HP 9130K Service Manual

~===========

SERVICE

MANUAL

HP 9130K

Flexible

Disc

Drive

Service Documentation

Hewlett-Packard Greeley Division

3404 East Harmony Road, Fort Collins, Colorado 80525

ii

Table of Contents

Chapter

Chapter

1:

General

Introduction

General Description

Available

Environmental

Recording Specifications

Environmental Specifications

Physical Dimensions

Performance Specifications

Flexible Disc Media

Intro.duction

Operating Cleanliness

Handling Discs

Do

..................................................................

Don't

................................................................

Write Protection

2:

Interface

Introduction

Interface

Primary Power Requirements

Signal Line Description

Input Control Lines

Output

Typical Interface Drive/Receiver Circuit

Status Lines

Information

..............................................................

.......................................................

Options

and

..............................................................

.............................................................

......................................................

Physical Specifications

................................................

and

Weight

Use

....................................................

..........................................................

..................................................

........................................................

.......................................................

Information

....................................................

....................................................

....................................................

....................................

............................................

.........................................

..............................................

............................................

.......................................

1-1

1-1

1-2

1-2

1-2

1-2

1-3

1-3

1-4

1-4

1-5

1-5

1-6

1-7

1-9

2-1

2-1

2-1

2-3

2-3

2-4

2-8

Chapter

3:

Theory

Introduction

Flexible Disc Recording Fundamentals

Index Pulse

Write Protect

Track 0 Switch

Spindle Motor Drive Control

Head

Position Control

Power

Data Circuitry

Writing Data

Reading Data

On

of

Operation

..............................................................

Shaping

Sensor

Circuit

..........................................................

Network

............................

......................................................

.........................................................

.........................................................

......................................

.................

.......................

.............................................

..................................................

,

...........................

"

...........................

,

...........................

3-1

3-1

3-3

3-3

3-3

3-3

3-4

3-4

3-4

3-4

3-7

iii

Chapter

4:

Assembly

Access

Introduction

..............................................................

4-1

Chapter

5:

Maintenance

Introduction

..............................................................

5-1

Service

Kit

Contents

....................................................

5-1

Drive Failure Analysis

..................................................

5-2

Head

Cleaning

...................................................

"

....

5-3

Termination Resistor

IC

U2F

.............................................

5-3

Shunt

Block U1E

......................................................

5-3

Alignment

and

Adjustments

.................................................

5-3

Introduction

.....................................................

,

....

5-3

Spindle Motor

Speed

Adjustment

....................................

,

....

5-3

Spindle Drive Belt Adjustment

...........................................

5-4

Radial

Head

Alignment

.................................................

5-7

Head

Azimuth Alignment

................................................

5-8

Track 0 Switch Adjustment

..............................................

5-9

Index Emitter/Detector Adjustment

......................................

5-10

Write Protect Switch Adjustment

........................................

5-12

Read/Write Test

......................................................

5-12

DSU Controls

and

Indicators

...........................................

5-13

Disc Service Unit Operation

............................................

5-16

Packaging Instructions

.................................................

5-17

Test Point Location

and

Waveforms

......................................

5-19

Chapter

6:

Schematic

Diagrams

Introduction

..............................................................

6-1

Chapter

7:

Replaceable

Parts

Introduction

..............................................................

7-1

Figures

1-1 Physical Dimensions

.................................................

1-4

1-2 Head/Media Critical Requirements

......................................

1-6

1-3 Damaged Media

.....................................................

1-8

1-4 Loading the Disc

....................................................

1-9

1-5 Write

Protect Tab Installation

..........................................

1-9

2-1

Connector

J2

Pin Out

................................................

2-1

2-2

Connector

J1

Pin Out (Circuit Side)

....................................

2-2

2-3 General Control

and

Data Requirements

.................................

2-5

2-4

Connector

Location

...................................................

2-6

2-5

Connector

J4

Pin Out

................................................

2-6

iv

2-6

Connector

J3

Pin

Out

................................................

2-7

2-7 Servo Electronics Board

Jl

............................................

2-8

2-8 Typical Interface DriverlReceiver Circuit

.................................

2-9

3-1

ID

and

Data Field

Content

............................................

3-1

3-2 Media

Sector

and

Track Structure

......................................

3-2

3-3

Head

Positioning Assembly

............................................

3-3

3-4

9130K Functional Block Diagram

.......................................

3-5

3-5 Write Timing Diagram

................................................

3-6

3-6

Read Timing Diagram

................................................

3- 7

4-1

9130K Flexible Disc Drive Exploded View

...............................

4-2

4-2 Drive Board

and

Servo Board Removal

..................................

4-3

4-3 Front Panel

and

Latch Removal

........................................

4-4

5-1 Spindle Motor

Speed

Adjustment

.......................................

5-4

5-2 Spindle Drive Belt Adjustment

.........................................

5-5

5-3 9130K Test

Setup

...................................................

5-6

5-4

Radial

Head

Alignment Waveform

......................................

5-7

5-5

Head

Assembly Retaining Screws

.......................................

5-8

5-6

Head

Azimuth Waveform

.............................................

5-9

5-7 Track 0 Switch Retaining Screw

........................................

5-9

5-8

Track 0 Waveform

..................................................

5-10

5-9 Index Detector Retaining Screw

.......................................

5-11

5-10

Index to Burst Waveform

............................................

5-12

5-11 Write

IF

Waveform

.................................................

5-13

5-12

Write 2F Waveform

.................................................

5-13

5-13

DSU Controls

and

Indicators

.........................................

5-14

5-14 9130K/DSU Test

Setup

..............................................

5-16

5-15

Foam Latch Insert

..................................................

5-17

5-16

Inner Box

.........................................................

5-18

5-17

Foam End Caps

....................................................

5-18

5-18

Outer

Box

.........................................................

5-19

5-19

Test Point Locations (09130-66501)

...................................

5-19

5-20

Test Point Locations (82901-66515)

...................................

5-20

6-1 Drive Electronics Board PIN

09130-66501

Schematic Diagram

..............

6-3

6-2 Drive Electronics Board

PIN

82901-66515

Schematic Diagram

..............

6-5

6-3 Servo Electronics Board

PIN

09130-66500

Schematic Diagram

..............

6-9

6-4

Servo Electronics Board

Component

Locator

............................

6-11

6-5 Drive Board

PIN

82901-66515

Component

Locator

......................

6-12

6-6 Drive Board

PIN

09130-66501

Component

Locator

......................

6-13

Chapter 1

General Information

Introduction

This service

manual

provides detailed information for servicing

the

9130K

disc drive.

Service

Philosophy

The

9130K

Flexible Disc Drive

is

comprised of

three

serviceable areas:

the

mechanical drive

assembly,

the

drive electronics assembly

and

the

servo electronics assembly.

All

assemblies

are

serviced

on

the

exchange

program

with

the

exception of

some

parts

on

the

mechanical

assembly.

The

field replaceable parts are outlined in

the

maintenance

and

assembly access

sections.

General Description

The

HP

9130K

rnini

double

sided flexible disc drive

is a semi-random

access mass

storage

system employing a flexible magnetic medium.

It

consists of a mini disc drive, a

servo

electronics circuit

board

and

a drive electronics circuit board.

Each drive

module

contains all

the

mechanical parts necessary for physically handling

the

disc.

These

include

the

drive spindle

and

motor, 2

heads

each

having read/write

and

erase

capability, write

protect

sensor, track 0 sensor, index sensor,

and

activity LED

on

the

front

panel. Each

drive

module

also contains a servo control

board

which controls

the

DC drive

motor

speed

and

a drive electronics

board

which interprets

and

generate

control signals,

controls

movement

of

the

read/write

head

to

the

correct position,

and

also

reads

and

writes

data.

The

flexible magnetic

medium

used

in

the

9130K

is

called a flexible disc.

The

flexible disc

measures

133.4

mm

(5.25 inches)

on

a side

and

has a

3.8

cm (1.5 inch) hole for alignment

on

the disc drive spindle.

The

disc

is

enclosed in a protective polyvinylchloride (PVC) jacket

with a slot for access to

the

recording surface. Both sides of

the

flexible disc are

used

for

data

storage.

The

recording

head

in

the

drive

module

is

positioned by a mechanism driven by a

stepper

motor

and

taut

metal

band.

The

head

positioning mechanism

operates

in

an

open

loop

configuration,

that

is,

there

is

no

feedback to the drive electronics

board

to

determine

the

actual position of

the

head.

The

heads

are

mechanically

coupled

to

the

door

mechanism so

that

closing of

the

door

causes

the

heads

to

make

contact

with

the

media.

1-2

General

Information

Available

The

following

Option

This

Option

This

Option

This

4040-1838

Option

This

4040-1915

Option

This

4040-1915

#010

option

#011

option

#050

option

#051

option

#052

option

Options

options

consists of drive

consists of drive

consists of

and

latch PIN 4040-1836

consists of

and

grey latch PIN 4040-1914

consists of

and

brown

are

available with

board

board

the

mechanical

the

mechanical

the

mechanical drive assembly with servo

latch PIN 4040-1913

the

9130K flexible disc drive:

PIN 09130-66501.

PIN 82901-60015

drive assembly with

and

associated hardware.

drive assembly with

and

associated hardware.

and

associated hardware.

found

servo

servo

in

the

8290X series drives.

board

board

board

and

and

and

front

front

front

panel

panel

panel

PIN

PIN

PIN

Environmental

Recording

HP

Physical

Recordng

Rotational

Bit Density: 5456 BPI Track 34

Tracks

Sides

Tracks

Sectors

Bytes

Bytes

Per

Per

Per

Per

Per

Per

Transfer

164,000 bits

Access

Track

Head

Spindle

Time

to

Settling Time: 15 msec. max.

Motor

Environmental

Operating

Temperature:

Specifications

Track

Mode: Modified

Speed:

Inch: 48

Disc: 2

Side: 35

Track: 16

Sector: 256 (362 including

Disc: 286,720 (formatted) 420,000 (unformatted)

Rate

per

Track

Format

Frequency

300 RPM ± 1.5%

second

Seek:

Start

nominal

5 msec. max.

Time: 250 msec. max.

Specifications

Limits

0

+ 10

e to + 44°e (50° F to 111.2°

and

burst

Physical

Modulated

(±

4.5 RPM)

overhead

rate.

Specifications

(MFM)

bytes)

F)

General

Information

1-3

Relative Humidity:

20%

to

80%

with

maximum

wet

bulb

temperature

not

to

exceed

29.4°C

(85°

F)

Altitude: 0

to

4572M

(0 to

15000

feet)

Storage

Limits

Temperature: -41

° C to 71 ° C ( -

40.5°

F to

159.8°

F)

Relative Humidity:

20%

to

80%

with

maximum

wet

bulb

temperature

not

to

exceed

29.4°

C

(85°

F)

Alignment Limits

Radial Alignment: 1.1 mils

maximum

of track

center

at

track

16

measured

at

20° C (68°

F)

and

50%

humidity.

Azimuth:

18°

maximum

clockwise

or

counterclockwise

on

tracks

16

and

34.

Power

Requirements: + 12VDC ± 0.6V @

900ma

nominal

+ 5VDC ±

0.25V @ 600ma

nominal

Media Life

Revolutions

2,500,000

revolutions

on

any

track.

Head

Life: More

than

15,000

hours

of

operation

with

HP

media.

Physical

Dimensions

and Weight

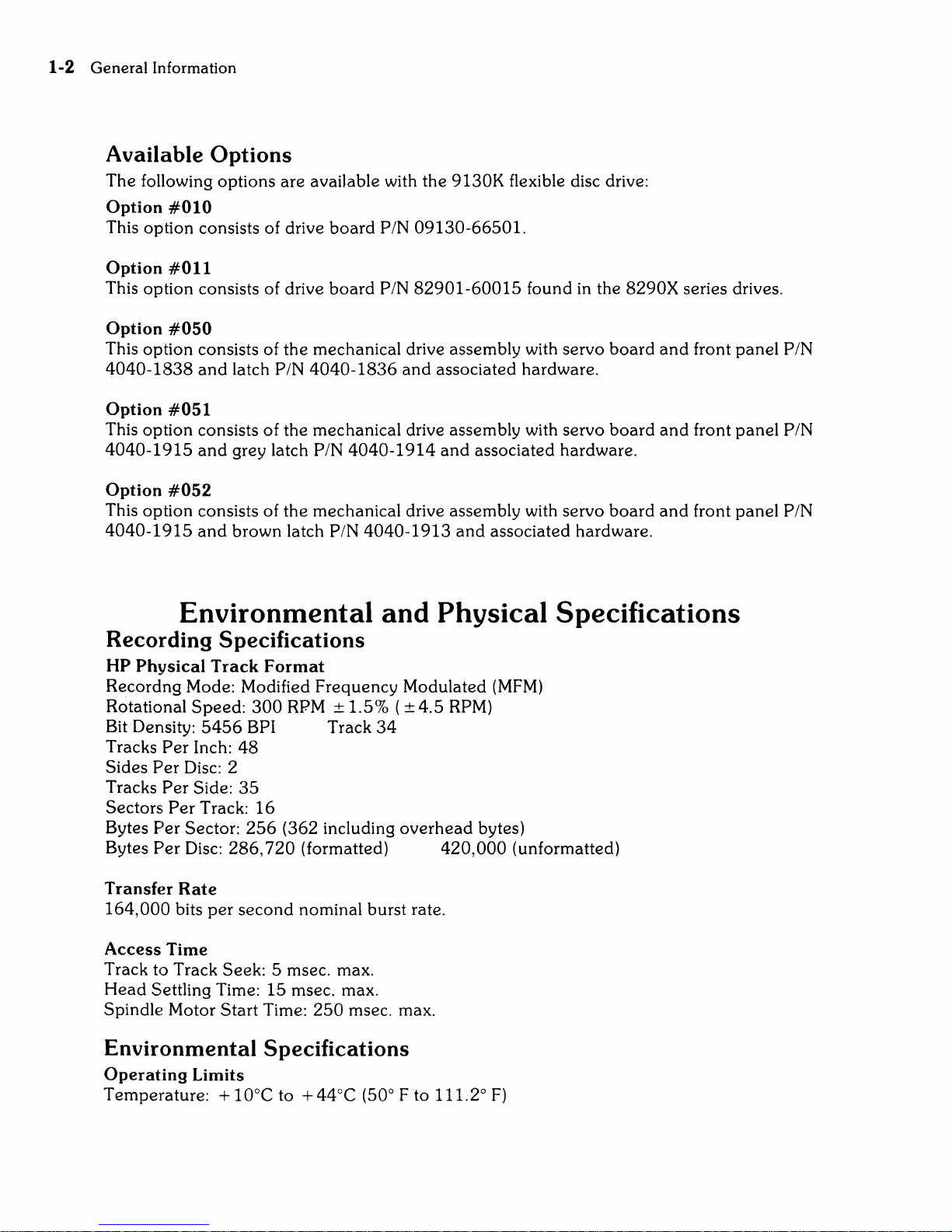

Figure 1-1 illustrates

the

physical dimensions.

Weight:

2.04Kg

(4.5 lbs)

Height:

85.85mm

(3.38

inches)

Width:

149.1mm

(5.87

inches)

Length:

203.2mm

(8 inches)

Performance

Specifications

Soft

Read

Errors: 1 in

109 bits

read

on

inner

most

track

Seek

Errors: 1 in

106 seeks

See

the

9130K

Specification

Document

for further details.

