Page 1

HP StorageWorks

2/8q Fibre Channel Switch

First Edition (November 2004)

Part Number: A7540-96010

Installation Guide

This manual describes the features of, and installation procedures for, the HP StorageWorks 2/8q Fibre

Channel Switch.

Sections include:

■ Introduction—provides an overview of LEDs, connections, and user controls.

■ Planning—describes the factors to consider when planning a fabric.

■ Installing—explains how to install and configure the switch.

■ Troubleshooting—describes the diagnostic methods and troubleshooting procedures.

■ Regulatory Compliance Notices—includes notices about the switch.

■ Electrostatic Discharge—discusses static electricity concerns.

■ Specifications —ists the switch specifications.

Page 2

© Copyright 2004 Hewlett-Packard Development Company, L.P.

Hewlett-Packard Company makes no warranty of any kind with regard to this material, including, but not limited to, the implied

warranties of merchantability and fitness for a particular purpose. Hewlett-Packard shall not be liable for errors contained herein or for

incidental or consequential damages in connection with the furnishing, performance, or use of this material.

This document contains proprietary information, which is protected by copyright. No part of this document may be photocopied,

reproduced, or translated into another language without the prior written consent of Hewlett-Packard. The information contained in this

document is subject to change without notice. The only warranties for HP products and services are set forth in the express warranty

statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP

shall not be liable for technical or editorial errors or omissions contained herein.

Microsoft® and Windows® are U.S. registered trademarks of Microsoft Corporation.

Linux® is a U.S. registered trademard of Linus Torvalds.

Hewlett-Packard Company shall not be liable for technical or editorial errors or omissions contained herein. The information is provided

“as is” without warranty of any kind and is subject to change without notice. The warranties for Hewlett-Packard Company products are

set forth in the express limited warranty statements for such products. Nothing herein should be construed as constituting an additional

warranty.

HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

First Edition (November 2004)

Part Number: A7540-96010

Page 3

Contents

About this Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Intended audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Related documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Document conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Text symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Equipment symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Rack stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Getting help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

HP installation and configuration assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

HP technical support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

HP storage web site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

HP authorized reseller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Switch chassis features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Serial port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Chassis LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Input Power LED (green) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Heartbeat LED (green) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

System Fault LED (solid amber). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Ethernet port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Maintenance button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Resetting the switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Placing the switch in maintenance mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Exiting maintenance mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Fibre Channel ports and LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Port Logged-in LED (green) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Port Activity LED (green) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

SFP transceivers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Port types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Switch management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Switch Manager user interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Command Line Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

File Transfer Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Simple Network Management Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Contents

3HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 4

Contents

2 Planning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Device access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Hard zones (Access Control Lists). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Soft zones. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Latency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Fabric security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

User account security. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Simple Network Management Protocol security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Fabric management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

3 Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Site requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Installing and initially configuring the switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Unpack the switch and verify carton contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Mount the switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Install SFP transceivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Connect the cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Connect Fibre Channel devices to the switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Connect power to the switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Configure the switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Installing Switch Manager on Windows® systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Installing Switch Manager on Linux® systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Backing up the switch configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Powering down the switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Updating switch firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Using Switch Manager to install firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Using the CLI to install firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

4 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

POST diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Heartbeat LED blink patterns. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Internal firmware failure blink pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

System error blink pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Configuration file system error blink pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Over temperature blink pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Logged-In LED indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Port Error blinking pattern. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Chassis diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Input Power LED is extinguished . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

System Fault LED is illuminated. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Maintenance mode options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Maintenance menu – Exit . . . . . . . . . . . . . . . . . . . . . . . . 48

Maintenance menu – Image Unpack . . . . . . . . . . . . . . . . . . . . 48

Maintenance menu – Reset Network Config . . . . . . . . . . . . . . . . 48

Maintenance menu – Reset User Accounts to Default . . . . . . . . . . . 48

Maintenance menu – Copy Log Files . . . . . . . . . . . . . . . . . . . 48

4 HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 5

Contents

Maintenance menu – Remove Switch Config . . . . . . . . . . . . . . . . 48

Maintenance menu – Remake Filesystem . . . . . . . . . . . . . . . . . . 49

Maintenance menu – Reset Switch . . . . . . . . . . . . . . . . . . . . 49

Maintenance menu – Show Firmware Versions . . . . . . . . . . . . . . . 49

Maintenance menu – Set Active Image . . . . . . . . . . . . . . . . . . 49

Maintenance menu – Update Boot Loader . . . . . . . . . . . . . . . . . 49

A Regulatory Compliance Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Federal Communications Commission Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Class A equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Class B equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Declaration of conformity for products marked with the FCC logo - United States only . . . . . . . . . . . . . .52

Canadian Notice (Avis Canadien) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Class A equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Class B equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

European Union Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

BSMI Notice. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Japanese Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Japanese Power Cord Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Korean notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Class A equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Laser compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Battery replacement notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

B Electrostatic Discharge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Prevention methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Grounding methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

C Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Fabric specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Maintainability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Fabric management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Electrical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Environmental. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Regulatory certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

D Management System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Management system requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Cable pin configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Indirect Ethernet cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Direct Ethernet cross-over cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Serial cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Establishing an Ethernet or serial connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Ethernet connection information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Serial connection information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

5HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 6

Contents

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figures

1 Chassis features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2 Chassis LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3 Ethernet port and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 Fibre Channel port and LED locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5 Switch carton contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6 Using the rack template . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7 Attaching the right rail to the rack - rear view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8 Moving the rail retaining bracket on the right rail - rear view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

9 Attaching the mounting adapter brackets to the switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

10 Placing the switch on the rails - rear view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

11 Securing the switch flanges to the rear of the rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

12 Securing the rail retaining brackets to the switch - front view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

13 Installing an SFP transceiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

14 Heartbeat LED location and blinking patterns. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

15 Logged-In LED location and blinking patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

16 Chassis LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Tables

1 Document conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Zoning database limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3 Environmental requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4 Fabric specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5 Maintainability options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6 Fabric management options and requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

7 2/8q FC Switch chassis dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8 Electrical requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9 Environmental requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

10 Regulatory certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

11 Workstation requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

12 Ethernet and serial Cable Pin Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6 HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 7

About This Guide

About this Guide topics include:

■ Intended audience, page 7

■ Related documentation, page 7

■ Document conventions, page 8

■ Text symbols, page 8

■ Equipment symbols, page 9

■ Rack stability, page 10

■ Getting help, page 10

Intended audience

This guide is intended for use by the system administrator responsible for the 2/8q FC Switch

and the MSA1000 storage system.

Related documentation

The following MSA1000 SAN Kit and 2/8q FC Switch documents are on the MSA1000 Small

Business SAN documentation CD:

■ HP StorageWorks Modular Smart Array 1000 Small Business SAN Kit Installation

Instructions (also printed)

■ HP StorageWorks 2/8q Fibre Channel Switch Management User Guide

■ HP StorageWorks 2/8q Fibre Channel Switch SNMP Reference Guide

About this Guide

About this Guide

■ HP StorageWorks 2/8q Fibre Channel Switch Event Messages Reference Guide

The following MSA1000-specific documents are on the MSA1000 documentation CD:

