Page 1

HP StorageWorks

Enterprise Virtual Array 3000/5000 user

guide

Part number: 5697–5480

enth edition: March 2006

T

Page 2

Legal and notice information

© Copyright 2003-2006 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth

in the express warranty statements accompanying such products and services. Nothing herein should be construed as constituting

an additional warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

Microsoft®,MS-DOS®,MSWindows®,Windows®,WindowsNT®, and Windows Server® are U.S. registered trademarks of

Microsoft Corporation.

Java™ and Solaris™ are trademarks of Sun Microsystems, Inc.

Red Hat® and Red Hat® Enterprise Linux are registered trademarks of Red Hat, Inc.

Linux® is a registered trademark of Linus Torvalds.

Page 3

Contents

Aboutthisguide ......................... 11

Overview......................................... 11

Intendedaudience................................... 11

Relateddocumentation................................. 11

Documentconventionsandsymbols ............................. 12

Rackstability ....................................... 13

HPtechnicalsupport.................................... 13

HP-authorizedreseller ................................. 13

Helpfulwebsites ................................... 13

Subscribingtoproactiveupdates............................. 14

HPproductdocumentationsurvey .............................. 14

1EnterpriseVirtualArraydescription................. 15

IntroductiontotheEnterpriseVirtualArray........................... 15

Featuresandenhancements................................. 15

Easeofmanagement.................................. 16

Dataavailability.................................... 16

Performance ..................................... 16

Scalability ...................................... 16

Operatingsystemsupport................................ 17

Faultmanagementanddiagnostics............................ 17

EVAremotesupporttools................................ 17

Storagesystemcomponents................................. 17

HPCommandViewEVA ................................ 18

Controllersoftware................................... 18

VCSfeaturesandfunctionality............................ 18

Optionalsoftwarelicensing............................. 18

Hardware ...................................... 19

Physicallayoutofthestoragesystem ......................... 19

FibreChanneldriveenclosure............................ 19

FibreChannelloopswitches............................. 20

HSV110andHSV100controllers .......................... 20

Racks ...................................... 21

2EnterpriseVirtualArraystartup .................. 23

EVA5000storagesystemconnections............................. 23

EVA3000storagesystemconnections............................. 24

Proceduresforgettingstarted ................................ 25

Gatheringinformation ................................. 25

Hostinformation.................................. 26

SettingupacontrollerpairusingtheOCP......................... 26

EnteringtheWWN ................................ 27

EnteringtheWWNchecksum............................ 27

Enteringthestoragesystempassword......................... 28

InstallingHPCommandViewEVA ............................ 28

InstallingoptionalEVAsoftwarelicenses ......................... 29

3EnterpriseVirtualArrayoperation ................. 31

Bestpractices....................................... 31

Enterprise Virtual Array 3000/5000 user guide

3

Page 4

Operatingtipsandinformation ............................... 31

Reservingadequatefreespace ............................. 31

UsingFATAdiskdrives ................................... 31

FailbackpreferencesettingforHSVcontrollers......................... 31

Changingvirtualdiskfailover/failbacksetting....................... 34

Storagesystemshutdownandpowerup............................ 35

Shuttingdownthestoragesystem ............................ 35

Poweringupthestoragesystem ............................. 35

Saving storage system configurationdata ........................... 36

Addingdiskdrivestothestoragesystem ........................... 38

Guidelinesforaddingdiskdrives ............................ 38

Creatingdiskgroups.................................. 38

Addingadiskdrive .................................. 39

Removingthedriveblank.............................. 39

ChangingtheDeviceAdditionPolicy......................... 40

Installingthediskdrive............................... 40

Checkingstatusindicators.............................. 40

Addingthedisktoadiskgroup ........................... 41

Handling fiberopticcables................................. 42

4EnterpriseVirtualArrayhardwarecomponents............ 43

FibreChanneldriveenclosures................................ 43

Enclosurelayout.................................... 43

I/Omodules ..................................... 44

I/Omodulestatusindicators ............................ 45

FibreOpticFibreChannelcables ............................ 47

CopperFibreChannelcables .............................. 47

FibreChanneldiskdrives................................ 47

Diskdrivestatusindicators ............................. 48

Diskdrivestatusdisplays .............................. 48

Diskdriveblank.................................. 49

Powersuppliesandblowers............................... 49

Powersupplies .................................. 50

Blowers ..................................... 50

DriveenclosureEMU.................................. 51

Controlsanddisplays ............................... 51

EMUfunctions................................... 52

EMUmonitoringfunctions.............................. 53

EMUdisplays................................... 53

EMUindicatordisplays............................... 54

Usingthealphanumericdisplay ........................... 54

EMUpushbuttonstatusindicators .......................... 55

Audiblealarmoperations.............................. 55

Enablingtheaudiblealarm............................. 56

Mutingorunmutingtheaudiblealarm ........................ 57

Disablingtheaudiblealarm............................. 57

Enclosurenumberfeature.............................. 58

ErrorConditionReporting.............................. 60

Reportinggroupfeature .............................. 63

FibreChannelloopswitches................................. 64

Power-onselftest(POST) ................................ 65

Readingtheswitchindicators .............................. 65

Problemisolation ................................... 66

HSVcontrollers ...................................... 67

Highavailabilityfeatures................................ 68

Operatorcontrolpanel................................. 68

Statusindicators.................................. 69

Navigationbuttons................................. 70

Alphanumericdisplay ............................... 70

DisplayingtheOCPmenutree............................ 70

4

Page 5

Displayingsysteminformation............................ 71

Displayingversionssysteminformation ........................ 71

Shuttingdownthesystem.............................. 72

Shuttingthecontrollerdown............................. 72

Restartingthesystem................................ 73

Uninitializingthesystem .............................. 73

Passwordoptions ................................. 73

Changingapassword ............................... 73

Clearingapassword................................ 74

SettingupacontrollerpairusingtheOCP....................... 74

Powersupply/blowerassembly ............................. 74

Cachebattery..................................... 75

HSVcontrollercabling ................................. 75

Racks .......................................... 75

Rack configurations .................................. 75

Powerdistribution ................................... 75

PDUs ...................................... 76

PDMs ...................................... 77

RackACpowerdistribution............................. 78

RackSystem/Epowerdistributioncomponents..................... 79

Movingandstabilizingarack.............................. 80

5Customerreplaceableunits.................... 83

Customerselfrepair(CSR) ................................. 83

Partsonlywarrantyservice ............................... 83

Bestpracticesforreplacinghardwarecomponents ....................... 84

Componentreplacementvideos ............................. 84

Verifyingcomponentfailure............................... 84

Procuringthesparepart ................................ 84

Replacingthefailedcomponent ............................. 87

Returningthedefectivepart............................... 87

Replacingadiskdrive ................................... 87

Beforeyoubegin ................................... 87

Verifyingcomponentfailure............................... 88

Removingadisk.................................... 89

ChangingtheDeviceAdditionPolicy........................... 89

Installingadiskdrive.................................. 90

Verifyingproperoperation ............................... 90

Addingadisktoadiskgroup.............................. 90

Returningthefailedcomponent ............................. 91

Replacingthediskenclosurepowersupply/blower....................... 91

Beforeyoubegin ................................... 91

Verifyingcomponentfailure............................... 91

Removingablower .................................. 92

Installingablower................................... 92

Removingapowersupply................................ 93

Installingapowersupply................................ 94

Verifyingproperoperation ............................... 94

Returningthefailedcomponent ............................. 95

A Regulatory notices and specifications................ 97

Regulatorynotices..................................... 97

FederalCommunicationsCommission(FCC)notice..................... 97

FCC Class A certification.............................. 97

ClassAequipment................................. 98

ClassBequipment................................. 98

Declaration of conformity for products ma rked with the FCC logo, United States only . . . . . 98