"Hard

Error"

is

defined

as

an

error

that

cannot

be

recovered

from using

an

HP

approved

retry

scheme.

1-4

General

8.37

(212.72)

Information

~-----(l~~6)---

3.12

(79.37)

1.37

(34.92)

SEE

NOTE

*1.87*

*(47.62)*

3

~===~=====::::~~

14--------

6.12(155.57)

*5.87(149.22)*

__

Figure 1-1:

Flexible

Introduction

The

storage

floppy. The flexible disc

(1.125 inch) hole for alignment

plastic jacket with a slot for

are

disc

By

using flexible discs indentified as

stored

amount

appropriate

(HP

discs

catalog, by calling

medium

used

in the

measures

head

used

for

data

storage.

on

each

disc. Since

some

available for user storage

mainframe programming

part

number

the

92190A,

toll free

~I

~

NOTES:

I.

2. * DENOTES

3.

HP

on

the

DIMENSIONS

THIS

133.4

GIVEN

AS

INCHES(MILLIMETRES).

DIFFERING

DIMENSION

9130K

Disc

9130K

TANDON

FROM

BACK

Physical Dimensions

Media

disc drive,

mm (5.25 inches) in diameter

disc drive spindle. The disc

DRIVE

OF

FACEPLATE.

14---

DIMENSIONS.

Use

is

a flexible disc commonly called a

337

=]

(85.72)

and

is

enclosed in a protective

access to the recording surface. Both sides of

"double-sided",

of the storage

depends

or

reference manual for details. Double-sided flexible

package

order

number

upon

of ten) are available from

800-538-8787.

up

to

.25

megabytes of

is

used

in subsystem

overhead,

the controller subsystem. Refer to

HP's

has a

the

data

computer

27.5

mm

flexible

can

the

exact

the

supplies

be

Each flexible disc must

procedure

ies. Refer to

marks

the

mainframe programming

be

initialized before it

each

disc track, checks for defective tracks,

can

be

used

for

data

storage.

and

may establish file director-

or

reference manual for correct procedures.

The

initialization

General Information 1-5

CAUTION

ONLY HP

MEDIA

IS

APPROVED FOR USE

IN

THE 9130K

FLEXIBLE DISC

DRIVE.

USE OF OTHER

MEDIA

MAY

RESULT

IN

PREMATURE DISC FAILURE OR

DAMAGE

TO THE

DRIVE.

HP

MEDIA

WILL

ALWAYS

HAVE

AN/HP

LABEL

ON

IT.

HP RIGOROUSLY TESTS EACH BATCH OF

MEDIA

FOR

ERROR

RATE

AND

WEAR

PERFORMANCE

IN

ADDITION TO

INITIAL

VENDOR QUALIFICATION.

ONLY

IN

THIS

WAY

CAN

HP ASSURE RELIABLE

MEDIA

PERFORMANCE.

THE USE OF NON-HP

MEDIA

FOR SINGLE USE APPLICA-

TlONS SUCH

AS

DATA

INTERCHANGE WILL PROBABLY

NOT

DAMAGE

THE

DRIVE

OR

MEDIA

BUT,

IF

EXTENDED

USE

IS

ANTICIPATED, THE

DATA

MUST

BE

TRANSFERRED

TO HP

MEDIA.

EXTENDED USE OF NON-HP APPROVED

MEDIA

WILL

VOID

WARRANTY

AND

SERVICE CONTRACTS

ON

THE INSTRU-

MENTS.

Operating

Cleanliness

To

prevent

potential

damage

or

data

loss, it is

extremely

important

to

maintain

the

cleanli-

ness

of

the

disc

and

air within

the

disc drive.

The

disc drive

should

not

be

operated

in

an

environment

in which dust,

smoke,

moisture, oil

or

chemical

vapor

or

other

foreign

matter

are

present.

Also,

be

sure

to

strictly follow

the

disc

handling

gUidelines.

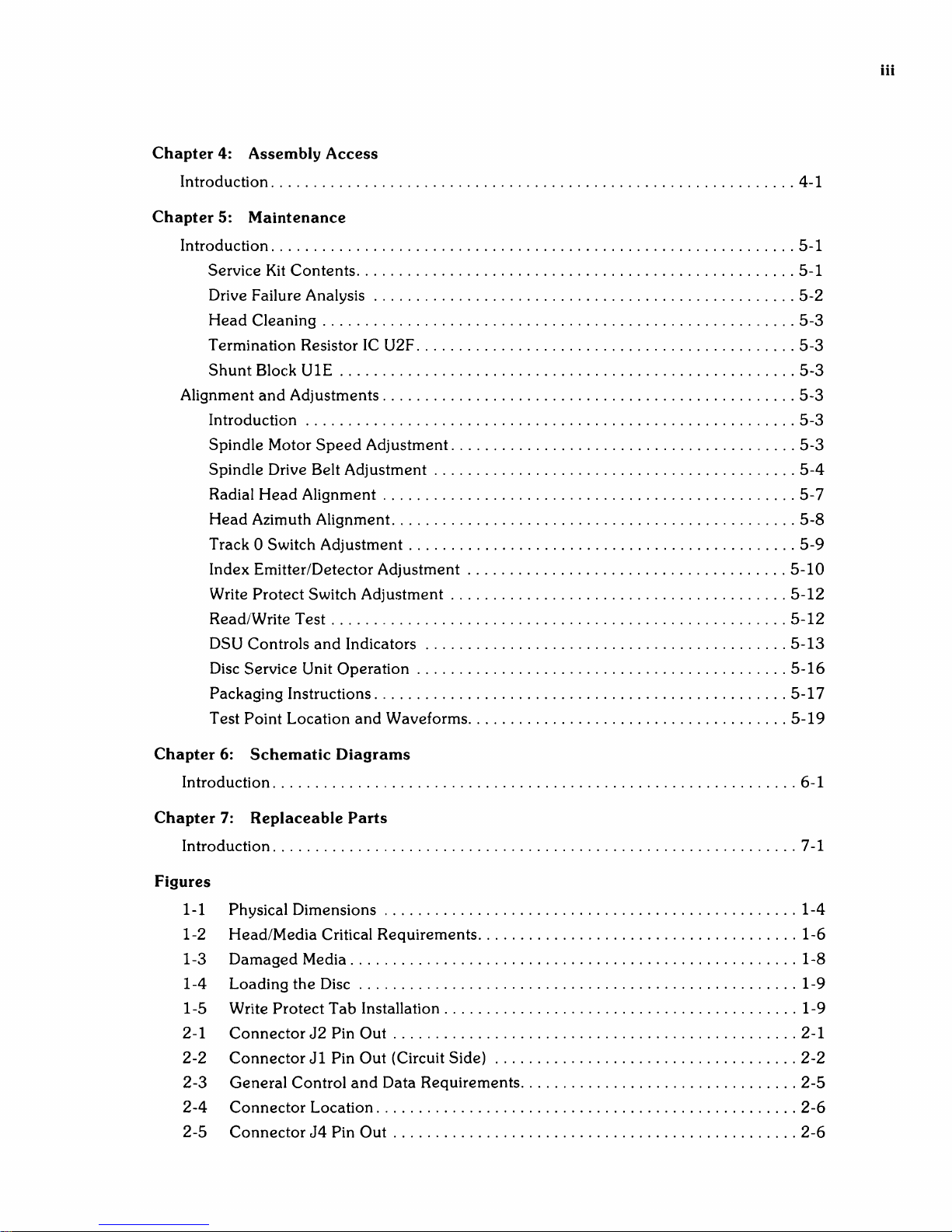

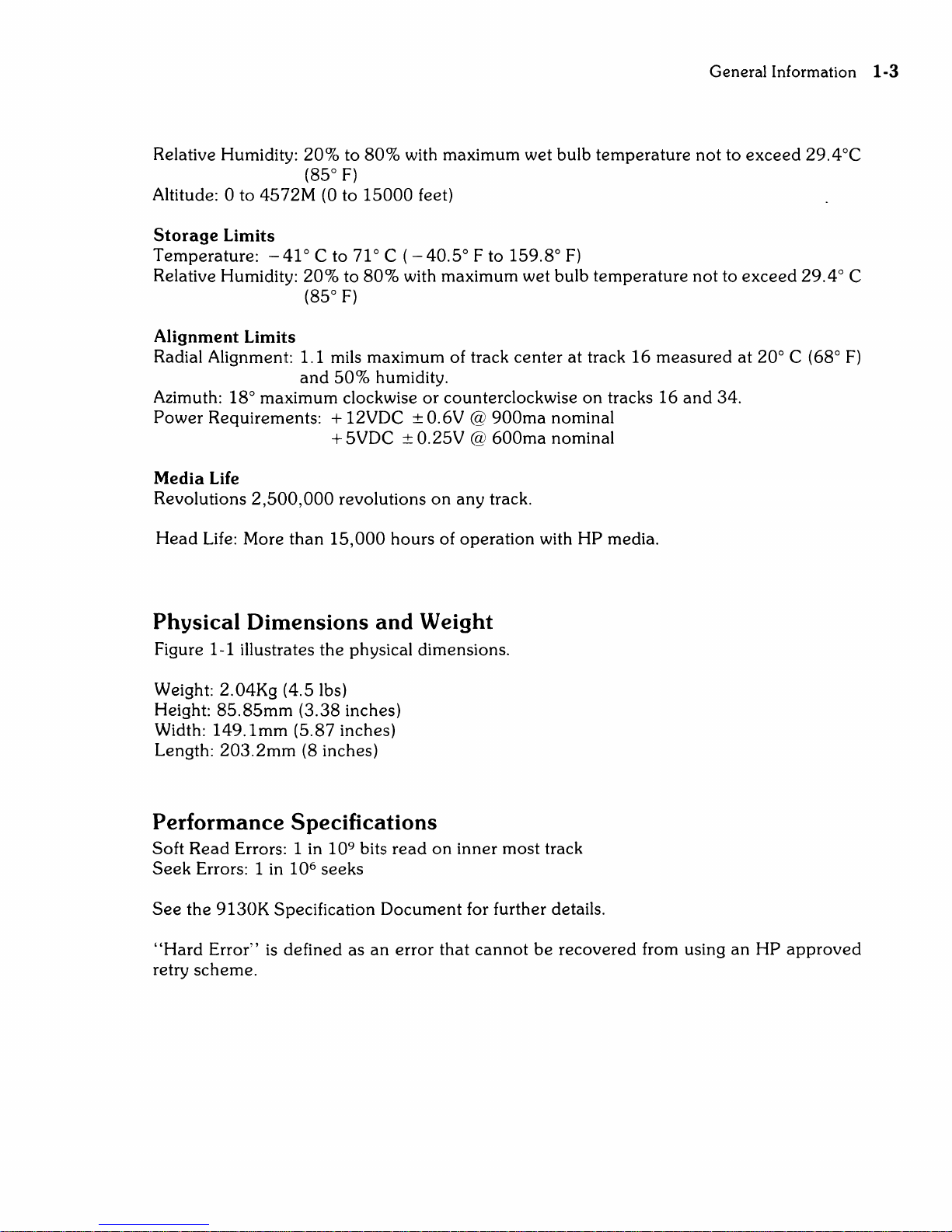

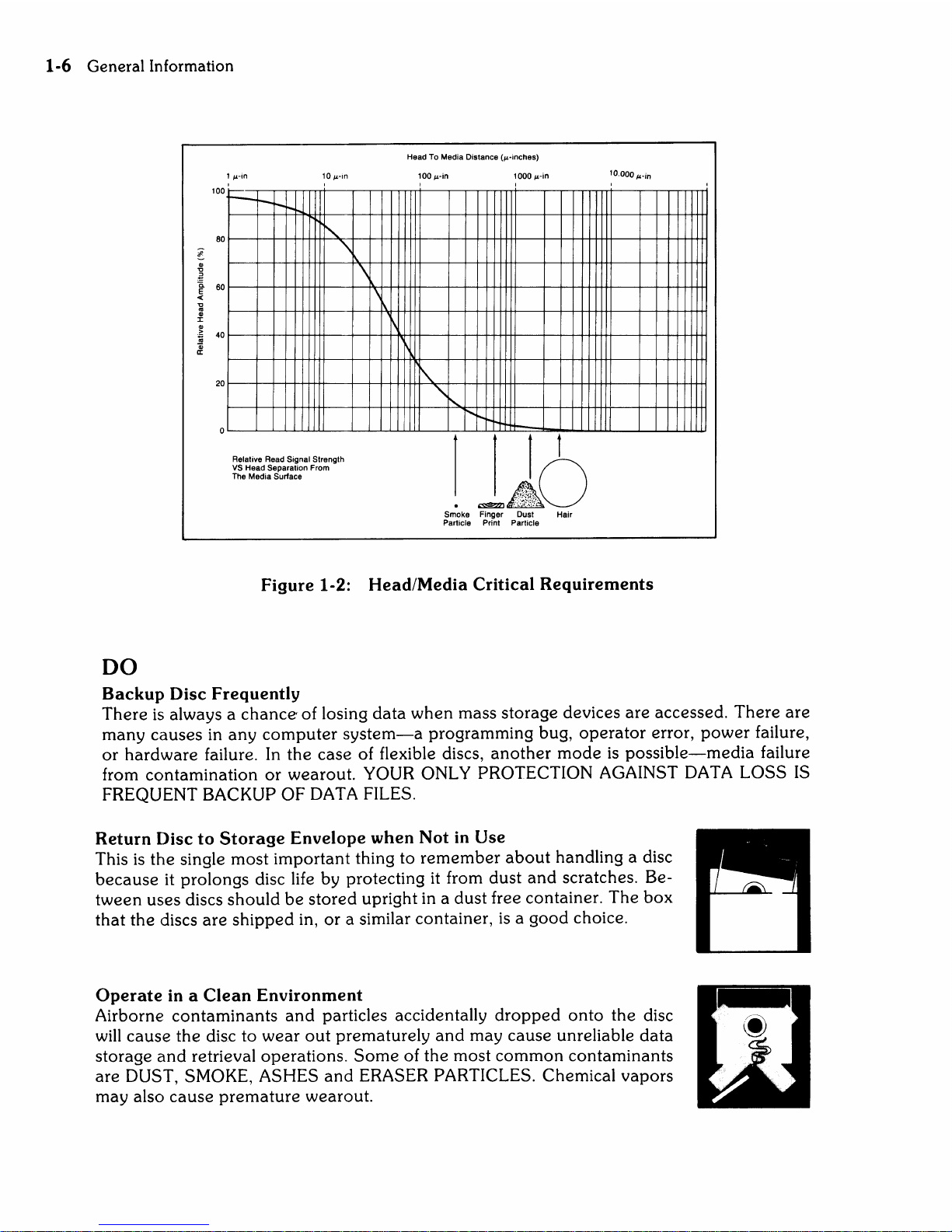

The

critical

elements

involved in

the

read/write

process

are

shown

in Figure 1-2.

The

read/write

heads

must

maintain

contact

with

the

media

during

the

read

and

write

opera-

tions. Also

shown

are

various

types

of

contaminants

and

their size relationships. A

contami-

nant

particle.

hard

enough

and

of

the

right size

may

scratch

either

the

oxide

coating

of

the

disc

or

the

head

surface. Even

if

the

particle is

not

hard

enough

to

scratch, it

may

be

hard

enough

to

lift the

head

from

the

disc

surface

and

cause

data

errors.

