Page 1

HP 5642 Rack

User Guide

November 2004 (First Edition)

Part Number 366309-001

Page 2

© Copyright 2004 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products

and services are set forth in the express warranty statements accompanying such products and services.

Nothing herein should be construed as constituting an additional warranty. HP shall not be liable for

technical or editorial errors or omissions contained herein.

HP 5642 Rack User Guide

November 2004 (First Edition)

Part Number 366309-001

Audience Assumptions

This document is for the person who installs racks and rack products. This procedure is performed only by

trained personnel. HP assumes you are qualified in performing installations and trained in recognizing

hazards in rack products.

Page 3

3

Contents

Overview 5

HP 5642 Rack ......................................................................................................................................5

Ordering Rack Options ........................................................................................................................5

Installation Overview...........................................................................................................................6

Installation Service...............................................................................................................................7

Assembling the HP 5642 Rack 9

Maximum Load Capacity.....................................................................................................................9

Rack Caution........................................................................................................................................9

Kit Contents .......................................................................................................................................10

Required Tools................................................................................................................................... 14

Assembling the HP 5642 Rack ..........................................................................................................14

Configuration Factors 31

Maximum Load Capacity...................................................................................................................31

Rack Caution......................................................................................................................................31

Configuration Factors ........................................................................................................................32

Rack Configuration Software.............................................................................................................32

Custom Builder Online Modes of Operation .....................................................................................32

Component Placement .......................................................................................................................33

Additional Considerations..................................................................................................................33

Optimum Environment ......................................................................................................................35

Space Requirements................................................................................................................35

Power Requirements...............................................................................................................35

Temperature Requirements.....................................................................................................36

Airflow Requirements ............................................................................................................36

Multiple Racks................................................................................................................................... 37

Installing Components 39

General Guidelines.............................................................................................................................39

Preparing the Rack for Component Installation.................................................................................41

Checking the Hardware ..........................................................................................................41

Removing the Side Panels ......................................................................................................41

Removing the Rack Doors...................................................................................................... 43

Installing Components .......................................................................................................................44

Using the Rack Template........................................................................................................45

Installing the Cage Nuts..........................................................................................................46

Page 4

4 HP 5642 Rack User Guide

Specifications 49

HP 5642 Rack Specifications............................................................................................................. 49

Electrostatic Discharge 51

Preventing Electrostatic Discharge ....................................................................................................51

Grounding Methods to Prevent Electrostatic Discharge.................................................................... 52

Technical Support 53

HP Contact Information.....................................................................................................................53

Before You Contact HP .....................................................................................................................53

Acronyms and Abbreviations 55

Index 57

Page 5

5

Overview

In This Section

HP 5642 Rack.................................................................................................................................5

Ordering Rack Options...................................................................................................................5

Installation Overview .....................................................................................................................6

Installation Service .........................................................................................................................7

HP 5642 Rack

The HP 5642 Racks offer the following features:

• Simple installation

• Split rear doors

• Split side panels

• Cable access area below rear door

Ordering Rack Options

In addition to the standard racks, HP also provides rack options to complement or

complete your rack solution. The following list is only a sampling of the many

rack option kits available. For information about ordering rack option kits visit

the HP website (http://www.hp.com/products/rackoptions

HP authorized reseller or service provider.

Rack Option Description

Stabilizer Rack Option Kit Increases the stability of free-standing

Baying Rack Option Kit Joins multiple racks of the same series,

Monitor/Utility Rack Option Kit Holds a monitor or other rack

) or contact the nearest

racks, or for use with modified side feet

height, and depth

component

Page 6

6 HP 5642 Rack User Guide

Rack Option Description

Server Console Switch Programmable switch panel with

1U Keyboard Drawer Option Kit Holds and conceals a keyboard

connection hardware used to switch a

keyboard, monitor, and mouse among

multiple servers

100 Kilo Sliding Shelf Rack Option

Kit

TFT5600 RKM Rack-mountable 1U keyboard and flat-

Blanking Panel Rack Option Kit Covers open areas of the rack to better

TFT7210R Flat Panel Monitor

Rackmount

Installation Overview

HP recommends the following sequence of events for the most safe and efficient

installation of your rack and components.

1. Install the Customer Builder software from the HP website

(http://h30099.www3.hp.com/configurator/eco-cb/custombuilder.asp

the Custom Builder, plan the rack component location and installation

sequence.

2. Select a location to set up your rack. This should be the permanent site for

your rack.

Allows easy access to various rack

components

panel monitor on a drawer with room in

the rear to add a switchbox

control airflow

Rack-mountable 1U flat-panel monitor

with room in the rear to add a

switchbox

). Using

3. Assemble the rack. For your convenience, rack contents are packaged to

follow the installation steps.

4. Stabilize the rack by adjusting the leveling feet.

5. Bay multiple racks together (recommended if more than one rack is being

used side by side).

6. Install products, such as PDUs or console switches, in sidewall or 0U

locations.

Page 7

Overview 7

7. Install products, such as UPS units, starting from the bottom of the rack.

8. Install the appropriate support rails and tray for the first rack-mountable

component.

9. Install the first individual component.

10. Attach a cable management arm if required.

11. Attach the appropriate cables and power cords to the component, being sure

to adhere to all cautions and warnings.

12. Install the remaining components in the appropriate sequence.

13. Reinstall any doors and side panels.

14. Power up and configure the systems.

Installation Service

In the US, HP can make arrangements to have your rack system installed by

qualified guaranteed service providers. This installation service covers the entire

hardware installation sequence, from unpacking the components to routing

cabling and running a test of the system. For more information, visit the HP

website (http://www.hp.com/products/racks

).

Page 8

Page 9

9

Assembling the HP 5642 Rack

In This Section

Maximum Load Capacity ...............................................................................................................9

Rack Caution ..................................................................................................................................9

Kit Contents..................................................................................................................................10

Required Tools .............................................................................................................................14

Assembling the HP 5642 Rack.....................................................................................................14

Maximum Load Capacity

Rack Caution

CAUTION: Do not exceed the maximum load capacity, 680.38

kg (1,500 lb), for this rack.

CAUTION: To reduce the risk of personal injury or damage to

the equipment, be sure that:

• This procedure is performed after you have read these instructions

completely.

• You select a location to set up your rack. This location should be as

close as possible to the permanent site for your rack.

• The leveling feet are extended to the floor to stabilize the rack.

• Two or more people are available to lift and stabilize the product

pieces during assembly.

• After you install the side panels, they are secured to the rack frame

before releasing them.

• The maximum load capacity for this rack is 680.38 kg (1,500 lb).

