Page 1

DisplayMaker Legacy 72S, 72SR

User Manual

Part Number 0700022F

1

Page 2

Legal notices

© Copyright 2008 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP

products and services are set forth in the express warranty statements accompanying such

products and services. Nothing herein should be construed as constituting an additional warranty.

HP shall not be liable for technical or editorial errors or omissions contained herein.

Printed in the US

For additional technical support and user documentation please refer to:

www.hp.com/go/graphicarts

2

Page 3

Revision Log The following is a list of major changes and additions that have

been made to this manual since the previous revision.

See the accompanying Release Notes for specific changes to the

soft ware and hardware between manual updates.

Revision Description

Revision E Chapter 1: Turnbuckle installation added. Grounding

tests added. Print pausing added.

Chapter 2: Menu items added. Menu tree updated.

Chapter 3: “Left Only” print modes changed to “Unidi-

rectional.” Edge-to-edge printing added. Saran Wrap

replaced with SolaChrome Capping Film.

Chapter 4: “Hard” and “soft” jetouts documented.

Chapter 5: Stopcock on waste ink tube added. Clean-

ing doctor blade added. Cyan Heads Maintenance

function documented.

iii

Page 4

Regulatory Statements

FCC-A This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his or her own expense.

This equipment must be installed exactly as instructed in this

manual using only the components supplied. If a supplied component ever needs to be replaced, it must be replaced with the

same part supplied by the manufacturer. It is your responsibility

to follow these instructions in order to maintain compliance

with the FCC regulations. Changes or modifications not

expressly approved by ColorSpan Corporation could void your

authority to operate this equipment. In particular, this device

must be operated with shielded cables to maintain FCC

compliance.

A booklet is available from the Federal Communications Commission entitled, How to Identif y and Resolve Radio-TV Interfer-

ence Problems (#004-000-00345-4). Write to the U.S.

Government Printing Office, Washington, DC 20402.

DOC (Canada) This digital apparatus does not exceed the Class A limits for

radio noise for digital apparatus set out in the Radio Interference Regulations of the Canadian Department of Communications.

Normes de Sècuritè (Canada)

Le présent appariel numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils numériques

de la Classe A prescrites dans le réglements sur le brouillage

radioélectrique édictés par le Ministére des Communications du

Canada.

iv

Page 5

Telecommunications

Network Statement

The ColorSpan VideoNet port on this device is not intended to

be connected to a public telecommunications network. Connection of this device to a public telecommunications network in a

European Community Member State will be in violation of

national law implementing Directive 91/263/EEC on the approximation of laws of the Member States concerning telecommunication terminal equipment, including the mutual recognition of

their conformity.

Der VideoNet port ist nicht dafür vorgesehen an ein öffentliches

Telefonnetz angeschlossen zu werden. Der Anschluß dieses

Gerätes an ein öffentliches Telefonnetz in einem Mitgliedstaat

der EU, verstößt gegen nationale Gesetze zur Ausführung der

Direktive 91/263/EEC, die sich mit der Annäherung von

Gesetzen von Mitgliedstaaten beschäftigt, betreffend Telekommuniktionsanlagen und die gegenseit ige Anerkennung ihrer

Konformität.

v

Page 6

About This Manual Read this manual to unpack, set up, and use the ColorSpan

“Gator” digital color printers.

◆ Chapter 1, Getting Started, shows you how to unpack and

assemble the printer, and introduces you to its main features.

◆ Chapter 2, Using the Control Panel, shows you how to use

the control panel to specify printer options.

◆ Chapter 3, Ink and Media, shows you how to install ink and

media.

◆ Chapter 4, Calibrating the Printer, shows you how to cali-

brate the printer for optimal print quality.

◆ Chapter 5, Maintaining the Printer, explains scheduled

maintenance, how to recover clogged printheads, how to

prepare the printer for extended power-down (such as for

shipping or storage), and more.

◆ Chapter 6, Print Server Setup, shows you how to specify

ColorSpan print server options.

◆ Chapter 7, Printer Driver Setup, shows you how to control

output options from the client workstation via the ColorSpan printer driver software.

◆ Appendix A, Technical Specifications, lists the printer’s

technical specifications.

◆ Appendix B, Troubleshooting, shows you how to trouble-

shoot common printing problems and interpret Action and

Warning messages.

For further information, refer to the following ColorSpan

documentation:

◆ Quick Start Guide — START HERE to set up and install a brand

new ColorMark print server, and connect and configure

printers to it.

◆ Site Preparation Guide — explains how to prepare your site for

the printer’s arrival and installation.

◆ ColorSpan Print Server Documentation — the System Control

User Guide and Printing Tools User Guides shows you how to

print and RIP files through the ColorSpan print server. If the

printer is connected to a non-ColorSpan print server (RIP),

refer to the documentation that accompanies the server.

◆ Release Notes and Update Notes — late-breaking information,

update descriptions, and update instructions.

◆ ColorSpan web site — http://www.colorspan.com.

vi

Page 7

Conventions This manual uses the following informational conventions:

Note

Hinweis

Caution

Vorsicht

WARN ING

WARN UNG

Other WARNING symbols used:

A special technique or information that may help

you perform a task or understand a process.

Ein Hinweis beschreibt eine spezielle technik zur

Lösung einer Aufgabe oder enthällt Informationen,

die Ihnen eine Prozedur näher erläutert.

Alerts you to something that has the potential to

cause damage to hardware, software, or data.

Dieses Feld weist auf einen Umstand hin, der einen

Hardware-oder Software-Schaden oder Datenverlust

verursachen könnte.

Alerts you to something that has the potential to

cause physical harm to you or others around you.

Eine Warnung auf weist auf einen Umstand hin,

durch den Ihnen und anderen Personen ein physischer Schaden erwachsen könnte.

Electrical Hazard

Vorsicht steht unter Spannung

Lifting Hazard

Vorsicht beim Anheben

Hot Surface

Heiß, nicht berühren

Moving Parts

Bewegliche Teile, Verletzungsgefahr.

vii

Page 8

viii

Page 9

TABLE OF CONTENTS

Revision Log..............................................................................................iii

Regulatory Statements.............................................................................. iv

FCC-A ....................................................................................................iv

DOC (Canada)...................................................................................... iv

Telecommunications Network Statement..............................................v

About This Manual ...................................................................................vi

Conventions............................................................................................. vii

Getting Started

Operating Requirements ....................................................................... 1-2

Electrical............................................................................................. 1-2

Environmental.................................................................................... 1-2

Important Operating Notes............................................................... 1-3

Safety Warnings ................................................................................. 1-5

Unpacking and Assembly ...................................................................... 1-7

Required Tools ................................................................................... 1-7

Unpacking.......................................................................................... 1-7

Stand Assembly.................................................................................. 1-8

Printer Assembly .............................................................................. 1-10

Off Head Supply (OHS) Assembly................................................... 1-13

Final Assembly ................................................................................. 1-15

Connecting to Power....................................................................... 1-21

Connecting to the Print Server ........................................................ 1-22

First-Time Power-Up and Test Print ..................................................... 1-23

Unpack the Printheads..................................................................... 1-23

Power Up the Printer ....................................................................... 1-25

Install Ink for the First Time in the Printer ....................................... 1-26

Load Media...................................................................................... 1-27

Send a Test Print from Server........................................................... 1-27

What’s Next?.................................................................................... 1-28

Workflow Overview ............................................................................. 1-29

Daily Startup .................................................................................... 1-29

Printing ............................................................................................ 1-29

Daily Shutdown ............................................................................... 1-30

Parts Overview..................................................................................... 1-31

Special Features ................................................................................... 1-35

Printheads ........................................................................................ 1-35

Ink System........................................................................................ 1-35

Calibration ....................................................................................... 1-36

Media Handling............................................................................... 1-36

Performance and Ease-of-Use .......................................................... 1-37

Table of Contents ix

Page 10

Using the Control Panel

Overview................................................................................................ 2-2

Ready Screen...................................................................................... 2-2

Front Page.......................................................................................... 2-2

Menu.................................................................................................. 2-2

User Assistance................................................................................... 2-3

Front Page.............................................................................................. 2-4

Navigation Keys ..................................................................................... 2-8

Menu...................................................................................................... 2-9

Calibrate Printer ................................................................................. 2-9

Printer Settings................................................................................. 2-10

Maintenance .................................................................................... 2-14

Service Printer .................................................................................. 2-16

Other Functions ...........................................................................2-16

User Diagnostics .............................................................................. 2-17

Warnings & Actions ......................................................................... 2-17

Menu Tree............................................................................................ 2-18

Front Page........................................................................................ 2-18

Menu................................................................................................2-19

Ink and Media

Ink System Overview.............................................................................. 3-2

Idle Jet Maintenance.............................................................................. 3-3

Selecting a Print Mode........................................................................... 3-4

General Printing Tips ............................................................................. 3-5

Checking Jet Health ............................................................................... 3-6

Print Prime Bars.................................................................................. 3-7

Purge-n-Wipe Printheads................................................................... 3-7

Print Jet-Out Lines.............................................................................. 3-8

Map Out Missing Jets ........................................................................ 3-8

Refilling Ink ............................................................................................ 3-9

Capping the Printheads ....................................................................... 3-11

Cap the Printheads .......................................................................... 3-11

Uncap the Printheads....................................................................... 3-12

Loading Roll-Fed Media....................................................................... 3-14

Loading 72-Inch Media ................................................................... 3-20

Unloading and Cutting Roll-Fed Media............................................... 3-21

Takeup Spool Pin Release ................................................................ 3-22

Respooling Media ................................................................................ 3-23

Loading Rigid Media............................................................................ 3-25

Loading and Aligning the Sheet ......................................................3-27

Edge-to-Edge Printing.......................................................................... 3-29

Unloading and Reloading Rigid Media ............................................... 3-30

x Table of Contents

Page 11

Media Wizard ...................................................................................... 3-31

Setting Heater Temperatures............................................................... 3-34

Calibrating the Printer

When to Calibrate.................................................................................. 4-2

AutoJet ................................................................................................... 4-3

AutoTune ............................................................................................... 4-4

Quality Check .................................................................................... 4-5

AutoRecover........................................................................................... 4-6

Auto Calibrations ................................................................................... 4-7

Manual Calibrations .............................................................................. 4-8

Media Feed........................................................................................ 4-9

Manual X Head Registration............................................................ 4-11

Manual BiDi Registration................................................................. 4-13

Manual Jet Mapping........................................................................ 4-15

Report Individual Bad Jets ........................................................... 4-17

Clear Individual Bad Jets ............................................................. 4-18

View Current Bad Jets.................................................................. 4-19

