Page 1

HP A3100 v2 Switch Series

Installation Guide

HP A3100-8 v2 SI Switch (JG221A)

HP A3100-16 v2 SI Switch (JG222A)

HP A3100-24 v2 SI Switch (JG223A)

HP A3100-8 v2 EI Switch (JD318B)

HP A3100-16 v2 EI Switch (JD319B)

HP A3100-24 v2 EI Switch (JD320B)

HP A3100-8-PoE v2 EI Switch (JD311B)

HP A3100-16-PoE v2 EI Switch (JD312B)

HP A3100-24-PoE v2 EI Switch (JD313B)

Part number: 5998-1961

Document version: 6W100-20110909

Page 2

Legal and notice information

© Copyright 2011 Hewlett-Packard Development Company, L.P.

No part of this documentation may be reproduced or transmitted in any form or by any means without prior

written consent of Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice.

HEWLETT-PACKARD COMPANY MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS

MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE. Hewlett-Packard shall not be liable for errors contained herein or for

incidental or consequential damages in connection with the furnishing, performance, or use of this material.

The only warranties for HP products and services are set forth in the express warranty statements

accompanying such products and services. Nothing herein should be construed as constituting an additional

warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

Page 3

Contents

Product overview ······························································································································································ 1

Switch models ···································································································································································· 1

Panel views ········································································································································································ 1

A3100-24 v2 SI/A3100-24 v2 EI ························································································································· 1

A3100-16 v2 SI/A3100-16 v2 EI ························································································································· 2

A3100-8 v2 SI/A3100-8 v2 EI ······························································································································ 3

A3100-24-PoE v2 EI ················································································································································ 3

A3100-16-PoE v2 EI ················································································································································ 4

A3100-8-PoE v2 EI ··················································································································································· 5

Preparing for installation ················································································································································· 7

Safety recommendations ·················································································································································· 7

Examining the installation site ········································································································································· 7

Electricity safety ························································································································································ 7

ESD prevention ························································································································································· 7

Laser safety ······························································································································································· 8

Temperature/humidity ············································································································································· 8

Cleanness ·································································································································································· 9

EMI ············································································································································································· 9

Grounding ······························································································································································ 10

Cooling ··································································································································································· 10

Space ······································································································································································ 10

Installation tools ······························································································································································ 11

Installing the switch ························································································································································ 12

Installing the switch ························································································································································ 12

Selecting an installation method ·························································································································· 12

Installation accessories ········································································································································· 13

Installing the switch into the 19-inch rack ··········································································································· 15

Mounting the switch on a workbench ················································································································· 20

Grounding the switch ···················································································································································· 21

Grounding cable ··················································································································································· 21

Grounding the switch with a grounding strip····································································································· 21

Grounding the switch with a grounding conductor buried in the earth ground············································· 23

Grounding the switch by using the AC power cord ·························································································· 24

Connecting the power cord ·········································································································································· 24

Connecting an AC power cord to the switch ····································································································· 24

Connecting the DC power cord ··························································································································· 25

Verifying the installation ················································································································································ 26

Accessing the switch for the first time ·························································································································· 27

Setting up the configuration environment ···················································································································· 27

Connecting the console cable ······································································································································ 27

Console cable ························································································································································ 27

Connection procedure ·········································································································································· 27

Setting terminal parameters ·········································································································································· 28

Powering on the switch ················································································································································· 31

Verification before power-on ······························································································································· 31

Powering on the switch ········································································································································· 31

Initially configuring the switch ······································································································································ 32

Configuring a login authentication method ········································································································ 32

i

Page 4

Configuring the basic access function ················································································································ 33

Connecting the switch to the network ·························································································································· 34

Connecting your switch to the network through twisted pair cables ········································································ 34

Connecting your switch to the network through optical fibers ·················································································· 34

Installing an SFP transceiver module ··················································································································· 35

Connecting an optical fiber connector to an SFP transceiver module ····························································· 35

Troubleshooting ······························································································································································ 37

Configuration terminal problems ·································································································································· 37

Power supply failure ······················································································································································ 37

Interface failure ······························································································································································ 38

PoE system failure ·························································································································································· 38

Appendix A Technical specifications··························································································································· 39

A3100 v2 SI Switch Series technical specifications ·································································································· 39

A3100 v2 EI Switch Series technical specifications ·································································································· 40

Non PoE switches technical specifications ········································································································· 40

PoE switches technical specifications ·················································································································· 41

Appendix B Ports and LEDs ·········································································································································· 44

Ports ················································································································································································· 44

Console port ·························································································································································· 44

10/100Base-TX Ethernet port ······························································································································ 44

Combo interface ···················································································································································· 44

10/100/1000Base-T Ethernet port ···················································································································· 45

100/1000Base-X SFP port ·································································································································· 45

LEDs ················································································································································································· 46

LEDs for the non PoE switches ······························································································································ 47

LEDs on the PoE switches ······································································································································ 48

Appendix C Ethernet twisted pair cable ····················································································································· 50

Ethernet twisted pair cable ············································································································································ 50

RJ-45 connector ····················································································································································· 50

Cable pinouts ························································································································································· 50

Cable type ····························································································································································· 50

Pin assignments ····················································································································································· 52

Making an Ethernet twisted pair cable ··············································································································· 53

Index ················································································································································································ 54

ii

Page 5

Sub-series

Model

Product code

Description

Alias

HP A3100 v2 SI

Switch Series

Non

PoE

JG221A

HP A3100-8 v2 SI Switch

A3100-8 v2 SI

JG222A

HP A3100-16 v2 SI Switch

A3100-16 v2 SI

JG223A

HP A3100-24 v2 SI Switch

A3100-24 v2 SI

HP A3100 v2 EI

Switch Series

Non

PoE

JD318B

HP A3100-8 v2 EI Switch

A3100-8 v2 EI

JD319B

HP A3100-16 v2 EI Switch

A3100-16 v2 EI

JD320B

HP A3100-24 v2 EI Switch

A3100-24 v2 EI

PoE

JD311B

HP A3100-8-PoE v2 EI Switch

A3100-8-PoE v2 EI

JD312B

HP A3100-16-PoE v2 EI Switch

A3100-16-PoE v2 EI

JD313B

HP A3100-24-PoE v2 EI Switch

A3100-24-PoE v2 EI

1

2 3

456

78

(1) Speed LED for a 10/100Base-TX Ethernet port

(2) 10/100Base-TX Ethernet port

(3) Speed LED for a combo interface

(4) Console port

(5) Combo interface (10/100/1000Base-T Ethernet port on the left, 100/1000Base-X SFP port on the right)

