Page 1

HP LaserJet 9000/9040/9050

Service Manual

Page 2

Page 3

HP LaserJet 9000, 9040, and 9050 Series printers

Service _____________________

Page 4

Copyright and License

© 2005 Copyright Hewlett-Packard

Development Company, LP

Reproduction, adaptation or translation

without prior written permission is prohibited,

except as allowed under the copyright laws.

Part number: Q3721-90963

Edition 1, 4/2005

The information contained herein is subject to

change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products and

services. Nothing herein should be construed

as constituting an additional warranty. HP

shall not be liable for technical or editorial

errors or omissions contained herein.

Trademark Credits

®

Adobe

and PostScript® are trademarks of

Adobe Systems Incorporated.

MS-DOS

®

is a U.S. registered trademark of

Microsoft Corporation.

E

NERGY STAR

®

is a U.S. registered service

mark of the United States Environmental

Protection Agency.

Page 5

Table of contents

Table of contents

List of tables

List of figures

1 Product information

Product features of the HP LaserJet 9000 Series printers . . . . . . . . . . . . . . . . . .2

Product features of the HP LaserJet 9040/9050 Series printers. . . . . . . . . . . . . . 4

Product specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Product overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

External view of the printer and accessories . . . . . . . . . . . . . . . . . . . . . . . . 10

Interface connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Optional accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Regulatory information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Regulatory requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

FCC regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Environmental product stewardship program . . . . . . . . . . . . . . . . . . . . . . . .13

Service approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Parts and supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Limited warranty for print-cartridge life . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2 Product requirements

Site requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Operating environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Space requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Media specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Guidelines for selecting print media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Special media specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Storing print media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Media input/output options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Trays, bins, and paper handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Supported sizes of paper for input and output . . . . . . . . . . . . . . . . . . . . . . .26

3 Product configuration

Using the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Control-panel buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Numeric keypad commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Settings and defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Setting the display language. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Setting the tray registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Printer driver information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Control-panel menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Using a menu map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

iii

Page 6

Retrieve job menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Information menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Paper-handling menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Configure device menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Printing submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Print-quality submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

System setup submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

I/O submenu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Resets submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Diagnostics menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Service menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Remote firmware upgrade (RFU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Upgrading firmware to a single printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4 Product maintenance

Preventative maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Preventive maintenance kit contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Cleaning the printer and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

General cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Internal cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Fuser cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Print cartridge information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Handling instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Refilled print cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Print-cartridge weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Print-cartridge life expectancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Saving toner by using EconoMode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5 Theory of operation

Basic operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Sequence of operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Power-on sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Timing chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

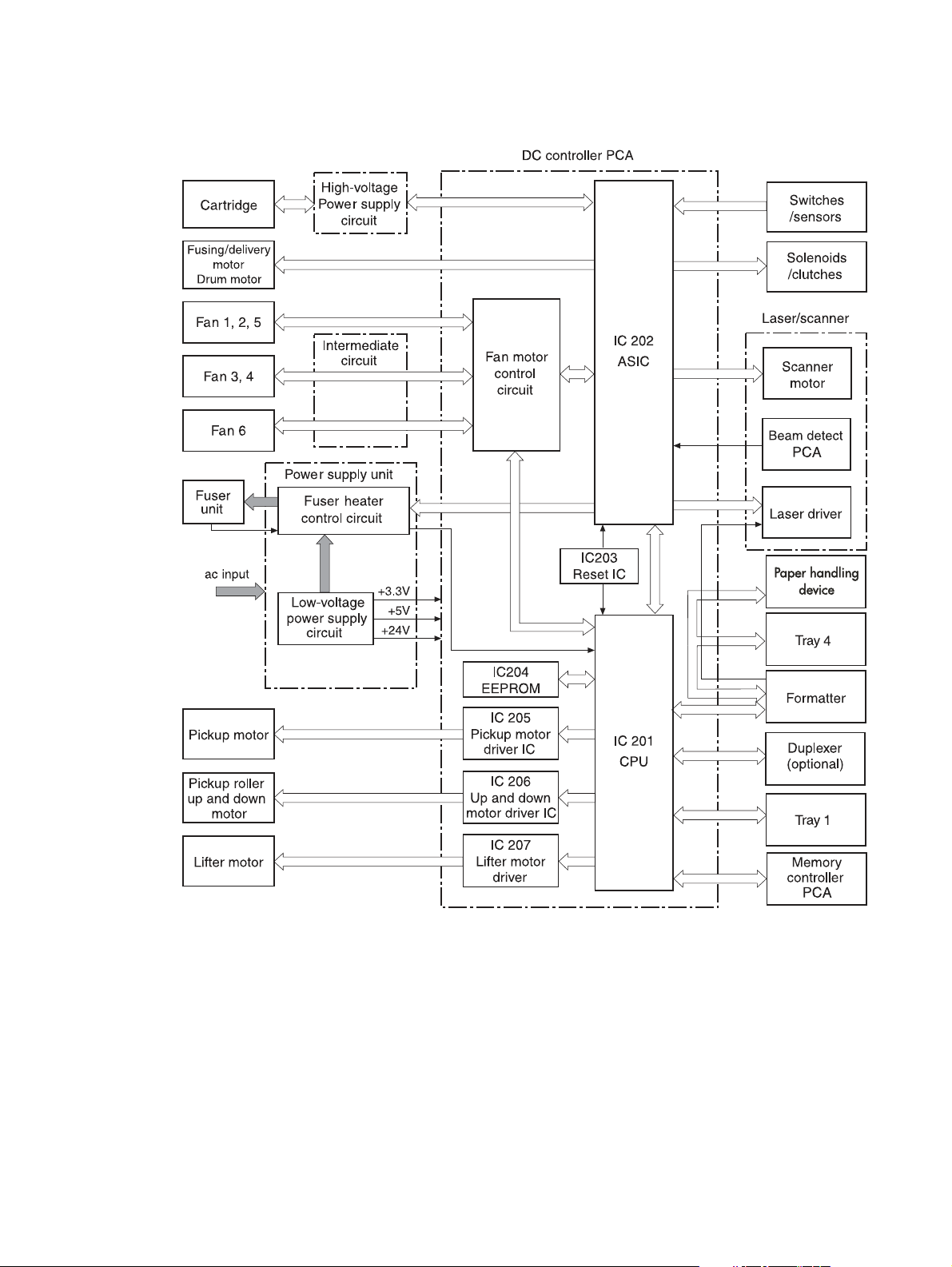

Engine control system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

DC controller PCA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

DC controller operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

High-voltage power supply circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Low-voltage power supply unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Formatter system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Formatter hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Laser/scanner system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Image formation system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

The eight processes of image formation . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Print cartridge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Pickup and feed system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Media-size detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Media-level detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Multifeed prevention. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Overhead-transparency detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Fuser-wrapping-jam detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Jam detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Tray 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Tray 1 driver PCA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Sequence of operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Pickup and feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Jam detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

iv Table of contents

Page 7

Tray 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Tray 4 driver PCA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Sequence of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Pickup and feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Media-level and media-size detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Jam detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

6 Removal and replace ment

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Removal and replacement strategy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Repair notices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Electrostatic discharge (ESD). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Required tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Orientation of the printer (with tray 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Right top cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Left top cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Front cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Right door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

Right lower cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Left door and diverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Left back cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Back cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Right and left rail covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Top assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Control panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Laser/scanner assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Delivery assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Delivery-fan assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Delivery-assembly fans and face-down-bin fan (fans 3, 6, and 4) . . . . . . . 115

Delivery motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Cartridge release lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Front assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Print cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Transfer-roller assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Tray 2 and tray 3 (interchangeable) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Rollers (pickup, feed, or separation). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Fuser-jam-removal knob. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

Registration-jam-removal knob. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Right assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Tray 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Paper-input unit (PIU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Registration assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Transfer-guide assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Left assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Duplexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Fuser assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Back assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Formatter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135

Low-voltage power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136

High-voltage power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

DC controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

Toner-sensor contact assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Drum motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .141

Feed-drive assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Power-supply fan (fan 1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Cartridge fan (fan 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

v

Page 8

Controller fan (fan 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Jetlink connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Fuser-connector holder assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Fuser delivery-drive assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Tray 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Left side cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Right side cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Back covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Tray 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Rollers (pickup, feed, and separation) . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Registration assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Drive motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Drive assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Controller board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Paper-size detection switch PCA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Pickup assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Paper-connecting unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

7 Troubleshooting

Troubleshooting process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Basic troubleshooting process flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Preliminary operating checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

General troubleshooting information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Abnormal noises are evident, such as grinding or

chattering when the main motor is turned on. . . . . . . . . . . . . . . . . . . . . . . 171

Media does not feed from tray x when printing from a software

program; the paper-path test is successful . . . . . . . . . . . . . . . . . . . . . . . . 171

Media does not print from tray 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

The printer stops printing and hangs on certain jobs. . . . . . . . . . . . . . . . . 171

Envelopes are wrinkling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Fusing is poor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

The printer feeds from an incorrect tray when different media

is selected for the first page of the job . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Power-on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Troubleshooting by using control-panel messages . . . . . . . . . . . . . . . . . . . . . 175

Event log page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Control-panel messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Control-panel and event-log message format . . . . . . . . . . . . . . . . . . . . . . 179

Printer-message tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Alphabetical error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Numerical error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

User- and service-level diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Paper-path test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Service test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Service-level diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Engine test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Service menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Diagnostics flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Other diagnostics for the HP LaserJet 9000, 9000mfp, and 9000Lmfp . . . . . . 217

Cold reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Other diagnostics for the HP LaserJet 9040/9050, 9040mfp, and 9050mfp. . . 219

