Page 1

Errata

Title & Document Type: HP5501B Laser Head Operating & Service Manual

Manual Part Number: 05501-90035

Serial Prefixes: 2632

Revision Date: September 1986

HP References in this Manual

This manual may contain references to HP or Hewlett-Packard. Please note that HewlettPackard's former test and measurement, semiconductor products and chemical analysis

businesses are now part of Agilent Technologies.

Changes to this Manual

No changes have been made to this manual, with the exception of correcting the odd

spelling and grammatical errors. In some places original photographs may be replaced

or augmented with modern digital photographs. (it’s weird looking at an old BW HP

manual and seeing a color photograph… still gets me)

About this Manual

This manual is reproduced from high-resolution scans of an original document, which

was then converted to Word format using custom designed OCR software for my

personal use.

This means that what you see here is not a scan of a scan/copy.

OCR errors may exist and as such the user of this document should take care and use

common sense when referencing this documentation.

Copyright Notice

This documentation is © Copyright 1980 Hewlett Packard and © Copyright 2006, Jack Hudler,

hpdocs@hudler.org.

Permission to use and redistribute this documentation for non-commercial and internal corporate

purposes is hereby granted, free of charge.

Any redistribution of this documentation or its derivates must include this copyright notice.

You may not sell this documentation or its derivations without written consent.

You may modify this documentation as necessary, but you may not sell derivative works based

on it.

You may include this documentation with the equipment/hardware on which it is used for the

purposes of selling the equipment/hardware. If you advertise that a copy of this documentation is

included in the sale, you must state that is for “Free”.

Meaning if you want to gratuitously toss in a copy of the manual on an eBay sale, it’s ok with me

as long as you state it’s for free. No you can’t sell a digital archive of manuals and say it includes

a free copy of this documentation. You must give it away with equipment.

I think you get the spirit of the copyright; it takes a lot of hours to scan and replicate a manual. I

just want this used in the spirit in which is it given.

Agilent if you have questions or wish to include this in your archive email me.

Page 2

ii

Page 3

OPERATING AND SERVICE MANUAL

HP5501B

LASER HEAD

SERIAL NUMBER PREFIX: 2632A

This manual applies directly to HP5501B Laser Heads

with serial numbers prefixed 2632A. Lower number serial

prefixes are covered in Section 7 while higher number

serial prefixes are documented with "Manual Changes"

Supplements described in Section 7.

© HEWLETT-PACKARD COMPANY 1986

5301 Stevens Creek Blvd., Santa Clara, CA 95051-7299

Portions © by Jack Hudler 2006

hpdocs@hudler.org

MANUAL PART NUMBER 05501-90035

Microfiche Part Number 05501-90036 Printed: SEPTEMBER 1986

Page 4

ELECTRICAL SAFETY CONSIDERATIONS

GENERAL

The product and related documentation must be reviewed for

familiarization with safety markings and instructions before

operation.

This product is a Safety Class I instrument (provided with a

protective earth terminal).

BEFORE APPLYING POWER

Verify that the product is set to match the available line voltage

and the correct fuse is installed. Refer to

Section 2, Installation.

SAFETY EARTH GROUND

An uninterruptible safety earth ground must be provided from

the main power source to the product input wiring terminals,

power cord, or supplied power cord set.

SAFETY SYMBOLS

Instruction manual symbol: the product

will be marked with this symbol when it

is necessary for the user to refer to the

instruction manual.

Indicates hazardous voltages.

Indicates earth (ground) terminal.

The WARNING sign denotes a hazard. It

calls attention to a procedure, practice,

or the like, which, if not correctly

performed or adhered to, could result in

personal injury. Do not proceed beyond

a WARNING sign until the indicated

conditions are fully understood and met.

LASER HEAD SAFETY CONSIDERATIONS

The CAUTION sign denotes a

hazard. It calls attention to an

operating procedure, practice, or the

like, which, if not correctly performed

or adhered to, could result in

damage to or destruction of part or

the entire product. Do not continue

beyond a CAUTION sign until the

indicated conditions are fully

understood and met.

Any interruption of the protective (grounding) conductor (inside

or outside the instrument) or disconnecting the protective earth

terminal will cause a potential shock hazard that could result in

personal Injury. (Grounding one conductor of a two conductor

outlet is not sufficient protection).

Whenever it is likely that the protection has been impaired, the

instrument must be made inoperative and be secured against

any unintended operation.

If this instrument is to be energized via an autotransformer (for

voltage reduction) you must make sure the common terminal is

connected to the neutral (earthed pole) of the power source.

Servicing instructions are for use by service-trained personnel

only. To avoid dangerous electric shock, do not perform any

servicing unless qualified to do so.

Adjustments described in the manual are performed with power

supplied to the instrument while protective covers are removed.

Energy available at many points may, if contacted, result in

personal injury.

Capacitors inside the instrument may still be charged even if the

instrument has been disconnected from its source of supply.

For continued protection against the fire hazard, replace the line

fuse(s) only with 125V fuse(s) of the same current rating and

type (for example, normal blow, time delay, etc.). Do not use

repaired fuses or short circuited fuse holders.

From 1.2 kilovolts to 12 kilovolts dc is present on the anode of

the laser tube in the 5501B. Exercise extreme caution when

working inside the instrument. The high voltage could cause

serious personal injury if contacted. Any adjustments performed

should be by service trained personnel only.

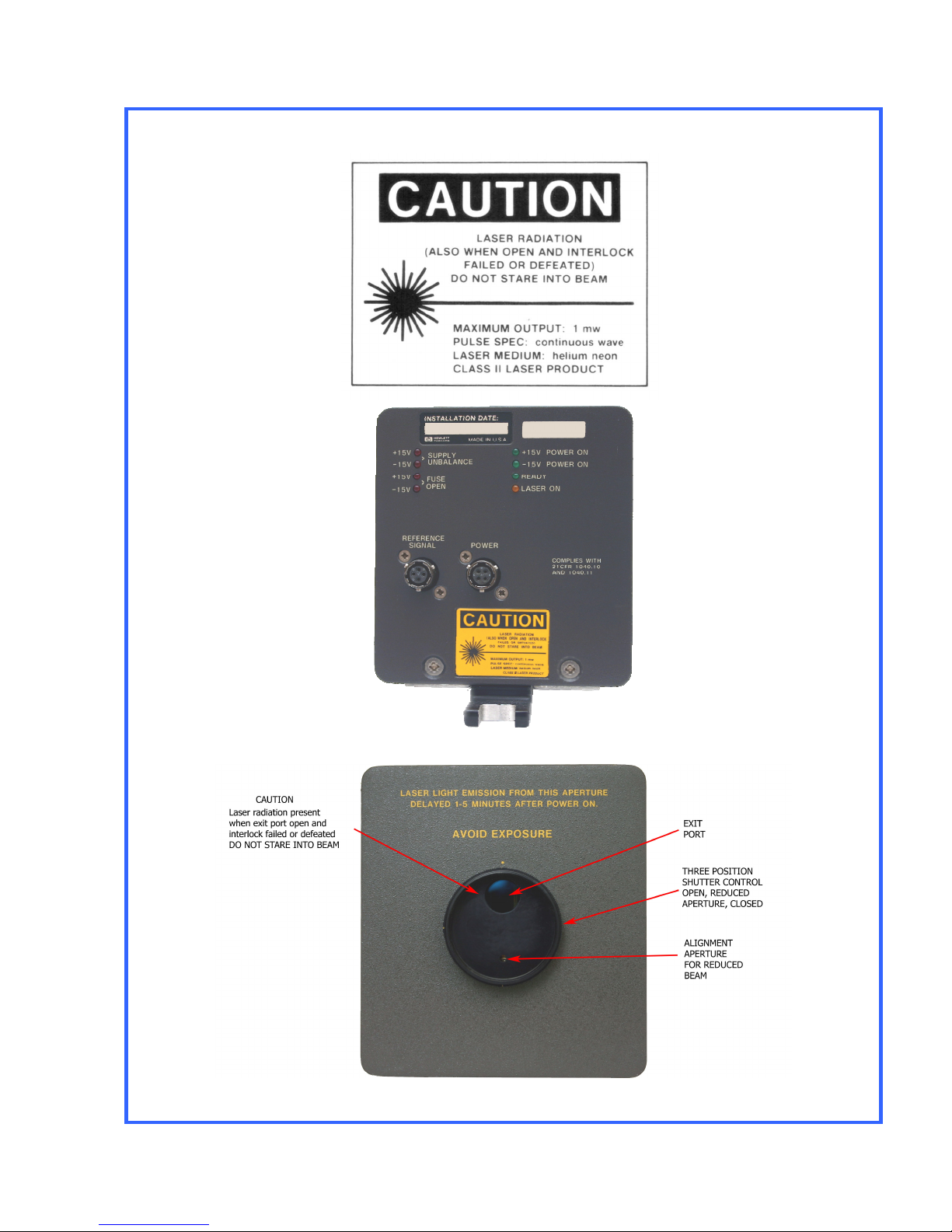

LASER RADIATION IS EMITTED FROM THE APERTURE ON THE 5501B LASER HEAD AS

ILLUSTRATED ON THE FOLLOWING PAGE. DO NOT STARE INTO BEAM. THIS PRODUCT IS A

CLASS II LASER PRODUCT CONFORMING TO U.S. NATIONAL CENTER FOR DEVICES AND

RADIOLOGICAL HEALTH REGULATIONS 21 CFR 1040.10 AND 1040.11. THE MAXIMUM RADIANT

POWER OUTPUT IS 1 MILLIWATT, THE PULSE SPECIFICATION IS CONTINUOUS WAVE, THE

LASER MEDIUM IS HELIUM-NEON, AND THE WAVELENGTH IS 632.991 NANOMETRES.

LASER RADIATION IS ACCESSIBLE WHEN THE 5501B COVERS ARE REMOVED AND THE TESTNORM SWITCH, A1S2, IS IN THE TEST POSITION.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN

THOSE SPECIFIED HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

ii

Page 5

LASER HEAD SAFETY LABELS

iii

Page 6

END PRODUCT LASER SAFETY

CONSIDERATIONS

The 5501B Laser Head complies with U.S. National Center for

Devices and Radiological Health regulations 21 CFR 1040.10 and

1040.11.

