Page 1

Combined Service Manual

HP DOC

Back to Welcome

HP LaserJet 4L/ 4ML

(C2003A/ C2015A)

HP LaserJet 4P/ 4MP

(C2005A/ C2040A)

Page 2

Warranty

The information contained

in this document is subject

to change without nc,tice.

Hewlett-Packard makes

no warranty of any kind

with regard to this material, including, but not

limited to, the implied

warranties or merchantability and fitness for a

particular purpose.

Hewlett-Packard shall not

be liable for errors cmtained herein or for incidental or consequential

damaged in connecti~m

with the furnishing, performance, or use of this material.

WARNING

Electrical Shock Hazard

To avoid electrical shock,

use only supplied power

cords and connect only to

properly grounded (3-hole)

wall outlets.

Page 3

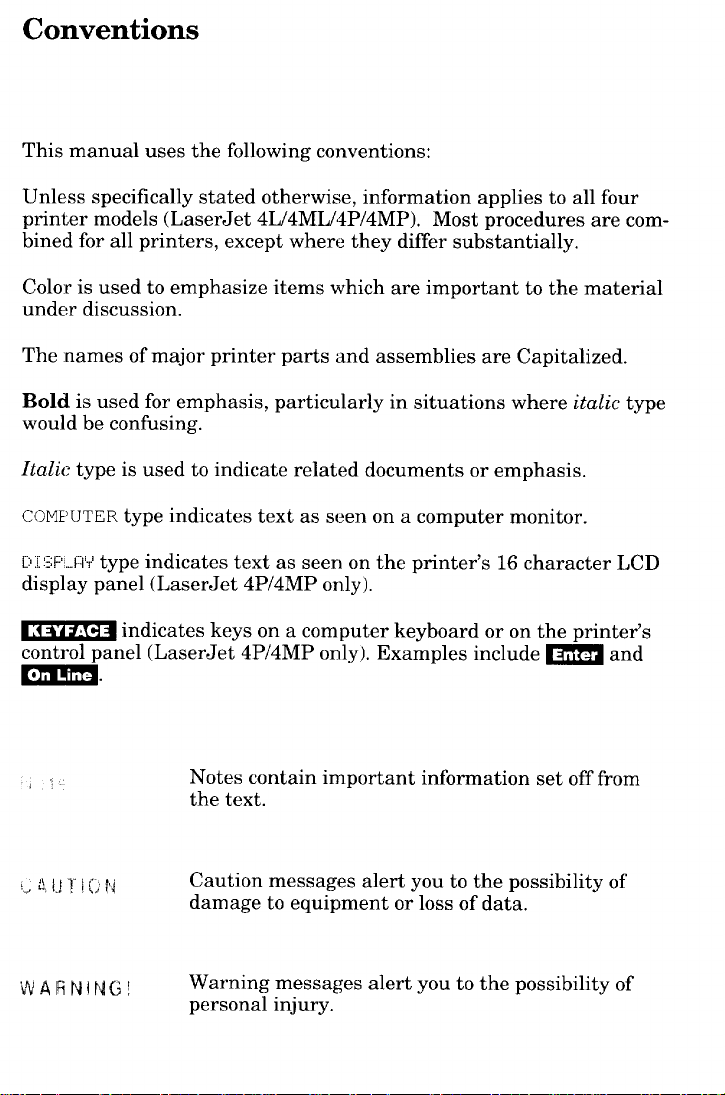

Conventions

This manual uses the following conventions:

Unless specifically stated otherwise, information applies to all four

printer models (LaserJet 4L/4ML/4P/4MP), Most procedures are combined for all printers, except where they differ substantially.

Color is used to emphasize items which are important to the material

under discussion.

The names of major printer parts and assemblies are Capitalized.

Bold is used for emphasis, particularly in situations where italic type

would be confusing.

Italic type is used to indicate related documents or emphasis.

COME’UTER type indicates text as seen on a computer monitor.

Di;W.-ii’+type indicates text as seen on the printer’s 16 character LCD

display panel (LaserJet 4P/4MP only).

~ indicates keys on a computer keyboard or on the printer’s

control panel (LaserJet 4P/4MP only). Examples include ~ and

m.

,“

21.JII[,!’J

i,,

WARNING!

Notes contain important information set off from

the text.

Caution messages alert you to the possibility of

damage to equipment or loss of data.

Warning messages alert you to the possibility of

personal injury.

Page 4

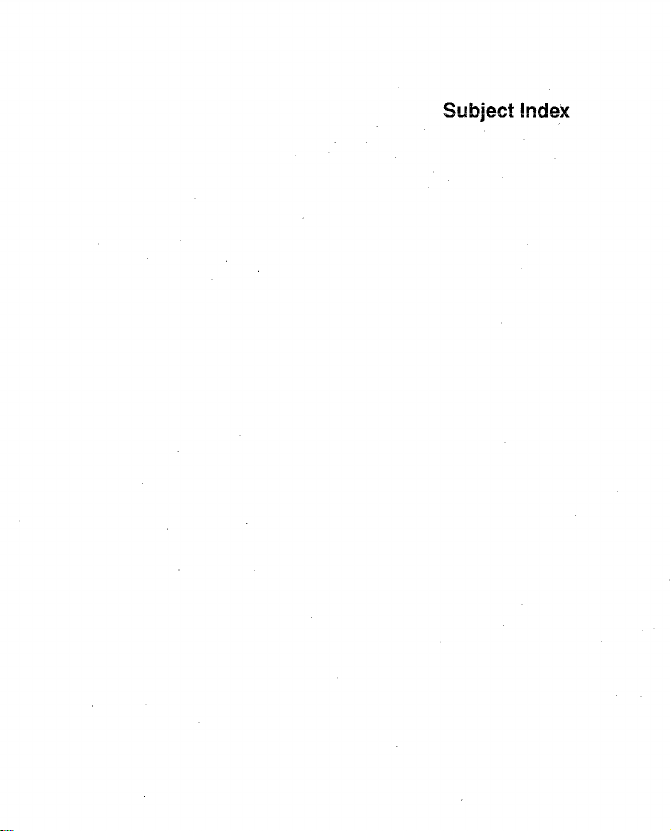

A detailed matrix of printer features is followed by general

information on the four printer models. Specifications, major

assembly locations, safety and regulatory information are all

included. The chapter ends with a discussion of the service

and repair philosophy along with useful information on

obtaining technical help.

Recommendations pertaining to the physical location of the

printer and consumables are followed by general print media

specifications (including specifications for paper, envelopes,

labels and transparencies).

Chapter 3 provides the step-by-step installation and setup

procedure, along with detailed information on using the

Control Panel for each printer model. Sample self tests and

printer reset information are also included.

Turn to this chapter for information on routine printer

maintenance, including consumables and printer cleaning

procedures. Paper jam procedures are also included.

Here you will find the basic theory-of-operation information

required to understand the various printer systems and how

they function together.

This chapter contains the step-by-step procedures for

replacing all the printer’s field replaceable units (FRUS).

Assemblies are grouped by physical location in the printer.

...

Page 5

Turn to Chapter 7 for diagnosing and troubleshooting printer

problems. Start with the general troubleshooting flowchart,

referencing the paper path and printer component location

diagrams for assistance. Error message tables and image

defect samples are followed by engine test and other

diagnostic procedures. The chapter ends with more

troubleshooting tools such as an image defect ruler and

wiring diagram.

I-JseChapter 8 to find any field replaceable unit (FRU) in the

printers. Exploded view drawings are accompanied by

complete part number and description tables.

The parts index is a convenient tool for looking up any field

replaceable unit (FRU). All parts are sorted both by part

number and by part name. Parts are cross-referenced to their

corresponding exploded view illustrations in Chapter 8.

This appendix contains cabling and pin-out information for

the serial, parallel and LocalTalk interfaces which are

supported by the printers.

lJse the subject index to quickly locate any information in the

manual.

