HP 3PAR StoreServ 8000 Service And Upgrade Manual

HPE 3PAR StoreServ 8000 Storage Service and Upgrade Guide: Customer Edition

Abstract

This document provides information and instructions to guide you in servicing and upgrading

the HPE 3PAR StoreServ 8000 Storage system without the assistance of an authorized

service provider. If assistance is needed, contact your HPE Sales Representative or HPE

Partner.

Part Number: QL226-10543

Published: December 2018

Edition: 2

©

Copyright 2015-2018 Hewlett Packard Enterprise Development LP

Notices

The information contained herein is subject to change without notice. The only warranties for Hewlett

Packard Enterprise products and services are set forth in the express warranty statements accompanying

such products and services. Nothing herein should be construed as constituting an additional warranty.

Hewlett Packard Enterprise shall not be liable for technical or editorial errors or omissions contained

herein.

Confidential computer software. Valid license from Hewlett Packard Enterprise required for possession,

use, or copying. Consistent with FAR 12.211 and 12.212, Commercial Computer Software, Computer

Software Documentation, and Technical Data for Commercial Items are licensed to the U.S. Government

under vendor's standard commercial license.

Links to third-party websites take you outside the Hewlett Packard Enterprise website. Hewlett Packard

Enterprise has no control over and is not responsible for information outside the Hewlett Packard

Enterprise website.

Acknowledgments

Microsoft® and Windows® are either registered trademarks or trademarks of Microsoft Corporation in the

United States and/or other countries.

UNIX® is a registered trademark of The Open Group.

Revision history

Part Number Publication

QL226-10543 December 2018 3

QL226-99885 June 2018 2

QL226-99284 March 2017 1

Edition Summary of changes

date

• Added a link to the HPE Parts Store in "Spare

part number"; removed parts catalog

• Updated "Guidelines for cabling"

• Support for a new physical service processor,

HPE ProLiant DL360 Gen10 Server

• Support for direct-current (DC) physical service

processor, DC breaker panel, DC power cooling

module, and DC switch only qualified and

supported with HPE 3PAR OS 3.3.1 or later

• The HPE StoreFront Remote (SFRM) content

has been replaced with HPE InfoSight content.

• Correction for replacing a drive; Maintenance

Mode not set during replacement of a failed

drive

• Support for HPE 3PAR OS 3.2.2 and 3.3.1 or

later

• Support for HPE 3PAR Service Processor

SP4.x and 5.x or later

Contents

Preparation.............................................................................................. 7

Service..................................................................................................... 8

Videos for service and upgrade.................................................................................................... 7

Customer self repair......................................................................................................................8

Breaker panel replacement...........................................................................................................8

Controller node replacement—Two-node system only................................................................. 9

Replacing a controller node—Two-node system only—SP 4.x..........................................9

Replacing a controller node—Two-node system only—SP 5.x........................................12

Drive replacement.......................................................................................................................16

Replacing a drive—SP 4.x............................................................................................... 16

Replacing a drive—SP 5.x............................................................................................... 21

Power cooling module or battery replacement............................................................................25

Replace the alternating-current power cooling module battery in a controller node

enclosure—SP 5.x............................................................................................................25

Replacing an alternating-current power cooling module in a controller node

enclosure—SP 5.x............................................................................................................29

Replacing an alternating-current power cooling module in a drive enclosure—SP 5.x....33

Replacing a direct-current power cooling module battery in a controller node

enclosure—SP 5.x............................................................................................................36

Replacing the direct-current power cooling module in a controller node enclosure—

SP 5.x...............................................................................................................................41

Replacing a direct-current power cooling module in a drive enclosure—SP 5.x..............46

SFP transceiver replacement......................................................................................................50

Replacing an SFP transceiver—SP 4.x........................................................................... 50

Replacing an SFP transceiver—SP 5.x........................................................................... 53

Switch replacement.....................................................................................................................55

Upgrade..................................................................................................57

Customer self upgrade................................................................................................................57

Drive additions............................................................................................................................ 57

Guidelines for the drive installation ................................................................................. 57

Guidelines for a drive addition .........................................................................................61

Adding drives—SP 4.x..................................................................................................... 61

Adding drives—SP 5.x..................................................................................................... 64

More information...................................................................................68

About the software on a virtual service processor or physical service processor.......................68

Connection methods for the HPE 3PAR Service Processor............................................ 68

Connecting to HPE 3PAR Service Processor 5.x from a web browser................. 69

Connecting to the HPE 3PAR Service Processor 4.x from a web browser........... 69

Connecting to the Linux console of the HPE 3PAR Service Processor

through a Secure Shell session.............................................................................69

Connecting to the Linux console of the HPE 3PAR Service Processor

through a VMware vSphere Client........................................................................ 69

3

Connecting a service laptop to the physical HPE 3PAR Service Processor

through the service port.........................................................................................69

Interfaces for the HPE 3PAR Service Processor software............................................... 70

Accessing the SP 5.x Service Console interface.................................................. 71

Accessing the SP 5.x Text-Based User Interface.................................................. 71

Accessing the Service Processor Onsite Customer Care interface—SP 4.x........ 71

Accessing the SP 4.x SPMaint interface directly...................................................71

Accessing the CLI session from the Service Console interface, HPE 3PAR

Service Processor 5.x............................................................................................71

Accessing the interactive CLI interface from the Text-Based User Interface,

HPE 3PAR Service Processor 5.x......................................................................... 72

Accessing the CLI session from the Service Processor Onsite Customer

Care interface, HPE 3PAR Service Processor 4.x ............................................... 72

Accessing the interactive CLI interface from the SPMaint interface, HPE

3PAR Service Processor 4.x................................................................................. 73

Network and firewall support access................................................................................73

Firewall and proxy server configuration.................................................................73

About the HPE 3PAR StoreServ Management Console.............................................................74

HPE 3PAR StoreServ Management Console connection................................................ 75

HPE 3PAR StoreServ Management Console interfaces.................................................. 75

About the HPE InfoSight platform............................................................................................... 75

Accessing the HPE InfoSight platform and registering the storage system: Process

overview........................................................................................................................... 76

Creating an account to access the HPE InfoSight web portal..........................................76

Registering the storage system with the HPE InfoSight web portal using the HPE

3PAR StoreServ Management Console...........................................................................76

Removing a storage system from the HPE InfoSight platform.........................................78

Accounts and credentials for service.......................................................................................... 78

Time-based password (strong password)........................................................................ 78

Encryption-based password (strong password)............................................................... 78

HPE 3PAR Service Processor accounts for service.........................................................79

Setting time-based or encryption-based password option from the Service

Console interface of the HPE 3PAR Service Processor 5.x.................................. 81

Generating the encryption-based ciphertext from the Service Console

interface of the HPE 3PAR Service Processor 5.x................................................ 82

Setting time-based or encryption-based password option from the Text-

Based User Interface of the HPE 3PAR Service Processor 5.x............................ 82

Generating the encryption-based ciphertext from the Text-Based User

Interface of the HPE 3PAR Service Processor 5.x................................................ 83

HPE 3PAR StoreServ Storage system accounts for service............................................83

Setting time-based or encryption-based password option for a storage

system account......................................................................................................84

Generating the encryption-based ciphertext for a storage system account.......... 85

Regenerating the encryption-based ciphertext for a storage system account...... 85

Alert notifications for the storage system—SP 5.x......................................................................85

Browser warning when connecting to the service processor...................................................... 86

Component information...............................................................................................................89

Adapters information (optional component)..................................................................... 89

Four-Port 16 Gb FC Host PCIe Adapter information.............................................89

Two-Port 10 Gb iSCSI/FCoE CNA Host PCIe Adapter information...................... 90

Two-Port 10 GbE NIC Host PCIe Adapter information..........................................91

Four-Port 1 GbE NIC Host PCIe Adapter information........................................... 91

Four-port 16 Gb FC/10 Gb Ethernet Combo Adapter information.........................92

Four-port 10 Gb iSCSI/10 Gb Ethernet Combo Adapter information.................... 92

Two-port 32Gb FC HBA information......................................................................93

Breaker panel information................................................................................................ 93

Direct-current E-T-A Breaker Panel and Grounding Bar information.................... 93

4

Controller node information..............................................................................................93

Drive information.............................................................................................................. 97

Enclosures information.....................................................................................................97

Controller node enclosure and drive enclosures information front view................97

Controller node enclosure information rear view...................................................99

Drive enclosure information rear view................................................................. 100

I/O module information...................................................................................................102

Power cooling module information................................................................................. 103

Power cooling module information, alternating-current, controller node

enclosure.............................................................................................................103

Power cooling module information, alternating-current, drive enclosure.............104

Power cooling module information, direct-current system...................................105

Power distribution unit information................................................................................. 106

Service processor information........................................................................................106

Physical service processor information, HPE ProLiant DL120 Gen9 Server...... 106

Physical service processor information, HPE ProLiant DL360 Gen10 Server.... 108

Switch information..........................................................................................................109

Direct-current switch information.........................................................................109

Component LEDs......................................................................................................................109

Adapter LEDs.................................................................................................................109

Four-Port 16 Gb FC Host PCIe Adapter LEDs....................................................109

Two-Port 10 Gb iSCSI/FCoE CNA Host PCIe Adapter LEDs..............................110

Two-Port 10 GbE NIC Host PCIe Adapter LEDs................................................. 110

Four-Port 1 GbE NIC Host PCIe Adapter LEDs...................................................111

Four-Port 16 Gb FC/10 GbE NIC Host PCIe Combo Adapter LEDs................... 112

Four-port 10 Gb iSCSI/10 Gb Ethernet Combo Adapter LEDs............................112

Two-Port 32 Gb FC HBA LEDs............................................................................113

Controller node LEDs..................................................................................................... 114

Drive LEDs..................................................................................................................... 118

I/O module LEDs............................................................................................................120

Power cooling module LEDs.......................................................................................... 122

Power cooling module LEDs, alternating-current, controller node enclosure......122

Power cooling module LEDs, alternating-current, drive enclosure......................123

Power cooling module LEDs, direct-current system............................................124

Service processor LEDs.................................................................................................125

Physical service processor LEDs, HPE ProLiant DL120 Gen9 Server............... 126

Physical service processor LEDs, HPE ProLiant DL360 Gen10 Server............. 128

System status LEDs.......................................................................................................130

Controller node rescue..............................................................................................................131

Initiating an automatic node-to-node rescue.................................................................. 132

Customer self repair..................................................................................................................134

Guidelines for cabling............................................................................................................... 134

Removing the cable restraint shipping brackets....................................................................... 136

Spare part number.................................................................................................................... 136

Troubleshooting.................................................................................. 138

Alerts issued by the storage system and processed by the service processor.........................138

Components functions.............................................................................................................. 138

alert ............................................................................................................................139

ao ..................................................................................................................................139

cabling ....................................................................................................................... 140

cage ..............................................................................................................................141

cert ..............................................................................................................................145

dar ................................................................................................................................145

date ..............................................................................................................................146

5

file ..............................................................................................................................146

fs ..................................................................................................................................148

host ..............................................................................................................................149

ld ..................................................................................................................................150

license ....................................................................................................................... 152

network ....................................................................................................................... 152

pd ..................................................................................................................................153

pdch ..............................................................................................................................157

port ..............................................................................................................................158

qos ................................................................................................................................160

rc ..................................................................................................................................161

snmp ..............................................................................................................................162

sp ..................................................................................................................................162

task ..............................................................................................................................162

vlun ..............................................................................................................................163

vv ..................................................................................................................................164

Controlled thermal shutdown.................................................................................................... 165

Log files collection.....................................................................................................................165

Collecting HPE 3PAR SmartStart log files—OS 3.2.2 and SP 4.x................................. 165

Collecting service processor log files—SP 5.x...............................................................165

Collecting the service processor log files—SP4.x..........................................................166

Websites.............................................................................................. 167

Support and other resources.............................................................168

Accessing Hewlett Packard Enterprise Support....................................................................... 168

Accessing updates....................................................................................................................168

Customer self repair..................................................................................................................169

Remote support........................................................................................................................ 169

Warranty information.................................................................................................................169

Regulatory information..............................................................................................................170

Documentation feedback.......................................................................................................... 170

Acronyms.............................................................................................171

6

Preparation

Videos for service and upgrade

Customer self repair video

With HPE 3PAR OS 3.3.1, the customer self repair (CSR) video is available at the hpe.com website:

www.hpe.com/support/3PAR8000CSRVideo

With HPE 3PAR OS 3.2.2, the customer self repair (CSR) videos are available at the CSR Services

Media Library website:

www.hpe.com/support/sml-csr

1. From the Product category list, select Storage.

2. From the Product family list, select 3PAR StoreServ Storage.

3. From the Product series list, select the product.

Links to the available videos are displayed.

Customer self upgrade video

With HPE 3PAR OS 3.3.1, the customer self upgrade (CSU) video is available at the hpe.com website:

www.hpe.com/support/3PAR8000CSUVideo

Preparation 7

Service

Customer self repair

Customer self repair (CSR) is a key component of Hewlett Packard Enterprise warranty terms. Once the

failure of a hardware component has been confirmed, CSR enables Hewlett Packard Enterpriseto ship

replacement parts directly to you. Parts are usually shipped overnight. CSR warranty terms and

conditions are included in the warranty statement for the product, which can be found in the box with the

product.

