Page 1

HP 783Xx Series and HP 788Xx Series

Service Manual Volume 2

Patient Monitors and Neonatal Monitors

HEWLETT

Fia

HP Part No. 78354-90108

Printed in Germany

PACKARD

Edition 8

March 1993

Page 2

Notice

The information contained in this docuement is subject to change without notice.

Hewlett-Packard makes no warranty of any kind with regard to this material, including, but

not limited to, the implied warranties of merchantability and fitness for a particular purpose.

Hewlett-Packard shall not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance, or use of this material.

Hewlett-Packard assumes no responsibility for the use or reliability of its software on

equipment that is not furnished by Hewlett- Packard.

This document contains proprietary information, which is protected by copyright. All rights

are reserved. No part of this document may be photocopied, reproduced or translated to

another language without the prior written consent of Hewlett-Packard Company. The

information contained in this document is subject to change without notice.

Hewlett-Packard Company

Medical Products Group (Europe)

Schickardstrasse 4

7030 Boeblingen

Federal Republic of Germany

@ Copyright Hewlett-Packard Company, 1991. All rights reserved.

Page 3

Printing History

New editions are complete revisions of the manual. Update packages, which are issued

between editions, contain additional and replacement pages to be merged into the manual by

the customer. The dates on the title page change only when a new edition or a new update is

published.

Preface

This manual covers the following models:

n

MODELS 78352A/78352C/78353A/78353B/78354A/78354C PATIENT MONITORS

n

MODELS 78832A/78833A/78833B/78834A/78834C NEONATAL MONITORS

n

MODEL 78356A GAS MONITOR

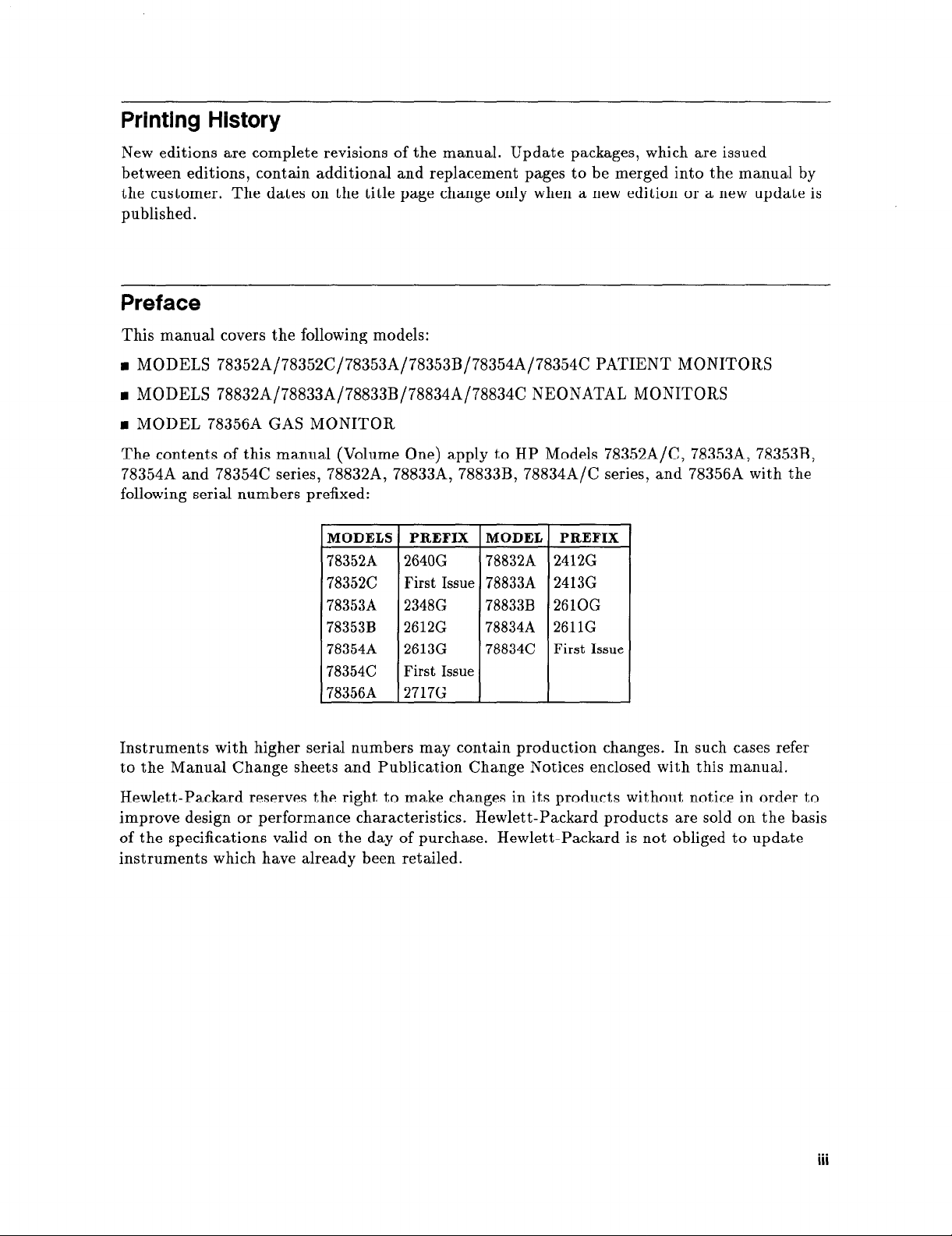

The contents of this manual (Volume One) apply to HP Models 78352A/C, 78353A, 78353B,

78354A and 78354C series, 78832A, 78833A, 78833B, 78834AfC series, and 78356A with the

following serial numbers prefixed:

MODELS PREFIX

78352A 2640G

78352C

78353A

78353B 2612G

78354A 2613G

78354C

78356A 2717G

First

2348G

First Issue

Issue

MODEL

78832A

78833A

78833B

788348

78834C

PREFIX

2412G

24136

2610G

2611G

First Issue

Instruments with higher serial numbers may contain production changes. In such cases refer

to the Manual Change sheets and Publication Change Notices enclosed with this manual.

Hewlett-Packard reserves the right to make changes in its products without notice in order to

improve design or performance characteristics. Hewlett-Packard products are sold on the basis

of the specifications valid on the day of purchase. Hewlett-Packard is not obliged to update

instruments which have already been retailed.

Page 4

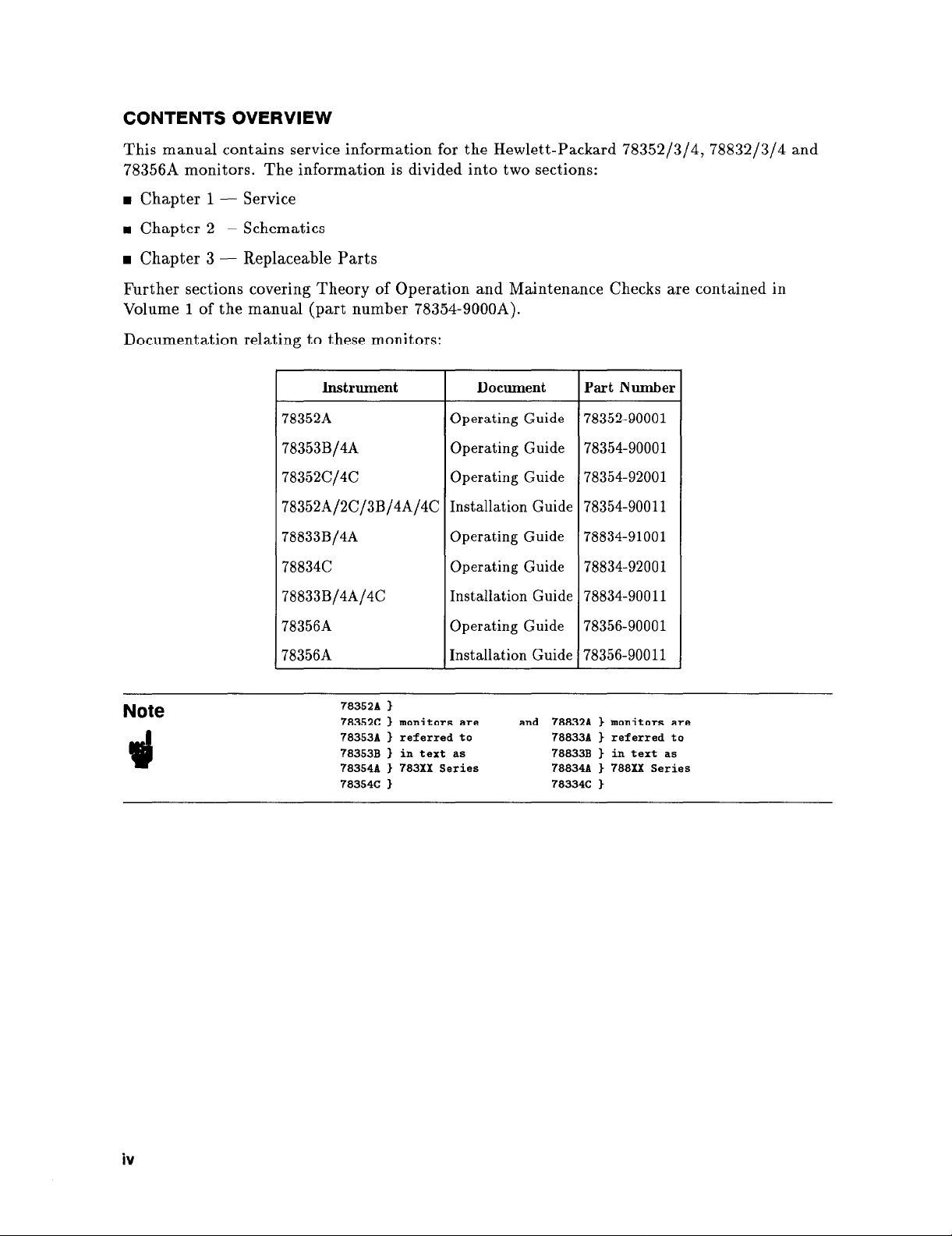

CONTENTS OVERVIEW

This manual contains service information for the Hewlett-Packard 78352/3/4, 78832/3/4 and

78356A monitors. The information is divided into two sections:

w Chapter 1 - Service

n

Chapter 2 - Schematics

n

Chapter 3 - Replaceable Parts

Further sections covering Theory of Operation and Maintenance Checks are contained in

Volume 1 of the manual (part number 78354-9000A).

Documentation relating to these monitors:

Instrument Document Part Number

Note

78352A

Operating Guide 78352-90001

78353B/4A Operating Guide 78354-90001

78352C/4C

Operating Guide 78354-92001

78352A/2C/3B/4A/4C Installation Guide 78354-90011

78833B/4A Operating Guide 78834-91001

78834C

78833B/4A/4C

78356A

78356A

78352A

78352C ) monitors are and 78832A 1 monitors are

78353~ 1 referred to 78833A ) referred to

78353~ 1 in text as

783548 ) 783Xx

78354C ) 78334C )

>

Operating Guide 78834-92001

Installation Guide 78834-90011

Operating Guide 78356-90001

Installation Guide 78356-90011

Series

78833~ ) in text as

788348 ) 788Xx Series

iv

Page 5

Special Notation

Notes, cautions, and/or warnings may accompany the instructions in this manual. They are

defined below:

Note

3

Caution

0

Warning

Notes provide emphasis to information or additional information “off line”

from a procedure.

Cautions highlight procedures that must be followed to avoid damage to the

recorder.

Warnings highlight procedures that must be followed to avoid hazards to human

life or safety.

