Page 1

HP 3000 Series 9X8LX/RX PA-RISC Computer System

Installation and Configuration Guide

Series 9X8LX/RX Family

rli~

~~ PACKARD

HP Part No. A2051·90006

Printed in U.S.A. 1993

HEWLETT

First Edition

E1093

Page 2

Notice

Hewlett-Packard makes no warranty of any kind with regard to this material, including,

but not limited to, the implied warranties of merchantability and fitness for a particular

purpose. Hewlett-Packard shall not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance, or use of this material.

Hewlett-Packard assumes no responsibility for the use or reliability of its software on

equipment that is not furnished by Hewlett-Packard.

This document contains proprietary information which is protected by copyright. All rights

are reserved. No part of this document may be photographed, reproduced, or translated to

another language without prior written consent of Hewlett-Packard Company.

The information contained in this document is subject to change without notice.

@

Copyright Hewlett-Packard Company, 1993. All rights reserved.

Page 3

Printing History

New editions are complete revisions of the manual. Update packages, which are issued

between editions, contain additional and replacement pages to be merged into the manual by

the customer. The dates on the title page change only when a new edition or a new update

is published. No information is incorporated into a reprinting unless it appears as a prior

update; the edition does not change when an update is incorporated.

Many product updates and fixes do not require manual changes and, conversely, manual

corrections may be done without accompanying product changes. Therefore, do not expect a

one-to-one correspondence between product updates and manual updates.

First Edition October 1993

List of Effective Pages

The List of Effective Pages gives the date of the current edition and of any pages changed

in updates to that edition. Within the manual, any page changed since the last edition

is indicated by printing the date the changes were made on the bottom of the page. No

information is incorporated into a reprinting unless it appears as a prior update.

All October 1993

iii

Page 4

Safety and Regulatory Information

For your protection this product has been tested to various national and international

regulations and standards. The scope of this regulatory testing includes electrical/mechanical

safety, radio frequency interference, ergonomics, acoustics, and hazardous materials. Where

required, approvals obtained from third-party test agencies are shown on the product label. In

addition, various regulatory bodies require someinformation under the followingheadings.

FCC Statement (USA only)

The United States Federal Communications Commission (in SubpartJ,of Part 15, Docket

20780) has specified that the followingnotice be brought to the attention of the users of this

product:

Warning

This equipment generates, uses, and can radiate radio frequency energy and if

not installed and used in accordance with the instructions manual, may cause

interference to radio communications. It has been tested for compliance with

the limits of ClassAcomputing devices pursuant to Subpart J of Part

FCC Rules, which are deSigned to provide reasonable protection against such

interference.

Operation of this equipment in a residential area is likely to cause interference

in which case the user at his own expense will be required to take whatever

measures may be required to correct the interference.

Japanese Radio Frequency Interference

i:.

0)~i1i!

C'