Modifications................................... 98

Cables...................................... 98

Enterprise Virtual Array 3000/5000 user guide

5

Page 6

Laserdevice ..................................... 98

Lasersafetywarnings ............................... 99

CompliancewithCDRHregulations ......................... 99

Certification and classificationinformation......................... 99

Canadiennotice(avisCanadien) ............................ 99

ClassAequipment................................. 99

ClassBequipment................................. 99

Europeanunionnotice ................................. 100

NoticeforFrance ................................... 100

WEEERecyclingNotices ................................ 100

Englishnotice................................... 100

Dutchnotice ................................... 100

Czechoslovakiannotice............................... 100

Estoniannotice .................................. 101

Finnishnotice................................... 101

Frenchnotice ................................... 101

Germannotice .................................. 101

Greeknotice ................................... 102

Hungariannotice ................................. 102

Italiannotice ................................... 102

Latviannotice................................... 103

Lithuaniannotice ................................. 103

Polishnotice ................................... 103

Portuguesenotice ................................. 103

Slovakiannotice.................................. 104

Sloveniannotice.................................. 104

Spanishnotice .................................. 104

Swedishnotice .................................. 104

Germanynoisedeclaration............................... 105

Japanesenotice.................................... 105

Harmonicsconformance(Japan)........................... 105

Taiwanesenotice ................................... 105

Japanesepowercordnotice............................... 105

Country-specific certifi cations .............................. 105

Fibre Channel drive enclosure specifications.......................... 106

Physical specifications ................................. 106

Environmental specifications............................... 107

Power specifications .................................. 107

Fibre Channel switch specifications.............................. 109

Controller specifications .................................. 109

Physical specifications ................................. 109

Power specifications .................................. 110

Environmental specifications............................... 110

Rack specifications..................................... 111

Physical specifications ................................. 111

Environmental specifications............................... 112

Power specifications .................................. 112

BEMU-generatedconditionreports ................. 115

Conditionreportformat................................... 115

Correctingerrors ..................................... 116

Driveconditions.................................... 116

0.1.en.01 CRITICAL condition—Drive configurationordrivelinkrate ........... 116

0.1.en.02INFORMATIONcondition—Drivemissing .................. 117

0.1.en.03INFORMATIONcondition—Drivesoftwarelockactive............. 117

0.1.en.04CRITICALcondition—Loopadrivelinkrateincorrect.............. 118

0.1.en.05CRITICALcondition—Loopbdrivelinkrateincorrect.............. 118

Powersupplyconditions ................................ 118

0.2.en.01NONCRITICALCondition—PowersupplyACinputmissing........... 119

0.2.en.02UNRECOVERABLEcondition—Powersupplymissing.............. 119

6

Page 7

0.2.en.03CRITICALcondition—Powersupplyloadunbalanced.............. 119

Blowerconditions ................................... 120

0.3.en.01NONCRITICALcondition—Blowerspeed .................. 120

0.3.en.02CRITICALcondition—Blowerspeed ..................... 120

0.3.en.03UNRECOVERABLEcondition—Blowerfailure................. 121

0.3.en.04UNRECOVERABLEcondition—Blowerinternal ................ 121

0.3.en.05NONCRITICALcondition—Blowermissing.................. 121

0.3.en.06UNRECOVERABLEcondition—Noblowersinstalled.............. 121

Temperatureconditions................................. 121

0.4.en.01NONCRITICALcondition—Hightemperature................. 122

0.4.en.02CRITICALcondition—Hightemperature ................... 122

0.4.en.03NONCRITICALcondition—Lowtemperature ................. 123

0.4.en.04CRITICALcondition—Lowtemperature.................... 123

0.4.en.05UNRECOVERABLEcondition—Hightemperature ............... 123

EMUconditions.................................... 124

ResettingtheEMU................................. 124

07.01.01CRITICALcondition—EMUinternalclock ................... 124

07.01.02UNRECOVERABLEcondition—EMUinterrupted ................ 124

0.7.01.03UNRECOVERABLECondition—Powersupplyshutdown............. 125

0.7.01.04INFORMATIONcondition—EMUinternaldata................ 125

0.7.01.05UNRECOVERABLEcondition—BackplaneNVRAM .............. 125

0.7.01.10NONCRITICALcondition—NVRAMinvalidreaddata............. 125

0.7.01.11NONCRITICALcondition—EMUNVRAMwritefailure............. 125

0.7.01.12NONCRITICALcondition—EMUcannotreadNVRAMdata .......... 126

0.7.01.13UNRECOVERABLEcondition—EMUloadfailure ............... 126

0.7.01.14NONCRITICALcondition—EMUenclosureaddress .............. 126

0.7.01.15UNRECOVERABLEcondition—EMUhardwarefailure ............. 127

0.7.01.16INFORMATIONcondition—EMUinternalESIdatacorrupted.......... 127

0.7.01.17UNRECOVERABLEcondition—Powershutdownfailure............. 127

0.7.01.18UNRECOVERABLEcondition—EMUhardwarefailure ............. 127

0.7.01.19UNRECOVERABLEcondition—EMUESIdriverfailure ............. 128

Transceiverconditions ................................. 128

0.F.en.01CRITICALcondition—Transceiverincompatibility................ 128

0.F.en.02CRITICALcondition—Transceiverdatasignallost ............... 128

0.F.en.03 CRITICAL condition—Transceiver fibrechanneldriveenclosurebusfault...... 128

0.F.en.04CRITICALcondition—Transceiverremoved .................. 129

0.F.en.05 CRITICAL condition—Invalid fibrechannelcharacter.............. 129

Voltagesensorandcurrentsensorconditions........................ 129

1.2.en.01NONCRITICALcondition—Highvoltage................... 130

1.2.en.02CRITICALcondition—Highvoltage ..................... 130

1.2.en.03NONCRITICALcondition—Lowvoltage ................... 130

1.2.en.04CRITICALcondition—Lowvoltage...................... 130

1.3.en.01NONCRITICALcondition—Highcurrent ................... 130

1.3.en.02CRITICALcondition—Highcurrent...................... 130

Backplaneconditions.................................. 130

8.2.01.10NONCRITICALcondition—BackplaneNVRAMread ............. 131

8.2.01.11NONCRITICALcondition—BackplaneNVRAMwritefailure .......... 131

8.2.01.12NONCRITICALcondition—BackplaneNVRAMreadfailure .......... 131

8.2.01.13NONCRITICALcondition—BackplaneWWNisblank............. 131

I/OModuleconditions................................. 131

8.7.en.01CRITICALcondition—I/Omoduleunsupported ................ 132

8.7.en.02CRITICALcondition—I/Omodulecommunication............... 132

8.7.en.10NONCRITICALcondition—I/OmoduleNVRAMread ............. 132

8.7.en.11NONCRITICALcondition—I/OmoduleNVRAMwrite............. 132

8.7.en.12NONCRITICALcondition—I/OModuleNVRAMreadfailure.......... 132

8.7.en.13NONCRITICALcondition—I/Omoduleremoved ............... 132

Hostconditions .................................... 133

CControllerfaultmanagement ................... 135

Using H P Command View EVA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Enterprise Virtual Array 3000/5000 user guide