These regulations may also apply to the end product into which

the 5501B will be designed. Care must be taken to insure that the

end product complies with all applicable national and local laser

safety regulations.

iv

Page 7

Table of Contents

1 GENERAL INFORMATION ...................................................................................................................1-2

1-1. Introduction..............................................................................................................................1-2

1-4. Equipment Description ............................................................................................................1-2

1-8. Manual Organization................................................................................................................1-3

1-10. Instruments covered by this manual........................................................................................1-3

1-14. Safety Considerations..............................................................................................................1-4

1-16. Equipment Supplied ................................................................................................................1-4

1-18. Available Accessories ..............................................................................................................1-4

1-20. Specifications...........................................................................................................................1-5

1-22. Recommended Test Equipment..............................................................................................1-6

1-24. Warranty...................................................................................................................................1-6

2 INSTALLATION.....................................................................................................................................2-1

2-1. Introduction..............................................................................................................................2-1

2-3. Unpacking, Inspection, and Reshipment.................................................................................2-1

2-5. Unpacking and Inspection.......................................................................................................2-1

2-7. Warranty Claims.......................................................................................................................2-1

2-9. Laser Tube Shipment...............................................................................................................2-1

2-11. Tagging for Service..................................................................................................................2-2

2-13. Packaging for Reshipment.......................................................................................................2-2

2-14. Installation ................................................................................................................................2-2

2-16. System Cabling........................................................................................................................2-2

2-19. Power and Signal Connections................................................................................................2-5

2-21. Cable Fabrication.....................................................................................................................2-5

2-23. Grounding Considerations.......................................................................................................2-7

2-25. Power Supply Requirements ...................................................................................................2-7

2-27. Power Dissipation ....................................................................................................................2-7

2-29. Fusing.......................................................................................................................................2-7

2-31. Dimensions ..............................................................................................................................2-8

2-33. Mounting and Fixturing............................................................................................................2-9

3 OPERATION.......................................................................................................................................3-10

3-1. Introduction............................................................................................................................3-10

3-4. Power Application ..................................................................................................................3-10

3-6. HP5501B Laser Head Front Panel Controls ..........................................................................3-10

3-8. HP5501B LASER HEAD REAR PANEL INDICATORS AND CONNECTORS.........................3-11

3-10. OPERATING MODES.............................................................................................................3-13

3-12. Warmup Time Operating Notes .............................................................................................3-14

3-13. HP 10740A Coupler Based Systems - Manual Monitoring....................................................3-14

3-14. Systems with HP10745A or HP10746A Cards - Automatic Monitoring.................................3-14

3-16. HP10740A Coupler - Error Signal Information.......................................................................3-14

3-17. HP10746A Error Signal Processing.......................................................................................3-15

3-18. HP 10745A Background Information .....................................................................................3-15

3-19. Program Modifications...........................................................................................................3-15

4 PERFORMANCE TESTS ......................................................................................................................4-1

4-1. Introduction..............................................................................................................................4-1

4-3. RECOMMENDED TEST EQUIPMENT .....................................................................................4-1

4-5. TEST RECORD.........................................................................................................................4-1

4-7. HP5501B PERFORMANCE TEST ............................................................................................4-1

4-9. Input Voltage Check.................................................................................................................4-1

4-11. Laser Power Output Test .........................................................................................................4-1

4-13. Procedure.................................................................................................................................4-2

v

Page 8

Table of Contents

5 ADJUSTMENTS....................................................................................................................................5-1

5-1. Introduction ..............................................................................................................................5-1

5-3. Safety Considerations..............................................................................................................5-1

5-5. Recommended test equipment ...............................................................................................5-1

5-7. Factory Selected Components ................................................................................................5-1

5-9. Adjustment Procedures............................................................................................................5-2

5-11. Reference Temperature Adjustments ......................................................................................5-2

5-14. Preliminary Procedure..............................................................................................................5-2

5-17. Laser Tube Current Adjustment...............................................................................................5-4

6 REPLACEABLE PARTS........................................................................................................................6-1

6-1. Introduction ..............................................................................................................................6-1

6-4. Exchange Assemblies..............................................................................................................6-1

6-6. ABBREVIATIONS AND REFERENCE DESIGNATIONS...........................................................6-1

6-8. ORDERING INFORMATION .....................................................................................................6-1

6-11. DIRECT MAIL ORDER SYSTEM...............................................................................................6-2

6-14. Exploded View........................................................................................................................6-11

7 MANUAL CHANGES ............................................................................................................................7-1

7-1. Introduction ..............................................................................................................................7-1

7-3. Newer Instruments ...................................................................................................................7-1

8 SERVICE ..............................................................................................................................................8-1

8-1. Introduction ..............................................................................................................................8-1

8-3. Theory of Operation .................................................................................................................8-1

8-5. Recommended Test Equipment..............................................................................................8-1

8-7. Service Aids..............................................................................................................................8-1

8-9. Schematic Diagram Symbols and Reference Designations....................................................8-1

8-12. Safety Considerations..............................................................................................................8-3

8-14. Safety Symbols ........................................................................................................................8-4

8-16. Before and After Service Product Safety Checks ....................................................................8-5

8-18. LASER HEAD BLOCK DIAGRAM DESCRIPTION ....................................................................8-5

8-26. Laser Tuning ............................................................................................................................8-7

8-29. Warmup Mode Tuning .............................................................................................................8-7

8-34. Optical Mode Tuning................................................................................................................8-9

8-40. Laser Assembly Optics ..........................................................................................................8-12

8-42. Reference Receiver ................................................................................................................8-12

8-44. Shutter Mechanism ................................................................................................................8-12

8-46. ASSEMBLY/SCHEMATIC LOCATIONS OF HP5501B BLOCK DIAGRAM ELEMENTS.........8-12

8-47. REAR PANEL LED INDICATORS ...........................................................................................8-12

8-52. ASSEMBLY REMOVAL INSTRUCTIONS ...............................................................................8-14

8-62. TROUBLE ISOLATION ...........................................................................................................8-19

8-63. Quick Tuning Checkout Procedure .......................................................................................8-19

8-67. Testing the Liquid Crystal Switch...........................................................................................8-21

8-70. HP5501B Trouble Isolation Procedures.................................................................................8-23

8-72. Procedure...............................................................................................................................8-24

8-73. A1 CONNECTOR BOARD CIRCUIT THEORY........................................................................8-26

8-76. High Voltage Power Supply Switch (A1Q3 and A1Q4)..........................................................8-26

8-79. Power Distribution..................................................................................................................8-26

8-83. A1 CONNECTOR BOARD TROUBLESHOOTING..................................................................8-27

8-85. Rear Panel LED Operational Check.......................................................................................8-27

8-87. A2 HIGH VOLTAGE POWER SUPPLY CIRCUIT THEORY.....................................................8-29

8-89. HIGH VOLTAGE POWER SUPPLY TROUBLESHOOTING....................................................8-29

8-91. A3 CONTROLLER/REFERENCE BOARD AND A4 SAMPLER BOARD CIRCUIT THEORY...8-32

8-92. Introduction ............................................................................................................................8-32

8-95. Clock Ⓐ..................................................................................................................................8-32

vi

Page 9

Table of Contents

8-97. Dividers Ⓑ..............................................................................................................................8-32

8-99. State Machine Ⓕ....................................................................................................................8-33

8-105. Liquid Crystal Ⓓ .....................................................................................................................8-34

8-109. Photodiode and Amplifier Ⓔ..................................................................................................8-34

8-111. Warmup Error Amplifier and Comparator Ⓙ .........................................................................8-34

8-114. Subtracting Sample and Hold Ⓗ ...........................................................................................8-34

8-118. A1/A3 Power Amplifier Ⓘ .......................................................................................................8-35

8-121. Reference Receiver Ⓛ ...........................................................................................................8-36

8-125. Line Driver Ⓚ..........................................................................................................................8-36

8-127. Power-On Reset (POR) Ⓖ......................................................................................................8-36

8-129. Laser Head Power Ⓒ .............................................................................................................8-36

8-131. A4 Sampler Board..................................................................................................................8-36

8-133. A3 CONTROLLER/REFERENCE BOARD TROUBLESHOOTING..........................................8-37

8-135. Standard Troubleshooting Procedures .................................................................................8-37

8-137. Digital Troubleshooting..........................................................................................................8-38

8-140. Photodiode and Amplifier Troubleshooting...........................................................................8-41

8-142. Liquid Crystal Troubleshooting..............................................................................................8-42

8-144. Subtracting Sample and Hold Troubleshooting ....................................................................8-42

8-146. Power Amplifier Troubleshooting...........................................................................................8-44

8-148. Warm-Up Error Amplifier Troubleshooting ............................................................................8-46

8-150. Power Supply Troubleshooting .............................................................................................8-46

8-152. Reference Receiver Troubleshooting.....................................................................................8-47

9 SERVICE NOTES .................................................................................................................................9-1

9-1. Service Note 5501-02A July 2001............................................................................................9-1

vii

Page 10

List of Figures

Figure 1-1 HP5501B Laser Head..................................................................................................................1-1

Figure 2-1. HP 107788 Power Cable ............................................................................................................2-3

Figure 2-2. HP 107798 Reference Cable......................................................................................................2-4

Figure 2-3. Typical Transducer System Interconnections............................................................................2-5

Figure 2-4. Interconnecting Plug Details ......................................................................................................2-5

Figure 2-5. HP 5501B Laser Head Interconnect Wire Fabrication ...............................................................2-6

Figure 2-6. Mounting Details and Physical Characteristics..........................................................................2-8

Figure 3-1. HP5501B Front Panel Controls ................................................................................................3-10

Figure 3-2. HP5501B Rear Panel Connectors and Indicators....................................................................3-11

Figure 3-2. HP5501B Rear Panel Connectors and Indicators (Continued)................................................3-12

Figure 4-1. HP5501B Power Connection......................................................................................................4-2

Figure 5-1. A 1 Connector Board, TEST-NORM Switch and Adjustment Locations....................................5-2

Figure 5-2. A3 Controller/Ref Board, Jumpers, Test Points, and Adjustment Locations.............................5-3

Figure 5-3. 55018 High Voltage Areas and Anode Lead..............................................................................5-5

Figure 6-1. HP5501B Laser Head Exploded View......................................................................................6-11

Figure 8-1. Schematic Diagram Notes..........................................................................................................8-2

Figure 8-2.HP5501B Laser Head Block Diagram.........................................................................................8-6

Figure 8-3. Flow Diagram for State Machine................................................................................................8-7

Figure 8-4. Feedback Loop during Warmup Mode......................................................................................8-8

Figure 8-5. Warmup Mode Timing Diagram.................................................................................................8-9

Figure 8-6. Feedback Loop During Optical Mode........................................................................................8-9

Figure 8-7. A6 Sampler Assembly, Exploded View....................................................................................8-10

Figure 8-8. Liquid Crystal Timing Diagram (Optical Mode)........................................................................8-11

Figure 8-9. Logic Clip Monitoring of Test IC U9 .........................................................................................8-14

Figure 8-10. HP5501B Front Panel and Side Cover Removal....................................................................8-16

Figure 8-11. Factory-adjusted Sampler Mount (MP1)................................................................................8-18

Figure 8-12. Laser Tube Tuning Characteristics.........................................................................................8-19

Figure 8-13. Quick Tuning Check Test Setup ............................................................................................8-20

Figure 8-14. Quick Tuning Check Waveform Display.................................................................................8-21

Figure 8-15. Liquid Crystal Removal...........................................................................................................8-21

Figure 8-16. Liquid Crystal Test Setup .......................................................................................................8-22

Figure 8-17. HP5501B TEST-NORM Switch A1S2 .....................................................................................8-23

Figure 8-18. High Voltage Power Supply, Schematic Diagram..................................................................8-31

Figure 8-19. State Machine Timing Diagram..............................................................................................8-33

Figure 8-20. Test Point 11 Waveform (HEATER SENSE)...........................................................................8-44

Figure 8-21. E-REF [U20 (Pin 9)]................................................................................................................8-45

Figure 8-22. REFerence Signal Waveforms................................................................................................8-47

Figure 8-23. A1 Connector Board Component Locator .............................................................................8-50

Figure 8-23. A1 Connector Board Component Schematic Diagram..........................................................8-51

Figure 8-23. A1 ↔ A3 Connector Pin Table................................................................................................8-52

Figure 8-24. A3 Controller/Reference Board (05501-60027) and A4 Sampler Board (05501-60029)

Schematic Diagram (Sheet 1 of 2)..............................................................................................................