V

Page 6

Page 7

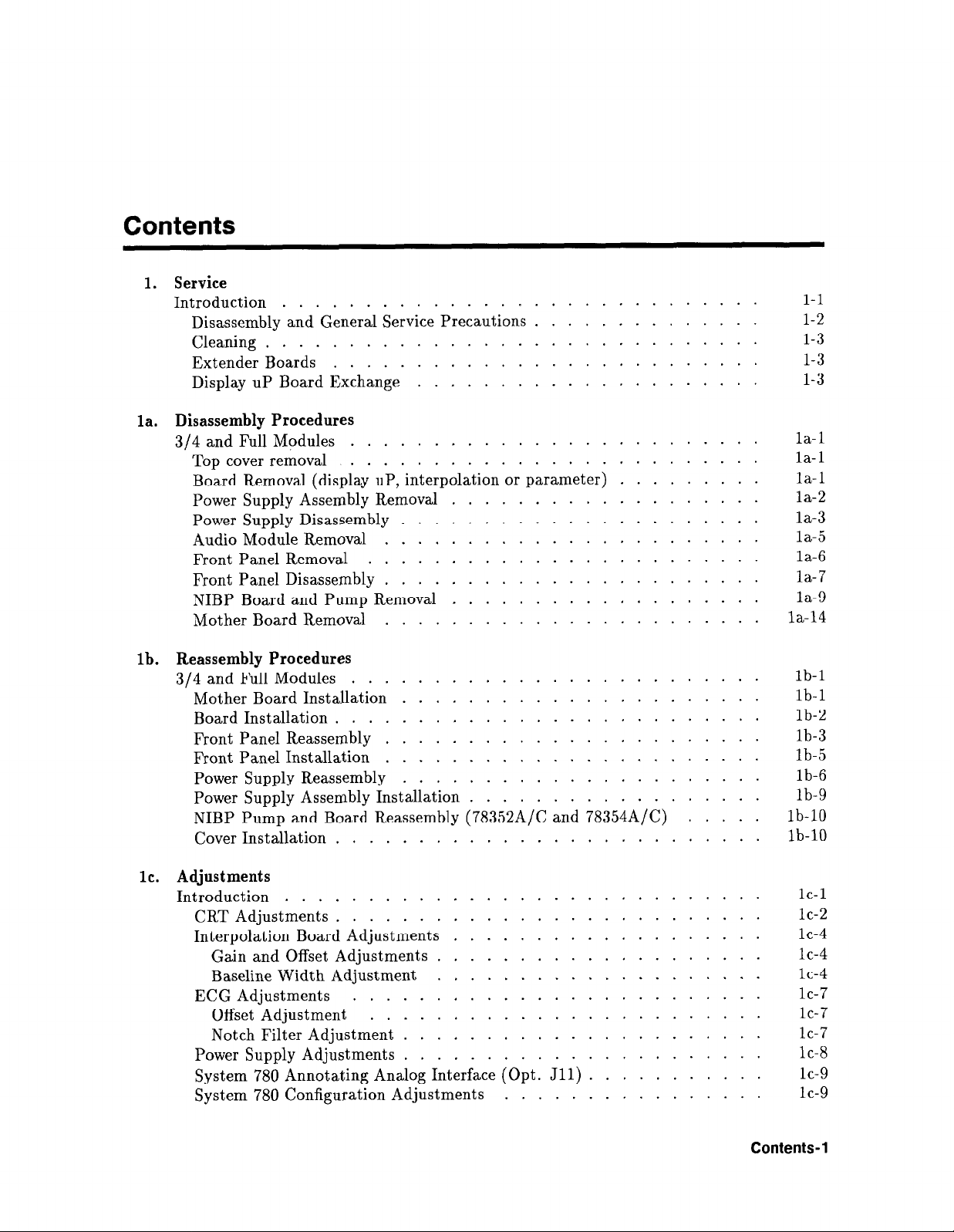

Contents

1.

Service

Introduction

Disassembly and General Service Precautions

Cleaning

Extender Boards

Display uP Board Exchange

.............................

..............................

..........................

.....................

..............

1-1

1-2

1-3

1-3

1-3

la. Disassembly Procedures

3/4 and Full Modules

Top cover removal

Board Removal (display uP, interpolation or parameter)

Power Supply Assembly Removal

Power Supply Disassembly

Audio Module Removal

Front Panel Removal

Front Panel Disassembly

NIBP Board and Pump Removal

Mother Board Removal

lb. Reassembly Procedures

3/4 and Full Modules

Mother Board Installation

Board Installation

Front Panel Reassembly

Front Panel Installation

Power Supply Reassembly

Power Supply Assembly Installation

NIBP Pump and Board Reassembly (78352A/C and 78354A/C)

Cover Installation

..........................

..........................

.........................

.........................

...................

......................

.......................

........................

.......................

...................

.......................

.........................

......................

.......................

.......................

......................

..................

.........

.....

1a-1

1a-1

1a-1

1a-2

1a-3

1a-5

1a-6

1a-7

1a-9

1a-14

1b-1

1b-1

1b-2

1b-3

1b-5

1b-6

1b-9

1b-10

1b-10

1c. Adjustments

Introduction

CRT Adjustments

Interpolation Board Adjustments

Gain and Offset Adjustments

Baseline Width Adjustment

ECG Adjustments

Offset Adjustment

Notch Filter Adjustment

Power Supply Adjustments

System 780 Annotating Analog Interface (Opt. J11)

System 780 Configuration Adjustments

.............................

..........................

.........................

........................

......................

......................

...................

....................

....................

................

...........

1c-1

1c-2

1c-4

1c-4

1c-4

1c-7

1c-7

1c-7

1c-8

1c-9

1c-9

Contents-1

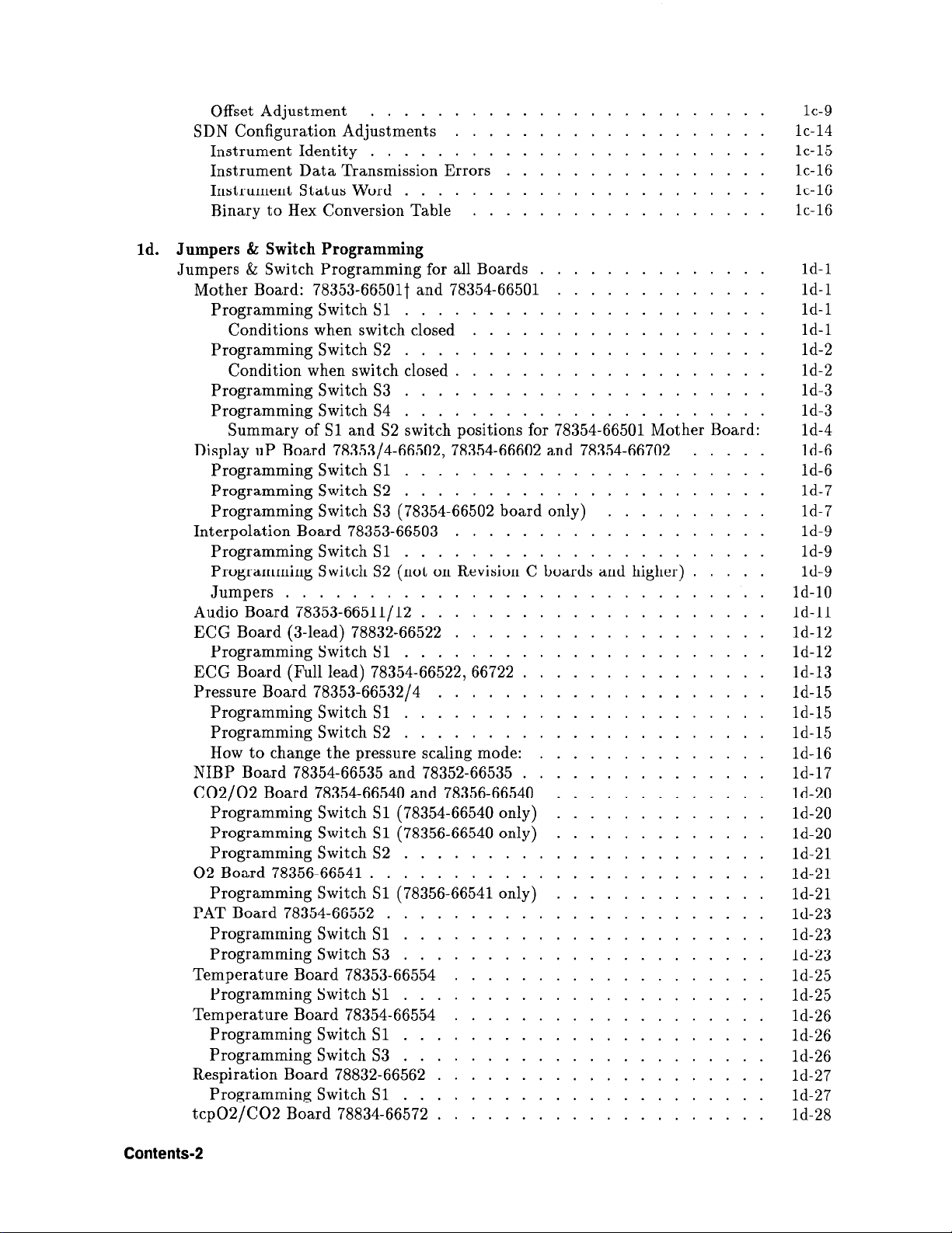

Page 8

Offset Adjustment ........................

SDN Configuration Adjustments

Instrument Identity ........................

Instrument Data Transmission Errors

Instrument Status Word

Binary to Hex Conversion Table

1d. Jumpers & Switch Programming

Jumpers & Switch Programming for all Boards

Mother Board: 78353-66501t and 78354-66501

Programming Switch S1

Conditions when switch closed

Programming Switch S2

Condition when switch closed

Programming Switch S3

Programming Switch S4

Summary of S1 and S2 switch positions for 78354-66501 Mother Board:

Display uP Board 78353/4-66502, 78354-66602 and 78354-66702

Programming Switch S1

Programming Switch S2

Programming Switch S3 (78354-66502 board only)

Interpolation Board 78353-66503

Programming Switch S1

Programming Switch S2 (

Jumpers

Audio Board 78353-6651 1/12

ECG Board (3-lead) 78832-66522

Programming Switch S 1

ECG Board (Full lead) 78354-66522, 66722

Pressure Board 78353-66532/4

Programming Switch S1

Programming Switch S2

How to change the pressure scaling mode:

NIBP Board 78354-66535 and 78352-66535

CO2/02 Board 78354-66540 and 78356-66540

Programming Switch S1 (78354-66540 only)

Programming Switch S1 (78356-66540 only)

Programming Switch S2

02 Board 78356-66541

Programming Switch S1 (78356-66541 only)

PAT Board 78354-66552

Programming Switch S1

Programming Switch S3

Temperature Board 78353-66554

Programming Switch S1

Temperature Board 78354-66554

Programming Switch S1

Programming Switch S3

Respiration Board 78832-66562

Programming Switch S1

tcp02/C02 Board 78834-66572

.............................

......................

......................

......................

......................

......................

......................

......................

......................

no on Revision C boards and higher) t

.....................

......................

....................

......................

......................

......................

........................

.......................

......................

......................

......................

......................

......................

....................

......................

....................

...................

................

..................

..................

...................

...................

...................

...............

...............

...................

...................

..............

.............

..............

.............

.............

.............

.............

..........

.....

.....

1c-9

1c-14

1c-15

1c-16

1c-16

1c-16

1d-1

1d-1

1d-1

1d-1

1d-2

1d-2

1d-3

1d-3

1d-4

1d-6

1d-6

1d-7

1d-7

1d-9

1d-9

1d-9

1d-10

1d-11

1d-12

1d-12

1d-13

1d-15

1d-15

1d-15

1d-16

1d-17

1d-20

1d-20

1d-20

1d-21

1d-21

1d-21

1d-23

1d-23

1d-23

1d-25

1d-25

1d-26

1d-26

1d-26

1d-27

1d-27

1d-28

Contents-2

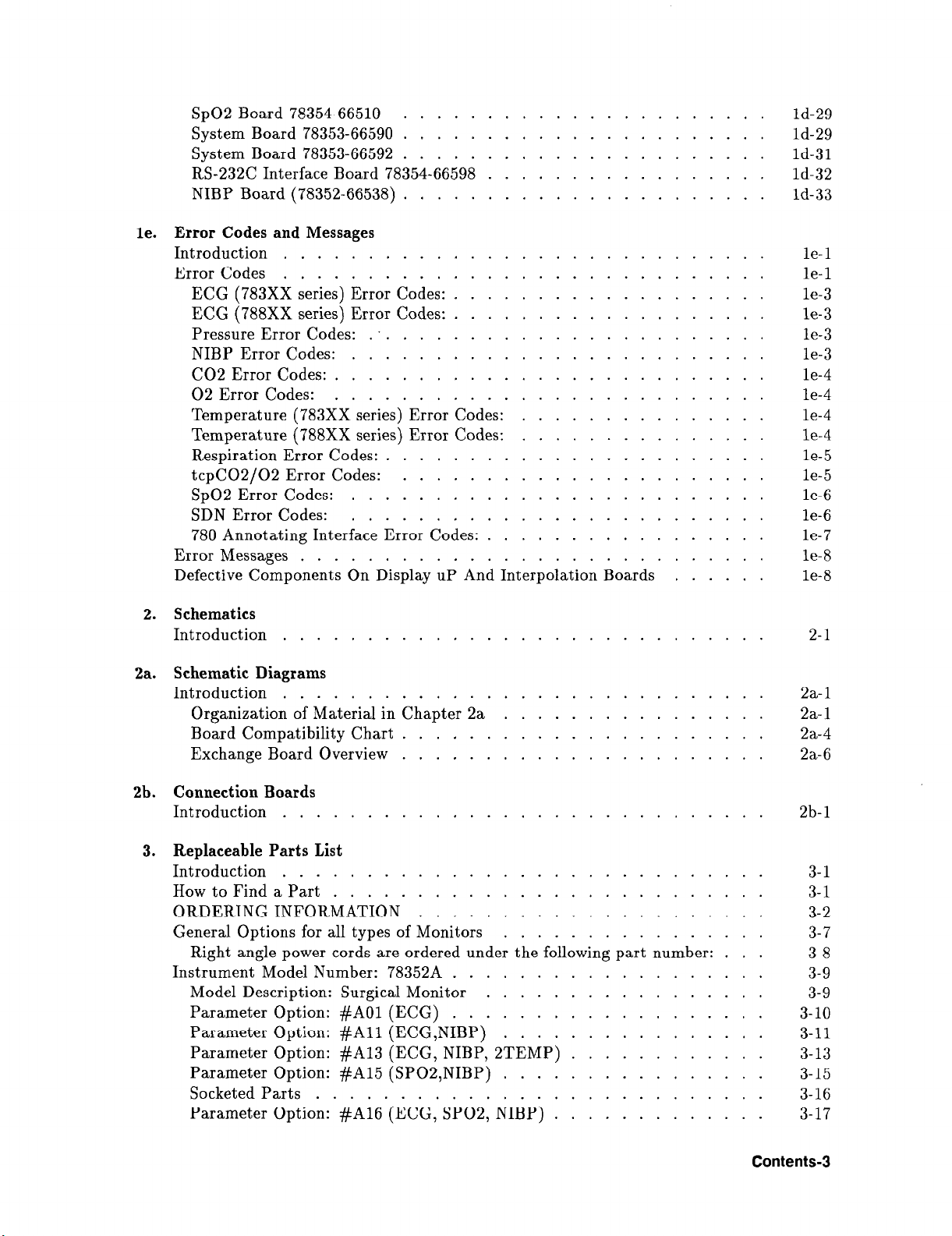

Page 9

SpO2 Board 78354-66510 ......................

