Page 1

HPE Apollo 4520 Gen9 Chassis Setup and Installation Guide

Abstract

This document contains setup, installation, and configuration information for the HPE Apollo

4520 Gen9 Chassis. This document is for the person who installs, administers, and

troubleshoots servers and storage systems. Hewlett Packard Enterprise assumes you are

qualified in the servicing of computer equipment and trained in recognizing hazards in

products with hazardous energy levels.

Part Number: 819251-006

Published: September 2018

Edition: 6

Page 2

©

Copyright 2015-2018 Hewlett Packard Enterprise Development LP

Notices

The information contained herein is subject to change without notice. The only warranties for Hewlett

Packard Enterprise products and services are set forth in the express warranty statements accompanying

such products and services. Nothing herein should be construed as constituting an additional warranty.

Hewlett Packard Enterprise shall not be liable for technical or editorial errors or omissions contained

herein.

Confidential computer software. Valid license from Hewlett Packard Enterprise required for possession,

use, or copying. Consistent with FAR 12.211 and 12.212, Commercial Computer Software, Computer

Software Documentation, and Technical Data for Commercial Items are licensed to the U.S. Government

under vendor's standard commercial license.

Links to third-party websites take you outside the Hewlett Packard Enterprise website. Hewlett Packard

Enterprise has no control over and is not responsible for information outside the Hewlett Packard

Enterprise website.

Page 3

Contents

Planning the installation.........................................................................5

Identifying components and LEDs........................................................ 9

Verifying the pallet contents..........................................................................................................5

Warnings and cautions..................................................................................................................6

Space and airflow requirements................................................................................................... 7

Temperature requirements............................................................................................................7

Power requirements......................................................................................................................7

Grounding requirements............................................................................................................... 8

Front panel components............................................................................................................... 9

Storage display LEDs.........................................................................................................9

Server front panel components........................................................................................ 10

Server front panel LEDs and buttons............................................................................... 11

Rear panel components..............................................................................................................12

Power supply LEDs .........................................................................................................12

Management module components...................................................................................13

Management module LEDs..............................................................................................14

I/O module components................................................................................................... 14

I/O module LEDs..............................................................................................................15

PCIe slot definitions (standard I/O module)..................................................................... 15

PCIe slot definitions (I/O module with x16 riser option)................................................... 16

HPE H240 Smart Host Bus Adapter port identification.................................................... 18

I/O module power connector identification..................................................................................18

LFF drive bay identification......................................................................................................... 19

Expander module LEDs.............................................................................................................. 19

Expander link mapping............................................................................................................... 19

Installing the chassis............................................................................20

Setting up and installing the chassis...........................................................................................20

Disassembling the chassis..........................................................................................................20

Installing the chassis into the rack.............................................................................................. 24

Installing the system components into the chassis..................................................................... 27

Installing a server............................................................................................................. 27

Installing a hot-plug drive................................................................................................. 28

Installing a flex slot power supply.....................................................................................29

Installing the system fan...................................................................................................30

Installing a management module..................................................................................... 31

Installing the expansion board......................................................................................... 31

Installing an I/O module................................................................................................... 33

Cabling and powering up the chassis.................................................35

Cabling the chassis.....................................................................................................................35

Installing the cable management arm.............................................................................. 35

Converting the cable management arm for opposite side mounting................................37

I/O module option cabling........................................................................................................... 38

HPE H240 Smart Host Bus Adapter cabling.................................................................... 38

3

Page 4

Powering up the system..............................................................................................................40

Hot-plug power supply calculations..................................................................................40

Power capping............................................................................................................................ 41

Power capping modes......................................................................................................41

Configuring a power cap.................................................................................................. 41

Setting the chassis power cap mode with the PPIC utility.....................................42

Setting the chassis power cap mode with HPE APM............................................ 42

Troubleshooting.................................................................................... 44

Important safety information ...................................................................................................... 44

Symbols on equipment.....................................................................................................44

Troubleshooting resources..........................................................................................................45

Specifications........................................................................................46

Environmental specifications ..................................................................................................... 46

Chassis specifications ................................................................................................................46

Power supply specifications........................................................................................................46

HPE 800W Flex Slot Platinum Hot-plug Low Halogen Power Supply..............................47

HPE 800W Flex Slot -48VDC Hot-plug Low Halogen Power Supply...............................47

HPE 800W Flex Slot Titanium Hot-plug Low Halogen Power Supply..............................49

HPE 800W Flex Slot Universal Hot-plug Low Halogen Power Supply.............................49

HPE 1400W Flex Slot Platinum Plus Hot-plug Power Supply..........................................50

Hot-plug power supply calculations............................................................................................ 51

Environmental considerations.............................................................52

Communications interference..................................................................................................... 52

Preventing electrostatic discharge.............................................................................................. 52

Grounding methods to prevent electrostatic discharge...............................................................52

Websites................................................................................................ 54

Support and other resources...............................................................55

Accessing Hewlett Packard Enterprise Support......................................................................... 55

Accessing updates......................................................................................................................55

Customer self repair....................................................................................................................56

Remote support.......................................................................................................................... 56

Warranty information...................................................................................................................56

Regulatory information................................................................................................................57

Documentation feedback............................................................................................................ 57

Acronyms and abbreviations...............................................................58

4

Page 5

Planning the installation

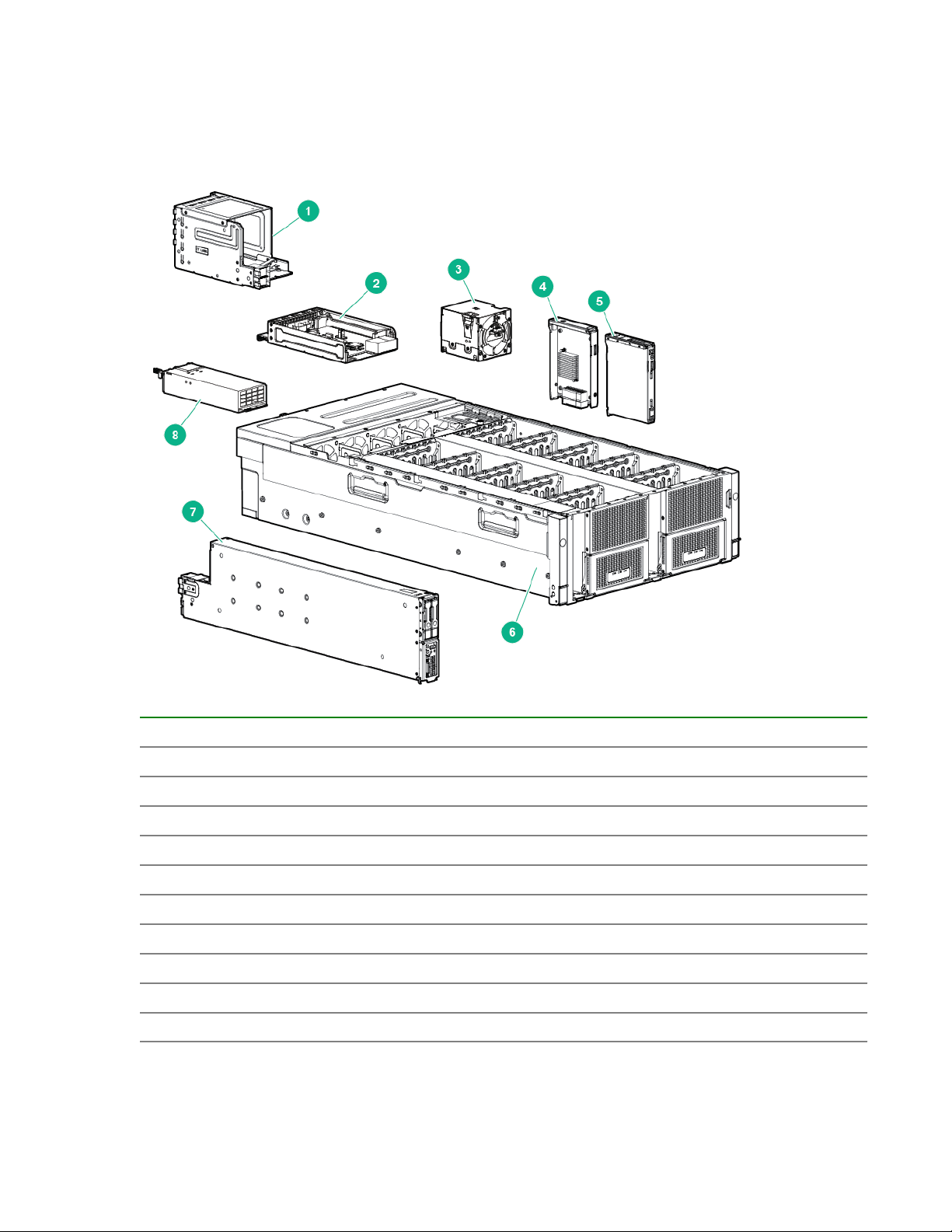

Verifying the pallet contents

Item Description

1 I/O module

2 Management module

3 System fans (5)

4 SAS expander module

5 Drive

6 HPE Apollo 4520 Gen9 Chassis

7 Server

8 Power supply

9 Power supply blank

10 Rack rails and cable management arm

1

The quantity depends on the configuration ordered.

2

Not shown

1

1

2

2

Planning the installation 5

Page 6

Warnings and cautions

WARNING: To reduce the risk of personal injury or damage to equipment, heed all warnings and

cautions throughout the installation instructions.

WARNING: To reduce the risk of personal injury or damage to the equipment, be sure that:

• The rack is bolted to the floor using the concrete anchor kit.

• The leveling feet extend to the floor.

• The full weight of the rack rests on the leveling feet.

• The racks are coupled together in multiple rack installations.

• Only one component is extended at a time. If more than one component is extended, a rack

might become unstable.

WARNING: The chassis is very heavy. To reduce the risk of personal injury or damage to the

equipment:

• Observe local occupational health and safety requirements and guidelines for manual material

handling.

• Remove all installed components from the chassis before installing or moving the chassis.

• Use caution and get help to lift and stabilize the chassis during installation or removal, especially

when the chassis is not fastened to the rack.

WARNING: To reduce the risk of personal injury or damage to the equipment, you must adequately

support the chassis during installation and removal.

WARNING: Always have at least two people to lift the chassis into the rack. If the chassis is being

loaded into the rack above chest level, an additional person must assist with aligning the chassis

with the rails while the other people support the weight of the chassis.

WARNING: Be sure to install enclosures starting from the bottom of the rack and work your way up

the rack.

WARNING: To reduce the risk of personal injury from hot surfaces, allow the drives and the internal

system components to cool before touching them.

WARNING: To reduce the risk of electric shock or damage to the equipment:

• Never reach inside the chassis while the system is powered up.

• Perform service on system components only as instructed in the user documentation.

CAUTION: Always be sure that equipment is properly grounded and that you follow proper

grounding procedures before beginning any installation procedure. Improper grounding can result in

ESD damage to electronic components. For more information, see Preventing electrostatic

discharge.

6 Planning the installation

Page 7

CAUTION: When performing non-hot-plug operations, you must power down the chassis and/or the

system. However, it may be necessary to leave the chassis powered up when performing other

operations, such as hot-plug installations or troubleshooting.

Space and airflow requirements

To enable servicing and ensure adequate airflow, observe the following spatial requirements when

deciding where to install a rack:

• Leave a minimum clearance of 121.9 cm (48.0 in) in front of the rack and between rows of racks.