Cold reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Tray 4 diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Diagnostics label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Motor test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Standalone running test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

vi Table of contents

Page 9

Sensor test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Light-pattern interpretation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Jam troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Customer print job. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Clearing jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .225

Evaluate the information pages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Configuration page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .226

Jetdirect page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .229

Supplies status page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Usage page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

File directory page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .232

Image-formation troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Check the print cartridge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

EconoMode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Skew. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Image-defect tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .235

Repeating defect ruler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .243

Media troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Determine the problem source: media or printer . . . . . . . . . . . . . . . . . . . . 244

Isolate a paper path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .244

Isolate a media brand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .245

Isolate a media type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Communication troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .246

Communications check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Jetdirect configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Embedded LAN troubleshooting

(HP LaserJet 9040n/9050n, HP LaserJet 9040dn/9050dn,

HP LaserJet 9050mfp, and HP LaserJet 9040mfp only). . . . . . . . . . . . . . .247

Wiring diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

8 Parts and diagrams

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Ordering parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .256

Consumables, supplies, accessories, FRUs, and documentation . . . . . . .257

Common hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .261

Illustrations and parts lists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

External covers and panels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .262

Left door and diverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Right cover assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Internal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Internal components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .266

Drum feed drive assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Fuser delivery drive assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .275

Cartridge lifter assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

500-sheet trays (tray 2 and tray 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Paper input unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Registration assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Transfer roller assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .280

Delivery assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

PCA assembly location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .283

Tray 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Tray 4 main body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Tray 4 drive assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Tray 4 PCA location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .289

Tray 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

Alphabetical parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

Numerical parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .296

vii

Page 10

Index

viii Table of contents

Page 11

List of tables

Table 1. Features of the HP LaserJet 9000 Series printers . . . . . . . . . . . . . . . . .2

Table 2. Features of the HP LaserJet 9040/9050 Series printers . . . . . . . . . . . .4

Table 3. Configuration comparison . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 4. Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 5. Electrical specifications (HP LaserJet 9000) . . . . . . . . . . . . . . . . . . . . .7

Table 6. Electrical specifications (HP LaserJet 9040) . . . . . . . . . . . . . . . . . . . . .8

Table 7. Electrical specifications (HP LaserJet 9050) . . . . . . . . . . . . . . . . . . . . .8

Table 8. Environmental specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Table 9. Acoustical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 10. Paper weight equivalence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 11. Control-panel button functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 12. Printer state and numeric key effect . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 13. Storing print cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Table 14. Normal sequence of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Table 15. Failure sequence of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Table 16. Pickup-and-feed system sensors and switches . . . . . . . . . . . . . . . . . 90

Table 17. Pickup-and-feed system motors and solenoids . . . . . . . . . . . . . . . . . 92

Table 18. Primary steps for troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . .167

Table 19. Power-on defects or a blank display . . . . . . . . . . . . . . . . . . . . . . . . 174

Table 20. Alphabetic error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Table 21. Numeric error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Table 22. Service test abnormality codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Table 23. Service menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Table 24. DIP switch settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Table 25. Tray 4 light-pattern interpretation . . . . . . . . . . . . . . . . . . . . . . . . . . .223

Table 26. General jam troubleshooting questions . . . . . . . . . . . . . . . . . . . . . . 224

Table 27. Printer devices troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Table 28. Image-quality checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Table 29. Image defects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .236

Table 30. Consumables, supplies, accessories, FRUs, and documentation . 257

Table 31. Hardware table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Table 32. Common torque values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .261

Table 33. Printer external covers and panels . . . . . . . . . . . . . . . . . . . . . . . . . 263

Table 34. Left door and diverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Table 35. Right cover assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Table 36. Internal components (1 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Table 37. Internal components (2 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

Table 38. Internal components (3 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Table 39. Internal components (4 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Table 40. Drum feed drive assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .274

Table 41. Fuser delivery drive assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . .275

Table 42. Cartridge lifter assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Table 43. 500-sheet trays (tray 2 and tray 3) . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Table 44. Paper input unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Table 45. Registration assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Table 46. Transfer roller assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .280

Table 47. Delivery assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Table 48. PCA location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Table 49. Tray 4 main body (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .285

ix

Page 12

Table 50. Tray 4 main body (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Table 51. Tray 4 drive assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Table 52. Tray 4 PCA location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Table 53. Tray 1 assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

Table 54. Alphabetical parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

Table 55. Numerical parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

x List of tables

Page 13

List of figures

Figure 1. Sample identification label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Figure 2. External view of the printer and accessories . . . . . . . . . . . . . . . . . . . . 10

Figure 3. Interface connections (HP LaserJet 9040/9050 Series printer) . . . . .11

Figure 4. Interface connections (HP LaserJet 9000 Series printer) . . . . . . . . . . 11

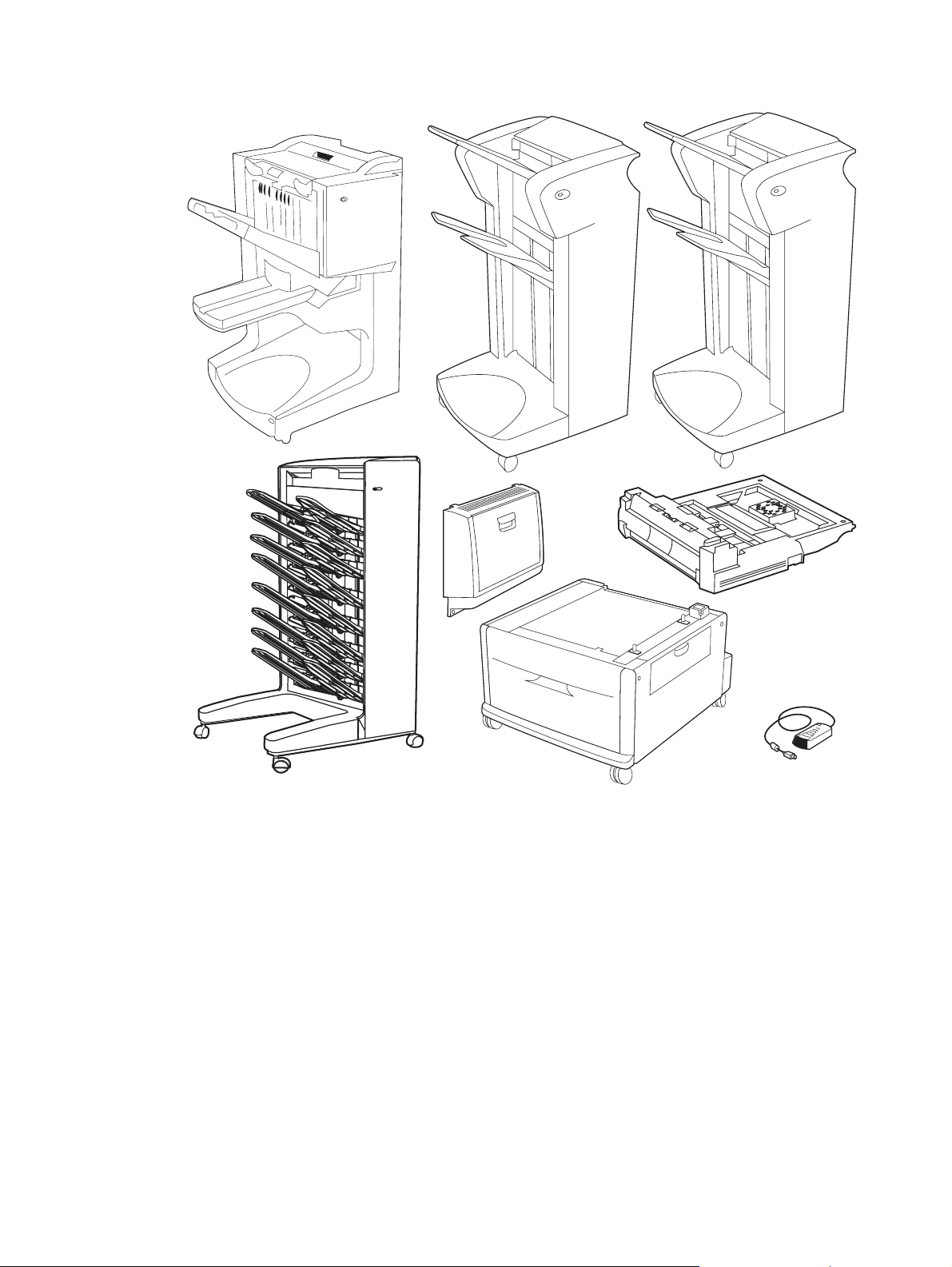

Figure 5. Optional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Figure 6. Space requirements for the base model . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 7. Space requirements with a finishing device

(3,000-sheet stapler/stacker shown) and tray 4 installed . . . . . . . . . . . . . . .18

Figure 8. Sample seams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 9. Adhesive labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 10. Media trays, bins, and paper handling . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 11. Control-panel layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 12. Registration page (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Figure 13. Registration page (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Figure 14. Turn off the printer and remove the power cords . . . . . . . . . . . . . . . 62

Figure 15. Remove the print cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 16. Wipe any residue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 17. Replace the print cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 18. Lock the print cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 19. Close the front cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 20. Sample cleaning page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 21. Printer systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Figure 22. Sequence-of-operation block diagram . . . . . . . . . . . . . . . . . . . . . . . 71

Figure 23. Timing chart block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Figure 24. Engine-control-system block diagram . . . . . . . . . . . . . . . . . . . . . . . .75

Figure 25. DC controller PCA block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Figure 26. High-voltage power supply block diagram . . . . . . . . . . . . . . . . . . . . 78