For more details about CSR, contact an authorized service provider or see the Hewlett Packard

Enterprise Customer Self Repair website:

www.hpe.com/info/selfrepair

IMPORTANT: Some components are not designed for CSR. To satisfy the customer warranty for

service of non-CSR components, an authorized service provider has to service the non-CSR

components.

CSR types

• Mandatory CSR parts (warranty only)—On-site or return-to-depot support for replacement of this

part is not provided under the warranty. You can install a mandatory CSR part yourself or pay Hewlett

Packard Enterprise service personnel to do the installation. A mandatory CSR part typically does not

need tools to replace, consists of a single part, has minimum cabling, and is plug-and-play.

• Optional CSR parts—You can replace this optional CSR part yourself or have it replaced by Hewlett

Packard Enterprise service personnel at no additional charge during the warranty period. Replacement

may require tools, the removal of other parts, more involved cabling, and configuration and setup

following replacement.

Breaker panel replacement

The E-T-A Breaker Panel is a direct-current component supported for the HPE 3PAR StoreServ 8000

Storage system.

WARNING: Since there is a risk of injury from electric shock or high energy levels, only a certified

electrician who knows about the procedures, precautions, and hazards associated with directcurrent (DC) power should perform the power wiring, cabling, routine maintenance, and service of a

storage system installed in a direct-current power environment. Hewlett Packard Enterprise and

partner service personnel are not authorized to perform DC power wiring or cabling.

IMPORTANT: The storage system ordered for installation in a direct-current (DC) power

environment requires the installation of DC-specific components. Use of components with

alternating-current (AC) power in the DC storage system is prohibited.

IMPORTANT: The direct-current components are qualified and supported only with a direct-current

HPE 3PAR StoreServ 8000 Storage system running HPE 3PAR OS 3.3.1 and later versions.

When support is needed for the direct-currentE-T-A Breaker Panel, see www.e-t-a.com/ for support

contact information.

8 Service

Controller node replacement—Two-node system only

IMPORTANT: Only a controller node for a two-node system that does not contain a host PCIe

adapter qualifies for customer self repair (CSR). It is the entire controller node that qualifies for CSR

and excludes the repair of internal components within the controller node. Any internal components

within the controller node are only serviceable by an authorized service provider (ASP).

Replacing a controller node—Two-node system only—SP 4.x

This procedure is for the replacement of an HPE 3PAR StoreServ 8000 Storage controller node using

HPE 3PAR Service Processor (SP) 4.x.

IMPORTANT:

• To avoid possible data loss, shut down (halt) and remove only one controller node at a time from

the storage system.

• To prevent overheating, do not leave the controller node bay empty for more than 30 minutes.

• Verify that host multipathing is functional.

Prerequisites

Order a replacement component by contacting your Hewlett Packard Enterprise authorized service

provider.

Shut down (halt) the failed controller node by contacting your Hewlett Packard Enterprise authorized

service provider for assistance.

Procedure

Preparation

1. Unpack the component and place on an ESD safe mat.

2. Connect to the HPE 3PAR Service Processor.

Browse to either the IP address or hostname: https://<sp_ip_address> or https://

<hostname> .

3. Log in to the HPE 3PAR Service Processor (SP).

With the 3parcust account credentials, the Service Processor Onsite Customer Care (SPOCC)

interface displays.

4. Initiate a maintenance window to stop the system from sending alerts to Hewlett Packard Enterprise.

a. From the SPOCC interface main menu, select SPMAINT in the left navigation pane.

b. From the SPMaint interface main menu under Service Processor - SP Maintenance, select

StoreServ Configuration Management.

c. Under Service Processor - StoreServ Configuration, select Modify under Action.

d. Under Service Processor - StoreServ Info, select On for the Maintenance Mode setting.

5. Initiate Check Health on the storage system.

Service 9

a. From the SPOCC interface main menu, click Support in the left navigation pane.

b. From the Service Processor - Support page, under StoreServs, click Health Check in the

Action column.

A pop-up window displays a status message while the health check runs.

When running the Health Check using Internet Explorer, the screen might remain blank while

information is gathered. This process could take a few minutes before displaying results. Wait for

the process to complete and do not attempt to cancel or close the browser.

c. To review the report, click either Details or View Summary.

CAUTION: If health issues are identified during the Check Health scan, resolve these issues

before continuing. Refer to the details in the Check Health results and contact Hewlett Packard

Enterprise Support if necessary.

6. Locate the failed and shut down controller node by referring to the LEDs.

Some faults illuminate the blue UID/Service LED, which helps you locate the failed component.

When the UID/Service LED is solid blue and the Status LED is rapidly flashing green, a controller

node is shut down. Depending on the nature of the controller node failure, the Fault LED might be

solid amber.

The Fault LED for the other active controller node in the cluster will be flashing, indicating that one of

the other controller nodes in the cluster is shut down.