Page 6

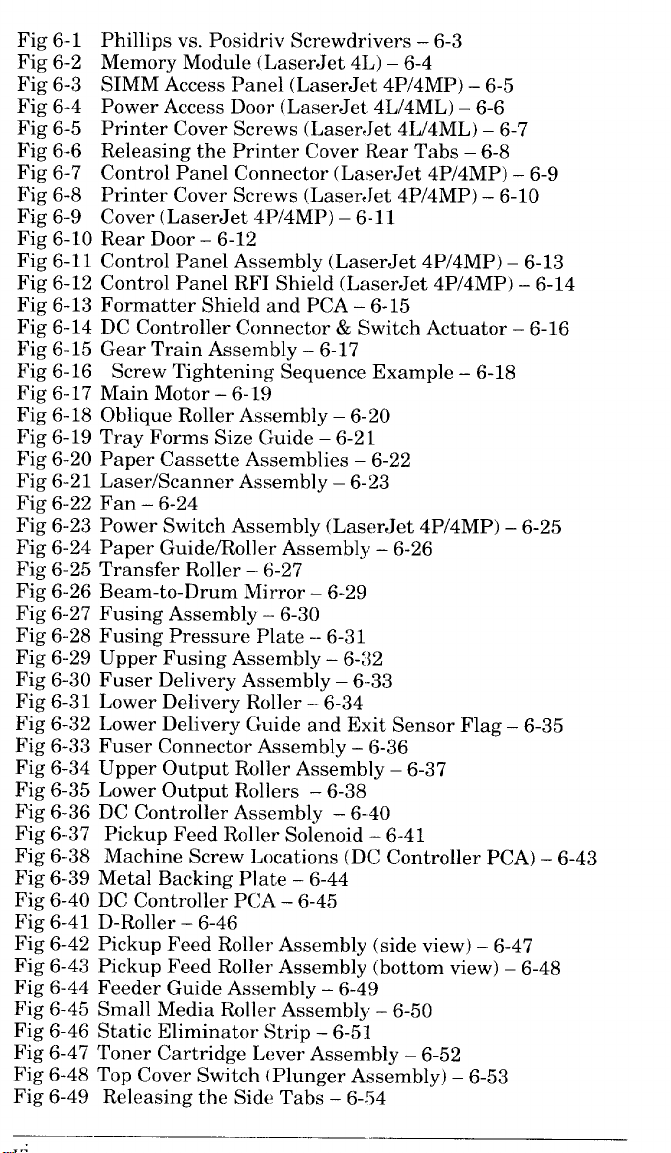

Fig l-l

Fig I-2

Fig I-3

Fig I-4

Fig I-5

Fig I-6

Fig 2-1

Fig 2-2

Fig 3-1

Fig 3-2

Fig 3-3

Fig 3-4

Fig 3-5

Fig 3-6

Fig 3-7

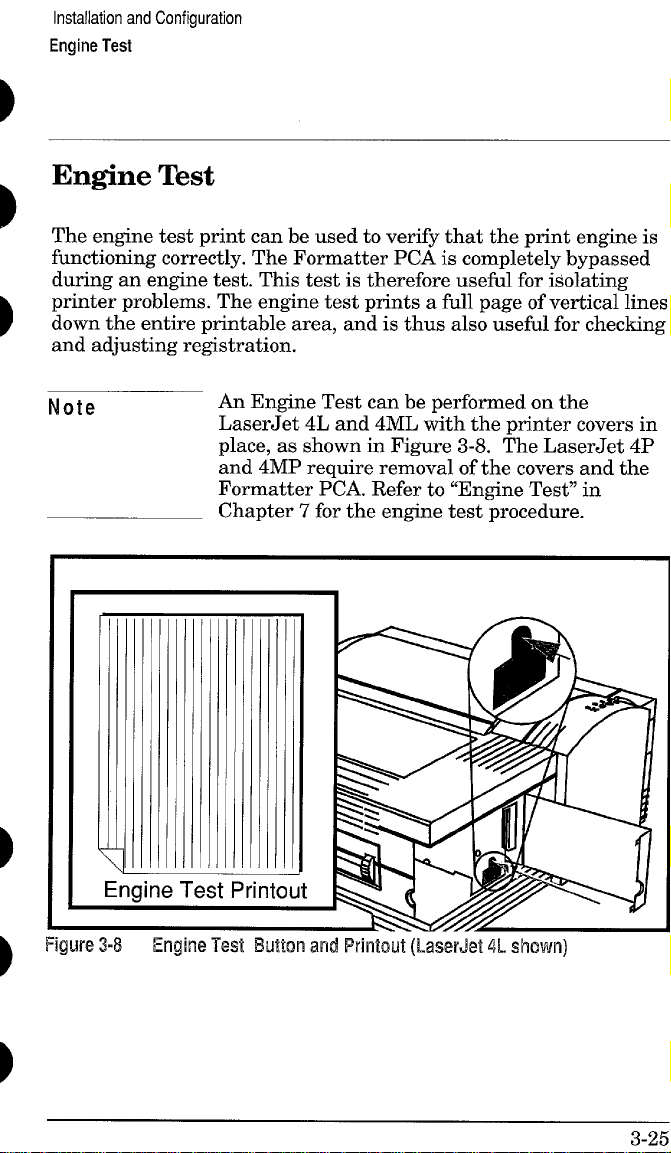

Fig 3-8

Fig 4-1

Fig 4-2

Fig 4-3

Fig 4-4

Fig 4-5

Fig 4-6

Fig 4-7

Fig 5-1

Fig 5-2

Fig 5-3

Fig !i-4

Fig 5-5

Fig 5-6

Fig 5-7

Fig 5-8

Fig 5-9

Fig 5-10 Drum Surface Potential --5-24

Fig 5-11 Drum Cleaning – 5-25

Fig 5-12 Primary Charging Roller – 5-26

Fig 5-13 Image Writing – 5-27

Fig 5-14 Image Development – 5-29

Fig 5-15 Developing Potentials – 5-30

Fig 5-16 Transferring Stage – 5-3:1

Fig 5-17 Fusing Film and Pressure Roller – 5-32

Fig 5-18 Printer Paper Path – 5-34

Fig 5-19 Oblique Roller Paper Alignment – 5-37

Sample Model and Serial Number Labels – 1-3

External Assembly Locations (LaserJet 4L/4ML) -1-6

External Assembly Locations (LaserJet 4P/4MP) -1-7

Internal Assembly Locations (all printers) – 1-8

LaserJet 4L Internal Assembly Locations – 1-9

LaserJet 4P Internal Assembly Locations – 1-10

Printer Space Requirements – 2-3

Distributing Toner – 2-6

Attaching the Help Labe”ls (LaserJet 4L/4ML) – 3-6

LaserJet 4L/4ML Front Control Panel – 3-9

LaserJet 4P/4MP Front (;ontrol Panel – 3-12

LaserJet 4P/4MP Menu Map – 3-14

Service Mode Menu Map (LaserJet 4ML/4P/4MP) -3-16

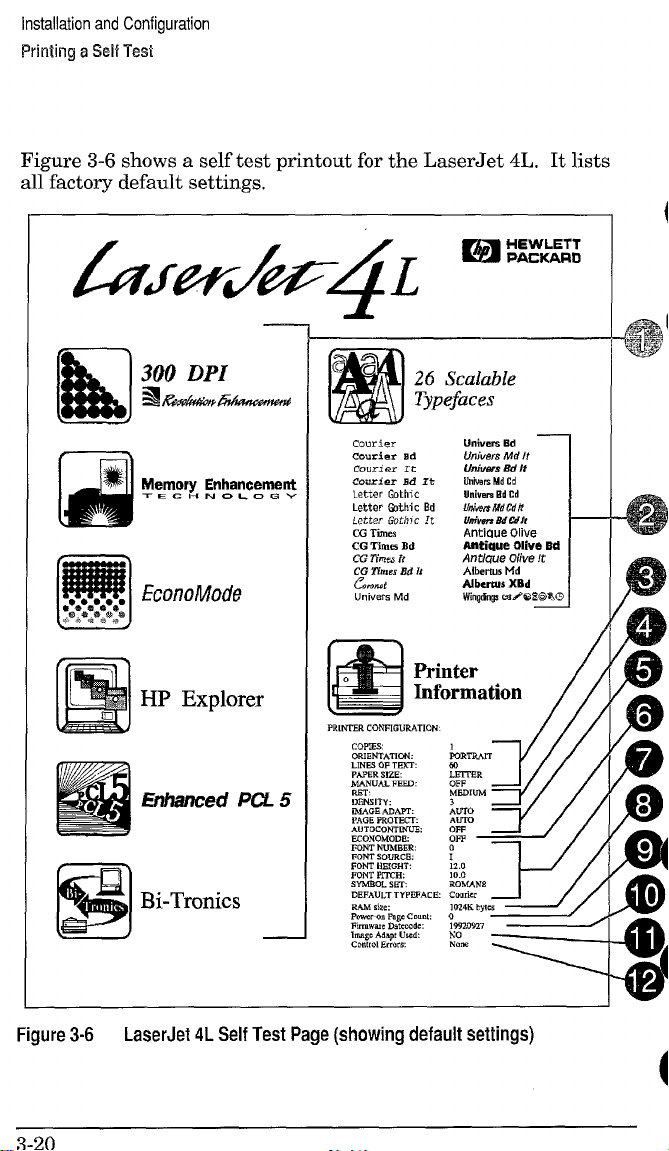

LaserJet 4L Self Test Page – 3-20

LaserJet 4MP Service Mt]de Self Test Page – 3-22

Engine Test Button and Printout (LaserJet 4L) – 3-25

Service Checkpoints – 4-2

Sample 5% Page Coverage – 4-4

Paper Feed Area Jam – 4-9

Clearing Jams from the Toner Cartridge Area – 4-10

Clearing Jams from the l’aper Guide – 4-10

Releasing Paper from the Fusing Assembly – 4-11

Clearing Jams from the Fuser Area – 4-12

Printer Functional Block Diagram – 5-2

DC Controller Loads – 5-3

Top Cover/Toner Cartridge Plunger – 5-6

Power Supply Block Diagram – 5-9

High Voltage Power Timing – 5-11

Formatter Block Diagram – 5-12

EconoMode vs. Regular F’rint – 5-18

Image Formation Block Diagram – 5-22

Photosensitive Drum – 5-23

Page 7

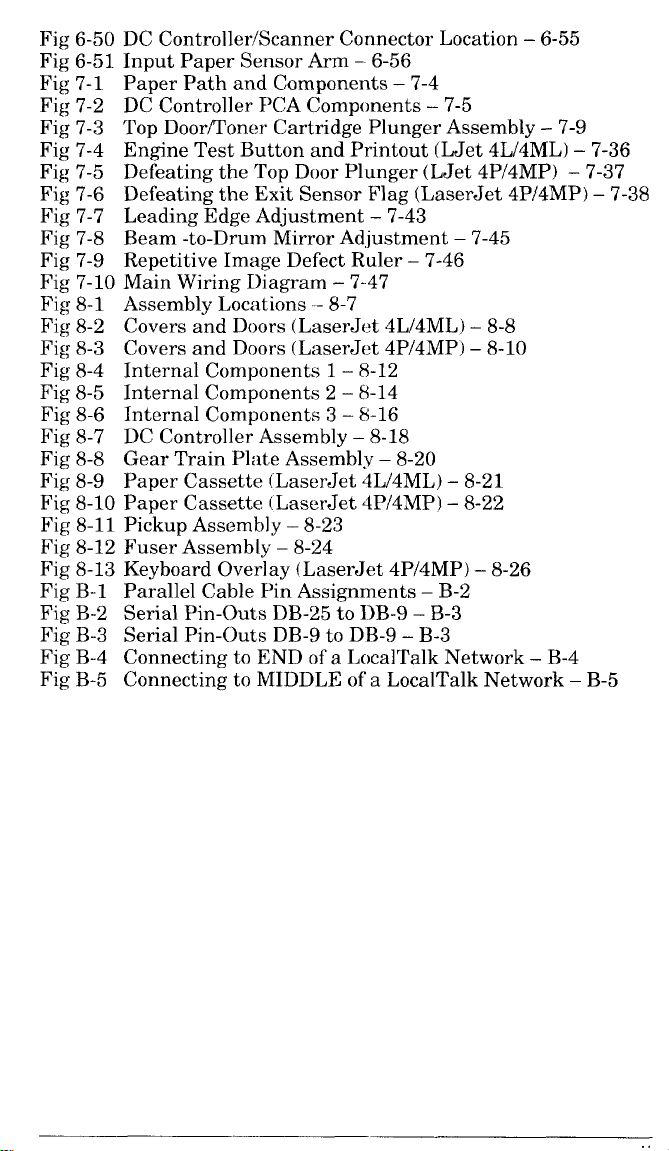

Fig 6-1

Fig 6-2

Fig 6-3

Fig 6-4

Fig 6-5

Fig 6-6

Fig 6-7

Fig 6-8

Fig 6-9

Fig 6-10

Fig 6-11

Fig 6-12

Fig 6-13

Fig 6-14

Fig 6-15

Fig 6-16

Fig 6-17

Fig 6-18

Fig 6-19

Fig 6-20

Fig 6-21

Fig 6-22

Fig 6-23

Fig 6-24

Fig 6-25

Fig 6-26

Fig 6-27

Fig 6-28

Fig 6-29

Fig 6-30

Fig 6-31

Fig 6-32

Fig 6-33

Fig 6-34

Fig 6-35

Fig 6-36

Fig 6-37

Fig 6-38

Fig 6-39

Fig 6-40

Fig 6-41

Fig 6-42

Fig 6-43 Pickup Feed Roller Assembly (bottom view) – 6-48

Fig 6-44 Feeder Guide Assembly – 6-49

Fig 6-45 Small Media Roller Assembly – 6-50

Fig 6-46 Static Eliminator Strip – 6-51

Fig 6-47 Toner Cartridge Lever Assembly – 6-52

Fig 6-48 Top Cover Switch {Plunger Assembly) -6-53

Fig 6-49 Releasing the Side Tabs – 6-.54

Phillips vs. Posidriv Screwdrivers – 6-3

Memory Module (LaserJet 4L) – 6-4

SIMM Access Panel (LaserJet 4P/4MP) – 6-5

Power Access Door (LaserJet 4L/4ML) – 6-6

Printer Cover Screws (Laser,Jet 4L/4ML) – 6-7

Releasing the Printer Cover Rear Tabs – 6-8

Control Panel Connector (LaserJet 4P/4MP) – 6-9

Printer Cover Screws (Laser, Jet 4P/4MP) – 6-10

Cover (LaserJet 4P/4MP) – 6-11

Rear Door – 6-12

Control Panel Assembly (LaserJet 4P/4MP) -6-13

Control Panel RFI Shield (LaserJet 4P/4MP) -6-14

Formatter Shield and PCA – 6-15

DC Controller Connector& Switch Actuator – 6-16

Gear Train Assembly – 6-17

Screw Tightening Sequence Example – 6-18

Main Motor – 6-19

Oblique Roller Assembly – 6-20

Tray Forms Size Guide – 6-21

Paper Cassette Assemblies – 6-22

Laser/Scanner Assembly – 6-23

Fan – 6-24

Power Switch Assembly (LaserJet 4P/4MP) – 6-25

Paper Guide/Roller Assembly – 6-26

Transfer Roller -6-27

Beam-to-Drum Mirror – 6-29

Fusing Assembly – 6-30

Fusing Pressure Plate – 6-31

Upper Fusing Assembly – 6-32

Fuser Delivery Assembly – 6-33

Lower Delivery Roller – 6-34

Lower Delivery Guide and Exit Sensor Flag – 6-35

Fuser Connector Assembly – 6-36

Upper Output Roller Assembly – 6-37

Lower Output Rollers – 6-38

DC Controller Assembly – 6-40

Pickup Feed Roller Solenoid – 6-41

Machine Screw Locations (DC Controller PCA) – 6-43

Metal Backing Plate – 6-44

DC Controller PCA – 6-45

D-Roller – 6-46

Pickup Feed Roller Assembly (side view) – 6-47

Page 8

Fig 6-50 DC Controller/Scanner Connector Location – 6-55

Fig 6-51 Input Paper Sensor Arm -6-56

Fig 7-1 Paper Path and Components – 7-4

Fig 7-2 DC Controller PCA Components – 7-5

Fig 7-3 Top Door/T’oner Cartridge Plunger Assembly – 7-9

Fig 7-4 Engine Test Button and Printout (LJet 4L/4ML) -7-36

Fig 7-5 Defeating the Top Door Plunger (LJet 4P/4MP) – 7-37

Fig 7-6 Defeating the Exit Sensor Flag (LaserJet 4P/4MP) – 7-38

Fig 7-7 Leading Edge Adjustment – 7-43

Fig 7-8 Beam -to-Dru]m Mirror Adjustment – 7-45

Fig 7-9 Repetitive Image Defect Ruler – 7-46

Fig 7-10 Main Wiring Diagram – 7-47

Fig 8-1 Assembly Locations – 8-7

Fig 8-2 Covers and Doors (LaserJet 4L/4ML) – 8-8

Fig 8-3 Covers and Doors (LaserJet 4P/4MP) – 8-10

Fig 8-4 Internal Components 1 – 8-12

Fig 8-5 Internal Components 2 – 8-14

Fig 8-6 Internal Components 3 – 8-16

Fig 8-7 DC Controller Assembly – 8-18

Fig 8-8 Gear Train Plate Assembly – 8-20

Fig 8-9 Paper Cassette (LaserJet 4L/4ML) – 8-21

Fig 8-10 Paper Cassette (LaserJet 4P/4MP) – 8-22

Fig 8-11 Pickup Assemb] y – 8-23

Fig 8-12 Fuser Assembly – 8-24

Fig 8-13 Keyboard Overlay (LaserJet 4P/4MP) – 8-26

Fig B-1 Parallel Cable Pin Assignments – B-2

Fig B-2 Serial Pin-outs DB-25 to DB-9 – B-3

Fig B-3 Serial Pin-outs DB-9 to DB-9 – B-3

Fig B-4 Connecting to END of a LocalTalk Network – B-4

Fig B-5 Connecting to MIDDLE of a LocalTalk Network – B-5

