Page 1

HP StorageWorks

4Gb SAN Director

Port Blade

installation instructions

Overview

Read these instructions to install the followi ng optional 4Gb SAN

Director Port Blades:

• HP StorageWorks 16 Port 4Gb Blade (FC4–16),

Part Number A7990A, installs in the HP StorageWorks

SAN Director 2/128 or HP StorageWorks 4/256 SAN Director

models

• HP StorageWorks 32 Port 4Gb Blade (FC4–32),

Part Number A7991A, installs in the HP StorageWorks

4/256 SAN Director model

• HP StorageWorks 4/48 SAN Director Blade (FC4–48),

Part Number AG561A, installs in the the HP StorageWorks 4/256

SAN Director model

Refer to the HP Storage Works SAN Director installation guide for a

complete list of 4Gb SAN Director Port Blade technical specifications.

Intended audience

These installation instructions are intended for use by system technicians

who are experienced with:

• Setting up devices in a SAN

• HP StorageWorks Fibre Channel Directors

only

only

only

NOTE:

For simplicity, the port blades are referred to as FC4–16,

FC4–32 and FC4–48 throughout this document.

© Copyright 2006 Hewlett-Packard Development Company, L.P.

First edition (November 2006)

Product names mentioned herein may be trademarks of their

respective companies as reflected by an associated footnote.

The information in this document is subject to change without

notice.

Printed in the US

www.hp.com

Relate

For the

visit t

h

ttp://www.hp.com/country/us/eng/prodserv/storage.html

ddocumentation

latest information, documentation, and firmware releases, please

he following HP StorageWorks web site:

Compatibility

Refer to Table 1 to determine which SAN Director models are

compatible with your specific 4Gb SAN Director Port Blade.

IMPORTANT:

Install 4Gb Port Blades in the SAN Director models l isted only.

Table 1 4Gb SAN Director Port Bl ade compatibility

SAN Director

2/128

4/256 SAN

Director

4/16 SAN

Director Port

Blade (FC4-16)

Compatible

Compatible Compatible Compatible

4/32 SAN

Director

Por t Blade

(FC4–32)

Not

compatible

4/48 SAN

Director

Port Blade

(FC4–48)

Not

compatible

7990-90003*

*A

Page 1

NOTE:

Installation procedures for the B-Series Multi-protocol Router

Blade are not included in this document. Please refer to

the

HP StorageWorks B-Series Multi-protocol Router Blade

installation guide

Related documentation.

available via the link provided above in

Page 2

Chassis configuration setting

When migrating a SAN Director with two domains (two lo g ical

switches) to a 4/256 SAN Director, the result will be a SAN Director

with only one domain. Depending on your configuration, this

may change the topology of the fabric and should be taken into

consideration when planning your installation.

The 4/256 SAN Director supports chassis configuration options 1 or

5only. UsethechassisConfig command to change the chassis

configuration. The valid options are:

• Option 1 — One (up to) 128-port logical switch. This chassis mode

supports CP4 control processor blades managing FC4–16.

• Option 5 — One (up to) 384-port logical switch. This chassis mode

supports CP4 control processor blades managing the FC4–16,

FC4–32, and F C 4–48.

