Page 1

User’s Guide

HP 8753E Network Analyzer

HP

Rut

No. 08753-90367

Printed iu USA February 1999

Supersedes October 1998

Page 2

Notice.

The information contained in this document is subject to change without notice.

Hewlett-Packard makes no warranty of any kind with regard to this material, including

but not limited to, the implied warranties of merchantability and fitness for a particular

purpose.

Hewlett-Packard

shall

not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance, or use of this material.

@

Copyright Hewlett-Packard Company 1998, 1999

Page 3

Certification

Hewlett-Packard Company certifies that this product met its published specifications at the

time of shipment from the factory. Hewlett-Packard further certifies that its calibration

measurements are traceable to the United States National Institute of Standards and

‘lbchnology,

to the extent allowed by the Institute’s calibration facility, and to the calibration

facilities of other International Standards Organization members.

Wmanty

Note

The actual warranty on your instrument depends on the date it was ordered

as well as whether or not any warranty options were purchased at that time.

lb determine the exact warranty on your

insment,

contact the nearest

Hewlett-Packard sales or service office with the model and serial number of

your instrument. See the table titled “Hewlett-Packard Sales and Service

Offices,” later in this section, for a list of sales and service offices.

This Hewlett-Packard instrument product is warranted against defects in material and

workmanship for the warranty period. During the warranty period, Hewlett-Packard Company

will, at its option, either repair or replace products which prove to be defective.

If the warranty covers repair or service to be performed at Buyer’s facility, then the service or

repair will be performed at the Buyer’s facility at no charge within HP service travel areas

Outside HP service travel areas, warranty service will be performed at Buyer’s facility only

upon HP’s prior agreement, and Buyer shall pay HP’s round-trip travel expenses. In all other

areas, products must be returned to a service facility designated by HP

If the product is to be returned to Hewlett-Packard for service or repair, it must be returned

to a service facility designated by Hewlett-Packard. Buyer shall prepay shipping charges to

Hewlett-Packard and Hewlett-Packard shall pay shipping charges to return the product to

Buyer. However, Buyer shall pay all shipping charges, duties, and taxes for products returned

to Hewlett-Packard from another country.

Hewlett-Packard warrants that its software and

lirmware

designated by Hewlett-Packard for

use with an instrument will execute its programming instructions when properly installed on

that instrument. Hewlett-Packard does not warrant that the operation of the instrument, or

software, or

firmware

will be uninterrupted or error-free.

L

IMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from improper or inadequate

maintenance by Buyer, Buyer-supplied software or interfacing, unauthorized modification or

misuse, operation outside of the environmental specifications for the product, or improper

site preparation or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. HEWLETT-PACKARD SPECIFICALLY

DISCLAIMS THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

A

PARTICULAR PURPOSE.

E

XCLUSIVE

RE

MEDIES

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

HEWLETT-PACKARD SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT, TORT,

OR ANY OTHER LEGAL THEORY.

. . .

III

Page 4

Maintenance

Clean the cabinet, using a damp cloth only.

Assistance

are

Product maintenance agreements

Hewlett-&hrd

Rw an@ assistance, wnmct gour nearest Hewlett-Rzchmd Saks and Service Om

products

and other customer

assktmm

agremnmts

available for

Shipment for Service

If you are sending the instrument to Hewlett-Packard for service, ship the analyzer to the

nearest HP service center for repair, including a description of any failed test and any error

message. Ship the analyzer, using the original or comparable anti-static packaging materials.

iv

Page 5

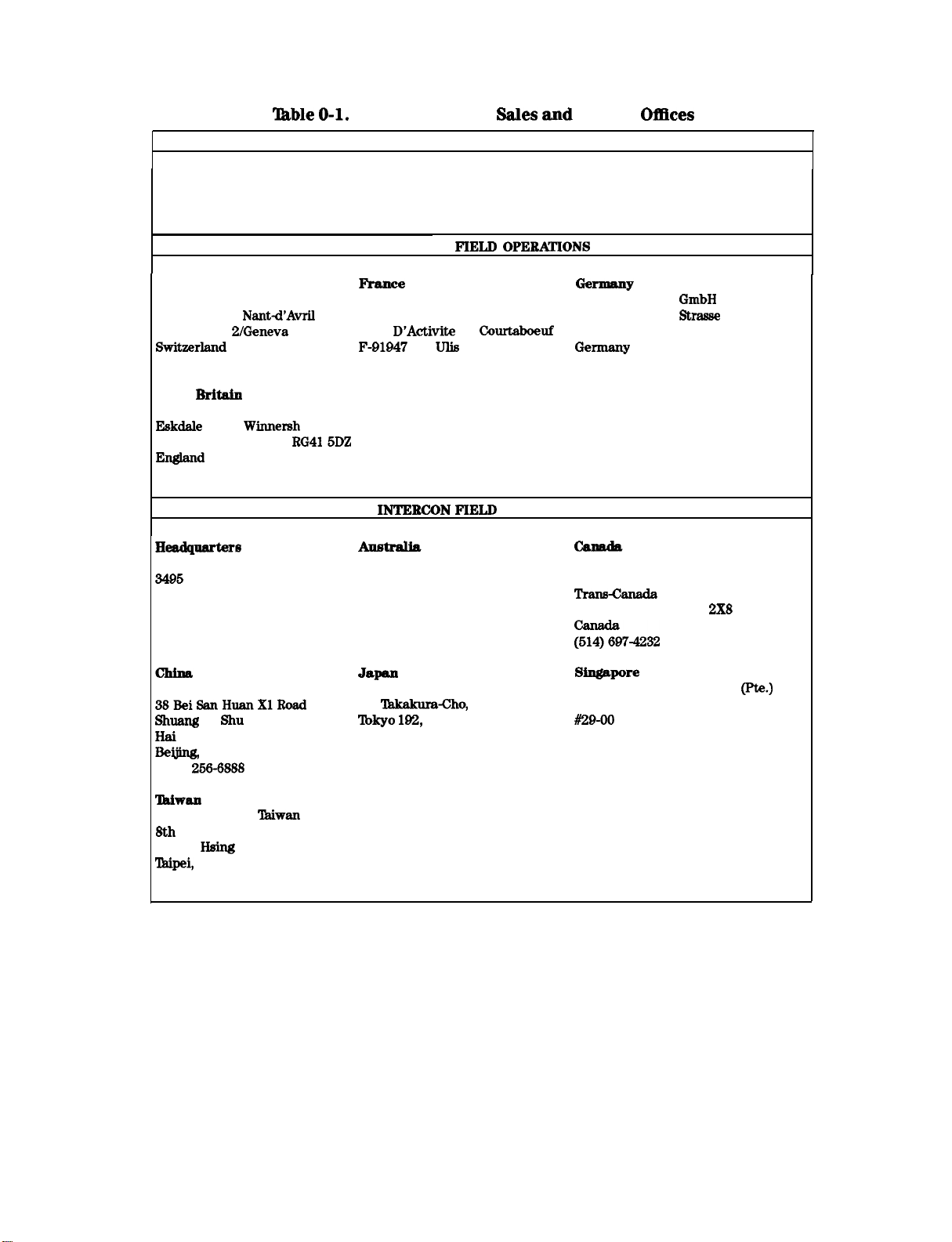

‘Iktble O-1.

Instrument Support Center

Hewlett-Packard Company

(800) 403-0801

Hewlett-Packard

UNITED STATES

Sales

and Service

OfEces

EUROPEAN

Headquarters

Hewlett-Packard S.A.

150, Route du

1217 Meyrin

&vi&&and

(41 22) 780.8111 France

Great

Hewlett-Packard Ltd.

E&dale Road,

Woldngham, Berkshire

England

(44 734) 696622

HWkpWtt%S

Hewlett-Packard Company

3495

Deer Creek Road

Palo Alto, California, USA

94304-1316

(415) 857-5027

Nantd’Avril

Z/Geneva

Britah

Whmersh

RG415DZ

Triangle

Prame

Hewlett-Packard France Hewlett-Packard

1 Avenue Du Canada

Zone D’Activite De

F-91947

(33 1) 69 82 60 60

Hewlett-Packard Australia Ltd.

31-41 Joseph Street

Blackbum, Victoria 3130

(61 3) 895-2895

Les

INTERCON

JspaJp

China Hewlett-Packard Company Hewlett-Packard Japan, Ltd.