Page 9

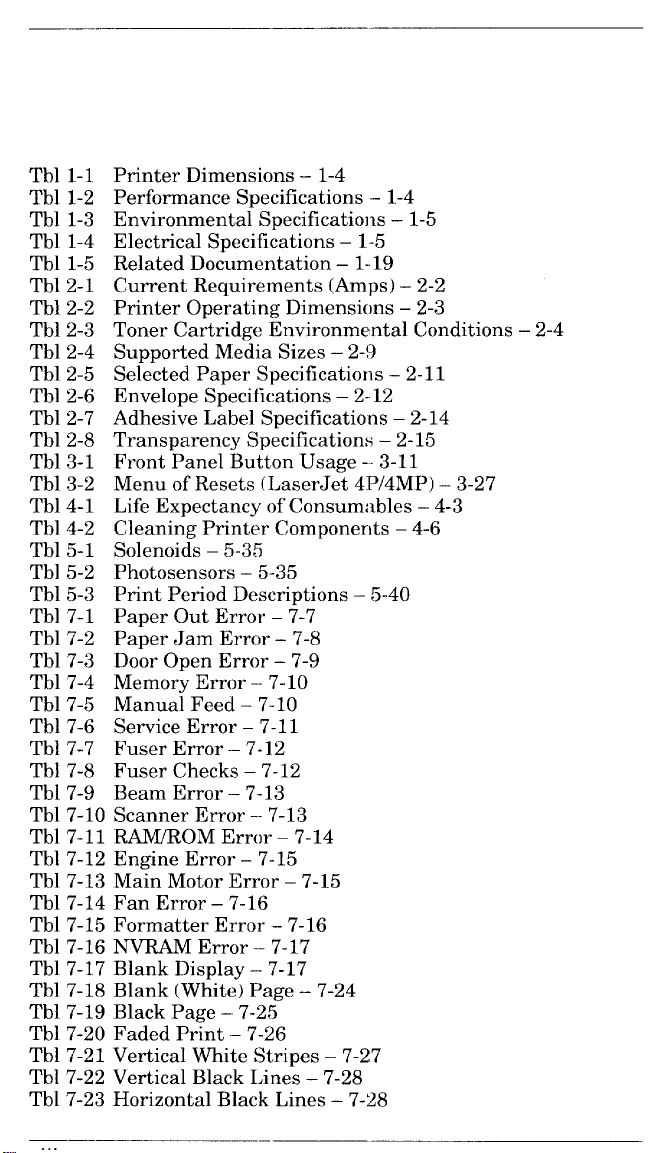

Tbl 1-1

Tbl 1-2

Tbl 1-3

Tbl 1-4

Tbl 1-5

Tbl 2-1

Tbl 2-2

Tbl 2-3

Tbl 2-4

Tbl 2-5

Tbl 2-6

Tbl 2-7

Tbl 2-8

Tbl 3-1

Tbl 3-2

Tbl 4-1

Tbl 4-2

Tbl 5-1

Tbl 5-2

Tbl 5-3

Tbl 7-1

Tbl 7-2

Tbl 7-3

Tbl 7-4

Tbl 7-5

Tbl ‘7-6

Tbl 7-7

Tbl ‘7-8

Tbl 7-9

Tbl 7-10 Scanner Error --7-13

Tbl 7-11 WROM Error – 7-14

Tbl 7-12 Engine Error – 7-15

Tbl ‘7-13 Main Motor Error – 7-15

Tbl 7-14 Fan Error – 7-16

Tbl 7-15 Formatter Error – 7-16

Tbl 7-16 NVRAM Error – 7-17

Tbl 7-17 Blank Display – 7-17

Tbl 7-18 Blank (White) Page – 7-24

Tbl 7-19 Black Page -7-25

Tbl 7-20 Faded Print -7-26

Tbl 7-21 Vertical White Stripes – 7-27

Tbl 7-22 Vertical Black I.ines – 7-28

Tbl 7-23 Horizontal Black Lines – 7-28

Printer Dimensions – 1-4

Performance Specifications -1-4

Environmental Specifications – 1-5

Electrical Specifications – 1-5

Related Documentation – 1-19

Current Requirements (Amps) – 2-2

Printer Operating Dimensions – 2-3

Toner Cartridge Environmental Conditions – 2-4

Supported Media Sizes – 2-!3

Selected Paper Specifications – 2-11

Envelope Speciilcations–212

Adhesive Label Specifications – 2-14

Transparency Specifications – 2-15

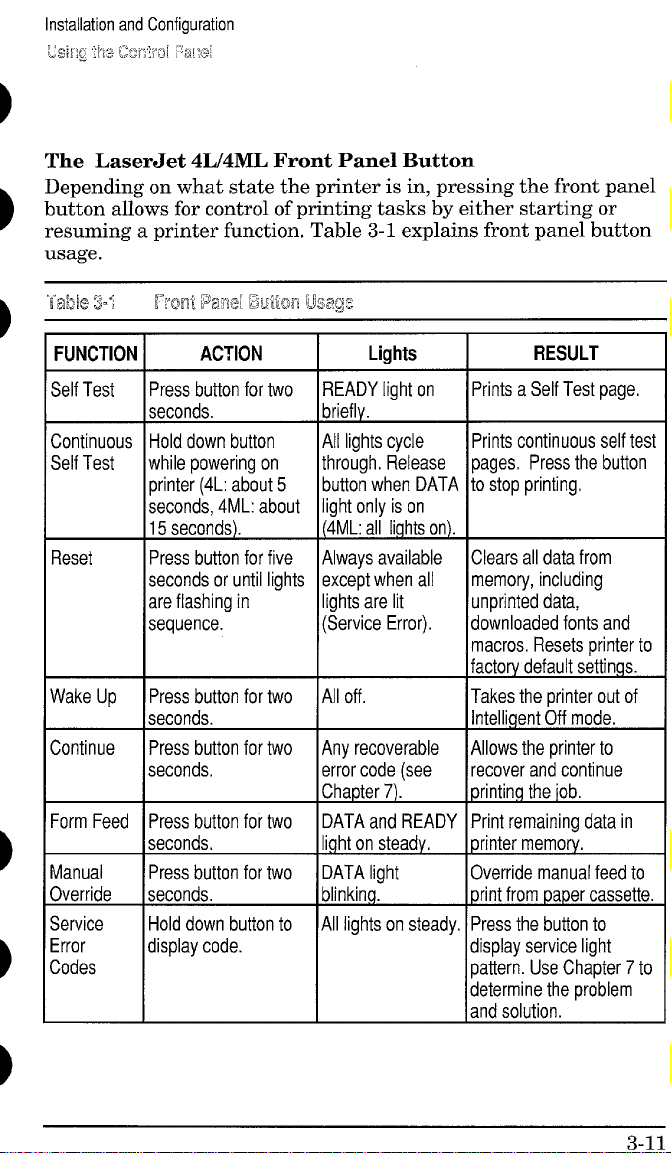

Front Panel Button Usage --3-11

Menu of Resets (LaserJet 4“P/4MP) – 3-27

Life Expectancy of Consumi~bles – 4-3

Cleaning Printer Components – 4-6

Solenoids – 5-35

Photosensors – 5-35

Print Period Descriptions – 5-40

Paper Out Error -7-7

Paper Jam Error – 7-8

Door Open Error – 7-9

Memory Error – 7-10

Manual Feed – 7-10

Service Error -7-11

Fuser Error --7-12

Fuser Checks – 7-12

Beam Error – 7-13

. .

Page 10

Tbl 7-24 Repetitive Defects – 7-29

Tbl 7-25 Staining -7-30

Tb”l 7-26 Dropout – 7-31

Tbl 7-27 Character Voids – 7-31

Tbl 7-28 Background Scatter – 7-32

Tbl 7-29 Bottom Portion of Page Blank – 7-32

Tbl 7-30 Faulty Registration – 7-33

Tbl 7-31 Smeared Print – 7-34

Tbl 7-32 Image Skew – 7-35

Tbl 7-33 Compressed Print – 7-35

Tbl 7-34 High-Voltage System Checks – 7-41

Tbl 7-35 Causes of Paper Curl – 7-42

Tbl 8-1 Fasteners IJsed in the Printer – 8-4

Tbl 8-2 Covers and Doors (LaserJet 4L/4ML only) – 8-9

Tbl 8-3 Covers and Doors (LaserJet 4P/4MP only) – 8-11

Tbl 8-4 Internal Components 1 – 8-13

Tbl 8-5 Internal Components 2 – 8-15

Tbl 8-6 Internal Components 3 – 8-17

Tbl 8-7 DC Controller Assembly – 8-19

Tbl 8-8 Gear Train Plate Assembly – 8-20

Tbl 8-9 Paper Cassette (LaserJet 4L/4ML) -8-21

Tb[ 8-10 Paper Cassette (LaserJet 4P/4MP) -8-22

Tb~ 8-11 Pickup Assembly – 8-23

Tbl 8-12 Fuser Assembly -8-25

Tb\ 8-13 Keyboard Overlays (Laser,Jet 4P/4MP) – 8-26

Page 11

x

Page 12

Chapter Contents

Product Information

Printer Features – 1-2

Identification – 1-3

Model and Serial Numbers – 1-3

Specifications – 1-4

Product Overview – 1-6

External Assembly Locations (LaserJet 4L/4ML) – 1-6

External Assembly Locations (LaserJet 4P/4MP) – 1-7

Internal Assembly Locations – 1-8

Safety Information – 1-11

Laser Safety – 1-11

Laser Statement (Finland) – 1-12

Declaration of Conformity – 1-13

Toner Safety – 1-14

MSDS Information – 1-14

By mail: – 1-14

By fax: – 1-14

Ozone Emission – 1-14

FCC Statement (Class B) – 1-15

VCCI Statement (Japan) – 1-16

Service Approach – 1-17

Exchange Program – 1-17

Ordering Parts – 1-17

Ordering Consumables – 1-17

Ordering Related Documentation – 1-18

Print Utilities – 1-19

Technical Assistance – 1-20

HP ASAP 1-800-333-1917 (U.S.) – 1-20

HP FIRST -1-20

HP FIRST, U.S. – 1-20

HP FIRST, Europe – 1-20

HP AUDIO-TIPS – 1-21

HP CompuServe Forum – 1-21

Customer Information Centers – 1-21

Customer Support Center (Assist Line) – 1-21

European Customer Support Center – 1-22

Other Areas – 1-22 ‘

Chapter 1

Contents Page 1

Page 13

CI!-mpttwcamtemrts

2 Q@a=ating Rmq@7mflmmfx

Site Requirements – 2-2

Operating Environment – 2-2

Printer Space Requirements – 2-3

The HP 92274A Toner Cartridge – 2-4

Storage Conditions – 2-4

Storing Opened Toner Cartridges – 2-5

Toner Cartridge Handling Suggestions – 2-6

Refilled Toner Cartridges – 2-7

Recycling Toner Cartridges – 2-7

Media Specifications – 2-8

Media Sizes Supported – 2-9

Media Selection Guidelines – 2-10

Envelope Specifications – 2-12

Adhesive Label Specifications – 2-13

Transparency Specifications – 2-15

Storing Print Media – 2-16

Shipping Print Media – 2-16

Chapter 2

Contents Page 1

Page 14

0&@x5w’ Q3mr&?mts

hs’tdktimoi and Cmfigmlmtilm

Unpacking and Installation – 3-2

A. Choose the best location. – 3-2

B. Unpack the printer. – 3-2

C. Check package contents. – 3-3

D. Install the toner cartridge. – 3-3

E. Load the paper cassette. – 3-4

F. Attach the interface cable(s). – 3-4

G. Attach the power cord. – 3-5

H. Attach the Help Labels (Lase’Jet 4L/4ML only) – 3-6

I. Install Printer Drivers and Utilities (optional) – 3-7

How to Obtain Printer Drivers – 3-7

Using the Printing Software Package – 3-8

Using the Control Panel – 3-9

LaserJet 4L/4ML Control Panel Overview – 3-9

The LaserJet 4L/4ML Lights – 3-10

The LaserJet 4L/4ML Front Panel Button – 3-11

LaserJet 4P/4MP Control Panel Overview – 3-12

LaserJet 4P/4MP Control Panel Display and Lights – 3-13

Service Mode (LaserJet 4ML/4P/4MP) – 3-15

LaserJet 4ML – 3-15

LaserJet 4P/4MP – 3-15

Setting the Page Count (LaserJet 4P/4MP) -3-17

Setting the Cold Reset Default (LaserJet 4P/4MP) -3-18

Other Service Mode Items – 3-18

Printing a Self Test – 3-19

LaserJet 4L/4ML: – 3-19

LaserJet 4P/4MP: – 3-19

The LaserJet 4L Self Test Fields – 3-21

The LaserJet 4ML/4P/4MP Self Test Fields – 3-23

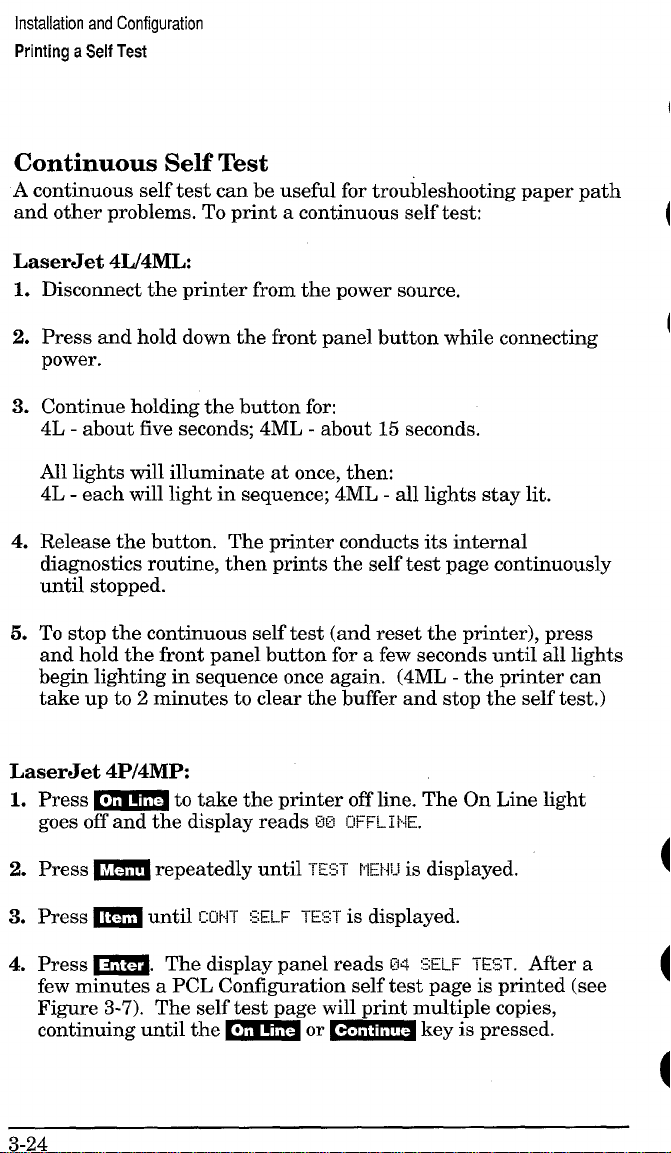

Continuous Self Test – 3-24

LaserJet 4L/4ML: – 3-24

LaserJet 4P/4MP: – 3-24

Engine Test – 3-25

(continued on back)

