Page 1

TM 11-6625-2751-14&P

TECHNICAL MANUAL

OPERATOR’S, ORGANIZATIONAL,

DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS

FOR

OSCILLOGRAPH RECORDER RO-460(V)1/U

(HEWLETT-PACKARD MODEL 7702B)

(NSN 6625-00-464-2957)

HEADQUARTERS, DEPARTMENT OF THE ARMY

MAY 1979

Page 2

This manual contains copyright material reproduced by permission of the Hewlett-Packard Company.

TM 11-6625-2751-14&P

TECHNICAL MANUAL HEADQUARTERS

No. 11-6625-2751-14&P WASHINGTON, DC,

OPERATOR’S, ORGANIZATIONAL, DIRECT SUPPORT, AND GENERAL SUPPORT

You can improve this manual by recommending improvements using DA Form 2028-2 located in the

back of the manual. Simply tear out the self-addressed form, fill it out as shown on the sample, fold it

where shown, and drop it in the mail.

If there are no blank DA Forms 2028-2 in the back of your manual, use the standard DA Form 2028

(Recommended Changes to Publications and Blank Forms) and forward to the Commander, US Army

Communications and Electronics Materiel Readiness Command, ATTN: DRSEL-ME-MQ, Fort Monmouth,

NJ 07703.

In either case a reply will be furnished direct to you.

}

MAINTENANCE MANUAL INCLUDING

REPAIR PARTS AND SPECIAL TOOLS LISTS

FOR

OSCILLOGRAPH RECORDER RO-460(V)1/U

(HEWLETT-PACKARD MODEL 7702B)

(NSN 6625-00-464-2957)

REPORTING OF ERRORS

DEPARTMENT OF THE ARMY

11 May 1979

This manual is an authentication of the manufacturer’s commercial literature which, through

usage, has been found to cover the data required to operate and maintain this equipment.

Since the manual was not prepared in accordance with military specifications , the format has

not been structured to consider levels of maintenance.

i

Page 3

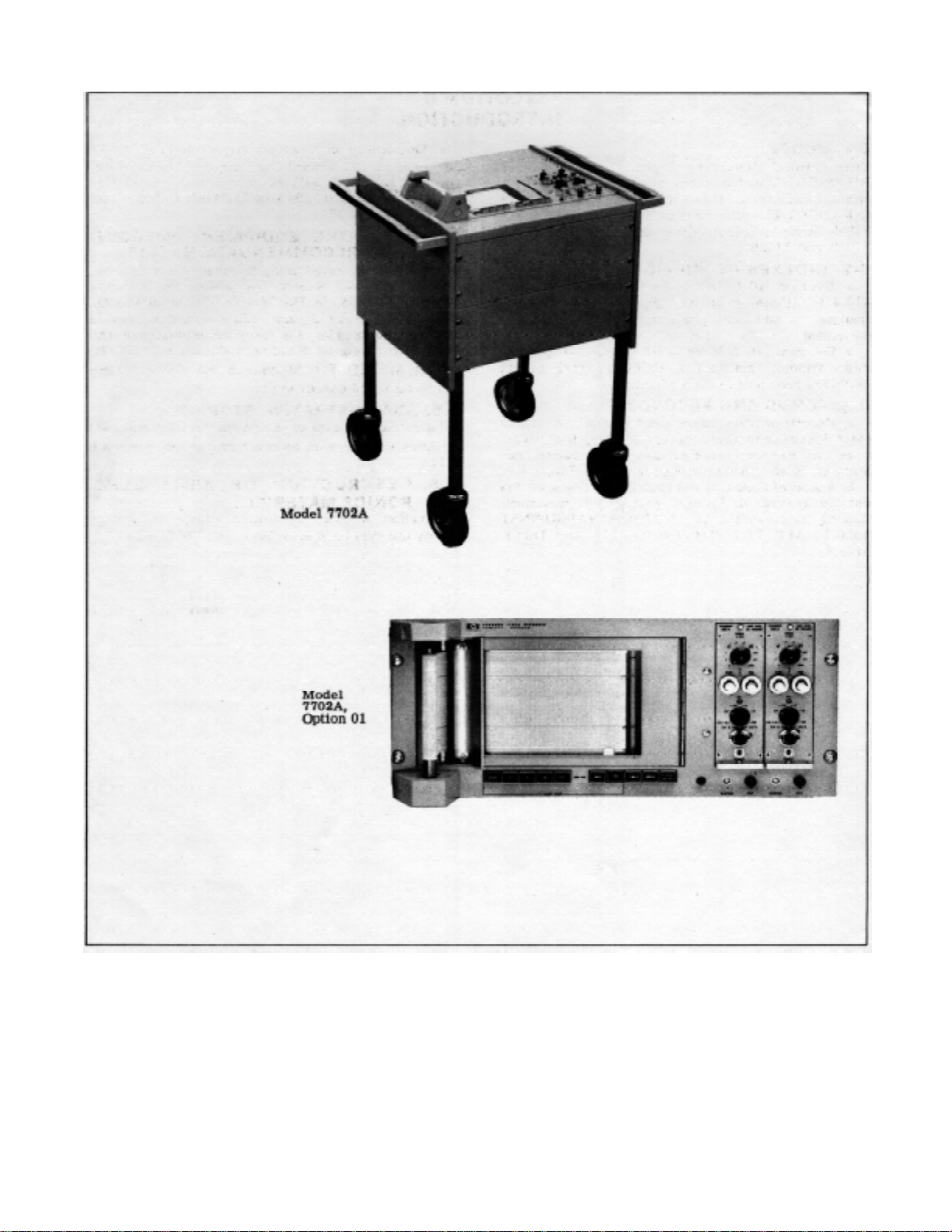

Model 7702A TM 11-6625-2751-14&P

TABLE OF CONTENTS

Section Page

O INTRODUCTION 0-1 Section Page

I. GENERAL INFORMATION .......................1-1 IV. PRINCIPLES OF OPERATION............................ 4-1

1-1. Description ......................................1-1 4-1. Introduction.............................................. 4-1

1-6. Component Identification ...........1-1 4-3. Basic Circuits........................................... 4-1

1-8. Standard System Options..........1-1 4-4. Diodes................................................ 4-1

1-10. Special Options .........................1-1 4-9. Transistors ......................................... 4-1

1-12. Component Description ..................1-1 4-12. Component Circuit Description ................ 4-3

1-13. Model 7702-OlA Recorder.........1-1 4-13. Preamplifiers. ..................................... 4-3

1-16. Model 7700-02A Driver.............. 4-16. Driver Amplifier................................... 4-3

Amplifier.....................................1-3 4-26. System Power Supply ....................... 4-5

1-18. Preamplifiers, 8800 Series.........1-3 4-33. Recorder Description .............................. 4-9

1-20. Model 1069-02A Mobile Cart.....1-3 4-35. Chart Drive Components.................... 4-9

1-22. System Specifications................1-3 4-37. Drive Motor and Speed

............................................... Reduction Gears ................................4-9

II. INSTALLATION..........................................2-1 4-40. Push-button Actuated Clutch

2-1. Introduction .....................................2-1 Assemblies ..................................... 4-11

2-3. Initial Inspection .............................2-1 4-44. Chart Drive Circuits.................................. 4-11

2-4. Mechanical Inspection ...............2-1 4-47. Stylus Heat Circuits ................................. 4-12

2-6. Electrical Check ........................2-1 4-51. Marker and Timer Circuit ......................... 4-13

2-8. Claims and Repackaging ................2-1

2-9. Claims for Damage ....................2-1 V. MAINTENANCE ................................................... 5-1

2-11. Repacking for Shipment ............ 5-1. Introduction ............................................. 5-1

or Storage ..............................2-1 5-3. Test Equipment ....................................... 5-1

2-13. Installation.......................................2-1 5-5. Performance Checks .............................. 5-1

2-15. Environment...............................2-1 5-6. General .............................................. 5-1

2-19. Rack Mounting Instructions........2-1 5-8. Variable Line Voltage............................... 5-1

2-21. System in Portable Case ...........2-1 5-10. Preventive Maintenance .......................... 5-9

2-23. AC Power Requirements ...........2-1 5-12. Mechanical......................................... 5-9

2-26. Input Signal Connections...........2-2 5-16. Electrical ............................................ 5-10

2-28. Signal Input Connectors ............2-2 5-18. Cleaning ............................................. 5-10

2-30. Signal Input Cable .....................2-2 5-20. Lubrication ......................................... 5-10

2-33. Input Connector Wiring for......... 5-23. Brake and Drive Roll

Non-Guarded Preamplifiers .......2-3 Maintenance Procedures ................... 5-10

2-35. Input Connector Wiring for .............. 5-24. Brake Roll Lubrication........................ 5-10

Guarded Preamplifiers...............2-3 5-25. Brake Roll Adjustment........................ 5-11

2-37. 8805A Carrier Preamplifier.............. 5-29. Drive Roll Replacement...................... 5-12

Input Cables...............................2-4 5-36. Paper Take-Up Maintenance

2-39. Cable Assembly for use with........... Procedures ........................................5-14

Sanborn Transducers ................2-4 5-37. Paper Take-Up Adjustment ................ 5-14

2-41. Instructions for Assembling ............. 5-38. Paper Take-Up Assembly

Signal Input and Reference ....... Lubrication ..................................... 5-14

Cables........................................2-4 5-41. Stylus Adjustments and Repairs.............. 5-15

2-43. 8806A Phase Sensitive Demod- ..... 5-42. Stylus Pressure ................................. 5-15

ulator Signal Cables ..................2-4 5-44. Stylus Mechanical Stop...................... 5-16

2-47. Signal Monitor Connections ...........2-5 5-46. Stylus Mechanical Center

2-49. Remote Recorder Operation ...........2-5 (Zero).............................................. 5-16

2-51. Remote Chart Drive................... 5-48. Corrective Maintenance........................... 5-16

START-STOP control.............2-5 5-49. Disassembly of System

2-54. Remote Marker Control..............2-5 Components ................................... 5-16

2-57. Auxiliary Marker Operation.........2-5 5-56. Disassembly and Lubrication of

2-59. Initial System Check .......................2-5 Chart Drive Components.................... 5-17

2-63. To Check Recorder Drive .......... 5-59. Chart Drive Lubricants........................ 5-17

Functions................................2-5 5-61. Shaft Disassembly and

2-64. To Check Recorder Marker............. Lubrication .....................................5-18

and Timer Functions .................2-5 5-63. Shaft A Servicing ............................... 5-18

............................................... 5-64. Shaft B Servicing ............................... 5-18

III. OPERATION..............................................3-1 5-66. Shaft C Servicing ............................... 5-18

3-1. Introduction .....................................3-1 5-67. Shaft D Servicing ............................... 5-18

3-3. Controls and Connectors.................3-1 5-69. Shaft E Servicing 5-20

3-5. Operating Procedures ....................3-1 5-70. Shaft F Servicing .................................... 5-20

ii

Page 4

TM 11-6625-2751-14&P

Model 7702A

TABLE OF CONTENTS (Cont.)

Section ..................................................Page Section ...................................................Page

V. MAINTENANCE (Cont.) ............................. V. MAINTENANCE (Cont.)

5-72. Drive Motor Sprocket and................. 5-85. Troubleshooting ................................5-24

Chain Lubrication ........................5-20 5-87. Electrical Performance Check............5-24

5-73. Gear Lubrication ..............................5-20 5-89. Mechanical Problems.........................5-24

5-75. Results of Incorrect Lubrica-............. 5-92. Etched Circuit Board Repair...............5-24

tion Procedure ............................. 5-20 5-95. Component Replacement..................5-24

5-77. Galvanometer Assembly .................5-20 VI. UPDATING SUPPLIES. ................................6-1

5-80. Galvanometer Magnet

Replacement.............................5-20 VII. MANUAL CHANGES.....................................7-1

5-82. Galvanometer Insert

Replacement................................5-20

LIST OF ILLUSTRATIONS

Figure ..................................................Page Figure ...................................................Page

1-1. Model 7702A Recording System and......... 4-9. Unregulated ± 18 V Supply ..........................4-6

Option 01 ..........................................1-0 4-10. Unregulated ± 18 V Power Distribution..........4-7

1-2. Model 7702-0lA Recorder ..........................1-2 4-11. Regulated ± 12 V Supply...............................4-7

1-3. Model 7700-02A Driver Amplifier................1-2 4-12. Regulated ± 12 V Power Distribution.............4-8

1-4. 8800 Series Preamplifier (8801Ashown)....1-2 4-13. 440 Hz Plug-In Oscillator Block Diagram

1-5. Model 1069-02A Mobile Cart .....................1-3 With Associated Circuits ...............................4-8

1-6. 7702A System Power Supply. ...................1-3 4-14. 2400 Hz Plug-In Oscillator Block

.................................................. Diagram ...................................................4-9

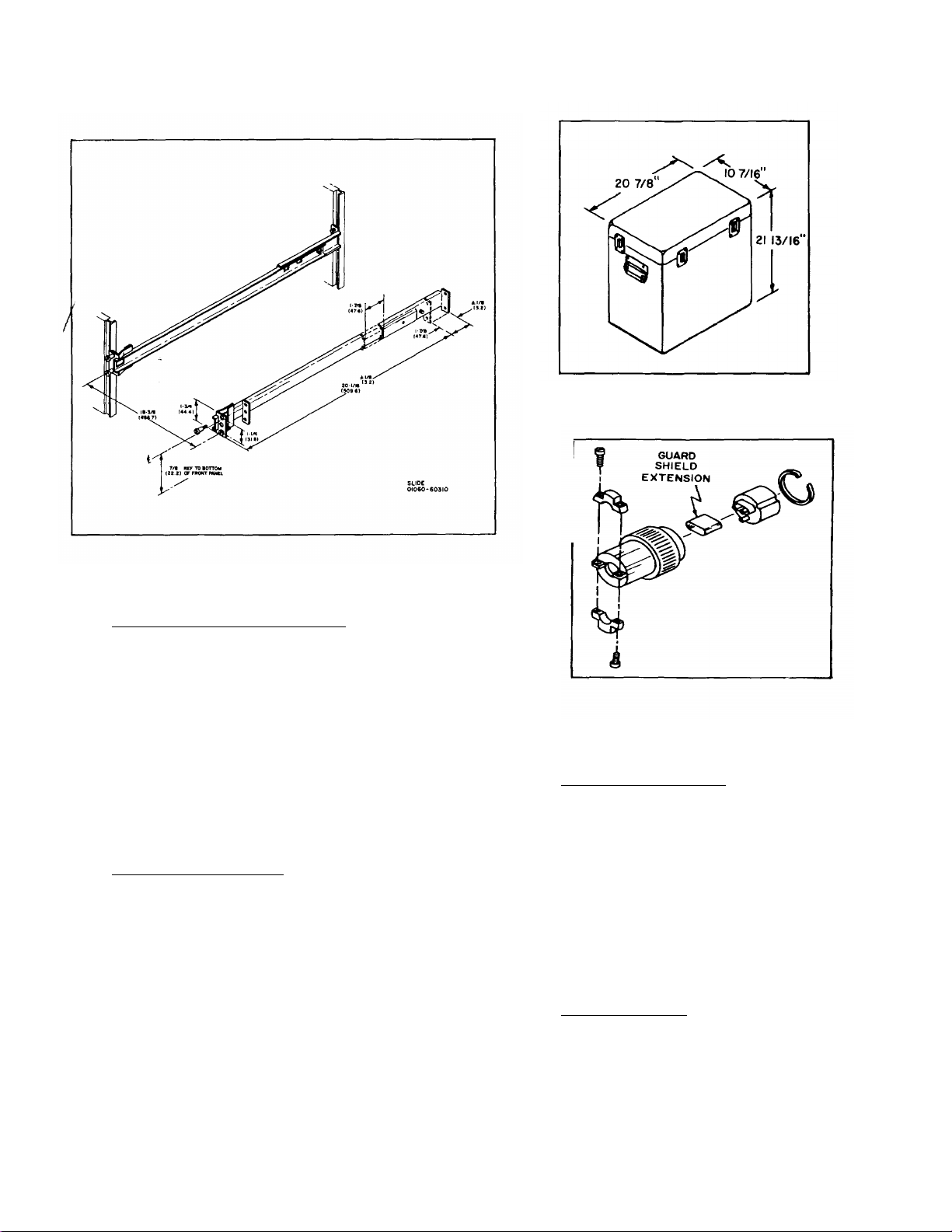

2-1. Slide Kit - 01060-60310 .............................2-2 4-15. Chart Drive Motor and Speed

2-2. Portable Case ............................................2-2 Reduction Gears............................................4-10

2-3. 10G3-34FW Connector ..............................2-2 4-16. First Speed Reduction Assembly

2-4. Cable Preparation.......................................2-3 Operation ...................................................4-11

2-5. Input Connector Wiring, Non-Guarded.......2-3 4-17. Chart Drive Circuit ........................................4-12

2-6. Input Connector Wiring, Guarded. .............2-4 4-18. Stylus Heat Control Circuit ............................4-13

2-7. Y-Cable Sanborn No. 5060-4602 ...............2-4 4-19. Marker and Timer Control Circuitry ...............4-14

2-8. Remote Run Circuit Diagram .....................2-5

2-9. Remote Marker Circuit Diagram.................2-5 5-1. Recorder Platen Writing Edge.......................5-8

2-10. System Controls.........................................2-6 5-2. Stylus Adjustment Screws and Limits............5-9

.................................................. 5-3. Brake Roll Adjusting Screw Location.............5-11

3-1. Typical 2-Channel Recording ....................3-1 5-4. Brake Roll Removal.......................................5-11

3-2. Front Panel Controls ..................................3-2 5-5. Bearing Retainer and Gears .........................5-12

3-3. Rear Panel Controls .................................3-3 5-6. Paper Table Removal....................................5-13

3-4. Permapaper Loading Procedures ..............3-4 5-7. Paper Take-Up Adjustment...........................5-14

3-5. System Operating Procedures .................3-6 5-8. Calibrating and Measuring Stylus

3-6. Remote System Operation .........................3-7 Pressure ............................................5-15

.................................................. 5-9. Stylus Pressure Adjustment ..........................5-16

.................................................. 5-10. Heated Stylus Part No. 398............................5-17

4-1. Model 7702A System Block Diagram.........4-1 5-11. Chart Drive Shafts .......................................5-19

4-2. Basic Diode Circuits ..................................4-2 5-12. Shaft A Lubrication Procedures..................... 5-21

4-3. Transistor Operation ................................4-2 5-13. Clutch Sleeve Clearance...............................5-23

4-4. Signal Distribution Diagram .......................4-4 5-14. Shaft C Inspection.........................................5-23

4-5. Model 7700-02A Driver Amplifier................ 5-15. Excessive Wear in Clutch Assembly.............5-23

Block Diagram .................................4-4 5-16. Checking Galvanometer Sensitivity...............5-24

4-6. Feedback Circuit - Simplified Schematic....4-5 5-17. (a) Troubleshooting Chart

4-7. Galvanometer Frequency Response and... Problems in One Channel ............................5-27

Transient Response..........................4-5 (b) Troubleshooting Chart

4-8. 7702A System Frequency Response .......4-6 Problems in Both Channels ....................................5-28

iii

Page 5

TM 11-6625-2751-14&P

Model 7702A

LIST OF ILLUSTRATIONS (Cont.)

