Page 1

HP Archive

This vintage Hewlett Packard document was

preserved and distributed by

www.hparchive.com

Please

visit

us

on the web !

Scanned by on-line curator: Tony Gerbic

** For FREE Distribution Only ***

Page 2

01081-1

PRELIMINARY

OPERATING

MANUAL

MODEL

S62A

DIGITAL

RECORDER

Serials

Prefixed:

134-

Copy.l,h,

HfWUTJ.PAClCARD

CO"'PANY

1961

1501

PAGf""L

ROAD.

PALO

ALTO.

CALIFORNIA.

USA.

Printed:

9/61

Page 3

Model

562A

TABLE

OF

CONTENTS

Section

GENERAL

DESCRIPTION

I

1-1.

1-2.

1-3.

1-4.

1-

5.

1-6.

Description

Data

Entry

Standard

Instrument

Options

Available

Power

Requirements

Uses

. .

.

.

. .

Page

1-1

1-1

1-1

1-1

1-2

1-2

1-2

2-1

2-1

2

...

1

2-1

2-1

2-1

2-1

· .

· .

. .. .

INSTALLATION.

2-

•

Gene

ral

Inforn1ation

2-2.

Rack

Mounting

•

2-3.

Connection

to

the

~Transistorized

Counters

2-4.

Connection

to

~

Counters

and

Digital

Voltmeter

2-5.

Operation

from

Two

Data

Sources

2-6.

Cable

Fabrication

II

III

OPERATION

3

-1

3-1.

Ope

rating

Controls

•

·

•

3

-1

3-2.

Paper

Tape

3-1

3-3.

Inked

Ribbon

·

·

3-2

3-4.

Taped

Duplicates

•

•

3-3

3

-5.

Programming

the

Recorder

·

·

3-3

3

-6.

Prograrnming

th.e

Control

Board

(AI3)

3-3

3-7.

Data

Source

Connections

3-4

3-8.

Programming

the

Column

Boards

3-4

3-9.

Reference

Voltages

3-5

3-1O.

Reference

Voltages

Adjustment

3-6

3-11.

Power

Supply

and

Internal

Reference

Voltages

3-6

3-12.

Printing

a

Minus

(-)

·

·

3-6

3-13.

Setting

the

Analog

Controls

(optional)

•

3-7

3-14.

Recording

with

Galvanometer

Graphic

Recorders

3-7

3-15.

Using

Graphic

Recorders

Having

Different

Input

Sensitivities

3-8

ii

,

Page 4

Model

562A

TABLE

OF

CONTENTS

(Cont'd)

Section

IV

THEOR

Y

OF

OPERATION

•

TROUB

LESHOOTING

V

4-1.

4-2.

4-3.

4-4.

5-1.

5-2.

5-3.

Introduc

tion

• •

Control

Board

Operation

•

Column

Board

Operation.

Analog

Circuitry

Operation

•

Introduction

Localizing

the

Trouble

Semi-Conductor

Replacement

Page

4-1

4-1

4..1

•

•

4-2

• •

4-3

•

•

•

•

5-1

•

5-1

•

5-2

5-2

iii

Page 5

Section

I

Model

562A

Table1-1.

Specifications

Accuracy:

Printing

Rate:

Column

Capacity:

Print

Wheels:

Dri

ving

Source:

Print

Command

Signal:

Transfer

Time:

Paper

Required:

Power

Requirements:

Dimensions:

Identical

to

input

device

used

5

lines

per

second,

nlaximum

To

11

columns

(12

available

on

special

order)

12

positions,

numerals

0

through

9,

a

minus

sign,

andablank,

Other

symbols

available.

*

Para11e1entry4-Ii

ne

BCD,

1 - 2 - 2 -

4.

at

her

codes

available.

Source

reference

voltage

establishes

"0"

state.

"0"

or

"1"

state

m'..lst

not

be

nlore

than

150

volts

above

or

below

ground.

The

binary

swing

should

be

between

4

and

75

volts.

Positive

or

negative

pulse,

20

\J.s

or

greater

in

width,

6

to

20

volts.

Approximately

2

rns

Standard

3

-inch

roll

or

folded

paper

115/230

volts

±

10%,

50/60

cps

(4

prints

per

second

maximum

at

50

cps)

Cabinet

Mount:

20-3/4

in.

wide,

12-1/2

in.

high,

18-1/2

in.

deep

Rack

Mount:

19

in.

wide,

10-1/2

in.

high,

16-7/8

in.

deep

behind

panel

Weight:

Cabinet

Mount:

Net

35

lbs,

shipping

70

lbs

(app

roximat

el

y)

Rack

Mount:

Net

30

Ibs,

shipping

63

lbs

(app

roxilna

LeI

y)

1-0

*

See

0j)

A ppIicat

ion

Not

e #32forinf

0 r

mat

ion

0 n s

pee

i a I p r i nt wh

eel

s .

01081-1

Page 6

Model

562A

1-1.

DESCRIPTION.

SECTION

I

GENERAL

DESCRIPTION

Section

I

The

Hewlett-Packard

Model

562A

Digital

Recorder

isatransistorized

electro-

IT!echanical

device

providing

a

printed

record

of

digital

inforrnation.

Parallel

data

entry

and

low-inertia

moving

parts

allow

printing

rates

as

high

as5lines

per

second,

each

line

containing

up

to

11

digits;

12

digit

capacity

is

available

on

special

order.

Throughout

this

nlanual

the

Model

562A

will

be

referred

to

as

the

recorder.

1-2.

DATA

ENTRY.

Standard

input

for

the

recorder

is

parallel-entry

4-line

BCD

code,

either

1224

or

1248.

Input

to

the

recorder

is

through

rear-l1'.lounted

connectors.

Internal

connectors

route

the

inforn1ation

to

any

desired

sequence

of

columns.

Each

column

has

binary

storage

for

one

decimal

nunlber.

When

a

print

COITlmand

is

supplied,

each

storage

unit

assumes

the

condition

of

the

decade

counting

unit

(or

other

driving

source)

connected

to

it.

The

data

transfer

takes

place

in

approximately

2

milliseconds,

after

which

tinle

the

d

riving

source

is

free

to

gather

more

infornlation.

1-3.STANDARD

INSTRUMENT.

Each

storage

unit

is

mounted

onaplug-in

board

(column

board)

withade-coding

matrix.

The

nlatrix

converts

the

stored

data

into

positioning

inforIT!ation

for

the

print

wheels.

The

recorder

is

supplied

to

translate

1224

BCD

codes,

but

other

4-line

codes

are

accoIYlmodated

by

substituting

plug-in

boards.

Unless

otherwise

specified,

the

recorder

is

supplied

from

the

factory

with

the

following:

a.

Six

+1224

coluIYln

boards.

b.

Printer

nlechanism,

11

print

wheels

and

associated

components,

five

prints/second

with

60

cps

power

line

frequency.

c.

One

input

connector

at

rear

of

recorder

JI01.

d.

One

input

cable.

e.

One

control

board.

f.

One

power

supply

board.

01081-1

1-1

Page 7

Section

I

1-4.

OPTIONS

AVAILABLE.

The

following

options

are

available:

a.

+

or

-1224

column

boards.

b.

+

or

-1248

column

boards.

c.

Analog

circuitry.

d.

Pinion

gear,

allows

5

prints

per

second

with

50

cps

power.

Model

562A

e.

Input

connector

(J201)

and

associated

connectors

(for

dual

input

operation

or

over9-column

capacity).

f.

Data

input

cable.

1-5.

POWER

REQUIREMENTS.

The

recorder

has

been

designed

to

operate

frorr!

115/230

volt,

50/60

cps

power.

A

switch,

located

at

the

rear

of

the

recorder

selects

operation

for

either

115

or

230

volts.

The

three-conductor

power

cable

supplied

with

the

instrument

is

terminated

in

a

three-prong

polarized

male

connector

recommended

by

the

Electrical

Manu-

facturers'

Association

(NEMA).

The

third

contact

is

an

offset

round

pin,

added

toastandard

two-blade

ac

plug

which

grounds

the

recorder

chassis

when

used

with

the

proper

receptacle.

An

adapter

should

be

used

to

connect

the

NEMA

plug

toastandard

two-contact

receptacle.

When

the

adapter

is

used,

the

ground

connector

becomes

a

short

green

lead.

The

green

lead

should

be

connected

to

a

suitable

ground

for

protection

of

the

operating

personnel.

1-6.

USES.

Because

of

the

extreme

flexibility

of

the

recorder,

it

can

be

used

with

electronic

counters,

digital

voltmeters

etc.

orawide

variety

of

individual

and

system

applications.

The

recorder

will

operate

with+or

-1224,

+

or

-1228

BCD,

and

10

-line

code

information

depending

on

column

boards

installed.

Two

separate

sources,

unsynchronized,

can

be

used

to

provide

data

if

option

e

is

installed.

The

recorder

supplies

the

synchronization.

When

the

analog

circuitry,

option

c,

is

installed,

the

operator

may

select

analog

voltage

of

columns

1

through

9

in

3

-column

groups.

1

-2

01081-1

Page 8

Model

562A

SECTION

II

INSTALLATION

2-1.

GENERAL

INFORMATION.

Section

II

Section

II

contains

information

relating

to

installation

and

input

connections.

2-2.

RACK

MOUNTING.

If

the

recorder

is

to

be

rack

mounted,

be

certain

to

allow

sufficient

open

space

for

cooling

air

to

enter

and

exhaust.

Do

not

rnount

the

recorder

next

to

equip-

ment

which

will

discharge

hot

air

into

the

recorder

air

intake.

2-3.

CONNECTION

TO

THE

$p

TRANSISTORIZED

COUNTERS.

The

recorder

may

be

directly

connected

to

the

~

transistorized

counters

by

means

of

the

input

cable

supplied

with

the

recorder.

The

transistorized

counters

have

the

correct

connector

installed.

Recorder

connector

J101

is

connected

to

the

counter

recorder

connector.

If

a

second

transistorized

counter

is

to

be

connected

to

the

recorder,

connection

is

made

froIn

the

second

counter

to

recorder

connector,

J201.

The

transistorized

counter

output

is

+1224

BCD.

2-4.

CONNECTION

TO

rfiJ

COUNTERS

AND

DIGITAL

VOLTMETER.

If

the

recorder

is

to

be

connected

to

the

above

tube

type

instruments

a

modifi-

cation

kit

can

be

installed.

The

kit

provides

a

+1224

BCD

output.

2-5.

OPERATION

FROM

TWO

DATA

SOURCES.

The

recorder

can

be

operated

fronl

two

data

sources,

synchronized

or

unsyn-

chronized,

by

connecting

the

data

inputs

to

connectors

J101

and

J201.

The

two

data

inputs

can

be

±1224

or

±1248

code.

The

appropriate

coluInn

boards

Inust

be

installed

in

the

proper

connectors

in

the

recorder.

2-6.

CABLE

FABRICATION.

Connection

of

the

recorder

to

data

sources

other

than

the

above

Inay

require

construction

ofacable

terminated

withaconnector

that

will

mate

with

the

recorder

connectors.

Use

small

gage

telephone-type

wire.

Number

26

gage

wire

meeting

MIL-B

-76A,

with

7

strands

#34

gage

wire,

tinned

after

stranding,

with

10

SoC

plastic

insulation

has

been

found

satisfactory.

Select

a

sy

stematic

color

code

for

wires

to

avoid

errors.

Use

care

in

soldering.

Repairing

faulty

connections

after

all

wires

are

soldered

is

very

difficult.

A

length

of#14

gage

wire

makes

an

excellent

soldering

tip

for

use

on

closely-spaced

connector

terrninals.

01081-1

2

-1/2-2

Page 9

Model

562A

SECTION

III

OPERATION

3-1.

OPERATING

CONTROLS.

The

operating

controls

consist

of

the

following:

POWER

ON,

supplies

power

to

the

recorder

when

in

the

ON

position.

Section

III

RECORD

ON,

allows

the

printer

mechanism

to

operate

when

in

the

ON

position.