System Board 78353-66590 ......................

System Board 78353-66592 ......................

RS-232C Interface Board 78354-66598 .................

NIBP Board (78352-66538) ......................

Error Codes and Messages

le.

Introduction .............................

Error Codes .............................

ECG (783XX series) Error Codes: ...................

ECG (788XX series) Error Codes: ...................

Pressure Error Codes: .........................

NIBP Error Codes: .........................

CO2 Error Codes: ..........................

02 Error Codes: ..........................

Temperature (783XX series) Error Codes: ...............

Temperature (788XX series) Error Codes: ...............

Respiration Error Codes: .......................

tcpCO2/O2 Error Codes: ......................

SpO2 Error Codes: .........................

SDN Error Codes: .........................

780 Annotating Interface Error Codes: .................

Error Messages ............................

Defective Components On Display uP And Interpolation Boards ......

1d-29

1d-29

1d-31

1d-32

1d-33

1e-1

1e-1

1e-3

1e-3

1e-3

1e-3

1e-4

1e-4

1e-4

1e-4

1e-5

1e-5

1e-6

1e-6

1e-7

1e-8

1e-8

2.

Schematics

Introduction ............................. 2-1

Schematic Diagrams

2a.

Introduction .............................

Organization of Material in Chapter 2a ................

Board Compatibility Chart ......................

Exchange Board Overview ......................

2b.

Connection Boards

Introduction .............................

Replaceable Parts List

3.

Introduction .............................

How to Find a Part ..........................

ORDERING INFORMATION .....................

General Options for all types of Monitors ................

Right angle power cords are ordered under the following part number: ...

Instrument Model Number: 78352A ...................

Model Description: Surgical Monitor

.................

Parameter Option: #A01 (ECG) ...................

Parameter Option: #A11 (ECG, NIBP) ................

Parameter Option: #A13 (ECG, NIBP, 2TEMP) ............

Parameter Option: #A15(SPO2, NIBP)

Parameter Option: #A16 (ECG, SP02, NIBP) .............

2a-1

2a-1

2a-4

2a-6

2b-1

3-1

3-1

3-2

3-7

3-8

3-9

3-9

3-10

3-11

3-13

3-15

3-16

3-17

Contents-3

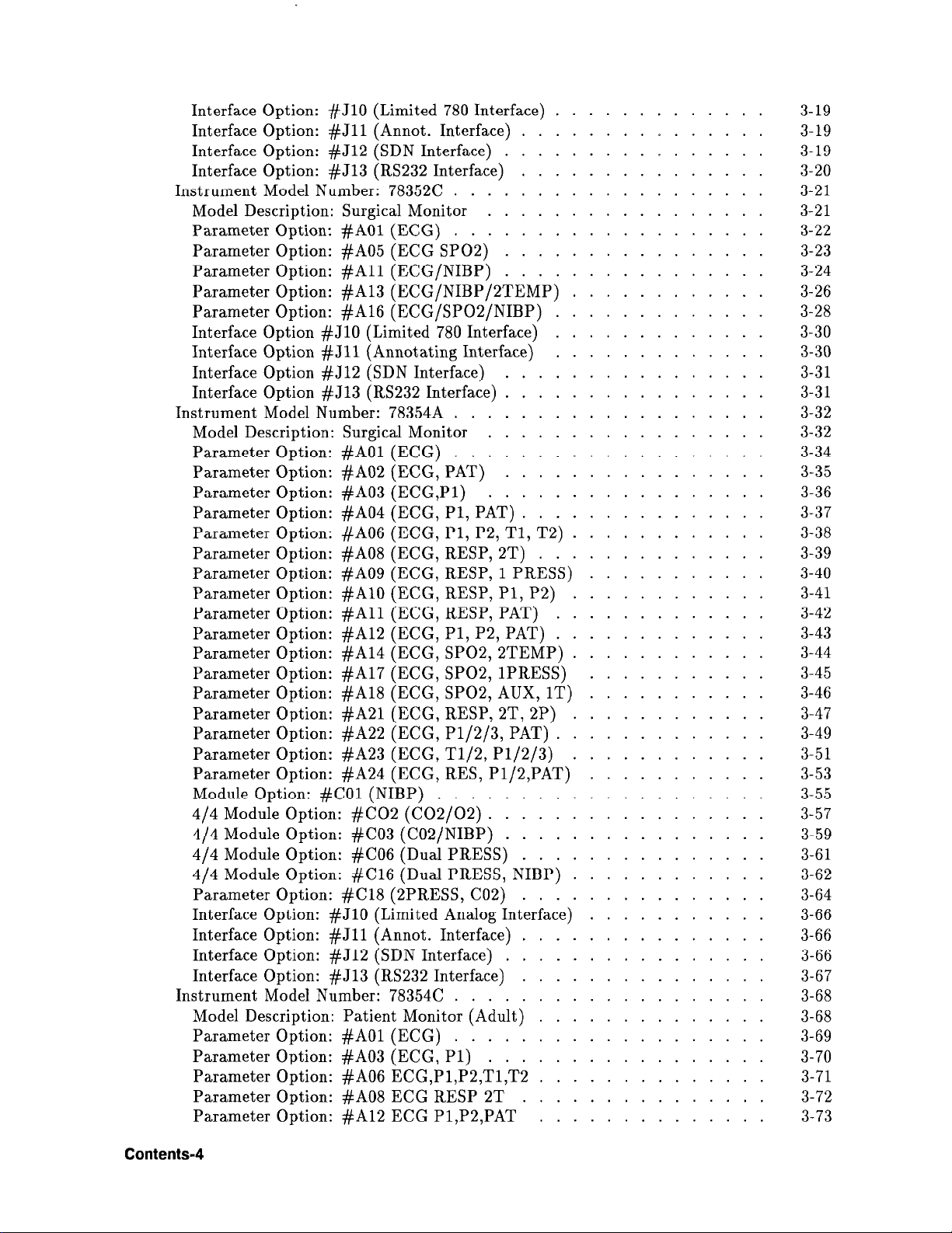

Page 10

Interface Option: #J10 (Limited 780 Interface)

Interface Option: #J11 (Annot. Interface)

Interface Option: #J12 (SDN Interface)

Interface Option: #J13 (RS232 Interface)

Instrument Model Number: 78352C

...................

Model Description: Surgical Monitor

Parameter Option: #A01 (ECG)

...................

Parameter Option: #A05 (ECG SP02)

Parameter Option: #A11 (ECG/NIBP)

...............

................

...............

.................

................

................

Parameter Option: #A13 (ECG/NIBP/2TEMP)

Parameter Option: #A16 (ECG/SPO2/NIBP)

Interface Option #J10 (Limited 780 Interface)

Interface Option #J11 (Annotating Interface)

Interface Option #J12 (SDN Interface)

Interface Option #J13 (RS232 Interface)

Instrument Model Number: 78354A

...................

Model Description: Surgical Monitor

Parameter Option: #A01 (ECG)

...................

Parameter Option: #A02 (ECG, PAT)

Parameter Option: #A03 (ECG,P1)

Parameter Option: #A04 (ECG, P1, PAT)

................

................

.................

................

.................

...............

Parameter Option: #A06 (ECG, P1, P2, T1, T2)

Parameter Option: #A08 (ECG, RESP, 2T)

Parameter Option: #A09 (ECG, RESP, 1 PRESS)

Parameter Option: #A10 (ECG, RESP, P1, P2)

Parameter Option: #A11 (ECG, RESP, PAT)

Parameter Option: #A12 (ECG, P1, P2, PAT)

Parameter Option: #A14 (ECG, SPO2, 2TEMP)

Parameter Option: #A17 (ECG, SPO2, 1PRESS)

Parameter Option: #A18 (ECG, SPO2, AUX, 1T)

Parameter Option: #A21 (ECG, RESP, 2T, 2P)

Parameter Option: #A22 (ECG, P1/2/3, PAT)

Parameter Option: #A23 (ECG, T1/2, P1/2/3)

Parameter Option: #A24 (ECG, RES, P1/2,PAT)

Module Option: #C01 (NIBP)

4/4 Module Option: #CO2 (CO2/O2)

4/4 Module Option: #C03 (C02/NIBP)

4/4 Module Option: #C06 (Dual PRESS)

....................

.................

................

...............

4/4 Module Option: #C16 (Dual PRESS, NIBP)

Parameter Option: #C18 (2PRESS, C02)

...............

Interface Option: #J10 (Limited Analog Interface)

Interface Option: #J11 (Annot. Interface)

Interface Option: #J12 (SDN Interface)

Interface Option: #J13 (RS232 Interface)

Instrument Model Number: 78354C

...................

...............

................

...............

Model Description: Patient Monitor (Adult)

Parameter Option: #A01 (ECG)

Parameter Option: #A03 (ECG, P1)

...................

.................

Parameter Option: #A06 ECG,P1,P2,T1,T2

Parameter Option: #A08 ECG RESP 2T

...............

Parameter Option: #A12 ECG P1,P2,PAT

.............

............

.............

.............

.............

............

..............

...........

............

.............

.............

............

...........

...........

............

.............

............

...........

............

...........

..............

..............

..............

3-19

3-19

3-19

3-20

3-21

3-21

3-22

3-23

3-24

3-26

3-28

3-30

3-30

3-31

3-31

3-32

3-32

3-34

3-35

3-36

3-37

3-38

3-39

3-40

3-41

3-42

3-43

3-44

3-45

3-46

3-47

3-49

3-51

3-53

3-55

3-57

3-59

3-61

3-62

3-64

3-66

3-66

3-66

3-67

3-68

3-68

3-69

3-70

3-71

3-72

3-73

Contents-4

Page 11

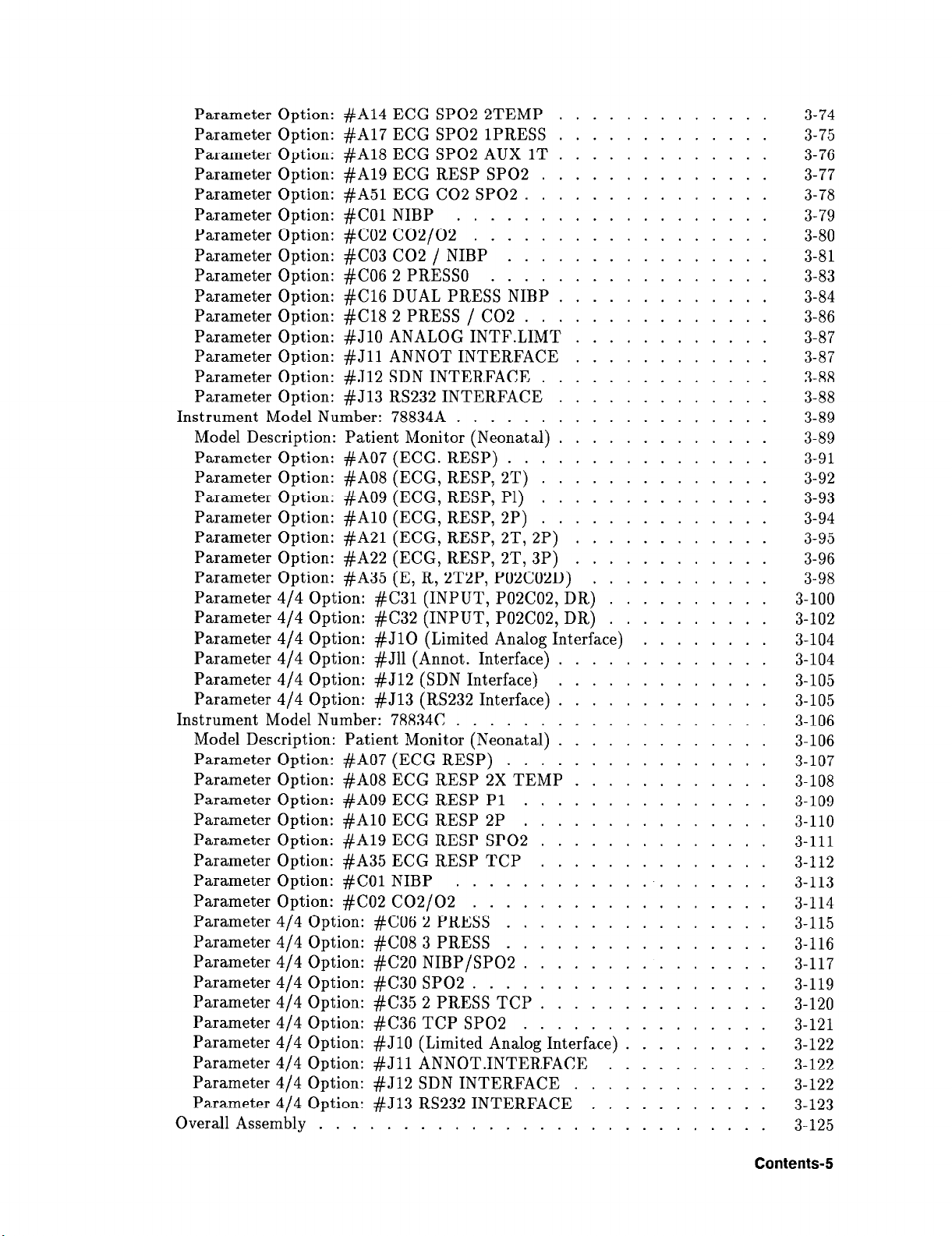

Parameter Option: #A14 ECG SPO2 2TEMP

Parameter Option: #A17 ECG SPO2 1PRESS

Parameter Option: #A18 ECG SPO2 AUX 1T

.............