Illustrated Parts Breakdown

Figure ..................................................Page Figure ...................................................Page

1. Two-Channel Thermal Recording Sub-...... 13. Power Supply Assembly, Top View

System (Model 7702A) ................... 5 (07702-60030) ...................................27

2. Two-Channel Thermal Recorder................ 14. Power Supply Assembly, Bottom View

115/230V, 60Hz (Model 7702-01A).. 7 (07702-60030)....................................29

3. Driver Amplifier Assembly.......................... 15. Regulator Card and Bracket Assembly

(Model 7700-02A) ............................ 9 (868-500A-C6)...................................31

4. Printed Circuit Board Assembly.................. 16. Diode Board Assembly (07702-60070).........33

(07700-62010)............................................11 17. Oscillator Card Assembly, 2400 Hz

5. Amplifier Housing Assembly ....................13 (868-500A-C13).................................35

6. Galvanometer Assembly Complete............ 18. Oscillator Card Assembly, 440 Hz

(320-200-Cl0)....................................15 (868-500A-C14)............................37

7. Front Panel, Door and Paper Take-Up....... 19. Timer Assembly (14002S - 14002T -

Assembly (07702-60220) .......................... 17 14002R- 14002V)...............................39

8. Ten-Button Push Switch (3101-1001)........19 20. MM/Min Drive Motor Kit - 60:1

9. Paper Drive Assembly (table, brake........... (07702-60110) (07702-60220)...........39

and associated parts)....................... 21 21. Mobile Cart (1069-02A) ...............................41

10. Paper Drive Assembly (gear train and........ 22. Portable Case (7702-14A).............................43

associated parts) ..................................... 23 23A.7702-01A Recorder Schematic.....................47

11. Table, Drive Roll and Brake Assembly....... 25 23B.Model 7702A Power Supply Plug-In

12. Clutch Actuator Assembly (07702-60100).. 25 Assemblies, Schematic Diagram.......49

LIST OF TABLES

Table ..................................................Page Table ...................................................Page

1-1. Model 7702-01lA Specifications ................1-4 5-1.Recommended Test Equipment ...................5-1

1-2. Model 7700-02A Specifications .................1-5 5-2.Performance Checks ....................................5-2

1-3. 8800 Series Preamplifiers .........................1-5 5-3.Recorder Minor Repairs and

1-4. System Specifications................................1-6 Adjustments...................................................5-5

1-5. System Accessories...................................1-7 5-4.Timing Calibration..........................................5-12

.................................................. 5-5.Lubricants....................................................5-17

4-1. Speed Reduction Ratios ............................4-11

4-2. Timer Assembly Part Numbers ................4-15

APPENDIXES

A. ILLUSTRATED PARTS BREAKDOWN.........................................................................................................A-1

B. REFERENCES ...............................................................................................................................................B-1

C. COMPONENTS OF END ITEM LIST (not applicable)

D. ADDITIONAL AUTHDRIZATION LIST (not applicable)

E. MAINTENANCE ALIOCATION ......................................................................................................................E-1

F. EXPENDABLE SUPPLIES AND MATERIALS LIST (not applicable)

G. REPAIR PARTS AND SPECIAL TOOLS LISTS (PART NUMBER - NATIONAL STOCK

NUMBER CROSS REFERENCE INDEX) ...............................................................................................G-1

iv

Page 6

Model 7702A

TM 11-6625-2751-14&P

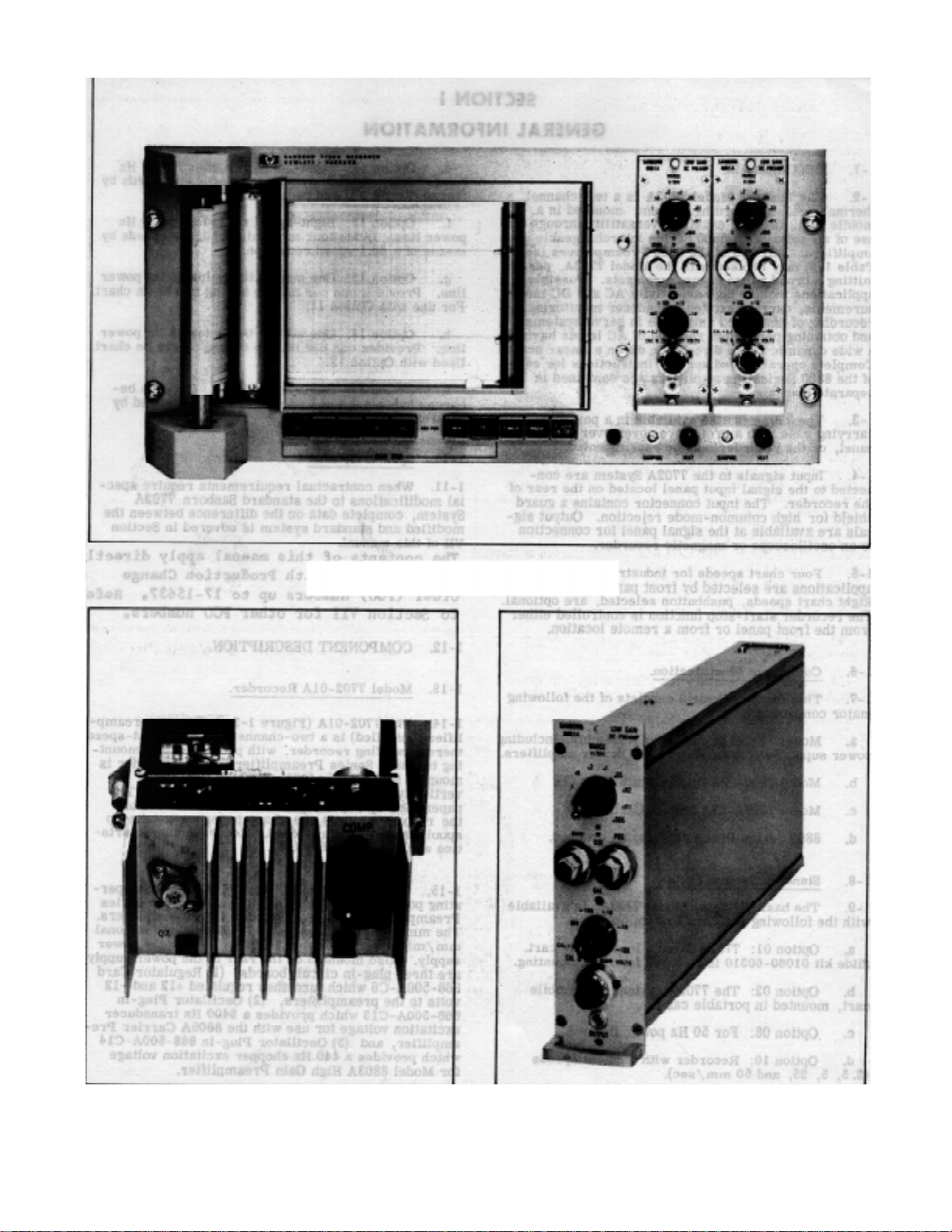

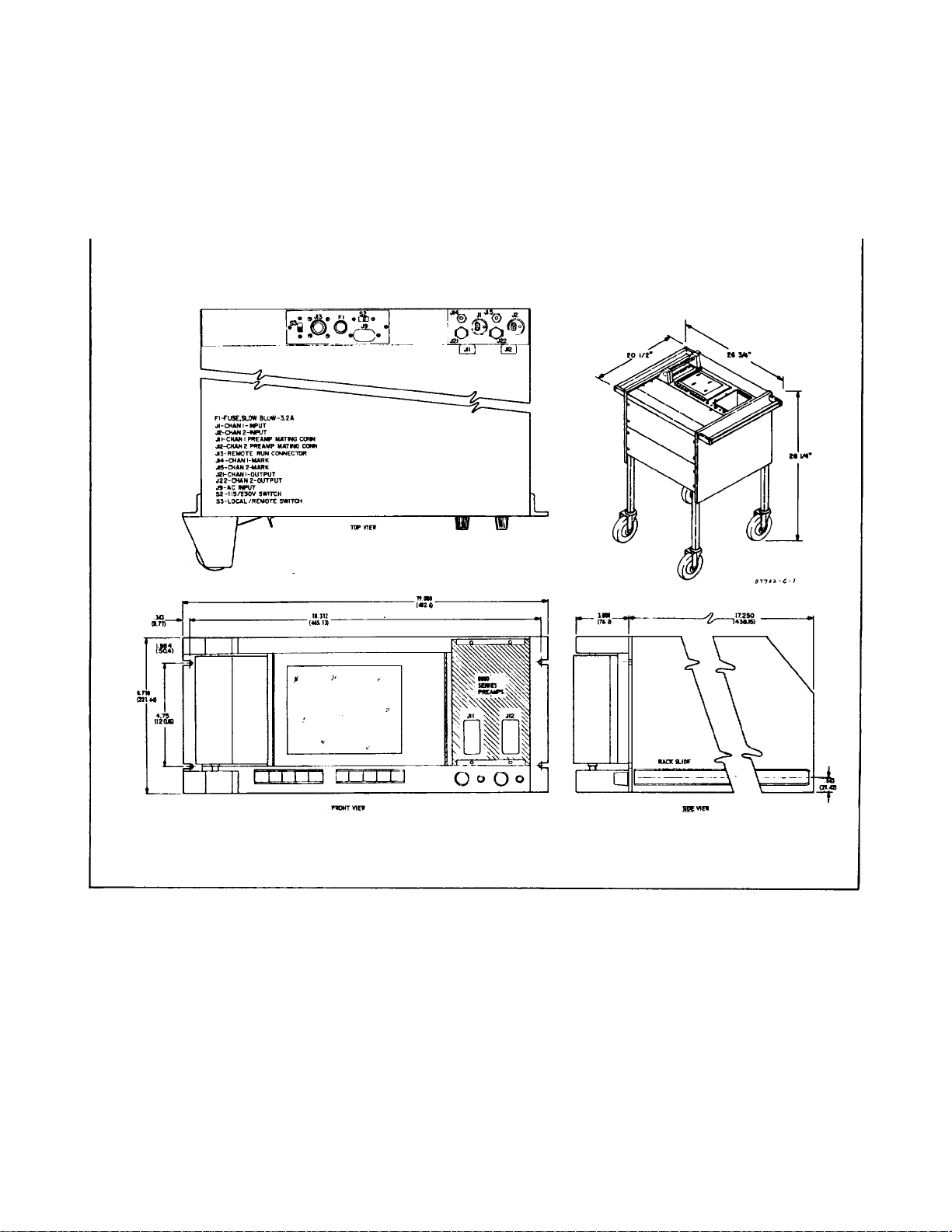

Figure 1-1. Model 7702A Recording System and Option 01

0-0

Page 7

SECTION O.

INTRODUCTION

0-1. SCOPE.

This manual describes Oscillograph Recorder RO460(V)1/U and provides instructions for operation and

maintenance. Throughout this manual, the RO-460(V)

1/U is referred to as Hewlett-Packard Model 7702B.

Refer to Section VI for differences between the 7702A

and 7702B.

0-2. INDEXES OF PUBLICATIONS.

a. DA Pam 310-4. Refer to the latest issue of DA

Pam 310-4 to determine whether there are new editions,

changes, or additional publications pertaining to the

equipment.

b. DA Pam 310-7. Refer to DA Pam 310-7 to

determine whether there are modification work orders

(MWO’s) pertaining to the equipment.

0-3. FORMS AND RECORDS.

a. Reports of Maintenance and Unsatisfactory

Equipment. Maintenance forms, records, and reports

which are to be used by maintenance personnel at all

maintenance levels are listed in and prescribed by TM

38-750.

b. Report of Packaging and Handling

Deficiencies. Fill out and forward DD Form 6 (Pack aging

Improvement Report) as prescribed in AR 70058/NAVSUPINST 4030.29/AFR 71-13/MCO P4030.29A

and DSAR 4145.8.

TM 11-6625-2751-14&P

c. Discrepancy in Shipment Report (DISREP) (SF 361).

Fill out and forward Discrepancy in Shipment Report

(DISREP) (SF 361) as prescribed in AR 55-38/NAVSUPINST 4610.33B/AFR 75-18/MCO P4610.19C

and DLAR 4500.15.

0-4. REPORTING EQUIPMENT IMPROVEMENT RECOMMENDATIONS (EIR).

EIR’s will be prepared using Standard Form SF 368,

Quality Deficiency Report. Instructions for preparing

EIR’s are provided in TM 38-750, The Army Maintenance Management System. EIR’s should be mailed

direct to Commander, US Army Communications and

Electronics Materiel Readiness Command, ATTN:

DRSEL-ME-MQ, Fort Monmouth, NJ 07703. A reply will

be furnished directly to you.

0-5. ADMINISTRATIVE STORAGE.

Administrative storage of equipm ent issued to and used

by Army activities shall be in accordance with paragr aph

2-11.

0-6. DESTRUCTION OF ARMY ELECRONICS MATERIEL.

Destruction of Army electronics materiel to prevent

enemy use shall be in accordance with TM 750-244-2.

0-1

Page 8

SECTION I.

GENERAL INFORMATION

1-1. DESCRIPTION.

1-2. The Sanborn Model 7702A is a two-channel

thermal writing recording system, mounted in a mobile

cart, that has excellent versatility through the use of all

solid-state 8800 Series interchangeable pre- amplifiers.

Any two of the 8800 Preamplifiers (see Table 1-3) may

be used with the Model 7702A, permitting a broad range

of measurements. ’Possible applications include high

sensitivity AC and DC measurements, carrier excited

transducer monitoring, rec ording of phase and amplitude

in servo systems, and obtaining permanent records of

AC levels having a wide dynamic range directly in dB on

a linear scale. Complete operating and service

instructions for eac h of the 8800 Ser ies Pream plif iers are

contained in separate manuals.

TM 11-6625-2751-14&P

e. Option 11: Eight-speed recorder for 60 Hz power

line. (Adds four mm/min recorder speeds by means of a

60:1 speed reduction.)

f. Option 12: Eight-speed recorder for 50 Hz power

line. (Adds four mm/min recorder speeds by means of a

60:1 speed reduction.)

g. Option 13: One minute timer for 60 Hz power

line. Provides one per minute timing marks on chart. For

use with Option 11.

h. Option 14: One minute timer for 50 Hz power

line. Provides one per minute timing marks on chart.

Used with Option 12.

i. Option 15: Auxiliary marker. Records between

channels 1 and 2 on chart paper; actuated by external

contact closure.

1-10. Special Options.

1-3. The 7702A is also available in a portable carrying

case with a protective cover over the front panel, or the

recorder may be rack mounted.

