Page 1

OWNER’S MANUAL

ECONO-MIZER

GRAIN SPREADERS

Models 982, 986 & 996

PNEG-1139

Date: 10-8-07

PNEG-1139

Page 2

Page 3

Econo-Mizer

Safety

SAFETY GUIDELINES

This manual contains information that is important for you, the owner/operator , to know and

understand. This information relates to protecting personal safety and preventing

equipment problems. It is the responsibility of the owner/operator to inform anyone

operating or working in the area of this equipment of these safety guidlines.T o help you

recognize this information, we use the symbols that are defined below.

Please read the manual and pay attention to these sections. Failure to read this manual

and it’s safety instructions is a misuse of the equipment and may lead to serious injury or death.

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid

possible injury or death.

DANGER indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury .

WARNING indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury .

CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury .

CAUTION used without the safety alert symbol indicates a potentially

hazardous situation which, if not avoided, may result in property

damage.

NOTE indicates information about the equipment that you should pay

special attention to.

3

Page 4

Econo-Mizer

1. Disconnect all power before servicing or adjusting. Have bin properly grounded.

2. Do not enter a bin while the unit is operating without proper eye protection.

3. Do not attempt to service or adjust the unit from a ladder unless the ladder is

4. Power cords, plug and receptacles should be the grounded type to prevent injury.

5. All wiring should be done according to the National Electric Code and by a

6. Read and understand the operator’s manual.

WARNING:

Failure to follow these instructions may result in personal injury or property damage.

secured to another piece of equipment or to the bin. The grain spreader can

swing and will not support a ladder. Be sure electrical power is disconnected.

qualified electrician.