• Leave a minimum clearance of 76.2 cm (30.0 in) in back of the rack for a single row of racks or after

the final row of racks.

Hewlett Packard Enterprise Rack products draw cool air in through the front and expel warm air through

the rear of the enclosure. Therefore, the front of the rack enclosure must be adequately ventilated to

enable ambient room air to enter the enclosure, and the rear of the enclosure must be adequately

ventilated to enable the warm air to escape from the enclosure.

IMPORTANT: Do not block the ventilation openings.

If the front of the rack is not completely filled with components, the remaining gaps between the

components can cause changes in the airflow, which can adversely affect cooling within the rack. Cover

these gaps with blanking panels.

CAUTION: Always use blanking panels to fill empty vertical spaces in the rack. This arrangement

ensures proper airflow. Using a rack without blanking panels results in improper cooling that can

lead to thermal damage.

Racks provide proper server cooling from flow-through perforations in the front and rear doors that

provide a 65% open area for ventilation.

Temperature requirements

To ensure continued safe and reliable equipment operation, install or position the rack in a well-ventilated,

climate-controlled environment.

The operating temperature inside the rack is always higher than the room temperature and is dependent

on the configuration of equipment in the rack. Check the TMRA for each piece of equipment before

installation.

CAUTION: To reduce the risk of damage to the equipment when installing third-party options:

• Do not permit optional equipment to impede airflow around the chassis or to increase the internal

rack temperature beyond the maximum allowable limits.

• Do not exceed the manufacturer’s TMRA.

Power requirements

Installation of this equipment must comply with local and regional electrical regulations governing the

installation of IT equipment by licensed electricians. This equipment is designed to operate in installations

covered by NFPA 70, 1999 Edition (National Electric Code) and NFPA-75, 1992 (code for Protection of

Electronic Computer/Data Processing Equipment). For electrical power ratings on options, refer to the

product rating label or the user documentation supplied with that option.

Planning the installation 7

Page 8

WARNING: To reduce the risk of personal injury, fire, or damage to the equipment, do not overload

the AC supply branch circuit that provides power to the rack. Consult the electrical authority having

jurisdiction over wiring and installation requirements of your facility.

CAUTION: Protect the chassis from power fluctuations and temporary interruptions with a regulating

UPS. This device protects the hardware from damage caused by power surges and voltage spikes

and keeps the chassis in operation during a power failure.

Grounding requirements

This equipment must be grounded properly for proper operation and safety. In the United States, you

must install the equipment in accordance with NFPA 70, 1999 Edition (National Electric Code), Article

250, as well as any local and regional building codes.

In Canada, you must install the equipment in accordance with Canadian Standards Association, CSA

C22.1, Canadian Electrical Code.

In all other countries, you must install the equipment in accordance with any regional or national electrical

wiring codes, such as the International Electrotechnical Commission (IEC) Code 364, parts 1 through 7.

Furthermore, you must be sure that all power distribution devices used in the installation, such as branch

wiring and receptacles, are listed or certified grounding-type devices.

Because of the high ground-leakage currents associated with this equipment, Hewlett Packard Enterprise

recommends the use of a PDU that is either permanently wired to the building’s branch circuit or includes

a nondetachable cord that is wired to an industrial-style plug. NEMA locking-style plugs or those

complying with IEC 60309 are considered suitable for this purpose. Using common power outlet strips to

supply power to this equipment is not recommended.

8 Planning the installation

Page 9

Identifying components and LEDs

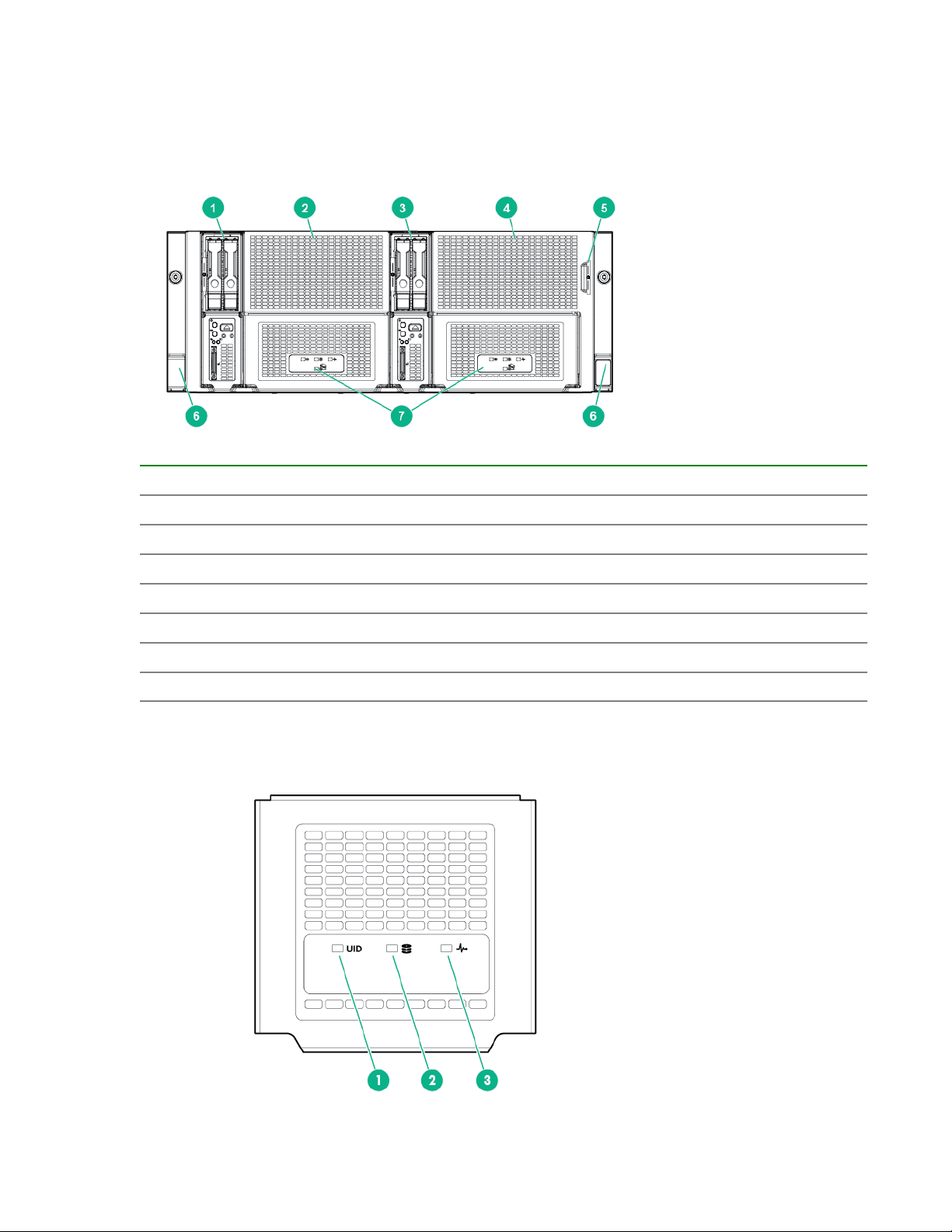

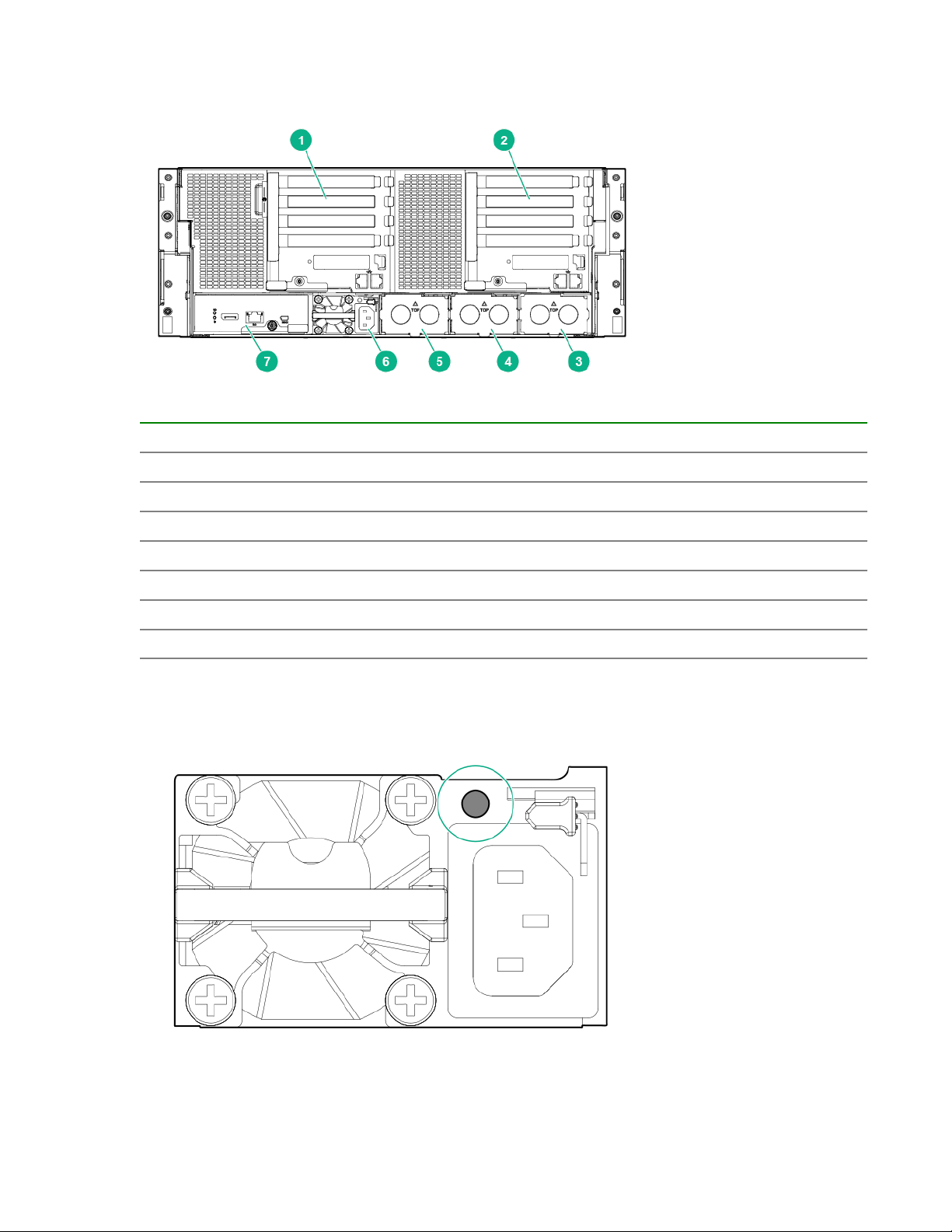

Front panel components

Item Description

1 Server bay 1

2 Server bay 1 LFF drives

3 Server bay 2

4 Server bay 2 LFF drives

5 Chassis serial label pull tab

6 Quick-release levers (2)

7 Storage LED display

Storage display LEDs

Identifying components and LEDs 9

Page 10

Item LED description LED state

1 UID LED

2 Drive health LED

3 Backplane health

LED

Off = Normal operating mode

Solid blue = One or more drives is in locate mode.

Flashing blue = Firmware update is in progress.

Off = No drives are configured.