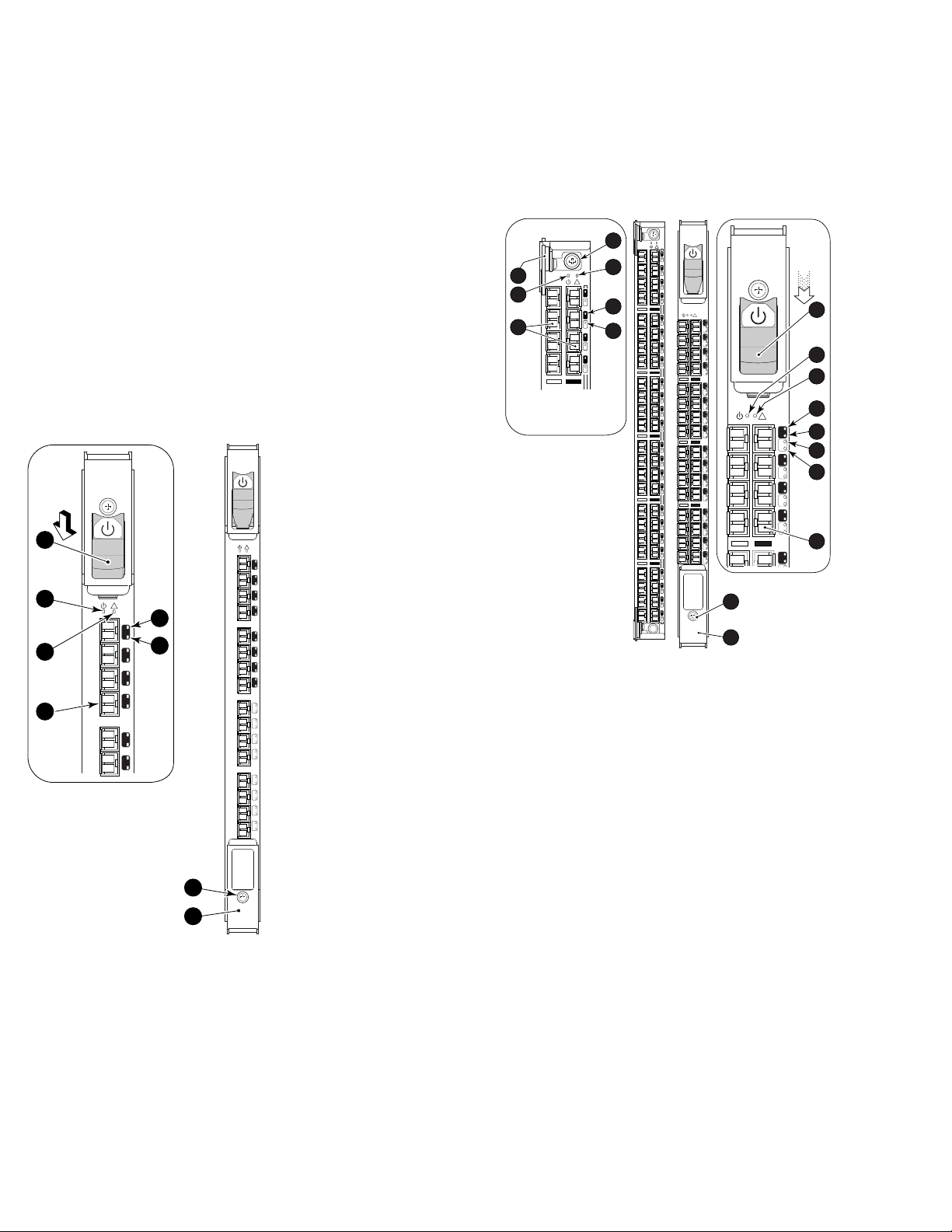

Blade components and port numbering

The following sections illustrate 4Gb SAN Di rector Port Blade

components.

FC4–16 Port Blade components

Figure 1 identifies FC4–16 blade components and the port numbering

scheme. P

Figure 1 FC4–16 components

Callouts

1. On/Off switch (On position)

2. Power LED

3. Status LED

4. Fibre Channel port

orts are numbered from 0 through 15 from bottom to top.

56-0000590-01 Rev A

1

56-0000590-01 Rev A

2

3

!

5

15

6

14

13

12

4

11

10

!

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

FC4

16

7

8

25027a

5. Port speed LED

6. Por t status LED

7. Thumb screw

8. Ejector

FC4–32 and FC4–4

Figure 2 identif

numbering schem

ies FC4–32 and FC4–48 blade components and port

es.

8 Port Blade components

For the FC4–32, ports are numbered from 0 through 15 from bottom to

top on the left s

et of ports, and 16 through 31 from bottom to top on

the right set of ports.

For the FC4–48

, ports are numbered from 0 through 23 from bottom to

topontheleftsetofportsand24through47frombottomtotopon

the right set

1

2

3

of ports.

!

47

23

46

22

45

21

44

20

4

!

47

23

5

6

7

46

22

45

21

44

20

!

43

31

19

15

42

30

18

14

41

29

17

13

40

28

16

12

39

27

15

11

38

26

14

10

37

25

13

9

36

24

12

8

35

23

11

7

34

22

10

6

33

21

9

5

32

20

8

4

31

19

7

3

30

18

6

2

29

17

5

1

28

16

4

0

27

3

26

FC4

2

32

25

1

24

0

!

8

10

11

12

13

31

14

15

15

30

14

16

29

13

28

12

17

27

9

25225a

Figure 2 FC4–48 (left) and FC4–32 (right) components

Callouts

Off switch (on position)

1. On/

/Off Switch (Off position)

10. On

2. FC4–48 power LED 11. FC4–32 power LED

3. FC4–48 Fibre Channel ports

umb screw

4. Th

12. FC4–32 status LED

C4–32 port speed LED

13. F

5. FC4–48 status LED 14. FC4–32 port status LED

6. FC4–48 port status LED

15. Port speed LED for FC4–32

(for FC4–32 this LED indicates

the port speed for the left port)

rt status LED for FC4-32

7. Po

FC4-48 (for FC4–32 and

and

–48, this LED indicates the

FC4

t status for the left port)

por

ort status LED for FC4–32

16. P

FC4–48 (for FC4–32 and

and

–48, this LED indicates the

FC4

t status for the left port)

por

8. Thumb screw 17. Fibre Channel port

9. Ejector

Page 2

Page 3

Time and items required for install

The installatio

• 4Gb SAN Director

• Minimum of two P

• Electrostati

• Replacement f

Director)

