Page 1

HP 5500 EI & 5500 SI Switch Series

Installation Guide

Part number: 5998-1710

Document version: 6W101-20130630

Page 2

Legal and notice information

© Copyright 2011-2013 Hewlett-Packard Development Company, L.P.

No part of this documentation may be reproduced or transmitted in any form or by any means without

prior written consent of Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice.

HEWLETT-PACKARD COMPANY MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS

MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE. Hewlett-Packard shall not be liable for errors contained

herein or for incidental or consequential damages in connection with the furnishing, performance, or

use of this material.

The only warranties for HP products and services are set forth in the express warranty statements

accompanying such products and services. Nothing herein should be construed as constituting an

additional warranty. HP shall not be liable for technical or editorial errors or omissions contained

herein.

Page 3

Contents

Preparing for installation ············································································································································· 1

Safety recommendations ·················································································································································· 1

Examining the installation site ········································································································································· 1

Temperature/humidity ············································································································································· 1

Cleanness ·································································································································································· 2

EMI ············································································································································································· 2

Laser safety ································································································································································ 2

Installation tools ································································································································································· 3

Installing the switch ······················································································································································ 4

Installing the switch in a 19-inch rack ····························································································································· 5

Mounting brackets ···················································································································································· 6

Rack-mounting by using only front mounting brackets ························································································· 7

Rack-mounting by using front mounting brackets and a rack shelf ····································································· 8

Rack-mounting by using front and rear mounting brackets ·················································································· 9

Mounting the switch on a workbench ·························································································································· 12

Grounding the switch ···················································································································································· 12

Grounding the switch with a grounding strip ····································································································· 13

Grounding the switch with a grounding conductor buried in the earth ground ············································· 15

Grounding the switch by using the AC power cord ·························································································· 16

Installing/removing a power supply ···························································································································· 16

Installing a power supply ····································································································································· 16

Removing a power supply ···································································································································· 17

Connecting the power cord ·········································································································································· 18

Connecting the AC power cord ··························································································································· 18

Connecting the PSR150-D/PSR150-D1 to a –48 VDC power source ····························································· 19

Connect the switch to a +12 VDC output RPS ··································································································· 20

Connecting the switch to a –52 to –55 VDC output RPS ·················································································· 20

Installing/removing an interface card ························································································································· 21

Installing an interface card ··································································································································· 21

Removing an interface card ································································································································· 22

Installing/removing a dedicated CX4/SFP+ cable ··························································································· 23

Verifying the installation ················································································································································ 23

Accessing the switch for the first time ······················································································································· 24

Setting up the configuration environment ···················································································································· 24

Connecting the console cable ······································································································································ 24

Console cable ························································································································································ 24

Connection procedure ·········································································································································· 24

Setting terminal parameters ·········································································································································· 25

i

Page 4

Powering on the switch·················································································································································· 28

Setting up an IRF fabric ············································································································································· 29

IRF fabric setup flowchart ·············································································································································· 29

Planning IRF fabric setup ··············································································································································· 30

Planning IRF fabric size and the installation site ································································································ 30

Identifying the master switch and planning IRF member IDs ············································································ 30

Planning IRF topology and connections ·············································································································· 31

Identifying physical IRF ports on the member switches ····················································································· 32

Planning the cabling scheme ······························································································································· 32

Configuring basic IRF settings ······································································································································· 33

Connecting the physical IRF ports ································································································································ 34

Accessing the IRF fabric to verify the configuration ··································································································· 34

Maintenance and troubleshooting ···························································································································· 35

Power supply failure ······················································································································································ 35

Built-in power supply failure ································································································································· 35

Hot swappable power supply failure ·················································································································· 36

Fan failure ······································································································································································· 36

Configuration terminal problems ·································································································································· 37

Appendix A Chassis views and technical specifications ························································································ 38

Chassis views ································································································································································· 39

5500-24G EI (2 slots)/5500-24G EI TAA (2 slots)/5500-24G SI (2 slots) ··················································· 39

5500-48G EI (2 slots)/5500-48G EI TAA (2 slots)/5500-48G SI (2 slots) ··················································· 40

5500-24G-SFP EI (2 slots)/5500-24G-SFP EI TAA (2 slots) ············································································· 41

5500-24G-PoE+ EI (2 slots)/5500-24G-PoE+ EI TAA (2 slots)/5500-24G-PoE+ SI (2 slots) ······················ 42

5500-48G-PoE+ EI (2 slots)/5500-48G-PoE+ EI TAA (2 slots)/5500-48G-PoE+ SI (2 slots) ······················ 43

Technical specifications ················································································································································· 43

Chassis dimensions and weights ························································································································· 43

Ports and interface card slots ······························································································································· 44

Environmental specifications ········································································································································· 45

Power specifications ······················································································································································ 45

Power input types ·················································································································································· 45

AC input voltage specifications ··························································································································· 45

RPS DC input voltage specifications and RPS compatibility ············································································· 46

Power consumption specifications for non-PoE switches ··················································································· 46

Power consumption specifications for PoE switches ·························································································· 46

Cooling system ······················································································································································ 47

Appendix B FRUs and compatibility matrixes ·········································································································· 48

Hot swappable power supplies ···································································································································· 48

Interface cards ································································································································································ 48

SFP/SFP+/XFP transceiver modules and SFP+/CX4 cables ····················································································· 49

GE SFP transceiver modules ································································································································· 50

FE SFP transceiver modules ·································································································································· 50

ii

Page 5

10-GE SFP+ transceiver modules ························································································································· 51

SFP+ cables ···························································································································································· 52

10-GE XFP transceiver modules ··························································································································· 52

CX4 cables ····························································································································································· 53

Appendix C Ports and LEDs ······································································································································ 54

Ports ················································································································································································· 54

Console port ·························································································································································· 54

10/100/1000Base-T Ethernet port ···················································································································· 54

SFP port ·································································································································································· 54

Combo interface ···················································································································································· 55

LEDs ················································································································································································· 55

System status LED··················································································································································· 56

Power supply status LEDs ······································································································································ 56

RPS status LED ························································································································································ 56

Port mode LED ························································································································································ 57

Seven-segment LED ················································································································································ 57

10/100/1000Base-T Ethernet port LED ············································································································· 58

SFP port status LED ················································································································································ 59

Interface card status LED ······································································································································· 60

Support and other resources ····································································································································· 61

Contacting HP ································································································································································ 61

Subscription service ·············································································································································· 61

Related information ························································································································································ 61

Documents ······························································································································································ 61

Websites ································································································································································· 61

Conventions ···································································································································································· 62

Index ··········································································································································································· 64

iii

Page 6

Preparing for installation

Safety recommendations

To avoid any equipment damage or bodily injury caused by improper use, read the following safety

recommendations before installation. Note that the recommendations do not cover every possible

hazardous condition.

• Before cleaning the switch, unplug all power cords. Do not clean the switch with wet cloth or liquid.

• Do not place the switch near water or in a damp environment. Prevent water or moisture from

entering the switch chassis.

• Do not place the switch on an unstable case or desk. The switch might be severely damaged in case

of a fall.

• Ensure proper ventilation of the equipment room and keep the air inlet and outlet vents of the switch

free of obstruction.

• Make sure the operating voltage is in the required range.

• To avoid electrical shocks, do not open the chassis while the switch is operating or when the switch

is just powered off.

• When replacing FRUs, wear an ESD-preventive wrist strap to avoid damaging the units.

Examining the installation site

The 5500 EI and 5500 SI switches must be used indoors. You can mount your switch in a rack or on a

workbench, but make sure:

• Adequate clearance is reserved at the air inlet and exhaust vents for ventilation.

• The rack or workbench has a good ventilation system.

• The rack is sturdy enough to support the switch and its accessories.

• The rack or workbench is well earthed.

To ensure normal operation and long service life of your switch, install it in an environment that meets the

requirements described in the following subsections.

Temperature/humidity

Maintain appropriate temperature and humidity in the equipment room.

• Lasting high relative humidity can cause poor insulation, electricity creepage, mechanical property

change of materials, and metal corrosion.

• Lasting low relative humidity can cause washer contraction and ESD and bring problems including

loose captive screws and circuit failure.

• High temperature can accelerate the aging of insulation materials and significantly lower the

reliability and lifespan of the switch.

For the temperature and humidity requirements, see "Environmental specifications."

1

Page 7

p

g

W

g

Cleanness

Dust buildup on the chassis may result in electrostatic adsorption, which causes poor contact of metal

components and contact points, especially when indoor relative humidity is low. In the worst case,

electrostatic adsorption can cause communication failure.

Table 1 Dust concentration limit in the equipment room

EMI

Substance Concentration limit (

Dust

NOTE:

Dust diameter ≥ 5 μm

≤ 3 x 104 (no visible dust on the tabletop over three days)

articles/m³)

The equipment room must also meet strict limits on salts, acids, and sulfides to eliminate corrosion and

premature aging of components, as shown in Table 2.

Table 2 Harmful gas li

Gas Maximum concentration (m

SO

2

H2S 0.006

NH3 0.05

Cl2 0.01

mits in the equipment room

/m3)

0.2

All electromagnetic interference (EMI) sources, from outside or inside of the switch and application

system, adversely affect the switch in a conduction pattern of capacitance coupling, inductance coupling,

electromagnetic wave radiation, or common impedance (including the grounding system) coupling. To

prevent EMI, take the following actions:

• If AC power is used, use a single-phase three-wire power receptacle with protection earth (PE) to

filter interference from the power grid.

• Keep the switch far away from radio transmitting stations, radar stations, and high-frequency

devices.

• Use electromagnetic shielding, for example, shielded interface cables, when necessary.

• Route interface cables only indoors to prevent signal ports from getting damaged by overvoltage or

overcurrent caused by lightning strikes.

Laser safety

The 5500 EI and 5500 SI switches are Class 1 laser devices.

ARNING!

Do not stare into any fiber port when the switch has power. The laser li

may hurt your eyes.

ht emitted from the optical fiber

2

Page 8

Installation tools

• Flathead screwdriver

• Phillips screwdriver

• Needle-nose pliers

• Wire-stripping pliers

• Diagonal pliers

• ESD-preventive wrist strap

• Blow dryer

All these installation tools are user supplied.

3

Page 9

g

g

Installing the switch

CAUTION:

Keep the tamper-proof seal on a mountin

chassis, contact your local HP a

caused thereby.

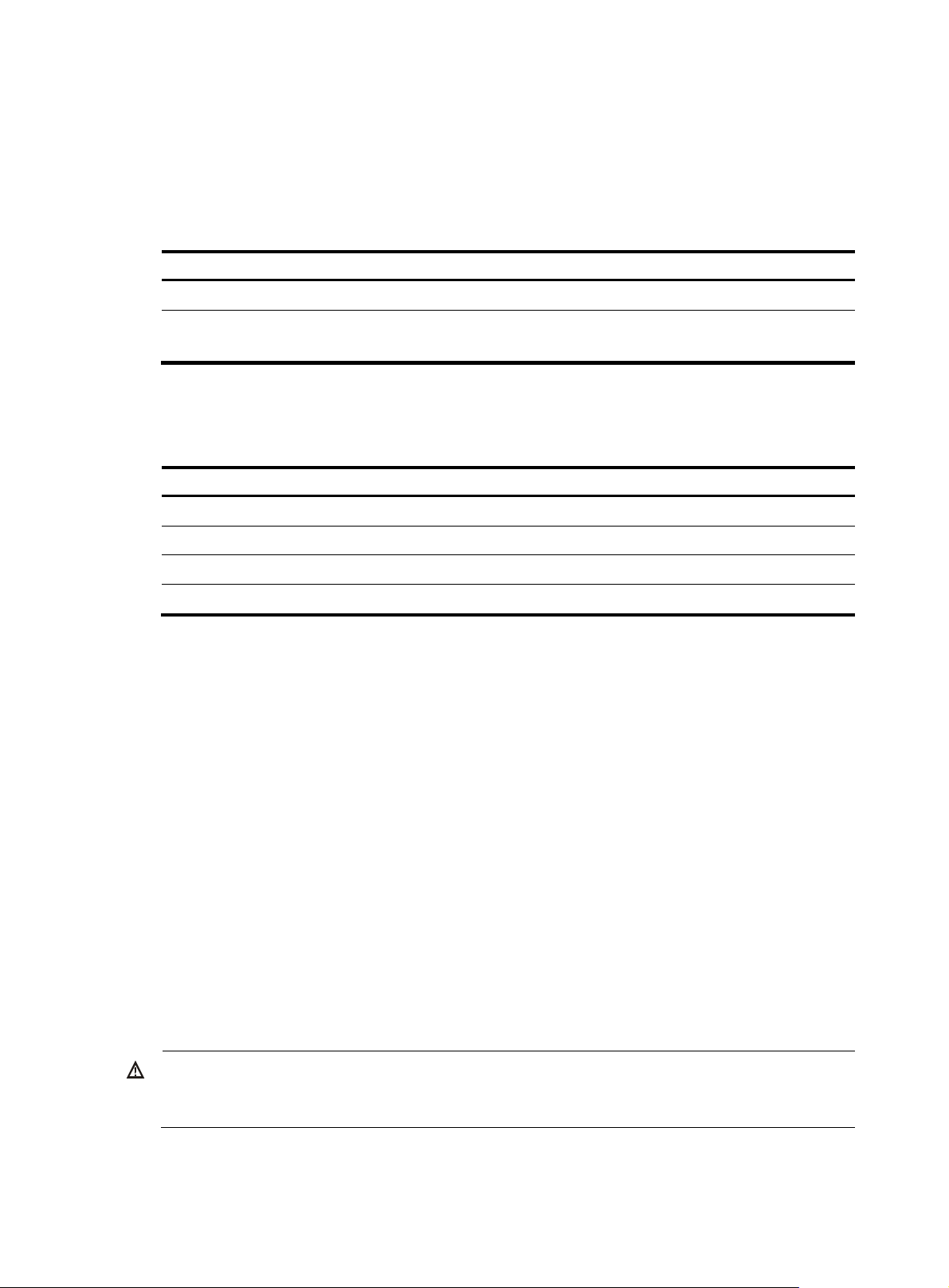

Figure 1 Hardware installation flow

ent for permission. Otherwise, HP shall not be liable for any consequence

screw on the chassis cover intact, and if you want to open the

4

Page 10

y

weight

Installing the switch in a 19-inch rack

You can install the switch in a 19-inch standard rack by using different mounting positions. Table 3 shows

the installation methods available for the switches of different depths.