Solid green = One or more drives are members of a logical drive.

Flashing green = One or more drives are rebuilding or performing a RAID

migration, stripe size migration, capacity expansion, logical drive extension,

or erasing.

Flashing amber = One or more drives are predicted to fail.

Solid amber = One or more drives have failed.

Green = Backplane health is normal.

Amber = Backplane error detected

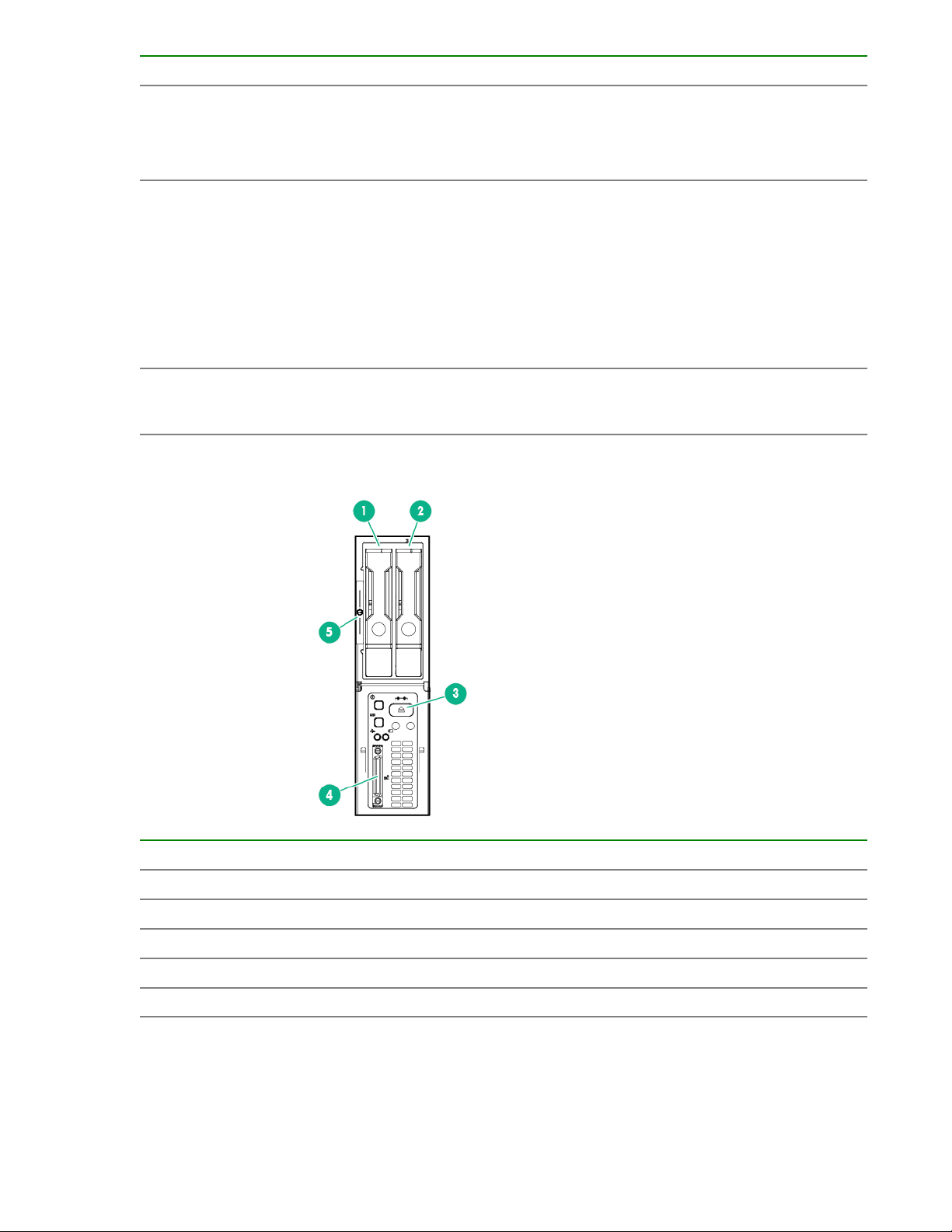

Server front panel components

Item Description

1 Drive bay 1

2 Drive bay 2

3 Server ejector button

4 SUV cable connector

5 Server serial label pull tab

10 Identifying components and LEDs

Page 11

Server front panel LEDs and buttons

Item Description Status

1 Power On/Standby

button and system power

LED

Solid green = System on

Flashing green (1 Hz/cycle per sec) = Performing power on

sequence

2 UID button/LED

3 Server health LED

4 Server backup LED

Solid amber = System in standby

Off = No power present

Solid blue = Activated

Flashing blue:

• 1 Hz/cycle per sec = Remote management or firmware upgrade

in progress

• 4 Hz/cycle per sec = iLO manual reboot sequence initiated

• 8 Hz/cycle per sec = iLO manual reboot sequence in progress

Off = Deactivated

Solid green = Normal

Flashing green (1 Hz/cycle per sec) = iLO is rebooting

Flashing amber = System degraded

Flashing red (1 Hz/cycle per sec) = System critical

Off = Normal operations. No backup in progress.

Flashing white = Backup in progress. Do not remove drives or

associated system components, and do not power down the server.

Identifying components and LEDs 11

Page 12

Rear panel components

Item Description

1 Server bay 2 I/O module

2 Server bay 1 I/O module

3 Power supply bay 4

4 Power supply bay 3

5 Power supply bay 2

6 Power supply bay 1

7 Management module

Power supply LEDs

The power supply LED is located on each power supply.

12 Identifying components and LEDs

Page 13

LED Status Description

Off System is off or power supply has failed.