Chapter 3

Contents Page 1

Page 15

Resetting the Printer – 3-26

LaserJet 41J4ML:– 3-26

LaserJet 4P/4MP: – 3-26

Simple Reset – 3-26

The Menu of Resets – 3-27

The Cold Reset (LaserJet 4ML/4P/4MP) – 3-28

LaserJet 4ML: – 3-28

LaserJet 4P14MP:– 3-28

PJL Software Commands – 3-29

Contents Page 2 Chapter 3

Page 16

chapter CkDntc?nts

4 Maintenancx2

Service Checkpoints – 4-2

Life Expectancy of Consumables – 4-3

Toner Cartridge Life –

Saving Toner with EconoMode – 4-5

Cleaning Printer Components – 4-6

Cleaning Spilled Toner – 4-7

(leafing Paper Jams – 4-8

Paper Jams in the Paper Feed Area – 4-9

Paper Jams Inside The Printer – 4-10

Paper Jams in the Paper Output Area – 4-12

4-4

Chapter 4 Contents Page 1

Page 17

Chapter Contents

5 Functional Overview

Basic Printer Functions – 5-2

DC Controller/Power System – 5-3

Print Engine Control – 5-5

Laser and Scanner Drive – 5-5

Paper Motion Monitoring and Control – 5-5

Top Door/Toner Cartridge Microswitch (SW201) – 5-6

Engine Test MicrosWitch (SW301) -5-7

Motors – 5-7

Power System (on DC Controller PCA) – 5-8

AC Power Distribution – 5-8

DC Power Distribution – 5-8

Overcurrent/Overvoltage Protection – 5-10

Intelligent ON/OFF (LaserJet 41J4ML only) – 5-10

High Voltage Power Distribution – 5-11

Formatter System – 5-12

CPU – 5-13

Read Only Memory (ROM) -5-13

Random Access Memory (RAM) -5-13

Non-Volatile Memory (NVRAM) – 5-14

Parallel Interface – 5-14

High Speed (Yes/No) – 5-14

Advanced Functions (On/Off) – 5-14

Serial I/O (LaserJet 4P/4MP) -5-15

Pacing (Serial Modes of Operation) – 5-15

LocalTalk I/O (LaserJet 4ML/4MP) – 5-15

Control Panel – 5-16

LaserJet 4L/4ML – 5-16

LaserJet 4P/4MP – 5-16

Resolution Enhancement (REt) – 5-17

Print Density Adjustment – 5-17

EconoMode – 5-18

Memory Management – 5-19

Memory Enhancement technology (MEt) – 5-19

Image Adapt (LaserJet 4L/4ML) – 5-20

Page Protect – 5-20

PJL Overview – 5-21

(continued on back)

Chapter 5

Contents Page 1

Page 18

Image Formation System – 5-22

Photosensitive Drum – 5-23

Drum Sensitivity – 5-24

Cleaning Stage – 5-25

Conditioning Stage – 5-26

Writing Stage – 5-27

Developing Stage – 5-29

Transferring Stage – 5-31

Fusing Stage – 5-32

Paper Feed System – 5-33

Paper Movement Overview – 5-34

Solenoids – 5-35

Photosensors – 5-35

Paper Out Sensor (PS2) – 5-35

Input Paper Sensor (PS1) – 5-36

Printing from the Paper Cassette – 5-37

Manual Feed Printing – 5-38

Small Media Rollers (LaserJet 4P/4MP) – 5-38

Paper Jam Detection – 5-39

Power-On Jams – 5-39

Pickup Jams – 5-39

Delay Jams – 5-39

Basic Sequence of Operation – 5-40

Standard Printer Operation – 5-40

General Timing Diagram – 5-41

Contents Page 2

Chapter 5

Page 19

Cx’-?.apbfckmiw?i’Nts

JRmmKmd and W@wmnm?nt

Removal and Replacement Strategy – 6-2

Required Tools – 6-3

User Installable Assemblies – 6-4

Memory Upgrade (LaserJet 4L) – 6-4

Memory/Language SIMMS(LaserJet 4P/4MP) – 6-5

Cover and Doors – 6-6

Power, I/O and Memory Doors (LaserJet 41J4ML) -6-6

Printer Cover (LaserJet 4L/4ML) -6-7

Printer Cover (LaserJet 4P/4MP) -6-9

Rear Door – 6-12

Control Panel (LaserJet 4P/4MP) ~ 6-13

Left Side Assemblies – 6-15

Formatter Shield and PCA – 6-15

Gear Train Assembly – 6-17

Main Motor – 6-19

Front Assemblies – 6-20

Front Oblique Roller Assembly – 6-20

Paper Cassette Assembly – 6-21

Tray Forms Size Guide (LaserJet 4L/4ML) -6-21

Compression Springs – 6-22

Internal Assemblies – 6-23

Laser/Scanner Assembly – 6-23

Fan – 6-24

Power Switch Assembly (LaserJet 4P/4MP only) -6-25

Paper Guide/Top Oblique Roller Assembly – 6-26

Transfer Roller and Guide – 6-27

Transfer Roller Bushings – 6-28

Beam-to-Drum Mirror Assembly – 6-29

‘1

(continued on back)

Chapter 6

Contents Page 1

Page 20

Rear Assemblies – 6-30

Fusing Assembly – 6-30

Fusing Assembly Components – 6-31

Pressure Plate – 6-31

Upper Fusing Assembly

(Teflon Sleeve and Heater Element) -6-32

Pressure Roller – 6-33

Delivery Assembly – 6-33

Lower Delivery Roller – 6-34

Lower Delivery GuidelExit Sensor Flag – 6-35

Connector Assembly (Fuser Entrance Guide) – 6-36

Upper Output Roller Assembly – 6-37

Lower Output Rollers – 6-38

Bottom Assemblies – 6-39

DC Controller Assembly – 6-39

Pickup Solenoid (SL2) – 6-41

DC Controller Fuses – 6-42

High Voltage Connector Assembly – 6-42

DC Controller PCA – 6-43

Pickup Feed D-Roller – 6-46

Pickup Assembly – 6-47

Feeder Guide Assembly and High Voltage Shield – 6-49

Small Media Roller Assembly (LaserJet 4P/4MP) -6-50

Static Eliminator Strip Assembly – 6-51

Toner Cartridge Lever Assembly – 6-52

Top Door Switch (Plunger Assembly) – 6-53

DC Controller/Scanner Connector Assembly -6-54

PS1 Input Paper Sensor Arm – 6-56

Contents Page 2

Chapter 6

Page 21

... -’

TmlldMeshmtintg

Troubleshooting Flowchart – 7-2

Paper Path and Components – 7-4

DC Controller Diagram – 7-5

Printer Error Troubleshooting – 7-6

LaserJet 4L/4ML: – 7-6

LaserJet 4P/4MP: – 7-6

Priority of Errors – 7-7

Recoverable Errors – 7-7

Service Errors – 7-11

LaserJet 4L/4ML – 7-11

LaserJet 4P/4MP – 7-11

Clearable Warnings (LaserJet 4P/4MP) – 7-18

Image Formation Troubleshooting – 7-19

Engine Test – 7-36

Engine Test Button Location – 7-36

Printing an Engine Test - LaserJet 4L/4ML – 7-36

Printing an Engine Test - LaserJet 4P/4MP – 7-37

Half Self Test Functional Check – 7-39

Drum Rotation Functional Check – 7-40

High-Voltage Power Supply Check – 7-41

Paper Curl – 7-42

Adjustment Procedures – 7-43

Leading Edge Adjustment – 7-43

Beam-to-Drum Mirror Adjustment – 7-44

Troubleshooting Tools – 7-46

Repetitive Image Defect Ruler – 7-46

Main Wiring Diagram – 7-47

Chapter 7

Contents Page 1

Page 22

Chapter Contents

$ Parts and Diagrams

How to Use the Part Lists and Diagrams – 8-2

Orderhw Parts – 8-2

Orderin~ Consumables – 8-3

Common Hardware – 8-4

Accessories and Supplies -8-5

Assembly Locations -8-7

Covers and Doors (LaserJet 4L/4ML) -8-8

Covers and Doors (LaserJet 4P/4MP) -8-10

Internal Components 1 – 8-12

Internal Components 2 – 8-14

Internal Components 3-8-16

DC Controller Assembly – 8-18

Gear Train Plate Assembly -8-20

Paper Cassette (LaserJet 4L/4ML) – 8-21

Paper Cassette (LaserJet 4P/4MP) – 8-22

Pickup Assembly – 8-23

Fuser Assembly -8-24

Keyboard Overlay (LaserJet 4P/4MP) – 8-26

Chapter 8

Contents Page 1

Page 23

AppendixA

Parts Index

Page 24

Appendk B

170IMorrnation

Page 25

Page 26

Product Itiormation

Page 27

Product Information

Printer Features

Printer Features

Features

Print Speed

Text &Graphics Resolution 300 dpi;

Printer Language

Stsndard Enhanced PCL5

Optionat

Monthly Usage (pages)

Output Tray Capacity I 50 50

LaserJet 4L

(C2003A)

I

I 4ppm

@JS

Res Enhancement

technology (REt)

None

I Upto6000

*

Standard Interfaces Parallel (13-tronics)

LsaarJet 4ML

I

(C2015A)

300 dpi;plus

Res Enhancement

technology (REt)

Enhanced PCL 5

PostScript Level 2

None

UP tO 8000

1

45 PCL, 35 PS

o

Parallel (8i-tronics)

LocalTalk

600 dpi;plus 600dpi;

Res Enhancement

technology (REt)

Enhanced PCL 5 Enhanced PCL 5

PS L2 (with SIMM

+4 Mb opt memory)’

up to 8000 UPto8000

plus

Res Enhancement

technology (REt)

PostScript Level 2

None

=--l=-

Setial (9 pin) Serial (9 pin)

Parallel (8i-tronics) Parallel (!3-tronics)

LocalTalk

I

Power Control

EconoMode (toner saving)

Min. Paper Size

(using flat paper path)

1bteligentC)n/Ofl

1

Yes

3 x6.75inch

(76x 171mm)

1

See“Accessories&Supplies”in Cha

Intelligent On/Ofl I Power switch lF’owerswitch I

ter

8 foroptionproductnumbers.

2PrintermemoryisoptimizedwithMemoryEnhancementTechnology(MEt).

Page 28

Product Information

Identification

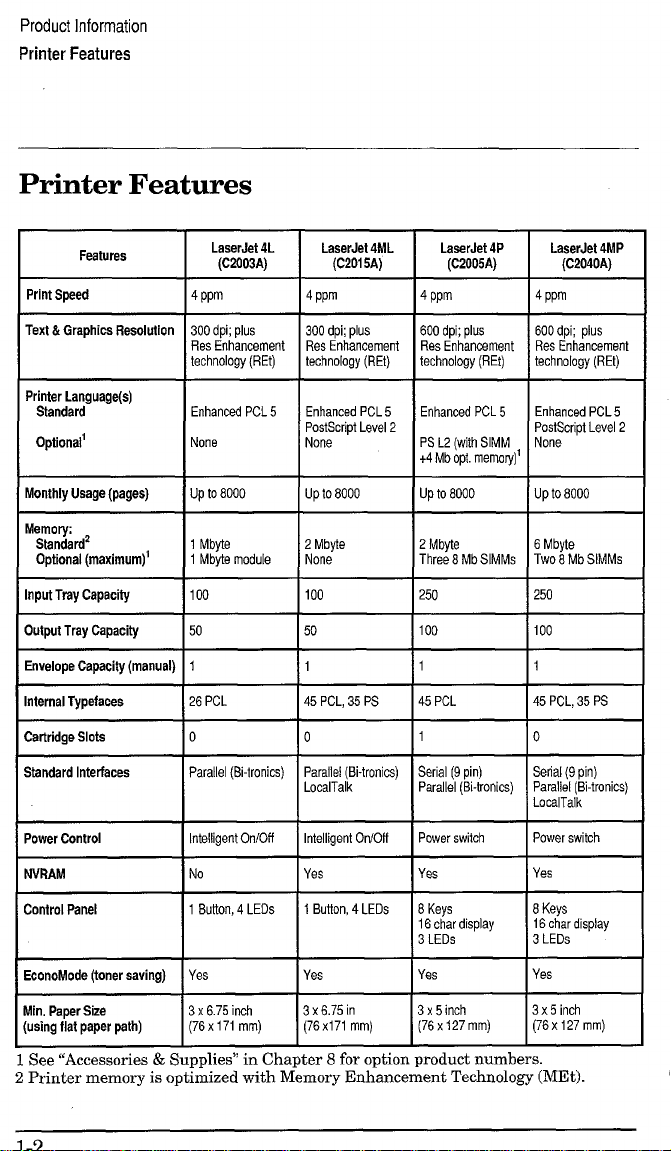

Identification

Model and Serial Numbers

The model number and serial numbers are listed on identification

labels located on the rear of the printer. The model number is

alphanumeric, such as C2003A for the HP LaserJet 4L.