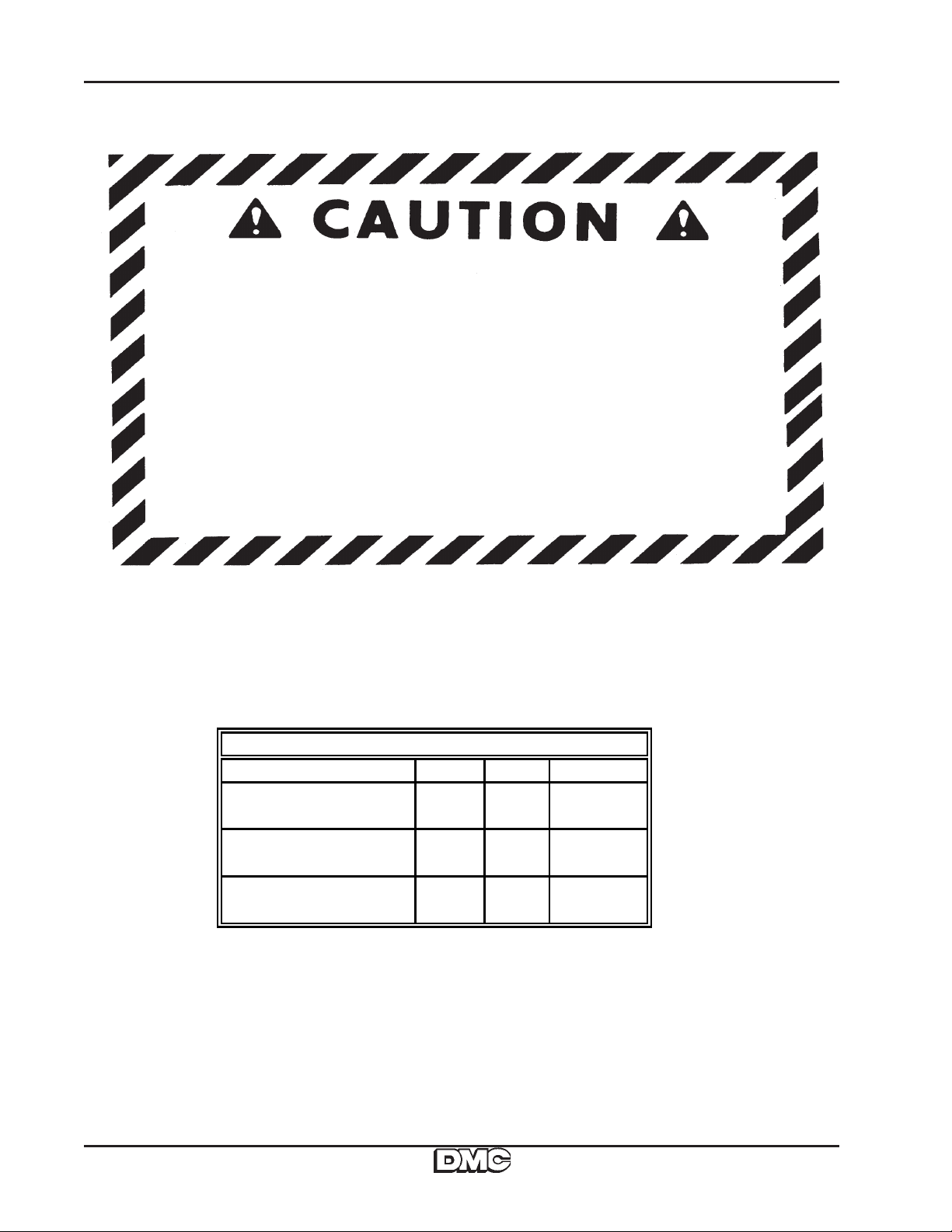

SPREADING CAPACITIES

Econo-Mizer 982 986 996

Heavy Grain 18'-30' 31'-48' 31'-48'

2500 BPH 3500 BPH

Heavy Grain 18'-27' 28'-42' 28'-42'

3500 BPH 5000 BPH

Light Grain 18'-24' 25'-36' 25'-36'

3500 BPH 5000 BPH

4

Page 5

Econo-Mizer

Installation

Figure 1: Hanger Brackets and Chains

The hanger brackets should be positioned

equally spaced around the outer fill hole lip of

the bin. Do not tighten the bracket hardware

until the spreader has been installed and

leveled. Hang the spreader from these brackets by hooking the two chains that are attached to each of the spreader support arms

to two adjacent hanger brackets. When

properly hung, each set of chains will form a

“V” and will restrict random movement of the

spreader.

The spreader can be installed at various

heights in the bin depending on the bin diameter and roof angle. The spreader should be

installed as level as possible by checking with

a level and adjusting the position of the hanger

brackets and/or the lengths of the chains.

Fig. 3

Fig. 4

Installation and Operation

Fig. 1

Fig. 2

Finish the installation by securely tightening

the hanger brackets.

Wiring: Refer to the Wiring Diagram and Tables A & B on the next p age.

ADJUSTMENT & OPERATION

Figure 2: Slide Gate Adjustment

The slide gates are provided in the pan to allow grain to be spread in the center of the bin. These are

usually to be open wider for smaller diameter bins.

Figure 3: Center Cone Adjustment

It is important that the incoming grain be directed onto the center of the baffle cone in order to disperse the grain evenly in the hopper . This cone functions as a flow control and can be adjusted by

lifting it from the spreader and placing the hairpin clip in one of the holes in the baffle post. The cone

needs to be adjusted higher above the spreader pan for greater capacities and lower for lesser

rates. Best spreading results are obtained when the cone is adjusted to maintain a cushion of grain

in the hopper .

Item 4: Slinger Adjustment

982, 986 & 996 Econo-Mizers have slingers that can be adjusted to accommodate various sizes of

bins and grain densities. The slingers will throw grain farther when in the most advanced position

(hole #1) and will not throw as far when in the swept back position (hole #3). A guide line to use for

adjusting is to use the third hole for 18 foot diameter bins, the middle hole for 24 - 30 foot bins and

the first hole for 33 foot and larger bins.

5

Page 6

Installation and Operation

(

)

)

Econo-Mizer

INSTALLATION

Use Tables A & B to determine the proper size of fuse protection and the length and size

of wiring required. Portable extension cords, if used, should be as short as possible to

minimize voltage drop. Cords that are too long, or cords that are made of inadequate wire

gauge, can cause the motor to fail.