38BeiSanHuanXlRoad

aulaug

Yu

shu

Hai Dian District

Beijin&

china

(86 1)

256-6888

Q-l %kakuraCho, Hachioji

lblcyo 192,

(81 426) 60-2111

FIELD OPEEA!l’IONS

Courtaboeuf

Ulis

Cedex

FIELD

OPERATIONS

Japan

G-m=w

Hewlett-Packard

61352 Bad Homburg v.d.H

Germany

(49 6172)

Hewlett-Packard (Canada) Ltd.

17500 South Service Road

TramCanada

Kirkland, Quebec HQJ

z7-4232

fb@me

Hewlett-Packard Singapore (Pte.) Ltd.

150 Beach Road

#29-00

Singapore 0718

(65) 291-9088

GmbH

Strasse

16-O

Highway

2X8

Gateway West

IkbiWSn

Hewlett-Packard

8th Floor, H-P Building

337 Fu

I-king

Tkdpei,

Taiwan

(886 2) 712-0404

‘&wan

North Road

.

V

Page 6

Safety Symbols

The following safety symbols are used throughout this manual.

of the symbols and its meaning before operating this instrument.

Caution

Warning

Caution denotes a hazard. It calls attention to a procedure that, if not

correctly performed or adhered to, would result in damage to or destruction

of the instrument. Do not proceed beyond a caution note until the indicated

conditions are fully understood and met.

Rkning

correctly performed or adhered to, could result in injury or loss of life.

Do not proceed beyond a warning note until the indicated conditions are

fully understood and met.

denotes a hazard. It calls attention to a procedure which, if not

Familiarize

yourself with each

Instrument Markings

!

A

is necessary for the user to refer to the instructions in the documentation.

“CE” The CE mark is a registered trademark of the European Community. (If accompanied by

a year, it is when the design was proven.)

The instruction documentation symbol. The product is marked with this symbol when it

“ISMl-A”

“CSA” The CSA mark is a registered trademark of the Canadian Standards Association.

This is a symbol of an Industrial Scientific and Medical Group 1 Class A product.

vi

Page 7

General Safety Considerations

Note

Warning

Warning

Caution

Warning

This instrument has been designed and tested in accordance with IEC

Publication 1010, Safety Requirements for Electronics Measuring Apparatus,

and has been supplied in a safe condition. This instruction documentation

contains information and warnings which must be followed by the user to

ensure safe operation and to maintain the instrument in a safe condition.

This is a

ground incorporated in the power cord). The mains plug shall only be

inserted in a socket outlet provided with a protective earth contact. Any

interruption of the protective conductor, inside or outside the instrument,

is likely to make the instrument dangerous. Intentional interruption is

prohibited.

No operator serviceable parts inside. Refer servicing to qualified

personnel. lb prevent electrical shock, do not remove covers.

Before switching on this instrument, make sure that the line voltage selector

switch is set to the voltage of the power supply and the correct fuse is

installed. Assure the supply voltage is in the specified range.

The opening of

voltages.

being opened.

safety

Class I product (provided with a protective earthing

covers

DiSCOMeCt

or removal of parts is likely to expose dangerous

the instrument from all voltage sources while it is

Warning

Warning

Warning

Warning

Warning

The power cord is connected to

for 10 seconds after disconnecting the plug from its power supply.

For continued protection against

same type and rating (F

prohibited.

lb prevent electrical shock, disconnect the HP 87533 from mains before

cleaning. Use a dry cloth or one slightly dampened with water to clean

the external case parts. Do not attempt to clean internally.

If this product is not used as

equipment could be impaired. This product must be used in a normal

condition (in which all means for protection are intact) only.

Always use the three-prong AC power cord supplied with this product.

FMlure

cause product damage.

to ensure adequate earth grounding by not using this cord may

3A/250V).

internal capacitors that may remain live

fire

hazard replace line fuse only with

The use of other fuses or material is

specitled,

the protection provided by the

Page 8

Caution

This product is designed for use in Installation Category II and Pollution Degree

2 per IEC 1010 and 664 respectively.

Caution

Warning

VENTILATION REQUIREMENTS: When

convection into and out of the product must not be restricted. The ambient

temperature (outside the cabinet) must be less than the maximum operating

temperature of the product by 4O C for every 100 watts dissipated in the

cabinet. If the total power dissipated in the cabinet is greater that 800 watts,

then forced convection must be used.

Install the instrument according to the enclosure protection provided.

This instrument does not protect against the ingress of water. This

iustrument protects agaius

enclosure.

finger

instaIling

access to hazardous parts within the

the product in a cabinet, the

Compliance with German FTZ Emissions Requirements

This network analyzer complies with German

Emission requirements.

FlZ

526/527 Radiated Emissions and Conducted

Compliance with German Noise Requirements

This is to declare that this instrument is in conformance with the German Regulation on

Noise Declaration for Machines (Laermangabe nach der Maschinenlaermrerordung -3. GSGV

Deutschland).

Acoustic Noise

LpA<70 dB

Emission/Geraeuschemission

Lpa<70 dD

Page 9

User’s Guide Overview

n

Chapter 1, “HP 8753E Description and Options, ndescribes features, functions, and available

options.

n

Chapter 2, “Making Measurements,” contains step-by-step procedures for making

measurements or using particular functions.

n

Chapter 3, “Making Mixer Measurements,

contains step-by-step procedures for making

n

calibrated and error-corrected mixer measurements.

w

Chapter 4, “Printing, Plotting, and Saving Measurement Results,” contains instructions

for saving to disk or the analyzer internal memory, and printing and plotting displayed

measurements.

n

Chapter 5, “Optimizing Measurement Results,

n

describes techniques and functions for

achieving the best measurement results

n

Chapter 6, “Application and Operation Concepts,

n

contains explanatory-style information

about many applications and analyzer operation.

n

Chapter 7, “Specifications and Measurement Uncertainties,” defines the performance

capabilities of the analyzer.

n

Chapter 8, “Menu Maps,” shows softkey menu relationships.

n

Chapter 9, “Key Dell&ions,” describes all the front panel keys, softkeys, and their

corresponding HP-IB commands.

n

Chapter 10, “Error Messages,” provides information for interpreting error messages

n

Chapter 11, “Compatible Peripherals,

n

lists measurement and system accessories, and

other applicable equipment compatible with the analyzer. Procedures for configuring the

peripherals, and an HP-IB programming overview are

n

Chapter 12, “Preset State and Memory Allocation,”

also

included.

contains a discussion of memory

allocation, memory storage, instrument state definitions, and preset conditions.

n

Appendix A, “The

the

CITIGle

n

Appendix B, “Determining System Measurement Uncertainties,” contains information on how

data format as well as a list of

CITIlile

Data Format and Key Word Reference,

CITIflle

keywords

n

contains information on

to determine system measurement uncertainties.

lx

Page 10

Network Analyzer Documentation Set

The Installation and Quick Start Guide

familiarizes you with the network analyzer’s

front and rear panels, electrical and

environmental operating requirements, as well

as procedures for installing, configuring, and

verifying the operation of the analyzer.

The User’s Guide

shows how to make

measurements, explains commonly-used

features, and tells you how to get the most

performance from your analyzer.

The Quick Reference Guide

provides a

summary of selected user features.

The

HEW3

Programming and Command

Reference Guide

provides programming

information for operation of the network

analyzer under HP-IB control.

X

Page 11

The HP BASIC Programming Examples

Guide

provides a tutorial introduction using

BASIC programming examples to demonstrate

the remote operation of the network analyzer.

The System

Vertication

and

‘lkst

Guide

provides the system verification and

performance tests and the Performance Test

Record for your analyzer.

xl

Page 12

DECLARATION OF CONFORMITY

Manufacturer’s Name:

According to ISO/IEC Guide 22 and EN 45014

Hewlett-Packard Co.

Hewlett-Packard Japan, Ltd.