Page 10

10 HP 5642 Rack User Guide

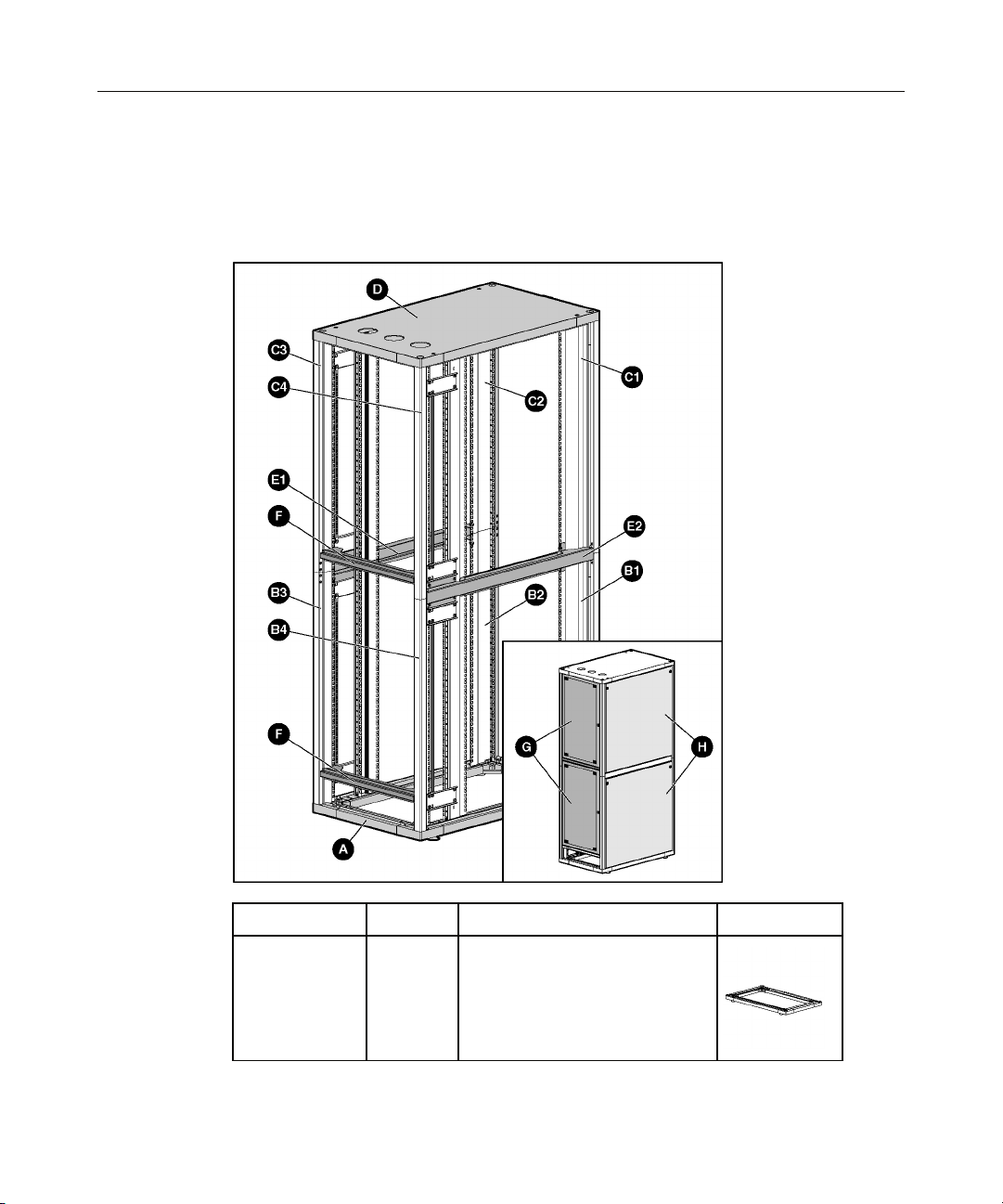

Kit Contents

If any of the following items are missing or damaged, contact your HP

authorized reseller. The following hardware pieces are included in this kit:

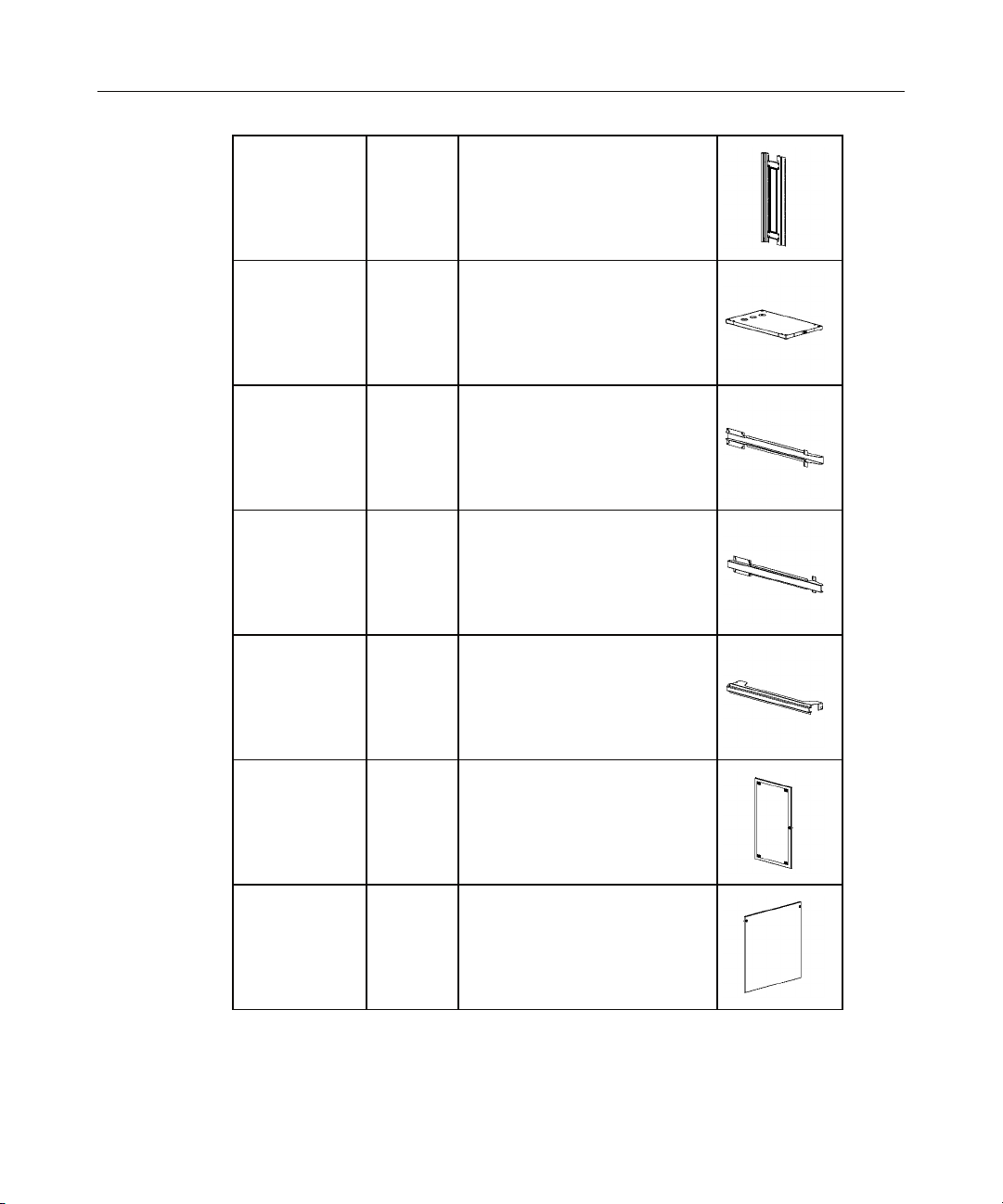

Identification Quantity Piece Description Picture

A

1 piece Rack base (with leveling feet

already attached)

Page 11

Assembling the HP 5642 Rack 11

B1

B2

B3

B4

C1

1 piece Lower left front vertical frame

piece

1 piece Lower right front vertical frame

piece

1 piece Lower left rear vertical frame

piece (with Retma rail attached)

1 piece Lower right rear vertical frame

piece (with Retma rail attached)

1 piece Upper left front vertical frame

piece

C2

1 piece Upper right front vertical frame

piece

C3

1 piece Upper left rear vertical frame

piece (with Retma rail attached)

Page 12

12 HP 5642 Rack User Guide

C4

D

E1

E2

F

1 piece Upper left rear vertical frame

piece (with Retma rail attached)