7

Page 8

GUIterminationeventdisplay................................ 135

GUIeventdisplay ................................... 135

Faultmanagementdisplays ............................... 136

DisplayingLastFaultInformation........................... 136

DisplayingDetailedInformation ........................... 136

Interpretingfaultmanagementinformation....................... 137

Glossary............................. 139

Index .............................. 155

8

Page 9

Figures

1Storagesystemhardwarecomponents ......................... 19

2EVA5000configuration ............................... 24

3EVA3000configuration ............................... 25

4LocationoftheWorldWideNamelabels ....................... 27

5Diskdriveactivityindicator.............................. 38

6Sequentialbuildingofverticaldiskgroups ....................... 39

7Removingthedriveblank .............................. 40

8Installingthediskdrive ............................... 40

9Diskdrivestatusindicators.............................. 41

10FCdriveenclosure—frontandrearviews ....................... 44

11I/Omodule.................................... 45

12Inputandoutputports ............................... 45

13FibreOpticFibreChannelcable........................... 47

14CopperFibreChannelcable ............................ 47

15Diskdrivestatusindicators ............................. 48

16Powersupplyandblowerassemblycomponents .................... 49

17EMUcontrolsanddisplays ............................. 52

18EnclosurenumberingwithenclosureIDexpansioncables ................ 59

19 Enclosure address bus components with enclosure ID expansion cables . . . . . . . . . . 60

20Displayingerrorconditionvalues........................... 63

21FCloopswitch .................................. 65

22HSVcontroller................................... 68

23ControllerOCP .................................. 69

2460–Hzand50–Hzwallreceptacles ......................... 76

25DualPDUassembly ................................ 77

26RackPDM .................................... 78

27RackACpowerdistribution............................. 79

28 Single rack configuration floorspacerequirements ................... 80

29Raisingalevelerfoot................................ 81

30Typicalproductlabel................................ 85

31Diskdrivelabel .................................. 85

32Diskdrivestatusindicators ............................. 89

33Removingadiskdrive ............................... 89

34Installingadiskdrive................................ 90

35Powersupply/blowerstatusindicator......................... 92

36Removingablower ................................ 92

37Installingablower................................. 93

38Removingapowersupply.............................. 94

39Installingapowersupply.............................. 94

40 Typical enclosure certificationlabel.......................... 106

41Powersupplyelementnumbering........................... 119

42Blowerelementnumbering ............................. 120

43DisconnectingACpower.............................. 127

44Transceiverelementnumbering ........................... 128

45I/Omoduleelementnumbering ........................... 131

46GUIterminationeventdisplay............................ 135

47 Typical HP Command View EVA Event display . . . . . . . . . . . . . . . . . . . . . 136

Enterprise Virtual Array 3000/5000 user guide

9

Page 10

Tables

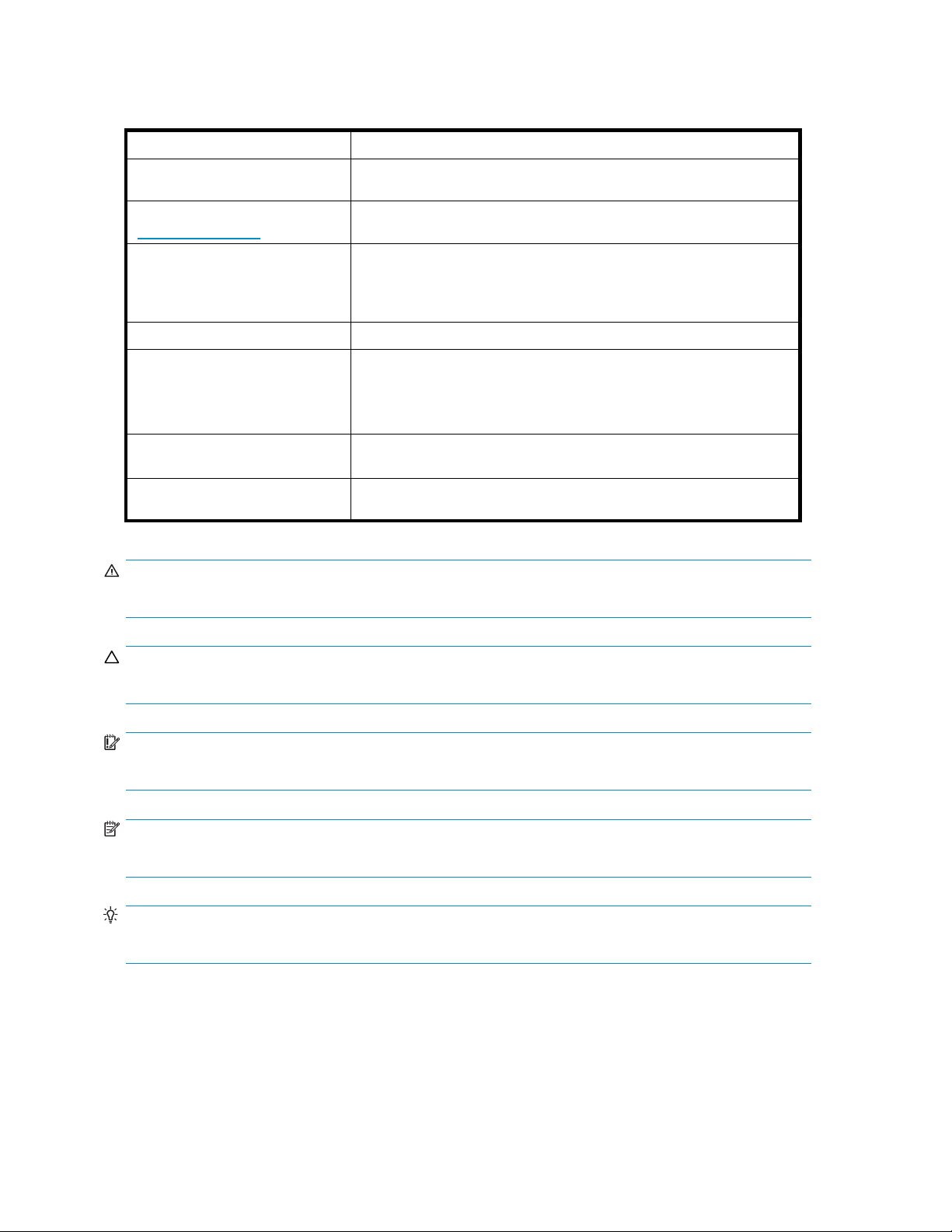

1Documentconventions................................ 12

2WWNpushbuttonfunctions............................. 26

3Systempasswordpushbuttonfunctions......................... 28

4Failbackpreferencesettings ............................. 32

5FailbackSettingsbyOperatingSystem......................... 34

6 Impact on virtual disk presentation when changing failover/failback setting . . . . . . . . . 34

7OperationalI/Omodulestatusindicators ....................... 46

8Non-operationalI/Omodulestatusindicators...................... 46

9Diskdrivestatusindicatordescriptions......................... 48

10Operationaldiskdrivestatusindications ....................... 49

11Non-operationaldiskdrivestatusindications...................... 49

12Powersupply/blowerstatusindicators ........................ 51

13EMUmonitoringfunctions.............................. 53

14EMUstatusdisplays ................................ 53

15EMUstatusindications............................... 54

16EMUdisplaygroups................................ 55

17Audiblealarmsoundpatterns............................ 56

18Errorconditionreportingcharacteristics........................ 61

19FibreChannelswitchsystemindicators ........................ 66

20FibreChannelswitchportindicators ......................... 66

21FibreChannelswitchbasictroubleshooting ...................... 67

22Controllerstatusindicators ............................. 69

23Controllerportstatusindicators ........................... 69

24Navigationbuttonfunctions............................. 70

25MenuoptionswithintheOCPdisplay......................... 71

26Shutdownmethods................................. 72

27HardwarecomponentCSRsupport.......................... 86

28 Drive enclosure physical specifications ........................ 106

29 Environmental operating specifications ........................ 107

30 Environmental shipping or short-term storage specifications................ 107

31EnterprisestoragesystemACinputlinevoltages .................... 108

32ACinputcurrentandwattage............................ 108

33 Output voltage and current specifications ....................... 108

34 Power specifications ................................ 109

35 Fibre Channel switch specifications.......................... 109

36 Controller enclosure physical specifications ...................... 109

37ControllerpowersupplyACpowerrequirements .................... 110

38 Controller power supply output specifications ..................... 110

39ACinputcurrentandwattage............................ 110

409000-SeriesEnterprise42URackPhysicalDimensions.................. 111

419000-SeriesEnterprise42URackShippingDimensions ................. 111

429000-SeriesEnterprise41URackPhysicalDimensions.................. 111

439000-SeriesEnterprise41URackShippingDimensions ................. 111

4410000-SeriesEnterprise42URackPhysicalDimensions................. 112

4510000-SeriesEnterprise42URackShippingDimensions ................ 112

46 Environmental operating specifications ........................ 112

47 Environmental shipping or short term storage specifications ............... 112

48 Enterprise Virtual Array AC power specifications.................... 113

49Assignedelementtypecodes ............................ 116

50Temperaturesensorelementnumbering........................ 122

51Voltageandcurrentsensorlocations ......................... 129

52 Controller event text description file.......................... 137

10

Page 11

About this guide

This user guide provides the following information:

• Description of the HP StorageWorks Enterprise Virtual Array family and its components.

• Starting your storage system.

• Operating your storage system.

• Regulations and specifications.

• EMU-generated error condition reports.

• HSV fault management concepts.

• Installing customer replaceable units.

This chapter contains the following sections:

•Overview

• D ocument conventions and symbols

•Rackstability

• HP technical support

Overview

This secti

• Intended audience

• Related documentation

on contains the following topics:

Intended audience

This book is intended for use by Enterprise Virtual Array customers involved in the installation, operation,

and management of EVA3000/5000 storage systems and who are experienced with the following:

• SANs and storage systems.

• Networking and virtual storage concepts.

• Enterprise V irtual Array pr oducts.

Related documentation

Additional product documentation is available from the following HP web site:

ttp:/www.hp.com/support/manuals

h

Click St

Virtual Array Systems.

orage Array Systems under Storage, and then select the appropriate product under Enterprise

Enterprise Virtual Array 3000/5000 user guide

11

Page 12

Document conventions and symbols

Table 1 Documen

tconventions

Convention

Medium blue text: Related

documentation

Medium blue, u

ttp://www.

(h

Bold font

Italic font

Monospace font

Monospace, italic font

Monospace, bold font

nderlined text

hp.com)

Element

Cross-reference links and e-mail addresses

Web site addre

• Key names

• Text typed into a GUI element, s uch as into a box

• GUI elements that are clicked or selected, such as menu and list

items, buttons, and check boxes

Text emphasis

• File and directory names

• System output

• Code

• Text typed at the command line

• Code variables

• Command-line variables

Emphas

typed a

is of file and directory names, system output, code, and text

t the command line

sses

WARNI

Indic

NG!

ates that failure to follow directions could result in bodily harm or death.

CAUTION:

Indicates that failure to follow directions could result in damage to equipment or data.

IMPORTANT:

Provides clarifying information or specific instructions.

NOTE:

Provides additional information.

TIP:

Provides helpful hints and shortcuts.

12

About this guide

Page 13

Rack stability

WARNING!

To reduce the risk of personal injury or damage to equipment:

• Extend leveling jacks to the floor.

• Ensure that th

• Install stabilizing feet on the rack.

• In multiple-rack installations, secure racks together.

• Extend only o

is extended.

e full weight of the rack rests on the leveling jacks.

ne rack component at a time. Racks may become unstable if more than one component

HP technical support

Telephone numbers for worldwide technical support are listed on the HP support web site:

ttp://www.hp.com/support/.

h

Collect the following information before calling:

• Technical support registration number (if applicable)

• Product serial numbers

• Product model names and numbers

• Applicable error messages

• Operating system type and revision level

• Detailed, specificquestions

For continuous quality improvement, calls may be recorded or monitored.

HP strongly recommends that customers sign up online using the Subscriber’s choice web site:

ttp://www.hp.com/go/e-updates.

h

• Subscribing to this service provides you with e-mail updates on the latest product enhancements,

newest versions of drivers, and firmware documentation updates as well as instant access to

numerous other product resources.

• After signing up, you can quickly locate your products by selecting Business support and then

Storage under Product Category.

HP-authorized reseller

For the name of your nearest HP-authorized reseller:

• In the United States, ca ll 1-800-282-6672.

• Elsewhere, visit the HP web site: h

telephone numbers.

Helpful web sites

For other product information, see the following HP web sites:

ttp://www.hp.com

•h

•http://www.hp.com/go/storage

•http://www.hp.com/support/

•http://www.docs.hp.com

ttp://www.hp.com.ThenclickContact HP to find locations a nd

Enterprise Virtual Array 3000/5000 user guide

13

Page 14

Subscribing to proactive updates

Receive support alerts (such as Customer Advisories), as well as updates on drivers, software, firmware,

and customer re

up for Subscrib

placeable components, proactively via em ail through HP Subscriber’s Choice. Sign

er’s Choice at the following URL:

h

ttp://www.hp

.com/go/myadvisory

HP product documentation survey

Are you the person who installs, maintains, or uses this HP storage product? If so, we would like to

know more about your experience using the product documentation. If not, please pass this notice to

the person who is responsible for these activities.

Our goal is to provide you with documentation that makes our storage hardware and soft ware products

easy to install, operate, and maintain. Your feedback is invaluable in letting us know how we can

improve your experience with HP documentation.

Please take 10 minutes to visit the following web site and complete our online survey. This will provide us

with valuable information that we will use to improve your experience in the future.

h

ttp://www.hpwebgen.com/questions.cfm?id=4601&pass=3712

Thank you for your time and your investment in HP storage products.

14

About this guide

Page 15

1 Enterprise Virtual Array

description

This chapter provides an overview of Enterprise Virtual Array and its components. Topics to be covered

include:

• Introduction to the Enterprise Virtual Array

• N ew features and enhancements

• Storage system components

Introduction to the Enterprise Virtual Array

The HP StorageWorks Enterprise Virtual Array family is a high performance, scaled capacity, on

demand, "vi

rtual" RAID storage system.

This storag

meets appli

rate perfo

storage administration.

The Enterprise Virtual Array (EVA) is available in multiple configurations—each optimized for

general-purpose commercial environments and high-performance technical computing environments. The

solutions include support for multivendor operating system platforms and stringent data center availability

enhancements, such as multipathing and clustering.

This guide includes information for two Enterprise Virtual Array products: EVA5000 and EVA3000.

• EVA5000

to the mu

switches.

• EVA3000—available in configurations ranging from the 2C2D configuration to the 2C4D

configuration. The EVA3000 includes two HSV100 controllers and no loop switches. Multiple

EVA300

Refer t

infor

e system is designed for environments where improved storage use and scalability is critical. It

cation-specific dem ands for consistently high transaction I/O (input/output) and MB data

rmance, and provides seamless capacity expansion, instantaneous replication, and simplified

—available in multiple configurations ranging from the single-rack 2C2D configuration

lti-rack 2C18D. The EVA5000 includes two HSV110 controllers and four FC loop

0scanbeinstalledinasinglerack.

otheHP StorageWorks Enterprise Virtual Array 3000/5000 hardware con figuration guide for more

mation about configurations. See "Related documentation" on page 11 for links to this document.

Features and enhancements

The E nterprise Virtual Array provides many features and enhancem ents which are detailed in the sections

that follow.

• Ease of management

• Data availability

•Performance

• Scalability

• Operating system support

• Fault management and diagnostics

• EVA remote support tools

Enterprise Virtual Array 3000/5000 user guide

15

Page 16

Ease of management

Easy-to-use st

• Software tools that allow you to manage larger SAN configurations with more servers and more

storage solutions

• HP-supplied di

• State-of-the-art controller software

• Completely integrated configurations with a single part number, plus disk drives and storage

system software

Data availability

• Redundant hardware design and value—added software eliminate single points of failure from

server to storage in clustered or single server configurations with multipathing.

• Full support for local and remote data replication using optional HP StorageWorks Business Copy

EVA and HP StorageWorks Continuous Access EVA applications.

• Dual– and multi–node cluster support provided for host–level fault tolerance and high system

availability.

• Support for a ctive-active failover, allowing the use of industry popular multipathing solutions and

native host bus adapters.

Performance

Outstanding self-tuning performance includes:

• Virtuali

• Both online high-performance disk drives and FATA (Fibre Attached Technology Adapted) disk

• State-of-the-art controller software that improves performance, increases capacity, and allows for

zation technology—Vraid, enables data to be distributed from 8 to 240 disks to increase

disk spin

storage for the b est performance of a specificconfiguration and application. Enterprise Virtual

Array eliminates tedious management functions to provide the best performance possible.

drives.

easy dynamic storage expansion.

orage management tools:

sk drives conform to the enclosure-initiated Enclosure Services Interface (ESI)

dle count far beyond traditional RAID sets. This virtualization method also optim izes

Scalability

The EVA5000 provides:

• Up to 32 TB of usable capacity. Total maximum raw capacity will vary based upon the

• A maximum of 240 disk drives

• Support for 1024 virtual disks

The EVA3000 provides:

• Up to 22.4 TB of raw capacity (2C4D configuration using 400 GB FATA disks).