Figure 27. Power-supply-block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Figure 28. Laser/scanner system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Figure 29. Image formation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Figure 30. Print cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Figure 31. Pickup-and-feed system sensors and switches . . . . . . . . . . . . . . . . 89

Figure 32. Pickup-and-feed system motors and solenoids . . . . . . . . . . . . . . . . 91

Figure 33. Tray 1 block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Figure 34. Tray 4 block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Figure 35. View of front and right side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Figure 36. View of back and left side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Figure 37. Right top cover (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Figure 38. Right top cover (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

Figure 39. Left top cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Figure 40. Front cover (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

Figure 41. Front cover (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

Figure 42. Right door (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Figure 43. Right door (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Figure 44. Right lower cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Figure 45. Left door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Figure 46. Left back cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

Figure 47. Back cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Figure 48. Rail covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

xi

Page 14

Figure 49. Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Figure 50. Laser/scanner assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Figure 51. Delivery assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Figure 52. Delivery-fan assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Figure 53. Delivery-assembly fans and face-down-bin fan (1 of 2) . . . . . . . . . 115

Figure 54. Delivery-assembly fans and face-down-bin fan (2 of 2) . . . . . . . . . 115

Figure 55. Delivery motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Figure 56. Cartridge release lever (1 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Figure 57. Cartridge release lever (2 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Figure 58. Cartridge release lever (3 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Figure 59. Print cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Figure 60. Transfer-roller assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Figure 61. Tray 2 or tray 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Figure 62. Rollers (pickup, feed, or separation) . . . . . . . . . . . . . . . . . . . . . . . 122

Figure 63. Fuser-jam-removal knob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Figure 64. Registration-jam-removal knob . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Figure 65. Tray 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Figure 66. Paper-input unit (1 of 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Figure 67. Paper-input unit (2 of 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Figure 68. Paper-input unit (3 of 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Figure 69. Paper-input unit (4 of 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Figure 70. Paper-input unit (5 of 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Figure 71. Registration assembly (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Figure 72. Registration assembly (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Figure 73. Transfer-guide assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Figure 74. Reinstalling the transfer-guide assembly . . . . . . . . . . . . . . . . . . . . 132

Figure 75. Duplexer (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Figure 76. Duplexer (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Figure 77. Fuser assembly (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Figure 78. Fuser assembly (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Figure 79. Formatter (HP LaserJet 9000 shown) . . . . . . . . . . . . . . . . . . . . . . 135

Figure 80. Low-voltage power supply (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . 136

Figure 81. Low-voltage power supply (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . 136

Figure 82. High-voltage power supply (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . 137

Figure 83. High-voltage power supply (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . 137

Figure 84. DC controller (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Figure 85. DC controller (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Figure 86. Toner-sensor contact assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Figure 87. Reinstalling the toner-sensor contact assembly . . . . . . . . . . . . . . . 140

Figure 88. Drum motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Figure 89. Feed-drive assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Figure 90. Power-supply fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Figure 91. Cartridge fan (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Figure 92. Cartridge fan (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Figure 93. Controller fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Figure 94. Jetlink connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Figure 95. Fuser-connector holder assembly (1 of 3) . . . . . . . . . . . . . . . . . . . 147

Figure 96. Fuser-connector holder assembly (2 of 3) . . . . . . . . . . . . . . . . . . . 147

Figure 97. Fuser-connector holder assembly (3 of 3) . . . . . . . . . . . . . . . . . . . 148

Figure 98. Fuser delivery-drive assembly (1 of 3) . . . . . . . . . . . . . . . . . . . . . . 149

Figure 99. Fuser delivery-drive assembly (2 of 3) . . . . . . . . . . . . . . . . . . . . . . 149

Figure 100. Fuser delivery-drive assembly (3 of 3) . . . . . . . . . . . . . . . . . . . . . 150

Figure 101. Left side cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Figure 102. Right side cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Figure 103. Back covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Figure 104. Tray 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Figure 105. Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Figure 106. Registration assembly (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Figure 107. Registration assembly (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

xii List of figures

Page 15

Figure 108. Drive motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Figure 109. Drive assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Figure 110. Controller board (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Figure 111. Controller board (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Figure 112. Paper-size switch PCA (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Figure 113. Paper-size switch PCA (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Figure 114. Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Figure 115. Pickup assembly (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Figure 116. Pickup assembly (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Figure 117. Paper-connecting unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Figure 118. Basic troubleshooting process flow (1 of 2) . . . . . . . . . . . . . . . . . 168

Figure 119. Basic troubleshooting process flow (2 of 2) . . . . . . . . . . . . . . . . . 169

Figure 120. Sample event log (HP LaserJet 9000 series printer page shown) 176

Figure 121. Example of events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .177

Figure 122. Diagnostics flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Figure 123. Tray 4 label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Figure 124. Sample configuration page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Figure 125. Sample Jetdirect configuration page . . . . . . . . . . . . . . . . . . . . . . .229

Figure 126. Sample supplies status page . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Figure 127. Sample usage page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Figure 128. Sample file directory page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Figure 129. Image defect examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Figure 130. Repeating defect ruler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .243

Figure 131. Printer wiring diagram (HP LaserJet 9000 series printer) . . . . . . .251

Figure 132. Printer wiring diagram (HP LaserJet 9040/9050 series printer) . . 252

Figure 133. Tray 4 wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .253

Figure 134. Printer external covers and panels . . . . . . . . . . . . . . . . . . . . . . . . 262

Figure 135. Left door and diverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Figure 136. Right cover assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .265

Figure 137. Internal components (1 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .266

Figure 138. Internal components (2 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .268

Figure 139. Internal components (3 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .270

Figure 140. Internal components (4 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .272

Figure 141. Drum feed drive assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Figure 142. Fuser delivery drive assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Figure 143. Cartridge lifter assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Figure 144. 500-sheet trays (tray 2 and tray 3) . . . . . . . . . . . . . . . . . . . . . . . .277

Figure 145. Paper input unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Figure 146. Registration assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .279

Figure 147. Transfer roller assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Figure 148. Delivery assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Figure 149. PCA assembly location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Figure 150. Tray 4 main body (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Figure 151. Tray 4 main body (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Figure 152. Tray 4 drive assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Figure 153. Tray 4 PCA location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Figure 154. Tray 1 assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

xiii

Page 16

xiv List of figures

Page 17

1 Product infor mation

Chapter contents

Product features of the HP LaserJet 9000 Series printers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Product features of the HP LaserJet 9040/9050 Series printers. . . . . . . . . . . . . . . . . . . . . . . . . . .4

Product specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Product overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

External view of the printer and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Interface connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Optional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Regulatory information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Regulatory requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

FCC regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Environmental product stewardship program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Service approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Parts and supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Limited warranty for print-cartridge life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Limited warranty for print-cartridge life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter contents 1

Page 18

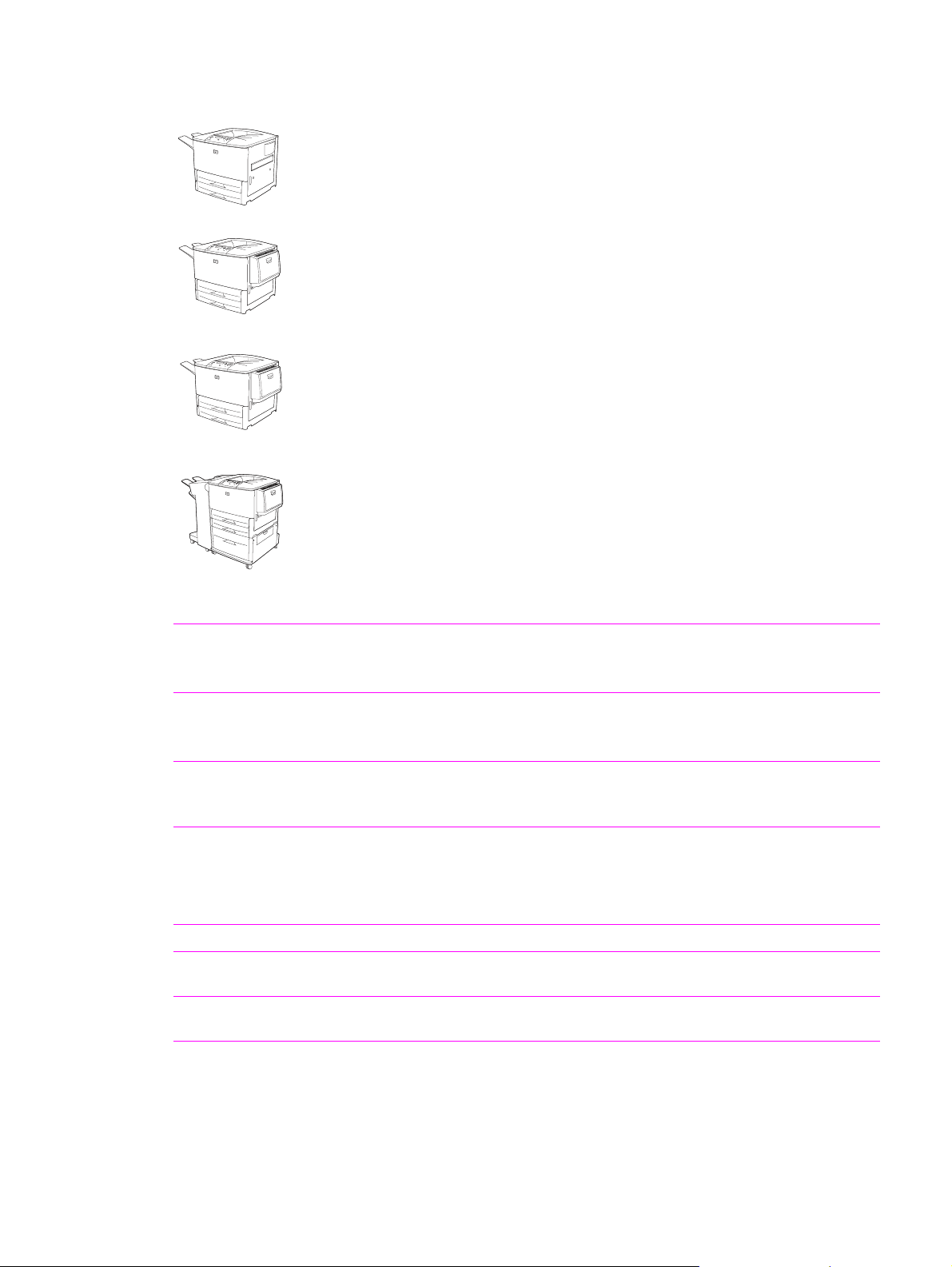

Product features of the HP LaserJet 9000 Series printers

HP LaserJet 9000 printer (C8519A)

The HP LaserJet 9000 printer comes standard with 64 MB RAM, wide-format

printing, and two 500-sheet trays (tray 2 and tray 3).

