Page 1

User’s Guide

Publication number 54753-97010

Second edition, January 1999

For Safety information, Warranties, and Regulatory information, see pages

behind the index

© Copyright Hewlett-Packard Company 1999

All Rights Reserved

HP 54753A and HP 54754A TDR

Plug-in Modules

Page 2

HP 54753A and HP 54754A Plug-in Modules

The HP 54753A and 54754A TDR plug-in modules provide you with TDR

and TDT measurement features. In addition to the TDR and TDT

measurement features, the TDR plug-ins provide two accurate

oscilloscope measurement channels with user selectable bandwidths of

12.4 or 18 GHz. The lower bandwidth mode provides excellent

oscilloscope noise performance for accurate measurement of small

signals. The high bandwidth mode provides high-fidelity display and

measurement of very high-speed waveforms.

The HP 54753A TDR plug-in module provides:

• Automatic and manual single-ended TDR and TDT measurement

capability

• Automatic and manual waveform, histogram, FFT, waveform math,

eye pattern measurements, statistical measurements, and limit

testing capabilities.

• User selectable 12.4 or 18 GHz bandwidth (Channel 1).

• User selectable 12.4 or 20 GHz bandwidth (Channel 2).

• 2.5 GHz bandwidth trigger channel.

• 3.5 mm (m) connectors.

The HP 54754A TDR plug-in module provides:

• Automatic and manual single-ended and differential TDR and TDT

measurement capability.

• Automatic and manual waveform, histogram, FFT, waveform math,

eye pattern measurements, statistical measurements, and limit

testing capabilities.

• User selectable 12.4 or 18 GHz bandwidth.

• 2.5 GHz bandwidth trigger channel.

• 3.5 mm (m) connectors.

ii

Page 3

Accessories Supplied

The following accessories are supplied with the TDR plug-in modules:

One 50 ohm SMA (m) terminator, HP part number 1250-2153

Two SMA shorts (m), HP part number 0960-0055

TDR Demo Board, HP part number 54754-66503

One User’s Guide

One Programmer’s Guide

One Service Guide

Accessories Available

The following accessories are available for use with the TDR plug-in

modules.

Options

Option 0B1 Additional set of user documentation

Option 001 HP 83480A mainframe operating system upgrade

Option 002 HP 54750A mainframe operating system upgrade

Option 003 Delete demo board

HP 54755A TDR option for HP 83480A mainframe operating system upgrade

Optional Accessories

HP 10086A ECL terminator

HP 54006A 6 GHz divider probe

HP 54007A accessory kit

HP 54008A 22 ns delay line

HP 54118A 500 MHz to 18 GHz trigger

HP 54701A 2.5 GHz Active Probe with Option 001

Connection Devices

SMA (f-f) adapter, HP part number 1250-1158

APC 3.5 (f-f) adapter, HP part number 1250-1749

iii

Page 4

In This Book

This book is the operating manual for the HP 54753A and HP 54754A TDR plugin modules, and contains 13 chapters.

General Information Chapter 1 contains overview information, menu

and front panel key information, trigger information, and calibration

information. Chapter 2 contains important information on the care of the

TDR plug-in connectors.

TDR Front Panel and Menu Keys Chapter 3, 4, 5 and 6 describe the

front panel keys and all the menu keys.

Task Oriented Examples Chapter 7 contains example single-ended

TDR measurements using a demo board included with each TDR plug-in

module. Chapter 8 contains example differential TDR measurements.

TDR Theory Chapters 9, 10, and 11 contain in-depth theory of TDR

transmission lines and how to use TDR in designing systems.

Specifications and Characteristics Chapter 12 contains the

specifications and characteristic for the TDR plug-in modules.

Problems and Error Messages Chapter 13 contains troubleshooting

information and error messages.

iv

Page 5

Contents

1 The Instrument at a Glance

Menu and Key Conventions 1-3

The HP 54753A, 54754A TDR Plug-In Modules 1-4

Plug-in Module Purpose 1-4

Front Panel of the Plug-in Module 1-4

Getting the Best Performance 1-5

Installing a Plug-in Module 1-6

Trigger 1-6

2 Care and Handling of Precision Connectors

3.5 mm Connector Care 2-3

Connector Wear 2-3

Operator Skill 2-3

Device Specifications 2-3

Accuracy Considerations 2-6

Visual Inspection 2-8

Mechanical Inspection 2-8

Connecting the Devices 2-16

3 Setup Channel Menu

Displaying the Setup Channel menu 3-4

Display 3-4

Scale 3-4

Offset 3-5

Bandwidth. . . 3-6

Alternate scale. . . 3-6

Calibrate . . . 3-8

Calibration Overview 3-12

Factory Mainframe Calibration 3-13

User Calibrations 3-16

4 HP 54753A TDR/TDT Setup Menu

Displaying the TDR/TDT Setup Menu 4-4

Stimulus 4-4

TDT 1 dest 4-4

Contents-1

Page 6

Contents

TDR 1 dest 4-5

Normalize response . . . 4-5

TDR rate automatic . . . (250 kHz) 4-8

Preset TDR/TDT 4-8

5 HP 54754A TDR/TDT Setup Menu

Displaying the TDR/TDT Setup Menu 5-7

Stimulus 5-7

TDT 1 dest 5-8

Normalize response . . . 5-8

TDR rate automatic . . . (250 kHz) 5-11

Preset TDR/TDT 5-12

TDT 2 dest 5-13

Normalize response . . . 5-13

TDR rate automatic . . . (250 kHz) 5-16

Preset TDR/TDT 5-17

TDT 1 dest 5-18

TDT 2 dest 5-18

Normalize 1 response . . .

Normalize 2 response . . . 5-19

TDR rate automatic . . . (250 kHz) 5-21

Preset TDR/TDT 5-22

TDR/TDT 5-23

TDR response 1 5-23

TDR response 2 5-24

TDT response 1 5-25

TDT response 2 5-25

Establish ref plane 5-26

TDR rate automatic . . . (250 kHz) 5-27

Preset TDR/TDT 5-28

TDT 1 dest 5-30

TDR 1 dest 5-30

Normalize response . . . 5-31

TDR rate automatic . . . (250 kHz) 5-34

Preset TDR/TDT 5-34

6 Measure and Other TDR Specific Menus

TDR/TDT Measure Menu 6-4

Contents-2

Page 7

Marker Menu 6-9

Reference 6-9

Marker units . . . 6-9

Response Menu Items 6-10

7 Single-ended TDR Measurements

Single-ended TDR Features 7-3

Establishing the Reference Plane and Normalizing 7-8

Measuring Transmission Line Impedance 7-19

Measuring Transmission Line Percent Reflection 7-25

Measuring Excess L/C 7-32

Measuring the Distance to a Discontinuity 7-37

8 Differential TDR Measurements

Differential TDR Features 8-3

Measuring Differential and Common Mode Impedance 8-5

Making Differential TDT Measurements 8-15

Contents

9 TDR Fundamentals

Propagation on a Transmission Line 9-4

Step Reflection Testing 9-6

Instrument Configuration 9-20

10 Improving Time Domain Network Measurements

Sources of Measurement Error 10-3

Removing Measurement Errors 10-6

11 Transmission Line Theory Applied to Digital Systems

Transmission Line Design 11-2

Signal Propagation Delay for Microstrip and Strip Lines with Distributed or Lumped

Loads 11-15

Microstrip Transmission Line Techniques Evaluated Using TDR Measurements 1121

References 11-38

Contents-3

Page 8

Contents

12 Specifications and Characteristics

Specifications 12-3

Vertical Specifications 12-4

Environmental Specifications 12-5

Power Requirements 12-6

Weight 12-6

Characteristics 12-6

Trigger Input Characteristics 12-6

Product Regulations 12-7

13 In Case of Difficulty

If You Have Problems 13-3

If the Mainframe Does Not Operate 13-3

If the Plug-in Does Not Operate 13-4

Error Messages 13-5

Contents-4

Page 9

1

The Instrument at a Glance

Page 10

The Operating the Instrument

What you’ll find in this chapter

This chapter describes:

• the key conventions used in this manual

not

• the front panel, rear panel and keys that do

Understanding the information in this chapter will help you successfully operate

the instrument.

display menus on the screen

CAUTION

The input circuits can be damaged by electrostatic discharge (ESD). Therefore,

avoid applying static discharges to the front-panel input connectors. Before

connecting any coaxial cable to the connectors, momentarily short the center

and outer conductors of the cable together. Avoid touching the front-panel

input connectors without first touching the frame of the instrument. Be sure

the instrument is properly earth-grounded to prevent buildup of static charge.

1-2

Page 11

The Instrument at a Glance

Menu and Key Conventions

Menu and Key Conventions

The keys labeled Trigger, Disk, and Run are all examples of front-panel keys.

Pressing some front-panel keys accesses menus of functions that are displayed

along the right side of the display screen. These menus are called softkey

menus.

Softkey menus list functions other than those accessed directly by the frontpanel keys. To activate a function on the softkey menu, press the unlabeled key

immediately next to the annotation on the screen. The unlabeled keys next to

the annotation on the display are called softkeys.

Additional functions are listed in blue type above and below some of the frontpanel keys. These functions are called shifted functions. To activate a shifted

function, press the blue front-panel Shift key and the front-panel key next to

the desired function.

Throughout this manual front-panel keys are indicated by bold lettering of the

key label, for example, Time base. Softkeys are indicated by italic lettering of

the key label, for example,

panel key pressed and which menu is selected. Shifted functions are indicated

by the front-panel Shift key followed by the shaded shifted function, for example

the Local function (above the Stop/Single front-panel key) will be shown as Shift,

Local.

A softkey with On and Off in its label can be used to turn the softkey’s function

on or off. To turn the function on, press the softkey so On is highlighted. To

turn the function off, press the softkey so Off is highlighted. An On or Off softkey

function will be indicated throughout this manual as:

A softkey such as

this case you could choose Triggered by pressing the softkey until Triggered is

highlighted, or choose Freerun by pressing the softkey until Freerun is

highlighted. Softkey choices will be indicated throughout this manual as:

Triggered Freerun

When some softkeys, such as

calibration will be made. Some softkeys, such as

numeric value. To enter or change the value, use the general purpose knob

located below the front-panel Measure section.

Sweep Triggered Freerun

Triggered.

Scale

. The softkeys displayed depend on the front-

Tes t

On.

offers you a choice of functions. In

Calibrate Probe

, are pressed the first time, a

Offset

require the entry of a

Sweep

1-3

Page 12

The Instrument at a Glance

The HP 54753A, 54754A TDR Plug-In Modules

The HP 54753A, 54754A TDR Plug-In Modules

The TDR plug-in modules are two of several plug-in modules available for the

HP 83480A and HP 54750A mainframes.

Plug-in Module Purpose

The purpose of the plug-in module is to provide measurement channels,

including sampling, for the mainframe. The plug-in module scales the input

signal, sets the bandwidth of the system, and allows the offset to be adjusted so

the signal can be viewed. The output of the plug-in module is an analog signal

that is applied to the ADCs on the acquisition boards inside the mainframe. The

plug-in module also provides a trigger signal input to the time base/trigger board

inside the mainframe.