Clear All Bad Jets.......................................................................... 4-19

Jet Status Lines................................................................................. 4-21

Default Registration Data ................................................................ 4-21

Calibration Summary........................................................................... 4-22

Straightening the Media Path.............................................................. 4-23

Linearization ........................................................................................ 4-24

Maintaining the Printer

Maintenance Schedule .......................................................................... 5-2

Clean the Rail and Bearings................................................................... 5-3

Pinch Rollers....................................................................................... 5-3

Rail ..................................................................................................... 5-4

Carriage Bearings............................................................................... 5-4

Cleaning the Encoder Strip................................................................ 5-5

Empty Excess Ink.................................................................................... 5-6

Printhead Maintenance ......................................................................... 5-7

Cleaning Clogged Ink Jets ..................................................................... 5-8

Set the Printhead and Camera Height................................................. 5-11

Calibrate the Service Station ............................................................... 5-16

Replace Ink Filters................................................................................ 5-18

Extended Power Down and Restart..................................................... 5-21

Power Down .................................................................................... 5-21

Restart .............................................................................................. 5-21

Table of Contents xi

Page 12

Print Server Setup

Configuring and Controlling the Printer................................................ 6-2

Viewing Printer Status........................................................................ 6-3

Printer Status.................................................................................. 6-4

Software ......................................................................................... 6-4

ColorMark CMS.............................................................................. 6-4

Approximate Ink Remaining .......................................................... 6-4

Configuring the Printer...................................................................... 6-5

Printer Name.................................................................................. 6-5

ColorMark CMS.............................................................................. 6-6

Dithering........................................................................................ 6-6

Ink Level......................................................................................... 6-6

Lighter Prints—Darker Prints........................................................... 6-6

Selecting Server Options........................................................................ 6-7

Configuring the Input Port ................................................................ 6-8

Port Name ...................................................................................... 6-8

EPS/TIFF Options............................................................................ 6-9

RIP Options .................................................................................... 6-9

Printing Options...........................................................................6-10

Attention Queue Jobs ...................................................................... 6-13

Tiling ................................................................................................ 6-14

Color Management.............................................................................. 6-18

ColorSpan Workflow........................................................................6-18

ColorMark CMS............................................................................6-18

Color Profile ................................................................................. 6-19

ICC Workflow................................................................................... 6-20

Color Calibration..................................................................................6-22

Spectrolino SpectroScan................................................................... 6-24

ColorMark Calibrator .......................................................................6-24

Printer Driver Setup

Specifying Windows Device Options..................................................... 7-2

Details ................................................................................................ 7-2

Printer Features .................................................................................. 7-2

Selecting an Output Color Space........................................................... 7-4

Specifying Macintosh Device Options................................................... 7-6

Selecting Printer Features................................................................... 7-6

Selecting an Output Color Space........................................................... 7-8

xii Table of Contents

Page 13

Technical Specifications

Specifications ......................................................................................... A-2

Supplies and Accessories ....................................................................... A-6

Troubleshooting

Troubleshooting Checklist ..................................................................... B-2

Warranty Claims .................................................................................... B-5

Diagnostics ............................................................................................ B-7

MacDermid ColorSpan Technical Services .......................................... B-14

Help From Your Reseller .................................................................. B-14

Help From ColorSpan ...................................................................... B-14

If All Else Fails .................................................................................. B-14

Index

Table of Contents xiii

Page 14

xiv Table of Contents

Page 15

CHAPTER 1

Getting Started

This chapter shows you how to get started using your printer. It includes

these topics:

◆ Operating Requirements (page 1-2)

◆ Unpacking and Assembly (page 1-7)

◆ Workflow Overview (page 1-30)

◆ Parts Overview (page 1-32)

◆ Special Features (page 1-36)

Getting Started 1-1

Page 16

Operating

Requirements

Choose a location for the printer before you unpack it. Keep the

following requirements in mind:

Electrical ◆ Use the supplied power cord. Plug it directly into a grounded

electrical outlet. Do not lengthen the power cord with an

extension cord; the resulting voltage drop could damage the

printer.

◆ Make sure the line voltage meets the requirements: 220 VAC

±10%, 20 Amps, with NEMA L6-20R locking wall receptacle

(North America and Japan), OR 220 VAC ±10%, 16 Amps,

single phase, with IEC 60309 wall receptacle (Europe).

Install a voltage regulator or similar device if the power

source is not stable within these specifications. See Appen-

dix A, Technical Specifications, for details.

◆ To maintain vacuum to the printheads during printer powerdown, use the auxiliary 24 volt power supply (included in

the accessory kit with universal power adapters). Connect

the 24 VDC jack on the vacuum/pressure assembly to either

of two options:

◆ 1. UPS — customer-supplied uninterruptable power sup-

ply, output 100-240 VAC, 50/60 Hz, minimum of 15 watts

of power, provides battery backup to the vacuum system in the event of a power failure.

◆ 2. Wall outlet — 100-240 VAC, 50/60 Hz, provides tem-

porary power to the vacuum system when it is necessary to power down the printer for service.See Appendix

A, Technical Specifications, for details.

◆ Connect the print server or RIP to a separate electrical circuit

from the printer.

Environmental ◆ Make sure the room is well ventilated, with a temperature

and relative humidity within specifications (see “Specifications” on page A-2). Optimal printing and drying occurs

within these ranges.

◆ The printer uses solvent-based inks. The printer does not

include an integrated exhaust hood or shielding for collecting the volatile organic compound (VOC) emissions from the

inks and cleaning solvent. The owner is responsible for ventilation and VOC recovery as required by local regulations.

Connection kits are available from MacDermid ColorSpan to

vent VOC emissions to the customer’s exhaust system or

VOC recovery equipment. Consult your MacDermid ColorSpan reseller for details.

1-2 Operating Requirements

Page 17

◆ Store media and ink in an area with similar temperature and

humidity conditions as the printer.

◆ Locate the printer close enough to the print server (RIP) so

that they can be connected with the required cable.

◆ Locate the printer on a flat, level floor.

◆ Locate the printer where its normal operating noise will not

disturb quiet work areas.

◆ DO NOT install the printer near humidifiers, refrigerators,

fans, water faucets, heaters or similar equipment.

◆ DO NOT install the printer in areas where the temperature

changes abruptly, such as near air conditioners or in the path

of direct sunlight.

◆ DO NOT expose the printer to flames or dust.

Important Operating

Notes

◆ DO NOT POWER DOWN THE PRINTER. Constant vacuum at

the printheads is required to prevent ink from flowing from

the printheads when not printing, even when the printheads

are capped. If the printer must be powered down for shipping, empty and cap the printheads (See “Extended Power

Down and Restart” on page 5-21) or apply auxiliary 24 volt

power (see “Connecting to Power” on page 1-22).

◆ If the printer has been idle for more than several minutes,

press the Prime Bars button on the printer control panel to

check for missing inkjets. To recover missing inkjets, see

“Checking Jet Health” on page 3-6.

◆ If the printer will be idle for more than one hour, cap the

printheads to conserve ink. When the printheads are

uncapped and the printer is not printing, the printheads

periodically expel a small amount of ink into the excess ink

reservoir to keep them working. (“Capping the Printheads”

on page 3-11 for instructions.)

◆ Refill the ink and cleaning solvent reservoirs only when the

Ready-for-Refill LED is on. Refill only with an entire bottle of

ColorSpan SolaChrome HR ink or cleaning solvent, and

replace the profiler. USE OF OTHER INKS AND CLEANING

SOLVENTS COULD DAMAGE THE PRINTER, WILL REQUIRE A

SERVICE CALL, AND WILL VOID THE WARRANTY. (“Refilling

Ink” on page 3-9.)

◆ To wipe the printheads, use only ColorSpan cleaning solvent

applied with a 100% polyester Class 100 cleanroom wipe.

(See “Cleaning Clogged Ink Jets” on page 5-8 for instructions.) DO NOT USE ISOPROYPL ALCOHOL.

Operating Requirements 1-3

Page 18

◆ To cap the printheads, use only SolaChrome Printhead Capping Film. Damage to printheads resulting from the use of

poorly performing plastic films is not covered by the printer

warranty.

◆ The maximum diameter allowed on the takeup spool is 7.5

inches (190.5 mm) on a 3-inch core. When the takeup spool

has a diameter of 6.5-7.5 inches (165.0-190.5 mm), the control panel displays a warning about possible print quality

issues.

◆ The media supply may be wound either printed-side-out or

printed-side-in, but the takeup, if used, must be loaded

printed-side-in.

◆ The default head height set to 0.100 inches, which allows

wide variety of media thicknesses to be utilized without need

to adjust head height. If you do adjust the head height, you

should also adjust the camera height and verify the service

station height. See “Set the Printhead and Camera Height”

on page 5-11 for instructions.

◆ The Media Wizard stores a set of operational parameters for

predefined and user-defined media types. When you load a

new media type, select an existing Media Wizard set, or create a custom set. Media Wizard parameter sets can be

selected at any time from the control panel. (See “Media

Wizard” on page 3-32 for details.)

◆ Enable AutoTune during long periods of unattended printing. AutoTune runs AutoJet at user-defined intervals to

ensure that all jets are either working or substituted with

working jets. (See “AutoTune” on page 4-4 for instructions.)

◆ Wear cotton gloves when loading media to prevent fingerprints that could show after printing.

◆ DO NOT rest or store a media roll on end, or you could

cause edge creases that could strike the printheads during

printing.

◆ DO NOT clean the printhead surfaces with a dry cloth or

paper towel.

◆ DO NOT reprint over any output that has not completely

dried. The rubber pinch rollers could be damaged by wet

ink. If ink does get onto the pinch rollers, clean them with

SolaChrome HR Cleaning Solvent and dry them thoroughly

before printing.

1-4 Operating Requirements

Page 19

Safety Warnings

◆ DO NOT set heavy objects on the power cord or printer

cable; do not bend the cables or force them into contorted

positions.

◆ DO NOT place heavy objects anywhere on the printer.

WAR NIN G WITH THE POWER SWITCH IN THE OFF POSITION, POWER

WARNUNG WENN DER NETZSCHALTER IN OFF POSITION STEHT,

WAR NIN G The printer is too heavy to be lifted safely by one person.

WARNUNG Der Drucker ist zu schwer für eine Person. Mindestens 3

WAR NIN G THE PRINTER ELECTRONICS ASSEMBLY CONTAINS A LITH-

MAY STILL BE SUPPLIED TO THE PRINTER COMPONENTS.

To completely cut power from the printer, you must unplug

the power cords from the power outlets.