Figure 8-24. A3 Controller/Reference Board (05501-60027) and A4 Sampler Board (05501-60029)

Schematic Diagram (Sheet 2 of 2)..............................................................................................................

Figure 8-24 A3 Controller/Reference Board and A4 Sampler Board Photos & Data ....................................57

8-55

8-56

viii

Page 11

List of Tables

Table 1-1. HP5501B Laser Head Specifications and Performance Characteristics.....................................1-5

Table 1-2. Recommended Test Equipment..................................................................................................1-6

Table 2-1. Laser Head System Signal Chart.................................................................................................2-6

Table 2-2. HP 5501B Power Supply Requirements......................................................................................2-7

Table 3-1. Proper 55018 Rear Panel LED Power-up Sequence.................................................................3-13

Table 3-1. Program Modifications for Table 4-12 in the HP5501A System Manual ...................................3-16

Table 3-2. Program Modifications for Table 4-13 in the HP5501A System Manual ...................................3-17

Table 3-3. Modified HP10745A HP-IB Interface Program...........................................................................3-18

Table 3-4 Modified HP10746A Binary Interface Program...........................................................................3-19

Table 4-1. Input Voltage................................................................................................................................4-1

Table 6-1. Exchange Assemblies .................................................................................................................6-1

Table 6-2. Reference Designations and Abbreviations ................................................................................6-3

Table 6-3. HP5501B Board Assemblies Replaceable Parts .........................................................................6-4

Table 6-3. HP5501B Board Assemblies Replaceable Parts (Continued).....................................................6-5

Table 6-3. HP5501B Board Assemblies Replaceable Parts (Continued).....................................................6-6

Table 6-3. HP5501B Board Assemblies Replaceable Parts (Continued).....................................................6-7

Table 6-3. HP5501B Board Assemblies Replaceable Parts (Continued).....................................................6-8

Table 6-3. HP5501B Board Assemblies Replaceable Parts (Continued).....................................................6-9

Table 6-3. HP5501B Miscellaneous Chassis Parts (Continued) ................................................................6-10

Table 6-4. Manufacturer's Code List...........................................................................................................6-12

Table 8-1. A3 U9 Test IC Signal Summary.................................................................................................8-13

Table 8-2. DC Unbalanced Failures............................................................................................................8-26

Table 8-3. IC A3U4 and A3U6 Divider Check.............................................................................................8-39

Table 8-4. Signature Table..........................................................................................................................8-41

Table 8-5. Voltage Testpoints and Limits ...................................................................................................8-46

Table 8-6. A3U17 Reference Receiver Test Voltages.................................................................................8-48

ix

Page 12

Page 13

HP5501B

Installation

Figure 1-1 HP5501B Laser Head

1-1

Page 14

HP5501B

Installation

1 GENERAL INFORMATION

1-1. Introduction

1-2. This Operating and Service Manual contains information required to install, operate, test, adjust,

and service the Hewlett-Packard Model 5501B Laser Head. The information in this manual is

specific to the HP5501B and supplements other publications available for Hewlett-Packard Laser

Transducer products. Also available is the HP5501A Laser Transducer System Manual (HP Part

Number 05501-90028) that describes how to setup, align, and use the laser system to make

interferometer measurements.

1-3. The HP part number of this manual is listed on the title page. Also listed is a microfiche part

number for ordering 4 X 6" microfilm transparencies of this manual. The microfiche package also

includes the latest "Manual Changes" supplement and any pertinent Service Notes.

1-4. Equipment Description

1-5. The HP5501B Laser Head consists of a thermally-tuned laser tube, control circuits, a reference

receiver, and a high-voltage power supply. The laser head requires ±15 Volt supplies, each with

a minimum capacity of 1 Amp. The HP5501B produces a frequency stabilized laser beam, a

balanced reference output (see paragraph 16), a +15 Volt fused output, and a +5 Volt output.

Diagnostic LED’s, mounted on the 5501B's rear panel, provide status information on power

supply input (±15 Volts), fuses, laser output and tuning, and the reference frequency output.

1-6. The 5501B laser beam consists of two linearly polarized and mutually perpendicular (orthogonal)

components separated in frequency by approximately 1.8 MHz. The two components have light

frequencies of F1 and F2. The higher frequency component (F2) is oriented parallel to the laser

base, while the lower frequency component (F1) is perpendicular to the laser base. An optical

receiver inside the HP5501B detects the 1.8 MHz frequency difference and places it at the rear

panel REFERENCE SIGNAL connector as a balanced output (called the REFerence Frequency).

The reference output is one signal used by the external electronics to measure distance traveled.

1-7. During a typical measurement application, the laser beam travels through external optics where

the horizontal and vertical components of the beam are separated. One component travels along

a fixed path and returns to an external optical receiver. The other component travels along the

path (axis) to be measured and then returns to the external receiver. The external receiver

detects the frequency difference between the two components and outputs a signal called the

MEASure Frequency. The MEASure Frequency from the external receiver and the REFerence

Frequency from the laser head are compared by external, customer selected electronics. If the

distance between the external optics is fixed, the MEASure and REFerence frequencies are

equal. As the relative distance between the external optics changes, the MEASure Frequency

changes due to a Doppler frequency shift. This relative change between the MEASure and

REFerence Frequencies is used by the system electronics to compute distance traveled. The

laser transducer system can be configured for computer control of open- and closed-loop

positioning and measuring applications, having single or multiple axes. For more detailed

information, refer to the HP5501A Laser Transducer System manual (HP Part Number 05501-

90028).

1-2

Page 15

HP5501B

Installation

1-8. Manual Organization

1-9. This Service Manual is organized as follows:

SECTION 1, GENERAL INFORMATION: covers Equipment Description, Manual Organization,

Instruments Covered by this Manual, Safety Considerations, Equipment Supplied, Available

Accessories, Specifications, Recommended Test Equipment, and Warranty Information.

SECTION 2, INSTALLATION: covers Grounding Considerations, Power Requirements, Interconnecting

Cabling, Operating and Storage Environments, Storage and Shipment, and Packaging.

SECTION 3, OPERATION: provides operating information and covers Equipment Front and Rear Panel

Features, Warm-up Time Considerations, and Program Notes.

SECTION 4, PERFORMANCE TESTS: provides Safety Considerations, Performance Tests, and a Test

Record.

SECTION 5, ADJUSTMENTS: covers Safety Considerations, Test Equipment Required, Adjustment

Procedures, and an Adjustment Record.

SECTION 6, REPLACEABLE PARTS: includes Tables of Replaceable Parts including illustrated parts

breakdowns of chassis and mechanical assemblies, Abbreviations, Ordering Information, and

the HP Direct Mail Order System.

SECTION 7, MANUAL CHANGES: describes how to update or backdate the manual for prefixes other

than those listed on the title page.

SECTION 8, SERVICE: contains Safety Considerations, Theory and Block Diagram Descriptions,

Trouble Isolation, Troubleshooting, Schematics, and Component Locations.

1-10. Instruments covered by this manual

1-11. Attached to each instrument is a serial plate. The serial number is in the form: OOOOAOOOOO.

It is in two parts; the first four digits and the letter are the serial number prefix and the last five

digits are the suffix. The prefix is the same for all identical instruments; it changes only when a

change is made to the instrument. The suffix is assigned sequentially and is unique to the

individual instrument. This manual applies to instruments with the serial number prefix listed on

the title page of this manual.

1-12. An instrument manufactured after the printing of this manual may have a serial number prefix

that is not listed on the title page. This unlisted serial number prefix indicates the instrument is

different from those described in this manual. The manual for this newer instrument is

accompanied by a yellow "Manual Changes" supplement. This supplement contains updating

information that explains how to change the manual to be applicable to newer instruments.

1-13. In addition to the new serial number prefix change information, the supplement may contain

information for correcting errors in the manual (errata). To keep this manual as current and as

accurate as possible, Hewlett-Packard recommends that you periodically request the latest

"Manual Changes" supplement. The supplement for this manual is identified with the manual

print date and part number, both of which appear on the manual title page. Complementary

copies of the supplement are available.

1-3

Page 16

HP5501B

Installation

1-14. Safety Considerations

1-15. The HP5501B Laser Head is designed to receive its power from a Safety Class 1 product. It is

designed and tested in accordance with international safety standard IEC* 348. It is also a Class

1/ Laser product certified as conforming to U. S. National Center for Devices and Radiological

Health Regulations 21 CFR ** 1040.10 and 1040.11. The instrument and the manual should be

inspected and reviewed for safety markings and instructions before operation. A safety summary

is included on the page following the title page.

1-16. Equipment Supplied

1-17. The HP5501B Laser Head is supplied with a test polarizer and two 4-pin connectors for use in

fabricating the power and reference cables. The HP Part Numbers for the three items are:

Test Polarizer 1000-0616

Reference Signal Connector (P1) 1251-3450

Power Connector (P2) 1251-3447

1-18. Available Accessories

1-19. The HP 10778B and HP 10779B cables may be ordered from Hewlett-Packard. Figures 2-1 and

2-2 show photos of the cables, identify the connector markings, and give the pin numbers and

corresponding wire color codes.

*IEC, International Electrotechnical Commission

**CFR, Code of Federal Regulations (U.S.A.)

1-4

Page 17

HP5501B

Installation

1-20. Specifications

1-21. Table 1-1 lists the specifications and performance characteristics for the HP5501B Laser Head.

Table 1-1. HP5501B Laser Head Specifications and Performance Characteristics

Description: The HP5501B Laser Head contains an automatically tuned

Helium-Neon laser, circuits to control the laser, and a reference

optical receiver. The laser generates a coherent, collimated, two

frequency beam of light. This is a Class II Laser Product

conforming to U.S. National Center for Devices and Radiological

Health Regulations 21 CFR 1040.10 and 1040.11.

Environmental Conditions:

Temperature (Operating): 0 to 40°C (32 to 104°F)

Temperature (Non Operating): Can be stored or shipped in environments within the range of -

40 to +75°C.

NOTE

This unit should also be protected from temperature extremes that could

cause condensation within the instrument.

Relative Humidity (Operating): 0 to 95% Non-condensing

Vacuum Wavelength (Nominal): 632.991372 nanometers

Vacuum Wavelength Accuracy: 1 X 10-7

Vacuum Wavelength Stability: 2 X 10-8, typical

Beam Diameter: 6 mm typical

Maximum Beam Power Output: 1 milliwatt

Minimum Beam Power Output: 120 microwatts

Warm-Up Time: less than 10 minutes

Power Requirements: The HP5501B requires the following power inputs:

+15 Volts ±0.3 Volts at 0.8 Amperes maximum

-15 Volts ±0.3 Volts at 0.7 Amperes maximum

NOTE

Internal laser head 1.5 amp fuses permit power distribution to other laser

equipment.

Safety Features: Front shutter to block Laser Beam.

Outputs:

Reference signal: Differential square wave at approximately 1.8 MHz. Levels

Enclosure: NEMA Type 12

Dimensions: 32.5 X 13.2 X 12.7 cm

Weight:: 3.4 Kg (7.5 Ibs)

A safety switch disables high voltage when cover is removed.

compatible with all Laser Transducer System inputs.