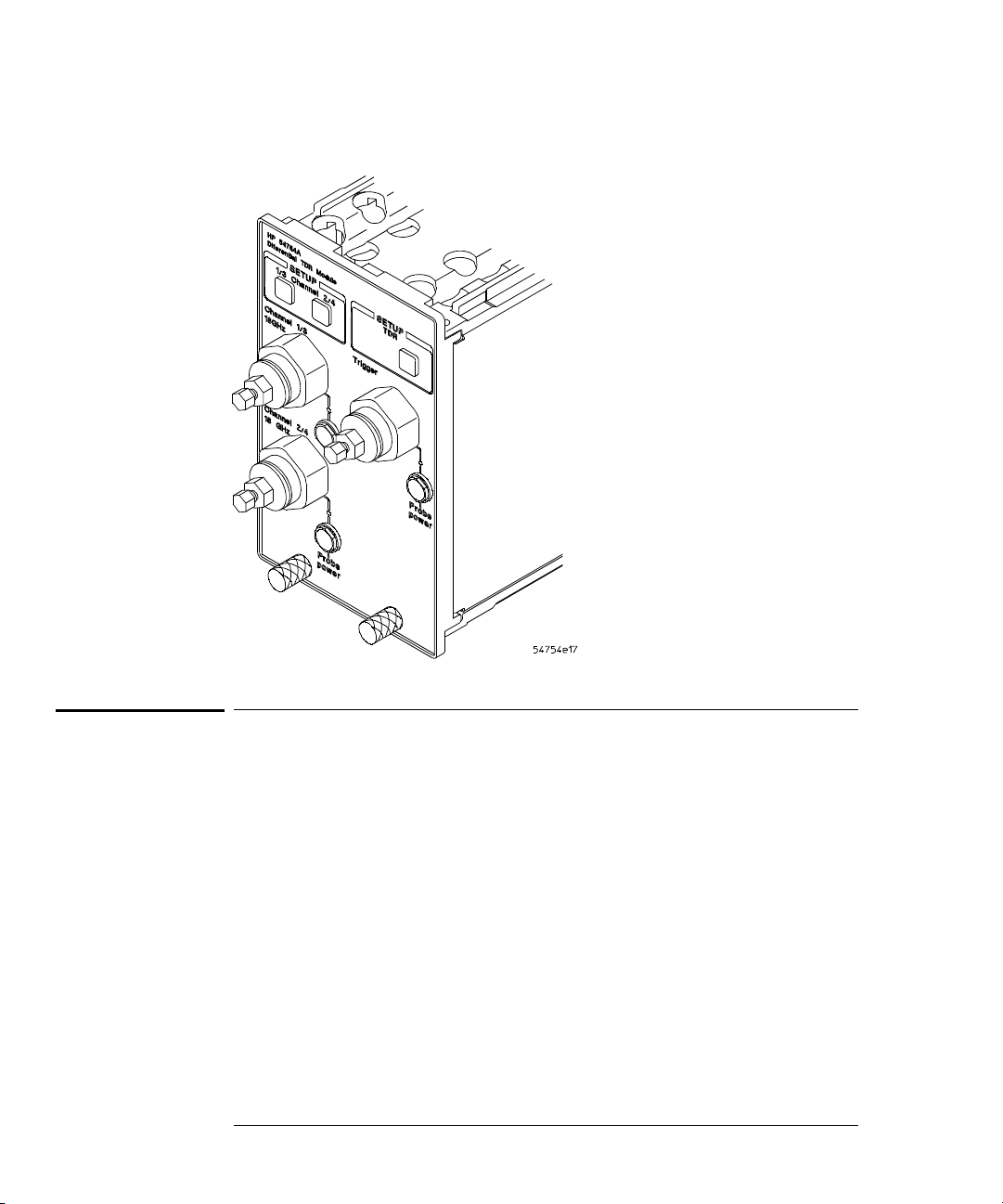

Front Panel of the Plug-in Module

The plug-in module takes up two, of the four, mainframe slots. The front panel

of the plug-in module has two channel inputs and an external trigger input. The

front panel also has two probe power connectors for HP 54700-series probes,

an auxiliary power connector for general purpose use, and a key for each

channel that displays the softkey menu. The softkey menu allows you to access

the channel setup features of the plug-in module for the selected input.

The front-power Probe Power connector allows automatic channel scaling and

probe calibration with HP 54700 series probes. The front-panel Aux Power

connector provides only power to HP 54700 series probes for use as a trigger

input. Probe calibration and scaling are not required for a trigger input.

1-4

Page 13

Figure 1-1

The Instrument at a Glance

Getting the Best Performance

Front panel of the plug-in module.

Getting the Best Performance

To ensure you obtain the specified accuracy, you must perform a plug-in module

vertical calibration. The calibration must also be performed when you move a

plug-in module from one slot to another or to a different mainframe. Refer to

"Performing a Plug-in Module Vertical Calibration" in Chapter 3 for information

on performing a plug-in module vertical calibration.

1-5

Page 14

The Instrument at a Glance

Installing a Plug-in Module

Installing a Plug-in Module

You do not need to turn off the mainframe to install or remove a plug-in module.

The plug-in module can be installed in slots 1 and 2 or 3 and 4 on the HP 83480A,

54750A mainframe. The plug-in module will not function if it is installed in slots

2 and 3.

To make sure the instrument meets all of the published specifications, there

must be a good ground connection from the plug-in module to the mainframe.

The RF connectors on the rear of the plug-in module are spring loaded, so fingertighten the knurled screw on the front panel of the plug-in module to make sure

the plug-in is securely seated in the mainframe.

CAUTION

CAUTION

CAUTION

Do not use extender cables to operate the plug-in module outside of the

mainframe. The plug-in module and/or mainframe can be damaged by

improper grounding when using extender cables.

Trigger

The external trigger level range for this plug-in module is ±1 V. The trigger

source selection follows the slots the plug-in module is installed in. For example,

if the plug-in module is installed in slots 1 and 2, then the trigger source is listed

as trigger 2. If it is installed in slots 3 and 4, then the trigger source is listed as

trigger 4. Because the external trigger capability of this module is restricted to

signals of 2.5 GHz or less, use of the HP 54753A and HP 54754A modules with

Option 100, extended trigger, is not recommended.

The maximum safe input voltage is ±2 V + peak ac (+16 dBm). Therefore, to

!

avoid damaging the trigger input circuitry, do not apply any voltage outside

this range.

The input circuits can be damaged by electrostatic discharge (ESD).

Therefore, avoid app lying static discharges to the front-panel i nput connectors.

Before connecting any coaxial cable to the connectors, momentarily short the

center and outer conductors of the cable together. Avoid touching the frontpanel input connectors without first touching the frame of the instrument. Be

sure the instrument is properly earth-grounded to prevent buildup of static

charge.

1-6

Page 15

2

Care and Handling of Precision Connectors

Page 16

The Care and Handling of Precision

Connectors

What you’ll find in this chapter

This chapter describes:

• 3.5 mm connector care

• connector wear

• device specifications

• accuracy considerations

• visual inspection

• mechanical inspection

• connecting devices

Understanding the information in this chapter will help you successfully operate

the instrument.

CAUTION

The input circuits can be damaged by electrostatic discharge (ESD). Therefore,

avoid applying static discharges to the front-panel input connectors. Before

connecting any coaxial cable to the connectors, momentarily short the center

and outer conductors of the cable together. Avoid touching the front-panel

input connectors without first touching the frame of the instrument. Be sure

the instrument is properly earth-grounded to prevent buildup of static charge.

2-2

Page 17

Care and Handling of Precision Connectors

3.5 mm Connector Care

3.5 mm Connector Care

This chapter shows you how to take care of 3.5 mm connectors so that you can

maintain high levels of accuracy, repeatability, and system performance. Taking

appropriate care of your connectors will also extend their service life. Most of

the information can also be applied to 2.4 mm connectors. For additional

information on 2.4 mm connectors, refer to operating note "2.4 mm Adapters

and Calibration Accessories" HP part number 11900-90903.

Connector Wear

Connector wear will eventually degrade performance. The calibration devices,

which are typically used only a few times each day, should have a very long life.

However, because the connectors often undergo many connections a day, they

wear rapidly. Therefore, it is essential that all connectors on the HP 54753A or

HP 54754A TDR plug-in modules be inspected regularly, both visually (with a

magnifying glass) and mechanically (with a connector gage), and replaced as

necessary. Procedures for visual and mechanical inspection are given in the

next section of this manual. It is easier and cheaper to replace a worn adapter

than a worn channel connector.

Operator Skill

Operator skill in making good connections is essential. The mechanical

tolerances of the precision 3.5 mm connectors used in the HP 54007A kit are

two or three times better than the tolerances in regular 3.5 mm connectors.

Slight errors in operator technique that would go unnoticed with regular

connectors often appear with precision connectors in the calibration kit.

Incorrect operator technique can often result in lack of repeatability. Carefully

study and practice the connection procedures that are explained later in this

manual until your calibration measurements are consistently repeatable.

Device Specifications

Electrical specifications depend upon several mechanical conditions. A 3.5 mm

connector is a precision connector dedicated to very specific tolerances. SMA

connectors are not precision mechanical devices. They are not designed for

repeated connections and disconnections and are very susceptible to

2-3

Page 18

Care and Handling of Precision Connectors

Device Specifications

mechanical wear. They are often found, upon assembly, to be out of

specification. This makes them potentially destructive to any precision 3.5 mm

connectors to which they might be mated.

Use extreme caution when mating SMA connectors with 3.5 mm precision

connectors. Prevent accidental damage due to worn or out-of-specification

SMA connectors. Such connectors can destroy a precision 3.5 mm connector,

even on the first connection.

Hewlett-Packard recommends that you keep three points clearly in mind when

you mate SMA and precision 3.5 mm connectors: SMA inspection, alignment,

and mechanical mismatch.

SMA Inspection

Before mating an SMA connector (even a new one) with a precision 3.5 mm

connector, carefully inspect the SMA connector, both visually and mechanically

with a precision connector gauge designed to measure SMA connectors. A male

SMA connector pin that is too long can smash or break the delicate fingers on

the precision 3.5 mm female connector. Gauging SMA connectors is the most

important step you can take to prevent damaging your equipment.

Alignment

Be careful when aligning the connectors. Push the two connectors together

with the male contact pin precisely concentric with the female. Do not

overtighten or rotate either center conductor. Turn only the outer nut of the

male connector and use a torque wrench (5 lb.in., 60 N-cm) for the final

connection. Note that this torque is less than that when mating precision 3.5

mm connectors with each other. A torque wrench suitable for SMA connectors

preset to 5 lb.in. is available (HP part number 8710-1582, CD 0).

The TDR plug-in modules come with adaptors already installed to prevent

damage to the channel connectors. Then, if accidental damage does occur, the

adapter is all that needs to be replaced. It is easier and cheaper to replace a

damaged adapter than a channel connector. SMA connectors can then be mated

with precision 3.5 mm connectors without difficulty or fear of expensive and

time-consuming repairs.