TABLE A

MOTOR 25 FT 50 FT 100 FT 200 FT

982 (1/3 hp-115V) #18 GA #16 GA #12 GA #10 GA

986 (1 HP-230V) #14 GA #14 GA #12 GA #10 GA

996 (1-1/2 hp-220V) #14 GA #14 GA #12 GA #10 GA

TABLE B (FUSE SIZE

MOTOR

982 (1/3 hp-115V)

986 (1 HP-230V)

996 (1-1/2 hp-220V)

NON-TIME DELAY

15

15

20

WIRE SIZE

DISTANCE

TYPE OF FUS E

DUAL ELEMENT TIME DELAY

12

12

15

6

Page 7

Econo-Mizer

Installation and Operation

ADJUSTMENT & OPERATION OF

CONE HOPPER BAFFLE

The cone hopper baffle is used to restrict the entering grain and slow it down

enough to ensure that the cone will always be full and overflowing with grain. The

cone baffle should be adjusted high enough above the spreading pan to allow the

overflowing grain to flow between the hopper and the cone baffle and to not flow

over the sides of the main hopper. Entering grain should be directed onto the

expanded metal restrictor on top of the cone baffle.

ECONO-MIZER

305B007 (982, 986)

306B1001 (996)

CONE BAFFLE

7

Page 8

Parts

Econo-Mizer

Models 982, 986, & 996 Econ-Mizer Grain Spreaders

8

Page 9

Econo-Mizer

Parts

MODELS 982, 986 & 996 ECONO-MIZER

GRAIN SPREADERS PARTS LIST

Model s 982, 986, & 996 Econo-Mizer Gr ai n Spreader Part Li st s

Re f. Part No . Part No. P ar t No . De scri p t i o n

No. 982 986 996 982 986 996

1 301A0110 301A0110 301A0110 2 1 1 Sl ide Gat e

2 301A0122 302A0313 302A0313 1 1 1 Rubber Drive wheel

3 301B0220 301B0220 301B0220 3 3 3 Hanger Bracket

4 301B0221 301B0221 301B0221 3 3 3 Hanger U-Bolt Hook

5 302A0304 302A0304 302A0304 1 1 1 Mot or M ount P l ate

6 302A0311 302A0311 302A0311 1 1 1 Torsion Spring

7 304A0002 305A002 305A002 1 1 1 Hopper Bas e & Braces

8 304A0005 305A005 305A005 1 1 1 P an with S li ngers

9 304A0015 305A012 305A012 1 2 2 A djust abl e Sli nger

10 304B0001 304B0001 3061010 1 1 1 Hopper

11 304B0006 305B004 305B004 6 6 6 S upport Chain

12 304N0004 ---- ---- 1 - - 115V P ower Cord wi t h Loose Cli ps

---- 305N005 305N005 - 1 1 220V Power Cord with Loose Clips

13 305B007 305B 007 3061001 1 1 1 Hopper Baffle

14 P T0106 PT0109 P T0109 1 2 2 1" Bearing with Cast Housi ng

15 P T0202 PT0215 P T0215 1 2 2 1" Bearing with Lock i ng Collar

16 P T0401 PT0401 P T0401 1 2 2 1" Locking Coll ar

17 P T0415 ---- ---- 1 - - Bearing Housing-2 Hole

18 1EL0530 1EL0530 1EL0530 2 2 2 Flag Quick Disconnect Cli p

19 3EL5055 ---- ---- 1 - - 1/3 HP 115V

---- ---- 3EL 5088 - - 1 1-1/ 2 HP 230V TENV Motor

---- 3EL5082 ---- - 1 - 1HP TENV Motor

20 S-4198 S -4198 S -4198 2 1 1 1/4" W i ngnut

21 S-4663 ---- S -4663 3 - 1 3/ 8" Hex Lock Nut

22 ---- S-4 663 -- -- - 1 - 3/8 " He x Lo ck Nut

23 S-396 S-396 S -396 10 10 10 5/ 16" Hex Nut

24 ---- S -4663 S -4663 - 2 2 3/8" Hex Nut

25 S-3611 S-3611 S-3611 6 6 6 5/16" Hex F l ange Lock Nut

26 S-7186 S-7186 S-7186 2 2 2 1/4" x 1/ 4" S ock et Hd Set Screw

27 S-6369 S-6369 S-6369 2 1 1 1/4" x 3/ 4" Carraige Bolt

28 S-8072 S-8072 S-8072 4 4 4 5/16" x 3/4" Hex Hd B ol t

29 S - 7105 ---- ---- 2 - - 3/8" x 3/4" H ex Hd Bolt