When

the

switch

is

in

the

spring-loaded

position(down),

the

recorder

prints

at

maximum

rate.

The

middleposition

isastandby

position(allows

analog

to

be

taken).

SPACE

SELECTOR,

selects

the

number

of

spaces

between

readout

prints.

PAPER

ADVANCE,

manually

advances

paper.

ANALOG

CONTROLS,

(optional)

refer

to

text.

3-2.

PAPER

TAPE.

Special

~folded

tape

is

recommended

for

use

with

the

recorder.

High-quality

standard

3

-inch

rolled

adding

machine

type

may

also

be

used.

Folded

tape

permits

convenient

take

-up

in

the

paper

drawer

and

allows

easy

inspection

of

any

portion

of

the

type.

It

is

perforated

at

each

fold

to

allow

neat

separation

of

portions

of

recorded

data.

Folded

tape

may

be

reversed

and

re-

run

to

use

both

sides.

With

single

spacing,

about

15,

000

prints

can

be

made

on

one

side

ofafolded

pad.

One

pad

will

last

about

40

minutes

at

maximum

print

rate.

To

install

the

paper

tape

proceed

as

follows:

a.

Open

front

panel.

b.

Load

paper

in

compartment.

c.

Fold

paper

back

one

inch

and

crease.

Insert

paper

between

roller

and

guide

plate.

01081-1

3-1

Page 10

Section

III

Model

562A

d.

Manually

advance

paper.

Paper

will

feed

easier

and

can

be

reversed

with

SPACE

SELECTOR

set

to

"0".

e.

Feed

paper

under

inked

ribbon.

f.

Feed

paper

through

slot.

Close

front

panel.

g.

Collect

printed

paper

in

drawer.

Follow

these

additional

instructions

if

roll

tape

is

used:

a.

Insert

spindle

through

roll.

Spindle

is

taped

to

bottom

of

paper

compart-

ment

when

instrument

is

shipped

from

the

factory.

b.

Hang

roll

by

ends

of

spindle

from

ledges

on

both

sides

of

paper

compartment.

c.

Paper

must

feed

out

from

the

bottom

of

the

roll.

d.

Continue

with

loading.

To

feed

paper

rapidly

use

the

PAPER

ADVANCE

thumb

wheel.

To

manually

feed

paper

backward,

set

the

SPACE

SELECTOR

to

"0"

and

roll

the

PAPER

ADVANCE

wheel

in

the

reverse

(up)

direction.

Paper

feed

may

be

reversed

on!l.

with

the

SPACE

SELECTOR

set

to

"0".

Be

sure

paper

is

inserted

squarely

in

the

paper

feed

mechanism

to

prevent

jamming.

If

paper

doesnot

feed

smoothly,

place

the

RE

CORD

switch

in

the

centerposition,

and

re

move

all

paper

from

the

feed

mechanism.

Use

tweezers

to

pick

out

torn

bits

of

paper.

3-3.

INKED

RIBBON.

The

printer

mechanism

uses

a

special

heavily-inked

silk

ribbon

available

from

the

Hewlett-Packard

Company.

Standard

typewriter

ribbon

on

an

Underwood

spool,

with

reversing

rivets

near

the

ribbon

ends,

may

also

be

used;

however,

impressions

will

be

lighter

than

with

the

Hewlett-Packard

ribbon.

To

install

new

ribbon,

proceed

as

follows:

a.

Open

the

hinged

front

panel

to

gain

access

to

the

printer

mechanism.

b.

Loosen

the

two

printer

mechanism

retaining

screws

located

on

the

lower

front

corners

of

the

mechanism

by

turning

1/4

turn

counterclockwise.

c..Slide

mechanism

out

of

cabinet

until

ribbon

spools

are

readily

accessible.

d.

Wind

all

the

ribbon

onto

one

spool.

3-2

01081-1

Page 11

Model

562A

Section

III

01081-1

e.

Shift

the

two

ribbon

spool

retaining

springs

away

from

the

spools,

and

remove

spools.

f.

Take

the

ribbon

out

of

the

mechanism.

Save

the

empty

spool.

g.

Hook

end

of

new

ribbon

on

empty

spool.

Wind

about

10

inches

of

ribbon

on

the

spool

so

that

the

rever

sing

rivet

is

on

the

spool.

h.

Install

new

ribbon

by

feeding

it

over

the

ribbon

rollers

and

between

the

print

wheels

and

paper

tape.

i.

Feed

ribbon

through

the

slots

in

the

reversing

arms

and

around

the

lower

guides.

Ribbon

must

be

twisted

900between

the

ribbon

roller

and

the

slot

in

the

rever

sing

arm.

j.

Place

ribbon

spools

on

their

shafts.

Fasten

spools

in

place

with

the

spool

retaining

springs.

Ribbon

must

feed

out

from

the

bottom

of

each

spool.

k.

Replace

printer

mechanism

in

cabinet

and

tighten

retaining

screws.

3-4.

TAPE

DUPLICATES.

Transparent

paper,

~stock

no.

9251-0052

is

recommended

for

use

in

the

recorder.

This

paper

produces

much

less

paper

dust

and

copies

can

be

easily

made

with

duplication

machines.

If

duplicate

tape

records

are

required

from

standard

paper,

contact

print

duplicating

methods,

such

as

the

ozalid

process,

can

be

used

by

printing

directly

from

the

original

tape

records.

3-5.

PROGRAMMING

THE

RECORDER.

The

recorder

can

be

programmed

to

accept

different

codes

if

the

proper

column

boards

are

installed.

The

column

boards

may

be

inter-mixed

if

desired.

The

standard

recorder

is

supplied

with

six

+1224

BCD

column

boards,

with

connectors

installed

to

accept

a

total

of

nine

column

boards.

If

more

than

nine

column

operation

is

desired,

J201

must

be

installed

with

the

connectors

that

attach

to

the

rear

of

the

column

boards

(PIIO-PIl5).

Normally

JIOl

supplies

data

to

column

boards

Al-A9,

but

connectors

PIOl-

PI09

can

be

connected

to

supply

data

to

any

of

the

column

boards

the

operator

desires.

J201

can

supply

data

to

any

of

the

remaining

column

boards.

Con-

nectors

PIIO-Pll5

can

be

connected

to

supply

data

to

six

column

boards.

3-6.

PROGRAMMING

THE

CONTROL

BOARD

(AI3).

Connectors

P20l

and

P202

supply

control

signals

to

the

data

sources,

and

return

data

source

signals

to

the

control

board.

Connector

P20l

is

con-

3-3

Page 12

Section

III

Model

562A

nected

to

one

data

source

through

JI01.

and

P202

toasecond

data

source

through

J201.

The

control

board

senses

when

commands

from

both

sources

have

been

received,

then

starts

the

printing

cycle.

If

only

'one

data

source

is

used,

the

control

board

connector

that

is

not

being

used

must

be

disconnected,

otherwise

the

recorder

will

not

operate

but

will

wait

until

the

control

boarq

receives

a

second

print

command

signal.

When

the

control

board

connector

that

is

not

being

used

is

disconnected,

the

associated

print

command

binary

remains

in

the

proper

state

of

unbalance.

Thus

a

print

command

is

required

from

only

one

data

source

to

start

the

printing

cycle.

3-7.

DATA

SOURCE

CONNECTIONS.

Data

can

be

supplied

continuously

from

two

data

sources.

If

six

column

read-

out

is

desired

for

one

data

source

and

five

column

readout

is

desired

for

the

second

data

source,

then

one

data

source

is

connected

to

JI01

and

the

other

data

source

to

J201.

The

column

board

connectors

can

be

connected

as

the

operator

desires.

Other

combinations

the

operator

may

want

can

be

had

by

changing

the

connectors

at

the

rear

of

the

column

boards.

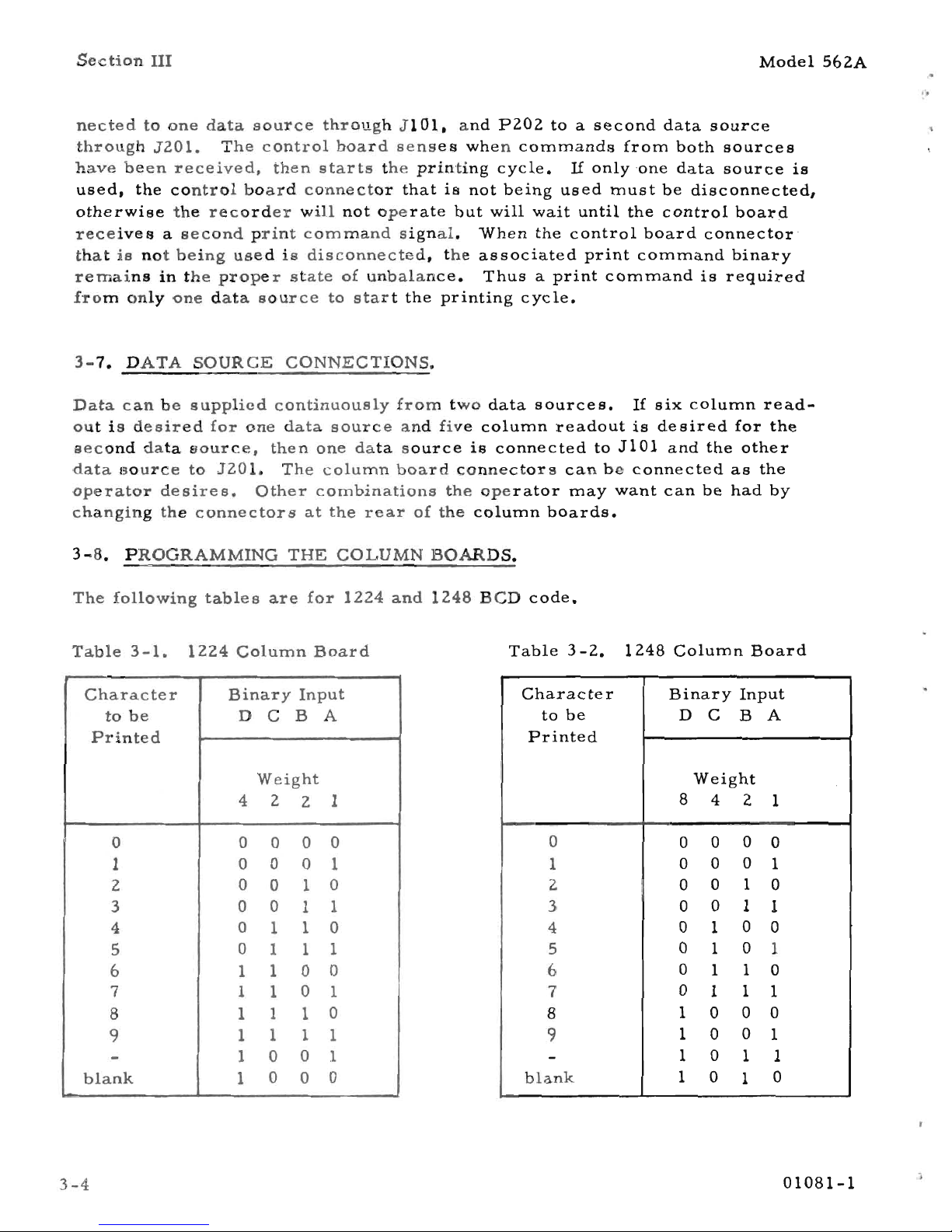

3-8.

PROGRAMMING

THE

COLUMN

BOARDS.

The

following

tables

are

for

1224

and

1248

BCD

code.

Table3-1.

1224

Column

Board

Character

Binary

Input

to

be

D C

B

A

Printed

Weight

4 2

2

1

0 0 0

0

0

1

0

0

0

1

2

0

0

1

0

3

0 0

1

1

4

0

1

1

0

5

0

1 1 1

6 1 1

0 0

7

1

1

0 1

8 1 1 1

0

9

1

1

1 1

-

1

0 0

1

blank

1

0 0

0

3-4

Table3-2.

