Page 1

r------------

HEWLETT

i:/;

PACKARD

HP

3000

SERIES

II

COMPUTER SYSTEM

SYSTEM

SERVICE

MANUAL

o:l1t

Manual Part No. 30000-90018

Microfiche Part No. 30000-90032

Printed in U.S.A. 8/76

Updates through

#2

incorporated 2/77

Update 3 3/77

HEWLETT

PACKARD

5303

STEVENS

CREEK

BLVD.,

SANTA

CLARA,

CALIFORNIA,

95050

J

Page 2

\

\

NOTICE

The information contained in this document is subject to change without notice.

HEWLETT-PACKARD MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE. Hewlett-Packard shall not be liable for errors

contained herein or for incidental or consequential

damage~

in connection with the furnishing, perfor-

mance or use of

this

material.

This document containsproprietary information which is protected by copyright. All

rights

are

reserved.

No

partofthis

document

may

be photocopied or reproduced

without

the

prior

written

consent of

Hewlett-Packard Company.

Copyright © 1976byHEWLETT·PACKARD COMPANY

ii

Page 3

r

LIST

OFEFFECTlVEPAGES

I

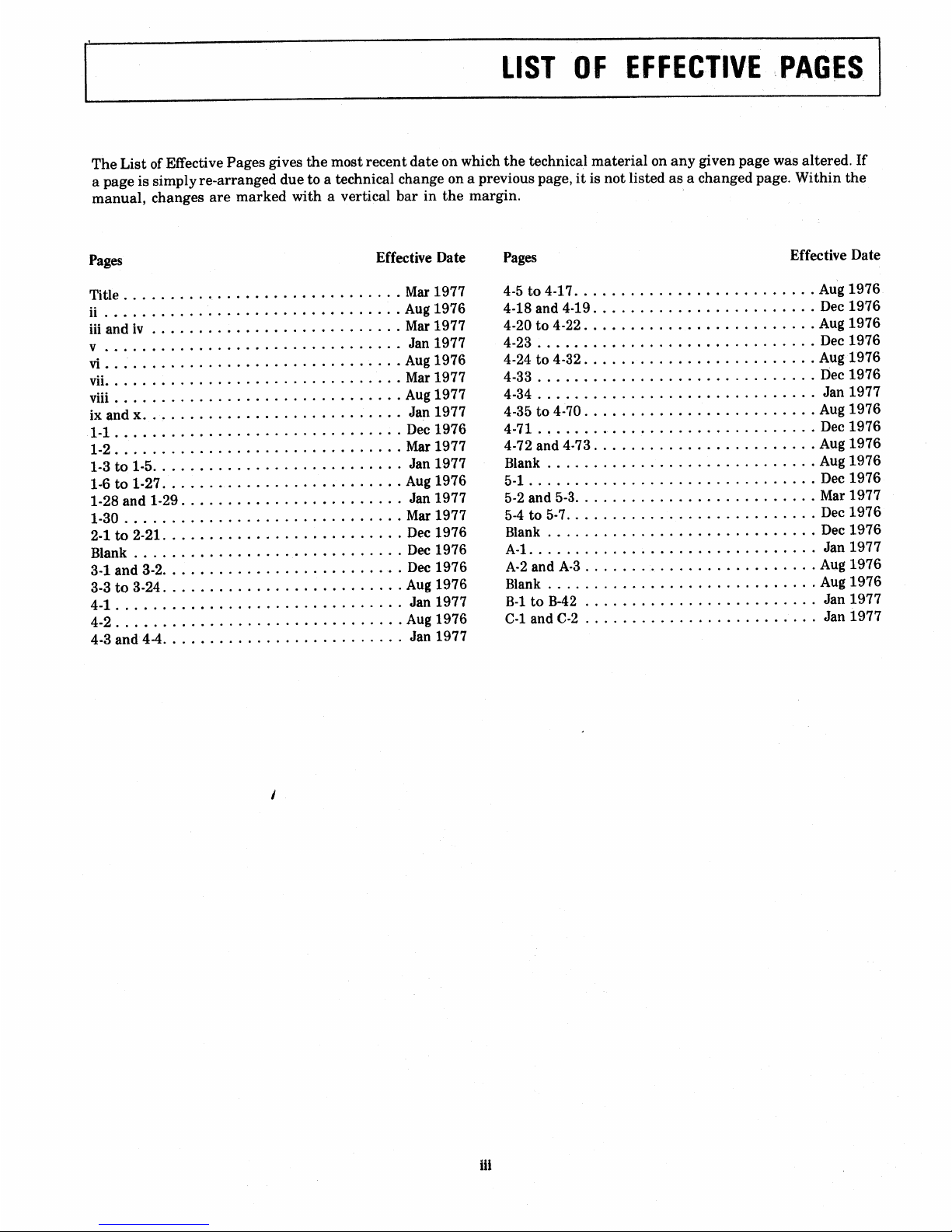

The

List

of EffectivePages gives

the

mostrecent

date

on which

the

technical

materialonany

given page was altered.

If

a pageissimplyre-arranged due to a technical change on a previous page,itis not listedasa changed page. Within

the

manual,

changes

are

marked

with a vertical

barinthe

margin.

Pages

Effective Date

Pages

Effective Date

Title

Mar

1977

ii

Aug

1976

iii

and

iv

Mar

1977

v Jan 1977

vi

Aug

1976

vii.

Mar

1977

viii

Aug

1977

ix and x Jan 1977

1-1

Dec

1976

1-2

Mar

1977

1-3

to

1-5 Jan 1977

1-6

to

1-27

Aug

1976

1-28 and 1-29 Jan 1977

1-30

Mar

1977

2-1to2-21

Dec

1976

Blank

Dec

1976

3-1 and 3-2

Dec

1976

3-3

to

3-24

Aug

1976

4-1 Jan 1977

4-2

Aug

1976

4-3 and 4-4 Jan 1977

iii

4-5

to 4-17

Aug

1976

4-18 and 4·19

Dec

1976

4-20 to 4-22 Aug 1976

4-23 Dec 1976

4-24 to 4-32

Aug

1976

4-33

Dec

1976

4-34 Jan 1977

4-35 to 4-70

Aug

1976

4-71 Dec 1976

4-72 and 4·73 Aug 1976

Blank Aug 1976

5-1

Dec

1976

5-2 and

5-3

Mar

1977

5-4to5-7

Dec

1976

Blank

Dec

1976

A-I Jan 1977

A-2

and

A·3

.......•..................

Aug

1976

Blank

Aug

1976

B-1toB-42

Jan 1977

C-1

and

C-2

Jan 1977

Page 4

I

PRINTING

HISTORY

New editions incorporate all update

material

since

the

previous edition.

Update

packages, which

are

issued between

editions, contain additional

and

replacement pages to be merged into

the

manualbythe

customer. The

dateonthe

title

page

and

back cover changes only when a new edition is published.Ifminor corrections

and

updates

are

incorporated,

the

manualisreprinted

but

neither

the

dateonthe

title

page

and

back cover nor

the

edition change.

First

Edition

June

1976

Second Edition

Aug

1976

Update 1

Dec

1976

Update 2 Jan 1977

Update 3

Mar

1977

iv

Revised

and

reprinted

in Aug 1976 to incorporate infor-

mation

concerning

Fault

Correcting Memory. Appendix.A

(IC

Logic Symbology)

has

been removed from

this

manual

and

will

appearinthe

Engineering

Diagrams

Set,

part

number

30000-90076.

Update 1 adds troubleshooting information to Section II

and

card cage for replacement proceduresinSection

V.

Update 2 adds information about the 7920A Verifier Program

to

Section I and two new appendices(Band C).

Update 3 adds information about the 30360A HSI

PCA

Diagnostic (D432)toSection

I.

Page 5

PREFACE

I

This

manualisintended

for

usebya

trained

Hewlett-Packard

Customer

Engineer

(CE)

trainedinthe

principlesofoperation

and

troubleshooting

procedures

for

the

HP

3000

SeriesIIComputer

System.

This

maintenance

manual

contains

the

following sections:

Section I

System

Verification-Verification

procedures

that

permit

the

CEtodetermine

the

system

operates

properly.

Section II

System

Troubleshooting-Troubleshooting

procedures

designedtoaidinthe

location

of a

system

problem.

Section

III

Maintenance

Panel

Operating

Procedures-Description

and

useofthe

HP

30354A

Maintenance

Paneltoaid

the

CE

analyzing

system

operation.

Section IV

Maintenance

Procedures

-

Repair

philosophy

and

general

servicing

information

(PCA

jumper

and

switch

position

information),

and

system

servicing

pointstoaid

the

CE

when

troubleshooting

the

system.

Principlesofoperationofthe

memory

moduleisincludedinthis

section to

assistintroubleshooting

memory

problems.

Section V

Replaceable

Parts

- A

listofreplaceable

assemblies

and

their

part

numbers.

Also

included

is a

listofreplaceable

cables

and

their

part

numbers,

and

miscellaneous

items

that

may

require

replacement.

Appendix

A Microdiagnostics -

Instructions

for

executing

the

microdiagnostics

that

are

built

into

the

system.

AppendixBSystem

Power

Supplies -

Detailed

information

on

the

system

power

supplies.

AppendixCBattery

Care -

Background

material

about

system

batteries

and

their

care.

Related

manuals

and

other

documents

the

CE

may

require

or find

usefultomaintain

the

system

are:

HP

3000

SeriesIIEngineering

Diagrams

Set,

part

number

30000-90076

HP

3000

SeriesIIComputer

System

Reference

Manual,

part

number

30000-90020

(System

description

from a

hardware

standpoint.)

HP

3000

SeriesIIComputer

System

Operator's

Guide,

part

number

30000-90013

HP

3000

SeriesIIComputer

System

ManualofDiagnostics

HP

3000

SeriesIIComputer

System

Installation

Manual,

part

number

30000-90019.

JAN

1977

v

Page 6

I

CONVENTIONS

USED

IN

THIS

MANUAL

NOTATION

[ ]

DESCRIPTION

An

element

inside

brackets

is optional.

Several

elements

stacked

insideapairofbrackets

means'

the

user

may

select

anyoneornone of

these

elements.

Example:

[~]

user

may

select

A or Borneither

{}

italics

underlining

When

several

elements

are

stacked

within

braces

the

user

must

select one of

these

elements.

Example:

{~}

user

must

selectAorBor

C,

Lowercase italics denote a

parameter

wnich

mustbereplacedbya user-supplied

variable.

Example: CALL

name

name

one to 15

alphanumeric

characters.

Dialogue:

Whereitis

necessarytodistinguish

user

input

from

computer

output,

the

input

is

underlined.

Example:

NEW

NAME?

ALPHA

1

superscript

C

return

linefeed

Control

characters

are

indicated

by a

superscript

C

Example:

yc

return

in

italics

indicatesacarriage

return

linefeed

in

italics

indicates

a linefeed

A horizontal ellipsis indicates

that

a previous bracketed element may be repeated,orthat

elements

have been omitted.

vi.

Page 7

Section I

Page

SYSTEM

VERIFICATION

Introduction

~

1-1

Diagnostic

and

Verification

Programs

1-1

On-Line Verification

Programs

1-1

Stand-Alone Diagnostic

Programs

1-1

Microdiagnostics 1-2

Purpose 1-2

Facilities Required 1-3

System

Verification Procedures 1-3

SLEUTH 3000 1-3

System

Control

Panel

1-4

Maintenance

Panel

1-4

Cold Load (Diagnostic) 1-6

HP

30129

Cartridge

Disc Diagnostic

(D419) 1-6

HP

30008A!30009A

Fault

Correction

Memory Diagnostic (D430)

..

. 1-7

HP

30036A Multiplexer

Channel

Diagnostic (D422) 1-9

HP

30102A Disc File Diagnostic (D423) 1-10

HP

30110A

Cartridge

Disc Diagnostic

(D424)

..