1-5

Page 18

HP5501B

Installation

1-22. Recommended Test Equipment

1-23. The equipment required to maintain the HP5501B Laser Head is listed in Table 1-2. Other

equipment may be substituted if it meets or exceeds the critical specifications listed in the table.

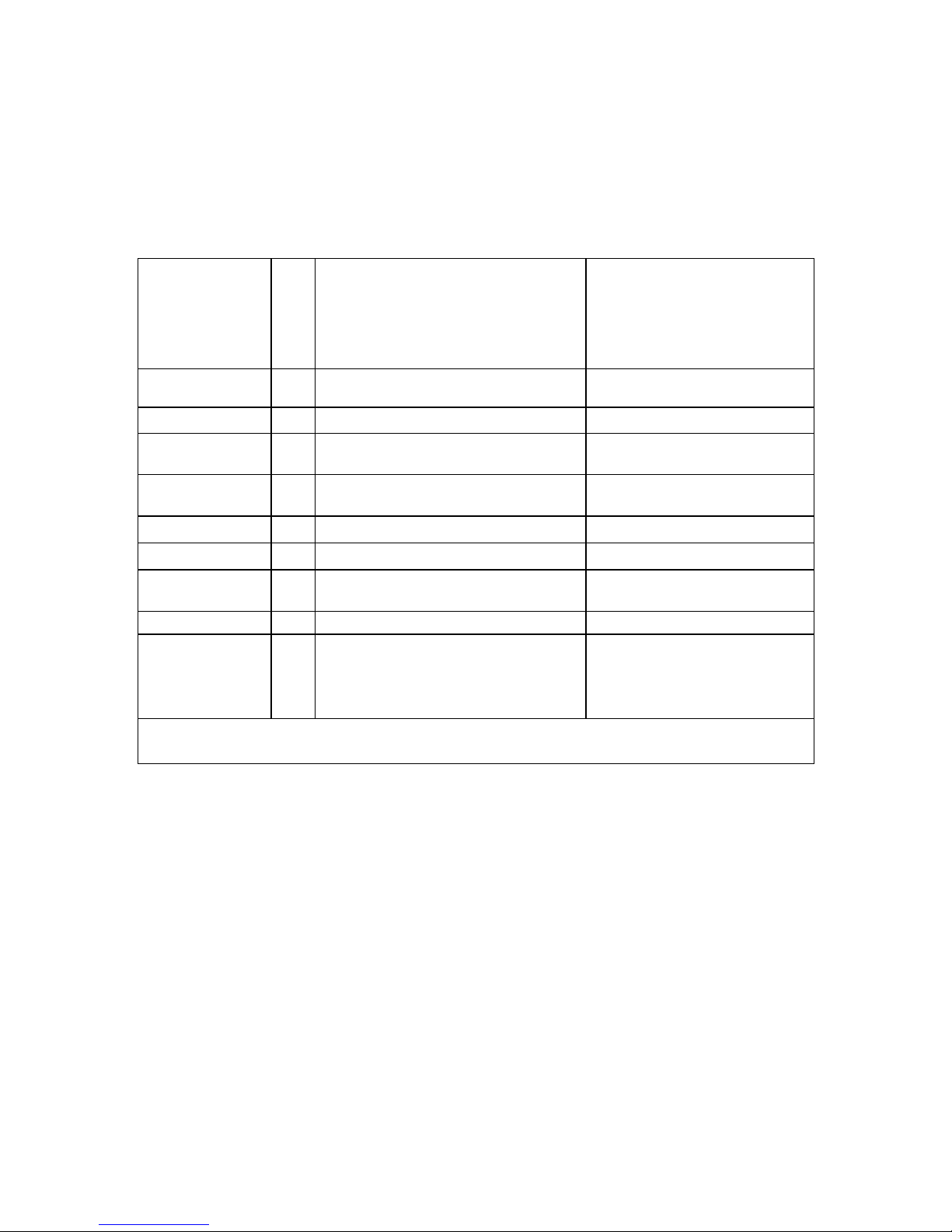

Table 1-2. Recommended Test Equipment

RECOMMENDED

EQUIPMENT

INSTRUMENT USE*

CRITICAL SPECIFICATIONS

(Equipment Having

Equivalent Characteristics

May Be Substituted)

Signature

Multimeter

Oscilloscope T 100 MHz Bandwidth HP 1740A (if available)

Laser Power

Meter

Clip-on

Milliammeter

Logic Pulser T TTL level HP 546A

Current Tracer T Sensitivity: 1 ma to 1 amp HP 547A

Logic Clip T TTL Compatible 16-pin IC. mounting HP 548A

Logic Probe T

Digital Voltmeter T

*P = Performance Test; C = Calibration; A = Adjustments; T = Troubleshooting; S = Shortened

1-24. Warranty

T Detect TTL level signals HP 5005A/B

Range: 1 microwatt to 1 milliwatt

T

Accuracy: ±10%

United Detector Technology

Model 351L

T,A 10 ma range accuracy ±0.1 ma HP 428B

TTL/CMOS Capability with Pulse

HP 545A

DC Volts: Floating Inputs

Input Resistance: >10 MΩ

Range: 1, 10, 20 Volts DC

HP 3435A

Accuracy: 0.1%

Performance Test

1-25. The warranty statement for the instrument including the laser tube is located on the inside cover

of this manual.

1-6

Page 19

HP5501B

Installation

2 INSTALLATION

2-1. Introduction

2-2. This section provides installation instructions for the HP5501B Laser Head including unpacking,

inspection and reshipment, installation, operating environment, and storage. Installation includes

information on grounding considerations, power supply requirements, power dissipation, fusing,

dimensions, and mounting and fixturing.

2-3. Unpacking, Inspection, and Reshipment

2-4. The following paragraphs contain information for unpacking and inspection, warranty claims,

laser tube shipment, tagging for service, and packaging for reshipment.

TO AVOID HAZARDOUS ELECTRIC SHOCK, DO NOT PERFORM ELECTRICAL TESTS WHEN THERE ARE SIGNS OF SHIPPING DAMAGE TO ANY

PORTION OF THE OUTER ENCLOSURE (COVERS, PANELS, CONNECTORS,

LEOS, ETC.).

2-5. Unpacking and Inspection

2-6. Inspect the shipping container for damage. If the shipping container or cushioning material is

damaged, it should be kept until the contents of the shipment have been checked for

completeness and the instrument has been checked mechanically and electrically. Procedures

for checking electrical performance are given in

is mechanical damage or defect, or if the instrument or some component fails the performance

tests, notify the nearest Hewlett-Packard office. If the shipping container is damaged, or the

cushioning material shows signs of stress, notify the carrier as well as the Hewlett-Packard office.

Keep the shipping materials for the carrier's inspection. The HP office will arrange for repair or

replacement at HP's option without waiting for a claim settlement.

Section 4. If the contents are incomplete, if there

2-7. Warranty Claims

2-8. Contact the nearest HP Sales and Support Office (see list at the end of this manual) for

information relative to warranty claims.

2-9. Laser Tube Shipment

NOTE

The laser tube assembly MUST be shipped in an approved HP container.

2-10. The laser tube assembly (HP Part Number 05501-60102) should only be shipped in an HP

container designed for that purpose. In addition, the container must indicate that the laser tube

contains magnetic material. If it is necessary to ship a laser tube, contact your nearest HP Sales

and Support Office for an approved container.

2-1

Page 20

HP5501B

Installation

2-11. Tagging for Service

2-12. If the instrument is being returned to Hewlett-Packard for service, please complete one of the

blue repair tags (HP Part Number 9320-3896) located at the end of this manual and attaches it to

the instrument.

2-13. Packaging for Reshipment

1. Original Packaging

a. The same containers and materials used in factory packaging can be obtained through

Hewlett-Packard Sales and Support Offices listed at the rear of this manual.

b. In any correspondence refer to the equipment by model number.

2. Other Packaging Methods

a. If it becomes necessary to reship equipment, good commercial packing should be used.

b. Contract packaging companies can provide dependable custom packaging on short

notice. The following general instructions should be followed when repackaging with

commercially available materials.

c. If shipping to a Hewlett-Packard Support Office or Center, attach a blue tag indicating

the type of service required, return address, and model number.

d. Wrap the equipment in heavy paper or plastic.

e. Use a strong shipping container. A double-wall carton made of 350 pound test material

is adequate.

f. Use enough shock-absorbing material (three to four inch layer) around all sides of the

equipment to provide a firm cushion and prevent movement inside the container.

g. Seal the shipping container securely.

h. Mark the shipping container FRAGILE to assure careful handling.

2-14. Installation

2-15. The following paragraphs provide installation information for the HP5501B Laser Head including

system cabling, grounding considerations, power supply requirements, power dissipation, fusing,

and mounting and fixturing.

2-16. System Cabling

2-17. The HP5501B Laser Head is designed for use with the HP5501A Laser Transducer System and

is a direct replacement for the HP5501A Laser Head. The HP10778B Power and HP10779B

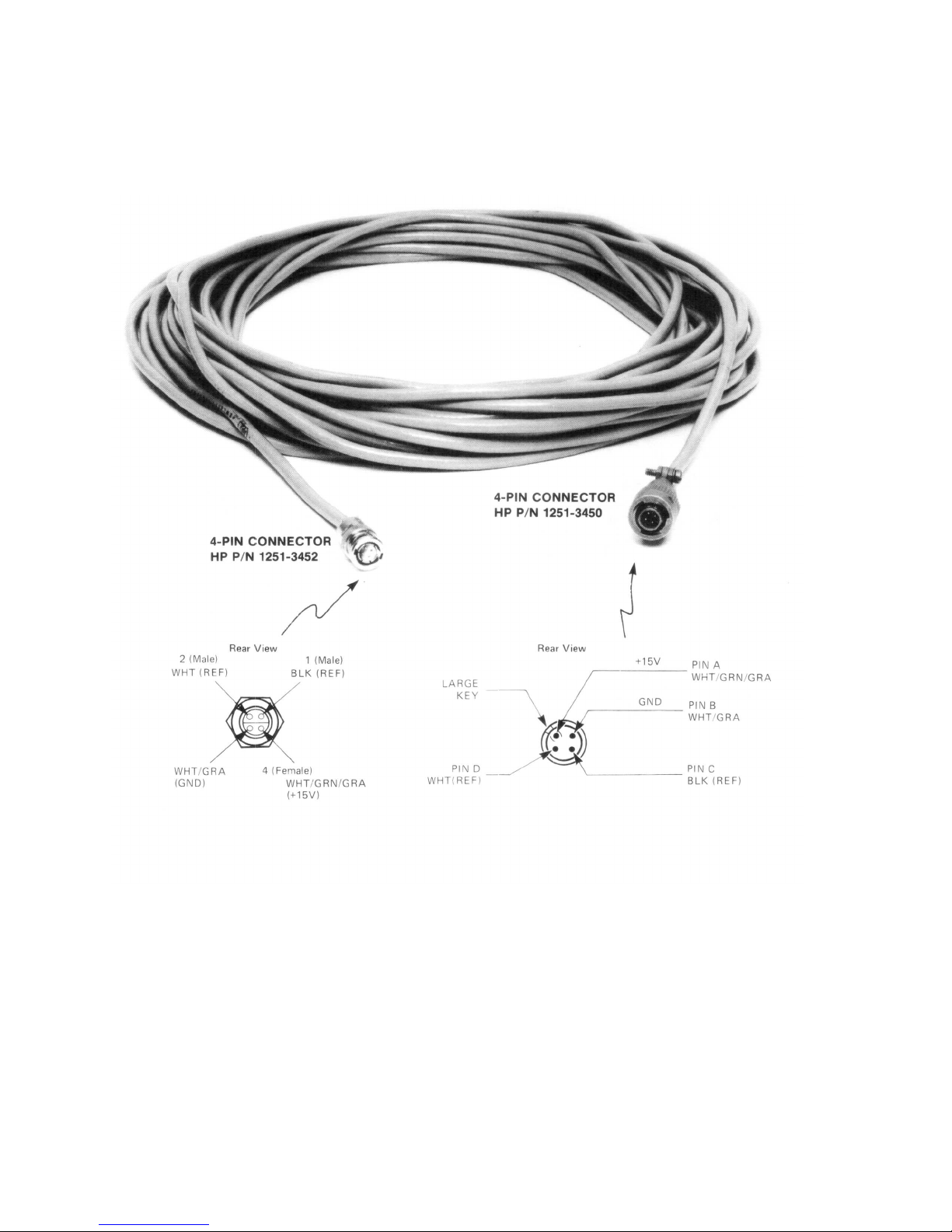

Reference cables (Figures 2-1 and 2-2 respectively), are available for connecting the laser head

to the laser transducer system.