■ HP StorageWorks MSA1000 Configuration Overview

■ HP StorageWorks MSA1000 Installation Guide

■ HP StorageWorks Modular Smart Array 1000 Maintenance and Service Guide

■ HP StorageWorks Modular Smart Array 1000/1500 cs Command Line Interface User

Guide

■ HP StorageWorks Modular Smart Array 1000 Controller Reference Guide

■ HP Array Configuration Utility User Guide

7HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 8

About this Guide

Document conventions

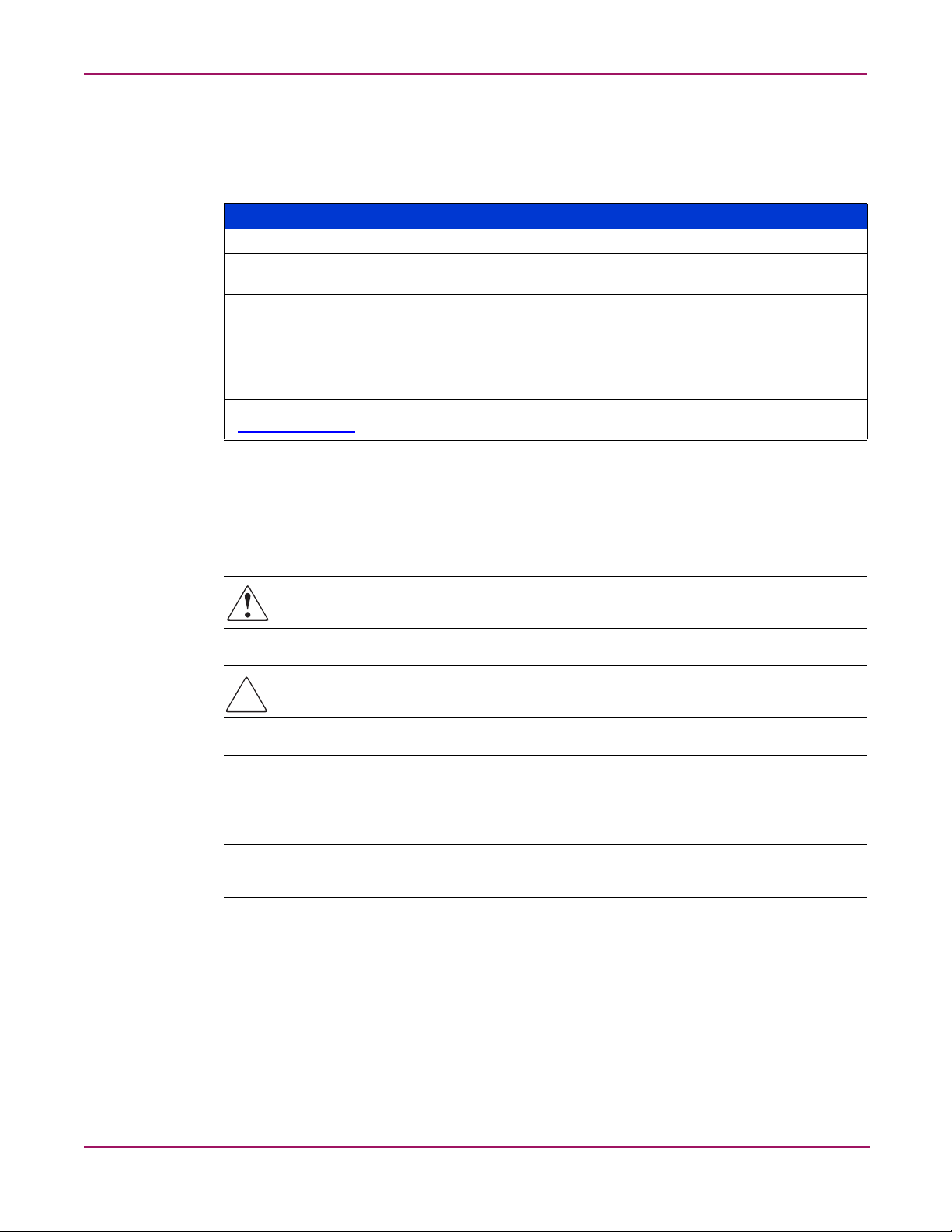

This document follows the conventions in Tabl e 1.

Table 1: Document conventions

Blue text: Figure 1 Cross-reference links

Bold Menu items, buttons, and key, tab, and box

Italics

Monospace font User input, commands, code, file and

Monospace, italic font Command-line and code variables

Blue underlined sans serif font text

(

http://www.hp.com

Text symbols

Convention Element

names

Text emphasis and document titles in body text

directory names, and system responses (output

and messages)

Web site addresses

)

The following symbols may be found in the text of this guide. They have the following

meanings:

WARNING: Text set off in this manner indicates that failure to follow directions in the

warning could result in bodily harm or death.

Caution: Text set off in this manner indicates that failure to follow directions could result in

damage to equipment or data.

Tip: Text in a tip provides additional help to readers by providing nonessential or optional

techniques, procedures, or shortcuts.

Note: Text set off in this manner presents commentary, sidelights, or interesting points of

information.

8 HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 9

Equipment symbols

The following equipment symbols may be found on hardware for which this guide pertains.

They have the following meanings:

About this Guide

Any enclosed surface or area of the equipment marked with these symbols indicates

the presence of electrical shock hazards. Enclosed area contains no operator

serviceable parts.

WARNING: To reduce the risk of personal injury from electrical shock hazards, do

not open this enclosure.

Any RJ-45 receptacle marked with these symbols indicates a network interface

connection.

WARNING: To reduce the risk of electrical shock, fire, or damage to the equipment,

do not plug telephone or telecommunications connectors into this receptacle.

Any surface or area of the equipment marked with these symbols indicates the

presence of a hot surface or hot component. Contact with this surface could result in

injury.

WARNING: To reduce the risk of personal injury from a hot component, allow the

surface to cool before touching.

Power supplies or systems marked with these symbols indicate the presence of

multiple sources of power.

WARNING: To reduce the risk of personal injury from electrical shock,

remove all power cords to completely disconnect power from the power

supplies and systems.

Any product or assembly marked with these symbols indicates that the component

exceeds the recommended weight for one individual to handle safely.

WARNING: To reduce the risk of personal injury or damage to the equipment,

observe local occupational health and safety requirements and guidelines for

manually handling material.

9HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 10

About this Guide

Rack stability

Getting help

Rack stability protects personnel and equipment.

WARNING: To reduce the risk of personal injury or damage to the equipment, be sure

that:

■ The leveling jacks are extended to the floor.

■ The full weight of the rack rests on the leveling jacks.

■ In single rack installations, the stabilizing feet are attached to the rack.

■ In multiple rack installations, the racks are coupled.

■ Only one rack component is extended at any time. A rack may become unstable if

more than one rack component is extended for any reason.

If you still have a question after reading this guide, contact an HP Authorized Service Provider

or access our web site:

http://www.hp.com

.

Note: HP call centers use product and serial numbers to validate warranty entitlement. Most HP

products can provide product number, serial number and firmware revision electronically through

the use of supplied management or diagnostic utilities, eliminating the need to physically inspect or

remove products from installed enclosures. You may be directed by HP to run these utilities to

gather required entitlement information.

HP installation and configuration assistance

A moderate level of SAN-related knowledge is required to successfully install this product. If

you are not familiar with installing and configuring storage array systems in a SAN, HP can

install it for you.

For more information, access our web site at

http://www.hp.com/hps/storage/ns_implementation.html

Depending on your needs, different levels of assistance are available.

For example, the HP Installation and Startup for HP StorageWorks Disk Arrays Service

Package includes:

■ Physical installation of the MSA

■ Virtual disk design and configuration of the MSA

■ Service planning

■ Service deployment

.

■ Installation Verification Testing (IVT)

■ Customer orientation

10 HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 11

HP technical support

Telephone numbers for worldwide technical support are listed on the following HP web site:

http://www.hp.com/support/

Note: For continuous quality improvement, calls may be recorded or monitored.

Be sure to have the following information available before calling:

■ Technical support registration number (if applicable)

■ Product serial numbers

■ Product model names and numbers

■ Applicable error messages

■ Operating system type and revision level

■ Detailed, specific questions

HP storage web site

About this Guide

. From this web site, select the country of origin.

The HP web site has the latest information on this product, as well as the latest drivers. Access

storage at:

select the appropriate product or solution.

HP authorized reseller

For the name of your nearest HP Authorized Reseller:

■ In the United States, call 1-800-282-6672

■ In Canada, call 1-800-863-6594

■ Elsewhere, see the HP web site for locations and telephone numbers:

http://www.hp.com/country/us/eng/prodserv/stora g e.html

. From this web site,

http://www.hp.com

.

11HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 12

About this Guide

12 HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 13

Introduction

This chapter describes switch features, including the LEDs, user controls, and connections. An

overview of the switch management tools is also provided.

Included sections:

■ Switch chassis features, page 13

■ Switch management, page 19

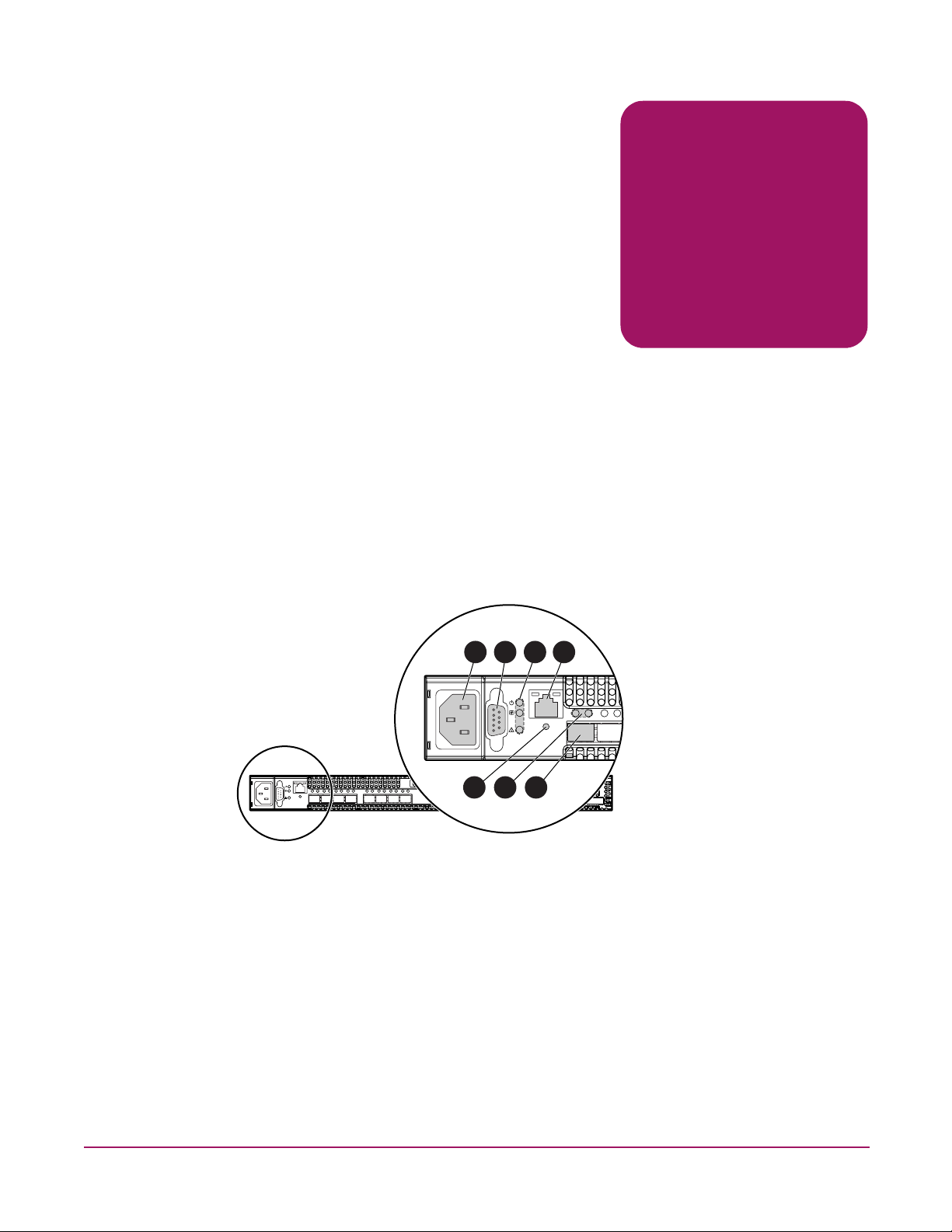

Switch chassis features

1

1 2 3 4

5 6 7

1 Power supply, page 14

2 Serial port, page 14

3 Chassis LEDs, page 14

4 Ethernet port, page 15

5 Maintenance button, page 16

6,7 Fibre Channel ports and LEDs, page 17

Figure 1: Chassis features

13HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 14

Introduction

Power supply

Serial port

The power supply converts standard 110 or 230 VAC to DC voltages for the various switch

circuits. Four internal fans provide cooling. The switch monitors internal air temperature, and

therefore does not monitor or report fan operational status. Air flows into the switch from the

bezel side and is exhausted from the port side of the switch.

To apply power to the switch, plug the power cord into the switch AC receptacle, and then into

a 110 or 230 VAC power source.

Note: The power supply and fans are not field replaceable units.

The switch is equipped with an RS-232 serial port, to access the Command Line Interface for

advanced configuration tasks and maintenance purposes. (Figure 1)

The serial port connector requires a null-modem female/female DB9 cable, using the pin

configuration and connection information as detailed in “Cable pin configurations” on

page 64.

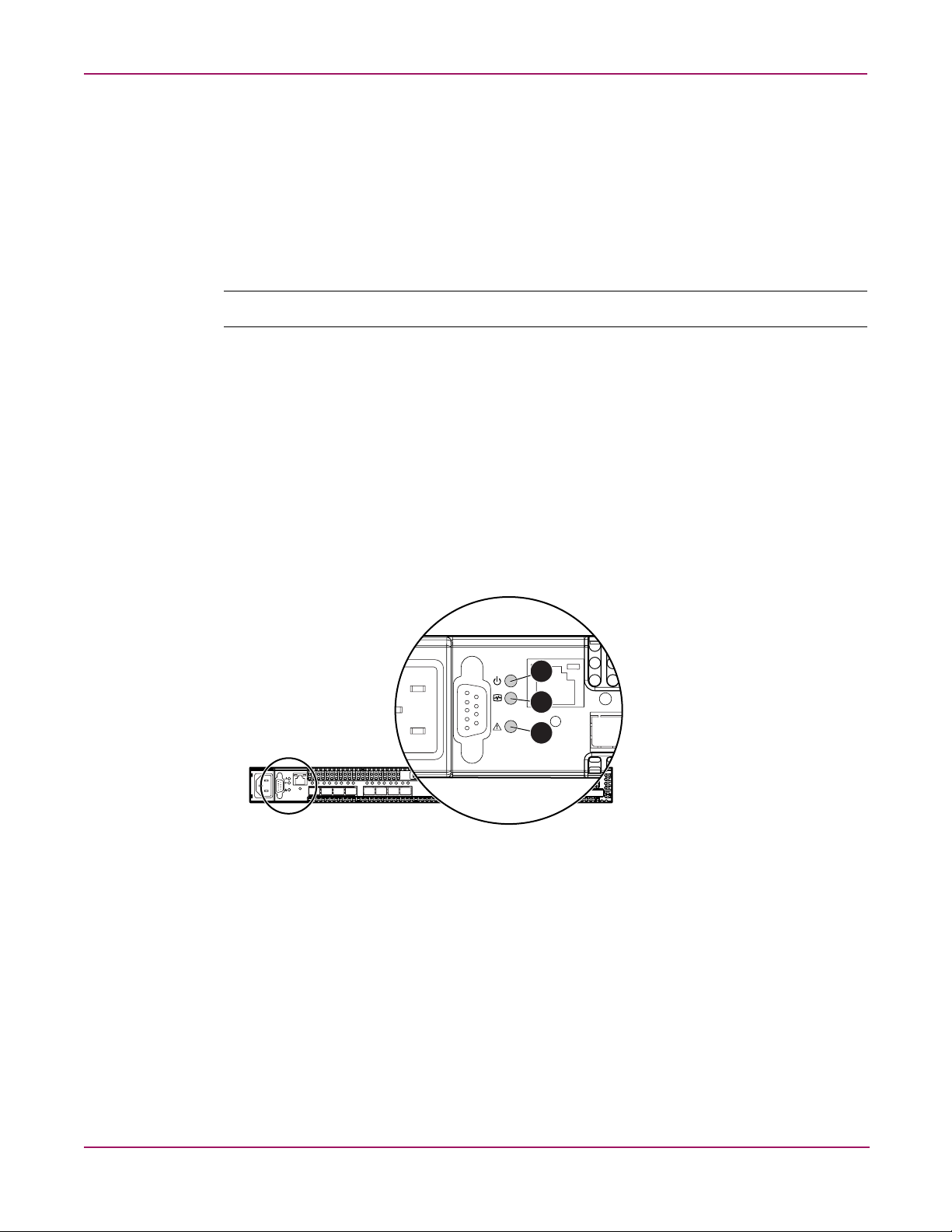

Chassis LEDs

The chassis LEDs (Figure 2) provide status information about switch operation.