~

1-11

HP

30031A System Clock Console

Interface Diagnostic (D425) 1-11

HP

30032A

Terminal

Data

Interface (TDD

PCA Diagnostic (D427) 1-13

HP

2660A Fixed Head Disc Diagnostic

(D428) 1-15

HP

30033A Selector

Channel

Diagnostic

(D429) 1-15

HP

30012A Extended Instruction

Set

Diagnostic (D431) 1-17

HP

30115A Nine-Track Magnetic Tape

Diagnostic (D433) 1-17

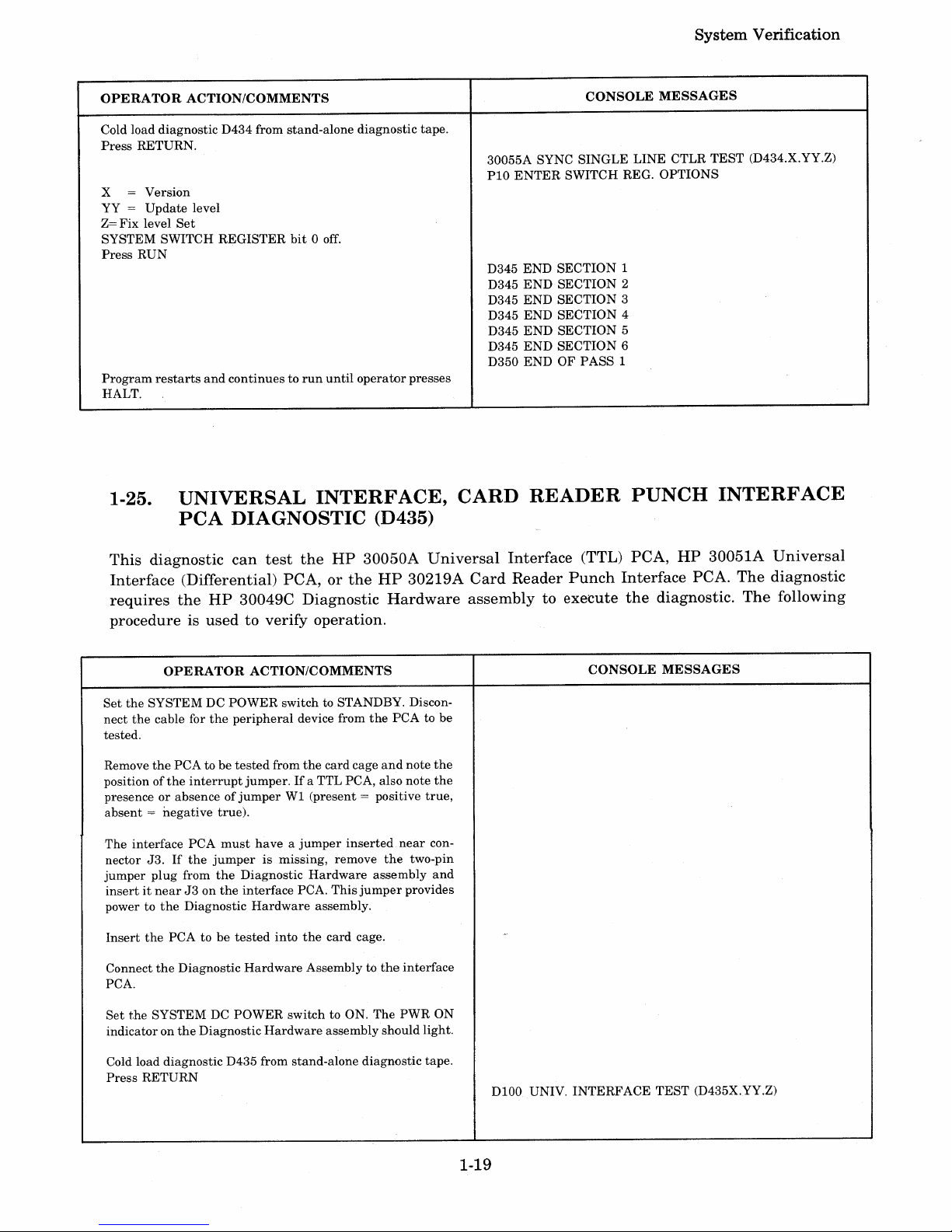

HP30055A

Synchronous Single Line

Controller (SSLC) PCA Diagnostic (D434) 1-18

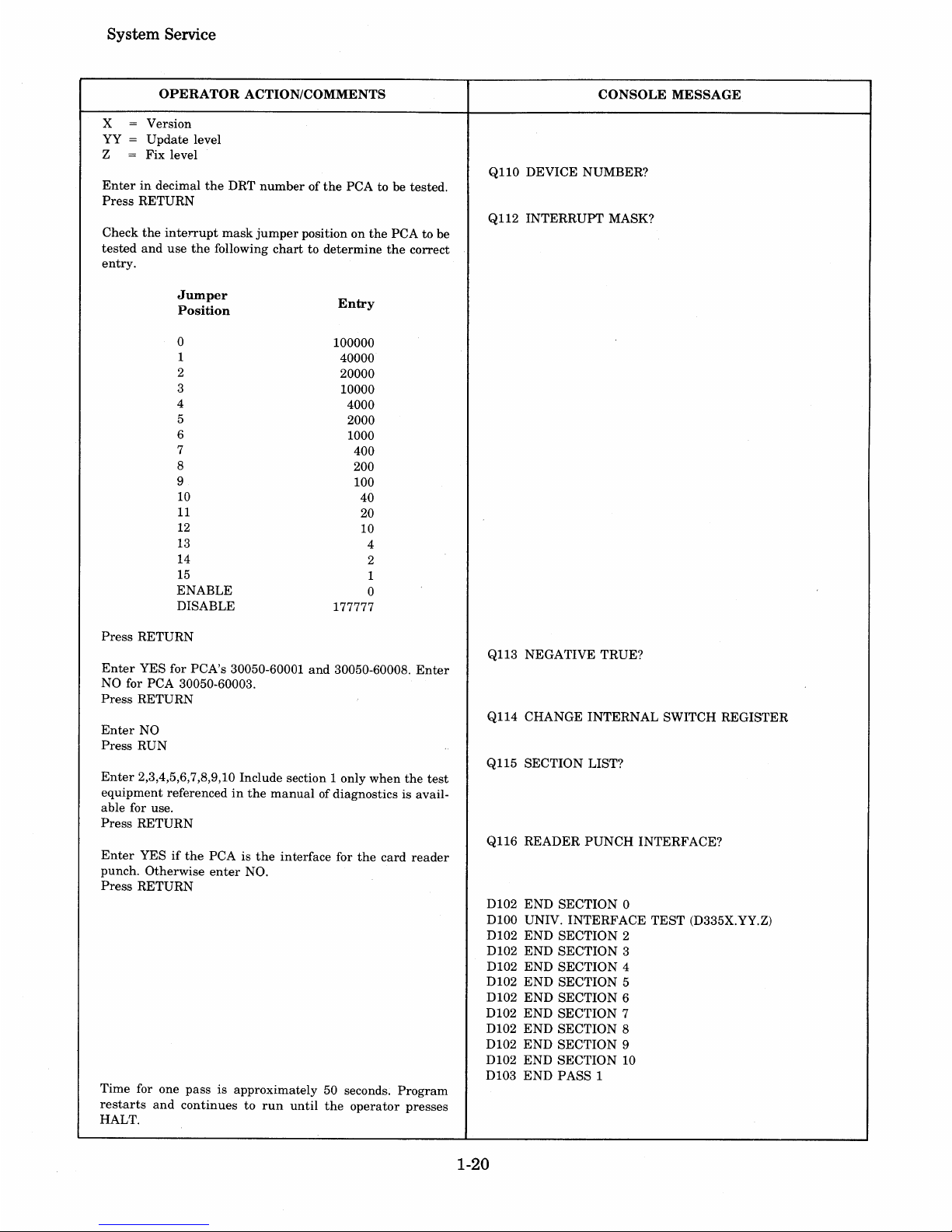

Universal

Interface,

Card

Reader

Punch

Interface PCA Diagnostic (D435) 1-19

HP

30061A

Terminal

Controller Interface

(TCI) PCA Diagnostic (D438) 1-21

HP

30226A

Plotter

Interface Diagnostic

(D439) 1-23

HP

3000 Series II Computer System

CPU

Diagnostic (D420) 1-25

HP

30104A

Paper

Tape Reader,

HP

30105A

Paper

Tape

Punch

On-Line Verification

Program

1-26

Paper

Tape

Punch

Verification

1-26

Paper

Tape

Reader Verification 1-27

HP

7920A

Disc

Drive Verifier, SLEUTH07 1-28

HP

30360A Hardwired Serial Interface (HSI)

peA

Diagnostic (D432) 1-30

Section II

Page

SYSTEM TROUBLESHOOTING

Introduction 2-1

Purpose 2-1

MAR 1977

vii

CONTENTS

Facilities Required 2-1

CPU

Register

Test'

- Diagnosis

and

Repair

2-6

Memory Configuration

Test

- Diagnosis

and

Repair 2-6

CPU

Stand-Alone Diagnostic -

Diagnosis

and

Repair 2-6

Error

Correcting Memory Diagnostic -

Diagnosis

and

Repair 2-7

System Test - Diagnosis

and

Repair

2-7

Cold Load Procedure - Diagnosis

and

Repair 2-7

System

Test-

(Load) 2-7

Cold Load Procedure (Tape) 2-7

Section III

Page

MAINTENANCE

PANEL

OPERATING

PROCEDURES

Purpose of Maintenance

Panel

3-1

Items

Supplied 3-1

Additional

Equipment

3-1

Options 3-16

Switches

and

Lamps 3-16

Operating

Methods 3-18

Precautions 3-18

Preparation

for Use 3-19

General

Operating

Method 3-19

Switches

and

Indicators on Bay 1

Control

Panel

3-19

Stack Register Loading 3-19

CPU

Register Displays 3-21

General Use Display 3-21

Maintenance

Panel

Test

3-21

Lamp

Test

3-21

Switch

Test

3-22

Section IV

Page

MAINTENANCE

PROCEDURES

Introduction 4-1

Safety Precautions 4-1

Repair Philosophy 4-1

General

Servicing Information 4-1

I/O

Error

Logging 4-2

Memory

Error

Logging 4-2

Adjusting System Voltages 4-2

Selector

Channel

Maintenance

PCA

(SCMB) 30033-60001 4-4

Jumpers

" '" , . 4-4

Selector

Channel

Installation

4-5

Multiplexer

Channel

Installation.'

4-5

SCMB Verification 4-5

SCMB

State

Display 4-6

Programming

4-7

I/O Instructions 4-8

I/O

Program

Orders

4-9

Control Word 4-9

Status

Word 4-12

Program

Execution 4-13

PCA

Jumpers

and

Switches

..........•...........

4-14

ROM PCA 30003-60001 4-15

ROM Loading 4-15

Page 8

I

CONTENTS

(continued)

Skip

and

Special Field PCA 30003-60002 4-15

Sync

Jumpers

, 4-15

S-Bus PCA 30003-60005 4

..

16

Memory Size 4-16

Memory Module Selection 4-17

Current

Instruction

Register (CIR)

PCA 30003-60006, Extended Instruction

Set

(EIS) PCA 30012-60001 4-18

Jumpers

4-18

MCU PCA 30003-60007 4-19

Enable

4-19

Ready 4-19

CPU

Number

4-19

CPU

Module

Number

4-19

MCU Reset 4-19

lOP

PCA 30003-60008 4-20

Enable/Disable 4-20

Memory Size 4-20

Memory Module Selection 4-20

Semiconductor Memory

Array

(SMA)

PCA 30008-60002 4-21

Memory Module Configuration 4-21

Memory Control

and

Logging (MCL)

PCA 30007-60002 4-22

Memory Module Configuration 4-22

Fault

Logging Interface (FLD PCA 30009-60002 4-24

DRT

Number

4-24

Fault

Correction

Array

(FCA) PCA 30009-60001..4-25

System Clock/Console Interface PCA

30031-60001 4-26

Frequency Divider

Input

Selection

WI,

W2,

W3

4-27

CR

Count

Rate

Input

W4 4-27

Group

Mask

Interrupt

Mask W5 4-27

Serial

Interface Clock

Input

W6

4-27

Device

Number

W7

thru

W6

4-27

Baud

Rate Selection

S1

4-27

Multiplexer Channel PCA

30036-60001 4-27

Device

Number

4-27

Selector

Channel

Register PCA

30030-60018 4-29

Channel

Number

4-29

Memory Size 4-30

Memory Module Selection 4-30

Selector

Channel

Control PCA

30030-60003 4-30

Selectable Trigger/Freeze 4-30

Error

Logging Register 4-30

Indicators 4-32

Selector

Channel

Maintenance PCA

(SCMB) 30033-60001 4-32

Configuration 4-32

System Control

Panel

30003-60012 4-33

DRT

Number

4-33

Memory IC Replacement " 4-33

Memory Module . . . . . . . . . . . . . . . . . . . . . . . 4-34

Pre

ventiveMaintenance 4-34

viii

Error

Correction 4-36

Memory

Error

Logging Facility 4-39

Output

4-42

Errors

4-44

CE

Operating

Procedures " 4-44

FLI PCA

Programming

4-44

TIO Command 4-45

CIO Command 4-46

WIO Command 4-47

RIO Command 4-48

Interfacing 4-48

CTL

Data

Bus 4-48

lOP

Bus 4-49

Fault

Logging Interface Bus 4-49

Power Bus 4-49

Error

Correcting.Memory Module 4-51

SMA PCA , 4-52

MCL PCA 4-52

Refresh 4-52

Memory Operations 4-58

Read ; 4-58

Write 4-63

RWI 4-64

NOP 4-64

Fault

Correction

and

Error

Logging 4-64

Fault

Correction 4-64

Fault

Logging Interface PCA 4-66

Power Fail 4-71

PCA

Jumpers

4-72

Section V Page

REPLACEABLE

PARTS

Introduction.

. . . . . . . . . . . . . . . ....

5-1

Replaceable

Parts

5-1

Card Cages 5-2

HP

30002B

Card

Cage 5-2

HP

30002C Card Cage 5-2

HP

30002B

Card

Cage -

Fan

Replacement 5-3

HP

30002C

Card

Cage -

Fan

Replacement 5-4

Appendix A

Page

MICRODIAGNOSTICS

Microdiagnostics A-I

CPU

Register

Test

A-I

Memory

Test

A-2

I/O

Test

A-2

Appendix B

SYSTEM POWER SUPPLIES

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . .

..

B-1

HP

30310A Power Supply. . . . . . . .... . . . . . .

..

B-1

TheoryofOperation.

. . . . . . . . . . . . . . . . .

..

B-2

Block Diagram Description... . . . . . . . . .

..

B-4

Functional Description . . . . . . . . . . . . . . .

..

B-

7

HP

30310A Maintenance B-15

High-Voltage Points B-16

Page 9

Test Equipment Ground B-16

Test Equipment Common B-17

Preventive Maintenance B-17

HP

30310A Adjustments B-18

Preregulator Adjustment B-18

20-Volt Adjustment . . . . . . . . . . . . . . . . .

..

B-19

Voltage Protect

PCA

Adjustment B-19

Troubleshooting an

HP

30310A . . . . . . . . . . . . . B-20

tIP

30311A Power

Supply.

. . . . . . . . . .... . . ...B-21

TheoryofOperation

B-21

Block Diagram Description . . . . . . . . . . . ...B-23

Detailed Block Diagram Description . . . . . ...B-23

Controls and Indicators B-28

HP

30311A Maintenance. . . . . . . . . . . . . . . ...B-30

Wiring Information B-30

Principal Servicing Points

B-31

Troubleshooting anHP30311A

B-31

Preventive Maintenance B:31

Voltage Checks

B-31

Battery Test

~

. . . B-32

HP

30311A Adjustments B-32

Battery (Float) Voltage Adjustment B-32

+12 Volt Adjustment B-35

+5.00 Volt Internal Reference Adjustment B-35

CONTENTS

(continued)

I

Replacement Procedures . . . . . . . . . . . . . . . . . . B-36

Power Supply Replacement B-36

Battery Pack Replacement. . . . . . . . . . . . . . . B-36

Control

PCA

Replacement B-36

Motherboard

PCA

Replacement B-37

HP

30312A Power Supply B-39

Theory of Operation B-39

Overcurrent Protection . . . . . . . . . . . . . . . . . B-39

Under Voltage Protection B-41

Power Failures B-41

DC

Enable . . . . . . . . . . . . . . . . . . . . . . . . .

B-41

HP

30312A Maintenance

B-41

Wiring Information B-41

Troubleshooting an

HP

30312A B-42

Appendix C

BATTERY CARE

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . .

..

C-1

Environment. . . . . . . . . . . . . . . . . . . . . . . . . .

..

C-1

Shelf Life . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

C-1

Restoring Damaged Cells. . . . . . . . . . . . . . . . . .

..

C-2

Shipping Batteries . . . . . . . . . . . . . . . . . . . . . .

..

C-2

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

C-2

TABLES

I

Table

Title

Page

Table

Title

Page

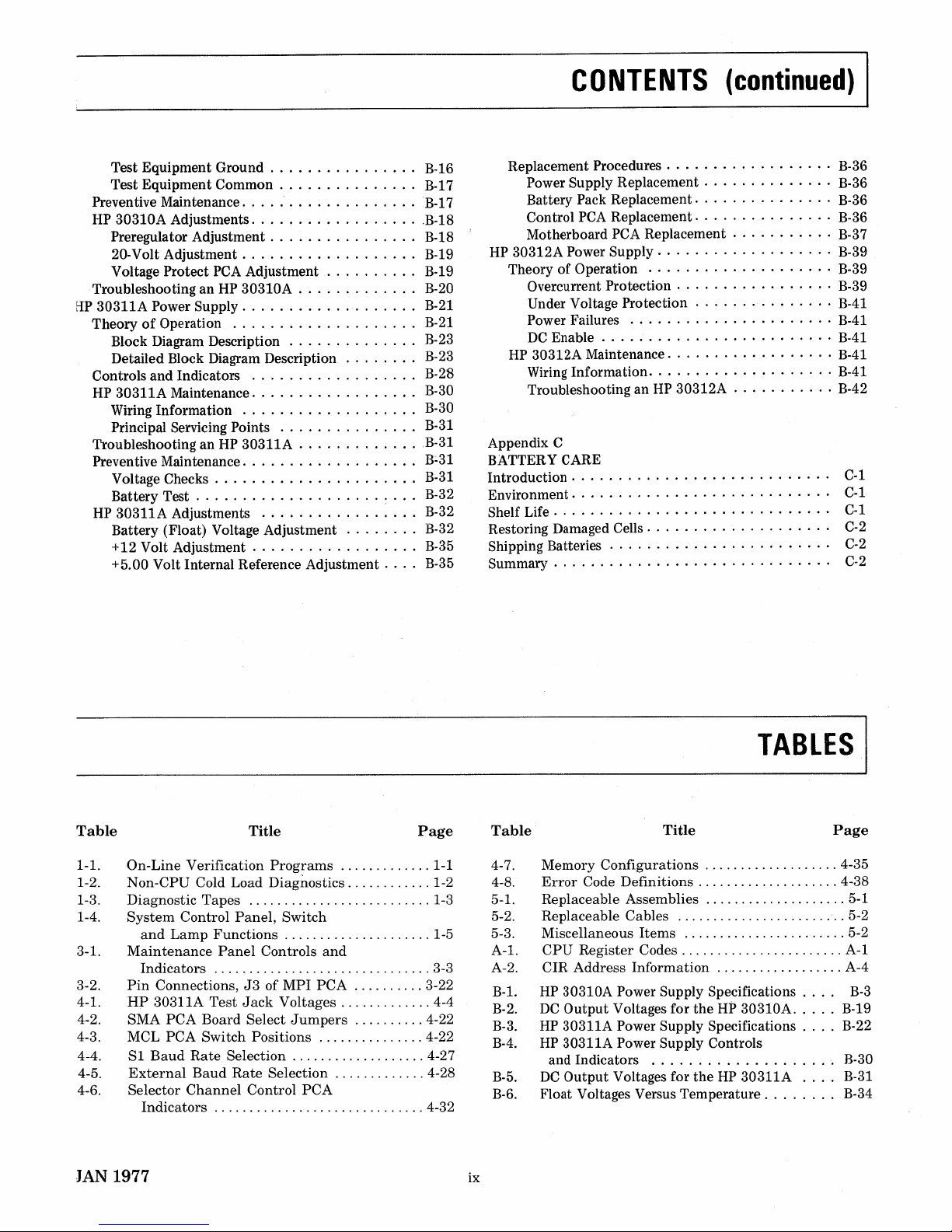

1-1. On-Line Verification

Programs

1-1

1-2. Non-CPU Cold Load Diagnostics 1-2

1-3. Diagnostic Tapes 1-3

1-4.

System

Control

Panel,

Switch

and

Lamp

Functions

1-5

3-1.

Maintenance

Panel

Controls

and

Indi~ators

3-3

3-2.

Pin

Connections,J3of MPI

PCA

3-22

4-1.

HP

30311A

Test

Jack

Voltages 4-4

4-2. SMA

PCA

Board Select

Jumpers

4-22

4-3. MCL PCA Switch Positions 4-22

4-4.

SI

Baud

Rate

Selection 4-27

4-5.

External

Baud

Rate

Selection 4-28

4-6. Selector

Channel

Control

PCA

Indicators 4-32

JAN 1977

ix

4-7. Memory Configurations 4-35

4-8.

Error

Code Definitions 4-38

5-1. Replaceable Assemblies 5-1

5-2. Replaceable Cables 5-2

5-3. Miscellaneous Items 5-2

A-I.

CPU

Register

Codes

A-I

A-2. CIR Address Information A-4

B-l.

HP

30310A Power Supply Specifications. .