WIRD DEN KOMPONENTEN TROTZDEM STROM

ZUGEFÜHRT. Um den Drucker komplett stromfrei zu

machen, müssen Sie den Netzstecker ziehen.

At least three persons are required to lift the printer.

Personen sind erforderlich um den Drucker anzuheben.

IUM BATTERY DEVICE. THERE IS A DANGER OF EXPLOSION

IF THE BATTERY IS INCORRECTLY REPLACED. The battery

must be replaced only by ColorSpan authorized personnel,

and must be replaced only with the same or equivalent

type. Dispose of this lithium battery device in accordance

with local, state (or province), and Federal (or country)

solid waste requirements.

WARNUNG DIE ELEKTRONIK DES DRUCKERS ENTHÄLT EINE LITHIUM

BATTERIE. ES BESTEHT EXPLOSIONSGEFAHR WENN DIESE

UNSACHGEMÄSS AUSGEWECHSELT WIRD. Die Batterie

darf nur durch einen ColorSpan authorisierten Technicker

ausgewechselt werden und muss mit dem gleichen oder

einem gleichwertigen Typ Batterie ersetzt werden. Bitte

entsorgen Sie die Lithium Batterie gemäss Ihren Landesoder Bundesgesetzen.

Operating Requirements 1-5

Page 20

WARN ING

Hot surfaces. Do not touch.

WARN UNG

WARN ING

WARN UNG

Heiß, nicht berühren.

Moving parts. Keep fingers away from media path.

Bewegliche Teile, Verletzungsgefahr.

1-6 Operating Requirements

Page 21

Unpacking and

Assembly

This procedure assumes that the printer is in its final location.

See the Site Preparation Guide for moving and unpacking hints.

WAR NING

WAR NUNG

Note

The printer is too heavy to be lifted safely by one

person. At least three persons are required to lift the

printer.

Der Drucker ist zu schwer für eine Person. Mindestens 3 Personen sind erforderlich um den Drucker

anzuheben.

If you will be installing a ColorSpan Print Server, set

it up now and power it on. This will allow the server

to perform its automatic one-time new system check

while you unpack and assemble the printer.

Required Tools ◆ Claw hammer to remove the fasteners from the triwall corru-

gated outer box from the pallet

◆ #3 Phillips head screwdriver

◆ #2 Phillips head screwdriver

◆ Socket wrench with 10 mm socket

◆ Bubble level

It is recommended that three persons be available to lift the

printer onto the stand and a fourth person to assemble the

printer to the stand. The remainder of the installation can be

performed by one person.

Unpacking 1. Examine the shipping packaging for shipping damage.

The printer is delivered to your site packed in one cardboard

box, attached to a wooden pallet. Report any damage or

apparent rough handling immediately to the shipper.

For the DisplayMaker 72

shipped in a separate box.

2. Cut and remove the bands that secure the box to the pallet.

3. Remove the nails that attach the box to the pallet.

4. Open the top flaps of the box.

Unpacking and Assembly 1-7

SR, the input and output tables are

Page 22

5. Lift the box straight up and off of the pallet.

6. Remove the protective shipping material from around the

printer, but leave the printhead carriage shrink wrapped.

7. Retain the Unpacking and Assembly Instructions (part number

0700024), which is shrink wrapped to the printer.

You can refer to the Unpacking and Assembly Instructions

(includes a parts list) with this manual during the unpacking and assembly process.

8. Remove all of the parts and boxed kits, except for the printer

chassis, from the pallet.

9. Take an inventory of the parts, using the parts list in the

Unpacking and Assembly Instructions.

Report any missing or damaged parts to MacDermid

ColorSpan.

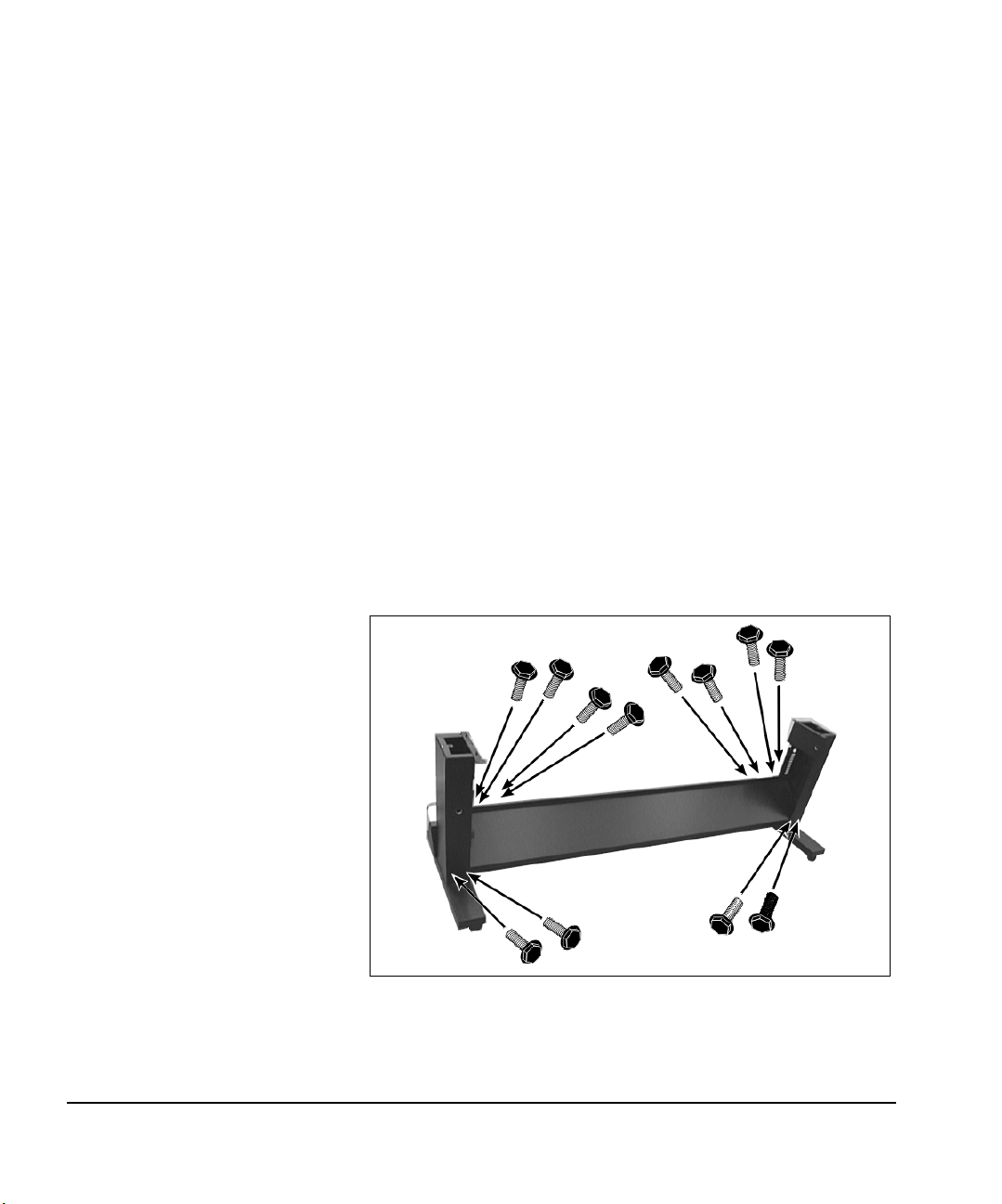

Stand Assembly 10. Locate the stand legs and the crossbar.

11. Lock the casters on both stand legs.

12. Using the twelve 10 mm hex-head screws provided, assemble

the stand (see Fig. 1-1).

Align the holes on the crossbar with the holes in the stand

legs, and attach the screws, but do not tighten them fully yet.

Fig. 1-1. Stand assembly

1-8 Unpacking and Assembly

Page 23

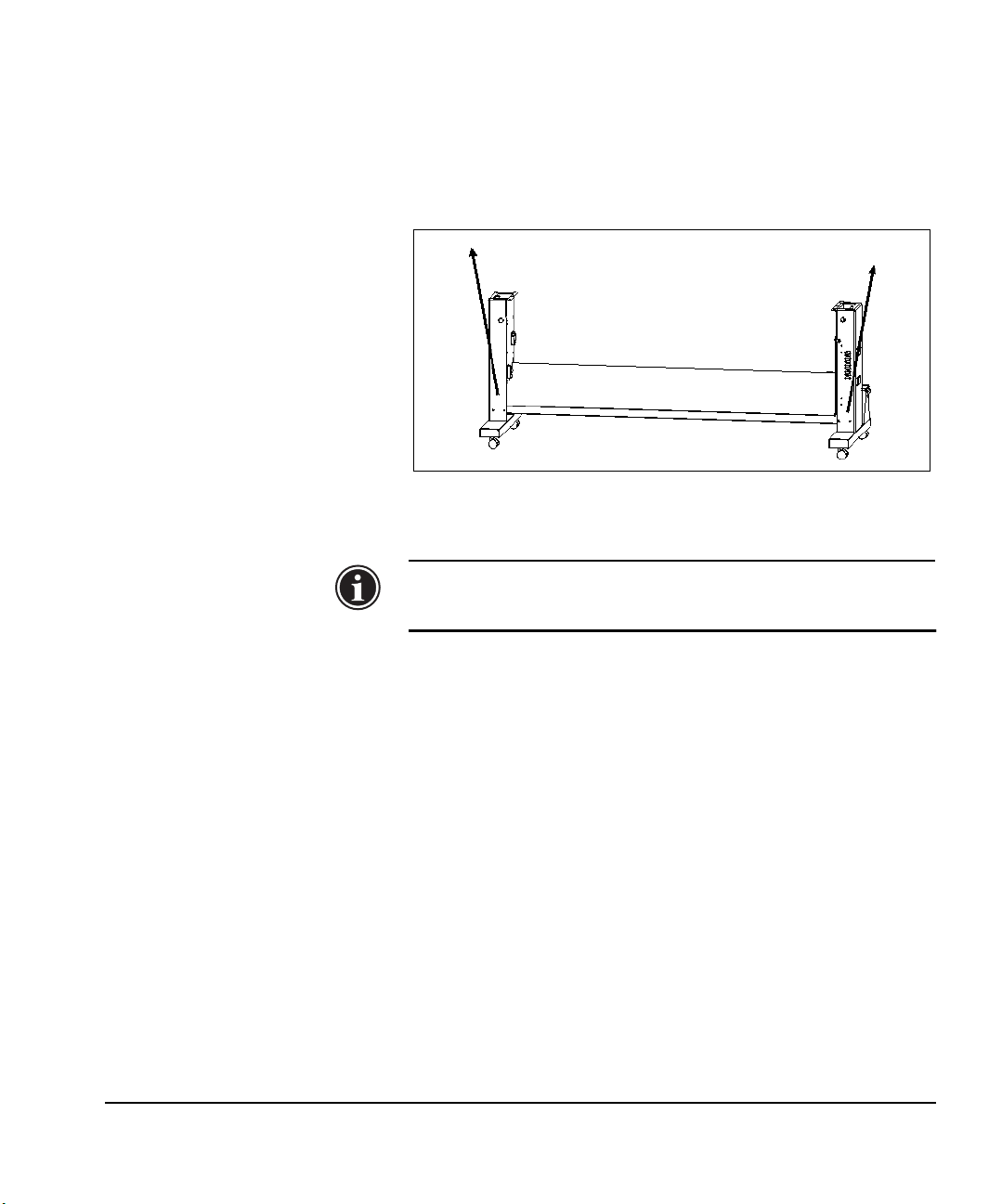

13. Bias the stand legs outward at the top, then tighten the

screws firmly (see Fig. 1-2) but not all the way.