1248

Column

Board

Character

Binary

Input

to

be

D

C B

A

Printed

Weight

8

4

2

1

0

0 0

0

0

1

0 0 0

1

2 0 0 1

0

3

0

0

1

1

4

0

1

0 0

5

0

1

0

1

6

0

1

1

0

7

0

1

1

1

8 1

0 0

0

9

1

0 0

1

-

1

0

1

1

blank

1

0

1

0

01081-1

Page 13

Model

562A

The

following

notes

refer

to

tables3-1

and3-2:

1

and0definitions

1)

1

indicates

"1"

level

binary

input.

2)

0

indicates

"0"

level

binary

input.

Section

III

"1"

and

"0"

levels

(BCD

input)

1)

Ina+1224

code,

the"

1"

level

is

positive

with

respect

to

the

"0"

level.

2)

Ina-1224

code,

the"

1"

level

is

negative

with

respect

to

the

"0"

level.

The

+

or

-

prefix

is

deterrnined

by

the

polarity

of

the"

1"

level

with

respect

to

the

"0"

level.

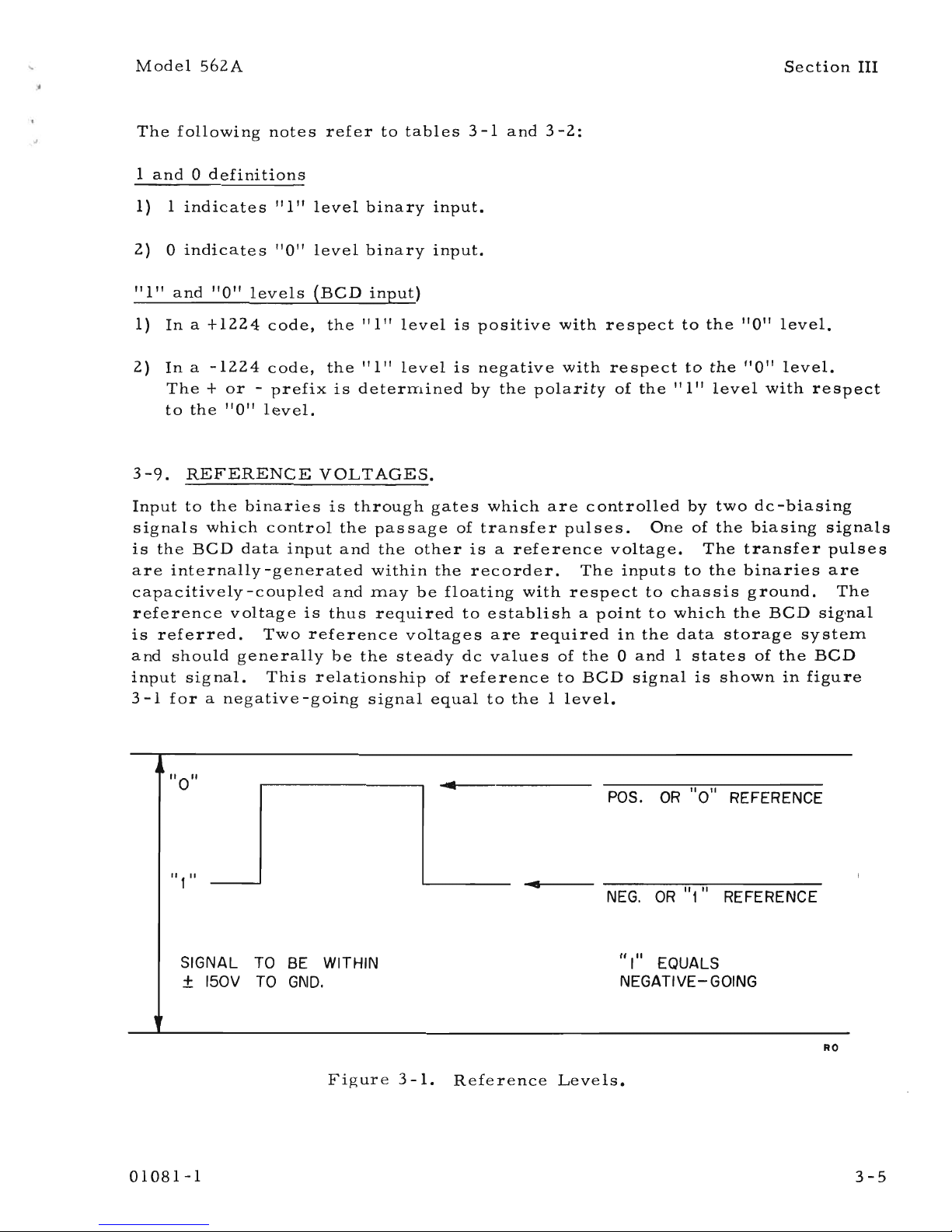

3-9.

REFERENCE

VOLTAGES.

Input

to

the

binaries

is

through

gates

which

are

controlled

by

two

dc

-biasing

signals

which

control

the

passage

of

transfer

pulses.

One

of

the

biasing

signals

is

the

BCD

data

input

and

the

other

is

a

reference

voltage.

The

transfer

pulses

are

internally-generated

within

the

recorder.

The

inputs

to

the

binaries

are

capacitively-coupled

and

may

be

floating

with

respect

to

chassis

ground.

The

reference

voltage

is

thus

required

to

establish

a

point

to

which

the

BCD

sig'nal

is

referred.

Two

reference

voltages

are

required

in

the

data

storage

system

and

should

generally

be

the

steady

dc

values

of

the0and1states

of

the

BCD

input

signal.

This

relationship

of

reference

to

BCD

signal

is

shown

in

figure

3-1

for

a

negative-going

signal

equal

to

the1level.

"0"

"1"

SIGNAL

TO

BE

WITHIN

±

150V

TO

GND.

POS.

OR

"0"

REFERENCE

NEG.

OR"

1" REFERENCE

It

I"

EQUALS

NEGATIVE-GOING

RO

Figure

3

-1.

Reference

Levels.

01081-1

3-5

Page 14

Section

III

3-10.

REFERENCE

VOLTAGE

ADJUSTMENT.

Model

562A

The

input

voltage

applied

for

any

column

board

must

not

exceed

150

volts.

That

is

the

refe

renee

voltage

plus

theBCD

It1It

level

should

not

be

greater

than

150

volts.

For

instance,

if

the

BCD

swing

is

from

100

volts

(tiD"

level)

to

160

volts

(til"

level)

then

attenuation

must

be

introduced

to

reduce

the

"0"

level

to

94

volts

and

the

"1"

level

to

150

volts.

The

minus

reference

voltage

can

then

be

adjusted

for

94

volts.

The

plus

reference

level

must

then

be

adjusted

to

150

volts.

Before

a

reference

voltage

can

be

chosen,

the

"0"

and"

I"

levels

of

the

equip-

ment

supplying

the

BCD

signals

must

be

known.

For

instance

if

the

recorder

is

connected

toabinary

counter

with

a

-1248

code,

each

column

board

will

be

driven

byadecade

in

the

counter.

Sometimes

binaries

in

the

decades

have

different"

1"

and"

0"

levels,

thus

a

proper

reference

voltage

must

be

chosen.

If

the

column

board

is

a

-1248

code,

then

the

-reference

voltage

must

be

chosen

that

includes

the

"1"

levels

applied

to

the

A,

B,

C,

and

D

binaries.

A

+reference

voltage

must

be

chosen

that

will

include

the

"0"

levels

for

the

A,

B,

C,

and

D

binaries.

If

high

impedance

reference

levels

are

used

(above

5000

ohms),

suitable

by-

passing,

providing

a

time

constant

of

150

~s,

should

be

used.

If

the

BCD

drive

is

derived

from

an

unregulated

supply,

then

it

is

desirable

to

obtain

the

reference

voltage

from

the

same

unregulated

supply.

3-11.

POWER

SUPPLY

AND

INTERNAL

REFERENCE

VOLTAGES.

The

power

supply

board,

A16,

supplies

the

de

voltages

required

by

the

recorder.

The

power

supply

also

has

provisions

for

providing

reference

voltages

of

-9

to

+17

volts.

The

operator

can

select

a

value

of

resistors

or

breakdown

diodes

needed

to

provide

the

proper

reference

voltages.

Connectors

P301

and

P302

(optional)

supply

the

reference

voltages

to

the

column

boards.

When

using

an

external

reference

voltage,

connectors

P30l

and

P302

must

be

disconnected

from

the

power

supply

board

if

resistors

are

installed.

Unless

specified

by

the

customer,

resistors

are

not

installed.

The

proper

mounting

holes

are

in

the

power

supply

board

and

the

operator

can

install

the

resistors

or

break-

down

diodes

required

to

give

the

desired

voltage.

3

-12.

PRINTING

A

MINUS(-).

The

recorder

will

normally

print

a

blank

with

no

BCD

input.

If

the

operator

wishes

to

print

a

-(minus)

for

a

1224

code,

in

place

ofablank,

proceed

as

follows:

In

table

3-1

under

the

column

headed

"character

to

be

printed",

find

-(minus).

Under

the

"Binary

Input"

column,

the-charac

ter

must

have

a

"l"

input

for

the

A

and

D

binaries.

If

the

column

board

isa+1224

code,

then

the

external

voltage

applied

to

the

A

binary

input

must

be

at

least

4

volts

more

positive

than

the

negative

reference

voltage.

Since

the

D

binary

has

a

11

I"

supplied

3-6

01081-1

Page 15

Model

562A

Section

III

01081-1

by

the

transfer

pulse

when

the

nOll

level

is

not

present,

no

external

voltage

is

required

for

the

D

binary.

A

-1224

code

req

uiresthe

same

voltagesbut

of

different

polarity.

If

the

column

board

isa+1248

code,

in

table

3-2

find

-(minus).

Under

the

"Binary

Input"

column,

the-character

must

have

a

"l"

input

for

the

A,

B,

and

D

binaries.

An

external

voltage

applied

to

the

A

binary

must

be

at

least

4

volts

more

positive

than

the

negative

reference

voltage.

The

Band

D

binaries

do

not

require

an

external

voltage

as

the

transfer

pulse

supplies

the"

1"

level

when

"0"

level

is

not

present.

A

-1248

code

requires

the

same

external

voltages,

but

of

different

polarity.

3-13.

SETTING

THE

ANALOG

CONTROLS

(ortional).

The

POTENTIOMETER

RECORDER

binding

posts

on

the

562A

are

designed

to

operate

potentiometer

type

(voltage

operated)

recorders

having

lOO-millivolt-

full-scale

sensitivity,

and

greater

than

50K

ohm

input

resistance.

The

562A

can

also

drive

recorders

having

other

values

of

input

sensitivity

and

resistance

by

making

minor

addiqons

or

modification

to

the

POTENTIOMETER

RE-

CORDER

ANALOG

OUTPUT.

To

use

the

562A

onapotentiometer

recorder,

proceed

as

follows:

a.

Set

the

COLUMN

SELECTOR

to

include

the

three

number

columns

to

be

recorded

gr

aphically.

b.

Connect

the

potentiometer

recorder

to

the

POTENTIOMETER

RECORDER

binding

postson

the

56

2A.

c.

Set

the

OPERATE

lever

switch

to

the

G8.LV.

ZERO

position

(the

GALV.

ZERO

control

has

no

effect

on

the

POTENTIOMETER

RECORDER

output)

but

does

supply

zero

output

at

potentiometer

jack.

d.

Zero

set

the

potentiometer

recorder

with

its

own

controls.

e.

Set

the

OPERATE

lever

switch

to

the

CALIBRATE

position.

f.

Adjust

the

CALIBRATE

control

to

obtain

full-scale

deflection

of

the

recorder

pen.

g.

Repeat

steps

c,

d,

e,

and

f.

h.

Set

the

OPERATE

lever

switch

to

OPERATE.

The

graphic

recorder

will

now

plot

the

number

columns

indicated

by

the

COLUMN

SELECTOR.

3-14.

RECORDING

WITH

GALVANOMETER

GRAPHIC

RECORDERS.