(6) Link/Act LED for a combo interface

(7) Link/Act LED for a 10/100Base-TX Ethernet port

(8) Power LED

Product overview

Switch models

Table 1 Switch models in the HP A3100 v2 Switch Series

Panel views

A3100-24 v2 SI/A3100-24 v2 EI

Front panel

Figure 1 A3100-24 v2 SI/A3100-24 v2 EI front panel

1

Page 6

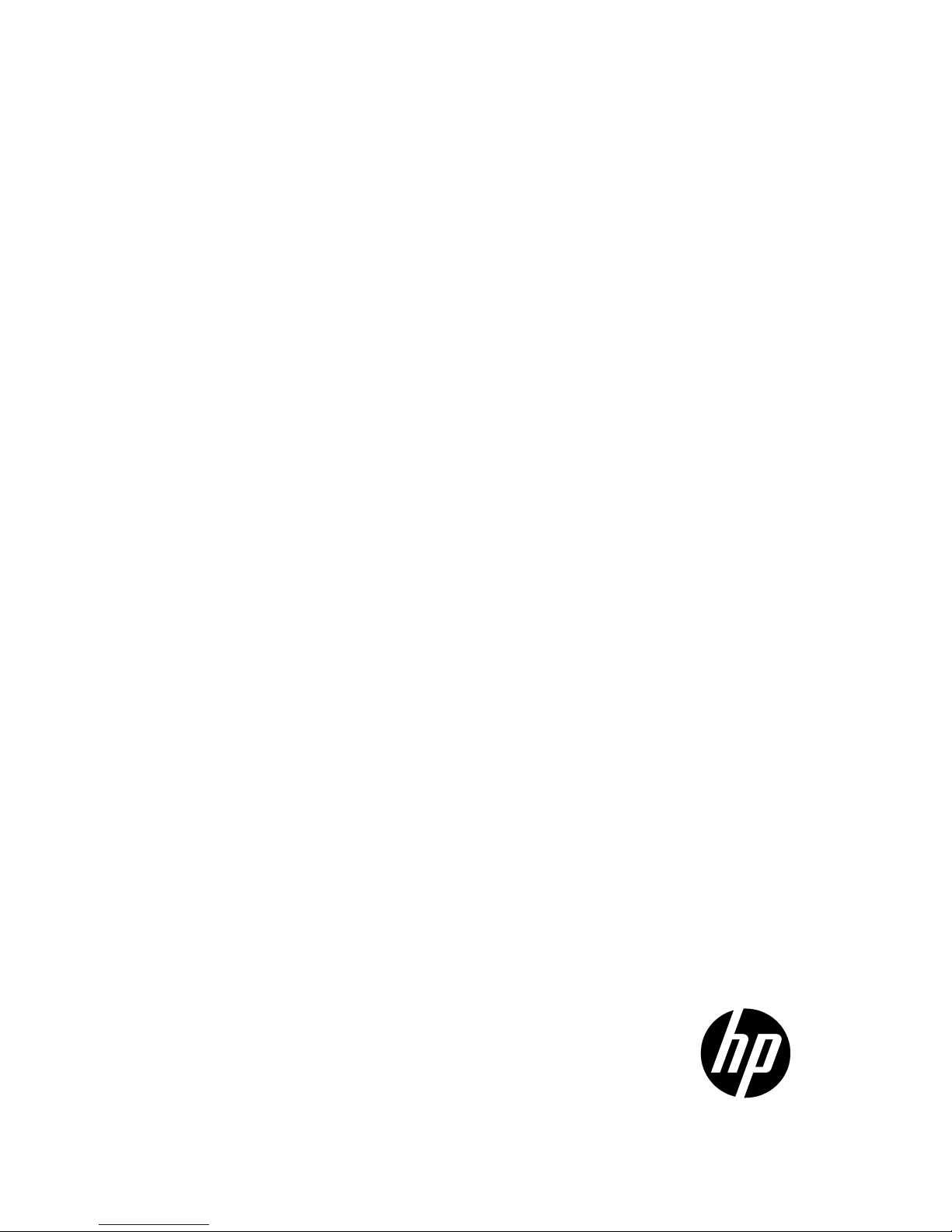

1

2

(1) Grounding screw

(2) AC-input power receptacle

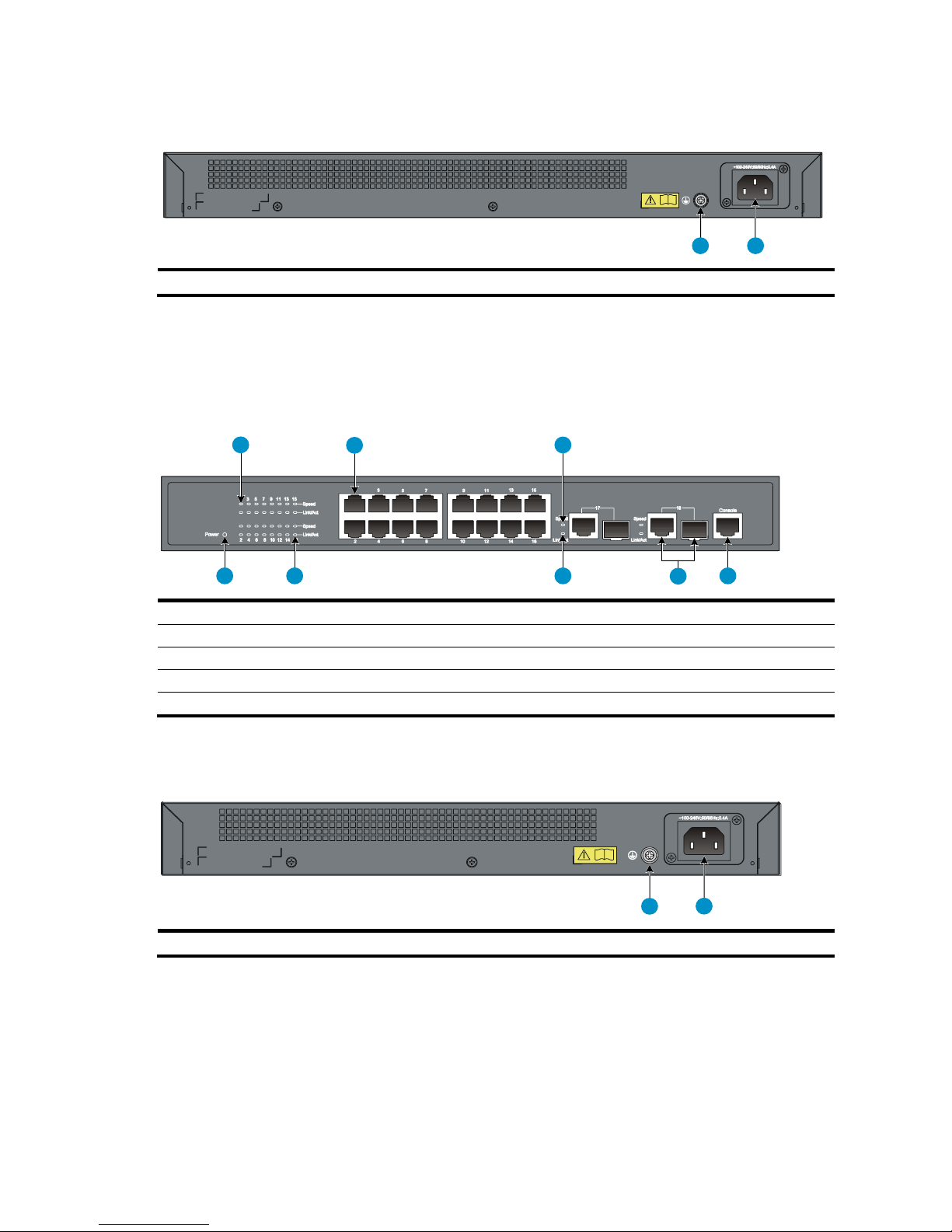

1

2

3

4

5

678

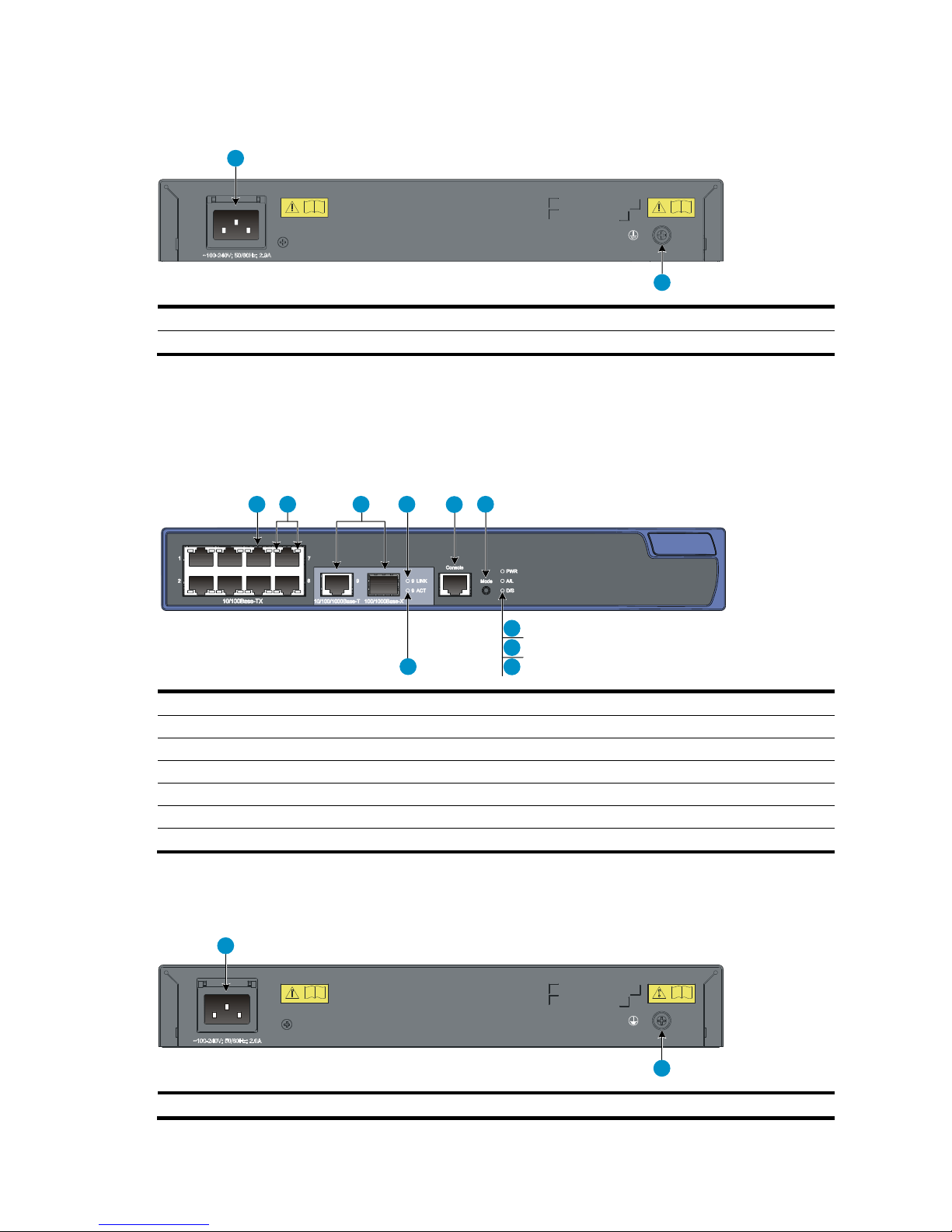

(1) Speed LED for a 10/100Base-TX Ethernet port

(2) 10/100Base-TX Ethernet ports

(3) Speed LED for a combo interface

(4) Console port

(5) Combo interface (10/100/1000Base-T Ethernet port on the left, 100/1000Base-X SFP port on the right)