..

B-3

B-2.

DC

Output Voltages for

the

Hi>

30310A B-19

B-3.

HP

30311A Power Supply Specifications B-22

B-4.

HP

30311A Power Supply Controls

and Indicators B-30

B-5.

DC

Output Voltages for

theHP30311A B-31

B-6.

Float Voltages Versus Temperature B-34

Page 10

I

ILLUSTRATIONS

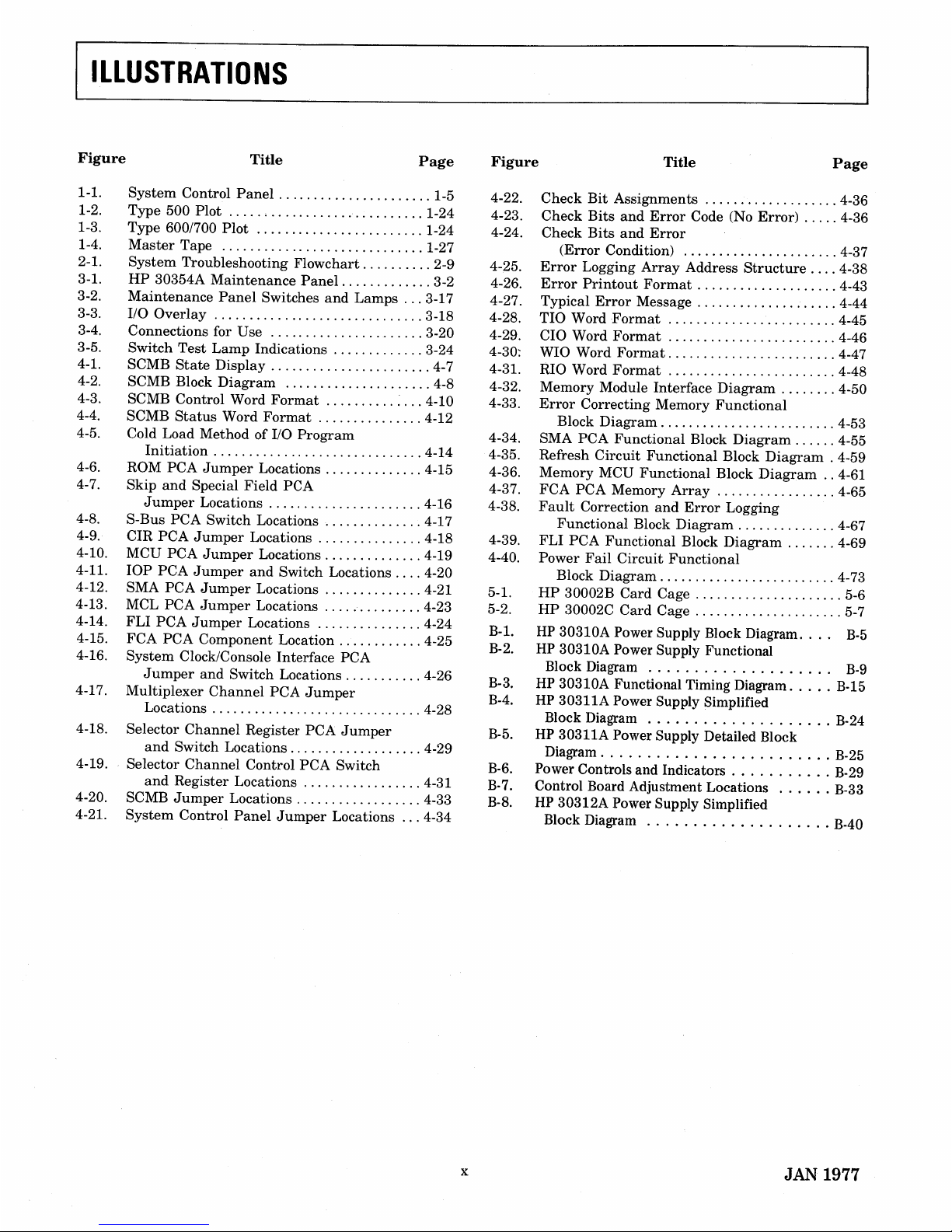

Figure

Title

Page

Figure

Title

Page

1-1.

1-2.

1-3.

1-4.

2-1.

3-1.

3-2.

3-3.

3-4.

3-5.

4-1.

4-2.

4-3.

4-4.

4-5.

4-6.

4-7.

4-8.

4-9.

4-10.

4-11.

4-12.

4-13.

4-14.

4-15.

4-16.

4-17.

4-18.

4-19.

4-20.

4-21.

System

Control

Panel

1-5

Type

500

Plot

1-24

Type

600/700

Plot

1-24

Master

Tape 1-27

System

Troubleshooting Flowchart 2-9

HP

30354A

Maintenance

Panel

3-2

Maintenance

Panel

Switches

and

Lamps

3-17

110

Overlay

3-18

Connections for Use 3-20

Switch

Test

Lamp

Indications 3-24

SCMB

State

Display 4-7

SCMB Block

Diagram

4-8

SCMB Control Word

Format

, ,..: 4-10

SCMB

Status

Word

Format

4-12

Cold Load Method

of

110

Program

Initiation

4-14

ROM

PCA

Jumper

Locations 4-15

Skip

and

Special

Field

peA

Jumper

Locations 4-16

S-Bus

PCA

Switch Locations 4-17

eIR

PCA

Jumper

Locations 4-18

MCU

PCA

Jumper

Locations 4-19

lOP

PCA

Jumper

and

Switch Locations 4-20

SMA

PCA

Jumper

Locations 4-21

MCL

PCA

Jumper

Locations 4-23

FLI

PCA

Jumper

Locations 4-24

FCA

PCA

Component Location 4-25

System

Clock/Console Interface

PCA

Jumper

and

Switch Locations 4-26

Multiplexer

Channel

PCA

Jumper

Locations 4-28

Selector

Channel

Register

PCA

Jumper

and

Switch Locations 4-29

Selector

Channel

Control

PCA

Switch

and

Register

Locations 4-31

SCMB

Jumper

Locations 4-33

System

Control

Panel

Jumper

Locations 4-34

x

4-22.

4-23.

4-24.

4-25.

4-26.

4-27.

4-28.

4-29.

4-30:

4-31.

4-32.

4-33.

4-34.

4-35.

4-36.

4-37.

4-38.

4-39.

4-40.

5-1.

5-2.

B-l.

B-2.

B-3.

B-4.

B-5.

B-6.

B-7.

B-8.

Check

Bit

Assignments

4-36

Check

Bits

and

Error

Code (No

Error)

4-36

Check

Bits

and

Error

(Error

Condition) 4-37

Error

Logging

Array

Address

Structure

4-38

Error

Printout

Format

4-43

Typical

Error

Message 4-44

TIO Word

Format

4-45

CIO Word

Format

4-46

WIO Word

Format

4-47

RIO Word

Format

4-48

Memory Module

Interface

Diagram

4-50

Error

Correcting

Memory

Functional

Block

Diagram

4-53

SMA

PCA

Functional

Block

Diagram

4-55

Refresh

Circuit

Functional

Block

Diagram

. 4-59

Memory MCU

Functional

Block

Diagram..4-61

FCA

PCA

Memory

Array

4-65

Fault

Correction

and

Error

Logging

Functional

Block

Diagram

4-67

FLI

PCA

Functional

Block

Diagram

4-69

Power

Fail

Circuit

Functional

Block

Diagram

4-73

HP

30002B

Card

Cage , 5-6

HP

30002C

Card

Cage 5-7

HP

30310A Power Supply Block Diagram. .

..

B-5

HP 30310A Power Supply Functional

Block Diagram

B-9

HP 30310A Functional Timing Diagram B-15

HP 30311A Power Supply Simplified

Block Diagram B-24

HP 30311A Power Supply Detailed Block

Diagram B-25

Power Controls and Indicators B-29

Control Board Adjustment Locations B-33

HP 30312A Power Supply Simplified

Block Diagram B-40

JAN 1977

Page 11

SYSTEM

VERIFICATION

I~

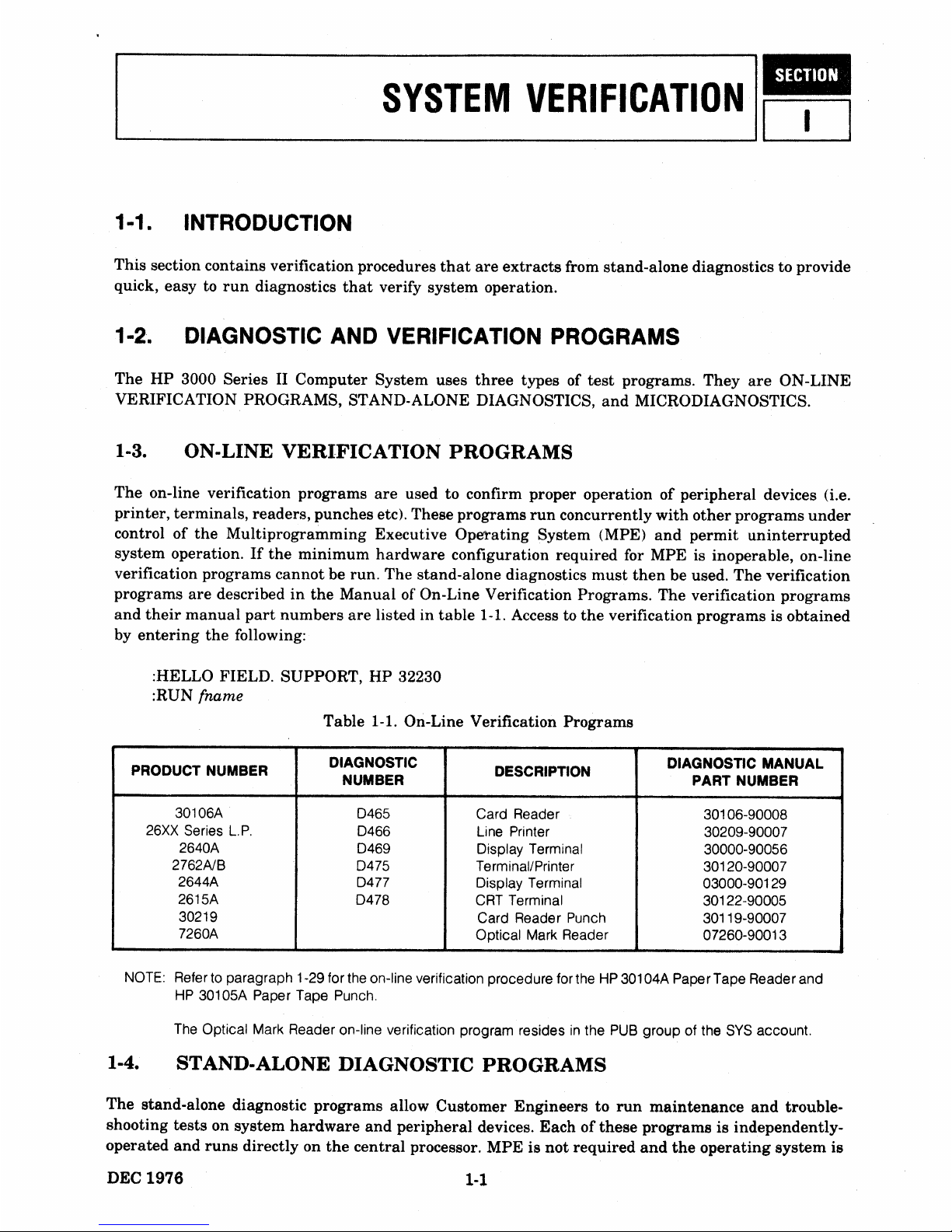

1-1. INTRODUCTION

This section contains verification procedures

that

are

extracts

from stand-alone diagnostics to provide

quick, easy to

run

diagnostics

that

verify system operation.

1-2. DIAGNOSTIC AND VERIFICATION PROGRAMS

The

HP

3000 Series II Computer System uses

three

types of

test

programs. They

are

ON-LINE

VERIFICATION PROGRAMS, STAND-ALONE DIAGNOSTICS,

and

MICRODIAGNOSTICS.

1-3. ON-LINE

VERIFICATION

PROGRAMS

The

on-line verification programs

are

used to confirm proper operationofperipheral

devices (i.e.

printer,

terminals,

readers, punches etc). These programs

run

concurrently

with

other

programs

under

controlofthe

Multiprogramming Executive Ope'tating System (MPE)

and

permit

uninterrupted

system operation.Ifthe

minimum

hardware

configuration required for MPE is inoperable, on-line

verification programs

cannot

be run. The stand-alone diagnostics

must

then

be used.

The

verification

programs

are

describedinthe

Manual

of On-Line Verification Programs. The verification

programs

and

their

manual

part

numbers

are

listed in

table

1-1. Access to

the

verification programs is obtained

by

entering

the

following:

:HELLO FIELD. SUPPORT,

HP

32230

:RUN

{name

Table 1-1. On-Line Verification Programs

PRODUCT NUMBER

DIAGNOSTIC

DESCRIPTION

DIAGNOSTIC MANUAL

NUMBER PART NUMBER

30106A

0465

Card Reader 30106-90008

26XX Series

L.P.

0466

Line Printer 30209-90007

2640A

0469

Display Terminal 30000-90056

2762A1B

0475

Terminal/Printer 30120-90007

2644A

0477

Display Terminal 03000-901

29

2615A

0478

CRT Terminal

30122-90005

30219

Card Reader Punch

30119-90007

7260A

Optical Mark Reader

07260-90013

NOTE: Refer to paragraph 1-29 for the on-line verification procedure forthe

HP

301

04A PaperTape Reader and

HP

30105A Paper Tape Punch.

The Optical Mark Reader on-line verification program resides

in

the

PUB

group of the

SYS

account.

1-4. STAND-ALONE DIAGNOSTIC

PROGRAMS

The stand-alone diagnostic programs allow Customer Engineerstorun

maintenance

and

trouble-

shooting tests on system

hardware

and

peripheral

devices.

Eachofthese

programs

is independently-

operated

and

runs

directly on

the

central

processor. MPE is

not

required

and

the

operating

system

is

DEC

1976

1-1

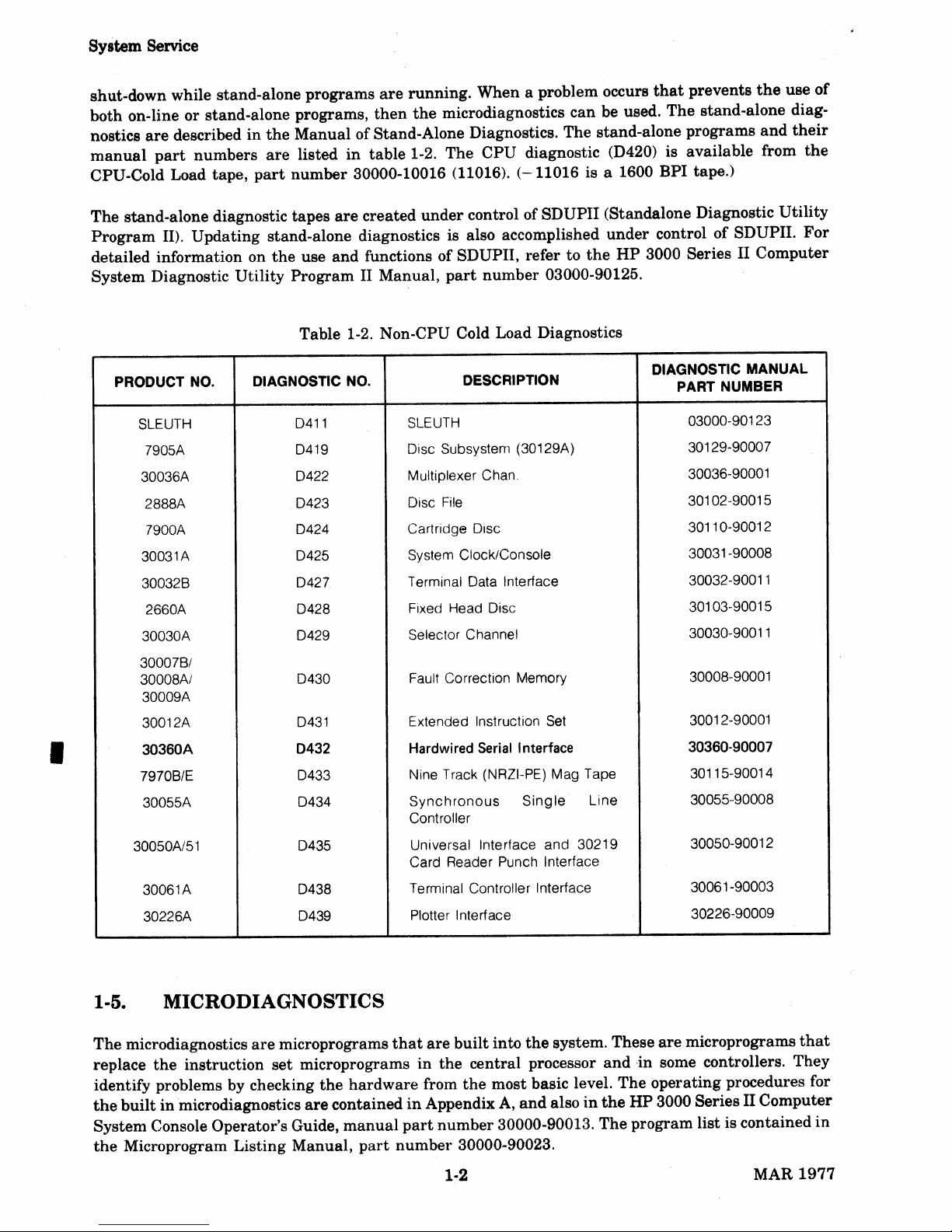

Page 12

I

System Service

shut-down while stand-alone programs

are

running.