The

GALVANOMETER

RECORDER

output

jack

on

the

562A

is

designed

to

operate

galvanometer

type

(current

operated)

recorders

having

I-milliampere-

3-7

Page 16

Section

III

Model

562A

3-8

full-scale

se

nsitivity

and

Ie

s s

than

5000

ohnlS

input

re

sis

tance.

The

562A

can

also

drive

recorders

having

other

values

of

input

sensitivity

and

resistance

by

making

minor

additions

or

modifications

to

the

GALVANOMETER

RECORDER

ANALOG

OUTPUT.

To

use

the

562A

withagalvanometer

recorder,

proceed

as

follows:

a.

Before

connecting

the

recorder

to

the

562A,

deternline

which

three

of

the

number

columns

are

to

be

plotted.

Then

set

the

COLUMN

SELECTOR

to

in-

clude

these

three

number

columns.

b.

Zero

set

the

galvanometer

recorder

with

its

own

controls.

c.

Connect

the

recorder

to

the

GALVANOMETER

RECORDER

jack

using

a

standard,

1/4-inch

diameter

three-circuit

phone

plug.

The

positive

recorder

terminal

is

connected

to

the

ring

contact

on

the

plug,

and

the

negative

terminal

to

the

tip

on

the

plug.

d.

Set

the

OPERATE

lever

switch

to

the

GALV.

ZERO

position.

e.

If

necessary,

zero

set

the

recorder

with

the

GALV.

ZERO

set

control

on

the

562A.

f.

Set

the

OPERATE

lever

switch

to

the

CALIBRATE

position.

g.

Adjust

the

CALIBRA

TE

control

to

obtain

full-scale

deflection

of

the

recorder

pen.

h.

Set

the

OPERATE

lever

switch

to

the

OPERATE

position.

The

recorder

will

now

plot

the

number

columns

indicated

by

the

COLUMN

SELECTOR.

3-15.

USING

GRAPHIC

RECORDERS

HAVING

DIFFERENT

INPUT

SENSITIVITIES.

To

use

a

potentiometer

recorder

having

greater

than

specified

voltage

sensi-

tivity,

shunt

the

recorder

with

a

value

of

resistance

which

results

in

full-scale

deflection

of

the

recorder

pen

while

the

562A

is

set

to

CALIBRATE

and

the

CALIBRATE

control

is

cente

red.

Potentiometer

recorders

having

less

than

50K

ohm

input

resistance

may

be

used,

but

the

POTENTIOMETER

RECORDER

output

will

than

provide

less

than

100

millivolts

for

full-scale

deflection.

The

internal

resistance

at

the

POTENTIOMETER

RECORDER

output

is

approximately

2500

ohms

and

when

loaded

with

this

value,

provides

only

50

millivolts

for

full

scale

deflection.

If

the

potentiometer

recorder

has

sufficient

sensitivity

to

operate

with

the

lower

input

level,

no

modification

is

required

to

use

the

recorder.

However,

as

the

external

resistance

on

the

POTENTIOMETER

RECORDER

binding

posts

is

decreased,

so

is

the

range

of

the

CALIBRATE

control,

until

at

sonle

low

resistance

it

may

be

necessary

to

provide

an

external

calibrating

control

01081-1

Page 17

Model

562A

Section

III

01081-1

consisting

ofapotentiometer

connected

asavariable

shunt

for

the

signal

which

is

fed

to

the

graphic

recorder.

If

a

potentiometer

or

galvanometer

recorder

is

to

be

used

which

requires

slightly

greater

output

voltage

or

current,

it

is

possible

to

increase

the

562A

ANALOG

OUTPUT

by

changing

the

values

of

certain

resistors

in

the

analog

circ

ufts.

3-9/3-10

Page 18

Model

562A

SECTION

IV

THEOR

Y

OF

OPERATION

4-1.

INTRODUCTION.

Section

IV

Operation

of

the

562A

is

dependent

uponaseries

of

timing

and

reference

volt-

ages.

The

timing

voltages

are

supplied

by

the

control

board

(Al3).

Reference

voltages

can

be

supplied

by

the

power

supply

(A14)

or

by

an

external

source.

The

following

paragraphs

will

describe

the

functions

of

various

circuits

in

the

recorder.

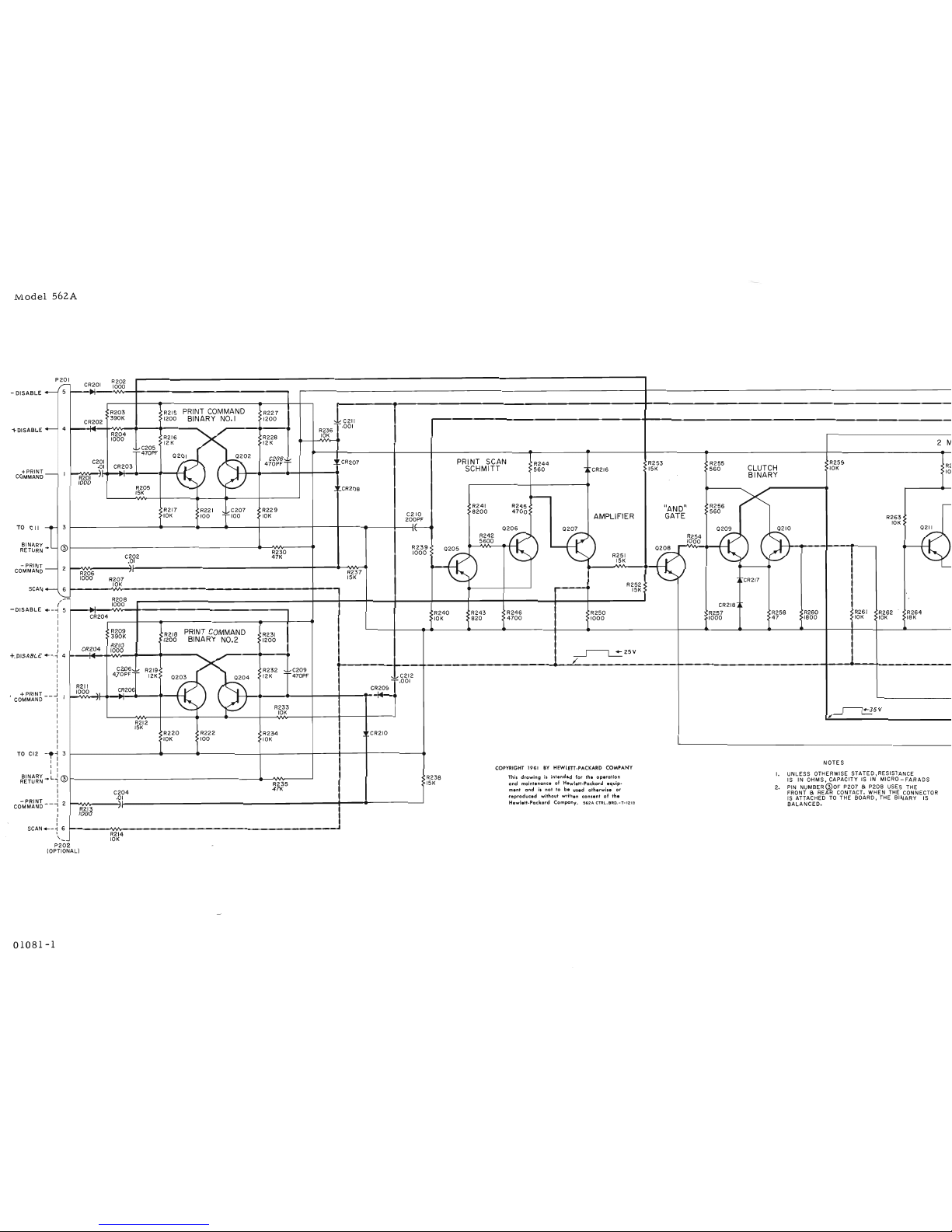

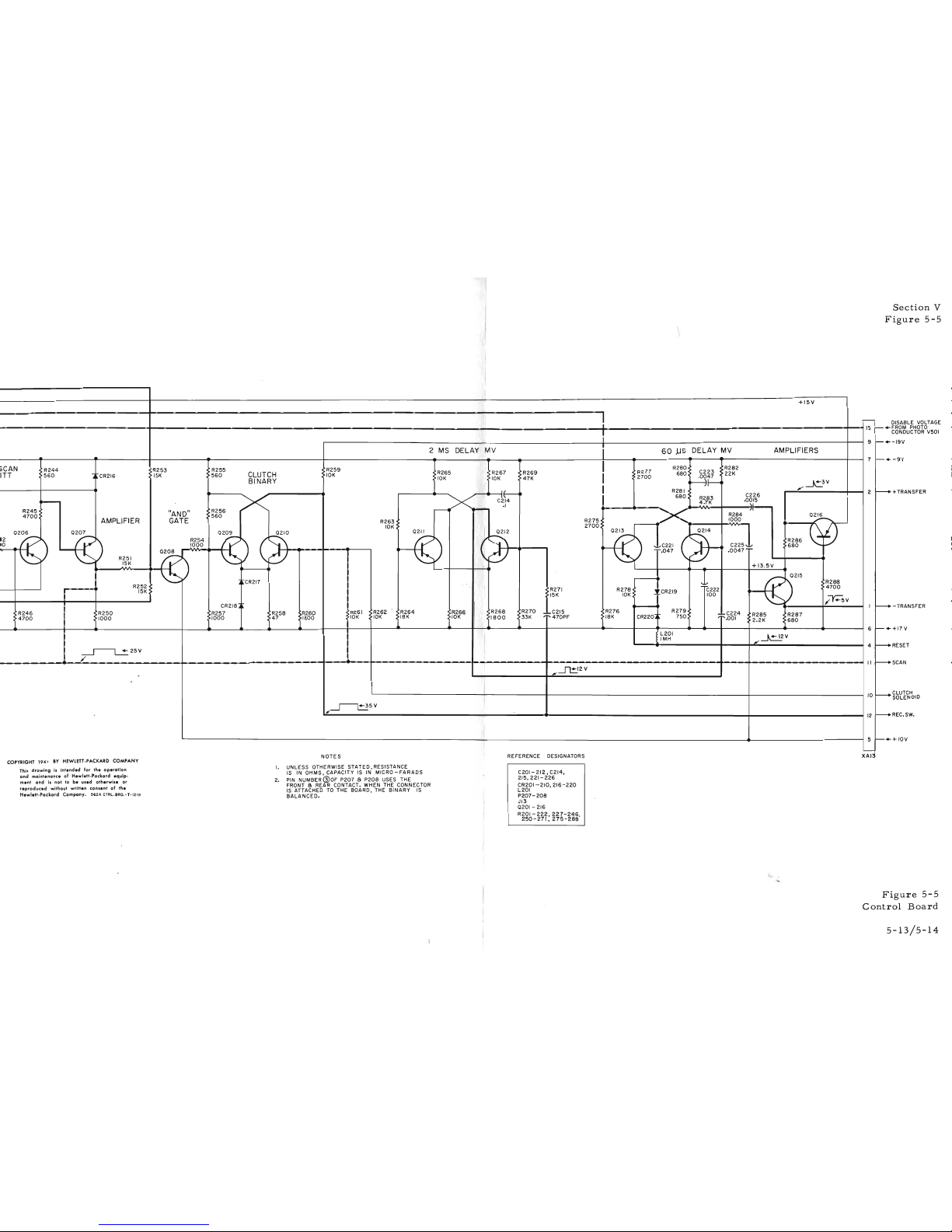

4-2.

CONTROL

BOARD

OPERATION.

Operation

of

the

recorder

is

dependent

upon

a

series

of

timing

voltages

developed

by

the

control

board.

Refer

to

the

functional

diagram,

figure

5-2.

Assume

the

data

source

initiates

a

print

command.

Print

Command

Binary

Number

1

changes

state

and

immediately

supplies

the

data

source

withadisable

voltage.

Assume

Print

Command

Binary

Number

2

has

its

input

connector

arranged

so

only

one

print

is

required.

The

Print

Scan

Schmitt

is

in

the

proper

state

because

the

shutter

is

open.

The

Print

Scan

Schmitt

applies

the

proper

signal

to

the

"And"

Gate.