Table 3 Installation methods

Use front

Chassis Depth

mounting

brackets

onl

5500-24G EI (2 slots)

5500-24G EI TAA (2 slots)

5500-24G SI (2 slots)

5500-48G EI (2 slots)

5500-48G EI TAA (2 slots)

5500-48G SI (2 slots)

5500-24G-SFP EI (2 slots)

5500-24G-SFP EI TAA (2 slots)

5500-24G-PoE+ EI (2 slots)

5500-24G-PoE+ EI TAA (2 slots)

5500-24G-PoE+ SI (2 slots)

5500-48G-PoE+ EI (2 slots)

5500-48G-PoE+ EI TAA (2 slots)

5500-48G-PoE+ SI (2 slots)

300 mm

(11.81 in)

360 mm

(14.17 in)

420 mm

(16.54 in)

Yes (see

"Rack-mounti

ng by using

only front

mounting

brac

kets"

No

No

Use front mounting

brackets and a rack

shelf

Yes (see

"Rack-mounting by

using front mounting

brackets and a rack

shelf")

Yes (see

"Rack-mounting by

using front mounting

brackets and a rack

shelf")

Yes (see

"Rack-mounting by

using front mounting

brackets and a rack

shelf")

Use front and

rear mounting

brackets

No

Yes (see

"Rack-mounting

by using front

and rear

mounting

brac

kets")

Yes (see

"Rack-mounting

by using front

and rear

mounting

brac

kets")

NOTE:

For a switch with a depth greater than 300 mm (11.81 in), the front mounting brackets are not

-bearing.

5

Page 11

g

Mounting brackets

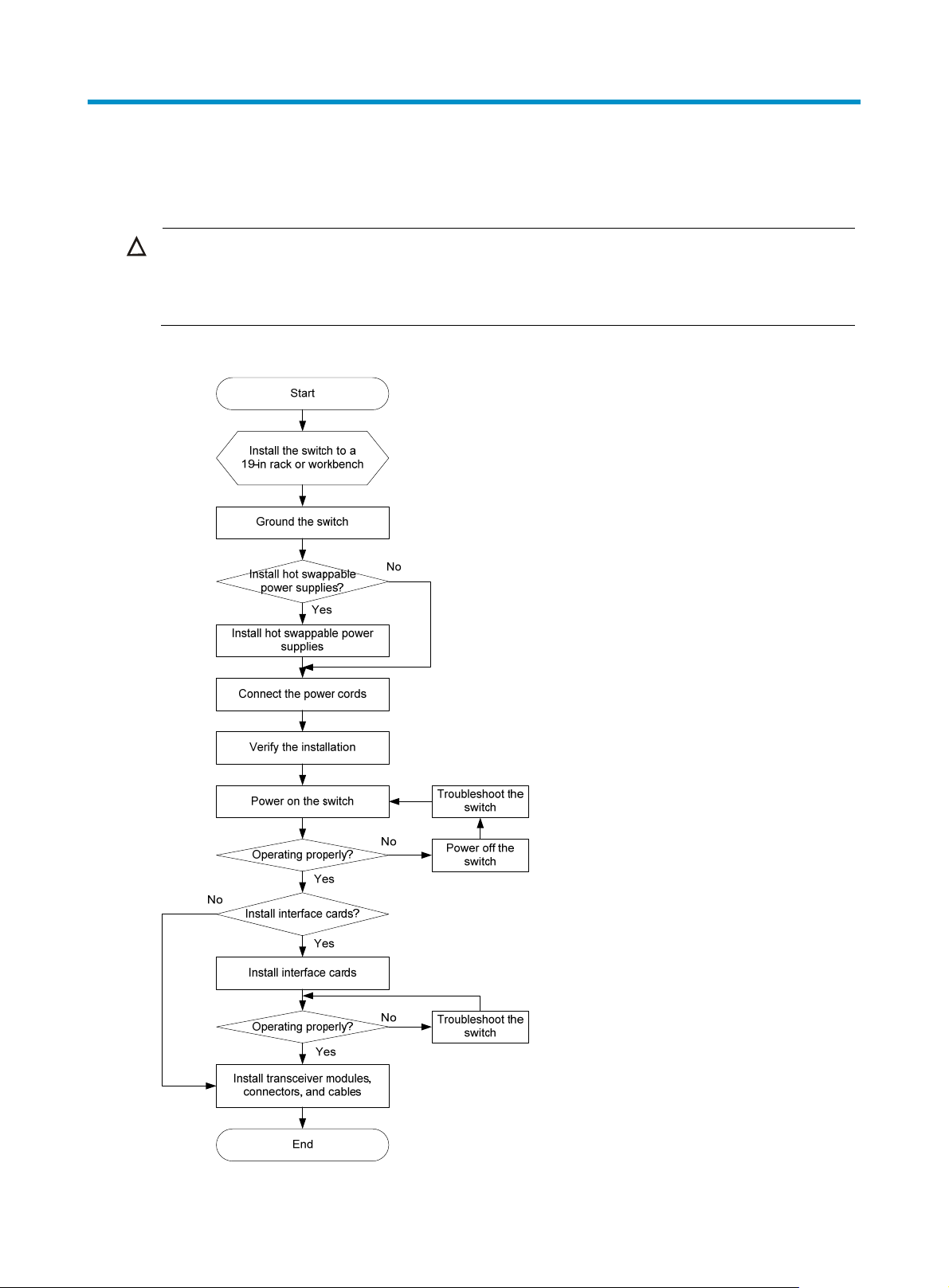

Figure 2 Front mounting bracket

(1) Hole for attaching to a rack (by using an M6 screw)

(2) Hole for attaching to the switch chassis

Figure 3 Rear mounting bracket

(1) Hole for attaching to a rack (by using an M6 screw)

NOTE:

The M6 screws for attaching the brackets to a rack are user supplied.

Table 4 shows the mounting bracket shipment for different switch models.

Table 4 Mounting bracket kit shipped with the 5500 EI and 5500 SI switches

Chassis Front mountin

5500-24G EI (2 slots)

5500-24G EI TAA (2 slots)

5500-48G EI (2 slots)

5500-48G EI TAA (2 slots)

5500-24G SI (2 slots)

5500-48G SI (2 slots)

One pair N/A

6

brackets

Rear mounting brackets

Page 12

Chassis Front mounting brackets

5500-24G-SFP EI (2 slots)

5500-24G-SFP EI TAA (2 slots)

5500-24G-PoE+ EI (2 slots)

5500-24G-PoE+ EI TAA (2 slots)

5500-48G-PoE+ EI (2 slots)

5500-48G-PoE+ EI TAA (2 slots)

5500-24G-PoE+ SI (2 slots)

5500-48G-PoE+ SI (2 slots)

One pair One pair

One pair One pair

Rear mounting brackets

Rack-mounting by using only front mounting brackets

This installation method is available only for the 5500-24G EI (2 slots), 5500-24G EI TAA (2 slots),

5500-48G EI (2 slots), 5500-48G EI TAA (2 slots), 5500-24G SI (2 slots), and 5500-48G SI (2 slots)

switches.

This task requires two persons.

To mount a switch in a 19-inch standard rack by using only the front mounting brackets:

1. Wear an ESD-preventive wrist strap and make sure it makes good skin contact and is well

grounded.

2. Verify that the rack is well grounded and can support the weight of the switch chassis and all its

accessories.

3. Unpack the front mounting brackets and the screws for attaching the brackets to the switch chassis.

4. Align the round holes in one bracket with the holes in the front mounting position of the switch

chassis, and use the screws to attach the mounting bracket to the chassis, as shown in Figure 4.

5. R

epeat the previous step to attach the other mounting bracket to the chassis.