The serial number contains information about the Country of

Origin, the Revision Level, the Production Code, and production

number of the printer.

The rear labels also contain power rating and regulatory

information as shown in Figure 1-1.

I

Figure 1-1

Sample Model and Serial Number Labels

I

Page 29

Product Information

Specifications

Specifications

Table 1-1

Width

Depth

Heiaht 116.5 cm (6.5 in.) 118 cm (7 in.)

Table 1-2 Performance Specifications

I

Print Speed * Up to 4 pages per minute

Monthly Usage (Duty Cycle)

Life Expectancy of toner cartridge** Approximately 3000 pages

IFirst Print lApproximately 34 seconds

*Actual speed depends on data complexity and software handling efficiency.

**Toner

Printer Dimensions

Dimension

CATEGORY

Cartridge life can be extended by using EconoMocle.

LaserJet 4L/4ML LaserJet 4P/4MP

(C2003A/C2015A) (C2005A/C2040A)

36 cm (14,25 in.)

137 cm (14.5 in.) 139 cm (15.5 in.)

, 1

I

Up to 8000 pages

40 cm (15.75

SPECIFICATION

in.)

I

I

I

Page 30

Product Information

Specifications

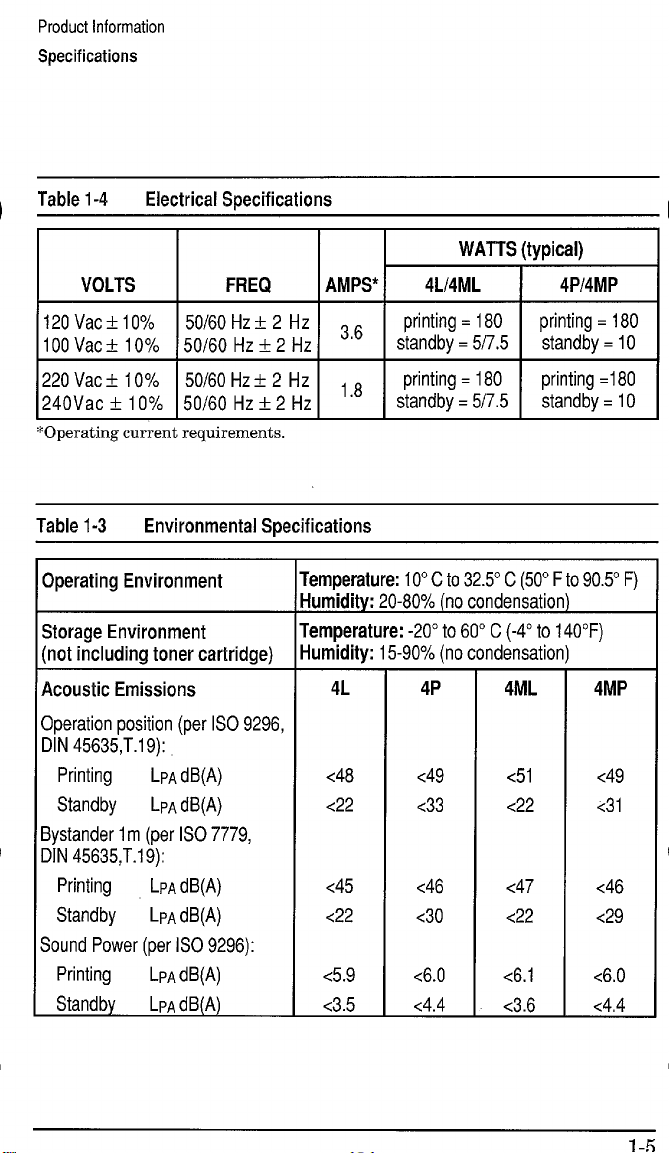

Table 1-4

Electrical Specifications

VOLTS FREQ

120 Vact10%

100 Vac ? 10%

220 Vac f 1O%

240Vac k 10%

*Operating current requirements.

Table 1-3

50/60 Hz k 2 Hz

50/60 Hz? 2 Hz

50/60 Hz+ 2 tiz

50/60 Hz k 2 Hz

Environmental Specifications

Operating Environment

Storage Environment

(not including toner cartridge)

Acoustic Emissions

Operation position (per ISO 9296,

DIN 45635,T.1 9):

Printing

Standby

LPA dB(A)

LPAdB(A)

Bystander 1m (per ISO 7779,

DIN 45635,T.1 9):

Printing

LPA dB(A)

Standby LPA dB(A)

Sound Power (per ISO 9296):

Printing

Standby

LPA dB(A)

LPA dB(A)

WATTS (typical)

AMPS*

4L14ML I 4P14MP

36

,8

“

‘temperature: 10° C to 32.5° C (50° F to90.5° F)

Iumidity: 20-80% (no condensation)

‘temperature: -20° to 60° C (-4° to 140”F)

Iumidity: 15-90% (no condensation)

4L

<48

<22

<45

<22

<5.9

<3.5

4P

<49

<33

<46

<30

<6.0

<4.4

4ML

<51

<22

<47

<22

<6.1

<3.6

4MP

<49

<31

<46

<29

<6.0

<4,4

Page 31

Product Information

Product Overview

Product Overview

External Assembly Locations (LaserJet 4L/4ML)

Figure 1-2

External Assembly Locations, Laserdef 4L/4ML

Page 32

Product Information

Product Overview

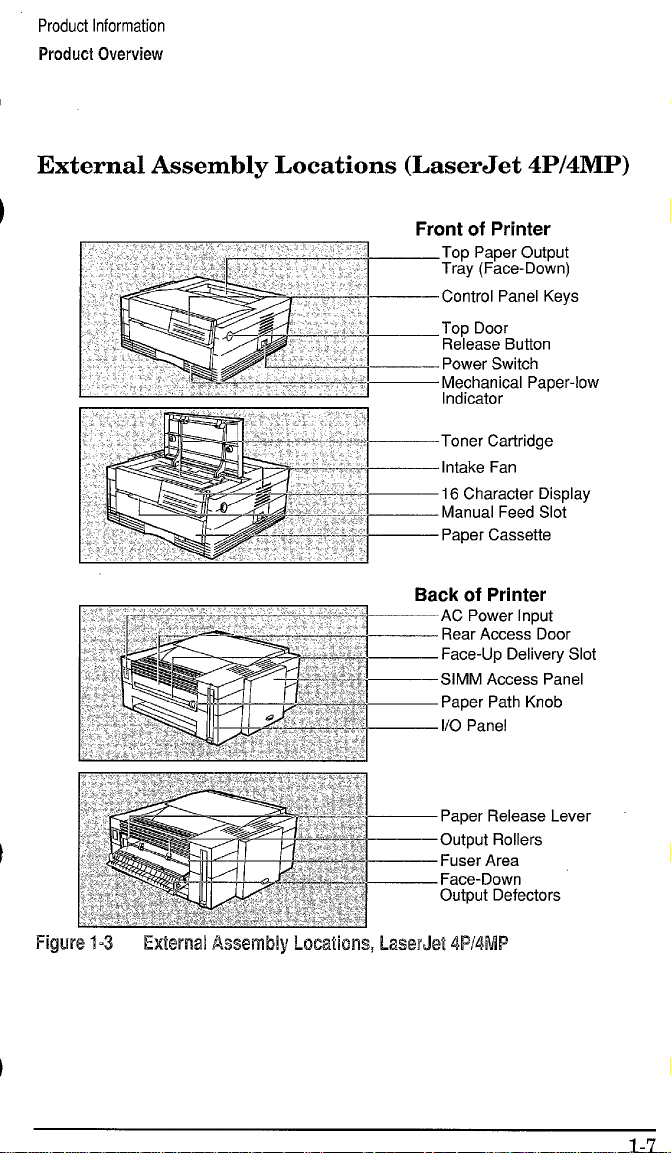

External Assembly Locations (LaserJet 4P/4MP)

Page 33

Product Information

Product Overview

Internal Assembly Locations

Figure 1.4 Internal Assembly Locations (all printers)

1, Face-Down Output Rollers

2. Upper Fusing Assembly

3. Laser/Scanner Assembly

4. Primary Charging Roller

5. Beam-to-Drum Mirror

6. Developing Cylinder

7. Toner Cartridge

8. Registration Roller

9. Oblique Rollers

10, Pickup Feed D-Roller

11. Transfer Roller Assembly

12, Photosensitive Drum

13. DC Controller PCA

14. Paper Cassette

15. Fusing Pressure Roller

16. Face-up Delivery Roller

17. Face-Up/Face-Down Deflector

Page 34

Product Information

Product Overview

Fim.me 1-5 shows the location of assemblies visible from the ton of

th; LaserJet 4L printer with the printer cover removed. ‘

~lgure 1-5 LaserJet 4L Internal Assembly Locations

1. Transfer Roller 8. Fusing Assembly

2. Paper Guide/Top Oblique Roller 9. Lower Output Rollers (Face-Down)

3. Front Oblique Roller

4, Switch Actuator

5. Formatter PCA

6. Main Motor

10. Upper Output Rollers (Face-Down)

11. Fan (FM1)

12. Beam-to-Drum Mirror

13. Laser/Scanner Assembly

7. Gear Train Assembly

Page 35

Product Information

Product Overview

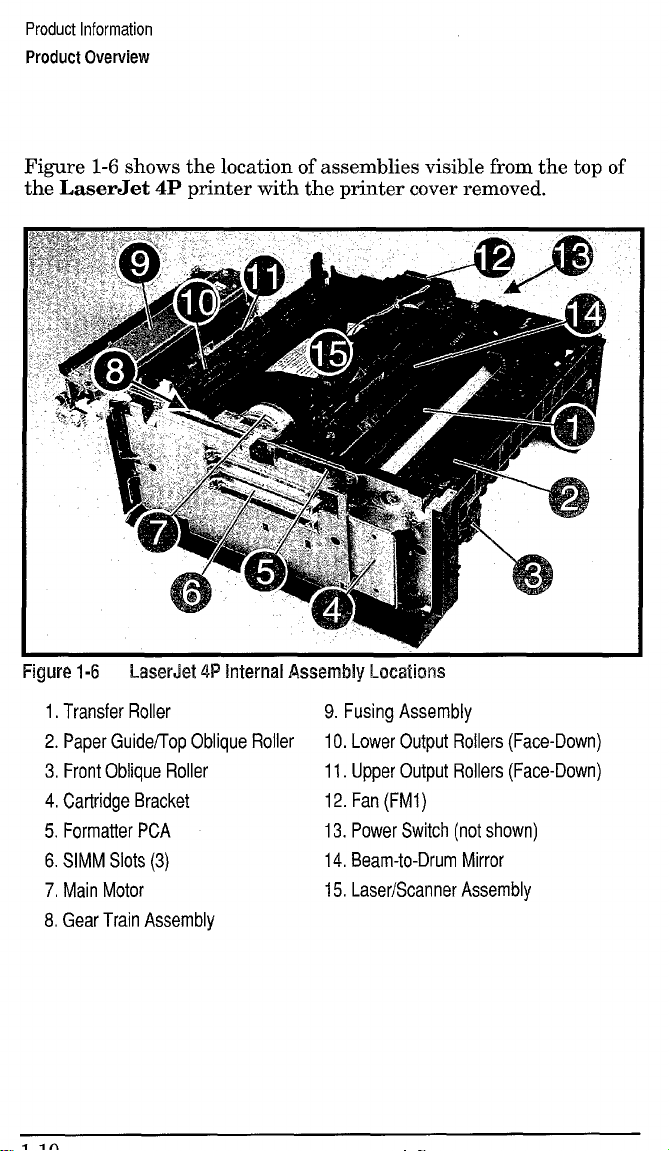

Figure 1-6 shows the location of assemblies visible from the top of

the LaserJet 4P printer with the printer cover removed.

Figure 1-6 LaserJet 4P Internal Assembly Locations

1. Transfer Roller

9. Fusing Assembly

2. Paper Guideflop Oblique Roller 10. Lower Output Rollers (Face-Down)

3. Front Oblique Roller 11. Upper Output Rollers (Face-Down)

4. Cartridge Bracket 12. Fan (FM1)

5. Formatter PCA

6. SIMM Slots (3)

7, Main Motor

13. Power Switch (not shown)

14, Beam-to-Drum Mirror

15, Laser/Scanner Assembly

8. Gear Train Assembly

Page 36

Product Information

Safety Information

Safety Information

Laser Safety

The Center for Devices and Radiological Health (CDRH) of the

U.S. Food and Drug Administration implemented regulations for

laser products manufactured since August 1, 1976. Compliance is

mandatory for products marketed in the United States.

This printer is certified as a “Class 1“ laser product under the U.S.

Department of Health and Human Services (DHHS) Radiation

Performance Standard according to the Radiation Control for

Health and Safety Act of 1968. Since radiation emitted inside this

printer is completely confined within protective housings and

external covers, the laser beam cannot escape during any phase of

normal user operation.