7. Verify that all cables are labeled with their location.

Removal

8. Remove the cables from the controller node.

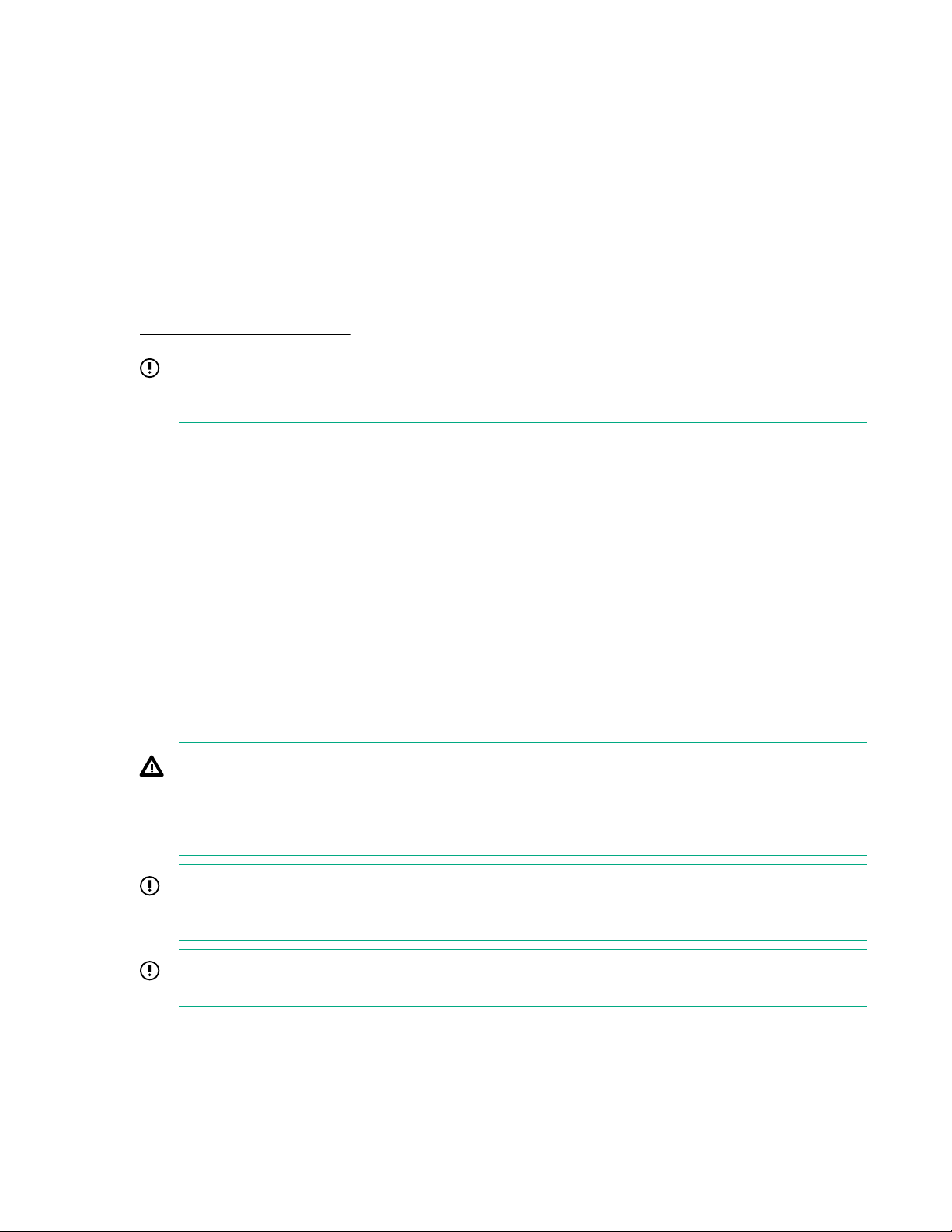

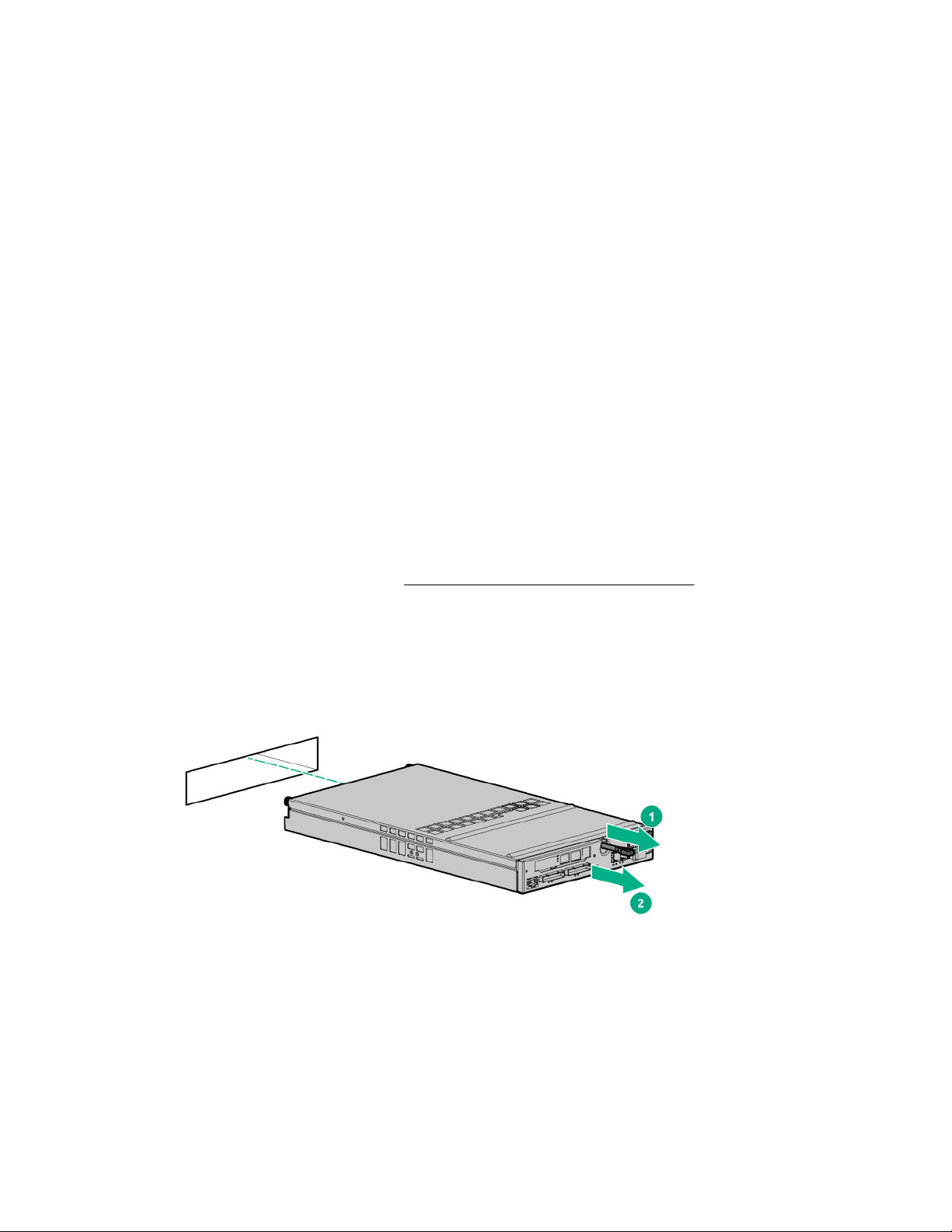

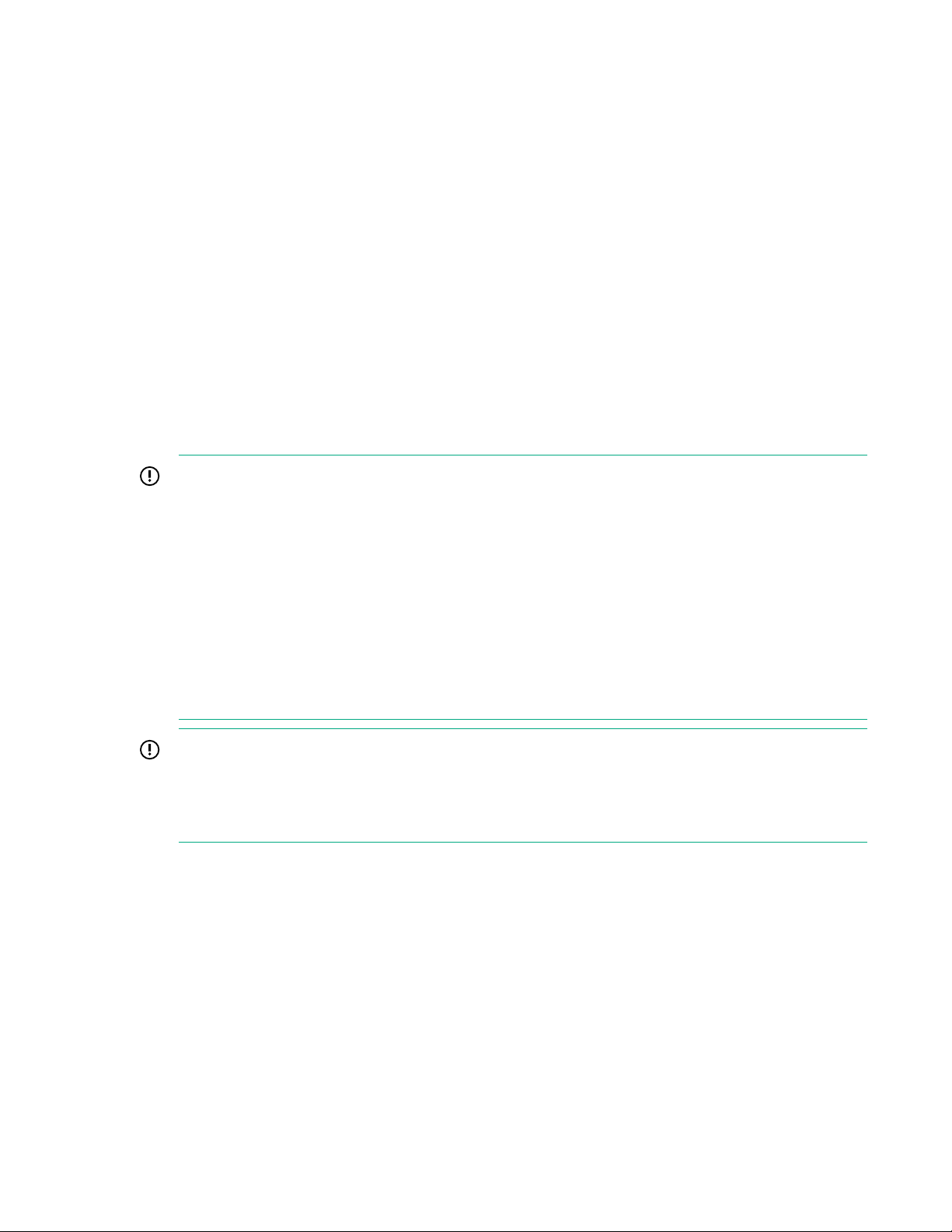

9. Remove the controller node. See Figure 1: Removing the controller node on page 10.

a. Pull to extend the gray rod of the controller node to the extracted position (1).

b. When the controller node is halfway out of the enclosure, support it from underneath and slide it

out completely (2).

c. Place the controller node on the ESD safe mat.

10. Push in the gray rod to ready it for packaging and to provide differentiation from the replacement

Replacement

11. Partially install the controller node.

10 Service

Figure 1: Removing the controller node

controller node.

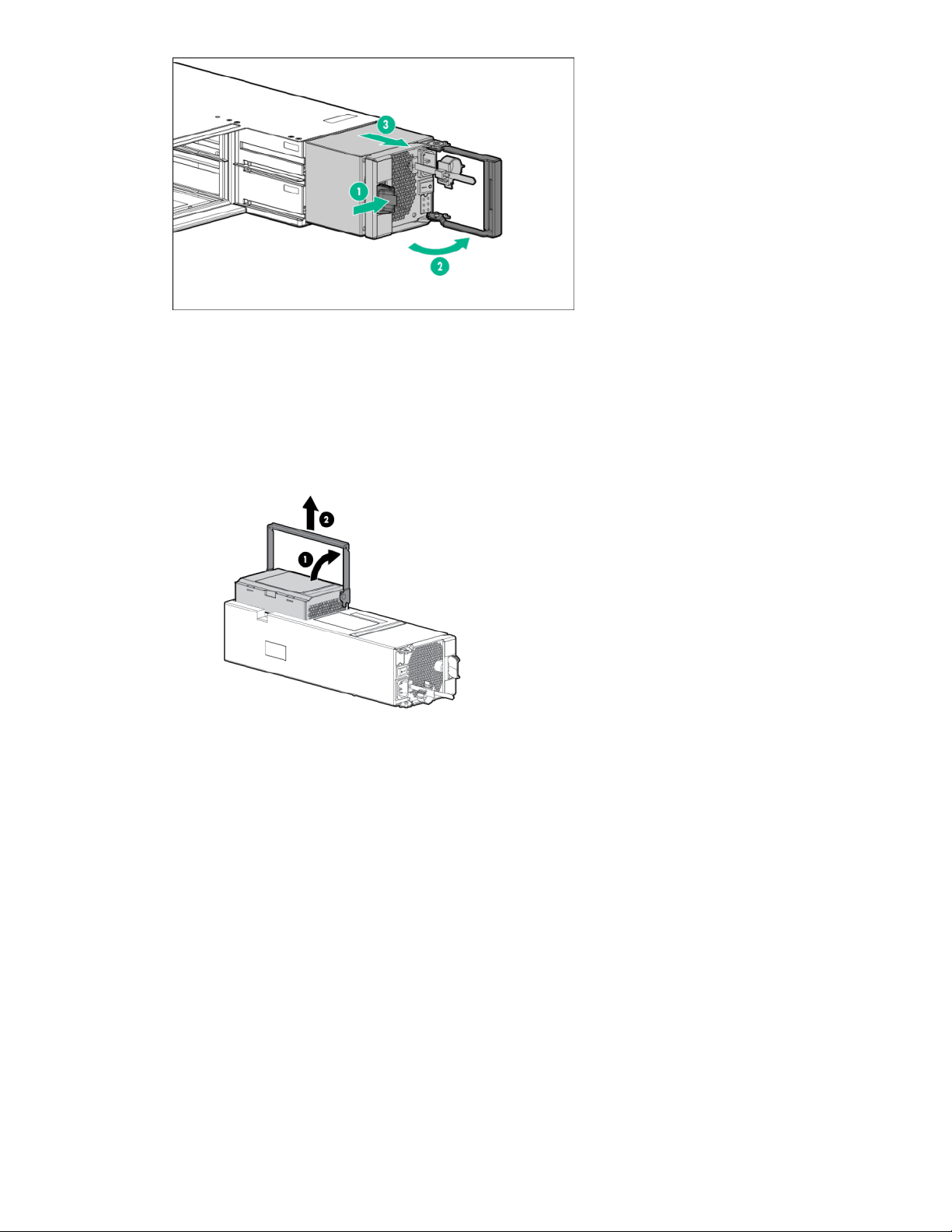

a. Pull to extend the gray rod of the controller node to the extracted position.

