Page 1

~--------------------HEWLETTiPPACKARD--------------------~

OPERATING

7970B/7970C

DIGITAL

AND

MAGNETIC

TAPE TRANSPORT

Prin ted-Circuit Assemblies:

07970-60481, Series 1101

07970-61010, Series 1323

07970-61020, Series 1229

07970-61080, Series 1042

07970-61150, Series 1049

07970-62172,Series1322

07970-62173, Series 1329

07970-62086, Series 1013

07970-62089, Series 1206

SERVICE

PART

2

TAPE

MANUAL

UNIT

07970-90383

Copyright

11000

Wolfe

HEWLETT-PACKARD

Road,

Cupertino,

COMPANY

California

95014,

1972

U.S.A.

PRINTED: AUG 1973

Page 2

7970B/7970C

Description

SECTION

DESCRIPTION

1-1.

1-2. This section describes the transport for the HewlettPackard

vides a functional description

critical assemblies are defined and optional assemblies are

described.

1-3.

1-4. The tape unit consists

sembly and a sheet metal housing assembly. The housing

assembly contains the power supply, the power distribution

assembly, the control and status assembly, and interfacing

provisions. The read and write modules are also contained

in the housing assembly.

1-5. The transport casting assembly consists

moving assemblies, reel motors, capstan servo motor,

sion arm assemblies and the circuits associated with these

assemblies. The magnetic tape head assembly, photosense

assembly, write interconnect assembly, and read

fier assembly are also mounted

sembly.

mounted

are accessible and

assembly open.

INTRODUCTION.

7970B/7970C Digital Magnetic Tape Units and pro-

of

the transport circuits. Speed

PHYSICAL DESCRIPTION.

of

a transport casting

to

the transport casting

All

standard and optional switch assemblies are

to

the transport casting assembly.

all

circuits will operate with the transport

All

assemblies

of

all tape

ten-

preampli-

as-

as-

1-10.

1-11. Capstan Motor Assembly MG1,

60140,

10 ips and 37.5 ips. Capstan Motor Assembly MG1, part

number 07970-60141,

ranges between 37.6 ips and 45 ips.

1-12.

1-13. The capstan servo

connector

dummy connector

pending upon the speed range

motor

A9

CAPSTAN MOTOR ASSEMBLY.

part

number 07970-

is

used on tape units with tape speed ranges between

is

used on tape units with tape speed

Note

Capstan Motor Assembly MG1, part number

07970-60140, may be used

ating

at

45 ips. However, program restrictions

must be maintained.

CAPSTAN SERVO PRINTED-CIRCUIT

ASSEMBLY.

that

functions

is

installed in one

assembly used. See figure 7-10, Capstan Servo PCA

Schematic Diagram, for details

CAUTION

on

tape units oper-

PCA

is

equipped with a dummy

as

a strapping network. The

of

six positions, de-

of

the tape unit and capstan

of

dummy connector.

1-6. SPEED

1-7. The tape

10

ips and 45 ips. The actual tape speed

fied when the unit

to

critical

1-8. REEL MOTORS.

1-9. Reel Motors B1/B2, part number 07970-60170, are

used on tape units with tape speed ranges between

and 37.5 ips. Reel Motors B1/B2, part number

are used on tape units with tape speed ranges between 37.6

and 45 ips.

Part 2

tape speed:

Reel Motor Assembly.

a.

Capstan Motor Assembly.

b.

c. Capstan Servo

Magnetic Tape Head Assembly.

d.

Read Modules.

e.

f.

Write Modules.

CRITICAL

unit

will operate

is

ordered. The following are limited or

PC

ASSEMBLIES.

at

Assembly.

tape speeds between

of

the unit

07970-60171,

is

speci-

10

ips

Ensure

that

dummy connector

proper position prior

unit. Attempting to operate the unit without the

connector installed

wrong position may result in damage

1-14.

1-15. The magnetic tape head assembly consists

guides, a tape cleaner, and, depending upon configuration,

read, write, and erase heads. The tape head assembly

critical; refer

of

1-16. READ MODULES.

1-17. The read modules are described in detail in part 3

or

1-18. WRITE MODULES.

1-19. The write modules are described in detail in

of

MAGNETIC

to

section VI for

the magnetic tape head assembly.

part 5 of

this manual.

this manual.

to

or

with the connector in the

TAPE HEAD ASSEMBLY.

is

installed in the

applying power

part

numbers and speed ranges

to

the unit.

to

the

is

of

speed

part

tape

1-1

4

Page 3

Description

7970Bj7970C

1-20. BASIC AND OPTIONAL ASSEMBLIES.

1-21. The tape unit

tions. Regardless

basic and applicable

a. Transformer Assembly.

b.

Photosense Assembly.

c. Tension Assemblies (two).

d. Capstan Assembly.

e.

Reel Motor Assemblies (two).

f.

Reel Servo Printed-Circuit Assembly.

g.

Capstan Servo Printed-Circuit Assembly.

Control and Status Printed-Circuit Assembly.

h.

is

available in a variety

of

tape speed, the following assemblies are

to

all tape units.

of

configura-

i. Power Distribution Assembly.

j. Power Regulator Printed-Circuit Assembly.

1-22. The control switch assembly

however, if the tape unit

is

equipped with write data cir-

cuits, the control switch assembly

is

a basic assembly;

wHi

contain the write en-

able indicator.

1-23. The following assemblies are optional and, depend-

of

ing upon the use

of

the tape unit.

a.

Write Enable Assembly.

b.

Density Select Assembly.

c.

Unit Select Assembly.

the tape unit,

mayor

may

not

be a part

1-2

Part 2

Page 4

7970B/7970C

Theory

of

Operation

SECTION

THEORY

2-1. INTRODUCTION.

2·2. This section provides an overall functional descrip·

tion

of

the tape transport and description

circuits. Block diagrams are included

ing the operation

2-3.

2-4. The tape transport controls the movement

netic tape, provides power for read and write

and supplies status signals

mands (High-Speed, Reverse, Forward, Rewind, and Off-

Line) are generated by the interface. The off-line and online commands are processed by the control and status circuits and result in controlling signals for the capstan servo,

reel servo,

and front panel indicators are also provided by the control

and status circuits. Figure 2-1

of

OVERALL

the tape transport circuits.

of

the transport circuits.

FUNCTIONAL DESCRIPTION.

to

the interface. Off-line com-

and

data circuits. Status signals for the interface

is

a functional block diagram

of

the transport

to

aid in understand-

data

OF

of

mag-

circuits,

II

OPERATION

the

2-9. A Rewind command generated by

will initiate the rewind sequence. The control and status

circuits place the capstan servo circuits

verse mode and switch the reel servo feedback circuits. The

capstan rewinds tape

with current feedback. When the trailing edge

beginning-of-tape

status circuits terminate

second delay, establish a load

2-10. Pressing RESET releases the tape unit from interface control. Pressing REWIND in this condition rewinds

the tape

take-up reel, the tension arms

switches, the capstan

motors are shorted. This provides dynamic braking

reel motors.

2-11.

on

the supply reel. When the tape

CIRCUIT

at

160

ips and the reel servo operates

(BOT) tab

motor

is

detected, the control and

the

rewind mode, and after a one-

point

contact

circuit

DESCRIPTIONS.

in

search mode.

the tension arm limit

is

broken and the reel

interface

a high-speed re-

of

is

run-off

of

of

the

the

the

2-5. At initial power-on, the capstan

open, and the reel servo motors are shorted. When the LOAD

switch

are completed. When tape tension

arms swing away from the tension limit switches. With tape

tensioned, the capstan and reel

When the

circuits initiate a load

the reel servo circuit operates with voltage feedback and the

capstan servo pulls tape forward

sense assembly, the control and status circuits terminate the

load point search, and tape motion stops. The control and

status circuits provide a load

and the

control

controls have

of

data

voltage feedback and tension

of-tape tab

vide the interface with an end-of-tape (EOT) status.

is

pressed, the capstan

LOAD switch

point

2-6. When the load

front

panel LOAD indicator illuminates.

2-7. Pressing the ON-LINE switch establishes interface

of

the tape unit. Except for RESET, the front panel

no

control

releases the interface control and allows

the tape unit.

2-8. When the tape unit

is

being processed, the tape unit pulls tape

nous speed

as

required. The reel servo circuits operate with

is

detected, the control and status circuits pro-

motor

is

motor

is

released, the control and status

search. During load

at

20

point

tab

is

point

of

the tape unit. Pressing RESET

is

under interface control and

is

maintained. When the end-

motor

circuit

and reel

established, the tension

returns are maintained.

detected by the photo-

status

ips.

motor

to

the interface,

front

panel control

point

at

synchro-

circuits

search,

is

2-12. The following paragraphs describe the power supply circuits, control and status circuits, capstan servo circuits

and reel servo circuits

of

the circuits are provided

operation

schematic diagrams

2-13.

2-14. The power supply

a power transformer, three center-tapped bridge rectifiers,

filter capacitors, and bleeder resistors.

primary circuit

switch

power on-off switch, and a line filter/power connector_

When 115

of

vides overload protection. When 230 Vac power

the two primary windings

series, and fuse F2

ing

2-15. The power distribution circuits are

distribution

and connectors for power distribution. The assembly also

contains a printed-circuit connector for the power regulator

printed-circuit assembly.

cuits and the ±12 volt distribution circuits provide circuit

protection.

of

the circuits. Refer

POWER SUPPLY AND POWER DISTRIBUTION

CIRCUITS.

that

allows selection

Vac power

the power transformer are in parallel and fuse F1 pro-

to

provide overload protection.

PCA. The assembly contains secondary fuses

of

the tape transport. Block Diagrams

as

an aid in understanding the

to

section VII for detailed

of

the tape transport.

of

the tape transport consists

(See figure 7 -2.) The

of

the power supply transformer includes a

of

115

or

230 Vac operation, a

is

selected, the

of

the power transformer are

is

placed in series with the primary wind-

Silicon diodes in the ±20 volt cir-

two

primary windings

is

selected,

on

the power

of

in

Part 2

2-1

Page 5

Theory

of

Operation

SUPPL Y REEL

TENSION ARM

TAKEUP

TENSION ARM

REEL

SERVO

REEL

CIRCUITS

SUPPLY REEL MOTOR

M

TAKEUP

REEL MOTOR

M

7970B/7970C

bl

7970 508

TENSION

SWITCHES

OFF-LINE

COMMANDS

(FRONT

PANEL!

STATUS

(FRONT

PANEL!