Never operate or service the printer with the

protective cover removed from the

Laser/Scanner Assembly. The reflected beam,

although invisible, can damage your eyes.

1-11

Page 37

Product Information

Safety Information

Laser Statement (Finland)

The following applies to printer operation and servicing in Finland.

LASERTURVALLISUUS

LUOKAN

1 LASERLAITE

KLASS1LASERAPPARAT

HPLaserJet(s)4L,4ML,

luokan 1 laeerlaite. Normaalissa kaytossa kirjoittimen suojakotelointi estaa

lasersateen paasyn laitteen ulkopuolelle.

Kirjoittimen on hyvaksynyt Suomessa laserturvallisuuden osalta

Stikotarkastuskeskus. Laitteen turvallisuusluokka on maaritetty valtioneuvoston

paatoksen N:o 472/1985 ja standardin EN 60825 (1991)

4P &. 4MP Iaserkirjoitin on kayttajan kannalta turvallinen

mukaisesti.

VAROITUS ! Laitteenkayttaminenmuullakuinkayttoohjeessamainitullatavalla

saattaaaltistaakayttajanturvallisuusluokan

lasersateilylle.

1 ylittavalle nakymattomalle

VARNING! Omapparatenanvandspaannatsattw ibruksanvisning

specificerats,kananvandarenutsattasforosynliglaserstr~lning,somoverskrider

griinsenforlaserklass1.

HUOLTOHPLaserJet(s)4L,4ML,4P&4MP-kirjoittimensisalliieiolekayttajan

huollettavissaoleviakohteita.Laitteensaaavataja huoltaaainoastaansen

huoltamiseenkoulutettuhenkilo.Tallaiseksihuoltotoimenpiteeksieikatsota

variainekasetinvaihtamista,paperiradanpuhdistustataimuitakayttajiin

kasikirjassalueteltuja,kayttajantehtavaksitarkoitettujayllapitotoimia,jotka

voidaansuorittaailmanerikoistyokaluja.

VARO ! Mikalikirjoittimensuojakoteloavataan,oletalttiinanakymattomalle

lasersateilyllelaitteenollessatoiminnassa.~a katsosateeseen.

VARNING! Omlaserprinternsskyddsholjeoppnasd5.apparatenari fanktion,

utsattasanvandarenforosynliglaserstr~lning.Betraktaejstr?alen.

Tiedotlaitteessakaytettavanlaserdiodinsateilyominaisuuksista:

Aallonpituus777-795nm

Teho5mW

Luokan

3B laser

Page 38

Product Information

Safety Information

Declaration of Conformity

According to ISO/IEC Guide 22 and EN 45014:

Manufacturer’s Name:

Manufacturer’s Address:

Hewlett-Packard Company

11311 Chinden Boulevard

Boise, Idaho 83714-1021, USA

declares, that the product

Product Name(s):

Model Number(s):

Product Options:

LaserJet 4L/4ML/4P/4MP

C2003A, C2015A, C2005A, C2040A

All

conforms to the following Product Specifications:

Safet~

EN 60950:1988+ A1,A2

IEC 825:1984 + A1:1990 laser class 1

EMC: CISPR-22:1985 / EN 55022:1988 class Bl)

EN 50082-1:1992

IEC 801-2:1991/ prEN55024-2:1992 - 3kV CD, 8 kV AD

IEC 801-3:1984/ prEN55024-3:1991 - 3V/m

IEC 801-4:1988/ prEN55024-4: 1992-1 kV Power lines

Supplementary Information:

The product herewith complies with the requirements of the Low

Voltage Directive 73/23/EEC and the EMC Directive 89/336/EEC.

1)The product was tested in a typical configuration with

Hewlett-Packard Personal Computer and Test Systems.

Office of Quality Manager

Boise, Idaho USA

June 15, 1993

European Contact: Your Local Hewlett-Packard Sales and Service OffIce or

Hewlett-Packard GmbH, Department ZQ / Standards Europe, Herrenberger

Strae 130, D-7030 Bblingen (FAX + 49-7031-14-3143)

1-13

Page 39

Product Information

Safety Information

Toner Safety

Note

MSDS Information

A Material Safety Data Sheet (MSDS) for toner or any other

chemical used in the printer is available through

Hewlett-Packard’s Customer Information Center by either mail or

fax.

By mail:

To obtain an MSDS for the HP 92274A toner cartridges through

the mail, call the Customer Information Center (CIC) at

1-800-752-0900 between 6 A.M. and 5 P.M. Pacific Standard Time.

By fax

To obtain an MSDS for the HP 92274A toner cartridges by fax, call

HP ASAP (Automated Support Access Program) at 1-800-333-1917

and follow the instructions for using the HP FIRST fax service.

Note

In case of toner spills, skin and clothing are best

cleaned by removing as much toner as possible

with a dry tissue, then washing with cold water.

Hot water causes toner to permanently set into

clothing.

See “Technical Assistance” later in this chapter

for more information on the HP FIRST service.

Ozone Emission

These printers do not use high voltage corona wires in the

electrophotographic process, and therefore generate no measurable

ozone gas (03). The printers instead use charging rollers in the

toner cartridge and in the print engine.

Page 40

Product Information

FCC Statement (Class B)

FCC Statement (Class B)

Note: This equipment has been tested and found to comply with

the limits for a Class B digital device, pursuant to part 15 of the

FCC rules. These limits are designed to provide reasonable

protection against harmful interference in a residential

installation. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does

cause hmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the

following measures:

●

Reorient or relocate the receiving antenna.

●

Increase the separation between the equipment and the receiver.

●

Connect the equipment into an outlet on a circuit different from

that to which the receiver is connected.

●

Consult the dealer or an experienced radio/TV technician for

help.

Any changes or modifications not expressly approved by

Hewlett-Packard could void the user’s authority to operate this

equipment.

Note

Use of a shielded interface cable is required to

comply within the Class B limits in Part 15 of

FCC rules.

1-15

Page 41

Product Information

VCCI Statement (Japan)

VCCI Statement (Japan)

The VCCI statement below is required in Japan. It is similar to the

FCC regulatory statement. -

Page 42

Product Information

Service Approach

Service Approach

Repair of the printer normally begins with use of the printer’s

internal diagnostics in conjunction with the troubleshooting

procedures in Chapter 7. Once a faulty part is located, repair is

accomplished generally by assembly-level replacement of Field

Replaceable Units (FRUS). Some mechanical parts maybe

repaired at the sub-assembly. PCA component replacement is not

supported by HP. Part numbers for all FRUS are located in

Chapter 8 of this manual.

Exchange Program

HP offers remanufactured assemblies for some selected parts.

These are identified in Chapter 8 and can be ordered through HP’s

Parts Direct Ordering, or Parts Center Europe (PCE).

Ordering Parts

Field replaceable part numbers are found in Chapter 8 of this

manual. Replacement parts may be ordered from HP’s Parts Direct

Ordering, or Parts Center Europe (PCE). Adresses and phone

numbers for both organizations are also found in Chapter 8.

Ordering Consumables

Consumables may be ordered directly from Hewlett-Packard. The

phone numbers for ordering consumables are found in Chapter 8.

1-17

Page 43

Product Information

Service Approach

Ordering Related Documentation

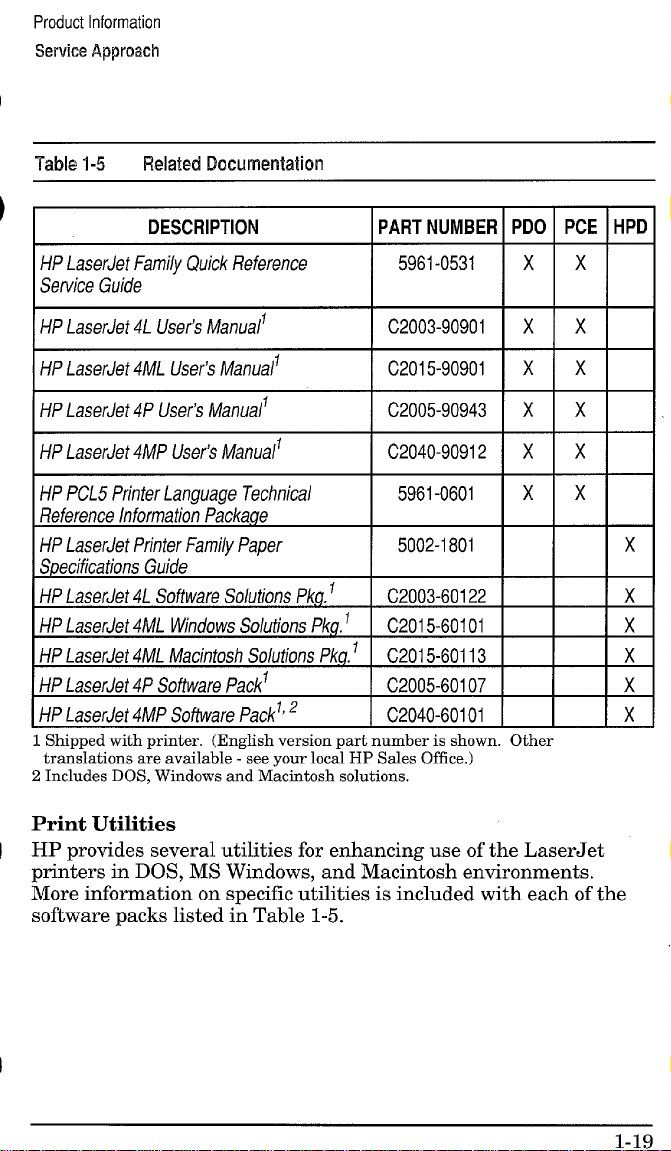

Table 1-5 shows where to order related documentation. Phone

numbers for the various sources are:

. PDO (Parts Direct Ordering)

1-S00-227-8164 (U.S. only)

. PCE (Parts Center Europe)

(49 7031) 14-2253.

e HP’s Distribution Center (HPD)

303-353-7650 (U.S.

Ody)

Page 44

Product Information

Service Approach

Table 1-5 Relaiecl Documentation

DESCRIPTION

PART NUMBER

HP LaserJet Family Quick Reference

Service Guide

HP LaserJet 4L User’s Manuall

HP LaserJet 4ML User!s Manuali

HP LaserJet 4P User’s Manualf

HP LaserJet 4MP User% Manual’

HP PCL5 Printer Language Technics/

Reference Information Package

HP LaserJet Printer Family Paper

Specifications Guide

HP LaserJet 4L Software Solutions Pkg, f

HP LaserJet 4ML Windows Solutions Pkg. 1

HP LaserJet 4ML Macintosh Solutions Pkg.1

HP LaserJet 4P Software Packl

HP LaserJet 4MP Software Packl’2

Shiu~ed with Drinter. (English version Dart

tra;~lations a;e available --see your loc~l HI

.

z Includes DOS. Windows and Macintosh solutions.

number is shown

Sales Office.)

5961-0531

C2003-90901

C2015-90901

C2005-90943

C2040-90912

5961-0601

5002-1801

C2003-60122

C201 5-60101

C201 5-60113

C2OO5-6O1O7

C2040-60101

PDO IPCE

I

x x

xx

xx

xx

xx

xx

;

1

Other

HPD

x

x

x

x

~

x

Print Utilities

HP provides several utilities for enhancing use of the LaserJet

printers in DOS, MS Windows, and Macintosh environments.

More information on specific utilities is included with each of the

software packs listed in Table 1-5.

1-19

Page 45

Product Information

Technical Assistance

Technical Assistance

HP ASAP 1-800-333-1917 (U. S.)

HP ASAP (Automated Support Access Program) provides free

technical support information 24 hours a day, 7 days a week. The

ASAP system includes HP FIRST and HP AUDIO-TIPS, both

explained below. The ASAP service requires a touch-tone phone.

HP FIRST

HP FIRST (Fax Information Retrieval Support Technology) is a

phone-in fax service providing technical information for HP

LaserJet users as well as service personnel. Receiving a fax

requires a group 3 facsimile machine or fax card. Service-related

information includes:

Service notes (HP Authorized dealers).

Application notes.

Product Data Sheets.

Material Safety Data Sheets (MSDS).

Typeface and accessory information.

Printer support software information.

Toner information.

Driver request form and Software Matrix.

HP FIRST, U.S.

Call the HP ASAP system (1-800-333-1917) and follow the voice

prompts to enter HP FIRST.

HP FIRST, Europe

Call HP FIRST at one of the following numbers:

U.K., 0800-96-02-71 Netherlands, 06-0222420

Belgium (Dutch), 078-111906

Switzerland (German), 155-1527 Austria, 0660-8128

For English service outside the above countries, (31) 20-681-5792

Germany, 0130-810061

Page 46

Product Information

Technical Assistance

HP AUDIO-TIPS

HP AUDIO-TIPS, available within HP ASAP, is an interactive

voice response system providing pre-recorded answers to the

questions most frequently asked by HP LaserJet printer users.

Helpful “System Maps” to the HP AUDIO-TIPS recordings are

available by fax through HP FIRST.

CompuServe members can download a variety of support materials

including product data sheets, software application notes, and

printer drivers for many popular software applications. Members

may also post and reply to questions in an interactive format. To

access the HP Forum, type GO HPPER at any prompt. For more

information, or to join CompuServe, call 1-800-524-3388.