ffii

I~!iB~

~~~ (VCCI)

.vt..,

3 /

§tf~~~

-c.

Ii.

m-f~IH~ffl~i?1-CFmI*Jt!r~K

-Z:-.0).il[.1&:~~~J.7:L1:.

~·§-it.]-c

1iJ;ifKJljiSl-C:Jol)iTv

~"8:tt!!~

Ie:

~{§

't

t:

lIf'J;~

(;:I:

-t-

O)~ng

i-4;t ~

i:.

L

C

i;.~'

-l,

t:.:ffl~~:~~.~

t:.ttB~C'~ffl

t.J~

it>

I)

't

To

-C{fJf~

T ~

2'

n

{,«

~·ffl~·~·~) .

~:~·ilR:~~:§±:1J!J1jIJ:

C,

'7:;;t, T

i-

15

of

t:

y

~ 1&~

iv

B~• Ie:

itE ..,-cIf.

L ~\

1&

I)

1&~\i-l-cF

Japanese Radio Frequency Notice

tt

~'o

Page 5

Finland (only)

LASERTURVALLISUUS

LUOKAN 1 LASERLAITE KLASS 1 LASER APPARAT

HP 3000 Series 9x8LX/RX -tietokoneisiin voidaan asentaa Iisavarusteena muistilaitteeksi

laitteensisainen CD-ROM-levyasema,joka on laserlaite.

Kyseinen CD-ROM-levyasema on kayttajan kannalta turvallinen luokan llaserlaite.

Normaalissa kaytossa levyaseman suojakotelo estaa lasersateen paasyn laitteen ulkopuolelle.

CD-ROM-levyaseman on tyyppihyvaksynyt Suomessa laserturvallisuuden osalta

Tyoministerion tyosuojeluosasto. Laitteen turvallisuusluokka on maaritetty valtioneuvoston

paatoksen N:o 472/1985 ja standardin SFS-EN 60825 (1992) mukaisesti.

Tiedot CD-ROM-levyasemassa kaytettavan laserdiodin sateilyominaisuuksista:

Aallonpituus 790 nm

Teho 1,1 pW

Luokan 1 laser

Acoustics (Germany only)

Laermangabe (SchalldruckpegelLpA) gemessen an Arbitplatzbei norrnalen Betrieb nach DIN

45635,teil 19:

Acoustic noise (A-weight sound pressure level LpA) measured at operator's position, normal

operation, to 1807779:

HP

300 9X8LX/RX:

59dB bis (up to) 37°C, 62dB ueber (above) 37°C

v

Page 6

Safety Considerations

This product and related documentation must be reviewed for familiarization with safety

markings and instructions before operation. The following figure shows some of the safety

symbols used on the product to indicate various safety considerations.

Warning

Caution

I

The WARNING sign denotes a hazard. It calls attention to a procedure,

practice, of the like, which if not done correctly or adhered to, could result in

injury. Do not proceed beyond a WARNING sign until the indicated conditions

are fully understood and met.

The CAUTION sign denotes a hazard. It calls attention to an operating

procedure, practice, of the like, which if not done correctly or adhered to,

could damage or destroy part or all of the product. Do not proceed beyond a

CAUTION sign until the indicated conditions are fully understood and met.

Preface

This manual is intended for use by trained and experienced Hewlett-Packard field maintenance

personnel. This edition of the Installation and Configuration Guide contains technical

information about the HP 3000 Series 9X8LXjRX Family of computers listed in the table

below.

Computer Type

Description"

HP 3000 928LX

HP 3000 928RX

HP 3000 968LX

HP 3000 968RX

Other Documents Referenced in this Guide:

Part Number Title

5958-5859

5958-2370

50779-90012

2 slot Ij0chassis with a 48MHz CPU

4 slot 110 chassis with a 48MHz CPU

2 slot 110 chassis with a 64MHz CPU

4

slot 110 chassis with a 64MHz CPU

HP 3000 and HP 9000 CE HandbookA1707-90016

Computer Products Site Preparation Resources Guide

HP CEO Site Preparation Handbook

HP Predictive Support User's Guide

vi

Page 7

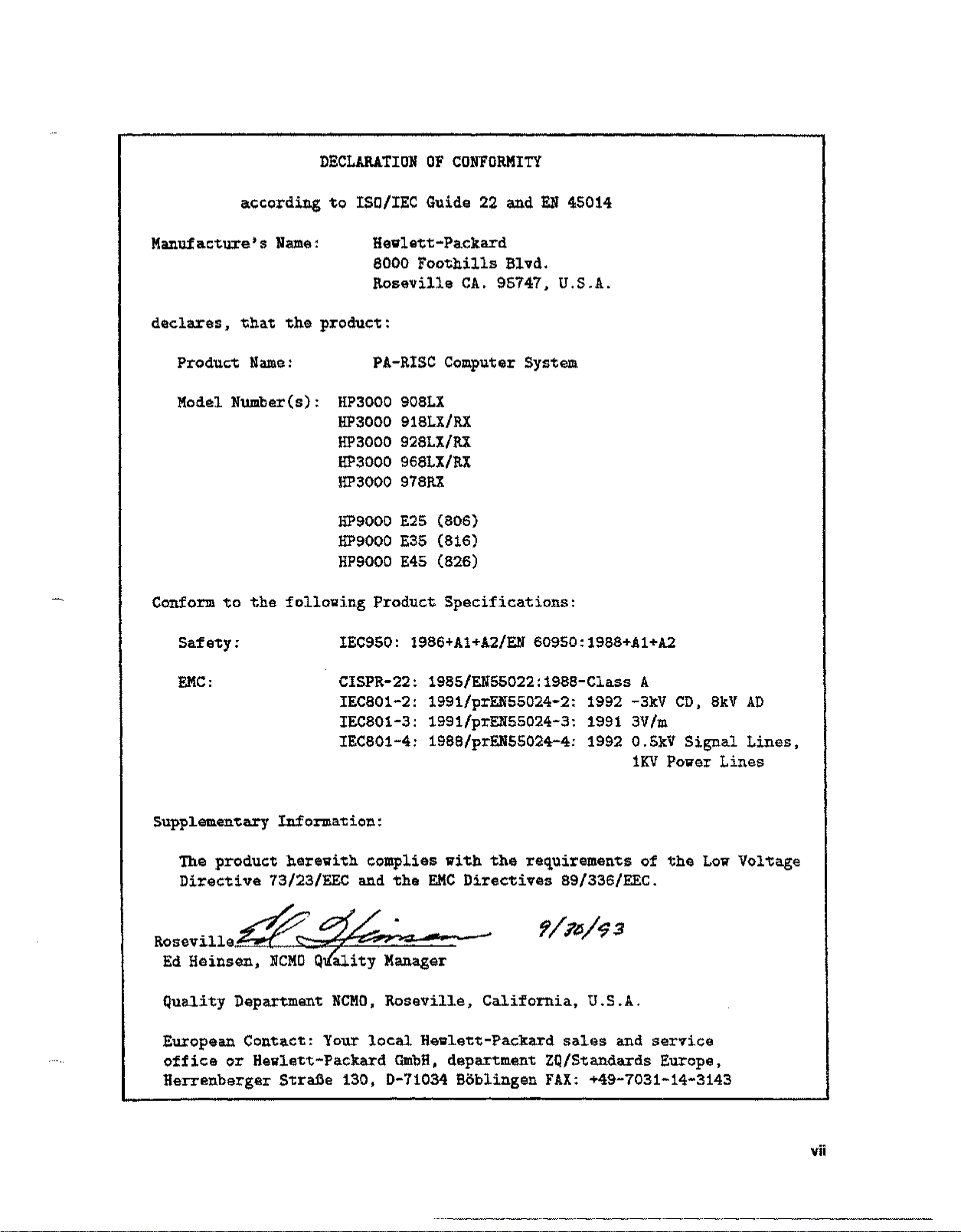

DECLARATION OF CONFORMITY

according to ISO/IEC Guide 22 and EN 45014

Manufacture's Name:

Hewlett-Packard

8000 Foothills Blvd.

Roseville CA. 95747, U.S.A.

declares, that the product:

Product Name: PA-RISC Computer System

Model Number(s): HP3000908LX

HP3000 918LX/RX

HP3000 928LX/RX

HP3000 968LX/RX

HP3000 978RX

HP9000 E25 (806)

HP9000 E35 (816)

HP9000 E45 (826)

Conform to the following Product Specifications:

Safety:

EMC:

IEC950: 1986+Al+A2/EN 60950: 1988+Al+A2

CISPR-22: 1985/EN55022:1988-Class A

IEC801-2: 1991/prEN55024-2: 1992 -3kV CD, 8kV AD

IEC801-3: 1991/prEN55024-3: 1991 3V/m

IEC801-4: 1988/prEN55024-4: 1992 0.5kV Signal Lines,

1KV Power Lines

Supplementary Information:

The product herewith complies with the requirements of the Low VOltage

Directive 73/23/EEC and the EKC Directives 89/336/EEC.

RoseVille~~

e. -~

Ed Heinsen, NCMOQality Manager

Quality Department NCMO, Roseville, California, U.s.A.

European Contact: Your local Hewlett-Packard sat.esand service

office or Hewlett-Packard GmbH, department ZQ/Standards Europe,

Herrenberger Strafie 130, D-71034 Boblingen FAX: +49-7031-14-3143

vii

Page 8

Page 9

Contents

1. About This Manual

2. Site Considerations

Site Preparation Considerations .

Physical Considerations .

Electrical Considerations. . .

Specifications . . . . . . . .

Hewlett-Packard Responsibilities

Third Party Service . .

Customer Responsibilities

Local Codes . . . . .

Data Communications Equipment .

3. Receiving The System

Unpacking and Inspection . . . . . . . . .

Unpack the HP 3000 9X8LX/RX Computer

In Case of Damage

Physical Inventory

Manuals.

Equipment .

Computer .

Claims Procedures

Repacking ....

Storage Requirements

2-1

2-1

2-2

2-2

2-5

2-5

2-7

2-7

2-7

3-1

3-1

3-4

3-4

3-4

3-4

3-4

3-4

3-5

3-5

4. Installation

Installation Procedures

SPU Installation

System Console Installation

Peripheral Equipment

DTC Installation ..

PowerTrust UPS

External Disk Cabinet

Installation Completion

4-1

4-1

4-3

4-4

4-4

4-4

4-5

4-5

Contents-1

Page 10

5. Starting the Computer System

Turning On the Computer System

Initial Power On . . . . . . .

Power On Selftest and PDC Displays

Installation Verification . . . .

Verifier global status messages

Verifier log file . . . . . . .

A. Remote Support Modem Configuration

Quick Reference .

HP Support Link (HP50759A) . . .

Hayes Smartmodem 2400 .....

Black Box V.32 Plus (Version 2.01.01)

Multitech MT224EH7

HP 37212B .

Modem Cable Pin-out . . . . . . .

Multifunction I/O PCA Modem Line Behavior

CCITT Mode AP protocol 0 . .

Bell Mode AP protocol 1 .

CCITT _BIS Mode AP protocol 2 . . .

Modem Settings (HP Predictive Support)

5-1

5-1

5-2

5-4

5-4

5-5

A-2

A-2

A-4

A-5

A-6

A-7

A-8

A-9

A-9

A-9

A-lO

A-I0

Contents-2

Page 11

Figures

3-1. Removing Loose Parts

3-2. Positioning the Shipping Box

3-3. Raising the Flap . . . . .

3-4. Removing the Computer from the Box .

Tables

2-1. Environmental Specifications . . . . . . . . . .

2-2. 2-Slot and 4-slot Chassis Power Specifications

2-3. 2-Slot and 4-Slot Chassis DC Power Specifications

2-4. Electromagnetic Susceptibility Specifications . .

2-5. 2-S1otand 4-Slot Chassis Physical Specifications

2-6. Technical Tasks/Personnel . . . . . . . . . .

4-1. A2941A Line Cord Options .

A-I. Settings for Remote Support Modem (Quick Reference)

A-2. 8-Position DIP Switch Option Settings (Set S)

A-3. 4-Position DIP Switch Option Settings (Set X)

A-4. Switch Option Settings ....

A-5. HP 37212B Switch Configuration . . . . . .

A-6. 92219QCable Pin-out . . .

A-7. Predictive Support Modems and Switch Settings

3-2

3-2

3-3

3-3

2-2

2-3

3

2-4

2-4

2-4

2-6

4-3

A-2

A-3

A-3

A-4

A-8

A-9

A-ll

Contents-3

Page 12

Page 13

About This Manual

1

This manual contains the installation instructions for the HP 3000 Series

Computer Systems.

This manual also contains information for installing the Distributed Terminal Subsystem and

for configuring modems for remote support. This manual does not include instructions for

installing networks.

This manual is organized as follows:

Chapter 1 About This Manual. Introduces the manual and describes its organization.

Chapter 2 Site Considerations. This chapter defines HP organizations and lists site