When a problem occurs

that

prevents

the

use

of

both on-lineorstand-alone programs,

then

the

microdiagnostics

can

be used.

The

stand-alone diag-

nostics

are

describedinthe

Manual

ofStand-Alone Diagnostics. The stand-alone programs

and

their

manual

part

numbers

are

listed

in

table

1-2. The

CPU

diagnostic (D420) is available from

the

CPU-Cold Load tape,

part

number

30000-10016 (11016).

(-11016

is a 1600 BPI tape.)

The

stand-alone diagnostic tapes

are

created

under

control of SDUPII (Standalone Diagnostic

Utility

Program

II). Updating stand-alone diagnostics is also accomplished

under

controlofSDUPII.

For

detailed information on

the

use

and

functions of SDUPII, refer to

the

HP

3000 Series II

Computer

System

Diagnostic

Utility

Program

II Manual,

part

number

03000-90125.

Table 1-2. Non-CPU Cold Load Diagnostics

PRODUCT NO.

DIAGNOSTIC NO. DESCRIPTION

DIAGNOSTIC

MANUAL

PART NUMBER

SLEUTH 0411

SLEUTH

03000-90123

7905A 0419

Oisc Subsystem (30129A)

30129-90007

30036A 0422 Multiplexer Chan 30036-90001

2888A

0423

Oisc

File

30102-90015

7900A 0424 Cartridge Oisc 30110-90012

30031A

0425

System Clock/Console

30031

-90008

300328 0427 Terminal

Oata

Interface 30032-90011

2660A

0428

Fixed Head Oisc 30103-90015

30030A 0429 Selector Channel 30030-90011

300078/

30008A/

0430 Fault Correction Memory

30008-90001

30009A

30012A 0431

Extended Instruction

Set

30012-90001

30360A

0432

Hardwired Serial Interface

30360-90007

79708/E 0433 Nine Track (NRZI-PE) Mag Tape

30115-90014

30055A

0434

Synchronous

Single

Line 30055-90008

Controller

30050A/51

0435 Universal Interface and 30219 30050-90012

Card Reader Punch Interface

30061

A

0438 Terminal Controller Interface 30061-90003

30226A

0439 Plotter Interface 30226-90009

1-5. MICRODIAGNOSTICS

The

microdiagnostics

are

microprograms

that

are

built

into

the

system. These

are

microprograms

that

replace

the

instruction

set

microprogramsinthe

central

processor

and

,in some controllers. They

identify problems by checking

the

hardware

from

the

most

basic level.

The

operating

procedures for

the

builtinmicrodiagnostics

are

containedinAppendixA,and

alsointhe

HP

3000 Series II

Computer

System

Console Operator's Guide,

manual

part

number

30000-90013.

The

program list is contained

in

the

Microprogram Listing Manual,

part

number

30000-90023.

1-2

MAR

1977

Page 13

System

Verification

1-6. PURPOSE

System

verification

procedures

are

usedtoverify

that

the

system

operates

correctly.

The

procedures

mayberun

afterarepair

has

been

made,

afterasystem

modificationorupdate

has

been

completed,

or

as a confidence

checkifsome

functional

areaofthe

systemissuspectedofa

malfunction.

SectionIIof

this

manual

contains

procedurestoisolateafault

to a

functional

area.

A

detected

malfunction

will

provide

an

error

message

that

canbeinterpreted

by

referring

to

the

specific

diagnostic

containedinthe

manualofstand-alone

diagnostics.

The

diagnostic

manuals

also

provide

detailed

operating

instructions

that

allow

additional

testing

and

analysistobe

performedona

suspected

subsystem.

1-7. FACILITIES REQUIRED

Table

1-3

lists

the

diagnostic

tapes

requiredtoperform

the

system

verification.

Table

1-2

lists

the

contentsofthe

Non-CPU

Cold

Load

diagnostic

tape.

This

table

lists

the

contents

ofamaximum

configured

system.

Consult

the

System

Configuration

Guide

shipped

with

the

systemtodetermine

the

specific

subsystems

availableata

particular

installation.

Diagnostics

on

the

tape

areinthe

order

listedinthe

table.

Table

1-1

lists

the

contentsofthe

on-line

diagnostic

tape.

Table

1-3.

Diagnostic

Tapes

TITLE

PART NUMBER

CPU-Cold Load

30000-10016/11016

Non CPU-Cold Load

30000-10017/11017

NOTE:

-11016

and

-11017

are 1600 bpi tapes.

1-8. SYSTEM VERIFICATION PROCEDURES

The

system

verification

procedures

contain

the

instructions

requiredtoexecute

the

diagnostic

pro-

grams.

Each

programisloaded

using

the

Cold Load

procedure.

The

verification

procedures

presented

in

this

section

were

preconfigured

using

SDUP.Ifa

diagnosticisrun

that

has

not

been

preconfigured,

operating

instructions

and

console

messages

will differ from

those

presented

in

this

section.

In

addition

to

the

verification

procedures

provided

in

this

section,

the

on-line

diagnostics

for

the

peripheral

equipment

should

alsobeexercised

for a

total

system

verification.

Refertothe

appropriate

on-line

diagnostic

manual

for

the

peripheralsinthe

system.

1-9.

SLEUTH

3000

SLEUTH

3000

is a

stand-alone

utility

writteninSPL/3000.Itis designedtogive service

personnel

the

capabilityofgenerating

unique

I/O

test

programs

that

run

under

the

controlofSLEUTH

3000.

These

programs

allow

isolation

of

I/O

problems

and

ease

the

troubleshooting

of

these

problems.

SLEUTH

3000

has

the

abilitytorun

uptofive

different

types

of

I/O

device

concurrently.Itcan

also

write

and

execute

SIO

programs,

store

and

restore

programs

on

magnetic

tape,

and

edit

the

programs.

Peripheral

devices

that

do

not

have on-line

and/or

stand-alone

verification

programs

require

that

SLEUTH

3000

programs

be

written

to

test

these

devices. Several

such

test

programs

have

been

written

for

specific

I/O

peripherals

(for

example,

the

SLEUTH07

program

describedinparagraph

1-32).

JAN

1977

1-3

Page 14

System

Service

SLEUTH

3000

will

runona

minimum

HP

3000

Series

II.

Refertothe

HP

ManualofDiagnostics

for

complete

information

on

the

useofSLEUTH

3000

I/O

Diagnostic

D411,

manual

part

number

03000-90123.

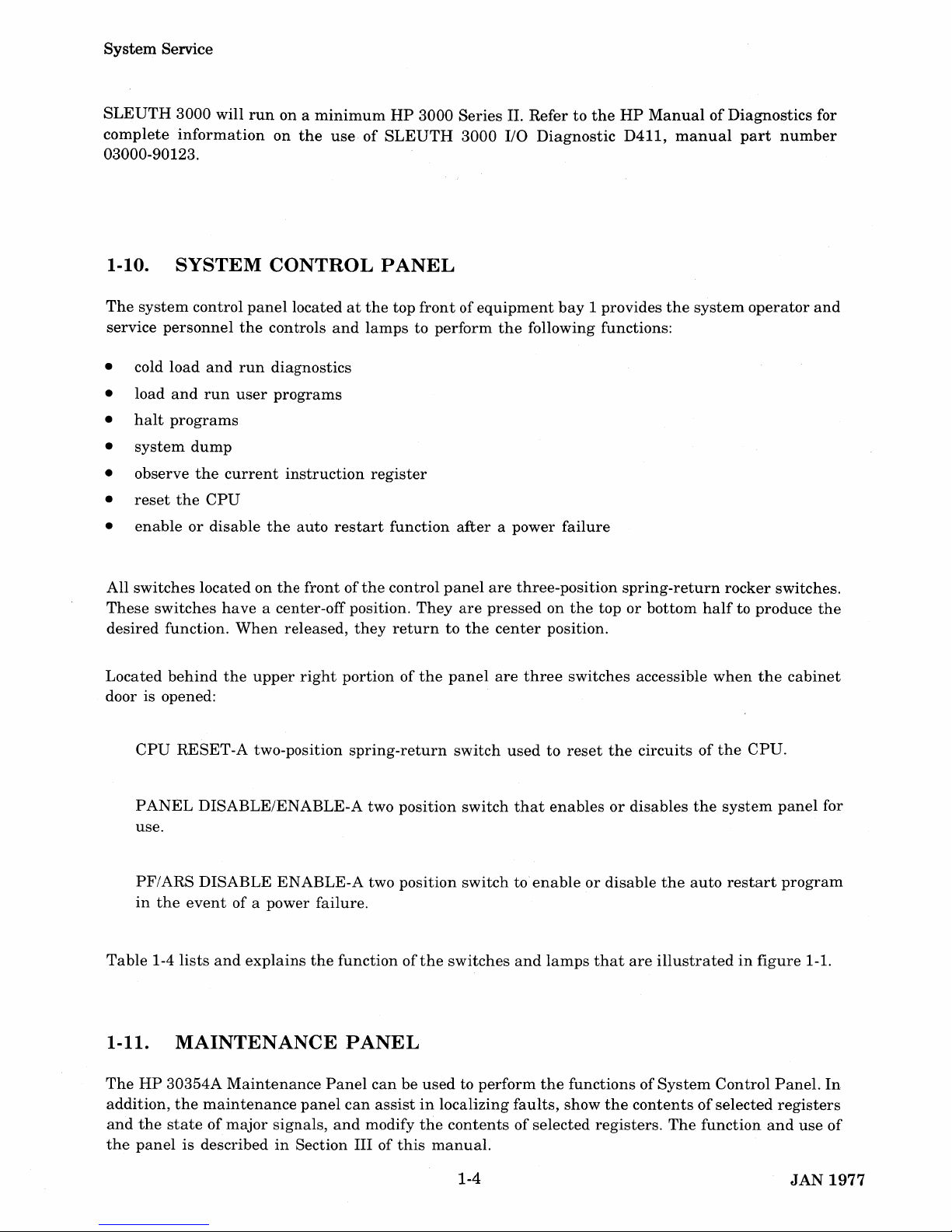

1-10.

SYSTEM CONTROL

PANEL

The

system

control

panel

locatedatthe

top

frontofequipment

bay1provides

the

system

operator

and

service

personnel

the

controls

and

lampstoperform

the

following functions:

• cold

load

and

run

diagnostics

•

load

and

run

user

programs

•

halt

programs

•

system

dump

• observe

the

current

instruction

register

•

reset

the

CPU

•

enableordisable

the

auto

restart

function

afterapower

failure

All

switches

locatedonthe

frontofthe

control

panel

are

three-position

spring-return

rocker

switches.

These

switches

have

a center-off position.

They

are

pressedonthe

toporbottom

halftoproduce

the

desired

function.

When

released,

they

returntothe

center

position.

Located

behind

the

upper

right

portionofthe

panel

are

three

switches

accessible

when

the

cabinet

door is opened:

CPU

RESET-A

two-position

spring-return

switch

usedtoreset

the

circuitsofthe

CPU.

PANEL

DISABLE/ENABLE-A

two

position

switch

that

enablesordisables

the

system

panel

for

use.

PF/ARS

DISABLE

ENABLE-A

two

position

switchtoenableordisable

the

auto

restart

program

in

the

eventofa

power

failure.

Table

1-4

lists

and

explains

the

functionofthe

switches

and

lamps

that

are

illustratedinfigure

1-1.

1-11. MAINTENANCE

PANEL

The

HP

30354A

Maintenance

Panel

canbeusedtoperform

the

functionsofSystem

Control

Panel.

In

addition,

the

maintenance

panel

can

assistinlocalizing

faults,

show

the

contentsofselected

registers

and

the

stateofmajor

signals,

and

modify

the

contentsofselected

registers.

The

function

and

use

of

the

panel

is describedinSection

IIIofthis

manual.