Figure 2: Extending the controller node rod

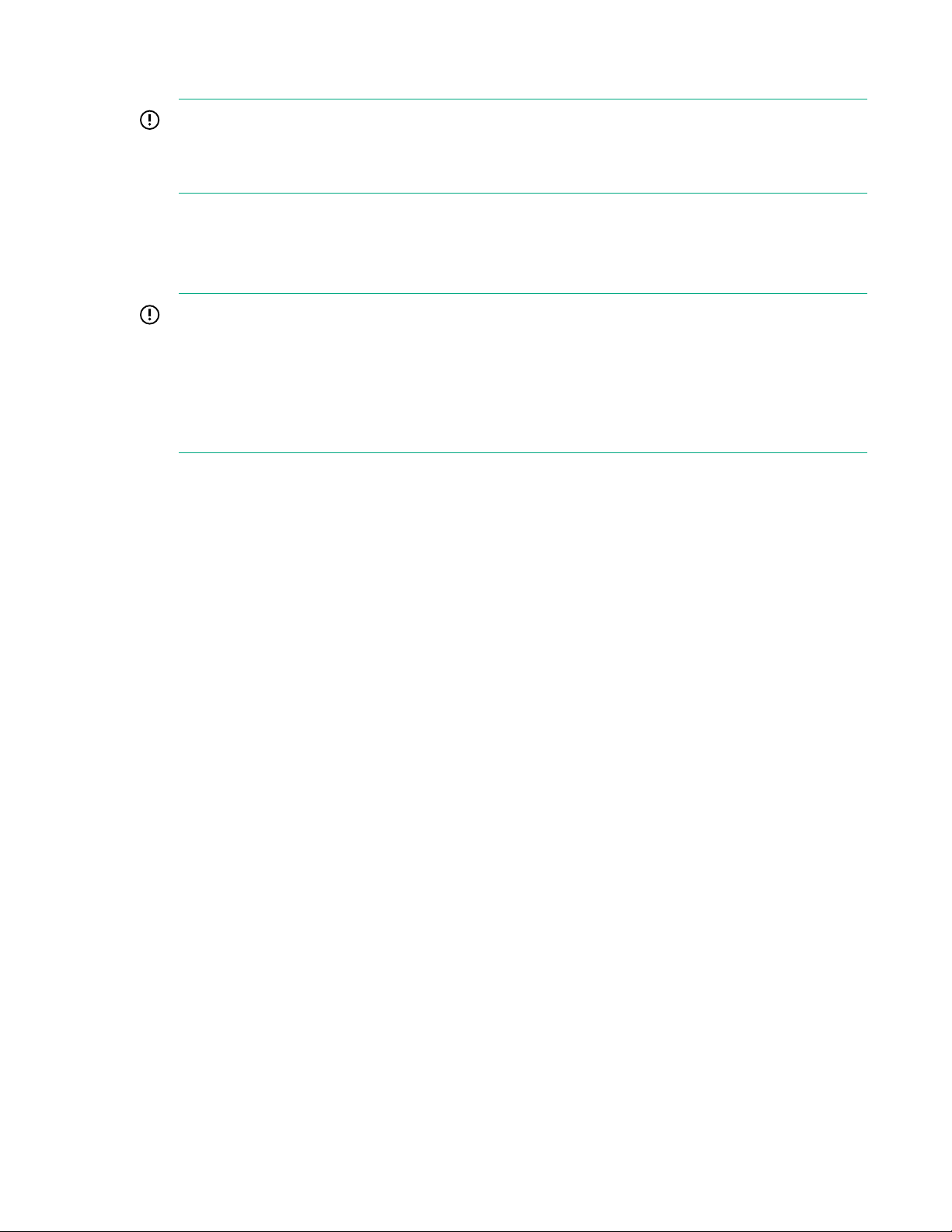

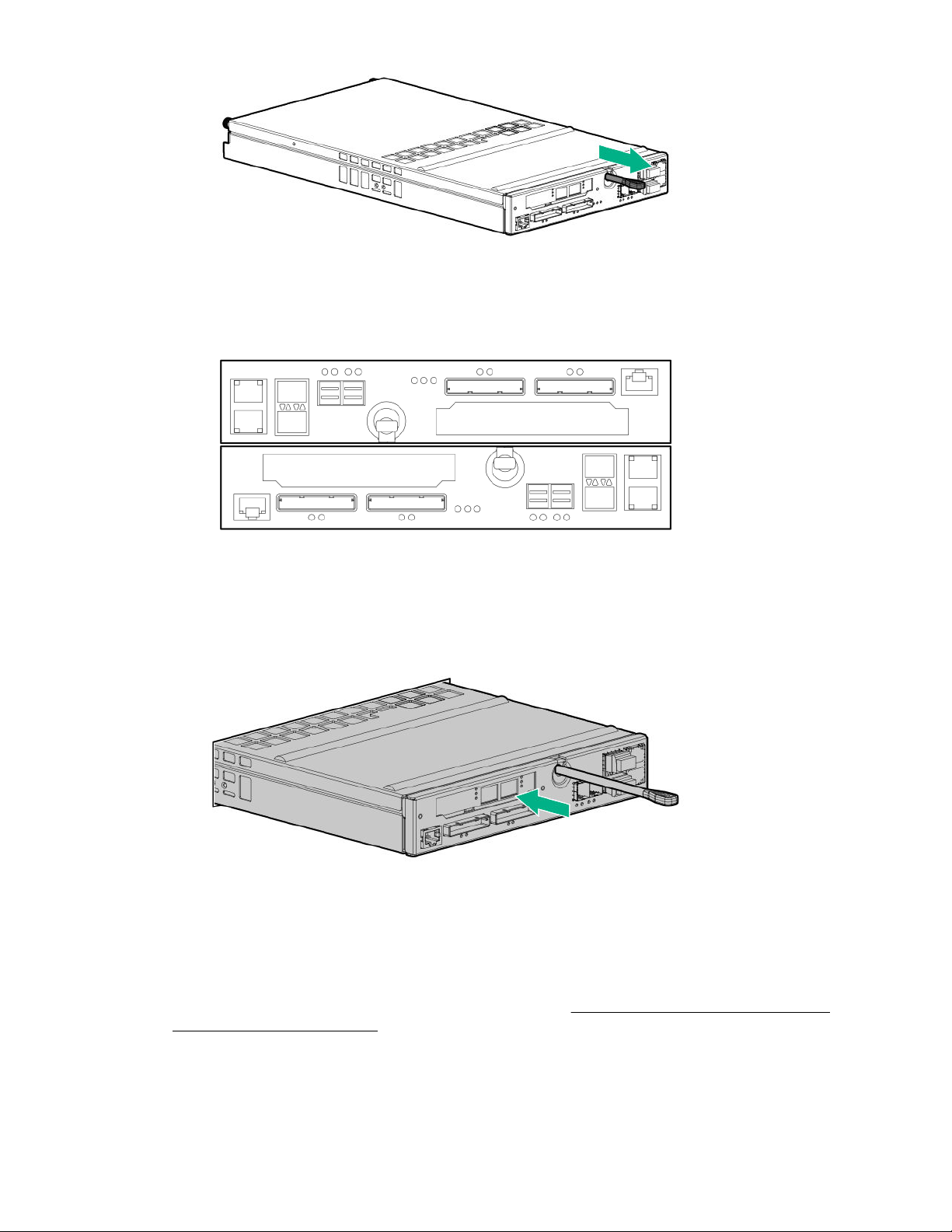

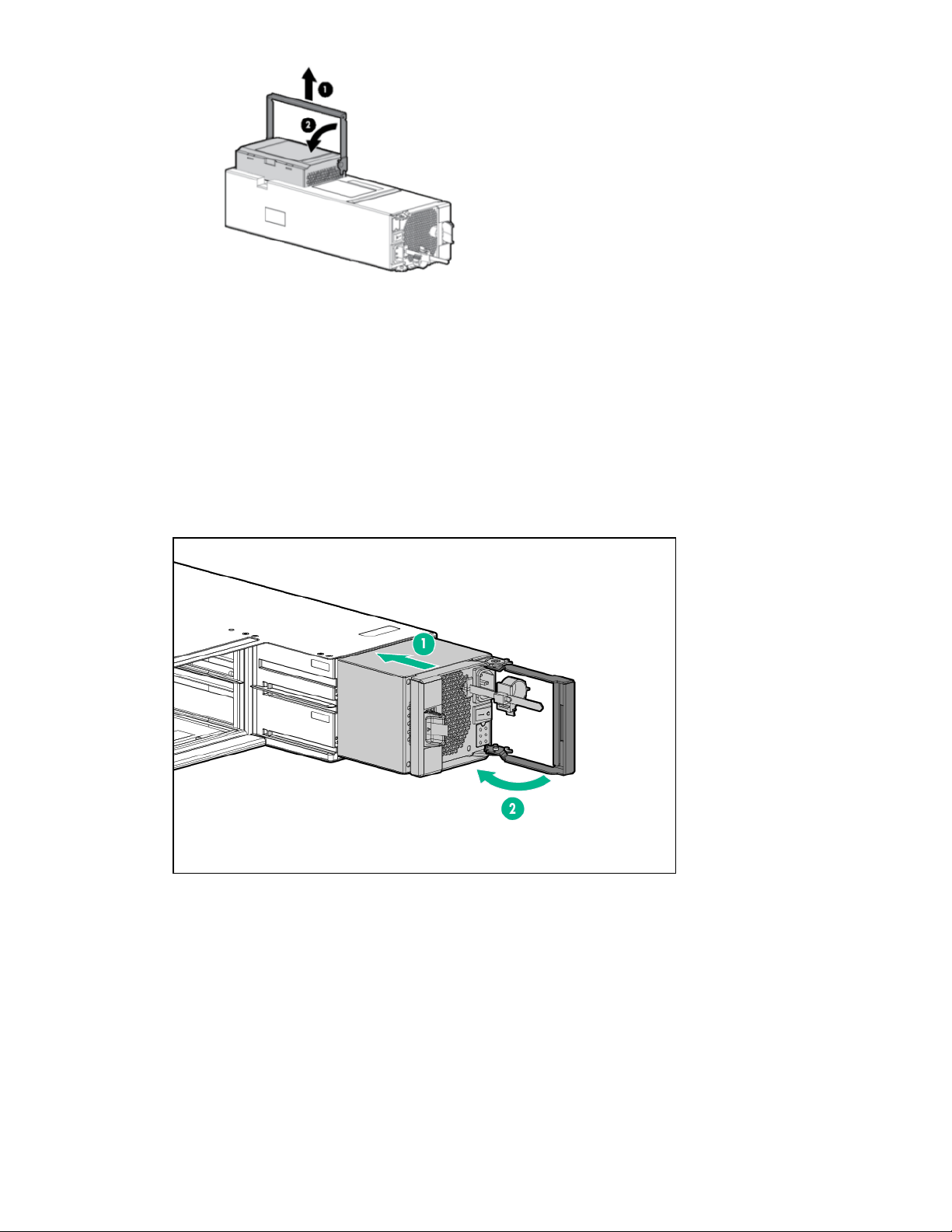

b. Confirm that the controller node is correctly oriented. In the controller node enclosure, the pair is

installed with each controller node oriented 180° from each other.

Figure 3: Orientation of a controller node pair

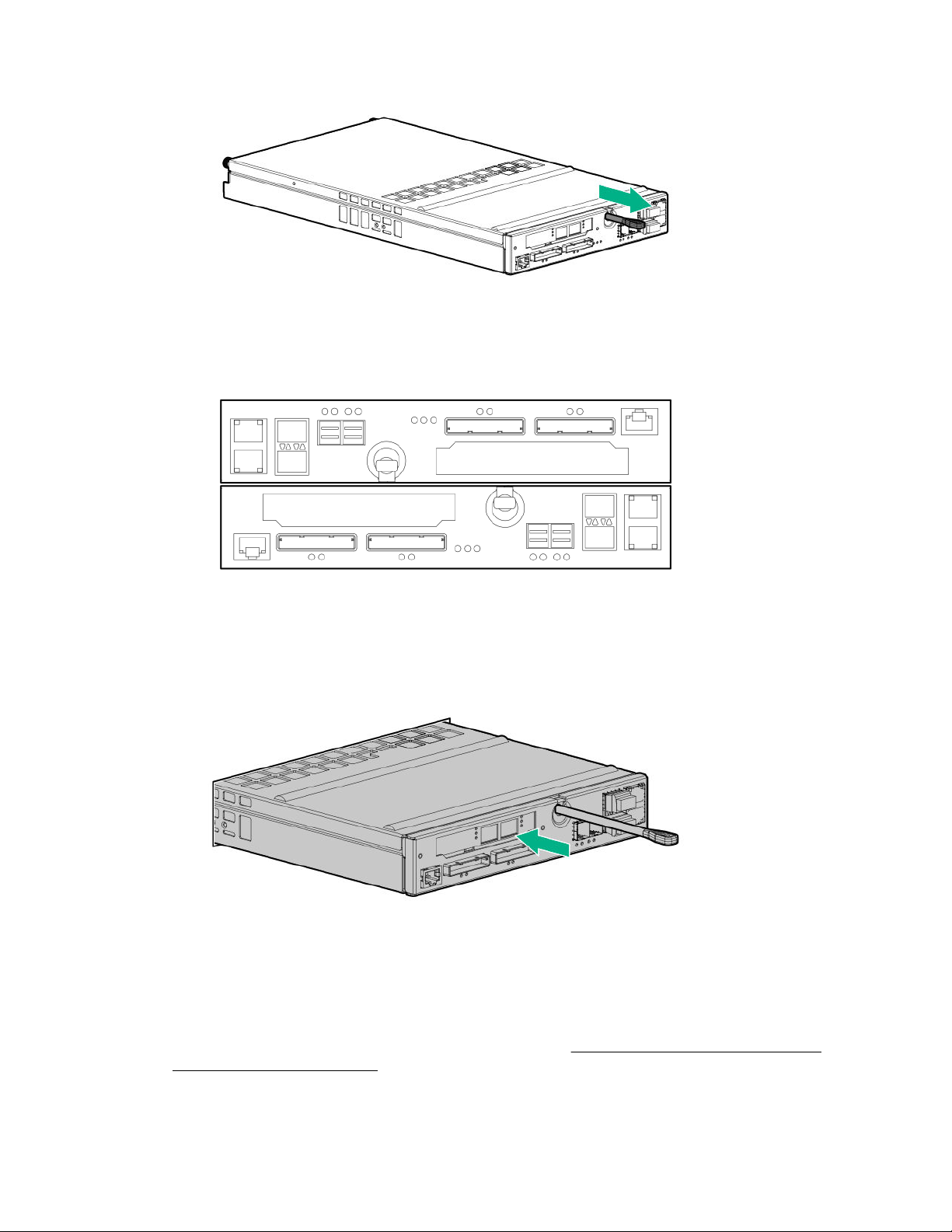

c. Partially install the controller node into the slot. Using two hands to grasp each side of the

replacement controller node, align it with the grooves in the slot, and slide it into the slot until it

halts against the insertion mechanism that is inside of the slot. Do not fully insert the controller

node in the slot at this time, because the cables must be reconnected before it is fully seated.

Figure 4: Partially install the controller node into the slot

12. Reconnect the cables to the controller node.

While the controller node is still only partially inserted in the slot, reconnect the cables to the

controller node.