Manufacturer’s Address:

Microwave Instruments Division

1400 Fountaingrove Parkway

Santa Rosa, CA

95403-I

799

USA

Kobe Instrument Division

l-3-2,

Murotani, Nishi-ku, Kobe-shi

Hyogo, 651-22

Japan

Declares that the product:

Product Name:

Model Number:

Product Options:

Network Analyzer

8753E

HP

This declaration covers all options of the above

product

Conforms to the following Product specifications:

Safety: IEC

61010-1:199O/EN 61010-I:1993

CAN/CSA-C22.2 No. 1010.1-92

EMC:

CISPR 11:1990/EN

IEC

801-2:199l/EN

IEC

801-3:1984/EN

IEC

801-4:1988/EN 50982-I :I

5501

I:1991

Group I, Class A

50082-I:1992 4 kV CD, 8 kV AD

50082-I:1992 3 V/m, 27-500 MHz

992 0.5 kV sig. lines, 1 kV power lines

Supplenientary Information:

The product herewith complies with the requirements of the Low Voltage Directive

73/23/EEC

Jo HiaWQuality

d

Europeen Contact: Your knxl Hewlett-Packard Sales and Servke Oftice or Hewlett-Packard GmbH Department HQ-

TFIE, Heneneberger Strasse 130. D71034 Boblingen, Germany (FAX +49-7031-U-3143

and the EMC Directive

Engineering Manager

Santa Rosa, 21 Jan. 1998

89/336/EEC

&A

and carries the CE-marking accordingly.

c

Obara/Quality Engineering Manager

Mike

Kobe, 14 Jan. 1998

xii

Page 13

Contents

1.

HP 8753E Description and Options

Where to Look for More Information

Analyzer Description

Front Panel Features

Analyzer Display

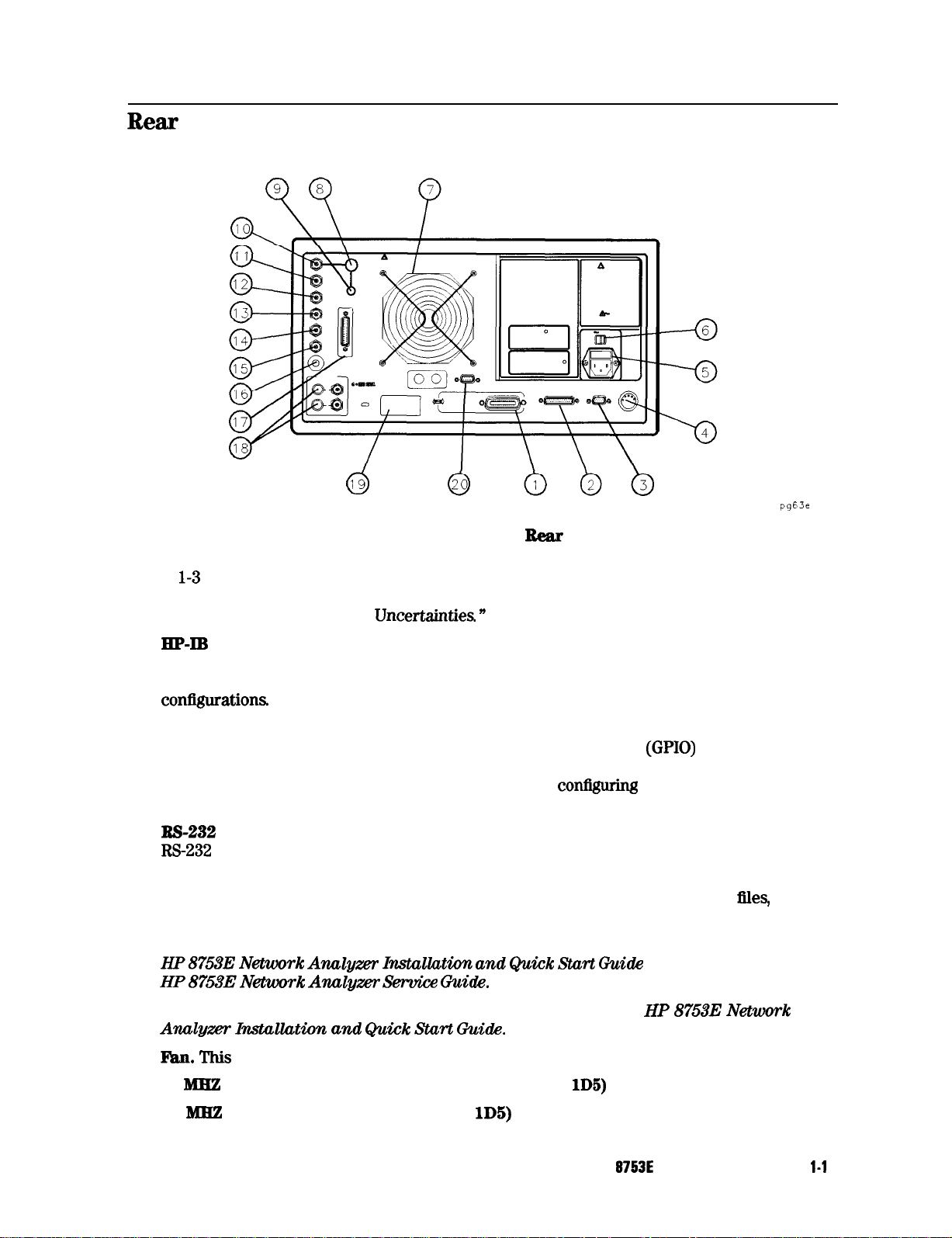

Rear Panel Features and Connectors

Analyzer Options Available

Option lD5, High Stability Frequency Reference

Option 002, Harmonic Mode

Option

Option 010, Time Domain

Option 011, Receiver Configuration

Option 075,750 Impedance

Option

Option

Option

Service and Support Options

Differences among the HP 8753 Network Analyzers

2.

B¶akiug

Where to Look for More Information

Principles of Microwave Connector Care

Basic Measurement Sequence and Example

Basic Measurement Sequence

Basic Measurement Example

Using the Display Functions

‘Ib

‘Ib

lb View the Measurement Data and Memory Trace

lb

lb Subtract the Memory Trace from the Measurement Data Trace

‘IbRatioMeasurementsinChannelland2

‘Ib Title

Using the Four-Parameter Display

Four-Parameter Display and Calibration

‘lb

Quick Four-Parameter Display

006,6 GHz

lDT,

Delete Display

lCM,

Rack Mount Flange Kit Without Handles

lCP,

Rack Mount Flange Kit With Handles

Measurements

Step 1. Connect the device under test and any required test equipment.

Step 2. Choose the measurement parameters.

Setting the Frequency Range

Setting the Source Power.

Setting the Measurement

Step 3. Perform and apply the appropriate error-correction.

Step 4. Measure the device under test.

Step 5. Output the measurement results.

View Both Primary Measurement Channels

Save a Data Trace to the Display Memory

Divide Measurement Data by the Memory Trace

the Active Channel Display

View AR Four S-Parameters of a Two-Port Device

lb Activate and Configure the Auxiliary Channels

.............................

.............................

..............................

..........................

Operation

.........................

.........................

.........................

.........................

........................

........................

........................

.........................

.....................

.....................

........................

........................

.....................

.....................

......................

.......................

.....................

.......................

.......................

...............

............

..............

..............

...................

..................

..

...............

........

..................

.................

................

................

.............

.............

.......

.................

...................

.............

.............