1 piece Rack top

1 piece Right depth rail

1 piece Left depth rail

2 pieces Rear door support

G

2 pieces Rear door

H

4 pieces Side panel

Page 13

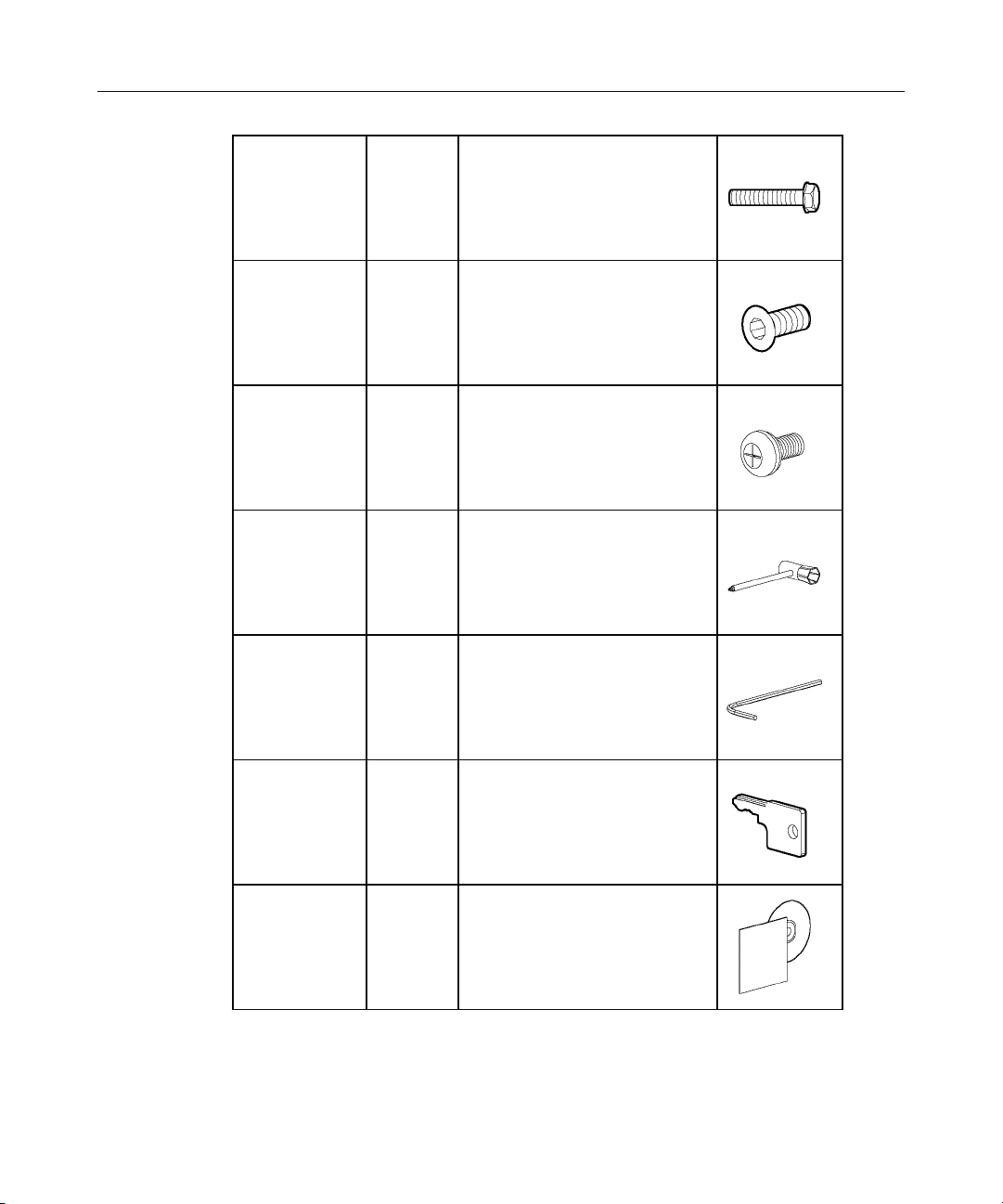

Assembling the HP 5642 Rack 13

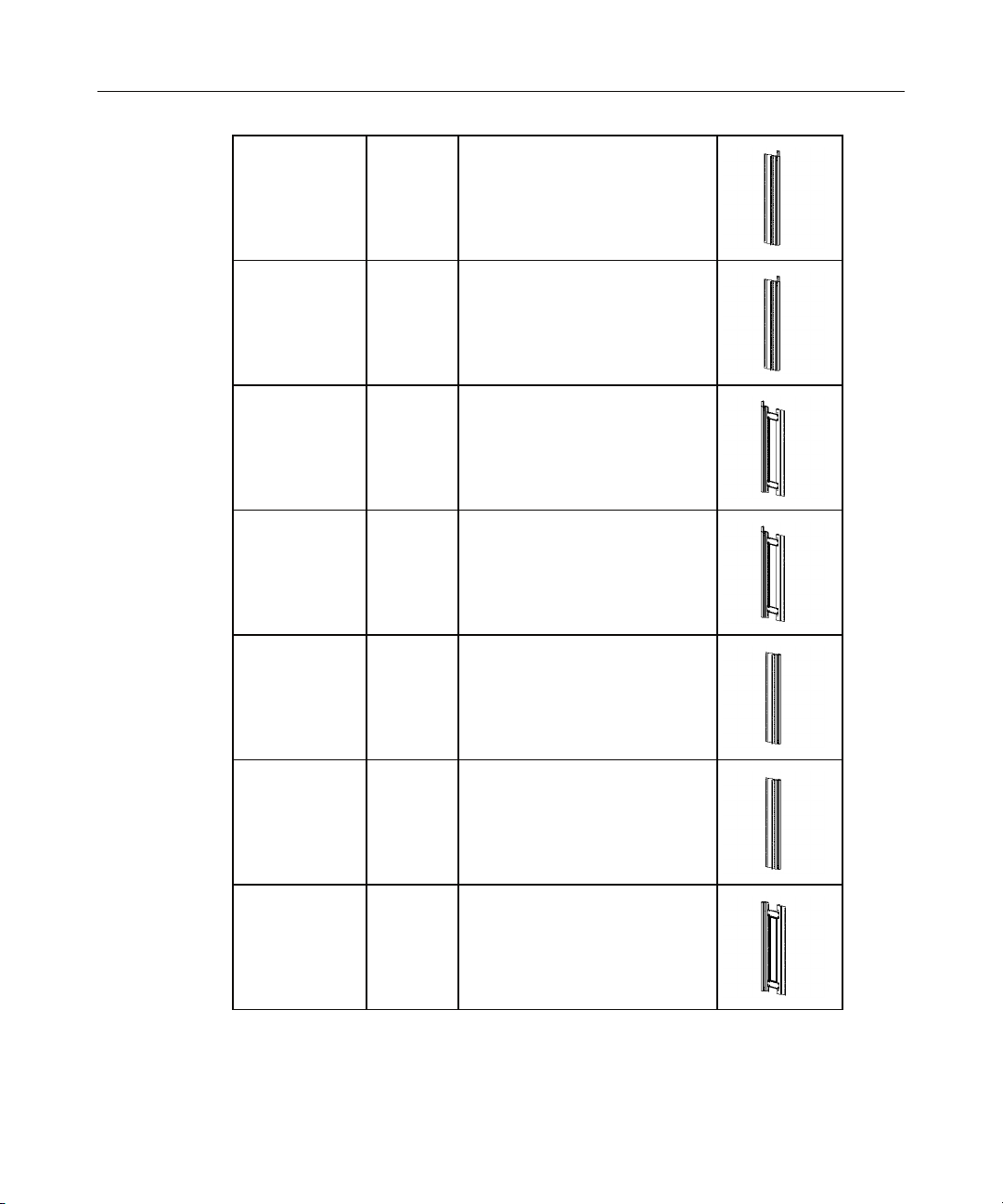

I

J

K

—

—

1 bag Bolts

1 bag Screws

1 bag Screws

1 tool Phillips screwdriver with socket

tool

1 tool Allen wrench

—

1 set Key

—

1 set Documentation Kit

Extra hardware might be included for your convenience.

Page 14

14 HP 5642 Rack User Guide

Required Tools

The following tools are required for some procedures:

• Included with this kit

− Allen wrench

− Phillips screwdriver with socket tool

− Keys

• Not included with this kit

− Step ladder

− Flat-head screwdriver (quarter-wide)

For comfort and efficiency while setting up your rack, use power tools where

applicable.

Assembling the HP 5642 Rack

CAUTION: Be sure that the HP 5642 Rack parts are

assembled in the correct locations according to the following

illustrations.

CAUTION: Do not exceed the maximum load capacity, 680.38

kg (1,500 lb), for this rack.

NOTE: For your convenience, the rack components are packaged to

follow the installation steps.

1. Place the rack base A in the location you have selected for the HP 5642

Rack.

2. Adjust the leveling feet if necessary.

CAUTION: Two people might be needed to lift and stabilize

certain components during this assembly.