(6) Link/Act LED for a combo interface

(7) Link/Act LED for a 10/100Base-TX Ethernet port

(8) Power LED

1

2

(1) Grounding screw

(2) AC-input power receptacle

Rear panel

Figure 2 A3100-24 v2 SI/A3100-24 v2 EI rear panel

A3100-16 v2 SI/A3100-16 v2 EI

Front panel

Figure 3 A3100-16 v2 SI/A3100-16 v2 EI front panel

Rear panel

Figure 4 A3100-16 v2 SI/A3100-16 v2 EI rear panel

2

Page 7

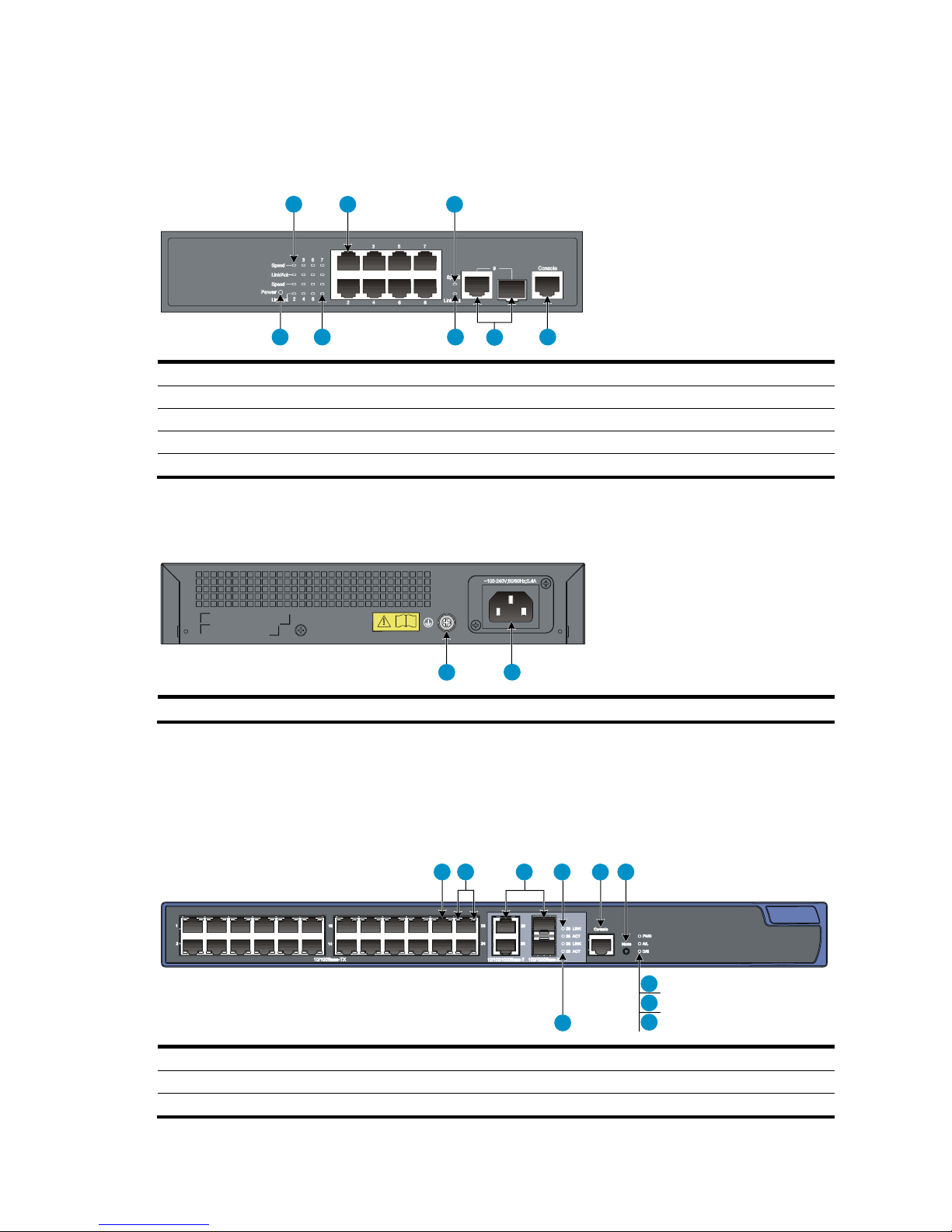

1 2 3

4

5

678

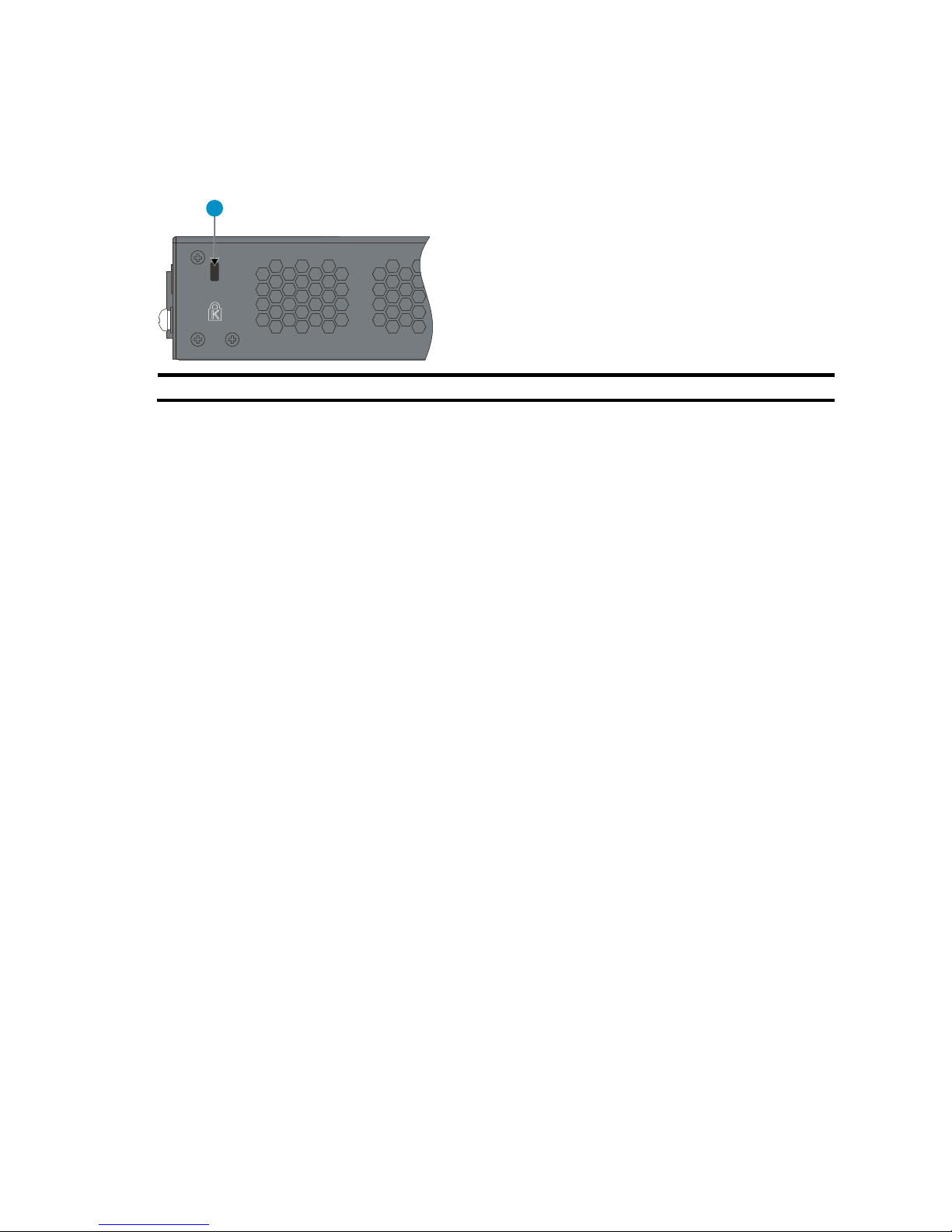

(1) Speed LED for a 10/100Base-TX Ethernet port

(2) 10/100Base-TX Ethernet ports

(3) Speed LED for a combo interface

(4) Console port

(5) Combo interface (10/100/1000Base-T Ethernet port on the left, 100/1000Base-X SFP port on the right)

(6) Link/Act LED for a combo interface

(7) Link/Act LED for a 10/100Base-TX Ethernet port

(8) Power LED

1

2

(1) Grounding screw

(2) AC-input power receptacle

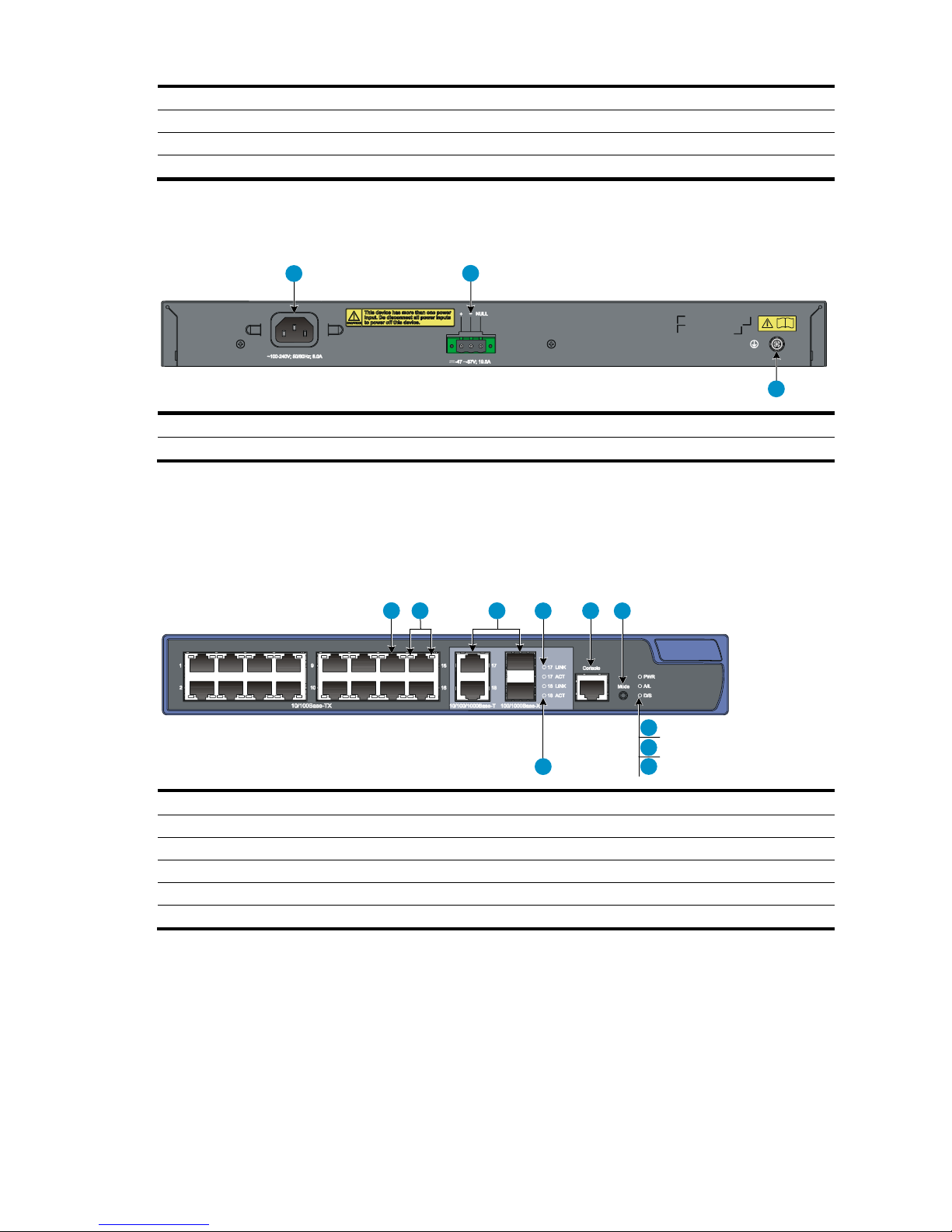

1

2 3 4

5

6

7

8

9

10

(1) 10/100Base-TX Ethernet port

(2) 10/100Base-TX Ethernet port LEDs (left: yellow, right: green)

(3) Combo interface (10/100/1000Base-T Ethernet port on the left, 100/1000Base-X SFP port on the right)

A3100-8 v2 SI/A3100-8 v2 EI

Front panel

Figure 5 A3100-8 v2 SI/A3100-8 v2 EI front panel

Rear panel

Figure 6 A3100-8 v2 SI/A3100-8 v2 EI rear panel

A3100-24-PoE v2 EI

Front panel

Figure 7 A3100-24-PoE v2 EI front panel

3

Page 8

(4) LINK LED for a combo interface

(5) Console port

(6) Port LED mode switching (Mode) button

(7) Power (PWR) LED

(8) Port mode (A/L) LED

(9) Port mode (D/S) LED

(10) ACT LED for a combo interface

1

2

3

(1) AC-input power receptacle

(2) DC-input terminal block

(3) Grounding screw

1 2 3

4

5

6

7

8

9

10

(1) 10/100Base-TX Ethernet port

(2) 10/100Base-TX Ethernet port LEDs (left: yellow, right: green)

(3) Combo interface (10/100/1000Base-T Ethernet port on the left, 100/1000Base-X SFP port on the right)

(4) LINK LED for a combo interface

(5) Console port

(6) Port LED mode switching (Mode) button

(7) Power (PWR) LED

(8) Port mode (A/L) LED

(9) Port mode (D/S) LED

(10) ACT LED for a combo interface

Rear panel

Figure 8 A3100-24-PoE v2 EI rear panel

A3100-16-PoE v2 EI

Front panel

Figure 9 A3100-16-PoE v2 EI front panel

4

Page 9

1

2

(1) AC-input power receptacle

(2) DC-input terminal block

(3) Grounding screw

1

2 3 4

5

6

7

8

9

10

(1) 10/100Base-TX Ethernet port

(2) 10/100Base-TX Ethernet port LEDs (left: yellow, right: green)

(3) Combo interface (10/100/1000Base-T Ethernet port on the left, 100/1000Base-X SFP port on the right)