• A maximum of 56 disk drives

• Support for 1024 virtual disks

All models support the following disk capacities:

• 300 GB FC disk drives

• 250 GB, 400 GB, and 500 GB FATA disk drives

• 146 GB FC disk drives

• 72 GB FC disk drives

• 36 GB FC disk drives

16

redundancy (Vraid) selected.

Enterprise Virtual Array description

Page 17

For the most current information on supported disk drives, refer to the HP StorageWorks Enterprise

Virtual Array 3000/5000 release notes.See"Related documentation"onpage11forlinksto

this document.

Operating sys

• HP–UX

• Microsoft Win

• Microsoft windows 2000

• HP Open VMS

• Tru64

• Sun Solaris

• IBM AIX

• Linux

• VMware

• Novell NetWare

For the most

documents

tem support

dows 2003

current information on supported operating systems, refer to the appropriate connectivity

.See"Related documentation" on page 11 for links to these documents.

Fault management and diagnostics

WEBES must be i nstalled to ensure proper customer alerts for their EVA products.

WEBES can be used as part of the HP ISEE remote service offering. Or, for those customers who

do not wish to have remote suppor t, it can be configuredtosendalocalnotification (e-mail) to a

customer-identified account only. The e-mail option is also available to the customer when ISEE is used.

WEBES is a powerful service tool that provides real-time diagnosis of hardware events ranging from

single errors (or faults) to multiple event correlation and complex analysis. It is designed to send a

notification only when an event or series of events has occurred that requires a service action.

AServiceToolsCDisincludedwiththeHPCommandViewEVApackage. However,itisalwaysbest

to check the HP web site for the latest updates.

The latest WEBES kit can be downloaded from this URL: h

ttp://h18000.www1.hp.com/support/svctools

EVA remote support tools

As a nowarran

reduc

trans

your local HP Services departm ent for details.

charge option, HP will install ISEE remote service tool f or any Enterprise Virtual Array under

ty or service support. This tool enables EVA self-monitoring and diagnosis. ISEE can significantly

e the time required to isolate a nd correct problems. If desired, the tool can be configured to

mit status information directly to an HP service center for proactive problem resolution. Contact

Storage system components

The Enterprise Virtual Array comprises three main components:

• Hardware—the physical components, such as disk d rives, enclosures, controllers, and Fibre

Channel switches. These pieces are installed in a rack and connected to the SAN.

• HP StorageWorks Controller Soft ware—manages operation of the storage system hardware and

provides the communication link to HP Command View EVA.

• HP Command View EVA—management software that communicates with the controllers.

Together, HP Command View EVA and the controllers control and monitor Enterprise Virtual

Array storage systems.

These components work together to create an entire storage system solution. Management is

accomplished by accessing HP Command View EVA through your browser.

Enterprise Virtual Array 3000/5000 user guide

17

Page 18

HP Command View E

HP Command View EVA is the primary software application for managing the EVA. HP Command View

EVA is used to perform the following administrative tasks.

• Creating virtual disk families, including selection of Vraid level, cache policy, and host

presentation.

• Managing the presentation of Vraid drives to hosts.

• Managing and monitoring storage system hardware.

• Creating snap

clones and snapshots of virtual disks.

VA

An online help

Controller software

HP StorageWorks Virtual Controller Software (VCS) manages all aspects of storage system operation.

VCS provides scalable capacity on-demand, improves performance, increases disk utilization efficiency,

and allows for easy dynamic storage expansion. VCS is installed on the storage system and is also

included in the VCS for HSV Controller software kit.

VCS feature

s and functionality

• Support for up to 240 disk d rives per controller pair

• Managemen

disk pool

• Dynamic capacity expansion (if supported by your operating system)

• Virtual di

• Distributed sparing of disk capacity

• Virtually capacity-free snapshot (Vsnap)

• Virtuall

• Dual redundant controller operation for increased fault tolerance

• Multi-path failover support

• Battery

• Asynchronous disk swap (Hot Swap)

• Clustered server support

• Mirror

• Read-ahead and adaptive read caching support

• Virtual RAID storage system (Vraid0, Vraid1, Vraid5)

• Non-di

• Supports connection of up to 256 hosts

• Multivendor platform support

• Contr

• Selective storage presentation

• SAN-based data zoning

skdataloadleveling

y Instantaneous Snapclone (VIS) and 3–phase Snapclones

backup for cache memory

ed write-back cache support

sruptive software upgrade capability

oller password protection for configuration control

system is available within the interface, including page-level help.

t of up to 1024 virtual disks, ranging in size from 1 G B to 2 TB per virtual disk, per

Optional software licensing

HP Business Copy and HP StorageWorks Continuous Access require a separate license for each controller

pair. Instructions for obtaining licenses are included with the soft ware documentation.

Additional information about HP Business Copy and HP Continuous Access can be found online at

ttp://h18006.www1.hp.com/storage/software.html.

h

18

Enterprise Virtual Array description

Page 19

Hardware

A

The Enterprise Virtual Array includes the following hardware components:

• Fibre Channel drive enclosure—Contains disk drives, power supplies, blowers, I/O modules,

and an Environm

• Fibre Channel loop switch—Provides twelve-port central interconnect for Fibre Channel drive

enclosure FC Arbitrated Loops. Fibre Channel loo p switches are used only on the EVA5000.

• HSV controlle

between host s

Virtual Array.

• Rack—A variety of free-standing racks are available.