preparation responsibilities.

Chapter

instructions for unpacking the system, and putting it into position.

Chapter 4 Installation. Contains installation procedures and configuration information.

Chapter 5 Starting the Computer System. Provides instructions for turning on the

equipment, booting MPEjiX, and running the verification program.

Appendix A Support Link Modem Configuration. Provides configuration information on a

number of modems that can be used for the support link modem.

3

Receiving The System. This chapter provides information on receiving the system,

9X8jLXjRX

Family

About This Manual 1-1

Page 14

Page 15

2

Site Considerations

The HP 3000 9X8LX/RX family of computers are office environment computer systems that

do not require special environmental controls. For this reason, no specific site preparation is

required before the system is installed. Even though the computer does not require any site

preparation, there are some site considerations and responsibilities that need to be addressed.

This chapter provides the environmental and electrical specifications for the HP 3000

9X8LX/RX systems. These specifications are provided to ensure the installation site is within

the limits for the system. This chapter also lists the HP organizations and services available

for site preparation for the HP 3000 9X8LX/RX family computers. It also lists and describes

the responsibilities of the customer.

Site Preparation Considerations

The HP 3000 Series 9X8LX/RX computers are primarily designed to be used in commercial

office environments. Except for verifying the environment and AC power, very little site

preparation is required. When the computer is configured into a larger system employing

numerous peripherals and mass storage devices, you should study and become more familiar

with the contents of this chapter.

The CE or Site Preparation Specialist provides peripheral equipment power and

environmental specifications contained in the

3000 and HP 9000 CE Handbook.

It is the customers responsibility to ensure that the facility conditions are maintained in

accordance with the information and specifications contained in this chapter.

This allows Hewlett-Packard to provide support services in accordance with the

Support Services Agreement.

Physical Considerations

Since the HP 3000 9X8LX/RX is a small physical package (refer to physical specs Table 2-5 it

can be located next to a desk or placed in a dedicated computer room. Allow room for cables

and access to the front and rear of the computer cabinet.

Be sure to allow for the peripheral equipment that comes with a computer system, such as

peripheral cabinets, PowerTrust UPS, terminals, printers and other supporting equipment.

Also allow for computer materials storage.

HP CEO Site Preparation Handbook

and the

Customer

HP

Site Considerations 2-1

Page 16

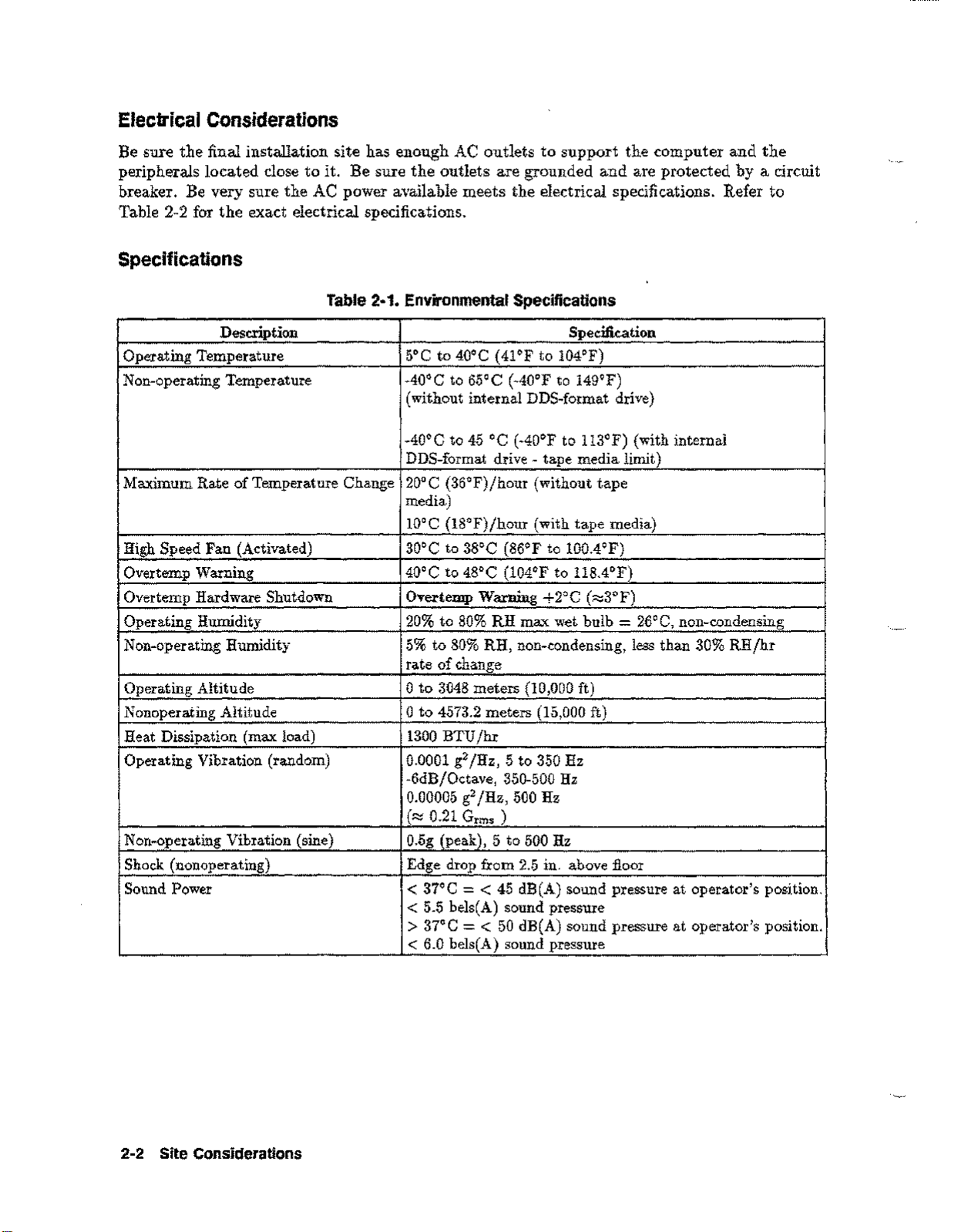

Electrical Considerations

Be sure the final installation site has enough AC outlets to support the computer and the

peripherals located close to

breaker. Be very sure the AC power available meets the electrical specifications. Refer to

Table 2-2 for the exact electrical specifications.

Specifications

Description Specification

Operating Temperature 5°C to 40°C (41°F to 104°F)

Non-operating Temperature -40°C to 65°C (-40°F to 149°F)

Maximum Rate of Temperature Change

High Speed Fan (Activated) 30°C to 38°C (86°F to 100.4°F)

Overtemp Warning

Overtemp Hardware Shutdown

Operating Humidity

Non-operating Humidity 5% to 80% RH, non-condensing, less than 30% RH/hr

Operating Altitude

Nonoperating Altitude

Heat Dissipation (max load)

Operating Vibration (random) 0.0001 g2/Hz, 5 to 350 Hz

Non-operating Vibration (sine)

Shock (nonoperating) Edge drop from 2.5 in. above floor

Sound Power

it.

Be sure the outlets are grounded and are protected by a circuit

Table 2·1. Environmental Specifications

(without internal DDS-format drive)

-40°C to 45°C (-40°F to 113°F) (with internal

DDS-format drive - tape media limit)

20°C (36°F)/hour (without tape

media)

lOoC (18°F)/hour (with tape media)

40°C to 48°C (104°F to 118.4°F)

Overtemp Warning +2°C (~3°F)

20% to 80% RH max wet bulb=26°C, non-condensing

rate of change

°

to 3048 meters (10,000 ft)

°

to 4573.2 meters (15,000 ft)

1300 BTU/hr

-6dB/Octave, 350-500 Hz

0.00005 g2/Hz, 500 Hz

(~ 0.21 G

0.5g (peak), 5 to 500 Hz

rms

)

< 37°C=< 45 dB(A) sound pressure at operator's position.

< 5.5 bels(A) sound pressure

> 37°C=< 50 dB(A) sound pressure at operator's position.

< 6.0 bels(A) sound pressure

2-2 Site Considerations

Page 17

Table 2-2. 2-Slot and 4-slot Chassis Power Specifications

Description

AC Input Voltage Rangel

AC Input Current-

AC Inrush Current

AC Input Power 380 watts maximum, 230 watts typical

Power Supply Output Rating 240 watts DC continuous

AC Input Line Frequency 47 to 63 Hz

Transient Tolerance:

Low Energy

High Energy

Holdup without System Reset

90 to 132 VAC and 180 to 264 VAC

6.5 A maximum load @ 100 VAC

3.5 A maximum load @ 240 VAC

2.4 A typical load @ 100 VAC&50 Hz

2.1 A typical load@120 VAC&60 Hz

1.3 A typical load @ 208 VAC&60 Hz

1.3 A typical load @ 220 VAC&50 Hz

1.2 A typical load @ 240 VAC&50 Hz

50 amperes peak, one cycle

3000 volts, lOps, 500 ns rise/fall

1000 volts, 1.2j.lsrise

20 ms @ 50 Hz (1 cycle)

Specification

Battery Backup Time

1

Note

"

The power supply is an auto-ranging power supply. It does not have to be

recon:figured to operate over its rated operating ranges. However, the system

should not be operated at voltages between the two input voltage ranges.

2

Typical load assumes 192MB memory, two internal disk drives, two

peripherals, PSI I/O card, 802.3 LAN, and a 64MHz CPU.

The power supply can provide power for up to three internal peripherals.

15 minutes with optional

600 VA PowerTrust UPS

Site Considerations 2-3

Page 18

Table 2·3. 2·Slot

and

4·510t Chassis

DC

Power Specifications 3

Note

"

Nominal

Voltage Current

+5V4

+5V_S OA

+12V

-12V OA

3

Total power must not exceed 240 watts.

4

+5V current includes +5V_S current.

Radiated 3V

Conducted

Radiated Magnetic Field Immunity

Electrostatic Air Discharge

Electrostatic Contact Discharge

Minimum

3A 27A

OA 6.67A

Table 2·4. Electromagnetic Susceptibility Specifications

Maximum

Current Voltage Voltage

5A +5.10V

2A

Minimum

+5.10V +5.25V

+lL69V +12.36V

-11.69V

3V rrns, 30 Hz to 100 MHz

1V rrns, 100 MHz to 400 MHz

1 gauss p-p, 48 Hz to 198 kHz

5 kV - no effect

25 kV - no hardware failure

4 kV

Maximum

+5.25V

-12.60V 100 mV

jm,

28 MHz to 1 GHz

p-p Ripple

50 mV

100mV

100 mV

Table 2·5. 2·Slot and 4·Slot Chassis Physical Specifications

Description

Width 222 mm (8.74 in.)

Height

Depth

Weight

Specification

430 mm (16.93 in.)

533 mm (20.98 in.)

31.8 kg (70 lbs)

2·4 Site Considerations

Page 19

Hewlett-Packard Responsibilities

Each member of the Hewlett-Packard service organization is dedicated to making sure that

each customer realizes the maximum benefit from their computer system. HP is responsible

for the installation and initial verification of the computer system. Table 2-6 summarizes a

number of site preparation technical tasks and lists the personnel who should be responsible

for completing each task.

Third Party Service

If an HP 3000 Series 9X8LX/RX Computer system and/or applications software is purchased

from a "third party vendor", that third party is responsible for providing consultation services