Customer Information Centers

For further technical assistance, service-authorized HP and dealer

service personnel can contact the nearest Hewlett-Packard

Customer Information Center, 1-800-752-0900 in North America.

Customer Support Center (Assist Line)

The HP Customer Support Center, (208-323-2551) is available to

answer technical questions regarding setup, configuration,

installation and operation of HP printers in the PC and Macintosh

environments. The CSC Assist Line is available weekdays from

7AM to 6 PM Mountain Time (Wednesdays until 4 PM).

Questions relating to operating systems such as MS-DOS and

UNIX, your network conjuration, or network operating system

cannot be answered by the Center and should be referred to your

authorized reseller.

1-21

Page 47

Product Information

Technical Assistance

European Customer Support Center

The HP European Customer Support Center, located in

Amsterdam, Holland, is open from 8:30 am to 6:00 pm central

European time (Wednesdays until 4:00 pm). Multilingual customer

support representatives can answer technical questions similar to

the U.S. CSC, described on the previous page. This service is

available at no charge for a period equivalent to the original HP

hardware warranty period.

Each time you call the HP European Customer Support Center,

you will be required to provide the printer’s serial number and

original date of purchase.

To receive a fax listing the supported languages on a countries’

phone number, call HP FIRST (refer to “HP FIRST,” earlier in this

section). You can also call the nearest HP sales and service office to

obtain the telephone number for the Center. The Center features

automated call-routing technology, so you will receive faster

service if calling from a touchtone phone or tone dialer.

Other Areas

Outside of North America and Europe, contact your local HP sales

office for assistance in obtaining technical support.

Page 48

2

=.~

Operating Requirements

Page 49

Operating Requirements

SiteRequirements

Site Requirements

Operating Environment

The environmental specifications listed in the “Specifications”

section of Chapter 1 must be maintained to ensure the proper

operation of this printer. Consider the following points before

installing the printer:

Install in a well-ventilated, dust-free area. (Excess dust or

smoke will contaminate the printer’s Beam-to-Drum mirror,

affecting print quality. )

Install on a hard, flat and continuous surface, with all four

printer feet level. Do not install on carpet or other soft surfaces.

Ensure adequate power supply circuitry. Printer current

requirements can be found under “Specifications,” in Chapter 1.

Lighting Flicker: In an effort to reduce energy consumption,

the fuser is turned on only when needed during printing.

During standby mode, the fuser is not kept warm. When the

printer is installed in a home, the instant-on fuser may cause

some house lights to flicker when printing. This phenomenon is

seen in many instant-on products, such as copiers, and will NOT

affect printing, nor will it harm the electrical system in any way.

To reduce a flicker effect, plug the printer into a different outlet

that may be on a separate circuit, or try fluorescent lighting. If

possible, add to the room’s natural lighting. (Surge suppressers

will not prevent flickering lights.)

Install where there is stable temperature and humidity,

with no abrupt changes (away from water sources, humidifiers,

air conditioners, refrigerators, or other major appliances).

Install away from direct sunlight, open flames, or ammonia

fumes. If the printer is placed near a window, make sure the

window has a curtain or blind to block any direct sunlight.

Install with enough space around the printer for proper

access and ventilation (see Figure 2-l).

Page 50

Operating Requirements

Site Requirements

Printer Space Requirements

A

.............

;...................

‘ ~m“~‘1

,.,

,--,’

. . ,------------- ------

F.-. m ---- .

Hgwe z--l

-i-able 2-1 Printer Operating Dimensions

Operating

Dimensions

A (l-m)))

El(Dqm)

C (Width)

D (Rear Dow) I 2 inches (5 cm)

E (Height - Top

Door Cqoxw))

wmer space ~equ~remenls

LaserJet 4L/4ML

I

I 14 inches (35.5cm)

14.5 inches (37 cm)

14.25 inches (36 cm) 15,75 inches (40 cm)

13 inches (33 cm) 14 inches (35 cm)

I

*j

F

B

;..;

~

~,

-----””----------”?

\

‘i \

\

‘,‘,;,

\

II

I

I 15 inches (38 cm)

I 2 inches (5 cm)

c

-“==4

LaserJet 4P/4MP

I

15.5 inches (39 cm)

I

I

2-3

Page 51

Operating Requirements

HP 92274A Toner Cartridge

The

The HP 92274A Toner Cartridge

Toner cartridges contain components which are sensitive to light,

temperature, and humidity. Follow the recommendations in this

section to ensure the highest quality and longest life of HP toner

cartridges.

Table 2-2 Toner Cartridge Environmental Conditions

1 1 I

CATEGORY

Operating

Storage -20° to 40° c

I TEMPERATURE I HUMIDITY

10° to 32,Y c

tO85% RH

35

(50° to 90.5° F)

15 to 90% RH

(-4° to 104° F)

I

Storage Conditions

The toner cartridge is affected by its environment. Packaging

protects the toner cartridge from light and increases its storage

life. It is important to store the cartridge in its original packaging

until the cartridge is ready to be installed in the printer.

When storing the toner cartridge in a warehouse or work area,

make sure the storage place meets the conditions specified in

Table 2-2.

Note

The expiration date of the toner cartridge is

stamped on the cartridge box. This date allows

for up to 2V2 years after manufacture.

Page 52

Operating Requirements

The 1+ 92274A Toner Cartridge

Storing Opened Toner Cartridges

Because the cartridge does not have a shutter to cover the laser

beam access slot, it should be kept inside the printer until empty.

Toner cartridges which have had the toner sealing tape removed

are also more vulnerable to environmental extremes (such as high

humidity).

If the toner cartridge must be removed from the printer, always

store the cartridge:

Inside the protective bag in which it was originally packaged.

In a dark cabinet, away from direct sunlight.

Correct side up and in a horizontal position (not standing on

end).

In a temperature between 10° and 35° C (50° -95° F).

Away from ammonia or other organic solvent fumes.

CAUTION

Never ship the printer with a toner cartridge

installed. Excessive vibration during shipping

can cause toner to leak, contaminating the

printer.

Never expose the toner cartridge to direct

sunlight, or to room light for more than a few

minutes. Bright light and direct sunlight can

permanently damage a toner cartridge.

2-5

Page 53

Operating Requirements

HP 92274A Toner Cartridge

The

Toner Cartridge Handling Suggestions

● Before installing a cartridge, distribute the toner evenly by

rotating the cartridge back and forth five to six times (see

Figure 2-2). Repeat this action when toner begins to run low.

Figure 2-2

●

Do not touch the sutiace of the photosensitive drum in the

cartridge. Protect the drum from light and contamination.

●

Do not disassemble or refill a toner cartridge,

●

Do not expose the cartridge to unnecessary vibrations or shock.

●

Do not expose the photosensitive drum to strong light. White

areas on the page may indicate that the drum has been exposed

to light for too long. If white areas appear, stop the printer and

wait a few minutes. This process should eliminate most

defective images, If not, the toner cartridge maybe placed in a

dark environment for an extended period of time, which may

restore some life to the drum.

●

Never manually rotate the drum, especially in the reverse

direction; internal damage and toner spills may result.

2-6

Distributing Toner

●

●

Page 54

Operating Requirements

The W 92274.4 Toner Cartridge

Refilled Toner Cartridges

While Hewlett-Packard does not prohibit the use of refilled toner

cartridges during the warranty period or while under a

maintenance contract, we do not recommend their use. The

reasons for this are:

Hewlett-Packard has no control or process to ensure that a

refilled toner cartridge functions at the high level of reliability

of a new HP LaserJet toner cartridge. Hewlett-Packard also

cannot predict what the long term reliability effect on the

printer is from using different toner formulations found in

refilled cartridges.

Hewlett-Packard has no control over the actual print quality of

a refilled toner cartridge. The print quality of HP LaserJet toner

cartridges influences the customer’s perception of the printer.

Re~airs resultimz from the use of refilled toner cartridges are

no{ covered und& the HP warranty or maintenance contract.

Recycling Toner Cartridges

In order to reduce the amount of plastics and other wastes

entering our landfllls, Hewlett-Packard has established a program

for recycling used toner cartridges. Parts that do not wear are

re-used in manufacture of new cartridges. Plastic and other

materials are recycled. HP pays the shipping costs. In addition, a

one dollar donation is shared by the Nature Conservancy and the

National Wildlife Federation for each cartridge returned under

this program. To join this recycling effort, follow the instructions

included inside each toner cartridge box.

2-7

Page 55

Operating Requirements

Media Specifications

Media Specifications

Several types of print media can be used with HP LaserJet

printers, provided the media specifications are met, Using media

that does not meet the specifications listed in this section may

increase the incidence of paper jams, cause premature printer

wear, and contribute to repair costs.

Note

It is possible that print media can meet all of the general

specifications listed and still not print satisfactorily because of the

printing environment or other variables over which

Hewlett-Packard has no control.

Hewlett-Packard neither warrants nor recommends the use of any

particular media brand. Properties are subject to change by

manufacturers and HP has no control over such changes. The

operator should test particular media prior to large purchases.

All media should be stable at the 392° F / 200° C temperatures

encountered in the printer’s fusing process.

CAUTION

More detailed media specifications are available

in the HP LaserJet Printer Family Paper

Specification Guide, part number 5002-1801. To

order additional copies, refer to “Ordering

Related Documentation” in Chapter 1.

Use ordy media recommended for use in laser

printers. Printer damage resulting from use of

incompatible media will not be covered by HP

warranty or service agreements.

2-8

Page 56

Operating Requirements

Media Specificatkms

Media Sizes Supported

The following media sizes are supported by the printer’s paper

cassette and manual feed slot.

-i-able2-3

Minimum size:*

3 x 7.5 in. (76x 190 mm)

3x5in. (76x 127mm)

Letter, 8.5 x 11 in. (216x279 mm)

Legal, 8.5 x 14 in. (216x 356 mm)

IExec, 7.25 x 10.5 in. (184x 267 mm) I X I X

A4, 210 x 297 mm (8,27 x 11.69 in.)

Envelopes:

Com-10, 4.1 x9.5 in. (105 x241 mm)

Monarch, 3.87 x 7.5 in. (98x 191 mm)

DL, 110 x220 mm (4.3 x 8.6 in,)

C5, 162x 229 mm (6.4 x 9 in.)

Use the “flat paper path” only (manual feed and rear outpu

“

SupportedMediaS3zes

Sizes

LaserJet 4L/4ML

-

x

-1-

X1X

x x

LaserJet 4P/4MP

Universal Manual

Cassette Feed

7

Y

x

+=

r

r

r

r

x x

x

X1X

x

r

r

x

x

Page 57

Operating Requirements

Media Specifications

Media Selection Guidelines

To achieve the best possible print quality and avoid paper jams,

follow these guidelines for selecting paper:

Use only high quality, copier grade paper. Avoid paper with

embossed lettering, perforations, or texture that is too smooth

or too rough.

Colored paper should be of the same high quality as white

photocopy paper. The pigments must withstand the printer’s

fusing temperature of 392° F (200° C) for 0.1 second without

deterioration. Do not use paper with a colored coating that was

added after the paper was produced.

Pre-printed forms must be printed with non-flammable,

heat-resistant inks that do not melt, vaporize, or release

hazardous emissions when subject to the printer’s

approximately 392° F (200° C) fusing temperature for

0.1 second.

Always test a small sample of a new print media before

purchasing large quantities.

Give a copy of the table on the next page to your paper vendor to

ensure that the paper you purchase meets the specifications for

this printer. More detailed specifications are in the HP LaserJet

Printer Family Paper Specification Guide, HP Part No.

5002-1801. (See “Ordering Related Documentation” in

Chapter 1.)

Page 58

Operating Requirements

Media Specifications

Basis Weight Paper Cassette: 16 to 28 pound (60 to 105 g/m2).

Manual Feed Slot: 16 to 36 pound (60 to 135 g/m2).*

Finishing Precision

Cut sheet to within 0.3 inch (0.8 mm) of nominal, 0.20°

square.

Furnish (Composition) 100% chemical wood pulp and/or cotton fiber.

Grain Long grain.

Moisture Content

4,7 *I% by weight.

Packaging Polylaminated moisture proof ream wrap.