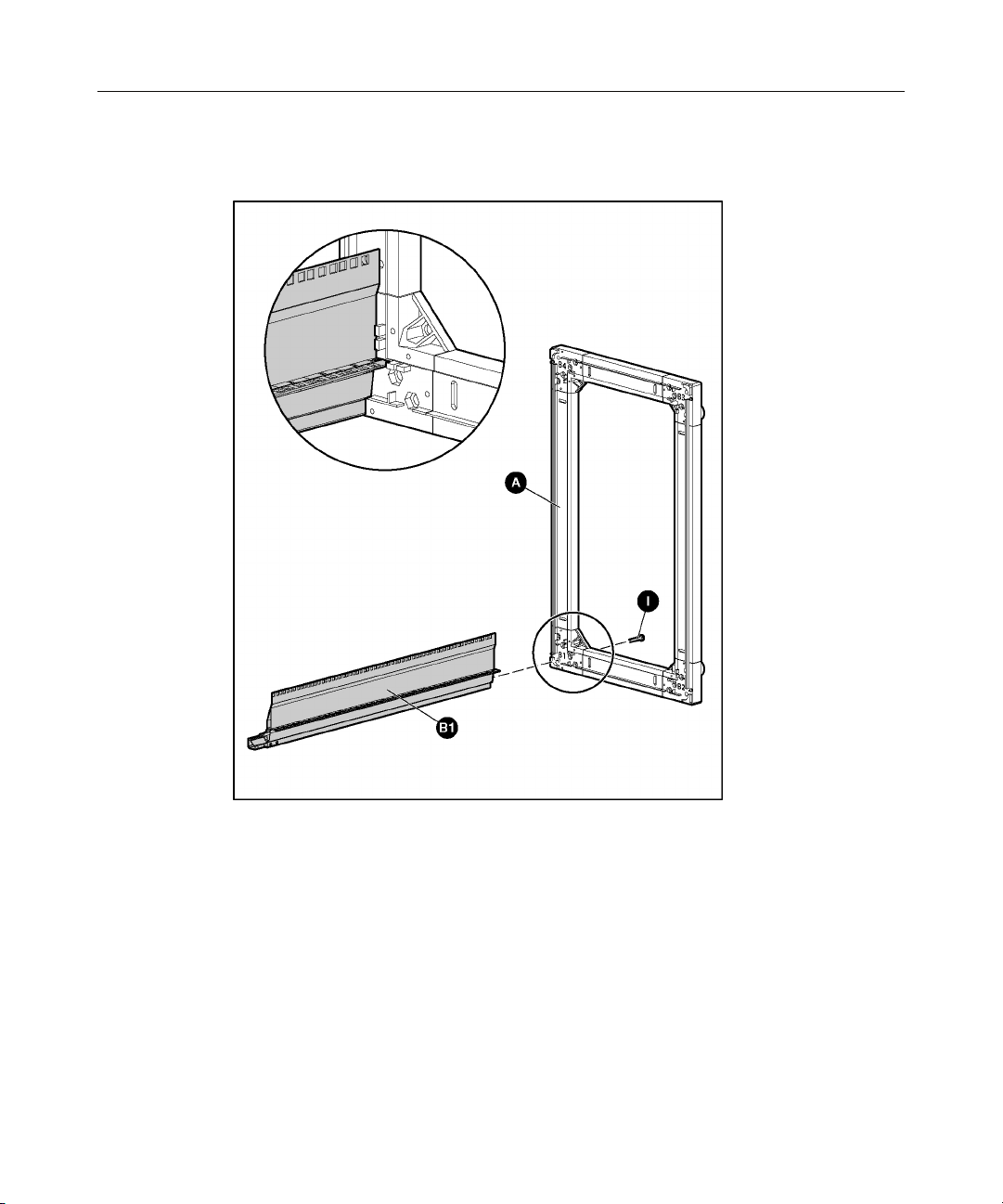

Page 15

Assembling the HP 5642 Rack 15

3. Attach B1 to A using one I hardware bolt. Fully tighten the I hardware bolt

before proceeding to the next step.

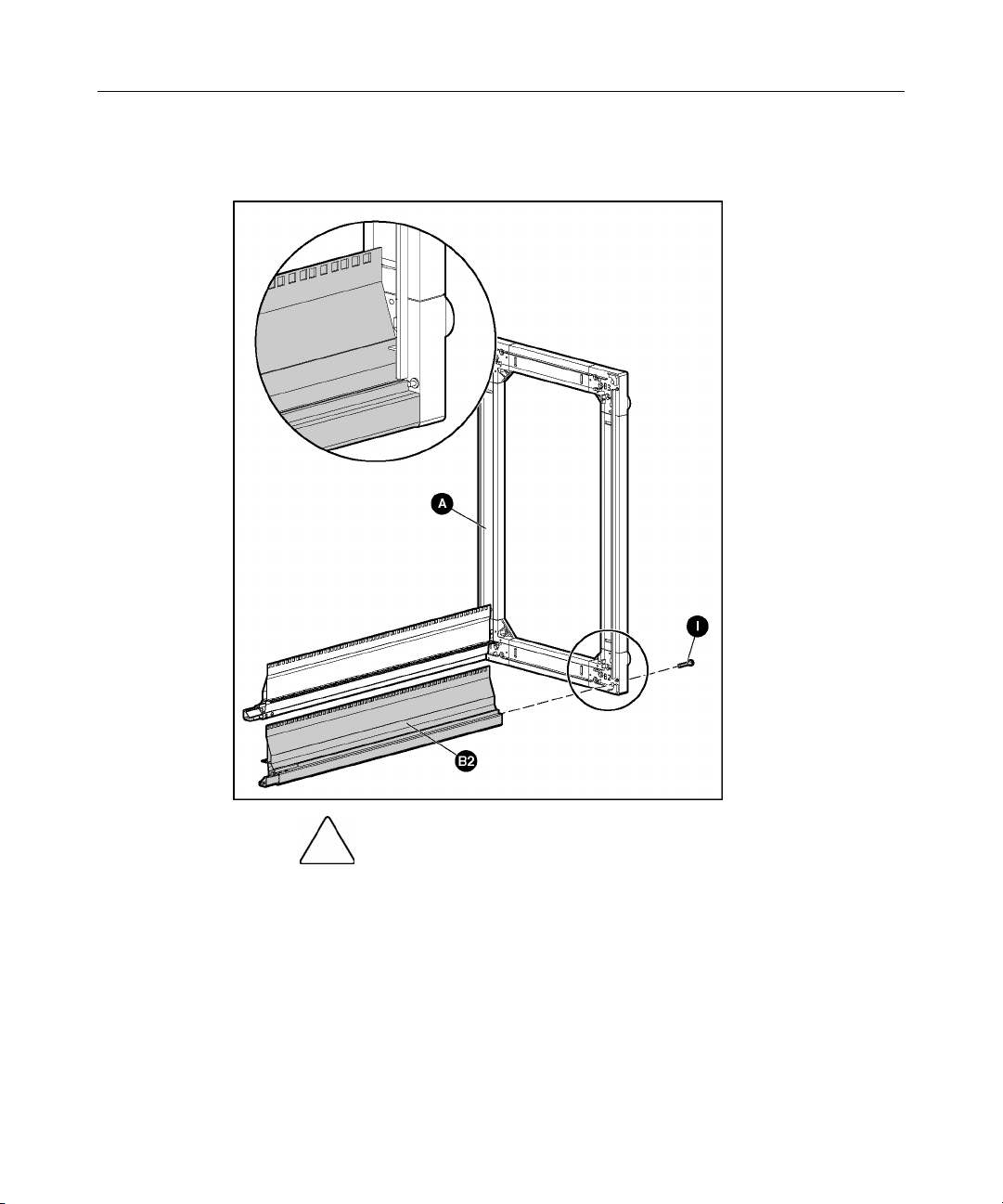

Page 16

16 HP 5642 Rack User Guide

4. Attach B2 to A using one I hardware bolt. Fully tighten the I hardware bolt

before proceeding to the next step.

CAUTION: Two people might be needed to lift and stabilize

certain components during this assembly.