2-18. The HP10778B and HP10779B cables are both 10 Meters (32.8 ft) in length.

2-2

Page 21

HP5501B

Installation

10778B LENGTH 10 METRES (32.8 FT)

Figure 2-1. HP 10778B Power Cable

2-3

Page 22

HP5501B

Installation

Figure 2-2. HP 10779B Reference Cable

2-4

10779B LENGTH 10 METRES (32.8 FT)

Page 23

HP5501B

Installation

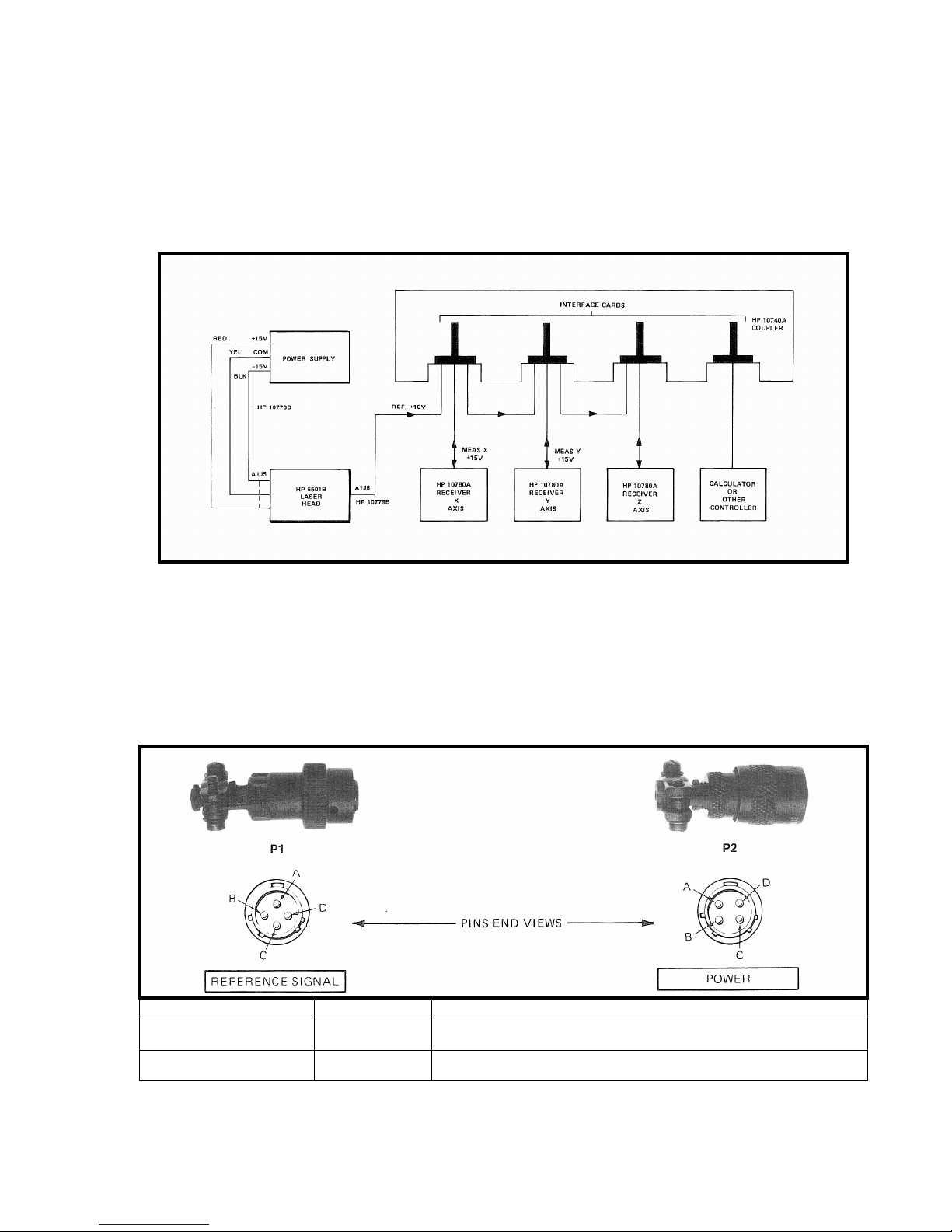

2-19. Power and Signal Connections

2-20. The laser head rear panel contains two multi-pin connectors used for connecting HP5501B

power and signal lines to other laser transducer system components. (Refer to Figure 2-3 for an

interconnection diagram of a typical system.) Table 2-2 lists all power and signal lines that are

available at the rear-panel connectors. The laser transducer system manual gives additional

system wiring information.

Figure 2-3. Typical Transducer System Interconnections

2-21. Cable Fabrication

2-22. Power and signal interconnecting cables of suitable length may be fabricated using the two

plugs included with the laser head. Figures 2-4 and 2-5 illustrate the physical details of the two

plugs supplied and give part numbers for both the plugs and the recommended cables. Refer to

Table 2-1 for rear-panel connector pin numbers of all available power and signal lines.

PLUG CABLE DESCRIPTION

REFERENCE SIGNAL

HP Part No. 1251-3450

POWER

HP Part No. 1251-3447

HP 10779B or

equivalent

HP 10778B or

equivalent

Dual coax; two #22 power wires.

Everything enclosed by a second insulated shield.

Three # 20 wires

Figure 2-4. Interconnecting Plug Details

2-5

Page 24

HP5501B

Installation

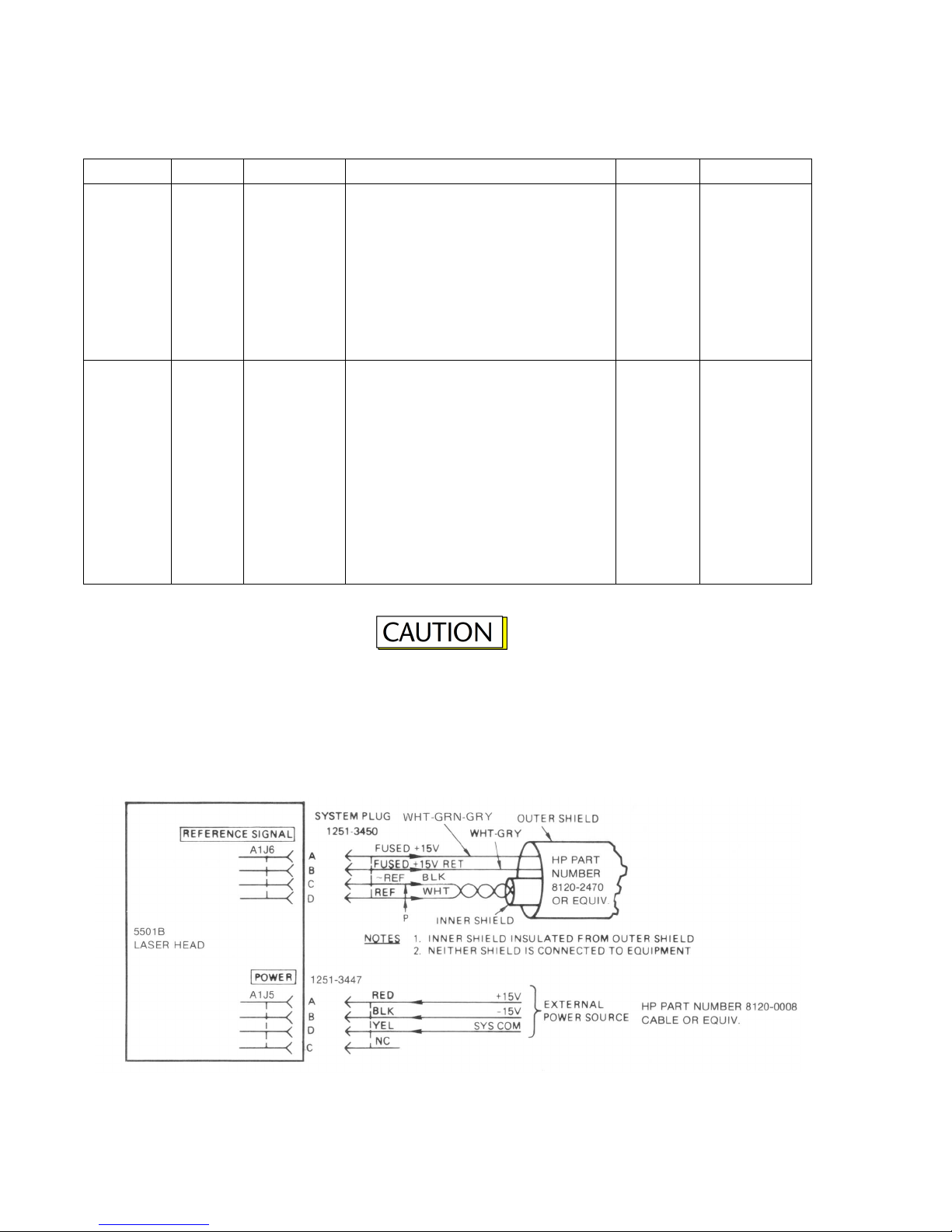

Table 2-1. Laser Head System Signal Chart

Input Output Signal Name Function Source Destination

A1J6-A Fused +15V Accessory +15V Operating Power

A1J6-B

A1J6-C REF

Fused +15V

RET

Accessory +15V Return

System REFerence signal, equal to

the difference in frequency between

A1J6-D -REF

laser beam components F1 and F2.

A1J5-A +15V External +15V Power Input

A1J5-B -15V External -15V Power Input

A1J5-C +5V +5V power test point

A1J5-D GND Power Ground

REF AND -REF OUTPUTS ARE CAPABLE OF DRIVING ONLY ONE UNIT

Ext. Pwr.

Sup.

Ext. Pwr.

Sup..

Ext. Pwr.

Sup

Accessory

Equipment

Accessory

Equipment

Accessory

Equipment

Accessory

Equipment

(test use only)

NOTE

THE RUBBER COLLAR WHICH GOES OVER THE CABLES IS A VERY

TIGHT FIT. USE SILICON GREASE TO FACILITATE INSTAILATION ON

CABLE.