Solid Green Normal

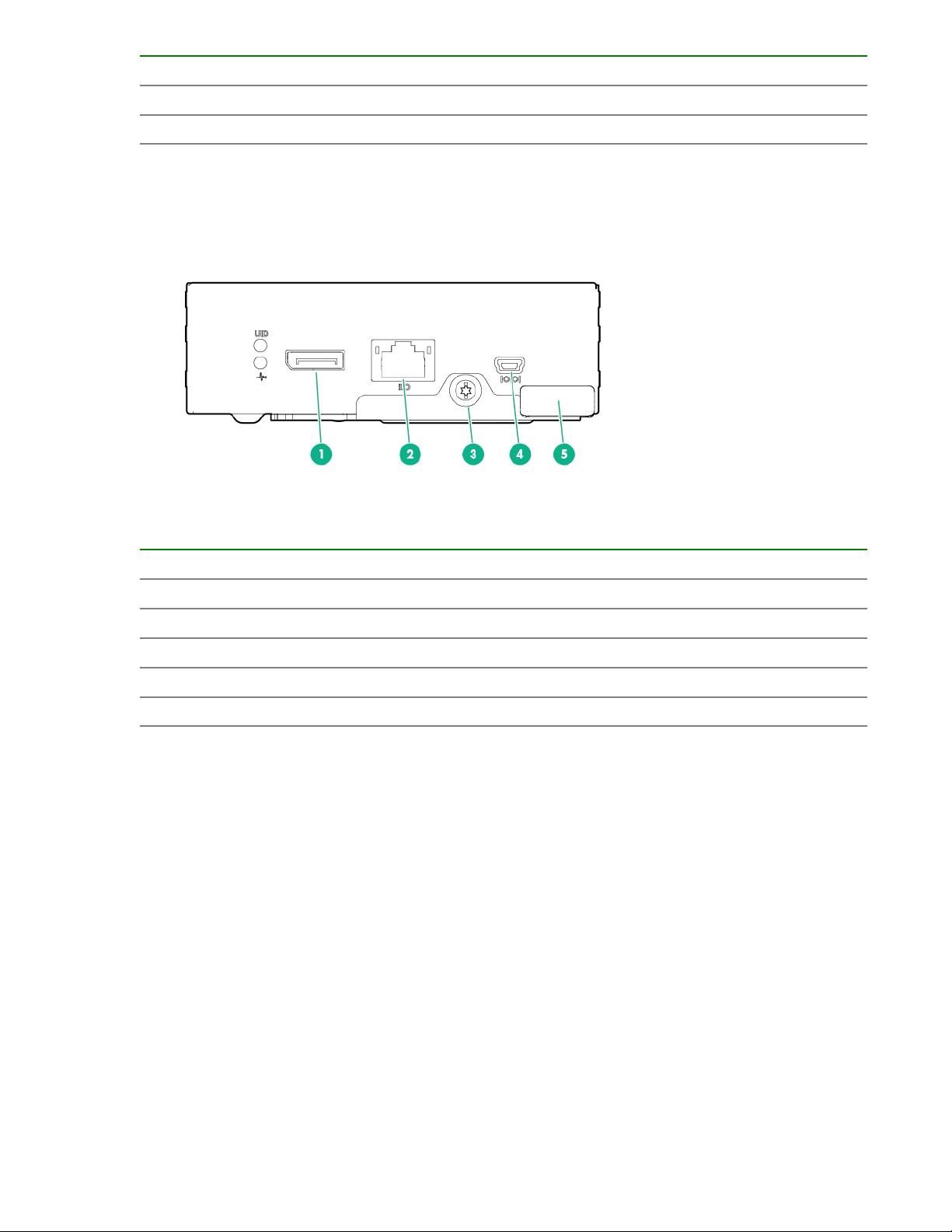

Management module components

Item Description

1 HPE APM connector

2 HPE iLO connector

3 Management module thumbscrew

4 Reserved

5 Management module release lever

Identifying components and LEDs 13

Page 14

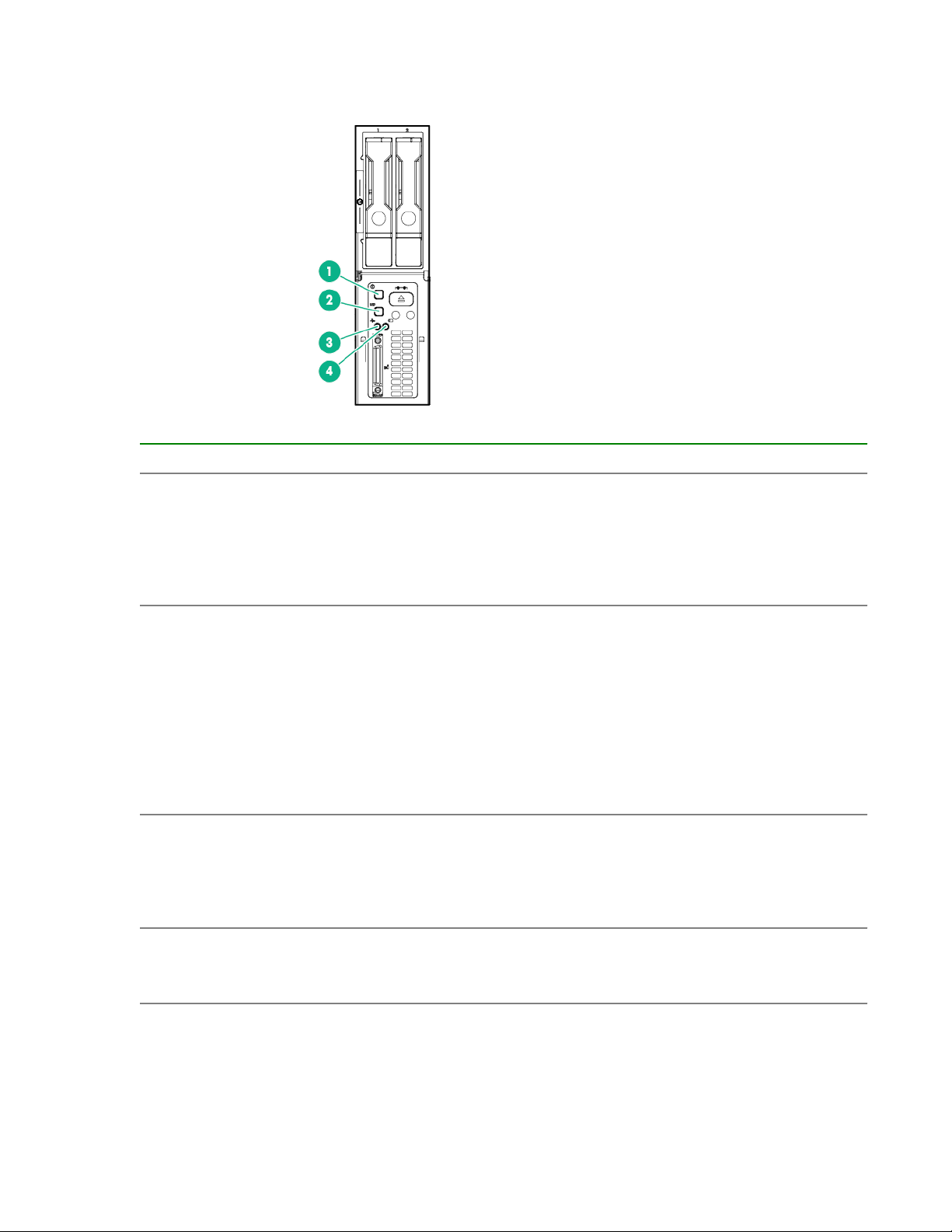

Management module LEDs

Item Description

1 Management module UID LED

2 Management module health LED

3 iLO link LED

4 iLO activity LED

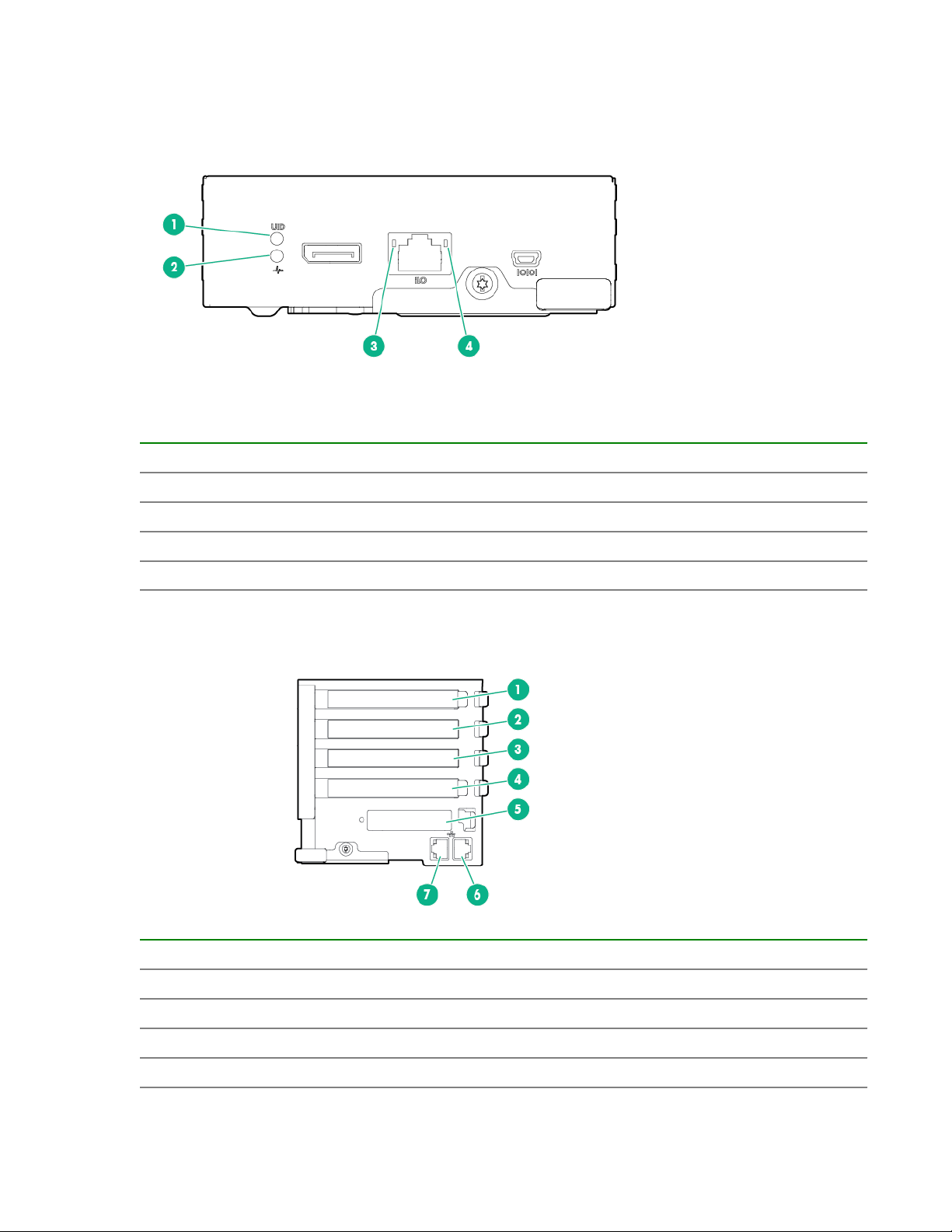

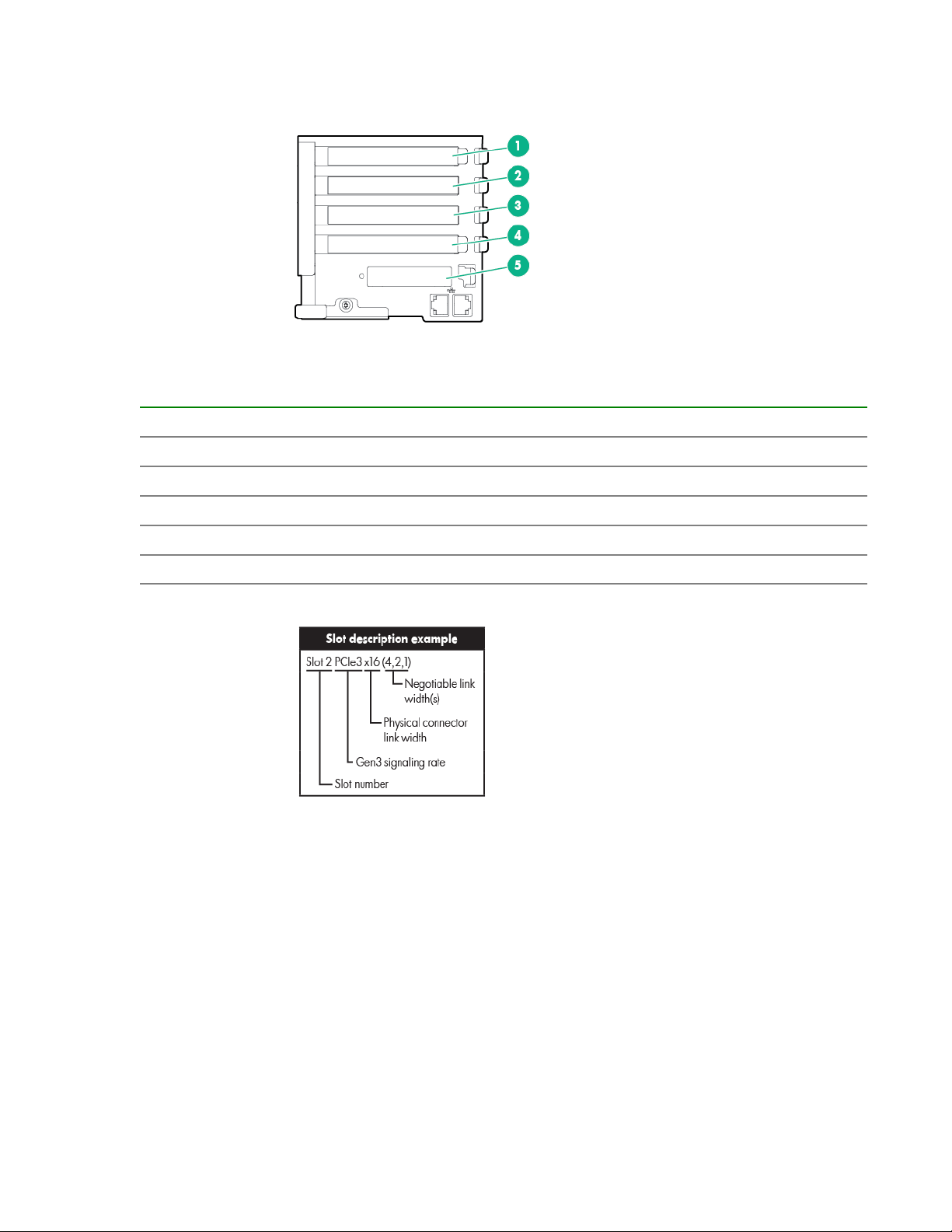

I/O module components

Item Description

1 PCIe expansion slot 4

2 PCIe expansion slot 3

3 PCIe expansion slot 2

4 PCIe expansion slot 1

14 Identifying components and LEDs

Table Continued

Page 15

Item Description

5 FlexibleLOM slot

6 NIC 2

7 NIC 1

The FlexibleLOM slot is not available on the I/O module with the x16 PCIe riser option.