ON-LINE

COMMANDS

(INTERFACEI

STATUS

(INTERFACEI

PHOTOSENSE

ASSEMBLY

t

CONTROL

AND

STATUS

CIRCUITS

BOT/EOT

t

CONTROL

r-~,

I

DATA

CIRCUITS I

(SEE

PARTS I

3,4

I

L

OR

__

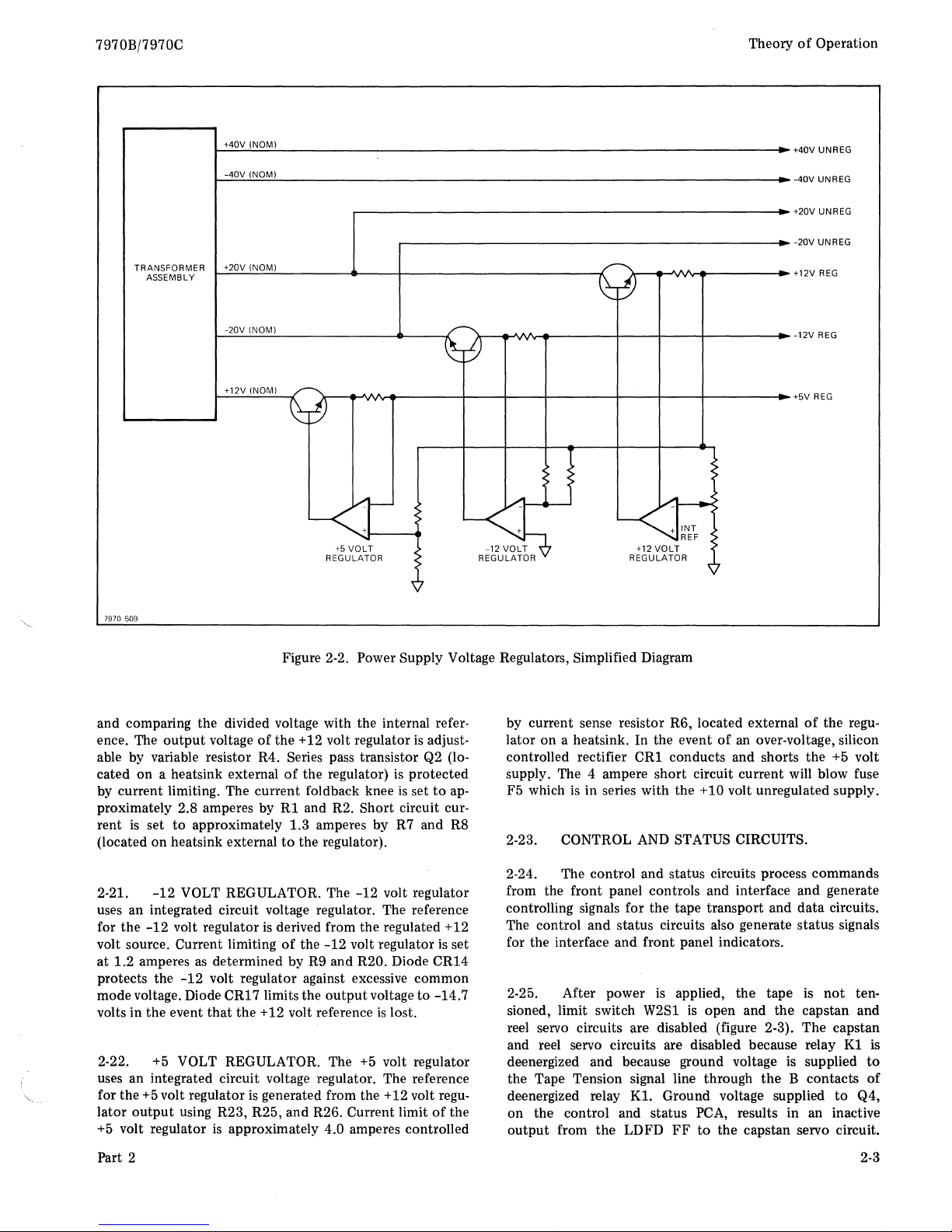

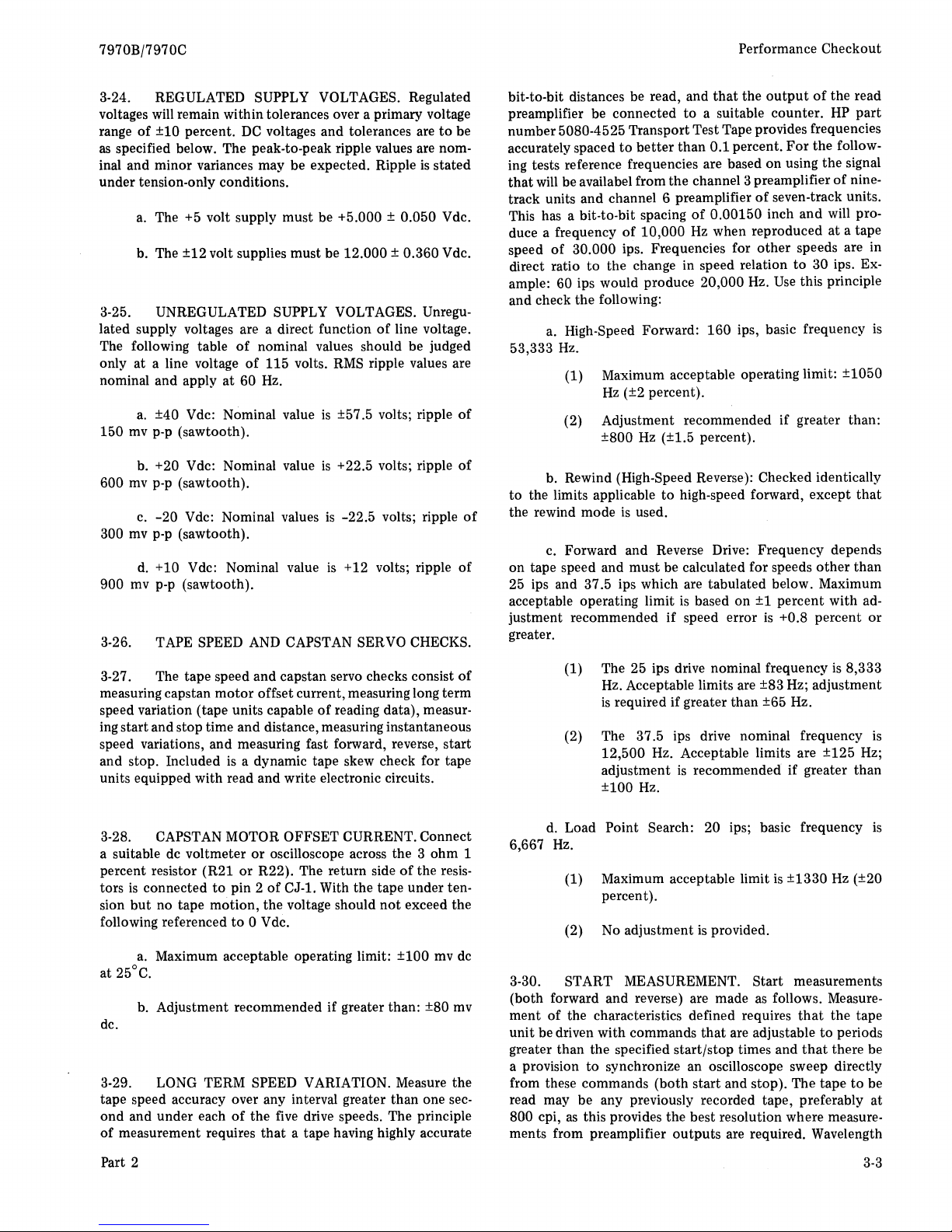

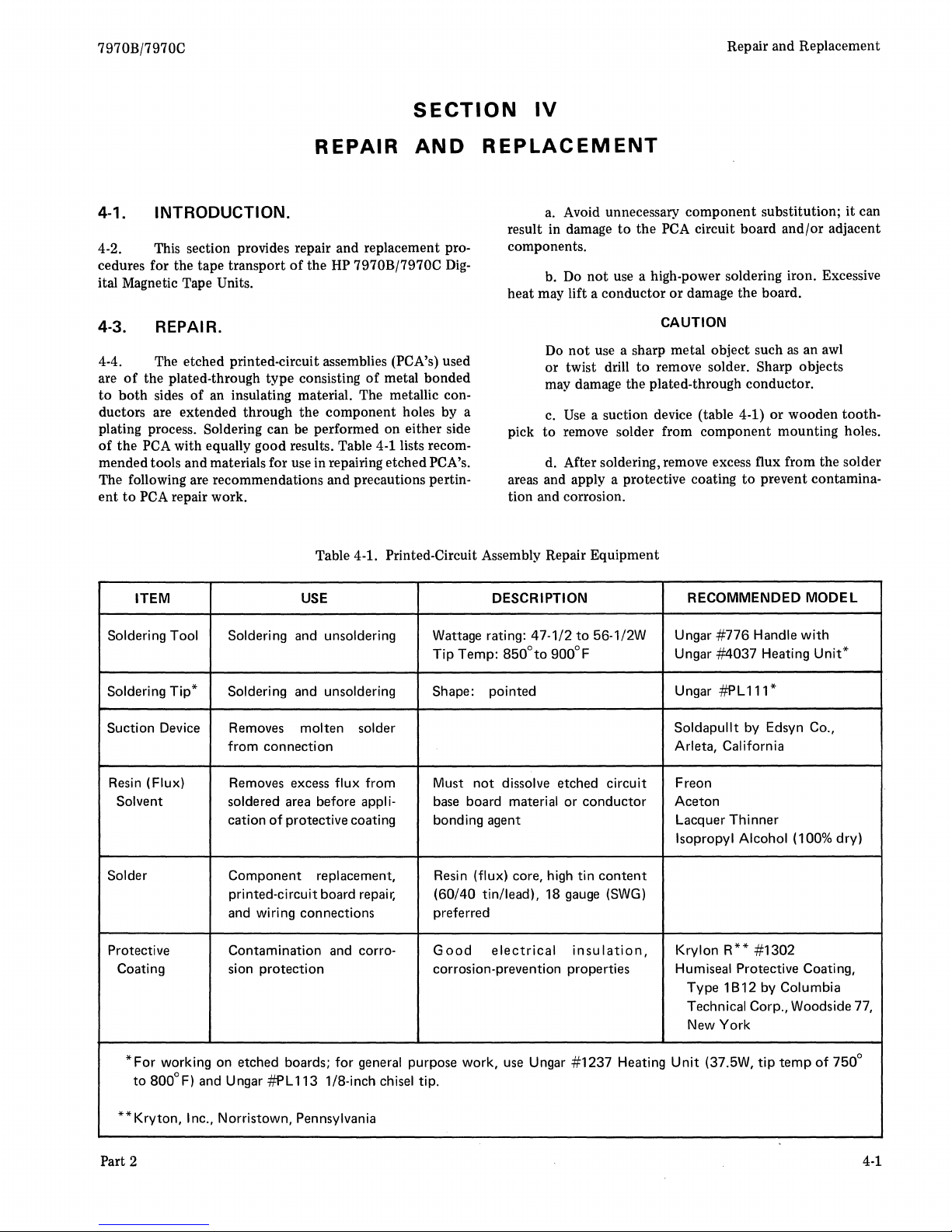

Figure 2-1. Tape Transport Functional Block Diagram

51

I

AND

FEEDBACK

STATUS

-.J

CONTROL

MOTION

CONTROL

TENSION/TENSION

LATCH

CAPSTAN

SERVO

CIRCUITS

CAPSTAN MOTOR

M

'1

TACHOMETER I

'-.J

I

1

I

I

I

I

I

I

I

I

·1

I

1

I

I

I

I

Kl

(LOCATED

REEL SERVO

ON

PC

AI

2-16.

tributed

to

Unregulated power from the power supply

to

the power regulator printed-circuit assembly and

heatsink-mounted power transistors. Unregulated ±40

volts (57.5 volts nominal) from the power supply

through heatsink-mounted resistors to the power regulator

printed-circuit assembly. Regulated power (+5

-12V) from the regulator-controlled transistors

mounted) are distributed

to

the transport circuits and data

circuits by the power distribution printed-circuit assembly.