(4) LINK LED for a combo interface

(5) Console port

(6) Port LED mode switching (Mode) button

(7) Power (PWR) LED

(8) Port mode (A/L) LED

(9) Port mode (D/S) LED

(10) ACT LED for a combo interface

后面板

1

2

(1) AC-input power receptacle

(2) Grounding screw

Rear panel

Figure 10 A3100-16-PoE v2 EI rear panel

A3100-8-PoE v2 EI

Front panel

Figure 11 A3100-8-PoE v2 EI front panel

Rear panel

Figure 12 A3100-8-PoE v2 EI rear panel

5

Page 10

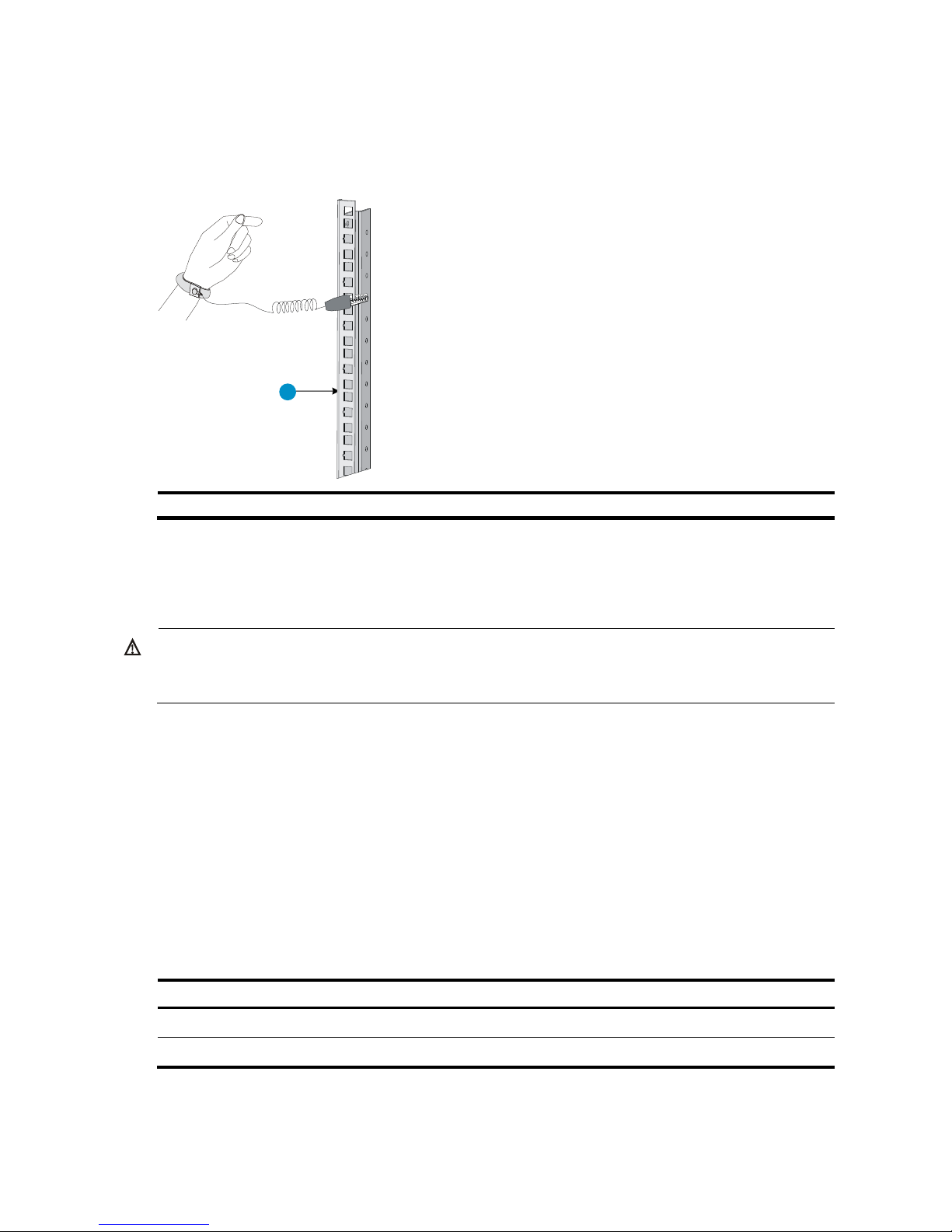

1

(1) Security lock slot

Right side panel

The A3100-8-PoE v2 EI switch has one security lock slot on the right-side panel to prevent theft. You must

purchase a cable lock separately.

Figure 13 A3100-8-PoE v2 EI left side panel

6

Page 11

Preparing for installation

Safety recommendations

To avoid any equipment damage or bodily injury caused by improper use, read the following safety

recommendations before installation. Note that the recommendations do not cover every possible hazardous

condition.

Before cleaning the switch, unplug all power cords from the switch. Do not clean the switch with wet

cloth or liquid.

Do not place the switch near water or in a damp environment. Prevent water or moisture from entering

the switch chassis.

Make sure that the ground is dry and flat and anti-slip measures are in place.

Do not place the switch on an unstable case or desk. The switch might be severely damaged in case of

a fall.

Keep the chassis and installation tools away from walk areas.

Do not wear loose clothing, jewelry (for example, necklace), or any other objects that could get caught

in the chassis when you install and maintain the switch.

To avoid electrical shocks, do not open the chassis while the switch is operating or when the switch is

just powered off.

Examining the installation site

The A3100 v2 Switch Series must be used indoors. To ensure normal operation and long service life of your

switch, install it in an environment that meets the requirements described in the following subsections.

Electricity safety

Clear the work area of possible hazards, such as ungrounded power extension cables, missing safety

grounds, and wet floors.

Make sure that the operating voltage is as required.

Locate the emergency power-off switch in the room before installation. Shut the power off at once in

case accident occurs.

Unplug all the external cables (including power cords) before moving the chassis.

Always check that the power has been disconnected.

ESD prevention

To prevent the electronic components from being damaged by the electrostatic discharge (ESD), you should

not only take ESD measures where the switch is located, but also take the following precautions:

Make sure the switch is well grounded. For how to ground the switch, see ―Grounding the switch.‖

Always wear an ESD-preventive wrist strap when installing hot swappable modules.

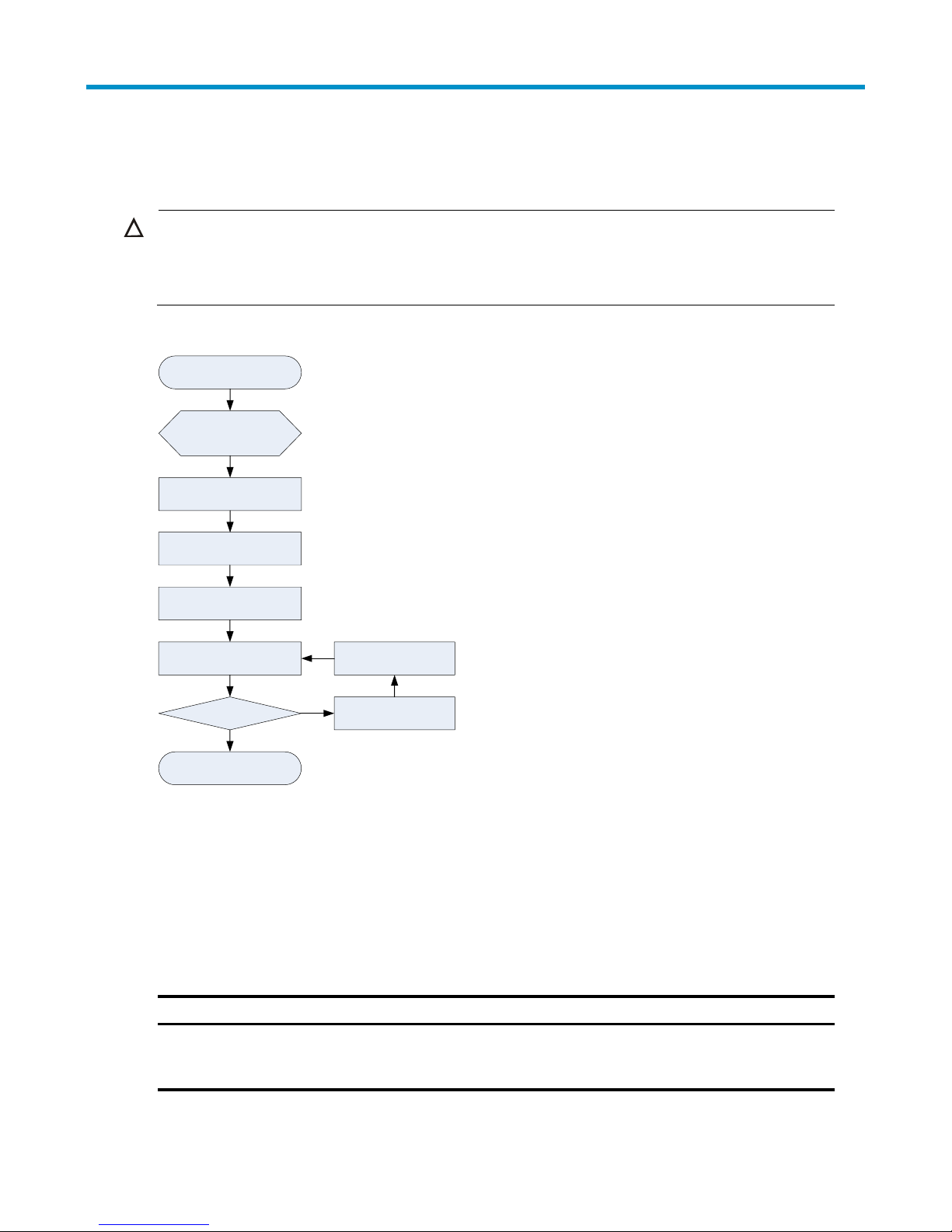

To use the ESD-preventive wrist strap:

7

Page 12

1

(1) Rack post

WARNING!

Do not stare into any fiber port when the switch has power. The laser light emitted from the optical fiber

may hurt your eyes.

Temperature

Range

Operating temperature

0°C to 45°C (32°F to 113°F)

Storage temperature

–40°C to +70°C (–40°F to +158°F)

1. Wear the wrist strap on your wrist.

2. Lock the wrist strap tight around your wrist to keep good contact with the skin.

3. Attach the ESD-preventive wrist strap to a post on the rack or ground it by using other methods.

Figure 14 Use an ESD-preventive wrist strap

Laser safety

The A3100 v2 switches are Class 1 laser devices.

Temperature/humidity

Maintain appropriate temperature and humidity in the equipment room.

Lasting high relative humidity can cause poor insulation, electricity creepage, mechanical property

change of materials, and metal corrosion.

Lasting low relative humidity can cause washer contraction and ESD and bring problems including

loose captive screws and circuit failure.

High temperature can accelerate the aging of insulation materials and significantly lower the reliability

and lifespan of the switch.

Table 2 Temperature requirements

8

Page 13

CAUTION:

If condensation appears on the switch when you move it to a high-temperature environment, dry the switch

before powering it on to avoid short circuits.

Humidity

Range

Operating humidity (noncondensing)

10% to 95%

Storage humidity (noncondensing)

5% to 95%

Substance

Concentration limit (particles/cu m)

Dust particles

≤ 3 x 104 (no visible dust on the tabletop over three days)

NOTE:

Dust diameter ≥ 5 µm

Gas

Max. (mg/m3)

SO2

0.2

H2S

0.006

NH3

0.05

Cl2

0.01

Table 3 Humidity requirements

Cleanness

Dust buildup on the chassis may result in electrostatic adsorption, which causes poor contact of metal

components and contact points, especially when indoor relative humidity is low. In the worst case,

electrostatic adsorption can cause communication failure.

Table 4 Dust concentration limit in the equipment room

EMI

The equipment room must also meet strict limits on salts, acids, and sulfides to eliminate corrosion and

premature aging of components, as shown in Table 5.

Table 5 Harmful gas limits in the equipment room

All electromagnetic interference (EMI) sources, from outside or inside of the switch and application system,

adversely affect the switch in a conduction pattern of capacitance coupling, inductance coupling,

electromagnetic wave radiation, or common impedance (including the grounding system) coupling. To

prevent EMI, take the following actions:

If AC power is used, use a single-phase three-wire power receptacle with protection earth (PE) to filter

interference from the power grid.

Keep the switch far away from radio transmitting stations, radar stations, and high-frequency devices.

Use electromagnetic shielding, for example, shielded interface cables, when necessary.

9

Page 14

1

2

(1) Air intake

(2) Air exhaust

Route interface cables only indoors to prevent signal ports from getting damaged by overvoltage or

overcurrent caused by lightning strikes.

Grounding

Using a good grounding system to protect your switch against lightning shocks, interferences, and ESD is

essential to the operating reliability of your switch. Make sure that the resistance between the chassis and

ground is less than 1.5 ohm. For more information about grounding the A3100 v2 Switch Series, see

―Grounding the switch.‖

Cooling

The cooling system of the A3100 v2 Switch Series varies by the switch model:

Non PoE switches (fanless): There are openings on the left, right, and rear of the switch for natural heat

dissipation.