l-l

l-2

l-4

l-7

l-11

1-13

1-13

1-13

1-13

1-13

1-13

1-13

1-13

1-13

1-14

1-14

1-15

2-l

2-2

2-3

2-3

2-3

2-3

2-3

2-3

2-4

2-4

2-4

2-5

2-5

2-6

2-6

2-7

2-7

2-8

2-8

2-8

2-9

2-10

2-10

2-10

2-12

2-13

conttmts-1

Page 14

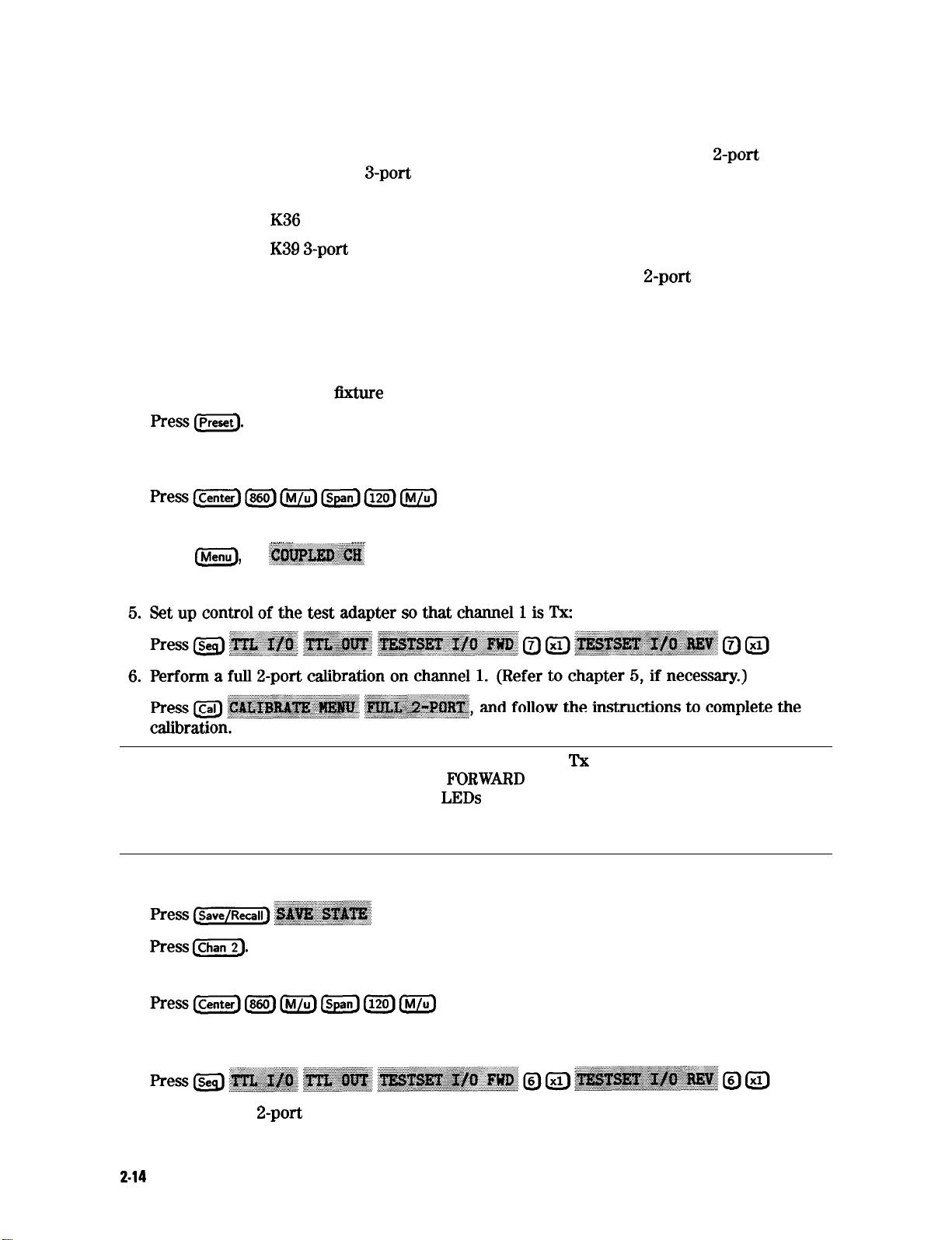

Characterizing a Duplexer . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure for Characterizing a Duplexer . . . . . . . . . . . . . . . . . .

Using Analyzer Display Markers . . . . . . . . . . . . . . . . . . . . . . .

‘Ib

Use Continuous and Discrete Markers . . . . . . . . . . . . . . . . . .

lb

Activate Display Markers . . . . . . . . . . . . . . . . . . . . . . . .

lb

Move Marker Information off of the Grids . . . . . . . . . . . . . . . .

‘Ib

Use Delta (A) Markers . . . . . . . . . . . . . . . . . . . . . . . . . .