1

2

3

1 Input Power LED (green)

2 Heartbeat LED (green)

3 System Fault LED (amber)

Figure 2: Chassis LEDs

Input Power LED (green)

The Input Power LED indicates the voltage status at the switch logic circuitry. During normal

operation, this LED illuminates to indicate that the switch logic circuitry is receiving the

proper DC voltages. When the switch is in maintenance mode, this LED is extinguished.

14 HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 15

Heartbeat LED (green)

The Heartbeat LED indicates the status of the internal switch processor and the results of the

Power On Self Test (POST).

Following a normal power-up, the Heartbeat LED blinks about once per second to indicate

that the switch passed the POST and that the internal switch processor is running. In

maintenance mode, the Heartbeat LED illuminates continuously. The Heartbeat LED also

shows a blink code for POST errors and the over temperature condition. See “Heartbeat LED

blink patterns” on page 42 for more information.

System Fault LED (solid amber)

The System Fault LED illuminates to indicate an over temperature condition or a POST error

and the Heartbeat LED shows a blink code that defines the condition. See “Heartbeat LED

blink patterns” on page 42 for more information.

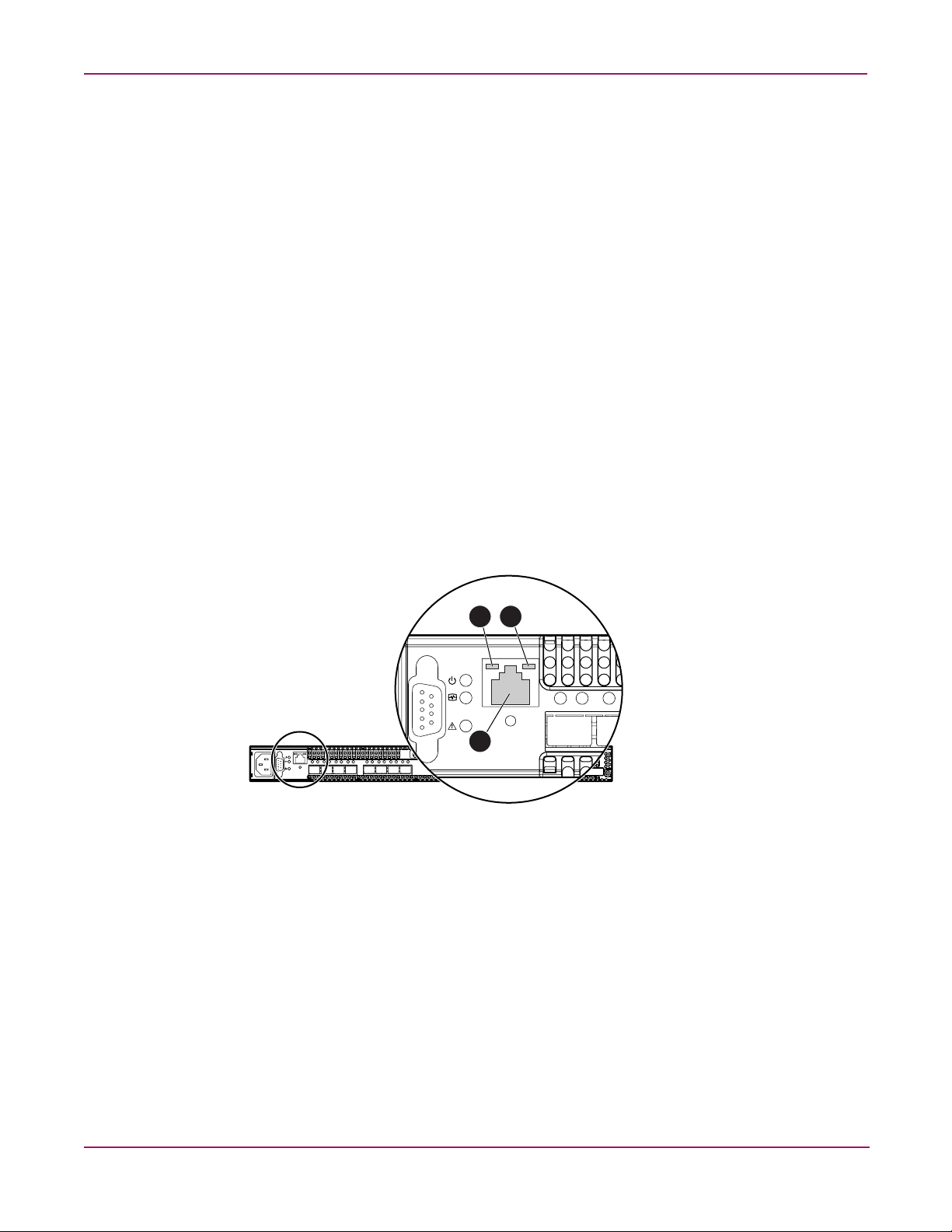

Ethernet port

The Ethernet port (Figure 3) is an RJ-45 connector that provides a connection to a

management workstation through a 10/100 Base-T Ethernet cable. The workstation can be a

Windows® or a Linux® workstation that is used for advanced configuration and management

tasks. You can manage the switch over the Ethernet connection using Switch Manager, the

Command Line Interface (CLI), or SNMP. The switch through which the fabric is managed is

called the fabric management switch.

Introduction

132

1 Link Status LED (green)

2 Activity LED (green)

3 Ethernet port

Figure 3: Ethernet port and LEDs

The Ethernet port has two LEDs that provide activity and status information. (Figure 3)

■ The Activity LED illuminates when data is being transmitted or received.

■ The Link Status LED illuminates continuously when an Ethernet connection has been

established.

15HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 16

Introduction

Maintenance button

The Maintenance button is a dual-function momentary switch on the front panel. (Figure 1)

Its purpose is to reset the switch or place the switch in maintenance mode. See “Maintenance

mode options” on page 47 for more information.

Resetting the switch

Use a pointed tool, such as an opened paper clip, to momentarily press and release (less than 2

seconds) the Maintenance button.

The switch responds as follows:

■ All chassis LEDs illuminate, and then the System Fault LED extinguishes, leaving only

the Input Power LED and Heartbeat LED illuminated.

■ After approximately 1 minute, the power-on self test (POST) begins, extinguishing the

Heartbeat LED.

■ When the POST is complete, the Input Power LED is illuminated and the Heartbeat LED

flashes once per second.

Placing the switch in maintenance mode

1. Isolate the switch from the fabric.

2. Press and hold the Maintenance button with a pointed tool until the Heartbeat LED alone

is illuminated (between 2–7 seconds).

3. After approximately 1 minute, the POST begins illuminating all chassis LEDs.

4. When the POST is complete, the chassis LEDs extinguish, leaving only the Heartbeat

LED illuminated. The Heartbeat LED illuminates continuously while the switch is in

maintenance mode.

Exiting maintenance mode

To exit maintenance mode and return to normal operation, momentarily press and release the

Maintenance button to reset the switch.