Handling

Discs

The

flexible disc

is

basically

maintenance

free,

but

it

is

delicate

and

MUST BE HANDLED

CAREFULLY.

Remember,

the

disc

contains

your

valuable

data

and

programs

and

should

be

treated

accordingly. A

good

rule of

thumb

is

to

treat

the

disc

as

you

would a valuable

record

album.

Here

are

some

specific

DO's

and

DON'Ts

to

avoid

loss of

data

or

damage

to

the

discs.

EVEN A LITTLE

CARELESSNESS

IN

DISC HANDLING CAN DRAMATICALLY REDUCE

THE LIFE

OF

THE

DISC.

1-6 Generallnformation

100

80

!

~

60

«

'C

os

Q)

J:

Q)

~

40

Qi

II:

20

1

win

r--

r-

r-I'-o

"

'\

Relative Read Signal Strength

VS

Head Separation From

The Media

Surface

\

\

1\

~

Head To Media Distance

(winches)

100W

in

1000

win

I

I

I\.

,,~

........

"

"'t--

1

t

~~

~:;;;~.;~.~.

.

..-AO

Smoke Finger Dust Hair

Particle Print Particle

10.0001'-in

Figure

1-2:

Head/Media

Critical

Requirements

DO

Backup

Disc

Frequently

There

is

always a chance' of losing

data

when

mass

storage

devices

are

accessed.

There

are

many

causes

in

any

computer

system-a

programming

bug,

operator

error,

power

failure,

or

hardware

failure. In

the

case

of flexible discs,

another

mode

is

possible-media

failure

from

contamination

or

wearout.

YOUR ONLY PROTECTION AGAINST DATA

LOSS

IS

FREQUENT BACKUP

OF

DATA FILES.

Return

Disc

to

Storage

Envelope

when

Not

in

Use

This

is

the

single

most

important

thing to

remember

about

handling a disc

because

it

prolongs

disc life by protecting it from

dust

and

scratches. Be-

tween

uses

discs

should

be

stored

upright in a

dust

free container.

The

box

that

the

discs

are

shipped

in,

or

a similar container,

is a good

choice.

Operate

in a

Clean

Environment

Airborne

contaminants

and

particles accidentally

dropped

onto

the

disc

will

cause

the

disc to

wear

out

prematurely

and

may

cause

unreliable

data

storage

and

retrieval

operations.

Some

of

the

most

common

contaminants

are

DUST, SMOKE, ASHES

and

ERASER PARTICLES. Chemical

vapors

may

also

cause

premature

wearout.

General Information

1-7

Maintain

Proper

Temperature

and

Environment

The

proper

operating

range

for

the

9130K

is

10

C (500 F)

to

44

C (1110 F)

and

20%

to

80%

relative humidity. While

temperature

is

usually

easy

to

control, it

may

be

necessary

to

make

special provisions to

keep

the

humid-

ity in

the

proper

range. Although

the

disc

will

continue

to

operate

outside

the

normal

recommended

humidity range,

it

will

wear

out

more

quickly

and

will

produce

a higher

error

rate.

Avoid

Magnetic

Fields

Since

the

data

is

stored

as a pattern

of magnetic fields

on

the

disc, it

can

easily

be

erased

by

an

external

magnetic field. Avoid placing a disc

near

power

transformers,

magnets

or

large disc memories. Additionally, while

HP

goes

to

great

lengths to confine

the

magnetic fields

produced

by CRT

deflection shields,

CRT's

with

magnetic

deflection

systems

have

been

known

to

destroy

data

on

discs,

and

it

is a good

idea

to avoid placing discs

on

top

of CRT's.

Remove

Disc

from

Drive

when

Not

in

Use

Remove

the

disc completely from

the

drive

when

access

is

not

needed

for

an

extended

period

of time.

Use a Felt

Tip

Pen

to

Label

Discs

Use a soft felt tip

pen

to label

the

disc,

and

be

careful to write only in

the

label

area

provided.

Avoid

the

exposed

media

while labeling

the

disc.

If

possible, write

on

the

large labels BEFORE applying

them

to

the

disc

jacket.

Replace

Discs

Frequently

j l

~

Although discs

are

designed

to provide several million revolutions of useful life

(approx-

imately 2

to 4 months

of

use),

they

will eventually

wear

out.

The

life of a disc

is

VERY

dependent

upon

how carefully it

is

handled

and

how

much

it

is

used.

If

there

are

ever

visible

signs of

abrasions

on

the

disc,

do

an

immediate

backup

and

discard

the

worn disc.

DON'T

Do

Not

Touch

the

Exposed

Surface

of

the

Disc

The

thickness of a fingerprint

is

enough

to lift

the

head

off

the

disc

and

cause

errors

(See

Figure 1-2).

The

oils in a fingerprint will also collect

dust

which

can

cause

a disc to

wear

out

sooner

than

it normally would. Be

especially careful

when

handling

the

disc as it

is

very

easy

to grasp

the

disc

with a

thumb

directly

over

the

exposed

media.

1-8

General

Information

Do

Not

Bend

or

Fold

the

Disc

The

disc

is

flexible

but

will

not

operate

if

it

is

creased.

Using ball

point

pens,

rubber

bands,

paper

clips, etc.

can

crease

the

disc.

Do

Not

Try

to

Clean a Disc

The

inside

surface

of

the

disc

jacket

is

covered

with a special material

that

cleans

the

disc

as

it

rotates. Any

other

method

of

cleaning

may

cause

solvent

damage

to

the

media

or

scratch

the

disc,

causing

loss of data.

If

a disc

becomes

dirty

or

scratched,

immediately

copy

the

data

to a

new

disc

and

dispose

of

the

old disc.

Disc

Loading

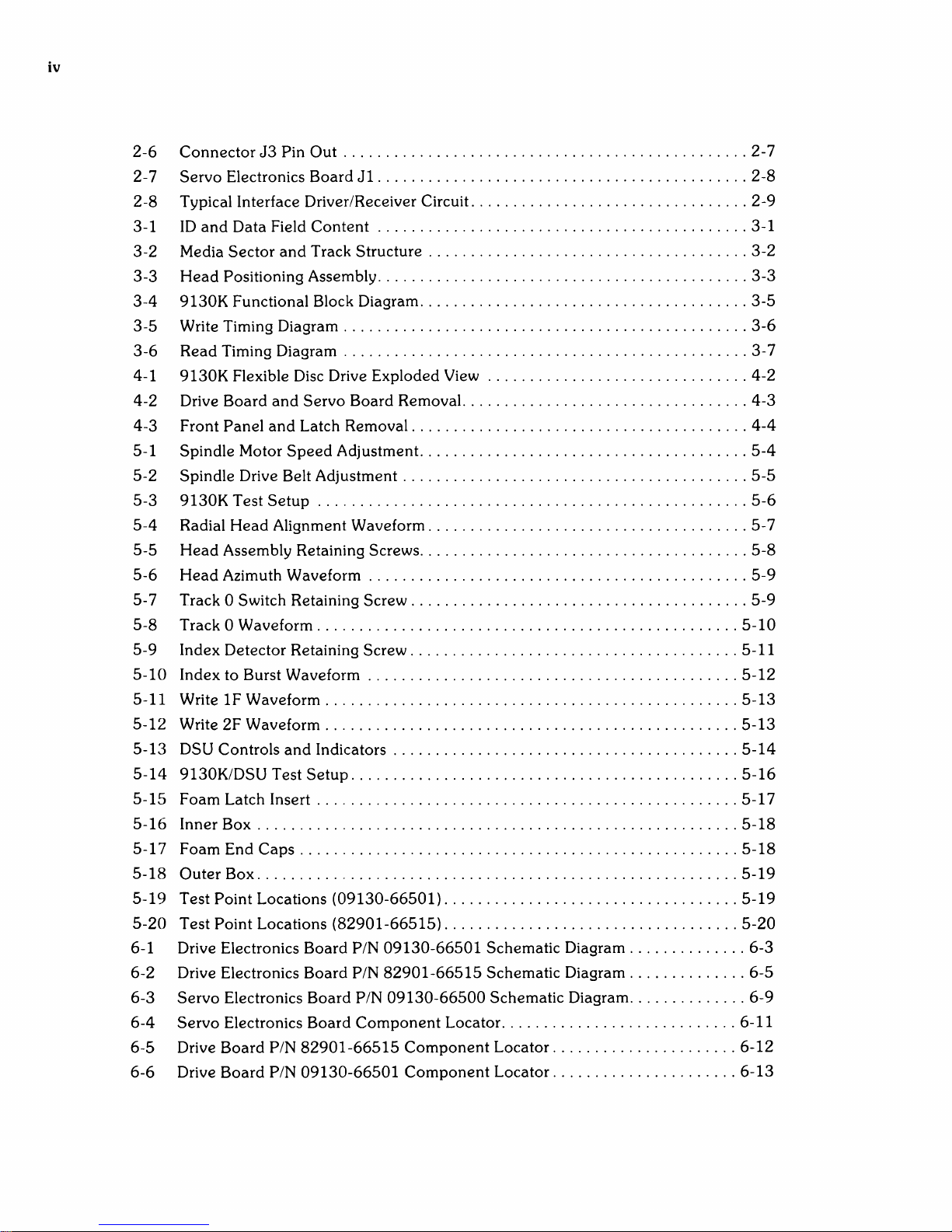

CAUTION

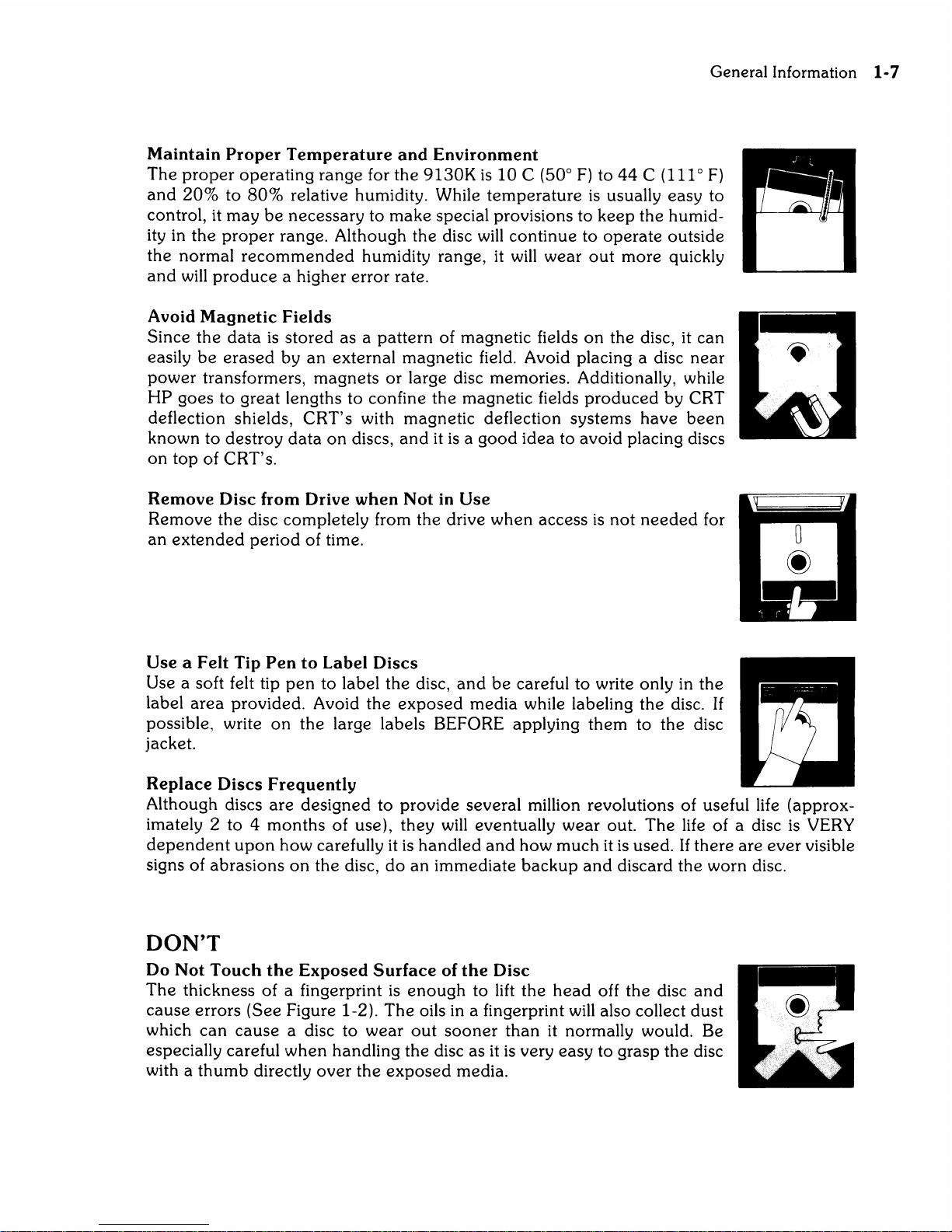

IF

MEDIA

IS

EVER

DESTROYED

(IF

IT

LOOKS ANYTHING

LIKE

THE PHOTO BELOW)

IN

YOUR 9130K DISC

DRIVE,

STOP USING THE

DRIVE

UNTIL

IT

CAN

BE

SERVICED. THIS

IS

EXCEPTIONALLY IMPORTANT,

AS

CONTINUED

USE

OF

THE

DRIVE

WILL

DESTROY

MORE

MEDIA.

IMMEDIATELY

CALL YOUR NEAREST HP SALES SERVICE OFFICE (SEE THE

LIST

IN

THE

BACK

OF

THIS

MANUAL

FOR THE NEAREST

OFFICE).