With your foot braced against the outside of the left caster

support, gently tug the top of the stand leg toward you,

while a second person tightens the screws. Repeat this process with the right stand leg. This step is required to ensure

proper clearance for the media spools.

Fig. 1-2. Bias the stand legs outward as shown

(angle exaggerated for clarity)

Note

14. If purchased, install the VOC plenum kit.

Refer to the instructions included with the kit.

Leave the threading strings inside the stand legs. You

will use them later to pull the ink drain tubes

through the legs.

Unpacking and Assembly 1-9

Page 24

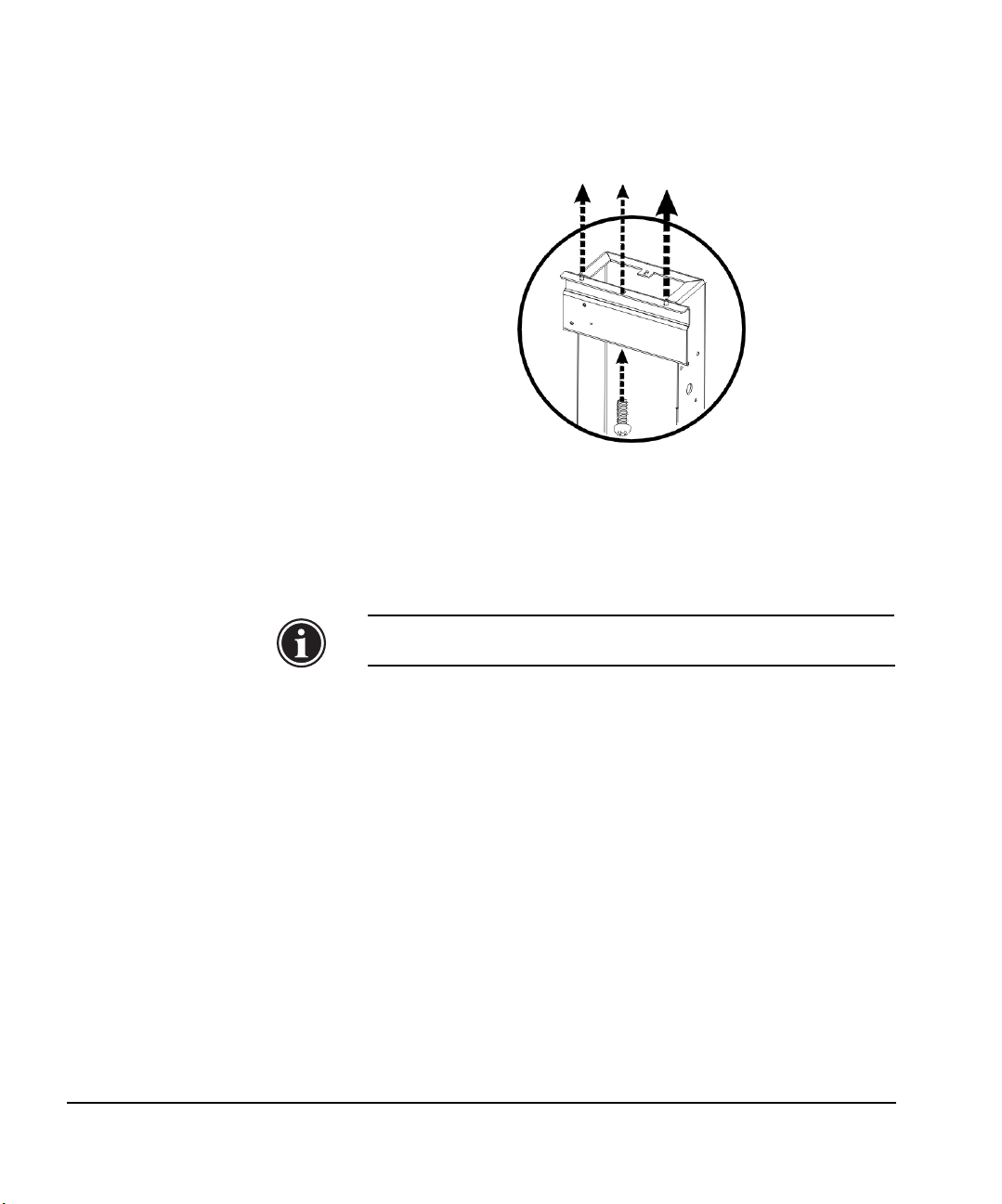

Printer Assembly 15. Attach the lift handle to the lef t end of the printer, using four

#2 screws on the back and one screw on the front (see

Fig. 1-3).

Fig. 1-3. Lift handle

16. Remove and discard the “DO NOT LIFT” label.

17. Detach the printer chassis from the pallet.

The printer chassis is attached with 10 mm hex-head bolts

and shock-absorbing washers to two wooden frames on the

pallet. Access the screws from the rear of the pallet.

18. Position the stand behind the printer.

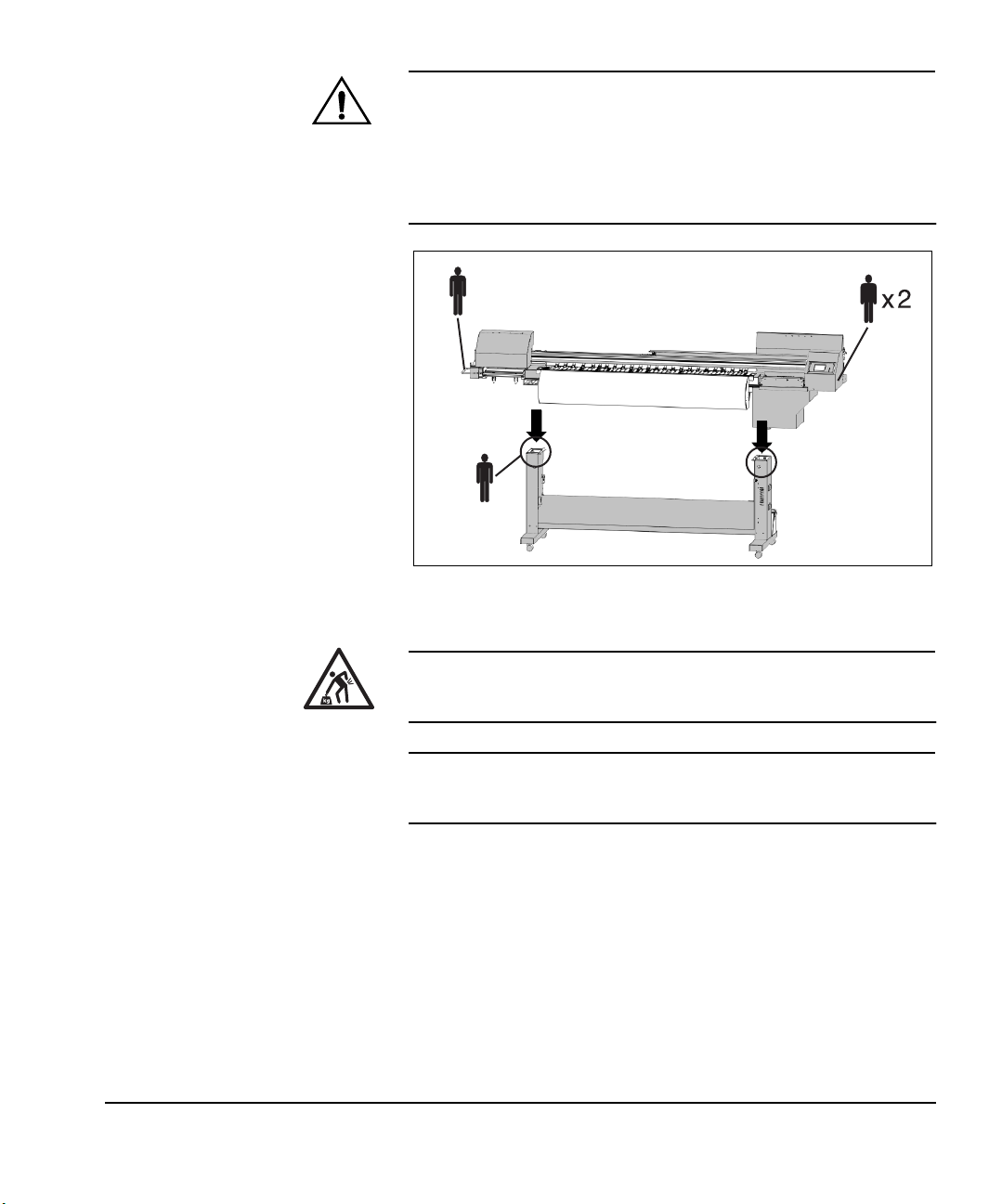

19. Lift printer straight up and lower onto the stand legs (see Fig.

1-4).

1-10 Unpacking and Assembly

Page 25

Caution

When assembling the printer onto the stand, be

careful to avoid damaging the turnbuckles underneath the postheater by allowing them to strike the

stand legs. The turnbuckles are precisely adjusted at

the factory, and will clear the stand legs by less than

one inch (25 mm) during assembly. Damaging them

could result in misalignment of the media path.

Fig. 1-4. Lowering the printer onto the stand

WAR NING

WAR NUNG

20. Align the two pins on each stand leg with the holes in printer

(see Fig. 1-5).

Have a fourth person perform steps 20 and 21 while three

persons hold the printer.

Unpacking and Assembly 1-11

The printer is too heavy to be lifted safely by one

person. At least three persons are required to lift the

printer.

Der Drucker ist zu schwer für eine Person. Mindestens 3 Personen sind erforderlich um den Drucker

anzuheben.