2-17.

the power supply

ing diodes CR1 and CR2 allows the

switch from 22.5 volts dc

Unregulated ±20 volts (22.5 volts nominal) from

is

provided for the reel servo circuit. Steer-

±20/40

to

57.5 volts dc.

2-2

is

routed

V,

+ 12V, and

(heatsink-

volt lines

is

dis-

2-18.

POWER REGULATOR CIRCUITS.

2-19. The power regulator printed-circuit assembly contains a +

and a +5 volt regulator circuit.

12

volt regulator circuit, a

-12

volt regulator circuit,

(See figure 2-2.) The power

regulator printed-circuit assembly also contains a reel servo

voltage switching circuit and

a delay circuit. These circuits

are described with related circuits.

2-20. +12 VOLT REGULATOR. The +12 volt regulator

uses an integrated circuit voltage regulator with an internal

to

temperature compensated voltage reference. Regulation

obtained by dividing the

output

voltage (R3,

R4,

is

and R5)

Part 2

Page 6

7970B/7970C

Theory

of

Operation

TRANSFORMER

ASSEMBLY

+40V (NOM)

-40V

(NOM)

(NOM)

+20V

-20V (NOM)

+12V (NOM)

~&

J

+5

VOLT

REGULATOR

'"'"

~:9

~

~&

/1-

+

-12 VOLT +12

REGULATOR REGULATOR

~

VOLT

REF

~

+40V UNREG

-40V UNREG

+20V UNREG

-20V UNREG

+12V

REG

-12V

REG

+5V

REG

7970·509

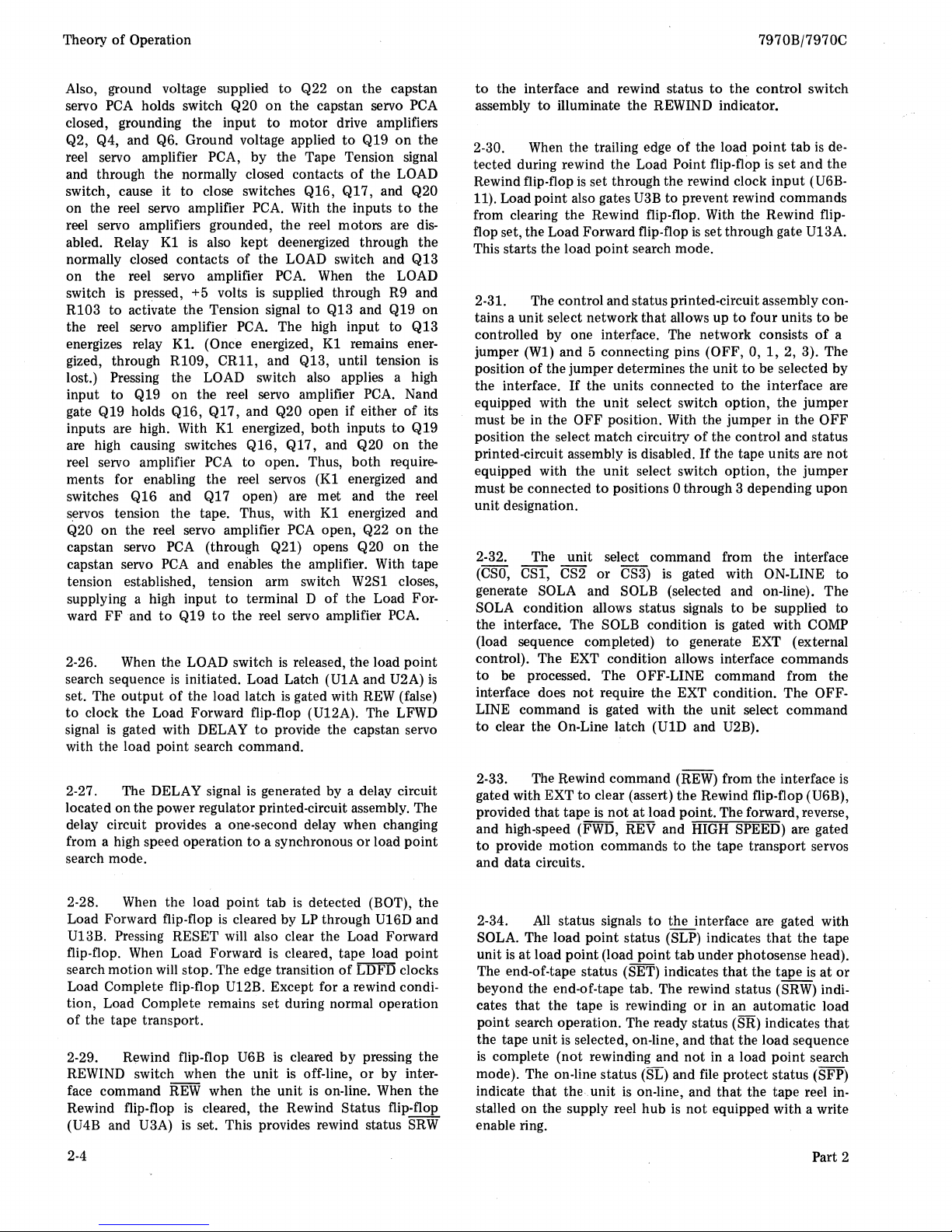

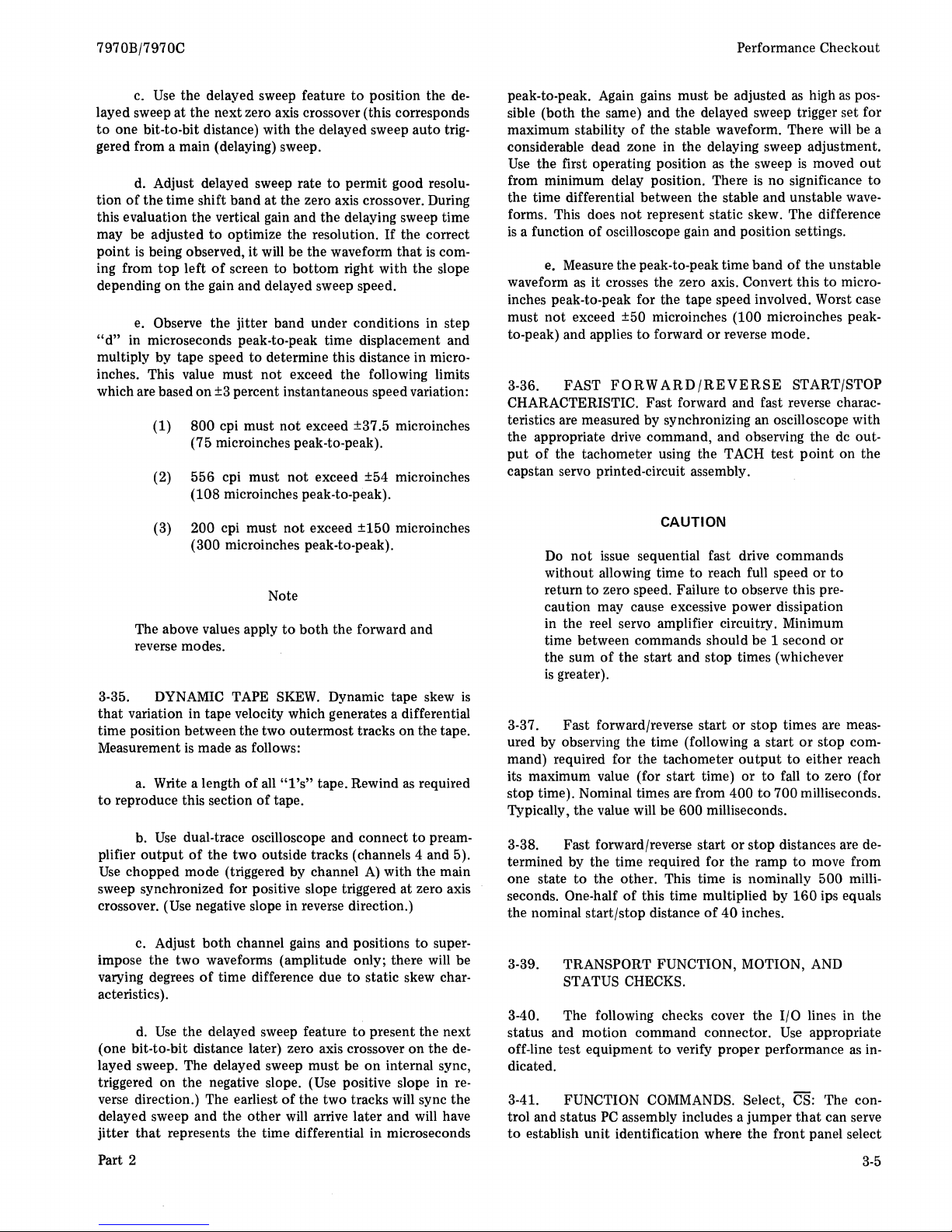

Figure 2-2. Power Supply Voltage Regulators, Simplified Diagram

and comparing the divided voltage with the internal refer·

ence. The

able by variable resistor R4.

cated on a heatsink external

by current limiting. The current foldback knee

output

voltage

of

the +12 volt regulator

Series pass transistor

of

the regulator)

is

adjust·

Q2

is

protected

is

set

to

(lo-

approximately 2.8 amperes by R1 and R2. Short circuit current

is

set

to

approximately 1.3 amperes by R7 and R8

(located on heatsink external

-12

2-21.

VOLT REGULATOR. The

to

the regulator).

-12

volt regulator

uses an integrated circuit voltage regulator. The reference

for the

volt source.

at

protects the

mode voltage. Diode

volts in the event that the + 12 volt reference

2-22.

-12

volt regulator

Current limiting

1.2 amperes

+5

VOLT REGULATOR. The

is

derived from the regulated + 12

of

the

-12

volt regulator

as

determined by R9 and R20. Diode CR14

-12

volt regulator against excessive common

CR17 limits the

output

+5

voltage

is

lost.

volt regulator

to

is

set

-14.7

uses an integrated circuit voltage regulator. The reference

+5

for the

lator

output

+5

volt regulator

volt regulator

using R23, R25, and R26. Current limit

is

generated from the + 12 volt regu-

is

approximately 4.0 amperes controlled

of

the

by current sense resistor R6, located external

of

lator on a heatsink. In the event

controlled rectifier

CR1 conducts and shorts the +5 volt

an over-voltage, silicon

of

the regu-

supply. The 4 ampere short circuit current will blow fuse

is

F5 which

in series with the +10 volt unregulated supply.

2-23. CONTROL AND STATUS CIRCUITS.

2-24. The control and status circuits process commands

from the front panel controls and interface and generate

controlling signals for the tape transport and data circuits.

The control and status circuits also generate status signals

for the interface and front panel indicators.

2-25. After power

sioned, limit switch

is

applied, the tape

W2S1

is

open and the capstan and

is

not

ten-

reel servo circuits are disabled (figure 2-3). The capstan

and reel servo circuits are disabled because relay

deenergized and because ground voltage is supplied

the Tape Tension signal line through

deenergized relay

on the control and status

output from

the

Kl.

Ground voltage supplied

PCA,

LDFD

FF

to

the

B contacts

results in an inactive

the capstan servo circuit.

to

K1

to

of

Q4,

is

Part 2

2-3

Page 7

Theory

of

Operation

7970B/7970C

Also, ground voltage supplied

servo

PCA

holds switch Q20

closed, grounding the input

Q2, Q4, and Q6. Ground voltage applied

reel servo amplifier

PCA, by the Tape Tension signal

and through the normally closed contacts

switch, cause it

to

close switches Q16, Q17, and Q20

on the reel servo amplifier

reel servo amplifiers grounded,

abled. Relay

K1

is

also kept deenergized through the

normally closed contacts

on

the reel servo amplifier

switch

is

pressed, +5 volts

R103 to activate the Tension signal

the reel servo amplifier

energizes relay K1.