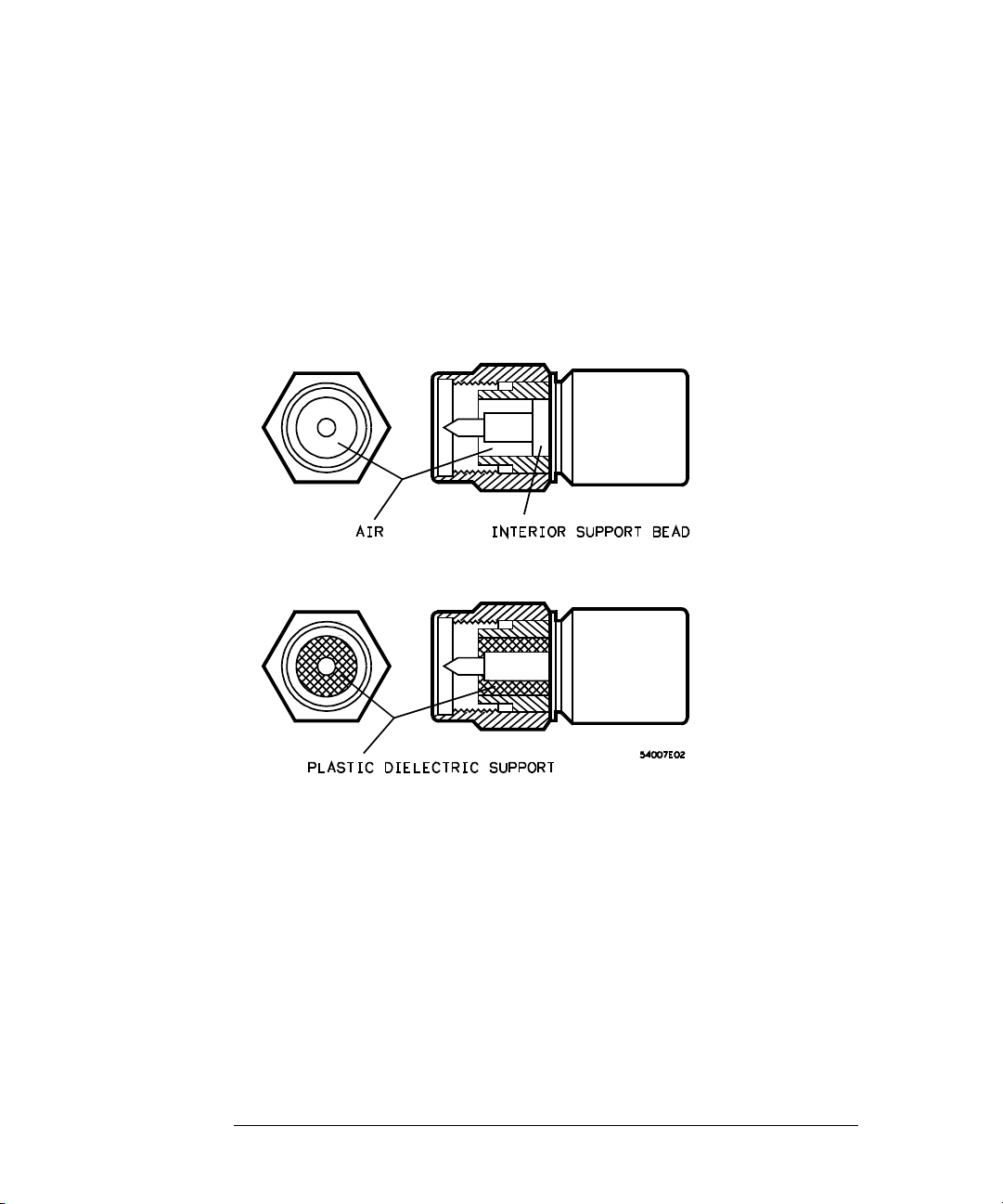

Mechanical Mismatch

Significant structural and dimensional differences exist between these two

types of connectors. Precision 3.5 mm connectors, also known as APC-3.5

connectors, are air-dielectric devices. Only air exists between the center and

outer conductors. The male or female center conductor is supported by a plastic

"bead" within the connector. In SMA connectors, a plastic dielectric supports

2-4

Page 19

Figure 2-1

Care and Handling of Precision Connectors

Device Specifications

the entire length of the center conductor. In addition, the diameter of both the

center and outer conductors of an SMA connectors differ from that of a precision

3.5 mm connector.

If these precautions and recommendations are followed, SMA connectors can

be mated with 3.5 mm precision connectors without fear of expensive and time

consuming repairs.

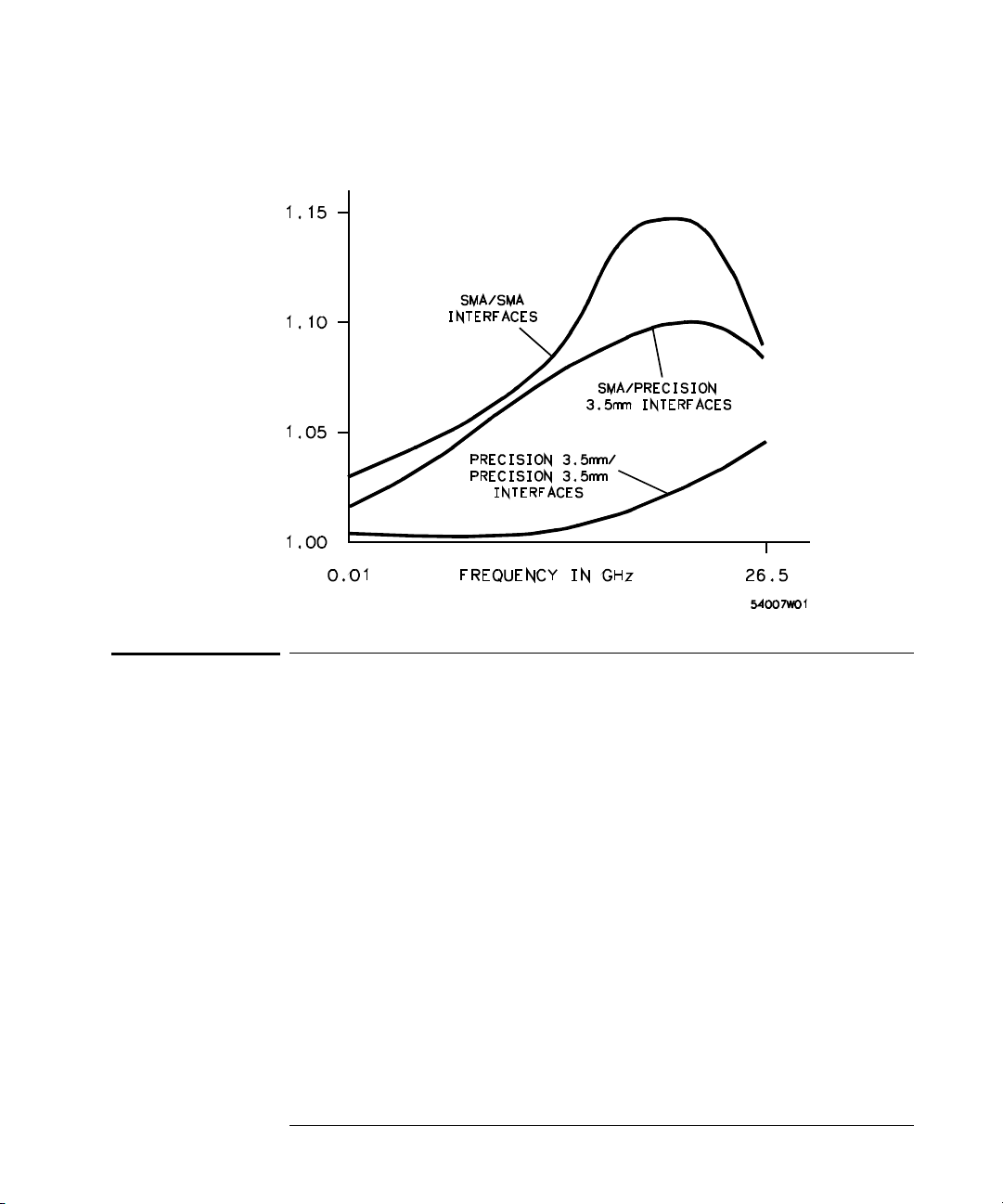

SMA and a Precision 3.5 mm Connectors

When an SMA connector is mated with a precision 3.5 mm connector, the

connection exhibits a continuity mismatch (SWR), typically about 1.10 at 20

GHz. This mismatch is less than when precision 3.5 mm connectors are mated.

Keep this fact in mind when making measurements on SMA and precision 3.5

mm coupled junctions.

2-5

Page 20

Figure 2-2

Care and Handling of Precision Connectors

Accuracy Considerations

Typical SWR of SMA and Precision 3.5 mm Connectors

Accuracy Considerations

Accuracy requires that 3.5 mm precision connectors be used. However, SMA

connectors can be used if special care is taken when mating the two, and all

connectors are undamaged and clean. Before each use, the mechanical

dimensions of all connectors must be checked with a connector gauge to make

sure that the center conductors are positioned correctly. All connections must

be made for consistent and repeatable mechanical (and therefore electrical)

contact between the connector mating surfaces.

Carefully study and practice all procedures in this chapter until you can

successfully perform them repeatedly. Accuracy and repeatability are critical

for good high frequency measurements. Note that the device connection

procedures differ in several important ways from traditional procedures used

in the industry. Hewlett-Packard procedures have been developed through

careful experimentation.

2-6

Page 21

Care and Handling of Precision Connectors

Accuracy Considerations

Handling Precision 3.5 mm Connectors

• Precision 3.5 mm connectors must be handled carefully if accurate

calibrations and measurements are to be obtained.

• Store the devices in the foam-lined storage case when not in use.

• Avoid bumping or scratching any part of the mating surfaces.

• Be careful to align the center connectors.

• Check the alignment carefully before tightening the connector nuts.

• Use a torque wrench for all final connections in order to avoid

overtightening.

• Support the devices being used in order to avoid vertical or lateral force on

any connectors. This precaution is critical when using the airline, 6 cm "L",

or cables.

When Disconnecting Devices:

• Do not rock or bend any connections.

• Pull the connector straight out without unscrewing or twisting.

• Before storage, screw the connector nut all the way out to help protect the

surfaces, and use the plastic caps provided. These plastic caps can be taken

off easily by unscrewing, rather than pulling.

CAUTION Do not use a damaged or defective connector. It will damage any good

connector to which it is attached. Throw the connector away or have it

repaired.

A connector is bad if it fails either the visual or mechanical examinations or

when an experienced operator cannot make repeatable connections. The time

and expense involved in replacing channel connectors warrants considerable

caution when any connector might be less than perfect.

If any doubts exist about a connector, call your Hewlett-Packard representative.

Hewlett-Packard field offices offer limited professional advice and have access

to the factory for information.

2-7

Page 22

Care and Handling of Precision Connectors

Visual Inspection

Visual Inspection

Always begin a calibration with a careful visual inspection of the connectors,

including the test set connectors to make sure they are and undamaged.

CAUTION

Make sure that you and your equipment are grounded before touching any

center conductor so you won't cause static electricity and create a potential

for electrostatic discharge. When using or cleaning connectors, be aware that

you are touching exposed center connectors that are connected directly to the

internal circuits of the oscilloscope. Touching the center conductor, especially

with a wiping or brushing motion, can cause an electrostatic discharge (ESD)

and severely damage these sensitive circuits.

Use an illuminated, 4-power magnifying glass for visual inspection.

1

Before you begin, make sure you and any equipment you are using are

grounded to prevent electrostatic discharge.

2

Examine the connectors first for obvious problems, such as deformed

threads, contamination, or corrosion.

3

Next concentrate on the mating surfaces of each connector. Look for

scratches, rounded shoulders, misalignment, or any other signs of wear

or damage.

4

Make sure that the surfaces are clean, free of dust and solvent residues.

Dirt or damage visible with a 4-power magnifying glass can cause

degraded electrical performance and possible connector damage. All

connectors should be repaired or discarded immediately.