---- S-7521 S-7521 - 2 2 3/8" x 1" Hex Hd B ol t

30 S-7744 S-7744 S-7744 1 1 1 3/8" x 5-1/2" Hex Hd Bolt

31 2FH0988 2FH0988 2FH0988 5 7 7 5/16" x 1/2" Hex F lange W hi z Loc k S c rew

32 S-6606 S-6606 S-6606 3 3 3 5/16" x 3/4" Hex

33 3FH0769 3FH0769 3FH0769 1 1 1 .08" x 1-5/8" Hair Pi n

34 S-2041 S -2041 S -2041 2 1 1 1/4" Loc k was her

35 S-1147 S -1147 S -1147 10 10 10 5/16" Loc k was her

36 S-1430 S -1430 S -1430 6 5 5 1/4" Loc k was her

37 S-1937 S-1937 S-1937 5 7 7 5/16" SAE Flat Washer

38 S-7409 ---- ---- 2 - - 3/8" SAE Flat Washer

---- S -1054 S -1054 - 2 2 3/8" Loc k W asher

39 S-6371 ---- ---- 1 - - 1/8" x 1" Square Key

---- S -8426 S -8426 - 1 2 1" x 3/ 16" Square K ey

No. Req.

9

Page 10

Trouble Shooting Guide

Econo-Mizer

TROUBLE SHOOTING

PROBLEM

Grain is high on

one side of bin.

Grain is high at the

center of bin.

Grain is low at the

center of bin.

Grain forms “donut”

a few feet from wall.

CORRECTION

a. Spreader is not hung level.

b. Grain is not hitting the center of the baffle

c. The baffle is too high causing the grain to slide off one side.

d. The flow of grain is not adequate to fill the center hopper ,

see instructions for cone baffle hopper .

a. Slide gate is open too far .

b. Check to make sure spreader is running.

c. Grain is overflowing the main hopper - raise center baffle

or slow grain flow rate.

a. Slide gate is not open enough.

b. Slingers on pan are set too far out.

a. Slingers on pan are set too far out (grain is hitting the wall

and bouncing back).

b. Open slide gate to fill center of bin.

c. Spreader model is not adequate for bin size.

Grain not getting

all the way to wall.

Spreader swings

when starting.

Spreader does

not run.

Spreader pan slows

down when loaded.

a. S preader pan is turning the wrong direction: Pan should

turn clockwise when viewed from the top.

b. Rubber drive wheel is slipping - replace if badly worn.

c. Spreader is hanging too high in the center of the bin.

d. Spreader model is not adequate for bin size.

a. Hanging chains are not installed correctly - they should

be equally spaced and positioned as in Figure 2 of

installation instructions.

a. Rubber drive wheel may be slipping due to excessive

moisture or broken motor mount spring.

b. Motor overload may have tripped. It will reset auto matically after the motor has cooled.

c. Blown fuse or circuit breaker.

d. Too much voltage drop. See T able A for proper wiring

size.

a. S preader pan is turning the wrong direction: Pan should

turn clockwise when viewed from the top.

10

Page 11

The GSI Group, Inc. Warranty

THE GSI GROUP, INC. (“GSI”) WARRANTS ALL PRODUCTS WHICH IT MANUFACTURES TO

BE FREE OF DEFECTS IN MATERIAL AND WORKMANSHIP UNDER NORMAL USAGE AND

CONDITIONS FOR A PERIOD OF 12 MONTHS AFTER RETAIL SALE TO THE ORIGINAL END

USER. THE PURCHASER’S SOLE REMEDY AND GSI’S ONLY OBLIGATION SHALL BE TO

REPAIR OR REPLACE, AT GSI’S OPTION AND EXPENSE, PRODUCTS THAT, IN GSI’S SOLE

JUDGMENT, CONTAIN A MATERIAL DEFECT DUE TO MATERIALS OR WORKMANSHIP.