1-4

JAN

1977

Page 15

System

Verification

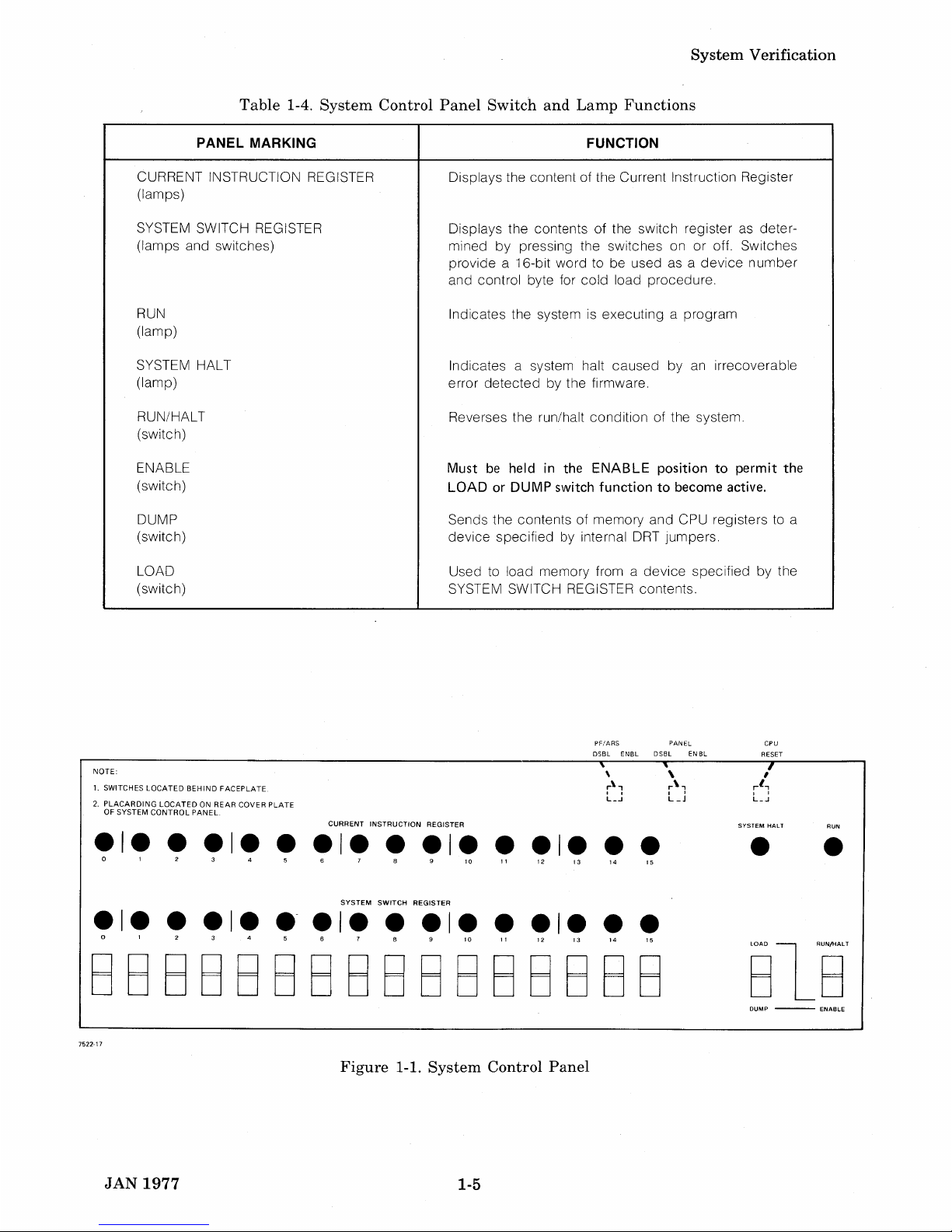

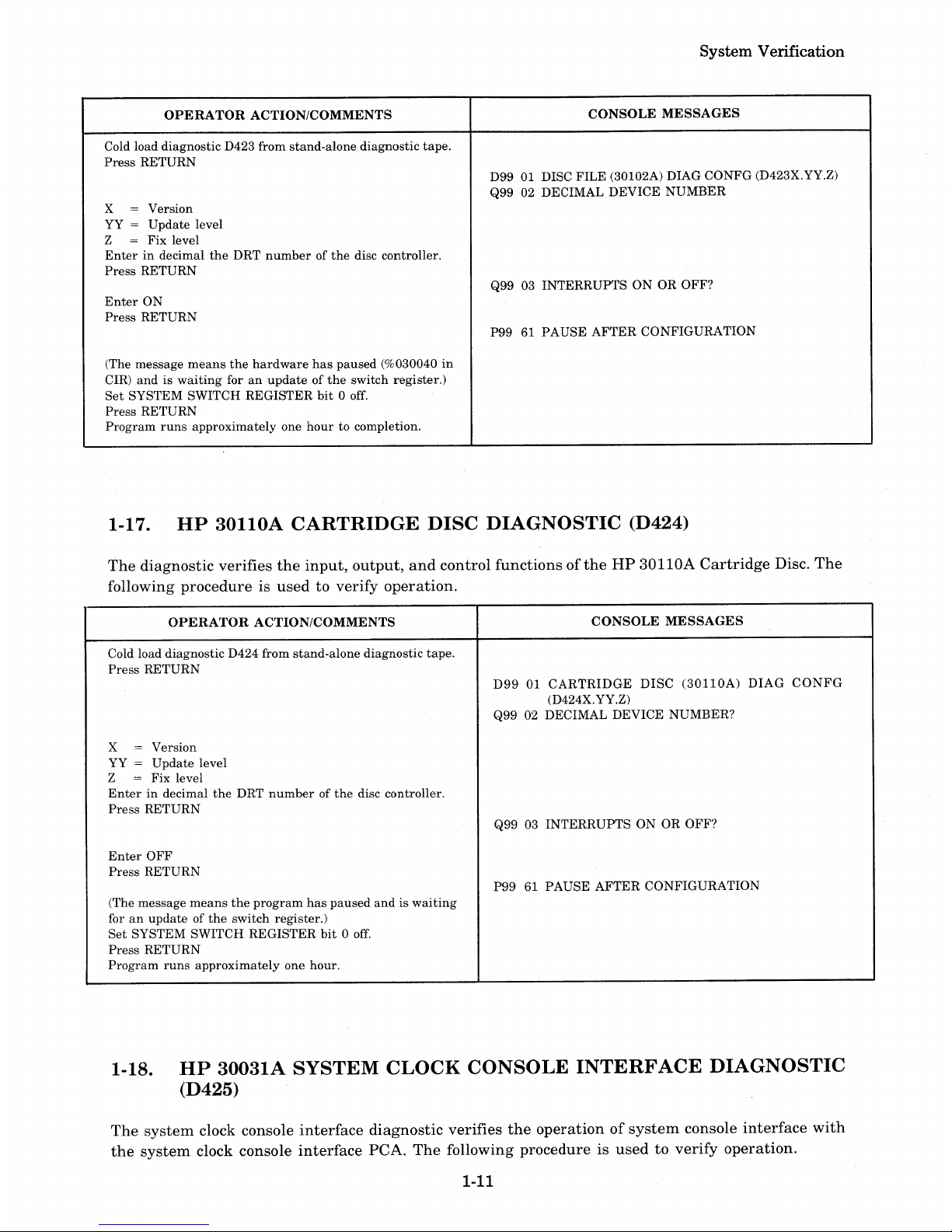

Table 1-4. System Control Panel Switch and Lamp Functions

PANEL MARKING

CURRENT INSTRUCTION REGISTER

(lamps)

SYSTEM SWITCH REGISTER

(lamps and switches)

RUN

(lamp)

SYSTEM HALT

(lamp)

RUN/HALT

(switch)

ENABLE

(switch)

DUMP

(switch)

LOAD

(switch)

FUNCTION

Displays the content of the Current Instruction Register

Displays the contents

of

the switch register as deter-

mined

by

pressing the switches onoroff. Switches

provide a 16-bit word to be used as a

device

number

and control byte for

cold

load procedure.

Indicates the system is executing a program

Indicates a system halt

caused

by an irrecoverable

error

detected

by the firmware.

Reverses the run/halt condition of the system.

Mustbeheldinthe

ENABLE

position to permit the

LOADorDUMP

switch function to become active.

Sends the contents of memory and CPU registers to a

device

specified by internal DRT jumpers.

Used to load memory from a

device

specified by the

SYSTEM SWITCH REGISTER contents.

NOTE:

1.

SWITCHES LOCATED BEHIND FACEPLATE

2.

PLACARDING

LOCATEDONREAR COVER

PLATE

OF

SYSTEM

CONTROL

PANEL

PF/ARS

PANEL

DSBL

ENBL

DSBLENBL

,

,

\

\

...

\,

...

\,

L_J

L

_J

CPU

RESET

CURRENT

INSTRUCTION

REGISTER

ele

e

ele

e

ele

e

ele

e

ele

e e

o 1 2 3 4 5 6 7 8 9

13

SYSTEM

SWITCH

REGISTER

SYSTEM

HALT

RUN

ele

e

ele

e-

ele

e

ele

e

ele

e e

o 1 2 3 4 5 6 7 8 9

10

11

13

14

BBBBBBBBBBBBBBBB

DUMP

--

ENABLE

7522-17

Figure 1-1.

System

Control Panel

JAN

1977

1-5

Page 16

System

Service

1-12. COLD LOAD (DIAGNOSTIC)

Perform

the

following

steps

to cold load a

diagnostic

tape.

NOTE

When

the

SYSTEM

SWITCH

REGISTER

bit

8 is

set

to 0,

all

memoryisinitialized

withaHALT

%10

instruction

(%030370)

priortoexecuting

the

cold load.Ifbit

8 is

setto1, no

initialization

occurs

priortothe

cold load.

a.

Load

tape

on

tape

unit

O.

b..Enter

%003006 on SYSTEM

SWITCH

REGISTER.

Simultaneously

press

LOAD

and

ENABLE

switches.

c.

Select

the

appropriate

diagnostic

file

number

from

the

tape

and

enter

this

octal

number

in

the

SYSTEM

SWITCH

REGISTER.

d.

Press

RUN.

The

diagnostic

loads

and

the

tape

rewindsatthe

endofthe

load.

e.

Set

SYSTEM

SWITCH

REGISTER

to 000000.

NOTE

The

following

verification

procedures

can

onlybeused

with

tapes

shipped

with

the

system

and

listedinTable

1-2.

Unless

directed

otherwise,

all

operator

entries

are

made

using

the

system

console.

NOTE

Priortoperforming

any

maintenance

or

shutdown

procedures,

have

the

System

Operator

verify

that

all

jobs/sessions

have

been

termina

ted

before proceeding.

NOTE

Do

not

power-uporpower-down

any

peripheral

device

when

a

diagnosticisrunning.

Failure

to observe

this

note

could

adversely

effect

the

diagnostic

thatisexecuting.

1-13.

HP

30129 CARTRIDGE DISC DIAGNOSTIC (D419)

The

diagnostic

verifies

the

input,

output,

and

control

functionsofthe

HP

30129A

Cartridge

Disc

subsystem.

The

following

procedureisusedtoverify

operation.

NOTE

A

SYSDUMP

should

be

performed

priortoexecuting

the

diag-

nostic.ARELOAD

must

be

performed

after

completing

the

diagnostic.

1-6

Page 17

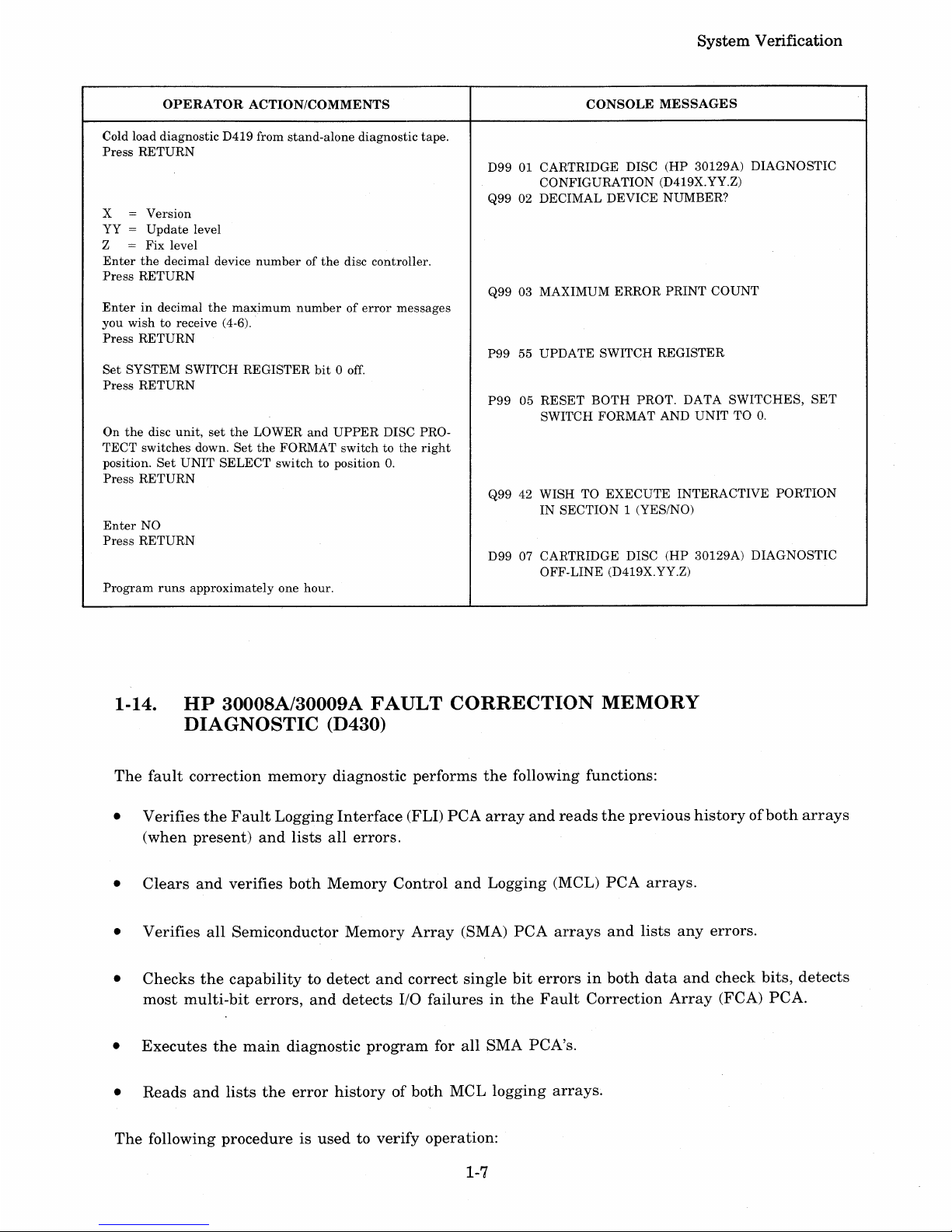

OPERATOR

ACTION/COMMENTS

Cold load diagnostic D419 from

stand-alone

diagnostic tape.

Press

RETURN

x = Version

YY

=

Update

level

Z

= Fix level

Enter

the

decimal device

numberofthe

disc controller.

Press

RETURN

Enterindecimal

the

maximum

numberoferror

messages

you

wish to receive (4-6).

Press

RETURN

Set

SYSTEM SWITCH REGISTER

bit0off.

Press

RETURN

On

the

disc

unit,

set

the

LOWER

and

UPPER

DISC PRO-

TECT switches down.

Set

the

FORMAT switch to

the

right

position.

Set

UNIT

SELECT

switch to position

O.

Press

RETURN

Enter

NO

Press

RETURN

Program

runs

approximately

one hour.

System

Verification

CONSOLE

MESSAGES

D99 01 CARTRIDGE DISC (HP 30129A) DIAGNOSTIC

CONFIGURATION (D419X.YY.Z)

Q99 02 DECIMAL DEVICE NUMBER?

Q99 03 MAXIMUM ERROR

PRINT

COUNT

P99

55 UPDATE SWITCH REGISTER

P9905RESET

BOTH

PROT. DATA

SWITCHES,

SET

SWITCH FORMAT AND

UNIT

TO

O.

Q99 42 WISH TO

EXECUTE

INTERACTIVE PORTION

IN

SECTION

1 (YES/NO)

D99 07 CARTRIDGE DISC

(HP

30129A) DIAGNOSTIC

OFF-LINE

(D419X.YY.Z)

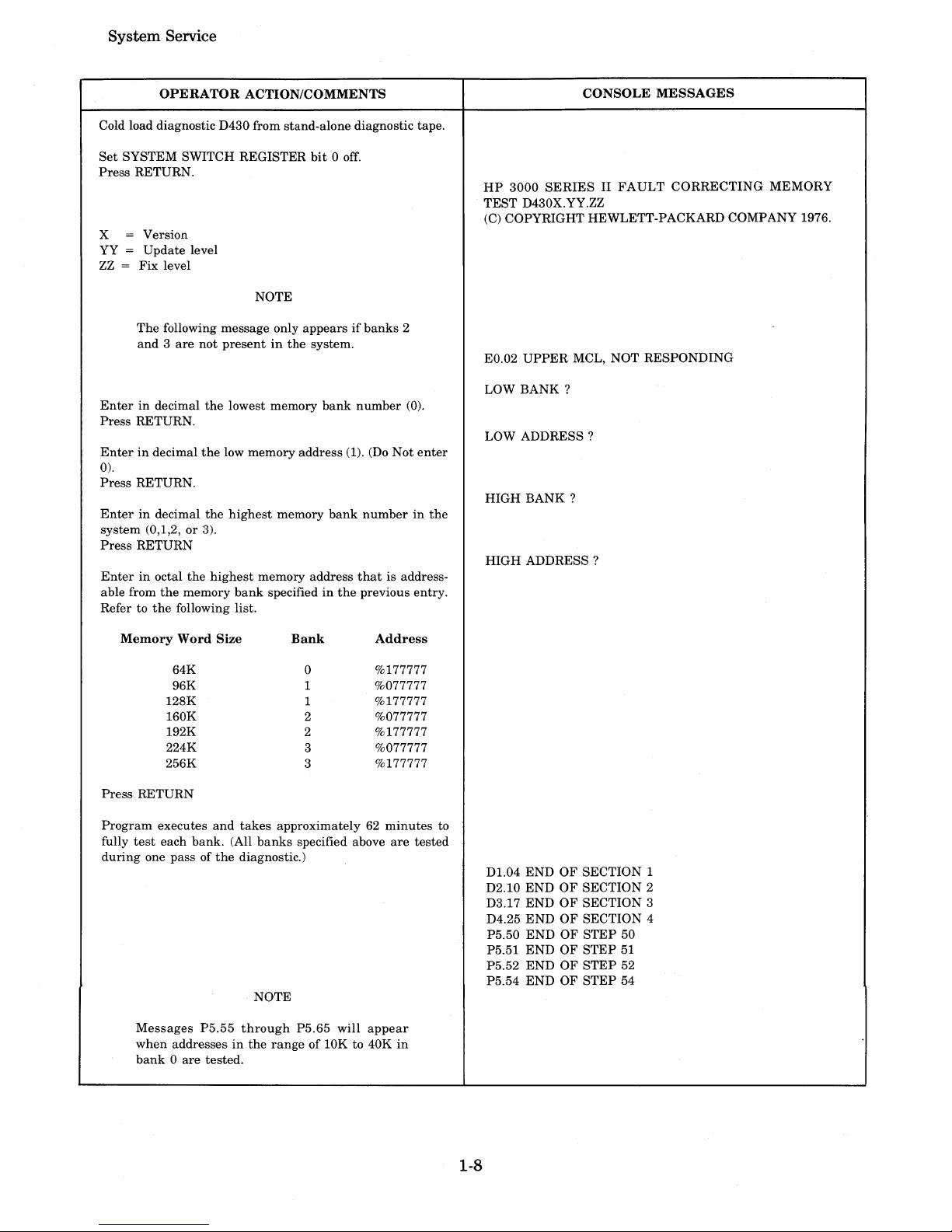

1-14.

HP

30008A/30009A

FAULT

CORRECTION

MEMORY

DIAGNOSTIC

(D430)

The

fault

correction

memory

diagnostic

performs

the

following functions:

• Verifies

the

Fault

Logging

Interface

(FLI)

PCA

array

and

reads

the

previous

historyofboth

arrays

(when

present)

and

lists

all

errors.

•

Clears

and

verifies

both

Memory

Control

and

Logging

(MCL)

PCA

arrays.

•

Verifies

all

Semiconductor

Memory

Array

(SMA)

PCA

arrays

and

lists

any

errors.

•

Checks

the

capabilitytodetect

and

correct

single

bit

errorsinboth

data

and

check

bits,

detects

most

multi-bit

errors,

and

detects

I/O

failuresinthe

Fault

Correction

Array

(FCA)

PCA.

•

Executes

the

main

diagnostic

program

for

all

SMA PCA's.