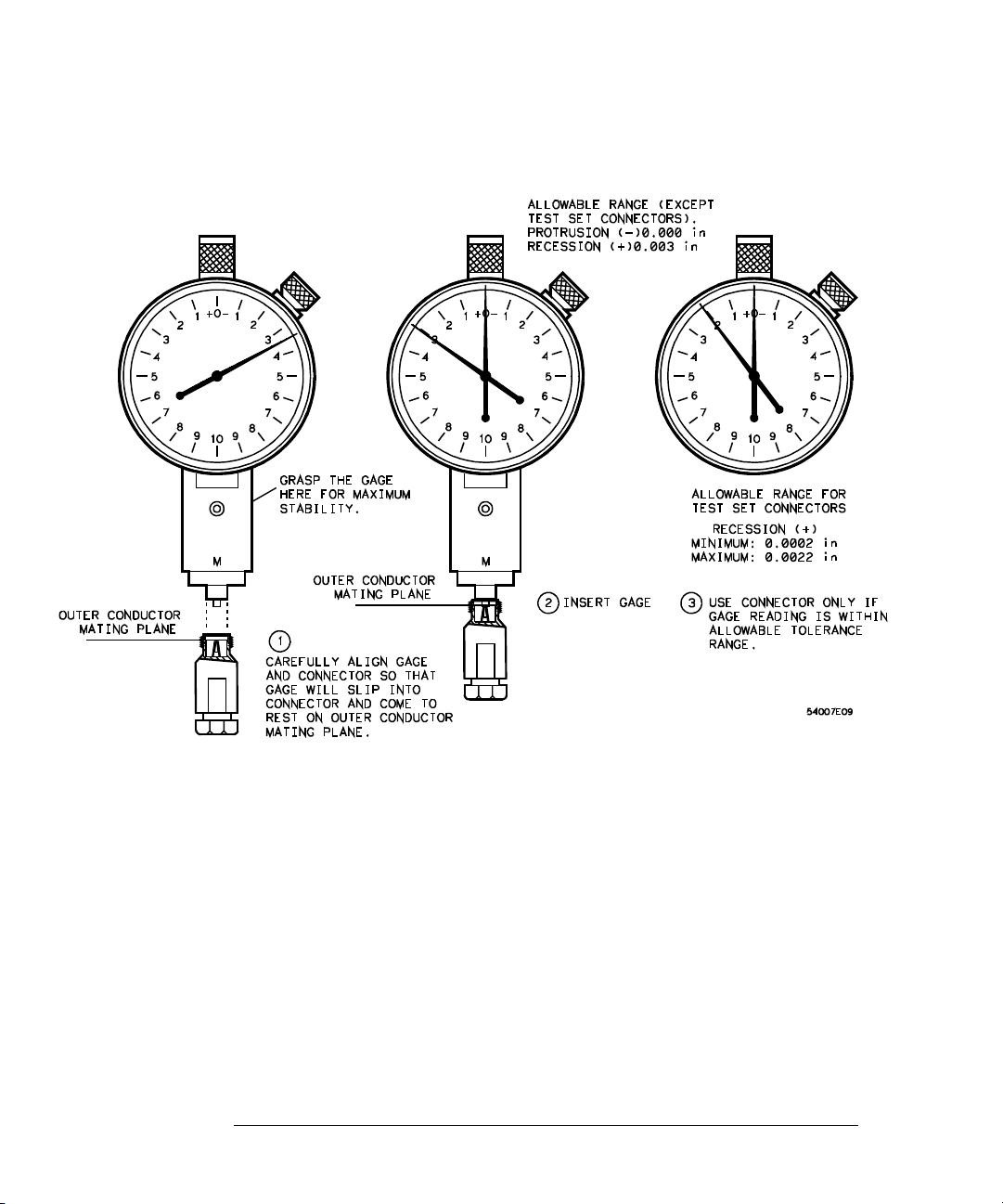

Mechanical Inspection

Mechanical inspection of the connectors is the next step. This inspection

consists of using the appropriate male or female precision 3.5 mm connector

gauge to check the mechanical dimensions of all connectors, including those on

the test set. The purpose of doing this is to make sure that perfect mating will

occur between the connector surfaces. Perfect mating assures a good electrical

match and is very important mechanically to avoid damaging the connectors

themselves, especially on the oscilloscope.

2-8

Page 23

Care and Handling of Precision Connectors

Mechanical Inspection

Center Conductor

The critical dimension to be measured is the recession of the center conductor.

This dimension is shown as MP and FP in Figure 2-3 and Figure 2-4. No

protrusion of the center conductor's shoulder is allowable on any connector.

The maximum allowable recession of the center conductor shoulder is 0.003 in.

(0.08 mm) on all connectors, except those on the channel connectors.

On the channel connectors, not only is no protrusion allowable, the shoulder of

the center conductor must be recessed at least 0.0002 in. (0.005 mm). The

maximum allowable recession of the center conductor shoulder on the channel

connectors is 0.0021 in. (0.056 mm).

2-9

Page 24

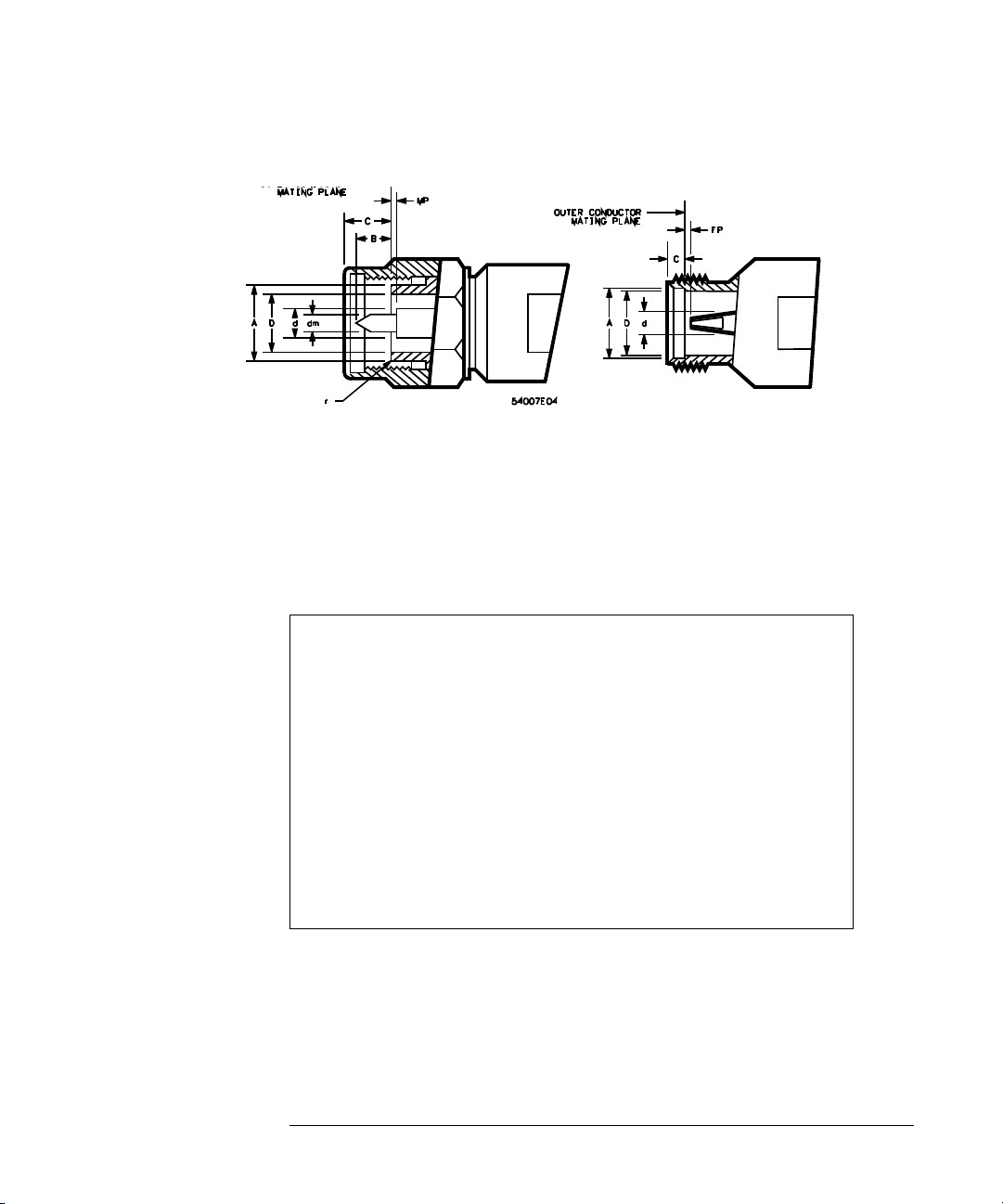

Figure 2-3

Care and Handling of Precision Connectors

Mechanical Inspection

D = inside diameter of the outer conductor

d = diameter of male/female center connector

A = outside diameter of outer conductor at the mating plane

r = corner relief for male connector

B = protrusion of the male contact pin tip beyond the outer conductor mating plane

C = recession of the outer conductor mating plane behind outer face of connector

MP = recession of male contact pin shoulder behind outer conductor mating plane

Male Connectors Female Connectors

inches millimeters inches millimeters

D = 0.1378 ± 0.0005 3.500 ± 0.013 D = 0.1378 ± 0.0005 3.500 ± 0.013

d = 0.0598 ± 0.0003 1.519 ± 0.008 d = 0.0598 ± 0.0003 1.519 ± 0.008

A = 0.1803 + 0.000

- 0.002

r = 0.003 0.08 r = 0.003 0.08

B = 0.085 +0.005

- 0.015

C = 0.120 ± 0.015 3.05 ± 0.38 C = 0.176 ± 0.002 1.93 ± 0.05

Mp = 0.00 + 0.003

- 0.000

dm = 0.037 + 0.000

- 0.001

Mechanical Dimensions of Connector Faces

4.580 + 0.00

- 0.05

2.16 + 0.13

- 0.38

0.000 + 0.08

- 0.00

0.94 + 0.00

- 0.03

A = 0.1807 + 0.002

- 0.000

N/A

Fp = 0.000 + 0.003

- 0.00

N/A

4.590 + 0.05

- 0.00

0.000 + 0.08

- 0.00

2-10

Page 25

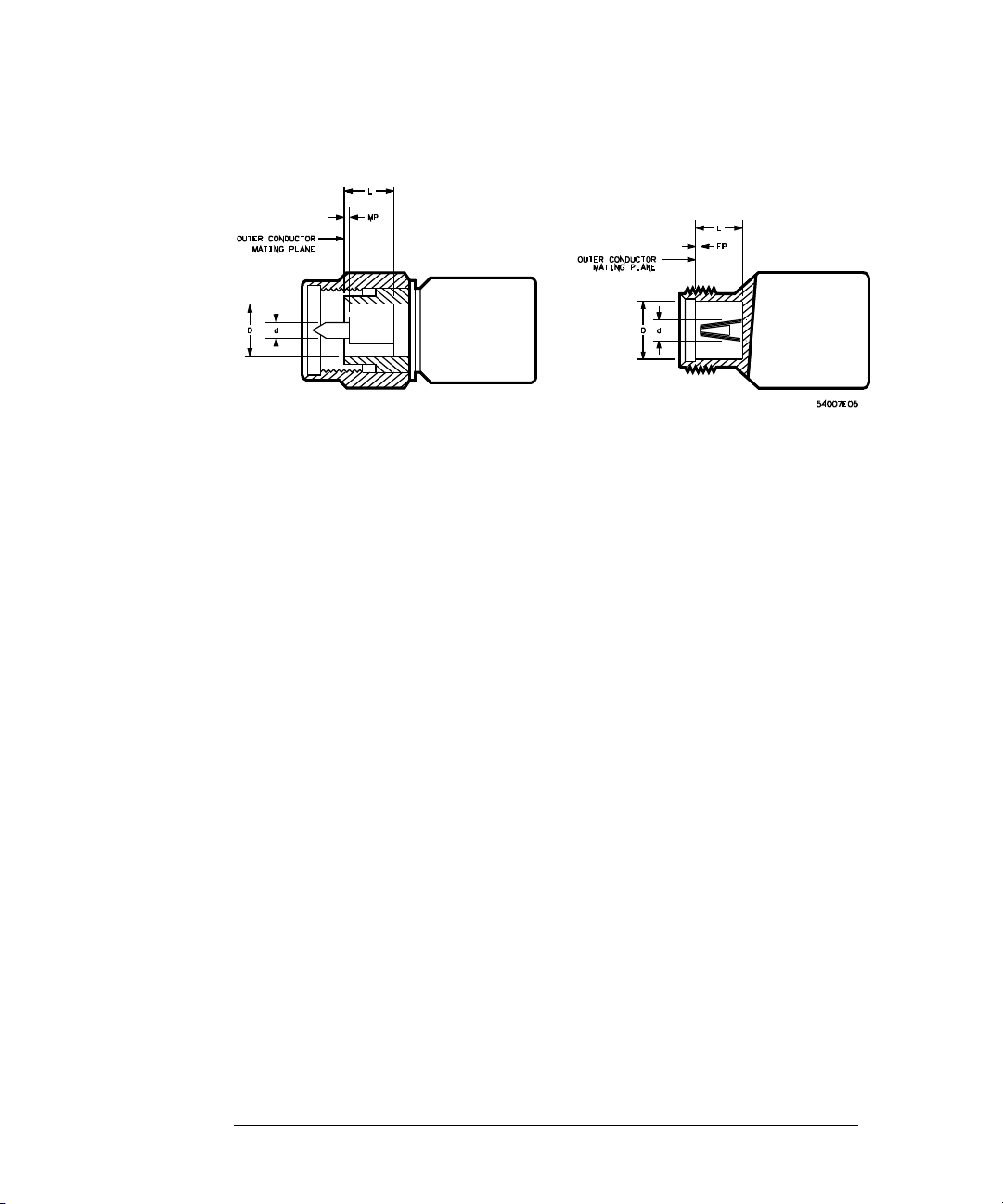

Figure 2-4

Care and Handling of Precision Connectors

Mechanical Inspection

Mechanical Dimensions of the Short Circuit

Outer Conductor

If any contact protrudes beyond the outer conductor mating plane, the contact

is out of tolerance and must be replaced. If the center conductor is not recessed

at least 0.0002 in. (0.005 mm), it is out of tolerance and must be replaced. In

both cases the out-of-tolerance connector will permanently damage any

connector attached to it. Destructive electrical interference will also result due

to buckling of the female contact fingers. This is often noticeable as a power

hole several dB deep occurring at about 22 GHz.