HP LaserJet 9000n printer (C8520A)

The HP LaserJet 9000n printer comes standard with 64 MB RAM, wide-format

printing, two 500-sheet trays (tray 2 and tray 3), a 100-sheet multipurpose tray

(optional tray 1), and an embedded HP Jetdirect print server.

HP LaserJet 9000dn printer (C8521A)

The HP LaserJet 9000dn printer comes standard with 64 MB RAM, wide-format

printing, two 500-sheet trays (tray 2 and tray 3), a 100-sheet multipurpose tray

(optional tray 1), an embedded HP Jetdirect print server, and an optional duplex

printing accessory (duplexer) for printing on both sides of paper.

HP LaserJet 9000hns printer (C8522A)

The HP LaserJet 9000hns printer contains the HP LaserJet 9000dn with a 2,000sheet feeder (optional tray 4) and an optional 3,000-sheet stapler/stacker, an

optional 3,000-sheet stacker, or an optional multifunction finisher.

Table 1. Features of the HP LaserJet 9000 Series printers

Speed

Resolution z 600 dots per inch (dpi) with Resolution Enhancement technology (REt).

Toner

PCL printer

language and fonts

PS language

Automatic language

switching

Enhanced memory

and memory expansion

z 50 pages per minute (ppm) for letter-size print media and A4-s ize media.

z First page out in less than 8 seconds.

z Transmit Once, Raster Image Processing (RIP) Once technology.

z HP FastRes 1200 (1200-dpi-like quality at up to 50 ppm letter and A4).

z Up to 256 levels of gray.

z HP UltraPrecise print cartridge. The capacity is rated at an average

30,000 pages with 5% coverage.

z EconoMode capability.

z Fast printing performance, built-in Intellifont and TrueType

technologies, built-in HP-GL/2 vector graphics, and advanced imaging

capabilities are benefits of the printer control language (PCL) 6 printer

language. PCL 6 also includes 80 scalable TrueType fonts and one

bitmapped Line Printer Font.

z PostScript

z The printer automatically determines and switches to the appropriate

language for the print job.

z The HP LaserJet 9000 Series printers come with 64 MB of memory and

can be expanded to 384 MB.

®

3 (PS) emulation.

scaling

2 Chapter 1 Product information

Page 19

Table 1. Features of the HP LaserJet 9000 Series printers (continued)

Expandability All models accept the following accessories:

z Optional tray 1, a 100-sheet or 10-envelope multipurpose tray for

automatic and manual feeding of envelopes, labels, transparencies,

custom-sized media from 98 x 191 mm (3.8 x 7.5 inches) to

312 x 470 mm (12.3 x 18.5 in), and heavy paper.

z Optional tray 4, a 2,000-sheet feeder that supports letter, legal, B4, A4,

11 x 17 inches, A3, executive, B5, and custom 182 x 210 mm

(7.2 x 8.3 inches) to 297 x 431.8 mm (11.7 x 17 inches) print media.

z Optional duplexer.

z Optional 3,000-sheet stapler/stacker, 3,000-sheet stacker, or

multifunction finisher.

z Enhanced input/output (EIO) cards.

z Dual inline memory module (DIMM) slots for adding memory and fonts.

z Hard disk for RIP Once capability, job retention features, and font

storage.

Wireless printing

Interface connecti on z Bidirectional ECP type-C parallel port (IEEE-1284 compliant).

z The printer supports wireless printing with the installation of a Fast

InfraRed Connect pod.

z Three EIO slots for hard-disk-accessor y or print-server installation.

z Wireless Fast InfraRed port (IrDA compliant).

z Foreign interface connector.

z HP Jet-Link connector.

Networking

Duty cycle

z Three EIO slots for hard-disk-accessor y or print-server installation.

z An HP 610N Jetdirect print server is included with HP LaserJet 9000n,

9000dn, and 9000hns.

z 300,000 images per month.

Product features of the HP LaserJet 9000 Series printers 3

Page 20

Product features of the HP LaserJet 9040/9050 Series printers

HP LaserJet 9040/9050 printe r

The HP LaserJet 9040/9050 printer (product number Q7697A/Q3721A) comes

standard with 64 MB RAM, wide-format printing, and two 500-sheet trays (tray 2

and tray 3).

HP LaserJet 9040n/9050n printer

The HP LaserJet 9040n/9050n printer (product number Q7698A/Q3722A) comes

standard with 128 MB RAM, wide-format printing, two 500-sheet trays (tray 2 and

tray 3), a 100-sheet multipurpose tray (tray 1), and an embedded HP Jetdirect print

server.

HP LaserJet 9040dn/9050dn printer

The HP LaserJet 9040dn/9050dn printer (product number Q7699A/Q3723A)

comes standard with 128 MB RAM, wide-format printing, two 500-sheet trays

(tray 2 and tray 3), a 100-sheet multipurpose tray (tray 1), an embedded HP

Jetdirect print server, and a duplex printing accessory (duplexer) for printing on

both sides of paper.

Table 2. Features of the HP LaserJet 9040/9050 Series printers

Speed

Resolution z 600 dpi with REt.

Toner

PCL printer

language and fonts

PS language

Automatic language

switching

Enhanced memory

and memory expansion

z 40 pages per minute (ppm) (HPLaserJet 9040 series printer) or 50 ppm

(HP LaserJet 9050 series printer) on letter or ISO A4 paper.

z First page out in less than 8 seconds.

z Transmit Once, RIP Once technology.

z FastRes 1200 provides 1200 dpi quality at full speed.

z Up to 256 levels of gray.

z HP UltraPrecise print cartridge. The capacity is rated at an average

30,000 pages with 5% coverage.

z EconoMode capability.

z Fast printing performance, built-in Intellifont and TrueType scaling

technologies, built-in HP-GL/2 vector graphics, and advanced imaging

capabilities are benefits of the printer control language (PCL) 6 printer

language. PCL 6 also includes 80 scalable TrueType fonts and one

bitmapped Line Printer Font.

z PostScript 3 (PS) emulation.

z The printer automatically determines and switches to the appropriate

language for the print job.

z The HP LaserJet 9040/9050 Series printers come with 64 or 128 MB of

memory and can be expanded to 512 MB.

4 Chapter 1 Product information

Page 21

Table 2. Features of the HP LaserJet 9040/9050 Series printers (continued)

Expandability All models accept the following accessories:

z Optional tray 1, a 100-sheet or 10-envelope multipurpose tray for

automatic and manual feeding of envelopes, labels, transparencies,

custom-sized media from 98 x 191 mm (3.8 x 7.5 inches) to

312 x 470 mm (12.3 x 18.5 inches), and 64 to 216 g/m² (17- to 58-lb

bond).

z Optional tray 4, a 2,000-sheet feeder that supports letter, legal, B4, A4,

11 x 17 inches, A3, executive, B5, and custom 76 x 127 mm

(3 x 5 inches) to 297 x 431 mm (11.7 x 17 inches) print media.

z Optional duplexer.

z Optional 3,000-sheet stapler/stacker, 3,000-sheet stacker, multifunction

finisher, or 8-bin mailbox.

z EIO cards.

z DIMM slots for adding memory.

z Hard disk for RIP Once capability, job retention features, and font

storage.

z Compact Flash slots for printer firmware forms or fonts.

Wireless printing z The printer supports wireless printing with the installation of a Fast

InfraRed Connect pod.

Interface connecti on z Bidirectional ECP type-B parallel port (IEEE-1284 compliant).

z Two EIO slots for accessory installation.

z HP Jet-Link connector.

Networking

z Two EIO slots for hard-disk-access ory or print server installation.

z A Jetdirect print server is included with HP LaserJet 9040n/9050n and

9040dn/9050dn.

Duty cycle z 300,000 images per month.