•

Reads

and

lists

the

error

historyofboth

MCL

logging

arrays.

The

following

procedureisusedtoverify

operation:

1-7

Page 18

System·Service

OPERATOR

ACTION/COMMENTS

Cold load diagnostic D430 from stand-alone diagnostic tape.

Set

SYSTEM SWITCH REGISTER

bit

0 off.

Press

RETURN.

x = Version

YY

=

Update

level

ZZ

= Fix level

NOTE

The

following message only

appearsifbanks

2

and3are

not

presentinthe

system.

Enterindecimal

the

lowest

memory

bank

number

(0).

Press

RETURN.

Enterindecimal

the

low

memory

address

(1). (Do

Not

enter

0).

Press

RETURN.

Enterindecimal

the

highest

memory

bank

numberinthe

system

(0,1,2,or3).

Press

RETURN

Enterinoctal

the

highest

memory

address

that

is address-

able from

the

memory

bank

specifiedinthe

previous

entry.

Refer to

the

following list.

Memory

Word

Size

Bank

Address

64K

0

%177777

96K 1

%077777

128K

1

%177777

160K 2

%077777

192K

2

%177777

224K

3

%077777

256K

3

%177777

Press

RETURN

Program

executes

and

takes

approximately62minutes

to

fully

test

each

bank.

(All

banks

specified above

are

tested

during

one pass of

the

diagnostic.)

NOTE

Messages

P5.55

through

P5.65

will

appear

when

addressesinthe

rangeof10K to 40K

in

bank0are

tested.

1-8

CONSOLE

MESSAGES

HP

3000

SERIESIIFAULT

CORRECTING

MEMORY

TEST

D430X.YY.ZZ

(C)

COPYRIGHT HEWLETT-PACKARD COMPANY 1976.

EO.02

UPPER

MCL, NOT

RESPONDING

LOW

BANK?

LOW

ADDRESS?

HIGH

BANK?

HIGH

ADDRESS?

D1.04 ENDOFSECTION

1

D2.10 END

OF

SECTION

2

D3.17

ENDOFSECTION 3

D4.25

ENDOFSECTION 4

P5.50

ENDOFSTEP

50

P5.51

ENDOFSTEP

51

P5.52

ENDOFSTEP

52

P5.54

ENDOFSTEP

54

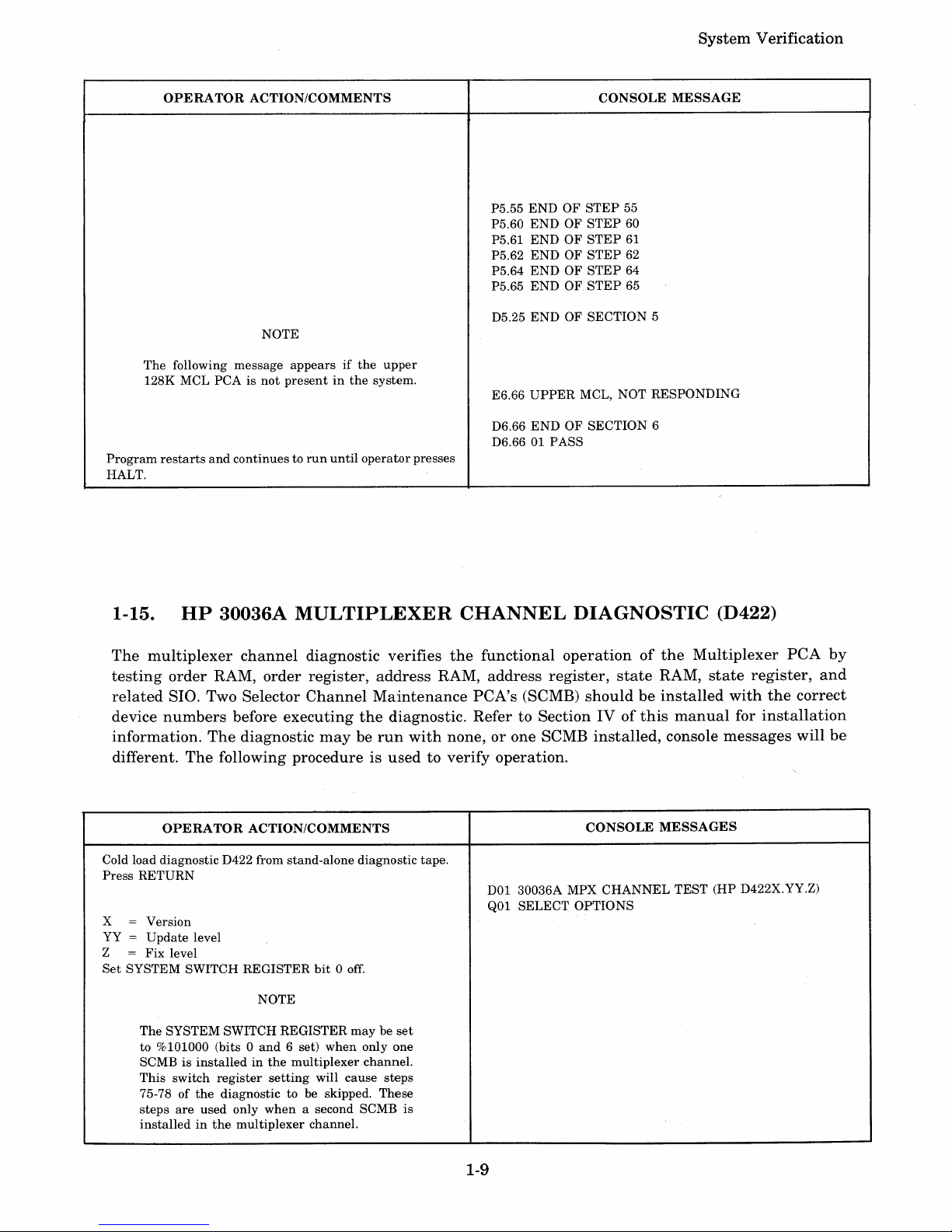

Page 19

System

Verification

OPERATOR

ACTION/COMMENTS

CONSOLE

MESSAGE

P5.55

ENDOFSTEP

55

P5.60

ENDOFSTEP

60

P5.61

ENDOFSTEP

61

P5.62

ENDOFSTEP

62

P5.64

ENDOFSTEP

64

P5.65

ENDOFSTEP

65

D5.25

ENDOFSECTION

5

NOTE

The

following

message

appearsifthe

upper

128K MCL PCA is

not

presentinthe

system.

E6.66

UPPER

MCL, NOT

RESPONDING

D6.66

ENDOFSECTION

6

D6.66 01 PASS

Program

restarts

and

continuestorun

until

operator

presses

HALT.

1-15.

HP

30036A

MULTIPLEXER

CHANNEL

DIAGNOSTIC

(D422)

The

multiplexer

channel

diagnostic

verifies

the

functional

operationofthe

Multiplexer

PCA

by

testing

order

RAM,

order

register,

address

RAM,

address

register,

state

RAM,

state

register,

and

related

SIO. Two

Selector

Channel

Maintenance

PCA's

(SCMB)

shouldbeinstalled

with

the

correct

device

numbers

before

executing

the

diagnostic.

Refer

to SectionIVof

this

manual

for

installation

information.

The

diagnostic

mayberun

with

none,orone SCMB

installed,

console

messages

will

be

different.

The

following

procedureisusedtoverify

operation.

OPERATOR

ACTION/COMMENTS

CONSOLE

MESSAGES

Cold load diagnostic D422 from

stand-alone

diagnostic tape.

Press

RETURN

DOl 30036A MPX

CHANNEL

TEST

(HP D422X.YY.Z)

Q01 SELECT

OPTIONS

X

=

Version

YY

=

Update

level

Z

=

Fix

level

Set

SYSTEM SWITCH REGISTER

bit

0 off.

NOTE

The

SYSTEM SWITCH REGISTER

maybeset

to %101000 (bits 0

and

6 set)

when

only one

SCMB is

installedinthe

multiplexer

channel.

This

switch

register

setting

will

cause

steps

75-78ofthe

diagnostic to be skipped. These

steps

are

used only

when

a second SCMB

is

installedinthe

multiplexer

channel.

1-9

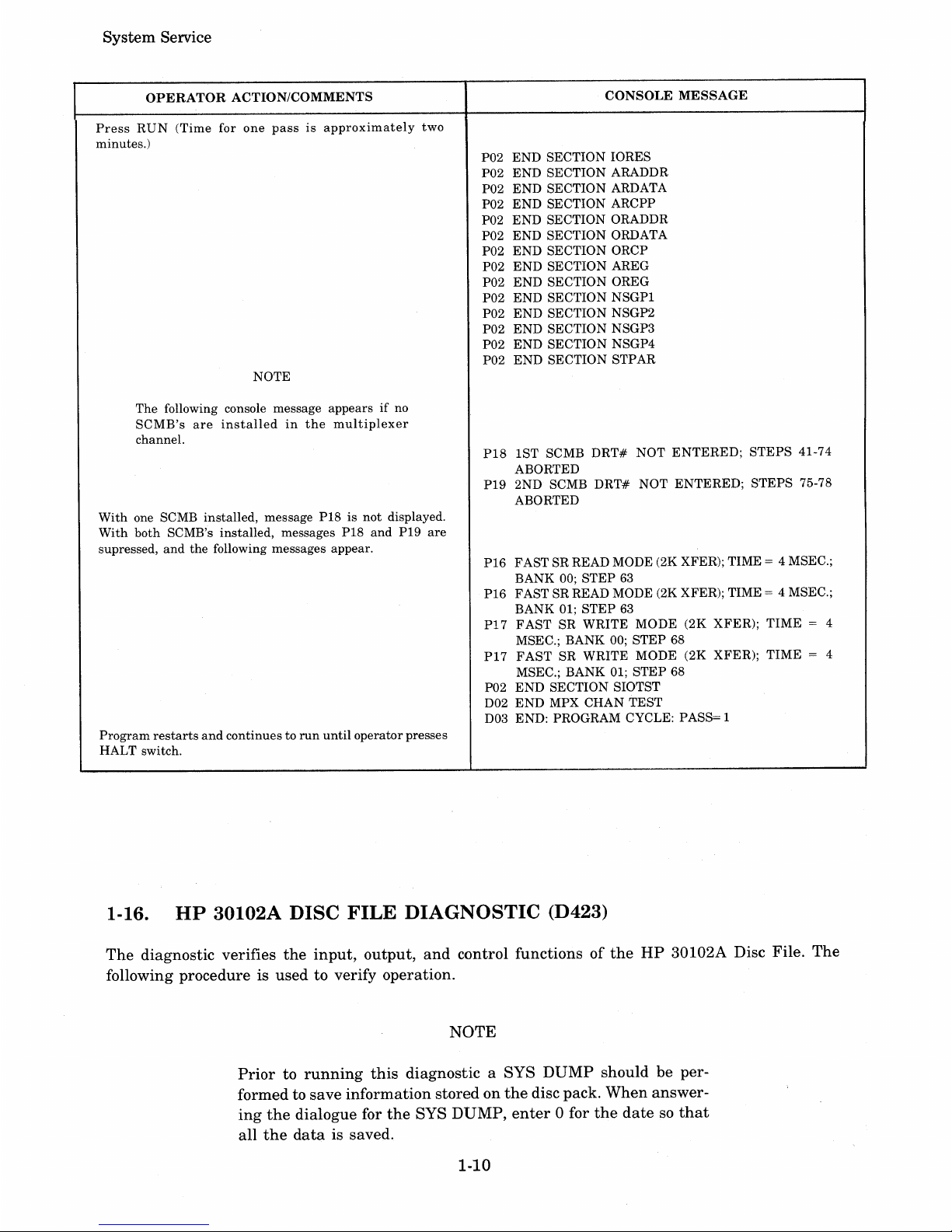

Page 20

System

Service

OPERATOR

ACTION/COMMENTS

Press

RUN

(Time

for

one

passisapproximately

two

minutes.)

NOTE

The following console message appears

if

no

SCMB's

are

installed

in

the

multiplexer

channel.

With

one SCMB installed, message P18 is

not

displayed.

With

both SCMB's installed, messages P18

and

P19

are

supressed,

and

the

following messages appear.

Program

restarts

and

continues to

run

until

operatorpresses

HALT switch.

CONSOLE

MESSAGE

P02

END

SECTION IORES

P02 END SECTION ARADDR

P02

END

SECTION ARDATA

P02

END

SECTION ARCPP

P02

END

SECTION ORADDR

P02 END SECTION ORDATA

P02

END

SECTION ORCP

P02

END

SECTION AREG

P02

END

SECTION OREG

P02

END

SECTION

NSGPI

P02

END

SECTION NSGP2

P02

END

SECTION NSGP3

P02

END

SECTION NSGP4

P02

END

SECTION STPAR

P18

1ST SCMB

DRT#

NOT

ENTERED;

STEPS

41-74

ABORTED

P19 2ND SCMB

DRT#

NOT

ENTERED;

STEPS

75-78

ABORTED

P16 FAST SR READ MODE (2K XFER); TIME = 4 MSEC.;

BANK 00;

STEP

63

P16 FAST SR READ MODE (2K XFER); TIME = 4 MSEC.;

BANK 01;

STEP

63

PI7

FAST

SR

WRITE

MODE

(2K XFER);

TIME

= 4

MSEC.; BANK 00;

STEP

68

P17

FAST

SR

WRITE

MODE (2K XFER);

TIME

= 4

MSEC.; BANK 01;

STEP

68

P02

END

SECTION SIOTST

D02

END

MPX CHAN

TEST

D03 END: PROGRAM CYCLE: PASS= 1

1..16.

HP

30102A DISC FILE DIAGNOSTIC (D423)

The

diagnostic verifies

the

input,

output,

and

control functionsofthe

HP

30102A Disc File.

The

following procedure is

used

to verify operation.

NOTE

Priortorunning

this

diagnostic a SYS

DUMP

should

be per-

formed to

save

information

storedonthe

disc pack.

When

answer-

ing

the

dialogue for

the

SYS

DUMP,

enter

0 for

the

datesothat

all

the

data

is saved.

1-10

Page 21

OPERATOR

ACTION/COMMENTS

Cold load

diagnostic

D423 from

stand-alone

diagnostic

tape.

Press

RETURN

x =

Version

YY =

Update

level

Z

=

Fix

level

Enterindecimal

the

DRT

numberofthe

disc controller.

Press

RETURN

Enter

ON

Press

RETURN

(The

message

means

the

hardware

has

paused

(%030040

in

CIR)

andiswaiting

foranupdateofthe

switch

register.)

Set

SYSTEM SWITCH

REGISTER

bit

0 off.

Press

RETURN

Program

runs

approximately

one

hour

to completion.

System Verification

CONSOLE

MESSAGES

D99 01 DISC

FILE

(30102A) DIAG

CONFG

(D423X.YY.Z)

Q99 02 DECIMAL

DEVICE

NUMBER

Q99 03

INTERRUPTSONOR

OFF?

P99 61

PAUSE

AFTER

CONFIGURATION

1-17.

HP

30110A

CARTRIDGE

DISC

DIAGNOSTIC

(D424)

The

diagnostic

verifies

the

input,

output,and

control

functionsofthe

HP

30110A

Cartridge

Disc.

The

following

procedureisusedtoverify

operation.

OPERATOR

ACTION/COMMENTS

Cold load

diagnostic

D424 from

stand-alone

diagnostic

tape.

Press

RETURN

x =

Version

YY =

Update

level

Z

=

Fix

level

Enterindecimal

the

DRT

numberofthe

disc controller.

Press

RETURN

Enter

OFF

Press

RETURN

(The

message

means

the

program

has

paused

andiswaiting

foranupdateofthe

switch

register.)

Set

SYSTEM

SWITCH

REGISTER

bit0off.

Press

RETURN

Program

runs

approximately

one

hour.

CONSOLE

MESSAGES

D99

01

CARTRIDGE

DISC

(30110A)

DIAG

CONFG

(D424X. YY.Z)

Q99 02 DECIMAL

DEVICE

NUMBER?

Q99 03

INTERRUPTSONOR

OFF?