The

"And"

Gate

conducts

and

causes

the

Clutch

Binary

to

change

state.

The

clutch

solenoid

starts

to

energize.

When

the

Clutch

Binary

changes

state,

a

signal

is

applied

to

the

Delay

Multivi-

brator

(2MS).

The

output

of

the2ms

delay

multivibrator

produces

a

reset

pulse

which

is

applied

to

the

storage

binaries.

This

removes

stored

information

and

sets

the

storage

binaries

in

the

proper

state

to

receive

new

information.

The

output

of

the2ms

delay

multivibrator

is

also

applied

toa60

J-Ls

delay

multi-

vibrator.

The

output

of

the

60

J-LS

multivibrator

is

applied

to

the

storage

binary

gate

diodes

by

way

of

the+and-Transfer

Amplifiers,

then

data

transfer

takes

place.

The

output

of

the

60

f.LS

multivibrator

is

also

applied

to

the

Print

Command

Binaries

and

resets

them.

While

this

action

is

occurring,

the

clutch

solenoid

is

completing

its

pull-in

cycle.

When

the

clutch

solenoid

has

engaged

the

clutch,

the

clutch

will

remain

engaged

for

one

complete

revolution

of

the

clutch

assembly

because

of

mechanical

action.

As

the

clutch

assembly

rotates,

the

shutter

closes,

de-energizing

the

photo

conductor.

This

causes

the

schmitt

to

change

state,

initiating

the

scan

signal.

The

scan

signal

then

resets

the

clutch

binary

and

opens

the

Inhibit

Gate

circuits

which

can

allow

the

pawl

magnets

to

energize.

When

the

brush

senses

the

correct

voltage,

the

pawl

magnets

de

-energize

and

lock

the

print

wheels

at

the

proper

position.

Then

the

character

is

printed

as

the

clutch

assembly

finishes

its

one

revolution,

disengages,

and

opens

the

shutter.

The

photo

conductor

is

energized

and

the

system

is

ready

for

the

next

print

command.