Page 17

Assembling the HP 5642 Rack 17

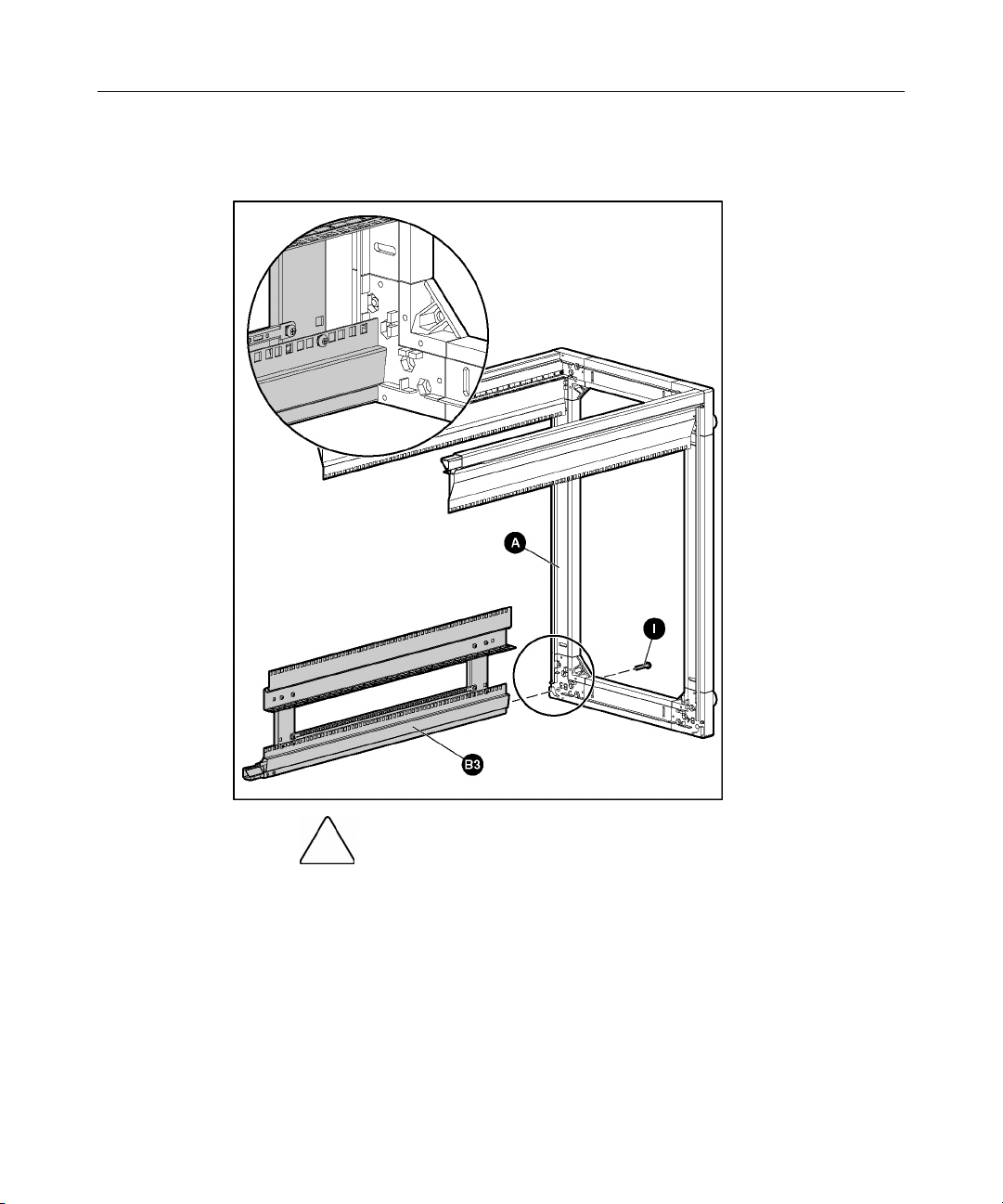

5. Attach B3 to A using one I hardware bolt. Fully tighten the I hardware bolt

before proceeding to the next step.

CAUTION: Two people might be needed to lift and stabilize

certain components during this assembly.

Page 18

18 HP 5642 Rack User Guide

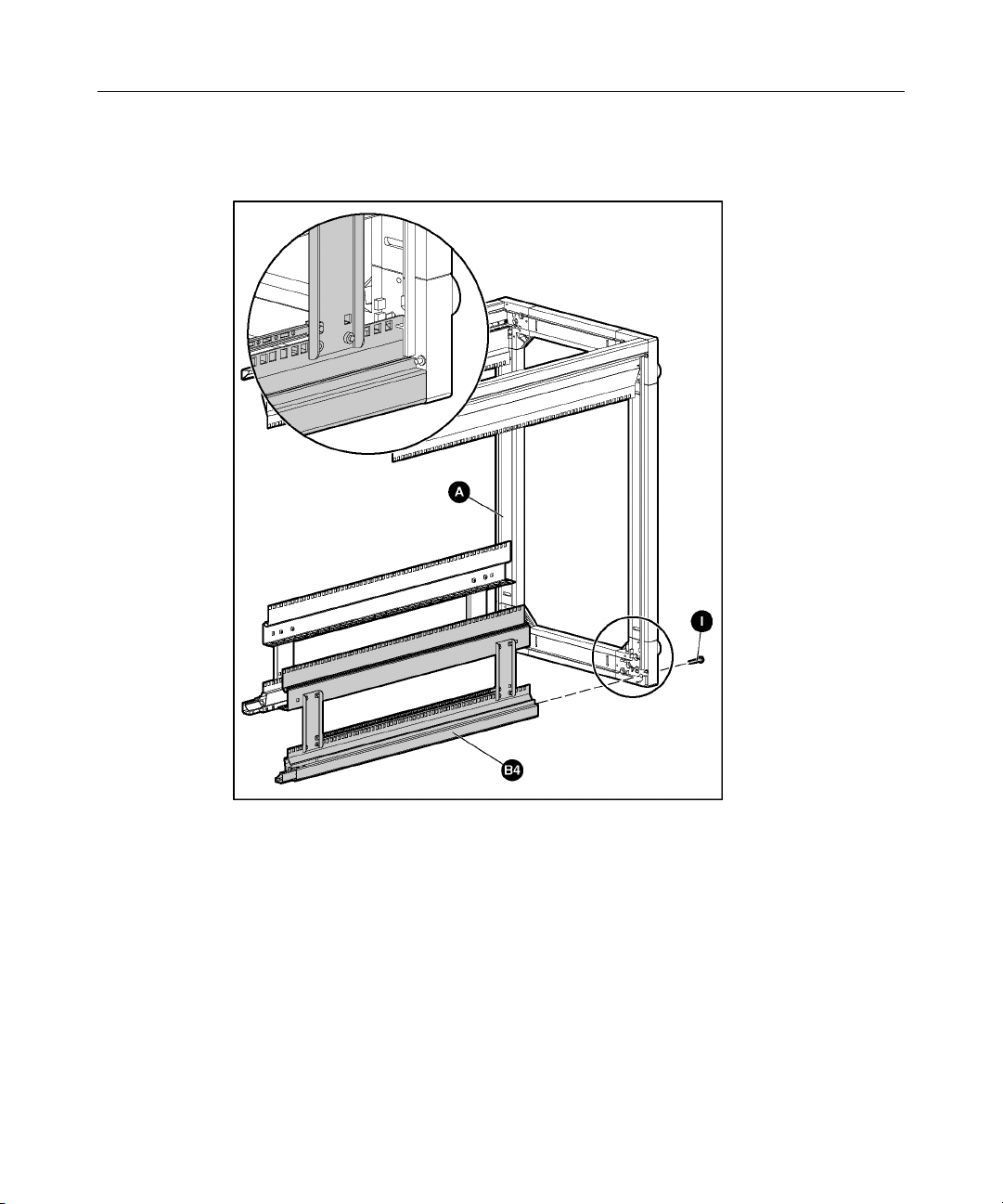

6. Attach B4 to A using one I hardware bolt. Fully tighten the I hardware bolt

before proceeding to the next step.

Page 19

Assembling the HP 5642 Rack 19

7. Attach C1 to B1 using four J hardware screws. Fully tighten the J hardware

screws before proceeding to the next step.

Page 20

20 HP 5642 Rack User Guide

8. Attach C2 to B2 using four J hardware screws. Fully tighten the J hardware

screws before proceeding to the next step.

Page 21

Assembling the HP 5642 Rack 21

9. Attach C3 to B3 using four J hardware screws. Fully tighten the J hardware

screws before proceeding to the next step.

Page 22

22 HP 5642 Rack User Guide

10. Attach C4 to B4 using four J hardware screws. Fully tighten the J hardware

screws before proceeding to the next step.