Page 26

21. Align center hole on each leg (between pins) with center

hole in printer (see Fig. 1-5).

To speed this alignment, you can use a screwdriver inserted

into the holes in the stand and printer.

Fig. 1-5. Stand alignment

22. Lower the printer chassis onto the stand.

23. Ensure that the printer lies flat on both of the stand brackets.

Realign if necessary.

Note

24. Attach the printer to the stand with one silver #3 screw in the

center hole on each leg (see Fig. 1-5). Tighten all stand

screws securely.

The silver screws provide a ground path between the printer

engine module and the stand. Use an ohmmeter to verify a

ground path between the silver electronics box and the silver locating pin on the supply & takeup assembly, which is

visible on the stand leg facing the spools. Resistance should

be 5 ohms or less.

If the stand screws are not silver (in other words, “coated”),

the wrong screws were installed. Replace the stand screws

with the silver screws provided by MacDermid ColorSpan.

1-12 Unpacking and Assembly

The printer must lie flat on the stand brackets to

avoid media feed problems during printer operation.

Page 27

Caution

Failure to assemble the printer to the stand with silver screws could isolate the supply and takeup system from ground, which could result in damage to

the printer from electrostatic discharge.

Unpacking and Assembly 1-13

Page 28

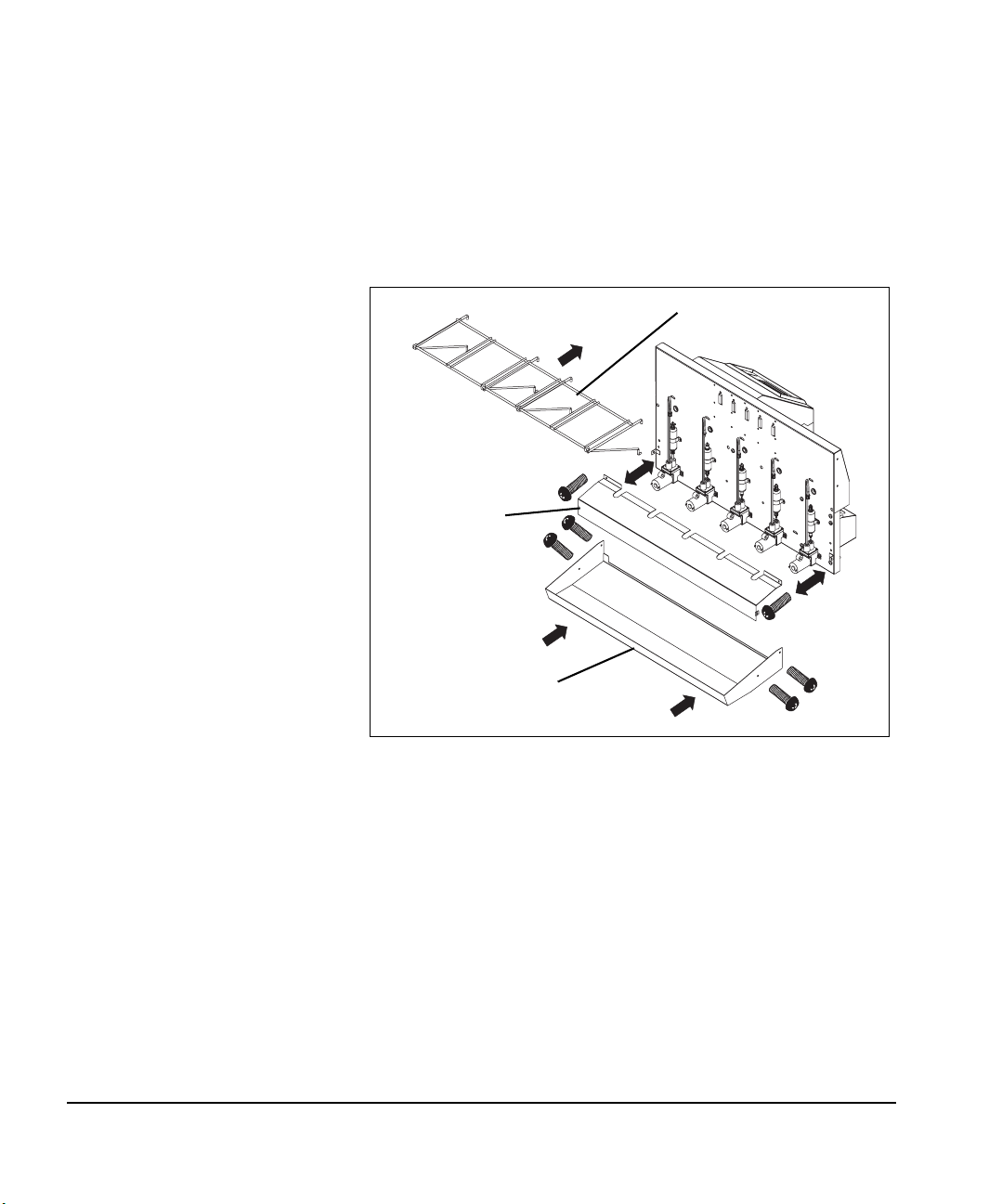

Off Head Supply (OHS)

Assembly

25. Remove the pump cover (see Fig. 1-6).

This is necessary to access the lower mounting holes for the

reservoir wire rack. The pump cover attaches to the printer

with two Phillips head screws.

26. Install the reservoir wire rack (see Fig. 1-6).

Insert the top pieces, hooks pointing down, into the mounting holes. Then insert the bottom pieces into the mounting

holes.

Reservoir rack

Pump cover

Catch tray

Fig. 1-6. Reservoir wire rack and ink catch tray

27. Reinstall the pump cover (see Fig. 1-6).

28. Attach the ink catch tray to the back of the printer with the

four #3 screws (see Fig. 1-6).

1-14 Unpacking and Assembly

Page 29

29. Install the five reservoirs.

You may want to wear gloves during this procedure to protect your hands from pigment ink stains.

◆ Place the reservoir into the wire rack. Match the color or

cleaning solvent label on the reservoir with the corresponding label on the printer.

◆ Remove the packing material from the ink level floats

inside the ink buckets.

◆ Unscrew the plastic seal on the hook-shaped tube

attached to the filter. Discard, or retain for subsequent

use. A small amount of ink may come out of the tube

(ink will be present in the tubes from factory testing).

◆ Connect the hook-shaped tube to the reservoir’s draw

tube, by pressing down until it seats with a click, and

turning the screw-on connector 3/4 to 1 turn. See

Fig. 1-7 below for location.

Note

◆ Connect the float sensor cable from the reservoir to the

Do not connect the hook-shaped tube to the air vent.

Doing so will result in no ink being drawn from the

reservoir.

data port on printer. See Fig. 1-7 below for location.

Fig. 1-7. Installing the reservoirs

Unpacking and Assembly 1-15

Page 30

Final Assembly 30. Install the vacuum reservoir (see Fig. 1-8).

Ensure that the o-ring is in place inside the reservoir opening, and screw on the reservoir. Hand tighten firmly, but do

not overtighten.

Fig. 1-8. Vacuum reservoir

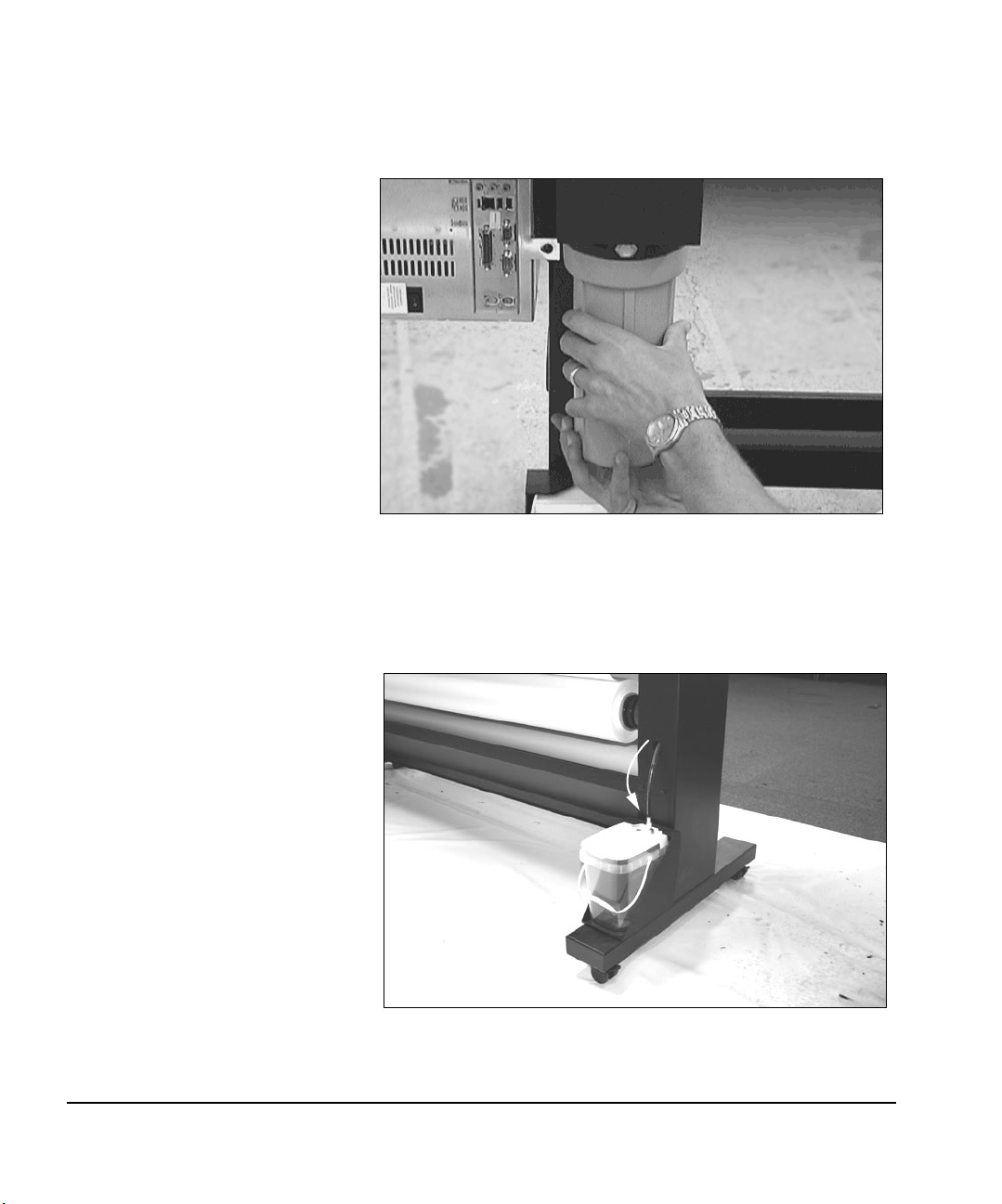

31. Using the threading string attached to the stand leg, pull the

drain tube that is connected to the left-side spittoon through

the stand leg to the rear of the printer, and connect it to the

left-side excess ink reservoir (see Fig. 1-9).