01081-1

4-1

Page 19

Section

IV

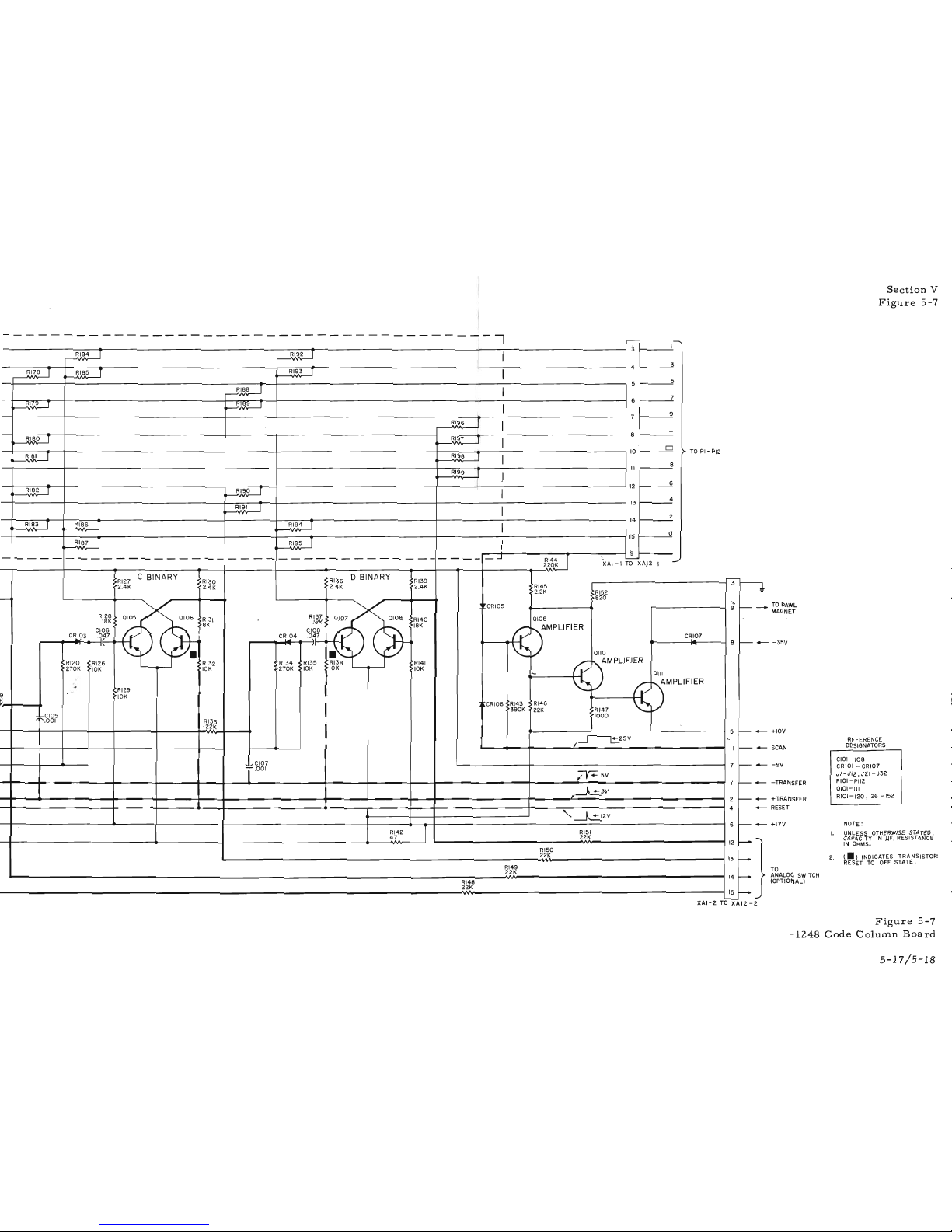

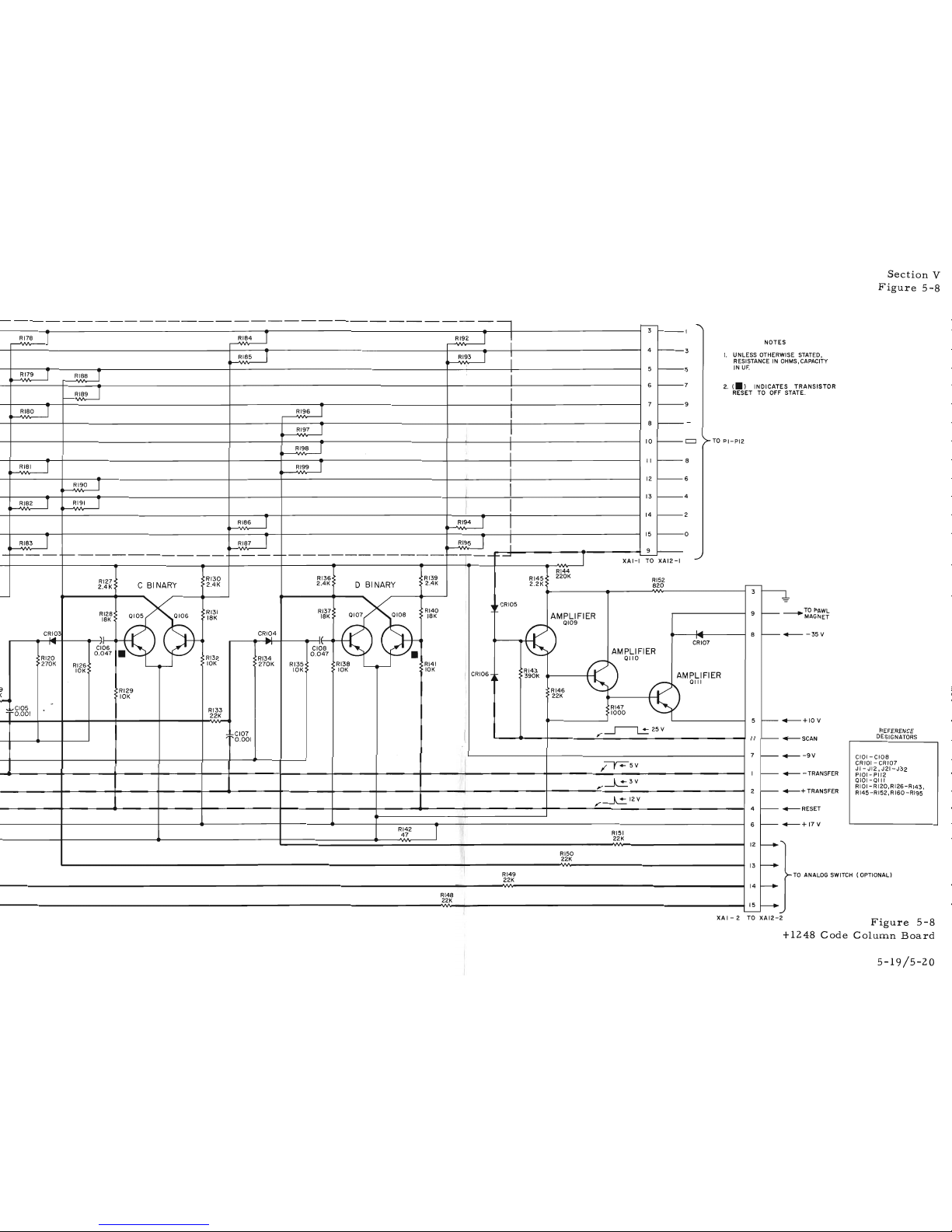

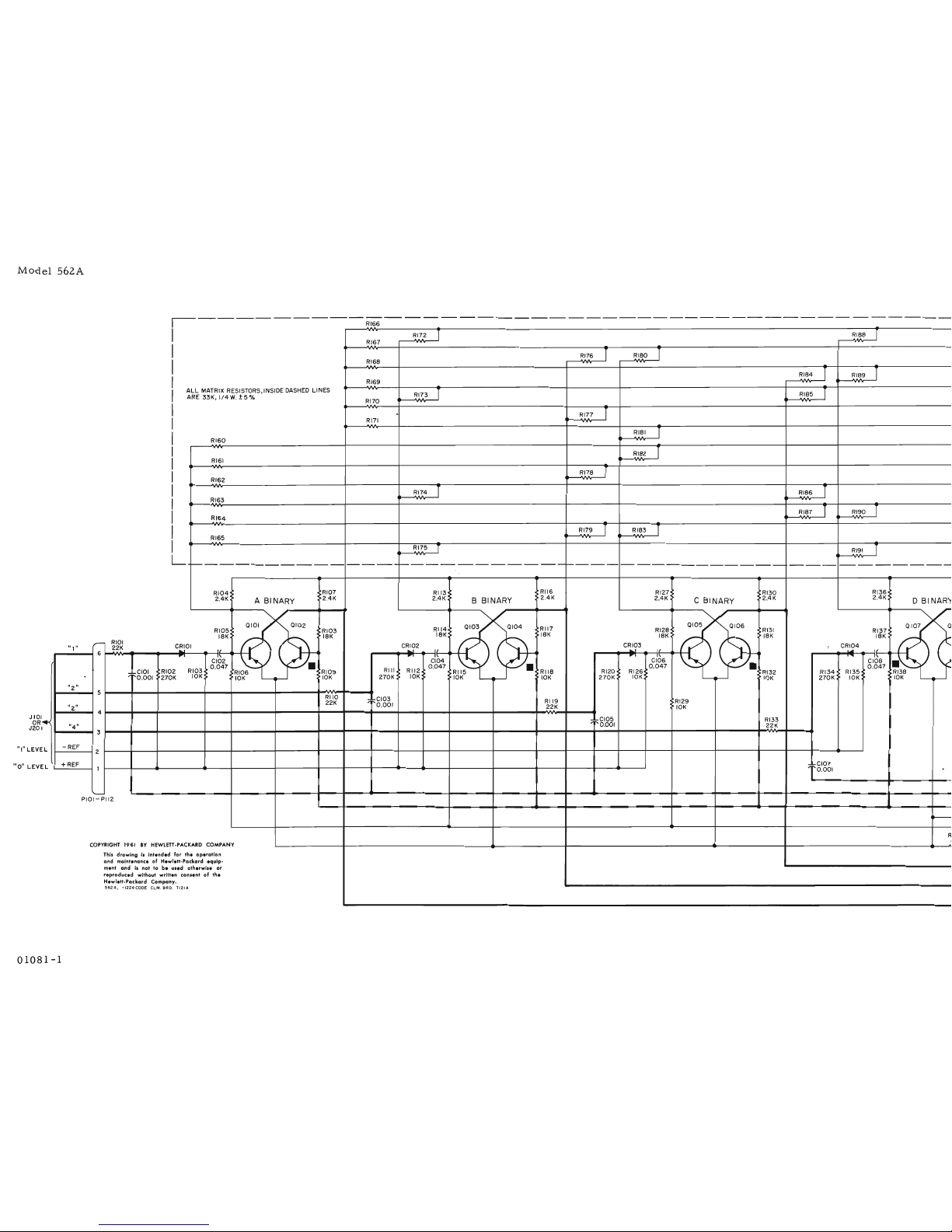

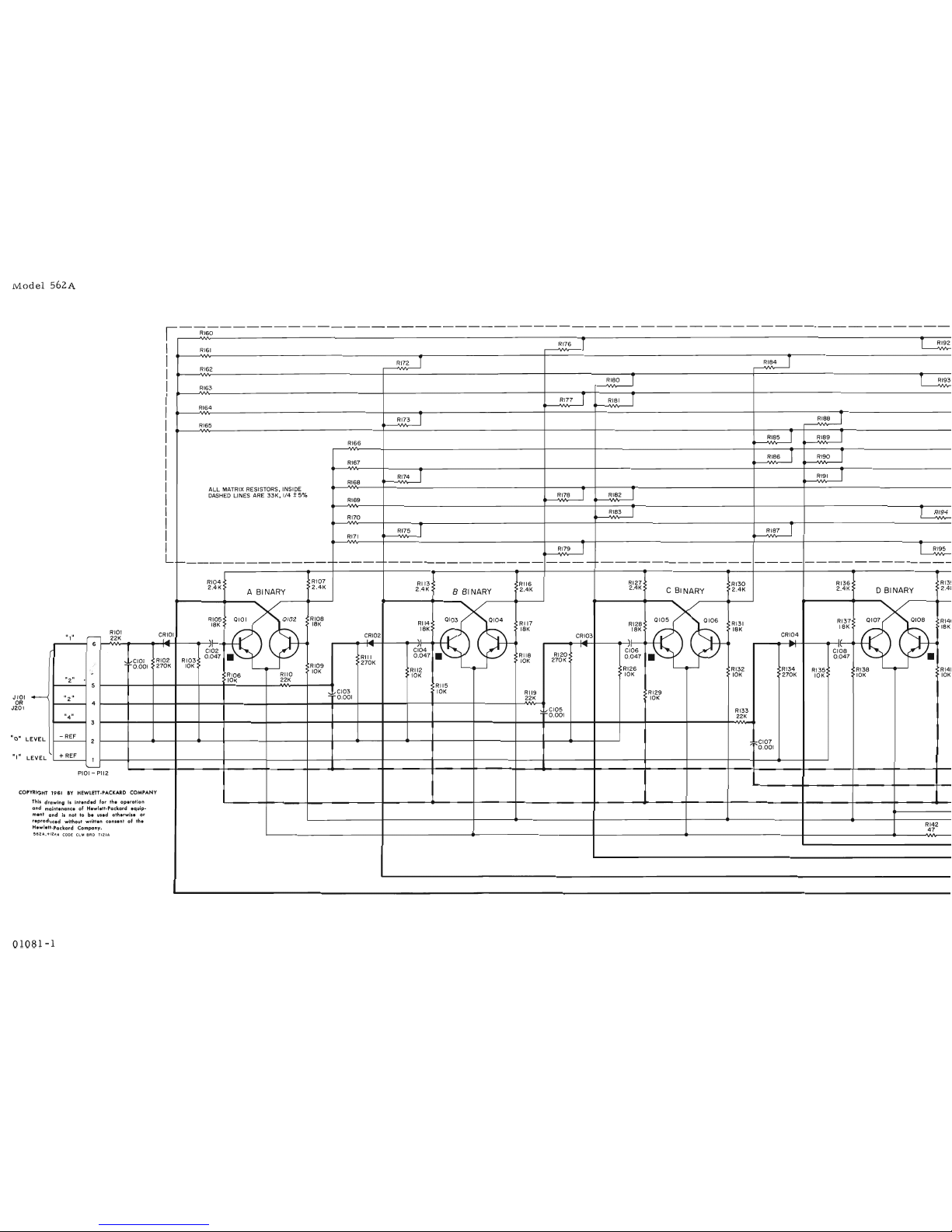

4-3.

GOLUMN

BOARD

OPERATION.

Model

S62A

4-2

The

following

theory

is

for

operation

ofa-1248

code

column

board.

Assume

a

data

source

has

initiated

a

print

command,

the

AND

GATE

in

the

control

board

conducts,

and

the

clutch

solenoid

starts

to

energize.

A

signal

is

then

applied

to

the

2

MS

DELA

Y

lY1ULTIVIBRA

TOR

by

the

clutch

binary.

After

2

ms,

the

nlultivibrator

applies

a

positive

reset

pulse

to

the

column

boards.

The

binaries

reset

as

follows:

A

BINARY:

Q

101,

on;

0102,

off

B

BINARY:

a 1

03,

off;

0104,

on

G

BINAR

Y:

a

105,

on;

a

106,

off

D

BINARY:

Q

107,

off;

a

108,

on

The

data

source

is

supplying

bcd

information

to

the

four

binarie

s.

Suppose

the

bcd

information

supplied

is

for

the

decimal

number

8.

According

to

table

3-1,

"0"

level

information

will

be

supplied

to

the

G,

B,

and

A

binaries.

The

D

binary

will

have

"l"

level

information

supplied.

The

"0"

or

"l'"

do

not

change

the

state

of

the

binaries.

The

-

and+transfer

pulses

cause

the

binaries

to

change

state

if

the

1t0"

orIIlit

levels

needed

are

present.

At

the

D

binary,

if

the

"1"

level

is

pre

sent

GR104

is

forward

biased

and

-

transfer

pulse

will

go

through

diode

gate

GR104.

Since

a

107

is

off,

the

D

binary

will

change

state,

a107

on

and

a108

off.

The

G

binary

has

"0"

level

information

applied

to

diode

gate

GRI03.

A +

trans-

fer

pulse

is

applied

to

GRI03.

Since

the

"a"

level

information

applied

to

GRI03

is

equal

to

the

+

reference

voltage,

the

diode

will

pass

the+transfer

pulse.

Thus

QIOS

is

off

and

al06

is

on.

The

B

binary

has"

0"

level

information

applied

to

diode

gate

GR102.

Since

the

"Olt

level

information

is

(at

least

4

volts)

more

positive

than

the

-reference

voltage,

diode

GRl02

is

reverse

biased

and

will

not

pass

the-transfer

pulse.

The

binary

will

not

change

state.

Transis

tora103

re

mains

off

anda104

re

nlains

on.

The

A

binary

has

"a"

level

information

applied

to

diode

gate

GRIOI.

The

"0"

level

mllst

be

equal

to

the

positive

reference

voltage.

This

causes

GRlOI

to

be

forward

biased

and

pass

the+transfp.r

pulse.

The

A

binary

changes

state,

QIOI

off

and

QI02

on.

Three

of

the

halves

of

the

binaries

that

are

"on"

will

return,

through

matrix

resistors,

to

pin

11

of

connectors

XAl-l

to

XA12

-1.

This

is

the

line

which

corresponds

to

the

decimal

number

8.

In

this

case,

R161,

R175,

and

Rl99

return

to

the

line

for

the

decimal

number

8.

These

resistors

make

the

line

for

the

number

8

go

to

app

roximatel

y +

15

volts.

Diode

gateGRl

a5

andGRl

Oh

sense

when

the

line

gets

to

approximately

+15

volts

and

cause

amplifiers

al09»

a

110,

and

Q

III

to

de

-energize

the

pawl

magnet.

The

pawl

then

locks

the

01081-1

Page 20

Model

S62A

Section

IV

print

wheel

at

that

position.

The

number

is

then

printed.

When

the

data

source

initiates

another

print

command,

the

scan

signal

occurs

a

short

time

later

and

causes

amplifiers

0109,0110,

and

0111

to

energize

the

pawl

magnet

if

the

data

input

has

changed.

The

print

wheel

rotates.

The

magnet

remains

energized

until

diode

CRI0S

has

+lS

volts

applied

from

the

matrix.

4-4.

ANALOG

CIRCUITRY

OPERATION.

Sincethe

column

boardscontain

stored

binary

information,

an

analog

function

can

be

derived

to

drive

a

strip

chart

recorder.

The

analog

circuitry

provides

the

following:

a.

A

graphic

presentation

whereby

the

trend

of

recorded

data

can

be

seen

at

a

glance.

b.

Three

digits

of

analog

information

where

full

scale

on

the

recorder

may

beafew

parts

per

million

of

the

original

printed

reading.

c.

A

recording

where

an

increasing

numerical

count

is

always

an

upward

direction

on

the

strip

chart

recording.

d.

An

analog

recording

which

is

always

on

scale.

To

derive

the

analog

voltage

a

switching

arrrangement

is

used

which

utilIzes

the

stored

binary

data

from

three

consecutive

columns

of

the

printed

data.

Any

three

of

the

first

nine

columns

may

be

used

as

well

as

the

first

two

right

hand

digits.

The

binary

output

data

is

weighted

according

to

the

code

required

by

the

storage

units.

Four

resistors

are

used

to

develop

a

staircase

function

from

the

four

storage

binaries.

The

four

weighting

resistors

are

in

the

ratio

4221.

Refer

to

the

analog

circuitry

schematic.

Each

of

the

three

storage

decades

then

produces

a

staircase

function

withalevel

proportional

to

the

numerical

value

of

its

stored

binary

data.

The

three

staircase

voltages

are

then

mixed

in

proportion

to

their

decade

value

or

in

the

ratio

of

1,

10,

100,

to

produce

a

single

staircase

function

1000

part

in

amplitude.

Each

discrete

step

then

represents.

10/0

of

full

scale

and

for

practical

purposes

is

an

analog

function.

This

output

voltage

is

then

attenuated

and

applied

directly

toapotentiometer

type

strip

chart

recorder.

The

analog

signal

is

also

applied

to

an

amplifier

whose

output

can

be

used

to

drive

a 1

rna

type

galvanometer

recorder.

Diode

clamps

insure

accurate

voltage

levels

before

mIXIng.

Compensation

elements

maintain

constant

output

over

wide

temperature

extremes.