• Workstation

• Phillips scr

• SFP transce

n takes less than 10 minutes. Obtain the following items:

Port Blade

ower Supplies installed in the SAN Director

c Discharge (ESD) grounding strap

iller panel for each empty slot (ships with the SAN

computer

ew driver

iversandopticalcables(asneeded)

Remove the filler panel

b. Pull on the top an

d bottom pulling tabs to slide the filler panel

out of the chassis.

IMPORTANT:

Remove a filler panel only when installing a port blade. Any

slot that is not occupied by a port blade requires a filler panel to

ensure correct cooling of the chassis and protection from dust.

Installing the por t blade

The FC4–16 and FC4–32 port blades use the same procedure.

However, the FC4–48 differs slightly in design. Port blade-specific

instructions are called out where applicable, as follows:

Remove the fi

see Figure 3

ller panel, if installed. There are three filler panel types,

:

!

!

5

4

3

2

1

!

5

6

-

0

0

0

0

5

9

0

-

0

1

R

e

v

A

!

!

15

14

I O I O I RS - 232

13

I O I O I RS - 232

12

11

10

k

n

b

i

L

M

0

0

1

/

0

1

9

P

s

C

/

k

n

b

e

i

L

v

i

M

t

c

0

A

0

1

/

8

0

1

P

C

e

v

i

t

c

A

7

6

5

4

3

2

1

0

CP4

CP4

FC4

16

-60 Hz

0

0 VAC 12A 5

200-24

0

1

9

8

7

6

5

6

-

0

0

0

0

5

9

0

-

0

1

R

e

v

A

!

15

14

13

12

11

10

9

8

7

s

/

6

5

4

3

2

1

0

FC4

16

-60 Hz

AC 12A 50

-240 V

200

Y 4

ER SUPPL

POW

Y 3

PL

UP

S

ER

POW

!

!

Y 2

ER SUPPL

POW

!

!

Y 1

Y 1

PL

PL

ER SUP

ER SUP

OW

OW

P

P

1

7

6

5

2

3

4

25043a

Figure 3 Removing three different filler panel types

Callouts

1. Filler panel with handle

2. Captive screws (2)

5. Ejectors (2)

6. Pull tabs (2)

3. Handle 7. Filler panel with pull tabs

ller panel with ejectors

4. Fi

1. To remove a filler panel with a handle:

a. Unscrew the two captive screws securing the filler panel.

b. Grasp the handle in the middle of the filler panel and remove.

2. To remove a filler panel with ejectors:

a. Push in the yellow tab on each ejector.

b. Lever both ejectors all the way open, and remove the filler

panel from the chassis.

3. To remove a filler panel with p ull tabs:

a. Unscrew the top and bottom captive screws on the filler panel.

CAUTION:

Wear a ground

ed ESD strap when handling the port blade.

The 4/256 SAN Director chassis has a grounding connection

above the power connectors.

1. Locate an appropriate slot. Install port blades in slots 1 through 4;

and 7 through 10.

NOTE:

For details on supported mixed blade configurations, refer to

the

HP StorageWorks SAN Director installation guide

.

2. Orient the port blade so that the ports are at the front of the chassis

and the flat side of the port blade is on the left, see Figure 4.Hold

the port blade by the edges of the metal pan. Do not use the

ejectors to hold the port blade.

CAUTION:

ure to gently apply pressure to the port blade, in order

Make s

perly seat the card all the way into the slot. Applying

to pro

sive pressure may damage the VHDM connectors on the

exces

tor’s backplane.

Direc

1

!

!

6

5

4

3

2

1

!

5

6

-

00

0

0

59

0

-0

1

R

e

v

A

!

!

5

1

4

1

I O I O I RS - 232

3

1

I O I O I RS - 232

2

1

1

1

0

1

s

/

k

b

in

L

M

0

0

1

/

0

1

9

P

s

C

/

k

b

e

in

L

iv

M

t

c

0

A

0

1

/

8

0

1

P

e C

iv

t

c

A

7

6

5

4

3

2

1

0

CP4

CP4

FC4

16

0 VA

-24

200

0-60 Hz

C 12A 5

200-240 VA

7

C 12A 50-60 Hz

!

!

0

1

9

8

POWER SUPPLY 4

5

6

-

0

0

00

5

9

0

-01

R

ev A

!

!

!

5

1

4

1

3

1

2

1

ER SUPPLY 3

1

1

POW

0

1

9

8

!