To Activate a.Fixed.@.arker

Using the ~~~~~~~~~.~

Using

the

~~~~~~~

lb

Couple and Uncouple Display Markers . . . . . . . . . . . . . . . . . .

..:...i .:: .i

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Key

I..

.,.::

;.:::

. . . . .

;;..:.:.:

. . . . . .

Key

to Activate a Fixed Reference Marker

to A&iv&e a F&d Reference Marker

. .

. . . . . .

lb Use Polar Format Markers . . . . . . . . . . . . . . . . . . . . . . . .

TbUseSmithChartMarkers

. . . . . . . . . . . . . . . . . . . . . . . .

lb Set Measurement Parameters Using Markers . . . . . . . . . . . . . . .

Setting the Start Frequency . . . . . . . . . . . . . . . . . . . . . . .

Setting the Stop Frequency . . . . . . . . . . . . . . . . . . . . . . . .

Setting the Center Frequency . . . . . . . . . . . . . . . . . . . . . . .

Setting the Frequency Span . . . . . . . . . . . . . . . . . . . . . . .

Setting the Display Reference Value . . . . . . . . . . . . . . . . . . . .

Setting the Electrical Delay. . . . . . . . . . . . . . . . . . . . . . . .

Setting the CW Frequency . . . . . . . . . . . . . . . . . . . . . . . . .

‘RI

Search for a Specific Amplitude . . . . . . . . . . . . . . . . . . . . .

Searching for the Maximum Amplitude . . . . . . . . . . . . . . . . . .

Searching for the Minimum Amplitude . . . . . . . . . . . . . . . . . .

Searching for a

‘lhrget

Amplitude . . . . . . . . . . . . . . . . . . . . .

Searching for a Bandwidth . . . . . . . . . . . . . . . . . . . . . . . .

Tracking the Amplitude that You Are Searching . . . . . . . . . . . . . .

‘RI

Calculate the Statistics of the Measurement Data . . . . . . . . . . . . .

Measuring Magnitude and Insertion Phase Response . . . . . . . . . . . . . .

Measuring the Magnitude Response . . . . . . . . . . . . . . . . . . . . .

Measuring Insertion Phase Response . . . . . . . . . . . . . . . . . . . .

Measuring Electrical Length and Phase Distortion . . . . . . . . . . . . . . .

Measuring Electrical Length . . . . . . . . . . . . . . . . . . . . . . . .

Measuring Phase Distortion . . . . . . . . . . . . . . . . . . . . . . . . .

Deviation From Linear Phase . . . . . . . . . . . . . . . . . . . . . . .

Group Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TestingADevicewithLimitLines

. . . . . . . . . . . . . . . . . . . . . .

Setting Up the Measurement Parameters . . . . . . . . . . . . . . . . . .

Creating Flat Limit Lines . . . . . . . . . . . . . . . . . . . . . . . . . .

CreatingaSlopingLimitLine

. . . . . . . . . . . . . . . . . . . . . . . .

Creating Single Point Limits . . . . . . . . . . . . . . . . . . . . . . . .

Editing Limit Segments. . . . . . . . . . . . . . . . . . . . . . . . . . .

Deleting Limit Segments . . . . . . . . . . . . . . . . . . . . . . . . .

RtmningaLimitTest

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reviewing the Limit Line Segments . . . . . . . . . . . . . . . . . . . .

ActivatingtheLimitlbst

. . . . . . . . . . . . . . . . . . . . . . . . .

Offsetting Limit Lines . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measuring Gain Compression . . . . . . . . . . . . . . . . . . . . . . . . .

Measuring Gain and Reverse Isolation Simultaneously . . . . . . . . . . . . .

Measurements Using the Swept List Mode . . . . . . . . . . . . . . . . . . .

Connect the Device Under

Test

. . . . . . . . . . . . . . . . . . . . . . .

Observe the Characteristics of the Filter . . . . . . . . . . . . . . . . . .

Choose the Measurement Parameters . . . . . . . . . . . . . . . . . . . .

2-13

2-14

2-14

2-17

2-17

2-18

2-19

2-20

2-21

2-22

2-23

2-24

2-24

2-25

2-26

2-27

2-27

2-28

2-29

2-30

2-31

2-31

2-32

2-32

2-33

2-34

2-35

2-35

2-36

2-37

2-37

2-38

2-40

2-40

2-42

2-42

2-43

2-46

2-46

2-47

2-49

2-51

2-52

2-52

2-53

2-53

2-53

2-54

2-55

2-59

2-61

2-61

2-62

2-62

Page 15

Set Up the Lower

Set Up the

Passband

Set Up the Upper

Calibrate and Measure

Measurements Using the Tuned Receiver Mode

Typical test setup

Tuned receiver mode in-depth description

Frequency Range

Compatible Sweep Types

External Source Requirements

Test Sequencing

Creating a Sequence

Running a Sequence

Stopping a Sequence

Editing a Sequence

Deleting Commands

Inserting a Command

Modifying a Command

Clearing a Sequence from Memory

Changing the Sequence

Naming

Files

Generated by a Sequence

Storing a Sequence on a Disk

Loading a Sequence from Disk

Purging a Sequence from Disk

Printing a Sequence

Cascading Multiple Example Sequences

Loop Counter Example Sequence

Generating

Limit

Files

Test

Example Sequence

Measuring Swept Harmonics (Option 002

Measuring a Device in the Time Domain (Option 010

Transmission Response in Time Domain

Reflection Response in Time Domain

Non-coaxial Measurements

Stopband

Parameters

Stopband

Parameters

.....................

Parameters

..................

..................

...........................

................

.............................

..................

............................

.........................

......................

...............................

.............................

............................

............................

............................

...........................

..........................

..........................

.....................

Title

........................

....................

........................

.......................

.......................

............................

...................

......................

in a Loop Counter Example Sequence

............

........................

only)

................

only)

...................

....................

..........................

...........

2-63

2-63

2-63

2-64

2-66

2-66

2-66

2-66

2-66

2-67

2-68

2-69

2-70

2-70

2-71

2-71

2-71

2-72

2-72

2-73

2-73

2-74

2-75

2-75

2-75

2-76

2-77

2-78

2-79

2-81

2-83

2-83

2-88

2-91

3.

Making Mixer Measurements

Where to Look for More Information

Measurement Considerations

.........................

Source and Load Mismatches

Reducing the Effect of Spurious Responses

EliminatingUnwantedMirringandLeakageSignals.

HowRFandIFAreDefIned

Frequency Offset Mode Operation

.....................

..................

.................

.............

........................

......................

Differences Between Internal and External R Channel Inputs

Power Meter Calibration

Conversion Loss Using the Frequency Offset Mode

High Dynamic Range Swept RF/IF Conversion Loss

Fixed IF Mixer Measurements

Tuned Receiver Mode

Sequence 1 Setup

Sequence 2 Setup

.............................

.............................

Phase or Group Delay Measurements

Amplitude and Phase Tracking

Conversion Compression Using the Frequency Offset Mode

Isolation Example Measurements

..........................

...............

..............

........................

...........................

.....................

........................

...........

.......................

.........

3-l

3-2

3-2

3-2

3-2

3-2

3-4

3-4

3-6

3-7

3-12

3-17

3-17

3-17

3-21

3-24

3-27

3-28

3-33

Page 16

LO to RF Isolation

RF Feedthrough

4.

Printing, Plotting, and Saving Measurement Results

Where to Look for More Information

Printing or Plotting Your Measurement Results

Configuring a Print Function

DeIIning

a Print Function

IfYouAreUsingaColorPrinter

‘Ib

Reset the Printing Parameters to Default Values

Printing One Measurement Per Page

Printing Multiple Measurements Per Page

Conllguring

a Plot Function

If You Are Plotting to an

If You Are Plotting to a Pen Plotter

If You Are Plotting to a Disk Drive

Defining

a Plot Function

Choosing Display Elements

Selecting Auto-Feed

Selecting Pen Numbers and Colors

Selecting Line Types

Choosing

Scale.

Choosing Plot Speed

lb Reset the Plotting Parameters to Default Values

Plotting One Measurement Per Page Using a Pen Plotter

Plotting Multiple Measurements Per Page Using a Pen Plotter

If You Are Plotting to an HPGL Compatible Printer

Plotting a Measurement to Disk

TbOutputthePlotFiles

TbViewPlotFilesonaPC

usingAmiPr0

Using Freelance

Outputting Plot Files from a PC to a Plotter

Outputting Plot Files from a PC to an HPGL Compatible Printer

Step 1. Store the HPGL initialization sequence.

Step 2. Store the exit HPGL mode and form feed sequence.

Step 3. Send the HPGL

Step 4. Send the plot

.............................

..............................

.....................

................. 4-3

......................... 4-3

..........................

...................... 4-6

..............

.....................

...................

.........................

HPGLIB

Compatible Printer

............. 4-8

.....................

.....................

...........................

.........................

............................

.....................

............................

..............................

............................

..............

............

..........

.............

........................

..........................

..........................

...............................

..............................

..................

........

...............

.........

initiahzation

flIe

to the printer.

sequence to the printer.

...................

.........

Step 5. Send the exit HPGL mode and form feed sequence to the printer.

OutputtingSiiePagePlotsUsingaPrinter.

Outputting Multiple Plots to a Siie Page Using a Printer

Plotting Multiple Measurements Per Page From Disk

ToPlotMultipleMeasurementsonaFullPage

‘Ib

Plot Measurements in Page Quadrants

Titling the Displayed Measurement

......................

Con6guringtheAnalyzertoProduceaTimeStamp

AbortingaPrintorPlotProcess

Printing or Plotting the List

IfYouWantaSiiePageofValues

Values

.......................

or Operating Parameters

.....................

IfYouWanttheEntireListofVaIues

Solving Problems with Printing or Plotting

Saving and

Places Where You Can Save

Recalling

Instrument States

........................

What You Can Save to the Analyzer’s Internal Memory

WhatYouCanSavetoaFloppyDisk

.................

...........

..............

................

..................

..............

..........

....................

..................

....................

............

....................

...

3-33

3-35

4-2

4-5

4-6

4-6

4-7

4-8

4-10

4-11

4-12

4-12

4-12

4-13

4-14

4-15

4-15

4-16

4-16

4-17

4-18

4-19

4-20

4-20

4-21

4-22

4-22

4-23

4-23

4-24

4-24

4-24

4-24

4-24

425

4-26

4-26

4-28

4-29

4-30

4-30

4-30

4-30

4-31

4-32

4-33

4-33

4-33

4-33

Contentsll

Page 17

What You Can Save to a Computer

Saving an Instrument State

Saving Measurement Results

ASCII Data Formats

CITIille

S2P

.................................

Data Format.

Re-Saving an Instrument State

Deleting a File

................................

..........................

.........................

............................

............................

........................