16 HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 17

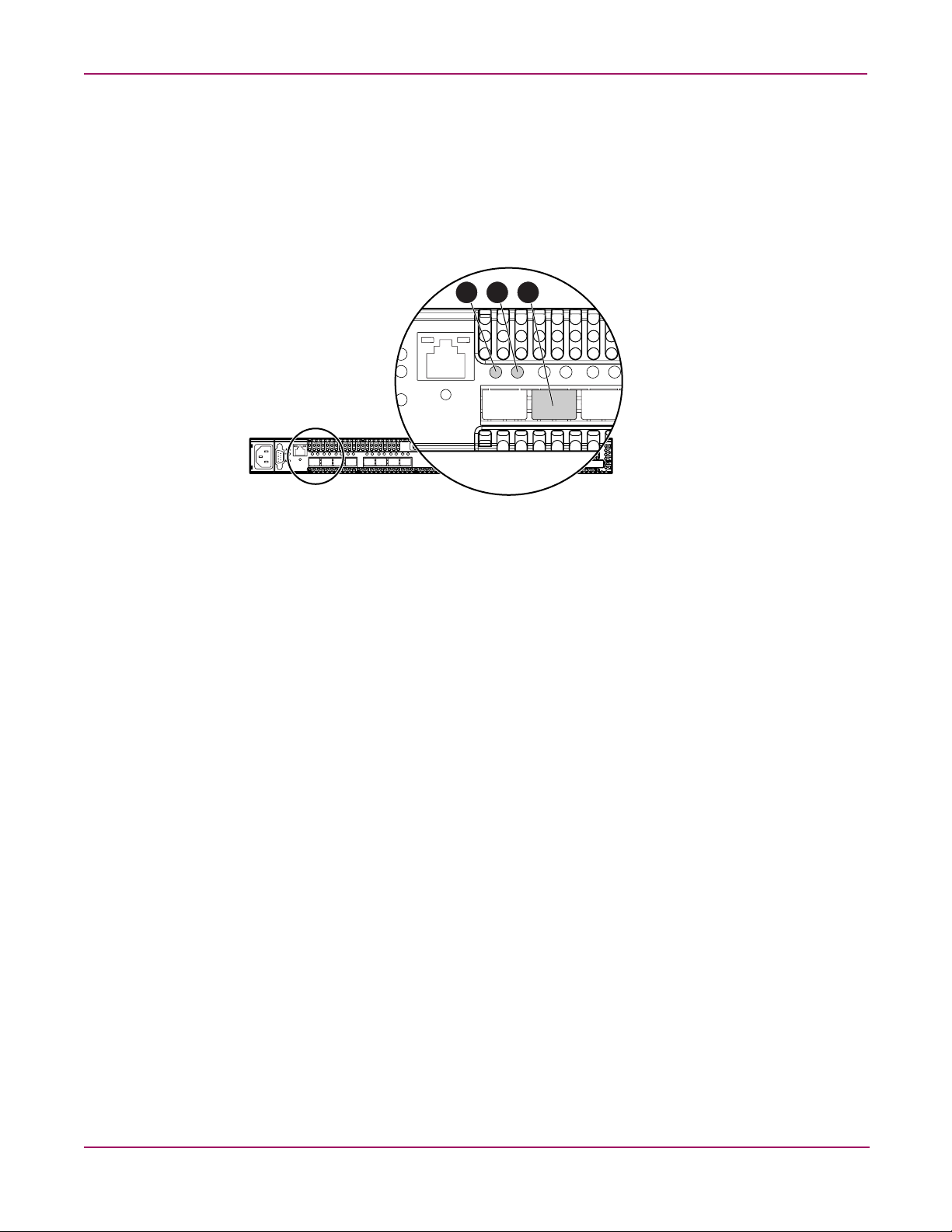

Fibre Channel ports and LEDs

The switch has eight Fibre Channel ports, numbered 0–7. (Figure 4)

Each Fibre Channel port is served by a 2 Gbps Small Form-Factor Pluggable (SFP) optical

transceiver. SFPs are hot-pluggable. User ports self-discover both the port type and

transmission speed of the connected devices. The Fibre Channel port LEDs are located above

their respective ports and provide port log-in and activity status information.

Introduction

1 2 3

1 Port Logged-in LED (green)

2 Port Activity LED (green)

3 Fibre Channel port

Figure 4: Fibre Channel port and LED locations

Port Logged-in LED (green)

The Logged-in LED indicates the logged-in or initialization status of the connected devices.

After successful completion of the POST, the switch extinguishes all Logged-in LEDs.

Following a successful loop initialization or port login, the switch illuminates the

corresponding logged-in LED. This shows that the port is properly connected and able to

communicate with its attached devices. The Logged-in LED remains illuminated as long as the

port is initialized or logged in. If the port connection is broken or an error occurs that disables

the port, the Logged-in LED flashes. See “Logged-In LED indications” on page 44 for more

information.

Port Activity LED (green)

The Activity LED indicates that data is passing through the port. Each frame that the port

transmits or receives causes this LED to illuminate for 50 milliseconds. This makes it possible

to observe the transmission of a single frame. When extending credits, the Activity LED for a

donor port will reflect the traffic of the recipient port. See “Distance” on page 24 for more

information about extended credits and donor ports.

17HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 18

Introduction

SFP transceivers

Port types

The switch supports SFP optical transceivers for the Fibre Channel ports. A transceiver

converts electrical signals to and from optical laser signals to transmit and receive data.

Duplex fiber optic cables plug into the transceivers, which then connect to the devices. A Fibre

Channel port is capable of transmitting at 1 Gbps or 2 Gbps; however, the transceiver must be

capable of 2 Gbps for the port to deliver at that rate.

SFP transceivers are hot pluggable. This means that you can remove or install a transceiver

while the switch is operating, without harming the switch or the transceiver. However,

communication with the connected device is interrupted. See “Install SFP transceivers” on

page 34 for information.

The switch supports generic ports (G_Port, GL_Port) and fabric ports (F_Port, FL_Port).

Switches come from the factory with all Fibre Channel ports configured as GL_Ports.

Ports function as follows:

■ A GL_Port self-configures as an FL_Port when connected to a public loop device, and as

an F_Port when connected to a single public device.

■ A G_Port self-configures as an F_Port when connected to a single public device.

■ An FL_Port supports a loop of up to 126 public devices. An FL_Port can also configure

itself during the fabric login process as an F_Port when connected to a single public device

(N_Port).

■ An F_Port supports a single public device. If the device is a single device on a loop, the

GL_Port will attempt to configure first as an F_Port, then if that fails, as an FL_Port.

18 HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 19

Switch management

Fabrics are managed with following tools:

■ Switch Manager user interface

■ Command Line Interface

■ File Transfer Protocol

■ Simple Network Management Protocol

Switch Manager user interface

Switch Manager is a workstation-based Java® application that provides a graphical user

interface for fabric management. This application runs on a Windows or Linux workstation. A

management workstation connects to the fabric through the Ethernet port of one or more

switches and can provide in-band management for all other switches in the fabric. See

“Management System Requirements” on page 63 for connection information and to the HP

StorageWorks 2/8q Fibre Channel Switch Management User Guide for information about

Switch Manager.

Command Line Interface

Introduction

The CLI provides monitoring and configuration functions by which the administrator can

manage the fabric and its switches, and can be accessed over an Ethernet connection or a serial

connection. See “Management System Requirements” on page 63 for connection information

and refer to the HP StorageWorks 2/8q Fibre Channel Switch Management User Guide for

information about the CLI.

File Transfer Protocol

FTP provides the command line interface for exchanging files between the switch and the

management workstation. These files include firmware image files, configuration files, and

log files.

Simple Network Management Protocol

SNMP provides monitoring and trap functions for the fabric. This switch supports SNMP

versions 1 and 2, the Fibre Alliance Management Information Base (FA-MIB) version 4.0, and

the Fabric Element Management Information Base (FE-MIB) RFC 2837. Traps can be

formatted using SNMP version 1 or 2. Refer to the HP StorageWorks 2/8q Fibre Channel

Switch SNMP Reference Guide for more information.

19HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 20

Introduction

20 HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 21

Planning

2

Consider the following when planning a fabric:

■ Devices, page 22

■ Device access, page 22

■ Performance, page 24

■ Fabric security, page 25

■ Fabric management, page 25

21HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 22

Planning

Devices

Device access

When planning a fabric, consider the number of public devices and the anticipated demand.