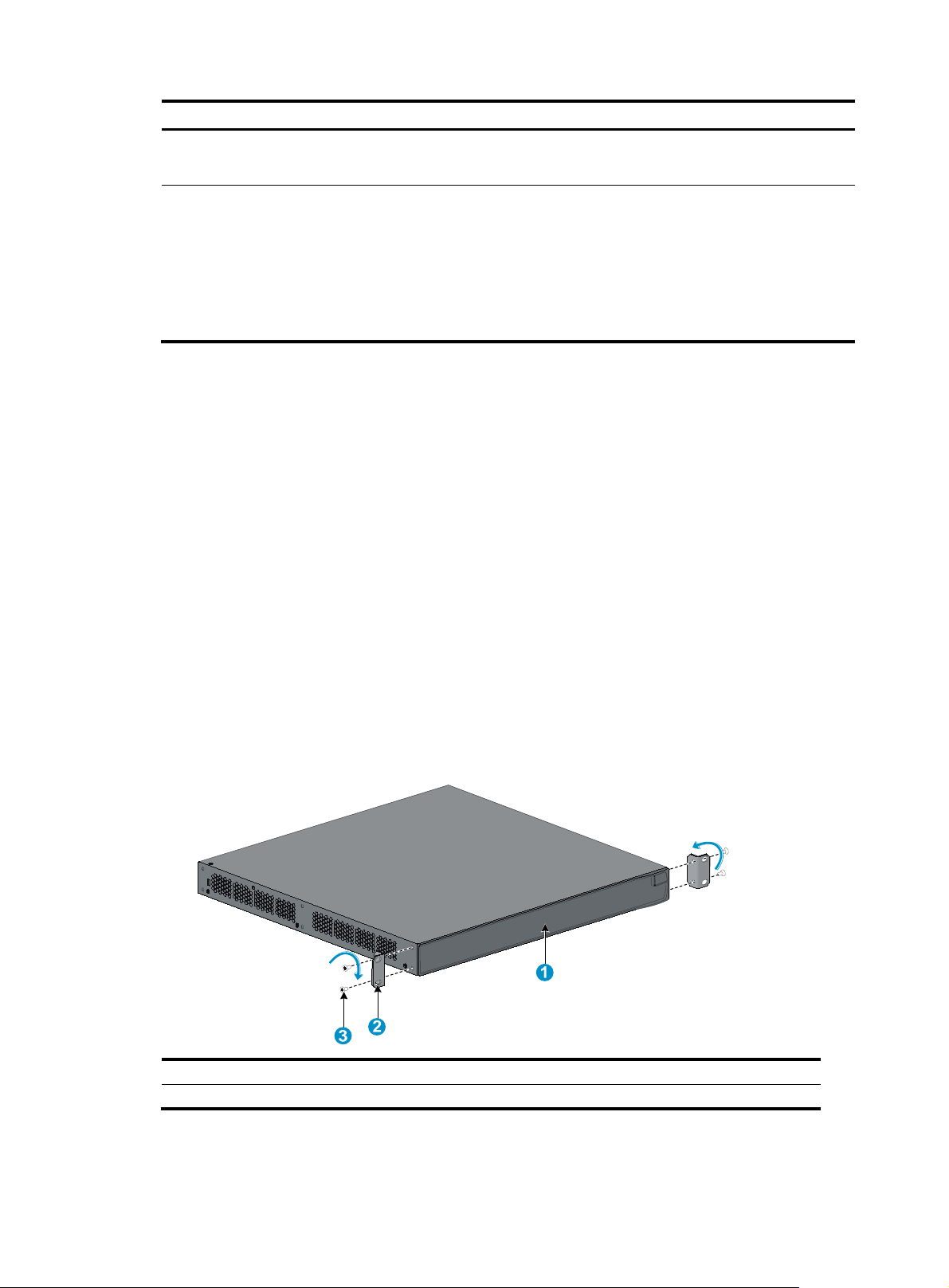

Figure 4 Attaching the front mounting brackets to the chassis

(1) Front panel of the switch (2) Front mounting bracket

(3) Screw

6. Install cage nuts (user-supplied) in the mounting holes in the rack posts.

7

Page 13

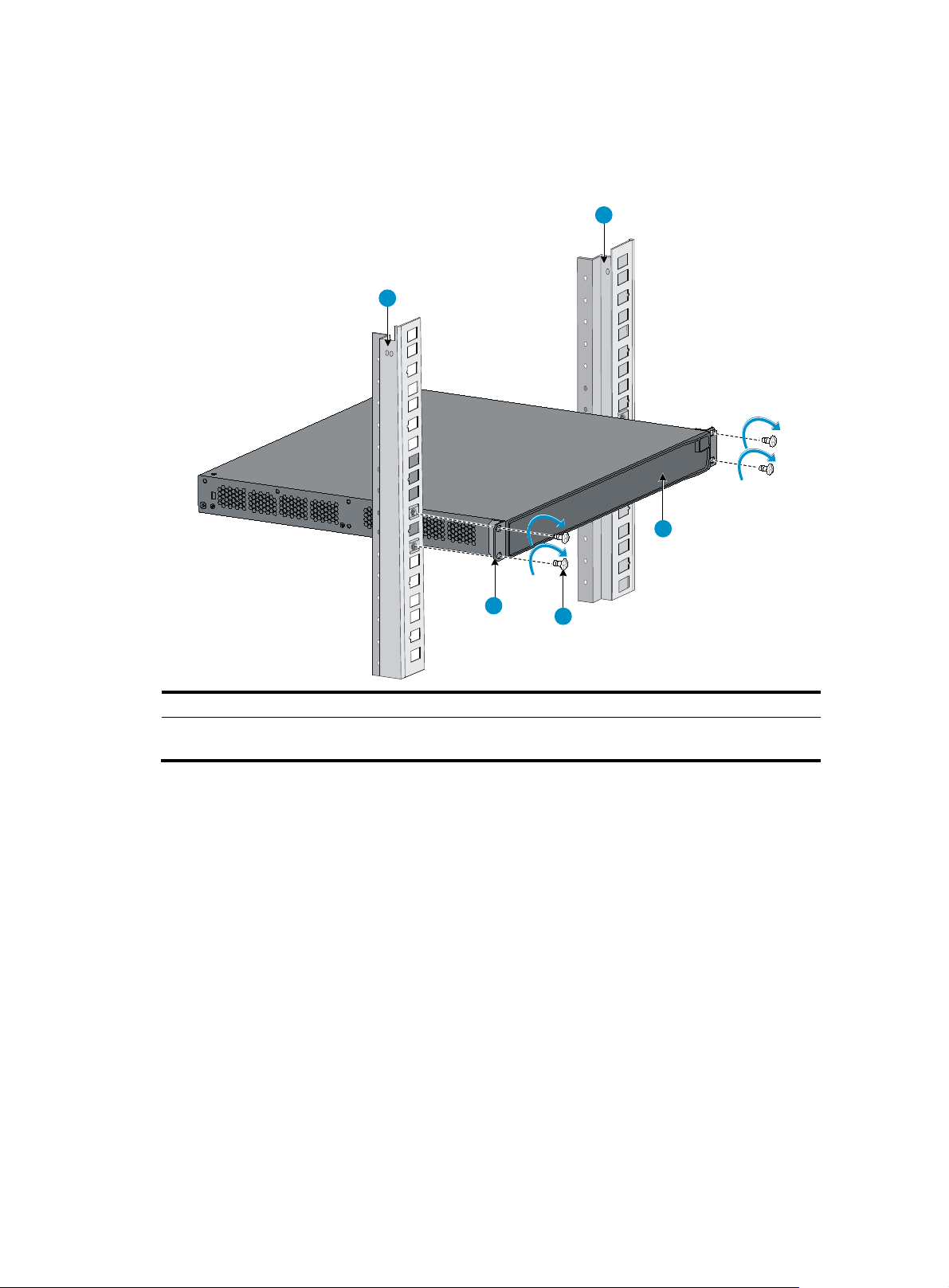

7. One person holds the switch chassis and aligns the oval holes in the brackets with the mounting

holes in the rack posts, and the other person attaches the mounting brackets with M6 screws

(user-supplied) to the rack, as shown in Figure 5.

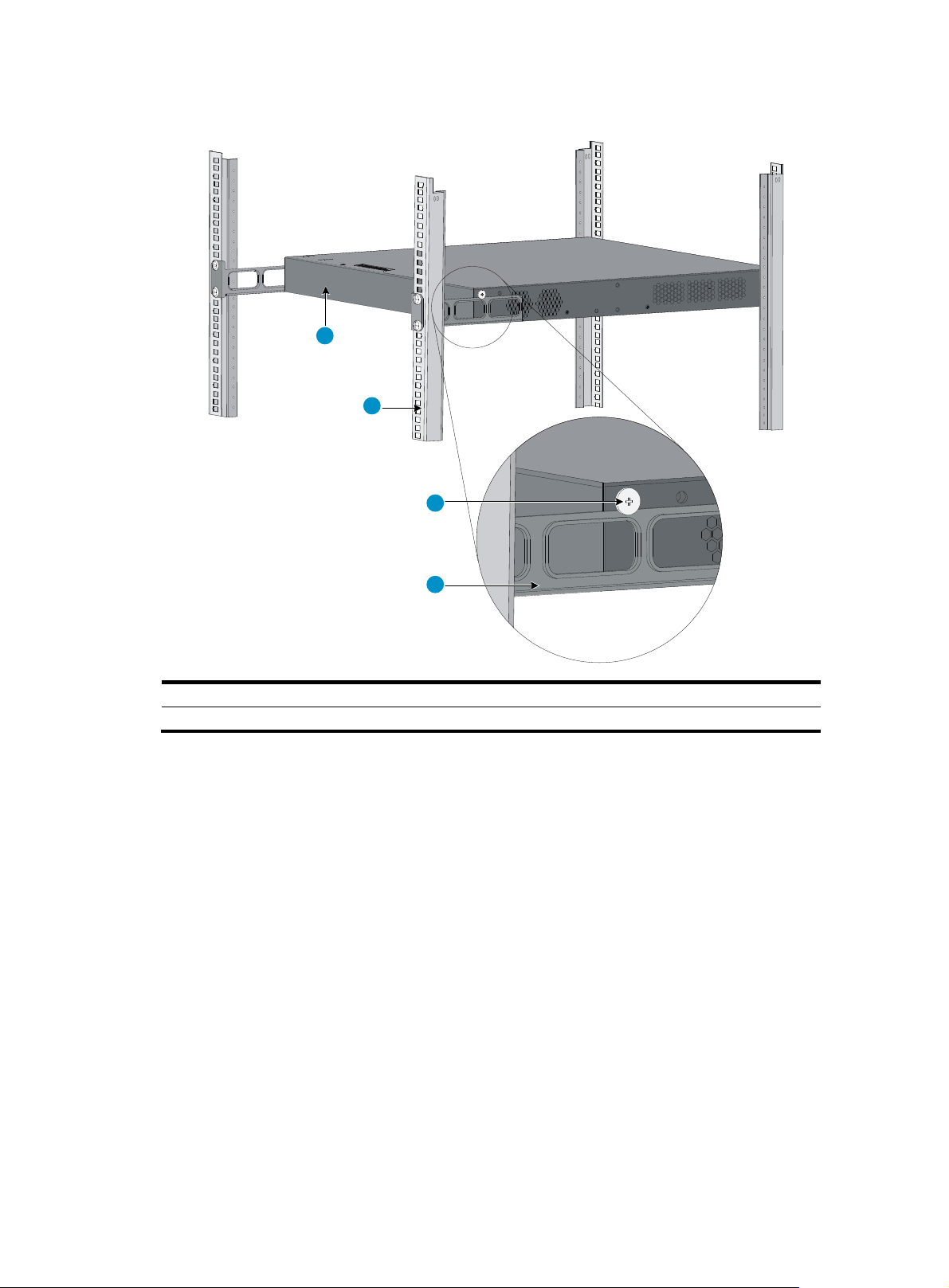

Figure 5 Attaching th

e front mounting brackets to the rack

1

4

3

1

2

(1) Front square-holed post (2) Front panel

(3) Screw for attaching the front mounting brackets to the square-holed

post

(4) Front mounting bracket

Rack-mounting by using front mounting brackets and a rack shelf

This installation method is available for all 5500 EI and 5500 SI switches.

To mount a switch in a 19-inch rack by using the front mounting brackets and a rack shelf:

1. Wear an ESD-preventive wrist strap and make sure it makes good skin contact and is well

grounded.

2. Verify that the rack is well grounded and can support the weight of the switch chassis and all its

accessories.

3. Attach the rack shelf horizontally in a proper position in the rack.

4. Unpack the front mounting brackets and the screws for attaching the brackets to the switch chassis.

5. Align the round holes in one bracket with the holes in the front mounting position of the switch

chassis, and use the removed screws to attach the mounting bracket to the chassis, as shown

in Figure 4.

epeat the previous step to attach the other mounting bracket to the chassis.

6. R

8

Page 14

weig

7. Install cage nuts (user-supplied) in the mounting holes in the rack posts.

8. Place the switch on the rack shelf, push it into the rack until the brackets touch the rack posts, and

attach the mounting brackets with M6 screws (user-supplied) to the rack, as shown in Figure 5.

Rack-mounting by using front and rear mounting brackets

This installation method is available only for the 5500-24G-PoE+ EI (2 slots), 5500-24G-PoE+ EI TAA (2

slots), 5500-48G-PoE+ EI (2 slots), 5500-48G-PoE+ EI TAA (2 slots), 5500-24G-PoE+ SI (2 slots),

5500-48G-PoE+ SI (2 slots), 5500-24G-SFP EI (2 slots), and 5500-24G-SFP EI TAA (2 slots) switches.

This task requires two persons.

To install the switch in a 19-inch rack by using the front and rear mounting brackets:

1. Wear an ESD-preventive wrist strap and make sure it makes good skin contact and is well

grounded.

2. Unpack the front mounting brackets and the screws for attaching the brackets to the switch chassis.

3. Align the round holes in one front mounting bracket with the holes in the front mounting position of

the switch chassis, and use the removed screws to attach the mounting bracket to the chassis, as

shown in Figure 4.

4. R

epeat the previous step to attach the other front mounting bracket to the chassis.