Figure

1-3:

Damaged

Media

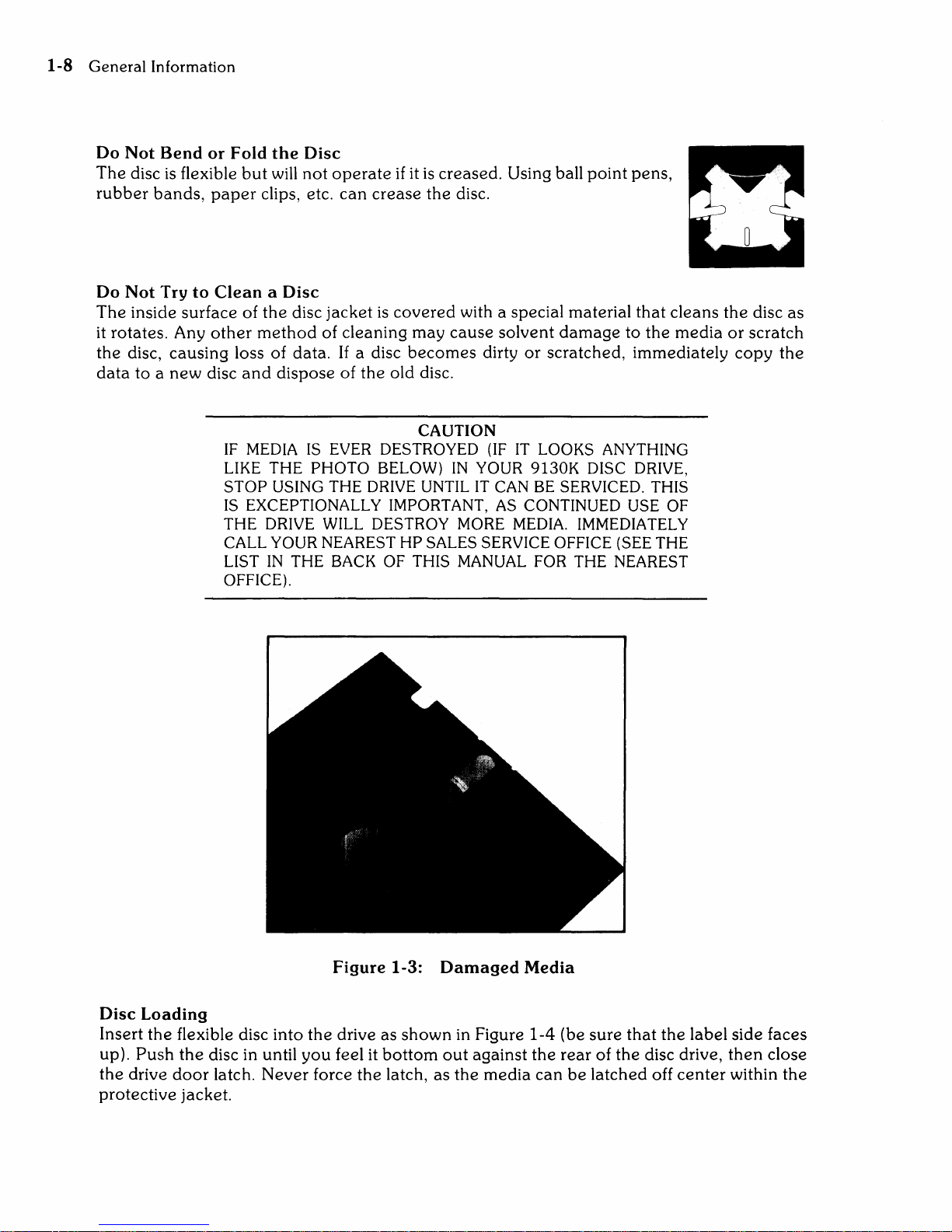

Insert

the

flexible disc into

the

drive as

shown

in Figure

1-4

(be

sure

that

the

label side faces

up).

Push

the

disc in until

you

feel it

bottom

out

against

the

rear

of

the

disc drive,

then

close

the

drive

door

latch.

Never

force

the

latch,

as

the

media

can

be

latched

off

center

within

the

protective

jacket.

General

Information

1-9

Figure 1-4: Loading

the

Disc

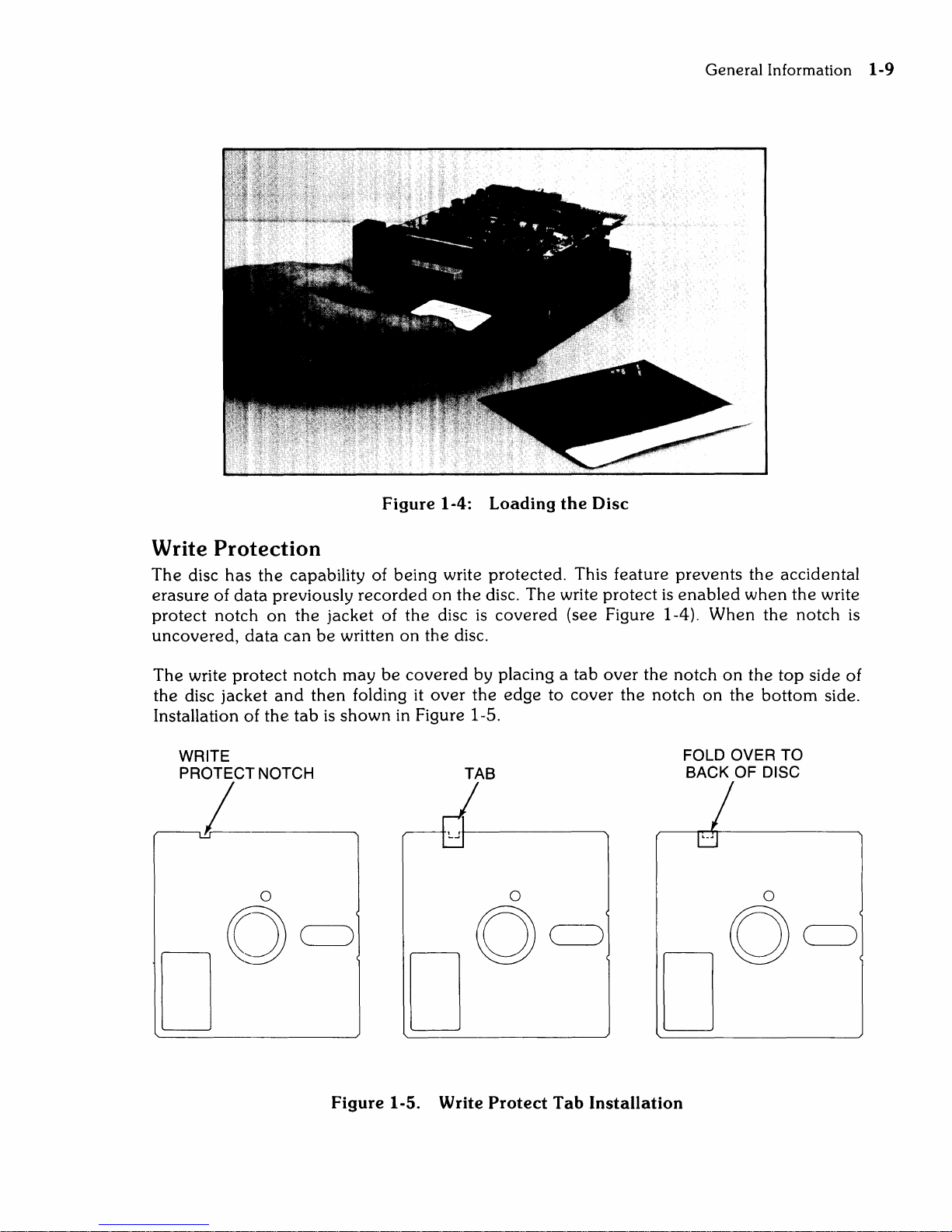

Write Protection

The

disc

has

the

capability of

being

write protected. This feature

prevents

the

accidental

erasure

of

data

previously

recorded

on

the

disc.

The

write

protect

is

enabled

when

the

write

protect

notch

on

the

jacket

of

the

disc

is

covered

(see Figure 1-4).

When

the

notch

is

uncovered,

data

can

be

written

on

the

disc.

The

write

protect

notch

may

be

covered

by placing a

tab

over

the

notch

on

the

top

side

of

the

disc

jacket

and

then

folding it

over

the

edge

to

cover

the

notch

on

the

bottom

side.

Installation of

the

tab

is

shown

in Figure 1-5.

WRITE

PROTECT NOTCH

.,,--------,L

o

TAB

o

Figure 1-5. Write Protect Tab Installation

FOLD OVER TO

BACK OF DISC

o

Chapter

2

Interface Information

Introduction

This

chapter

provides

the

interface information for

the

9130K

Flexible Disc Drive.

The

information

provided

in this

chapter

includes

connector

locations

and

pin-outs, signal line

descriptions

and

typical interface driver

and

receiver circuits.

Interface

The

flexible disc drive

110

connector

(J1)

is

located

on

the

rear

edge

of

the

drive electronics

board.

The

34

pin

edge

connector

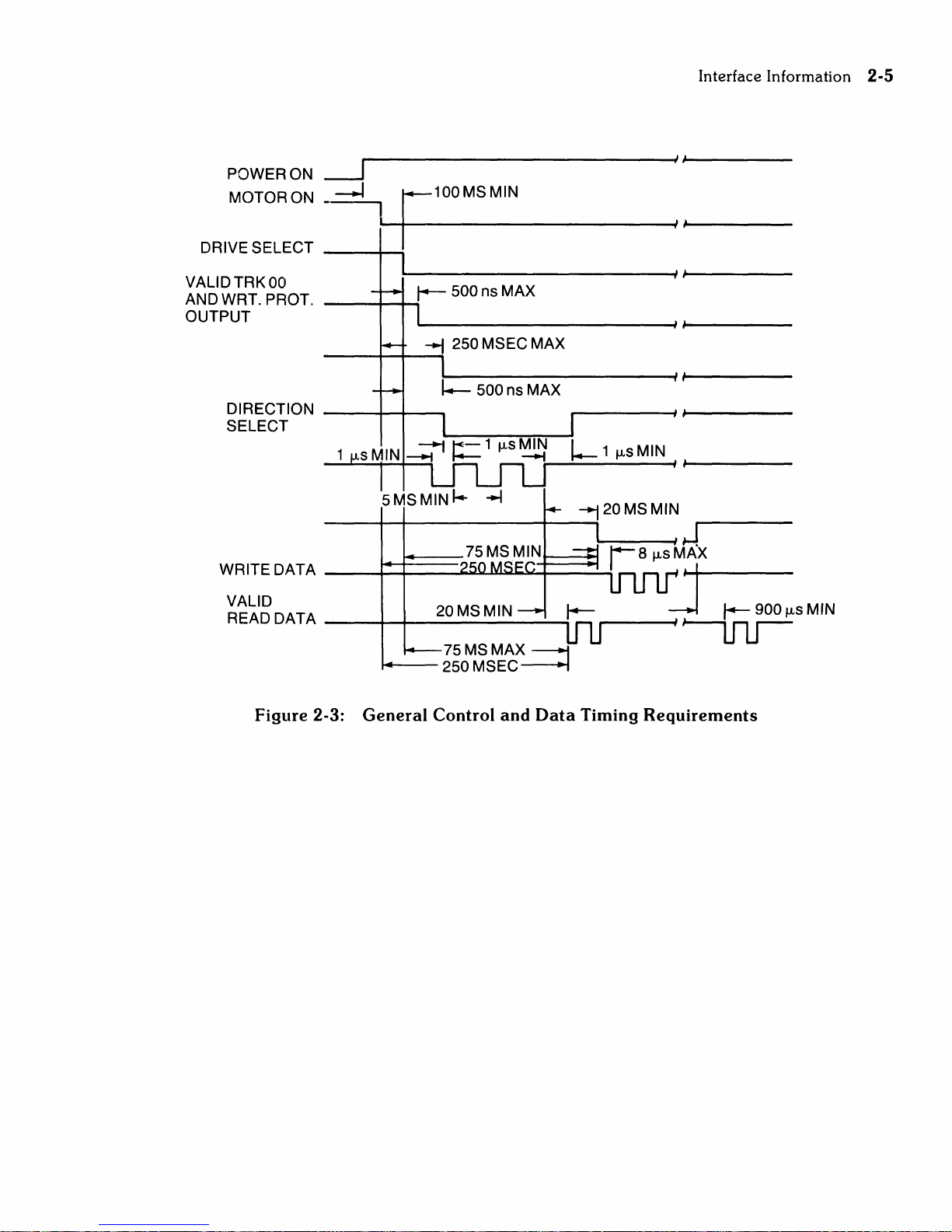

mates

with

the

HP

connector

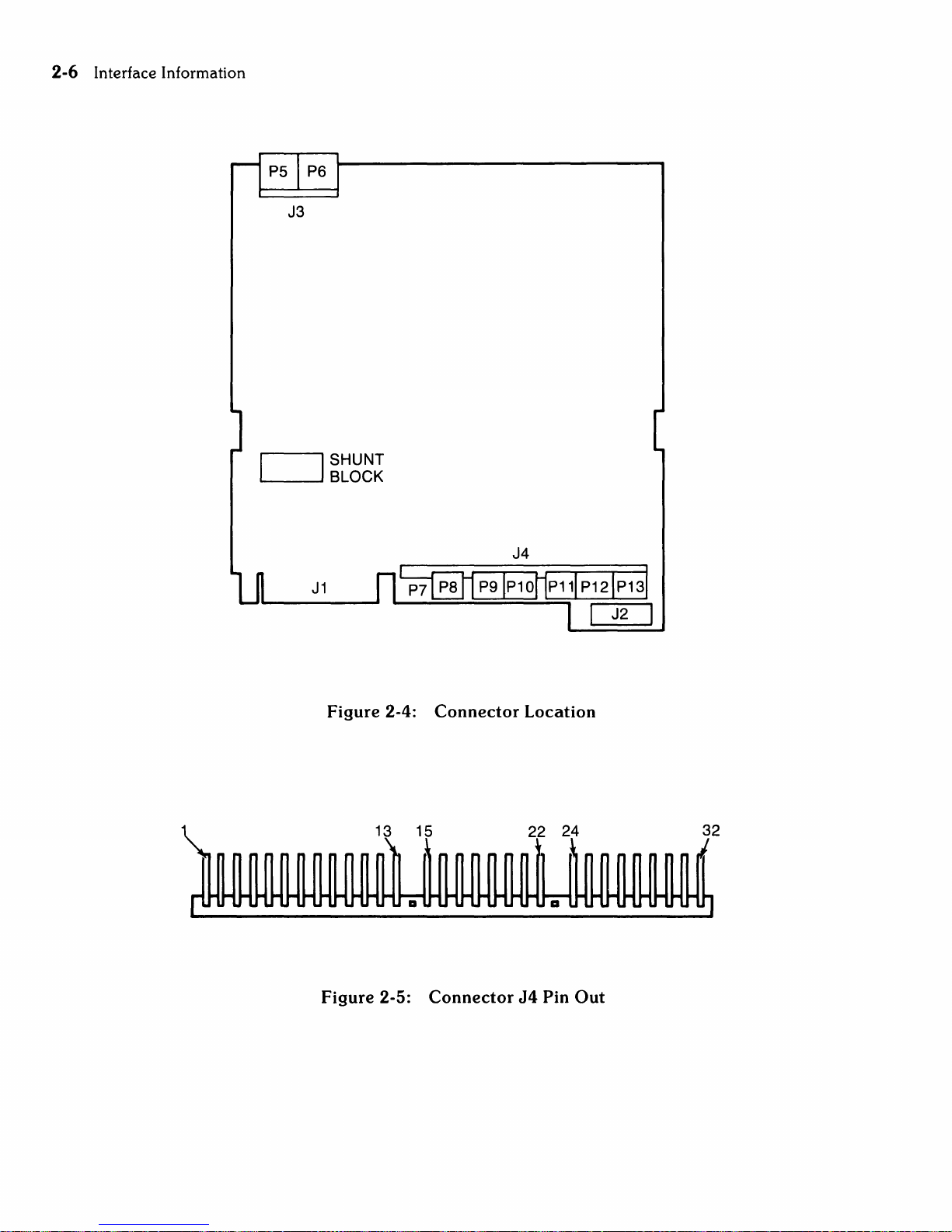

part

number

1251-3916.