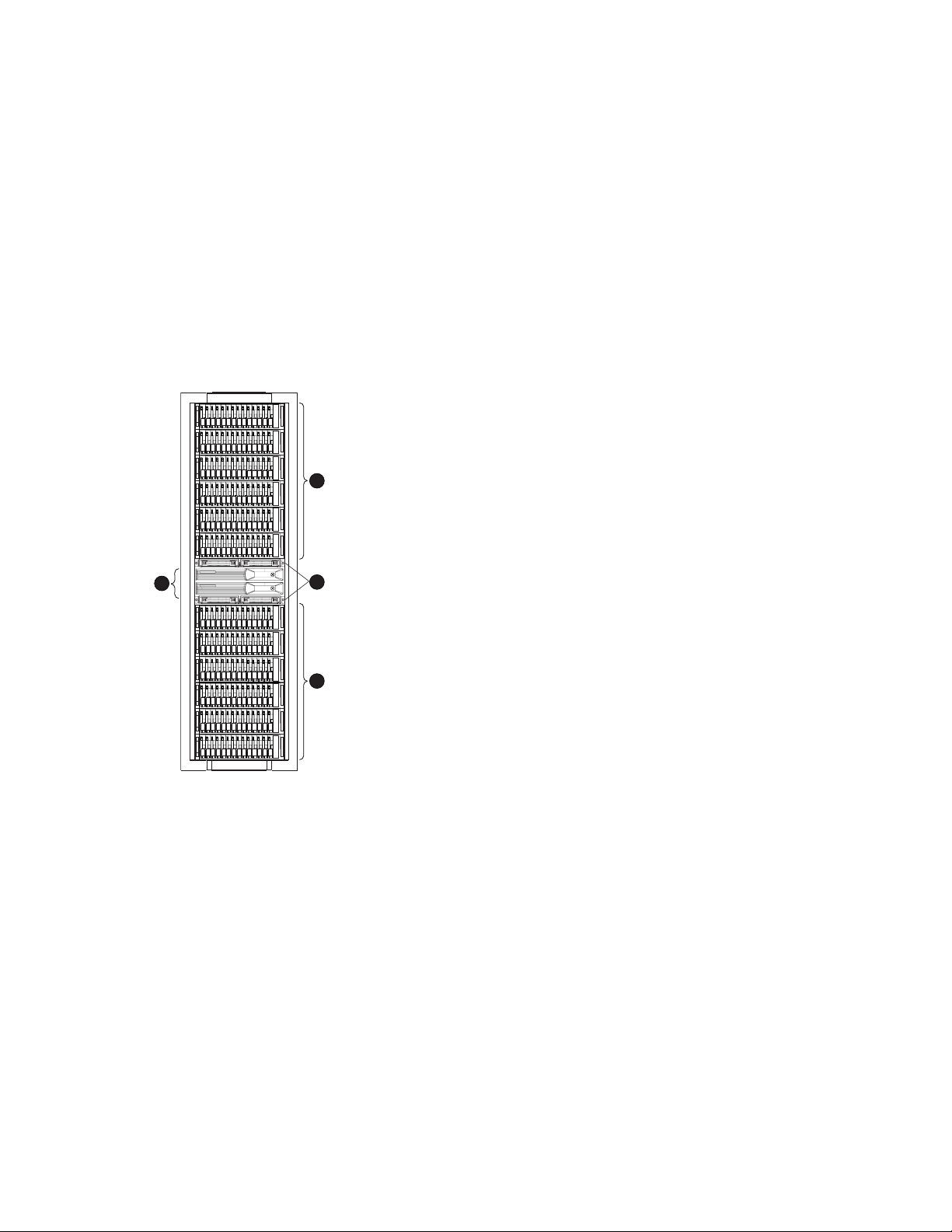

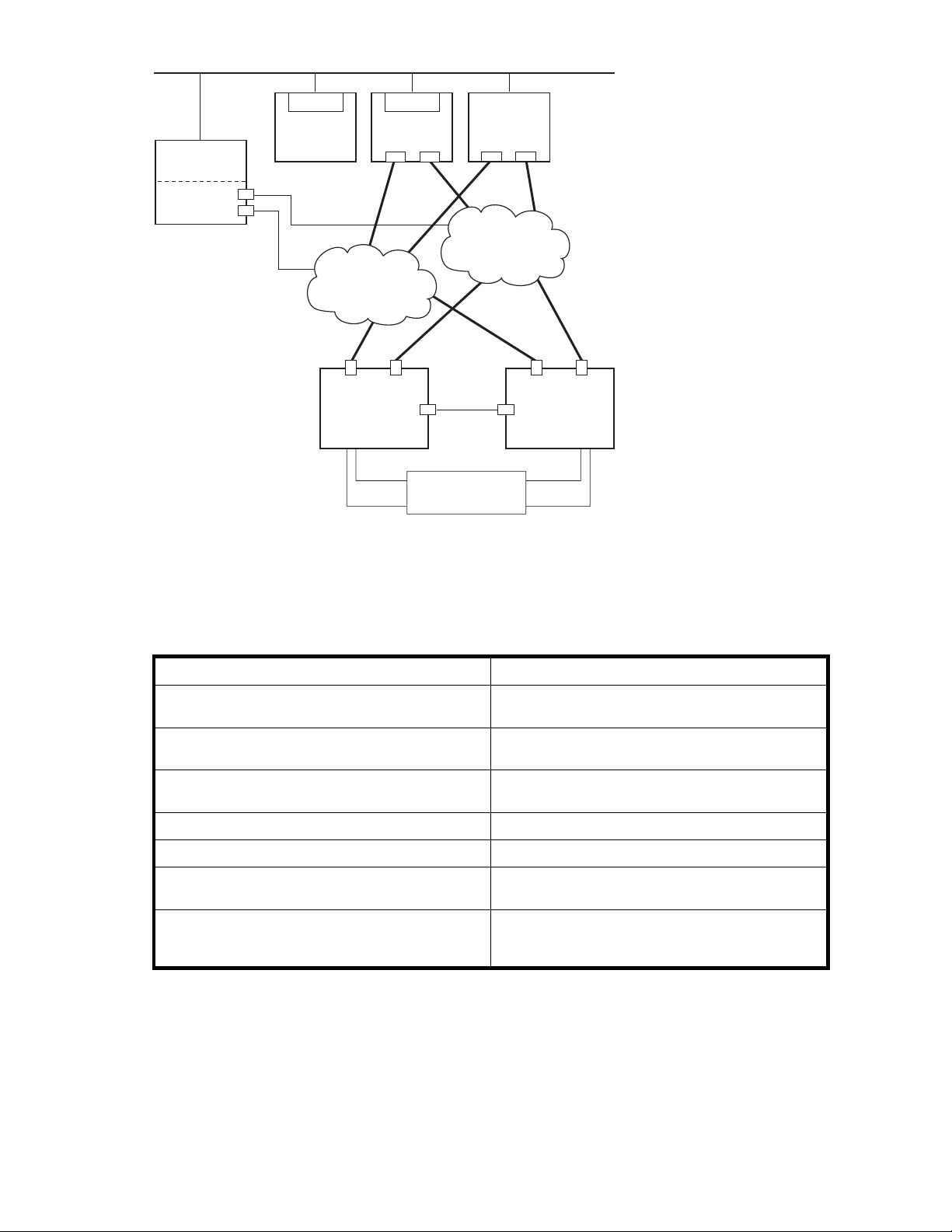

Physical layout of the storage system

The basic physical components are shown in Figure 1. The disk drives are installed in the disk enclosures,

which connect to Fibre Channel (FC) loop switches. The controller pair also connects to the FC loop

switches.

ental Monitoring Unit (EMU).

r—Manages all aspects of storage system operation, including communications

ystems and other devices. A pair of HSV controllers is included in Enterprise

3

1

CXO7941

Figure 1 Storage system h ardware components

1. Drive enclosures 2. FC switches

3. Controllers

The hardware components shown in Figure 1 are discussed in the following sections and in Storage

System Hardware Components.

Fibre Channel drive enclosure

Each Fibre Channel drive enclosure includes the following features. For additional information, see

Fibre Channel drive enclosures.

• 3U enclosure

• Dual-redundant, active-to-active, 2–Gbps FC loops

• Fourteen bays for 1–inch FC disks

2

3

Enterprise Virtual Array 3000/5000 user guide

19

Page 20

• Environmental Monitoring Unit (EMU)

• Dual 2–Gbps FC I/O modules—A and B loops

• Dual redundant 500W power supplies and blowers

• Dual redundant blowers

For ease of management, the disk drives are referred to by their physical location, the drive bay number.

Fibre Channel loop switches

The Fibre Channel loop switch acts as a central point of interconnection and establishes a fault-tolerant

physical loop topology between the controllers and the disk enclosures. The EVA5000 uses four loop

switches to co

The FC loop switches provide the following features. For detailed information on Fibre Channel loop

switches, see Fibre Channel loop switches.

• 2.125–Gbps o

• Twelve ports

• Half-width, 1U size

• System and p

• Universal power supply that operates between 100 to 250 VAC and 50 to 60 Hz

NOTE:

Each bezel covers two FC loop switches in a space of 1U.

nnect the drive enclosures to the controller pair.

perating speed

ort status indicators

HSV110 and HSV100 controllers

Two controllers are contained in each rack. Each controller is c ontained in a separate enclosure and

provides the features listed below. For detailed information, see HSV controllers.

• High-performance microprocessor

• An Operator Control Panel (OCP)

• Two 2–Gbps Fibre Channel-Switched fabric host ports

• Four 2–Gbps Fibre Channel drive enclosure device ports (two device ports in HSV100 controller)

• Arranged in redundant pairs

• Data load/performance balanced across a pair

• S uppor t for up to 240 disks with HSV110 and 56 with HSV100

• 1.25 GB cache per controller, mirrored, with battery backup

• 2–GBpsFCcachemirroringportswithdeviceportbackups

• Dual power supplies

In addition to managing the operation of the storage system, the HSV controllers serve as the interface

between the storage system hardware and the SAN. All host I/Os and all HP Command View EVA

management commands are processed by the controllers. Up to 18 drive enclosures are supported

by one controller pair.

NOTE:

To avoid impacting Secure Path operation, the internal identification of the controllers has been changed

for VCS v4.001. For VCS v4.001 and later firmware, the EVA3000 controller is now identified as

HSV101 and the EVA5000 controller is identified as HSV111.

20

Enterprise Virtual Array description

Page 21

Racks

The rack provides the capability for mounting standard 483 mm (19 in) wide controller and drive

enclosures. For additional information, see Racks.

The following racks are available:

• 22U Rack

• 25U Rack

• 33U Rack

• 36U Rack

• 41U Rack

• 42U Rack

• Universal Ra

NOTE:

Racks and rack-mountable components are typically described using “U” measurements. “U”

measurements are used to designate panel or enclosure heights.

Theracksprovidethefollowing:

• Unique frame and rail design—Allows fast assembly, easy mounting, and outstanding structural

integrity.

• Thermal integrity—Front-to-back natural convection cooling is greatly enhanced by the innovative

multi-angled design of the front door.

• Security provisions—The front and rear door are lockable, which prevents unauthorized entry.

• Flexibility—Provides easy access to hardware components for operation monitoring.

• Custom expandability—Several options allow for quick and easy expansion of the racks to

create a custom solution.

ck

Enterprise Virtual Array 3000/5000 user guide

21

Page 22

22

Enterprise Virtual Array description

Page 23

2 Enterprise Virtual Array startup

This chapter describes the procedures necessary to complete the installation and configuration of the

Enterprise Virtual Array. When these procedures are complete, you can begin using your storage system.

NOTE:

InstallationoftheEnterpriseVirtualArrayshouldbedoneonlybyanHPauthorizedservice

representative. The information in this chapter provides an overview of the steps involved in the

installation and configuration of the storage system.

This chapter consists of:

• Storage system connections

• Procedures for getting started

• G athering information

• Setting up the storage system hardware

• Entering data using the Operator Control Panel (OCP)