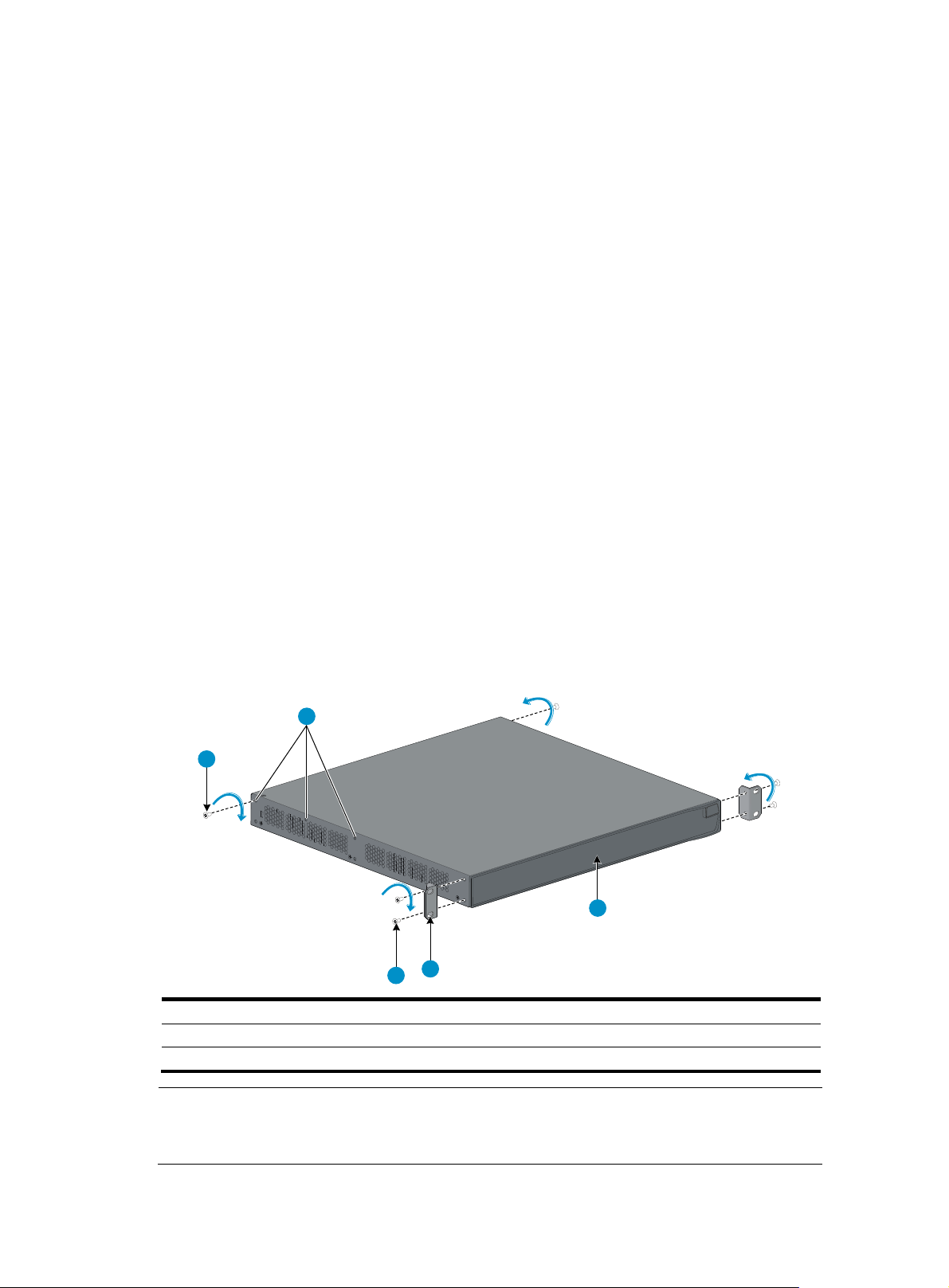

5. Unpack the rear mounting brackets and the load-bearing screws.

6. Attach the load-bearing screws in one of the rear mounting positions (see callout 2 in Figure 6) a

needed.

The 5500-24G-SFP EI (2 slots) and 5500-24G-SFP EI TAA (2 slots) switches have only two of the

rear mounting positions.

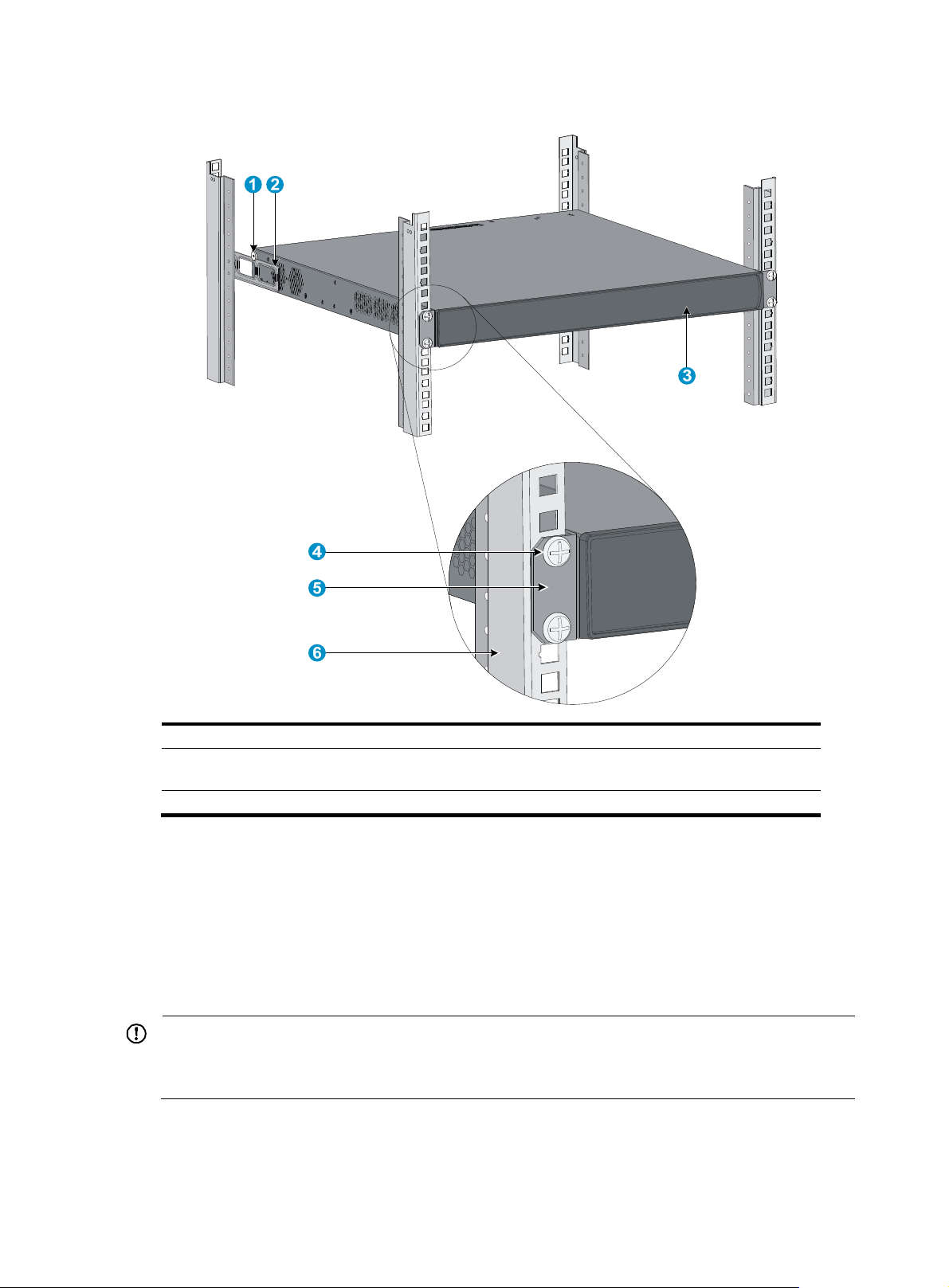

Figure 6 Attaching the front mounting brackets and load-bearing screws to the switch chassis

2

1

3

4

5

s

(1) Load-bearing screw (2) Rear mounting positions

(3) Front panel (4) Front mounting bracket

(5) Screw for attaching the front mounting brackets to the switch

NOTE:

The rear mounting brackets must closely contact with the load-bearing screws to support the chassis

ht.

9

Page 15

7. Install cage nuts (user-supplied) in the mounting holes in the front and rear rack posts.

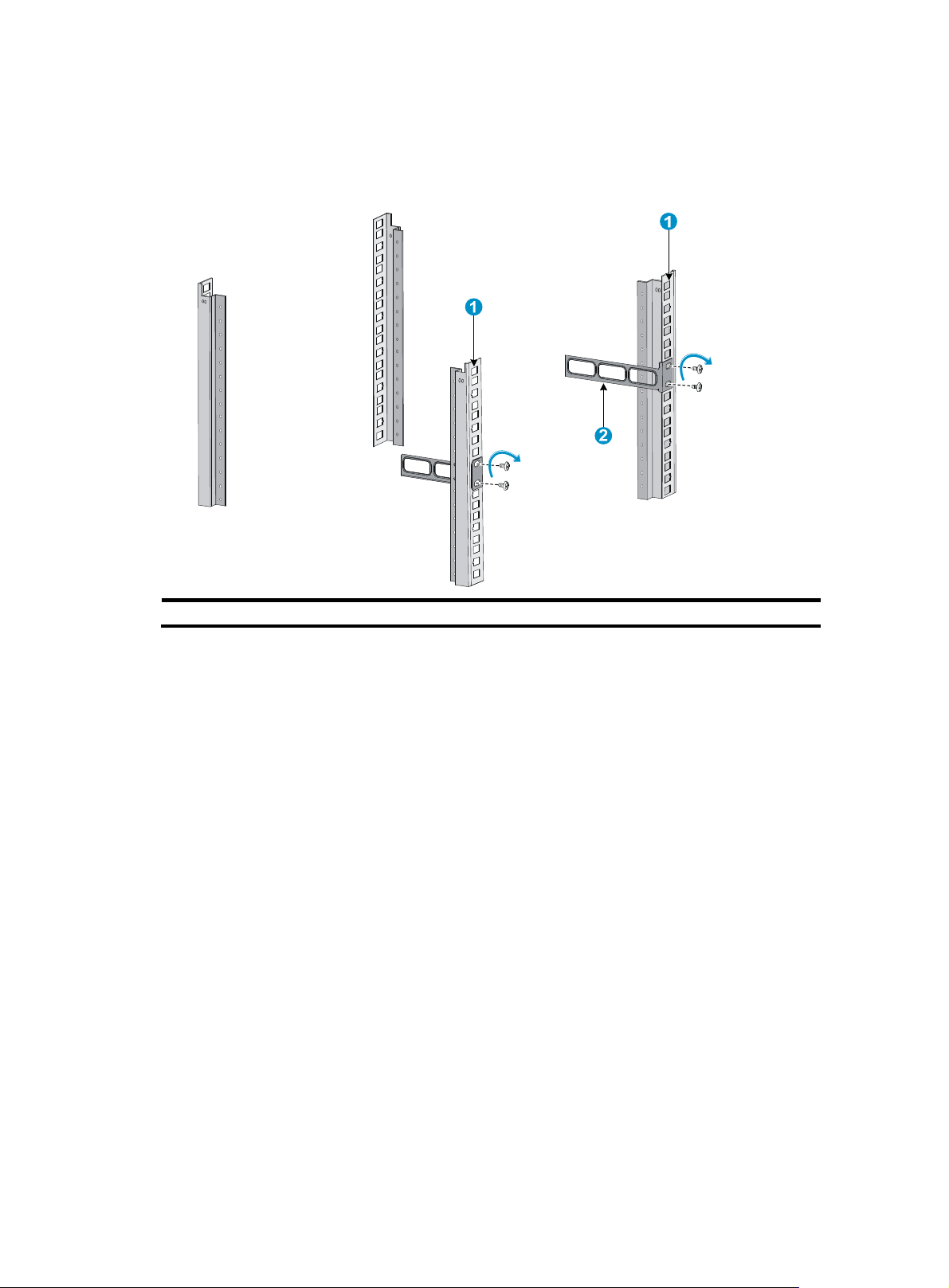

8. Attach the rear mounting brackets to the rear posts with M6 screws (user supplied), as shown

in Figure 7.

Figure 7 Attaching th

e rear mounting brackets to a rack

(1) Rear square-holed post (2) Rear mounting bracket

9. One person supports the chassis bottom with one hand, holds the front part of the chassis with the

other hand, and pushes the chassis into the rack gently.

Make sure the load-bearing screws closely contact with the upper edges of the rear mounting

brackets, as shown in Figure 8.

10

Page 16

Figure 8 Mounting the switch in the rack

1

2

3

4

(1) Rear panel (2) Rear square-holed post

(3) Load-bearing screw (4) Rear mounting bracket

10. The other person aligns the oval holes in the front brackets with the mounting holes in the front rack

posts, and attaches the front mounting brackets with M6 screws (user supplied) to the front rack

posts, as shown in Figure 9.

Make sure the front and rear mou

nting brackets have securely attached the switch in the rack.

11

Page 17

Figure 9 Attaching the front brackets to the rack

(1) Load-bearing screw (2) Rear mounting bracket

(3) Front panel (4) Screw used to attach front mounting brackets to front

brackets

(5) Front mounting bracket (6) Front square-holed post

Mounting the switch on a workbench

1. Verify that the workbench is sturdy and well grounded.

2. Place the switch with bottom up, and clean the round holes in the chassis bottom with dry cloth.

3. Attach the rubber feet to the four round holes in the chassis bottom.

4. Place the switch with upside up on the workbench.

IMPORTANT:

• Ensure good ventilation and 10 cm (3.9 in) of clearance around the chassis for heat dissipation.

• Avoid placing heavy objects on the switch.

Grounding the switch

12

Page 18

W

W

g

ARNING!

Correctly connecting the switch grounding cable is crucial to lightning protection and EMI protection.

The power and grounding terminals in this section are for illustration only.

The power input end of the switch has a noise filter, whose central ground is directly connected to the

chassis to form the chassis ground (commonly known as PGND). You must securely connect this chassis

ground to the earth so the faradism and leakage electricity can be safely released to the earth to

minimize EMI susceptibility of the switch.