Primary

Power

Requirements

+12VDC

±0.6VDC

@ 900MA

(MAX)

+5VD ± 0.25VDC @ 600MA

(MAX)

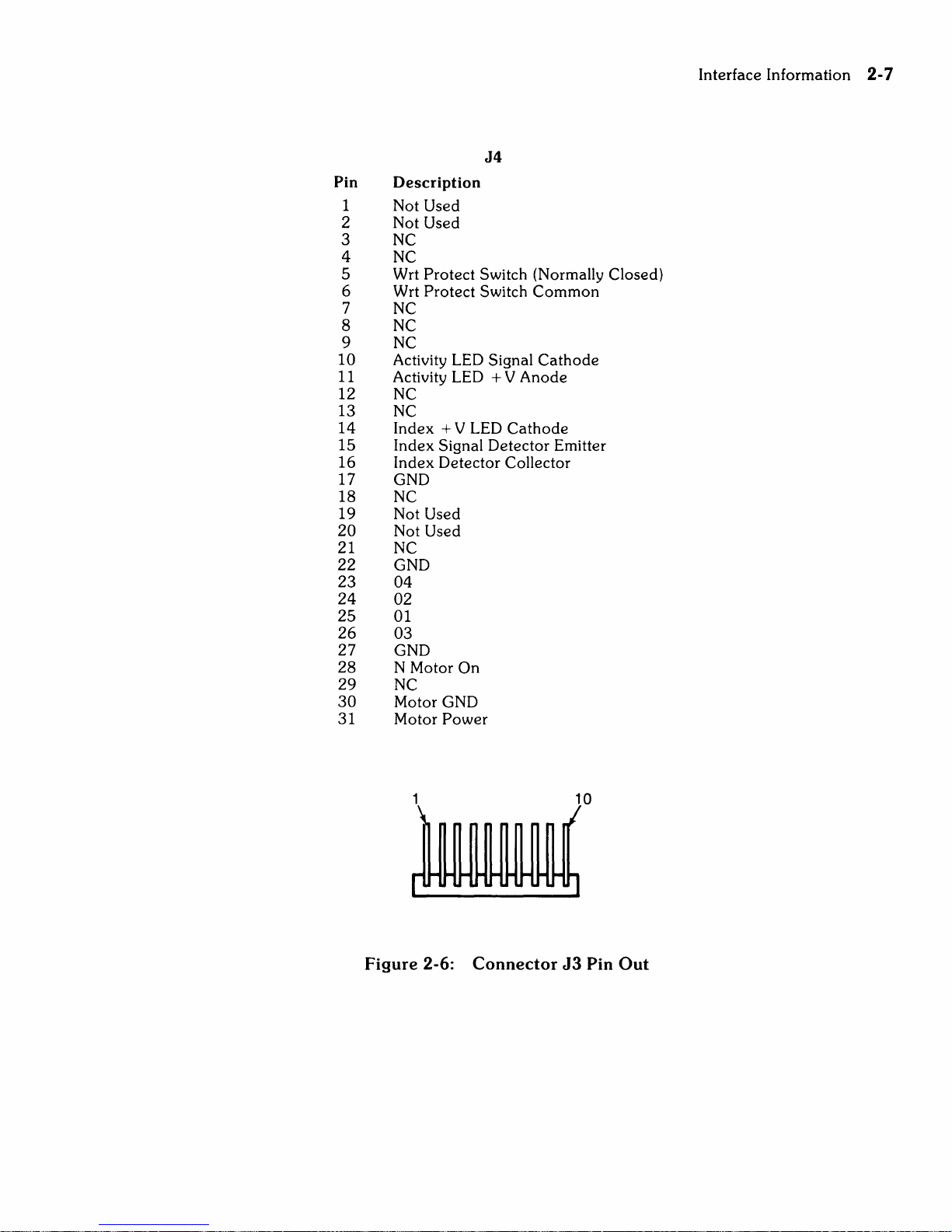

Maximum ripple

100

MV

PP

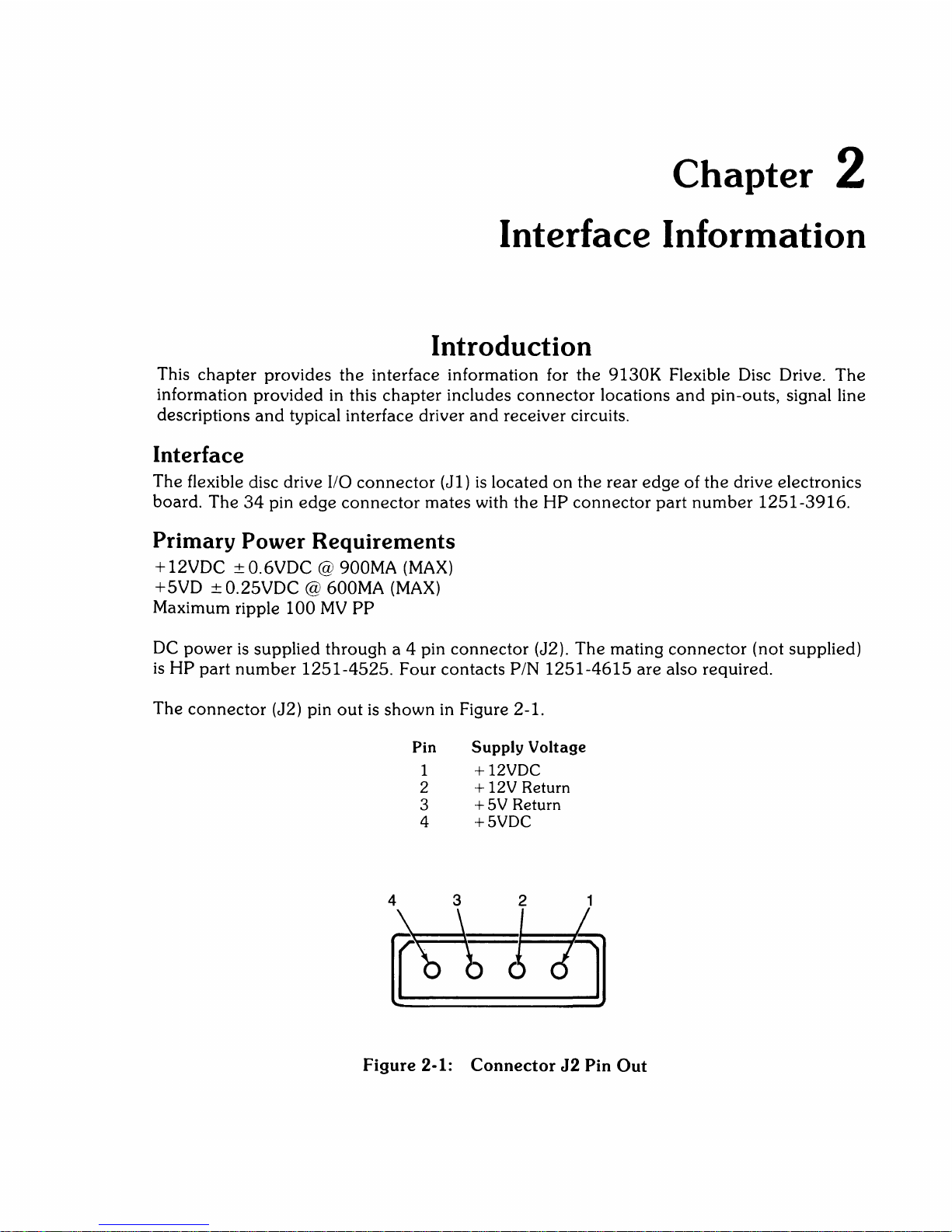

DC

power

is

supplied

through

a 4 pin

connector

(J2).

The

mating

connector

(not supplied)

is

HP

part

number

1251-4525.

Four

contacts

PIN

1251-4615

are also required.

The

connector

(J2) pin

out

is

shown

in Figure 2-1.

Pin

Supply

Voltage

1 + 12VDC

2 + 12V Return

3

+5V

Return

4

+5VDC

Figure

2-1:

Connector

J2

Pin

Out

2-2

Interface Information

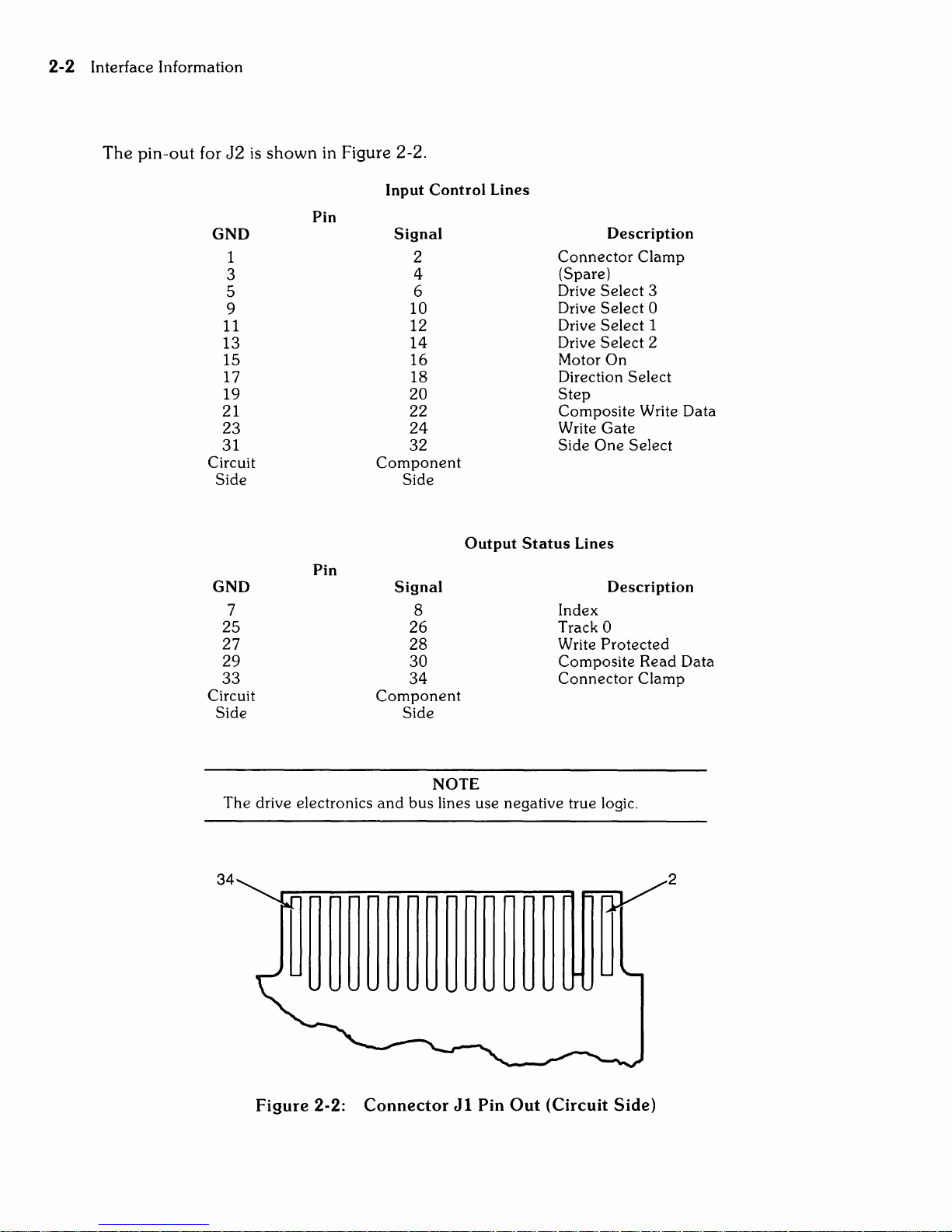

The

pin-out

for

J2

GND

1

3

5

9

11

13

15

17

19

21

23

31

Circuit

Side

is

shown

in Figure 2-2.

Input Control Lines

Pin

Signal

Component

2

4

6

10

12

14

16

18

20

22

24

32

Side

Description

Connector

(Spare)

Drive Select 3

Drive Select 0

Drive Select 1

Drive Select 2

Motor On

Direction Select

Step

Composite Write Data

Write

Side

Gate

One

Clamp

Select

Output

Pin

GND

7

25

27

29

33

Circuit

Side

The

drive electronics

34 2

Signal

8

26

28

30

34

Component

Side

NOTE

and

bus lines use negative true logic.

Status

Lines

Description

Index

0

Track

Write

Protected

Composite Read Data

Connector

Clamp

Figure 2-2: Connector

Jl

Pin Out (Circuit

Side)

Interface

Information

2-3

Signal

Line Description

Input Control Lines

Drive

There

disc drives

When

the drive

The drive select line must remain stable in

command

When

status lines

There

The disc drive

electronics circuit board.

chaining a maximum of

if

select lines are low simultaneously.

Select

more

Lines

are

four drive select lines which are

attached

the

logic level

will

is

the

logic level

are

is

also a

than

respond

completed.

one

to the controller.

on

the

to

step

on

the drive select lines

disabled.

user

installed option

address

drive

is

three

is

drive select line

or

Read/Write commands.

determined

The

drive select lines 1 through 3 provide a

disc drives to a controller. An undefined

assigned the

jumper

by a select

same

used

is

available

for selecting

low, the disc drive electronics

the

low state until the

are

high, the input control lines

to

code

select

code

and

de-selecting

step

utilize a fourth drive select line.

shunt

block located

or

if

more

operation

than

one

are

enabled

or

Read/Write

and

on

means

may

one

of the drive

of

three

and

output

the

drive

of daisy

result

Motor On

A low logic level

250

msec.

Direction

When a disc drive

appearing

determined by

issued. A high logic level

direction of motion

direction select line results in the inward direction (step in) of motion toward

ensure

To

prior to the

motion

Consecutive trailing

The drive electronics

•

The

• The direction select

•

The

When

Select

on

proper

is

initiated

write gate line

drive

on

this line causes the drive motor to accelerate

this line goes high,

and

Step

Lines

is

selected, a low pulse greater

the

step

line initiates

the

logic level

is

outward (step-out) away from the

positioning, the direction select line should

step

pulse

on

the

edges

will

is

is

not

selected.

appearing

on

the direction select line when the

and

remain stable until 1

trailing

of

step

ignore

low.

is

high

the

drive

motor

head

assembly motion. The direction of this motion

on

the direction select line

edge

of the step pulse.

pulses should not

step

and

pulses

the

if

any of the following conditions exist:

head

position

and

decelerates to a stop.

than 1 /-Lsec.

center

/-Lsec.

be

is

after

less

then

at track

of the disc. A logic low

but

when

step

be

stable 1 msec. minimum

the

step

5 msec. apart.

O.

stabilize in less

less

pulse

pulse.

than

the

step

is

the

disc center.

The

2 msec.

pulse

issued

on

access

than

is

is

the

the

2-4

Interface

Information

Composite

When

that

control

be

must

Write Gate

When

disabled). This line

is

Data

Changes

the

write

If

a write

of

the

Side

One

The

Side

transfer.

A high logic level selects

read/write

Write

the

disc drive

the

enabled

this line

written

write gate

is

of

state

gate

line

protected

Select

One

head.

Data

is

switching of

by

the

low,

the

enables

under

Select

the

on

the

is

high, all write electronics are disabled.

disc

and

side

line defines which side of a two sided disc

selected, this line provides

the

write

current

write gate line.

write electronics are

write

current

control of the composite write

write

gate

line

is

installed;

one

the

side'

the

select lines.

'0"

to flow in

should

write electronics are disabled irrespective of

read/write

in

enabled

occur before

head

the

bit serial composite write

the

selected head.

for writing

the

selected read/write head.

data

line

the

first write

and

a low logic level selects

data

and

is

The

used

data

pulses

write electronics

(read electronics

side

one

select line.

data

pulse.

for information

the

the

When

side 1

are

state

Output

Index

An

index

begining of a track.