.............

.............

Parameter Option: #A19 ECG RESP SPO2 ..............

Parameter Option: #A51 ECG CO2 SP02

Parameter Option: #C01 NIBP

Parameter Option: #C02 CO2/O2

...................

..................

Parameter Option: #C03 CO2 / NIBP

Parameter Option: #C06 2 PRESS0

Parameter Option: #C16 DUAL PRESS NIBP

Parameter Option: #C18 2 PRESS / CO2

Parameter Option: #J10 ANALOG INTF.LIMT

Parameter Option: #J11 ANNOT INTERFACE

Parameter Option: #J12 SDN INTERFACE

Parameter Option: # J13 RS232 INTERFACE

...............

................

.................

.............

...............

............

............

..............

.............

Instrument Model Number: 78834A ...................

Model Description: Patient Monitor (Neonatal)

Parameter Option: #A07 (ECG. RESP)

................

Parameter Option: #A08 (ECG, RESP, 2T)

Parameter Option: #A09 (ECG, RESP, P1)

Parameter Option: #A10 (ECG, RESP, 2P)

Parameter Option: #A21 (ECG, RESP, 2T, 2P)

Parameter Option: #A22 (ECG, RESP, 2T, 3P)

.............

..............

..............

..............

............

............

Parameter Option: #A35 (E, R, 2T2P, P02C02D)

Parameter 4/4 Option: #C31 (INPUT, P02C02, DR)

Parameter 4/4 Option: #C32 (INPUT, P02C02, DR)

Parameter 4/4 Option: #J10 (Limited Analog Interface)

Parameter 4/4 Option: #J11 (Annot. Interface)

Parameter 4/4 Option: #J12 (SDN Interface)

Parameter 4/4 Option: #J13 (RS232 Interface)

Instrument Model Number: 78834C

...................

Model Description: Patient Monitor (Neonatal)

Parameter Option: #A07 (ECG RESP)

................

Parameter Option: #A08 ECG RESP 2X TEMP

Parameter Option: #A09 ECG RESP P1

Parameter Option: #A10 ECG RESP 2P

Parameter Option: #A19 ECG RESP SPO2

Parameter Option: #A35 ECG RESP TCP

Parameter Option: #C01 NIBP

Parameter Option: #C02 CO2/O2

Parameter 4/4 Option: #C06 2 PRESS

Parameter 4/4 Option: #C08 3 PRESS

...................

..................

................

................

Parameter 4/4 Option: #C20 NIBP/SPO2

Parameter 4/4 Option: #C30 SPO2

..................

Parameter 4/4 Option: #C35 2 PRESS TCP

Parameter 4/4 Option: #C36 TCP SPO2

.............

.............

.............

.............

............

...............

...............

..............

..............

...............

..............

...............

Parameter 4/4 Option: #J10 (Limited Analog Interface)

Parameter 4/4 Option: #J11 ANNOT.INTERFACE

Parameter 4/4 Option: #J12 SDN INTERFACE

............

Parameter 4/4 Option: #J13 RS232 INTERFACE

Overall Assembly

...........................

...........

..........

..........

.........

..........

...........

........

3-74

3-75

3-76

3-77

3-78

3-79

3-80

3-81

3-83

3-84

3-86

3-87

3-87

3-88

3-88

3-89

3-89

3-91

3-92

3-93

3-94

3-95

3-96

3-98

3-100

3-102

3-104

3-104

3-105

3-105

3-106

3-106

3-107

3-108

3- 109

3-110

3-111

3-112

3-113

3-114

3-115

3-116

3-117

3-119

3-120

3-121

3-122

3-122

3-122

3-123

3-125

Contents-5

Page 12

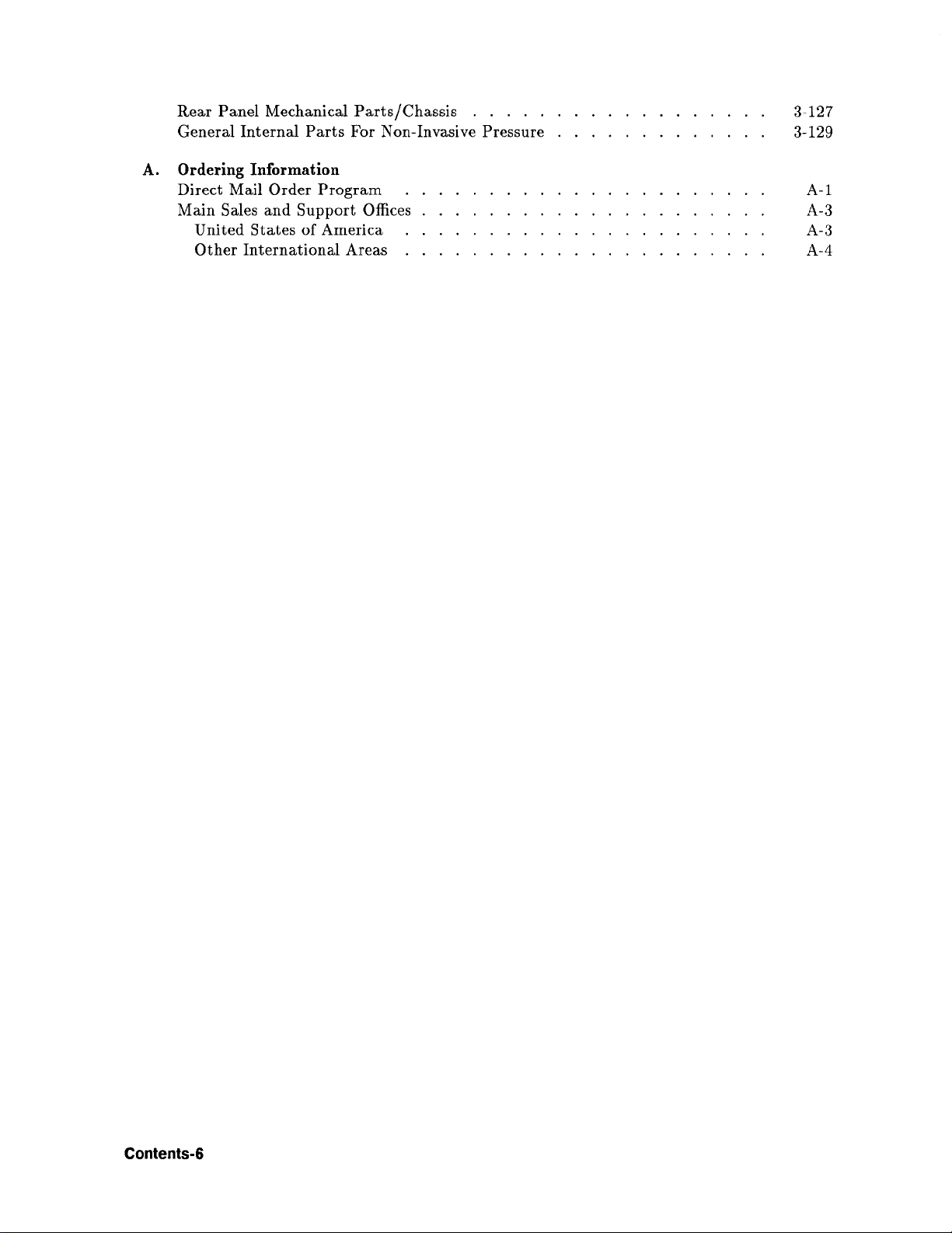

Rear Panel Mechanical Parts/Chassis

General Internal Parts For Non-Invasive Pressure

A. Ordering Information

Direct Mail Order Program

Main Sales and Support Offices

United States of America

Other International Areas

......................

.....................

......................

......................

..................

3-127

............. 3-129

A-1

A-3

A-3

A-4

Contents-6

Page 13

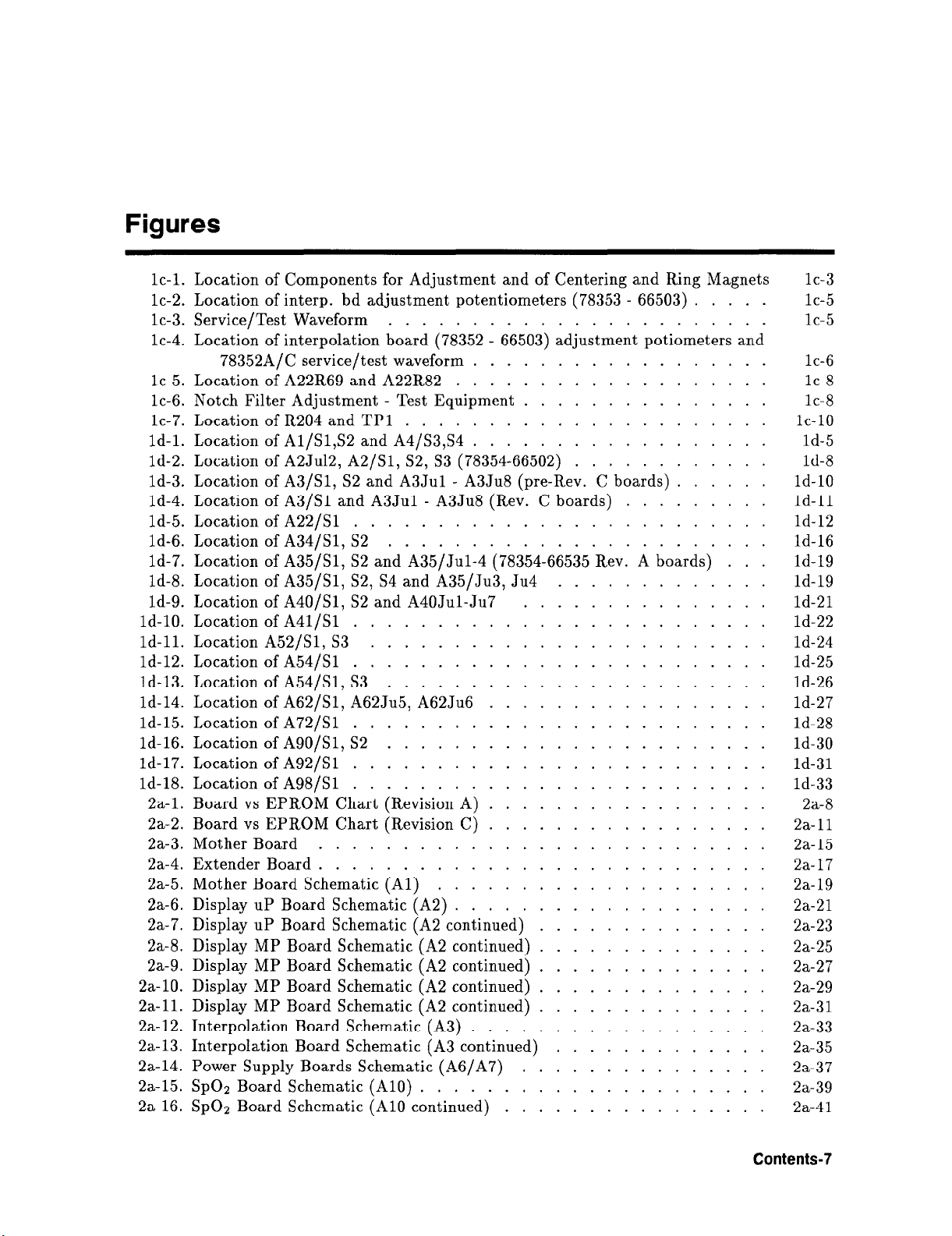

Figures

1c-1. Location of Components for Adjustment and of Centering and Ring Magnets

1c-2. Location of interp. bd adjustment potentiometers (78353 - 66503) .....