I/O module LEDs

Item Description

1 NIC 1 activity LED

2 NIC 1 link LED

3 NIC 2 activity LED

4 NIC 2 link LED

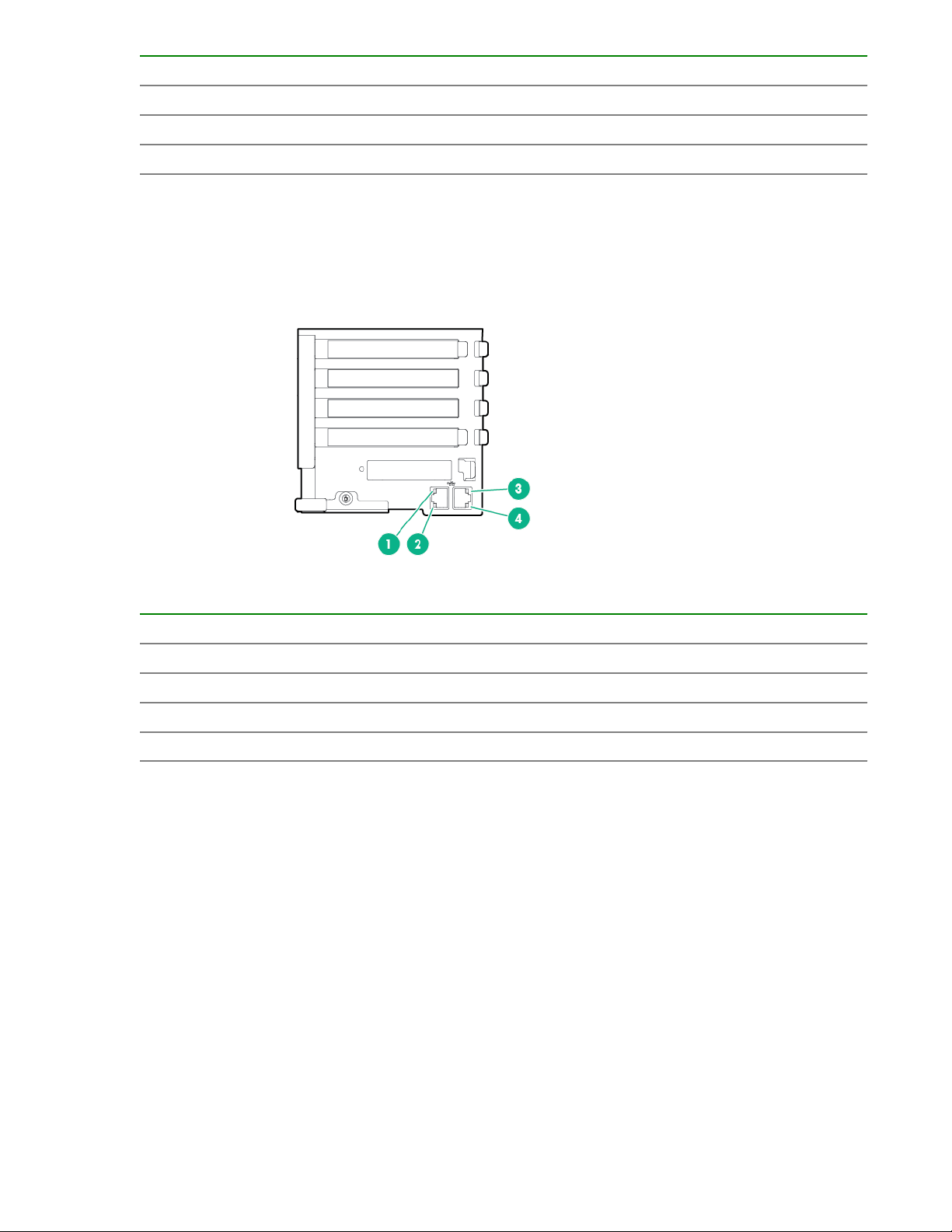

PCIe slot definitions (standard I/O module)

Processor 2 must be installed to support options installed in PCIe expansion slots 3 and 4.

Identifying components and LEDs 15

Page 16

Item Description

1 PCIe expansion slot 4 — PCIe3 x8 (8, 4, 2, 1)

2 PCIe expansion slot 3 — PCIe3 x8 (8, 4, 2, 1)

3 PCIe expansion slot 2 — PCIe3 x8 (8, 4, 2, 1)

4 PCIe expansion slot 1 — PCIe3 x8 (8, 4, 2, 1)

5 FlexibleLOM slot — PCIe3 x8

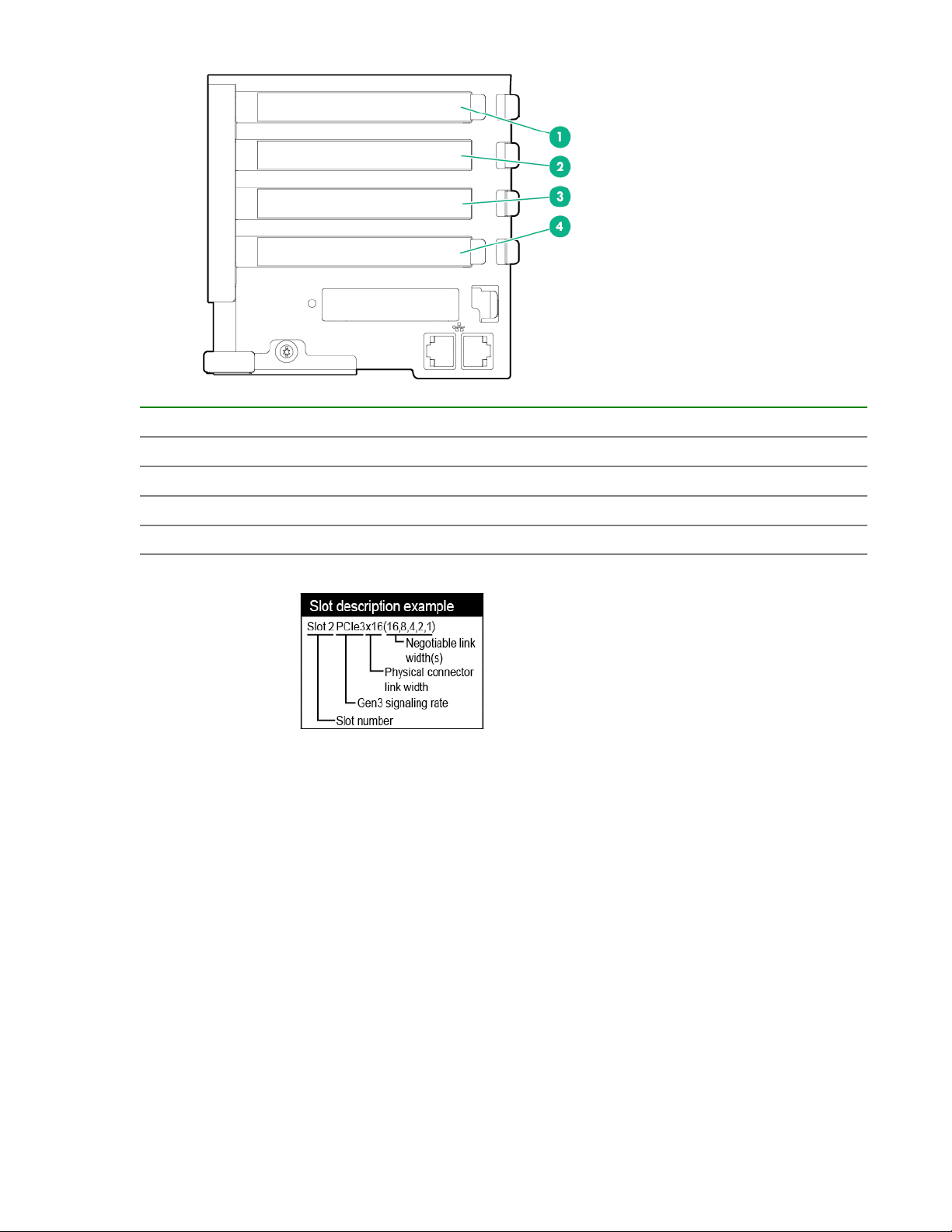

PCIe slot definitions (I/O module with x16 riser option)

Processor 2 must be installed to support options installed in PCIe expansion slots 3 and 4.

16 Identifying components and LEDs

Page 17

Item Description

1 PCIe expansion slot 4 — PCIe3 x8 (8, 4, 2, 1)

2 PCIe expansion slot 3 — PCIe3 x8 (8, 4, 2, 1)

3 PCIe expansion slot 2 — PCIe3 x16 (16, 8, 4, 2, 1)

4 PCIe expansion slot 1 — PCIe3 x8 (8, 4, 2, 1)

Identifying components and LEDs 17

Page 18

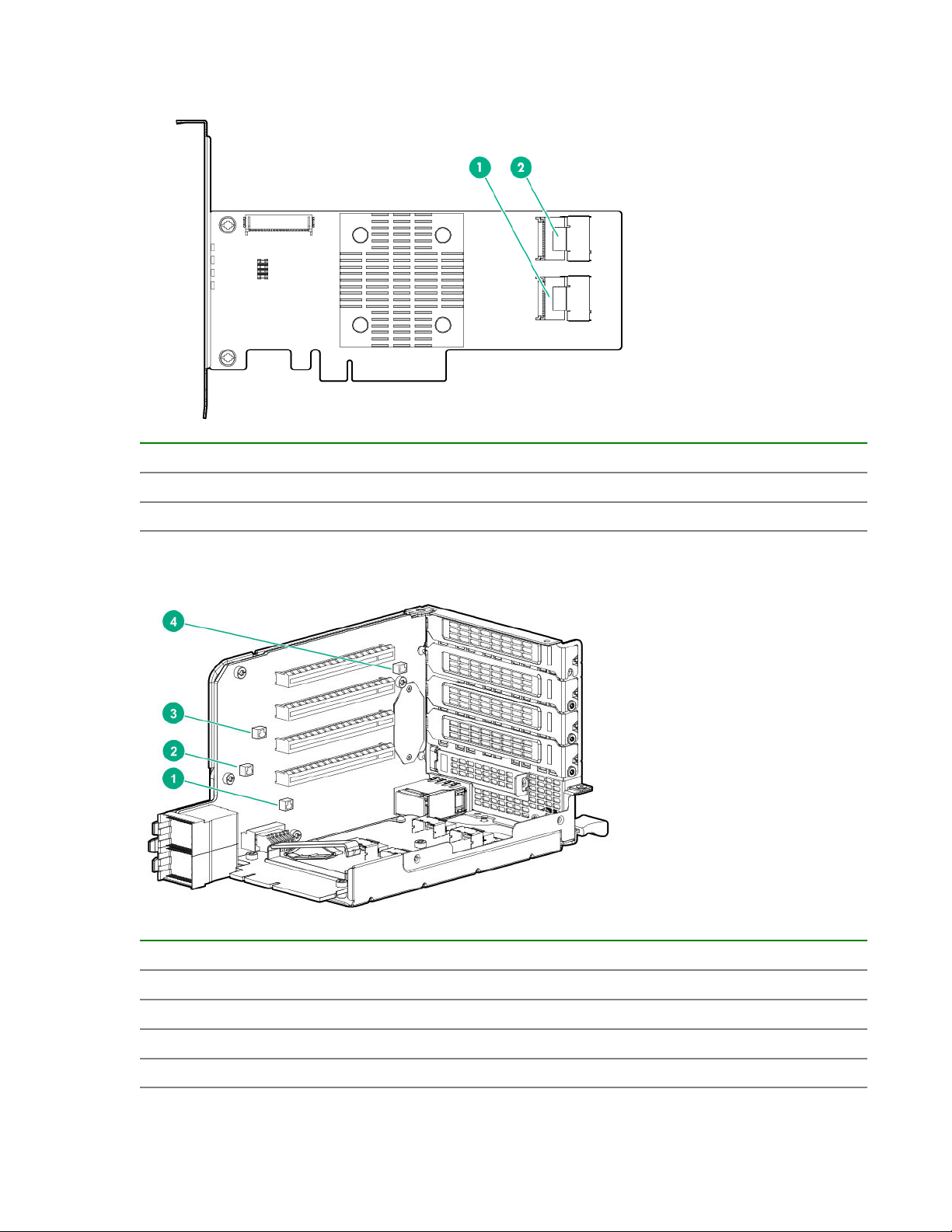

HPE H240 Smart Host Bus Adapter port identification

Item Description

1 Port 2i

2 Port 1i

I/O module power connector identification

Item Description

1 PCIe expansion slot 1 power connector

2 PCIe expansion slot 2 power connector

3 PCIe expansion slot 3 power connector

4 PCIe expansion slot 4 power connector

18 Identifying components and LEDs

Page 19

LFF drive bay identification

This chassis supports 23 LFF drives and 2 expander modules (numbered A and B) per server. The first

digit in the illustration represents the server associated with the drive and the second set of digits

represent the drive bay number.