(Once energized,

to

Q22

on

the capstan

on

the capstan servo

to

motor drive amplifiers

to

Q19

of

the LOAD

PCA.

With the inputs

the

reel motors are dis-

of

the LOAD switch and Q13

PCA.

When the LOAD

is

supplied through R9 and

to

Q13 and Q19 on

PCA.

The high input

K1

remains ener-

to

on

to

PCA

the

the

Q13

gized, through R109, CR11, and Q13, until tension

lost.) Pressing the LOAD switch also applies a high

on

input to Q19

gate Q19 holds Q16, Q17, and

inputs are high. With

the reel servo amplifier

Q20 open if either

K1

energized,

both

are high causing switches Q16, Q17, and

reel servo amplifier

ments for enabling

PCA

to

open. Thus,

the

reel servos (K1 energized and

PCA.

inputs

Q20

both

Nand

of

its

to

Q19

on

the

require-

switches Q16 and Q17 open) are met and the reel

servos tension the tape. Thus, with K1 energized and

Q20

on

the reel servo amplifier

PCA

capstan servo

capstan servo

(through Q21) opens Q20

PCA

and enables the amplifier. With tape

tension established, tension arm switch

supplying a high input

ward

FF

and

to

Q19

to

to

the reel servo amplifier

2-26. When the LOAD switch

search sequence

set. The

to

signal

output

clock the Load Forward flip-flop (U12A). The LFWD

is

gated with DELAY

is

initiated. Load Latch (U1A and U2A)

of

the load latch

PCA

open, Q22

W2S1

terminal D

to

provide the capstan servo

of

the Load For-

is

released, the load point

is

gated with

REW

on

on

closes,

PCA.

(false)

the

the

with the load point search command.

to

the interface and rewind status

to

assembly

illuminate the REWIND indicator.

2-30. When the trailing edge

of

the load

to

the

tected during rewind the Load Point flip-flop

is

Rewind flip-flop

11). Load point also gates U3B

set through the rewind clock input (U6B-

to

prevent rewind commands

from clearing the Rewind flip-flop. With the Rewind

flop set, the Load Forward flip-flop

This starts the load

point

search mode.

is

set through gate U13A.

2-31. The control and status printed-circuit assembly

tains a unit select network

that

allows up

to

controlled by one interface. The network consists

(W1)

is

jumper

position

the interface.

and 5 connecting pins (OFF, 0,

of

the jumper determines the unit

If

the units connected

to

to

the interface are

equipped with the unit select switch option, the jumper

must be in the

position the select match circuitry

printed-circuit assembly

OFF position. With the jumper in the

of

the control and status

is

disabled.

If

the tape units are

equipped with the unit select switch option, the jumper

must be connected

to

positions 0 through 3 depending upon

unit designation.

2-32. The unit select command from

(CSO,

CS1, CS2 or CS3)

is

gated with ON-LINE

generate SOLA and SOLB (selected and on-line). The

SOLA condition allows status signals

the interface. The SOLB condition

to

is

gated with

(load sequence completed) to generate EXT (external

control). The EXT condition allows interface commands

to

is

be processed. The OFF-LINE command from the

not

interface does

LINE command

to

clear the On-Line latch (U1D and U2B).

require the EXT condition. The OFF-

is

gated with the unit select command

control switch

point

tab

is

de-

is

set and the

flip-

con-

four units

to

of

1,

2,

3)_

The

be selected by

OFF

not

the

interface

be

supplied

COMP

be

a

to

to

2-27. The DELAY signal

is

generated by a delay circuit

located on the power regulator printed-circuit assembly. The

delay circuit provides a one-second delay when changing

to

from a high speed operation

a synchronous

search mode.

is

2-28. When the load point tab

is

Load Forward flip-flop

cleared by

detected (BOT), the

LP

U13B. Pressing RESET will also clear the Load Forward

flip-flop.

search motion

Load Complete flip-flop

When

will

Load Forward

is

cleared, tape load point

stop. The edge transition

U12B. Except for a rewind condition, Load Complete remains set during normal operation

of

the tape transport.

2-29. Rewind flip-flop

REWIND switch when the unit

face command

Rewind flip-flop

(U4B and U3A)

REW

is

is

U6B

is

cleared

is

off-line,

when the unit

is

cleared, the Rewind Status flip-flop

set. This provides rewind status

2-4

or

load point

through U16D and

of

LDFD clocks

by

pressing the

or

by inter-

on-line. When the

SRW

2-33. The Rewind command (REW) from the interface

gated with EXT

provided

and high-speed (FWD, REV and

to

provide motion commands

that

to

clear (assert) the Rewind flip-flop (U6B),

tape

is

not

at

load

point. The forward, reverse,

HIGH SPEED) are gated

to

the tape transport servos

and data circuits.

All

2-34.

status signals

SOLA. The load point status (SLP) indicates

is

at

unit

load point (load point tab under photosense head).

The end-of-tape status (SET) indicates

to

the interface are gated with

that

the tape

that

the tape

is

at

beyond the end-of-tape tab. The rewind status (SRW) indi-

cates that the tape

point search operation. The ready status (SR) indicates

the tape unit

is

complete

is

(not

mode). The on-line status (SL) and file protect status

indicate

that

stalled on the supply reel hub

is

rewinding

or

in an automatic load

selected, on-line, and that the load sequence

rewinding and

not

in a load point search

(SFP)

the. unit

is

on-line, and that the tape reel

is

not

equipped with a write

that

enable ring.

Part 2

is

or

in-

Page 8

Page 9

7970B/7970C

Theory

of

Operation

2,35.

The one-second delay (generated on the power

regulator printed-circuit assembly) following a high-speed

reverse command prevents additional high speed commands

from being processed by the control and status circuits. The

delay also prevents the load point search from occurring for

one-second following a rewind operation.

2-36.

CAPSTAN SERVO CIRCUITS.

2-37. The capstan servo circuits control the speed and

direction

The capstan servo consists

and a capstan servo printed-circuit assembly. The servo

of

tape motion across the magnetic head assembly.

of

a capstan motor/tachometer

cir-

cuit employs current and velocity feedback. The velocity

is

feedback

ometer attached to the capstan

back

is

motor

provided by the magnetic moving coil tach-

motor

shaft. Current feed-

provided by a pair

return circuit. Figure

of

sensing resistors in the capstan

2-4

is

a block diagram

of

the

capstan servo circuit.

2-38. Motion commands from the control and status

printed-circuit assembly control switching circuits and a

polar ramp generator. The

output

of

the ramp generator

bi-

and high-speed control signals control the capstan closedloop servo amplifier. The capstan servo amplifier consists

of

an integrated circuit servo preamplifier (U4) and a capstan

power amplifier

(Ql

through Q6).

2-39. The forward and reverse switching circuits contain

temperature compensated zener diodes

that

provide a basic

reference voltage for forward and reverse speeds. When a

FWD

command from the control and status circuits

service switch

verse biased. Bias current for CR6

R33

to

(U2 and U3). A REV command

switch

in

S2

is

placed in the on position (up),

is

then provided through

establish a

the

-6.2

volt reference for the ramp generator

or

placing the REV service

on position (up) will provide bias current for

of

Q7

FWD

is

re-

CR2 through R27. CR2 will provide a +6.2 volt reference

for the ramp generator. The forward and reverse reference

voltages

to

at

the

output

control the forward

of

U3

are independently adjustable

or

reverse speeds.

HSFWD------~----------------~_:~::~

LPSEARCH-----------------+~----~

TENSION

----------------4~

7970511A

'-

....