1c-3. Service/Test Waveform .......................

1c-4. Location of interpolation board (78352 - 66503) adjustment potiometers and

78352A/C service/test waveform ..................

1c-5. Location of A22R69 and A22R82 ...................

1c-6. Notch Filter Adjustment - Test Equipment ...............

1c-7. Location of R204 and TP1 ......................

1d-1. Location of A1/S1,S2 and A4/S3,S4 ..................

1d-2. Location of A2Ju12, A2/S1, S2, S3 (78354-66502) ............

1d-3. Location of A3/S1, S2 and A3Ju1 - A3Ju8 (pre-Rev. C boards) ......

1d-4. Location of A3/S1 and A3Jul - A3Ju8 (Rev. C boards) .........

ld-5. Location of A22/S1 .........................

1d-6. Location of A34/S1, S2 .......................

1d-7. Location of A35/S1, S2 and A35/Ju1-4 (78354-66535 Rev. A boards) ...

1d-8. Location of A35/S1, S2, S4 and A35/Ju3, Ju4 .............

1d-9. Location of A40/S1, S2 and A40Ju1-Ju7 ...............

1d-10. Location of A41/S1 .........................

1d-11. Location A52/S1, S3 ........................

1d-12. Location of A54/S1 .........................

1d-13. Location of A54/S1, S3 .......................

1d-14. Location of A62/S1, A62Ju5, A62Ju6 .................

1d-15. Location of A72/S1 .........................

1d-16. Location of A90/S1, S2 .......................

1d-17. Location of A92/S1 .........................

1d-18. Location of A98/S1 .........................

2a-1. Board vs EPROM Chart (Revision A) .................

2a-2. Board vs EPROM Chart (Revision C) .................

2a-3. Mother Board ...........................

2a-4. Extender Board ...........................

2a-5. Mother Board Schematic (A1) ....................

2a-6. Display UP Board Schematic (A2) ...................

2a-7. Display UP Board Schematic (A2 continued) ..............

2a-8. Display MP Board Schematic (A2 continued) ..............

2a-9. Display MP Board Schematic (A2 continued) ..............

2a-10. Display MP Board Schematic (A2 continued) ..............

2a-11. Display MP Board Schematic (A2 continued)

2a-12. Interpolation Board Schematic (A3) ..................

2a-13. Interpolation Board Schematic (A3 continued)

2a-14. Power Supply Boards Schematic (A6/A7)

2a-15. SpO2 Board Schematic (A10) .....................

2a-16. SpO2 Board Schematic (A10 continued) ................

..............

.............

...............

1c-3

1c-5

1c-5

1c-6

1c-8

1c-8

1c-10

1d-5

1d-8

1d-10

1d-11

1d-12

1d-16

1d-19

1d-19

1d-21

1d-22

1d-24

1d-25

1d-26

1d-27

1d-28

1d-30

1d-31

1d-33

2a-8

2a-11

2a-15

2a-17

2a-19

2a-21

2a-23

2a-25

2a-27

2a-29

2a-31

2a-33

2a-35

2a-37

2a-39

2a-41

Contents-7

Page 14

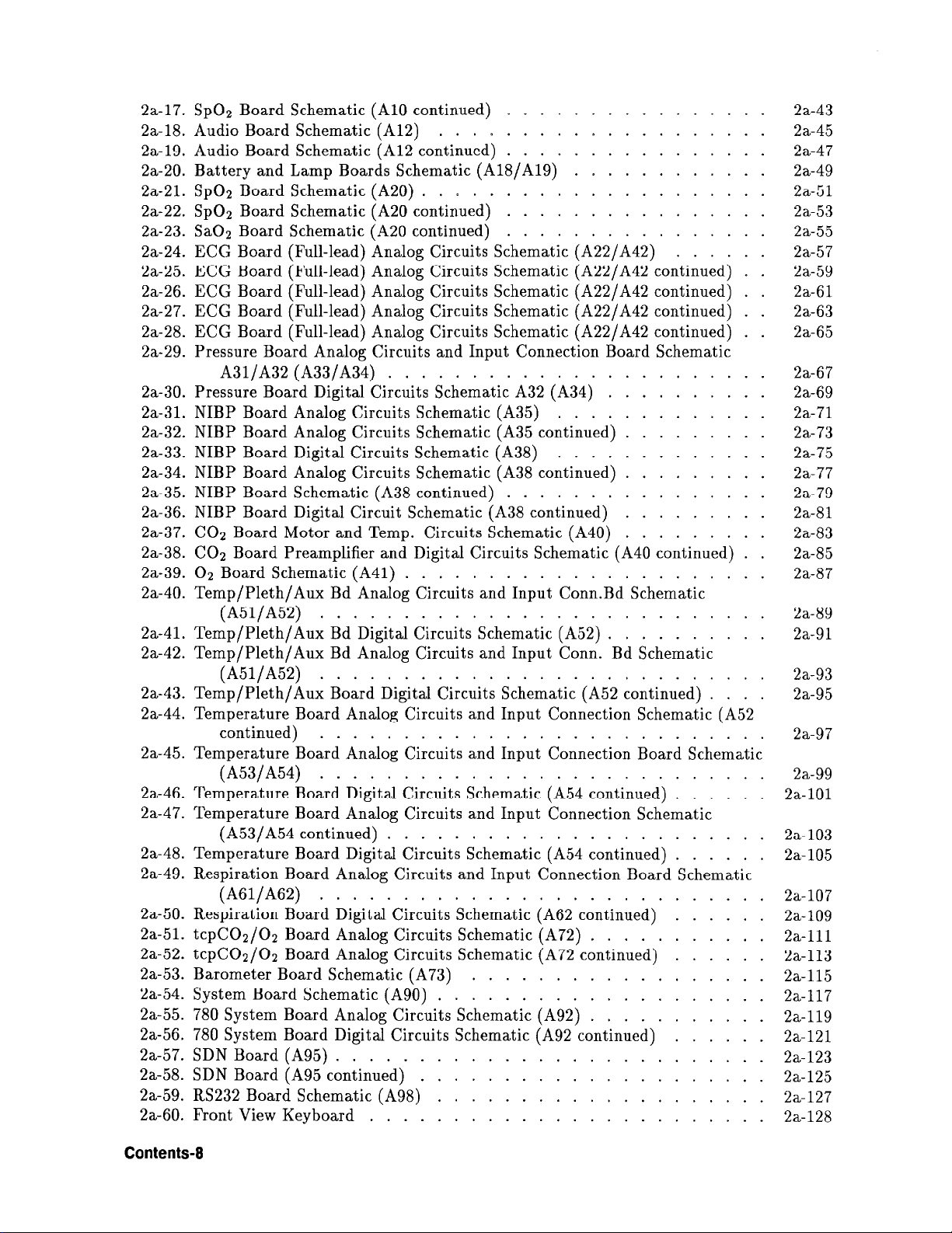

2a-17. SpO2 Board Schematic (A10 continued)

2a-18. Audio Board Schematic (A12)

2a-19. Audio Board Schematic (A12 continued)

2a-20. Battery and Lamp Boards Schematic (A18/A19)

2a-21. SpO2 Board Schematic (A20)

2a-22. SpO2 Board Schematic (A20 continued)

2a-23. SaO2 Board Schematic (A20 continued)

2a-24. ECG Board (Full-lead) Analog Circuits Schematic (A22/A42)

2a-25. ECG Board (Full-lead) Analog Circuits Schematic (A22/A42 continued) . .

2a-26. ECG Board (Full-lead) Analog Circuits Schematic (A22/A42 continued) . .

2a-27. ECG Board (Full-lead) Analog Circuits Schematic (A22/A42 continued) . .

2a-28. ECG Board (Full-lead) Analog Circuits Schematic (A22/A42 continued) . .

2a-29. Pressure Board Analog Circuits and Input Connection Board Schematic

A31/A32 (A33/A34) .......................

2a-30. Pressure Board Digital Circuits Schematic A32 (A34)

2a-31. NIBP Board Analog Circuits Schematic (A35)

2a-32. NIBP Board Analog Circuits Schematic (A35 continued)

2a-33. NIBP Board Digital Circuits Schematic (A38)

2a-34. NIBP Board Analog Circuits Schematic (A38 continued)

2a-35. NIBP Board Schematic (A38 continued)

2a-36. NIBP Board Digital Circuit Schematic (A38 continued)

2a-37. CO2 Board Motor and Temp. Circuits Schematic (A40)

2a-38. CO2 Board Preamplifier and Digital Circuits Schematic (A40 continued) . .

2a-39. O2 Board Schematic (A41)

2a-40. Temp/Pleth/Aux Bd Analog Circuits and Input Conn.Bd Schematic

(A51/A52) ...........................

2a-41. Temp/Pleth/Aux Bd Digital Circuits Schematic (A52)

2a-42. Temp/Pleth/Aux Bd Analog Circuits and Input Conn. Bd Schematic

(A51/A52) ...........................

2a-43. Temp/Pleth/A ux Board Digital Circuits Schematic (A52 continued)

2a-44. Temperature Board Analog Circuits and Input Connection Schematic (A52

continued) ...........................

2a-45. Temperature Board Analog Circuits and Input Connection Board Schematic

(A53/A54) ...........................

2a-46. Temperature Board Digital Circuits Schematic (A54 continued)

2a-47. Temperature Board Analog Circuits and Input Connection Schematic

(A53/A54 continued) .......................

2a-48. Temperature Board Digital Circuits Schematic (A54 continued)

2a-49. Respiration Board Analog Circuits and Input Connection Board Schematic

(A61/A62) ...........................

2a-50. Respiration Board Digital Circuits Schematic (A62 continued)

2a-51. tcpCO2/O2 Board Analog Circuits Schematic (A72)

2a-52. tcpCO2/O2 Board Analog Circuits Schematic (A72 continued)

2a-53. Barometer Board Schematic (A73)

2a-54. System Board Schematic (A90)

2a-55. 780 System Board Analog Circuits Schematic (A92)

2a-56. 780 System Board Digital Circuits Schematic (A92 continued)

2a-57. SDN Board (A95)

2a-58. SDN Board (A95 continued)

2a-59. RS232 Board Schematic (A98)

2a-60. Front View Keyboard

..........................

........................

....................

.....................

......................

....................

.....................

....................

................

................

............

................

................

......

..........

.............

.........

.............

.........

................

.........

.........

..........

....

......

......

......

...........

......

..................

...........

......

2a-43

2a-45

2a-47

2a-49

2a-51

2a-53

2a-55

2a-57

2a-59

2a-61

2a-63

2a-65

2a-67

2a-69

2a-71

2a-73

2a-75

2a-77

2a-79

2a-81

2a-83

2a-85

2a-87

2a-89

2a-91

2a-93

2a-95

2a-97

2a-99

2a-101

2a-103

2a-105

2a-107

2a-109

2a-111

2a-113

2a-115

2a-117

2a-119

2a-121

2a-123

2a-125

2a-127

2a-128

Contents-6

Page 15

3-1. Overall Assembly for Revison A,B and C

3-2. Power Supply Assembly

.......................

3-3. Rear Panel Mechanical Parts/Chasis

............... 3-125

................. 3-127

3-4. General Internal Parts for Non-Invasive Pressure

3-126

............ 3-129

Contents-9

Page 16

Tables

1c-1. System Output Configurations

1e-1. Error Code Key - Fault Diagnosis

2a-1. Index of Schematics contained in Chapter II

2a-2. Board Compatibility Chart

3-1. List of Abbreviations

3-2. Rear Panel Mechanical Parts / Chasis ................. 3-127

3-3. General Internal Parts for Non-Invasive Pressure

........................

.................... 1c-12

................... 1e-2

.............. 2a-2

......................

............

2a-4

3-129

3-3

Contents-10

Page 17

Service

Introduction

Chapters la, lb, lc, Id and le provide all the Service information required for the 78XxX

Series Patient and Neonatal Monitors. The Service Chapters cover the following:

n

Chapter la Disassembly Procedures

q

Top cover removal

o Board removal

(Display UP, Interpolation, Parameter)

q

Power supply assembly removal

q

Power supply disassembly

q

Audio module removal

q

Front panel removal

q

Front panel disassembly

q

NIBP Board and Pump removal

78354A/C monitor..78352A/C monitor

q

Mother Board removal

n

Chapter lb Reassembly Procedures

q

Mother Board installation

q

Board installation

o Front panel reassembly

q

Front panel installation

q

Power supply reassembly

o Power supply assembly installation

o NIBP reassembly

0 Cover installation

1

n

Chapter lc Adjustments

H Chapter Id Jumpers and Switch Programming

n

Chapter le Error Codes and Messages

Service l-1

Page 18

Disassembly and General Service Precautions

Caution

Read the following precautions thoroughly before performing any of the

disassembly procedures. Serious damage to the instrument can result if the

precautions are not strictly followed.