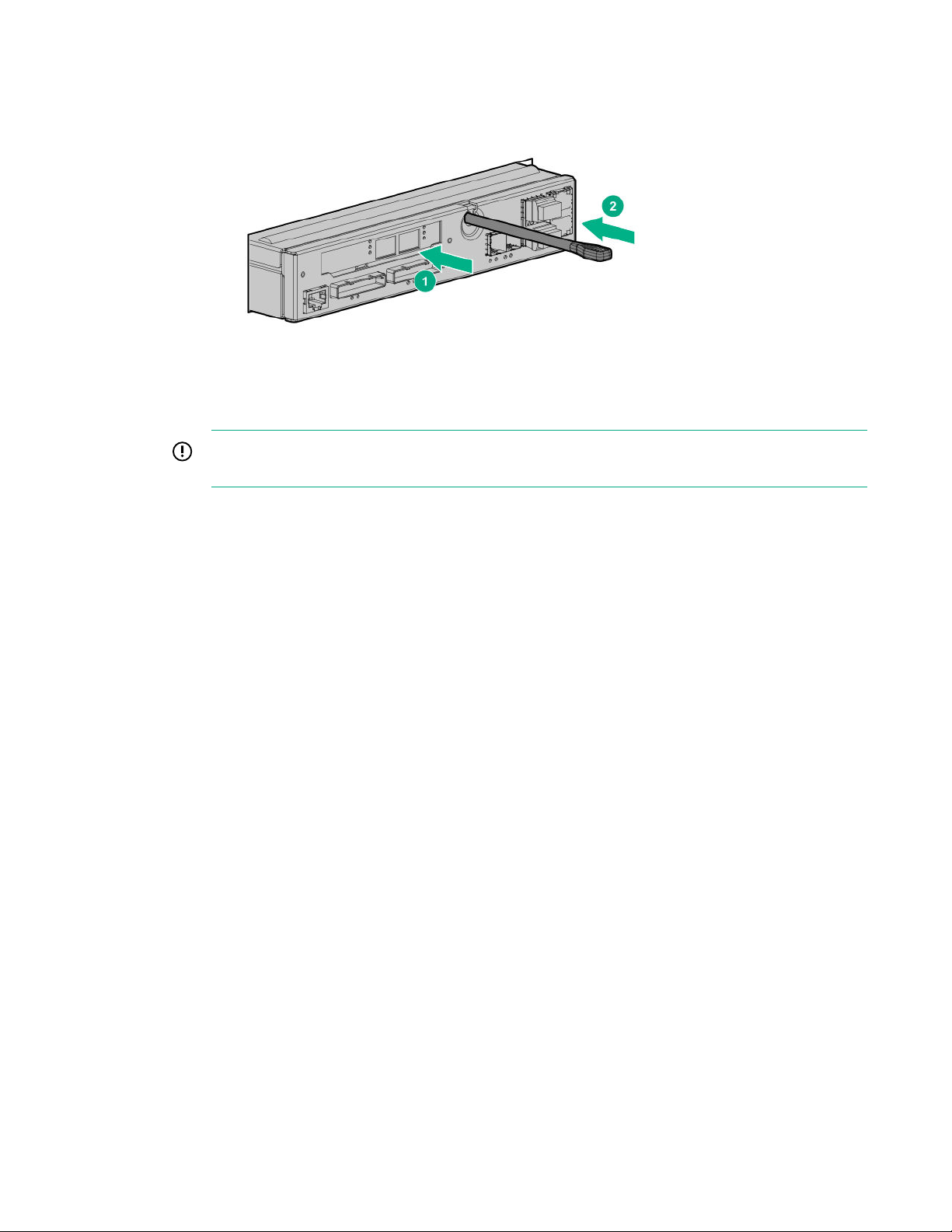

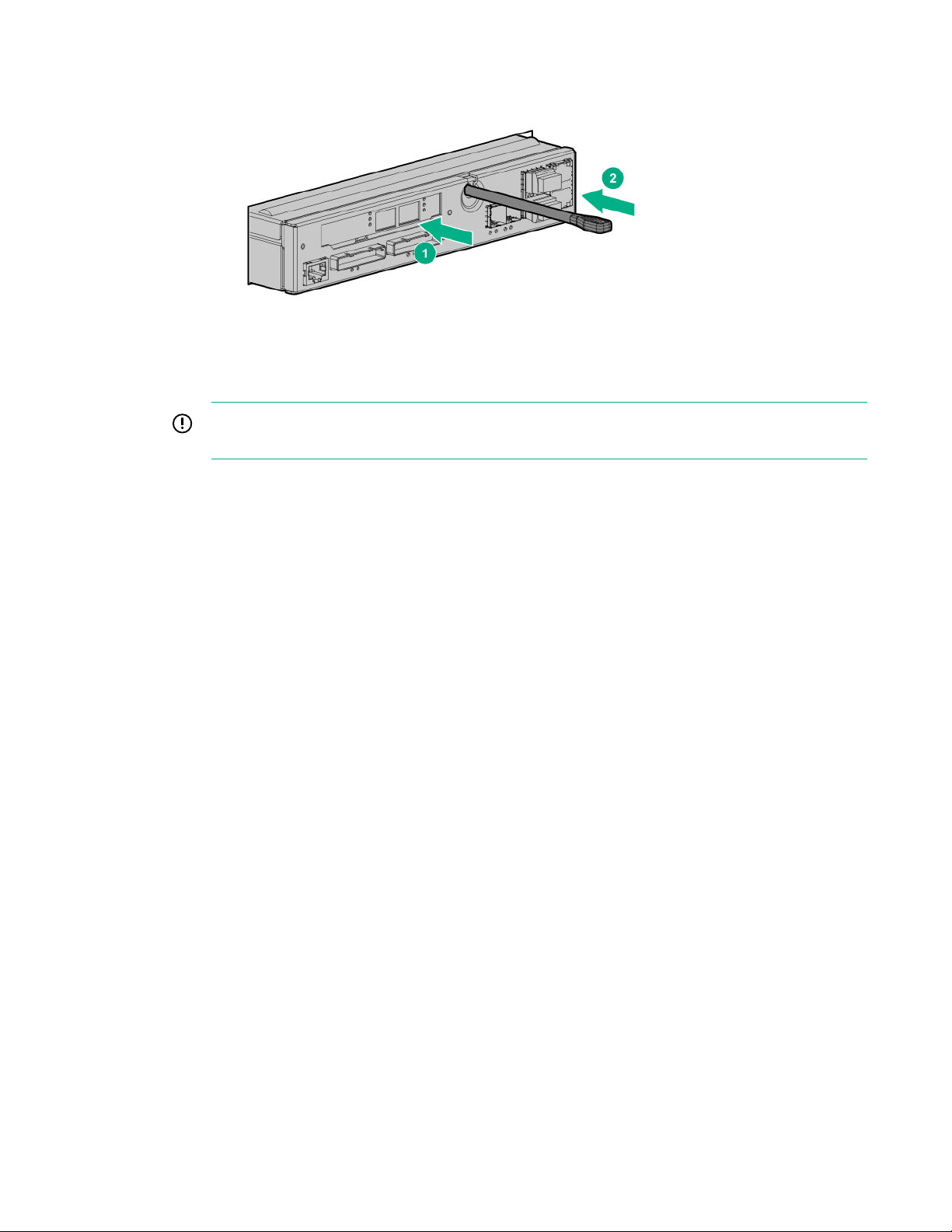

13. Fully install and seat the controller node into the slot. See Figure 5: Fully install and seat the

controller node into the slot on page 12.

Service 11

Slide in the controller node (1) while pushing in on the gray rod until it stops (2).

If the UID LED is flashing blue after two minutes, this LED status indicates that the replacement

controller node is not properly seated, so repeat this step.

Figure 5: Fully install and seat the controller node into the slot

Once inserted, the replacement controller node powers up and goes through the automatic node-tonode rescue before joining the cluster. This process might take up to 10 minutes.

IMPORTANT: If the automatic node-to-node rescue does not start automatically, contact your

authorized service provider.

Verification

14. Verify that the controller node has joined the cluster.

Confirm that the green Status LED on the controller node is flashing in synchronization with the other

controller nodes, indicating that it has joined the cluster.

15. From the SPOCC interface, verify that the State for the component and the storage system are

Normal (green).

16. After the component replacement, initiate Check Health on the storage system.

a. From the SPOCC interface main menu, click Support in the left navigation pane.

b. From the Service Processor - Support page, under StoreServs, click Health Check in the

Action column.

17. If significant time is left in the maintenance window, end the Maintenance Mode.

a. From the SPOCC interface main menu, select SPMAINT in the left navigation pane.

b. From the SPMaint interface main menu under Service Processor - SP Maintenance, select

StoreServ Configuration Management.

c. Under Service Processor - StoreServ Configuration, select Modify under Action.

d. Under Service Processor - StoreServ Info, select Off for the Maintenance Mode setting.

18. Follow the return instructions provided with the replacement component.

Replacing a controller node—Two-node system only—SP 5.x

This procedure is for the replacement of an HPE 3PAR StoreServ 8000 Storage controller node using

HPE 3PAR Service Processor (SP) 5.x.

12 Service

IMPORTANT:

• To avoid possible data loss, shut down (halt) and remove only one controller node at a time from

the storage system.

• To prevent overheating, do not leave the controller node bay empty for more than 30 minutes.

• Verify that host multipathing is functional.

Prerequisites

Order a replacement component by contacting your Hewlett Packard Enterprise authorized service

provider.

Procedure

Preparation

1. Unpack the component and place on an ESD safe mat.

2. Connect to the service processor in the Service Console interface:

Browse to the IP address: https://<sp_ip_address>:8443

3. Log in to the HPE 3PAR SP and enter the admin account credentials.

4. Initiate a maintenance window to stop the flow of alerts to Hewlett Packard Enterprise.

a. From the Service Console interface, select Systems.

b. Select Actions > Set maintenance mode and then follow the instructions.

TIP: When you put the storage system in maintenance mode or edit the maintenance mode,

specify the duration in hours and a reason.

To edit the maintenance window, select Actions > Set maintenance mode and then click

the Edit icon next to the maintenance window.

5. Initiate Check Health on the storage system.

a. From the Service Console interface, select Systems.

b. Select Actions > Check health.

A check of the storage system runs to ensure that there are no additional issues.

CAUTION: If health issues are identified during the Check Health, resolve these issues before

continuing. Refer to the details in the Check Health results and review the documentation.

6. Locate information about the failed controller node:

a. From the Service Console interface, select Storage Systems > Systems.

b. Review the following information:

• The alert banner at the top of the page states that the controller node has failed and is offline.

Service 13

To see the Recommended Action, click the banner and Details.

• Under the Health pane, the State is Degraded.

This status refers to the state of the storage system, not the state of an individual component.

• Under the Health pane, the Details indicate that the drive enclosures and drives connected to

the failed controller node are Degraded.

To see a graphical overview of these degraded components, select the Map view.

• Under the Configuration Summary pane, only one controller node is active in the system

because the failed controller node is offline.

The failed controller node does not appear on the controller node page of the SC interface.

7. Locate the failed and shut down controller node by referring to the LEDs.

Some faults illuminate the blue UID/Service LED, which helps you locate the failed component.

When the UID/Service LED is solid blue and the Status LED is rapidly flashing green, a controller

node is shut down. Depending on the nature of the controller node failure, the Fault LED might be

solid amber.

The Fault LED for the other active controller node in the cluster will be flashing, indicating that one of

the other controller nodes in the cluster is shut down.

8. Verify that all cables are labeled with their location.

Removal

9. Remove the cables from the controller node.

10. Remove the controller node. See Figure 6: Removing the controller node on page 14.

a. Pull to extend the gray rod of the controller node to the extracted position (1).

b. When the controller node is halfway out of the enclosure, support it from underneath and slide it

out completely (2).

c. Place the controller node on the ESD safe mat.

Figure 6: Removing the controller node

11. Push in the gray rod to ready it for packaging and to provide differentiation from the replacement

Replacement

12. Partially install the controller node.

14 Service

controller node.

a. Pull to extend the gray rod of the controller node to the extracted position.

Figure 7: Extending the controller node rod

b. Confirm that the controller node is correctly oriented. In the controller node enclosure, the pair is

installed with each controller node oriented 180° from each other.

Figure 8: Orientation of a controller node pair

c. Partially install the controller node into the slot. Using two hands to grasp each side of the

replacement controller node, align it with the grooves in the slot, and slide it into the slot until it

halts against the insertion mechanism that is inside of the slot. Do not fully insert the controller

node in the slot at this time, because the cables must be reconnected before it is fully seated.

Figure 9: Partially install the controller node into the slot

13. Reconnect the cables to the controller node.

While the controller node is still only partially inserted in the slot, reconnect the cables to the

controller node.

14. Fully install and seat the controller node into the slot. See Figure 10: Fully install and seat the

controller node into the slot on page 16.

Slide in the controller node (1) while pushing in on the gray rod until it stops (2).

Service 15

If the UID LED is flashing blue after two minutes, this LED status indicates that the replacement

controller node is not properly seated, so repeat this step.

Figure 10: Fully install and seat the controller node into the slot

Once inserted, the replacement controller node powers up and goes through the automatic node-tonode rescue before joining the cluster. This process might take up to 10 minutes.

IMPORTANT: If the automatic node-to-node rescue does not start automatically, contact your

authorized service provider.

Verification

15. Verify that the controller node has joined the cluster.

Confirm that the green Status LED on the controller node is flashing in synchronization with the other

controller nodes, indicating that it has joined the cluster.

16. From the Service Console interface, verify that the State of the component and the storage system

are Normal (green).

17. After the component replacement, initiate Check Health on the storage system.

a. From the Service Console interface, select Systems.

b. Select Actions > Check health.

18. If significant time is left in the maintenance window, end the Maintenance Mode.

a. From the Service Console interface, select Systems.

b. Select Actions > Set maintenance mode.

c. To end the maintenance window associated with the replacement, click X.

The flow of support information and local notifications of system alerts will be sent to Hewlett

Packard Enterprise again.

19. Follow the return instructions provided with the replacement component.

Drive replacement

Replacing a drive—SP 4.x

This procedure is for the replacement of a drive using HPE 3PAR Service Processor (SP) 4.x.

16 Service

CAUTION:

• The replacement drive must match the failed drive exactly in terms of drive type, capacity, and

speed.

• To avoid damage to hardware and the loss of data, never remove a drive without first confirming

that the drive status/activity LED is solid amber and the UID/service LED is solid blue.

• If you require more than 10 minutes to replace a drive, install a slot-filler blank in the drive bay to

prevent overheating while you are working.

• If the storage system is enabled with HPE 3PAR Data Encryption feature, only use Federal

Information Processing Standard (FIPS) capable drives. Using a non-self-encrypting drive might

cause errors during the replacement process.

• To avoid potential damage to equipment and loss of data, handle drives carefully following

industry-standard practices and ESD precautions. Internal storage media can be damaged when

drives are shaken, dropped, or roughly placed on a work surface.

• Before installing drives into enclosures, make sure that the enclosures are free of obstructions

(such as loose screws, hardware, or debris). Inspect the drives before installing them in the

enclosure to make sure that they are not damaged.

IMPORTANT:

• This replacement procedure applies only to a drive that has failed. If a drive replacement is

needed for a drive that has not failed, contact your authorized service provider.

• If more than one drive is degraded or failed, contact your authorized service provider to

determine if the repair can be done in a safe manner, preventing downtime or data loss.

IMPORTANT: When replacing a drive that is Failed, Maintenance Mode is not required. By not

setting Maintenance Mode, alerts for other issues that might arise will continue to be sent to HPE.

Prerequisites

Order a replacement component by contacting your Hewlett Packard Enterprise authorized service

provider.

Procedure

Preparation

1. Unpack the component and place on an ESD safe mat.

2. Connect to the HPE 3PAR Service Processor.

Browse to either the IP address or hostname: https://<sp_ip_address> or https://

<hostname> .

3. Log in to the HPE 3PAR Service Processor (SP).

With the 3parcust account credentials, the Service Processor Onsite Customer Care (SPOCC)

interface displays.

4. Initiate Check Health on the storage system.

Service 17

a. From the SPOCC interface main menu, click Support in the left navigation pane.

b. From the Service Processor - Support page, under StoreServs, click Health Check in the

Action column.

A pop-up window displays a status message while the health check runs.

When running the Health Check using Internet Explorer, the screen might remain blank while

information is gathered. This process could take a few minutes before displaying results. Wait for

the process to complete and do not attempt to cancel or close the browser.

c. To review the report, click either Details or View Summary.

CAUTION: If health issues are identified during the Check Health scan, resolve these issues

before continuing. Refer to the details in the Check Health results and contact Hewlett Packard

Enterprise Support if necessary.

5. Locate information about the failed drive.

The alert notification specifies which drive is in a Failed state. Notice that the health of the storage

system will be in a Degraded state due to the failed drive.

6. Locate the drive enclosure (cage) that contains the failed drive.

From the enclosure front, locate the enclosure that has a solid amber drive status LED on the left ear

cap (bezel).

7. Remove the bezel from the enclosure front.

a. Unlock the bezel if necessary.

b. Press the release tab.

c. Rotate the bezel away from the enclosure left side.

d. Pull the bezel out from the enclosure right side.

8. Locate the failed drive by the LEDs.

CAUTION: To avoid damaging the hardware or losing data, always confirm that the drive is

ready for removal by its solid amber fault LED.

IMPORTANT: If you do not see a solid amber fault LED on the drive, it could be the data has

not been vacated yet. When the drive has failed and been spun down, the fault LED becomes

lit solid amber and only then can you proceed with removal. This process may take several

hours.

Removal

IMPORTANT: Do not remove the failed drive until you have the replacement drive ready. To prevent

overheating, do not leave the drive bay unpopulated for more than 10 minutes.