on the system operation and applications software.

In the situation of a third party purchase, a maintenance agreement for hardware and Account

Management Service CAMS)for software are available directly from Hewlett-Packard.

Site Considerations 2-5

Page 20

Table 2·6. Technical TasksjPersonnel

Technical Task

Line voltage measured

Electrician and HP CE

Power line frequency measured HP CE

Power line noise levels measured HP CE

Neutral to ground levels measured HP CE

Safety and ground connections verified

Advice on correct circuit breakers and wire sizes

Electrician and HP CE

Electrician and HP CE

Verification that maintenance power outlets (those used for Electrician

floor cleaning, etc.) are on separate circuits from the

computer system.

Person Responsible

Recommendations about lightning protection

HP CE

Measurements and recommendations on radiated interference HP CE

Answers to questions concerning modems and modem

HP CE

options

Thermal load of HP equipment

Thermal load of non-HP equipment

Total air conditioning required

HP CE

Customer/Vendor

Customer/Contractor

2-6 Site Considerations

Page 21

Customer Responsibilities

The customer is responsible for scheduling, planning, and preparing a suitable environment

for the complete computer system. The Hewlett-Packard CE will be available to assist the

customer throughout the planning and preparation for and the installation of the system.

In the

Warranty Information (Section 1) and the On-Site Customer Documents (Section 2). Pay

particular attention to the contents of the Customer Responsibilities page in Section 1 and the

forms contained in Section 2. (The forms in Section 2 will be completed as the site planning

preparation and equipment installation progresses.)

Computer Products Site Preparation Resource Guide,

read the Site Planning and

Local Codes

Special local codes exist in some locations regulating the installation of computer equipment.

The customer is responsible for making sure the system is in compliance with all local laws,

regulations, and codes for mechanical, building, and electrical distribution systems prior to

system installation.

Data Communications Equipment

The customer is responsible for ordering and installing all required data communications

equipment such as:

• Modems (Consult with CE for Hewlett-Packard requirements.)

• Telephone equipment

• Equipment supplied by companies other than Hewlett-Packard

• Any hardware or cables for connection or installation

Site Considerations 2-7

Page 22

Page 23

3

Receiving The System

This chapter contains information for unpacking and inspecting the computer, taking

inventory of shipped goods, filing claims, repacking, and storing the system.

Unpacking and Inspection

The computer and-its accessories may be shipped in more than one container. First, check to

ensure that all the containers ordered by the customer are present, as specified in the carrier's

Bill of Lading. Inspect each container for evidence of mishandling during transit. If any of

the containers are damaged, request that the carrier's agent be present when the container is

opened.

Unpack the shipping containers and inspect each item for damage. Look for damage such as

broken controls and connectors, dented corners, scratches, bent panels, and loose components.

Check the rigid foam packing material for signs of damage, which could indicate rough

handling during transit.

Unpack the HP 3000 9X8LX/RX Computer

The unpacking of the computer is shown on the flap of the shipping box. To remove the

computer from the shipping box, perform the following steps:

Warning

DO NOT try to lift the computer out of the shipping box. The shipped weight of

the computer exceeds 70 pounds (32 kg). If the computer is dropped it could

cause injury and will cause damage to the internal components of the computer.

Receiving The System 3-1

Page 24

1. Remove all loose parts inside the shipping box, and the inside shock absorbing packing

materials. See Figure 3-1.

Figure 3-1. Removing Loose Parts

2. Close the flap with the handles cut in

3. Position yourself so that you must reach across the box to grasp the handles. See

Figure 3-2.

Figure 3-2. Positioning the Shipping Box

it,

the other three flaps should be open.

3-2 Receiving The System

Page 25

4. Grasp the handles and carefully pull the shipping box toward yourself until the shipping

box rests on its side, with the handles on top. This positions the computer in an upright

position, resting on its feet. See Figure 3-2.

Note

5. Open the top

the left and right side.

The feet on the bottom of the computer slide easily on cardboard. They

should also slide easily over hard floors or carpets.

flap.

See Figure 3-3. Reach into the shipping box and grasp the computer on

Figure 3-3. Raising the Flap

6. Pulling alternately with your left and right hand, slowly slide the computer out of the

shipping box. See Figure 3-4. Save the shipping box and packing materials in case the

computer needs to be moved to another location.

Figure 3-4. Removing the Computer from the Box

Receiving The System 3-3

Page 26

In Case of Damage

If damage

is

observed, refer to the claims Procedures section later in this chapter.

Physical Inventory

When the shipping containers is opened, locate the picklist which contains a list of equipment

supplied. Compare the product and option numbers on the picklist with the purchase order to

verify that the shipment is correct.

Manuals

Ensure that all of the manuals listed have been received. If any of the manuals are damaged

or missing, refer to the Claims Procedure section.

Equipment

Ensure that all of the equipment on the list has been received. If any of the equipment is

damaged or missing, refer to the Claims Procedures section.

Computer

Ensure that the model and serial numbers are identical to those specified on the picklist. The

model and serial numbers are printed on a general information label, located on the back of

the computer.

The computer comes with some peripherals embedded in the SPU cabinet. Check that these

peripherals are integrated and that they match the equipment list. The general information

label contains the serial numbers of the embedded peripherals, along with regulatory approvals

and electrical ratings.

Claims Procedures

Notify the nearest Hewlett-Packard Sales and Service Office if the shipment is incomplete,

damaged, or fails to meet specifications. If damage occurred in transit, notify the carrier as

well.

Hewlett-Packard will arrange for replacement or repair without waiting for settlement of

claims against the carrier. In the event of damage in transit, retain the packing container and

packing materials for inspection.

3-4 Receiving The System

Page 27

Repacking

When computers must be reshipped, use the original shipping and packing materials,

if available. Contact the local Hewlett-Packard Sales and ServiceOfficefor repacking

information and materials.

Storage Requirements

Hewlett-Packard computer equipment can be stored or shipped in environments that fall

within the followinglimits:

• Storage Temperature (with tape media): -400to 450C (-400to 1130F)

• Storage Temperature (without tape media): -400to 650C (-400to 149.0F)

• Rate of change (with tape media): <100Cjhr.

• Rate of change (without tape media): <200Cjhr.

• Non-operating humidity; 5% to 80% non-condensing

• Humidity rate of change: <30% RHjhr.

Caution

•

The computer and components should be protected from environmental