Expander module LEDs

State Description

Green Expander module health is good

Amber Expander module fault detected

Expander link mapping

All 46 hard drives are accessible from either server 1 or server 2:

• Expander A in backplane 1 connects to node 1 I/O module ports 1A/1B.

• Expander B in backplane 1 connects to node 2 I/O module ports 2A/2B.

• Expander A in backplane 2 connects to node 2 I/O module ports 1A/1B.

• Expander B in backplane 2 connects to node 1 I/O module ports 2A/2B.

Identifying components and LEDs 19

Page 20

Installing the chassis

Setting up and installing the chassis

Procedure

1. Set up and install the rack. For more information, see the documentation that ships with the rack.

2. Disassemble the chassis.

3. Install the chassis into the rack.

4. Install the system components into the chassis.

Disassembling the chassis

Prerequisites

• Before installing the chassis into the rack, you must remove the pluggable modules and system

components from the chassis.

• Because a fully populated chassis can weigh up to 99.79 kg ( 220.00 lb), remove the components from

the chassis to make moving and installing the chassis easier.

Procedure

1. With the chassis still on the pallet, remove all components from the front and rear of the chassis:

• Power supplies

• Management module

20 Installing the chassis

Page 21

• I/O module

CAUTION: To avoid damage to the server, always support the bottom of the server when

removing it from the chassis.

• Server

Installing the chassis 21

Page 22

CAUTION: To avoid damage to the device, do not use the removal handle to carry it.

2. Remove the access panel.

3. Remove all LFF drives.

22 Installing the chassis

Page 23

4. System fans (bays 1 through 4):

a. In bay 5, open the fan bay door.

b. Remove the system fans from all 5 fan bays.

Installing the chassis 23

Page 24

Installing the chassis into the rack

WARNING: Always have at least two people to lift the chassis into the rack. If the chassis is being

loaded into the rack above chest level, an additional person must assist with aligning the chassis

with the rails while the other people support the weight of the chassis.

WARNING: The chassis is very heavy. To reduce the risk of personal injury or damage to the

equipment:

• Observe local occupational health and safety requirements and guidelines for manual material

handling.

• Remove all installed components from the chassis before installing or moving the chassis.

• Use caution and get help to lift and stabilize the chassis during installation or removal, especially

when the chassis is not fastened to the rack.

WARNING: To avoid risk of personal injury or damage to the equipment, do not stack anything on

top of rail-mounted equipment or use it as a work surface when extended from the rack.

CAUTION: Always plan the rack installation so that the heaviest item is on the bottom of the rack.

Install the heaviest item first, and continue to populate the rack from the bottom to the top.

CAUTION: Hewlett Packard Enterprise has not tested or validated the chassis with any third-party

racks. Before installing the chassis in a third-party rack, be sure to properly scope the limitations of

the rack. Before proceeding with the installation, consider the following:

• You must fully understand the static and dynamic load carrying capacity of the rack and be sure

that it can accommodate the weight of the chassis.

• Be sure sufficient clearance exists for cabling, installation and removal of the chassis, and

actuation of the rack doors.

24 Installing the chassis

Page 25

The chassis requires rails for installation in a rack. To install the rack rails, see the Quick Deploy Rail

System Installation Instructions that ship with the rack hardware kit.

You can install up to nine chassis in a 36U, 1200mm deep rack. If you are installing more than one

chassis, install the first chassis in the bottom of the rack, and then install additional chassis by moving up

the rack with each subsequent chassis. Plan the rack installation carefully because it is difficult to change

the location of components after they are installed.

WARNING: To reduce the risk of personal injury or damage to the equipment, be sure that:

• The rack is bolted to the floor using the concrete anchor kit.

• The leveling feet extend to the floor.

• The full weight of the rack rests on the leveling feet.

• The racks are coupled together in multiple rack installations.

• Only one component is extended at a time. If more than one component is extended, a rack

might become unstable.

WARNING: To reduce the risk of personal injury or equipment damage, be sure that the rack is

adequately stabilized before installing the chassis.

WARNING: To reduce the risk of personal injury or damage to the equipment, you must fully extend

the rails. To fully extend the rails, press the push tabs and extend the rails until the rails click twice.

Procedure

1. Extend the rails until they stop.

2. Fully extend the rails by pressing the push tabs and extending the rails until the rails click two times.

Installing the chassis 25

Page 26

CAUTION: Be sure to keep the product parallel to the floor when installing the chassis. Tilting

the product up or down could result in damage to the rails.

3. Install the chassis into the J-slot on the rails, and then pull it forward.

26 Installing the chassis

Page 27

4. Press the Push tabs on each rail, and then slide the chassis into the rack. When the chassis stops

midway, press the push tabs on each rail to release the chassis and slide it fully into the rack.

CAUTION: Press and hold the "Push" tab on each rail until the chassis begins to slide into the

rack. Then, release the "Push" tabs and continue to slide the chassis into the rack. Press and

hold the "Push" tab on each rail again when the rails lock at a 76.2-cm (30-inch) extension.

Then, release the "Push" tabs again and finish sliding the chassis into the rack. Failure to

release the "Push" tabs may cause damage to the rails.

Installing the system components into the chassis

Once the chassis is installed in the rack, begin installing the components in the chassis.

Installing a server

CAUTION: To prevent improper cooling and thermal damage, do not operate the chassis unless all

bays are populated with a component or a blank.

Installing the chassis 27

Page 28

Procedure

1. Prepare the server for installation

2. Install the server. When seated properly, the server will be flush with the front of the chassis and the

release lever will close completely without resistance.

Installing a hot-plug drive

WARNING: To reduce the risk of injury from electric shock, do not install more than one drive carrier

at a time.

Procedure

1. Remove the drive blank.

2. Prepare the low-profile LFF hot-plug drive for installation.

28 Installing the chassis

Page 29

3. Install the LFF hot-plug drive in the chassis.

4. Determine the status of the drives using the drive LEDs located on the storage display LEDs.

To configure arrays, see the HPE Smart Storage Administrator User Guide on the Hewlett Packard

Enterprise website (http://www.hpe.com/info/smartstorage/docs).

Installing a flex slot power supply

WARNING: To reduce the risk of electric shock or damage to the equipment:

• Do not disable the power cord grounding plug. The grounding plug is an important safety feature.

• Plug the power cord into a grounded (earthed) electrical outlet that is easily accessible at all

times.

• Unplug the power cord from the power supply to disconnect power to the equipment.

• Do not route the power cord where it can be walked on or pinched by items placed against it.

Pay particular attention to the plug, electrical outlet, and the point where the cord extends from

the server.

Procedure

Install the component as indicated.

Installing the chassis 29

Page 30

Installing the system fan

Procedure

1. To install a fan in bay 5, open the fan door. For all other fans, proceed to step 2.

2. Push in on the tabs, and then insert the system fan into the chassis.

IMPORTANT: Use the tabs to insert the system fan into the chassis. Do not push in on the

system fan grill to install it.

30 Installing the chassis

Page 31

Installing a management module

Procedure

Install the component as indicated.

Installing the expansion board

Prerequisites

When planning installation of the I/O module expansion board options, review the following requirements:

• Single and dual installation of the HPE H240 Smart Host Bus Adapter is supported.

• Multipath I/O (MPIO) is supported in dual installation of the HPE H240 Smart Host Bus Adapter.

• RAID mode is not supported.

Installing the chassis 31

Page 32

Procedure

1. Remove the I/O module.

2. Remove the I/O module access panel.

3. Remove the PCIe blank from the expansion slot.

32 Installing the chassis

Page 33

4. Install a supported expansion board option in one of the PCIe expansion slots.

If installing an expansion board option in an I/O module with the x16 riser option, be sure to install the

x16 expansion board in PCIe slot 2. For more information, see the "PCIe slot definitions (I/O module

with x16 riser option)."

5. Cable the board according to the option installed. For more information, see "I/O module option

cabling."

Installing an I/O module

Install any I/O module options before installing the I/O module into the chassis.

WARNING: To reduce the risk of electric shock, fire, or damage to the equipment, do not plug

telephone or telecommunications connectors into RJ-45 connectors.

Procedure

Install the component as indicated.

Installing the chassis 33

Page 34

34 Installing the chassis

Page 35

Cabling and powering up the chassis

Cabling the chassis

After all system hardware is installed, cable the components.

WARNING: To reduce the risk of electric shock or injury due to high-current electrical energy, be

sure that all power is completely disconnected at the source before beginning any power

connections to the power bus bars or power bus box.

WARNING: Be sure that all circuit breakers are locked in the off position before connecting any

power components.

CAUTION: To avoid damaging the fiber cables, do not drape cables from one side of the rack to the

other and do not run cables over a hard corner or edge.

Procedure

1. Connect the network cables to the Ethernet ports on the I/O module (I/O module components on

page 14).

2. Connect a network cable to the iLO connector on the management module (Management module

components on page 13).

3. Connect the APM cable to the APM connector on the management module (Management module

components on page 13).

Installing the cable management arm

IMPORTANT: If you need to hinge the cable management arm on the rear right-hand side of the

rack, see the instructions in Converting the cable management arm for opposite side mounting.

Perform these steps to convert the arm to a right-hand swing and install the arm on the right side of

the rack.

Procedure

1. Install the rack rail brace.

Cabling and powering up the chassis 35

Page 36

2. Align and install the cable management arm.

3. Press the latch and slide the cable management arm into place.

36 Cabling and powering up the chassis

Page 37

Converting the cable management arm for opposite side mounting

The cable management arm is designed for ambidextrous implementation. You can convert the arm for

right-hand swing.

IMPORTANT: When converting the cable arm, always be sure to orient the arm with the cable

trough facing upward.

NOTE: To access some components on the rear of the product, you may need to remove the cable

management arm.

Procedure

1. Press the latch to release the cable management arm and remove the cable management arm.

2. Move the cable management arm to the right rack rail and align the tab for opposite side mounting.

Cabling and powering up the chassis 37

Page 38

3. Align and install the cable management arm on the right rack rail.

I/O module option cabling

The chassis supports two I/O modules. Each I/O module contains four PCIe slots and one FlexibleLOM

slot. Each PCIe slot has a power connector. For power connector locations, see I/O module power

connector identification on page 18.

This section describes the cable routing for the options installed in the I/O modules.

HPE H240 Smart Host Bus Adapter cabling

The HPE Apollo 4520 Gen9 Chassis supports single and dual installation for the HPE H240 Smart Host

Bus Adapter. The dual installation of the HPE H240 Smart Host Bus Adapter supports Multipath I/O

(MPIO) redundancy at the server (node) level and at the HPE H240 Smart Host Bus Adapter controller

level. RAID mode is not supported.

When an I/O module with the x16 riser option is installed, PCIe slot 2 is reserved for x16 options and the

HPE H240 Smart Host Bus Adapter options must be installed in PCIe slots 1 and 3.

38 Cabling and powering up the chassis

Page 39

• Single-board option (standard I/O module and I/O module with x16 riser option)

• Dual-board option (standard I/O module)

• Dual-board option (I/O module with the x16 riser option)

Cabling and powering up the chassis 39

Page 40

• Dual-board option (MPIO)

Powering up the system

Procedure

1. Connect the power cables to the power supplies.

2. Connect the power cables to the power source (UPS or wall outlet) or to an installed PDU.

3. Press the Power On/Standby button on the server.

Hot-plug power supply calculations

For hot-plug power supply specifications and calculators to determine electrical and heat loading for the

server, see the Hewlett Packard Enterprise Power Advisor website (http://www.hpe.com/info/

poweradvisor/online).