PoE switches (built-in fans): Fans blow air from the left to the right of the chassis for heat dissipation. See

Figure 15.

Figure 15 Airflow through a PoE switch

For adequate heat dissipation, plan the installation site according to the airflow of your switch, and adhere

to the following requirements:

Leave a clearance of at least 10 cm (3.94 in) around the air intake and exhaust vents.

Consider the heat dissipation of the installation site when determining air-conditioning requirements to

Make sure the hot air generated by equipment at the bottom of the rack is not drawn in the intake of the

The installation site has a good cooling system.

Space

For adequate ventilation and ease of maintenance, adhere to the following requirements:

The clearance between the rack and walls or other devices is at least 1 m (3.28 ft).

The headroom in the equipment room is no less than 3 m (9.84 ft).

ensure that cool air can enter the switch.

equipment above.

10

Page 15

Category

Tool

Measuring and marking tools

Long tape, ruler of 1 m (3.28 ft), gradienter, marker, chalk line, and pencil

Drills

Percussion drill, electric drill, and several auxiliary drill bits

Fastening tools

Flat-blade screwdriver P4-75 mm

Phillips screwdriver P1-100 mm, P2-150 mm, and P3-250 mm

Socket wrench M5

Socket wrench M6

Small tools

Needle-nose pliers, diagonal pliers, combination pliers, wire-stripping pliers,

crimping pliers, RJ-45 crimping pliers

Auxiliary tools

ESD-preventive wrist strap, hair brush, tweezers, paper knife, hand bellows,

electric iron, solder wire, ladder, cable stripper, vacuum cleaner, crowbar,

rubber hammer, and blower

Tools for fiber-optic cleaning

Lint-free paper and optical fiber microscope

Equipment

Multimeter, 500 V Megohmmeter for measuring the insulation resistance,

error detector, optical power meter, and earth resistance tester

NOTE:

Tools and equipment are not supplied with the switch. Prepare them yourself as needed.

Installation tools

Table 6 Tool list

11

Page 16

CAUTION:

Keep the tamper-proof seal on a mounting screw on the chassis cover intact, and if you want to open the

chassis, contact the local agent of HP for permission. Otherwise, HP shall not be liable for any

consequence caused thereby.

Ground the switch

Install the switch

to a specific

position

Start

Connect the power cord

Verify the installation

Power on the switch

Operating properly? Power off the switch

Troubleshoot

the switch

No

Yes

End

Switch model

Installation methods

Installation accessories

A3100-24 v2 SI

A3100-24 v2 EI

Installing the switch into the

19 -inch rack (Rack mounting by

using front mounting brackets)

Front mounting bracket. See callout A in

Figure 17 (supplied with the switch).

Installing the switch

Figure 16 Hardware installation flow

Installing the switch

Selecting an installation method

The A3100 v2 Switch Series supports multiple installation methods. You can select one as needed.

Table 7 A3100 v2 Switch Series installation methods

12

Page 17

Switch model

Installation methods

Installation accessories

Mounting the switch on a

workbench

Rubber pad: See Figure 19 (supplied

with the switch).

A3100-16 v2 SI

A3100-16 v2 EI

Installing the switch into the

19 -inch rack (Rack mounting by

using front mounting brackets)

Front mounting bracket: HP A3100-16

Rack Mount Kit (JD321A).

See callout C in Figure 17 (optional).

Mounting the switch on a

workbench

Rubber pad: See Figure 19 (supplied

with the switch).

A3100-8 v2 SI

A3100-8 v2 EI

Installing the switch into the

19 -inch rack (Rack mounting by

using front mounting brackets)

Front mounting bracket: HP A3100-8

Rack Mount Kit (JD322A).

See callout B in Figure 17 (optional).

Mounting the switch on a

workbench

Rubber pad: See Figure 19 (supplied

with the switch).

A3100-24-PoE v2 EI

Installing the switch into the

19 -inch rack (Rack mounting by

using front and rear mounting

brackets)

Front mounting bracket. See callout A in

Figure 17 (supplied with the switch).

Rear mounting bracket: See Figure 18

(supplied with the switch).

Mounting the switch on a

workbench

Rubber pad: See Figure 19 (supplied

with the switch).

A3100-16-PoE v2 EI

A3100-8-PoE v2 EI

Installing the switch into the

19 -inch rack (Rack mounting by

using front mounting brackets)

Front mounting bracket: HP

A3100-16-PoE and 8-PoE Rack Mount

Kit (JD323A).

See callout D in Figure 17 (optional).

Mounting the switch on a

workbench

Rubber pad: See Figure 19 (supplied

with the switch).

Installation accessories

Mounting brackets for rack mounting

The A3100 v2 Switch Series provides different mounting brackets for different models. Select them as

required.

13

Page 18

(A) (B:JD322A)

(C:JD321A)

(D:JD323A)

1

2

3

1

2

3

1

2

3

1

2

3

(1) Screw hole (for M6 screw) for fixing the front mounting bracket to the rack

(2) Screw hole for fixing the front mounting bracket to the switch

(3) M4 screws for fixing the front mounting bracket to the switch

1

2

(1) Screw hole (for M6 screw) for fixing the rear mounting bracket to the rack

(2) Load-bearing screw (installed to the switch)

Figure 17 Front mounting brackets

Figure 18 Rear mounting bracket

14

Page 19

1

(1) Rubber pad

CAUTION:

Ensure a clearance of 1U (44.45 mm, or 1.75 in) between equipment for heat dissipation.

For a switch with a depth greater than 300 mm (11.81 in), the front mounting brackets only secure the

switch rather than bear its weight. To mount this switch to a rack, you need to use front mounting

brackets and other accessories. For example, use front mounting brackets and rear mounting brackets

(for more information, see “Rack mounting by using front and rear mounting brackets.”), or use front

mounting brackets and a rack shelf (if there is a rack shelf on the rack, put the switch on the rack shelf,

move the switch to an appropriate position, and fix the switch by using front mounting brackets.).

NOTE:

The installation procedures for front mounting brackets with different length are similar. The following uses

front mounting brackets supplied with the switch as an example.

Rubber pads

Each A3100 v2 switch provides four rubber pads, as shown in Figure 19. Before mounting the switch to a

workbench, attach the four rubber pads to the switch bottom first.

Figure 19 Rubber pad appearance

Installing the switch into the 19-inch rack

Rack mounting by using front mounting brackets

To install the switch to the rack by using front mounting brackets:

1. Wear an ESD-preventive wrist strap and make sure it makes good skin contact and is well grounded,

check that the rack is sturdy and well grounded.

2. Unpack the screws (packed with the front mounting brackets), and install the front mounting brackets

to the switch with the screws. See Figure 20.

15

Page 20

1

(1) Chassis front panel

1

2

3

1

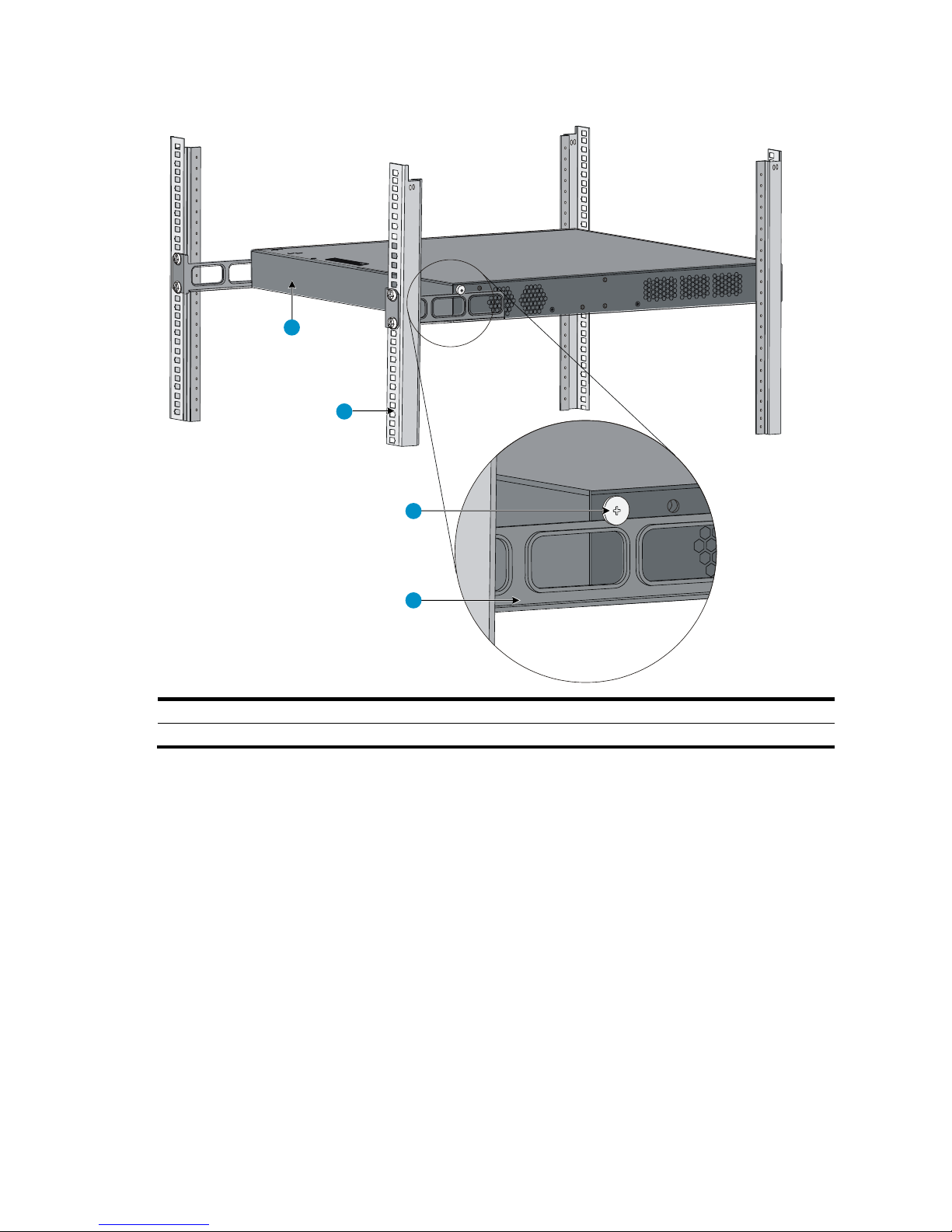

(1) Front rack posts

(2) Chassis front panel

(3) Front mounting bracket

Figure 20 Install the front mounting brackets

3. Determine where to install the switch in the rack, and install the cage nuts to the corresponding

positions on the front rack posts.

4. Supporting the bottom of the switch, move the switch to the appropriate position. Have another person

to install the mounting brackets to the rack posts with the M6 screws. See Figure 21.

Figure 21 Mount the switch to the rack by using front mounting brackets

Rack mounting by using front and rear mounting brackets

To mount the switch to the rack by using front and rear mounting brackets:

1. Wear an ESD-preventive wrist strap and make sure it makes good skin contact and is well grounded.

2. Check that the rack is sturdy and well grounded.

16

Page 21

1

2

3

4

5

(1) Load-bearing screw

(2) Load-bearing screw positions (select one as needed)

(3) Chassis front panel

(4) Front mounting bracket

(5) Screw (packaged with the front mounting bracket) for fixing the front mounting bracket to the switch

NOTE:

The switch provides three positions on both sides to mount a load-bearing screw. Select a proper position

according to the actual requirements. The rear mounting brackets support the switch by the load-bearing

screws.