Fig. 1-9. Connecting the drain tube to the reservoir

1-16 Unpacking and Assembly

Page 31

32. Remove the front cover, and leave it off until the printer is

powered up and normal operation is verified.

33. Using the threading string supplied, pull the drain tube that

is connected to the right-side spittoon through the stand leg

to the rear of the printer, and connect it to the right-side

excess ink reservoir (see Fig. 1-10 and Fig. 1-11).

Fig. 1-10. Drain tube routing (with front cover removed)

Sensor cable

Drain tube

Fig. 1-11. Connect the excess ink sensor cable

Unpacking and Assembly 1-17

Page 32

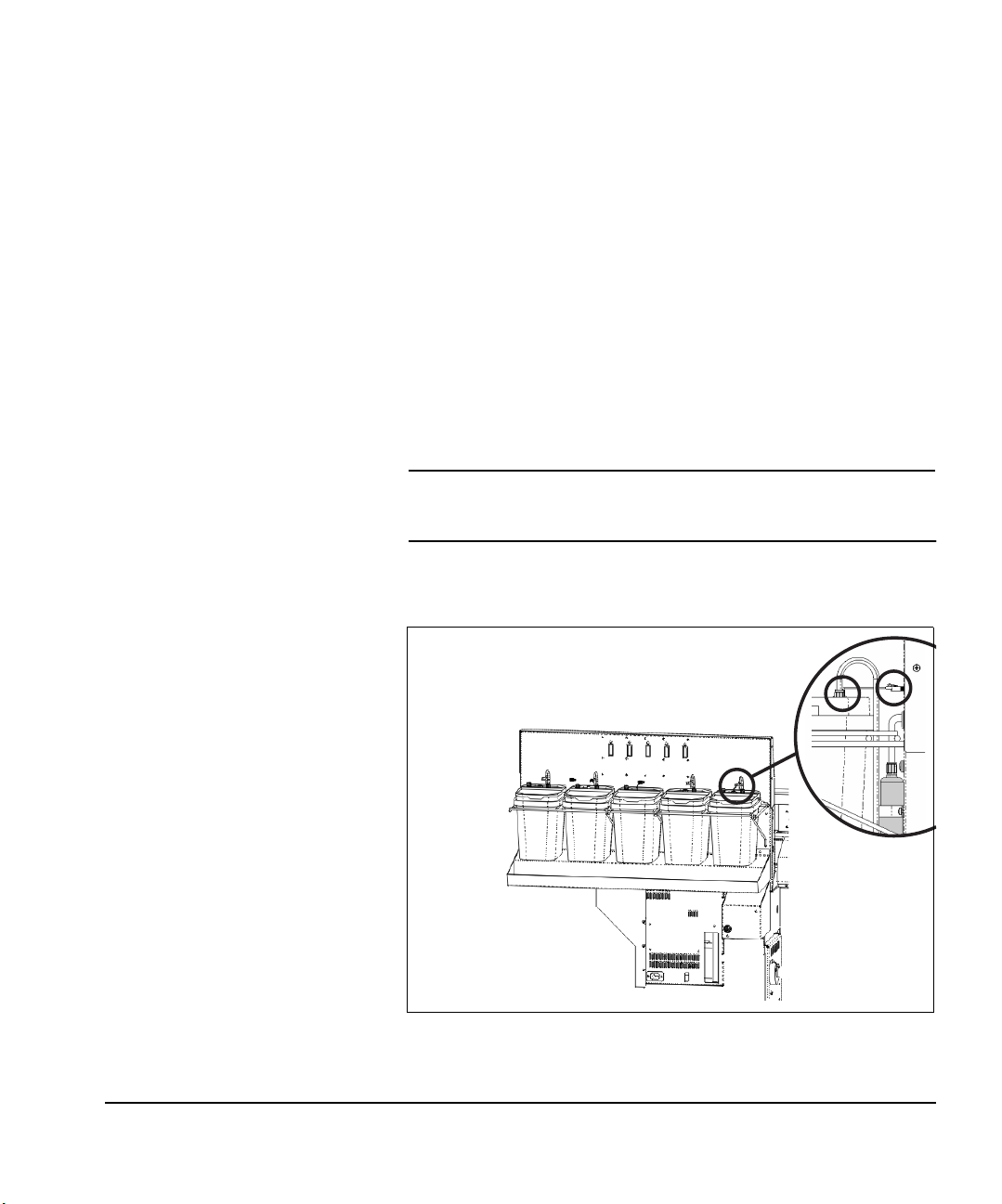

Note

34. Connect the cable to the sensor on the excess ink reservoir

(see Fig. 1-11).

35. Connect the supply and takeup cable to the port on the side

of the electronics box (see Fig. 1-12).

As you look at the front of the printer, the port is located on

the left side of the electronics box, near two other cables

that area already connected to ports. Connect the cable

firmly to the port.

Ensure that the drain tube is fully attached to the reservoir with a “click.” Partial attachment will not

allow ink to drain into the reservoir, which will eventually cause the service station to overflow with

excess ink.

Supply & takeup cable

Fig. 1-12. Connecting the supply & takeup cable

36. Remove the two Phillips head screws on the front of the vacuum/pressure system cover, and remove the cover.

1-18 Unpacking and Assembly

Page 33

37. Connect the power cable to the connector on top of the vacuum/pressure assembly.

Fig. 1-13. Vacuum/pressure system with cable connection

(cover removed)

38. Reinstall the vacuum/pressure system cover.

39. (DisplayMaker 72SR only) Connect the cable from the mediaout sensor cable to the cable from the vacuum/pressure

system.

Both of these cables are marked with a label that says

“MEDIA SNSR.”

From sensor

From V/P system

Fig. 1-14. (DisplayMaker 72SR only)

Connecting the media-out sensor.

Unpacking and Assembly 1-19

Page 34

40. (Optional) Connect the optional VOC plenum to building

ventilation or VOC recovery equipment.

Install and connect the optional VOC plenum to a building

exhaust duct or charcoal filter device. Refer to the documentation that accompanies the kit for instructions.

41. Level and stabilize the printer.

Leveling the printer and removing its weight from the stand

casters is required to ensure proper media tracking and

high-quality prints. Locate the printer on a flat, level floor.

Lower all four leveling feet so they contact the floor, then

continue lowering them until the printer’s weight is off the

casters. Next, use a bubble level to ensure that both legs are

level front-to-back by adjusting the leveling feet (raise the

lower end, and keep the printer’s weight off the casters).

42. In the accessory kit, locate the two turnbuckles marked “A”

and “B.”

Caution

43. From the rear of the printer, install the turnbuckle marked “A”

to the location behind the postheater marked “A,” using the

turnbuckle pins and ring clips.

44. From the rear of the printer, install the turnbuckle marked “B”

to the location behind the postheater marked “B,” using the

turnbuckle pins and ring clips.

45. Check the ground path between the takeup spool and the

electronics box.

Set your ohmmeter to check continuity at low voltage (to

measure resistance of no more than 3 or 4 ohms). Touch one

lead to the takeup spool and the other lead to the steel cover

of the electronics box. Manually turn the spool a few rotations to make sure that the spool finger is engaged into the

supply & takeup shaft. A resistance reading greater than 2 or

3 ohms could indicate a ground path problem.

Do not turn the nut on the turnbuckle. Turning the

nut will change the post-heater alignment. If the nut

is turned, the post heater will need to be re-aligned

to ensure proper media tracking.

1-20 Unpacking and Assembly

Page 35

46. Check the ground path between the spool and the finger that

protrudes from the end of the spool. If this fails, replace the

spool.

47. Check the ground path between the electronics box and the

supply & takeup assembly.

Touch one lead to the stainless steel pin located between the

two Phillips-head screws above the spool collet on the

takeup. Place the other lead on the stainless steel cover of

the electronics assembly. If this fails, check the grounding

between the stand and the printer.

48. (Optional) Assemble and install the input and output tables

for rigid cut-sheet media.

If purchased, assemble and install the roller tables as

described in the documentation that accompanies them

(DisplayMaker 72SR Table Assembly Instructions, part number

0706246). The tables are designed to be easily attached to

and removed from the printer as needed for cut-sheet or roll

fed media.

Once assembled, position the tables as shown in the instructions. Use the supplied shock cords to secure the tables to

the printer.

To ensure smooth media advance, level the tables with the

platen, using a bubble level. Hold the level on top of and

perpendicular to the platen, over each table. Adjust the

table’s leveling feet until the top of the table is level with the

platen.

One of the roller bars on each table is not permanently

attached to the table frame. You can reposition this bar as

needed to support the far side of any width of media. Simply

slide the white plastic clips under the frame support to

secure the bar.

Unpacking and Assembly 1-21

Page 36

Connecting to Power See Appendix A, Technical Specifications, or refer to the Site

Preparation Guide, for detailed power requirements. Consult a

qualified electrician if you have any doubt as to how the circuits

in your facility can accommodate the printer and print server.

WARN ING

WARN UNG

The printer includes an auxiliary 24 volt power jack for the vacuum system. This option enables you to provide temporary

power to the vacuum system to prevent ink from flowing from

the printheads, in the event of a power failure or if the printer

must be powered down for maintenance. The power supply provided in the printer accessory kit includes interchangeable

adapter plugs for international use.

To provide battery backup power to the vacuum system, connect

the 24 volt power supply from the auxiliary power jack into a

UPS (uninterruptable power supply) that you purchase separately. To provide temporary power during maintenance, simply

plug the 24 volt power supply directly into a wall outlet (see

Appendix A, Technical Specifications, for detailed specifications).

WITH THE POWER SWITCH IN THE OFF POSITION,

POWER MAY STILL BE SUPPLIED TO THE PRINTER

COMPONENTS. To cut power completely from the

printer, you must unplug the power cords from the

power outlets.

WENN DER NETZSCHALTER IN OFF POSITION

STEHT, WIRD DEN KOMPONENTEN TROTZDEM

STROM ZUGEFÜHRT. Um den Drucker komplett

stromfrei zu machen, müssen Sie den Netzstecker

ziehen.

Fig. 1-15. Auxiliary vacuum power

1-22 Unpacking and Assembly

Page 37

Connecting to the

Print Server

Connect the printer to the print server with the included

VideoNet (for ColorSpan print servers) or Ethernet cable (nonColorSpan RIPs). See Fig. 1-16.