extremes that can cause condensation within the equipment. When installing

the equipment, allow time for the temperature of the equipment to stabilize to

the site environment.

Receiving The System 3·5

Page 28

Page 29

Installation

4

This chapter contains information for installing the

Computer systems. All installation tasks should be performed by trained and experienced

personnel only. The installation tasks are as follows:

• System Processor Unit (SPU) Installation

• System Console Installation

• Peripheral or Optional Equipment consisting of:

Datacommunication Terminal Controller (DTC) Installation

PowerTrust UPS Installation

External Disk Cabinet Installation

Warning

Be sure the SPU is not plugged into a wall outlet or PowerTrust UPS before

starting the Installation Procedures.

HP

3000 Series 9X8LX/RX Family

Installation Procedures

Tools required: Standard CE hand tool set, plus a #10 Torx driver.

SPU Installation

To install the SPU, perform the following steps:

1. Observe all ESD precautions while performing installation procedures on any electronic

equipment.

2. Remove the I/O RFI covers from the slots that will hold any I/O cards to be installed.

Note

Refer to the

I/O card slot loading and configuration information .

CE Handbook

(part number A2051-90003) for specific details on

•

3. Install optional I/O cards into an appropriate I/O slot. Make a note of the type of card

inserted into the I/O slot, as well as the slot number. This information will be used during

system configuration.

4. Connect all external peripherals to the appropriate I/O connector at the back of the SPU.

Installation 4-1

Page 30

a. The top connector on the multifunction I/O card is for SCSI peripherals. If there are

no additional SCSI peripherals to connect, install a SCSI terminator (part number

1252-3932)to the SCSI connector.

b. Refer to the documentation that came with the peripheral device for specificinstallation

instructions for that device.

c. Use only the cables that comewith the peripheral device.

Note

d. Make a note of all device addresses that apply to system configuration, along with the

slot number that they are connected to. Refer to the note in step 1.

e. Connect a BNC T connector to the ThinLAN connector on the Multifunction I/O card.

Note

f. Do not leave any open I/O slots after all I/O cards are installed. This would violate the

RFI specifications accommodated by the I/O slot covers.

5. Plug one end of the line cord into the AC receptacle at the rear of the SPU.

Note

•

SCSI cable part numbers are listed in

Chapter4of the

information.

The ThinLAN connector is enabled at the factory, and the AUI LAN

connector is disabled. If the AUI LAN connector needs to be enabled, the

Multifunction I/O card has to be removed and jumper block WI needs to be

repositioned. Refer to the

information.

Be sure the appropriate localized line cord (refer to Table 4-1 for line cord

selection) is available with the SPU.

Also, if the computer comes with a PowerTrust UPS, the UPS has to be

installed before the SPU is powered up. The lime cord that comes with the

SPU is used as the AC line cord for the UPS, and the SPU connects to the

UPS with one of the conveniencecords that come with the UPS.

CE Handbook

CE Handbook, Chapter4for more configuration

has external SCSI cabling and configuration

Chapter

8 of the

CE Handbook.

4-2 Installation

Page 31

Table 4·1. A2941A Line Cord Options

Part Number

Country

8120-1351 United Kingdom

8120-1369 Australia

Male Type

BS1363

AS3112

8120-1689 Europe CEE7jVII

8120-1751 US 120V

8120-3996 US 240V

8120-2104

8120-2956

Swiss SEV type 12

Denmark

8120-4211 South Africa

8120-4753

Japan

5-15P

6-15P

DHCR

SABS

JIS C 8303

System Console Installation

The recommended system console terminal for the HP 3000 9X8LXjRX family of computers

is the HP 700/96 terminal. If the customer uses any other type of terminal for the system

console, refer to the documentation that comes with the equipment for any installation

information.

HP 700/96 System Console

1. Connect the system console cable (part number A1703-63003) to the Multifunction I/O

card connector labeled Console, on the rear of the SPU.

2. Connect the other end of the system console cable to the console connector labeled

DATACOMM., located on the back of the console. Refer to the documentation that came

with the console for specific installation instructions that apply to the device being used as

the system console.

3. The HP 700/96 terminal default settings match the system requirements for terminal

configuration.

Installation 4·3

Page 32

Peripheral Equipment

Be sure to refer to the documentation that comes with any peripheral equipment for specific

installation instructions.

DTC Installation

There may be multiple DTCs to be installed on the system. Repeat the installation

instructions for each DTC installed on the system.

1. The DTCisconnected to the SPU through the LAN link.

2. Connect another BNC T connector (part number 92227N)to the connectorlabeled

Interface

3. Connect the LAN cable (all ready connected to the SPU) to the DTC BNC T connector.

4. If there is another DTC, connect a LAN cable from the other end of the BNC T connector

to the next DTC.

5. On the last DTC installed, connect a LAN terminator (part number 92227P) to the

remaining side of the BNC T connector assembly.

6. Cover all the BNC T connector assemblieswith the fabric anti-static coverthat came with

the T connector.

7. Refer to the documentation that came with the DTC for complete installation and

configuration instructions.

Note

PowerTrust UPS

To connect the PowerTrust UPS to the SPU, perform the followingsteps:

on the back of the DTC.

Be sure that each end of the system LAN link has a BNC LAN Terminator

(part number 92227P) installed.

LAN

1. Locate the PowerTrust System Guide (part number 5961-8383).

2. Take the time to thoroughly read and understand all the necessary procedures outlined in

the PowerTrust Guide. The PowerTrust requires recharge time beforeit is considered ready

for normal operation.

Note

The line cord for the computer is used as the line cord for the UPS. The

computerisconnected to the UPS with a conveniencecord supplied with the

UPS. Be sure the appropriate localized line cord is used with the UPS (refer

to Table 4-1).

"

4-4 Installation

Page 33

External Disk Cabinet

To connect the external disk cabinet to the SPU, perform the following steps:

1. Be sure the disk cabinet ON/OFF switch is in the OFF (0) position.

2. Plug the power cord into the back of the disk cabinet, just below the ON/OFF switch.

3. Connect the end of the SCSI cable (part number 5062-3383 or

connector on the back of the disk cabinet.

4. Connect the other end of the SCSI cable to the top connector labeled SCSI on the

computer back panel. Be sure the connector is securely fastened to the computer back

panel.

5. Connect the external disk SCSI terminator (part number 1252-3920 or

connector on the back of the disk cabinet.

6. Plug the disk cabinet power cord into an appropriate ac wall outlet.

7. This completes the hardware installation of the external disk cabinet. Refer to the

documentation that comes with the disk cabinet for any additional information.

K2296)

to the bottom SCSI

K2291)

to the top

Installation Completion

1. Make sure all (SPU and peripheral devices) power switches are in the OFF position.

2. Connect the SPU power cord to an appropriate AC outlet, or PowerTrust UPS outlet.