P9961PAUSE

AFTER

CONFIGURATION

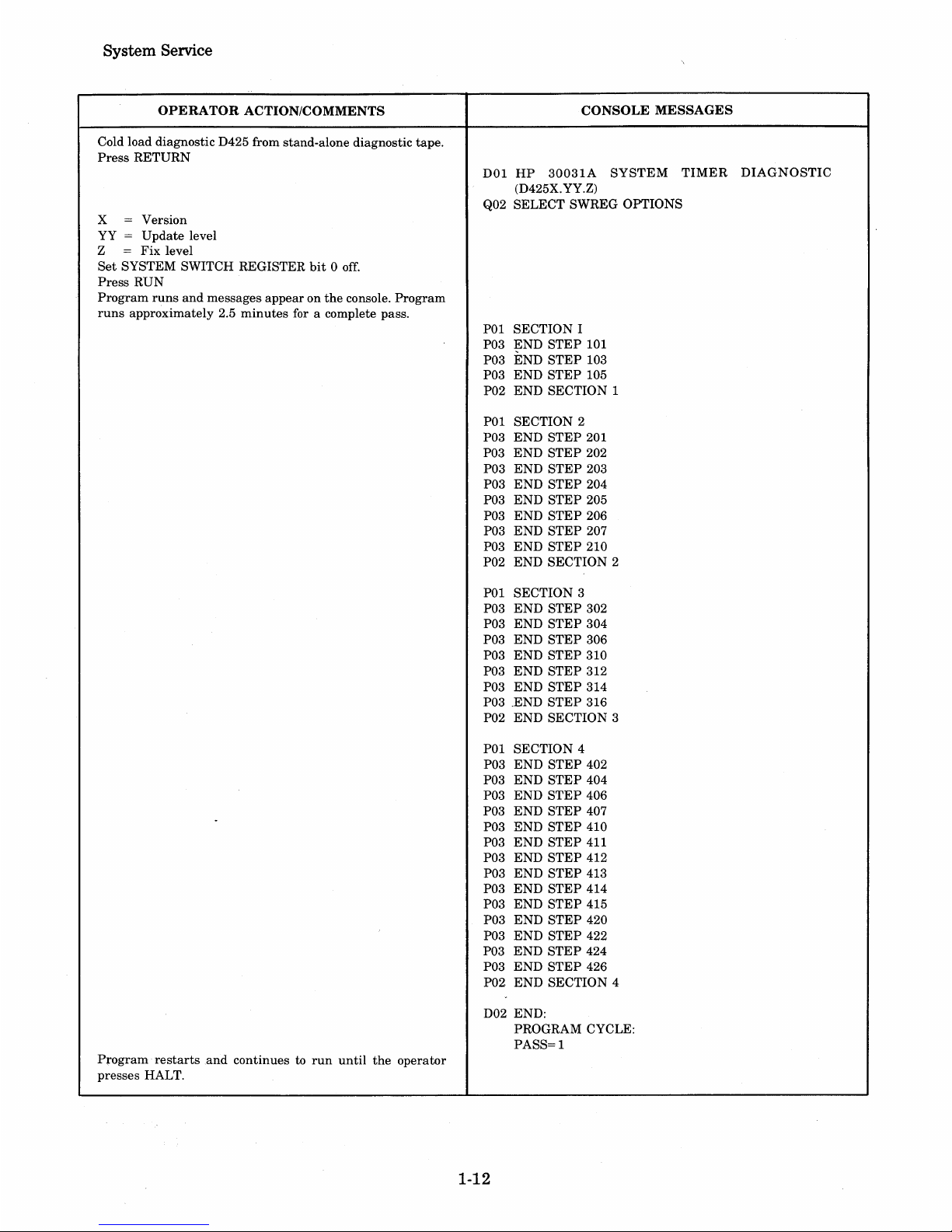

1-18.

HP

30031A

SYSTEM

CLOCK

CONSOLE

INTERFACE

DIAGNOSTIC

(D425)

The

system

clock console

interface

diagnostic

verifies

the

operationofsystem

console

interface

with

the

system

clock console

interface

PCA.

The

following

procedureisusedtoverify

operation.

1-11

Page 22

System Service

OPERATOR ACTION/COMMENTS

Cold load diagnostic D425 from stand-alone diagnostic tape.

Press

RETURN

x = Version

YY =

Update

level

Z =

Fix

level

Set

SYSTEM SWITCH REGISTER

bit0off.

Press

RUN

Program

runs

and

messages

appearonthe

console.

Program

runs

approximately 2.5

minutes

for a complete pass.

Program·

restarts

and

continues to

run

until

the

operator

presses HALT.

CONSOLE MESSAGES

DOl

HP

3003lA

SYSTEM

TIMER

DIAGNOSTIC

(D425X.YY.Z)

Q02 SELECT SWREG OPTIONS

POI SECTION I

P03

~ND

STEP

101

P03 END

STEP

103

P03

END

STEP

105

P02

END

SECTION 1

POI SECTION 2

P03

END

STEP

201

P03

END

STEP

202

P03

END

STEP

203

P03

END

STEP

204

P03

END

STEP

205

P03

END

STEP

206

P03

END

STEP

207

P03

END

STEP

210

P02

END

SECTION 2

POI SECTION 3

P03

END

STEP

302

P03 END

STEP

304

P03

END

STEP

306

P03

END

STEP

310

P03

END

STEP

312

P03

END

STEP

314

P03 .END

STEP

316

P02

END

SECTION 3

POI SECTION 4

P03

END

STEP

402

P03

END

STEP

404

P03

END

STEP

406

P03

END

STEP

407

P03

END

STEP

410

P03

END

STEP

411

P03 END

STEP

412

P03

END

STEP

413

P03

END

STEP

414

P03

END

STEP

415

P03

END

STEP

420

P03

END

STEP

422

P03

END

STEP

424

P03

END

STEP

426

P02

END

SECTION 4

D02 END:

PROGRAM CYCLE:

PASS=l

1-12

Page 23

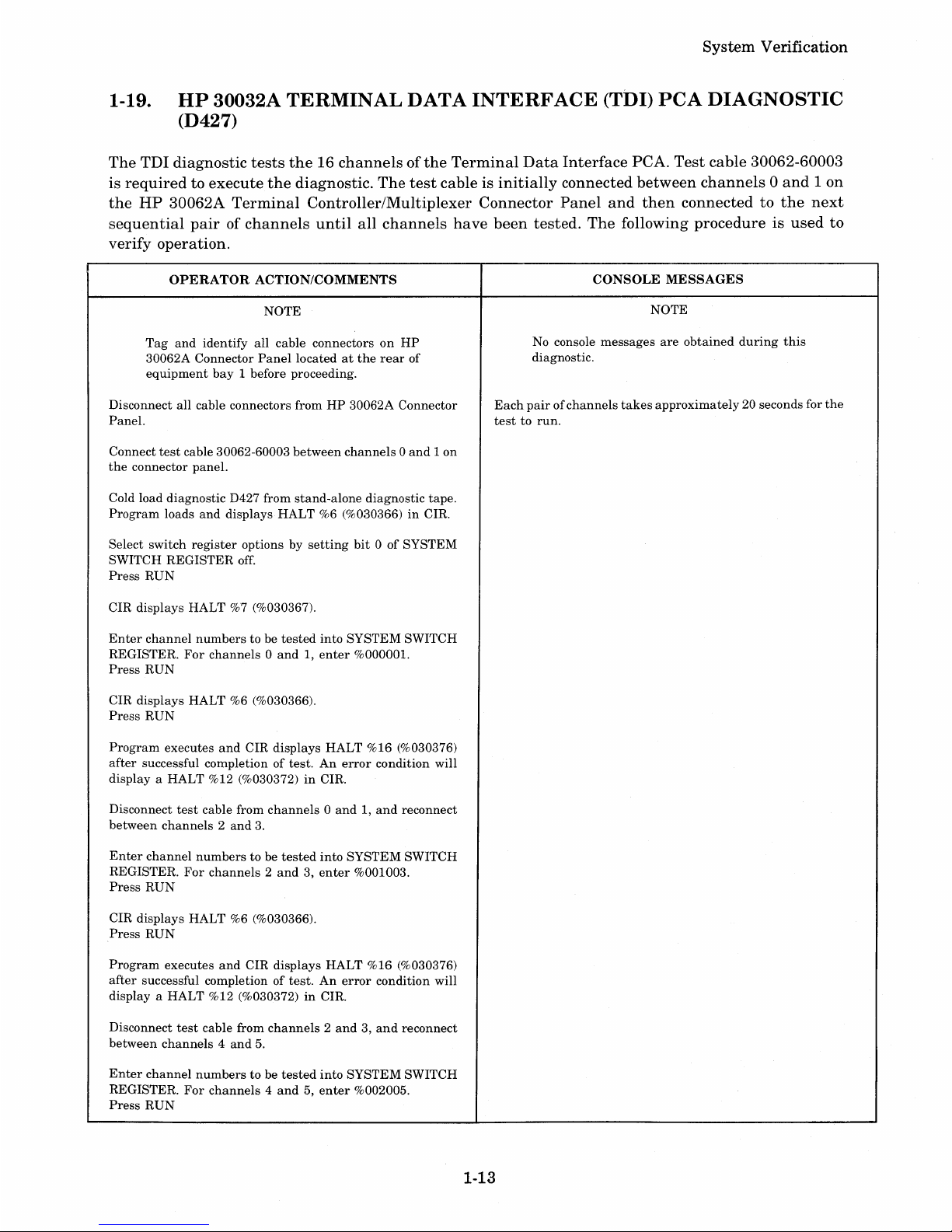

1-19.

System

Verification

HP

30032A TERMINAL

DATA

INTERFACE

(TDI)

peA

DIAGNOSTIC

(D427)

The

TDI

diagnostic

tests

the16channelsofthe

Terminal

Data

Interface

PCA.

Test

cable

30062-60003

is

requiredtoexecute

the

diagnostic.

The

test

cable is

initially

connected

between

channels0and1on

the

HP

30062A

Terminal

Controller/Multiplexer

Connector

Panel

and

then

connectedtothe

next

sequential

pairofchannels

until

all

channels

have

been

tested.

The

following

procedureisused

to

verify

operation.

OPERATOR

ACTION/COMMENTS

CONSOLE

MESSAGES

NOTE

NOTE

Tag

and

identify

all

cable

connectorsonHP

No console

messages

are

obtained

during

this

30062A

Connector

Panel

locatedatthe

rear

of

diagnostic.

equipment

bay

1 before proceeding.

Disconnect

all

cable connectors

fromHP30062A

Connector

Each

pairofchannels

takes

approximately

20 seconds for

the

Panel.

testtorun.

Connect

test

cable 30062-60003

between

channels0and1on

the

connector

panel.

Cold load

diagnostic

D427 from

stand-alone

diagnostic

tape.

Program

loads

and

displays

HALT

%6 (%030366)inCIR.

Select

switch

register

optionsbysetting

bit0of

SYSTEM

SWITCH

REGISTER

off.

Press

RUN

CIR

displays

HALT

%7 (%030367).

Enter

channel

numbers

to be

tested

into

SYSTEM

SWITCH

REGISTER.

For

channels0and1,enter

%000001.

Press

RUN

CIR

displays

HALT

%6 (%030366).

Press

RUN

Program

executes

and

CIR

displays

HALT

%16 (%030376)

after

successful completionoftest.Anerror

condition

will

displayaHALT

%12 (%030372)inCIR.

Disconnect

test

cable

from

channels0and1,and

reconnect

between

channels2and

3.

Enter

channel

numberstobe

tested

into

SYSTEM

SWITCH

REGISTER.

For

channels2and3,enter

%001003.

Press

RUN

CIR

displays

HALT

%6 (%030366).

Press

RUN

Program

executes

and

CIR

displays

HALT

%16 (%030376)

after

successful completionoftest.Anerror

condition

will

displayaHALT

%12 (%030372)inCIR.

Disconnect

test

cable from

channels2and3,and

reconnect

between

channels4and

5.

Enter

channel

numberstobe

tested

into

SYSTEM

SWITCH

REGISTER.

For

channels4and5,enter

%002005.

Press

RUN

1-13

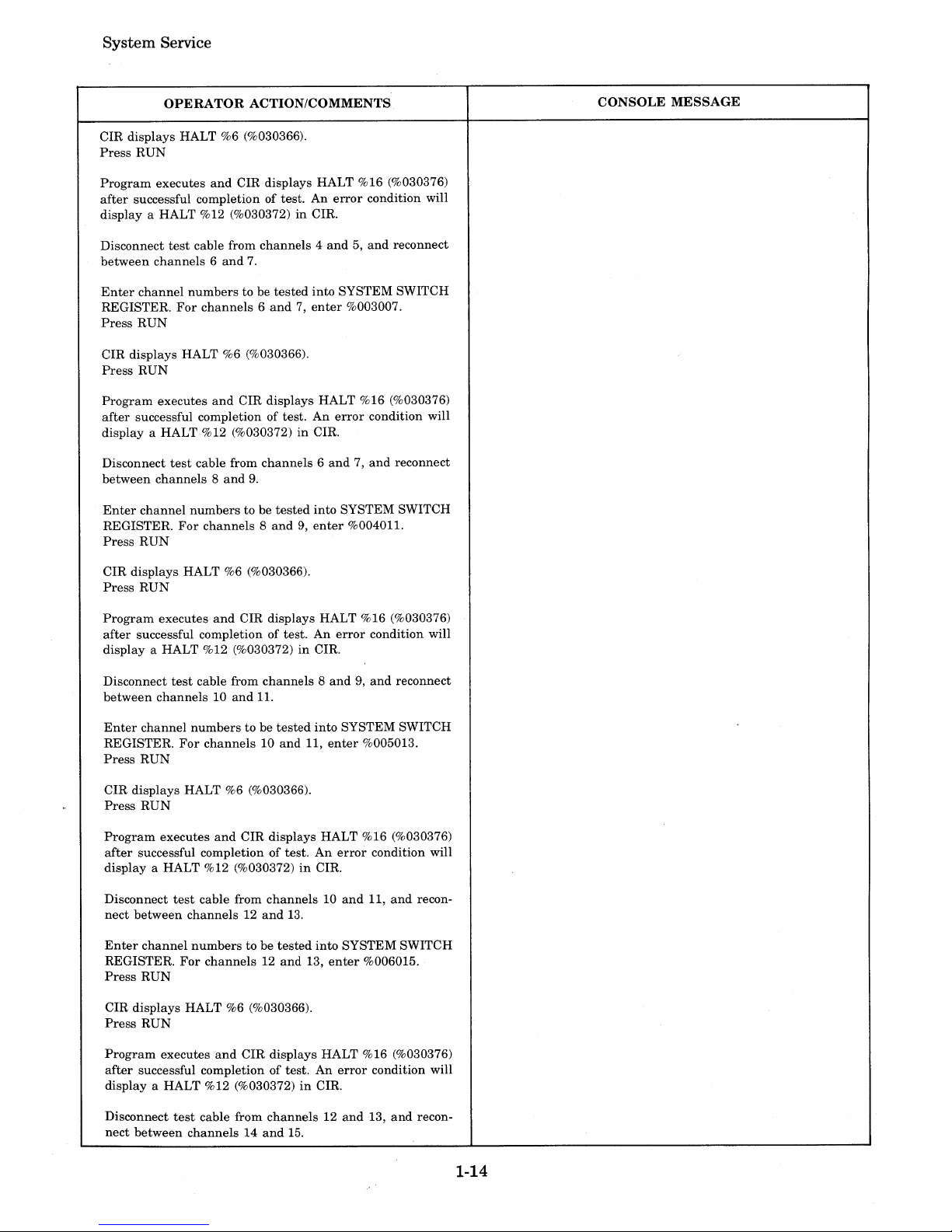

Page 24

System

Service

OPERATOR

ACTION/COMMENTS

CONSOLE

MESSAGE

CIR

displays

HALT

%6 (%030366).

Press

RUN

Program

executes

and

CIR

displays

HALT

%16 (%030376)

after

successful

completionoftest.Anerror

condition

will

displayaHALT

%12 (%030372)inCIR.

Disconnect

test

cable

from

channels4and5,and

reconnect

between

channels6and

7.

Enter

channel

numbers

to be

tested

into

SYSTEM

SWITCH

REGISTER.

For

channels6and7,enter

%003007.

Press

RUN

CIR

displays

HALT

%6 (%030366).

Press

RUN

Program

executes

and

CIR

displays

HALT

%16 (%030376)

after

successful

completionoftest.Anerror

condition

will

displayaHALT

%12 (%030372)inCIR.

Disconnect

test

cable

from

channels6and7,and

reconnect

between

channels8and

9.

Enter

channel

numbers

to be

tested

into

SYSTEM

SWITCH

REGISTER.

For

channels8and9,enter

%00401L

Press

RUN

CIR

displays

HALT

%6 (%030366).

Press

RUN

Program

executes

and

CIR

displays

HALT

%16 (%030376)

after

successful

completionoftest.Anerror

condition

will

displayaHALT

%12 (%030372)inCIR.

Disconnect

test

cable from

channels8and9,and

reconnect

between

channels10and

II.

Enter

channel

numberstobe

tested

into

SYSTEM

SWITCH

REGISTER.

For

channels10and

11,

enter

%005013.

Press

RUN

CIR

displays

HALT

%6 (%030366).

Press

RUN

Program

executes

and

CIR

displays

HALT

%16 (%030376)

after

successful

completionoftest.Anerror

condition

will

displayaHALT

%12 (%030372)inCIR.

Disconnect

test

cable

from

channels10and

11,

and

recon-

nect

between

channels12and

13.