3. Unpack the screws (packed with the front mounting brackets), and install the front mounting brackets

to the switch with the screws. See Figure 20.

4. Unpack the load-bearing screws (packed with the rear mounting brackets), and install them to the

appropriate positions on the two sides of the switch. See Figure 22.

Figure 22 Rack mounting by using front and rear mounting brackets

5. Determine where to install the switch to the rack, and install the cage nuts to the corresponding

positions on the front and rear rack posts.

6. Fix the rear mounting brackets to the rear rack posts by using the M6 screws. See Figure 23.

17

Page 22

1

2

1

(1) Rack posts

(2) Rear mounting bracket

CAUTION:

Make sure the thinner edge of the rear mounting bracket faces upwards to ensure that the mounting

bracket can make close contact with the load-bearing screws.

Figure 23 Mount the switch to the rack by using rear mounting brackets

7. Supporting the switch bottom with one hand, use the other hand to push the switch into the rack until

the load-bearing screws on the switch make close contact with the upper edge of the rear mounting

bracket. See Figure 24.

18

Page 23

1

2

3

4

(1) Chassis rear panel

(2) Rear rack post

(3) Load-bearing screw

(4) Rear mounting bracket

Figure 24 Mount the switch to the rack by using front and rear mounting brackets

8. Have another person to fix the front mounting brackets to the front rack posts by using the M6 screws,

making sure that the front and rear mounting brackets can fix the switch steadily into the rack. See

Figure 25.

19

Page 24

1 2

3

4

5

6

(1) Load-bearing screw

(2) Rear mounting bracket

(3) Chassis front panel

(4) M6 screw for fix the front mounting bracket to the rack

(5) Front mounting bracket

(6) Front rack post

IMPORTANT:

Ensure good ventilation and 10 cm (3.94 in) of clearance around the chassis for heat dissipation.

Avoid placing heavy objects on the switch.

Non PoE switches are fanless. Install them in an environment with good ventilation. To stack switches one

on another, keep at least a vertical distance of 1.5 cm (0.59 in) between equipment.

Figure 25 Mount the switch to the rack by using front and rear mounting brackets

Mounting the switch on a workbench

To mount the switch on a workbench:

1. Check that the workbench is sturdy and well grounded.

2. Place the switch with bottom up, and clean the round holes in the chassis bottom with dry cloth.

3. Attach the rubber feet to the four round holes in the chassis bottom.

4. Place the switch with upside up on the workbench.

20

Page 25

WARNING!

Correctly connecting the switch grounding cable is crucial to lightning protection and EMI protection.

NOTE:

The power and grounding terminals in this section are for illustration only.

1

(1) OT terminal of the grounding cable

WARNING!

Connect the grounding cable to the grounding system in the equipment room. Do not connect it to a fire

main or lightning rod.

NOTE:

The grounding cable supplied with the A3100 v2 Switch Series does not have an auxiliary OT terminal.

Grounding the switch

The power input end of the switch has a noise filter, whose central ground is directly connected to the chassis

to form the chassis ground (commonly known as PGND). You must securely connect this chassis ground to the

earth so the faradism and leakage electricity can be safely released to the earth to minimize EMI

susceptibility of the switch.

You can ground the switch in one of the following ways, depending on the grounding conditions available

at the installation site:

Grounding the switch with a grounding strip

Grounding the switch with a grounding conductor buried in the earth ground

Grounding the switch by using the AC power cord

Grounding cable

The A3100 v2 Switch Series is provided with a yellow-green grounding cable. One end of the cable has an

OT terminal, and the other end is naked and soldered. See Figure 26.

Figure 26 Grounding cable

Grounding the switch with a grounding strip

If a grounding strip is available at the installation site, connect the grounding cable to the grounding strip.

Connecting the grounding cable to the switch

To connect the grounding cable:

1. Remove the grounding screw from the rear panel of the switch chassis.

21

Page 26

1 2 3

4

5

6

(1) Chassis rear panel

(2) Grounding sign

(3) Grounding hole

(4) OT terminal

(5) Grounding cable

(6) Grounding screw

(B)

(A)

2. Attach the grounding screw to the OT terminal of the grounding cable.

3. Use a screwdriver to fasten the grounding screw into the grounding screw hole.

Figure 27 Connect the grounding cable to the grounding hole of the switch

4. Remove the hex nut of a grounding post on the grounding strip.

5. Cut the grounding cable as appropriate for connecting to the grounding strip.

6. Make the connector on the grounding cable:

If you have an OT terminal, follow callout A in Figure 28 to make the connector: Peel 5 mm (0.20

in) of insulation sheath by using a wire stripper, and insert the bare metal part through the black

insulation covering into the end of the OT terminal. Secure the metal part of the cable to the OT

terminal with a crimper, cover the joint with the insulation covering, and heat the insulation covering

with a blow dryer to completely cover the metal part.

If you do not have an OT terminal, follow callout B in Figure 28 to make the connector: Peel the

insulation sheath by an appropriate length with a wire stripper, and then bend the naked metal

part.

7. Connect the connector to the grounding strip, and fasten it with the removed hex nut. See Figure 29.

Figure 28 Make the grounding cable connector

22

Page 27

(A)

(B)

1 2

3

4

3

4

(1) Grounding post

(2) Grounding strip

(3) Grounding cable

(4) Hex nut

1

2

3

4

5

6

(1) Grounding screw

(2) Grounding cable

(3) Earth

(4) Joint

(5) Grounding conductor

(6) Chassis rear panel

Figure 29 Connect the grounding cable to a grounding strip

Grounding the switch with a grounding conductor buried in the

earth ground

If the installation site has no grounding strips, but earth ground is available, hammer a 0.5 m (1.64 ft) or

longer angle iron or steel tube into the earth ground to serve as a grounding conductor.

The dimensions of the angle iron must be at least 50 × 50 × 5 mm (1.97 × 1.97 × 0.20 in). The steel tube

must be zinc-coated and its wall thickness must be at least 3.5 mm (0.14 in).

Weld the yellow-green grounding cable to the angel iron or steel tube and treat the joint for corrosion

protection.

Figure 30 Ground the switch by burying the grounding conductor into the earth

23

Page 28

NOTE:

If the ground contact in the power outlet is not connected to the ground, report the problem and reconstruct

the grounding system.

1

2

(1) Three-wire AC power cord

(2) Chassis rear panel

CAUTION:

Before powering on the switch, you must connect the power cord and make sure the switch is well

grounded.

Grounding the switch by using the AC power cord

If the installation site has no grounding strips, you can ground an AC-powered switch through the protective

earth (PE) wire of the power cord, but must make sure:

The power cord has a PE terminal.

The ground contact in the power outlet is securely connected to the ground in the power distribution

room or on the AC transformer side.

The power cord is securely connected to the power outlet.

Figure 31 Ground through the PE wire of the AC power cord

Connecting the power cord

Connecting an AC power cord to the switch

To connect the AC power cord:

1. Wear an ESD-preventive wrist strap, and make sure the wrist strap makes good skin contact and is

well grounded.

2. Connect one end of the AC power cord to the AC-input power receptacle on the switch (see Figure

32).

3. Connect the other end of the power cord to the AC power outlet.

24

Page 29

+: Chassis ground

—: Input voltage range (–47 VDC to –57 VDC)

NULL: Reserved

1

2

2

4. Check the power LED (Power/PWR) on the front panel. If the LED is on, the power cord is properly

connected.

Figure 32 Connect the AC power cord (I)

Connecting the DC power cord

The A3100-24 -PoE v2 EI provides a DC power receptacle as shown in Figure 33. You can use the –48 VDC

power in the equipment room or the HP RPS DC power input.

Figure 33 DC power receptacle

To connect the DC power cord:

1. Wear an ESD-preventive wrist strap and make sure it makes good skin contact and is well grounded.

2. Unpack the DC power cord, correctly orient the plug at one end of the cable with the power receptacle

on the power supply, and insert the plug into the power receptacle (see callout 1 in Figure 34).

Figure 34 Connect the DC power cord

25

Page 30

CAUTION:

The length of a DC power cord must be shorter than 3 m (9.84 ft).

3. Tighten the screws on the plug with a flat-blade screwdriver to secure the plug in the power receptacle

(see callout 2 in Figure 34).

4. Connect the two wires at the other end of the power cord to a –48 VDC power source.

5. Check the power LED (PWR) on the front panel. If the LED is on, the power cord is properly connected.

Verifying the installation

After you complete the installation, verify that:

The grounding cable is securely connected.

The selected power supply matches that required by the switch.

The power cords are properly connected.

26

Page 31

Main label

1

8

B side

B

Pos.9

Pos.1

A side

A

Accessing the switch for the first time

Setting up the configuration environment

The first time you access the switch you must use a console cable to connect a console terminal, for example,

a PC, to the console port on the switch.

Figure 35 Connect the console port to a terminal

Connecting the console cable

Console cable

A console cable is an 8-core shielded cable, with a crimped RJ-45 connector at one end for connecting to

the console port of the switch, and a DB-9 female connector at the other end for connecting to the serial port

on the console terminal.

Figure 36 Console cable

Connection procedure

To connect a terminal, for example, a PC, to the switch:

27

Page 32

NOTE:

Identify the mark on the console port and make sure that you are connecting to the correct port.

The serial ports on PCs do not support hot swapping. If the switch has been powered on, connect the console cable

to the PC before connecting to the switch, and when you disconnect the cable, first disconnect from the switch.

1. Plug the DB-9 female connector of the console cable to the serial port of the PC.

2. Connect the RJ-45 connector to the console port of the switch.

Setting terminal parameters

To configure and manage the switch, you must run a terminal emulator program on the console terminal.

The following are the required terminal settings:

Bits per second—9,600

Data bits—8

Parity—None

Stop bits—1

Flow control—None

Emulation—VT100

To set terminal parameters, for example, on a Windows XP HyperTerminal:

1. Select Start > All Programs > Accessories > Communications > HyperTerminal.

The Connection Description dialog box appears.

2. Enter the name of the new connection in the Name field and click OK.

Figure 37 Connection description

3. Select the serial port to be used from the Connect using list, and click OK.

28

Page 33

Figure 38 Set the serial port used by the HyperTerminal connection

4. Set Bits per second to 9600, Data bits to 8, Parity to None, Stop bits to 1, and Flow control to None,

and click OK.

Figure 39 Set the serial port parameters

5. Select File > Properties in the HyperTerminal window.

29

Page 34

Figure 40 HyperTerminal window

6. On the Settings tab, set the emulation to VT100 and click OK.

Figure 41 Set terminal emulation in Switch Properties dialog box

30

Page 35

CAUTION:

If you log in to the switch through the console port after powering on the switch, no boot information is

displayed, and you will enter the command line interface (CLI).

The output information varies depending on the software version.

Powering on the switch

Verification before power-on

Before powering on the switch, verify that:

The power cord is properly connected.

The input power voltage meets the requirement of the switch.

The console cable is properly connected, the terminal or PC used for configuration has started, and the

configuration parameters have been set.

Powering on the switch

Power on the switch, and you can see the following information.

Starting......

************************************************************************

* *

* HP A3100-24-PoE v2 EI Switch BOOTROM, Version 109 *

* *

************************************************************************

Copyright (c) 2010-2011 Hewlett-Packard Development Company, L.P.