lb Delete an Instrument State File

IbDeleteaIlFiles

RenamingaFile

RecallingaFile

Formatting a Disk

.............................

...............................

...............................

..............................

Solving Problems with Saving or Recalling

IfYouAreUsinganExtemalDiskDrive.

.....................

.....................

Files

................

..................

4-34

4-35

4-36

4-39

4-39

4-39

4-41

4-41

4-41

4-41

4-42

4-42

4-43

4-43

4-43

5. Optimizing Measurement

Where to Look for More Information

Increasing Measurement Accuracy

Connector Repeatability

Interconnecting Cables

Temperature Drift

Frequency Drift

..............................

Performance Verification

Reference Plane and Port Extensions

Measurement Error-Correction

Conditions Where Error-Correction is Suggested

Types of Error-Correction

Error-Correction Stimulus State

Calibration Standards

Compensating for the Electrical Delay of Calibration Standards

Clarifying Type-N Connector Sex

When to Use Interpolated Error-Correction

Procedures for Error-Correcting Your Measurements

Frequency Response Error-Corrections

Response Error-Correction for Reflection Measurements

Response Error-Correction for Transmission Measurements

Receiver Calibration

Frequency Response and Isolation Error-Corrections

Response and Isolation Error-Correction for Reflection Measurements

Results

.....................

......................

..........................

...........................

.............................

..........................

....................

........................

...............

.........................

.......................

...........................

.......

.....................

.................

..............

....................

...........

..........

............................

..............

.....

Response and Isolation Error-Correction for Transmission Measurements

One-Port Reflection Error-Correction

Full Two-Port Error-Correction

TRL*

and

TRM*

Error-Correction

TRL Error-Correction

TRM Error-Correction

...........................

...........................

Modifying Calibration Kit Standards

Definitions

................................

Outline of Standard Modification

Modifying Standards

Modifying TRL Standards.

Modifying TRM Standards

............................

.........................

.........................

Power Meter Measurement Calibration

Entering the Power Sensor Calibration Data

Editing Frequency Segments

.....................

........................

.......................

......................

......................

....................

.................

.......................

...

5-2

5-2

5-2

5-2

5-2

5-3

5-3

5-3

5-4

5-4

54

5-5

5-6

5-6

5-6

5-6

5-8

5-9

5-9

5-11

5-12

5-14

5-14

5-16

5-18

5-21

5-24

5-24

5-25

5-27

5-27

5-27

5-27

5-29

5-31

5-34

5-35

5-35

Contents-6

Page 18

Deleting Frequency Segments

Compensating for Directional Coupler Response

Using Sample-and-Sweep Correction Mode

Using Continuous Correction Mode

lb Calibrate the Analyzer Receiver to Measure Absolute Power

Calibrating for Noninsertable Devices

Adapter Removal

.............................

Perform the 2-port Error Corrections

Remove the Adapter

Verify the Results

Example Program

Matched Adapters

...........................

............................

............................

.............................

ModifytheCalKitThruDellnition

Making Accurate Measurements of Electrically Long Devices

The Cause of Measurement Problems

lb Improve Measurement Results

Decreasing the Sweep Rate

Decreasing the Time Delay

Increasing Sweep Speed

‘IbUseSweptListMode

Detecting IF Delay

lb

Decrease the Frequency Span

...........................

..........................

............................

TbSettheAutoSweepTimeMode

To

Widen the System Bandwidth

lb Reduce the Averaging Factor

lb

Reduce the Number of Measurement Points

‘IbSettheSweepType.

To

View a Siie Measurement Channel

To

Activate Chop Sweep Mode

..........................

lb Use External Calibration

lb

Use Fast

Increasing Dynamic Range

TIbIncreasetheTestPortInputPower

2-Port

Calibration

..........................

lb Reduce the Receiver Noise Floor

Changing System Bandwidth

Changing Measurement Averaging

Reducing Trace Noise

‘lb Activate Averaging

............................

...........................

‘Ib Change System Bandwidth

Reducing Receiver Crosstalk

Reducing

RecaIl

Time

............................

Understanding Spur Avoidance

......................

...............

..................

.....................

.......

.....................

...................

.....................

..........

....................

......................

........................

........................

......................

.....................

......................

......................

................

...................

.......................

........................

.......................

....................

.....................

.......................

....................

.......................

.........................

.......................

5-36

5-36

5-37

5-38

5-39

5-40

5-41

5-42

5-43

5-44

5-45

5-46

5-47

5-48

5-48

5-48

5-48

5-49

5-50

5-50

5-50

5-51

5-51

5-52

5-52

5-52

5-53

5-53

5-54

5-54

5-54

5-56

5-56

5-56

5-56

5-56

5-57

5-57

5-57

5-57

5-58

5-59

6.

Application and Operation Concepts

Where to Look for More Information

HP 8753E System Operation

The

Built-In

Synthesized Source

The Source Step Attenuator

The Built-In

Test

The Receiver Block

The Microprocessor

............................

Set

............................

............................

Required Peripheral Equipment

Data Processing

Processing Details

TheADC

Contents-6

...............................

.............................

................................

.....................

.........................

......................

.......................

.......................

6-l

6-2

6-2

6-2

6-3

6-3

6-3

6-3

6-4

6-5

6-5

Page 19

IF Detection

Ratio Calculations

Sampler/IF Correction

Sweep-lb-Sweep Averaging

Pre-Raw Data Arrays

Raw Arrays

Vector Error-correction (Accuracy Enhancement)

Trace

Math Operation

Gating (Option 010

The Electrical Delay Block

Conversion

Transform (Option 010

Format

Smoothing

Format Arrays

OffsetandScaIe

Display Memory

Active Channel Keys

AuxiIiary

Channels and Two-Port Calibration

Enabling AuxiIiary

Multiple Channel Displays

Uncoupling StimuIus

Coupled Markers

Entry Block Keys

Units Terminator.

Knob

...................................

StepKeys

...............................

............................

..........................

........................

..........................

...............................

.............

..........................

only)

.........................

........................

...............................

only)

.......................

.................................

................................

..............................

.............................

.............................

.............................

................

Channels

........................

.........................

Values

Between Primary Channels

...........

..............................

..............................

.............................

.................................

gqiif)

-

......................................................................

Modifying or Deleting Entries

TurningofftheSoftkeyMenu

.....................................

0

....................................

a

StimuIus Functions

Defining Ranges with

StimuIus Menu.

The Power Menu.

.............................

Stimulus

..............................

..............................

Understanding the Power Ranges

Automatic mode

Manual mode

Power

Coupling

Channel

Test

port

SweepTime

coupling

couphng

.................................

.............................

..............................

Options

............................

............................

Manual Sweep Time Mode

Auto Sweep Time Mode

Minimum Sweep Time

TriggerMenu..

...........................

..............................

Source Attenuator Switch Protection

Allowing Repetitive Switching of the Attenuator

Channel

Sweep Type Menu

Linear

stimulus Coupling

..............................

Frequency Sweep (Hz)

Logarithmic Frequency Sweep (Hz)

Stepped List Frequency Sweep (Hz)

.......................

......................

Keys

....................

......................

..........................

.........................

..........................

.....................

..............

..........................

........................

.....................

.....................

6-5

6-5

6-5

6-5

6-6

6-6

6-6

6-6

6-6

6-6

6-6

6-7

6-7

6-7

6-7

6-7

6-7

6-8

6-8

6-9

6-9

6-9

6-9

6-9

6-10

6-10

6-10

6-11

6-11

6-11

6-11

6-11

6-11

6-12

6-12

6-13

6-14

6-14

6-14

6-14

6-16

6-16

6-16

6-17

6-17

6-17

6-17

6-19

6-20

6-20

6-21

6-22

6-22

6-23

6-23

Contentsd

Page 20

Segment Menu.

Stepped Edit List Menu

Stepped Edit

Swept List Frequency Sweep (Hz)

Swept Edit List Menu

Swept Edit

Setting Segment Power

Setting Segment IF Bandwidth

Power Sweep

CW Time Sweep (Seconds)

Selecting Sweep Modes

Response Functions

S-Parameters

Understanding S-Parameters

The S-Parameter Menu

Analog In Menu

Conversion Menu

Input Ports Menu

The Format Menu

Log Magnitude Format

Phase Format

Group Delay Format

Smith Chart Format

Polar Format

Linear Magnitude Format.

SWRFormat

RealFormat

Imaginary Format

Group Delay Principles

Scale

Reference Menu

Electrical Delay

Display Menu

Dual

Channel Mode

Dual

Channel Mode with Decoupled Stimulus

.............................

.........................

Subsweep

Menu

......................

...................... 6-25

..........................

Subsweep

Menu

....................... 6-25

..........................

......................

(dBm)

............................ 6-27

.........................

...........................

.............................

................................

........................ 6-29

...........................

.............................

............................

............................

..............................

...........................

...............................

............................

............................

...............................

.........................

................................

................................

.............................

...........................

............................

..............................

................................

............................

...............

Dual Channel Mode with Decoupled Channel Power

Four-Parameter Display Functions