40 Cabling and powering up the chassis

Page 41

Power capping

The HPE ProLiant XL family of products provides a power capping feature that operates at the server

enclosure level. The capping feature can be activated with PPIC.EXE, a stand-alone utility that runs in the

environment of one of the resident servers in the chassis to be power capped. After a power cap is set for

the enclosure, all the resident servers in the enclosure will have the same uniform power cap applied to

them until the cap is either modified or canceled.

With HPE APM, the enclosure-level power capping feature can be expanded without the need to use the

PPIC.EXE utility. A global power cap can be applied to all enclosures with one HPE APM command, or

different caps can be applied to user-defined groups by using flexible zones within the same rack.

Power capping modes

The following Power Management modes are standard and are configurable in the power management

controller:

• Mode 0: No Redundancy

All power-capping is disabled. This mode can be used to minimize any possible performance impact of

power-capping logic.

• Mode 1: Max Performance with Redundancy

This is the default power capping mode. This mode allows the maximum number of nodes to run by

engaging power-capping if the power draw from the chassis attempts to exceed the load supported by

the active power supplies. In this mode, the system is expected to survive (with the possibility of

degraded performance) an unexpected power loss to one or more of the power supplies.

• Mode 2: Full AC/DC Redundancy Mode

Power-capping is enforced such that system has N+1 power redundancy. In this mode, the system will

throttle the nodes allowing for one of the available power supplies to be held in reserve. If only one

power supply is available, the system will throttle the nodes as to allow the full use of that power

supply’s capacity.

• Mode 3: User Configurable Mode

The user can specify a valid power cap value from a pre-defined range. A cap cannot be set below a

minimum or above a maximum. The cap includes all server nodes, fans, and drives. User configurable

mode requires an iLO Scale Out or iLO Advanced license.

• Mode 4: Rack Level Dynamic Power Capping Mode

In conjunction with APM, the user can specify a maximum power capacity for the entire rack. The APM

dynamically allocates power to the applicable chassis within the rack to maximize performance given

the available power. For more information, see the HPE Apollo Platform Manager User Guide on the

Hewlett Packard Enterprise website.

• Mode 5: Power Feed Redundancy Mode

When used with an A+B power feed configuration, Power Feed Redundancy Mode throttles the

system 100%, bringing the nodes to a complete stop if a power feed loss is deduced. Full throttling

continues until the power feed is brought back online. In this mode, the system is expected to survive

an unexpected loss of an entire power feed to half of the power supplies.

Configuring a power cap

To configure power capping, you can use the following utilities:

• HPE ProLiant Power Interface Control Utility

Cabling and powering up the chassis 41

Page 42

PPIC is a standalone utility that runs on a single server within the enclosure. For more information, see

the ProLiant Power Interface Control (PPIC) Utility User Guide on the Hewlett Packard Enterprise

website.

• Apollo Platform Manager

HPE APM is a rack level device that can control power caps for all enclosures in the rack. For more

information, see the HPE Apollo Platform Manager User Guide on the Hewlett Packard Enterprise

website.

Setting the chassis power cap mode with the PPIC utility

1. Download and install the ProLiant Power Interface Control Utility from the

Enterprise website.

2. Log in to the server, and then run the PPIC utility.

3. To set the power capacity mode, perform one of the following steps:

• To set mode 0, 1, and 2, enter the following command at the prompt:

-s -mmode

The following example sets the power capacity to mode 0:

-s -m0

• To set mode 3, enter the following command at the prompt:

-s -mmode -lpower

The following example sets the power capacity to mode 3 with a 1500W maximum power limit:

-s -m3 -l1500

Power capping modes show the valid values for mode. Power is required when setting Power Control

Configuration to User Configurable.

For more information, see the ProLiant Power Interface Control (PPIC) Utility User Guide on the Hewlett

Packard Enterprise website.

Hewlett Packard

Setting the chassis power cap mode with HPE APM

1. Log in to APM:

a. When the system boots, a Login prompt appears.

b. At the prompt, enter Administrator.

2. Before setting the power cap, enter the following command to review the power baseline:>show

power baseline

The information displayed provides the minimum cap value, the maximum cap value, and the chassis

that meet the requirements for power capping.

3. To set the power cap for eligible chassis connected to the APM, enter the following command at the

prompt:>SET POWER CAP<wattage>|NONE[zone_name]

The wattage value, if provided, represents the total wattage to be allocated among all the chassis that

are part of the baseline or partial baseline of a zone, if specified. This value is divided by the total

maximum wattage established by the baseline to calculate a percentage cap value. This percentage is

then multiplied against each chassis maximum wattage value to arrive at an appropriate cap value for

that individual chassis.

42 Cabling and powering up the chassis

Page 43

If NONE is specified instead of a cap wattage value, then APM removes all (or the specified zone) of

the power caps.

To remove baseline data from the EEPROM and to remove the power cap setting, enter the following

command:

>SET POWER BASELINE NONE

After this command is issued, the only way to re-establish a power baseline is to issue the SET POWER

BASELINE command. The system returns to the default power cap mode (mode 1).

Cabling and powering up the chassis 43

Page 44

Troubleshooting

Important safety information

Familiarize yourself with the safety information in the following sections before troubleshooting the server.

Important safety information

Before servicing this product, read the Important Safety Information document provided with the server.

Symbols on equipment

The following symbols may be placed on equipment to indicate the presence of potentially hazardous

conditions.

This symbol indicates Hewlett Packard Enterprise systems and peripherals that

contain assemblies and components that are sensitive to electrostatic discharge.

Carefully observe the precautions and recommended procedures in this document to

prevent component damage from static electricity.

This symbol indicates the presence of hazardous energy circuits or electric shock

hazards. Refer all servicing to qualified personnel.

WARNING: To reduce the risk of injury from electric shock hazards, do not open this

enclosure. Refer all maintenance, upgrades, and servicing to qualified personnel.

99.79 kg

220.00 lb

This symbol indicates the presence of electric shock hazards. The area contains no

user or field serviceable parts. Do not open for any reason.

WARNING: To reduce the risk of injury from electric shock hazards, do not open this

enclosure.

This symbol on an RJ-45 receptacle indicates a network interface connection.

WARNING: To reduce the risk of electric shock, fire, or damage to the equipment, do

not plug telephone or telecommunications connectors into this receptacle.

This symbol indicates the presence of a hot surface or hot component. If this surface is

contacted, the potential for injury exists.

WARNING: To reduce the risk of injury from a hot component, allow the surface to cool

before touching.

This symbol indicates that the component exceeds the recommended weight for one

individual to handle safely.

WARNING: To reduce the risk of personal injury or damage to the equipment,

observe local occupational health and safety requirements and guidelines for manual

material handling.

44 Troubleshooting

Page 45

These symbols, on power supplies or systems, indicate that the equipment is supplied

by multiple sources of power.

WARNING: To reduce the risk of injury from electric shock, remove all power cords to

disconnect power from the system completely.

Troubleshooting resources

Troubleshooting resources are available for HPE ProLiant Gen9 servers in the following documents:

• The HPE ProLiant Gen9 Troubleshooting Guide, Volume I: Troubleshooting provides procedures for

resolving common problems and comprehensive courses of action for fault isolation and identification,

issue resolution, and software maintenance on ProLiant servers and server blades.

• The HPE ProLiant Gen9 Troubleshooting Guide, Volume II: Error Messages provides a list of error

messages and information to assist with interpreting and resolving error messages on ProLiant

servers and server blades.

To access the troubleshooting resources, see the Hewlett Packard Enterprise website (http://

www.hpe.com/info/Gen9-troubleshooting).

Troubleshooting 45

Page 46

Specifications

Environmental specifications

Specification Value

Temperature range

Operating 10°C to 35°C (50°F to 95°F)

Shipping -40°C to 70°C (-40°F to 158°F)

Maximum wet bulb temperature 28°C (82.4°F)

Relative humidity (noncondensing)

Operating 10% to 90%

Nonoperating 5% to 95%

1

All temperature ratings shown are for sea level. An altitude derating of 1°C per 300 m (1.8°F per 1,000 ft) to 3,048 m

(10,000 ft) is applicable. No direct sunlight allowed.

2

Storage maximum humidity of 95% is based on a maximum temperature of 45°C (113°F). Altitude maximum for

storage corresponds to a pressure minimum of 70 kPa.

Chassis specifications

1

2

Specification Value

Height 18.96 cm (7.46 in)

Depth 84.91 cm (33.43 in)

Width 44.33 cm (17.45 in)

Weight (fully loaded, with three XL450 servers) 99.79 kg (220.00 lb)

Weight, empty 43.09 kg (95.00 lb)

Power supply specifications

Depending on installed options, the server is configured with one of the following power supplies:

• HPE 800W Flex Slot Platinum Hot-plug Low Halogen Power Supply on page 47

• HPE 800W Flex Slot -48VDC Hot-plug Low Halogen Power Supply on page 47

• HPE 800W Flex Slot Titanium Hot-plug Low Halogen Power Supply on page 49

• HPE 800W Flex Slot Universal Hot-plug Low Halogen Power Supply on page 49

• HPE 1400W Flex Slot Platinum Plus Hot-plug Power Supply on page 50

For detailed power supply specifications, see the QuickSpecs on the Hewlett Packard Enterprise website

(http://www.hpe.com/info/proliant/powersupply).

46 Specifications

Page 47

HPE 800W Flex Slot Platinum Hot-plug Low Halogen Power Supply

Specification Value

Input requirements —

Rated input voltage

Rated input frequency

Rated input current

Maximum rated input power

BTUs per hour

Power supply output —

100 VAC to 127 VAC

200 VAC to 240 VAC

240 VDC for China only

50 Hz to 60 Hz

Not applicable to 240 VDC

9.1 A at 100 VAC

4.4 A at 200 VAC

3.6 A at 240 VDC for China only

899 W at 100 VAC

867 W at 200 VAC

864 W at 240 VDC for China only

3067 at 100 VAC

2958 at 200 VAC

2949 at 240 VAC for China only

Rated steady-state power

Maximum peak power

800 W at 100 VAC to 127 VAC input

800 W at 100 VAC to 240 VAC input

800 W at 240 VDC input for China only

800 W at 100 VAC to 127 VAC input

800 W at 100 VAC to 240 VAC input

800 W at 240 VDC input for China only

HPE 800W Flex Slot -48VDC Hot-plug Low Halogen Power Supply

Specification Value

Input requirements —

Rated input voltage

-40 VDC to -72 VDC

-48 VDC nominal input

Table Continued

Specifications 47

Page 48

Specification Value

Rated input current

Rated input power (W)

Rated input power (BTUs per hour)

Power supply output —

Rated steady-state power (W) 800 W at -40 VDC to -72 VDC

Maximum peak power (W) 800 W at -40 VDC to -72 VDC

Maximum peak power

WARNING: To reduce the risk of electric shock or energy hazards:

22.1 A at -40 VDC input

18.2 A at -48 VDC input, nominal input

12.0 A at -72 VDC input

874 W at -40 VDC input

865 W at -48 VDC input, nominal input

854 W at -72 VDC input

2983 at -40 VDC input

2951 at -48 VDC input, nominal input

2912 at -72 VDC input

800 W at -40 VDC to -72 VDC input

• This equipment must be installed by trained service personnel.