--------------------------------------------------------------_

HSFWD

L---o-~

.12V

12V

OFFSET

TENSION

TO

REE L

cCA

SE

RVO

Part 2

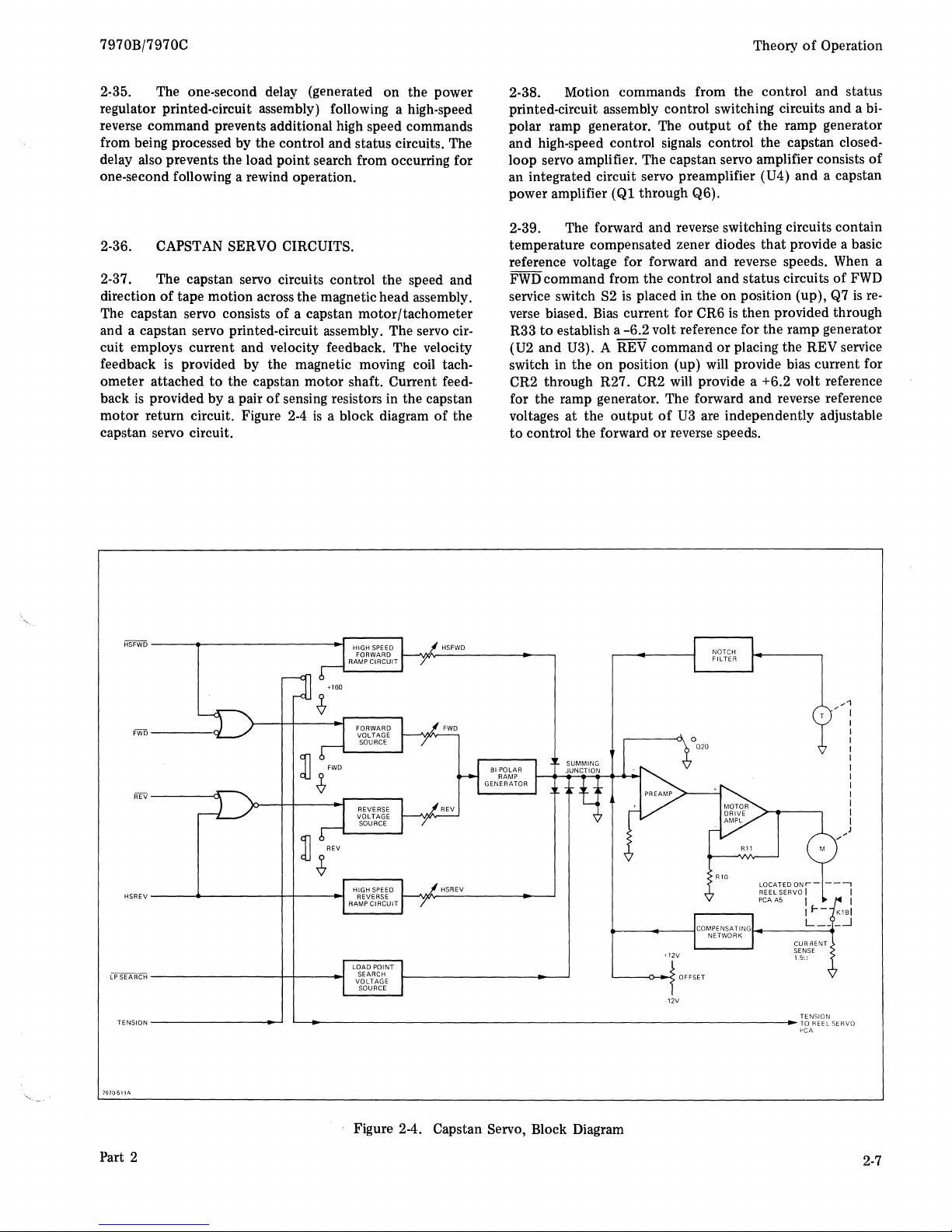

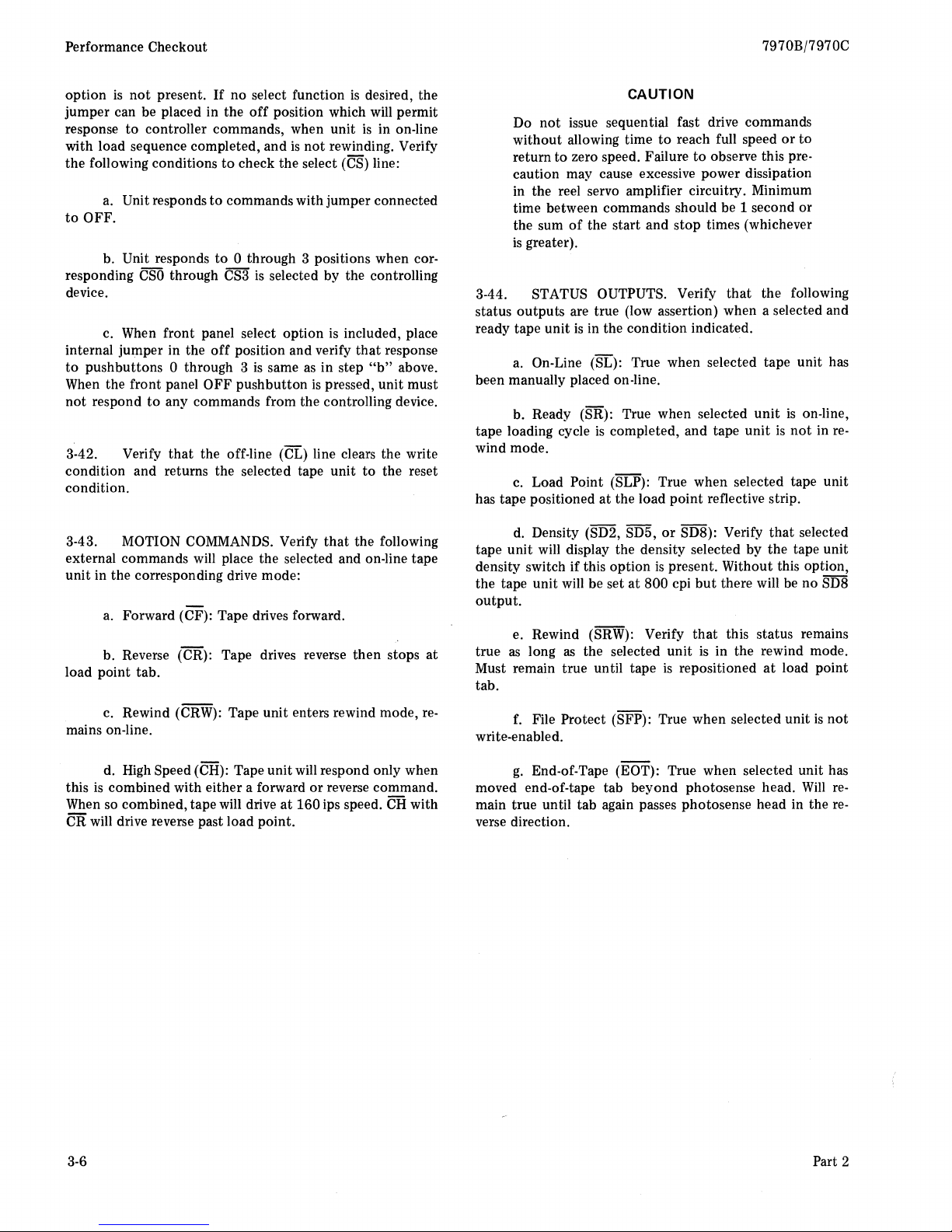

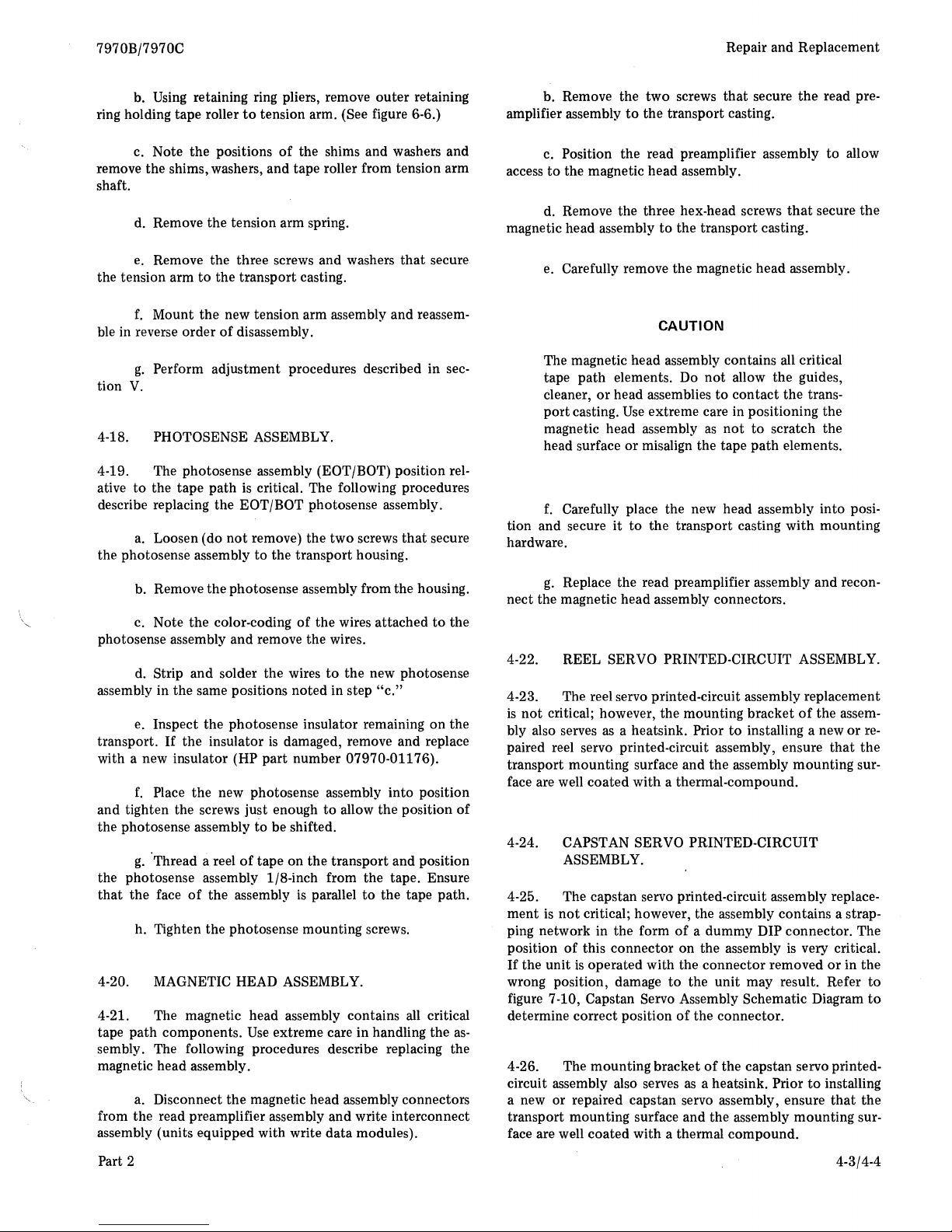

Figure 2-4. Capstan Servo, Block Diagram

2-7

Page 10

Theory

2-40.

of

Operation

The bi-polar ramp generator consists

grated circuit operational amplifiers

cal 8-volt clipping network

ramp control network

(CR7 through CR11), and a

(R42/C28).

of

two inte-

(U2 and U3), a symetri-

is

10

volts

per

volt determined by RIO and R11. The power

amplifier

is

operated in class B with Q6 providing negative

current for forward motion and

rent

for reverse motion.

7970B/7970C

Q5

providing positive cur-

2-41. Operational amplifier

saturating

is

given

down

comparator

or

removed. Near the end

U2

changes from a saturating comparator

when a forward

amplifier with the non-inverting input

2-42. The

clipping network

output

of

U2

(CR7 through CR11) which establishes

current for the ramp control network. The slope

ramp

is

determined by the current through R42 (RAMP

is

U2

initially operates

of

at

held

to

8 volts by a symetrical

or

reverse command

a ramp-up

or

to

a linear

O-volts.

as

ramp-

of

the

control) into integrating capacitor C28. Feedback through

R66 nulls the reference input voltage

voltage

of

the ramp generator (U3-6)

ratio determined by R66 (R35 + R34)

2-43. When the Forward or Reverse command

the current through R66 drives operational amplifier

to

saturation and the ramp integrates the 0 volts.

output

of

the ramp generator (U3-6) approaches 0 volts,

reverts

generator

to

a linear amplifier and the

is

maintained

at

0 volts.

to

U2

and the

is

held steady by the

or

R66 (R29 + R28).

output

is

removed,

As

output

of

the ramp

U2

in-

the

U2

2-44. A High-Speed Forward command (HSFWD) from

the control and status circuits or placing the +

switch in the on position (up) will allow

conduct

is

of

and reverse bias Q8. With Q8 reverse biased, C25

charged through R49. The exponential voltage at the base

Q9 rises

to

+ 12 volts

but

is clipped at +6 volts when Q9

CR12 and CR13

saturates. When the HSFWD command

+160 service switch

is

placed in the

off

U1B conducts placing U1B-4, CR12, and CR13

This allows Q8

to

conduct and C25 discharges through R48.

The threshold caused by the base emitter turn-on voltage

Q9

and the diode drop across CR14 results in a delay

approximately 100 ms before motion starts

2-45. A High-Speed Reverse command (HSREV)

ing the

-160

service switch

the high-speed reverse ramp circuit

in

the

on

position, (up) will cause

to

function the same

the high-speed forward ramp circuit, except

polarities are reversed. Capacitor

C26

is

160 service

is

removed

or

position (down),

at

0 volts.

or

stops.

or

plac-

that

voltage

charged through

to

the

of

of

as

R56 and discharged through R54 and R55.

2-46. The

circuits does

the capstan servo

amplifier resulting in a nominal

2-47. The

LOAD command from the control and status

not

control a ramp circuit. The load switch

is

a single step input

to

the capstan servo

of

20 ips tape motion.

outputs

of

the bi-polar ramp generator, highspeed forward ramp generator, high-speed reverse ramp generator and load switch form a summing junction at the input

of

the capstan servo preamplifier (U4). Diodes CR17 and

CR18 provide clipping

load. The preamplifier drives the capstan

plifier (Q1 through Q6). The dc gain

to

protect

the amplifier from over-

motor

power am-

of

the power amplifier

a

2-48. A

the tachometer

sponse

notch

filter in the velocity feedback circuit from

is

selected

of

the motor-tachometer combination. A compensat-

to

attenuate

the mechanical re-

ing network in the current feedback circuit

depending upon synchronous speed

of

the tape unit.