This determines the number of ports that are needed and in turn the number of switches.

Consider how many and what types of switches are needed.

Consider the distribution of targets and initiators. An F_Port supports a single public device.

An FL_Port can support up to 126 public devices in an arbitrated loop.

Consider device access needs within the fabric. Access is controlled by the use of zones and

zone sets.

Some zoning strategies include:

■ Grouping devices by operating system.

■ Separating devices that have no need to communicate with other devices in the fabric or

have classified data.

■ Separating devices into department, administrative, or other functional group.

■ Reserving a path and its bandwidth from one port to another.

A zone is a named group of devices that can communicate with each other. Membership in a

zone can be defined by domain ID and switch port number, port Fibre Channel address, or by

device worldwide name (WWN). Devices can communicate only with devices within the same

zone. A zone can be a member of more than one zone set. Several zone sets can be defined for

a fabric, but only one zone set can be active at one time. The active zone set determines the

current fabric zoning.

A zoning database is maintained on each switch consisting of all inactive zone sets, the active

zone set, all zones, aliases, and their membership. Refer to the HP StorageWorks 2/8q Fibre

Channel Switch Management User Guide for more information about zoning.

The two types of zones are:

■ Hard zones (Access Control Lists)

■ Soft zones

Table 2: Zoning database limits

Zoning item Description Limit

MaxZoneSets Maximum number of zone sets.

MaxZones Maximum number of zones.

MaxAliases Maximum number of aliases.

MaxTotalMembers Maximum number of zone and alias members

that can be stored in the switch’s zoning

database.

256

256

256

2000

22 HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 23

Table 2: Zoning database limits (Continued)

Zoning item Description Limit

MaxZonesInZoneSets Maximum number of zones that are

MaxMembersPerZone Maximum number of members in a zone that

MaxMembersPerAlias Maximum number of members in all zones

Hard zones (Access Control Lists)

Access Control List (ACL) zoning divides the fabric for purposes of controlling discovery and

inbound traffic. ACL zoning is a type of hard zoning that is hardware enforced. This type of

zoning is useful for controlling access to certain devices without totally isolating them from

the fabric. Members can communicate with each other and transmit outside the ACL zone, but

cannot receive inbound traffic from outside the zone. The following rules apply to ACL zones:

■ The ACL zone boundary is secure against inbound traffic.

Planning

1000

components of zone sets, excluding the

orphan zone set, which can be stored in the

switch zoning database. Each instance of a

zone in a zone set counts toward this

maximum.

2000

can be stored in the switch zoning database.

2000

and aliases.

Soft zones

■ ACL zones can overlap; that is, a port can be a member of more than one ACL zone.

■ ACL zone boundaries supersede soft zone boundaries.

■ Membership can be defined only by domain ID and port ID. A switch port can be a

member of multiple ACL zones whose combined membership does not exceed 128.

Soft zoning divides the fabric for purposes of controlling device discovery. Devices in the

same soft zone automatically discover and communicate freely with all other members of the

same zone. The soft zone boundary is not secure; traffic across soft zones can occur if

addressed correctly. The following rules apply to soft zones:

■ Soft zone boundaries yield to ACL zone boundaries.

■ Soft zones can overlap; that is, a port can be a member of more than one soft zone.

■ Membership can be defined by Fibre Channel address, domain ID and port number, or

worldwide name.

■ Soft zoning supports FL_Ports and F_Ports.

23HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 24

Planning

Performance

Distance

The switch supports class 2 and class 3 Fibre Channel service at transmission rates of 2 Gbps,

with a maximum frame size of 2148 bytes.

Related performance characteristics include:

■ Distance

■ Bandwidth

■ Latency

Consider the physical distribution of devices and switches in the fabric. See “Specifications”

on page 59 for more information about cable types and transceivers.

Each Fibre Channel port is supported by a data buffer with a 16 credit capacity; that is, 16

maximum sized frames. For fiber optic cables, this enables full bandwidth over a distance of

13 kilometers at 2 Gbps (1.2 credits/Km). Beyond this distance, however, there is some loss of

efficiency because the transmitting port must wait for an acknowledgement before sending the

next frame.

Longer distances can be spanned at full bandwidth by extending credits to the ports. Each port

can donate 15 credits to a pool from which a recipient port can borrow. The recipient port also

loses a credit in the process. For example, you can configure a recipient port to borrow 15

credits from one donor port for a total of 30 credits (15+15=30). This supports communication

over approximately 25 Km at 2 Gbps (30÷1.2).

Bandwidth

Latency

Bandwidth is a measure of the volume of data that can be transmitted at a given transmission

rate. The Fibre Channel ports transmit and receive at a rate of 2 Gbps, for a maximum

bandwidth of 200 MB.

Latency is a measure of how fast a frame travels from one port to another. Factors that affect

latency include transmission rate and the source/destination port relationship. 2 Gbps to

2 Gbps transmissions have a latency factor < 0.4

µsec.

24 HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 25

Fabric security

Fabric security consists of the following:

■ User account security

■ Simple Network Management Protocol security

User account security

User account security consists of account names, passwords, expiration dates, and authority

levels. If an account has Admin authority, all management tasks can be performed by that

account in both Switch Manager and the CLI. Without Admin authority, only monitoring tasks

are available. The default account name, Admin, is the only account that can create or change

account names and passwords. Account names and passwords are required when connecting to

a switch. Consider your management needs and determine the number of user accounts, their

authority needs, and expiration dates.

Simple Network Management Protocol security

SNMP is the protocol governing network management and monitoring of network devices,

and is enabled by default. SNMP security consists of a read community string and a write

community string, which are the passwords that control read and write access to the switch.

The read community string ("public") and write community string ("private") are set at the

factory to these well-known defaults and should be changed. If the read and write community

strings have not been changed from their defaults, you risk unwanted access to the switch.

Planning

Fabric management

Switch Manager and the CLI execute on a management workstation that provides for the

advanced configuration, control, and maintenance of the fabric. Supported platforms include

Windows and Linux. Consider how many fabrics will be managed, how many management

workstations are needed, and whether the fabrics will be managed with the CLI or Switch

Manager.

A switch supports a combined maximum of 19 logins reserved as follows:

■ 4 logins or sessions for internal applications such as management server and SNMP

■ 9 high priority Telnet sessions

■ 6 logins or sessions for Switch Manager logins and Telnet logins. Additional logins are

refused.

See “Management System Requirements” on page 63 for connection information and refer to

the HP StorageWorks 2/8q Fibre Channel Switch Management User Guide for information

about using these management tools.

25HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 26

Planning

26 HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 27

Installing

This section describes how to install and initially configure the 2/8q FC Switch. It also

describes how to backup and update switch firmware.

Topics include:

■ Site requirements, page 27

■ Installing and initially configuring the switch, page 28

■ Backing up the switch configuration, page 37

■ Powering down the switch, page 37

■ Updating switch firmware, page 38

Site requirements

Consider factors that affect the climate in your facility, such as equipment heat dissipation and

ventilation. The switch requires the following operating conditions (See “Specifications” on

page 59 for a detailed list):

3

Table 3: Environmental requirements

Item Requirement

Power requirements 1 Amp at 120 VAC or 0.5 Amp at 240 VAC

Operating temperature range 5

Operating relative humidity 15%-80%, non-condensing

°-40°C (41°-104°F)

27HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 28

Installing

Installing and initially configuring the switch

Installing a 2/8q FC Switch involves the following steps, each of which is discussed in the

following sections:

■ Unpack the switch and verify carton contents, page 28

■ Mount the switch, page 29

■ Install SFP transceivers, page 34

■ Connect the cables, page 35

■ Configure the switch, page 36

Unpack the switch and verify carton contents

The 2/8q FC Switch is shipped with the components shown in Figure 5.