You can ground the switch in one of the following ways, depending on the grounding conditions

available at the installation site:

• Grounding the switch with a grounding strip

• Grounding the switch with a grounding conductor buried in the earth ground

• Grounding the switch by using the AC power cord

Grounding the switch with a grounding strip

If a grounding strip is available at the installation site, connect the grounding cable to the grounding

strip.

ARNING!

Connect the

main or lightning rod.

CAUTION:

rounding cable to the grounding system in the equipment room. Do not connect it to a fire

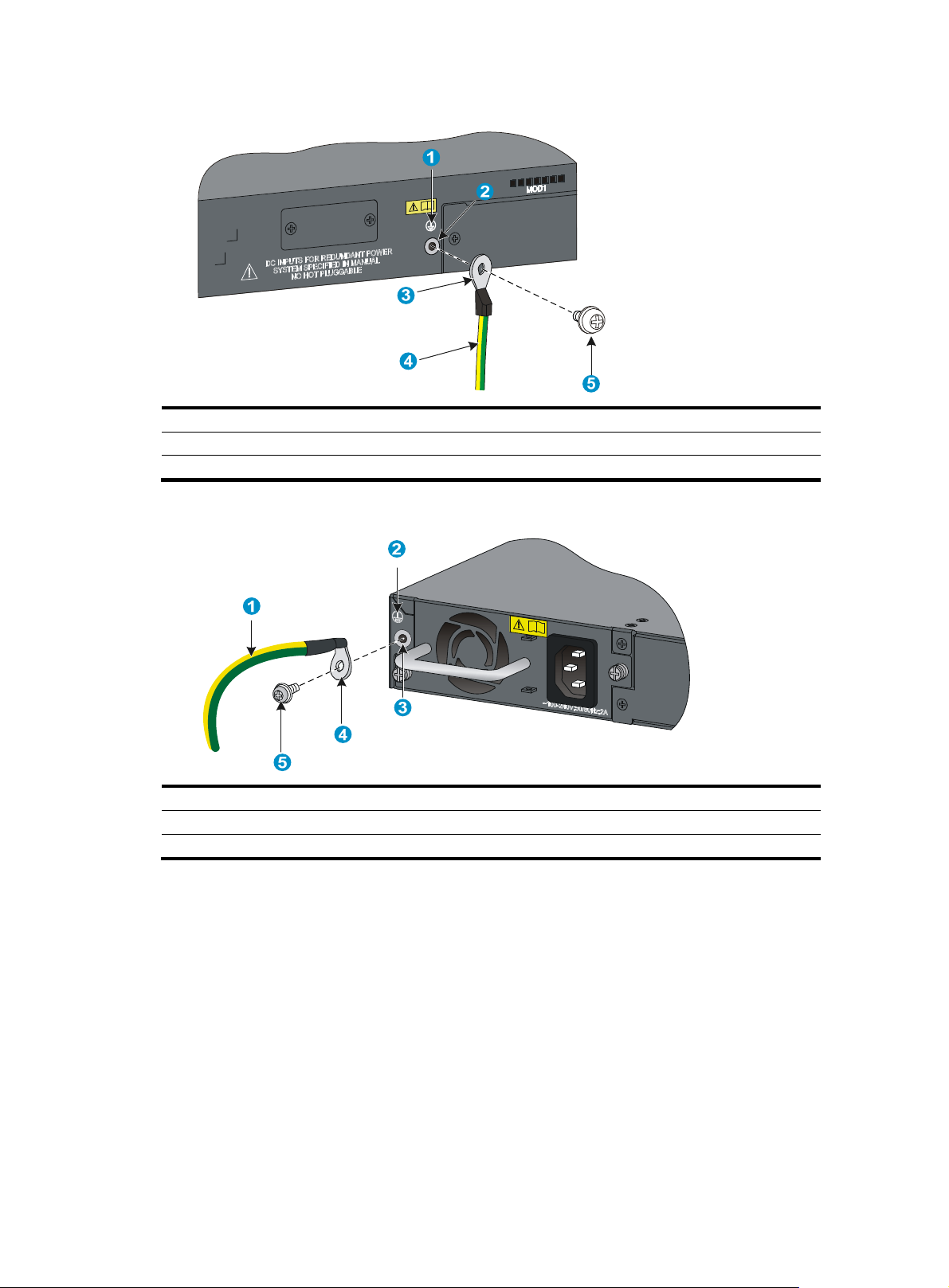

For the 5500-24G-SFP EI (2 slots) and 5500-24G-SFP EI TAA (2 slots) switches, follow the direction

shown in Figure 11 to

connect the grounding cable to avoid affecting the installation and removal of the

power supply.

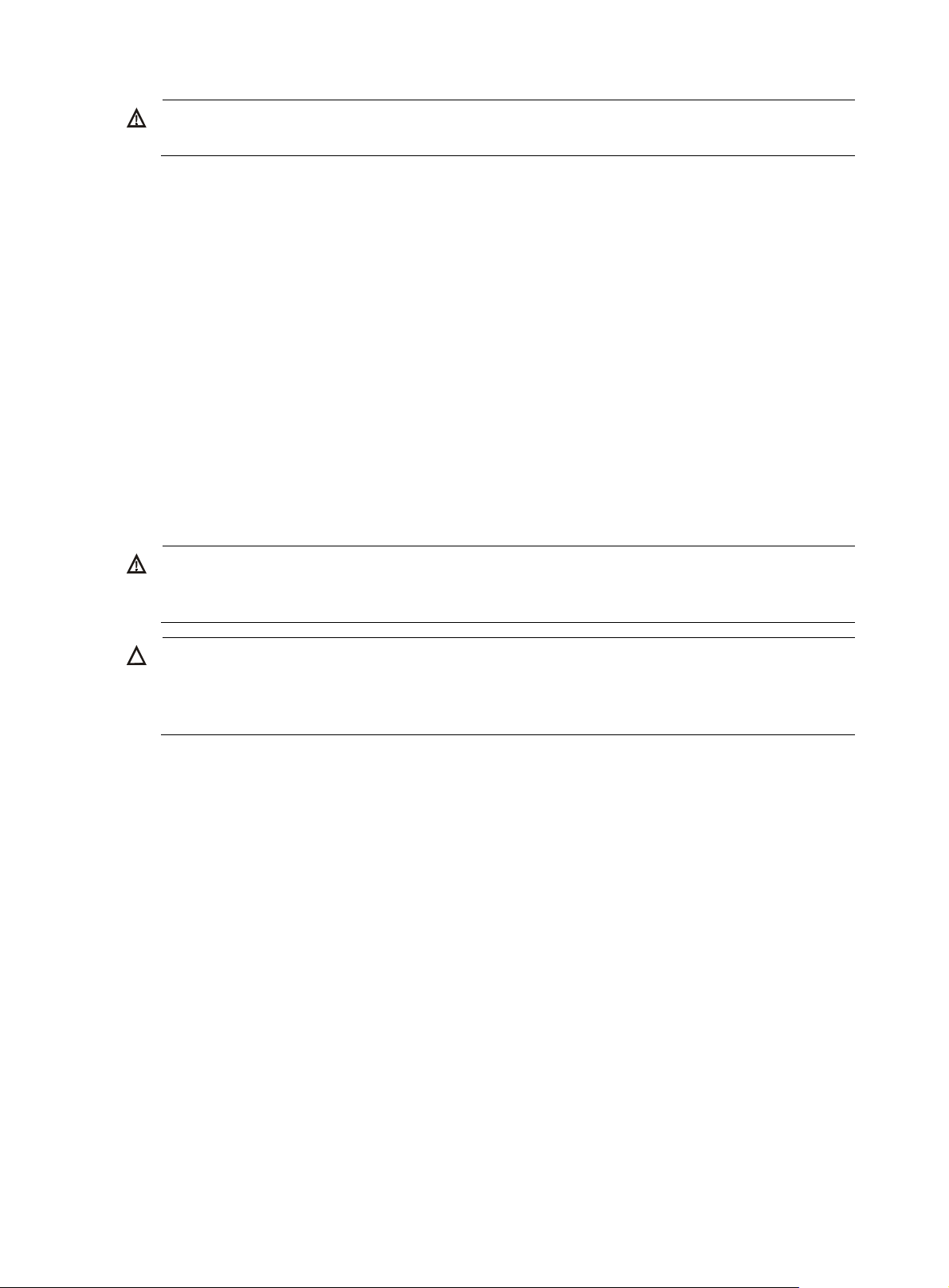

To connect the grounding cable, for example, to an HP 5500-48G EI (2 slots) switch:

1. Identify the grounding point (with a grounding sign) on the rear panel of the switch chassis, and

remove the grounding screw from the grounding point.

2. Attach the grounding screw to the ring terminal of the grounding cable.

3. Use a screwdriver to fasten the grounding screw into the grounding screw hole.

Figure 10 sho

ws the grounding terminal position of all 5500 EI and 5500 SI switches but the

5500-24G-SFP EI (2 slots) and 5500-24G-SFP EI TAA (2 slots).

Figure 11 sho

ws the grounding terminal position of the 5500-24G-SFP EI (2 slots) and

5500-24G-SFP EI TAA (2 slots) switches.

13

Page 19

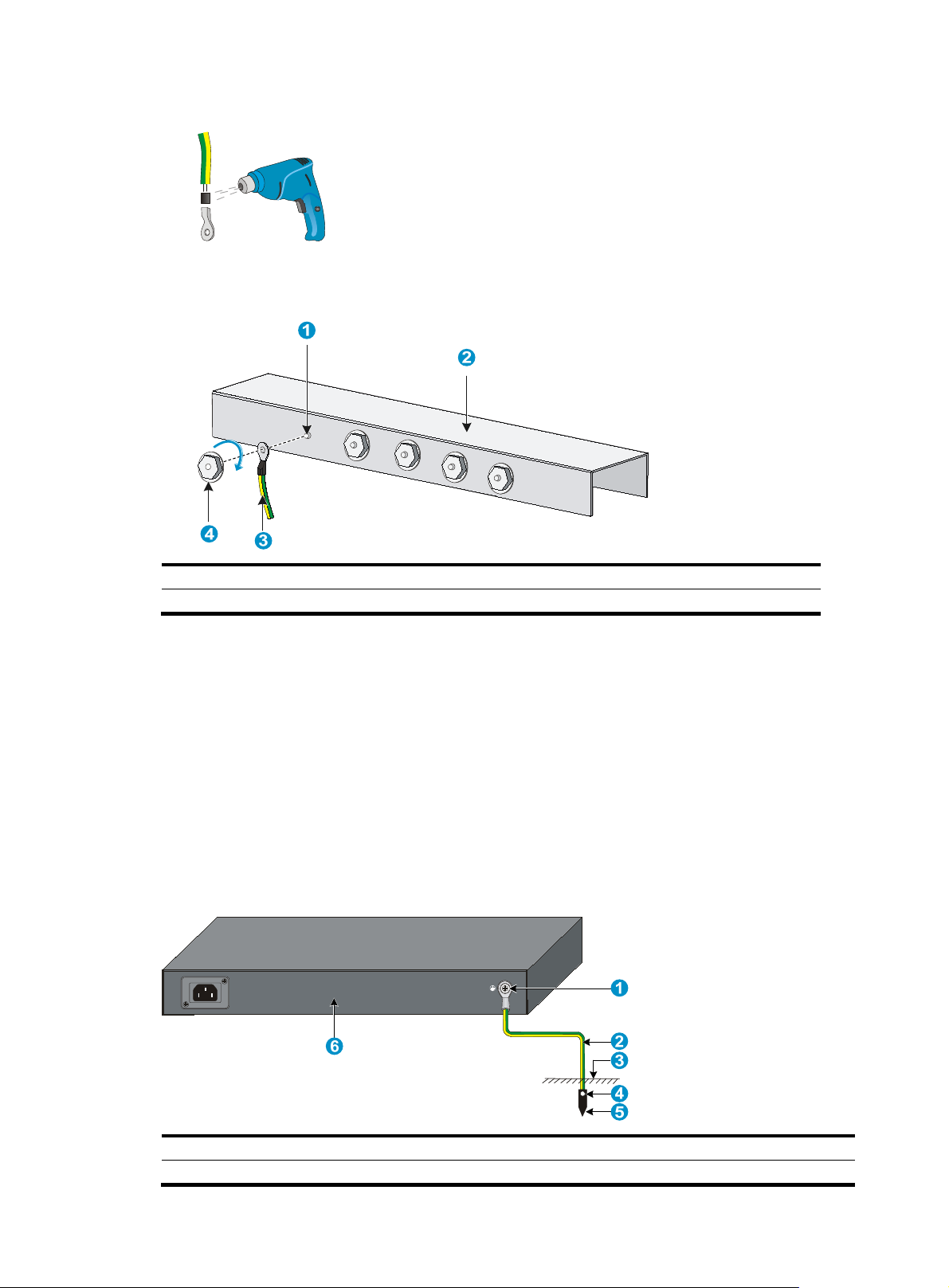

Figure 10 Connecting the grounding cable to the chassis (I)

(1) Grounding sign

(3) Ring terminal (4) Grounding cable

(5) Grounding screw

(2) Grounding hole

Figure 11 Connecting the grounding cable to the chassis (II)

(1) Grounding cable (2) Grounding sign

(3) Grounding hole (4) Ring terminal

(5) Grounding screw

4. Remove the hex nut of a grounding post on the grounding strip.

5. Cut the grounding cable as appropriate for connecting to the grounding strip.

6. Peel 5 mm (0.20 in) of insulation sheath by using a wire stripper, and insert the bare metal part

through the black insulation covering into the end of the ring terminal.