If any contact is recessed too far behind the outer conductor mating plane

(0.0021 in. 0.056 mm, except in test sets), poor electrical contact will result,

causing high electrical reflections. Careful gauging of all connectors will help

prevent this condition.

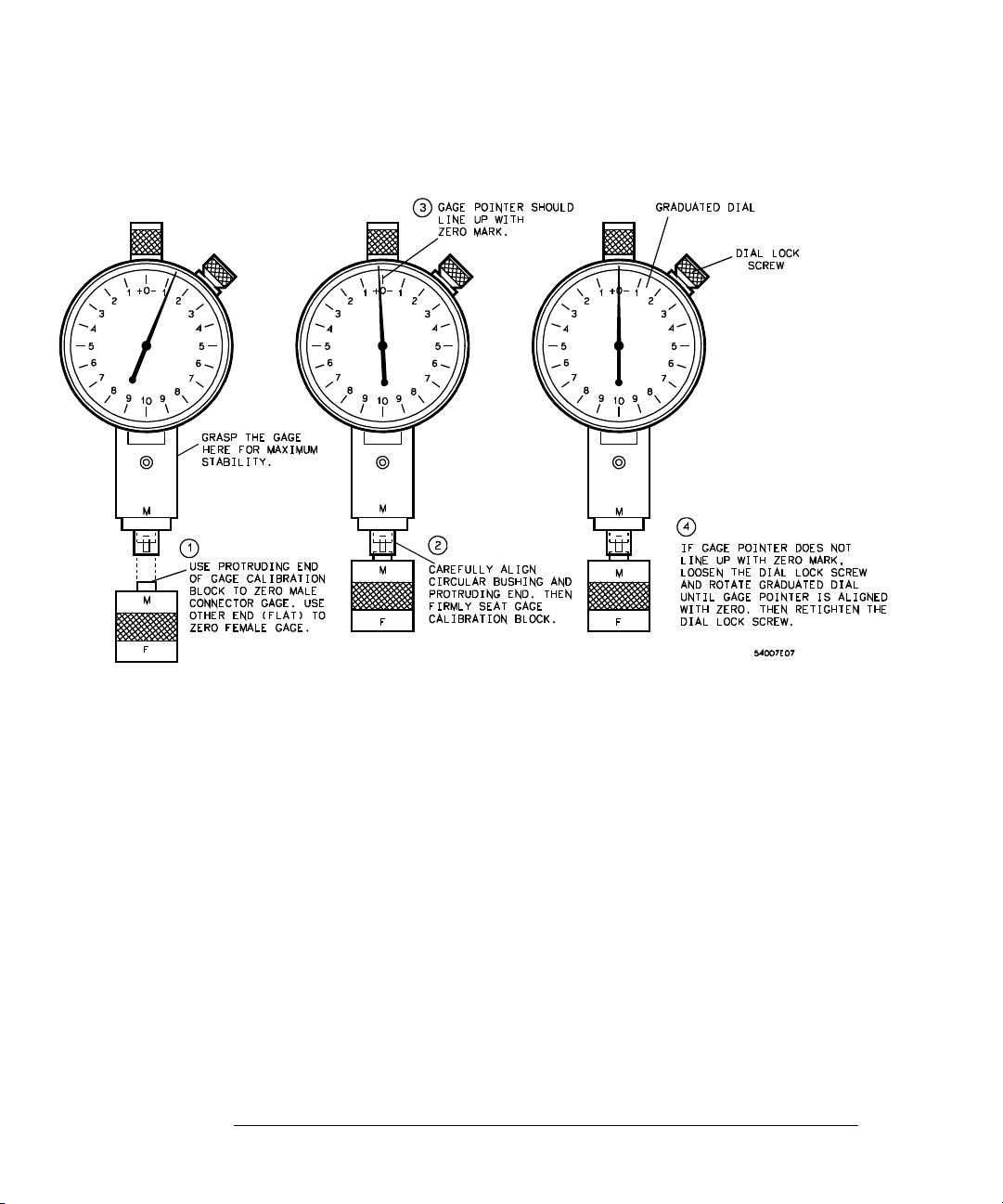

Before using the connector gauge to measure the connectors, visually inspect

the end of the gauge and the calibration block in the same way that you

inspected the connectors. Dirty or damaged gauge facings can cause dirty or

damaged connectors. Two connector gauges are available from HewlettPackard, one for each connector type, male and female. Refer to Figure 2-5.

The part number for one gauge is HP 11752D. This gauge has a 3.5 mm

connector (male and female). Or, you can use the 85052-60043 gauge with 3.5

mm female connector with an 85052-60042 3.5 mm male gauge.

Figure 2-5 to Figure 2-8 show how to use the connector gauges. Zero the gauge

with the calibration block. Refer to Figure 2-5. It is recommended that you

zero both gauges first, then measure each of the terminations and/or adapters

that will be used. Then, as the last step, measure the channel connectors.

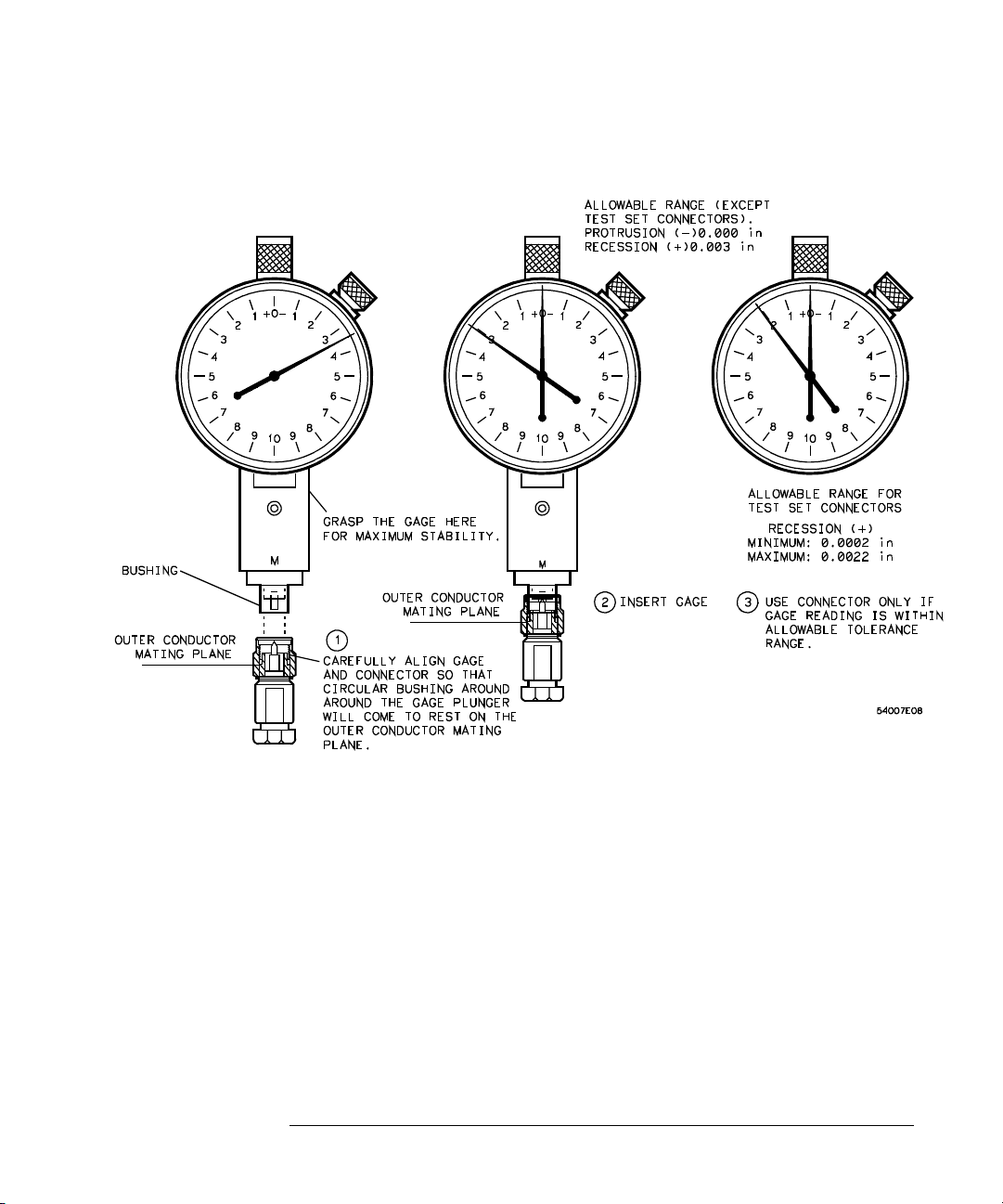

Figure 2-7 and Figure 2-8 show how to measure precision 3.5 mm connectors.

Note that a plus (+) reading on the gauge indicates recession of the center

conductor and a minus (-) reading indicates protrusion. Since no protrusion of

either connector is allowable, readings for connectors within the allowable

2-11

Page 26

Figure 2-5

Care and Handling of Precision Connectors

Mechanical Inspection

range will be on the plus (+) scale of the gauge. Also note that the allowable

tolerance range for the test set connectors is different from the range for other

connectors. Both ranges are shown in Figure 2-7 and Figure 2-8. Before

measuring test set connectors, be sure that the power to the test set is off and

that you and your equipment are grounded to prevent electrostatic discharge.

Precision 3.5 mm Connector Gauges

2-12

Page 27

Figure 2-6

Care and Handling of Precision Connectors

Mechanical Inspection

Zeroing Precision 3.5 mm Connector Gauge

2-13

Page 28

Figure 2-7

Care and Handling of Precision Connectors

Mechanical Inspection

Measuring Precision 3.5 mm Male Connectors

2-14

Page 29

Figure 2-8

Care and Handling of Precision Connectors

Mechanical Inspection

Measuring Precision 3.5 mm Female Connectors

2-15

Page 30

Care and Handling of Precision Connectors

Connecting the Devices

Connecting the Devices

Figure 2-9 and Figure 2-10 illustrate the Hewlett-Packard recommended

procedures for making connections with the calibration devices. Notice that

these recommended procedures differ from traditional procedures used in the

microwave industry, especially the counter-rotation technique and procedure

for connecting the airline.

The counter-rotation technique, recommended here, involves a slight rotation

of the termination or adapter just before the final tightening of the connector

nut. This eliminates the very small air wedge between the outer conductors

that frequently occurs when the body is held stationary during tightening, as it

is in the traditional procedure. The HP 54753A or HP 54754A plug-in modules

will detect the reflections caused by such small wedges.

The counter-rotation technique does not harm the connectors. The gold plating

on the outer conductor surface will become burnished in time. This is normal,

and as long as the surface remains smooth, the connector is still good. After

much use the gold plating may eventually wear through and expose the

beryllium-copper substratum. This too is normal, and if it is smooth the

connector is still good, although the beryllium-copper surface may oxidize if the

connector is used infrequently.

If the burnished surface is rough, scratched, rippled, or has other irregularities,

too much tightening force is being used. If the roughness is severe, the

connector is ruined and should not be used.

CAUTION

Damage can result if SMA connectors are overtightened to precision 3.5 mm

connectors. Use a torque wrench designed for SMA connectors, set to a 5 in

lb (60 N/cm). A torque wrench suitable for SMA connectors is available, HP

part number 8710-1582.