• Connect the equipment to a reliably grounded secondary circuit source. A secondary circuit has

no direct connection to a primary circuit and derives its power from a transformer, converter, or

equivalent isolation device.

• The branch circuit overcurrent protection must be rated 27 A.

CAUTION: This equipment is designed to permit the connection of the earthed conductor of the DC

supply circuit to the earthing conductor at the equipment.

If this connection is made, all of the following must be met:

• This equipment must be connected directly to the DC supply system earthing electrode

conductor or to a bonding jumper from an earthing terminal bar or bus to which the DC supply

system earthing electrode conductor is connected.

• This equipment must be located in the same immediate area (such as adjacent cabinets) as any

other equipment that has a connection between the earthed conductor of the same DC supply

circuit and the earthing conductor, and also the point of earthing of the DC system. The DC

system must be earthed elsewhere.

• The DC supply source is to be located within the same premises as the equipment.

• Switching or disconnecting devices must not be in the earthed circuit conductor between the DC

source and the point of connection of the earthing electrode conductor.

48 Specifications

Page 49

HPE 800W Flex Slot Titanium Hot-plug Low Halogen Power Supply

Specification Value

Input requirements —

Rated input voltage

Rated input frequency

Rated input current

Maximum rated input power

BTUs per hour

Power supply output —

Rated steady-state power

200 VAC to 240 VAC

240 VDC for China only

50 Hz to 60 Hz

Not applicable to 240 VDC

4.35 A at 200 VAC 3.62 A at 240 VAC

3.62 A at 240 VDC for China only

851 W at 200 VAC

848 W at 240 VAC

848 W at 240 VDC for China only

2905 at 200 VAC

2893 at 240 VAC

2893 at 240 VDC for China only

800 W at 200 VAC to 240 VAC input

800 W at 240 VDC input for China only

Maximum peak power

800 W at 200 VAC to 240 VAC input

800 W at 240 VDC input for China only

HPE 800W Flex Slot Universal Hot-plug Low Halogen Power Supply

Specification Value

Input requirements —

Rated input voltage

Rated input frequency 50 Hz to 60 Hz

Rated input current

200 VAC to 277 VAC

380 VDC

4.4 A at 200 VAC

3.1 A at 277 VAC

2.3 A at 380 VDC

Table Continued

Specifications 49

Page 50

Specification Value

Maximum rated input power

BTUs per hour

Power supply output —

Rated steady-state power

Maximum peak power

869 W at 200 VAC

865 W at 230 VAC

861 W at 277 VAC

863 W at 380 VDC

2964 at 200 VAC

2951 at 230 VAC

2936 at 277 VAC

2943 at 380 VDC

800 W at 200 VAC to 277 VAC input

800 W at 200 VAC to 277 VAC input

HPE 1400W Flex Slot Platinum Plus Hot-plug Power Supply

Specification Value

Input requirements

Rated input voltage

Rated input frequency

Rated input current

Maximum rated input power

BTUs per hour

200 to 240 VAC

240 VDC for China only

50 Hz to 60 Hz

Not applicable to 240 VDC

8.0 A at 200 VAC

6.7 A at 240 VAC

6.7 A at 240 VDC for China

only

1600 W at 200 VAC

1600 W at 240 VAC

1600 W at 240 VDC for China

only

5459 at 200 VAC

5459 at 240 VAC

5459 at 240 VDC for China

only

Power supply output

50 Specifications

Table Continued

Page 51

Rated steady-state power

1400 W at 200 VAC to 240

VAC input

1400 W at 240 VDC input for

China only

Maximum peak power

1400 W at 200 VAC to 240

VAC input

1400 W at 240 VDC input for

China only

Hot-plug power supply calculations

For hot-plug power supply specifications and calculators to determine electrical and heat loading for the

server, see the Hewlett Packard Enterprise Power Advisor website (http://www.hpe.com/info/

poweradvisor/online).

Specifications 51

Page 52

Environmental considerations

Communications interference

Hewlett Packard Enterprise system compliance tests are conducted with Hewlett Packard Enterprise

supported peripheral devices and shielded cables, such as those received with the system. The system

meets interference requirements of all countries in which it is sold. These requirements provide

reasonable protection against interference with radio and television communications.

Installing and using the system in strict accordance with Hewlett Packard Enterprise instructions

minimizes the chances that the system might cause radio or television interference. However, Hewlett

Packard Enterprise does not guarantee that the system does not interfere with radio and television

reception.

Take these precautions:

• Use only shielded cables.

• Install and route the cables according to the instructions provided.

• Ensure that all cable connector screws are firmly tightened.

• Use only Hewlett Packard Enterprise supported peripheral devices.

• Before system operation, ensure that all panels and cover plates are in place and secure.

Preventing electrostatic discharge

To prevent damaging the system, be aware of the precautions you must follow when setting up the

system or handling parts. A discharge of static electricity from a finger or other conductor may damage

system boards or other static-sensitive devices. This type of damage may reduce the life expectancy of

the device.

Procedure

• Avoid hand contact by transporting and storing products in static-safe containers.

• Keep electrostatic-sensitive parts in their containers until they arrive at static-free workstations.

• Place parts on a grounded surface before removing them from their containers.

• Avoid touching pins, leads, or circuitry.

• Always be properly grounded when touching a static-sensitive component or assembly.

Grounding methods to prevent electrostatic discharge

Several methods are used for grounding. Use one or more of the following methods when handling or

installing electrostatic-sensitive parts:

• Use a wrist strap connected by a ground cord to a grounded workstation or computer chassis. Wrist

straps are flexible straps with a minimum of 1 megohm ±10 percent resistance in the ground cords. To

provide proper ground, wear the strap snug against the skin.

• Use heel straps, toe straps, or boot straps at standing workstations. Wear the straps on both feet

when standing on conductive floors or dissipating floor mats.

52 Environmental considerations

Page 53

• Use conductive field service tools.

• Use a portable field service kit with a folding static-dissipating work mat.

If you do not have any of the suggested equipment for proper grounding, have an authorized reseller

install the part.

For more information on static electricity or assistance with product installation, contact the Hewlett

Packard Enterprise Support Center.

Environmental considerations 53

Page 54

Websites

General websites

Hewlett Packard Enterprise Information Library

www.hpe.com/info/EIL

Subscription Service/Support Alerts

www.hpe.com/support/e-updates

Insight Remote Support

www.hpe.com/info/insightremotesupport/docs

For additional websites, see Support and other resources.

54 Websites

Page 55

Support and other resources

Accessing Hewlett Packard Enterprise Support

• For live assistance, go to the Contact Hewlett Packard Enterprise Worldwide website:

http://www.hpe.com/assistance

• To access documentation and support services, go to the Hewlett Packard Enterprise Support Center

website:

http://www.hpe.com/support/hpesc

Information to collect

• Technical support registration number (if applicable)

• Product name, model or version, and serial number

• Operating system name and version

• Firmware version

• Error messages

• Product-specific reports and logs

• Add-on products or components

• Third-party products or components

Accessing updates

• Some software products provide a mechanism for accessing software updates through the product

interface. Review your product documentation to identify the recommended software update method.

• To download product updates:

Hewlett Packard Enterprise Support Center

www.hpe.com/support/hpesc

Hewlett Packard Enterprise Support Center: Software downloads

www.hpe.com/support/downloads

Software Depot

www.hpe.com/support/softwaredepot

• To subscribe to eNewsletters and alerts:

www.hpe.com/support/e-updates

• To view and update your entitlements, and to link your contracts and warranties with your profile, go to

the Hewlett Packard Enterprise Support Center More Information on Access to Support Materials

page:

www.hpe.com/support/AccessToSupportMaterials

Support and other resources 55

Page 56

IMPORTANT: Access to some updates might require product entitlement when accessed through

the Hewlett Packard Enterprise Support Center. You must have an HPE Passport set up with

relevant entitlements.

Customer self repair

Hewlett Packard Enterprise customer self repair (CSR) programs allow you to repair your product. If a

CSR part needs to be replaced, it will be shipped directly to you so that you can install it at your

convenience. Some parts do not qualify for CSR. Your Hewlett Packard Enterprise authorized service

provider will determine whether a repair can be accomplished by CSR.

For more information about CSR, contact your local service provider or go to the CSR website:

http://www.hpe.com/support/selfrepair

Remote support

Remote support is available with supported devices as part of your warranty or contractual support

agreement. It provides intelligent event diagnosis, and automatic, secure submission of hardware event

notifications to Hewlett Packard Enterprise, which will initiate a fast and accurate resolution based on your

product's service level. Hewlett Packard Enterprise strongly recommends that you register your device for

remote support.

If your product includes additional remote support details, use search to locate that information.

Remote support and Proactive Care information

HPE Get Connected

www.hpe.com/services/getconnected

HPE Proactive Care services

www.hpe.com/services/proactivecare

HPE Proactive Care service: Supported products list

www.hpe.com/services/proactivecaresupportedproducts

HPE Proactive Care advanced service: Supported products list

www.hpe.com/services/proactivecareadvancedsupportedproducts

Proactive Care customer information

Proactive Care central

www.hpe.com/services/proactivecarecentral

Proactive Care service activation

www.hpe.com/services/proactivecarecentralgetstarted

Warranty information

To view the warranty information for your product, see the links provided below:

HPE ProLiant and IA-32 Servers and Options

www.hpe.com/support/ProLiantServers-Warranties

HPE Enterprise and Cloudline Servers

www.hpe.com/support/EnterpriseServers-Warranties

HPE Storage Products

www.hpe.com/support/Storage-Warranties

HPE Networking Products

www.hpe.com/support/Networking-Warranties

56 Support and other resources

Page 57

Regulatory information

To view the regulatory information for your product, view the Safety and Compliance Information for

Server, Storage, Power, Networking, and Rack Products, available at the Hewlett Packard Enterprise

Support Center:

www.hpe.com/support/Safety-Compliance-EnterpriseProducts

Additional regulatory information

Hewlett Packard Enterprise is committed to providing our customers with information about the chemical

substances in our products as needed to comply with legal requirements such as REACH (Regulation EC

No 1907/2006 of the European Parliament and the Council). A chemical information report for this product

can be found at:

www.hpe.com/info/reach

For Hewlett Packard Enterprise product environmental and safety information and compliance data,

including RoHS and REACH, see:

www.hpe.com/info/ecodata

For Hewlett Packard Enterprise environmental information, including company programs, product

recycling, and energy efficiency, see:

www.hpe.com/info/environment

Documentation feedback

Hewlett Packard Enterprise is committed to providing documentation that meets your needs. To help us

improve the documentation, send any errors, suggestions, or comments to Documentation Feedback

(docsfeedback@hpe.com). When submitting your feedback, include the document title, part number,

edition, and publication date located on the front cover of the document. For online help content, include

the product name, product version, help edition, and publication date located on the legal notices page.

Support and other resources 57

Page 58

Acronyms and abbreviations

AC

alternating current

APM

advanced power management

CSA

Canadian Standards Association

CSR

Customer Self Repair

ESD

electrostatic discharge

IEC

International Electrotechnical Commission

iLO

Integrated Lights-Out

LFF

large form factor

LOM

LAN on Motherboard

PCIe

Peripheral Component Interconnect Express

PDU

power distribution unit

TMRA

recommended ambient operating temperature

UID

unit identification

UPS

uninterruptible power system

USB

universal serial bus

58 Acronyms and abbreviations

Loading...

Loading...