1-4. Input signals to the 7702A System are connected to the signal input panel located on the rear of the

recorder. The input connector contains a guard shield for

high common-mode rejection. Output signals are

available at the signal panel for connection to an

oscilloscope or magnetic recorder.

1-5. Four chart speeds for industrial or medical

applications are selected by front panel pushbuttons.

Eight chart speeds, pushbutton selected, are optional.

The recorder start-stop func tion is controlled either from

the front panel or from a remote location.

1-6. Component Identification.

1-7. This Sanborn System consists of the following

major components:

a. Model 7702-OlA Recorder Assembly, including

power supply for preamplifiers and driver amplifiers.

b. Model 7700-02A Driver Amplifiers (2).

c. Model 1069A-02A Mobile Cart.

d. 8800 Series Preamplifiers, as ordered.

1-8. Standard System Options.

1-9. The basic System, Model 7702A, is available

with the following standard system options:

a. Option 01: 7702A System less mobile cart.

Slide kit 01060-60310 is included for rack mounting.

b. Option 02: The 7702A System less mobile

cart, mounted in portable case.

c. Option 08: For 50 Hz power line.

d. Option 10: Recorder with medical speeds

(2. 5, 5, 25, and 50 mm/sec).

1-11. When contractual requirements require special

modifications to the standard Sanborn 7702A System,

complete data on the difference between the modified

and standard system is covered in Section VII of this

manual.

The contents of this manual apply directly

to instruments with Production Change

Order (PCO) numbers up to 17-15637. Refer

to Section VII for other PCO numbers

1-12. COMPONENT DESCRIPTION.

1-13. Model 7702-01A Recorder.

1-14. The 7702-0lA (Figure 1-2 shown with preamp

lifiers installed) is a two-channel, four or eight-speed

thermal writing recorder, with provisions f or m ounting two

8800 Series Preamplifiers. The recorder is mounted

horizontally in the 7702A Mobile Cart, or vertically in the

portable case or rack mount. The paper take-up

assembly located on the left end of the recorder stores

the chart paper on a take-up spool that is easily

removed. Recorder charac teristics are given in Table 1-

1.

1-15. The power supply (Figure 1-6) provides oper-

ating power for the 7702-OlA Recorder, 8800 Series

Preamplifiers, and two 7700-02A Driver Amplifiers. The

mm/sec timer assembly 14002S and the optional

mm/min timer assembly 14002R plug into the power

supply. Also mounted on the rear of the power supply are

three plug-in circuit boards; (1) Regulator Card 868500A-C6 which furnishes regulated +12 and -12 volts to

the preamplifiers, (2) Oscillator Plug-in 868-500A-C13

which provides a 2400 Hz transducer excitation voltage

for use with the 8805A Carrier Pre- amplifier, and (3)

Oscillator Plug-in 868-500A-C14 which provides a 440

Hz chopper excitation voltage for Model 8803A High Gain

Preamplifier.

1-1

Page 9

TM 11-6625-2751-14&P

Figure 1-2. Model 77-01A Recorder

Figure 1-3. Model 7700-02A Driver Amplifier Figure 1-4. 8800 Series Preamplifier (8801A Shown)

1-2

Page 10

1-16. Model 7700-02A Driver Amplifier.

1-17. One plug-in driver amplifier (Figure 1-3) is

provided for each recording galvanometer. The combination of driver amplifier and galvanometer simulate

the characteristics of a galvanometer at 71% of critical

damping, by negative velocity-voltage feed- back from

the galvanometer in conjunction with a compensation

circuit in the driver amplifier. Driver Amplifier

specifications are listed in Table 1-2. 1-18.

Preamplifiers, 8800 Series.

1-19. Any of the solid-state high performance preamplifiers (Figure 1-4) for medical or industrial

applications may be installed in the recorder. Preamplifiers may be interchanged easily from the front

panel of the recorder by removing two panel mounting

screws. Preamplif iers c ontain built-in voltage cali- br ation

sources.

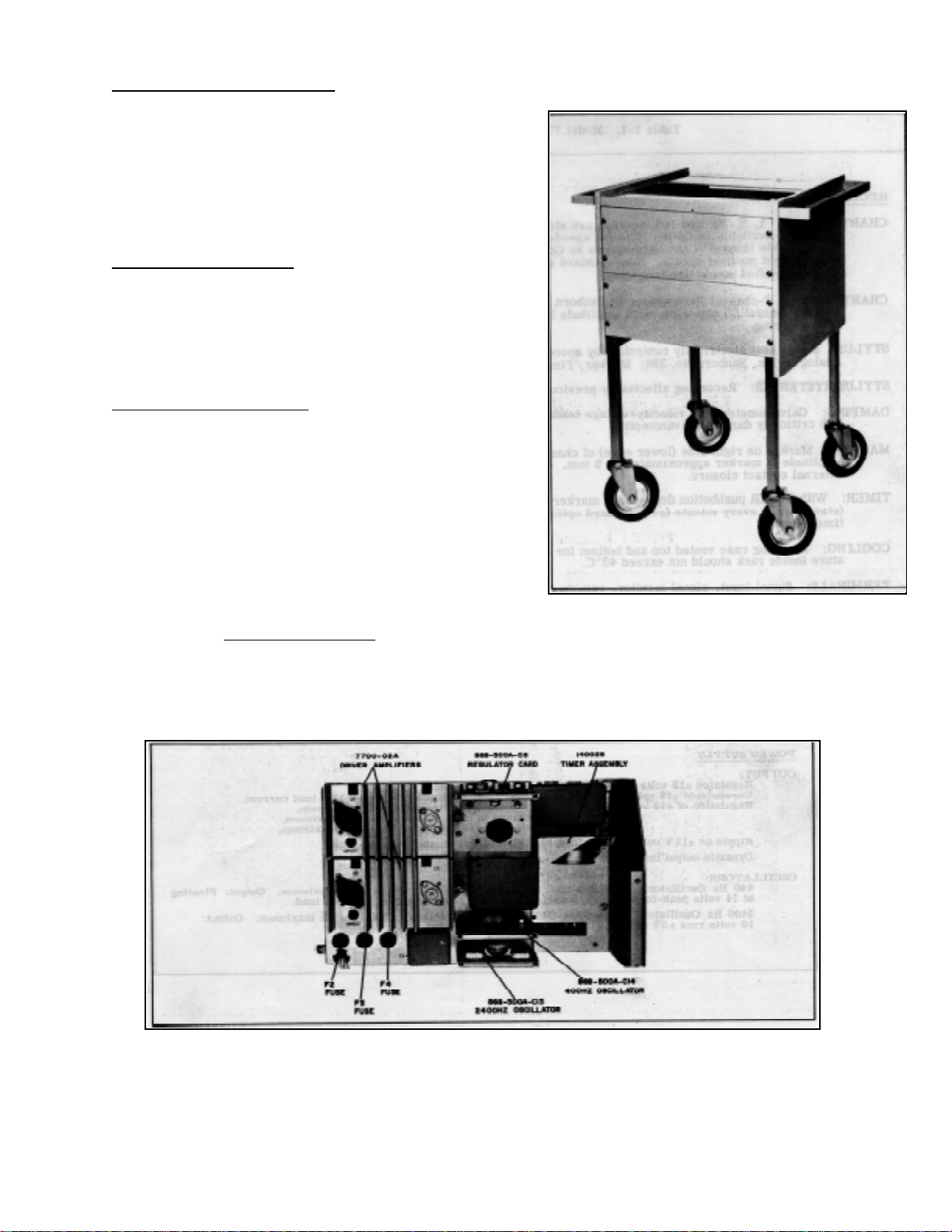

1-20. Model 1069-02A Mobile Cart.

1-21. The ruggedly constructed all-metal mobile cart

(Figure 1-5) is an ideal unit for many recording

applications. Metal bar handles mounted on both ends of

the cart and large diameter rubber wheels permit the

system to be moved from one location to another with

minimum effort. The line power cord, which is

permanently attached to the cart, is conveniently stored

behind the rear panel. Two AC accessory out- lets are

provided on the rear panel. A 5" high panel located on

the top of the cart and two 7" panels loc ate on the front

of the cart may be used to m ount signal panels or other

instrumentation. 1-22. System Specifications.

TM 11-6625-2751-14&P

Figure 1-5. Model 1069-02A Mobile Cart

1-23. The power, weight and dimensions for the Model

7702A are listed in Table 1-4.

1-24. Accessories provided with the System (or

available on order) are listed in Table 1-5.

Figure 1-6. 7702A System Power Supply

Figure 1-6. 7702A System Power Supply

1-3

Page 11

TM 11-6625-2751-14&P

Table 1-1. Model 7702-01A Specifications

RECORDER

CHART SPEEDS:1, 5, 20, and 100 mm/sec are standard; four additional s peeds : 1, 5, 20, 100, mm/min, available

as Option 11 (eight speeds total). Medical speeds of 2. 5, 5, 25, and 50 mm/ sec available instead of standard

speeds as Option 10. Options 10 and 11 may be combined for a total of eight medical speeds. Non-standard

speeds available on special order. Speed regulation 1% at specified power line frequency.

CHART PAPER: 2-channel Permapaper( Sanborn No. 651-52. Paper width 5" (127 mm). Each recording

channel 50 mm wide, with amplitude lines spaced 1 mm apart. Timing lines also have 1 mm spacing.

STYLUS: Stylus heat electrically controlled by speed selector and also adjustable by front panel control. Analog

Stylus, Sanborn No. 398; Marker/Timer Stylus, Sanborn No. 411-10.

STYLUS HYSTERISIS: Recording affected by previous signals by less than 0O. 1 divisions. DAMPING:

Galvanometer with velocity-voltage feedback in combination with drive circuit simulates a 71% critically

damped galvanometer.

MARKER: Marker on right side (lower edge) of chart is standard; center margin marker optional; amplitude of

marker approximately 1. 5 mm. Marker is operated by front panel switch or by external contact closure.

TIMER: With TIMER pushbutton depressed, marker pulse occurs on right side of chart every second (standard) or

every minute (see standard option, Paragraph 1-8). Marker operation over-rides

timer signal.

COOLING: Mounting case vented top and bottom for convection cooling. For rack mounting, temperature inside rack

should not exceed 40’C.

TERMINALS: Signal input, signal monitor, remote chart drive start-stop, and servo reference input

located on rear.

FRONT PANEL CONTROLS: Individual STYLUS heat adjustments; individual galvanometer DAMPING

screwdriver adjust; pushbutton TIMER, MARK and POWER switches; pushbutton SPEED

selector switches.

POWER SUPPLY

OUTPUT:

Regulated +12 volts at 500 milliamperes maximum, each polarity.

Unregulated ±18 volts at 1/2 ampere maximum, each polarity, less ±12V load current.

Regulation of ±12 volt output a) with 20% change in line voltage 1/o maximum.

b) with change in load, 0 to full load 2% maximum.

c) with change in temperature 3 mV/C' maximum.

Ripple on ±12 V output at full load 10 millivolts maximum, peak-to-peak.

Dynamic output impedance of +12V output: 1/2 ohm, DC to 10 kHz.

OSCILLATORS:

440 Hz Oscillator, 868-500-C14: Frequency Stability: 440 Hz ± 5% maximum. Output: Floating

at 14 volts peak-to-peak at 1/2 watt. Amplitude stability +2% of constant load.

2400 Hz Oscillator, 868-500A-C13: Frequency Stability: 2400 Hz + 2% maximum. Output:

10 volts rms ±5% at 50 milliwatts maximum. Grounded center tap.

1-4

Page 12

TM 11-6625-2751-14&P

Table 1-2. Model 7700-02A Specifications

DRIVER AMPLIFIER

FREQUENCY RESPONSE: DC to less than 3 dB down at 125 Hz for chart deflection of 10 divisions pp.

Damping set for 4% overshoot with a 10 division pp square wave.

SENSITIVITY: ±2. 5 volts nominal for full recording chart width deflection.

NOISE: Less than 0. 1 division pp with zero signal input.

RESPONSE TIME: Less than 5 msec, 10% to 90% for a 10 division square wave with damping set for 4%

overshoot.

DRIVER INPUT IMPEDANCE: (preamplifier output loading) 5K ohms, ±5%, single-ended, with signal

ground isolated from chassis ground.

LINEARITY:

Method 1: After setting mechanical zero of stylus within 0o. 1 division of chart center and calibrating for zero error at center scale and +20 divisions, error is less then ±0. 25 divisions at any point

on printed coordinates.

Method 2: After setting mechanical zero of stylus within +1 division of chart center and calibrating

for zero error at lower and upper ends of printed coordinates, error is less than t0. 5 division at

any point on the scale.

GAIN STABILITY (after one hour warmup): Temperature: Less than 0. 25%/10'C, 20° to 40°C.

Line Voltage: 0. 5%, 103 to 127 volts.

ZERO DRIFT (driver amplifier input shorted and after one hour warmup): Temperature: Less then

0.25 div/10°C, 20° to 40°C. Line Voltage: 0.1 div, 103 to 127 volts. Paper Drift: Less than

0.25 div.

LIMITING: Electrical limiting in drive circuit at approximately 125% of full scale. Stylus is mechani-

cally limited by spring stops.

Table 1-3. 8800 Series Preamplifiers

Preamplifier Description Sensitivity

8801A Low Gain DC Preamplifier 5 mV/div

8802A Medium Gain DC Preamplifier 1 mV/div

8803A High Gain DC Preamplifier 1 µV/div

8805A Carrier Preamplifier (with calibrated CAL factor) 10 µV/div

8806B Phase Sensitive Demodulator 0. 5 mV rms/div

8807A AC-DC Converter 1 mV rms/div (at x20

scale expansion)

8808A Log-Level Preamplifier 100 µV rms

8809A Special Purpose DC 20 mV/div

NOTE: All preamplifiers except 8806B and 8808A feature calibrated zero suppression.

1-5

Page 13

TM 11-6625-2751-14&P

Table 1-4. System Specifications

POWER: 115/230 volts ± 10%, 60Hz, approximately 200 watts. 115/230 volts ±10%, a50 Hz, specify Option 08.

WEIGHT: 130 lb. (59kg), includes 1069-02A Mobile Cart and two preamplifiers.

DIMENSIONS: (see illustrations below)

1-6

Page 14

TM 11-6625-2751-14&P

Table 1-5. System Accessories

Qty. Description Number

2 Signal Input Connector 10G3-34FW

2 Signal Output Connector 10B9-5MW

1 Remote Run Connector 10A5-3MW

1 Remote Run Connector Cable Clamp 10OA5-lFWA

1 Remote Marker Plug 10G2-22MW

1 Power Cord 3-wire 10G3-42MFW

1 Adapter, 3-wire to 2-wire 10G3-11MFW

2 Fuse 0.5 Amp Slo Blo (F2, F3) 26B-4

1 Fuse 0.8 Amp Slo Blo (Fl 220V) 26B-6

1 Screwdriver 37A-10A

2 Record Spool 94-104P1

1 Spline Wrench 100-600-C5

2 Galvanometer Stylus 398

1 Roll, Permapaper 651-52

1 Stylus Pressure Tester 14015A

1-7

Page 15

SECTION II.

INSTALLATION

TM 11-6625-2751-14&P

2-1. INTRODUCTION.

2-2. This section contains information on unpacking, inspection, repacking, and installation.

2-3. INITIAL INSPECTION.

2-4. Mechanical Inspection.

2-5. If external damage to the shipping carton is

evident, ask the carrier’s agent to be present when the

System is unpacked. Check the System for external

damage such as broken controls or connectors, and

dents or scratches on the panel surface. If damage is

found, refer to Paragraph 2-8 for recommended claim

procedure and repacking information. If the shipping

carton is not damaged, check the cushioning material

and note any signs of severe stress as an indication of

rough handling in transit. Retain the packaging material

for possible future use.

2-6. Electrical Check.

2-7. Check the electric al performance of the Sys- tem

as soon as possible after rec eipt; see Section V for the

recommended performance checks. The checks will

verify that the System is operating within the

specifications listed in Table 1-1. This check is a good

test procedure for incom ing quality control inspection and

for an operational check after repairs or adjustments

have been made.

2-8. CLAIMS AND REPACKAGING.

2-9. Claims for Damage.

2-10. If physical damage is evident or if the System

components do not meet specifications when received,

notify the carrier and the nearest Hewlett-Packard

Sales/Service Office (see list in back of manual). The

Sales/Service Office will arrange for repair or

replacement of the unit(s) without waiting for settlem ent

of the claim against the carrier.

2-11. Repacking for Shipment or Storage.

2-12. If the instrument is to be shipped to a HewlettPackard Sales/Service Office, attach a tag showing

owner and address, instrument model and serial number,

and the repair required. The original ship- ping carton

and packaging material, with the exc eption of accor dionpleated pads, may be reusable. The Hewlett-Packard

Sales/Service Office will also pro- vide information and

recommendations on materials to be used if the original

packaging material is not available or not reusable.