2-49. Transistor switch Q22 senses the presence

tape tension. While the tape is tensioned, Q22 is on,

keeping switch

Q22 turns off, allowing

input

of

Q20 off. However, when tension is lost

Q20

to

turn

on

motor

drive amplifiers Q2, Q4, and Q6

ground. This disables the capstan servo. The capstan

motor

relay

energized. Relay

button

circuit

K1

is

completed through

on

the reel servo amplifier

K1

is energized when the LOAD push-

is pressed. Once energized,

the

PCA

it

remains energized

until tension is removed.

2-50. REEL SERVO CIRCUITS.

2-51. The reel servo circuits consist

of

a tension circuit,

a voltage switching circuit, a delay circuit, voltage/current

feedback switches, tension arm photosense circuits, preamplifiers,

is

motor

power amplifiers, and reel motors. Figure 2-5

a block diagram

of

the reel servo circuit.

2-52. At initial power-on, the tension circuit

The normally closed contacts

prevent Q13

the

LOAD control allows Q13

K1. With

of

the tension circuit from conducting. Pressing

K1

energized, the capstan and reel servo

circuits are completed.

As

of

tape

LOAD

to

is

pushbutton

conduct, energizing relay

tensioned and the tension

arms swing away from the limit switches, power through the

limit switches maintain a forward bias

is

removed,

across the reel

or

tape tension

motor

is

windings

lost, the relay contacts short

to

2-53. The voltage switching circuit

of

Q13. When power

provide dynamic breaking.

is

power regulator printed-circuit assembly. During a highspeed operation forward or reverse, power

power amplifiers

is

switched from 22.5 volts

(nominal).

2-54. During a high-speed reverse operation (rewind), the

HSREV command from the control and status circuits

gated with TENSION. When

r/min, the

motor

voltage exceeds the break-down voltage

both

reel motors approach full

CR4. The condition established by the gating

and Tension allows current through

Q5. Voltage switch

the

+20/40

printed-circuit assembly

volts from entering the

Q6/Q7

conducts placing +57.5 volts on

line. Diode CR2

is

back-biased preventing +57.5

+20 volts line.

CR4

on

the power distribution

is

also selected

of

and switch the

to

B contacts

when

is

of

K1

is

disabled.

