transceiver modules

To verify transceiver modules, you can use the following commands to view the key parameters of the

transceiver modules, including transceiver module type, connector type, central wavelength of the

laser sent, transfer distance, and vendor name.

To display transceiver module information:

Task Command Remarks

Display key parameters of the transceiver

module in a specified interface.

display transceiver interface

[ interface-type interface-number ]

Available for all

transceiver modules.

Display part of the electrical label data for

the transceiver module in a specified

interface.

display transceiver manuinfo

interface [ interface-type interface-

number ]

Available for all

transceiver modules.

# Display the main parameters of the transceiver module plugged in interface GigabitEthernet 3/1/1.

<Sysname> display transceiver interface Gigabitethernet 3/1/1

GigabitEthernet3/1/1 transceiver information:

Transceiver Type : 1000_BASE_SX_SFP

Connector Type : LC

Wavelength(nm) : 850

Transfer Distance(m) : 550(50um),270(62.5um)

38

Page 44

Digital Diagnostic Monitoring : YES

Vendor Name : HP

Ordering Name : JD118B

Table 15 Command output

Field Descri

p

tion

transceiver

information

Transceiver information

Transceiver Type Transceiver type

Connector Type

Type of connector:

• Optical connectors, including SC (SC connector, developed by NTT) and LC (LC

connector, 1.25 mm/RJ-45 optical connector developed by Lucent).

• Other connectors, including RJ-45 and CX 4.

Wavelength(nm)

• Optical transceiver module—Central wavelength of the laser sent, in nm. If the

transceiver module, for example, 10GBASE-LX4, supports multiple wavelengths,

every two wavelength values are separated by a comma.

• Electrical transceiver module—Displayed as N/A.

Transfer

distance(xx)

Transfer distance, where xx represents km for single-mode transceiver modules and m

for other transceiver modules. If the transceiver module supports multiple transfer

medium, every two values of the transfer distance are separated by a comma. The

corresponding transfer medium is included in the bracket following the transfer

distance value. The following are the transfer media:

• 9 μ—9/125 μ single-mode optical fiber

• 50 μ—50/125 μ multi-mode optical fiber

• 62.5 μ—62.5/125 μ multi-mode optical fiber

• TP—Twisted pair

• CX4—CX4 cable

Digital Diagnostic

Monitoring

Whether the digital diagnosis function is supported:

• YES—Supported

• NO—Not supported

Vendor Name

Name of the vendor who manufactures or customizes the transceiver module.

Ordering Name

Transceiver module model.

# Display part of the electrical label data for the transceiver modules in a specified interface.

<Sysname> display transceiver manuinfo interface Gigabitethernet 3/1/1

GigabitEthernet3/1/1 transceiver manufacture information:

Manu. Serial Number : XXXXXXXXXXXXXXXXXX

Manufacturing Date : 2008-09-01

Vendor Name : HP

Table 16 Command output

Field Descri

p

tion

Manu. Serial Number Serial number of the transceiver module.

Manufacturing Date Manufacturing date of the transceiver module.

Vendor Name Name of vendor who customizes the transceiver module.

39

Page 45

Diagnosing transceiver modules

The device provides the alarm function and digital diagnosis function for transceiver modules. When

a transceiver module fails or inappropriately work, you can check for alarms present on the

transceiver module to identify the fault source or examine the key parameters monitored by the digital

diagnosis function, including the temperature, voltage, laser bias current, TX power, and RX power.

To display alarm information or fault detection parameters for a transceiver module:

Task Command Remarks

Display the current alarm information of the

transceiver module in a specified interface

display transceiver alarm

interface [ interface-type

interface-number ]

Available for all

transceiver modules.

Display the currently measured values of the

detection parameters of the transceiver module

in a specified interface

display transceiver diagnosis

interface [ interface-type

interface-number ]

Available for all

transceiver modules.

# Display the alarm information of the transceiver module plugged in GigabitEthernet 3/1/1.

<Sysname> display transceiver alarm interface GigabitEthernet 3/1/1

GigabitEthernet3/1/1 transceiver current alarm information:

RX loss of signal

Table 17 Command output

Field Remarks

SFP

RX loss of signal Receive (RX) signal is lost.

TX fault TX fault.

RX power high RX power is high.

RX power low RX power is low.

TX power high TX power is high.

TX power low TX power is low.

TX bias high TX bias current is high.

TX bias low TX bias current is low.

Temp high Temperature is high.

Temp low Temperature is low.

Voltage high Voltage is high.

Voltage low Voltage is low.

Transceiver info I/O error Transceiver information read and write error.

Transceiver info checksum error Transceiver information checksum error.

Transceiver type and port configuration

mismatch

Transceiver type does not match port configuration.

Transceiver type not supported by port

hardware

Transceiver type is not supported on the port.

40

Page 46

Field Remarks

XFP

RX loss of signal RX signal is lost.

RX not ready RX is not ready.

RX CDR loss of lock RX clock cannot be recovered.

TX fault TX fault.

TX not ready TX is not ready.

TX CDR loss of lock TX clock cannot be recovered.

Module not ready Module is not ready.

APD supply fault Avalanche Photo Diode (APD) supply fault.

TEC fault Thermoelectric Cooler (TEC) fault.

Wavelength unlocked

Wavelength of optical signal exceeds the manufacturer's

tolerance.

RX power high RX power is high.

RX power low RX power is low.

TX power high TX power is high.

TX power low TX power is low.

TX bias high TX bias current is high.

TX bias low TX bias current is low.

Temp high Temperature is high.

Temp low Temperature is low.

Voltage high Voltage is high.

Voltage low Voltage is low.

Transceiver info I/O error Transceiver information read and write error.

Transceiver info checksum error Transceiver information checksum error.

Transceiver type and port configuration

mismatch

Transceiver type does not match port configuration.

Transceiver type not supported by port

hardware

Transceiver type is not supported on the port.

# Display the currently measured values of the fault detection parameters for the transceiver module