Creation Date : Apr 12 2011,11:13:54

CPU Clock Speed : 200MHz

Memory Size : 128MB

Flash Size : 16MB

CPLD Version : 003

PCB Version : Ver.A

Mac Address : 000FE23060C1

Press Ctrl-B to enter Extended Boot menu...0

Starting to get the main application file--flash:/a3100 ei.bin!..............

...............................................

The main application file is self-decompressing................................

...............................................................................

...............................................................................

...............................................................................

......Done!

System is starting...

31

Page 36

Authentication method

Feature

Application scenarios

None

Easy to configure, allows any

user to Telnet to your switch, and

lowest in security

Lab environments and extremely secure

network environments

Password

Easy to configure, allows any

user knowing the password to

telnet to your switch, high in

security, but incapable of

assigning different privilege

levels to different users

Environments that do not need granular

privilege management

Username and password

Complex to configure, allows

users inputting the correct

username and password to

Telnet to your switch, high in

security, and capable of

assigning different privilege

levels to different users

Environments where multiple operators

cooperate to manage the switch

User interface aux0 is available.

Press ENTER to get started.

Press Enter at the prompt, and you can configure the switch when the prompt <HP> appears.

For more information about initial switch configuration, see ―Initially configuring the switch.‖

Initially configuring the switch

By default, the administrator can only log in to the switch through the console port without any authentication.

The default login method does not facilitate remote maintenance and management of the switch, and brings

vulnerabilities to the switch. After the first login, you can perform the following configurations.

Configure the login method so that you can remotely maintain and manage the switch and control login

user privileges.

Configure the access function of the switch to satisfy the requirements of different users.

Configuring a login authentication method

By configuring the authentication mode and the corresponding username, authentication method, and user

privilege level, you can perform login user privilege control, and improve switch security.

The switch supports login through the console port, telnet, SSH, and NMS.

The following section takes login through telnet for example. Login through telnet supports three login

authentication methods.

Table 8 Telnet login authentication methods

32

Page 37

Function

Description

IP addresses

Allows you to remotely manage the switch and use the switch in a network.

Static routing

Allows the switch to implement routing.

VLAN

Divides the network into multiple VLANs, and improves data security.

MSTP

Avoids loops in a network using dual uplinks to provide redundancy.

NOTE:

For more information about login methods and access function configuration, see

HP A3100 v2 Switch

Series Configuration Guides

.

Configuring the basic access function

When the switch with the default settings accesses the network, it can perform basic data transmission. To

implement more service requirements, you can configure the basic access function on the switch.

Table 9 Basic access function configurations

33

Page 38

NOTE:

HP recommends that you perform basic configuration for your switch before connecting it to the network.

NOTE:

For more information about twisted pair cables, see the chapter “Appendix C Ethernet twisted pair cable.”

IMPORTANT:

After connecting the switch to the network, you can use the ping or tracert command to check the

interoperability between the switch and the network. For more information, see

HP A3100 v2 Switch

Series Command References

.

If the port status LED on the switch flashes after you connect the switch to the network, and the switch

does not respond to your commands, the switch may be sending or receiving broadcasts. In this case,

disconnect the switch to the network, re-configure the switch, and connect the switch to the network

again.

Install an SFP transceiver module

to the switch and access device

Connect the optical fiber

connector to the SFP

module

Activate the SFP port

Connecting the switch to the network

Connecting your switch to the network through

twisted pair cables

The 10/100/1000Base-T ports of the A3100 v2 Switch Series use RJ-45 connectors and support MDI/MDI-X

auto-sensing. Use category-5 or higher twisted pair cables to connect the Ethernet ports of your switch to the

network.

To connect your switch to the network through twisted pair cables:

1. Make a straight-through or crossover Ethernet cable as needed.

2. Plug one end of the twisted pair cable into the RJ-45 Ethernet port of your switch.

3. Plug the other end of the twisted pair cable into the RJ-45 Ethernet port of the access device in the

network.

4. Check whether the LEDs of the RJ-45 Ethernet port are normal.

Connecting your switch to the network through

optical fibers

Figure 42 Connect the switch to the network through an optical fiber

34

Page 39

NOTE:

This section only briefly describes the installation and operation guidelines for an SFP transceiver module.

For more information, see

Pluggable SFP/SFP+/XFP Transceiver Modules Installation Guide

.

CAUTION:

Do not remove the dust plug on the SFP transceiver module before installing it.

Remove the fibers, if any, from the SFP transceiver module before installing it.

NOTE:

For more information about optical fibers and fiber connectors, see

HP A-Series Switches Transceiver

Modules User Guide

.

Installing an SFP transceiver module

To install an SFP transceiver module:

1. Wear an ESD-preventive wrist strap and make sure it makes good skin contact and is well grounded.

2. Unpack the SFP transceiver module. Do not touch the golden finger of the module.

3. Pivot the clasp of the transceiver module up so that it catches a knob on the top of the module.

4. Squeezing both sides of the module, gently push the module into the slot until it has firm contact with

the slot (you can feel that the top and bottom spring tabs catch in the slot). See Figure 43.

Figure 43 Install an SFP transceiver module

Connecting an optical fiber connector to an SFP transceiver

module

The SFP transceiver modules of the A3100 v2 Switch Series use LC connectors. See Figure 44.

35

Page 40

WARNING!

To avoid injury to your eyes, do not stare at the optical interfaces and optical fiber connectors when

connecting optical fibers.

LC plug

SFP module

IMPORTANT:

Each SFP port is a member port of a combo interface. After connecting the switch to the network through

the SFP port, you must use the combo enable fiber command to activate the SFP port.

After connecting the switch to the network, you can use the ping or tracert command to check the

interoperability between the switch and the network. For more information, see

HP A3100 v2 Switch

Series Command References

.

If the port status LED on the switch flashes after you connect the switch to the network, and the switch

does not respond to your commands, the switch may be sending or receiving broadcasts. In this case,

disconnect the switch to the network, re-configure the switch, and connect the switch to the network

again.

Figure 44 Appearance of an LC connector

To connect your switch to the network through optical fibers:

1. Remove the dust cover of the optical fiber connector, and clean the end of the optical fiber.

2. Take off the dust plug of the SFP transceiver module, plug one end of the optical fiber into the

transceiver module in the switch, and plug the other end into the transceiver module in the access

device. See Figure 45.

3. Check that the LEDs of the optical interfaces are normal.

Figure 45 Use the LC optical fiber connector to connect a transceiver module

36

Page 41

TIP:

Clean your switch periodically because the noncompliant operating environments of switches may cause

switch failures. At the same time, check the installation environments against the requirements in

“Preparing for installation.” Make sure the switch operates in a proper environment. Additionally,

periodically perform the power-on test for the spare switches.

Troubleshooting

Configuration terminal problems

If the configuration environment setup is correct, the configuration terminal displays booting information

when the switch is powered on. If the setup is incorrect, the configuration terminal displays nothing or

garbled text.

No terminal display

If the configuration terminal displays nothing when the switch is powered on, verify the following items:

The power supply is supplying power to the switch.

The console cable is properly connected.

The console cable has no problem and the terminal settings are correct.

Garbled terminal display

If terminal display is garbled, check that the following settings are configured for the terminal, for example,

HyperTerminal:

Baud rate—9,600

Data bits—8

Parity—none

Stop bits—1

Flow control—none

Emulation—VT100

Power supply failure

The PWR/Power LED on the front panel shows whether the power supply system of the switch operates

properly. The PWR/Power LED is steady green when the power supply system operates properly, and off

when the power supply system fails.

To troubleshoot the power supply failure:

1. Check the power cable connections. If a power cable is loose, re-plug the power cable. If a power

cable is broken, replace it.

2. Check the power supply system. Make sure that the power supply system works properly and outputs

a voltage required by the switch.

37

Page 42

NOTE:

Each combo interface has one fiber SFP port and one copper Ethernet port. These two ports share one

port name and port view and cannot work simultaneously. When you activate one port (by using the

combo enable { copper | fiber } command), the other port automatically shuts down.

After an interface fails, if the switch has an idle interface of the same type, you can plug the cable into

the idle interface.

Interface failure

Each interface has a corresponding LED. When an interface connected to the network works properly, the

corresponding LINK LED is on. If the LED of an interface connected to the network is off, the interface or the

connecting cable may fail.

To troubleshoot the interface:

1. Check whether the switch works properly.

2. Check the cable connection of the interface. For how to correctly connect the cable to an Ethernet

interface with a RJ-45 connector or an optical interface, see the chapter ―Connecting the switch to the

network.‖

3. Check whether the cable fails. Use the cable to connect two interfaces of the same type that work

properly. If the LEDs of the two interfaces are on, the cable is normal. Otherwise, the cable fails.

4. If the interface uses a transceiver module, check that the interface type is compatible with the

transceiver module and the transceiver module is compatible with the cable.

5. If the interface uses a transceiver module, make sure that the current transceiver module works

properly by replacing a normal transceiver module.

6. If the interface is a combo interface (which comprises a copper port and a fiber port), make sure that

the interface used for connecting is activated for the combo interface. Then, use the combo enable {

copper | fiber } command in interface view to activate the port, and check the LED.

7. Check that the speed and duplex settings of the interfaces of a link are the same. Make sure that two

interfaces can work together.

PoE system failure

If a PoE-capable switch cannot supply power to a powered device (PD) attached to the switch, follow these

steps to troubleshoot the PoE system:

1. Check that the power cable that connects the switch to the PD is a straight-through cable.

2. Make sure that the PoE-related configurations are correct. For how to configure PoE, see the related

configuration guide.

3. Check the temperature of the switch. The PoE-capable switch provides the overtemperature protection

mechanism. When the internal temperature of the switch exceeds 65°C (149°F), the switch performs

self protection and disables PoE on all ports. When the internal temperature drops below 60°C

(140°F), the switch enables PoE on all ports.

38

Page 43

Item

A3100-24 v2 SI

A3100-16 v2 SI

A3100-8 v2 SI

Dimensions (H ×

W × D)

43.6 × 440 × 160 mm

(1.72 × 17.32 × 6.30 in)

43.6 × 360 × 160 mm (1.72

× 14.17 × 6.30 in)

43.6 × 230 × 160 mm

(1.72 × 9.06 × 6.30 in)

Weight

≤ 3 kg (6.61 lb)

Fixed ports

24 × 10/100Base-TX

auto-sensing Ethernet ports

2 combo interfaces

(numbered 25 and 26)

16 × 10/100Base-TX

auto-sensing Ethernet ports

2 combo interfaces

(numbered 17 and 18)

8 × 10/100Base-TX

auto-sensing Ethernet

ports

1 combo interface

(numbered 9)

NOTE:

Each combo interface has one 100/1000Base-X fiber SFP port and one

10/100/1000Base-T auto-sensing copper Ethernet port. These two ports share one port

name and port view and cannot work simultaneously. When you activate one port (by using

the combo enable { copper | fiber } command), the other port automatically shuts down.