• Installing HP Command View EVA

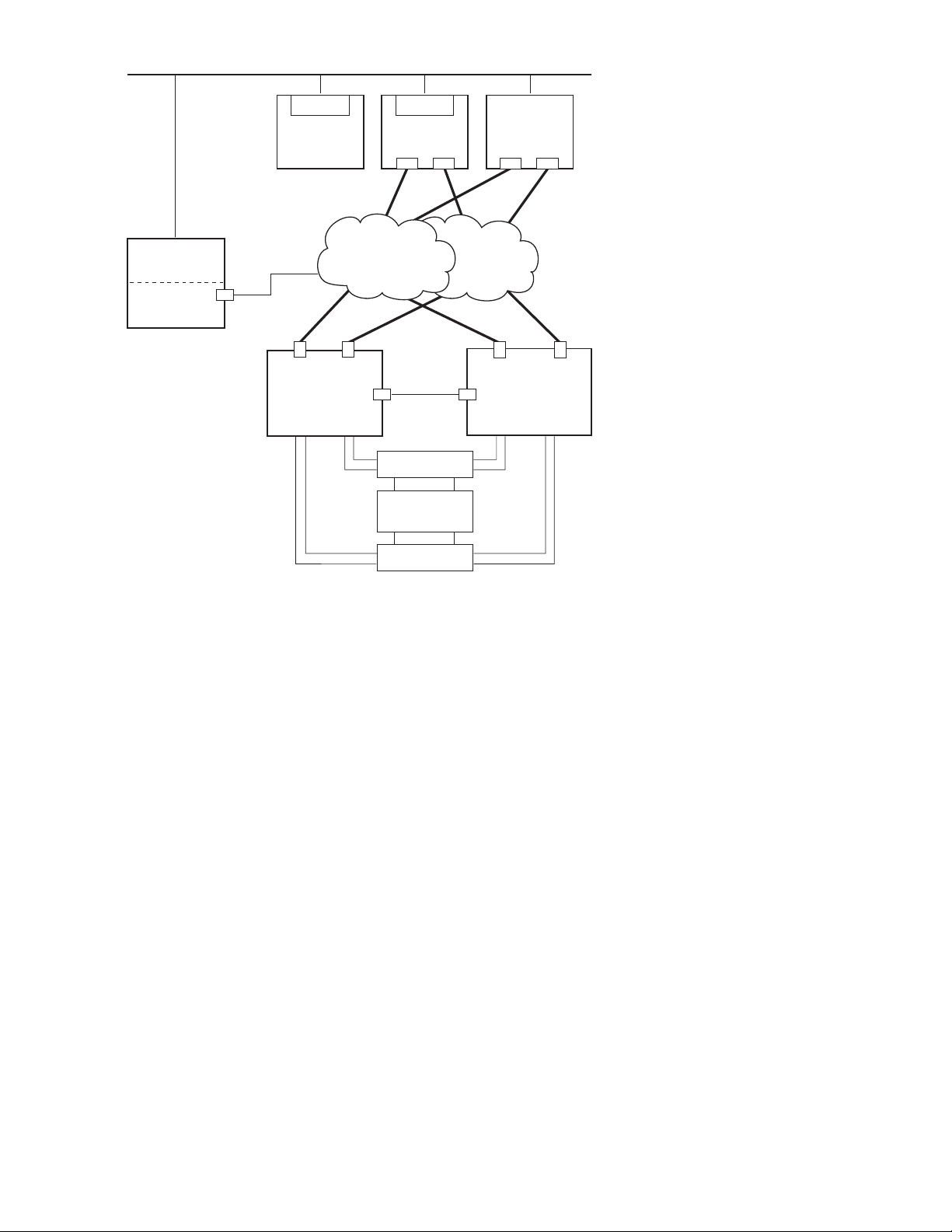

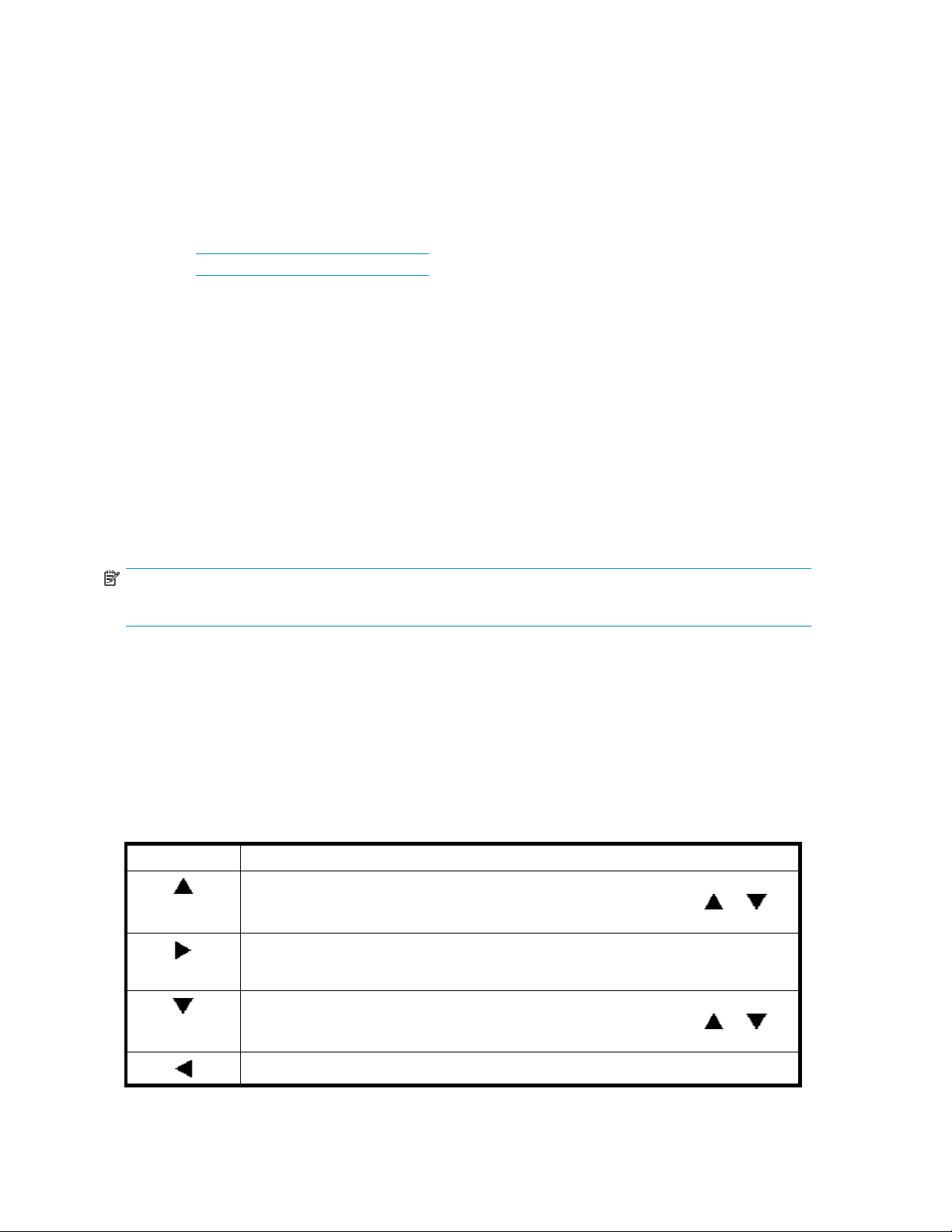

EVA5000 storage system connections

Figure 2 shows a typical EVA5000 SAN topology:

• The HSV110 controllers connect via two host ports (FP1 and FP2) to the Fibre Channel fabrics.

The hosts that will access the storage system are connected to the same fabrics.

• The HP Command View EVA management server also connects to the fabric.

• The controllers connect through two lo op pairs to the drive enclosures. Each loop pair consists of

two independent loops, each capable of managing all the disks should one loop fail. Four FC

loop switches are used to connect the controllers to the disk enclosures.

Enterprise Virtual Array 3000/5000 user guide

23

Page 24

B

Browser

Network Interconnection

F

F

Non-Host

Browser

Host X

FCA

FCA FCA FCA

Host Z

Management

Server

Command

View EVA

P = Fibre (Host) Port

CA = Fibre Channel Adapter

Figure 2 EVA5000 configuration

EVA3000

Figure 3 shows a typical EVA3000 SAN topology:

• The HSV100 controllers connect via two host ports (FP1 and FP2) to the Fibre Channel fabrics.

The hos

• The HP Command View EVA m ana gement ser ver also connects to the fabric.

• The controllers connect through one loop pair to the drive enclosures. The loop pair consists of

two independent loops, each capable of managing all the disks should one loop fail. The

contr

Fabric 2Fabric 1

FP1 FP2

Controller

A

Loop

Pair 1

Loop

Pair 2

Cache

Mirror Port

FC Loop Switches

A

Drive Enclosures

A

FC Loop Switches

B

B

FP1 FP2

Controller

B

Loop

Pair 2

Loop

Pair 1

CXO7947

storage system connections

ts that will access the storage system are connected to the same fabrics.

ollers connect directly to the disk enclosures.

24

Enterprise Virtual Array startup

Page 25

Management

a

Network Interconnection

F

F

Server

Command

View EVA

Browser

Non-Host

Fabric 1

Browser

Host X

FCA

FCA FCA FCA

Host Z

Fabric 2

FP1 FP2

Controller

A

Loop

Pair 1

B

A

P = Fibre (Host) Port

CA = Fibre Channel Adapter

Figure 3 EVA3000 configuration

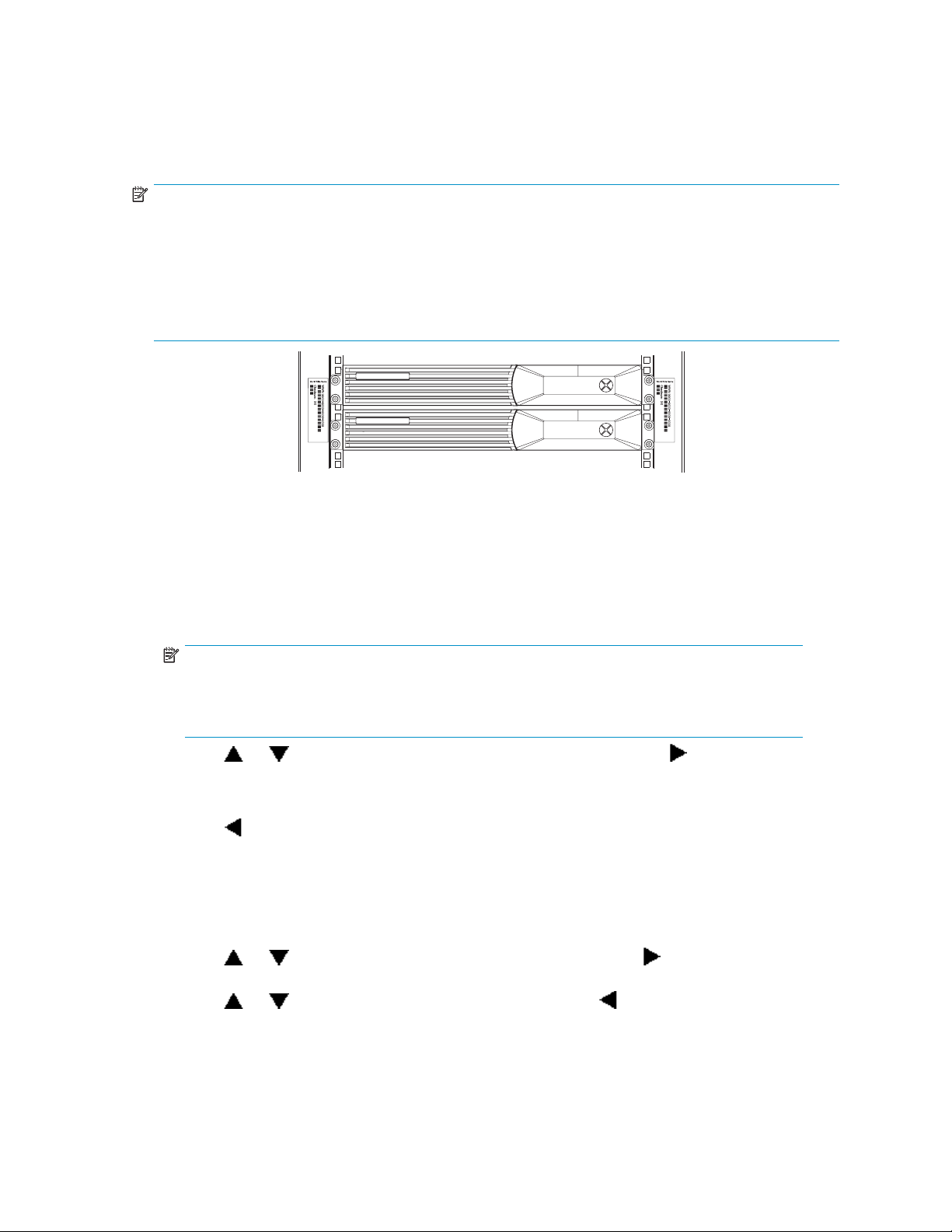

Procedures for getting started

Step

1. Gather information and identify all related storage

documentation.

2. Contact an authorized service representative for

hardware configuration information.

3. Enter the World Wide Name (WWN) into the

OCP.

4. Confi

5. Prepare the hosts.

6. Configure the system through HP Command View

EVA.

7. Make virtual disks available to their hosts. Refer to

the storage system software documentation for each

host’s operating system.

gure HP Command View EVA.

Cache

Mirror Port

Drive Enclosures

FP1 FP2

Controller

B

Loop

Pair 1

B

A

25060

Custome

r

Customer

HP Service Engineer

HP Service Engineer

Customer

HP Service Engineer

vice Engineer

HP Ser

Responsibility

Gathering information

The following items should be available when installing and configuring an Enterprise Virtual Array . They

provide information necessary to set up the storage system successfully.

• HP StorageWorks Enterprise Virtual Array 3000/5000 release notes.

Enterprise Virtual Array 3000/5000 user guide

25

Page 26

• HP StorageWorks Enterprise Virtual Array 3000/5000 read me first.

• HP StorageWorks Enterprise Virtual Array 3000/5000 World Wide Name label,whichis

shipped with the storage system

• The latest HP OpenView Storage Management Server Update, which consists of the management

server update CD and its associated documentation, or the latest Windows Server Update

• You can determine the latest update version available by checking the release notes or

contacting your authorized service representative to findouthowtoreceivethelatest

information.

• Additional documentation is available from the following HP web sites:

• h

• http://www.hp.com/go/eva5000

Locate these items and keep them handy. You will need them for the procedures in this manua l.