Customizing the Display

Channel Position Softkey

4

Param

Displays

Softkey

Memory Math Functions

.........................

.........................

.........................

..........................

Adjusting the Colors of the Display

Setting Display Intensity

Setting Default Colors

Blanking the Display

Saving

Modiiied

Colors

Recalling Modified Colors

The Modify Colors Menu

Averaging Menu

Averaging

Smoothing

...............................

.................................

.................................

IF Bandwidth Reduction

Markers

Marker Menu

...................................

...............................

Delta Mode Menu

Fixed Marker Menu

.........................

..........................

...........................

..........................

.........................

.........................

..........................

............................

..........................

.....................

.....................

............

6-23

6-23

6-24

6-25

6-25

6-26

6-27

6-27

6-28

6-29

6-30

6-30

6-30

6-31

6-32

6-32

6-33

6-33

6-34

6-35

6-36

6-36

6-37

6-37

6-38

6-41

6-41

6-42

6-43

6-43

6-43

6-45

6-45

6-46

6-46

6-48

6-48

6-48

6-49

6-49

6-49

6-49

6-49

6-51

6-51

6-52

6-52

6%&

6-55

6-55

Contents-ll

Page 21

Marker

Function

Menu

Marker Search Menu

lhrget Menu

..............................

Marker Mode Menu

Polar Marker Menu

Smith Marker Menu

Measurement Calibration

What Is Accuracy Enhancement?

What Causes Measurement Errors?

Directivity

Source Match

Load Match

...............................

..............................

...............................

Isolation (Crosstalk)

Frequency Response (Tracking)

Characterizing Microwave Systematic Errors

One-Port Error Model

Device Measurement

‘Iwo-Port Error Model

Calibration Considerations

Measurement Parameters

Device Measurements

Omitting Isolation Calibration

Saving Calibration Data

The Calibration Standards

Frequency Response of Calibration Standards

Electrical Offset

Pringe

Capacitance

How Effective Is Accuracy Enhancement?

Correcting for Measurement Errors

Ensuring a Valid Calibration

Interpolated Error-correction

The Calibrate Menu

Response Calibration

Response and Isolation Calibration

Sll

and s2 One-Port Calibration

Pull Two-Port Calibration.

TRL*/LRM*

Two-Port Calibration

Restarting a Calibration

CalKitMenu

................................

TheSelectCalKitMenu

Modifying Calibration Kits

Definitions

Procedure

................................

.................................

Modify Calibration Kit Menu

Defme

Standard Menus.

Specify Offset Menu

Label Standard Menu

Specify Class Menu

Label Class Menu

Label Kit Menu

Verify performance

TRL*/LRM*

Calibration

Why Use TRL Calibration?

TRL

YIhminology

How

TRL*/LRM*

Calibration Works

...........................

...........................

...........................

..........................

..........................

...........................

......................

.....................

...........................

......................

.................

..........................

...........................

..........................

..........................

..........................

...........................

........................

..........................

.........................

................

.............................

...........................

...................

......................

........................

........................

.............................

............................

.....................

......................

.........................

......................

...........................

..........................

..........................

........................

.........................

...........................

..........................

...........................

............................

.............................

............................

...........................

.........................

..............................

.....................

6-56

6-56

6-56

6-56

6-56

6-56

6-57

6-57

6-58

6-58

6-59

6-59

6-60

6-60

6-61

6-61

6-66

6-66

6-72

6-72

6-72

6-72

6-72

6-73

6-73

6-74

6-74

6-76

6-78

6-78

6-79

6-80

6-80

6-80

6-80

6-80

6-81

6-82

6-82

6-82

6-83

6-83

6-83

6-84

6-85

6-87

6-88

6-88

6-91

6-91

6-91

6-92

6-92

6-92

6-93

C0ti0ntr-8

Page 22

TRL*

Error Model

Isolation

................................

Source match and load match

Improving Raw Source Match and Load Match For

The TRL Calibration Procedure

Requirements for TRL Standards

............................

......................

TRL*/LRM*

.......................

.....................

Fabricating and defining calibration standards for

TRL Options

Power Meter Calibration

Primary Applications

Calibrated Power Level

Compatible Sweep Types

Loss of Power Meter Calibration Data

Interpolation in Power Meter Calibration

Power Meter Calibration Modes of Operation

Continuous Sample Mode (Each Sweep)

Sample-and-Sweep Mode (One Sweep)

Power Loss Correction List

Power Sensor Calibration Factor List

Speed and Accuracy

Test

Equipment Used

StimuIus

Notes On Accuracy.

Alternate and Chop Sweep Modes

Alternate

Chop

...................................

Calibrating for Noninsertable Devices

Adapter Removal

Matched Adapters

ModifytheCaIKitThruDefirdtion

Using the Instrument State Functions

HP-IB Menu

EBKey.uS I.ndicatbrs

...............................

...........................

............................

..........................

..........................

....................

..................

................

..................

...................

........................

....................

............................

..........................

Parameters

...........................

...........................

......................

.................................

.....................

.............................

.............................

.....................

.....................

.................................

..........................

..........................

System Controller Mode

‘IhIker/Listener

Mode

Pass Control Mode

Address Menu

Using the

...............................

Parallel

Port

The Copy Mode

The GPIO Mode

The System Menu

The Limits Menu.

.............................

..............................

.............................

Edit Limits Menu

Edit Segment Menu

Offset Limits Menu.

Knowing the Instrument Modes

Network Analyzer Mode

External Source Mode

Primary Applications

QpicaI

Test Setup

External Source Mode In-Depth Description

External Source Auto

External Source

..........................

............................

.............................

...........................

.............................

............................

...........................

...........................

........................

..........................

...........................

...........................

............................

................

.........................

Manual

........................

CW Frequency Range in External Source Mode

Calibration

TRL/LRM

........

.............

. .

6-93

6-94

6-95

6-95

6-97

6-97

6-98

6-100

6-102

6-102

6-102

6-102

6-103

6-103

6-103

6-103

6-104

6-105

6-105

6-106

6-106

6-106

6-107

6-108

6-108

6-108

6-109

6-109

6-109

6-109

6-110

6-111

6-111

6-112

6-112

6-112

6-112

6-112

6-113

6-113

6-113

6-114

6-114

6-115

6-115

6-116

6-117

6-117

6-117

6-117

6-118

6-118

6-118

6-118

6-119

Contents-10

Page 23

Compatible Sweep Types

External Source Requirements

Capture Range.

Locking onto a

Tuned

Receiver Mode

............................

signal

...........................

Frequency Offset Menu

Primary Applications

Typical Test Setup

...........................

............................

Frequency Offset In-Depth Description

The Receiver

Frequency

The Offset Frequency (LO)

Frequency Hierarchy

Frequency Ranges

...........................

Compatible Instrument Modes and Sweep Types

Receiver and Source Requirements

Display Annotations

Error Message

Spurious

.............................

SiiaI Passband

Harmonic Operation (Option 002

Typical Test Setup

Single-Channel

............................

Operation

Dual-Channel Operation

Coupling

Frequency

Power Between Channels 1 and 2

Range

............................

Accuracy and input power

Time Domain Operation (Option 010)

The Transform Menu.

General Theory

Time Domain

..............................

Bandpass

...........................

Adjusting the Relative Velocity Factor

Reflection Measurements Using

Interpreting the

Interpreting the

bandpass

bandpass

Transmission Measurements Using Bandpass Mode

Interpreting the

Interpreting the

Timedomainlowpass

bandpass

bandpass

...........................

Setting frequency range for time domain low pass

Minimum allowable

stop frequencies

Reflection Measurements In Time Domain Low Pass

Interpreting the low pass response horizontal axis

Interpreting the low pass response vertical axis

Fault

Location Measurements Using Low Pass

Transmission Measurements In Time Domain Low Pass

Measuring

smaII signal

........................

.....................

with a frequency modulation component

..........................

..................

........................

.......................

..........................

.............

...................

..........................

Frequencies

only)

..................

...................

.........................

.........................

................

........................

.....................

..........................

...................

Bandpass

Mode

..............

reflection response horizontal axis

reflection response vertical axis

.............

transmission response horizontal axis

transmission response vertical axis

.............

..................

............

............

.............

...............

...........

transient response using low pass step

Interpreting the low pass step transmission response horizontal axis

Interpreting the low pass step transmission response vertical axis

Measuring separate transmission paths through the test device using low

pass impulse mode

Time Domain Concepts

Masking

Windowing

Range

Resolution

.................................

...............................

..................................

................................

Response resolution

.........................

...........................

..........................

......

.......

........

.....

.......

......

...

.....

6-119

6-119

6-119

6-119

6-119

6-120

6-120

6-120

6-121

6-121

6-121

6-121

6-121

6-121

6-122

6-122

6-122

6-122

6-123

6-123

6-123

6-123

6-124

6-124

6-124

6-125

6-125

6-126

6-127

6-127