ALL DELIVERY AND SHIPMENT CHARGES TO AND FROM GSI’S FACTORY WILL BE

PURCHASER’S RESPONSIBILITY. EXPENSES INCURRED BY OR ON BEHALF OF THE

PURCHASER WITHOUT PRIOR WRITTEN AUTHORIZATION FROM AN AUTHORIZED

EMPLOYEE OF GSI SHALL BE THE SOLE RESPONSIBILITY OF THE PURCHASER.

EXCEPT FOR THE LIMITED WARRANTY EXPRESSED ABOVE, GSI MAKES NO FURTHER

WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION,

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR

USE IN CONNECTION WITH (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (ii) ANY

ADVICE, INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT,

REPRESENTATIVE OR EMPLOYEE OF GSI REGARDING OR RELATED TO THE

CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY FOR A PARTICULAR PURPOSE,

OR DESIGN OF SUCH PRODUCTS.

GSI SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, INCLUDING, WITHOUT LIMITATION, LOSS OF ANTICIPATED

PROFITS OR BENEFITS. PURCHASER’S SOLE AND EXCLUSIVE REMEDY IS AS SET FORTH

IN THE LIMITED WARRANTY EXPRESSED ABOVE, WHICH SHALL NOT EXCEED THE

AMOUNT PAID FOR THE PRODUCT PURCHASED. THIS WARRANTY IS NOT

TRANSFERABLE AND APPLIES ONLY TO THE ORIGINAL PURCHASER. GSI SHALL HAVE

NO OBLIGATION OR RESPONSIBILITY FOR ANY REPRESENTATIONS OR WARRANTIES

MADE BY OR ON BEHALF OF ANY DEALER, AGENT OR DISTRIBUTOR OF GSI.

GSI ASSUMES NO RESPONSIBILITY FOR CLAIMS RESULTING FROM ERECTION DEFECTS

OR UNAUTHORIZED MODIFICATIONS TO PRODUCTS WHICH IT MANUFACTURED.

MODIFICATIONS TO PRODUCTS NOT SPECIFICALLY DELINEATED IN THE MANUAL

ACCOMPANYING THE EQUIPMENT AT INITIAL SALE WILL NULLIFY THE PRODUCT

WARRANTY THAT MIGHT HAVE BEEN OTHERWISE AVAILABLE.

THE FOREGOING WARRANTY SHALL NOT EXTEND TO PRODUCTS OR PARTS WHICH

HAVE BEEN DAMAGED BY NEGLIGENT USE, MISUSE, ALTERATION OR ACCIDENT. THIS

WARRANTY EXTENDS SOLELY TO ONLY PRODUCTS MANUFACTURED BY GSI. THIS

WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES EXPRESS OR

IMPLIED. GSI RESERVES THE RIGHT TO MAKE DESIGN OR SPECIFICATION CHANGES AT

ANY TIME.

PRIOR TO INSTALLATION, PURCHASER HAS THE RESPONSIBILITY TO COMPLY WITH

ALL FEDERAL, STATE AND LOCAL CODES WHICH MAY APPLY TO THE LOCATION AND

INSTALLATION OF PRODUCTS MANUFACTURED OR SOLD BY GSI.

PHLEGAL: #1832020 v1 (139LG01!.DOC) (revised December 2005)

Page 12

This Equipment shall be installed in accordance

with the cur rent installation codes and applicable

regulations which should be carefully followed in

all cases. Authorities having jurisdiction should be

consulted before installation occurs.

For more information, contact the DMC Distribution Center closest to you.

Illiana Distribution Center

1004 E. Illinois S t.

Assumption, Illinois 62510

Phone: 217-226-5100

F AX : 217-226-5070

Clear Lake Distribution Center

5205 4th Ave South

Clear Lake, Iowa 50428

Phone: 641-357-3386

FAX : 641-357-1928

internet: http://www .dmc-davidmanufacturing.com

Copyright © 1999 by The GSI Group

Printed in the USA

Loading...

Loading...