Figure 2-5. HP 5501B Laser Head Interconnect Wire Fabrication

2-6

Page 25

HP5501B

Installation

Observe the current and grounding requirements described below.

2-23. Grounding Considerations

2-24. In order to avoid ground loops, the laser head base should be the only connection to earth

ground. To accomplish this, the outputs of the ±15 Volt power supplies used to power the laser

head should be floating. The +5 Volt power supply output required for either the HP10740A

based electronics or HP10781A Pulse Converters, should also be floating. Alternatively, any

other single point earth ground connection can be used to satisfy grounding requirements.

2-25. Power Supply Requirements

2-26. Table 2-2 lists the supply voltages, currents, and tolerances required by the HP5501B Laser

Head. Note that other components of the system also use ±15 Volts. Add these to the laser

head current requirements to obtain the overall system requirements.

Table 2-2. HP 5501B Power Supply Requirements

Supply Voltage Tolerance Current Requirement

+15 Volts ±0.3 Volts 0.8 Amperes

3.5 Amperes peak surge for

-15 Volts ±0.3 Volts 0.7 Amperes

Other Power Supply Requirements

Line Regulation 0.01%

Load Regulation 0.01%

Ripple + Noise 60 millivolts peak-to-peak

Isolated Output

Over Voltage Protection

(Recommended)

Under Voltage Protection

(current limited)

(Recommended)

approximately 2 milliseconds

at power-up

2-27. Power Dissipation

2-28. The HP5501B dissipates approximately 21 watts during operation.

2-29. Fusing

2-30. The HP5501B has two internal 1.5 Ampere fuses to protect the ±15V lines. Both fuses are

located on the A1 Connector Board and are accessible by removing the left and right covers of

the laser head.

2-7

Page 26

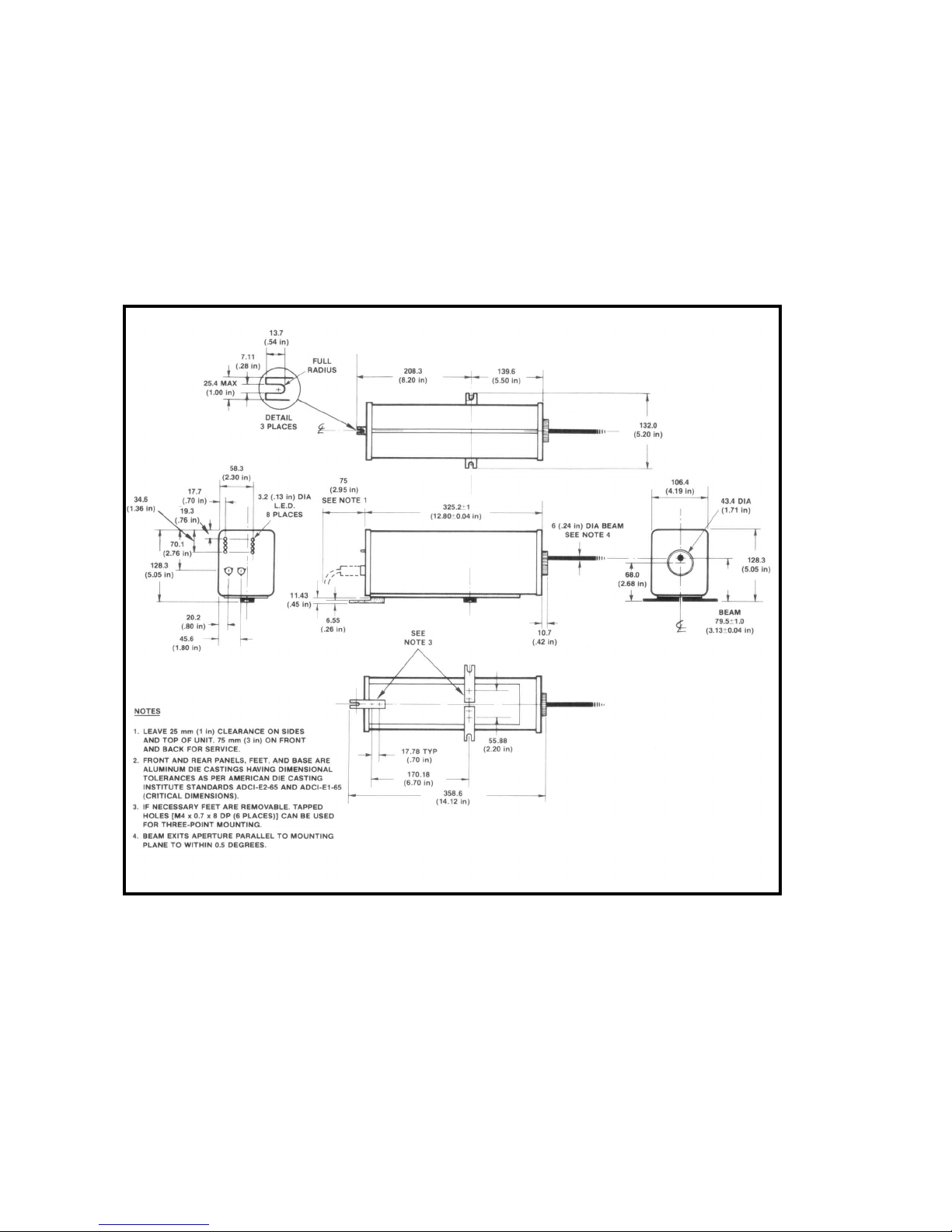

2-31. Dimensions

2-32. Figure 2-6 shows the HP5501B Laser Head dimensions.

DIMENSIONS IN MILLIMETERS

HP5501B

Installation

Figure 2-6. Mounting Details and Physical Characteristics

2-8

Page 27

HP5501B

Installation

2-33. Mounting and Fixturing

2-34. Heat Flow Considerations. The laser tuning technique of the HP5501B requires efficient heat

exchange with the ambient. Heat flow is primarily through the base of the laser head assembly to

the surrounding environment. An external heat sink is not required but free air circulation around

the laser head will ensure good performance.

2-35. In cases where vertical mounting of the HP5501B is desired, care should be taken to minimize

laser beam disturbances due to air turbulence caused by the HP5501B heat exchange. It is most

important to prevent differential effects which can occur due to turbulence in the beam path

between a polarizing beam splitter and a retroreflector or plane mirror. Differential turbulence

causes fluctuations in the optical path length difference that is being measured. Both differential

and common mode turbulence can cause fluctuations in alignment by bending the light beam.

Common mode turbulence is turbulence that is present in the beam path between the HP5501B

and a polarizing beam splitter. In either case some amount of noise can be present in the

interferometer measurement due to turbulence.

2-36. If interferometer components (optics) are mounted very close to the HP5501B such that the

operating temperature of the optics are affected, it is recommended that alignment and

operation of the interferometer be performed after the HP5501B has been running for a sufficient

period of time to allow thermal equilibrium to be established. In well ventilated installations, one

hour of running time should be sufficient. When enclosures are used and the ambient

temperature is changed by several degrees (centigrade) by the HP5501B, thermal equilibrium is

not established as quickly and the laser should be run for a longer period of time.

2-37. Mounting. Mount the laser head by means of the three slotted tabs that extend outward from the

bottom edges of the unit (refer to Figure 2-1 for exact locations and dimensions). The mounting

tabs may be secured to the work surface in any fashion that will not transmit stresses to the main

enclosure and, consequently, to the laser tube or printed-circuit assemblies. If necessary, the

tabs can be removed and the unit mounted on a flat surface with 4 mm machine screws; use the

same tapped holes that are used to secure the tabs, ensuring that the mounting method does

not stress the base casting and that the screws do not penetrate the base casting more than 7

mm.

2-38. Beam Alignment. Rotate the turret at the front of the laser head so that the beam exits through

the large aperture. DO NOT STARE DIRECTLY INTO THE BEAM APERTURE. Presence of the

red laser beam can be verified by placing a piece of paper in the beam path and observing the

beam reflection on the paper. The components of the laser transducer system must now be

aligned so that the laser beam strikes the photodetector of the receiver (HP10780A). Refer to the

HP10780A Receiver documentation and the Laser Transducer System Manual for further

alignment information.

2-39. Pointing Stability. The angle at which the laser beam exits the HP5501B can change from turn-

on through the time when the HP5501B and its surroundings reach thermal equilibrium.

2-40. The HP5501B should not be exposed to ambient temperature changes greater than ±5

Centigrade during operation to keep pointing stability variations to a minimum during

interferometer measurements.

2-9

Page 28

HP5501B

Operation

3 OPERATION

3-1. Introduction

3-2. This section provides operating information for the HP5501B Laser Head. Included are operation

features of the instrument's front and rear panel controls and connectors. Also provided is

supplemental operating information for HP5501A Laser Transducer Systems equipped with

HP5501B Laser Heads.

3-3. Installation instructions for the HP5501B Laser Head are given in

Section 2 of this manual.

3-4. Power Application

3-5. The laser head installed is activated when +15 Vdc and -15 Vdc are applied to the unit. ±15

Volts is applied by connecting the power cable (HP10778B or fabricated equivalent) to the rear

panel POWER connector (A1J5). Ensure that the power source is adjusted to conform to the

following requirements before connecting it to the HP5501B:

Measured Voltage +15V ± 0.3 Vdc -15V ± 0.3 Vdc

NOTE

REPETITIVE POWER-UP CYCLING SHOULD BE AVOIDED. THIS WILL

REDUCE THE EXPECTED LIFE OF THE HIGH VOLTAGE

COMPONENTS.