9. Remove the drive.

18 Service

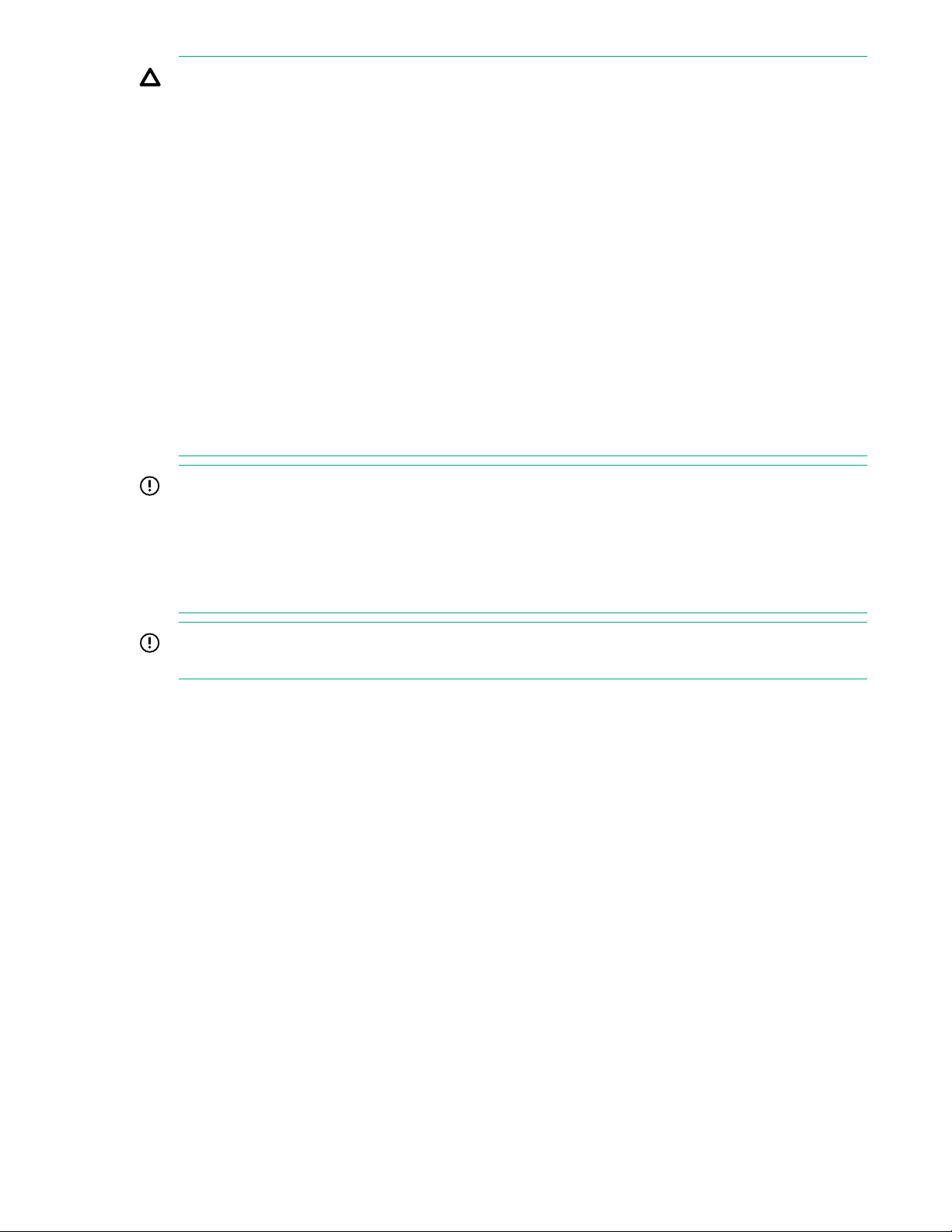

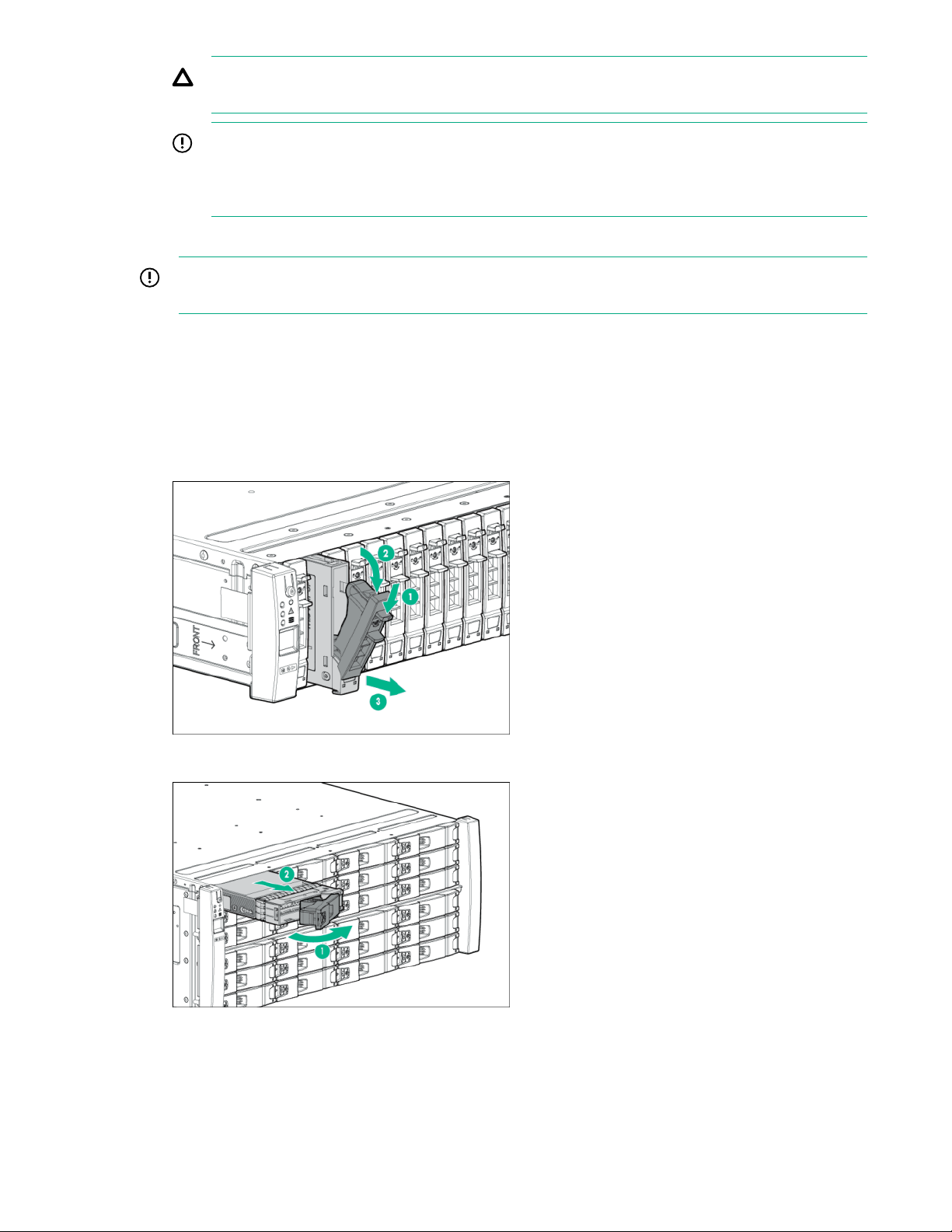

a. To release the handle into the open position, pinch the latch handle to release the handle into the

open position (1).

b. Extend the latch handle (2).

c. Slide the drive out of the bay (3) and place on an ESD safe mat.

Figure 11: Removing an SFF drive

Figure 12: Removing an LFF drive

Replacement

10. Install the drive.

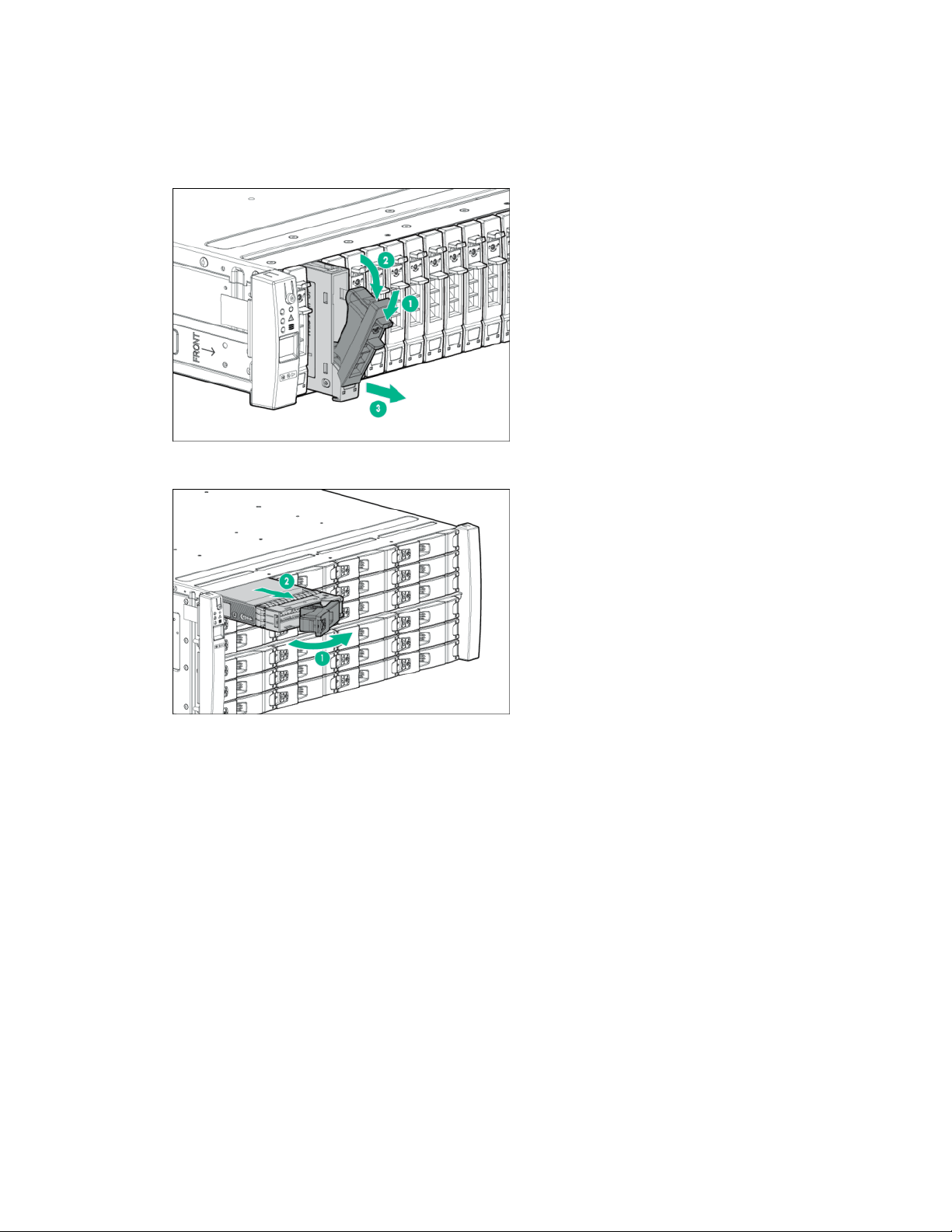

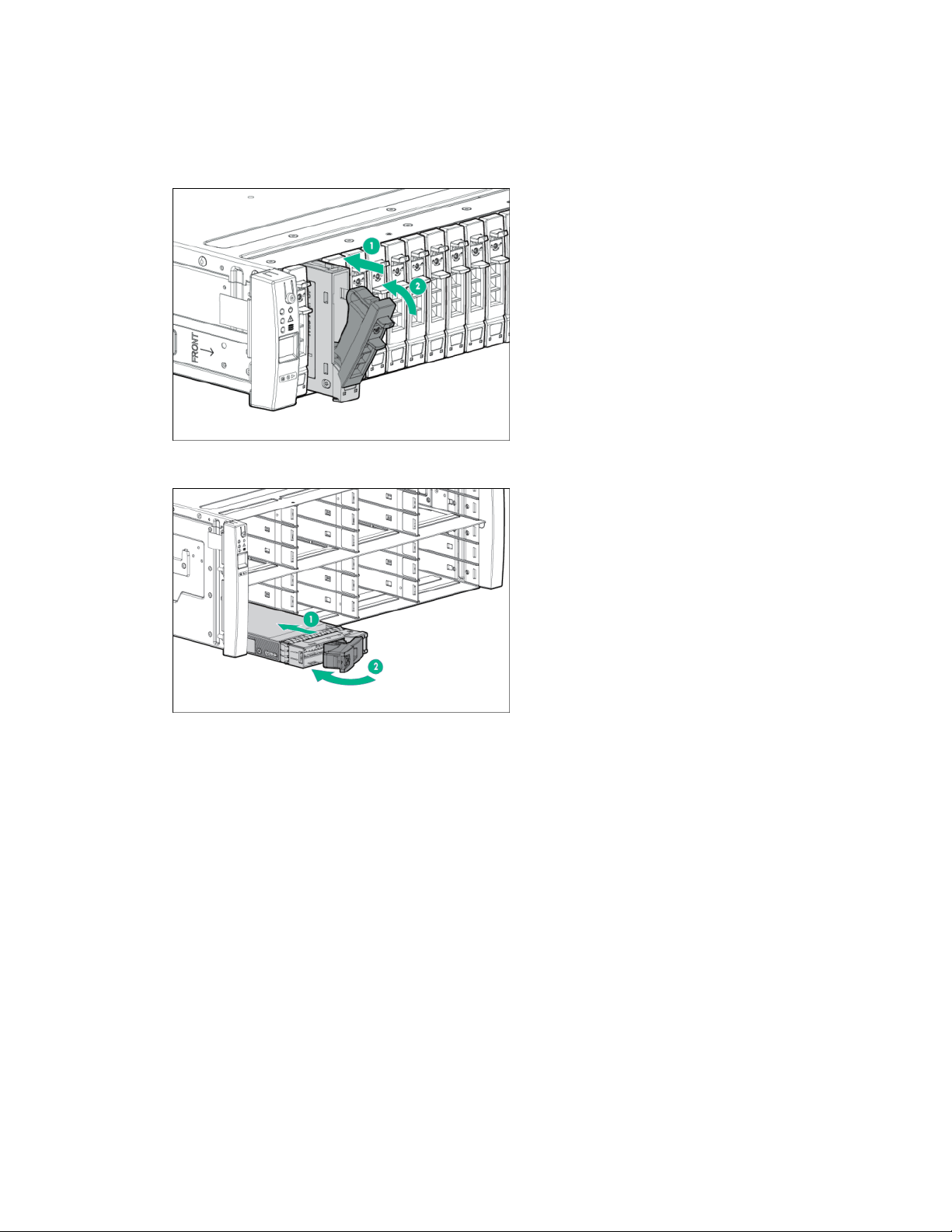

a. On the drive, press the release button to open the handle.

b. With the latch handle of the drive fully extended, align and slide the drive into the bay until the

handle begins to engage (1).

c. To seat the drive into the drive bay, close the handle (2).