1

3

4

2

7

6

5

1 2/8q FC Switch

2 2/8q FC Switch Quick Start Installation Instructions (printed)

3 Power cable (approved for use in the United States)

4 Mounting adapter brackets

5 Screws for the mounting adapter brackets (6)

6 Rubber feet (4)

7 Small Form Factor Pluggable (SFP) transceivers (4)

Figure 5: Switch carton contents

28 HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 29

Mount the switch

The 2/8q FC Switch can be placed on a stable flat surface or mounted in a 19” EIA rack. When

placing the switch on a flat surface, attach the provided adhesive rubber feet to the bottom of

the switch and then place the switch on work surface.

When mounting the switch in a rack, do the following:

Installing

WARNING: Mount devices in the rack so that the weight is distributed evenly. An

unevenly loaded rack can become unstable, possibly resulting in equipment damage or

personal injury.

Caution: If the switch is mounted in a closed or multi-unit rack assembly, make sure that

the operating temperature inside the rack enclosure does not exceed the maximum rated

ambient temperature. See “Environmental” on page 61.

■ Do not restrict chassis air flow. Allow 16 cm (6.5 in) minimum clearance at the front

and rear of the switch or rack for service access and ventilation.

■ Multiple rack-mounted units connected to the AC supply circuit may overload that

circuit or overload the AC supply wiring. Consider the power source capacity and the

total power usage of all switches on the circuit. See “Electrical” on page 61.

■ Reliable grounding in the rack must be maintained.

1. Obtain the 2U rack template and the 2U rail kit from the SAN Kit carton.

2. Obtain the switch mounting adapter brackets and screws from the 2/8q FC Switch carton.

3. Use the template as a guide to mark the location for the rails in the rack.

a. Hold the template up to the rack, and when the template is level, push the template

tabs into the rack holes to hold the template in place. (Figure 6)

b. Use a pencil to mark the locations of the rail pins on the rack.

Figure 6: Using the rack template

Note: If the holes in the rack are round instead of square, remove the standard pins from the rails

and replace them with the round-hole pins provided with the rail kit.

29HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 30

Installing

Note: The rails and the switch are installed from the rear of the rack. To ensure proper airflow

through the device, the port-side of the switch must face the rear of the rack.

4. Install the rails in the rack.

a. Identify the left (L) and right (R) rails by markings stamped into the rails.

b. From the rear of the rack, insert the right rail into the inside right rear of the rack, until

the pins extend through the holes marked in step 3 and the scissor-type locking latch

engages. (Figure 7)

c. Extend the other end of the rail toward the inside front of the rack until the pins extend

through the marked holes and the locking latch engages. (Figure 7)

Figure 7: Attaching the right rail to the rack - rear view

30 HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 31

d. Remove the locking nut on the rail retaining bracket and move the bracket to the

farthest position inside the rail. (Figure 8)

2

1

Figure 8: Moving the rail retaining bracket on the right rail - rear view

e. Repeat step a through step d for the other rail.

5. Fasten the mounting adapter brackets to the sides of the switch. (Figure 9)

a. Place the switch on a stable work surface, and then position the switch and the

brackets so that the port-side of the switch faces the flanges of the brackets.

b. Determine which mounting set-back on the brackets to use. The brackets can be

mounted so that the switch is flush with the rear of the rack, or set back approximately

three inches.

Installing

c. Use four of the provided screws to attach the brackets to the switch.

Figure 9: Attaching the mounting adapter brackets to the switch

31HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 32

Installing

6. From the rear of the rack, place the switch assembly onto the rails, and slide the assembly

back until the flanges of the mounting adapter brackets are flush with the rear uprights of

the rack. (Figure 10)

Figure 10: Placing the switch on the rails - rear view

7. Secure the switch to the back of the rack by inserting and tightening the 2 remaining

provided screws through the bracket flanges. (Figure 11)

Figure 11: Securing the switch flanges to the rear of the rack

32 HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 33

Installing

8. From the front of the rack, secure the switch by sliding the rail retaining brackets on the

rails toward the switch until they engage the mounting adapter brackets, and then tighten

the rail bracket thumbscrews to secure the device. (Figure 12)

2

1

Figure 12: Securing the rail retaining brackets to the switch - front view

33HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 34

Installing

Install SFP transceivers

The switch has been validated with transceivers that support a variety of interconnection

media. To install a transceiver, insert the transceiver into the port and gently push in on the

SFP until the it snaps in place. To remove a transceiver, gently press the transceiver into the

port to release the tension, and then pull out on the release tab to remove the transceiver from

the chassis.

Note: The transceiver fits only one way in the port. If the transceiver does not install under gentle

pressure, pull it out of the port, turn it over, and re-insert it.

Figure 13: Installing an SFP transceiver

34 HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 35

Connect the cables

■ Connect Fibre Channel devices to the switch

■ Connect power to the switch

Connect Fibre Channel devices to the switch

Connect cables to the SFP transceivers and their corresponding devices, and then apply power

to the devices. LC-type duplex fiber optic cable connectors are designed for use with the SFP

transceivers. Duplex cable connectors are keyed to ensure proper orientation.

GL_Ports self configure as FL_Ports when connected to loop of public devices or F_Ports

when connected to a single device. G_Ports self configure as F_Ports when connected to

single public devices.

Connect power to the switch

WARNING: This product is supplied with a 3-wire power cable and plug. Use this power

cable in conjunction with a properly grounded outlet to avoid electrical shock. An electrical

outlet that is incorrectly wired could place hazardous voltage on metal parts of the switch

chassis.

■ A different power cable than the one supplied may be required in some countries.

■ For 125 Volt electrical service, the cable must be rated at 10 Amps and be approved

by UL and CSA.

■ For 250 Volt electrical service, the cable must be rated at 10 Amps, meet the

requirements of H05VV-F, and be approved by VDE, SEMKO, and DEMKO.

Installing

1. Connect the power cord to the AC power port on the switch chassis and to a grounded AC

outlet or uninterruptible power supply.

2. Verify that the chassis LEDs illuminate, followed by all port Logged-in LEDs.

3. After a few moments, verify that the chassis System Fault LED is extinguished while the

Input Power LED and Heartbeat LED remain illuminated.

4. Wait approximately one minute for the POST to complete, and the following LED pattern

to begin:

— The Input Power LED remains illuminated indicating that the switch logic circuitry is

receiving DC voltage. If not, contact your authorized maintenance provider.

— The Heartbeat LED indicates the results of the POST. The POST tests the condition of

firmware, memories, data-paths, and switch logic circuitry. If the Heartbeat LED

blinks steadily about once per second, the POST was successful, and you can continue

with the installation process. Any other blink pattern indicates that an error has

occurred. See “Heartbeat LED blink patterns” on page 42 for more information about

error blink patterns.

35HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 36

Installing

Configure the switch

Note: Advanced switch configuration and monitoring tasks are executed using the Switch

Manager application or the Command Line Interface, using a workstation connected to the switch.

See “Management System Requirements” on page 63 for information about connecting the

workstation, and the

details about the interfaces.

The switch is initially configured during the set up and installation of the MSA1000 Small

Business SAN, using the Small Business SAN Software CD.

If Switch Manager is not installed on your system, do the following:

Installing Switch Manager on Windows® systems

1. Close all programs currently running, and then insert the Small Business SAN Software

CD into the server or management workstation CD-ROM drive.

The CD automatically starts, and displays the HP Small Business SAN Wizard.

2. In the Welcome window, click Next, and then follow the onscreen instructions.

HP StorageWorks 2/8q Fibre Channel Switch Management User Guide

for

Note: Switch Manager is installed and placed in the following system folder:

C:\Program Files\HP\HP_StorageWorks_Switch_Manager.

Installing Switch Manager on Linux® systems

1. Close all programs currently running, and then insert the Small Business SAN Software

CD into the server or management workstation CD-ROM drive.

The CD auto-mounts, and executes an installation script.