Materials should include, (1) a double-walled carton

(check with a freight carrier for test s tr ength requir ed), ( 2)

heavy paper or sheets of cardboard to protect all

instrument surfaces ; use extra m aterial ar ound projec ting

parts of the instrument, (3) at least four inches of tightlypacked shock-absorbing material surrounding the

instrument. Close the package securely with heavy paper

tape.

2-13. INSTALLATION.

2-14. The 7702A System is ready for use after removal from the packing case. No packing materials are

contained in the recorder section. T he system is shipped

without Permapaper mounted in the recorder; see paper

loading instructions in Section III.

2-15. Environment.

2-16. System location should be reasonably free from

vibration, dust, corrosive or explosive vapors or gases,

extremes of tem perature, humidity, etc. The floor should

be level and must supply support for all four wheels of

the System. For a cabinet mounted installation, allow

sufficient room at the f ront for operation with any part of

the System extended forward, and at the rear for

servicing with access door open.

2-17. The 7702A System requires no additional cooling. For rack mounting (7702A, Option 01), the tem per-

ature inside the rack cabinet should not exceed 40°C.

2-18. Check that the power line voltage, voltage regulation, power capacity, frequency, and frequency

stability are suitable for the requirements of the Sys- tem.

The time-axis accuracy of the recording will be directly

dependent upon the frequency stability of the power line.

2-19. Rack Mounting Instructions.

2-20. Model 7702A, Option 01, consists of the Model

7702-0lA Recorder, with Slide Kit 01060-60310, for

mounting in a cabinet. To install the recor der, attach the

slides to the side rails of the c abinet. Figure 2-1 shows

the location of the mounting holes for the slide kit. Slide

the recorder into the side rails and fasten the recorder in

place with panel screws.

2-21. System in Portable Case.

2-22. Model 7702A, Option 02, consists of the 7700OlA Recorder mounted in a portable transit case 770214A, shown in Figure 2-2. Two side handles are used f or

carrying the case. A removable metal c over protects the

recorder front panel when being transported. Signal input

and power cables are connected to the s ystem through

an open- ing in the rear of the case.

2-23. AC Power Requirements.

2-24. The Model 7702A may be operated from an ac

source of 155 or 230 volts (+10%), 60 Hz. Model 7702A,

Option 08, operates on 115 or 230 volts (+10%), 50 Hz.

With the instr ument power cord disconnected, move the

slide switch located on the rear panel (see Figure 3-3)

until the desired voltage numbers (115 or 230) are

visible. A narrow blade screwdriver may be used to

operate the switch. Fuse F1 should be 1.5 amp slowblow for 115 volt operation, or 0.8 amp slow-blow for 230

volt operation.

2-1

Page 16

TM 11-6625-2751-14&P

Figure 2-2. Portable Case

Figure 2-1. Slide Kit - 01060-60310

2-25. Three-Conductor Power Cable. To protect

operating personnel, the National Electrical

Manufacturers’ Association (NEMA) recommends that

the instrument and cabinet be grounded. The Model

7702A is supplied with a three-conductor power cable

which, when plugged into an appropriate receptacle,

grounds the instrument to the power line ground. The

round pin on the power cable is the ground c onnection.

To retain this protection feature when operating the

instrument from a two-contact outlet, use the 10G311lMFW three-conductor to two- conductor adapter

(supplied as an accessory with the instrument) and

connect the green wire to the outlet box.

2-26. Input Signal Connections.

2-27. The 8800 Preamplifier signal input circuits may

be divided into two types, guarded and non- guarded.

Preamplifiers having a guard shield terminal (8803A,

8806B, 8807A) feature a high comm on- mode rejection

ratio. To obtain the high rejection ratio, the signal input

cable must contain a guard shield. Non-guarded

preamplifiers (8801A, 8802A, 8805A, 8808A, 8809AY do

not require a guard shield in the signal input cable.

Additional information on input signal connections is

contained in the preamplifier instruction manuals.

Figure 2-3. 10G3-34FW Connector

2-28. Signal Input Connectors.

2-29. Two signal input connectors, 10G3-34FW(see

Figure 2-3), are supplied as access ories with the system.

The connectors plug into the signal input jac k s J 1 and J2

on the rear of the recorder. J1 signals (channel 1) are

internally cabled to the left pre- amplifier (viewed from the

front of the recorder) and r ecorded on the upper channel

of the chart paper. J2 input signals are cabled to the right

preamplifier, and are recorded on the lower channel of

the chart

paper.

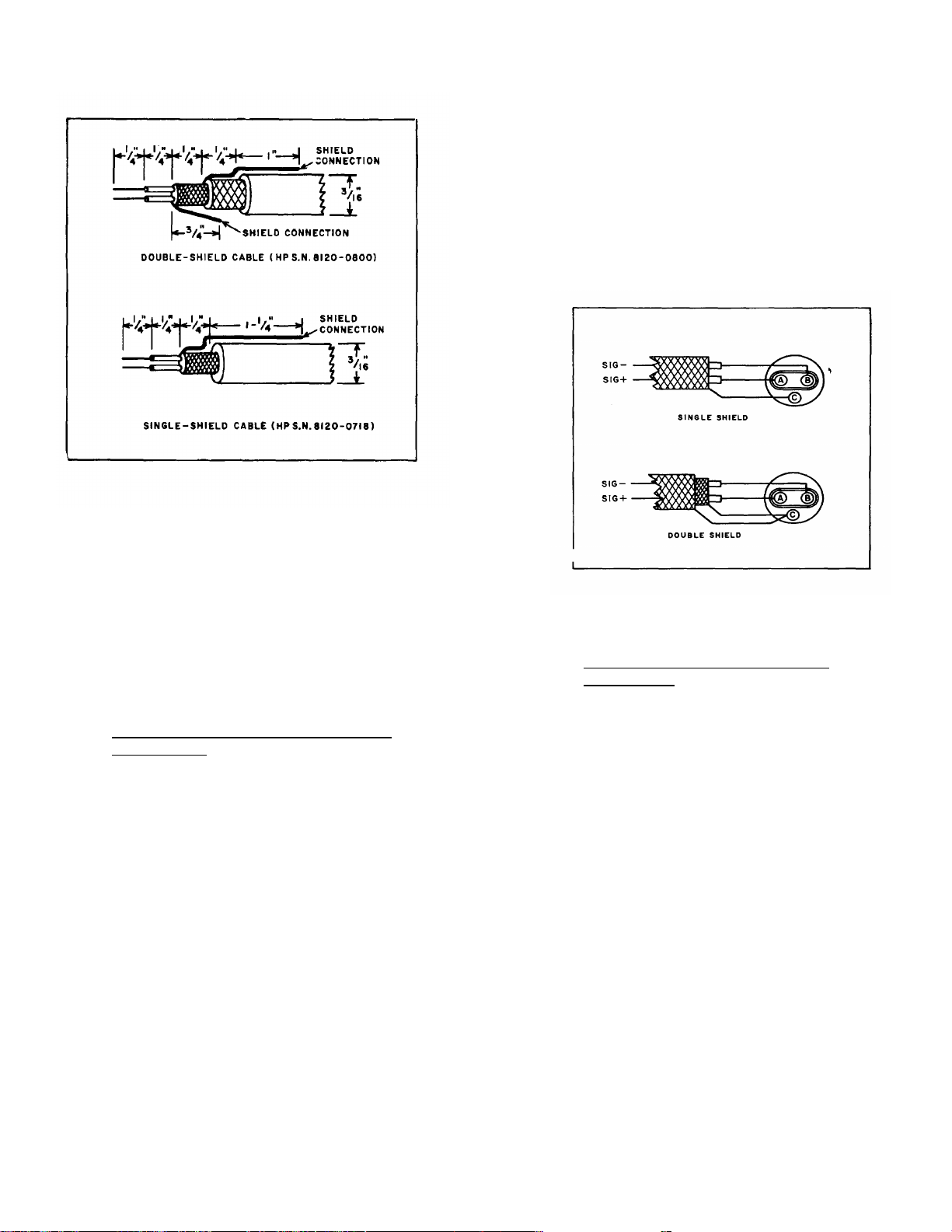

2-30. Signal Input Cable.

2-31. Two conductor shielded cable 3/16" O.D., with

single or doubled braided shield is required for connecting the signal source to the input connectors. See

Figure 2-4 for cable preparation information.

2-2

Page 17

TM 11-6625-2751-14&P

NOTE

Single conductor cable can be used

with the 8808A and 8809A Preamplifiers, which have single-ended input

circuits. Connect the cable center

conductor to pin A, and the shield to

pin B.

Figure 2-6. Input Connector Wiring, Guarded

2-32. Preamplifiers which have a guard shield input

terminal use double shielded cable for a fully guarded

input circuit. The inner shield connects to the common mode potential of the signal source to reduce

capacitive and resistive currents between the signal

conductors and ground. The outer shield is grounded,

to prevent capacitive coupling of the common mode

potential on the inner shield into other circuitry. In

many cases, the second (outer) shield may be omitted with no deterioration in performance.

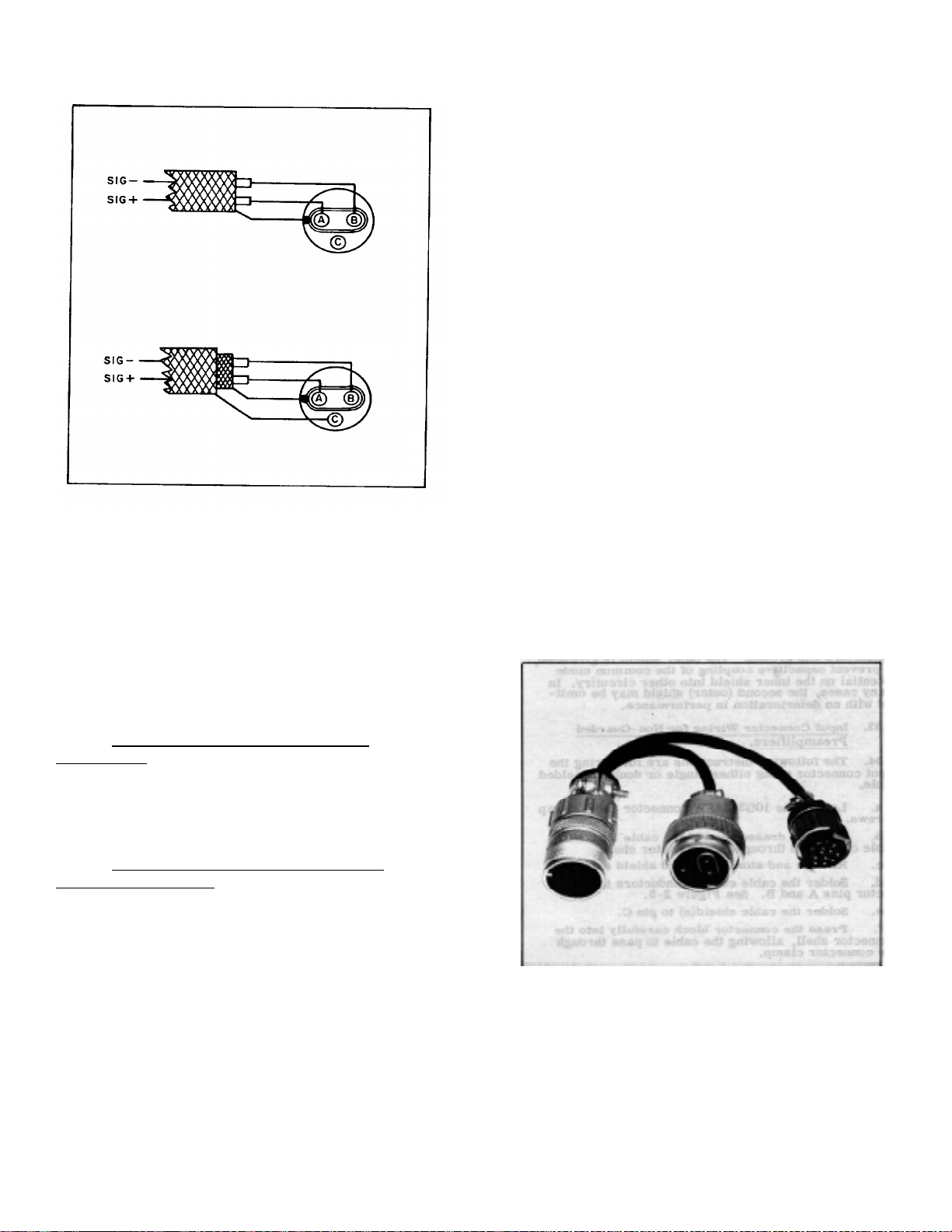

2-33. Input Connector Wiring for Non-Guarded

Preamplifiers.

2-34. The following instructions are for wiring the

input connector using either single or double shielded

cable.

a. Loosen the 10G3-34FW connector cable clamp

screws.

b. Slide the dressed end of the cable into the

cable clamp and through the connector shell.

c. Remove and store the guard shield extension.

d. Solder the cable center conductors to connector pins A and B. See Figure 2-5.

e. Solder the cable shield(s) to pin C.

f. Press the connector block carefully into the

connector shell, allowing the cable to pass through

the connector clamp.

g. Insert the retaining ring.

h. Tighten the cable clamp screws.

Figure 2-5. Input Connector Wiring, Non-Guarded

2-35. Input Connector Wiring for Guarded

Preamplifiers.

2-36. The following instructions are for wiring the

input connectors using either single or double shielded

cable.

a. Loosen the 10G3-34FW connector cable clamp

screws.

b. Slide the dressed end of the cable into the

cable clamp and through the connector shell.

c. Slide the guard shield extension down over the

cable shield(s) and onto the guard socket.

d. Solder the cable center conductors to pins A

and B. See Figure 2-6.

e. For single shield cable, solder the cable shield

to the guard shield extension.

f. For double shield cable solder the inner

(guard) shield to the guard shield extension, and solder the outer shield to pin C. Check that shields are

not shorted to each other or to the connector shell.

g. Press the connector block carefully into the

connector shell, allowing the cable to pass through

the cable clamp.

h. Insert the retaining ring.

i. Tighten the cable clamp screws.

2-3

Page 18

Figure 2-6. Input Connector Wiring, Guarded

2-37. 8805A CARRIER PREAMPLIFIER INPUT

CABLES.

2-38. Carrier preamplifier operation requires both a

non-guarded signal input cable and a carrier refer- ence

cable, connected between the strain gage or transducer

and the 7702A System. A cable assembly for use with

Sanborn transducers is shown in Figure 2-7. Cables for

other applications are assembled

following the instructions in Paragraph 2-41.

TM 11-6625-2751-14&P

(2) Connect the cable to jack J1 (for channel 1)

or jack J2 (for channel 2), located on the rear panel of

the recorder.

b. Carrier Reference Cable. (1) Connect a twoconductor shielded cable to the 10B9-5MW connector,

supplied as an accessory with the system. Solder the two

cable conductors to pins A and B, cable shield to pin E.

(2) Connect the cable to jack J21 (for channel 1)

or jack J22 (for channel 2) located on the rear panel of

the recorder.

2-43. 8806B PHASE SENSITIVE DEMODULATOR

SIGNAL CABLES.

2-44. Demodulator preamplifier operation requires both

a signal input cable and a servo reference cable.

Construction of the cables is described below.

2-45. Construct the two-conductor signal input cable

with a guard shield (see Paragraph 2-

35)

if a high

common-mode rejection is desired. If high commonmode rejection is not required, the input cable is wired

with an unguarded, single-shield cable (see Paragr aph 2-

33). Connect the signal input cable to J1 (channel 1) or

J2 (channel 2).

2-46. Construct the servo reference cable using twoconductor shielded cable and the 10B9-5MW con- nector

supplied as an accessory with the system. Normal

connection uses a single-shielded cable, in a nonguarded circuit. Solder the "+" servo ref erence signal to

pin K, and the "-" servo reference to pin F. Connect the

servo reference cable to J21 (c hannel 1) or J22 (channel

2), located on the rear panel of the 7702A Recorder.

2-39. Cable Assembly for use with Sanborn

Transducers.

2-40. Use the cable assembly no. 5060-4602 (Figure

2-7) to connect Sanborn Series 267, 268 and 270 Series

Transducers to the 7702A System. T his Y-cable contains

both a signal input cable and a carrier reference cable.

2-41. Instructions for Assembling Signal Input

and Reference Cables.

2-42. Signal input and carrier reference cables for

carrier preamplifier applications described in the

instruction manual IM-8805A-1 are assembled as follows:

a. Signal Input Cable.

(1) Connect a two-conductor shielded cable to the 10G334FW connector, supplied as an accessory with the

system. Solder the two cable conductors to pins A and B,

cable shield to pin C (see Paragraph 2-33).

2-4

Page 19

2-47. SIGNAL MONITOR CONNECTIONS.

2-48. The preamplifier single-ended output s ignals are

available at J21 (channel 1) and J22 (channel 2), located

on the rear panel of the recorder. Signal output is pin D,

signal common is pin H. For 8803A High Gain

Preamplifier, signal out is pin A, signal com mon is pin B.