Product features of the HP LaserJet 9040/9050 Series printers 5

Page 22

Product specifications

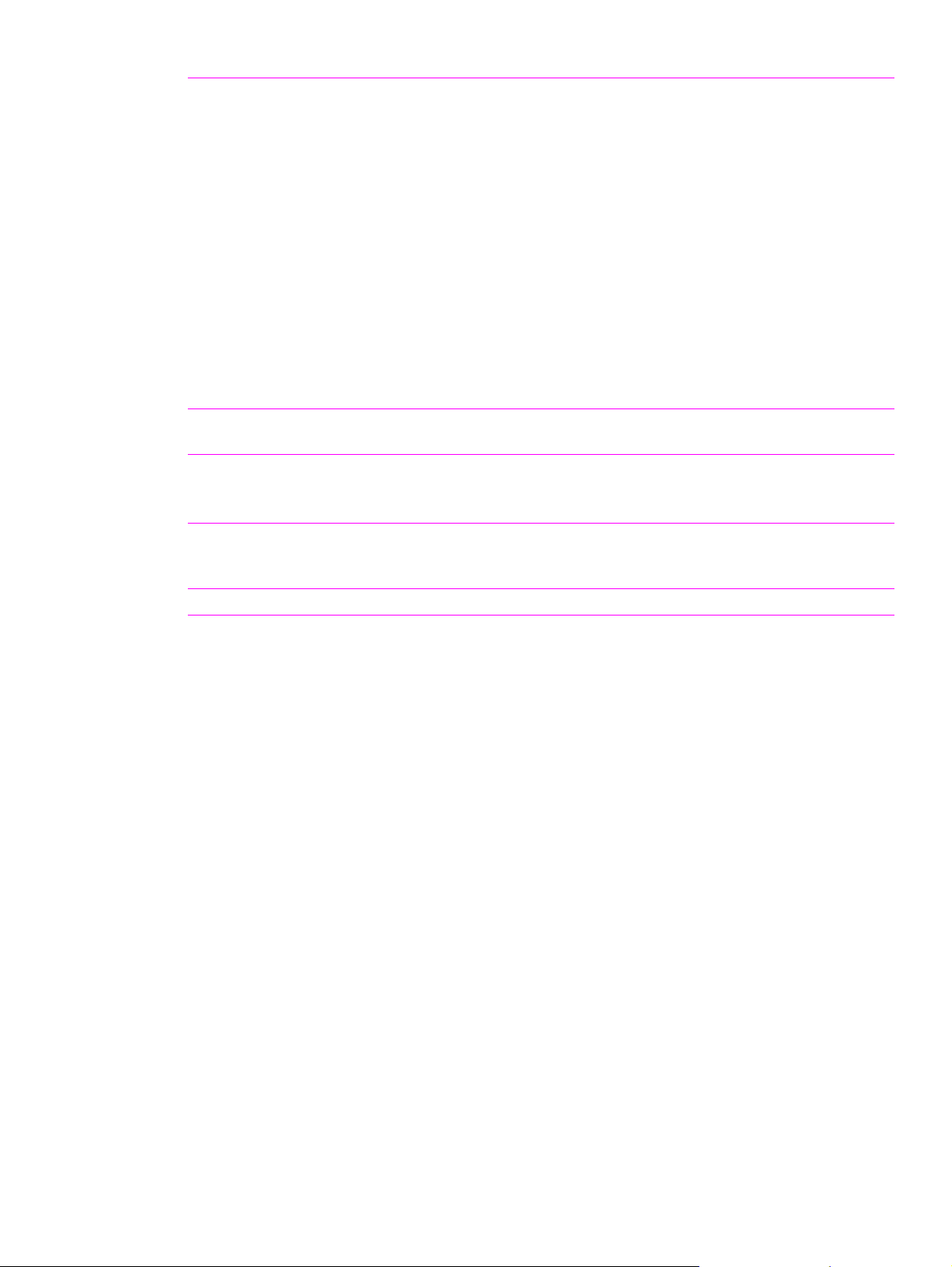

Identification

The model number and printer serial number are listed on an identification label located in two

places:

z on the rear cover

z on the chassis behind the right door

The model number is alphanumeric, such as C4270A.

The serial number contains information about the country/region of origin and the revision level, the

production code, and production number of the printer. An example of a serial number is

USBB123456.

The top label also contains power-rating and regulatory information. See figure 1.

Note The power-rating and regulatory information varies by country/region.