The

remains low for

Track 0

This line indicates to the controller

track a signal remains low until

anding

Write Protected

This line goes low

When

may

an

error

Composite

Data

flux transition

Status

pulse occurs

leading

the

be

and

edge

the

track a switch

write

performed.

condition will

Read

clock transitions are transmitted

Lines

of this signal

the

duration of

when

protect

If

the

Data

detected

once

every revolution of the disc (200 msec. nominal) to indicate

and

phase

the

disc

line

goes

controller issues a write

be

reported

by

the

is

used

the

the

is

high,

head

to insure

index

that

the

head

a of

the

write

protected

the

to

the

provides a logic low pulse of 1

data

accuracy during format.

pulse.

read/write

is

moved

stepper

write electronics are

command

host system.

on

this line

head

from track

motor

to disable the write electronics.

when

control.

when

the

is

enabled

positioned

O.

This

is

and

the disc

disc drive

J-lsec.

±.

The

index

on

track

O.

accomplished

write

operations

is

write

protected

is

selected. Each

25

on

this line.

the

line

The

by

Interface

Information

2-5

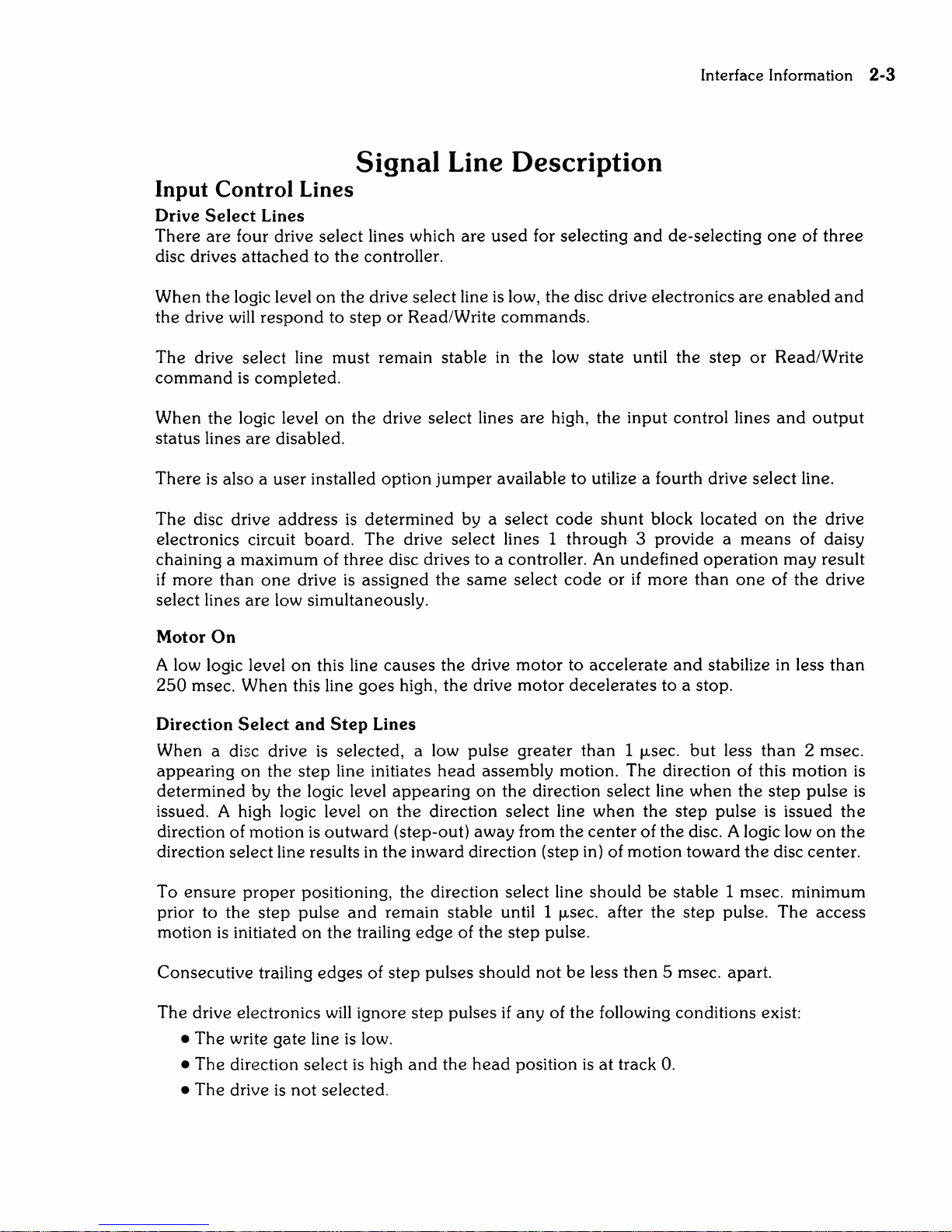

POWERON

MOTORON

DRIVE

VALlDTRKOO

AN D WRT. PROT.

OUTPUT

SELECT

DIRECT

SELECT

WR ITE

VALID

READ

10

N

DATA

DATA

~~------------------------~/I

-.l

----+--i

----+--+--t

---+--+--

-----t---t--_

~F~_1_0_0_M_S_M_I_N

~

250

...........

____________

MSEC

MAX

~/~/

______

__

I.-1 jJ.sMIN

__

-+--+-_-I-.JIO:....I..U.JiI~'-+-

___

-+--+-

__

2_0_M_S_M_IN

___

___

~

"""'"

Figure

2-3:

14----

General

75 MS

250

MSEC~

Control

MAX

and

---1

Data

Timing

Requirements

2-6

Interface

Information

J3

SHUNT

~_--'.

I

BLOCK

Figure

Figure

2-4:

2-5:

Connector

Connector

J4

Location

J4

Pin

:

Out

Pin

1

2

Description

Not

Used

Not

Used

3 NC

4 NC

5 Wrt

6 Wrt

Protect

Protect

7 NC

8 NC

9 NC

10 Activity LED

11

Activity LED + V

12 NC

13 NC

14

15

16

Index

Index

Index

+ V LED

Signal

Detector

17 GND

18 NC

19

20

Not

Not

Used

Used

21 NC

22 GND

23 04

24

25

02

01

26 03

27 GND

28 N

29

30

31

Motor

NC

Motor

Motor

On

GND

Power

J4

Switch (Normally Closed)

Switch

Common

Signal

Detector

Cathode

Anode

Cathode

Collector

Emitter

Interface

Information

2-7

Figure

2-6:

Connector

J3

10

Pin

Out

2-8 Interface Information

J3

Pin

1

2 Wrt

3

4 Wrt

5 Erase Coil

6 Erase Coil

7 Wrt

8

9 Wrt

10

Description

Head

Shield

Head

Center

Head

Head

Center

Head

Shield

1 (R/W Coil)

Tap

1 (R/W Coil)

2 (R/W Coil)

Tap

2 (R/W Coil)

J

10--

1~

J1

~

~

a I I

~

~

~

I

--

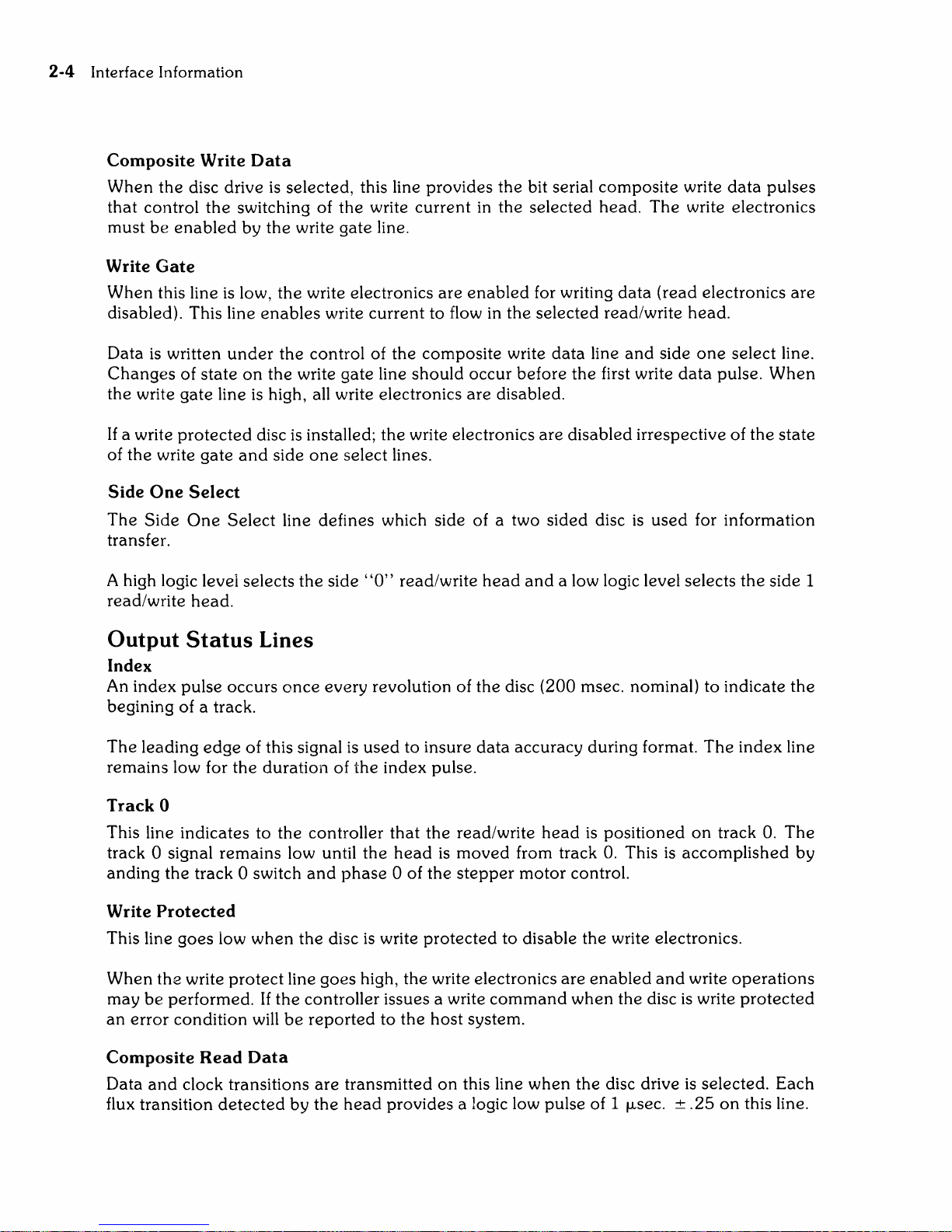

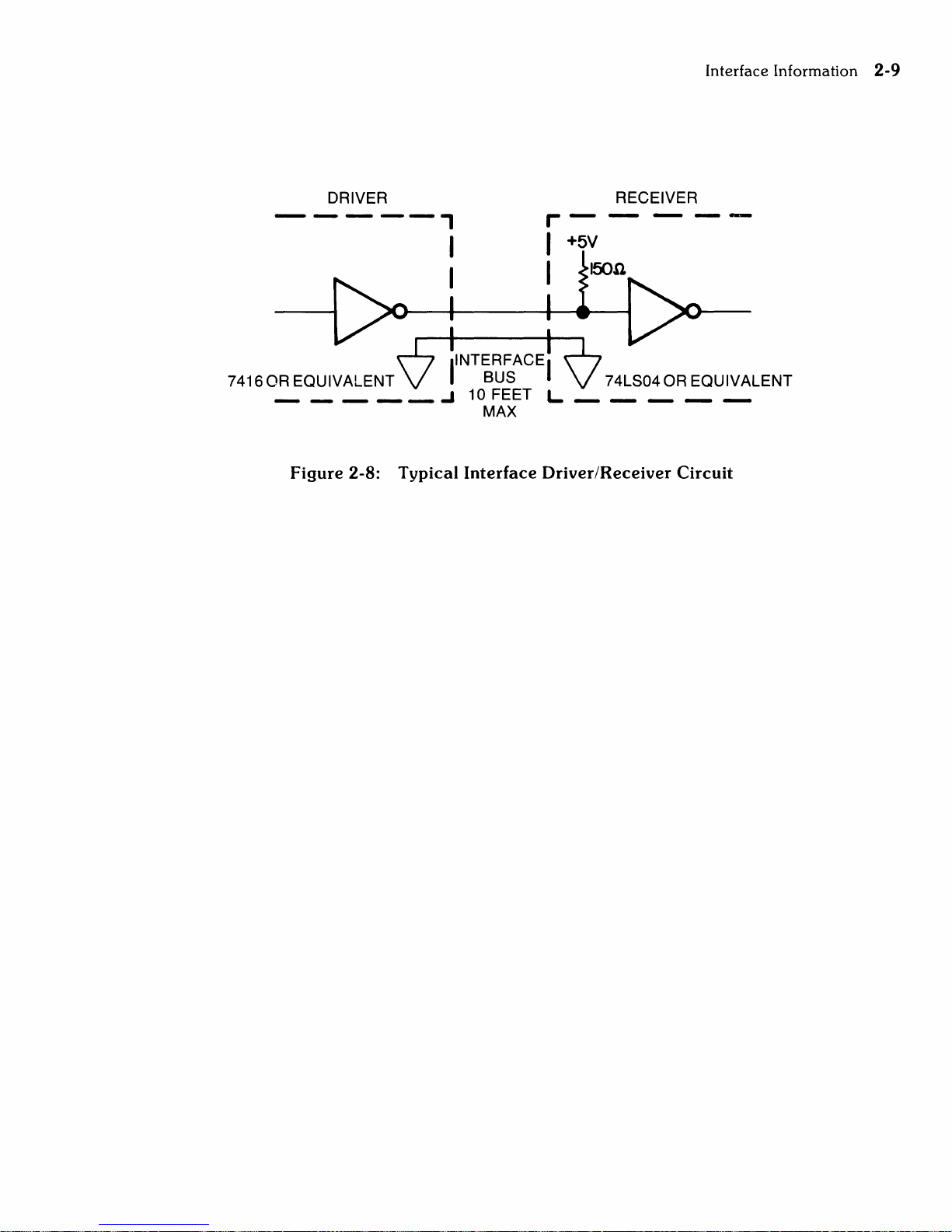

Typical

The

output

True

Interface

control

= Logical Zero =

False = Logical

Figure

2-7:

Pin

1 +

2 -

3 + Motor

4 Motor

5 NC

6 NC

7 N Motor

8 NC

9 GND

10

Drive/Receiver

lines

have

the

following electrical specifications:

Vout

+ O.4V (max.) @

One = Vout + 2.4V

Servo

Description

+ 12V

(min.)

Electronics

Tach

Tach

Power

Return

On

Circuits

lout

48ma

lout

250ma

Board

(MAX)

(max.)