7. Secure the metal part of the cable to the ring terminal with a crimper, cover the joint with the

insulation covering, and heat the insulation covering with a blow dryer to completely cover the

metal part.

8. Attach the ring terminal or the ring to the grounding strip through the grounding post, and fasten

it with the removed hex nut, as shown in Figure 13.

14

Page 20

Figure 12 Making a grounding cable connector

Figure 13 Connecting the grounding cable to a grounding strip

(1) Grounding post (2) Grounding strip

(3) Grounding cable (4) Hex nut

Grounding the switch with a grounding conductor buried in the earth ground

If the installation site has no grounding strips, but earth ground is available, hammer a 0.5 m (1.64 ft) or

longer angle iron or steel tube into the earth ground to serve as a grounding conductor.

The dimensions of the angle iron must be at least 50 × 50 × 5 mm (1.97 × 1.97 × 0.20 in). The steel tube

must be zinc-coated and its wall thickness must be at least 3.5 mm (0.14 in).

Weld the yellow-green grounding cable to the angel iron or steel tube and treat the joint for corrosion

protection.

Figure 14 Grounding the switch by burying the grounding conductor into the earth ground

(1) Grounding screw (2) Grounding cable

(4) Joint (5) Grounding conductor

15

(3) Earth ground

(6) Chassis rear panel

Page 21

g

t

Grounding the switch by using the AC power cord

If the installation site has no grounding strips or earth ground, you ground an AC-powered switch through

the PE wire of the power cord, but must make sure:

• The power cord has a PE terminal.

• The ground contact in the power outlet is securely connected to the ground in the power distribution

room or on the AC transformer side.

• The power cord is securely connected to the power outlet.

NOTE:

round contact in the power outlet is not connected to the ground, report the problem and reconstruc

If the

the grounding system.

Figure 15 Grounding through the PE wire of the AC power cord

(1) Three-wire AC power cable (2) Chassis rear panel

NOTE:

To guarantee the grounding effect, use the grounding cable provided with the switch to connect to the

grounding strip in the equipment room as long as possible.

Installing/removing a power supply

This section applies only to the 5500-24G-SFP EI (2 slots) and 5500-24G-SFP EI TAA (2 slots) switches.

This section uses a PSR150-A power supply as an example to describe the installation and removal of

power supplies.

Installing a power supply

16

Page 22

g

t

v

CAUTION:

• To prevent dama

e to the power supply or the connector on the backplane of the powered device, inser

the power supply gently. If you encounter a hard resistance while inserting the power supply, pull out the

power supply and then insert it again.

• If the captive screw cannot be tightly secured, verify the installation of the power supply.

To install a power supply:

1. Wear an ESD-preventive wrist strap and make sure it makes good skin contact and is well

grounded.

2. If the power supply slot is covered by a filler panel, remove the filler panel first.

Put away the filler panel for future use.

3. Unpack the power supply and verify that the power supply model is correct.

4. Correctly orient the power supply with the power supply slot, grasp the handle of the power supply

with one hand and support its bottom with the other, and slide the power supply slowly along the

guide rails into the slot (see callout 1 in Figure 16).

ot is foolproof. If you cannot insert the power supply into the slot, re-orient the power supply

The sl

rather than use excessive force to push it in.

5. Fasten the captive screws on the power supply with a Philips screwdriver to secure the power

supply in the chassis (see callout 2 in Figure 16).

Figure 16 Installing a po

wer supply

NOTE:

If you install only one power supply, install the filler panel over the empty power supply slot for good

entilation.

Removing a power supply

1. Wear an ESD-preventive wrist strap and make sure it makes good skin contact and is well

grounded.

2. Disconnect the power cord from the power supply and the power outlet.

17

Page 23

W

p

3. Loosen the captive screws of the power supply with a Philips screwdriver until they are completely

disengaged.

4. Grasp the handle of the power supply with one hand and pull it out a little, support the bottom with

the other hand, and pull the power supply slowly along the guide rails out of the slot.

NOTE:

Put away the removed power supply in an antistatic bag for future use.

Connecting the power cord

ARNING!

Make sure the grounding cable has been correctly connected before powering on the switch.

Use Table 5 to identify the power cord connection procedures available for your switch.

Table 5 Power cord connection methods at a glance

Chassis Connection

5500-24G EI (2 slots)

5500-24G EI TAA (2 slots)

5500-48G EI (2 slots)

5500-48G EI TAA (2 slots)

5500-24G SI (2 slots)

5500-48G SI (2 slots)

5500-24G-PoE+ EI (2 slots)

5500-24G-PoE+ EI TAA (2 slots)

5500-48G-PoE+ EI (2 slot)

5500-48G-PoE+ EI TAA (2 slot)

5500-24G-PoE+ SI (2 slots)

5500-48G-PoE+ SI (2 slots)

5500-24G-SFP EI (2 slots)

5500-24G-SFP EI TAA (2 slots)

AC-input:

Connecting the AC power cord

RPS input:

Connect the switch to a +12 VDC output RPS

AC-input:

Connecting the AC power cord

RPS input:

Connecting the switch to a –52 to –55 VDC output RPS

AC-input PSR150-A/PSR150-A1 power supply:

Connecting the AC power cord

DC

-input PSR150-D/PSR150-D1 power supply:

Connecting the PSR150-D/PSR150-D1 to a –48 VDC

power source

rocedure

Connecting the AC power cord

1. Wear an ESD-preventive wrist strap and make sure it makes good skin contact and is well

grounded.

2. Connect one end of the AC power cord to the AC-input power receptacle on the switch or the

power supply (see Figure 17).

3. Conne

ct the other end of the AC power cord to the AC power outlet.

18

Page 24

Figure 17 Connecting the AC power cord

Connecting the PSR150-D/PSR150-D1 to a –48 VDC power source

CAUTION:

Identify the positive (+) and negative (-) marks on the two wires to avoid connection mistakes.

To connect the PSR150-D/PSR150-D1 to a –48 VDC power source:

1. Wear an ESD-preventive wrist strap and make sure it makes good skin contact and is well

2. Unpack the DC power cord, correctly orient the plug at one end of the cable with the power

3. Tighten the screws on the plug with a flat-blade screwdriver to secure the plug in the power

4. Conne

grounded.

receptacle on the power supply, and insert the plug into the power receptacle (see callout 1

in Figure 18).

T

he power receptacle is foolproof. If you cannot insert the plug into the receptacle, re-orient the

plug rather than use excessive force to push it in.

receptacle (see callout 2 in Figure 18).

ct the two wires at the other end of the power cord to a –48 VDC power source.

Figure 18 Connecting a –48V DC power cord

NOTE:

You can also connect the PSR150-D/PSR150-D1 to an RPS that provides –48 VDC output. The connection

procedure is the same as described in "Connecting the switch to a –52 to –55 VDC output RPS."

19

Page 25

Connect the switch to a +12 VDC output RPS

This section applies to the 5500-24G EI (2 slots), 5500-24G EI TAA (2 slots), 5500-48G EI (2 slots),

5500-48G EI TAA (2 slots), 5500-24G SI (2 slots), and 5500-48G SI (2 slots) switches.

To connect these switches to the RPS that provides +12 VDC output:

1. Wear an ESD-preventive wrist strap and make sure it makes good skin contact and is well

grounded.

2. Loosen the captive screws on the RPS receptacle protective cover and remove the protective cover,

as shown in Figure 19.

If you do not

Figure 19 Removing the RPS receptacle protective cover

3. Unpack the RPS cable shipped with the RPS, identify the plug for connecting to the switch, correctly

orient the plug with the RPS receptacle on the switch chassis, and insert the plug into the receptacle

(see callout 1 in Figure 20).

The RPS recep

rather than use excessive force to push it in.

4. Tighten the screws on the plug with a flat-blade screwdriver to secure the plug in the RPS receptacle

(see callout 2 in Figure 20).

5. Connect the other end of th

Figure 20 Connecting the RPS cable to the +12 VDC RPS power receptacle of the switch

use the +12 VDC RPS receptacle, install the protective cover.

tacle is foolproof. If you cannot insert the plug into the receptacle, re-orient the plug

e power cord to the RPS.

1

2

Connecting the switch to a –52 to –55 VDC output RPS

This section applies to the 5500-24G-PoE+ EI (2 slots), 5500-24G-PoE+ EI TAA (2 slots), 5500-48G-PoE+

EI (2 slots), 5500-48G-PoE+ EI TAA (2 slots), 5500-24G-PoE+ SI (2 slots), and 5500-48G-PoE+ SI (2 slots)

switches.

To connect these switches to the RPS that provides –52 to –55 VDC output:

20

Page 26

1. Wear an ESD-preventive wrist strap and make sure it makes good skin contact and is well

grounded.

2. Unpack the RPS cable shipped with the RPS, identify the plug for connecting to the switch, correctly

orient the plug with the RPS receptacle on the switch chassis, and insert the plug into the receptacle

(see callout 1 in Figure 21).

The RPS recep

rather than use excessive force to push it in.

3. Tighten the screws on the plug with a flat-blade screwdriver to secure the plug in the RPS receptacle

(see callout 2 in Figure 21).

4. Connect the other end of th

Figure 21 Connecting the RPS cable to the –52 to –55 VDC RPS receptacle of the switch

tacle is foolproof. If you cannot insert the plug into the receptacle, re-orient the plug

e power cord to the RPS.

Installing/removing an interface card

This section applies to all 5500 EI and 5500 SI switches. For the interface cards available for the switches,

see "Interface cards."

This section uses the LSPM2SP2P interface card as an example to describe the procedures of installing

and removing an interface card.

IMPORTANT:

To set up an HP 5500 EI or 5500 SI IRF fabric, you must install interface cards. To choose a correct slot for

an interface card, see "Planning the cabling scheme."

Installing an interface card

1. Wear an ESD-preventive wrist strap and make sure it makes good skin contact and is well

grounded.

2. Loosen the mounting screws on the filler panel over the interface card slot with a Phillips

screwdriver and remove the filler panel.

21

Page 27

g

Figure 22 Removing the filler panel over an interface card slot

3. Hold the captive screws on the front panel of the interface card, and gently push the interface card

in along the slot guide rail until the interface card is in close contact with the switch chassis (see

callout 1 in Figure 23).

4. Tighten the captive screws with a Phillips screwdriver to attach the interface card in the slot (see

callout 2 in Figure 23).

Figure 23 Installing an interface card

NOTE:

• Put away the removed filler panel for future use.

• When you tighten the captive screws, the torque must not be higher than 0.4 N-m.

Removing an interface card

CAUTION:

• Do not touch the surface-mounted components directly with your hands.

• Do not use too much force during the operation.

• If no new card is to be installed, install the filler panel to prevent dust and ensure

switch.

To remove an interface card:

ood ventilation in the

22

Page 28

1. Wear an ESD-preventive wrist strap and make sure it makes good skin contact and is well

grounded.

2. Use a Phillips screwdriver to completely loosen the captive screws at both sides of the interface

card.

3. Pull the interface card along the guide rails until it completely comes out of the switch chassis.

Installing/removing a dedicated CX4/SFP+ cable

The dedicated CX4 and SFP+ cables for the 5500 EI and 5500 SI switches are hot swappable.

Installing a dedicated CX4/SFP+ cable

CAUTION:

The cable bending radius must be at least eight times the cable diameter.

To connect a CX4 or SFP+ cable to a port on a CX4/SFP+ interface card:

1. Wear an ESD-preventive wrist strap and make sure it makes good skin contact is well grounded.

2. Correctly orient one connector of the cable with the port and insert the cable connector into the

port.