Host information

Make a list o

the follow

• TheLANnameofthehost

• A list of World Wide Names of the FC adapters, also called host bus adapters, through which

the host will connect to the fabric or fabrics that provide access to the storage system

• Operatin

• Available LUN numbers

ttp://www.hp.com/go/eva3000

f information for each host computer that will be accessing the storage system. You will need

ing information for each host:

gsystemtype

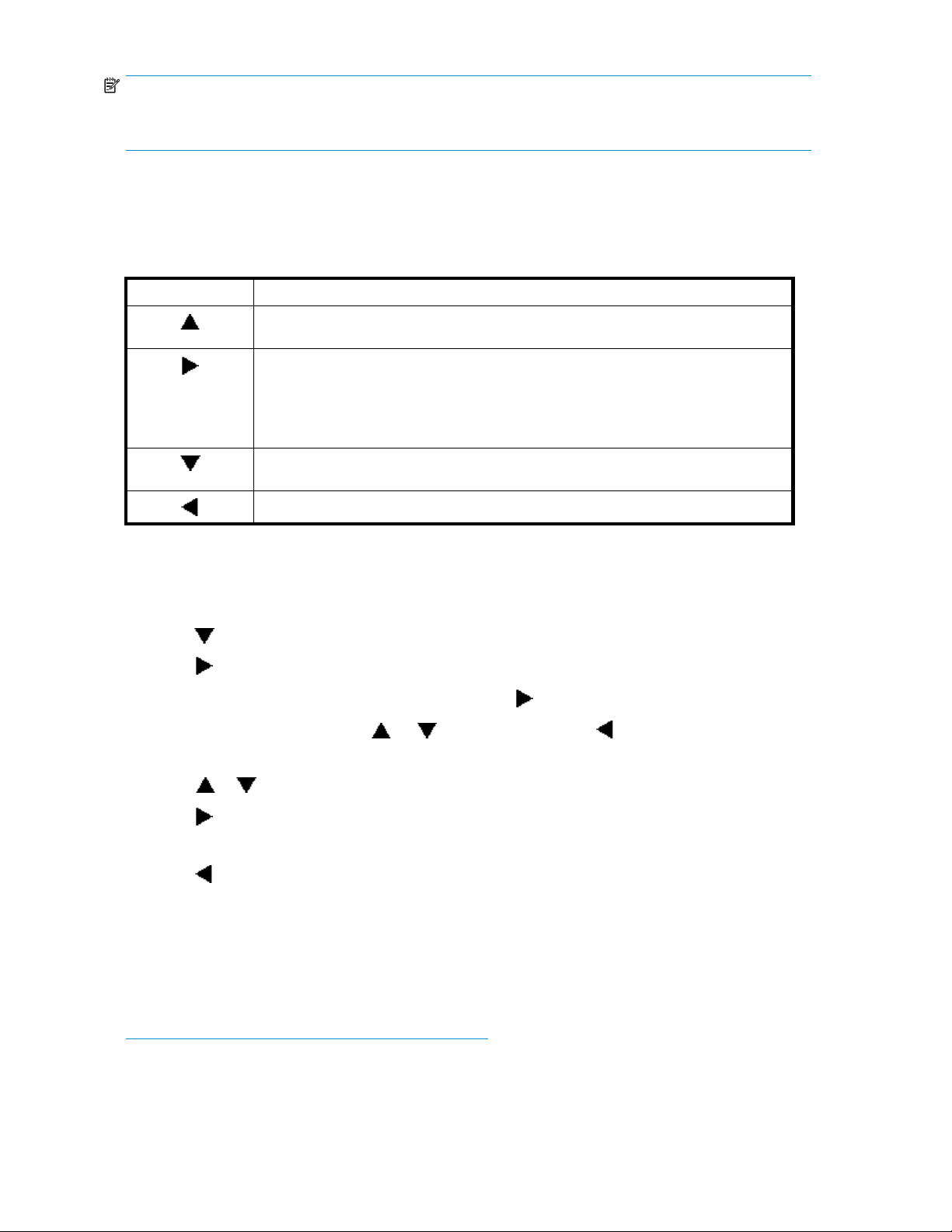

Setting up a controller pair using the OCP

NOTE:

ThisprocedureshouldbeperformedbyanHPauthorizedservicerepresentative.

Two pieces of data must be entered during initial setup using the controller OCP:

• World Wide Name (WWN)—Required to complete setup. This procedure should be performed

by an HP authorized service representative.

• Storage system p assword—Optional. A password provides security allowing only specific

instances of HP Command View EVA to access the storage system.

The OCP on either controller can be used to input the WWN and password data. For more information

about the OCP, see "Operator Control Panel" on page 68.

Table 2 lists the push button functions when entering the WWN, WWN checksum, and password data.

Table 2 WWN push button functions

Button

Selects a WWN or checksum character by scrolling up through the character list one

character at a time. If you select an incorrect character, you can use either

select the correct character.

Accepts the current character and selects the next character. If you accept an incorrect

character, you can move through all 16 characters, one character at a time, until you

display the incorrect character. You can then change the character.

Function

or to

Selects a WWN or checksum character by scrolling down through the character list one

character at a time. If you select an incorrect character, you can use either

the select correct character.

Accepts all the WWN or checksum characters.

26

Enterprise Virtual Array startup

or to

Page 27

Entering the WWN

C

Fibre Channel protocol requires that each controller pair have a unique WWN. This 16-character

alphanumeric name identifies the controller pair on the storage system. Two WWN labels attached to the

rack identify the storage system WWN and checksum. See Figure 4.

NOTE:

• TheWWNisuniquetoacontrollerpairandcannotbeusedforanyothercontrollerpairordevice

anywhere on the network.

• This is the onl

replacement controller.

• Once a WWN is assigned to a controller, you cannot change the WWN while the controller is part

of the same storage system.

Complete the following procedure to assign the WWN to each pair of controllers.

y WWN applicable to any controller installed in a specificphysicallocation,evena

CXO7601

Figure 4 Location of the World Wide Name labels

1. Turn the power switches on both controllers off.

2. Apply power to the rack.

3. Turn the power switch on both controllers on.

NOTE:

Notifications of the startup test steps that have been executed are displayed while the

controller is booting. It may take up to two minutes for the steps to display. The default

WWN entry display has a 0 i n each of the 16 positions.

4. Press or until the first character of the WWN is displayed. Press to accept this character

and select the next.

5. Repeat the p receding step to enter the remaining characters.

o accept the WWN and select the checksum entry mode.

6. Press

t

Entering the WWN checksum

The second p art of the WWN entry procedure is to enter the two-character checksum, as follows.

1. Verify that the initial WWN checksum displays 0 in both positions.

2. Press

select the second character.

3. Press

4. Verify that the default display is automatically selected. This indicates that the checksum is valid.

or until the first checksum character is displayed. Press to accept this character and

or until the second character is displayed. Press to accept the checksum and exit.

Enterprise Virtual Array 3000/5000 user guide

27

Page 28

NOTE:

If you enter an incorrect WWN or checksum, the system will reject the data and you must repeat the

procedure.

Entering the storage system password

The eight-character storage system password feature enables you to restrict management access to the

storage system. Table 3 describes the push button functions when using the password feature.

Table 3 System password push button functions

Button

Selects a password character by scrolling up through the character list one character

at a time.

• Movesfromthedefaultdisplaytothesystemmenutree.

• Moves from the system password display to the password entry display.

• Accepts the current character and selects the next character.

If you accept an incorrect character, you can loop through the display, one position at

time, to select the character to be changed.

Selects a password character by scrolling down through the character list one character

at a time.

Accepts all the password characters.

Function

Complete the following procedure to set the password:

1. Select a unique eight-character password using uppercase or lowercase letters A through Z.

2. From the default menu, press any push button to select the menu tree.

3. Press

4. Press

5. When the System Password function is flashing, press

6. To change the password, press

to cycle through the displays until System Password is displayed.

to select the system password function.

to select the change password function.

or to show Yes and press .

The default Enter Password function displays the default password, AAAAAAAA.

7. Press

8. Press

or until the first character of the password is displayed.

to accept this character and select the next character.

9. Repeat the process to enter the remaining password characters.

10. Press

to enter the password and return to the default menu display.

The controller pair setup is complete.

Installing HP Command View EVA

HP Command View EVA is installed on the HP Op enView Storage Management Server or a

Windows host and runs in the OpenView environment. Installation may be skipped if the latest

version of HP Command View EVA is running. Verify the latest version at the HP web site:

ttp://h18006.www1.hp.com/storage/software.html.

h

To install a new version, locate the management server update CD-ROM and the associated

documentation that was shipped with your storage system. Follow the instructions in the HP OpenView

Storage Management Server update installation card to install the new software.

28

Enterprise Virtual Array startup

Page 29

Installing opti

onal EVA software licenses

If you purchase

available for the Enterprise Virtual Array includes HP Business Copy and HP Continuous Access.

Installation instructions are included with the license.

doptionalEVAsoftware,itwillbenecessarytoinstallthelicense. Optionalsoftware

Enterprise Virtual Array 3000/5000 user guide

29

Page 30

30

Enterprise Virtual Array startup

Page 31

3 Enterprise Virtual Array

operation

This chapter presents the tasks that you might need to perform during normal operation of the storage

system.

Best practices

For useful information on managing and configuring your storage system, refer to the HP

StorageWorks Enterprise Virtual Array configuration best practices white paper available from

h

ttp://h71028.www7.hp.com/ERC/downloads/5982-9140EN.pdf.

Operating tips and information

Reserving adequate free space

To ensure efficient storage system operation, a certain amount of unallocated capacity, or free space,

should be reserved in each disk group. The recommended amount of free space is influenced by your

system configuration. For guidance on how much free space to reserve, refer to the HP StorageWorks

Enterprise Virtual Array configuration best practices white paper. See Best practices.

Using FATA disk drives

FATA drives are designed for lower duty cycle applications such as near on-line data replication for

back-up. These drives should not be used as a replacement for EVA’s high performance, standard

duty cycle, Fibre Channel drives. Doing so could shorten the life of the drive. Download the following

document for more information on FATA drives, their uses and benefits:

ttp://h71028.www7.hp.com/ERC/downloads/5982-7353EN.pdf

h

Failback preference setting for HSV controllers

Table 4 describes the failback preference mode for each of the operating systems supported with HSV

controllers and Command View EVA.

Table 5

indicates when Secure Path is used in conjunction with the operating system

describes the failback default behavior and settings allowed for each operating system. The table

Enterprise Virtual Array 3000/5000 user guide

31

Page 32

Table 4 Failback preference settings

Setting Point in time

No preference

Path A - Failover

Only

At initial pres

On dual boot or controller resynch

On controller failover

On controller failback

At initial presentation The units are brought online to Controller

On dual boot or controller resynch

On contr

On controller failback

oller failover

entation

Behavior

The units are al

to Controller

If cache data for a LUN exists on a

particular controller, the unit will be

brought online there. Otherwise, the

units are alternately brought online to

Controller A or to Controller B.