Smoothness 100 to 250 (Sheffield)*

LaserJet 4P/4MP only Heavier paper stock, in the range of 36 to 42 pound

*

(135 to 158 gid) may be used, but must use the “flat paper path” (manual

feed, rear output) and have a Sheffield smoothness rating not greater than 180.

~~~~~

The “flat paper patlf (manual feed slot and rear

face-up delivery door) is recommended for

envelopes, overhead transparencies, and labels.

2-11

Page 59

Operating Requirements

Media Specifications

Envelope Specifications

Choose envelopes that are well-constructed. They should lay flat

and be sharply creased. They should not be wrinkled, nicked, or

otherwise damaged. Envelopes with a peel-off adhesive strip, or

more than one fold-over flap to seal, must use adhesives

compatible with the heat and pressure of the printer’s fusing

process. When printing envelopes, always use the “flat paper path”

~manual feed siot

and the rear face-up delivery door).

CAUTION

TaMe 2-5

Paper Paper used for envelope construction must meet the

Basis Weight

Caliper

Curl (Pre-printed) Envelopes must lay flat with no more than 0.2 in. (5 mm)

Finishing Envelopes must not have any adhesive exposed to the

Furnish (Composition) 1100% chemical wood pulp and/or cotton fiber.

Fusing Compatibility Must not scorch, melt, offset, or release hazardous

Grain Long grain.

Moisture Content

Smoothness 1100 to 250 (Sheffield)

Envelope Specifications

To prevent severe printer damage, do not use

envelopes having windows, clasps, snaps, or

synthetic materials.

requirements in the table under “Media Selection

Guidelines.”

20 to 24 pound (75 to 90 g/m2), single thickness

3.3 to 5.5 roils (0.084 to 0.14 mm), single thickness

curl across the entire surface.

printer. They must be folded accurately, within f 0.04”

(1 mm). There must be no more than two thicknesses of

paper anywhere along the leading edge. All folds must be

well scored and sharply creased, and construction must be

tight (not baggy). Envelopes must not be stuck together

with excess seam sum.

emissions when heated to 392° F (20V C) for 0.1 second,

4.7 +1% bv weiaht.

I

I

I

Page 60

Operating Requirements

Specifications

Media

Adhesive Label Specifications

Use the following guidelines when selecting labels:

The top sheet (printing surface) must be of copier quality and

provide good toner adhesion.

The carrier sheet (backing sheet) must be compatible with the

temperatures and pressure of the fusing process, and must be

coated for easy release of the top sheet.

The adhesive must be stable at the 392° F (200° C)

temperatures encountered for 0.1 second in the printer’s fusing

process, and must not produce emissions that exceed exposure

levels or threshold limits established by OSHA and other safety

agencies. Adhesives must not come into direct contact with any

part of the printer.

Labels must be arranged on the carrier sheet so that any

exposed spaces run lengthwise down the sheet. Using label

stock with spaces between the horizontal rows of labels can

often result in labels peeling off during printing, causing serious

jamming and possible printer damage.

wide selection of suitable labels is available through

Hewlett-Packard. A list of available sizes is in the H“PLaserJet

Printer Family Paper Specification Guide, HP Part No. 5002-1801.

See Chapter 1 for ordering information, or contact your local

authorized HP dealer.

CAUTION -

Do not attempt to print on label sheets after any

of the labels have been removed from the sheet.

Damage to the printer may result.

2-13

Page 61

Operating Requirements

Media Specifications

Adhesive Must not be on any external surfaces of the label

before, during or after printing. Label construction

and die-cutting must not allow labels to peel off

during transport, printing, or fusing.

Caliper

Curl

Must not exceed 0.007 in. (0,1 9 mm)

In ream: flat within 0,2 in, (5 mm)

Finishing Precision Cut sheet within 0.031 in. (0.79 mm) of nominal

and 0.20° square.

Fusing Compatibility

All adhesives, carrier sheets, top sheets, and other

materials used in label construction must be

compatible with the heat and pressure of the fusing

iprocess, Materials must not discolor, melt, offset,

or release hazardous emissions when heated to

392° F (20V C) for 0.1 second,

Packaging

Moisture proof wrap to preserve properties.

—

The “flat paper path” (manual feed slot and rear

face-up delivery door) is recommended for

printing adhesive labels.

Page 62

Transparency Specifications

Overhead transparencies used in HP LaserJet printers must be

able to withstand the 392° F (200° C) temperatures encountered in

the printer’s fusing process for 0.1 second. Suitable transparency

film is available through Hewlett-Packard. Refer to Chapter 3 of

the HP LaserJet Printer Family Paper Specification Guide, HP

Part No. 5002-1801 for details.

Caliper 13.9 to 4.3 roils (0.100 to 0.110 mm)

Cutting Angle

Finishing precision Cut sheet to within 0.03 in. (0.8 mm) of nominal

Fusing Compatibility Overhead transparency material must be

The “flat paper pat~ (manual feed slot and rear

face-up delivery door) is recommended for

printing transparencies.

90° * 0.2°

and t 0.2° of square.

compatible with the heat and pressure of the fusing

process. Materials must not discolor, melt, offset

material, or release hazardous emissions when

heated to 392° F (200° C) for 0,1 second.

2-15

Page 63

Operating Requirements

Media Specifications

Storing Print Media

Follow these guidelines when stacking and storing print media:

Store paper in its ream wrapper until ready to use.

DO NOT store cartons or reams directly on the floo~ place

cartons on a pallet or on shelves.

DO NOT store individual reams in a manner that causes them

to curl or warp along the edges.

Re-wrap partially used packages of media before storing.

DO NOT stack more than six cartons on top of each other.

Stack each carton squarely on top of the one underneath.

Stack each carton upright.

DO NOT place anything on top of media, regardless of whether

the paper is packaged or unpackaged.

Store envelopes in a protective box to avoid damaging the

envelope edges.

Keep stored media away from temperature and humidity

extremes.

DO NOT store printed documents in vinyl folders (which may

contain plasticizers) or expose the documents to petroleum

based solvents.

Shipping Print Media

When shipping print media through different environments,

plastic wrap all cartons on the shipping pallet. When shipping

media across bodies of water, wrap individual cartons as well.

Packaging must protect the media from physical damage.

Page 64

Installation and

Configuration

Page 65

Installation and Configuration

Unpacking and Installation

Unpacking and Installation

Before unpacking the printer, inspect the shipping container for

signs of physical damage. Since a damaged shipping box is an

indication of improper handling during shipping, the printer may

also be damaged.

Note

If the shipping container has any sign of

damage, unpack and power the printer ON with

the carrier’s agent present. If the printer

appears damaged or fails self test, do not

accept it.

A. Choose the best location.

Verify that the printer location meets all requirements listed in

Chapter 2.

B. Unpack the printer.

Remove the power cord, the manuals, and the toner package.

1.

Remove the printer from its box.

2.

Remove the outer packing material from the printer.

3.

Open the printer top door by pressing the door release button

4.

on the right side of the printer (see Chapter 1, Figure 1-2 or 1-3

for location).

Pull out the paper cassette.

5.

Remove the packing spacers from the inside of printer (2 on the

6.

Transfer Roller) and from the paper cassette (2).

.

Page 66

Installation and Configuration

Wy3acking and installation

C. Check package contents.

Nate

If any of the package contents are missing or

damaged, contact your HP dealer immediately.

The package should include the following:

● Printer.

. Power cord.

. Software Solutions package.

● User’s Manual.

● Toner cartridge.

Note

D. Install the

1.

Press the top door release button to open its top door.

2.

Remove toner cartridge from its box and cut it open. Save the

Interface cables are sold separately. Refer to

Chapter 8 for part numbers.

toner cartridge.

packing materials for possible cartridge storage.

Shake the cartridge vigorously to distribute the toner evenly

3.

inside the cartridge (see Figure 2-2 in Chapter 2).

4.

Grasp the toner sealing tape tab on the right side of the

cartridge. Pull firmly to remove the strip of sealing tape.

5.

Grasp the plastic cartridge body (not the metal shutter

linkage), and slide the cartridge into the printer, pushing it

firmly into place. Close the top door.

—

3-3

Page 67

Installation and Configuration

Llnpacking and Installation

E. Load the paper cassette.

1. Pull out the paper cassette located at the lower front of printer

and load approximately 100 sheets (4L/4ML) or 250 sheets

(4P/4MP) of paper. The rear of the stack should fit loosely under

the two backstops at the rear of the paper cassette.

2. Insert the front corner of the paper stack under the metal clip

at the front of the cassette.

Note

3. Resting the paper cassette on a flat surface, slide it into the

printer.

Failure to insert the paper under the metal clip

will cause skewing or paper jams.

F. Attach the interface cable(s).

1. Open the 1/0 Door on the printer’s left rear side (LaserJet

4L/4ML only). Attach the 1/0 cable securely to the printer.

Note

LaserJet 41J4ML: Align the cable with

2.

the 1/0 Door.

Attach the I/O cable to the computer.

3.

Failure to attach the cable securely may result

in an 1/0 error.

the cable hole and close

Page 68

Installation and Configuration

LJnpwking and

hsbllattm

G. Attach the power cord.

LaserJet 4L/4ML: Open the Power Door at the right rear of the

1.

printer by pressing on the back end of the door and swinging it

outward.

2.

Connect the power cord. On the LaserJet 4P/4MP, turn on the

power switch on the right side of the printer.

All front panel lights briefly illuminate, then the green Ready

light comes on. (LaserJet 4P/4MP: There is a brief self test

period before the Ready and the On Line lights are illuminated

and the display reads %3 FZIXW.)

LaserJet 4L/4ML: Align the power cord with the hole at the

3.

rear of the door and close the Power Door.

4.

LaserJet 4L/4ML: Briefly press the front panel button to

generate a self test and verify that the printer is working.

LaserJet 4P/4MP: Press the - key, then Menu

repeatedly until “%;;;T !%+:!..!appears. Then press _ once to

display SZL.FT’zx-~.Press_ to print a self test.

Id ~ J.~ Refer to the section “Printin~ a Self Test.” later

U.JW L=

in this chapter, for a detaile~ description’ of self

test information.

~y~~

Power On/OfX The LaserJet 4P/4MP uses a

conventional on/off power switch. The LaserJet

4L and 4ML printers do not have a power,

switch, but use Intelligent On/Off sensing

instead. (See “Intelligent On/Off in Chapter 5.)

Page 69

Installation and Configuration

Unpacking and installation

H. Attach the Help Labels (L-erJet 4~4ML onlY)

Packaged with the User’s Manual is a sheet of help labels. These

labels explain the meanings of the front control panel lights.

Attach the large help label to the inside of the printer’s top door,

and the small label next to the front panel lights, as shown in

Figure 3-1.

Figure 3-1

3-6

Attaching the Help Labels (LaserJet 4L/LMUW

Page 70

I. Install Printer Drivers and Utilities (optional)

Printer drivers are specialized programs designed to allow specific

software applications to function with the HP LaserJet printers.

Printer utilities include such things as the HP Explorer program

modules, which enhance the usability of the printer and provide

convenient access to printer features outside of specific software

applications.

How to Obtain Printer Drivers

First, check the software’s printer selection feature to see if the

printer is listed among the available printers. If it is not, run the

software’s SETUP or INSTALL program to install a “ptinter

driver” or “printer file” for the printer.

Here are some ways to obtain printer drivers and Software

Application Notes for HP LaserJet printers:

● Check the Printing Software package to see if it includes a driver ‘

for your software.

. Order an updated driver from the software vendor.

. Call Hewlett-Packard at 303-353-7650.

. Obtain a driver request form by fax through HP FIRST

(call 1-800-333-1917).

. Download a driver through CompuServe’s HP Forum. To sign up

for CompuServe, call 1-800-848-8199.

,,.,.., _

J’., .-;

While waiting for a specific HP LaserJet printer

driver, you can substitute a similar printer

driver (such as a driver for the HP LaserJet III,

111P,or 4 printer), These substitute drivers will

allow you to use the printer, but they do not

support all of the printer’s features.

Page 71

Installation and Configuration

Unpacking and k“istallaiion

Using the Printing Software Package

The Printing Software package supplied with the printer provides

many useful programs and utilities, including:

Printer drivers for several popular software applications.

Utilities for automatically copying printer drivers onto your

hard disk.

Software Application Notes for the above applications.

The HP Explorer utilities, including

. A setup program which installs other HP Explorer modules

and automatically updates the computer’s AUTOEXEC.BAT

and CONFIG. SYS files. Use the setup program to add or

delete any of HP Explorer’s utilities at any time.

. The HP Explorer Remote Control Panel allows changes to

printer settings from the computer’s screen. It supplements

the software’s printer support to permit complete control over

the printer’s features.

● The HP Explorer Status Monitor is a “Terminate-and-Stay-

Resident” (TSR) program that automatically displays

messages from the printer on the computer’s screen whenever

the printer’s status changes.

. The HP Explorer Travel Guide is a guide to the printer’s

features. It also serves as an on-line help utility when using

other HP Explorer modules.

Page 72

Installation and Configuration

L/sing M Cbi’m91 FJWEd

Using the Control Panel

LaserJet 4L/4ML Control Panel Overview

The HP LaserJet 4L/4ML printer’s front control panel consists of 4

status lights and a front panel button situated on top of the printer.

-’ Front Panel

Aw%.. ~

jwe 3-2

LaserJet4L/4ML

Front Ckmtrd Panel

3-9

Page 73

Installation and Configuration

The LaserJet 4L/4ML Lights

The LED lights provide a quick way to check the printer’s status.

Ready (Green)

STEADY: The printer is ready to print a job from the paper

cassette,

BLINKING: If this light is blinking and the Data light is on steadily,

the printer is receiving or processing data,

Data (Green)

STEADY: [f the Data light is on steadily and the Ready light is

blinking, the printer is receiving or processing data. If the Data

light and the Ready light are both on steadily, there is unprinted

data still in the printer. Briefly press the front panel button to print

the remaining data.

BLINKING: The printer is in Manual Feed mode, Either insert a

sheet of paper into the manual feed slot, or press the front panel

button briefly to print from the paper cassette instead.

Paper (Amber)

STEADY: The paper cassette is empty or missing, Add more

paper.

BLINKING: There is a paper jam. Jam locations include the paper

cassette, under the toner cartridge, or inside the printer’s rear

access door. See Chapter 4 for clearing paper jams.

Error (Amber)

STEADY: The printer’s top door is open or the toner cartridge is

either missing or not installed correctly. To correct the problem,

make sure the toner cartridge is installed completely and close the

top cover until it snaps shu~

BLINKING: The page is too complex. Press the front panel button

to continue printing. There maybe some data loss on the page.

Try setting Page Protect to On or Auto in the Printer Memory

category of the HP Explorer Remote Control panel. If the page still

doesn’t print correctly, you may need to install the optional printer

memory.

Page 74