Jl

Interface

Information

2-9

-----,

74160R

_____

DRIVER

INTERFACEI

EQUIVALENT BUS

Figure

2-8:

Typical

I

-'

10 FEET L

MAX

Interface

RECEIVER

74LS040R

Driver/Receiver

EQUIVALENT

Circuit

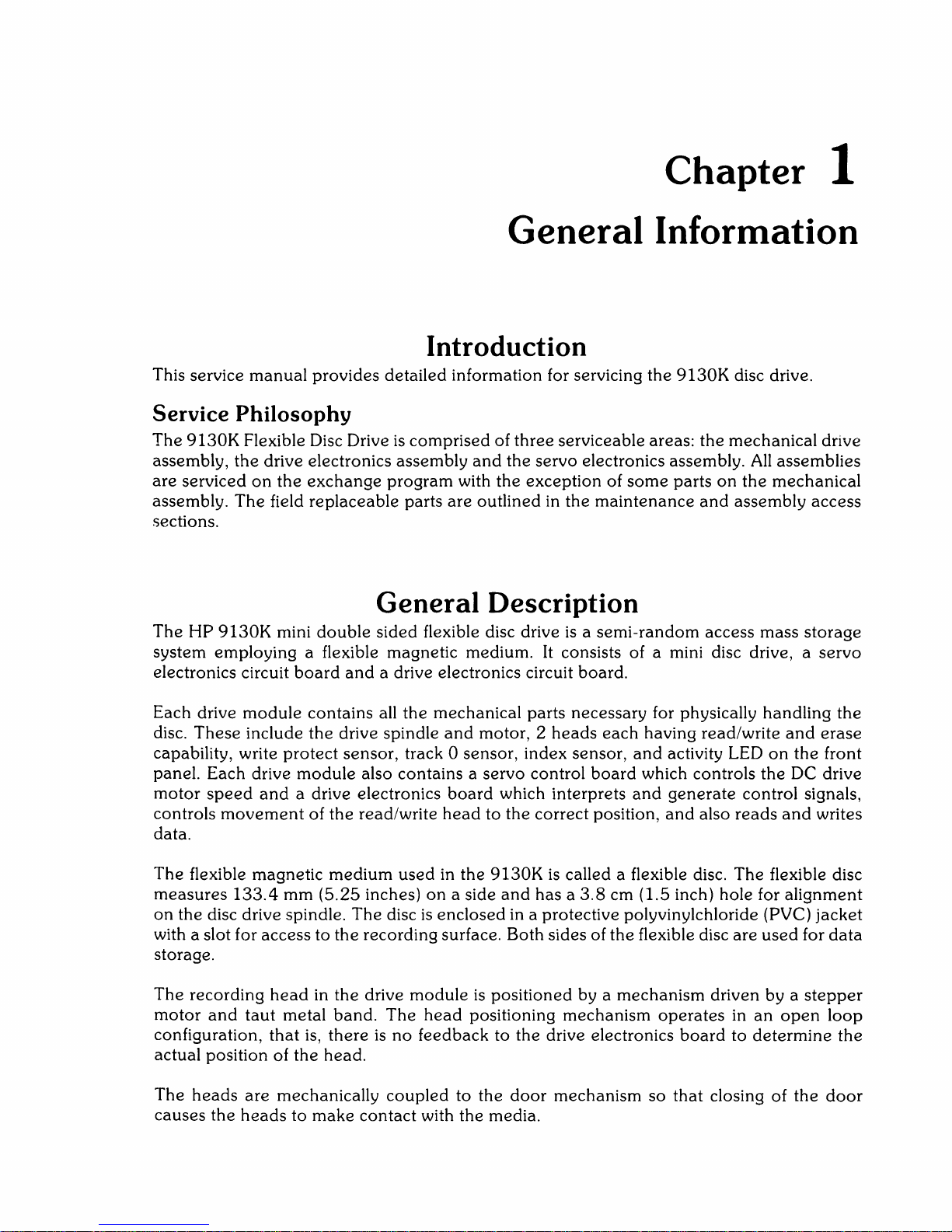

Chapter 3

Theory

of

Operation

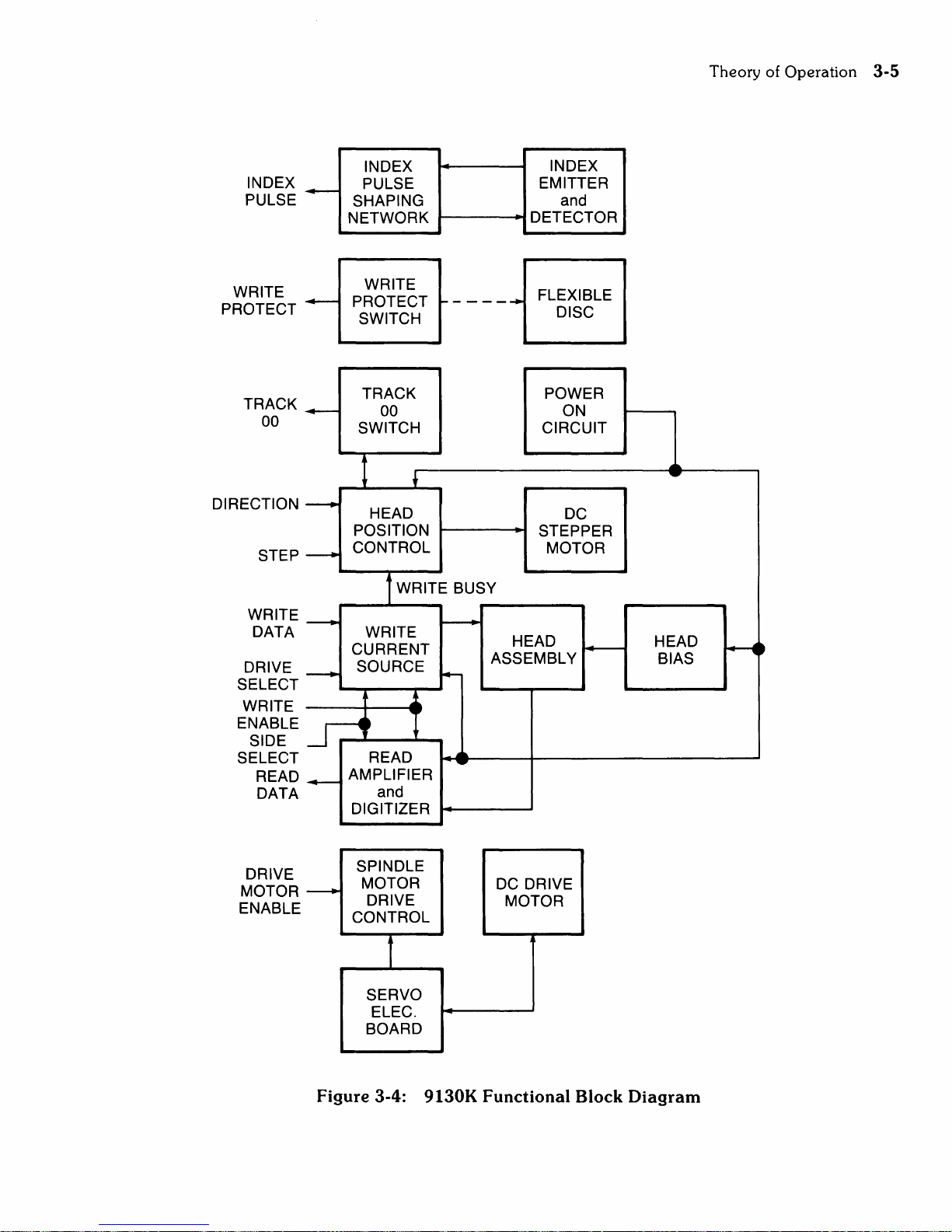

Introduction

This

chapter

describes

the

flexible disc recording fundamentals,

and

functional block dia-

gram theory of operation. Refer to Figures 3-1 through 3-3 while reading

the

following

description.

Flexible

Disc

Recording Fundamentals

To

better

understand

the

operation

of

the

flexible disc drive,

read

this brief description of

disc recording principles. Refer to Figure 3-1

and

3-2

while reading this section.

The flexible magnetic

media

used

with the

9130K

disc drive

measures

5.25

inches in

diameter. Both surfaces

are

coated

with a ferromagnetic iron oxide. Both sides

are

used

for

data

storage. Each side contains

35

circular tracks. Each track

is

divided into

16

pie slice

shaped

regions called sectors. Each sector

can

contain

up

to

256

bytes of data. Surface,

track

and

sector information

is

used

to reference

data

location

on

the disc. Data

is

encoded

on

the disc (ones

and

zeros) by changing

the

orientation of small magnetic dipoles in

the

magnetic coating

on

the disc. There

is

no

correlation

between

the magnetic polarity of

the

dipoles

and

the

ones

and

zeros.

The

ones

and

zeros are indicated by the location of

the

dipole polarity transitions.

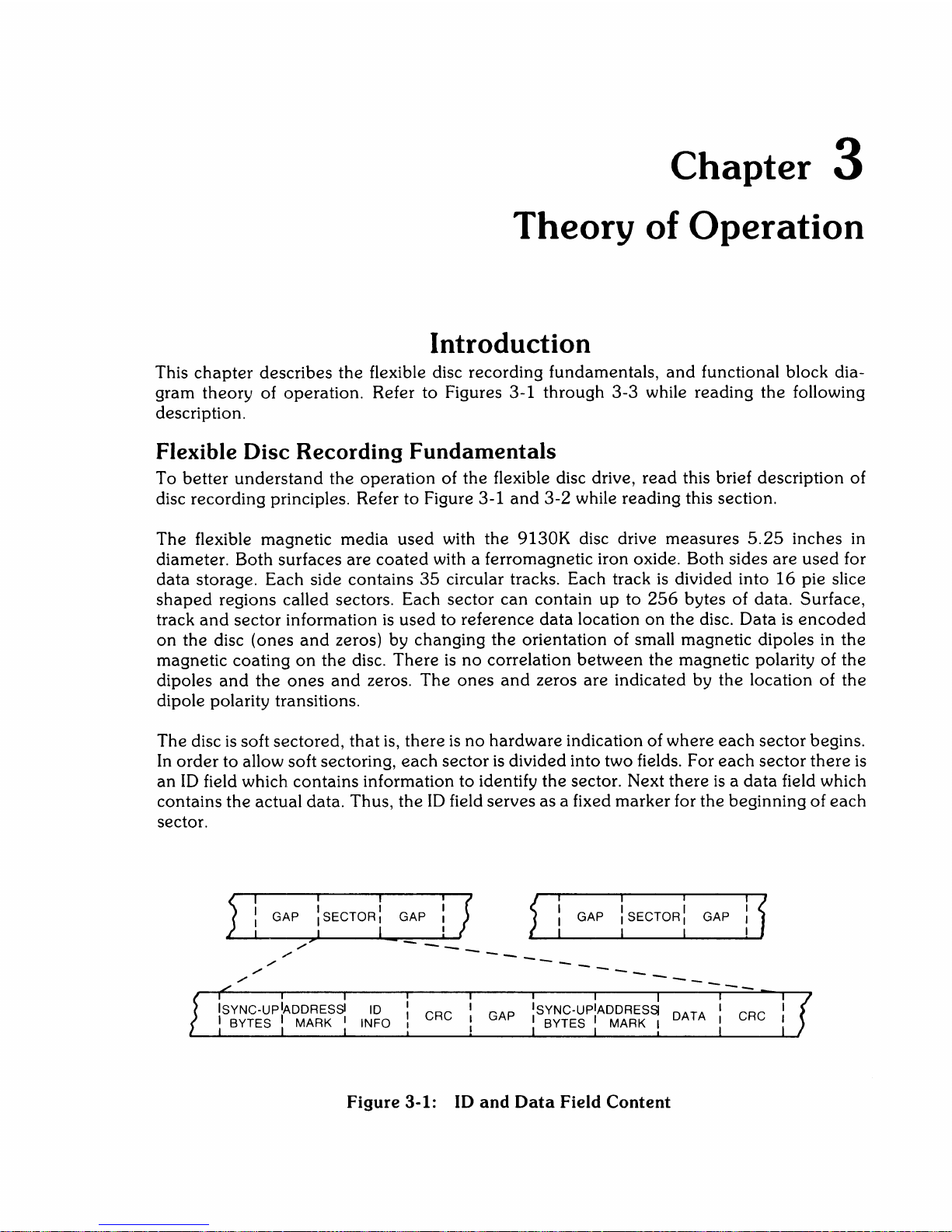

The disc

is

soft sectored,

that

is,

there

is

no

hardware indication of

where

each

sector begins.

In

order

to allow soft sectoring,

each

sector

is

divided into two fields. For

each

sector

there

is

an

ID

field which contains information to identify the sector. Next

there

is a data

field which

contains the actual data. Thus,

the

ID

field serves as a fixed marker for the beginning of

each

sector.

",..

,/

,/

---

---

---

---

---

Figure 3-1:

ID

and

Data

Field Content

3-2

Theory of Operation

The

makeup

of

the

ID

and

DATA fields is similar.

Both

fields

begin

with a series of

synchro-

nization bytes.

These

bytes

allow

the

decoder

circuitry of

the

controller time

to

synchronize

itself with

the

data

on

the

disc. Following

the

synchronizing bytes, is

the

address

mark

byte

which indicates

that

the

beginning

of

an

ID

or

DATA field

has

been

located.

The

first bit

of

an

address

mark

is

the

opposite

polarity of

the

last bit of

the

previous

synchronizing byte.

This

feature

simplifies

detection

of

address

marks.

A series of

information

bytes

follows

the

address

mark. In

an

ID

field,

these

bytes

indicate

the

logical cylinder,

head

and

sector

address.

In

a DATA field,

these

bytes

are

the

data

being

stored

in

the

sector.

At

the

end

of

each

field

are

two cyclic

redundance

check

(CRC) bytes. This

check

word

(16

bits long) allows

detection

of

most

errors

that

occur

in

the

data

storage

and

recovery

of

information from a disc.

There

are

two

gaps

following

each

field

on

a track.

The

gaps

allow for variations in disc

rotational

speed,

index

detector

alignment

variations

and

time for

the

hardware

to

prepare

for

the

next

field.