Removing a dedicated CX4/SFP+ cable

1. Wear an ESD-preventive wrist strap and make sure it makes good skin contact and is well

grounded.

2. Hold the cable connector and pull the pull latch of the connector to remove the cable from the

switch.

Verifying the installation

After you complete the installation, verify that:

• There is enough space for heat dissipation around the switch, and the rack or workbench is stable.

• The grounding cable is securely connected.

• The correct power source is used.

• The power cords are correctly connected.

• All the interface cables are cabled indoors. If any cable is routed outdoors, verify that the socket

strip with lightning protection and lightning arresters for network ports have been correctly

connected.

23

Page 29

Accessing the switch for the first time

Setting up the configuration environment

The first time you access the switch you must use a console cable to connect a console terminal, for

example, a PC, to the console port on the switch.

Figure 24 Connecting the console port to a terminal

Connecting the console cable

Console cable

A console cable is an 8-core shielded cable, with a crimped RJ-45 connector at one end for connecting

to the console port of the switch, and a DB-9 female connector at the other end for connecting to the

serial port on the console terminal.

Figure 25 Console cable

Connection procedure

To connect a terminal, for example, a PC, to the switch:

1. Plug the DB-9 female connector of the console cable to the serial port of the PC.

24

Page 30

2. Connect the RJ-45 connector to the console port of the switch.

NOTE:

• Identify the mark on the console port and make sure you are connecting to the correct port.

• The serial ports on PCs do not support hot swapping. If the switch has been powered on, connect the

console cable to the PC before connecting to the switch, and when you disconnect the cable, first

disconnect from the switch.

Setting terminal parameters

To configure and manage the switch, you must run a terminal emulator program on the console terminal.

The following are the required terminal settings:

• Bits per second—9,600

• Data bits—8

• Parity—None

• Stop bits—1

• Flow control—None

• Emulation—VT100

To set terminal parameters, for example, on a Windows XP HyperTerminal:

1. Select Start > All Programs > Accessories > Communications > HyperTerminal.

The Connection Description dialog box appears.

2. Enter the name of the new connection in the Name field and click OK.

Figure 26 Connection description

3. Select the serial port to be used from the Connect using list, and click OK.

25

Page 31

Figure 27 Setting the serial port used by the HyperTerminal connection

4. Set Bits per second to 9600, Data bits to 8, Parity to None, Stop bits to 1, and Flow control to None,

and click OK.

Figure 28 Setting the serial port parameters

5. Select File > Properties in the HyperTerminal window.

26

Page 32

Figure 29 HyperTerminal window

6. On the Settings tab, set the emulation to VT100 and click OK.

Figure 30 Setting terminal emulation in Switch Properties dialog box

27

Page 33

Powering on the switch

Before powering on the switch, verify that the following conditions are met:

• The power cord is correctly connected.

• The input power voltage meets the requirement of the switch.

• The console cable is correctly connected.

• The configuration terminal (a PC, for example) has started, and its serial port settings are consistent

with the console port settings on the switch.

Power on the switch. During the startup process, you can access Boot ROM menus to perform tasks such

as software upgrade and file management. The Boot ROM interface and menu options differ with

software versions. For more information about Boot ROM menu options, see the software-matching

release notes for the device.

After the startup completes, you can access the CLI to configure the switch.

For more information about the configuration commands and CLI, see the configuration guides and

command references for the switch.

28

Page 34

A

Setting up an IRF fabric

You can use HP Intelligent Resilient Framework (IRF) technology to connect and virtualize 5500 EI

switches or 5500 SI switches into a virtual switch called an "IRF fabric" or "IRF virtual device" for

flattened network topology, and high availability, scalability, and manageability.

NOTE:

n IRF fabric cannot have both 5500 EI and 5500 SI switches.

IRF fabric setup flowchart

Figure 31 IRF fabric setup flowchart

To set up an IRF fabric:

29

Page 35

A

t

P

Step Description

Plan the installation site and IRF fabric setup parameters:

• Planning IRF fabric size and the installation site

1. Plan IRF fabric setup

• Identifying the master switch and planning IRF member IDs

• Planning IRF topology and connections

• Identifying physical IRF ports on the member switches

• Planning the cabling scheme

2. Install IRF member

switches

3. Connect the grounding

cable, power supplies

(optional), and power

cords

4. Power on the switches

5. Install interface cards

6. Configure basic IRF

settings

7. Connect the physical IRF

ports

See "Installing the switch in a 19-inch rack" a

workbench."

See "Grounding the switch" a

If an HP 5500-24G-SFP EI (2 slots) or 5500-24G-SFP EI TAA (2 slots) switch

is used, also see "Installing/removing a power supply."

N/A

See "Installing/removing an interface card."

See "Configuring basic IRF settings."

See "Connecting the physical IRF ports."

All switches except the master switch automatically reboot, and the IRF fabric

is established.

nd "Connecting the power cord."

nd "Mounting the switch on a

Planning IRF fabric setup

Planning IRF fabric size and the installation site

Choose switch models and identify the number of required IRF member switches, depending on the user

density and upstream bandwidth requirements. The switching capacity of an IRF fabric equals the total

switching capacities of all member switches.

NOTE:

s your business grows, you can plug a switch into an IRF fabric to increase the switching capacity withou

any topology change or replacement.

Identifying the master switch and planning IRF member IDs

Determin e which swi tch you wa nt to use as the mas ter for man aging a ll memb er swi tch es in th e IRF fabric.

An IRF fabric has only one master switch. You configure and manage all member switches in the IRF

fabric at the command line interface of the master switch.

NOTE:

IRF member switches will automatically elect a master. You can affect the election result by assigning a

high member priority to the intended master switch. For more information about master election, see

5500 EI & 5500 SI Switch Series IRF Configuration Guide

30

.

H

Page 36

g

Prepare an IRF member ID assignment scheme. An IRF fabric uses member IDs to uniquely identify and

manage its members, and you must assign each IRF member switch a unique member ID.

Planning IRF topology and connections

You can create an IRF fabric in daisy chain topology, or more reliably, ring topology. In ring topology,

the failure of one IRF link does not cause the IRF fabric to split as in daisy chain topology. Rather, the IRF

fabric changes to a daisy chain topology without interrupting network services.

You connect the IRF member switches through IRF ports. An IRF port is a logical interface for the internal

connection between IRF member switches. Each IRF member switch has two IRF ports: IRF-port 1 and

IRF-port 2. To use an IRF port, you must bind physical ports to it.

When connecting two neighboring IRF member switches, you must connect the physical ports of IRF-port

1 on one switch to the physical ports of IRF-port 2 on the other switch.

You can bind several physical ports to an IRF port to create an aggregate IRF link for increased

bandwidth and availability.

NOTE:

• Figure 32 an

d Figure 33 show the topologies of an IRF fabric made up of three 5500 EI or 5500 SI

switches.

• The IRF port connections in the two fi

ures are for illustration only, and more connection methods are

available.

Figure 32 IRF fabric in daisy chain topology

Figure 33 IRF fabric in ring topology

Master

IRF

fabric

Slave

Slave

31

Page 37

A

t

Identifying physical IRF ports on the member switches

Only the 10-GE ports on the IRF-capable interface cards listed in "Interface cards" can provide IRF

connections for the 5500 EI and 5500 SI switches. To use the IRF feature, you must order the cards

separately.

IMPORTANT:

ll the switches in a ring topology and the non-edge switches in a daisy chain topology must have at leas

one two-port interface card or two one-port interface cards.

Planning the cabling scheme

When you plan the cabling scheme, follow these guidelines:

• Ports assigned to the same IRF port must be on the same interface card.

• For long-distance connections, use XFP/SFP+ transceiver modules and fibers. For short-distance

connections, use CX4/SFP+ cables or twisted-pair cables. For more information, see "Interface

rds" and "SFP/SFP+/XFP transceiver modules and SFP+/CX4 cables."

ca

• If 2-port interface cards are used and the IRF links are not aggregate:

{ You can connect the interface card in slot 1 (MOD 1) on a member switch to the MOD 1 or

MOD 2 card on its neighboring switch.

{ Connect the left port on one interface card to the right port on the other interface card, as shown

in Figure 34.

Figure 34 Use 2-port interface cards to set up singl

• If 2-port interface cards are used and IRF links are aggregate:

{

Connect the interface card MOD 1 on one switch to the interface card MOD 2 on the other

e-link IRF connection

switch.

{ A port on one interface card can connect to any port on the other interface card, as shown

in Figure 35. F

or example, you can connect the left port on one interface card to the left or right

port on the other interface card.

32

Page 38

Figure 35 Use 2-port interface cards to set up multi-link IRF connection

• If both of the neighboring switches use 1-port interface cards, the port on MOD 1 on one switch

must connect to the port on MOD 2 on the other switch (see callout 1 in Figure 36).

• If one switch uses a 1-port interface card but the other switch uses a 2-port interface card:

{ If the 1-port interface card is in the MOD 1 slot, the port on the card must connect to the right

port on the 2-port interface card (see callout 2 in Figure 36.)

{ If the 1-port interface card is in the MOD 2 slot, the port on the card must connect to the left port

on the 2-port interface card.

Figure 36 Cable connections for an IRF fabric with 1-port interface cards

Configuring basic IRF settings

After you install the IRF member switches, power on the switches, and log in to each IRF member switch

(see HP 5500 EI & 5500 SI Switch Series Fundamentals Configuration Guide) to configure their member

IDs, member priorities, and IRF port bindings.

Follow these guidelines when you configure the switches:

• Assign the master switch higher member priority than any other switch.

• Bind physical ports to IRF port 1 on one switch and to IRF port 2 on the other switch.

• Execute the irf-port-configuration active command to activate the IRF port configuration.

• Execute the display irf configuration command to verify the basic IRF settings.

33

Page 39

W

For more information about configuring basic IRF settings, see HP 5500 EI & 5500 SI Switch Series IRF

Configuration Guide.

Connecting the physical IRF ports

Connect the IRF member switches as planned.

NOTE:

ear an ESD-preventive wrist strap when you connect the physical IRF ports. For how to connect them,

see

Pluggable SFP/SFP+/XFP Transceiver Modules Installation Guide

.

Accessing the IRF fabric to verify the configuration

When you are finished configuring basic IRF settings and connecting IRF ports, follow these steps to

verify the basic functionality of the IRF fabric:

1. Log in to the IRF fabric through the console port of any member switch.

2. Create a Layer 3 interface, assign it an IP address, and make sure the IRF fabric and the remote

network management station can reach each other.

3. Use Telnet, web, or SNMP to access the IRF fabric from the network management station.

See HP 5500 EI & 5500 SI Switch Series Fundamentals Configuration Guide.

4. Verify that you can manage all member switches as if they were one node.

5. Display the running status of the IRF fabric by using the commands in the table bellow.

Task Command…

Display information about the IRF fabric display irf

Display all members’ configurations that take

effect after switch reboots

Display topology information about the IRF

fabric

display irf configuration

display irf topology

NOTE:

To avoid IP address collision and network problems, configure at least one multi-active detection (MAD)

mechanism to detect the presence of multiple identical IRF fabrics and handle collisions. For more

information about MAD detection, see

HP 5500 EI & 5500 SI Switch Series IRF Configuration Guide

.

34

Page 40

Maintenance and troubleshooting

Power supply failure

Built-in power supply failure

Except the 5500 -24G-SFP EI (2 slots) and 5500 -24G-SFP EI TAA (2 sl ot s) switches, all 5500 EI and 5500

SI switches use built-in power supplies and support three input modes: AC input, RPS DC input, and

concurrent AC and RPS DC inputs.

You can look at the system status LED and the RPS status LED on the front panel of the switch to identify

a power failure. For more information, see "LEDs."

AC input

If the system status LED is off, an AC input failure has occurred. Verify the following items:

• The AC power cord is securely connected to the switch, and the AC-input power receptacle on the

switch and the connected AC power outlet are in good condition.

• The external AC power system is correctly working.

• The operating temperature of the switch is in the normal range, and the power module has good

ventilation. Over-temperature can cause the power module to stop workin g and enter the protection

state.

RPS DC input

If the system status LED or RPS status LED is off, an RPS input failure has occurred. Verify the following

items:

• The switch is securely connected to the RPS.

• The RPS is correctly working.

• The operating temperature of the switch is in the normal range, and the power supply has good

ventilation. Over-temperature can cause the power supply to stop working and enter the protection

state).

Concurrent RPS and AC inputs

1. If the system status LED is off, the AC power supply and the RPS both have an input failure.

Verify the following items:

{ The AC power cord is securely connected to the switch, and the AC-input power receptacle on

the switch and the connected AC power outlet are in good condition.

{ The external AC power system is correctly working.

{ The switch is securely connected to the RPS.