switch

motor

located

to

the

to

57.5 volts

on

the

motor

is

of

of

HSREV

to

forward bias

2-8

Part 2

Page 11

7970B/7970C

+SV

~~~~-4~~~~~~~~~~~AI

Theory

KIA

(ENERGIZED)

).

of

Operation

I

I

I

I

I

I

I

I

L

+20V

------------iM-----

-----------t4----i>---+---,--II

-20V

HSFWD

__

_

R26

...

---+-..

">cHI-_

-20/40V

R27

+20/40V

..

-20/40V

MOTOR VOLTAGE

DELAY

CONTROL

STATUSPCA

FEEDBACK CONTROL

TO

AND

R47

VOLTAGE

FEEDBACK

SUPPLY

REEL

MOTOR

-SV

7970-512

Part 2

VOLTAGE

>-

.... -__

-20/40V

RB

R7

-<11-

____

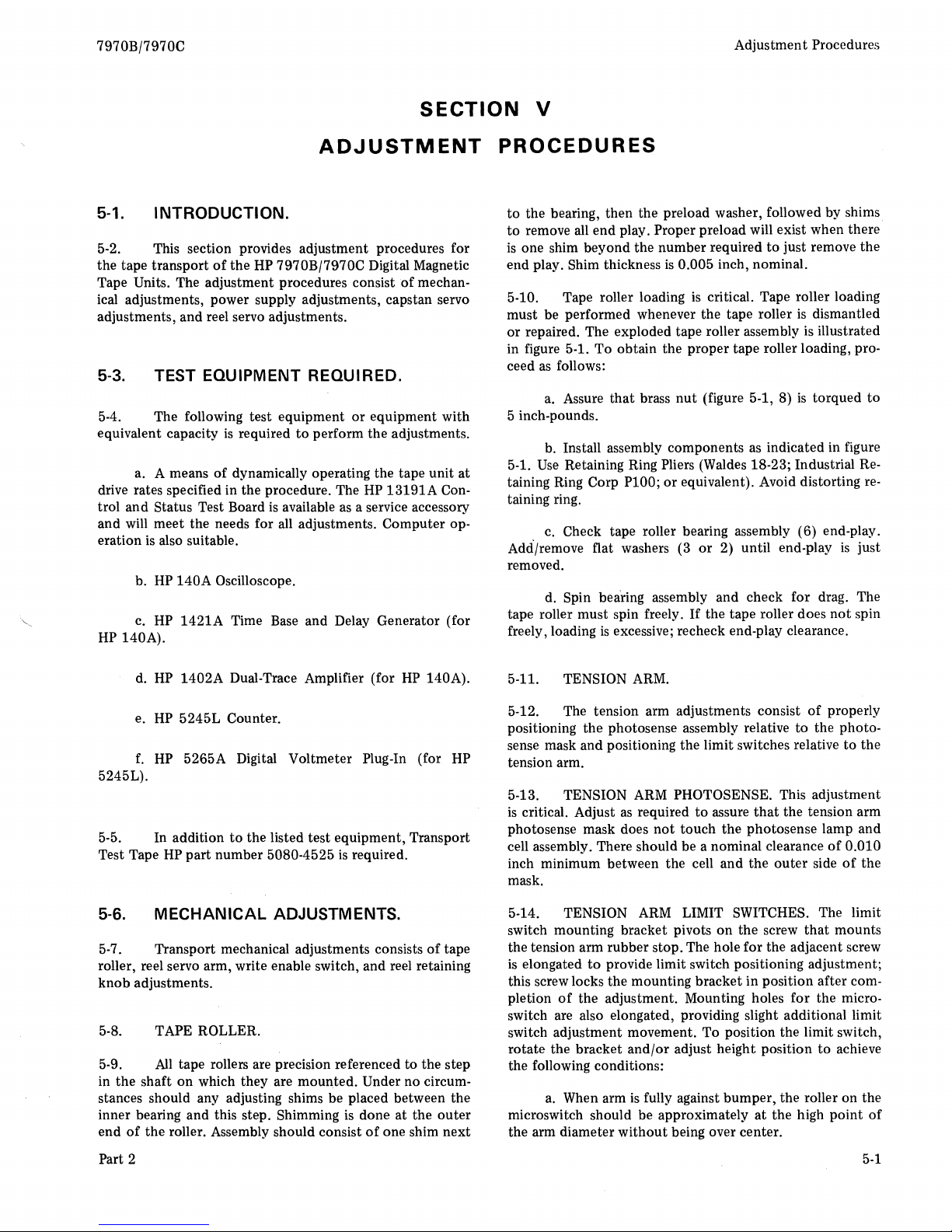

Figure 2-5. Reel Servo, Block Diagram

RIOS

FEEDBACK

-----------

...

I

.J..

KIC

TAKEUP

REEL

MOTOR

(ENERGIZED)

2·9

Page 12

Theory

2-55. During a high-speed forward operation, the voltage

switching circuits function the same

operation.

voltage

of

Operation

HSFWD

to

switch the

is

gated with tension

-40

volt switch

as

in the fast reverse

to

allow

(QI2/QI3).

motor

7970B/7970C

C8

is

then charged through R33 (one-second time constant).

is

When C8

feedback control changes from

switches

charged

to

0 volts.

to

+5V, Q16 and Q18

-8V

conduct

to

+8V. The DELAY

and the

2-56. The delay circuit

printed-circuit assembly. The delay circuit provides an

tional one-second delay following the end

command. The one-second delay prevents further high-speed

commands from the interface from being processed during

the one-second period. The one-second delay

switch the reel servo operating mode from voltage feedback

to

current feedback. The additional one-second following a

high speed operation allows the reel servo

current feedback mode until reels are slowed.

2-57. During normal operation, U5A-3 and U5B-4 rest

o volts. A HSFWD

and status circuits will cut-off U5A

for Q15

ducts, capacitor C8 immediately discharges through Q15

causing Q16 and Q18

reel servo changes from approximately +8 volts

mately

Q17 and the DELAY line switches

2-58. When the high-speed command

HSREV)

is

supplied through R28

-8

volts. The negative potential also reverse biases

is

removed and Q15 loses base current, capacitor

is

located on the power regulator

of

a high-speed

is

also used

to

operate in a

or

HSREV command from the control

or

U5B

and base current

or

R29. When Q15 con-

to

be cut-off. Feedback control

to

approxi-

to

+5

volts.

(HSFWD

addi-

to

to

at

the

or

2-59. The reel servo tension arm assemblies contain dual

that

element photo-conductors

shining through a slotted disc. The slot

spiral attached

slot exposes different areas

result, the

to

the position

2-60. The reel servo preamplifier

tional amplifier

sion arm. The tension arm photo-conductor

ended, therefore, an off-set

The preamplifier drives a class B

The

motor

2-61. When operating in a normal mode (synchronous

or

load speed), the servo operates with voltage feedback.

The +8 volts from the feedback switching network

back control) back-biases the feedback FET switch (Q14

and

QI5).

RI05.

During a high-speed operation, the feedback control

changes

biased and feedback

to

the tension arm.

output

to

of

the photo-conductor

of

the tension arm.

that

amplifies the position

power amplifier has a gain

Feedback

-8

is

volts. The feedback FET switch

is

current through the switch.

are illuminated by a lamp

is

in

the

form

of

As

the arm moves, the

of

the photo-conductor.

is

proportional

is

an integrated opera-

error

output

is

provided by R39

motor

then provided through R47 and

drive amplifier.

of

10 volts

of

the ten-

is

or

per

is

forward

As

single-

R41.

volt.

(feed-

a

a

2-10

Part 2

Page 13

7970B/7970C

Performance Checkout

SECTION

PERFORMANCE

3-1.

3-2. This section provides checkout instructions

ify

specifications. The test procedure assumes

ing general conditions apply

structions

3-3. TEST EQUIPMENT REQUI RED.

3-4. For the purpose

that

computer

the

ing instructions for the equipment

tation applicable

3-5.

available

all adjustments. Computer operation

following electronic test instruments (or equivalent) are

also required:

Generator.

meter Plug-In.

3·6.

port

various signals for accurate speed measurements

3-7. CHECKOUT PROCEDURES.

3-8. Performance checkout procedures for the tape unit

consist of:

I NTRODUCTI ON.

that

the tape unit conforms

to

the contrary are stated as part

the person conducting

or

an off-line test set

following requirements.

to

the

equipment.

a.

Provides all standard functional commands.

b. Responds

An

as

a.

HP

HP

b.

c.

HP

In addition

test tape

a.

Preliminary Power-Off Checks.

Operator Control Checks.

b.

to

all status outputs.

HP

13191A Control and Status Test Board

a service accessory and will meet the needs for

140A Oscilloscope with

1421A Dual-Trace Preamplifier (for

5245L Counter with

to

the listed test equipment, a trans-

HP

part number 5080-4525

to

published performance

at

all times unless specific

of

this procedure,

the

test will be using either a

that

is

It

is

also presumed

is

provided by documen-

is

HP

HP

5265A Digital Volt-

to

that

the follow-

of

a test routine.

it

is

presumed

capable

of

meeting

that

operat-

also suitable. The

1421A

that

Time

HP

140A).

generates

is

required.

Base

ver-

in-

III

CHECKOUT

c.

Service Switches and Accessory Checks.

d. Tape

e.

f.

g.

3-9.

3-10. Preliminary power-off checks are performed

follows:

a.

and have no end play.

b.

should operate freely and should have clearance between

of

face

ness without binding).

is

c. Tension Arm Limit Switches: The three limit

switches associated with the tension arms must operate

when the arm

stop. The roller on the switch arm should be approximately

on the center

stop. There should be positive travel

yond

the

check can

or

with an ohmmeter if room noise

d.

finger nominal location dimensions should be

Path Evaluation.

Power Supply Voltage Checks.

Tape Speed and Capstan Servo Checks.

Transport Function, Motion, and Status Checks.

PRELIMINARY POWER-OFF CHECKS.

Tape Rollers: The tape rollers must operate freely

Head Crosstalk Shield: The head crosstalk shield

head and shield (room

is

approximately 1/8 inch from the rubber

of

the arm when the arm

point

at

which it actuates the microswitch. The

be

made audibly if ambient noise level permits,

Write Enable Sensing: The write enable sensing

(1) The distance between the outside surface

the write enable sensing finger and the outside flange diameter

should be 3/32-inch (nominal).

(2) In the file protected position (inoperative),

the dimension between the

sensing finger and the

turntable should be 3/16-inch (nominal)

above the turntable surface.

(3) In the write enable position (with solenoid

energized) the

should be 1/16-inch below the turntable surface.

(4) The sensing finger must

table under any condition.

to

slip a punched card thick-

is

fully against

of

the switch lever be-

is

too

high.

as

of

the reel turntable

outer

outer

face

of

outer

tip

of

the sensing finger

not

touch the turn-

follows:

tip

of

the reel

the

as

of

the

Part 2

3-1

Page 14

Performance Checkout

7970B/7970C

e. Reel Retaining Knob: With the locking lever

re-

leased, the reel should slip over the rubber grip ring easily,

and it should be possible

lever

is

closed, positive resistance should be felt

ber

is

compressed. In the locked position,

possible

place a piece

the

should

hours

to

move the reel by hand.

of

masking tape

hUb.

A mark placed in alignment on

not

become misaligned by more

of

operation. To correct tape reel slippage, release

locking lever and loosen the pozidrive screw,

retainer

knob

clockwise, and tighten the screw. Repeat until

tape reel mounts firmly and does

3-11.

OPERATOR CONTROL CHECKS.

3-12. Verify position

connect unit

to

appropriate power source and check the

to

easily rotate the reel. When the

as

the rub-

it

should

If

of

115/230

slippage

on

the reel, and another on

not

slip.

volt selector switch;

both

than

is

suspected,

pieces

of

1/8 inch in

rotate

the reel

not

be

tape

16

following operating modes.

3-13.

reel

the power switch on. After threading tape, press

verify

TAPE LOADING AND WRITE ENABLE. Place a

of

tape (with write enable ring) on unit and thread with

LOAD and

that

the following takes place.

a.

Tape tension

is

established. RESET indicator

il-

luminates.

the load command and will return the tape to the

position (LOAD indicator

may be terminated prior

Transfer

to

on-line

on

with tape stopped). Rewind

to

load

point

by pressing RESET.

is

also possible immediately following

load

point

this sequence.

3-17. SERVICE SWITCHES AND

ACCESSORY

CHECKS.

in

3-18. There are three service switches incorporated

the

capstan servo card. These together with the REWIND and

LOAD controls provide a means

modes for service and

lor adjustment purposes. There

of

operating all five drive

is

no

capability for cyclic drive operation.

HP

3-19. The

13191A

available for use with the tape unit. With this test board

is

possible

of

the control and status function

to

completely adjust and verify the performance

Control and Status

of

a tape unit

Test

Board

under

is

it

offline conditions. Complete operating details are included with

the test board. The

Board provides normal drive modes

gramming which

HP 13191A Control and Status Test

as

well

as

cyclic pro-

is

suitable for adjustment

of

the capstan

start/stop ramp. The board also includes status indicator

lamps

to

verify all normal status functions. The test board

is

installed in the connector

status

PCA.

of

the tape unit control and

b.

WRITE ENABLE indicator illuminates.

20 ips

to

load

point

c. Tape moves forward at

tab

(BOT tab).

d.

LOAD indicator illuminates.

3-14.

control and status

OFF

and load tape. Following completion

with tape positioned

press

commands.

process will also result in

pleting the search (LOAD indicator

the unit will

tion

3-15. DYNAMIC BRAKING AND

POWER

well

turn

stop

ON-LINE TRANSFER AND RESET. Place the

PC

assembly unit select jumper

pin (this

ON-LINE and verify

is

not

the same

at

as

OFF

on unit select option)

of

a load sequence

load point (LOAD indicator on),

that

unit will respond

to

Pressing ON-LINE while load point search

ON-LINE operation upon com-

is

ON). While ON-LINE,

not

of

RESET.

respond

to

local controls with the excep-

RECOVERY FROM

FAILURE. Place unit in rewind mode after tape

into

take-up reel. When full rewind speed

power switch

without

off

to

any damage

simulate power failure. Tape should

to

tape. Proceed with recovery

is

in

the

external

is

in

reached,

to

on-line status by following normal load sequence. Except

that

when tape unit goes into the load

load

point

tab may be simulated by pressing the RESET

button.

3-16. REWIND

This can then be followed by an on-line command.

OPERATION. The REWIND control

operational only while the unit

point

search mode,

is

in the reset state which

permits local control. The rewind command will override

3-20. TAPE PATH

3-21. With undamaged tape threaded

EVALUATION.

on

and with the unit in the appropriate operating mode,

ate the following characteristics

a.

Capstan Height: Capstan height should be such

the tape

edge

is

guided equal distance in from the

of

the capstan. The air escape grooves provide a means

of

the tape path.

for judging.

b.

Tension Position: Arms should be aligned with the

centering marks on the rear

ceptable provided the arm

than the diameter

of

the arm.

c. Tape Tracking

of

the casting. Position

is

not

out

of

location by more

Over the Tape Guides: Tracking

over the guides should be smooth with no evidence

forces anywhere in the tape path. Transverse reflected light

may be used

is

the 1/2-inch width

points

d.

sembly should be parallel

tioned

3-22.

to

assist in judging. Light reflections across

of

the tape should

of

stress.

Photosense Position: Face

to

the path

1/8

inch from the tape.

not

of

photosense head

of

the tape and posi-

POWER SUPPLY VOLTAGE CHECKS.

is

3-23. Both regulated and unregulated supplies should be

checked for the following specifications.

the

outer

be

bent

tape unit

evalu-

that

and inner

is

ac-

of

edge

due

to

as-

3-2

Part 2

Page 15

7970B/7970C

3-24. REGULATED SUPPLY VOLTAGES. Regulated

voltages will remain within tolerances over a primary voltage

of

range

as

±10 percent.

specified below. The peak-to-peak ripple values are nom-

inal and minor variances may be expected. Ripple

DC

voltages and tolerances are

is

stated

to

be

under tension-only conditions.

+5

a. The

volt supply must be +5.000 ± 0.050 Vdc.

b. The ±12 volt supplies must be 12.000 ± 0.360 Vdc.

3-25. UNREGULATED SUPPLY VOLTAGES. Unregu-

lated supply voltages are a direct function

The following table

only at a line voltage

nominal and apply at

a.

±40 Vdc: Nominal value

150 mv

POp

(sawtooth).

of

nominal values should be judged

of

115 volts.

60

Hz.

is

of

line voltage.

RMS

ripple values are

±57.5 volts; ripple

of

Performance Checkout

that

the

output

of

For

the follow-

the read

HP

part

bit-to-bit distances be read, and

preamplifier be connected

number

accurately spaced

50S0-4525 Transport Test Tape provides frequencies

to

better

to

than

a suitable counter.

0.1 percent.

ing tests reference frequencies are based on using the signal

that

will

be avail abel from the channel 3 preamplifier

track units and channel 6 preamplifier

This has a bit-to-bit spacing

duce a frequency

of

speed

30.000 ips. Frequencies for

direct ratio

of

10,000

to

the change in speed relation to 30 ips. Ex-

of

Hz

of

0.00150 inch

when reproduced at a tape

other

ample: 60 ips would produce 20,000 Hz.

seven-track units.

Use

of

nine-

and

will pro-

speeds are in

this principle

and check the following:

a. High-Speed Forward:

53,333

Hz.

160

ips, basic frequency

(1) Maximum acceptable operating limit: ±1050

Hz

(±2 percent).

(2) Adjustment recommended if greater than:

±SOO

Hz

(±1.5 percent).

is

+20 Vdc: Nominal value

b.

600

mv

Pop

(sawtooth).

c.

-20

Vdc: Nominal values

300 mv

900 mv

3-26. TAPE SPEED

Pop

(sawtooth).

+10 Vdc: Nominal value

d.

POp

(sawtooth).

AND

3-27. The tape speed and capstan servo checks consist

measuring capstan

motor

offset current, measuring long term

speed variation (tape units capable

is

+22.5 volts; ripple

is

-22.5 volts; ripple

is

+12 volts; ripple of

of

CAPSTAN SERVO CHECKS.

of

of