Note

Refer to the print server (RIP) documentation for further instructions on connecting the printer to the print server.

Do not connect the printer VideoNet cable to your

local area network. The VideoNet protocol is not

compatible with other network protocols.

Fig. 1-16. Power and RIP connections

Unpacking and Assembly 1-23

Page 38

First-Time Power-Up

and Test Print

After the printer is assembled and connected to power, you can

power up the printer, load media and ink, and print a test print.

Unpack the Printheads Have a paper towel ready to blot any cleaning fluid that has

escaped from the printheads and foam pad during shipping.

Most of the fluid should run off the SolaChrome Capping Film

into the drip tray.

1. Remove the shipping straps and shrink wrap from around the

carriage.

2. Remove the white shipping blocks on the sides of the capping station, and the white shipping pad between the capping station levers as shown in Fig. 1-17.

3. With the printhead carriage over the capping station as

shipped, tip the carriage back until it just lifts off the pad

below it.

Caution

Carriage

4. Remove the thin black foam pad that is pressed against the

printheads, and save it for future use.

When saturated with cleaning fluid, this pad can be used to

recover stubbornly clogged jets (see Cleaning Solvent Soak

on page 5-9).

Tipping the carriage back too far could damage the

encoder, requiring its replacement. Also ensure that

the encoder does not disengage from carriage.

REMOVE and

REMOVE

REMOVE

Fig. 1-17. Capping station as shipped

save thin pad

REMOVE

1-24 First-Time Power-Up and Test Print

Page 39

5. Remove and discard the Capping Film from the capping station.

6. Leave the capping station, in the lowered position.

7. Slowly lower the carriage back down over the capping station.

8. Move the carriage as needed to locate and remove the white

protective strips (for shipping) from the rail.

9. Fill the small squirt bottle (part number 0602448), located in

the accessory kit, with SolaChrome HR Cleaning Solvent.

You can use this squirt bottle to moisten a cloth to clean the

carriage, platen, and other parts of the printer. Use only a

100% polyester Class 100 cleanroom cloth to clean the

printheads.

Caution

Use of any solvents other than SolaChrome HR Cleaning Solvent could damage the printer and WILL

VOID THE WARRANTY.

10. At the service station (right end of the printer), squirt a small

amount of SolaChrome cleaning solvent into the entire length

of the wiper bar to loosen any dried ink and solvent.

Wiper bar

Fig. 1-18. Service station wiper bar

First-Time Power-Up and Test Print 1-25

Page 40

Power Up the Printer 1. Turn on the power switch to observe the typical power-up

sequence.

2. The control panel backlight illuminates. Move the contrast

lever (located to the right of the control panel screen) up and

down until the control panel graphics and messages are easily visible.

3. The printer runs a series of self-tests, and reports any errors it

finds.

4. The printhead carriage moves to the service station.

5. The control panel prompts you to load media.

6. You may load media or skip loading media for now. See

“Loading Roll-Fed Media” on page 3-14 for instructions.

7. The control panel displays the status screen.

1-26 First-Time Power-Up and Test Print

Page 41

Install Ink for the First

Time in the Printer

1. Shake each bottle of ink for one minute to redisperse the

pigments.

It is not necessary to shake the cleaning solvent.

The green “ready for refill” LEDs should be illuminated,

indicating that you may fill the reservoirs.

2. Empty the refill bottles into their corresponding reservoirs,

and install the profilers into their corresponding positions in

the docking station.

Profiler docking station:

Solvent Y M C K

Cleaning solvent Yellow Magenta BlackCyan

Fig. 1-19. Ink color locations

First-Time Power-Up and Test Print 1-27

Page 42

When you empty a refill bottle into a reservoir, the green

LED will blink until you install the corresponding profiler.

Then the LED will turn off. Do not refill the inks until the

green LED illuminates again.

3. After all four inks and the cleaning solvent reservoirs are full,

press the Online/Offline key to display the Front Page screen.

4. From the Front Page screen, press the (Menu) key to enter

the menu system.

5. Press the ) key repeatedly to highlight Maintenance.

6. Press the (Menu In) key to display the Maintenance menu.

7. Press the ) key repeatedly to highlight Fill Service Station.

8. Press the (Menu In) key.

The solvent trough in the service station fills with solvent.

9. From the Maintenance Menu, press the ) key repeatedly to

highlight Fill Heads With Ink.

10. Press the (Menu In) key.

The printheads are filled with cleaning solvent, emptied,

and filled with ink. This process takes approximately 30

minutes and is fully automated. During this process, occasionally check that the ink and cleaning fluid purged from

the printheads is draining into the service station’s excess

ink reservoir. If not, ensure that the drain tube is fully

attached to the reservoir (see page 1-18).

Load Media To load media in the printer for the first time, see “Loading Roll-

Fed Media” on page 3-14 for instructions. The printer ships with

a starter roll of media and a cardboard takeup core pre-loaded

on the spools.

Send a Test Print from

Server

1-28 First-Time Power-Up and Test Print

1. Install and set up the RIP.

Refer to the Quick Start Guide for the ColorSpan print server,

or the manual that accompanies the third party RIP you will

be using.

2. Run the jet health routine to detect, recover, and replace

unrecoverable jets.

See “Checking Jet Health” on page 3-6 for instructions.

3. Send a test print from the ColorSpan server or RIP to the

printer, to verify your installation.

Page 43

What’s Next? ◆ To familiarize yourself with the printer, refer to the remain-

der of this chapter.

◆ For a complete description of using the control panel, see

Chapter 2, Using the Control Panel.

First-Time Power-Up and Test Print 1-29

Page 44

Workflow Overview

Daily Startup 1. Uncap the printheads (for instructions, see “Uncap the Print-

heads” on page 3-12).

This procedure includes, while the carriage is still at the capping station, wiping the printheads with SolaChrome HR

Cleaning Solvent, using a 100% polyester Class 100 cleanroom wipe. DO NOT USE ISOPROPYL ALCOHOL ON THE

PRINTHEADS.

n

p

2. Ensure the functioning or substitution of all inkjets (for

instructions, see “Checking Jet Health” on page 3-6):

◆ Print Prime Bars

◆ Run Purge-n-Wipe

◆ Repeat once or twice to recover missing inkjets

3. Map out missing jets (see “AutoJet” on page 4-3 or “Manual

o

Jet Mapping” on page 4-15).

Under normal circumstances, these procedures should adequately prepare the printer to print. For instructions on recovering stubbornly clogged printheads, see “Cleaning Clogged Ink

Jets” on page 5-8.

Printing When the printer is connected to a ColorMark Pro print server,

here is how a ty pical print job progresses from the client workstation to the printer. If you are using a non-ColorSpan RIP, refer

to the documentation that accompanies it for details.

1. The operator sends a file to be printed from a client

workstation.

2. The print job is received by the print server.

Once it reaches the print server, the print job may be reprioritized, combined with other jobs, re-routed, or otherwise

manipulated. Refer to the print server online help or manual

for instructions.

3. The print server RIPs the job.

The raster image processing (RIP) process translates the

PostScript language data that comprises the print job into

the data required by the printer.

1-30 Workflow Overview

Page 45

4. The server sends the image to the printer for printing.

Printing can be paused and resumed at the control panel,

enabling you to purge the printheads to recover jets or make

other adjustments. During the pause, the carriage goes to the

service station and idle spits.

Daily Shutdown 1. Cap the printheads (for instructions, see “Capping the Print-

heads” on page 3-11).

2. DO NOT POWER DOWN THE PRINTER.

If the printheads will be capped longer than overnight, follow

the instructions under “Daily Startup” twice a week to prevent

excessive ink clogging, then recap the printheads. If this is not

possible or impractical, or if the printer must be shipped, see

“Extended Power Down and Restart” on page 5-21 for instruc-

tions.

For further idle maintenance tips, see “Idle Jet Maintenance” on

page 3-3.

Workflow Overview 1-31

Page 46

Parts Overview

13

12

19

14

4

5

11

15 & 16

11 b

17

18

29

26

61 2 3

5

10

11 a

7

15 & 16

27

8

9

20

25

24

21

23

22

28

Fig. 1-20. Major parts of the printer

1-32 Parts Overview

Page 47

Index Description

1Encoder strip — allows precise positioning of the print-

head carriage across the length of the platen.

2 Main carriage drive belt — moves the carriage across

the length of the platen.

Transport chain (not shown) — supports the ink sup-

ply tubes that carry ink from the ink reservoirs to the

printheads, power, and electrical signal cables.

3Platen — supports the media under the printheads

during printing, warms the media in the print zone,

includes vacuum to hold the media against the platen.

4 Printhead carriage — carries the printheads, digital

imaging sensor, and photodiode across the length of

the platen.

Digital image sensor (on carriage, not shown) —

detects the location of printed pixels for precise alignment of the printheads, enables the automatic replacement of poorly-printing ink jets with substitute jets.

Photodiode (on carriage, not shown) — enables the

creation of color transforms without an external spectrophotometer (requires print server support), and the

linearization of existing transforms.

5 Spittoons — located at both ends of the platen,

receives ink “spits” that keep the printheads at their

optimal performance.

6AutoClean

TM

Service station — catches purged ink

from the printheads, wipes the printheads with cleaning solvent. Wipers are automatically cleaned and

cleaning solvent applied before wiping. Ink is periodically spit when idle to keep the inkjets working.

7 Ready-for-Refill LEDs — illuminates when there is room

for a refill bottle of ink, or when the cleaning solvent

reservoir is empty. Blinks when either the ink has been

refilled and profiler not replaced, or when the profiler

has been replaced but the ink has not been refilled.

8 Control panel — displays messages and allows control

of certain printer operations. Includes a contrast adjustment lever and audio feedback.

9Electronics module — contains the printer’s power

supply and control electronics.

Parts Overview 1-33

Page 48

Index Description

10 Post he at e r — helps to dry the output prior to the

takeup. Incorporates turnbuckles that can be adjusted

to straighten the media path.

11 Pinch rollers (23 places) — grip the media during

loading and printing. If installed, a pinch roller adjust-

ment lever (11a) allows you to adjust the force or

release the pinch rollers to feed rigid cut-sheet media.

A media out sensor (11b) detects whether media ig1

s loaded.

12 Capping station — protects the printheads from drying

out while idle (not printing) for extended periods.

13 H a n d l e — for pulling the printer on its casters and lift-

ing the end of the printer.

14 S t an d — supports the printer.

15 Casters (four places) — enables easy relocation of the

printer, can be locked in place.

16 Leveling pads (four places) — allows the printer to be

stabilized and leveled for consistent media feeding.