{ The RPS is correctly working.

{ The operating temperature of the switch is in the normal range, and the power supply has good

ventilation. Over-temperature can cause the power supply to stop working and enter the

protection state.

35

Page 41

k

2. If the system status LED is on but the RPS status LED is steady yellow, an AC input failure has

occurred.

Verify the following items:

{ TThe AC power cord is securely connected to the switch, and the AC-input power receptacle on

the switch and the connected AC power outlet are in good condition.

{ The external AC power system is correctly working.

3. If the system status LED is on but the RPS status LED is off, an RPS input failure has occurred.

Verify the following items:

{ The switch is securely connected to the RPS.

{ The RPS is correctly working.

NOTE:

If the problem persists, contact the HP technical support for help.

Hot swappable power supply failure

This section applies to the 5500-24G-SFP EI (2 slots) and 5500-24G-SFP EI TAA (2 slots) switches.

You can look at the PWR1 or PWR2 LED (see Table 13)

slots) or 5500-24G-SFP EI TAA (2 slots) switch and the LEDs on the power supply to identify a power

supply failure.

If the power supply system is correctly working, the power supply LEDs are steady green. If the LEDs

behave in any other way (see Table 13)

• The power cord is correctly connected.

• The power supply meets the requirement.

• The operating temperature of the switch is in the normal range and the power supply has good

ventilation.

NOTE:

If the problem persists, contact your local sales agent or service engineer.

To replace a hot swappable power supply, see "Installing/removing a power supply."

Fan failure

You can look at the system status LED and the seven-segment LED of the switch to identify a fan failure.

If both LEDs are behaving as described in Table 6,

Table 6 LED behaviors that identify a fan failure

on the front panel of an HP 5500-24G-SFP EI (2

, verify the following items:

a fan failure occurs.

LED Mar

System status LED PWR/SYS Steady red

Seven-segment LED Unit

State

The LED flashes F for fan failure.

36

Page 42

The 5500 EI and 5500 SI switches use built-in fans. If a fan failure occurs, contact the HP technical

support for help and do not attempt to fix the problem yourself.

Configuration terminal problems

If the configuration environment setup is correct, the configuration terminal displays booting information

when the switch is powered on. If the setup is incorrect, the configuration terminal would display nothing

or garbled text.

No terminal display

If the configuration terminal displays nothing after the switch is powered on, verify the following items:

• The power supply is supplying power to the switch.

• The console cable is correctly connected.

• The console cable has no problem and the terminal settings are correct.

Garbled terminal display

If terminal display is garbled, verify that the following settings are configured for the terminal, for

example, HyperTerminal:

• Baud rate—9,600

• Data bits—8

• Parity—none

• Stop bits—1

• Flow control—none

• Emulation—VT100

37

Page 43

yp

Appendix A Chassis views and technical specifications

The HP 5500 EI & 5500 SI Switch Series includes the models in Table 7.

Table 7 Models in the HP 5500 EI & 5500 SI Switch Series

T

e Product code HP description

Alias

Non-PoE

JD377A

JG250A

JD375A

JG251A

JD374A

JG249A

JD369A

JD370A

JG241A

JG252A

HP 5500-24G EI Switch with 2 Interface

Slots

HP 5500-24G EI TAA Switch with 2

Interface Slots

HP 5500-48G EI Switch with 2 Interface

Slots

HP 5500-48G EI TAA Switch with 2

Interface Slots

HP 5500-24G-SFP EI Switch with 2

Interface Slots

HP 5500-24G-SFP EI TAA Switch with 2

Interface Slots

HP 5500-24G SI Switch with 2 Interface

Slots

HP 5500-48G SI Switch with 2 Interface

Slots

HP 5500-24G-PoE+ EI Switch with 2

Interface Slots

HP 5500-24G-PoE+ EI TAA Switch with 2

Interface Slots

5500-24G EI (2 slots)

5500-24G EI TAA(2 slots)

5500-48G EI (2 slots)

5500-48G EI TAA (2 slots)

5500-24G-SFP EI (2 slots)

5500-24G-SFP EI TAA (2

slots)

5500-24G SI (2 slots)

5500-48G SI (2 slots)

5500-24G-PoE+ EI (2 slots)

5500-24G-PoE+ EI TAA (2

slots)

JG240A

PoE

JG253A

JG238A

JG239A

HP 5500-48G-PoE+ EI Switch with 2

Interface Slots

HP 5500-48G-PoE+ EI TAA Switch with 2

Interface Slots

HP 5500-24G-PoE+ SI Switch with 2

Interface Slots

HP 5500-48G-PoE+ SI Switch with 2

Interface Slots

38

5500-48G-PoE+ EI (2 slots)

5500-48G-PoE+ EI TAA (2

slots)

5500-24G-PoE+ SI (2 slots)

5500-48G-PoE+ SI (2 slots)

Page 44

Chassis views

5500-24G EI (2 slots)/5500-24G EI TAA (2 slots)/5500-24G SI (2 slots)

Figure 37 Front panel

(1) 10/100/1000Base-T auto-sensing Ethernet port (2) 10/100/1000Base-T Ethernet port LED

(3) 1000Base-X SFP port (4) 1000Base-X SFP port LED

(5) Console port (6) Seven-segment LED (Unit)

(7) Port mode LED (Mode) (8) System status LED (PWR)

(9) RPS status LED (RPS) (10) Interface card 1 status LED (MOD1)

(11) Interface card 2 status LED (MOD2) (12) Port LED mode switching button

Figure 38 Rear panel

(1) AC power input (2) RPS receptacle (shipped with a protective cover)

(3) Grounding screw (4) Interface card slot 1 (MOD1)

(5) Interface card slot 2 (MOD2)

NOTE:

The 5500-24G EI (2 slots), 5500-24G EI TAA (2 slots), and 5500-24G SI (2 slots) switches come with the

expansion interface card slots covered by filler panels.

39

Page 45

5500-48G EI (2 slots)/5500-48G EI TAA (2 slots)/5500-48G SI (2 slots)

Figure 39 Front panel

(1) 10/100/1000Base-T auto-sensing Ethernet port (2) 10/100/1000Base-T Ethernet port LED

(3) Console port (4) Seven-segment LED (Unit)

(5) Port mode LED (Mode) (6) System status LED (PWR)

(7) RPS status LED (RPS) (8) Interface card 1 status LED (MOD1)

(9) Interface card 2 status LED (MOD2) (10) Port LED mode switching button

(11) 1000Base-X SFP port (12) 1000Base-X SFP port LED

Figure 40 Rear panel

(1) AC power input (2) RPS receptacle (shipped with a protective cover)

(3) Grounding screw (4) Interface card slot 1 (MOD1)

(5) Interface card slot 2 (MOD2)

NOTE:

The 5500-48G EI (2 slots), 5500-48G EI TAA (2 slots), and 5500-48G SI (2 slots) switches come with the

expansion interface card slots covered by filler panels.

40

Page 46

y

5500-24G-SFP EI (2 slots)/5500-24G-SFP EI TAA (2 slots)

Figure 41 Front panel

(1) SFP port (2) SFP port LED

(3) 10/100/1000Base-T auto-sensing Ethernet

port

(5) Console port (6) Port LED mode switching button

(7) Interface card 1 status LED (MOD1)

(9) System status LED (SYS) (10) Power supply 1 status LED (PWR1)

(11) Power supply 2 status LED (PWR2)

(13) Seven-segment LED (Unit)

(4) 10/100/1000Base-T Ethernet port LED

(8) Interface card 2 status LED (MOD2)

(12) Port mode LED (Mode)

Figure 42 Rear panel

(1) Grounding screw (2) Power supply slot 1

(3) Power supply slot 2 (4) Interface card slot 1 (MOD1)

(5) Interface card slot 2 (MOD2)

NOTE:

• The 5500-24G-SFP EI (2 slots) and 5500-24G-SFP EI TAA (2 slots) switches come with the expansion

interface card slots covered by filler panels.

• The 5500-24G-SFP EI (2 slots) and 5500-24G-SFP EI TAA (2 slots) switches come with one power

supply filler panel. If you use only one power supply, install the filler panel over the empty power suppl

slot to prevent dust and ensure normal ventilation of the chassis. In this figure, a PSR150-A is installed in

power supply slot 1 and a PSR150-D is installed in power supply slot 2.

41

Page 47

5500-24G-PoE+ EI (2 slots)/5500-24G-PoE+ EI TAA (2 slots)/5500-24G-PoE+ SI (2 slots)

Figure 43 Front panel

(1) 10/100/1000Base-T auto-sensing Ethernet port (2) 10/100/1000Base-T Ethernet port LED

(3) 1000Base-X SFP port (4) 1000Base-X SFP port LED

(5) Console port (6) Seven-segment LED (Unit)

(7) Port mode LED (Mode) (8) System status LED (PWR)

(9) RPS status LED (RPS) (10) Interface card 1 status LED (MOD1)

(11) Interface card 2 status LED (MOD2)

(12) Port LED mode switching button

Figure 44 Rear panel

(1) RPS receptacle (2) AC power input

(3) Grounding screw (4) Interface card slot 1 (MOD1)

(5) Interface card slot 2 (MOD2)

NOTE:

The 5500-24G-PoE+ EI (2 slots), 5500-24G-PoE+ EI TAA (2 slots), and 5500-24G-PoE+ SI (2 slots)

switches come with the expansion interface card slots covered by filler panels.

42

Page 48

5500-48G-PoE+ EI (2 slots)/5500-48G-PoE+ EI TAA (2 slots)/5500-48G-PoE+ SI (2 slots)

Figure 45 Front panel

(1) 10/100/1000Base-T auto-sensing Ethernet port (2) 10/100/1000Base-T Ethernet port LED

(3) Console port (4) Seven-segment LED (Unit)

(5) Port mode LED (Mode) (6) System status LED (PWR)

(7) RPS status LED (RPS) (8) Interface card 1 status LED (MOD1)

(9) Interface card 2 status LED (MOD2) (10) Port LED mode switching button

(11) 1000Base-X SFP port (12) 1000Base-X SFP port LED

Figure 46 Rear panel

(1) RPS receptacle (2) AC power input

(3) Grounding screw (4) Interface card slot 1 (MOD1)

(5) Interface card slot 2 (MOD2)

NOTE:

The 5500-48G-PoE+ EI (2 slots), 5500-48G-PoE+ EI TAA (2 slots), and 5500-48G-PoE+ SI (2 slots)

switches come with the expansion interface card slots covered by filler panels.

Technical specifications

Chassis dimensions and weights

Chassis Dimensions Dimensions (H × W × D) Weight

5500-24G SI (2 slots)

43.6 × 440 × 300 mm

(1.72 × 17.32 × 11.81 in)

43

< 4.5 kg (9.92 lb)

Page 49

p

Chassis Dimensions Dimensions (H × W × D) Weight

5500-24G EI (2 slots)

5500-24G EI TAA (2 slots)

5500-48G EI (2 slots)

5500-48G EI TAA (2 slots)

5500-48G SI (2 slots)

43.6 × 440 × 300 mm

(1.72 × 17.32 × 11.81 in)

< 5 kg (11.02 lb)

5500-24G-SFP EI (2 slots)

5500-24G-SFP EI TAA (2 slots)

5500-24G-PoE+ SI (2 slots)

5500-24G-PoE+ EI (2 slots)

5500-24G-PoE+ EI TAA (2 slots)

5500-48G-PoE+ SI (2 slots)

5500-48G-PoE+ EI (2 slots)

5500-48G-PoE+ EI TAA (2 slots)

43.6 × 440 × 360 mm

(1.72 × 17.32 × 14.17 in)

43.6 × 440 × 420 mm

(1.72 × 17.32 × 16.54 in)

43.6 × 440 × 420 mm

(1.72 × 17.32 × 16.54 in)

43.6 × 440 × 420 mm

(1.72 × 17.32 × 16.54 in)

Ports and interface card slots

Chassis

5500-24G EI (2 slots)

5500-24G EI TAA (2 slots)

5500-24G SI (2 slots)

5500-24G-PoE+ EI (2 slots)

5500-24G-PoE+ EI TAA (2 slots)

5500-24G-PoE+ SI (2 slots)

Console

ports

1 24 4 2

1 24, PoE+ 4 2

10/100/1000Base-T

auto-sensing Ethernet

orts

< 6 kg (13.23 lb)

< 7.0 kg (15.43 lb)

< 7.5 kg (16.53 lb)

< 8.0 kg (17.64 lb)

SFP ports

Interafce

card slots

5500-24G-SFP EI (2 slots)

5500-24G-SFP EI TAA (2 slots)

5500-48G EI (2 slots)

5500-48G EI TAA (2 slots)

5500-48G SI (2 slots)