Electrical information Regional certification

Model and serial number

Manufacture date

Figure 1. Sample identification label

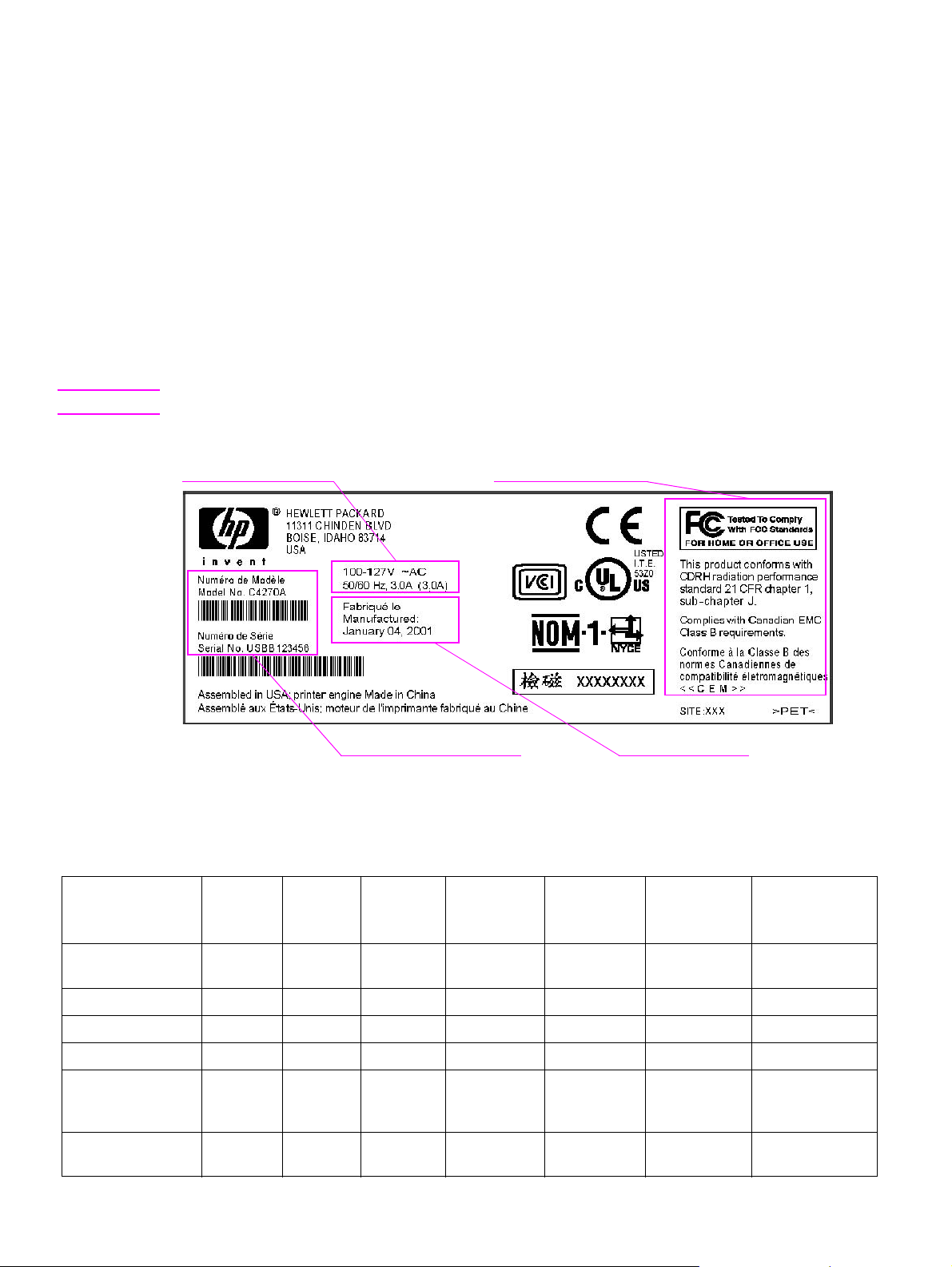

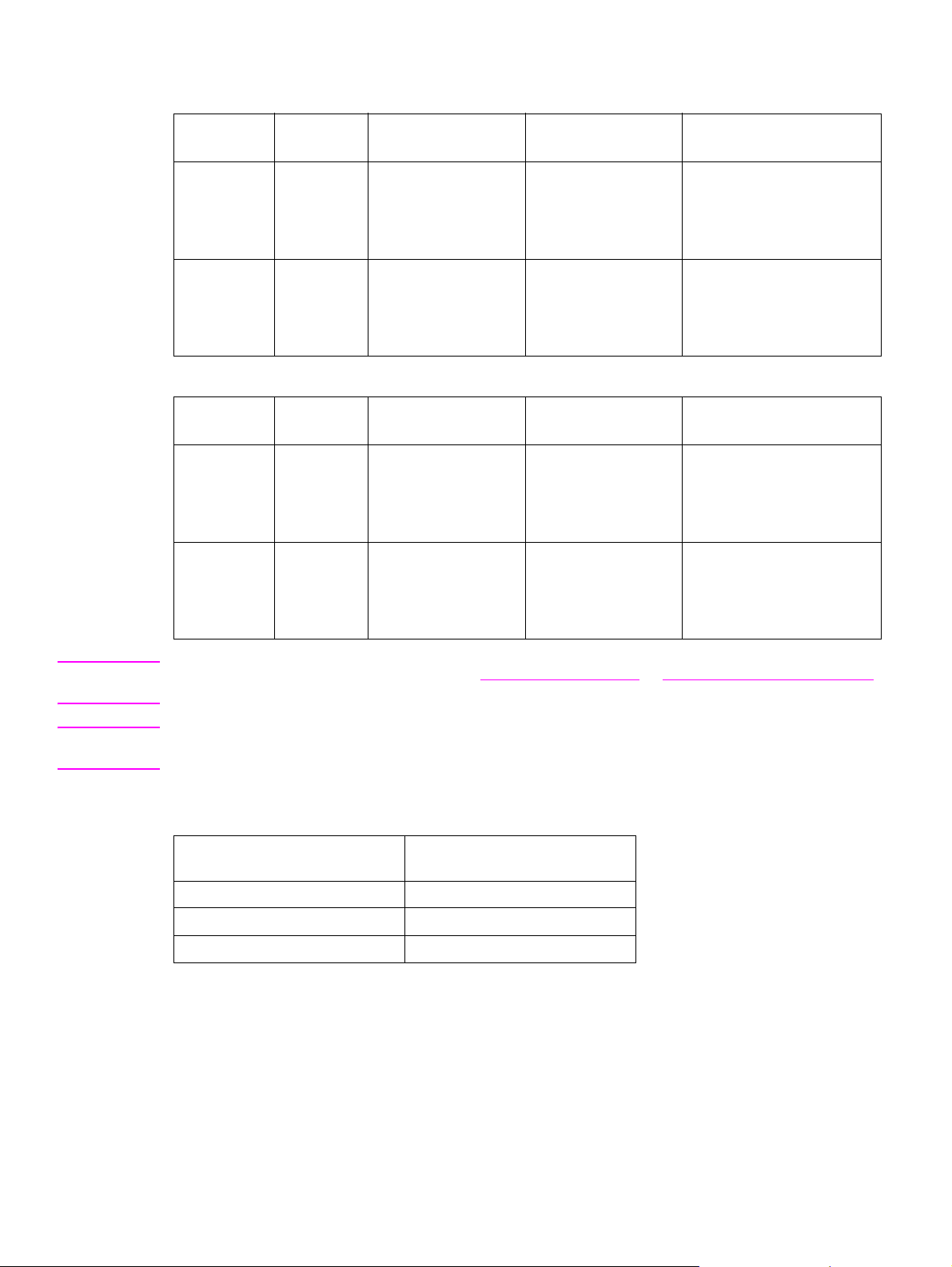

Table 3. Configuration comparison

HP

LaserJet

9000

Standard memory

Maximum memory

PS emulation Standard Standard Standard Standard Standard Standard Standard

Jetdirect print server Optional Standard Standard Standard Optional Standard Standard

Optional duplexer Optional Optional Standard Standard Optional Optional Standard

Optional tray 1,

100-sheet

multipurpose tray

Optional tray 4,

2,000-sheet feeder

64 MB

384 MB

Optional Standard Standard Standard Optional Standard Standard

Optional Optional Optional Standard Optional Optional Optional

HP

LaserJet

9000n

64 MB

384 MB

HP

LaserJet

9000dn

64 MB

384 MB

HP

LaserJet

9000hns

64 MB

384 MB

HP

LaserJet

9040/9050

64 MB

512 MB

HP

LaserJet

9040n/9050n

128 MB

512 MB

HP

LaserJet

9040dn/9050dn

128 MB

512 MB

6 Chapter 1 Product information

Page 23

Table 3. Configuration comparison

HP

LaserJet

9000

Optional 3,000sheet stacker

Optional 3,000sheet stapler/stacker

Optional

multifunction finisher

Optional 8-bin

mailbox

Optional hard disk Optional Optional Optional Optional Optional Optional Optional

Optional Optional Optional Optional Optional Optional Optional

Optional Optional Optional Standard Optional Optional Optional

Optional Optional Optional Optional Optional Optional Optional

N/A N/A N/A N/A Optional Optional Optional

HP

LaserJet

9000n

HP

LaserJet

9000dn

HP

LaserJet

9000hns

HP

LaserJet

9040/9050

HP

LaserJet

9040n/9050n

HP

LaserJet

9040dn/9050dn

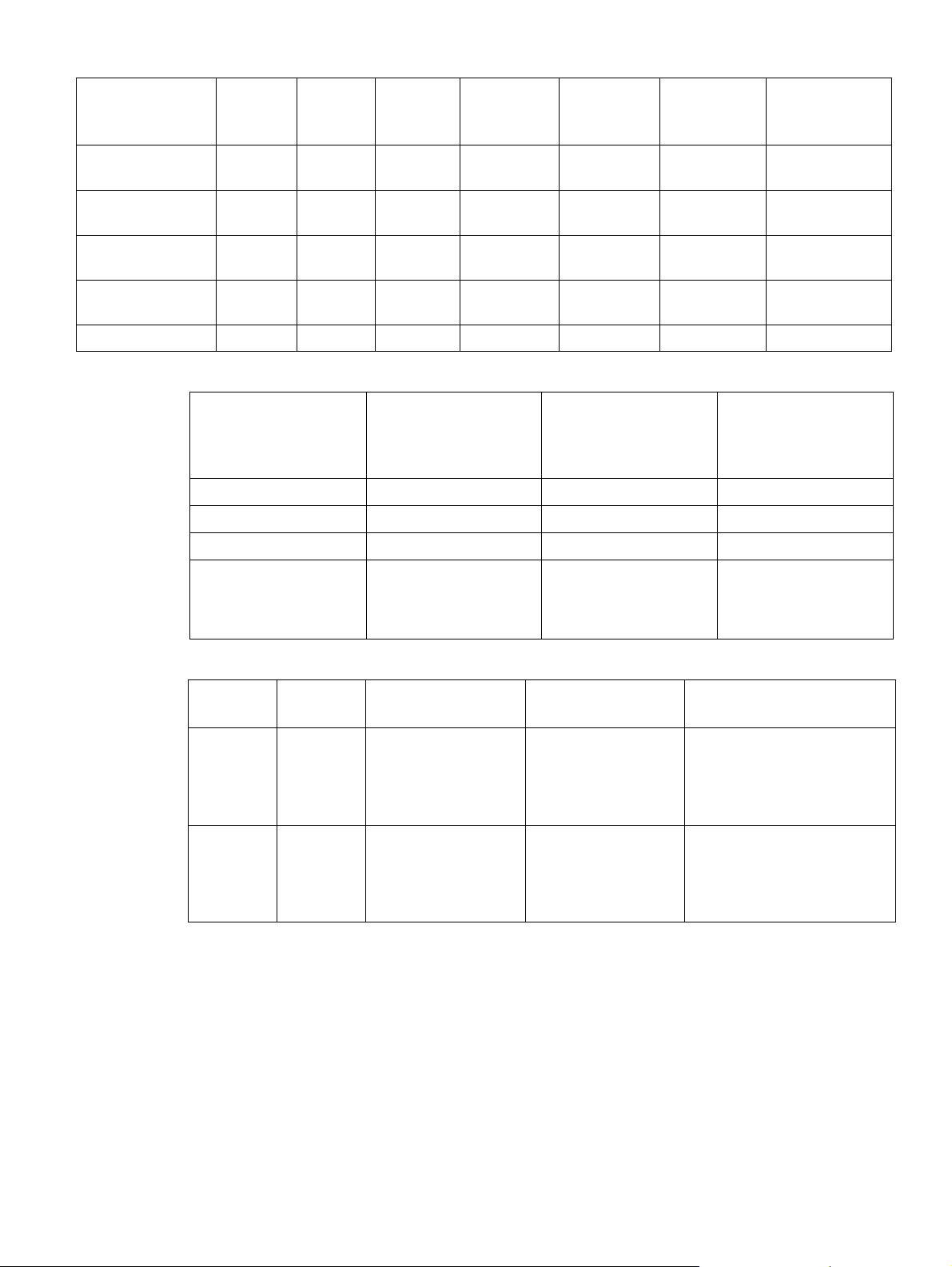

Table 4. Physical specifications

HP LaserJet

9000, 9040, and 9050

HP LaserJet

9000n/9000dn,

HP LaserJet

9000hns

9040n/9040dn, and

9050n/9050dn

Height 600 mm (23.6 inches) 600 mm (23.6 inches) 1,036.4 mm (40.8 inches)

Width 990.8 mm (39.0 inches) 1,115.8 mm (44.4 inches) 1,788.2 mm (70.4 inches)

Depth 1,001 mm (42.7 inches) 1,001 mm (42.7 inches) 1,001 mm (42.7 inches)

Weight

(without print cartridge)

63.5 kg (140 lb) 9000n/9040n/9050n:

69.4 kg (153 lb)

9000dn/9040dn/9050dn:

76.2 kg (168 lb)

76.2 kg (168 lb)

Table 5. Electrical specifications (HP LaserJet 9000)

Volts Frequency Amperes (A) Watts (W) (typical) Thermal units per hour

(BTu/hr)

100-127 V ac

± 10%

220-240 V ac

± 10%

50/60 Hz

± 2 Hz

50/60 Hz

± 2 Hz

Minimum

recommended current

capacity =

15 A dedicated circuit

Minimum

recommended current

capacity =

6.5 A dedicated circuit

printing = 1,040 W

standby = 265 W

PowerSave 1 = 40 W

PowerSave 2 = 25 W

off = 0 W

printing = 995 W

standby = 265 W

PowerSave 1 = 40 W

PowerSave 2 = 25 W

off = 0.2 W

printing = 3,550.36 BTU/hr

standby = 904.71 BTU/hr

PowerSave 1 = 136.56 BTU/hr

PowerSave 2 = 85.35 BTU/hr

off = 0 BTU/hr

printing = 3,396.93 BTU/hr

standby = 904.71 BTU/hr

PowerSave 1 = 136.56 BTU/hr

PowerSave 2 = 85.35 BTU/hr

off = 0.69 BTU/hr

Product specifications 7

Page 24

Table 6. Electrical specifications (HP LaserJet 9040)

Volts Frequency Ampres Watts (W) (typical) Therma l units per hour

(BTu/hr)

100-127 V ac ±

10%

220-240 V ac ±

10%

50/60 Hz

± 2 Hz

50/60 Hz

± 2 Hz

Minimum

recommended current

capacity =

12 A dedicated circuit

Minimum

recommended current

capacity =

5.3 A dedicated circuit

printing = 900 W

standby = 200W

PowerSave 1 = 158 W

PowerSave 2 = 21 W

off = 0.5 W

printing = 900 W

standby = 200 W

PowerSave 1 = 40 W

PowerSave 2 = 21 W

off = 0.5 W

printing = 3,550.36 BTu/hr

standby = 904.71 BTu/hr

PowerSave 1 = 136.56 BTu/hr

PowerSave 2 = 85.35 BTu/hr

off = 0 BTu/hr

printing = 3,396.93 BTu/hr

standby = 904.71 BTu/hr

PowerSave 1 = 136.56 BTu/hr

PowerSave 2 = 85.35 BTu/hr

off = 0.69 BTu/hr

Table 7. Electrical specifications (HP LaserJet 9050)