01081

-1

4-3/4-4

Page 21

Model

562A

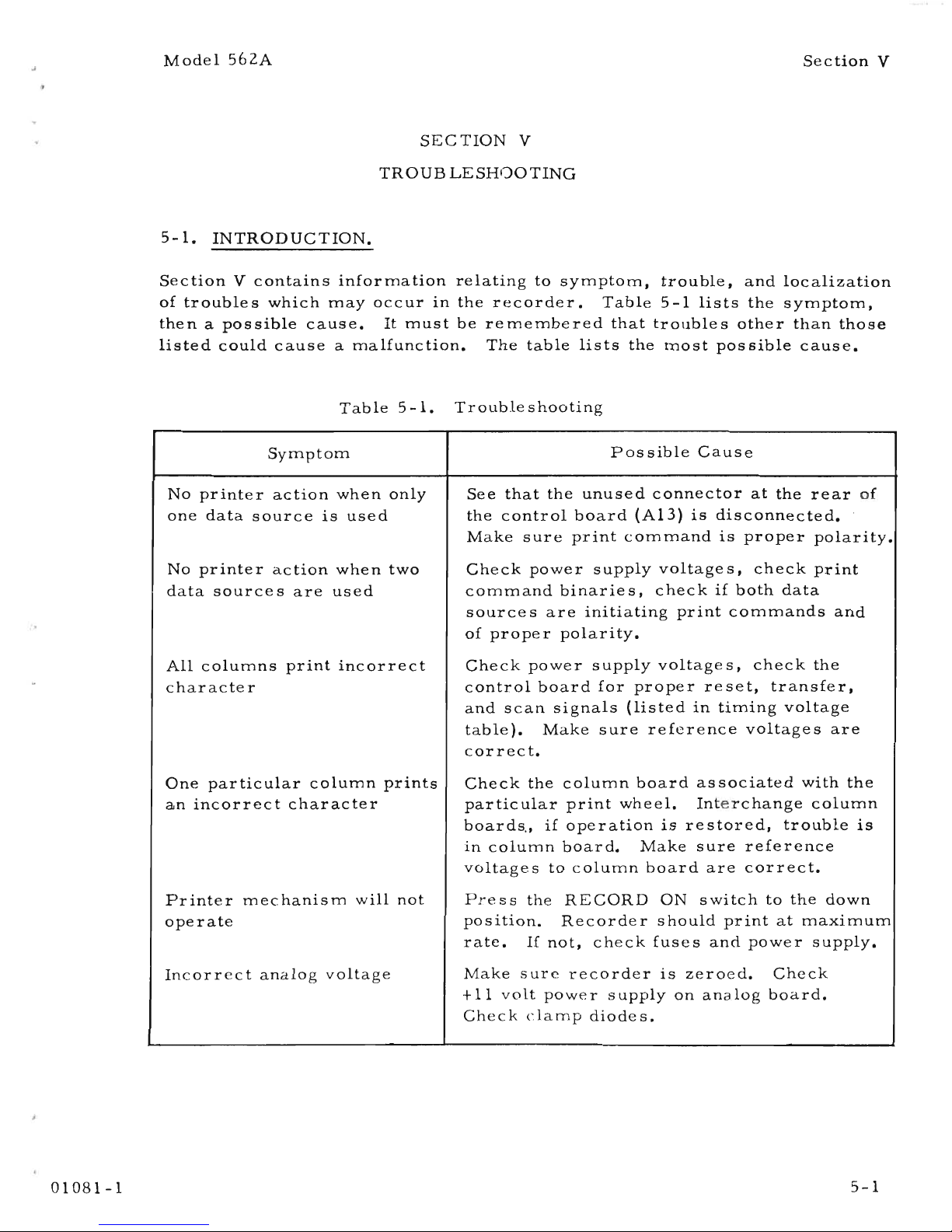

5-1.

INTRODUCTION.

SECTION

V

TROUBLESHOOTING

Section

V

Section

V

contains

information

relating

to

symptom,

trouble,

and

localization

of

troubles

which

may

occur

in

the

recorder.

Table

5-1

lists

the

symptom,

then

a

possible

cause.

It

must

be

remembered

that

troubles

other

than

those

listed

could

cause

a

malfunction.

The

table

lists

the

most

possible

cause.

01081-1

Table

5-1.

Symptom

No

printer

action

when

only

one

data

source

is

used

No

printer

action

when

two

data

sources

are

used

All

columns

print

incorrect

character

One

particular

column

prints

an

incorrect

character

Printer

mechanism

will

not

operate

Incorrect

analog

voltage

Trouble

shooting

Possible

Cause

See

that

the

unused

connector

at

the

rear

of

the

control

board

(AI3)

is

disconnected.

Make

sure

print

command

is

proper

polarity.

Check

power

supply

voltages,

check

print

command

binarie

s,

check

if

both

data

sources

are

initiating

print

commands

and

of

proper

polarity.

Check

power

supply

voltages,

check

the

control

board

for

proper

reset,

transfer,

and

scan

signals

(listed

in

timing

voltage

table).

Make

sure

reference

voltages

are

correct.

Check

the

column

board

as

sociated

with

the

particular

print

wheel.

Interchange

column

boards"

if

operation

is

restored,

trouble

is

in

column

board.

Make

sure

reference

voltages

to

column

board

are

correct.

Press

the

RECORD

ON

switch

to

the

down

position.

Recorder

should

print

at

maximum

rate.

1£

not,

check

fuses

and

power

supply.

Make

sure

recorder

is

zeroed.

Check

tIl

volt

power

supply

on

analog

board.

Check

clamp

diodes.

5-1

Page 22

Section

V

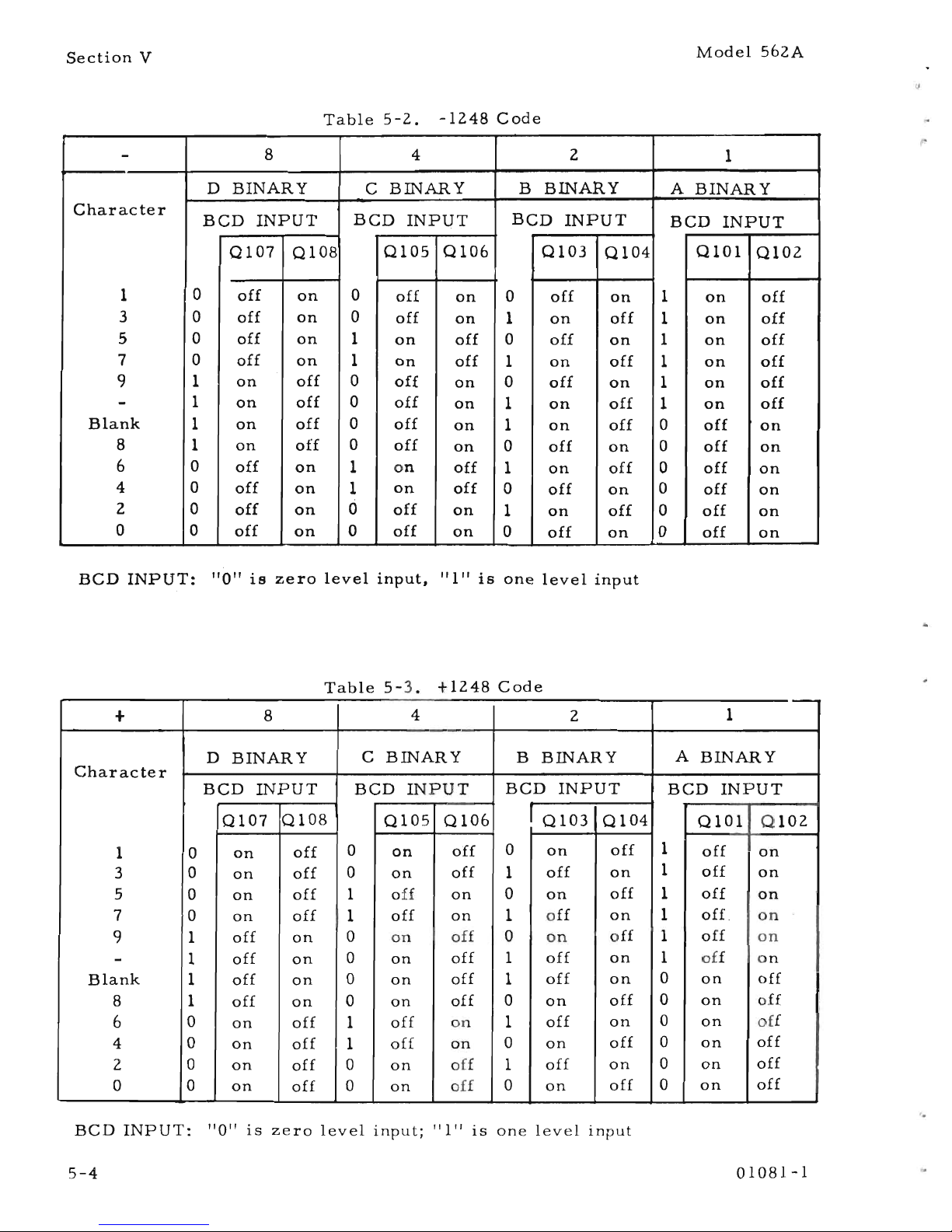

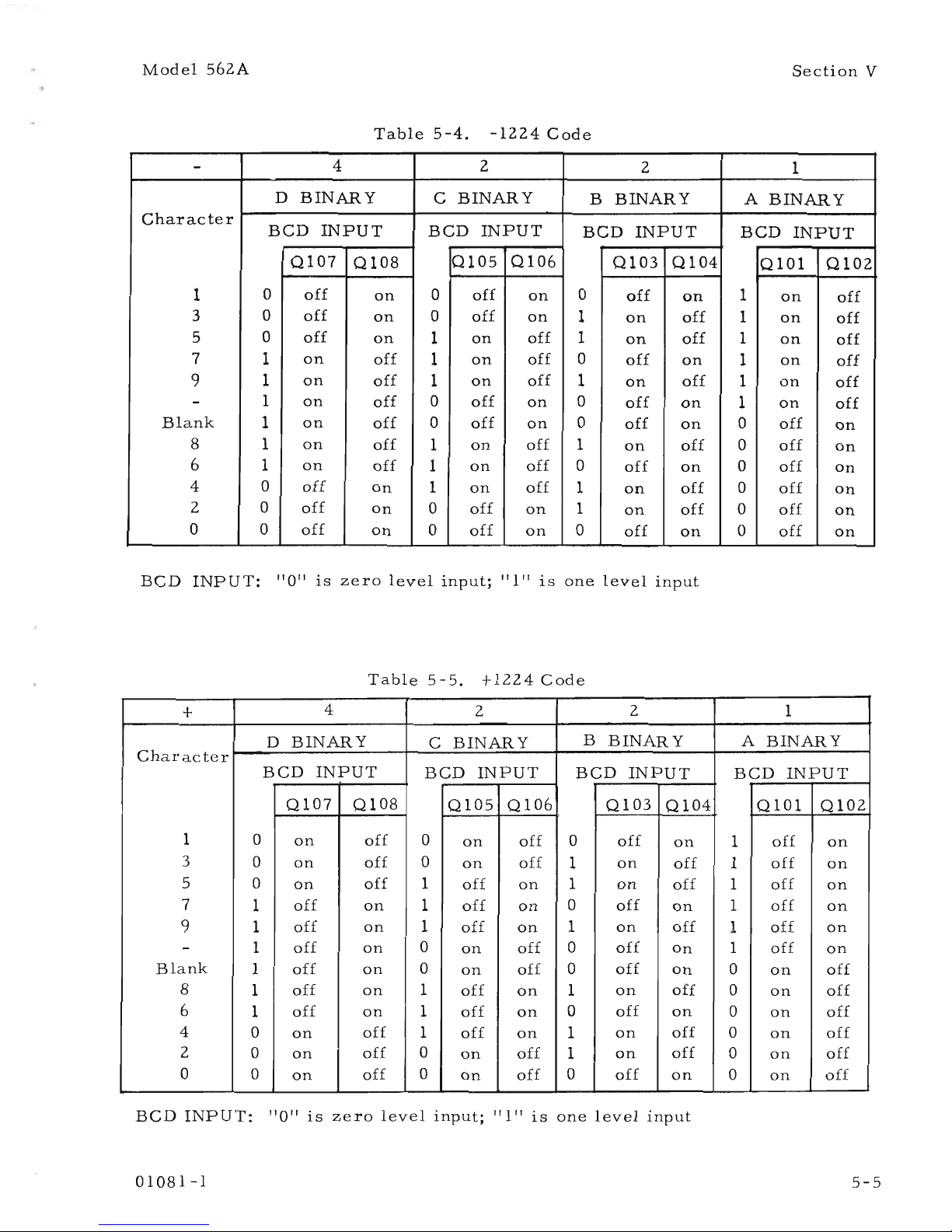

5-2.

LOCALIZING

THE

TROUBLE.

Model

562A

5-2

Whenatrouble

has

been

traced

toaspecific

board,

make

voltagp.

meas

ure-

ments

on

base,

emitter,

and

collector

of

transistors.

On

the

column

board

binaries,

transistors

that

are

"turned

on"

will

have

approximately

t15

volts

on

the

collector,

transistors

that

are

"turned

off"

will

have

approximately

-5

volts

on

the

collectors.