WARNING: Be sure that D is assembled in the correct

location according to the following illustration. C1 and C2 should

meet D where the HP logo is located, while C3 and C4 should meet

D where the cable egress holes are located. The HP logo is on the

front of the rack.

Page 23

Assembling the HP 5642 Rack 23

11. Attach D to C1, C2, C3, and C4 using four I hardware bolts. Fully tighten

the I hardware bolts before proceeding to the next step.

Page 24

24 HP 5642 Rack User Guide

12. Attach E1 to C2, C3, B2, and B3 using six K hardware screws. Fully tighten

the K hardware screws before proceeding to the next step.

Page 25

Assembling the HP 5642 Rack 25

13. Attach E2 to B1, B4, C1, and C4 using six K hardware screws. Fully tighten

the K hardware screws before proceeding to the next step.

Page 26

26 HP 5642 Rack User Guide

14. Attach F to C3 and C4 using two K hardware screws. Fully tighten the K

hardware screw before proceeding to the next step.

Page 27

Assembling the HP 5642 Rack 27

15. Attach F to B3 and B4 using two K hardware screws. Fully tighten the K

hardware screws before proceeding to the next step.

16. Attach G to F.

a. Position the bottom corner of G so that the pin on F is inserted into the

hole on G.

b. Using a tool, push down on the pin spring through the slot on G until the

pin is de-pressed.

c. Slide the top corner of G under the corner of the rack frame.

d. Remove the tool from the slot on G. The pin pops into place.

Page 28

28 HP 5642 Rack User Guide

e. Repeat for the other G piece.

WARNING: To reduce the risk of personal injury or

damage to the equipment, be sure that the H pieces are secured to

the rack frame by turning the quarter locks before releasing them.

17. Attach H to A.

a. Position H so that the pins on A are inserted into the holes on H.

b. Rotate H toward the rack.

c. Using a tool, turn the quarter locks on H to latch it into place.

Page 29

Assembling the HP 5642 Rack 29

d. Repeat for the other side of the rack.

WARNING: To reduce the risk of personal injury or

damage to the equipment, be sure that the H pieces are secured to

the rack frame by turning the quarter locks before releasing them.

18. Attach H to E.

a. Position H so that the pins on E are inserted into the holes on H.

b. Rotate H toward the rack.

c. Using a tool, turn the quarter locks on H to latch it into place.

Page 30

30 HP 5642 Rack User Guide

d. Repeat for the other side of the rack.

Installation is complete.

Page 31

31

Configuration Factors

In This Section

Maximum Load Capacity .............................................................................................................31

Rack Caution ................................................................................................................................31

Configuration Factors...................................................................................................................32

Rack Configuration Software .......................................................................................................32

Custom Builder Online Modes of Operation................................................................................32

Component Placement..................................................................................................................33

Additional Considerations............................................................................................................33

Optimum Environment.................................................................................................................35

Multiple Racks..............................................................................................................................37

Maximum Load Capacity

Rack Caution

CAUTION: Do not exceed the maximum load capacity, 680.38

kg (1,500 lb), for this rack.

CAUTION: To reduce the risk of personal injury or damage to

the equipment, be sure that:

Page 32

32 HP 5642 Rack User Guide

• This procedure is performed after you have read these instructions

completely.

• You select a location to set up your rack. This location should be as

close as possible to the permanent site for your rack.

• The leveling feet are extended to the floor to stabilize the rack.

• Two or more people are available to lift and stabilize the product

pieces during assembly.

• After you install the side panels, they are secured to the rack frame

before releasing them.

• The maximum load capacity for this rack is 680.38 kg (1,500 lb).

Configuration Factors

Before populating your new rack, you must plan the placement of each

component. Factors of each component, such as weight, accessibility, power,

temperature, and airflow requirements, affect installation order and component

placement in the rack.

Rack Configuration Software

To help you plan your rack configuration more efficiently, HP provides Custom

Builder, a powerful Web-based service enabling you to build, store, and export

end-to-end rack configurations. The latest version of the software is available on

the HP website (http://h30099.www3.hp.com/configurator/eco-

cb/custombuilder.asp).

Custom Builder Online Modes of Operation

Custom Builder has two modes of operation:

• Help-Me-Build-A-New-Solution Mode—Includes a simple interview session

to help determine your rack and component needs, as well as the necessary

power products and rack assembly devices needed to complete the final rack

assembly

• Let-Me-Build-A-New-Solution-Myself Mode—Enables you to select the

individual devices that are required for your rack configuration

Page 33

Configuration Factors 33

Component Placement

Apply the following rules to the physical placement of components in the HP

5642 Rack:

• Weight—Sort all of the components by weight, placing the heaviest

components at the bottom of the rack.

• KVM Switch—Mount the switch either behind the keyboard or within a

sidewall cavity to provide a 0U space solution.

• RKM—Install the RKM at a level that is the correct ergonomic position

where your shoulders and neck are relaxed.

• Monitor—Arrange the screen a minimum of 4Us above the keyboard tray.

• Rack-mountable flat-panel monitor—Select a position to accommodate the

desired viewing height (a minimum of 4Us above the keyboard tray).

• Balance—Be sure to balance the weight load between the racks, placing the

heaviest components at the bottom of the rack. For example, if you have

several UPS units and several servers, do not put all of the UPS units into

one rack. Distribute them evenly in the bottom positions of each rack.

For further information regarding component placement, refer to the Important

Safety Instructions that are shipped with the rack. Also, refer to the Safety and

Comfort Guide—Precautions for Server and Network Products on the HP

website (http://www.hp.com

) (search for Safety and Comfort Guide).

Additional Considerations

The following are additional items to consider, based on your specific rack

configuration:

• Power—If a UPS is installed, do not exceed its output rating. Be sure to

review the installation instructions provided with each component for

important cautions and warnings.

• PDUs—Install PDUs before installing other components.

Page 34

34 HP 5642 Rack User Guide

• Height—The height of the rack and of rack-mountable components is

measured in U increments. When you are configuring your rack installation,

remember that the total U measurement of the components you want to

install cannot exceed the stated U height of the rack.

• Keyboard—The rack keyboard requires installation of a 1U Keyboard

Drawer Rack Option Kit.

• Monitor—The monitor requires installation of a Monitor/Utility Shelf rack

Option Kit unless you are using a rack-mountable flat-panel monitor.

• Server Console Switch—If a console switch is configured, use the CPU-to-

console switch cable included with the server. The standard distance between

the console switch and the keyboard, monitor, and mouse can vary by 3-, 7-,

12-, 20-, and 40-ft lengths.

NOTE: National electrical regulations governing the installation of

building wiring require that an appropriate cable, meeting fire-safety

standards, must be used any time cabling is routed:

• Through an overhead drop-ceiling

• Under raised flooring

• From room to room

• From floor to floor

Be sure that the cable jacket or sleeving is made of material that does

not burn easily and does not exude toxic fumes when exposed to heat.

Be sure that the cable you have selected is appropriate for your

installation site. If you require a U.S. plenum-rated (CL2P) cable,

contact your local HP authorized reseller to obtain any of the following

options:

• 149363-B21-20-foot plenum cable

• 149364-B21-40-foot plenum cable

• Baying Rack Option Kits—The number of baying kits needed to join a

series of racks is one less than the number of racks in the suite. Each baying

kit supplies parts to bay two cabinets on 600 mm (24 inches) center line

spacing.

• Side Panels—Only one set of side panels is required for each row of bayed

racks.

• Stabilizing Kit—A stand-alone rack requires a stabilizing kit.

Page 35

Configuration Factors 35

Optimum Environment

Specific requirements for space, power, temperature, and airflow must be met to

provide optimum performance with minimum maintenance for your rack

environment.

For additional information, refer to the Best Practices document on the HP

website (http://www.hp.com).

Space Requirements

When deciding where to place your rack:

• At least 1,219 mm (48 inches) of clearance is needed all the way around the

pallet and above the rack to enable the removal of the packing material.

• At least 1,219 mm (48 inches) of clearance is needed in front of the rack to

enable the door to open completely.

• At least 762 mm (30 inches) of clearance is needed in the rear of the rack to

provide access to components.

• At least 380 mm (15 inches) of clearance is needed around a power supply to

facilitate servicing.

Power Requirements

When planning for power distribution requirements for your rack configuration:

• The power load must be balanced between available AC supply branch

circuits.