2-16

Page 31

Care and Handling of Precision Connectors

Connecting the Devices

Counter-Rotation Technique

The recommended Hewlett-Packard counter-rotation technique is for precision

3.5 mm connectors. Before making any connections to the channel connectors,

ground yourself with a grounded wrist strap. Also, it is good practice to grasp

the outer shell of the test port before you make any connections to the channel

connectors in order to discharge any static electricity on your body. This is the

most effective single safeguard to prevent ESD damage to your instruments.

If the device has a retractable connector nut, fully retract the nut before

1

mating the connectors. Carefully align the male and female contact pins

and slide the connectors straight together until the center and the two

outer conductors meet. Be careful not to twist or bend the contact pins.

You should feel a slight resistance as the connectors mate.

Make the preliminary connection by attaching the connector nut of the

2

male connector to the female. The male connector is held stationary

as the female connector is tightened and draws the male pin into the

female connector. Refer to Figure 2-9. Any other method used may

cause the male pin to damage the female connector. Support the body

of the device and turn the connector nut until the mating surfaces make

light contact. Do not overtighten. All you want is a connection of the

outer conductors with gentle contact at all points of both mating

surfaces.

Figure 2-9

Connecting 3.5 mm Devices

2-17

Page 32

Figure 2-10

Care and Handling of Precision Connectors

Connecting the Devices

3 When you are satisfied with this preliminary connection, use the

following counter-rotation technique to eliminate air wedges between

the mating planes. Refer to Figure 2-10. If the calibration device is male,

hold the connector nut firmly. Very slowly rotate the body of the device

about 10-20 ° counterclockwise. Note that this slight rotation or

backwiping is sufficient. Greater rotation does not improve electrical

performance and increases wear on the connector surfaces.

Counter-rotation Technique

If the calibration device is female (the connector nut is on the TDR plug-in

module), very slowly rotate both the connector nut and the body of the device

clockwise 10-20 ° (counterclockwise rotation will loosen the connection).

Light, smooth frictional resistance felt during the counter-rotation indicates you

have made the preliminary connection correctly and that the counter-rotation

technique has been successful. Roughness felt during counter-rotation

indicates either that the connectors are damaged or that there is roughness in

the connector nut/thread contact. Inspect both connectors again before

proceeding, to make sure that the roughness is due to roughness in the

connector nut interface rather than on the connector mating planes.

4 Tighten the connector nut finger tight, allowing the device to turn with

the nut if it tends to do so. A small rotation of the body of the device at

this point is acceptable and tends to occur naturally.

5 Use a torque wrench to make the final connection. Use of the torque

wrench assures the final connection will be tight enough for optimum

electrical performance, but not so tight as to distort or damage the

connectors.

2-18

Page 33

Care and Handling of Precision Connectors

Connecting the Devices

To disconnect, follow this procedure:

1 Loosen the connector nut on the male connector with the torque

wrench. Leave the connection finger tight.

2 While supporting the calibration device, gently unfasten the connectors

and pull the calibration device straight out of the channel connector.

Do not twist either the center conductor or the outer conductor housing

or exert lateral or vertical (bending) force on the connection.

Some precision 3.5 mm female connector fingers are very tight and can pull the

center pin of their mates out past specifications as they are disconnected. If such

a male pin is inserted into a female connector, it can cause considerable damage

by pushing the female center conductor back too far. Be aware of this possibility

and check all connectors before mating them again.

2-19

Page 34

2-20

Page 35

3

Setup Channel Menu

Page 36

Setup Channel Menu

What you’ll find in this chapter

This chapter describes the Setup Channel menu. A key tree and description of the

available functions are included. At the end of the chapter, you’ll find a discussion

of mainframe and plug-in module calibrations.

CAUTION

The input circuits can be damaged by electrostatic discharge (ESD). Therefore,

avoid applying static discharges to the front-panel input connectors. Before

connecting any coaxial cable to the connectors, momentarily short the center

and outer conductors of the cable together. Avoid touching the front-panel

input connectors without first touching the frame of the instrument. Be sure

the instrument is properly earth-grounded to prevent buildup of static charge.

The top left keys of the plug-in module are the Channel keys. These keys give

you access to the Setup Channel menu for each input. The Setup Channel menu

is displayed on the right side of the screen when the Channel key is pressed.

There are several types of softkeys available. A description of the different

softkeys and their functions is provided in the HP 83480A, 54750A User’s

Quick Start Guide supplied with the mainframe.

3-2

Page 37

Figure 3-1

Setup Channel Menu

Electrical Setup Channel menu.

3-3

Page 38

Setup Channel Menu

Displaying the Setup Channel menu

Displaying the Setup Channel menu

To display the Setup Channel menu, press the Channel key.

Display

The

Display

display is on, a waveform is displayed for that channel, unless the offset is

adjusted so the waveform is clipped off of the display or the instrument is not

triggering.

The channel number, vertical scaling, and offset are displayed at the bottom left

of the waveform area. They remain on the display until the channel is turned

off, or an automatic measurement is performed. The automatic measurement

results share the same area of the display as the channel setups.

When the channel display is off, the waveform display for that channel is turned

off, pulse parameter measurements are stopped and acquisition on that channel

is stopped, unless it is needed as an operand for waveform math functions or

TDR/TDT responses.

Even though the channel display is off, you can still use the plug-in as a function

source in the Math menu or as a source for four normalize, differential, or

common mode responses. However, the instrument will not trigger unless one

or more of the other channel displays are turned on, or unless a math function

or TDR/TDT response is using one of the channels.

Key Path Channel

Scale

The

Scale

is off, then the knob and arrow keys change the vertical scaling in a 1-2-5

sequence. When fine mode is on, the knob and arrow keys change the vertical

scaling in 1 mV increments. You can also use the keypad to enter values in

1 mV increments, independent of the fine mode selection.

The units the scale is displayed in depend on the unit of measure selected with

the

Units

reflect, gain, or unknown.

softkey turns the channel display off and on. When the channel

Display

softkey controls the vertical scaling of the waveform. If the fine mode

softkey. The choices for units are volts, watts, amperes, ohms, %

3-4

Page 39

Setup Channel Menu

Offset

When the ohm, % reflect, or gain units are selected, the control changes to

Magnify scale

behaves as it would when the units mode is selected for all stimulus except for

differential or common mode.

If the TDR/TDT stimulus is set to differential or common mode, the control also

changes to

displayed waveform is never clipped. The

scaling control.

. In this mode of operation, the TDR plug-in’s hardware scale

Magnify scale

. However, the hardware scale is set so that the

Magnify scale

control is a software

Key Path Channel

Offset

The

Offset

control on analog oscilloscopes. The advantage of digital offset is that it is

calibrated. The offset voltage is the voltage at the center of the graticule area,

and the range of offset is 500 mV. You can use the knob, arrow keys, or keypad

to change the offset setting. The fine mode also works with offset.

When an HP 54700-series active probe is used with the plug-in module and is

connected to the probe power connector adjacent to the channel input, the

offset control adjusts the external scale factor and offset of the hybrid inside

the active probe. A probe connected to the auxiliary power connector adjacent

to the trigger input will function, but the channel scale factor will not be adjusted

automatically.

The units the offset is displayed in depend on the unit of measure selected with

the

Units

reflect, gain, or unknown.

When the ohm, % reflect or gain units are selected, the control changes to

Magnify offset

behaves as it would when the units mode is selected for all stimulus except for

differential or common mode.

If the TDR/TDT stimulus is set to differential or common mode, the control also

changes to

displayed waveform is never clipped. The

offset control.

Scale

softkey moves the waveform vertically. It is similar to the position

softkey. The choices for units are volts, watts, amperes, ohms, %

. In this mode of operation, the TDR plug-in’s hardware offset

Magnify offset

, however, the harrower scale is set so that the

Magnify offset

control is a software

Key Path Channel

Offset

3-5

Page 40

Setup Channel Menu

Bandwidth. . .

Bandwidth. . .

You can use the

bandwidth. For the HP 54753A TDR plug-in module, channel 2 can be either

12.4 GHz or 20 GHz bandwidth.

Key Path Channel

Alternate scale. . .

The

Alternate Scale

vertical scale of the display. It also allows you to select the attenuation units

and the attenuation factor.

Key Path Channel

Atten units

The

Atten Units

factor represented. The choices are either decibel or ratio. The formula for

calculating decibels is:

The

Atten Units

or gain.

Bandwidth

Bandwidth. . .

function to select either 12.4 GHz or 18 GHz

function allows you to change the units used to label the

Alternate scale . . .

function lets you select how you want the probe attenuation

20

V

out

----------

V

or 10

in

P

out

----------loglog

P

in

function is not available when the units are set to ohm, % reflect,

Attenuation

The

Attenuation

function lets you select an attenuation that matches the device

connected to the instrument. When the attenuation is set correctly, the

instrument maintains the current scale factors, if possible. All marker values

and voltage or wattage measurements will reflect the actual signal at the input

to the external device.

3-6

Page 41

Setup Channel Menu

Alternate scale. . .

The attenuation range is from 0.0001:1 to 1,000,000:1. When you connect a

compatible active probe to the probe power connector, adjacent to the

corresponding channel input, the instrument automatically sets the

attenuation. For all other devices, set the probe attenuation with the knob,

arrow keys, or keypad.

Refer to "Calibrating Voltage Probes" for information on calibrating to the tip of the

probe.

The Attenuation function is not available when ohm, % reflect, or gain units are

selected.

Key Path Channel

Units

The Units function lets you select the unit of measure appended to the channel

scale, offset, trigger level, and vertical measurement values. For the plug-in

module, the units are volts, watts, amperes, ohms, % reflect, gain, or unknown.

Use volt for voltage probes, ampere for current probes, watt for optical-toelectrical (O/E) converters, and unknown when there is no unit of measure or

when the unit of measure is not one of the available choices. The gain selection

is only available when the channel has been chosen as a TDT destination.

The two additional choices, ohms and % reflect are selectable once a TDR/TDT

normalization and reference plane have been established (see the 54753A Setup

Menu or 54754A Setup Menu chapter under

for more information). Use Ohms when TDR/TDT vertical scale units of ohms/

div are required for making measurements. Use % reflect when TDR/TDT

percentage of reflection units are required.

Key Path Channel

Ext gain and Ext offset

When you select ampere, watt, or unknown on an electrical channel, two

additional functions become available: External Gain and External Offset.

These two additional functions allow you to compensate for the actual

characteristics of the probe rather than its ideal characteristics. For example,

you might have an amplified lightwave converter with ideal characteristics of

300 V/W with 0 V offset. But, its actual characteristics are 324 V/W with 1 mV

of output offset. Therefore, set the External Gain to 324 V/W and the External

Offset to 1 mV.

Alternate scale . . . Attenuation

Alternate scale . . . Units

Establish normalization & ref plane

3-7

Page 42

Setup Channel Menu

Calibrate . . .

Key Path Channel

Channel

Channel

Calibrate . . .

The calibrate menu allows you to null out any skew between probes or cables

and to check the present calibration status of the instrument.

Key Path Channel

Skew

The Skew function changes the horizontal position of a waveform on the display.

The Skew function has a range of approximately 100 µs. You can use skew to

compensate for differences in cable or probe lengths. It also allows you to place

the triggered edge at the center of the display when you are using a power

splitter connected between the channel and trigger inputs. Another use for

skew is when you are comparing two waveforms that have a timing difference

between them. If you are more interested in comparing the shapes of two

waveforms rather than the actual timing difference between them, you can use

Skew to overlay one waveform on top of the other waveform.

To adjust the skew on two channels

External scale . . . Units Volt Ext gain

External scale . . . Units Watt Ext gain

or

Ext Offset

or

External scale . . . Units Unknown Ext gain

Calibrate

. . .

Ext Offset

or

Ext Offset

1. Turn both channels on and overlay the signals vertically.

2. Expand the time base, so the rising edges are about a 45 degree angle.

3. Adjust the skew on one of channels, so that the rising edges overlap at the 50

percent points.

Key Path Channel

3-8

Calibrate . . . Skew

Page 43

Setup Channel Menu

Calibrate . . .