Enter

channel

numberstobe

tested

into

SYSTEM

SWITCH

REGISTER.

For

channels12and

13,

enter

%006015.

Press

RUN

CIR

displays

HALT

%6 (%030366).

Press

RUN

Program

executes

and

CIR

displays

HALT

%16 (%030376)

after

successful

completionoftest.Anerror

condition

will

displayaHALT

%12 (%030372)inCIR.

Disconnect

test

cable

from

channels12and

13,

and

recon-

nect

between

channels14and

15.

1-14

Page 25

System

Verification

OPERATOR

ACTION/COMMENTS

CONSOLE

MESSAGE

Enter

channel

numbers

to be

tested

into

SYSTEM SWITCH

REGISTER.

For

channels14and

15,

enter

%007017.

Press

RUN

CIR displays HALT %6 (%030366).

Press

RUN

Program

executes

and

CIR displays HALT %16 (030376)

after

successful completionoftest.Anerror

condition will

display a HALT %12 (%030372)

in

CIR.

Disconnect

test

cable

and

reconnect

cablestoconnector

panel for

normal

system

operation.

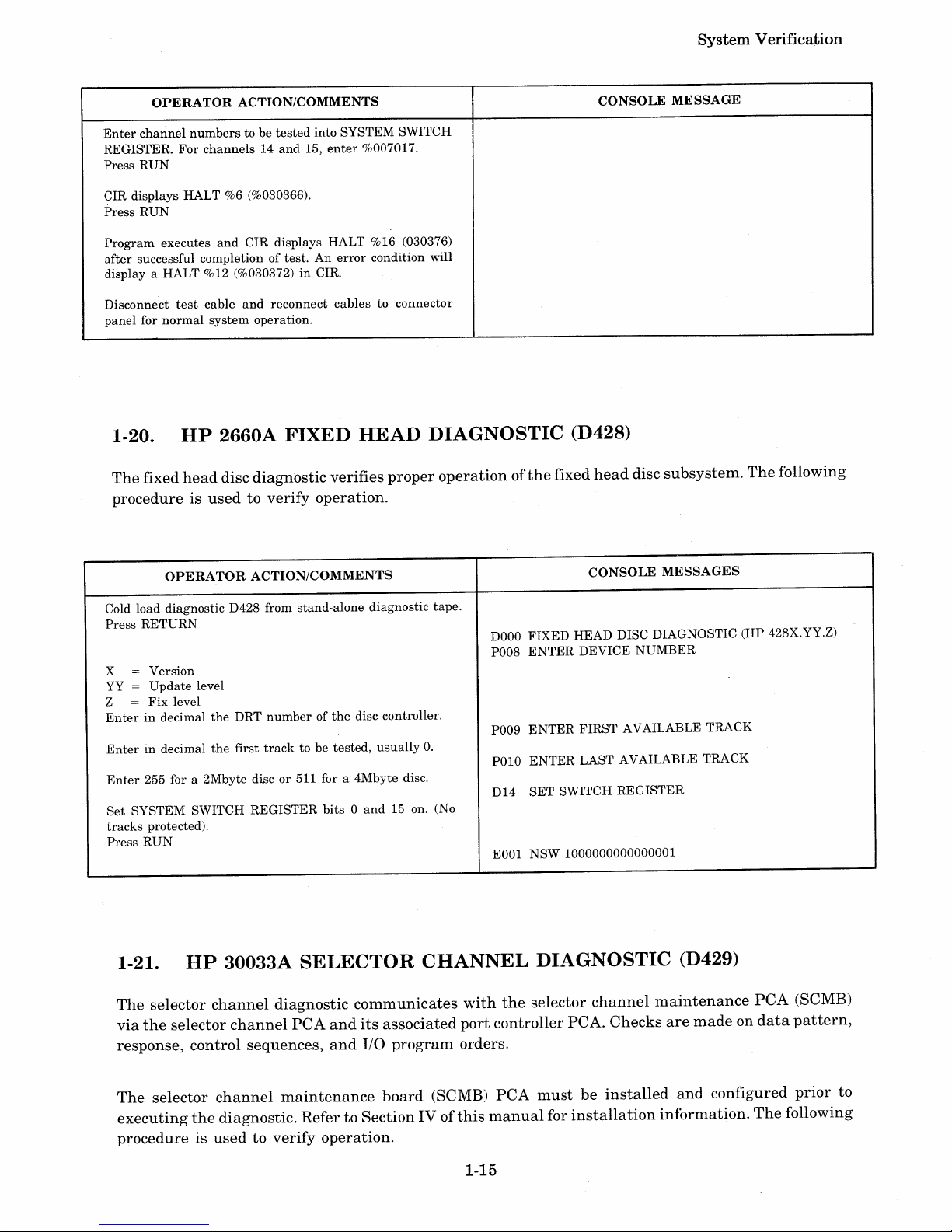

1-20.

HP

2660A

FIXED

HEAD

DIAGNOSTIC

(D428)

The

fixed

head

disc

diagnostic

verifies

proper

operationofthe

fixed

head

disc

subsystem.

The

following

procedureisusedtoverify

operation.

OPERATOR

ACTION/COMMENTS

Cold load diagnostic D428 from stand-alone diagnostic

tape.

Press

RETURN

X = Version

YY=Update

level

Z

=

Fix

level

Enterindecimal

the

DRT

numberofthe

disc controller.

Enterindecimal

the

first

track

to be

tested,

usually

O.

Enter

255 for a 2Mbyte discor511 for a 4Mbyte disc.

Set

SYSTEM SWITCH REGISTER

bits0and

15 on. (No

tracks

protected).

Press

RUN

CONSOLE

MESSAGES

DOOO

FIXED HEAD DISC DIAGNOSTIC (HP 428X.YY.Z)

P008

ENTER

DEVICE

NUMBER

P009

ENTER

FIRST

AVAILABLE TRACK

POlO

ENTER

LAST AVAILABLE TRACK

D14

SET

SWITCH REGISTER

E001 NSW 1000000000000001

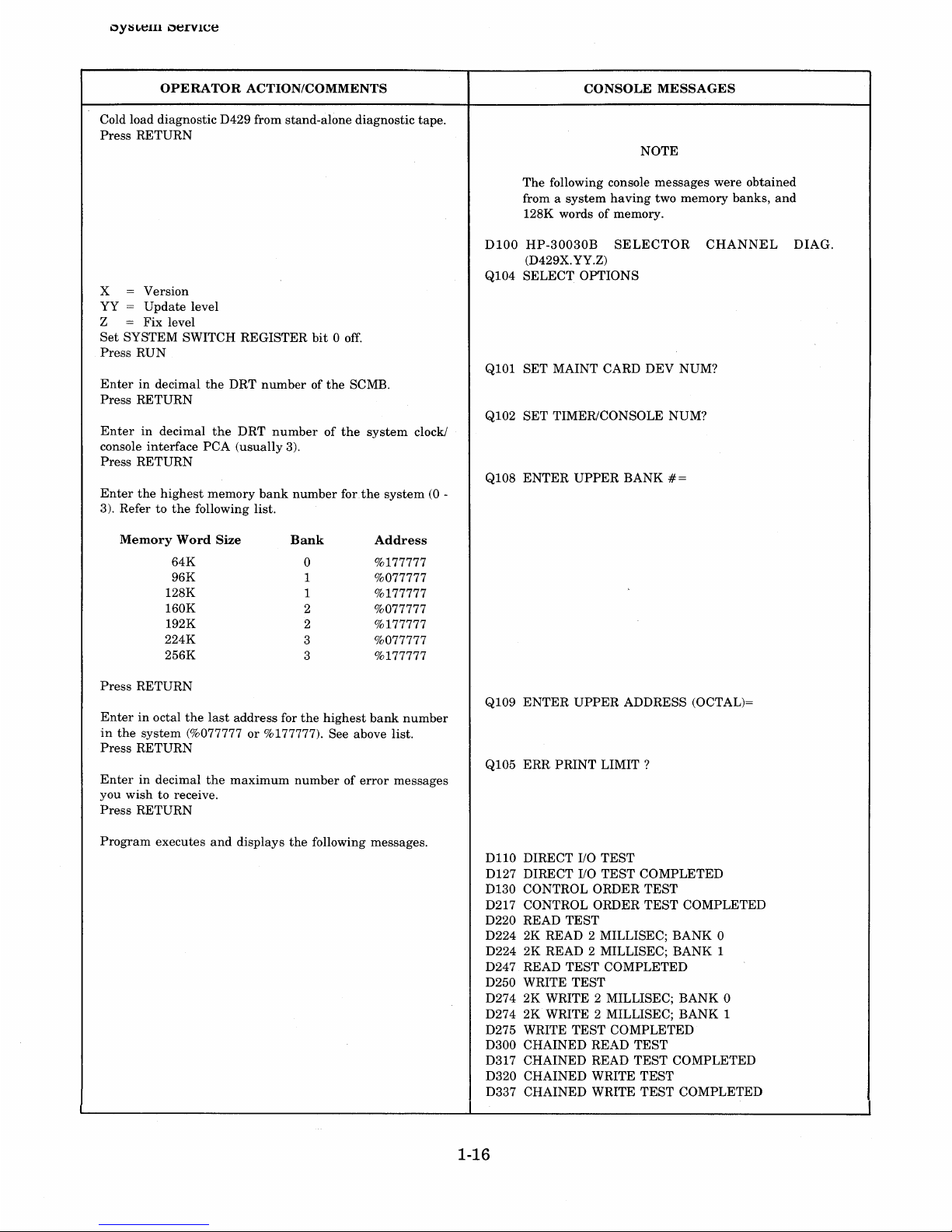

1-21.

HP

30033A

SELECTOR

CHANNEL

DIAGNOSTIC

(D429)

The

selector

channel

diagnostic

communicates

with

the

selector

channel

maintenance

PCA

(SCMB)

via

the

selector

channel

PCA

and

its

associated

port

controller

PCA.

Checks

are

madeondata

pattern,

response,

control

sequences,

and

I/O

program

orders.

The

selector

channel

maintenance

board

(SCMB)

PCA

must

be

installed

and

configured

prior

to

executing

the

diagnostic.

RefertoSection

IV of

this

manual

for

installation

information.

The

following

procedureisusedtoverify

operation.

1-15

Page 26

0YISLt:Hl

Ot:rVlCe

OPERATOR

ACTION/COMMENTS

Cold load diagnostic D429 from stand-alone diagnostic tape.

Press RETURN

x = Version

YY = Update level

Z = Fix level

Set

SYSTEM SWITCH REGISTER

bit0off.

Press

RUN

Enterindecimal

the

DRT

numberofthe

SCMB.

Press RETURN

Enterindecimal

the

DRT

numberofthe

system

clock/

console interface PCA (usually 3).

Press RETURN

Enter

the

highest

memory

bank

number

forthe

system(0-

3). Refer to

the

following list.

Memory

Word

Size

Bank

Address

64K

0

%177777

96K

1

%077777

128K

1

%177777

160K

2 %077777

192K

2 %177777

224K

3

%077777

256K

3 %177777

Press

RETURN

Enterinoctal

the

last

address for

the

highest

bank

number

in

the

system (%077777or%177777). See above list.

Press

RETURN

Enterindecimal

the

maximum

numberoferror

messages

you

wish

to receive.

Press

RETURN

Program

executes

and

displays

the

following messages.

CONSOLE

MESSAGES

NOTE

The following console messages were obtained

from a

system

having

two memory banks,

and

128K words of memory.

D100

HP-30030B

SELECTOR

CHANNEL

DIAG.

(D429X.YY.Z)

Q104 SELECT OPTIONS

Q101 SET MAINT CARD DEV NUM?

Q102

SET

TIMER/CONSOLE NUM?

Q108

ENTER

UPPER

BANK

#=

Q109

ENTER

UPPER

ADDRESS (OCTAL)=

Q105 ERR

PRINT

LIMIT?

DllO

DIRECT

110

TEST

D127 DIRECT

110

TEST

COMPLETED

D130 CONTROL ORDER TEST

D217 CONTROL ORDER

TEST

COMPLETED

D220 READ TEST

D224 2K READ 2 MILLISEC; BANK 0

D224 2K READ 2 MILLISEC; BANK 1

D247 READ TEST COMPLETED

D250 WRITE TEST

D274 2K WRITE 2 MILLISEC; BANK 0

D274 2K WRITE 2 MILLISEC; BANK 1

D275 WRITE

TEST

COMPLETED

D300 CHAINED READ

TEST

D317 CHAINED READ

TEST

COMPLETED

D320 CHAINED WRITE TEST

D337 CHAINED WRITE TEST COMPLETED

1-16

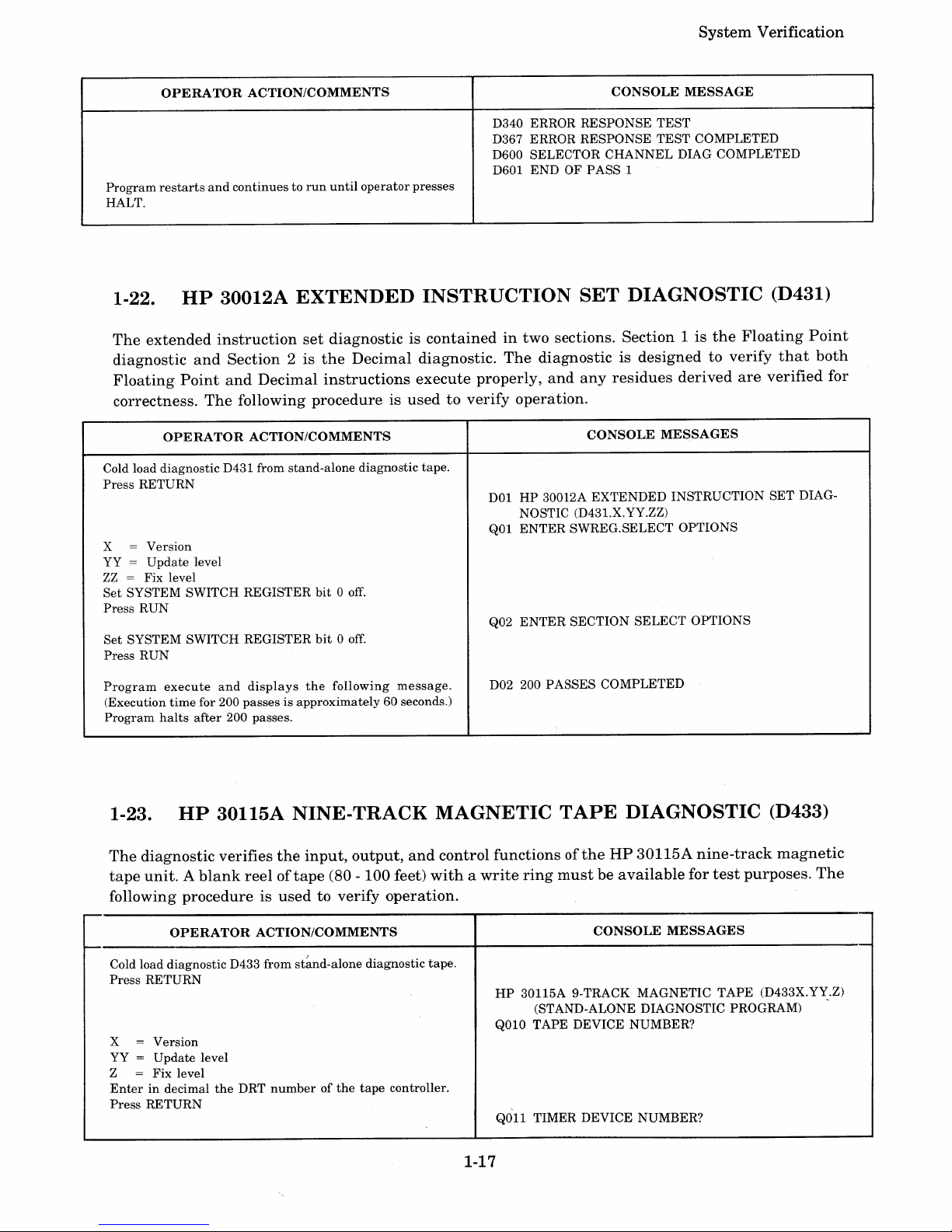

Page 27

System

Verification

OPERATOR

ACTION/COMMENTS

CONSOLE

MESSAGE

D340 ERROR

RESPONSE

TEST

D367 ERROR

RESPONSE

TEST

COMPLETED

D600 SELECTOR

CHANNEL

DIAG COMPLETED

D60l

ENDOFPASS

1

Program

restarts

and

continuestorun

until

operator

presses

HALT.

1-22.

HP

30012A

EXTENDED

INSTRUCTION

SET

DIAGNOSTIC

(D431)

The

extended

instruction

set

diagnosticiscontainedintwo

sections.

Section

1 is

the

Floating

Point

diagnostic

and

Section

2 is

the