• The overall system AC current load must not exceed 80% of the branch

circuit AC current rating.

• If a UPS is used, the load should not exceed 80% of the marked electrical

current rating for the UPS.

Page 36

36 HP 5642 Rack User Guide

This equipment must be installed in accordance with local and regional electrical

regulations governing the installation of information technology equipment by

licensed electricians. This equipment is designed to operate in installations

covered by the Nation Electric Code (ANSI/NFPA-70, 1993) and the code for

protection of Electronic Computer/Data Processing Equipment (NFPA-75, 1992).

For electrical power ratings on options, refer to the products rating label or user

documentation supplied with that option.

Temperature Requirements

To ensure continued safe and reliable equipment operation, install or position the

rack in a well ventilated, climate-controlled environment.

The operating temperature inside the rack is always higher than the room

temperature and is dependent on the configuration of equipment in the rack.

Check the TMRA for each piece of equipment before installation.

CAUTION: To reduce the risk of damage to the equipment

when installing third-party options:

• Do not permit optional equipment to impede airflow around the HP

5642 Rack or to increase the internal rack temperature beyond the

maximum allowable limits.

• Do not exceed the manufacturer’s TMRA.

Airflow Requirements

HP rack-mountable products typically draw in cool air through the front and

exhaust warm air out through the rear of the rack. The front door of the rack,

therefore, must be adequately ventilated to enable ambient room air to enter the

rack, and the rear door must be adequately ventilated to enable the warm air to

escape the rack. Do not block the ventilation apertures.

Blanking Panels

If the front of the rack is not completely filled with components, the remaining

gaps between the components can cause changes in the airflow, which can

adversely affect cooling within the rack. Cover these gaps with blanking panels.

Page 37

Configuration Factors 37

Multiple Racks

Increasing space and stability, HP 5642 Racks can be bayed together by

installing the HP 5642 Baying Rack Option Kit. The HP 5642 Baying Rack

Option Kit joins multiple racks of the same series, height, and depth.

Observe the following tips when using multiple-rack configurations:

• The stabilizing kit is optional with bayed racks.

• The number of baying kits needed is one less than the total number of racks.

• Position and install either baying option kit before populating the racks with

components.

Page 38

Page 39

39

Installing Components

In This Section

General Guidelines .......................................................................................................................39

Preparing the Rack for Component Installation ...........................................................................41

Installing Components..................................................................................................................44

General Guidelines

IMPORTANT: HP strongly recommends that you configure the rack

using the Custom Builder (http://h30099.www3.hp.com/configurator/eco-

cb/custombuilder.asp) before beginning the installation process.

WARNING: To reduce the risk of personal injury or

damage to the equipment, adequately stabilize the rack before

extending a component outside the rack. Extend only one

component at a time. A rack may become unstable if more than

one component is extended.

WARNING: To reduce the risk of personal injury or

damage to the equipment, always load the heaviest item first from

the bottom of the rack up. This makes the rack bottom-heavy and

helps prevent the rack from becoming unstable. Refer to

Configuration Factors (on page 32

WARNING: To reduce the risk of personal injury or

damage to the equipment, be sure that:

).

Page 40

40 HP 5642 Rack User Guide

• The leveling feet are extended to the floor.

• The full weight of the rack rests on the leveling feet.

• The stabilizing feet are attached to the rack if it is a single-rack

installation.

• The racks are coupled together in multiple-rack installations.

• Only one component is extended at a time. A rack may become

unstable if more than one component is extended for any

reason.

CAUTION: To reduce the risk of damage to the equipment

when installing third-party options:

• Do not permit optional equipment to impede airflow around the HP

5642 Rack or to increase the internal rack temperature beyond the

maximum allowable limits.

• Do not exceed the manufacturer’s TMRA.

Observe the general guidelines when loading your components:

• For detailed instructions on installing specific component or third-party

hardware, refer to the user documentation that was shipped with that

component.

• Before installing components into the rack, refer to Electrostatic Discharge

(on page 51

).

• Use the configuration prepared by the Custom Builder as a guideline for

installation components.

• Load the heavier components first from the bottom of the rack.

• Be sure to balance the weight load between bayed racks. For example, if you

have several UPS units and several servers, do not pull all of the UPS units

into one rack. Instead distribute them evenly in the bottom positions of each

rack.

• Allow a minimum clearance of 76 cm (30 inches) between the wall and the

rear of the rack to provide adequate access for installation and service.

Page 41

Installing Components 41

Preparing the Rack for Component Installation

• Checking the Hardware (on page 41)

• Removing the Side Panels (on page 41)

• Removing the Rack Doors (on page 43

Checking the Hardware

After unpacking the component to be installed, locate the documentation that was

shipped with that component. Verify that you received all of the listed hardware

pieces.

You will typically have extra fasteners after completing your component

installation.

IMPORTANT: Retain the extra fasteners for future use.

Removing the Side Panels

1. Remove H from A.

a. Place one of your palms on H. Using your other hand and a tool, turn the

quarter-turn locks on H to unlatch H.

b. Slowly rotate H so that you are able to remove it from the pins on A.

)

Page 42

42 HP 5642 Rack User Guide

c. Repeat for the other side of the rack.

2. Remove H from E.

a. Place one of your palms on H. Using your other hand and a tool, turn the

quarter-turn locks on H to unlatch H.

b. Slowly rotate H so that you are able to remove it from the pins on E.

Page 43

Installing Components 43

c. Repeat for the other side of the rack.

Removing the Rack Doors

To provide access to all sides of the rack while you are installing the various

components, first remove the rack doors. If your rack has side panels, also

remove them before installing mounting brackets and other hardware.

To remove the rear rack doors:

1. Using a tool, push down on the pin spring through the slot on G.

2. Slide the top corner of G out from under the corner of the rack.

Page 44

44 HP 5642 Rack User Guide

3. Remove the tool from the slot on G.

4. Remove the bottom corner of G from the pin on F.

Installing Components

NOTE: Install the stabilizer foot before any component.

IMPORTANT: These installation instructions are for standard

installations. For specific installation instructions, refer to the

documentation included with your component.

Page 45

Installing Components 45

The following steps outline the sequence for installing rack-mountable

components in a rack. Install 0U devices first, such as PDUs, console switches,

and so on.

1. Use the rack template ("Using the Rack Template" on page 45

and mark the rack for correct placement of the installation hardware.

2. Install the cage nuts ("Installing the Cage Nuts" on page 46

required).

3. Prepare and install the rails into the rack.

4. Prepare and install the component into the rack and secure it.

5. Install the component into the rack and secure it.

6. Attach the cable management arm to the rack and then to the component.

7. Attach any cables and power cords, being sure that you adhere to all cautions

and warnings contained in the individual component installation instructions.

8. Remove the cable access panel and route the cables.

Using the Rack Template

Use the template that was shipped with your rack-mountable component to mark

the location of the mounting hardware on the mounting rails of the rack.

Align the lower edge of the rack template with the top of the previous rack

component, and push the tabs in to hold the rack template in place. Mark the rack

to indicate where the components are to be located.

) to measure

) into the rack (if

Page 46

46 HP 5642 Rack User Guide

CAUTION: Always plan the rack installation so that the

heaviest item is on the bottom of the rack. Install the heaviest item first,

and continue to populate the rack from the bottom to the top.

NOTE: Rack components are removed for clarity.

Installing the Cage Nuts

Use the cage nut insertion tool to install the cage nuts on the inside of the

mounting rails.

NOTE: The cage nut insertion tool and the cage nuts are not included

with this rack.

1. Hook the bottom lip of the cage nut in the square-rail perforation.

2. Insert the tip of the insertion tool through the perforation, and hook the top

lip of the cage nut.

Page 47

Installing Components 47

3. Use the insertion tool to pull the cage nut through the hole until the top lip

snaps into position.