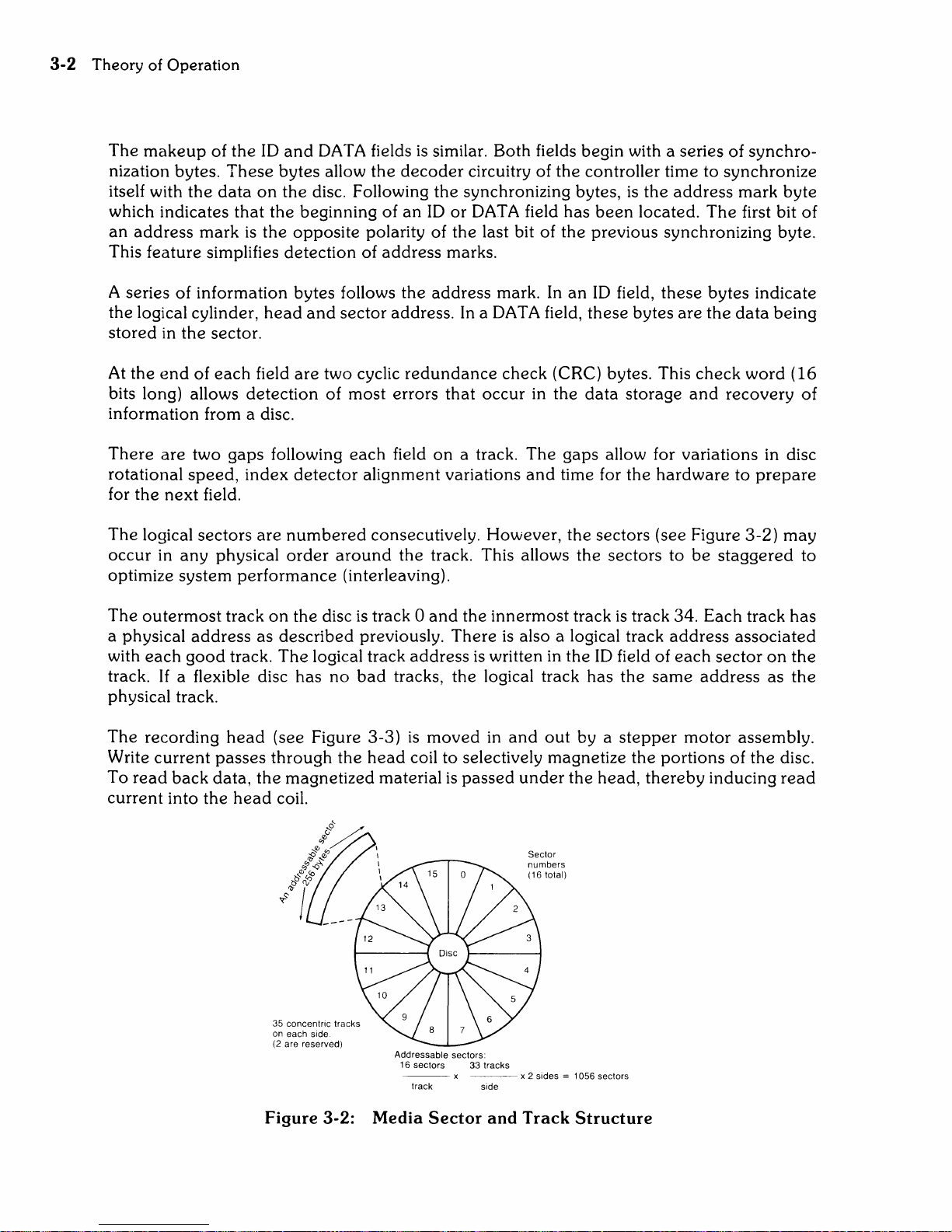

The

logical

sectors

are

numbered

consecutively. However,

the

sectors (see Figure

3-2)

may

occur

in

any

physical

order

around

the

track. This allows

the

sectors

to

be

staggered

to

optimize

system

performance

(interleaving).

The

outermost

track

on

the

disc

is

track 0

and

the

innermost

track

is

track

34.

Each

track

has

a physical

address

as

described

preViously.

There

is

also a logical track

address

associated

with

each

good

track.

The

logical track

address

is written in

the

ID

field of

each

sector

on

the

track.

If

a flexible disc

has

no

bad

tracks,

the

logical track

has

the

same

address

as

the

physical track.

The

recording

head

(see Figure

3-3)

is

moved

in

and

out

by a

stepper

motor

assembly.

Write

current

passes

through

the

head

coil

to

selectively magnetize

the

portions

of

the

disc.

To

read

back

data,

the

magnetized

material

is

passed

under

the

head,

thereby

indUcing

read

current

into

the

head

coil.

35 concentric tracks

on each side

(2

are reserved)

Addressable sectors:

16 sectors 33 tracks

Sector

numbers

(16

total)

--

x

~~-

x 2 sides = 1056 sectors

track side

Figure

3-2:

Media

Sector

and

Track

Structure

Theory of Operation

3-3

Figure 3-3: Head Positioning

Assembly

Index Pulse

Shaping

Network

The

index

pulse circuitry consists of

an

index

LED,

photo

transistor

and

pulse

shaping

network.

The

index

hole in

the

flexible disc

passes

between

the

index

LED

and

photo

transistor, causing

the

photo

transistor to conduct.

The

detected

signal

is

then

shaped

and

buffered

and

output

on

the

Index Pulse interface line (J 1-8). This signal

although

inverted

may

be

observed

at

TP7

on

the

drive electronics board.

Write Protect

Sensor

The

write

protect

sensor

consists of a switch which

is

opened

when

a write

protected

disc

is

inserted into

the

drive. This signal

is

delayed

by

an

RF

filter to eliminate transient noise from

the

switch. This will

cause

the

write

protect

line

(Jl-28)

to go low

and

TP9

to go high.

Track 0

Switch

The

level

on

the

Track 0 interface line

is

a function of

the

head

assembly position.

When

the

head

assembly

is

positioned

at

track 0

and

the

stepper

motor

indicates

phase

0,

J4-19

is

pulled low, causing

TP8

and

the

Track 0 interface line to

be

pulled low.

Spindle Motor Drive Control

The

spindle drive system consists of a spindle assembly driven by a DC

motor-tachometer

combination

and

the

servo

electronics board.

The

servo electronics includes a

current

limiter

and

interface control line.

3-4

Theory

of

Operation

When

the

Drive Motor Enable line

is

low, the drive

motor

is

allowed to

come

up

to

speed.

This

speed

is

adjustable

by

potentiometer

R4 located

on

the servo electronics board.

A current sensing resistor, also

located

on

the

servo electronics

board

limits

the

motor

current to

900ma.

If

this limit

is

exceeded,

the

motor

is

disabled.

Head

Position

Control

The

head

position Control consists of a four

phase

stepper

motor

drive which

changes

one

phase

for

each

track

advancement

of

the

head

assembly.

In

addition to

the

logic for motion

control, a

gate

is

provided

to inhibit repositioning during a write operation.

Power On Circuit

This circuit detects

when

the

+5VDC

and

+ 12VDC are valid

and

prevents

writing/reading/

erasing/stepping until

such

time.

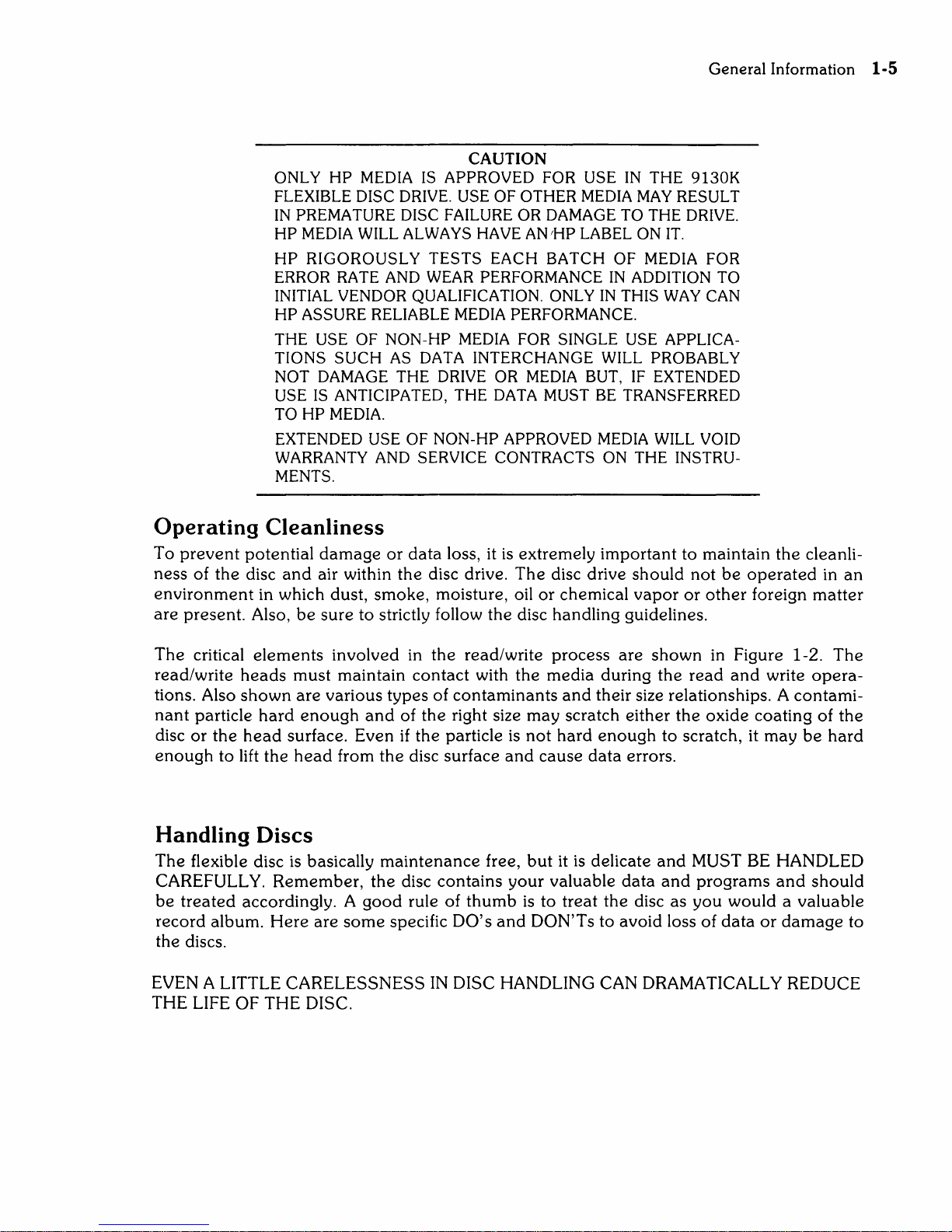

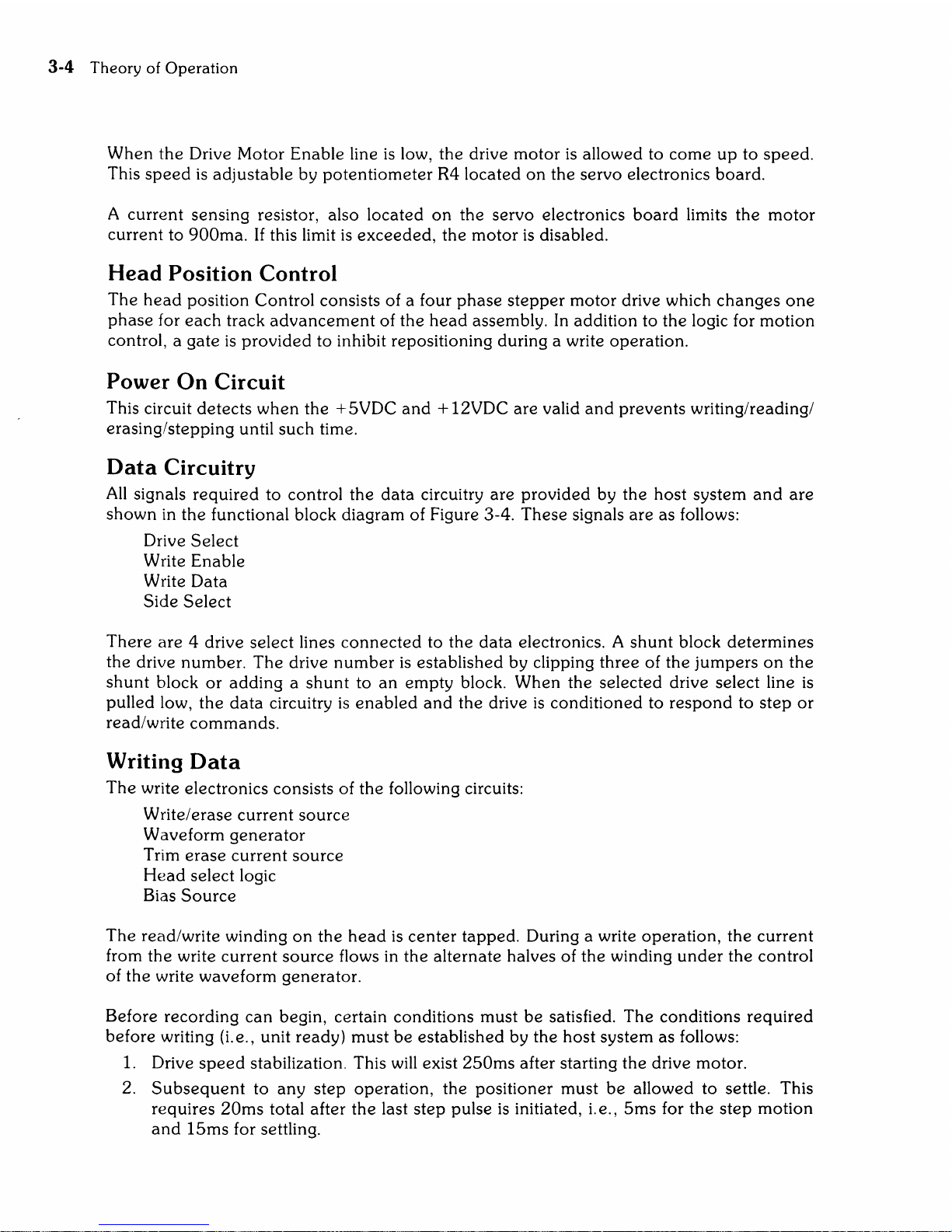

Data

Circuitry

All

signals

required

to control

the

data

circuitry are provided by

the

host system

and

are

shown

in

the

functional block diagram of Figure 3-4.

These

signals are as follows:

Drive

Select

Write Enable

Write Data

Side

Select

There

are

4 drive select lines

connected

to

the

data

electronics. A

shunt

block

determines

the drive

number.

The

drive

number

is

established by clipping

three

of

the

jumpers

on

the

shunt

block

or

adding a shunt

to

an

empty block.

When

the

selected drive select line

is

pulled low,

the

data

circuitry

is

enabled

and

the

drive

is

conditioned to

respond

to

step

or

read/write

commands.

Writing

Data

The

write electronics consists of

the

following circuits:

Write/erase

current

source

Waveform

generator

Trim

erase

current

source

Head

select logic

Bias

Source

The

read/write winding

on

the

head

is

center

tapped. During a write operation,

the

current

from

the

write

current

source

flows in

the

alternate halves of

the

winding

under

the

control

of

the

write waveform generator.

Before recording

can

begin, certain conditions must

be

satisfied.

The

conditions

required

before writing (i. e., unit ready) must

be

established by

the

host system

as

follows:

1.

Drive

speed

stabilization. This

will

exist

250ms

after starting

the

drive motor.

2.

Subsequent

to

any

step

operation,

the

positioner must

be

allowed to settle. This

requires

20ms

total after

the

last

step

pulse

is

initiated, i. e.,

5ms

for

the

step

motion

and

15ms

for settling.

INDEX

PULSE

~

INDEX

PULSE

SHAPING

NETWORK

INDEX

EMITTER

and

DETECTOR

WRITE WRITE FLEXIBLE

PROTECT

~

PROTECT ~ - - - -..... DISC

TRACK

00

DIRECTION

STEP

WRITE

DATA

DRIVE

SELECT

WRITE

ENABLE

SIDE

SELECT

READ

DATA

DRIVE

MOTOR

ENABLE

~

----

---

~

~

~

---+

SWITCH

TRACK POWER

00

ON

SWITCH CIRCUIT

,

HEAD

DC

POSITION

STEPPER

CONTROL

MOTOR

tWRITE

BUSY

~

WRITE

CURRENT

HEAD

f4---

ASSEMBLY

SOURCE

I+-

~

READ

AMPLIFIER

and

DIGITIZER

SPINDLE

MOTOR

DC DRIVE

DRIVE

MOTOR

CONTROL

f

SERVO

ELEC.

BOARD

HEAD

BIAS

Figure

3-4:

9130K

Functional

Block

Diagram

Theory of Operation

3-5

~.

Loading...

Loading...