The 10B9-5MW mating connectors are supplied as

accessories with the system.

2-49. REMOTE RECORDER OPERATION.

2-50. The 7702A Recorder chart drive ST ART- STOP

function and the MARKER function can be con- trolled

from a rem ote location. The circuits required ar e shown

in Figures 2-8 and 2-9.

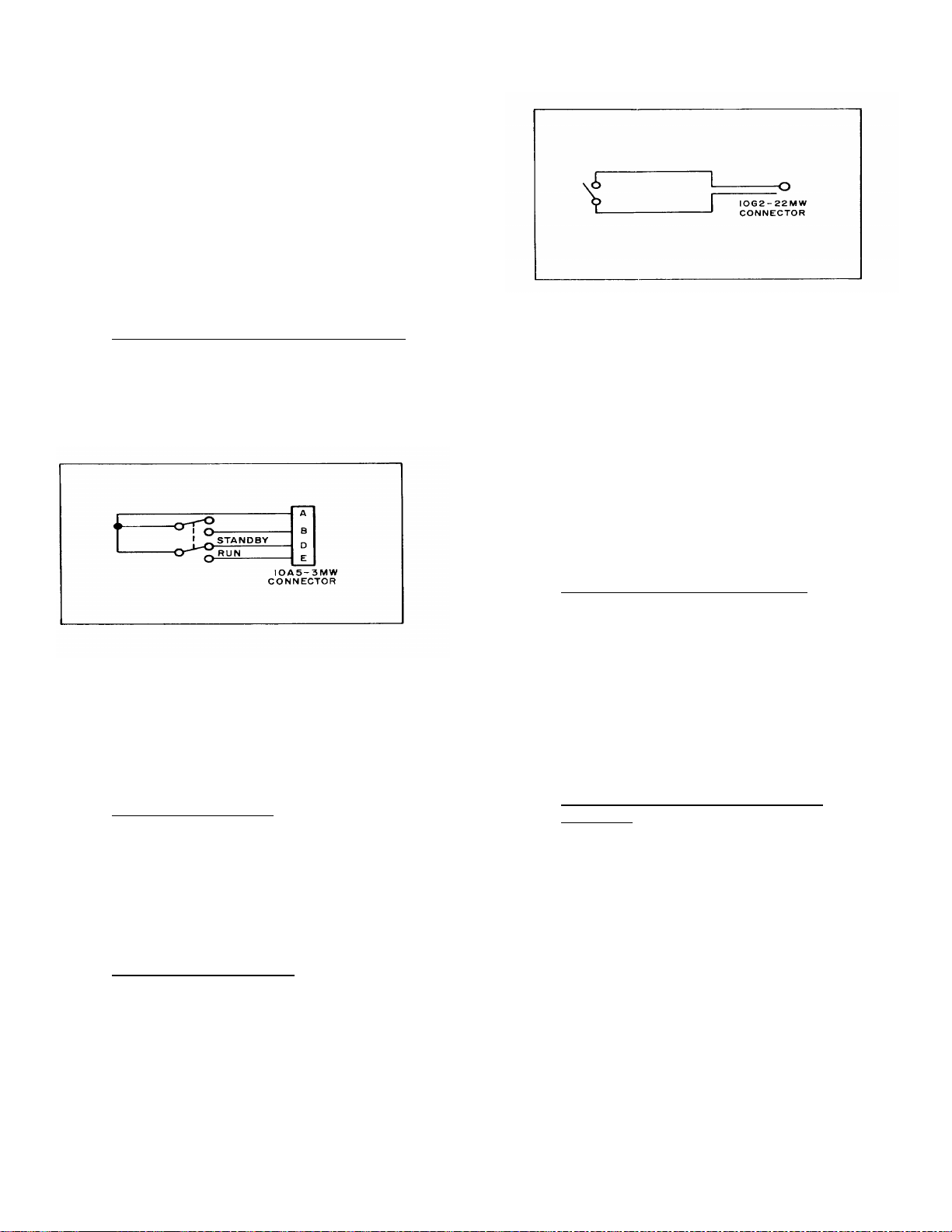

2-51. Remote Chart Drive START-STOP Control.

2-52. Construct the circuit shown in Figure 2-8.

The 10A5-3MW remote run connector and the 10A5lFWA cable c lamp are supplied as accessories with the

system. Any length of four conductor cable may be used.

The remote run circuit plugs into the J13 jac k on the rear

panel of the recorder.

Figure 2-8. Remote Run Circuit Diagram

2-53. To operate the recorder using the REMOTE

RUN circuit, switch the LOCAL-REMOTE switch S3

located on the rear panel of the recorder to the

REMOTE position and press the desired speed pushbutton on the recorder front panel. Operate the

remote STANDBY-RUN switch to control chart drive.

2-54. Remote Marker Control.

2-55. The marker may be operated from a remote

location or from the recorder front panel. To operate the marker from a remote location, construct

the circuit shown in Figure 2-9. The connector

10G2-22MW is supplied as an accessory with the

system. Any length of cable may be used.

2-56. The Remote marker circuit plugs into the J15

jack on the rear panel of the recorder.

2-57. Auxiliary Marker Operation.

2-58. To operate the auxiliary marker, available

as 7702A Option 15, construct a switch circuit as

shown in Figure 2-9. Plug the switch into the auxiliary marker Jack J14, located on the rear panel of

the recorder.

TM 11-6625-2751-14&P

Figure 2-9. Remote Marker Circuit Diagram

2-59. INITIAL SYSTEM CHECK.

2-60. The following procedures are designed to check

the recorder drive, marker, timer, and re- mote control

functions. To check the operation of the preamplifiers,

refer to the instruction manual for the 8800 Series

preamplifiers installed in the system.

2-61. Review the installation process, checking the

cables and connectors. Tighten all connections. Check

that the S3 power line switch (see Figure 3-3) indicates

the correct voltage. The recording system may be

damaged if the switch is set to the incorrect voltage

range.

2-62. Install a roll of Permapaper in the recorder,

following the instructions in Figure 3-4.

2-63. To Check Recorder Drive Functions.

a. Press the POWER pushbutton. The panel

indicator lamp will light.

b. Press the MM/SEC pushbutton.

c. Press each of the four speed-pushbuttons.

Check for proper paper travel at each speed selected. If

recorder is equipped with mm /min speeds, Option 11 or

Option 12, press MM/MIN pushbutton. Press each of the

four speed-pushbuttons, check ing for proper paper travel

at each speed selected.

d. Adjust the stylus HEAT controls for a dense,

well-defined baseline.

2-64. To Check Recorder Marker and Timer

Functions.

a. Press the MARKER pushbutton. A mark will be

recorded on the lower edge of the chart. To check

remote marker operation, connect the circuit shown in

Figure 2-9 to J15.

b. Press MM/SEC and TIMER pushbuttons. A

one per second timing mark will be recorded on the lower

edge of the chart. Press TIMER again to re- lease

pushbutton. If system is equipped with mm/min timer,

Option 13 or 14, press MM/MIN and T I MER pushbuttons .

A one per minute timing mark will be recorded on the

chart.

2-5

Page 20

TM 11-6625-2751-14&P

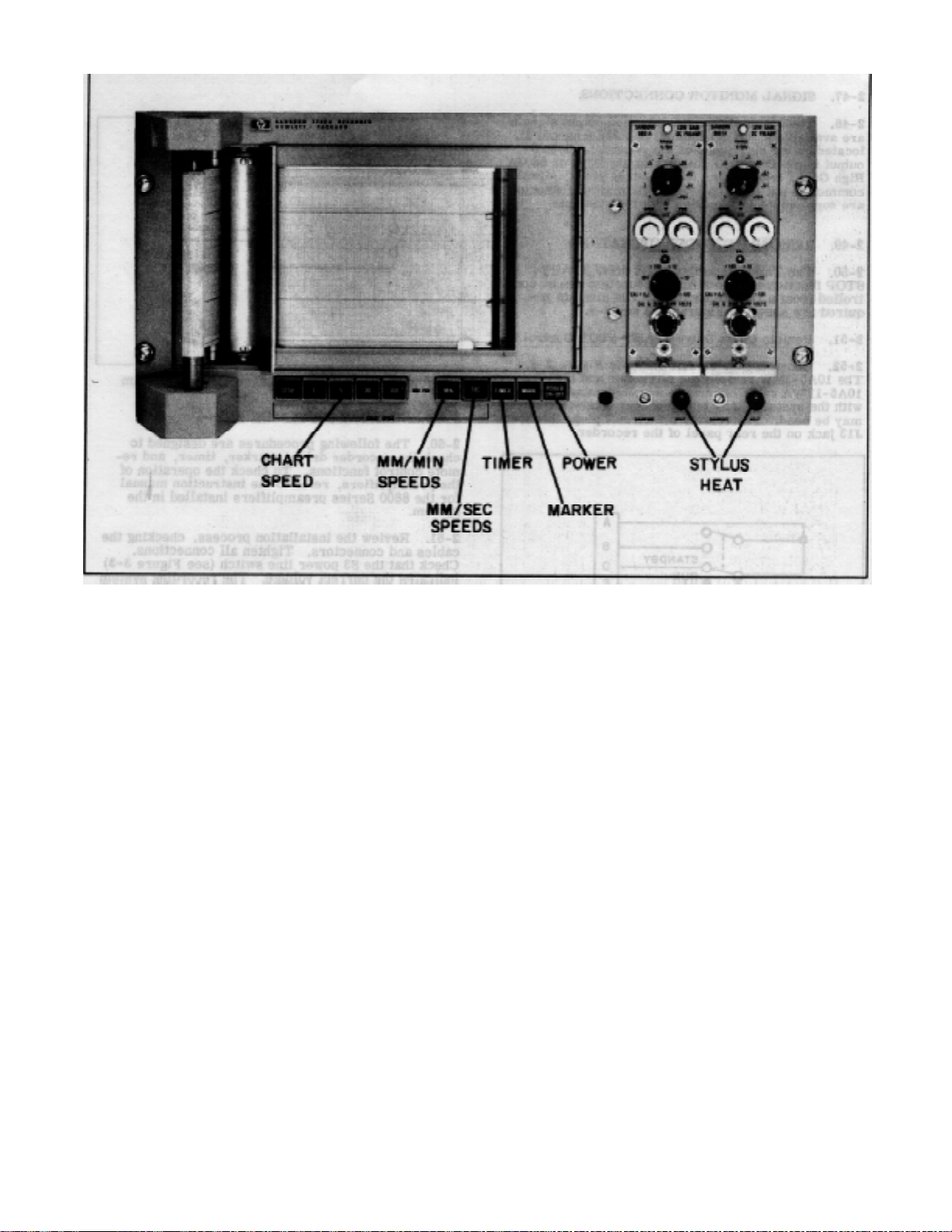

Figure 2-10. System Controls

2-6

Page 21

SECTION III.

OPERATION

3-1. INTRODUCTION.

3-2. The basic function of the 7702A System is to

produce graphic tracings on two-channel thermal sensitive Permapaper, using the heated stylus recording

technique. Input signals are amplified by the 8800 Series

signal conditioning preamplifiers, and displayed on 50

mm-wide channels on the chart paper. Preamplifiers

contain amplitude calibration standards which can be

recorded on the chart paper when desired. The chart

paper time scale unit is adjus table in fixed steps by the

setting of the pushbutton chart speed controls. Standar d

recorder speeds provide time scale calibration ranging

from 1 m m/sec to 100 mm/sec. W ith Option 11 (60 Hz)

or Option 12 (50 Hz), four chart speeds are added which

provide time scale calibration from 1 mm/min to 100 mm/

min.

TM 11-6625-2751-14&P

3-3. CONTROLS AND CONNECTORS.

3-4. Front and rear panel controls and c onnec tors ar e

shown in Figures 3-2 and 3-3.

3-5. OPERATING PROCEDURES.

3-6. The 7702A System is ready for use following

installation, discussed in Section II. Figure 3-4 describes

the Permapaper loading procedure, and Figure 3-5

provides step-by-step operating instructions, for normal

operation of the instrument. Figure 3-6 provides

instructions for rem ote operation of the c hart drive s tart stop and marker functions.