Binary

tables

5-2

to

5-5

list

the

states

of

the

column

board

binary

transistors

for

various

numbers

and

inputs.

Binaries

in

the

control

board

can

be

checked

for

switching

action

withadc

coupled

oscillo-

scope.

Whenabinary

changes

state,

the

dc

coupled

oscilloscope

will

show

a

definite

change

of

dc

level.

A

vac

uum

tube

voltme

ter

can

be

used

also.

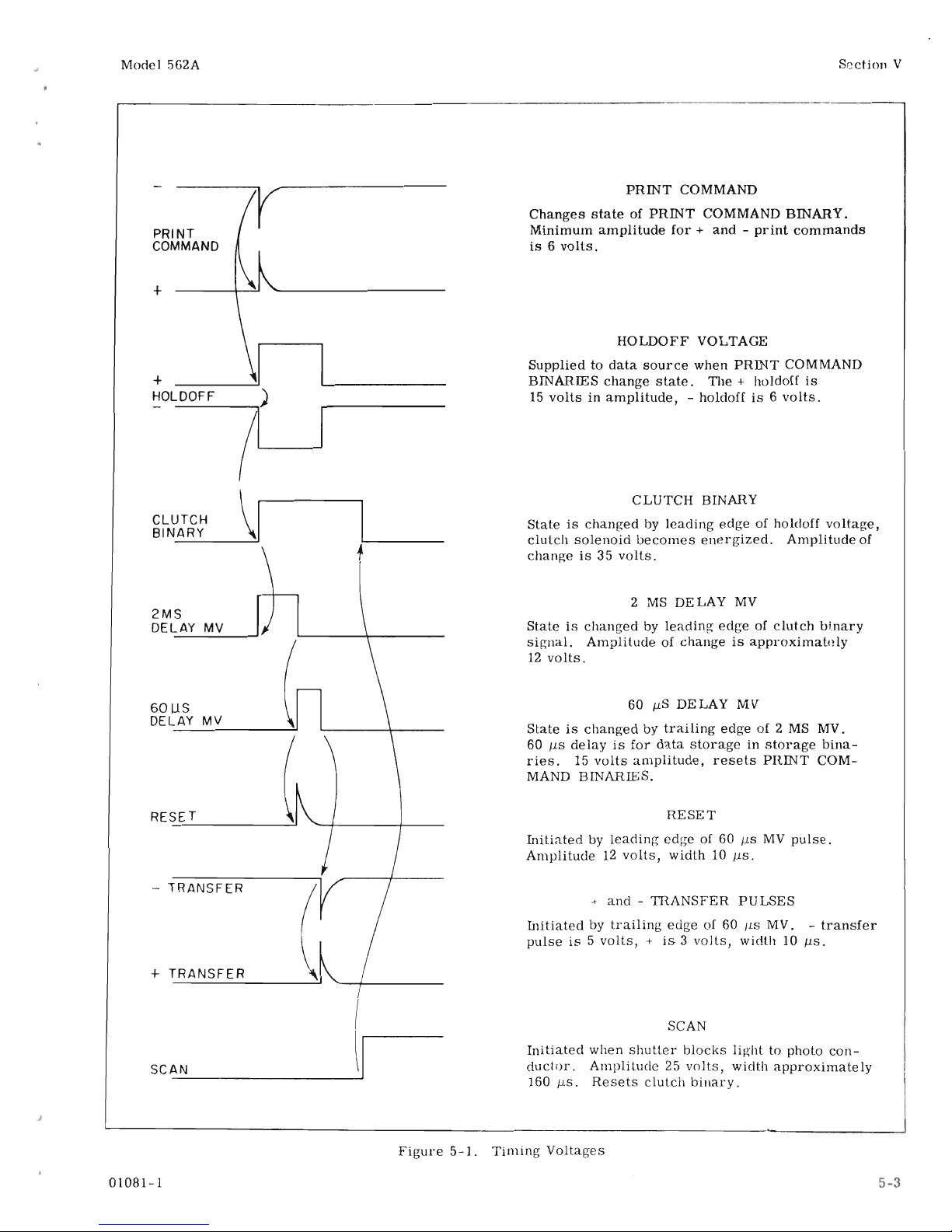

Figure

5-1

shows

the

timing

voltages

and

sequence.

Resistance

measurements

made

between

various

sockets

and

connectors

may

be

helpful.

For

this,

use

the

wiring

and

power

supply

diagram.

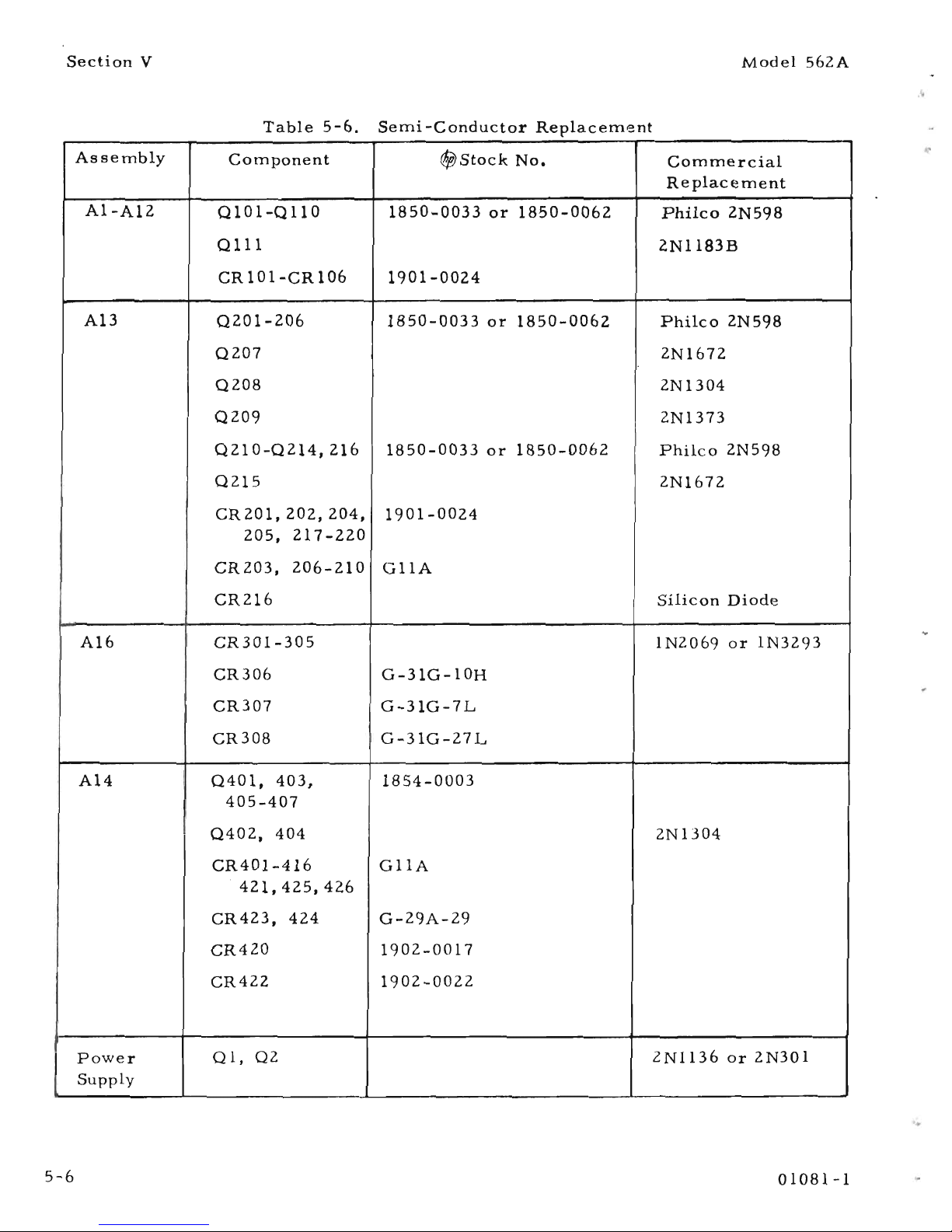

5-3.

SEMI-CONDUCTOR

REPLACEMENT.

Table

5-3

lists

the

various

transistors

and

diodes.

When

a

commercial

replacement

type

is

not

listed,

the

semi-conductor

should

be

ordered

from

the

Hewlett

Packard

Company.

When

two

rfiJ

stock

numbers

are

listed,

the

second

number

IS

the

correct

replacement.

01081-1

Page 23

J

Model

562A

PRINT

COMMAND

+

+

HOLDOFF

CLUTCH

BINARY

2MS

DELAY

MV

GOUS

DELAY

MV

RESET

-

TRANSFER

+

TRANSFER

SCAN

-----------

01081-1

Section

V

PRINT

COMMAND

Changes

stateofPRINT

COMMAND BINARY.

Minimum

amplitude

for+and-print

commands

is6volts.

HOLDOFF

VOLTAGE

Suppliedtodata

source

when

PRINT

COMMAND

BINAR.IES

change

state.

The

+ holdoff

is

15

voltsinamplitude,

- holdoffis6

volts.

CLUTCH

BINARY

Stateischangedbyleading

edge

of holdoff

voltage,

clutch

solenoid

becomes

energized.

Amplitude

of

changeis35

volts.

2

MS

DELAY

MV

Stateischangedbyleading

edgeofclutch

bi.nary

signal.

Amplitudeofchangeisapproximatnly

12

volts.

60

IJ.S

DELAY

MV

Stateischangedbytrailing

edge

of 2

MS

MY.

60

IJ.S

delayisfor

data

storageinstorage

bina-

ries.

15

volts

amplitude,

resets

PRINT

COM-

MAND BINARIES.

RESET

Initiatedbyleading

edge

of 60

IJ.SMVpulse.

Amplitude12volts,

width

10

IJ.S.

+

and-TRANSFER

PULSES

Initiatedbytrailing

edge

of 60 /lS MV. -

transfer

pulseis5

volts,+is3volls,

width

10

IJ.S.

SCAN

Initiated

when

shutter

blocks

lighttophoto

con-

ductor.

Amplitude25volts,

width

approximately

160

IJ.S.

Resets

clutch

binary.

Figure

5-1.

Timing

Voltages

5-3

Page 24

Section

V

Table

5

-2.

-1248

Code

Model

562A

-

8

4

2

1

D

BINARY

C

BINARY

B

BINARY

A

BINARY

Character

BCD

INPUT

BCD

INPt.JT

BCD

INPUT

BCD

INPUT

0107

0108

0105

0106

0103

0104

0101

0102

1

0

off

on

0

off

on

0

off

on

1

on

off

3 0

off

on

0

off

on

1

on

off

1

on

off

5 0

off

on

1

on

off

0

off

on

1

on

off

7 0

off

on

1

on

off

1

on

off

1

on

off

9

1

on

off

0

off

on

0

off

on

1

on

off

-

1

on

off

0

off

on

1

on

off

1

on

off

Blank

1

on

off

0

off

on

1

on

off

0

off

on

8

1

on

off

0

off

on

0

off

on

0

off

on

6 0

off

on

1

on

off

1

on

off

0

off

on

4 0

off

on

1

on

off

0

off

on

0

off

on

2

0

off

on

0

off

on

1

on

off

0

off

on

0

0

off

on

0

off

on

0

off

on

0

off

on

BCD

INPUT:

"0"

is

zero

level

input,

"1"

is

one

level

input

Tab

Ie 5 - 3 . +

1248

Cod

e

-

+

8

4

2

1

D

BINARY

C

BINARY

B

BINARY

A

BINARY

Character

BCD

INPUT

BCD

INPUT

BCD

INPUT

BCD

INPUT

0107

0108

0105

0106

I

0103

0104

0101

0102

1

0

on

off

0

on

off

0

on

off

1

off

on

3

0

on

off

0

on

off

1

off

on

1

off

on

5

0

on

off

1

off

on

0

on

off

1

off

on

7

0

on

off

1

off

on

1

off

on

1

off.

on

9

1

off

on

0

on

off

0

on

off

1

off

on

-

1

off