If the CD does not auto-mount, mount the CD and execute the HP Small Business Linux

Wizard script from the

2. Follow the onscreen instructions to complete the installation.

/linux directory. (install_smb.sh)

36 HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 37

Backing up the switch configuration

Backing up and restoring a configuration is useful to protect your work or to use as a template

in configuring other switches. The CLI

switch, named

configdata. This file can be used to restore a switch configuration only from

the command line interface; it cannot be used to restore a switch using Switch Manager.

configdata file contains all of the switch configuration information including:

The

■ All named switch configurations, including the default configuration. This includes port,

switch, port threshold alarm, and zoning configuration components.

■ All SNMP and network information defined with the Set Setup command.

■ The zoning database included all zone sets, zones, and aliases.

Use FTP to download the configdata file to your workstation for safe keeping and to

upload the file back to the switch for the restore function.

See “Management System Requirements” on page 63 for information about connecting a

workstation to the switch and refer to “Backing up a switch configuration” in the HP

StorageWorks 2/8q Fibre Channel Switch Management User Guide, for procedural details.

Powering down the switch

Installing

Config Backup command creates a file on the

Simply unplugging the switch from the power source does not allow the switch to complete

executing tasks and could lead to flash memory corruption.

To initiate an orderly shut down, access the CLI and execute the

Shutdown command. Then,

power down the switch by unplugging the power cord.

See“Management System Requirements” on page 63 for information about connecting a

workstation to the switch and refer to the HP StorageWorks 2/8q Fibre Channel Switch

Management User Guide for information about the CLI.

37HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 38

Installing

Updating switch firmware

The switch comes with firmware installed. You can upgrade the firmware from the

management workstation as new firmware becomes available. Firmware updates are availabe

on the MSA1000 web site at

See“Management System Requirements” on page 63 for information about connecting a

workstation to the switch and refer to the HP StorageWorks 2/8q Fibre Channel Switch

Management User Guide for detailed information about Switch Manager and the CLI.

Note: You can load and activate new firmware on an operating switch without disrupting data

traffic or having to re-initialize attached devices. If you attempt to perform a non-disruptive

activation without satisfying the following conditions, the switch will perform a disruptive activation:

■ No changes are being made to switches in the fabric including powering up, powering down,

and changing the switch configuration.

■ No port in the fabric is in the diagnostic state.

■ No zoning changes are being made in the fabric.

■ No changes are being made to attached devices including powering up, powering down,

disconnecting, connecting, and HBA configuration changes.

Ports that are stable when the non-disruptive activation begins, but then change states, are reset.

When the non-disruptive activation is complete, Switch Manager sessions reconnect automatically.

However, Telnet sessions must be restarted manually.

www.hp.com/go/msa1000

.

Using Switch Manager to install firmware

1. Select a switch in the topology display and double-click to open the Faceplate display.

Open the Switch menu and select Load Firmware.

2. In the Firmware Upload window, click Select to browse and select the firmware file to be

uploaded.

3. Click Start to begin the firmware load process. A warning message is displayed.

4. Click OK or Cancel.

■ If conditions exist for performing a non-disruptive firmware activation (outlined in the

previous note), Switch Manager performs a hot reset, to activate the firmware without

disrupting data traffic. During a non-disruptive activation, all Logged-in LEDs are

extinguished for several seconds.

■ If conditions do not exist for a non-disruptive activation, Switch Manager prompts for

a hard reset, and then performs a disruptive activation.

Using the CLI to install firmware

1. Enter the following command to download the firmware from a remote host to the switch,

install the firmware, and reset the switch to activate the firmware:

(admin) #> firmware install

Warning: Installing new firware requires a switch reset. Continuing with

this action will terminate all management sessions, including any Telnet

sessions. When the firmware activation is complete, you may log in to the

switch again.

Do you want to continue? [y/n]: y

Press 'q' and the ENTER key to abort this command.

38 HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 39

Installing

2. Enter your account name on the remote host and the IP address of the remote host. When

prompted for the source file name, enter the path for the firmware image file. When

prompted to install the new firmware, enter Yes to continue or No to cancel. This is the

last opportunity to cancel.

User Account : johndoe

IP Address : 10.20.20.200

Source Filename : 4.0.3.xx_mpc

About to install image. Do you want to continue? [y/n] y

Connected to 10.20.20.200 (10.20.20.200).

220 localhost.localdomain server (Version wu-2.6.1-18) ready.

3. The switch attempts a non-disruptive activation if possible; otherwise a disruptive

activation is performed. When prompted to install the new firmware, enter Yes to

continue or No to cancel. This is the last opportunity to cancel.

About to install image. Do you want to continue? [y/n] y

Connected to 10.20.20.200 (10.20.20.200).

220 localhost.localdomain server (Version wu-2.6.1-18) ready.

4. Enter the password for your account name.

331 Password required for johndoe.

Password:******

230 User johndoe logged in.

The firmware is downloaded from the remote host to the switch, is installed, and is

activated.

39HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 40

Installing

40 HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 41

Troubleshooting

Diagnostic information about the switch is available through the chassis LEDs and the port

LEDs. Diagnostic information is also available through the Switch Manager and CLI event

logs and error displays.

This section describes the following diagnostics and tasks:

■ POST diagnostics, page 42

■ Chassis diagnostics, page 46

■ Maintenance mode options, page 47

4

41HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 42

Troubleshooting

POST diagnostics

The switch performs a series of tests as part of its power-up procedure. The POST diagnostic

program performs checksum tests on the boot firmware in PROM and the switch firmware in

flash memory, internal data loopback tests on all ports, and access and integrity tests on the

ASIC.

During the POST, the switch logs any errors encountered. Some POST errors are critical,

others are not. The switch uses the Heartbeat LED and the Logged-In LED to indicate switch

and port status. A critical error disables the switch so that it does not operate. A non-critical

error allows the switch to operate, but disables the ports that have errors. Whether the problem

is critical or not, contact your HP Authorized Maintenance Provider.

If there are no errors, the Heartbeat LED blinks at a steady rate of once per second. If a critical

error occurs, the Heartbeat LED shows an error blink pattern and the System Fault LED will

illuminate. If there are non-critical errors, the switch disables the failed ports and flashes the

associated Logged-In LEDs.

Heartbeat LED blink patterns

The Heartbeat LED indicates the operational status of the switch. When the POST completes

with no errors, the Heartbeat LED blinks at a steady rate of once per second. When the switch

is in maintenance mode, the Heartbeat LED illuminates continuously. See “Maintenance mode

options” on page 47 for more information about maintenance mode. All other blink patterns

indicate critical errors.

The Heartbeat LED shows an error blink pattern for the following conditions:

Blinking pattern Description

1 blink Normal operation

2 blinks Internal firmware failure

3 blinks System error

4 blinks Configuration file system error

5 blinks Over temperature

Figure 14: Heartbeat LED location and blinking patterns

42 HP StorageWorks 2/8q Fibre Channel Switch Installation Guide

Page 43

Internal firmware failure blink pattern

An internal firmware failure blink pattern is 2 blinks followed by a two second pause. The

2-blink error pattern indicates that the firmware has failed, and that the switch must be reset.

Momentarily press and release the Maintenance button to reset the switch.

System error blink pattern

A system error blink pattern is 3 blinks followed by a two second pause. The 3-blink error

pattern indicates that a POST failure or a system error has left the switch inoperable. If a

system error occurs, contact your HP Authorized Maintenance provider. Momentarily press

and release the Maintenance button to reset the switch.

Configuration file system error blink pattern

A configuration file system error blink pattern is 4 blinks followed by a two second pause. The

4-blink error pattern indicates that a configuration file system error has occurred, and that the

configuration file must be recreated. See “Maintenance mode options” on page 47 for more

information. To recreate the configuration file:

Note: Recreating the configuration file deletes all switch configuration settings.

Troubleshooting

1. Place the switch in maintenance mode. Press and hold the Maintenance button for 2–7

seconds. See “Maintenance mode options” on page 47 for more information.

2. Establish a Telnet session using the default IP address 10.0.0.1, or the user assigned IP

address of the switch. (See“Management System Requirements” on page 63 for

information about connecting a workstation to the switch.)

telnet 10.0.0.1

3. Enter the account name (prom) and password (prom), and then press Enter.

switch login: prom

Password:xxxx