Service 19

Figure 13: Installing an SFF drive

Figure 14: Installing an LFF drive

Verification

11. Observe the newly installed drive and confirm that the fault LED is off and the status LED is solid

green.

The change in the LEDs may take several minutes as the drive is prepared for use by the system.

12. Verify the state of the replacement drive.

From the SSMC interface, the drive ID that you just replaced will be removed from the list, and the

replacement drive will be assigned a new drive ID and be in a healthy state.

13. From the SPOCC interface, verify that the State for the component and the storage system are

14. After the component replacement, initiate Check Health on the storage system.

15. Install the bezel on the enclosure front.

20 Service

Normal (green).

a. From the SPOCC interface main menu, click Support in the left navigation pane.

b. From the Service Processor - Support page, under StoreServs, click Health Check in the

Action column.

a. Insert the bezel into the enclosure right side.

b. Press in the release tab.

c. Insert the bezel into the enclosure left side.

d. Lock the bezel (optional).

16. Follow the return instructions provided with the replacement component.

Replacing a drive—SP 5.x

This procedure is for the replacement of a drive using HPE 3PAR Service Processor (SP) 5.x.

CAUTION:

• The replacement drive must match the failed drive exactly in terms of drive type, capacity, and

speed.

• To avoid damage to hardware and the loss of data, never remove a drive without first confirming

that the drive status/activity LED is solid amber and the UID/service LED is solid blue.

• If you require more than 10 minutes to replace a drive, install a slot-filler blank in the drive bay to

prevent overheating while you are working.

• If the storage system is enabled with HPE 3PAR Data Encryption feature, only use Federal

Information Processing Standard (FIPS) capable drives. Using a non-self-encrypting drive might

cause errors during the replacement process.

• To avoid potential damage to equipment and loss of data, handle drives carefully following

industry-standard practices and ESD precautions. Internal storage media can be damaged when

drives are shaken, dropped, or roughly placed on a work surface.

• Before installing drives into enclosures, make sure that the enclosures are free of obstructions

(such as loose screws, hardware, or debris). Inspect the drives before installing them in the

enclosure to make sure that they are not damaged.

IMPORTANT:

• This replacement procedure applies only to a drive that has failed. If a drive replacement is

needed for a drive that has not failed, contact your authorized service provider.

• If more than one drive is degraded or failed, contact your authorized service provider to

determine if the repair can be done in a safe manner, preventing downtime or data loss.

IMPORTANT: When replacing a drive that is Failed, Maintenance Mode is not required. By not

setting Maintenance Mode, alerts for other issues that might arise will continue to be sent to HPE.

Prerequisites

Order a replacement component by contacting your Hewlett Packard Enterprise authorized service

provider.

Procedure

Preparation

1. Unpack the component and place on an ESD safe mat.

2. Connect to the service processor in the Service Console interface:

Service 21

Browse to the IP address: https://<sp_ip_address>:8443

3. Log in to the HPE 3PAR SP and enter the admin account credentials.

4. Initiate Check Health on the storage system.

a. From the Service Console interface, select Systems.

b. Select Actions > Check health.

A check of the storage system runs to ensure that there are no additional issues.

CAUTION: If health issues are identified during the Check Health, resolve these issues before

continuing. Refer to the details in the Check Health results and review the documentation.

5. Locate information about the failed drive.

a. From the Service Console interface Systems page, click the link labeled Failed from the Health

pane to see the Overview page for the component. Notice that there is an alert banner at the top

of the page that provides additional information.

NOTE: On the Health pane of the Systems page, the State is Degraded and indicates the state

of the storage system and not the state of an individual component.

b. On the Physical Drives link in the Health pane, confirm that the drive State shows Failed and

Vacated.

c. In the Health pane, select the link next to the Failed drive, and then click the Overview drop-

down menu and select Schematic.

d. On the Schematic page, hover over the failed drive and note the positioning information within

the storage system.

CAUTION: If the drive is still in a Degraded state instead of a Failed state, do not attempt to

remove the drive from the drive enclosure. A drive in a Degraded state is still vacating the

data. If you remove a drive in a Degraded state, a loss of data may occur. Wait to remove the

drive once it enters a Failed state, which indicates that the data has been vacated and the

drive is safe to replace. This process may take several hours.

6. Locate the drive enclosure (cage) that contains the failed drive.

From the enclosure front, locate the enclosure that has a solid amber drive status LED on the left ear

cap (bezel).

7. Remove the bezel from the enclosure front.

a. Unlock the bezel if necessary.

b. Press the release tab.

c. Rotate the bezel away from the enclosure left side.

d. Pull the bezel out from the enclosure right side.

8. Locate the failed drive by the LEDs.

22 Service

CAUTION: To avoid damaging the hardware or losing data, always confirm that the drive is

ready for removal by its solid amber fault LED.

IMPORTANT: If you do not see a solid amber fault LED on the drive, it could be the data has

not been vacated yet. When the drive has failed and been spun down, the fault LED becomes

lit solid amber and only then can you proceed with removal. This process may take several

hours.

Removal

IMPORTANT: Do not remove the failed drive until you have the replacement drive ready. To prevent

overheating, do not leave the drive bay unpopulated for more than 10 minutes.

9. Remove the drive.

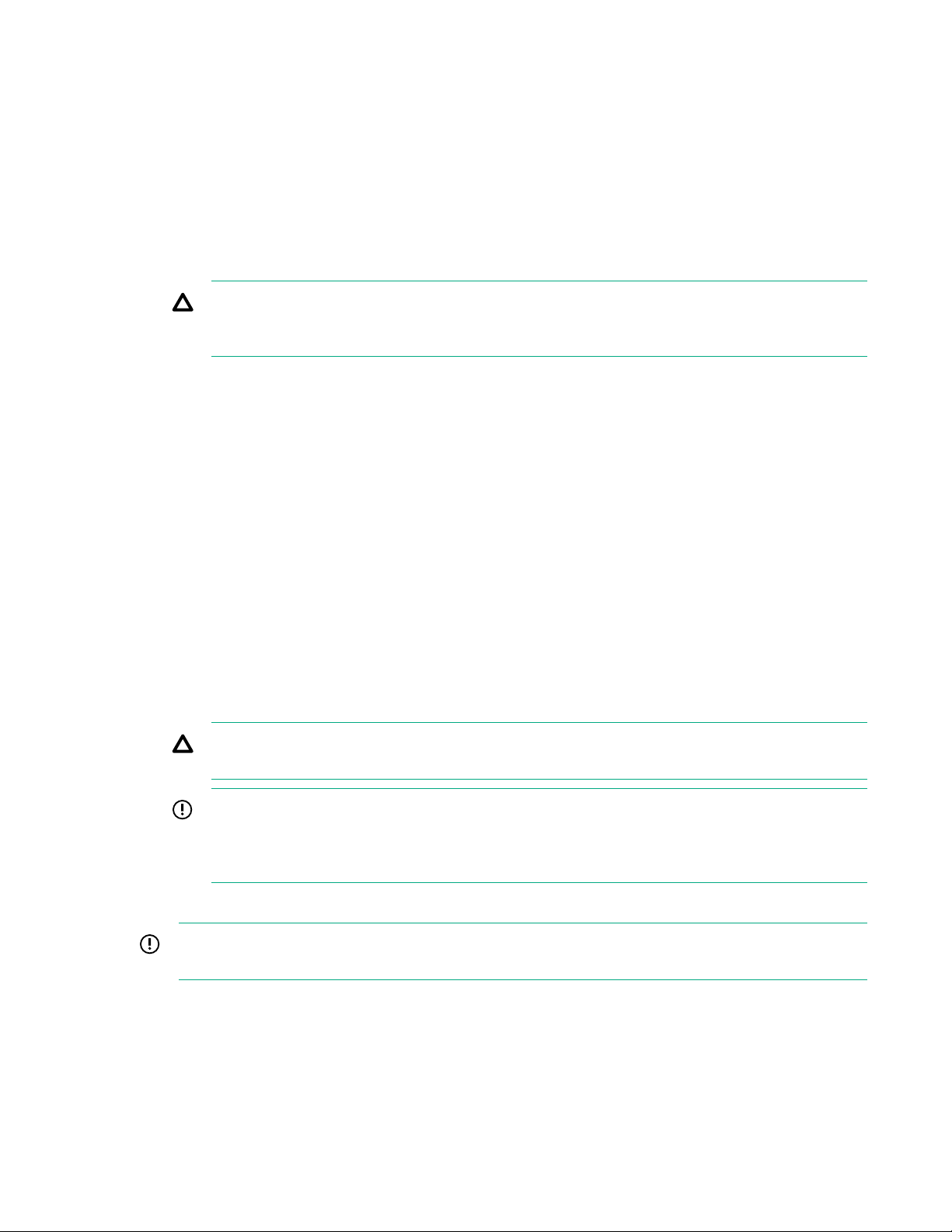

a. To release the handle into the open position, pinch the latch handle to release the handle into the

open position (1).

b. Extend the latch handle (2).

c. Slide the drive out of the bay (3) and place on an ESD safe mat.

Figure 15: Removing an SFF drive

Figure 16: Removing an LFF drive

Replacement

10. Install the drive.

Service 23

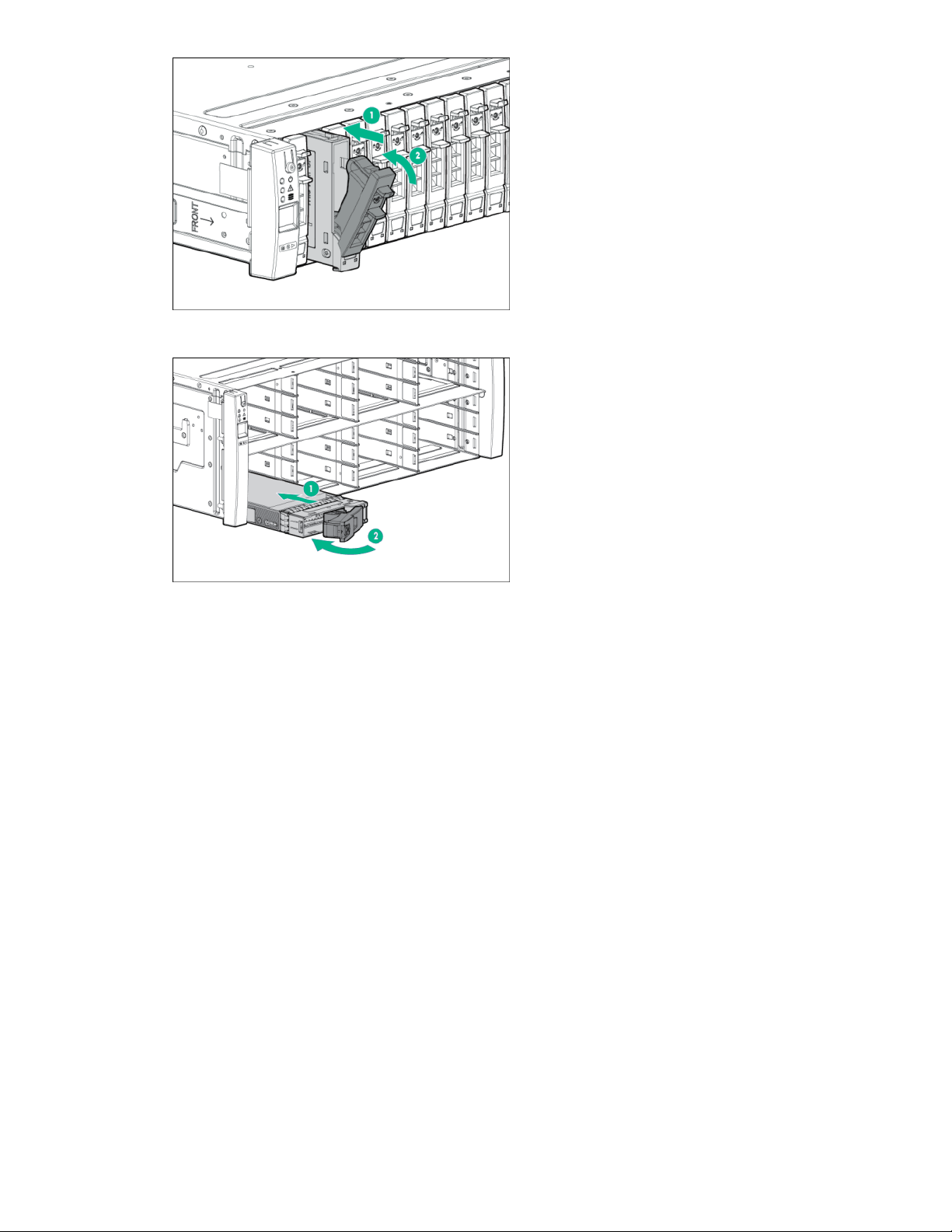

a. On the drive, press the release button to open the handle.

b. With the latch handle of the drive fully extended, align and slide the drive into the bay until the

handle begins to engage (1).

c. To seat the drive into the drive bay, close the handle (2).