Volts Frequency Ampres Watts (W) (typical) Therma l units per hour

(BTu/hr)

100-127 V ac ±

10%

220-240 V ac ±

10%

50/60 Hz

± 2 Hz

50/60 Hz

± 2 Hz

Minimum

recommended current

capacity =

12 A dedicated circuit

Minimum

recommended current

capacity =

6.5 A dedicated circuit

printing = 1,000 W

standby = 200 W

PowerSave 1 = 158 W

PowerSave 2 = 21 W

off = 0.5 W

printing = 1,000 W

standby = 200 W

PowerSave 1 = 40 W

PowerSave 2 = 21 W

off = 0.5 W

printing = 3,550.36 BTu/hr

standby = 904.71 BTu/hr

PowerSave 1 = 136.56 BTu/hr

PowerSave 2 = 85.35 BTu/hr

off = 0 BTu/hr

printing = 3,396.93 BTu/hr

standby = 904.71 BTu/hr

PowerSave 1 = 136.56 BTu/hr

PowerSave 2 = 85.35 BTu/hr

off = 0.69 BTu/hr

Note Electrical specifications might change. See www.hp.com/go/lj9000 or www.hp.com/go/lj9050_lj9040

for the current information.

WARNING! Power requirements are based on the country/region where the printer is sold. Do not convert operating

voltages. This can damage the printer and void the product warranty.

Table 8. Environmental specifications

Operating temperature 10°C to 32.5°C

°F to 91°F)

(50

Relative humidity 10% to 80%

Storage temperature -40ºF to +60ºF

Storage humidity 15% to 90%

8 Chapter 1 Product information

Page 25

Table 9. Acoustical specifications

Declared per ISO 9296

Sound power level

1

Printing (50 ppm) L

= 7.2 Bels (A) [72 dB(A)]

WAd

HP LaserJet 9050

= 5.6 Bels (A) [56 dB(A)]

WAd

= 7.0 Bels (A) [dB(A)]

WAd

= 5.6 Bels (A) [dB(A)]

WAd

= 56 dB(A)

pAm

Sound power level

2

HP LaserJet 9040

Sound pressure level

Ready L

Printing (40 ppm) L

Ready L

3

Printing (50 ppm) L

(Bystander position)

HP LaserJet 9050

Sound pressure level

(Bystander position)

Ready L

4

Printing (40 ppm) L

= 40 dB(A)

pAm

= 54 dB(A)

pAm

HP LaserJet 9040

Ready L

= 39 dB(A)

pAm

1.Values current as of October 16, 2003. Values subject to change, see

lj9050_lj9040 for current information.

2.Values current as of October 24, 2004. Values subject to change, see

lj9050_lj9040 for current information.

3.Values current as of October 16, 2003. Values subject to change, see

lj9050_lj9040 for current information.

4.Values current as of October 24, 2004. Values subject to change, see

lj9050_lj9040 for current information.

www.hp .com/support/

www.hp.com/support/

www.hp .com/support/

www.hp.com/support/

Product specifications 9

Page 26

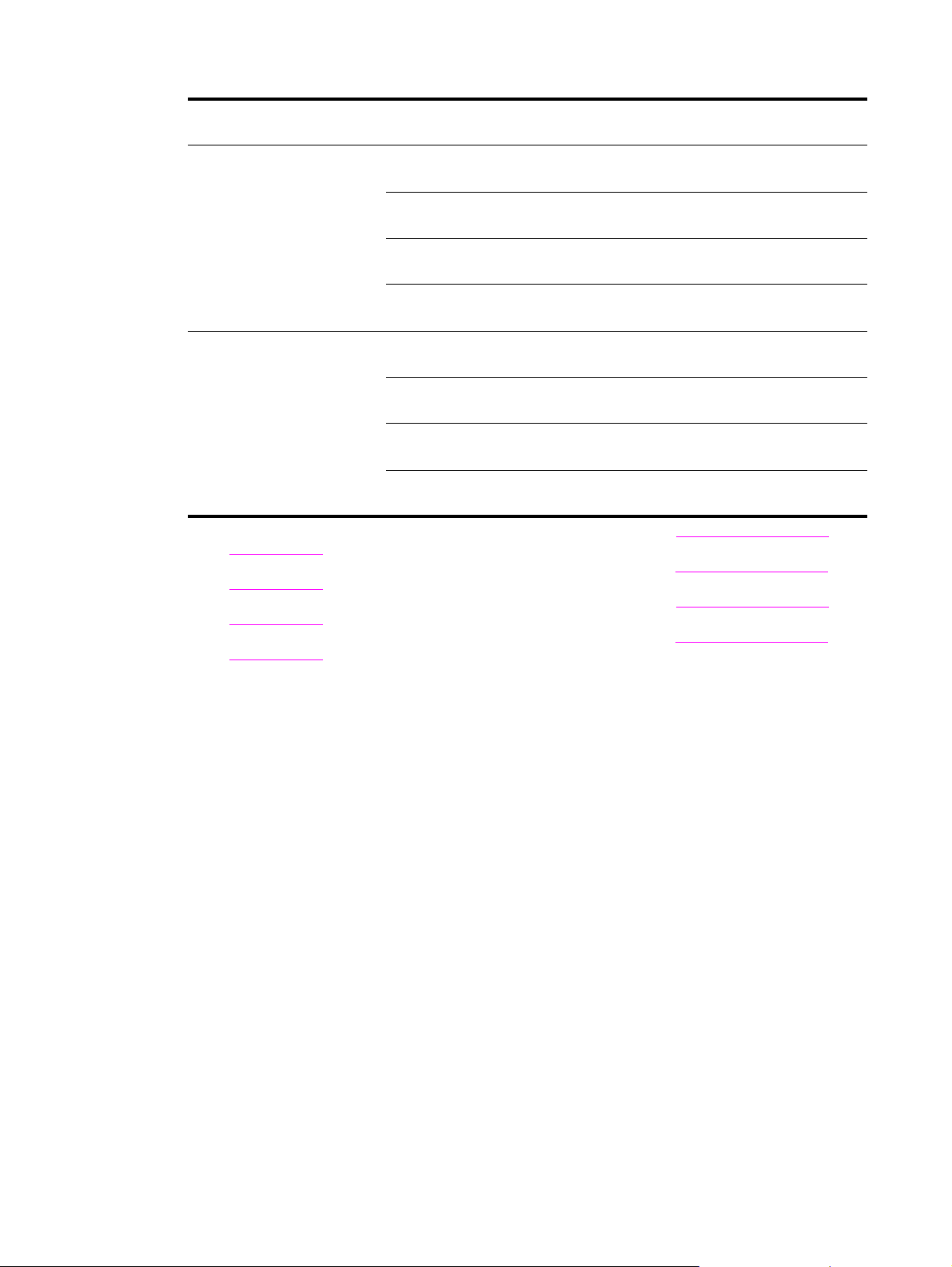

Product overview

External view of the printer and accessories

Face-up bin

Optional 3,000-sheet

stapler/stacker, 3,000sheet stacker, 8-bin

mailbox, or

multifunction finisher

Front door

Duplexer (inside

the printer)

Left door

(behind the

output

Tr ay 2

Tr ay 3

Optional tray 4

Figure 2. External view of the printer and accessories

Standard output bi n

(face-down bin)