Page 48

Page 49

49

Specifications

In This Section

HP 5642 Rack Specifications .......................................................................................................49

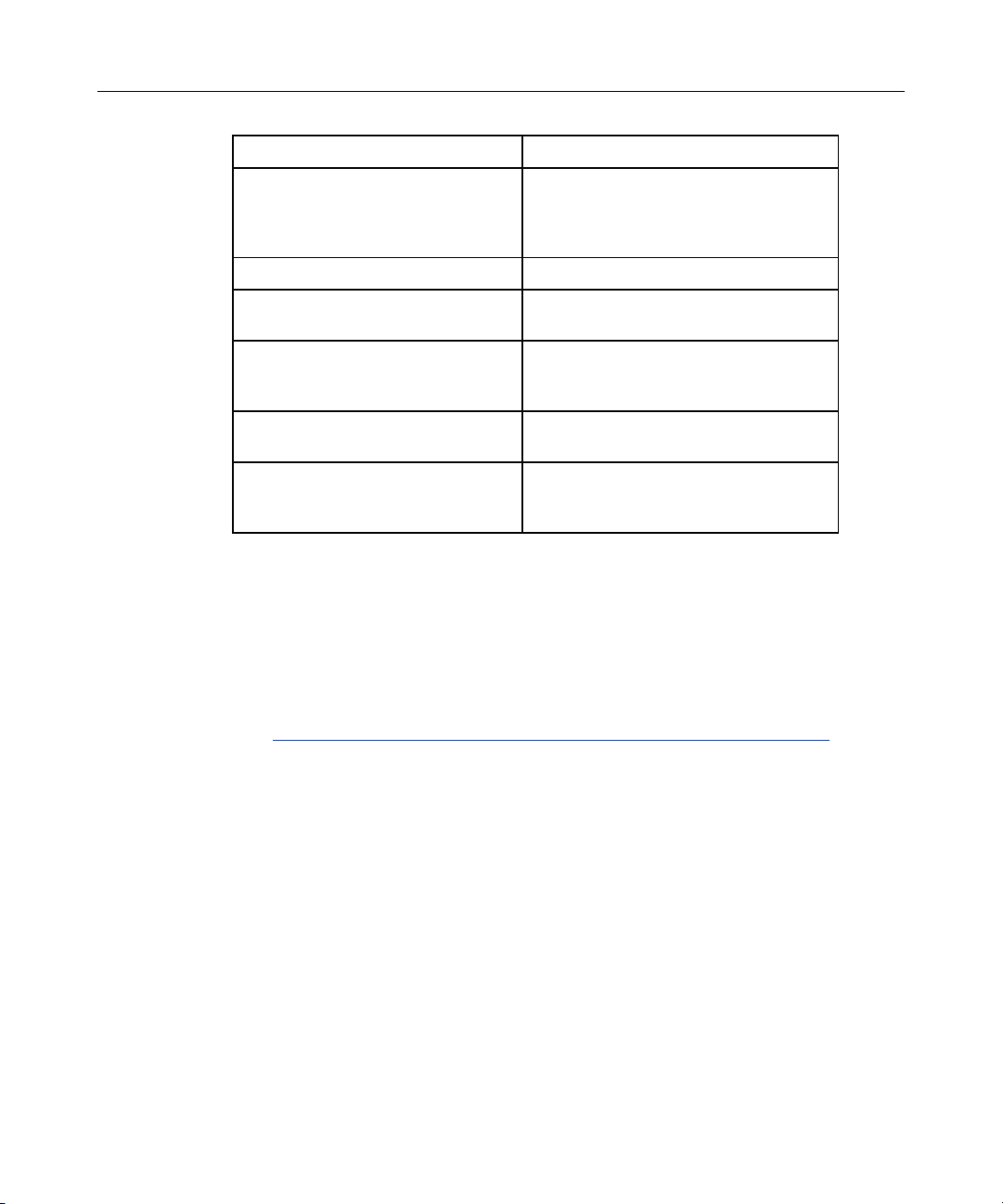

HP 5642 Rack Specifications

U height Width Depth Static

Load

42 U 600 mm

(23.62 in.)

1000

mm

(39.37

680.38

kg (1,500

lb)

in.)

Shipping

Options

Flat ship

(-B21)

Color

Graphite

metallic

Page 50

Page 51

51

Electrostatic Discharge

In This Section

Preventing Electrostatic Discharge...............................................................................................51

Grounding Methods to Prevent Electrostatic Discharge...............................................................52

Preventing Electrostatic Discharge

To prevent damaging the system, be aware of the precautions you need to follow

when setting up the system or handling parts. A discharge of static electricity

from a finger or other conductor may damage system boards or other staticsensitive devices. This type of damage may reduce the life expectancy of the

device.

To prevent electrostatic damage:

• Avoid hand contact by transporting and storing products in static-safe

containers.

• Keep electrostatic-sensitive parts in their containers until they arrive at staticfree workstations.

• Place parts on a grounded surface before removing them from their

containers.

• Avoid touching pins, leads, or circuitry.

• Always be properly grounded when touching a static-sensitive component or

assembly.

Page 52

52 HP 5642 Rack User Guide

Grounding Methods to Prevent Electrostatic Discharge

Several methods are used for grounding. Use one or more of the following

methods when handling or installing electrostatic-sensitive parts:

• Use a wrist strap connected by a ground cord to a grounded workstation or

computer chassis. Wrist straps are flexible straps with a minimum of

1 megohm ±10 percent resistance in the ground cords. To provide proper

ground, wear the strap snug against the skin.

• Use heel straps, toe straps, or boot straps at standing workstations. Wear the

straps on both feet when standing on conductive floors or dissipating floor

mats.

• Use conductive field service tools.

• Use a portable field service kit with a folding static-dissipating work mat.

If you do not have any of the suggested equipment for proper grounding, have an

authorized reseller install the part.

For more information on static electricity or assistance with product installation,

contact your authorized reseller.

Page 53

53

Technical Support

In This Section

HP Contact Information................................................................................................................53

Before You Contact HP................................................................................................................53

HP Contact Information

For the name of the nearest HP authorized reseller:

• In the United States, call 1-800-345-1518.

• In Canada, call 1-800-263-5868.

• In other locations, refer to the HP website (http://www.hp.com

For HP technical support:

• In North America:

− Call 1-800-HP-INVENT (1-800-474-6836). This service is available

24 hours a day, 7 days a week. For continuous quality improvement,

calls may be recorded or monitored.

− If you have purchased a Care Pack (service upgrade), call 1-800-633-

3600. For more information about Care Packs, refer to the HP website.

(http://www.hp.com

• Outside North America, call the nearest HP Technical Support Phone Center.

For telephone numbers for worldwide Technical Support Centers, refer to the

HP website (http://www.hp.com

Before You Contact HP

Be sure to have the following information available before you call HP:

• Technical support registration number (if applicable)

).

)

).

Page 54

54 HP 5642 Rack User Guide

• Product serial number

• Product model name and number

• Applicable error messages

• Add-on boards or hardware

• Third-party hardware or software

• Operating system type and revision level

Page 55

55

Acronyms and Abbreviations

KVM

keyboard, video, and mouse

PDU

power distribution unit

RKM

rackmount keyboard monitor

TMRA

recommended ambient operating temperature

UPS

uninterruptible power system

Page 56

Page 57

57

Index

A

additional information 53

airflow requirements 36

assembling the rack 14

authorized reseller 53

B

Baying Rack Option Kit 37

blanking panels 36

C

cage nuts, installing 46

checking the hardware 41

component placement 33

configuration factors 31, 32

contacting HP 53

Custom Builder 32, 33

E

electrostatic discharge 51

G

general guidelines 39

grounding methods 52

I

installation overview 6

installation services 7

installing components 39, 44

installing the cage nuts 46

K

kit contents 10

L

Let Me Build A New Solution Myself Mode 32

M

maximum load capacity 9

multiple racks 37

O

Offset Baying Rack Option Kit 37

optimum environment 35

overview of installation process 44

overview, HP 5642 Rack 5

P

phone numbers 53

power requirements 35

preparing the rack for component

installation 41

H

Help Me Build A New Solution Mode 32

help resources 53

HP 5642 Rack specifications 49

HP Technical Support 53

R

rack configuration software 32

rack doors, removing 43

rack options 5

rack template 45

removing the rear doors 43

removing the side panels 41

required information 53

Page 58

58 HP 5642 Rack User Guide

required tools 14

S

side panels, removing 41

space requirements 35

specifications 49

static electricity 51

support 53

T

technical support 53

telephone numbers 53

temperature requirements 36

U

using the rack template 45

W

website, HP 53

Loading...

Loading...