Management

ports

1 console port

Input voltage

(AC-input)

Rated voltage: 100 VAC to 240 VAC, 50 or 60 Hz

Max voltage: 90 VAC to 264 VAC, 47 Hz to 63 Hz

Input current

0.4 A

0.4 A

0.4 A

Melting current

of power supply

fuse

2 A

2 A

2 A

Power

consumption

(minimum

hardware and

software

configuration)

7 W

7 W

7 W

Power

consumption (full

hardware

configuration)

13 W

12 W

9 W

Max thermal

output

44.3573 BTU/h

40.9452 BTU/h

30.7089 BTU/h

Cooling system

Fanless, natural heat dissipation

Operating

temperature

0°C to 45°C (32°F to 113°F)

Appendix A Technical specifications

A3100 v2 SI Switch Series technical specifications

Table 10 A3100 v2 SI Switch Series technical specifications

39

Page 44

Item

A3100-24 v2 SI

A3100-16 v2 SI

A3100-8 v2 SI

Relative humidity

(noncondensing)

10% to 90%

Fire resistance

compliance

UL60950-1, EN60950-1, IEC60950-1, GB4943

Chassis leakage

current

compliance

UL60950-1, EN60950-1, IEC60950-1, GB4943

Item

A3100-24 v2 EI

A3100-16 v2 EI

A3100-8 v2 EI

Dimensions (H × W

× D)

43.6 × 440 × 160 mm

(1.72 × 17.32 × 6.30 in)

43.6 × 360 × 160 mm

(1.72 × 14.17 × 6.30 in)

43.6 × 230 × 160 mm

(1.72 × 9.06 × 6.30 in)

Weight

≤ 3 kg (6.61 lb)

Fixed ports

24 × 10/100Base-TX

auto-sensing Ethernet ports

2 combo interfaces

(numbered 25 and 26)

16 × 10/100Base-TX

auto-sensing Ethernet ports

2 combo interfaces

(numbered 17 and 18)

8 × 10/100Base-TX

auto-sensing Ethernet ports

1 combo interface

(numbered 9)

NOTE:

Each combo interface has one 100/1000Base-X fiber SFP port and one

10/100/1000Base-T auto-sensing copper Ethernet port. These two ports share one port

name and port view and cannot work simultaneously. When you activate one port (by

using the combo enable { copper | fiber } command), the other port automatically shuts

down.

Management ports

1 console port

Input voltage

(AC-input)

Rated voltage: 100 VAC to 240 VAC, 50 or 60 Hz

Max voltage: 90 VAC to 264 VAC, 47 Hz to 63 Hz

Input current

0.4 A

0.4 A

0.4 A

Melting current of

power supply fuse

2 A

2 A

2 A

Power consumption

(minimum hardware

and software

configuration)

7 W

7 W

7 W

Power consumption

(full hardware

configuration)

13 W

12 W

9 W

Max thermal output

44.3573 BTU/h

40.9452 BTU/h

30.7089 BTU/h

A3100 v2 EI Switch Series technical specifications

The A3100 v2 EI Switch Series includes the PoE switches and non PoE switches.

Non PoE switches technical specifications

Table 11 Non PoE switches technical specifications

40

Page 45

Item

A3100-24 v2 EI

A3100-16 v2 EI

A3100-8 v2 EI

Cooling system

Fanless, natural heat dissipation

Operating

temperature

0°C to 45°C (32°F to 113°F)

Relative humidity

(noncondensing)

10% to 90%

Fire resistance

compliance

UL60950-1, EN60950-1, IEC60950-1, GB4943

Chassis leakage

current compliance

UL60950-1, EN60950-1, IEC60950-1, GB4943

Item

A3100-24-PoE v2 EI

A3100-16-PoE v2 EI

A3100-8-PoE v2 EI

Dimensions (H × W ×

D)

43.6 × 440 × 420 mm

(1.72 × 17.32 × 16.54 in)

43.6 × 300 × 260 mm

(1.72 × 11.81 × 10.24 in)

43.6 × 300 × 220 mm

(1.72 × 11.81 × 8.66 in)

Weight

≤ 6.5 kg (14.33 lb)

≤ 3.5 kg (7.72 lb)

≤ 3 kg (6.61 lb)

Fixed ports

24 × 10/100Base-TX

auto-sensing Ethernet ports

2 combo interfaces

(numbered 25 and 26)

16 × 10/100Base-TX

auto-sensing Ethernet ports

2 combo interfaces

(numbered 17 and 18)

8 × 10/100Base-TX

auto-sensing Ethernet

ports

1 combo interface

(numbered 9)

NOTE:

Each combo interface has one 100/1000Base-X fiber SFP port and one

10/100/1000Base-T auto-sensing copper Ethernet port. These two ports share one port

name and port view and cannot work simultaneously. When you activate one port (by

using the combo enable { copper | fiber } command), the other port automatically shuts

down.

Management ports

1 console port

Input

voltage

AC-input

Rated voltage: 100 VAC to 240 VAC, 50 or 60 Hz

Max voltage: 90 VAC to 264 VAC, 47 Hz to 63 Hz

DC-input

Rated voltage: –47

VDC to –57 VDC

Max voltage: –47 VDC

to –-57 VDC

NOTE:

You can connect the switch

chassis to a –48 VDC power

source or an HP external

RPS A-RPS1600 (JG136A).

N/A

Input current

AC: 8 A

DC: 19.5 A

2.9 A

2 A

PoE switches technical specifications

Table 12 PoE switches technical specifications

41

Page 46

Item

A3100-24-PoE v2 EI

A3100-16-PoE v2 EI

A3100-8-PoE v2 EI

Melting current of

power supply fuse

AC: 10A

DC: 25A

10 A

3.15 A

Max output

power/PoE port

15.4 W

15.4 W

15.4 W

PoE ports

24 8 4

Total PoE output

power

370 W

135 W

70 W

Power consumption

(minimum hardware

and software

configuration)

20 W

16 W

20 W

Power consumption

(full hardware

configuration, all PoE

ports are supplying

power)

AC: 465 W

DC: 400 W

160 W

95 W

Max thermal output

AC: 1586.6265 BTU/h

DC: 1364.8400 BTU/h

545.936 BTU/h

324.1495 BTU/h

Cooling system

Built-in fans

Built-in fans

Built-in fans

Operating

temperature

0°C to 45°C (32°F to 113°F)

Relative humidity

(noncondensing)

10% to 90%

Fire resistance

compliance

UL60950-1, EN60950-1, IEC60950-1, GB4943

Chassis leakage

current compliance

UL60950-1, EN60950-1, IEC60950-1, GB4943

Item

A3100-24-PoE v2 EI

A3100-16-PoE v2 EI

A3100-8-PoE v2 EI

Fans

4 2 2

Airflow

direction

Left side to right side

Left side to right side

Left side to right side

Fan speed

8200 RPM

8200 RPM

6300 RPM

Max airflow

9.4 × 4 CFM

9.4 × 2 CFM

7.17 × 2 CFM

Max power

consumption

1.2 × 4 W

1.2 × 2 W

0.72 × 2 W

Min power

consumption

0.84 × 4 W

0.84 × 2 W

0.5 × 2 W

Table 13 PoE switches fan specifications

42

Page 47

NOTE:

An A3100 v2 EI Switch Series PoE switch automatically disables the PoE function of all ports when the

internal temperature exceeds 65°C (149°F), and re-enables the PoE function of all ports when the

internal temperature drops under 60°C (140°F).

The DC power input and the AC power input on the A3100-24-PoE v2 EI switch can simultaneously work

in redundancy mode.

For more information about the RPS power supplies, see the corresponding user guide of the RPS.

43

Page 48

Item

Specification

Connector type

RJ-45

Compliant standard

Asynchronous EIA/TIA-232

Transmission baud rate

9600 bps (default) to 115200 bps

Services

Provides connection to an ASCII terminal.

Provides connection to the serial port of a local or remote (through a pair of

modems) PC running terminal emulation program.

Item

Specification

Connector type

RJ-45

Interface attributes

10 Mbps, full/half duplex

100 Mbps, full/half duplex

MDI/MDI-X, auto-sensing

Max transmission

distance

100 m (328.08 ft)

Transmission medium

Category-5 twisted pair cable

Standards

IEEE 802.3i, 802.3u

Appendix B Ports and LEDs

Ports

Console port

All A3100 v2 switches have one console port on the front panel.

Table 14 Console port specifications

10/100Base-TX Ethernet port

All A3100 v2 switches provide 10/100Base-TX auto-sensing Ethernet ports on their front panels.

Table 15 10/100Base-TX Ethernet port specifications

Combo interface

All A3100 v2 switches offer combo interfaces. Each combo interface has one 100/1000Base-X fiber SFP

port and one 10/100/1000Base-T auto-sensing copper Ethernet port. These two ports share one port name

and port view and cannot work simultaneously. When you activate one port (by using the combo enable

{ copper | fiber } command, the other port automatically shuts down. For the number of combo interfaces

available on each A3100 v2 switch, see Table 10, Table 11, and Table 12.

44

Page 49

Item

Specification

Connector type

RJ-45

Interface attributes

10 Mbps, full/half duplex

100 Mbps, full/half duplex

1000 Mbps, full duplex

MDI/MDI-X, auto-sensing

Max transmission

distance

100 m (328.08 ft)

Transmission medium

Category-5 (or above) twisted pair cable

Standards

IEEE 802.3i, 802.3u, 802.3ab

Product

code

Description

Central

wavelength

(nm)

Fiber

diamete

r (µm)

Multimode fiber

modal

bandwidth

(MHz*km)

Maximum

transmission

distance

JD118B

HP X120 1G SFP LC SX

Transceiver

850

50/125

500

550 m (1804.46 ft)

400

500 m (1640.42 ft)

62.5/12

5

200

275 m (902.23 ft)

160

220 m (721.78 ft)

JD119B

HP X120 1G SFP LC LX

Transceiver

1310

9/125

N/A

10 km (6.21 miles)

50/125

500

550 m (1804.46 ft)

400

62.5/12

5

500

550 m (1804.46 ft)

JD098B

HP X120 1G

SFP LC BX

10-U

Transceiver

The two

modules

must be

used

together.

TX: 1310nm

RX: 1490nm

9/125

N/A

10 km (6.21 miles)

JD099B

HP X120 1G

SFP LC BX

10-D

Transceiver

TX: 1490nm

RX: 1310nm

9/125

N/A

10 km (6.21 miles)

10/100/1000Base-T Ethernet port

All A3100 v2 switches provide 10/100/1000Base-T auto-sensing Ethernet ports on their front panels.

Table 16 10/100/1000Base-T Ethernet port specifications

100/1000Base-X SFP port

All A3100 v2 switches provide 100/1000Base-X SFP ports on their front panels, and you can install the hot

swappable 100 Mbps or 1000 Mbps SFP transceiver modules in Table 17 or Table 18 in the ports for long

distance connections.

Table 17 Gigabit SFP transceiver module specifications

45

Page 50

Product

code

Description

Central

wavelength

(nm)

Fiber

diamete

r (µm)

Multimode fiber

modal

bandwidth

(MHz*km)

Maximum

transmission

distance

JD324A

HP A3600 Switch SFP

Stacking Kit

N/A

UTP/STP

N/A

1.5 m (4.92 ft)

Product

code

Description

Central

wavelength

(nm)

Fiber diameter

(µm)

Maximum

transmission

distance

JD102B

HP X110 100M SFP LC FX

Transceiver

1310

50/125

2 km (1.24 miles)

62.5/125

JD120B

HP X110 100M SFP LC LX

Transceiver

1310

9/125

15 km (9.32 miles)

JD100A

HP X115

100M SFP

LC BX 10-U

Transceiver

The two

modules

must be

used

together.

TX: 1310

RX: 1550

9/125

15 km (9.32 miles)

JD101A

HP X115

100M SFP

LC BX 10-D

Transceiver

TX: 1550

RX: 1310

9/125

15 km (9.32 miles)

NOTE:

To guarantee the functionality of the SFP ports, always use HP SFP transceiver modules on the A3100 v2

Switch Series.