Y

n

The front panel is vulnerable to scratching. Avoid rough handling of the panel.

n

When the chassis is removed from the case, bare metal edges are exposed which can scratch

the work surface. Be careful that the sharp edges and corners of the chassis do not scratch

the work area surface.

n

The input amplifiers have a floating ground section which is isolated from the remainder of

the board.

Never handle this section of the board - oil, dirt, dust, etc., deposited on this section can

cause leakage paths which can degrade floating circuit isolation and performance.

n

Handle all circuit boards by the edges; CMOS circuits operate with currents in the

nanoampere range and leakage paths caused by skin oils, dirt, dust, etc., can cause

inaccurate circuit performance.

w As all of the screws in the Monitor have been treated with a special varnish they should not

be screwed in and out more than about ten times. After this, replace with new screws.

n

Generally, the insulation resistance of the oxide layer in MOS IC structures is very high, and

the oxide layer is very thin. Because of this, it is possible that the static voltages usually

present on clothes and the human body will be enough to generate a potential difference

across the insulator, high enough to cause a breakdown of the insulating layer.

The following precautions should be taken while handling these ICs. Particular care should be

taken under conditions of low humidity.

1. Store new ICs by inserting them into a urethanepolyester cushion (which is conductive), or

wrapping them in aluminium foil, so that all the pins are at the same potential.

(The ICs should be stored in that manner until mounted on the circuit board.)

2. Check the soldering iron for possible power-line leakage current. To do this, connect an

ohmmeter to the tip of the soldering iron and the plug. If there is a leakage path, use

another soldering iron.

3. Equalize any potential difference between the clothes, the tools in use, the work bench,

the set being worked on, and the packaged IC by touching them all in succession with the

hands or a conductive wire or tool.

4. When it is necessary to handle the IC with the fingers, do not touch any pin, hold the IC

at the ends of its plastic package case.

Warning

AVOID ELECTROSTATIC DISCHARGE !

l-2 Service

Page 19

The following precautions should be observed prior to beginning disassembly:

1. Turn the instrument off.

2. Remove the power cord and all signal cables from the rear panel.

Warning

In Chapter la the disassembly procedures are arranged from top assembly downwards.

Chapter lb contains information on reassembly.

If the instrument is to be reconnected and the power turned on with the rear

panel removed, low voltage and dangerous high voltage sources would be

exposed. Be careful. Do not power up the chassis on a conductive surface

such as a bare metal table. Place the chassis on a non-conductive material,

such as heavy cardboard.

Cleaning

The instrument should be clean and free of dust and dirt. Clean as required with a lint-free

cloth or sponge dampened with warm soapy water or alcohol. The front panel is more

sensitive to scratching than the other surfaces of the Monitor. Be careful, especially when

cleaning this surface.

Caution

dl

Do not allow any liquid to enter the instrument case. Do not pour liquid on

the instrument while cleaning. Never use any abrasive material such as steel

wool or silver polish, and never use strong solvents as acetone to clean the

monitor.

Extender Boards

Four extender boards and one cable are needed for servicing the Monitor:

lx 5061-5640

1 x 5061-5641 Interpolation Board / Display UP Board

1 x 5060-1805

1 x 78353-66589 Power Supply Extender Board (15 pin connector)

1 x 78353-61607 Power Supply Extender Cable

Parameter Board / Display UP Board

System Board

Display UP Board Exchange

After exchanging the Display UP Board, wait at least 20 seconds before switching the

instrument back on, otherwise an error message will be generated

Service l-3

Page 20

Page 21

Disassembly Procedures

314 and Full Modules

Top cover removal

1. Undo and remove the 4 upper screws on the instrument case.

2. Raise the front of the top cover and lift cover off.

Die beiden oberen Fotos von alter Seite l-5 nebeneinander hier einfiigen

la

Board Removal (display UP, interpolation or parameter)

1. Lift out the board stabilizer which holds the boards in place.

2. Undo the colored plastic clips at either end of the board.

Die beiden unteren Fotos von alte Seite l-5 nebeneinander hier einfiigen

Disassembly Procedures 1 a-l

Page 22

3. Lift the board out.

Note

3

Das erste Foto von alte Seite l-6 hier einfiigen

For Parameter Boards, to remove the plastic cover pull forward. Be careful

with contact spring at reassembly.

Power Supply Assembly Removal

1. Undo the screw holding the power supply assembly in place. This screw has a compression

washer underneath which must be re-fitted. On monitors with NIBP, detatch pressure tube

from input connector and NIBP board, also detatch power supply lead from NIBP board.

2. Lift out the power supply assembly, complete with NIBP pump (if fitted).

Die zweiten und dritten Fotos von alte Seite l-6 hier einfiigen

la-2 Disassembly Procedures

Page 23

Power Supply Disassembly

1. Remove the power supply cover by undoing the two screws on the top and the three screws

on the side.

Das let&e Foto von alte Seite l-6 hier einfiigen

2. For access to the secondary power supply board A6, unscrew the rear panel assembly

(2 screws).

3. Disconnect the transformer and battery connector (not shown).

Die beiden oberen Fotos von alter Seite l-7 nebeneinander hier einfiigen

4. Loosen the potential equalisation connector with a socket wrench and remove.

5. Slide out rear panel insert. (On later models the label is removed from underneath).

Die beiden unteren Fotos von alter Seite l-7 nebeneinander hier einfiigen

Disassembly Procedures 1 a-3

Page 24

6. Undo two screws holding the power inlet in position (required only for access to power

inlet).

7. For access to the primary power supply board A7, undo the three screws holding it into

position.

Die beiden oberen Fotos von alter Seite 1-8 nebeneinander hier einfiigen

8. Power supply board A7 is now fully accessible.

Das letzte Foto von alte Seite l-8 hier einfiigen

1 a-4 Disassembly Procedures

Page 25

1. Press the button on the top of the audio module cover, and pull the cover off the module.

Later models have a screw in the rear panel to secure the audio cover.

2. Undo the 1 or 2 screws on the inside of the audio module. Later models have only one

screw, remove this and slide the complete audio module out after disconnecting audio

module cable and battery board cable (optional).

Die beiden oberen Fotos von alter Seite l-9 nebeneinander hier einfiigen

3. Pull audio module a little away from the rear of the instrument and disconnect the cable

from the battery board. The battery board can now be removed (optional).

4. Disconnect the ribbon cable from X9 (and X19 if applicable) on the mother board and feed

out through the slot in the rear bracket. The audio module can now be removed.

Die beiden unteren Fotos von alter Seite l-9 nebeneinander hier einfiigen

Disassembly Procedures

1 a-5

Page 26

Front Panel Removal

1. The parameter boards must be lifted out before the front panel can be removed.

2. Disconnect the CRT socket, the ground wire, the cable to the keyboard assembly, the HV

connection and the choke connection.

Die beiden oberen Fotos von alter Seite l-10 nebeneinander hier einfiigen

3. Undo the screw on the inside of the front panel, next to the CRT, and tilt the front panel

assembly forwards.

4. 788Xx series, 78352C, 78354C

Disconnect the three lamp board wires from the mother board.

Die beiden unteren Fotos von alter Seite l-10 nebeneinander hier einfiigen

la-6 Disassembly Procedures

Page 27

5. 788Xx Series only

Undo the one screw on the lamp board and remove as shown (push the lamps from the

front of the panel to access the board).

78352C, 78354C and 78834C

The LED lamp board is mounted with two screws to the keyboard assembly and can only

be removed with the complete keyboard assembly.

6. Lift front panel assembly out.

Die beiden oberen Fotos von alter Seite l-11 nebeneinander hier einfiigen

Front Panel Disassembly

1. Unscrew the two CRT holders, one on either side of the tube.

2. Lift out the CRT, the CRT holders, grounding spring (earlier models have a side hook

which needs to be unclipped, it is not necessary on later models and cannot be re-ordered).

Die beiden unteren Fotos von alter Seite l-11 nebeneinander hier einfiigen

Disassembly Procedures la-7

Page 28

3. Unscrew the parameter connector assemblies (the type and fitting of the connector

assemblies varies depending on parameter configuration).

4. The cover can now be lifted off the assembly

(as

shown) and the connector can also be

removed from the front panel.

Note

Some connector boards have spring contact for shield connection. Be careful

at reassembly to avoid damaging the spring.

Die beiden oberen Fotos von alter Seite 1-12 nebeneinander hier einfiigen

5. Not applicable to the 78352C, 78354C and 78834C monitors:

Undo three screws to remove the keyboard assembly. (The keyboard assembly on the

78352C, 78354C and 78834C monitors is not removable, it is glued to the front panel).

Das letzte Foto von alte Seite 1-12 hier einfiigen

1 a-8 Disassembly Procedures

Page 29

NIBP Board and Pump Removal

78354A Monitors with old ac pump:

1. Pull out NIBP parameter board until access to the tube connections are possible.

Das erste Foto von alte Seite 1-13 hier einfiigen

2. Disconnect the tubes from the front panel and the T-piece leading to the pump. Leave

tube attached to board.

Das zweite Foto von alte Seite 1-13 hier einfiigen

Disassembly Procedures la-9

Page 30

3. Disconnect cables from the pump control board to the parameter board. The board can

now be completely removed.

Das letzte Foto von Seite 1-13 hier einfuegen

4. Disconnect power supply to control board and to pump and remove the control board by

tilting towards pump to unclip it and then lift out.

Das erste Foto von Seite 1-14 hier einfuegen

la-10 Disassembly Procedures

Page 31

5. The four screws holding down the pump can now be removed (four outer X-headscrews).

Extender board with pump removed showing ribbon cable connections to the mother

board.

Das zweite Foto von Seite 1-14 hier einfuegen

6. The front panel can be removed by removing the screw shown and sliding out the panel.

Note the position of the switch assembly and LED board.

Das let&e Foto von Seite 1-14 hier einfuegen

Disassembly Procedures la-l 1

Page 32

78352A/C Monitor: 78354A/C with de pump:

1. Disconnect tubing from T-piece branch leading down to front panel connector and to

pump. Remove connector (brown and red wires) on NIPB board. This connects to the

pump control board.

Note

that

for the new NIBP Board (78352-66538),

orange wires) connects to the power supply and the pump.

th

e removed connector (black, brown, red,

Das erste Foto von alte Seite 1-15 hier einfuegen

2. The NIPB board and other parameter boards may now be removed.

Das zweite Foto von aIte Seite 1-15 hier einfuegen

la-12 Disassembly Procedures

Page 33

3. Pump:

to remove the pump remove connector (red and black wires) to pump control board

and remove the front 2 nuts securing the pump assembly to the vibration supports.(Refit

new external tooth lock washers if nuts are loosened p-n 2194-0413).

Note that for new NIBP Board, the pump is isolated when disconnected

supply and the board. The pump is removed by undoing two

the

power

4. Pump Control Board:

supply.

to remove the pump control board, disconnect from power supply,

nuts and

from

washers

the power

securing

remove screw (arrowed) and gently push down to free lower end of board from slot and

then rotate out. Note that the new NIBP Board has no pump control board.

Die beiden letzten Fotos von alter Seite 1-15 nebeneinander hier einfuegen

it to

Disassembly Procedures 1 a-l 3

Page 34

Mother Board Removal

1.

Note

2. Looking from front: Undo the screws holding the mother board in place: two on left (also

holding side LH bracket), three on right (one of which holds the Audio bracket), two on

rear (also holding rear bracket on some models) and one in center.

Die beiden oberen Fotos von alter Seite 1-16 nebeneinander hier einfuegen

3. Unscrew the green/yellow ground wire, which is also used to secure the Mother Board and

screening strip.

For access to the Mother Board, the front panel assembly does not necessarily

have to be removed. Simply tilt it forward - all cables are long enough to

permit this extension.

4. Undo the two screws which fasten the two grounding brackets to the Mother Board. Lift

grounding brackets out.

Die beiden unteren Fotos von alter Seite 1-16 nebeneinander hier einfuegen

la-14 Disassembly Procedures

Page 35

5. Lift up the Mother Board at the rear and pull out. (Picture shows side panels removed,

but this is not necessary).

6. The power on/off switch coupler rests in the bottom cover underneath the Mother Board.

Note position of nylon spacer ring.

Die beiden Fotos von alter Seite 1-17 nebeneinander hier einfuegen

Disassembly Procedures la-15

Page 36

Page 37

lb

Reassembly Procedures

3/4 and Full Modules

Mother Board Installation

1. Replace the Mother Board, making sure that the protrusion of the power on/off switch

coupler fits through the slot provided in the Mother Board.

2. Center the Mother Board with the center screw and replace LH side bracket and its 2

screws (early models also have a LH side center screw as shown). Replace the 3 screws on

the RH side (including Audio bracket and RH end of screening strip), the 2 rear screws and

screw holding green/yellow ground wire and LH end of screening strip. Do not tighten until

all 9 screws holding the Mother Board are back in position. (Some models may have upto

12 screws holding the board down).

Die beiden oberen Fotos von alter Seite 1-18 nebeneinander hier einfuegen

3. Reconnect the ground bracket (in later models this comes off with the Mother Board when

the two screws are released and a copper strip replaces the wire).

4. Reconnect the floating ground bracket (in later models this comes off with the Mother

Board when the two screws are released).