3. Connect all peripheral device power cords to appropriate AC outlets.

The computer system should now be ready for initial power up selftest, and system

configuration. Continue to

Starting the Computer System

Chapter 5.

Installation 4-5

Page 34

Page 35

5

Starting the Computer System

The procedures listed in this chapter show you how to interact with the computer to get you

to the ISL (Initial Software Load) prompt

command to load the MPEjiX operating system software can be issued.

Turning On the Computer System

The computer and its external equipment contain built in selftest programs. These programs

automatically run each time the computer and the equipment are turned off and then turned

on again.

Remember, depending on how much internal memory the computer has, the computer selftest

can take up to approximately 2 to 5 minutes to complete.

(IS1>_).

When the ISL prompt is displayed, the

Caution

Do not

equipment while power is on can cause disk damage and loss of data .

move the computer or disk cabinet while the power is on. Moving the

•

Initial Power On

When turning on the computer system (this includes all equipment) be sure to follow the

sequence listed below:

Caution

If any of the external equipment has been OFF due to any environmental

problem, such as heating or air conditioning failure, allow approximately 30

minutes for the temperature of the equipment to stabilize before turning on

the computer.

•

1. Turn on all the external equipment (except the DTC) connected to the computer first. The

DTC will be turned on later.

2. Check all READY or ONLINE indicator lights on the external equipment to be sure that

they indicate being powered up and ready.

3. When all external equipment indicate READY or ONLINE by their particular indicator

lights, press the computer ON

jOFF

switch to the ON position.

Startingthe Computer System 5·1

Page 36

Power On Selftest and

The primary display for the computer is the system console in conjunction with the status

display lightson the front of the computer.

1. The firstthing displayed on the computer console isa lineof messages along the bottom of

the console screen indicating the selftestprograms are running:

PDe

Displays

TEST nnnn REMOTE: disabled inactive multiple ACCESS FAULT:

l

While this display is activethe amber Attention light should be on. This indicates that a

testis being performed.

2. When selftestiscomplete, the console displays a screen similarto the following:

xx ME of memory configured and tested.

Primary boot path:

Alternate boot path:

Main Menu ------------------------------------------------------------

Command Description

BOot [PRIIALTI<path>]

PAth [PRIIALT] [<path>]

SEArch [DIsplayIIPL] [<path>]

56/52.6

56/52.0

(dec)

(dec)

Boot from specified path

Display or modify a path

Search for boot devices

yy

J

COnfiguration menu

INformation menu

SERvice menu

DIsplay

HElp [<menu> I<command>]

RESET

Main Menu: Enter command or menu>

5-2 Startingthe Computer System

Displays or sets boot values

Displays hard~are information

Displays service commands

Redisplay the current menu

Display help for menu or command

Restart the system

Page 37

The xx

commands or menu can be entered with the letters in capitals, for example; booting from

the primary boot path would be:

MB

indicates the amount of memory in the system. Within the main menu, the

Main Menu: Enter command or menu>BOPR1

or a menu request would be:

Main Menu: Enter command or menu>1N

Where the

3.

At the Main Menu: Enter commandor menu> prompt, enter the boot from primary boot

path command

4. The system returns a query of:

Type Y

enabled, you must interact with the Initial Program Loader (1PL) software. An Nentry will

still put you into 1PL.

5. At this point the Initial System Loader (ISL) prompt (ISL» is displayed. The system

should be waiting for your response to the 1SL>prompt.

6. Respond to the 1SL> prompt with the STARTcommand, (or any of the applications

available in 18L). The STARTcommand launches the

IN

entry would display the system hardware information.

(BO

PRI).

Interact with 1PL Y/N?>

(Enter).

The HP

ISL> START

3000

[Enter)

9X8LX/RX systems do not have the autoboot function

[Enter)

(Enter)

MPEjiX

operating system software.

7. After a few minutes, you are prompted to confirm the date and time as shown below.

you do not respond within

15

seconds, the system accepts the displayed date and time

default, and continues with the start-up process.

a. If the date and time displayed are accurate, type Y and press

time out.

b. If they are not, type!! and press

Enter the correct date and time when prompted. Time must be entered in 24-hour

format (for example,

specified.

MPE/iX launch facility

Initialize_genesis - Version «870204.1552»

TUE, AUG11, 1993, 10:20:03 AMCy/n)?

[TMDX_DAMJn n n n

Initialize genesis completed.

The fundamental operating software is starting.

5:00

pm, is entered as 17:00). Seconds default to 00 if not

(RetUffi)

within the 15 seconds allowed.

!

(Return),

or wait for the

If

by

Starting the Computer System 5-3

Page 38

During the launch of the MPW fiX operating system

ERROR

and

WARNING

messages will be

displayed on the console telling you that un configured devices are attached to the system.

These messages are normal during the first boot up. They appear during the first boot up

because the final configuration is not done. Among the messages you may see are these:

Dee;laming 103-5, Addldev to class failure (HLIOstatus FF6AOOBD,.

Dec;laming 103-5, Addldev to class failure (HLIOstatus FF6AOOBD,.

DCe STARTUP - ERROR

The system is making many internal checks and is reporting that the configuration is not

complete. When this checking process is complete a welcome message is displayed on the

console. You are automatically logged on to the system as

OPERATOR.SYS.

8. When the system prompt (:) is displayed, all the system selftests are complete. At this

time, turn on the DTC( s). The configuration process can begin.

Installation Verification

Once the configuration is complete, the system installation can be verified by the use of the

Verifier

The Verifier program usually resides in the

command file named

program.

VERIFY. PUB. SYS

DIAG

group of the

SYS

account. However, a

is provided to setup the proper environment for Verifier

operation.

To invoke MPEfiX Verifier log on as Manager.Sys (or any log on with SM, OP or DI

capability) and enter the following:

VERIFY

Follow the program prompts on the console screen. Verifier performs more than one task at

one time. For this reason, you will frequently see messages for assorted devices interspersed

with one another, this is normal.

Verifier global status messages

When Verify is finished it prints one of three status messages indicating:

If everything verified as

System verification is complete. Everything is okay.

Proceed ;lith the next operation ...

okay

a

.iessage

similar to the following appears:

If something needs

attention,

a message similar to the following appears:

5-4 Starting the Computer System

Page 39

ATTENTION: System verification indicates that noncritical

devices are not all working.

This message indicates a problem with a

except:

If there is an

system disks, nonsystem (private volume) disks and tape drive logical device 7.

error,

a message similar to the following appears:

noncritical

device. A noncritical device is everything

ERROR: System verification failed. Critical devices are