TDR Skew

The TDR Skew function changes the position of the TDR step. The TDR Skew

function has a range of ≅ ±400 pS. The units of the function are shown in % of

the maximum range, or ±100%. The Skew function and the TDR Skew function

differ in that Skew moves the acquired waveform with respect to the trigger,

while the TDR Skew function moves the TDR step with respect to the trigger.

TDR Skew can be used to align the TDR steps of the two TDR channels for more

accurate differential TDR measurements when cable or probe lengths are

different.

To deskew the two TDR channels

1. Turn on both channels and overlay the signals vertically with no cables attached.

2. Expand the time base so the rising edges are about a 45 degree angle.

3. Adjust the TDR skew on one of the channels, so that the rising edges overlap at

the 50 percent points.

4. Attach the cables. If the cables differ in length, then the waveforms will not

overlay each other.

5. Using the ∆Time auto measurement or manual markers, measure the ∆time (the

skew) between the TDR channels.

6. Adjust the channel Skew for the channel whose waveform is to the right of the

other channels waveform until the skew is ½ of the measured ∆time.

7. Adjust the TDR Skew for the right most waveform until the remaining skew is ≅ 0.

Key Path Channel

Calibrate . . . TDR Skew

3-9

Page 44

Setup Channel Menu

Calibrate . . .

Cal status

The Cal Status function displays a screen similar to Figure 3-8.

Key Path Channel

Figure 3-8

A typical Cal Status display.

Current Date This is the current date and time. You can compare this to

the last plug-in module calibration time. That way you will know how long

it has been since the last plug-in module calibration was performed.

Calibrate Cal Status

Current Frame ∆Temp This is the temperature change on the inside of

the instrument since the last mainframe calibration was performed. A

positive number indicates how many degrees warmer the mainframe is

currently as compared to the temperature of the mainframe at the last

mainframe calibration.

3-10

Page 45

Setup Channel Menu

Calibrate . . .

Channel 1 Calibration Status The instrument displays Calibrated

when the plug-in module has been calibrated in the current mainframe slot

otherwise the instrument displays Uncalibrated. Once a plug-in is

calibrated, the temperature difference (∆Temp) between when the plug-in

was calibrate and the current temperature is displayed. The plug-in module

will met dc accuracy specifications as long as the ∆Temp is within the range

of -5 °C to +5 °C. Also displayed, is a list of the plug-in module’s model

number, serial number, date of last calibration, and time of last calibration.

A calibration can be invalidated if:

• The mainframe has cycled power.

• The plug-in has been repaired, reprogrammed, or removed from the

mainframe.

• The instrument’s operating temperature has changed and remains more

than 5°C from the temperature at which the Plug-in calibration was

performed.

Calibrate probe

Connect a voltage probe to the plug-in and then press:

Calibrate probe

Continue

The instrument calibrates to the tip of the probe by setting the probe

attenuation to the actual attenuation ratio of the probe. The instrument also

automatically compensates for any offset that the probe may introduce.

Key Path Channel

Calibrate Calibrate probe Continue

3-11

Page 46

Setup Channel Menu

Calibration Overview

Calibration Overview

This section describes the calibration of the mainframe and TDR plug-in

modules vertical channel accuracy. It is intended to give you, or the calibration

laboratory personnel, an understanding of the various calibration procedures

available, and how they were intended to be used.

Proper calibration is critical to measurement accuracy and repeatability. The

HP 54750A/83480A and their associated modules and accessories require that

both factory and user calibrations be implemented at the recommended

intervals in order to perform measurements at their published specifications.

The following two sections describe factory and user calibrations. The first

section describes factory calibrations. A factory calibration consists of verifying

instrument performance to all specifications. If an instrument fails to meet

specifications, adjustment or repair may be necessary. For most users, this will

mean shipping the instrument back to an authorized service center. Some users

may purchase the required instrumentation and perform the factory timebase

calibrations themselves using the optional HP 83480A, 54750A Service Guide

or the TDR performance verification using the HP 54753A/54A Service Guide.

The second section addresses calibrations that are routinely performed by the

end user. In addition, there will be summary tables at the end of each of these

sections summarizing the main areas addressed. Both factory and user

calibrations must be performed regularly in order to ensure proper

measurement accuracy and repeatability.

CAUTION

NOTE

The input circuits can be damaged by electrostatic discharge (ESD). Avoid

applying static discharges to the front-panel input connectors. Before

connecting a coaxial cable to the connectors, momentarily short the center

and outer connectors of the cable together. Avoid touching the front panel

input connectors without first touching the frame of the instrument. Be sure

that the instrument is properly earth-grounded to prevent buildup of static

charge. It is strongly recommended that an antistatic mat and wristband be

used when connecting to TDR inputs.

For information about TDR/TDT normalized measurements, refer to

"Establishing the Reference Plane and Normalizing" located in Chapter 7.

Establishing normalization and a reference plane improves TDR measurement

accuracy.

3-12

Page 47

Setup Channel Menu

Factory Mainframe Calibration

Calibration interval

HP recommends that the factory calibration be performed on a periodic basis.

HP designs instruments to meet specifications over the recommended

calibration interval provided that the instrument is operated within the

specified operating environment. To maintain specifications, periodic

recalibrations are necessary. We recommend that the plug-in module be

calibrated at an HP service facility every 12 months. Users are encouraged to

adjust the calibration cycle based on their particular operating environment or

measurement accuracy needs.

Required warm-up time

The instrument requires a 1 hour warm-up period before any of the calibrations

mentioned in this chapter are performed. It is not enough for the instrument to

be in the standby setting. It must be turned on and running for the entire hour.

Remote operation

Remote programming commands for calibrations are included in the

HP 83480A/HP 54750A Programming’s Guide. Performing calibrations

remotely is slightly different than the operation of front-panel calibrations.

Factory Mainframe Calibration

Mainframe calibration improves timebase accuracy. All timebase measurements

such as rise time, fall time, and so forth are affected by the timebase accuracy.

The calibration factors are stored in the nonvolatile RAM of the instrument.

There is a switch on the back panel of the instrument that allows the mainframe

calibration to be protected or unprotected. Next to the switch there is a drawing

that shows each switch’s function and protected position. Refer to the optional

HP 83480A, 54750A Service Guide for more details about the mainframe

calibration, and the position of the rear-panel memory protect switches.

3-13

Page 48

Setup Channel Menu

Factory Mainframe Calibration

Factory Calibration Summary

Calibration What is calibrated

Mainframe Calibration Accuracy and continuity

of the timescale

Measurements

Affected

All time base

measurements.

Recommended

Interval

Annually at HP service

center or if operating

temp has changed and

remains 5°C or more

from calibration

temperature. See

service manual.

Softkey Path

Utility

Calibrate

Calibrate frame

CAUTION To prevent access to the mainframe calibration switch, place a sticker over the

access hole to this switch.

CAUTION Do not attempt a Mainframe calibration without consulting the HP 83480A,

54750A Service Guide.

A mainframe calibration should be performed on a periodic basis (at least

annually), or when the ambient operating has changed by and remains 5°C

different than the operating temperature at which the last mainframe

calibration was performed. To see how much the operating temperature has

changed since the last mainframe calibration and the date of the last mainframe

calibration, check the Calibration status by pressing the following key sequence:

Utility,

Calibrate

, and then

Cal status

on.

The temperature change is displayed at the top of the display as shown in the

following figure.

3-14

Page 49

Setup Channel Menu

Factory Mainframe Calibration

Current Frame ∆Temp condition

If the Current Frame ∆Temp listing is greater than ±5°C, then the mainframe

should either be calibrated at the current operating temperature or be placed

in an ambient air temperature that is within 5°C of the temperature of the

current calibration.

3-15

Page 50

Setup Channel Menu

User Calibrations

User Calibrations

The following calibrations can be performed by the user:

• Plug-in Module Vertical Calibration

• Probe Calibration

• Channel Skew

• External Scale

CAUTION

The input circuits can be damaged by electrostatic discharge (ESD). Avoid

applying static discharges to the front panel input connectors. Before

connecting a coaxial cable to the connectors, momentarily short the center

and outer connectors of the cable together. Avoid touching the front panel

input connectors without first touching the frame of the instrument. Be sure

the instrument is properly earth-grounded to prevent buildup of static charge.

An antistatic mat and wristband are strongly recommended, particularly when

working with TDR modules.

Channel User Calibration Summary

Calibration What is calibrated

Plug-in Vertical

Calibration

Vertical offset and

vertical scale accuracy.

Measurements

Affected

Any vertical

measurement

Recommended

Interval

Perform after any

power cycle or once

every 10 hours during

continuous use or if

operating temperature

changes by more than

2°C.

Key Path

Utility

Calibrate

Calibrate Plug-in

3-16

Page 51

Miscellaneous User Calibration Summary

Setup Channel Menu

User Calibrations

Calibration What is calibrated

Probe calibration Probe Attenuation Any measurement

Channel Skew Calibrates out the small

differences in delay

between channels.

Useful for looking at

timing differences

between channels

External Scale Compensates for gain o r

loss associated with

external devices

(calibrates vertical scale

to external device

Measurements

Affected

taken with the probe

Multiple channel

measurements, such as

Differential TDR

Any measurement

taken through an

external device

(component or

transducer

Plug-in Module Vertical Calibration

The plug-in module vertical calibration allows the instrument to establish the

calibration factors for a specific plug-in when the plug-in is installed in the

mainframe. The plug-in calibration factors are valid only for the specific

mainframe slot in which it was calibrated. The plug-in vertical calibration

establishes vertical accuracy.

A plug-in vertical calibration should be done if:

• the mainframe has cycled power,

• the plug-in has been repaired, reprogrammed, or removed from the

mainframe

• the instrument’s operating temperature has changed and remains more than

5°C from the temperature at which the Plug-in calibration was performed.

To obtain the best measurement results, it is recommended that a user vertical

calibration be performed after every 10 hours of continuous use or if the

temperature has changed by greater than 2°C from the previous vertical

calibration.

Recommended

Interval

Whenever a probe is

connected

Before multiple

channel measurements

when measuring timing

differences between

channels.

Whenever using

external devices

(component or

transducer)

Key Path

Channel Setup

Calibrate

Calibrate probe

Channel Setup

Calibrate

Skew

Channel Setup

External Scale

3-17

Page 52

Setup Channel Menu

User Calibrations

To view the temperature change

This procedure displays the temperature change that the instrument has

undergone since the last Plug-in Vertical Calibration.

1 Press the front-panel channel SETUP key.

2 Press

1 Remove any front-panel connections from channels.

2 Press Utility,

3 Select the plug-in module to be calibrated, press

4 Press

5 Follow the on-screen instructions.

Probe Calibration

Calibrate

The current plug-in ∆Temp value is listed for each installed module.

To perform a plug-in module vertical calibration

Start cal

No additional equipment is required to perform a plug-in vertical calibration.

Reference signals are both generated and routed internally.

For active probes such as the HP 54701A, which the instrument can identify

through the probe power connector, the instrument automatically adjusts the

channel vertical scale factors to the probe’s nominal attenuation, even if a probe

calibration is not performed.

For passive probes or non-identified probes, the instrument adjusts the vertical

scale factors only if a probe calibration is performed. Probe calibration allows

the instrument to establish the gain and offset of specific probes that are

connected to a channel of the instrument, and then apply those factors to the

calibration of that channel.

The analyzer calibrates to the tip of the probe by setting the probe attenuation

to the actual attenuation ratio of the probe. The CAL signal is internally routed

to the probe tip for HP active probes.

The mainframe’s CAL signal is a voltage source, therefore you can let the

instrument compensate for the actual characteristics of your probe by letting

the instrument calibrate to the tip of the probe. The instrument automatically

calibrates to the tip of the probe, sets the probe attenuation, and compensates

for any probe offset.

If you do not perform a probe calibration but want to use a passive probe, enter

the attenuation factor using the following steps:

and then

Calibrate. . .

to start the calibration.

Cal status on

, and then

Calibrate plug-in. . .

.

.

1 and 2

or

3 and 4

.