17 Docking station — holds the profilers, one for each res-

ervoir, that track ink and cleaning solvent usage, and

identify ink characteristics for the RIP.

18 Off-Head System (OHS) — reservoirs, electronics, vac-

uum (to maintain negative head pressure), and pressure (for purging the printheads) that provide ink and

cleaning solvent for cleaning the printheads.

19 Ink filters — user replaceable, one for each reservoir, fil-

ters out impurities from the ink or cleaning solvent

prior to being sent to the printheads.

20 Ink reservoirs — holds the ink and cleaning solvent

supply, 3.5 liter capacity.

21 Power inlet — connects the printer to electrical power.

22 Standby power switch — places printer in standby

mode (to disconnect from power, disconnect power

cord).

23 VideoNet port — connects printer to print server.

24 Vacuum/Pressure (VP) assembly — provides vacuum

and pressure to the OHS and printheads.

25 Media supply and takeup system — drives and pro-

vides tension to the media supply and takeup spools.

26 Media advance switch — enables user to advance

media forward or backward during loading.

1-34 Parts Overview

Page 49

Index Description

27 Preheater — warms the media for optimal printing.

28 Excess ink containers — collects ink from the spittoons

and service station.

29 Auxiliar y 24 volt power jack to vacuum system —

accepts the supplied 24 volt DC power supply to the

vacuum system, which can be connected to a user-supplied UPS for temporary battery backup power in the

event of a power failure, or to a wall outlet for temporary power during maintenance that requires the rest of

the printer to be powered down. See Appendix A, Technical Specifications, for details.

Parts Overview 1-35

Page 50

Special Features The printer has many advanced features to help you produce the

best printed output with the least effort.

Printheads ◆ Micro-Quad

TM

printheads — sixteen 600 dpi, 30 picoliter

piezoelectric printheads (four per color).

◆ AutoClean

TM

service station — a motorized service station

that wipes the printheads with cleaning solvent automatically to keep all jets firing properly.

◆ Purge-n-Wipe

TM

— combines an air pressure purge with a

cleaning solvent wipe of the printheads to recover clogged

jets.

◆ AutoRecover — performs a Purge-n-Wipe at the start of a

print job (before printing) if a Purge-n-Wipe has not been

performed for a specified amount of time.

◆ Automated printhead maintenance — to keep individual

inkjets from drying out, the printer periodically “spits” a

small amount of ink and performs a Purge-n-Wipe cycle.

◆ Capping station — manually-operated capping station prevents drying out of printheads when idle. The printer senses

the position of the capping station to prevent carriage movement while capped, or to prevent the carriage from moving

to the capping station if it is raised.

Ink System ◆ Off-Head System (OHS) — bulk ink and cleaning solvent res-

ervoirs allow refilling without taking the printer offline, even

during printing. The printer displays an alert when ink or solvent can be refilled.

◆ Onboard vacuum/pressure (VP) system — provides vacuum to maintain negative printhead pressure, and air pressure to purge the printheads or ink tubes without removing

them from the printer.

1-36 Special Features

Page 51

Calibration The Advanced Automation Eye uses a high-resolution imaging

sensor, colorimetric photodiode, and embedded software to

align the printheads, detect and replace missing jets, linearize

output, and color profile media.

◆ AutoSet

TM

calibration — uses a high-resolution digital imag-

ing sensor to automatically align printheads bidirectionally

for precise positioning of ink jet pixels, and runs AutoJet.

◆ AutoJet

TM

calibration— compensates for lost or misfiring jets

by locating them and using substitute jets without slowing

printing speed.

◆ AutoTune

TM

scheduling — runs Purge-n-Wipe and/or AutoJet at user-defined intervals, for highest quality during unattended printing. Optionally, if unsubstituted non-working

jets are found, printing stops until the problem is corrected.

◆ Automatic color calibration — uses an onboard photodiode

to linearize output over the entire density range (with print

server or RIP support).

◆ Color profiling — with print server or RIP support, the

onboard photodiode can be used to create custom Color-

®

Mark

and ICC color profiles for third-party media.

Media Handling ◆ Tensioned roll-to-roll media handler — supply and takeup

spools are tensioned to manage vinyl medias on heated surfaces. Tensioning is automatically maintained consistently on

the supply and takeup as the roll diameters change during

printing. Optionally, the supply or takeup motors can be

idled during printing. In roll-fed mode, the supply must be

loaded, but the media can optionally be left off the takeup.

◆ Steel media spools — the takeup supports up to 7.5 inch

(190.5 mm) diameter rolls of vinyl media on 3-inch cores.

The supply can also accept 2-inch cores with the supplied

2-inch collets.

◆ Rigid cut-sheet option — if installed, this combination of

hardware and software enables printing on rigid cut-sheet

media up to 3/16 inch (4.76 mm) thick.

◆ Media width sensing — automatically detects the width and

position of the media loaded, for precise image placement.

◆ AutoEdge — automatically aids the loading of rigid sheets by

detecting right, left and leading edges, and warns the user if

the sheet is skewed.

Special Features 1-37

Page 52

◆ Integrated contact heaters — preheater and platen heater

maintain uniform surface temperature across the printing

area to control dot gain on various media. Heated drying

surface allows prints to dry before being rolled onto the

take-up spool (results may vary based on media and color

profile characteristics).

Performance and

Ease-of-Use

◆ Media Wizard — stores and recalls a set of operating parameters by media type and print mode, for optimal printing

performance. Includes a set of predefined settings for standard media; user may add settings for other media.

◆ Speed/quality print modes — three print modes provided to

meet job and business requirements of speed and quality.

◆ Simplified control panel interface — Front Page screen presents frequently-used functions, with recommended preset

configurations. A menu provides access to less-frequently

used functions and troubleshooting help.

◆ User assistance — control panel features online help, interac-

tive procedures, and diagnostics to assist the user “on-thefly,” reducing training and troubleshooting time.

◆ Integrated Warning/Action system — the ATTN (Atten-

tion) key blinks on the control panel when the printer

detects an error condition, potential error condition, or when

you make a change that suggests recalibration or other

action to ensure best print quality. There are two types of

ATTN messages:

◆ Actions — the printer has detected an error condition

that stopped printing or will prevent printing from starting. You must correct the error before the printer will be

ready to print. When the printer senses that the error

condition has been addressed, the Action will be deleted

the next time the ATTN key is pressed.

◆ Warnings — the printer has detected a condition that, if

left unaddressed, could result in substandard prints or a

condition that will require an action before printing can

continue. Any action on your part is optional; printing is

not interrupted for a Warning message.

1-38 Special Features

Page 53

CHAPTER 2

Using the Control Panel

This chapter describes the functions of the control panel.

◆ Overview (page 2-2)

◆ Front Page (page 2-4)

◆ Navigation Keys (page 2-8)

◆ Menu (page 2-9)

◆ Menu Tree (page 2-17)

Using the Control Panel 2-1

Page 54

Overview The touch-screen control panel shows you the printer’s current

status, and enables you to interact with the printer when changing media and ink, respond to an error condition, or configure

options. There are three main control panel screens:

◆ Ready (Status) Screen

◆ Front Page

◆ Menu

Ready Screen When you press the Online/Offline button from the Front Page

screen, the printer goes online and the Ready screen appears.

The Ready screen displays the current status of the printer and

any currently printing job. It displays when the printer is online

(communicating with the print server) and either ready to print

or printing.

Fig. 2-1 Ready screen

Front Page When you press the Online/Off line button from the Ready

Screen, the printer goes offline and the Front Page screen

appears. This screen is the top level of the printer’s menu system. It provides access to the most frequently-used offline functions. For details, see “Front Page” on page 2-4.

Menu When you press the Menu key on the Front Page screen, the

Menu appears. The Menu provides access to advanced configuration options. For details, see “Menu” on page 2-9.

2-2 Overview

Page 55

User Assistance The control panel provides various forms of online user

assistance:

The ? button provides an explanation of the current function,

with some guidance for what to do next.

The ATTN (Attention) key blinks on the control panel when the

printer detects an error condition, potential error condition, or

when you make a change that suggests recalibration or other

action to ensure best print quality. There are two types of ATTN

messages:

◆ Actions — the printer has detected an error condition that

stopped printing or will prevent printing from starting. You

must correct the error before the printer will be ready to

print. When the printer senses that the error condition has

been addressed, the Action will be deleted the next time the

ATTN key is pressed.

◆ Warnings — the printer has detected a condition that, if left

unaddressed, could result in substandard prints or a condition that will require an action before printing can continue.

Any action on your part is optional, printing is not interrupted for a Warning message.

When the printer issues one of these messages, the ATTN key

will blink, and an alert beep will sound (unless disabled, see

page 2-14). Press the ATTN key to display a list of message titles,

and select a title to display a detailed cause-and-recovery screen.

If you choose to not correct a Warning condition and resume

printing, the ATTN key will remain displayed, but will not blink

until the printer issues a new Warning or Action message. The

messages can be dismissed by correcting the condition, or by

pressing the applicable key on the detail screen.

Tip

Overview 2-3

See page 2-13 for instructions for choosing an Expert

or Novice mode for displaying these messages

(Expert mode routes most messages to the Actions &

Warnings menu), and for disabling or enabling the

audible alarm. See the table beginning on page B-8

for a list of errors and recovery procedures.

Page 56

Front Page The Front Page provides access to the most frequently-used

printing and maintenance f unctions. For advanced configuration options, press the Menu key (see “Menu” on page 2-9 for

instructions).

Fig. 2-2. Front Page

◆ Printer Name — displays the name of the printer as defined

on the print server.

◆ Online/Offline — returns the printer to the Ready screen,

when it is online and ready to receive print jobs.

2-4 Front Page

Page 57

◆ Media & Ink — displays a listing of the media and ink cur-

rently installed in the printer. Press the ) and , keys to

highlight “Media” or one of the inks, then press ! (Pro-

ceed) to display information about the selection. From this

screen, you can press the and keys to scroll between

screens. Press ! (Proceed) to return to the list, then

(Menu Out) to display the Front Page screen.

Fig. 2-3. Media Info, Ink Info screens

Front Page 2-5

Page 58

◆ Status — displays system parameters and the status of all

user-configurable options. Press the and keys to scroll

between pages. To change an option, go to the Printer Configuration section of the menu.

Fig. 2-4. Status page 1

◆ Print Mode — sets print quality mode. See “Selecting a Print

Mode” on page 3-4 for instructions.

◆ Advance Media — press the ) key to advance the media forward. When you press and hold the ) key, the media moves

faster. Press the , key to reverse the media back onto the

supply spool. When you press and hold the , key, the media