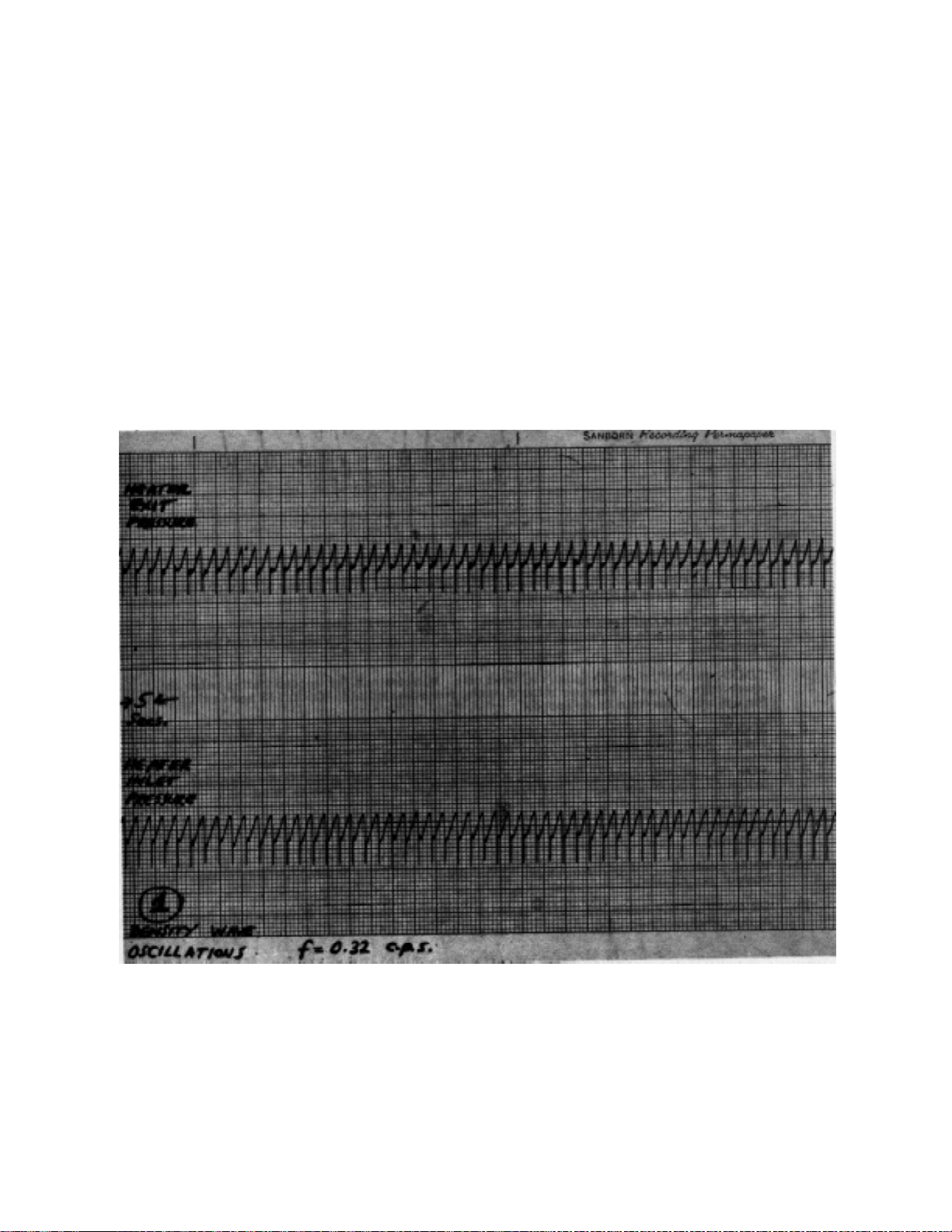

Figure 3-1. Typical 2-Channel Recording

3-1

Page 22

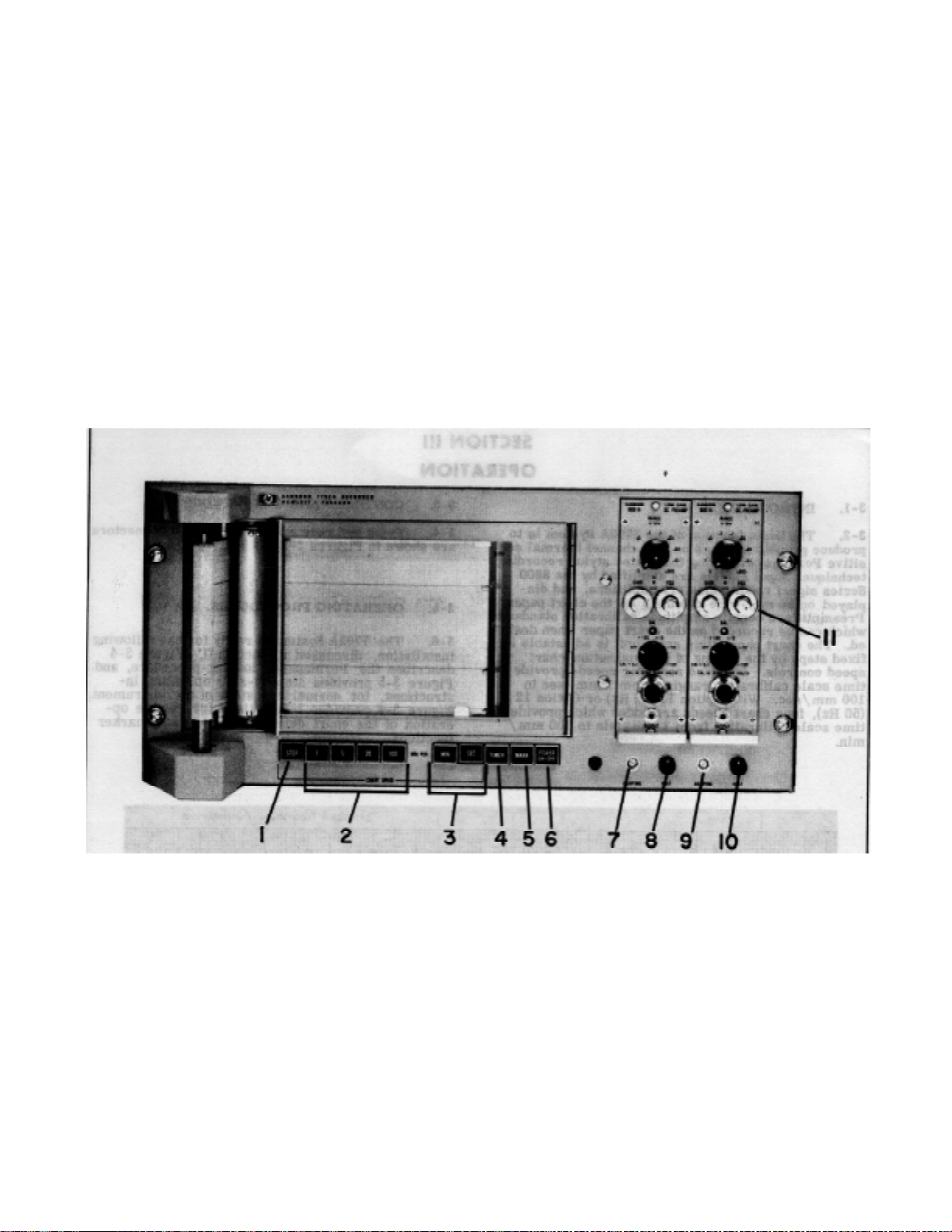

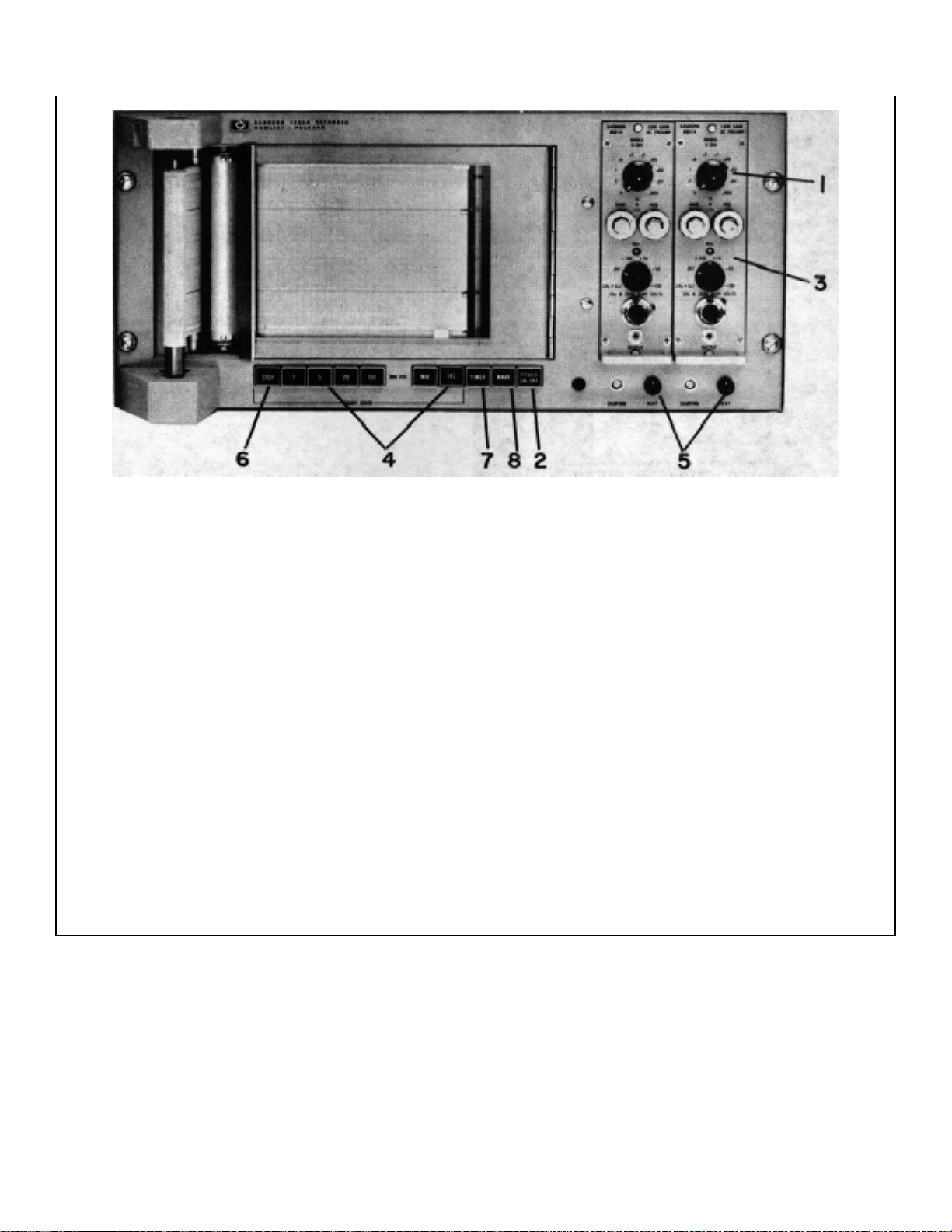

TM 11-6625-2751-14&P

1 STOP pushbutton switch (momentary). Controls chart drive.

2 CHART SPEED pushbutton switches select chart speed. Pressing any of four pushbuttons starts chart drive at

speed selected.

3 MM/SEC-MM/MIN pushbutton switches. Selects mm/sec drive speeds for standard recorder. Selects mm/min

drive speeds when Option 11 or Option 12 is installed in recorder.

4 TIMER pushbutton switch (push on, push off). Initiates one per second timing pulse on lower edge of chart. One

per minute timing pulse is available (Option 13 and Option 14) for use with mm/min drive speeds.

5 MARK pushbutton switch (momentary). Controls operation of marker at lower edge of chart. Reference mark is

recorded when pushbutton is pressed.

6 POWER pushbutton switch (push on, push off). Controls line power to the recorder. Indicator lamp to the right of

the power switch lights when the power is on.

7 9 DAMPING controls. Adjusts the amount of feedback from the galvanometer windings to the driver amplifiers, to

obtain optimum galvanometer pulse response. One control per channel

8 10 HEAT controls. Adjusts amount of stylus heat to obtain the desired trace intensity. One control per channel

11 PREAMPLIFIER controls. Refer to the preamplifier instruction manuals for a description of the panel controls.

Figure 3-2. Front Panel Controls

3-2

Page 23

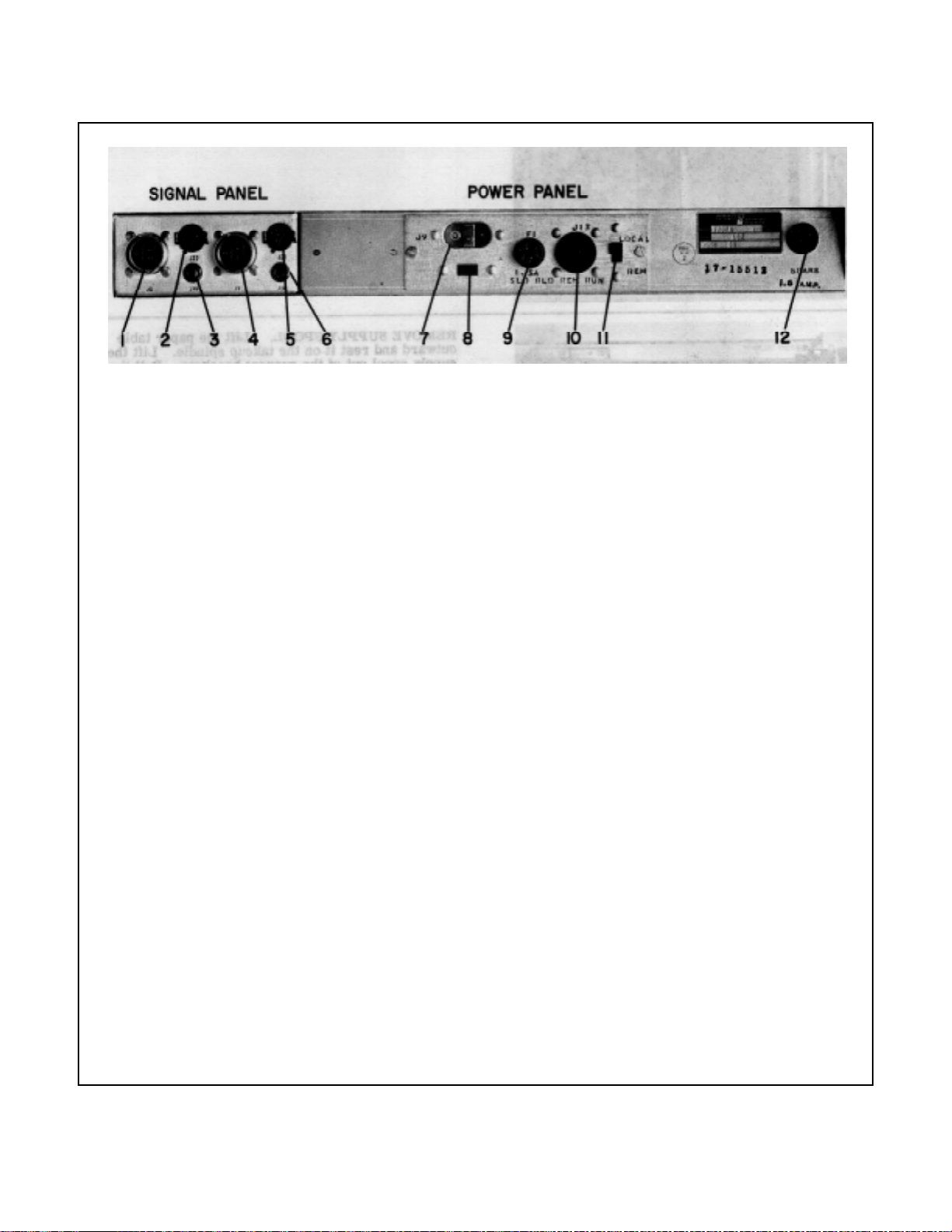

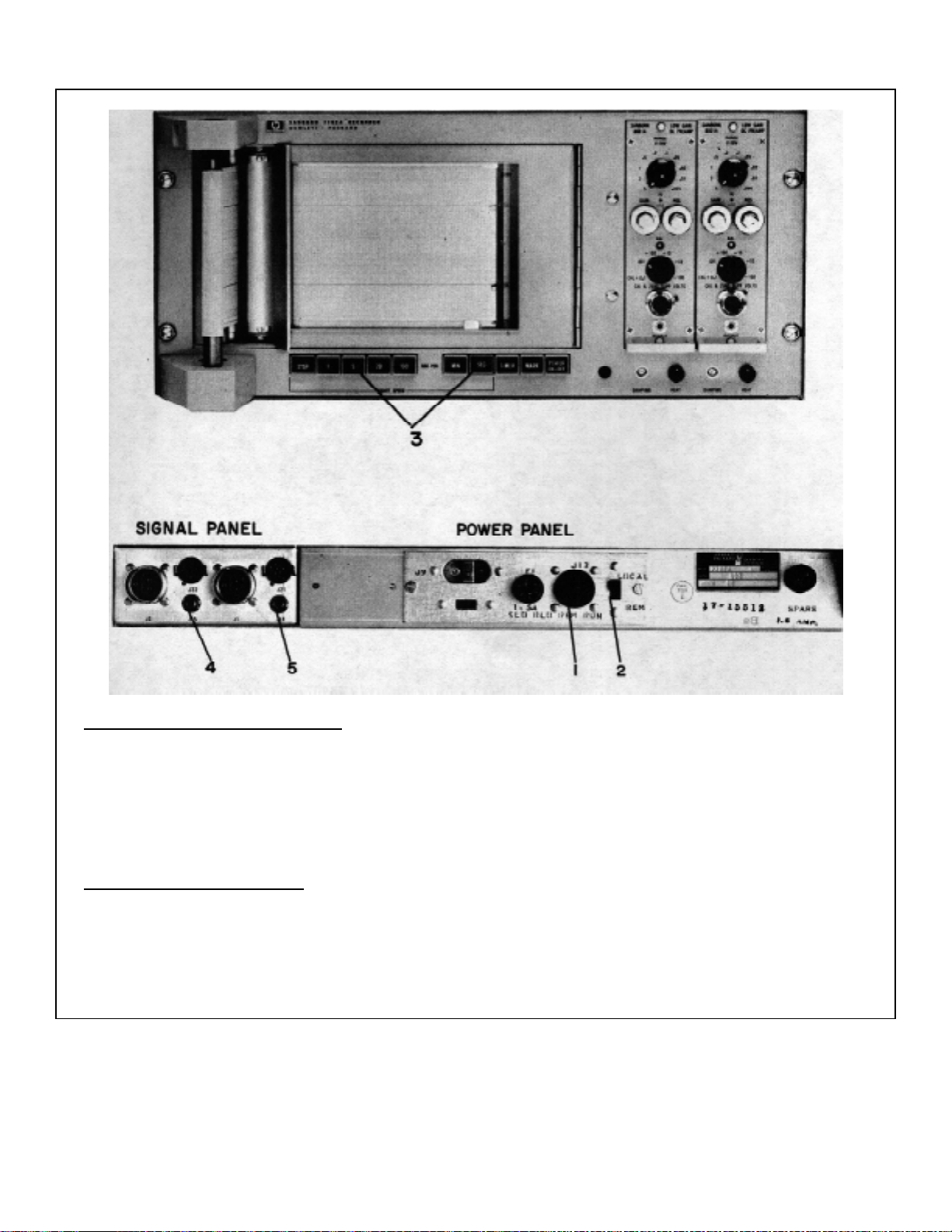

TM 11-6625-2751-14&P

1 SIGNAL INPUT connector. Input for Channel 2.

2 SIGNAL MONITOR connector. Output of Channel 2 preamplifier, for connection to

monitoring instruments. Includes connections for carrier excitation and servo

reference voltages.

3 REMOTE MARK jack. Mates with external marker switch circuit, for control of

marker on chart paper.

4 SIGNAL INPUT connector. Input for Channel 1.

5 SIGNAL MONITOR connector. Output of Channel 1 preamplifier, for connection to

monitoring instruments. Includes connections for carrier excitation and servo reference

voltages.

6 AUXILIARY MARK jack. Mates with external switch circuit for control of auxiliary

marker on chart paper.

7 POWER INPUT connector. Mates with power cable supplied with the instrument.

8 LINE VOLTAGE slide switch. Controls power supply input connections. CHECK THAT

SWITCH IS SET FOR NOMINAL VOLTAGE OF EXTERNAL POWER SOURCE.

9 FUSE holder. Contains the input power fuse (1.5 amp slow-blow for 115 volts, 0.8 amp

slow-blow for 230 volts).

10 REMOTE RUN connector. Mates with external switch circuit for control of recorder

chart drive start-stop function.

11 LOCAL-REMOTE switch. Selects either front panel switch or remote run circuit for

control of recorder start-stop function.