Die beiden unteren Fotos von alter Seite 1-18 nebeneinander hier einfuegen

Reassembly Procedures lb-l

Page 38

5. Screw both brackets back into place.

Bitte oberstes Foto von alter Seite 1-19 hier einfuegen

6. The Mother Board is now ready to receive the power supply assembly, boards, front panel

etc.

Bitte zweites Foto von alter Seite 1-19 hier einfuegen

Board Installation

1. Insert the Display up and the Interpolation Boards back into the corresponding connectors.

Bitte unterstes Foto von alter Seite 1-19 hier einfuegen

1 b-2 Reassembly Procedures

Page 39

Front Panel Reassembly

1. Make sure that the photo resistor on the keyboard assembly . . .

Bitte oberstes Foto von alter Seite l-20 hier einfuegen

2. . . . is positioned over the front-panel recess provided for this purpose.

Bitte zweites Foto von alter Seite l-20 hier einfuegen

3. Screw the parameter connector assemblies back into position (connectors facing upwards).

Bitte drittes Foto von alter Seite l-20 hier einfuegen

Reassembly Procedures 1 b-3

Page 40

4. Place

the CRT back into position - ensure no dirt or other material is trapped between

CRT and front panel screen.

5. Place screws in right-hand bracket. Do not tighten. Hook the grounding spring for the

CRT coating into position - do not bend the spring hook. Replace screws in left-hand

bracket remembering to include black wire from power lamp assembly.

Bitte letztes Foto von alter Seite l-20 hier einfuegen

6. Tighten all of the screws so that the CRT is positioned symmetrically. Hook up the other

end of the ground spring for the CRT coating.

Bitte erstes Foto von alter Seite 1-21 hier einfuegen

1 b-4 Reassembly Procedures

Page 41

Front Panel Installation

1. Fit the front panel assembly back into position.

Bitte zweites Foto von alter Seite 1-21 hier einfuegen

2. Reconnect the CRT socket, the ground wire, the cable to the keyboard assembly, the HV

connection and the choke connection. Reinsert parameter boards.

Bitte letztes Foto von alter Seite 1-21 hier einfuegen

Reassembly Procedures 1 b-5

Page 42

Power Supply Reassembly

1. Secure the power inlet connector back into position.

2. Insert primary power supply board A7.

Note: Make sure that Board fits exactly in slot of rear heat sink.

Bitte die beiden obersten Foto von alter Seite l-22 nebeneinander hier einfuegen

3. Screw back into place (two lower screws).

4. Reconnect transformer to the primary power supply board A7.

Bitte die beiden untersten Fotos von alter Seite l-22 nebeneinander hier einfuegen

1 b-6

Reassembly Procedures

Page 43

5. Position secondary power supply board A6 in slot provided and screw to rear panel.

6. Reconnect transformer to the secondary power supply board A6, making sure that all of

the connector pins make proper contact. Reconnect battery connection (if fitted).

Bitte die beiden obersten Fotos von alter Seite l-23 nebeneinander hier einfuegen

7. Reinstall power supply cover.

8. Screw two side screws back into position.

Bitte die beiden untersten Fotos von alter Seite l-23 nebeneinander hier einfuegen

Reassembly Procedures 1 b-7

Page 44

9. Screw rod back into position between the two power supply boards.

10. Secure top of cover with the two screws.

Bitte die beiden obersten Fotos von alter Seite l-24 nebeneinander hier einfuegen

11. Slot rear-panel insert back into position.

12. Secure rear panel insert by screwing the potential equalisation connector back into

position.

Bitte die beiden untersten Fotos von alter Seite l-24 nebeneinander hier einfuegen

1 b-8 Reassembly Procedures

Page 45

13. Check that the soldered ground connection is still intact.

Bitte oberstes Foto von alter Seite l-25 hier einfuegen

Power Supply Assembly Installation

1. Slot the power supply assembly into the bottom cover at the rear of the Monitor. Lower

the assembly back into position taking care not to clamp any of the cables underneath.

2. Screw power supply assembly back into position with the one screw required.

Bitte die beiden mittleren Fotos von alter Seite l-25 nebeneinander hier einfuegen

3. Check that power on/off switch coupler makes mechanical contact with the switch. Test

the on/off switch to see that it works.

Bitte unterstes Foto von alter Seite l-25 hier einfuegen

Reassembly Procedures 1 b-9

Page 46

NIBP Pump and Board Reassembly (78352A/C and 78354A/C)

Reassembly is the reverse of disassembly. With the 78352A monitor care should be taken

when sliding in the NIBP board not to trap the tubing leading to the transducer between the

NIBP board and any adjacent board. Fit tube leading down to front panel connector between

the board and RHS side panel. Note the correct tubing connections:-

78352A/C, 78354A/C

(dc pump)

78354A (ac pump)

Bitte die beiden obersten Fotos von alter Seite l-26 nebeneinander hier einfuegen

Cover Installation

Remount side covers (4 bottom screws) and put the board stabilizer back into position.

Remount top cover with 4 top screws.

Bitte die beiden unteren Fotos von alter Seite l-26 nebeneinander hier einfuegen

1 b-10 Reassembly Procedures

Page 47

lc

Adjustments

Introduction

In order to make any adjustments it is necessary to remove the top cover of the instrument;

so, during the adjustment procedures take care to avoid contact with exposed high voltage

sources.

To make any of the adjustments it is necessary to enter the monitor test mode.

To do this, first ensure that the monitor is switched off for at least 20 s.

Now press the softkeys labelled JL or (CalMark) and Z or (Suspend) simultaneously, then switch

the monitor on whilst keeping the buttons pressed. Hold pressed until the prompt tone is

heard. The CRT adjustment grid will now appear on the screen.

In this mode the softkeys have the following functions:

(cal,,,s;) n

Istopl STOP Press to display service/test waveform - non- overlapping

(used in “CRT Adjustments” and “Interpolation Board Adjustments”

See Figure lc-3*

(Overview) fi

(PatientData)~

(Record) q

The remainder of this section contains the detailed adjustment procedures.

*only one service/test waveform available in 78352A/C.

Press to display service /test waveform with channels 2

and 3 overlapping (used in “Interpolation Board Adjustments”.

Press to enter into system 780 configeration mode (only if

780 annotating system and SDN board is installed) (used in

“System 780 Configuration Adjustments”)

Press to display part numbers of ROMs loaded (hence

software revision status eg. 5180-XxXx, 5181-XxXx)

Adjustments 1 c-l

Page 48

CRT Adjustments

These adjustments are made using components on the motherboard and the CRT assembly

and are normally only required after a mother board or CRT exchange. The location of these

components is shown in Figure lc-1.

Display the CRT adjustment grid on the screen as described in “Introduction” then follow the

adjustment procedure below:

1. Optimize the display with cut-off adjust AlR55

2. If the horizontal synchronization is out of range, adjust with AlR21

3. Adjust the horizontal amplitude with AlR28. The vertical lines to the right and the left

of the grid should just be visible at the edge of the screen.

If the adjustment grid is not in a central position it will not be possible to make this

adjustment. In this case, rotate the centering magnets (see Figure lc-1) on the CRT until

the grid is centered then repeat the adjustment.

4. Adjust the linearity with AlR22. The horizontal grid subsections should all be of equal

length.

5. AlR28 and AlR22 are interactive, so repeat steps 3) and 4) until optimum result is

achieved.

6. Adjust the vertical amplitude with AlL2. The horizontal lines above and below the grid

should just be visible at the edge of the screen.

If the adjustment grid is not in a central position see paragraph 4) for centering

procedure.

7. Adjust the linearity with AlL3. The vertical grid subsections should all be of equal

length.

8. Next press the softkey labelled STOP to display the service/test waveform

(non-overlapping).

9. Check the interpolation - there should be no modulation of the test waveform intensity. If

there is modulation, adjust AlR55 again until it is reduced to a minimum.

10. Switch the instrument off then after 20 seconds back on again. The initial monitoring

display should appear.

11. Adjust the focus with AlR38.

lc-2 Adjustments

Page 49

12. Check the length of the baseline - it should be 97 mm.

13. Adjust the intensity with the rear panel screwdriver control.

14. Switch the monitor off and after 20 seconds on again, and display the CRT adjustment

grid. (see “Introduction”)

15. If the shape of the adjustment grid is distorted, i.e. the gridlines are curved, optimise the

shape by repositioning the small magnets on the ring at the front of the deflection yoke

assembly. See Figure lc-1.

Components for Adjustment Centering and Ring Magnets

Diagram und Photo von alte Seite l-29 hier einfiigen

Figure lc-1. Location of Components for Adjustment and of Centering and Ring Magnets

Adjustments lc-3

Page 50

Interpolation Board Adjustments

Note

The 78352A/C

monitor uses Interpolation Board 78352-66503, all other

monitors described in this manual use Interpolation Board 78353-66503.

78352A/C adjustments are contained in brackets.

Yll

All interpolation board adjustments are made using the nine potentiometers on the

78353-66503 board and three potentiometers on the 78352-66503 board.

Gain and Offset Adjustments

First enter the monitor test mode and press STOP key to display the service/test waveform in

non-overlapping mode (see “Introduction”). Now follow the adjustment procedure below:

a. Adjust the gain for channel 1 using A3RlO (78352A/C: A3/R19) until the distance between

the 1st (bottom) and 3rd levels of the step waveform is approximately the same as the

distance between the graticule lines.

b. Adjust the offset for channel 1 using A3R28 (78352A/C: A3/R29) until the two levels of

the step waveform are directly on the graticule lines

c. As A3RlO and A3R28 (78352A/C: A3/R19 and A3/R29) are interactive it may be

necessary to repeat steps a) and b) until an optimum result is obtained.

d. Adjust the gain and offset for.channels 2 and 3 as for channel 1 above but using A3R30,

A3R8 and A3R20, A3R18 respectively.

e. t To check the adjustment, press # or COverview) key to display the service test waveform

with channels 2 and 3 overlapping (see “Introduction”).

f. t The waveforms for channels 2 and 3 should be of equal size and the step waveforms level

with each other (Figure l-56). If not, adjust the offset and gain for channels 2 and 3 in this

mode until an optimum result is achieved.

Baseline Width Adjustment

Enter the monitor test mode and display the service/test waveform (see “Introduction”)

a. Adjust the width of the baseline of the channel 1 waveform using A3R37

A3/R12).

e waveform should have the same intensity at every point.

Th

(78352A/C:

b. t Adjust the baseline width of the channel 2 and 3 waveforms in the same way using

A3R39 and A3R38 respectively.

Note

t Not applicable to 78832A and 78352A/C)

lc-4 Adjustments

Page 51

OS1 Gl OS2

c2 OS3

G3

Wl W2

W3

r

Figure lc-2. Location of interp. bd adjustment potentiometers (78353 - 66503)

See Chapter lc for details on how to enter the following display modes:

Service/test waveform

(non-overlapping,

3 channel interp.)

Figure 103. Service/Test Waveform

Service/test waveform

(channels 2 + 3 overlapping,

3 channel Interp.)

Adjustments lc-5

Page 52

Figure 1 c-4.

Location of interpolation board (78352 - 66503) adjustment potiometers and 78352A/C

service/test waveform

1 c-6 Adjustments

Page 53

ECG Adjustments

Note

3

Offset Adjustment

1. Switch monitor on and connect ECG patient cable and lead set.

2. Short all the leads together.

3. Select diagnostic mode and ensure that switch 1 of A22Sl is closed.

4. Ensure that switch S2 on the mother board is programmed to output the ECG wave at the

rear panel phone jack (switch 4 closed and switches 1, 2 and 3 open).

5. Connect a DVM to the rear panel phone jack.

6. Adjust A22R69 so that the DVM reading equals OV f 20 mV.

Notch Filter Adjustment

60 Hz

50Hz

1. Connect the test equipment as shown in Figure lc-5

Note: all boards are already adjusted in the factory.

78832-66542, 78354-66542

78832-66522, 78354-66522

2. Ensure that switch S2 on the mother board is programmed to output the ECG wave at the

rear panel phone jack (switch 4 closed and switches 1, 2 and 3 open)

3. Switch monitor on and select diagnostic mode and lead II.

4. Apply a 5 V peak-to-peak sine wave at 50 or 60 Hz (main frequency) to the test circuit.

5. Trigger the oscilloscope to the line frequency (only possible when the line frequency equals

the notch frequency).

6. Adjust A22R82 until the wave ouput displayed on the oscilloscope is at minimum

amplitude.

Note

The Full Lead ECG board (78354-66522) has 3 switches, the positions and

location of which are shown in the Jumper & Switches in “ECG Board (Full

lead) 78354-66522, 66722” in Chapter Id.

Adjustments 1 c-7

Page 54

Figure lc-5. Location of A22R69 and A22R82

78SXX ser1er

14337A114336A

REAR-PANEL REAR-PANEL

PHONE JACK PHONE JACK

OSCILLOSCOPE OSCILLOSCOPE

P.N.