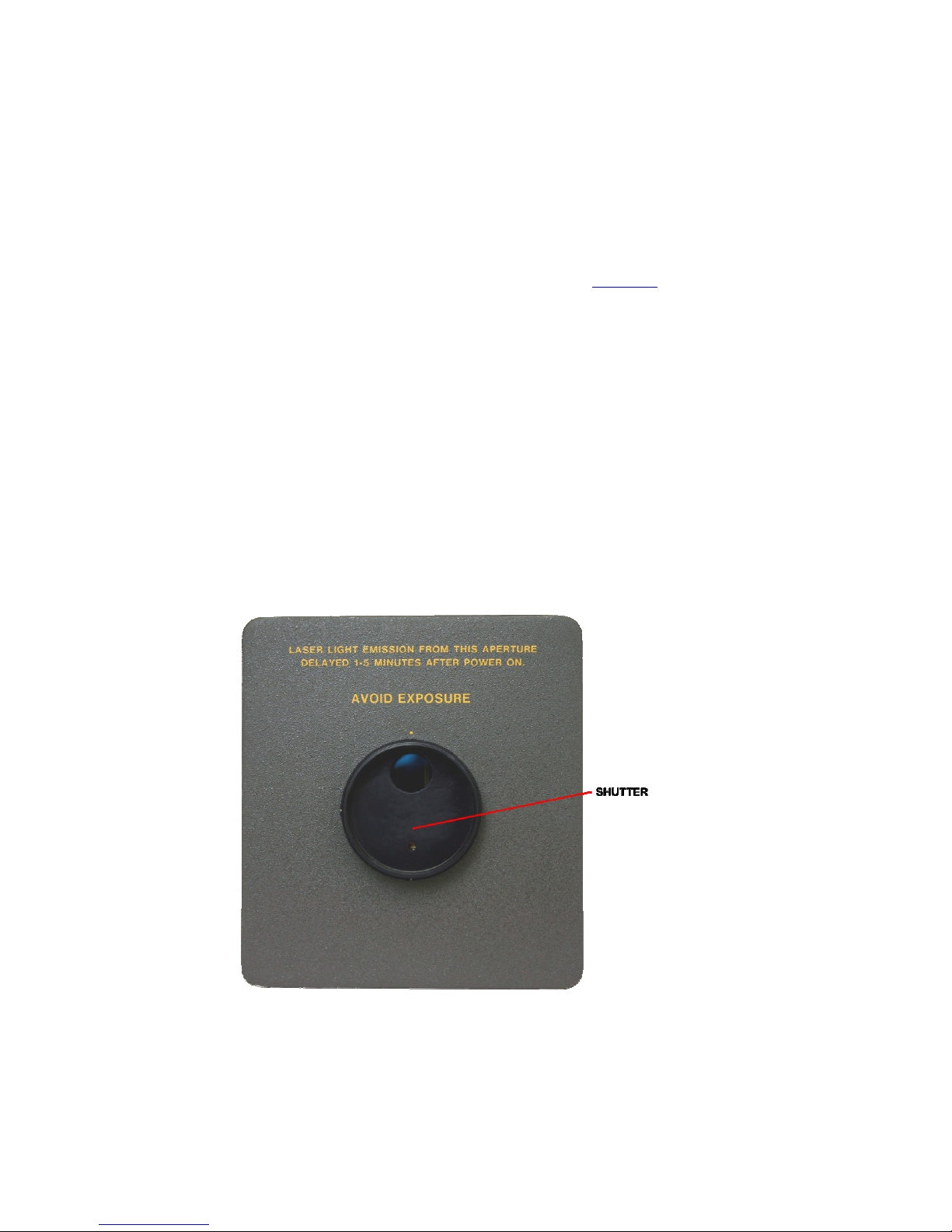

3-6. HP5501B Laser Head Front Panel Controls

3-7. Figure 3-1 identifies and describes each of the operating controls, connectors, and indicators.

Refer to Table 2-1 for information regarding the specific power and signal/lines at each of the

connectors.

Figure 3-1. HP5501B Front Panel Controls

1. Shutter: The shutter, also known as the aperture ring, allows for three aperture

settings: open, reduced, and closed. The open aperture position is used during

normal operation and the reduced aperture is used during alignment of

measurement axes.

3-10

Page 29

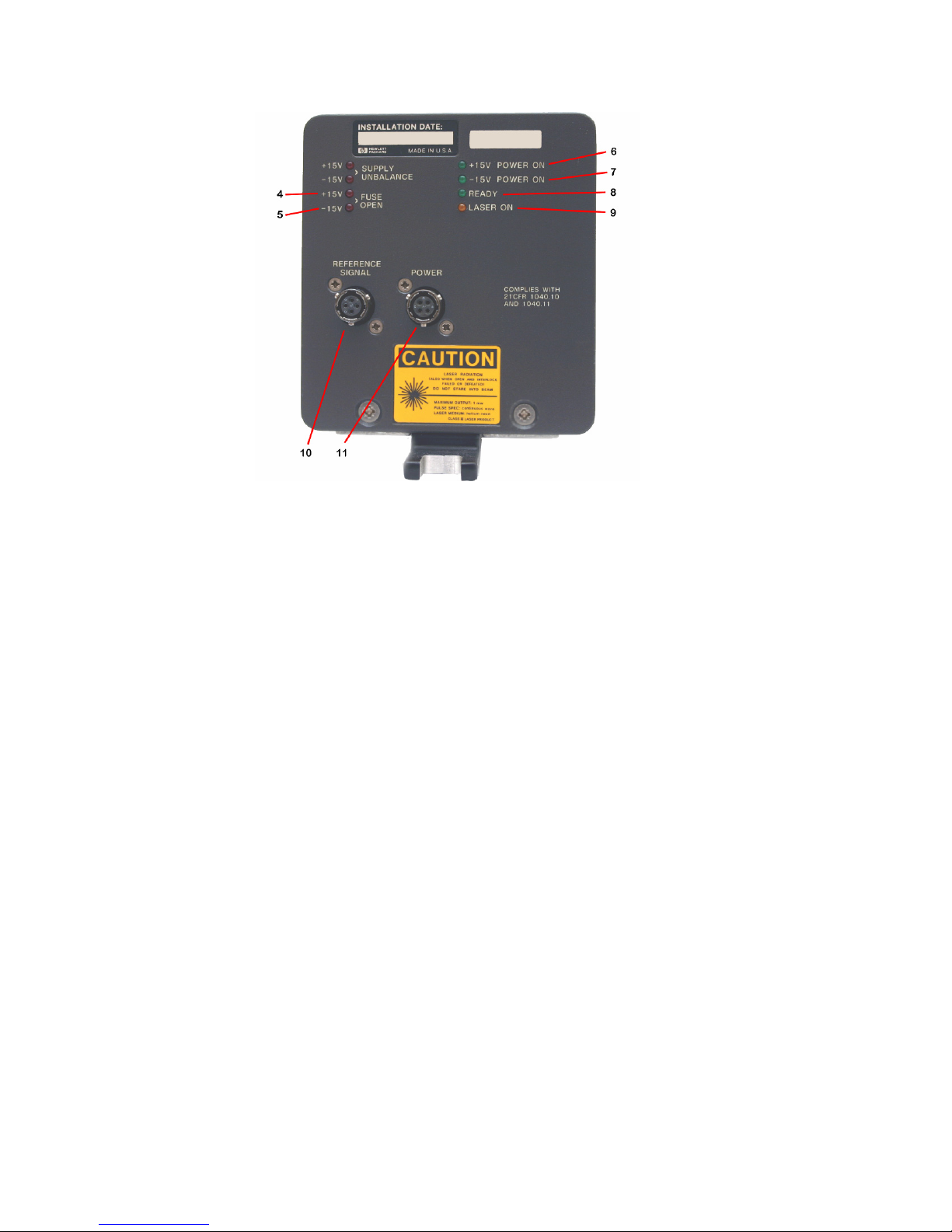

3-8. HP5501B LASER HEAD REAR PANEL INDICATORS AND CONNECTORS

NOTE

A TILDE ("~") PRECEDING A SIGNAL NAME INDICATES NEGATIVETRUE LOGIC LEVELS.

3-9. Following are descriptions of the HP5501B rear panel features shown in Figure 3-2.

HP5501B

Operation

2. +15V SUPPLY

UNBALANCE

3. -15V SUPPLY

UNBALANCE

Figure 3-2. HP5501B Rear Panel Connectors and Indicators

RED

LED

RED

LED

LED lights if the ±15V input voltages are unbalanced

in the positive direction by one Volt or more. For

example:

When the positive supply measures +16 Volts (or

more positive) and the negative supply remains at 15 Volts.

When the positive supply measures +15 Volts and

the negative supply is -14 Volts (or less negative).

LED lights if the ±15V input voltages are unbalanced

in the negative direction by one Volt or more. For

example:

When the negative supply measures -16 Volts (or

more negative) and the positive supply remains at

+15 Volts.

When the negative supply measures -15 Volts and

the positive supply is +14 Volts (or less positive).

Both ±15V SUPPLY UNBALANCE LED’s light if the

TEST-NORM switch (A1S2) is in NORM position with

cover off or in TEST with cover on.

3-11

Page 30

HP5501B

Operation

4. +15V FUSE OPEN RED LED LED lights if +15 Vdc fuse opens.

5. -15V FUSE OPEN RED LED LED lights if -15 Vdc fuse opens.

6. +15V POWER ON GREEN LED LED lights when +15 Vdc power is applied

to the HP5501B.

7. -15V POWER ON GREEN LED LED lights when -15 Vdc power is applied to

the HP5501B.

8. READY GREEN LED LED remains off while heating rod to normal

operating temperature. At this point the

READY LED begins to flash and continues to

do so until the laser head reaches operating

temperature. When the laser head is ready

for use, the READY LED stays on steady

(i.e., Laser has achieved lock and is now

generating a stable reference signal).

9. LASER ON AMBER LED LED lights to indicate that the high voltage

power supply (HVPS) is on and that laser

light is being emitted.

10. POWER CONNECTOR

(A1J5)

Provides connection point for external power

supply input (i.e., 10778B Power Cable

connector).

11. REFERENCE CONNECTOR

(A1J6)

Allows the reference signals (REF and -REF),

and +15 power to be connected to other

system components (i.e., 10779B Reference

Cable connector).

Figure 3-2. HP5501B Rear Panel Connectors and Indicators (Continued)

3-12

Page 31

HP5501B

Operation

3-10. OPERATING MODES

3-11. When power is applied to the HP5501B, an internal state machine resets the laser head to a

warmup mode. This mode is used to establish the initial operating temperature of a glass rod

that controls the laser cavity length. When this temperature is reached, the state machine

switches to an optical tuning mode. Upon successfully switching from warmup to optical mode,

the laser head enables the REFerence signal and lights a READY LED indicator on the rear panel

to indicate that the laser head is ready for use. The following table will give the proper operating

sequence for the HP5501B rear panel Led's from initial power-up (warmup mode) to when the

laser is ready to use (optical mode).

Table 3-1. Proper 55018 Rear Panel LED Power-up Sequence

OPERATING MODES*

WARMUP OPTICAL

LED’s

+15V SUPPLY

UNBALANCE

(Red LED)

-15V SUPPLY

UNBALANCE

(Red LED)

+15V

FUSE OPEN

(Red LED)

-15V

FUSE OPEN

(Red LED)

+15V

POWER ON

(Green LED)

-15V

POWER ON

(Green LED)

READY

(Green LED)

LASER ON

(Amber LED)

↑

15V Applied

to Laser

Head. Heater

Full On

*Time intervals reflect that laser tube was cold at turn-on; shorter times can be expected if tube is warm

at turn-on.

**Refer to paragraph 8-100 for further explanation of laser operating modes.

PREHEAT HEATER

LOCKING LOCKED

QUALIFIED

←3-6 Min**→

← 100 sec → ← 50 sec → Continuous use

OFF OFF OFF OFF

OFF OFF OFF OFF

OFF OFF OFF OFF

OFF OFF OFF OFF

ON ON ON ON

ON ON ON ON

OFF Flashing 2Hz Flashing

ON

2Hz

OFF OFF ON ON

↑

Glass rod

reaches

temperature

(begin 100

second

↑

HVPS Turns

on

Laser Beam

on

↑

Reference

signal

present

Laser now

ready for use

stabilization

period

3-13

Page 32

3-12. Warmup Time Operating Notes

• Allow a full 10 minute warmup period for the HP5501B.

• Warmup completion is indicated by the READY LED on the HP5501B rear panel.

• If warmup is not complete after 10 minutes, a failure may be indicated.

• If the READY indication at the laser head is not convenient to use because of the mounting

scheme, try the alternate monitoring suggestions that follow.

3-13. HP 10740A Coupler Based Systems - Manual Monitoring

• The REFerence and MEASurement signals terminate at either the HP10760A Counter Card

or the HP10764A/B/C Fast Pulse Converter Card.

• Each of these cards includes an LED to monitor the presence of the REFerence and

MEASurement signals.

• The REFERENCE LED will be extinguished until the HP5501B is ready for use.