12 Spare FUSE holder. Contains spare line fuse.

Figure 3-3. Rear Panel Controls

3-3

Page 24

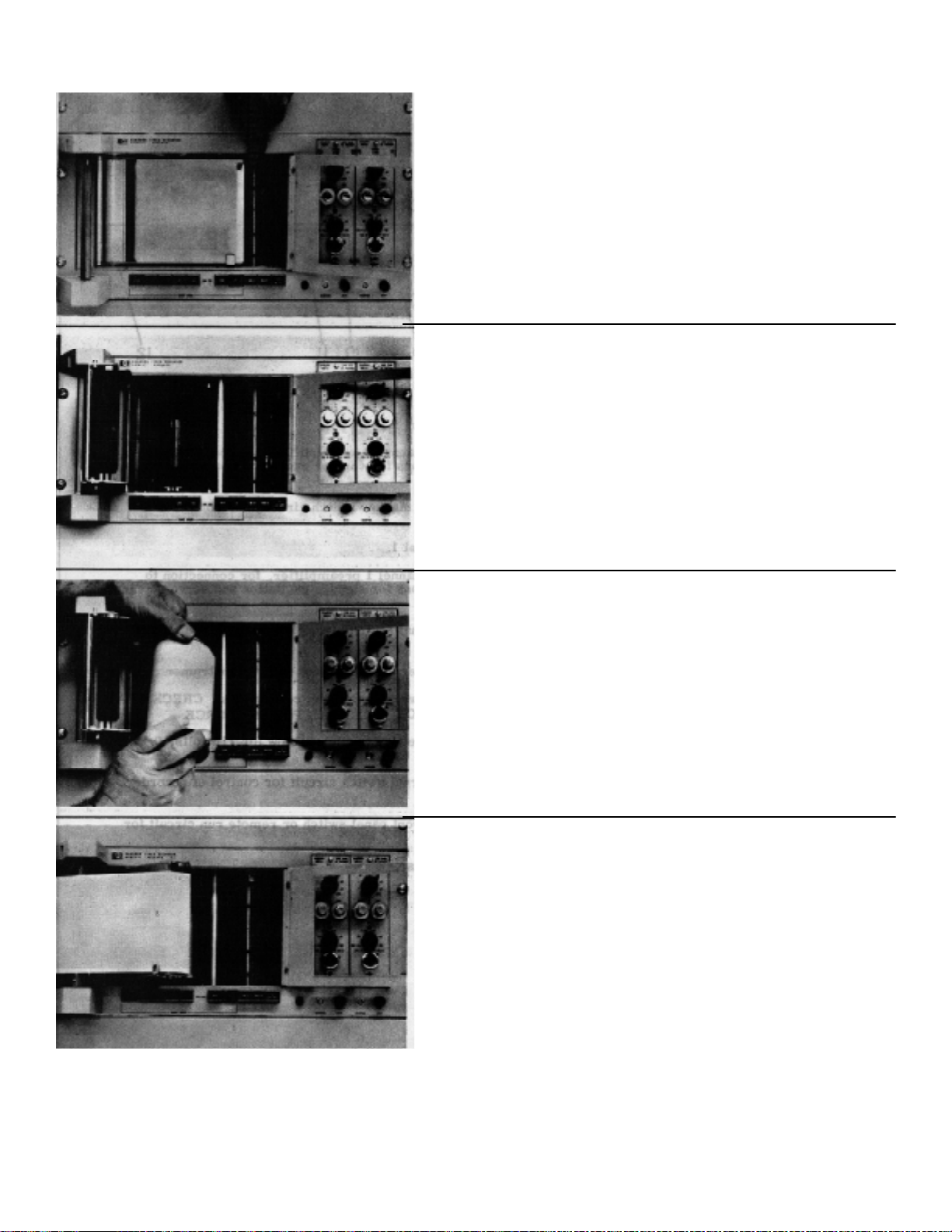

TM 11-6625-2751-14&P

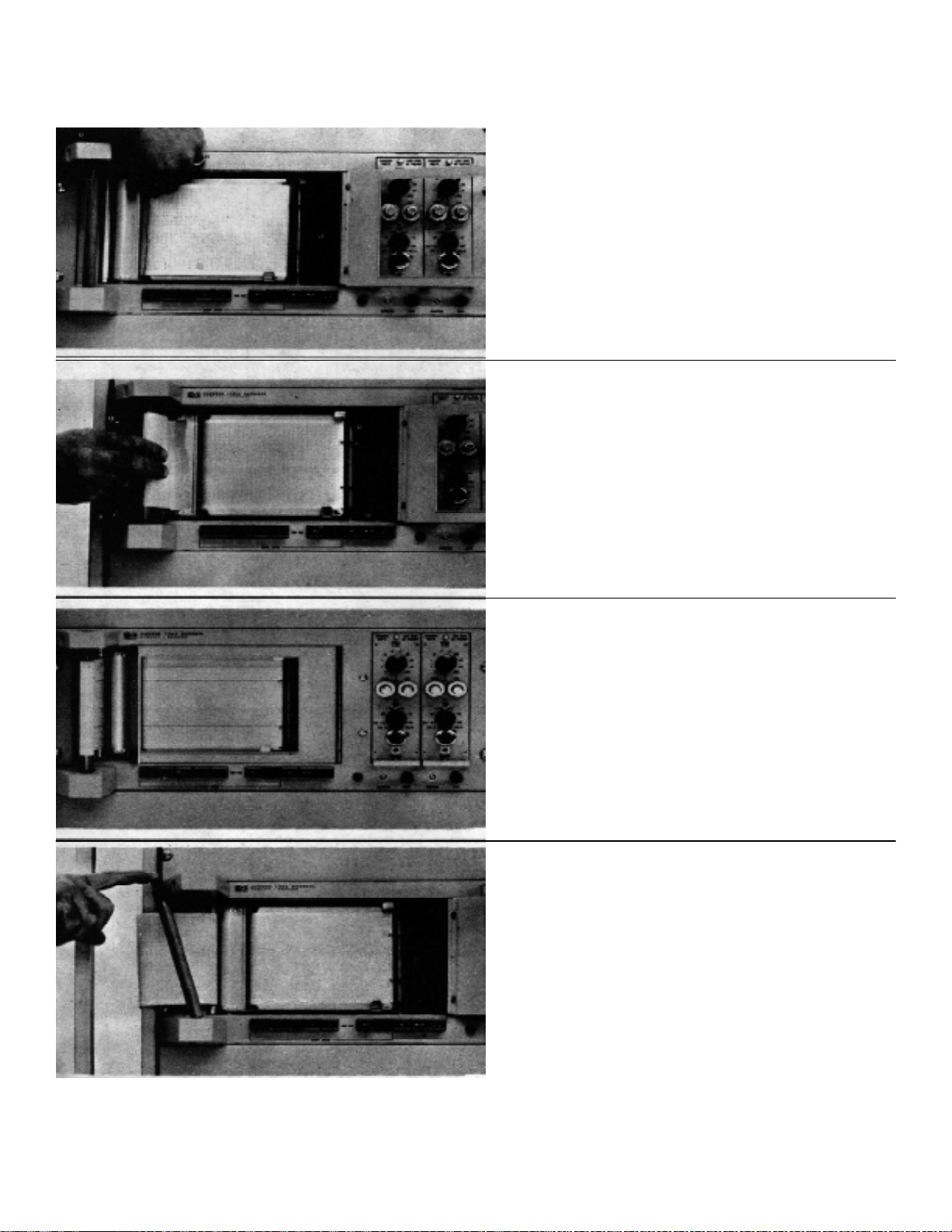

RELEASE PAPER TABLE. Turn instrument OFF,

and open the recorder cover. Push the writing

table lock lever toward the galvanometers.

REMOVE SUPPLY SPOOL. Lift the paper table

outward and rest it on the takeup spindle. Lift the

supply spool out of the support brackets. Pull the

end discs apart to remove the paper core.

RELEASE PAPER TABLE. Turn instrument OFF,

and open the recorder cover. Push the writing

table lock lever toward the galvanometers.

REMOVE SUPPLY SPOOL. Lift the paper table

outward and rest it on the takeup spindle. Lift the

supply spool out of the support brackets. Pull the

end discs apart to remove the paper core.

Figure 3-4. Permapaper Loading Procedures

3-4

Page 25

TM 11-6625-2751-14&P

FEED PAPER RNTO DRIVE ROLL. Fold back and

crease the paper about 1 inch from the end of the roll.

Start chart drive at 5 mm /sec. Insert the paper into the

drive roll squarely, so that the entire leading edge of the

paper contacts the drive roll. Stop the r ec order when the

paper is drawn tightly over the paper table. Lock the

paper table.

THREAD PAPER ONTO THE T AKEUP SPINDLE. Turn

on chart drive at 5 mm /sec, and loop paper around the

spindle tightly. The paper will be drawn onto the rotating

spindle. Stop the recorder. (The paper takeup f eature

must be used for satisfactory recorder operation.)

RECORDER IS READY FOR USE. Close the recorder

cover. A printed star appears on lower edge of chart, 30

feet from end of roll, to indicate remaining footage.

TO REMOVE PAPER AFTER RECORDING. Remove

the paper takeup spindle. Press the black plas tic button

on the end of the spindle. Pull out the upper and lower

ends of the spindle. After sliding the rec ording paper of f,

re-install the spindle, lower end first.

Figure 3-4. Permapaper Loading Procedures (Cont.)

3-5

Page 26

TM 11-6625-2751-14&P

1 Connect 7702A System to power line, and connect input signals to J1 and J2 on the rear recorder

panel. Rotate preamplifier attenuator or function switch to the OFF position. For 8801A, 8802A

preamplifiers, place signal use-off switch in OFF position.

2 Press POWER pushbutton. Indicator lamp on recorder will light. Allow three minutes warmup time.

3 Balance and calibrate pream plifiers following the procedures outlined in the pream plifier instruction

manual. When making calibration adjustments, set chart drive ON (see Step 4).

4 Press MM/SEC pushbutton, then press "5" pushbutton. Recorder will run at 5 mm /sec chart speed.

(When recording data, press numbered speed pushbutton to suit recording application. Select

mm/min speeds with recorder Options 11 or 12 by pressing MIN pushbutton.)

5 Adjust stylus heat for each channel to obtain a satisfactory trace intensity (when recording data which

is in the upper range of the recorder bandwidth, a higher stylus heat is required for good trace

definition).

6 Press STOP pushbutton to stop chart drive.

7 Press TIMER pushbutton to obtain one per second time markings on recording. For mm/min

speeds, optional timer records one mark per minute.

8 Press MARK pushbutton to record reference marks on lower edge of Permapaper.

Figure 3-5. System Operating Procedures

3-6

Page 27

TM 11-6625-2751-14&P

REMOTE CHART DRIVE CONTROL

1 Connect the switch circuit shown in Figure 2-8 to J13 on the rear panel of the recorder.

2 Place the LOCAL-REMOTE switch in the REMOTE position.

3 Press speed pushbuttons on the recor der front panel for the desired recor ding speed. W ith r emote

switch in RUN position, chart drive is ON. In STANDBY position, chart drive is OFF.

REMOTE MARKER CONTROL

4 Connect the switch circuit shown in Figure 2-9 to J15 on the r ecorder rear panel. Press the r emote

mark switch to record a reference mark on the lower edge of the Permapaper.

5 For systems with an auxiliary marker (Option 15), connect the switch circuit of Figure 2-9 to J14.

Press the auxiliary marker switch to record a reference mark between channels on the Permapaper.

Figure 3-6. Remote System Operation

3-7

Page 28

SECTION IV.

PRINCIPLES OF OPERATION

TM 11-6625-2751-14&P

4-1. INTRODUCTION.

4-2. This section of the manual contains the

principles of operation of the electrical and mechanical

components in the 7702A System. A block diagram of

the system is shown in Figure 4-1. Introductory

paragraphs 4-3 to 4-13 contain basic information on

semiconductor diode and transistor circuits used in the

recording system.

4-3. BASIC CIRCUITS.

4-4. Diodes.

4-5. Semiconductor diodes are used in the signal

handling circuits and in the power supply rectifier and

regulator circuits.

4-6. Diodes are used as lim iters or clipper s in circ uits

to remove positive or negative peaks of wavefor m s. T he

diode can be used either as a waveform shaping circuit

or as a protective device to pr event excessive voltages

being applied to a sensitive circuit. Figure 4-2 (a) s hows

a limiter which prevents the negative peak of a pulse

from going more negative than approxim ately 0.6 volts.

Note that for a conducting silicon diode, the cathode

voltage is about 0.6 to 0.8 volts more negative than the

anode.

4-7. A diode clamper or dc restorer is a c ircuit which

establishes either the positive or negative peak of a

waveform at a particular dc refer ence voltage to provide

a definite baseline voltage for the waveform . Figure 4-2

(b) shows a clamper which provides a baseline of about

+20 volts for a negative pulse.

4-8. A diode regulator circuit uses either the constant

reverse-bias breakdown voltage characteristics of a

zener diode, or the constant forward bias voltage drop

characteristic of a s ilicon diode. Power supply reference

voltages are generally provided by break-down diodes

which maintains a constant voltage when supplied with a

reverse-bias voltage greater than their specified

breakdown voltage. Regulated voltages can also be

provided by a forward-biased silicon diode which

maintains a constant 0.6 to 0.8 volt drop. Figure 4-2 (c)

shows connections for both types of diodes.

4-9. Transistors.

4-10. Transistors are used throughout the 7702A in

amplifier and oscillator circuit configurations. Vacuum

tubes and transistors are functionally similar. In the tube,

a small grid-to-ca thode potential controls a large plate to

cathode current flow. In a transistor, a small base-toemitter current controls a large collector-to-emitter