3-18

Page 53

1 Press the plug-in module’s front-panel channel SETUP key.

Setup Channel Menu

User Calibrations

2 Press

3 You can use the probe calibration to calibrate any network, including probes or

1 Press the plug-in module’s front-panel-channel SETUP key.

2 Press

1 Connect the voltage probe to the plug-in.

2 Attach the probe tip to the CAL hook that is located near the floppy disk drive.

3 Press the plug-in module’s front-panel channel SETUP key.

4 Press

Alternate scale

cable assemblies. The instrument calibrates the voltage at the tip of the probe or

the cable input.

To calibrate an HP identifiable probe

Calibrate

To calibrate a non-identifiable probe

Calibrate

If the probe being calibrated has an attenuation factor that allows the

instrument to adjust the gain (in hardware) to produce even steps in the vertical

scale factors, the instrument will do so. Typically, probes have standard

attenuation factors such as divide by 10, divide by 20, or divide by 100.

To calibrate other devices

The information in this section applies to both optical and electrical

measurements. Since the mainframe’s CAL signal is a voltage source, it cannot

be used to calibrate to the probe tip when the units are set to Ampere, Watt, or

Unknown. Instead, set the external gain and external offset to compensate for

the actual characteristics of the probe or device. If you do not know the actual

characteristics, you can refer to the typical specifications that came with the

probe or device.

and then

and then

, and then

Attenuation

Calibrate Probe

Calibrate probe

.

.

.

1 Press the plug-in module’s front-panel channel SETUP key.

2 Press

3 Press

4 Press

5 Press

Alternate scale

Atten units Ratio, Attenuation 1:1

Ext gain

Ext offset

.

, and then

, and enter the actual gain characteristics of the probe or device.

, and enter the offset introduced by the probe or device.

Units Ampere

(Watt or Unknown).

3-19

Page 54

External Scale

Setup Channel Menu

User Calibrations

The channels have a setting which allows the user to enter in an offset value to

compensate for gains or losses not associated with the device under test. This

feature is useful for adjusting out the effects of devices such as test fixtures and

attenuators so that the reading on the display gives the measurement value

associated with only the actual device under test.

To adjust the external scale

1 Press the plug-in module’s front-panel channel SETUP key.

2 Press

3 Press

Alternate Scale

Attenuation

Channel Skew Calibration

The skew calibration changes the horizontal position of a waveform on the

display. The skew calibration has a range of approximately 100 µs. You can use

skew to compensate for the differences in cable or probe lengths. It also allows

you to place the trigger edge at the center of the display when you are using a

power splitter connected between the channel and trigger inputs. Another use

for skew is when you are comparing two waveforms that have a timing

difference. If you are interested in comparing the shapes of two waveforms

rather than the actual timing difference, you can use skew to overlay one

waveform on top of the other waveform.

To skew two channels

1 Turn both channels on and overlay the signals vertically.

2 Expand the time base so that the rising edges are at about a 45° angle.

3 Press the plug-in module’s front-panel channel SETUP key.

4 Press

5 Adjust the skew on one of the channels so that the rising edges overlap at the 50%

Calibrate

points.

, and set the

, and enter the appropriate values.

and then

Skew

Atten units

.

to "decibel".

3-20

Page 55

4

HP 54753A TDR/TDT Setup Menu

Page 56

HP 54753A TDR/TDT Setup Menu

What you’ll find in this chapter

This chapter describes the TDR/TDT Setup menu. A key tree and description of the

available functions is included.

CAUTION

The input circuits can be damaged by electrostatic discharge (ESD).

Therefore, avoid applying static discharges to the front-panel input connectors.

Before connecting any coaxial cable to the connectors, momentarily short the

center and outer conductors of the cable together. Avoid touching the front-

panel input connectors without first touching the frame of the instrument. Be

sure the instrument is properly earth-grounded to prevent buildup of static

charge.

The top right key of the plug-in module is the TDR/TDT Setup key. This key gives

you access to the TDR/TDT Setup menu. The TDR/TDT Setup menu is displayed

on the right side of the screen when the TDR/TDT Setup key is pressed. There

are several types of softkeys available.

4-2

Page 57

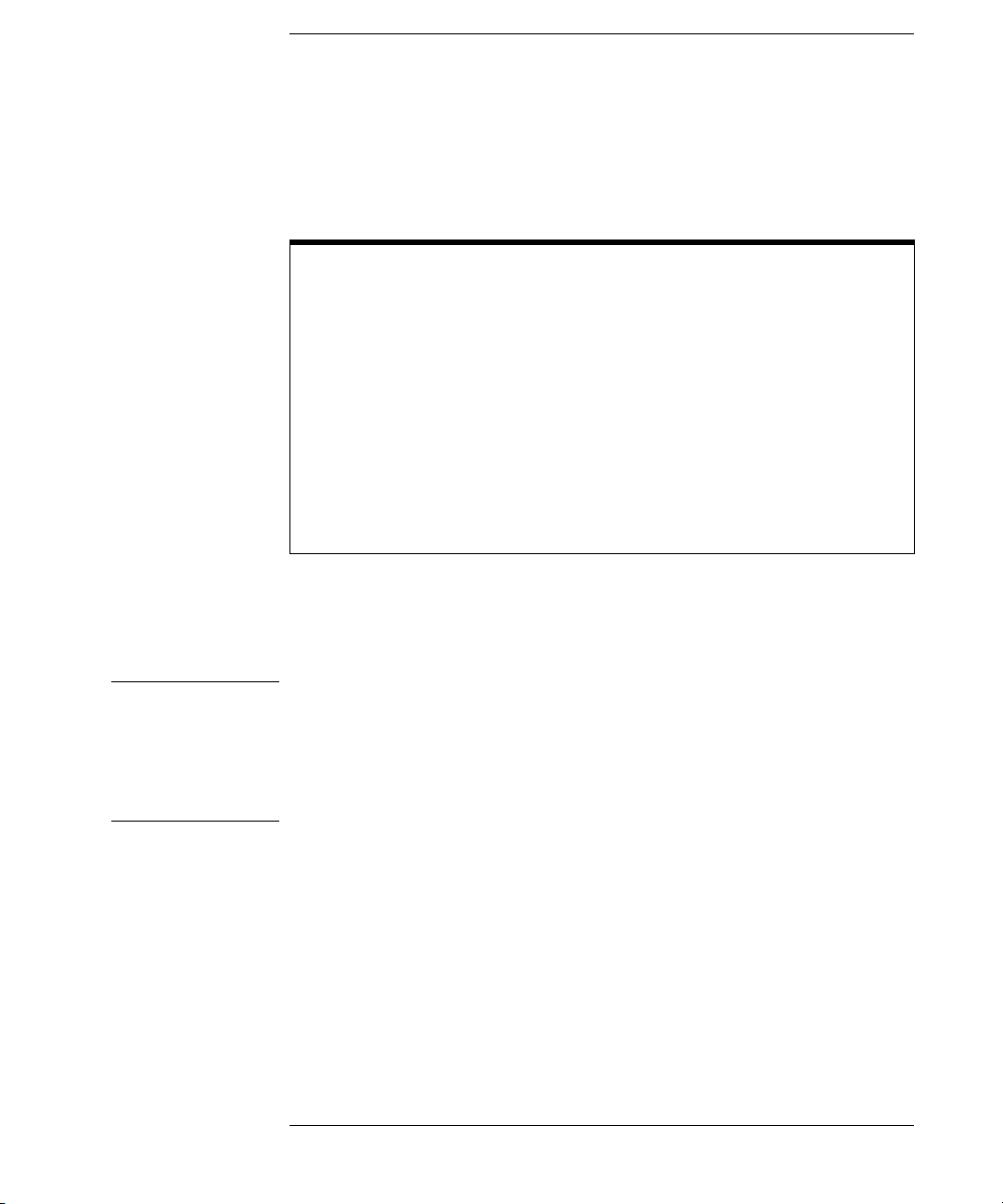

Figure 4-1

HP 54753A TDR/TDT Setup Menu

TDR/TDT Setup Stimulus

TDR/TDT help . . .

TDT 1 dest

Normalize response . . .

Off

On

External

Cancel

Enter

Single ended TDR/TDT

Differential common mode TDR/TDT

Done

channel 2

none

Cancel

Enter

Risetime

TDR/TDT

TDR normalize

TDR

TDT

off

on

TDR/TDT Setup Menus

TDR rate automatic . . . (250 kHz)

Preset TDR/TDT

Establish normalization & ref plane

Done

automatic

manual TDR rate

Done

4-3

Page 58

HP 54753A TDR/TDT Setup Menu

Displaying the TDR/TDT Setup Menu

Displaying the TDR/TDT Setup Menu

To display the TDR/TDT Setup menu, press the TDR/TDT Setup key on the TDR

plug-in module.

Stimulus

Pressing the

turn off the TDR step. The HP 54753A is a single-ended TDR plug-in and has

one TDR stimulus channel. The following table contains a list of the available

stimulus menu choices and their descriptions.

Table 4-1

Stimulus Menu Choices

Stimulus Description

off Turns the TDR step off and disables the TDR measurement system.

on Turns the TDR step on and enables the TDR measurement system.

external This setup provides control for and requires an external step

Key Path TDR/TDT Setup

Stimulus

TDT 1 dest

The

TDT 1 dest

Pressing the

channel used as the destination channel for TDT measurements. The choices

available for this pull-down menu depend on the other TDR or electrical plug-

in, if any, in the mainframe.

TDT 1 dest

softkey produces a pull-down menu used to turn on or

generator before measurements can be made.

Stimulus

softkey only appears when the

Stimulus

softkey produces a pull-down menu used to select the

is set to on or external.

Any electrical channel is a valid TDT destination channel. If external stimulus

is selected, the TDT destination may not be set to the currently defined TDR

destination channel.

4-4

Page 59

HP 54753A TDR/TDT Setup Menu

TDR 1 dest

If no other valid TDT destination channels are available, then "none" is the only

choice. If a TDT destination other than none is selected, then the

TDR/TDT

control will turn on and preset the TDT destination channel.

Preset

Key Path TDR/TDT Setup

TDR 1 dest

The

TDR 1 dest

Pressing the

channel used as the destination channel for TDR measurements. Any electrical

channel is a valid TDR destination channel. The TDR destination may not be

set to the currently defined TDT destination.

Key Path TDR/TDT Setup

Normalize response . . .

The

Normalize response

normalized step, to select TDR and TDT normalization, to turn on or off the

display of the normalized TDR or TDT trace, to change the scaling of the

normalized trace, and to establish the normalization filter values and reference

plane.

Risetime

The Risetime function allows you to change the normalized step’s risetime from

a minimum of

TDT 1 dest

softkey only appears when the stimulus is set to external.

TDR 1 dest

softkey produces a pull-down menu used to select the

TDR 1 dest

function allows you to change the risetime of the

10 ps

or

time per division (s/div) 10 divisions×

min 8 points

whichever is greater, to a maximum of

max 5 time per division (s/div)×=

---------------------------------------------------------------------------------------------

×=

record length

4-5

Page 60

HP 54753A TDR/TDT Setup Menu

Normalize response . . .

While the TDR step’s risetime applied to the system under test is fixed, the

measured response has a set of mathematical operations applied to it. These

mathematical operations effectively change the displayed response to the

system just as if a different TDR step risetime had actually been applied. This

allows you to select a risetime for TDR/TDT measurements that is close to the

actual risetime used in your system. This risetime value applies to both TDR

and TDT normalized channels. For more information on normalization, see the

chapter titled Improving Time Domain Network Measurements.

Key Path TDR/TDT Setup

TDR/TDT

TDR/TDT

The

Both TDR and TDT channels can be normalized. This control selects which

normalized trace is referred to for the following controls. Before TDT

normalization can be done, you must select a TDT destination (

Key Path TDR/TDT Setup

TDR or TDT normalize

The

TDR normalize

previous control; otherwise, the TDT normalize function is available. In either

case, this function turns on or off the display of the normalized trace. The TDR

and TDT normalization functions can be on at the same time.

Key Path TDR/TDT Setup

Normalize scaling . . .

Normalize scaling

The