Figure 17: Installing an SFF drive

Verification

11. Observe the newly installed drive and confirm that the fault LED is off and the status LED is solid

12. Verify the state of the replacement drive.

13. From the Service Console interface, verify that the State of the component and the storage system

14. After the component replacement, initiate Check Health on the storage system.

24 Service

Figure 18: Installing an LFF drive

green.

The change in the LEDs may take several minutes as the drive is prepared for use by the system.

From the Service Console interface, the drive ID that you just replaced will be removed from the list,

and the replacement drive will be assigned a new drive ID and be in a healthy state. The Schematic

view automatically refreshes.

are Normal (green).

a. From the Service Console interface, select Systems.

b. Select Actions > Check health.

15. Install the bezel on the enclosure front.

a. Insert the bezel into the enclosure right side.

b. Press in the release tab.

c. Insert the bezel into the enclosure left side.

d. Lock the bezel (optional).

16. Follow the return instructions provided with the replacement component.

Power cooling module or battery replacement

Replace the alternating-current power cooling module battery in a controller node enclosure—SP 5.x

This procedure is for the replacement of a battery in an alternating-current power cooling module (AC

PCM) of the controller node enclosure using HPE 3PAR Service Processor (SP) 5.x. The battery can be

replaced without replacing the entire PCM.

IMPORTANT:

• If both batteries in the power cooling modules in the same controller node enclosure have failed,

only replace one power cooling module battery at a time.

• Only one power cooling module can be serviced at a time. If another power cooling module is to

be serviced, verify that the first serviced power cooling module is healthy and functioning, and

then restart this servicing procedure from the beginning for the next power cooling module to be

serviced.

• To prevent overheating, the replacement of the power cooling module requires a maximum

service time of six minutes.

• Ensure that cables are clear of the power cooling module when installing.

IMPORTANT: Because each battery is a backup for both controller nodes in the controller node

enclosure, controller nodes 0 and 1 both report a problem with a single battery. The Qty appears as

2 in output because two controller nodes are reporting the problem. Battery 0 for controller node 0 is

in the left PCM, and battery 0 for controller node 1 is in the right side PCM (when looking at the

controller node enclosure from the rear).

Prerequisites

Only for the controller node enclosure, verify that at least one PCM Battery in each controller node

enclosure is functional before removing a PCM.

Procedure

Preparation

1. Unpack the component and place on an ESD safe mat.

2. Connect to the service processor in the Service Console interface:

Browse to the IP address: https://<sp_ip_address>:8443

Service 25

3. Log in to the HPE 3PAR SP and enter the admin account credentials.

4. Initiate a maintenance window to stop the flow of alerts to Hewlett Packard Enterprise.

a. From the Service Console interface, select Systems.

b. Select Actions > Set maintenance mode and then follow the instructions.

TIP: When you put the storage system in maintenance mode or edit the maintenance mode,

specify the duration in hours and a reason.

To edit the maintenance window, select Actions > Set maintenance mode and then click

the Edit icon next to the maintenance window.

5. Initiate Check Health on the storage system.

a. From the Service Console interface, select Systems.

b. Select Actions > Check health.

A check of the storage system runs to ensure that there are no additional issues.

CAUTION: If health issues are identified during the Check Health, resolve these issues before

continuing. Refer to the details in the Check Health results and review the documentation.

6. Review the information in the alert notification.

If notifications are enabled, information about the failed component is provided in the notification.

7. Locate the failed battery in an AC PCM by checking the LED status.

Confirm on the AC PCM that the battery fail LED is solid amber.

8. Verify that at least one battery in an AC PCM in each controller node enclosure is functional.

9. Turn off power to the AC PCM and disconnect the power cable.

a. Move the power switch to the off position.

b. Loosen the cord clamp, release the cable tie tab, and slide the cord clamp off the cable tie.

c. Disconnect the power cable, keeping the cord clamp on the power cable.

d. Secure the power cable and cable clamp.

Removal

10. Remove the AC PCM.

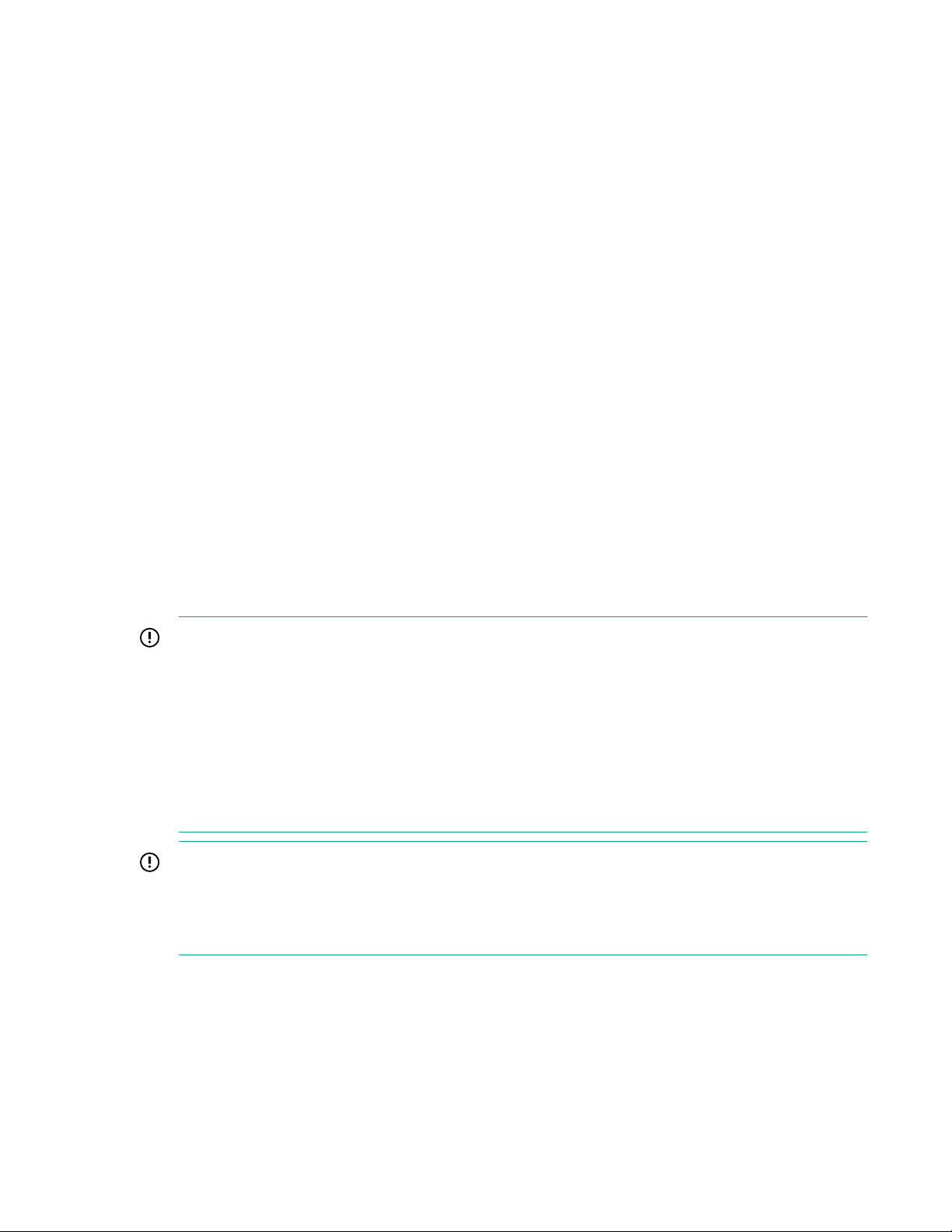

a. With thumb and forefinger, grasp and squeeze the PCM latch to release the handle (1).

b. Rotate the PCM release handle (2).

c. Slide the PCM out of the enclosure (3).

26 Service

d. Place the PCM on the ESD mat with the battery compartment facing up.

Figure 19: Removing the AC power cooling module

11. Remove the battery from the AC PCM.

a. At the back of the PCM, lift the battery release handle (1).

b. Remove the battery from the battery compartment (2).

c. Place on the ESD safe mat.

Figure 20: Removing the battery, AC power cooling module, controller node enclosure

Replacement

12. Install the battery for the AC PCM.

a. With the battery handle in the upright position, insert the replacement battery into the PCM (1).

b. Push down the handle to install (2).

When the battery is correctly seated, the battery and handle are aligned with the surface of the

PCM.

Service 27

Figure 21: Installing the battery, AC power cooling module, controller node enclosure

13. Install the AC PCM.

a. On the ESD mat, extend the PCM handle to the open position, and then carry it to the enclosure.

b. Slide the PCM into the enclosure and then push until the insertion mechanism starts to engage

(the handle starts to rotate).

Ensure that no cables get caught in the PCM insertion mechanism.

c. Close the handle until the latch clicks to fully seat the PCM in the enclosure.

d. Once inserted, pull back lightly on the PCM to ensure that it is properly engaged.

14. Connect the power cable and turn on the power to the AC PCM.

Verification

28 Service

Figure 22: Installing the AC power cooling module

a. Reconnect the power cable.

b. Slide the cable clamp onto the cable tie.

c. Tighten the clamp.

d. Move the power switch to the on position.

15. Verify that the replacement battery in the AC PCM has been successfully installed.

Confirm the battery good LED is solid green and the PCM OK LED is solid green.

16. From the Service Console interface, verify that the State of the component and the storage system

are Normal (green).

17. After the component replacement, initiate Check Health on the storage system.

a. From the Service Console interface, select Systems.

b. Select Actions > Check health.

18. If significant time is left in the maintenance window, end the Maintenance Mode.

a. From the Service Console interface, select Systems.

b. Select Actions > Set maintenance mode.

c. To end the maintenance window associated with the replacement, click X.

The flow of support information and local notifications of system alerts will be sent to Hewlett

Packard Enterprise again.

19. Follow the return instructions provided with the replacement component.

Replacing an alternating-current power cooling module in a controller node enclosure—SP 5.x

This procedure is for the replacement of an alternating-current power cooling module (AC PCM) in a

controller node enclosure using HPE 3PAR Service Processor (SP) 5.x.

IMPORTANT:

• Only one power cooling module can be serviced at a time. If another power cooling module is to

be serviced, verify that the first serviced power cooling module is healthy and functioning, and

then restart this servicing procedure from the beginning for the next power cooling module to be

serviced.

• To prevent overheating, the replacement of the power cooling module requires a maximum

service time of six minutes.

• Ensure that cables are clear of the power cooling module when installing.

IMPORTANT: Because each battery is a backup for both controller nodes in the controller node

enclosure, controller nodes 0 and 1 both report a problem with a single battery. The Qty appears as

2 in output because two controller nodes are reporting the problem. Battery 0 for controller node 0 is

in the left PCM, and battery 0 for controller node 1 is in the right side PCM (when looking at the

controller node enclosure from the rear).

Prerequisites

Order a replacement component by contacting your Hewlett Packard Enterprise authorized service

provider.

Service 29

Procedure

Preparation

1. Unpack the component and place on an ESD safe mat.

2. Connect to the service processor in the Service Console interface:

Browse to the IP address: https://<sp_ip_address>:8443

3. Log in to the HPE 3PAR SP and enter the admin account credentials.

4. Initiate a maintenance window to stop the flow of alerts to Hewlett Packard Enterprise.

a. From the Service Console interface, select Systems.

b. Select Actions > Set maintenance mode and then follow the instructions.

TIP: When you put the storage system in maintenance mode or edit the maintenance mode,

specify the duration in hours and a reason.

To edit the maintenance window, select Actions > Set maintenance mode and then click

the Edit icon next to the maintenance window.

5. Initiate Check Health on the storage system.

a. From the Service Console interface, select Systems.

b. Select Actions > Check health.

A check of the storage system runs to ensure that there are no additional issues.

CAUTION: If health issues are identified during the Check Health, resolve these issues before

continuing. Refer to the details in the Check Health results and review the documentation.

6. Review the information in the alert notification.

If notifications are enabled, information about the failed component is provided in the notification.

7. Locate the failed AC PCM by checking the LED status.

Confirm on the failed PCM that the AC input fail LED and DC output fail LEDs are solid amber.

8. Turn off power to the AC PCM and disconnect the power cable.

a. Move the power switch to the off position.

b. Loosen the cord clamp, release the cable tie tab, and slide the cord clamp off the cable tie.

c. Disconnect the power cable, keeping the cord clamp on the power cable.

d. Secure the power cable and cable clamp.

Removal

9. Remove the AC PCM.

30 Service

a. With thumb and forefinger, grasp and squeeze the PCM latch to release the handle (1).

b. Rotate the PCM release handle (2).

Loading...

Loading...