HOWEVER, FOR SYSTEMS WITH MULTIPLE HP 10760A CARDS

• Every ODD HP10760A that uses the replicated REF and -REF will have their REFERENCE

LED lit during the laser head warmup period. (This is due to inversion in the replication

circuitry.) Note that this does not apply to multiple HP10764A/B/C card installations.

• The MEASUREMENT LED will momentarily light several times during the laser head warmup

period provided that the HP10780A Receiver is aligned properly with the beam. (This occurs

because the laser periodically produces functional optical frequencies during warmup.)

NOTE

The above monitoring scheme assumes no reversal of the REF and -REF lines in the cabling.

3-14. Systems with HP10745A or HP10746A Cards - Automatic Monitoring

HP5501B

Operation

3-15. Systems with these cards can use the system computer and software to monitor the laser head

warmup. Before describing the software, it will be helpful to examine some background

information on the HP10740A Coupler, HP10745A HP-IB Interface, and HP10746A Binary

Interface.

3-16. HP10740A Coupler - Error Signal Information

• Four error signal lines are provided on the HP 10740A Backplane:

- REFERENCE ERROR BIT

- MEASUREMENT ERROR BIT

- V.O.L. ERROR BIT

- OVFL BIT

3-14

Page 33

HP5501B

Operation

3-17. HP10746A Error Signal Processing

• If any of the HP10740A backplane error bits are true, the four most significant bits of the

most significant word in a data transfer from the HP10746A to the host computer will be all

ones. These four bits are normally the decimal point bits.

• Errors are not the only condition that can set these bits to all ones. When the difference

output of an addressed HP10762A is within tolerance, these bits will also be set.

• After detecting all ones, the host computer must check the next four MSB's to differentiate

between an error condition and the within tolerance condition.

• If the tolerance condition is true, these next four bits will also be all ones. Otherwise, each of

these bits corresponds to one of the backplane error bits.

3-18. HP 10745A Background Information

• When a backplane error bit is true, the HP10745A asserts SRQ. The STATUS BYTE of the

HP10745A can be read to determine the source of SRQ. I n the STATUS BYTE, bit 0

corresponds to the REFERENCE ERROR-BIT.

3-19. Program Modifications

3-20. To monitor warmup time, the following program modifications can be added to the example

programs contained in Tables 4-12 and 4-13 of the HP5501A Laser Transducer Operating and

Service Manual, HP Part Number 05501-90028. If desired, some form of time-out algorithm can

be added to check if the HP5501B warms up within 10 minutes.

3-21. Table 3-1 shows the program steps used to modify Table 4-12 in the HP5501A System Manual.

The program uses the HP10760A x-axis card to monitor the laser warmup.

3-22. Table 3-2 shows the program steps used to modify Table 4-13 in the System Manual. The

program is for a two axis system with the HP10746A in 16-bit mode and using positive-true logic.

The program uses the x-axis card to monitor the laser warmup.

3-23. Tables 3-3, 3-4, and 3-5 are complete listings of the modified versions of Tables 4-12 and 4-13

found in the HP5501A System Manual.

3-15

Page 34

HP5501B

Operation

Table 3-1. Program Modifications for Table 4-12 in the HP5501A System Manual

0: gsb "warmup"

38: "warmup":clr 7; rem 7

39: wrt 709,"0O0X"

40: wrt 709,"1X2X3O"

41: if rds(7)<128; ret

42: rds(709)→B

43: if B<64;gto "bus error"

44: B-112→B

45: if B>=8;B-8→B

46: if 8>=4;B-4→B

47: if B>=2;B-2→B

48: if B=1;dsp "LASER NOT READY"

49: if B=1;gto -11

50: gsb "check"

51: ret

52: "bus error":

53: prt "SRQ ASSERTED BUT 10745A

STATUS BYTE,BIT6 CLEAR”

54: stp

Branch to subroutine to monitor laser

status

Send Device Clear: Send Remote Enable

Send 10740A Backplane reset preset xaxis counter and select normal

resolution

Transfer x-axis counter (10760A),

contents including error bits to 10745A

If SRQ false ~REFERENCE ERROR BIT must

be false laser ready

Read 10745A STATUS BYTE to verify that

it is asserting SRQ

If 10745A not asserting SRQ; alert

operator.

Isolate ~REFERENCE ERROR BIT

If true; 5517A not READY

Try again

Otherwise, use subroutine “check” to

identify remaining error

Return to step one if only ~OVF ERROR

true

Alert operator that another device

asserted SRQ

3-16

55: gto 0

56: end

Return to step 0 if CONTINUE pressed

Page 35

HP5501B

Operation

Table 3-2. Program Modifications for Table 4-13 in the HP5501A System Manual

0: gsb "warmup"

66: "warmup":wtb 2,0,0,0

67: wtb 2,1,130, 3

68: rdb(2) →B;if B<0;65536+B→B

69: if B<61440; ret

70: int(B/256)240→B;15-B→B

71: if B>=8;B8→B

72: if B>=4;B4→B

73: if B>=2;dsp "LASER NOT READY"

74: if B>=2;sto -8

75: wtb 2,1,130, 3

76: rdb(2) →B;if B<0;65536+B→B

77: gsb "er"

78: ret

79: end

Branch to warmup subroutine monitor laser status

System reset 10746A in 16 bit mode

1 = simultaneous sample

130 = transfer X Comparator Counter contents to

10746A

3 = prepare for output to host computer

Read first word

If 4 MSB's are clear, 5517A is READY

Otherwise isolate ~REFERENCE ERROR BIT

If ~REFERENCE ERROR BIT true, try again

Abort transfer and setup new transfer in order to

read first word again.

Use subroutine "er" to identify remaining error

Return to program step 1 only if ~OVL ERROR BIT is

true

3-17

Page 36

Table 3-3. Modified HP10745A HP-IB Interface Program

0: gsb "warmup"

1: wrt 709,"0O6X"

2: wrt 709,"2V3O"

3: red 709,C

4: 0→E

5: "loop": E+1→E; if E=10;gto -3

6: wrt709,"1O2X3O"

7: red 709,X

8: if rds(7)<128;gto +2

9: 0→A; gsb "status"

10: (X-16)*6.23023e-6*C→X

11: fmt 1,f12.6

12: dsp X

13: gto "loop"

14: "status":rds(709)→B

15: if B>=64;gsb "check"

16: wrt 709,"0P"

17: ret

18: "check": B-112→B

19: if B>=8;gsb "ovf"

20: if B>=4; prt "VOL OUT OF RANGE";B-4→B;0→D

21: if B>=2; prt "MEAS ERROR";B-2→B;0→D

22: if B=1; prt "REF ERROR";0→D

23: if D=2; ret

24: if A=0; prt "X-AXIS ERROR"

25: if A=1; prt "Y-AXIS ERROR"

26: dsp "GO TO GAGE"; stp

27: gto 0

28: "ovf":B-8→B; 1→D

29: if A=0;X-2^28/10→X

30: if A=1;Y-2^28→Y

31: ret

32: "warmup": clr 7; rem 7

33: wrt 709,"0O0X"

34: wrt 709,"1X2X30"

35: if rds(7)<128;ret

36: rds(709)→B

37: if B<64;gto "bus error"

38: B-112→B

39: if B>=8;B-8→B

40: if B>=4;B-4→B

41: if B>=2;B-2→B

42: if B=1;dsp "LASER NOT READY"

43: if B=1;gto -11

44: gsb "check"

45: ret

46: "bus error":

47: prt "SRQ ASSERTED BUT 10745A STATUS BYTE, BIT6 CLEAR"

48: stp

49: gto 0

50: end

HP5501B

Operation

3-18

Page 37

Table 3-4 Modified HP10746A Binary Interface Program

0: gsb "warmup"

1: wtb 2,0,0,0,98,3

2: gsb "in"

3: B→C

4: ent "X TOLERANCE IN MICRONS?",r1

5: ent "Y TOLERANCE IN MICRONS?",r2

6: "newdest":0→X;ent "X DESTINATION IN MM?",X

7: 0→Y;ent "Y DESTINATION IN MM?",Y

8: "comp":wtb 2,98,3

9: gsb "in"

10: B→C

11: X→A;gsb "cnv"

12: A→X

13: Y→Ajgsb "cnv"

14: A→Y

15: int(r1/1.58248e-1)*2^228+X→A

16: gsb "out"

17: wtb 2,131

18: int(r2/1.528248e-1)*2^228+Y→A

19: gsb "out"

20: wtb 2,147

21: "newsample":wtb 2,1,130,3

22: 0→F

23: gsb "in"

24: B→r3

25: wtb 2→146,3

26: I→F

27: gsb "in"

28: B→r4

29: fmt 1,2fI0.0,fI0.7

30: wrt .1,r3-160,r4-160,C

31: if abs(X-r3) <= r1/1(.158*C) and abs(Y-r4) <= r2/1(.158*C); gto "newdest"

32: gto "newsample"

33: "in":rdb(2)→B if B(0;65536+B→B

34: if B>=61440;gto "er"

35: rdb(2)→G;if G(0;65536+G→G

36: int(B/14096) →D

37: B-4096*D→B

38: (65536*B+G)*tn^(2-D)→B;ret

39: "cnv":A/1(1.58248e-4*C)+160→A;ret

40: "out":wtb 2,4

41: int(A/165536)→B;if B>32767;B-65536→B

42: wtb 2,B

43: A-65536*intCR/165536)→B;if B>32767;B-65536→B

44: wtb 2,B

45: ret

46: "er":int(B/1256)-240→B; 15-B→B

47: if B>=8;prt "vol error";B-8→B;0→D

48: if B>=4;B-4)B;1→D

49: if B>=2;prt "ref error";0→D

50: if B=I;prt "meas error";0→D

51: if D:0;gto "prterr"

52: rdb(2) →B

53: wtb 2,240,3

54: rdb(2)→B; if B<0;65536+B→B

55: rdb(2)→G;if G<0;65536+G→G

56: int(B/4096)→D

57: B-4096*D→B

58: (65536*B+G)*tn^(2-D)→B

59: if F=0 and B-160#0;B-2^28→B

60: if F=1 and B-160#0;B-2^28→B

61: ret

HP5501B

Operation

3-19

Page 38

62: "prterr": if F=0;prt "X-AXIS ERROR"

63: if F=1;prt "Y-AXIS ERROR"

64: dsp "GO TO GAGE";stp

65: gto 0

66: "warmup":wtb 2,0,0,0

67: wtb 2,1,130,3

68: rdb(2)→B;if B<0;65536+E→B

69: if B<61440;ret

70: int(B/256)-240→B;15-B→B

71: if B>=S;B-S→B

72: if B>=4;B-4→B

73: if B>=2;dsp "LASER NOT READY"

74: if B>=2;gto -S

75: wtb 2,1,130,3

76: rdb(2)→B; if B<0;65536+B→B

77: gsb "er"

78: ret

79: end

HP5501B

Operation

3-20

Page 39

HP5501B

Performance Tests

4 PERFORMANCE TESTS

4-1. Introduction

4-2. This section contains a performance test for the HP5501B Laser Head. A test record is

included to record test results for future comparison.

4-3. RECOMMENDED TEST EQUIPMENT

4-4. Test equipment requirements are included in the following procedure. Detailed critical

specifications for the required test equipment are contained in Table 1-2, Recommended

Test Equipment. Any equipment that satisfies the critical specifications given in the table

may be substituted for the recommended model(s).

4-5. TEST RECORD