not functional. Do not continue to use the system.

This message indicates a

the problem has been corrected.

volume) disks and tap e drive logical device 7.

critical

device failed. You should not attempt to use the system until

Critical

devices are all system disks, all non-system (private

Verifier log file

In addition to the messages described above, MPE/iX Verifier creates a log file named

This file contains a detailed history of the verification actions and status messages and a

system I/O map which shows the current status of each device and the overall system status.

VERLOG

equation can be used to redirect it to another location.

is created in the group and account from which Verifier is invoked. However, a file

VERLOG.

Starting the Computer System 5-5

Page 40

Page 41

A

Remote Support Modem Configuration

This section contains information for connecting specificmodems to the RP 30009XSLX/RX

Family Computer System. This section also discussesthe signal line behavior of the

Multifunction I/O modem interface to aid in configuringmodems that are not listed.

General rules for configuringmodems:

• The modem must be set up to respond to DTR.

• CTS should follow RTS.

• DSR must follow OR, not DCD.

• For Bell mode, the modem should disregard RTS.

• Set both local and remote modems to either:

o the same compression mode, OR

o to NO data compression.

If problems occur connecting two modems, usually the fault is that one is enabled for

some MNP level and the other modem is set for no data compression.

If the modem sends up-modem dialog with all of the signals asserted, it is possible for the user

to be logged offimmediately when a password is enabled for the Access Port. This can be

corrected by setting the modem so it does not report connection status via the data path.

Note

V.22bis/V.25bis modes are not supported on the A1703-60003or A1703-60022

Multifunction I/O interfaces.

Remote Support Modem Configuration A-1

Page 42

Quick Reference

Table A-I is a quick reference table for the supported modems for remote support. For

detailed information, refer to the appropriate section of this appendix.

Table A·1. Settings for Remote Support Modem (Quick Reference)

Modem Model Settings

HP50759A (Support Link)

Hayes Smartrnodem 2400 S3, S9, and S10: Down

Black Box V.32 Plus (2.01.01)

Multitech MT224EH7 Xl, X4, S3, S7, and S8: Down

HP 37212B

HP Support Link (HP50759A)

Supported modes:

• Bell

• CCITT_OM

• CCITT_AM

• CCITT_BIS_OM

• CCITT _BIS_AM

xi,

X2, X3, X4, and S8: Down

si,

S3, S4, S5, and S6: Up

S2 and S7: Do not care

si,

S4, S5, S6, and S7: Up

S2: Do not care

AT&D2&Sl&Cl&R

(See Black Box V.32 section for details)

X2, X3,

si,

S3, S8, S9, SI1, and S12: Up (1)

si,

S2, S4, S5, and S6: Up

S2, S4, S5, S6, S7, and S10: Down (0)

Supported cables:

• HP 922I9Q - Bell, CCITT_OM, CCITT_AM

• A1703-63006 - CCITT_BIS_OM, CCITT _BIS_AM

A-2 Remote Support Modem Configuration

Page 43

Auto-dial modes: Hayes

This modem is the standard HP Support Link. It supports V.22bis line discipline, but does

not support V.25bis auto-dialing. In order for V.22bis answer mode to work properly, DSR

must follow OH. Data Compression should be set

cause problems when connecting to other modems that do not have data compression.

Table A·2. 8·Position DIP Switch Option Settings (Set S)

OFF.

Setting data compression

ON

can

Note

Switch

Sl up DTR Normal

S2

S3

S4

S5

S6

S7

S8

xx means do not care.

Switch

Xl

X2

X3

X4

Position

xx

up Suppress Responses &QO

up Enable Echo of commands

up

up DCDjDSR Normal

xx

down Enable Command Mode

Table A·3. 4·Position DIP Switch Option Settings (Set X)

Position Description

down

down DSR Follows OR

down Use RP Defaults

down No ENQjACK Pacing

CTS Normal

Description

Verbose Responses

Enable Auto-Answer

Depends on phone line

&RO

&Sl

&EO &E3 &E6 &ElO &E14 $BA1

&E8

Option Command

&D2

VI

E1

SO=l

&C1 &Sl

Option Command

Note

•

An

AT1517

BO El Ml QO Vl XO &EO &E3 &E6 &E8 &El0 &E14 &QO

$MB2400 $SB2400 $BAl &Wl

&AO $AO

&Vl &Wl

command should have the following output:

&BO &BSl &Cl &D2 $DO $F1 &GO &10 &MO $MIO &RO $RO &S1 &T5

OK

Remote Support Modem Configuration A-3

Page 44

Hayes Smartmodem 2400

Supported modes:

• Bell

• CCITT_OM

• CCITT_AM

Supported cables:

• Must use 92219Qmodem cable.

Auto-dial modes: Hayes.

This modem drives circuit 111 (Pin 23) instead of using it as an input. With either cable

(92219Q or AI703-63006), the Multifunction I/O PCA and the modem, drive the same line.

Caution

I

Turn offall data compression modes.

The Hayes defaults for the modem lines must be changed to the following:

This modem should not be used because all HP cables connect circuit 111 to

the modem. If this modem is connected, both the Multifunction I/O PCA and

the modem drive circuit 111. This modem has been used in the past with the

CIa based AP card and had the same problem.

Table A-4. Switch Option Settings

Switch

SI

S2 xx

S3

S4 up Characters echoed

S5

S6

S7

S9

S10

Position Description Option

up DTR normal

down

up Auto-Answer enabled

up

up RJ-ll

down

down

Result codes disabled

Detect Carrier

CCITT

Return to command state

AT&D3&W

ATQl&W

ATEl&W

ATSO=I&W

AT&Cl&SI&W

AT&JO&W

ATBO&W

AT&D3&W

Command

Note

xx means do not care.

tI

A-4 Remote Support Modem Configuration

Page 45

Black Box V.32 Plus (Version 2.01.01)

Supported modes:

• Bell

• CCITT_OM

• CCITT_AM

Supported cables:

• Must use 92219Q modem cable.

Auto-dial modes: Hayes.

This modem does not work with v.22bis because it does not supply 112 and because the sense

of 111 is backwards (TRUE means low speed, FALSE means high speed). The fact that 111

is backwards is not too big a problem because the modem can be configured to ignore Ill.

Change so that DTE Fallback is

means that the Multifunction I/O PCA always thinks it is running at the lower speed. If you

set the speed for twice the desired speed, then it will work at the desired speed. It is best not

to use this modem with any of the CCITT bis protocols.

The Black Box defaults for all of the modem lines are incorrect and must be changed before

this modem will work properly. To do this from the front panel, go into the Change DTE

Parameters and set the

Responds to DTR

DSR is Normal

DCD is Normal

CTS follows RTS

following:

Disabled.

This is the factory default. Not supplying 112

This can be done with the following AT command:

For Hayes dialing, make certain that the AT command set is enabled. It is normally good to

disable status messages to the host by using the

The current configuration can become the power-on configuration by using the

command.

This modem does not do any rate shifting. So the DTE rate and the DCE rate must be the

same.

This modem seems to work in AP mode with the protocol set to either Bell or CCITT. It does

not work with the modem protocol set to CCITT _BIS. Make certain to configure the modem

to ignore 111, or configure the Access Port to set FS low. It also seems to work fine in normal

mode (i.e. under host control).

AT&D2&S1&C1&R

ATQ1

command.

AT&W

Remote Support Modem Configuration A·5

Page 46

Multitech MT224EH7

Supported modes:

• Bell

• CCITT_OM

• CCITT_AM

• CCITT_BIS_OM

• CCITT _BIS_AM

Supported cables:

• HP 92219Q - Bell, CCITT_OM, CCITT_AM

• A1703-64006- CCITT_BIS_OM, CCITT_BIS_AM

Auto-dial modes: Hayes, V.25bis.

Note

"

The configuration of the hardware switches on the modem are:

8-position DIP-Switch (S switches):

Switch:

4-position DIP-Switch (X switches):

Switch: 1 2 3 4

For Hayes mode to work correctly,

connection goes down. For Hayes,

must be set.

The version of the modem has a problem when dialing with V.25bis where if

the number that is dialed is busy, DSR does not drop. This same problem

causes V.25bis error indications to be improperly decoded, meaning that the

modem time-out timer must expire before we know that the attempt failed.

This also means that multiple dialing attempt will always fail. If the DSR

jumper is set so that DSR followsDCD, this problem goes away.

1

2

3

4

5

6

UP UP DOWN UP UP UP DOWN DOWN

DOWN UP UP DOWN

AT&RO

AT$VO

must be set so that it drops CTS when the

must be set. For V.25bis dialing,

7

8

VT$Vl

and

AT$BAl

Hayes dialing parameters:

BO El Ml QO RO Vl XO &El &E4 &E6 &E8 &El0 &E13 &E15

$MB2400 $SB2400 $BAl &WO

SO S2 S3 S4 S5 S6 S7 S8 S9 S10 Sll S12 S24 S25 S30

001 043 013 010 008 002 030 002 006 007 070 050 020 000 000

$AO &AO &BO &BSl &Cl $DO &D2 #DBO $EBO $F1 &GO #LO $MIO &MO

&PO #P2 &QO &Q3 $RO &R1 &Sl $T1 &T4 $VO $VDO &XO YO

$MB2400 $SB2400 $BA1 &WO

OK

A-6 Remote Support Modem Configuration

Page 47

For V.22bis auto-answer, internal jumper DSR must be set so that DSR follows OH. The

factory default is for DSR to follow CD. This is different from the Support Link where the

factory default was for DSR to follow OH. There does not seem to be an AT command that

does this.

V.25bis dialing parameters:

BO E1 M1 QO RO V1 XO &E1 &E4 &E6 &E8 &E10 &E13 &E15

$MB2400 $SB2400 $BA1 &WO

SO S2 S3 S4 S5 S6 S7 S8 S9 S10 S11 S12 S24 S25 S30

001 043 013 010 008 002 030 002 006 007 070 050 020 000 000

$AO &AO&BO&BSl &Cl $DO &D2 #DBO $EBO $Fl &GO#LO $MIO &MO

&PO #P2 &QO&Q3 $RO &Rl &Sl $Tl &T4 $Vl $VDO &XOYO

$MB2400 $SB2400 $BAl &WO

VAL

To modify a MT224E7B:

• Open modem and change the DSR jumper.

• Set switches on the bottom of the box to above.

• Send AT&RO

• For Hayes dialing, send AT$VO.

• For V.25bis dialing, send AT$V1.

HP 372128

Supported modes:

• Bell

• CCITT_OM

• CCITT_AM

• CCITT_BIS_OM

• CCITT_BIS_AM

Supported cables:

• HP 92219Q - Bell, CCITT_OM, CCITT_AM

• A1703-64006 - CCITT_BIS_OM, CCITT_BIS_AM

Auto-dial modes: None

It is best to use this modem in CCITT mode because it causes the Access Port to hang up if

used in Bell mode at 1200 baud. It can be used in Bell mode at 2400 baud, or either 1200 or

2400 in CCITT mode. This modem can not be dialed with either Hayes or V.25BIS auto-dial

protocols. Table A-5 describes the switch settings.

Remote Support Modem Configuration A-7

Page 48

Table A·5. HP 372128 Switch Configuration

Note

Switch

SI down

S2

S3

S4

S5

S6

S7

S8

S9

SID

S11

S12

Although this modem claims to be able to dial using V.25bis, it only uses the

V.25bis line discipline. The command set does not match the set specified in

the V.25bis specification.

Position

down

up

down Primary channel

down

down

down

up

up

down

up

up

Computer mode operation (HP command set)

1 start, 8 data and 1 stop

Error correction disabled

No Flow control

DSR/CTS/CD to RS-232-C definition

DTR behaves to RS-232-C definition

Description

Modem Cable Pin-out

Table A-6 list the pin-outs for the 92219Q cable, which is most often used to connect the

Access Port to the support modem.

A·a

Remote Support Modem Configuration

Page 49

Table A-S. 92219Q Cable Pin-out

Computer

End

2

3

8 RTS

22

20

6

9

4

and

23 FS

7

The pin-out for the A1703-63006 cable is the same except that pin 9 on the computer end

is routed to pin 12 on the modem end and that Line functions as Rate Select (RS). This

cable is only used with the A1703-60003 SCSI/Console/LAN Multifunction I/O interface for

V.22bis /V .25bis applications.

Signal

Name End

TD

RD

CTS

DSR

DTR

RI

5

DCD

GROUND 7

Modem

3

2

4

5

6

20

22

8

23

Multifunction I/O peA Modem Line Behavior

CCITT Mode AP protocol 0

This protocol is known as HP-UX CCITT. The card waits for RI before raising DTR. It

also raises RTS when it raises DTR. If DSR does not come up within 25 seconds, DTR goes

back down. The connection also depends on CTS and DCD. DCD can drop for up to 400ms

before the connection will drop. CTS must stay high always. Once CTS drops, the connection

starts to drop. A new connection cannot occur until DSR, DCD and CTS all drop. FS can be

programmed to either state via the

Bell Mode AP protocol 1

This is sometimes called Bell simple protocol. It raises DTR when it can accept a connection.

The connection is valid when it sees DCD. It drives RTS whatever it was when Remote is

enabled (usually, RTS is low) and does not look at DSR or CTS. When a disconnect is done,

DCD must drop before a new connection can be made (i.e. it will not raise DTR until DCD

drops).

CA

command.

Remote Support Modem Configuration A-9

Page 50

CCITT _BIS Mode AP protocol 2

This protocol is CCITT V.22bis. It requires the special cable A1703-63006 which is just like

the 92219Q cable with the exception that pin 9 on the computer end is routed to pin 12 (RS)

rather than pin 22 CRI). DTR

connection is established when DSR is high. CTS can drop for an indefinite amount of time

without dropping the connection. The card will not send data to the modem when CTS is

low. DCD can drop for up to 400ms before the connection is dropped. Once the connection

is dropped, DSR, DCD and CTS must all go low before a new connection can be made. RS

controls what speed the card sends to the modem. If RS is high, the programmed baud rate is

used. If RS is low, half of the programmed baud rate is used. If you use the 92219Q cable, the

baud rate will most certainly be half the programmed baud rate, since

be down. FS can be programmed to either state via the

is

raised whenever a connection is allowed. RTS follows DSR. A

RI

will almost always

CA

command.

Modem Settings (HP Predictive Support)

The

HP Predictive Support User's Guide for HP 3000 Series 900 (pin

additional information on HP predictive support modem settings. Table A-7 contains a quick

reference description of the modem switch settings for autodial modems connected to the

LAN jConsole port.

50779-90012) contains

Note

•

Some of the settings in Table A-7 are different than those described in the

first part of the Appendix. This is true for modems connected to a DTC or

manually dialed modems. Please refer to HP Predictive Support on-line help

for proper switch settings. Also be aware that the modems listed here are not

necessarily recommended or supported as Remote Support Modems.

A-10 Remote Support Modem Configuration

Page 51

Table A-7. Predictive Support Modems and Switch Settings

Modem Type

HP 50759A (Support Link)

HP 50759B S2, S3, S4, 57, S8, S9, S12, and S16; Down

HP 37212A All switches; Open

HP 37212B 53, 511, and 512; Up

Hayes Smartmodem S4, 58, and S10; Down

Support Link I

Support link II Option 1: Code 3

Xl, X2, X4, S4, and S8; Down

All others; Up

All others; Up

All others; Down

Option 1: Code 3

Option 1: Code 2

Option 8: Code 2

Option 15: Code 2

Option 16: Code 2

Option 22: Code 1 for pulse

Option 22: Code 2 for tone

Option 22: Code 3 for autoselect

Option 24: Code 2

Option 1: Code 2

Option 8: Code 2

Option 15: Code 2

Option 16: Code 2

Option 22: Code 1 for autoselect

Option 22:

Option 22: Code 3 for pulse

Switch Settings!

Code 2 for tone

Note

1

The switch settings are for aut adial modems connected to the LAN jConsole

port.

Remote Support Modem Configuration A-11

Page 52

Loading...

Loading...