Optional

tray 1

Right door

Vertical

transfer door

10 Chapter 1 Product information

Page 27

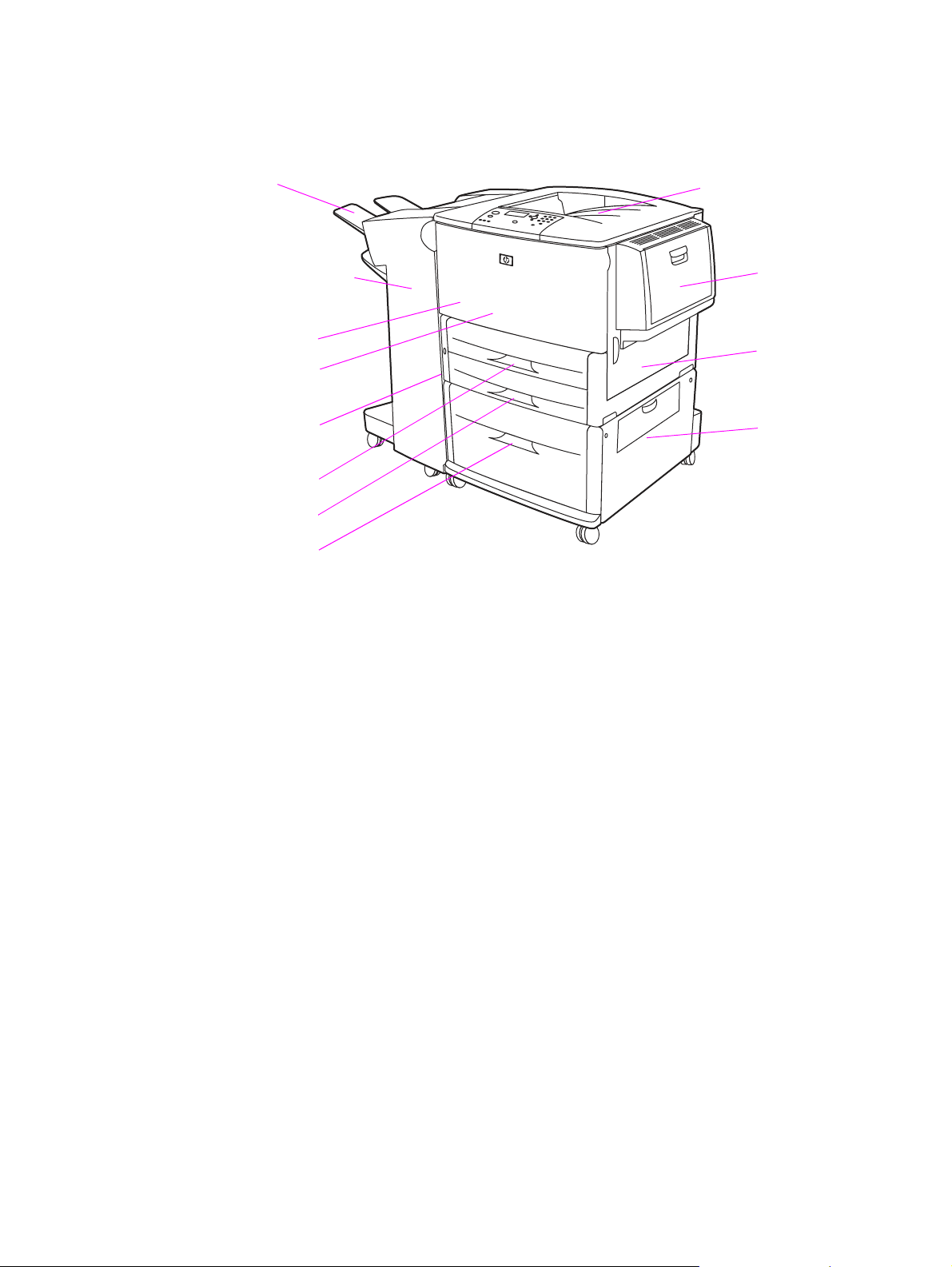

Interface connections

Local area network (LAN)

connector (RJ-45)

Parallel B connector

(Parallel)

HP Jet-Link connector

(for paper-handling

accessory)

Figure 3. Interface connections (HP LaserJet 9040/9050 Series printer)

Parallel connector

HP Jetdirect print server

(optional)

Foreign interface

connector (not used)

I/O

slots

HP Fast InfraRed Connect

(optional IR pod)

HP Jet-Link connector

(optional accessories

connection)

Figure 4. Interface connections (HP LaserJet 9000 Series printer)

Product overview 11

Page 28

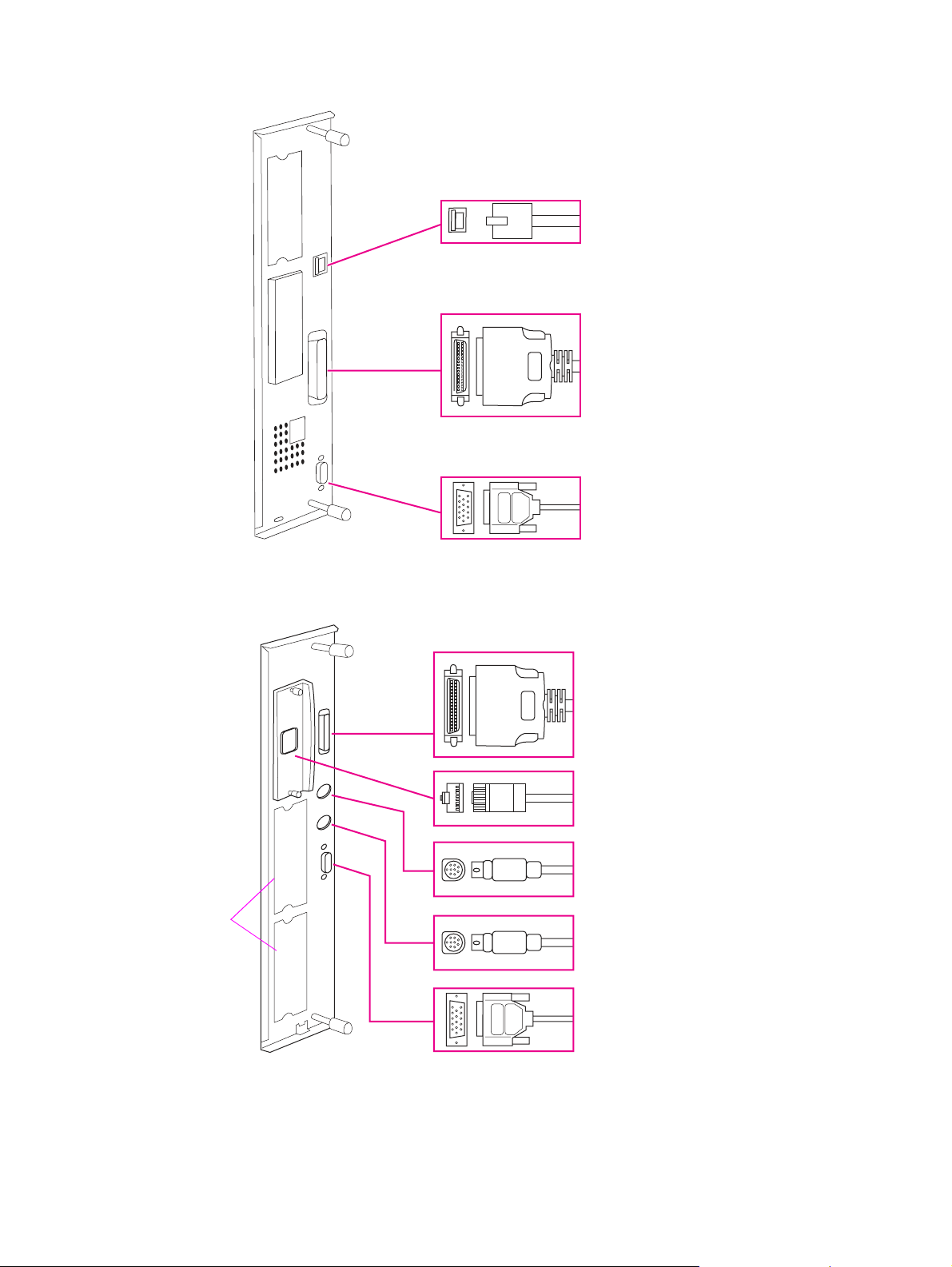

Optional accessories

Multifunction finisher

3,000-sheet stapler/stacker

3,000-sheet stacker

Figure 5. Optional accessories

8-bin mailbox

(HP LaserJet

9040/9050 Series

printer only)

Tray 4

Tray 1

Duplex printing

accessory

(duplexer)

HP Fast InfraRed

Connect (HP LaserJet

9000 Series printer only

12 Chapter 1 Product information

Page 29

Regulatory information

Regulatory requirements

For regulatory information and requirements, please see the HP LaserJet 9000 Start Guide or the

HP LaserJet 9040/9050 Start Guide.

FCC regulations

For FCC regulations, please see the HP LaserJet 9000 Start Guide or the HP LaserJet 9040/9050

Start Guide.

Declaration of conformity

For declaration of conformity information, please see the HP LaserJet 9000 Start Guide or the HP

LaserJet 9040/9050 Start Guide.

Environmental product stewardship program

For environmental product stewardship program information, please see the HP LaserJet 9000 Use

Guide or the HP LaserJet 9040/9050 Use Guide.

Regulatory information 13

Page 30

Service approach

Repair of the printer normally begins with a three-step process:

z isolate the problem to the major system (the host computer, the network and/or server, or the

printer system)

z determine whether the problem is located in one of the paper-handling devices or in the printer

engine

z troubleshoot the problem using the procedures in chapter 7

When a faulty part is located, repair is usually accomplished by assembly-level replacement of field

replaceable units (FRUs). Some mechanical assemblies can be repaired at the subassembly level.

Hewlett-Packard does not support replacement of components on the printed circuit assemblies.

Parts and supplies

The following information helps you locate parts and assistance.

Ordering information

"Ordering parts" in chapter 8 of this manual contains FRUS and replacement part numbers.

Replacement parts can be ordered from the HP Customer Services and Support Organization

(HPS).

"Consumables, supplies, accessories, FRUs, and documentation" in chapter 8 of this manual

contains information about accessories that are specifically designed for this printer. Order

accessories from HPS.

Phone listings

z HPS (for U. S.)

(800) 752-0900

z HPS (for Canada)

(800) 387-3867

z HPS (for Europe)

(49 7031) 142253

Exchange program

Hewlett-Packard offers remanufactured assemblies for some parts. These are identified in

"Illustrations and parts lists" in chapter 8, and can be ordered through HPS.

Consumables

The printer has two consumables: the print cartridge and the preventive maintenance kit. The

stapler/stacker and the 8-bin mailbox have one consumable: the staple cartridge. These are

identified in "Illustrations and parts lists" in chapter 8, and can be ordered through HPS.

Warranty

For warranty information and requirements, please see the HP LaserJet 9000 Start Guide or the HP

LaserJet 9040/9050 Start Guide.

Limited warranty for print-cartridge life

For print-cartridge warranty information, please see the HP LaserJet 9000 Start Guide or the HP

LaserJet 9040/9050 Start Guide.

14 Chapter 1 Product information

Page 31

2 Product requirements

Chapter contents

Site requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Operating environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Space requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Media specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Guidelines for selecting print media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Special media specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Storing print media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Media input/output options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Trays, bins, and paper handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Chapter contents 15

Page 32

Site requirements

Operating environment

The electrical and environmental specifications must be maintained to ensure the proper operation of

this printer. See "Product specifications" in chapter 1. Consider the following points before installing

the printer:

z Install in a well-ventilated, dust-free area.

z Install on a level, flat surface that can support the printer size and weight. Make sure that all four

printer feet are level. Do not install on carpet or on other soft surfaces.