current. A comparison of basic

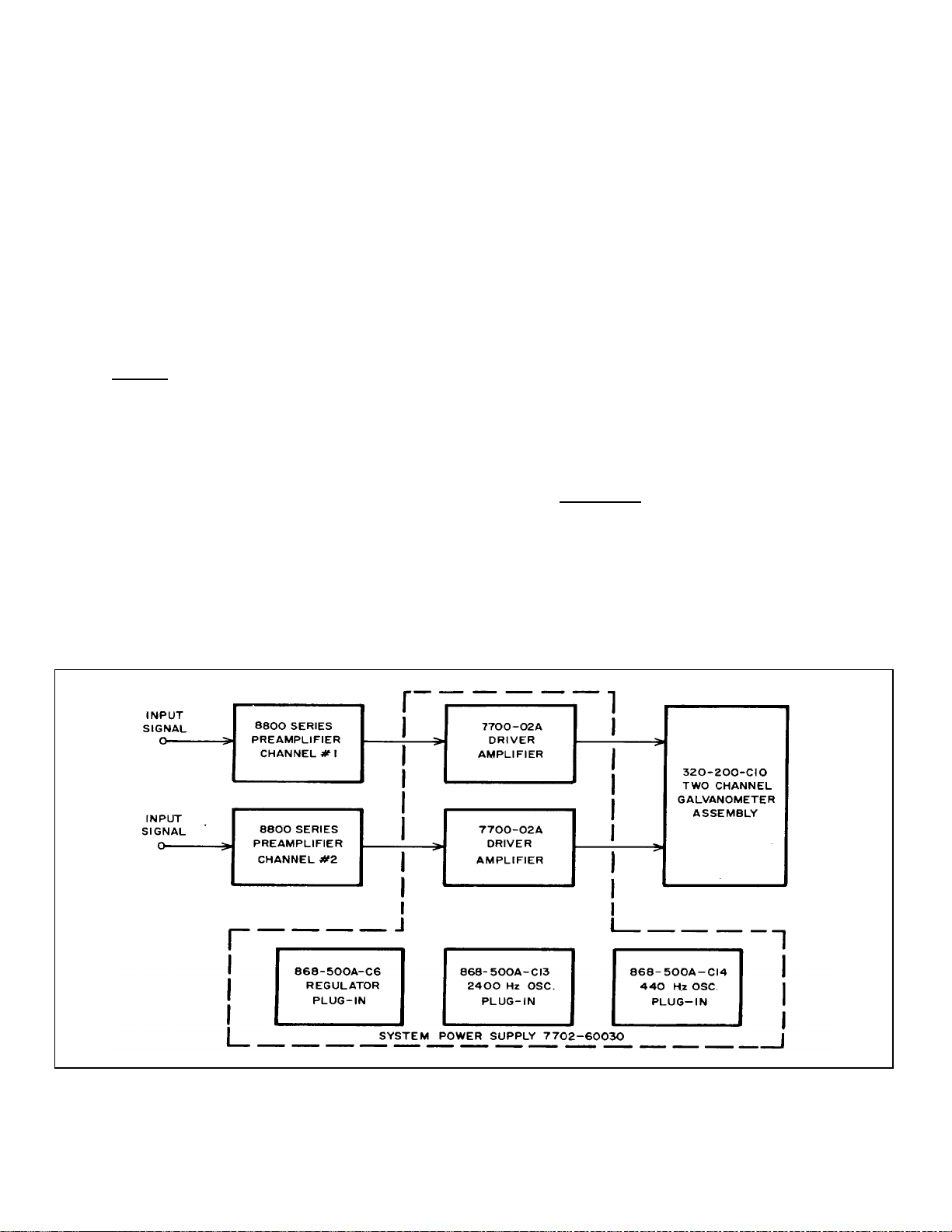

Figure 4-1. Model 7702A System Block Diagram

4-1

Page 29

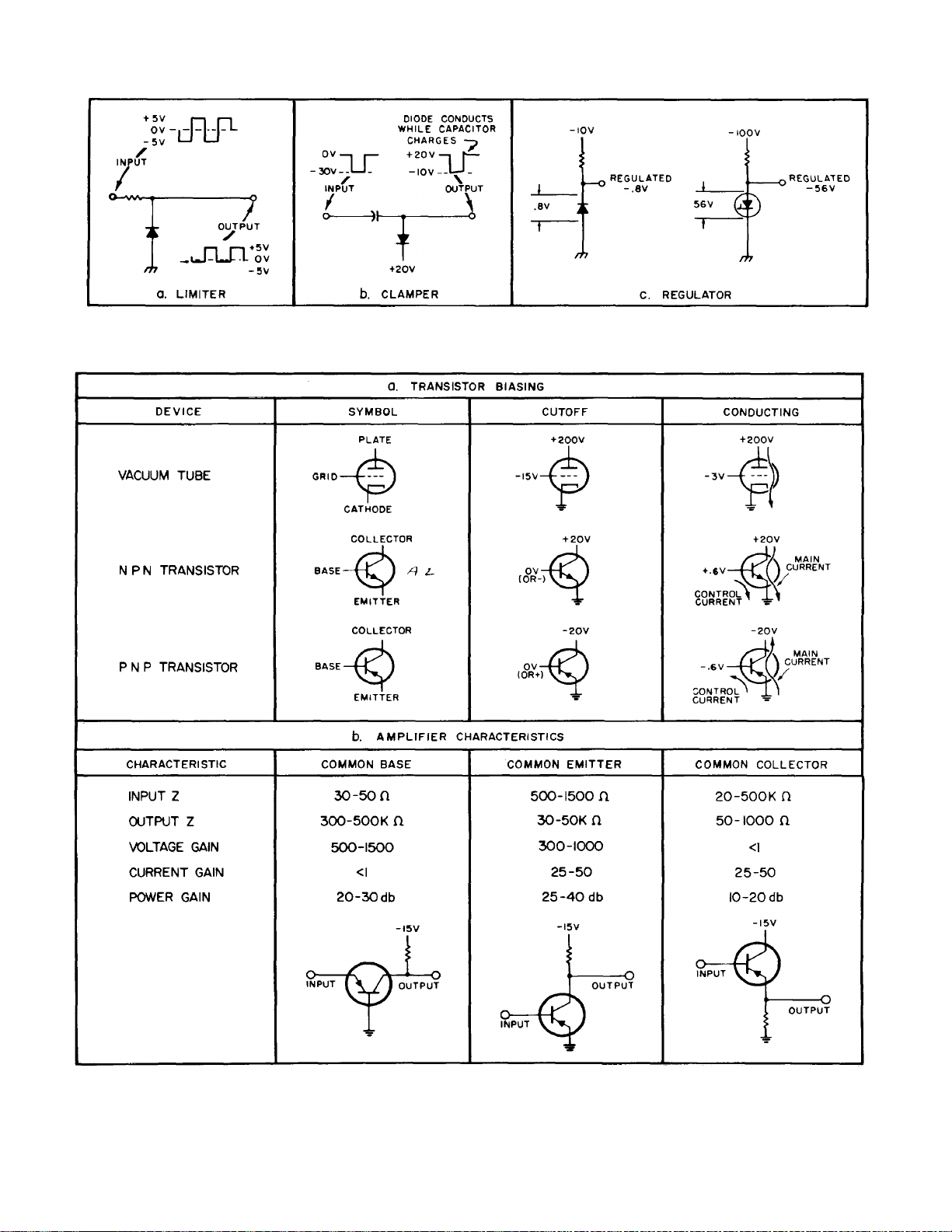

Figure 4-2. Basic Diode Circuits

TM 11-6625-2751-14&P

Figure 4-3. Transistor Operation

4-2

Page 30

TM 11-6625-2751-14&P

vacuum tube, NPN transistor, and PNP transistor

operation is shown in Figure 4-3 (a); indicated current

represents conventional flow of positive charges external

to the transistor and is not intended to indicate flow of

carriers inside the transistor structure. Notice that the

effect of emitter-base-collector voltages is totally

reversed between NPN and PNP transistors; circuits

which are arranged for an NPN transistor usually function

normally for a PNP transistor if supply voltages are

reversed.

4-11. There are three basic am plifier types, Figure 4-3

(b). These am plifiers are used alone or in com binations

to form complex circuits.

4-12. COMPONENT CIRCUIT DESCRIPTION.

4-13. Preamplifiers.

4-14. The principles of operation for the 8800 Series

Preamplifiers ar e contained in the particular preamplifier

Operating and Service Manual. A list of the preamplifiers

is shown in Section I, Table 1-3. The pream plifier s ignal

input connectors (J1, J2) mounted on the rear of the

recorder include provision f or us e of a guar d s hield in the

signal input cable. Use of a guard shield contributes to a

high common-mode rejection ratio when floating input

preamplifiers such as the 8803A are installed in the

system. Additional information on the preamplif ier guard

shield circuit is contained in the preamplifier manual.

4-15. The output signal of each preamplifier is

connected to the input of a 7700-02A galvanometer

driver amplifier. T he preamplif ier output signals are als o

available at connectors J21 and J22 at the rear of the

recorder, for connection to oscilloscopes or other

monitoring instruments . Signal distribution in the 7702A

System is shown in Figure 4-4.

4-16. Driver Amplifiers.

4-17. Two 7700-02A Galvanometer Driver Amplifiers

are mounted on the rear panel of the power supply 7702-

60030. The driver amplifier block diagram is shown in

Figure 4-5.

4-18. The input signal and the galvanometer feed-back

signal shown in the block diagram are amplified by the

balanced amplifier Q1, Q2, and directly coupled to the

differential amplifier Q3, Q4. The signal driving Q1 is

limited in amplitude by the transistors Q8 and Q9 to a

value which will not overload the driver amplifier or drive

the galvanometer writing arm excessively. The singleended output from the Q3, Q4 stage is obtained from the

collector of Q4 and is fed to the base of Q5. T ransistor

Q5 operates as a Class A driver f or the complem entarysymmetry Class B emitter-follower power amplifier Q6,

Q7.

The amplifier output is connected to the galvanometer

drive coil. A galvanometer feedback signal is obtained

from the galvanometer drive coil and velocity coil, and

returned as an input to the balanced amplifier.

4-19. FEEDBACK CIRCUIT. The feedback circuit

provides an adjustable amount of galvanometer damping

and galvanometer frequency compensation to obtain

optimum galvanometer transient response and frequency

response characteristics. Galvanometer damping is

obtained by generating a feedback voltage proportional

to the galvanometer coil velocity, and inserting this

voltage into the driver amplifier circuit with a polarity as to

reduce the coil velocity. Frequency compensation is

achieved by an RC network in the feedback c irc uit, which

determines the amplitude of high frequency feedback

voltages returned to the balanced amplifier.

4-20. The feedback voltage is derived from two

sources; the galvanometer velocity coil output, and the

voltage drop across R24 (see Figure 4-6). The velocity

voltage component is proportional to galvanometer coil

velocity, to damp the galvanometer motion. The

DAMPING control selects the amount of this velocity

voltage component which gives the best damping

characteristics. The drive coil current through R24

produces a voltage at the base of Q2 with an amplitude

approximately equal to the Q1 input signal due to the

high ratio of open loop to closed loop gain. This

feedback action forces a current through the

galvanometer drive coil alm os t ex ac tly proportional to the

input voltage.

4-21. The DAMPING control is adjusted for the best

transient response, and the COMPENSATIO N control is

adjusted to match the high-frequency roll-off of the

galvanometer. Figure 4-7 shows the galvanometer

response both in the frequency and time domains to

illustrate different degrees of damping.

4-22. The underdamped condition in Figure 4-7 (a)

depicts a partially damped system, with the damping

supplied only by the shorted coil frame of the galvanmeter. This shorted frame is equivalent to a low

resistence, one-turn short-circuited coil winding. The

currents induced in this coil frame develop a damping

force which is proportional to the coil velocity, and is in a

direction as to reduce the velocity. In this case, the

galvanometer oscillates around its final value before

coming to rest. The overdamped condition is the result

of excessive feedback damping voltage. In this case,

the galvanometer approaches its final value slowly,

giving too slow a rise time for recording short-period

transient voltages.

4-23. The ideal waveshape is the result of properly

adjusting the feedback voltage. In this case, the

galvanometer approaches the final value quickly, and

settles to the final value with a slight overshoot (about

4%). This corresponds to 71% of c ritic al damping, which

provides the desired transient and frequency response.

4-3

Page 31

TM 11-6625-2751-14&P

Figure 4-4. Signal Distribution Diagram

Figure 4-5. Model 7700-02A Driver Amplifier Block Diagram

4-4

Page 32

TM 11-6625-2751-14&P

(a) Transient response, step function input

Figure 4-6. Feedback Circuit-Simplified Schematic

4-24. The frequency response obtained with an underdamped, overdamped and 71% damped galvanometer is

shown in Figure 4-7 (b).

4-25. The frequency response for the 7702A

Recording System with an 8802A Preamplifier installed is

shown in Figure 4-8. The DAMPING c ontrol is adjusted

for 0.71 critical damping at 10mm deflection.

4-26. System Power Supply.

4-27. The 7702A System Power Supply (07706-

60030) furnishes operating power for the preamplifiers,

driver amplifiers, and the recorder chart drive circuits.

The power supply consists of the following sections:

a. ± 18 Vdc unregulated supply.

b. ± 12 Vdc regulated supply.

c. 440 Hz oscillator (provides chopper exc itation for

8803A Preamplifier).

d. 2400 Hz oscillator (provides transducer

excitation voltage for 8805A Carrier Preamplifier).

e. Control circuits for the chart drive motor, the

marker and timer assemblies, and the stylus heat circuit.

(b) Frequency response, sine-wave input

Figure 4-7. Galvanometer Frequency Response and

Transient Response

4-28. UNREGULATED DC SUPPLY. The

unregulated ± 18 Vdc supply (see Figure 4-9) consists of

transformer T1, diodes CR1 to CR8, and the filter

capacitors C13 to C16. Each pair of diodes (CR1, CR2,

CR3, CR4) connected across the T1 secondar y winding

forms a full wave rectifier circuit. The output of the

rectifiers is filtered by capacitors C13 to C16. The

distribution of the ± 18 volt power in the 7702A System is

shown in Figure 4-10.

4-29. REGULATED DC SUPPLY. The regulated ± 12

Vdc supply block diagram is shown in Figure 4-11, and in

the schematic diagram at the rear of the manual. The

+18 volt and -18 volt unregulated supply outputs are

connected to the series regulator transis tors Q1 and Q2,

which are controlled by the output of amplifiers Q3 and

Q6 in the 868-500A-C6 regulator card. Both regulated

voltages are controlled by one

4-5

Page 33

TM 11-6625-2751-14&P

voltage adjust control, R4. One input of differential

amplifier Q4, Q5 is maintained at 6.2 volts by zener

diode CR14; the other input is maintained at a fraction of

the -12 volt regulated output by the setting of R4. If the 12 volt regulated output voltage should vary slightly, this

will appear as a change in input signal levels between

the inputs to Q4 and Q5. This change is further

amplified by Q3, and applied to the series control

transistor Q1, with such polarity as to return the -12 volt

regulated output towards its original value. The +12 volt

regulated line is controlled in the sam e manner. In this

case, one input of the differential amplif ier Q7, Q8 is at

ground potential, and the other input is held at a value

determined by the voltage divider R12, R13. Assum ing

regulation of the -12 volt line, if the +12 volt output should

vary slightly, this will appear as a change in input signal

levels at the input to Q7, Q8. This change is further

amplified by Q6, and applied to the series control

transistor Q2 with such polarity as to return the -12 volt

regulated power in the 7702A System is shown in Figur e

4-12.

4-30. 440 HZ OSCILLATOR CARD. The 440Hz

Oscillator (868-500A-C14) is shown in the block diagram,

Figure 4-13. The frequency of the Q12, Q13 Os c illator is

determined by the transformer T4 and capacitor C15.

Output from T4 drives the power amplifier Q4, Q5.

Diodes CR21, CR22 control the

amplitude of oscillation at a level determined by zener

diode CR23. The power for the oscillator and power

amplifier is provided by the -18 volt unregulated supply

through regulator Q3. The base of Q3 is held at -12 volts

by the -12 V regulated supply.

Figure 4-8. 7702A System Frequency Response

Figure 4-9. Unregulated ± 18V Supply

4-6

Page 34

TM 11-6625-2751-14&P

Figure 4-10. Unregulated ± 18 V Power Distribution

Figure 4-11. Regulated ± 12 V Supply

4-7

Page 35

TM 11-6625-2751-14&P

Figure 4-12. Regulated ± 12 V Power Distribution

Figure 4-13. 440 Hz Plug-In Oscillator Block Diagram With Associated Circuits

4-8

Page 36

TM 11-6625-2751-14&P

4-31. 2400 HZ OSCILLATOR CARD. The 2400 Hz

Oscillator Plug-In Card (868-500A- C13) is shown in the

block diagram, Figure 4- 14. Q20 and Q21 oscillate at a

frequency determined by transformer T 7 and capacitors

C18 and C19 in parallel. Thermistors TM7 and TM8

provide oscillator stability. Diodes CR25, CR26 control

the amplitude of oscillation at a level determined by

zener diode CR24. Output from T7 is a 2400 Hz sine

wave balanced with respect to ground, which is used as

a transducer excitation voltage, and also provides a

reference voltage for the 8805A Carrier Preamplifier.

4-32. Oscillator power is provided by the -18 volt

unregulated supply through regulator Q19, located on the

plug-in card. The base of Q19 is held at a fixed voltage

by the regulated -12 volt supply. The Q19 emitter output

voltage (approximately 12 volts), supplies the Q20 and

Q21 oscillator circuit.

4-33. RECORDER DESCRIPTION.

4-34. Recorder consists of chart drive components to

transport the recording paper past the rec ording styluses

onto a paper takeup assembly, and a dual galvanometer

assembly. Also included are control circuits for the

following functions: chart drive, stylus heat, timer and

marker stylus.

4-35. Chart Drive Components.

4-36. The chart drive mechanism consists of: (1) a 450

rpm (60 Hz) synchronous drive motor, coupled to speed

reduction gears to obtain chart speeds f rom 1 m m /sec to

100 mm/sec; ( 2) pushbutton actuated c lutch assem blies,

located on the reduction gear shafts, to determ ine which

of the speed reduction gears are in the drive tr ain for the

chart speed selected; (3) a paper drive assembly, which

includes a paper supply spool, a brake roll to hold the

paper under tension as it passes over the paper table

and a paper drive roll driven by the output of the speed

reduction gears, and; (4) a paper takeup assembly,

which stores the chart paper following the recording

process.

4-37. Drive Motor and Speed Reduction Gears.

4-38. The drive motor (B1) is coupled to the input

shaft, see Figure 4-15(a), by means of a drive c hain and

sprockets. The input shaft rotates at 300 rpm for the 1 to

100 mm/sec chart speeds (50 or 60 Hz power line). Four

additional chart speeds are available (Option 11 or

Option 12) with the addition of a second synchronous

drive motor. The optional mm/min drive motor (B103)

rotates the input shaft at 5 rpm (50 or 60 Hz power line),

through a similar sprocket and chain coupling. An

overrunning clutch is installed on each drive motor

sprocket so that only one motor shaft rotates at a time.

Figure 4-14. 2400 Hz Plug-In Oscillator Block Diagram

4-9

Page 37

TM 11-6625-2751-14&P

Figure 4-15. Chart Drive Motor and Speed Reduction Gears

4-10

Page 38

TM 11-6625-2751-14&P

4-39. Two speed-reduction gear assemblies are

included in the recorder. The first speed reduction

assembly, Figure 4-15(b), contains a 5:1 speed reduction

gears. The second speed reduction, Figure 4-15 (c),

contains both 5:1 and 4:1 reduction gears, to obtain a

20:1 overall speed reduction for the second assembly.

4-40. Pushbutton Actuated Clutch Assemblies.

4-41. A spring clutch installed in each of the speed

reduction assemblies permits the reduction gears to be

by-passed, resulting in a 1:1 speed ratio. The spring

clutches are mechanically linked to the four-speed

pushbuttons on the front panel of the recorder by the

clutch actuator assembly shown in Figure 4-12 of

Section VI. Pressing one of the pushbuttons c auses the

appropriate clutch to be engaged for the speed selec ted.

Table 4-1 lists the speed reductions in effect for 1

mm/sec to 100 mm/sec recorder operation.

Table 4-1. Speed Reduction Ratios

DRIVE SPEED

SPEED REDUCTION

MM/SEC 1 ST 2 ND

CHART

DRIVE

MOTOR

1 5:1 20:1

5 1:1 20:1

20 5:1 1:1

100 1:1 1:1

CHART

DRIVE

ROLL

4-42. The power flow through the first speed reduction

assembly is shown in Figure 4-16. For 1:1 speed r atio,

the pushbutton linkage pulls the clutch actuator arm ( 1)

away from the clutch housing. This action locks the gear

(2) to shaft (3). The resulting power flow by-passes the