7

!

6

5

4

3

ER SUP

2

POW

1

0

4

FC

32

!

FC4

32

FC4

!

16

ER SUPPLY 1

ER SUPPLY 1

POW

POW

2

PLY 2

5

6

-

0

0

0

0

5

90-0

1

Rev A

!

5

1

4

1

3

1

2

1

3

1

1

0

1

9

8

7

6

5

4

3

2

1

0

FC4

16

4

25217a

Figure 4 Installing a FC4–16 or FC4–32 Port Blade

Callouts

1. SAN Director chassis

2. FC4-16

3. On/Off slider switch

Ejector

4.

Page 3

Page 4

3. If installing th

For FC4–16 and FC

a. Open the ejector

eFC4–48,gotostep4.

4–32 models (see Figure 4).

s to approximately 45 degrees.

b. Align the flat side of the port blade inside the upp er and lower

rail guides in the slot, and slide the port blade into the slot,

with slight pr

4. For FC4–48 mod

a. Adjust the ej

b. Align the fla

rail guides

c. Slide the po

1

essure to the left, until it is firmly seated.

els (see Figure 5):

ectors to the open position.

t side of the port blade inside the upper and lower

in the slot.

rt blade into the slot, until it is firmly seated.

1

!

!

8

7

6

5

5

6-0

0

00

590

-

0

1

R

ev

4

A

3

2

5

6

-00

0

0

59

0-

01

R

e

v

A

!

5

1

4

1

3

1

2

1

1

1

0

1

9

8

7

6

5

4

3

2

1

0

FC

16

0 VAC

-24

200

!

5

1

4

1

3

1

!

2

1

!

1

1

0

1

I O I O I RS - 232

9

8

I O I O I RS - 232

7

6

s

k

Lin

5

100 Mb/

10/

s

k

Lin

4

Active CP

100 Mb/

10/

Active CP

3

2

1

0

4

FC

16

CP4

4

CP4

50-60

AC 12A

0 V

200-24

50-60 Hz

12A

!

!

0

1

9

4

FC

32

4

FC

32

Hz

4

Y

L

PP

SU

R

E

W

O

P

!

!

3

Y

PL

UP

POWER S

!

!

PLY 2

SUP

POWER

!

!

Y 1

Y 1

PL

PL

POWER SUP

POWER SUP

2

!

7

4

3

2

6

4

2

2

5

4

1

2

4

4

0

2

3

4

9

1

2

4

8

1

1

4

7

1

0

4

6

1

9

3

5

1

8

3

4

1

7

3

3

1

6

3

2

1

5

3

1

1

4

3

0

1

3

3

9

2

3

8

1

3

7

0

3

6

9

2

5

8

2

4

7

2

3

6

2

2

5

2

1

4

2

0

3

4

7. Tighten the thum

b screw inside each handle using the Phillips

screw driver.

IMPORTANT:

Theupperandlowerthumbscrewsmustbecompletely

tightened, and the upper and lower ejectors must be in the

closed position for the FC4–48 to power on.

8. If installing the FC4–48, go to step 9.

For FC4–16 and FC4–32 models (see Figure 4):

a. To power on the port blade, move up the slider switch in the

top ejector.

b. Verify that the slider switch covers the thumbscrew.

9. For the FC4–48:

Verify that the power LED on the port blade displays a steady

green light (it might require a few seconds to turn on). If it does

not turn on

thumb scr

The LED pa

diagnost

10. Install

11. Refer to

, ensure that the port blade is firmly seated and that the

ews are tight.

tterns might temporarily change during POST and other

ic tests.

SFP transceivers and cables in the port blade, as required.

the HP StorageWorks SAN Director installation guide for

different ways to manage cables, including:

• Routing directly down, through the cable management tray,

d of across adjacent blades to keep LEDs visible.

instea

•Insta

•Insta

lling cable channels on the sides of the cabinet

lling patch panels

IMPORTANT:

Disassembling any part of the port blades voids the part

warranty and regulatory certifications. There are no

user-serviceable parts inside the port blade.

25223a

e 5 Installing an FC4–48 Port Blade

Figur

Callouts

per ejector

N Director chassis

1. SA

2. FC4–48

nstalling the FC4–48, go to step 6.

5. If i

FC4–16 and F C4–32 models (see Figure 4).

For

a. Pus

b. Ve

6.F

A

h the handles toward the center of the port blade, closing

eejectors.

th

rify that the handle’s levering action properly seats the port

ade in the slot.

bl

or the FC4–48:

djust the ejectors to the closed position (see Figure 5) by pulling

3. Up

4. Lower ejector

them away from the center of the port blade.

Waste Electrical and Electronic

Equipment ( WEEE) directive

Page 4

Loading...

Loading...