reading data), measur-

of

ing start and stop time and distance, measuring instantaneous

speed variations, and measuring fast forward, reverse, start

is

and stop. Included

a dynamic tape skew check for tape

units equipped with read and write electronic circuits.

3-2S. CAPSTAN MOTOR OFFSET CURRENT. Connect

or

a suitable dc voltmeter

percent resistor (R21

tors

is

sion

connected

but

no tape motion, the voltage should

to

following referenced

a.

Maximum acceptable operating limit: ±100 mv

oscilloscope across the 3 ohm 1

or

R22). The return side

pin 2

of

CJ-1. With the tape under ten-

not

to

0 V dc.

of

the resis-

exceed the

dc

at 25°C.

b. Adjustment recommended if greater than:

±SO

mv

dc.

3-29.

tape speed accuracy over any interval greater than one

ond and under each

of

LONG TERM SPEED VARIATION. Measure the

of

the

five

drive speeds. The principle

measurement requires

that

a tape having highly accurate

sec-

b. Rewind (High-Speed Reverse): Checked identically

to

the limits applicable

the rewind mode

is

to

high-speed forward, except

used.

that

c. Forward and Reverse Drive: Frequency depends

other

on tape speed and must be calculated for speeds

than

25 ips and 37.5 ips which are tabulated below. Maximum

is

acceptable operating limit

justment recommended if speed error

based on ±1 percent with ad-

is

+O.S

percent

or

greater.

is

(1) The 25 ips drive nominal frequency

Hz.

Acceptable limits are ±S3 Hz; adjustment

is

required if greater than ±65 Hz.

(2) The 37.5 ips drive nominal frequency

S,333

is

12,500 Hz. Acceptable limits are ±125 Hz;

adjustment

is

recommended if greater than

±100 Hz.

d. Load Point Search:

6,667

Hz.

(1) Maximum acceptable limit

20 ips; basic frequency

is

±1330

Hz

(±20

is

percent).

(2) No adjustment

3-30.

START

MEASUREMENT. Start measurements

(both forward and reverse) are made

ment of the characteristics defined requires

unit be driven with commands

greater than the specified start/stop times and

is

provided.

that

are adjustable

as

follows. Measure-

that

the tape

to

that

there be

periods

a provision to synchronize an oscilloscope sweep directly

to

from these commands (both start and stop). The tape

be

read may be any previously recorded tape, preferably at

SOO

cpi,

as

this provides the best resolution where measure-

ments from preamplifier

outputs

are required. Wavelength

Part 2

3-3

Page 16

Performance Checkout

7970B/7970C

accuracy

is

not

a factor in this test. Do

not

make measure-

ments during read-after write operation.

Note

The definitions apply for both forward and

reverse directions. The capstan tachometer voltage

will reverse polarity when direction

is

changed;

however, there will be no observable difference

in the preamplifier

a.

Start-Ramp Delay Time: The time (following a start

command) required for the capstan tachometer voltage

reach a value

cent

of

tion

is

b.

that

the value reached at normal drive speed. Specifica-

0.5 ± 0.5 ms.

Start-Ramp 100 Percent Time: The time (following a start command) required for the analog

preamplifier track

output

is

greater than a Vdc

to

first reach

waveforms.

100

but

percent

less than 3 per-

output

of

any

of

the peak-to-

to

peak (or O-to-peak) value established while reading an all

"1

's"

tape under steady state drive conditions. This

function

of

tape speed; the following limits apply with the

is

capstan ramp adjustment being made during the forward

start mode only.

(1) The 25 ips start-ramp

should be 14.5 ±

100 percent time

0.2 ms for forward ramp,

±0.3 ms for reverse ramp.

(2) The 37.5 ips start-ramp

should be 9.5 ±

0.2

100 percent time

ms

for forward ramp,

±0.3 ms for reverse ramp.

b. Start Balance Time: This

tween the start-ramp

100

is

the time difference be-

percent time and

start time for the tape speed involved. This period

is

allowed

the time delay

to

provide a balance in tape distance

at

full drive speed represented by the stop-

ramp delay time.

c.

One-half

of

the start-ramp time plus

ance time (both in milliseconds) multiplied by

in

inches per second equals the start distance (in inches x

3

10-

).

Specifications 0.187 ± 0.020 inch.

3-32.

forward and reverse) are made

command) required for the analog

fier

than

established

ing in all

a

STOP MEASUREMENT. Stop measurements

as

follows:

a.

Stop-Ramp Delay Time: The time (following a

output

of

to

fall

to

a peak-to-peak (or O-to-peak) value

100

percent

"l's"

b. Stop-Ramp

but

greater than 97 percent

under

steady-state drive conditions while read-

tape. Specification

is

0.5 ± 0.5 ms.

100 Percent Time: The time (following a stop command) required for the capstan tachometer

voltage

speed value and

speed and must

to

reach a level between 3 percent

a Vdc. Specification

not

exceed a time

is

a function

that

of

is

less than the specified stop time for the tape speed involved.

3-33.

STOP DISTANCE. Stop distance

is

follows:

a.

Determine stop-ramp delay time.

the

specified

of

as

it offsets

the

start

the

tape speed

(both

any preampli-

that

is

of

the value

normal drive

of

at

least 0.2 ms

calculated

time

bal-

stop

less

tape

as

3-31.

as

quires

adjustable

times and

START DISTANCE. Start distance

follows. Measurement

that

the tape unit be driven with commands

to

periods greater than the specified start/stop

that

there be a provision to synchronize an oscil-

of

the characteristics defined re-

is

calculated

that

are

loscope directly from these commands (both start and stop).

The tape

preferably

where measurements fram preamplifier

Wavelength accuracy

to

be read may be any previously recorded tape,

at

800 cpi

as

this provides the best resolution

outputs

is

not

a factor in this test. Do

are required.

not

make measurements during the read-after-write operation.

Note

The definitions apply for

both

forward and reverse directions. The capstan tachometer voltage

will reverse polarity when direction

is

changed;

however, there will be no observable difference

in the preamplifier

a.

Start-Ramp Time: This

celerate the tape from zero ips

output

waveforms.

is

the time required

to

the drive speed.

It

to

is

ac-

determined by subtracting the start delay time (measured)

from the start-ramp

100 percent time (also measured).

3-4

b. Determine Stop-Ramp Time: This

quired

speed.

to

decelerate the tape

It

is

determined by subtracting the stop-ramp delay

to

time (measured) from the stop-ramp

zero ips from the drive

100 percent time (also

is

the time re-

measured).

c. The stop-ramp delay time plus one-half the

ramp time

speed in inches

inches x

3-34.

taneous speed variation

departure

speed. Measurement

wind

of

tape.

fier

output,

(both

in milliseconds) multiplied by the tape

per

second equals the stop distance (in

Specification

is

0.187 ±0.020 inch.

10-

3

).

INSTANTANEOUS SPEED VARIATION. Instan-

is

a measurement

of

the tape velocity from its long

is

made

a.

Write a length

as

reqUired

of

to

be in position

all

b. Connect oscilloscope

position so

that

as

follows:

"l's"

to

to

any convenient preampli-

waveform

of

the short

term

tape

at

800 cpi and

reproduce this section

is

centered

and adjust main sweep sync for positive slope and

at

the zero crossover.

average

on

screen,

to

stop

term

re-

trigger

Part 2

Page 17

7970B/7970C

c.

Use

the delayed sweep feature

to

position the de-

layed sweep at the next zero axis crossover (this corresponds

to

one bit-to-bit distance) with the delayed sweep

auto

trig-

gered from a main (delaying) sweep.

d. Adjust delayed sweep rate

tion

of

the

time shift band

at

to

permit good resolu-

the zero axis crossover. During

this evaluation the vertical gain and the delaying sweep time

may be adjusted

point

is

being observed, it will be the waveform

ing from

top

left

optimize the resolution.

of

screen to

bottom

If

the correct

that

is

com-

right with the slope

to

depending on the gain and delayed sweep speed.

e. Observe the jitter band under conditions in step

"d"

in microseconds peak-to-peak time displacement and

to

multiply by tape speed

inches. This value must

which are based

(1)

on

±3 percent instantaneous speed variation:

800 cpi must

determine this distance in micro-

not

exceed the following limits

not

exceed ±37.5 micro inches

(75 microinches peak-to-peak).

not

(2) 556 cpi must

exceed ±54 microinches

(108 microinches peak-to-peak).

as

high

Checkout

as

pos-

Performance

peak-to-peak. Again gains must be adjusted

sible (both the same) and the delayed sweep trigger set for

maximum stability

of

the stable waveform. There will be a

considerable dead zone in the delaying sweep adjustment.

Use

the first operating position

from minimum delay position. There

the time differential between the stable and unstable

forms. This does

is

a function

not

represent static skew. The difference

of

oscilloscope gain and position settings.

e. Measure the peak-to-peak time band

waveform

as

it crosses the zero axis. Convert this

as

the sweep

is

moved

is

no significance to

of

the unstable

to

micro-

out

wave-

inches peak-to-peak for the tape speed involved. Worst case

must

not

exceed ±50 microinches (100 micro inches peak-

to-peak) and applies

3-36. FAST

to

forward

or

reverse mode.

FORWARD/REVERSE

START/STOP

CHARACTERISTIC. Fast forward and fast reverse characteristics are measured by synchronizing an oscilloscope with

the appropriate drive command, and observing the dc

put

of

the tachometer using the TACH test

point

out-

on the

capstan servo printed-circuit assembly.

(3)

200 cpi must

not

exceed ±150 microinches

(300 microinches peak-to-peak).

Note

The above values apply

to

both

the forward and

reverse modes.

3-35. DYNAMIC TAPE

that

variation in tape velocity which generates a differential

SKEW.

Dynamic tape skew

time position between the two outermost tracks on the tape.

Measurement

a.

to

reproduce this section

b.

plifier

Use

chopped mode (triggered by channel

sweep synchronized for positive slope triggered

is

made

as

follows:

Write a length

Use

dual-trace oscilloscope and connect

output

of

of

all

"l's"

of

tape.

the

two outside tracks (channels 4 and 5).

tape. Rewind

A)

with the main

as

required

to

at

zero axis

pream-

crossover. (Use negative slope in reverse direction.)

c. Adjust

impose

the

varying degrees

acteristics

d.

Use

(one bit-to-bit distance later) zero axis crossover

layed sweep. The delayed sweep must be

triggered on the negative slope. (Use positive slope in

verse direction.) The earliest

delayed sweep and the

jitter

that

both

channel gains and positions

to

super-

two waveforms (amplitude only; there will be

of

time difference due

to

static skew char-

).

the delayed sweep feature

of

the two tracks will sync the

other

will arrive later and will have

to

present the next

on

on

internal sync,

the de-

represents the time differential in microseconds

reo

CAUTION

Do

not

issue sequential fast drive commands

without allowing time to reach full speed

return to zero speed. Failure

caution may cause excessive power dissipation

in the reel servo amplifier circuitry. Minimum

time between commands should be 1 second

the sum

is

greater).

of

the start and stop times (whichever

is

3-37. Fast forward/reverse start

ured by observing the time (following a start

mand) required for the tachometer

its maximum value (for start time)

stop time). Nominal times are from 400

Typically,

the

value will be 600 milliseconds.

3-38. Fast forward/reverse start

termined by the time required for the ramp

to

one state

seconds. One-half

the other. This time

of

this time multiplied by

the nominal start/stop distance

3-39.

TRANSPORT FUNCTION, MOTION, AND

STATUS CHECKS.

3-40.

The following checks cover the

status and motion command connector.

to

off-line test equipment

verify proper performance

dicated.

3-41.

trol and status

to

FUNCTION COMMANDS. Select,

PC

assembly includes a jumper

establish

unit

identification where the front panel select

to

observe this pre-

or

stop times are meas-

output

or

to

fall

to

700 milliseconds.

or

stop distances are de-

is

nominally 500 milli-

of

40

inches.

1/0

Use

or

to

or

or

stop com-

to

either reach

to

zero (for

to

move from

160

ips equals

lines in the

appropriate

CS:

The con-

that

can serve

as

in-

Part 2

3-5

Page 18

Performance Checkout

7970Bj7970C

option

jumper can be placed in the

response

with load sequence completed,

the following conditions

to

responding

is

not

present.

to

controller commands, when unit

a.

Unit responds

OFF.

b. Unit responds

CSO

If

no select function

to

to

commands with jumper connected

to

0 through 3 positions when cor-

through CS3

is

desired, the

off

position which will permit

is

in on-line

and

is

not

rewinding. Verify

check the select (CS) line:

is

selected by the controlling

device.

c. When front panel select option

internal jumper in the

to

push buttons 0 through 3

When the front panel

not

respond

to

3-42. Verify

off

position and verify

is

same

OFF pushbutton

any commands from the controlling device.

that

the off-line (CL) line clears the write

condition and returns the selected tape unit

is

included, place

that

response

as

in step

is

"b"

pressed, unit must

to

the reset

above.

condition.

3-43.

MOTION COMMANDS. Verify

that

the following

external commands will place the selected and on-line tape

unit in the corresponding drive mode:

a.

Forward (CF): Tape drives forward.

b. Reverse (CR): Tape drives reverse

then

stops

at

load point tab.

CAUTION

Do

not

issue sequential fast drive commands

without

return

allowing time

to

zero speed. Failure

to

reach full speed

to

observe this pre-

or

to

caution may cause excessive power dissipation

in the reel servo amplifier circuitry. Minimum

time between commands should be 1 second or

the sum

is

3-44.

status

outputs

ready tape unit

a.

of

the start and

stop

times (whichever

greater).

STATUS OUTPUTS. Verify

that

the following

are true (low assertion) when a selected and

is

in the condition indicated.

On-Line (SL): True when selected tape unit has

been manually placed on-line.

b. Ready (SR): True when selected

tape loading cycle

is

completed, and tape unit

unit

is

is

on-line,

not

in

re-

wind mode.

c. Load Point (SLP): True when selected tape unit

has tape positioned

d.

Density (SD2, SD5,

at

the load

point