All LUNs are brought online to the

surviving controller.

All LUNs rem

controller. There is no failback except

if a host moves the LUN using SCSI

commands.

A.

If cache data for a LUN exists on a

particular controller, the unit will be

brought online there. Otherwise, the

units are brought online to Controller A.

All LUNs are brought online to the

surviving controller.

All LUNs remain on the surviving

controller. There is no failback except

if a host moves the LUN using SCSI

commands.

ternately brought online

AortoControllerB.

ain on the surviving

Path B - Failover Only

At initial presentation The units are brought online to Controller

On dual boot or controller resynch

On controller failover

On controller failback

B.

he data for a LUN exists on a

If cac

icular controller, the unit will be

part

ght online there. Otherwise, the

brou

s are brought online to Controller B.

unit

All LUNs are brought online to the

surviving controller.

All LUNs remain on the surviving

controller. There is no failback except

if a host moves the LUN using SCSI

commands.

32

Enterprise Virtual Array operation

Page 33

Setting Point in time

Behavior

Path A - Failover/

Failback

Path B - Failover/

Failback

At initial presentation The units are brought online to Controller

On dual boot or controller resynch

On controller failover

On controller failback

At initia

On dual boot or controller resynch

On controller failover

l presentation

A.

If cache data fo

particular co

brought onlin

units are brou

All LUNs are brought online to the

surviving controller.

AllLUNsremainonthesurviving

controller. After controller restoration,

the units that are online to Controller B

and set to Path A are brought online

toControllerA.Thisisaonetime

occurrence. If the host then moves the

LUN using SCSI commands, the LUN will

remain where moved.

The units

B.

If cache data for a LUN exists on a

particular controller, the unit will be

brought online there. Otherwise, the

units are brought online to Controller B.

All LUNs are brought online to the

surviving controller.

raLUNexistsona

ntroller, the unit will be

ethere. Otherwise,the

ght online to Controller A.

are brought online to Controller

On controller failback

All LUN

controller. After controller restoration,

the units that are online to Controller

A and set to Path B are brought online

toControllerB.Thisisaonetime

occurrence. If the host then moves the

LUN using SCSI commands, the LUN will

remain where moved.

sremainonthesurviving

Enterprise Virtual Array 3000/5000 user guide

33

Page 34

Table 5 Failback Settings by Operating System

Operating system

HP-UX

Tru64 UNIX

OpenVMS (7.3-

Windows®

Sun Solaris®

IBM AIX

Linux

Novell NetWare

VMware

1andgreater)

Default behavior

Autoback done by the host

Host follows the unit

Host follows the unit

Auto failback done by the host No Preference, Path A/B - Failover

Auto failback done by the host No Preference, Path A/B - Failover

Auto failback done by the host No Preference, Path A/B - Failover

Auto failback done by the host No PreferencePath A/B - Failover

Auto failback done by the host No PreferencePath A/B - Failover

Auto failback done by the host No PreferencePath A/B - Failover

Settings supported

No Preference, Path A/B - Failover

Only.

All settings allowed.

Recommended setting: Path

A/B - Failover/Failback.

All settings a

Recommended

A/B - Failover/Failback.

Only.

Only.

Only.

Only

Only

Only

llowed.

setting: Path

Changing virtual disk failover/failback setting

Changing the failover/failback setting of a virtual disk may impact which controller presents the disk.

Table 6 identifies the presentation behavior that results when the failover/failback setting for a virtual

disk is c

NOTE:

If the new setting causes the presentation of the virtual disk to move to a new controller, any snapshots

or snapclones associated with the virtual disk will also be moved.

Table 6 Impact on virtual disk presentation when c h angin g failover/failback setting

New setting

No Preference

Path A Failover

Path B Failover

Path A Failover/Failback If the disk is currently presented on controller B, it is moved to

Path B Failover/Failback If the disk is currently presented on controller A, it is moved to

hanged.

Impact on virtual disk presentation

None. The disk maintains its original presentation

If the disk is currently presented on controller B, it is moved to

controller A. If the disk is on controller A, it remains there.

If the disk is currently presented on controller A, it is moved to

controllerB.IfthediskisoncontrollerB,itremainsthere.

controller A. If the disk is on controller A, it remains there.

controllerB.IfthediskisoncontrollerB,itremainsthere.

34

Enterprise Virtual Array operation

Page 35

Storage system s

hutdown and powerup

The storage sys

following func

1. Flushes cache

2. Removes power from the controllers

3. Disables cach

4. Removes power from the drive enclosures

5. Disconnects the system from HP Command View EVA

NOTE:

The storage s

shutdown whe

are used, or

tem is shut down using HP Command View EVA. The shutdown process performs the

tions in the indicated order:

e battery power

ystemmaytakealongtimetocompletethenecessarycacheflush during controller

n snapshots are being used. The delay may be particularly long if multiple child snapshots

if there has been a large amount of write activity to the snapshot source Vdisk.

Shutting down the storage system

To shut the storage system down, per form the following steps:

1. Start HP Command View EVA.

2. Select the appropriate storage system in the Navigation pane.

The Initialized Storage System Properties window for the selected storage system opens.

3. Click System options.

The System Options window opens.

4. Click Shut down.

The Shutdown Options window opens.

5. Under System Shutdown click Power Down. If you want to delay the initiation of the shutdown, enter

the number of minutes in the Shutdown delay field.

The controllers complete an orderly shutdown and then power off. The disk enclosures then power

off. Wait for the shutdown to complete.

6. Turn off the power switch on the rear of each HSV controller.

7. Turn off the circuit breakers on both of the EVA rack Power Distribution Units (PDU).

8. If your management server is an SMA and you are not using it to manage other storage arrays, shut

down the SMA. From the SMA user interface, click Settings > Maintenance > Shutdown.

Powering up the storage system

To power up a storage system, perform the following steps:

1. Verify that each fabric Fibre Channel switch to which the HSV controllers are connected is powered

up and fully booted. The power indicator on each switch should be on.

If you must power up the SAN switches, wait for them to comp lete their power-on boot process

before proceeding. This may take several minutes.

2. If the management server you shut down is an SMA, power it o n and wait for it to completely b oot.

Verify the SMA is running by logging into it using the web interface.

Enterprise Virtual Array 3000/5000 user guide

35

Page 36

NOTE:

Before applying power to the rack, ensure that the power switch on each HSV controller

is off.

3. PoweronthecircuitbreakersonbothEVArackPDUs.Verifythatalldriveenclosuresareoperating

properly. The status indicator and the power indicator should be on (green).

4. Wait three minutes and then verify that all disk drives are ready. The drive ready indicator and

the drive online indicator should be on (green).

5. Power on the upper controller. It takes the roll of master controller.

6. Wait 10 seconds and then power on the lower controller. It takes the roll of slave controller.

7. Verify that the (Operator Control Panel) OCP display on each controller displays the storage system

name and the EVA WWN.

8. Start HP Command View EVA and verify connection to the storage system. If the storage system is

not visible, click HSV Storage Network in the N avigation pane then click Discover in the Content

pane to discover the array.

NOTE:

If the storage system is still not visible, reboot the management server to re-establish the

communication link.

9. Check the s

properly

service p

torage system status using HP Command View EVA to ensure everything is operating

. If any status indicator is not normal, check the log files or contact your HP—authorized

rovider for assistance.

Saving storage system configuration data

As part of an overall data protection strategy, storage system configuration data should saved during

initial installation, and whenever major configuration changes are made to the storage system. This

includes adding or removing disk drives, creating or deleting disk groups, and adding or deleting virtual

disks. The saved configuration data can save substantial time should it ever become necessary to

re-initialize the storage system. The configuration data is saved to a series of files stored in a location

other than on the storage system.

This procedure can be performed from the SAN Management Appliance (SMA) or management server

where the Command View EVA application is installed, or any host that can run the Storage System

Scripting Utilit y (SSSU) to communicate with the Command View EVA application server.

NOTE:

SSSU version 4 is required for HP Command View EVA 4.0 and later. For more information on using

SSSU, refer to the

from the following web site:

ttp://h18006.www1.hp.com/products/storage/software/cmdvieweva/index.html

h

Click Support & Documentation.

HP StorageWorks Storage System Scripting Utility reference

, which can be downloaded

1. Run SSSU on the platform and operating system of your choice.

2. Enter SELECT MANAGER and select the management server.

3. Enter SHOW SYSTEM to determine which storage systems are managed by this instance of HP

Command View EVA.

4. Enter SELECT SYSTEM to select the appropriate storage system from which to collect configuration

data.

36

Enterprise Virtual Array operation

Page 37

5. Enter CAPTURE CONFIGURATION, specifying the full path and fi lename of the output files for

the configu ration data.

The configuration data is stored in a series of from one to five files, which are SSSU scripts. The

file names begin with the name you choose, with the restore step appended. For example,

if you specify a file name of LargeEVA.txt,theresultantconfiguration files would be

LargeEVA_Step1A.txt, LargeEVA_Step1B,etc.

The contents of the configuration files can be viewed with a text editor.

NOTE:

If the storage system contains disk drives of different capacities, the SSSU procedures used do not

guarantee that disk drives of the same capacity will be exclusively added to the same disk group. If you

need to restore an array configuration that contains disks of different sizes and types, you must manually

recreate these disk groups. The controller software and the utility’s CAPTURE CONFIGURATION

command are not designed to automatically restore this type of configuration. For more information,

refer to the

HP StorageWorks Storage System Scripting Utility reference

.

The following examples illustrate how to save and restore the storage system configuration data using

SSSU on a Windows host.

Example 1. Saving configuration data using SSSU on a Windows Host

Run SSSU from a DOS Command Window on the SMA, a Windows Workstation or a Windows Server

that can access the SMA by TCP/IP or the management host running Command View.

1. Click Run on the Window Start menu.

2. Enter cmd in the Open field to open the DOS Command Window.

3. Change to the directory (CD) in which you have installed SSSU. For example, C:> cd \SSSUDir

4. Enter SSSU to run the application.

5. Enter SELECT MANAGER <SMAname or ip_addr> user=<username> pass=<userpass-

word>.

6. Enter SHOW SYSTEM to display the EVA storage systems managed by the SMA or Windows Host.

7. Enter SELECT SYSTEM <EVA_Name>,whereEVA_name isthenameofthestoragesystem.

The storage system name is case sensitive. If there are spaces between the letters in the name, quotes

must enclose the name. For example, SELECT SYSTEM “Large EVA”.