6-127

6-128

6-128

6-129

6-129

6-129

6-130

6-130

6-131

6-131

6-131

6-131

6-131

6-133

6-133

6-134

6-134

6-134

6-135

6-135

6-136

6-138

6-139

6-139

Contents-11

Page 24

Range resolution

Gating

.................................

Setting the gate

Selecting gate shape

Transforming CW Time Measurements Into the Frequency Domain

Forward Transform Measurements

Interpreting the forward transform vertical axis

Interpreting the forward transform horizontal axis

Demodulating the results of the forward transform

Forward transform range

Test Sequencing

...............................

In-Depth Sequencing Information

Features That Operate Differently When Executed In a Sequence

............................

............................

..........................

......

....................

.............

............

...........

........................

......................

......

6-140

6-141

6-141

6-142

6-142

6-143

6-143

6-143

6-143

6-145

6-146

6-146

6-146

Commands That Sequencing Completes Before the Next Sequence Command

Begins

Commands That Require a Clean Sweep

Forward Stepping In Edit Mode

Titles.. ................................

Sequence Size

Embedding the

Autostarting Sequences

The GPIO Mode

The Sequencing Menu

Gosub

Sequence Command

‘lTLI/OMenu

‘ITL

Output for

‘ITL Input Decision Making

TI'LOutMenu

Sequencing Special Functions Menu

Sequence Decision Making Menu

Decision Making Functions

................................

..................

......................

..............................

Value

of the Loop Counter In a Title

............

.........................

.............................

...........................

.........................

...............................

Controlling

Peripherals

..................

........................

..............................

.....................

......................

.........................

6-146

6-147

6-147

6-147

6-147

6-147

6-147

6-147

6-148

6-148

6-148

6-148

6-148

6-150

6-150

6-150

6-150

Decision making functions jump to a softkey location, not to a specific

sequence

Having a sequence jump to itself

‘ITL

input decision making

Limit test decision making

Loop counter decision making

Naming

Files

HP-GL Considerations

Entering HP-GL Commands

Special Commands

Entering Sequences Using HP-IB

Reading Sequences Using HP-IB

Amplifier Testing

AmpIifier

Gain Compression

Metering the power level

MixerTesting..

Frequency Offset

Tuned

Receiver

Mixer Parameters That You Can Measure

Accuracy Considerations

Attenuation at Mixer Ports

Filtering

Frequency Selection

title

............................

.....................

........................

........................

......................

Generated by a Sequence

....................

...........................

........................

............................

.....................

.....................

..............................

parameters

...........................

.............................

..........................

..............................

.............................

..............................

..................

..........................

........................

.................................

...........................

6-150

6-150

6-150

6-150

6-151

6-151

6-151

6-151

6-152

6-152

6-152

6-153

6-153

6-154

6-156

6-157

6-157

6-157

6-158

6-158

6-159

6-160

6-161

Contents-12

Page 25

LO Frequency Accuracy and

StabiIity

...................

Up-Conversion and Down-Conversion Definition

Conversion Loss

Isolation

LOFeedthru/LOtoRFLeakage

RFFeedthru

SWRlRetumLoss

Conversion Compression

Phase Measurements

Amplitude and Phase Tracking

Phase Linearity and Group Delay

Connection Considerations

Adapters

Fixtures

..................................

..............................

.................................

.....................

...............................

.............................

..........................

............................

.......................

......................

..........................

.................................

IfYouWanttoDesignYourOwnFixture.

Reference Documents

............................

General Measurement and Calibration Techniques

Fixtures and Non-Coaxial Measurements

On-Wafer Measurements

7.

Specifications and Measurement Uncertainties

DynamicRange

...............................

..........................

HP 8753E Measurement Port Specifications

HP87533(5013)with7mmTestPorts

HP87533(509)withType-NTestPorts

HP87533(509)with3.5-nunT&tPorts

HP 8753E

HP 8753E

Instrument Specifications

(75n)

with Type-N Test Ports

(75Q)

with Type-F

Test

...........................

....................

...................

...................

...................

Ports

...................

HP 8753E Network Analyzer General Characteristics

Measurement Throughput Summary

Remote Programming

Interface

................................

Transfer Formats

Interface Function Codes

Front Panel Connectors

Probe Power

Rear

Panel

...............................

Connectors

...........................

............................

.........................

..........................

...........................

.....................

External Reference Frequency Input (EXT REF INPUT)

High-Stability Frequency Reference Output (10 MHz)(Option

External

ExtemaIAMInput(EXTAM).

External Trigger (EXT TRIGGER)

Test Sequence Output (TEST SEQ)

LimitTestOutput(LIMlTTEST).

Test

Video Output (VGA OUT)

Display Pixel Integrity

AuxiIiary

Input (AUX INPUT)

......................

.....................

....................

.....................

Port Bias Input (BIAS CONNECT)

..........................

...........................

...................

Red, Green, or Blue Pixels Specifications

Dark Pixels

HP-IB

...................................

Parallel Port

RS-232

Specifications

................................

..................................

Mini-DIN Keyboard

LinePower..

..............................

............................

........................

..............

.................

..............

..................

..................

..............

..........

......

lD5)

..................

.................

6-161

6-161

6-164

6-164

6-164

6-165

6-165

6-166

6-166

6-167

6-167

6-169

6-169

6-170

6-170

6-171

6-171

6-171

6-172

7-l

7-2

7-2

7-4

7-5

7-6

7-8

7-9

7-16

7-16

7-17

7-17

7-17

7-17

7-17

7-17

7-17

7-17

7-17

7-18

7-18

7-18

7-18

7-18

7-18

7-18

7-19

7-19

7-19

7-19

7-19

7-19

7-19

7-19

Contents-13

Page 26

Environmental Characteristics

General Conditions

Operating Conditions

............................

...........................

Non-Operating Storage Conditions

Weight

Cabinet Dimensions

Internal Memory

..................................

............................

..............................

.......................

....................

8. Menu Maps

9. Key Definitions

Where to Look for More Information

Guide Terms and Conventions

Analyzer

Functions

.............................

........................

.....................

Cross Reference of Key Function to Programming Command

Softkey

Locations

..............................

10. Error Messages

Where to Look for More Information

Error Messages in Alphabetical Order

Error Messages in Numerical Order

.....................

.....................

......................

..........

7-20

7-20

7-20

7-20

7-21

7-21

7-21

9-l

9-2

9-2

9-54

9-75

10-l

10-2

lo-28

11. Compatible Peripherals

Where to Look for More Information

Measurement Accessories Available

Calibration Kits

Verification Kit

HP

85029B 7-mm

Test

Port Return Cables

HP

11857D ?-mm

..............................

..............................

Verification Kit

..........................

Test Port Return Cable Set

HP11857B75OhmType-N%stPortReturnCableSet

Adapter Kits.

...............................

HP11852B50to75OhmMinimumLossPad.

Transistor Test Fixtures

HP

116OOB

HP

11608A

HP

11858A

Power Limiters

and

11602B

Option 003 Transistor Fixture.

Transistor

..............................

System Accessories Available

System Cabinet

System

Testmobile

..............................

Plotters and Printers

..........................

Transistor Fixtures.

F’ixture

Adapter.

.........................

.............................

............................

These plotters are compatible:

These printers are compatible:

Mass Storage

HP-IB Cables

Interface Cables

Keyboards

Controller

Sample Software.

External Monitors

Connecting Peripherals.

...............................

...............................

..............................

.................................

.................................

.............................

.............................

...........................

Connecting the Peripheral Device

Configuing the Analyzer for the Peripheral

If the

PeripheraiisaPrinter

........................

.....................

......................

.....................

...............

...........

...............

................

.................

..................

......................

......................

......................

..................

11-l

11-l

11-l

11-2

11-2

11-2

11-2

11-2

11-2

11-2

11-3

11-3

11-3

11-3

11-3

11-4

11-4

11-4

11-4

11-4

11-4

11-5

11-5

11-5

11-6

11-7

11-7

11-7

11-8

11-8

11-9

11-9

Contents-14

Page 27

If the Peripheral Is a Plotter

HPGLIB

Pen Plotter

Compatible Printer (used as a plotter)

...............................

If the Peripheral Is a Power Meter

If the Peripheral Is an External Disk Drive

If the Peripheral Is a Computer Controller

Conhguring

HP-IB

HP-IB Operation

Device Types

IhIker

Listener

Controller

HP-IB Bus Structure

Data Bus

Handshake Lines

Control Lines

HP-IB Requirements

the Analyzer to Produce a Time Stamp

Progr

ammingtlverview

...............................

...............................

..................................

.................................

................................

............................

................................

............................

..............................

............................

HP-IB Operational Capabilities

HP-IB Status Indicators

Bus Device Modes

.............................

System-Controller Mode

‘IaIkerListener

Pass-Control Mode

Mode

............................

Setting HP-IB Addresses

Analyzer Command Syntax

Code

Naming Convention

Valid

Characters

units

HP-II3

...................................

Debug Mode

User Graphics

..............................

..............................

................................

........................

.....................

.................

..................

........................

.......................

.........................

.........................