10501A

FUNCTION

GENERATOR

TEST

CIRCUIT

769XX serie*

149678114467A

PATIENT CABLE

,- ----1

#$

Figure 106. Notch Filter Adjustment - Test Equipment

Power Supply Adjustments

-4 Volt Adjustment

a. Switch the monitor on.

b. Connect a DVM to ground and to the -4 V test pin at the top of the power supply board

A6.

c. Adjust A6, R5, located next to this pin, so that the DVM reading equals -4 V f 3 mV.

1 c-8 Adjustments

Page 55

System 780 Annotating Analog Interface (Opt. Jll)

The annotating 780 system board (78353-66592) provides full parameter, alarm and recorder

information. There are six alternative output- connector configurations which are shown in

table 1. (For more detailed information please refer to pages l-42 to l-44)..

System 780 Configuration Adjustments

The system interface is configured using the softkeys. First, enter the system 780

configuration mode as described in “Introduction”.

The functions of the softkeys are now as follows:

Cal Mark JL

Press to select one of the seven possible configurations of

the signals at the system output connector (see Table lc-1).

(Stop) STOP

(Overview) #

Press to select latching or nonlatching system alarms.

Press to change temperature offset (see offset adjustment

below). This should not be necessary as the value is set at the

factory.

[PatientData)D

Press to change general parameter offset (see offset adjustment

below). This should not be necessary as the value is set at the

factory.

Record IL

Press to store configuration values. When store procedure is

successfully completed the monitor returns to the previous

operating level and the CRT adjustment grid is displayed.

Off set Adjustment

It may be necessary to adjust the system 780 board if the EAROM has lost information. In

this case follow the procedure below:

a. General parameter offset

With the monitor in system ‘780 configuration mode, measure the general offset at TPl. If

it is zero volts the offset is correct. If it is not zero volts the offset must be adjusted using

the softkey indicated above.

The softkey label will show the offset correction step number and will rotate over the full

positive and negative range, increasing the number by one each time the key is pressed.

Press the softkey until the value is zero volts. The step size is 2.5 mV.

b. Temperature parameter offset

Note

With option N12 (G erman temperature standards) this adjustment is not

possible.

With the monitor in system 780 configuration mode, measure the temperature offset on pin

10 of system output connector (J91). If it is zero volts the offset is correct. If it is not zero

volts the offset should be adjusted. To enable the adjustment procedure, connect X3 pin 2

to ground.

Adjustments 1 c-9

Page 56

For adjustment, use the temperature offset softkey. The procedure is the same as for the

general parameter offset described above. Press the softkey until the value is zero volts.

The step size is 1.25 mV.

c. Store the offset correction values by pressing the store softkey. The monitor returns to the

previous operating level (monitor test mode) when store procedure is complete.

Note

d. Temperature gain adjustment

Note

With the monitor in

signal on pin 10 of system output connector (J91). The measurement value in this

operating level should be 2.558V f 0 mV, otherwise adjust with potentiometer R204.

A gain adjustment is necessary in monitor test mode for temperature.

With option N12

possible.

monitor test

(G erman temperature Standards) this adjustment is not

mode (grid raster display) measure the temperature

lc-10 Adjustments

Figure 1~7. Location of R204 and TPl

Page 57

Explanation of Configurations in Table lc-I.

Configuration 0:

Configuration 1:

Configuration 2:

Configuration 3:

Configuration 4:

Configuration 5:

Configuration 6:

Monitor with 7811B control center without arrhythmia

system. Bedside recorder 78171/2/3.

Monitor with 78501/2/4/8 Speakeasy control center without

arrhythmia system.

Monitor with 7811B control center with arrhythmia system.

No parameter values Systole and Diastole for invasive blood

pressure 2.

Monitor with 78501/2/4/8 Speakeasy control center with

arrhythmia system. No Resp. or CO2 curve.

Corresponds to Config. 0, but with a fixed allocation of

the recorder channels 1 and 2 with “Delayed ECG” on channel

1 and “Delayed Press 1” on channel 2. This corresponds to

the default configuration in Config. 0.

Special neonatal version with CRG-option. Cannot be

selected on the adult-monitor mode. Switch Sl must be

opened in operation with 8232 alarm recorder.

Only on OR multi-channel recorder. This version cannot be

selected on the German language option as there is no

allowance by PTB on 2. temperature.

Warning

In configurations O-4 and 6, the switch Sl must be closed.

Adjustments 1~11

Page 58

Table lc-1. System Output Configurations

J92

pin

no.

1 ECG wave

2 pleth wave encoded pleth wave encoded pleth wave

3 signal gnd.

4 recorder encoded recorder encoded recorder tcpcoz

5

6

7 INOP

8 reset

9

10 temp 1.

11 resp. rate

12

0 1 1*

deselect deselect

data alarm data alarm

recorder

return INOP return INOP return

encoded recorder encoded recorder ‘Temp.2 ***

Configurations O-6

2 3 4

analog

alarm gnd.

heart rate average

patient alarm

5s 6

tcpo2

data

***

A

scaled

pressure 2 pressure 2 pressure 2 pressure 2 pressure 2

wave

B

C

absolute

(6’3)

scaled absolute scaled absolute

pressure 1 pressure 1 pressure 1 pressure 1

wave

scaled

wave

systolic

pressure 1

D diastolic

pressure 1

E

F

H

CO2 /resp. resp. CO2 wave resp scaled

wave wave wave pressure 2 wave

systolic absolute systolic cardio

pressure 2 pressure 1 pressure 2

mean heart rate

pressure 2

wave (300) mode

absolute scaled tcpco* ECG wave

(60)

(300)

wave

wave

wave

absolute

pressure 2

wave

absolute

pressure 3

wave

CO2 wave

b-to-b

**

pleth wave

respirogram

resp.

wave

1~12 Adjustments

Page 59

Table 1~1. System Output Configurations (continued)

592

pin

no. 0

J

K

L diastolic

M mean

N

*

**

***

****

output configuration for CO2 /02 parameter

for cardiorespirogram mode, switch Sl on system board should be open

no Aux Wave because it is available as analog signal

output configuration not available in German Language Option (PTB)

recorder ET COz recorder scaled delayed delayed NIBP wave

channel 2 channel 2 pressure 1 pressure 1

pressure 2 pressure 2 pressure 2

recorder control control recorder control delayed

channel 1 state 1 state 5 channel 1 state 1 ECG wave HR b-to-b

1

Fi 02

Configurations O-6

1* 2 3 4 5# 6

resp.

wave wave wave

ALARM ON/

OFF

absolute diastolic Fi 02

wave (60)

ET CO2

pressure 1

delayed HR b-to-b

***

#

only available in 788Xx series

Adjustments 1~13

Page 60

SDN Configuration Adjustments

The system distribution network board is configured using the softkeys.

To do this, first ensure that the monitor is switched off for at least 20s. Now press the keys

labelled JL or [Cal) and E or (Suspend) simultaneously, then switch the monitor on

whilst keeping the buttons pressed. Hold pressed until the prompt tone is heard. The CRT

adjustment grid now appears on the screen.

Enter the SDN configuration mode by pressing m or (Patient] key and the following

display will appear:

SYSTEM

NETWORK TEST (CalMark) J-L

FACTORY DATA (Stop) STOP

ECHO (Overview) #

(Patient-a

BACK TO SETUP (Record) H Press to return screen to grid display

When the NETWORK TEST softkey is pressed the following display appears:

NEXT BRANCH

(Cal)

Press to select branch connection information

Press to select sensitivity, R/Y or INOP alarms,

alarm mode and arrhythmia on/off.

Press to initiate test - comprises of a 500 TEST

word message transmitted to the SDN board

(performed in the factory only)

. . .

JL Press for next branch

(up to 321

BRANCH 0 (Stop) STOP

OOlC

28

f&xi-) #

BACK TO SETUP

Pressing the NEXT BRANCH softkey advances the display to the next branch in the network

upto the maximum number of 32 branches. The information in the center of the screen

indicates the branch being observed and the identity of the downstream instrument (in this

case a 78504A Patient Information Center - see following “Instrument Identity”). The second

entry (OOlC) encodes the instrument status (see following “Instrument Data Transmission

Errors” and “Instrument Status Word”).

(iGi-- 8.. Press

to return softkeys

to

SYSTEM display

1~14 Adjustments

Page 61

Pressing the FACTORY DATA softkey gives the following display;

FACTORY DATA SYSTEM

AL CONF =RYI [Mark) n

Select sensitivity RY, RI or RYI

alarm configuration

AL MODE =AUTO lstopl STOP

Select either AUTO or DEMAND for

alarm display t

AR WAVE=ON (Overvie;v) @

Select on or off arrhythmia

delayed ECG wave

(Patient-a

STORE CONF ljj) L-51

. . .

Press to store and return

display to previous

Pressing the ECHO TEST softkey clears the display of all other functions and only the

words ECHO TEST are left on the screen. This function is performed in the factory during

service checks and a 500 word message is transmitted to the SDN board for processing and

re-transmission back to the board testing device.

Note

t DEMAND mode is the standard setting on the 78352A/C monitor and on

other instruments with SDN the standard setting is AUTO.

3

Note

The alarm latching/non-latching function of the SDN board is selected on

switch block Sl, visual alarm switch 7, on the Display UP Board.

Instrument Identity

YY Instrument

03 785348

28 785048

48 785048

68 78504A

88 785048

A8 7850411

C8 785046

28 785088

48 785088

68 78508A

8A 785088

AA 78508A

CA 7850811

ID no.

Adjustments lc-15

Page 62

Instrument Data Transmission Errors

BIT

76543210

l....... False SPS Event Flag

1 . . . Fatal Control Error Flag

l.....

1 Physical Data Error Flag

l... Logical Data Error Flag

1..

1. System Cycle Failure Flag

. . . . . .

Recoverable Control Flag Error

Poll Cycle Overflow Flag

Bo Error

Instrument Status Word

BIT

76543210

x.. .

x.. .

0

1

. . .

. . .

x..

0 . .

1.

x

0 .

1..

Self Test State (=l during Self Test)

Configuration State

Autopoll

SDU

DLC Line State

Offline

Online

System Cycle State

Local

Betaork

xx

Start/Restart Indicators

2 .

starting = 1

2

Restarting = 1

Binary to Hex Conversion Table

Binary Her

0 0000

0 0001

0 0010

0 0011

0 0100

0 0101

0 0110

0 0111

0 1000

0 1001

0 1010

0 1011

0 1100

0 1101

0 1110

0 1111

1 0000

0

1

2

3

4

5

6

7

8

9

A

B

c

D

E

F

10

lc-16 Adjustments

Page 63

Id

Jumpers & Switch Programming

Jumpers & Switch Programming for all Boards

Mother Board: 78353-665013 and 7835446501

Switches Sl and S2 on the Mother board are accessible when the top cover and parameter

boards are removed.

Programming Switch Sl

The Switch functions are shown below:

Conditions when switch closed.

1 Aux alarm to XlOC/18 (78353-66552

PAT Board only)

2 +5V buffered from A19 to XlOC/18

(OPEN = No Trend)

3 RESET signal is routed to X19 pin

14

Switch Sl

4 RESET signal is routed to System -

connector X91 pin 13

5 No contact

6 ICU alarm volume, possible to turn

alarm volume down to zero

7 QRS tone for Japan (switch closed

for option 202)

8 Standard QRS tone (OPEN for

option ZO2)

76366A

Jumpers & Switch Programming Id-1

Page 64

Note

Either 2 or 1 must be open

The QRS tone is not available on the 78356A monitor. Switches Sl-7 and 8

should OPEN.

Note

t78354-66501 board replaces 78353-66501.

If replacement board is ordered check that the Revision number of the board

is B-2513, C or greater. If it is not then for monitor 78834A Opt A22 only,

connect pin 11 on X83 to pin 6 on X4 (see wiring diagram). This is already

done on boards 78354-66501 with Revision B-2513, C or greater.

Programming Switch S2

This switch controls which parameter wave is present at the phone jack output on the rear

panel.

Condition when switch closed.

1 Not connected

2 Parameter wave from XlOC

3 Parameter wave from XlOB

4 Parameter wave from XlOA

Note

Standard settings are listed in summary table opposite.

Switches 4 should be in the CLOSED position to get the

ECG wave on limited I/F output. If this is abered the

label on the side panel should be changed.

The parameter wave options are not available on the

73352A

78356A

78356A monitor. Switches S2-2 and 3 should be open.

Switch S2

ld-2 Jumpers & Switch Programming

Page 65

Programming Switch S3

Switch S3 is located on the Extender Board.

1 OPEN: No parameter wave from Mother Board

CLOSED: Parameter wave from Mother Board

2 Parameter wave from Y/X6C} Sl

3 Parameter wave from Y/XGB} must be

open

Switch S3

4 Parameter wave from Y/XGA} OPEN

Note

Standard setting is SI CLOSED, S2/S3/S4 OPEN.

Sl is OPEN if 2 or 3 or 4 switch are CLOSED.

Programming Switch S4

Switch S4 is located on the Extender Board and configured according to the instrument and

option:

78354A #A22, #A23

1 CLOSED } K4 to 1 OPEN } K5 to

2 OPEN } Keyboard 2 CLOSED } Keyboard

3 OPEN }

4 CLOSED } code-2 4 OPEN } code-3